Novel rapid molding device and powder feeding and spreading method thereof

A molding equipment and fast technology, applied in the field of 3D printing, can solve the problems such as difficult to control the heating temperature uniformly, unable to heat the powder, and difficult to control the temperature, so as to improve the way of powder feeding and spreading, the heating and preheating temperature is easier to control, The effect of uniform temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

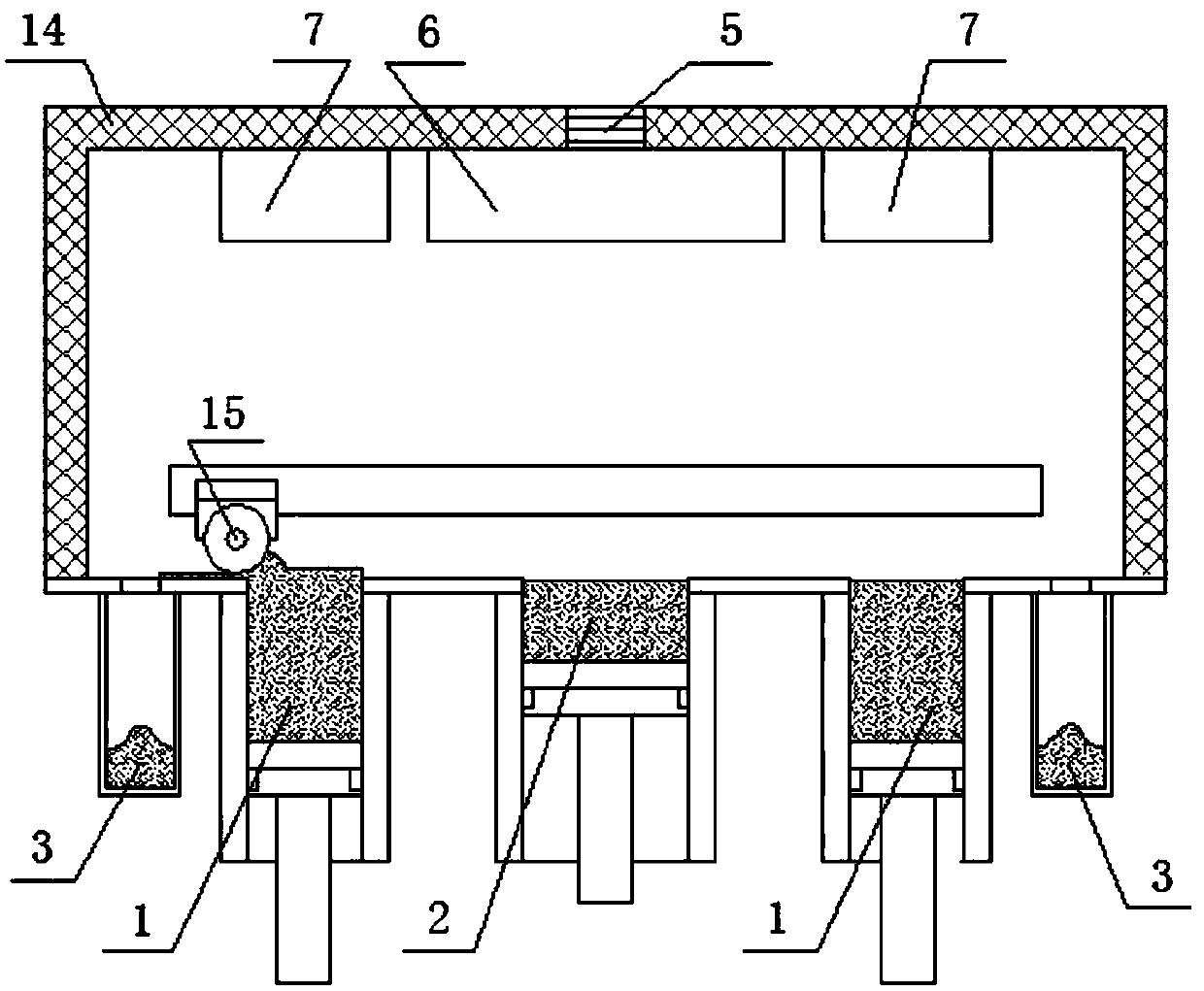

