Patents

Literature

1449results about How to "Improved thermal shock stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature-resisting heat-insulation coating as well as preparation method and application thereof

ActiveCN103725074AEasy to use in constructionPlay the role of saving energy and reducing consumptionReflecting/signal paintsPetroleumEnergy consumption

The invention relates to the field of functional coatings and particularly relates to a high-temperature-resisting heat-insulation coating and a preparation method thereof. The high-temperature-resisting heat-insulation coating is composed of the following raw materials in percentage by mass: 10%-40% of high-reflection paint with a shell-core structure, 10%-40% of heat-insulation powder with the shell-core structure, 1%-5% of a toughening agent, 10%-50% of a high-temperature bonding agent, 1%-10% of a coating auxiliary agent, and the balance of water. The preparation method comprises the following steps: mixing, dispersing and grinding raw materials; carrying out homogenization to enable an average grain diameter to be 325-400 meshes; and filtering and packaging to obtain a finished product. The high-temperature-resisting heat-insulation coating can be applied to high-temperature fields of industrial furnaces, industrial boilers, high-temperature steam pipelines, petroleum cracking equipment, engine parts, high-temperature smelting, sintering furnaces and the like, and can be used under a higher temperature for long time; the energy consumption can be saved and the service life of the furnaces is prolonged.

Owner:武汉双虎涂料股份有限公司

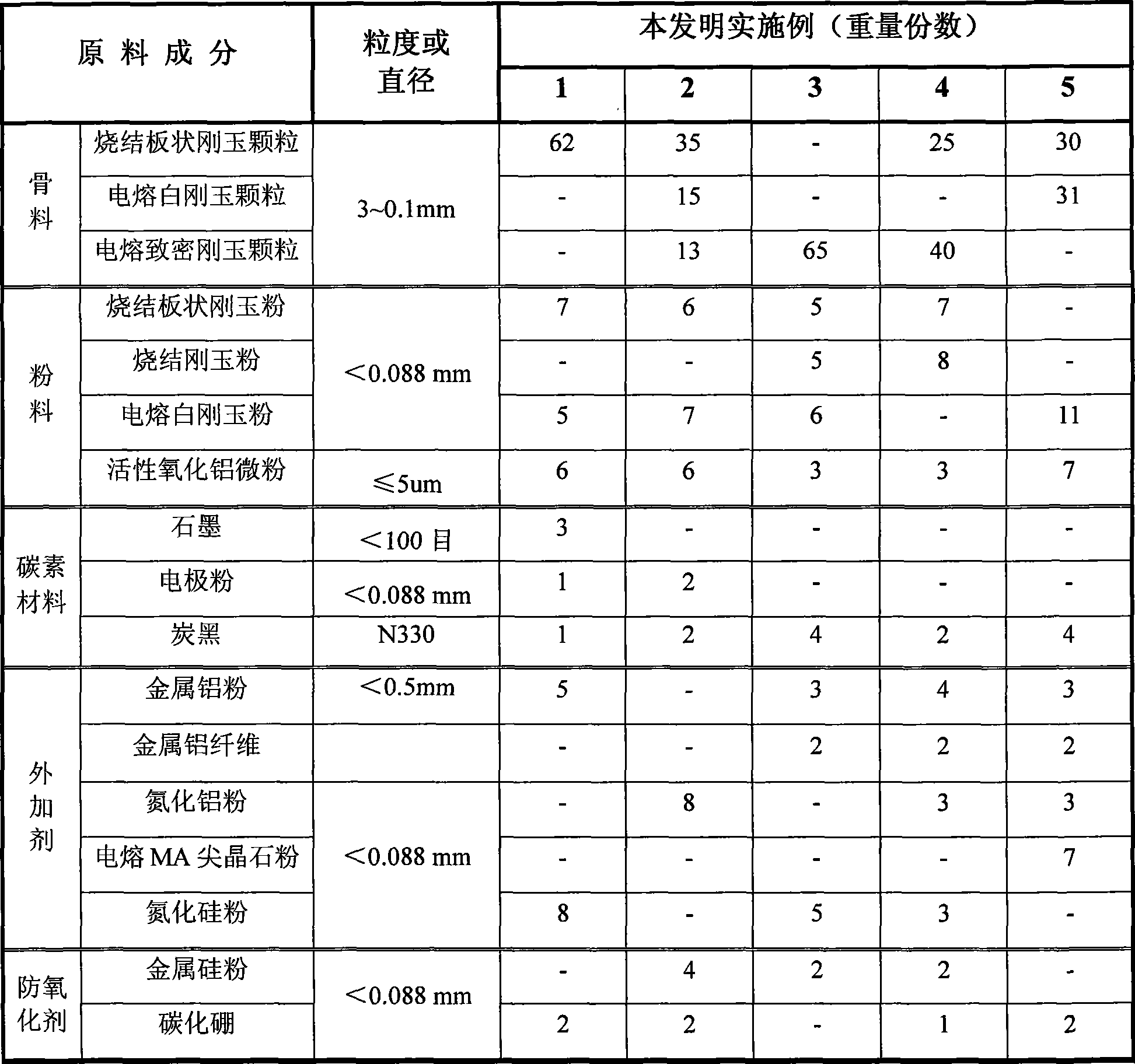

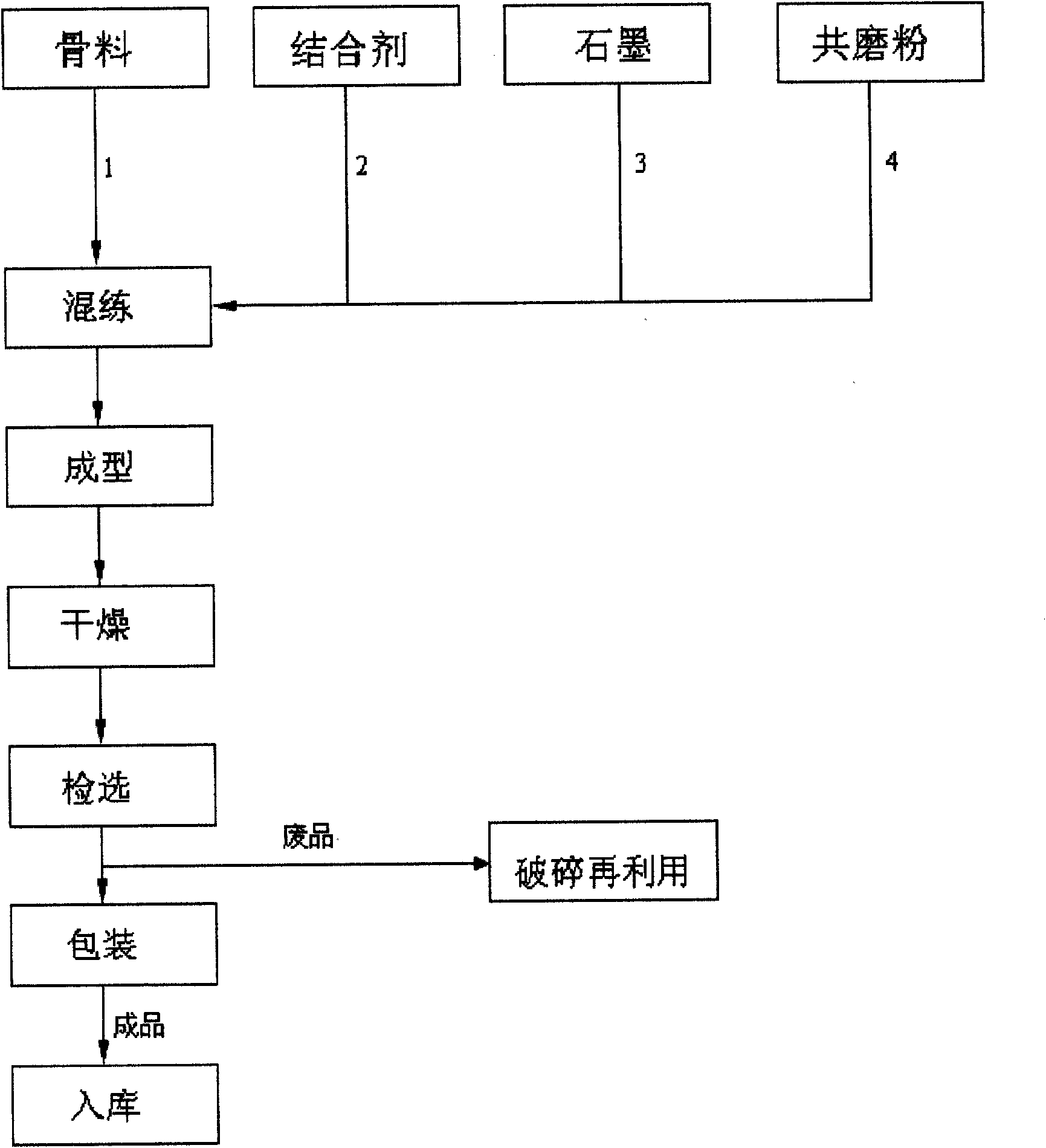

Aluminum-carbon sliding tile and method of producing the same

The invention provides an aluminum-carbon sliding brick, which comprises the following compositions: 60 to 75 percent of aggregate, 15 to 30 percent of powder, 1 to 6 percent of carbon element materials, 2 to 7 percent of antioxidant and 3 to 20 percent of additive. The production method for the aluminum-carbon sliding brick comprises the following steps: firstly, the powder in the raw materials is premixed and prepared into mixed powder for standby; secondly, mixing is performed according to the feeding order of granular materials, a binder and the mixed powder; thirdly, the mixture is discharged and subjected to mechanical pressing; and fourthly, a green brick is dried and prepared into the aluminum-carbon sliding plate brick by an unfired technology or a light burning technology. The method adds nitride and spinel materials in the sliding brick to substantially improve the thermal shock stability of the sliding brick, so as to achieve the level of the aluminum-zirconium-carbon sliding brick; and because the addition of Al metals is adequately increased, air holes can be filled, and the method reduces the brittleness of materials, is favorable for green brick formation, and improves the volume density, the normal temperature strength and the high temperature strength, so as to improve the oxidation resistance of the sliding brick. The aluminum-carbon sliding brick produced by the method not only has good product quality and high strength but also has simple procedure and saves the sintering cost.

