Patents

Literature

359results about How to "Crystal stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing hydroxyapatite/nano silver antimicrobial composite coating by pulse electrochemical deposition

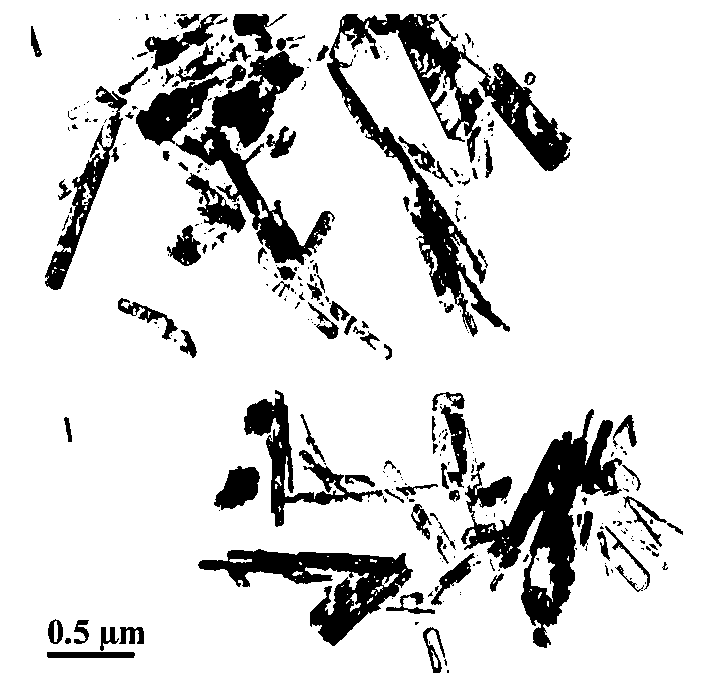

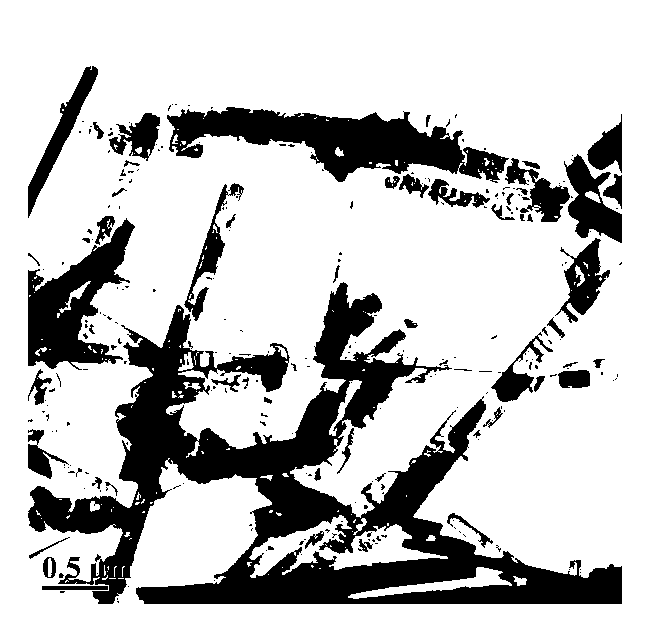

InactiveCN101485901AReduce concentration polarizationCrystal denseCoatingsProsthesisElectrolytic agentPhosphate

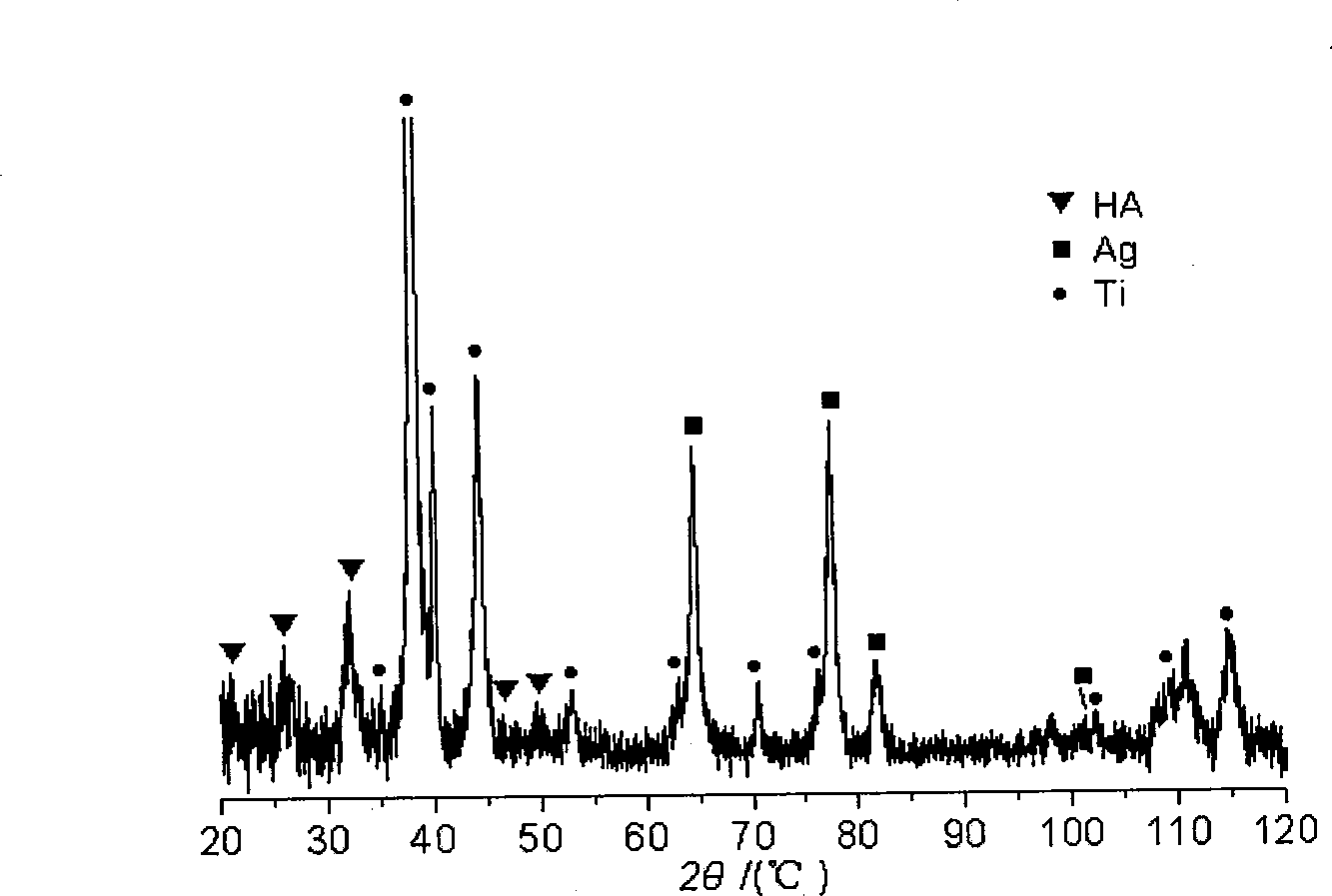

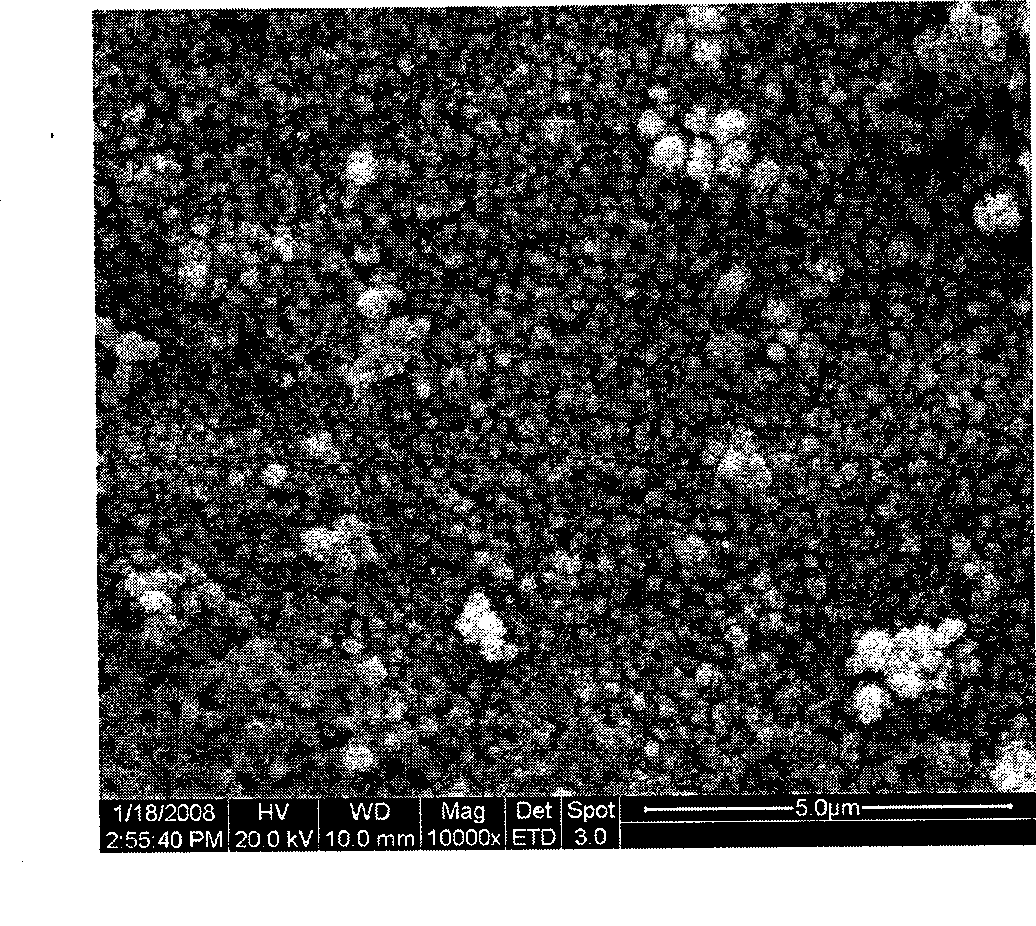

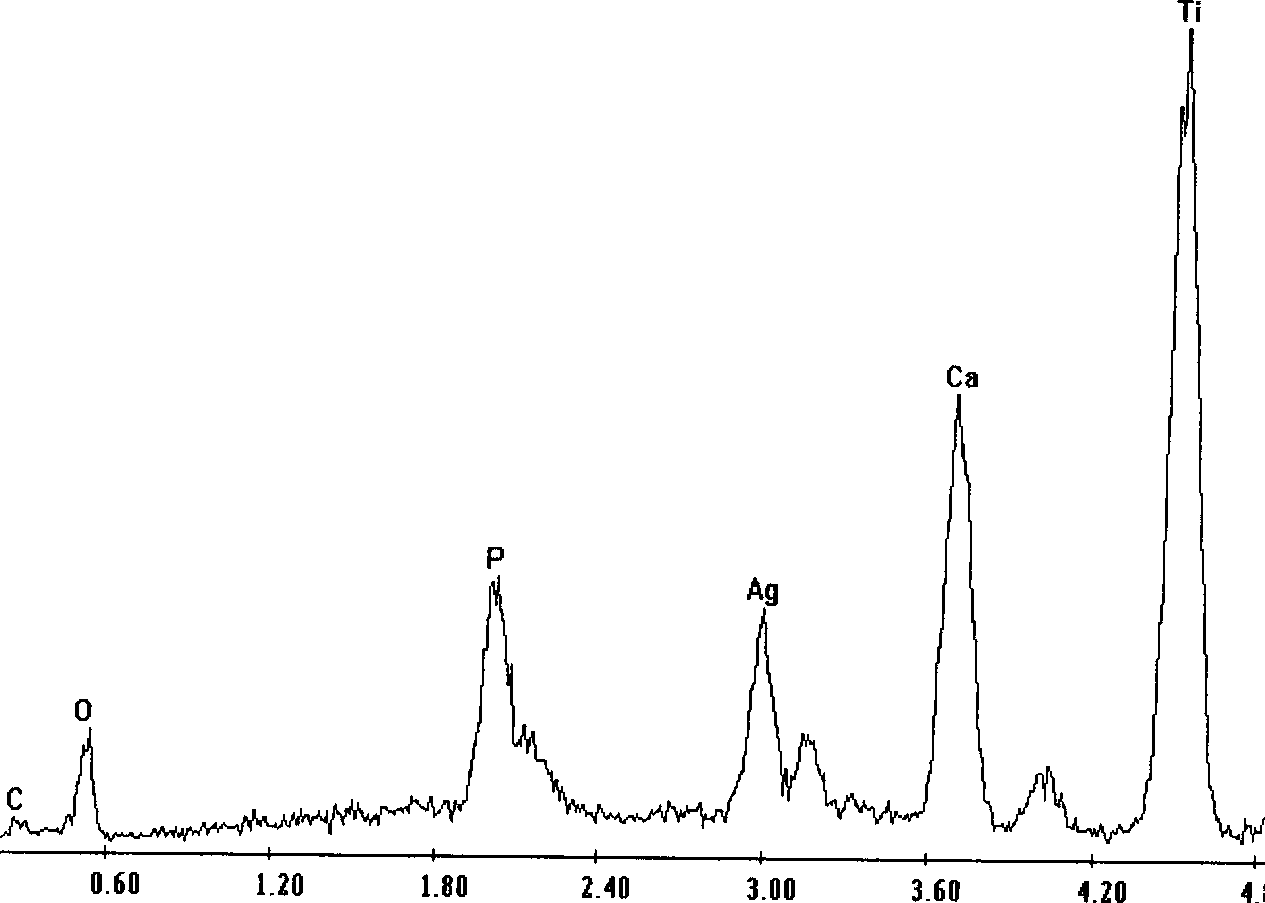

The invention discloses a method for preparing a hydroxyapatite / nano silver antibacterial composite coating through pulse electrochemical deposition, which comprises: using a calcium salt, phosphate, silver nitrate and a proper amount of coordination agent to prepare electrolyte with certain concentration and pH value, and performing electrodeposition in a electrolytic cell provided with a three-electrode system; taking a saturated calomel electrode as a reference electrode, a platinum sheet as a counter electrode and biological medical metal to be coated as a working electrode, wherein the pulse high electric potential is 0 volt, the pulse low electric potential is -2.0 volts, the pulse width is 100 seconds, and the deposition time is 2 hours; and depositing compositions in the coating on a base material in a mode of ions, uniformly dispersing nano silver generated during deposition in the composite coating, and finally preparing the hydroxyapatite / nano silver antibacterial compositecoating.

Owner:SOUTHWEST JIAOTONG UNIV

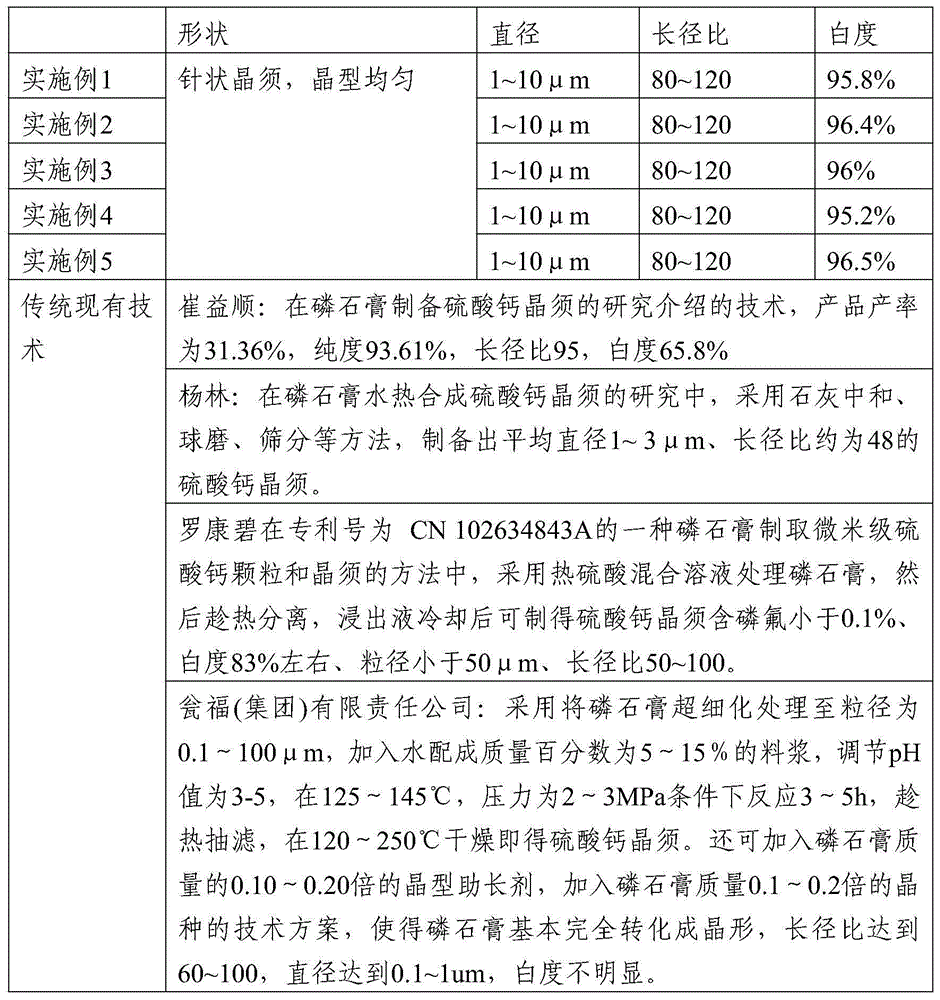

Method for preparing calcium sulfate dihydrate crystal whisker from phosphorus gypsum

InactiveCN104005086ANot to be wastedReduce generation influence ratePolycrystalline material growthFrom normal temperature solutionsProduction rateSulfate

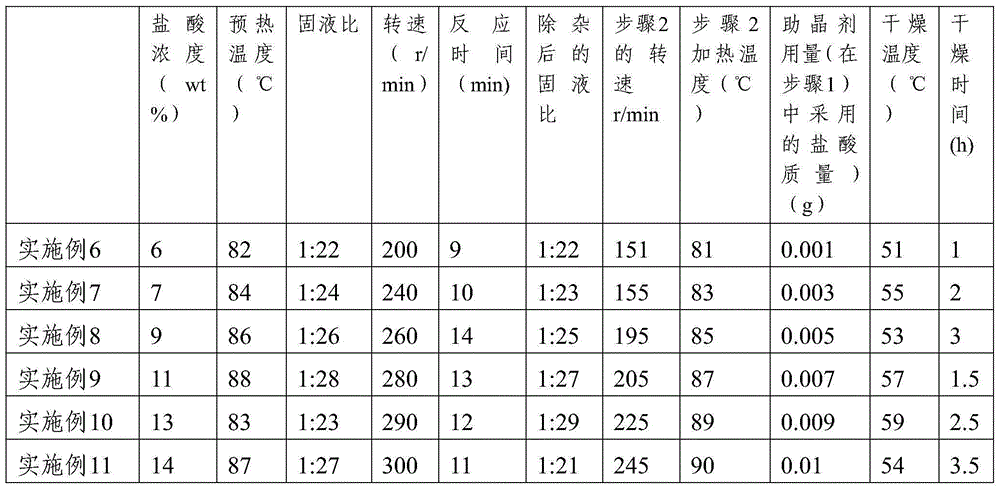

The present invention relates to the technical field of chemical raw material preparation, and particularly to a method for preparing calcium sulfate dihydrate crystal whisker from phosphorus gypsum. The method comprises the following steps: preparing calcium sulfate dihydrate without impurities, preparing a crystal whisker, washing, and drying to obtain the calcium sulfate dihydrate crystal whisker. By preheating hydrochloric acid and matching the hydrochloric acid with phosphorus gypsum at a certain ratio at a constant temperature, the reaction can proceed and the materials is not wasted, the impurities contained in the phosphorus gypsum can be properly removed maximatily, the impact rate of impurities on the generation of calcium sulfate dihydrate crystal whisker is decreased, the content of calcium sulfate component is increased, the production rate of calcium sulfate dihydrate crystal whisker is improved and the production costs of calcium sulfate dihydrate crystal whisker prepared by comprehensively utilizing phosphorus gypsum are reduced.

