Method for preparing water-soluble nanometer iron oxide

A ferroferric oxide, water-soluble technology, applied in the field of materials, can solve the problems of easy aggregation of particles, low zeta potential, uneven particle size dispersion, etc., and achieve less surface ligands, simple equipment, and uniform particle size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Add 0.5g of iron(III) acetylacetonate and 20mL of benzyl alcohol solution into a 100mL three-necked reaction flask, stir to dissolve them, in an open system, raise the temperature to 190°C at a rate of 6°C / min, and react for 2h. A black ferric oxide nanoparticle crystal with a mass of about 0.11 g was prepared.

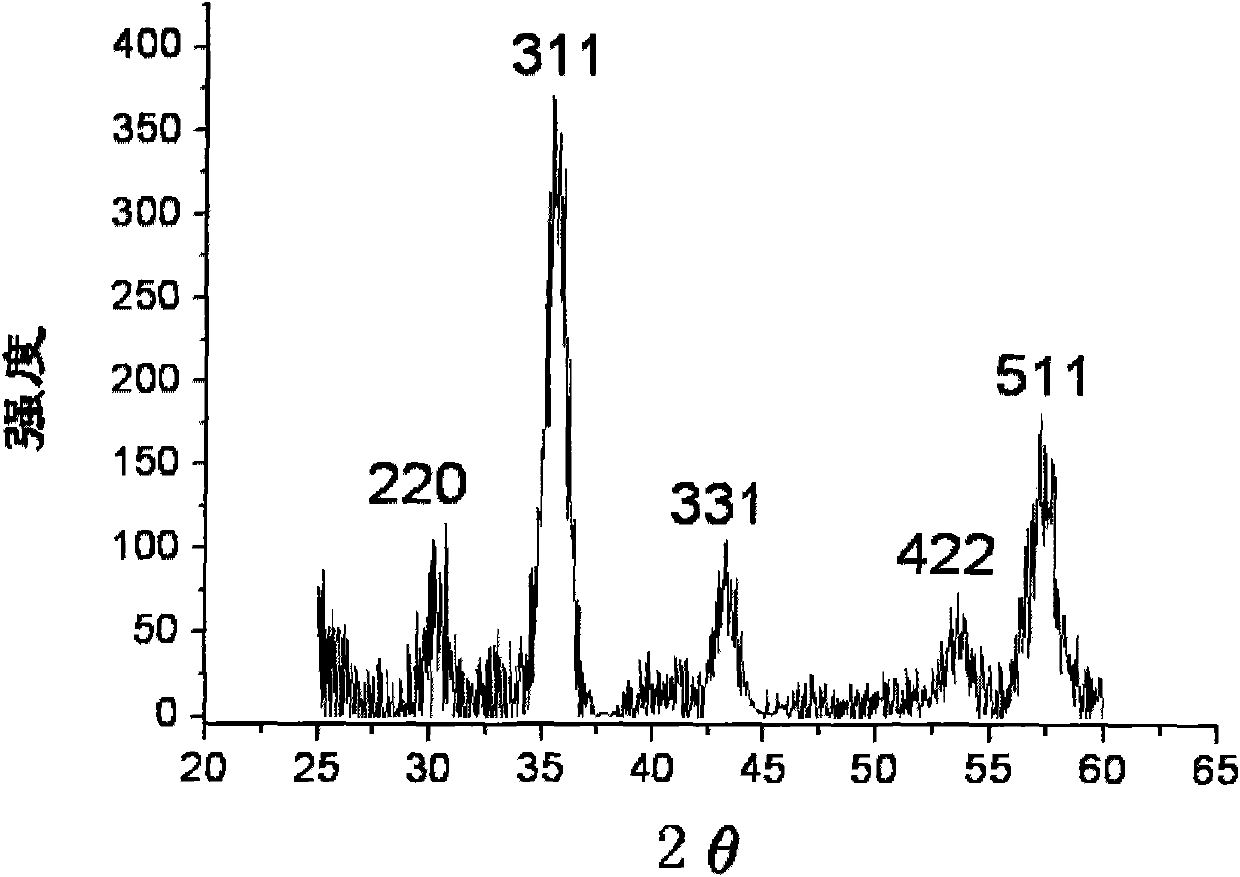

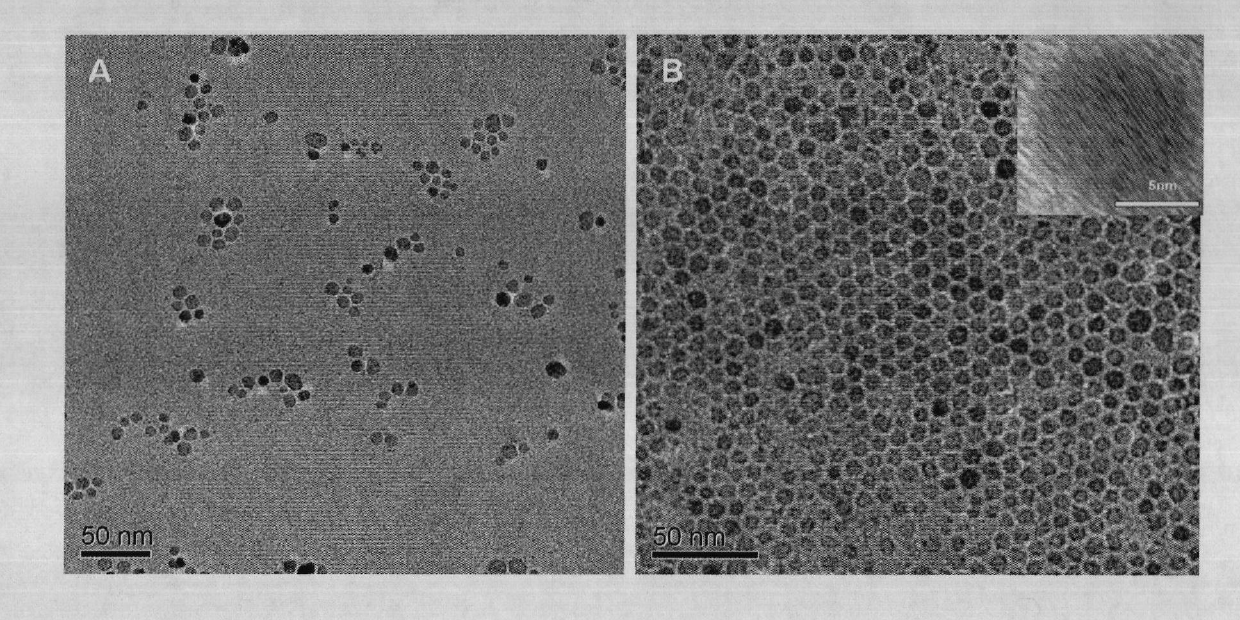

[0029] Such as figure 1 As shown, the X-ray diffraction figure shows that the black solid prepared in the present embodiment is ferric oxide nanocrystal; the transmission electron microscope figure of the magnetic ferric oxide nanocrystal of preparation is as follows figure 2 As shown in A, it can be seen from the transmission electron microscope image that the size distribution of the nanocrystals is relatively uniform, and the diameter is about 6.8 nm.

[0030] 2) Take 1 mL of ferric oxide nanoparticles (about 5 mg) wrapped in benzyl alcohol, use magnetic separation, add appropriate amount of ethanol to wash, and use magnetic separation again, repeat twi...

Embodiment 2

