Patents

Literature

90results about How to "Reduce evaporation energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

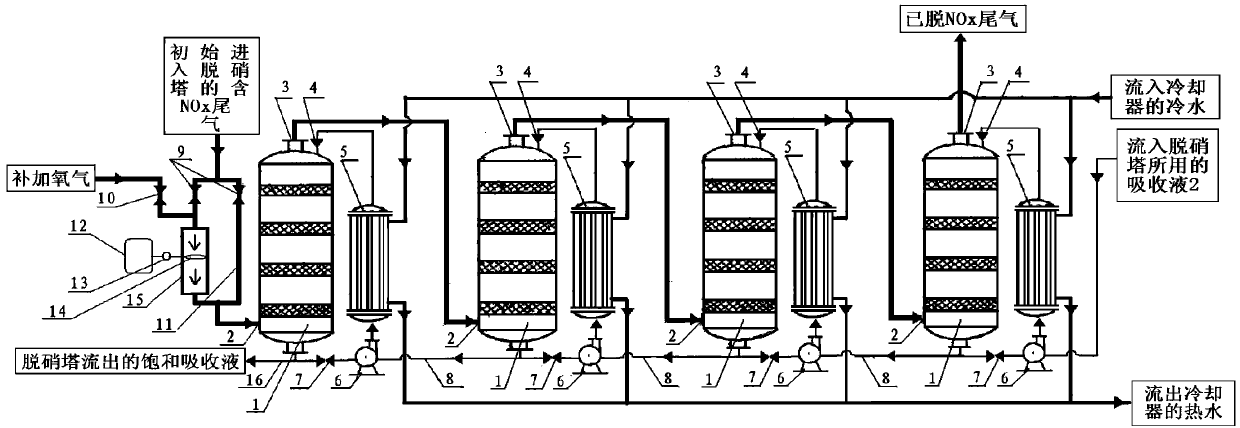

Desulfurization and denitrification method for tail gas, used equipment and product application thereof

InactiveCN105080307AReduce material costsLow costOther chemical processesDispersed particle separationCorrosion preventionChemistry

The present invention discloses a desulfurization and denitrification method for tail gas, used equipment and product application thereof. According to the method provided by the present invention, an oxidative catalyst is not used in a desulfurization column or a denitration column, or a small amount of the oxidative catalyst with a simplified formula added is used outside the desulfurization column and the denitration column, so that the cost is reduced significantly. The oxidative catalyst is not used in the desulfurization column or the denitration column to avoid the severe corrosion of the desulfurization column and denitration column texture by the material, so that the texture cost of the desulfurization column and the denitration column is reduced significantly; The volume of the processed material is small: only 30%-10% of the material in volume in the desulfurization column and the denitration column, and the cost for equipment corrosion prevention is lowered, so that a small amount of the oxidative catalyst used and a simplified formula can be facilitated.

Owner:陈汇宏 +2

Production method of cement-based grouting material

The invention provides a production method of a cement-based grouting material. The method comprises the steps that aggregate and / or a binding material are mixed with a liquid additive, weight ratio of the aggregate and / or the binding material with the liquid additive in the mixture is (90-110) : (0.1-30); the obtained mixture is subjected to a drying process and can be mixed with polymer rubber powder which can re-disperse to obtain the cement-based grouting material. According to the production method, a liquid additive which is not easy to dehydrate and dry, which relates to polycarboxylate superplasticizer particularly, can be dried easily, the performance of the additive can be retained to the greatest extent, the aggregate or the binding material which is subjected to preprocessing of the liquid additive is mixed into other materials according to a specified proportion of the cement-based grouting material, and a cement-based grouting material product with good performance can be produced.

Owner:SHANGHAI TAIJIE CHEM

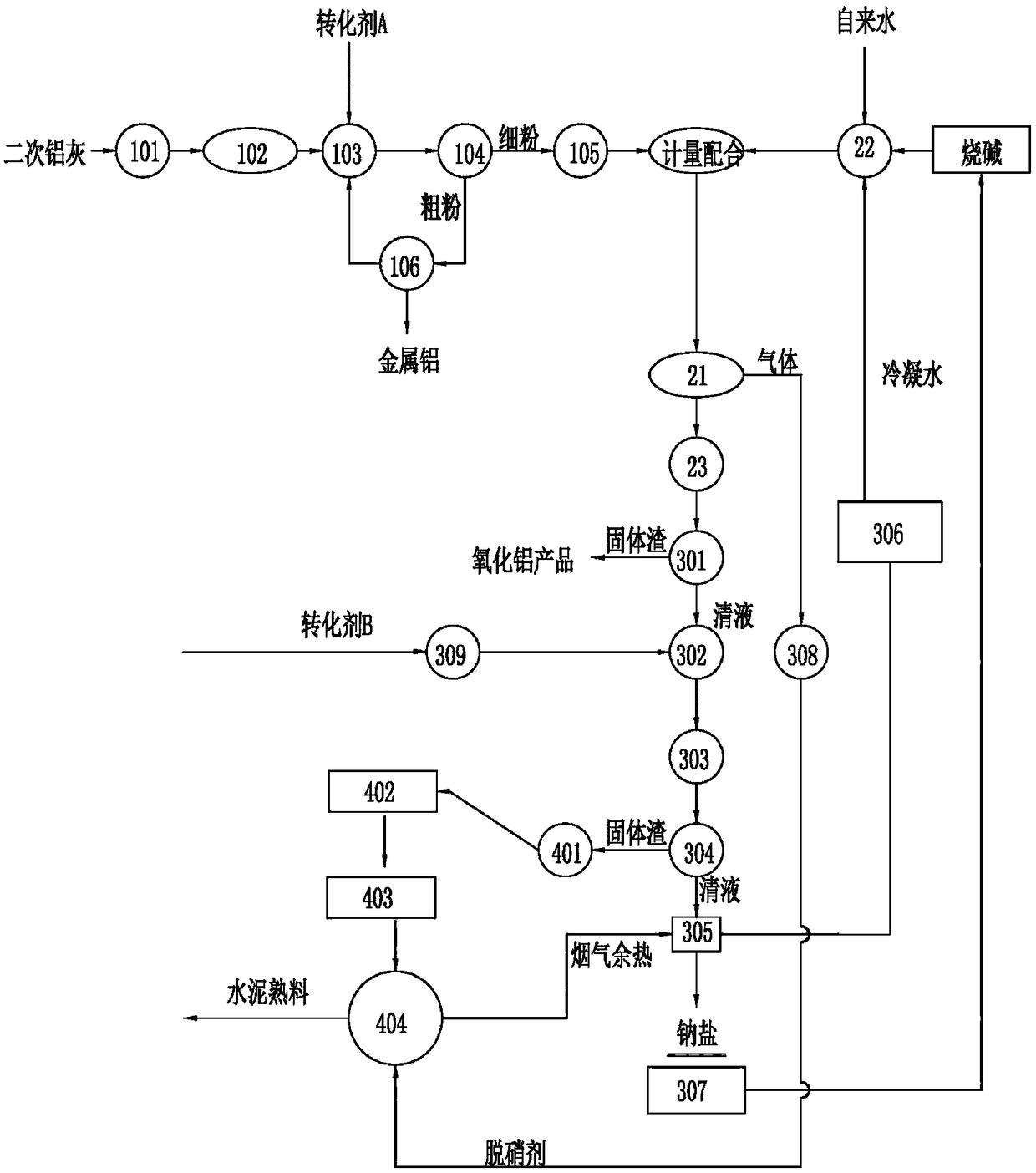

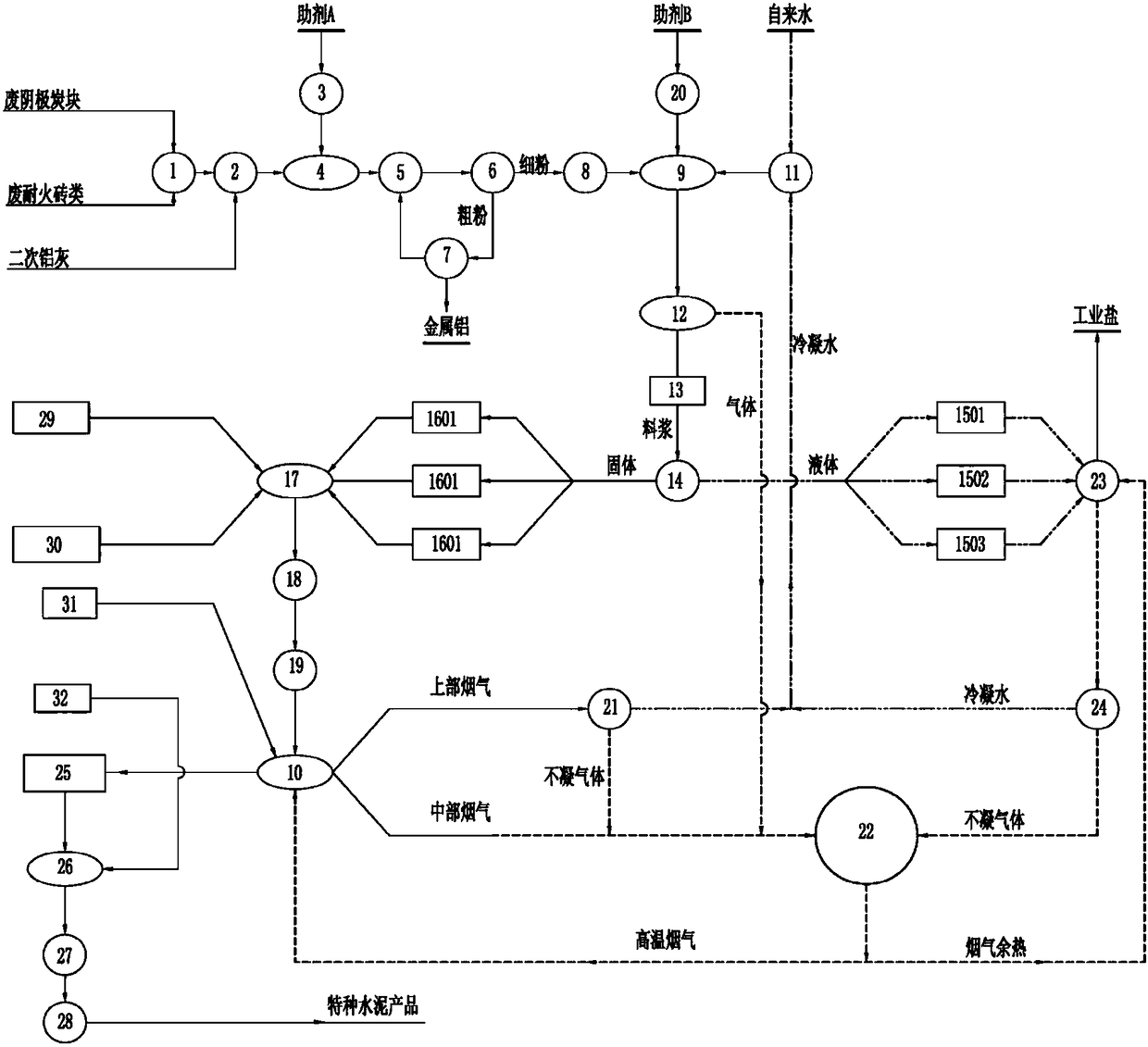

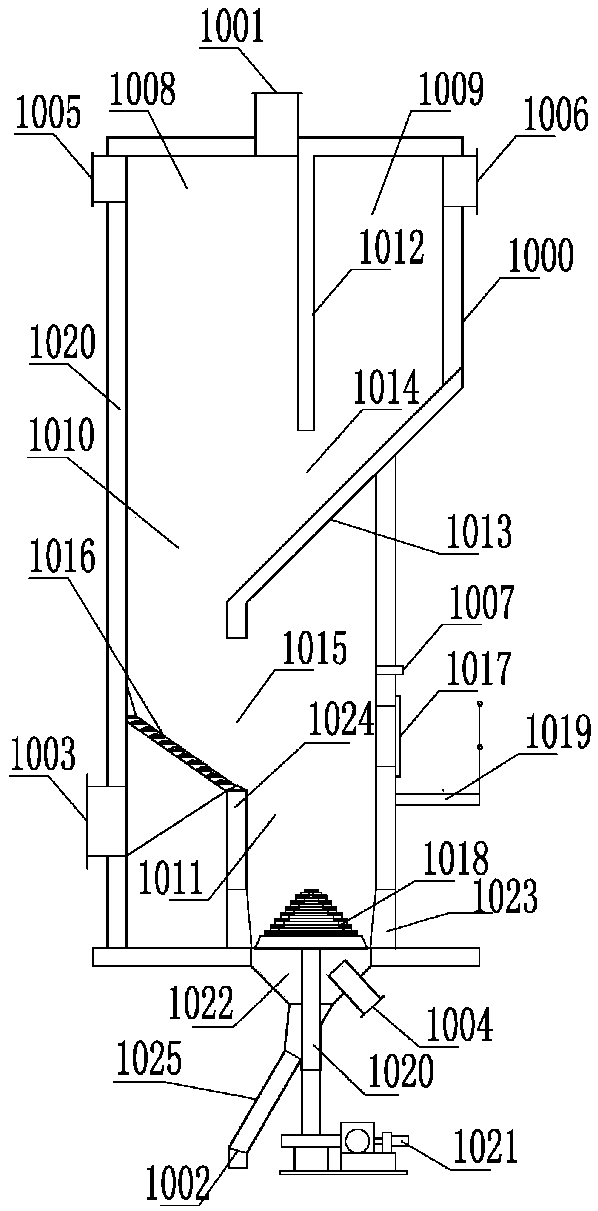

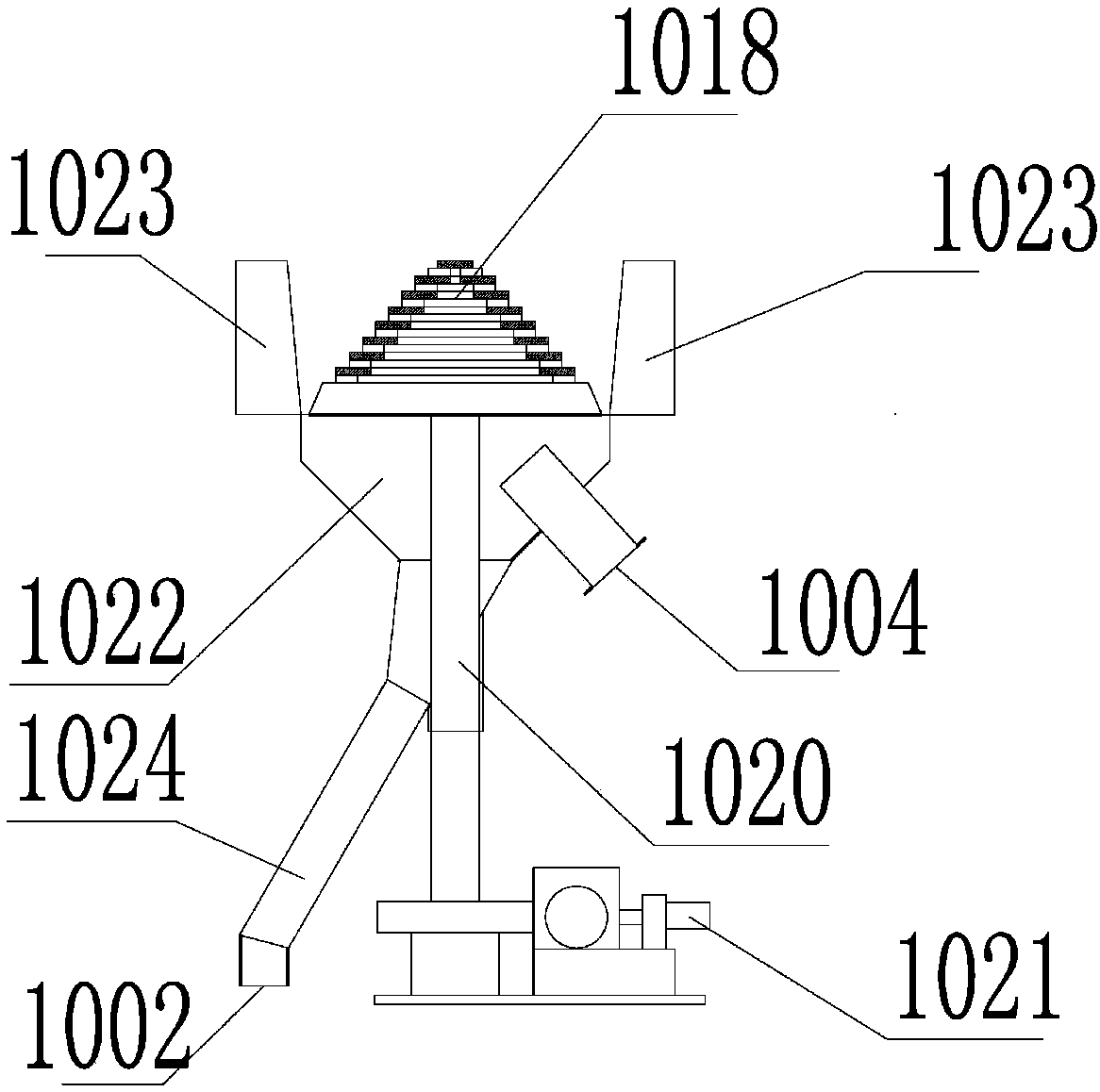

System and method for cooperatively processing secondary aluminum ash by virtue of cement kiln

PendingCN108773849AEliminate toxicityEliminate Toxic HazardsCement productionAlkali metal hydroxidesPre treatmentWet grinding

The invention provides a system and a method for cooperatively processing secondary aluminum ash by virtue of a cement kiln. The system comprises a waste residue preprocessing system, an anaerobic wet-grinding conversion system, an alkali metal salt leaching system and a cement kiln resourceful treatment system which are sequentially connected, wherein all equipment and connecting pipelines in thesystem are sealed, and a suction machine is arranged so as to generate a micro-negative pressure. The method comprises the following steps: (S1) secondary aluminum ash preprocessing, (S2) anaerobic wet-grinding conversion, (S3) alkali metal salt leaching, and (S4) cement kiln resourceful treatment. According to the system and the method, the harmless and resourceful final treatment of the secondary aluminum ash can be realized, 0.1t-0.3t of alkali metal salt, 0.02t-0.1t of caustic soda and 0.5t-0.8t of aluminum oxide byproducts can be extracted during the treatment of 1t of secondary aluminumash, and 0.2t-0.3t of cement raw materials and 0.05t-0.2t of a denitration agent can be provided for a cement plant. By utilizing an anaerobic wet-grinding conversion machine, H2 and CH4 generated inthe conversion process do not burn and explode, the disinfection and conversion of solid waste residue materials can be realized, and converted gas can be extracted.

