Patents

Literature

61results about How to "Good resistance to slag erosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Corundum spinel castable with micro-nano pore structure and preparation method of corundum spinel castable

The invention relates to a corundum spinel castable with a micro-nano pore structure and a preparation method of the corundum spinel castable. The technical scheme of the invention is as follows: the preparation method comprises the following steps of: dry-blending 45-82 percent by weight of tabular corundum particles and 1-15 percent by weight of magnesium aluminate spinel particles to obtain mixed aggregate, and dry-blending 1-10 percent by weight of magnesium aluminate spinel fine powder, 4-12 percent by weight of corundum fine powder, 5-15 percent by weight of Alpha-Al2O3 micropowder, 2-8 percent by weight of pure calcium aluminate cement and 0.1-0.5 percent by weight of SiO2 micropowder to obtain mixed powder; then adding a water reducing agent, water and foams which respectively account for 0.2-1.0 percent by weight, 3.5-4.5 percent by weight and 5-15 percent by weight of the aggregate and the powder to the mixed powder, and stirring to prepare mixed slurry; and pouring the mixed aggregate into the mixed slurry, stirring, moulding by casting, curing, demoulding, baking, heating to 1450-1760 DEG C and maintaining the temperature for 2-4 hours. The preparation method disclosed by the invention has the characteristics of simple process and easiness for construction and industrial production; and the prepared corundum spinel castable is high in comprehensive property, good in thermal shock resistance and long in service life.

Owner:WUHAN UNIV OF SCI & TECH

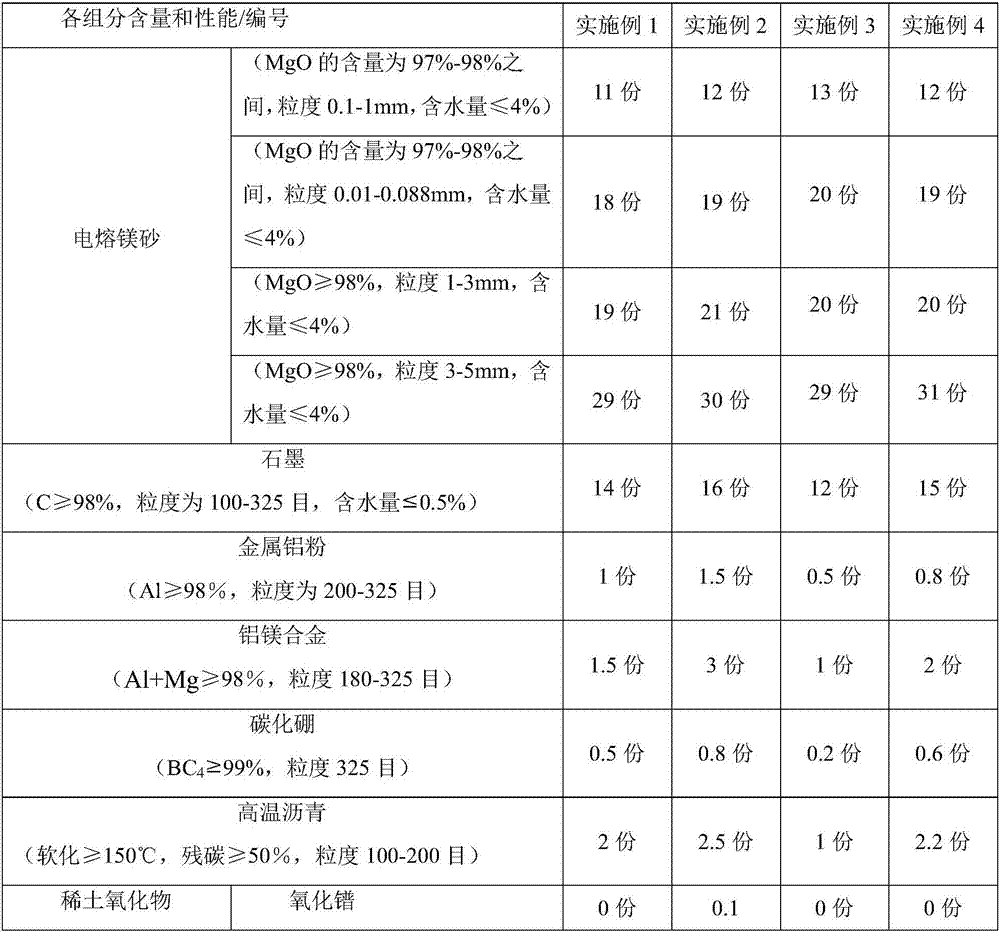

Low carbon magnesium carbon brick containing B4C-C composite powder and nano TiC powder, and method of manufacturing the same

The invention belongs to the technical field of low carbon magnesium carbon brick fire proof materials, in particular to a low carbon magnesium carbon brick containing B4C-C composite powder and nanometer TiC powder and a preparation method thereof. The adopted technical proposal comprises: mixing 60-75wt percent magnesia particles, 15-30wt percent magnesia fine powder, 1-5wt percent coarse-grained squama graphite, 1-5wt percent thin-grained squama graphite, 0.5-1.5wt percent carbon soot, 1-3wt percent metal aluminium powder, 1-3wt percent metal silicon powder, 0.1-1.0wt percent B4C-C composite powder and 0.05-0.4wt percent nanometer TiC powder, additionally adding 3-5wt percent organic bond, press forming after calendaring, and heat treatment 24 hours under the condition of 180 DEG C to 240 DEG C. The carbon content of prepared carbon magnesium carbon brick is less than 6 percent, and the carbon magnesium carbon brick has the characteristics of obvious antioxidant effect, strong high temperature strength, good thermal shock resistance, strong anti-slag corrosion and low cost.

Owner:WUHAN UNIV OF SCI & TECH

Composite spinel-zirconium refractory material for smelting colored heavy metal

The invention discloses a composite spinel-zirconium refractory material for smelting colored heavy metal. The technical scheme is as follows: the material comprises 30-45 parts of 5mm-0mm emery, 10-30 parts of 5mm-0mm magnesia chromite clinker,15-25 parts of 3mm-1mm magnalium spinel clinker, 7-20 parts of 3mm-0mm magnesite clinker, 1-5 parts of chrome green less than or equal to 0.045mm and 2-8 parts of zirconium dioxide less than or equal to 0.045mm by weight part and a bonding agent is aluminium dihydrogen phosphate liquid the adding amount of which is 3-15% of the total weight of the emery, the magnesia chromite clinker, the magnalium spinel clinker, the magnesite clinker, the chrome green and the zirconium dioxide. A hydraulic press is adopted for molding and the composite spinel-zirconium refractory material is sintered by a hyperthermia tunnel kiln. The content of Cr2O3 of the composite spinel-zirconium refractory material is less than 10%, so that the composite spinel-zirconium refractory material not only is environment-friendly, but also has better slag erosion resistance, high-temperature melt washing resistance, metal melt permeation resistance and thermal shock stability performance.

