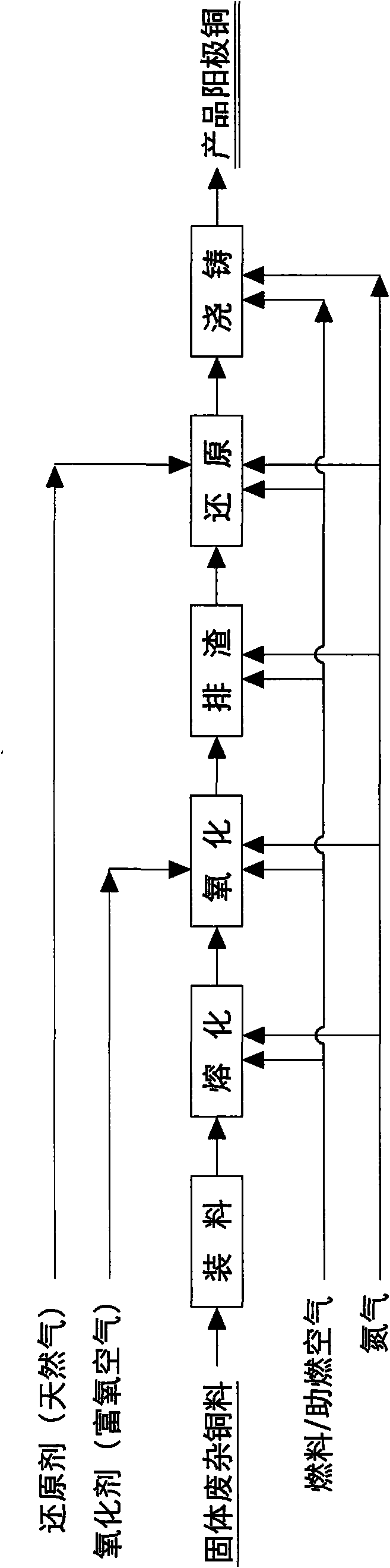

Process and apparatus thereof for refining copper scraps by using nitrogen gas stirring and oxygen-enriched oxygen gas

A technology for oxygen-enriched gas and waste copper, which is applied in the field of recycled copper metallurgy, can solve the problems of poor oxidative removal effect of impurities, poor adaptability of charge materials, low heat and mass transfer capacity of melt, etc., and is beneficial to environmental protection and production. The effect of improving efficiency and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