Owner:长沙中硅环保科技有限公司

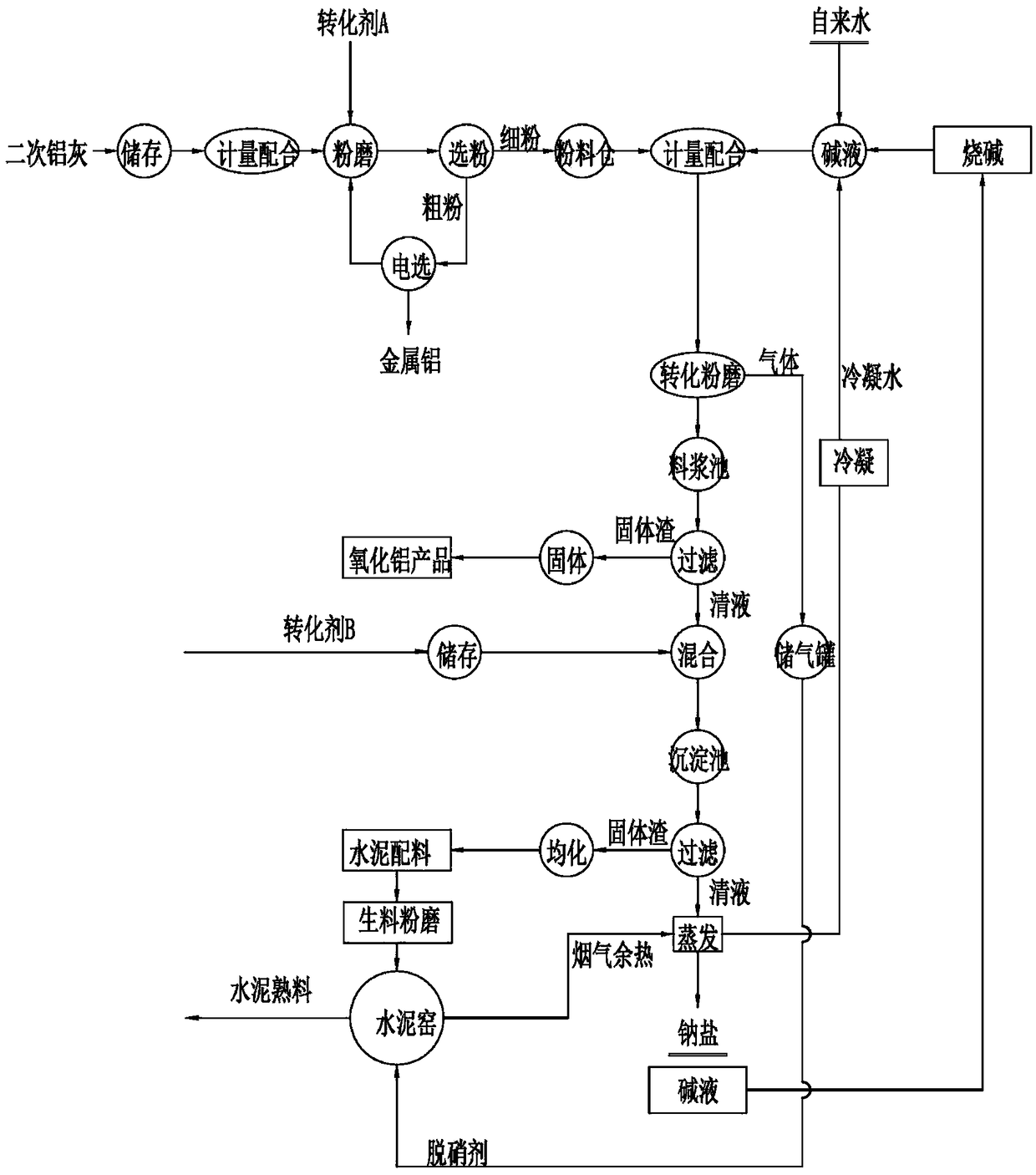

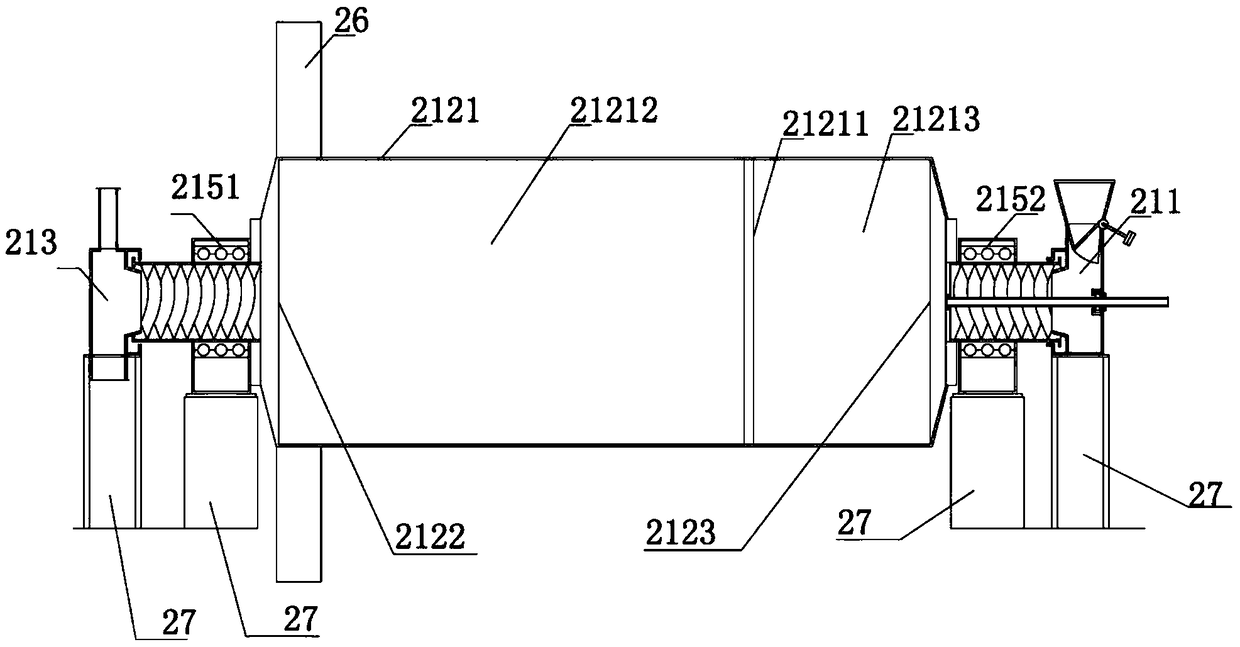

System and method to treat electrolytic aluminum waste residue and co-produce quick-setting quick-hardening cement under cooperation of cement kiln

The invention provides a system and method to treat electrolytic aluminum waste residue and co-produce quick-setting quick-hardening cement under cooperation of a cement kiln, wherein the system comprises a waste residue pretreatment system, a conversion reaction system, an alkaline metal salt extraction system and a cement kiln-based parallel production system of quick-setting quick-hardening cement, which are connected in sequence; all units in the system are hermetically connected, and a suction unit is provided to form micro negative pressure. The method comprises the steps: waste residuepretreatment; conversion reaction; extraction of alkaline metal salts and cement-kiln-based parallel production of quick-setting quick-hardening cement. The system and method herein have the advantages that electrolytic aluminum industrial waste residue can be centrally and uniformly treated at a time to eliminate its toxicity and hazard, and harmless, resourceful and final treatment of the electrolytic aluminum waste residue is achieved. The system and method are also capable of producing special quick-setting quick-hardening cement under low energy consumption and low cost, with no three wastes discharged and no secondary pollution caused.

Owner:长沙中硅环保科技有限公司 +1

Alumina mother liquor MVR circulation evaporation device and process

InactiveCN105540626AImprove qualityIncreased capacity of evaporation processAluminium oxides/hydroxidesVapor–liquid separatorEvaporation

The present invention provides an alumina mother liquor MVR circulation evaporation device and process, technical features are as follows: seed precipitation mother liquor first enters a preheater for heat exchange with vapor condensate water, then enters an evaporator for evaporation, and then enters a vapor-liquid separator; vapor flows out from the top of the vapor-liquid separator, then enters a vapor compression machine to form secondary vapor by temperatures and pressure increase under the effect of the vapor compression machine, and re-enters the evaporator to form a vapor circulation loop; at the same time, the separated mother liquor flows out from the bottom of the vapor-liquid separator, one part of the separated mother liquor flows again back to the evaporator to form a mother liquor circulation loop, and the other part of the separated mother liquor is discharged from a discharge port. The alumina mother liquor MVR circulation evaporation device can be used for alumina mother liquor circulation evaporation, and improves the quality of alumina evaporation mother liquor; the secondary vapor and the condensate water both can be recycled, the evaporation energy consumption is effectively reduced, and the producing capacity of the evaporation process can be improved.

Owner:SUZHOU CNPT SOURCETECH ENVIRONMENTAL TECH

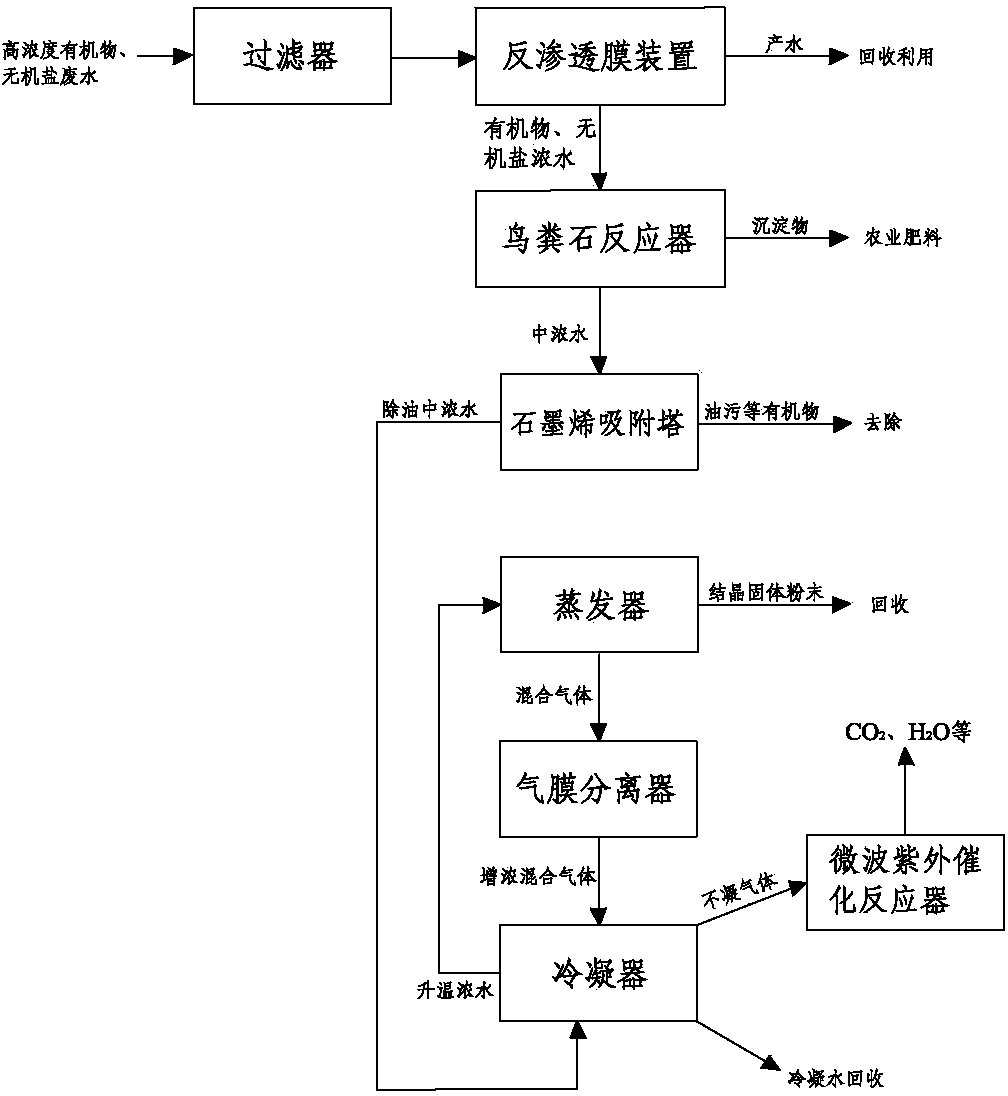

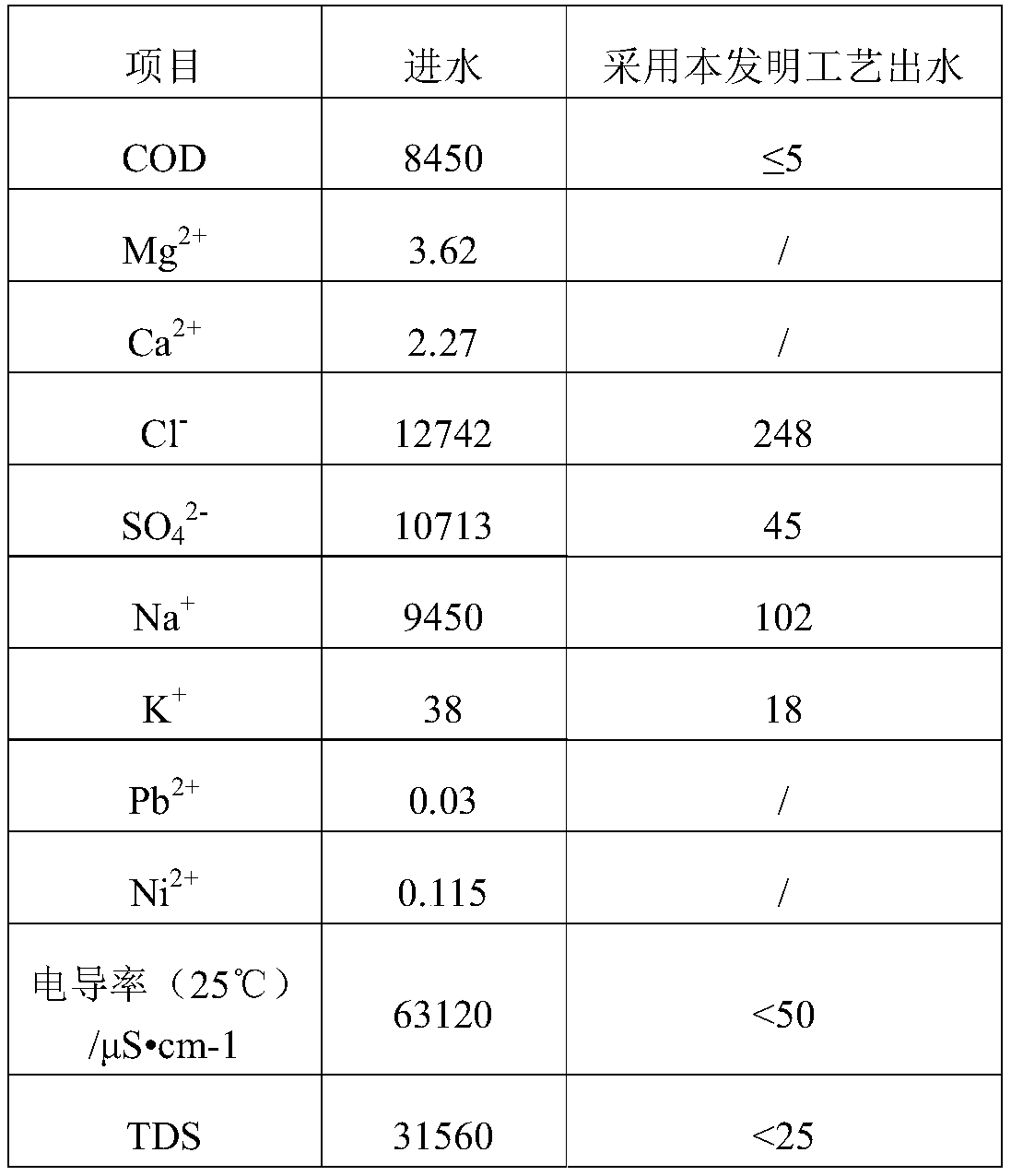

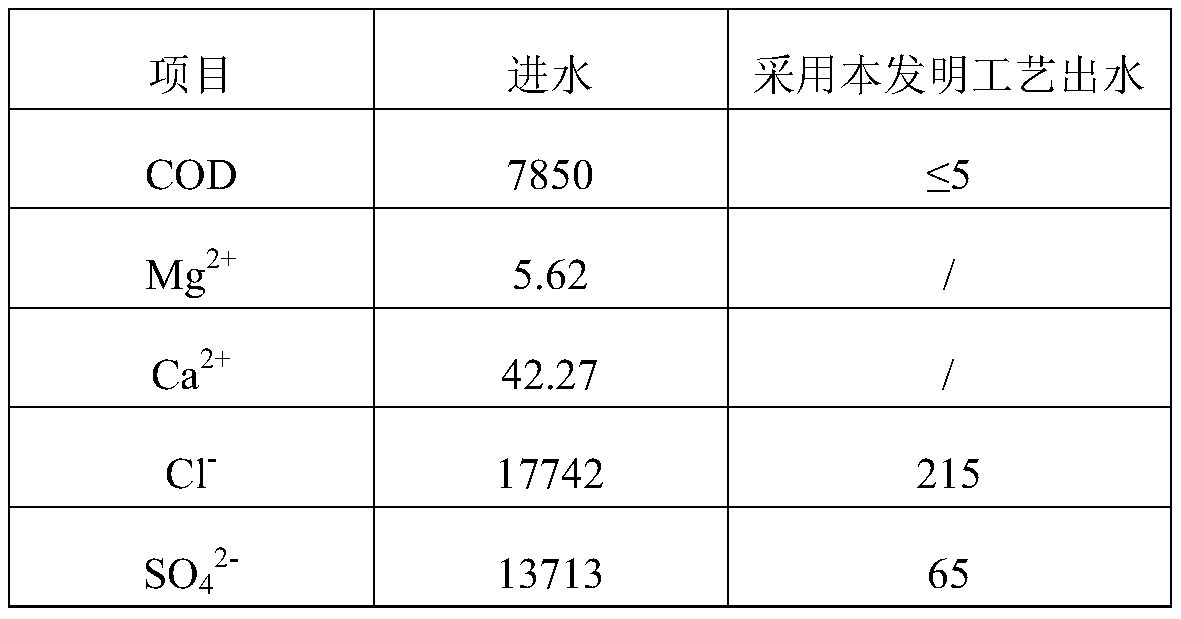

Method for treating wastewater containing high-concentration organic matters and inorganic salts

ActiveCN104058540AReduce pollutionImprove resource recyclingDispersed particle separationWater/sewage treatment bu osmosis/dialysisMagnesium saltFiltration

The invention relates to the technical field of sewage treatment and in particular relates to a method for treating wastewater containing high-concentration organic matters and inorganic salts. The method comprises the following steps: feeding the wastewater into a filter and a reverse osmosis membrane device for treatment, thus obtaining produced water and concentrated water; feeding the concentrated water into a struvite reactor and then adding a proper quantity of magnesium salt, MgO and phosphates to the struvite reactor, thus obtaining an agricultural fertilizer and medium concentrated water; feeding the medium concentrated water into a graphene adsorption tower for adsorption filtration, thereby removing organic matters such as oil contamination; feeding the medium concentrated water with oil contamination removed into an evaporator to obtain a crystalline slid powder and mixed gases; feeding the mixed gases into a gas membrane separator for separation, thus obtaining pure water and thickened mixed gases; feeding the thickened mixed gases into a condenser for condensation treatment, thus obtaining water and non-condensable gases; feeding the non-condensable gases into a microwave ultraviolet catalytic reactor for decomposition, thus obtaining CO2 and H2O. The method is capable of effectively treating the wastewater containing high-concentration organic matters and inorganic salts, and further is simple in process, hardly causes environmental pollution and is capable of changing waste into things of value.

