Patents

Literature

345results about How to "Achieve warm-up" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

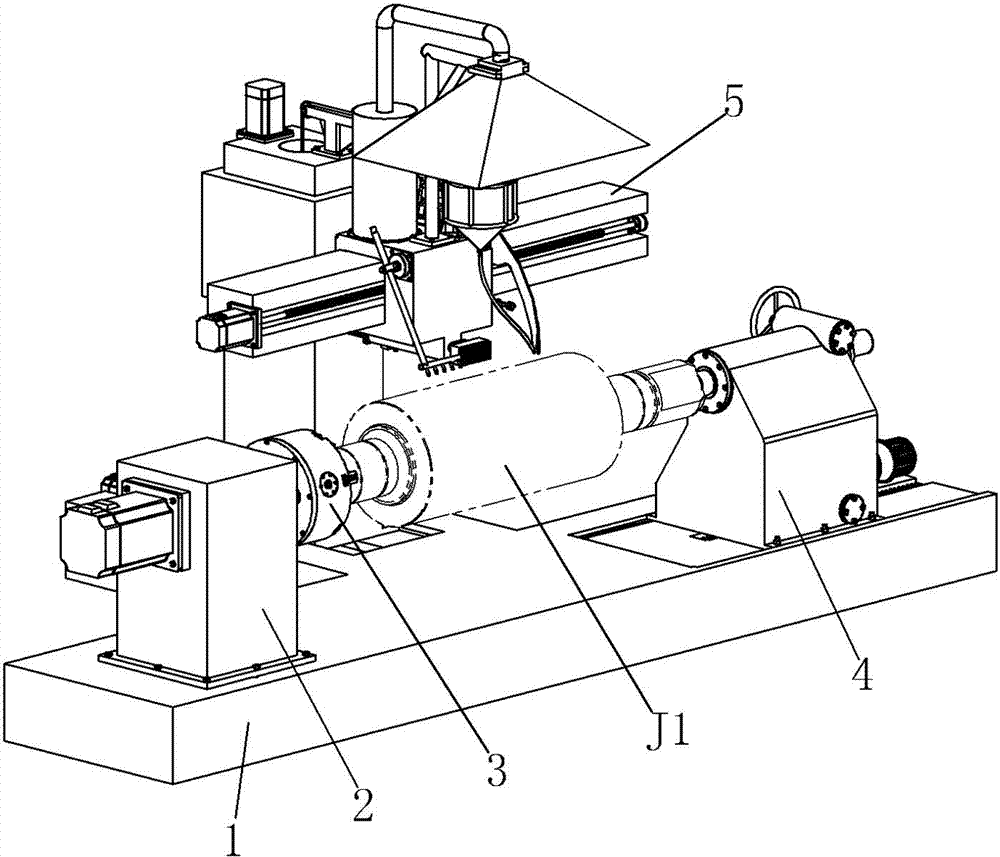

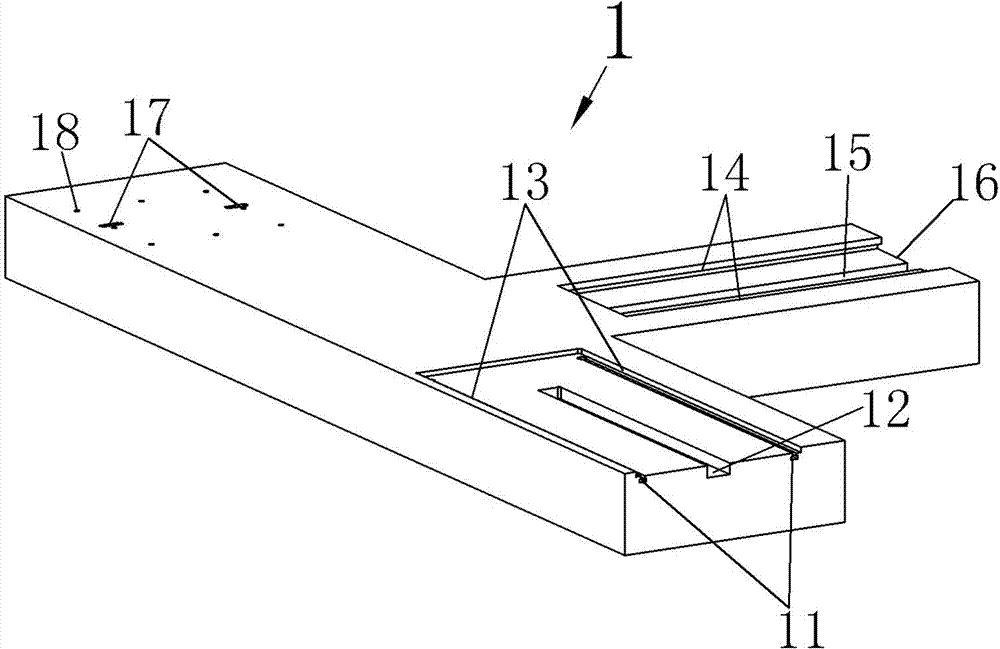

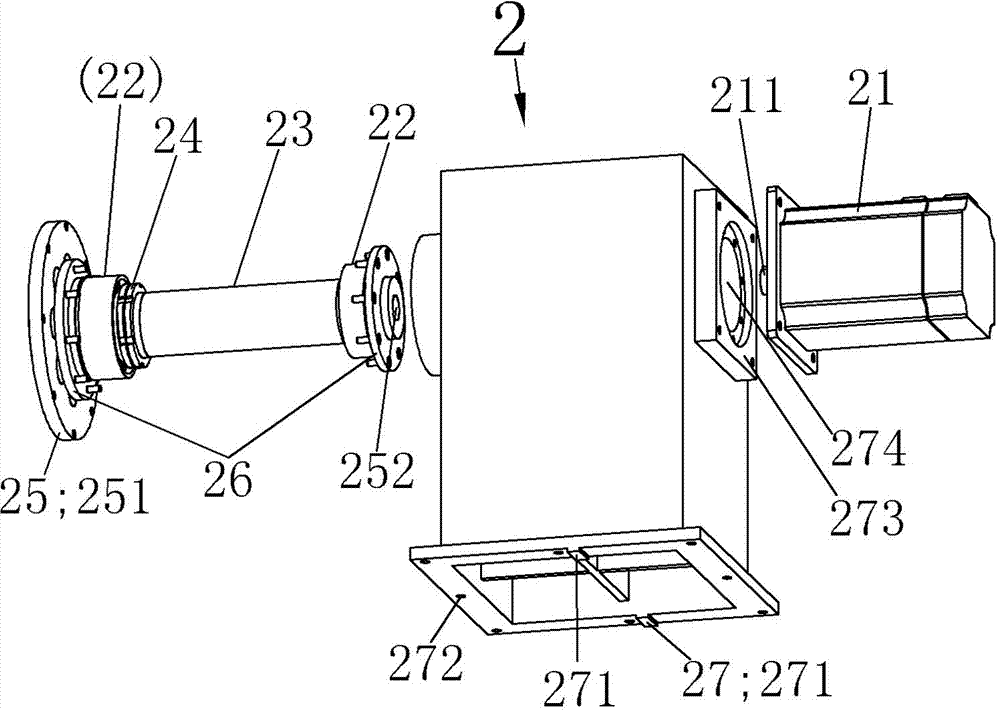

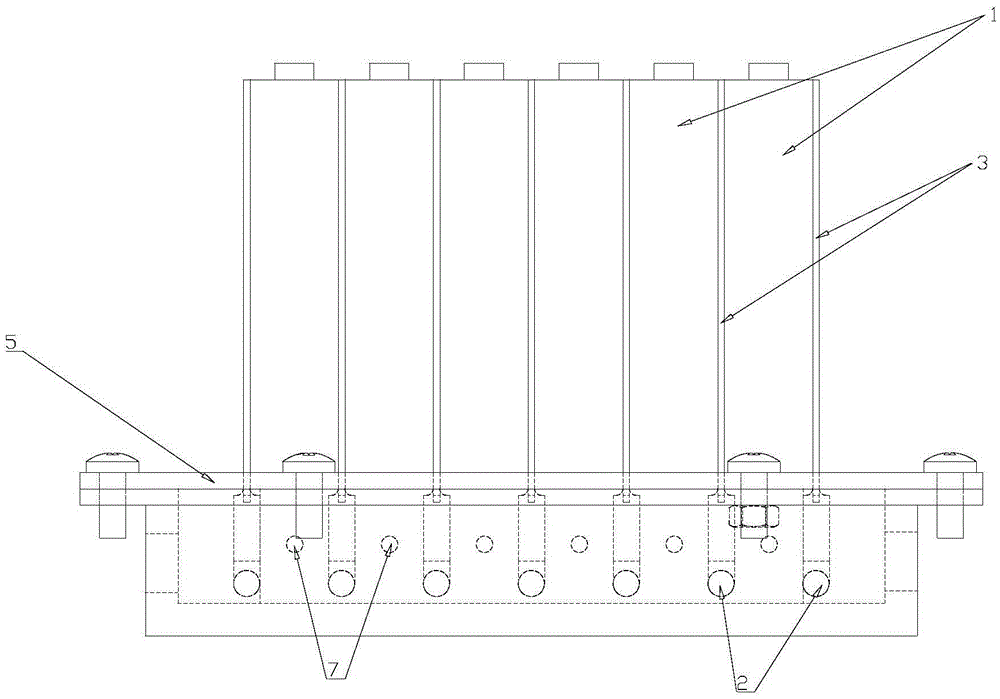

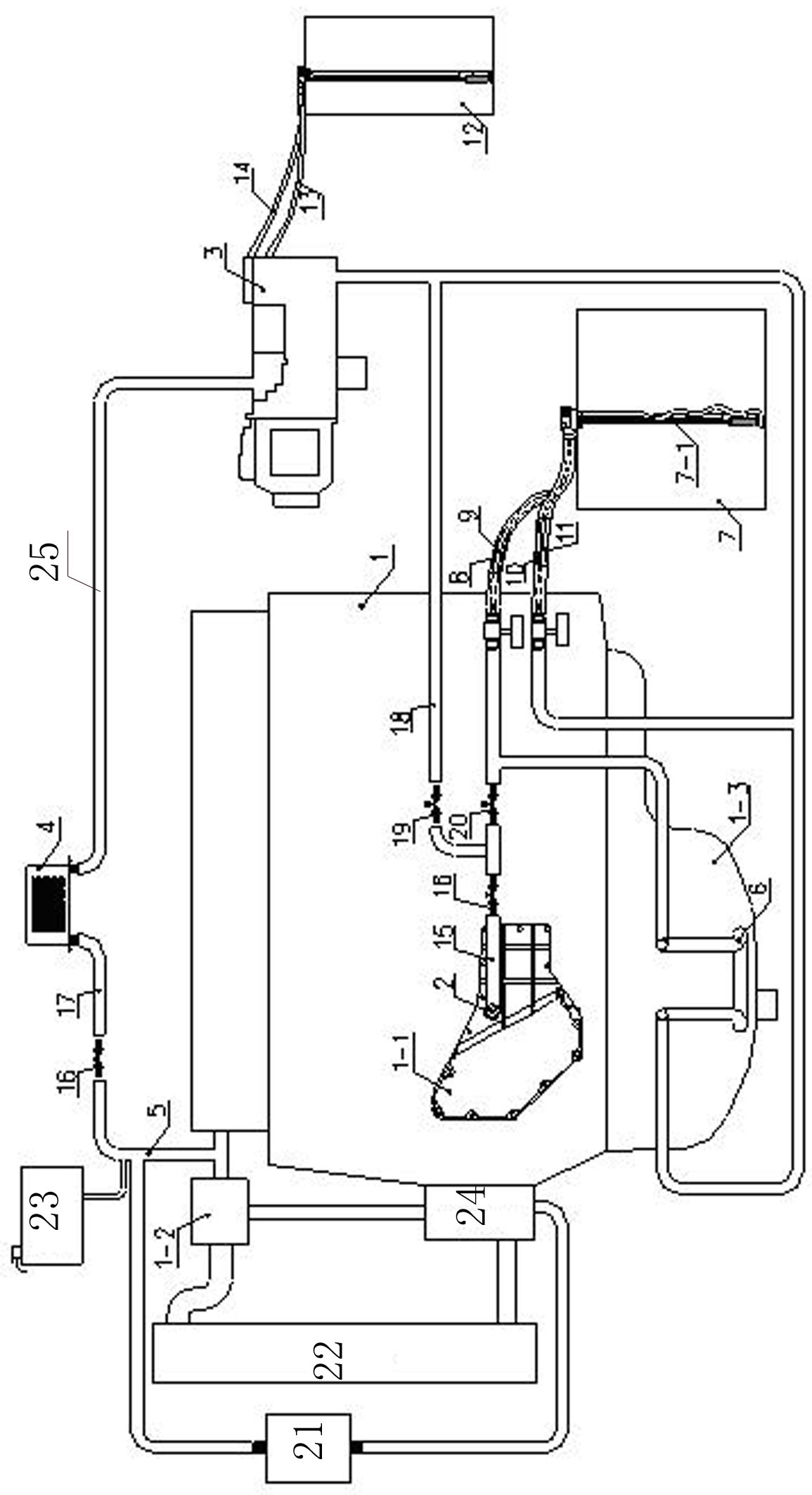

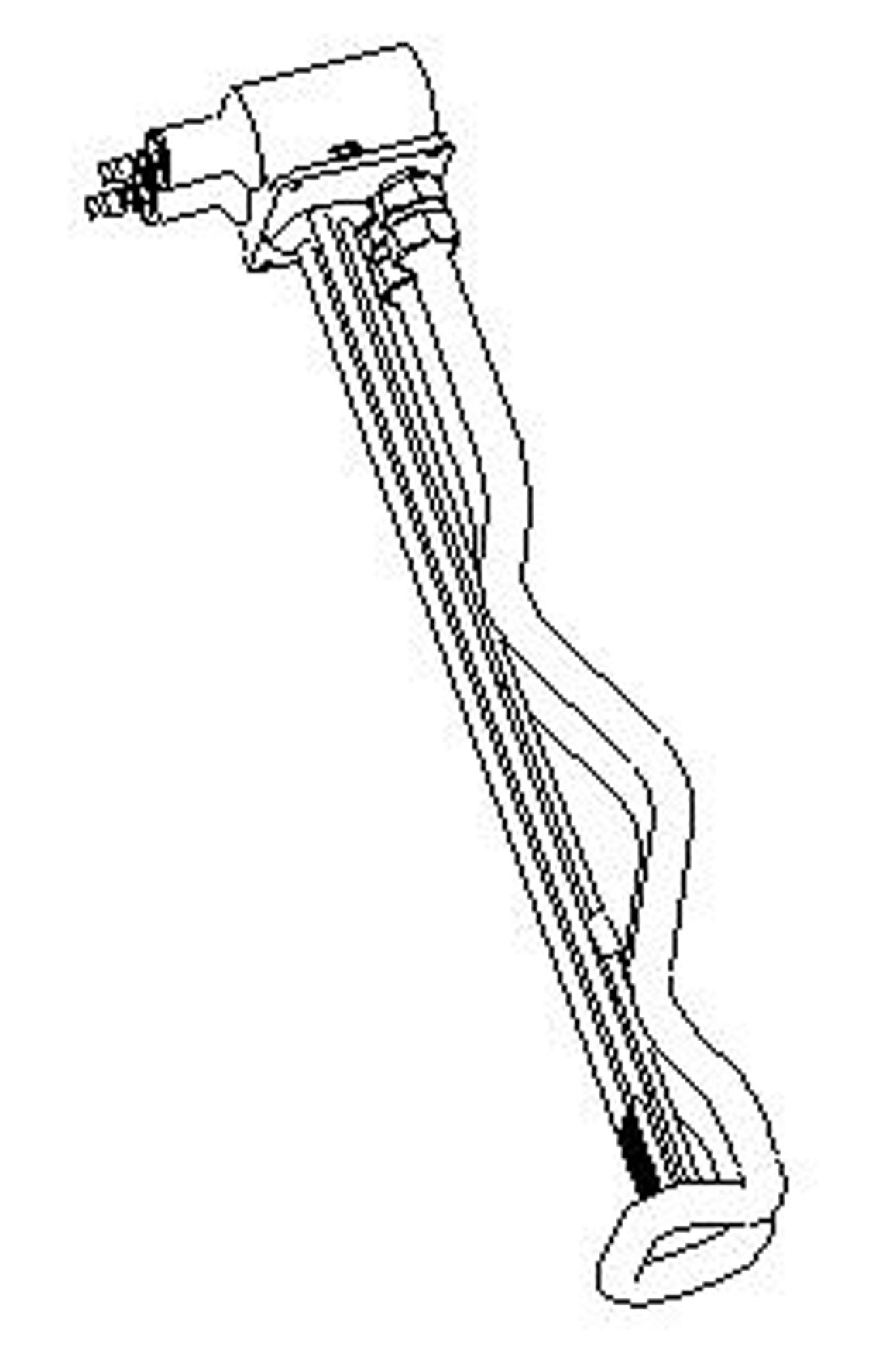

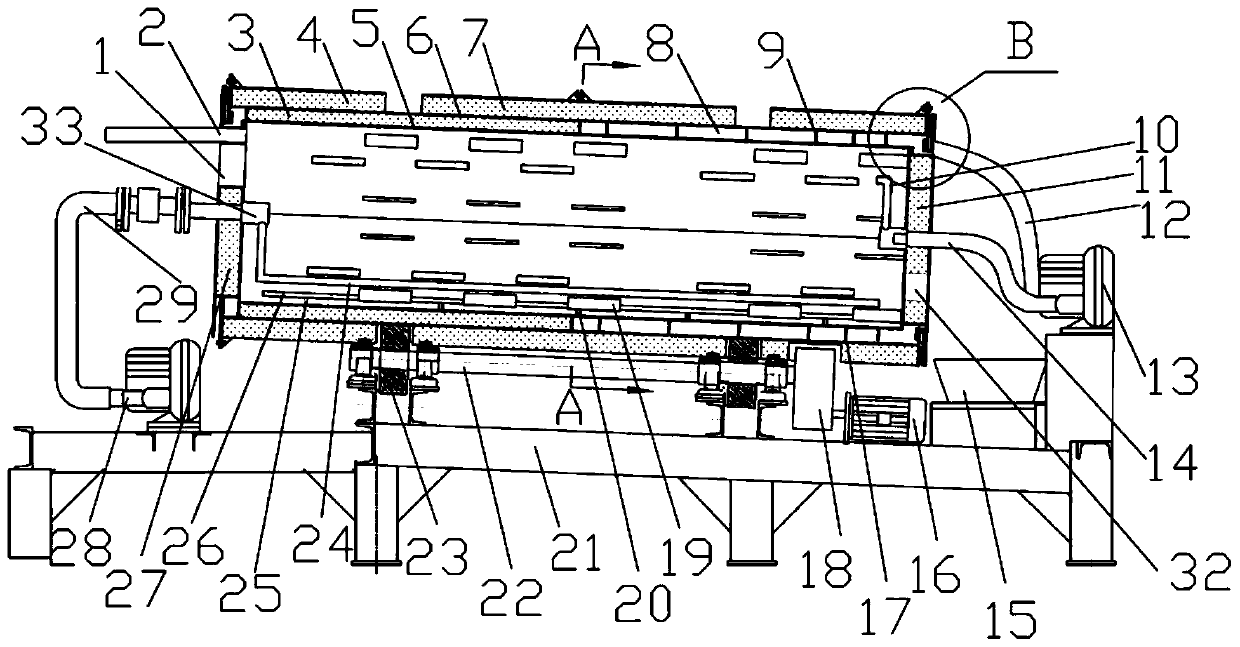

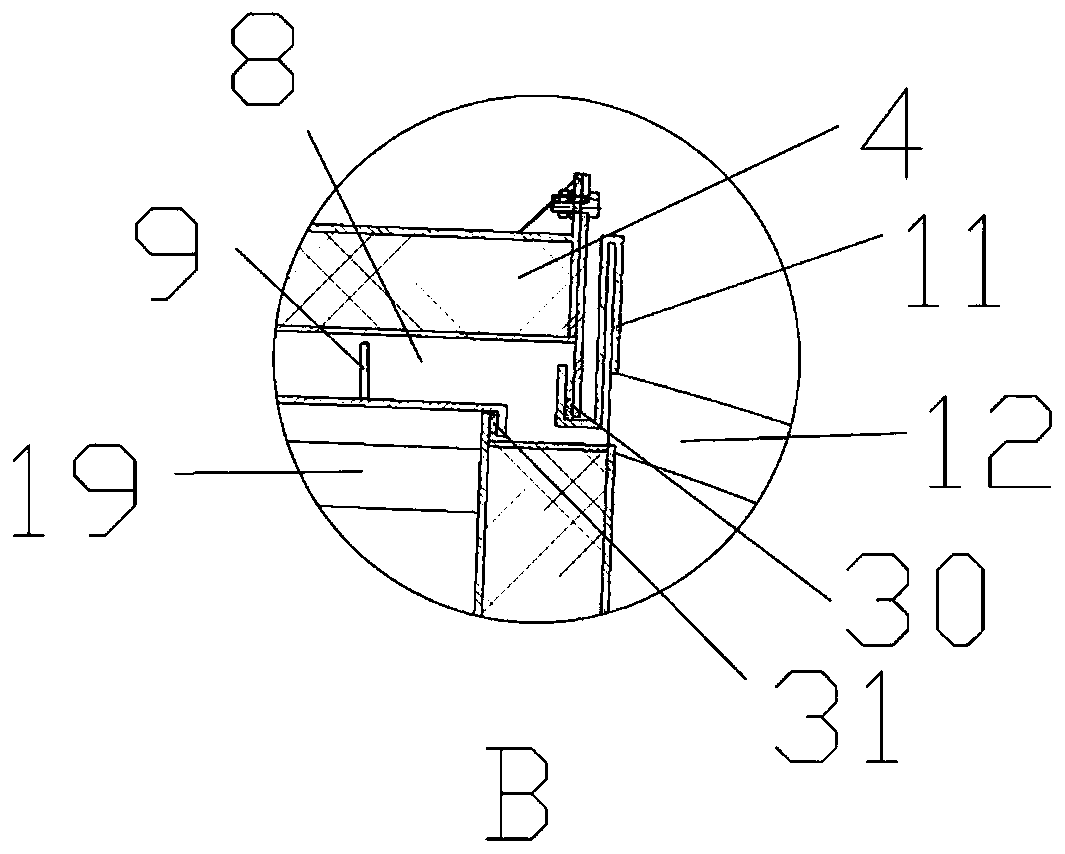

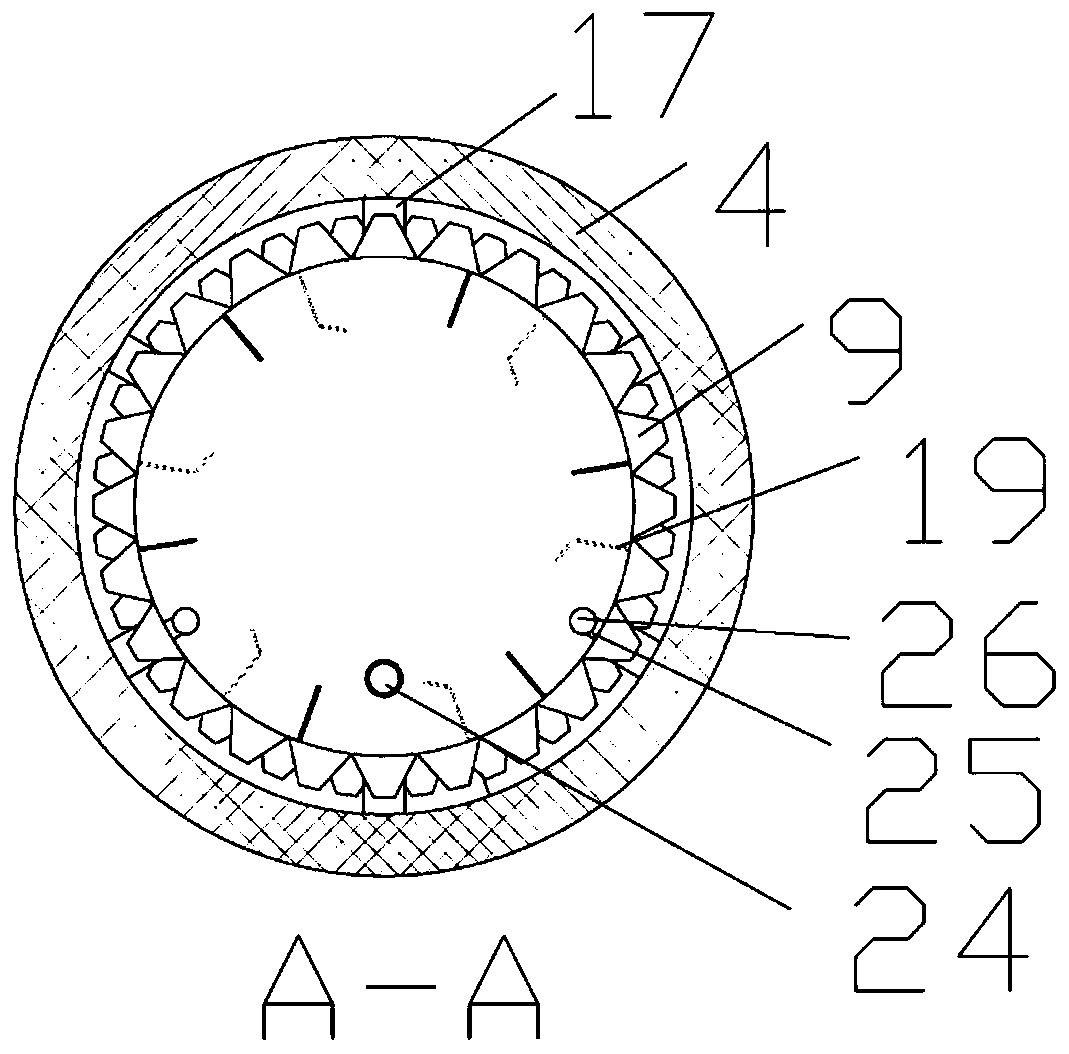

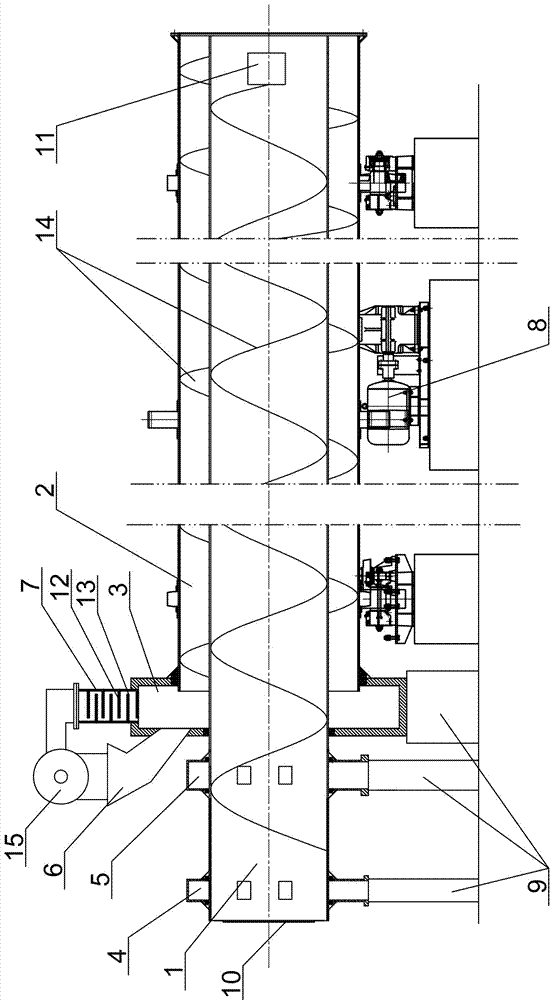

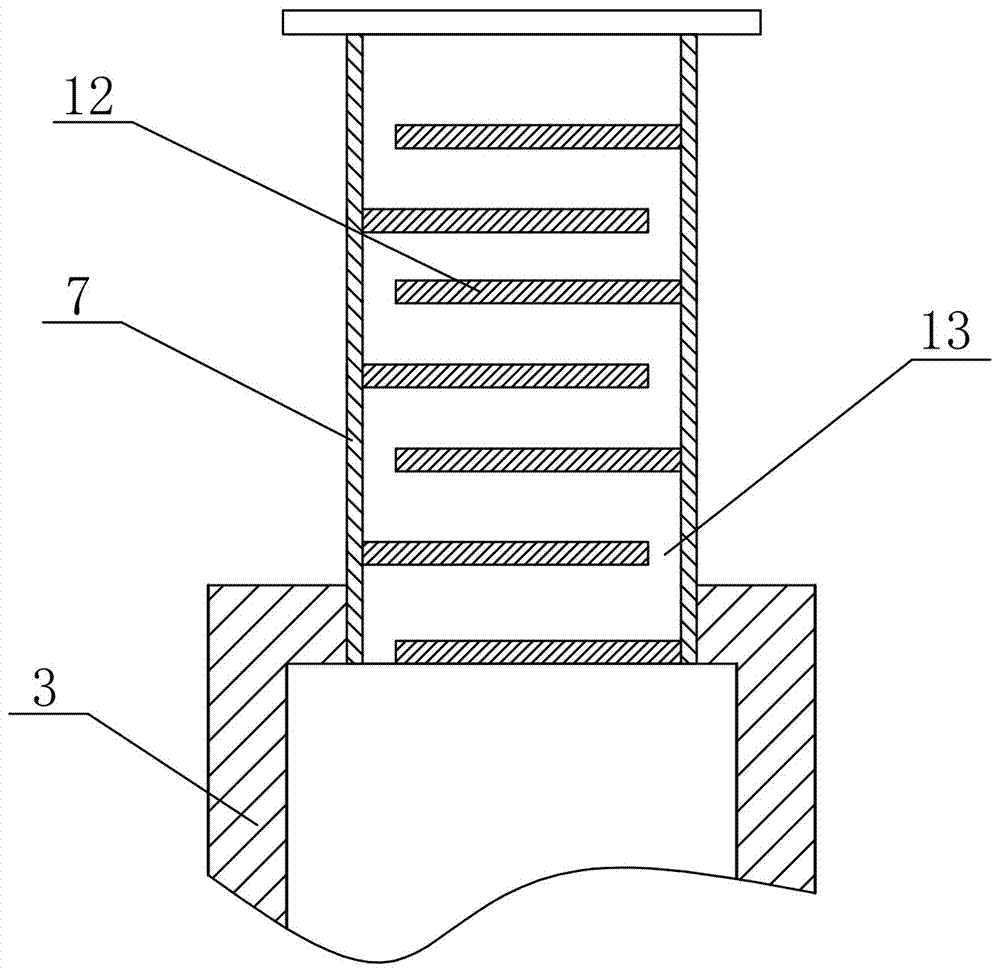

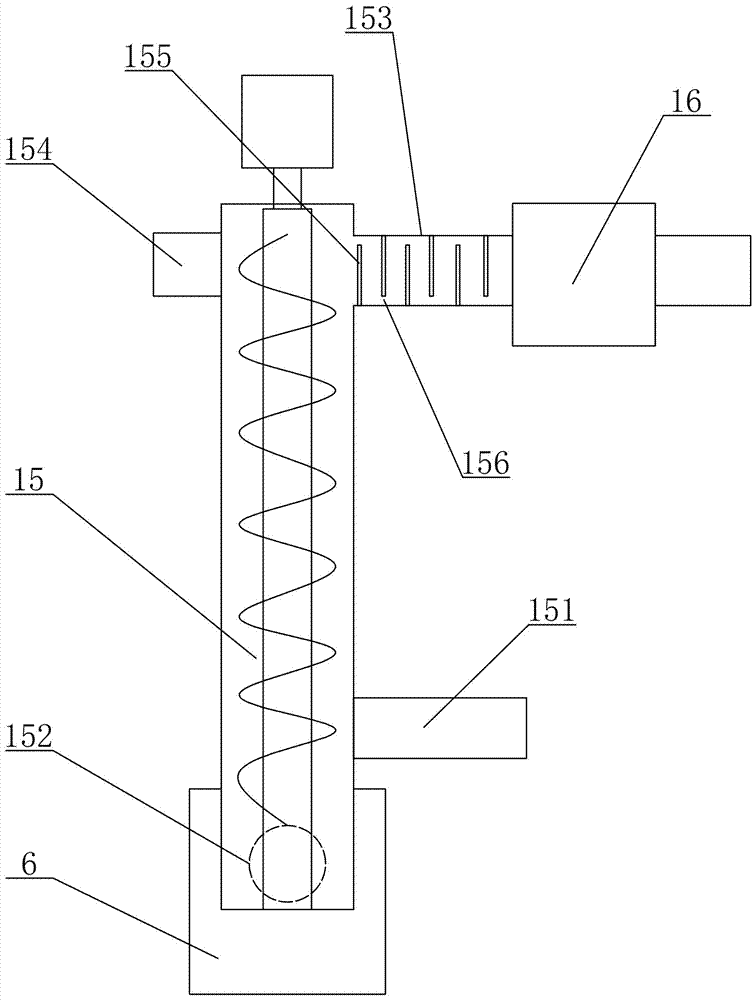

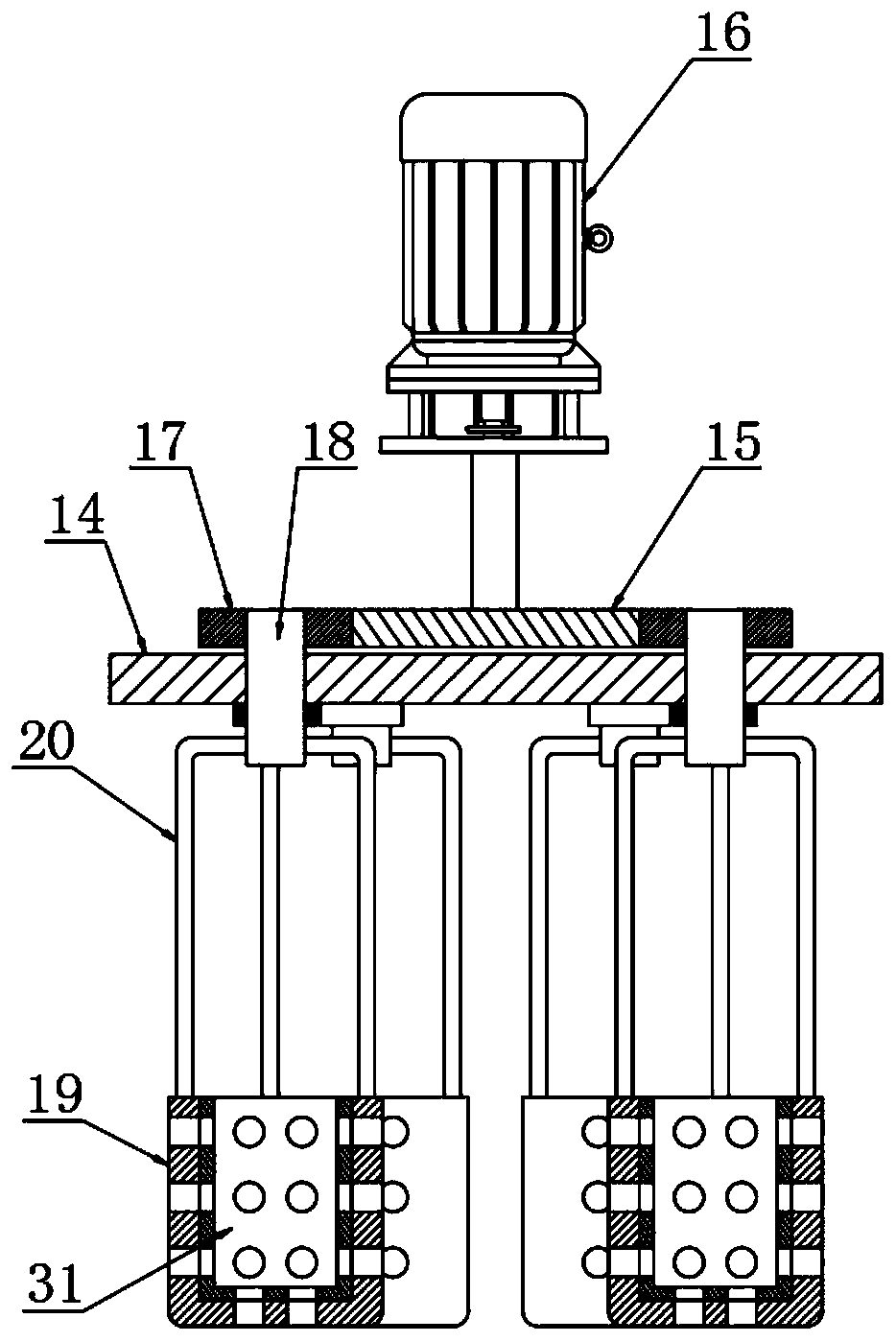

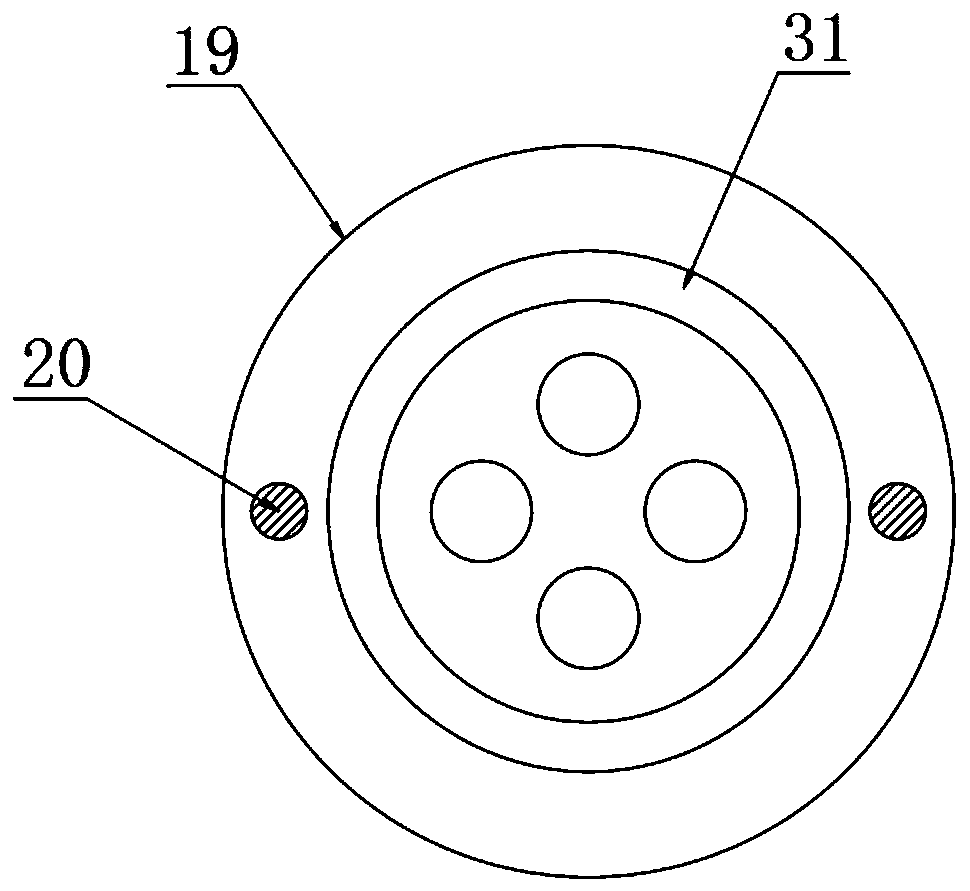

Roller repairing surfacing machine

InactiveCN107088696AReliable clamping functionReduce distortionWelding/cutting auxillary devicesAuxillary welding devicesSurface cleaningTailstock

The invention discloses a roller repairing surfacing machine and belongs to the field of metal welding. The roller repairing surfacing machine has a pre-welding preheating function, an automatic surfacing function, a welding fume removing function and a welding surface cleaning function, and also has the characteristics that a surfacing station can be adjusted rapidly, and the dimension expansion capacity of a surfacing workpiece is high. The roller repairing surfacing machine is provided with a foundation base, a headstock, a six-jaw chuck, a tailstock centre device and a working device. According to the technical scheme, a single stand column cross beam structure is adopted by the working device, surfacing, preheating, welding fume removing and welding surface cleaning are integrated onto one working head, thus, the structure is compact, and energy saving and environmental friendliness are achieved; a repairing roller is clamped through the six-jaw chuck and the tailstock center device, and clamping is fast and reliable; and the roller repairing surfacing machine is simple in structure, easy to manufacture and convenient to maintain.