[0035] 1) Add 0.5g of iron(III) acetylacetonate and 20mL of benzyl alcohol solution into a 100mL three-necked reaction flask, stir to dissolve them, pass nitrogen gas to remove oxygen for 30min, and carry out the following reactions under nitrogen atmosphere at 6°C / min The speed was increased to 190° C., and the reaction was carried out for 2 hours to produce black iron ferric oxide nanoparticle crystals with a mass of about 0.11 g and a particle size of about 5 nm.

[0036] 2) Take 1 mL of ferric oxide nanoparticles (about 5 mg) wrapped in benzyl alcohol, use magnetic separation, add appropriate amount of ethanol to wash, and use magnetic separation again, repeat twice.

[0037] 3) Add 5 mL of 0.2M phosphate double salt solution, and ultrasonicate at room temperature for 5 minutes to obtain a uniform and transparent iron ferric oxide nanocolloid solution.

Embodiment 3

[0039] 1) Add 0.5g of iron(III) acetylacetonate and 20mL of benzyl alcohol solution into a 100mL three-necked reaction flask, stir to dissolve them, in an open system, raise the temperature to 190°C at a rate of 6°C / min, and react for 2h. A black iron ferric oxide nanoparticle crystal with a mass of about 0.11 g and a diameter of about 6.8 nm was prepared. .

[0040] 2) Take 1 mL of ferric oxide nanoparticles (about 5 mg) wrapped in benzyl alcohol, use magnetic separation, add appropriate amount of ethanol to wash, and use magnetic separation again, repeat twice.

[0041] 3) Add 5 mL of 0.1 M phosphate double salt solution, and ultrasonicate at room temperature for 5 minutes to obtain a uniform and transparent iron ferric oxide nanocolloid solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com