Aluminum-carbon sliding tile and method of producing the same

A technology of aluminum-carbon sliding bricks and carbon sliding bricks, which is applied in the field of refractory materials, can solve the problems of large amount of metal aluminum added, high production cost, and complicated nitriding firing process, so as to save firing costs, good product quality, considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below by way of examples.

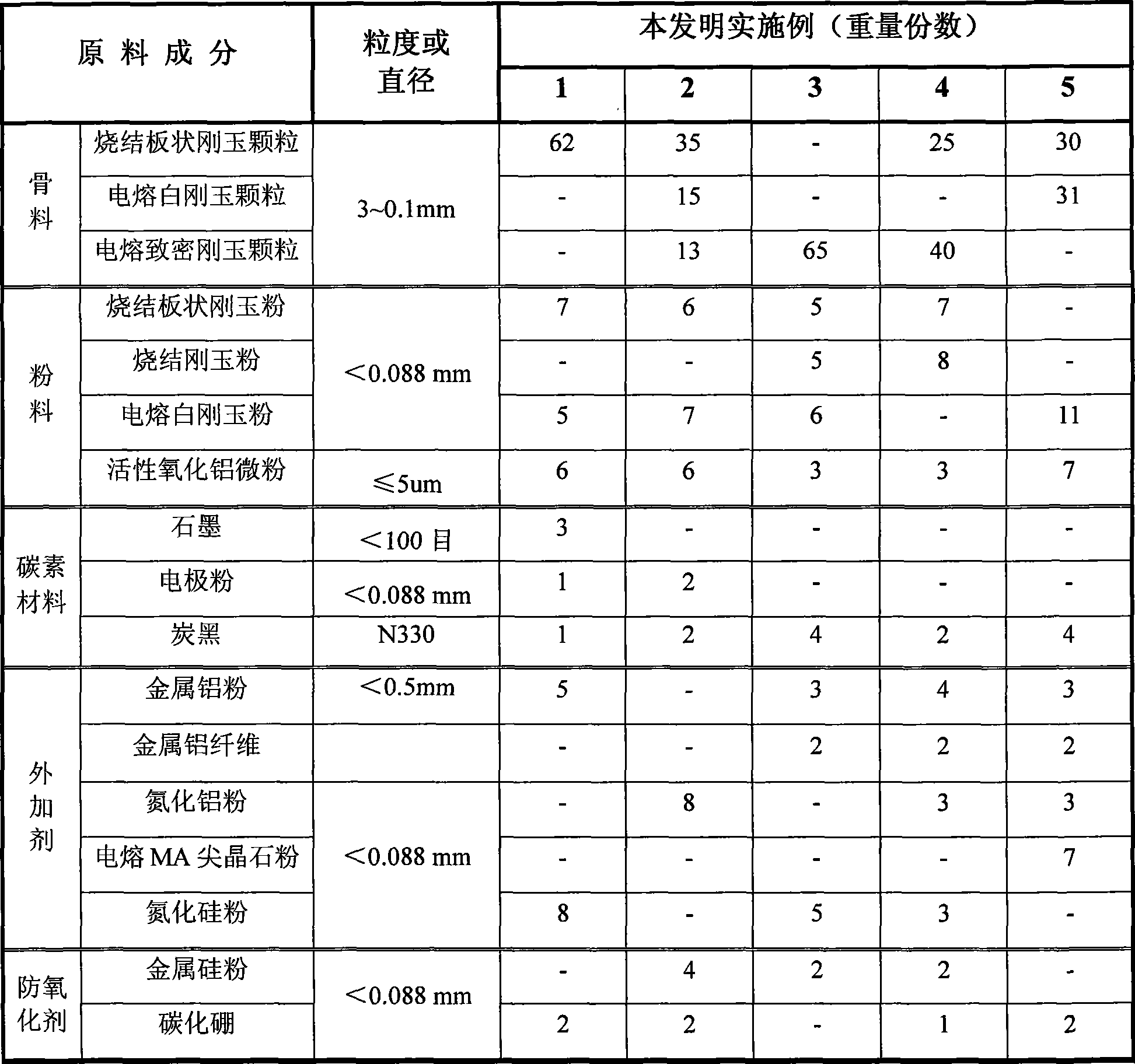

[0015] First, the ratio and particle size of the particles and powder used in the aluminum-carbon sliding brick of the present invention given in the embodiment of Table 1 are equipped, and then all the powders are premixed in the pre-mixer to make a mixed powder for subsequent use, and then Use a high-speed kneader to knead according to the following feeding order: granular material→dry mixing for 3 minutes (adding metal aluminum fiber at the same time)→bonding agent (5% phenolic resin)→mixing for 7 minutes→mixing powder→mixing for 30 minutes, out The material is formed by a 1,000-ton friction brick press, and the adobe is dried at 200°C for 48 hours. Finally, it is drilled, hooped, ground, and coated to obtain a non-fired aluminum-carbon sliding brick. The inspection indexes of finished aluminum-carbon sliding bricks are shown in Table 2.

[0016] Table 1 The proportioning ratio of each compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com