Unpowered automatic liquid-transferring method in production and evaporation procedures of tanning extracts

A power and process technology, which is applied in the field of unpowered automatic liquid transfer in the evaporation process of tannin extract production, can solve the problem of large energy consumption for liquid transfer, and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

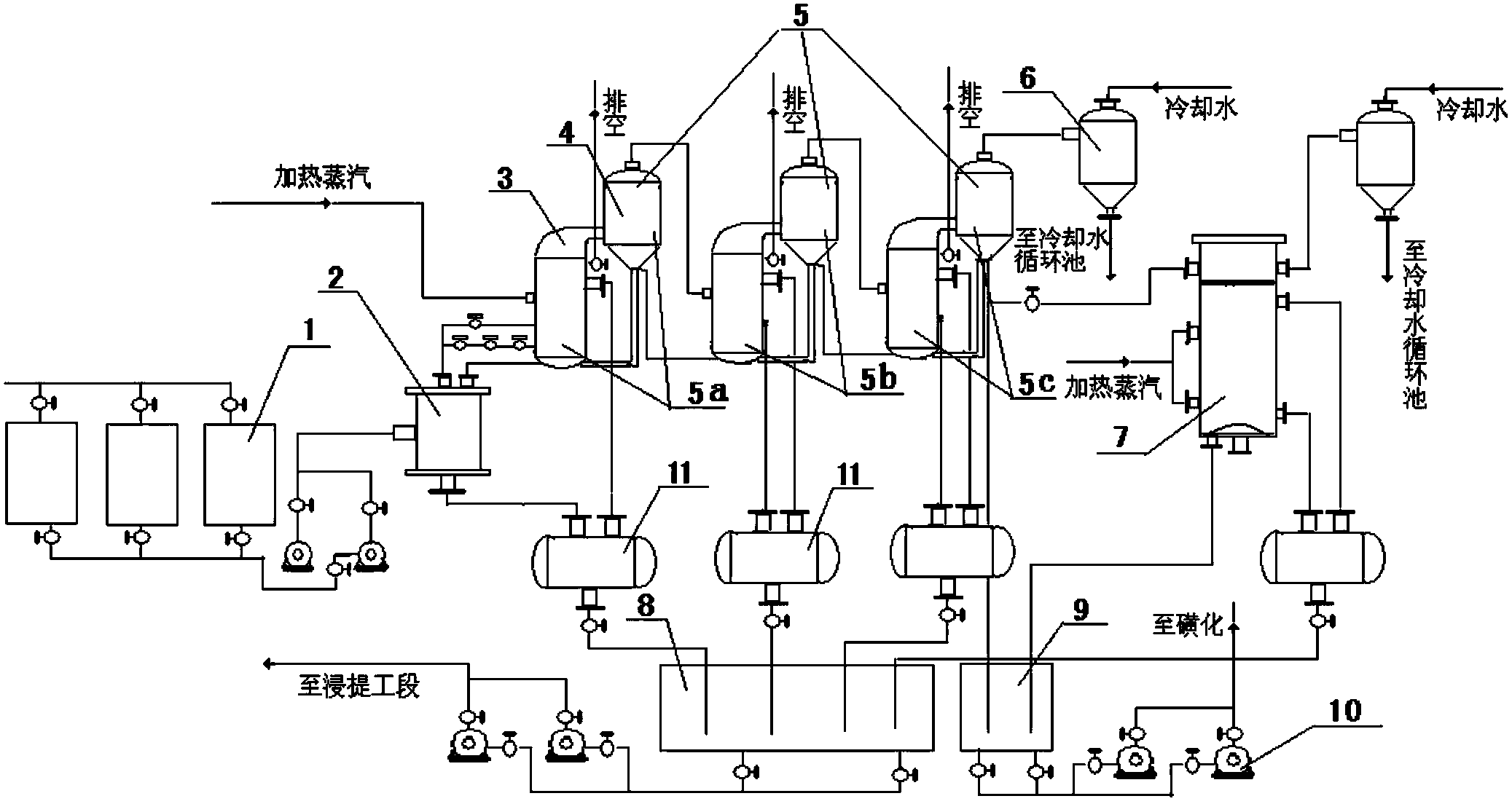

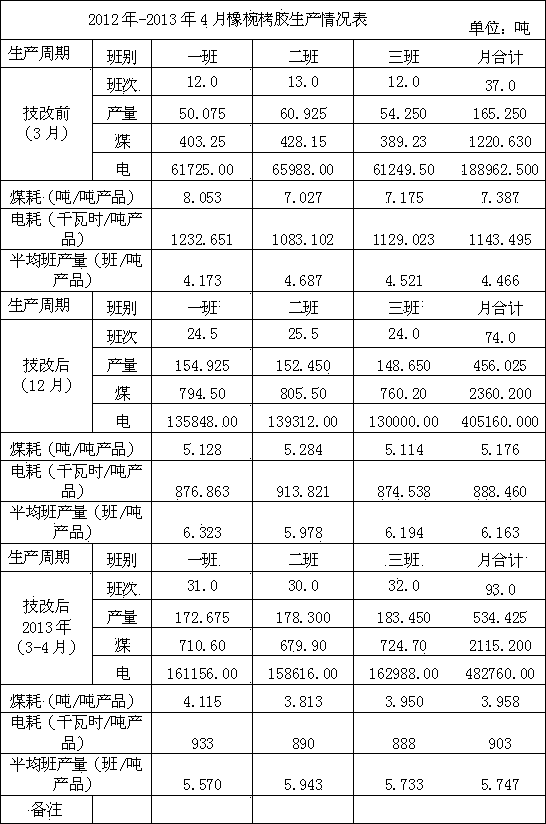

[0019] The system used in the unpowered automatic liquid transfer method of the extract production evaporation process in this embodiment includes: an extraction liquid storage tank 1, an extraction liquid spiral plate heater 2, an evaporator heating chamber 3, and an evaporator separation chamber 4, Three-effect evaporator 5, first-effect evaporator 5a, second-effect evaporator 5b, third-effect evaporator 5c, water jet condenser 6, scraper-type evaporator 7, steam resistance and drainage tank 8, condensed water storage tank 9 , thick glue tank 10, centrifugal pump 11, see the specific system structure diagram figure 1 . After the tannin extraction liquid enters the extraction liquid storage tank 1, it is pumped into the extraction liquid spiral plate heater 2 through the centrifugal pump 11, and the evaporated tannin extract liquid enters the three-effect evaporator (5) and the scraper type evaporation A four-effect down-flow evaporation system connected with the device (7)....

Embodiment 2

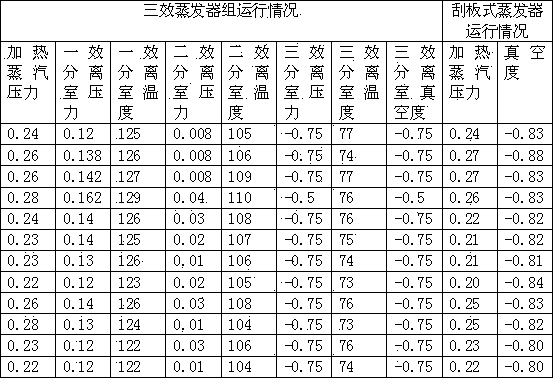

