Decarburization annealing process for cold-rolled non-oriented silicon steel with high carbon content and low grade

A technology of decarburization annealing and oriented silicon steel, applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of production and operation difficulties, decline in magnetic properties of finished products, and lower qualification rate of grades, so as to improve the qualification rate and yield of products, avoid The effect of reduced magnetism and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below by embodiment the present invention will be further described.

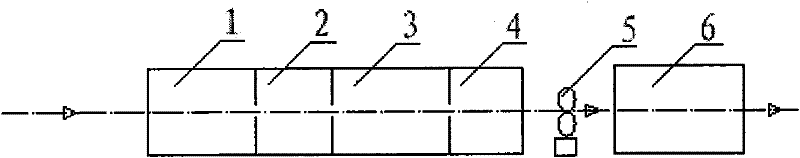

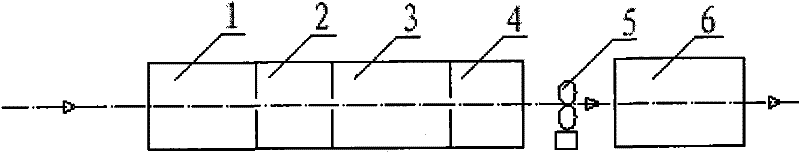

[0017] The decarburization annealing process of the high-carbon-content medium-low grade cold-rolled non-oriented silicon steel in the embodiment of the present invention adopts a horizontal continuous decarburization annealing coating unit. C content > 0.005%, cold-rolled steel coils with a thickness of 0.50mm go through the preheating / non-oxidation heating section (PH / NOF) of the continuous decarburization annealing furnace 1, the radiant tube heating section (RTF) of the continuous decarburization annealing furnace 2. Furnace temperature (SF) in soaking section of continuous decarburization annealing furnace 3, cooling section 4 of continuous decarburization annealing furnace, coating machine 5 and drying furnace 6, through decarburization, recrystallization annealing, coating and coating drying And after curing, the C content of the finished product is less than 0.003%, and the magnetic propertie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com