Owner:KUNMING UNIV

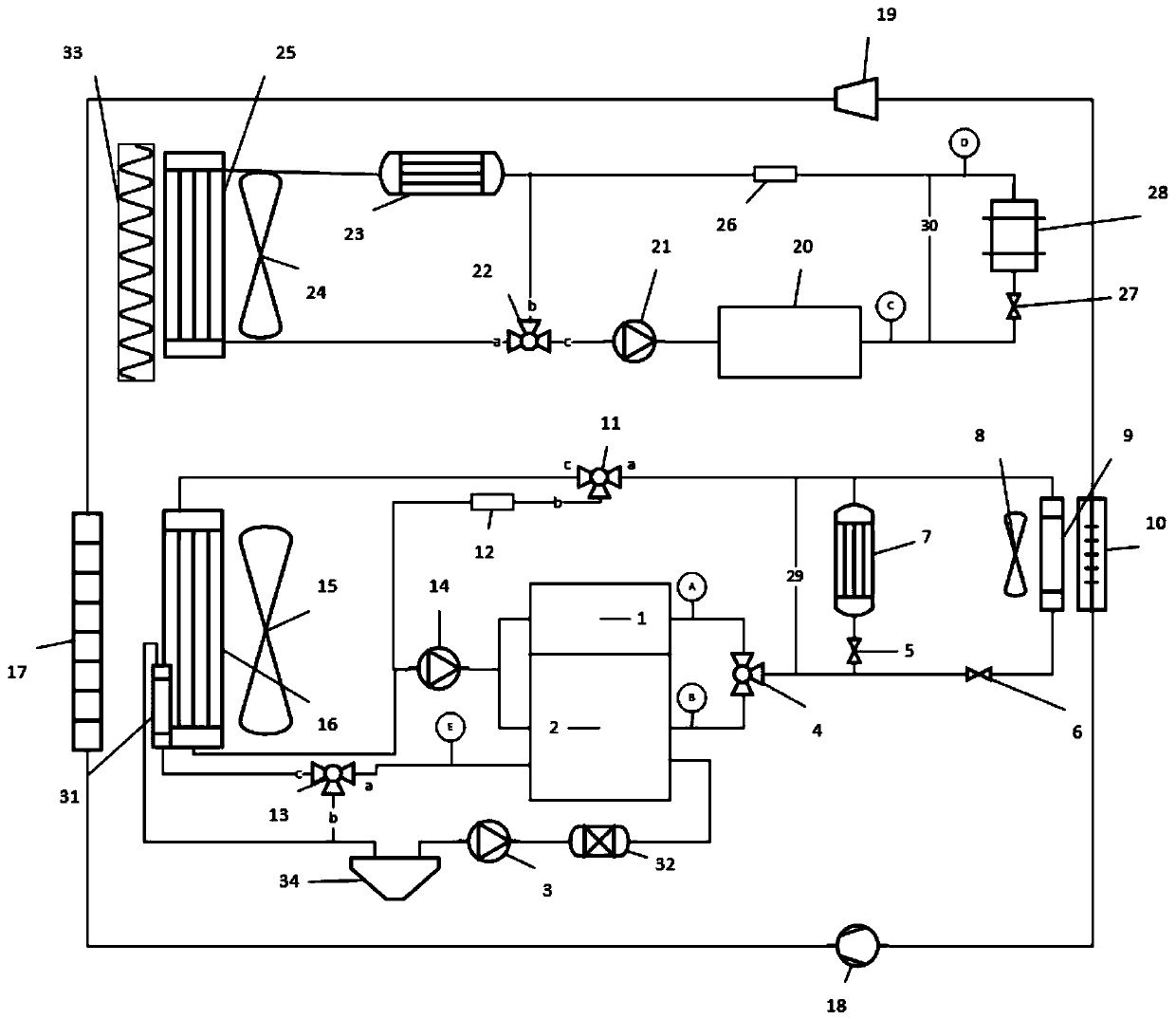

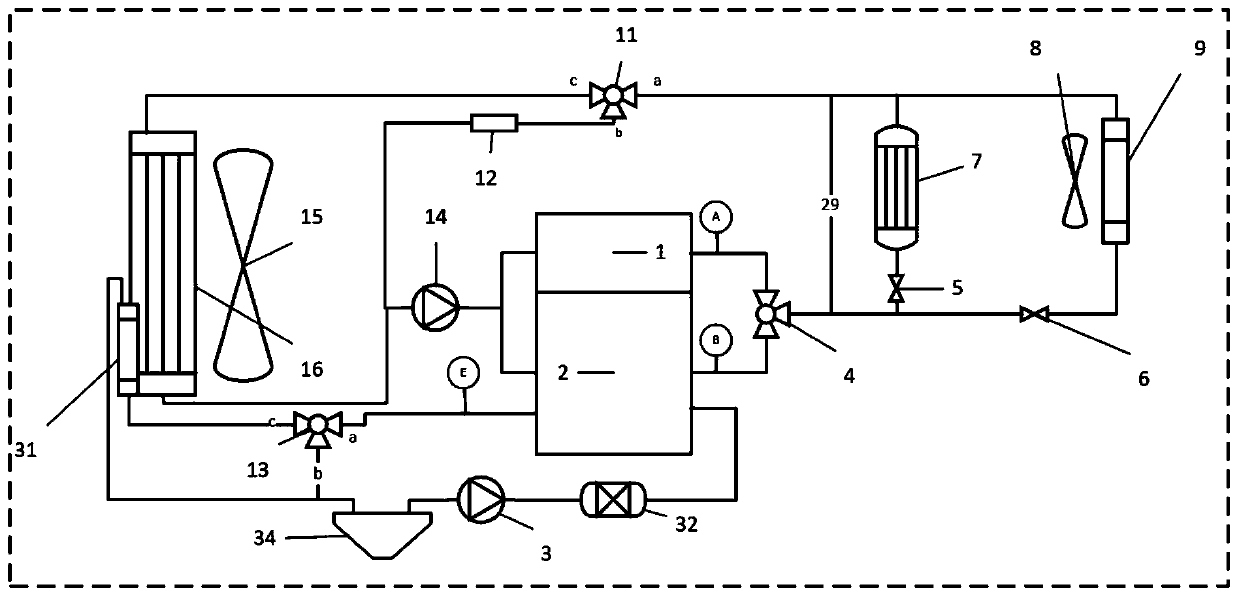

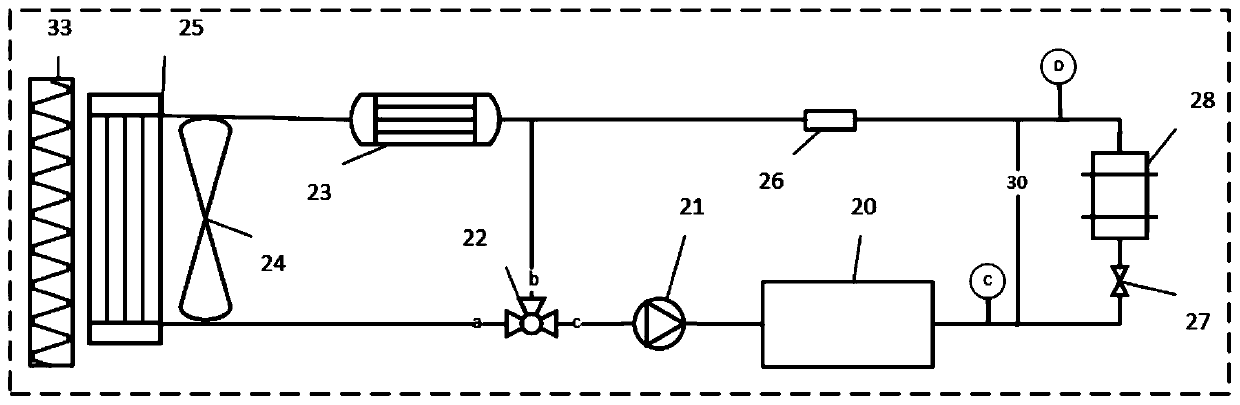

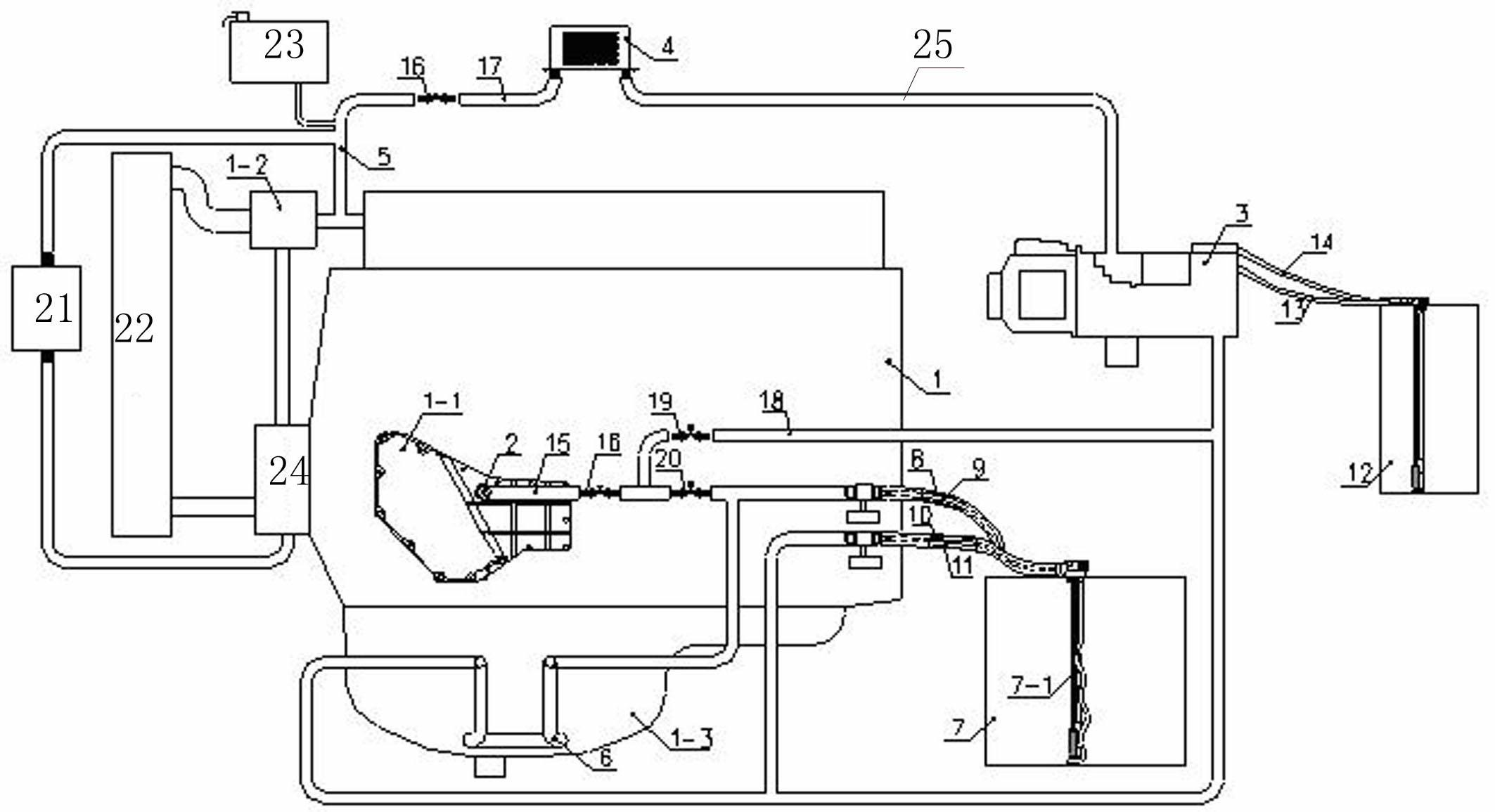

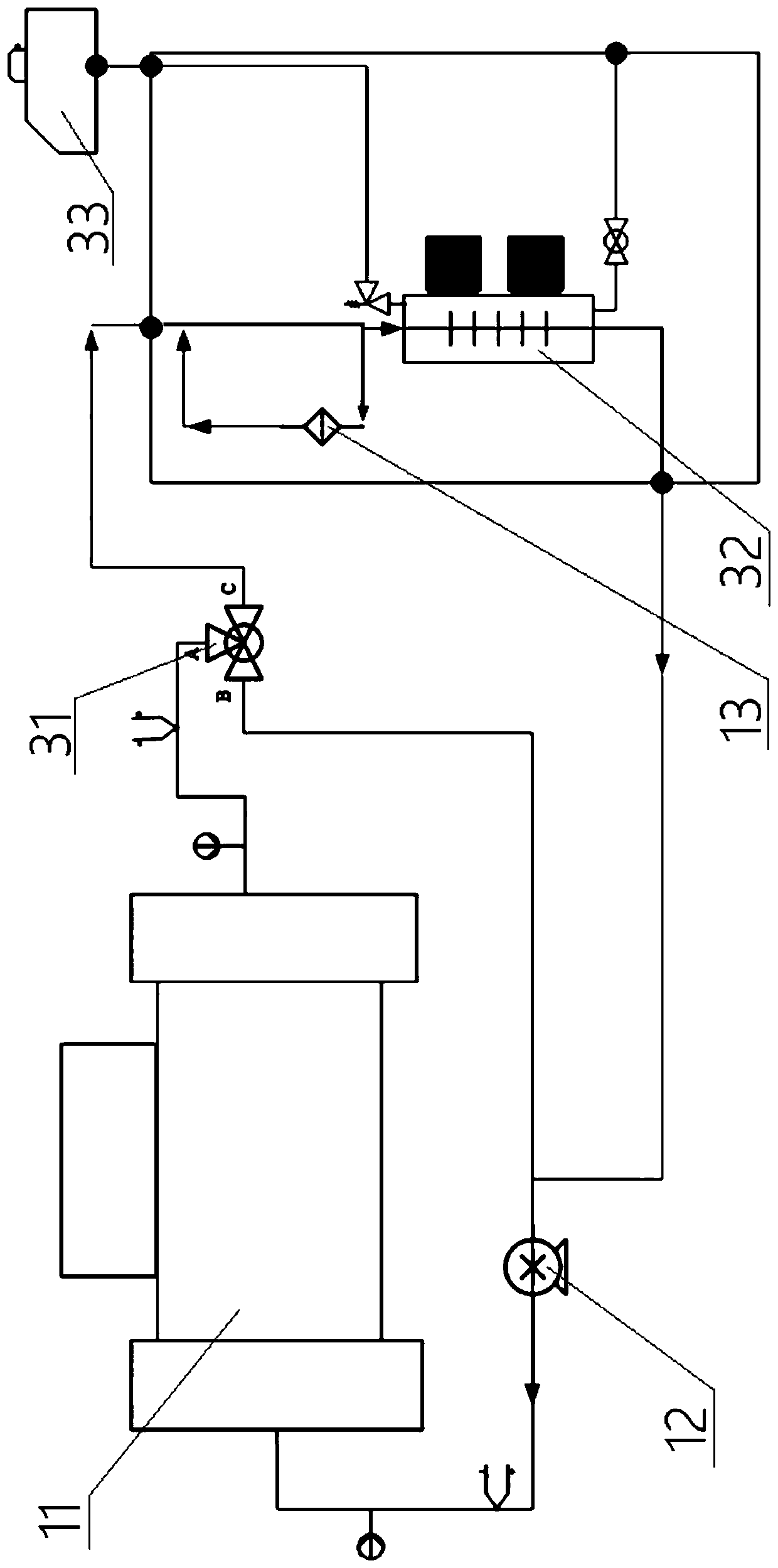

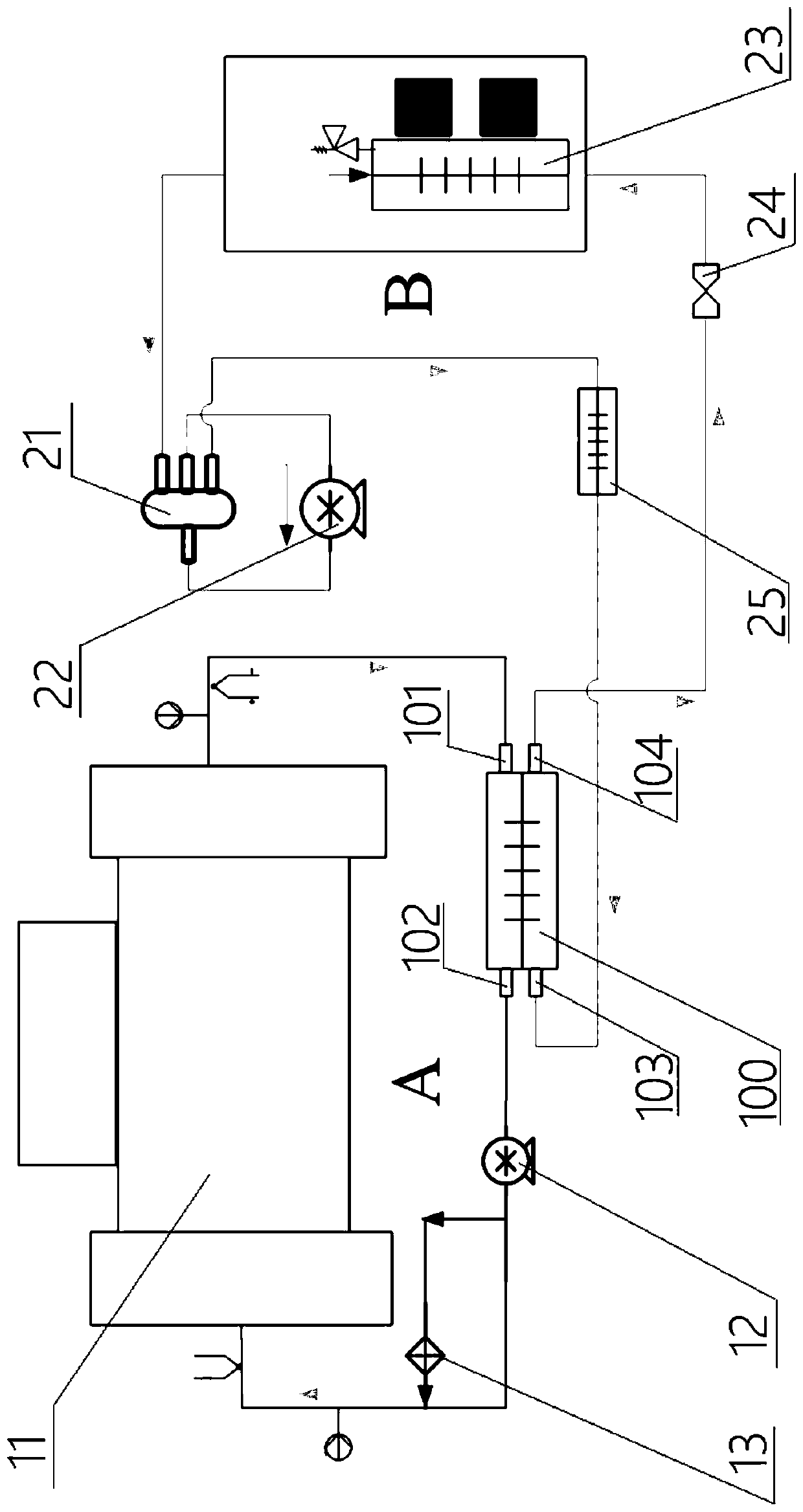

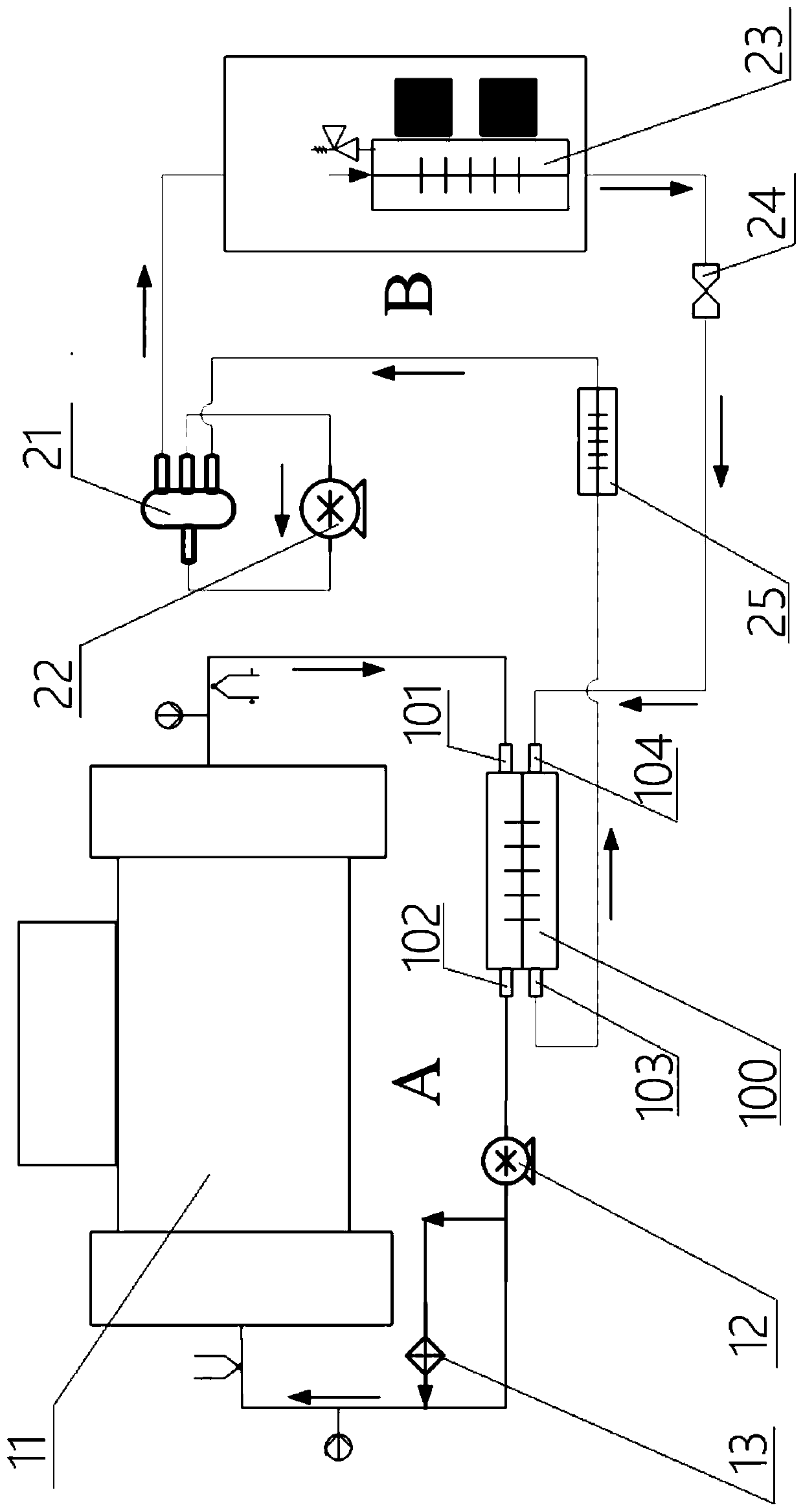

Thermal management system of hybrid power heavy truck and control method

ActiveCN109927534AImprove economyReduce consumptionAir-treating devicesInternal combustion piston enginesPower batteryCost effectiveness

The invention discloses a thermal management system of a hybrid power heavy truck and a control method. According to the thermal management system, components with different thermal demands are integrated in different cooling subsystems respectively, and the thermal management system can be divided into a high-temperature-level cooling system, a low-temperature-level cooling system and an air conditioner cooling system, wherein the high-temperature-level cooling system comprises an engine water circulation cooling device and an engine oil circulation cooling device, the low-temperature-level cooling system comprises a power battery and a motor, and the air conditioner cooling system is provided with a double-drive air conditioner compressor. The provided thermal management system of the heavy truck provides a control method for vehicle warming, driving and post-cooling and can achieve distribution of heat dissipation amount of each component under various working conditions as required, reasonably utilize waste heat and reduce the energy consumption of accessories of the thermal management system, so that the cost-effectiveness of a whole vehicle is improved.

Owner:TIANJIN UNIV

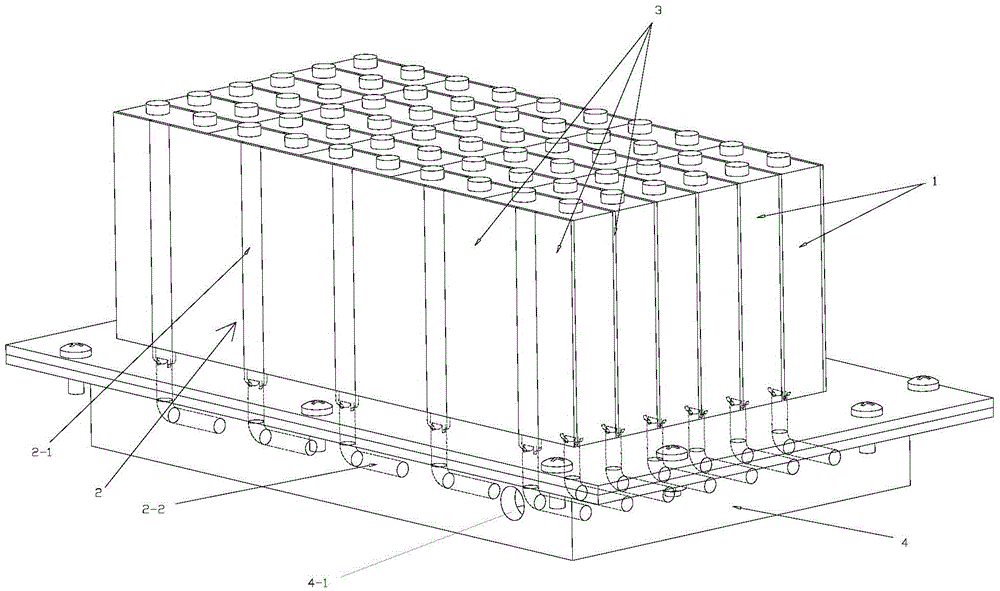

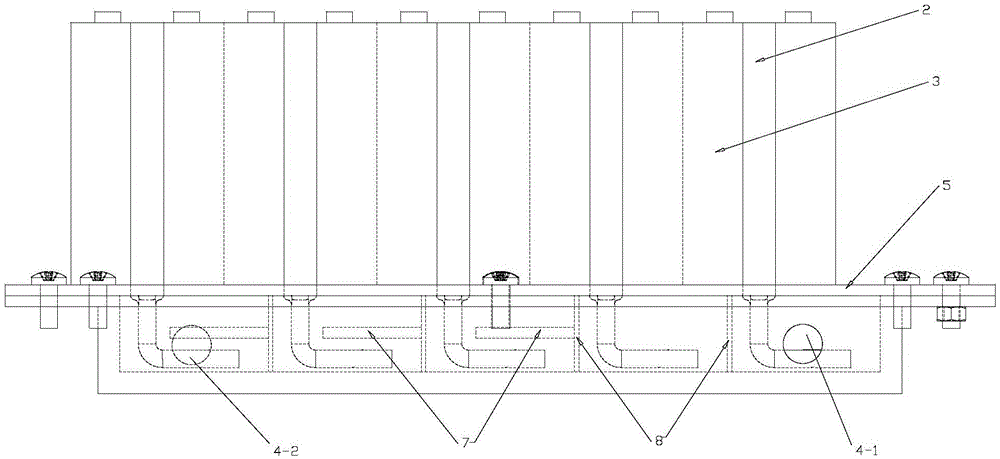

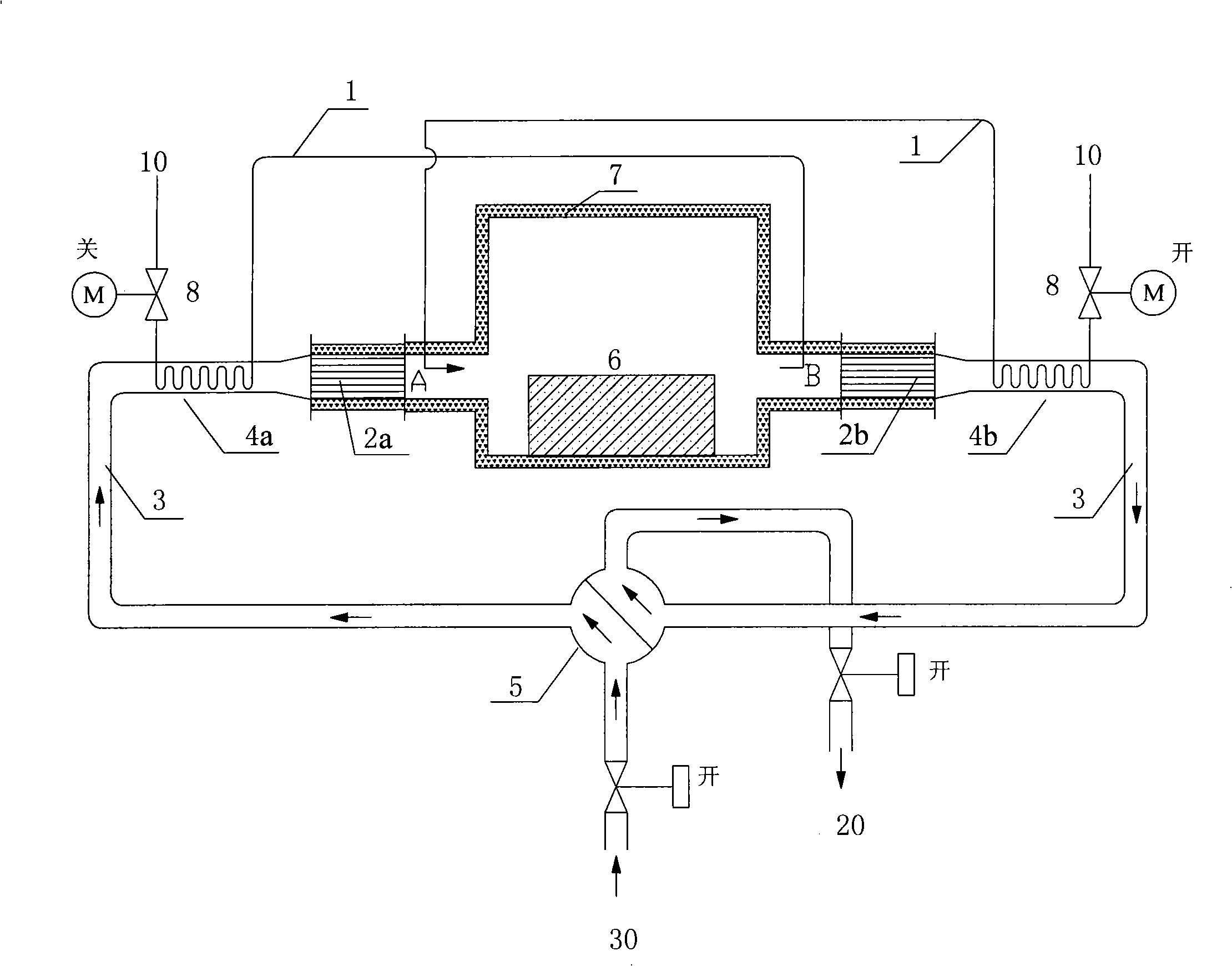

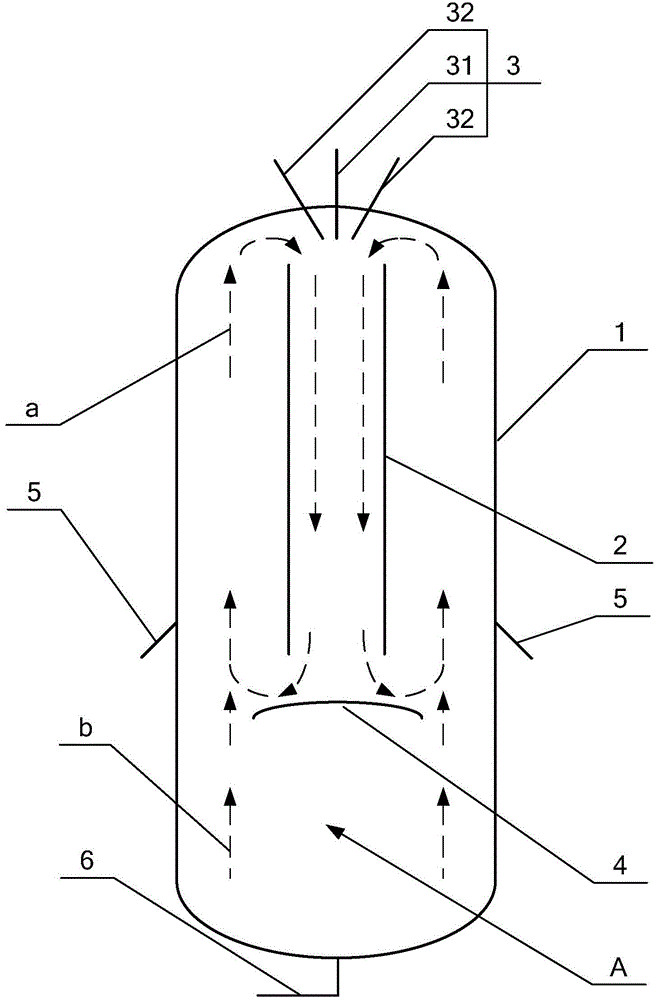

Power battery composite heat management system and method thereof

ActiveCN105633509AImprove thermal conductivityReduce weightSecondary cellsPower batteryHeat management

The invention discloses a power battery composite heat management system and a method thereof. The power battery composite heat management system comprises a water tank filled with a circulating fluid, a circulating pump, a sealing cover plate of the water tank, and a battery pack array which is fixedly mounted above the sealing cover plate and is composed of a