Patents

Literature

639results about How to "Uniform temperature field" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

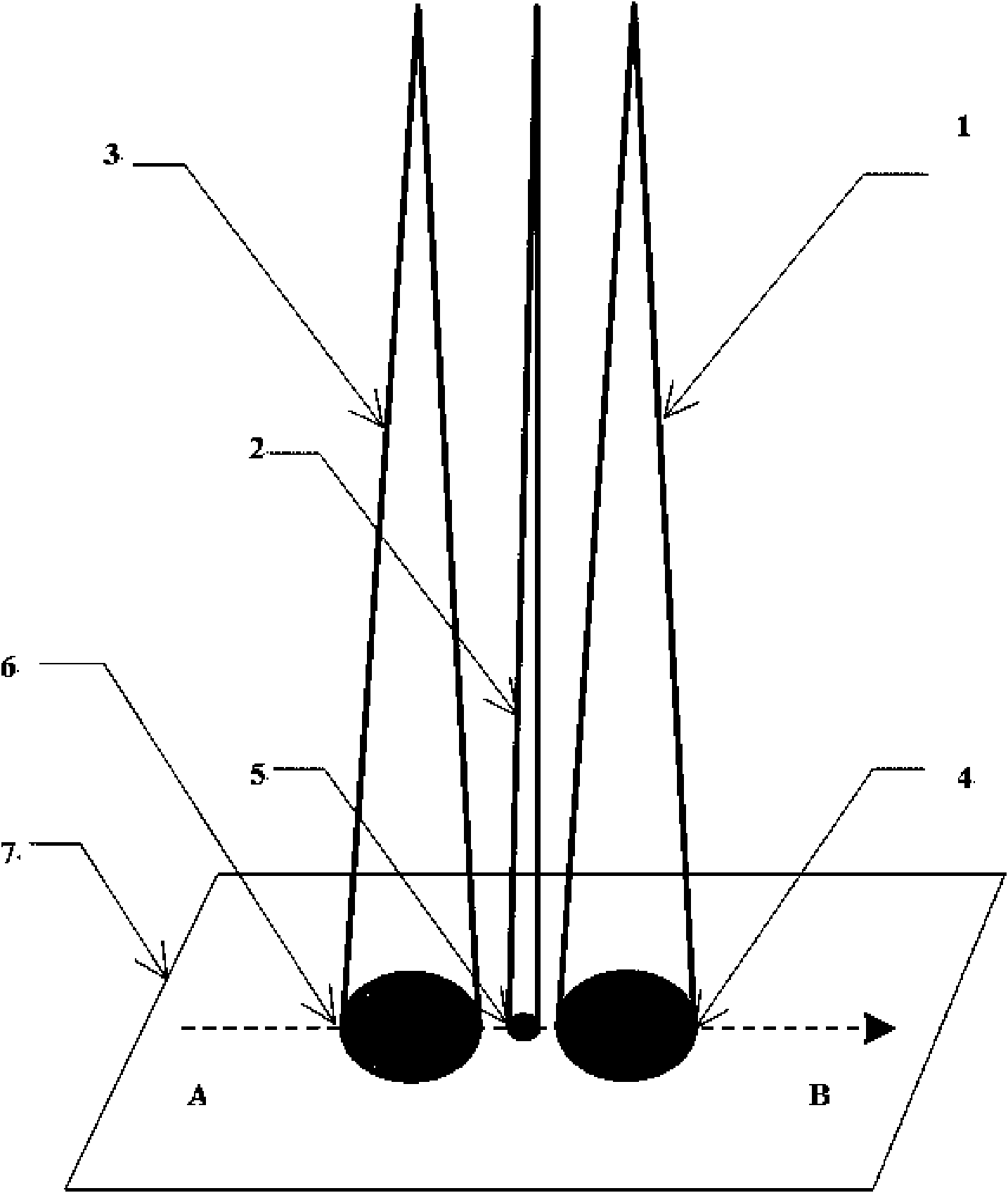

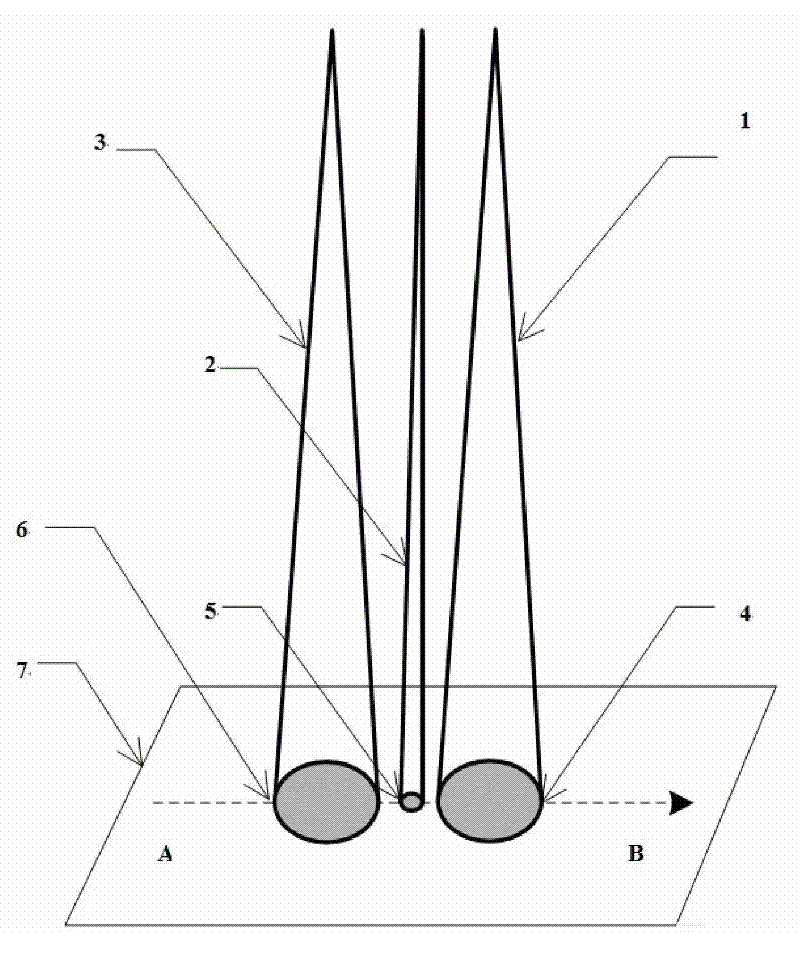

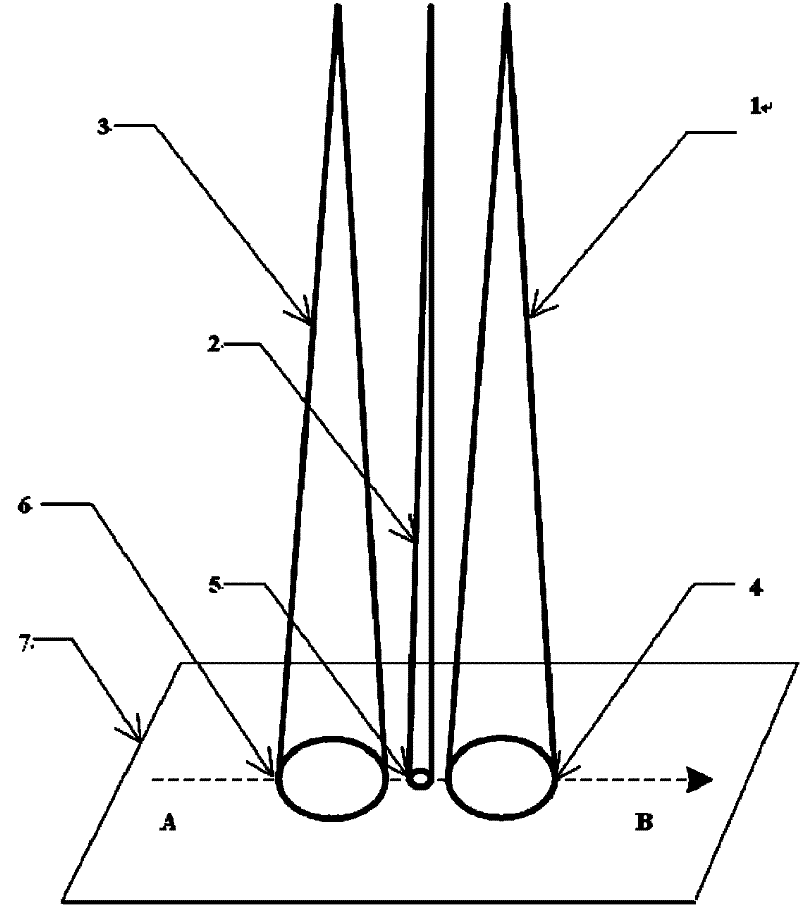

Fast forming method of fusion of metal powder of three beams of laser compound scanning

The invention discloses a fast manufacturing method of three-beam laser compound scanning. The method comprises the following steps of: firstly utilizing long-wavelength laser (CO2 laser) for preheating the metal powder, then utilizing short-wavelength laser (YAG or optical fiber laser) for fusing the metal powder and finally utilizing long-wavelength laser (CO2 laser) to carry out heat treatment to the frozen metal. The fast manufacturing method uses the three beams of laser to carry out compound scanning, namely uses long-wavelength laser to preheat, short-wavelength laser to fuse and then long-wavelength laser to carry out heat treatment, can realize the compound process of preheating, fusion and heat treatment of the metal powder. The three beams of laser compound scanning mode can reduce internal stress of the metal part, avoid warping and cracking, improve organization and improve performance.

Owner:HUAZHONG UNIV OF SCI & TECH

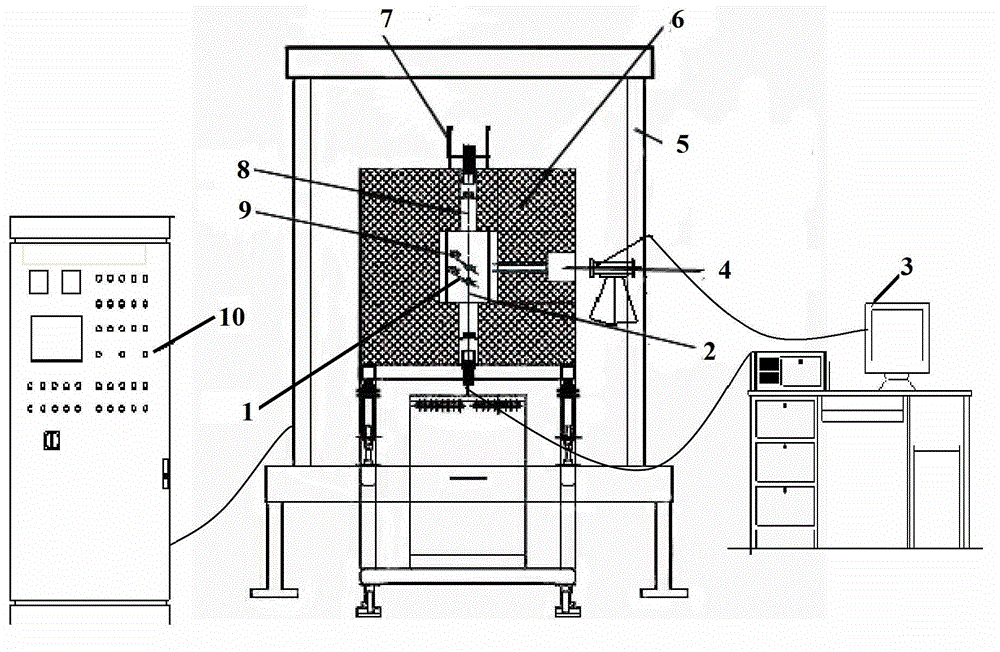

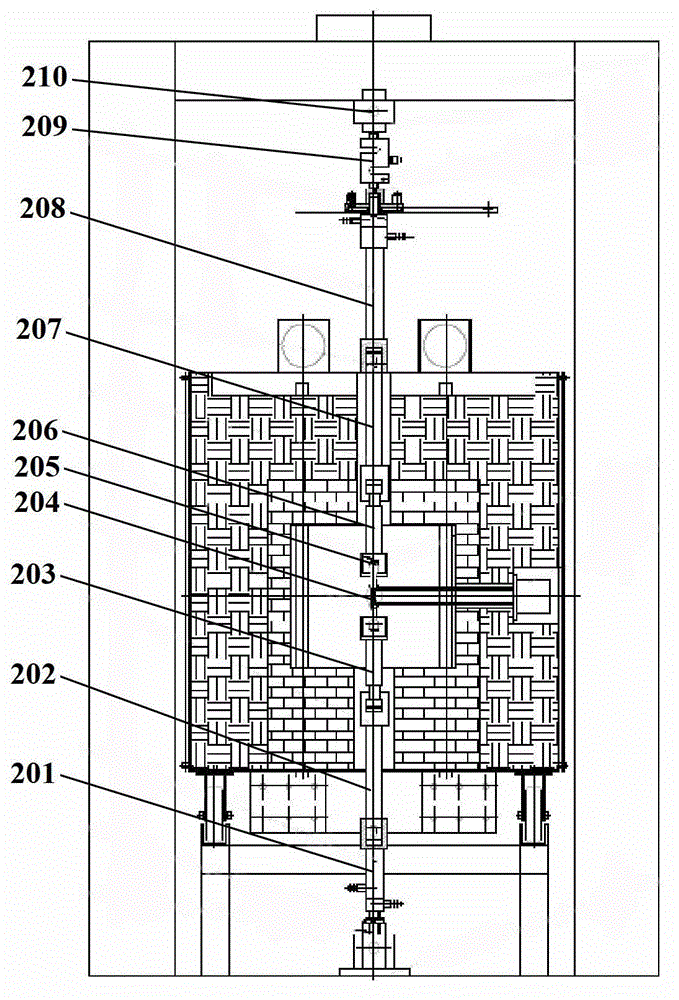

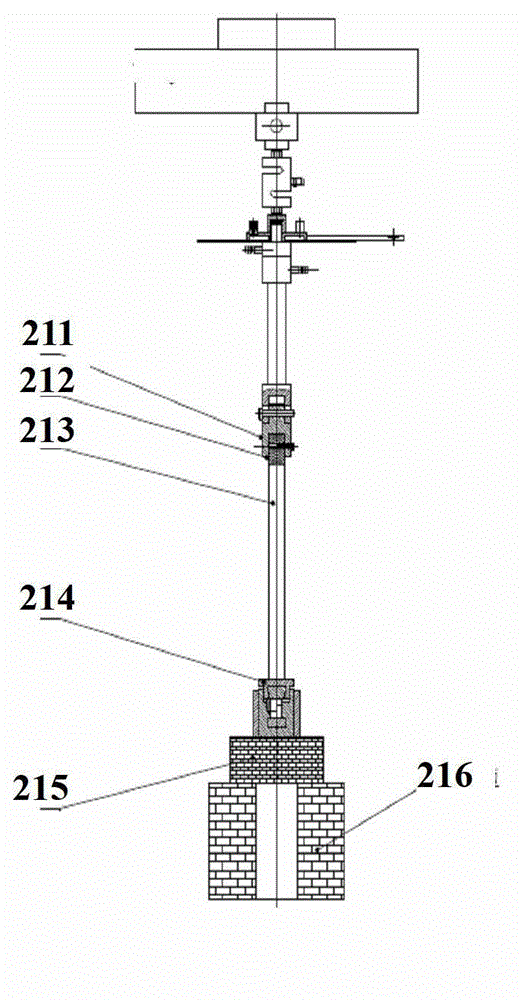

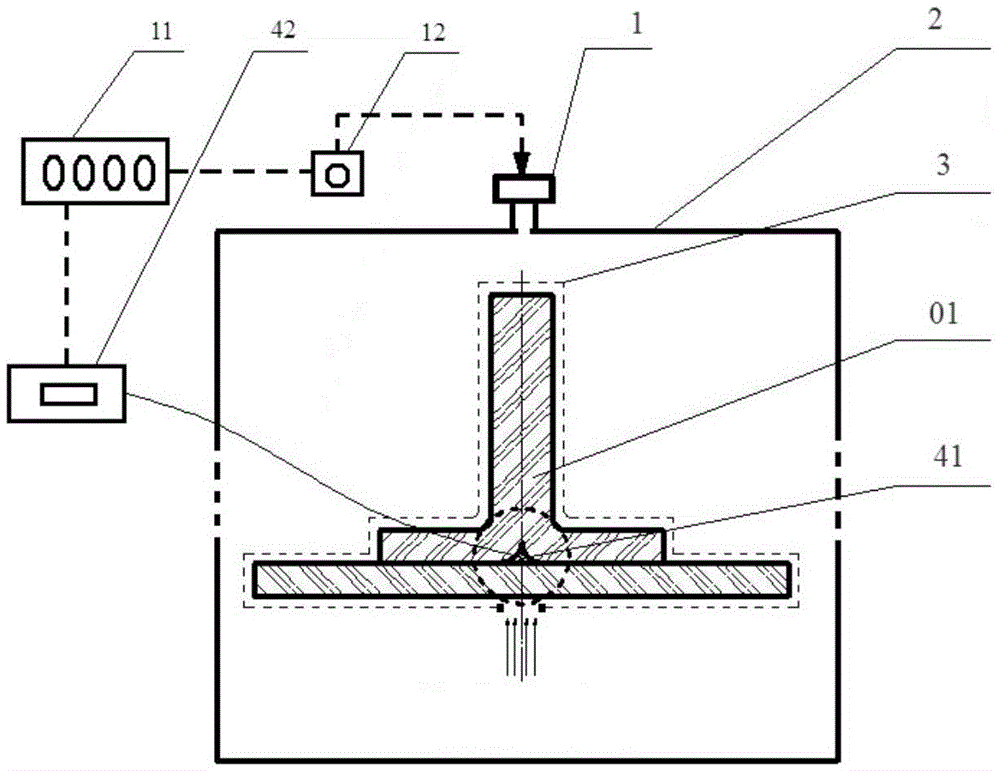

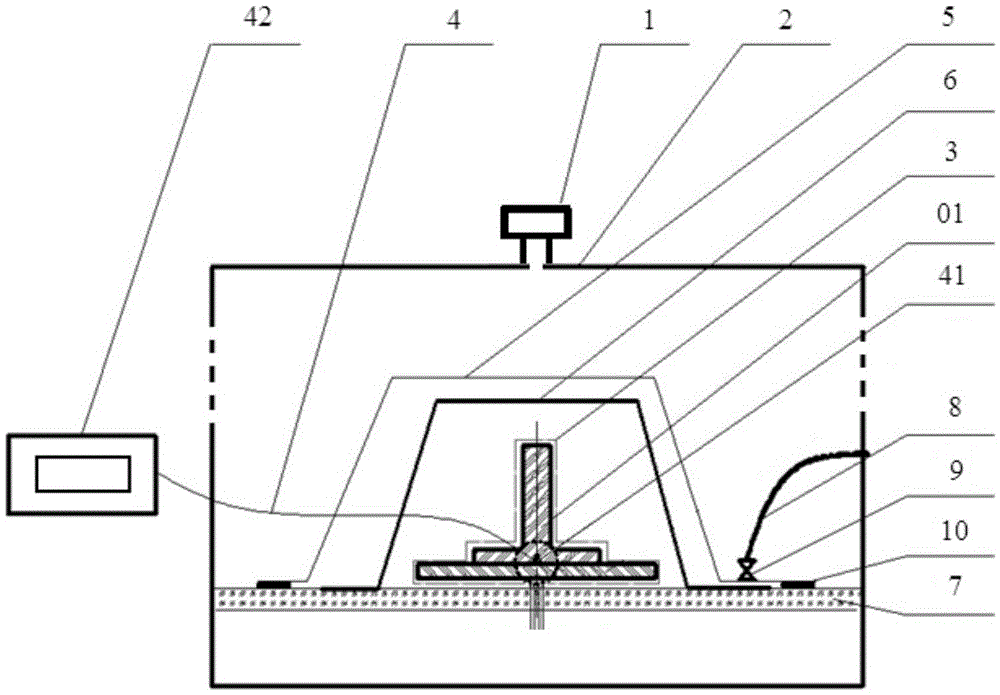

Device and method for testing mechanical property in ultrahigh temperature oxidation environment

ActiveCN102944466AMeasuring Tensile StrengthMeasuring Compressive StrengthMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesElectric controlMeasurement precision

The invention provides a device and a method for testing mechanical properties such as stretching, compression, bending, fracture toughness, shear strength and deformation of a high-temperature material in an ultrahigh temperature oxidation atmosphere in a temperature range from normal temperature to 1,800 DEG C. The experimental device is formed by assembling an electric control cabinet, a loading clamp, a load control and deformation sensing measurement system, a furnace body, a non-contact deformation measurement system, a display recording system and the like. According to the method, a furnace oxidation environment is uniformly and stably heated and kept through a heating body, so that the mechanical properties can be tested at temperature range from the room temperature to 1,800 DEG C, and mechanical property parameters such as stretching, compression, bending, shear strength and strain are captured by utilizing the contact sensing system and the non-contact measurement system. The device has the greatest characteristics of multiple testing parameters, high data measurement precision and high experimental repeatability.

