Patents

Literature

412 results about "Ammonium metatungstate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of rare-earth-based composite multi-component denitrification and dioxin removal catalyst

ActiveCN104226301AImprove catalytic oxidation abilityImprove surface acidity and alkalinityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPolymerDenitrification

The invention discloses a preparation method of a rare-earth-based composite multi-component denitrification and dioxin removal catalyst. According to the preparation method, titanium dioxide (titanium white) and silicon powder as carriers and ammonium metatungstate, ammonium metavanadate, cerous nitrate and lanthanum nitrate as active components, the steps of mixing, kneading, molding, drying and roasting are carried out in the presence of auxiliary materials to prepare the catalyst, wherein the auxiliary materials include monoethanolamine, citric acid, ammonium hydroxide, lactic acid, stearic acid, glass fibers, macromolecular polymer fibers RP-CHOP, hydroxypropyl methyl cellulose, polyoxyethylene and water. The prepared catalyst can simultaneously decompose nitric oxides and dioxin and can improve the mercury removal efficiency of the existing smoke control device. The prepared catalyst is not only applicable to new power plants, but also suitable for the modification of a wet-method desulphurization device of an old power plant, 80 to 95 percent of HgO generated in a coal burning power plant can be oxidized to Hg<2+> by utilizing the prepared catalyst, and a majority of particle-state Hg<2+> can be removed by utilizing a dust removal device.

Owner:山东信义汽车配件制造有限公司

Preparation method of high-strength and antioxidant rare-earth-based smoke denitration catalyst

ActiveCN104209117AReduce escape rateReduce productionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumGlass factory

The invention discloses a preparation method of a high-strength and antioxidant rare-earth-based smoke denitration catalyst. The preparation method of the high-strength and antioxidant rare-earth-based smoke denitration catalyst comprises the following steps: by taking titanium dioxide and montmorillonite as carriers and ammonium metatungstate, cerous nitrate and lanthanum nitrate as active components, mixing, ageing, kneading, forming, drying and roasting with the accompanying of auxiliary materials. The auxiliary materials comprise ammonia water, lactic acid, citric acid, stearic acid, glass fiber, wood pulp, hydroxypropyl methyl cellulose, polyoxyethylene, monoethanolamine and water. The product prepared by the method is separated under a high SO2 smoke condition, nitric oxide in the smoke can be decomposed; meanwhile, the purpose of removing mercury and dioxin can be achieved. According to the preparation method of the high-strength and antioxidant rare-earth-based smoke denitration catalyst, the rare earth elements, namely cerium and lanthanum are used as the active components, so that the addition amount of vanadium is reduced, the toxicity of the product is reduced or the product is non-toxic product, the pressure of the post treatment of the product is reduced; the environmental protection pressure is reduced; the product is environmentally friendly; the product can be widely used in the field of thermal power plants, glass factories and chemical plants.

Owner:山东信义汽车配件制造有限公司

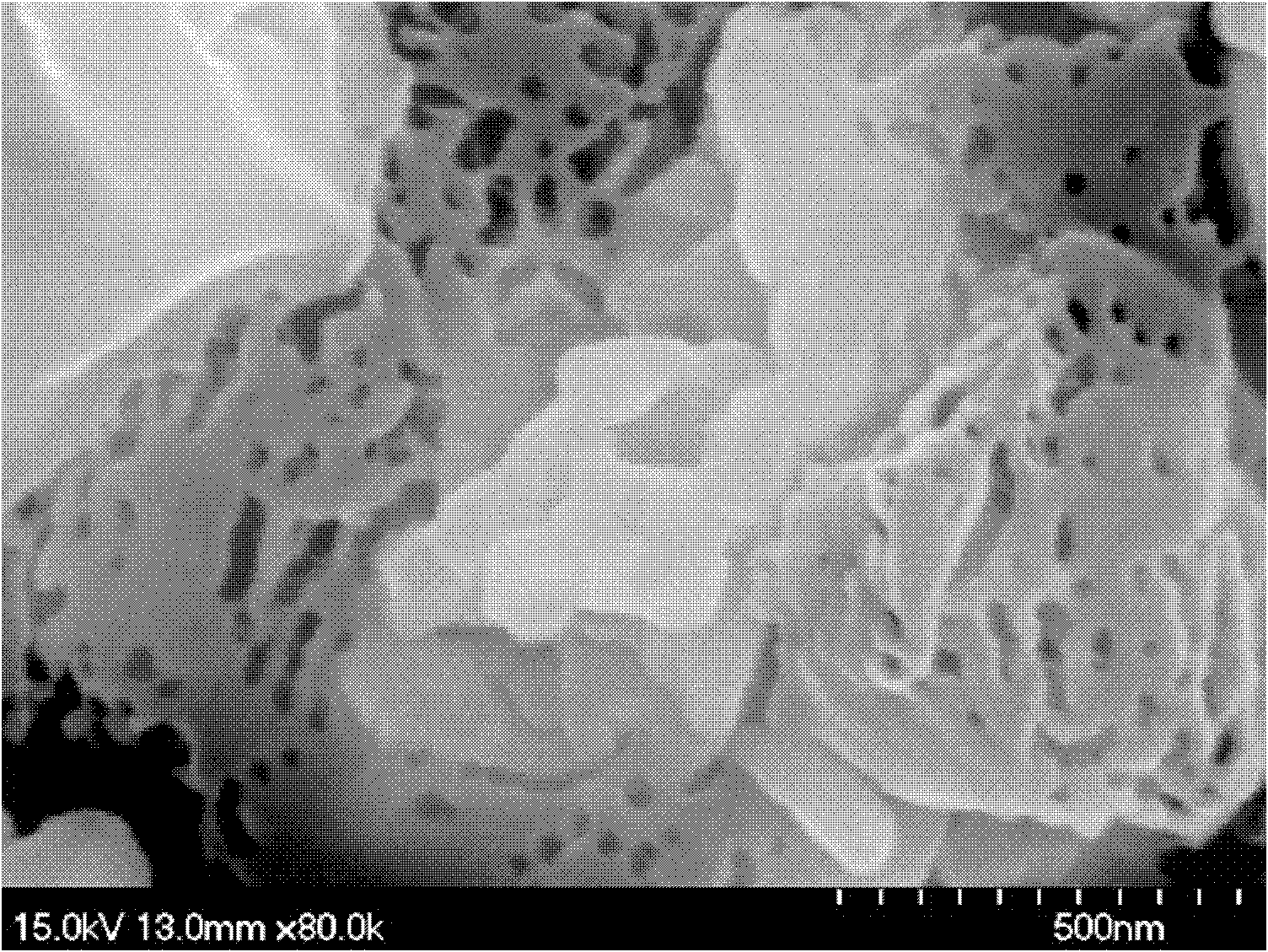

Nano-rare earth tungsten powder and its preparation method

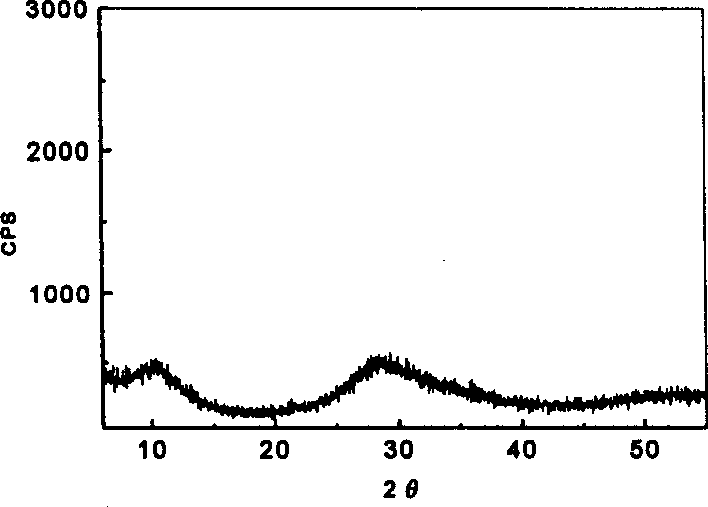

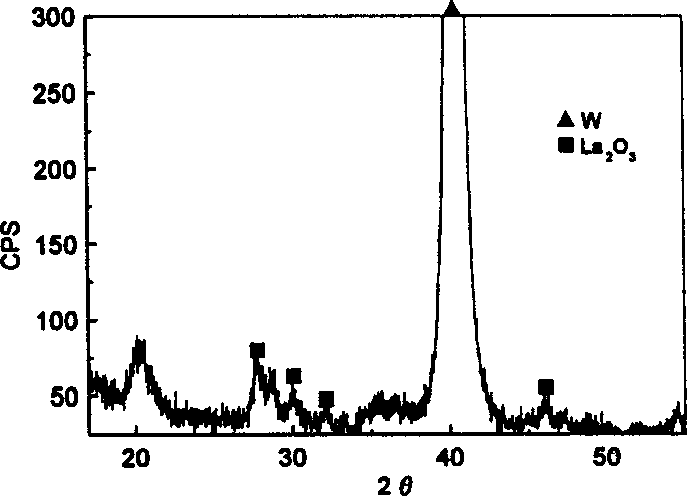

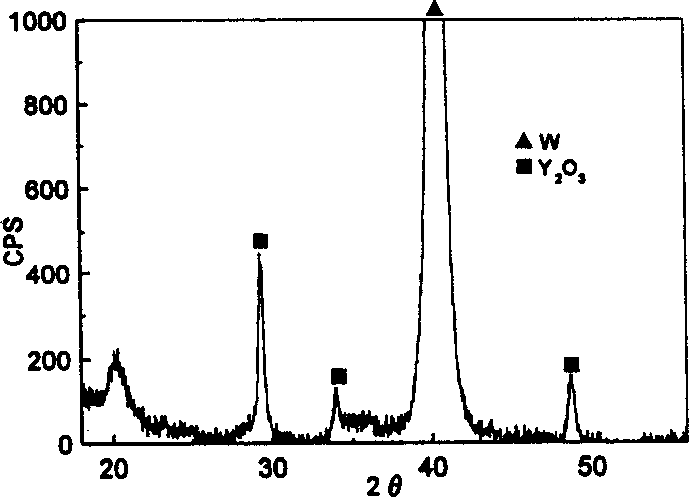

A nano-class RE-W particle contains RE oxide powder (CeO2, La2O3, or Y2O3) (0.5-30 wt%) and W (70-99.5 wt%), and is prepared through dissolving the ammonium metatungstate powder and RE oxide powder in water respectively, mixing, clarifying, dispersing it in liquid nitrogen by nitrogen sprayer for pre-freezing, vacuum freeze drying, and secondary reducing in hydrogen atmosphere. Its advantage is molecule-class mixing uniformly.

Owner:BEIJING UNIV OF TECH

Fluorination catalyst, and preparation method and use thereof

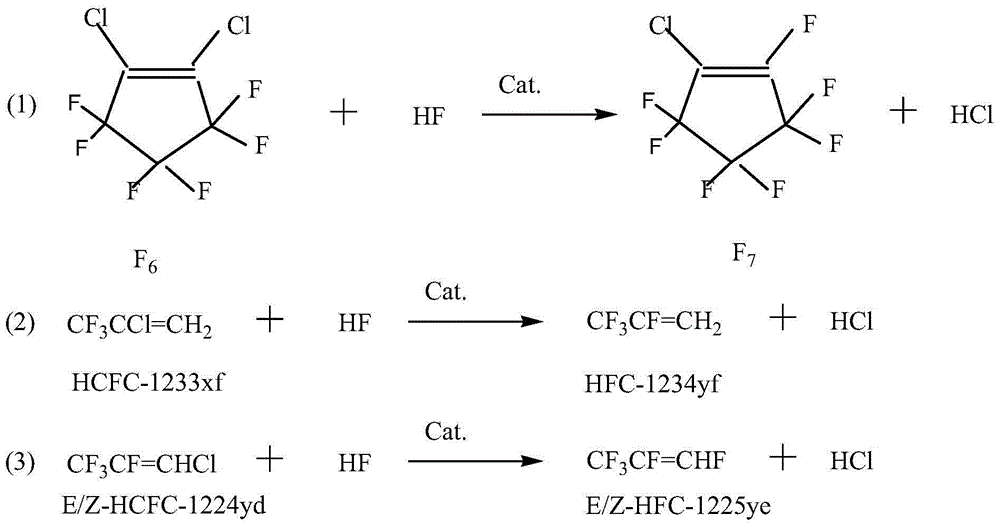

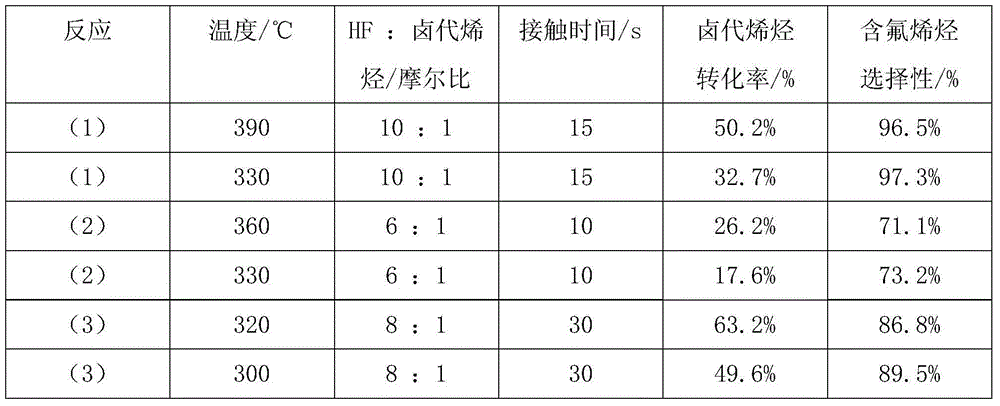

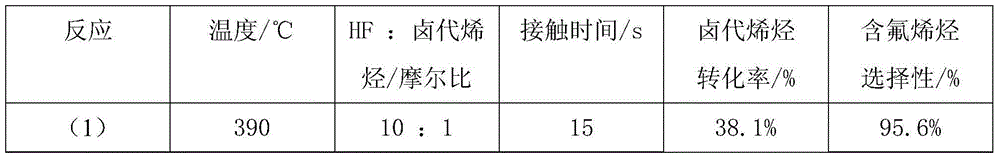

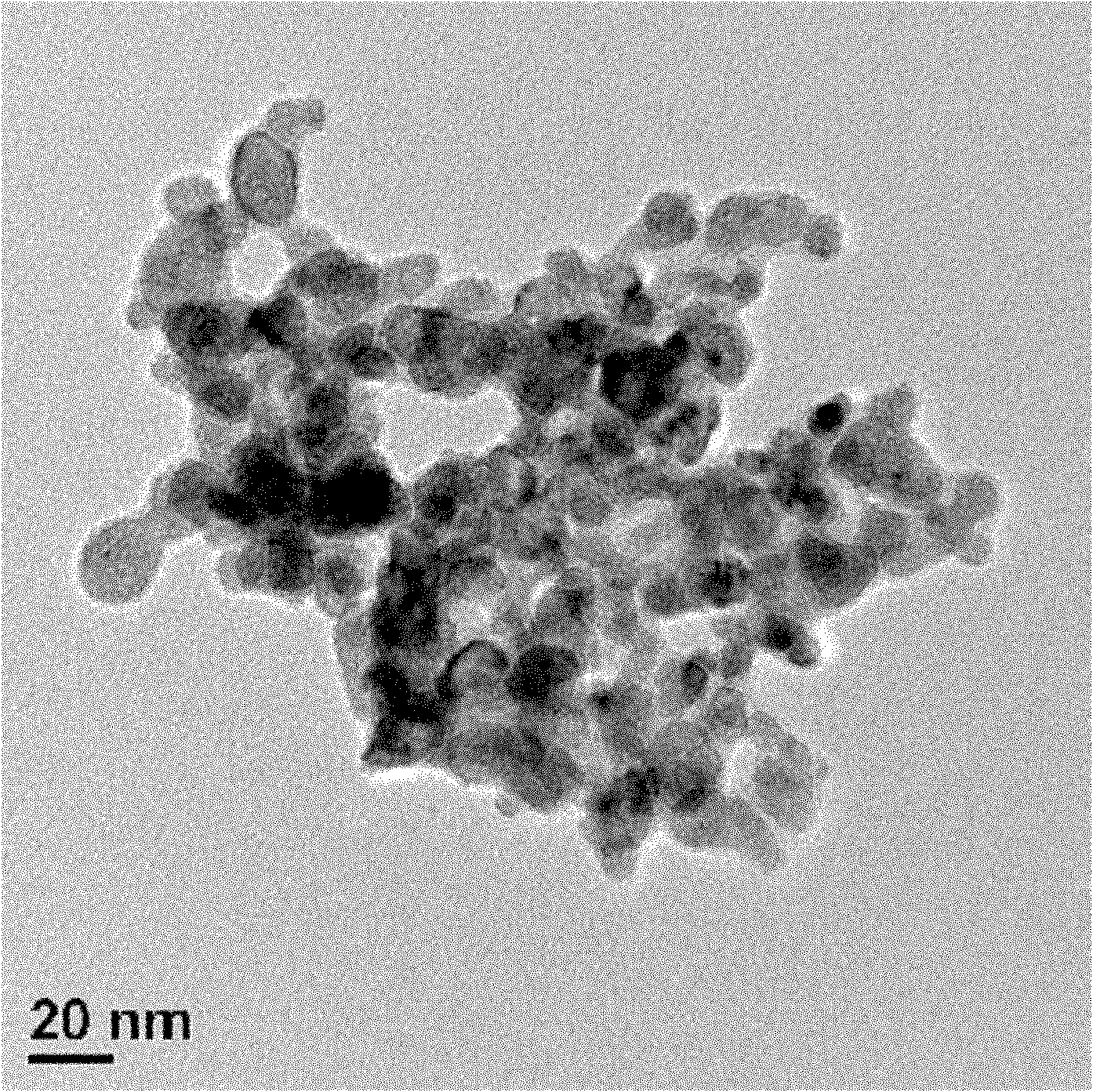

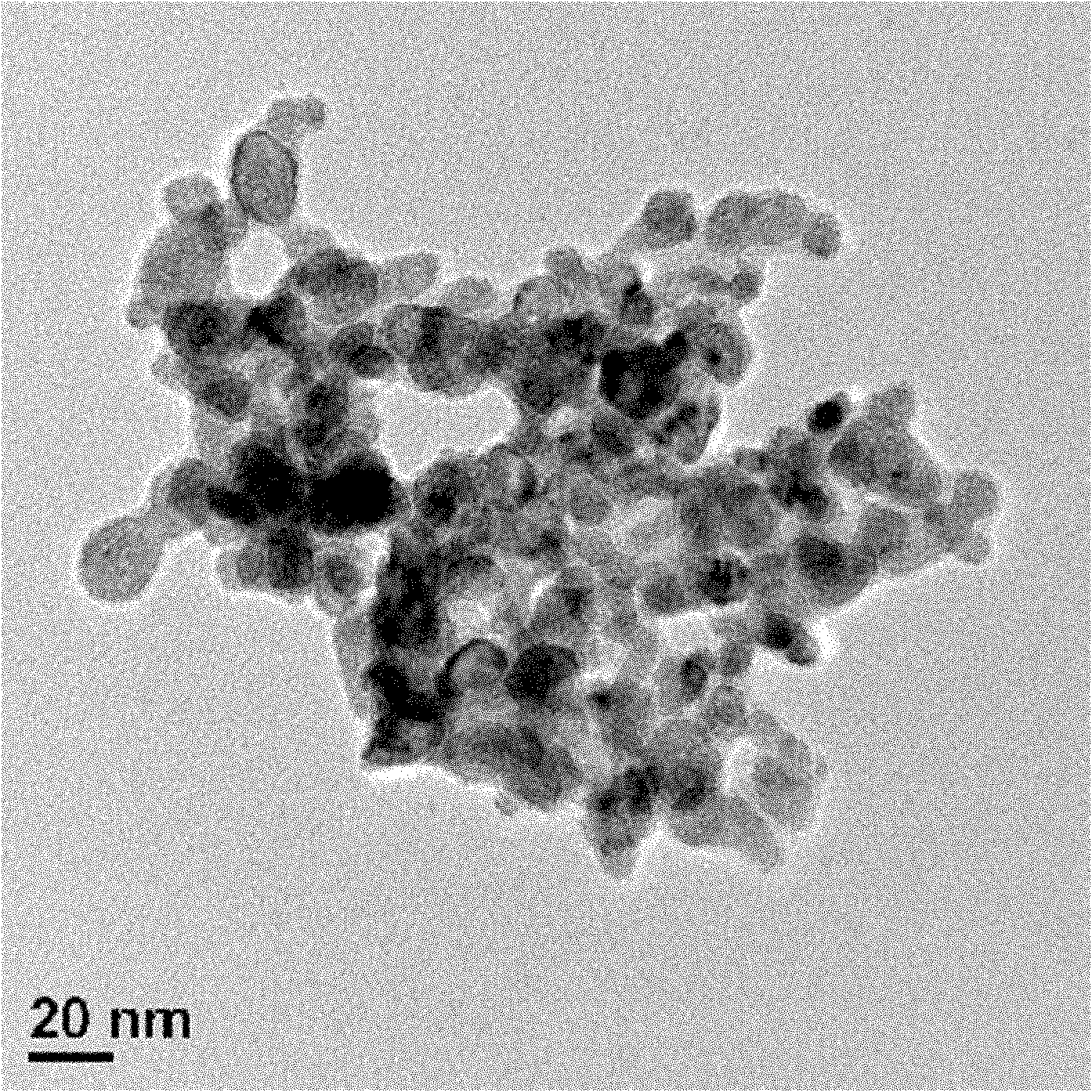

ActiveCN104907065AIncrease the areaHigh pore volumePreparation by halogen replacementMetal/metal-oxides/metal-hydroxide catalystsChromium CompoundsChemical synthesis

