Patents

Literature

47results about How to "Avoid severe corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

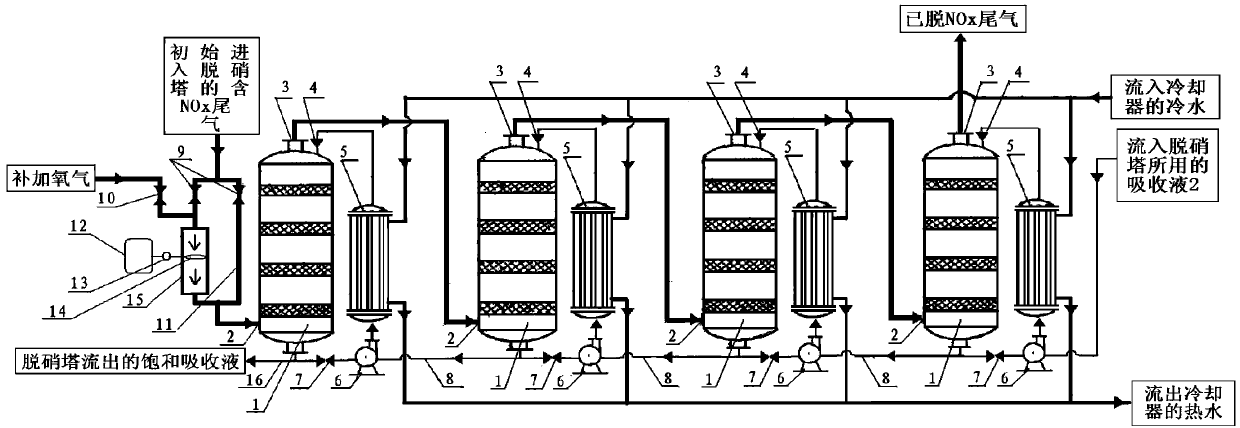

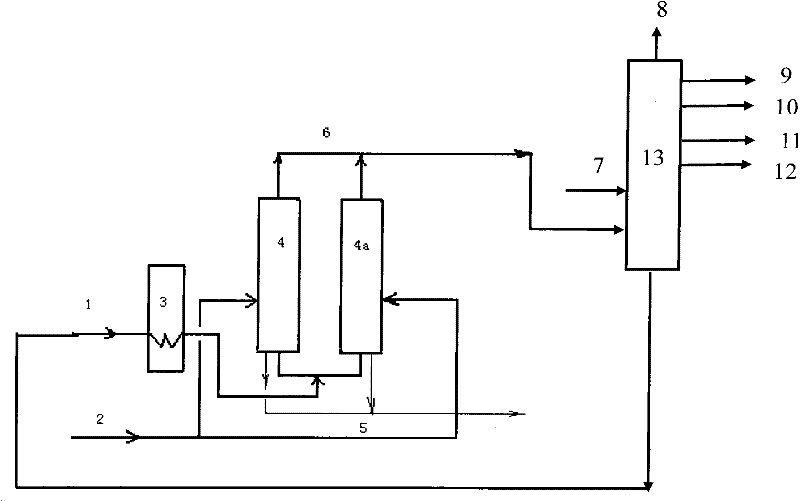

Desulfurization and denitrification method for tail gas, used equipment and product application thereof

InactiveCN105080307AReduce material costsLow costOther chemical processesDispersed particle separationCorrosion preventionChemistry

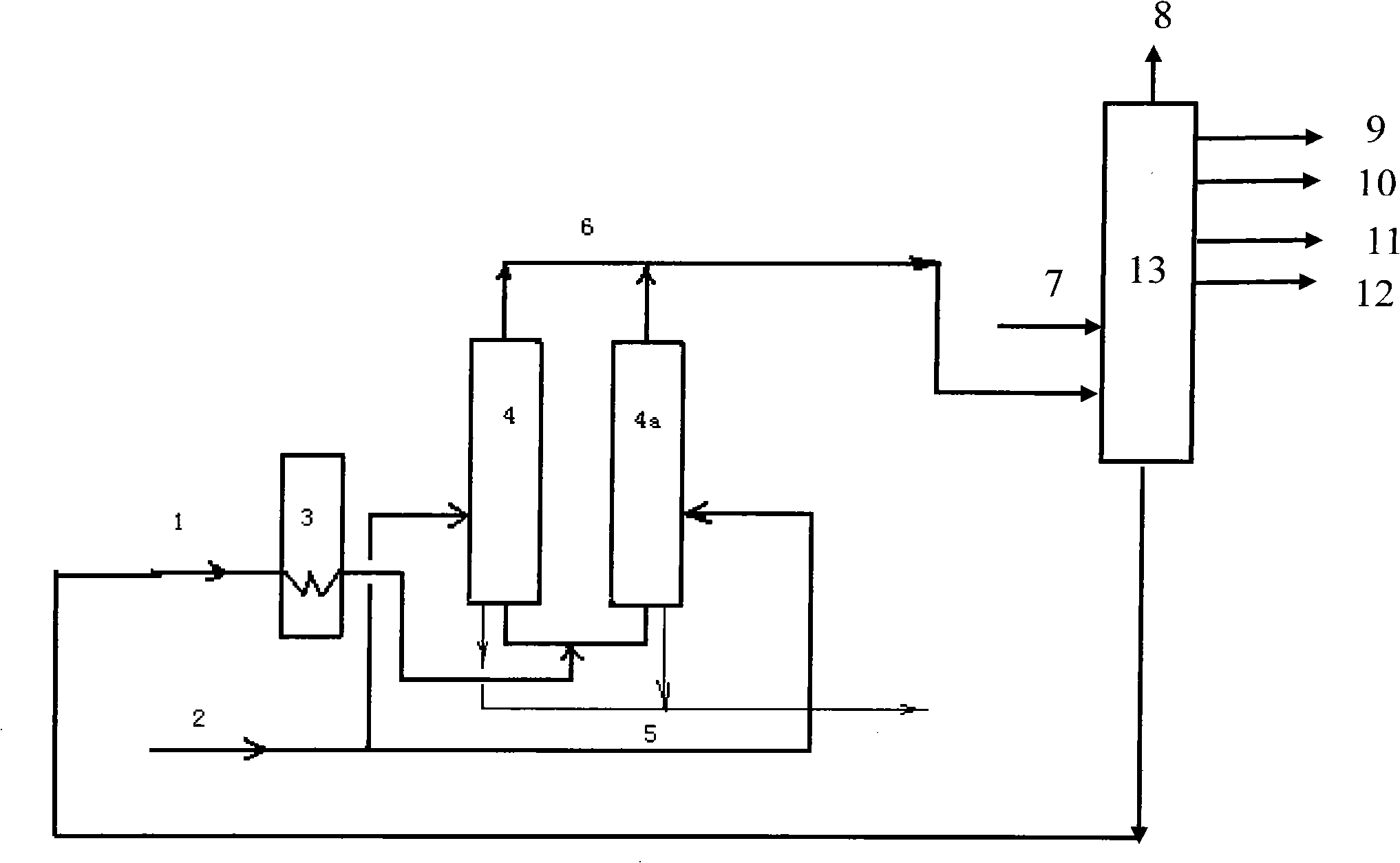

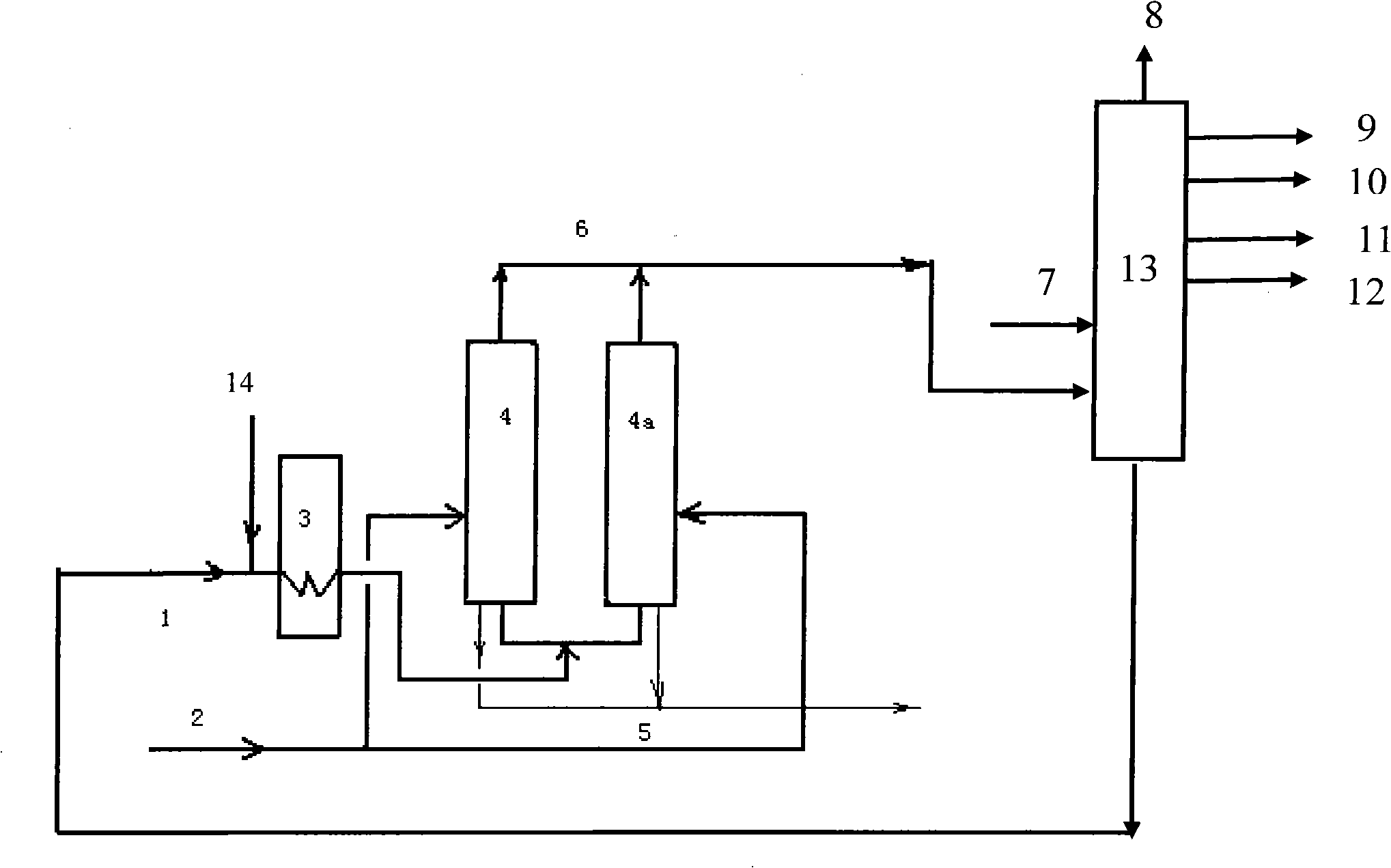

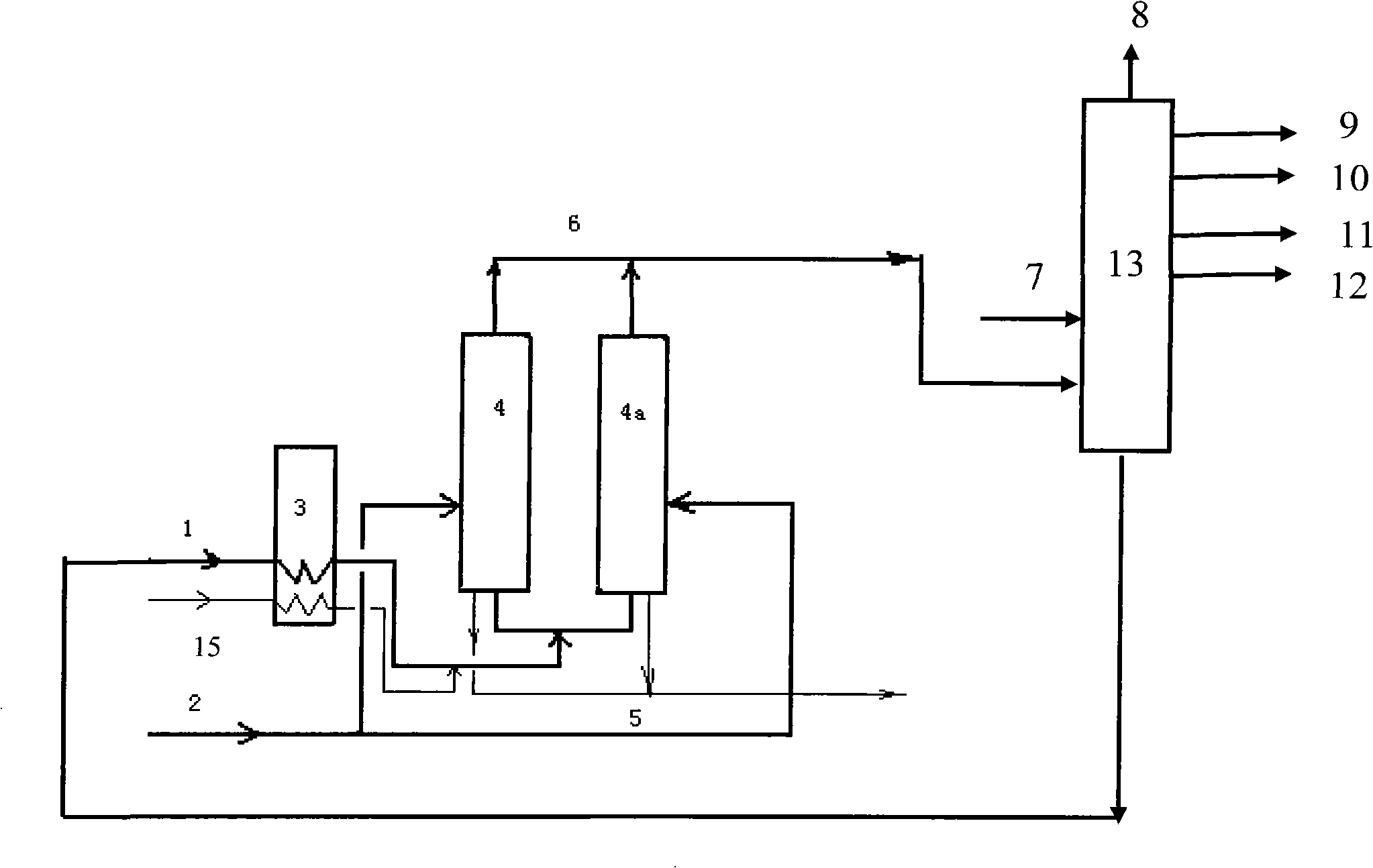

The present invention discloses a desulfurization and denitrification method for tail gas, used equipment and product application thereof. According to the method provided by the present invention, an oxidative catalyst is not used in a desulfurization column or a denitration column, or a small amount of the oxidative catalyst with a simplified formula added is used outside the desulfurization column and the denitration column, so that the cost is reduced significantly. The oxidative catalyst is not used in the desulfurization column or the denitration column to avoid the severe corrosion of the desulfurization column and denitration column texture by the material, so that the texture cost of the desulfurization column and the denitration column is reduced significantly; The volume of the processed material is small: only 30%-10% of the material in volume in the desulfurization column and the denitration column, and the cost for equipment corrosion prevention is lowered, so that a small amount of the oxidative catalyst used and a simplified formula can be facilitated.

Owner:陈汇宏 +2

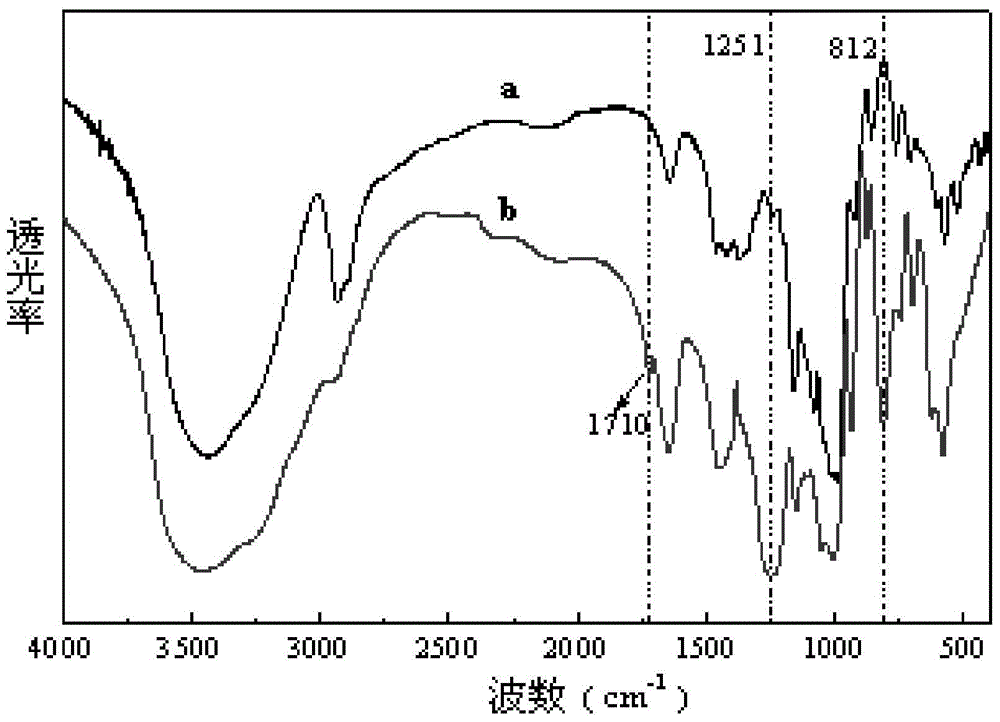

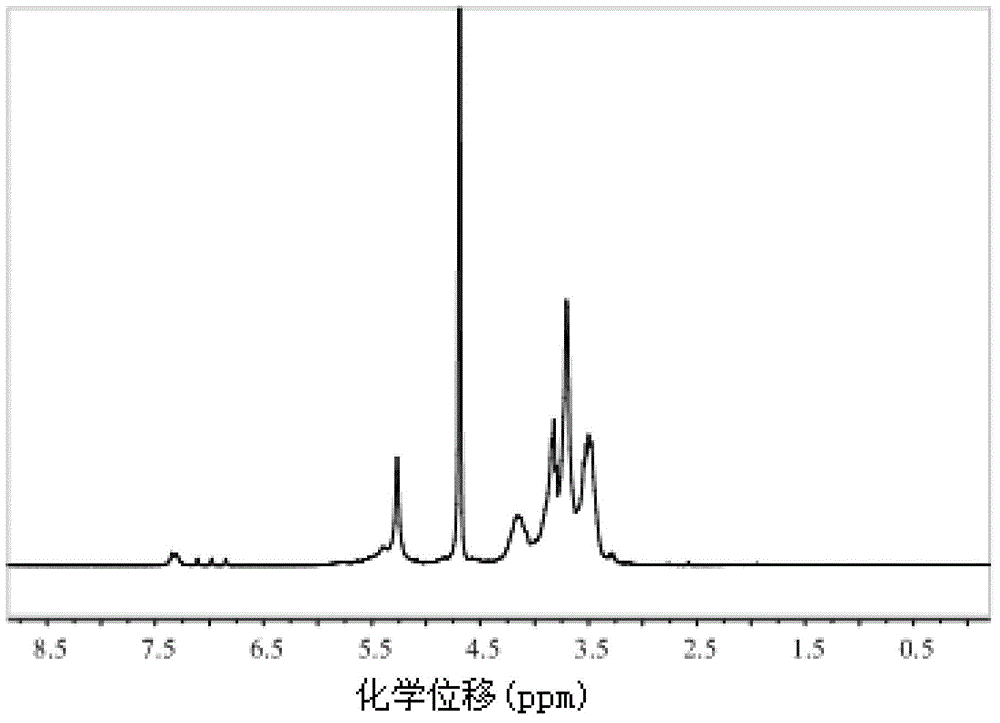

Preparation method and application of hydrophobic starch sulfate ester in cement water-reducing agent

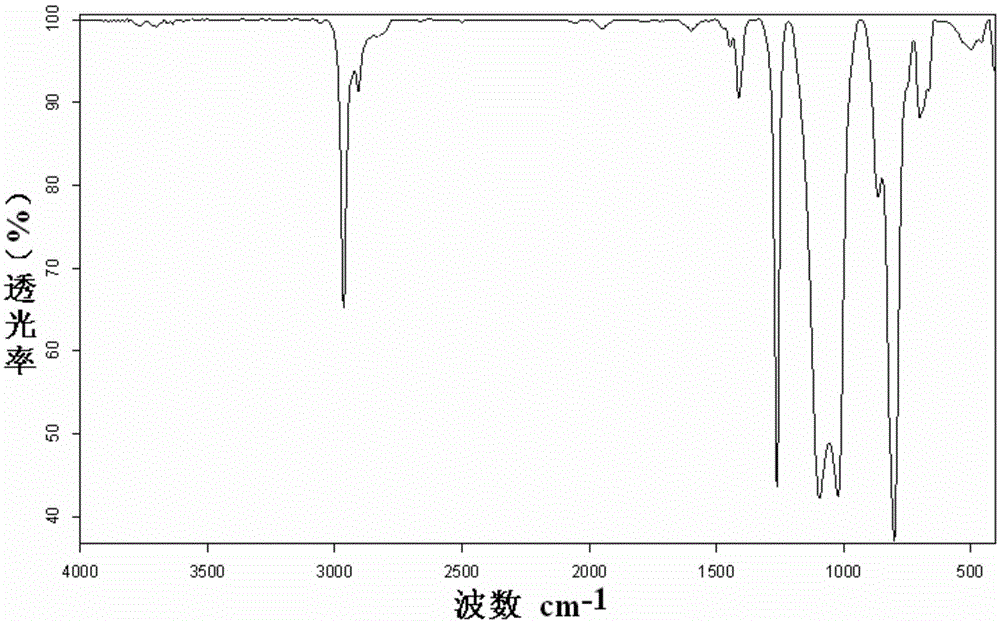

The invention relates to a preparation method and an application of a hydrophobic starch sulfate ester in a cement water-reducing agent, and belongs to the fields of chemistry and chemical engineering. The preparation method comprises the following steps: adding a sulfamic acid, starch, urea, aliphatic tertiary alcohol or aryl methyl alcohol and water into a reactor under the conditions that the molar ratio of the sulfamic acid to the starch is (0.5-3.0):1, the molar ratio of the urea to the starch is (0.1-3.0):1, the molar ratio of the aliphatic tertiary alcohol or the aryl methyl alcohol to the starch is (0.1-1) and the adding amount of the water accounts for 10% to 30% of the dry weight of the starch; and reacting for 1 to 10 hours at a temperature of 80 DEG C to 150 DEG C, thereby obtaining the hydrophobic starch sulfate ester in which the sulfonyl substitution degree is between 0.04 and 0.89 as well as the alkyl substitution degree is between 0.01 and 0.2. The hydrophobic starch sulfate ester is applied to the cement water-reducing agent, wherein the mass percent of the hydrophobic starch sulfate ester accounts for 0.1% to 1.0% of that of cement. According to the method, a dry method and one-pot reaction are adopted, so that the environmental pollution caused by the application of an organic solvent is avoided. Thus, the production cost is decreased.