Owner:GUIZHOU KAILIN GRP CO LTD

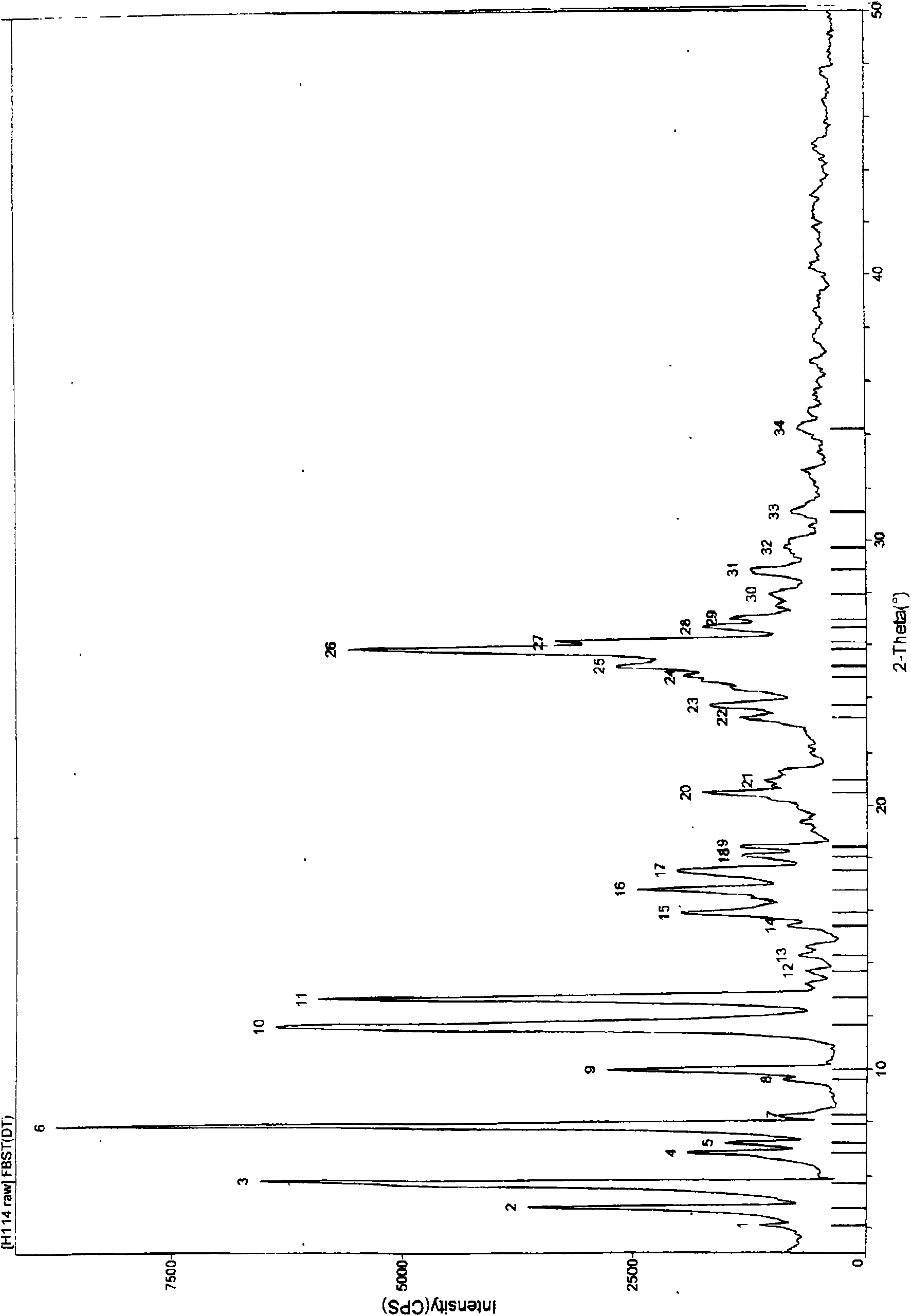

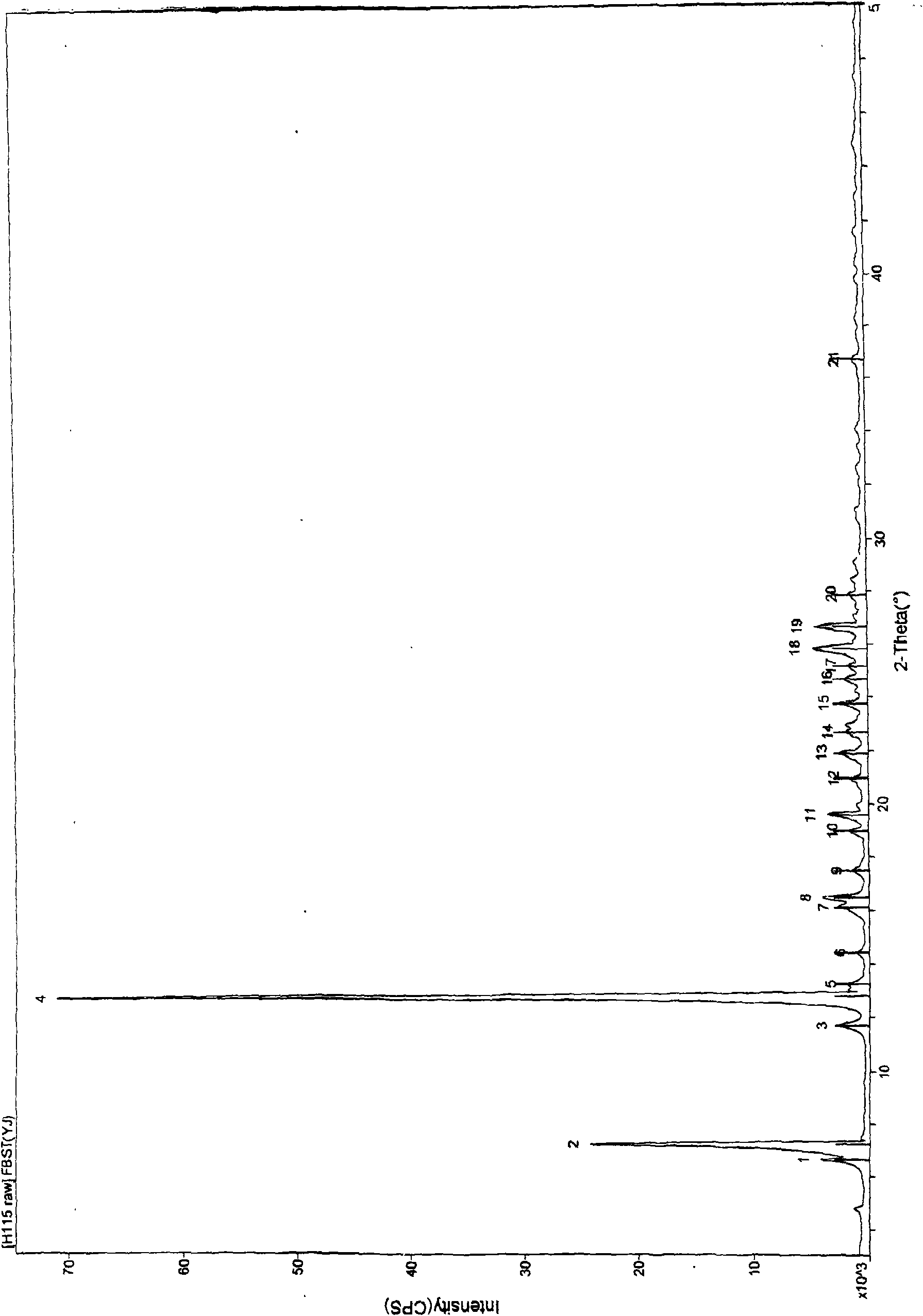

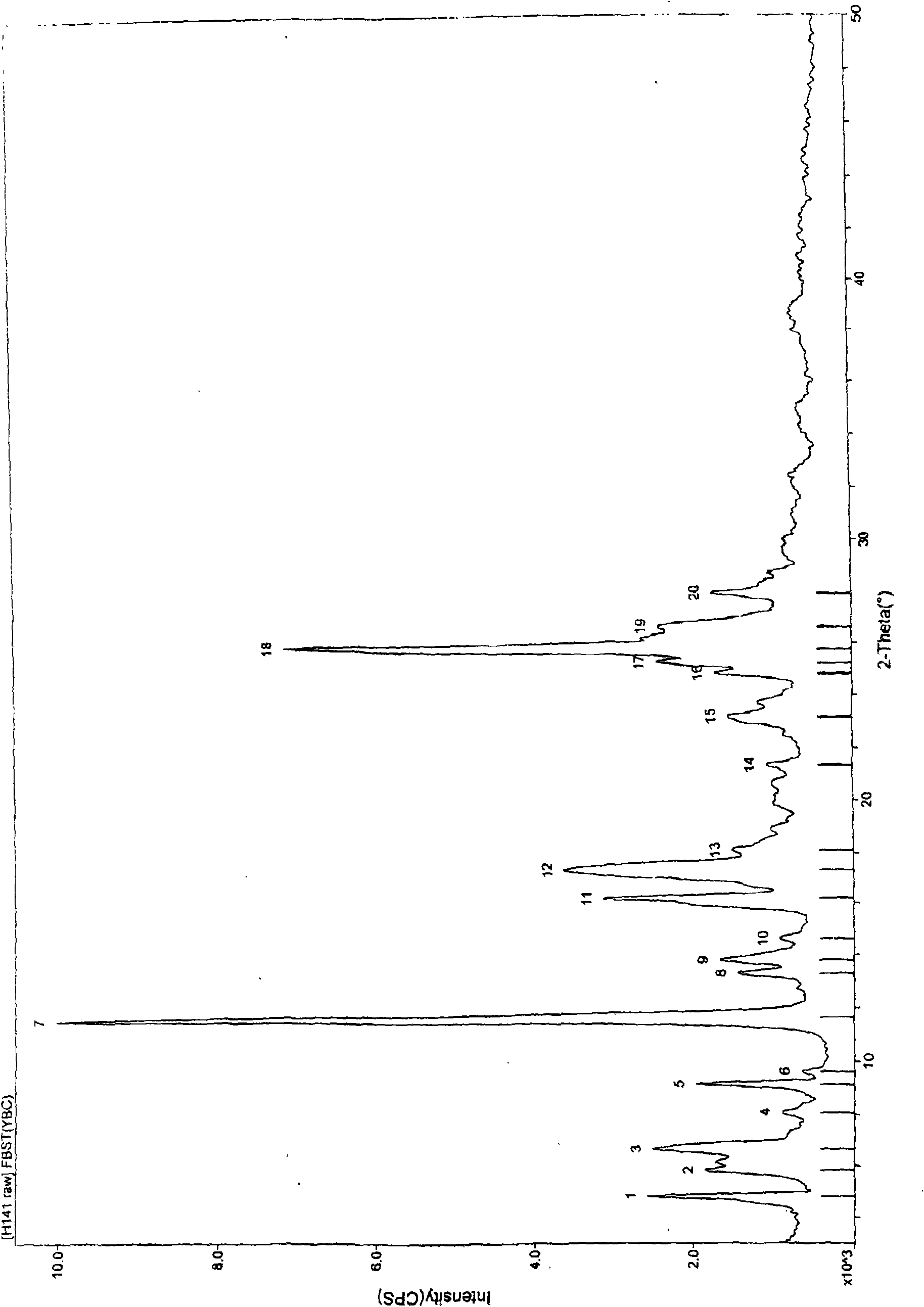

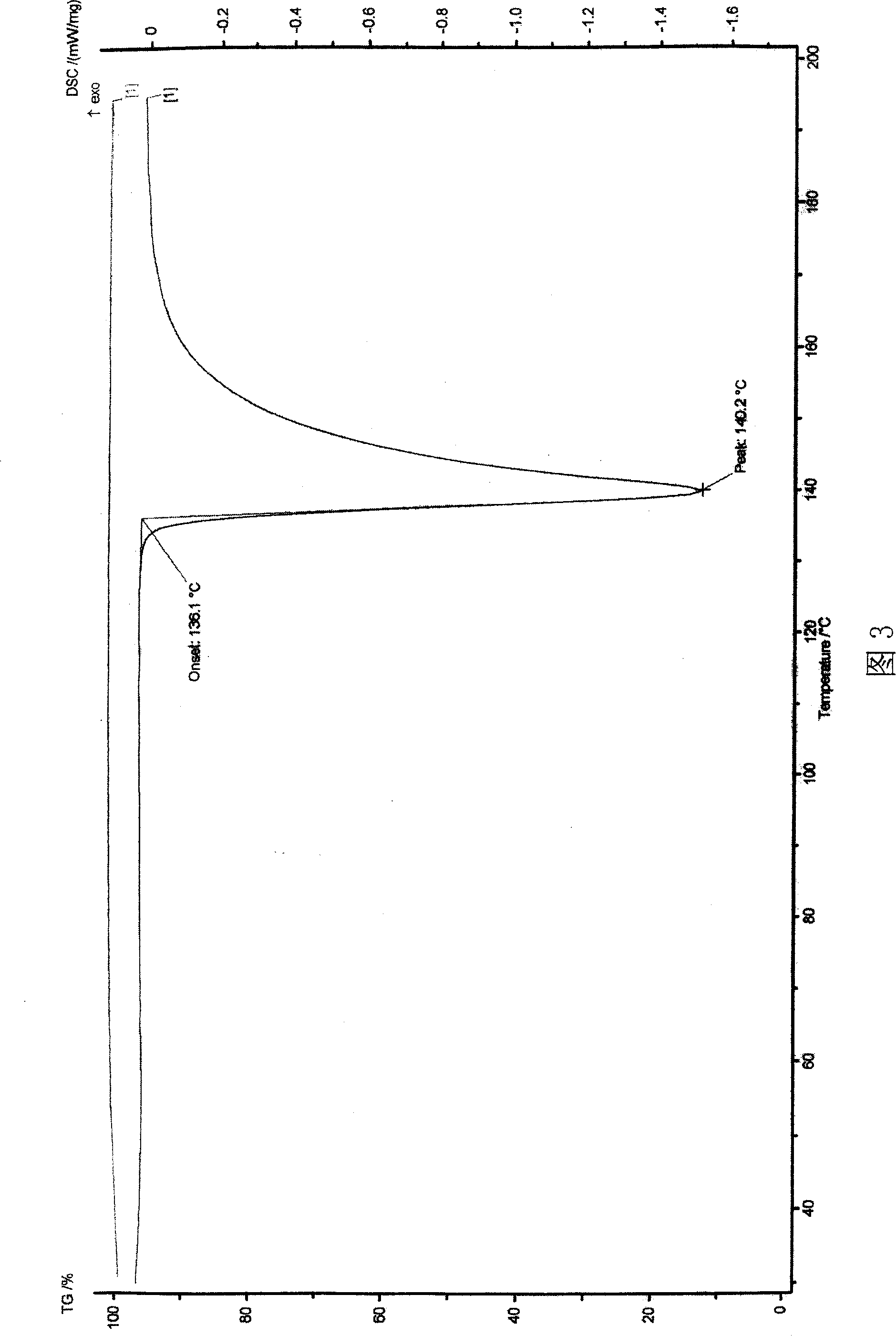

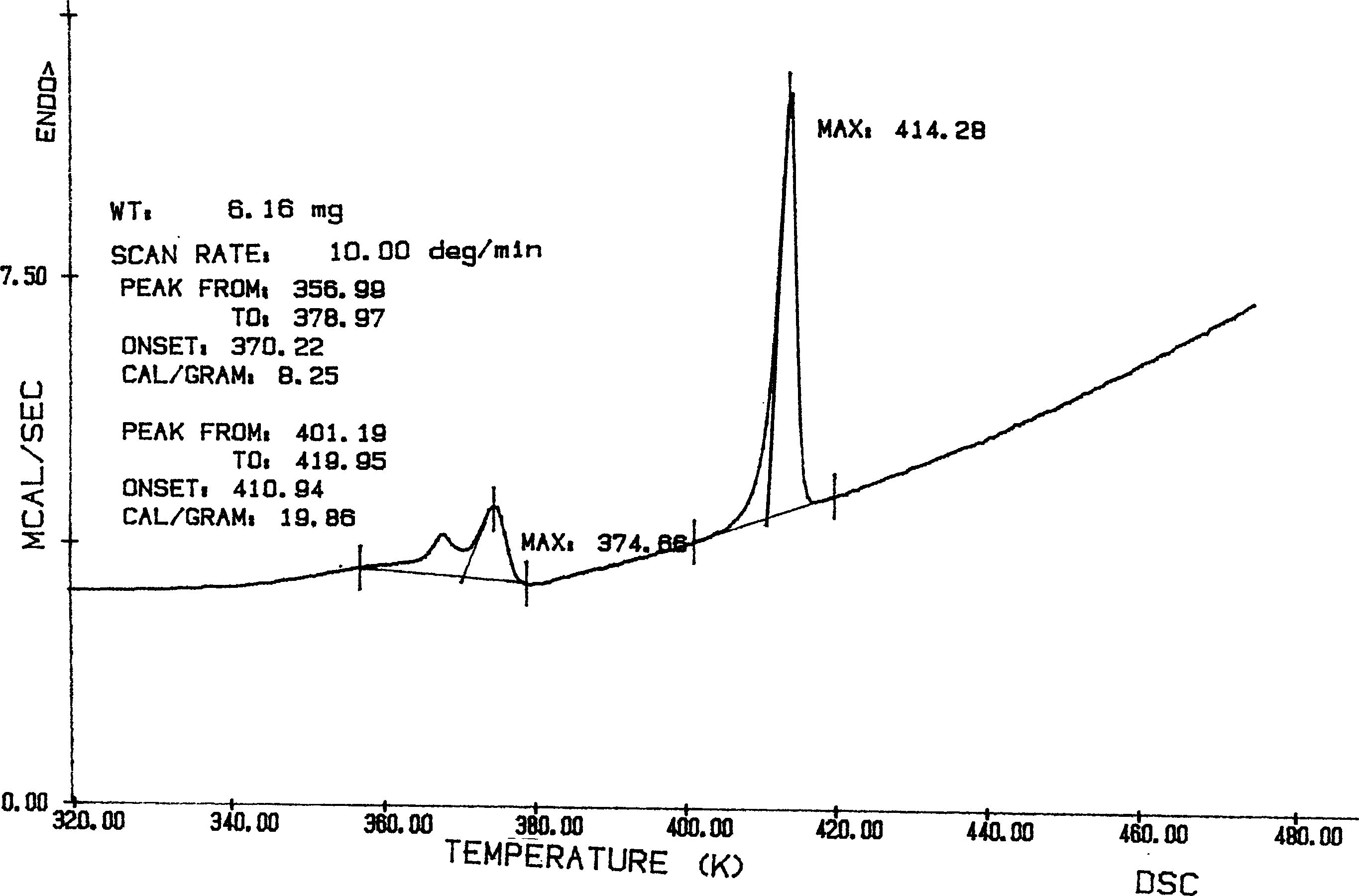

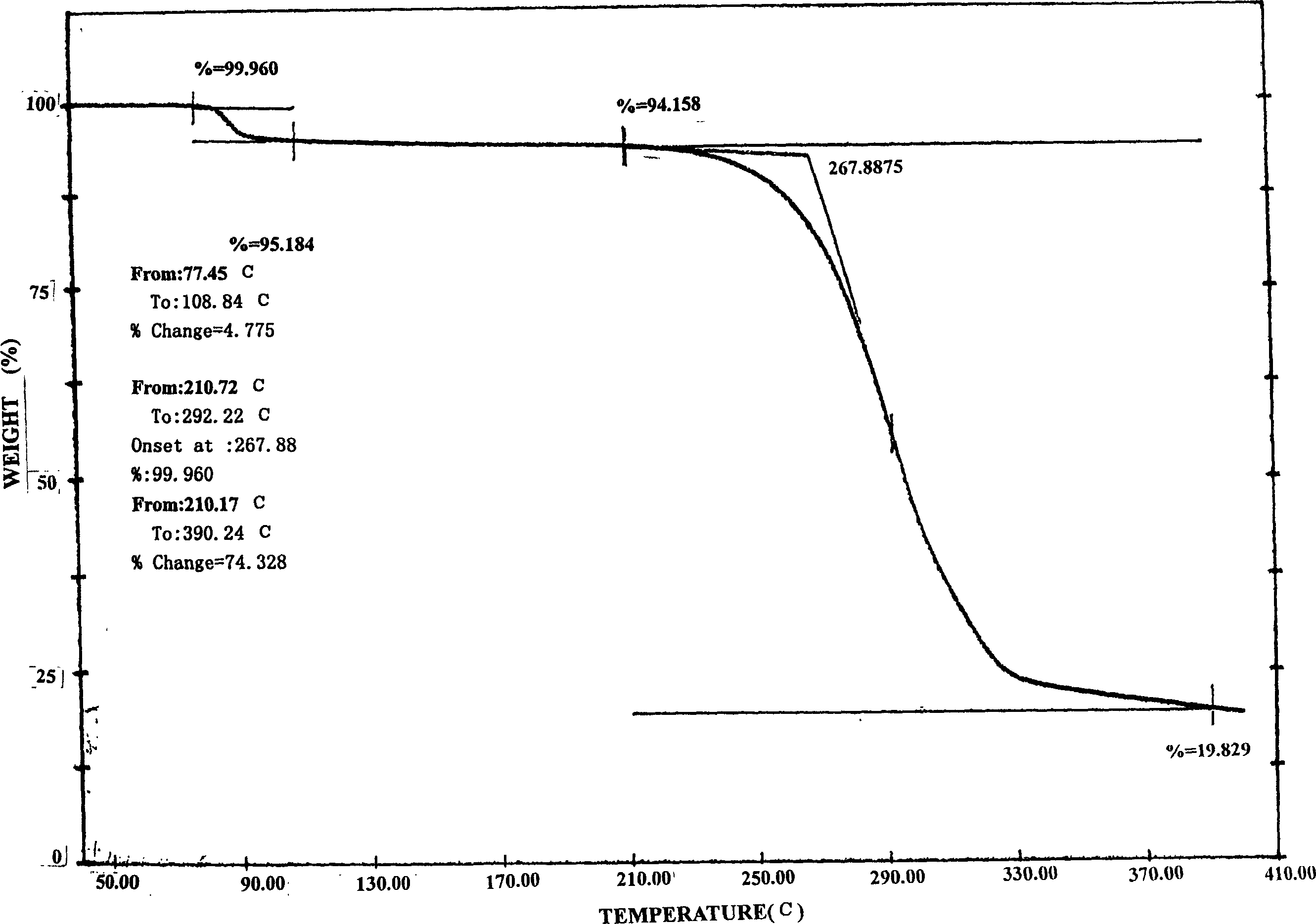

New febuxostat crystal form and preparing method thereof

InactiveCN101684107AEasy to removeEasy to operateOrganic chemistrySkeletal disorderSolventFebuxostat

The invention discloses a new crystal form X, Y and Z of 2-(3-cyanogroup-4-isobutoxy) phenyl-4-methyl-5-thiazole formic acid (febuxostat for short) with the formula of I and a preparing method thereof, and is confirmed by a melting point and a powder X diffraction pattern. The febuxostat prepared with the method is stable in temperature, illumination and humidity and is favourable for storage fora long term; adopted solvent is safe and easy to remove, and the method has easy operation, is suitable for industrial production and is suitable for directly producing preparation.