plurality of battery cells, wherein a temperature equalizing plate and a heat pipe are adhered onto the surface of each battery cell respectively, and cooing sections of the heat pipes pass through the sealing cover plate to be arranged in the circulating fluid in the water tank; a circulating fluid inlet is formed in one side end of the water tank, a circulating fluid outlet is formed in the other side end of the water tank, and a circulating fluid turbulent flow structure is arranged inside the water tank, so that the circulating fluid flows into the circulating fluid outlet from the circulating fluid inlet of the water tank in a curve flowing manner. The system and the method thereof can solve the technical problems such as heat dissipation, battery pack temperature difference reduction, battery preheating and heat cyclic utilization under different working conditions of batteries; and meanwhile, the system is compact and simple in structure and convenient in installation and maintenance, accords with the development tendency of battery heat management systems and electric automobiles, and has good application prospects.

Owner:SOUTH CHINA UNIV OF TECH

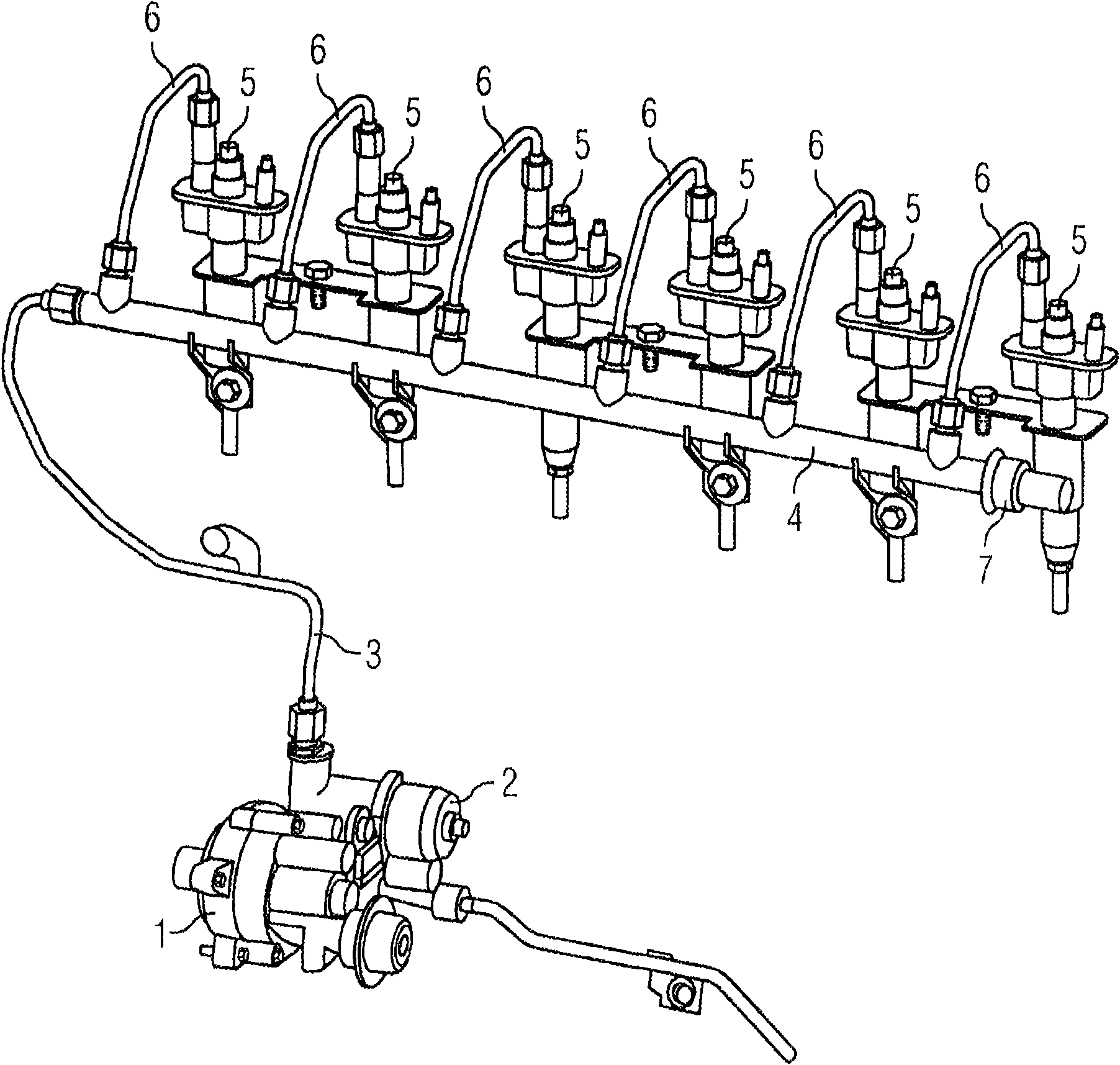

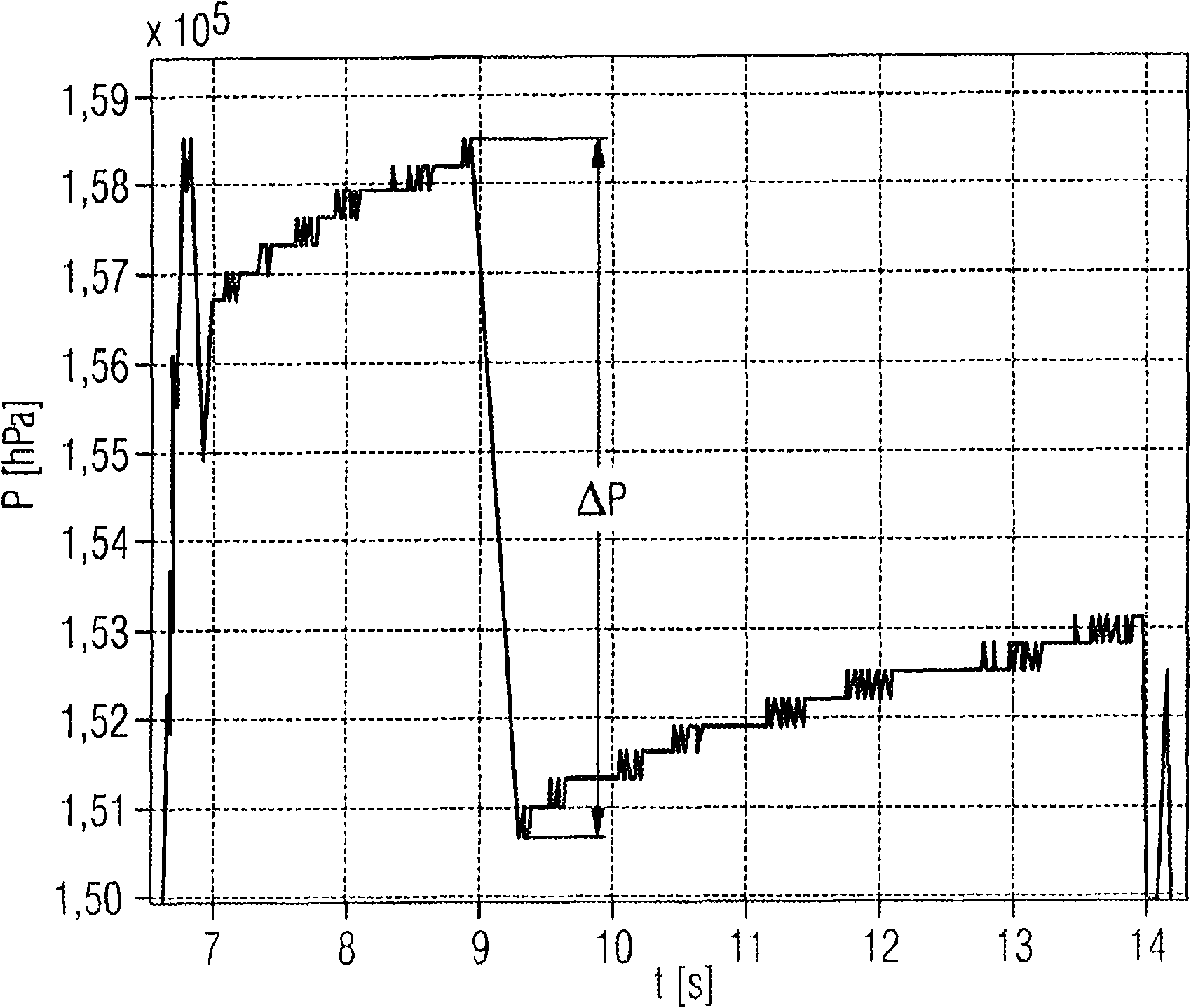

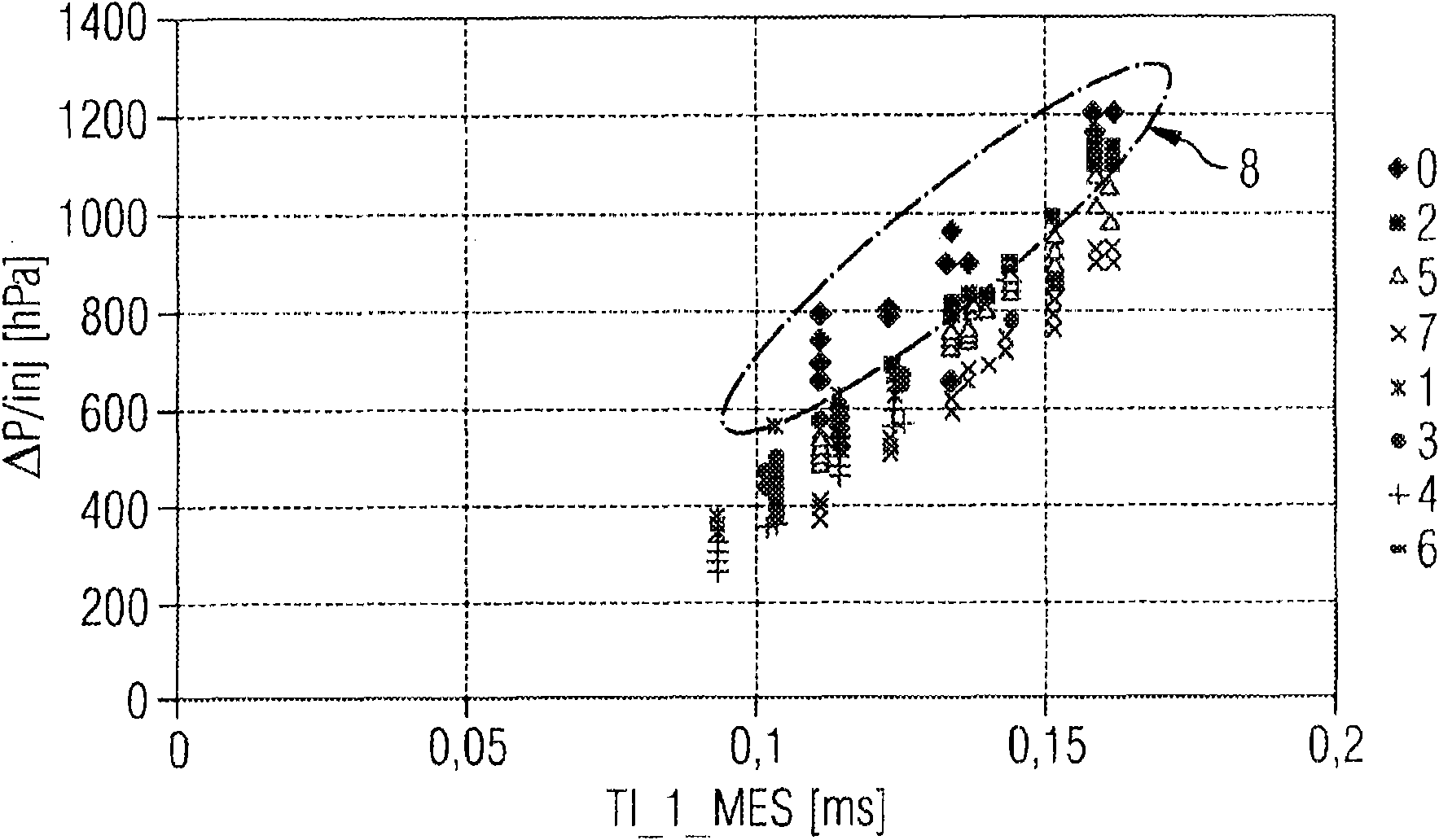

Method and device for diagnosing an injection valve, connected to a fuel rail, of an internal combustion engine

ActiveCN101688491AReduce jerky runningAchieve warm-upElectrical controlMachines/enginesDifferential pressureInternal combustion engine

The invention relates to a method for diagnosing an injection valve (5), wherein in an overrun fuel cut-off phase the fuel supply to the fuel rail (4) is closed, and after the fuel supply has been closed off a first fuel pressure in the fuel rail (4) is measured, and after the first measurement of the fuel pressure an injection valve (5) is actuated for a test injection, after the test injection a second fuel pressure in the fuel rail (4) is measured, a differential pressure value (Delta P) is formed from the first and second measured fuel pressures and a difference of an operating parameter from a reference parameter is determined from the differential pressure value (Delta P), and when a previously defined maximum difference is exceeded the injection valve (5) is detected as being defective. The invention also relates to a device for diagnosing an injection valve (5).