Owner:DALIAN UNIV OF TECH

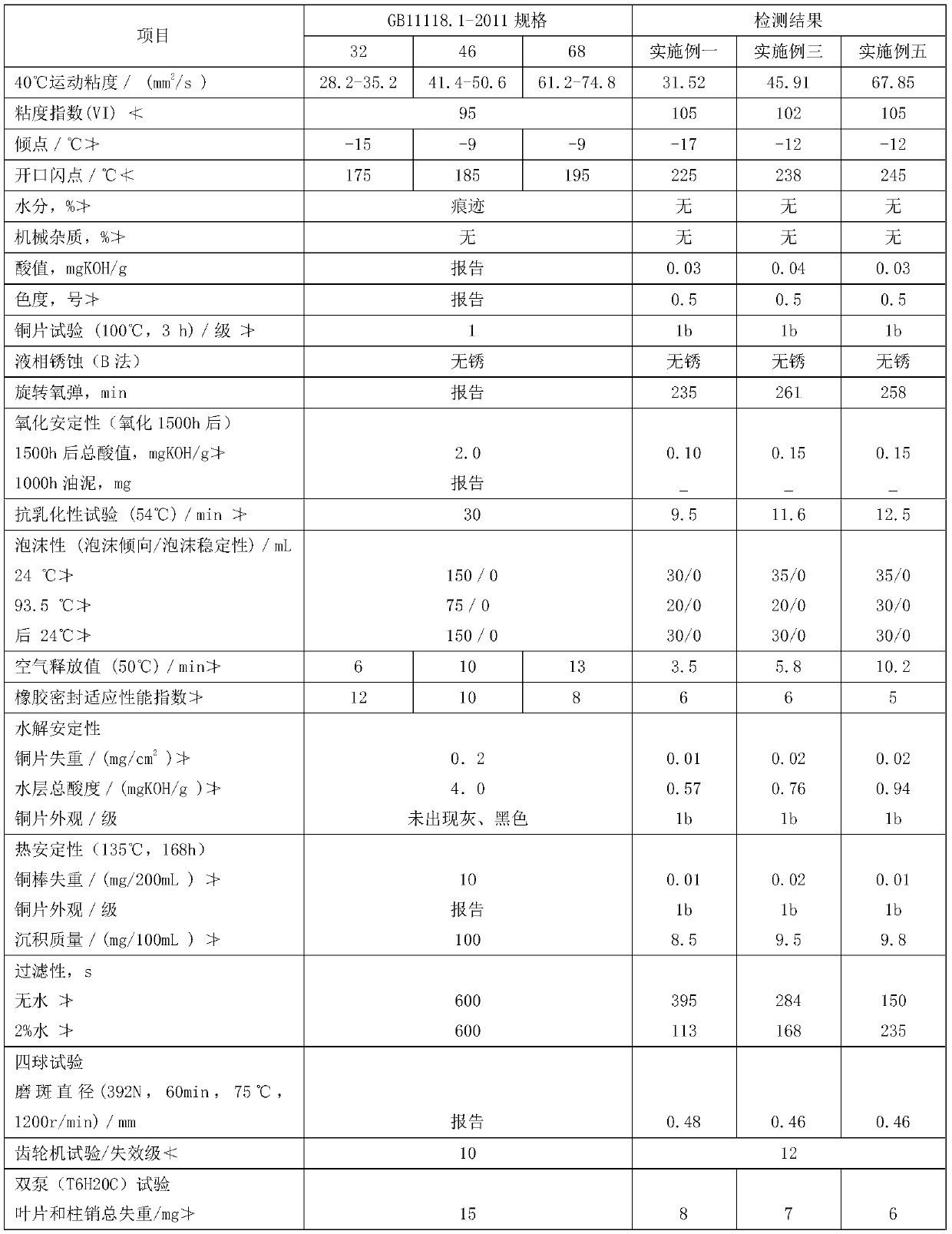

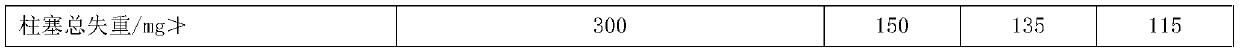

High-pressure anti-wear hydraulic oil

InactiveCN111363608AGood demulsibilityImprove rust resistanceLubricant compositionFoaming agentThermal stability

The invention discloses high-pressure anti-wear hydraulic oil, and belongs to the hydraulic oil field. The hydraulic oil comprises the following components in percentage by mass: 95-99% of base oil, 1.0%-1.5% of an extreme pressure anti-wear agent, 0.1-0.3% of a friction modifier; 0.4-1.0% of an antioxidant, 0.1-0.5% of an antirust agent, 0.1-0.5% of a metal deactivator, 0.02-0.1% of a detergent dispersant, 0.001-0.005% of an anti-foaming agent, and 0.1-0.5% of a demulsifying agent. Compared with the prior art, the hydraulic oil has the advantages of good viscosity-temperature performance, extreme pressure abrasion resistance, oxidation resistance stability, hydrolysis stability and thermal stability, and is not prone to aging and deterioration; the service life is prolonged, a friction pair can be normally lubricated under high-pressure and high-speed harsh conditions, and abrasion is reduced. The foam generated under the condition of violent mechanical stirring in the operation process can be quickly eliminated; air mixed in the oil can be released in a short time, and a static pressure can be accurately, sensitively and stably transmitted.

Owner:无锡中石油润滑脂有限责任公司

Coking method for processing highly acid crude oil

ActiveCN101280213AReduce corrosionCorrosion is reduced or even avoidedThermal non-catalytic crackingTowerCorrosion

The invention discloses a method of processing highly-acidic crude oil through the delayed coking process; the method includes that the low temperature highly-acidic crude oil is fed from the middle-lower part and the high temperature low-acidic coking raw material is fed from the bottom; the high temperature oil gas generated by the high temperature cracking of the low-acidic coking raw material is mixed with the low temperature highly-acidic crude oil so that the highly-acidic crude oil is enabled to realize the purpose of the deacidification through the pyrolysis deacidification under high temperature; meanwhile, the cracking temperature of the low-acidic coking raw material is lowered; the high temperature cracking time of the conventional raw materials; thereby, the coking yield is reduced and the stable operation period of the single tower is prolonged; besides, the preheating temperature of the highly-acidic crude oil can avoid the strong corrosion stage of the acid; the corrosion on the heating device caused by the acid can be reduced or avoided when the temperature is even lower than the corrosion temperature.

Owner:CHINA PETROLEUM & CHEM CORP +1

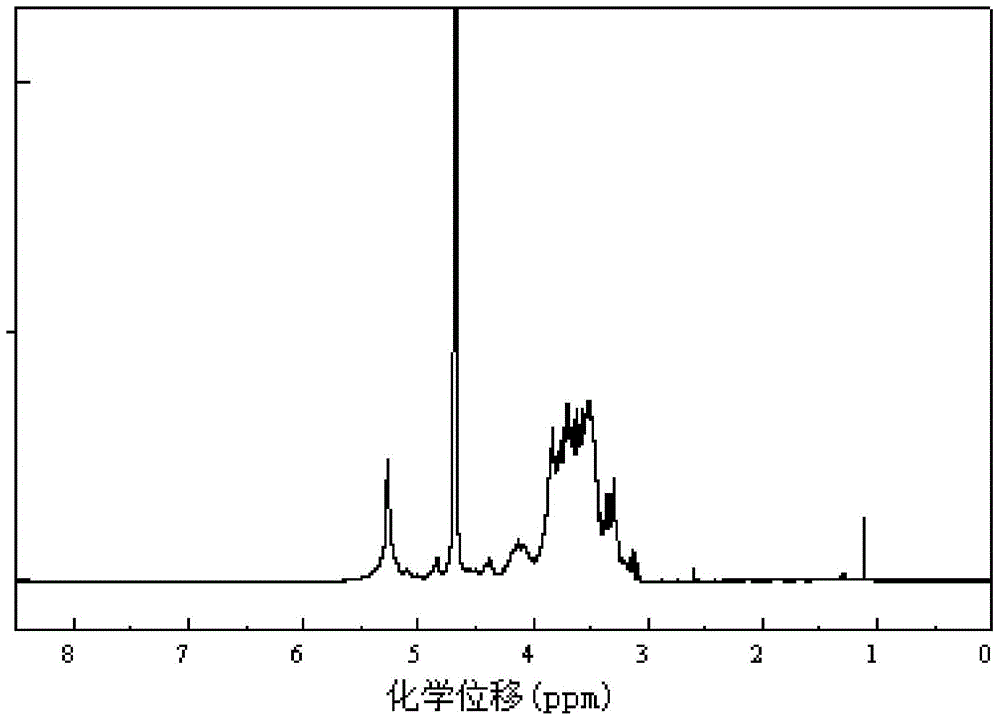

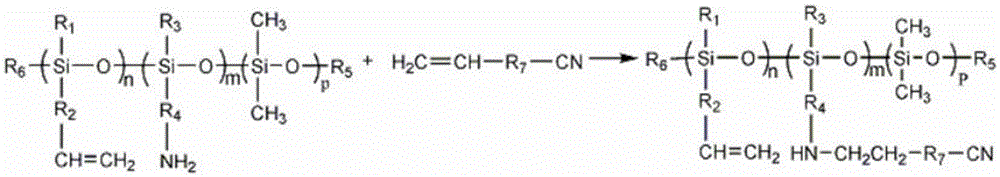

Synthesis method of high molecular weight polysiloxane containing nitrile group and vinyl at the same time and preparation method of addition type heat vulcanized nitrile silicone rubber

The invention relates to a synthesis method of high molecular weight polysiloxane containing nitrile group and vinyl at the same time and a preparation method of addition type heat vulcanized nitrile silicone rubber. The high molecular weight polysiloxane containing nitrile group and vinyl at the same time is prepared by performing amino group and double bond addition reaction on polysiloxane containing amino group and vinyl at the same time and compound containing unsaturated bonds and nitrile group. The addition type heat vulcanized nitrile silicone rubber is prepared through the synthesized high molecular weight polysiloxane containing nitrile group and vinyl at the same time. The synthesis method is simple and controllable, and high in synthesis efficiency; as the synthesized polysiloxane containing nitrile group and vinyl at the same time contains nitrile groups, the polarity and solubility parameters of polysiloxane are changed, and the prepared addition type heat vulcanized nitrile silicone rubber can have the performance of solvent oil resistance, and can be applied to various oil resistance and low temperature resistance places.

Owner:SHANDONG UNIV

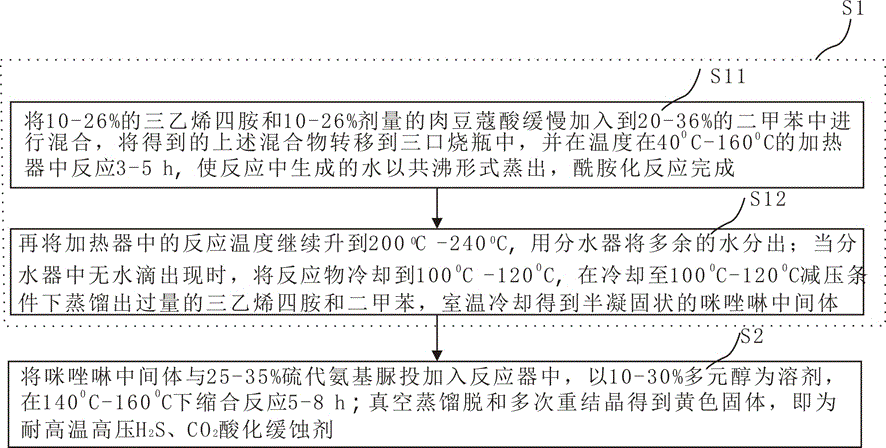

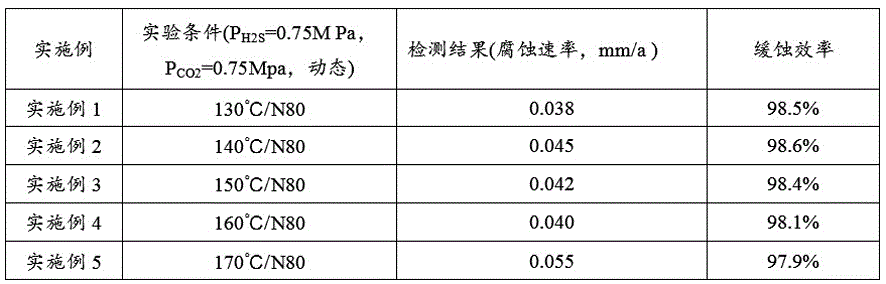

Preparation method and application of high-temperature high-pressure corrosion inhibitor capable of resisting corrosion by H2S and CO2

ActiveCN105542737AAccelerated corrosionExcellent corrosion inhibition efficiencyOrganic chemistryDrilling compositionPolyolTetramine

The invention discloses a preparation method and application of a high-temperature high-pressure corrosion inhibitor capable of resisting corrosion by H2S and CO2. The corrosion inhibitor is prepared from the following raw materials by mol: 10 to 26% of triethylene tetramine, 10 to 26% of myristic acid, 20 to 36% of xylene, 25 to 35% of thiosemicarbazide and 10 to 30% of polyol. The preparation method for the corrosion inhibitor comprises the following steps: step 1, subjecting myristic acid and triethylene tetramine to amidation so as to obtain an imidazoline intermediate; and step 2, subjecting the imidazoline intermediate and thiosemicarbazide to a condensation reaction so as to obtain the corrosion inhibitor. The preparation method for the corrosion inhibitor is simple and does not need special equipment; the prepared corrosion inhibitor has excellent corrosion inhibition efficiency and corrosion resistant, is applicable to yield increase operation in an oil and gas well containing H2S with a concentration of as high as more than 30 mg / L and saturated CO2; and after addition of the corrosion inhibitor, the corrosion rate of a steel disc is less than 0.05 mm / a, which accords with national corrosion standards in China.

Owner:DONGGUAN ZHIYUAN ELECTRONICS TECH

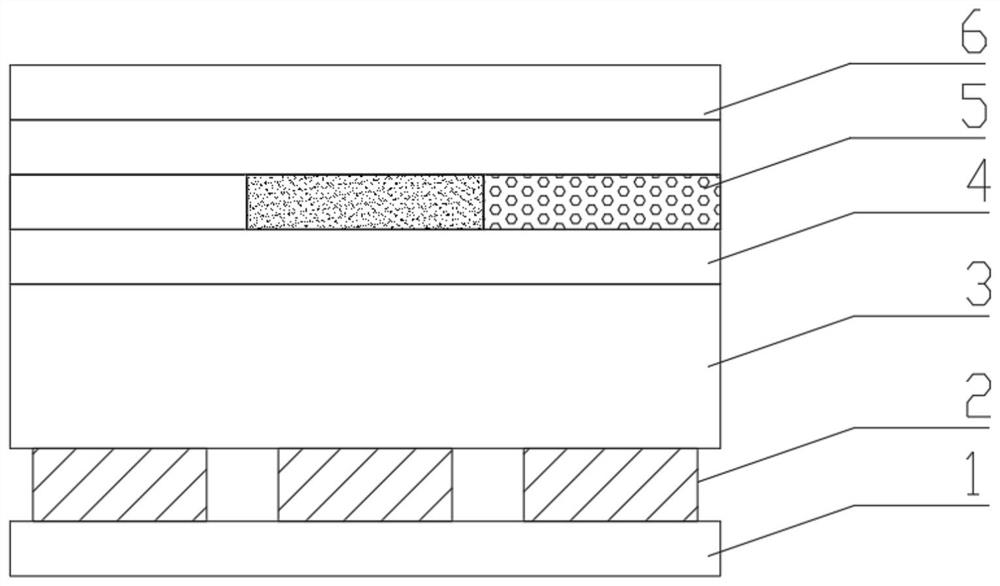

High-color-saturation silicon-based OLED micro display device and preparation method thereof

PendingCN112201678AReduce manufacturing costMake up for the gap in the marketSolid-state devicesSemiconductor/solid-state device manufacturingGlass coverDisplay device

The invention relates to the technical field of organic light-emitting diode manufacturing, particularly to a silicon-based OLED micro display device and a preparation method thereof. The display device is composed of a silicon-based CMOS drive circuit substrate, a top light-emitting multilayer composite anode, a blue light organic light-emitting layer, an antireflection layer, a quantum dot colorfilter layer, an inorganic or polymer composite film sealing layer and a glass cover plate. In the preparation of the display device, a dry etching process is used for preparing composite anode pixelpoints, and a doping mode is used for realizing the preparation of a blue light organic light-emitting layer. The display device has the characteristic of low optical loss.