Owner:鞍山钢铁集团耐火材料有限公司

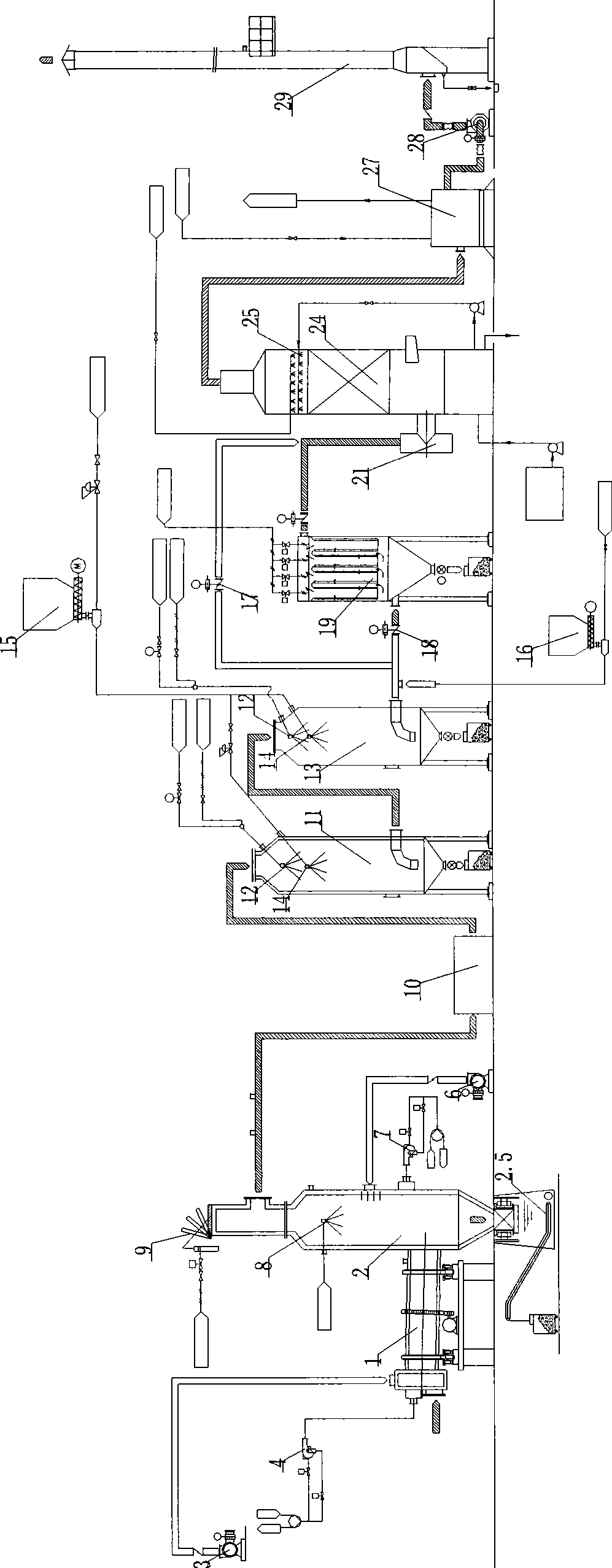

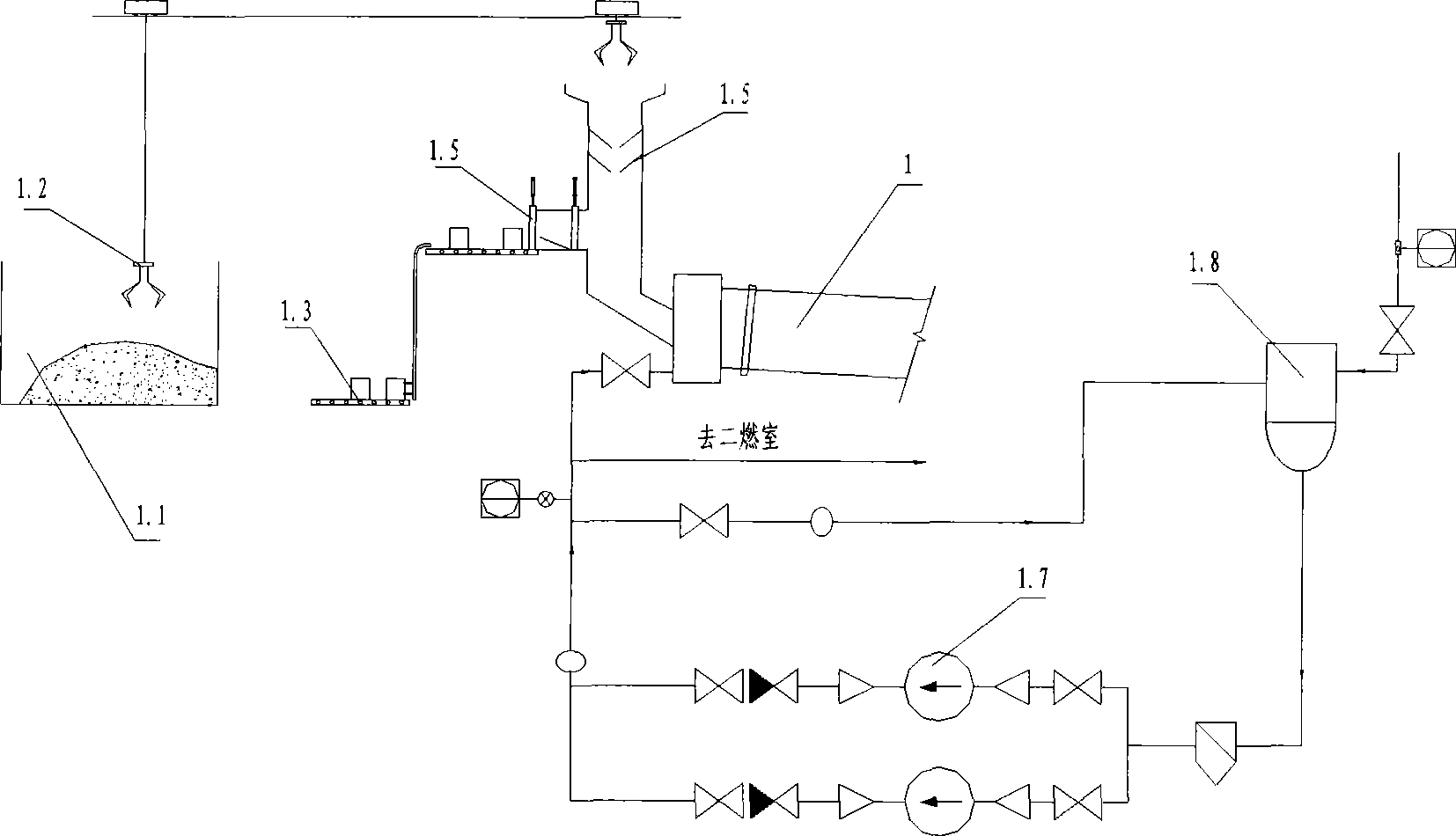

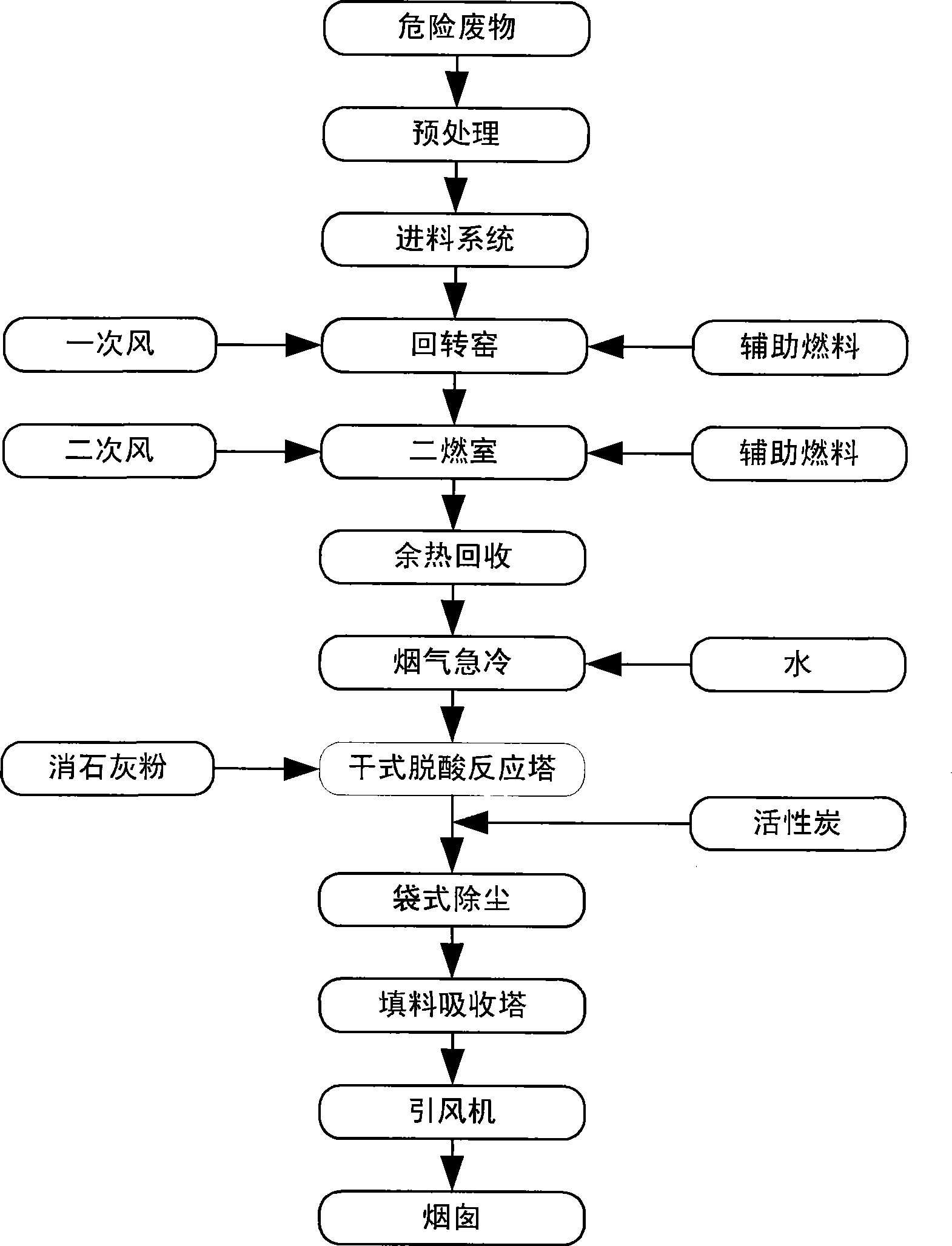

Industrial dangerous waste incineration processing system for realizing multiple physical states

A system for implementing multiple-physical state industry dangerous waste incineration and disposal relates to the garbage disposal technology of the environment protection technical field. Two seal doors are arranged at a bulk waste material feed port or a barreled waste material feed port on a rotary kiln feed hopper. The rotary kiln and a second combustion chamber frame all adopt carbon steel materials, refractory materials a working layer of the rotary kiln select chromium fused alumina abrasion-proof plastic materials, refractory materials of the second combustion chamber select abrasion-proof pouring materials. The rotary kiln is provided with a primary fan and a combustion-supporting combustor 1 which are connected with the rotary kiln, the second combustion chamber is provided with a second fan and a combustion-supporting combustor 2 which are connected with the second combustion chamber, a stuffing absorbing tower and a flue gas heater are connected in turn between the bag-type dust remover and a draught fan. Compared to the prior art, the invention can effectively destroy large quantities of toxic and noxious high molecule organic matters, can effectively avoid phenomenon of the collapse fall of the rotary kiln incineration furnace wall and the burning ring of the steel body, and can avoid high-temperature corrosion and low-temperature corrosion, the invention has advantages of good operation economical performance, fluent slag system and low pollution discharge index.

Owner:TONGFANG ENVIRONMENT

Non-transparent quartz crucible for polysilicon crystallization and manufacturing method thereof

InactiveCN101348324AHighlight substantive featuresSignificant progressGlass shaping apparatusSilicon compoundsCrack resistanceSlurry

The invention provides an opaque quartz crucible used in multicrystal silicon crystallization and a method for manufacturing the same. The crucible is of a regular square structure, and the compositions in mass ratio of the crucible are more than 99.7 Wt percent of silicon dioxide, less than 600ppm of aluminum oxide and less than 30ppm of ferric oxide. The method comprises the following steps: firstly, a raw material, i.e. high purity quartz is put into granulation equipment for wet method granulation, the grain size is controlled between 70 and 100mu m; then, slurry is fully stirred and then is fed into a gypsum mould under a pressure of between 2 and 3bar after being deposited for 24 to 48 hours; moreover, early grouting is assisted by slight vibration; the slurry is further settled for 5 to 8 hours, and is demoulded after fully dewatered; the slurry is dried inside a drier; and finally, a blank is put in a kiln for sintering so as to obtain the opaque quartz crucible. The proposal adopts grouting forming by a high-purity quartz material, and the sintered crucible has uniform inner structure; moreover, the crucible has excellent thermal shock stability and cracking resistance, and can meet the technological requirements for manufacturing multicrystal silicon cast ingots.

