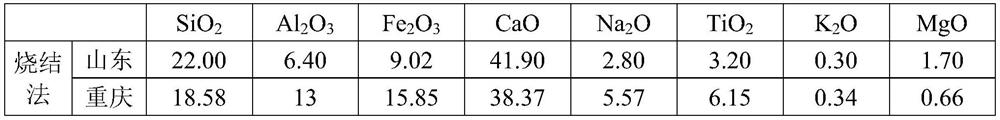

Patents

Literature

45results about How to "Reduce energy consumption index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

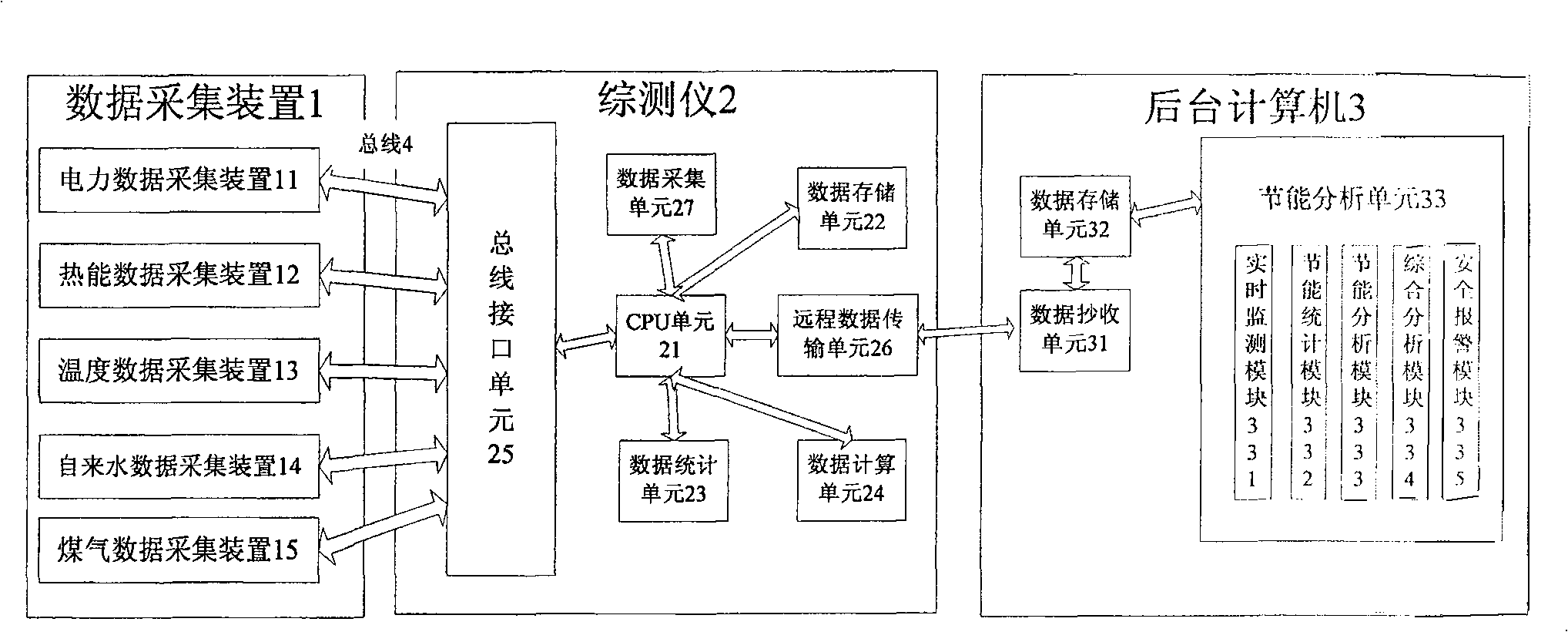

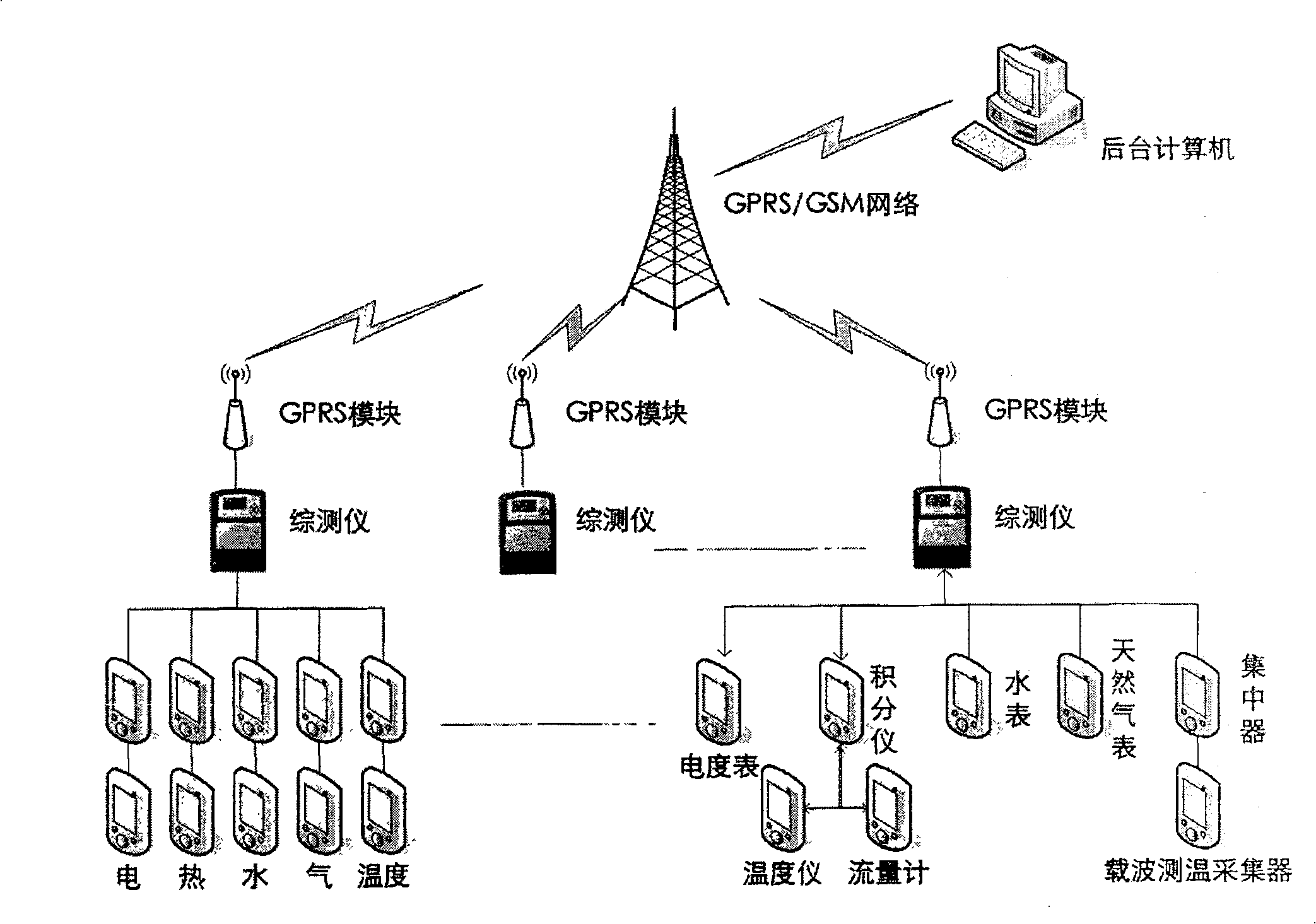

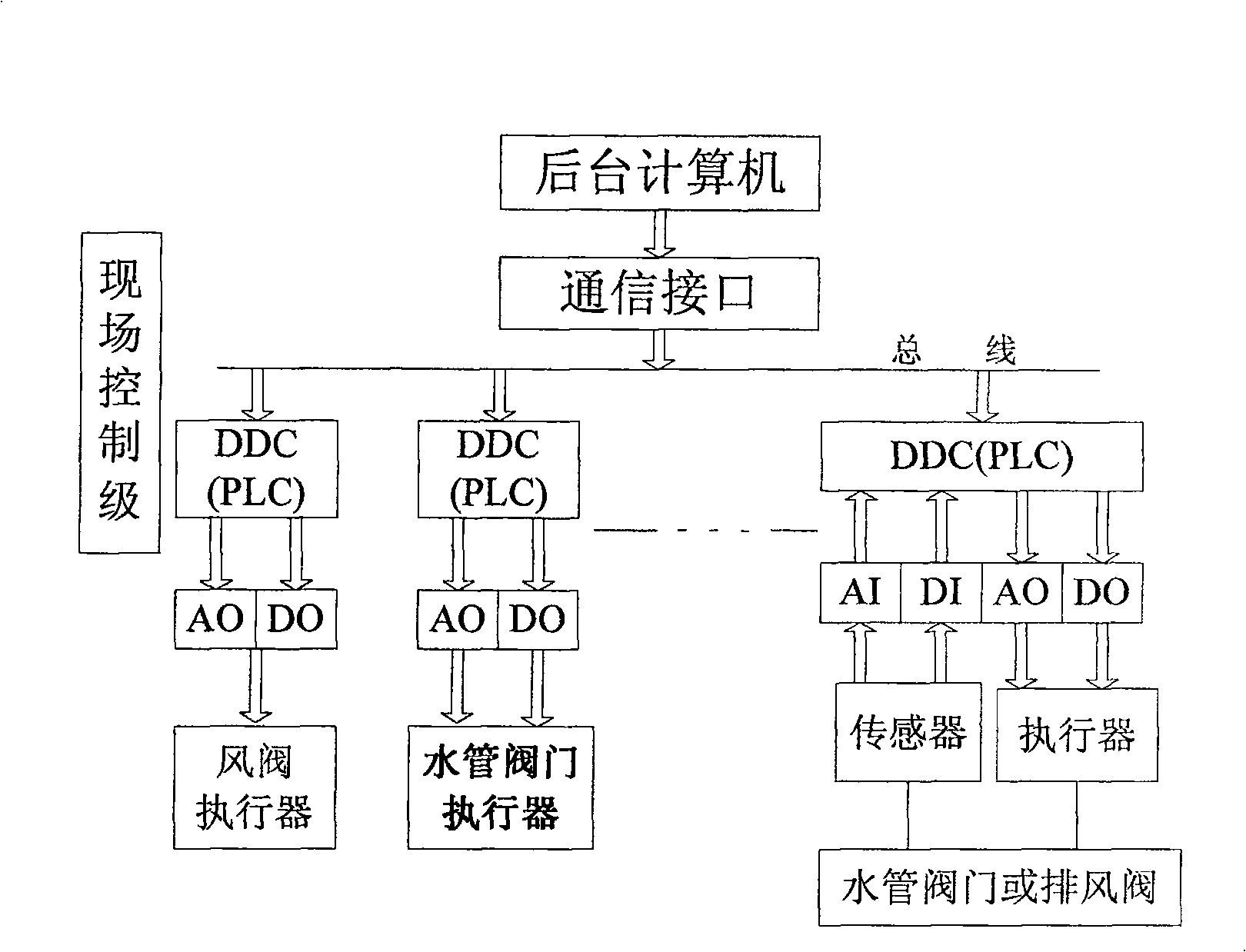

Energy-saving monitoring system

ActiveCN101174364AHigh energy consumptionGood compensationEnergy efficient ICTElectric signal transmission systemsThermal energyData acquisition

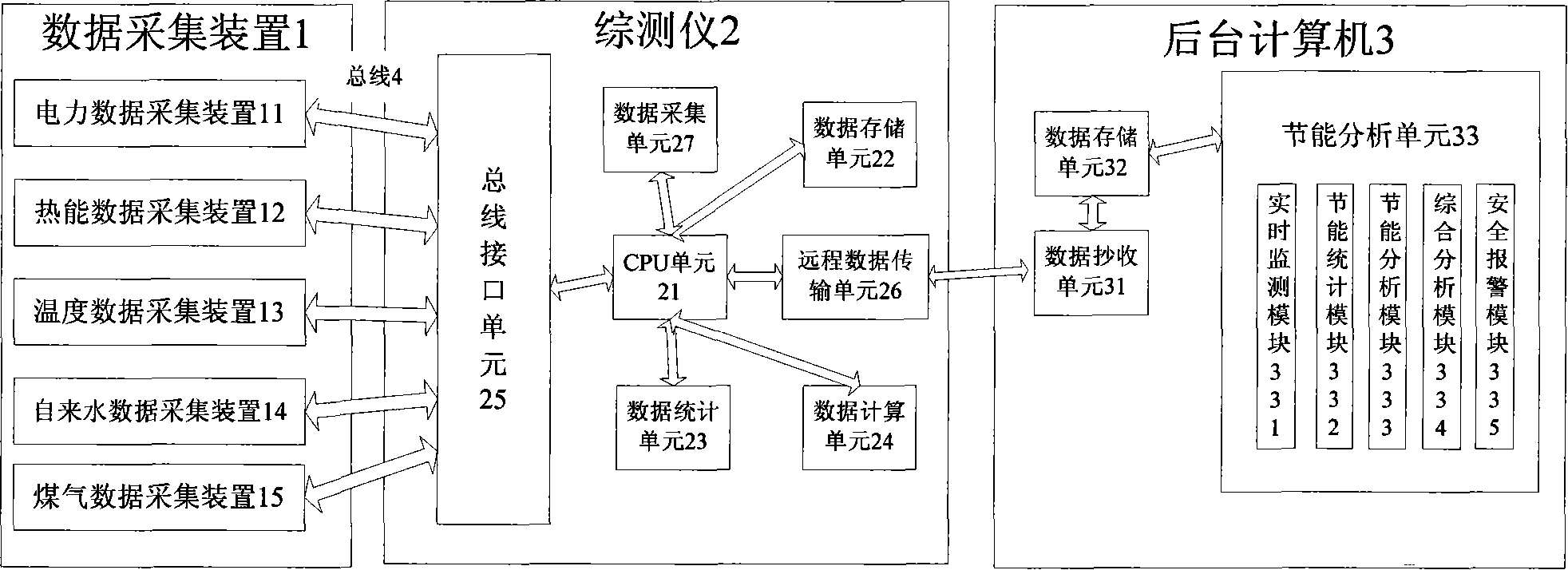

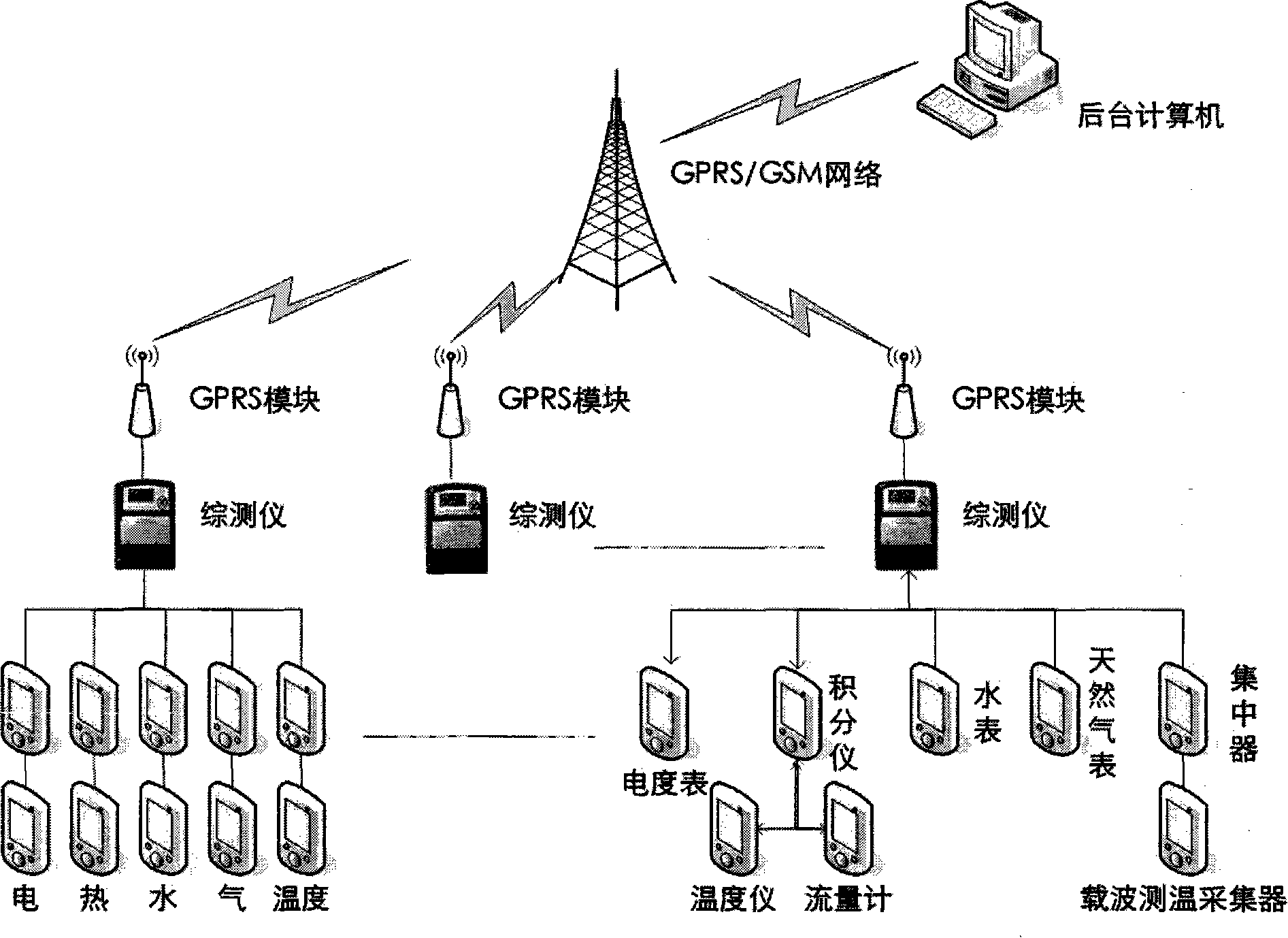

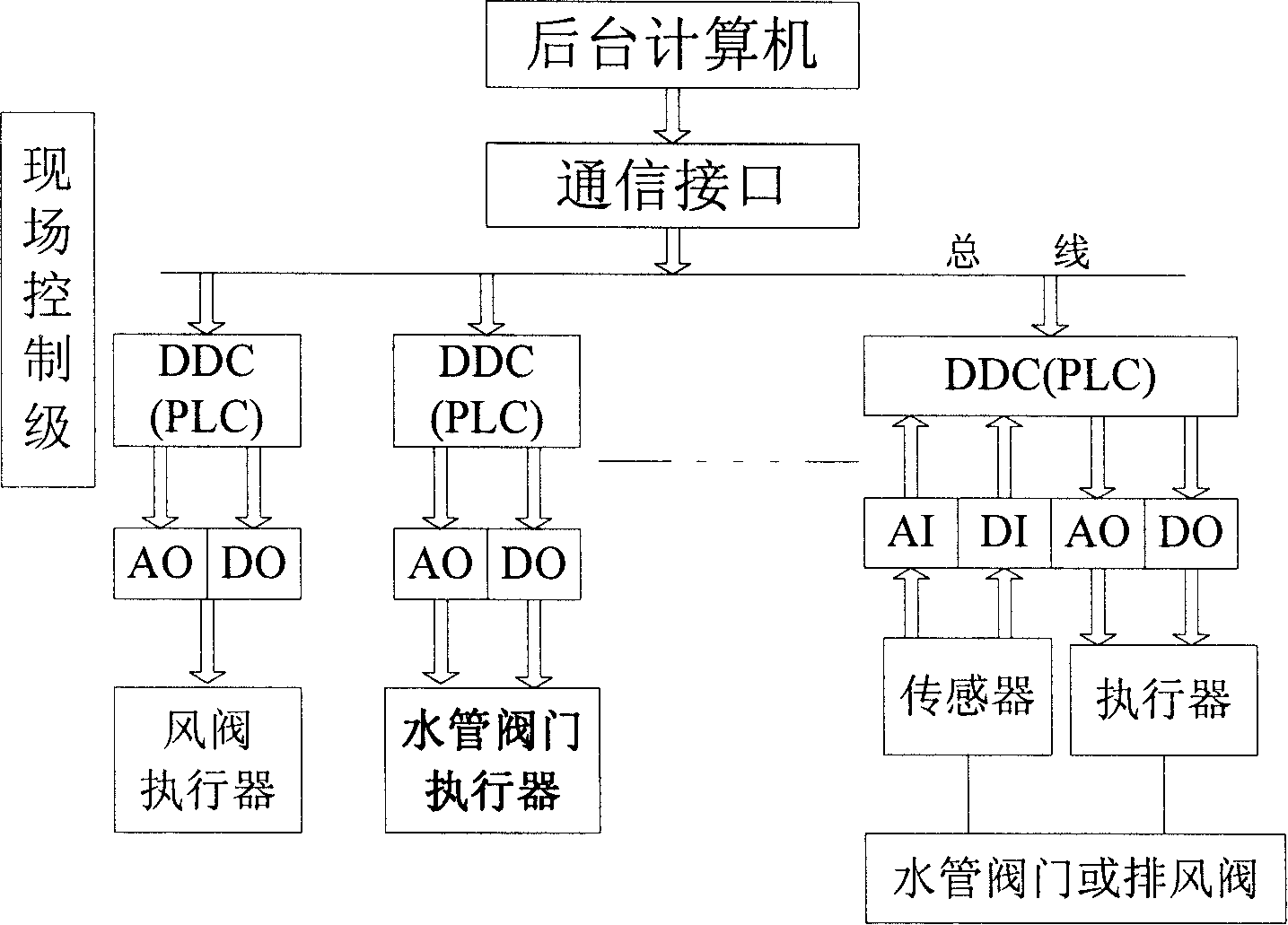

The invention discloses an energy-saving monitoring system, which comprises a plurality of data acquisition devices, a synthesis tester connected with the data acquisition devices, and a background computer connected with the synthesis tester; the data acquisition devices comprise electric data acquisition devices, heat energy data acquisition devices, and other devices, and are connected with the synthesis tester through bus lines; the synthesis tester comprises a CPU unit, and a data storage unit, a data statistic unit, data computing unit, a bus interface unit, and a long-distance data transmission unit which are connected with the CPU unit; the background computer comprises a data collecting unit, a data storage Unit, and an energy-saving analysis unit connected with the long-distance data transmission unit of the synthesis tester through the data collecting unit by adopting long-distance transmission means. The invention can effectively reduce the energy source waste through the monitoring to the energy consumption condition, thus realizing the preliminary behavior energy conservation; and completes energy saving renovation and realizes technical energy conservation by using technical means.