Owner:YUNNAN NORTH OLIGHTEK OPTO ELECTRONICS TECH

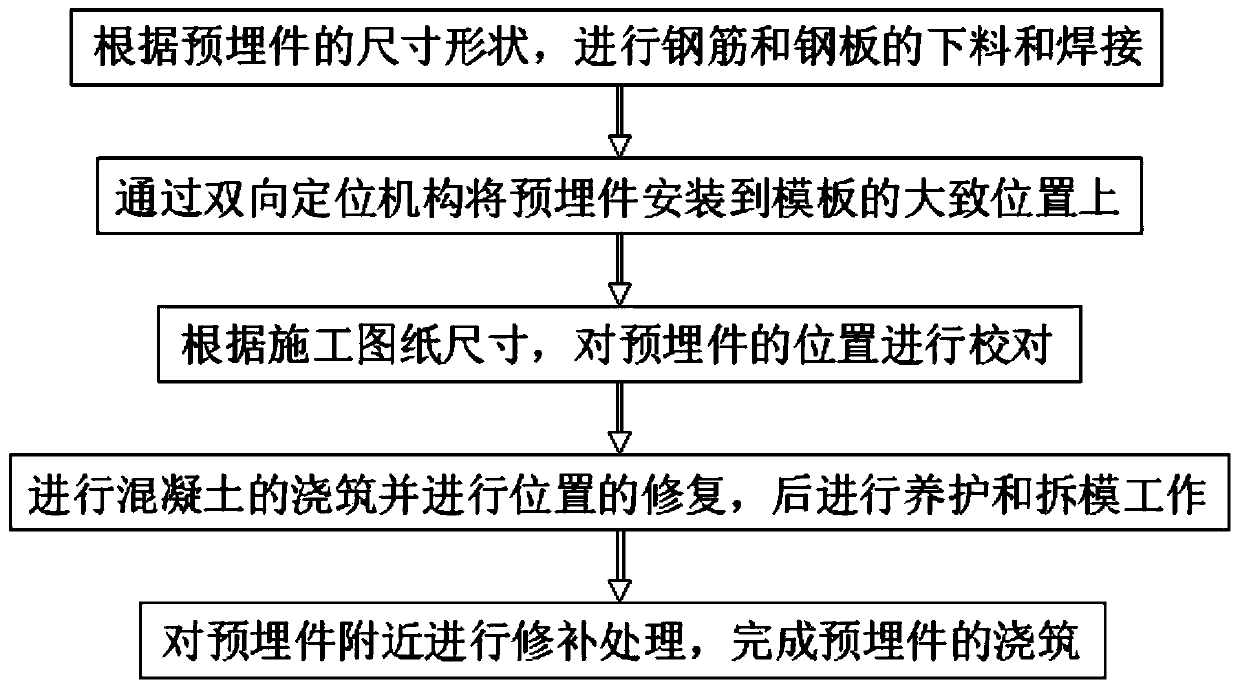

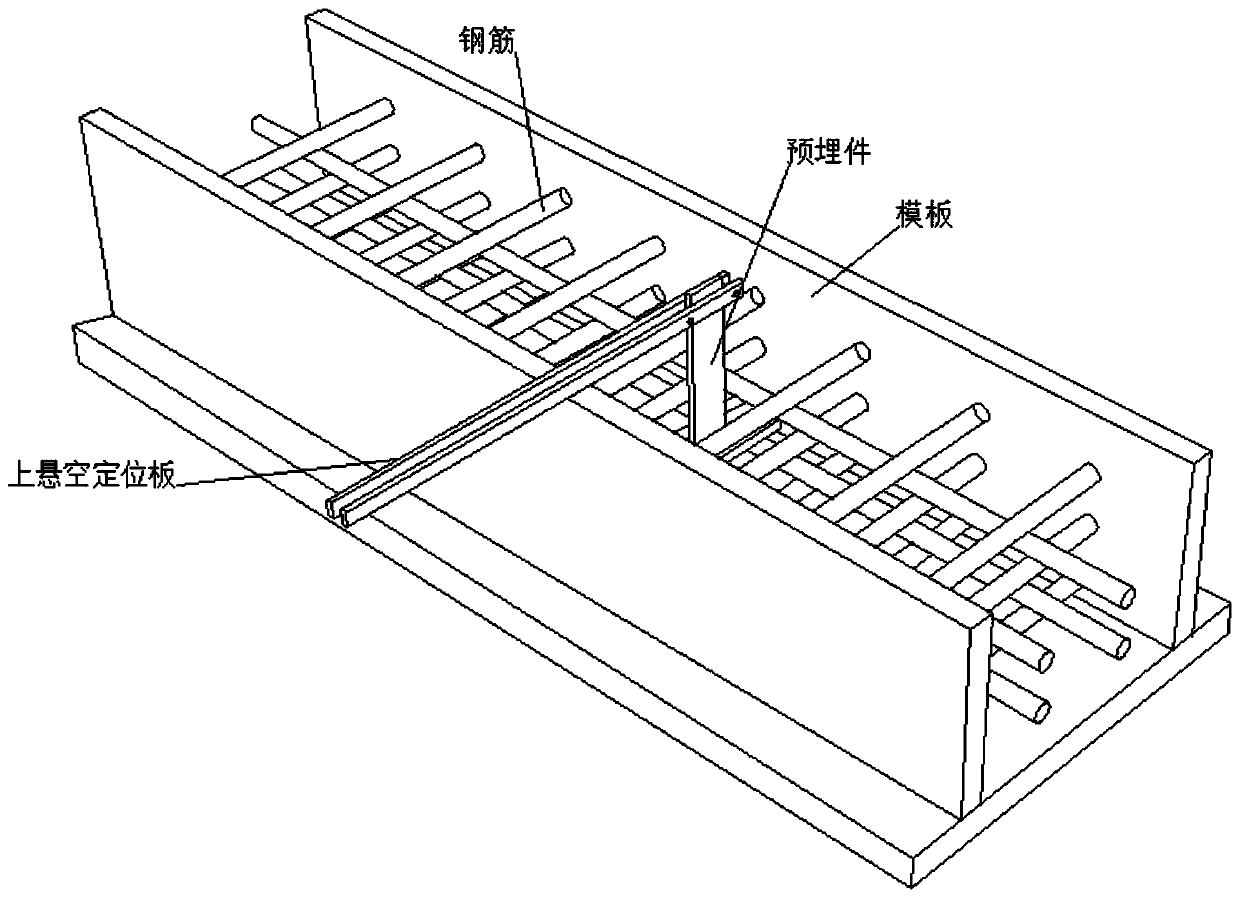

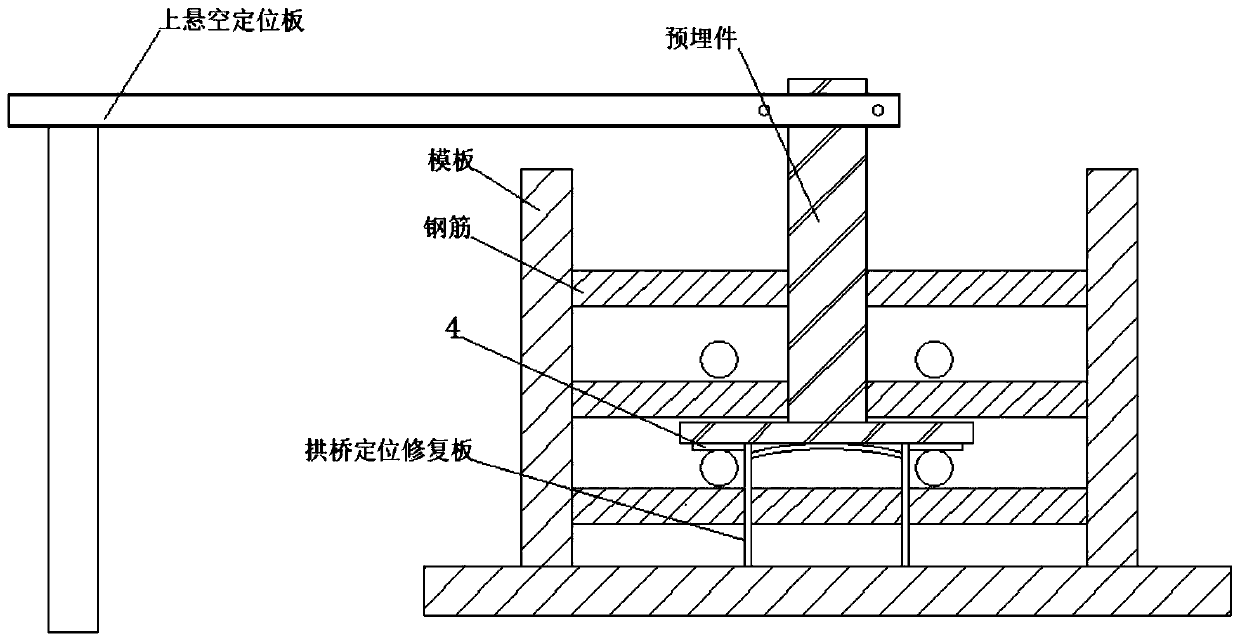

Embedded part construction process for assembled building

ActiveCN110924535AGuaranteed stabilityImprove efficiencyBuilding constructionsArchitectural engineeringRebar

The invention discloses an embedded part construction process for an assembled building and belongs to the field of embedded part construction. According to the embedded part construction process forthe assembled building, by means of a double-way positioning mechanism, under the action of an upper hang-in-the-air positioning plate, an embedded part can be fixed into a form board from above in ahang-in-the-air state of no contact with the form board and a steel bar; meanwhile, under the action of an arch bridge positioning repair plate, a certain supporting force can be provided for the embedded part from below, thus the stability of the embedded part is effectively maintained, and occurrence of skewing of the embedded part during pouring is reduced; by means of the double-way fixing function on the embedded part, the workload of position adjustment of the embedded part at later stage is effectively reduced, and thus the efficiency of pouring the embedded part into a concrete layer of a pre-fabricated part is improved remarkably; and under the action of a foam board and a rainfall factor, moisture nearby the steel bar and the embedded part can be effectively absorbed, and the situation of severe rusting of the steel bar and the embedded part caused by too much accumulated water in the position where the steel bar and the embedded part are close to each other is effectively avoided.