Owner:DONGGUAN SANRENXING ENVIRONMENTAL TECH CO LTD

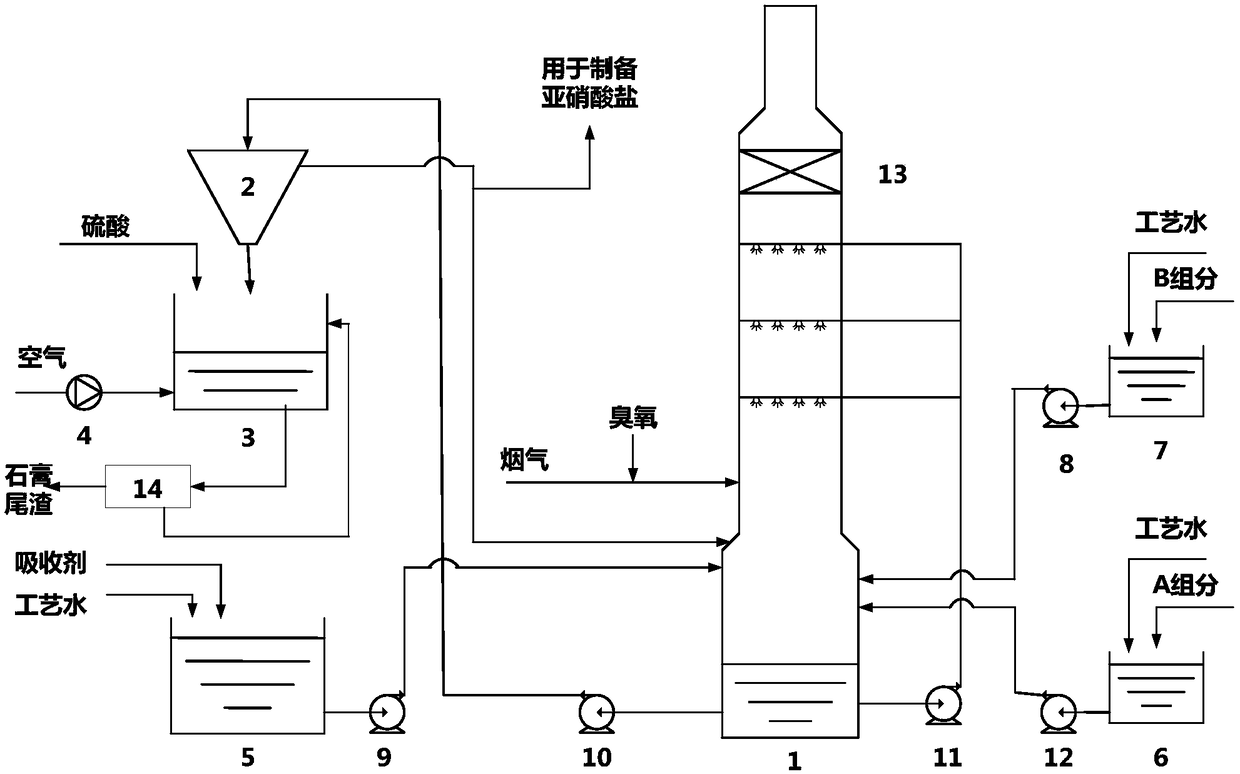

Technology for enhancing low temperature flue gas while performing desulfurization and denitrification by using combined additive

InactiveCN108159862AHigh removal rateEfficient removalDispersed particle separationAir quality improvementNitrite ionSorbent

The invention provides a technology for enhancing low temperature flue gas while performing desulfurization and denitrification by using a combined additive. Flue gas is firstly mixed with ozone, andNO in the flue gas is oxidized into NO2. The oxidized flue gas enters an absorption tower and is in contact with slurry containing a calcium-based sorbent and the combined additive, and SO2 and Nox inthe flue gas are removed. The purified flue is demisted through a demister and then is discharged. The addition of combined additive significantly improves the NOx removal efficiency, promotes NOx tobe converted into nitrite in an orientated manner, and high denitration ratio can still be kept in a condition of high accumulated concentration of nitrite ion, and the technology is beneficial to the reducing of the resource recycling cost of nitrite. The technology has the advantages of small amount of ozone, high NOx removal rate and low comprehensive cost, and is suitable for low-cost desulfurization and denitrification of low temperature flue gas from coke ovens, sintering and industrial boilers.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

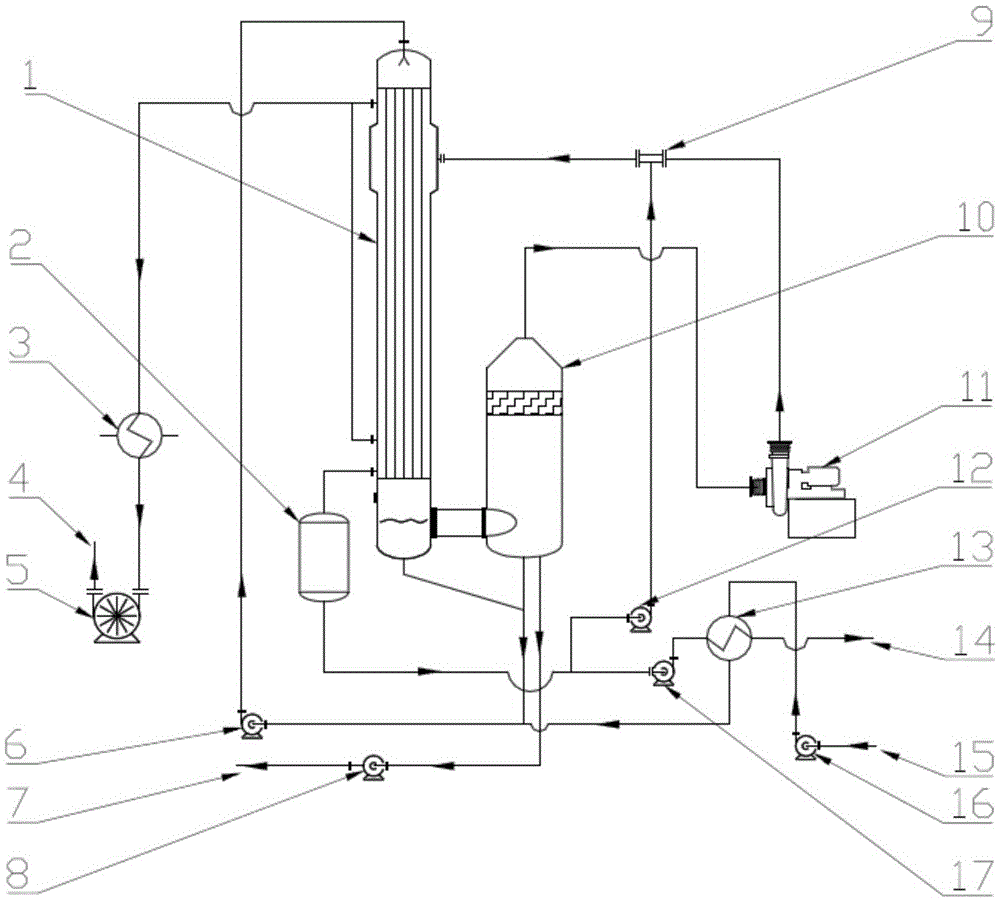

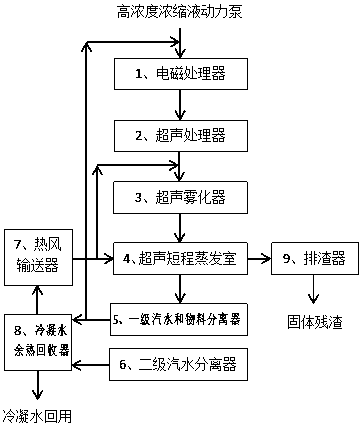

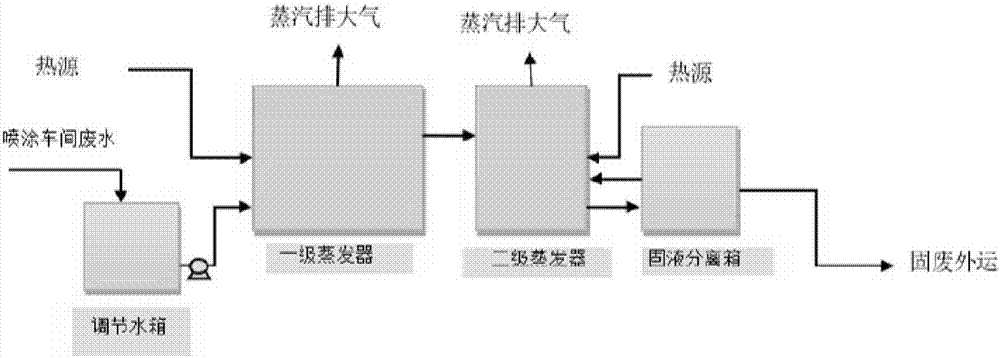

Fast evaporation system and method used for high-salt wastewater

ActiveCN107555699AEliminate hazardsImprove evaporation efficiencyEvaporator accessoriesMultistage water/sewage treatmentBurn treatmentShortest distance

The invention discloses a fast evaporation system used for high-salt wastewater. The system includes a feeding pump, an electromagnetic processor, an ultrasonic processor, an ultrasonic atomizer, an ultrasonic short-distance evaporating chamber, a steam-water and material separator, an air dehumidifier, a dry-air conveyer, an ultrasonic spiral deflector and a residue discharging device. The ultrasonic spiral deflector includes a spiral deflector and a first ultrasonic transducer, wherein the spiral deflector is arranged at the middle part of the ultrasonic short-distance evaporating chamber, and the first ultrasonic transducer is arranged at the external wall of the ultrasonic short-distance evaporating chamber and is connected to the spiral deflector, and the electromagnetic processor isarranged above the spiral deflector and includes a vertically-arranged titanium alloy pipe. Correspondingly, the invention further provides a fast evaporation method for high-salt wastewater. The problem that high-salt wastewater is poor in flowability and quite prone to scale is solved, the high-salt wastewater can be continuously efficiently dried till a water content suitable for burning treatment is reached in one time, and the hazard of the high-salt wastewater is totally removed.

Owner:SHANGHAI BIANJIE ENVIRONMENTAL PROTECTION TECH CO LTD

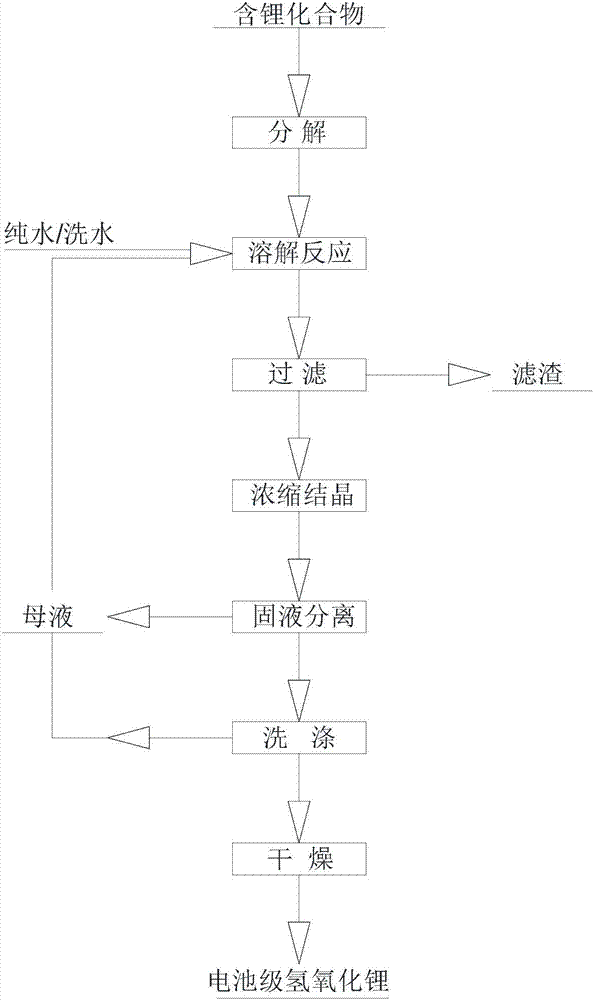

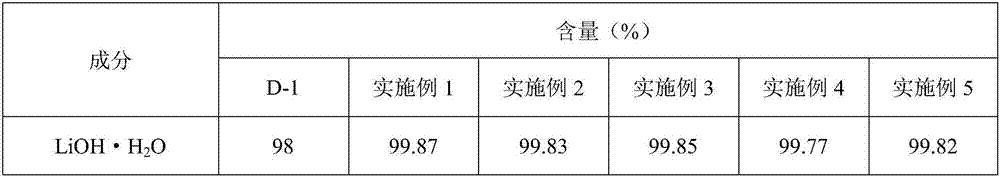

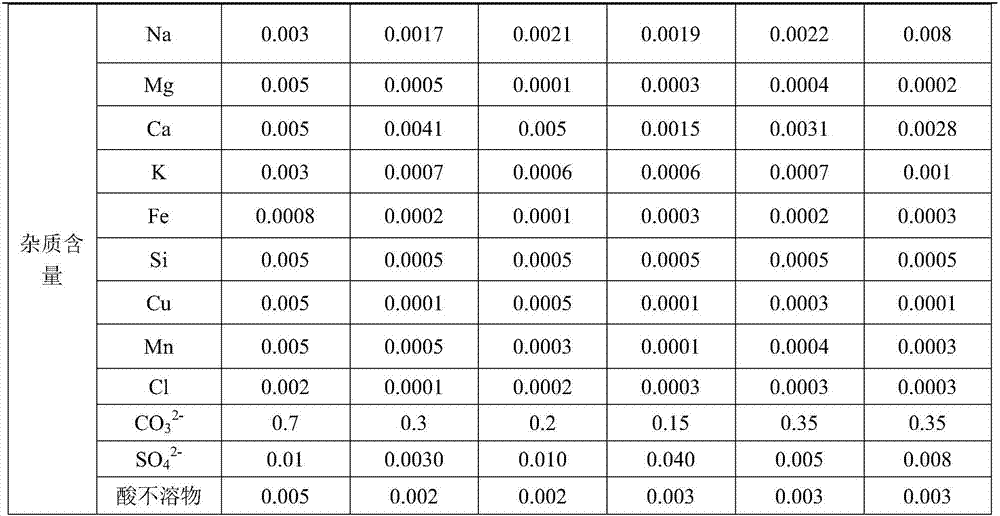

Producing process of battery-level lithium hydroxide

ActiveCN107055575AReduce the introductionHigh purityCell electrodesLithium oxides/hydroxidesLithium oxideLithium hydroxide

The invention provides a producing process of battery-level lithium hydroxide, and belongs to the technical field of lithium hydroxide. The producing process includes the steps that A, a lithium-containing compound is placed into a decomposing furnace to be decomposed; B, the product obtained in the step A and water react to generate a lithium hydroxide solution; C, the lithium hydroxide solution obtained in the step B is filtered; D, the filter liquor obtained in the step C is evaporated, concentrated and crystallized until the solid content is 5-10%, and crystal is cooled; E, solid-liquid separation and washing are carried out on the crystal slurry obtained in the step D; F, the lithium hydroxide crystal obtained in the step E is dried to obtain the battery-level lithium hydroxide. The lithium-containing compound is decomposed first and reacts with the water solution to generate lithium hydroxide, the raw material comprises the lithium-containing compound only, and introduction of impurities such as calcium and magnesium is reduced; the lithium hydroxide solution formed by lithium oxide dissolution approaches saturation, energy consumption for follow-up evaporation and concentration is low, and production cost is effectively reduced; side reaction is avoided, the lithium yield is high, the obtained product is high in purity and quality.