Owner:PEKING UNIV +2

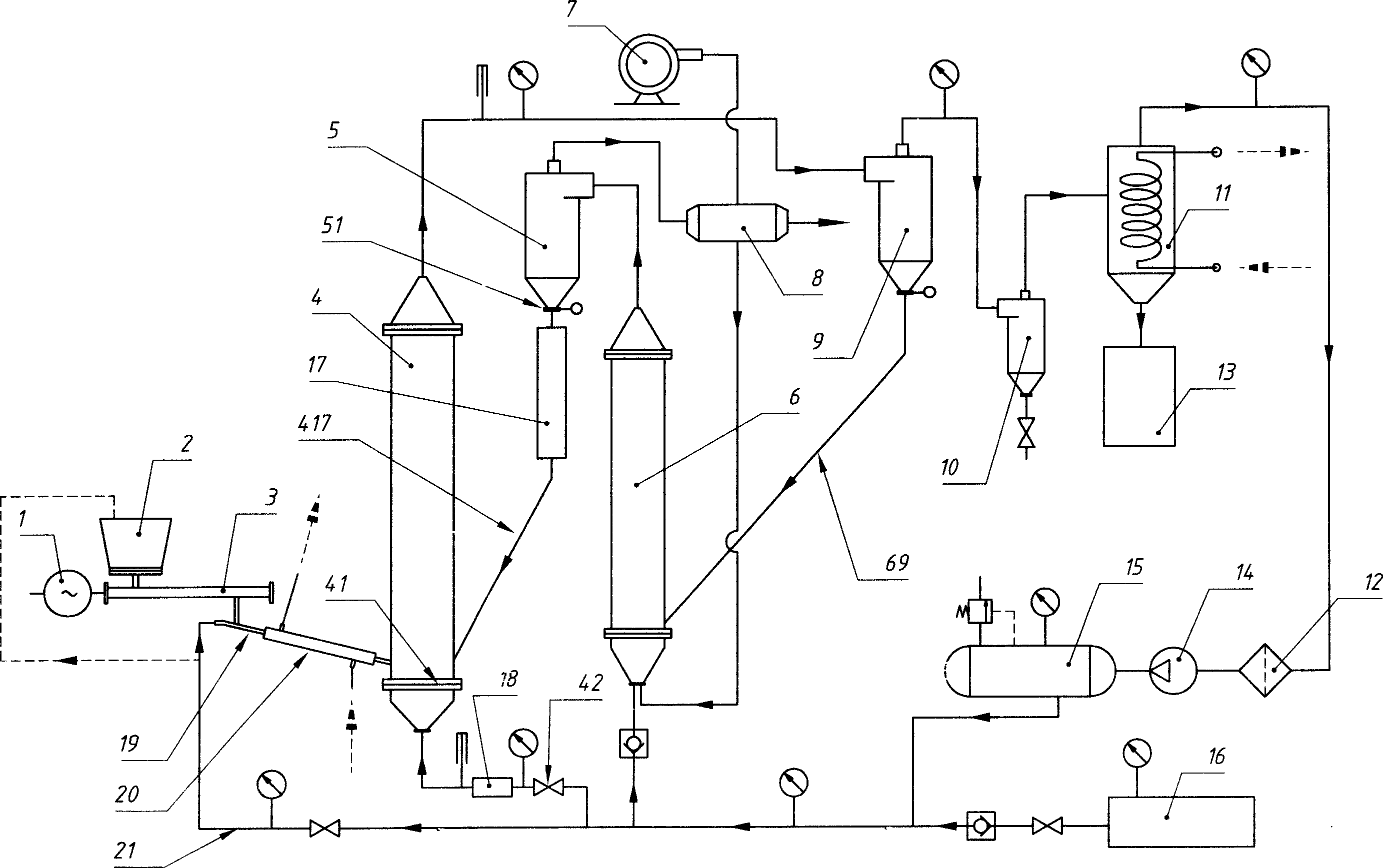

Biomass pyrolysis liquefied technique and double tower apparatus system thereof

InactiveCN1730177AImprove pyrolysis efficiencyWell mixedSolid waste disposalGas phaseProcess engineering

The invention relates to a biomass analgesic liquidation method and its twin-tower set system, the processes of which comprise the following steps: sending biomass to pyrolytic reaction tower and blending it with high-heat fluidized gas to subject biomass to pyrolytic cracking; separating thermal cracking gas with carbon residue and ash content in separator; and condensing thermal cracking gas to biological oil in condenser. In the process, heat-carrying agent is exported from pyrolytic reaction tower along with thermal cracking gas, carbon residue and so on, and carbon residue is used to preheat heat-carrying agent. The invention is special for heat-carrying agent heating tower to burn carbon residue and primary separator to separate heat-carrying agent, carbon residue and other materials. The invention can not only increase circulation rate to ensure uniform and stable temperature field in pyrolytic reaction tower, higher heating rates and shorter detention period of gas phase, but also make use of carbon residue as heat source by using existing apparatus.

Owner:CHONGQING UNIV

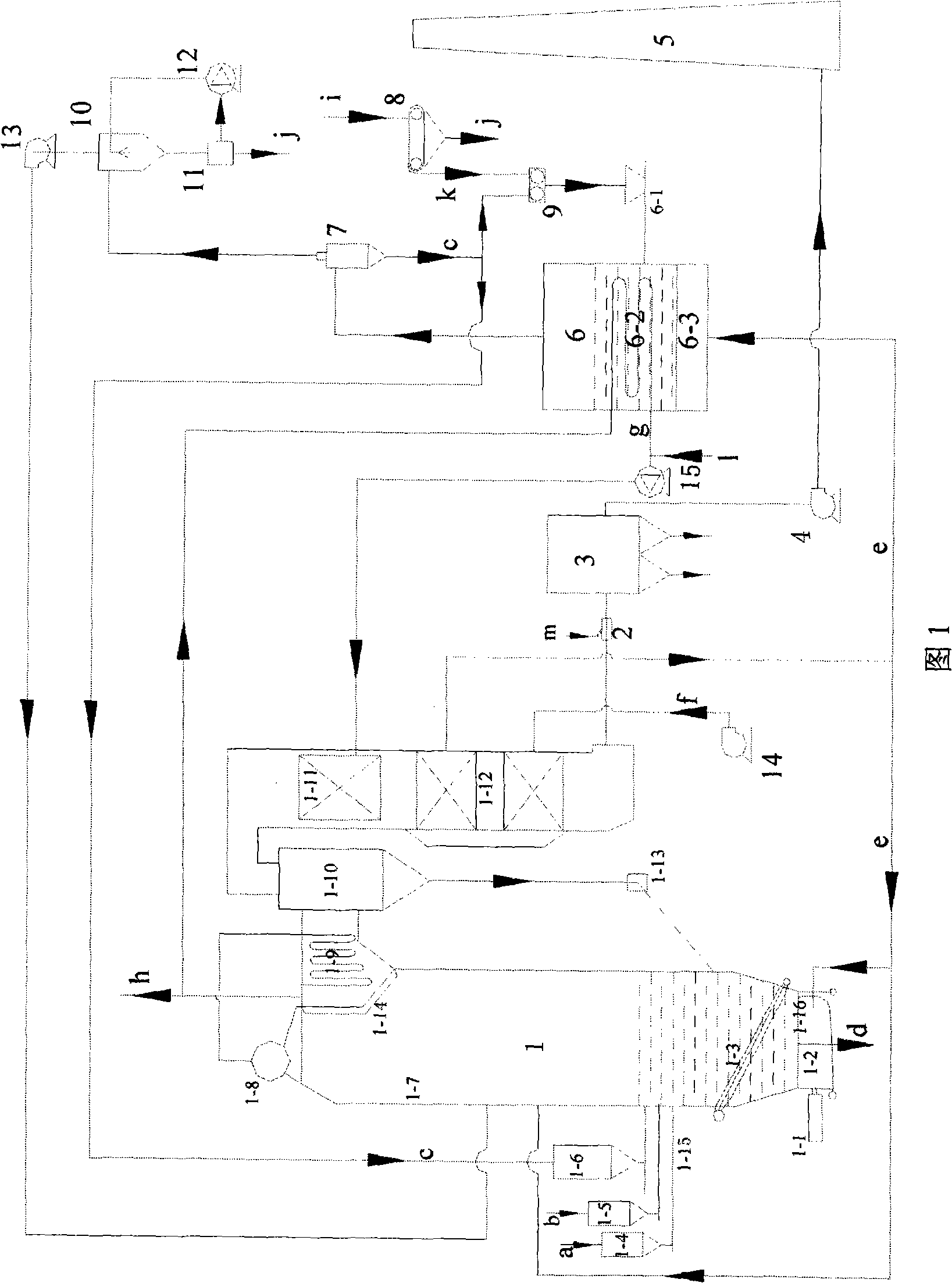

Sludge drying burning combination treatment method

ActiveCN101265008ASimple processLower the altitudeSludge treatment by de-watering/drying/thickeningIncinerator apparatusFluidized bed dryingTreatment effect

The invention relates to a sludge drying and incineration combined treatment method with good treatment effect, wide sludge adaptability, and safe and stability system. To avoid agglomeration of mechanically dewatered sludge (k) in a fluidized bed dryer (6), a part of dried sludge (c) is premixed with the mechanically dewatered sludge (k) and then fed into the fluidized bed dryer (6). The dried sludge (c) is incinerated into a circulating fluidized bed incinerator (1) to generate superheated vapor. The superheated vapor is condensed to hot water in a heat exchange tube (6-2) of the fluidized bed dryer (6) and then recycled to the circulating fluidized bed incinerator (1). The arrangement of buried pipes (1-3) and fractional air supply inside the circulating fluidized bed incinerator (1) can effectively control the lower temperature of the circulating fluidized bed incinerator (1) to prevent deflagration of dried sludge. The entire system has no emission of pollutants such as unpleasant odor, acidic gases, heavy metals and dioxin; is safe and reliable; and can operate for a long time.

Owner:JIANGSU JINSHAN SOLID WASTE RESOURCE TECH

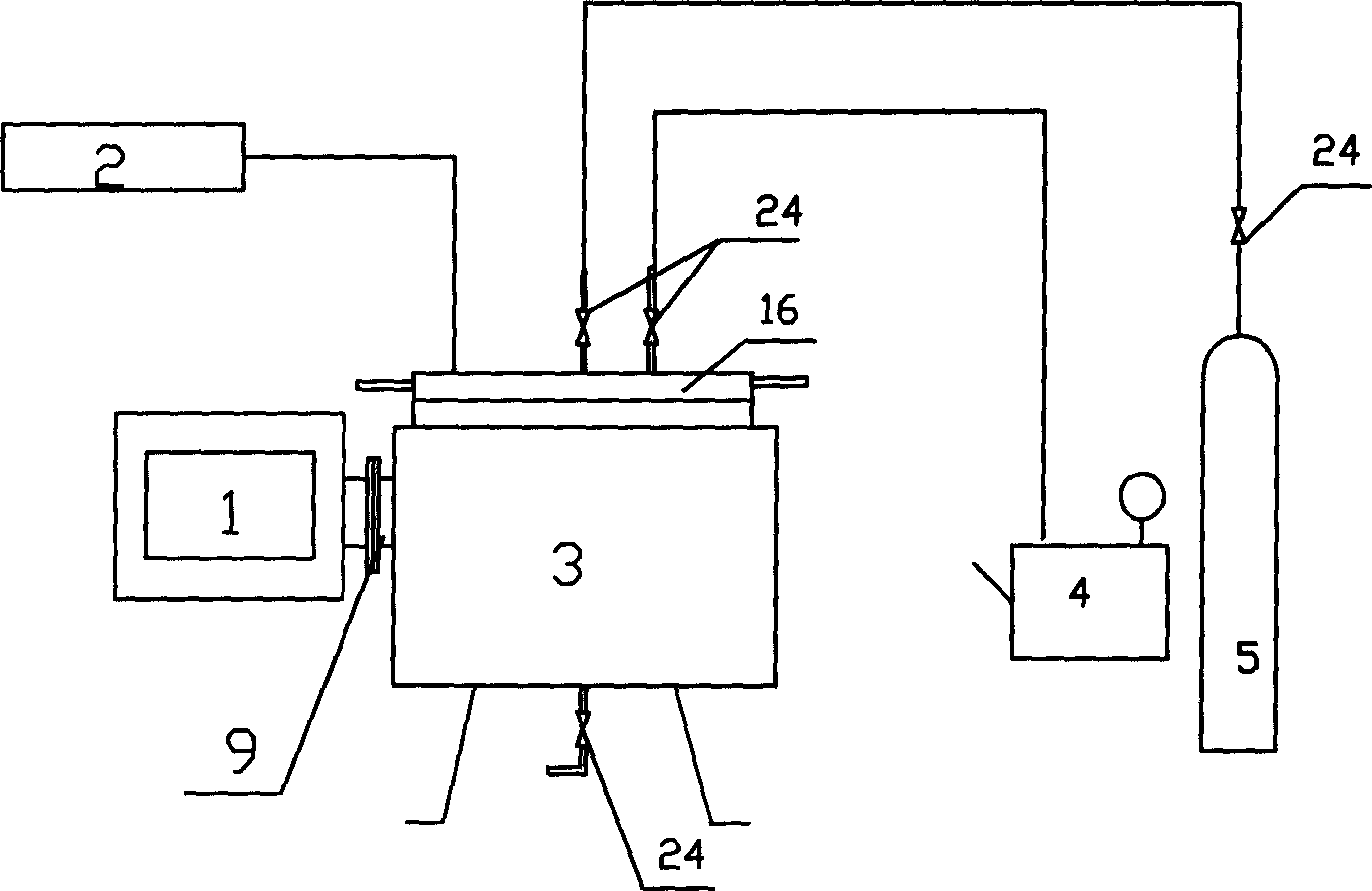

Pressure type microwave reactor

InactiveCN1861249AReduce lossNot easy to corrodeEnergy based chemical/physical/physico-chemical processesPressure vessels for chemical processNuclear engineeringGas cylinder

A pressure-type microwave reactor system is composed of a microwave generator, a waveguide tube with rectangular flange and quartz glass window, a cylindrical microwave reactor with external jacket made of stainless steel, enclosing head, internal high-pressure wall and insulating layer, controller for microwave reactor, hydraulic water pump and high-pressure gas cylinder.