Owner:UTOPHARM SHANGHAI

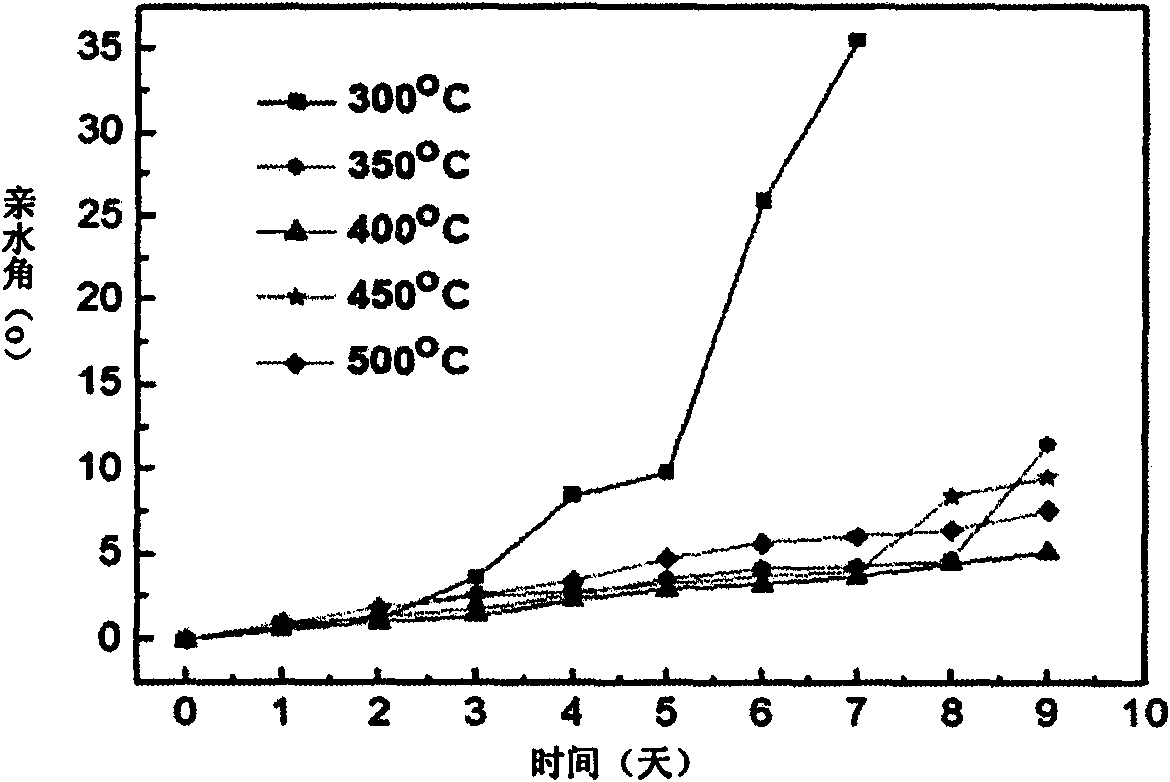

Self-cleaning super-hydrophilic thin film and preparation method thereof

InactiveCN101602933AOvercoming easy reunionOvercoming the weakness of not being easy to recycleOther chemical processesMetal/metal-oxides/metal-hydroxide catalystsRare earthSolvent

The invention provides a self-cleaning super-hydrophilic thin film and a preparation method thereof. The preparation method comprises the steps of using tetra-n-butyl titanate as a precursor of TiO2, using anhydrous ethyl alcohol as solvent, adding glacial acetic acid, and magnetically agitating at room temperature to obtain solution A; synchronously, taking distilled water and anhydrous ethyl alcohol, adding doping salts, and magnetically agitating the mixture to obtain solution B; slowly adding the solution B to the solution A, adding hydrochloric acid to adjust pH value to 3-5, agitating to obtain TiO2 sol, and preparing a rare-earth-doped nanometer-sized TiO2 thin film by using a film drawing machine; immersing a substrate into the sol, drawing and plating a film after glass sheet and liquid surface are stable; drying after plating a layer of film and cooling at room temperature; repeating the steps to prepare the rare earth-doped nanometer-sized TiO2 thin film with different layers; thermally treating the base plated with the TiO2 thin film, and directly using the film-plated base. The thin film of the invention overcomes the weak points that nanometer-sized powder easily aggregates and is not easily recovered, the obtained crystal form is table, and the thin film has excellent self-cleaning and hydrophilic capacities.

Owner:CENT SOUTH UNIV

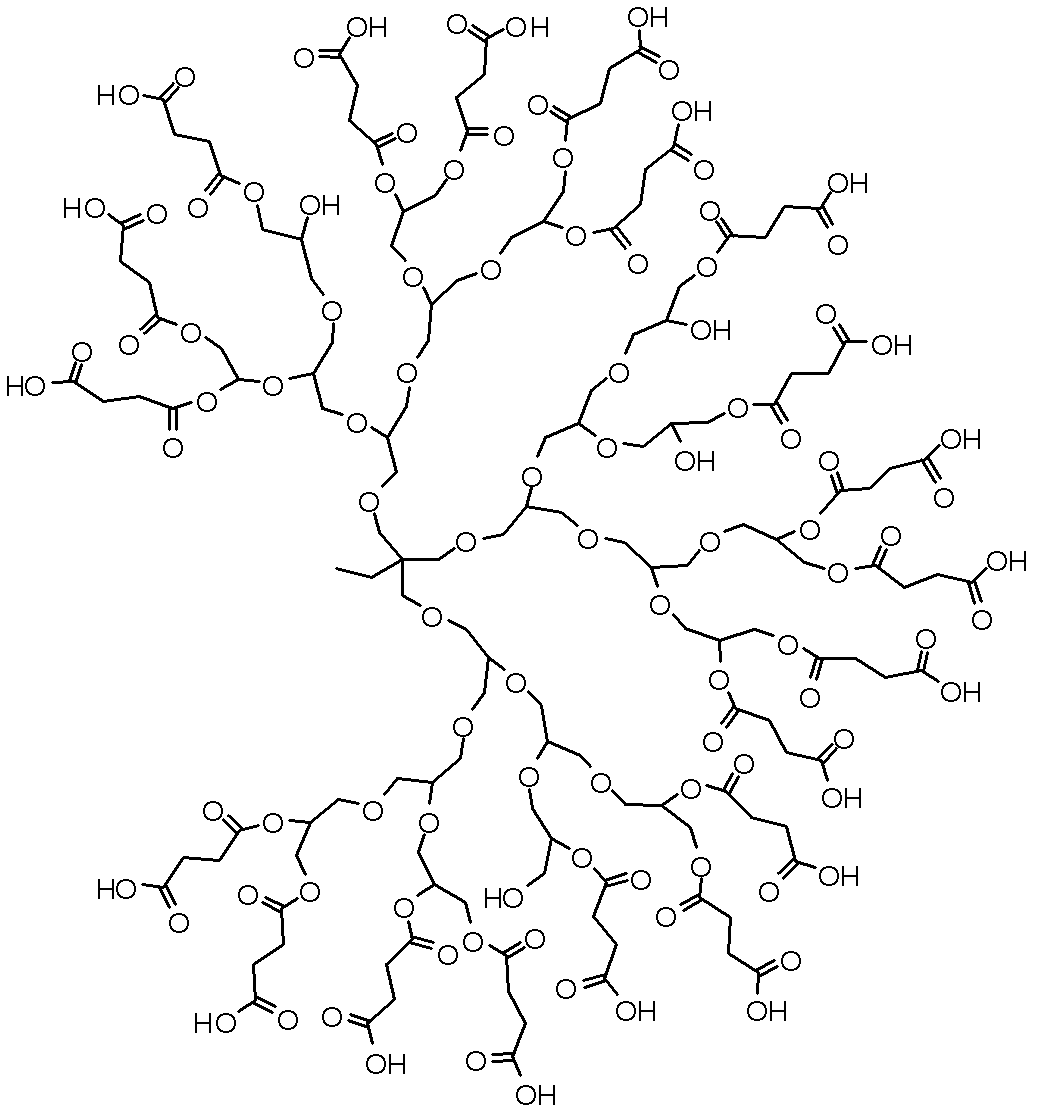

Monodispersed vaterite type calcium carbonate microsphere and preparation method thereof

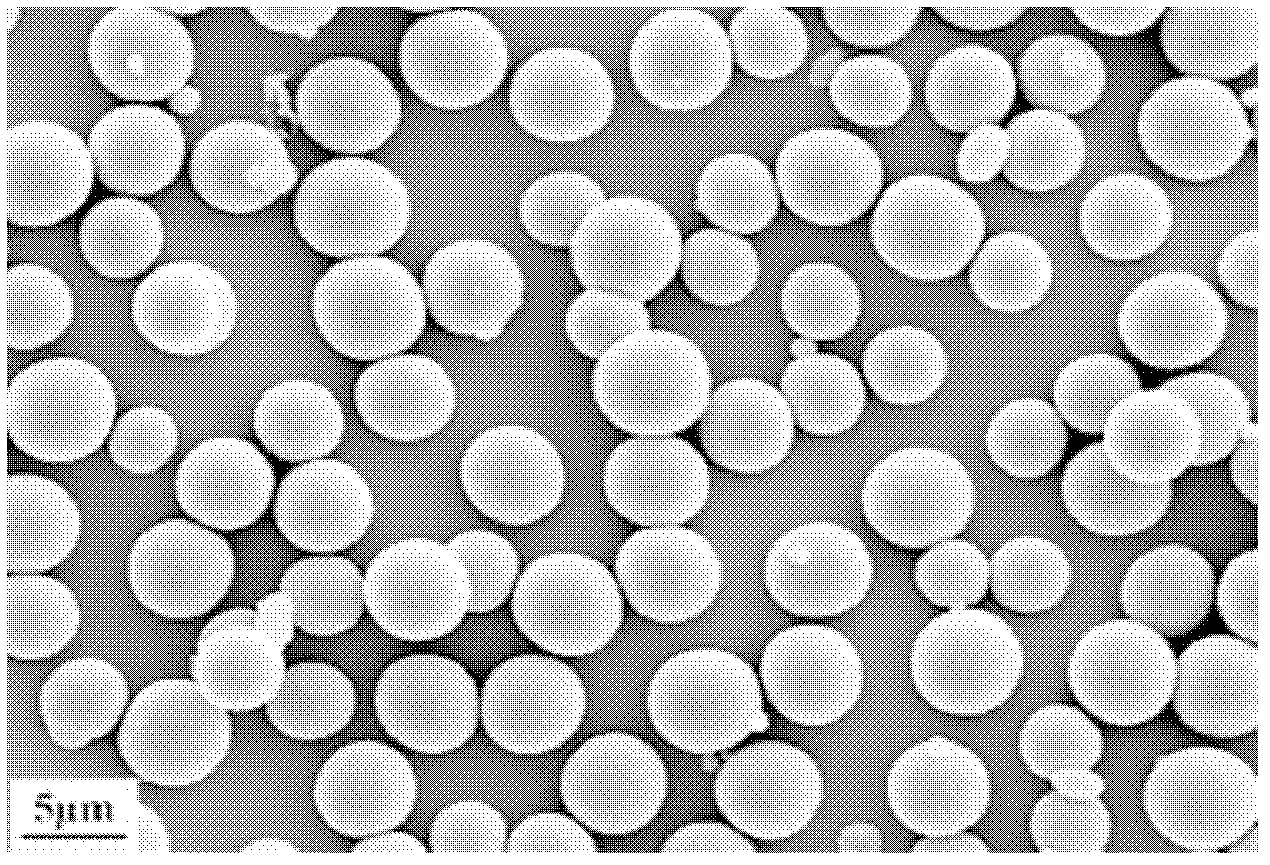

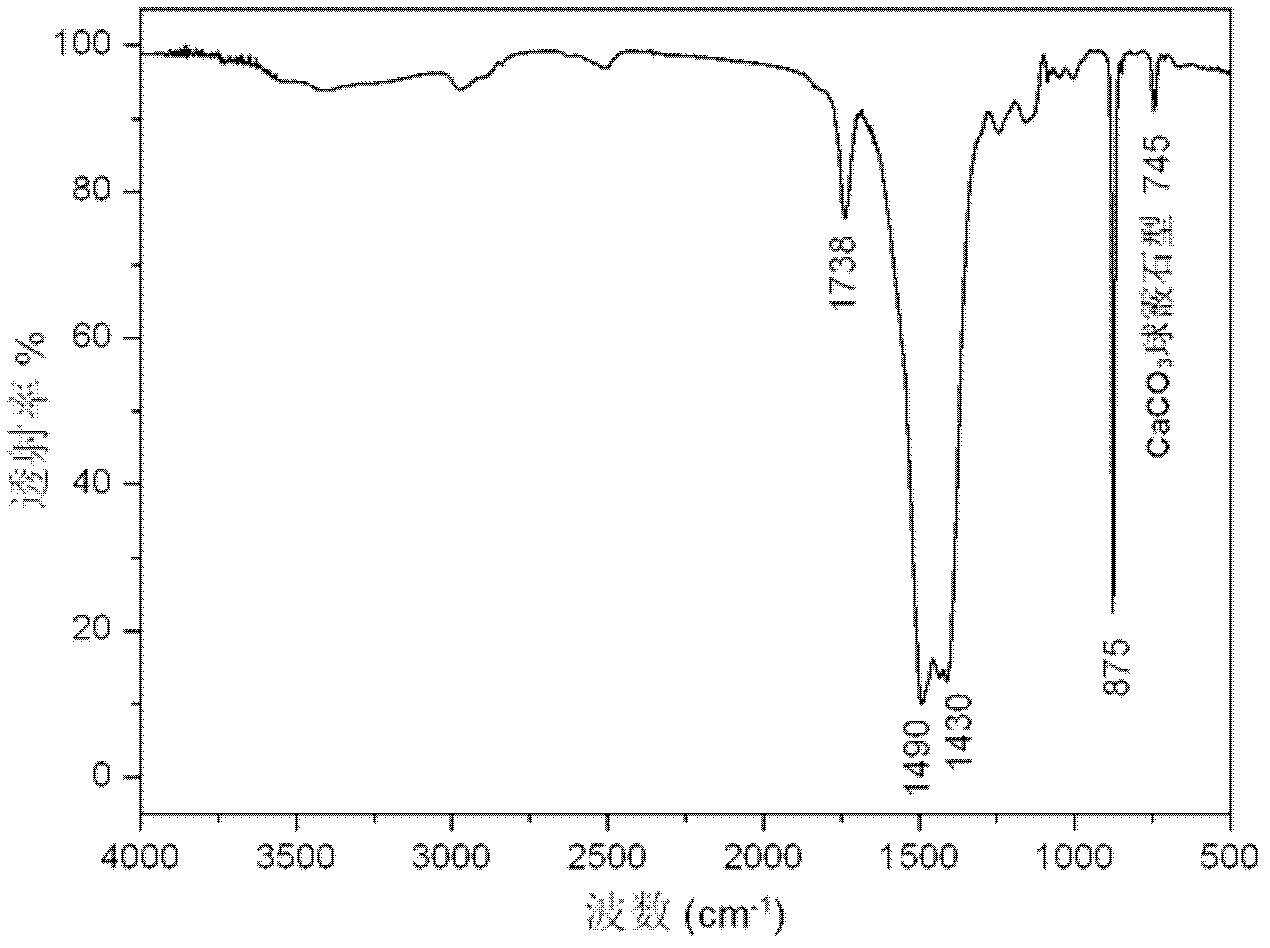

InactiveCN102583485AIncrease the degree of branchingHigh density of surface functional groupsCalcium/strontium/barium carbonatesBicarbonateCalcium carbonate

The invention relates to a preparation method of a monodispersed vaterite type calcium carbonate microsphere, which comprises the following steps of: (1) preparing a calcium salt aqueous solution with the concentration of 30-150mmol / L, and then, adjusting the pH value of the calcium salt aqueous solution to 8.5-10; (2) preparing a carbonate or hydrocarbonate aqueous solution with the concentration of 30-150mmol / L, and then, adjusting the pH value of the carbonate or hydrocarbonate aqueous solution to 8.5-10; (3) preparing a functional hyperbranched polyglycerol aqueous solution with the concentration of 20-400mg / L, and then, adjusting the pH value of the functional hyperbranched polyglycerol aqueous solution to 8.5-10; (4) mixing and uniformly stirring the carbonate or hydrocarbonate aqueous solution, the calcium salt aqueous solution and the functional hyperbranched polyglycerol aqueous solution at the temperature of 10-35 DEG C, and aging for 1-12h; and (5) centrifuging or filtering the mixed solution, cleaning a sediment, and drying to obtain the monodispersed vaterite type calcium carbonate microsphere. The monodispersed vaterite type calcium carbonate microsphere prepared by using the preparation method provided by the invention has the advantages of uniform particle size, stable crystal form and industrial application value.

Owner:NANJING UNIVERSTIY SUZHOU HIGH TECH INST +1

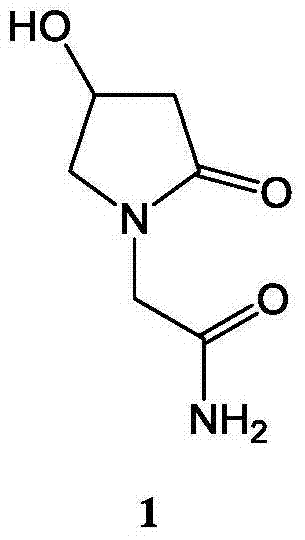

Oxiracetam capsule and preparation method thereof

ActiveCN103494790AHigh purityLow impurity contentOrganic active ingredientsNervous disorderMedicinal chemistryImpurity

The invention relates to an oral capsule preparation of oxiracetam and a preparation method thereof. The oxiracetam capsule contains 80.0-85.5% by weight of oxiracetam, 9.7-15.2% by weight of xylitol and 4.8% by weight of an emollient, wherein the oxiracetam is in a crystal form. The oxiracetam in the crystal form is a good crystal with excellent mobility. Compared with the crystal form provided in the prior art, the oxiracetam in the crystal form has higher purity, less impurity, better quality stabilizer and better crystal form stability. The quality stability of the disclosed oxiracetam capsule is improved remarkably, the preparation process is simple, and the production cost is lowered.