Owner:杨涛

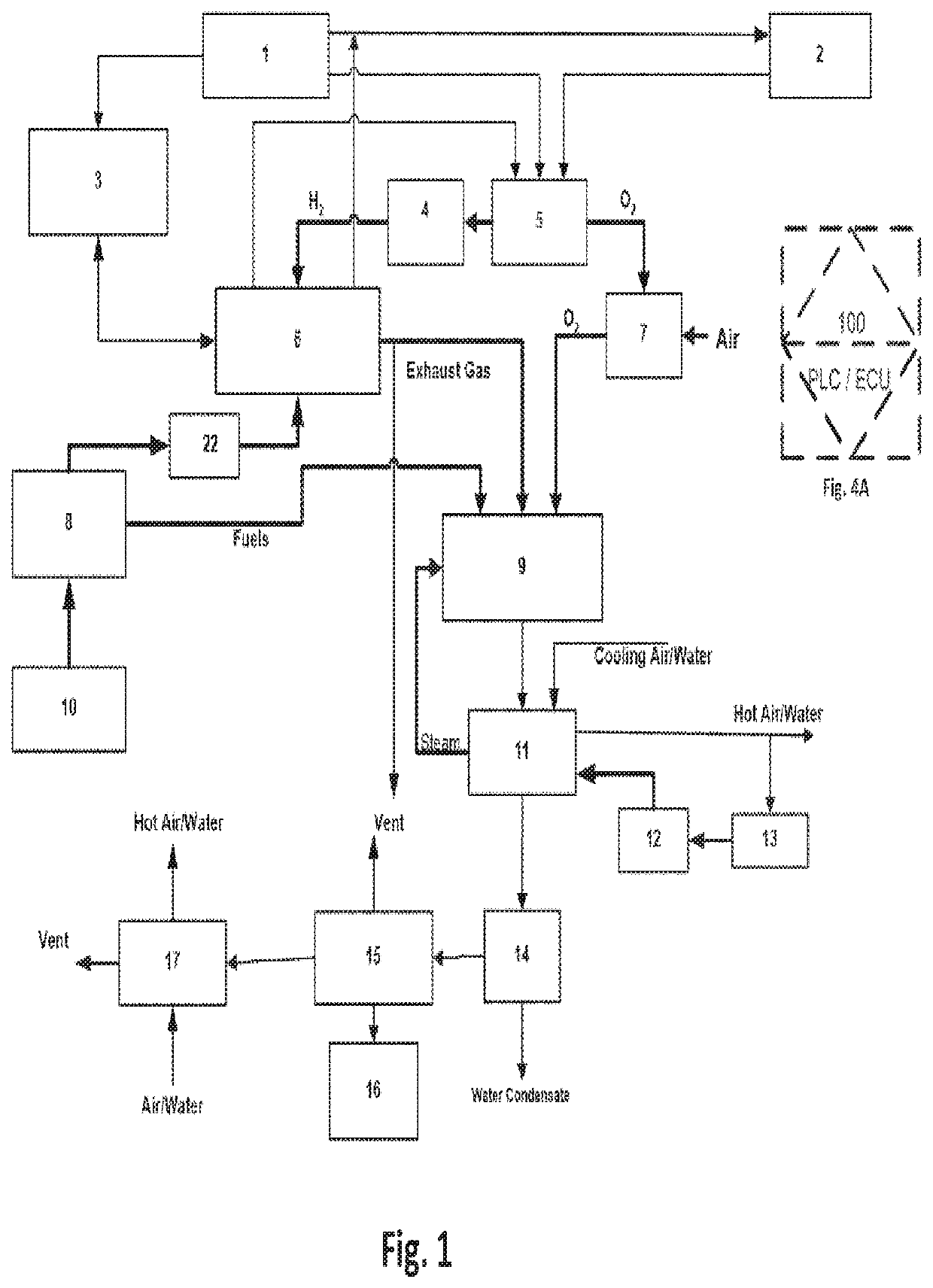

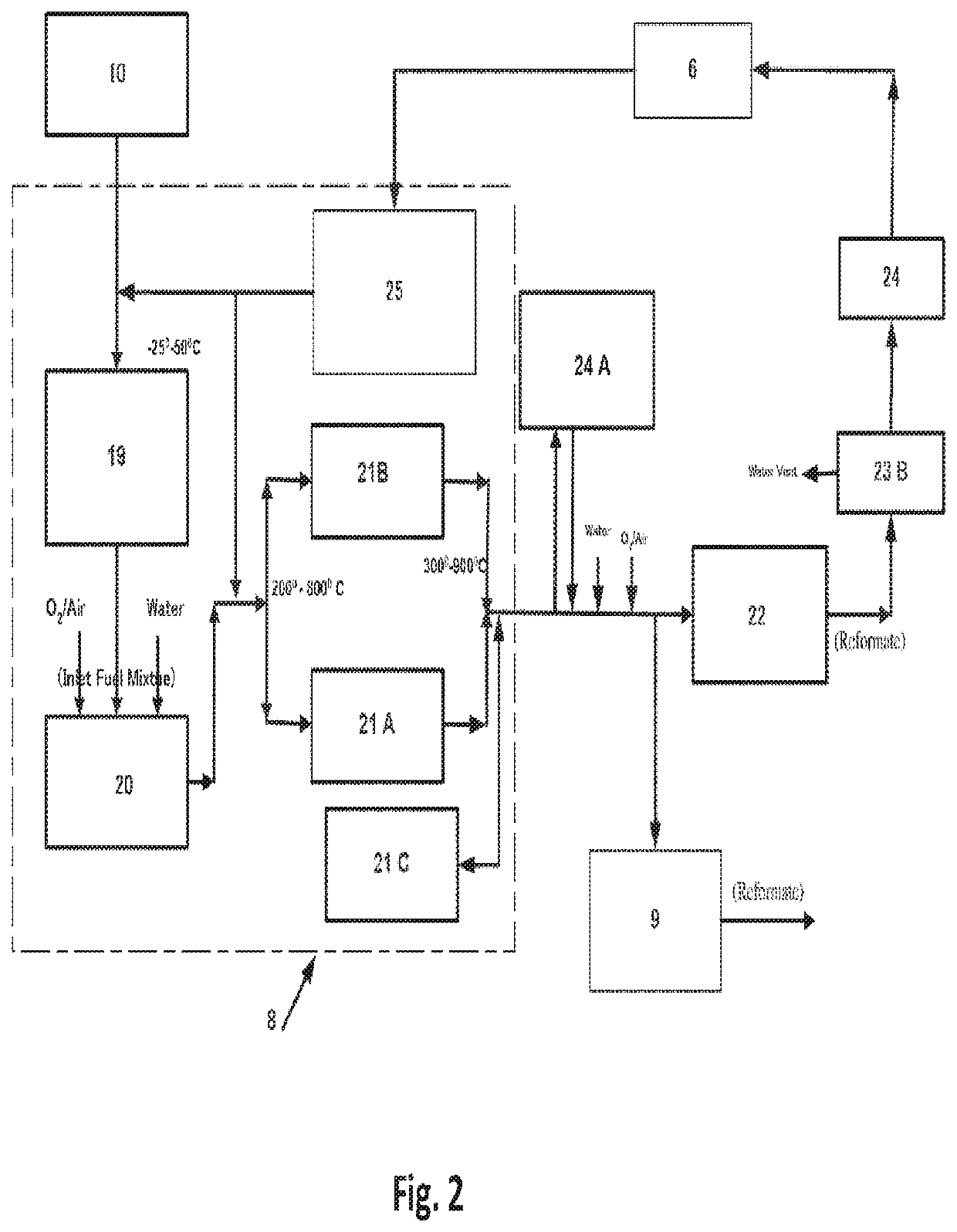

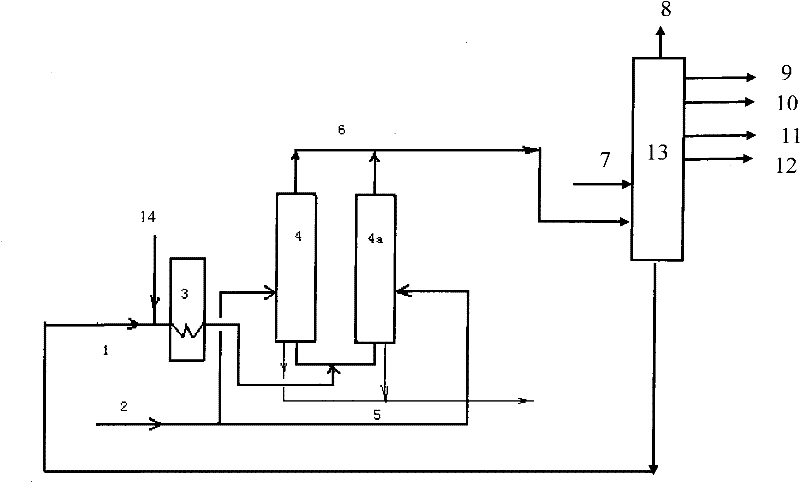

Catalytic biogas combined heat and power generator

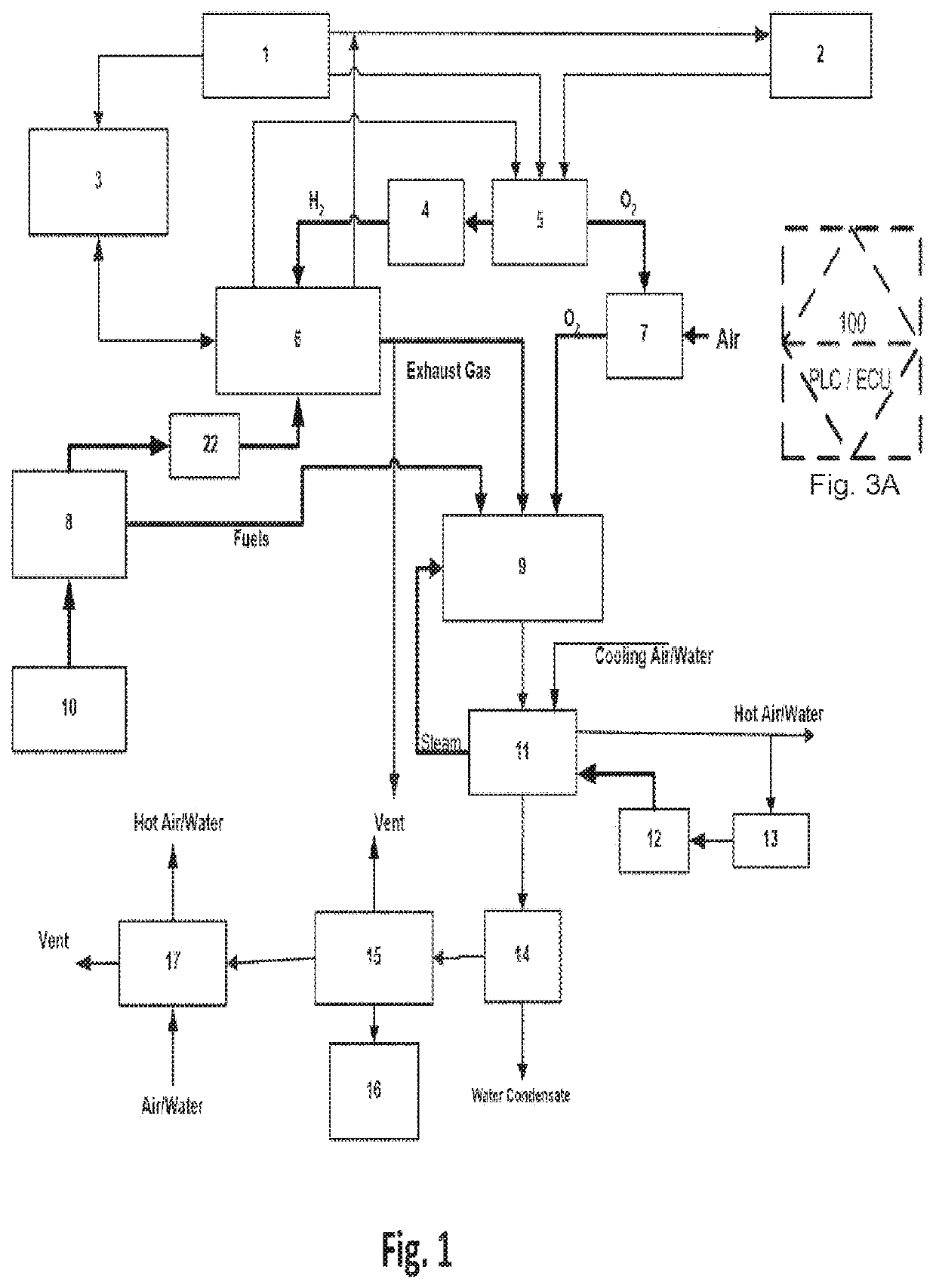

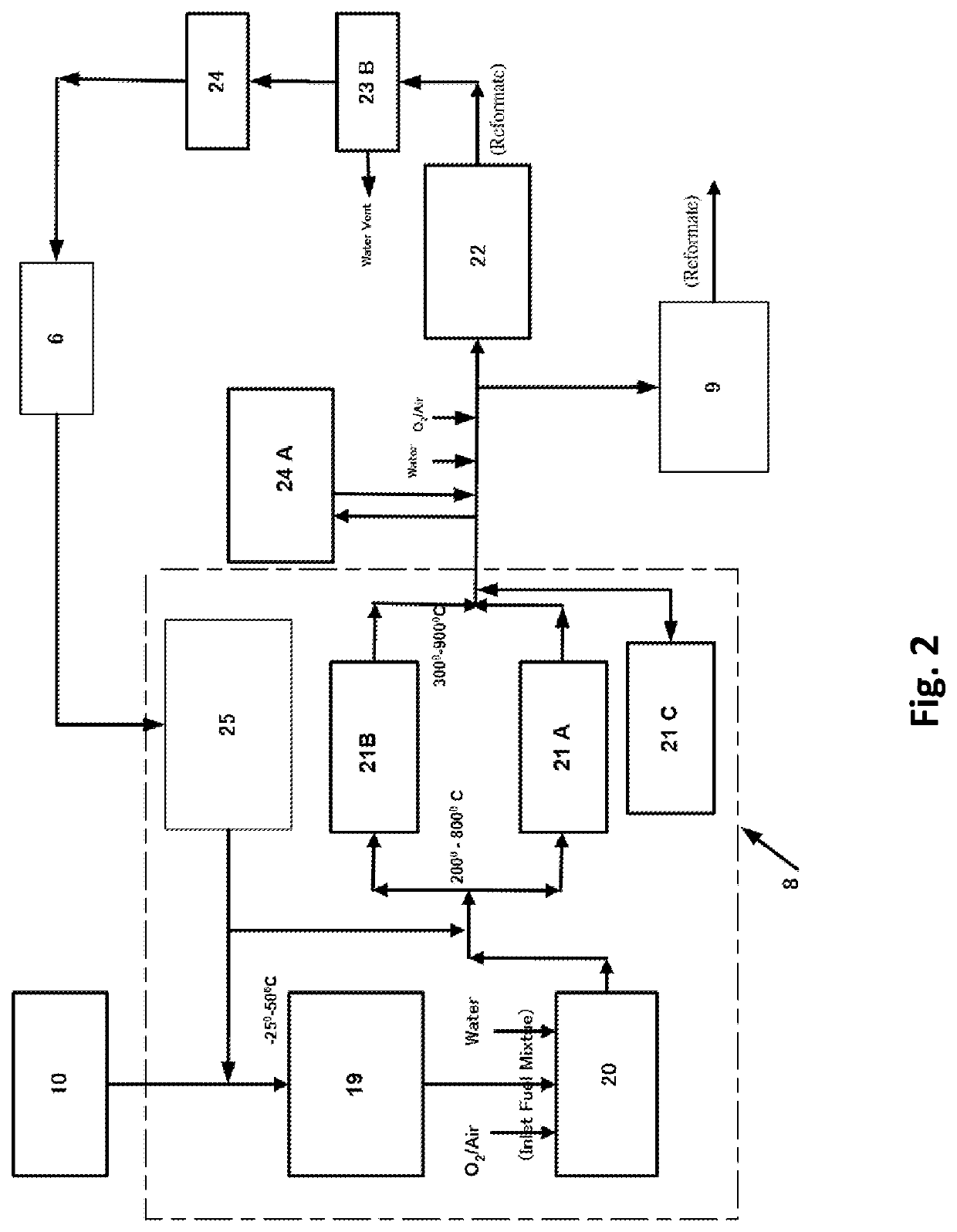

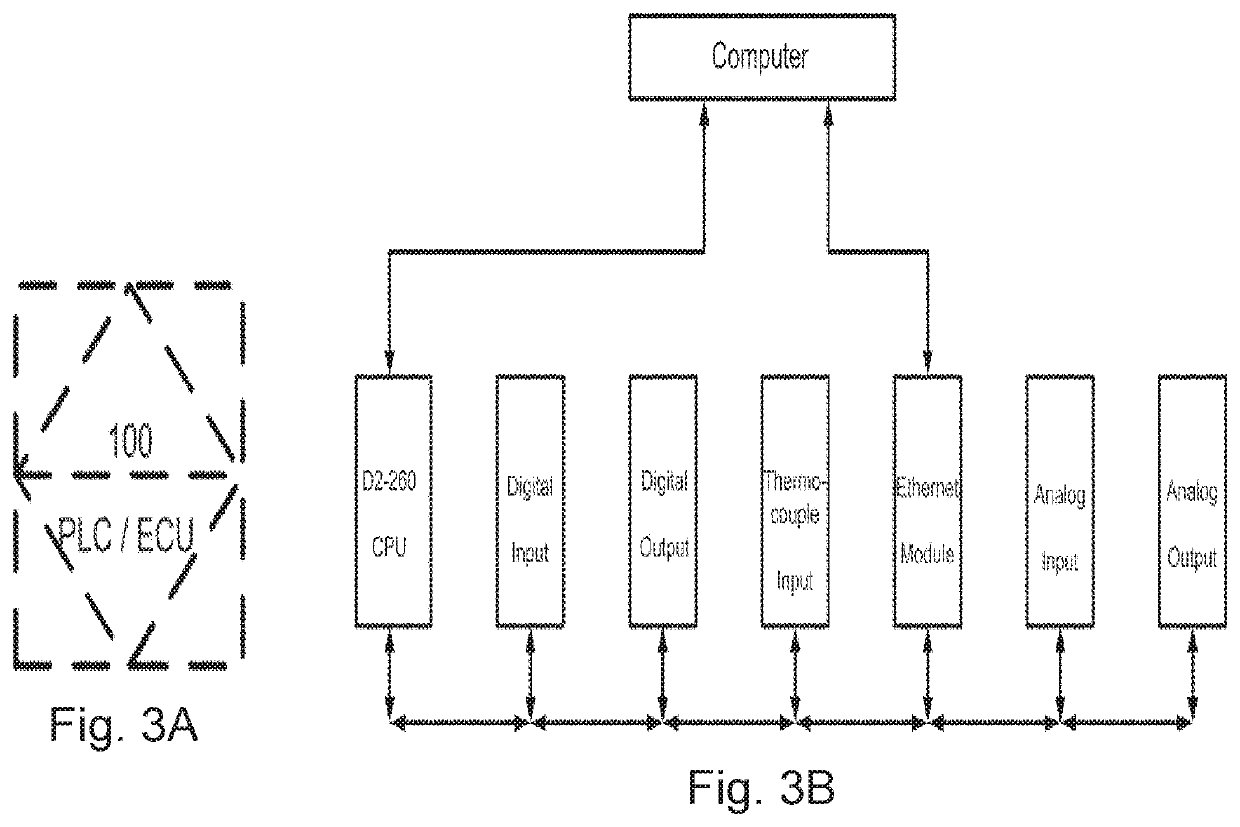

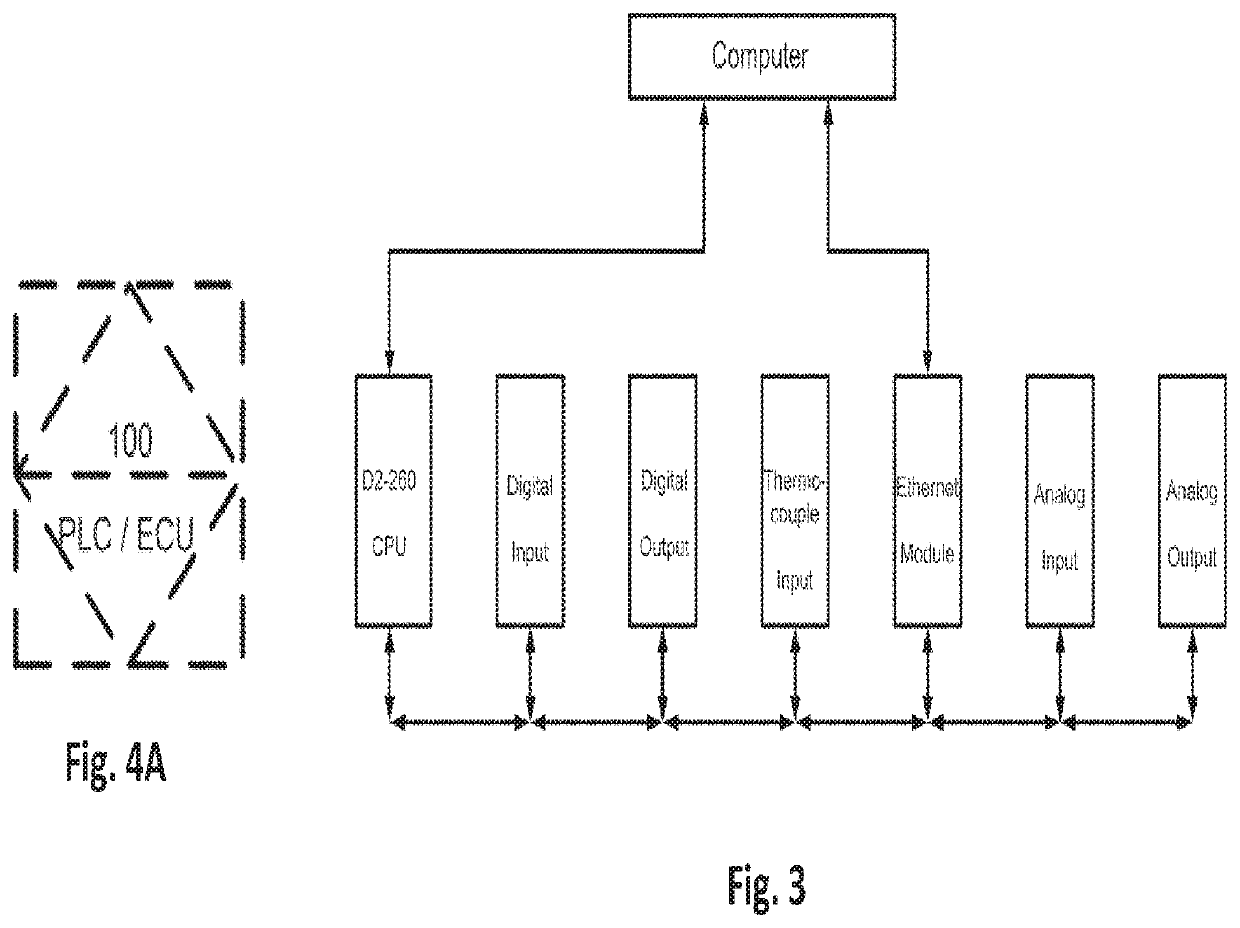

ActiveUS10626790B2Avoid severe corrosionIncrease the H<subInternal combustion piston enginesGaseous engine fuelsPtru catalystCogeneration

A distributed Biogas Combined Heat and Power (CHP) Generator can provide automatically hot water and electricity for local applications. Since biogas is produced by an anaerobic digester from human, animal, kitchen and agriculture's wastes, it is a short term recycled product from the photosynthesis of CO2, and has a net zero carbon emission. The sulfur compounds in the biogas can be removed by the following steps: (1), converting all sulfur compounds into H2S by the hydrogen produced from the biogas over Pt group metal catalysts; (2). adsorbing the H2S at high temperature by the regenerable Pt group metal catalyst and adsorbents. The desulfurized biogas is further converted by an ATR / CPO reformer or a steam generating reformer to produce various reformates, which can be connected to a downstream 1C engine / gas turbine, and / or a steam turbine to drive electric generators for generating electricity. The hot reformate and the exhaust gases can be cooled in heat exchangers to produce hot water / hot air.