Owner:CHENGDU CHEMPHYS CHEM IND

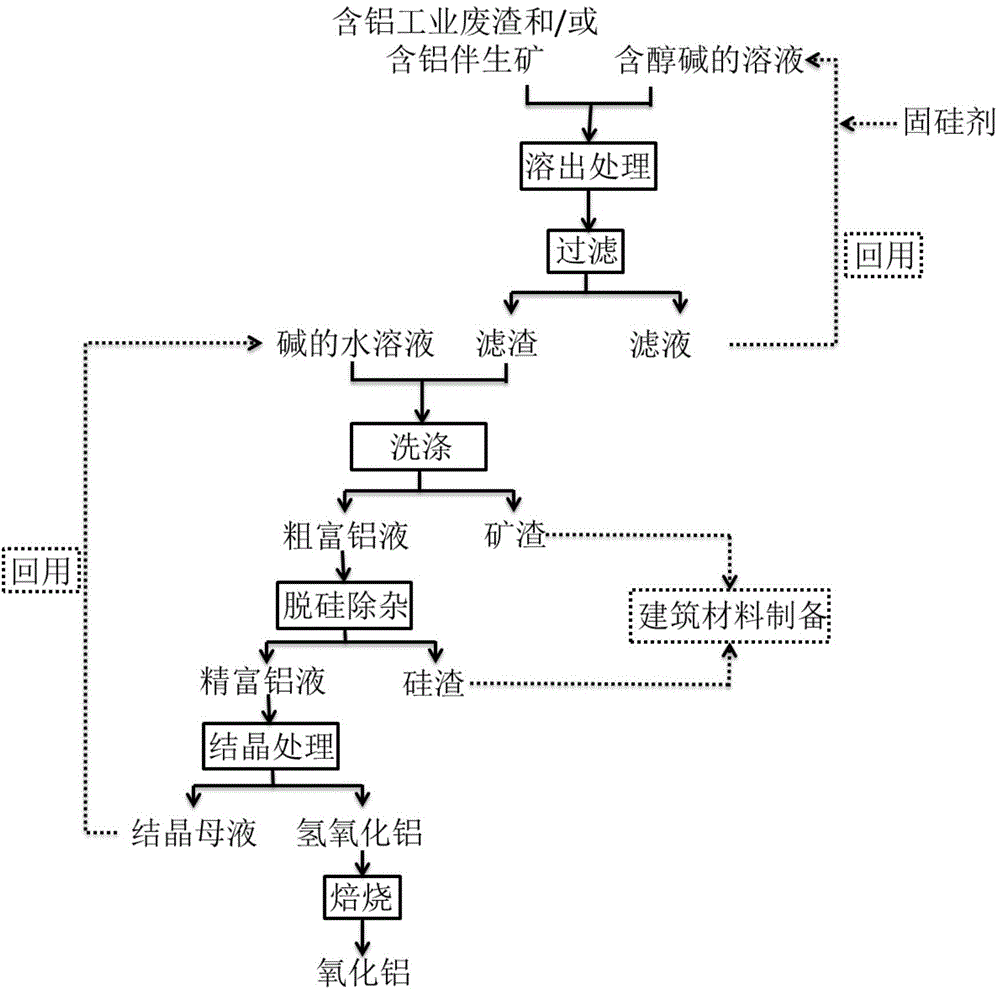

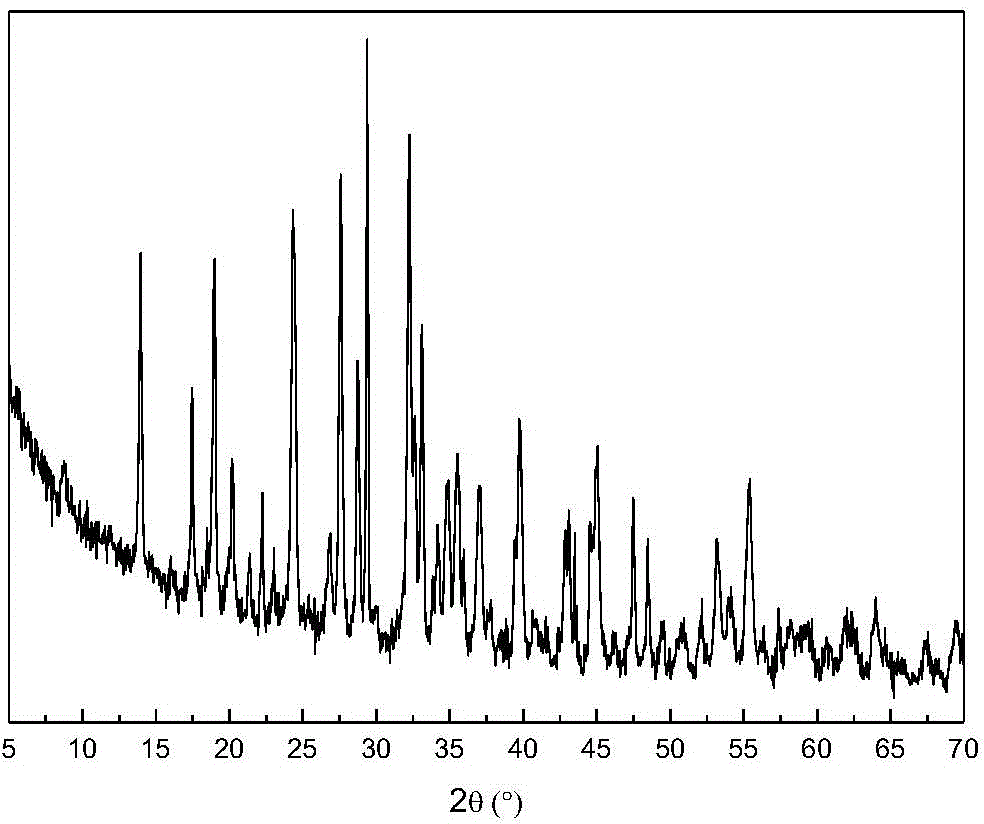

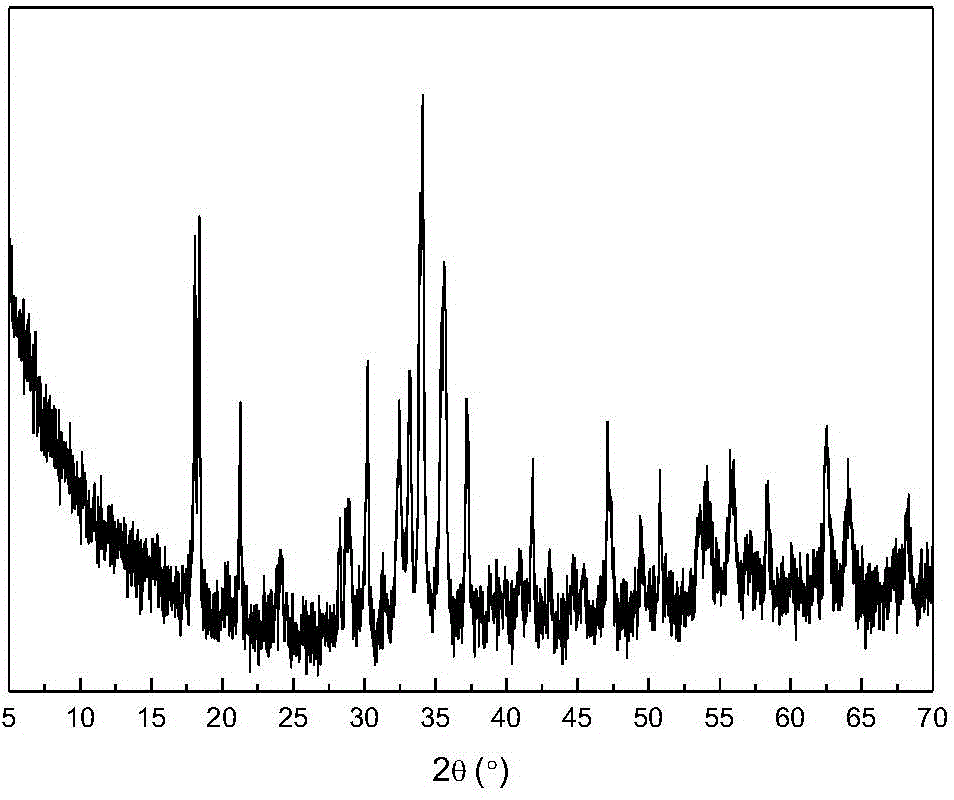

Method for recovering alumina

ActiveCN106032285AHigh recovery rateImprove separation efficiencySolid waste disposalAluminium oxides/hydroxidesRecovery methodAlcohol

The invention discloses a method for recovering alumina. The method comprises: dissolving out industrial waste containing aluminum and / or associated ore containing aluminum in a solution containing alcohol-alkali; and conducting washing, silicon impurity removal, crystallization treatment and roasting treatment to obtain alumina. Compared with the existing alumina recovery method, the alumina recovery method of the present invention has higher recovery rate and lower energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

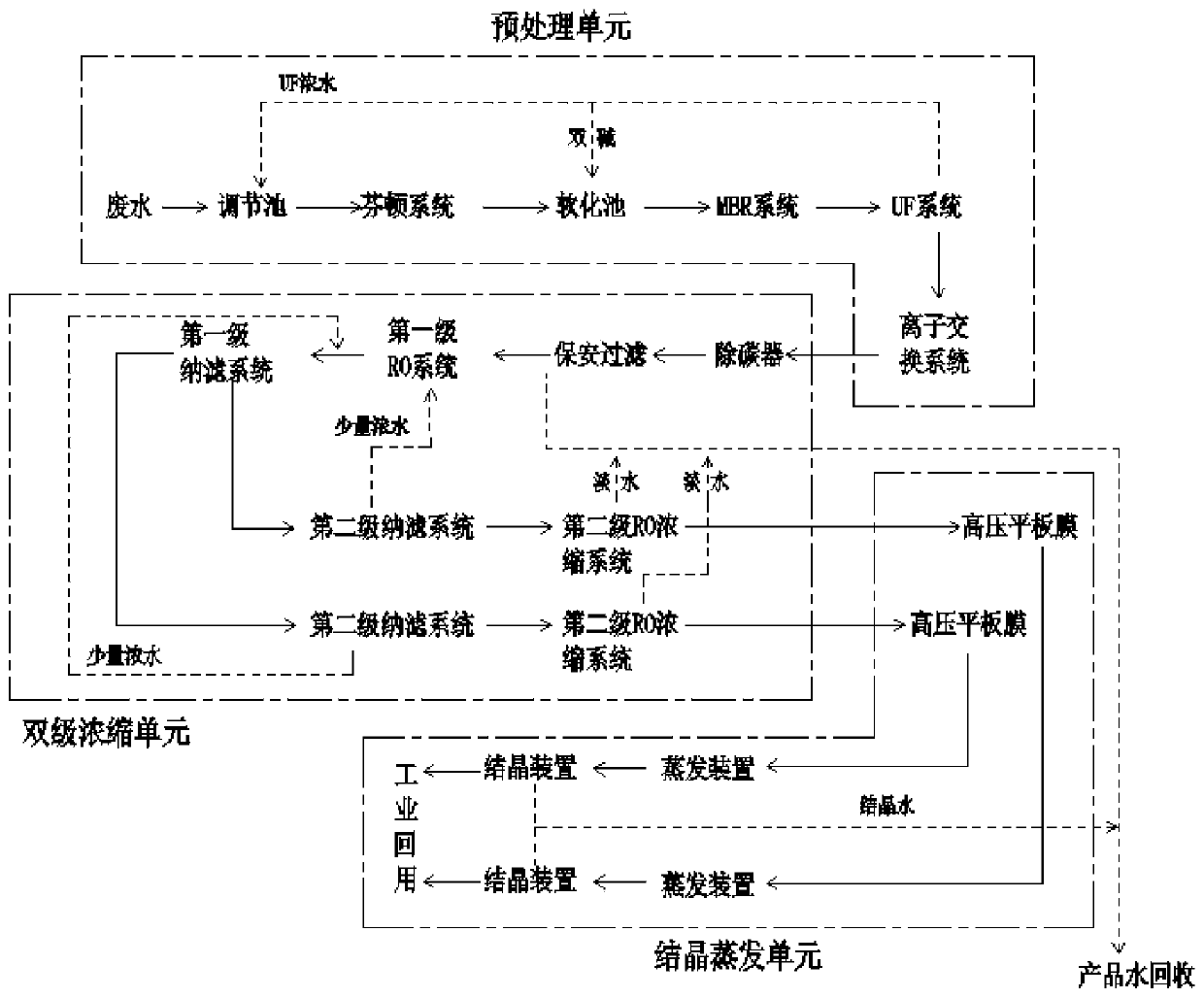

High-salt high-COD wastewater recovery zero-discharge system and technology

ActiveCN110526512AHigh salt separation efficiencyIncrease the concentration factorWater treatment compoundsWater/sewage treatment by ion-exchangeHigh concentrationWastewater

The invention discloses a high-salt and high-COD wastewater recovery zero-discharge technology which comprises the following steps: 1, pre-treating high-salt high-COD wastewater to remove COD, total nitrogen, SS and heavy metal ions; 2, carrying out double-stage concentration on pretreated wastewater by adopting RO-NF-NF-RO concentration so as to obtain a high-concentration Na2SO4 solution and a high-concentration NaCl solution; and 3, filtering the high-concentration Na2SO4 solution and the NaCl solution by adopting a high-pressure flat sheet membrane, and evaporating and concentrating to obtain crystalline salt with the purity of higher than 99%. According to the technology, high-salinity wastewater is progressively treated step by step, no wastewater is discharged in the whole process,characteristic target pollutants can be removed, the water inlet requirement of the next step reaction can be guaranteed, and the wastewater recovery rate of the system process is close to 100%.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

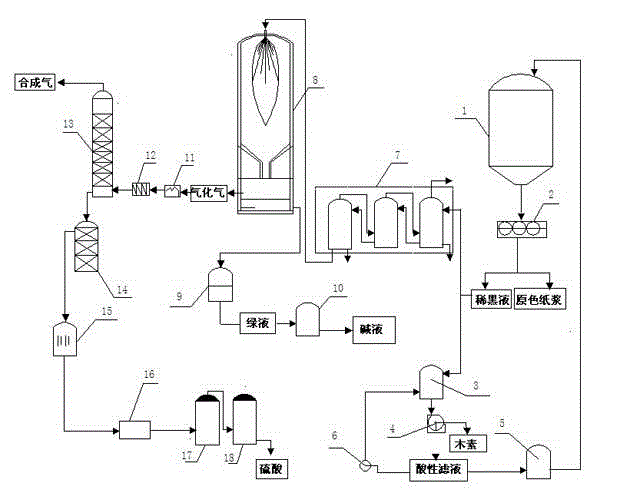

Black liquor treatment method combining lignin extraction and synthesis gas production

ActiveCN102943404AReduce evaporation energy consumptionReduce energy consumptionRegeneration of alkali lyeChemistryEvaporator

The invention discloses a black liquor treatment method combining lignin extraction and synthesis gas production. The method comprises the following steps: lignin extraction, acidic filtrate recycling, dilute black liquor evaporation and concentration, black liquor gasification, alkali fusant dissolution, green liquor causticization, gasified gas desulfurization, and sulfuric acid preparation. Dilute black liquor produced by boiling is divided into two parts; 30-50 wt% of the dilute black liquor is subjected to lignin extraction; part of the acidic filtrate generated from lignin extraction separation is used for acidification of the dilute black liquor, and the other part is subjected to alkalization, and used as a cooking liquor; 50-70 wt% of the dilute black liquor is conveyed into an evaporator for concentration to obtain 60-75% strong thick black liquor, which is sprayed into a gasification furnace for gasification, so as to obtain alkali liquor containing sodium hydroxide and sodium sulfide, and sulfuric acid. The method provided by the invention can recycle lignin (extraction rate of 30-50%) and alkaline substances (recycling rate of 80-90%) from the black liquor, produce synthesis gas and sulfuric acid for recycling within the system, and save energy by 5-10%.

Owner:GUANGXI UNIV

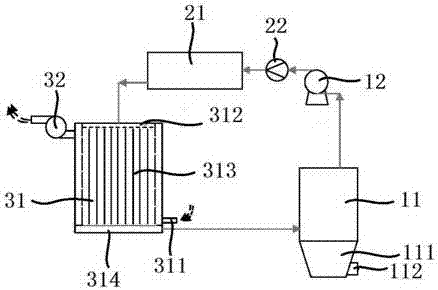

Low-energy treatment method of high-density hydrometallurgical process wastewater

InactiveCN101525197AReduce the temperatureReduce evaporation energy consumptionGeneral water supply conservationWaste water treatment from metallurgical processMulti effectEngineering

The invention relates to a method for treating wastewater, in particular to a method for treating hydrometallurgical process wastewater, and pertains to the field of energy saving, emission reducing and environmental protection. The method utilizes solar energy or boiler residual heat to preheat high-density hydrometallurgical process wastewater; then the wastewater is sent to a multi-effect evaporator for at least trifle-effect vacuum continuous evaporation and flash crystallization under 0.01MPa to 0.09 MPa vacuum degree; part of the steam after the previous evaporation sequentially enters into the next evaporator and is utilized as the heat source; the condensed hot condensate of evaporators at all levels is recycled. The invention solves the problem that the high-density hydrometallurgical process wastewater is difficult to treat. The invention also has low energy consumption and the complex salt products after evaporation and crystallization can be reutilized.

