Additive manufacturing method and additive manufacturing device with preheating functions

An additive manufacturing and functional technology, applied in the field of additive manufacturing, can solve the problems of unable to detect the deformation of the powder bed surface and uneven temperature field in real time, so as to improve the yield rate and manufacturing success rate, uniform temperature field, and avoid charge concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

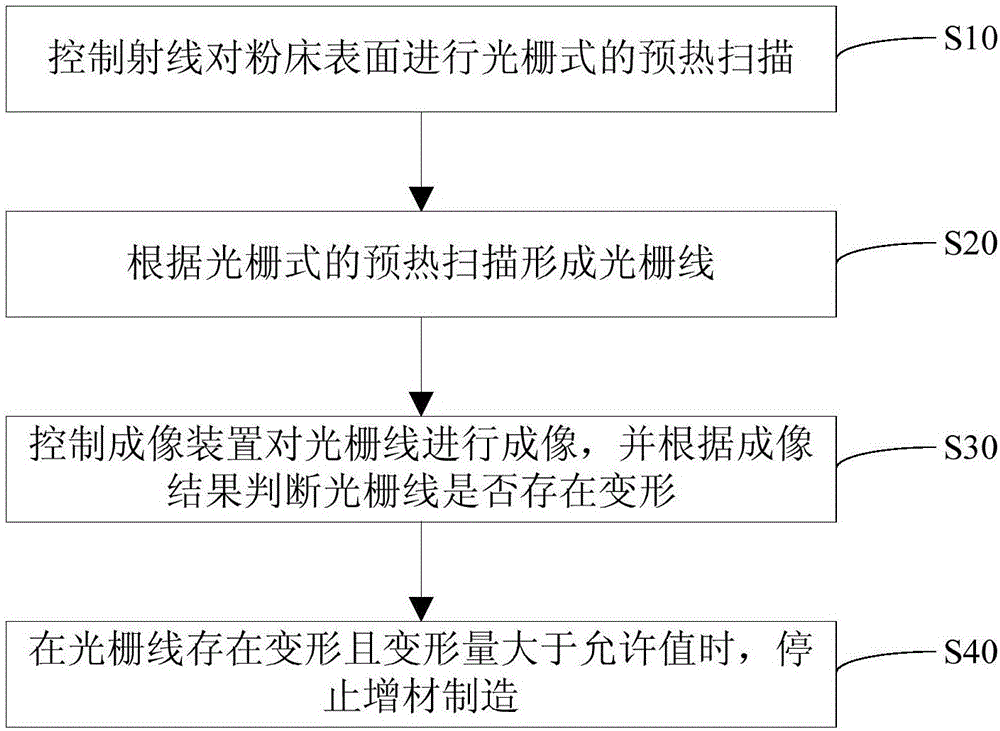

[0049] This embodiment provides a method for additive manufacturing with a preheating function, such as figure 1 As shown, the additive manufacturing method includes the following steps:

[0050] S10, controlling the ray to perform a raster preheating scan on the surface of the powder bed.

[0051] Specifically, the radiation is emitted by the radiation generating device, and the powder bed is scanned by the radiation. In this embodiment, the above-mentioned radiation is laser or electron beam.

[0052] The raster-type preheating scan is as follows: the ray scans the surface of the powder bed alternately along the horizontal scanning path and the vertical scanning path.

