Corundum spinel castable with micro-nano pore structure and preparation method of corundum spinel castable

A technology for corundum spinel and castables, which is applied in the field of corundum spinel castables with micro-nanopore structure and its preparation, which can solve the problem of difficulty in ensuring the stability of size and quantity, affecting human health, increasing production costs, etc. problems, to achieve the effect of improving thermal shock stability, good mechanical properties and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

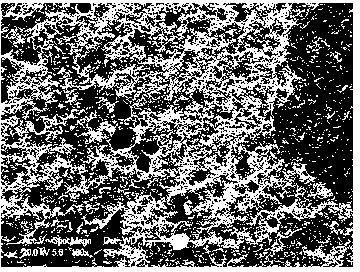

Embodiment 1

[0032] A corundum spinel castable with micro-nano pore structure and a preparation method thereof. With 45~56wt% tabular corundum particles and 12~15wt% magnesium aluminum spinel particles as aggregate, 7~10wt% magnesium aluminum spinel fine powder, 10~12wt% corundum fine powder, 12 ~15wt% α-Al 2 o 3 Micropowder, 6~8wt% pure calcium aluminate cement and 0.4~0.5wt% SiO 2 The micropowder is a powder; dry mix the aggregate for 5-15 minutes to make a mixed aggregate, dry mix the powder for 3-5 minutes to make a mixed powder; then add 0.1-0.2 Wt% of ADS, 0.7~0.8wt% of ADW, 4.2~4.5wt% of water and 5~7.5wt% of foam, stirred for 3~5 minutes to make a mixed mud; then pour the mixed aggregate into the mixed mud , stirred for 1.5-4.5 minutes, vibrating casting, curing for 18-28 hours, and demoulding; baked at 100-120°C for 18-28 hours, heated to 1450-1550°C, and kept for 2-3 hours, that is, micro-nano Corundum spinel castable with porous structure.

[0033] In this embodiment: the c...

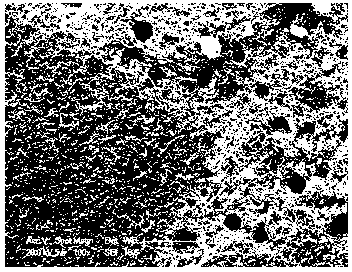

Embodiment 2

[0036] A corundum spinel castable with micro-nano pore structure and a preparation method thereof. With 56~64wt% tabular corundum particles and 8~13wt% magnesium aluminate spinel particles as aggregate, 5~8wt% magnesium aluminate spinel fine powder, 8~10wt% corundum fine powder, 10 ~12wt% α-Al 2 o 3 Micropowder, 5~6wt% pure calcium aluminate cement and 0.3~0.4wt% SiO 2 The micropowder is a powder; dry mix the aggregate for 5-15 minutes to make a mixed aggregate, dry mix the powder for 3-5 minutes to make a mixed powder; then add 0.1-0.2 Wt% of ADS, 0.5~0.6wt% of ADW, 4.0~4.2wt% of water and 7.5~10wt% of foam, stirred for 3~5 minutes to make a mixed mud; then pour the mixed aggregate into the mixed mud, Stir for 1.5~4.5 minutes, vibrate casting, curing for 18~28 hours, demoulding; bake at 100~120°C for 18~28 hours, heat up to 1550~1600°C, keep warm for 2.5~3.5 hours, then you can get micro-nano pores Structural corundum spinel castables.

[0037] In this embodiment: the co...

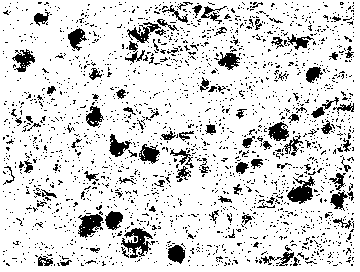

Embodiment 3

[0040] A corundum spinel castable with micro-nano pore structure and a preparation method thereof. With 64~72wt% of tabular corundum particles and 4~9wt% of magnesium aluminate spinel particles as aggregate, 3~7wt% of magnesium aluminate spinel fine powder, 6~9wt% of corundum fine powder, 7 ~10wt% α-Al 2 o 3 Micropowder, 4~5wt% pure calcium aluminate cement and 0.2~0.3wt% SiO 2 The micropowder is powder; dry mix the aggregate for 5-15 minutes to make mixed aggregate, dry mix the powder for 3-5 minutes to make mixed powder; then add 0.4-0.6 Wt% ADW, 3.7~4.0wt% water and 10~12.5wt% foam, stir for 3~5 minutes to make a mixed slurry; then pour the mixed aggregate into the mixed slurry, stir for 1.5~4.5 minutes, vibrate Casting molding, curing for 18-28 hours, demoulding; baking at 100-120°C for 18-28 hours, heating up to 1550-1650°C, and keeping warm for 2.8-3.8 hours to obtain corundum spinel casting with micro-nanoporous structure material.

[0041] In this embodiment: the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com