Owner:辽宁青花耐火材料股份有限公司

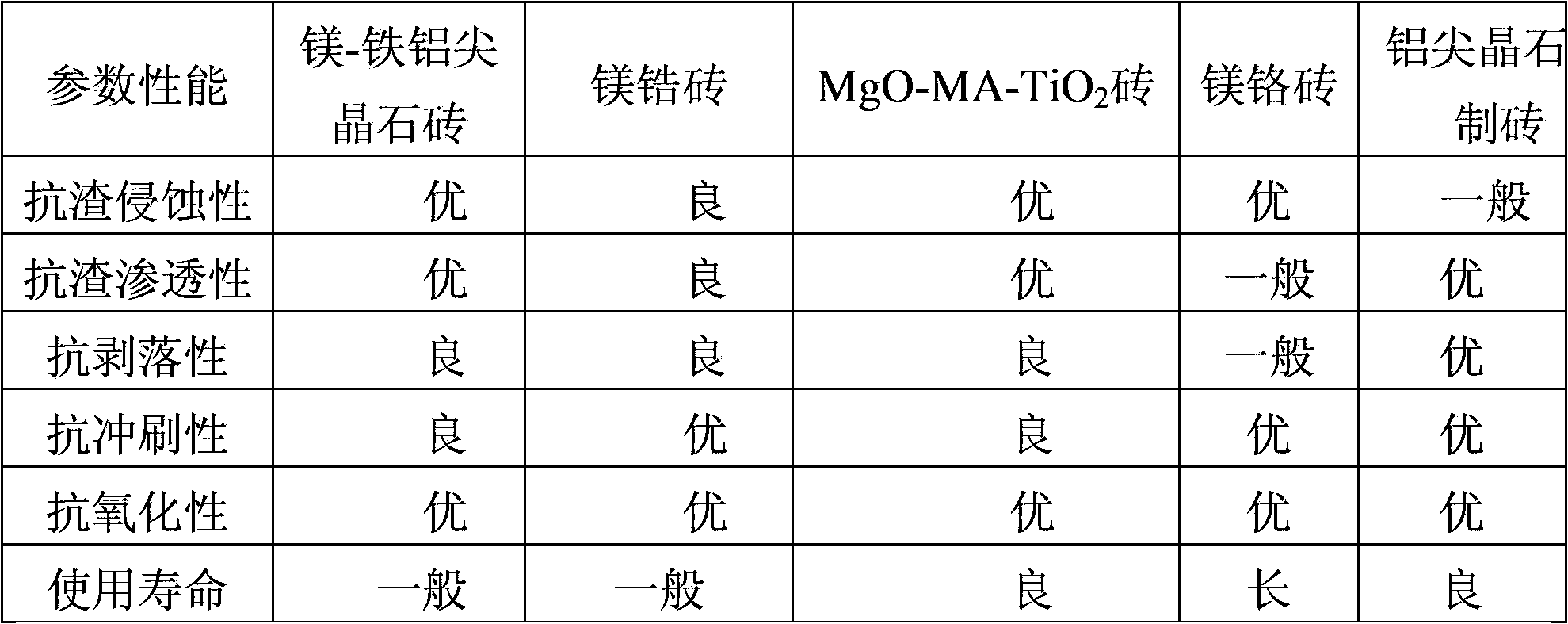

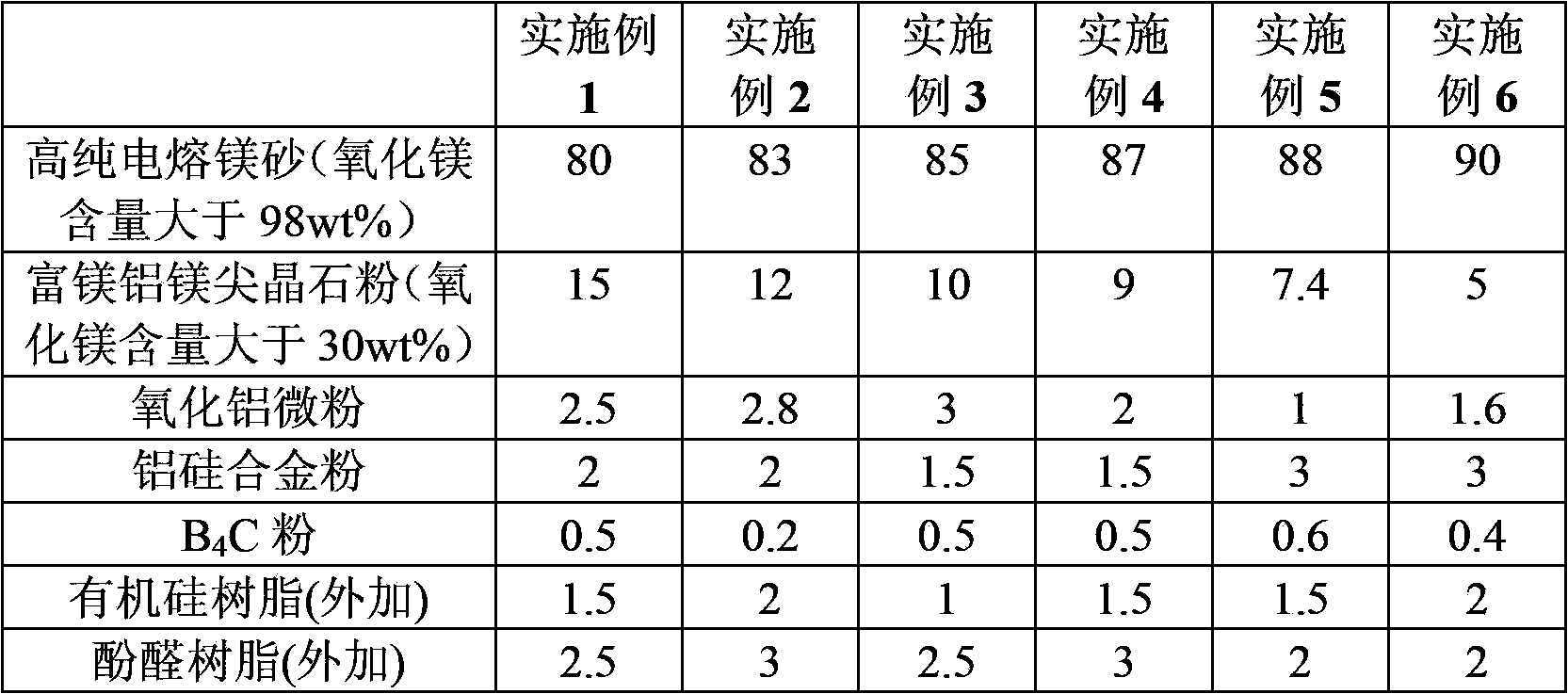

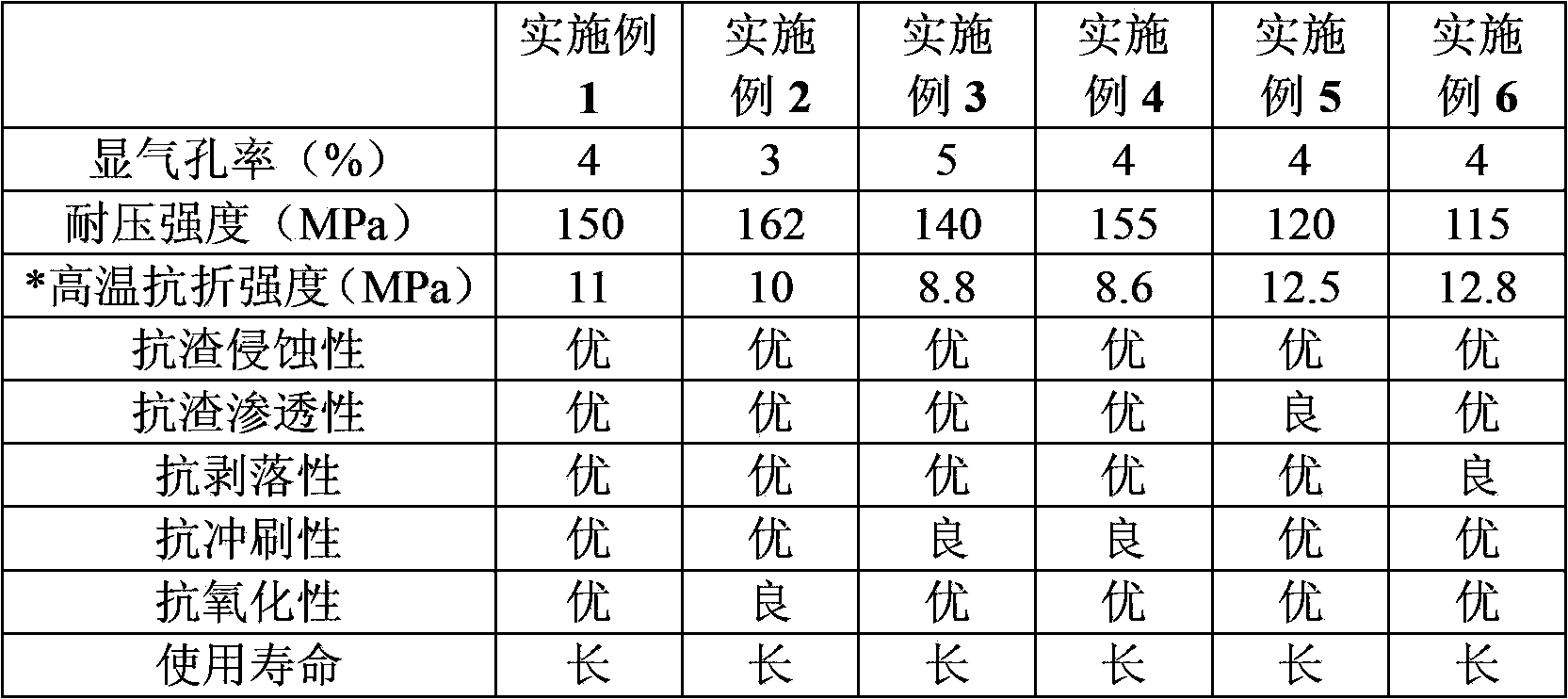

Unfired magnesia-alumina spinel brick

The invention discloses an unfired magnesia-alumina spinel brick. The unfired magnesia-alumina spinel brick comprises the following chemical components by mass: 80 to 90% of fused magnesia, 5 to 15% of magnesium-rich magnesia-alumina spinel, 1 to 3% of micro alumina powder, 1 to 3% of aluminum-silicon alloy powder and 0.2 to 0.6% of B4C. The chemical components are bonded together by using 3.5 to 5 wt% of an added binder. The content of magnesium oxide in the fused magnesia is greater than 98 wt%, and the content of magnesium oxide in the magnesium-rich magnesia-alumina spinel is greater than 30 wt%. The unfired magnesia-alumina spinel brick provided by the invention has excellent slag reaction resistance, slag penetration resistance, anti-stripping performance, anti-scouring performance, resistance to oxidation and a long service life, does not include the harmful element--chromium, avoids pollution and harm to human beings and the environment, needs low production cost and has a wide application scope.

Owner:BAOSHAN IRON & STEEL CO LTD

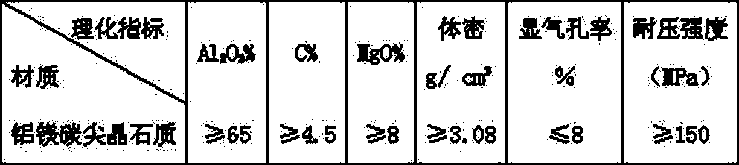

Novel slide plate brick for automatic slag-retaining slide gate of converter and preparation method of slide plate brick

The invention discloses a novel slide plate brick for an automatic slag-retaining slide gate of a converter and a preparation method of the slide plate brick. The slide plate brick is characterized by containing the following components in percentage by weight: 58%-68% of tabular corundum, 6%-8% of 98 magnesia, 8%-11% of electrically-fused spinel, 3%-5% of graphite, 4%-7% of a-aluminum oxide powder, 1%-2% of sintering agent, 2%-7% of aluminum-silicon alloy powder and 4%-5% of resin. The slide plate brick can be prepared from the components through the processes of mixing, shaping, drying, sintering, oil immersing, roasting, and machining. By virtue of adjustment on the formula of the slide gate brick and simplification on the production technology of the slide gate brick, the comprehensive performance of the slide gate brick is enhanced, the direct benefit of slag-free tapping with the slide plate brick is high, and beneficial conditions are provided for development of good-quality steel grades, so that the slide plate brick and the preparation method of the brick have a very wide application prospect and remarkable economic and social benefits.