Owner:BEIJING JIUZHOU HENGSHENG CONSTR ENG

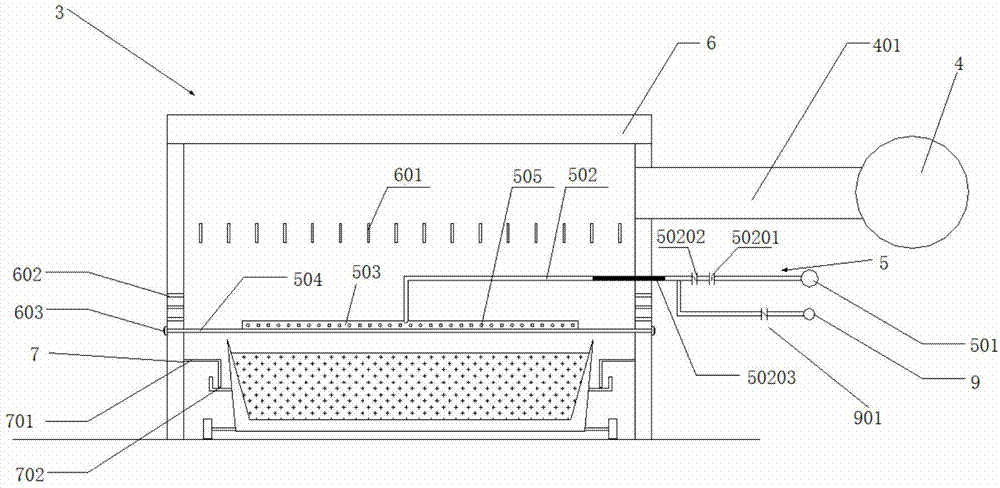

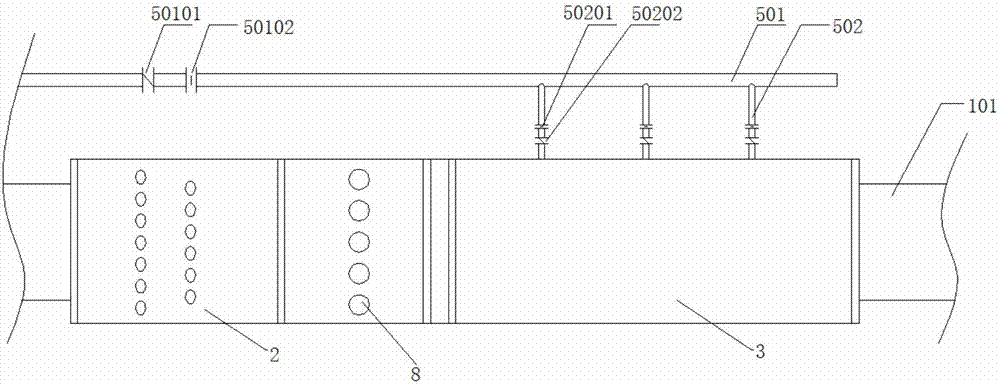

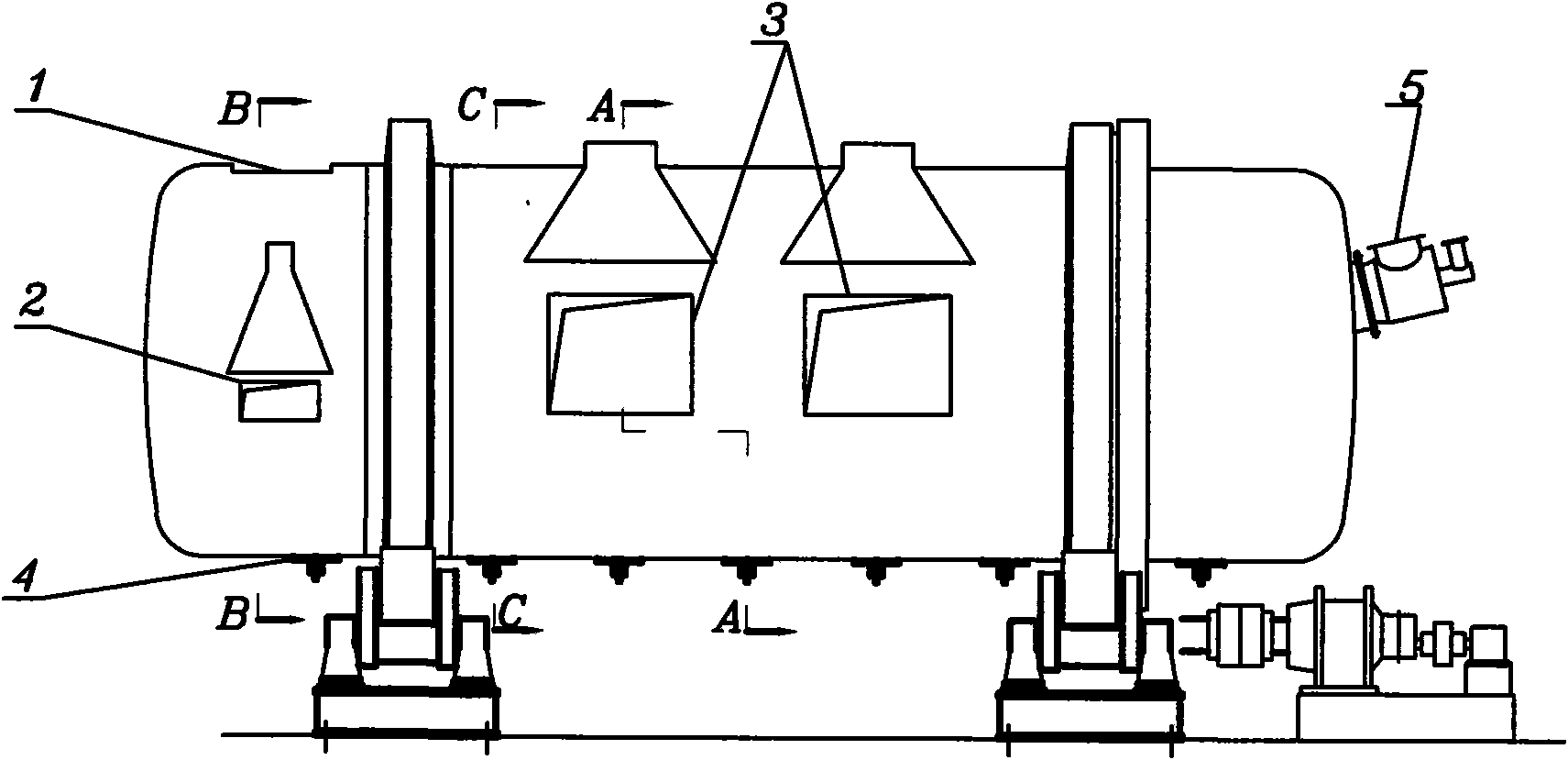

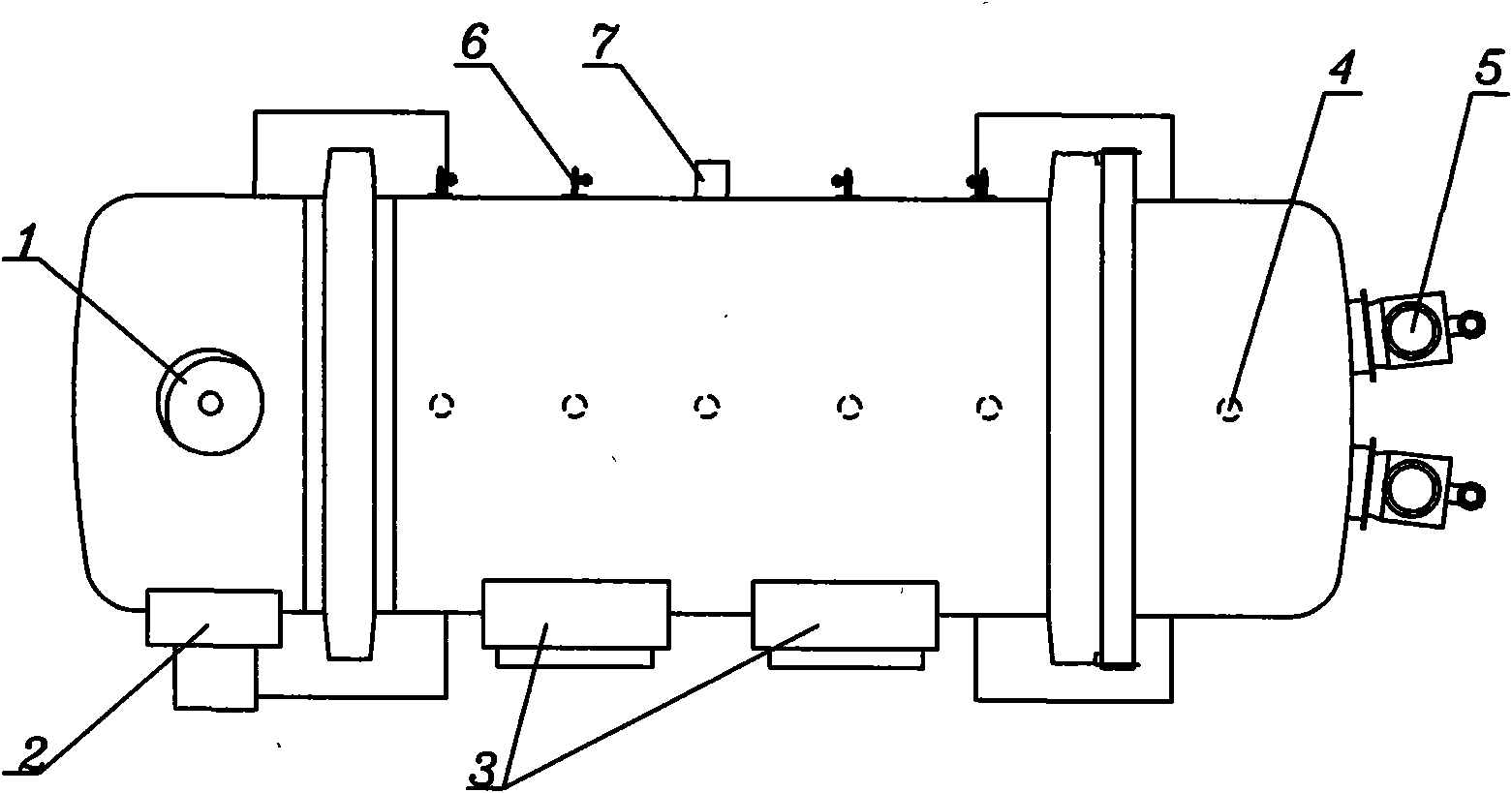

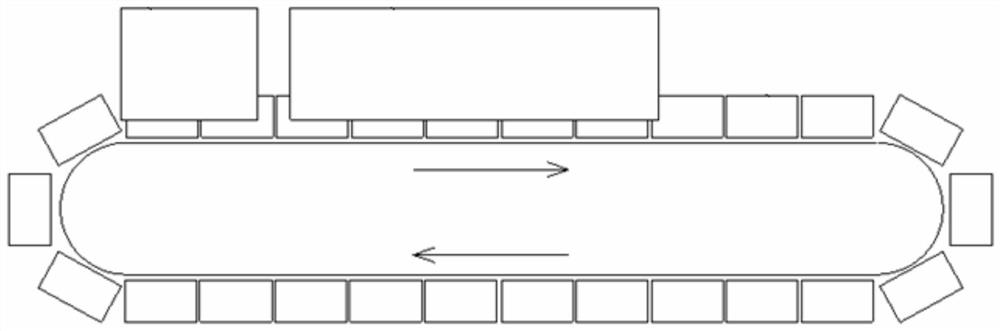

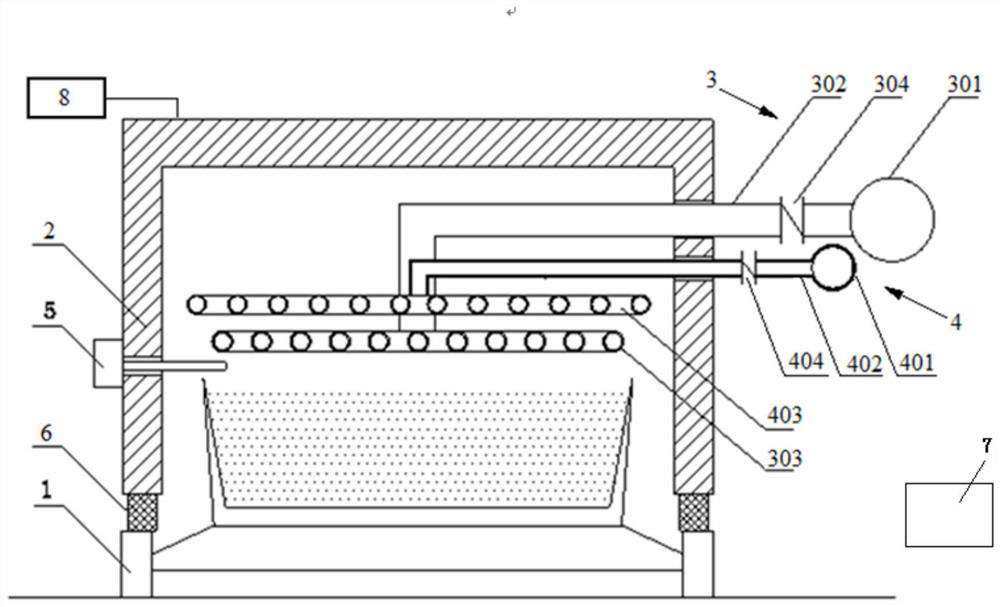

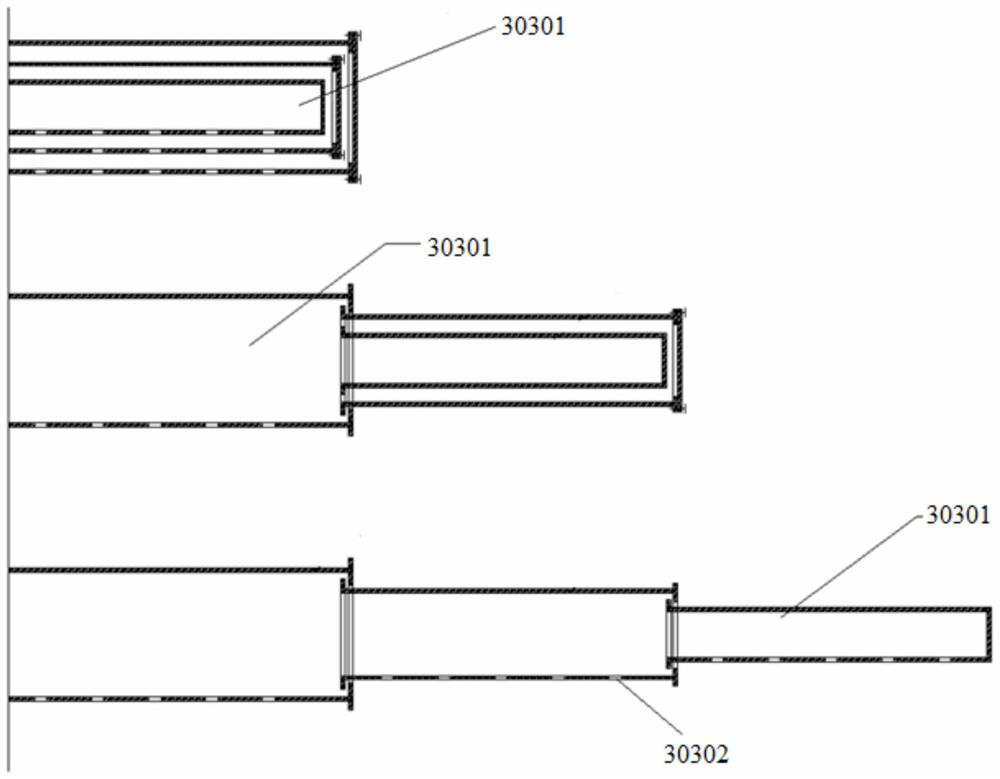

Multi-stage intensifying auxiliary sintering type ignition holding furnace and use method of same

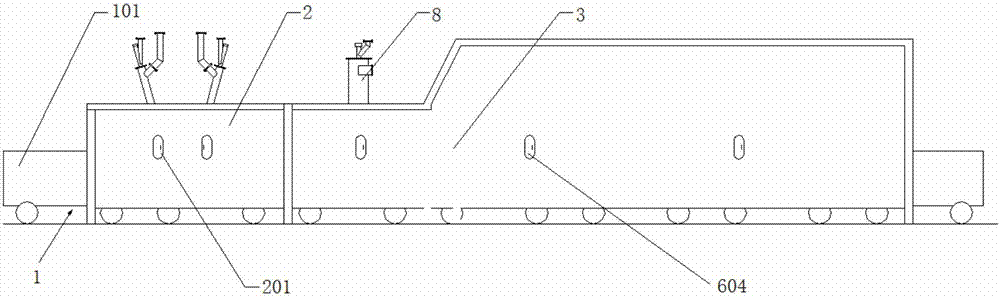

PendingCN107356119AIncrease freedomEnsure the effect of auxiliary sinteringCharge treatment typeFurnace typesPhase conversionEngineering