Owner:CSPC OUYI PHARM CO LTD

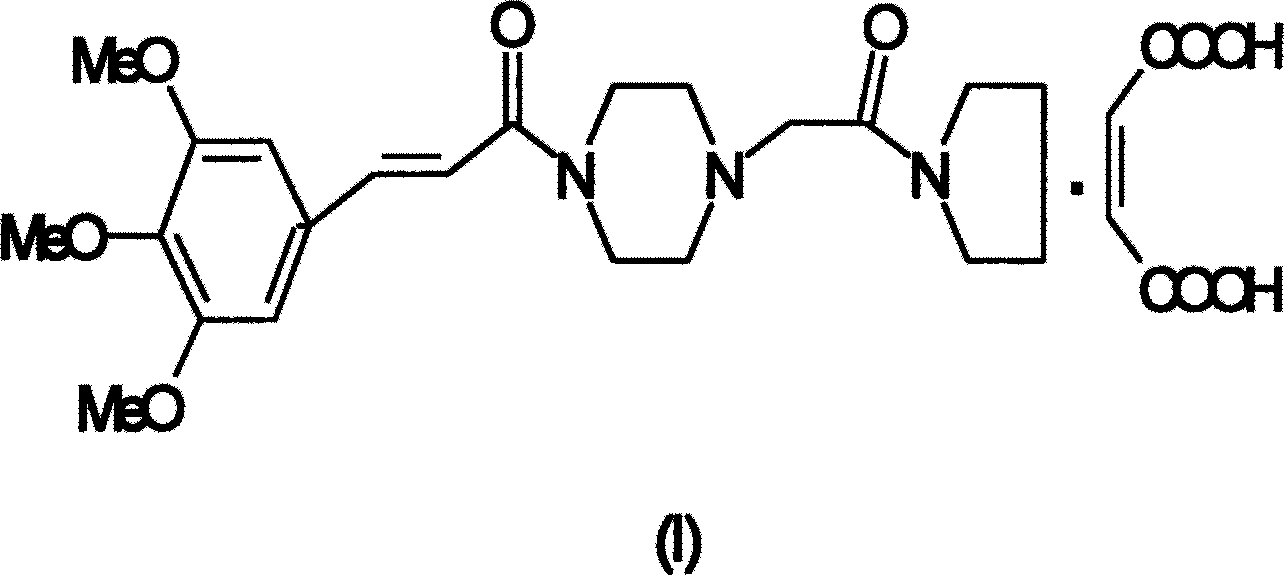

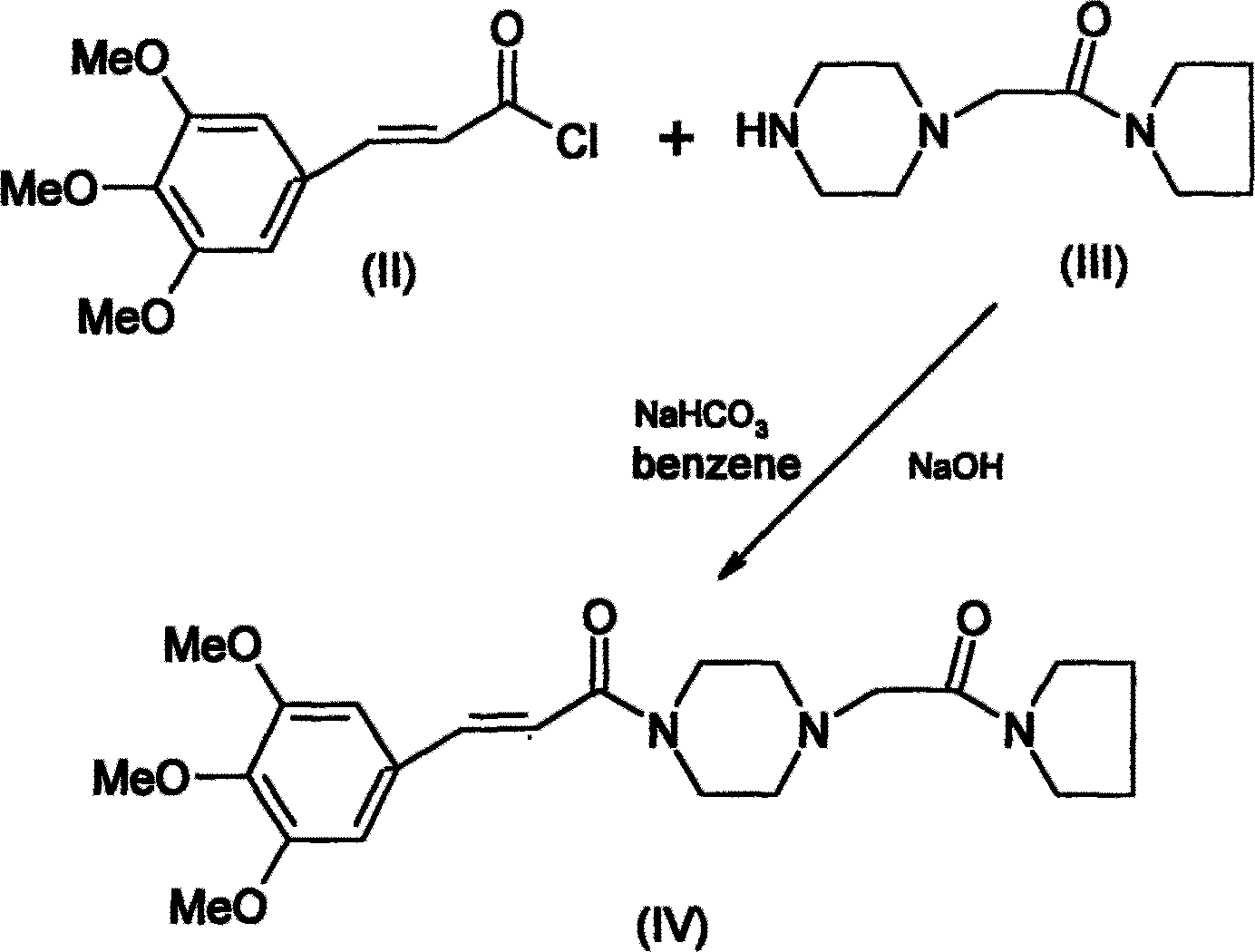

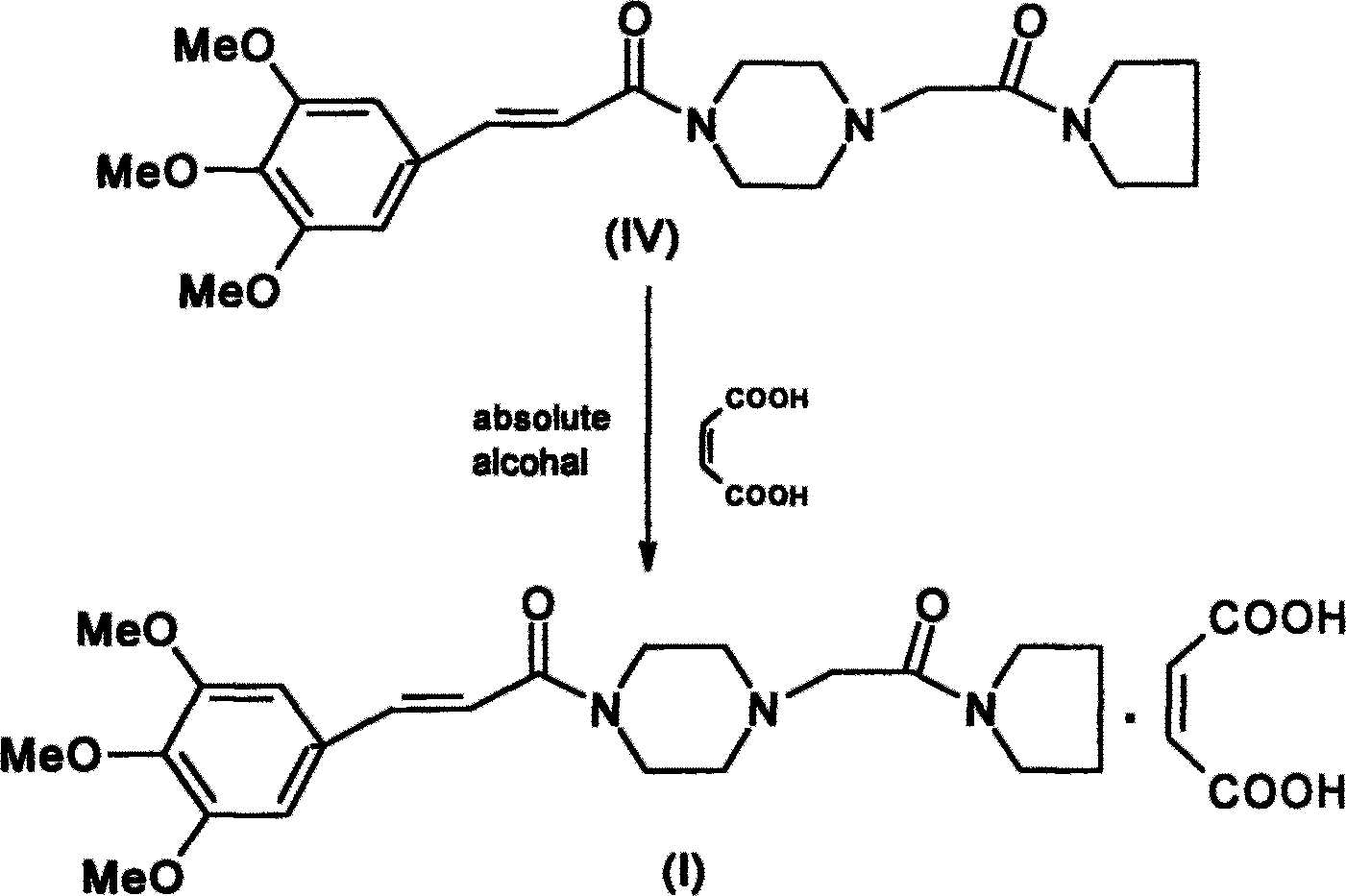

Improved cinepazide maleate preparation method

ActiveCN1876646AHigh melting pointCrystal stableOrganic active ingredientsOrganic chemistrySolventPyrrolidine

The invention relates the preparing method of maleic acid cinprazole. The method comprises the following steps: preparing chloracetyl pyrrolyl; preparing 1- [(1- pyrrolidine carbonyl) methyl] ethyleneamine; preparing 3, 4, 5- trimethoxyl cinnamomum cassia acyl; preparing 1- [(1- pyrrolidine carbonyl) methyl]-4- 3, 4, 5- trimethoxyl cinnamomum cassia acyl) ethyleneamine; preparing 1-[(1- pyrrolidine carbonyl) methyl]-4- 3, 4, 5- trimethoxyl cinnamomum cassia acyl) ethyleneamine maleate; preparing the purification of maleic acid cinprazole. The invention has the character that the solvent is one of chloroform and acetone. The fusing point of the product is 170-175Deg.C. The product has the advantages of high fusing point and stable crystal shape.

Owner:BEIJING SIHUAN PHARMA

Lenalidomide composition tablets and preparation method thereof

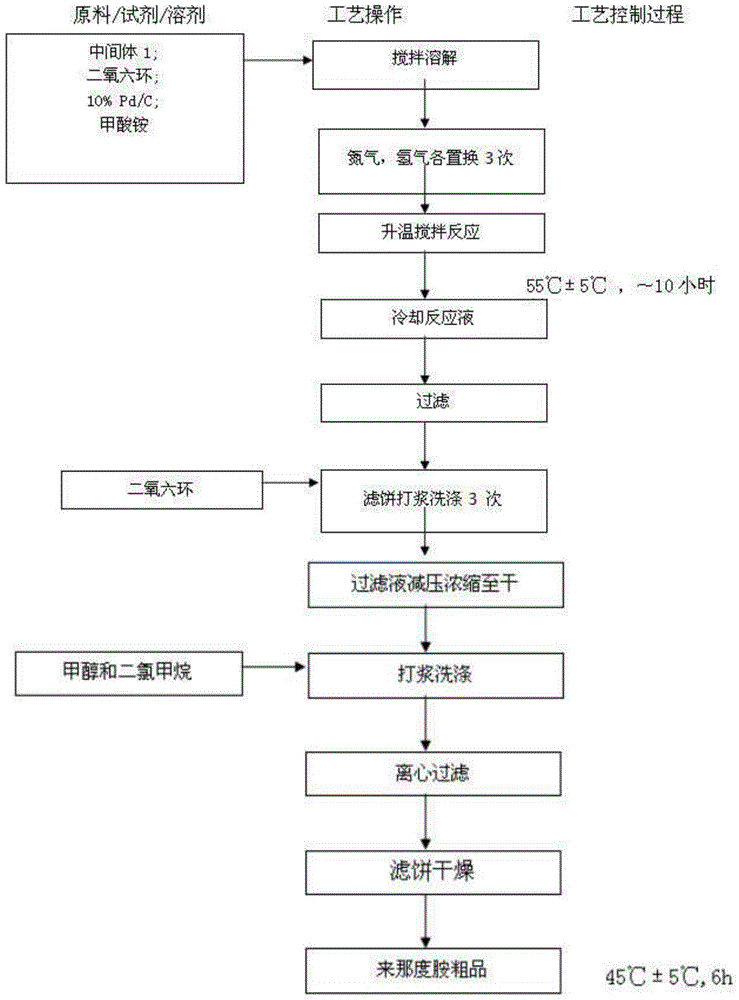

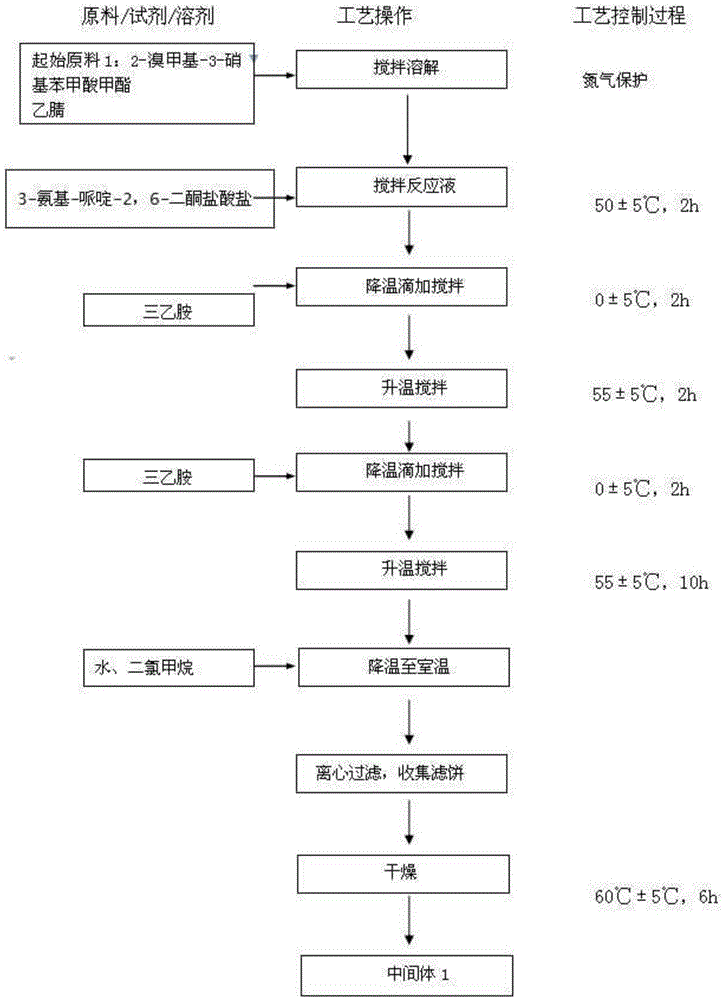

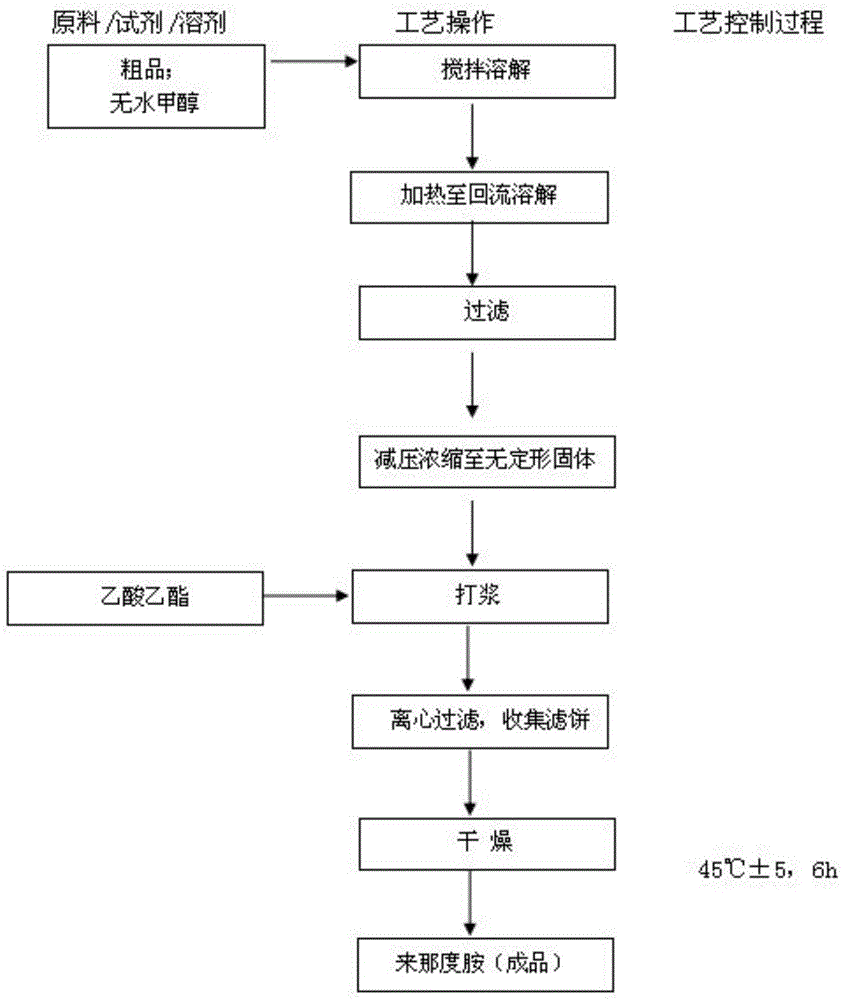

ActiveCN105534981AThe preparation process is stableStable manufacturing processOrganic active ingredientsOrganic chemistryBeta-CyclodextrinsSodium stearyl fumarate

The invention discloses lenalidomide composition tablets and a preparation method thereof. The tablets comprise components in percentage by weight as follows: 10%-18% of lenalidomide crystals, 28%-40% of lactose, 28%-40% of microcrystalline cellulose, 1%-5% of konjac glucomannan, 10%-15% of beta-cyclodextrin, 5%-10% of sodium carboxymethyl starch, 0.5%-1.5% of sodium stearyl fumarate and 0.5%-1.5% of powdered cellulose. The preparation technology of the lenalidomide composition tablets is stable, simple and easy to operate, technological parameters are reliable, and the production cycle is shorter; experimental research shows that the lenalidomide raw material is stable in crystal form, higher in purity and capable of meeting the quality requirement of final products; the synthesis technology is concise, stable, feasible and applicable to mass production; the quality is controllable, the stability is better, and the lenalidomide raw material is unchanged under conditions of affecting factors such as the high temperature, high humidity and 10 days of illumination and is stable after being stored for 6 months under the acceleration condition.

Owner:DEYANG HUAKANG PHARMA

Porous, controllable and low-modulus bone defect repair bracket and preparation method thereof

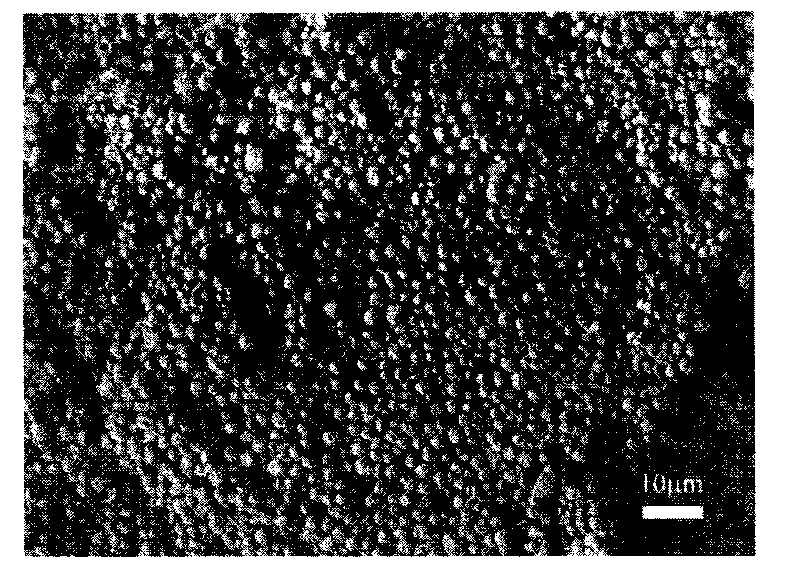

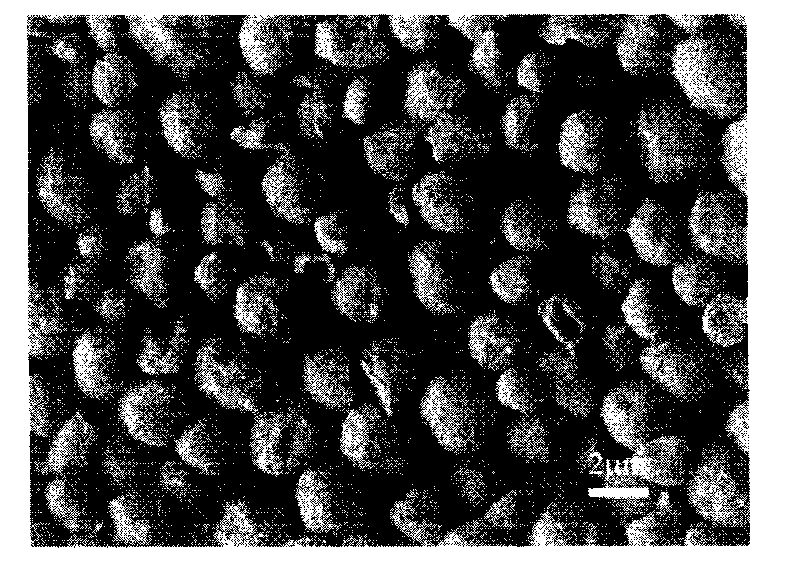

ActiveCN103751840APromote ingrowthSolve the interface stress problemElectrolytic inorganic material coatingProsthesisApatiteRapid prototyping

The invention discloses a porous, controllable and low-modulus bone defect repair bracket which consists of a porous, controllable and low-modulus titanium alloy bracket and a biological activity coating on the surface of the titanium alloy bracket. The invention further discloses a preparation method of the bone defect bracket. The method comprises the steps that the low-modulus and porous titanium alloy bracket in a controllable internal microstructure is prepared by a quick forming technique; a uniform hydroxyapatite coating and a strontium doped hydroxyapatite coating are prepared on the surface of the bracket in the controllable microstructure; an electrolyte with certain concentration is prepared; a potential is controlled in an electrolytic bath of a three-electrode system; and pulse electrochemical deposition is performed. The elastic modulus of the prepared titanium alloy bracket is equivalent to that of a bone; the prepared hydroxyapatite coating or strontium doped hydroxyapatite coating is combined with a titanium alloy well; the concentration of strontium is controllable; and an implant provided with the biological activity coating can be used for a bone defect of a massive bearing part clinically.