Owner:VTESCO TECH GMBH

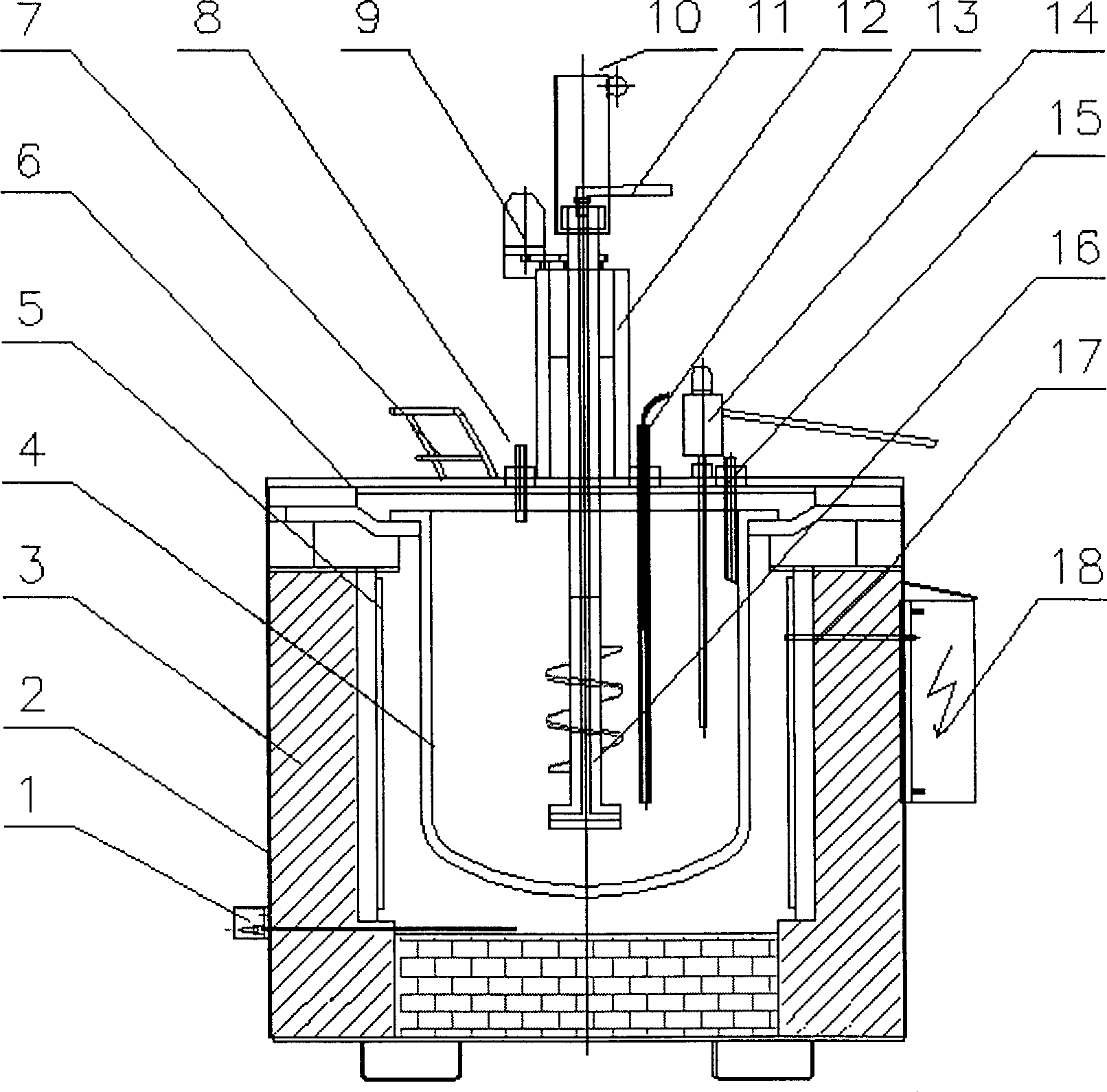

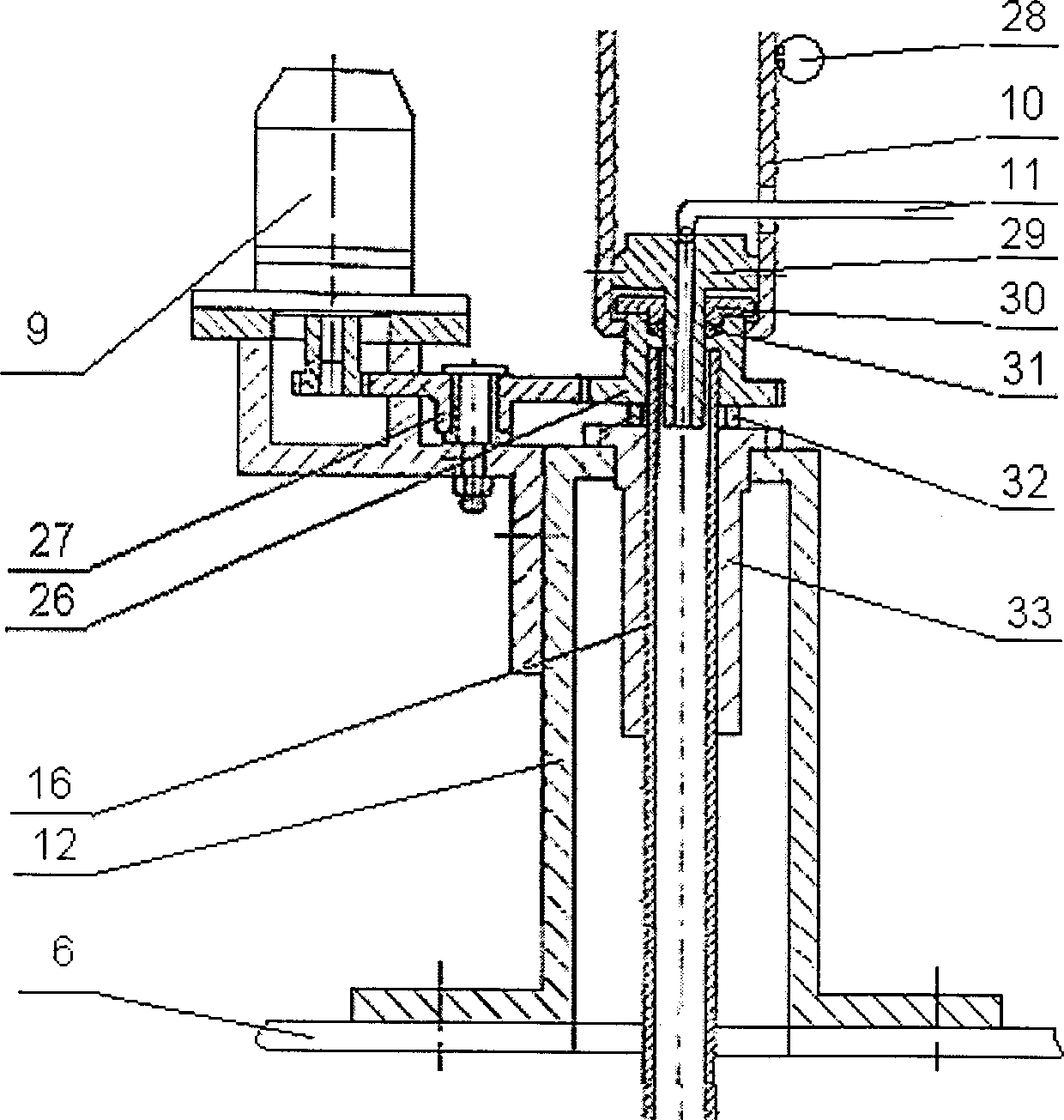

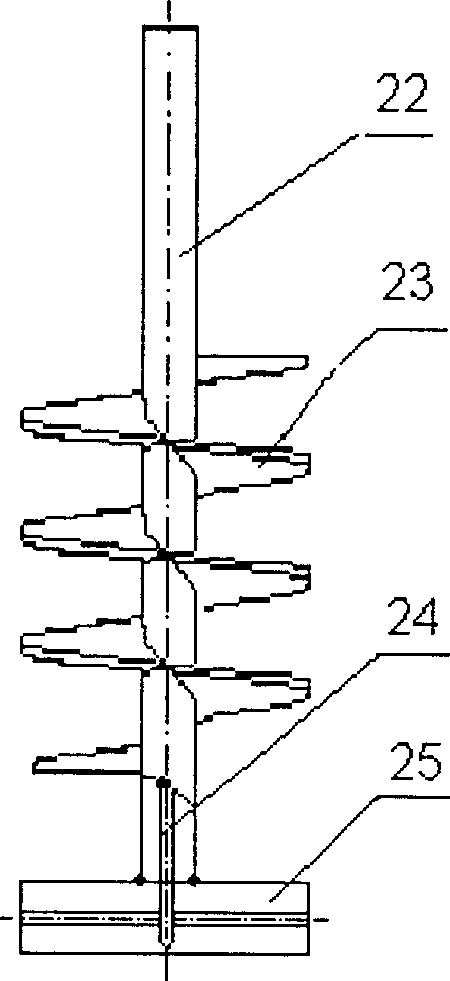

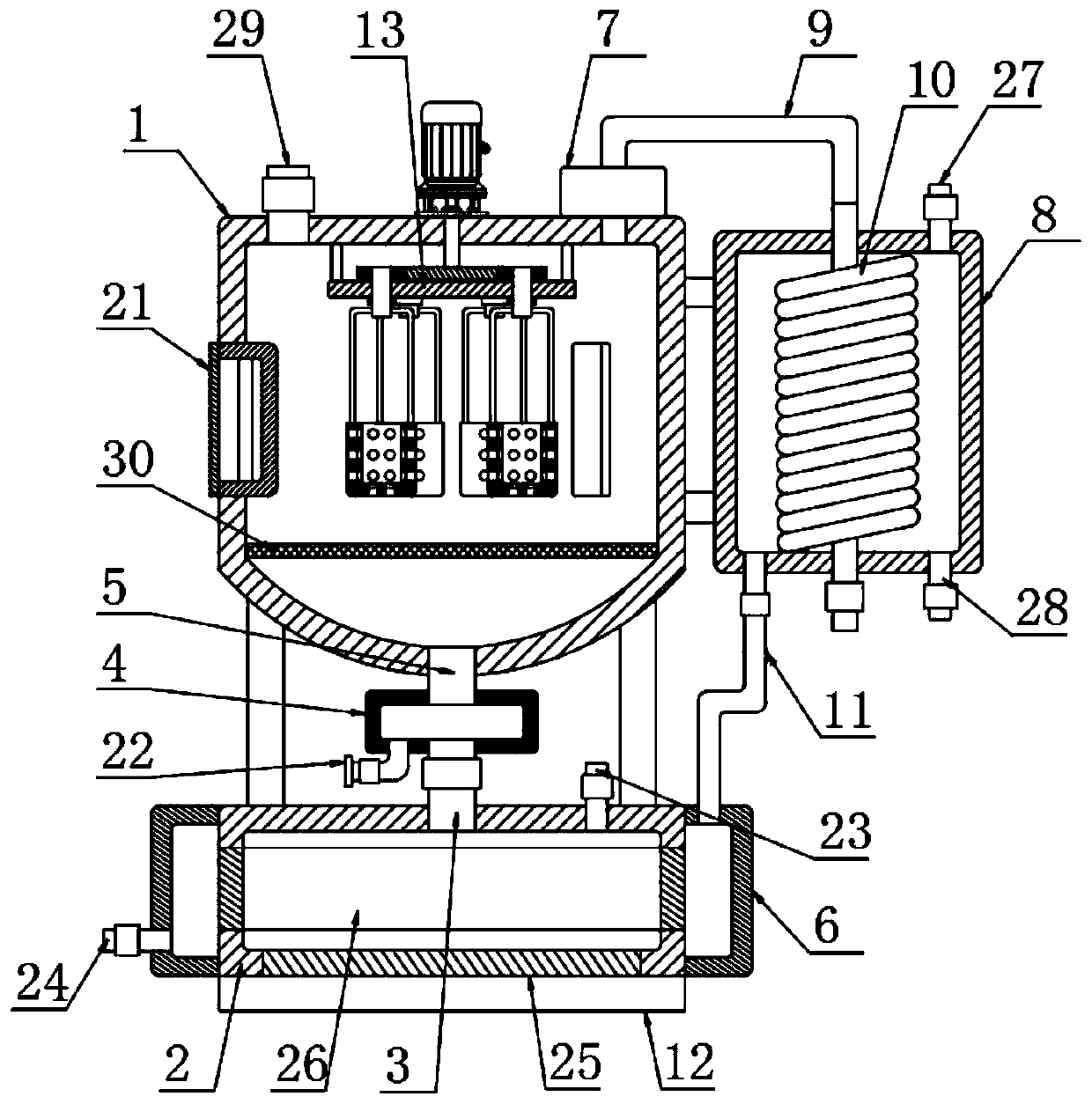

Magnesium alloy waste regenerator

InactiveCN1436865AReduce recycling costsImprove refining effectCrucible furnacesCombustionSpiral blade

The magnesium alloy waste regenerator consists of furnace body, feeding and discharge system and refining system. The apparatus has a stirrer comprising stirring rod with spiral blades and stirring head and these is a through hole in the stirring rod and the stirring head and connected to the refining gas passage via fixing flange. There are dynamic sealing structure in the upper part of the stirring rod and partitioned bin feeder comprising partitioned bin, rotary opened upper cover and withdrawable partition boards. The present invention can realize mechanical composite stirring of gas during refining and isolate magnesium alloy waste in smelting and refining from outside, and these results in less oxidation and combustion, saving in flux and protective gas, improved refining effect, regeneration quality and efficiency, low cost and less environmental pollution.

Owner:TSINGHUA UNIV

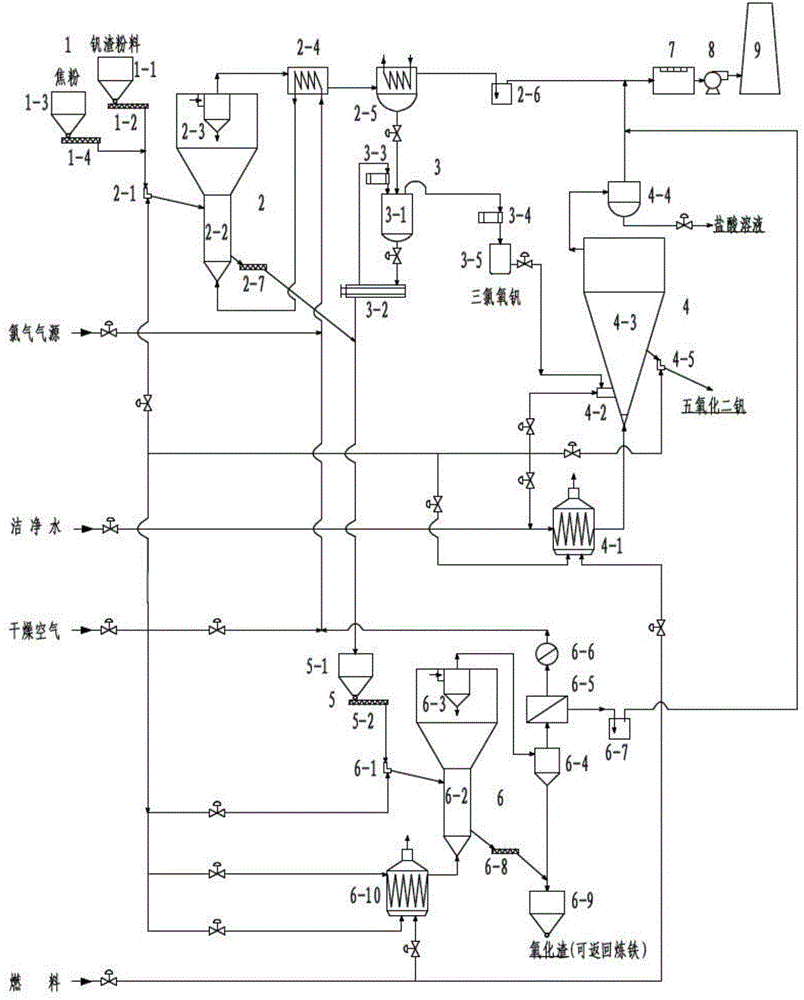

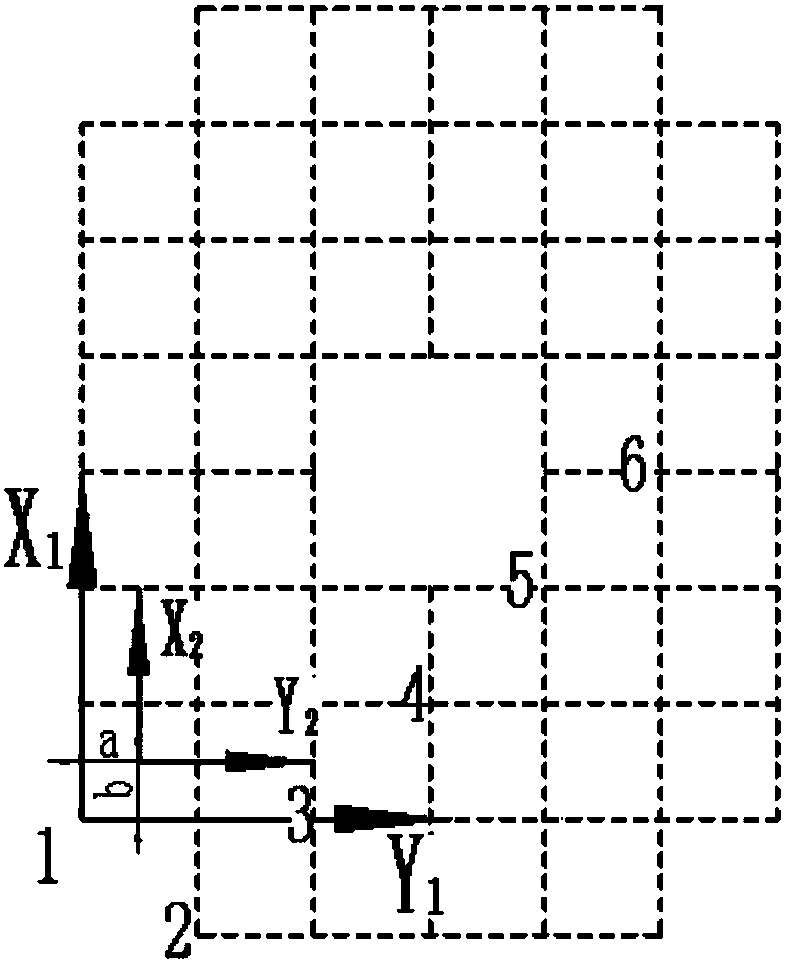

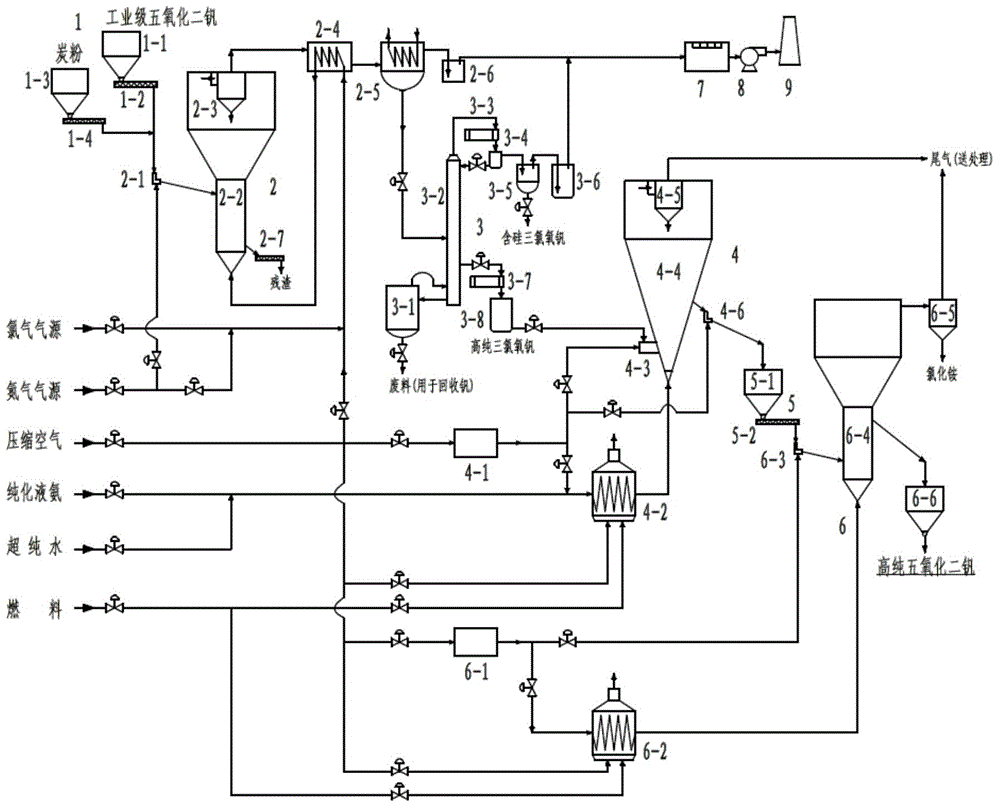

System and method for high-efficiency extraction of vanadium from vanadium slag through chlorination

ActiveCN105986126AAchieve warm-upUniform temperature distributionVanadium oxidesProcess efficiency improvementFlue gasPrecipitation

The invention specifically discloses a system and method for high-efficiency extraction of vanadium from vanadium slag through chlorination, belonging to the fields of chemical engineering and metallurgy. By means of heat exchange between chlorination gas and chlorination flue gas, the chlorination gas is preheated; a proper amount of air is added to allow a part of coke powder to combust, thus providing a balanced supply of heat during the process of chlorination; by means of high-temperature fluidization oxidation of chlorinated slag, the chlorinated slag is treated in a comprehensive manner, and the chlorine gas is recycled; furthermore, by means of vapor-phase hydrolysis of the chlorination product vanadium oxytrichloride, a powdered vanadium pentoxide product and a hydrochloric acid byproduct are obtained; so the efficiency of chlorination is improved, the consumption of chlorine gas is reduced, the harm of the chlorinated slag is eliminated, and the problem of ammonia-nitrogen pollution caused by conventional ammonium salt precipitation is prevented. The system and method provided by the invention are applicable to extraction of vanadium from vanadium slag containing 10 to 28 wt% of V2O5 through chlorination and have the advantages of high efficiency, low energy consumption, no pollution, good economic performance, etc.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