A multi-stage intensifying auxiliary sintering type ignition holding furnace comprises a sintering machine (1), an ignition device (2) and an auxiliary combustion device (3), wherein the sintering machine (1) has a trolley (1); the ignition device (2) and the auxiliary combustion device (3) are orderly arranged on the trolley (1); the auxiliary combustion device (3) has a hot air device (4), a blow-injection device (5) and an auxiliary combustion cover (6); the hot air device (4) has a hot air pipeline (401); and the blow-injection device (5) has a fuel gas total pipe (501), a fuel gas branch pipe (502), a blow-injection pipe (503) and a rack (504). The multi-stage intensifying auxiliary sintering type ignition holding furnace can replace coke by partial fuel gas and hot smoke and achieves sintering bed segregation coke distribution effect via phase conversion; blow-injection device adjustability and freedom can be enhanced; multi-procedure multi-medium coupling blow-injection can be achieved; and the multi-stage intensifying auxiliary sintering type ignition holding furnace has great safety performance and high sintering quality.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

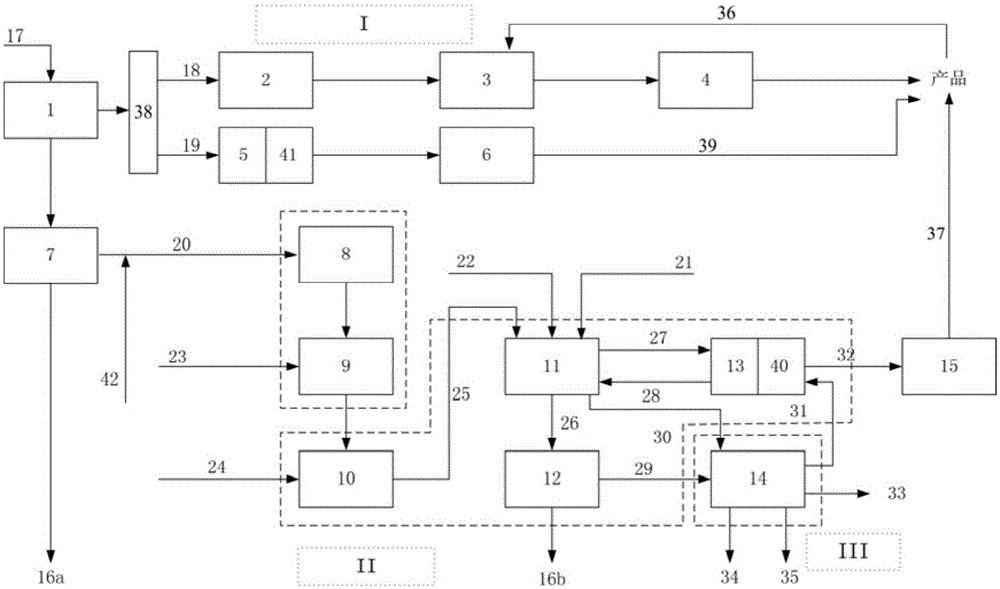

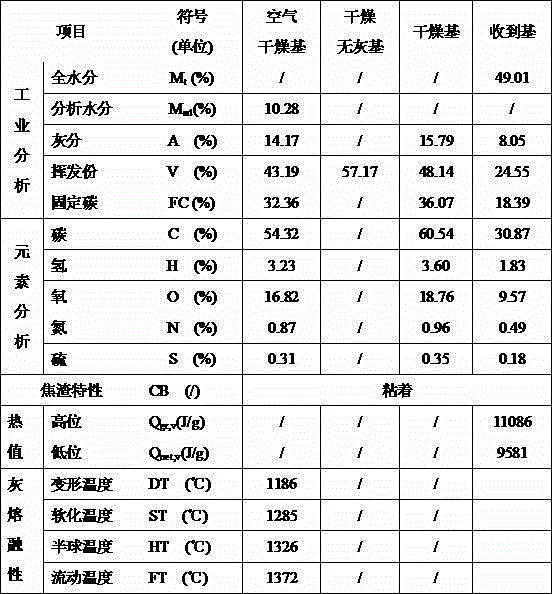

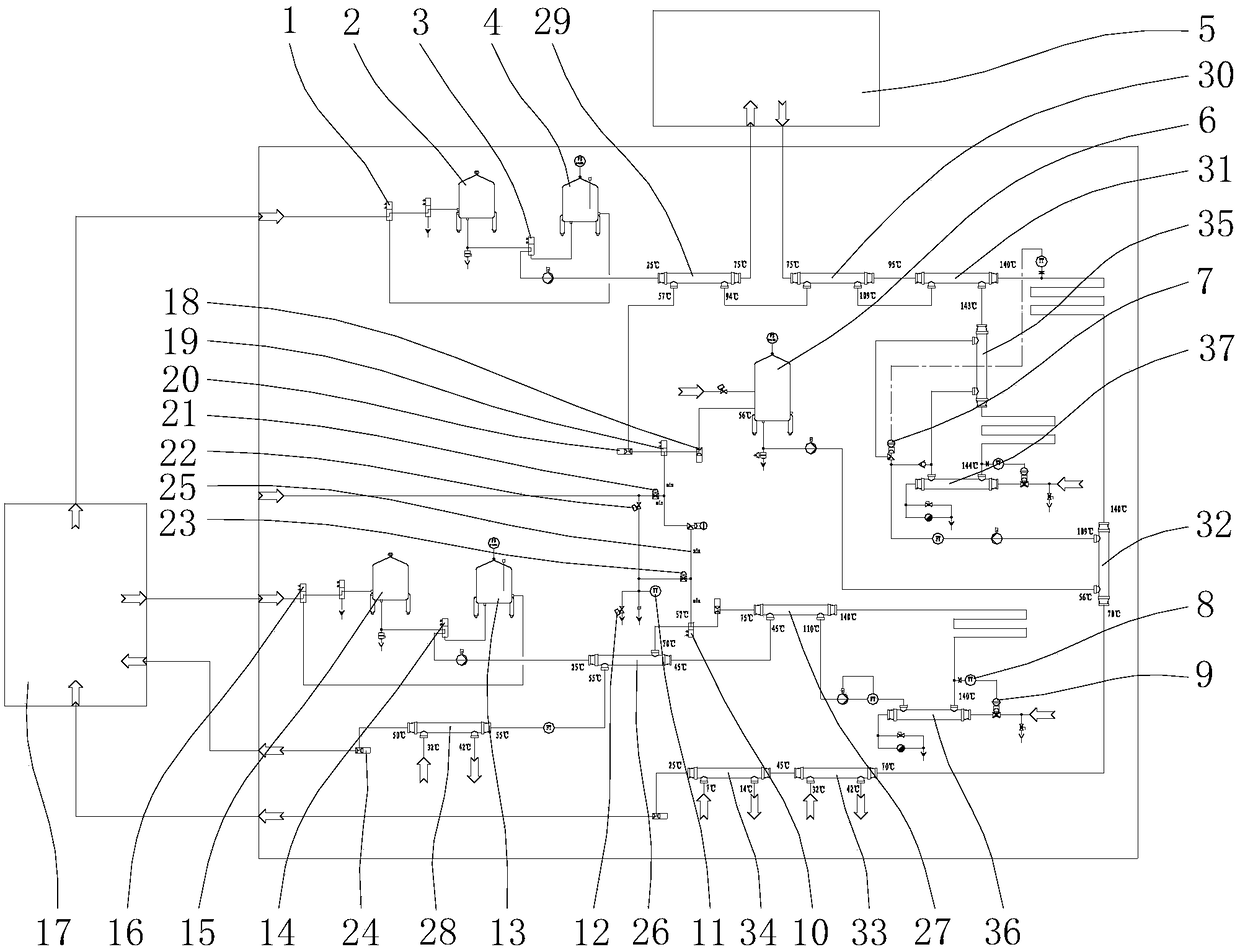

Low-rank coal gradation usage poly-generation system and method

InactiveCN105154121AStrong complementarityRich varietyCombustible gas chemical modificationCoke ovensChemical synthesisSyngas

The invention discloses a low-rank coal gradation usage poly-generation system and a method thereof. The low-rank coal gradation usage poly-generation system comprises a feed coal pyrolysis carbonization system and an entrained bed dry powder gasification system, wherein in the pyrolysis carbonization system, high water / high ash low-rank coal is subjected to pyrolysis and carbonization treatment, so as to obtain crude gas, tar and semi-coke; an oil product is obtained through coal tar hydrogenation; crude gas is purified to obtain coal gas; semi-coke is fed into an entrained bed for gasification; dry powder feeding is adopted during entrained bed gasification; semi-coke is grinded and fed in a powder form; after gasification, a synthesis gas is purified and changed to obtain hydrogen needed during coal tar hydrogenation and a synthesis gas needed during chemical synthesis. The low-rank coal gradation usage poly-generation system and the method thereof have the characteristics of stable and reliable operation, easy large-scale amplification, environmental protection, energy conservation, and the like.

Owner:SHANGHAI BOILER WORKS

Method for reburning denitration of cement kiln by using alternative fuel

ActiveCN103551016ALow running costComprehensive environment is goodDispersed particle separationAutomotive engineeringDecomposition

The invention discloses a method for reburning denitration of a cement kiln by using alternative fuel. The reburning alternative fuel is added to a reducing combustion area inside a decomposing furnace of adopting a grading combustion technology; the adding amount of the reburning alternative fuel is 0-80% of total mass of fuel of the decomposing furnace; the reburning alternative fuel is a refuse derived fuel of which the volatile content is greater than or equal to 30% and / or waste alternative fuel of which the amino content is greater than or equal to 3%. By leading in a reburning process of the alternative fuel, atmosphere control is flexible; no significant effect is generated on operation of a cement kiln system; a burning intermediate product is high in decomposition degree, and small in impact on the existing fractional combustion system, and does not generate a new atmospheric pollutant; the operation of the existing cement kiln system is not affected in the transformation process. Compared with the conventional denitrified reburning fuel, the alternative fuel has higher volatile content and amino content, and has higher denitration efficiency in the burning process.

Owner:天津中材工程研究中心有限公司

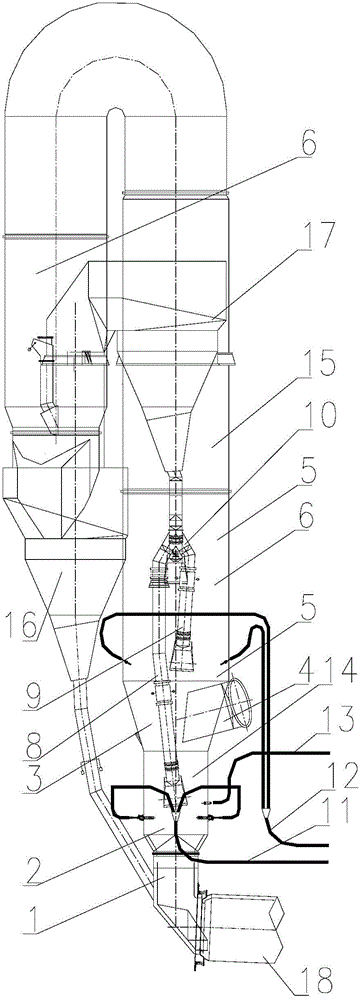

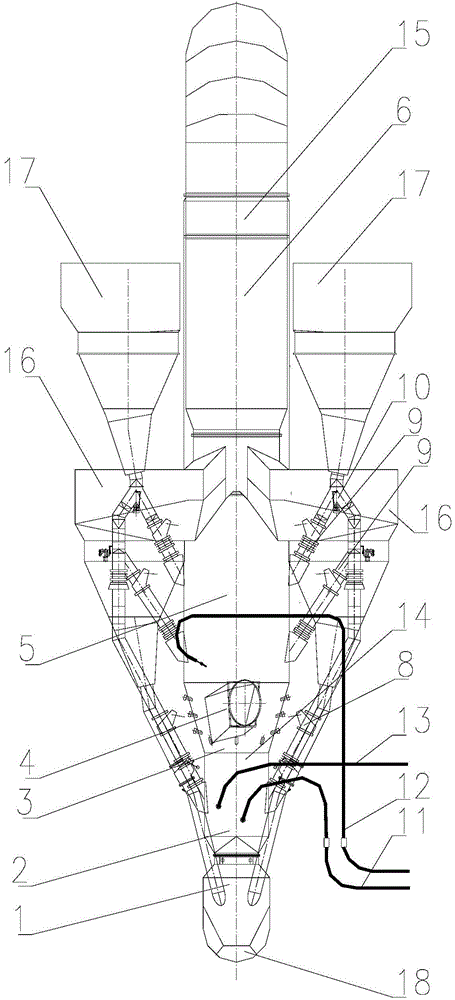

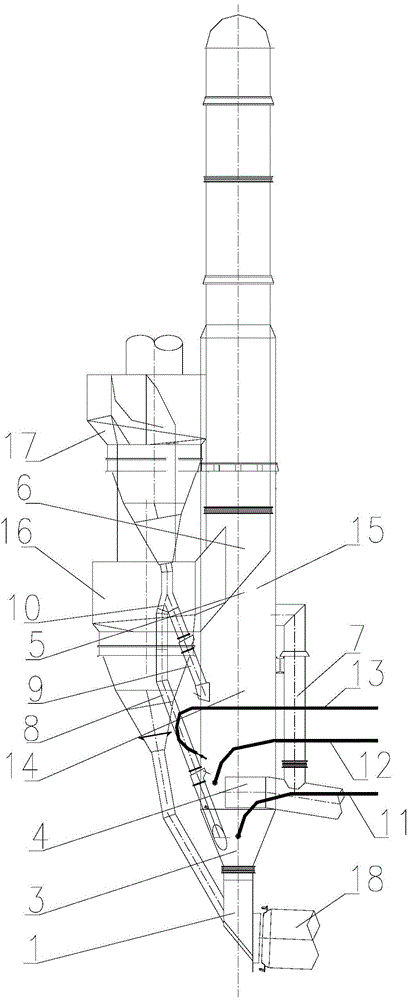

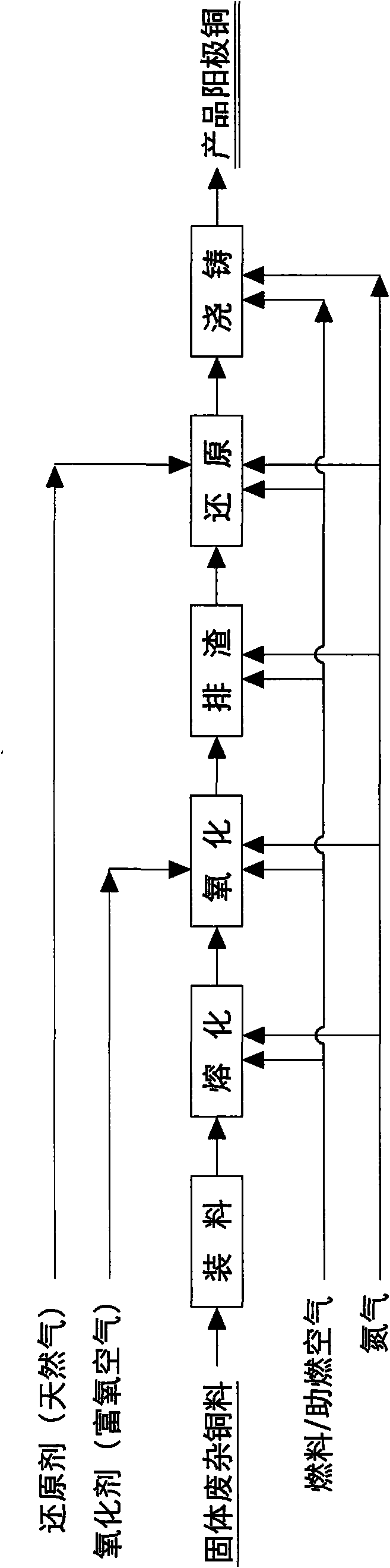

Process and apparatus thereof for refining copper scraps by using nitrogen gas stirring and oxygen-enriched oxygen gas

ActiveCN101638724ARefining reaction speed upIncrease productivityRotary drum furnacesProcess efficiency improvementNitrogen gasImpurity

Owner:CHINA NERIN ENG +1

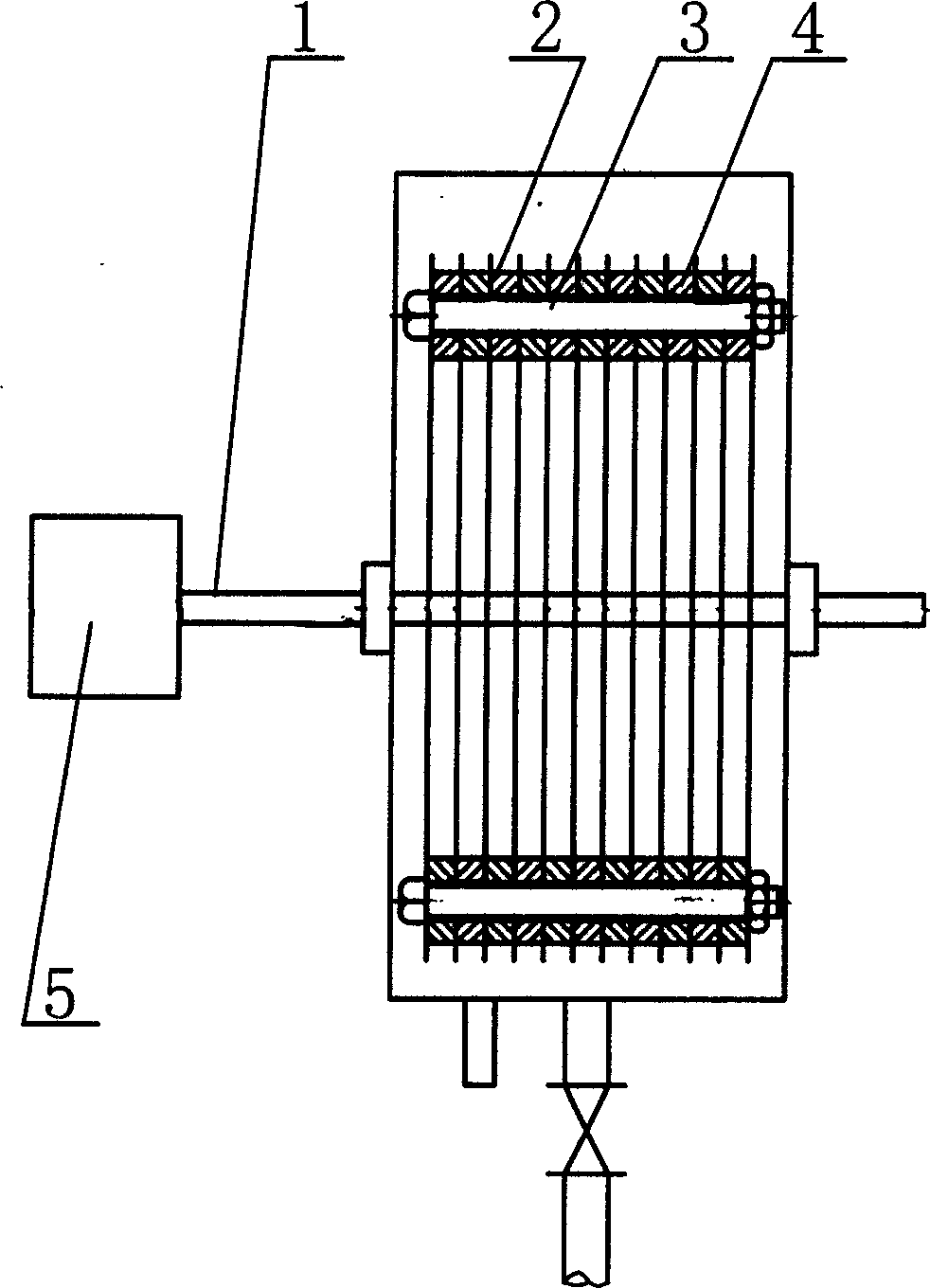

Lead melting copper removal refining process for industrial frequency coreless-type electric induction furnace

ActiveCN103540762ANo emissionsMeet the technical requirements of the processPhotography auxillary processesProcess efficiency improvementElectrolysisLead sheet

The invention relates to a lead melting copper removal refining process for an industrial frequency coreless-type electric induction furnace. The process comprises the following steps: heating and melting a lead bullion raw material through the industrial frequency coreless-type electric induction furnace, pressing slag, and performing quick cooling to liquate copper from lead bullion; injecting the lead bullion obtained after copper removal into an anode casting unit to cast an anode plate, putting a lead anode plate into an electrolytic tank, applying direct current, and liquating anode lead on a cathode after the anode lead forms lead ions and enters an electrolyte; melting the liquated lead through the industrial frequency coreless-type electric induction furnace, sequentially performing oxidation refining and alkaline refining, dredging the slag, and then injecting a lead solution into a pouring unit to obtain an electrolytic lead ingot and oxidized slag; pumping the lead solution after slag dredging into a cathode sheet unit to enable a lead-solution-adhered roller to rotate so as to obtain a cathode lead sheet. The lead melting copper removal refining process for the industrial frequency coreless-type electric induction furnace is respectively applied to the working procedures such as lead melting copper removal, liquated lead refining ingot casting and cathode sheet manufacturing with electric energy, which is conveniently and easily obtained, through the industrial frequency coreless-type electric induction furnace, and has the advantages of reasonable process, low equipment investment, low energy consumption, great economic benefit, good environment-friendly effect and the like.