The invention discloses a fluorination catalyst, and a preparation method and a use thereof, and belongs to the field of chemical synthesis. The precursor of the catalyst is formed by blending 40-95mass% of a trivalent chromium compound with 5-60mass% of tungstate, wherein the trivalent chromium compound can be chromic oxide or chromium hydroxide, and the tungstate can be zinc tungstate, nickel tungstate, magnesium tungstate, aluminum tungstate, silicotungstic acid, ammonium tungstate, ammonium paratungstate or ammonium metatungstate. The fluorination catalyst has the advantages of high use temperature, high catalysis activity and long service life, and can be mainly used in reactions for preparing fluorinated alkenes through gas phase catalysis of fluorination of alkenyl halides at a high temperature.

Owner:泉州宇极新材料科技有限公司

Preparation method of nano-tungsten powder

InactiveCN102019429ASimple preparation processThe preparation process is practicalAir atmosphereAmmonium metatungstate

The invention discloses a preparation method of nano-tungsten powder. The preparation method comprises the following steps: preparing ammonium metatungstate and citric acid into clear mixed aqueous solution; performing complex reaction at the temperature of 60 to 90 DEG C; filtering and drying to obtain the precursor of tungsten oxide; calcining in air to obtain tungsten oxide (WO3) powder; introducing ammonia gas to the tungsten oxide powder for nitridation to obtain tungsten nitride (W2N) powder; and finally performing thermal treatment on the tungsten nitride powder to obtain the nano-tungsten powder. The preparation process disclosed by the invention is simple and practical and has the high operability and is easy in implementation of scale production; the prepared powder has small particle size of which the average particle size is 20-50 nm; the particle size distribution is uniform; and the degree of aggregation is low and high sintering activity is realized. The technology disclosed by the invention can promote the progress of high-quality tungsten material in China and the performance level, and provide means for transforming advantages in tungsten ore resources into industrial and economical advantages.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Preparation method of tio2-wo3 composite powder used as catalyst carrier

InactiveCN102294273AImprove performanceEasy to processCatalyst carriersDispersed particle separationPtru catalystAmmonium metatungstate

The invention discloses a preparation method for TiO2-WO3 composite powder used as a catalyst carrier. The method comprises the following steps: dispersing the raw material metatitanic acid through beating, and adjusting the concentration of obtained slurry to be 15 to 25% on the basis of the mass percentage of TiO2; adding ammonia liquor into the slurry and adjusting the pH value of the slurry to be 6.5 to 9.0; filtering the slurry to obtain a solid phase filter cake; beating the solid phase filter cake again, and adjusting the concentration of obtained slurry to be 24 to 30% on the basis ofthe mass percentage of TiO2; adding an ammonium metatungstate solution in proportion, wherein, the proportion of addition amount of ammonium metatungstate is 4.0% to 10.0% with the mass of titanium dioxide as reference; directly pumping the slurry treated in the previous steps into a drying calcination apparatus for drying and calcining, and crushing blanking materials of a calcination kiln to obtain a finished product. The preparation method has the characteristics of low manufacture cost and a simple process; the prepared product has the advantages of a high specific surface area, high surface chemical activity, high catalysis efficiency and good processing performance.

Owner:四川华铁钒钛科技股份有限公司

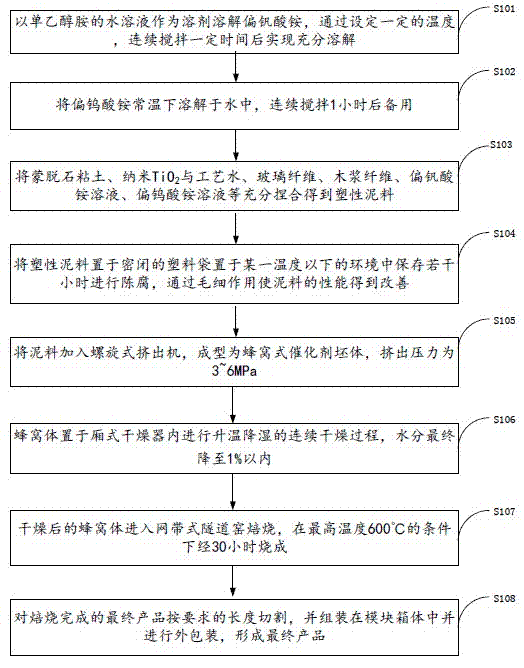

Low-cost denitration catalyst and preparation process thereof

InactiveCN103495413ALow costImprove distributionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsTunnel kilnFiber

The invention discloses a low-cost denitration catalyst and a preparation process thereof. The catalyst comprises the following components: nanometer TiO2 powder, montmorillonite, ammonium metatungstate, ammonium metavanadate, chopped glass fiber, broad-leaf forest wood pulp fiber, carboxymethyl cellulose, polyoxyethylene and stearic acid. The preparation process of the low-cost denitration catalyst comprises the steps: dissolving the ammonium metavanadate by taking an aqueous solution of monoethanolamine as a solvent, dissolving the ammonium metatungstate into water under normal temperature, and continuously stirring the solution for 1h for later use; and sufficiently kneading the raw material of the catalyst to obtain a plastic pug, placing the plastic pug into a sealed plastic bag to store for a plurality of hours to age, forming the pug into a honeycomb-shaped catalyst blank, entering a dried honeycomb body into a mesh band type tunnel kiln for roasting, cutting a final roasted product according to the required length, assembling the product into a module box body, and externally packaging the product. The low-cost denitration catalyst is low in cost and capable of effectively improving the denitration performance, enhancing the mechanical strength of the product and improving the wear resistance.