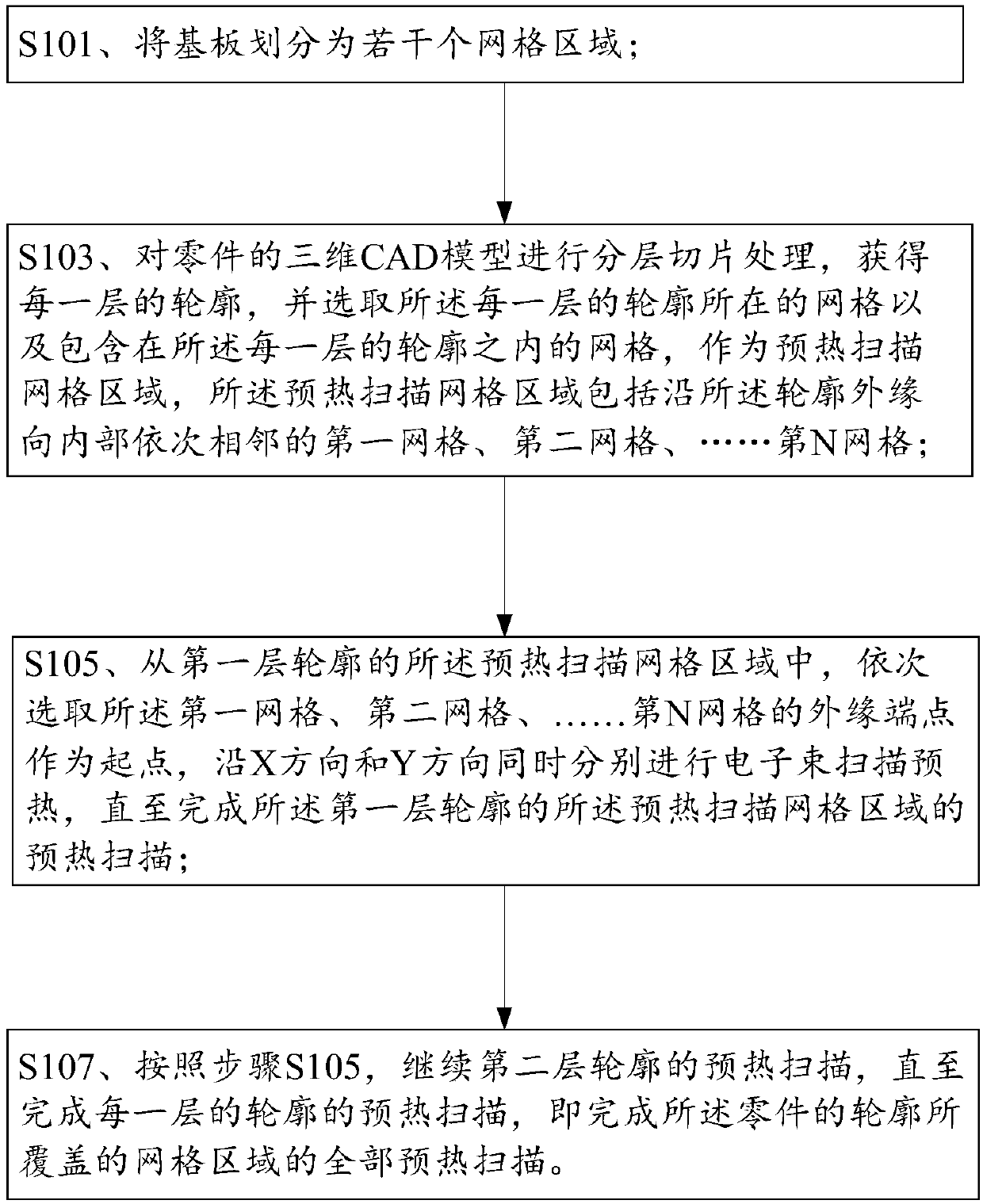

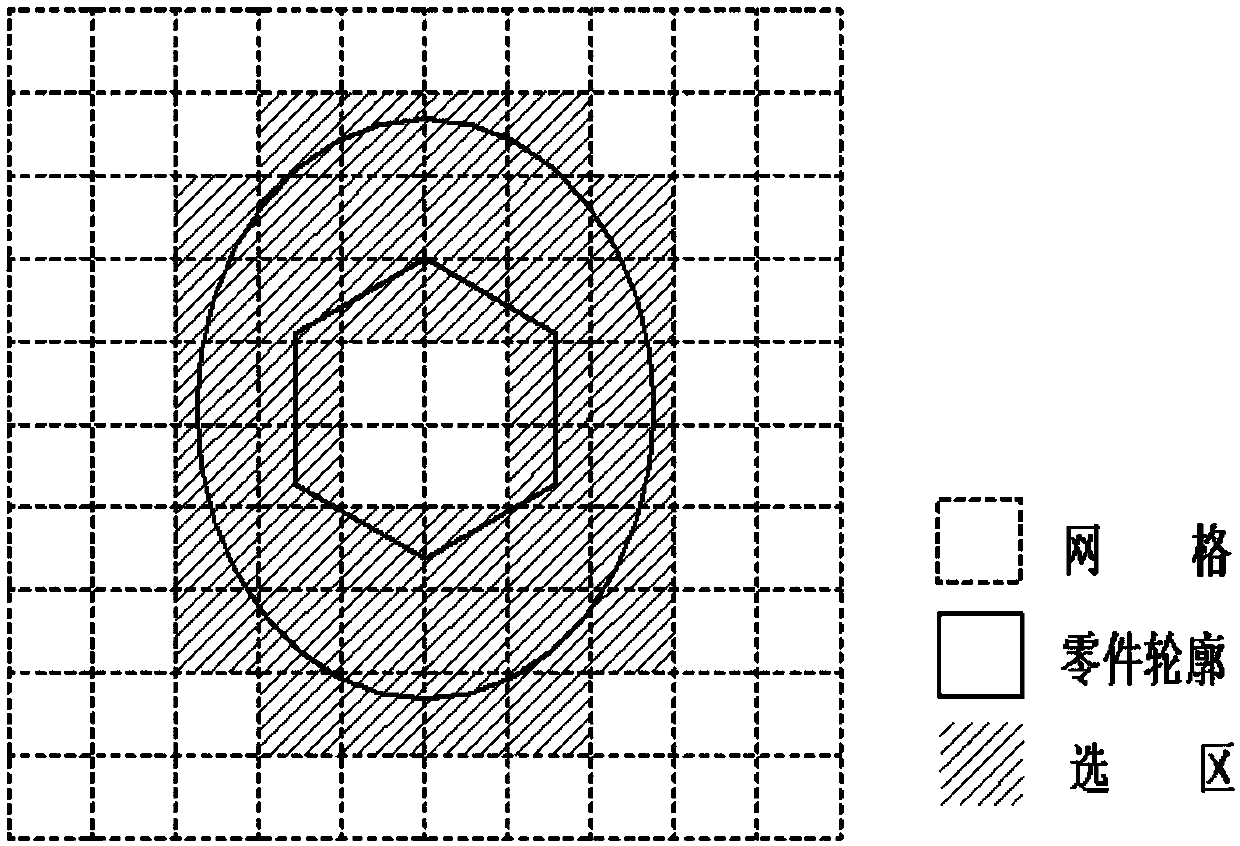

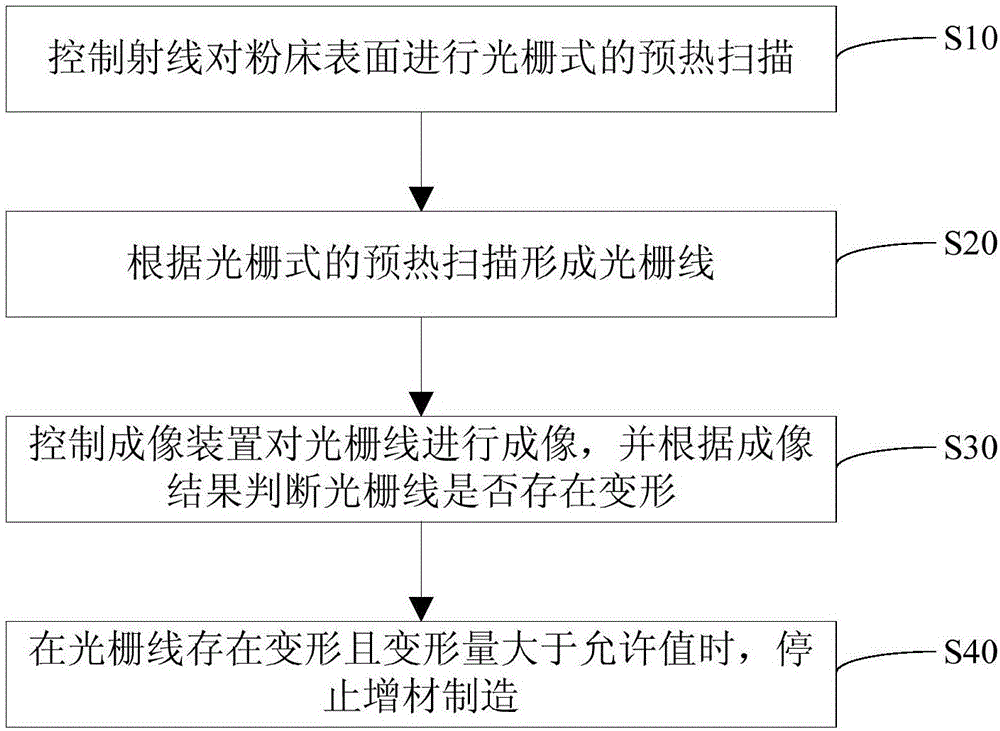

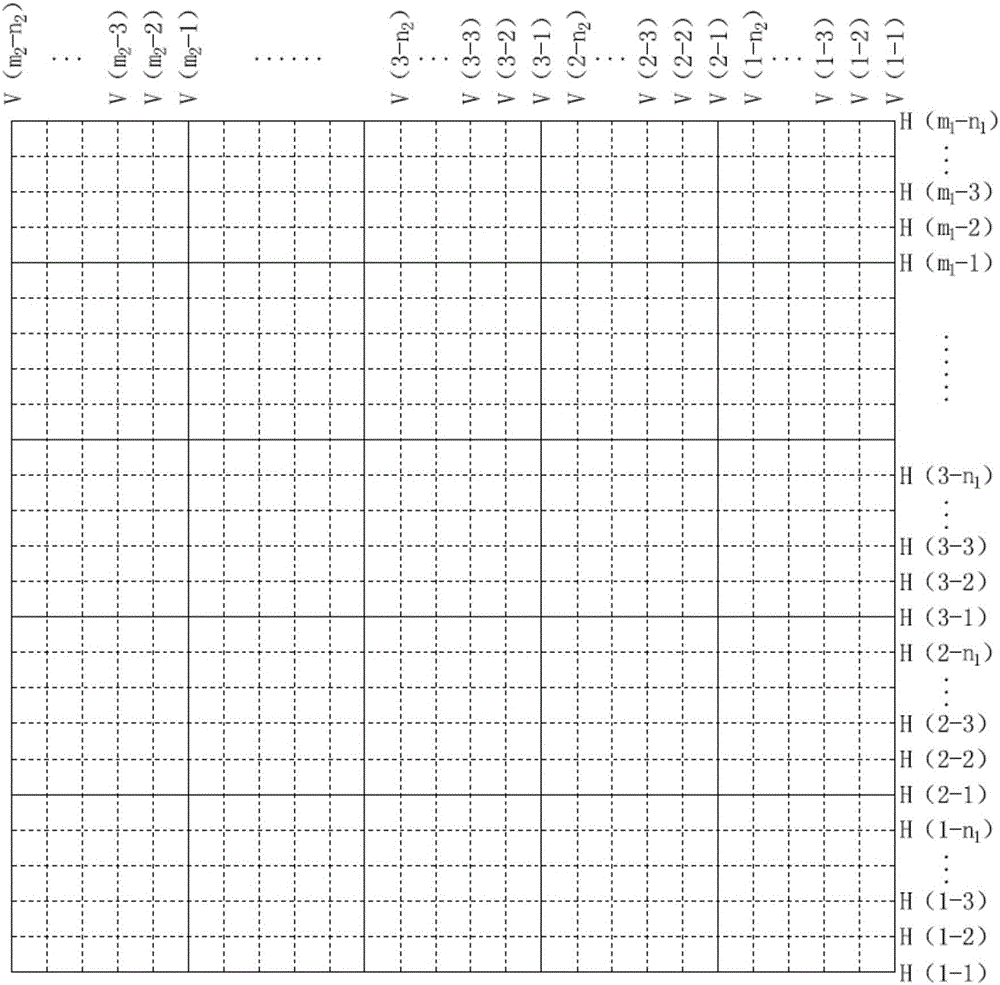

Electron beam selective preheating scanning method

InactiveCN107755696AAchieve warm-upWays to improve warm-upAdditive manufacturing apparatusElectronMesh grid

The invention provides an electron beam selective preheating scanning method. The electron beam selective preheating scanning method comprises the steps that S101, a base plate is divided into a plurality of grid areas; S103, a three-dimensional CAD model of a part is subjected to layered slicing so as to obtain a contour of each layer, and grids where the contours of all the layers are located and grids contained in the contours of all the layers are selected to serve as preheating scanning grid areas which each comprise the first grid, the second grid...the N grid which are sequentiallyadjacent from the outer edges of the contours to the interiors; S105, the outer edge end points of the first grid, the second grid...the N grid in the preheating scanning grid area of the contourof the first layer are sequentially selected to serve as starting points, and electron beam preheating scanning is conducted in the X and Y directions simultaneously; and S107, according to the step 105, preheating scanning of the contour of the second layer is continued till preheating scanning of the contour of each layer is completed. According to the electron beam selective preheating scanningmethod, a powder bed can be preheated, temperature unevenness is reduced, warping deformation is reduced, and the material utilization rate can also be increased.

Owner:XIAN ZHIRONG METAL PRINTING SYST CO LTD

A system and method for efficiently chlorinating vanadium from vanadium slag

ActiveCN105986126BAchieve warm-upUniform temperature distributionVanadium oxidesProcess efficiency improvementSlagGas phase

Provided are a system and method for highly effective chlorination and vanadium extraction from vanadium slag. By means of heat exchange between a chlorination gas and a chlorination flue gas, a chlorination gas is preheated and an appropriate amount of air is added, which causes coke powder to partially combust, thus providing a balanced supply of heat during the process of chlorination; also, by means of high-temperature fluidization oxidation of the chlorinated slag, the chlorinated slag is used in a comprehensive manner, and the chlorine gas is recycled; further, by means of vapor-phase hydrolysis of the vanadium oxytrichloride product of chlorination, a powdered divanadium pentoxide product is obtained; the reaction efficiency of chlorination is improved, the consumption of chlorine gas is reduced, the harm of chlorinated slag is eliminated, and the pollution problem caused by conventional ammonium salt precipitation is prevented.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

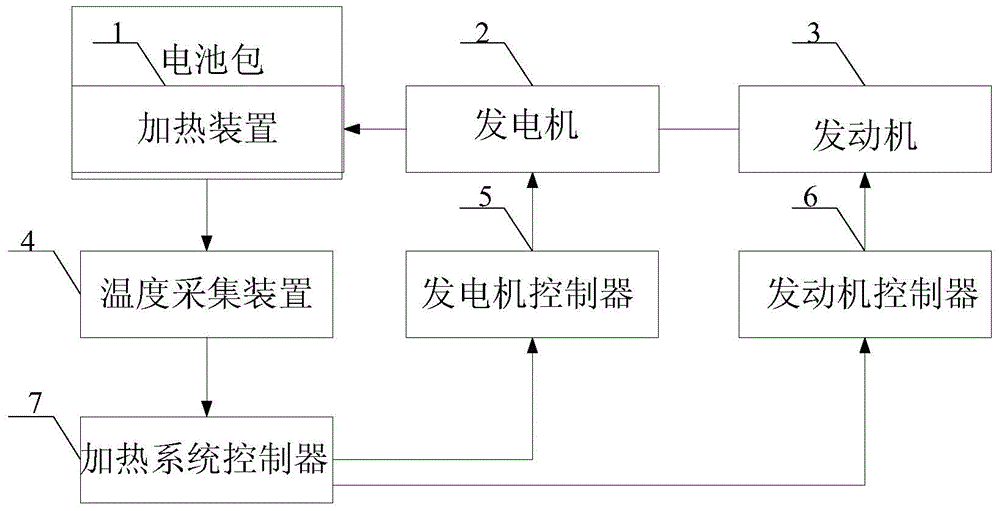

Low-temperature preheating system for battery pack of electric car and method for preheating battery pack

InactiveCN104577257AAchieve temperature controlAchieve warm-upSecondary cellsElectricityControl signal

The invention discloses a low-temperature preheating system for a battery pack of an electric car and a method for preheating the battery pack, relates to the technical field of low-temperature operation of the electric car, and aims at preheating batteries of the electric car under a low-temperature condition. The heating device disclosed by the invention is used for heating the battery pack; a temperature collecting device is used for collecting temperature in the battery pack; a power supply signal output end of an electric generator is connected with a power supply signal input end of the heating device; an engine is used for driving the electric generator to generate electricity; a control signal output end of an electric generator controller is connected with a power generation control signal input end of the electric generator; a control signal output end of an engine controller is connected with a control signal input end of the engine; a heating control signal output end of a heating system controller is simultaneously connected with the control signal input end of the engine controller and the control signal input end of the electric generator controller; and the heating system controller is used for judging the temperature, which is collected by the temperature collecting device, in a box body of the battery pack, and achieving control on the heating device. The low-temperature preheating system is suitable for preheating the batteries of the electric car.

Owner:HARBIN UNIV OF SCI & TECH

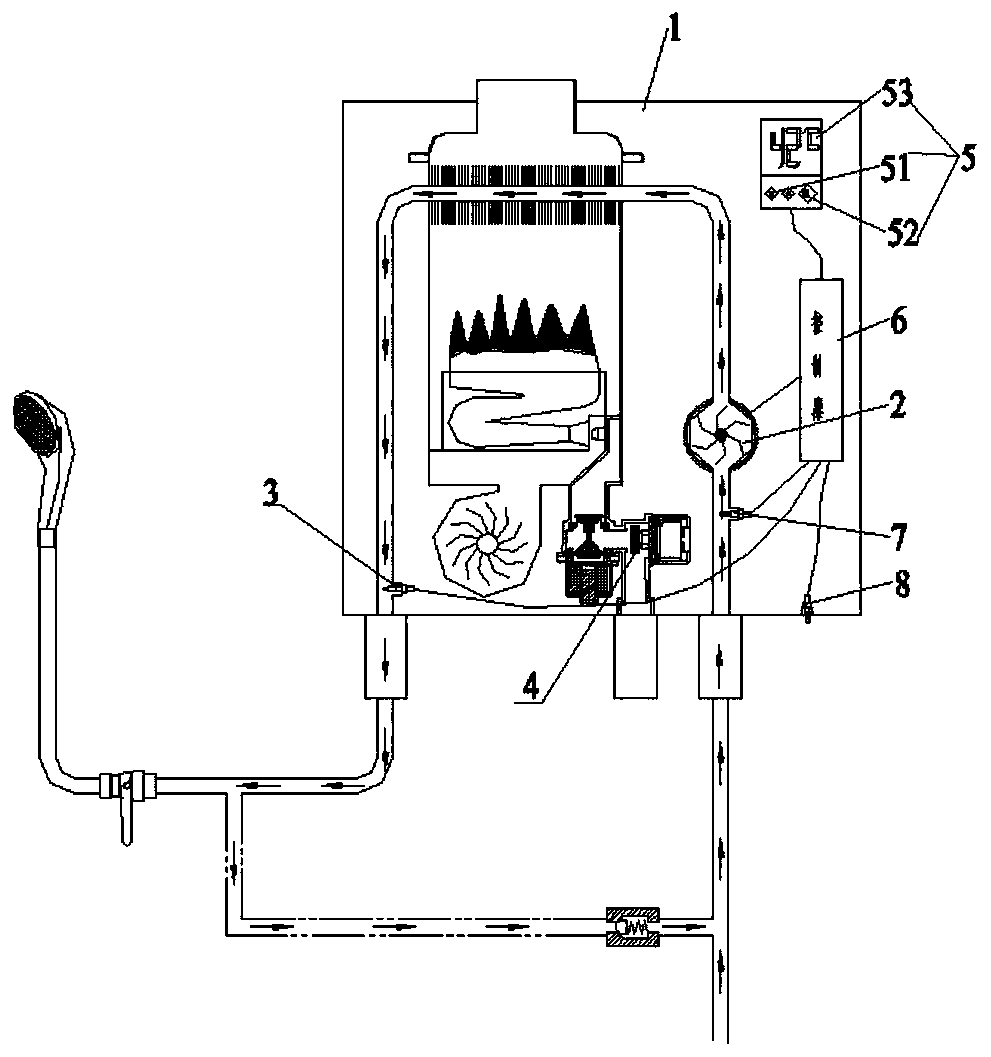

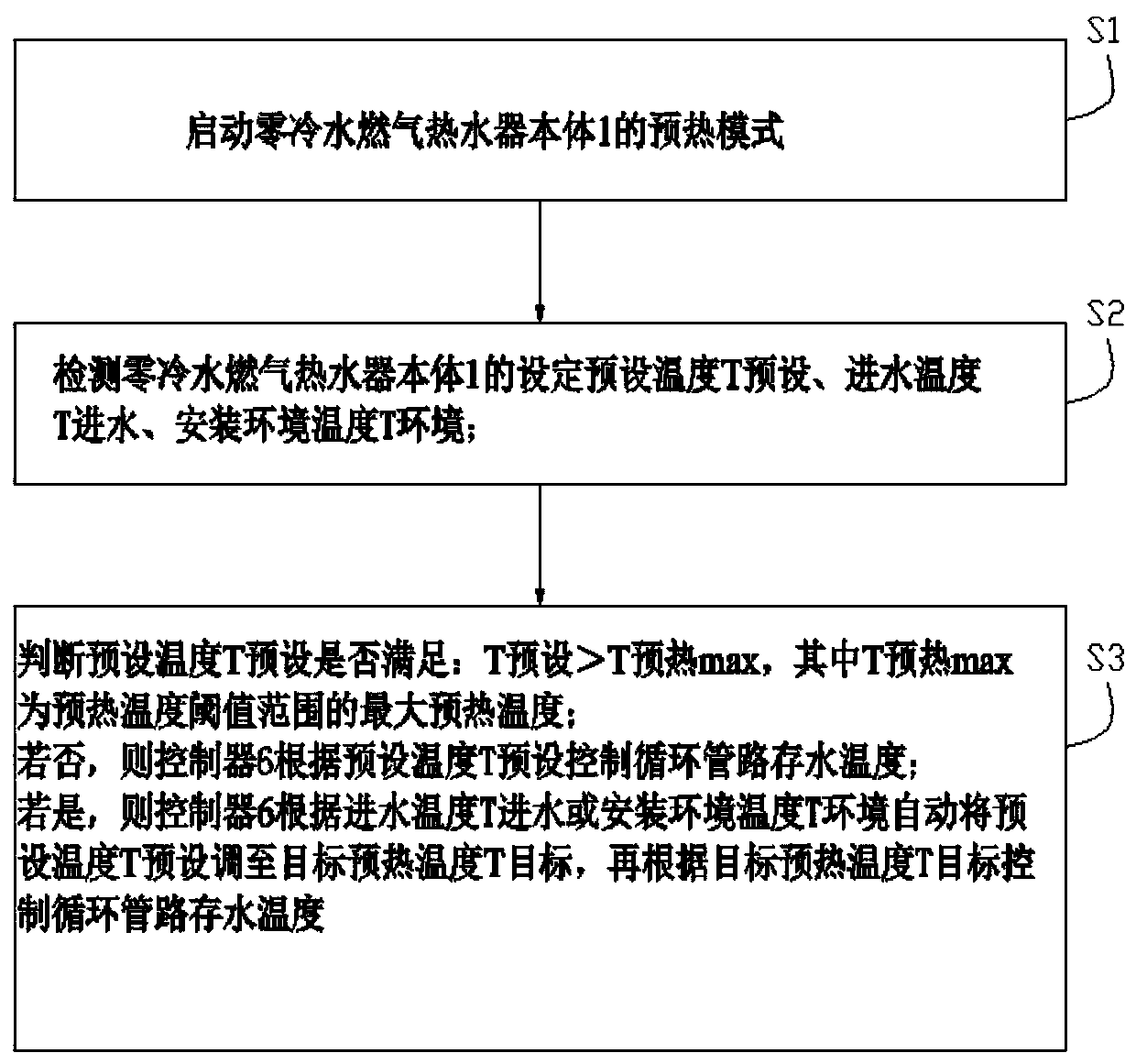

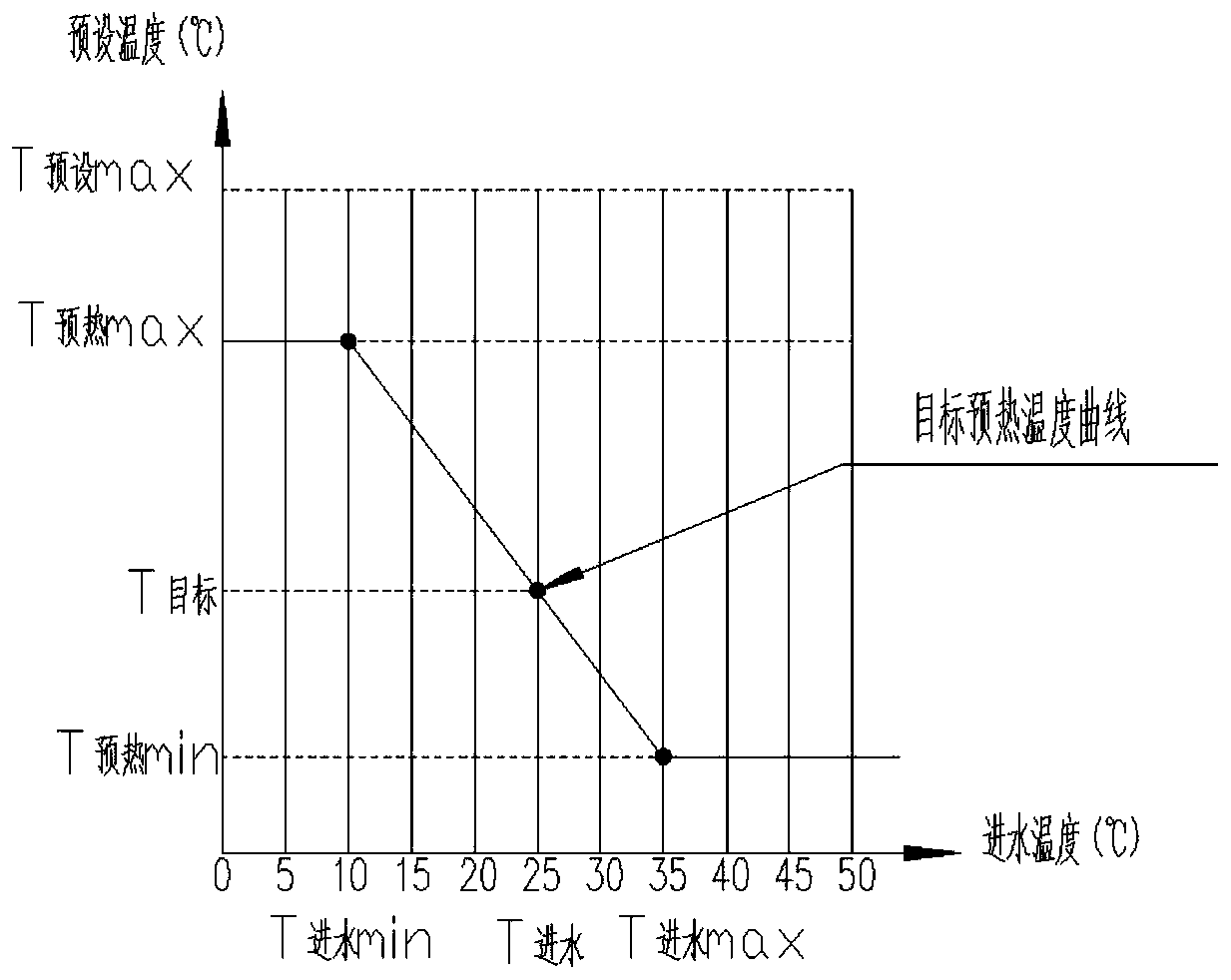

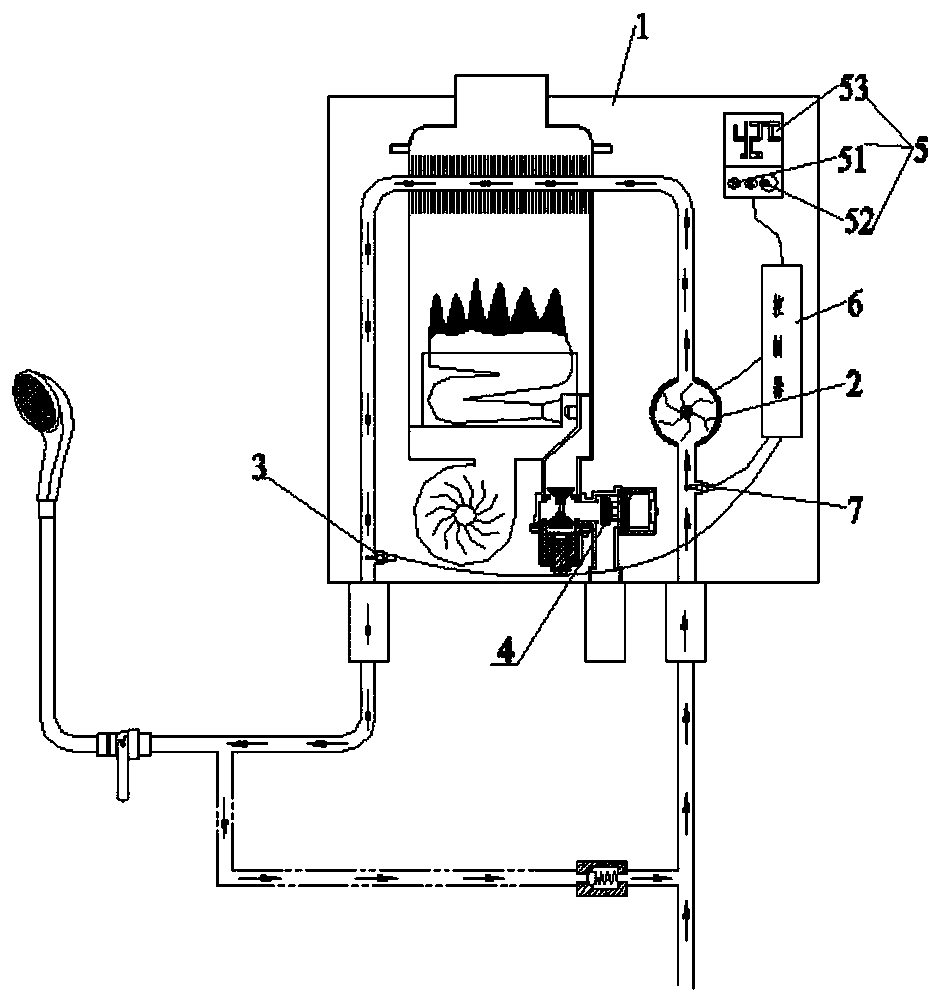

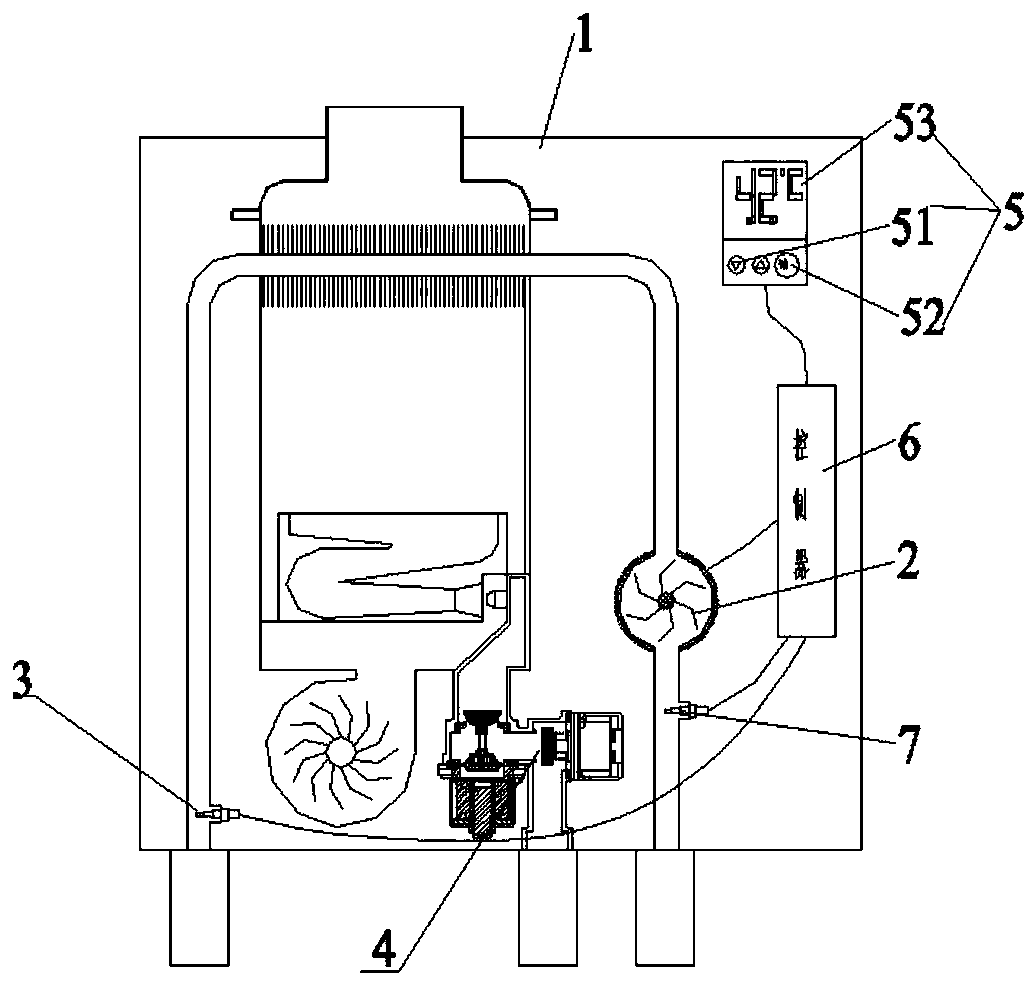

Self-adaptive temperature-controlling zero-cold water gas water heater and control method thereof

ActiveCN110398054APrevent the problem of excessive preheating temperatureIncrease temperatureWater heatersSolar thermal energy generationTemperature controlEngineering

The invention discloses a self-adaptive temperature-controlling zero-cold water gas water heater. The water heater comprises a zero-cold water gas water heater body, a built-in water pump, a water outlet temperature detection module, a water inlet temperature detection module, a gas control valve, an operation display module and an environment temperature detection module, wherein the built-in water pump, the water outlet temperature detection module, the water inlet temperature detection module, the gas control valve, the operation display module and the environment temperature detection module are electrically connected with a controller. The invention further discloses a control method of the water heater. The method comprises the following steps that a preheating mode is started; preset temperature Tpreset, water inlet temperature Twater inlet, and mounting environment temperature Tenvironment are detected; whether the preset temperature Tpreset satisfies the condition that Tpresetis larger than Tpreheating max or not is judged; if not, stored water temperature of a circulating pipeline is controlled according to the preset temperature Tpreset; and if yes, after the Tpreset isautomatically adjusted to target preheating temperature Ttarget according to the Twater inlet or the Tenvironment, then the stored water temperature of the circulating pipeline is controlled according to the target preheating temperature Ttarget. According to the self-adaptive temperature-controlling zero-cold water gas water heater and the control method thereof, the problem that existing storedwater temperature in the circulating pipeline is too high can be solved.

Owner:VATTI CORP LTD

Low-temperature preheating device used for motor vehicle

ActiveCN102072062AIngenious ideaAdvanced technologyAir-treating devicesVehicle heating/cooling devicesAutomotive engineeringWater pipe

The invention discloses a low-temperature preheating device used for a motor vehicle. The device comprises a fuel oil heating unit, a driving cab heating unit, an oil pan heating unit and an oil supply system heating unit, wherein the fuel oil heating unit is provided with a fuel oil heater; the driving cab heating unit comprises a radiator arranged in the driving cab; the oil pan heating unit comprises an oil pan heating pipe arranged in an oil pan of an engine; and the oil supply system heating unit comprises a heating oil tank, a water inlet pipeline, a water return pipeline, an oil outlet pipeline and an oil return pipeline. The device has the characteristics that: the device has an ingenious conception, advanced technology, a compact structure, environment friendliness and high practicability, is safe in use and convenient to install, saves energy and the like.