Owner:SHAANXI ZINC IND

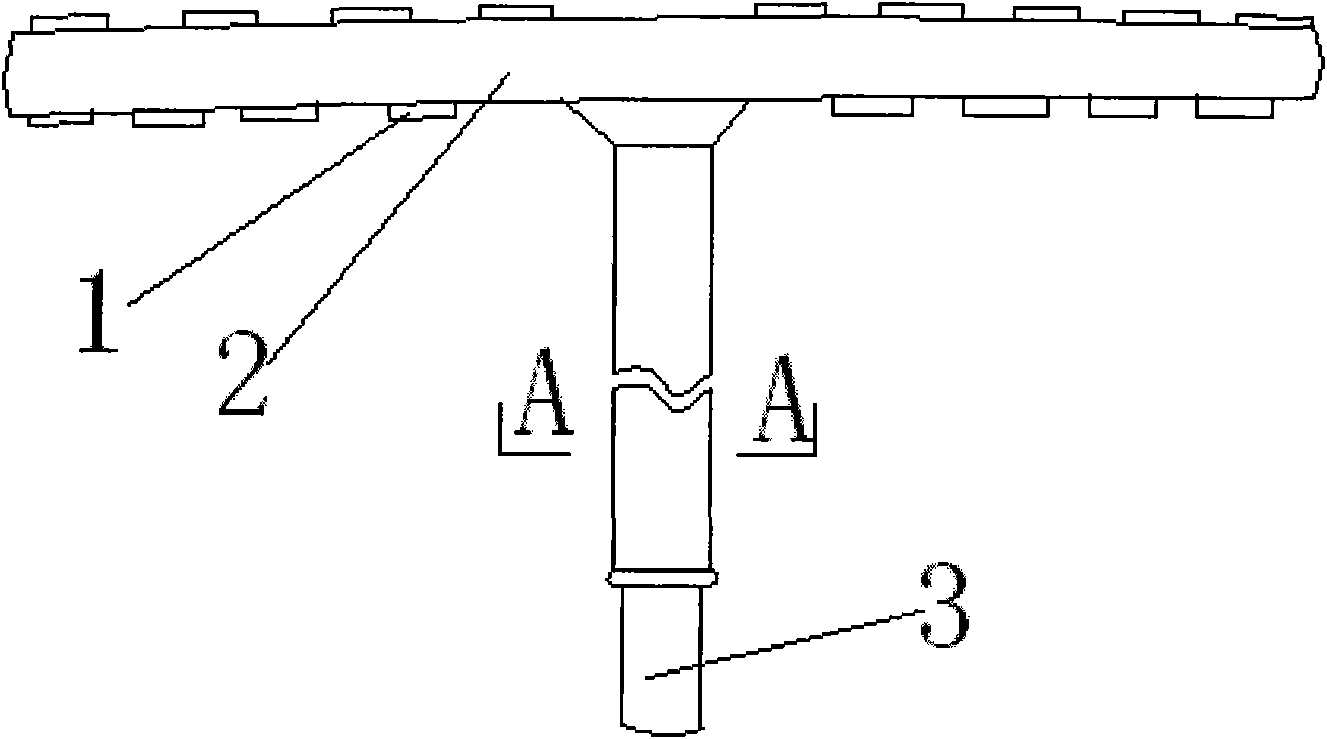

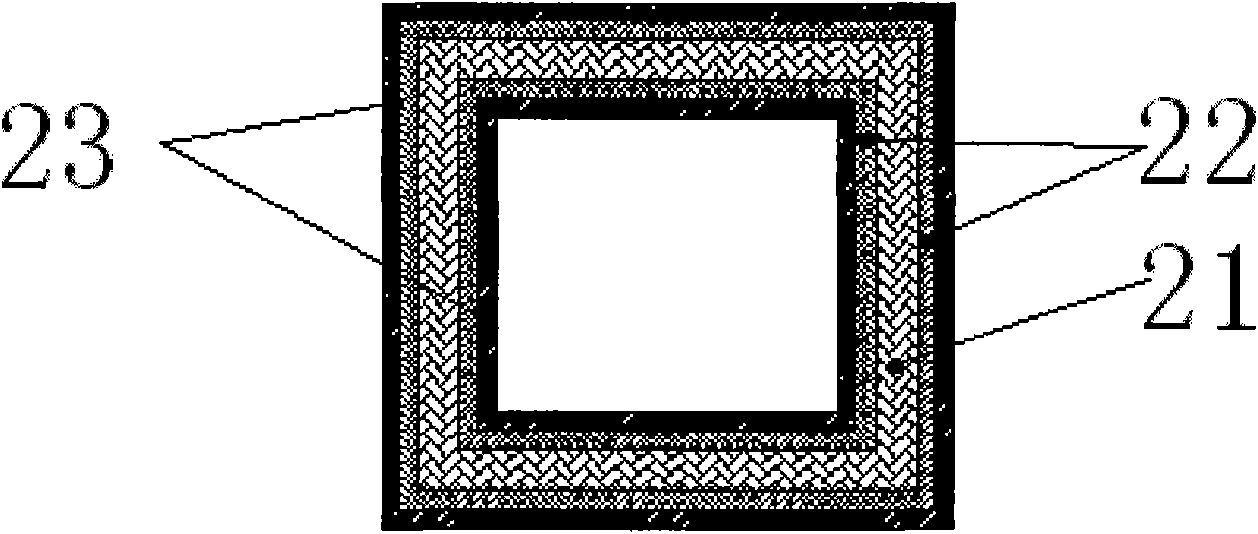

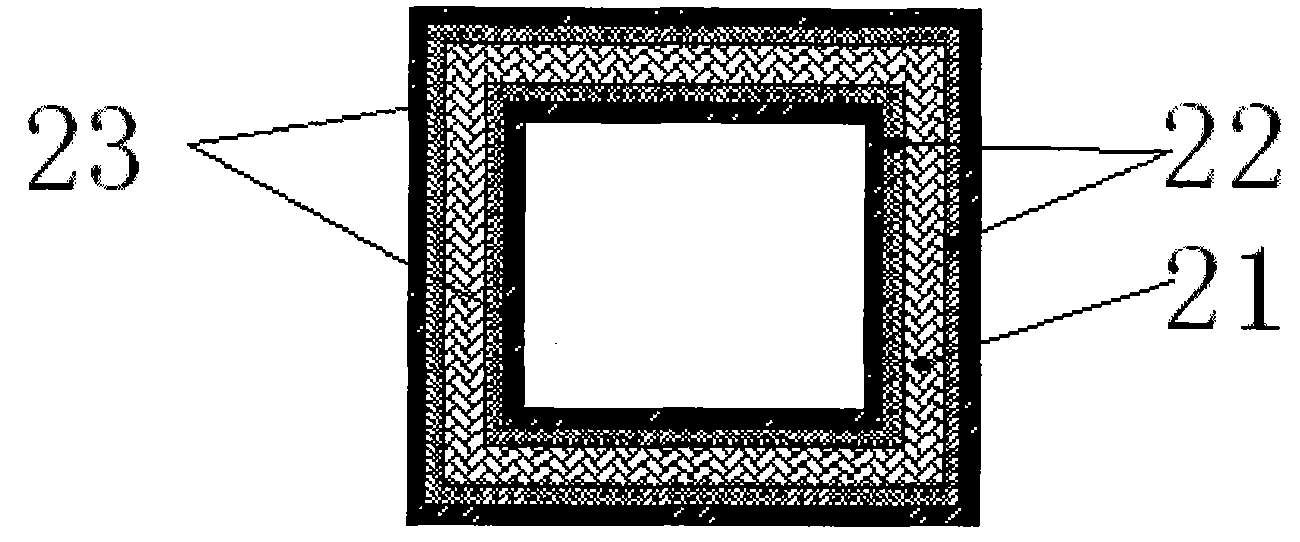

Carbon fiber tooling arm for robot

The invention aims at providing a carbon fiber tooling arm for a robot, wherein the carbon fiber tooling arm for the robot has strong rigidity, fatigue resistance and light weight, and comprises a T-shaped body, an installation part and an fixed end socket; and the installation part is arranged on the cross bar of the T-shaped body, and the fixed end socket is arranged at the end of the vertical bar of the T-shaped body. The invention is characterized in that the T-shaped body is in a hollow square column shape, the inner layer of a column wall is carbon fiber woven fabric, the outer layer of the column wall is continuous carbon fiber, and the entirety is impregnated and cured by epoxylite.

Owner:谢万有

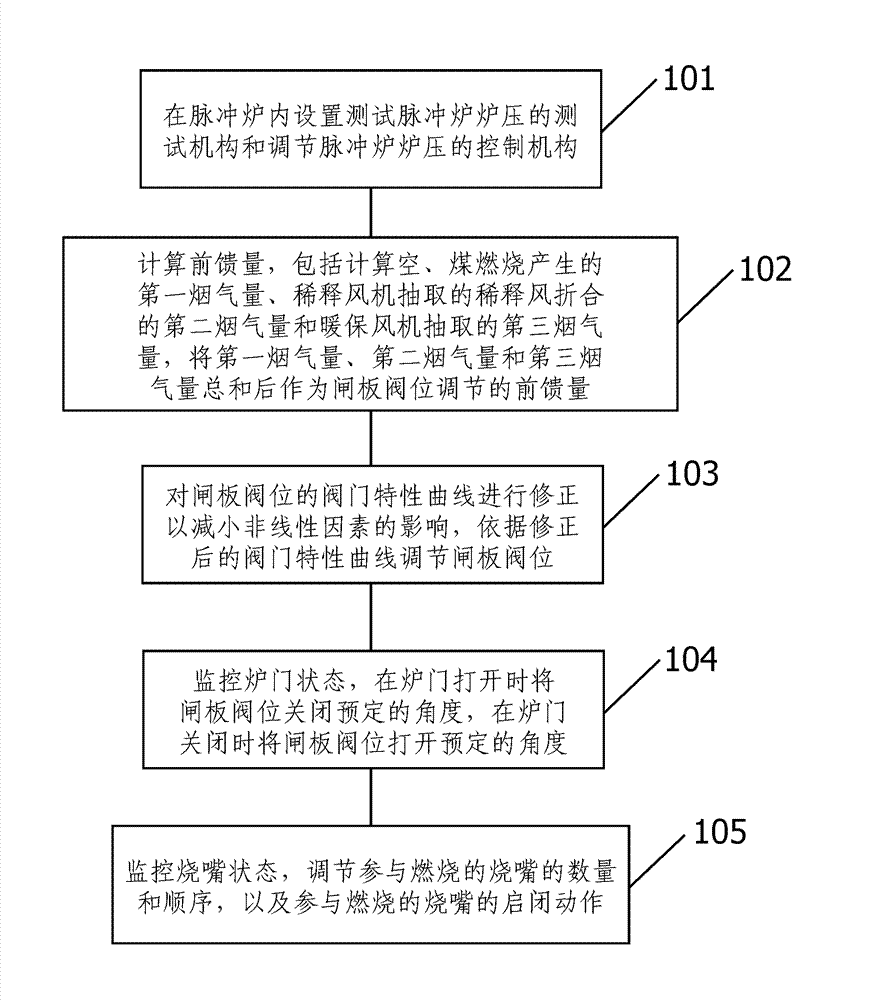

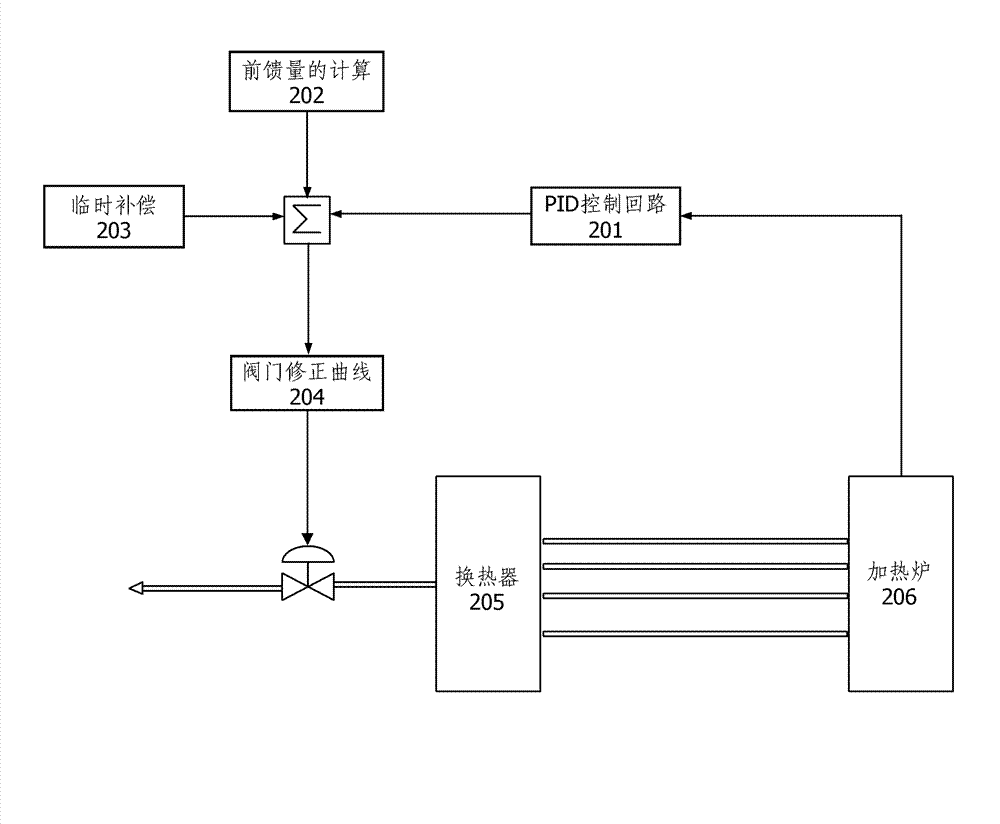

Method for controlling furnace pressure of pulse furnace

An embodiment of the invention discloses a method for controlling the furnace pressure of a pulse furnace. The method includes the steps: arranging a test mechanism for testing the furnace pressure of the pulse furnace and a control mechanism for adjusting the furnace pressure of the pulse furnace in the pulse furnace; calculating feed-forward quantities including a first flue gas quantity, a second flue gas quantity and a third flue gas quantity and then summarizing the first flue gas quantity, the second flue gas quantity and the third flue gas quantity to serve as the adjusting feed-forward quantity of a gate valve position; correcting a valve characteristic curve of the gate valve position to reduce the influence of nonlinear factors, and adjusting the gate valve position according to the corrected valve characteristic curve; monitoring the state of a furnace door, closing the gate valve position by a preset angle when the furnace door is opened, and opening the gate valve position by the preset angle when the furnace door is closed; and monitoring the state of burners, and adjusting the number, the sequence and opening-closing action of the burners involved in combustion. The control mechanism comprises the adjustable gate valve position, first flue gas is generated by air and coal combustion, second flue gas is reduced by dilution wind extracted by a dilution fan, and third flue gas is extracted by a warm protection fan.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