Owner:YIXING YIGANG ENVIRONMENTAL PROTECTION ENG & MATERIALS

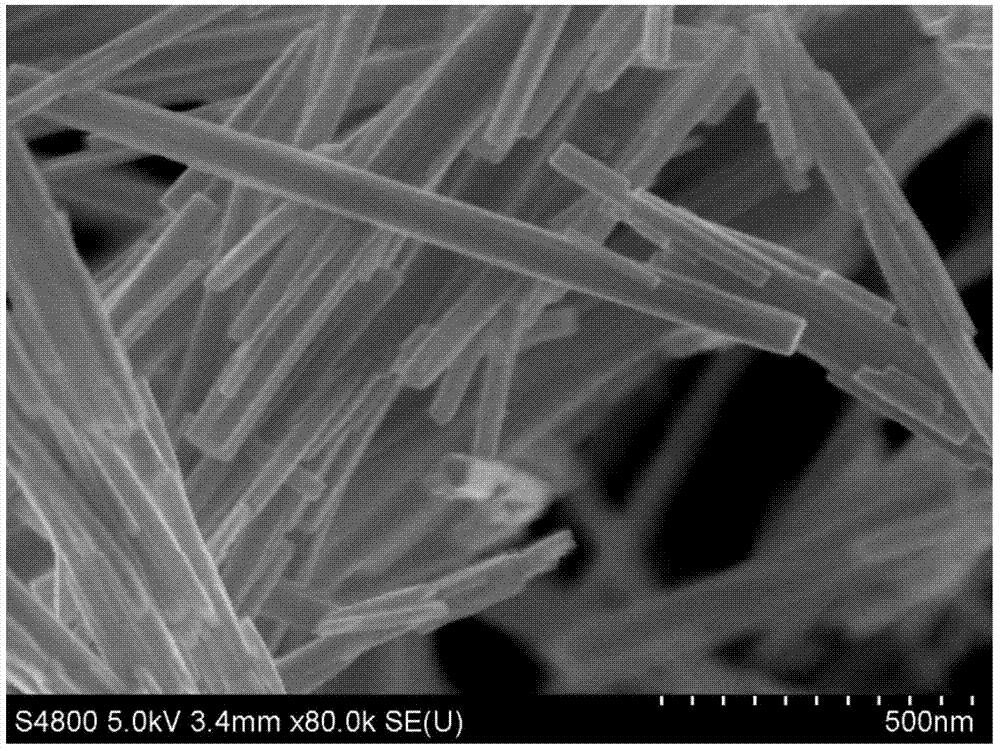

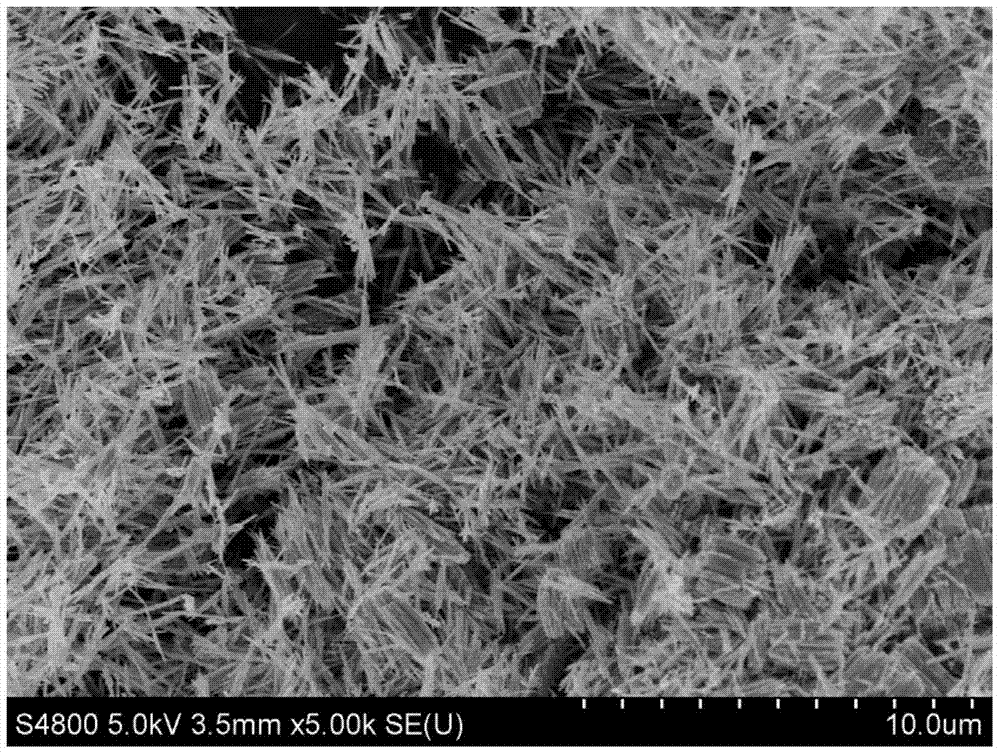

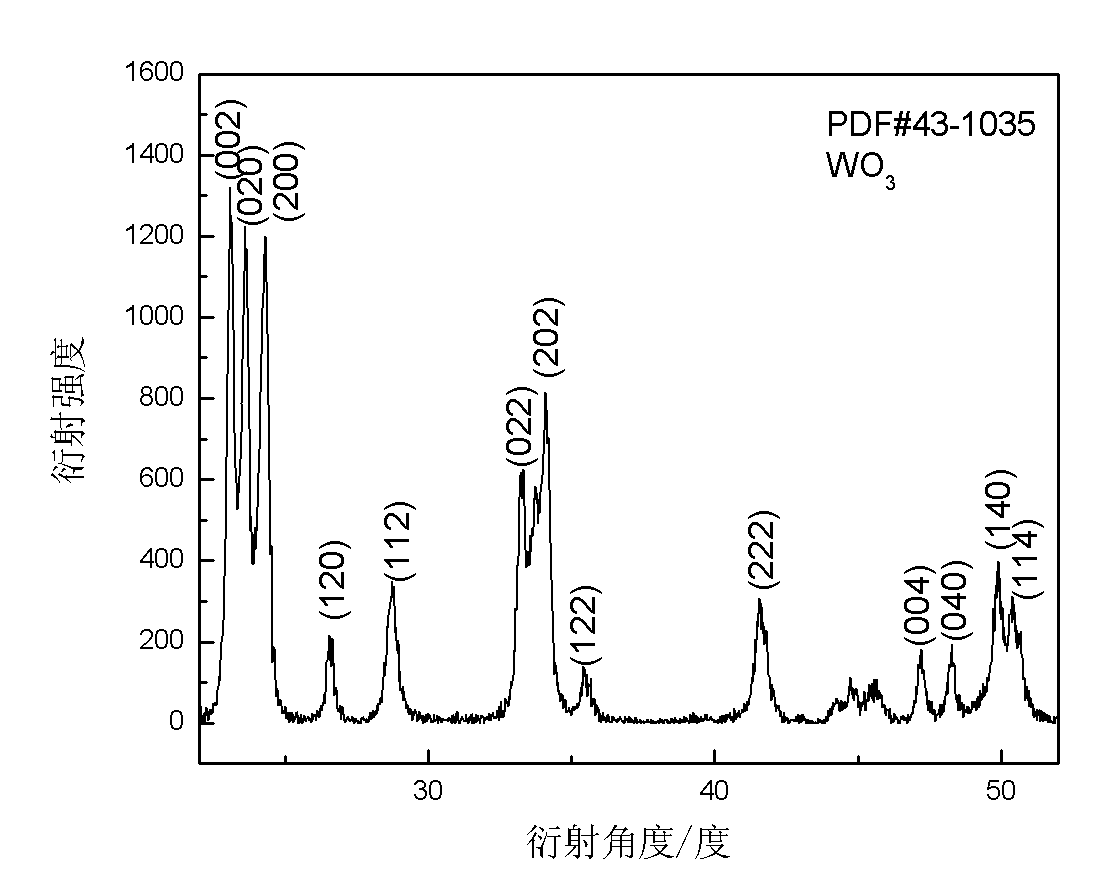

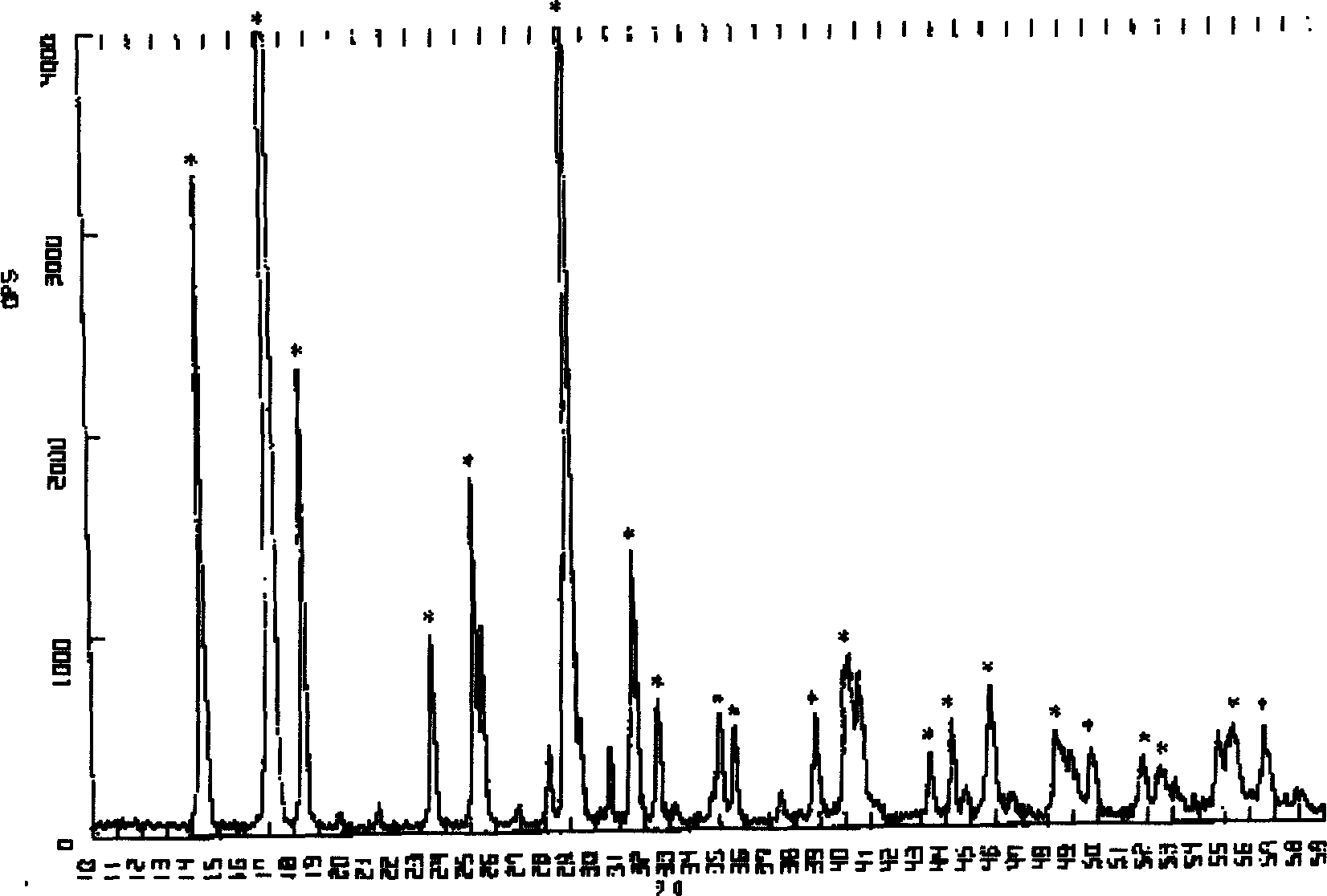

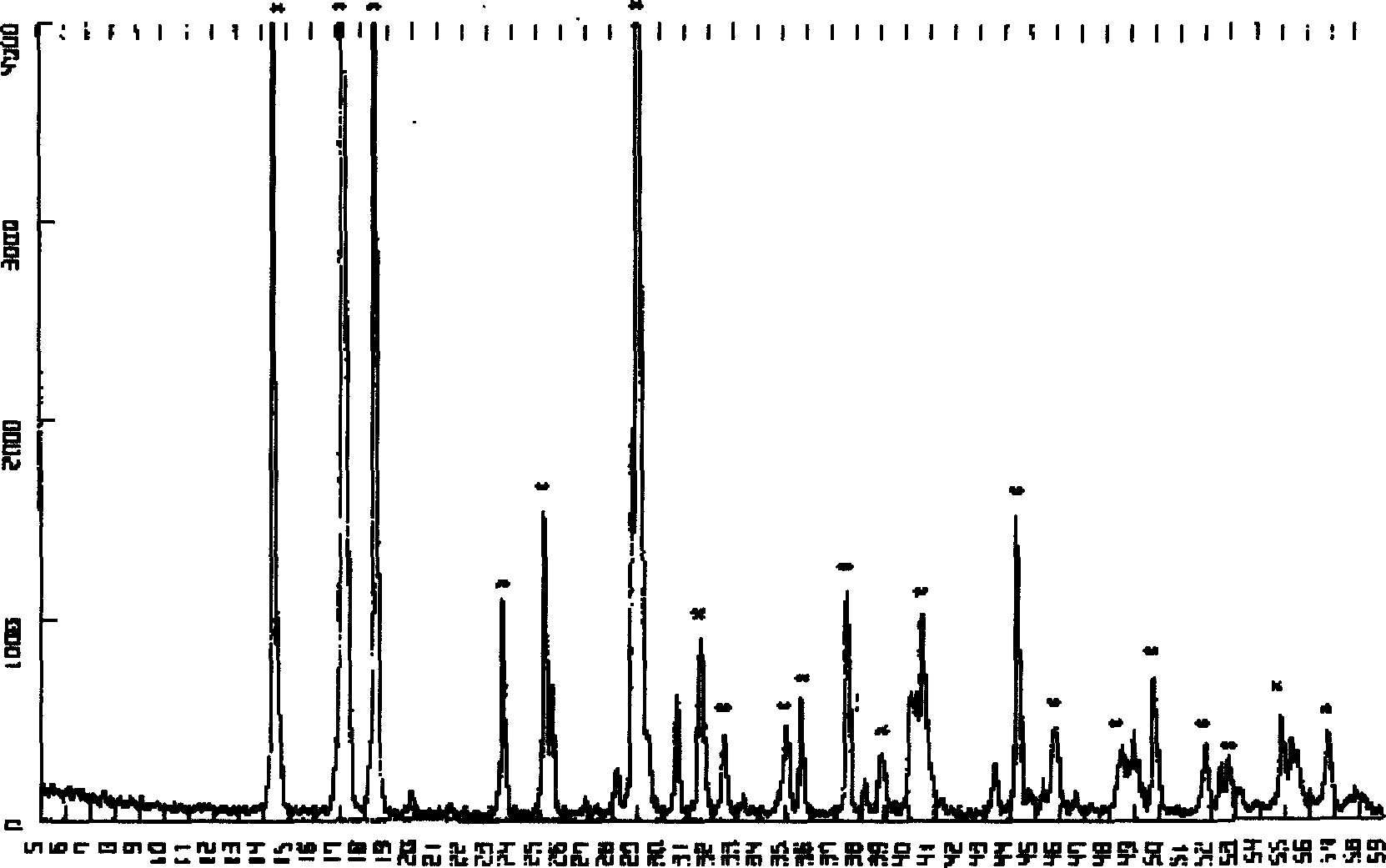

Method for synthesizing superfine tungsten trioxide all nanorods by use of hydrothermal process

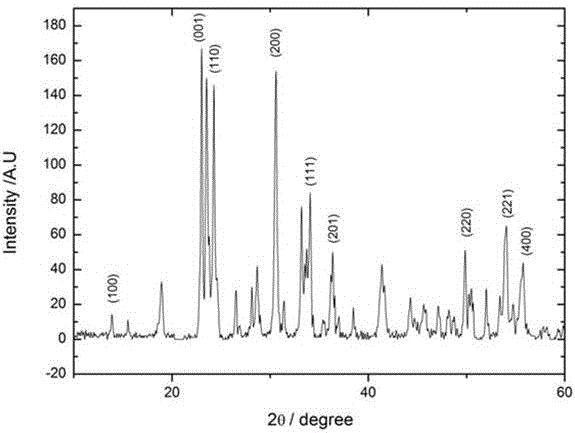

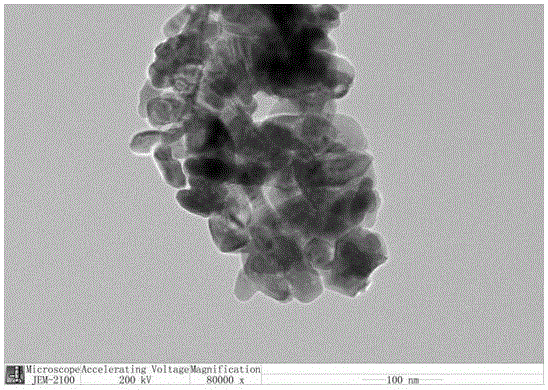

InactiveCN103936074ASmall diameterEvenly distributedMaterial nanotechnologyTungsten oxides/hydroxidesMaximum diameterX-ray

The invention provides a method for synthesizing superfine tungsten trioxide all nanorods by use of a hydrothermal process. The method is used for preparing the superfine tungsten trioxide nanorods by taking ammonium metatungstate as a tungsten source, and citric acid and sodium sulfate in a specific ratio as composite catalysts, and by adjusting the pH value with hydrochloric acid and ammonium hydroxide, and finally, the superfine tungsten trioxide nanorods are analyzed by FESEM (Field Emission Scanning Electron Microscope), XRD (X-Ray Diffraction), TEM (Transmission Electron Microscopy) and HRTEM (High Resolution Transmission Electron Microscopy) analysis methods; an XRD analysis test result indicates that the prepared tungsten trioxide is in hexagonal crystal form WO3, the JCPDS (Joint Committee On Powder Diffraction Standards) card of the prepared tungsten trioxide is #33-1387, the diameter of the tungsten trioxide is about 30-60 nanometers and the maximum length of the tungsten trioxide is 2.5 microns. The maximum diameter-to-length ratio of the tungsten trioxide is 1:80. The superfine tungsten trioxide full nanorods prepared by the method are high-purity hexagonal crystal tungsten trioxide, the diameter of the nanorods is small and the distribution of rod shapes is even, and all superfine tungsten trioxide nanorods are present without particles in other forms.

Owner:CHANGAN UNIV

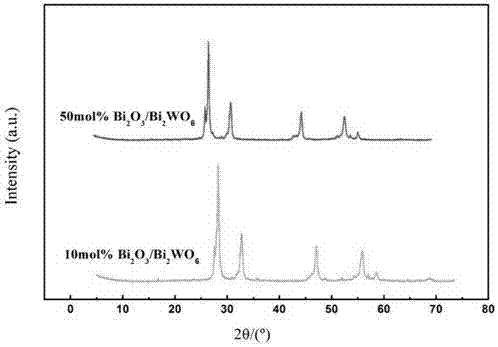

Bismuth trioxide-bismuth tungstate heterojunction photocatalyst and preparation method thereof

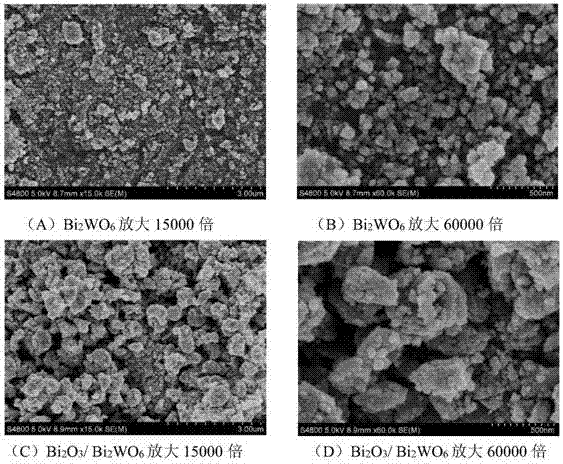

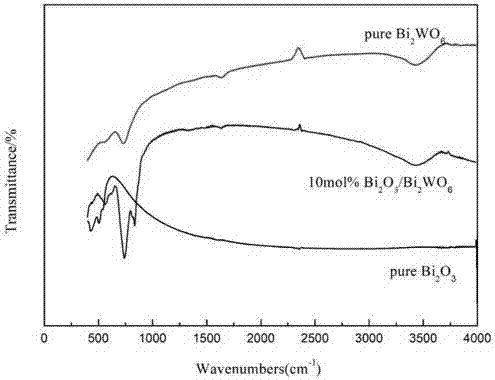

InactiveCN107486199AAchieve separationHigh activityWater/sewage treatment by irradiationWater contaminantsHeterojunctionSpectral response

The invention belongs to the field of semiconductor catalysis, and discloses a preparation method of a bismuth trioxide-bismuth tungstate heterojunction photocatalyst. The method comprises the steps of compounding bismuth trioxide and bismuth tungstate with the molar ratio being 0.1:1 to 0.5:1, so as to form a heterojunction structure, and ensuring that bismuth trioxide is loaded on the surface of bismuth tungstate. According to the method, bismuth nitrate and ammonium metatungsten are taken as raw materails, and the bismuth trioxide-bismuth tungstate heterojunction photocatalyst is formed by one step through a solvothermal method. The preparation method is simple, the synthesis period is short, and a formed sample is high in purity and has a typical p-n heterojunction structure, can effectively restrain the compounding of photo-induced electron and holes, promotes the separation of photon-generated carriers, has the characteristics of high activity and wide spectral response, and is of great importance.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Wear-resisting tungsten alloy and preparation method thereof

The invention discloses a wear-resisting tungsten alloy and a preparation method thereof. The method includes the steps that firstly, aluminum nitrate, citric acid and ammonium metatungstate are adopted as raw materials and prepared into solutions, the solutions are mixed, a sol-gel reaction is carried out, and gel is dried and roasted to obtain Al2O3 / WO3 mixed powder; then, the Al2O3 / WO3 mixed powder is subjected to hydrogen reduction to obtain Al2O3 / W mixed powder, and then the Al2O3 / W mixed powder is subjected to ball milling with a planetary ball mill; finally, sintering is carried out to obtain the tungsten alloy. In the prepared tungsten alloy material, both the alumina grain size and the tungsten grain size are very small, the tungsten grain size is 0.5-2.1 micrometers, and the alumina grain size is 50-200 nanometers. The recrystallization temperature of the prepared tungsten alloy can reach 1600 DEG C or so. Compared with a pure tungsten material, microhardness is improved by 3-20%, and high-temperature wear resistance is improved by 5-15%.