Owner:SINO TRUK JINAN POWER

Low heat value burnt gas high-temperature air combustion system and method

InactiveCN101285576APrevent accidental burningPrevent leakageIndirect carbon-dioxide mitigationGaseous fuel burnerCombustion systemCombustion chamber

The invention provides a novel high temperature air combustion system with lower calorific value, comprising a combustion chamber, a fuel pipeline, a gas passage, a fuel gas pre-heater, a heat retainer and a burner nozzle. The heat retainer is arranged in the air passage, and the fuel gas pre-heater is arranged at the back of the heat retainer. When the combustion system is operated, the fuel is pre-heated through smoke gas on one side of the gas passage, and the fuel is conveyed to the other side of the gas passage to burn. After one period, the fuel is conveyed reversely. The combustion is carried out by matching with the pre-heated air at a high temperature, which can improve the heat exchanging condition inside a furnace and improve the energy source utilization rate.

Owner:TONGJI UNIV

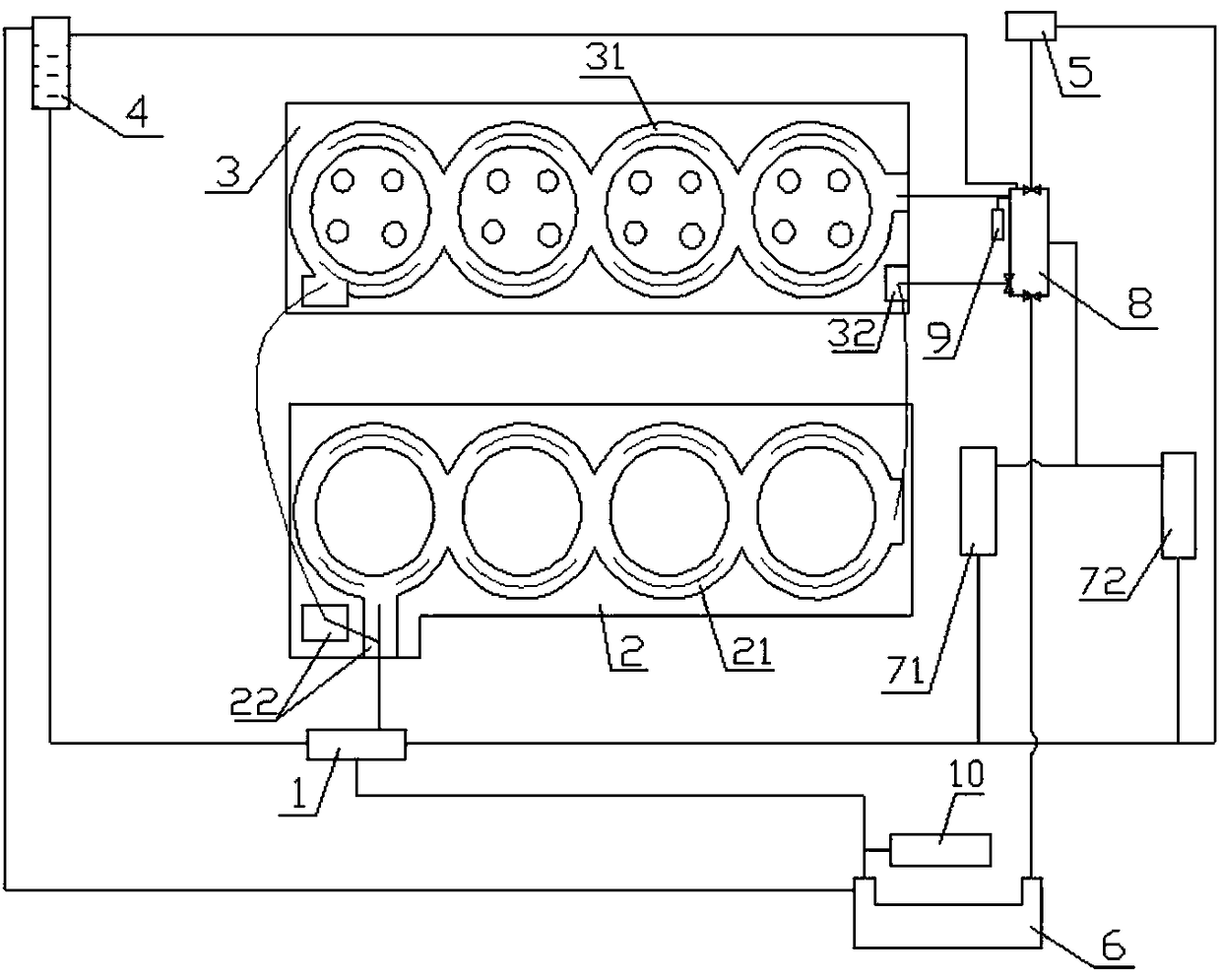

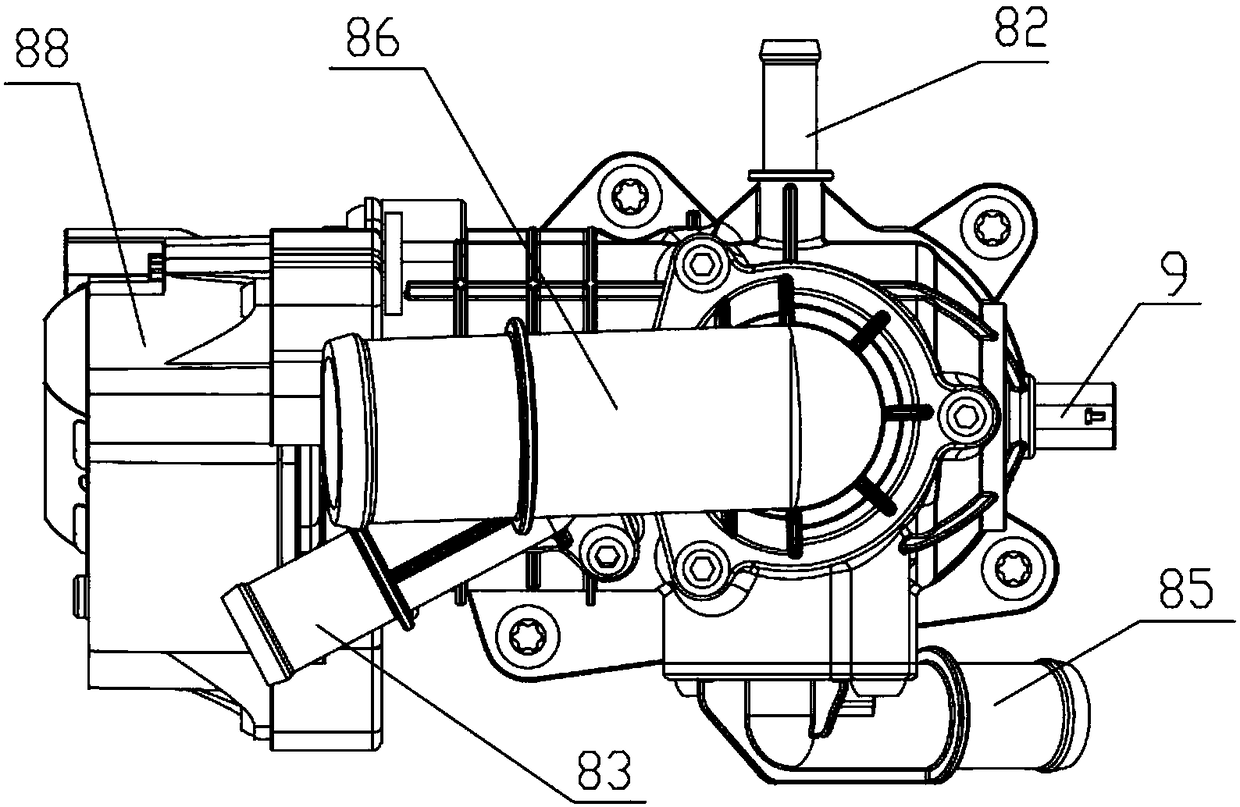

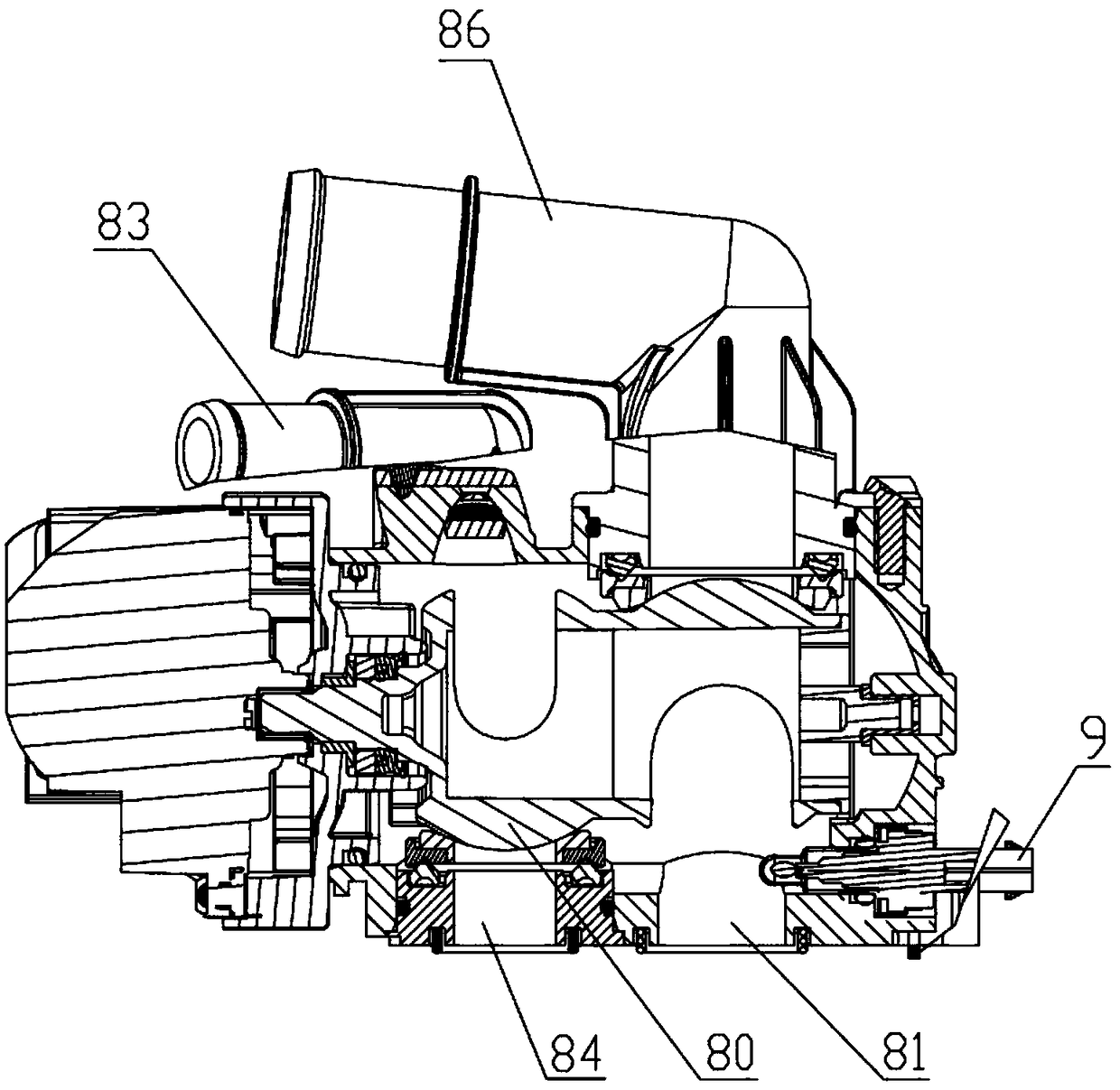

Cooling system and cooling method for automobile engine

ActiveCN108278172AControl allocationHeating up fastLiquid coolingCoolant flow controlHeat managementControl valves

The invention discloses a cooling system and a cooling method for an automobile engine. The automobile engine cooling system comprises a cylinder body, a cylinder cover, a water storage pot, a heat exchanging part, a radiator, engine oil coolers and a heat management module, wherein the heat management module is provided with a control valve, a normally-communicated cylinder cover water jacket connector, a water storage pot connector, an engine oil cooler connector, a cylinder cover water passing channel connector capable of adjusting a connecting area through the control valve, a heat exchanging part connector and a radiator connector. During a cold start, a connecting area of the cylinder cover water passing channel connector, the heat exchanging part connector and the radiator connectoris enabled to be zero; when the engine is heated, the connecting area of the cylinder cover water passing channel connector and the radiator connector is enabled to be zero, and the connecting area of the heat exchanging part connector is enabled to be 100 percent; and when temperature of the engine is in a high working state, the connecting area of the cylinder cover water passing channel connector, the heat exchanging part connector and the radiator connector is enabled to be 100 percent. According to the cooling system and the cooling method for the automobile engine, the heating speed ofthe engine and the engine oil heating speed can be increased, and the oil consumption can be reduced.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Entrained-bed gasifier

ActiveCN104611063AExtended stayImprove utilization efficiencyGranular/pulverulent flues gasificationCombustionSpray nozzle

The invention discloses an entrained-bed gasifier, relates to the technical field of gasifiers, and solves the problems that the hydrogen consumption is relatively high and the carbon converting efficiency is relatively low in coal hydrogenation gasification process because during gasification reaction of the existing entrained-bed gasifier, combustion of a part of hydrogen is required for preheating, and semicoke is not effectively utilized. The entrained-bed gasifier provided by the invention comprises a gasifier outer barrel, wherein a reaction inner barrel is fixed in an upper area inside the gasifier outer barrel; a solid material nozzle is formed in the top end of the gasifier outer barrel; the solid material nozzle is formed by facing a top inlet of the reaction inner barrel; a baffle is arranged below a bottom outlet of the reaction inner barrel; a feed gas nozzle is formed in the side wall of the gasifier outer barrel; the feed gas nozzle is formed in the upper side of the baffle; a gasifying agent inlet is formed in the bottom end of the gasifier outer barrel. The entrained-bed gasifier is mainly applied to hydrogenation gasification reaction of coal.

Owner:ENN SCI & TECH DEV

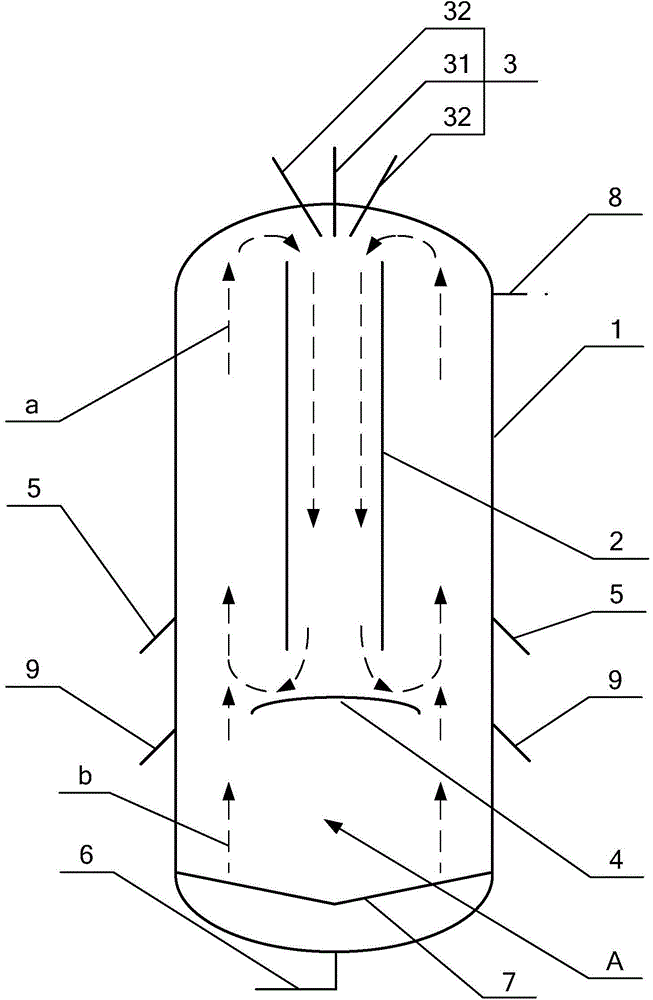

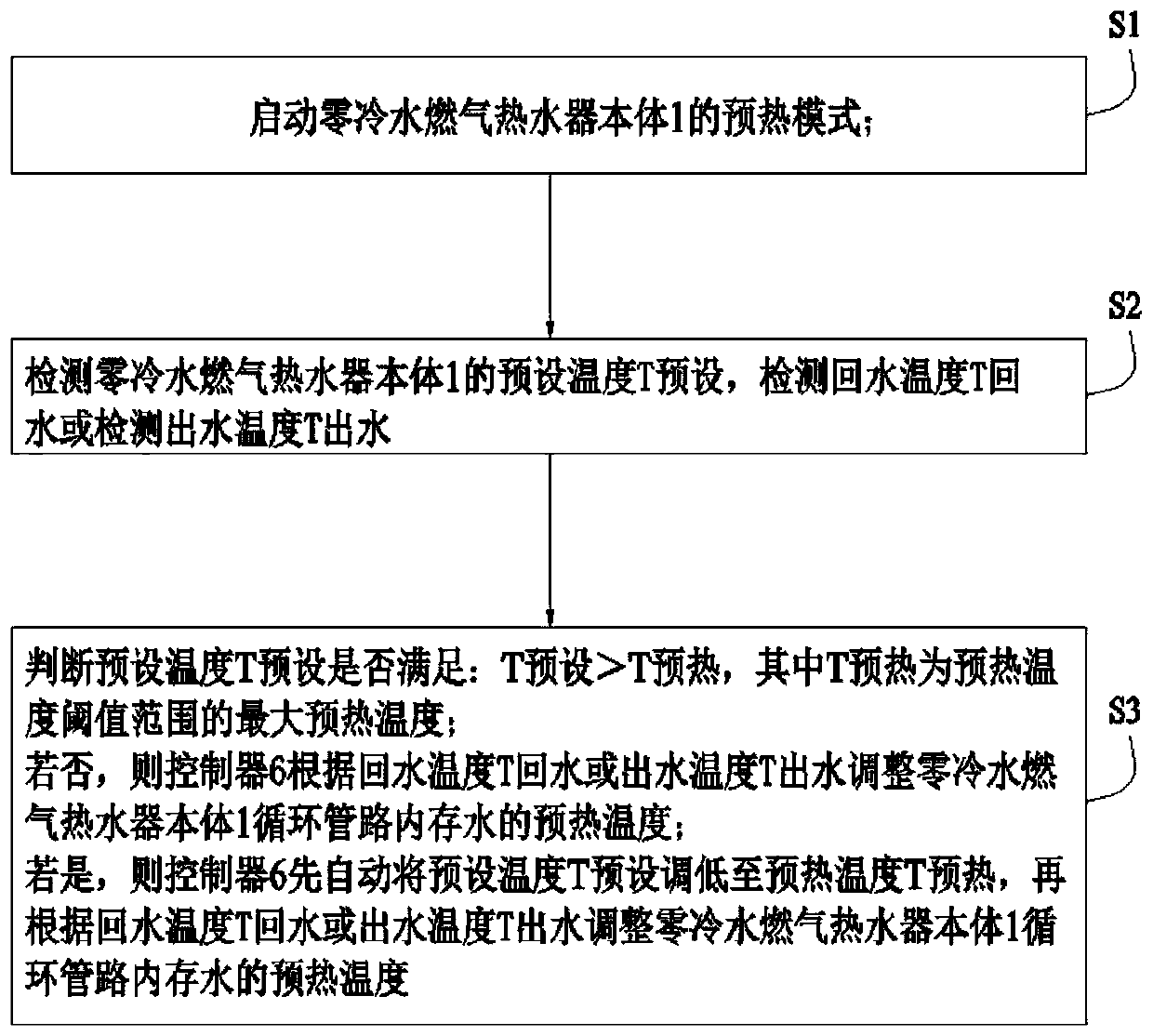

Zero-cold water gas water heater capable of limiting preheating temperature and control method of heater

PendingCN110398055AReal-time detection of return water temperatureAchieve warm-upWater heatersWater storageEngineering

The invention discloses a zero-cold water gas water heater capable of limiting the preheating temperature. Thezero-cold water gas water heatercomprisesa zero-cold water gas water heater body, and further comprises a built-in water pump, an outlet water temperature detecting module, a return water temperature detecting module, a gas control valve and an operation display module which are electrically connected to a controller. The invention also discloses a control method of the zero-cold water gas water heater capable of limiting the preheating temperature. The control method comprises the following steps ofstarting a preheating mode; detecting a preset temperature T preset; determining whether the preset temperature T preset satisfies the condition that T preset is larger than T preheating max; if not, controlling the water storage temperature of a circulating pipeline according to the preset temperature T preset; and if yes, lowering the preset temperature T preset to a target preheating temperature T target, and controlling the water storage temperature of the circulating pipeline according to the target preheating temperature T target. The zero-cold water gas water heater and the control method thereof can solve the problem that the water storage temperature of the circulating pipeline of an existing zero-cold water gas water heater is too high.

Owner:VATTI CORP LTD

Fuel cell engine cooling system

The invention relates to a fuel cell engine cooling system which comprises an inner circulation pipeline and an outer circulation pipeline which are connected through a pipeline, wherein the internalcirculation pipeline comprises a fuel cell stack, a heat exchanger, a cooling liquid pump and a deionization filter, the heat dissipation outlet end of the fuel cell stack is sequentially connected tothe heat exchanger, the cooling liquid pump and the deionization filter and returns to the heat dissipation inlet end of the fuel cell stack, and cooling liquid circularly flows in the pipeline. Theouter circulation pipeline comprises a heat exchanger, a four-way valve, a booster pump, a whole vehicle radiator and an expansion valve, wherein the heat absorption outlet end of the heat exchanger is sequentially connected with the four-way valve, the booster pump, the whole vehicle radiator and the expansion valve and returns to the heat absorption inlet end of the heat exchanger, and the phasechange coolant circularly flows in the outer circulation pipeline. Since the heat exchanger is introduced, a traditional single cooling loop is changed into a double-circulation cooling loop, so thatthe problems that an original system radiator is too large in area, a pipeline is too long, ion precipitation is difficult to control and the like are solved, the cooling effect is good, and the design cost of a cooling system is reduced.

Owner:BEIJING NOWOGEN TECH CO LTD

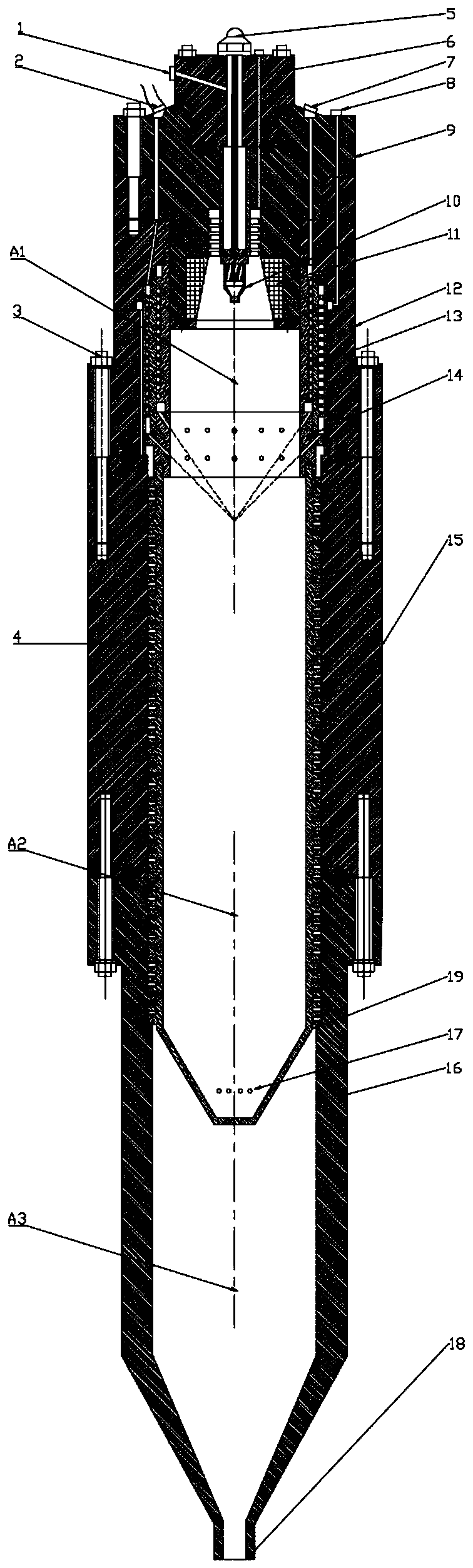

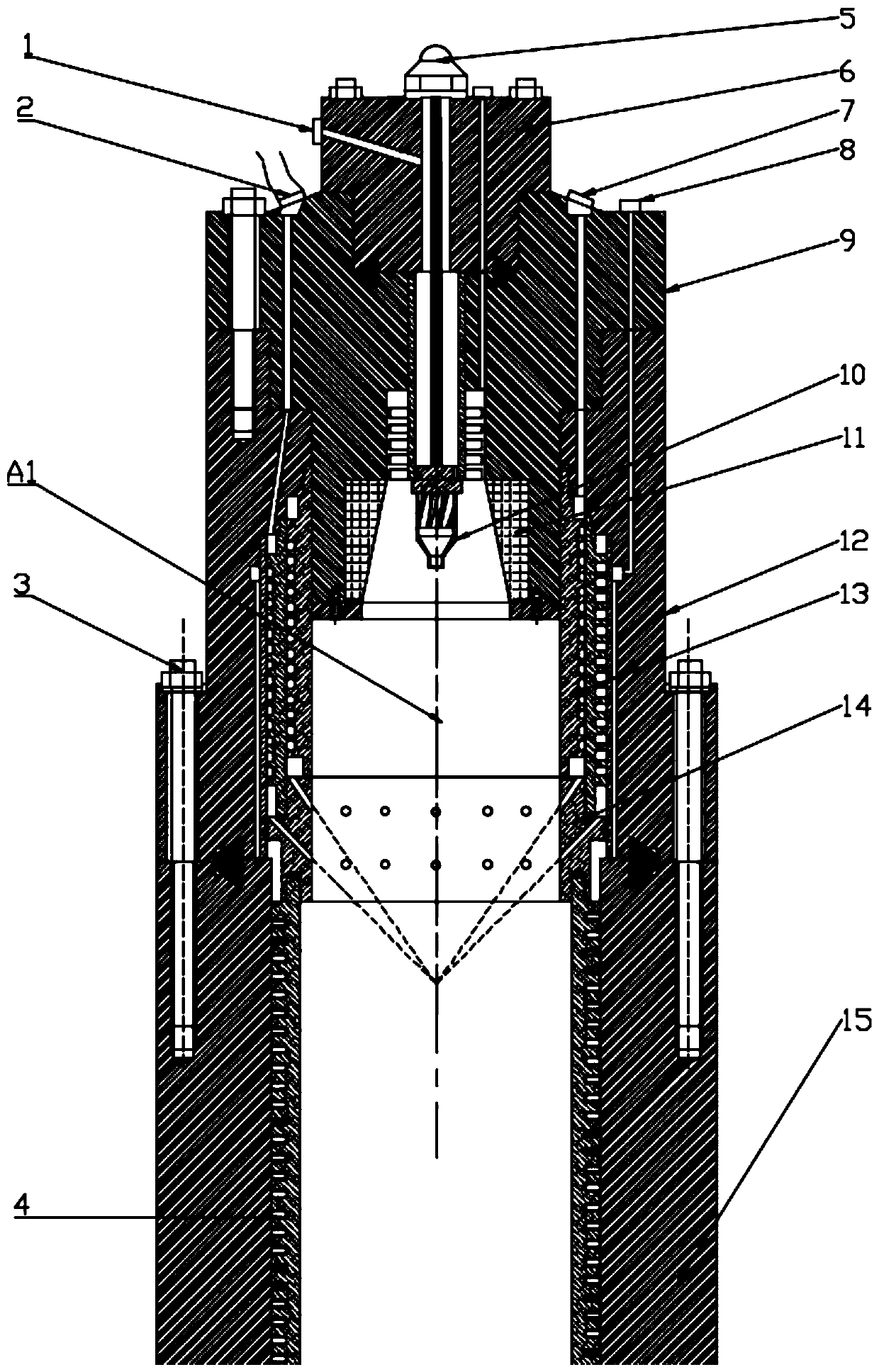

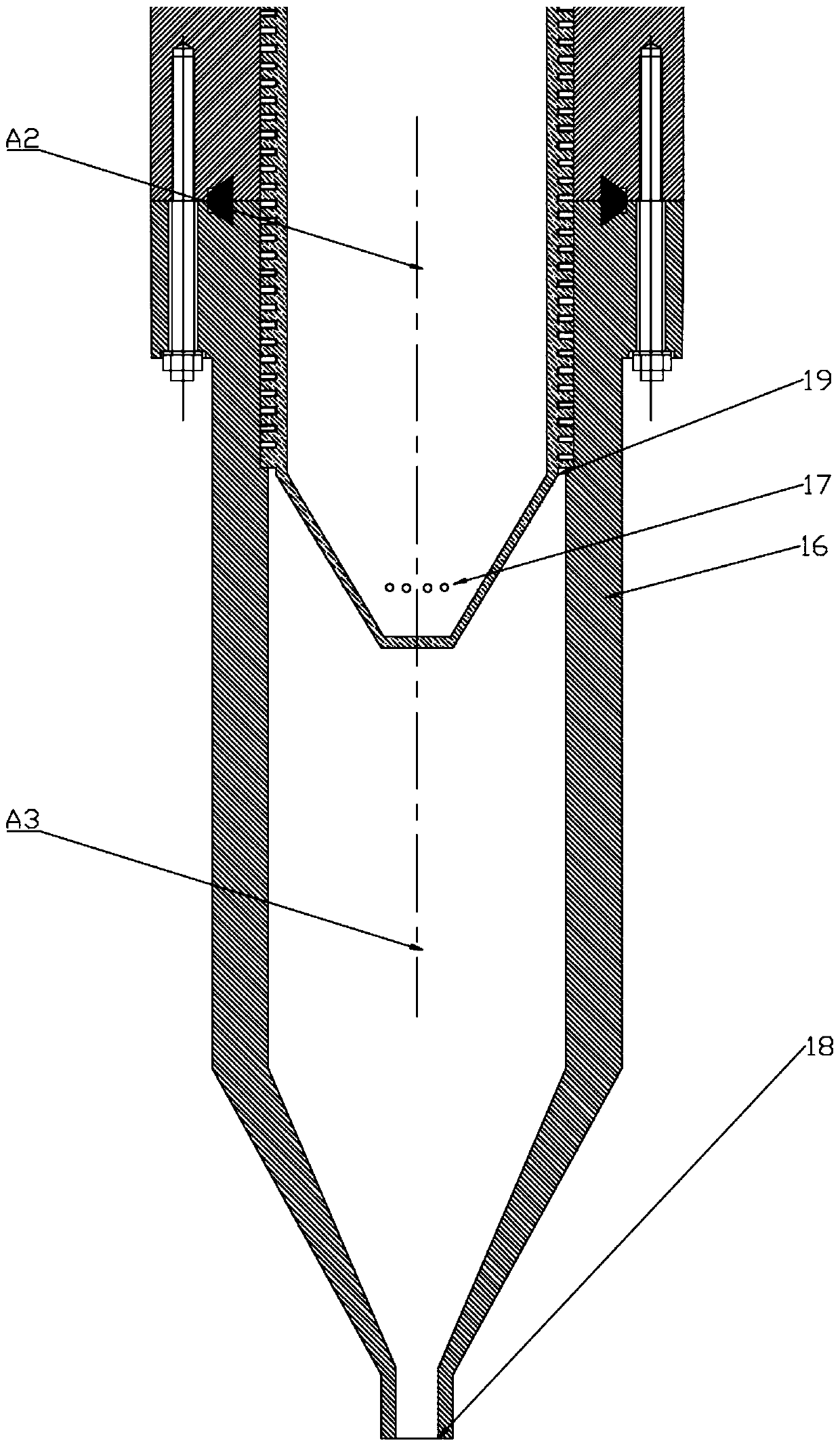

Supercritical hydrothermal combustion type downhole steam generator for heavy oil thermal recovery

PendingCN110644962AGuaranteed mixPrevent high temperature burning or even explosionFluid removalCombustionHeater Rod

A supercritical hydrothermal combustion type downhole steam generator for heavy oil thermal recovery mainly comprises a top end cover, a middle end cover, a reflux stable combustion area shell, a mainreaction area shell and a blending area shell which are connected and assembled sequentially; a cyclone fuel inlet and a heating rod are arranged on the top end cover; a heating rod inserting hole runs through the center of the middle end cover; the middle end cover is provided with a main combustion hole jet fuel inlet, a main combustion hole jet oxidizing agent inlet, a cooling water inlet anda swirl nozzle; the swirl nozzle communicates with the cyclone fuel inlet; the inner side of the reflux stable combustion area shell is wrapped with a composite spiral wall circumferentially; a main combustion nozzle structure is arranged at the bottom end of the reflux stable combustion area shell; the inner wall of the main reaction area shell is a spiral cooling wall; the main combustion hole jet oxidizing agent inlet, the main combustion hole jet fuel inlet and the cooling water inlet communicate with the main combustion nozzle structure and the spiral cooling wall correspondingly throughinner, middle and outer channels of the composite spiral wall; and steam can be efficiently generated in the stratum directly and heat loss in the steam conveying process is avoided.