Owner:无锡市南方耐材有限公司

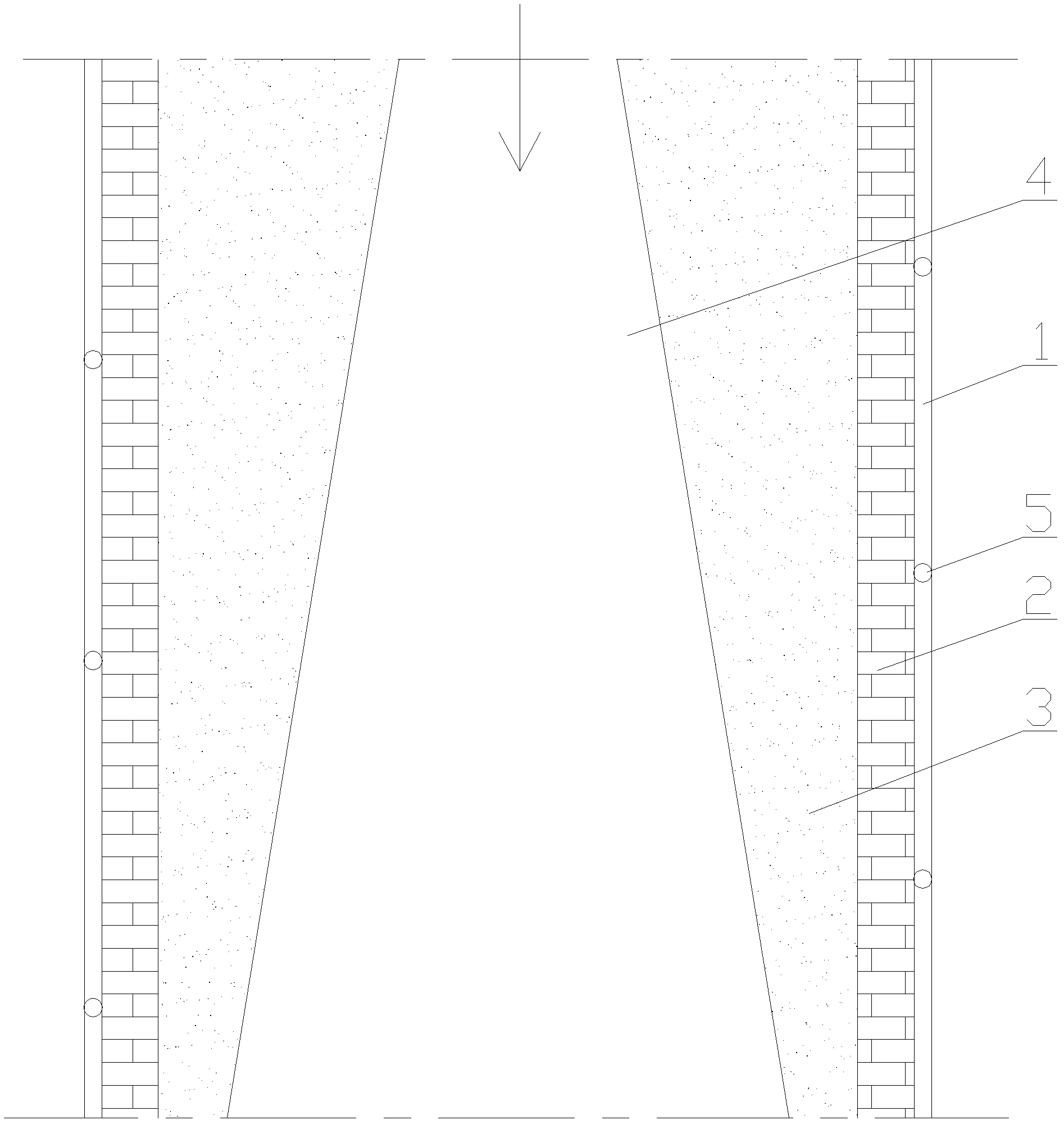

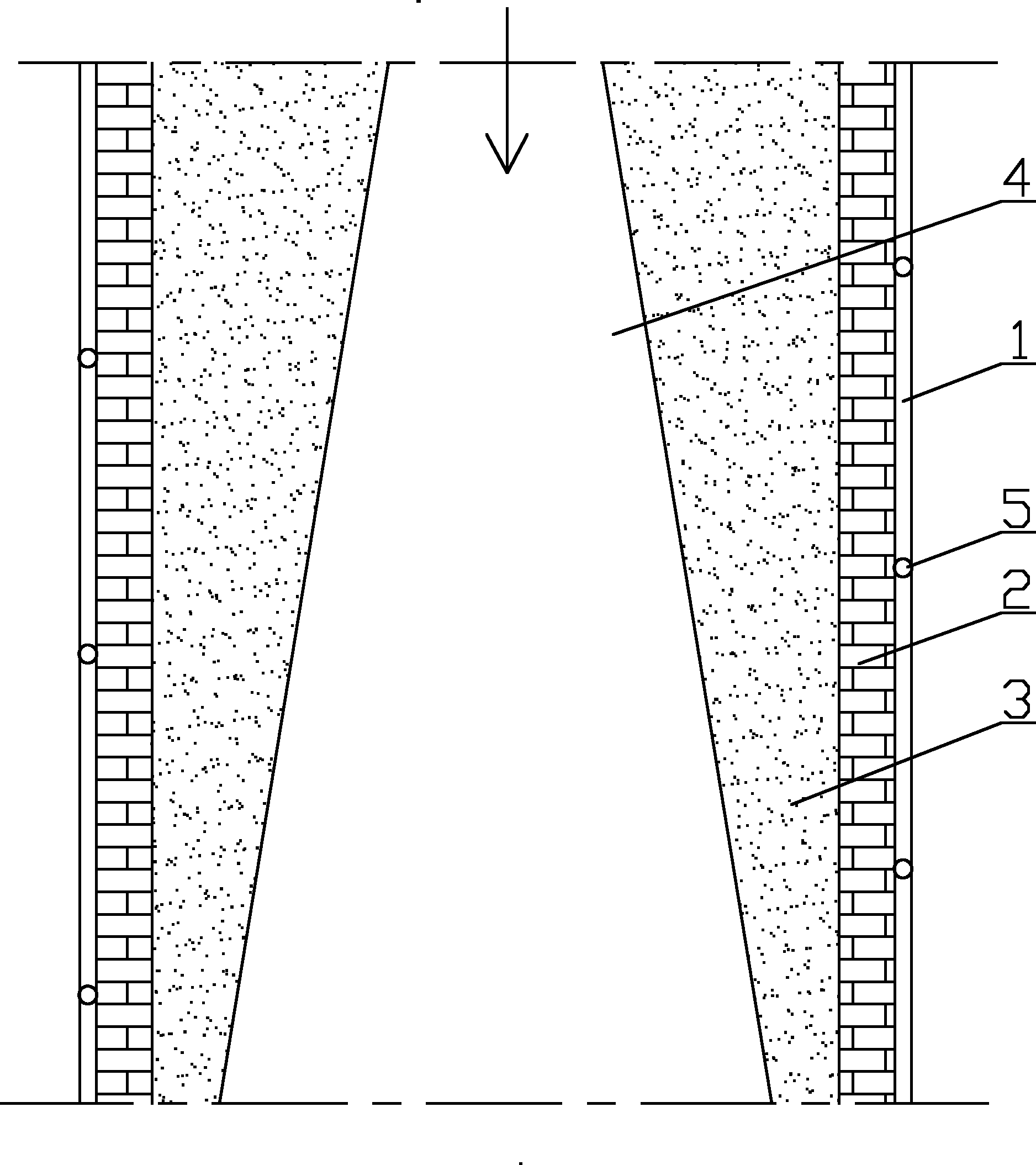

Pouring material and single-iron notch blast furnace iron storage type tapping main channel using same

The invention discloses a pouring material and a single-iron notch blast furnace iron storage type tapping main channel using the same; the single-iron notch blast furnace iron storage type tapping main channel comprises a steel mould, a brick layer and the pouring material, wherein the brick layer is laid at the inner side of the steel mould; and the pouring material is poured at the inner side of the brick layer. The single-iron notch blast furnace iron storage type tapping main channel is characterized in that a channel is arranged at the inner side of the pouring material, so that the width of the channel is gradually increased from front to back. According to the invention, the scouring force of molten iron for the main channel can be reduced, the labor intensity of workers pushing slag can be reduced, and the front half part and rear half part of the main channel can be repaired synchronously, so that the waste can be avoided. The repairing material can be saved by about 40-50 tons every year, so that the cost is greatly saved; and about 10 ton of material can be saved for a new main channel which is poured for the first time after the structural design is improved, so that the material cost is greatly saved, the annual total cost is greatly saved, and the economic benefit is greatly improved.

Owner:CHANGXING MINGTIAN FURNACE CHARGE

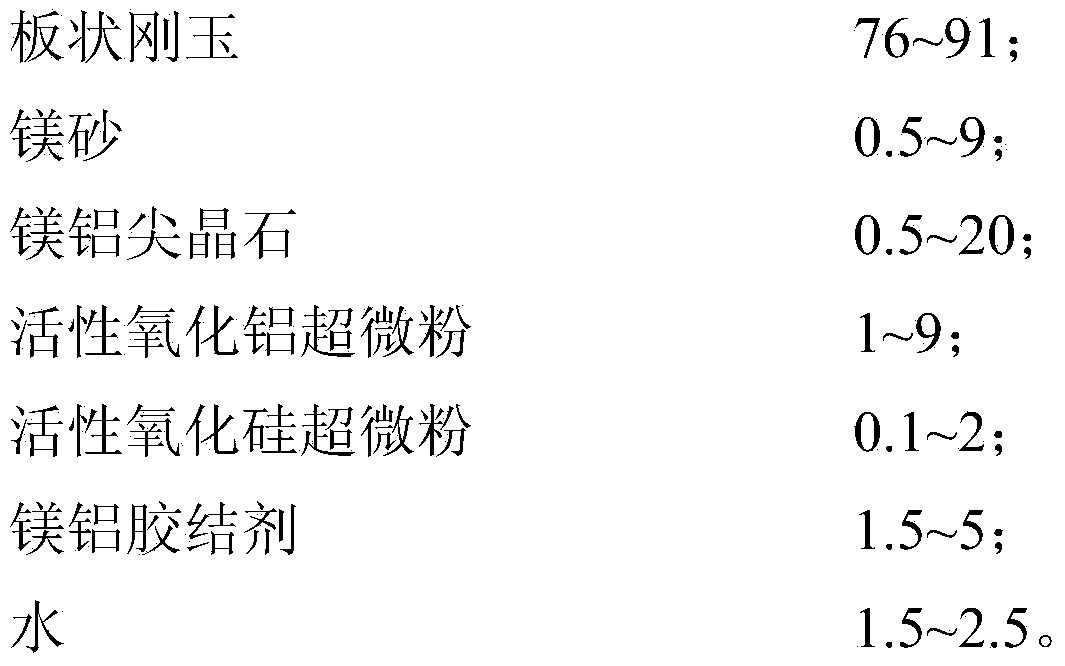

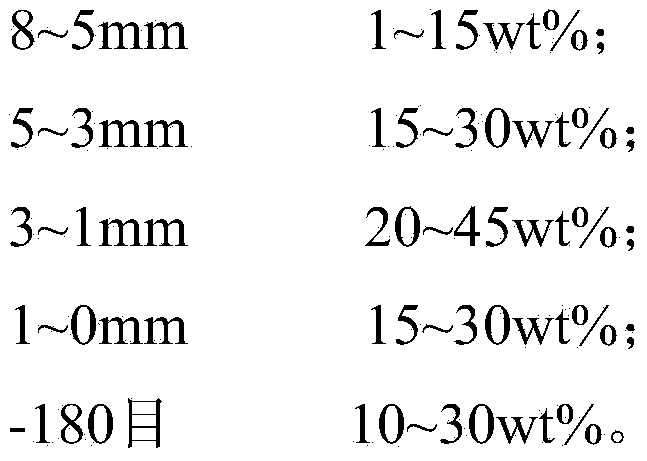

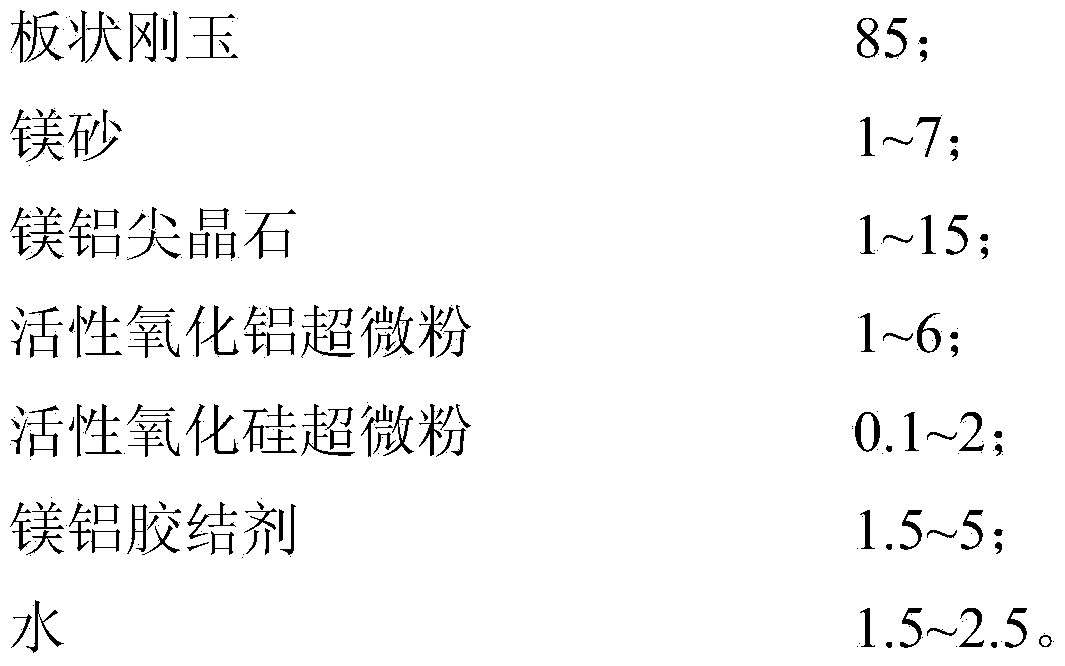

Method for preparing tabular corundum brick for working lining of carbon-free steel ladle

ActiveCN103992126AImproved thermal shock stabilityReduce the content of CaOSteelmakingCompression molding

The invention discloses a method for preparing a tabular corundum brick for a working lining of a carbon-free steel ladle. The method comprises the steps of uniformly mixing the raw materials of the tabular corundum brick, and sequentially carrying out compression molding pressing and low-temperature baking to obtain the tabular corundum brick, wherein the tabular corundum brick comprise the following raw materials in parts by weight: 76-91 parts of tabular corundum, 0.5-9 parts of magnesia, 0.5-20 parts of magnesium-aluminum spinel, 1-9 parts of activated aluminum oxide ultrafine powder, 0.1-2 parts of activated silicon oxide ultrafine powder, 1.5-5 parts of a magnesium-aluminum cementing agent and 1.5-2.5 parts of water. The method for preparing the tabular corundum brick for the working lining of the carbon-free steel ladle is simple, the service life of the tabular corundum brick is long and free of carbon, and the tubular corundum brick can satisfy the demands on clean steelmaking.

