Preparation method of SCR (Selective Catalytic Reduction) vanadium-series catalyst used in denitration of tail gas of diesel vehicle

A catalyst, diesel vehicle technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. problems such as poor performance, to achieve the effects of easy operation, improved distribution, and wide temperature window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

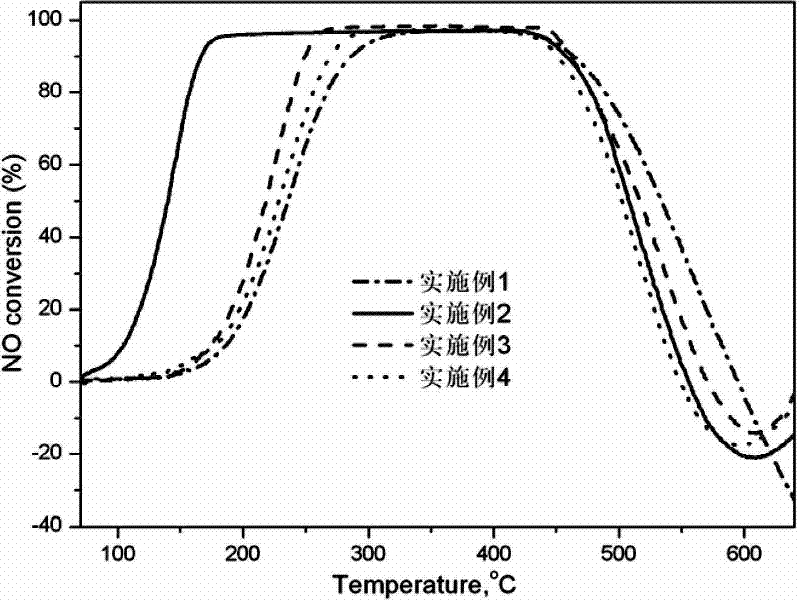

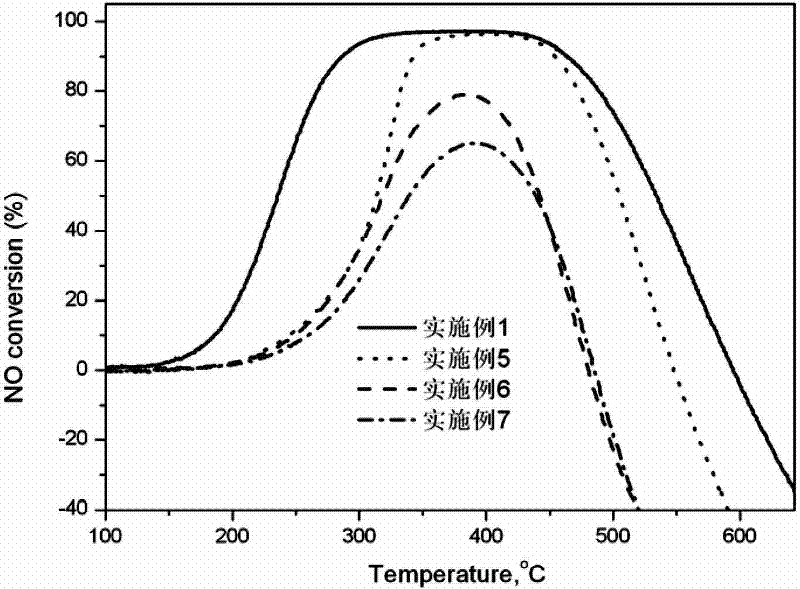

Embodiment 1

[0035] Preparation V 2 o 5 / WO 3 / TiO 2 : First, put 0.03-0.06mol titanium dioxide carrier 300-400 o C roasting for 2-5 hours, then dissolve 0.001-0.004 mol ammonium metavanadate and 0.0001-0.0003 mol ammonium metatungstate in deionized water, and add 0.003-0.008 mol oxalic acid, stir and mix evenly to obtain the active component solution, the concentration of ammonium metavanadate in the active component solution is 0.2-0.5mol / L, the concentration of ammonium metatungstate is 0.01-0.02mol / L, and the concentration of oxalic acid is 0.3-0.8mol / L; Titanium dioxide was added to the above active component solution, and after natural drying, it was heated at 80-120 o C drying 8-12 hours, 300~600 o C roasting for 2~5 hours, finally at 500-670 o C is calcined for 2-5 hours to obtain the target catalyst.

Embodiment 2

[0037] Prepare 1-V 2 o 5 / WO 3 / TiO 2 : First, put 0.03-0.06mol titanium dioxide carrier 300-400 oC roasting for 2-5 hours, then dissolve 0.001-0.004 mol ammonium metavanadate and 0.0001-0.0003 mol ammonium metatungstate in deionized water, and add 0.003-0.008 mol oxalic acid, stir and mix evenly to obtain the active group Separate the solution, the concentration of ammonium metavanadate in the active component solution is 0.2-0.5mol / L, the concentration of ammonium metatungstate is 0.01-0.02mol / L, and the concentration of oxalic acid is 0.3-0.8mol / L; then roast The final titanium dioxide was added to the above-mentioned active component solution, and after natural drying, it was dried at 80-120 o C drying 8-12 hours, 300~600 o C roasting for 2~5 hours, finally at 680-800 o C is calcined for 2-5 hours to obtain the target catalyst.

Embodiment 3

[0039] Prepare 2-V 2 o 5 / WO 3 / TiO 2 : First, put 0.03-0.06mol titanium dioxide carrier 300-400 o C roasting for 2-5 hours, then dissolve 0.001-0.004 mol ammonium metavanadate and 0.0001-0.0003 mol ammonium metatungstate in deionized water, and add 0.003-0.008 mol oxalic acid, stir and mix evenly to obtain the active group Separate the solution, the concentration of ammonium metavanadate in the active component solution is 0.2-0.5mol / L, the concentration of ammonium metatungstate is 0.01-0.02mol / L, and the concentration of oxalic acid is 0.3-0.8mol / L; then roast The final titanium dioxide was added to the above solution, and dried naturally at 80-120 o C drying 8-12 hours, 300~600 o C roasting for 2~5 hours, finally at 820-900 o C is calcined for 2-5 hours to obtain the target catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com