Owner:XI AN JIAOTONG UNIV

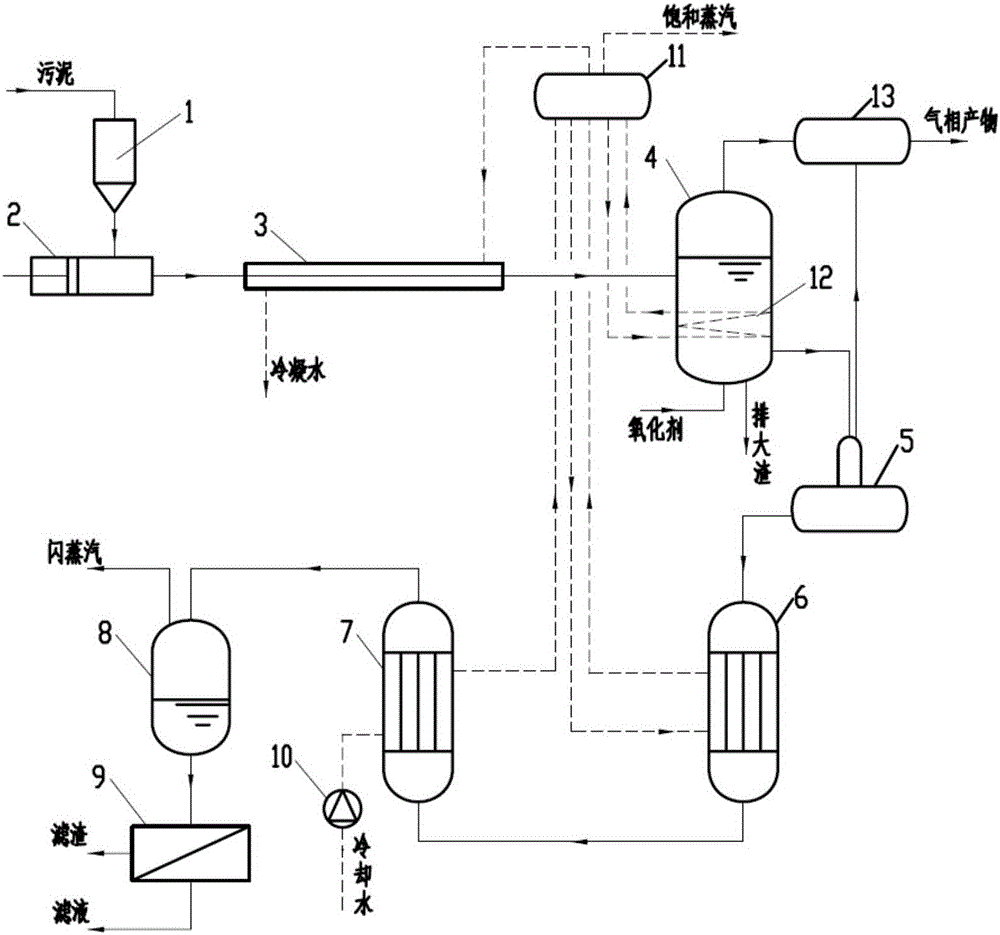

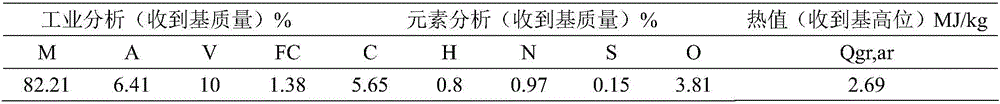

Method and continuous system for treating wet organic waste

PendingCN105967490AImprove mobilitySolve pipeline blockageSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningChemistryCorrosion

The invention discloses a method and a continuous system for treating wet organic waste, and belongs to the field of environmental protection / sewage treatment / sludge treatment. The method includes steps of conveying and preheating raw materials; carrying out hydrothermal oxidation reaction; removing oxygen from oxidation reaction products; recycling reaction heat; carrying out flash dehydration; carrying out mechanical dehydration; treating filter liquid; treating tail gas. The continuous system comprises a wet organic waste raw material pump, a sleeve heater, a hydrothermal oxidation reactor, an oxygen remover, waste heat recycling heat exchangers, a byproduct steam plant, a flash plant, a dehydration plant and a tail gas treatment plant. The method and the continuous system have the advantages that the continuous system is simple, the wet organic waste can be directly treated without being dried, the reaction is easy to maintain under self-heating conditions without external heat, a large quantity of heat of the high-temperature materials can be recycled, the method and the continuous system are high in energy utilization rate, and a large quantity of economic byproducts (steam) can be generated; problems that existing raw material preheating heat exchangers are vulnerable to blocking and existing waste heat recycling heat exchangers are vulnerable to corrosion can be solved by the aid of the method and the continuous system.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

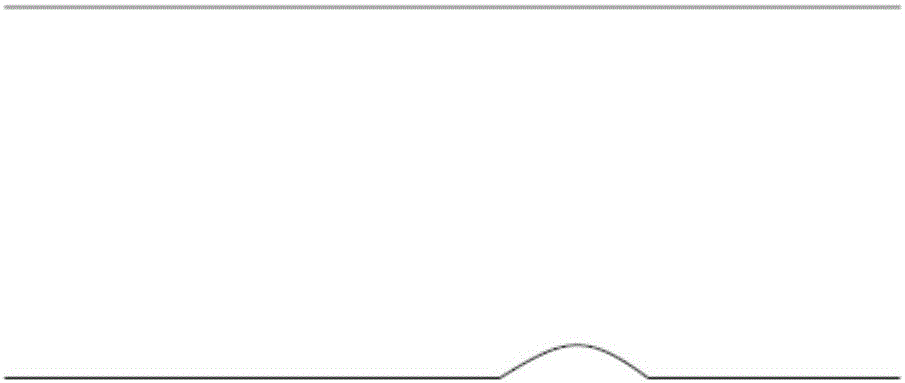

Additive manufacturing method and additive manufacturing device with preheating functions

ActiveCN106825569AAchieve warm-upAvoid concentrationAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing technologyWaste product

The invention belongs to the field of additive manufacturing technologies, and discloses an additive manufacturing method and an additive manufacturing device with preheating functions. The additive manufacturing method includes carrying out raster preheating scanning on the surfaces of powder beds by the aid of rays under the control. The raster preheating scanning includes alternately scanning the surfaces of the powder beds by the rays along scanning paths in the horizontal directions and scanning paths in the vertical directions. The additive manufacturing method and the additive manufacturing device have the advantages that the surfaces of the powder beds can be comprehensively preheated and can be alternately scanned via the scanning paths in the horizontal directions and the scanning paths in the vertical directions, accordingly, temperature fields formed by means of preheating can be uniform, electric charge concentration can be prevented to the greatest extent, and excellent foundations can be laid for 3D (three-dimensional) printing; the problem that three-dimensional entity components become waste products due to incapability of detecting deformation of the surfaces of existing powder beds or low detection reliability of existing additive manufacturing devices and inaccurate detection results can be effectively solved, and wastage of materials and time can be prevented.

Owner:QUICKBEAM CO LTD

Direct current motor EGR valve controller

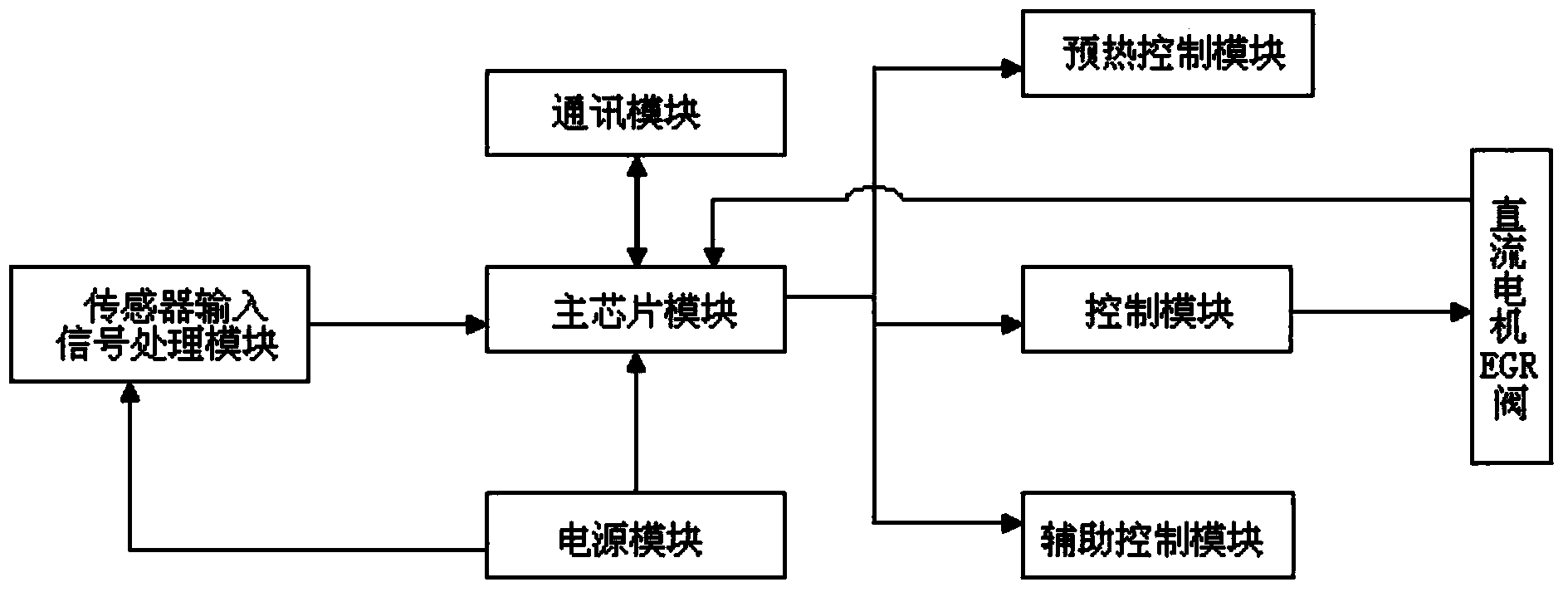

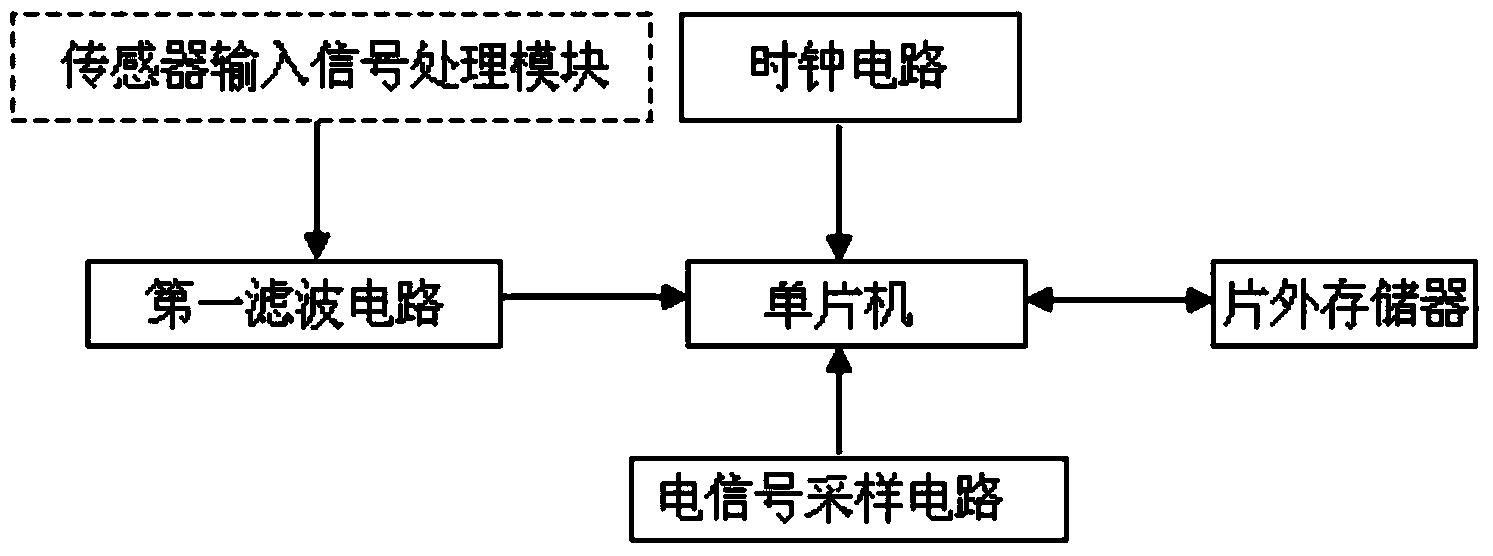

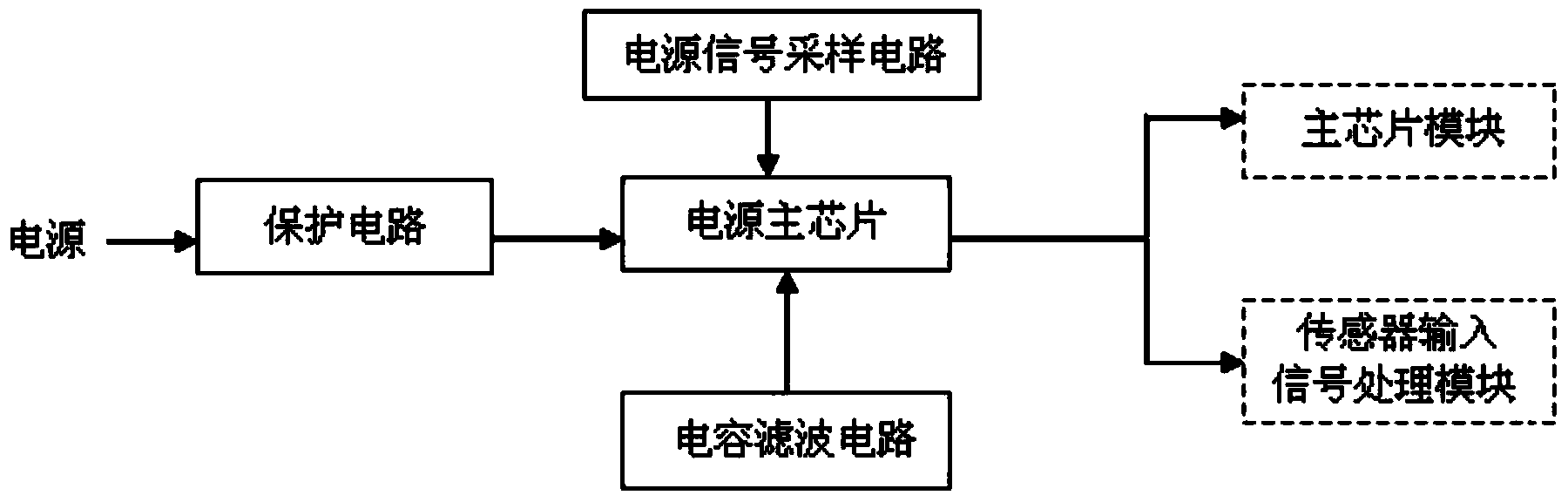

ActiveCN104074639AEmission reductionAchieve warm-upElectrical controlNon-fuel substance addition to fuelComputer moduleControl theory

The invention discloses a direct current motor EGR valve controller which comprises a master chip module, a power module, a direct current motor EGR valve control module, a sensor input signal processing module, a communication module, a preheating control module and an auxiliary control module. Signals obtained by the sensor input signal processing module are logically processed through the master chip module, corresponding signals are output to control the control modules to work normally and logically, so that the opening degree of a direct current motor EGR valve is accurately controlled, and the direct current motor EGR valve is made to work or tested.

Owner:WUXI LONGSHENG TECH

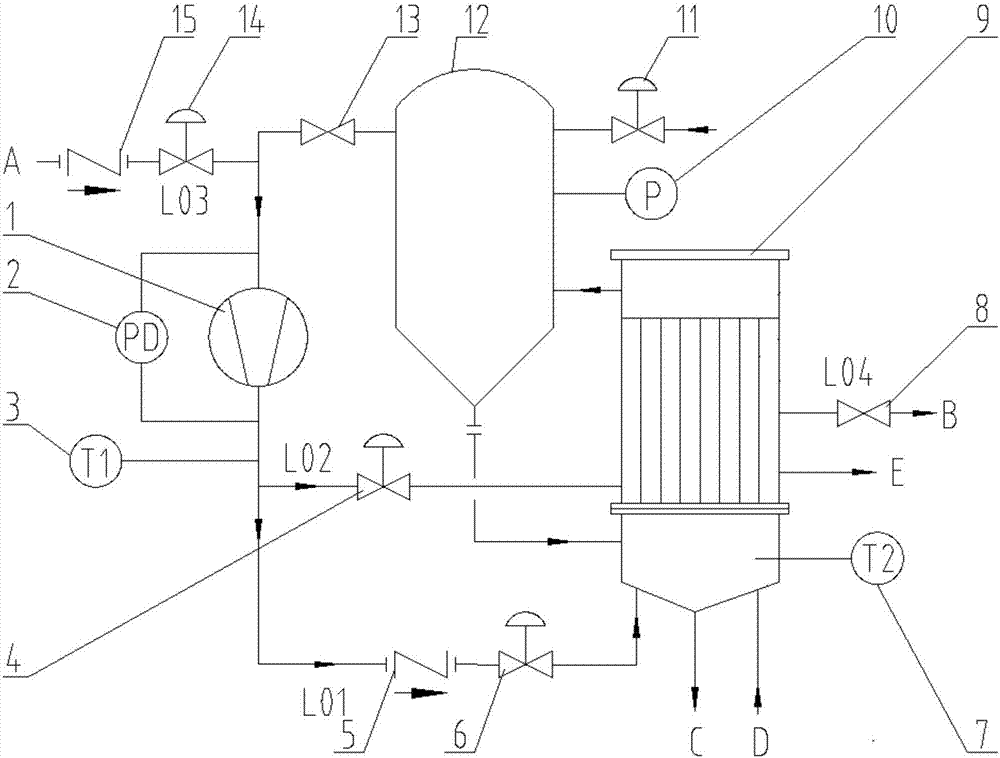

MVR evaporation system, and starting and preheating method thereof

The invention relates to a MVR evaporation system, comprising a vapor compressor, a cyclone separator and a shell-and-tube heat exchanger, wherein the outlet of the vapor compressor is connected with a tube-side inlet located in the bottom of the shell-and-tube heat exchanger via a first pipeline provided with a first valve and also connected with a shell-side inlet located in the bottom of the shell-and-tube heat exchanger via a second pipeline provided with a second valve; the tube side of the shell-and-tube heat exchanger is connected with an exhausting branch provided with a fourth valve; a tube-side outlet located in the upper part of the shell-and-tube heat exchanger is connected with the separation inlet of the cyclone separator; and the upper separation outlet and the lower separation outlet of the cyclone separator are respectively connected with the inlet of the vapor compressor and the tube-side inlet located in the bottom of the shell-and-tube heat exchanger. According to the invention, a direct heating pipeline, a heat exchange pipeline, a non-condensable-gas discharging pipeline, a water supplementing pipeline and the like are reasonably arranged to heat feed liquid to an evaporation temperature before evaporation, and an auxiliary electric heater, an energy-storing water tank, external vapor equipment and the like in the flow of a general MVR system are discarded; so the structure of the MVR evaporation system is simplified, and the independent operation capability of the system is enhanced.

Owner:AEROSUN CORP +1

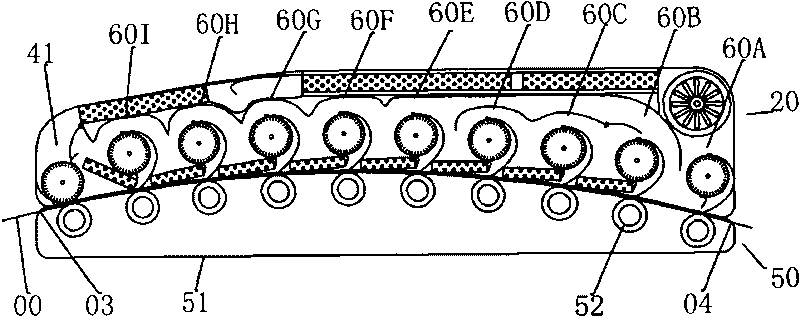

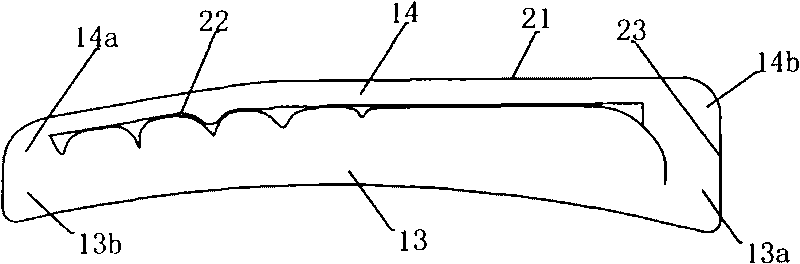

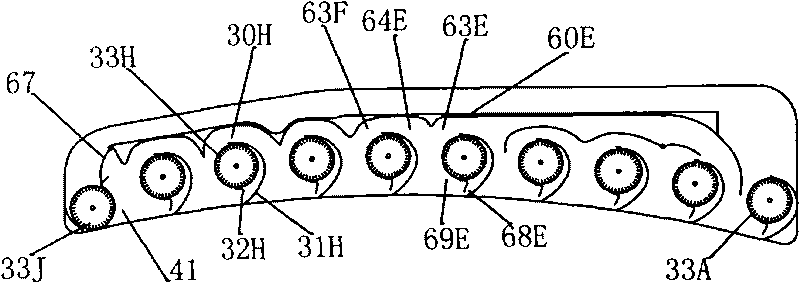

Energy-saving and environment-friendly printer

InactiveCN101700713AReduce consumptionThe effect of reducing consumption and realizing a closed loopPrinting press partsInlet channelMaterial consumption

The invention relates to an energy-saving and environment-friendly printer, comprising a printer body and a drying device (10). The energy-saving and environment-friendly printer is characterized in that the drying device (10) comprises an oven cap (20) and a base (50), and is provided with a printing product inlet (03) and a printing product outlet (04); the oven cap (20) is provided with a drying cavity (13) and a recovering cavity (14); an air supply unit (60), a heat pump condenser (88) and a refrigerating evaporator (96) are arranged in the oven cap (20); the air supply unit (60) comprises a fan (30) provided with an air inlet channel (63), an air exhaust channel (64) and an air outlet channel (68) to form an air blowing and circulating system; the heat pump condenser (88) is installed in the air supply unit (60), and the refrigerating evaporator (96) is installed in the recovering cavity (14). In the invention, drying equipment is firstly reformed, and an air channel with skillful interior is utilized to replace the original air channel with complicated structure and signal function, thereby the effects of compact structure, space saving and reduction of material consumption are achieved.

Owner:VERBOCA ENERGY SAVING TECH CO LTD

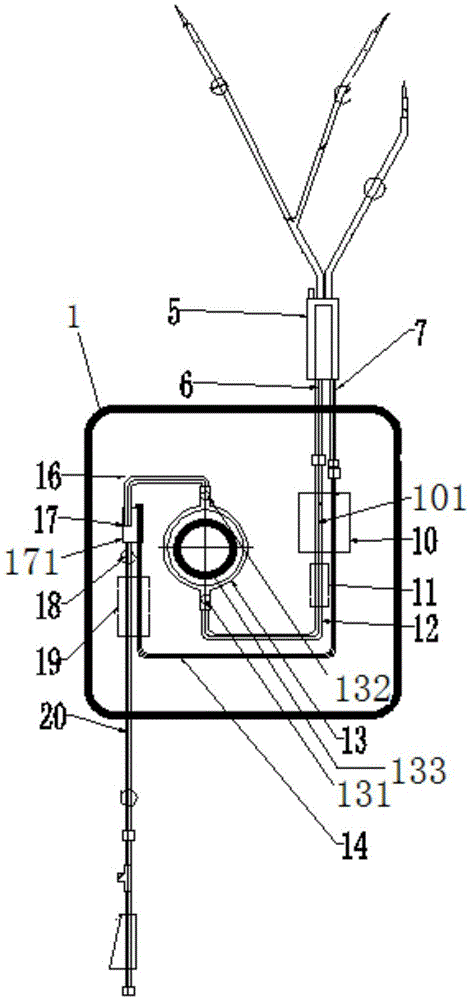

Rapid infusion equipment capable of achieving induction heating and using method of rapid infusion equipment

InactiveCN105521533AHeating safetyHeating evenlyMedical devicesPressure infusionLiquid temperatureControl valves

The invention belongs to the technical field of a medical apparatus, and in particular relates to rapid infusion equipment capable of achieving induction heating and a using method of the rapid infusion equipment. The rapid infusion equipment comprises a casing, a controller, a locating rack, a directional control valve, a pressure measurement device, an air detection sensor and a liquid running-out detection sensor 101, wherein an electromagnetic induction heater, which is used for heating an infusion apparatus, and an infrared temperature sensor, which is used for detecting the temperature of infusion liquid on the inlet and the outlet of the heat exchange ring, are arranged on the casing; the directional control valve, the pressure measurement device, the air detection sensor, the electromagnetic induction heater and the infrared temperature sensor are connected to the controller; and the controller is additionally connected to an infusion pump on the infusion apparatus. The rapid infusion equipment not only can meet the requirements on existing infusion functions but also can keep liquid temperature within a constant value, so that infusion is performed nearby human body temperature; therefore, the purpose of rapid constant-temperature infusion in emergency is effectively achieved.