Owner:PEKING UNION MEDICAL COLLEGE HOSPITAL CHINESE ACAD OF MEDICAL SCI

Extraction of natural capsaicine

InactiveCN1439630ACrystal stableOperating conditions are easy to controlCarboxylic acid amide separation/purificationDiethyl etherEthyl acetate

A process for extracting natural capsicine from hot pepper powder or the hot pepper extract as the by-product obtained after extracting rutilant pigment from hot pepper features that the alcohol, ethylether, acetone, petroleum ether, or ethyl acetate is used as extractant, a separation accelerator is used to prevent the generation of the third phase, a saponifying activator is used for speeding up saponifying reaction at low temp (28-35 deg.C) and a cleaner is used for stable crystallizing. Its advantages are high purity (more than 99%), and low cost.

Owner:贵州慧博科技开发有限公司

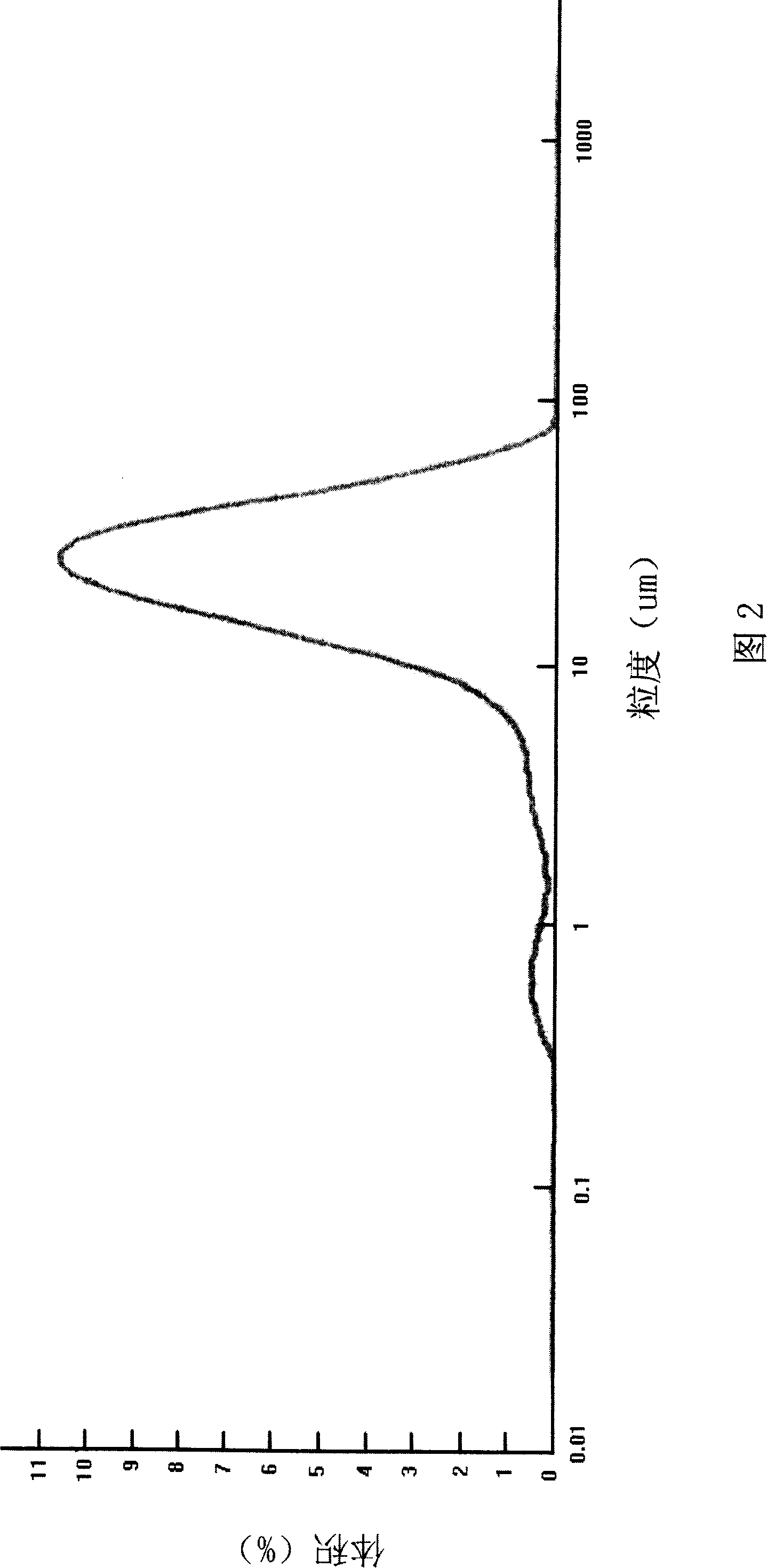

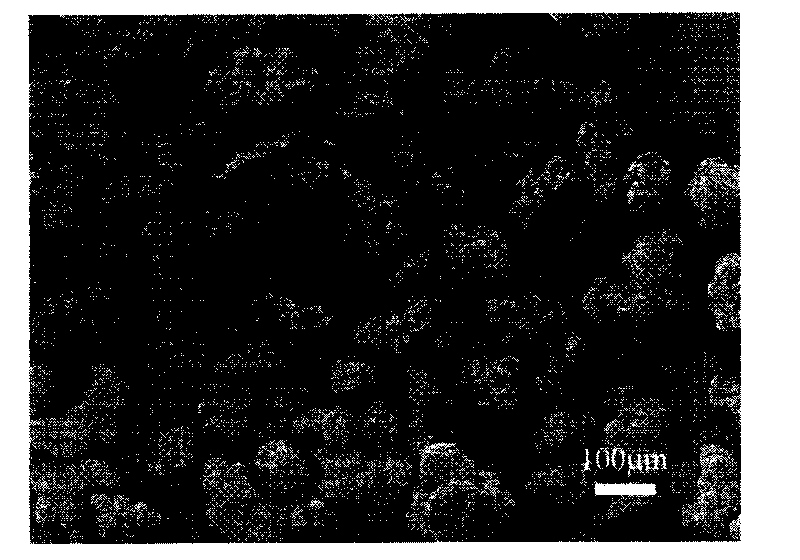

Method for producing aripiprazole crystallite

The invention belongs to the chemical filed, in particular to an aripiprazole minicrystal preparation method, and comprises the steps as follow: aripiprazole rough products and ethanol or ethanol and non-alcohol solvent are mixed and heated to back flow into aripiprazole for full dissolution; water with low temperature is added into the solution; and the solution is cooled, and crystal is participated quickly; and then the solution is filtered under 30 to 130 DEG C and depressurized and dried for 1 to 20 hours, thereby obtaining the minicrystal. The gain diameter of the crystal ranges from 100 to 10 micrometers with the average grain diameter of 35 micrometers or smaller. The minicrystal obtained with the invention is suitable to be used for preparing oral solid preparation such as tablet, thereby improving the biological utilization degree of the minicrystal.

Owner:重庆凯林制药有限公司 +1

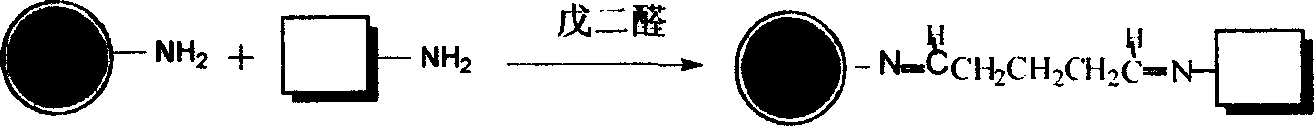

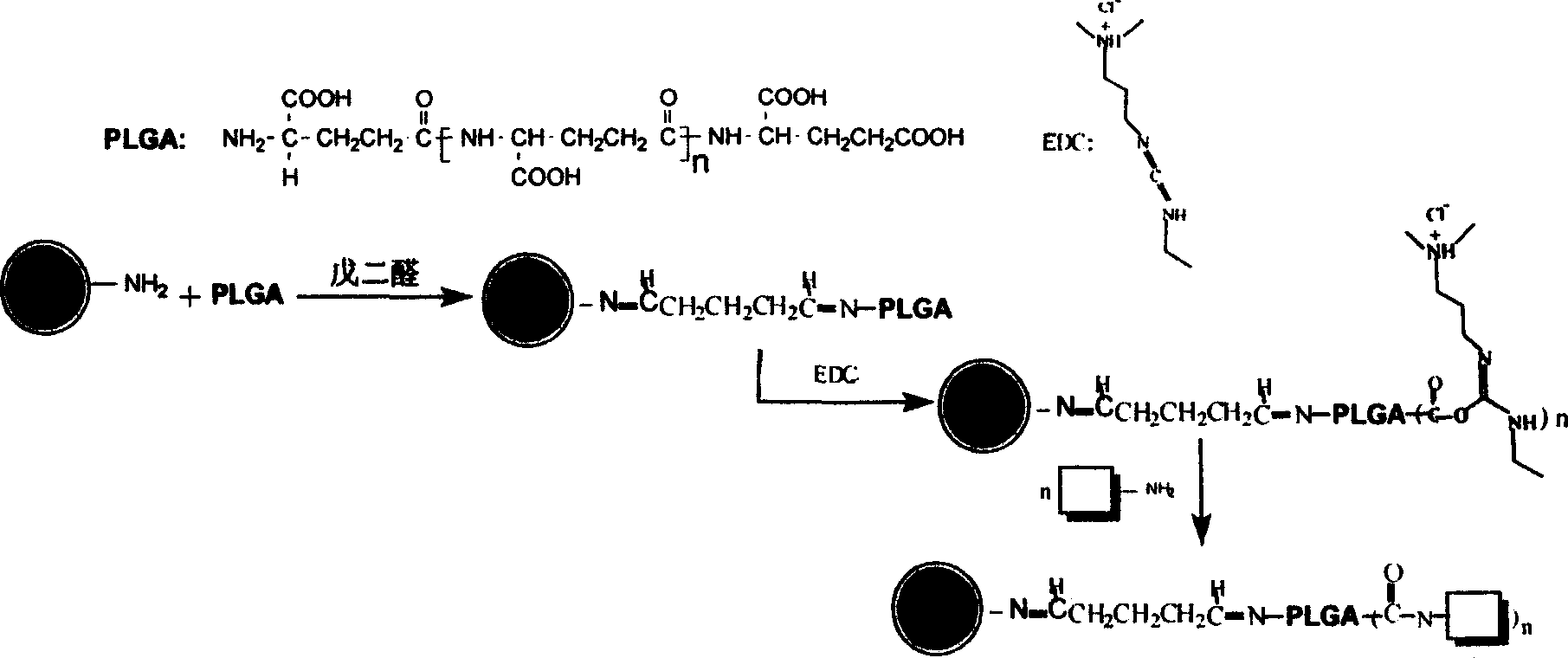

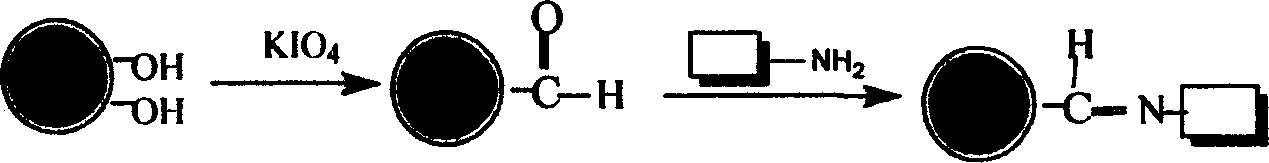

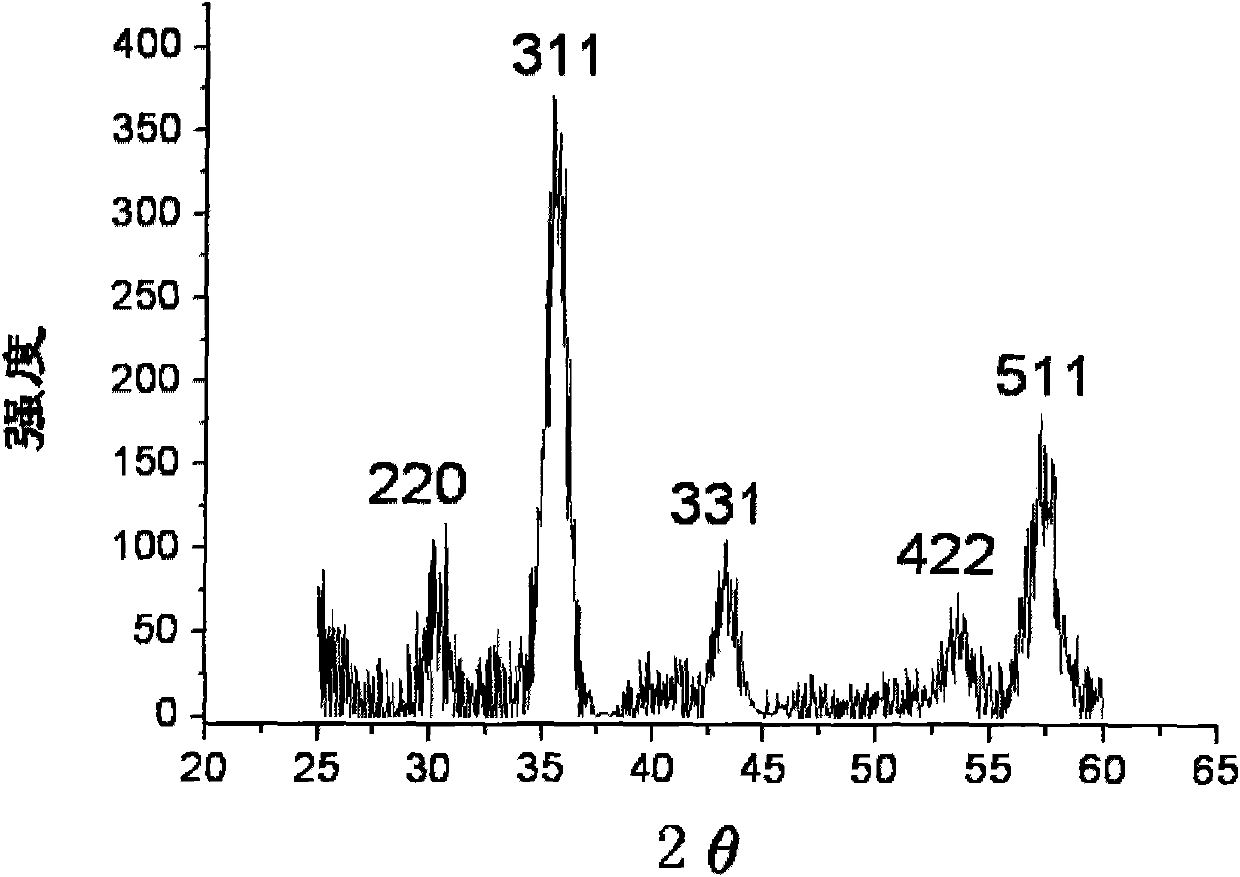

Biomagnetism nano target anti-cancer drug and its preparation

ActiveCN1927400AGood biocompatibilitySmall side effectsInorganic material magnetismRadioactive preparation carriersChemical reactionSide effect

The invention relates to a biological nanometer magnetic target anti-cancer drug, which is formed by coupled biological nanometer magnetic smalls and anti-cancer chemical drug. Wherein, the biological nanometer magnetic small is nanometer magnetic particle formed in magnetic bacterial cell, at 35-120nm diameter, while its main component is Fe3O4 or Fe3S4; single magnetic particle is packed by film; and the coupled anti-cancer chemical drug comprises chemotherapy drug, nucleic acid drug, radioactive nuclide or antibody drug. The invention also provides relative production that using physical adsorption couple or based on the active function group contained by smalls and anti-cancer drug, to select right coupler via chemical reaction to couple them. And the smalls has better bioavailability, less side effect, therefore, the anti-cancer drug can be accurately transmitted to ill part via external magnetic field, to reduce the contact between drug and normal organism., to realize target positioning treatment.

Owner:南京英睿杰生化科技有限公司

Preparation method of tobermorite

ActiveCN103708478ACrystal stableAlkaline concentration decreasedAlkaline-earth metal silicatesPulverized fuel ashSODIUM SILICATE SOLN

The invention discloses a preparation method of tobermorite. The preparation method comprises the following steps: removing amorphous activated SiO2 in pulverized fuel ash by use of sodium hydroxide alkaline liquor so as to obtain a sodium silicate solution with an appropriate concentration, wherein the sodium silicate solution is used as a siliceous material; further performing hydro-thermal synthesis with refined lime milk to finally obtain a tobermorite product.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

Method for producing large-sized zirconium ingot with the specification Phi of more than 600mm

The invention relates to a method for producing large-sized zirconium ingot with the specification Phi of more than 600mm, and the technical characteristics lie in that a consumable electrode with relatively uniform components is prepared by adopting dosing, mixing and vacuum plasma arc electrode assembly and welding technology, and vacuum consumable electric arc melting is carried out for at least twice by adopting technology of 'speed reducing melting' and 'component uniformity controlling' and the like under the conditions that the melting speed control parameter is 10-40kg / min and the arc stability control is carried out with the magnetic induction of 10-50 Gauss and the stable arc current alternate control time of 1-60 seconds. Compared with the prior art, the invention has the advantages that the large-sized zirconium ingot produced by the invention has uniform and stable chemical components and excellent ingot surface quality, is better than small ingot melted by vacuum consumable electric arc, and has the advantages of high yield, high production efficiency and being easy for producing large zirconium material and the like; and the invention is applicable to producing ingots for large zirconium material.

Owner:BAOJI TITANIUM IND CO LTD

Rubber tire tread and milling process thereof

The invention discloses a rubber tire tread and a milling process thereof. The rubber tire tread comprises the following components in parts by weight: 70-110 parts of natural rubber, 0-15 parts of styrene-butadiene rubber, 5-20 parts of tread rubber powder, 1.5-2.5 parts of stearic acid, 1-2 parts of sulfur powder, 2-18 parts of white carbon black, 12-15 parts of carbon block, 2-30 parts of aromatic oil, 1-8 parts of zinc oxide, 4-7 parts of an anti-aging agent, 1-4 parts of pine tar, 1-4 parts of an accelerating agent, 0.2-1 part of an anti-reversion agent and 2-5 parts of a binding agent. A three-section milling process is adopted, and the milling process can improve the abrasive resistance, tear resistance and chunking and chipping resistance of the tire tread.