Owner:DALIAN UNIV OF TECH

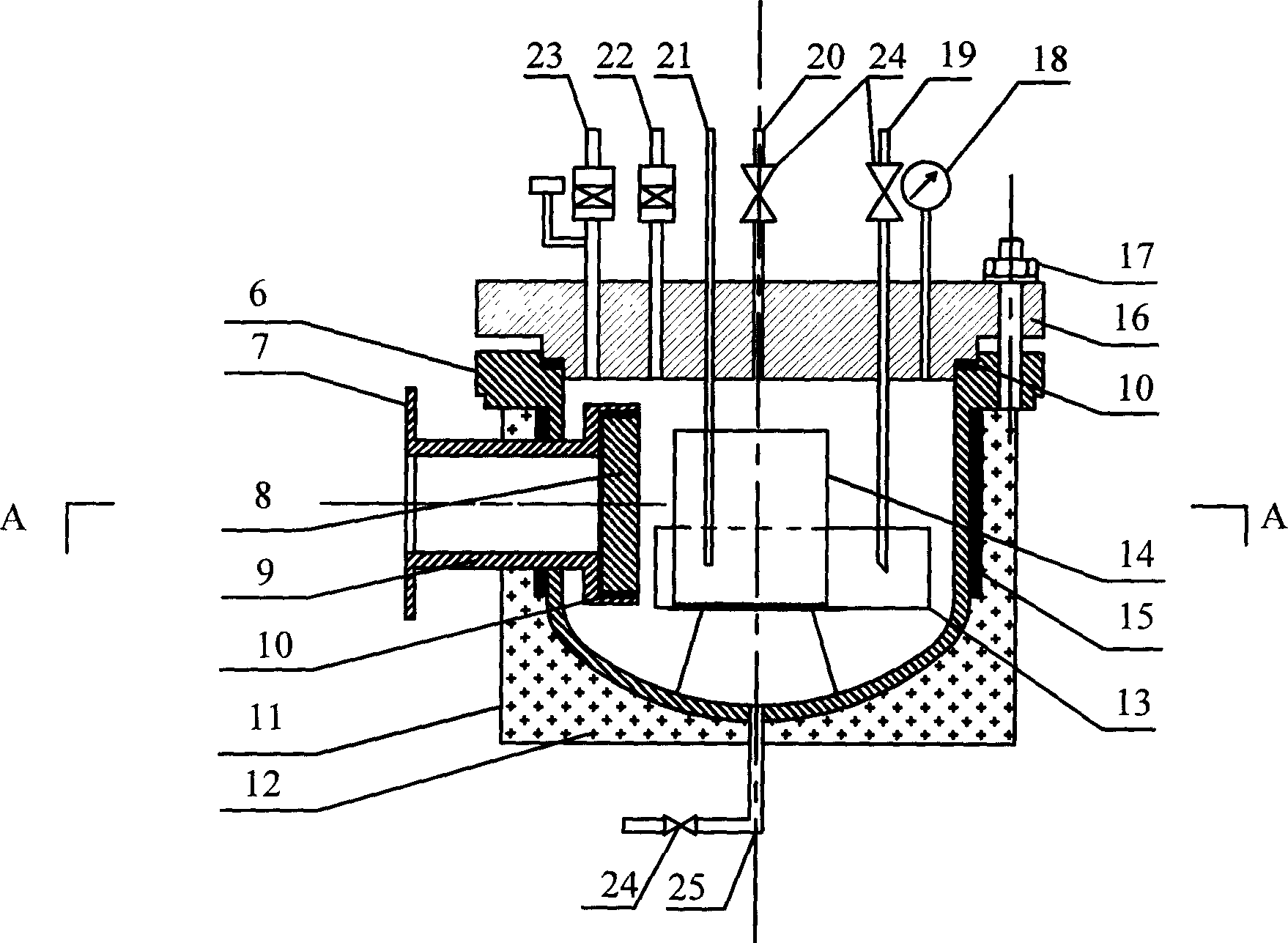

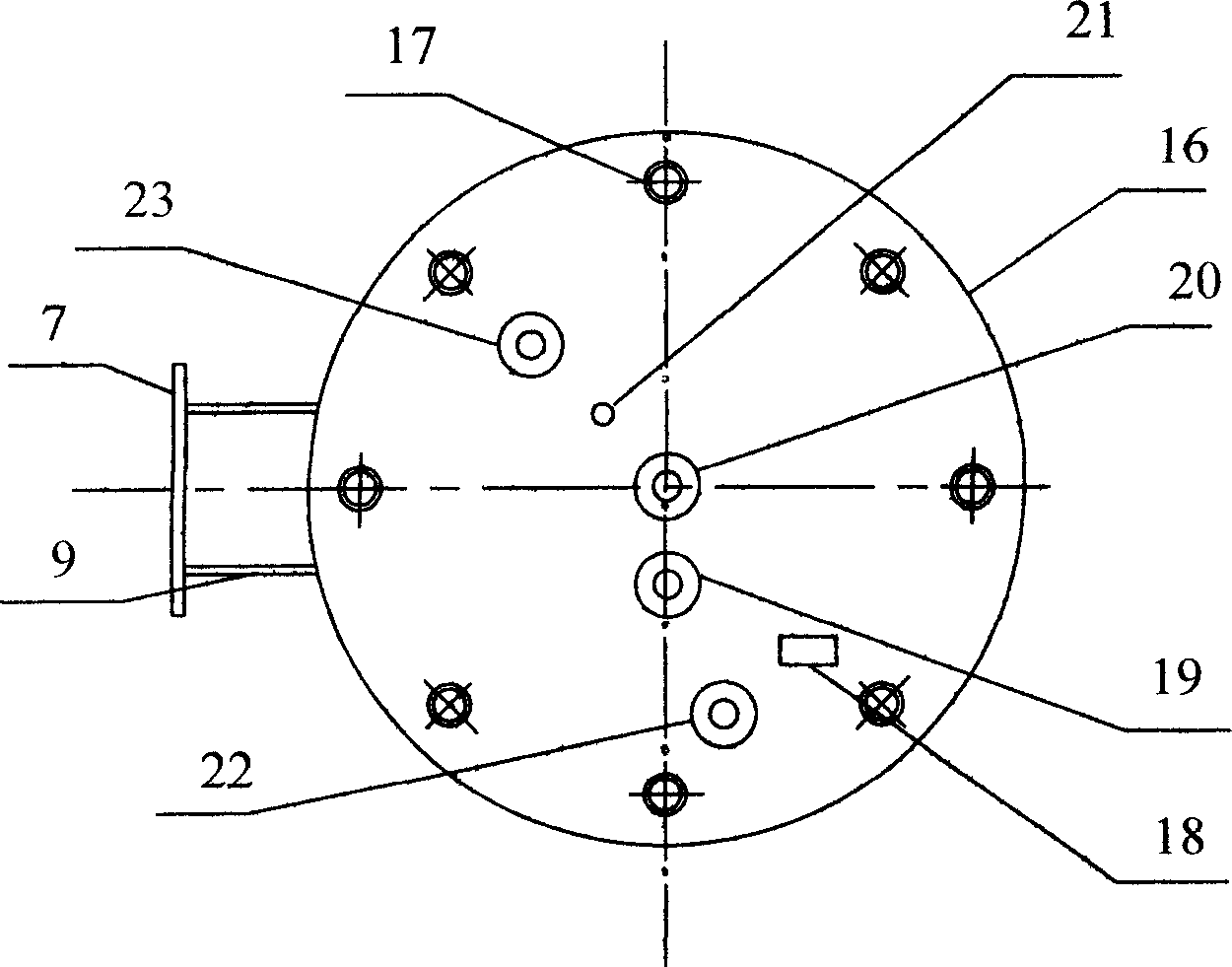

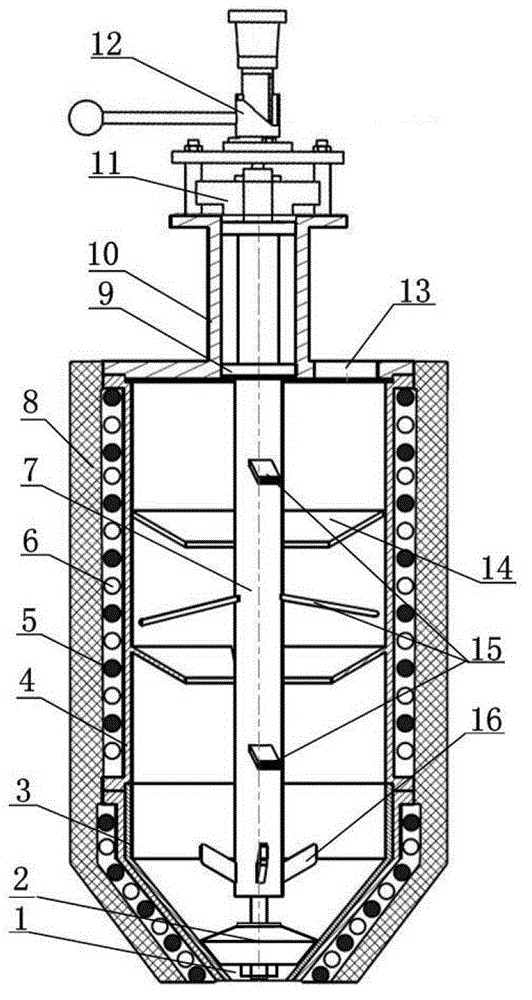

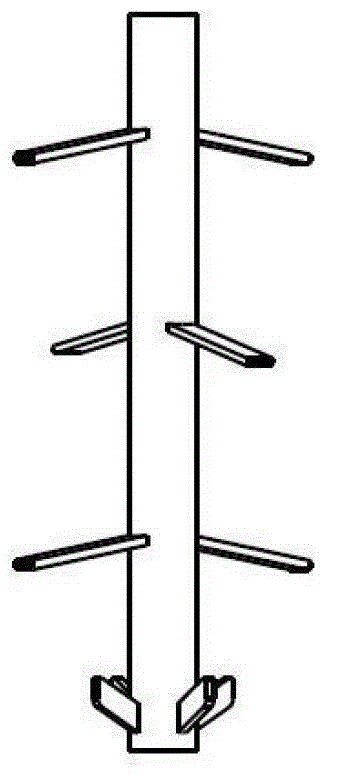

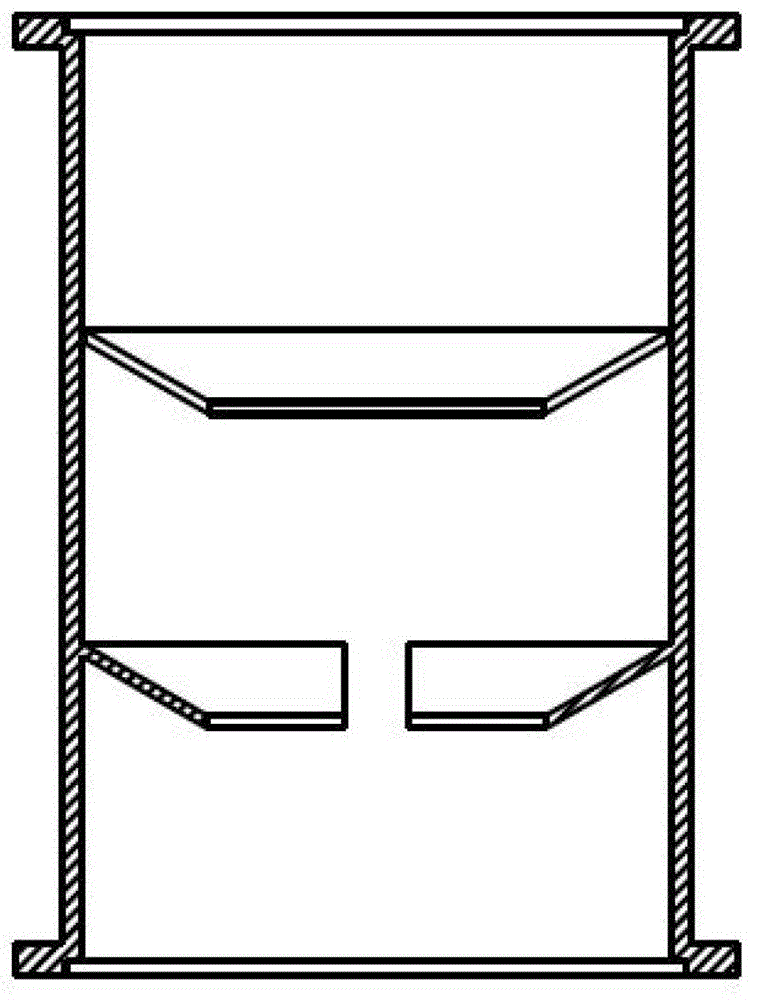

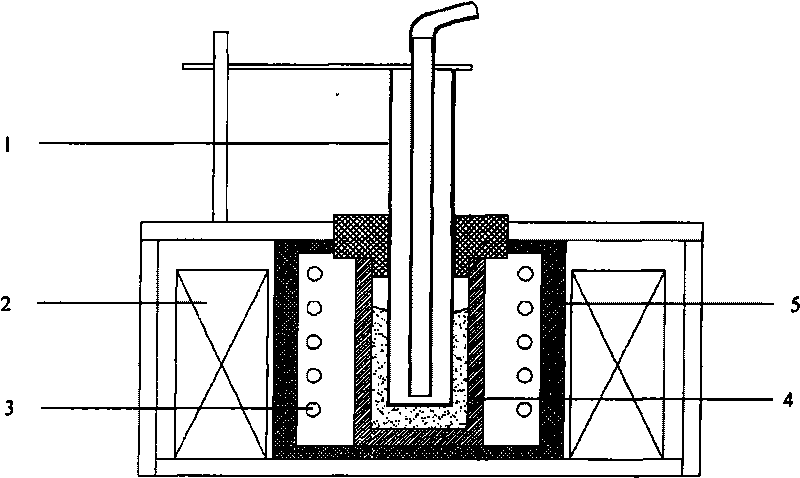

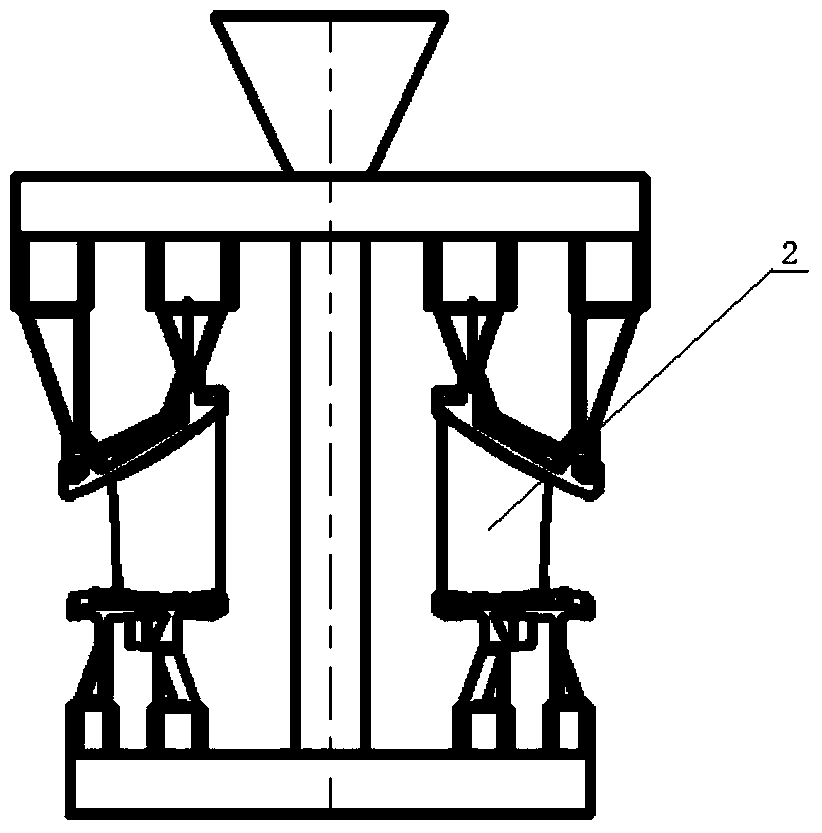

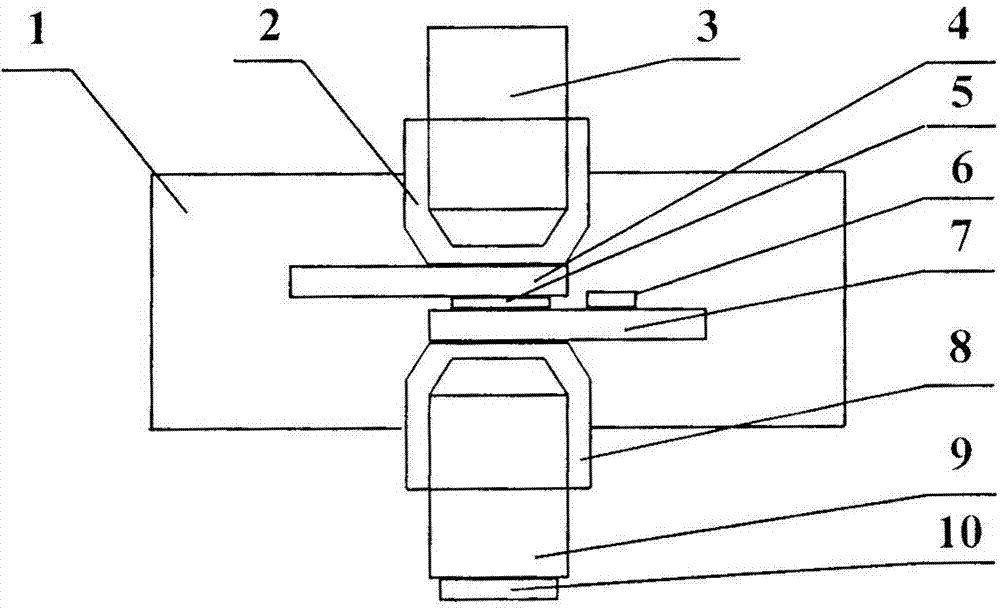

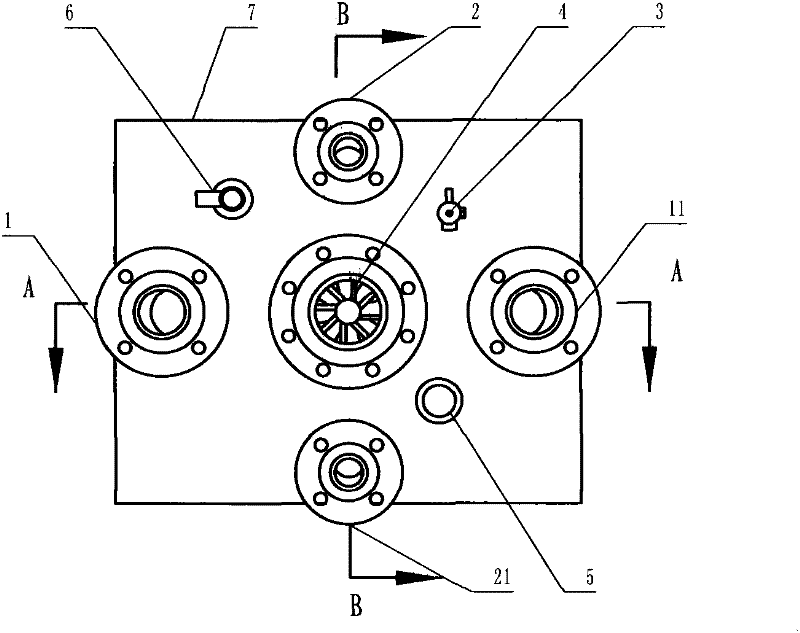

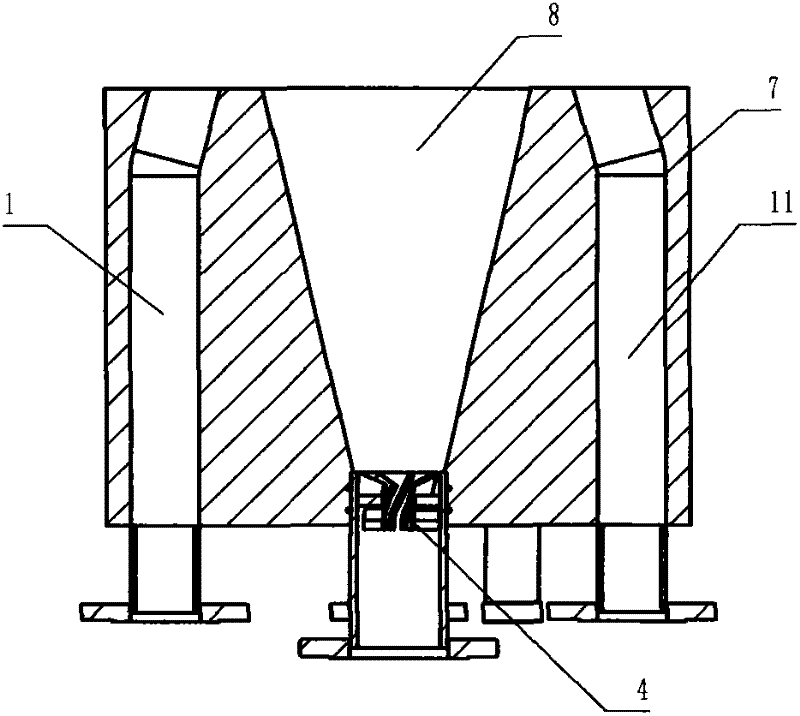

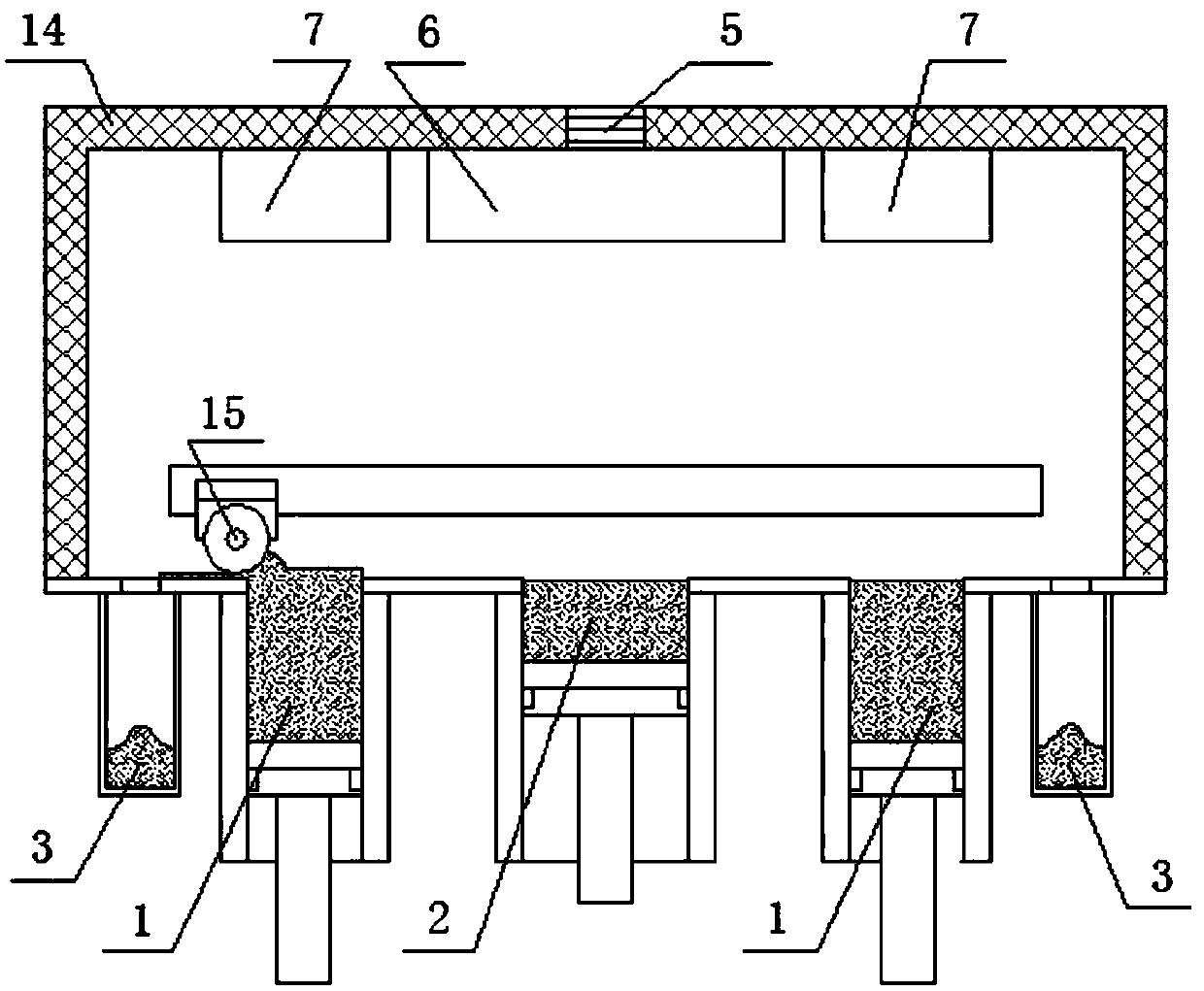

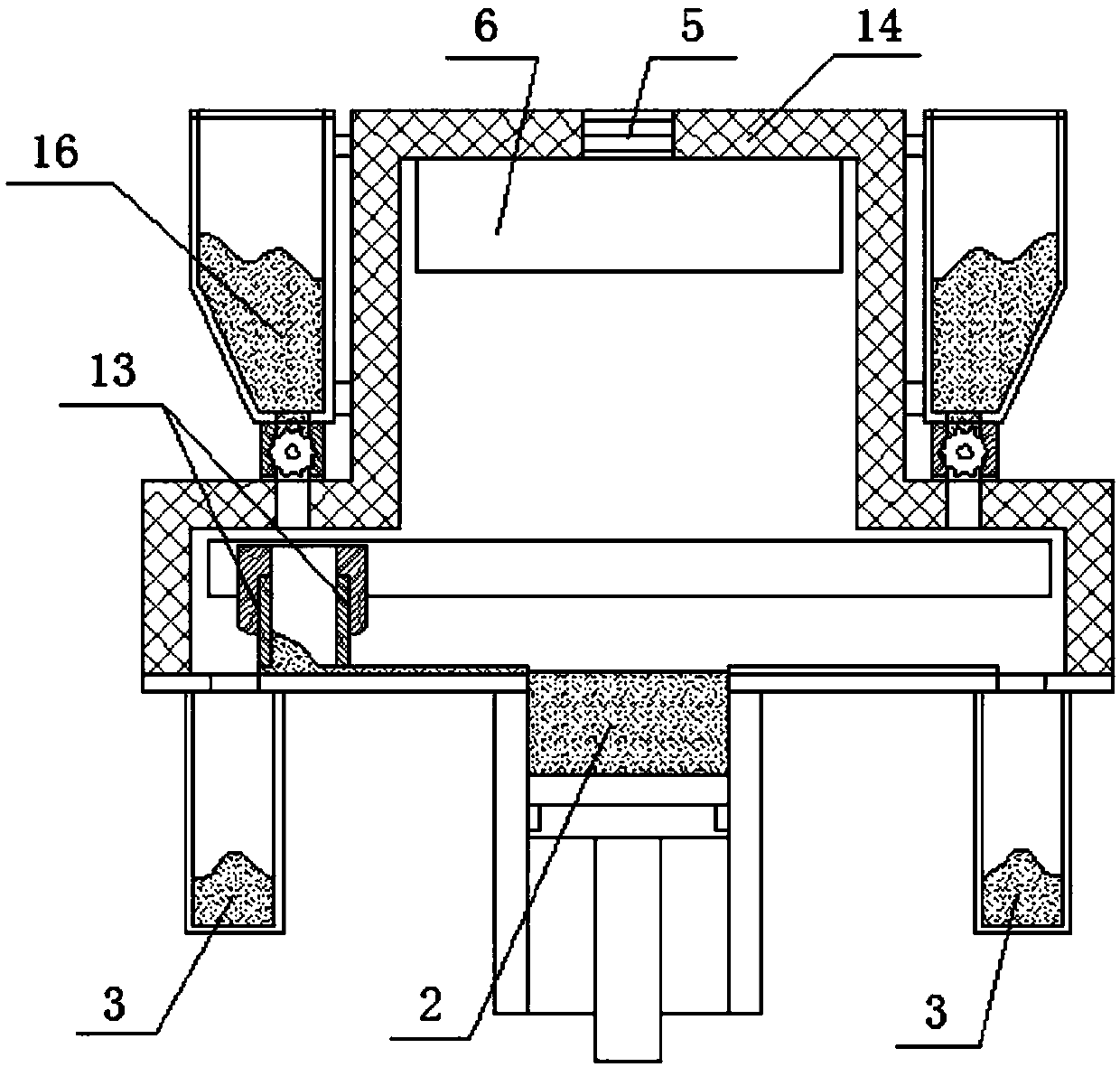

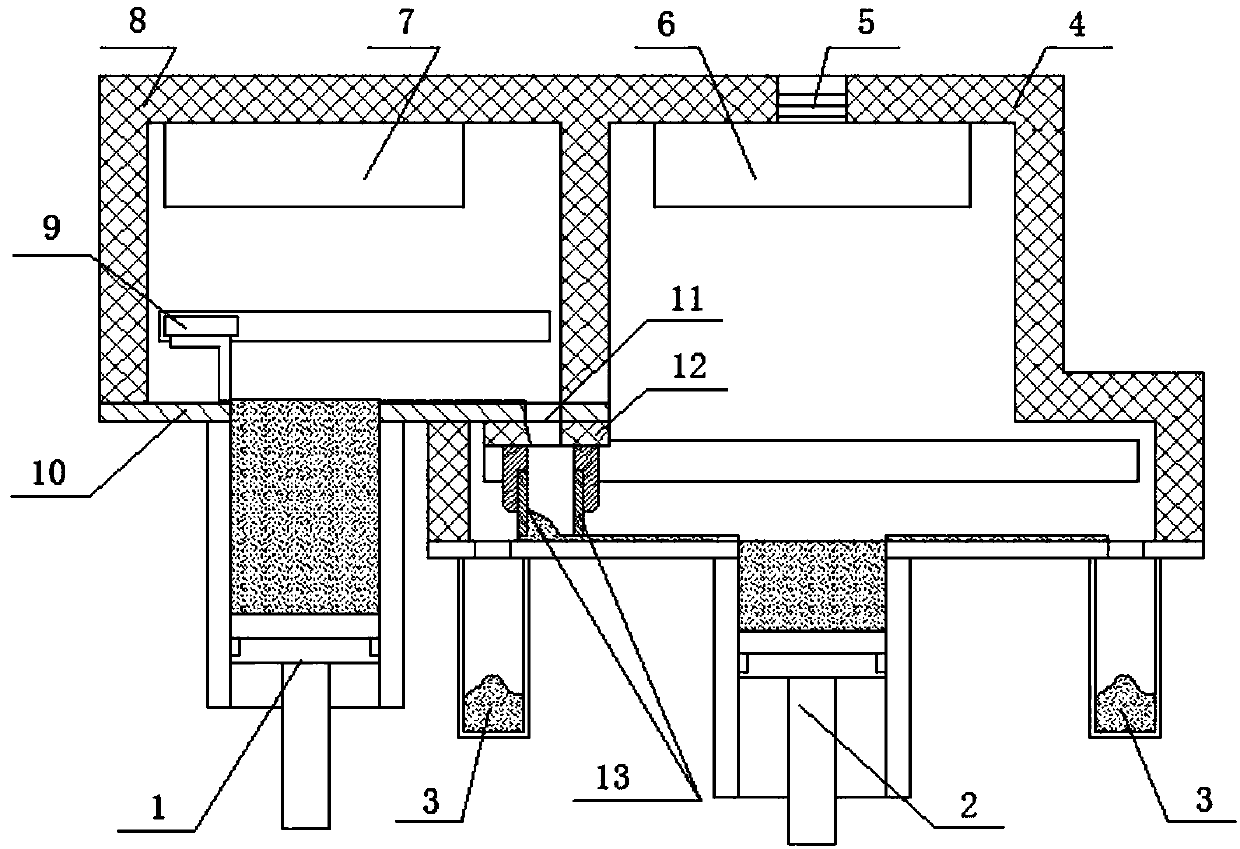

Continuous preparation device for composite stirred semi-solid slurry

The invention relates to a continuous preparation device for composite stirred semi-solid slurry, and belongs to the technical field of machining semi-solid metal machining. The device comprises a discharge outlet 1, a graphite plug 2, a graphite lining 3, a stainless steel tube 4, a heating element 5, a cooling element 6, a stirring shaft 7, a thermal insulating layer 8, a bearing 9, a bearing seat 10, a gear 11, a discharge handle 12, a feeding inlet 13, an oblique baffle 14, a rotary blade 15, a stirring blade 16 and the like. The semi-solid slurry is prepared through the following steps: after feeding an alloy fuse into the device, throwing onto the inner wall of a stirring chamber through the rotary blade rotating at high speed, enabling the fuse to flow downward along with the inner wall and flow downward along with the baffle when encountering the oblique baffle, then throwing the fuse on the inner wall of the stirring chamber by the rotary blade, after circulating the processes for two times, enabling the fuse to flow downward along the wall of the graphite lining at the lower part, carrying out convection at the bottom of a stirring bucket through driving of the stirring blade, generating a great deal of crystal nucleus in the fuse in the process, and directly growing into spheres. The flowing velocity of the slurry can be controlled through adjusting a gap between the graphite plug and the graphite lining, the semi-solid slurry can be subjected to rheoforming together with conventional equipment such as die casting, rolling and mold forging, and semi-solid ingot can also be continuously prepared.

Owner:UNIV OF SCI & TECH BEIJING

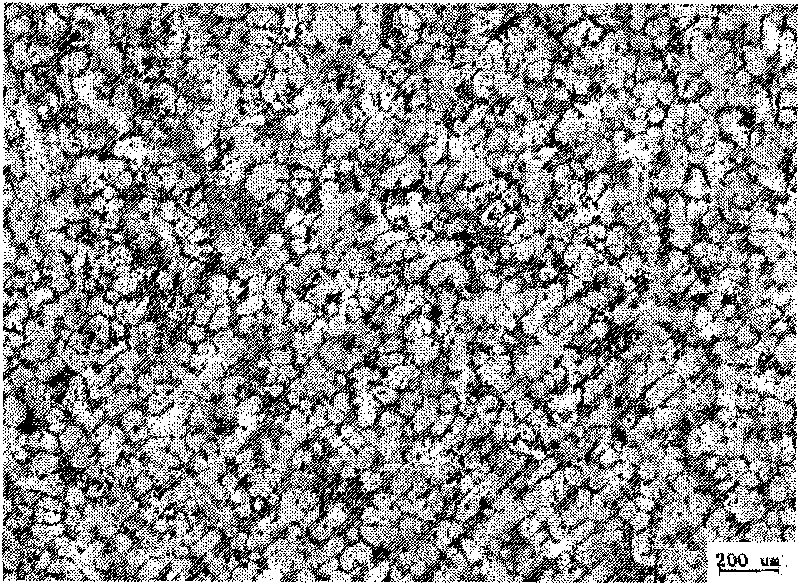

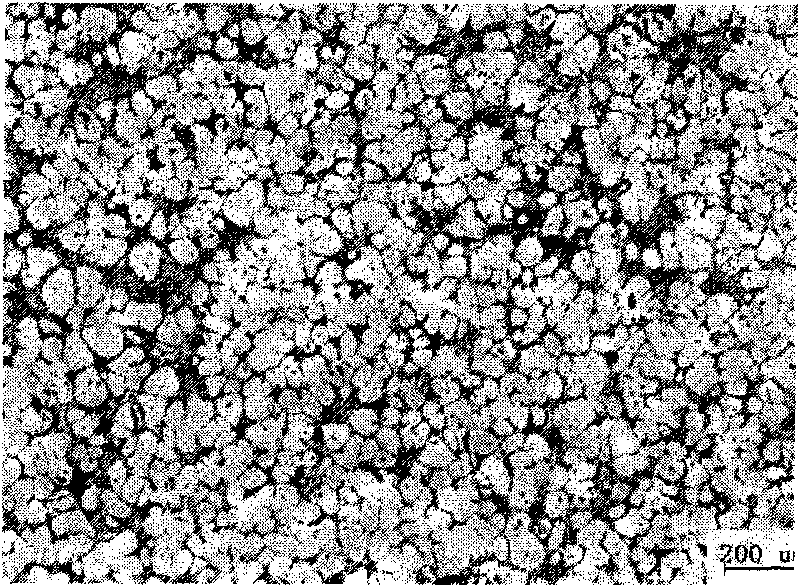

Method for preparing semi-solid alloy rheological slurry or billet through annular-gap type electromagnetic stirring

A method for preparing semi-solid metal or alloy slurry or billet through annular-gap type electromagnetic stirring is hereinafter referred to as an annular-gap type electromagnetic stirring method in which the liquid metal or alloy liquid with 5-100 DEG C higher than the liquidus temperature is cast in an annular gap formed between an inner side wall of a slurrying chamber and an outer wall of an internal cooling controller. The metal or the alloy liquid is strongly stirred under the action of an electromagnetic induction rotary stirrer. Meanwhile, the cooling medium flowing in an external cooling controller and the internal cooling controller lead the temperature field of the slurry to be more uniform, thereby obtaining the fine and uniform semi-solid structure. The method is characterized in that the width of the annular gap formed between the inner side wall of the slurrying chamber and the outer wall of the internal cooling controller is 3-100mm. During preparation, the cooling medium is flowed in the external cooling controller and the internal cooling controller so as to lead the temperature field of the slurry to be uniform. The preparation method leads the stirring force field and the temperature field of the slurry to be more uniform, thereby obtaining the high-quality semi-solid slurry. The method has the advantages of simple preparation process, convenient operation, excellent shape of the semi-solid structure, uniformity and fineness and low preparation cost, and is particularly applicable to preparation of semi-solid aluminum or aluminum alloy, magnesium and magnesium alloy and other metal and alloy or composite material slurry or billet.