Owner:KUNMING METALLURGY INST

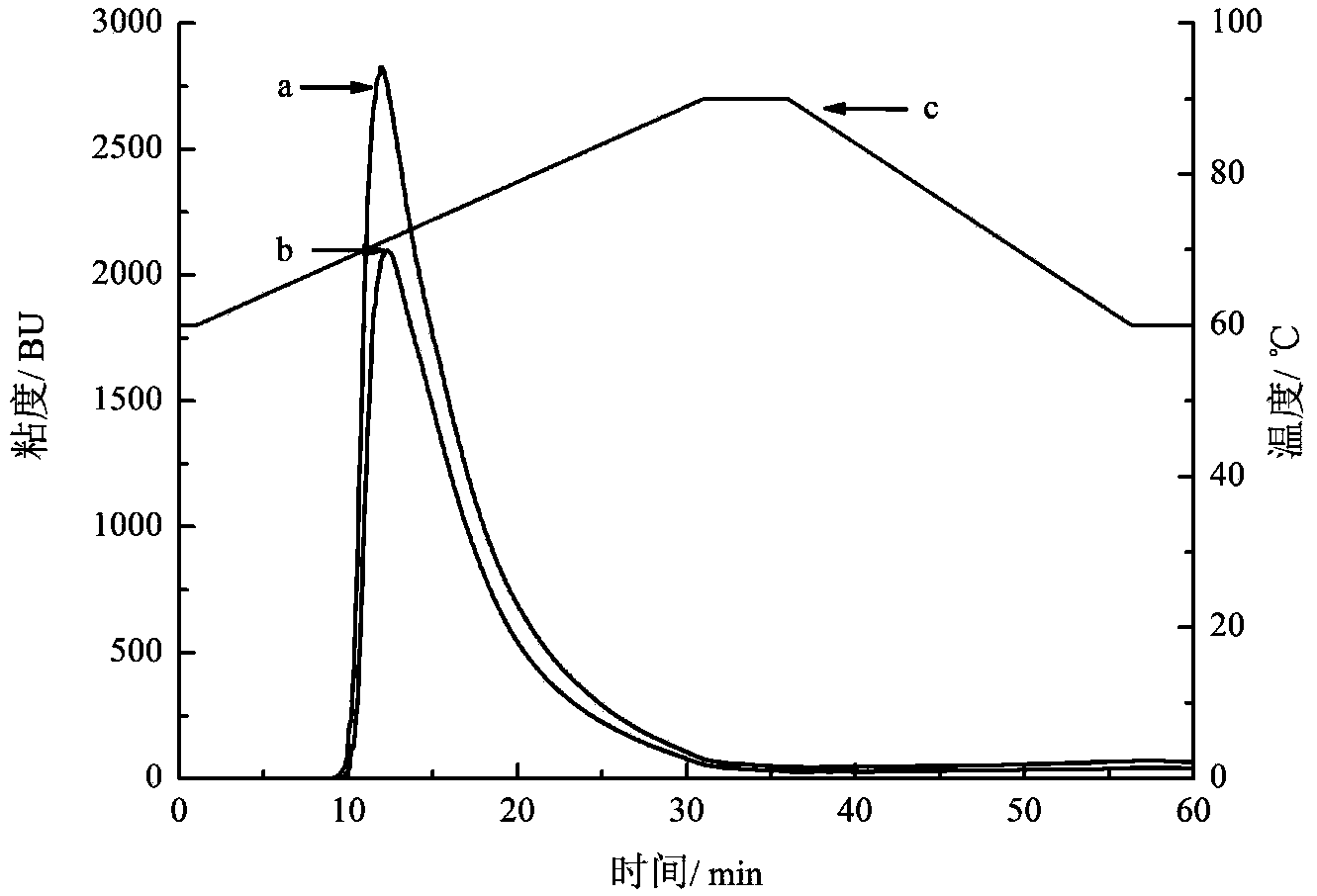

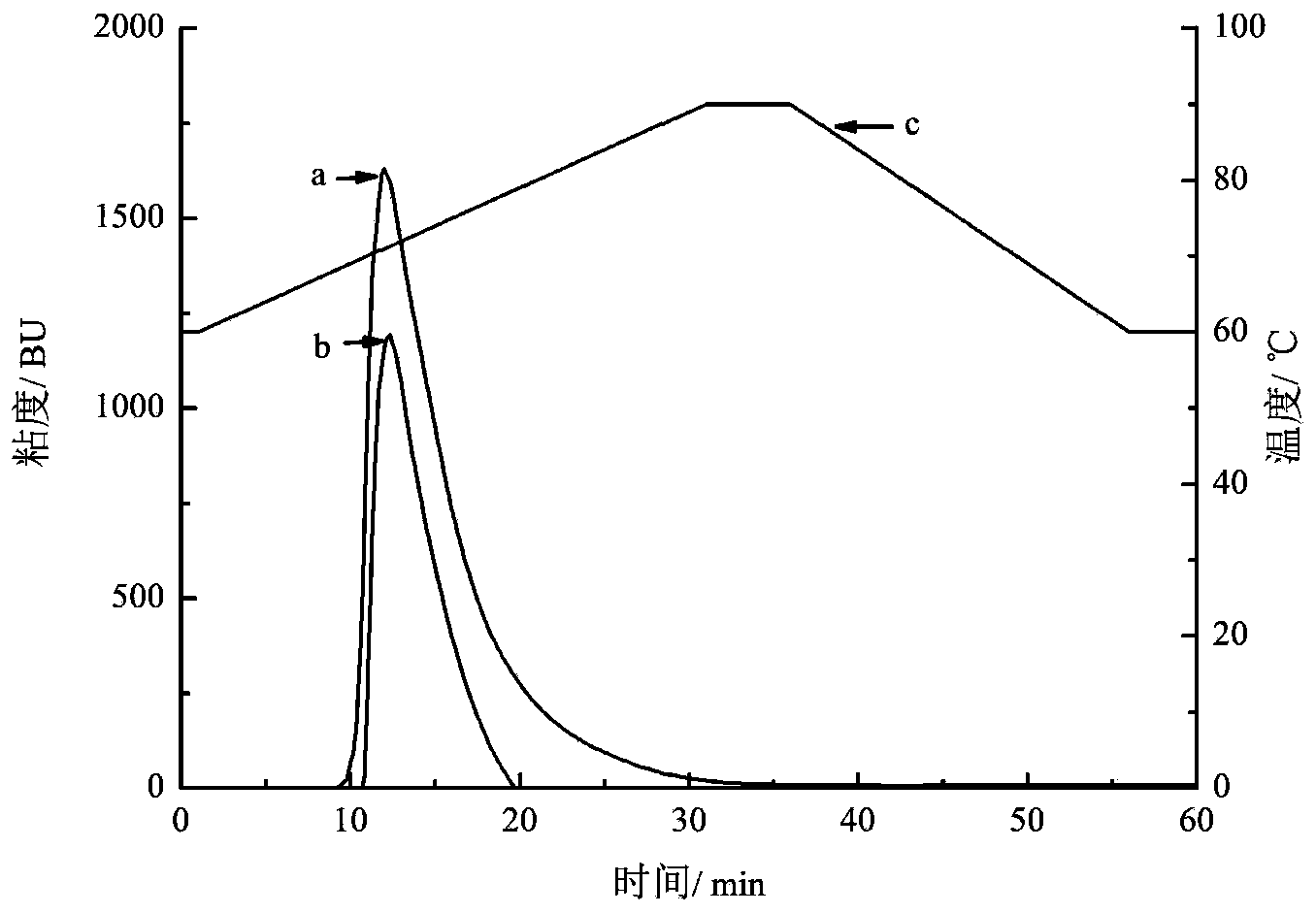

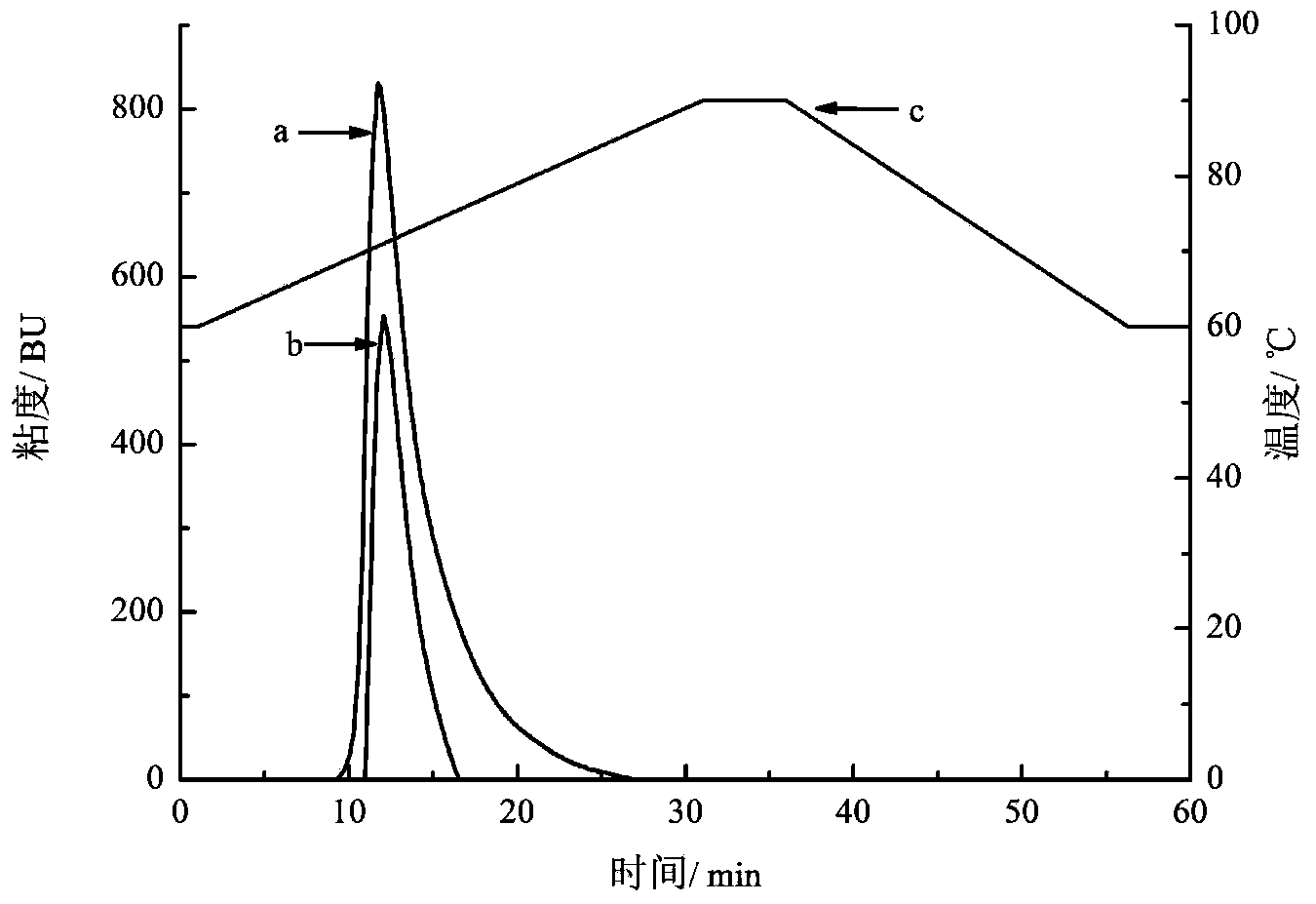

Pre-treatment method for promoting high concentration starch to liquefy

ActiveCN104293863AReduce evaporation energy consumptionLow viscosityFermentationLiquid glucoseHigh concentration

The invention discloses a pre-treatment method for promoting high concentration starch to liquefy and belongs to the technical field of sugar making by starch. The method comprises the following steps: by using high concentration starch milk as a substrate, carrying out heat preservation and pre-treating by using a medium-temperature alpha-amylase; and then, adding high-temperature-resistant alpha-amylase to heat and liquefy. According to the method disclosed by the invention, the substrate concentration is improved from about industrial 30% to 50-60%, the evaporation energy consumption of liquid glucose in the later stage of sugar making by starch can be reduced, and defects such as high water consumption and high energy consumption for sugar making by starch are overcome.

Owner:JIANGNAN UNIV

Alumina carbon mother liquid processing method

ActiveCN101780969AImprove economyReduce evaporation energy consumptionAluminium oxides/hydroxidesSodium bicarbonateAluminium hydroxide

The invention provides an alumina carbon mother liquid processing method, which relates to an alumina production process by a serial connection method or a sintering method. The invention is characterized in that the process comprises the following steps: (1) introducing carbon dioxide gas into the alumina carbon mother liquid so that all remained alumina can be separated out after the alumina carbon mother liquid is carbonated, and continuously introducing the carbon dioxide for converting the sodium carbonate in the carbon mother liquid into sodium bicarbonate; (2) adding the sodium carbonate into the over carbonated sodium bicarbonate solution so that the separation rate of the sodium bicarbonate reaches more than 90 percent; and (3) separating slurry after the separation of the sodium bicarbonate to obtain a mixture of the sodium bicarbonate, the aluminum hydroxide and the dawsonite with the attached water weight lower than 6 percent to be used for preparing raw material slurry. In the method of the invention, the carbon evaporation mother liquid with 220g / l sodium carbonate is converted into sodium bicarbonate crystals with the moisture content lower than 6 percent, the evaporation energy consumption is saved, in addition, the raw material moisture is reduced by 20 percent, and the energy consumption of the raw material sintering can be reduced by 40 percent.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

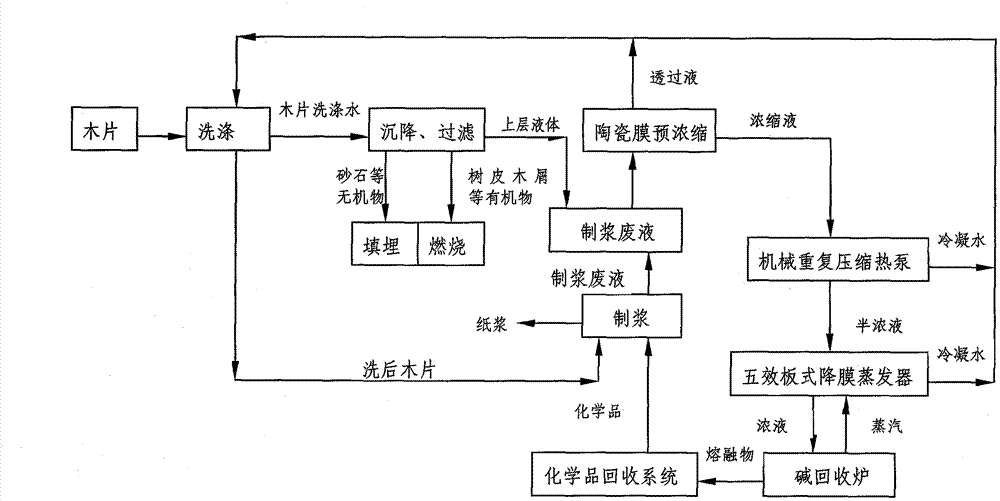

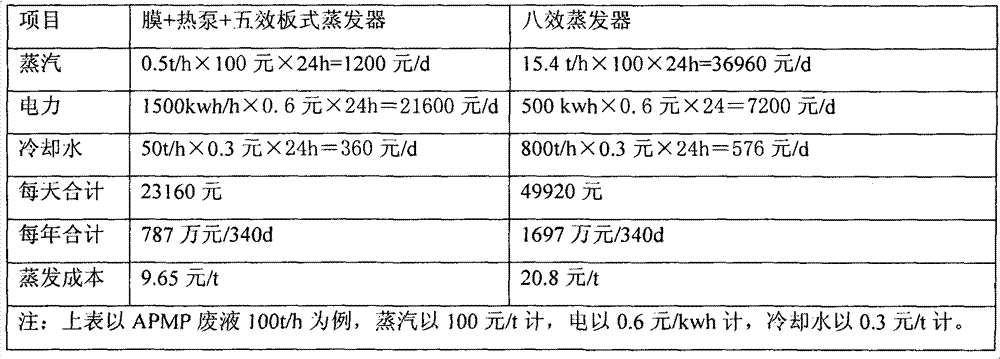

Method for low-energy consumption condensation of waste liquid produced by alkaline peroxide mechanical pulping

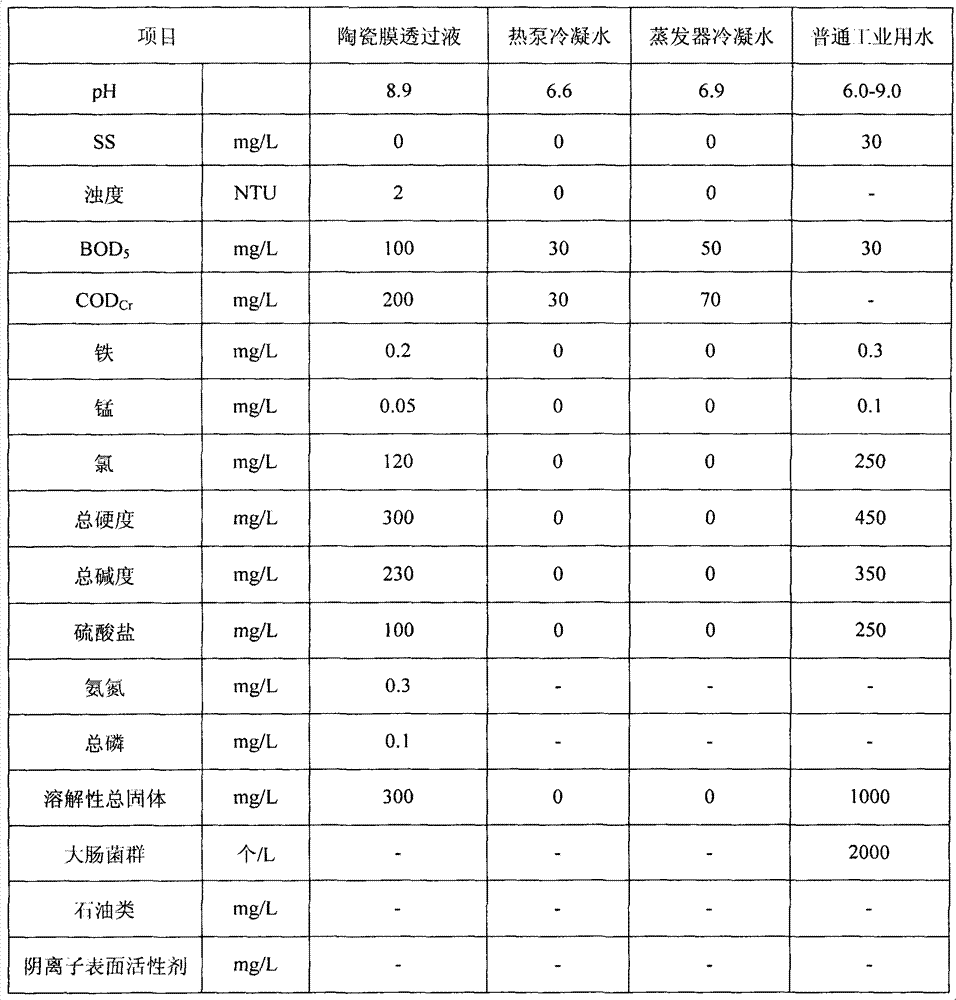

InactiveCN102897961AReduce evaporation energy consumptionSave on operating costsWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentHigh concentrationLiquid waste

The invention provides a method for low-energy consumption condensation of a waste liquid produced by alkaline peroxide mechanical pulping. The method fully combines characteristics of a ceramic ultrafiltration membrane, a mechanical repeat-compression heat pump and a plate-type falling-film evaporator, and utilizes the devices in concentration of waste liquids which have different properties and are obtained at different discharge points in chemithermomechanical pulping. In the method, the ceramic ultrafiltration membrane replaces an organic membrane, so that a high concentration grinding technology causes a high waste liquid temperature, and can be used for pre-concentration. The mechanical repeat-compression heat pump is used for concentration of a waste liquid from a low concentration to a middle concentration. The plate-type falling-film evaporator is used for concentration of a waste liquid from a middle concentration to a high concentration. The method integrates and optimizes multiple energy-saving technologies, greatly reduces evaporation energy consumption of a waste liquid produced by alkaline peroxide mechanical pulping, realizes waste liquid zero-discharge in the whole alkaline peroxide mechanical pulping process, thoroughly solves the problem that a waste liquid produced by alkaline peroxide mechanical pulping is treated difficultly, and has a simple process flow and a low operation cost.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

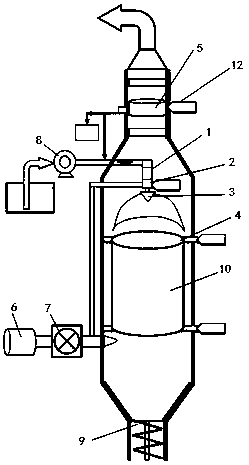

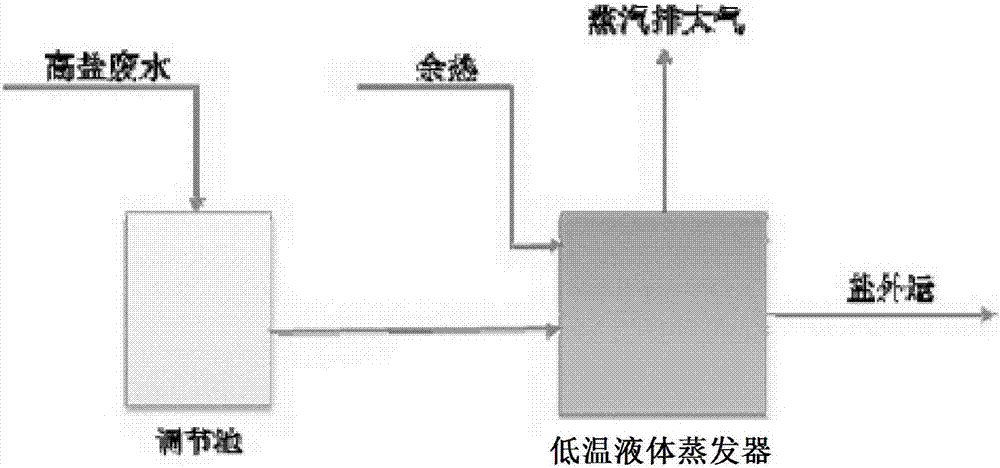

Low-temperature liquid evaporator

PendingCN106902532AAchieve evaporationLow water quality requirementsWater treatment parameter controlEvaporator accessoriesWater storageEcological environment

The invention relates to the field of liquid evaporation and concentration, especially to a low-temperature liquid evaporator. The low-temperature liquid evaporator comprises a water storage unit, a heat transfer unit and an evaporation unit which are connected through pipelines. The heat transfer unit at least heats a liquid by 3 DEG C. The evaporation unit comprises an evaporator and a drawing fan. The evaporator has an air inlet. The drawing fan can form a micro-negative pressure environment inside the evaporator. After the liquid flows through the heat transfer unit from the water storage unit, the liquid reaches the micro-negative pressure environment of the evaporation unit to be evaporated and become a concentrated liquid, and the concentrated liquid flows back to the water storage unit. By circulating and repeated concentration, crystals are precipitated out. According to the low-temperature liquid evaporator, by using difference between partial pressure of water vapor and partial pressure of saturated vapor as evaporation driving force, the evaporation process can meet the evaporation requirement only by heating by 3 DEG C under the micro-negative pressure condition, and low-temperature evaporation of the liquid is realized. Thus, evaporation condition and cost are greatly reduced, zero-discharge treatment of high-salinity wastewater such as high-sulfur wastewater, electroplating wastewater, etc. is achieved, and the ecological environment is protected.