Owner:ZHEJIANG ZILI HIGH TEMPERATURE TECH CO LTD

Special casting material for main iron runner of iron-making blast furnace

The invention discloses a special casting material for a main iron runner of an iron-making blast furnace. The special casting material is prepared from brown fused alumina granules, white alundum granules, white alundum powder, plate corundum micro powder, chromium concentrate, silicon carbide granules, silicon carbide powder, spherical asphalt, activated aluminum oxide, silica powder, pure calcium aluminate cement, metal silicon powder, metal aluminum powder, additives, anti-explosion fiber, carbon composite micro powder and the like according to a certain ratio. The special casting material has the advantages that aiming at problems that a main iron runner casting material of the blast furnace is generally poor in furnace slag corrosion resistance, slag lines are easy to deteriorate, the operation and the yield of the blast furnace can be affected, and the like, a refractory material which is good in slag corrosion resistance and good in abrasion and flushing resistance is compounded. According to the scheme, co-ground composite micro powder which is not easy to infiltrate by molten iron and slag is introduced, the silicon carbide granules, powder materials, plate corundum micro powder and chromium concentrate are introduced to improve the abrasion and flushing resistance, and by optimizing a binding agent and the additives, the comprehensive high temperature properties of the casting material for the main iron runner is ensured.

Owner:REWELL REFRACTORY ZHENGZHOU CO LTD

Silicon carbide ceramic rotor material prepared through gel injection molding and preparation method thereof

The invention provides a silicon carbide ceramic rotor material prepared through gel injection molding and a preparation method thereof. The ceramic rotor material comprises the following components in percentage by weight: 65-75% of silicon carbide powder, 22-32% of silicon powder, 1.2% of aluminum oxide, 0.9% of lanthanum oxide and 0.9% of yttrium oxide. The method comprises five steps of preparing a monomer premixed solution, preparing initial and stable ceramic slurry, defoaming the stable ceramic slurry, preparing a ceramic biscuit and sintering the ceramic biscuit. The silicon carbide ceramic rotor material prepared by adopting the method disclosed by the invention has the advantages of high compactness and high-temperature oxidation resistance, good thermal shock resistance, slag corrosion resistance and wear resistance and the like, can well meet processing and operating requirements for a silicon carbide ceramic rotor for rotary injection of an aluminum alloy melt, and has a broad market prospect.

Owner:重庆多耐达汽车零部件有限公司

Dry material for continuous casting tundish working lining and preparation method of dry material