Owner:HENAN UNIV OF SCI & TECH

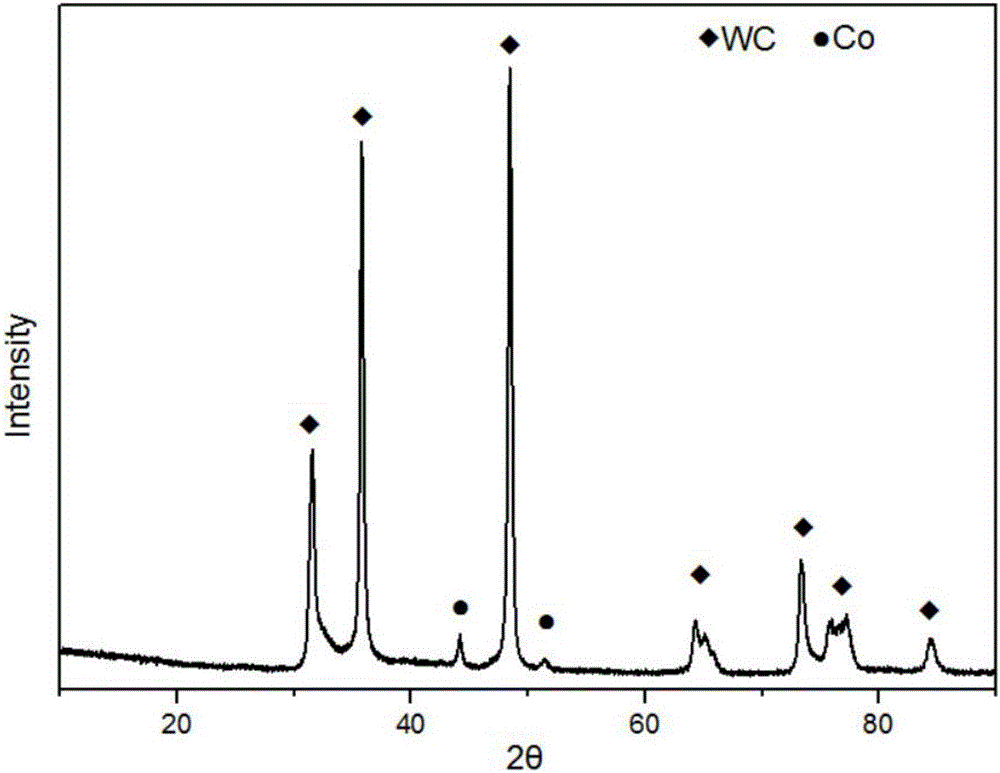

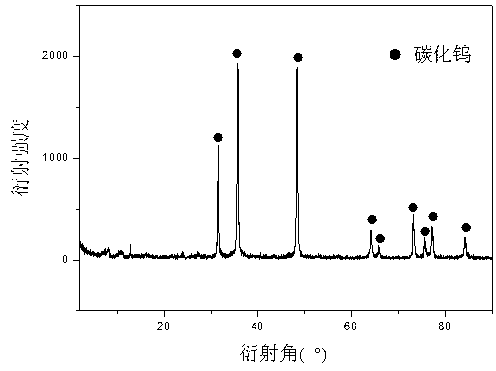

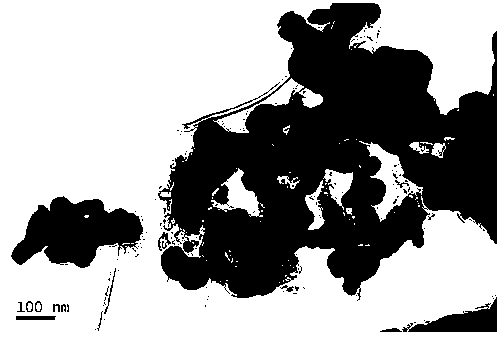

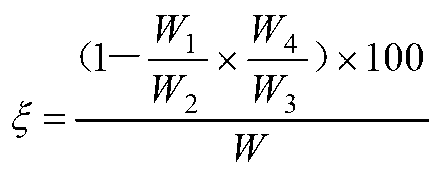

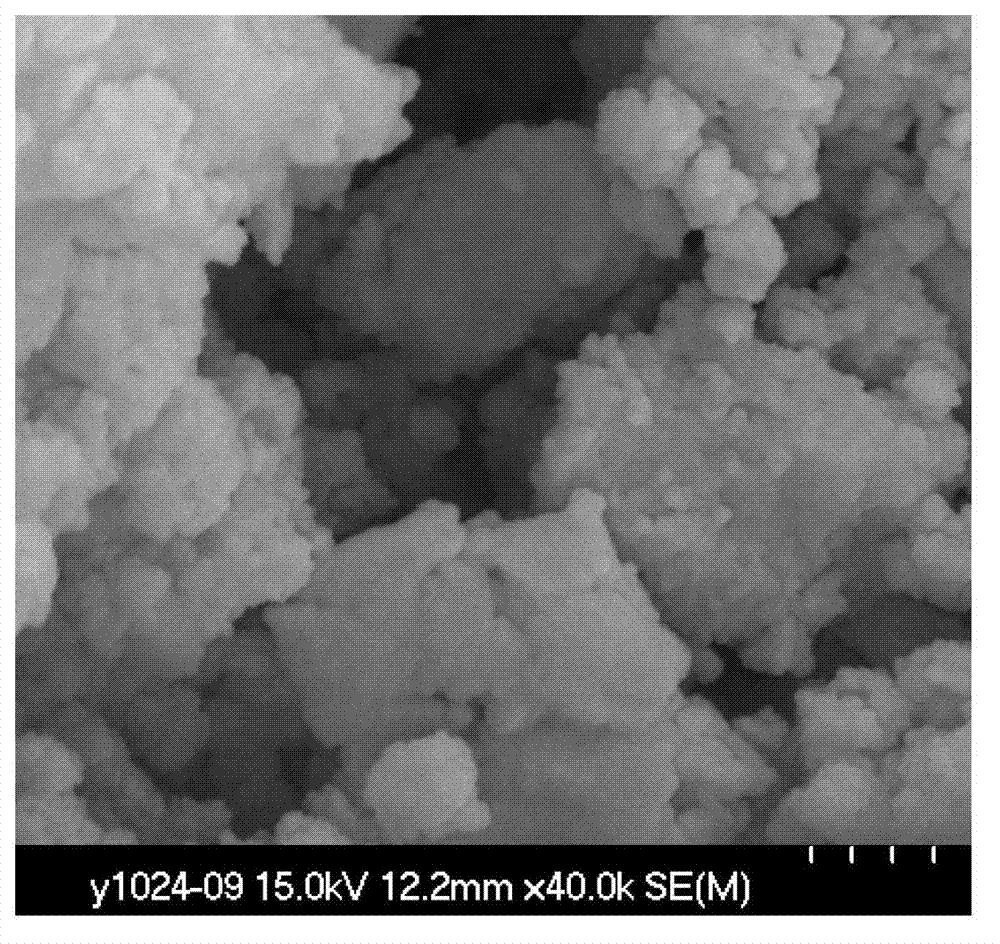

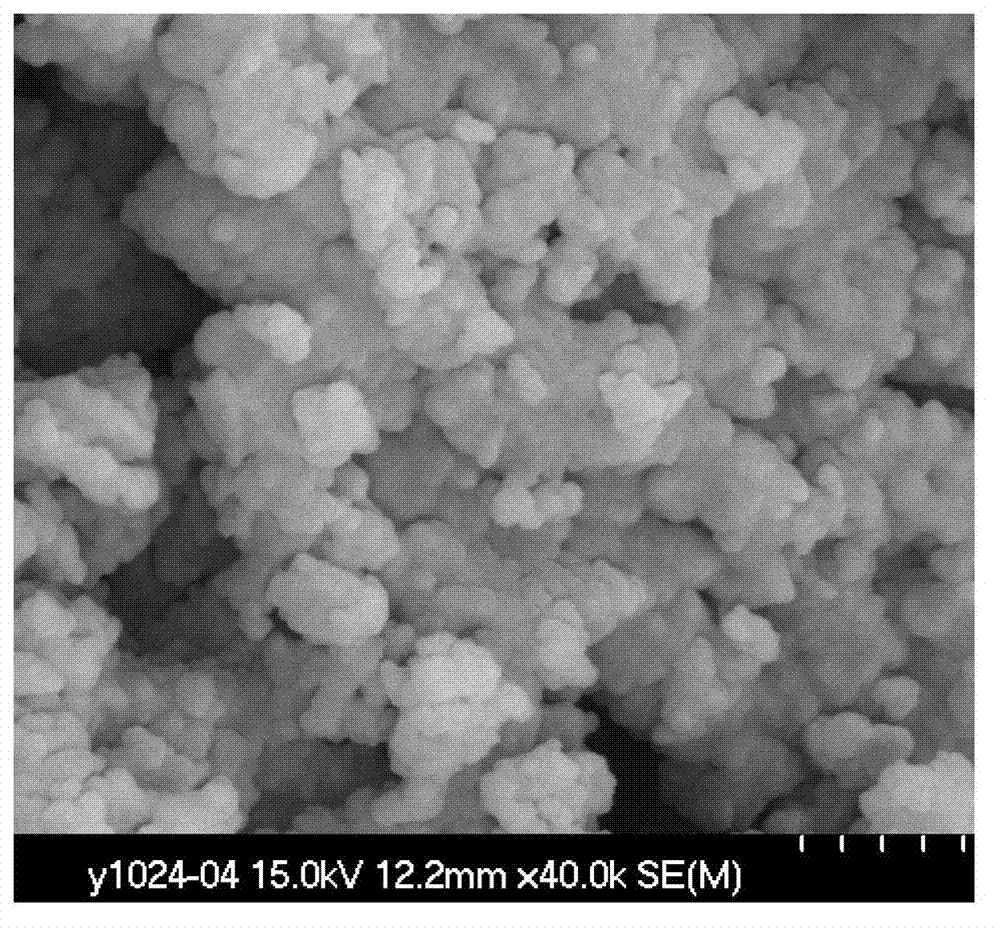

Preparation method of WC-Co nano powder added with grain growth inhibitor

The invention provides a preparation method of WC-Co nano powder added with a grain growth inhibitor, and belongs to the technical field of powder metallurgy and powder preparation. The preparation method comprises the following steps: ammonium metatungstate, cobalt nitrate, fuel, ammonium nitrate, metal salt with a needed amount of the added grain growth inhibitor and an organic carbon source are used as raw materials, and oxide / carbon composite powder is prepared by adopting a low-temperature combustion synthesis method; and then carbonization is carried out under atmosphere protection or vacuum to obtain the WC-Co nano powder mixed with the grain growth inhibitor. According to the preparation method, the low-temperature combustion synthesis method belongs to a liquid-phase synthesis method, molecular-level mixing is achieved, so that diffusion range of the carbon in the carbonization process is short, and the requirements for the reaction temperature requirement and the reaction time requirement are low; and in addition, the raw materials are simple to obtain, the equipment is simple, the process is fast, and large-scale production can be realized.

Owner:UNIV OF SCI & TECH BEIJING

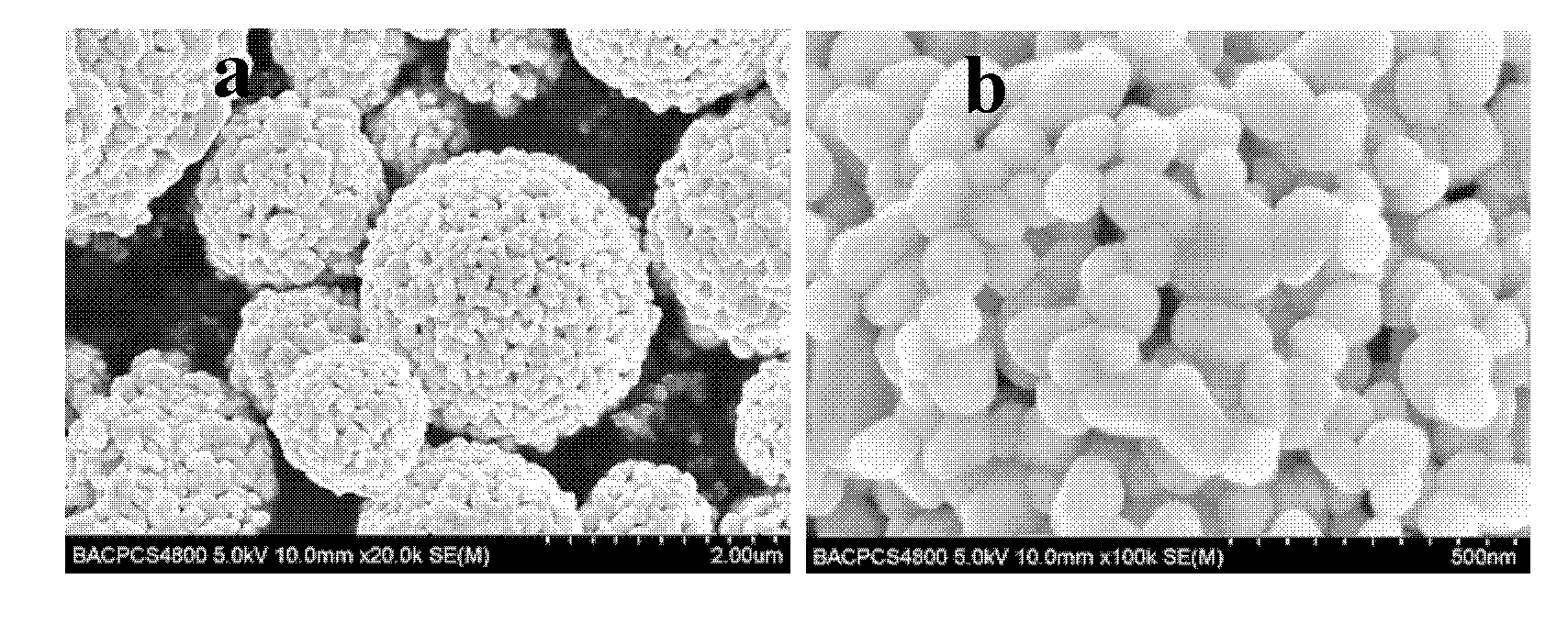

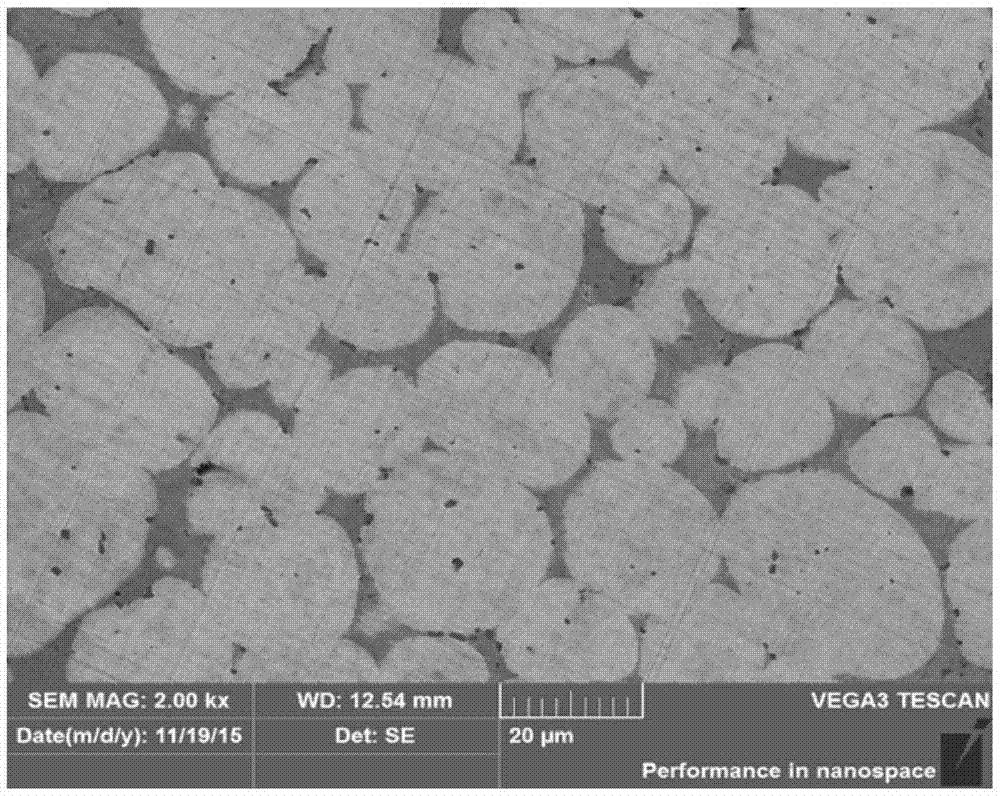

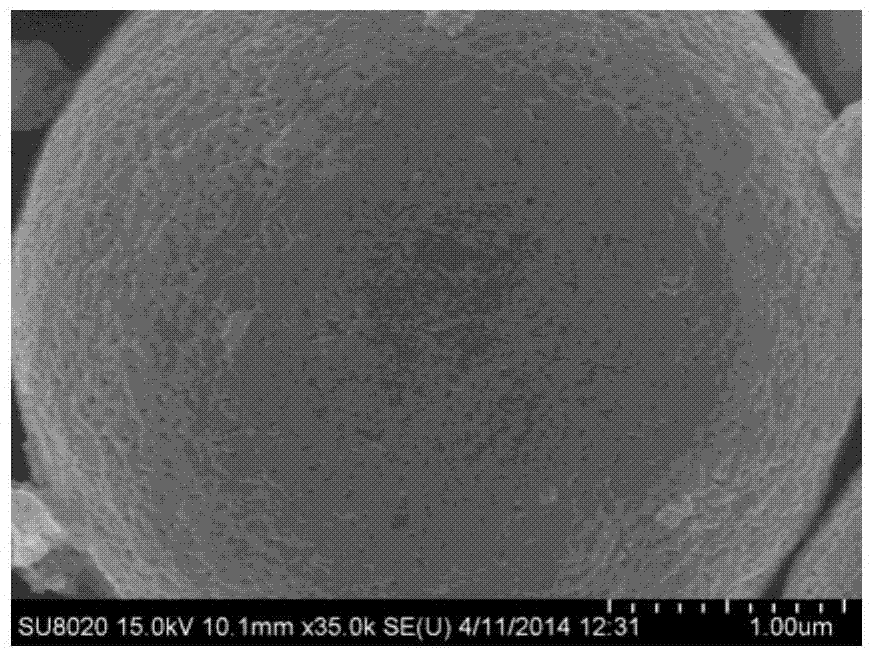

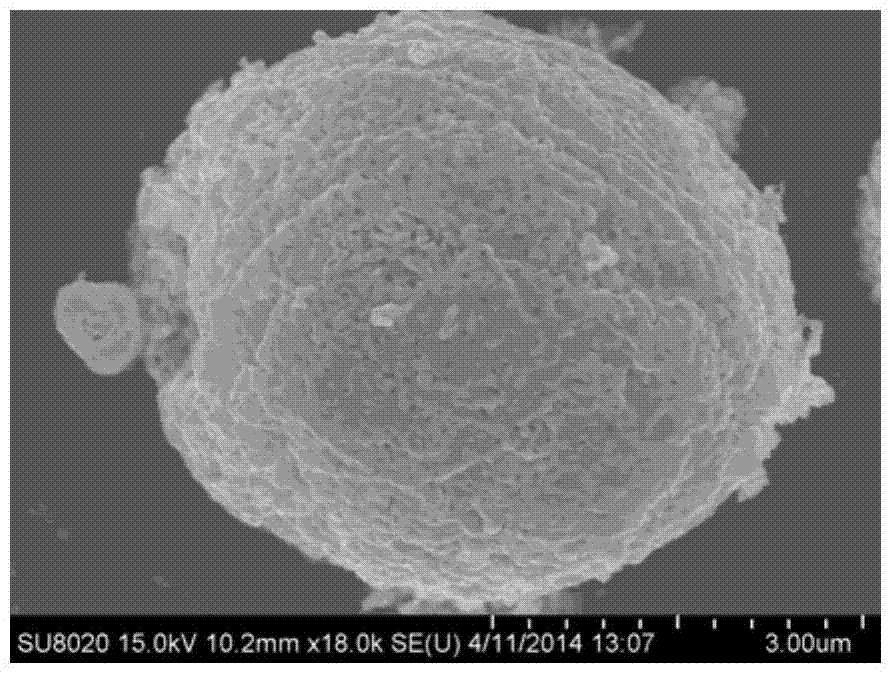

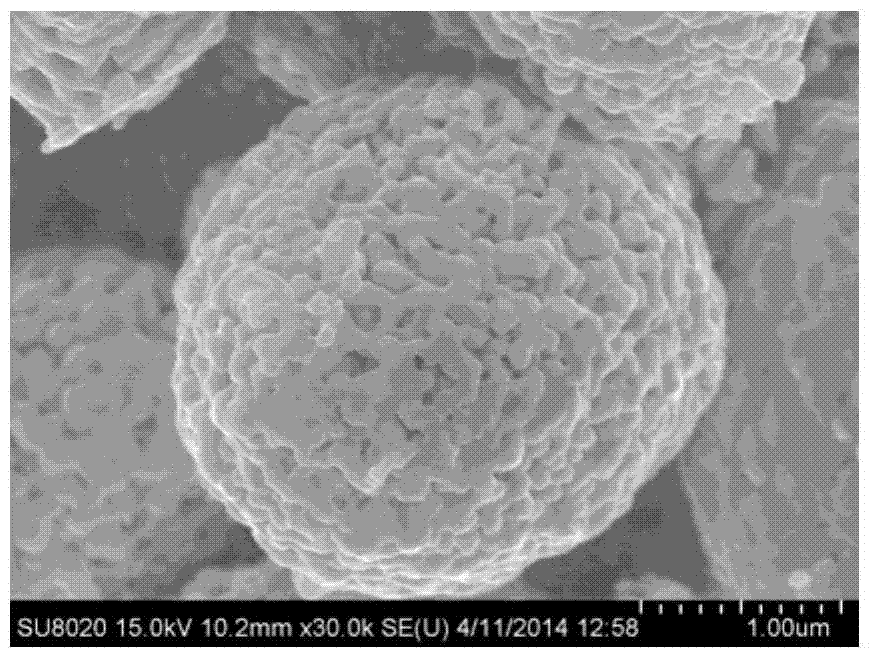

Preparation method of hollow porous tungsten oxide sphere

InactiveCN102161510ASmall specific surface areaTungsten oxides/hydroxidesTungstateAmmonium metatungstate

The invention provides a preparation method of hollow porous tungsten oxide spheres and belongs to the field of functional materials. The method comprises the following steps of: dissolving ammonium tungstate and / or ammonium metatungstate in water and stirring thoroughly to produce a solution with concentration of 1 g / L to 200 g / L; preparing hollow powder of ammonium tungstate, ammonium metatungstate or a mixture thereof by the spray drying of spray-drying equipment; and putting the powder in an electric furnace, heating up to a temperature of 400 DEG C to 1000 DEG C, and preserving heat for 15 minutes to 180 minutes to obtain hollow porous tungsten oxide spheres. The method needs simple equipment, shortens the process flow, increases the preparation efficiency and is simple and feasible for preparing porous tungsten oxide nano-spheres. The specific surface area of the hollow porous tungsten oxide spheres prepared by the method reaches 15 m<2> / g to 30 m<2> / g. The preparation method has good prospects for industrial applications.

Owner:BEIJING UNIV OF TECH

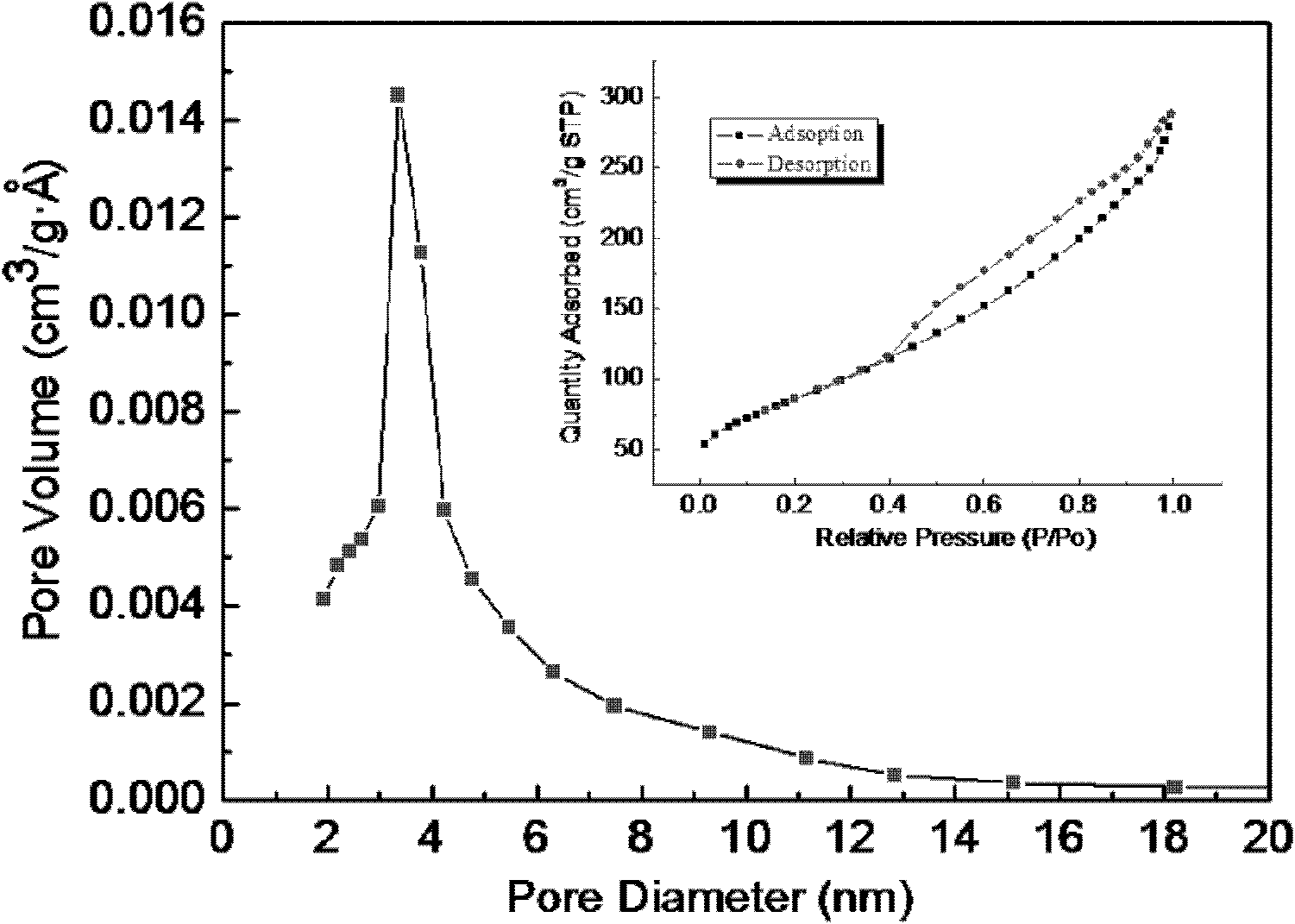

Preparation method of wolfram carbide-carbon (WC-C) composite material with large specific surface area

ActiveCN102069002AGood dispersionHigh surface areaCatalyst activation/preparationElectrodesAl powderAmmonium paratungstate

Owner:海宁市黄湾镇资产经营有限公司

Preparation method of wide-temperature range rare earth-based composite oxide denitration catalyst

ActiveCN104307553AShorten activation timeImprove temperature adaptabilityPhysical/chemical process catalystsDispersed particle separationCerium nitrateAmmonium metatungstate

The invention discloses a preparation method of a wide-temperature range rare earth-based composite oxide denitration catalyst. The preparation method comprises that titanium dioxide and montmorillonite as carriers, ammonium metatungstate, ammonium metavanadate, cerium nitrate and manganese oxide as active components and accessory materials are subjected to blending, ageing decaying, kneading, molding, drying and roasting to form the wide-temperature range rare earth-based composite oxide denitration catalyst, wherein the accessory materials comprise monoethanolamine, citric acid, ammonia water, lactic acid, stearic acid, glass fibers, wood pulp, hydroxypropyl methyl cellulose, polyoxyethylene, citric acid and water. The preparation method utilizes the rare earth-based composite oxide as an active ingredient, shortens catalyst activation time, effectively controls a SO2 / SO3 conversion rate, improves a catalyst temperature adaptation capability, widens a catalyst use temperature range from 320-400 DEG C to 150-420 DEG C, has denitration efficiency more than 90%, and can carry out ammonia spraying denitration operation at a denitration area temperature of 150 DEG C when a boiler is started.