Owner:HWANG HERNG SHINN

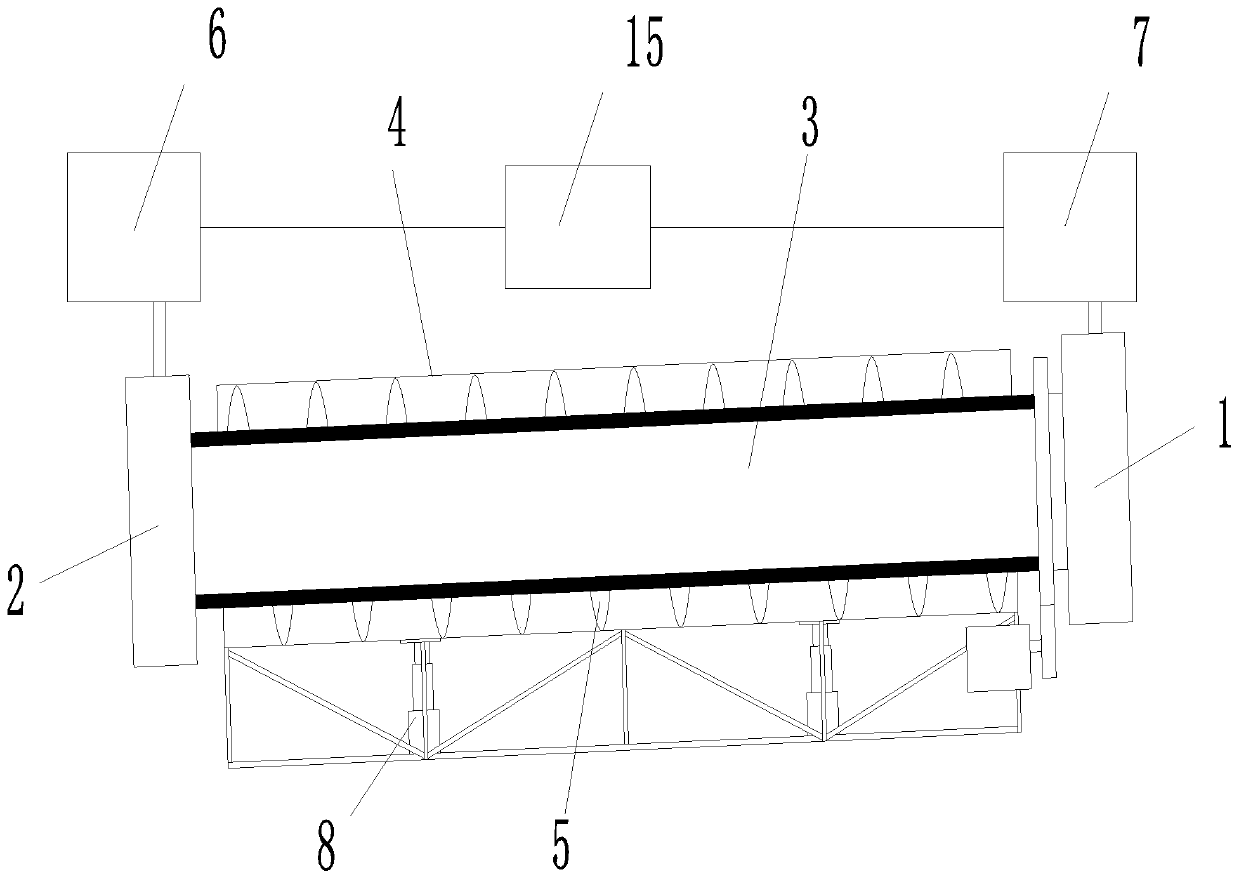

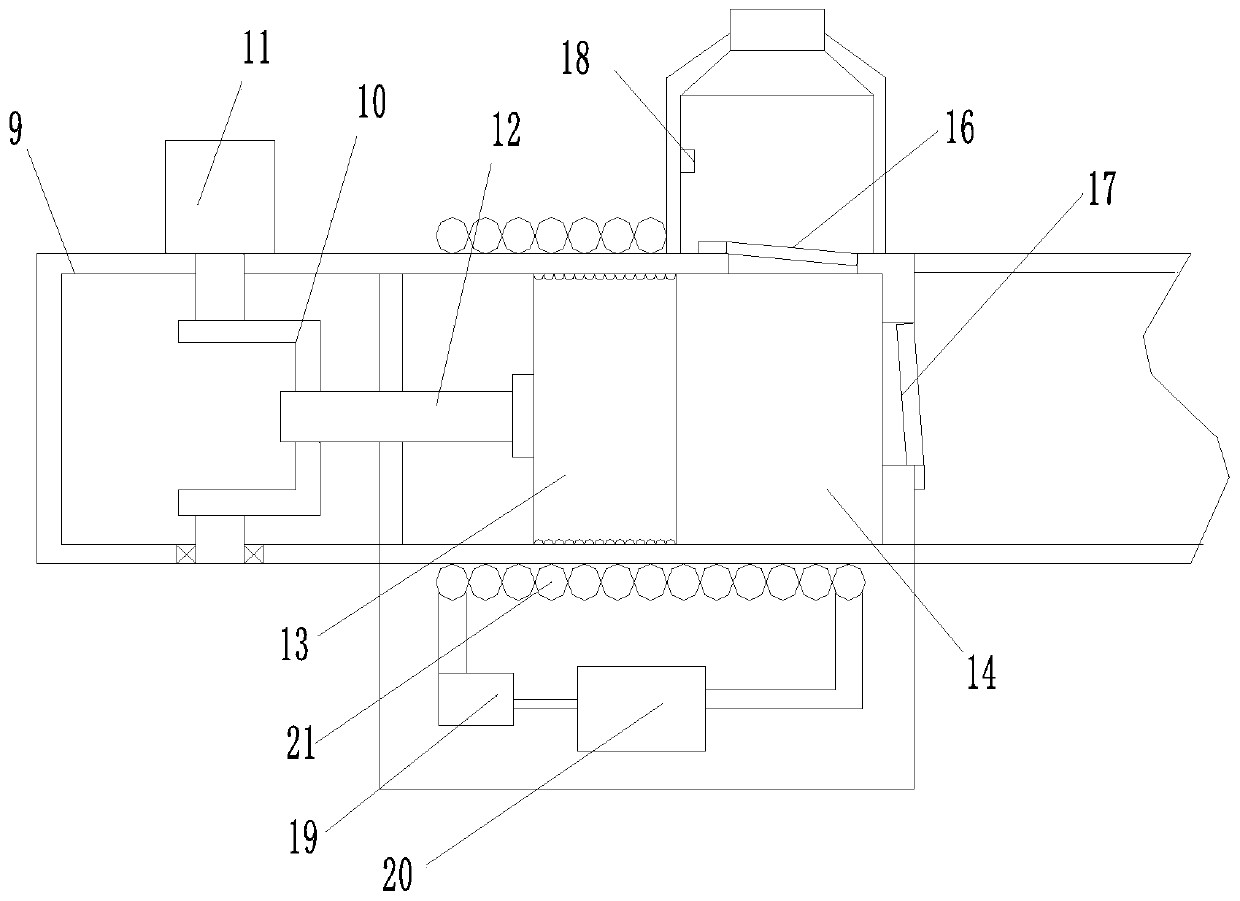

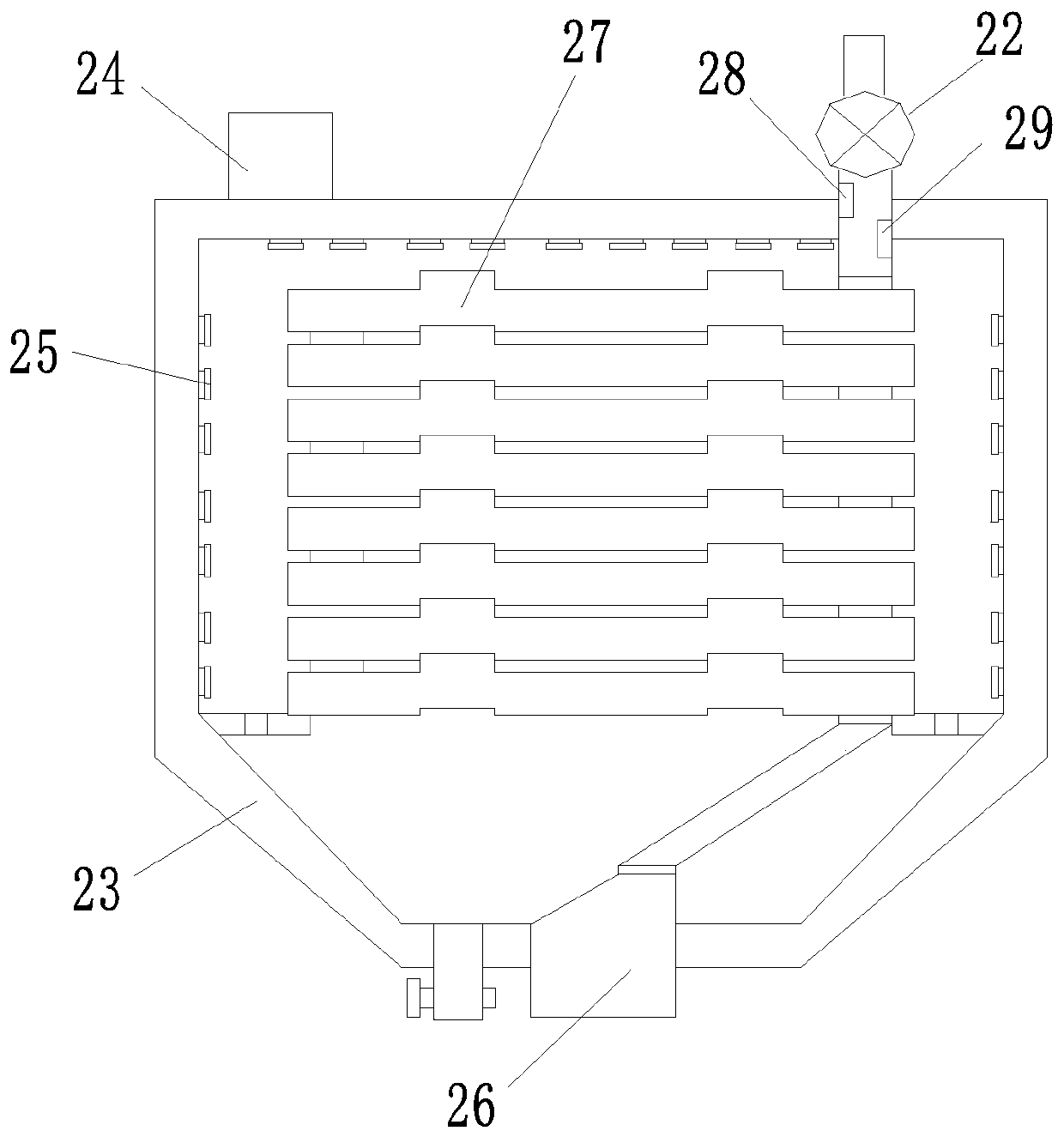

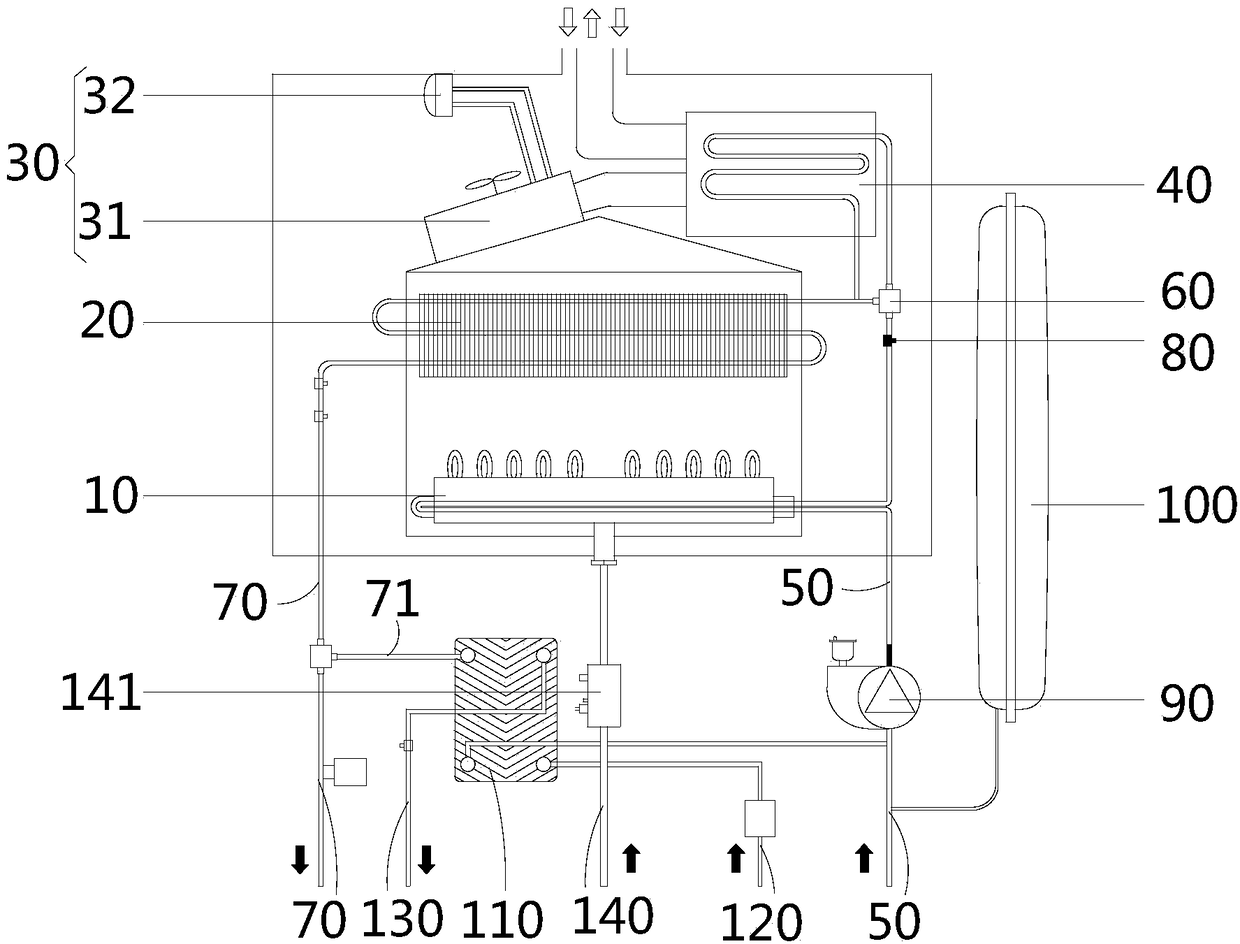

Electromagnetic heating rotary kiln with function of controlling reducing atmosphere

ActiveCN110836599AAvoid severe corrosionExtended service lifeRotary drum furnacesControl systemEngineering

The invention discloses an electromagnetic heating rotary kiln with the function of controlling reducing atmosphere, and belongs to the field of rotary kilns. The electromagnetic heating rotary kiln comprises a feeding portion, a main kiln portion and a discharging portion. The feeding portion and the discharging portion are in sealed connection to a front port and a rear port of the correspondingmain kiln portion correspondingly. The main kiln portion comprises a core resisting to high-temperature oxidization, a rear-end gas conveying device and a front-end tail gas exhaust device. The coreis made of a Cr-Ni-Mo-W-Fe-Si alloy material. The left portion of the core is lower than the right portion of the core, and a protection cover is arranged on the outer side of the core. A gap is reserved between the core and the protection cover, and an electromagnetic induction heating structure is arranged in the gap. The electromagnetic induction heating structure generates vortexes on the electric conduction core to emit heat, the heat is transmitted to materials turning over in the core, reduction gas is controllably input from the left end of the core through the rear-end gas conveying device under the action of a control system, and then tail gas generated after reacting in the whole core is controllably exhausted from the rear end of the core through the front-end tail gas exhaustdevice under the action of the control system.

Owner:上海江竑环保科技有限公司

Catalytic Biogas Combined Heat and Power Generator

ActiveUS20190383212A1Avoid severe corrosionIncrease the H<subInternal combustion piston enginesEngine controllersSorbentCogeneration

Owner:HWANG HERNG SHINN

Gas stove

PendingCN108645032AAvoid it happening againAvoid severe corrosionAir heatersCombustion technology mitigationPlate heat exchangerEngineering

The invention provides a gas stove. The gas stove comprises a burner assembly, a first-stage heat exchanger, a smoke absorbing assembly and a second-stage heat exchanger, wherein the first-stage heatexchanger is arranged in the burner assembly; the smoke absorbing assembly is connected to the burner assembly; the second-stage heat exchanger is arranged in the smoke absorbing assembly. The gas stove further comprises a water returning pipeline, a three-way valve, a heat supplying pipeline and a temperature detector; the water returning pipeline is correspondingly connected to a water inlet ofthe second-stage heat exchanger and a water inlet of the first-stage heat exchanger through the three-way valve; the temperature detector is used for detecting the water temperature of the water returning pipeline; and the controller is electrically connected to the temperature detector and the three-way valve. According to the technical scheme, the gas stove is capable of preventing smoke temperature from decreasing to be less than dew point temperature to generate a large number of condensate water through low-temperature in the water returning pipeline, and thus a smoke pipe is prevented from serious corrosion by excessive condensate water; and moreover, the potential risk caused by icing of the condensate water at an outlet of the smoke pipe can be solved.

Owner:GREE ELECTRIC APPLIANCES INC

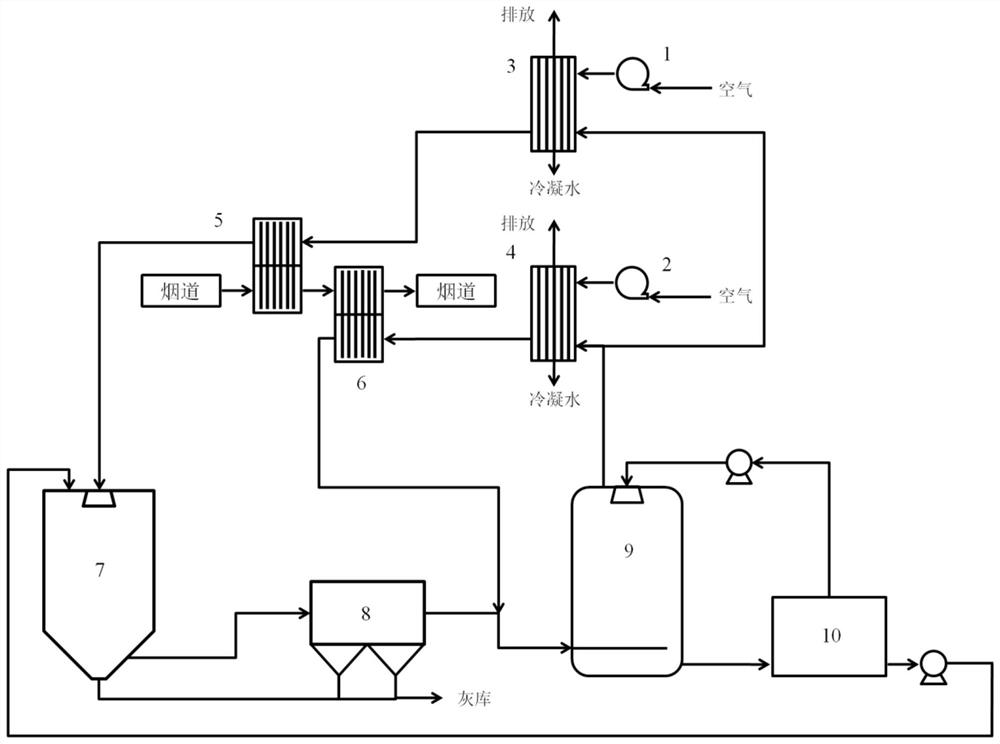

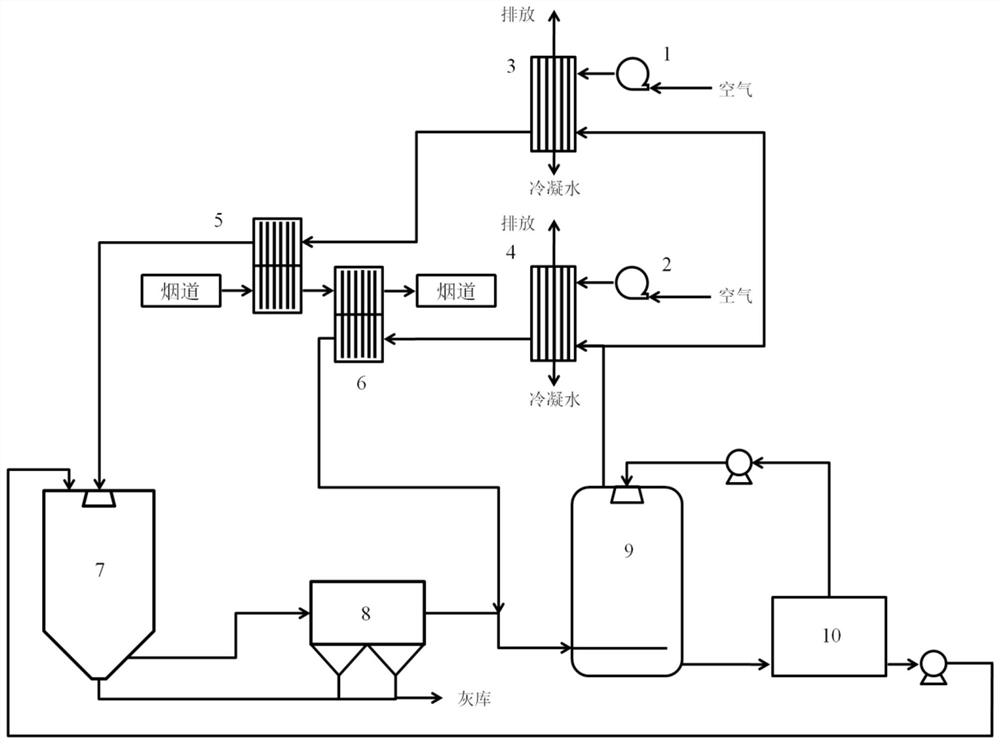

Desulfurization wastewater zero discharge system for gradient utilization of flue gas waste heat and working method thereof

ActiveCN112239242AReasonable designAchieve warm-upSpecific water treatment objectivesWaste water treatment from gaseous effluentsFlue gasSpray dried

The invention discloses a desulfurization wastewater zero discharge system for gradient utilization of flue gas waste heat and a working method of the desulfurization wastewater zero discharge system,and belongs to the technical field of desulfurization wastewater treatment. The system comprises a first air inlet device, a second air inlet device, a first air heat exchanger, a second air heat exchanger, a first flue gas heat exchanger, a second flue gas heat exchanger, a spray drying tower, a dust remover, an evaporation concentration tower and a desulfurization wastewater pool. High-temperature flue gas at the tail of a boiler is used for increasing the air temperature, desulfurization wastewater is evaporated and dried by high-temperature air through gradient utilization of the temperature, the cooled air is used for concentrating and reducing the desulfurization wastewater, the dust remover is used for recovering dried salt in the wastewater, and the air heat exchanger is used forrecovering heat in air at an outlet of a system for preheating the air. Compared with a conventional desulfurization waste water zero-discharge method, waste heat in flue gas is fully utilized, concentration and drying of waste water are synchronously achieved, the influence on water balance and material balance of gas in an original flue is small, and good application prospects are achieved.