Owner:上海泓毅环保科技有限公司

Treatment method of high-concentration salt-containing waste sulfuric acid

ActiveCN110627279ARealize resource utilizationReduce productionSludge treatment by de-watering/drying/thickeningWater contaminantsHigh concentrationResource utilization

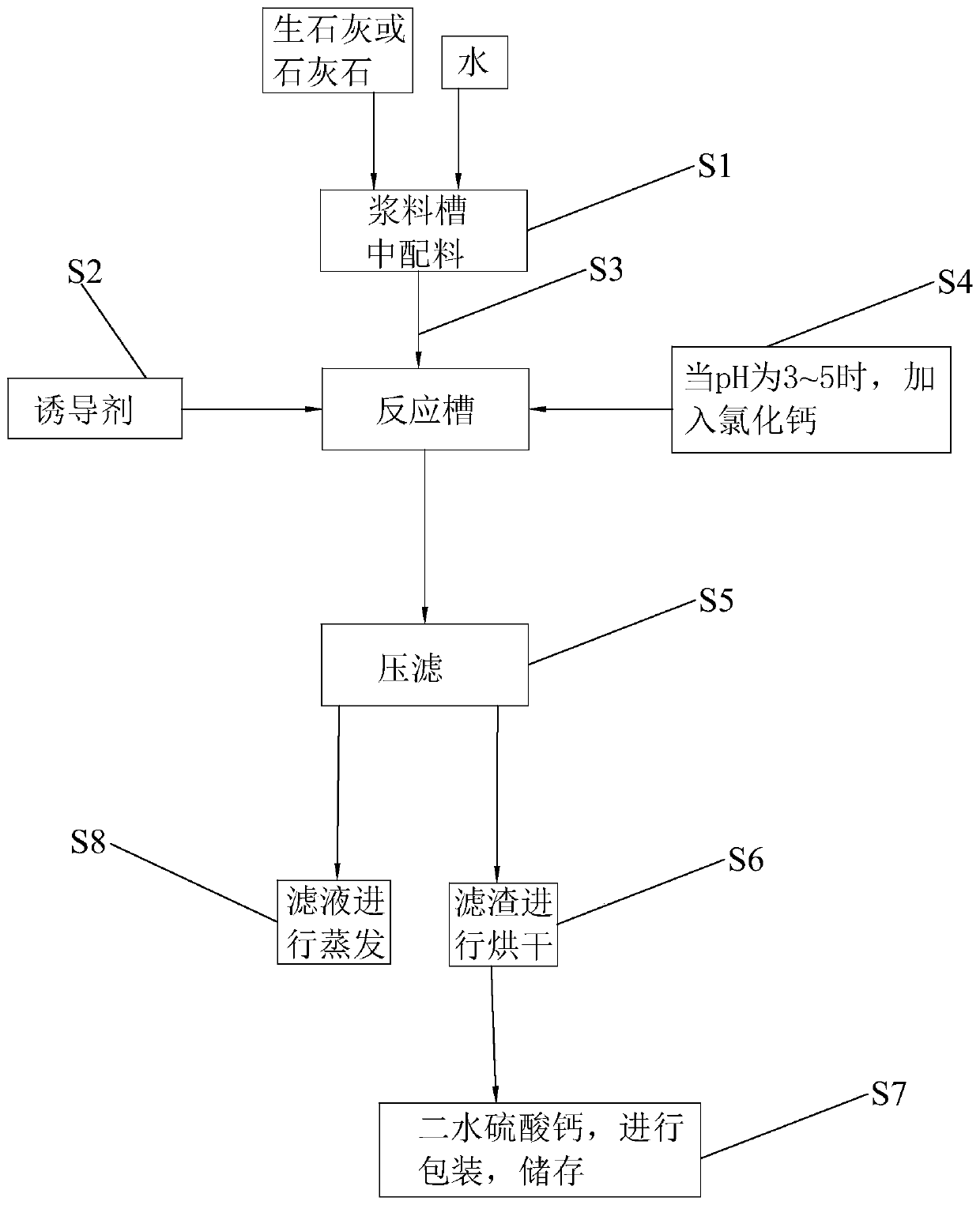

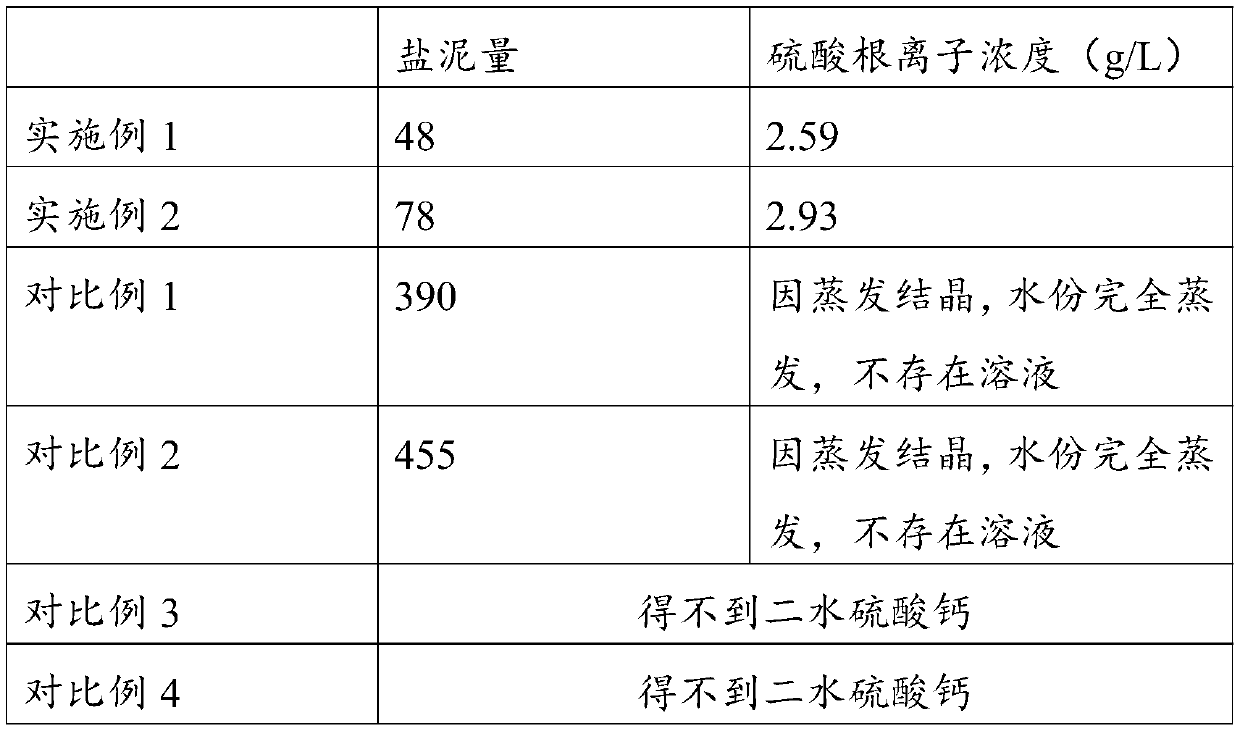

The invention provides a treatment method of high-concentration salt-containing waste sulfuric acid. The treatment method comprises: (1) preparing a material slurry with a certain concentration from quicklime or limestone and water; (2) adding a proper amount of an inducer into a reaction tank containing high-concentration salt-containing waste sulfuric acid; (3) adding the material slurry into the reaction tank, stirring, measuring the pH value, stopping the adding of the material slurry when the pH value is increased to 3-5, and continuously stirring for a certain time; (4) adding a proper amount of calcium chloride into the reaction tank, and stirring for a certain time; and (5) filtering the solution in the reaction tank, carrying out evaporative crystallization on the filtrate, and drying the filter residue to obtain calcium sulfate dihydrate. With the treatment method of the invention, the salt content of the wastewater entering the evaporator can be greatly reduced, the evaporation energy consumption can be reduced, the yield of salty mud can be greatly reduced, the calcium sulfate dihydrate can be obtained, and the resource utilization of the high-concentration salt-containing waste sulfuric acid can be achieved.

Owner:中广核宏达环境科技有限责任公司

Preparation method of cellulosic fibers

ActiveCN106222771ASimple preparation processEliminate security risksArtificial filament recoveryArtificial filament washing/dryingCellulose fiberDissolution

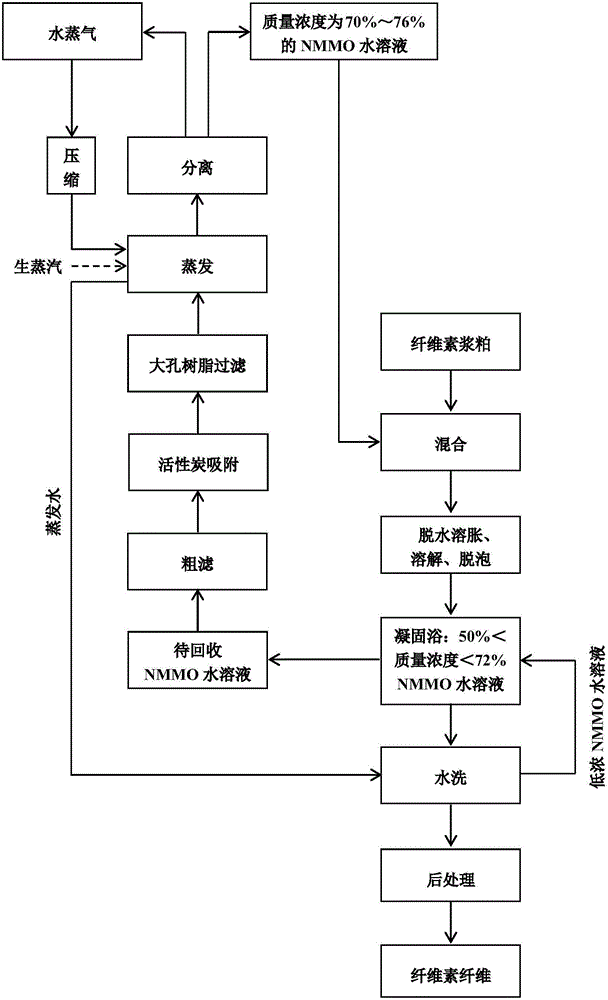

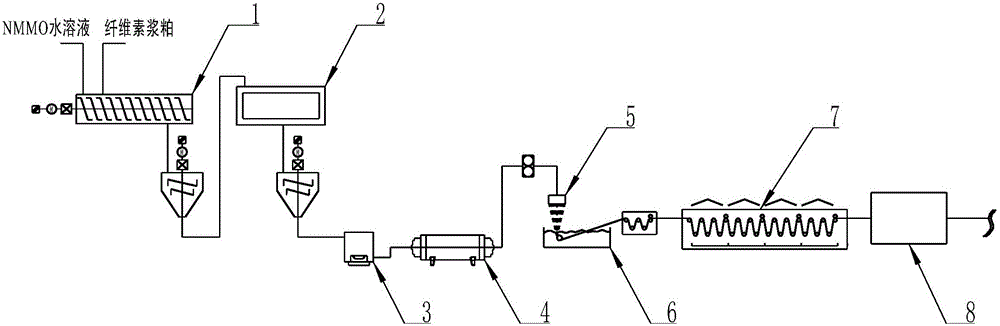

The invention discloses a preparation method of cellulosic fibers. The preparation method includes the following steps that 1, cellulose pulp is mixed with an NMMO water solution with the mass concentration of 60%-85%, preferably 70%-76% to obtain a uniform mixture; 2, the obtained uniform mixture is subjected to dehydration swelling and dissolution defoaming to obtain a cellulose spinning solution; 3, the obtained cellulose spinning solution is filtered and subjected to heat exchange and then enters a spinning machine, after the cellulose spinning solution is extruded through a spinning assembly and air-cooled, the cellulose spinning solution enters a solidification system and is solidified in an NMMO solidification bath with the mass concentration larger than 50% and smaller than 72%, and nascent fibers are obtained; 4, the obtained nascent fibers are washed to obtain cellosilk bundles, and then the cellulosic fibers are obtained through subsequent section treatment. Equipment investment can be greatly reduced, the process is simplified, energy consumption and industrialization cost are reduced, safety production is promoted, the homogeneity and mechanical performance of the fibers are improved, and therefore the preparation method is more suitable for efficient low-consumption industrial production.

Owner:CHINESE TEXTILE ACAD

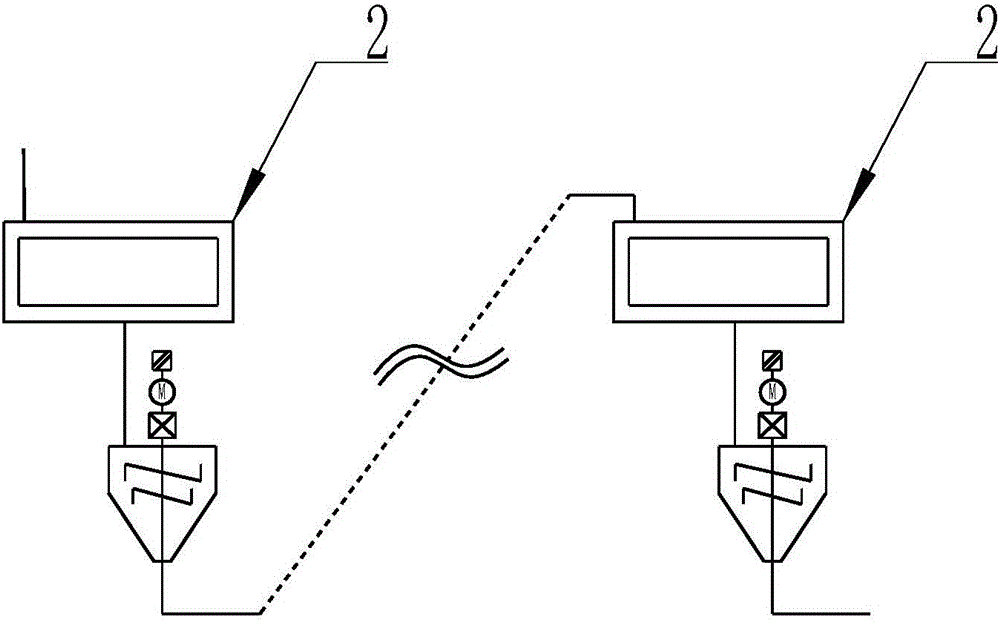

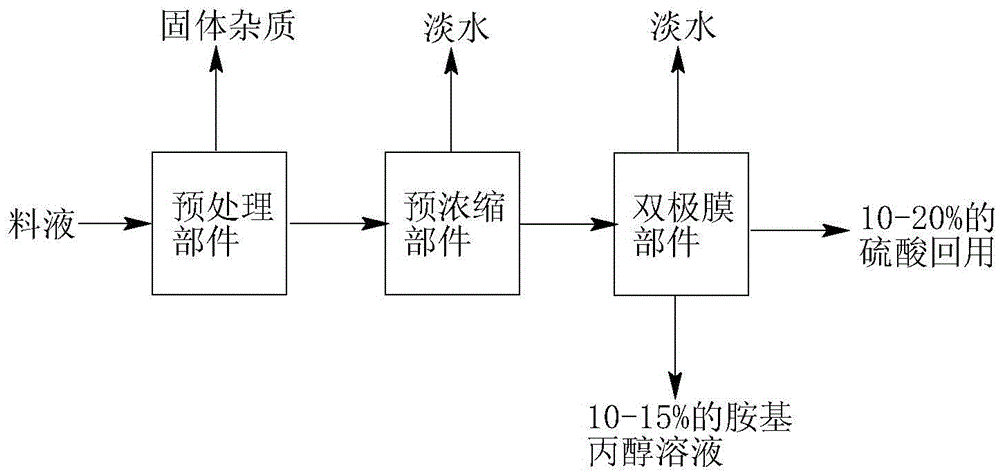

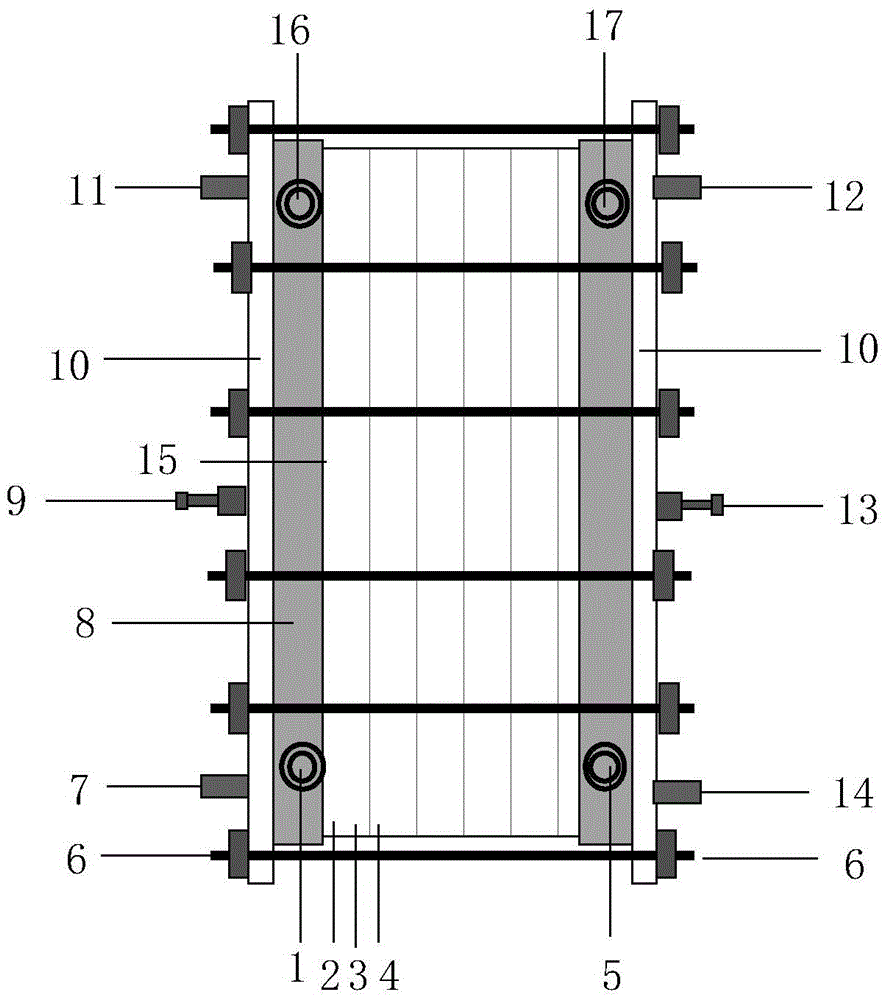

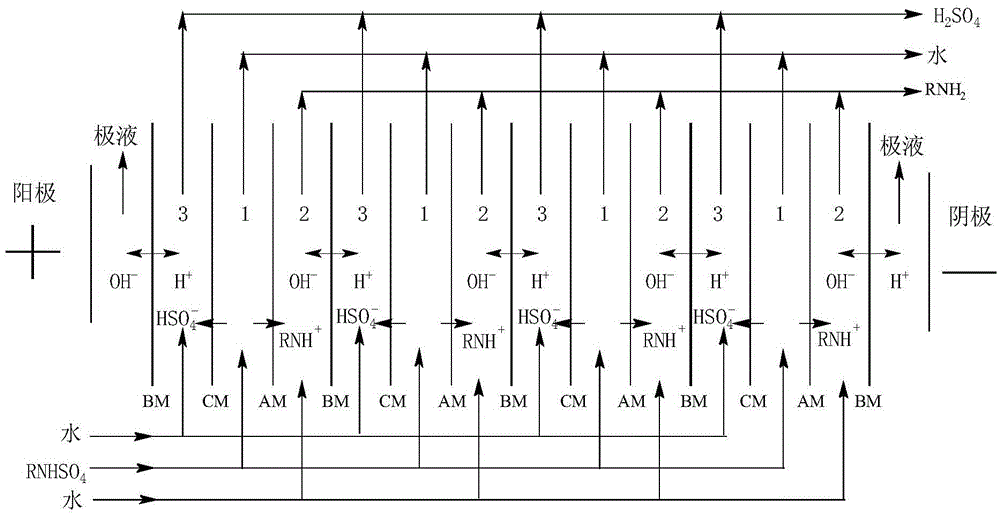

Bipolar membrane device for preparing amino-1-propanol

ActiveCN105622435AImprove current efficiencyIncrease concentrationMembranesOrganic compound preparationChemistryIridium

The invention discloses a membrane separation technology and particularly relates to a bipolar membrane device for preparing amino-1-propanol. The bipolar membrane device comprises a preprocessing part, a pre-concentrating part and a bipolar membrane part, wherein the preprocessing part is a teflon micro- and ultra-filtration membrane; electrodialysis is performed on the pre-concentrating part through a homogeneous membrane prepared by an impregnation method; the poles of the bipolar membrane part are nickel poles coated with tantalum, platinum and iridium; the bipolar membrane, which are resistant to strong acid and amino-1-propanol, of the bipolar membrane part is a single-plate-method perfluorinated-grafting bipolar membrane, the anode membrane, which is resistant to strong alkali and specially used for stopping alkali, of the bipolar membrane part is a perfluorinated-grafting carboxylic acid anode membrane, and the cathode membrane, which is resistant to strong acid and specially used for stopping acid, of the bipolar membrane part is a cathode membrane adopting a propyl quaternary amine functional group. The bipolar membrane device has the advantages that the overall service life of the device is greatly prolonged by more than 3 years, evaporation energy consumption is reduced greatly, product quality is increased, the material chamber conductivity of a bipolar membrane process is increased greatly, and energy consumption is reduced.