Owner:山东信义汽车配件制造有限公司

Preparation method of nano tungsten carbide

A preparation method of nano tungsten carbide comprises the following steps: (1) dissolving ammonium metatungstate, chromium nitrate and a water-soluble carbon source substance into in heated deionized water, sufficiently mixing, and performing spray drying, wherein the weight percentage of the water-soluble carbon source substance is 10-30%, the weight percentage of the chromium nitrate is 0.5-2% and the temperature of the deionized water is 70 DEG C; (2) performing auxiliary hydrogen reduction on powdery carbon obtained in the step (1), and before discharging the powder out of a furnace, passivating the powder with an inert gas, wherein the temperature is 710-850 DEG C, the heating rate is 10-15 DEG C / min and the reaction time is 2-5h; (3) annealing tungsten powder obtained in the step (2) at high temperature, wherein the annealing temperature is 1000-1300 DEG C and the annealing time is 1-3h; and (4) carbonizing the tungsten powder obtained in the step (3), and before discharging the powder out of the furnace, passivating the powder with the inert gas, wherein the carbonizing ratio is 6.21wt.%, hydrogen is used as a protective atmosphere, the carbonizing temperature is 1100-1400 DEG C and the carbonizing time is 1-4h. The particle size of the prepared tungsten carbide is 60-90nm; after the prepared tungsten carbide is crushed, agglomeration-free nano tungsten carbide powder can be obtained; the environment is polluted; and the development of a nanocrystalline WC-Co hard alloy can be effectively promoted.

Owner:NANCHANG UNIV

Wear-resistant SCR (Selective Catalytic Reduction) denitration catalyst and preparation method thereof

ActiveCN103240078AImprove compactnessHigh hardnessDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsWear resistantAmmonium metatungstate

The invention discloses a wear-resistant SCR (Selective Catalytic Reduction) denitration catalyst and a preparation method thereof. The wear-resistant SCR denitration catalyst comprises the following main components in parts by weight: 80-90 parts of titanium dioxide, 0.5-3 parts of vanadium pentoxide, 3-7 parts of tungsten trioxide, 1-5 parts of aluminum oxide and 3-8 parts of silicon dioxide. The preparation method comprises the following steps of: (1) adding aluminum isopropoxide into a nitric acid solution to prepare hydrated alumina sol; (2) uniformly and dryly mixing the titanium dioxide powder, ammonium metavanadate powder and ammonium metatungstate powder, then adding the hydrated alumina sol, deionized water and oxalic acid, and mixing and stirring the mixture; (3) adding silica sol into the material obtained in the step (2); (4) uniformly mixing the material obtained in the step (3), and then, adding a structure promoter; and (5) extruding the material obtained in the step (4), and drying and roasting the carrier blank. The wear resistant property of the wear-resistant SCR denitration catalyst disclosed by the invention is improved by 20-40%, and the service life of the catalyst is prolonged.

Owner:CHONGQING YUANDA CATALYST MFG

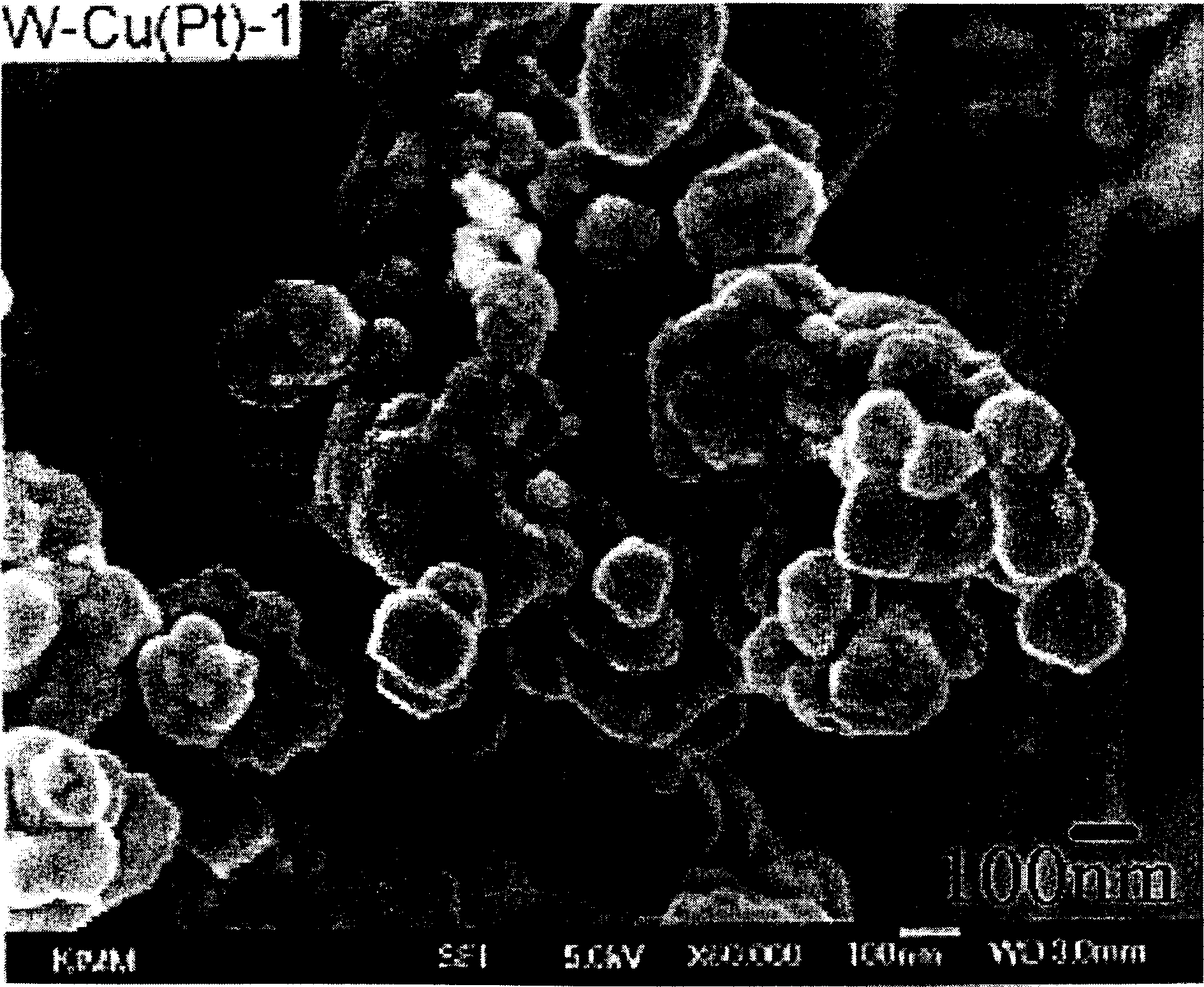

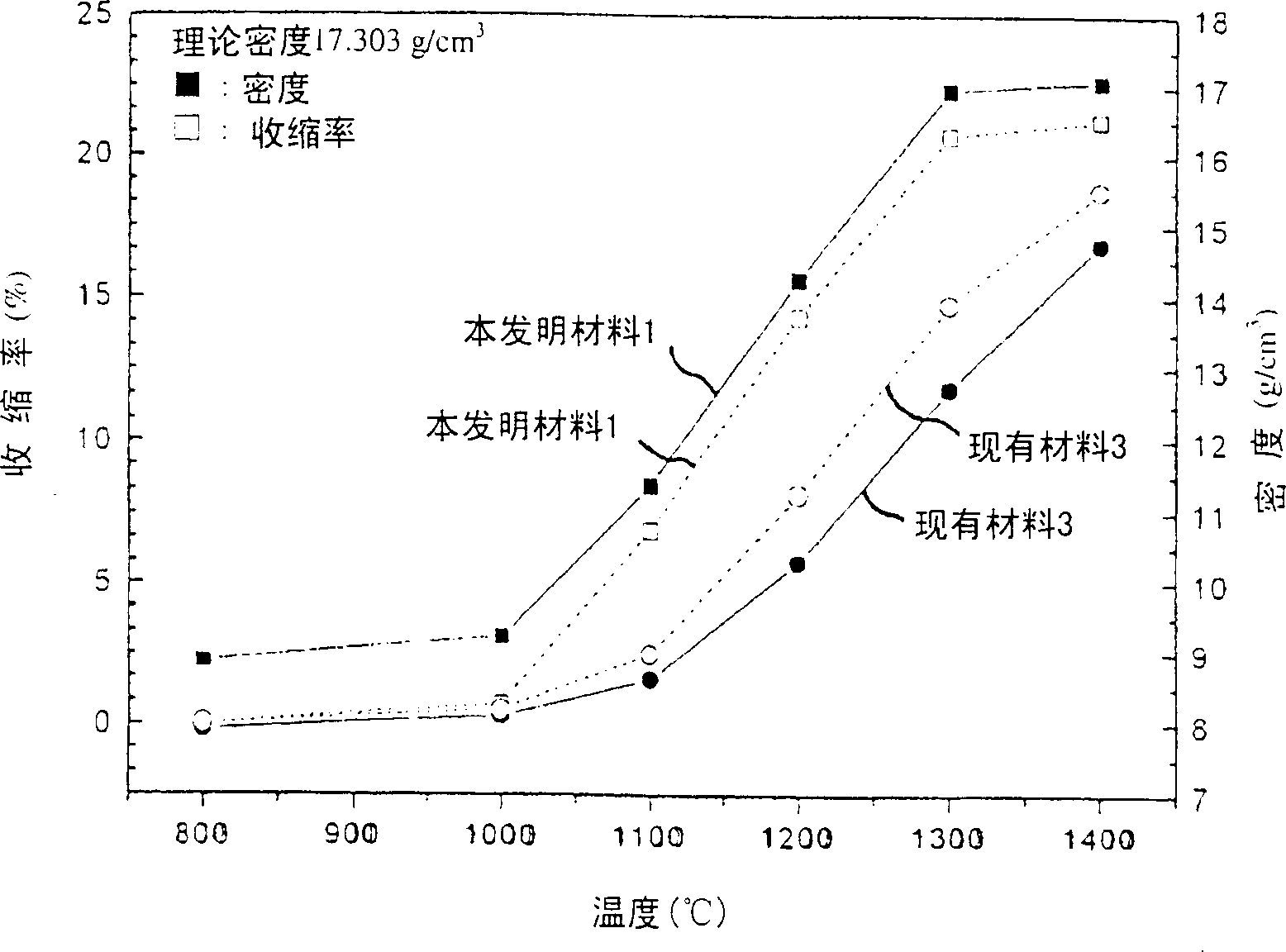

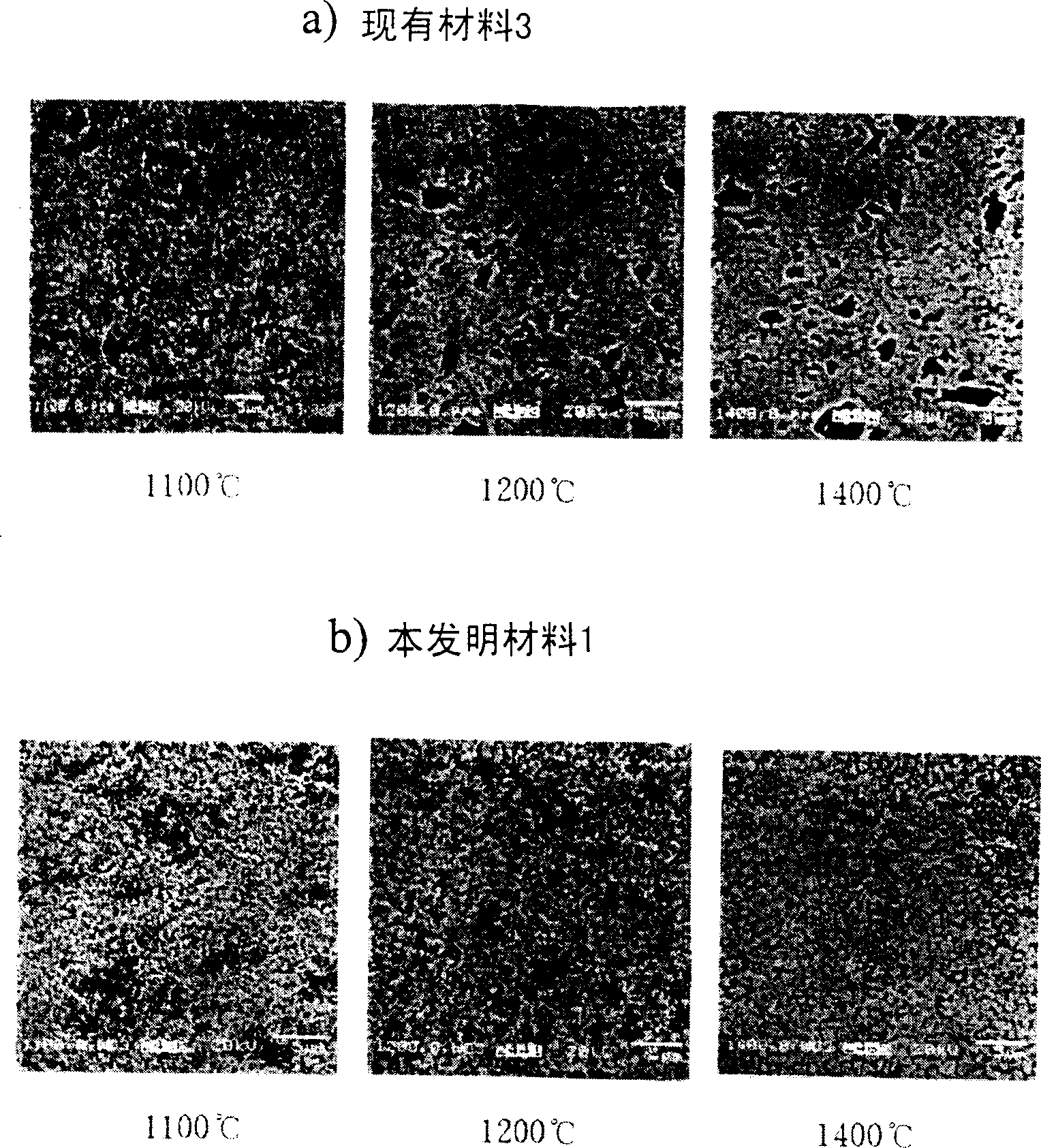

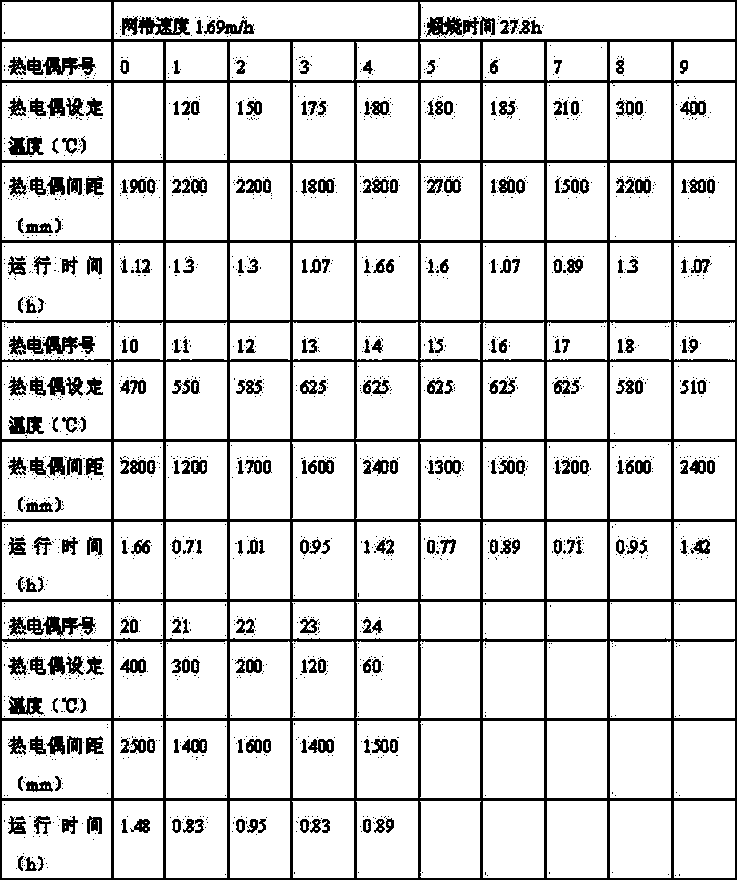

Method for preparing tungsten-copper base composite powder and sintered alloy made up by using said composite powder for making radiator

InactiveCN1428218AImprove sinterabilityImprove conductivityThin material handlingTungsten compoundsAmmonium paratungstateAmmonium metatungstate

The present invention relates to a method of producing W-Cu based composite powder, which is used in heat-sink materials for high-power integrated circuits, electric contact materials, etc, and to a method of producing a W-Cu based sintered alloy by using the composite powder. The method of producing tungsten-copper based composite powder includes first preparing composite oxide powder by dissolving ammonium metatungstate, [(NH4)6(H2W12O40).4H2O], as water-soluble tungsten salt, and copper nitrate or copper acetate in water to the desirable composition, followed by spray-drying and calcining; then preparing a tungsten oxide powder by separately calcining a tungsten-containing salt, such as ammonium paratungstate, (NH4)10(H10W12O46); forming ultra-fine tungsten-copper based composite oxide powder by mixing 20~75wt % of the composite oxide powder and 80~25wt % of the tungsten oxide powder to the desirable composition, followed by ball-milling; and reducing the ultra-fine tungsten-copper based composite oxide powder at temperature of 650~1,050 DEG C. If the composite powder is molded into a certain size and sintered thereafter in temperature of 1,110~1,450 DEG C., a W-Cu based sintered alloy of superior thermal and electric conductivities can be obtained thereby.

