Industrial by-product gypsum calcining furnace

A technology of industrial by-product gypsum and calciner, which is applied in the field of phosphogypsum calciner and industrial by-product gypsum production equipment, which can solve the problems of pollution and waste of gypsum raw materials, and achieve the effects of reducing costs, saving energy and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

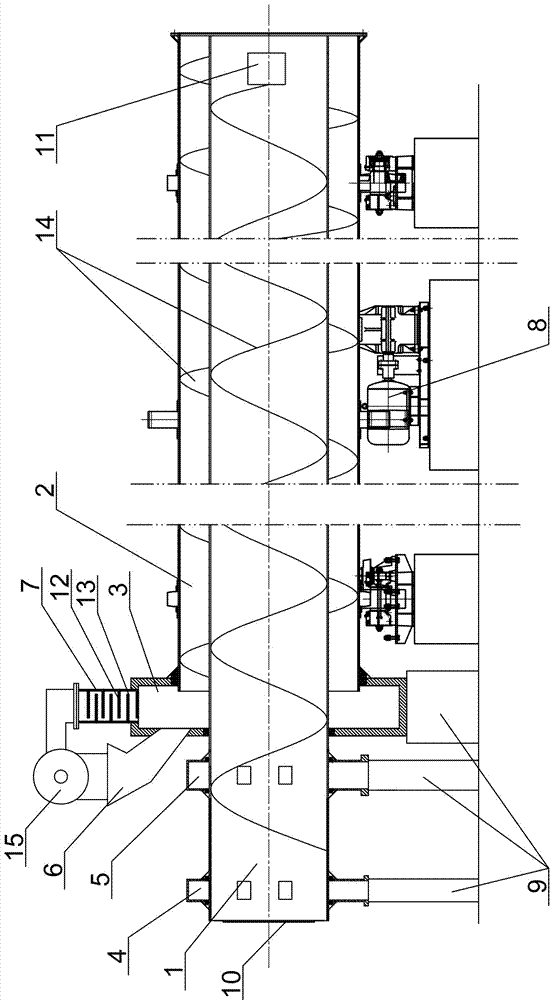

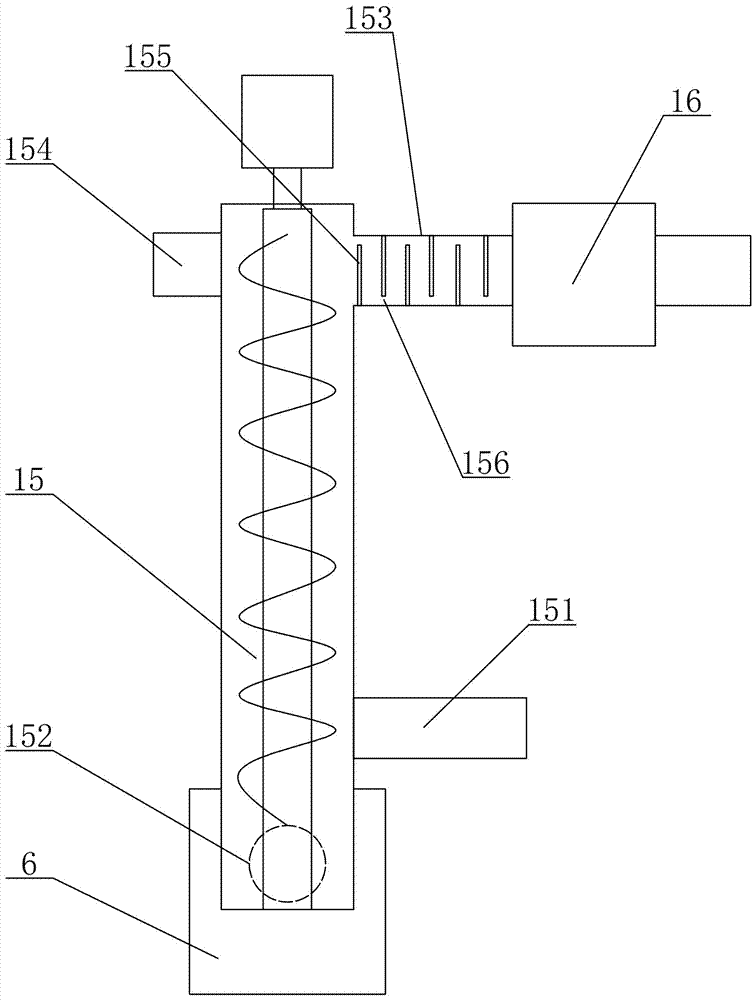

[0026] Such as figure 1 , figure 2 , image 3 As shown, an industrial by-product gypsum calciner includes an inner cylinder 1, an outer cylinder 2, a kiln head 3, anhydrous gypsum outlet 4, hemihydrate gypsum outlet 5, a feed hopper 6, an air outlet 7, The power transmission device 8 and the supporting device 9, the inner cylinder 1 is inserted in the outer cylinder 2, the length of the inner cylinder 1 is longer than the length of the outer cylinder 2, and the end of the inner cylinder 1 located outside the outer cylinder 2 is provided with a hot air inlet 10, and the hot air inlet 10 corresponds to the flame-throwing furnace, one end of the inner cylinder 1 located in the outer cylinder 2 is fixedly connected to the tail end of the outer cylinder 2, the front end of the outer cylinder 