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Tungsten titanium target material with high purity and high tungsten-rich phase, and preparation method thereof

ActiveCN101748365AUniform densityHigh strengthVacuum evaporation coatingSputtering coatingHigh densityRefractory

The invention relates to a refractory alloy tungsten titanium target material and a preparation method thereof, in particular to a tungsten titanium target material with high purity and high content of tungsten-rich phase, and a hot-pressing preparation method thereof, which belongs to the technical field of refractory alloy target materials. The method prepares high-density tungsten alloy targetmaterial by taking high-purity W powder and Ti powder, as well as high-purity Mo, Cr, Ta, Nb and other additive metal powder as raw materials and adopting a high-temperature high-pressure hot-pressing molding process, wherein the relative density of the target material reaches 95 to 99 percent, and the content of tungsten-rich phase reaches 80 to 93 percent. Relative to the prior art, the method adds part of high-purity Nb, Mo, Cr, Ta and other metal powder while mixing materials so as to stabilize the tungsten-rich phase in alloy, increase the content of the tungsten-rich phase in the alloy and improve the using quality of the target material.

Owner:有研资源环境技术研究院(北京)有限公司

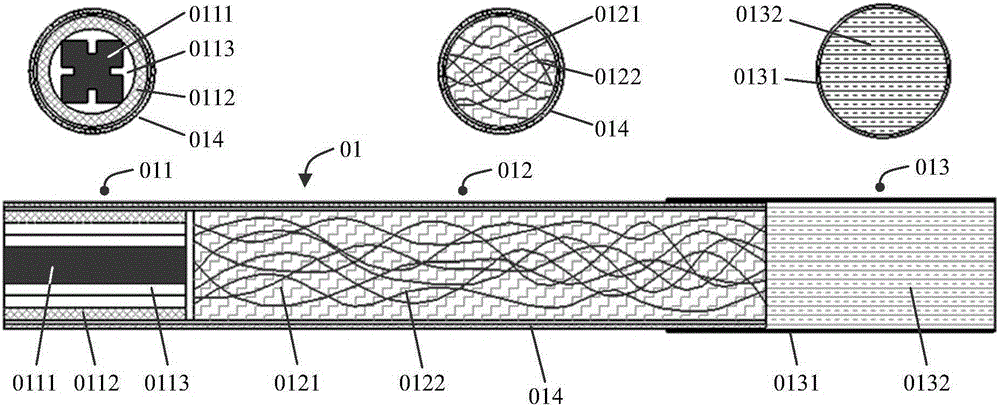

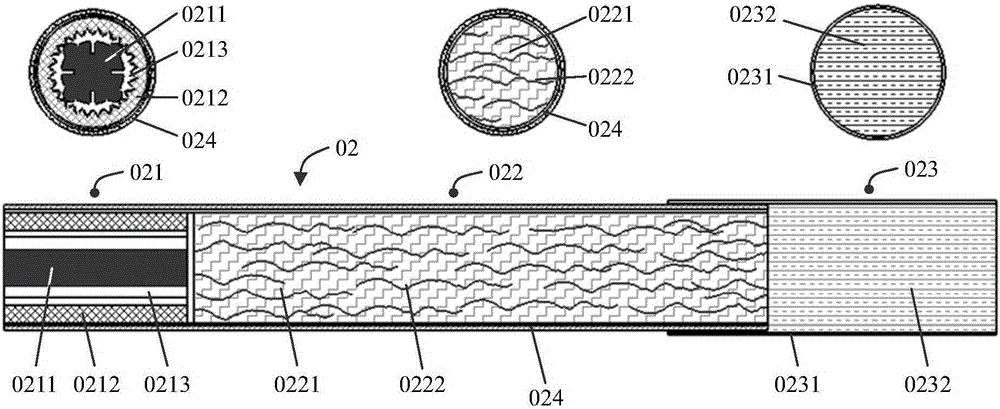

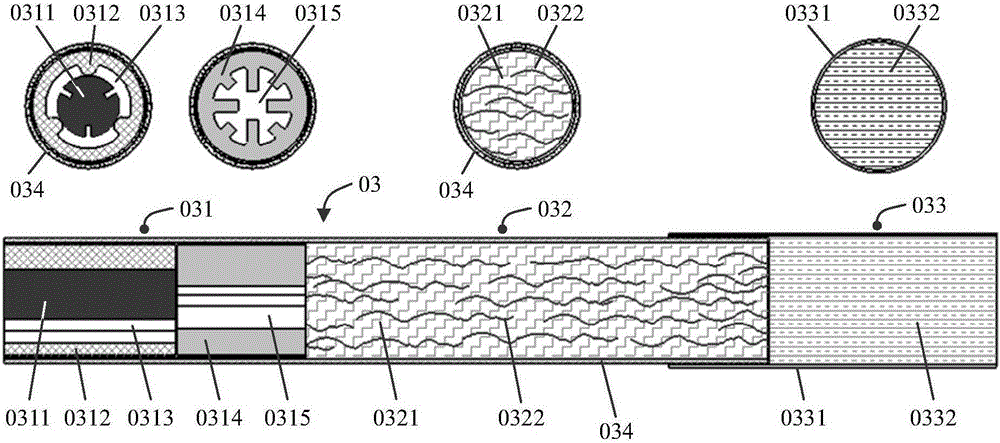

Non-combustion type low temperature cigarette product based on phase change temperature-controlled fuel assembly and preparation method of aerosol generating section

InactiveCN105167182AAvoid conduction heatingLow conduction heatingCigar manufactureFiberProduct base

The invention relates to a non-combustion type low temperature cigarette product based on a phase change temperature-controlled fuel assembly. The cigarette product comprises a phase change temperature-controlled fuel assembly section, an aerosol generating section and a filter section which are sequentially connected. Energy released in a combustion process is transmitted to the aerosol generating section through mainstream smoke, and under the action of a phase change heat storage material, adsorbing purification and oxidation catalysis on CO are achieved, so that unexpected pyrolysis on a smoke matrix due to excessive temperature is avoided. The aerosol generating section is prepared by uniformly blending and mixing the smoke matrix and high-thermal-conductivity MPCF carbon fiber long filaments or short filaments, so that the temperature of an aerosol generating system is reduced in a gradient mode in the axial direction of the cigarette and the entire aerosol generating section is uniformly heated; therefore, a smoking experience is prevented from being rapidly decreased with increase in smoking times. The phase change temperature-controlled fuel assembly section and the aerosol generating section are integrally covered and rolled by virtue of heat-insulating cigarette paper, so that consumption of heat energy is reduced, and effective thermal excitation of the smoke matrix is achieved under relatively low heat distribution.