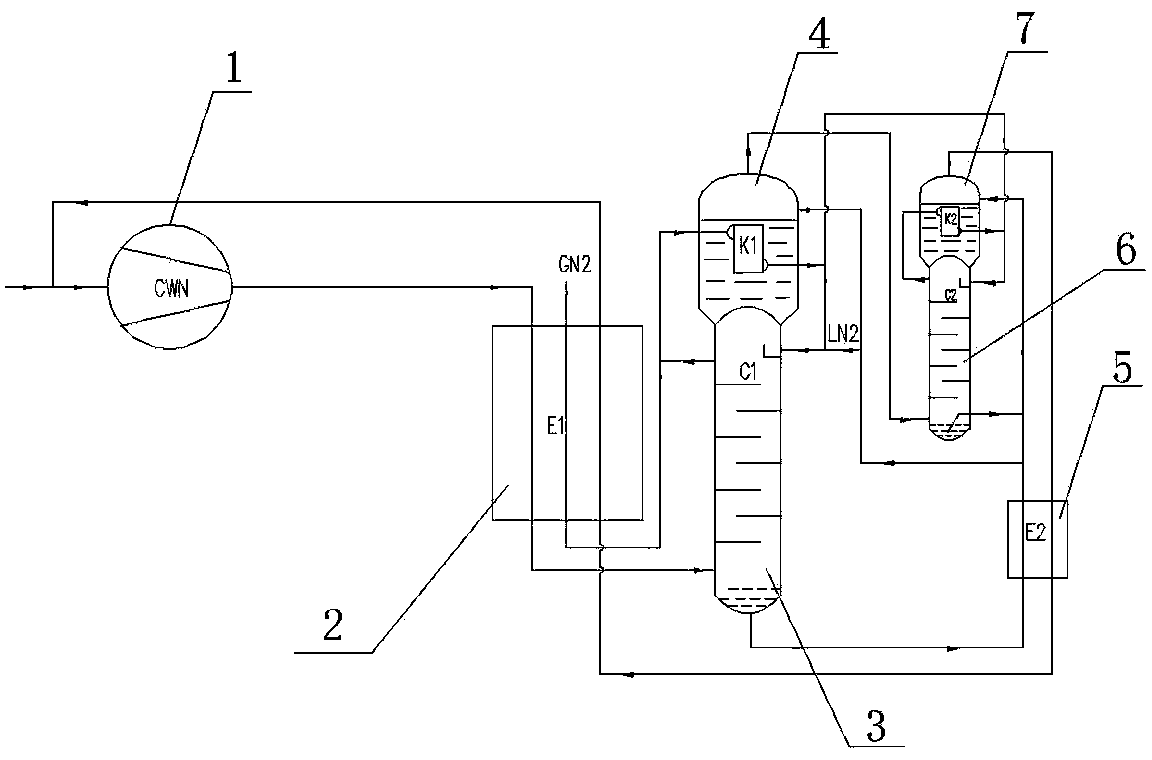

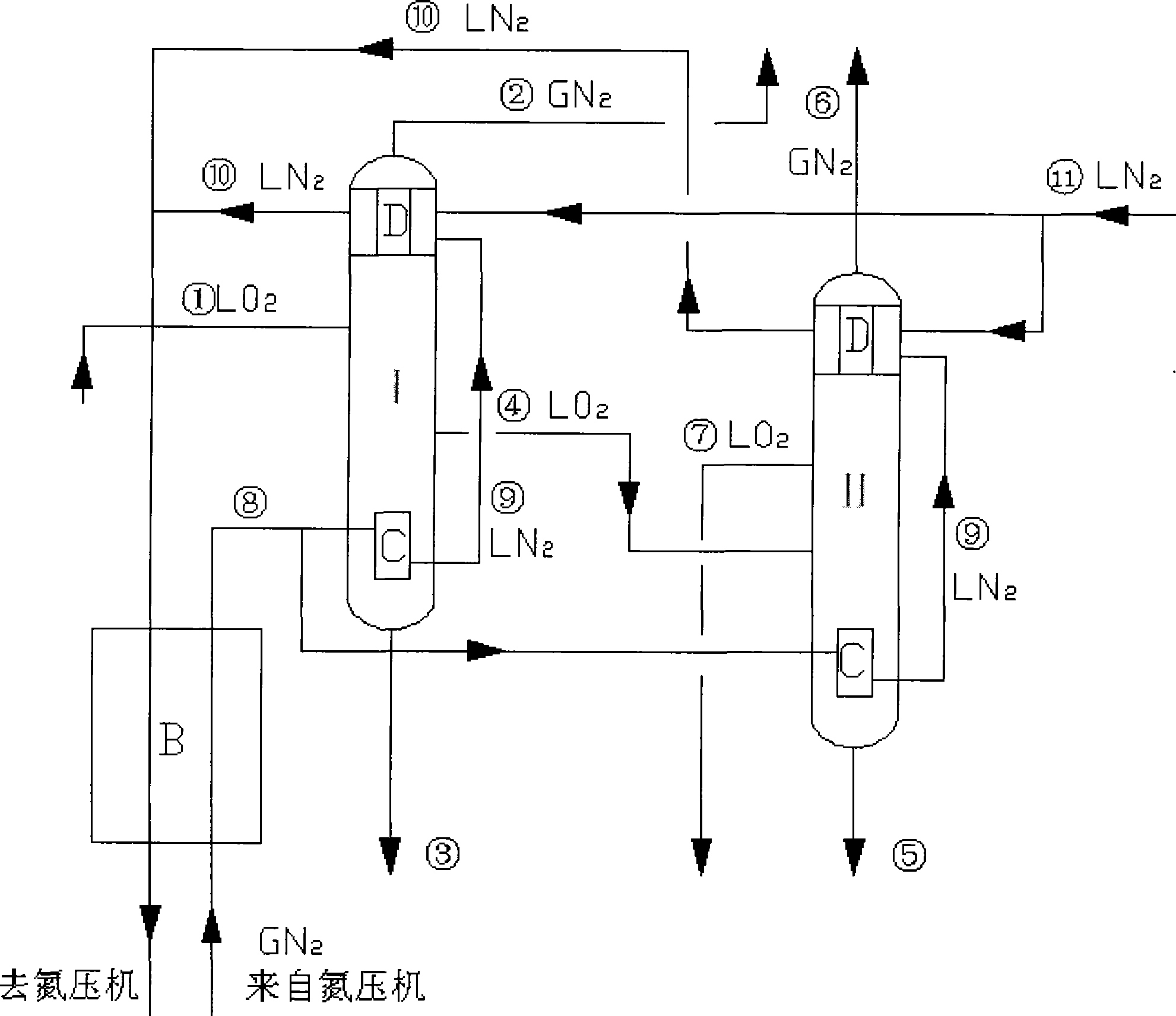

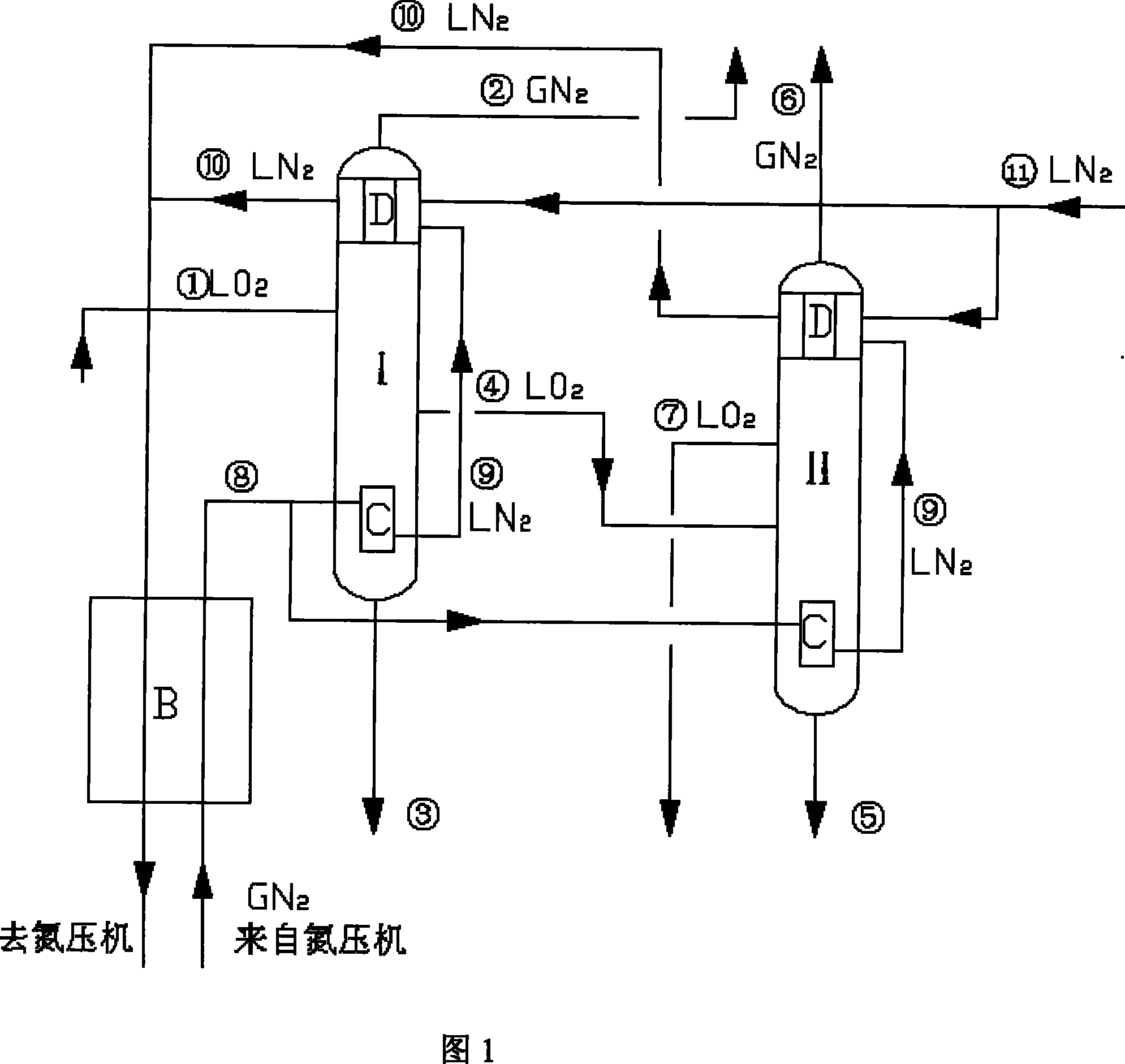

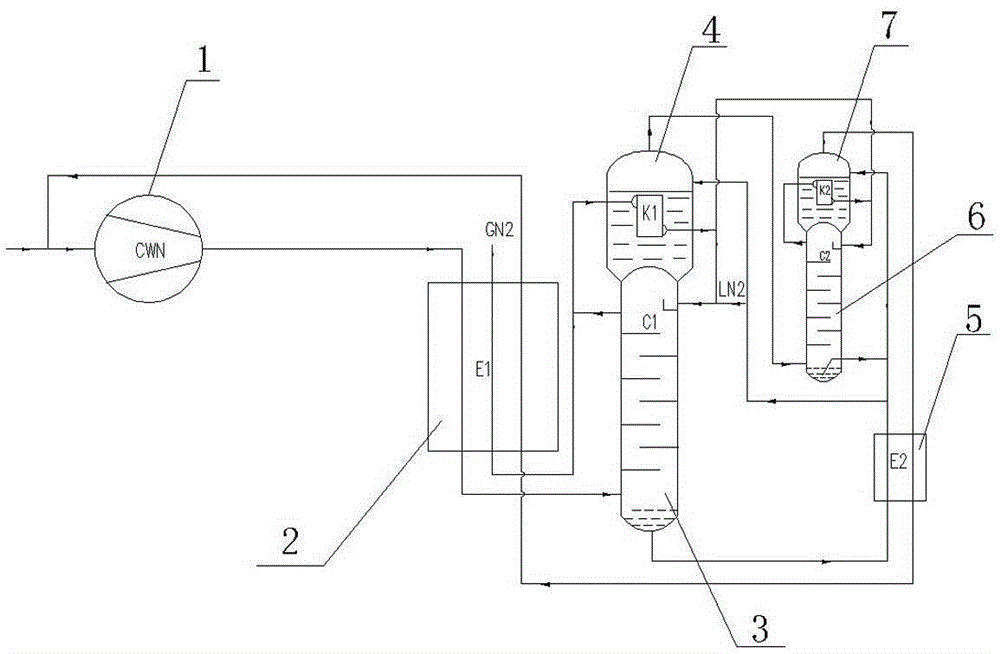

Device for extracting pure nitrogen from polluted nitrogen high in extraction rate and low in energy consumption and extracting method thereof

ActiveCN104048478AHigh extraction rateReduce the evaporating side temperatureSolidificationLiquefactionNitrogenTower

The invention discloses a method for extracting pure nitrogen from polluted nitrogen high in extraction rate and low in energy consumption. The method includes the following steps that polluted nitrogen enters a main tower and then conducts heat and mass transfer with top-to-bottom liquid on a tower plate or fillers in the main tower from bottom to top, part of pressure is pumped out at the tower top, and the polluted nitrogen serves as a product after being reheated through a main heat exchanger; after polluted liquid nitrogen discharged from the bottom of the main tower enters a subcooler to be cooled through the subcooler, polluted nitrogen evaporated from a main tower condenser is sent to a secondary tower, the polluted nitrogen conducts heat and mass transfer with top-to-bottom liquid on a tower plate or fillers in the secondary tower from bottom to top, the polluted nitrogen generated at the tower top is condensed through a secondary tower condenser, part of the condensed liquid returns to the secondary tower to serve as backflow liquid, and the other part of the liquid enters the main tower to serve as backflow liquid; the polluted nitrogen evaporated from the secondary tower condenser is reheated through the subcooler and the main heat exchanger, and then is sent to a polluted nitrogen compressor to be recycled and utilized. According to the method, the amount of the nitrogen extracted from the polluted nitrogen is higher than the amount of the nitrogen extracted from the air, and the nitrogen extraction rate reaches more than 90%.

Owner:ZHEJIANG DACHUAN AIR SEPARATION PLANT

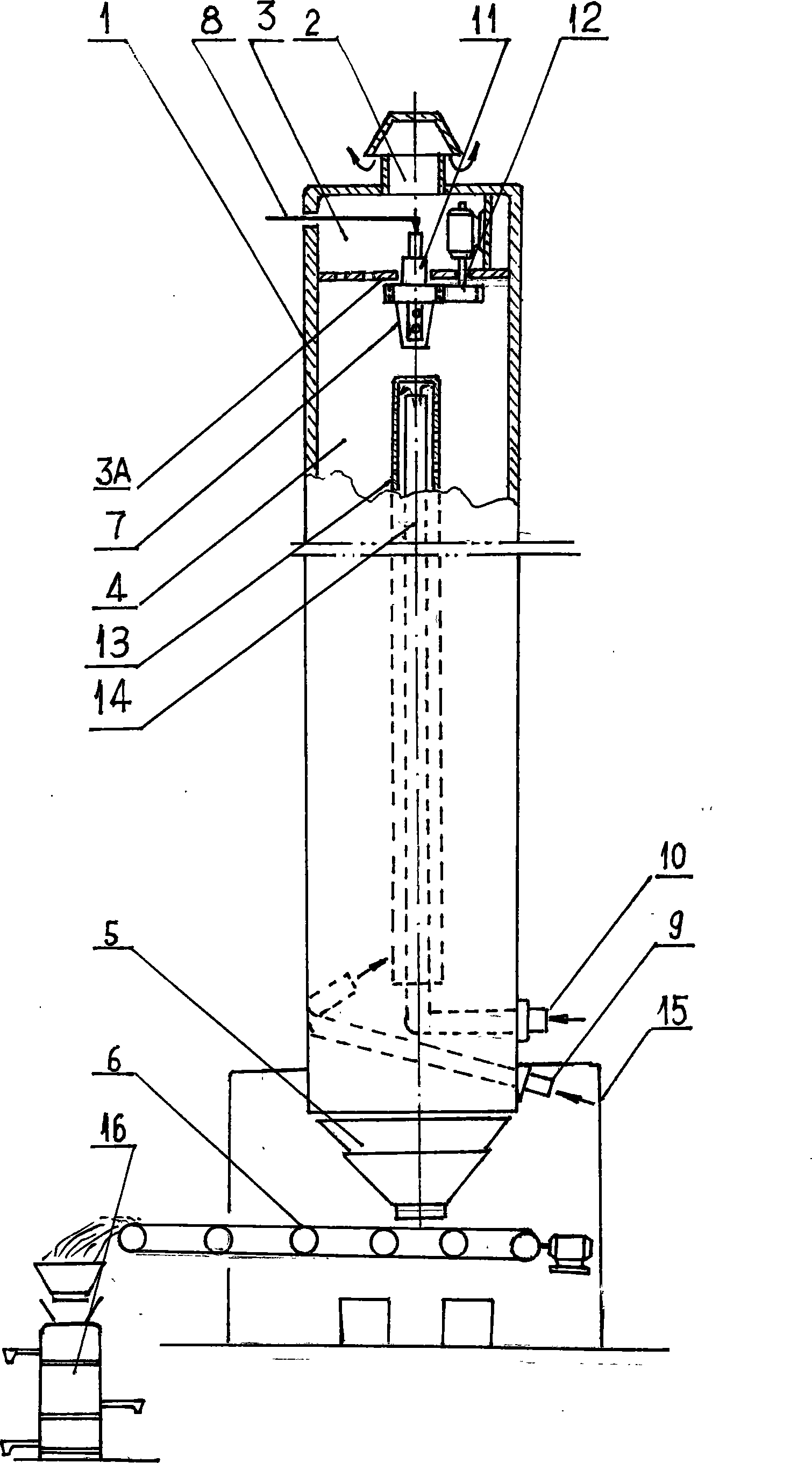

Sebacic acid molten atomizing granulating technology and device thereof

ActiveCN101164681AGuaranteed accuracyReduce energy consumption indexOrganic chemistryGranulation by liquid drop formationSieveMetallurgy

The present invention relates to an improvement on sebacic acid melting-spraying granulation process and its equipment. Said process is implemented by adopting the following procedures: (1), making the sebacic acid product be added into a melting kettle with stirrer, introducing saturated steam, heating and melting; (2), feeding the molten sebacic acid into a centrifugal chamber of centrifugal spraying machine by means of heat-insulating conveying pipeline; (3), utilizing jet holes which are uniformly distributed on the side wall of said centrifugal chamber and high-speed rotated centrifugal chamber to make the molten sebacic acid be ejected; (4), introducing the atomized molten sebacic acid into a countercurrent settling tower and undergoing the processes of cooling, forming and drying; and (5), feeding the formal products collected by trapper onto a vibration sieve, sorting and packaging so as to obtain the invented finished product. The improved equipment is a vertical tower-type structure, tower top is equipped with an air draught hole, a buffer chamber settling cavity and a trapper, and the lower portion of tower body is equipped with an air inlet structure.

Owner:韩厚义

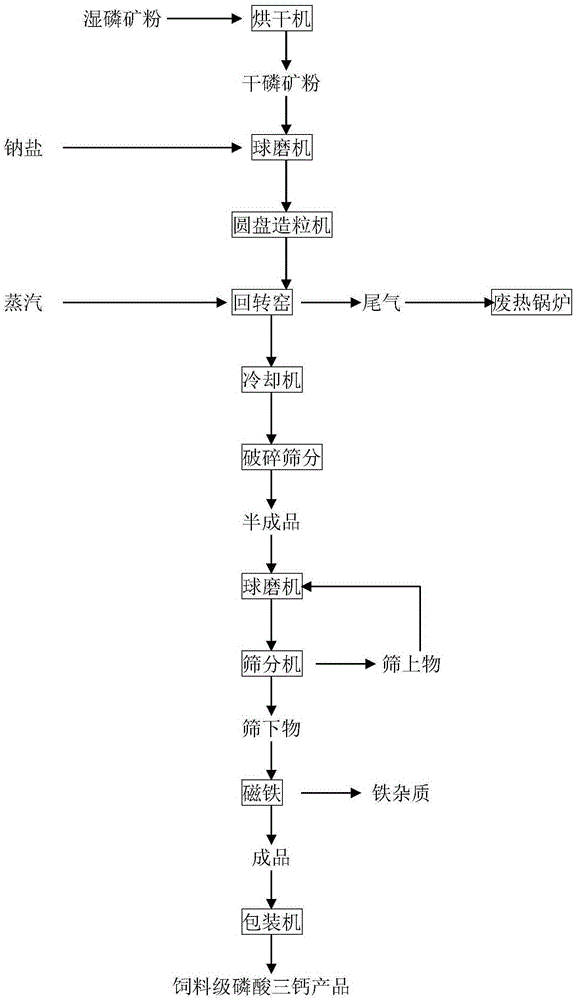

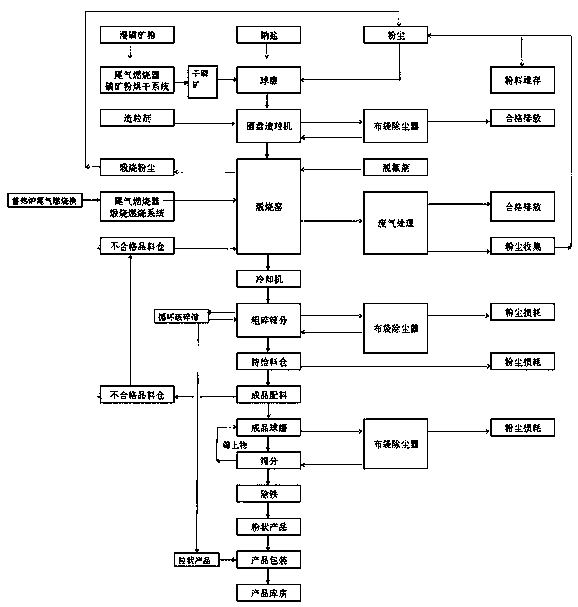

Production method of feed-grade tricalcium phosphate

InactiveCN106698377AFacilitate the decomposition and defluorinationDecomposition defluorination promotionEnergy inputPhosphorus compoundsDecompositionPhosphate product

The invention discloses a production method of feed-grade tricalcium phosphate. The method comprises the following steps: 1, drying of phosphorus rock powder; 2, mixing and ball milling; 3, disc granulation; 4, calcination defluorination; 5, cooling, crushing and sieving; 6, ball-milling of a semi-finished product; 7, screening deironing; and 8, product packaging. The method has the following advantages: 1, the raw material component and the granularity range of the phosphorus rock powder are prescribed; 2, addition of a sodium salt to raw materials facilitates decomposition defluorination of phosphorus rocks; 3, addition of phosphoric acid to the raw materials improves the content of phosphorus in the above product and facilitates granulation and calcination defluorination; 4, addition of steam in the calcining process promotes decomposition defluorination of the phosphorus rocks; 5, the product goes through the area of an electromagnet or a permanent electromagnet to remove iron fillings and other metal impurities, so operation control is simple, and the impurity removal efficiency is high; and 6, calcination tail gas is fully used to produce saturated steam and superheated steam, so energy is saved, and the energy consumption and the production cost are reduced. The method is suitable for producing the feed-grade tricalcium phosphate product.