Owner:常熟华融太阳能新型材料有限公司

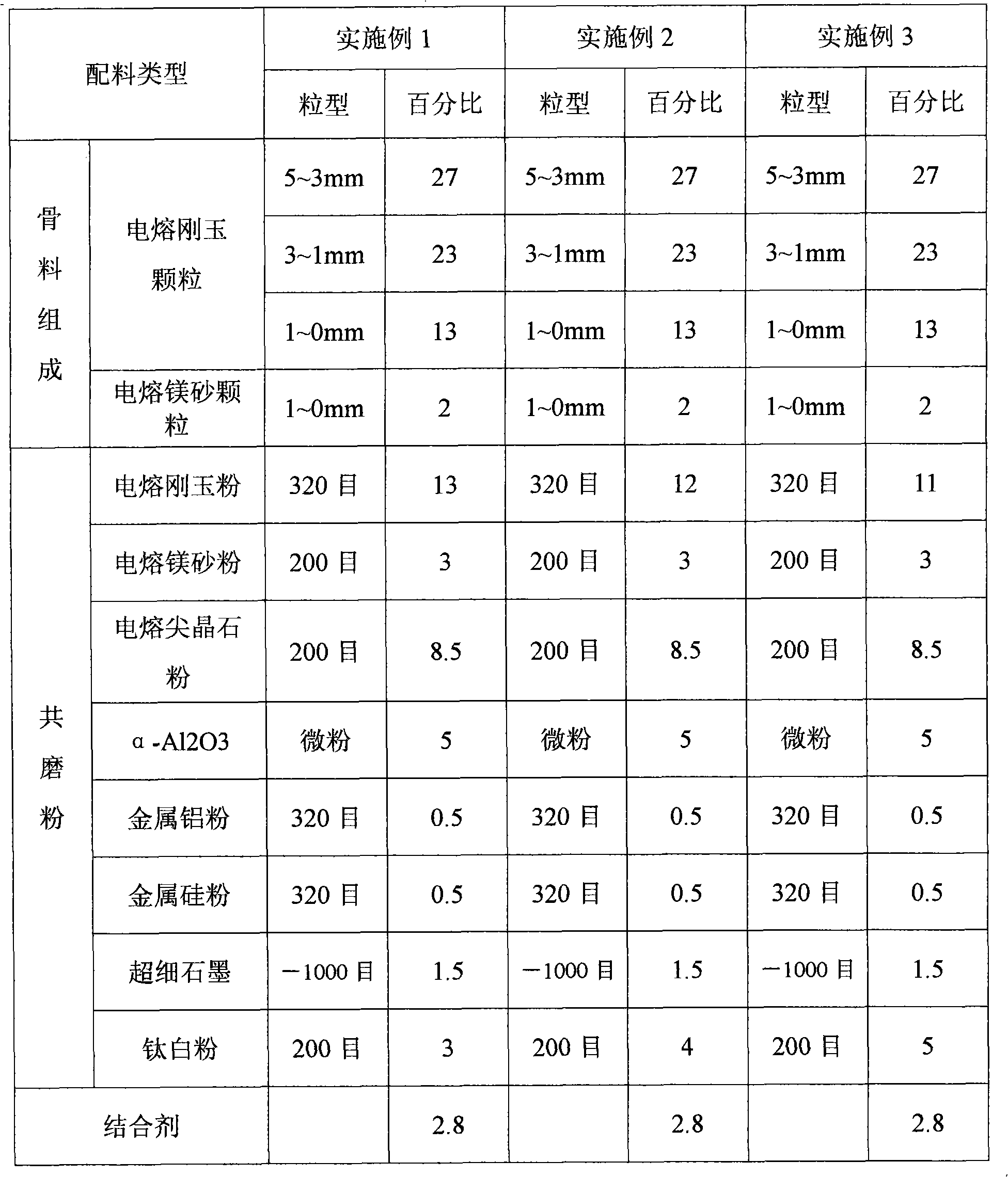

Low-carbon corundum spinelle brick for refined steel ladles and preparation method thereof

The invention relates to a low-carbon corundum spinelle brick for refined steel ladles and a preparation method thereof for overcoming the defect of overhigh carbon content in the prior carbon-contained fireproof material technology. The low-carbon corundum spinelle brick for refined steel ladles comprises the following components in percentage by weight: 60-70 fused corundum particles, 2-6 fused magnesite particles, 10-20 fused corundum fine powder, 2-10 fused magnesite fine powder, 5-15 fused spinelle fine powder, 3-6 alpha-Al2O3 micro powder, 0-2.0 metal aluminum fine powder, 0-2.0 metal silicon fine powder, 2-6 bond, 1-2 superfine graphite and 2-6 titanium white powder. The invention has good thermal stability at high temperature, resists high temperature and the erosion of molten steel and slag and has high mechanical strength, good thermal shock stability and high under-load softening point, thereby being widely applied to various steel ladles, in particular to steel ladles of refined low-carbon steel and ultra-low-carbon steel.

Owner:海城利尔麦格西塔材料有限公司 +2

Aerated food products with improved foam stability

InactiveUS20140335255A1Improved thermal shock stabilityLow amountMilk preparationFrozen sweetsFiberFood products