Owner:JIANDE LANXIN ENVIRONMENTAL SCI & TECH

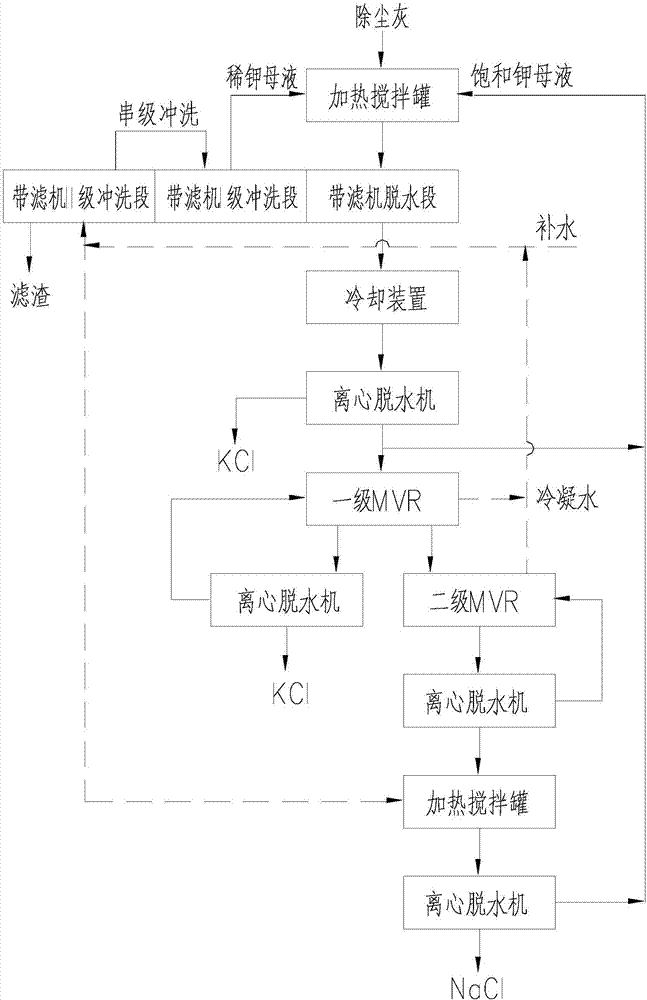

Rotary hearth furnace flue gas dedusting ash treatment process

ActiveCN106966410AReduce water consumptionReduce subsequent evaporative loadChemical industryAlkali metal chloridesFlue gasEvaporation

The invention discloses a rotary hearth furnace flue gas dedusting ash treatment process. According to the process, rotary hearth furnace flue gas dedusting ash and a circulating solution are mixed to form slurry, filter liquor and filter residue are separated by dehydration of a vacuum belt-type dehydrator, a dissolving and circulating mode is adopted by the filter liquor to wash, the filter residue is subjected to washing and dehydration in series, and a circulating solution is from subsequent slurry dehydration and filter residue washing processes; by the process, valuable elements in the rotary hearth furnace flue gas dedusting ash can be separated, and valuable utilization can be achieved respectively; the allocation and operation procedures of equipment are simple, comprehensive recycling use of secondary resource can be realized, the water consumption is reduced while a washing effect is guaranteed, the energy consumed during evaporation is reduced, and the purpose of energy conservation and emission reduction is achieved.

Owner:CHONGQING CISDI THERMAL & ENVIRONMENTAL ENG CO LTD

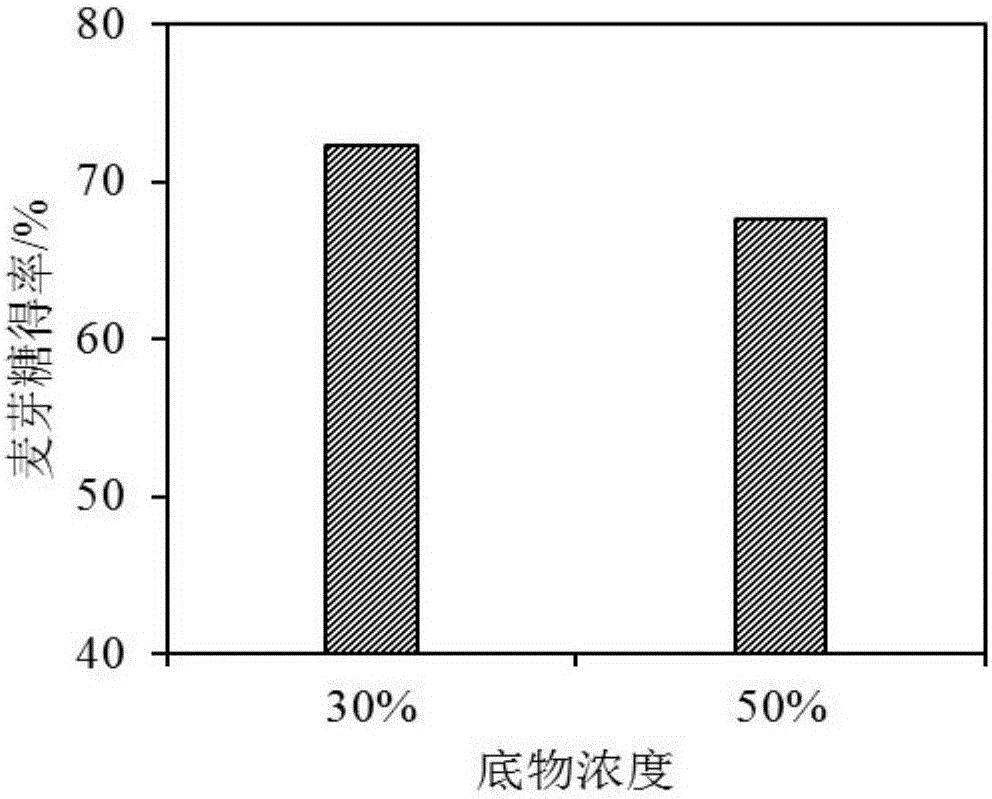

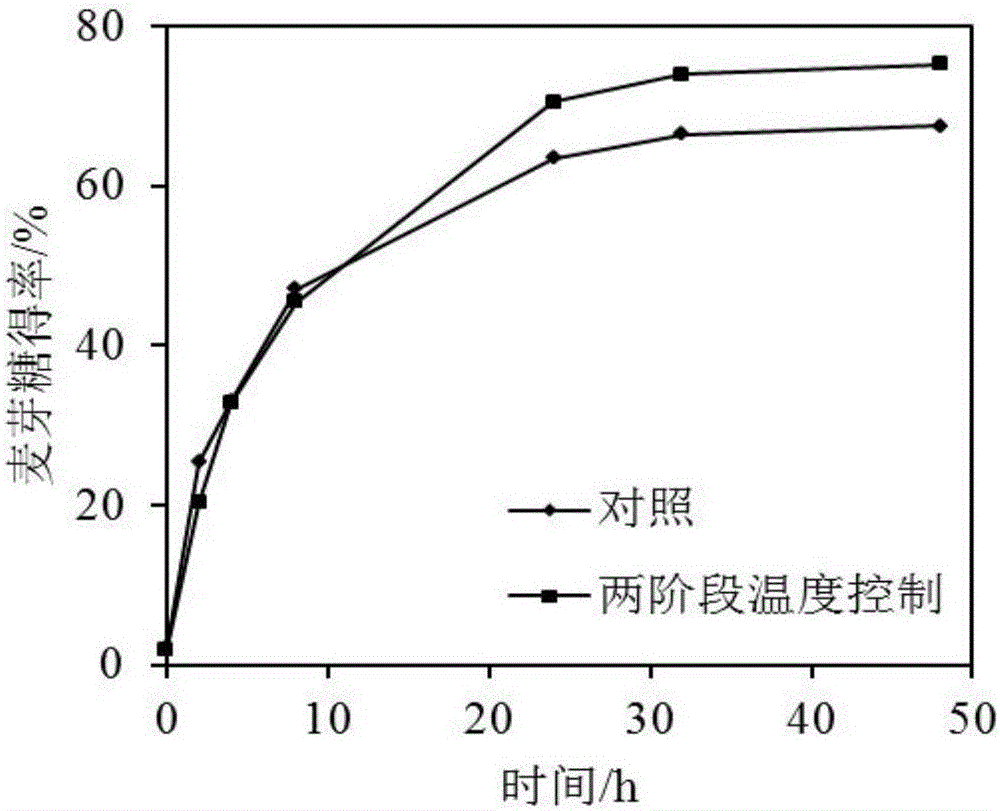

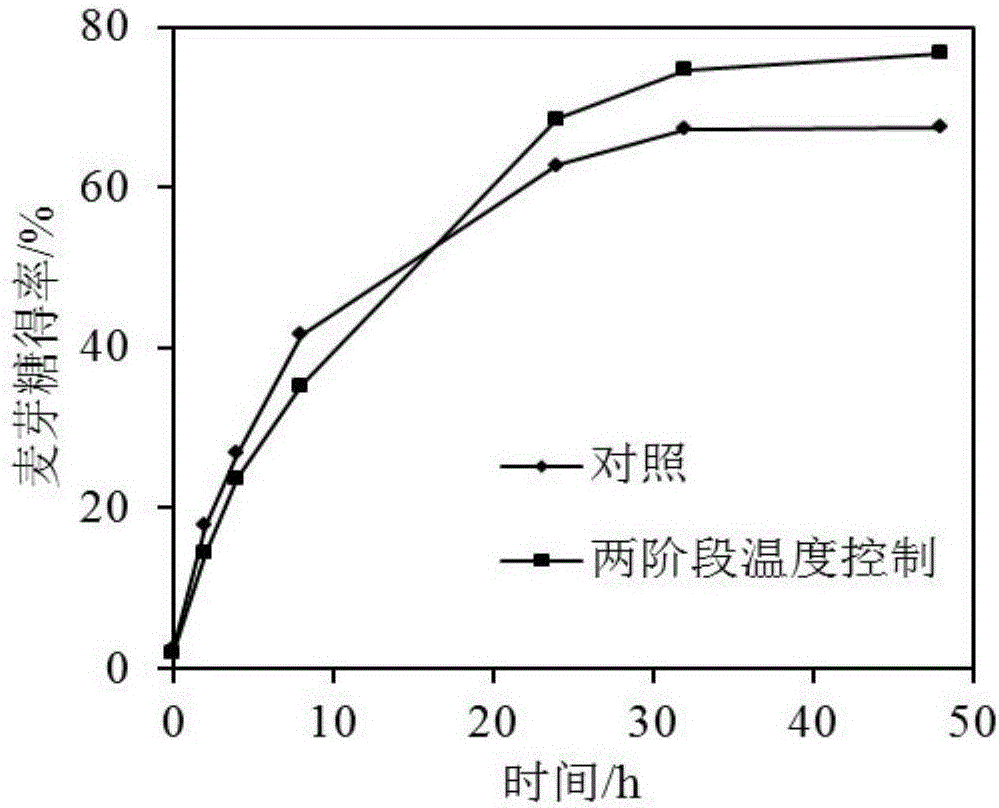

Method for improving maltose yield in malt syrup production adopting starch saccharification at high concentration

The invention discloses a method for improving the maltose yield in malt syrup production adopting starch saccharification at high concentration, belonging to the technical field of sugar preparation adopting starch. According to the method, a high-concentration starch emulsified product is taken as a substrate, and the maltose yield in the product is improved through two-stage temperature control and complex enzyme treatment. In the method, the concentration of the substrate is improved to be about 50% from the industrial level being about 30%, meanwhile, the yield of maltose in the malt syrup under the high-concentration condition is improved, the sugar liquor evaporation energy consumption in the later period of sugar preparation by adopting starch can be reduced, and moreover, the defects of high water consumption, high energy consumption and the like in the sugar preparation adopting starch are overcome.

Owner:JIANGNAN UNIV

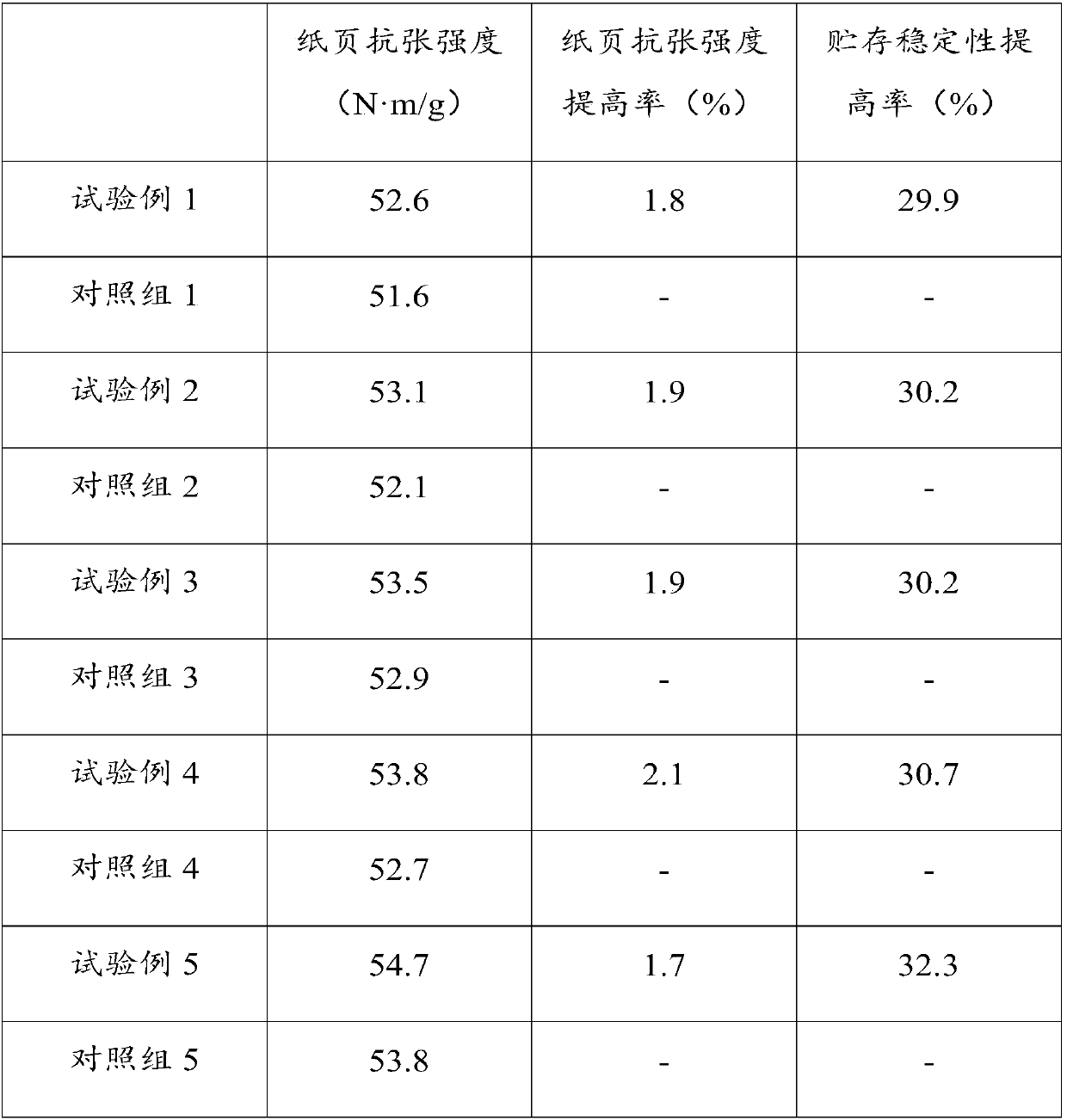

A kind of starch glue for paper sheet surface sizing and processing method thereof

ActiveCN106868940BReduce the number of broken headsImprove adhesionWater-repelling agents additionAdhesiveAlpha-amylase

The invention relates to paper sheet surface sizing starch glue and a processing method thereof and belongs to the field of starch glue. The processing method comprises the steps of mixing starch and water, then adding starch compound enzyme and heating and boiling to obtain a starch glue initial product; deactivating enzyme in the starch glue initial product, adding starch glue enhancer and mixing to obtain the paper sheet surface sizing starch glue. The starch complex enzyme is prepared from alpha-amylase, beta-amylase, glycerinum and salt, and the weight ratio of the alpha-amylase to the beta-amylase to the glycerinum to the salt is (50 to 65):(5 to 10):(10 to 20):(2 to 5). The starch glue enhancer is prepared from hydroxypropyl methyl cellulose, sodium carboxymethyl cellulose, liquid caustic soda and penetrant, and the weight ratio of the hydroxypropyl methyl cellulose to the sodium carboxymethyl cellulose to the liquid caustic soda to the penetrant is (30 to 40):(20 to 30):(2 to 4):(0.5 to 1). The processing method has a simple technology and low production cost and greatly reduces wastewater treatment load in a production process. In addition, the starch glue has good quality, can solve the problems of starch glue colloidal particle solution crystallization and poor storage viscosity stability and meets a requirement of common printing paper.