Owner:WENGFU (GRP) CO LTD

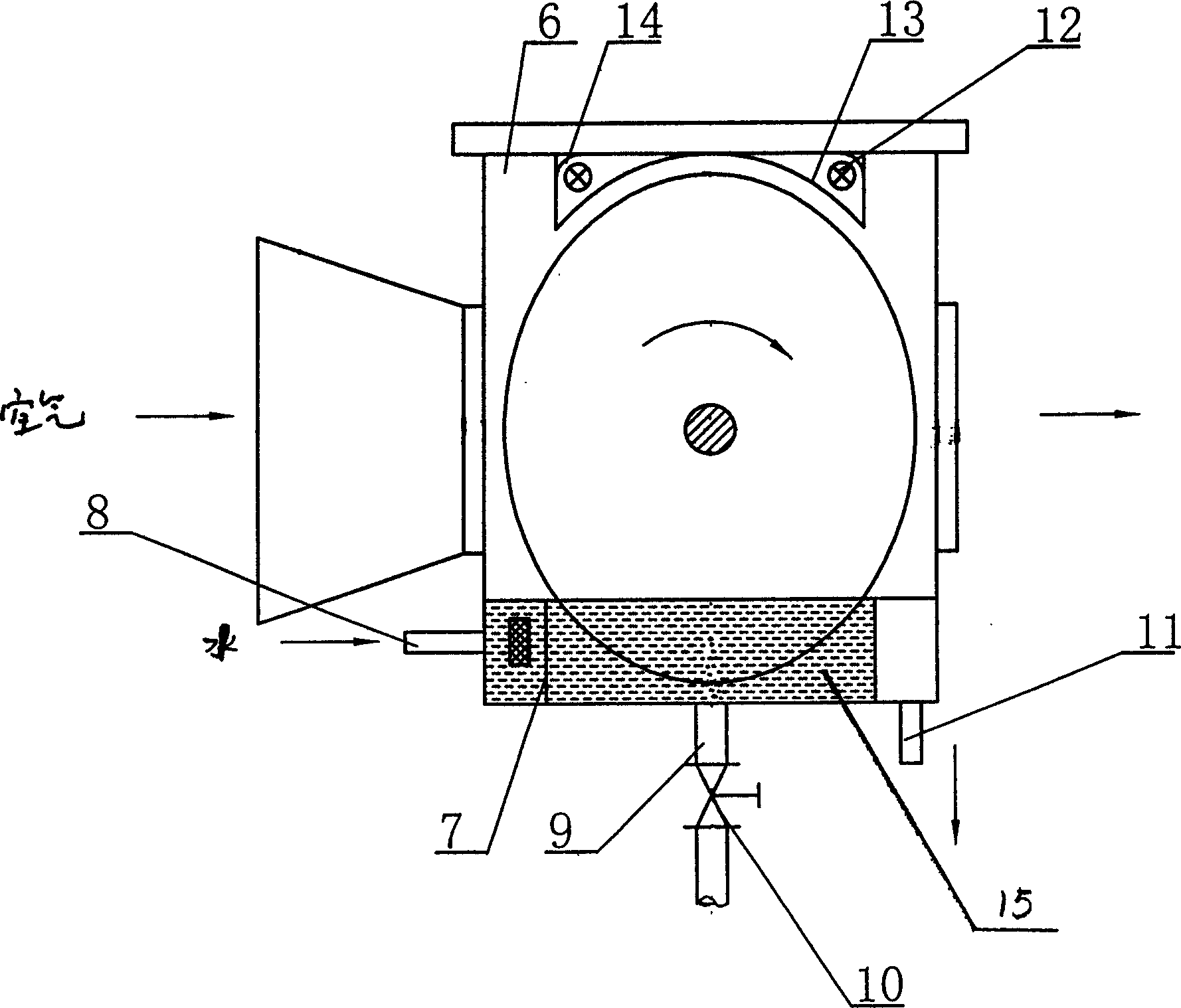

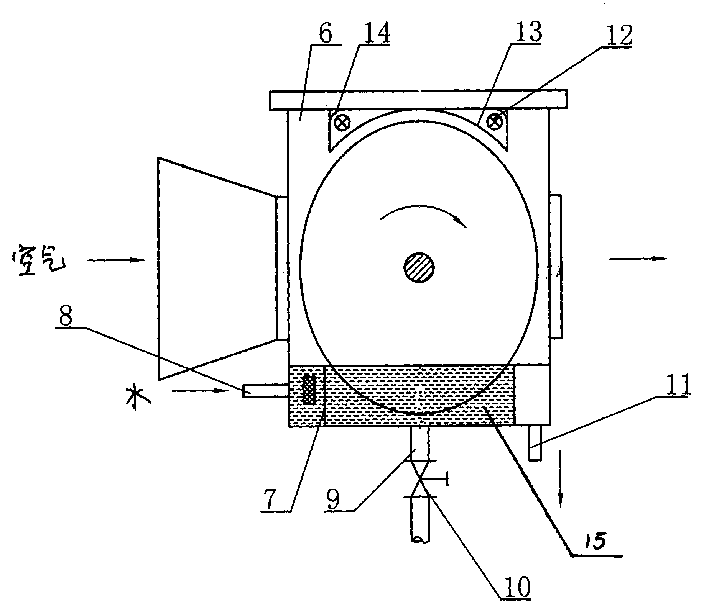

Rotary water film air treatment equipment

InactiveCN1460828ASolve the problem of disinfection and sterilizationSolve automatic cleaningTrickle coolersCircular discWater channel

The present invention relates to a new type air treatment equipment, including a shell body, a rotatable shaft and a driving device. The rotatable shaft is directly connected with driving device, in the interior of shell body several thin circular disks whose surfaces are mutually parallel and spaced are mounted on the rotatable shaft, and fixed together to form a circular disk group, and the place ahead of and over the circular disk group and the place behind and over the circular disk group are respectively equipped with UV lamps, the lower portion of said shell body can be used as water channel, and two ends in the interior of said water channel are equipped with two partion boards, one end of the water channel extrior is equipped with water inlet, and its another end is equipped with overflow tube.

Owner:XI AN JIAOTONG UNIV

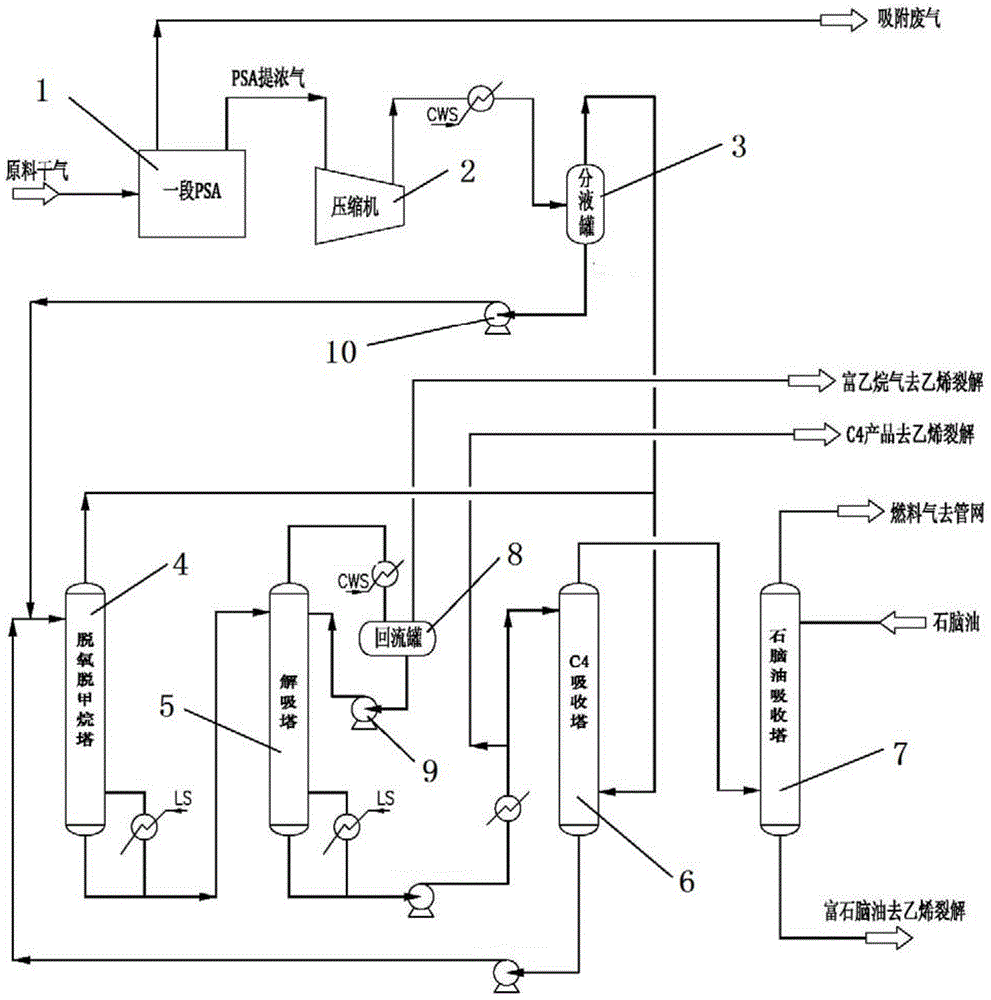

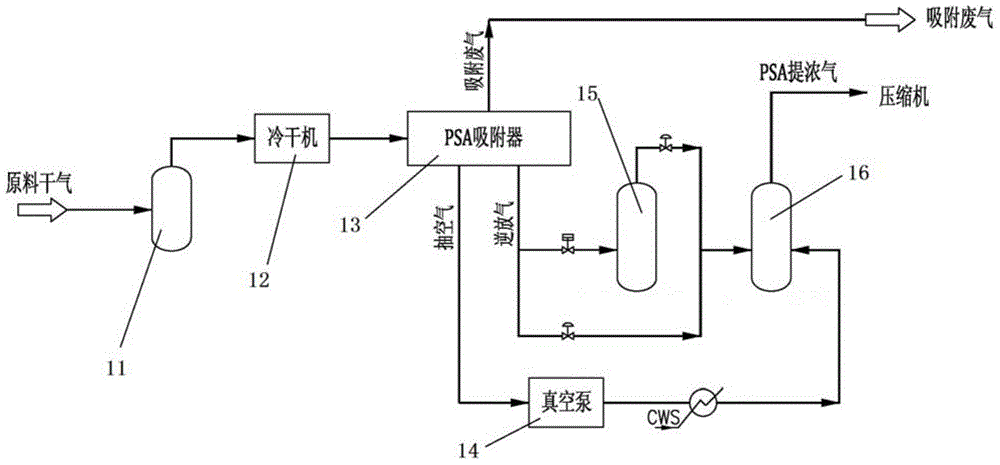

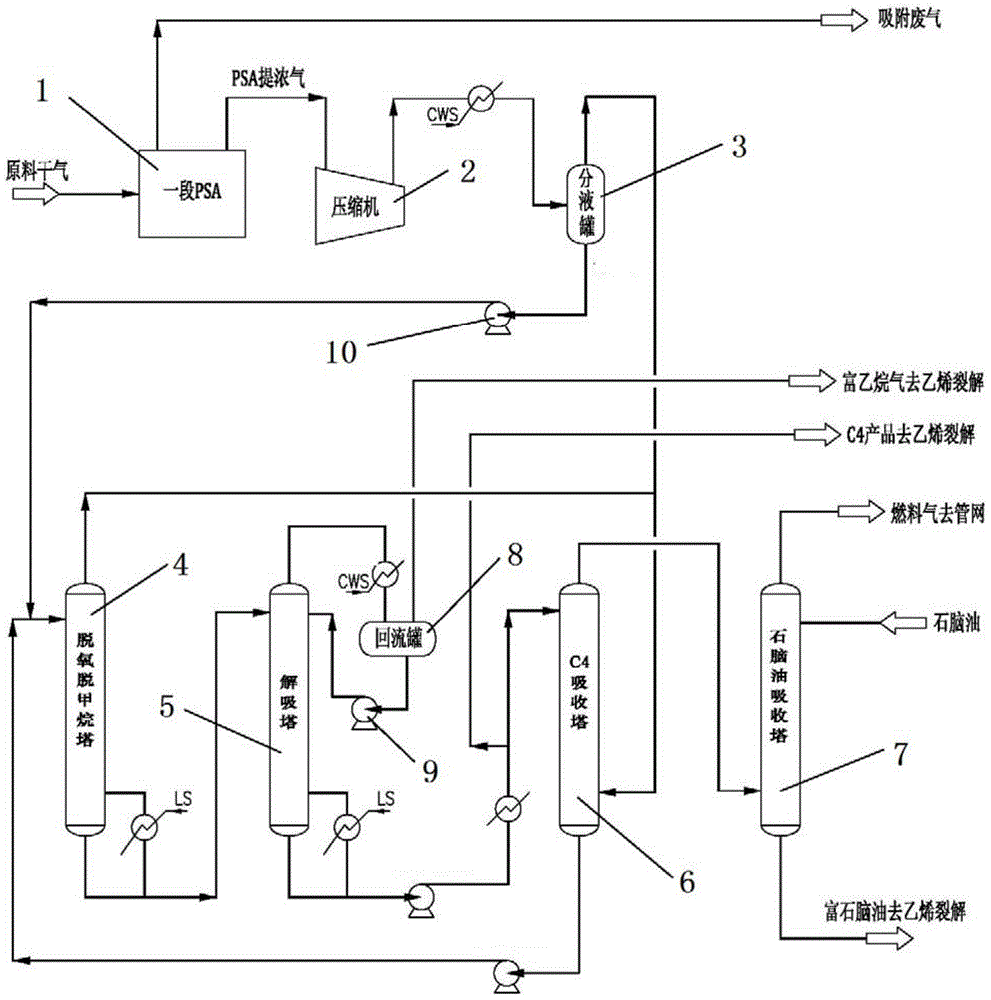

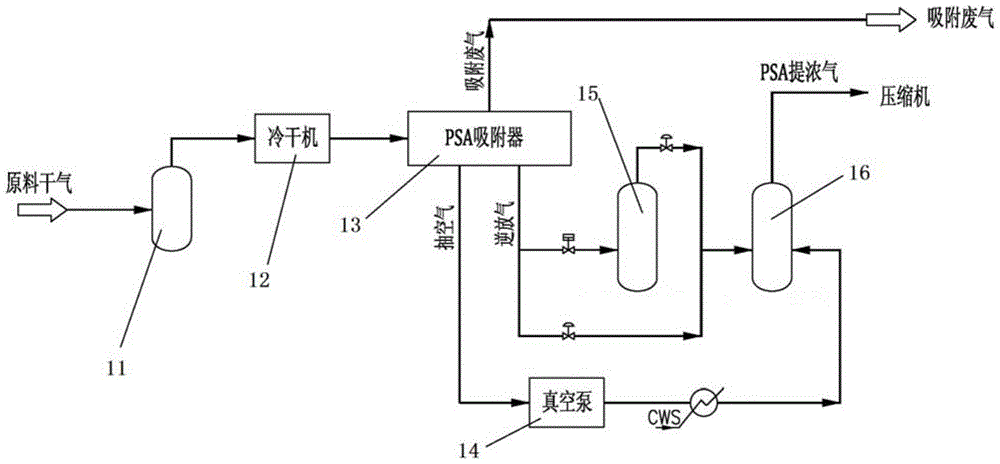

Device and method of recycling C2 from refinery dry gas

ActiveCN104830371AHigh recovery rateHigh purityDispersed particle separationGaseous mixture working upDesorptionCondensation temperature

The invention discloses a device of recycling C2 from refinery dry gas, which includes a PSA unit, a compression unit and an oil absorption unit. The PSA unit includes a first-section PSA device. The compression unit includes a compressor and a liquid separation pot. An inlet of the first-section PSA device is communicated with the raw material dry gas and an outlet of the first-section PSA device is communicated with the inlet of the compressor. The outlet of the compressor is communicated with the inlet of the liquid separation pot. The invention is advantaged in that firstly the raw material dry gas is subjected to primary concentration in the first-section PSA device being low in energy consumption, and then the PSA concentrated gas is further concentrated through an adsorption / desorption method being high in recycle rate and product purity, wherein the temperature of fed gas material, an absorbent and top reflux are all 40 DEG C in the absorption unit. By means of circulated cooling water, the cooling condensation temperature can be achieved without any refrigerating device. By means of the compressed condensate as the absorbent, it is unnecessary to feed a C4 absorbent from other apparatus. The invention also discloses a method of recycling C2 from the refinery dry gas.

