Corrosion-resistant magnesium-aluminum honeycomb ceramic heat accumulator and preparation method thereof

A technology of honeycomb ceramics and regenerators, applied in ceramic products, other household appliances, applications, etc., to achieve the effects of low extrusion pressure, good drying performance and large viscosity coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

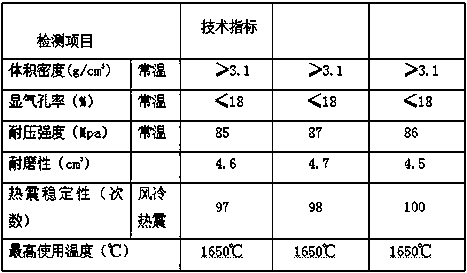

Embodiment 1

[0019] An erosion-resistant magnesium-aluminum honeycomb ceramic regenerator, characterized in that the ceramic regenerator mainly consists of the following components: 20 parts of silicon dioxide, 30 parts of titanium dioxide, 10 parts of dense fused corundum fine powder, 5 parts of iron oxide 15 parts of chromium oxide green micropowder, 15 parts of 0.1-1mm chrome ore powder, 2 parts of aluminate cement, 1 part of silicon micropowder, 3 parts of chlorinated polyethylene, 5 parts of maleic acid-acrylic acid copolymer, hydroxypropyl 12 parts of methyl cellulose, 3 parts of phthalate, 2 parts of monoethanolamine and 1 part of stearic acid are prepared by stirring, casting, drying and calcining.

[0020] The preparation method of the corrosion-resistant magnesium-aluminum honeycomb ceramic regenerator comprises the following steps:

[0021] (1) Mud kneading:

[0022] i) Weigh silicon dioxide, titanium dioxide, dense fused corundum fine powder, iron oxide, chromium oxide green f...

Embodiment 2

[0031] An erosion-resistant magnesium-aluminum honeycomb ceramic regenerator, characterized in that the ceramic regenerator mainly consists of the following components: 25 parts of silicon dioxide, 25 parts of titanium dioxide, 15 parts of dense fused corundum fine powder, 8 parts of iron oxide 10 parts of chromium oxide green micropowder, 10 parts of 0.1-1mm chrome ore powder, 3 parts of aluminate cement, 2 parts of silicon micropowder, 5 parts of chlorinated polyethylene, 4 parts of maleic acid-acrylic acid copolymer, hydroxypropyl 11 parts of methyl cellulose, 3 parts of phthalate, 2 parts of monoethanolamine and 2 parts of stearic acid are prepared by stirring, casting, drying and calcining.

[0032] The preparation method of the corrosion-resistant magnesium-aluminum honeycomb ceramic regenerator comprises the following steps:

[0033] (1) Mud kneading:

[0034] i) Weigh silicon dioxide, titanium dioxide, dense fused corundum fine powder, iron oxide, chromium oxide green...

Embodiment 3

[0043]An erosion-resistant magnesium-aluminum honeycomb ceramic regenerator, characterized in that the ceramic regenerator mainly consists of the following components: 30 parts of silicon dioxide, 20 parts of titanium dioxide, 20 parts of dense fused corundum fine powder, 10 parts of iron oxide 5 parts of chromium oxide green micropowder, 5 parts of 0.1-1mm chrome ore powder, 4 parts of aluminate cement, 3 parts of silicon micropowder, 6 parts of chlorinated polyethylene, 3 parts of maleic acid-acrylic acid copolymer, hydroxypropyl 10 parts of methyl cellulose, 2 parts of phthalate, 3 parts of monoethanolamine and 3 parts of stearic acid are prepared by stirring, casting, drying and calcining.

[0044] The preparation method of the corrosion-resistant magnesium-aluminum honeycomb ceramic regenerator comprises the following steps:

[0045] (1) Mud kneading:

[0046] i) Weigh silicon dioxide, titanium dioxide, dense fused corundum fine powder, iron oxide, chromium oxide green f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com