Owner:WUHAN SUNHY BIOLOGICAL

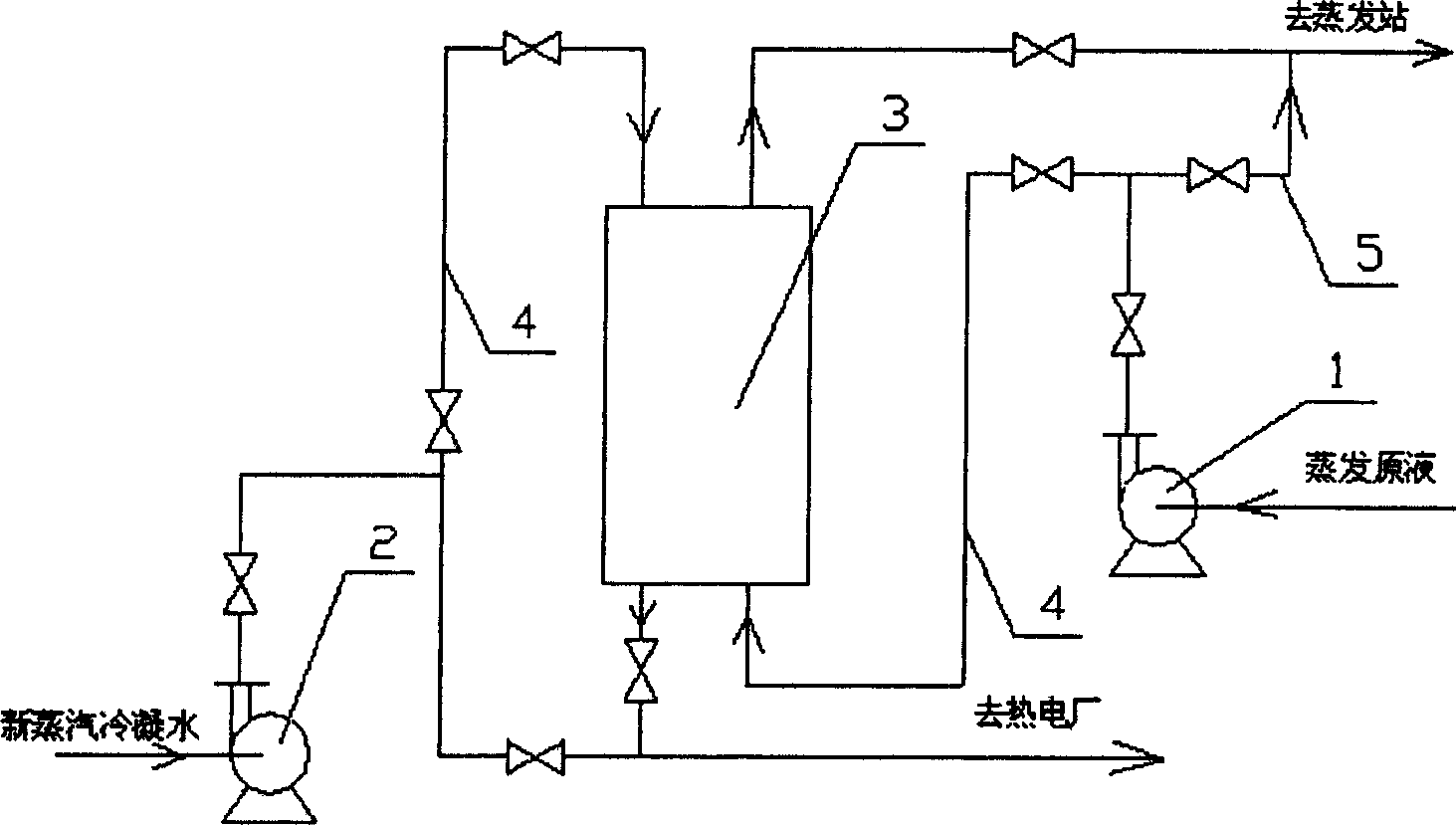

Method for raising temperature of vaporizing raw liquor

InactiveCN1796281AReduce evaporation energy consumptionIncrease temperatureAluminium oxides/hydroxidesEvaporationEngineering

This invention describes a process for raising the temperature of the evaporating primary liquid. In the process, the evaporating primary liquid from the primary liquid pump enters a plate-type heat exchanger for the exchange of heat with a live steam condensate that enters the plate-type heat exchanger from a stripping condensate pump. After the exchange of heat, the heated evaporating primary liquid enters an evaporator for evaporation, and the cooled live steam condensate enters a thermoelectricity plant for flash evaporation. This invention has such advantages as low energy consumption and prevents drastic vibration of the transportation pipes.

Owner:GUIYANG AL-MG DESIGN & RES INST

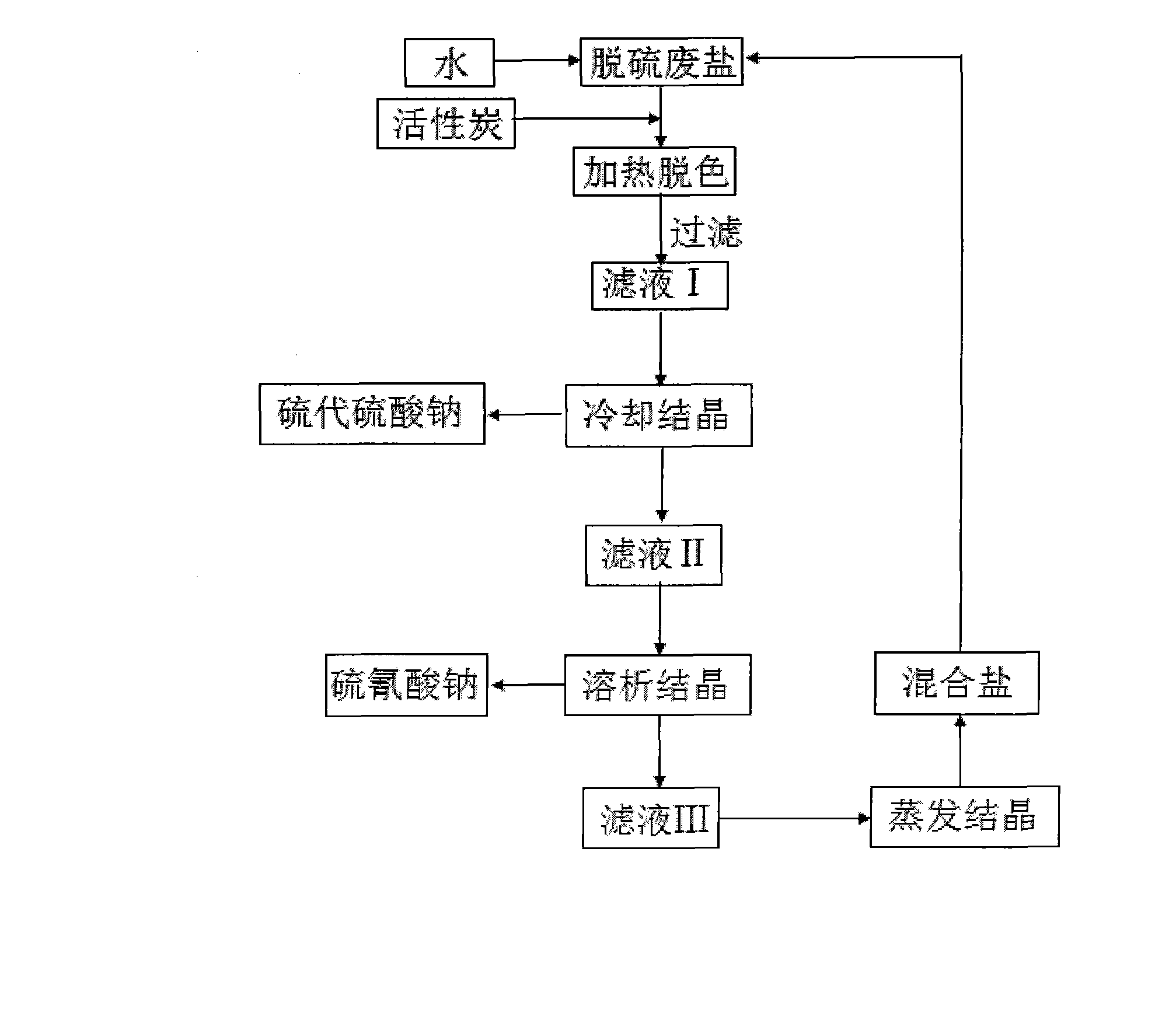

Method for extracting high-purity sodium thiocyanate and sodium thiosulfate in gas desulfurization waste salt

InactiveCN103072950AConcentrated particle size distributionControllable particle sizeThiosulfates/dithionites/polythionitesThiocyanic acidActivated carbonSodium thiocyanate

The invention relates to a method for extracting high-purity sodium thiocyanate and sodium thiosulfate in coal gas desulfurization waste salt. The technical scheme is that the method comprises the following steps: preparing the desulfurization waste salt as well as water and crystal mixed salt into solution, adding activated carbon to discolor, filtering, adding a sodium thiosulfate crystal seed into a filtrate, reducing the temperature to 25-30 DEG C at a speed of 1-3 DEG C / hour after crystallization and filtering to obtain secondary crystallization mother liquor and a sodium thiosulfate crystal with a purity of more than 95 weight percent; then adding a sodium thiocyanate crystal seed into the secondary crystallization mother liquor, adding a solventing-out agent at a velocity flow of 1-10 mL / min after crystallization and filtering to obtain tertiary crystallization mother liquor and a sodium thiocyanate crystal with a purity of more than 95 weight percent; and then evaporating and crystallizing the tertiary crystallization mother liquor to obtain the crystal mixed salt. The method has the characteristics of simple process, mild operation condition, low production cost, easiness in realizing large-scale production and high quality.

Owner:WUHAN UNIV OF SCI & TECH

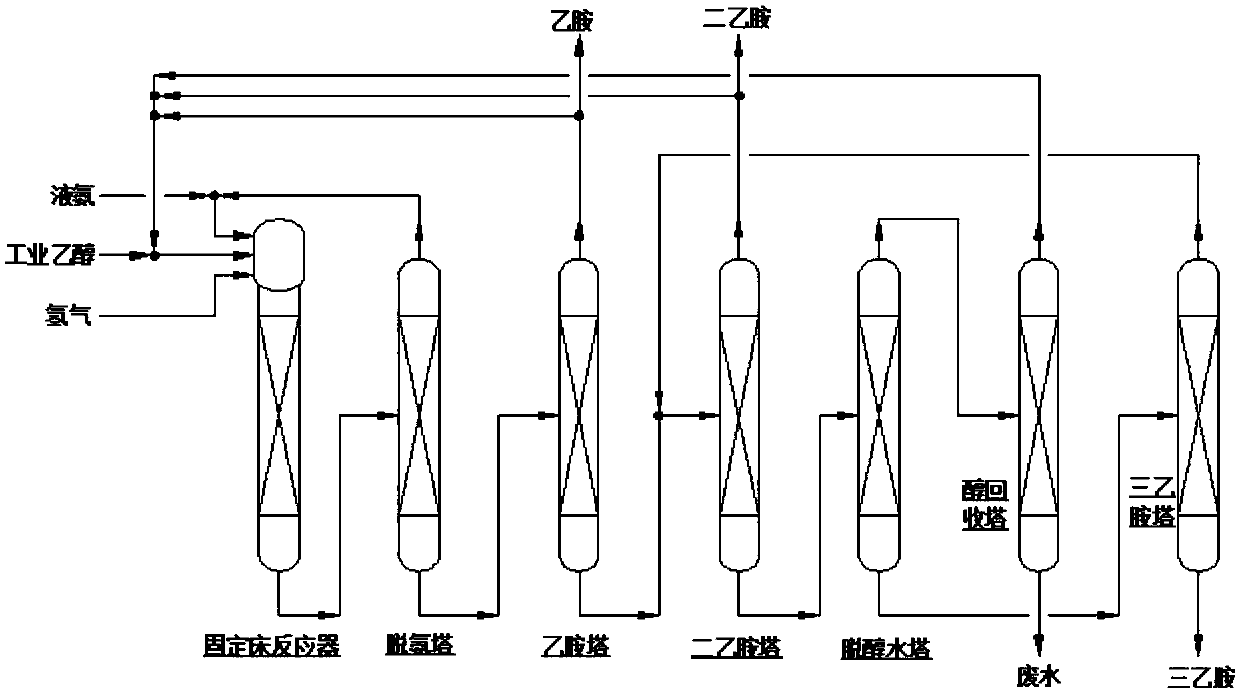

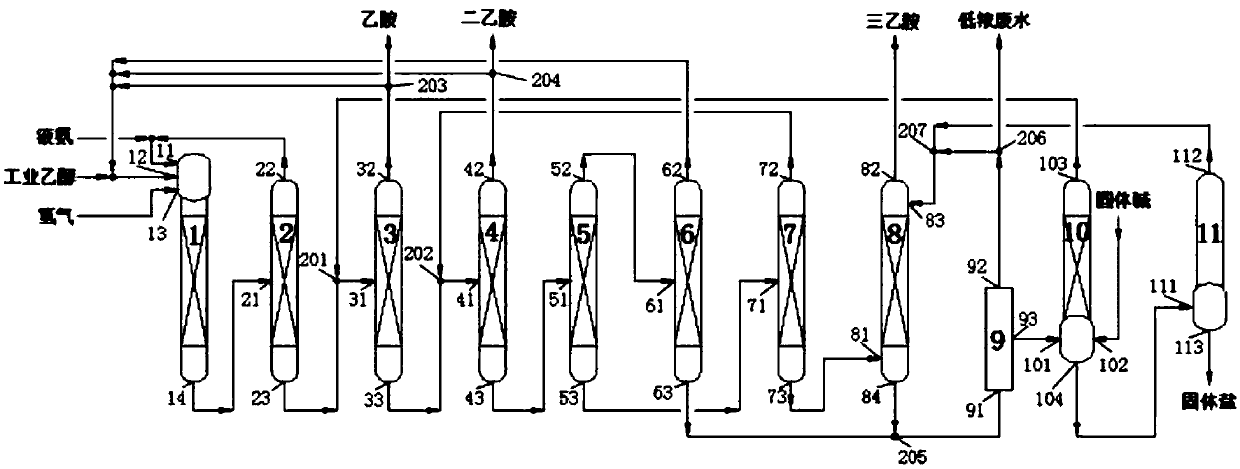

Ethylamine production system and technology for conducting membrane separation-hydrolysis treatment on wastewater

ActiveCN109607920AHigh purityReduce evaporation energy consumptionOrganic compound preparationWater contaminantsEthylamineEvaporator

The invention discloses an ethylamine production system for conducting membrane separation-hydrolysis treatment on wastewater. The ethylamine production system comprises a fixed bed reactor, a deamination tower, an ethylamine tower, a diethylamine tower, a dealcoholization water tower, an alcohol recycling tower, a triethylamine tower, an extracting tower, a reverse osmosis membrane separator, a hydrolysis rectifying tower and an evaporator; an outlet of the hydrolysis rectifying tower is communicated with an inlet of the evaporator; a tower top distillate opening of the hydrolysis rectifyingtower and a tower bottom outlet of the deamination tower are converged, and then the tower top distillate opening of the hydrolysis rectifying tower is communicated with a feeding port of the ethylamine tower; a dilute phase outlet of the reverse osmosis membrane separator is divided into two paths after running through a tee VI, one path is an outlet pipe for low-concentration wastewater, and theother path is converged with a distilled water outlet and then communicated with a heavy phase inlet. The invention further provides an ethylamine production technology for conducing membrane separation-hydrolysis treatment on wastewater through the production system. By the adoption of the method, the low-concentration wastewater is suitable for biochemical treatment.

Owner:ZHEJIANG JIANYE CHEM

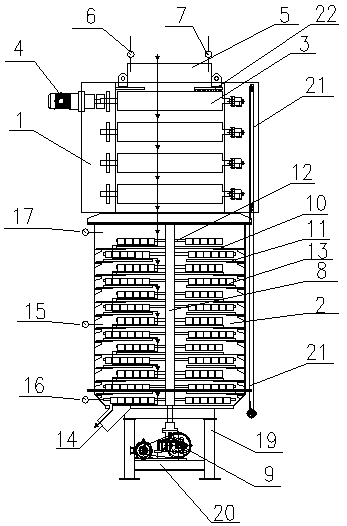

Dustproof and explosion-proof pelleting and drying equipment for oily sludge

PendingCN108558164ANo mechanical actionReduce productionSludge treatment by de-watering/drying/thickeningGranulation in rotating drumsSludgeCombustible gas

The invention discloses dustproof and explosion-proof pelleting and drying equipment for oily sludge. The equipment comprises a pelleting cabin and a drying cabin, multiple roller cylinders are horizontally installed in the pelleting cabin, and a motor A is installed at the exterior of the pelleting cabin; a feeding port is formed in the upper portion of the pelleting cabin, and a thermometer A and a pressure gauge A are installed at the feeding port; a rotation shaft is vertically installed in the drying cabin, a motor B is connected to the bottom of the rotation shaft, and a small heating disc and a large heating disc are alternatively installed on the rotation shaft; multiple rake arms are distributed on the small heating disc and the large heating disc from the center to the exterior,multiple rake blades are vertically installed on the rake arms, and a discharging port is formed in the lower end of the drying cabin; a thermometer B, a pressure gauge B and a combustible gas concentration detection meter are installed on the side wall of the drying cabin; communicated steam pipes are arranged in the pelleting cabin and the drying cabin. The dustproof and explosion-proof pelleting and drying equipment has the advantages that the safety is high, the running maintenance cost is low, the low-quality heat source can be used, the products are good in quality, and the water treatment amount in the later period and the water demand amount are small.

Owner:JIANGSU LV CHUAN ENVIRONMENTAL PROTECTION TECH

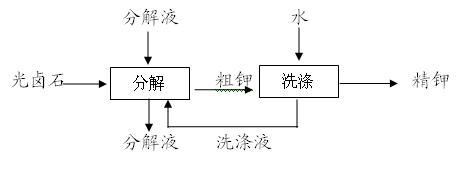

Potassium chloride production process for decomposing carnallite with cleaning solution

InactiveCN102167362AReduce band lossHigh extraction rateAlkali metal chloridesAlkali metal halide purificationPhysical chemistryProcess engineering

The invention discloses a potassium chloride production process for decomposing carnallite with a cleaning solution. The potassium chloride production process is realized by the following steps of: a, dispersing carnallite by using a cleaning solution and putting the dispersed carnallite into a crystallizer; b, adding water in the crystallizer for decomposition, and controlling the concentration to be 31.5-31.7OBe'; c, subjecting a solution obtained after the decomposition to dehydration and separation to obtain crude potassium chloride and a decomposition solution; d, then, adding water into the crude potassium chloride for cleaning to obtain a potassium chloride solution with the concentration controlled to be 27-27.2OBe'; e, dehydrating the potassium chloride solution to obtain a potassium clloride product and a cleaning solution; and f, decomposing the carnallite by using the cleaning solution and repeating the steps b-e. By using the process disclosed by the invention, the carnallite is completely decomposed and particle uniformity of a product is ensured, and because the added water volume is reduced in a cleaning process, the losses of potassium chloride in the cleaning process are reduced.

Owner:天津长芦汉沽盐场有限责任公司

Alumina carbon mother liquid processing method

ActiveCN101780969BImprove economyReduce evaporation energy consumptionAluminium oxides/hydroxidesSodium bicarbonateAluminium hydroxide

The invention provides an alumina carbon mother liquid processing method, which relates to an alumina production process by a serial connection method or a sintering method. The invention is characterized in that the process comprises the following steps: (1) introducing carbon dioxide gas into the alumina carbon mother liquid so that all remained alumina can be separated out after the alumina carbon mother liquid is carbonated, and continuously introducing the carbon dioxide for converting the sodium carbonate in the carbon mother liquid into sodium bicarbonate; (2) adding the sodium carbonate into the over carbonated sodium bicarbonate solution so that the separation rate of the sodium bicarbonate reaches more than 90 percent; and (3) separating slurry after the separation of the sodiumbicarbonate to obtain a mixture of the sodium bicarbonate, the aluminum hydroxide and the dawsonite with the attached water weight lower than 6 percent to be used for preparing raw material slurry. In the method of the invention, the carbon evaporation mother liquid with 220g / l sodium carbonate is converted into sodium bicarbonate crystals with the moisture content lower than 6 percent, the evaporation energy consumption is saved, in addition, the raw material moisture is reduced by 20 percent, and the energy consumption of the raw material sintering can be reduced by 40 percent.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Treatment technology of mother liquor of iron oxide red

InactiveCN108314240AIncrease the salt contentReduce evaporation energy consumptionWater aerationMultistage water/sewage treatmentChemistryBrown iron oxide

The invention discloses a treatment technology of mother liquor of iron oxide red. The treatment technology comprises the following six steps: preprocessing by flocculation and depositing, pre-oxidizing, adjusting acid, performing low-pressure reverse osmosis, performing high-pressure reverse osmosis and performing MVR concentration evaporation. The technology is low in energy consumption, high inresource utilization rate, high in wastewater treatment efficiency, complete to treat, and free from secondary pollution; in addition, a complete closed-ring system is formed in the whole technology;the wastewater is recycled and is not drained.

Owner:绍兴齐英膜科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com