Owner:BEIJING YANSHAN YULONG PEC

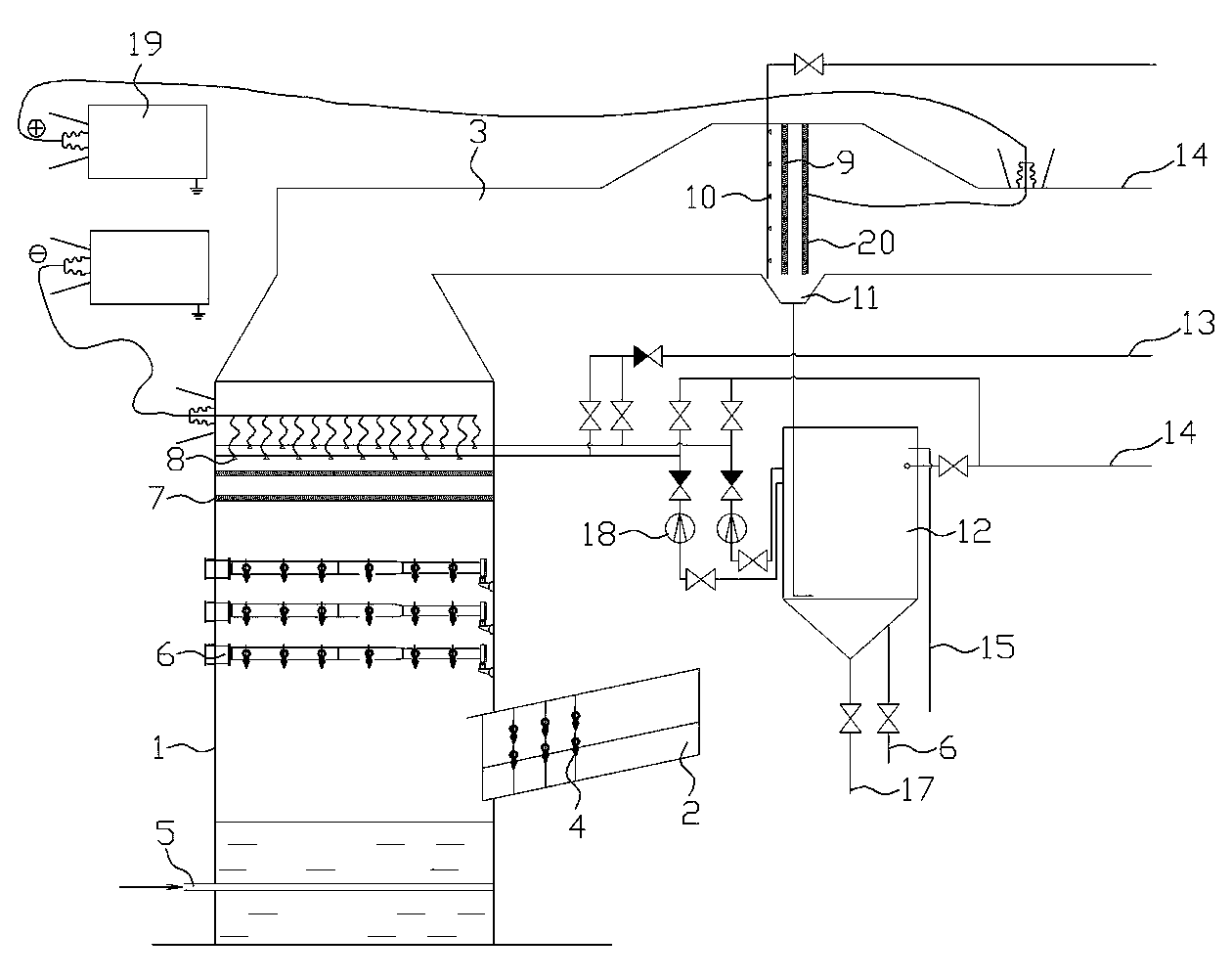

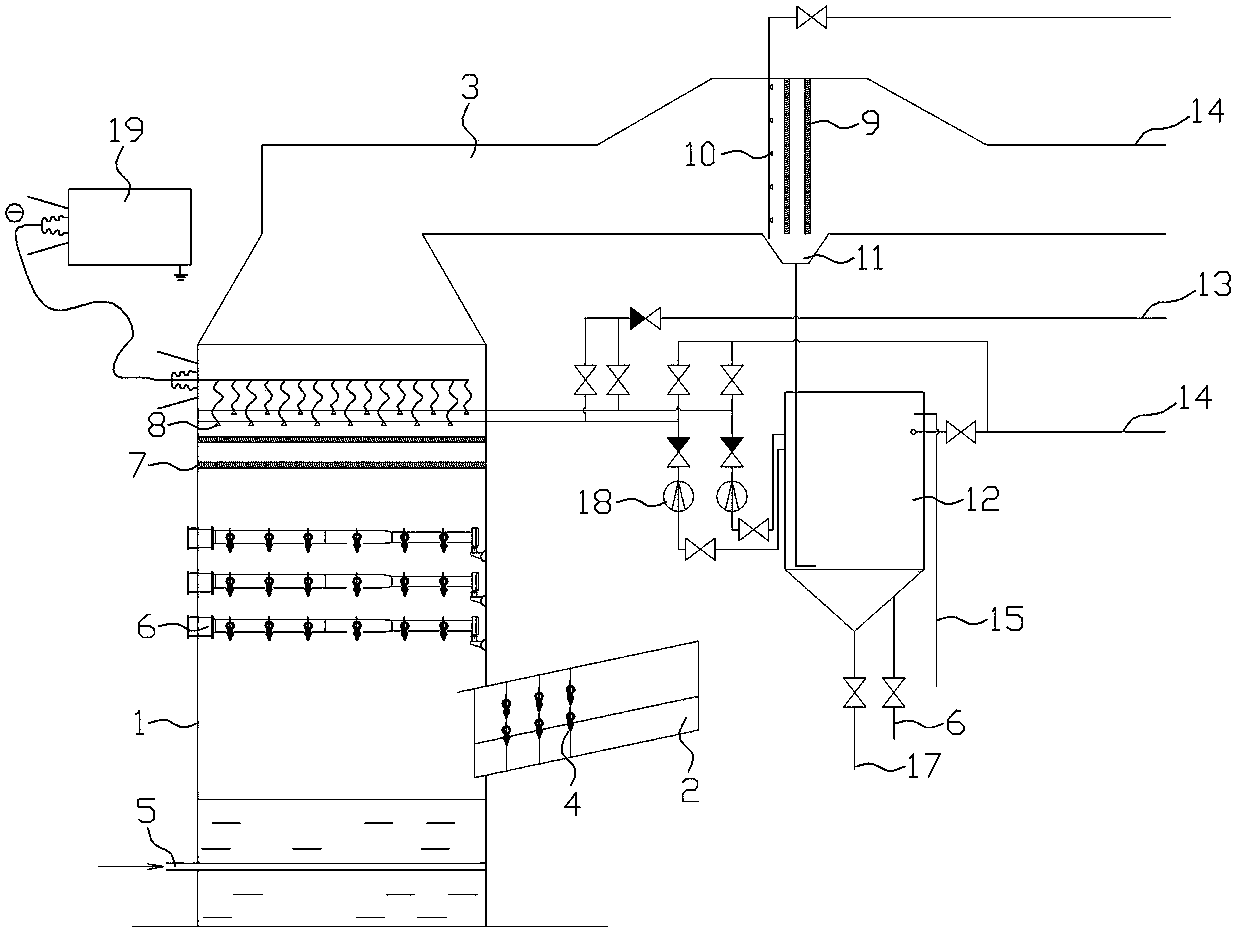

Wet desulfurization system with electrostatic humidifier and anode demister

ActiveCN103446837AEfficient collectionEmission reductionCombination devicesHigh pressureDevice failure

The invention provides a wet desulfurization system with an electrostatic humidifier and an anode demister, which relates to a purification apparatus in a thermal power plant, particularly an apparatus for lowering dust content in spray-type desulfurization absorption tower wet desulfurization fume. The wet desulfurization system comprises an absorption tower, wherein a spray layer and a demister are arranged in the tower; a humidification sprayer is arranged 0.3-1.0m behind the demister; the humidification sprayer is connected with a high-voltage electrostatic power supply; a last stage demister is arranged in a flue which is 4-10m behind the humidification sprayer; a flush sprayer for flushing the last stage demister is arranged in front of the last stage demister; an electrostatic demister is arranged behind the last stage demister and connected with the high-voltage electrostatic power supply. The wet desulfurization system effectively lowers the smoke dust discharge amount of the thermal power plant chimney, has the advantages of low energy consumption, lower investment, convenient maintenance of equipment, long service life, short construction cycle, extremely low equipment failure rate, simple operation regulation and high equipment safety, and can effectively collect fine particles, escape ammonia, heavy metal, organic pollutants and the like.

Owner:王利国 +2

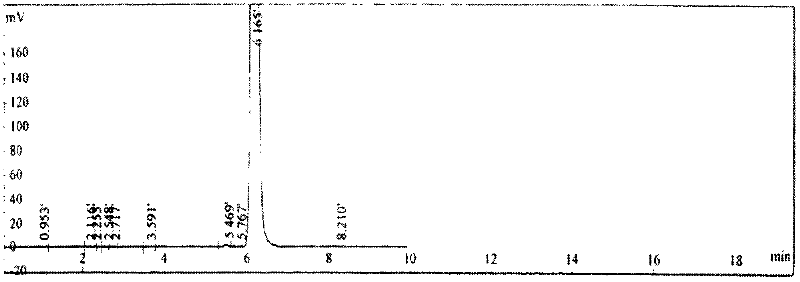

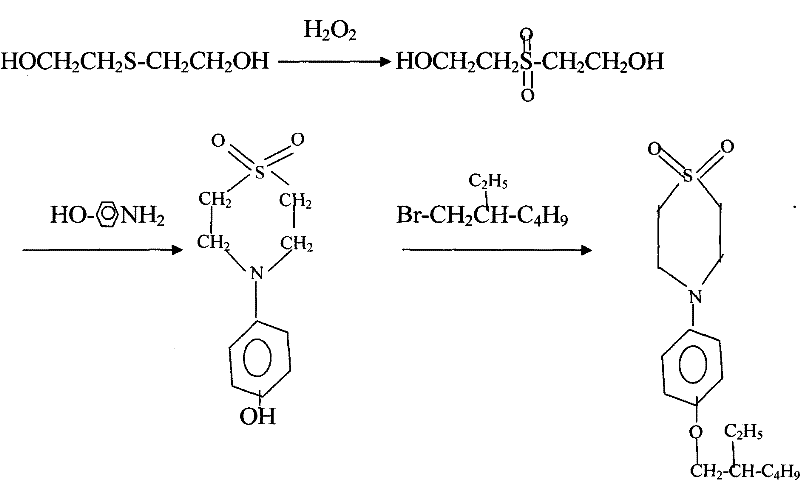

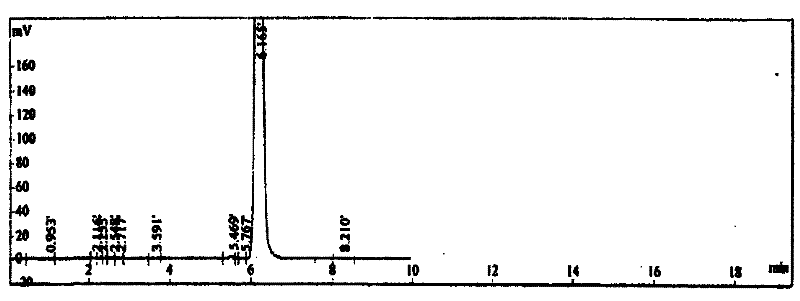

Preparation method of N-(4-(2-ethylhexyloxy) phenyl)-1, 1-dioxothiomorpholino

The invention relates to a preparation method of N-(4-(2-ethylhexyloxy) phenyl)-1, 1-dioxothiomorpholino. The method is characterized by comprising the following steps of: adding 10 parts by weight of thiodiglycol and 10 parts by weight of water to a reaction kettle, then adding 1-2 parts by weight of quaternary ammonium salt as a catalyst, adding 65-75 parts by weight of hydrogen peroxide dropwisely into the reaction kettle, after dropping, preserving the heat of the mixture and allowing it to stand for one hour so as to generate bishydroxyethylsulfone, adding p-aminophenol to conduct a condensation reaction for 3 hours, then adding bromoisooctane for a further condensation reaction for 3 hours, pouring n-heptane into a product stock solution, stirring the solution and allowing it to stand, taking out the extraction phase and evaporating the solvent to dryness, thus obtaining a finished product. Application of the method provided in the invention can prepare products with an overall yield of over 86% and effective content of more than 98%, so the method is completely applicable to large scale industrial production. With substantial economic benefit, social benefit and ecological benefit, the method provided in the invention fully meets the requirements of safety, environmental protection and high efficiency that are advocated by the nation in developing low carbon economy.

Owner:XIANTAO WYLSON CHEM

Sterilizing technology used for sterile filling production line

ActiveCN109502532AReduce energy consumptionReduce energy consumption indexHollow article cleaningPackage sterilisationProduction lineWater use

The invention discloses a sterilizing technology used for a sterile filling production line. A first pipeline is arranged between a high-temperature hot water circulation system and a sterile water circulation system; pre-cleaning is conducted on a material circulation system, the high-temperature hot water circulation system, the sterile water circulation system and the first pipeline, and afterwards, all the systems run and communicate with the first pipeline; in the high-temperature hot water circulation system, when the high-temperature hot water is heated to the first sterilizing temperature, heat insulation is conducted for the first time period, the high-temperature hot water is sterilized, and the sterile high-temperature hot water is obtained; and along with the situation that thefirst pipeline supplements the sterile high-temperature hot water into the sterile water circulation system gradually, the flow of sterile water supplied by the sterile water circulation system in the sterile water circulation system is reduced gradually, and meanwhile normal-temperature pure water is supplemented into the high-temperature hot water circulation system. By means of the sterilizingtechnology used for the sterile filling production line, energy consumption of steam, ice water and tower water used during running of the sterile water circulation system is effectively reduced, andenergy consumption of tower water and ice water at the rear end of the material circulation system is effectively reduced.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

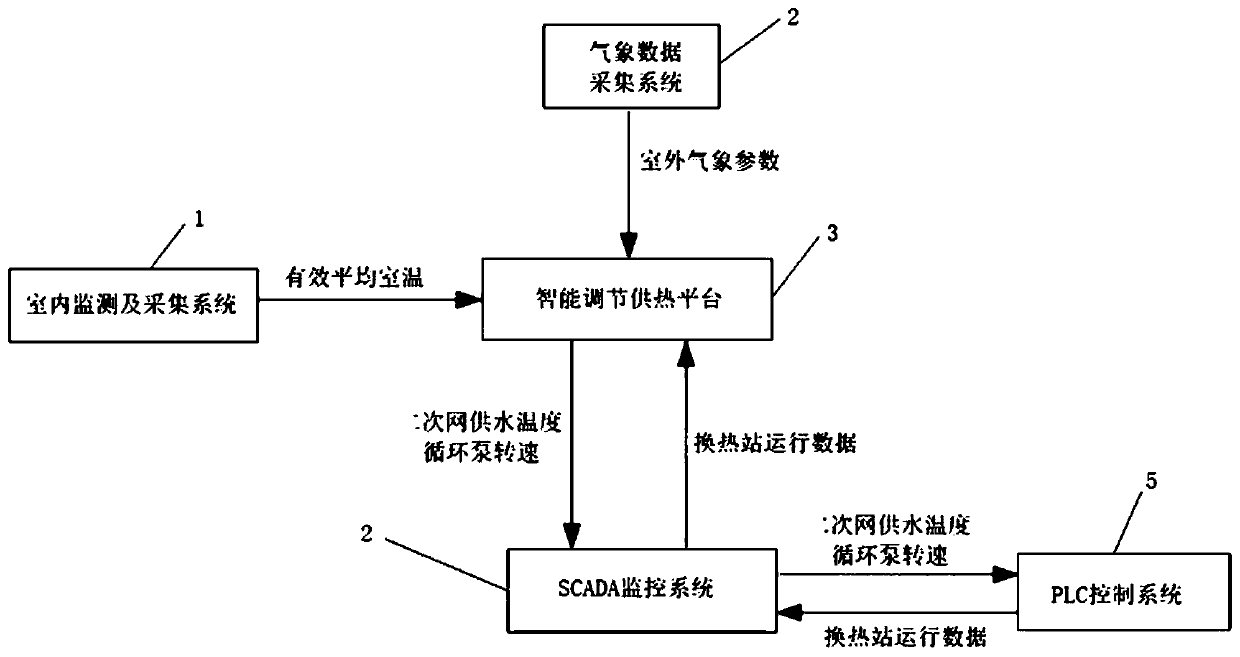

Secondary network intelligent adjustment system based on room temperature monitoring

InactiveCN111006302AAchieve self-awarenessIncrease profitLighting and heating apparatusSpace heating and ventilation detailsData packThe Internet

The invention relates to a secondary network intelligent adjustment system based on room temperature monitoring. The system comprises: a room temperature monitoring and data collecting system used formonitoring the room temperature of a typical user in real time and obtaining an effective average room temperature; a meteorological data acquisition system used for acquiring outdoor meteorologicaldata, wherein the outdoor meteorological data comprises outdoor temperature data; and an intelligent adjustment heat supply platform used for establishing a heat supply operation curve according to the outdoor temperature, the room temperature monitoring data and a preset indoor temperature, correcting the water supply temperature of the secondary network according to the established heat supply operation curve and issuing the corrected water supply temperature of the secondary network to each heat exchange station for automatic operation of the heat exchange stations. The internet of things is combined with big data, self-sensing and self-optimizing operation of the heat supply system is achieved through self-adaptive regulation of intelligent means, energy consumption indexes such as heat and electricity are reduced, and the energy utilization rate is increased.

Owner:DATANG DONGBEI ELECTRIC POWER TESTING & RES INST +1

Marine temperature self-adaptive air-cooled cabinet

PendingCN114286586AOrganizational clarityPrevent channelingCasings/cabinets/drawers detailsCooling/ventilation/heating modificationsCold airTemperature control

The invention discloses a marine temperature-adaptive air-cooled cabinet, the cabinet is a three-area cabinet composed of an air supply area, an equipment area and an air return area, the air supply area and the equipment area are further divided into a plurality of sub-areas in the vertical height, and the air supply sub-areas and the equipment sub-areas at the same height form a relatively independent heat dissipation unit; the public air return area collects hot air flowing out of the heat dissipation units. Through an air flow stabilizing and distributing mechanism composed of an air supply area cavity, an air supply pipe, a proportioning valve and a flow guide plate, air flow organization in the cabinet is clear, and heat exchange efficiency is improved. And the heat dissipation unit is combined with the multi-loop temperature control unit to form a temperature self-adaptive air cooling system with complete functions. According to the system, zoned control of temperature is realized, and the running condition of equipment in each heat dissipation unit is matched. And according to the temperature set value and the actual temperature feedback value, the branch cold air conveying amount is controlled as required, regional refined refrigeration management is achieved, and the energy consumption index of unit load is further reduced.

Owner:708TH RES INST OF CSSC

Method for producing feed-grade tricalcium phosphate by utilizing low-calorific-value tail gas

PendingCN111377423AReduce processing costsFacilitate the decomposition and defluorinationDrying solid materials with heatEnergy inputExhaust gasChemistry

The invention discloses a method for producing feed-grade tricalcium phosphate by utilizing low-calorific-value tail gas. The method comprises the following steps: (1) burning ground phosphate rock byutilizing the low-calorific-value tail gas and drying; (2) mixing and ball milling; (3) performing disc granulation; (4) calcining and defluorinating the low-calorific-value tail gas; (5) air heat storage and temperature rise; (5) cooling, crushing and sieving; (6) circularly crushing and screening, and ball-milling a semi-finished product; (7) screening and removing iron; and (8) packaging products. The method has the following advantages: (1) the raw material components and the particle size range of the ground phosphate rock are specified; (2) low-calorific-value tail gas combustion is fully utilized for heat storage and temperature rise of combustion-supporting air; (3) a low-calorific-value tail gas combustion technology and a co-combustion technology are fully utilized; (4) steam isadded in the calcining process to promote decomposition and defluorination of the phosphate ore; and (5) saturated steam and superheated steam are produced by fully utilizing calcined tail gas, so that energy is saved, and energy consumption and production cost are reduced. The method is very suitable for being popularized and used in enterprises producing feed-grade tricalcium phosphate products.

Owner:WENGFU (GRP) CO LTD

Wet desulfurization system with electrostatic humidifier

ActiveCN103446838AEfficient collectionEmission reductionCombination devicesHigh pressureDevice failure

The invention provides a wet desulfurization system with an electrostatic humidifier, which relates to a purification apparatus in a thermal power plant, particularly an apparatus for lowering dust content in spray-type desulfurization absorption tower wet desulfurization fume. The wet desulfurization system comprises an absorption tower, wherein a spray layer and a demister are arranged in the tower; a humidification sprayer is arranged 0.3-1.0m behind the demister; the humidification sprayer is connected with a high-voltage electrostatic power supply; a last stage demister is arranged in a flue which is 4-10m behind the humidification sprayer; a flush sprayer for flushing the last stage demister is arranged in front of the last stage demister. The wet desulfurization system effectively lowers the smoke dust discharge amount of the thermal power plant chimney, has the advantages of low energy consumption, lower investment, convenient maintenance of equipment, long service life, short construction cycle, extremely low equipment failure rate, simple operation regulation and high equipment safety, and can effectively collect fine particles, escape ammonia, heavy metal, organic pollutants and the like.

