A kind of pickling and rolling method of cold rolling parking spots

A technology of parking spots and pickling, which is applied in the direction of metal rolling, metal rolling, rolling mill control devices, etc., can solve the problem of low yield of ordinary carbon steel and achieve the effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

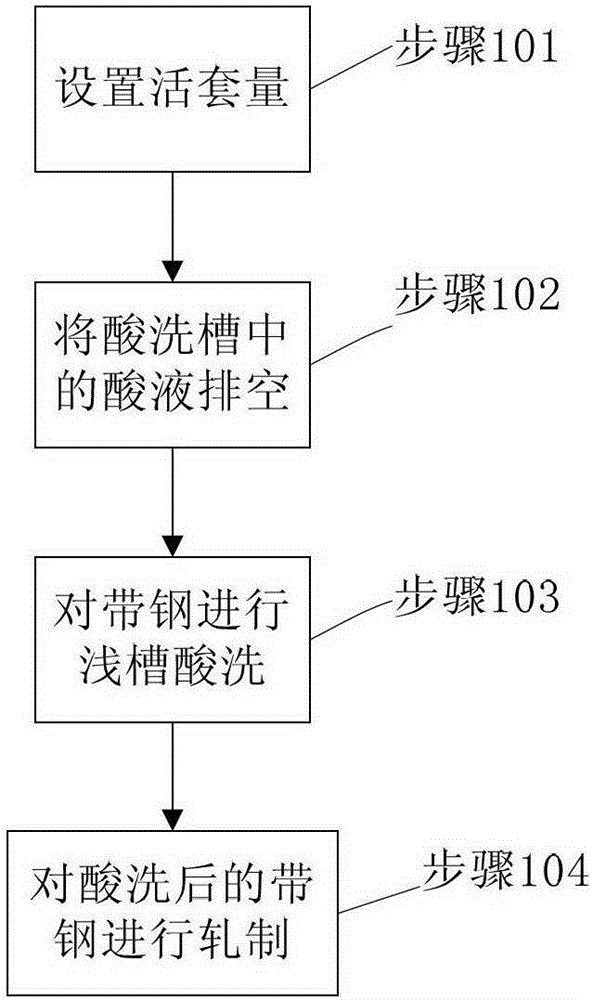

Method used

Image

Examples

Embodiment

[0041] Taking the cold rolling 1450 acid tandem rolling unit of Shougang Qiangang as an example, it is necessary to pickle and roll the 900-meter-long idle coil. Before the shutdown of the production line, the main pickling operator first sets the minimum loop volume of the outlet loop between the pickling section and the trimming section to 5%, and sets the minimum loop volume of the outlet loop between the trimming section and the rolling mill section to 5%. Set amount is also set to 5%. The pickling section and trimming section run at low speed, and when the actual loop volume reaches 5%, the speeds of the two sections are synchronized with the rolling mill. After the production line shut down, the master operator of the rolling mill stopped the strip head at the entrance of the rolling mill, and controlled the loop volume of the two exit loops at 5%, and the two loopers retained 15 meters and 17 meters of strip steel respectively. If the pickling section is moved forward,...

PUM

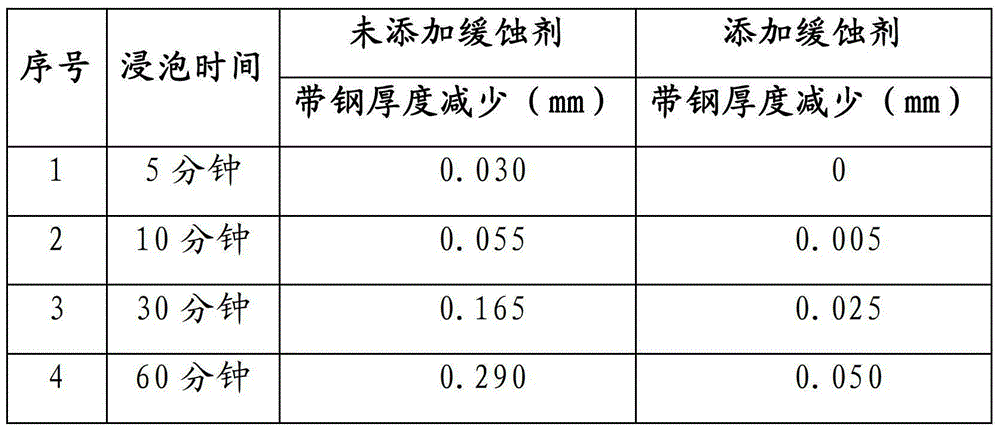

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com