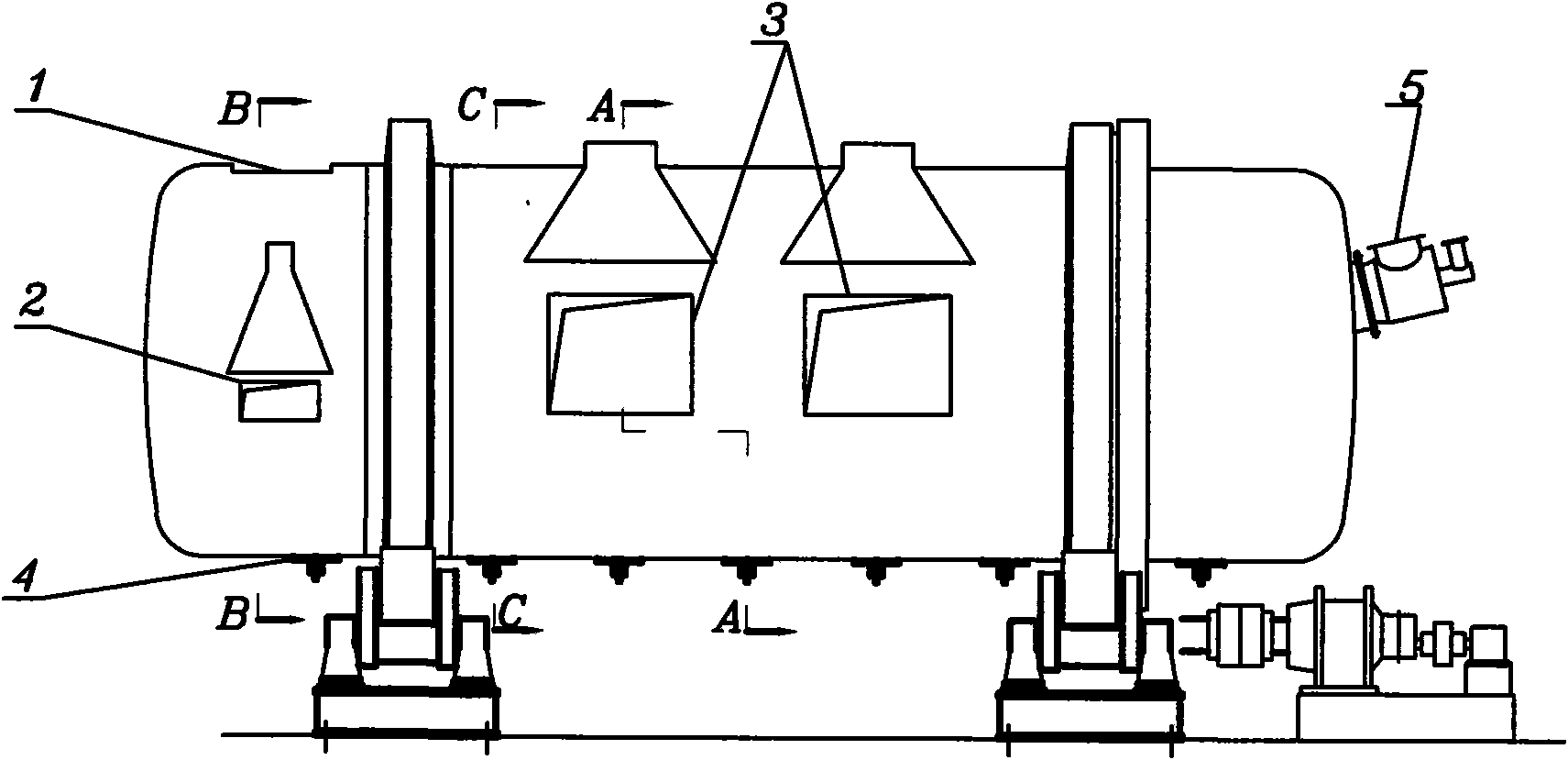

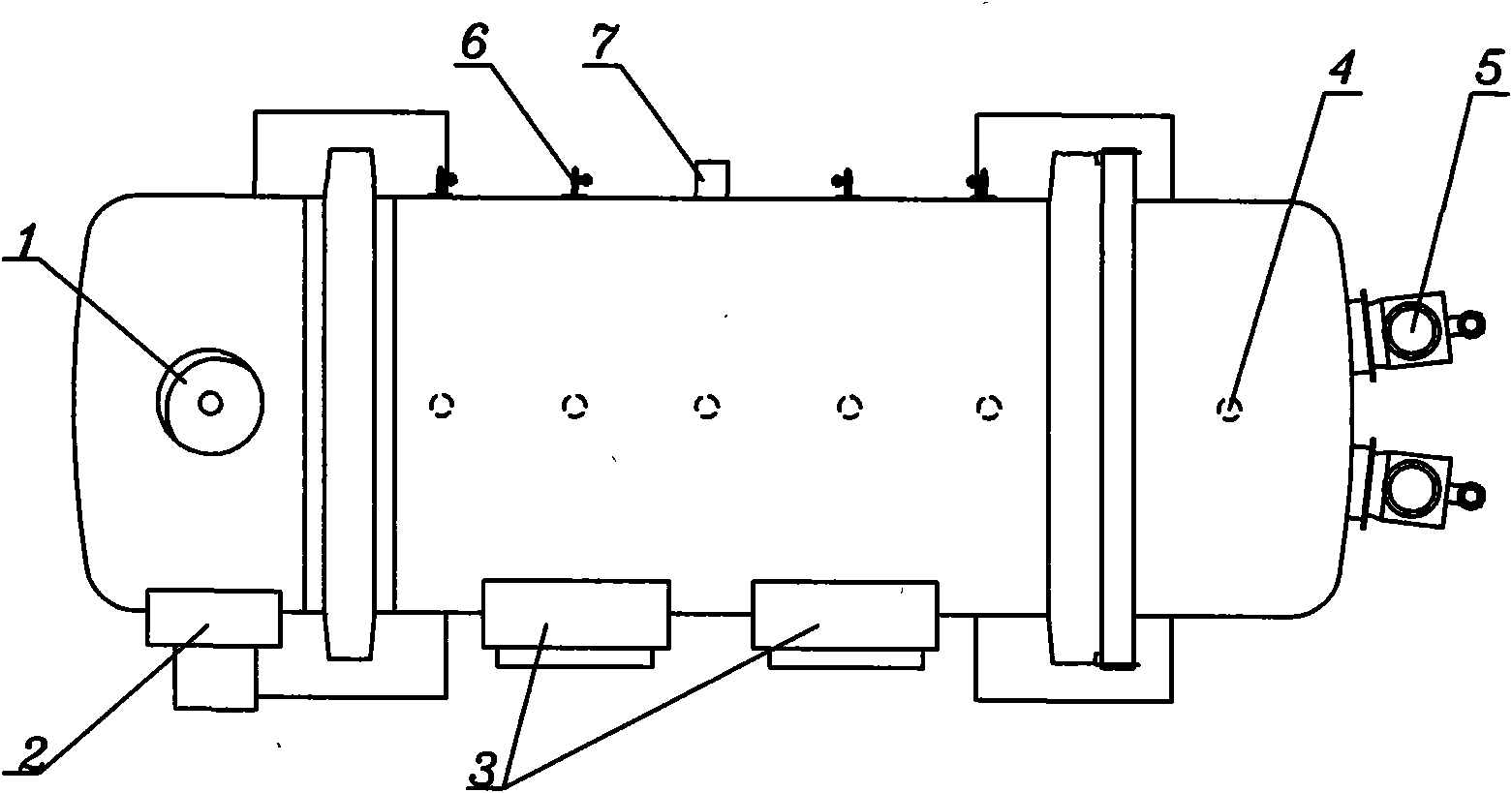

[0022] As one of the process implementation cases: the equipment can adopt a rotatable cylindrical furnace, and the axis of the furnace body is arranged horizontally. The furnace body has 2 horizontal feeding ports 3; a slag outlet 2; a copper outlet 7; and 1 or 2 burner holes on the end cover of the furnace body. 4; On the top of the other side of the burner end, there is an exhaust hole 1 for exhausting the flue gas; on the furnace body, there are several redox ports 5 that can be quickly replaced (determined according to the number); the bottom of the furnace There are several microporous devices 4 for nitrogen gas to enter. There are rolling rings, ring gears, supporting wheels and driving devices on the furnace body. The end cover is equipped with burners that can burn heavy oil, natural gas and other fuels and can use oxygen-enriched wind to support combustion.

[0023] The steps of the process for treating solid copper waste:

[0024] a. Charging: Use charging equipme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com