Method for preparing tungsten-copper base composite powder and sintered alloy made up by using said composite powder for making radiator

A copper-based composite and powder technology, used in tungsten compounds, chemical instruments and methods, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

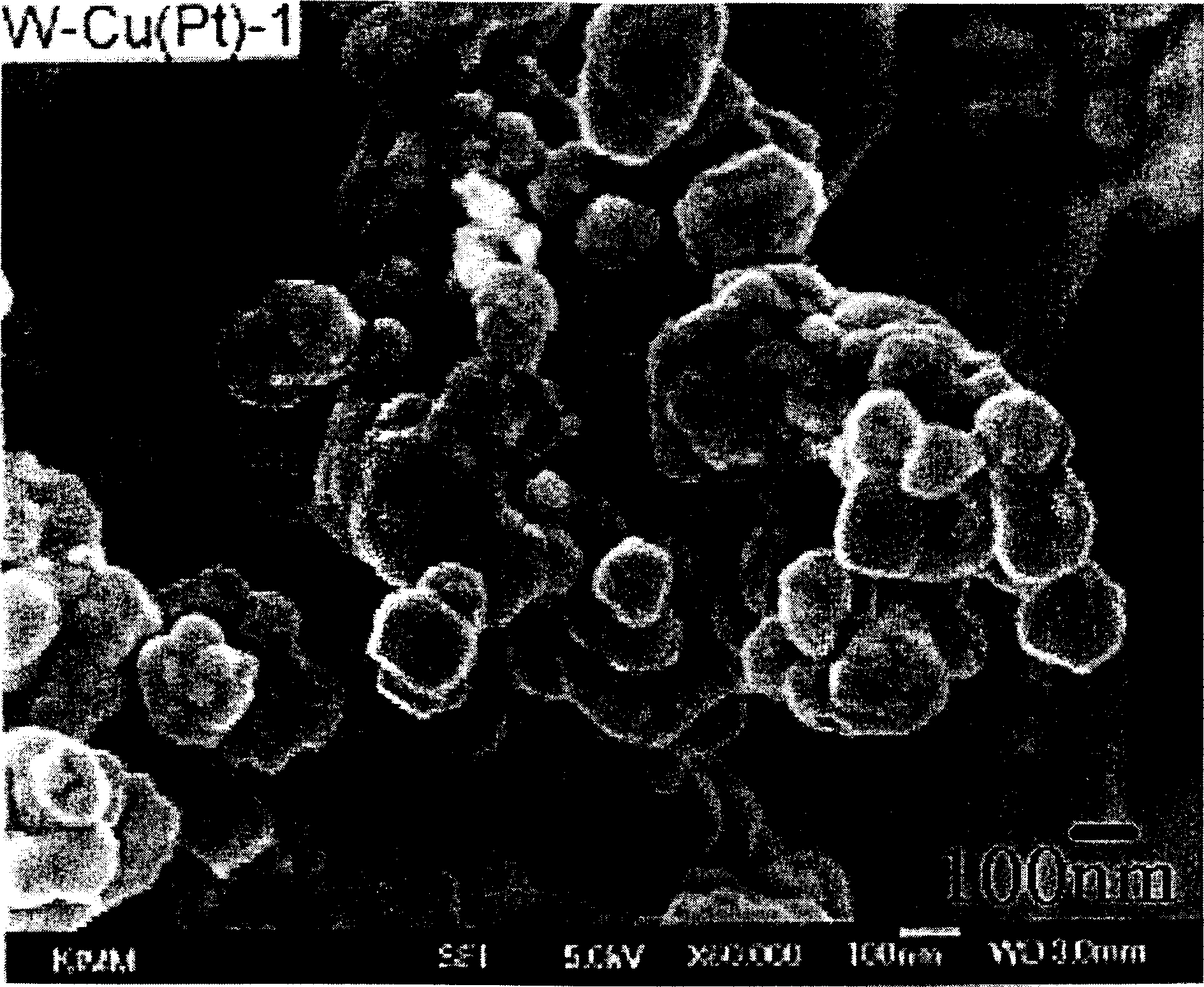

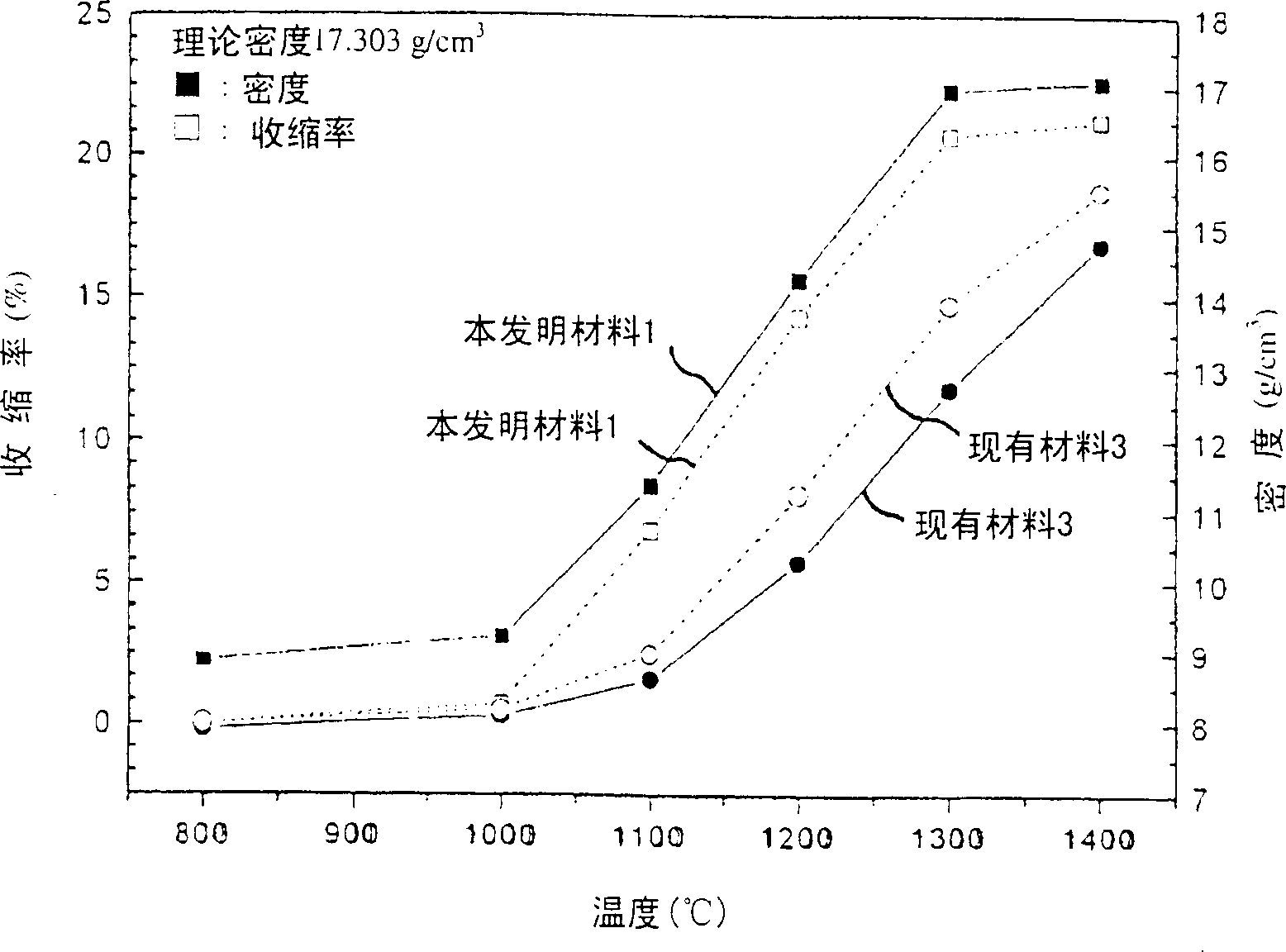

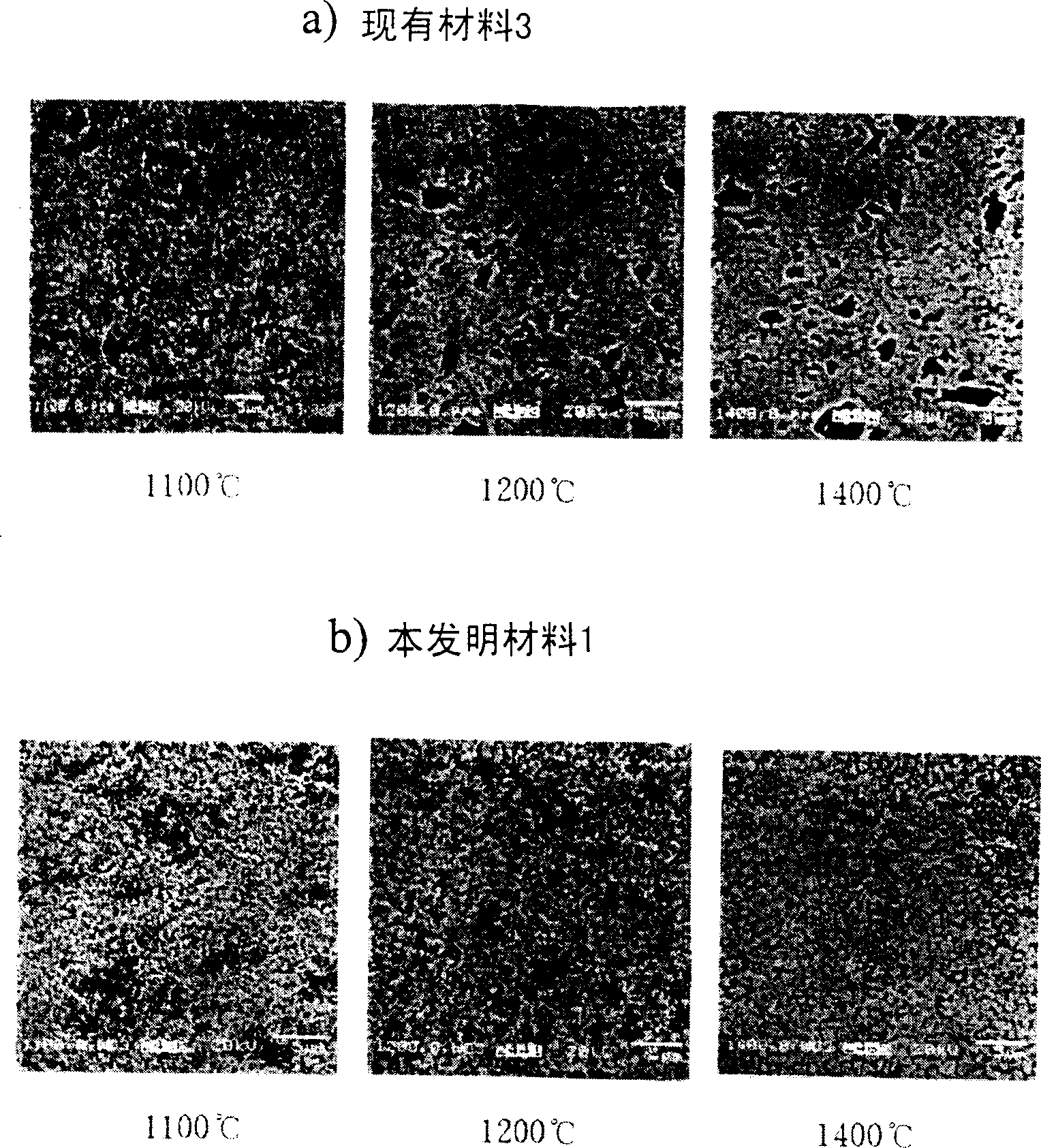

[0020] The method for preparing tungsten-copper matrix composite powder of the present invention is characterized in that the electrical conductivity and thermal conductivity of the sintered alloy prepared therein are substantially improved, wherein the method comprises: dissolving water-soluble tungsten salt and copper-containing salt A homogeneous mixture of tungsten and copper that does not have solid solubility and a large difference in specific gravity is formed in water, the composite oxide powder is calcined, and the calcined composite oxide powder is mixed with tungsten obtained by an additional calcining process at an appropriate ratio. Another tungsten oxide is mixed, and the mixed powder obtained by the above method is reduced.

[0021] Methods for preparing the tungsten-copper based material of the present invention are the following two methods. A method comprising: compacting the reduced composite powder produced by the method described above; and sintering the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com