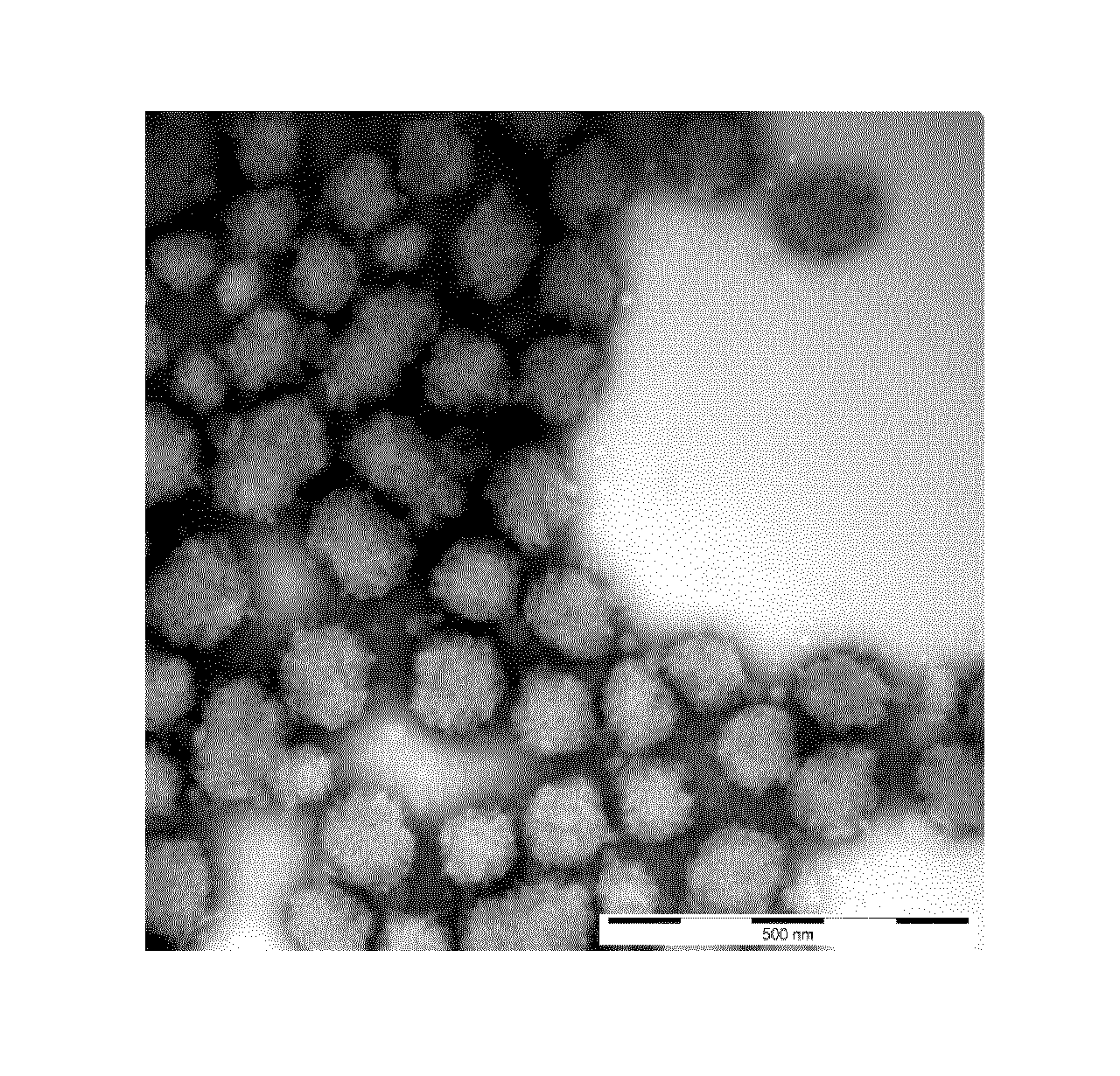

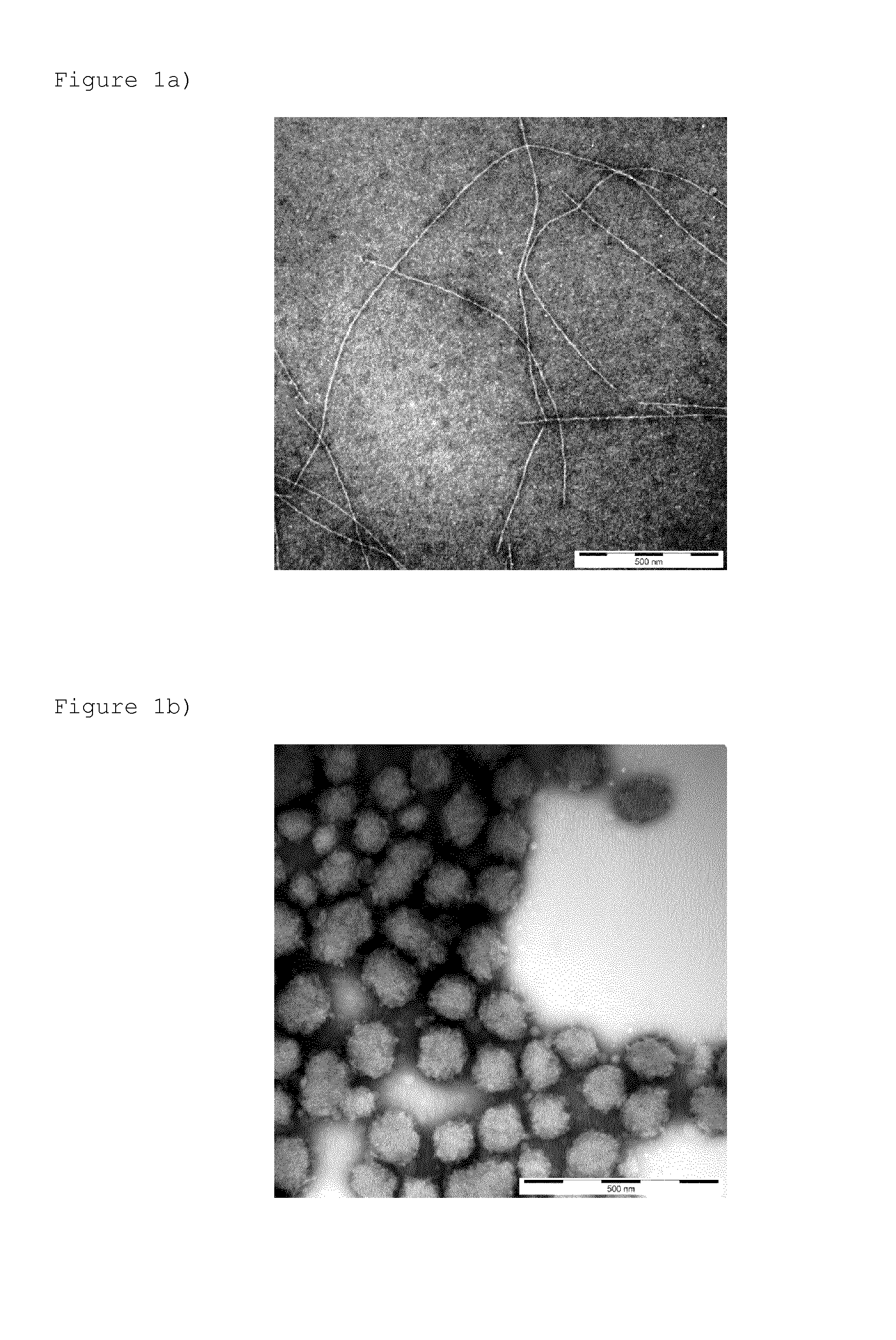

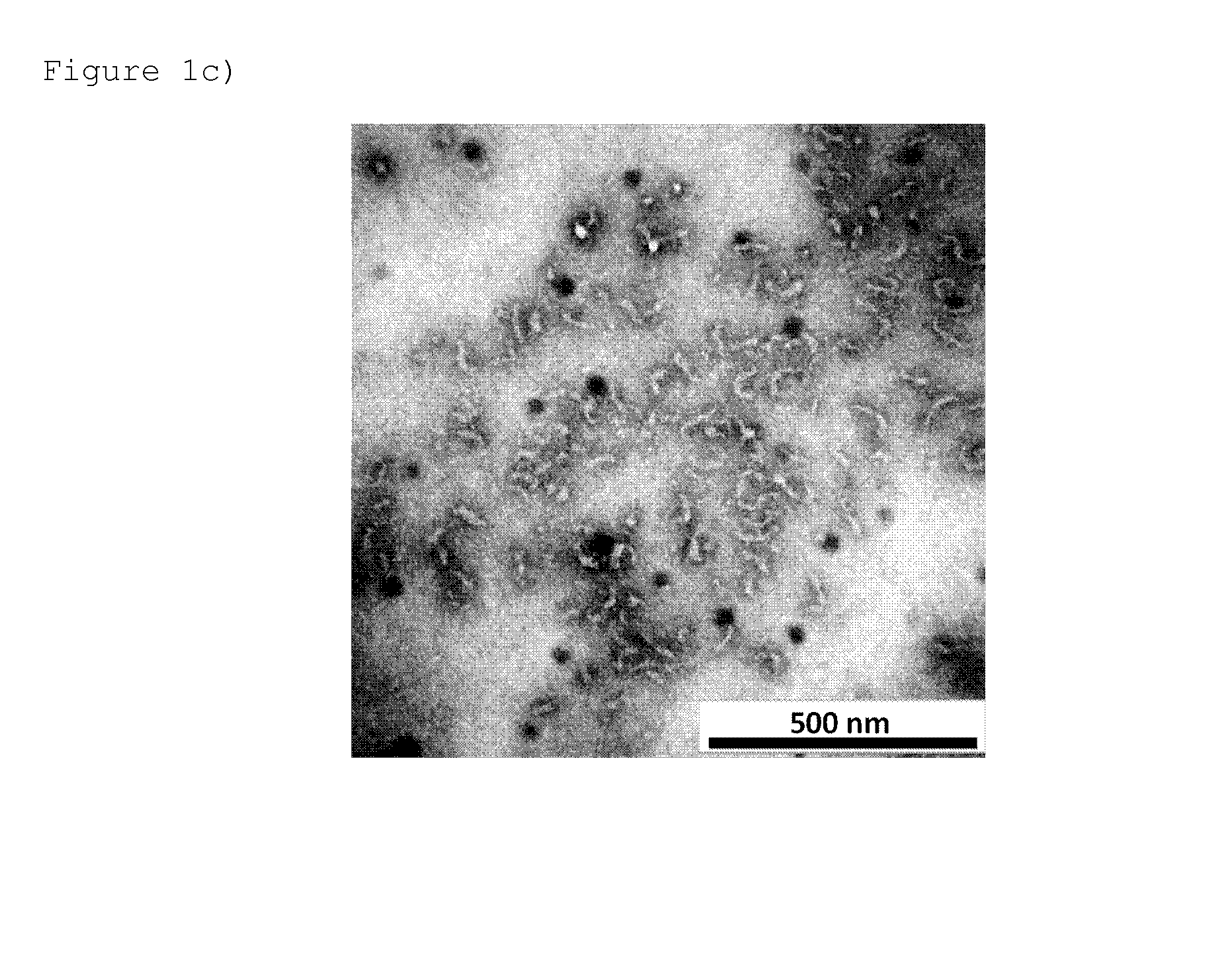

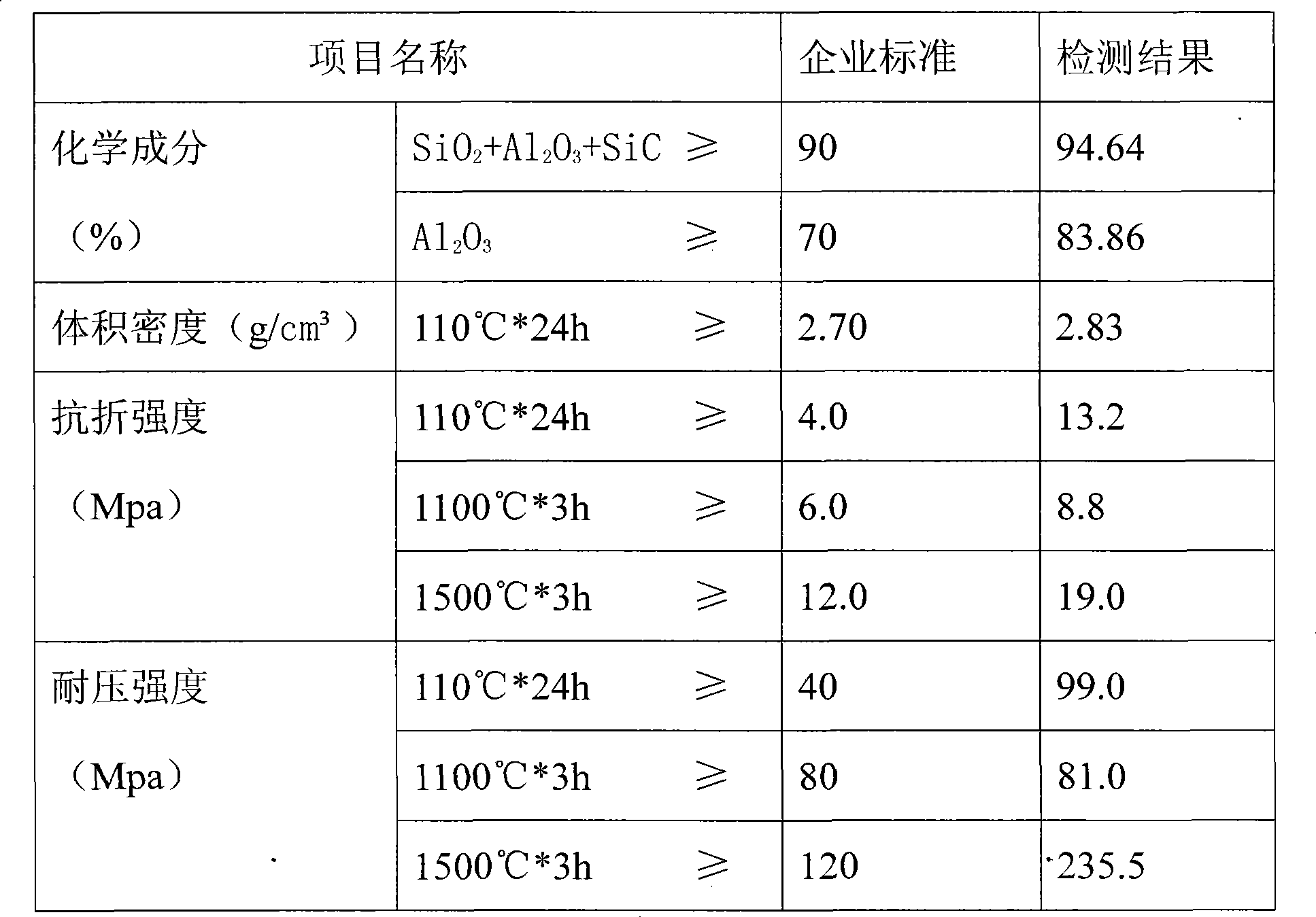

The present invention relates to aerated food products with enhanced foam stability comprising aggregated proteins in the form of mixtures of fibrils together with at least one other type or structure of aggregates such as worm-like aggregates and / or spherical like aggregates.

Owner:NESTEC SA

Corundum-mullite self-flow refractory castable

The invention discloses a corundum mullite artesian fireproof casting material, which comprises 30-35% of plate-shaped corundum, 5-8% of carborundum powder material, 4-5% of pure calcium aluminate cement, 35-45% of mullite, 10-15% of alpha-Al2O3 micropowder and 3-5% of bonite by mass percentage. The casting material is characterized by good fluidity, good resistance to thermal shock, low porosity rate of entity after casting, good chemical resistance, high intensity and long service life.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

A kind of carbon composite refractory material and preparation method thereof

The invention relates to a carbon composite fireproof material and a preparation method thereof. A technical scheme of the method is that: raw materials of the carbon composite fireproof material comprise: 55-75 wt% of oxide particles, 10-20 wt% of oxide fine powder, 5-10 wt% of oxide micropowder, 1-5 wt% of a carbonaceous material, 0.1-3 wt% of graphene, 2-8 wt% of an antioxidant and 3-6 wt% of an organic binding agent. The preparation process for the carbon composite fireproof material comprises: grinding the grapheme, the oxide micropowder and the antioxidant according to the correspondingcontents of the raw materials to obtain precast mixed powder; then uniformly mixing the precast powder, the oxide particles, the oxide fine powder, the carbonaceous material and the organic binding agent, and molding; carrying out heat treatment at a temperature of 180-240 DEG C, then carrying out light burning at the temperature of 700-850 DEG C or carrying out sintering at the temperature of 1100-1400 DEG C to obtain the carbon composite fireproof material. The carbon composite fireproof material provided by the present invention has characteristics of high strength, low thermal conductivity, excellent thermal shock resistance and excellent slag corrosion resistance, and meets the requirement of energy saving and emission reduction.