Owner:SHANDONG YONGTAI CHEM GROUP

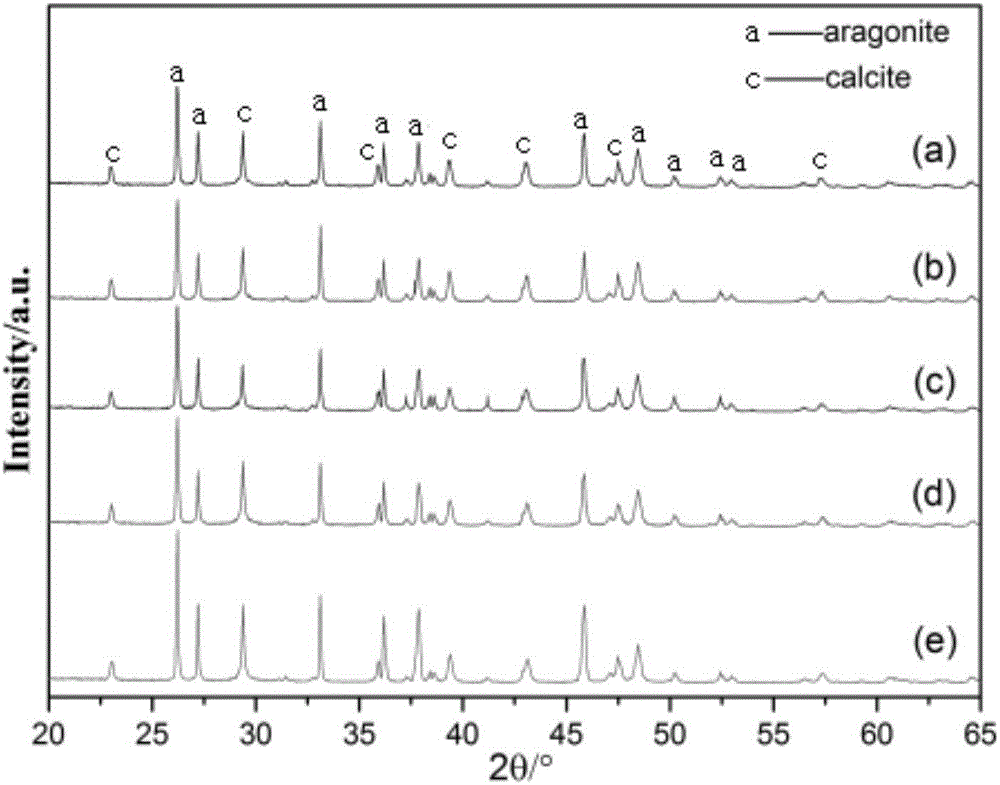

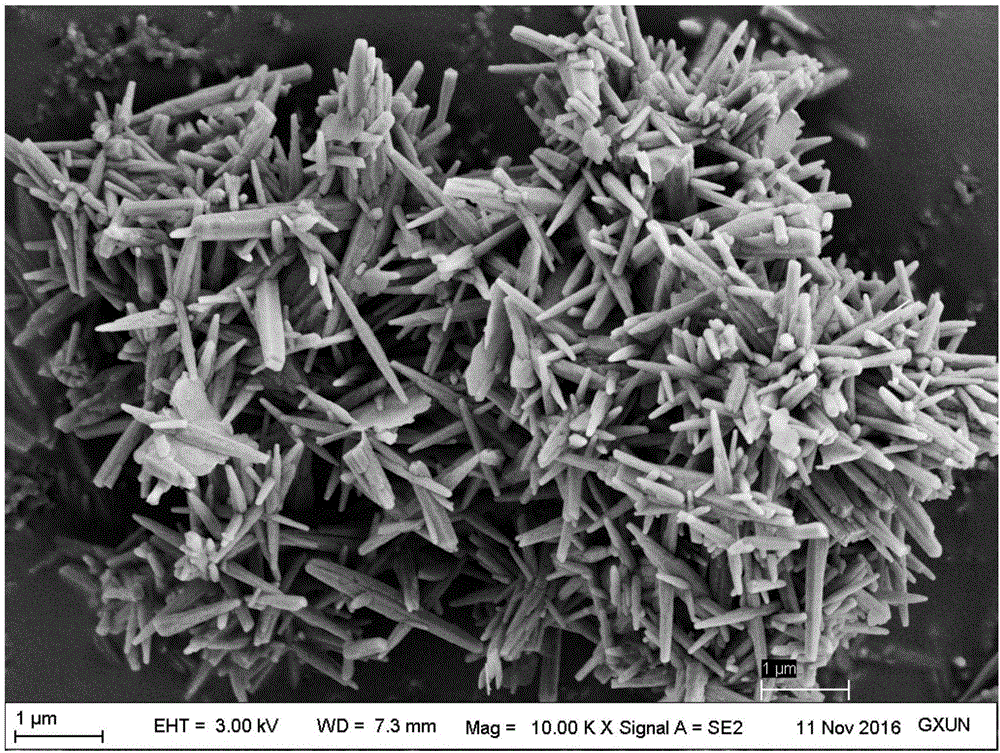

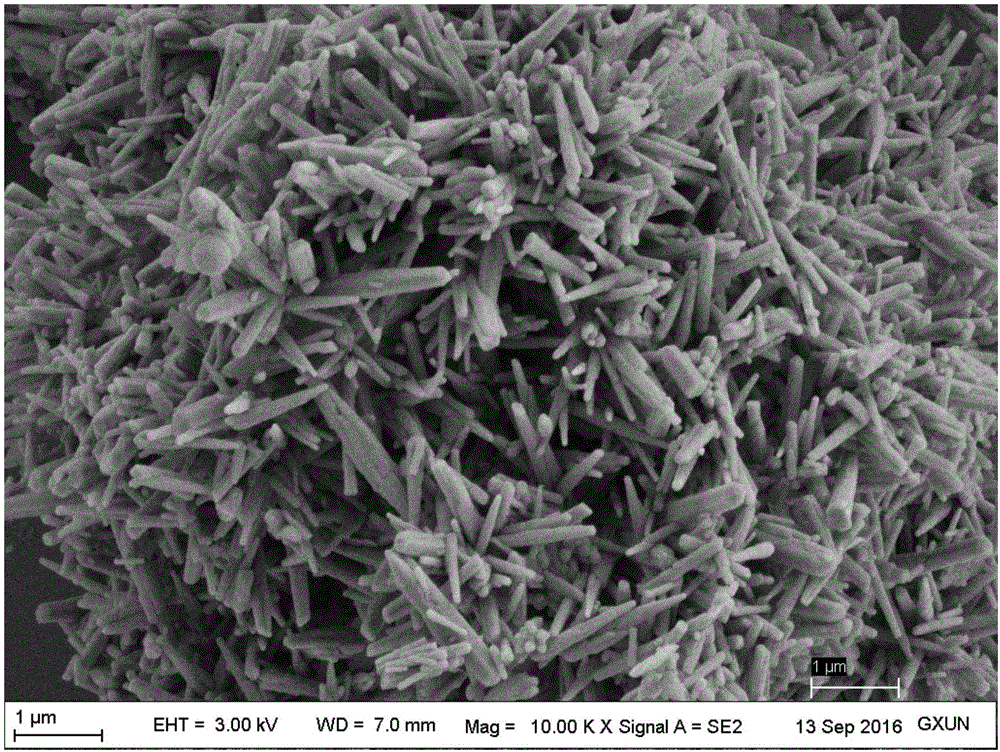

Rodlike aragonite calcium carbonate preparation method

ActiveCN106430272ACrystal stableLarge specific surface areaCalcium/strontium/barium carbonatesCalcium hydroxidePrecipitated calcium carbonate

The invention discloses a rodlike aragonite calcium carbonate preparation method. The method includes: crushing limestone, calcining, and digesting according to a lime-water mass ratio of 1:3-8 to obtain lime slurry; screening, filtering to remove residues, and adding water to adjust the solid content of the lime slurry to 7-20%, so that refined lime slurry is obtained; controlling the temperature of the refined lime slurry to 30-60 DEG C, adding a composite crystal form control agent being 0.5-2.0% of the mass of calcium hydroxide in the lime slurry, delivering to a carbonization tower, starting stirring, feeding kiln gas for carbonation, stopping gas feeding when pH reaches 8.0, and terminating carbonation to obtain precipitated calcium carbonate suspension; dewatering and drying according to a conventional method to obtain rodlike aragonite calcium carbonate. The calcium carbonate prepared according to the method is stable in crystal form, products are rodlike in appearance and large in specific surface area, and the aragonite phase content reaches 85% or above. In addition, the rodlike aragonite calcium carbonate preparation method has advantages of low energy consumption, high production efficiency, low cost, technical simplicity and the like and is easy for realization of industrial production.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

Hydrolysis-resistant glass, a method of making said glass and uses of same

InactiveUS20060264313A1High crystallization stabilityStable and resistant to reactionGlass furnace apparatusGlass drawing apparatusTitanium dioxideOxide

The glass for a fluorescent light with a high hydrolytic resistance, which has composition, in % by weight based on oxide content of: SiO2, 63-75; B2O3, 15-18; Al2O3, 2.5-4.5; Na2O, 0-10; K2O, 0-10; ΣNa2O+K2O, 2-10; MgO, 0-8; CaO, 0-10; SrO, 0-10; BaO, 0-10; ZnO, 0-5; ΣMgO+CaO+SrO+BaO+ZnO, 0-10; ZrO2, 0-3; CeO2, 0-10; Fe2O3, 0-1; WO3, 0-3; Bi2O3, 0-5; MoO3, 0-3; TiO2, 0-10; ΣHf+Ta+W+Re+Os+Ir+Pt+La+Pr+Nd+Sm+Eu+Gd+Tb+Dy+Ho+Er+Tm+Yb+Lu in oxidic form, 0 to 5% by weight, as well as one or more conventional refining agents. The glass is characterized in that it contains no lithium and has a weight ratio of Na2O to K2O of less than one.

Owner:SCHOTT AG

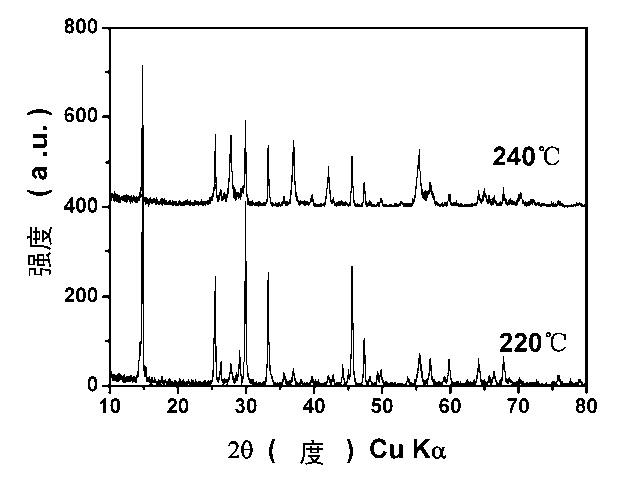

Method for preparing steady phase-A vanadium dioxide nanorod

InactiveCN102757094AImprove reaction efficiencyHigh crystallinityNanotechnologyVanadium oxidesVanadium dioxideAqueous solution

The invention provides a method for preparing a steady phase-A vanadium dioxide nanorod. The method includes directly adding aqueous solution containing tetravalent vanadium ions into a hydrothermal kettle for hydrothermal reaction, and enabling the filling ratio of the hydrothermal kettle in the hydrothermal reaction process to range from 50% to 90%; heating and controlling the hydrothermal reaction temperature to range from 180 DEG C to 220 DEG C and keeping the hydrothermal reaction temperature for 0-720 hours; and cooling, centrifuging, washing and drying a compound obtained by hydrothermal reaction to prepare the steady phase-A vanadium dioxide nanorod with the length-diameter ratio ranging from 1:1 to 1000:1. The method has the advantages that special equipment is omitted, operation is simple and convenient, and yield is high.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Technology of transforming common magnesium hydrexide into hexagonal sheel shaped magnesium hydroxide by hydrothermal method

ActiveCN1830788AImprove conversion rateImprove product qualityMagnesium hydroxideLithium hydroxidePotassium hydroxide

A process for preparing hexagonal flake type magnesium hydroxide from ordinary one by dydrothermal method includes such steps as proportionally mixing ordinary magnesium hydroxide with lithium hydroxide and / or potassium hydroxide, or their mixture with sodium hydroxide, stirring, hydrothermal reaction at 140-200 deg.C for 2-6 hr, cooling, filtering, washing, drying, and pulverizing.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Preparation method of ultra-hydrophilic nano TiO2 thin film

The invention discloses a preparation method of an ultra-hydrophilic nano TiO2 thin film. Tetrabutyl titanate is used as a precursor of TiO2, absolute ethyl alcohol is used as a dissolvent, acetylacetone as an inhibitor is added, and magnetic stirring is performed at the room temperature, so as to obtain a solution A; in addition, the absolute ethyl alcohol and deionized water are taken and added with a proper amount of PVP to obtain a solution B; under the strong stirring, the solution B is slowly dropped into the solution A, the pH value of a solution mixture is regulated to 3 by using acid, and stirring continuously lasts for 3 hours, so as to obtain stable TiO2 collosol, and the collosol is aged in 2-7 days for standby; a nano TiO2 thin film is prepared on a cleaned glass slide with a spin coater in a coating manner, the plated film is placed in a drying box for drying and then is subjected to thermal treatment and annealing, as a result, the ultra-hydrophilic nano TiO2 thin film is obtained, which has a smooth and uniform surface, is stable in the crystal type, and has no cranks; the contact angle between the surface of the thin film and water can reach 0 degree indoors; the nano TiO2 thin film has a very strong self-cleaning capacity.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

New brand of Aripipazole, and preparation method

ActiveCN1760183AGood reproducibilityLow costOrganic active ingredientsNervous disorderMedicineSchizophrenia

The novel crystal forms alpha and beta of airpiprazole, their preparing process, and their application in preparing medicine for treating schizophrenia are disclosed.

Owner:重庆凯林制药有限公司 +1

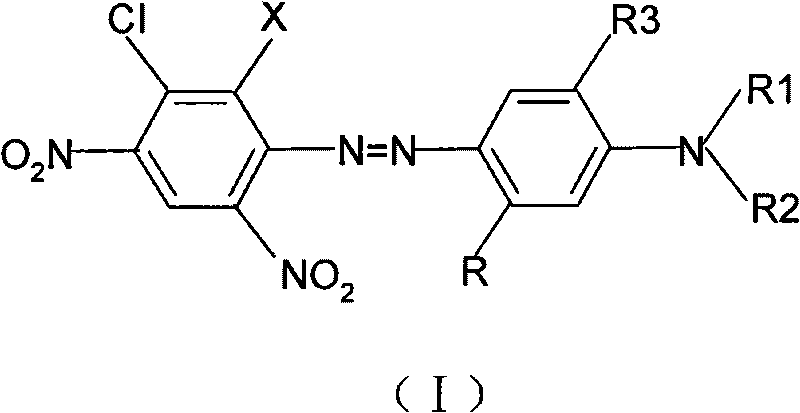

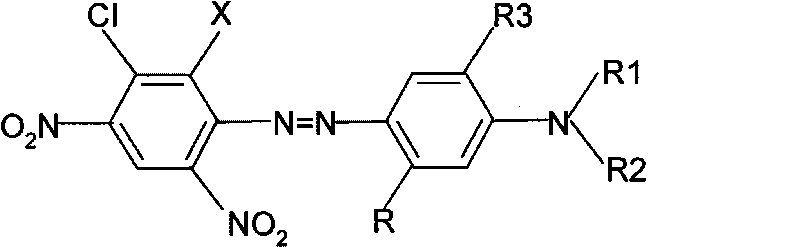

5-chloronitroaniline-containing azoic disperse dyes and preparation method and application thereof

InactiveCN101735665AImprove wet fastnessGood sublimation fastnessMonoazo dyesDyeing processDisperse dyeHydrogen

The invention provides 5-chloronitroaniline-containing azoic disperse dyes and a preparation method thereof. The structural general formula of the disperse dyes is shown in a formula (I), wherein X is hydrogen or bromine; R is hydrogen, methyl or -NHCO-C1-C4 alkyl; R1 is ethyl, cyanoethyl, phenmethyl, allyl or -CH2CH2OR4, wherein R4 is methyl, ethyl or carbonyl; R2 is independent of R1 but has the definition of the R1; and R3 is hydrogen, methoxyl or ethyoxyl. The 5-chloronitroaniline-containing azoic disperse dyes are characterized in that: a diazonium component contains 2,4-binitro-5-chloroaniline or bromide thereof. The dyes have the advantages of excellent wet fastness and sublimation fastness, are suitable for dyeing terylene and blend fabrics thereof, and have low cost and wide application prospect.

Owner:烟台澳土复合材料有限公司

Process for preparing polymer ultra-fine particles by applying supercritical fluid

InactiveCN101693768AHigh crystallinityCrystal stableBulk chemical productionPolymer scienceUltra fine

The invention relates to a process for preparing polymer ultra-fine particles, in particular to a process for preparing polymer ultra-fine particles by applying supercritical fluid, which utilizes the supercritical fluid to process one type of polymer or a mixture of various types of polymers to prepare polymer ultra-fine particles or polymer microcapsule ultra-fine particles. As dissolubility to polymer is increased in a supercritical fluid state, polymer can be precipitated from the supercritical fluid after the supercritical fluid state is eliminated, and then polymer ultra-fine particles or polymer microcapsule ultra-fine particles with high degree of crystallinity and fine shape can be prepared after thermostatic treatment. Besides, the prepared ultra-fine particles are narrow in distribution, and shapes thereof can be controlled into regular spheres. The process is simple in technique and easy in operation without complex devices, the prepared ultra-fine particles are regular in shapes, stable in crystalline form, higher in crystallinity and higher in application value and are adoptable to industrialized production.

Owner:INST OF CHEM CHINESE ACAD OF SCI

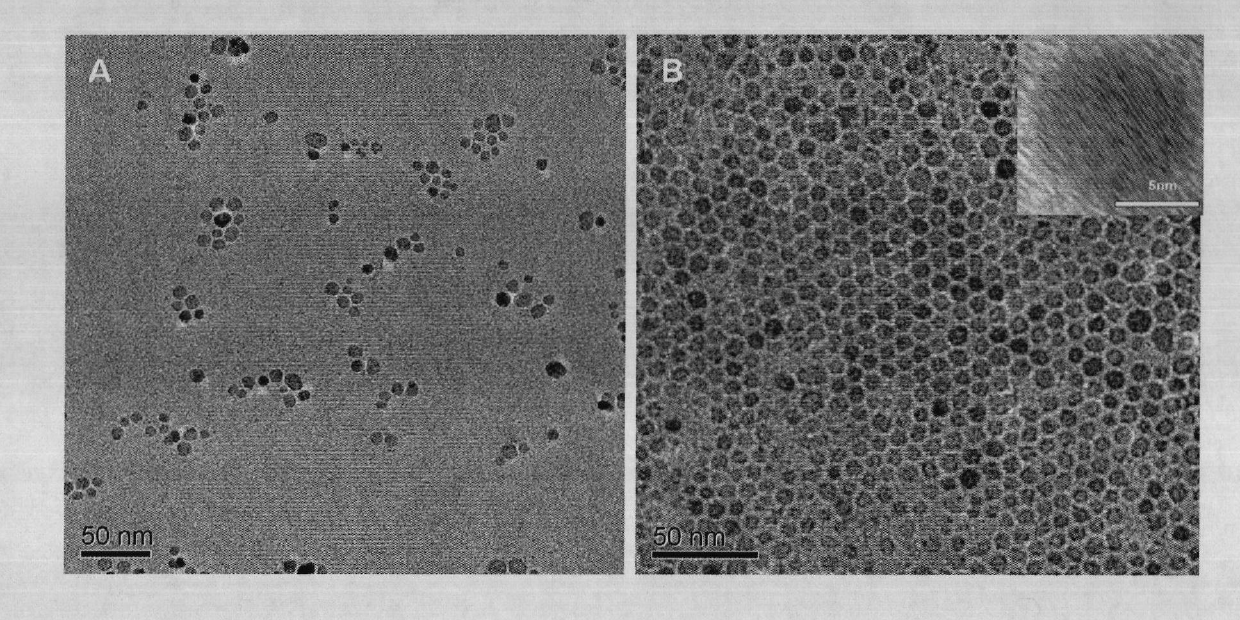

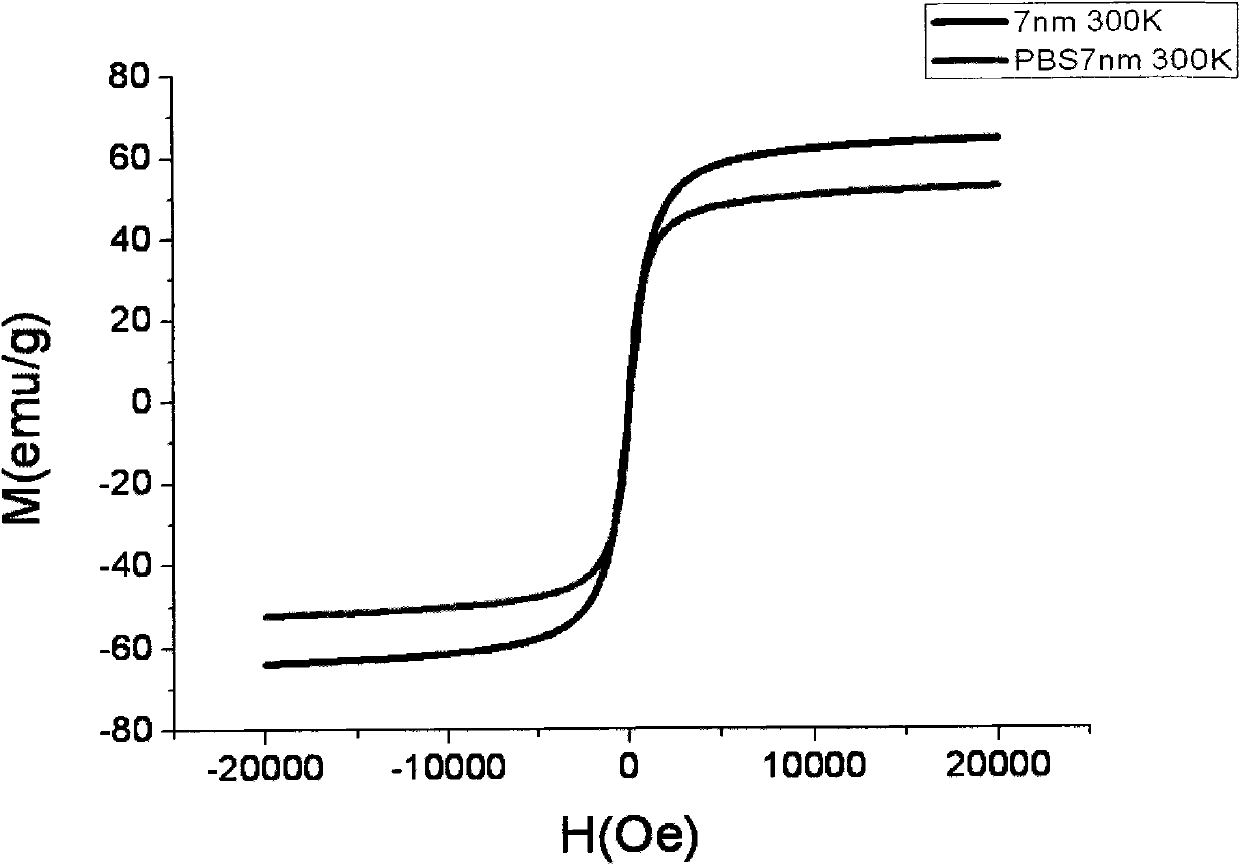

Method for preparing water-soluble nanometer iron oxide

InactiveCN102557149AImprove stabilitySimple preparation processElectrotherapyFerroso-ferric oxidesSuperparamagnetismBrown iron oxide

