Corundum-mullite self-flow refractory castable

A technology of refractory castables and mullite, applied in the field of refractory castables, can solve the problems of restricting the service life of refractory castables, the service life is only three months, and the service life is only five months, so as to ensure the demolding strength and High temperature use temperature, long service life and good thermal shock stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

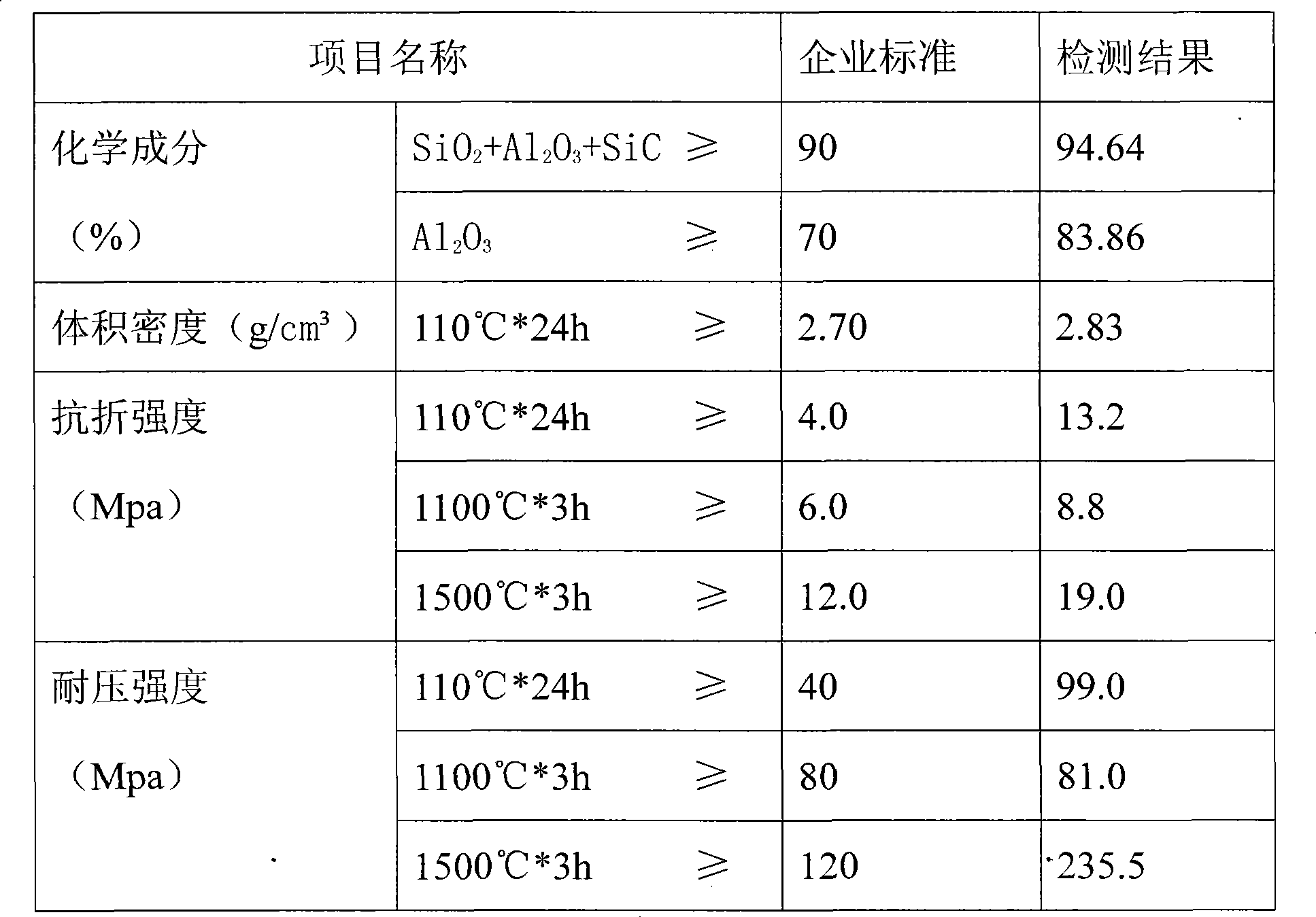

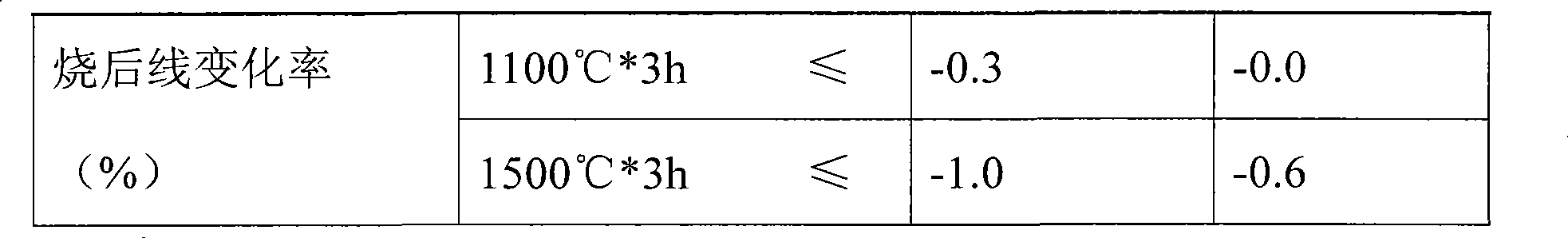

Embodiment 1

[0035] A corundum mullite self-flowing refractory castable, comprising the following components and the mass percentage of each component is:

[0036] Tabular alumina 30%

[0037] Silicon carbide powder 8%

[0038] Pure calcium aluminate cement 4%

[0039] Mullite 45%

[0040] α-Al 2 o 3 Micronized 10%

[0041] Bonet 3%.

[0042] α-Al 2 o 3 Micropowder is a common material on the market. The more common method is to use ammonium aluminum sulfate and ammonium bicarbonate as raw materials, and prepare a new precursor of aluminum oxide—ammonium aluminum carbonate [NH4AlO(OH)HCO3] by precipitation method. The precursor undergoes a phase transition during heat treatment, and the phase transition process is: amorphous (350°C)→γ(700°C)→γ+θ(1050°C)→θ+α(1100°C)→α(1200°C) , forming α-Al 2 o 3 Micronized.

[0043] Bonet is a new type of synthetic dense refractory aggregate based on calcium hexaaluminate CA6 mineral phase. Synthetic alumina-based tabular alumina and spinel a...

Embodiment 2

[0051] A corundum mullite self-flowing refractory castable, comprising the following components and the mass percentage of each component is:

[0052] Tabular alumina 33%

[0053] Silicon carbide powder 7%

[0054] Pure calcium aluminate cement 4%

[0055] Mullite 40%

[0056] α-Al 2 o 3 Micronized 12%

[0057] Bonet 4%.

Embodiment 3

[0059] A corundum mullite self-flowing refractory castable, comprising the following components and the mass percentage of each component is:

[0060] Tabular alumina 35%

[0061] Silicon carbide powder 5%

[0062] Pure calcium aluminate cement 5%

[0063] Mullite 35%

[0064] α-Al 2 o 3 Micronized 15%

[0065] Bonnet 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com