Accurate metering device capable of achieving rapid preheating

A metering device and heating device technology, applied in the direction of measuring devices, weighing, instruments, etc., can solve the problems of multi-equipment costs, multi-time, etc., and achieve the effects of improving production efficiency, reducing equipment use costs, and reducing raw material processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

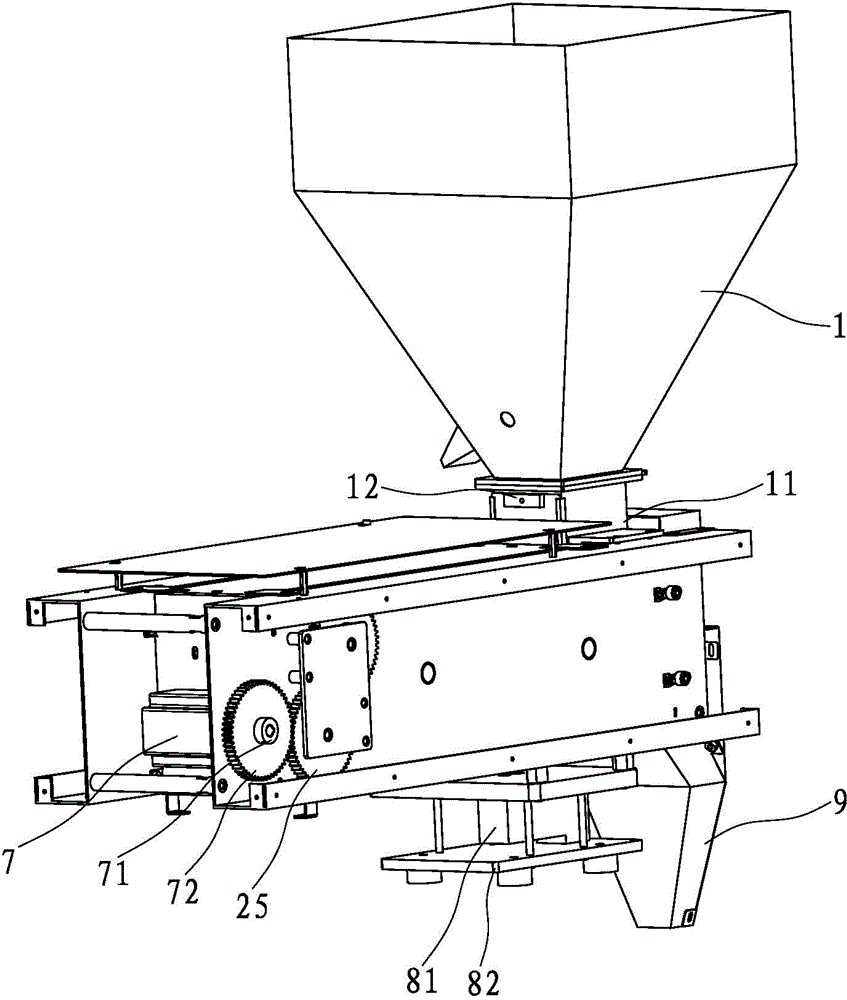

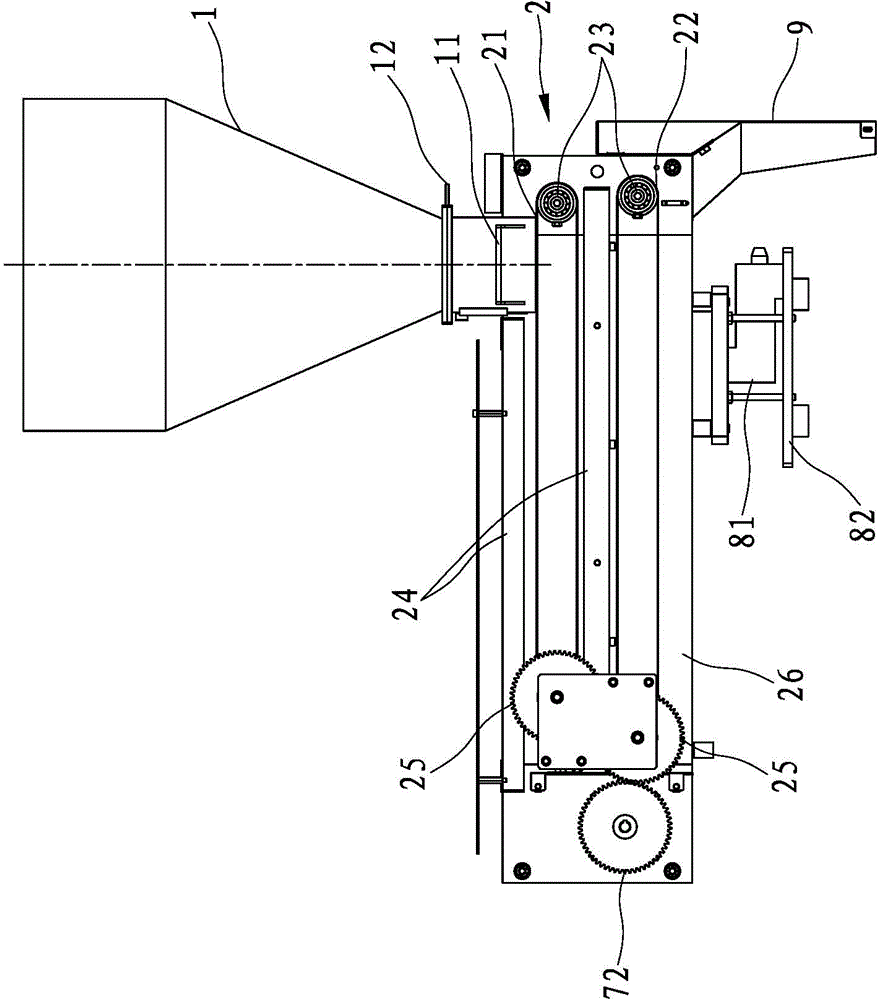

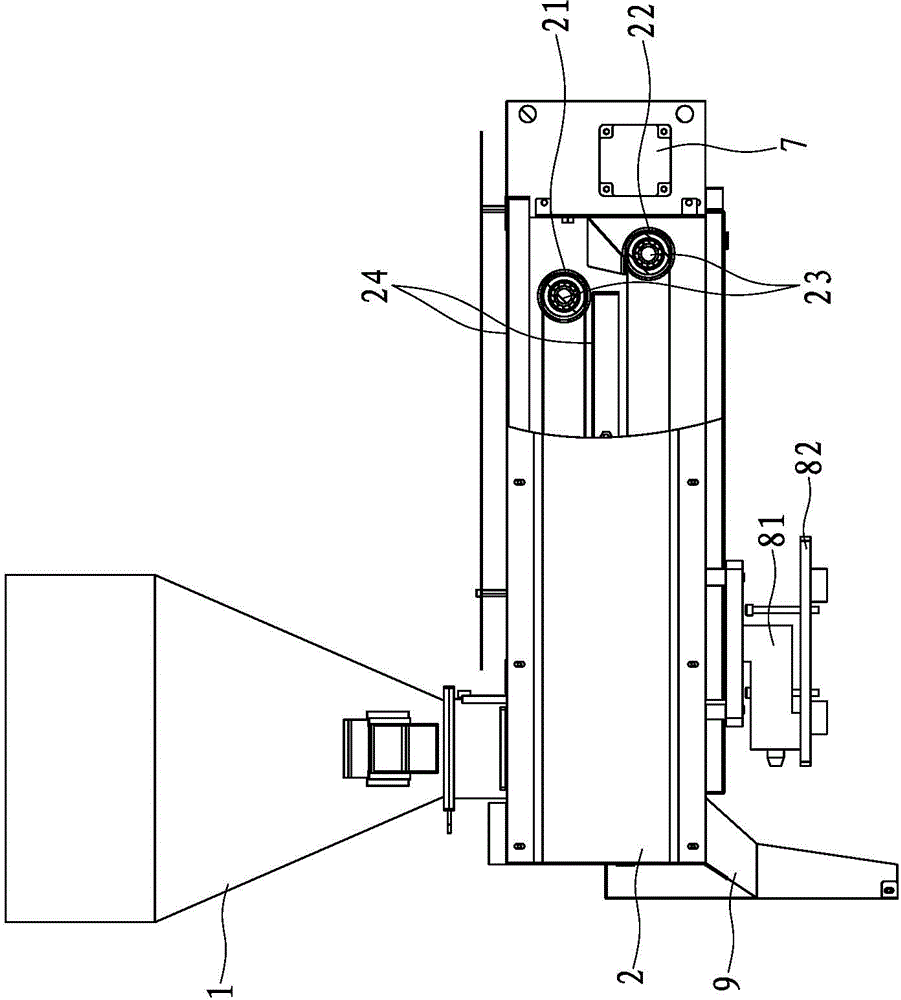

[0025] Such as figure 1 As shown, a rapid preheating accurate metering device disclosed by the present invention includes a feed hopper 1, a main frame 2, a radiation heating device 24, a conveyor belt, a metering mechanism 8, and a driving mechanism 7; the inside of the main frame is a heating chamber, The top is a radiant heating device 24, and the bottom is a support plate 26. Two pairs of rotating shafts 23 are installed in the heating chamber. 1 is installed on the upper end of the main frame 2;

[0026] The conveyor belt comprises an upper conveyor belt 21 and a lower conveyor belt 22. The upper conveyor belt 21 and the lower conveyor belt 22 are installed on two pairs of rotating shafts 23 of the main body frame 2 respectively. The upper conveyor belt 21 and the lower conveyor belt 22 are parallel to each other and the direction of transmission is opposite. Corresponding to the front end 221 of the conveyor belt, the front end 211 of the lower conveyor belt protrudes r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com