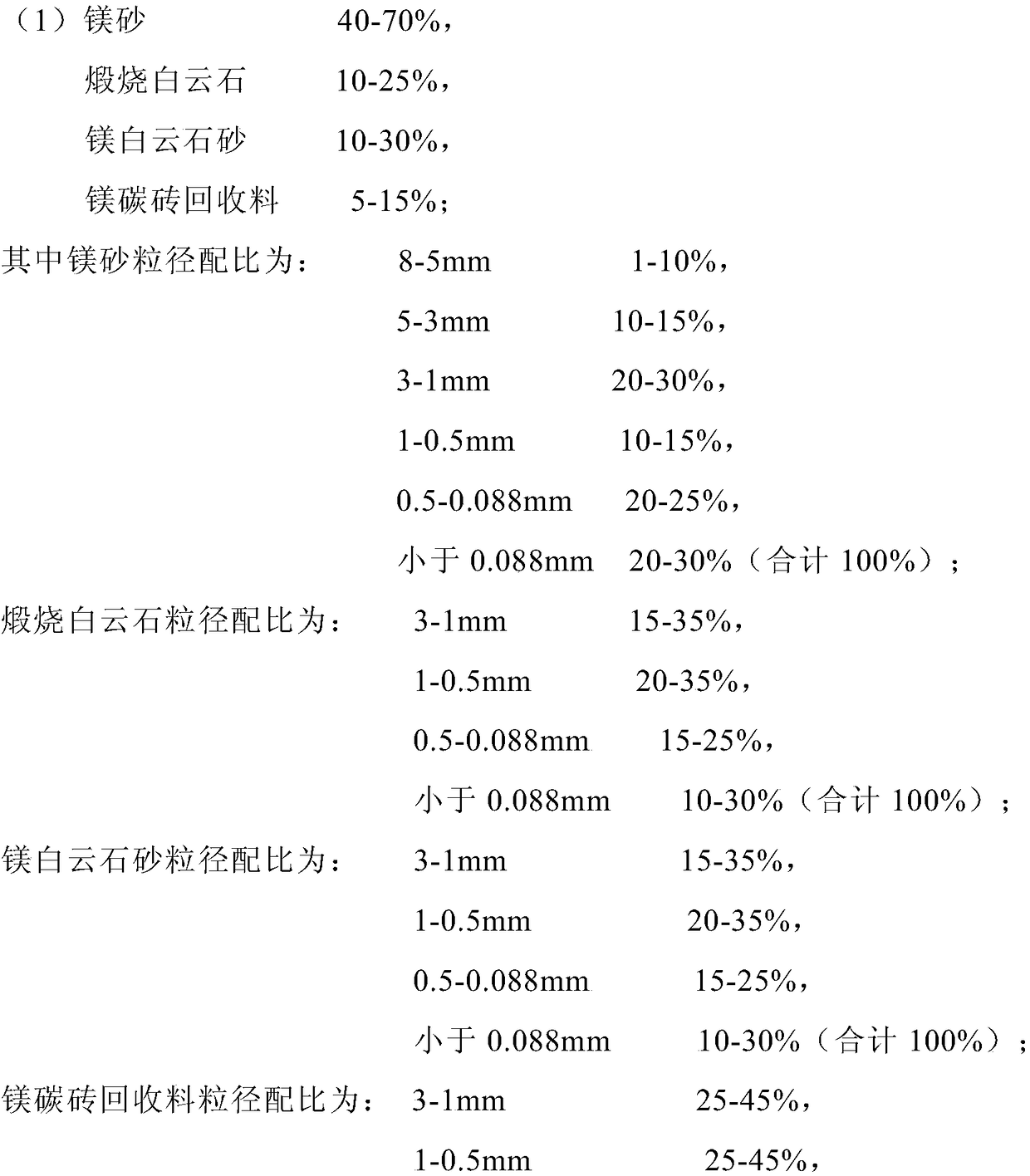

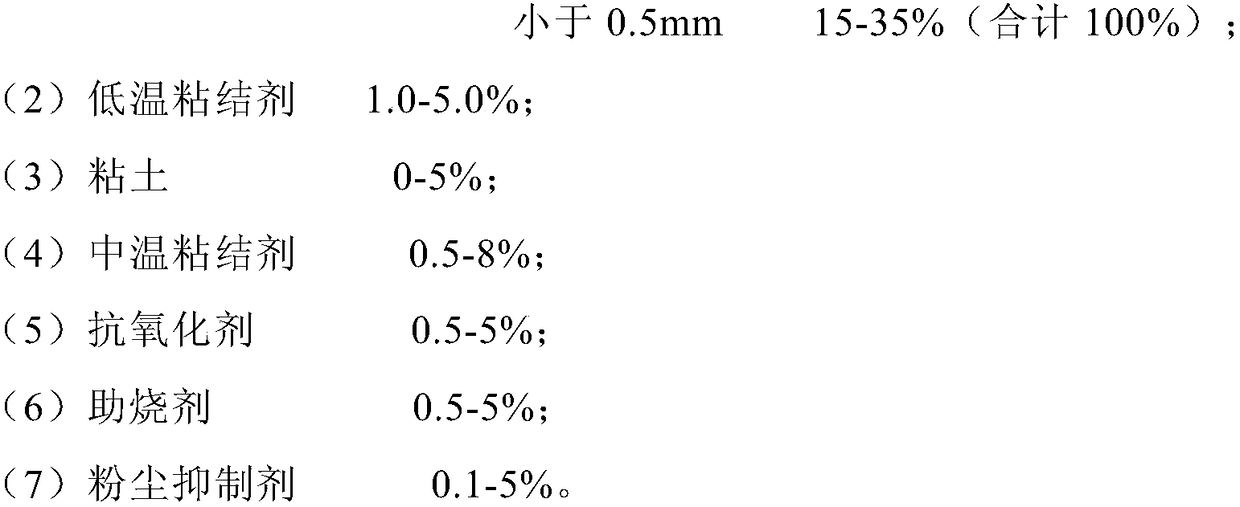

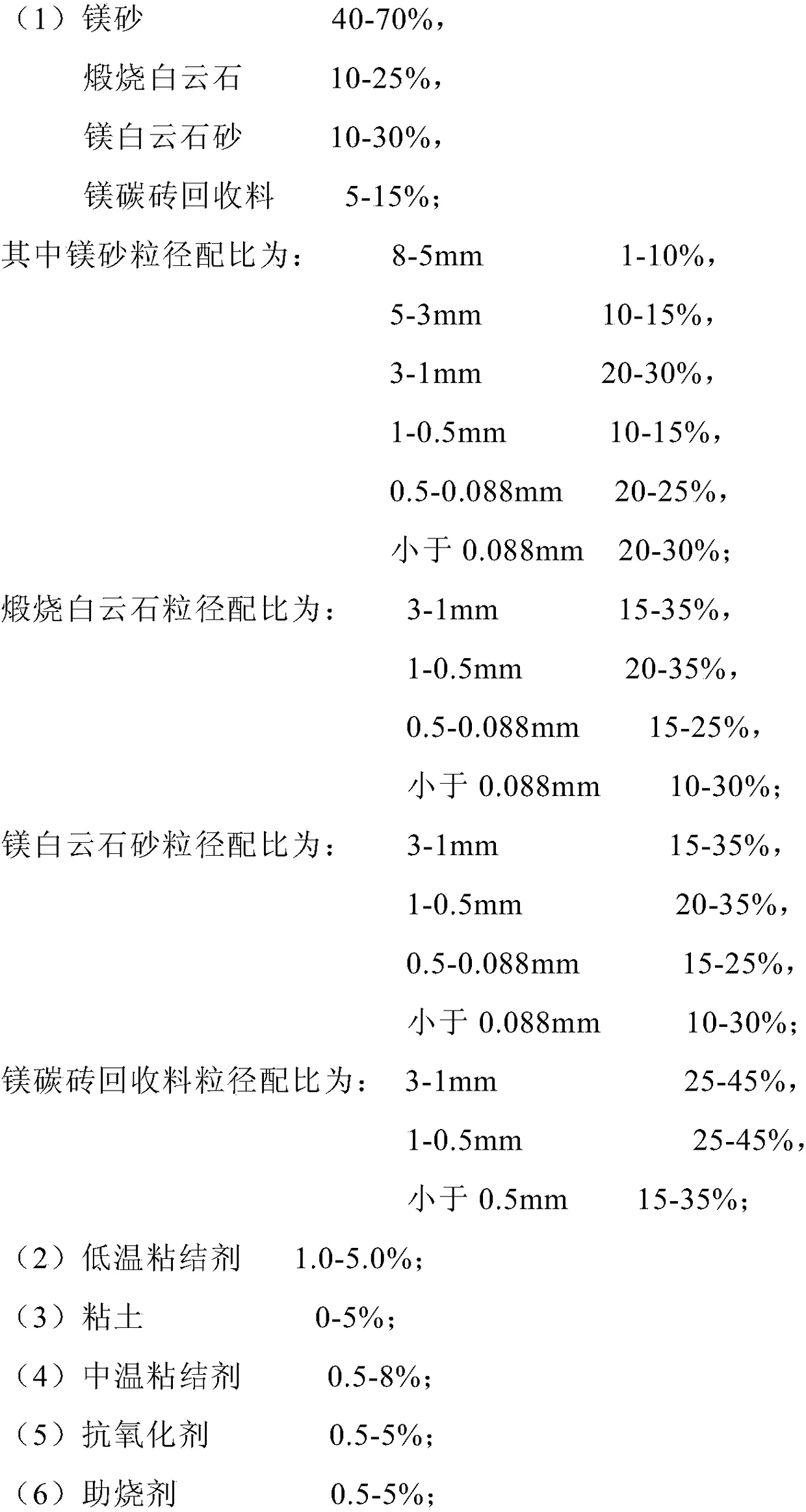

The invention relates to a dry material for a continuous casting tundish working lining and a preparation method of the dry material. The dry material contains the following raw material components inpercentage by weight: 40%-70% of magnesia, 10%-25% of burnt dolomite, 10%-30% of konite sand, 5%-15% of recycled magnesia carbon bricks, 1.0%-5.0% of a low-temperature binder, 0-5% of clay, 0.5%-8% of a medium-temperature binder, 0.5%-5% of an antioxidant, 0.5%-5% of a sintering aid and 0.1%-5% of a dust inhibitor. The volume density of the prepared tundish working lining is 1.8g / cm<3>-2.5g / cm<3>, the 110DEG C*20h compression strength is 2.5MPa-4MPa, the 1550DEG C*3h compression strength is 6MPa-12MPa, the refractoriness is more than 1750 DEG C, the linear change rate is (-4%)-(4%), the dry material does not crack after being cooled with water at 1100 DEG C for 50 times, the service life is more than 30h, and the dry material has the characteristics of high strength, good thermal shock resistance and scouring resistance, strong molten steel purifying capability, long life and environmental friendliness.

Owner:武汉钢铁有限公司

Flexible composite spinel tin refractory material for pyrometallurgical noble metal smelting and preparation method of flexible composite spinel tin refractory material

The invention discloses a flexible composite spinel tin refractory material for pyrometallurgical noble metal smelting and a preparation method of the flexible composite spinel tin refractory material. According to the flexible composite spinel tin refractory material for the pyrometallurgical noble metal smelting and the preparation method of the flexible composite spinel tin refractory material, eutectic aluminum chromium, magnesium chromium spinel and magnesium aluminum spinel are used as a main crystal phase; electric-melting zirconium oxide is introduced into a substrate part; the thermal shock resistance of a product is improved by producing micro-cracks by converting a crystal form of the zirconium oxide during a firing process, and meanwhile, the crystal lattice structure is changed by forming magnesium tin spinel by introducing tin oxide, so that the flexibility and the performance of resisting noble metal smelting slag erosion of a product are improved. The flexible composite spinel tin refractory material for the pyrometallurgical noble metal smelting and the preparation method of the flexible composite spinel tin refractory material have great significance on solving the problems about thermal spalling and structural spalling damage of a noble metal smelting furnace refractory lining material during a using process, and the overall service life of the noble metal smelting furnace refractory lining material is prolonged.

Owner:郑州汇特耐火材料有限公司

In-situ formed beta-Sialon combined corundum prefabricated member and production method thereof

InactiveCN102329126AExcellent high temperature mechanical propertiesImprove thermal shock resistanceChemical industryHydration reaction

The invention discloses an in-situ formed beta-Sialon combined corundum prefabricated member and a production method thereof. The prefabricated member is formed by adopting the following steps of: with elemental silicon powder, corundum particles and fine powder as raw materials and with hydrated alumina, activated alumina micropowder and silicon dioxide micropowder as binding agents, adding metal aluminum powder treated by adopting a sol-gel process; adding water, vibrating, pouring and forming; demoulding, curing and drying; and reacting and sintering in the nitrogen gas atmosphere to obtain the prefabricated member. The prefabricated member comprises the following components in parts by weight: 70-80 parts of corundum particles, 3-12 parts of alumina micropowder, 0-5 parts of silicon dioxide micropowder, 0.5-5 parts of hydrated alumina, 3-15 parts of elemental silicon powder, 0.3-2 parts of metal aluminum powder subjected to surface treatment and 0.05-0.30 part of organic water reducing agent as a dispersing agent, based on the total weight percentage of the raw materials. According to the invention, the defects of poor thermal shock resistance, poor stripping resistance, high temperature and low strength in the currently-general corundum-based castable are overcome; and the in-situ formed beta-Sialon combined corundum prefabricated member can be expected to be applied to ceramic cups of blast furnaces, ladle liners, permeable bricks for ladles, chemical industries and the like as well as has the characteristics of high strength, favorable stripping resistance and the like.

Owner:ZHENGZHOU UNIV

High-aluminum insulating refractory raw material with titanium-iron slag as main material and preparation method thereof

InactiveCN106904982ASimple processSave labor resourcesCeramic materials productionCeramicwareSlagFiltration

The invention relates to a high-aluminum insulating refractory raw material with titanium-iron slag as a main material and a preparation method thereof. The preparation method comprises the following steps: immersing crushed titanium-iron slag in water of 90-95 DEG C for 1-2 h, filtering, drying, and screening; adding a hydrochloric acid solution into the screened titanium-iron slag particles, stirring, washing and carrying out suction filtration, and wet-grinding to obtain wet-ground titanium-iron slag powder; adding the wet-ground titanium-iron slag powder and aluminum powder into a mixer, and mixing to obtain a mixture; Adding a phosphoric acid solution into the mixture, uniformly mixing, vibrating for moulding, and maintaining; finally placing the product into a muffle furnace, heating to 1355-1420 DEG C at the heating rate of 3-5 DEG C / min, carrying out thermal insulation, cooling with the furnace to room temperature, and crushing to obtain the high-aluminum insulating refractory raw material with titanium-iron slag as the main material. The method of the invention has characteristics of simple process, low production cost and no special requirements on equipment. The prepared high-aluminum insulating refractory raw material with titanium-iron slag as the main material has small heat conductivity coefficient, high cylinder compressive strength and good resistance to corrosion of slag.

Owner:WUHAN UNIV OF SCI & TECH

High-property spraying paint for slag pot and preparation method of high-property spraying paint

ActiveCN107827470AEasy to useReduce rebound rateCeramic materials productionClaywaresSocial benefitsSlag

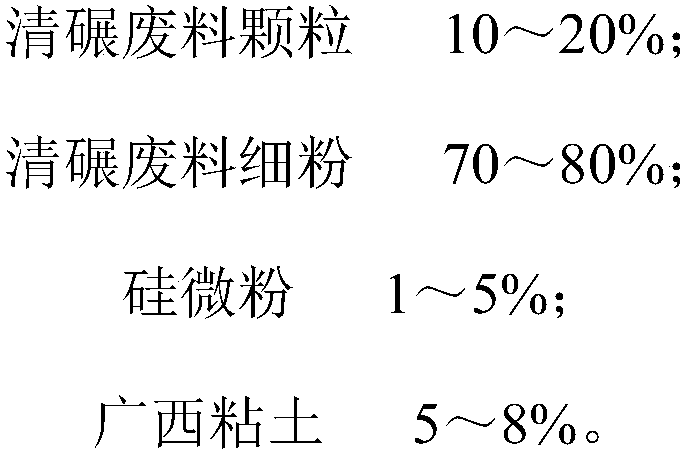

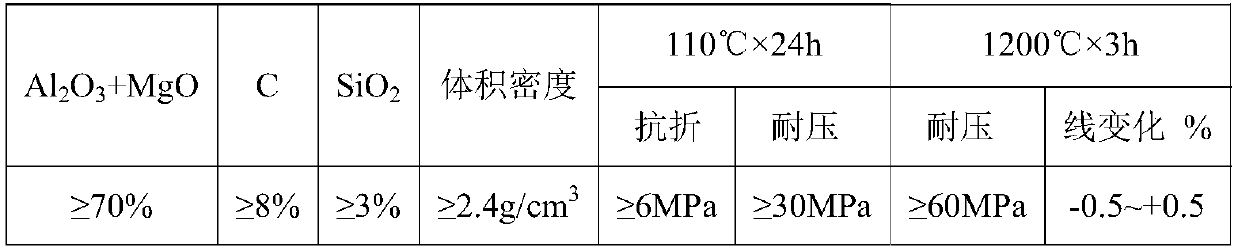

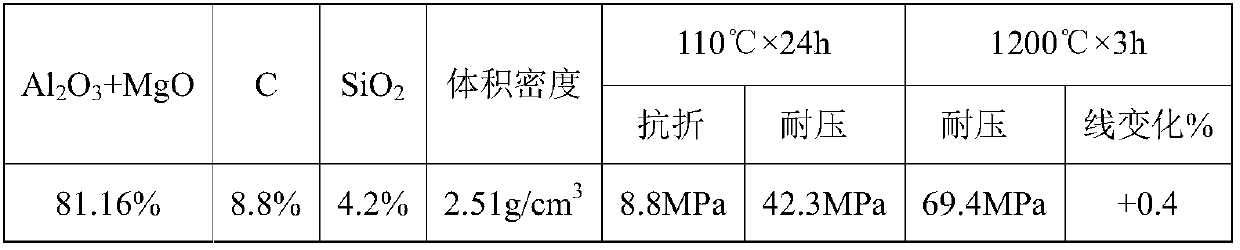

The invention discloses a high-property spraying paint for a slag pot and a preparation method thereof. The high-property spraying paint for the slag pot comprises a main material and additives, wherein the main material is prepared from the following raw materials in percentage by weight: 10 to 20% of mill-cleared waste particle, 70 to 80% of mill-cleared waste fine powder, 1 to 5% of silicon micropowder and 5 to 8% of Guangxi clay; the weight of the additive is 0.2 to 2% of that of the main material. The high-property spraying paint for the slag pot, disclosed by the invention, is better inall properties, has the characteristics of less than 8% of resilience rate, good adhesion property, no stickiness to slag, good slag-erosion resistance and easy slag overturning, and also has the beneficial effects that the service life of the pot can be prolonged, the manual clearing can be reduced, the economic and social benefits are obvious, and a pot returning rate is increased by 20% or more.