2 is provided with a kiln head 3, and the tail end of the outer cylinder 2 is closed , the head end of the outer cylinder 2 communicates with the inner cavity of the kiln head 3, and the kil...

Embodiment 2

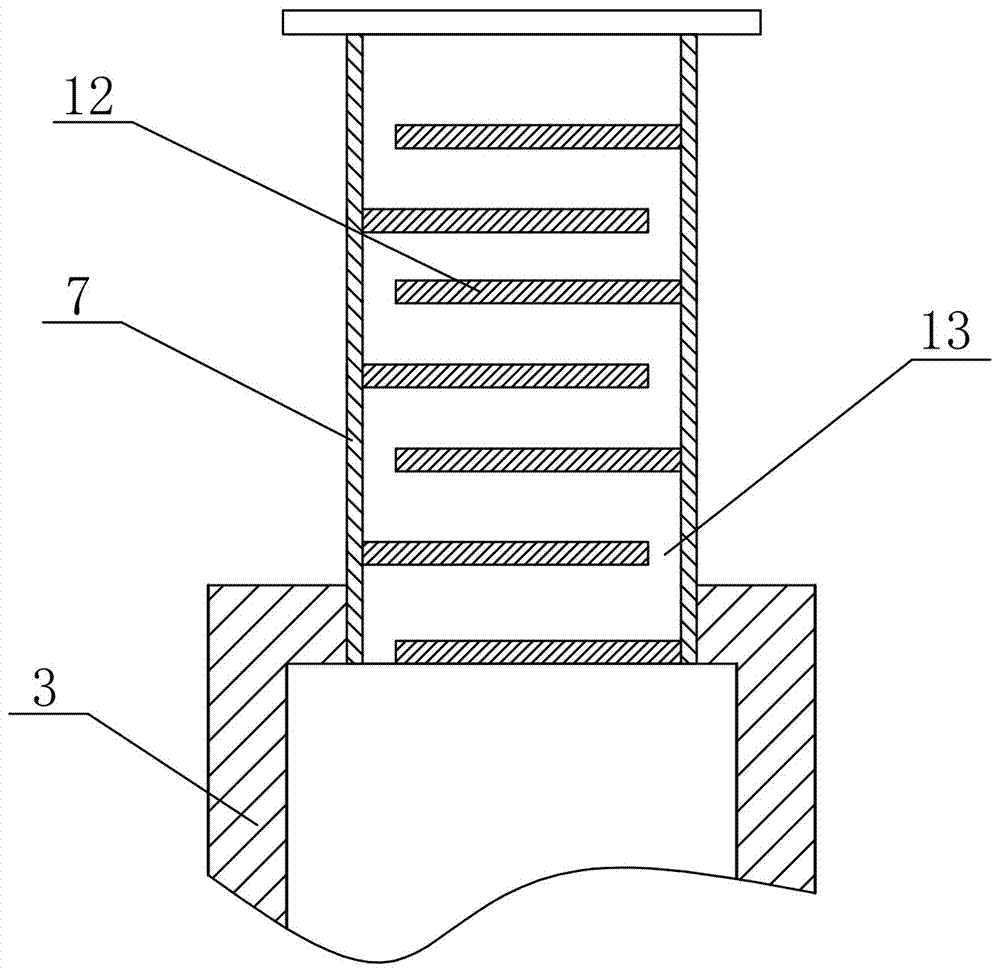

[0030] Such as Figure 4 As shown, repeating Example 1, there are the following differences: the baffle plate 12 is arranged obliquely downward in the air outlet 7, and the material contained in the airflow drawn by the air outlet 7 falls back on the baffle plate 12 after being blocked by the air outlet. On the surface of the plate 12 , the baffle 12 arranged obliquely downward is beneficial for the material to slide down along the baffle 12 back into the outer cylinder 2 .

[0031] The ventilation hole 13 of the present invention is a through hole arranged on the baffle plate 12, and the through holes on two adjacent baffle plates 12 are staggered from each other, and the baffle plate 12 closes the cross-section of the entire air outlet 7, and the through hole is set on the baffle plate 12. hole. The gaps between the mutually staggered through holes and the baffles 12 can also form a labyrinth ventilation channel. In order to ensure the blocking effect of the baffles 12, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com