Owner:HUANENG CLEAN ENERGY RES INST

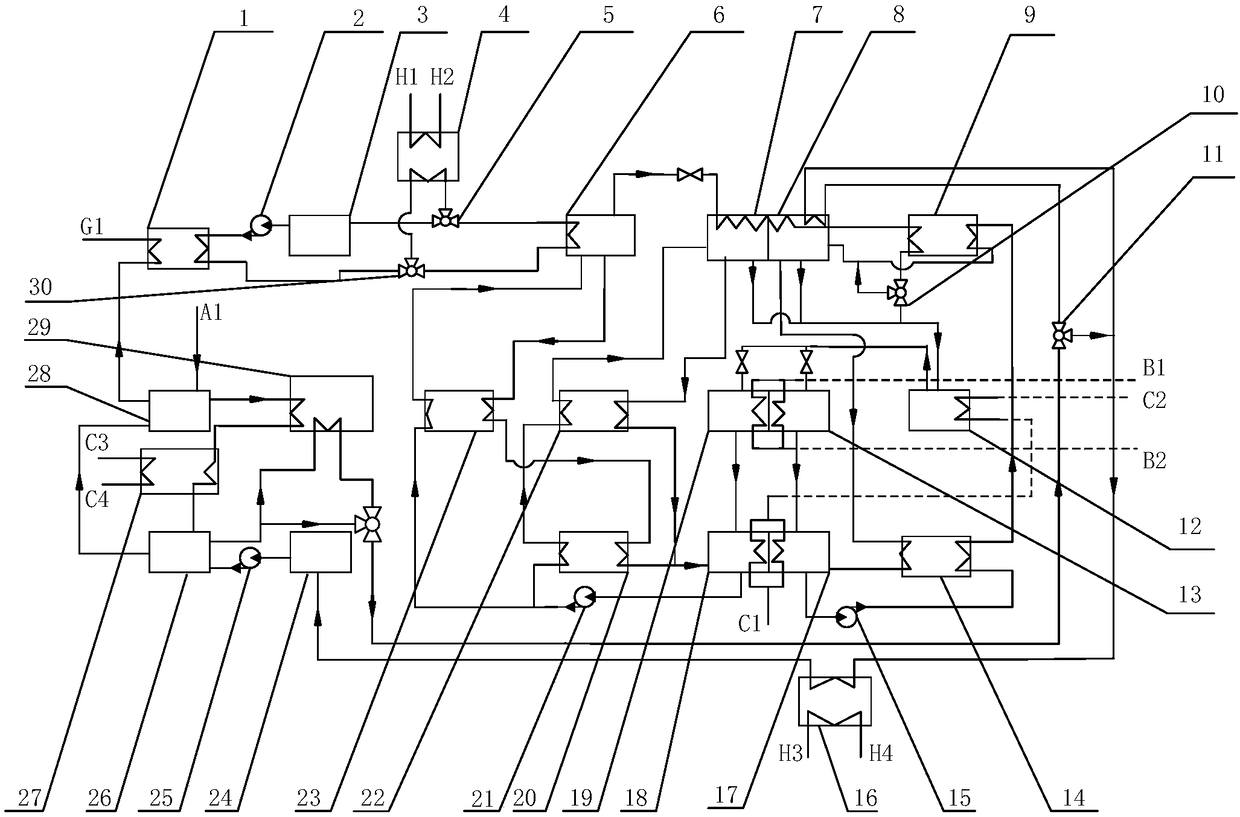

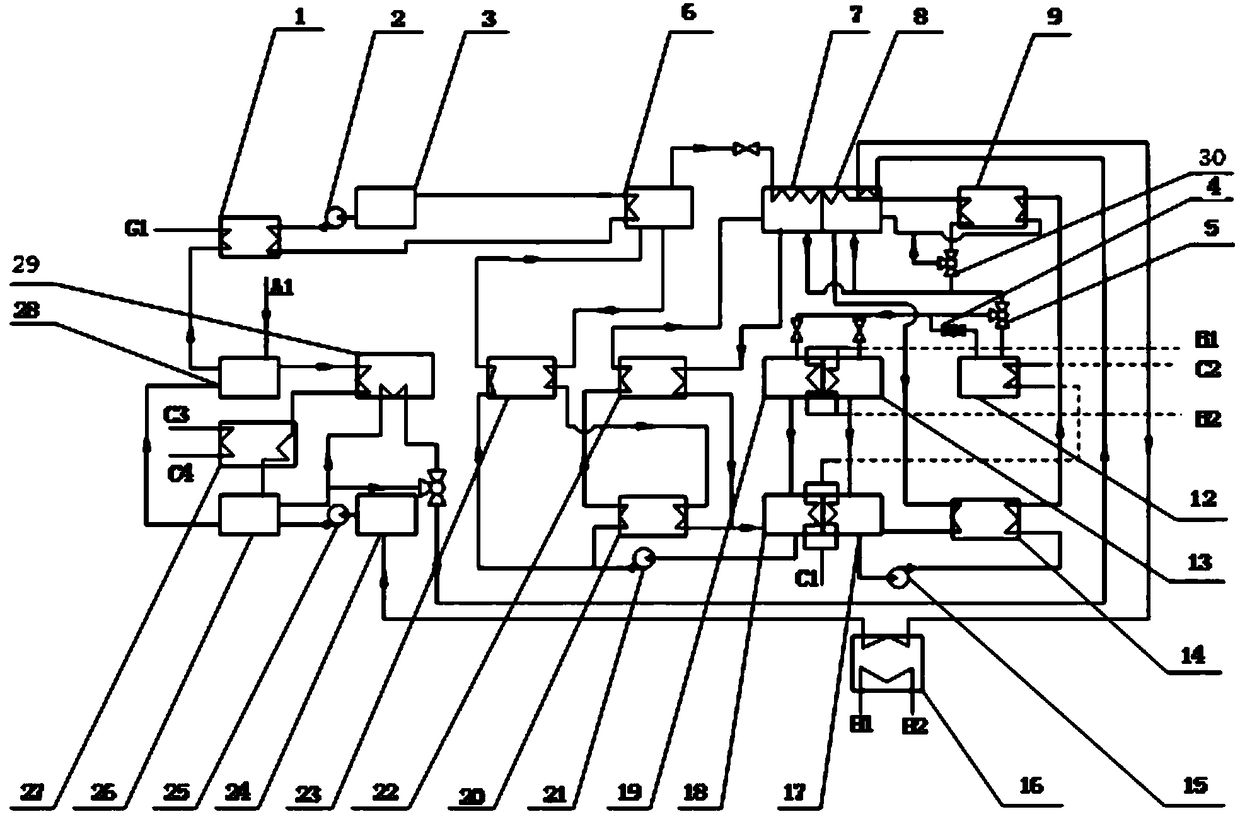

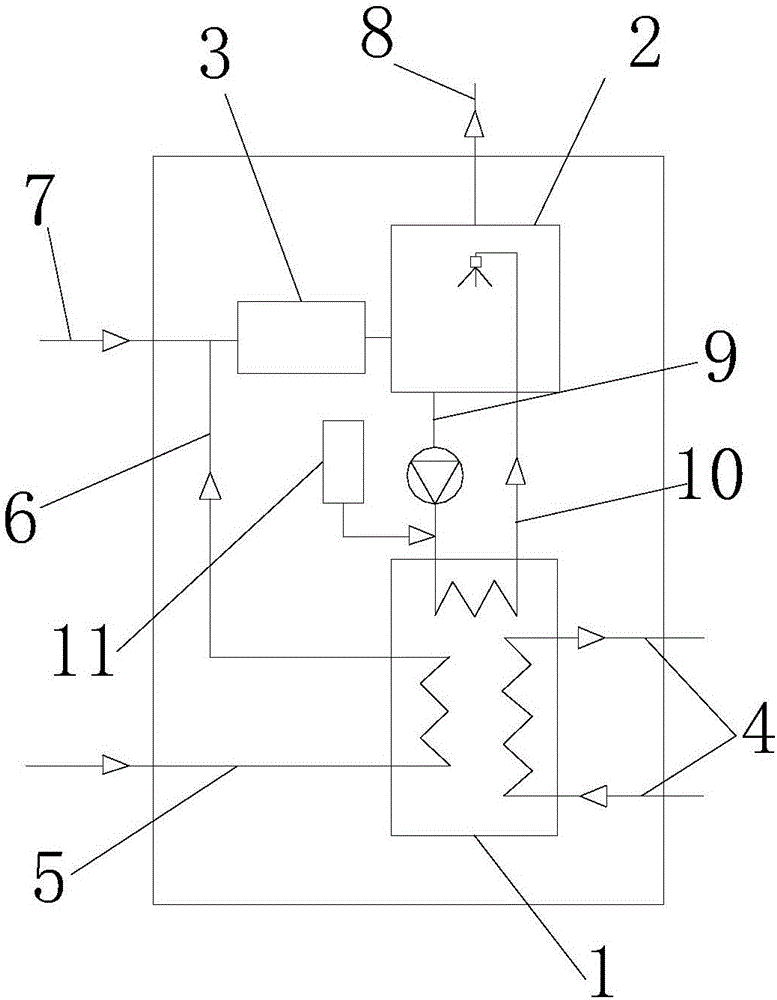

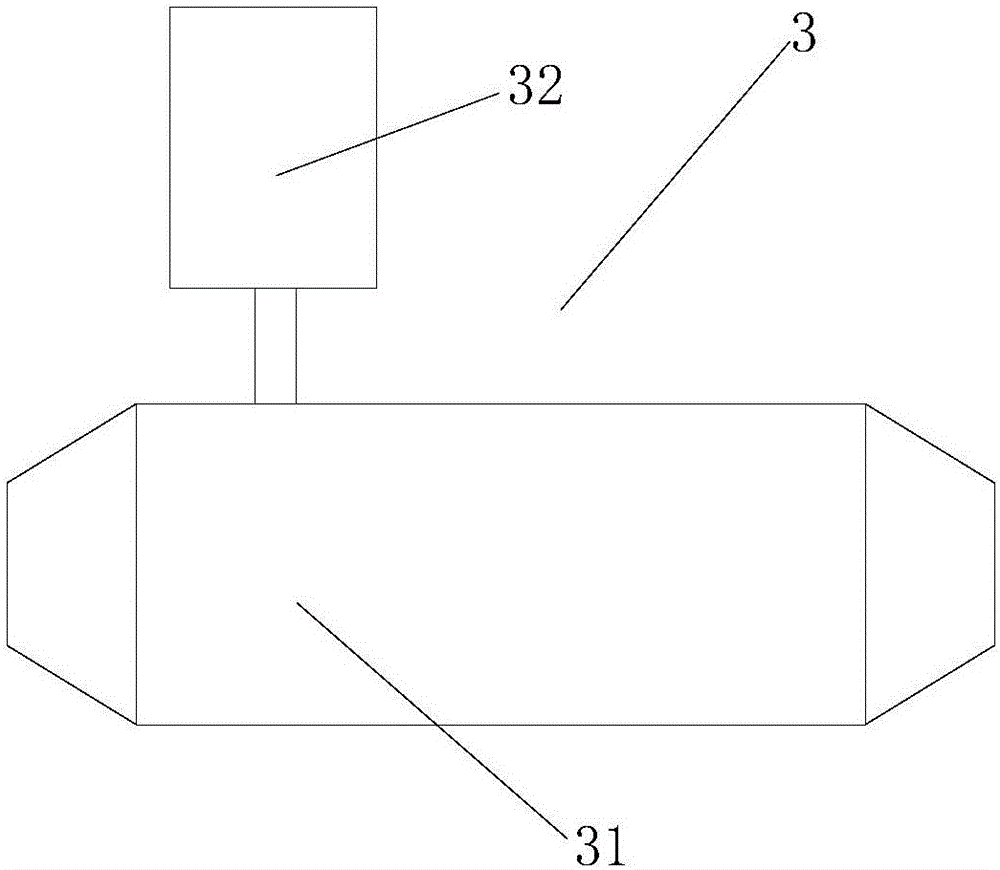

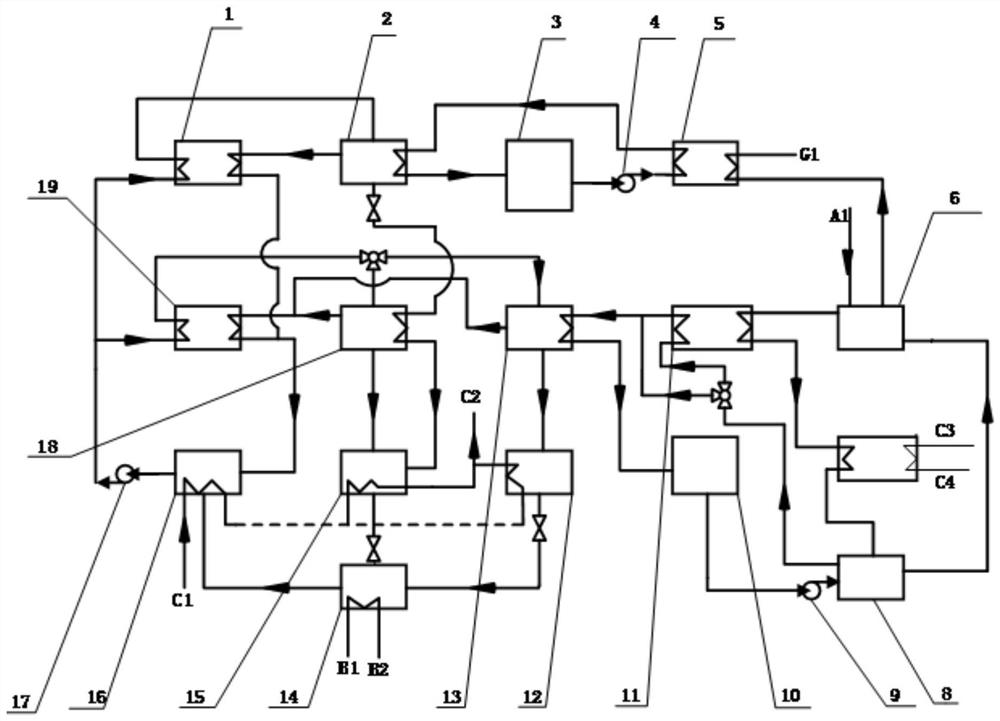

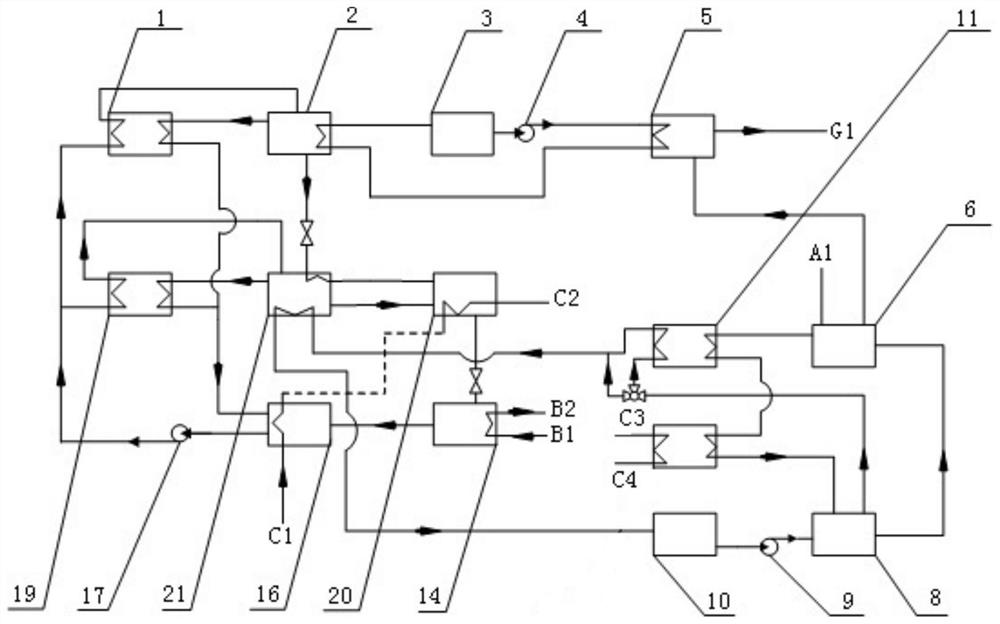

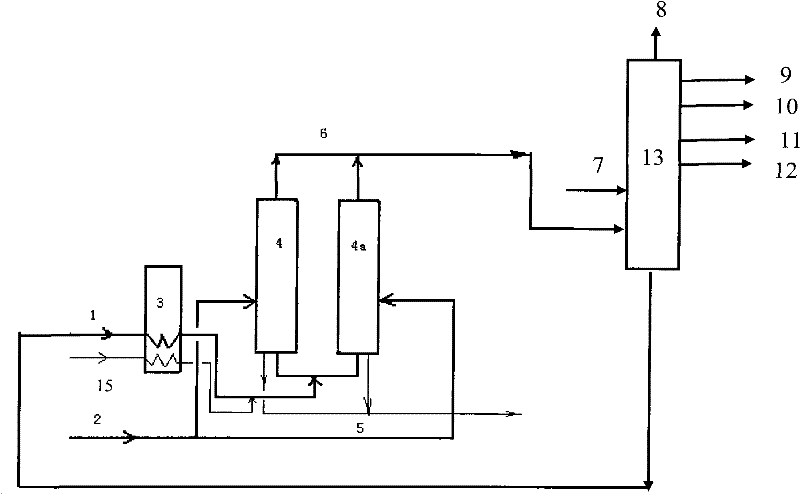

Efficient regeneration type lithium bromide absorbing refrigerating and heating system for cruise

ActiveCN109341134AControl heating temperatureAvoid severe corrosionClimate change adaptationEnergy efficient heating/coolingTurbochargerGas heater

The invention aims to provide an efficient regeneration type lithium bromide absorbing refrigerating and heating system for a cruise. Water serves as a refrigerating agent, a lithium bromide solutionserves as an absorbing agent, and a high-pressure generator, a first low-pressure generator, a second low-pressure generator, a condenser, a first evaporator, a second evaporator, a first absorber, asecond absorber, a first generator pump, a second generator pump, first to seventh heat exchangers, first to third three-way plug valves, a gas-gas heater, a high-temperature heat source water pump, ahigh-temperature heat source water tank, a turbocharger, a two-section type intercooler, a cylinder sleeve cooling water tank, a cylinder sleeve cooling water pump, a diesel engine cylinder sleeve cooling cavity, connection pipelines and throttling valves of all the components, and the like are included. The system can meet the refrigerating or heating requirements of the cruise under different working conditions and environments.

Owner:HARBIN ENG UNIV

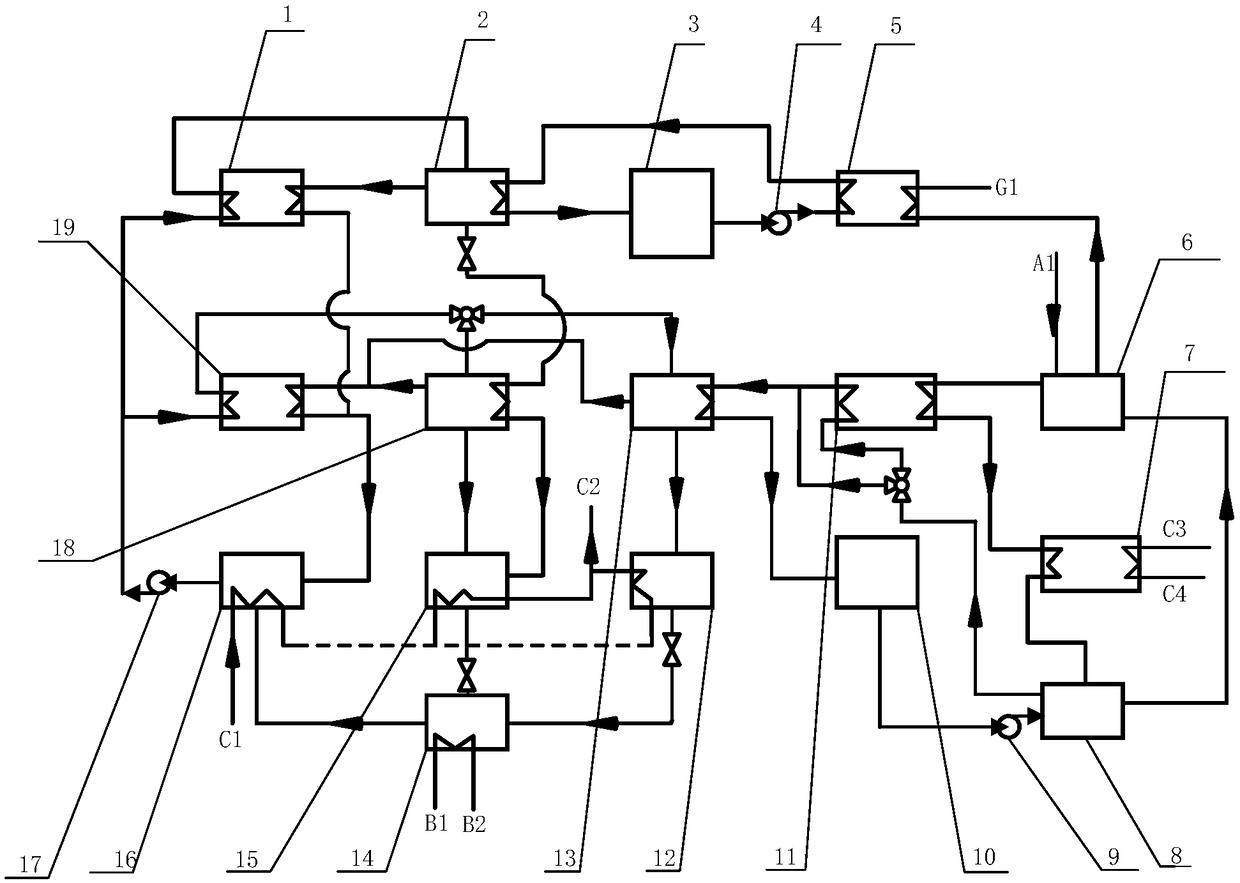

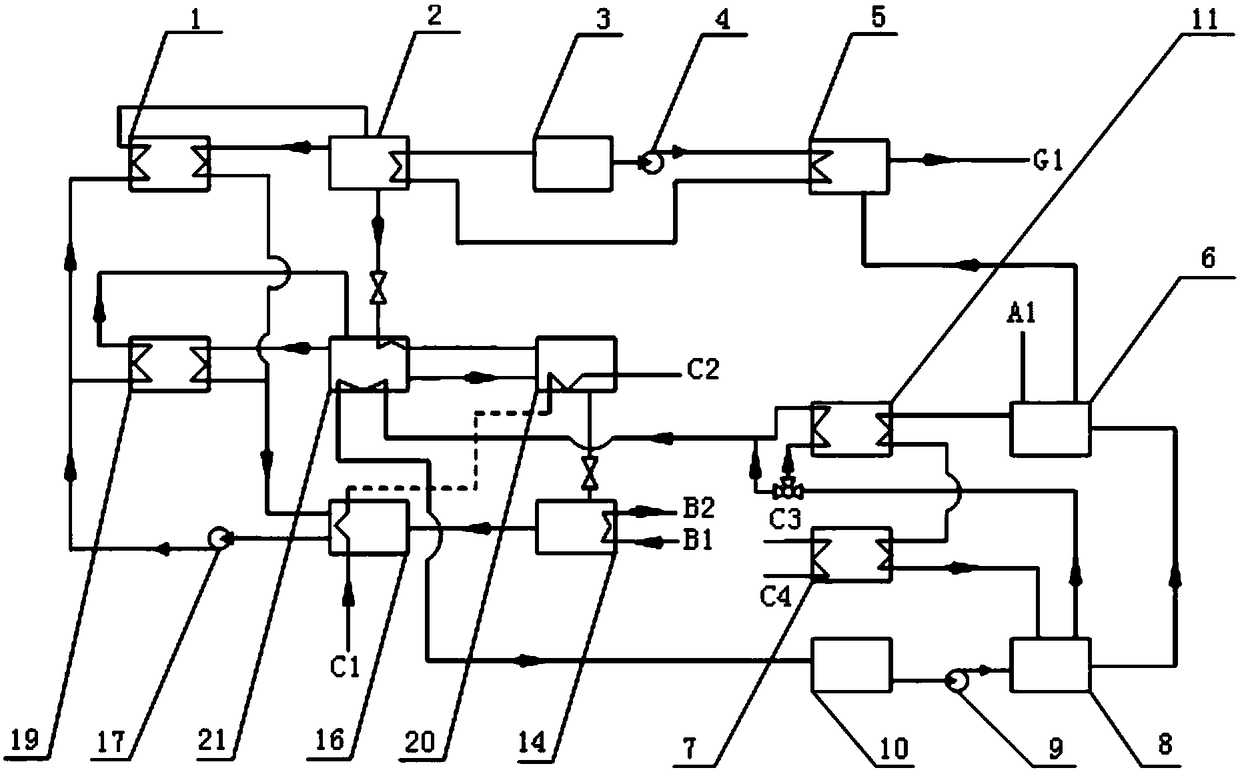

Lithium bromide absorption type refrigerating device driven by waste heat of cruise ship diesel engine

ActiveCN109323479AAvoid severe corrosionSimplify piping designClimate change adaptationEnergy efficient heating/coolingTurbochargerLithium bromide

The invention aims to provide a lithium bromide absorption type refrigerating device driven by waste heat of a cruise ship diesel engine. The device takes water as a refrigerant and takes a lithium bromide solution as an absorbent, and mainly comprises a high-pressure generator, low-pressure generators, a condenser, an evaporator, an absorber, a generator pump, heat exchangers, a flue gas heat exchanger, a high-temperature heat source water pump, a high-temperature heat source water tank, a turbocharger, a two-section intercooler, a cylinder sleeve cooling water tank, a cylinder sleeve coolingwater pump, a diesel engine, an exhaust air collecting pipe, an air inlet collecting pipe, and connecting pipelines of all components and a throttling valve and the like. According to the device, thewaste heat of the cruise ship diesel engine can be efficiently utilized, so that the refrigeration requirements under different working conditions and environments are met.