The invention provides a method for preparing water-soluble nanometer iron oxide. The method comprises the following steps of: pyrolyzing iron acetylacetonate (III) by using alcohol to obtain iron oxide nanoparticles, and adding a ligand aqueous solution at room temperature to obtain the water-soluble nanometer iron oxide. The preparation method is simple, conditions are mild, the required equipment is simple, and batch production can be realized; and the nanoparticles prepared by the method have the size of 5 to 15nm, superparamagnetism, and wide application prospects in the field of biomedicine such as nuclear magnetic resonance imaging, magnetic thermal therapy, catalysis and the like.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

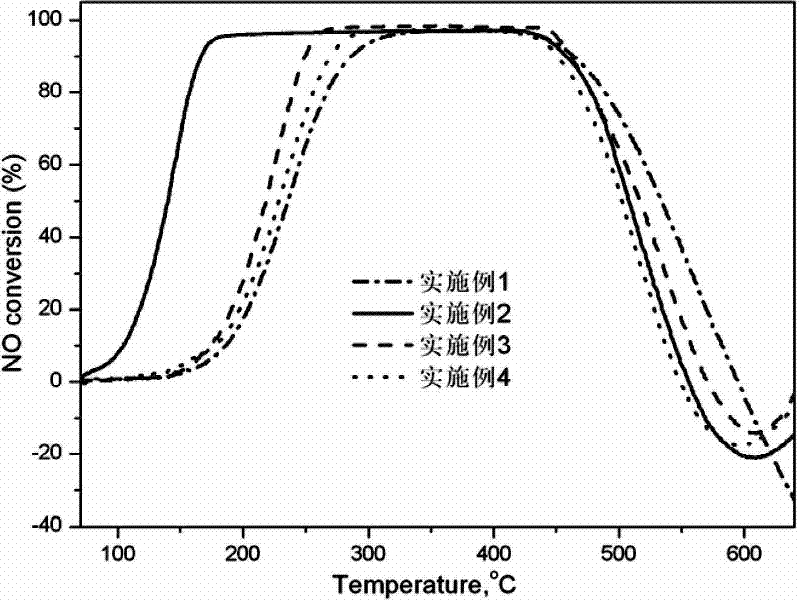

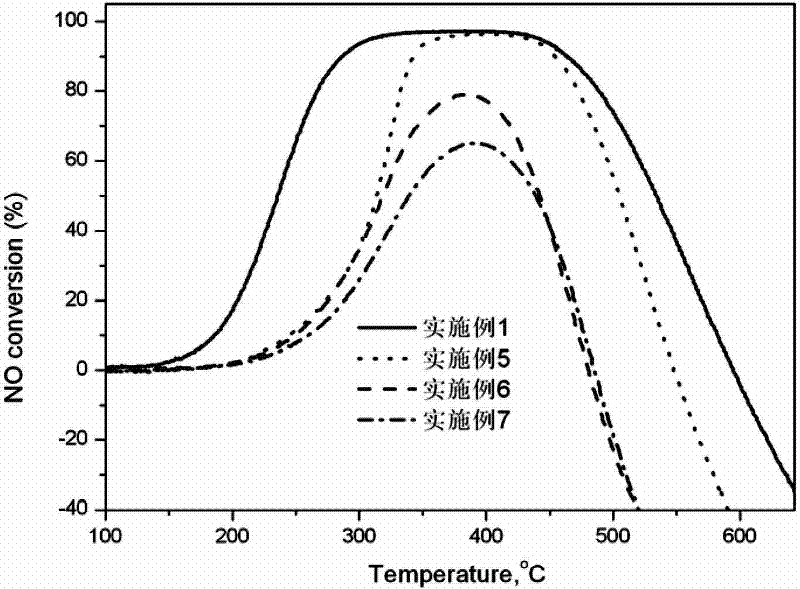

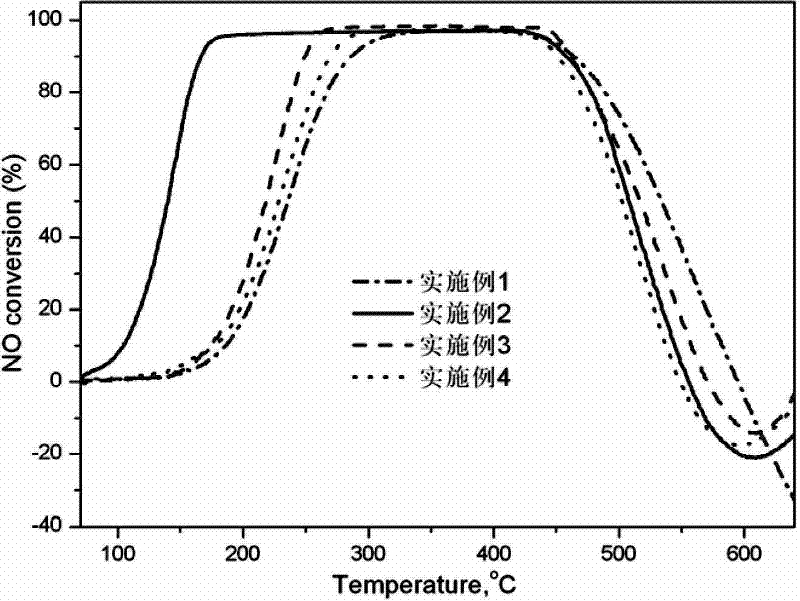

Preparation method of SCR (Selective Catalytic Reduction) vanadium-series catalyst used in denitration of tail gas of diesel vehicle

InactiveCN102416321AEasy to optimizeGood modification effectInternal combustion piston enginesDispersed particle separationDesorptionNitrogen oxide

The invention discloses a preparation method of an SCR (Selective Catalytic Reduction) vanadium-series catalyst used in denitration of tail gas of a diesel vehicle. Active ingredients are introduced into the catalyst by adopting a simple soaking method, and a catalyst carrier or the catalyst is baked at different temperatures, so that the catalytic performance of the obtained SCR vanadium-series catalyst is improved remarkably, the catalytic activity is greatly increased, and the intensity of the catalyst is greatly increased. The vanadium-series denitration catalyst provided by the inventionhas high denitration efficiency and a wide temperature window, and is suitable for the field of desorption of nitrogen oxides in the tail gas of the diesel vehicle. As proved by the simulated tail gas evaluation of the diesel vehicle in a laboratory, the NOx removing rate of the SCR vanadium-series catalyst prepared with the method is over 90 percent under the condition that the space speed is 30,000 h<-1>, the NO content is 500 ppm and the H2O content is 4 percent at the temperature of 170-469 DEG C.

Owner:广州市威格林环保科技有限公司

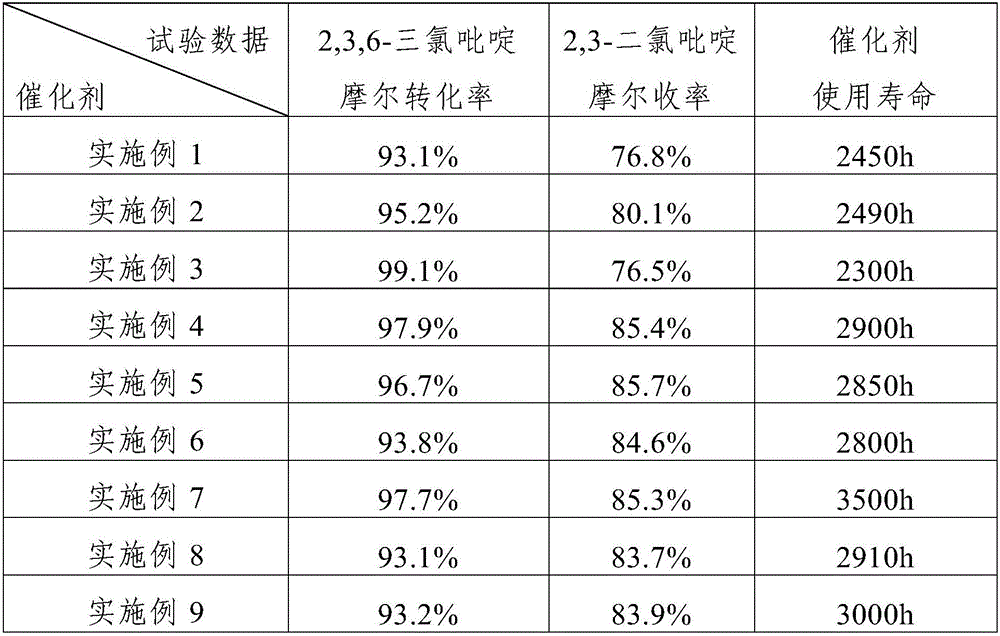

Catalyst for use in continuous production of 2,3-dichloropyridine, and preparation method and application thereof

The invention provides a catalyst for use in continuous production of 2,3-dichloropyridine. The catalyst comprises a gear-shaped alumina carrier, and Pt, Pd and a metal M loaded on the gear-shaped alumina carrier, wherein the metal M is Ag, Ru or Sn; the catalyst contains 0.3-0.8 percent by mass of Pt, 0.1-0.5 percent by mass of Pd and 0.05-0.5 percent by mass of metal M. The invention further provides a preparation method for the catalyst, and a method for continuously producing 2,3-dichloropyridine by catalyzing with the catalyst. The catalyst has very high catalytic activity, selectivity and stability, and can be used for catalyzing to efficiently and continuously prepare 2,3-dichloropyridine; the molar yield of 2,3,6-trichloropyridine serving as a raw material is greater than 93 percent, the molar yield of 2,3-dichloropyridine serving as a product is greater than 76 percent, and service life of the catalyst is not less than 2300h.

Owner:XIAN CATALYST NEW MATERIALS CO LTD

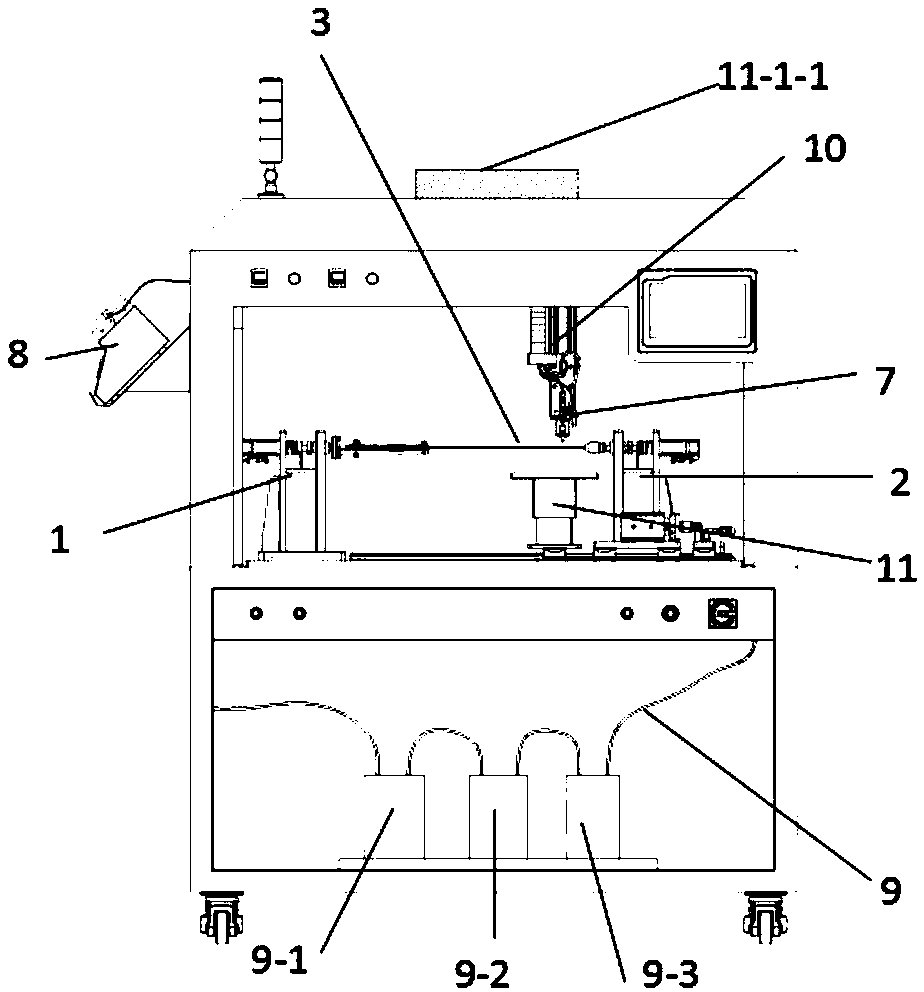

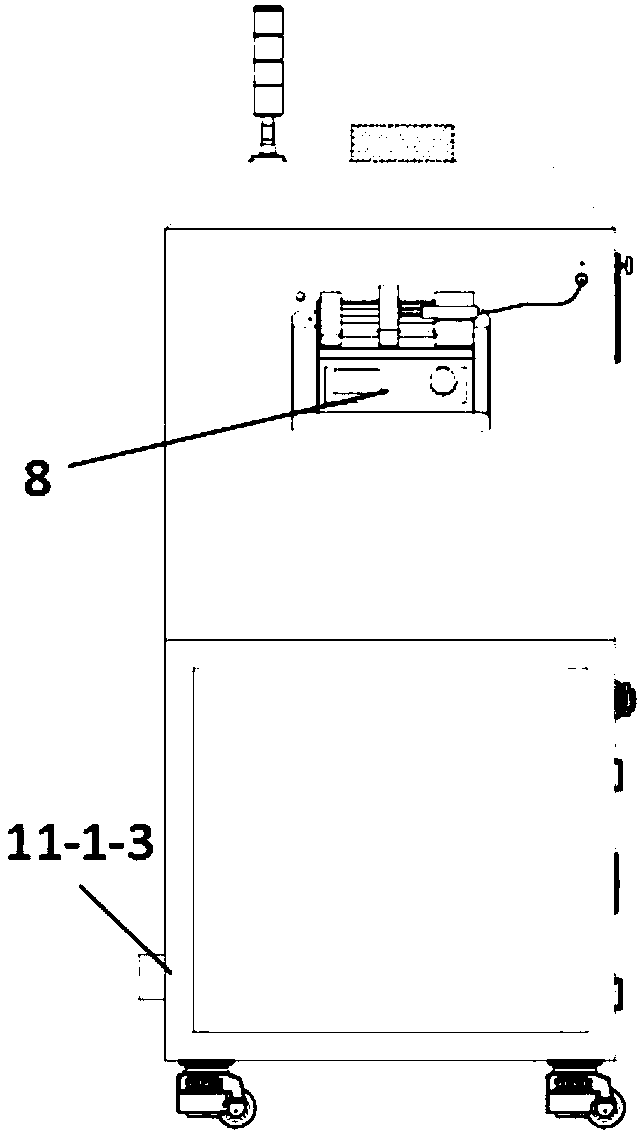

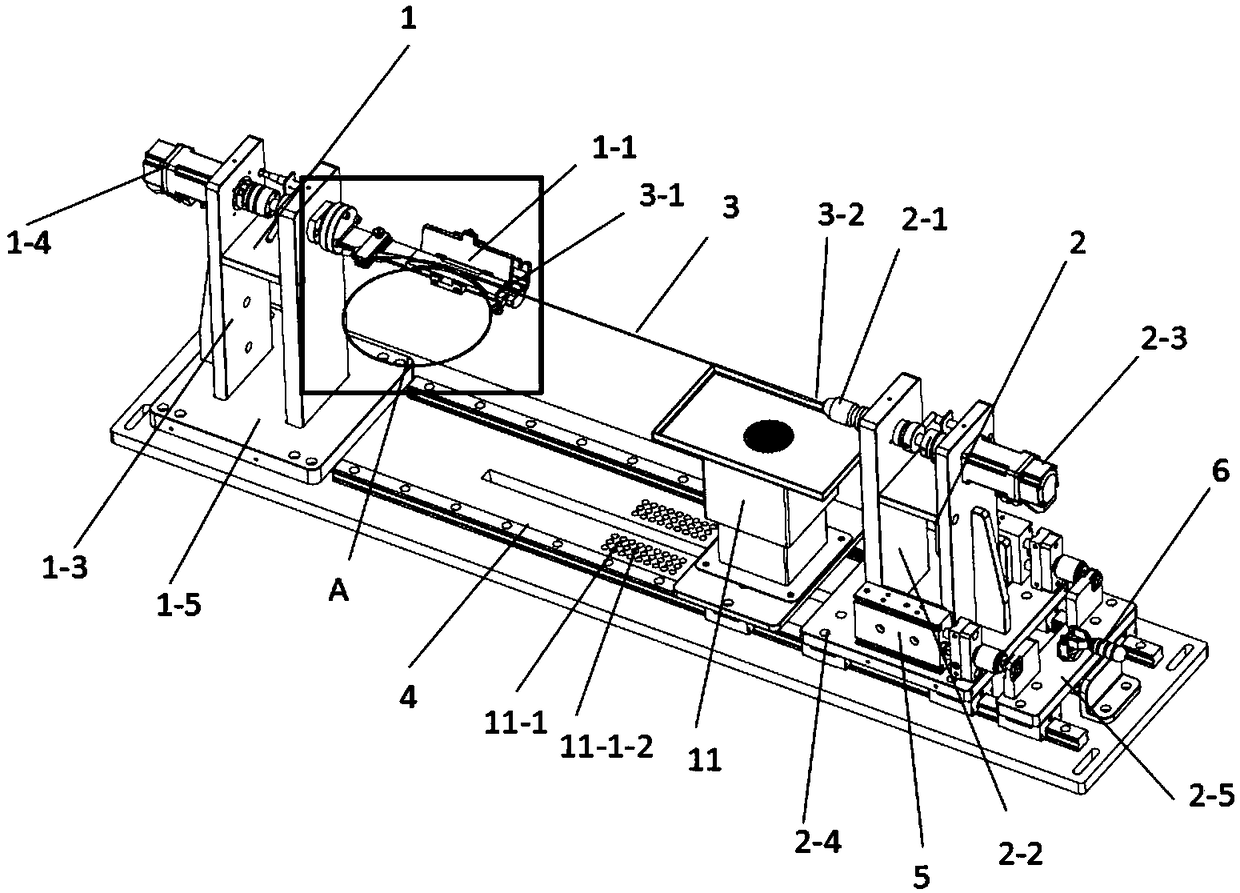

Medicine coating equipment with medicine balloons

PendingCN108295361AReduce crystallizationCrystal stableBalloon catheterPharmaceutical drugBalloon catheter

The invention relates to the technical field of medical apparatuses and instruments and discloses medicine coating equipment with medicine balloons. The equipment includes a spraying chamber, an ultrasound generating device, a medicine supply device, an air loading device, a clamping device used for clamping to-be-coated balloons and a recovery device; the clamping device comprises a first ballooncatheter clamp and a second balloon catheter clamp, and the second balloon catheter clamp can move relative to the first balloon catheter clamp; the air loading device consists of an air loading pipecommunicated with an air source, a drying mechanism, a doping mechanism and a heating mechanism, wherein the drying mechanism, the doping mechanism and the heating mechanism are arranged on the air loading pipe in sequence; the ultrasound generating device comprises an ultrasound generator and an ultrasound sprayer connected with the ultrasound generator; the ultrasound sprayer is connected withthe medicine supply device and the air loading pipe separately; medicine of the medicine supply device is atomized by ultrasonic waves generated by the ultrasound generator and then sprayed onto the to-be-coated balloons by the air loading pipe. Medicine coatings generated by the medicine coating equipment with the medicine balloons have high quality and high production efficiency, and the surfaces of core shaft catheters of the to-be-coated balloons cannot be damaged.

Owner:SIANSONIC TECH CO LTD

5'-guanosine-disodium phosphate crystallizing method

InactiveCN101654469ACrystal stablePromote conversionSugar derivativesSugar derivatives preparationDisodium phosphateNational standard

The invention discloses a 5'-guanosine-disodium phosphate crystallizing method comprising the following steps: adding sodium salt which is 0.2-2 times of 5'-guanosine-disodium phosphate and desolvation with a volume being 0.3-3 times of that of a 5'-guanosine-disodium phosphate solution into a 5'-guanosine-disodium phosphate crude product water solution with concentration of 5-20 percent by weight; controlling the crystallizing temperature of 10-60 DEG C; controlling the mixing rotating speed of 50-300r / min; and after the crystallization is completed, filtering and drying the solution to obtain a 5'-guanosine-disodium phosphate crystal. Due to the adoption of the method, the product quality of the obtained 5'-guanosine-disodium phosphate crystal reaches the national standard, and the 5'-guanosine-disodium phosphate crystal with a stable crystal grain diameter range can be obtained by controlling a crystallizing technical condition and a flow field state. The 5'-guanosine-disodium phosphate crystallizing method has simple operation, good repeatability and shorter crystallizing time and is suitable for the industrial production of the 5'-guanosine-disodium phosphate product.