Owner:瑞泰马钢新材料科技有限公司 +1

Low-carbon magnesia carbon brick with magnesia impregnated by tar and asphalt as aggregate and preparation method thereof

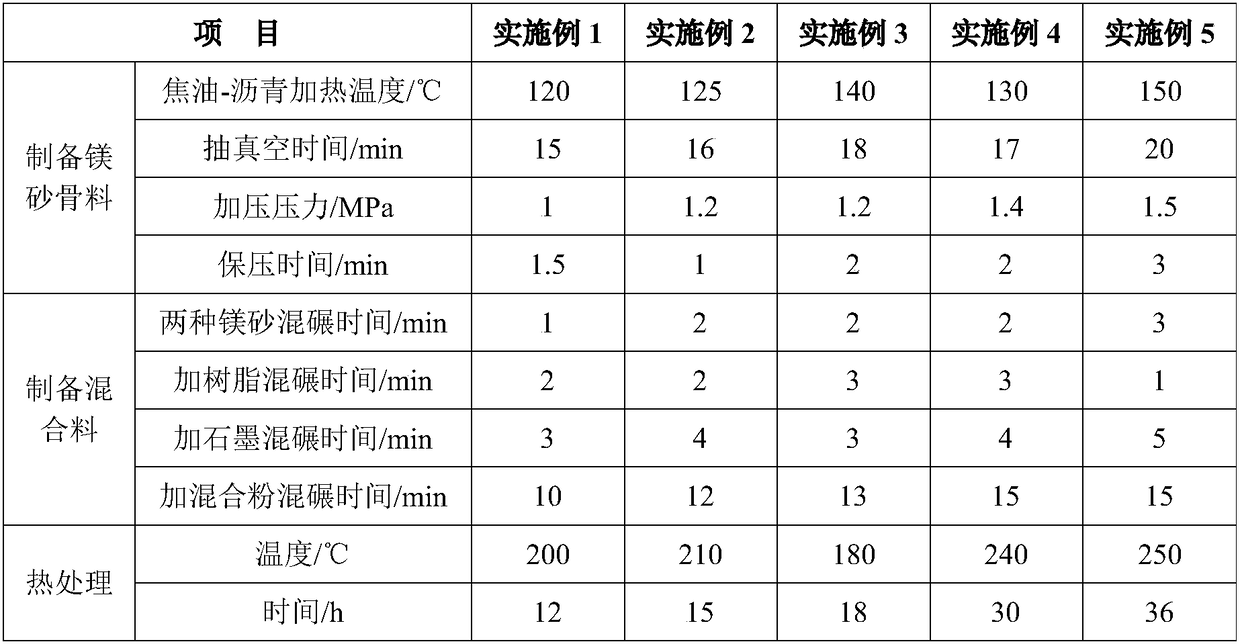

The invention discloses a Low-carbon magnesia carbon brick with magnesia impregnated by tar and asphalt as an aggregate and a preparation method thereof. The low-carbon magnesia carbon brick comprisesthe following components by weight: 45 to 55% of a magnesia aggregate impregnated by tar and asphalt, 35 to 45% of unimpregnated magnesia, 3 to 5% of graphite, 0.5 to 1.5% of high-temperature asphalt, 2 to 3% of an antioxidant and 2.5 to 3.5% of a binder. The preparation method comprises the following steps: 1) carrying out impregnating so as to obtain the magnesia aggregate impregnated by tar and asphalt; 2) weighing the components with the desired weight; 3) premixing unimpregnated magnesia powder, high-temperature asphalt and the antioxidant to obtain mixed powder; 4) subjecting the magnesia aggregate and the unimpregnated magnesia powder to dry mixing in a mixing and grinding machine, then successively adding the binder, graphite and the mixed powder, and carrying out mixing and grinding to form a mixture; and 5) carrying out briquetting, molding and heat treatment so as to obtain the low-carbon magnesia carbon brick with the magnesia impregnated by tar and asphalt as the aggregate. The low-carbon magnesia carbon brick has the advantages of good thermal shock resistance, good resistance to slag erosion and great high-temperature strength, and is significantly prolonged in service life.

Owner:WUGANG REFRACTORY CO LTD

Microporous corundum preparation method

InactiveCN110540414AEasy to prepareSuitable for industrial productionCeramicwareSlagThermal insulation

The invention discloses a microporous corundum preparation method, which comprises: mixing and grinding multiple raw materials into powder with a certain fineness, preparing a billet, and sintering the billet at a temperature of 1700-1950 DEG C to obtain the microporous corundum, wherein the raw materials comprise, by mass, 60-100% of industrial aluminum oxide, 0-20% of alpha-aluminum oxide, 0-30%of gamma-aluminum oxide, 0-10% of aluminum hydroxide, and 0-3% of polyvinyl alcohol. According to the present invention, the preparation method is simple, and is suitable for industrial production; and the product is mainly characterized in that the corundum crystal contains a large number of sub-micron and nano-scale closed gas pores, and have characteristics of low thermal conductivity, good thermal shock resistance, good slag corrosion resistance, energy saving, thermal insulation and high refractoriness, and can replace sintered corundum.

Owner:JIANGSU JINGXIN NEW MATERIAL

Anti-erosion gunning mix

The invention belongs to the technical field of unshaped refractory materials, and in particular relates to an anti-erosion gunning material. In the present invention, clay, glass fiber, and quartz stone are mixed and sieved to obtain a mixed powder, and then acrylic acid and sodium hydroxide solution are mixed and stirred with mixed powder and sodium dodecylbenzenesulfonate to obtain an emulsified mixed liquid, and the emulsified The mixed solution is reacted with Tween-80, ammonium persulfate, etc. to prepare a binder, and then the graphite, alumina and rice husk are crushed and sieved, and then calcined to obtain a calcined product, which is mixed with zirconium boride, aluminum-magnesium tip After the spar is ball milled and sieved, it is fully stirred evenly with magnesia, high-alumina bauxite, binder, etc. to obtain an anti-erosion gunning material. The gunning material prepared by the present invention has good high-temperature strength, good Volume stability and excellent corrosion resistance make it an ideal material for hot repair of refractory parts.

Owner:常州市泰英物资有限公司

Ramming material for iron notch of smelting reduction furnace

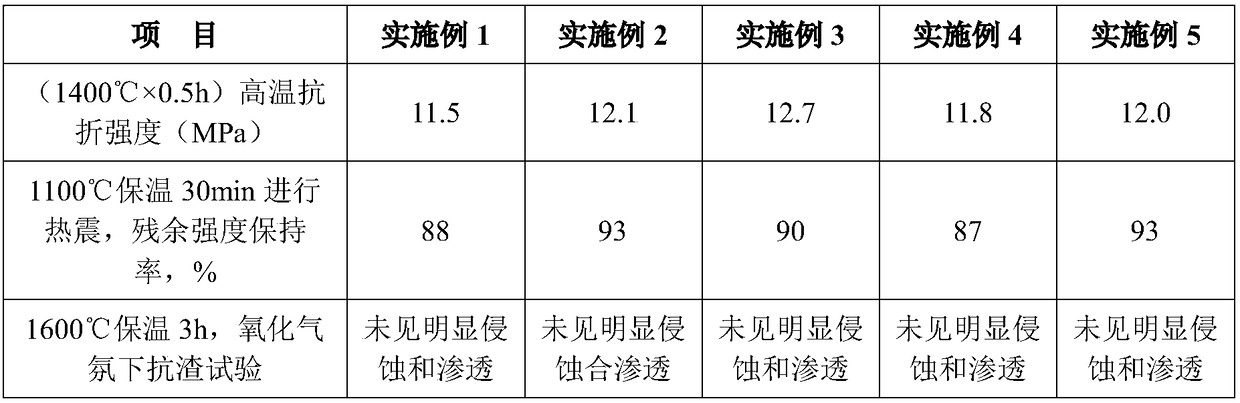

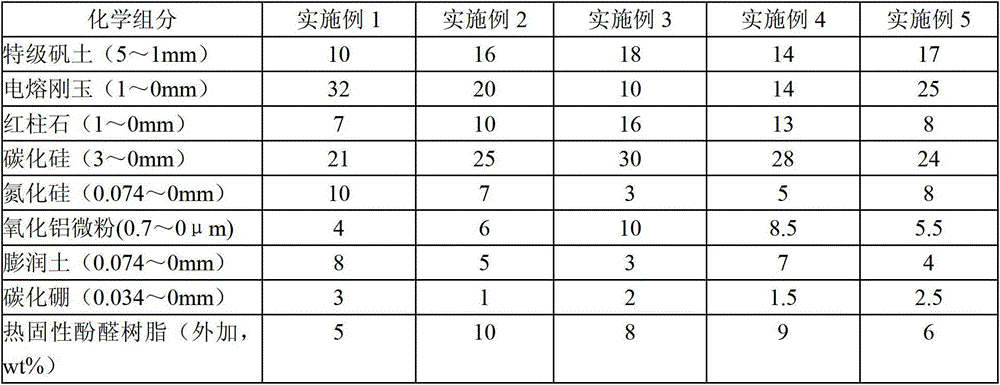

ActiveCN103936431AHigh strengthImprove corrosion resistanceFluidised-bed furnacesSodium BentoniteSlag

The invention discloses a ramming material for an iron notch of a smelting reduction furnace; the ramming material is Al2O3-SiC-Si3N4 ramming ramming material, and comprises the following chemical components by mass: 10-18% of bauxite; 10-32% of electricly-fused corundum; 6-16% of andalusite; 21-30% of silicon carbide powder; 3-10% of silicon nitride powder; 4-10% of alumina micro powder; 3-8% of bentonite; and 1-3% of boron carbide powder; and the chemical components are boned together by an externally added anhydrous binder. The ramming material for the iron notch of the smelting reduction furnace has high density, high strength, good resistance to high temperature melting slag, molten iron scouring resistance, resistance to slag corrosion, oxidation resistance and the like, is good in plasticity and construction performance, and can improve the smelting reduction furnace service life, improve safe production of the smelting reduction furnace, reduce the repair and downtime of the smelting reduction furnace, and avoid reducing of the iron and steel production.