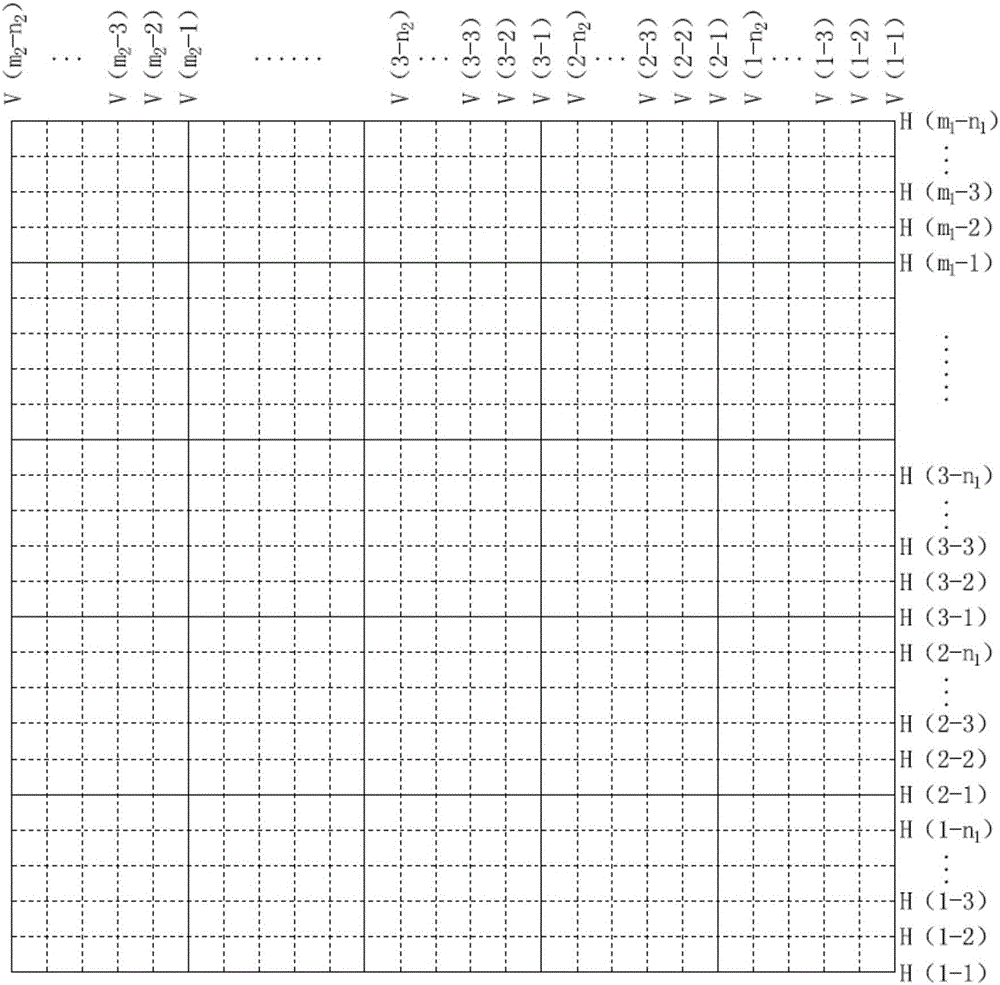

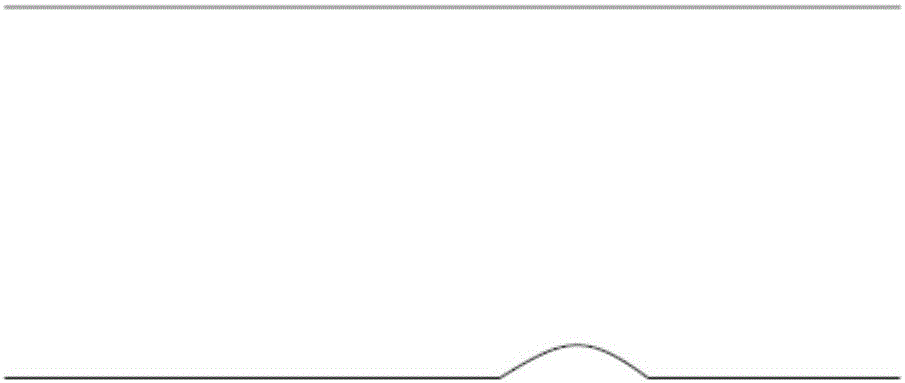

[0053] More specifically, refer to figure 2 , firstly, the powder bed surface is divided into M along the vertical direction in advance 1 horizontal areas, the above M 1 regions covering the cross-sectional area of the entire 3D part, and in each region there are N 1 scanning path H; after that, the ...

Embodiment 2

[0082] This embodiment provides an additive manufacturing device with a preheating function, such as Figure 4 As shown, the additive manufacturing device includes a working plane 1 with a powder bed, a radiation generating device 2 and an imaging device 3 above the working plane 1, and a control device 4 connecting the radiation generating device 2 and the forming device 3, wherein :

[0083] The above-mentioned ray generating device 2 is used to emit a ray 5, which can raster scan the surface of the powder bed on the above-mentioned working plane 1 and form a raster line; it can also melt the surface of the above-mentioned powder bed to form a three-dimensional solid part. section. Preferably, the above-mentioned rays are lasers or electron beams, and when the rays are electron beams, the accelerating voltage is 60kV, the power is 0-10kW, the working plane 1 is set in a vacuum chamber, and vacuum systems such as pumps and valves can be used in the vacuum chamber Maintain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com