Owner:HARBIN ENG UNIV

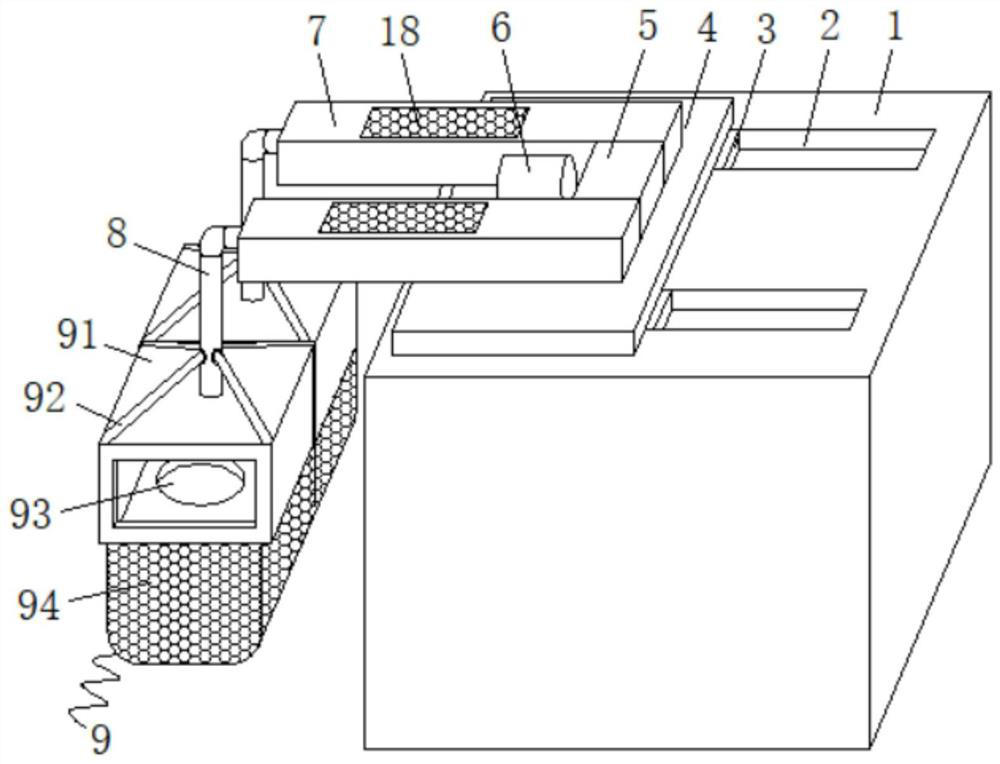

Overwater garbage salvaging solid-liquid separation device

InactiveCN111719527AEasy to cleanImprove fishing efficiencyWater cleaningWaterborne vesselsElectric machineEngineering

The invention discloses an overwater garbage salvaging solid-liquid separation device, and belongs to the technical field of overwater garbage salvaging. The device comprises a shell, a support plate,a first shell, second shells and salvaging mechanisms, wherein first sliding grooves are formed in the front side and the rear side of the upper surface of the shell correspondingly, first sliding blocks are slidably connected in the first sliding grooves, and the upper surfaces of the first sliding blocks are fixedly connected with the lower surface of the support plate. According to the device,a first motor, a winding wheel, fixing ropes and the two salvaging mechanisms are arranged, the first motor can drive the winding wheel to rotate when working, one of the fixing ropes can be unwoundand the other one of the fixing ropes is wound when the winding wheel rotates, at the moment, one of the salvaging mechanisms can move downwards when one of the fixing ropes is unwound, and the otherone of the fixing ropes can pull the other one of the salvaging mechanisms to move upwards, so that the salvaging mechanisms enter water to salvage garbage at any time, the situation that the salvaging mechanisms stop and cannot salvage the garbage is avoided, and the garbage salvaging efficiency is further improved.

Owner:杨长远

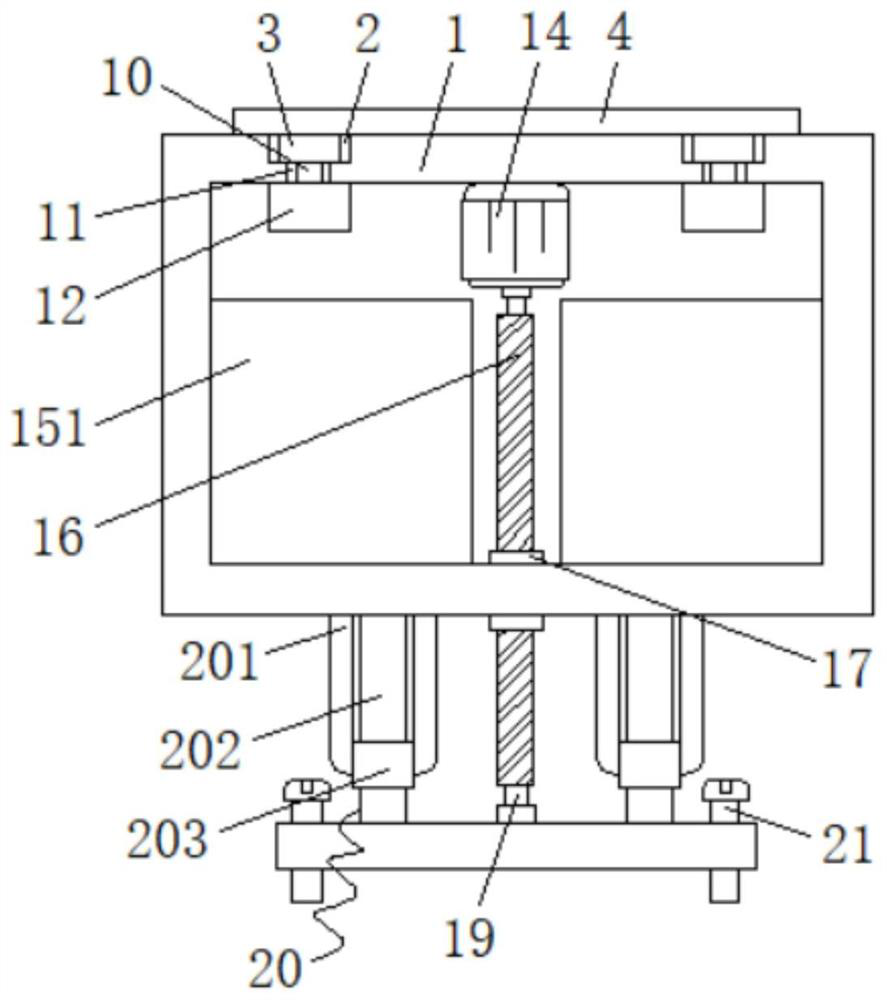

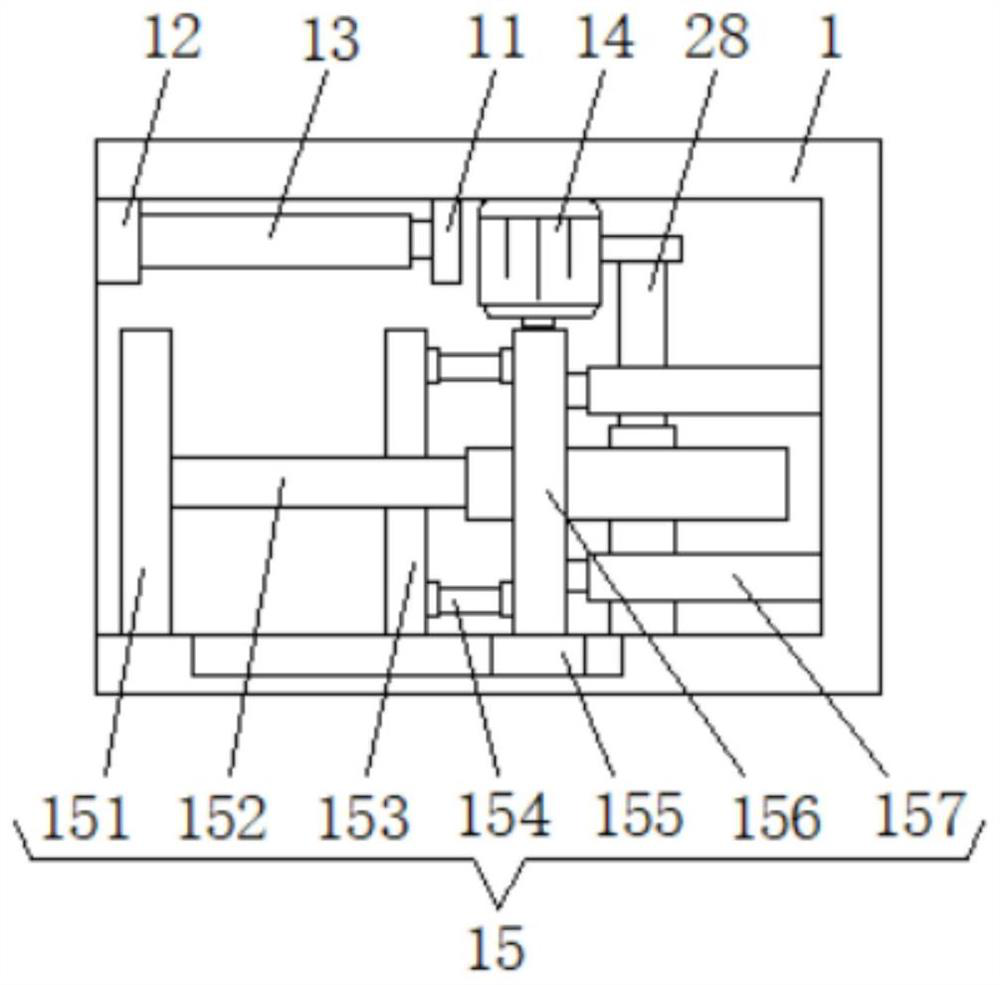

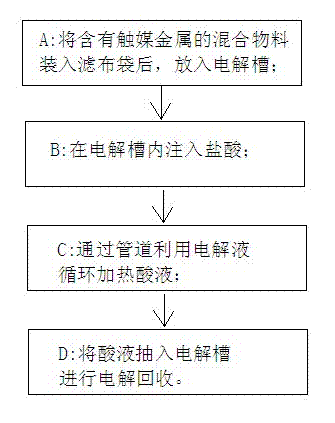

Recovery method of fine catalyst metal obtained after electrolysis and purification of synthetic diamond powder

InactiveCN102776526ATo achieve the purpose of recycling catalyst metalsReduce labor intensityPhotography auxillary processesProcess efficiency improvementRecovery methodChemical reaction

The invention discloses a recovery method of fine catalyst metal obtained after electrolysis and purification of synthetic diamond powder, which comprises the following steps of: 1, filling a mixture containing catalyst metal into a filter cloth bag and placing into an electrobath; 2, injecting a hydrochloric acid into the electrobath; 3, utilizing an electrolyte to cyclically heat an acid solution through a pipeline; and finally, pumping the acid solution into the electrobath for electrolysis recovery. According to the method, the mixed materials are soaked in the acid solution with intermediate concentration at a constant intermediate temperature, metals in the mixed materials are changed into a free ion state by a chemical reaction, and the metal ions are enriched on a cathode plate by a rapid electrolysis method so as to achieve the purpose of recovery of catalyst metal, accordingly, the phenomena that the anode is seriously passivated and precious metals are seriously corroded can be avoided, the fine catalyst metal can be recovered at high efficiency and high recovery rate, the labor intensity of staff is reduced, the side reaction occurring in the electrolysis process can be avoided, and the method has the advantages of safety and environmental protection.

Owner:ZHONGNAN DIAMOND CO LTD

Internal-pressurized laser-electric arc combined sealing welding method for edge joints

InactiveCN109352180AReduce porosityPrevent extensionWelding/soldering/cutting articlesLaser beam welding apparatusFuel tankEngineering

The invention provides an internal-pressurized laser-electric arc combined sealing welding method for edge joints and relates to the field of machining engineering. The internal-pressurized laser-electric arc combined sealing welding method aims to solve the problems that flaws such as collapse, welding leakage and the like are easy to arise in big gap positions of edge joints of a thin-wall fueltank, and crack might be caused by non-gentle transition in welding roots. According to the internal-pressurized laser-electric arc combined sealing welding method for the edge joints, a laser-electric arc combined welding method is adopted; argon or a mixed gas of argon and carbon dioxide is introduced into the interior of the fuel tank before welding; welding is started after a protective atmosphere is formed; a protective gas is introduced continuously in the welding process; and the protective gas flow quantity is determined according to the gap condition of assembling of the fuel tank. Inthe process, because certain pressure exists in the reverse-side protective gas, a molten pool is extruded upwards; with optimized technological parameters of laser-electric arc combined welding coordinated, upward dents are generated in the welding joint bottoms until after-welding transition in positions where the gaps are bigger is relatively gentle. The internal-pressurized laser-electric arccombined sealing welding method is applied to the field of vehicle fuel tank manufacturing.

Owner:HARBIN INST OF TECH

Low NOx discharge smoke waste heat heating system

InactiveCN106568117AAvoid severe corrosionLow costEmission preventionEnergy efficient heating/coolingEngineeringAtmospheric pollution

The invention discloses a low NOx discharge smoke waste heat heating system. The low NOx discharge smoke waste heat heating system is characterized in that a gas inlet pipeline is connected with a gas inlet of a generator of a heat pump; a gas outlet of the generator of a heat pump communicates with a smoke evacuation pipeline of a gas boiler through a smoke pipeline; the smoke evacuation pipeline is connected with a gas inlet of a denitration apparatus; a gas outlet of the denitration apparatus is connected with a gas inlet of a smoke-water heat transfer device through a pipeline; a gas outlet of the smoke-water heat transfer device communicates with the outside through an exhaust gas pipeline; a water outlet of the smoke-water heat transfer device is connected with a water inlet of an evaporator of the heat pump through a first circulating water pipe; and a water outlet of the evaporator of the heat pump is connected with a water inlet of the smoke-water heat transfer device through a second circulating water pipe to enable a heating pipeline to flow through the inside of the heat pump. The low NOx discharge smoke waste heat heating system can effectively reduce the content of NOx in the discharged smoke so as to achieve the newest discharge standard demand for key city atmospheric pollution abatement, and is higher in the utilization rate of heat energy, compared with the prior art, at the same time.

Owner:TONGFANG KAWASAKI ADVANCED ENERGY SAVING MACHINE

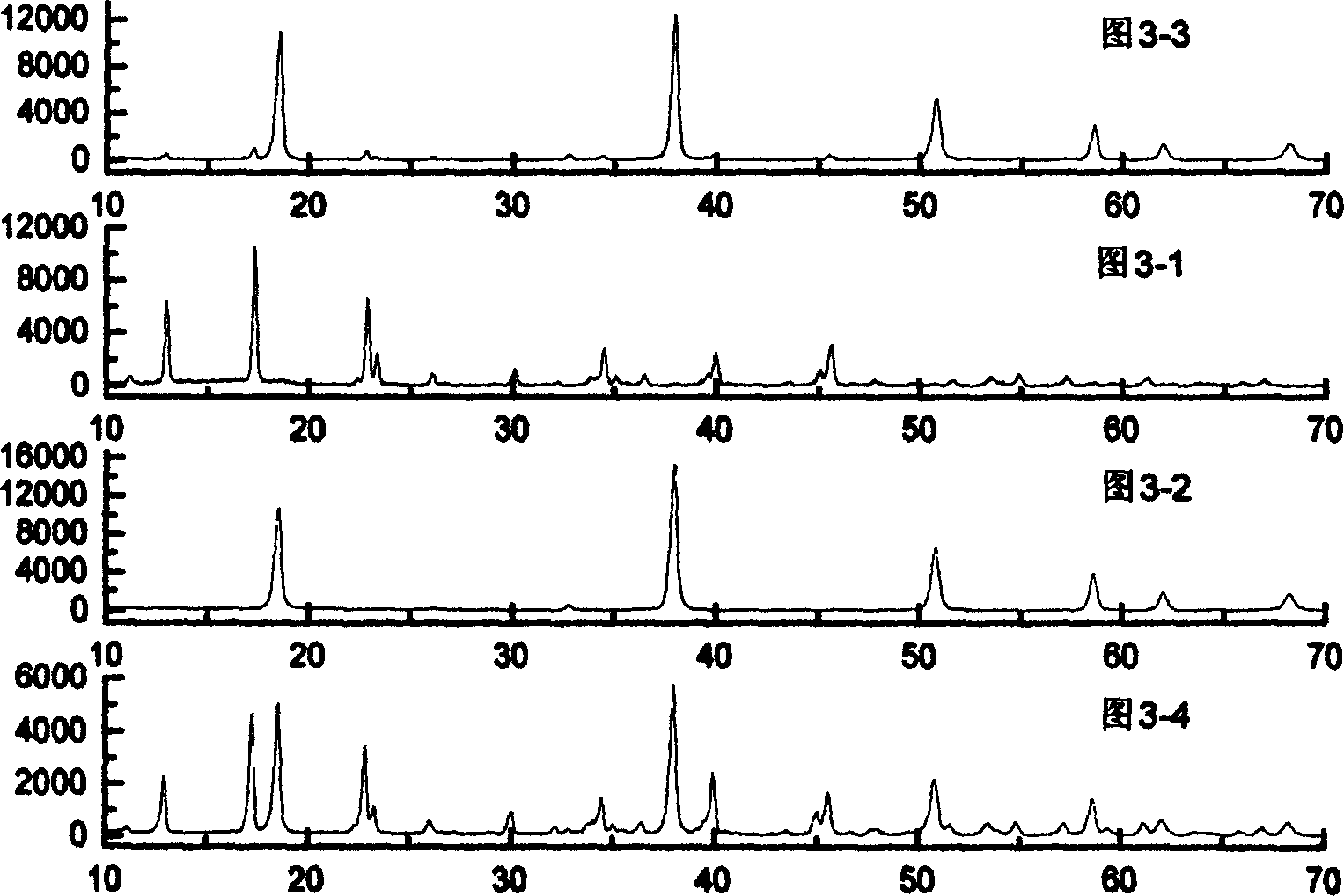

Process for preparing magnesium hydroxide whisker

InactiveCN1183037CImprove mechanical propertiesImprove physical performanceMagnesium hydroxideAlkaline earth metalMagnesium salt

The process of preparing magnesium hydroxide whisker features that the material magnesium salt whisker MgSO4.5Mg(OH)2.3H2O is made to react with the water solution of hydroxide of ammonia, alkali metal or alkali earth metal to obtain magnesium hydroxide whisker. The preparation process uses rich and low cost magnesite resource and prepares magnesium hydroxide whisker from magnesium salt whisker, resulting in short production period, high production efficiency and no serious corrosion of apparatus by chloride. In addition, the preparation process has simple process, low cost and no environmental pollution and is suitable for industrial production.