Owner:WUHAN UNIV OF SCI & TECH

Preparation method of fused silica refractory casting material unwetted by aluminum liquid

The invention belongs to the field of refractory materials and discloses a preparation method of a fused silica refractory casting material unwetted by an aluminum liquid, which comprises the following step of: enhancing a ground substance by adopting 10-20wt% of white alundum powder, 4-8wt% of calcium aluminate cement, 3-5wt% of hydrated alumina compound binding agent, 4-10wt% of silicon oxide micropowder and 3-6wt% of alumina micropowder, wherein 60-70wt% of fused silica is used as a main material, BaSO4 and Na3AlF6 is adopted as a compound aluminum liquid anti-wetting agent with the addition of 1-6wt%, and additional 0.12wt% of trimeric sodium phosphate and additional 0.03wt% of sodium hexametahposphate are adopted as dispensing agents. The casting material prepared by using the method has high strength, is unwetted by the aluminum liquid, has the highest use temperature of 1000 DEG C and can be used as the refractory materials, such as an aluminum flowing groove of an aluminum smelting furnace and the like.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Dispersive air brick and preparation method thereof

The present invention relates to a dispersive air brick and a preparation method thereof. According to the technical scheme of the invention, 50 to 80 wt% of plate-shaped corundum is adopted as an aggregate. 12 to 32 wt% of aluminum oxide fine powders, 5 to 10 wt% of alumina micro powders and 3 to 8 wt% of a binding agent are adopted as matrix materials. According to the method, firstly, the matrix materials are uniformly mixed, and then the matrix materials and the aggregate are put into a mixer. 0.1 to 0.3 wt% of a water reducing agent and 4 to 6 wt% of water, counted relative to the sum of the aggregate and the matrix materials, are additionally added. The obtained mixture is stirred for 3 to 5 minutes, and then is cast and molded. After an obtained product is standing at the room temperature for 20 to 30 hours, the obtained product is dried for 22 to 26 hours at the temperature of 90 to 120 DEG C. then the obtained product is thermally insulated for 3 to 6 hours at the temperature of 1450 to 1650 DEG C. In this way, the dispersive air brick can be obtained. The plate-shaped corundum is in the form of equal-diameter particles, and the particle sizes of the equal-diameter particles are 2 to 5 mm. The method has the advantages of simple process, low labor intensity, high production efficiency, no pollution to the environment, and low cost. The prepared dispersive air brick is good in air permeability, strong in impurity-removing capability, excellent in thermal shock stability and good in penetration resistance performance.

Owner:江苏锦耐新材料科技有限公司

Calcium titanium-aluminate prefabricated part for vanadium smelting reverberatory furnace lining and preparation method thereof

The invention relates to a calcium titanium-aluminate prefabricated part for a vanadium smelting reverberatory furnace lining and a preparation method thereof. According to the technical scheme, 60-75 wt% of calcium titanium-aluminate particles, 10-20 wt% of calcium titanium-aluminate fine powder, 2-7 wt% of titanium dioxide micro powder, 5-10 wt% of alpha-Al2O3 micro powder and 1-6 wt% of rho-Al2O3 micro powder are used as raw materials; 0.05-0.30 wt% of water reducing agent and 3.5-6.0 wt% of water of the raw materials are added; stirring is conducted for 5-8 minutes, vibration forming is achieved, maintenance is carried out for 18-24 hours under the natural condition, demolding is performed, heat preservation is conducted for 18-24 hours at the temperature of 90-110 DEG C, and accordingly the calcium titanium-aluminate prefabricated part for the vanadium smelting reverberatory furnace lining is obtained. The calcium titanium-aluminate prefabricated part has the advantages of being low in production cost, and capable of saving resources and protecting the environment. The obtained calcium titanium-aluminate prefabricated part for a vanadium smelting reverberatory furnace is high in high-temperature strength, good in acidity vanadium slag corrosion resistance and good in permeability.

Owner:WUHAN UNIV OF SCI & TECH

Light thermal-shield refractory castable

InactiveCN101792294ALight weightImproved thermal shock stabilitySolid waste managementCapacitanceMullite

The invention relates to a light thermal-shield refractory castable comprising the following components in percentage by weight: 40-60% of light aggregate, 10-20% of capacitance mullite, 5-10% of kyanite powder, 5-10% of high-aluminium clinker powder, 3-8% of silica micro powder, 3-8% of alpha-Al2O3 micro powder, 5-10% of high-aluminium cement, 0.5-10% of high-aluminium refractory fibre containing zirconium, 1.5-4% of thermal-shield steel fibre, 0.1-1% of melamine and 0.05-0.1% of organic anti-explosion fibre, wherein the granularity of the capacitance mullite is less than or equal to 1 mm, both the granularity of the silica micro powder and the granularity of the alpha-Al2O3 micro powder are less than or equal to 5 mu m, and the chemical modified light aggregate is obtained by drying after the light aggregate is dipped in inorganic chemical solution or sol. The light thermal-shield refractory castable of the invention can improve the service life of a furnace roller, lowers production consumption cost, reduces non-working hours caused by exchanging rollers and improves production efficiency.

Owner:武钢集团有限公司

Lightweight periclase-magnesium aluminate spinel refractory material for rotary cement kiln and preparation method thereof

The invention relates to a lightweight periclase-magnesium aluminate spinel refractory material for a rotary cement kiln and a preparation method thereof. According to the scheme, the preparation method comprises the following steps of: uniformly dispersing 0.2 to 4wt% of magnesite micro powder and 0.2 to 4wt% of active alpha alumina micro powder into 5 to 8wt% of binding agent to obtain a modified binding agent; adding 50 to 70wt% of porous periclase-magnesium aluminate spinel ceramic particles to a vacuum agitating machine; vacuumizing to be below 2.5kPa; maintaining the constant pressure for 3 minutes; adding the modified biding agent to the vacuum agitating machine; agitating for 10 minutes; closing a vacuumizing system; then adding 10 to 25wt% of porous periclase-magnesium aluminate spinel ceramic fine powder, 4 to 20wt% of fine magnesia powder, and 1.5 to 4wt% of magnesium aluminate spinel fine powder to the vacuum agitating machine; uniformly agitating; mechanically pressing and modeling; drying; and maintaining the temperature of 1,500 to 1,650 DEG C for 2 to 10 hours. The lightweight periclase-magnesium aluminate spinel refractory material for the rotary cement kiln has the advantages of being low in heat conductivity, high in intensity, high in thermal shock resistance, high in kiln coating performance, and high in resistance to medium erosion.

Owner:WUHAN UNIV OF SCI & TECH

Downconversion frequency shift infrared radiation enhanced coating and preparation method thereof

InactiveCN101712816AHigh heat conversion efficiencyImprove absorption rateCoatingsEmissivityFrequency shift

The invention relates to an infrared radiation enhanced coating and a preparation method thereof. The downconversion frequency shift infrared radiation enhanced coating is characterized by consisting of the following components in percentage by mass: 20 to 50 percent of radiation synergistic enhancer, 1 to 7 percent of downconversion frequency shift additive, 15 to 45 percent of high-temperature resistant base stock, 32 to 50 percent of high-temperature binder, 1 to 4 percent of flexibilizer and 1 to 4 percent of coating auxiliary agent, and the sum of the mass percentage of the components is 100 percent. The coating not only has high emissivity and good thermal shock resistance, but also can convert visible light into infrared radiation; and the thermal conversion efficiency of the coating is effectively improved.

Owner:WUHAN YINFURUI NEW MATERIAL

Refractory castable for molten iron pretreatment spray gun

The invention discloses refractory castable for a molten iron pretreatment spray gun, which is mixed by castable base stock and a proper amount of additive. The castable base stock is composed of 30-40% of sintering zirconium mullite, 10-20% of flint clay, 20-30% of andalusite, 5-10% of compact corundum fine powder, 2-5% of alpha-Al2O3 micro powder, 5-8% of rho-Al2O3 micro powder, 3-7% of silicon micro powder, 1-4% of carborundum powder and 1.5-3% of pure calcium aluminate cement by weight percent. The additive takes the total weight M of the castable base stock as a metering reference and is composed of 1-5% of heat resistant steel fiber, 0-0.1% of polypropylene fibre, 0-0.5% of aluminium lactate, 0-0.5% of metallic aluminium powder, 0-0.15% of sodium tripolyphosphate and 0-0.5% of melamine in weight percent. The castable has favorable thermal shock stability performance, high-temperature mechanical strength and corrosion resistance. The spray gun bushing manufactured by the refractory castable can effectively prolong the service life of the spray gun.

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

Thermal shock resistant corundum-magnesium aluminum spinel pouring material

InactiveCN101665367AImproved thermal shock stabilityEasy to adjust the dosageSuperplasticizerWater reducer

The invention relates to a corundum-magnesium aluminum spinel refractory pouring material, the combination is formed by relying on the reaction of polyacrylic acid, hydratable aluminum oxide and a substance containing magnesium oxide at normal temperature, and the combination is formed by relying on the sintering aiding role of a small amount of silicate at high temperature. The formula of the pouring material is as follows: 50-60% of corundum of 5-1mm, 8-16% of corundum or magnesium aluminum spinel of 1-0.088mm, 0-8% of desiliconized zirconium of small than 0.7mm, 16-25% of corundum or magnesium aluminum spinel with d90 of smaller than 0.088mm, 3-8% of magnesium aluminum spinel or alpha aluminum oxide with d90 of smaller than 0.010mm, 2-6% of hydratable aluminum oxide, 1-5% of magnesium-based additive, 0-1.5% of silica fume, 0.05-0.4% of added high-performance water reducing agent (polycarboxylic acid plus naphthalene sulfonation formaldehyde polymer plus sulfonated melamine polymer),0.5-4% of added polyacrylic acid system emulsion and 1-6% of water. The material has the advantages of good high temperature-resistant performance, very strong erosion-resistant ability, controllableafter-burning performance and higher thermal shock stability, thereby being applicable to being used as a senior refractory material for high temperature kilns of steel, iron and cement.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

Al-C fireproof material for continuous casting and its production method

A fireproof material containing aluminum and carbon for continuous casting. Taking aluminum oxide and carbon as the main components, it includes 0.5í½5.0úÑ boron nitride and 1.0í½5.0úÑ carborumdum by weight. The preparation method thereof comprises mixing white alundum, graphite, zirconium mullite, carborundum, industrial silicon ,2.0úÑ??.0úÑ solid phenol resin and 5úÑí½15úÑ liquid phenol resinby weight, and moulding at equal static pressure of 120í½150Mpa for 10-20 min, the moulded semi-product is dried and burned at 1280í½1350degree C for 60-70 hours. The product is suitable for columns of sagger, downspouts, with good heat-shock stability and resistibility of erosion.

Owner:山东淄川特种耐火材料有限公司

Aluminum-magnesium series lightweight pouring material and manufacturing method thereof

The invention discloses a making method of aluminium-magnesium systemic light-quality casting material, which comprises the following steps: adopting 40-70% aluminium-magnesium porous ceramic particle and 0-20% aluminium-magnesium particle as aggregate; selecting 15-55% fine aluminium-magnesium powder, 2-15% pure calcium aluminate and 2-8% active alpha-aluminium micropowder as substrate; blending the mass; adding 8-25% water, 0.1-0.8% silica powder and 0-3% dehydragent to stir evenly; casting; vibrating; moulding; drying for 8-48h under 110 deg.c.

Owner:WUHAN UNIV OF SCI & TECH

Corundum-silicon nitride-silicon carbide composite pouring material

The invention discloses a corundum-silicon nitride-silicon carbide compound castable used for a blast tuyere zone of an ironmaking blast furnace. The corundum, the silicon nitride, the silicon carbide, aluminate cement, aluminum powder, silicon metal, ultrafine silica powder, alumina powder and polypropylene fiber are mixed to form the castable. Residual brick of compound brown corundum refractory brick can be fast poured and repaired at the blast tuyere zone of the ironmaking blast furnace. When building a blast furnace, residual brick can be direct poured and formed to replace the compound brown corundum refractory forming brick and no high temperature is needed to fire during the production process; therefore, the invention is also an energy saving refractory for the blast tuyere zone of the ironmaking blast furnace and cast-place construction is not limited by space; fast pouring masonry is carried out and fast drying method is adopted, thereby being an inorganic nonmetal refractory applied to fast-drying quick furnace building and repairing during the blast furnace repairing and the tuyere zone of the newly-built blast furnace. The invention can normally furnace dry with the blast furnace.