Owner:叶菁 +2

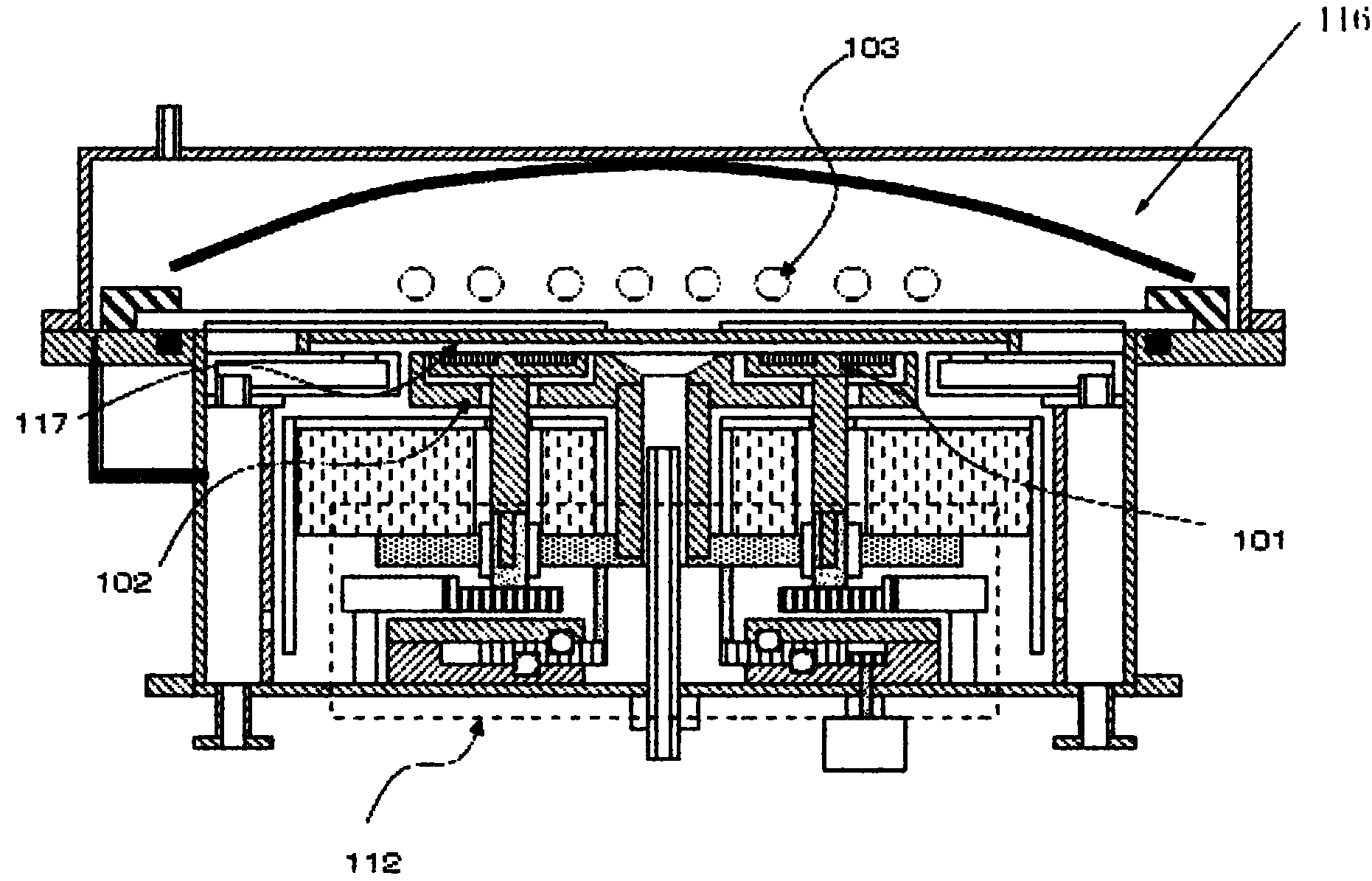

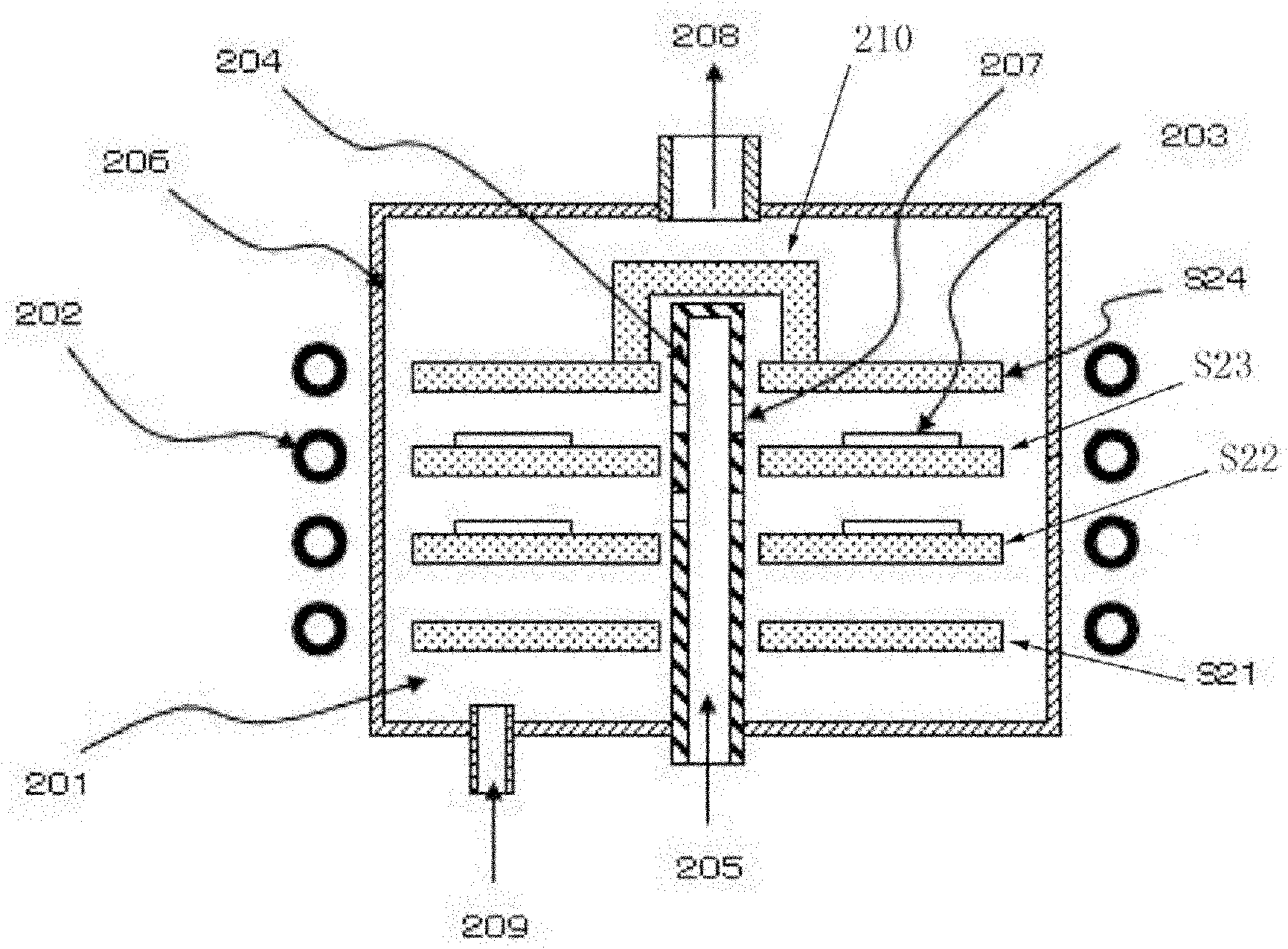

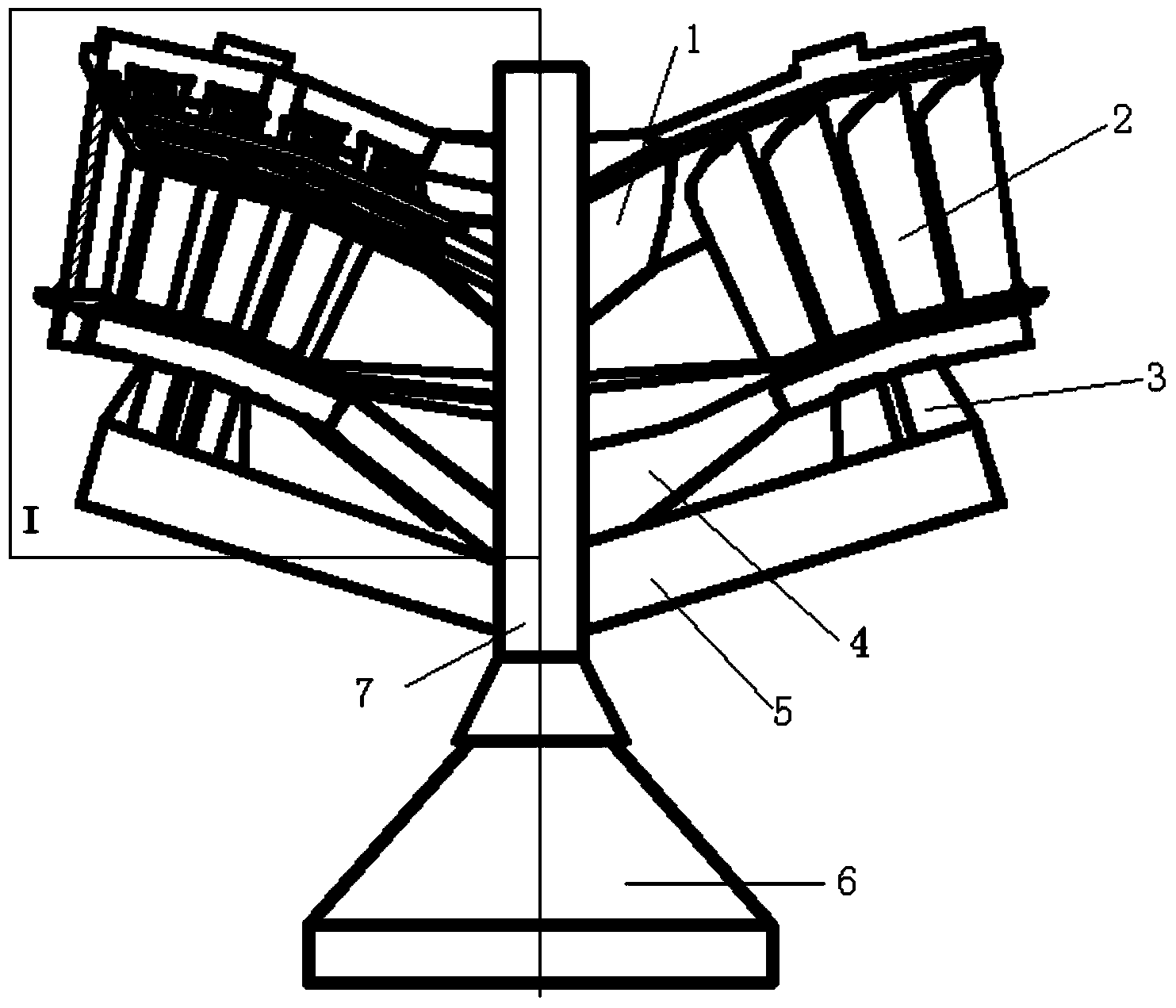

Pallet device and crystallized film growth device

ActiveCN102485953AIncrease production capacityIncrease profitSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringProduct gas

The invention, belonging to the technical field of crystallized film growth, particularly provides a pallet device for bearing processed substrates. The ballet device comprises a plurality of pallets arranged laminatedly along with a length wise direction, and certain space exists between adjacent pallets. In addition, the invention further provides a crystallized film growth device, comprising a process cavity, a process gas conveying system and an exhaust system, wherein the process cavity is provided with the pallet device for bearing the substrates in the process. The pallet device and the crystallized film growth device having the pallet device can increase the number of the substrates processed by the process at every time with low cost and increase the productivity.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

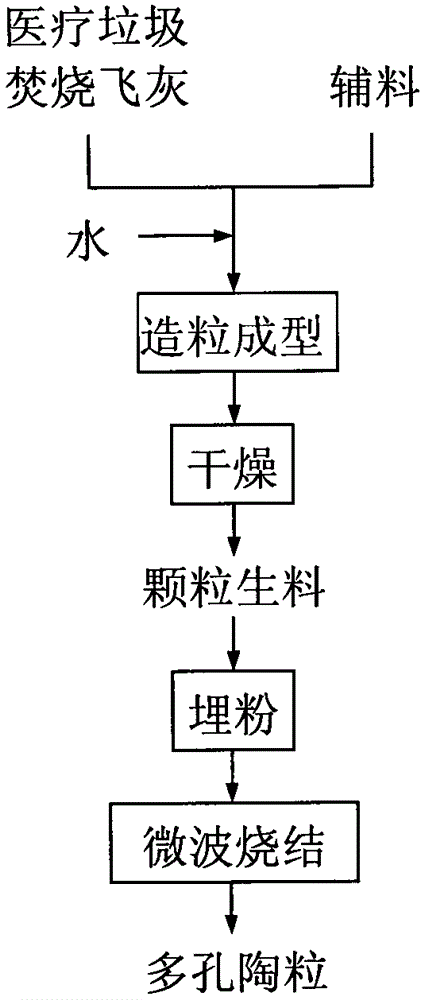

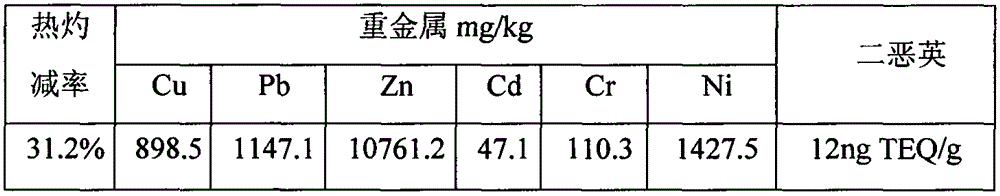

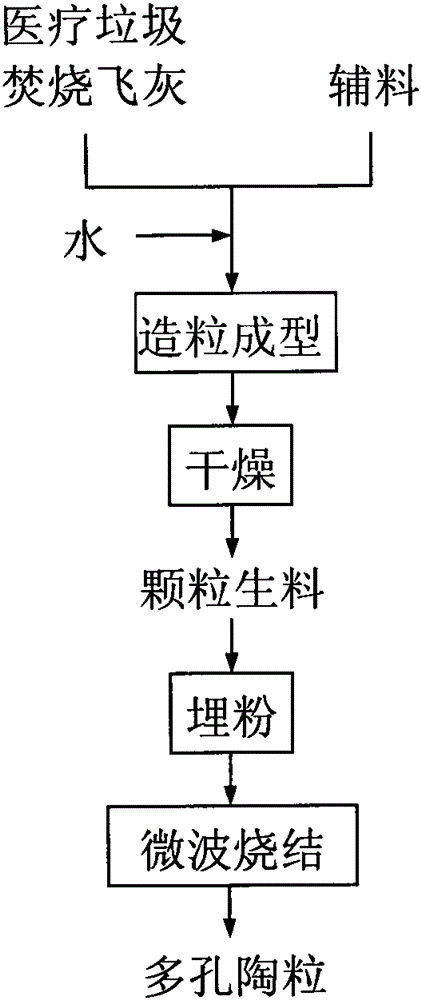

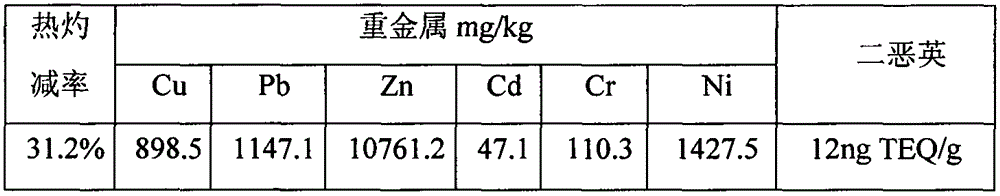

Method for microwave firing of porous ceramsites by adopting medical waste incineration fly ash

The invention discloses a method for microwave sintering of porous ceramsites by adopting medical waste incineration fly ash. The method comprises the following steps: (1) fully mixing the medical waste incineration fly ash with an auxiliary material, adding a small amount of water into the mixture, and carrying out granulation molding by a molding machine; (2) carrying out granulation molding, drying to obtain a particle raw material, filling the periphery of the particle raw material with a microwave coupling agent powder; and (3) carrying out microwave sintering of the particle raw material filled with the powder, and after sintering, cooling to the room temperature to obtain the porous ceramsites. The method can utilize a 'hot spot' effect of fly ash high-content active carbon in a microwave field to instantly completely decompose dioxins in the fly ash, at the same time, allows most heavy metals to be wrapped and cured in grids of the sintered product, and rapidly sinters the fly ash into the porous ceramsites; and the ceramsites can be used for building aggregates or wastewater filter materials, achieves further resource utilization while achieving harmlessness treatment of the medical waste incineration fly ash, and achieves many things at one stroke.

Owner:TIANJIN CHENGJIAN UNIV

Fast forming method of fusion of metal powder of three beams of laser compound scanning

ActiveCN101607311BSlow down drastic changesUniform temperature fieldIncreasing energy efficiencyLength waveMetal powder

Owner:HUAZHONG UNIV OF SCI & TECH

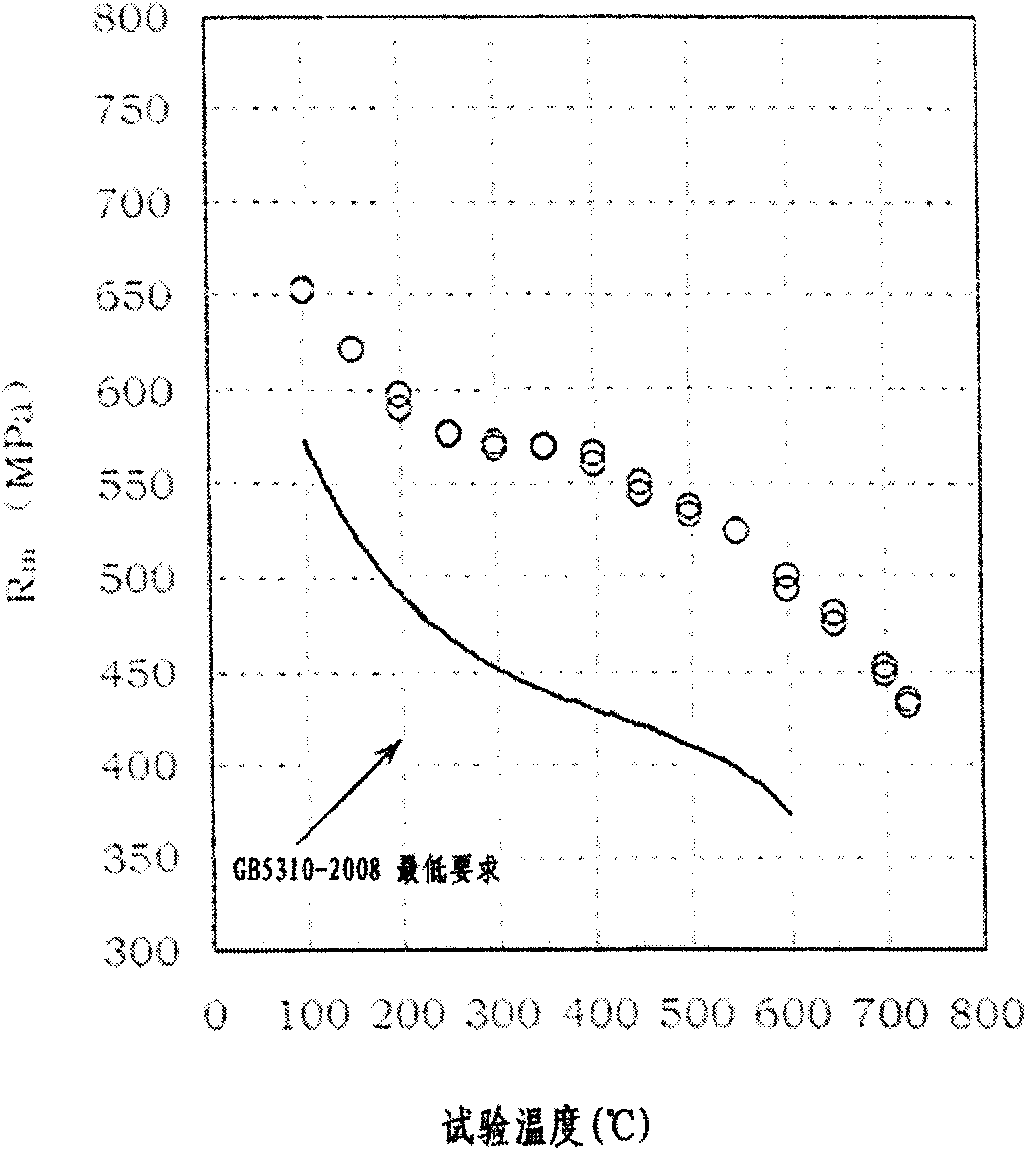

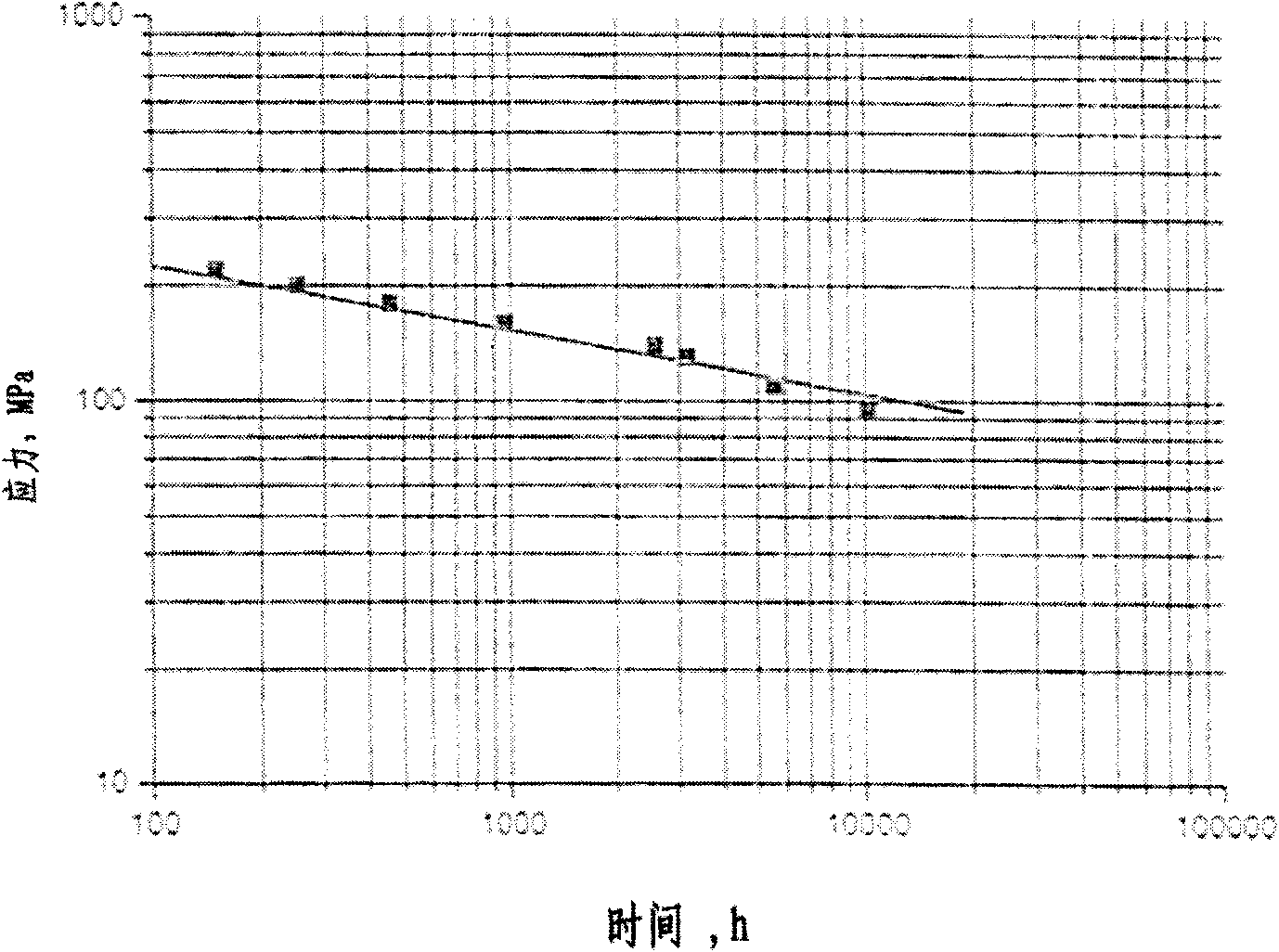

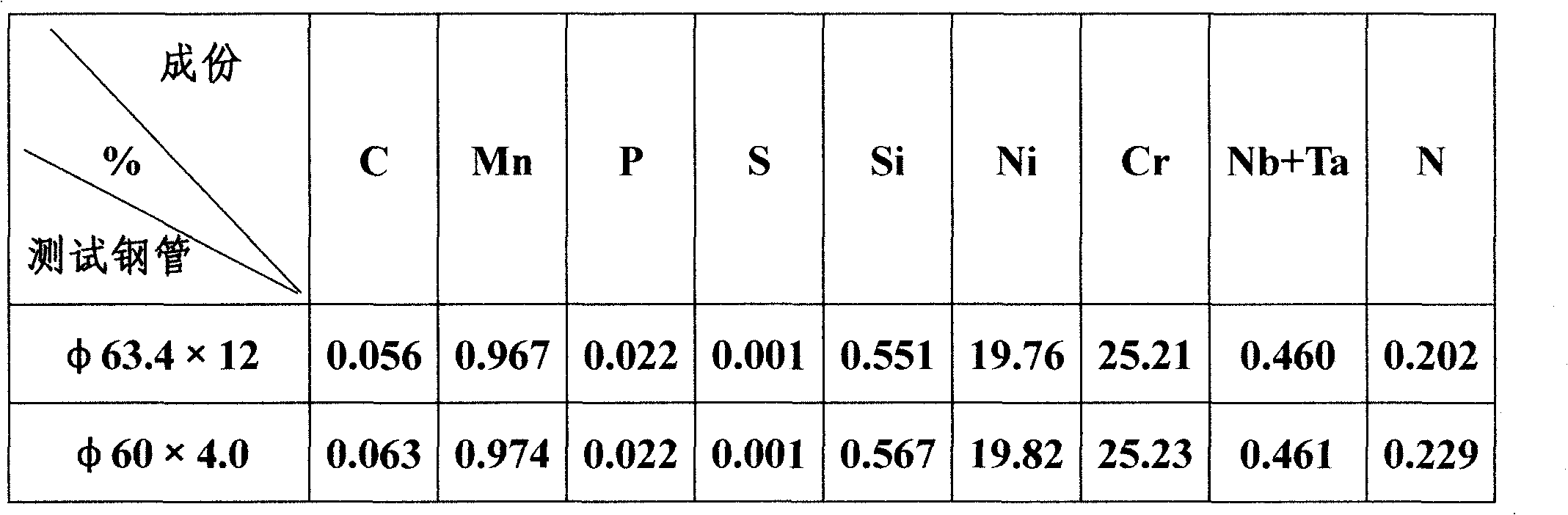

Stainless heat-resistant alloy steel seamless steel tube and preparation method thereof

InactiveCN101665891AEvenly preheated at low temperatureImprove densification performanceProcess efficiency improvementElectric furnaceAutomatic controlPower station

The invention relates to a stainless heat-resistant alloy steel seamless steel tube and a preparation method thereof. The seamless steel tube comprises the following chemical compositions by weight percent: 0.04-0.10% of C, 0.75% or less of Si, 2.00% or less of Mn, 0.03% or less of P, 0.03% or less of S, 17.00-23.00% of Ni, 24.00-26.00% of Cr, 0.20-0.60% of Nb+Ta, 0.15-0.35% of N and the balance Fe and inevitable trace elements. The preparation method of the invention adopts hot extrusion and cold rolling, computer automatic control solution heat treatment and other advanced technologies. Theproduct of the invention has excellent mechanical performance, high temperature resistant and corrosion resistance and various technical indexes of the product all meet or exceed Chinese relevant technical standards, thus successfully providing a new kind of qualified tube for the ultra supercritical power station boiler.