Owner:KOREA INST OF MACHINERY & MATERIALS

Honeycomb type selective catalytic reduction denitration catalyst and preparation method thereof

ActiveCN103586016AHigh mechanical strengthImprove wear resistanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActive componentAmmonium metatungstate

The invention relates to a honeycomb type selective catalytic reduction denitration catalyst and a preparation method thereof. According to the total mass of the catalyst, the catalyst comprises components of raw materials in percentage by mass as follows: 78%-84% of titanium dioxide, 4%-6% of clay, 0.5%-1.5% of an active component precursor, 4.5%-5% of a promoter precursor, 0.2%-0.5% of a static elimination agent, 0.1%-0.3% of a mold release, 0.1%-0.4% of an pH modifier, 0.3%-0.8% of a pore-forming agent, 4%-6% of a reinforcing agent and 1.8%-2.7% of a water retention binding agent, wherein the active component precursor is ammonium metavanadate, and the promoter precursor is ammonium metatungstate. A small quantity of the pore-forming agent, the reinforcing agent and the water retention binding agent is added, so that on one hand, the mechanical strength of the catalyst is improved, and the wear resistance of the catalyst is improved, and on the other hand, the specific surface area of the catalyst is increased, the activity of the catalyst can be improved and the contact area of the catalyst and NOx gas can be increased, and the conversion rate of the NOx is increased.

Owner:湖北景目环保科技有限公司

Denitration catalyst activity mother liquor preparation method and application of denitration catalyst activity mother liquor

InactiveCN104841420AWear-resistantCorrosion resistanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsOxalateAmmonium metatungstate

The invention discloses a denitration catalyst activity mother liquor preparation method, which comprises the following steps: dissolving ammonium metatungstate and ammonium metavanadate into oxalic acid solutions respectively; adding active TiO2 and SiO2 mixed powder into the oxalic acid solution which contains the ammonium metatungstate, mixing, then drying and calcining; adding obtained TiO2-SiO2 / WO3 mixed powder into the oxalic acid solution which contains the ammonium metavanadate, and mixing; finally adding binder to obtain denitration catalyst activity mother liquor. The invention further discloses an application of the denitration catalyst activity mother liquor. The denitration catalyst activity mother liquor is sprayed onto the inner side of a dedusting element; after drying and calcining are carried out, a dedusting unit provided with a denitration catalyst coating which contains TiO2-SiO2 / WO3 / V2O5 active matters is formed. By applying the preparation method disclosed by the invention, the stability of the active denitration catalyst mother liquor is high, the combinability of the active denitration catalyst on the dedusting element is high, and the active denitration catalyst can be widely applied to porous ceramic tube carriers for dedusting.

Owner:GUANGZHOU DEVOTION THERMAL TECH

Method for preparing (NH4)2WS4

The present invention relates to improved preparation process of high purity chemical. High purity ammonium tetrathiotungstate is prepared through the reaction between ammonium metatungstate or tungsten trioxide and ammonium sulfate solution. Preparing high purity ammonium tetrathiotungstate in the said process of the present invention has ammonium sulfate amount near the required stoichiometric amount, mild reaction condition, short reaction period, less waste exhaust, high product yield, high product purity, and no need of treating virulent and effluvial hydrogen sulfide gas.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

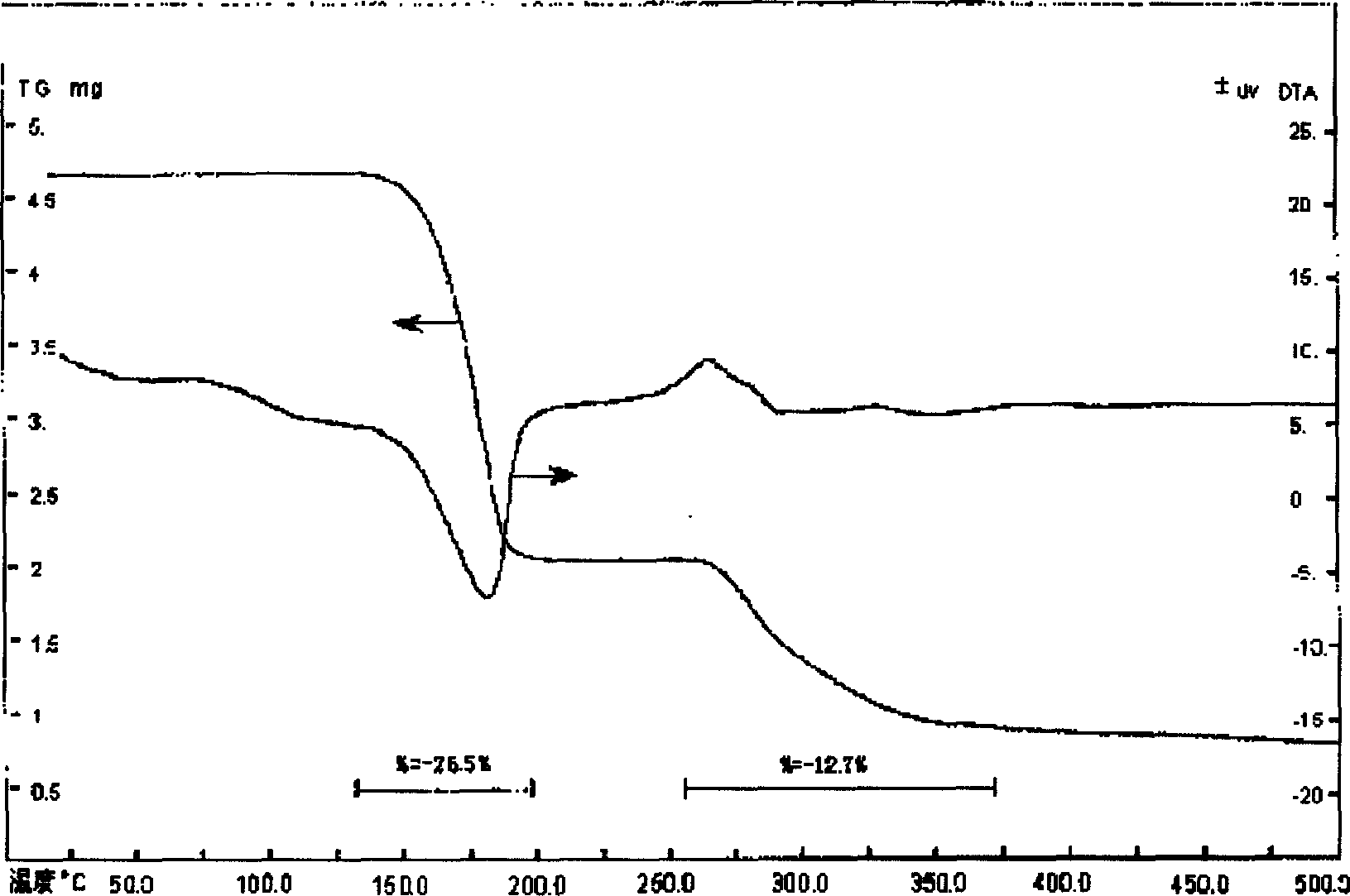

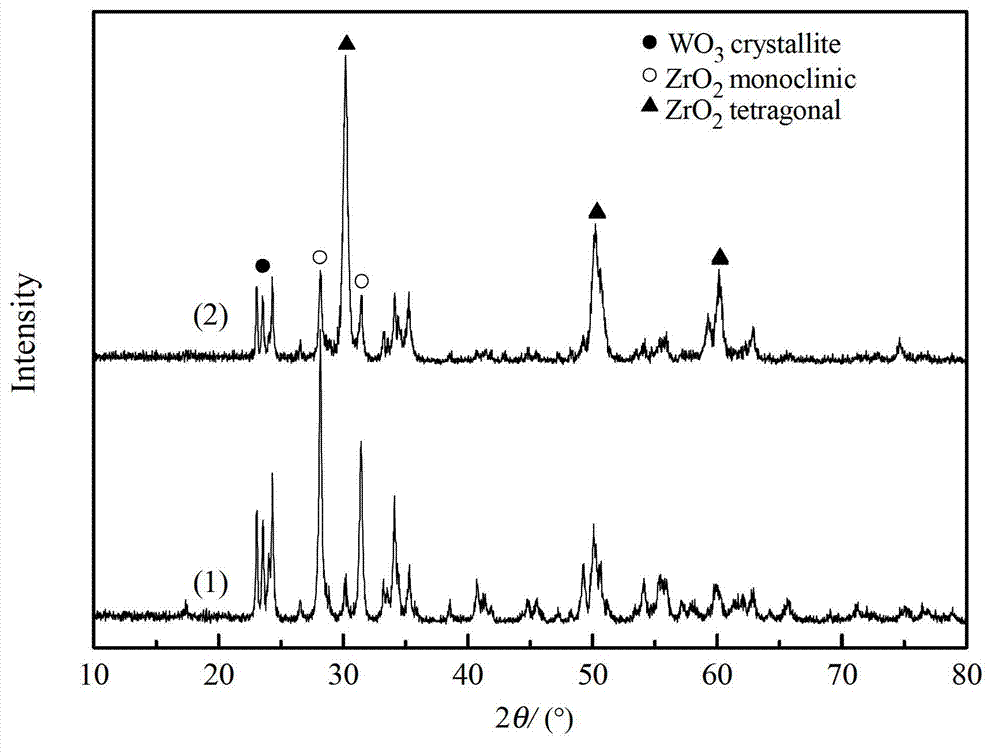

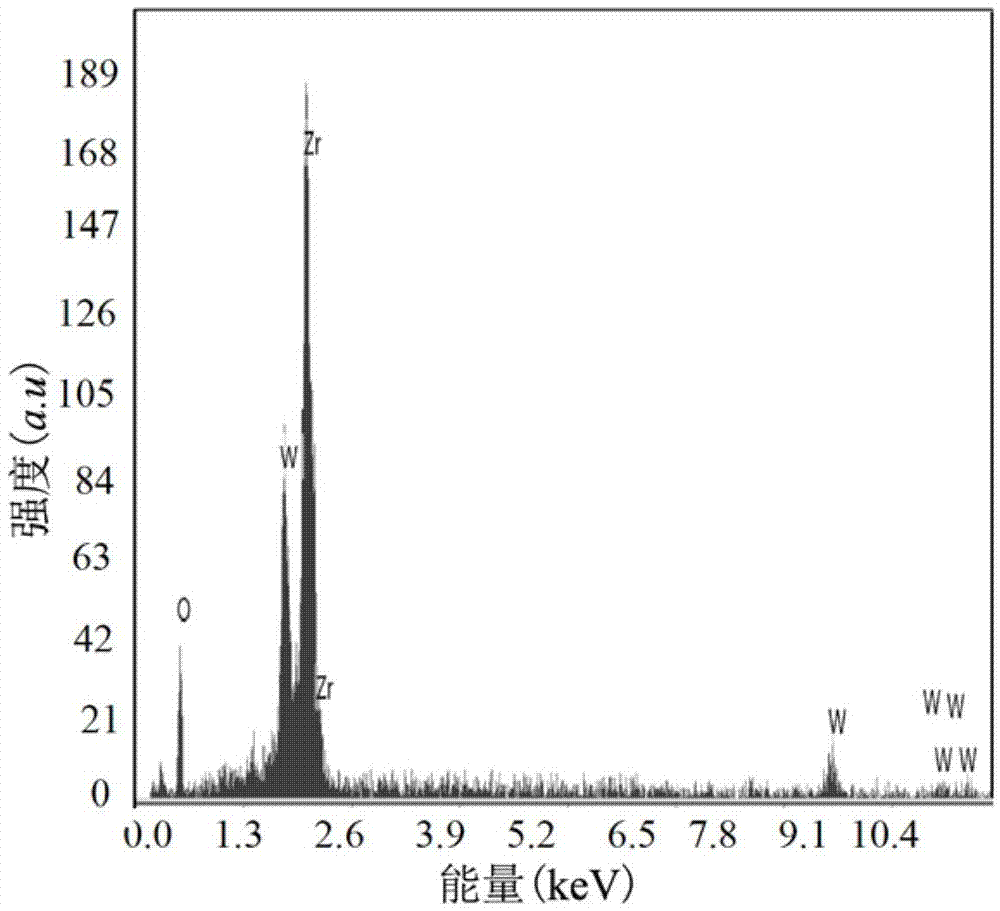

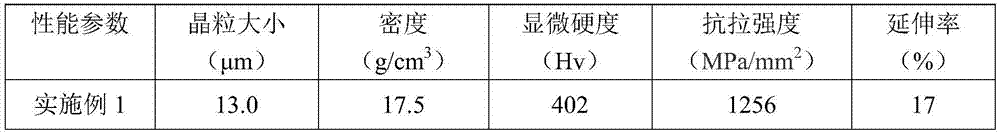

Preparation method of WO3/ZrO2 solid super acidic catalyst

InactiveCN103041800ARaise the ratioEvenly distributedHydrocarbon by isomerisationMetal/metal-oxides/metal-hydroxide catalystsEmulsionReaction temperature

The invention relates to a preparation method of a WO3 / ZrO2 solid super acidic catalyst. The method comprises the following steps that a zirconium hydroxide emulsion is heated in a round-bottom flask with a condenser pipe for 1-24h; a zirconium hydroxide solution is repeatedly leached and washed till a pH value of a filtrate is 6-8 and no chlorion exists; a zirconium hydroxide filter cake is soaked in C2H5OH with the concentration of 99% in a constant-temperature drying oven; drying is conducted after C2H5OH is removed; powdery zirconium hydroxide is obtained, and ground till a particle size is less than 80 meshes; and then ammonium metatungstate serves as a raw material, and is impregnated by an equal-volume method, dried and roasted to form the WO3 / ZrO2 solid super acidic catalyst. The method has the advantages of easiness and simplicity in operation, low reaction temperature, good stability and the like; in addition, in the WO3 / ZrO2 solid super acidic catalyst prepared by the method, the proportion of a tetragonal phase of zirconium dioxide is increased; a specific surface area is increased; the activity of catalytic reaction is improved obviously; and the cost is lowered effectively.

Owner:NORTHEAST GASOLINEEUM UNIV

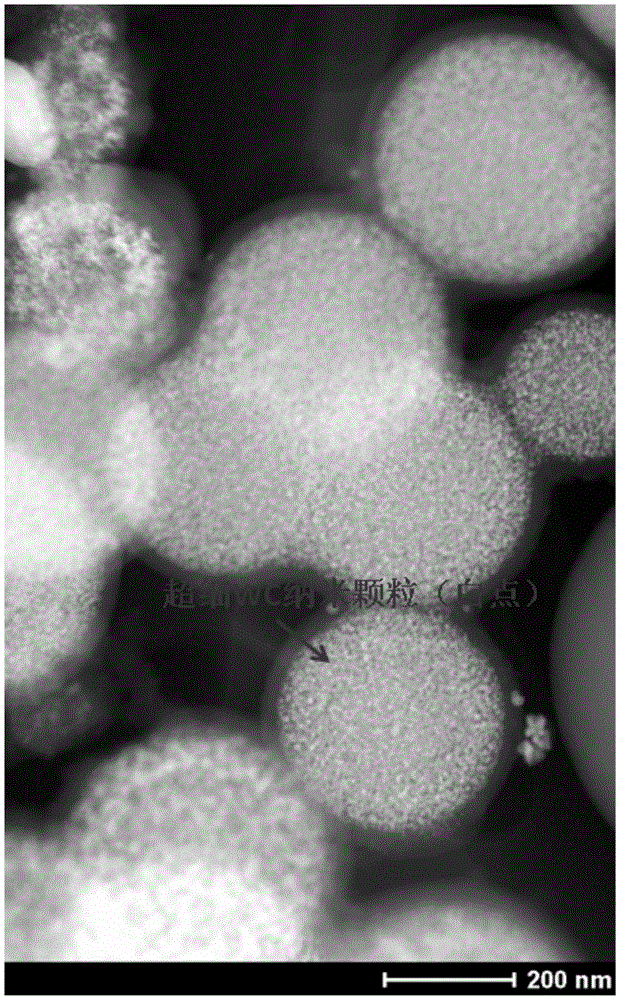

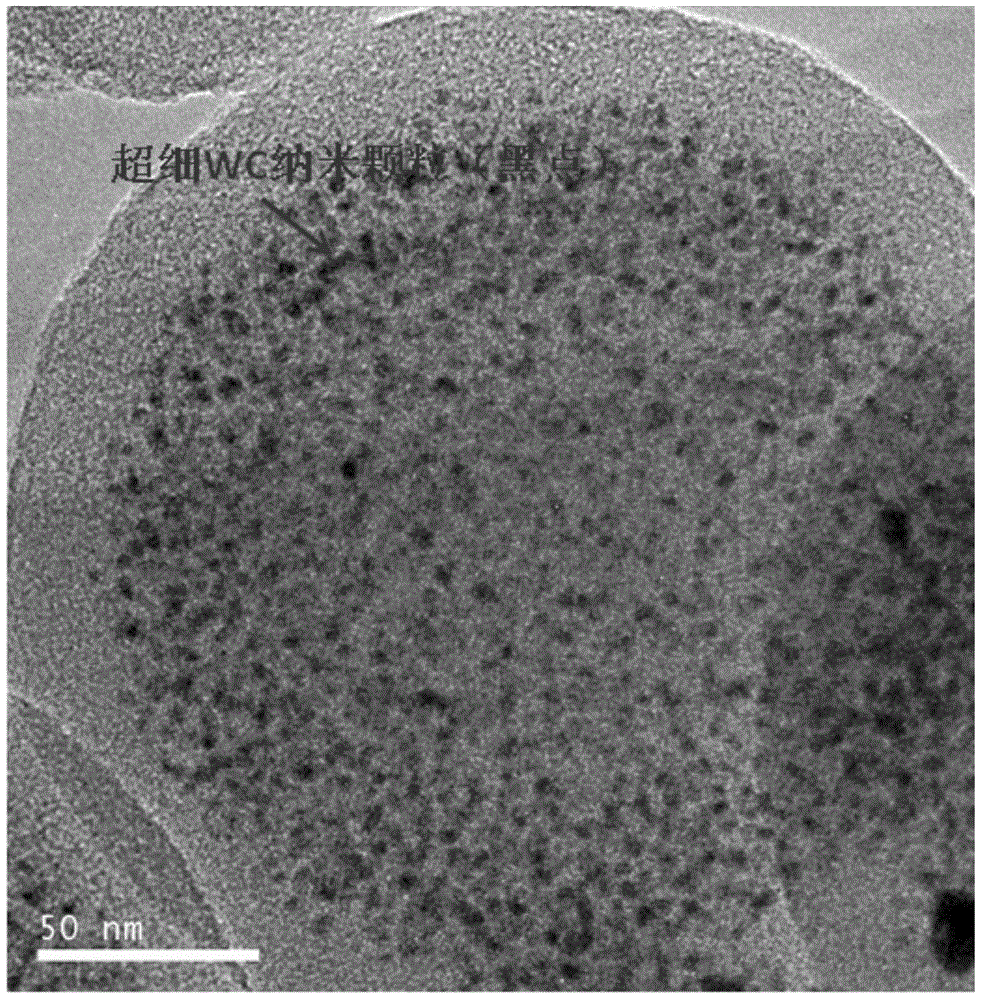

Carbon resistance superfine nano wolfram carbide material as well as preparation method and application thereof

InactiveCN103818906AHighly uniform dispersionAvoid reunionPigmenting treatmentPhysical/chemical process catalystsCarbon resistanceCarbonization

The invention discloses a carbon resistance superfine nano wolfram carbide (WC) material as well as a preparation method and application thereof. The preparation method of the carbon resistance superfine nano WC material comprises the following steps: (1) adding a deionized water solution of a wolfram source in a solution prepared from ethanol, stronger ammonia water and a surfactant, wherein the wolfram source is ammonium metatungstate, sodium tungstate or tungsten chloride, the surfactant is sodium dodecyl benzene sulfonate, hexadecyl trimethyl ammonium bromide or P123, stirring the solution uniformly, adding resorcinol to the solution, stirring uniformly and then adding formaldehyde, and stirring for 8-28 hours at the room temperature to obtain the mixed solution; (2) performing a hydrothermal reaction on the mixed solution, and drying the solution to obtain a mixed polymer; (3) performing high-temperature carbonization on the mixed polymer in a CO atmosphere to obtain the carbon resistance superfine nano WC material. The WC material can enable the WC particles to keep stable in the high temperature process without secondary agglomeration; the WC material can be taken as an electrocatalyst to be applied to an electrocatalysis nitroreduction reaction, or can also be taken as a carrier to prepare a platinum-carried catalyst, and the prepared platinum-carried catalyst can be applied to anode catalysis of a methanol fuel cell.