Owner:REFRACTORY MATERIAL OF SINOSTEEL CORP

Corundum spinel castable with micro-nano pore structure and preparation method of corundum spinel castable

The invention relates to a corundum spinel castable with a micro-nano pore structure and a preparation method of the corundum spinel castable. The technical scheme of the invention is as follows: the preparation method comprises the following steps of: dry-blending 45-82 percent by weight of tabular corundum particles and 1-15 percent by weight of magnesium aluminate spinel particles to obtain mixed aggregate, and dry-blending 1-10 percent by weight of magnesium aluminate spinel fine powder, 4-12 percent by weight of corundum fine powder, 5-15 percent by weight of Alpha-Al2O3 micropowder, 2-8 percent by weight of pure calcium aluminate cement and 0.1-0.5 percent by weight of SiO2 micropowder to obtain mixed powder; then adding a water reducing agent, water and foams which respectively account for 0.2-1.0 percent by weight, 3.5-4.5 percent by weight and 5-15 percent by weight of the aggregate and the powder to the mixed powder, and stirring to prepare mixed slurry; and pouring the mixed aggregate into the mixed slurry, stirring, moulding by casting, curing, demoulding, baking, heating to 1450-1760 DEG C and maintaining the temperature for 2-4 hours. The preparation method disclosed by the invention has the characteristics of simple process and easiness for construction and industrial production; and the prepared corundum spinel castable is high in comprehensive property, good in thermal shock resistance and long in service life.

Owner:WUHAN UNIV OF SCI & TECH

Light-weight corundum-magnesia alumina spinel refractory material and a preparation method of same

The invention relates to a light-weight corundum-magnesia alumina spinel refractory material and a preparation method of same, wherein porous corundum-magnesia alumina spinel ceramic material granules are used as an aggregate, wherein ceramic material being 3-5 mm in granular size accounts for 10-18 wt%, ceramic material being 1-2.8 mm in granular size accounts for 25-30 wt%, and ceramic material being 0.1-0.8 mm in granular size accounts for 15-20 wt%; a substrate includes 12-18 wt% of porous corundum-magnesia alumina spinel ceramic material fine powder with nano-scale pore diameter, 12-20 wt% of corundum fine powder, 2-5 wt% of magnesite fine powder and 3-8 wt% of alpha-Al2O3 micropowder. The preparation method includes the steps of: 1) placing the aggregate in a vacuum stirrer, vacuumizing the stirrer, and adding a magnesium chloride solution which accounts for 3-8 wt% of the total weight of the aggregate and the substrate, stirring the mixture, and turning off the vacuumizing system; 2) adding the substrate, stirring the materials, shaping and drying the materials, and performing temperature maintenance at 1450-1650 DEG C, cooling the material to produce the refractory material. In the refractory material, diameters of pores are nano-scale, so that the refractory material is low in heat conductivity and high in strength, has high anti-medium erosion performance and excellent thermal shock resistance.

Owner:WUHAN UNIV OF SCI & TECH

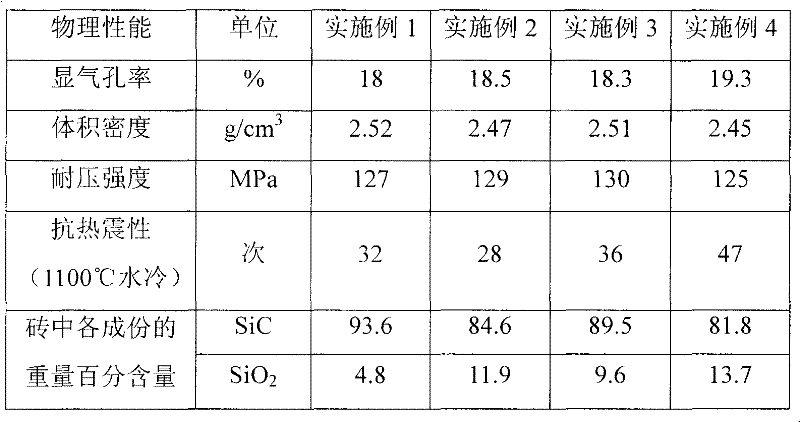

Silicon carbide brick for garbage incinerator and preparation method thereof

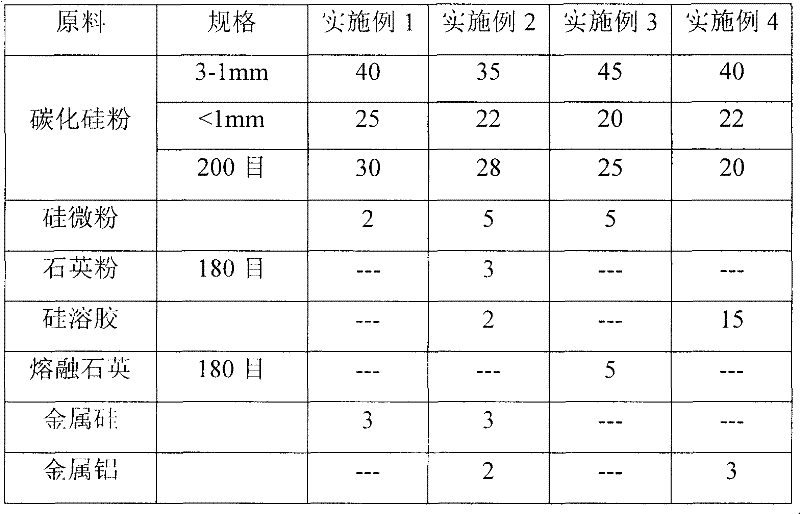

InactiveCN102391007AGood high temperature wear resistanceImproved thermal shock stabilityBrickCombustion chamber

The invention relates to a silicon carbide brick for a combustion chamber of a garbage incinerator and a preparation method thereof. The silicon carbide brick is combined by silicon oxide, and the content of SiC in the brick is more than or equal to 80 weight percent; the brick is formed by mixing, forming and calcining a major ingredient, a bonding agent and an antioxidant; the major ingredient is 80 to 98 weight percent of silicon carbide powder; the bonding agent is 2 to 20 weight percent of shaped or unshaped SiO2 micro powder or fine powder or solution; and the antioxidant is 0 to 5 weight percent of metal silicon powder or metal aluminum powder or mixture thereof. The preparation method comprises the following steps of: mixing raw materials in a ratio, forming under high pressure, and calcining in a kiln furnace at the high temperature of between 1,300 and 1,500 DEG C. The silicon carbide brick combined by the silicon oxide has high acid-base erosion resistant capacity, high high-temperature abrasion performance, high heat shock stability and high antioxidation performance, and meets the using requirements of environment friendliness and long service life.

Owner:TONGDA REFRACTORY TECH CO LTD +1

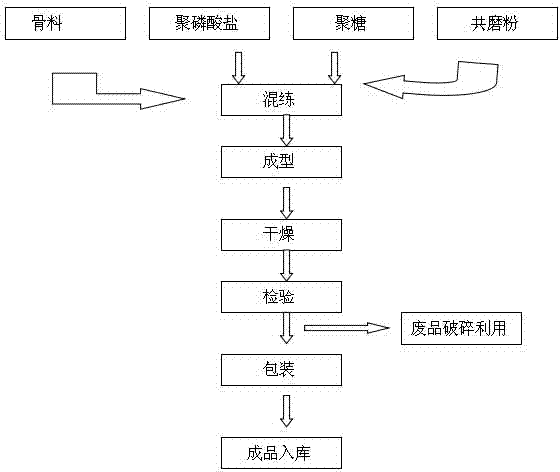

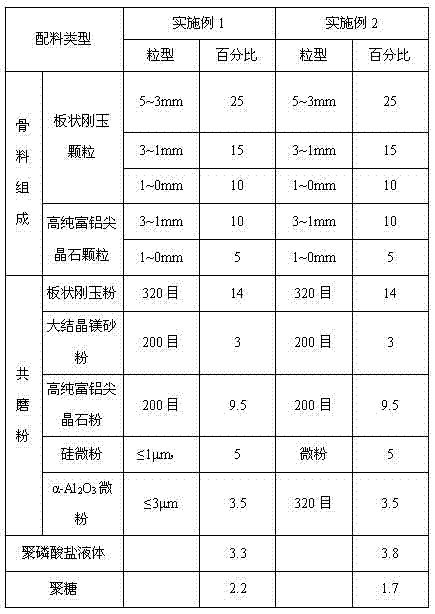

Mechanically-pressed carbon-free corundum spinel ladle brick as well as preparation method thereof

The invention discloses a mechanically-pressed carbon-free corundum spinel ladle brick. The mechanically-pressed carbon-free corundum spinel ladle brick comprises the following components in percentage by weight: 30%-50% of plate-shaped corundum particles, 10%-20% of high-purity aluminum-rich spinel particles, 10%-20% of plate-shaped corundum fine powder, 1%-9% of large crystallized magnesia fine powder, 5%-15% of high-purity aluminum-rich spinel fine powder, 1%-10% of high-purity silicon micro powder, 2%-10% of imported multimodal alpha-Al2O3 micro powder, 1%-4% of metal silicon and a bonding agent which is composed of 1%-5% of polyphosphate and 1%-3% of polysaccharide. The mechanically-pressed carbon-free corundum spinel ladle brick disclosed by the invention adopts an organic-inorganic compound combining system, is wet-milled and mixed under high pressure, formed under high pressure, high in density, good in thermal stability under high temperature, and resistant to molten steel and slag, and does not pollute the molten steel; moreover, production efficiency can be greatly improved, and therefore, the mechanically-pressed carbon-free corundum spinel ladle brick can be extensively applied to various ladles, especially refined low-carbon steel and ultralow-carbon ladles.

Owner:MAANSHAN LIER KAIYUAN NEW MATERIAL

Corundum-mullite honeycomb ceramic heat accumulator

The invention belongs to the inorganic nonmetal field, and relates to a corundum-mullite honeycomb ceramic heat accumulator for waste heat recovery of high-temperature kiln tail gas. The honeycomb ceramic heat accumulator is prepared by the following steps of: forming ceramic powder from corundum, mullite, alumina, clay and the like; adding cellulose, glycerol, glue and water to prepare plastic mud; and mixing, mixing mud, performing vacuum pug, forming, drying and performing high-temperature sintering. The honeycomb ceramic heat accumulator prepared by the method has the characteristics of superior high temperature strength, high heat accumulation capacity, high heat exchange speed, high thermal shock stability, low cost, easiness in operation and adaptation to industrial production.

Owner:晋城市富基新材料股份有限公司

Torpedo tank lining gunning repairing material, preparation method and applications thereof

The invention discloses a torpedo tank lining gunning repairing material, a preparation method and applications thereof, wherein the torpedo tank lining gunning repairing material comprises, by weight, 60-67 parts of a Al2O3-containing fireproof material after-using regenerating material, 3-7 parts of fireproof clay, 2-5 parts of flaky graphite, 3-7 parts of silicon carbide, 10-15 parts of an alumina homogeneous material, 3-6 parts of kyanite, 2-5 parts of alpha-Al2O3 micro-powder, 3-11 parts of a binder, and 1.2-3.4 parts of an admixture. According to the present invention, the torpedo tank lining gunning repairing material has characteristics of low raw material cost, wide regeneration material source, convenient cold-hot state gunning repairing, excellent thermal shock stability, strong repairing layer interface bonding strength, strong slag iron corrosion resistance, high torpedo tank operation rate, long service life, and the like.

