High intensity low conductivity magnesium aluminate spinel brick

A magnesia-alumina spinel brick and magnesia-alumina technology, which is applied in the field of refractory materials, can solve problems such as high temperature, energy waste, and affecting the normal operation of cement enterprises, and achieve excellent sintering performance, good economic and social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

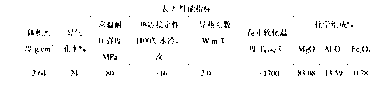

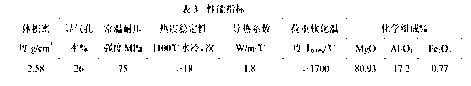

Embodiment 1

[0021] Example 1: A high-strength and low-conductivity magnesium-alumina spinel brick. The raw materials for its preparation are as follows: 24% of magnesium-aluminum composite material with a particle size of 5-3mm, 24% of magnesium-aluminum composite material with a particle size of 3-1mm. 15% of fused magnesia with a particle size of 1~0mm, 16% of fused magnesia with a particle size of 180F, 11% of magnesium-aluminum composite material with a particle size of 180F, 6% of fused magnesia-aluminum spinel with a particle size of 180F, а-Al 2 o 3 Fine powder is 4%, plus calcium lignosulfonate accounting for 4% of the total weight of the above raw materials;

[0022] The preparation method of the magnesium-aluminum synthetic material comprises the following steps:

[0023] (1) Raw materials: the raw materials of the magnesium-aluminum synthetic material are expressed in weight percentages, 93.85% of magnesite and 6.15% of industrial aluminum hydroxide;

[0024] (2) Grinding: we...

Embodiment 2

[0029] Example 2: A high-strength and low-conductivity magnesium-aluminum spinel brick, in terms of weight percentage, its preparation raw materials are as follows: 23% of magnesium-aluminum composite material with a particle size of 5-3mm, 24% of magnesium-aluminum composite material with a particle size of 3-1mm, 16% of fused magnesia with a particle size of 1~0mm, 16% of fused magnesia with a particle size of 180F, 11% of magnesium-aluminum composite material with a particle size of 180F, 6% of fused magnesia-aluminum spinel with a particle size of 180F, а-Al 2 o 3 Fine powder is 4%, plus calcium lignosulfonate accounting for 4% of the total weight of the above raw materials;

[0030] The preparation method of the magnesium-aluminum synthetic material comprises the following steps:

[0031] (1) Raw materials: the raw materials of the magnesium-aluminum synthetic material are expressed in weight percentages, 88.3% of magnesite and 11.7% of industrial aluminum hydroxide;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com