Owner:SOUTH CHINA UNIV OF TECH +1

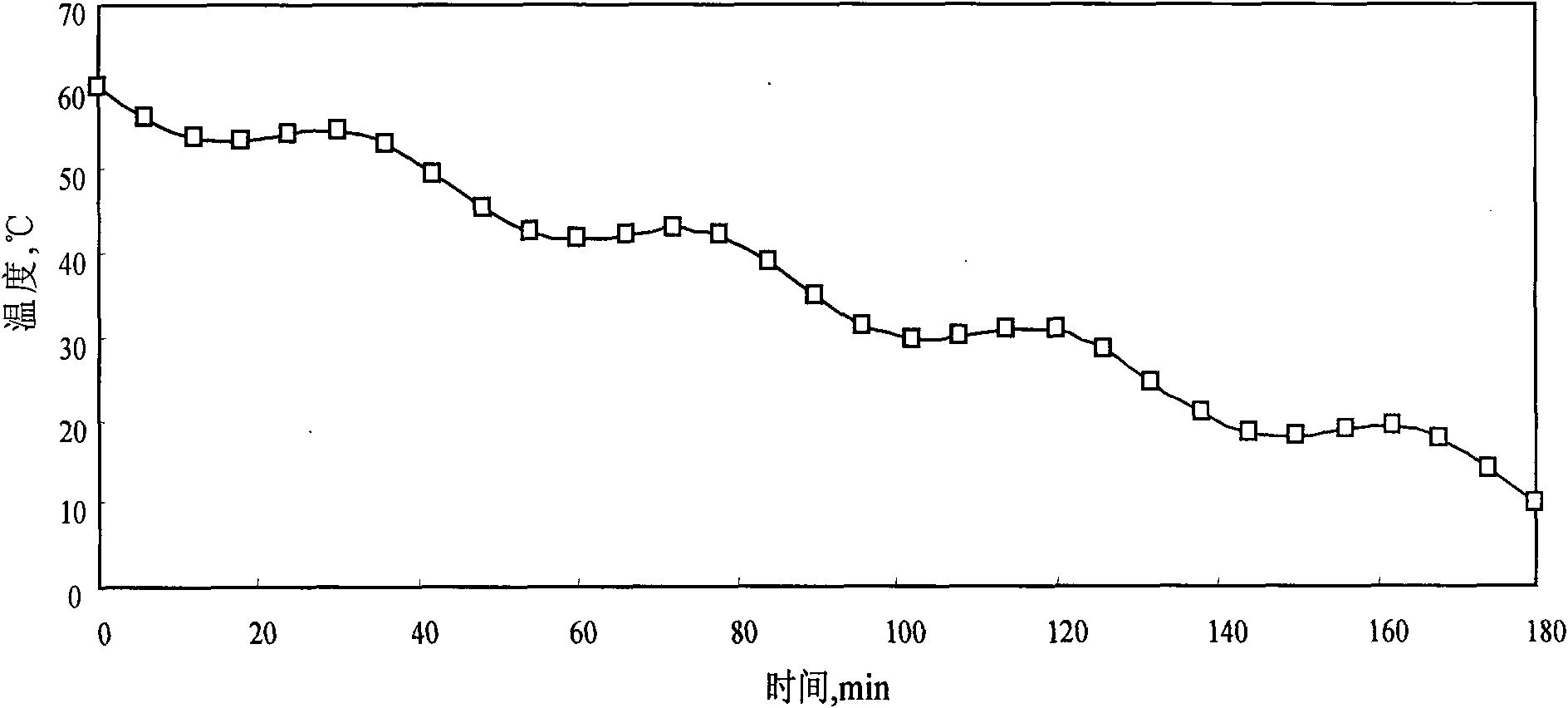

Donkey-hide gelatin chocolate and preparation method thereof

The invention discloses a donkey-hide gelatin chocolate and a preparation method thereof. The donkey-hide gelatin chocolate comprises cocoa butter, cocoa powder, granulated sugar, lactose, an emulsifier, vanillin and donkey-hide gelatin powder. According to the donkey-hide gelatin chocolate and the preparation method thereof, special functions of the donkey-hide gelatin are combined with the chocolate skillfully, and the donkey-hide gelatin chocolate is prepared through the steps including raw material preparation, smashing, mixing, grinding, accurate grinding, temperature adjusting, pouring, cooling forming, packaging and the like. Compared with the conventional chocolate food, the donkey-hide gelatin chocolate keeps the basic flavor and functions of the chocolate, special bitterness and aroma of the donkey-hide gelatin are blended simultaneously, and the donkey-hide gelatin chocolate has the health care function of blood enriching, yin nourishing and the like.

Owner:SOUTH CHINA UNIV OF TECH

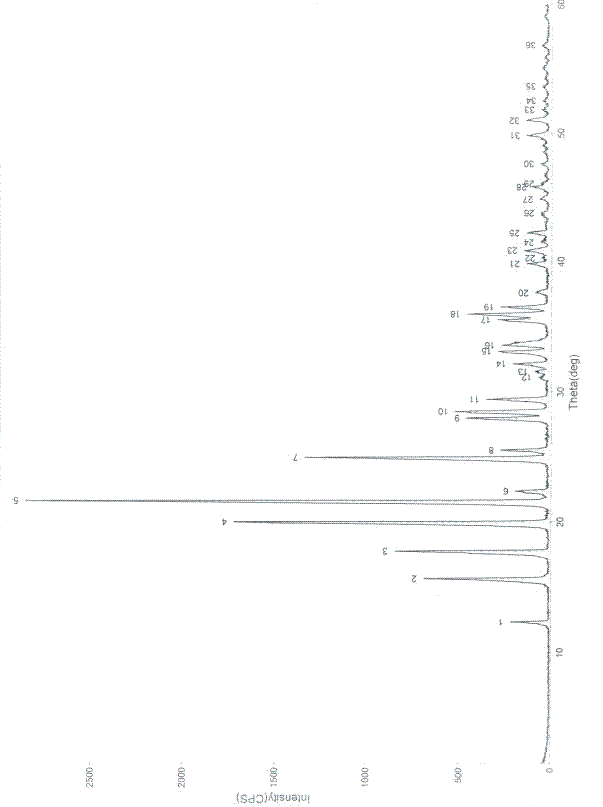

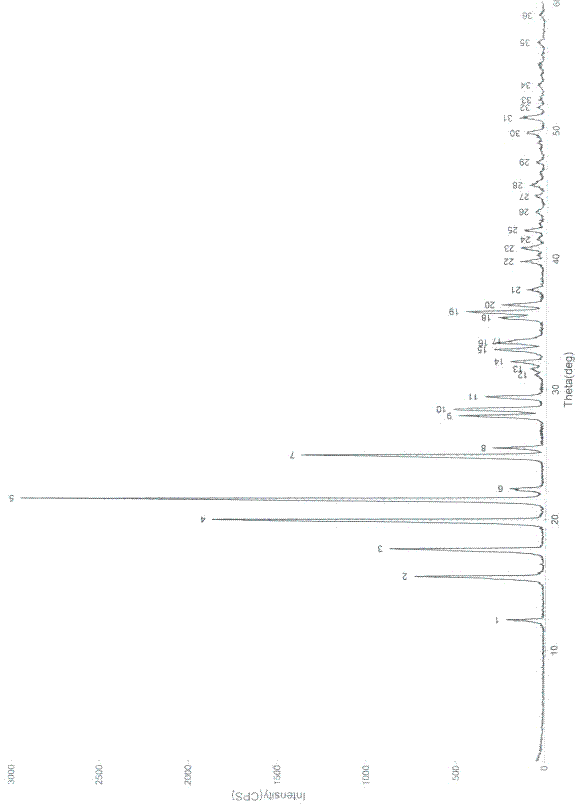

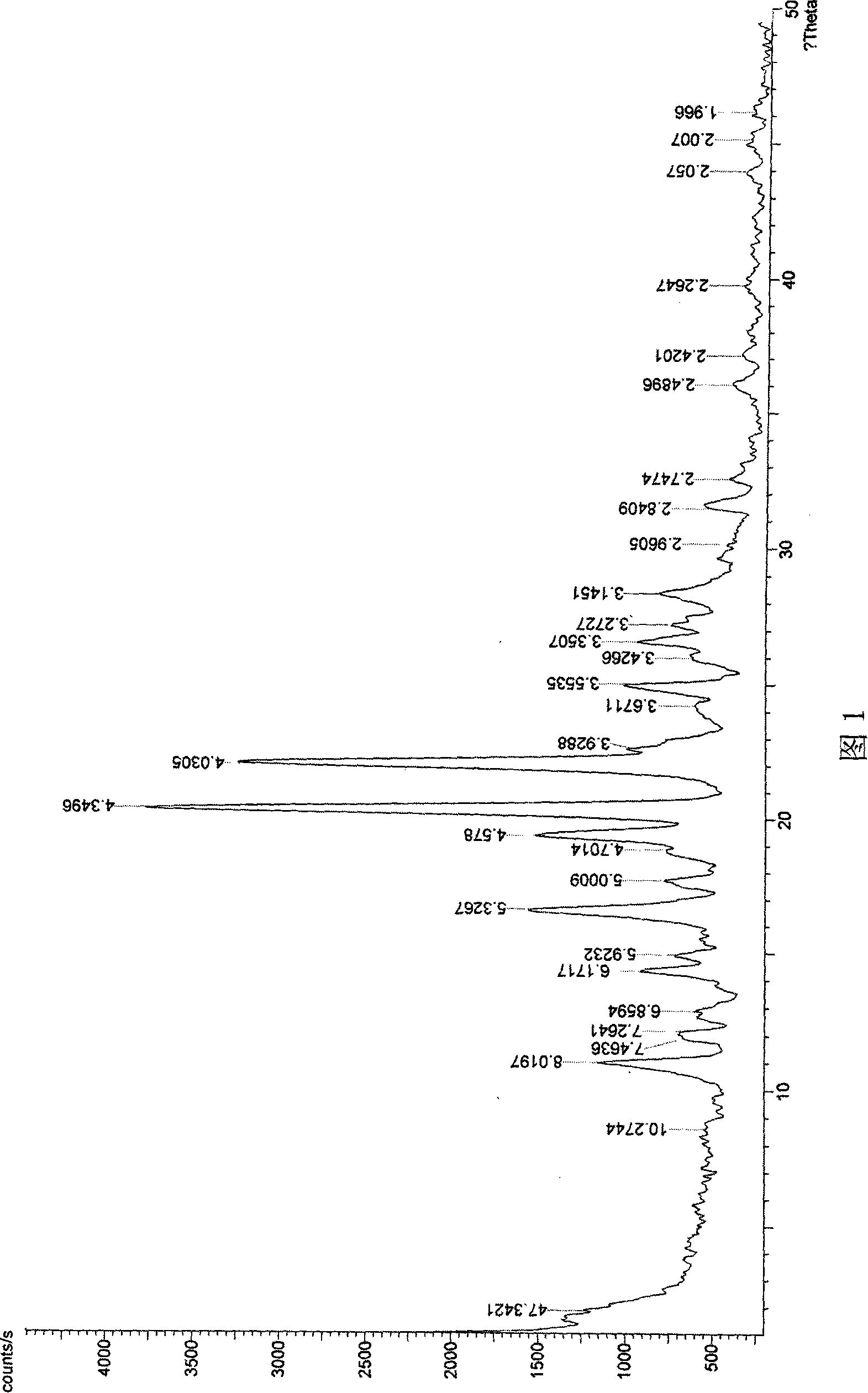

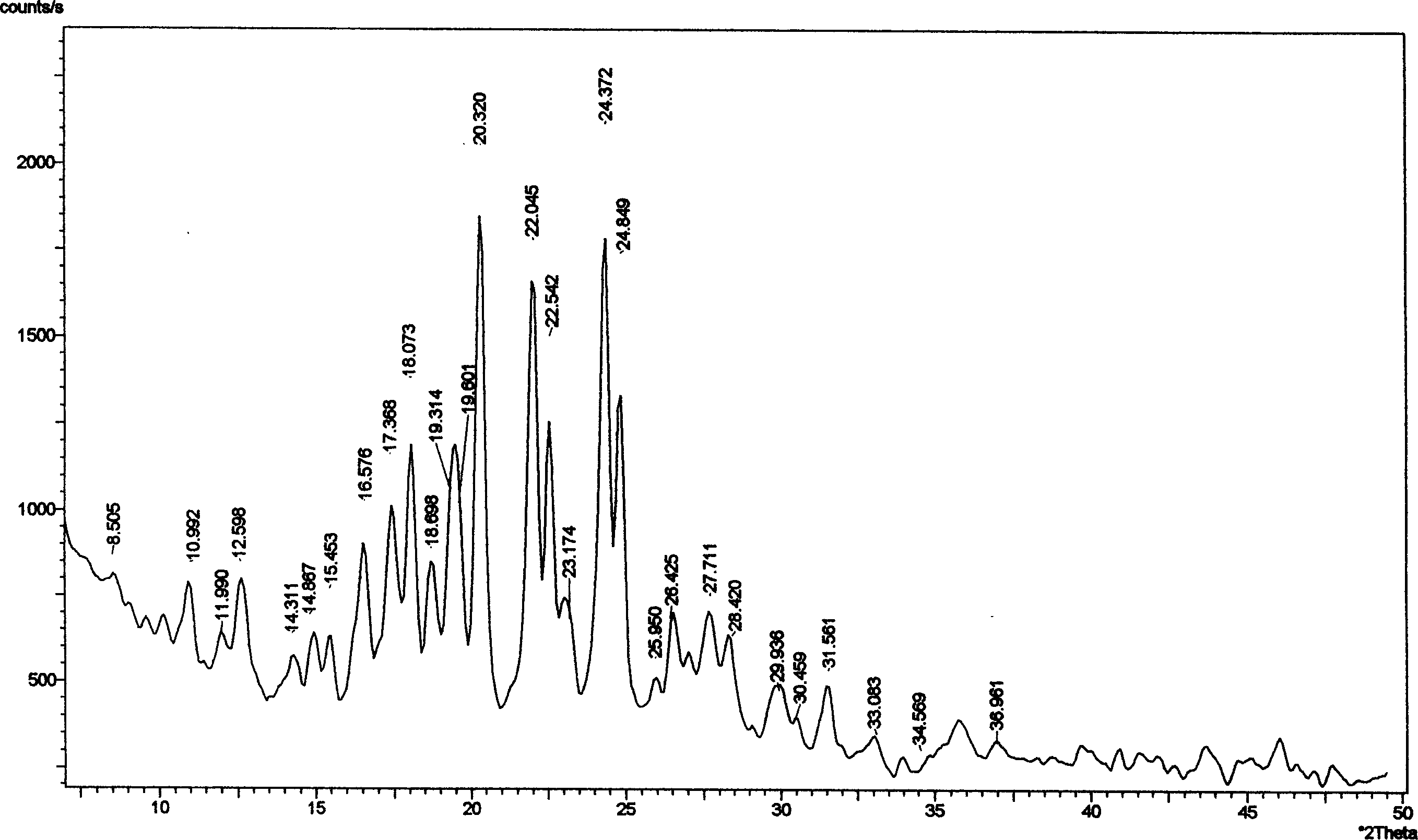

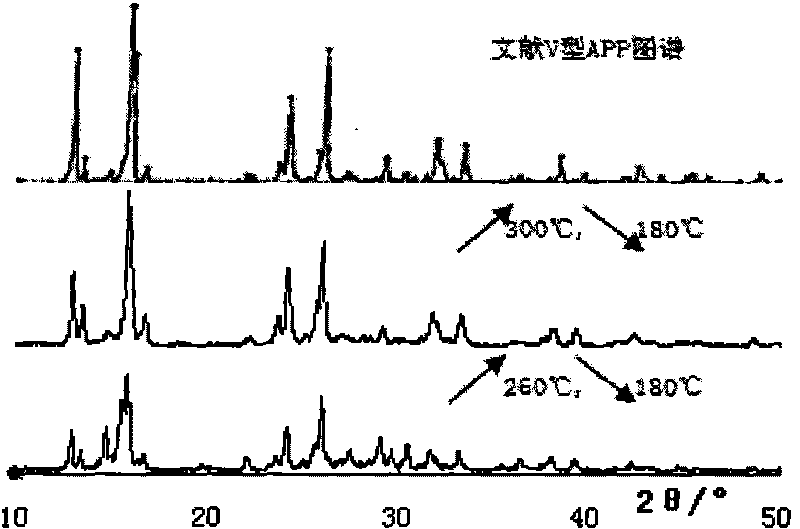

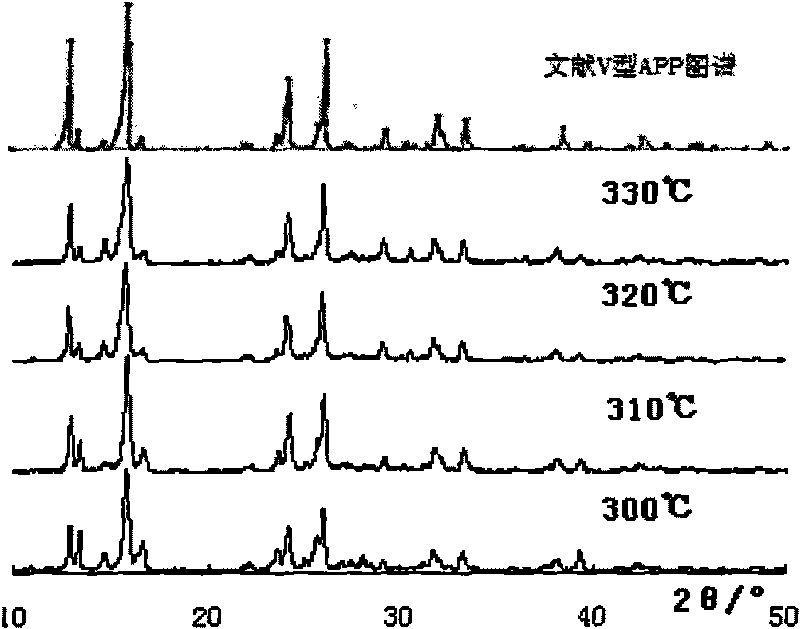

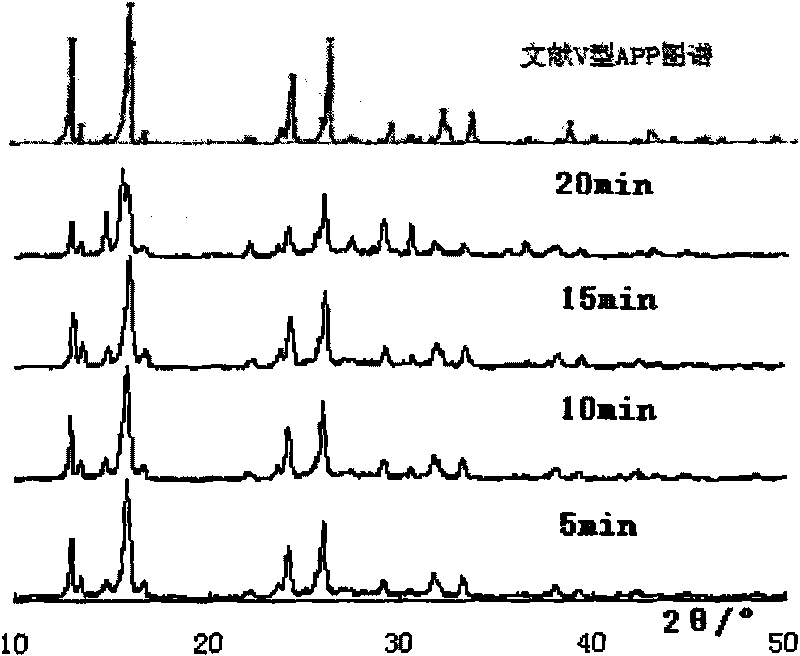

Method for preparing crystalline V-type ammonium polyphosphate with phosphoric acid

InactiveCN101700879AShort durationLow reaction temperaturePhosphorus compoundsPhosphoric acidReaction temperature

The invention relates to a method for preparing crystalline V-type ammonium polyphosphate with phosphoric acid, comprising the following steps: dehydrating 85% phosphoric acid, adding melamine which functions as condensing agent to a reactor, continuously heating the reactor to 280-330 DEG C and the keeping the reactor at the 280-330 DEG C for 5-30 min, guiding dry ammonia gas to the reactor for ammonifying 15-60min by controlling the partial pressure of the dry ammonia gas at 0.02-0.04 MPa and the flow of the dry ammonia gas at 0.3-1.0 L / min, curing the product of reaction, crushing and discharging to obtain the product. The phosphoric acid and the melamine are used as the raw materials, and the molar ratio of the phosphoric acid to the melamine is 1:1 / 8-1 / 6. Detected by the X-ray diffraction, the product prepared by the method is the crystalline V-type ammonium polyphosphate. Compared with the method for preparing crystalline V-type ammonium polyphosphate with the ammonium phosphate, the method for preparing crystalline V-type ammonium polyphosphate with the phosphoric acid needs shorter time and lower reaction temperature, has stronger operability, uses the melamine as the condensing agent, produces the product of dry and white powder and ensures that the product has high yield and stable crystal form, are easy to crush and can be stored for a long time.

Owner:EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com