Owner:ZHEJIANG UNIV OF TECH +1

Denitration catalyst and preparation method thereof

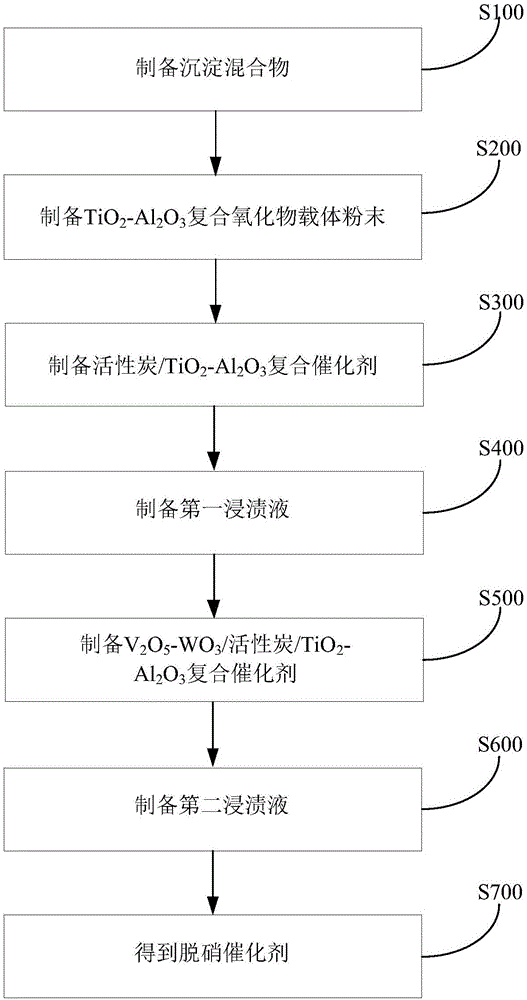

The invention discloses a denitration catalyst and a preparation method thereof. The preparation method comprises the following steps: preparing a precipitate mixture of titanium hydroxide and aluminium hydroxide; drying and roasting the precipitate mixture to obtain TiO2-Al2O3 compound oxide carrier powder; extruding, forming, sizing and drying the TiO2-Al2O3 compound oxide carrier powder, activated carbon powder, enamelled powder and an adhesive to obtain an activated carbon / TiO2-Al2O3 compound catalyst; dissolving ammonium metatungstate and ammonium metavanadate in oxalic acid to obtain first impregnation liquid; impregnating the activated carbon / TiO2-Al2O3 compound catalyst in the first impregnation liquid to obtain a V2O5-WO3 / activated carbon / TiO2-Al2O3 compound catalyst; preparing second impregnation liquid; and impregnating the V2O5-WO3 / activated carbon / TiO2-Al2O3 compound catalyst in second impregnation liquid to obtain the denitration catalyst. The denitration catalyst prepared by the method disclosed by the invention has relatively high denitration catalytic activity, is high in wear resistance and acid resistance and wide in active temperature region, and can recover waste heat while performs denitration treatment on to-be-treated flue gas.

Owner:SHENWU TECH GRP CO LTD

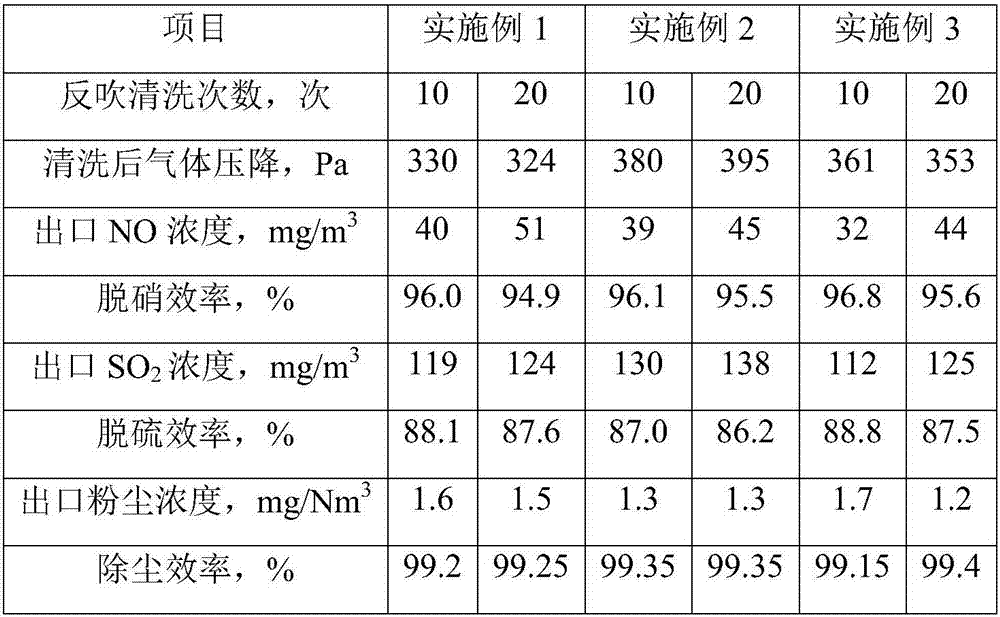

Ceramic catalytic filter element for flue gas purification and flue gas desulfurization and denitrification integrated dust removal method

ActiveCN107876043AExtended service lifeReduce loadDispersed particle filtrationTransportation and packagingActive matrixFlue gas

The invention relates to a ceramic catalytic filter element for flue gas purification and a flue gas desulfurization and denitrification integrated dust removal method. The ceramic catalytic filter element is prepared from the following steps that a microporous alumina ceramic filter tube with a pore diameter of 40-80 microns is taken as a matrix; the matrix is immersed in a mixed sol made of zincacetate, and after the matrix is impregnated under a negative pressure, the matrix is roasted to obtain a modified matrix modified by zinc oxide; an equal volume impregnation method is adopted, and the modified matrix is impregnated with an mixed oxalic acid solution containing ammonium metavanadate and ammonium metatungstate, so that total loading mass of V2O5 and WO3 in pores of the matrix reaches 4.0%-6.0% to obtain an active matrix; the active matrix is immersed in a mixed sol made of Al2O3-SiO2-TiO2, the active matrix is dried and roasted after the active matrix is taken out, and a densefilm with a thickness of 0.2-0.6 millimeter and a pore diameter of 1-10 microns is formed on the outer surface of the active matrix to obtain the ceramic catalytic filter element. A denitrification catalyst of the ceramic catalytic filter element has the advantages of being strong in load, high in denitrification efficiency, long in service life and applicable to popularizing and using.

Owner:济南玉泉生物发电有限公司

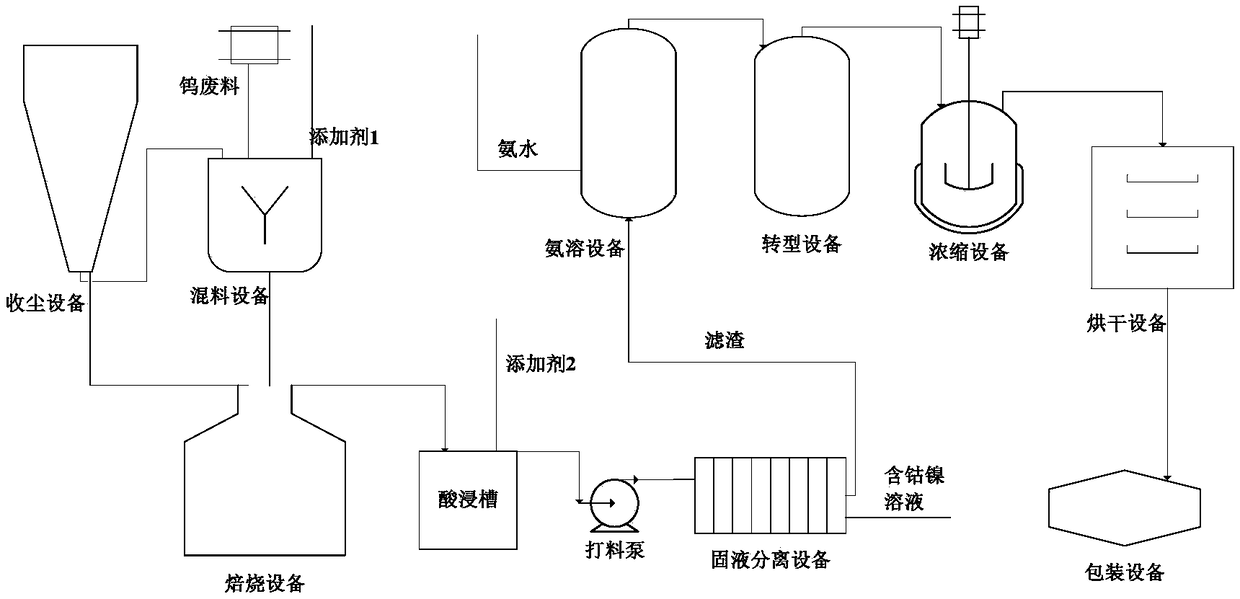

Method for producing ammonium metatungstate by wolfram-containing waste and device thereof

ActiveCN108751259ACobalt content is unlimitedEfficient use ofTungsten compounds preparationTungstateSlag

The invention relates to a method for producing ammonium metatungstate by a wolfram-containing waste and a device thereof. The method comprises the following steps: mixing the wolfram-containing wasteand an additive 1 to obtain a mixture; roasting the mixture, to obtain a roasted material; adding an additive 2 into the roasted material and reacting, to obtain a solid-liquid mixture; filtering thesolid-liquid mixture to obtain a filter residue and filtrate, adding the filter residue into ammonia water, performing extraction or ion exchange on an obtained ammonium tungstate solution, and evaporating and crystallizing an obtained ammonium metatungstate solution, to obtain the ammonium metatungstate. The method for producing the ammonium metatungstate by the wolfram-containing waste is suitable for recovering treatment of multiple wolfram-containing wastes, such as a floor material, a dust collecting material, a grinding material and a waste material generated in a hard alloy productionprocess, and a floor material, a dust collecting material and a waste material generated in production processes of wolfram carbide powder and tungsten powder; general material mixing devices and roasting devices are used, clotted slag is avoided, a tungsten recovery rate is high, and the method has great popularization significance.

Owner:XIAMEN TUNGSTEN +1

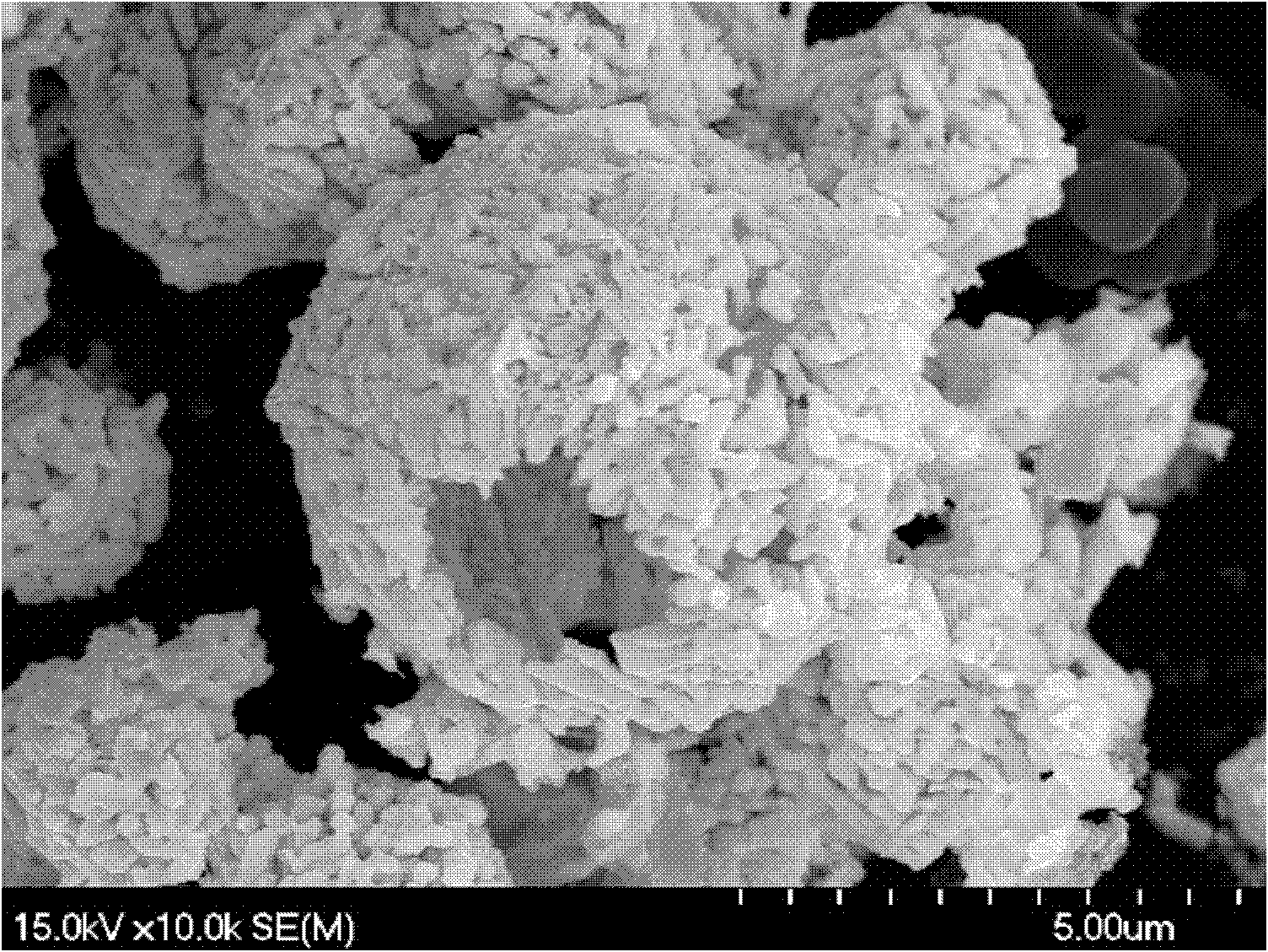

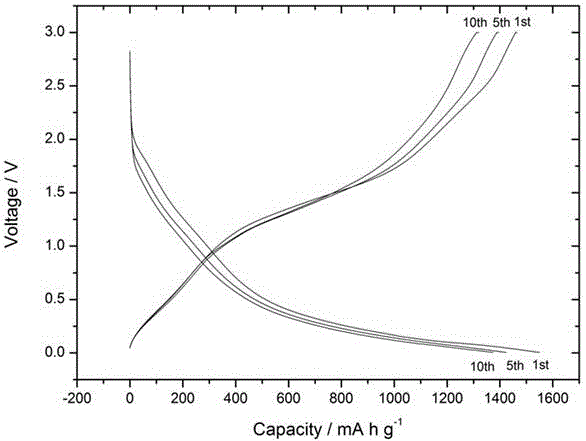

Preparation method of cobalt-doped nano tungsten oxide negative electrode material

ActiveCN106654245ASmall granularityUniform particle sizeMaterial nanotechnologyTungsten oxides/hydroxidesAqueous alcoholAmmonium metatungstate

The invention discloses a preparation method of a cobalt-doped nano tungsten oxide negative electrode material and belongs to the technical field of lithium-ion batteries. The method comprises the following steps of adding ammonium metatungstate, cobalt nitrate and dimethyl imidazole to deionized water to prepare a mixed solution, carrying out vibration dispersion by using an ultrasonic generator, adjusting the pH value to 1-2, transferring the solution into a stainless steel reaction kettle, reacting at 170 DEG C for 4-6 days and naturally cooling to a room temperature; filtering the solution, washing the solution by using the deionized water and ethyl alcohol for multiple times and drying; putting the dried uniform powder into an aluminum oxide crucible, putting the aluminum oxide crucible into an atmosphere furnace and roasting in an air environment, wherein the roasting temperature is 500-600 DEG C and the heat preservation temperature is 1-2 hours; carrying out furnace cooling after roasting is completed to obtain a roasted product, namely the cobalt-doped nano tungsten oxide material; and taking out the product and grinding the product to obtain fine cobalt-doped nano tungsten oxide material. The cobalt-doped nano tungsten oxide material prepared by the method has the advantage of being small and uniform in particle size, the heat preservation time in the roasting process is relatively short, uniform and fine particles are ensured and growth of the particles is avoided.