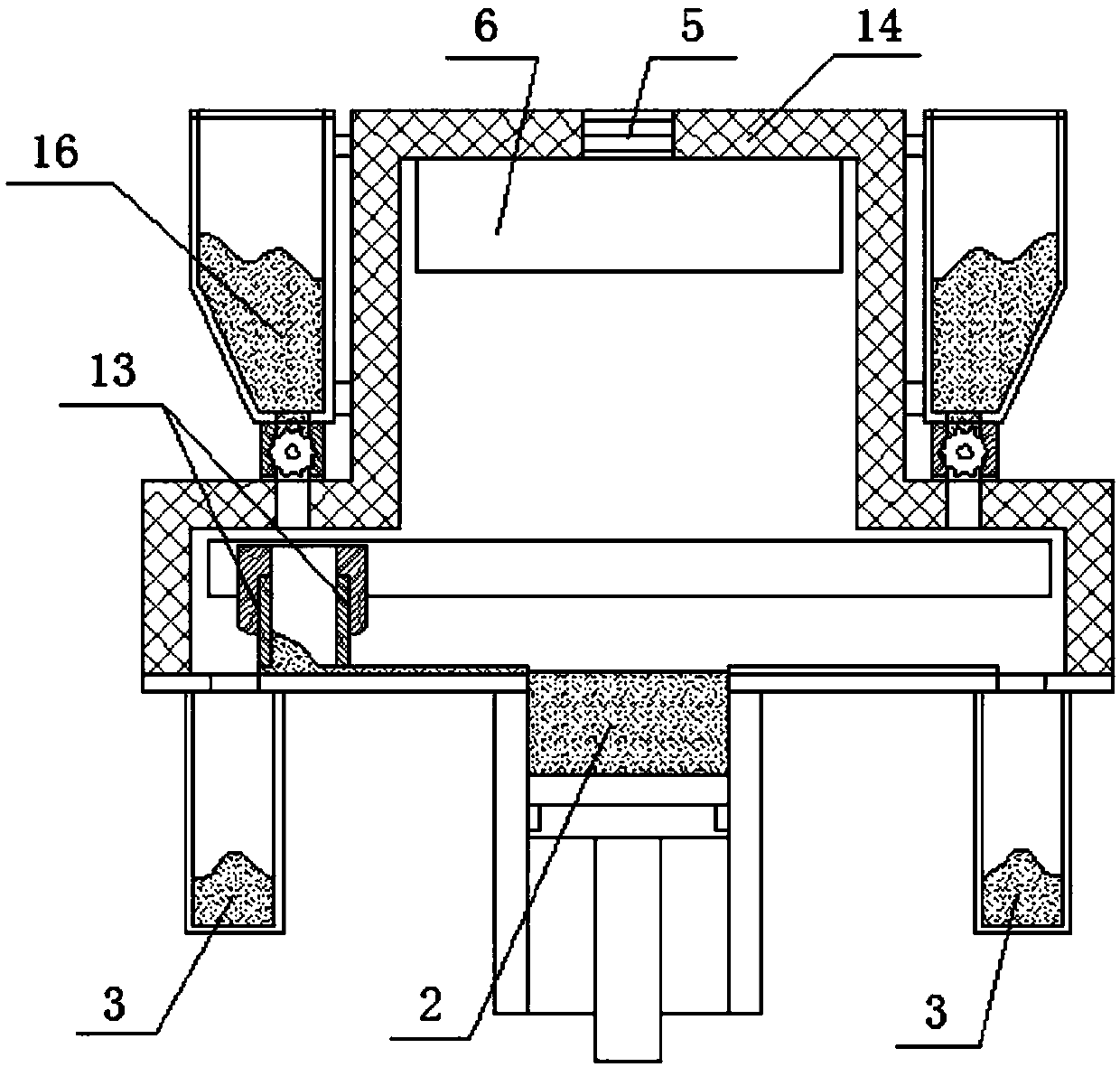

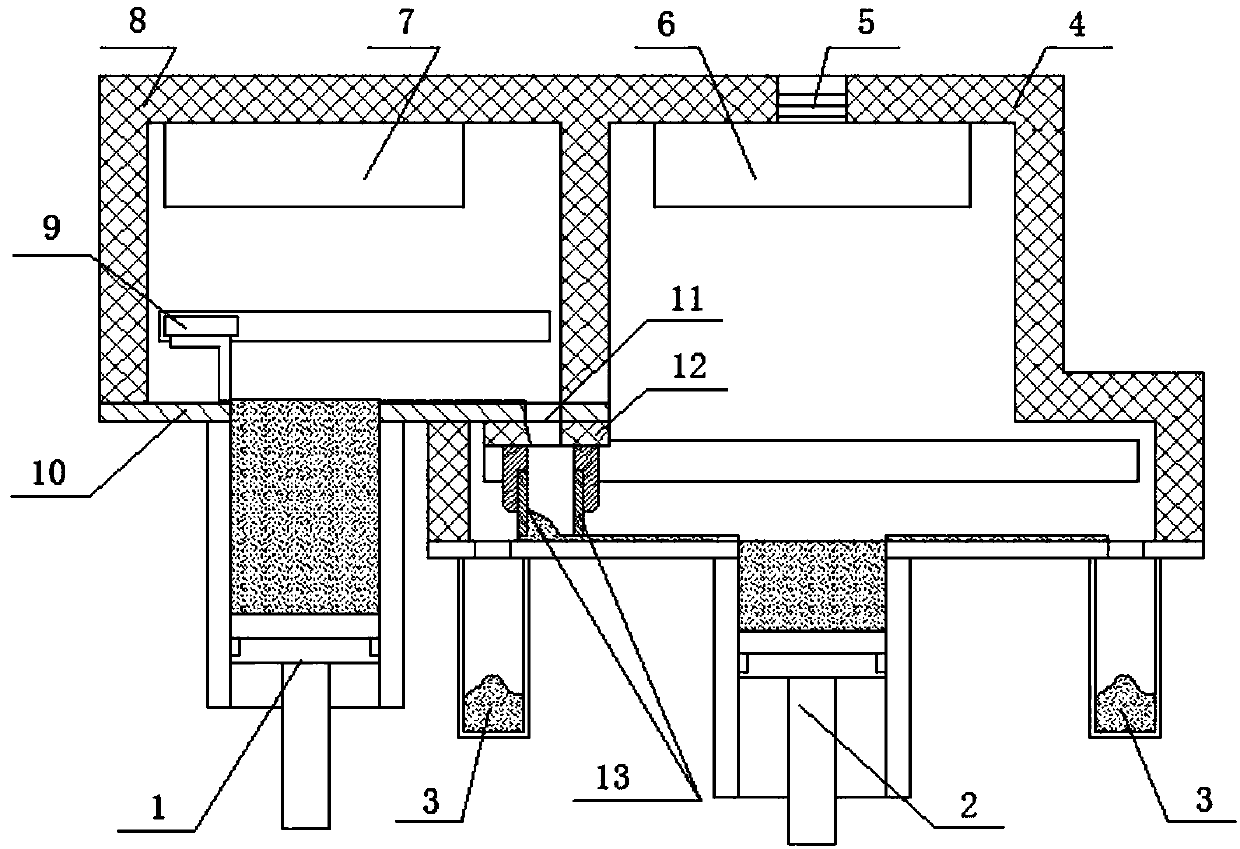

[0050] With the molding cylinder as the center of symmetry, place two powder overflow cylinders on the left and right sides of the molding cylinder to keep a certain distance. The bucket-type double-scraper powder spreading mechanism is placed above the working plane of the powder bed of the forming cylinder. It can move back and forth from side to side to realize powder spreading movement. The powder supply cylinder is placed on the left side of the forming cylinder, and the working plane of the powder bed of the powder supply cylinder is raised higher than the working plane of the powder bed of the forming cylinder, with a height difference of 130mm. The powder feeding scraper mechanism is placed above the working plane of the powder bed of the powder supply tank, and there is a distance of 3-5mm between the scraper plane of the powder feeding scraper and the working plane of the powder bed of the powder supply tank, and the powder feeding scraper can move back and forth to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com