Owner:武汉钢铁有限公司

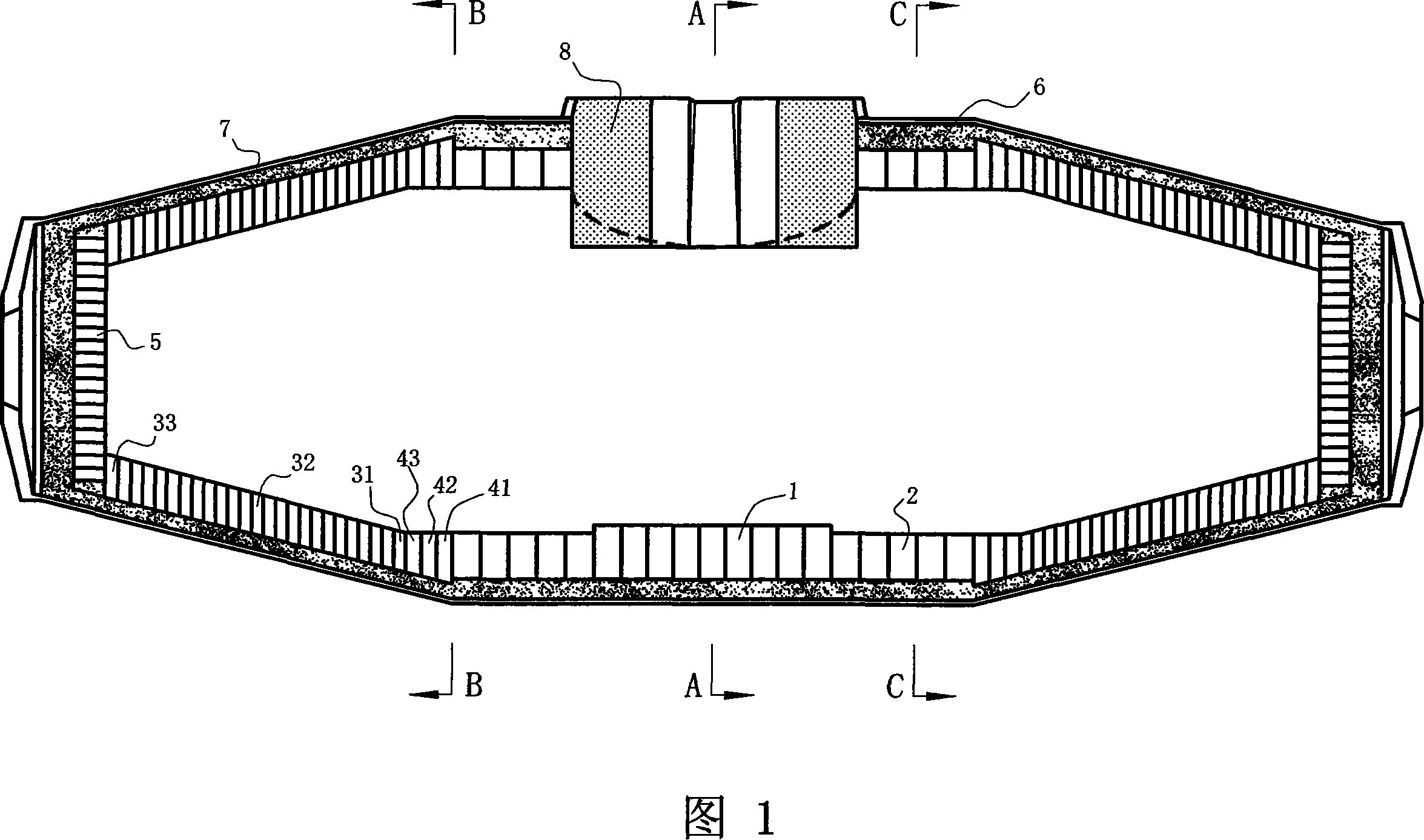

Inner lining structure for torpedo pot and aluminium carbonize silicon carbide brick and high aluminium brick used for torpedo pot

InactiveCN101058116ALifetime SynchronizationChange the phenomenon of less frequent useMelt-holding vesselsBrickCoesite

The invention relates to a torpedo pot liner structure and torpedo pot used aluminum carbonized silicon carbon brick, high aluminum brick. Bottom of the torpedo pot impact part uses nonburning aluminum carbonized silicon carbon brick, most of the rest using burnt stripping resistant high aluminum brick. Material for the aluminum carbonized silicon carbon brick comprises the alumina, electro-melting corundum, carbofrax, carbite, sintered corundum, aluminum, silicon, astringent, and so on, and the high aluminum brick comprises alumina, electro-melting corundum, carbofrax, silicon, silicon powder, bindeton and paper waste liquid. It is reasonable in formulation, mature in production process, with forming no need of high temperature baking with lower production cost. Using these two kinds of bricks, using durability of the overall torpedo can basically reach synchronic feature, application over 1700 times, with good effect and significant economical benefit.

Owner:GONGYI WINNA SCI & TECH DEV

Modified phenolic resin for fire resistive material and preparation method thereof

InactiveCN101245128AImprove antioxidant capacityImproved thermal shock stabilityFireproof paintsCarbon nanotubeSol-gel

The invention relates to a phenolic resin resin modified for refractories and a preparation method thereof. The technical scheme applied by the invention is that a sol-gel precursor of ferric, cobalt, or nickel metal oxide prepared by a sol-gel method are added into a dehydrated alcohol diluted phenolic resin, and the quantity of the sol-gel precursor of ferric, cobalt, or nickel metal oxide is 1-5 % by weight of the dehydrated alcohol diluted phenolic resin; the solution is stirred for 3-10 hours at the temperature of 40-85 DEG C, and then is put into a evaporator where the compound reacts for 5-10 hours at pressure of 0.08-0.09 MPa and temperature of 40-85 DEG C. Firstly, the phenolic resin modified for refractories prepared by the invention can transform the resin char from amorphous glassy carbon into crystalline graphitic carbon in-situ synthesizing a carbon nanotube in the refractories; secondly, availability of the carbon nanotube also can improve the carbon yield ratio of phenolic resin, thus improving the inoxidability, thermal shock resistance and mechanical strength for the refractories.