Owner:BAOSHAN IRON & STEEL CO LTD

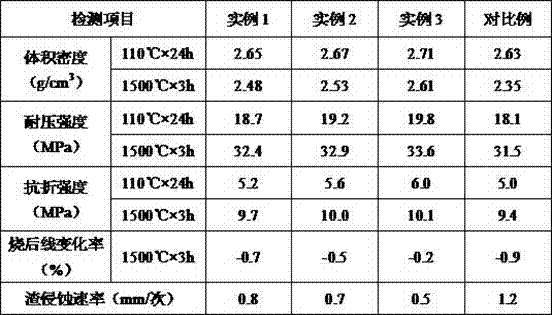

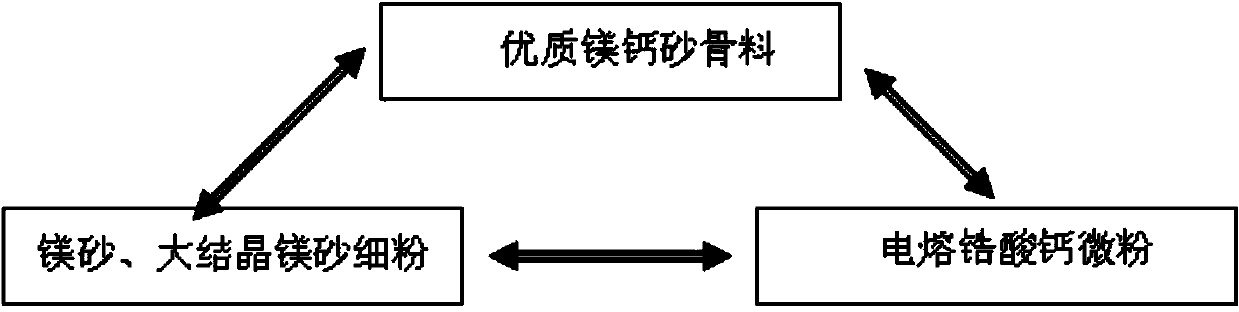

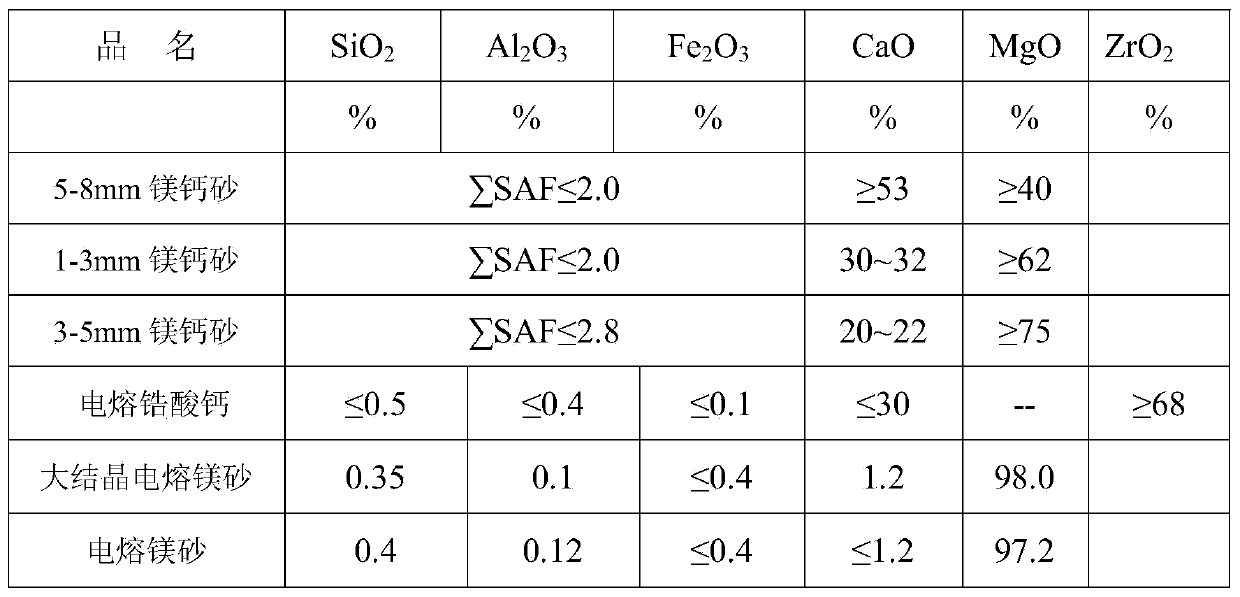

Dolomite-periclase-calcium zirconate composite fireproof material and preparation method thereof

The invention relates to a high-quality dolomite-periclase-calcium zirconate composite fireproof material suitable for smelting stainless steel, special steel AOD furnace and refining ladles. The adopted raw materials mainly comprise, by weight, 8-10% of magnesium calcium sand with a particle size of 5-8 mm, 9-18% of magnesium calcium sand with a particle size of 3-5 mm, 10-22% of magnesium calcium sand with a particle size of 1-3 mm, 5-10% of calcium zirconate with a particle size of 0.5-1 mm, 5-10% of magnesia with a particle size of 0.5-1 mm, 3-10% of 600 mesh electric melting calcium zirconate, 15-24% of magnesia with a particle size of less than or equal to 0.5 mm, 3-10% of 400 mesh 98 large crystal magnesia, 1-3% of a binding agent, and 1-2% of a sintering agent, wherein the raw materials are subjected to mixing, molding, sintering, finished product inspection, package and other steps to prepare the material.

Owner:LIAONING ZHONGMEI HIGH TEMPERATURE MATERIAL CO LTD

Environment-friendly magnesia carbon gunning mix for RH furnace and preparation method thereof

The invention relates to the technical field of amorphous refractory materials and specifically to an environment-friendly magnesia carbon gunning material for an RH furnace and a preparation method thereof. According to the gunning mix, a post-sintering regenerated magnesia carbon material and magnesia are used as main raw materials; high-grade aluminum oxide and magnesium oxide are added as basic raw materials; and a self-made aluminum-magnesium binding agent fully calcined at a high temperature and the like are utilized to prepare the environment-friendly magnesia carbon gunning mix for theRH furnace. After trial of the obtained gunning material, the gunning service life of the RH furnace is prolonged to 2-4 times from the original 1-2 times, and anti-scouring resistance and bonding strength are obviously improved. The magnesium carbon gunning material produced by adopting a scheme in the invention has the advantages that the capital is saved by 800 yuan per ton compared with original magnesium gunning materials, greater economic benefits can be brought to enterprises every year, and the purposes of reducing cost, increasing efficiency and recycling wastes are achieved.

Owner:瑞泰马钢新材料科技有限公司

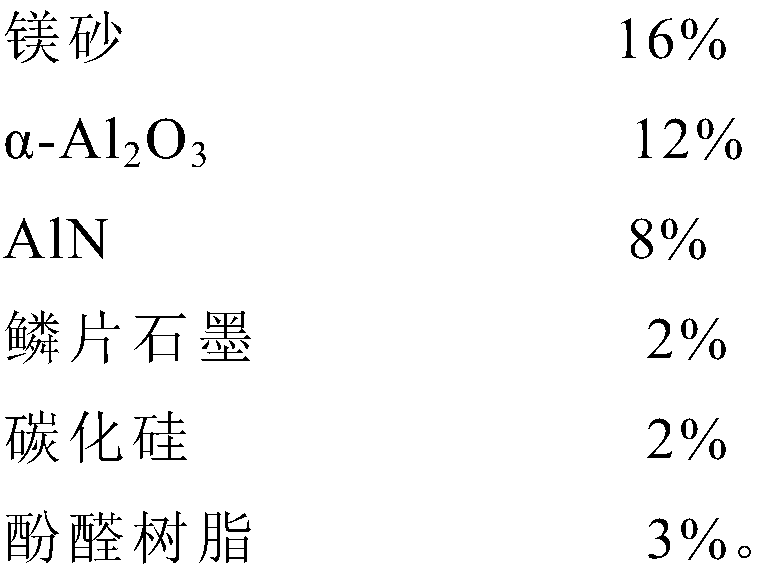

Unburned magnesia-carbon brick and preparation method thereof

The invention belongs to the technical field of high-duty refractory for electric furnace and converter linings and ladle linings and in particular relates to an unburned magnesia-carbon brick and a preparation method thereof. The unburned magnesia-carbon brick is characterized by comprising the following components in parts by weight: 80-90 parts of fused magnesite (more than or equal to 97% of MgO, the granularity of 0.1-5mm and the moisture content of less than or equal to 4%), 12-16 parts of graphite (more than or equal to 98% of C, the granularity of less than or equal to 400 meshes, and the moisture content of less than or equal to 0.15%), 0.5-1.5 parts of metal aluminum powder (more than or equal to 98% of Al and the granularity of less than or equal to 400 meshes), 1-3 parts of an aluminum magnesium alloy (more than or equal to 98% of Al+Mg and the granularity of less than or equal to 400 meshes), 0.2-0.8 part of boron carbide (more than or equal to 99% of BC4 and the granularity of 200-325 meshes), 1-2.5 parts of high temperature pitch (softening temperature of more than or equal to 150 DEG C, more than or equal to 50% of residual carbon and the granularity of 100-200 meshes), 0.2-0.5 part of a rare earth oxide (the granularity of 300-350 meshes), 3-5 parts of ceramic bond, 3-4 parts of a complex magnesium-aluminum cementing agent and 1-3 parts of water. The unburned magnesia-carbon brick disclosed by the invention has the advantages of simple and safe preparation method, low cost, no need of high-temperature firing, high density, high strength, high corrosion resistance, molten metal resistance, high oxidation resistance, energy conservation and emission reduction and the like.