Owner:ZHEJIANG JIULI HI TECH METALS

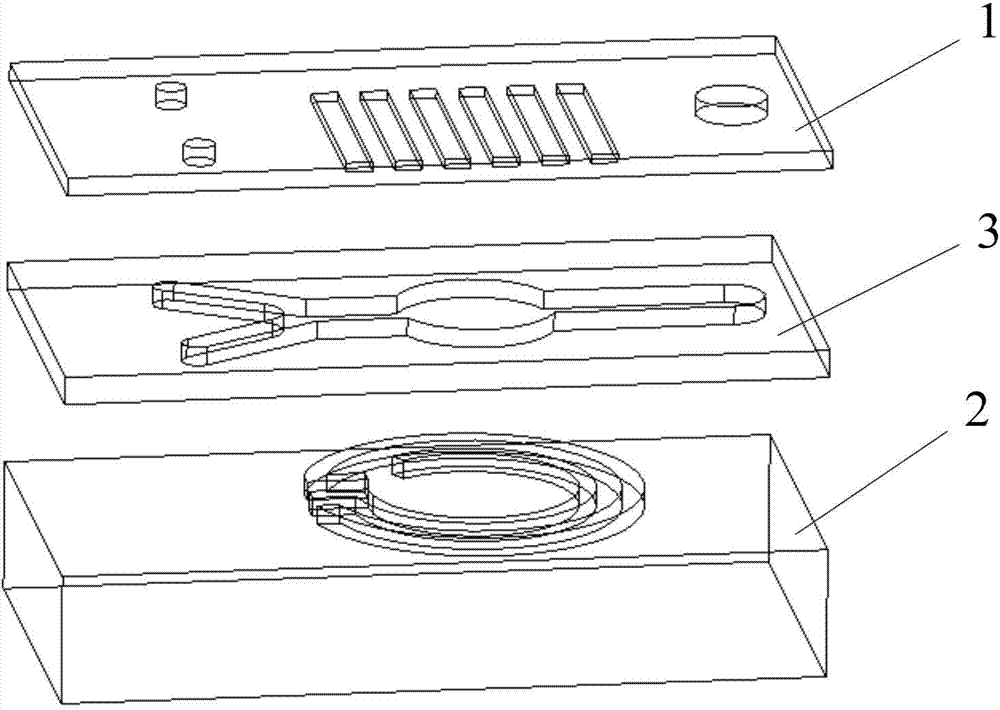

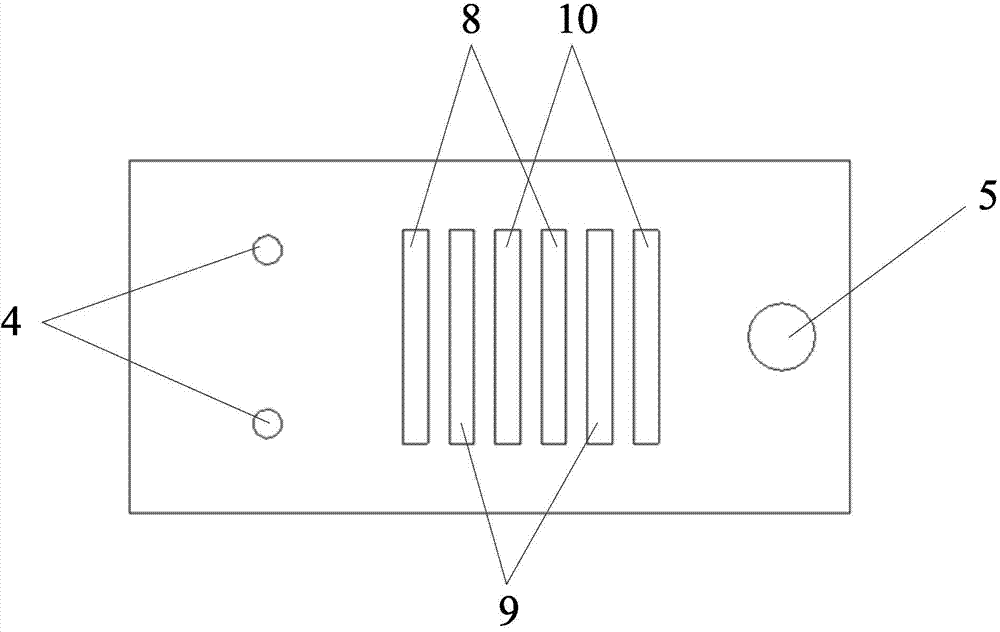

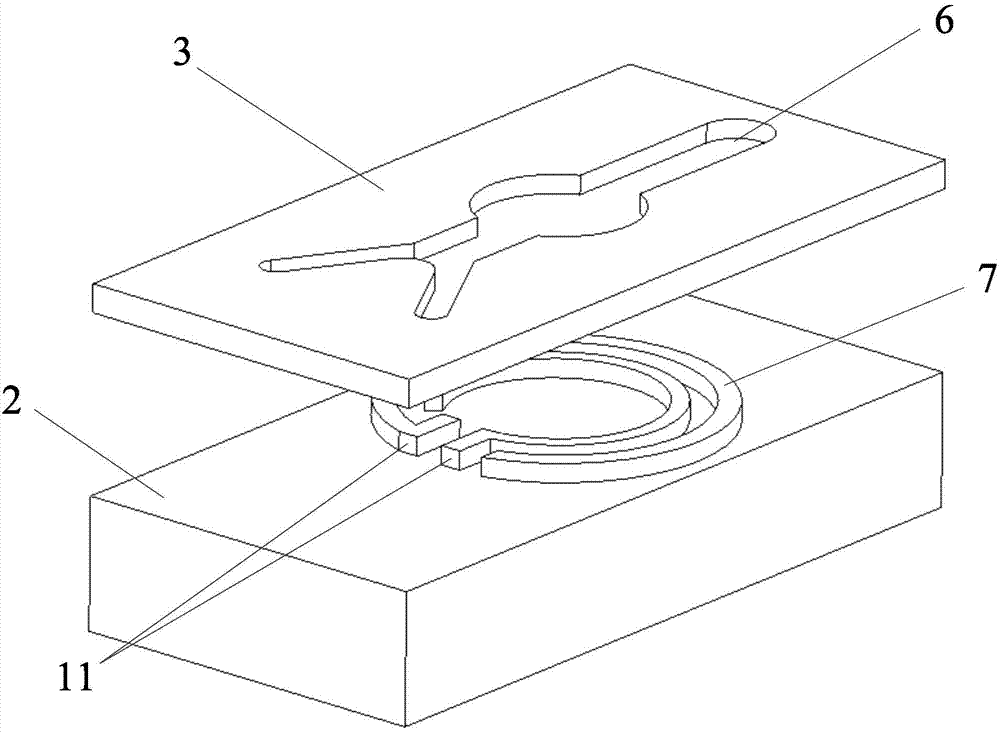

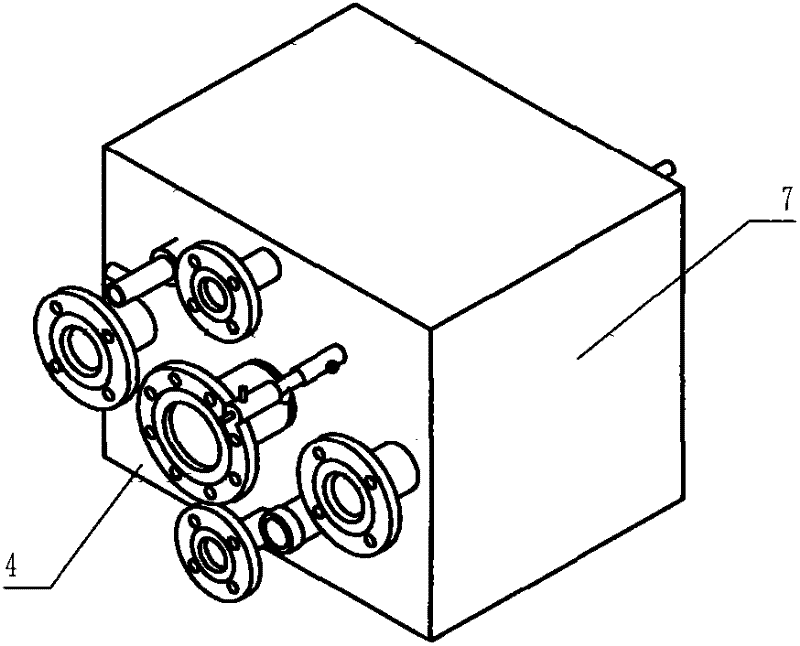

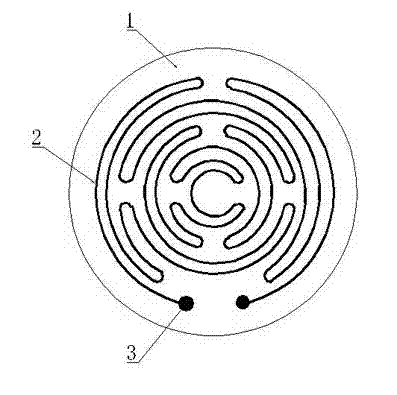

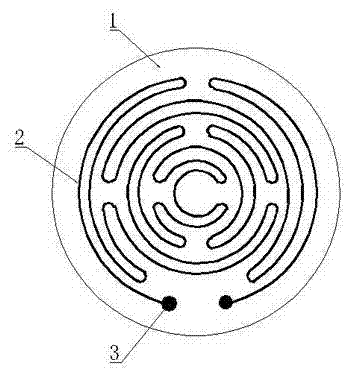

Micro-reactor suitable for micro-liquid mixing and biochemical reaction and manufacturing method thereof

InactiveCN103585943AUniform temperature fieldPromote aggregationEnergy based chemical/physical/physico-chemical processesMicroreactorElectricity

The invention discloses a micro-reactor suitable for micro-liquid mixing and biochemical reaction and a manufacturing method thereof. The micro-reactor comprises an upper cover plate and a lower base plate which is butted with the upper cover plate. A piezoelectric film is arranged between the lower base plate and the upper cover plate. The piezoelectric film is provided with a micro channel, an outlet and an inlet of which are respectively corresponding to a liquid outlet and a liquid inlet of the upper cover plate. A surface acoustic wave generator is also arranged between the lower base plate and the piezoelectric film. According to the invention, a temperature control system is integrated into the micro-reactor such that a reaction in the micro-reactor can be conducted under the condition of constant temperature. By the mechanism of surface acoustic wave, mechanical vibration can be generated to drive non-charged liquids to be mixed, and an alternating electric field also will be generated on an energy transducer. Thus, the micro-reactor is endowed with a liquid vibration function by surface acoustic wave, a liquid driving function by the alternating electric field and a microenvironment temperature control function, and efficiency of a micro-liquid chemiluminiscence reaction can be raised greatly. Therefore, the structure also has a wider application range, and will have a more obvious effect of driving charged liquids.

Owner:XI AN JIAOTONG UNIV

Preparation method of low heat expansion carbon fiber reinforced resin matrix composite material mold

The invention relates to a preparation method of a low heat expansion carbon fiber reinforced resin matrix composite material mold, belonging to the technical field of composite material preparation. The method is capable of forming a molding surface with a VARI (Vacuum Assisted Resin Infusion) technique, and ensuring low heat expansion performance of the mold by controlling the carbon fiber laying direction, precuring temperature, postcuring manner and postprocessing manner of the molding surface. With the adoption of the VARI technique, when a vacuum pressure reaches to 0.1MPa, carbon fiber cloth is compressed by vacuum, so that the product is internally dense after resin is guided in the product, and the volume content of composite material fibers is ensured; and meanwhile, bubbles between carbon fiber cloth layers are removed so as to ensure that the content of internal pores of the composite material is as few as possible and ensure the strength of the composite material.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

High purity zirconium boride / hafnium boride and preparation of superhigh temperature ceramic target material

The invention discloses a method for preparing a high-purity ultrahigh-temperature ceramic target material which belongs to the technical field of ceramic target materials, and in particular provides a method for preparing high-purity zirconium / hafnium boride powder and a ceramic target material thereof. The method comprises the steps of taking high-purity Zr powder, Hf powder and high-purity B powder as raw materials, adopting a self-propagating method to prepare high-purity ZrB2 and HfB2 powder respectively and then adopting a high-temperature high-pressure hot-pressing molding process to prepare a high-purity dense zirconium / hafnium boride ultrahigh-temperature ceramic target material, wherein the relative density of the target material reaches 95 to 99 percent. Relative to the prior art, metal powder in the method is slightly excessive when the materials are mixed, so as to make up for the metal loss during self-propagating reaction and further guarantee the component unicity of products. Relative to pressureless sintering, the sintering temperature needed in the method is greatly lowered; in addition, as the hot-pressing process adopts two-stage temperature, blank is uniform in temperature field, so as to ensure that the target material with uniform density can be obtained in the late hot-pressing process.

Owner:有研资源环境技术研究院(北京)有限公司

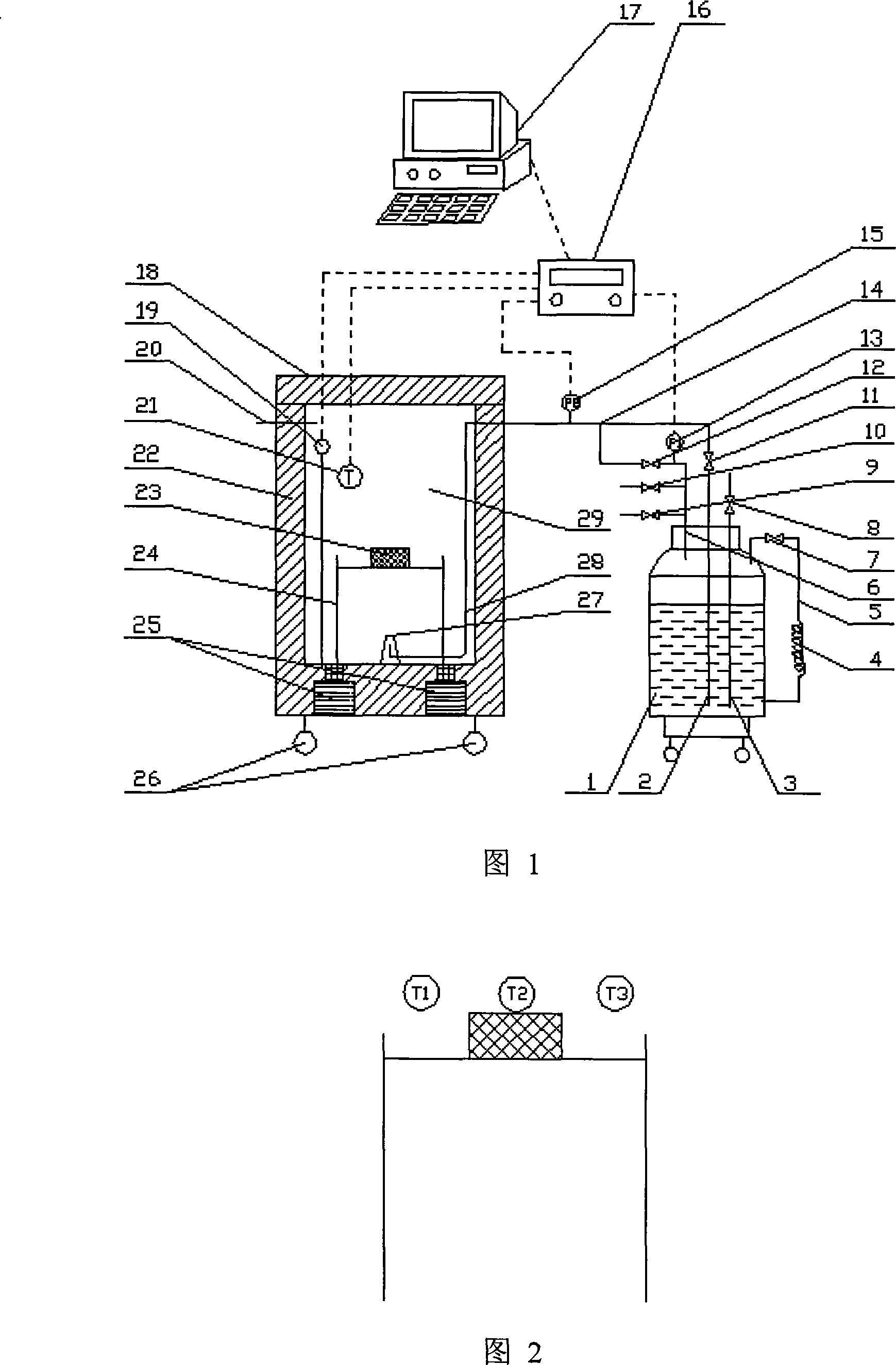

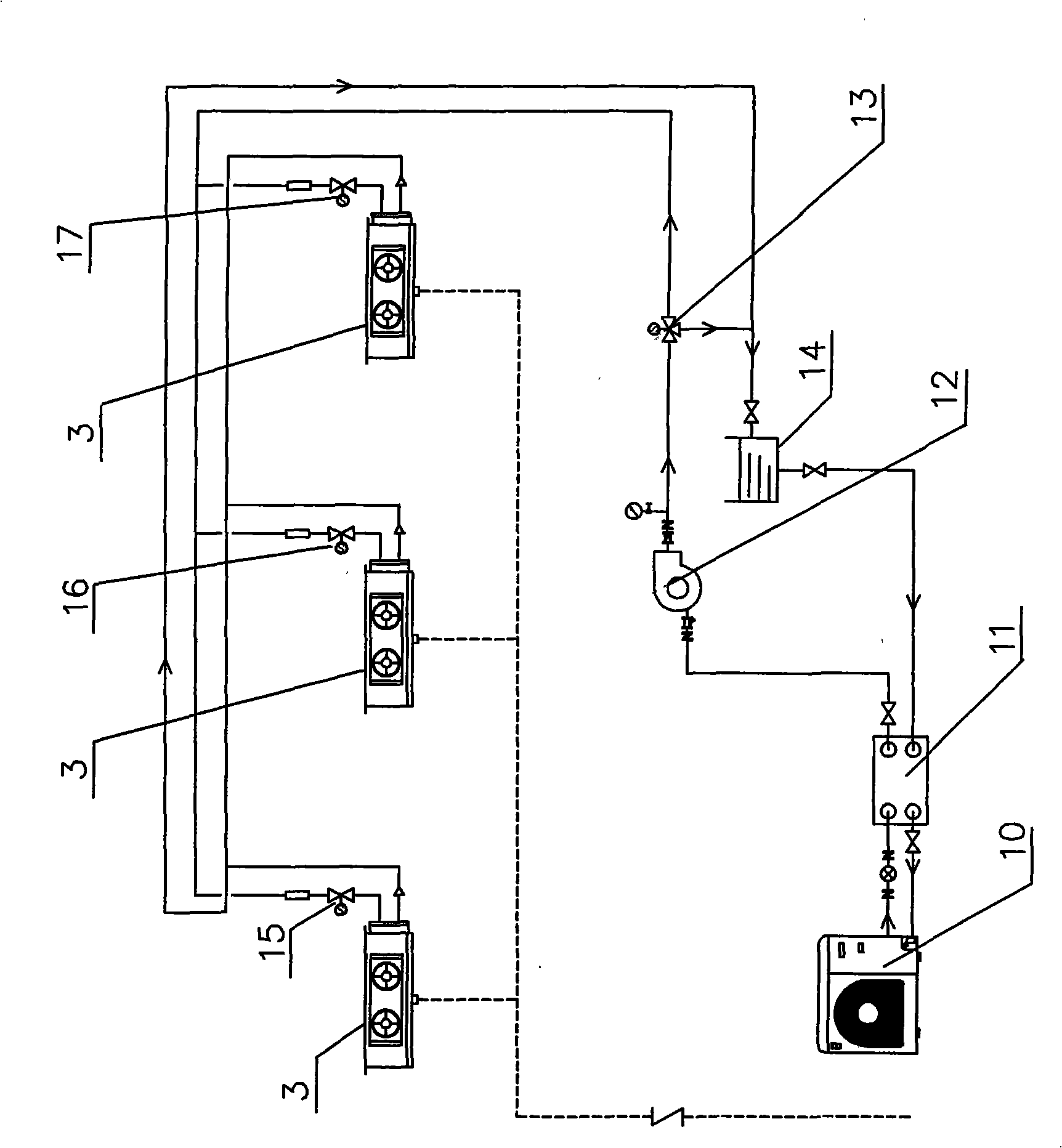

Controllable temperature deep cooling processing system based on self supercharging cryogenic fluids conveying technology

InactiveCN101216233AAdjust the flow rateAdjust cooling rateDomestic cooling apparatusLighting and heating apparatusData acquisitionEngineering

The invention discloses a temperature controllable subzero cooling system based on self-pressure cryogenic fluid delivery technique. The system comprises a liquid nitrogen storage tank, a liquid delivery pipe, a liquid injection pipe, a vaporizer, a self-pressure loop, an air delivery pipe, a self-pressure adjusting valve, a liquid injection valve, a safety valve, a manual pressure relief valve, a liquid delivery valve, an air delivery valve, a pressure sensor P1, a three-way pipe, a pressure sensor P2, a data collector, a computer, a subzero cooling treatment chamber top cover, a liquid level meter, an exhaust pipe, a thermometer, a subzero cooling treatment chamber cabinet, a workpiece to be treated, a rack, a supporting structure, a travelling wheel, a perforated baffle, a cooling medium delivery pipe and a subzero cooling treatment chamber. The invention has the advantages of self-pressure cryogenic cooling medium delivery, no need of extra driving source, liquid and air two subzero cooling processes, convenient temperature dropping rate and treatment temperature adjustment and uniform temperature field in the subzero cooling treatment chamber.