Owner:隗学礼

Production method for water-based zinc-rich polyacrylate anticorrosive paint modified by organic montmorillonite

InactiveCN107641410AGood suspensionStrong rust resistanceAnti-corrosive paintsWater basedMontmorillonite

The invention discloses water-based zinc-rich polyacrylate anticorrosive paint modified by organic montmorillonite. A production method for the water-based zinc-rich polyacrylate anticorrosive paint modified by organic montmorillonite is characterized by comprising the following steps: firstly, preparing organic modified montmorillonite; then, preparing hydroxyl-containing polyacrylate aqueous dispersion through step-by-step polymerization; and finally, taking the hydroxyl-containing polyacrylate aqueous dispersion as a film-forming agent, taking zinc phosphomolybdate as anticorrosive packing,taking the organic modified montmorillonite as an anti-sinking agent, supplementing by other auxiliaries, mixing, grinding and dispersing, thereby obtaining the water-based zinc-rich polyacrylate anticorrosive paint modified by organic montmorillonite. The anticorrosive paint provided by the invention is good in dispersion, and a film-formed coating is flat in surface, is compact, and is excellent in mechanical property and corrosion resistance.

Owner:ANHUI KUAILAI WATERPROOFING & ANTI CORROSION

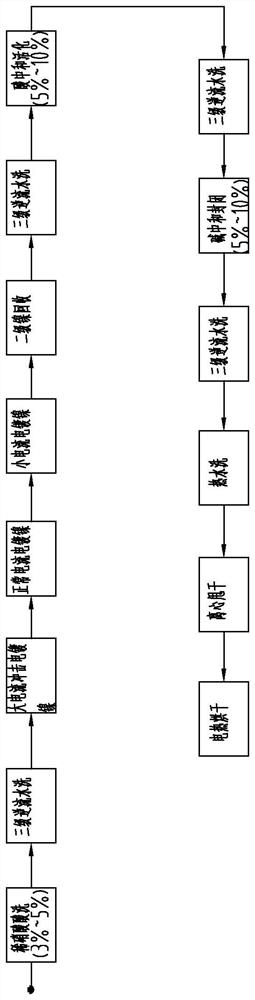

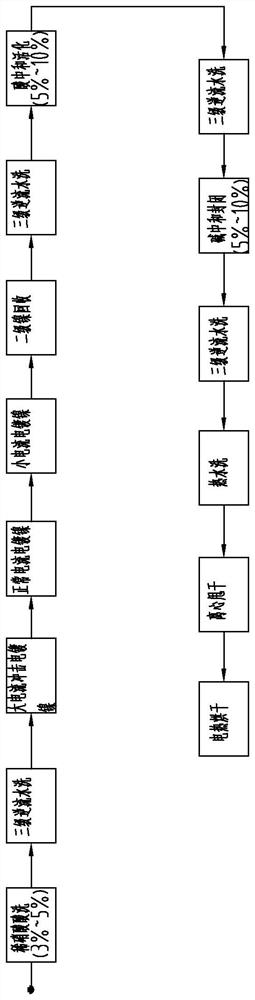

Electroplating method of samarium-cobalt magnetic steel

The invention discloses an electroplating method of samarium-cobalt magnetic steel. The electroplating method comprises the following steps of 1) carrying out pretreatment on the samarium-cobalt magnetic steel; (2) carrying out nickel electroplating treatment on the samarium-cobalt magnetic steel, specifically, firstly, carrying out nickel electroplating by adopting large-current impact with the electroplating time of T1, carrying out nickel electroplating by adopting normal current with the electroplating time of T2, and carrying out nickel electroplating by adopting low current with the electroplating time of T3, wherein T1 is less than T2 and T3; and 3) carrying out post-treatment on the samarium-cobalt magnetic steel subjected to nickel electroplating. During nickel electroplating, large-current nickel electroplating, normal-current nickel electroplating and low-current nickel electroplating are sequentially adopted to form different levels of current density electroplating combinations, samarium-cobalt magnetic steel parts are prevented from being corroded by an acid nickel plating solution during nickel plating, a nickel coating with a certain thickness and fine surface crystallization is formed, and the appearance and the protection performance of the nickel coating are ensured.

Owner:厦门金越电器有限公司

A kind of electroplating method of samarium cobalt magnet steel

The invention discloses a method for electroplating samarium-cobalt magnets, which comprises the following steps: 1) performing pretreatment on the samarium-cobalt magnets; The time is T1; then use normal current to electroplate nickel, and the electroplating time is T2; finally, use small current to electroplate nickel, and the electroplating time is T3; T1 is less than T2 and T3; 3) Post-treatment the nickel-plated SmCo magnet. The present invention adopts high current electroplating nickel, normal current nickel electroplating and low current electroplating nickel sequentially during nickel electroplating to form different levels of current density electroplating combinations, preventing samarium cobalt magnetic steel parts from being corroded by acid nickel plating solution during nickel plating, forming Nickel coating with a certain thickness and fine surface crystallization ensures the appearance and protective performance of the nickel coating.

Owner:厦门金越电器有限公司

A kind of preparation method of whitening foaming agent

The invention discloses a preparation method of a whitening foaming agent, comprising the following steps: S11, stirring and mixing sodium bicarbonate and a composite calcium-zinc stabilizer evenly; S12, performing jet crushing to obtain a semi-finished product A; S21, mixing citric acid After the salt and citric acid are mixed evenly, airflow milling is carried out; S22, the coating of the fatty acid and its derivatives on the citrate and citric acid is completed, and the semi-finished product B is obtained; S3, the preparation of the whitening foaming agent: the semi-finished product A Mix with the semi-finished product B, then add an appropriate amount of urea and its derivatives and epoxy compounds to obtain the whitening foaming agent; the mass ratio of the sodium bicarbonate to the composite calcium-zinc stabilizer is 100: (1-5) . The whitening foaming agent prepared by the preparation method of the whitening foaming agent of the present invention has an excellent foaming effect on polyvinyl chloride, moderate foaming rate, less heat in the foaming process, and can significantly improve the foaming effect of polyvinyl chloride. Whiteness, surface gloss, cell fineness, etc. of foam products.

Owner:浙江杰上杰新材料股份有限公司

A lithium bromide absorption refrigeration device driven by the waste heat of cruise diesel engine

ActiveCN109323479BAvoid severe corrosionSimplify piping designClimate change adaptationEnergy efficient heating/coolingTurbochargerLithium bromide

The invention aims to provide a lithium bromide absorption type refrigerating device driven by waste heat of a cruise ship diesel engine. The device takes water as a refrigerant and takes a lithium bromide solution as an absorbent, and mainly comprises a high-pressure generator, low-pressure generators, a condenser, an evaporator, an absorber, a generator pump, heat exchangers, a flue gas heat exchanger, a high-temperature heat source water pump, a high-temperature heat source water tank, a turbocharger, a two-section intercooler, a cylinder sleeve cooling water tank, a cylinder sleeve coolingwater pump, a diesel engine, an exhaust air collecting pipe, an air inlet collecting pipe, and connecting pipelines of all components and a throttling valve and the like. According to the device, thewaste heat of the cruise ship diesel engine can be efficiently utilized, so that the refrigeration requirements under different working conditions and environments are met.

Owner:HARBIN ENG UNIV

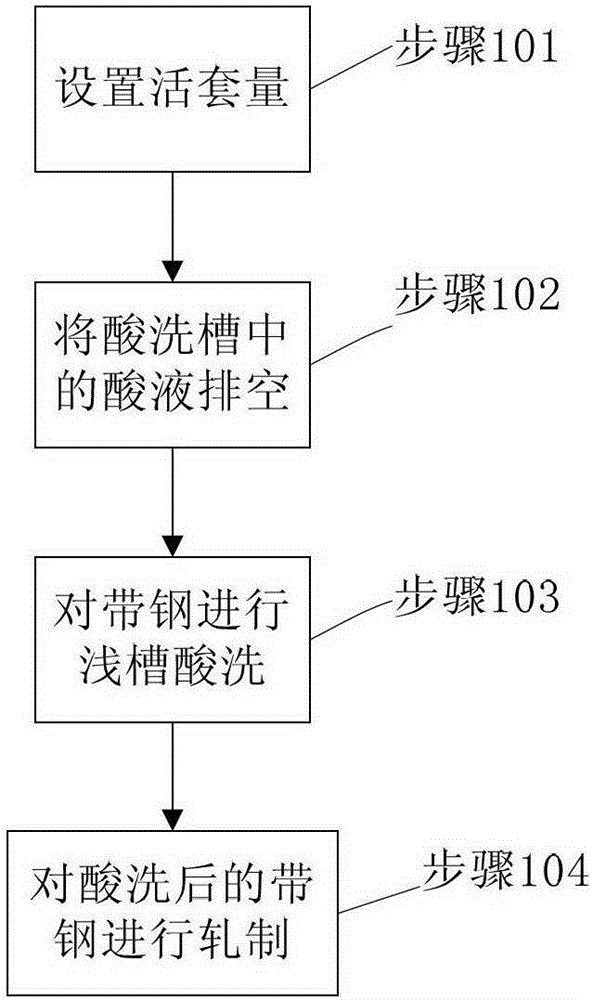

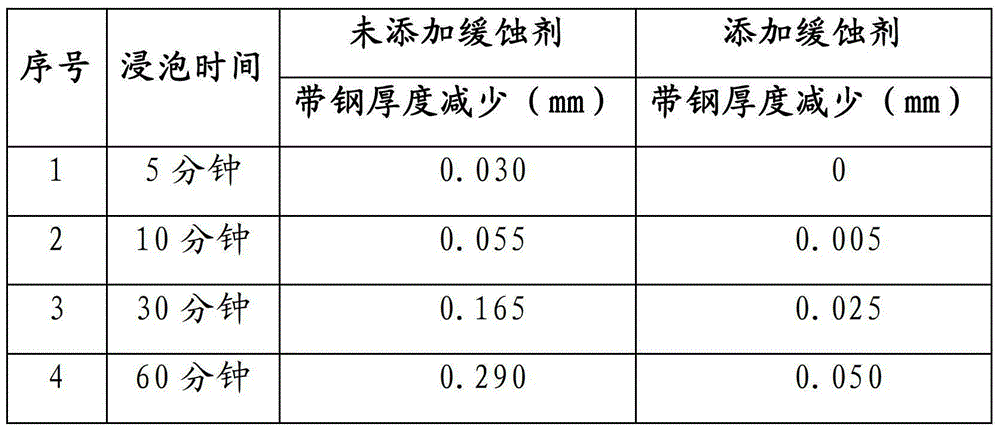

A kind of pickling and rolling method of cold rolling parking spots

ActiveCN103331303BAvoid severe corrosionHigh yieldRoll mill control devicesWork treatment devicesFurnace temperatureSteel ball

The invention relates to the technical field of steel rolling, and discloses an acid cleaning rolling method for cold rolling parking spots, which comprises the following steps: performing the shallow slot acid cleaning to strip steel, to be specific, moving the strip steel at the acid cleaning section when the temperature in an acid cleaning groove reaches the corrosion temperature of the strip steel and starting a vehicle normally when the temperature of the acid cleaning groove reaches the target temperature required by the strip steel acid cleaning; rolling the acid cleaned strip steel. According to the invention, serious corrosion of a certain section of the strip steel is avoided, the yield of cold rolling plain carbon steel is improved, the yield of the acid rolling is increased from 85% to 95.96%, the parking spots can be subjected to rolling and acid cleaning, and the practicability of the acid cleaning rolling method is improved as rolled steel coil can be used as adjusting material for continuous annealing lines to adjust furnace temperature in the connection of steel balls.

Owner:SHOUGANG ZHIXIN QIAN AN ELECTROMAGNETIC MATERIALS CO LTD

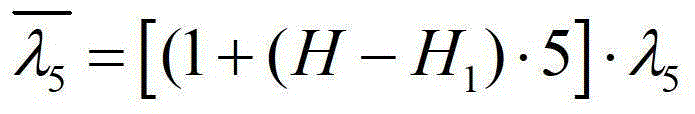

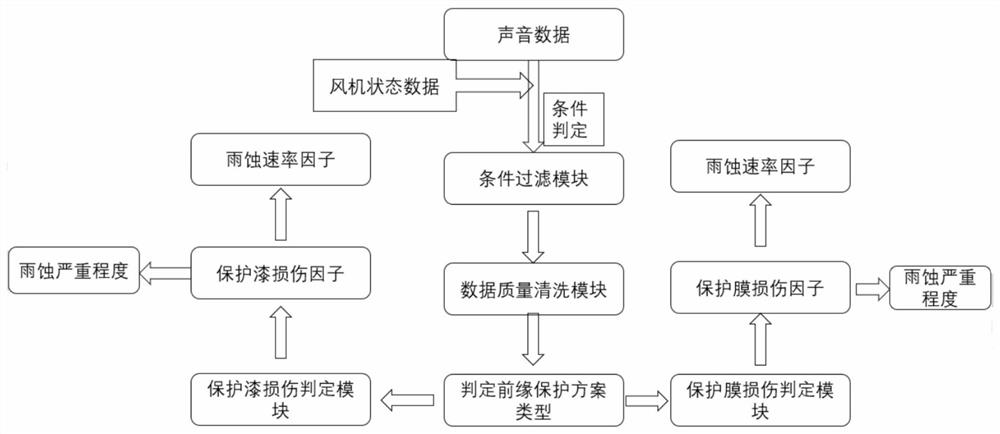

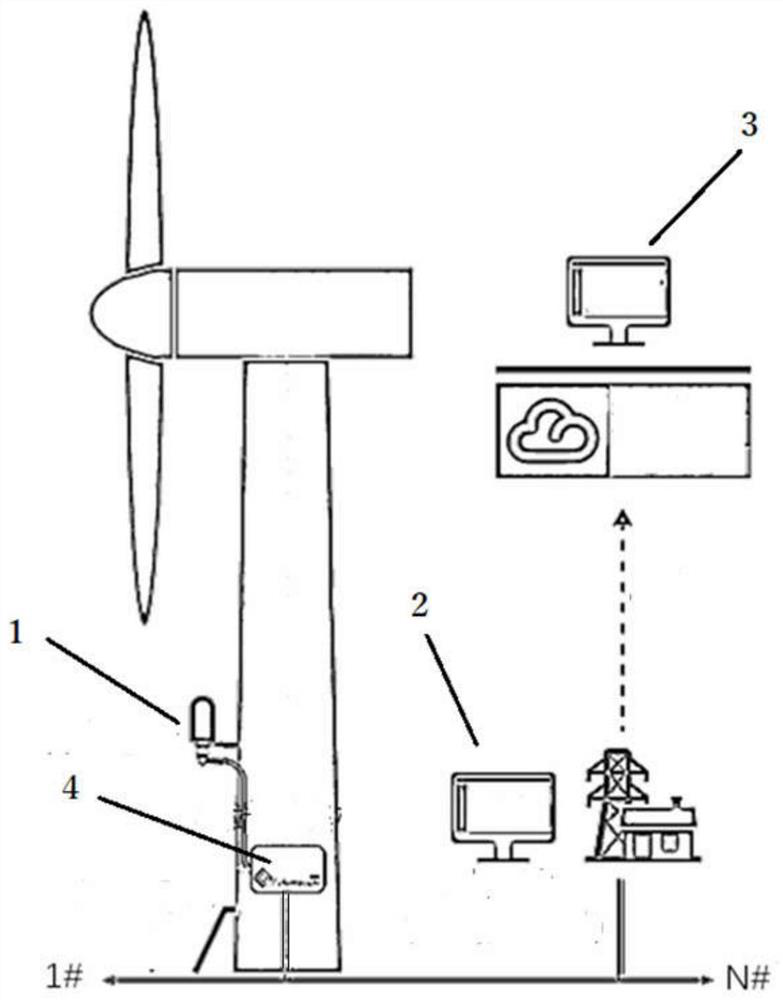

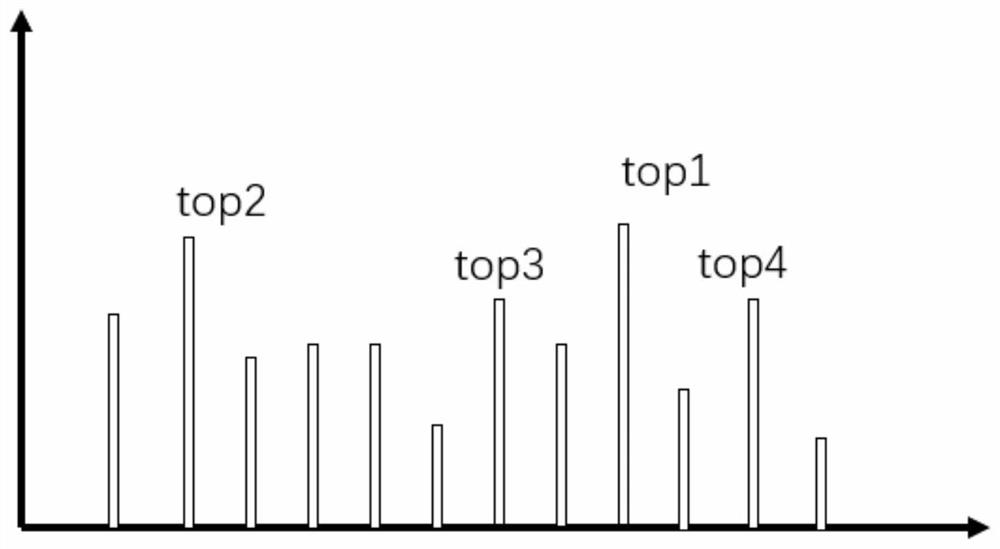

Method and system for monitoring blade leading edge corrosion

ActiveCN112727704BAvoid severe corrosionAvoid increased fatigue loadsSubsonic/sonic/ultrasonic wave measurementEngine fuctionsAlarm messageProcess engineering

The application relates to a method for monitoring blade leading edge erosion, comprising the following steps: collecting wind sweeping signals of blades through a sound sensor; The processing module performs quality inspection on the sound data, and screens out sound data with poor data quality; identifies whether there is corrosion on the leading edge of the blade and evaluates the severity of the corrosion, and gives an early warning message when the corrosion degree exceeds the set threshold. The method and system for monitoring blade leading edge corrosion of the present application can identify blade leading edge corrosion based on machine position level in time, provide alarm information before the blade leading edge corrosion damages to the structural layer, and support targeted and timely maintenance.

Owner:CYBERINSIGHT TECH CO LTD

A zero-discharge system for desulfurization wastewater with cascaded utilization of flue gas waste heat and its working method

ActiveCN112239242BReasonable designAchieve warm-upSpecific water treatment objectivesWaste water treatment from gaseous effluentsFlue gasSpray dried

Owner:HUANENG CLEAN ENERGY RES INST

Coking method for processing highly acid crude oil

ActiveCN101280213BReduce corrosionCorrosion is reduced or even avoidedThermal non-catalytic crackingTowerHot Temperature

Owner:CHINA PETROLEUM & CHEM CORP +1

Novel salt spray resistant cable

InactiveCN108610952AImproves anti-salt spray performanceImprove protectionFireproof paintsClimate change adaptationEpoxyElectrical conductor

The invention provides a novel salt spray resistant cable. The novel salt spray resistant cable comprises a conductor, an insulating layer, an inner sheath and a salt spray resistant outer sheath. Thenovel salt spray resistant cable effectively improves overall salt spray resistant performances of the cable, and the salt spray resistant outer sheath is arranged, and the formula of the salt sprayresistant outer sheath developed through scientific researches and multiple tests comprises silicone rubber, diphenyl silicon glycol, antimony trioxide, epoxy resin, potassium silicate, high temperature resistant composite powder, mica powder, an organic solvent, rapeseed oil, an anti-UV agent and nano-metallic oxide, therefore, the prepared salt spray resistant outer sheath has the excellent saltspray resistant function. In the using process, the rapeseed oil is gradually precipitated on the surface of the salt spray resistant outer sheath to effectively prevent crystal salt caused by seawater from adhering to the surface of the cable, so that the cable can be better protected, and then the service life of the cable can be greatly improved.

Owner:HEFEI PULFI WIRE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com