Owner:KUNMING UNIV OF SCI & TECH

Missile heavy-gravity tungsten alloy and preparation method thereof

Owner:HENAN UNIV OF SCI & TECH

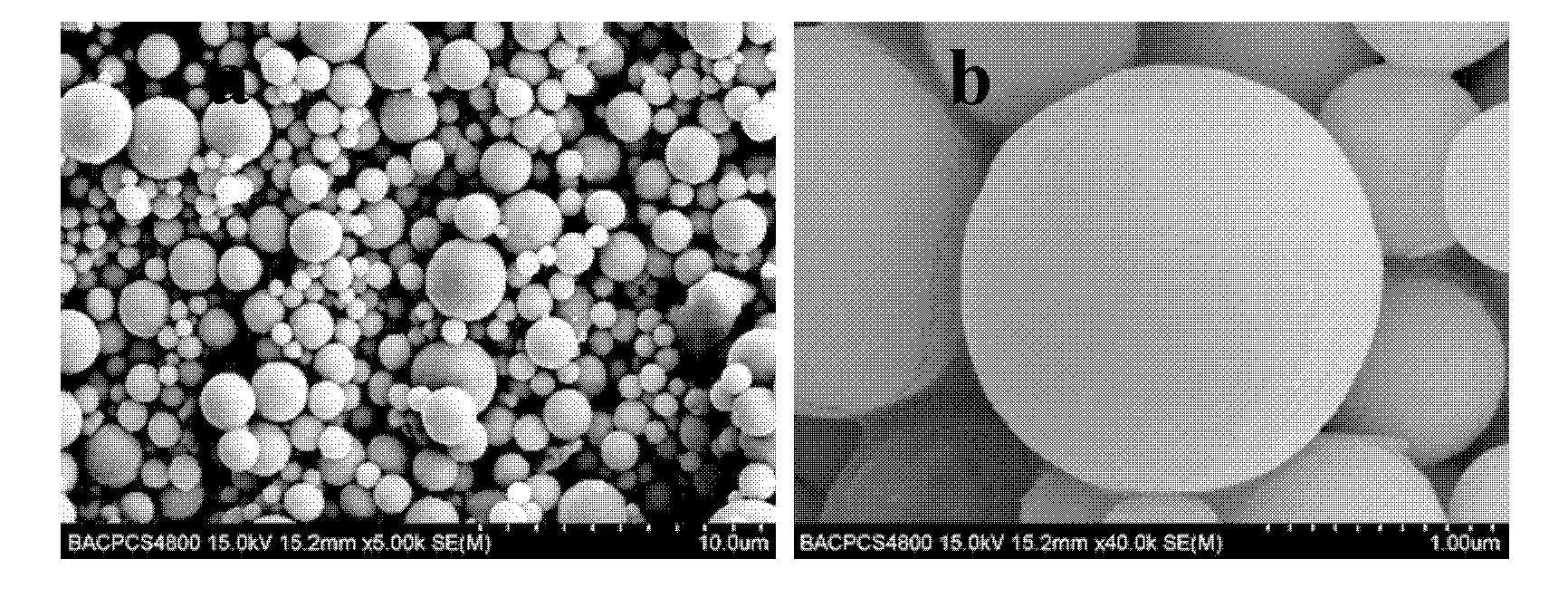

Porous spherical tungsten rhenium alloy powder and preparation method thereof

The invention relates to a porous spherical tungsten rhenium alloy powder and a preparation method thereof, and belongs to the technical field of alloy powder. The mixture of tungsten and rhenium is in the atomic level, the content of the tungsten in proportion by weight ranges from 25% to 90%, and the content of the rhenium in proportion by weight ranges from 10% to 75%. The method includes adopting ammonium perrhenate and ammonium metatungstate as raw materials, configuring into solution, and preparing precursor powder by the spray drying method; depositing and reducing in the atmosphere of hydrogen gas in two steps, namely in the first step,allowing the temperature to be 450 to 550 DEG C and insulating heat for 1 to 2 hours, in the second step, allowing the reducing temperature to be 850 to 950 DEG C, and insulating heat for 2 to 3 hours; and obtaining the porous spherical tungsten rhenium alloy powder. According to the method, process is simple, repeatability and operability are high, the introduction of impurity elements in the preparation process is avoided, the purity of prepared samples is high, and appearance control of a porous spherical tungsten rhenium alloy ball can be implemented by controlling the content of the tungsten, the reducing temperature and heat insulating time.

Owner:韶关元泰资源科技有限公司

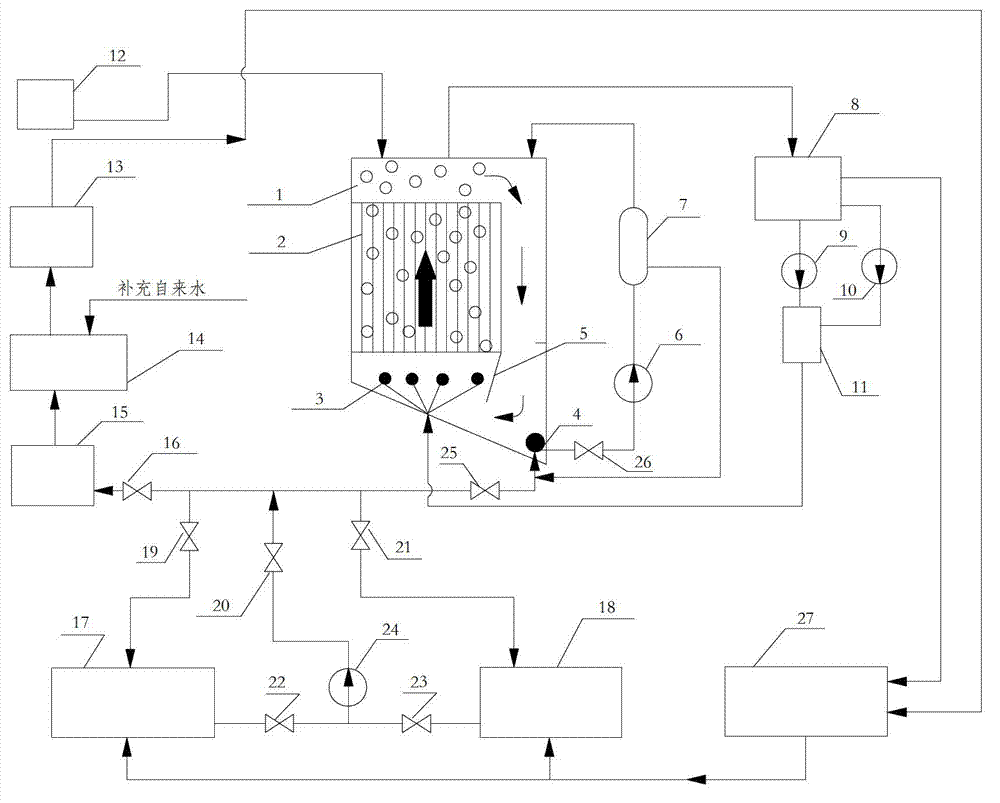

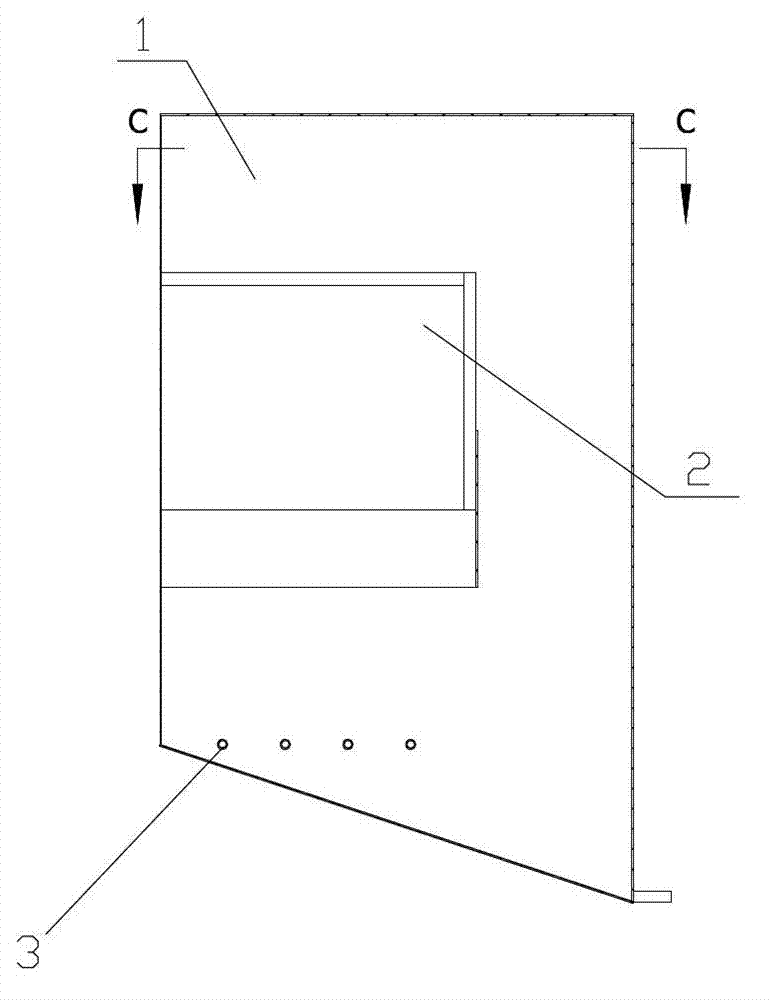

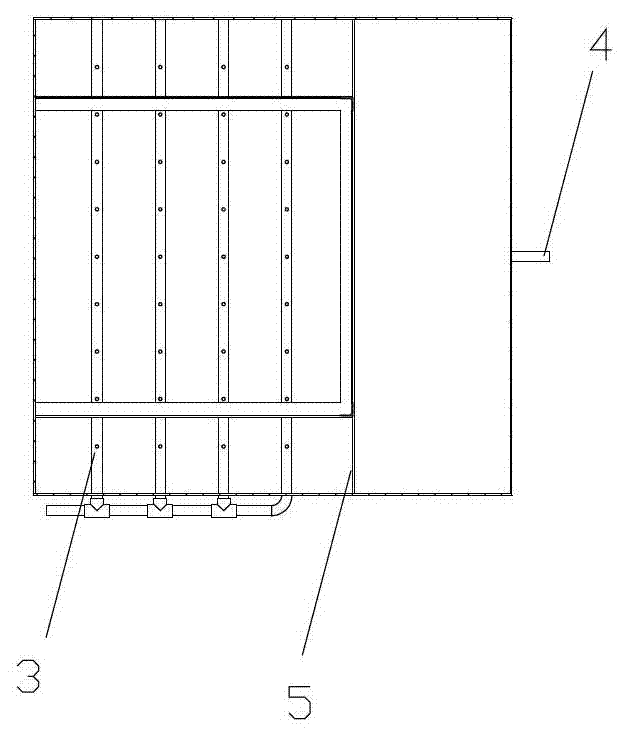

Technique and system device for regenerating exhaust gas denitration catalyst

InactiveCN103203239AReduce volumeEmission reductionWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentSodium ascorbateAmmonium metatungstate

The invention relates to a technique and a system device for regenerating exhaust gas denitration catalyst, and belongs to the technical field of exhaust gas processing of coal-fired power plant. The processing steps includes cleaning the denitration catalyst in a recirculation state and performing activation and dehydration on the denitration catalyst in the recirculation state. The detergent is composed of polyacrylic acid, nonylphenol polyoxyethylene ether, fatty alcohol-polyoxyethylene ether and sodium ascorbate; temperature is controlled at 40 DEG C; the activate fluid is composed of oxalic acid, ammonium metavanadate, ammonium metatungstate; and methane acid used for controlling PH value is 1% wt. The processes of soaking, cleaning, activating, dehydrating and the like for regenerating catalyst are integrated to implement in one container or two, so that volume of regeneration system is remarkably reduced, regeneration procedure and operation steps are simplified, energy consumption is reduced by 50%, and air pollution caused by exhaust gas is avoided.

Owner:深圳市水苑水工业技术设备有限公司

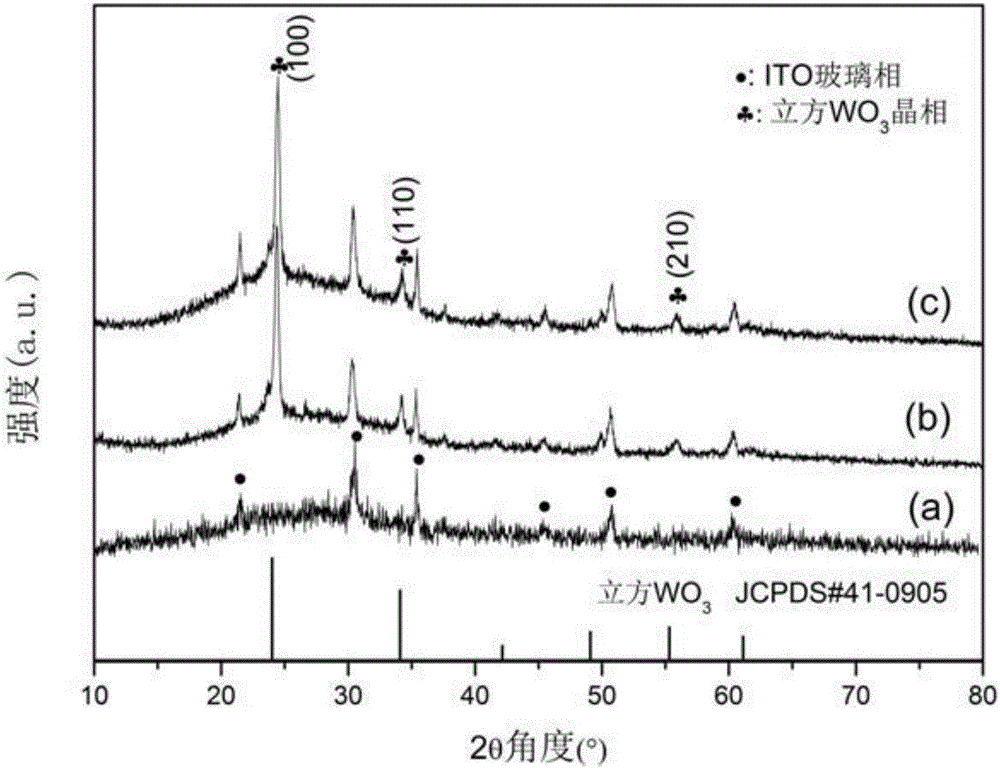

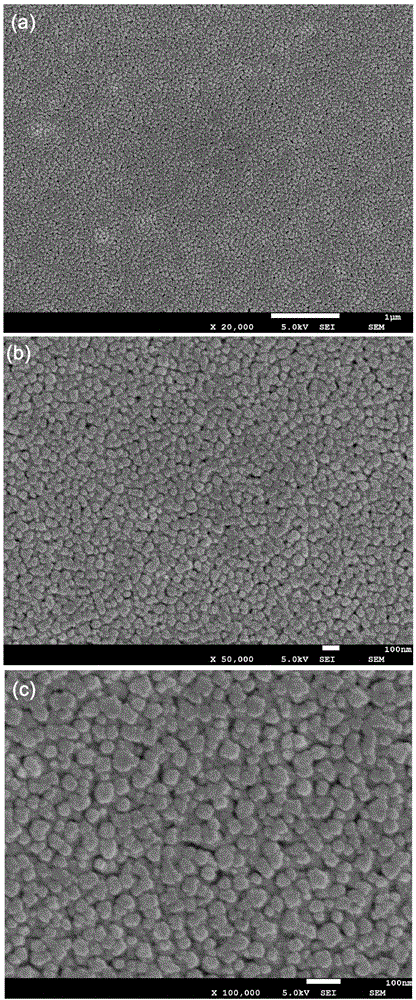

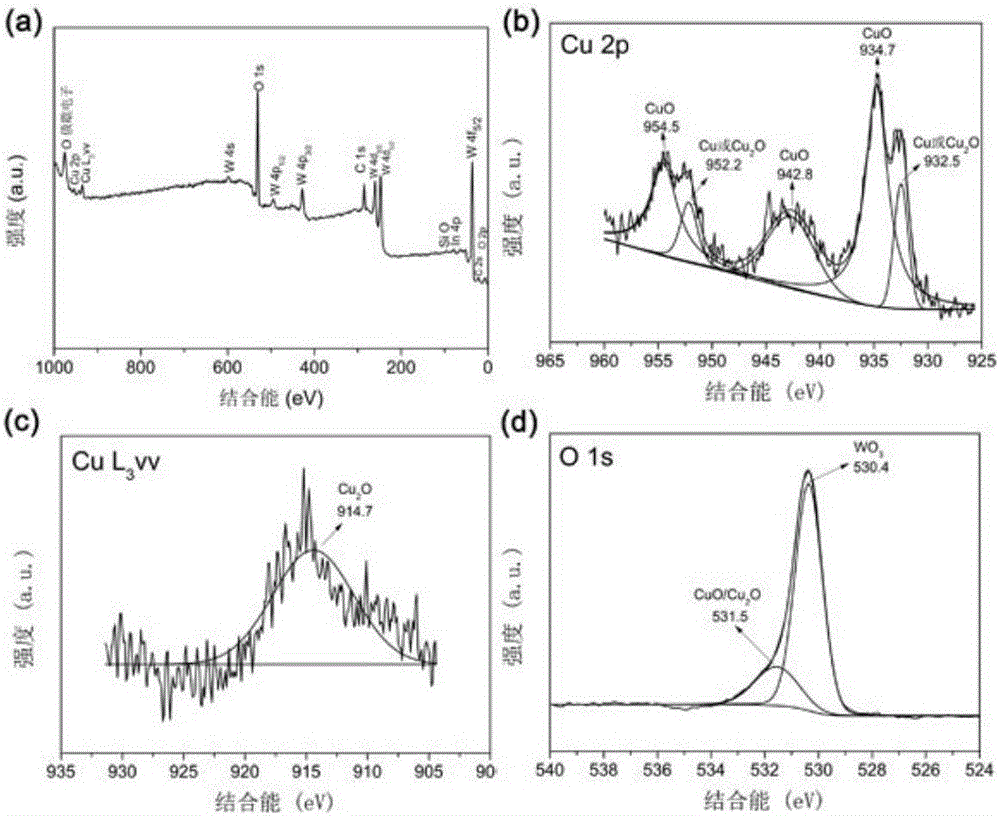

Preparation method of Cu2O/CuO/WO3 composite heterojunction thin film

InactiveCN106669716AEvenly distributedEasy transferWater/sewage treatment by irradiationWater treatment compoundsAir atmosphereHeterojunction

The invention discloses a preparation method of a Cu2O / CuO / WO3 composite heterojunction film. The preparation method comprises the following steps: preparing a precursor sol: weighing polyvinylpyrrolidone (PVP), adding distilled water, performing magnetic stirring, dissolving to obtain a PVP sol, then adding 0.5-5 g of ammonium metatungstate, stirring till the ammonium metatungstate is completely dissolved, adding 0.02-0.2 g of copper acetylacetonate and continuously stirring till complete dissolution to obtain the precursor sol; spin-coating the precursor sol on a substrate, drying in a drying box to obtain an initial film; finally calcining the initial film in an air atmosphere to obtain the Cu2O / CuO / WO3 ternary complex heterojunction thin film. Film-forming equipment required for the method disclosed by the invention is simple, required raw materials are low in cost, and the obtained thin film is level in surface, uniform in distribution and high in photo-catalytic activity.

Owner:JIANGSU JIANZHONG NEW MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com