Owner:ZHEJIANG UNIV

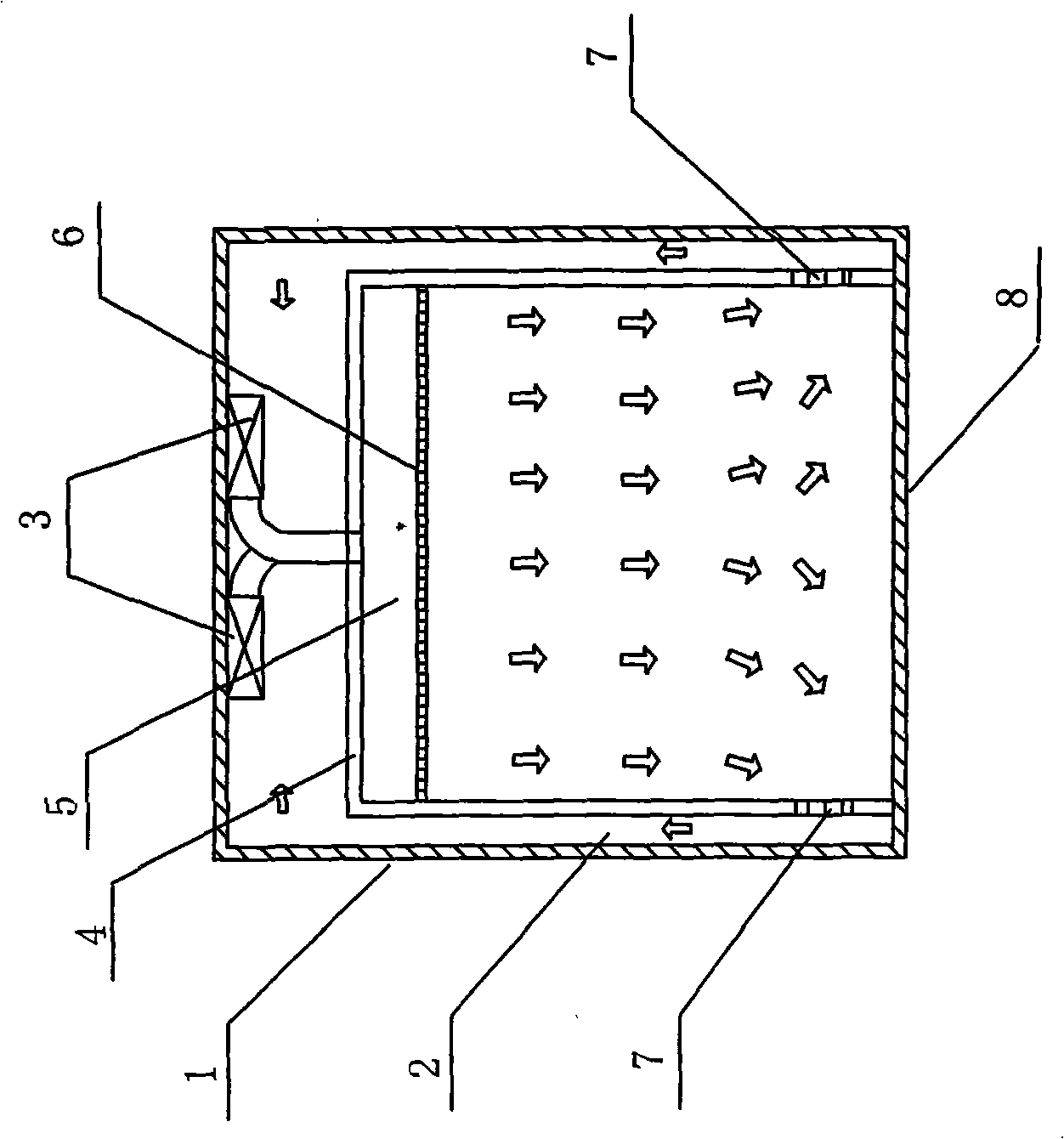

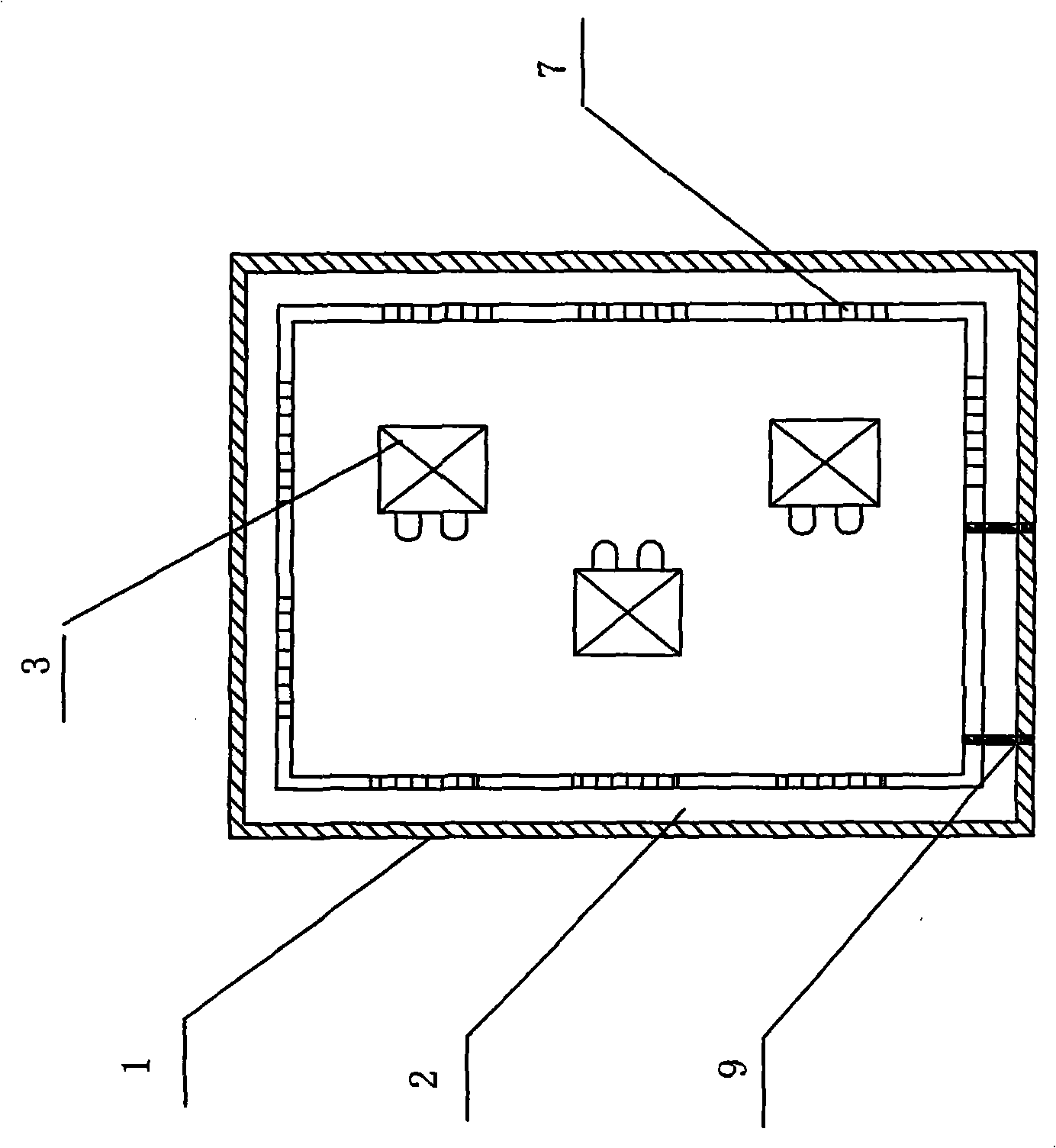

Ice-temperature vault

InactiveCN101551189AImprove stabilityReduce dry consumptionStationary refrigeration devicesCompression machines with several evaporatorsEngineeringWind speed

The present invention discloses an ice-temperature vault. The aim of the invention is to provide an ice-temperature vault which has the advantages of high-precision control, uniform wind speed field in the vault, uniform temperature field in the vault, and satisfaction to the requirement of ice-temperature storage. The vault body comprises a base layer heat insulation layer, an outer heat insulation vault body and an inner non-heat-insulation vault body which are connected with the base layer heat insulation layer. An air interlayer is provided between the inner non-heat-insulation vault body and the outer heat insulation vault body. A plurality of air coolers which are connected in parallel for alternately operating or defrosting are installed in the air interlayer at the top part of outer vault body. A top air supply aperture plate is provided in the inner vault body. A static pressure box layer is formed between the top air supply aperture plate and the inner non-heat-insulation vault body. The periphery at the base part of inner non-heat-insulation vault body is provided with a plurality of return air grilles. A temperature sensor is respectively installed at the lower part of static pressure box layer and at the return air grilles. The temperature in the ice-temperature vault is stable. The speed field and temperature field are extraordinarily uniform. The defrosting does not affect the temperature in the vault. The ice-temperature vault has high control precision. The temperature fluctuation of hollow vault does not exceed + / - 0.3 DEG C.

Owner:TIANJIN UNIV OF COMMERCE

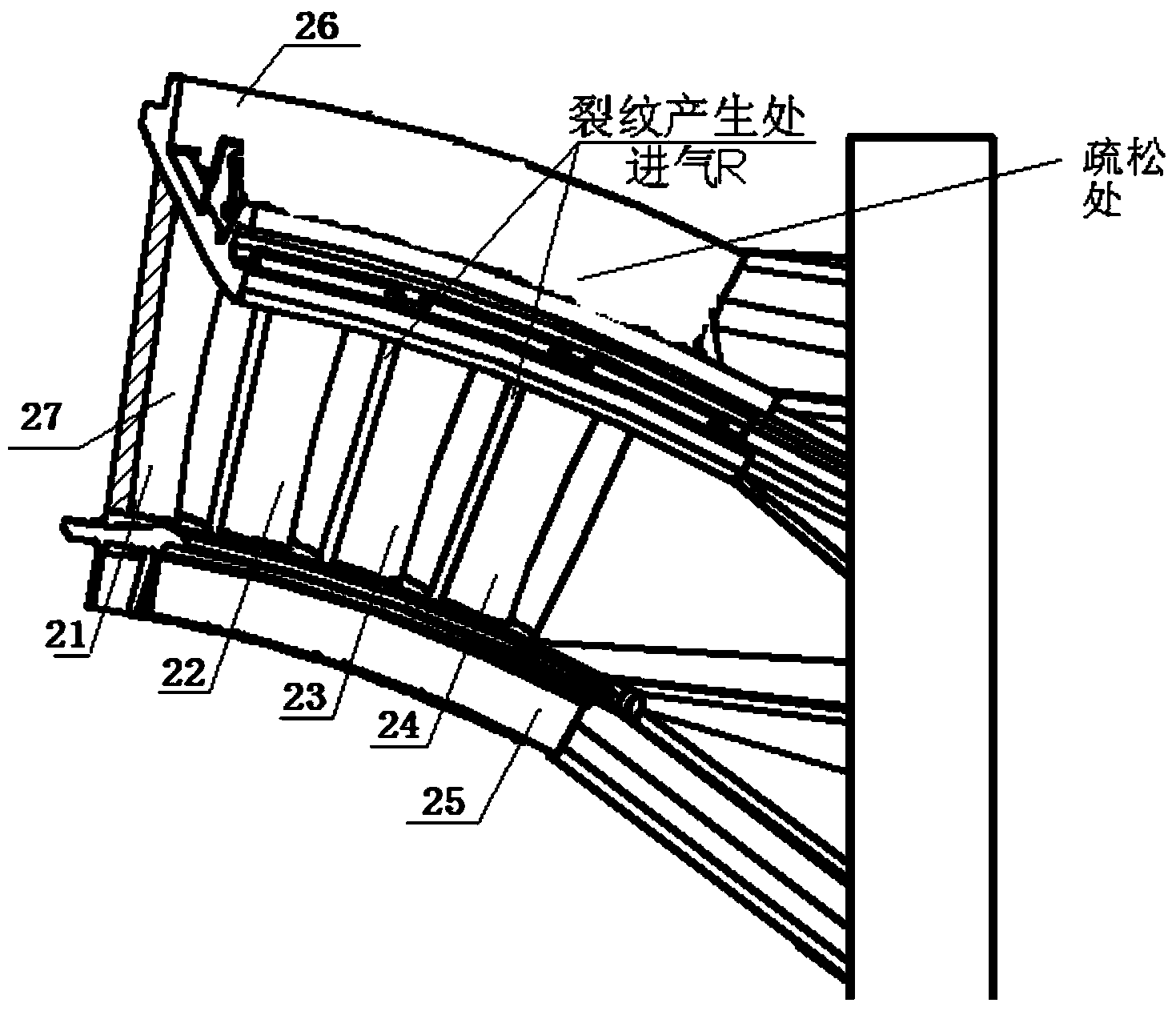

Wax mold combination of four-connection hollow turbine guide vane and precision casting method of wax mold combination

The invention provides a wax mold combination of a four-connection hollow turbine guide vane, which has high product quality and can completely solve the problems that a rotary connection R part of an edge plate and a vane body is hotly cracked and loosened, and a precision casting method of the wax mold combination. The wax mold combination comprises a sprue cup and a straight pouring gate which is communicated with an outlet end of the sprue cup, wherein inner sprue assemblies are arranged on the side wall of the straight pouring gate; each inner sprue assembly comprises a lower edge inner sprue communicated with one side of a vane lower edge plate cavity, and an upper edge inner sprue communicated with one side of a vane upper edge plate cavity; and each lower edge inner sprue and each upper edge inner sprue are sequentially arranged along the flow direction of the straight pouring gate. The precision casting method comprises the following steps: (1) manufacturing the wax mold combination; (2) carrying out shell making on the wax mold combination prepared in the step (1) to obtain a four-connection hollow turbine guide vane shell; and (3) covering one layer of ceramic heat-preservation cotton on a shell vane body part and covering two layers of ceramic cotton on the whole shell; and putting the treated shell into a roasting furnace for carrying out casting.

Owner:AECC AVIATION POWER CO LTD

A method of microwave firing porous ceramsite from medical waste incineration fly ash

ActiveCN103601526BPromote formationGood consolidationSolid waste disposalCeramicwarePrillResource utilization

The invention discloses a method for microwave sintering of porous ceramsites by adopting medical waste incineration fly ash. The method comprises the following steps: (1) fully mixing the medical waste incineration fly ash with an auxiliary material, adding a small amount of water into the mixture, and carrying out granulation molding by a molding machine; (2) carrying out granulation molding, drying to obtain a particle raw material, filling the periphery of the particle raw material with a microwave coupling agent powder; and (3) carrying out microwave sintering of the particle raw material filled with the powder, and after sintering, cooling to the room temperature to obtain the porous ceramsites. The method can utilize a 'hot spot' effect of fly ash high-content active carbon in a microwave field to instantly completely decompose dioxins in the fly ash, at the same time, allows most heavy metals to be wrapped and cured in grids of the sintered product, and rapidly sinters the fly ash into the porous ceramsites; and the ceramsites can be used for building aggregates or wastewater filter materials, achieves further resource utilization while achieving harmlessness treatment of the medical waste incineration fly ash, and achieves many things at one stroke.

Owner:TIANJIN CHENGJIAN UNIV

Resistance soldering method using graphite electrode and resistance soldering device

ActiveCN104259610ACombined with strong reliabilityImprove performanceSoldering apparatusWelding/soldering/cutting articlesPorosityChemical reaction

The invention discloses a resistance soldering method using a graphite electrode and a resistance soldering device. According to the resistance soldering method, the graphite electrode serves as a resistance soldering heating element which is used for soldering a hard alloy workpiece; the hard alloy soldered workpiece is placed in a closed steel soldering chamber; and when the graphite electrode is electrified and heated, carbon in the graphite electrode and oxygen surrounding the hard alloy soldering workpiece react chemically, so that oxygen in a local area at a soldering connection position is consumed. Oxygen-free porosity of a soldering connection brazing seam region between hard alloy and a steel substrate or between one piece of hard alloy and another piece of hard alloy can be realized, temperature fields of soldering connection portions are uniform, heating time is short, and efficiency is high. A graphite protecting device sleeves the graphite electrode and protects the graphite electrode from being damaged during resistance soldering pressurization. A pressure controller is arranged on the graphite electrode, pressure on the different soldering connection portions is not increased after the pressure of the graphite electrode reaches to a certain degree, and different demands of different soldering workpieces on external pressure are met.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Repair method of high temperature alloy vane by electron beam welding

InactiveCN101007366AShort residence time at high temperatureUniform temperature fieldWelding/cutting media/materialsWelding/soldering/cutting articlesRetention periodRetention time

The method of electron beam brazing repair high temperature alloy blades. The invention involves a brazing repair high temperature alloy blade method in order to solve the problems of complex repair art, long repair cycle, the need of integral heating when brazing repair, long retention period at high temperature when brazing work in original method of repair high temperature alloy blade. The method is realized by the following steps: (1) grinding off blade injury and polishing the injury part into trough, mixing the solder or alloy powder and acetone or general soldering bonding agent sold in market into cream status and putting it in groove; (2) setting process parameters and brazing; (3) when the solder or alloy powder are not melted completely, cooling it until room temperature and taking out high temperature alloy blade, the high temperature alloy blade is repaired. The electron beam brazing repair high temperature alloy blade method in the invention has simple repair process and short repair cycle, a cycle requires only 5 minutes to 10 minutes, it only heats the injury position, the retention time of blades when repaired is reduced to 0.1 ~ 10% of original method.

Owner:HARBIN INST OF TECH

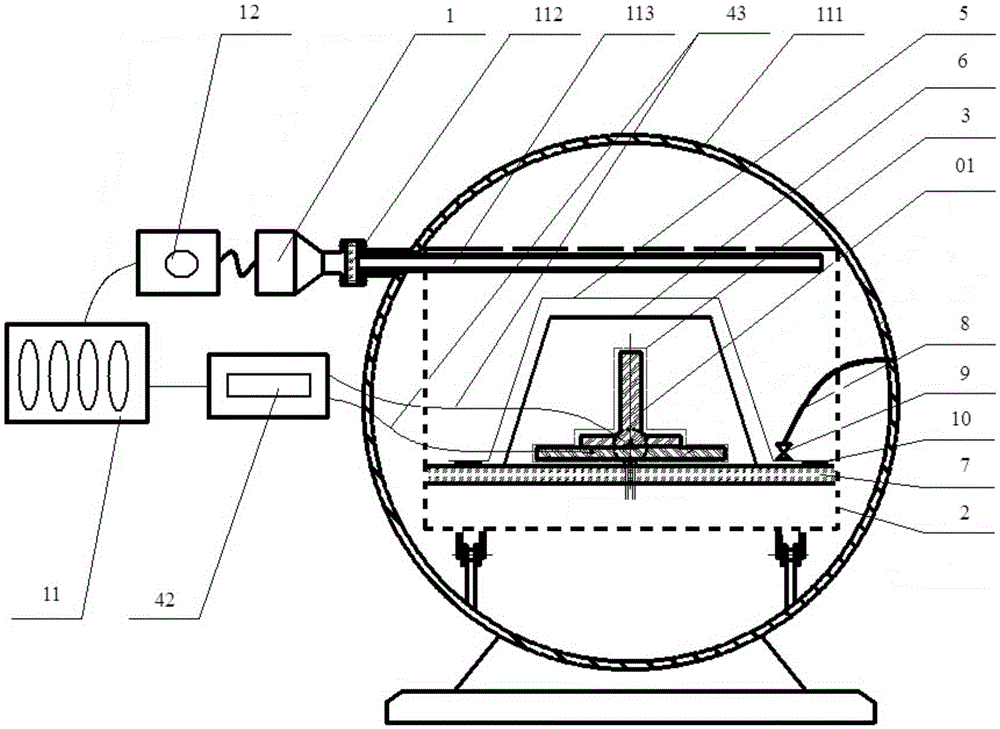

Composite energy field heating method

The invention provides a composite energy field heating method. The composite energy field heating method comprises the steps that a microwave heating device is used for carrying out fixed-point heating or directional heating on a wave absorbing material, and an autoclave is used for overall heating the wave absorbing material. The method is completed through a composite energy field heating device. The composite energy field heating device comprises the microwave heating device and the autoclave. The microwave heating device comprises a microwave generator, a microwave cavity and a microwave local shielding part. The microwave generator sends microwaves into the microwave cavity. The interior of the microwave cavity is used for containing the wave absorbing material. The microwave local shielding part is located in the microwave cavity and used for covering the outer surface of the wave absorbing material, and is composed of a microwave shielding area and a microwave transmitting area. The microwave transmitting area comprises one or more clearances so that the microwaves in the microwave cavity can enter the wave absorbing material through the clearances to be absorbed by the wave absorbing material. The composite energy field heating method can really achieve temperature consistency of all the portions in the wave absorbing material, and a high-quality cured product can be provided for the field of aerospace.