Owner:王利国 +2

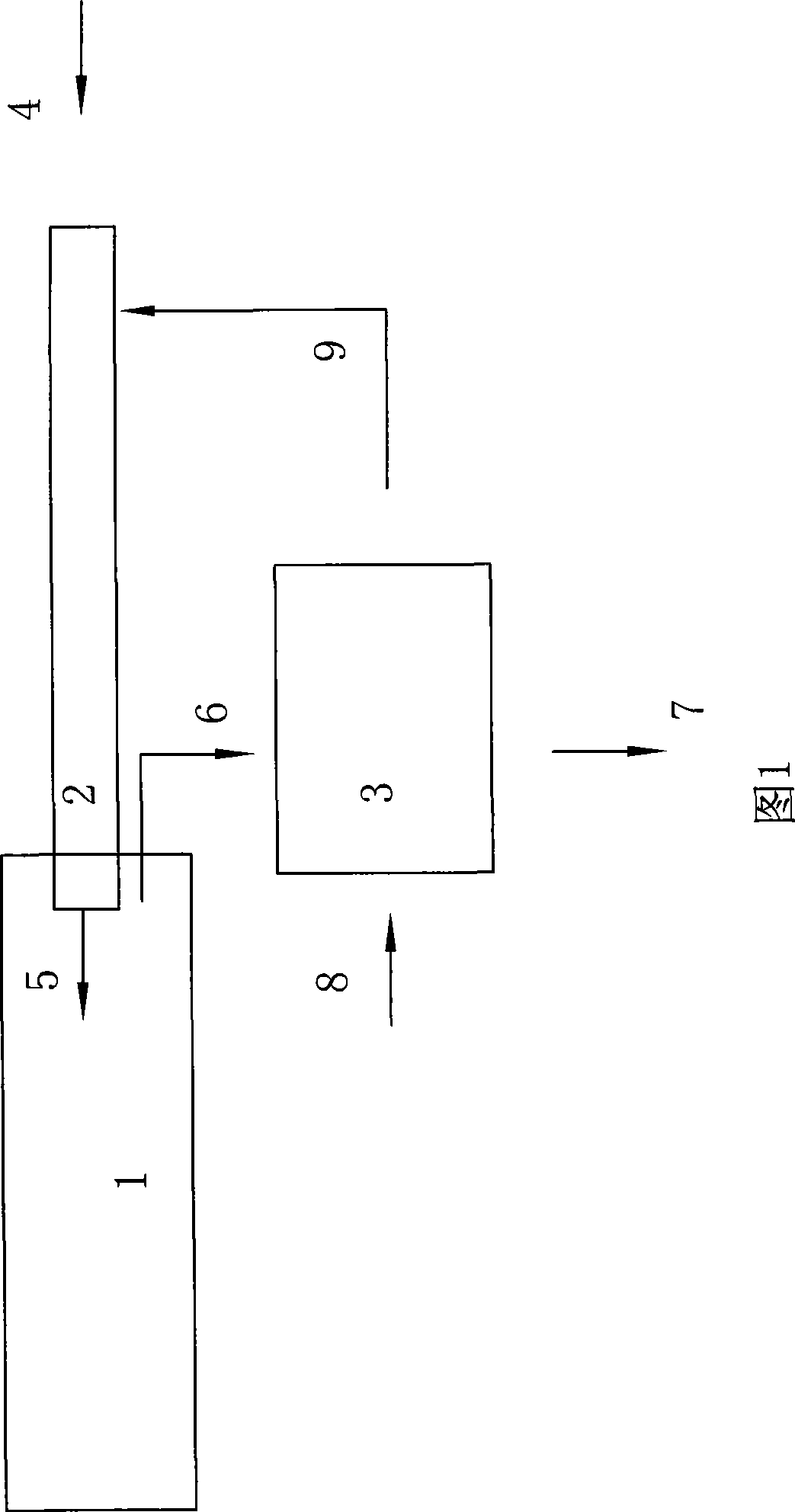

Dolomite calcination heat-recovering method and system

InactiveCN101376572AProtect the temperature environmentImprove working environmentRecovery methodThermal insulation

The invention discloses the dolomite calcination in the magnesium smelting field, and particularly relates to a residual heat recovery method for the dolomite calcination, and a system thereof. The waste heat recovery method comprises the following steps: materials in a dolomite rotary kiln rotate along with the kiln body; high-temperature combustion gas produced by the combustion of a rotary kiln combustion system is delivered into the dolomite rotary kiln; the calcined materials enter a heat exchanger through a kiln head chute; at the same time, cold air is delivered to the heat exchanger; and the cold air after the heat exchange is discharged out through the hot air hole of the heat exchanger, and is introduced to the rotary kiln combustion system through a thermal insulation pipeline. The invention has the advantages that the residual heat taken away by the materials during the dolomite calcination is recycled, and is applied to a combustion apparatus used for calcining the dolomite for reducing the fuel consumption thereof and achieving the purposes of energy conservation and emission reduction.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

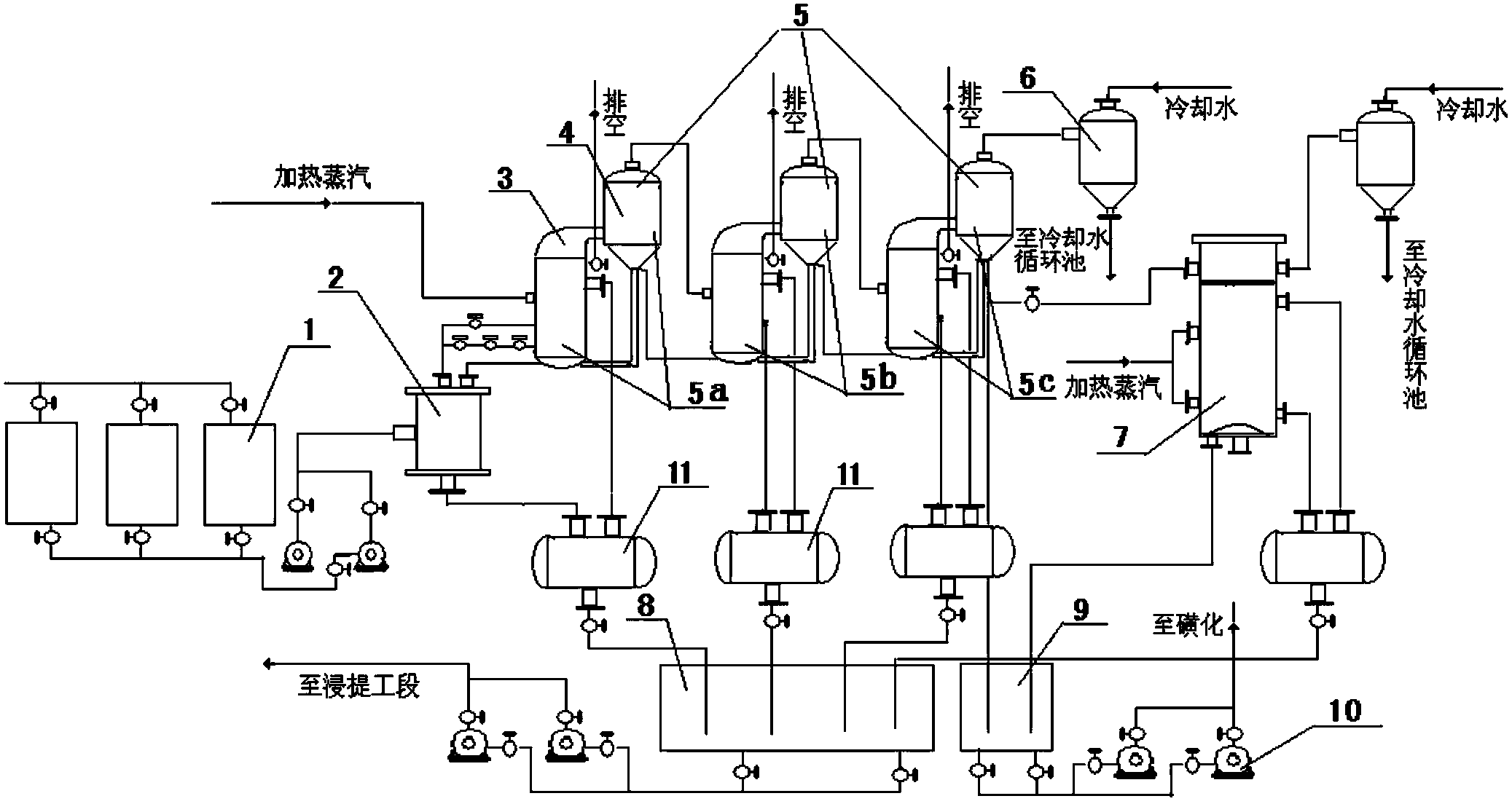

Unpowered automatic liquid-transferring method in production and evaporation procedures of tanning extracts

InactiveCN103908790AStable vacuum pressureReduce energy consumptionMultiple-effect evaporationVacuum pressurePulp and paper industry

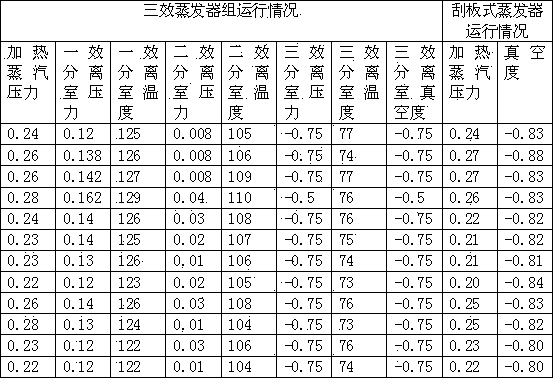

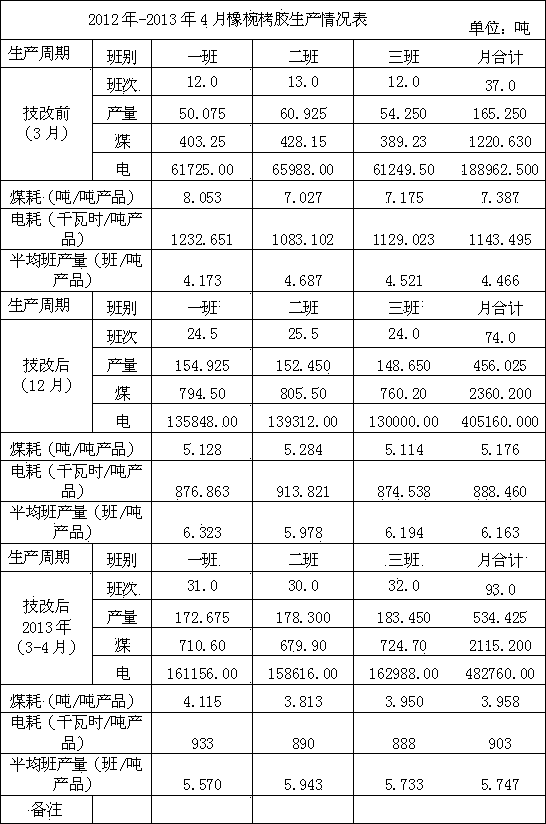

The invention relates to the field of tanning extracts and particularly relates to an unpowered automatic liquid-transferring method in the production and evaporation procedures of the tanning extracts. A triple-effect evaporator is connected with a scratching-plate type evaporator to form a quadruple-effect down-flow evaporation system. The unpowered automatic liquid-transferring method is characterized in that liquid-level difference exists between the triple-effect evaporator (5) and the scratching-plate type evaporator (7), and simultaneously the boiling circulation speed of glue solution in the triple-effect evaporator is accelerated, so that the vacuum degree of the triple-effect evaporator is less than that of the scratching plate type evaporator, a water column between the triple-effect evaporator and the scratching plate type evaporator and with the vacuum-degree pressure difference being more than or equal to 100mm forms differential pressure; and glue solution in the triple-effect evaporator is automatically transferred into the scratching type evaporator under the action of pressure difference power. The unpowered automatic liquid-transferring method has the advantages that concentrated glue is suctioned to the scratching type evaporator for further evaporation and concentration from the triple-effect evaporator by utilizing the power formed by vacuum pressure difference, and automatic liquid transferring between the triple-effect evaporator and the scratching-plate type evaporator in the evaporation procedure without mechanical power is realized, so that the energy consumption in the production process of the tanning extracts is reduced and the production efficiency is improved.

Owner:陈晓程

Lead melting copper removal refining process for industrial frequency coreless-type electric induction furnace

ActiveCN103540762BNo emissionsMeet the technical requirements of the processPhotography auxillary processesProcess efficiency improvementElectrolytic agentSlag

Owner:SHAANXI ZINC IND

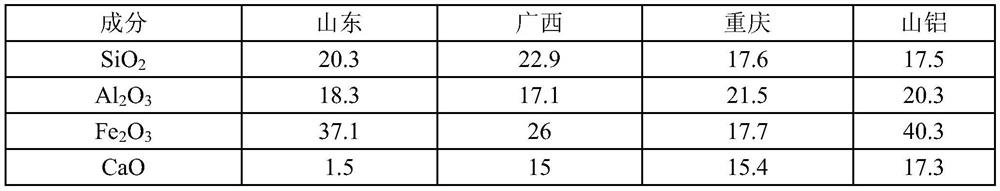

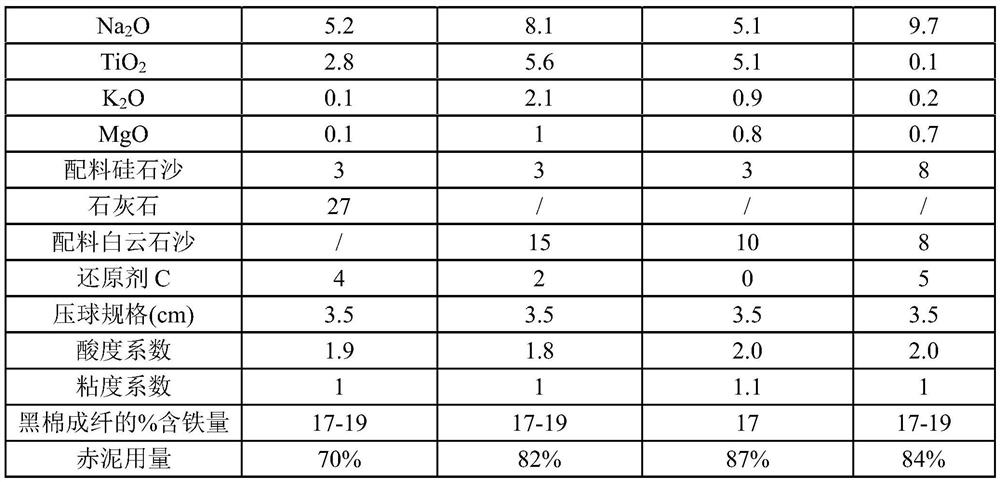

Method for producing fireproof black cotton by using red mud

PendingCN114804611ASolving the need to mine minesSolve environmental problemsGlass making apparatusFiberMetallurgy

The invention relates to a method for producing fireproof black cotton by using red mud, and belongs to the technical field of comprehensive utilization of solid waste resources. Comprising the following steps: (1) burdening; (2) mixing and pelletizing; (3) drying / preheating dehydration; (4) melting; (5) discharging; during material melting, the melting temperature is controlled to be 1450-1650 DEG C. According to the method disclosed by the invention, the content of iron in the fiber is effectively controlled and improved by burdening the Bayer process red mud, burdening the Bayer process red mud and mixing the Bayer process red mud and the sintering process red mud and controlling the MK value, the MB value, the furnace temperature and the reducing agent parameters, so that the red mud can be comprehensively utilized to produce fireproof black cotton series products.

Owner:王进

A device and method for recovering C2 in refinery dry gas

ActiveCN104830371BHigh recovery rateHigh purityDispersed particle separationGaseous mixture working upRefluxDesorption

The invention discloses a device of recycling C2 from refinery dry gas, which includes a PSA unit, a compression unit and an oil absorption unit. The PSA unit includes a first-section PSA device. The compression unit includes a compressor and a liquid separation pot. An inlet of the first-section PSA device is communicated with the raw material dry gas and an outlet of the first-section PSA device is communicated with the inlet of the compressor. The outlet of the compressor is communicated with the inlet of the liquid separation pot. The invention is advantaged in that firstly the raw material dry gas is subjected to primary concentration in the first-section PSA device being low in energy consumption, and then the PSA concentrated gas is further concentrated through an adsorption / desorption method being high in recycle rate and product purity, wherein the temperature of fed gas material, an absorbent and top reflux are all 40 DEG C in the absorption unit. By means of circulated cooling water, the cooling condensation temperature can be achieved without any refrigerating device. By means of the compressed condensate as the absorbent, it is unnecessary to feed a C4 absorbent from other apparatus. The invention also discloses a method of recycling C2 from the refinery dry gas.

Owner:BEIJING YANSHAN YULONG PEC

Energy-saving monitoring system

ActiveCN100477587CHigh energy consumptionGood compensationEnergy efficient ICTElectric signal transmission systemsThermal energyData acquisition

The invention discloses an energy-saving monitoring system, which comprises a plurality of data acquisition devices, a synthesis tester connected with the data acquisition devices, and a background computer connected with the synthesis tester; the data acquisition devices comprise electric data acquisition devices, heat energy data acquisition devices, and other devices, and are connected with the synthesis tester through bus lines; the synthesis tester comprises a CPU unit, and a data storage unit, a data statistic unit, data computing unit, a bus interface unit, and a long-distance data transmission unit which are connected with the CPU unit; the background computer comprises a data collecting unit, a data storage Unit, and an energy-saving analysis unit connected with the long-distance data transmission unit of the synthesis tester through the data collecting unit by adopting long-distance transmission means. The invention can effectively reduce the energy source waste through the monitoring to the energy consumption condition, thus realizing the preliminary behavior energy conservation; and completes energy saving renovation and realizes technical energy conservation by using technical means.

Owner:BEIJING JIUZHOU HENGSHENG CONSTR ENG

Method for preparing high purity oxygen by double-tower low temperature rectification

InactiveCN101148252BWide source of oxygenSimple processSolidificationLiquefactionOxygen contentTower

The present invention provides double tower low temperature rectification process of preparing high purity oxygen. Industrial liquid oxygen material with oxygen content of 99.6 % is low temperature rectified in two structured packing towers to obtain electronic industry level high purity oxygen of oxygen content not lower than 99.9998 % and impurity contents including N2 not more than 0.5 ppm, CH4 not more than 0.1 ppm, H2O not more than 0.1 ppm, and Ar not more than 0.5 ppm. The process of preparing high purity oxygen has best utilization of energy, low cold loss, low power consumption and low cost, and is suitable for industrial production.

Owner:WUHAN HUAXING IND & TECH +1

A precise gas concentration control device for injection-assisted sintering method and its control method

ActiveCN108088252BImprove adaptabilityReduce energy consumption indexFurnace typesControl devices for furnacesProcess engineeringGas concentration

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Equipment and method for purifying nitrogen from polluted nitrogen with high extraction rate and low energy consumption

ActiveCN104048478BHigh extraction rateReduce the evaporating side temperatureSolidificationLiquefactionNitrogenTower

The invention discloses a method for extracting pure nitrogen from polluted nitrogen high in extraction rate and low in energy consumption. The method includes the following steps that polluted nitrogen enters a main tower and then conducts heat and mass transfer with top-to-bottom liquid on a tower plate or fillers in the main tower from bottom to top, part of pressure is pumped out at the tower top, and the polluted nitrogen serves as a product after being reheated through a main heat exchanger; after polluted liquid nitrogen discharged from the bottom of the main tower enters a subcooler to be cooled through the subcooler, polluted nitrogen evaporated from a main tower condenser is sent to a secondary tower, the polluted nitrogen conducts heat and mass transfer with top-to-bottom liquid on a tower plate or fillers in the secondary tower from bottom to top, the polluted nitrogen generated at the tower top is condensed through a secondary tower condenser, part of the condensed liquid returns to the secondary tower to serve as backflow liquid, and the other part of the liquid enters the main tower to serve as backflow liquid; the polluted nitrogen evaporated from the secondary tower condenser is reheated through the subcooler and the main heat exchanger, and then is sent to a polluted nitrogen compressor to be recycled and utilized. According to the method, the amount of the nitrogen extracted from the polluted nitrogen is higher than the amount of the nitrogen extracted from the air, and the nitrogen extraction rate reaches more than 90%.

Owner:ZHEJIANG DACHUAN AIR SEPARATION PLANT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com