Owner:WUHAN UNIV OF SCI & TECH

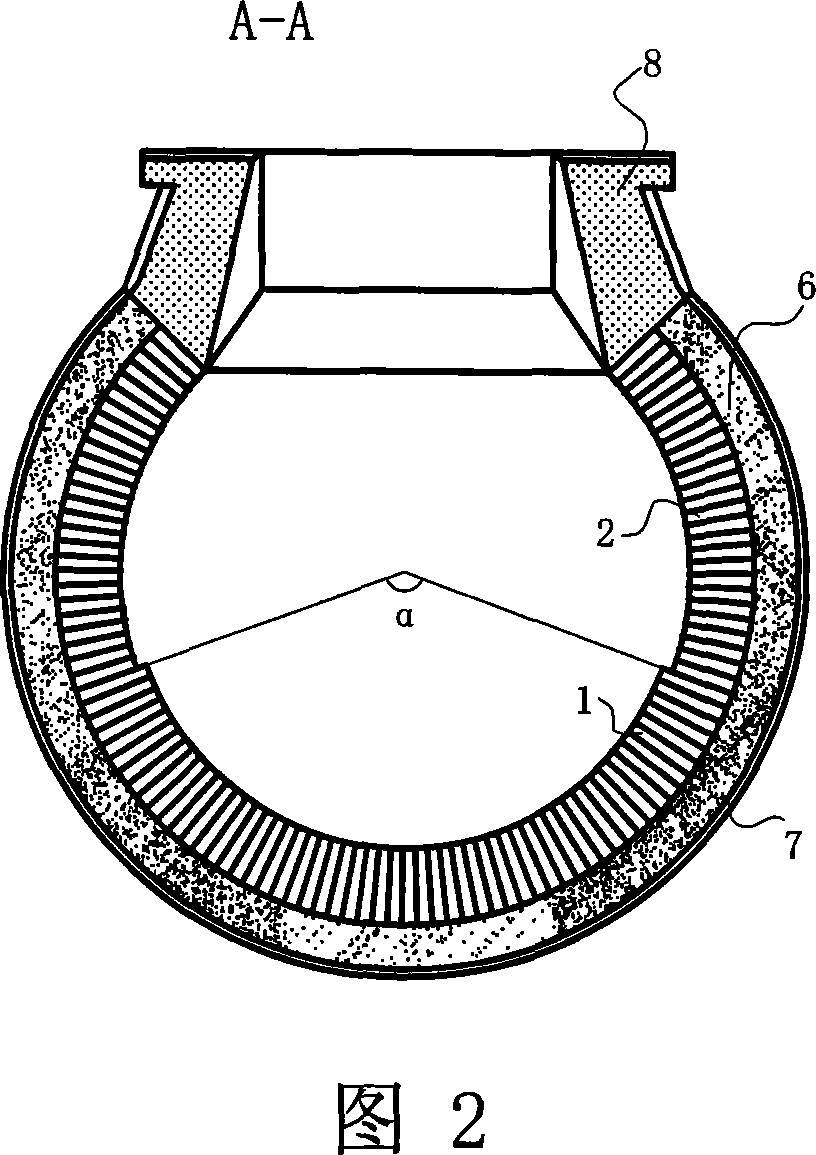

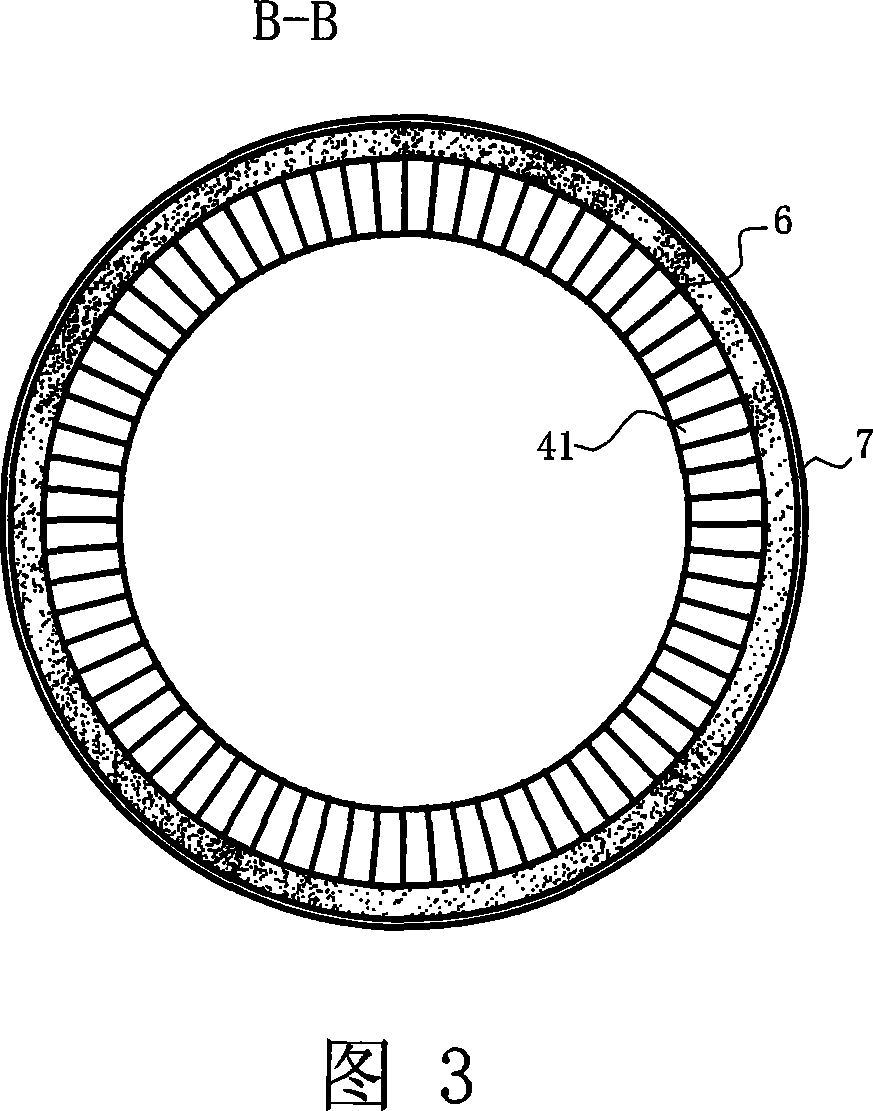

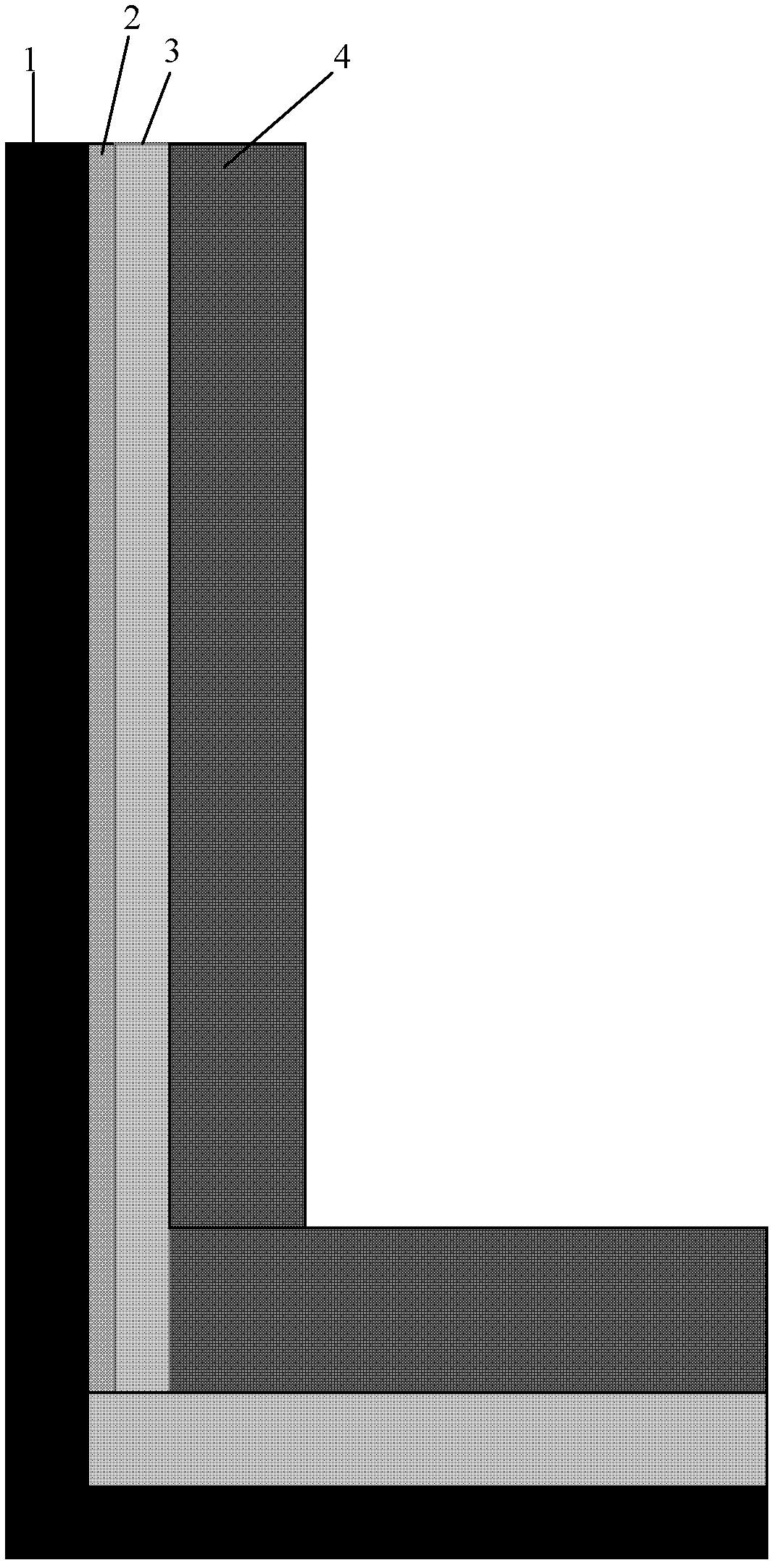

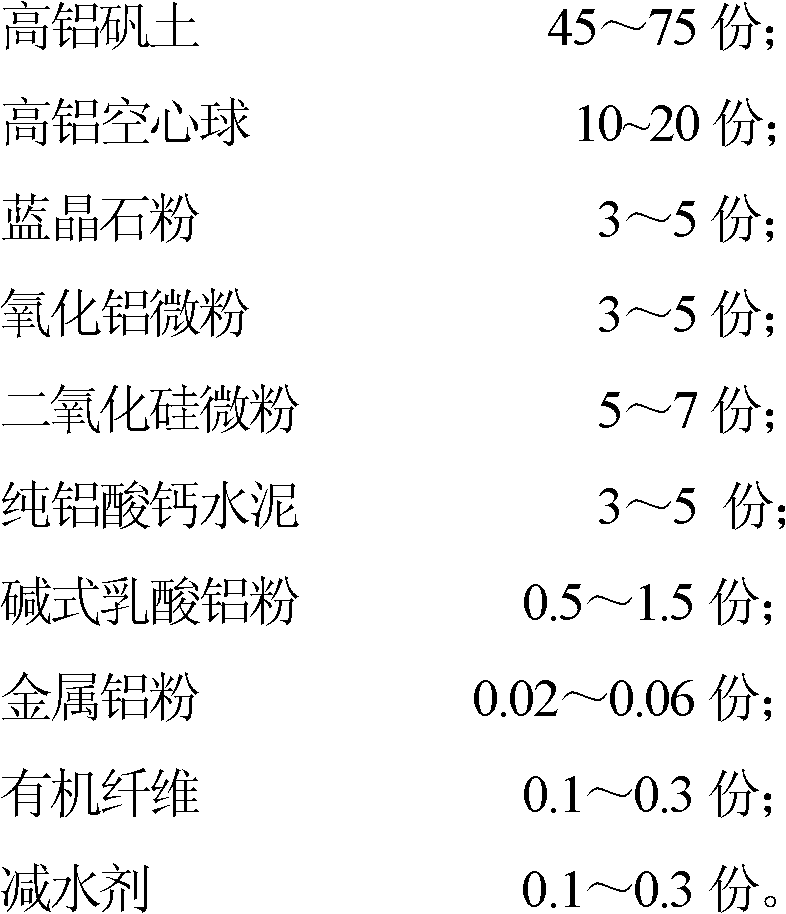

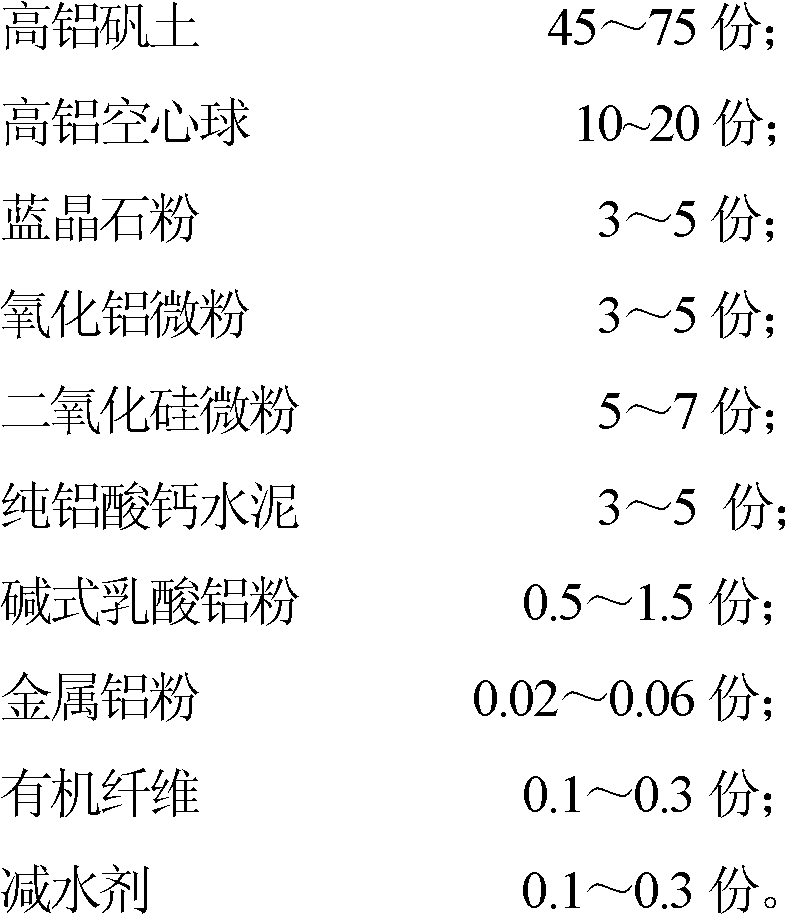

Ladle permanent lining pouring material capable of rapid roasting

The invention provides a ladle permanent lining pouring material capable of rapid roasting. The pouring material mainly comprises 45-75 parts of high bauxite, 10-20 parts of high-alumina hollow spheres, 3-5 parts of cyanite powder, 3-5 parts of alumina micro powder, 5-7 parts of silica micro powder, 3-5 parts of pure calcium aluminate cement, 0.5-1.5 parts of basic aluminium lactate powder, 0.02-0.06 part of metal aluminium powder, 0.1-0.3 part of organic fibres, and 0.1-0.3 part of water reducer. The pouring material capable of rapid roasting, provided by the invention, has the characteristics of being high in strength and refractoriness, good in thermal shock resistance, low in volume density and thermal conductivity, and considerable long in service life.

Owner:BAOSHAN IRON & STEEL CO LTD

Calcium aluminate cement bonded corundum castable containing calcium carbonate micropowder and preparation method of castable

The invention discloses a calcium aluminate cement bonded corundum castable containing calcium carbonate micropowder. The castable comprises tabular corundum aggregate and fine powder, activated aluminium oxide micropowder, calcium aluminate cement, CaCO3 micropowder and a water reducing agent, wherein the tabular corundum aggregate and fine powder, the activated aluminium oxide micropowder, the calcium aluminate cement and the CaCO3 micropowder are 85-95%, 2-10%, 0.1-2% and 0.1-5% of the total weight of the tabular corundum aggregate and fine powder, the activated aluminium oxide micropowder, the calcium aluminate cement and the CaCO3 micropowder respectively, and the water reducing agent is 0.1-0.5% of the total weight of the four raw materials. The castable adopts the calcium carbonate micropowder as an additive, so that the cost is lower, and the thermal shock stability of the castable is improved greatly.

Owner:ZHENGZHOU UNIV

Light-weight corundum-magnesium aluminate spinel castable and preparation method thereof

The invention relates to a light-weight corundum-magnesium aluminate spinel castable and a preparation method thereof. The technical scheme of the invention is taking nano-aperture porous corundum-magnesium aluminate spinel ceramic particles with the partical sizes successively being 3-5mm, 1-2.5mm and 0.1-0.5mm as aggregates, taking nano-aperture porous corundum-magnesium aluminate spinel ceramic fine powder with the partical size being smaller than 0.074mm, magnesium aluminate spinel fine powder, corundum fine powder, magnesia fine powder and alpha-Al2O3 micro powder as matrixes and taking aluminate cement as a binding agent; the preparation method comprises the following steps: mixing the matrixes, the binding agent and sodium hexametaphosphate firstly, then adding the aggregates, uniformly mixing, then adding water, uniformly stirring, moulding by casting, carrying out maintenance, demoulding and drying, and keeping the temperature for 2-6h at the condition with the temperature being 1450-1600 DEG C to obtain the light-weight corundum-magnesium aluminate spinel castable. By adopting the light-weight corundum-magnesium aluminate spinel castable and the preparation method, the process is simple, and a prepared product has the average pore size in a nanoscale, is low in heat conductivity coefficient, good in medium erosion and penetrability resistance and high in thermal shock resistance, and is suitable for parts, including bottoms, walls and the like, of steel ladles.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com