Owner:CENT SOUTH UNIV

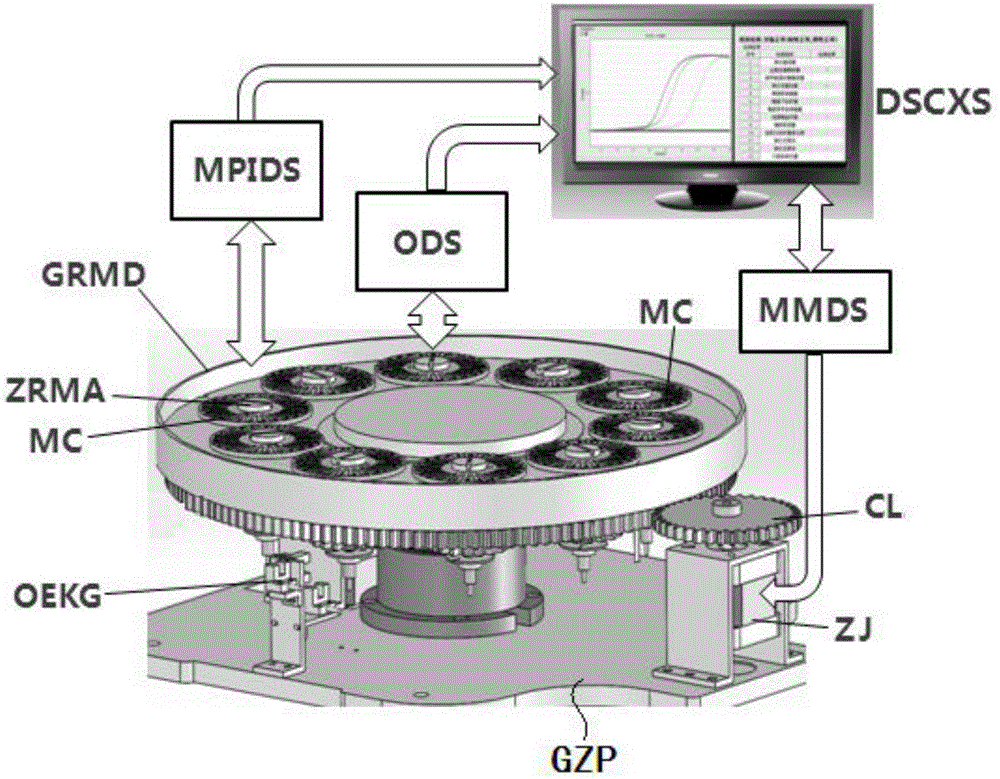

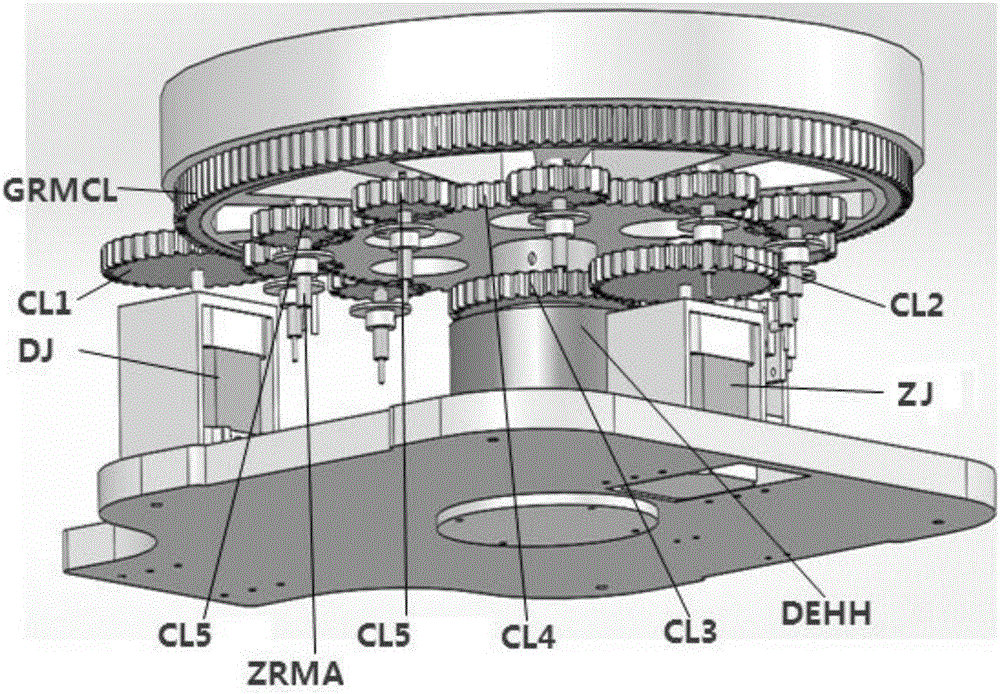

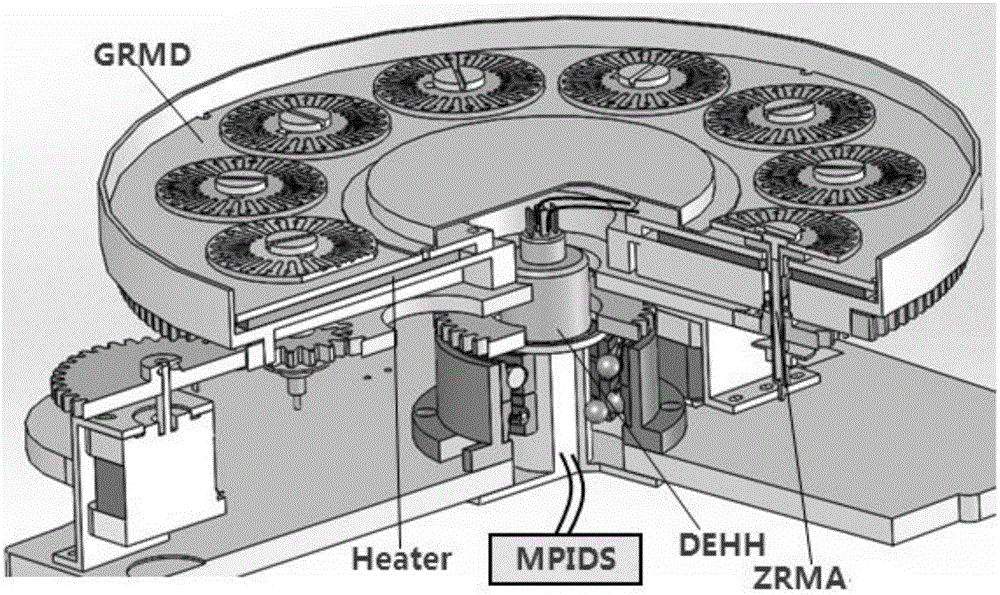

High-flux micro-fluidic chip nucleic acid amplification analysis detection system

ActiveCN106085842AEnable high-throughput detectionFast heatingBioreactor/fermenter combinationsBiological substance pretreatmentsTemperature controlHigh flux

The invention relates to a high-flux micro-fluidic chip nucleic acid amplification analysis detection system which is characterized by comprising a revolution-rotation composite movement platform, micro-fluidic chips, a multi-axis movement control system, a multi-way PID temperature control system, an optical detection system and a data acquisition processing and display system, wherein more than two revolution movement positioning shafts are arranged at circumference graduation intervals on the revolution-rotation composite movement platform; each micro-fluidic chip is fixedly arranged on the revolution movement positioning shaft of the revolution-rotation composite movement platform; the multi-axis movement control system is used for controlling movement of the revolution-rotation composite movement platform; the multi-way PID temperature control system is used for adjusting and controlling the temperature of each micro-fluidic chip; the optical detection system is used for detecting the high sensitivity of a trace sample placed inside each micro-fluidic chip in real time, and used for transmitting the detection result to the data acquisition processing and display system in real time. By adopting the high-flux micro-fluidic chip nucleic acid amplification analysis detection system, the high-flux nucleic acid amplification detection application requirement of dozens to two hundred of samples every day can be met.

Owner:TSINGHUA UNIV +1

Rare earth electrode slurry of rare earth thick film circuit based on metal plate and its preparation technology

ActiveCN1909748AIntermolecular bonding strength and improved manufacturabilitySolid combinationOhmic-resistance electrodesNon-conductive material with dispersed conductive materialSolid phasesYttrium

The invention relates to a rare-earth electrode slurry of rare-earth circuit, based on the metal base board and a relative production, wherein it is characterized in that: said slurry is formed by solid material and organic solvent carrier, while their mass ratio is 70-90:30-10; the solid component comprises: silver, palladium, and yttrium composite power and micro-crystal glass powder, while their mass percentage is 99.4-94:0.6-6; said composite power is formed by silver, palladium, and yttrium powders at the ratio as 0.6-10:99-82:0.4-8; said micro-crystal glass is the one in SiO2-Al2O3-CaO-B2O3-Bi2O3-La2O3 group. And the production comprises: (1), preparing rare-earth micro-crystal glass powder; (2), preparing silver, palladium, and yttrium composite powder; (3), preparing organic solvent carrier; (4), mixing material in three-dimension and rolling with three rollers; (5), preparing the rare-earth slurry; (6), bottling. The invention is environment friendly and better humidity compatibility.

Owner:GUANGDONGSHENG YUCHEN ELECTRONICS & TECH CO LTD

Multi-oxygen burner and combustion method thereof

ActiveCN102261651AAvoid ablationExtended service lifePulverulent fuel combustion burnersIndirect carbon-dioxide mitigationCycloneCombustor

The invention discloses an oxygen-enriched burning system and a combustion method thereof. A burner body is arranged. A fire ejecting hole is arranged in the middle of the burner body. A fuel distributor is arranged at one end of the small hole of the fire ejecting hole. Primary and secondary oxygen nozzles, an igniter, a flame monitor and a fire viewing hole passing through the burner body in the same direction of the fire ejecting hole are arranged on the periphery of the fire ejecting hole on the burner body. A flange plate connected with a fuel inlet pipe is arranged on the outer port of the fuel distributor. Both outer ports of the primary and secondary oxygen nozzles are provided with the flange plate connected with the fuel inlet pipe. The oxygen nozzles are connected with an oxygen supply system. A fuel cyclone separator is connected with a fuel supply system. A control cabinet is additionally arranged so that the full system of the whole burner is detected and controlled. The burner disclosed by the invention is applicable to combusting gases and powdered fuels. The burner has the advantages of complete structure, high combustion efficiency, little smoke discharge, environment protection, energy saving and high operation automation degree.

Owner:王立臣

Electric heating element of rare earth thick film circuit based on IR-LED (Infrared Light Emitting Diode) ceramic substrate and preparation method thereof

InactiveCN102340900AImprove radiation efficiencyAdjustable wavelength rangeHeating element materialsElectric heatingInfrared

The invention discloses an electric heating element of a rare earth thick film circuit based on an IR-LED (Infrared Light Emitting Diode) ceramic substrate and a preparation method thereof. The electric heating element is characterized by comprising a quartz ceramic substrate and serial rare earth electronic slurry. The serial rare earth electronic slurry is prepared on the quartz ceramic substrate in a form of a thick film circuit; and the thick film circuit is provided with an electrode connecting end for externally connecting with a power source. The invention has the advantages that the directly-heating type functional ceramic substrate is high in far infrared radiation efficiency, adjustable in wavelength range, uniform in temperature field, strong in thermal shock resistance, environment-friendly, efficient and energy-saving, safe and reliable as well as wide in application range.

Owner:佛山市海辰科技有限公司

Novel rapid molding device and powder feeding and spreading method thereof

ActiveCN107745517AAccurate powder supplyGuaranteed smoothAdditive manufacturing apparatusIncreasing energy efficiencyRapid prototypingPiston

The invention discloses a novel rapid molding device and a powder feeding and spreading method thereof. The novel rapid molding device comprises a powder feeding cylinder, a molding cylinder, an overflow powder cylinder, a laser window, a powder feeding scraper plate and a bucket type double-scraper plate powder spreading mechanism, and also comprises a powder feeding cylinder heat preservation chamber, a powder feeding cylinder heater, a molding cylinder heat preservation chamber, a molding cylinder heater and a powder feeding cylinder working panel, the powder feeding scraper plate linearlymoves from the left to the right and pushes powder extruded through the lifting of the piston of the powder feeding cylinder to a powder falling opening at the right end of the powder feeding cylinderheat preservation chamber, the powder freely falls into two bucket scraper plates from top to bottom, and the bucket scraper plates horizontally move from the left to the right to push the powder tothe molding cylinder, spread the powder on the molding cylinder and send superfluous powder outside the two bucket scraper plates into the overflow powder cylinder in order to complete one-time powderspreading. The novel rapid molding device and the powder feeding and spreading method thereof have the advantages of effective improvement of the powder feeding and spreading manner, improvement of the powder spreading quality, reduction of material wastes, and improvement of the 3D printing quality and the printing efficiency.

Owner:武汉华科三维科技有限公司

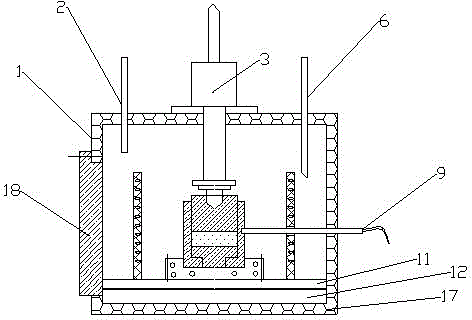

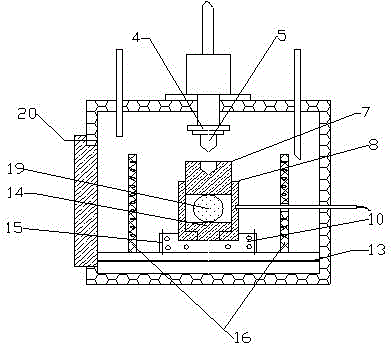

Moulding press for chalcogenide glass components

ActiveCN103145319AGuaranteed non-oxidizing atmosphereEasy to placeGlass pressing apparatusMetallurgyChalcogenide glass

The invention discloses a moulding press for chalcogenide glass components and belongs to the technical field of glass mould pressing and hot-forming. The moulding press is mainly used for solving the problem that the existing open-structured optical glass moulding press has devitrification, oxidation and forming defects. The moulding press is mainly characterized by comprising a pressing system, a mould system, a temperature control system, a heating system, a workbench, a press body and an atmosphere control system, wherein the press body is of a sealing structure; the atmosphere control system consists of two parts, namely an air extraction system and an inflation system; the workbench is arranged at the bottom of the inside of the press body, and the workbench is provided with a support plate through a semicircular guide rail; the heating system comprises a heating plate and an annular heating element, the heating plate is arranged in the middle of the support plate, and the annular heating element is arranged around the heating plate; and the pressing system is composed of a pneumatic pump, an air cylinder, a flange, and a replaceable press head. The moulding press disclosed by the invention has the characteristics that chalcogenide glass is internally heated uniformly in the process of secondary mould pressing, the oxidation is avoided, the material utilization rate is improved and the production efficiency is improved, and is mainly applied to secondary mould pressing devices for chalcogenide glass components.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

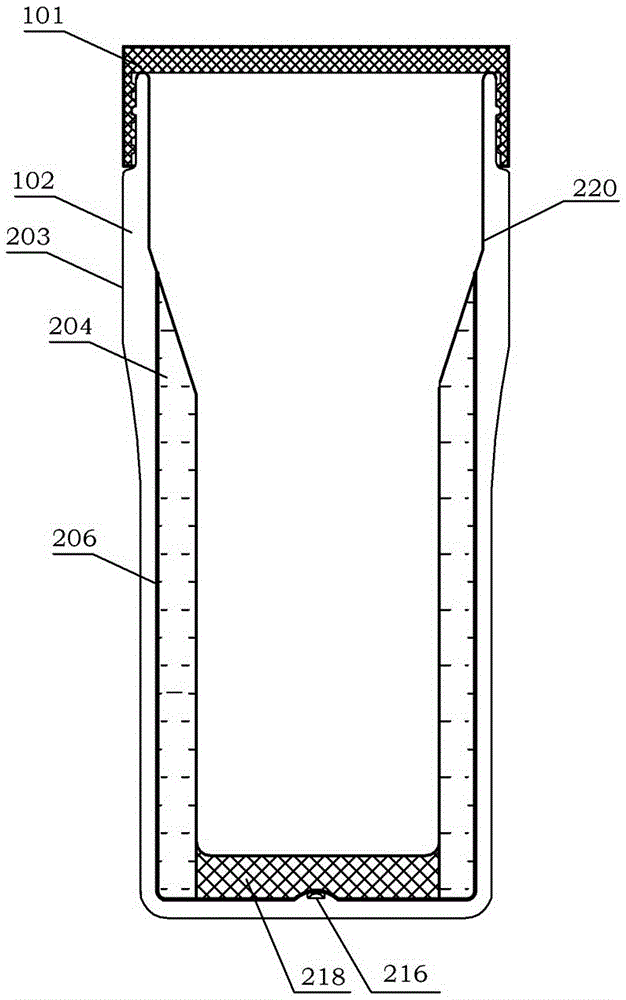

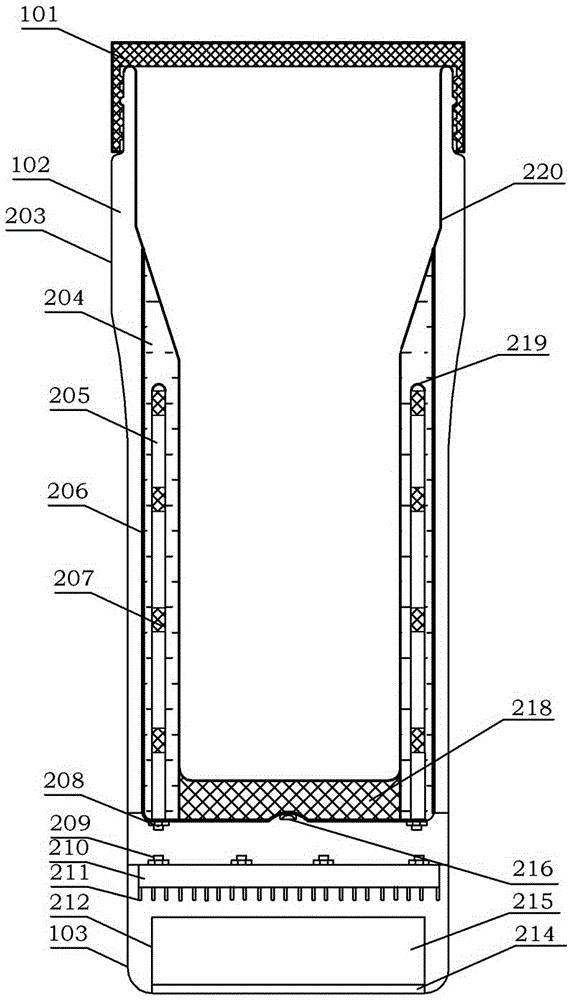

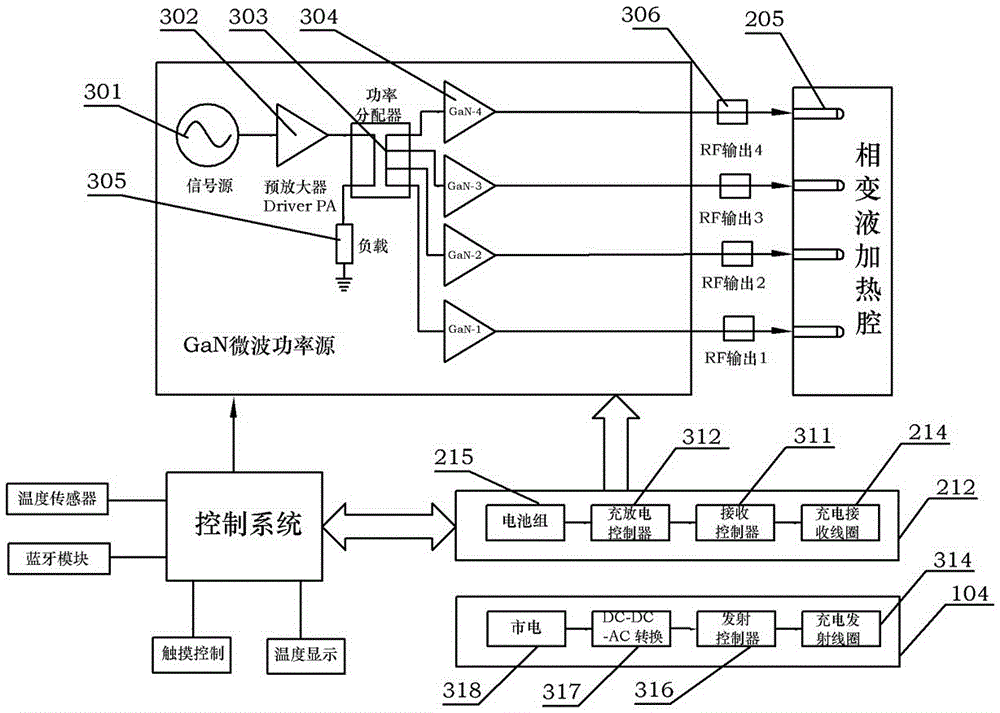

Solid-liquid compound-phase variable-speed cooling constant-temperature cup and microwave heating constant-temperature cup

ActiveCN106361101AEasy to useLarge latent heat of phase changeDwelling equipmentWarming devicesSolid-stateInternal cavity

The invention relates to a daily used vacuum cup, in particular to a compound-phase variable-speed cooling constant-temperature cup. The solid-liquid compound-phase variable-speed cooling constant-temperature cup comprises a cup lid and a cup body, wherein the cup lid is in sealed connection with the cup body, the cup body comprises an inner cup wall, a middle cup wall and an outer cup wall, the internal cavity of the inner cup wall forms a beverage containing cavity, the airtight cavity between the inner cup wall and the middle cup wall is filled with inorganic hydrous salt compound phase change liquid, the airtight cavity between the bottom of the inner cup wall and the bottom of the middle cup wall is designed into a phase change alloy rapid-cooling interlayer, and the phase change alloy rapid-cooling interlayer is provided with built-in low-melting-point phase change alloy. In a solid-liquid compound-phase variable-speed cooling microwave heating constant-temperature cup, the airtight cavity between the inner cup wall and the middle cup wall is filled with inorganic hydrous salt compound phase change liquid to form a phase change liquid heating cavity, one or more distributed rod-like microwave antennae are arranged in the phase change liquid heating cavity, and a solid-state microwave power source, a power supply part and a control system are arranged in a cup base.

Owner:陈鹏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com