Catalyst for use in continuous production of 2,3-dichloropyridine, and preparation method and application thereof

A technology of dichloropyridine and catalyst, which is applied in the field of catalyst for continuous production of 2,3-dichloropyridine and its preparation, can solve the problems of high yield, difficult control, complicated process, etc., achieve high catalytic activity, improve reaction Selectivity, the effect of enhancing selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

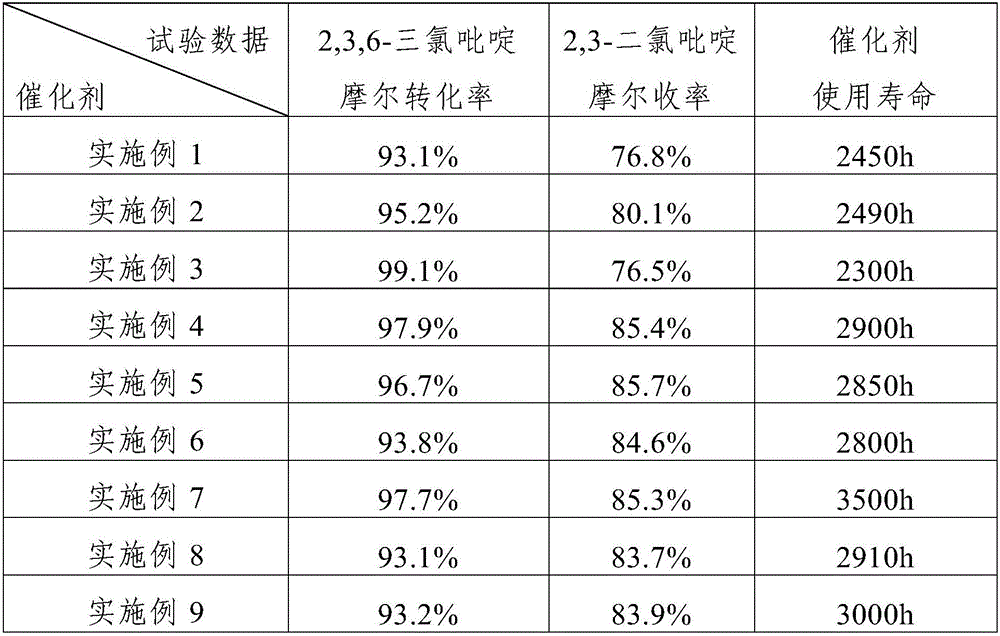

Examples

Embodiment 1

[0039] The catalyst for the continuous production of 2,3-dichloropyridine in this embodiment includes a gear-shaped alumina carrier and Pt, Pd and Ru loaded on the gear-shaped alumina carrier, and the mass percentage of Pt in the catalyst is 0.3 %, the mass percentage of Pd is 0.1%, the mass percentage of metal M is 0.4%, the outer diameter of the gear-shaped alumina carrier is 2.5mm, the inner diameter is 1.0mm, the depth of the tooth groove is 0.75mm, and the hole The capacity is 0.7mL / g, and the specific surface area is 210m 2 / g.

[0040] The preparation method of the catalyst for continuous production of 2,3-dichloropyridine in the present embodiment comprises the following steps:

[0041] Step 1, dissolving platinum chloride containing 0.3gPt, palladium chloride containing 0.1gPd and ruthenium chloride containing 0.4gRu in dilute nitric acid with a concentration of 0.5% by mass percentage to obtain solution A, then glycerin Alcohol is added to solution A, and the volume ...

Embodiment 2

[0046] The catalyst for the continuous production of 2,3-dichloropyridine in this embodiment includes a gear-shaped alumina carrier and Pt, Pd and Ru loaded on the gear-shaped alumina carrier, and the mass percentage of Pt in the catalyst is 0.5 %, the mass percentage of Pd is 0.3%, the mass percentage of Ru is 0.1%, the outer diameter of the gear-shaped alumina carrier is 2.5mm, the inner diameter is 1.0mm, the alveolar depth is 0.75mm, and the pore volume is 0.75mL / g, and the specific surface area is 230m 2 / g.

[0047] The preparation method of the catalyst for continuous production of 2,3-dichloropyridine in the present embodiment comprises the following steps:

[0048] Step 1, dissolving platinum chloride containing 0.5gPt, palladium chloride containing 0.3gPd and ruthenium chloride containing 0.1gRu in dilute nitric acid with a concentration of 1% by mass percentage to obtain solution A, and then glycerin Alcohol is added to solution A, and the volume of added glycerol...

Embodiment 3

[0053] The catalyst for the continuous production of 2,3-dichloropyridine in this embodiment includes a gear-shaped alumina carrier and Pt, Pd and Ru loaded on the gear-shaped alumina carrier, and the mass percentage of Pt in the catalyst is 0.8 %, the mass percentage of Pd is 0.5%, the mass percentage of Ru is 0.5%, the outer diameter of the gear-shaped alumina carrier is 2.5mm, the inner diameter is 1.0mm, the alveolar depth is 0.75mm, and the pore volume 0.75mL / g, the specific surface area is 250m 2 / g.

[0054] The preparation method of the catalyst for continuous production of 2,3-dichloropyridine in the present embodiment comprises the following steps:

[0055] Step 1, dissolving platinum chloride containing 0.8gPt, palladium chloride containing 0.5gPd and ruthenium chloride containing 0.5gRu in dilute nitric acid with a mass percentage concentration of 0.5% and mixing uniformly to obtain solution A, then glycerin Alcohol is added to solution A, and the volume of added...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com