[0022] The system used in the unpowered automatic liquid transfer method of the extract production evaporation process in this example is the same as that described in Example 1. The method of automatic liquid transfer without power during the evaporation process is: there is a liquid level difference of 2 to 3 meters between the three-effect evaporator (5) and the scraper evaporator (7), and at the same time accelerate the boiling cycle speed of the glue in the three-effect evaporator, so that The vacuum degree of the three-effect evaporator is lower than that of the scraper-type evaporator. The vacuum degree of the three-effect evaporator is about -750mm water column, and the vacuum degree of the scraper-type evaporator is about -900mm water column. The vacuum degree and pressure difference between the two The pressure difference power is formed for the 150mm water column, and the glue in the three-effect evaporator is automatically transferred to the scraper evaporator u...

Embodiment 3

[0024] The system used in the unpowered automatic liquid transfer method of the extract production evaporation process in this example is the same as that described in Example 1. The method of automatic liquid transfer without power during the evaporation process is: there is a liquid level difference of 2 to 3 meters between the three-effect evaporator (5) and the scraper evaporator (7), and at the same time accelerate the boiling cycle speed of the glue in the three-effect evaporator, so that The vacuum degree of the three-effect evaporator is lower than that of the scraper-type evaporator. The vacuum degree of the three-effect evaporator is about -900mm water column, and the vacuum degree of the scraper-type evaporator is about -1000mm water column. The vacuum degree and pressure difference between the two The pressure difference power is formed for the 100mm water column, and the glue in the three-effect evaporator is automatically transferred to the scraper type evapor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com