Owner:孙光 +3

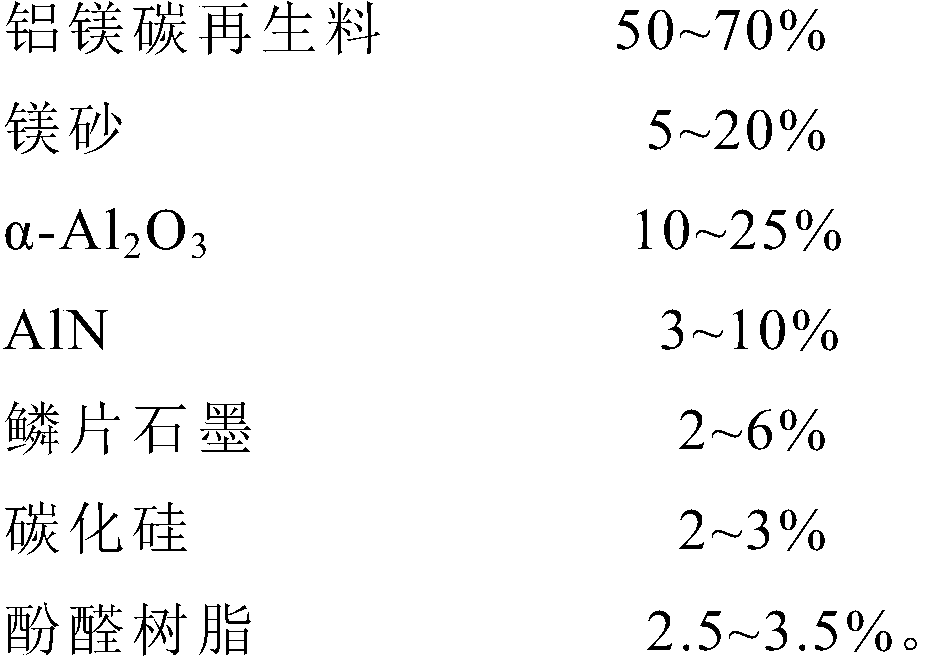

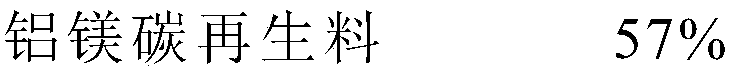

Al-Mg-C brick for steel ladle lining

The invention discloses an Al-Mg-C brick for a steel ladle lining. The Al-Mg-C brick is prepared from 50%-70% by weight of Al-Mg-C reclaimed materials, 5%-20% by weight of magnesia, 10%-25% by weightof alpha-Al2O3, 3%-10% by weight of AlN, 2%-6% by weight of crystalline flake graphite, 2%-3% by weight of SiC and 2.5%-3.5% by weight of phenolic resin. Due to addition of AlN, compared with a traditional Al-Mg-C brick, the Al-Mg-C brick is more resistant to high-temperature scouring, expansion coefficient of a brick body is reduced at the use temperature, volume stability is maintained, AlN is not corroded by molten metal, and slag resistance of the material is improved; a small amount of graphite is added, so that molten steel decarburization is facilitated, and the type of ultra-low carbonsteel is smelted; a large quantity of the Al-Mg-C reclaimed materials are adopted, therefore, the use quantity of high-bauxite clinkers or corundum particles is greatly reduced, the production cost is lower, and the Al-Mg-C brick has better social benefits and economic benefits.

Owner:WUGANG REFRACTORY CO LTD

Vibrating material and preparation method thereof

The invention belongs to the technical field of preparation of refractory materials, and particularly relates to a vibrating material and a preparation method thereof. The method comprises the following steps: carrying out heating reaction on carob bean gum, sodium carboxymethyl starch and the like to prepare a carob bean gum reactant; subsequently, carrying out reaction on sodium alginate, the carob bean gum reactant and the like to obtain a reaction product, and then lyophilizing and pulverizing to obtain a viscous material; mixing the viscous material, silicon dioxide, lime powder and clay to obtain a binding agent; mixing fused magnesia, sintered magnesia and the like in parts by weight to obtain a refractory aggregate; mixing alpha-aluminum oxide micro-powder, diatomite and the like to obtain a powder material; grinding the refractory aggregate, the powder material and an admixture in a mixed manner and mixing with the binding agent to obtain a mixture; filling a mould with the mixture for jolt ramming; finally, baking and demoulding to obtain the vibrating material. The vibrating material has higher sintering strength and good slag corrosion resistance performance, and the service life of the vibrating material is effectively prolonged; meanwhile, the binding agent used by the invention has preferable physical performance, the pollution to molten steel is avoided after sintering, and a clean steel-making requirement can be met.

Owner:常州万博金属构件厂

Low-carbon magnesia carbon brick and preparation method thereof

The invention relates to a low-carbon magnesia carbon brick and a preparation method thereof. The technical scheme is as follows: 78-93 wt% of magnesia particles, 0.1-2 wt% of organic additives and 5-20 wt% of absolute ethyl alcohol are placed in a stirrer, stirred for 2-6 hours at a rotating speed of 300-600 rpm, dried at 80-110 deg c for 12-24 hours, and sieved to obtain pretreated magnesia particles with a particle size of 1-5 mm. Then, 63-75 wt% of the pretreated magnesia particles, 20-32 wt% of magnesia fine powder, 2-5 wt% of flake graphite, 1-3 wt% of an antioxidant and 2-5 wt% of thermosetting phenolic resin are used as raw materials to be uniformly mixed, pressed and molded at 150-200 MPa, and then cured at 180-240 deg c for 18-24 hours to prepare the low-carbon magnesia carbon brick. The invention has the characteristics of low production cost, simple process and easy industrial production, and the prepared low-carbon magnesia carbon brick has high thermal shock stability, high high-temperature bending strength and good slag erosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

Corrosion-resistant magnesium-aluminum honeycomb ceramic heat accumulator and preparation method thereof

InactiveCN108178620ALarge viscosity coefficientLow extrusion pressureCeramicwareAluminum honeycombStearic acid

The invention discloses a corrosion-resistant magnesium-aluminum honeycomb ceramic heat accumulator and a preparation method thereof, and the corrosion-resistant magnesium-aluminum honeycomb ceramic heat accumulator characterized by being prepared mainly from the following components: 20-30 parts of silica, 20-30 parts of titanium dioxide, 10 to 20 parts of dense fused corundum fine powder, 5 to 10 parts of iron oxide, 5 to 15 parts of chrome oxide green micro powder, 5 to 15 parts of chrome ore powder of 0.1 to 1 mm, 2 to 4 parts of aluminate cement, 1 to 3 parts of silicon micropowder, 3 to6 parts of chlorinated polyethylene, 3 to 5 parts of maleic acid-acrylic acid copolymer, 10 to 12 parts of hydroxypropyl methylcellulose, 2 to 3 parts of phthalic acid ester, 2 to 3 parts of monoethanolamine and 1-3 parts of stearic acid by stirring, casting molding, drying and calcining. The corrosion-resistant magnesium-aluminum honeycomb ceramic heat accumulator has a large viscosity coefficient and extrusion pressure lower than that of other mud systems, and has little wear on equipment. At the same time, the corrosion-resistant magnesium-aluminum honeycomb ceramic heat accumulator has good drying properties and does not crack in the air for two hours.

Owner:HUBEI SHENWU THERMAL ENERGY TECH

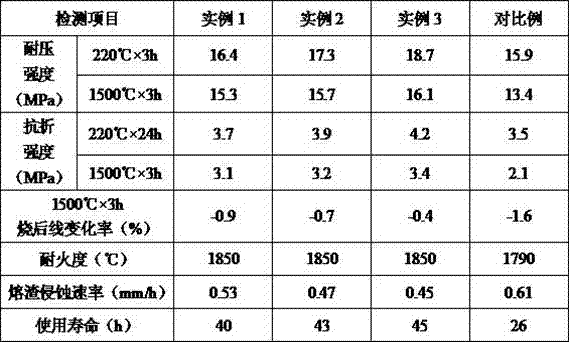

Refractory castable for converter sublance and preparation method of refractory castable

The invention discloses a refractory castable for a converter sublance. The refractory castable comprises the following components in percentage by mass: 50-55wt% of mullite particles; 17 to 22 wt% ofcordierite particles; 17 to 22 weight percent of mullite fine powder; 3-7 wt% of calcium aluminate cement; 1-3 wt% of elemental Si powder; 7 to 10 weight percent of alpha-Al2O3 micro powder; and water accounting for 4.5-5.5 wt% of said components. The invention has the characteristics of low cost and simple process; the prepared refractory castable for the converter sublance is high in volume density, high in normal-temperature strength, excellent in thermal shock resistance and good in slag corrosion resistance.

Owner:CHINA FIRST METALLURGICAL GROUP

Low carbon magnesium carbon brick containing B4C-C composite powder and nano TiC powder, and method of manufacturing the same

Owner:WUHAN UNIV OF SCI & TECH

Production process of unfired alumina-magnesia carbon brick for electric furnace steel ladle

The invention relates to a production process of an unfired alumina-magnesia-carbon brick for an electric furnace steel ladle. The unfired alumina-magnesia-carbon brick for the electric furnace steel ladle comprises the following components: 20-40% of an alumina-magnesia-carbon reclaimed material, 30-60% of corundum, 3-10% of magnesium aluminate spinel, 7-14% of magnesia, 4-12% of crystalline flake graphite, 1-5% of activated alumina micro powder, 1-3% of metal aluminum powder and 2.3-2.8% of phenolic resin. The sum of all the components is 100%; the refractory material has the advantages of slag corrosion resistance, stripping resistance, corrosion balancing, good thermal shock resistance, long service life, no shrinkage, safety in use, less steel and slag adhesion, no pollution to molten steel, easiness in unpacking, convenience in customer construction and the like, and is a high-quality refractory material for ladle linings. By using the steel mill recycled reworked material, the resource consumption is reduced, and the production cost is reduced; high-temperature firing is not needed, and environmental pollution is reduced.

Owner:YANSHI ZHONGYUE REFRACTORY MATERIALS

Microcrystalline graphite powder for carbonic refractory material and preparing method of microcrystalline graphite powder

The invention discloses microcrystalline graphite powder for a carbonic refractory material and a preparing method of the microcrystalline graphite powder. The preparing method comprises the preparing steps that firstly, 5-35wt% of phenolic resin is dissolved into 10-35wt% of alcohol, 40-80wt% of microcrystalline graphite is added, magnetic stirring is conducted for 2-10 minutes, and paste is obtained; secondly, the paste is put into an oven to be processed for 8-24 hours at the medium and low temperature, and a cured product is obtained after cooling; thirdly, the cured product is subjected to ball milling and then passes through a 325-mesh screen, and ball-milled powder is obtained; fourthly, the ball-milled powder is subjected to high-temperature carbonization for 1-4 hours under the condition of isolated air, and the microcrystalline graphite powder for the carbonic refractory material is obtained after cooling. The microcrystalline graphite powder is simple in technology and low in cost, the utilization rate of the microcrystalline graphite is increased, the added value of the product is increased, and the dilemma of resource exhaustion of crystalline flake graphite is relieved; in addition, the carbonic refractory material produced through the microcrystalline graphite powder prepared through the method has the good thermal shock stability and slag corrosion resisting performance, and can meet the use requirement.

Owner:JIAOZUO JINXIN HENGTUO REFRACTORIES

High-strength silicon carbide-oxide composite material and preparation method thereof

ActiveCN112479729ARaise room temperatureHigh strengthCombined combustion mitigationCarbide siliconChemical composition

The invention belongs to the field of refractory materials, and mainly relates to a silicon carbide-oxide composite material and a preparation method thereof. The high-strength silicon carbide oxide composite material is composed of silicon carbide particles, oxide fine powder and a special oxide additive, wherein the oxide fine powder is one or a combination of aluminum oxide, magnesium oxide, magnesium aluminate spinel and calcium hexaluminate, and the particle size of the oxide fine powder is less than or equal to 0.1 mm; the special oxide additive is one or a combination of high-valence oxides of variable valence elements of Fe2O3, V2O5, Mn2O7, Mn2O5, MnO2, CeO2, TiO2 and P2O5; the silicon carbide particles account for 60%-70% of the total mass of the whole raw material solid, the oxide fine powder accounts for 27%-39% of the total mass of the whole raw material solid, and the special oxide additive accounts for 1%-5% of the total mass of the whole raw material solid. The mechanical strength of the silicon carbide-oxide composite material is improved on the premise that the main chemical composition and functions of the silicon carbide-oxide composite material are not reduced.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com