Owner:XIAN LIBANG MEDICAL ELECTRONICS

Roller type composting reactor with composting tail gas waste heat recovery and purification functions

ActiveCN109970475AAchieve warm-upFast heating rateBio-organic fraction processingWaste processingAeration systemMonitoring system

The invention relates to a roller type composting reactor with composting tail gas waste heat recovery and purification functions. The roller type composting reactor includes a fermentation roller, anaeration system, a tail gas recovery system, a tail gas utilization system, a power system and monitoring system; the fermentation roller is installed on a base, and the feed end and discharge end ofthe fermentation roller are connected with a raw-material pretreatment system and a subsequent processing device respectively; the air discharge end of the aeration system is communicated with the inside of the fermentation roller through the feed end of the fermentation roller; the tail gas recovery system is communicated with the inside of the fermentation roller through the discharge end of the fermentation roller; the tail gas utilization system is used for recycling tail gas in the fermentation roller, the power system is installed on a base on the lower portion of the middle of the fermentation roller and used for providing power to operation of the fermentation roller; the monitoring system is connected with the fermentation roller, the aeration system, the tail gas recovery system, the tail gas utilization system and the power system through a communication network. The reactor can be widely used in the field of composting.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

System and method for purifying and producing high-purity vanadium pentoxide powder

ActiveCN105984896AAchieve warm-upUniform temperature distributionNitrogen compoundsTransportation and packagingDistillationCalcination

The invention discloses a system and method for purifying and producing high-purity vanadium pentoxide powder, belonging to the fields of chemical engineering and materials. According to the invention, fluidizing low-temperature chlorination is used for converting industrial-grade vanadium pentoxide into vanadium oxytrichloride; through heat exchange between fluidization gas and chlorination flue gas, chlorination gas is preheated; a proper amount of air is added to allow a part of coke powder to combust, thus providing a balanced supply of heat during the process of chlorination, improving chlorination efficiency, and ensuring good selectivity of low-temperature chlorination; and the vanadium oxytrichloride is subjected to fluidized-vapor-phase ammoniation after distillation and purification and further to fluidized calcination to produce a high-purity vanadium pentoxide product. The system and method have the advantages that raw materials are good in adaptability, only a small amount of ammonia-nitrogen wastewater is discharged, low energy consumption in production and low cost in operation are realized, product quality is stable, etc.; and the system and method are applicable to large-scale industrial production of high-purity vanadium pentoxide having a purity of 4N or higher and have good economic benefits and social benefits.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Industrial by-product gypsum calcining furnace

The invention relates to an industrial by-product gypsum calcining furnace. The furnace includes an inner cylinder, an outer cylinder, a grate cooler, an anhydrous gypsum discharge hole, a hemihydrate gypsum discharge hole, a feeding hole, a suction opening, a power drive device and a support device; a plurality of baffles are arranged in the suction opening, an air hole is reserved between each baffle and the inner wall of the suction opening, the air holes are alternately formed in the two sides of the inner wall of the suction opening, and gaps between the air holes and the baffles form a labyrinth-like air draft channel. According to the industrial by-product gypsum calcining furnace, the baffles arranged like a labyrinth are installed in the suction opening of the grate cooler of an existing gypsum drying calcining furnace, the baffles arranged like a labyrinth ceaselessly change the flow direction of air flow in the flowing process of the air flow, powdered gypsum particles contained in the air flow are settled and drop in the drying calcining furnace, waste of gypsum raw materials is thus avoided, and the purpose of reducing cost, saving energy and reducing pollutant emission is achieved.

Owner:ZHENGZHOU SUNDY BUILDING TECH

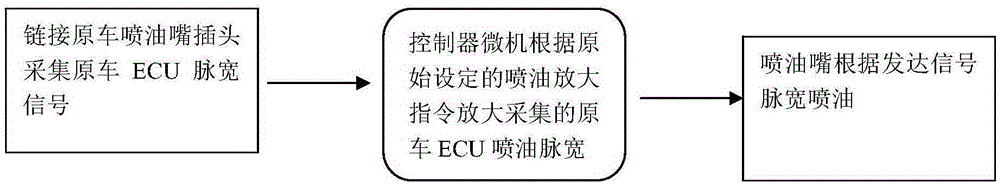

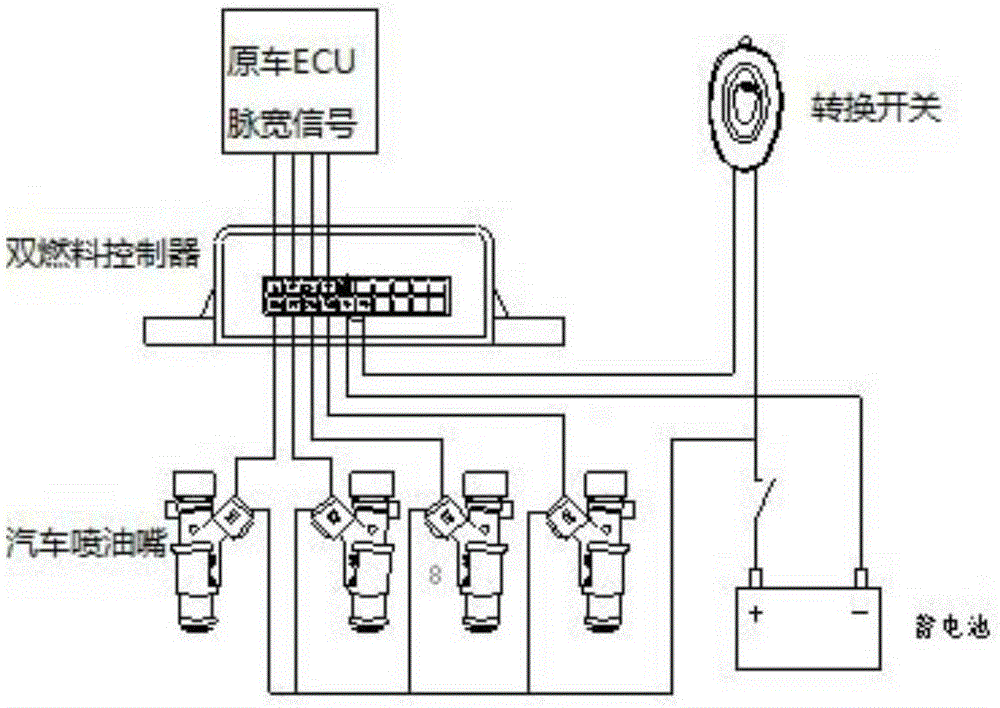

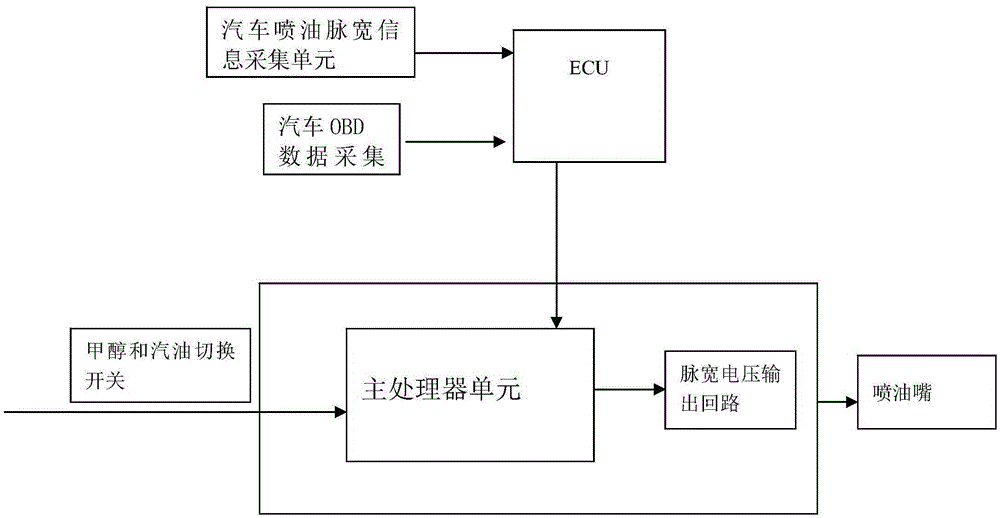

Method and equipment for improving heat efficiency of automobile fuel

ActiveCN105257437AHigh thermal efficiencyMake up for the disadvantage that the latent heat of vaporization cannot be directly used in gasoline enginesInternal combustion piston enginesFuel supply apparatusEngine powerMixed gas

The invention discloses a method and equipment for improving the heat efficiency of an automobile fuel. According to the method, the automobile fuel before entering a cylinder is heated, thus the heat efficiency of the fuel is improved; and in particular, an electromagnetic induction coil is used for heating, the operation is convenient, safe and reliable, and the electromagnetic induction heating efficiency is high. The equipment comprises a heating unit, wherein the heating unit comprises a heating control main board, a power supply acquisition module, a relay and a heating module; the power supply acquisition module, the relay and a heating control unit are sequentially connected, and the heating module is controlled by the heating control main board; the relay is connected with an automobile-mounted storage battery; and the heating module is arranged at an oil rail or an oil nozzle of an automobile oil supply system. The reaction speed and the flame propagation speed of a mixed gas in the cylinder are increased according to the detonation theory of the mixed gas, thus an engine power is improved; and more chemical energy of the fuel is converted to kinetic energy, thus the heat efficiency of the fuel is increased, and the effects of energy conservation and emission reduction are achieved.

Owner:杨记

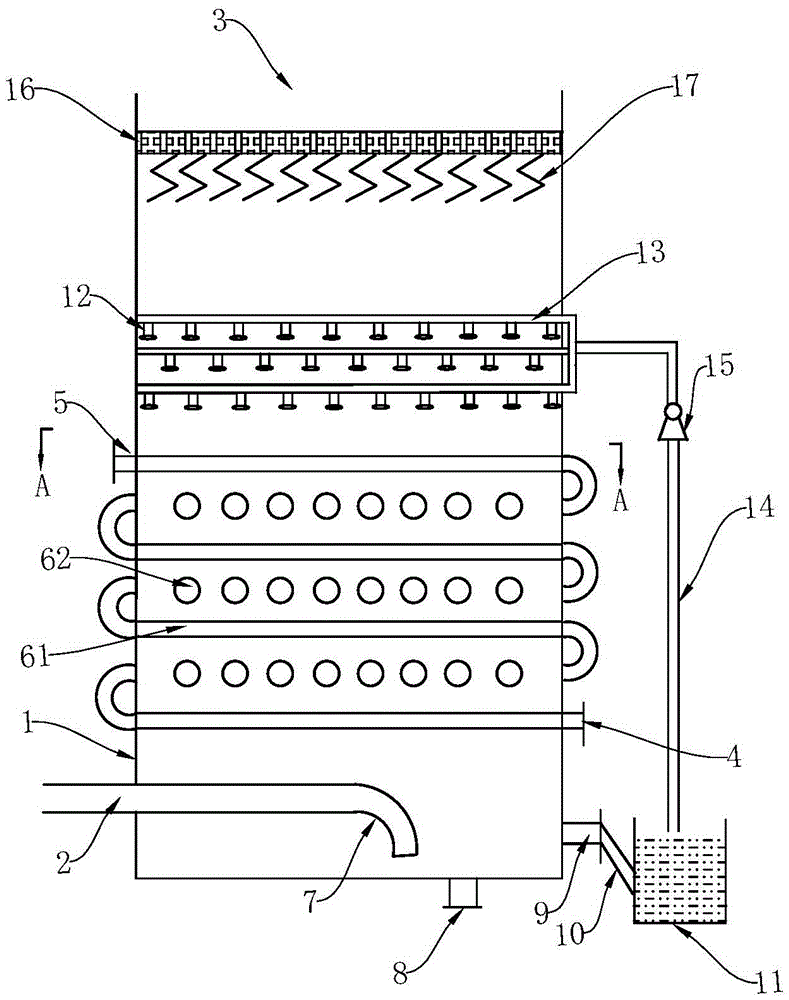

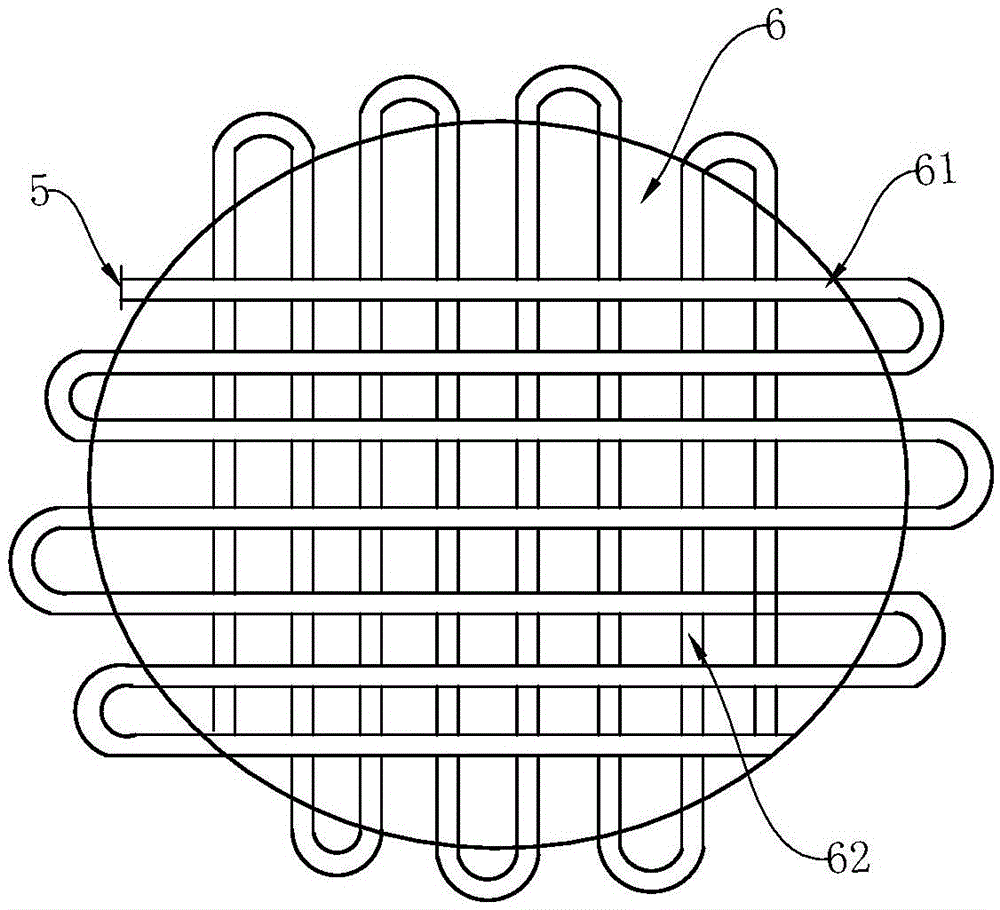

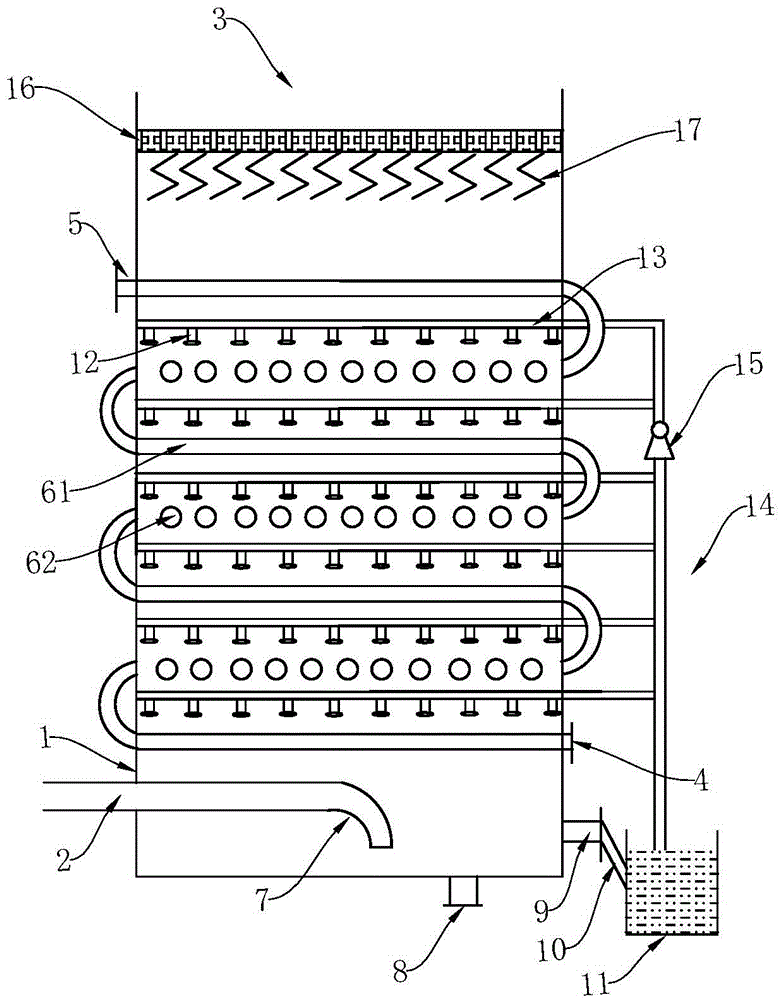

Multifunctional tail gas absorption tower

The invention relates to a tail gas treatment device, in particular to a multifunctional tail gas absorption tower. The multifunctional tail gas absorption tower comprises a tower body, a spraying device is arranged in the tower body, a tail gas inlet is formed in the bottom of the tower body, and an open tail gas outlet is formed in the top of the tower body; a liquid inlet is formed in the lower portion of the tower body, a liquid outlet is formed in the upper portion of the tower body, multiple layers of heat exchange pipelines are arranged between the liquid inlet and the liquid outlet in the tower body, and the heat exchange pipeline on each layer is circuitously arranged on one horizontal plane in an inner cavity of the tower body; at least two sets of heat exchange pipelines are arranged in the inner cavity of the tower body and are each arranged in a multi-layer mode, and the heat exchange pipelines, on all the layers, of one set and heat exchange pipelines, on all the layers, of the other set are alternated vertically, located on different horizontal planes and arranged in a criss-cross mode in the inner cavity of the tower body. According to the multifunctional tail gas absorption tower, dust settling is realized by means of a bent part arranged on the tail gas inlet, heat energy released by high-temperature tail gas can be absorbed by the heat exchange pipelines, and dust hanging on the wall, energy waste and absorption tower loss are avoided.

Owner:SHANDONG TIANJIAN WATER TREATMENT TECH CO LTD

Sterilization and disinfection device for medical nursing

InactiveCN111569123AGuaranteed sterilizationImprove the bactericidal effectDrying solid materials without heatLavatory sanitoryMedical equipmentNursing care

The invention discloses a sterilization and disinfection device for medical nursing, and particularly relates to the field of medical equipment. The sterilization and disinfection device for medical nursing comprises a treatment cylinder, wherein a heat insulation disinfectant box is arranged at the bottom of the treatment cylinder; a first pipeline is fixedly arranged at the top end of the heat insulation disinfectant box; a receiving box is fixedly arranged at the top end of the first pipeline, and a second pipeline is fixedly arranged at the top end of the receiving box; the second pipelineis fixedly arranged at the bottom end of the treatment cylinder; a heat insulation sleeve is fixedly arranged at the outer end of the heat insulation disinfectant box; a fan is fixedly arranged on one side of the top end of the treatment cylinder; a heat insulation box is arranged on one side of the treatment cylinder; a spiral pipe is arranged in the heat insulation box; and a plurality of ultraviolet sterilization mechanisms are arranged at the outer end of the treatment cylinder. Through high temperature, disinfectant and ultraviolet sterilization and disinfection, the sterilization effectis good, after disinfection, the rotating speed of an adjustable-speed motor is increased to drive a placement cylinder and instruments in the placement cylinder to rotate rapidly to spin-dry liquidon the instruments, disinfection and drying are integrated, and the working efficiency is improved.

Owner:LUOHE MEDICAL COLLEGE

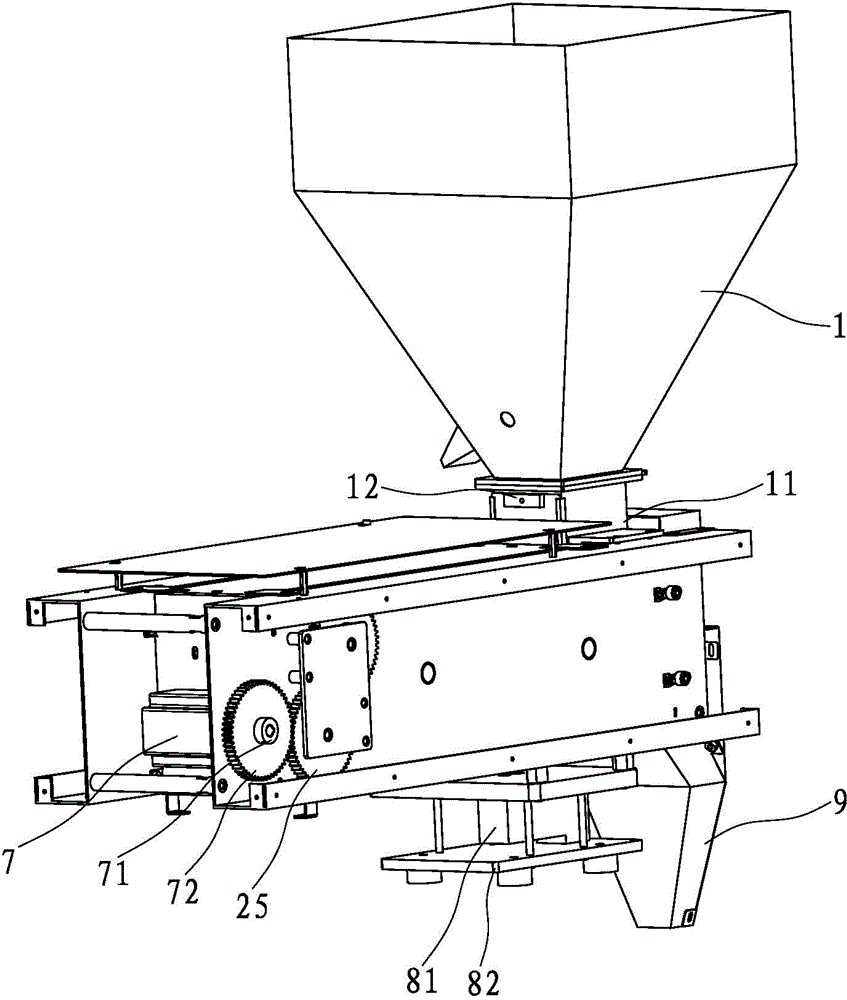

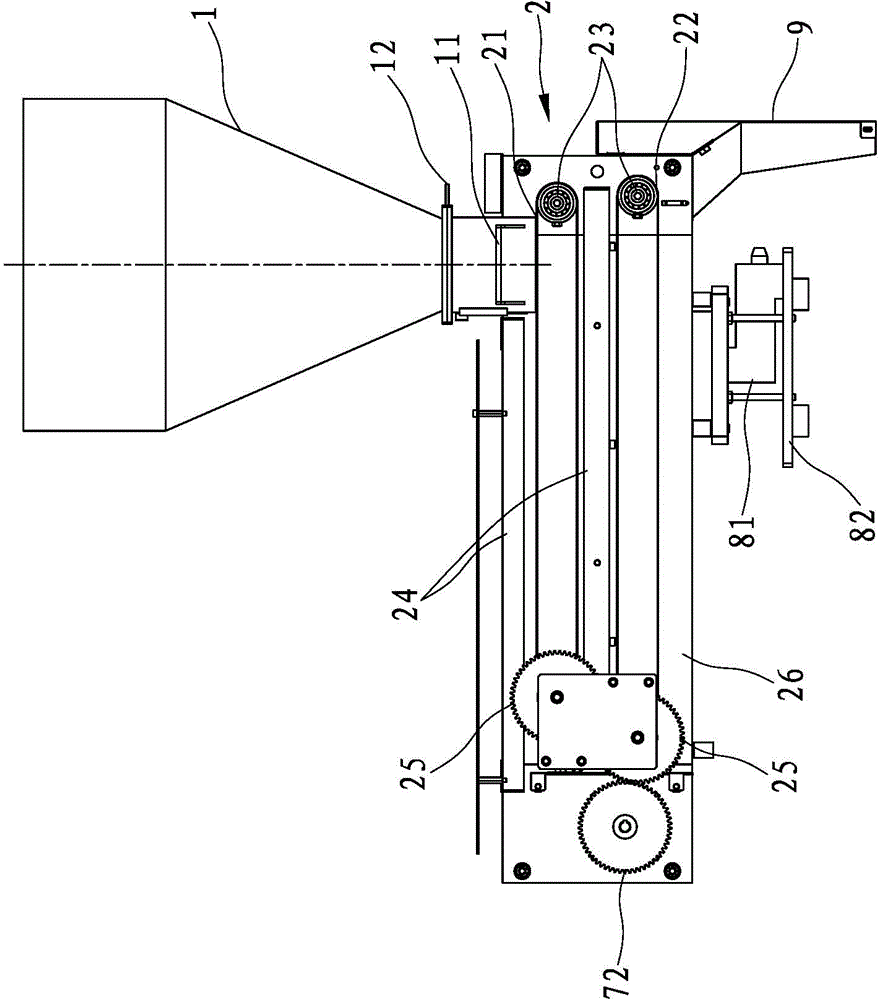

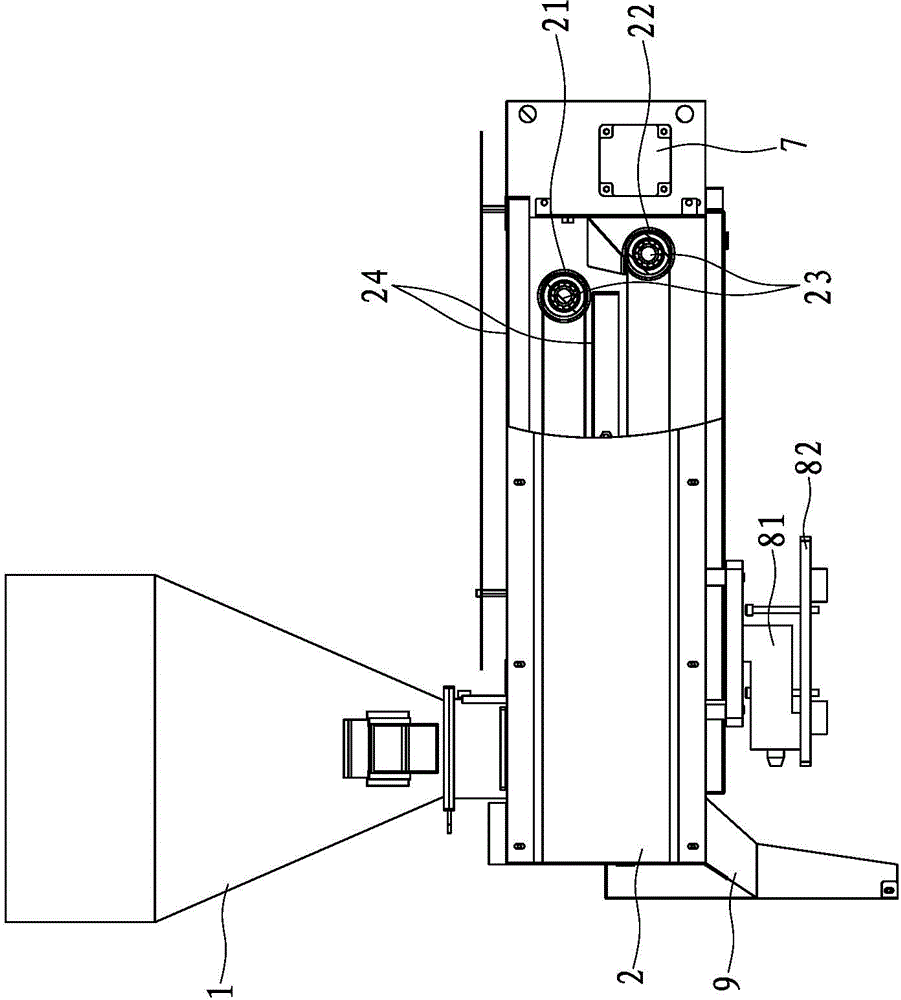

Accurate metering device capable of achieving rapid preheating

ActiveCN104568098AAchieve warm-upAchieve meteringSpecial purpose weighing apparatusElectricityLoad cell

The invention discloses an accurate metering device capable of achieving rapid preheating. The accurate metering device comprises a feeding hopper, a main frame, radiant heating devices, a conveying belt, a metering mechanism and a drive mechanism, wherein a heating cavity is arranged inside the main body; one radiant heating device is arranged on the top of the main frame; a supporting board is arranged at the bottom of the main frame; two pairs of rotary shafts are installed inside the heating cavity and connected with the drive mechanism; another radiant heating device is also arranged between the two pairs of rotary shafts; the feeding hopper is installed at the upper end of the main frame; the conveying belt comprises an upper conveying belt and a lower conveying belt which are installed on the two pairs of rotary shafts of the main frame respectively; the upper conveying belt and the lower conveying belt are parallel and opposite in conveying direction; the metering mechanism comprises a weighing sensor, a data conversion module and a tray; the upper end of the weighing sensor is installed on the supporting board at the bottom of the main frame; the tray is installed at the lower end of the weighing sensor; the data conversion module is electrically connected with the weighing sensor. The accurate metering device capable of achieving rapid preheating achieves rapid preheating and accurate metering of materials, lowers the use cost of equipment, and improves production efficiency.

Owner:XIAMEN BANGZHONG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com