Patents

Literature

62results about How to "Production goes straight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for adding rare earth metal into steel to improve performance

The invention relates to the field of manufacturing of high-quality metal materials, in particular to a method for adding rare earth metal into steel to improve the performance. In the smelting process of molten steel, the degree of purity of the molten steel and the degree of purity of the high-purity rare earth metal are strictly controlled; the high-purity rare earth metal is added into a steel ladle; the content of sulfur in the molten steel is below 200 ppm and the total oxygen content is below 40 ppm before the high-purity rare earth metal is added; and the total oxygen content of the added high-purity rare earth metal is below 200 ppm. The method is applicable to the processes such as a converter BOF-ladle refining LF-vacuum degassing RH or VD-continuous casting CC / mold casting MC flow, an electric arc furnace EAF-ladle refining LF-vacuum degassing RH or VD-continuous casting CC / mold casting MC flow and a converter BOF / intermediate frequency furnace GOR / AOD(-ladle refining LF)-continuous casting CC / mold casting MC flow, prepares high-quality carbon structural steel, low alloy steel, medium-high alloy steel, tool and mould steel, bearing steel, spring steel, stainless steel and electrical steel, and solves the bottleneck problems that due to a conventional rare earth adding process, the performance of rolled steel is not stable and a water gap is blocked in the production process.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Decarburization annealing process for cold-rolled non-oriented silicon steel with high carbon content and low grade

ActiveCN102268516AGuaranteed smoothSimple decarburization annealing processFurnace typesHeat treatment process controlHigh carbonShielding gas

The invention provides a decarburization and annealing process of high-carbon middle-and-low-grade cold rolling orientation-free silicon steel. In the process, a horizontal type continuous decarburization and annealing coating unit is adopted, the thickness of a steel belt is 0.35-0.65mm, the operation speed of the steel belt is controlled to 70-100m / min, the tension of the steel belt in a continuous decarburization and annealing furnace is 1800-2200N; the temperatures of various furnace sections are controlled as follows: the furnace temperature of a preheating / oxidation-free heating section is 1000-1100 DEG C, the furnace temperature of a radiant tube heating section is 900-920 DEG C, and the furnace temperature of a soaking section is 850-910 DGE C; apertures of a fan at a cooling section are 25-99% in turn; the pressures in the furnace are as follows: the pressure of an inlet is 25-30Pa, and the pressure of an outlet is 45-50Pa; and H2 and N2 are adopted as protective gas in the furnace, wherein the content of H2 is 25%-35%, the dew point value of the protective gas is 35+ / -5 DEG C, and the flux of the protective gas is 350-420m<3> / h. In the invention, the process is adopted so as to not only ensure that the steel belt is smooth, the magnetic property, magnetic ageing and the like of the steel belt meet technical requirements, the qualified rate of a finished product is improved and waste quantity is reduced but also ensure that production is smoothly carried out.

Owner:ANGANG STEEL CO LTD

Sodium-translated roasting method of vanadium minerals

The invention relates to a sodium-translated roasting method of vanadium minerals, belonging to the field of metallurgy and mainly aiming to solve the technical problem on providing a sodium-translated roasting method of vanadium minerals. The total vanadium content into a furnace in the method can reach more than 6%. The sodium-translated roasting method of the vanadium minerals comprises the following steps of: (a) mixing raw materials: pulverizing the vanadium minerals, removing metal iron, uniformly mixing sodium salt and the vanadium minerals with metal iron removed, wherein the weight of the sodium salt is 9-11% of the weight of the vanadium minerals with metal iron removed, and the sodium salt is at least one of NaCl, Na2SO4 and Na2CO3; and (b) roasting: roasting the mixed raw materials under aerobic conditions to obtain pentavalent salt of vanadium, wherein the roasting temperature is 700-900 DEG C, and the roasting time is 3.5-5.0 h. The method provides a new selection for the sodium-translated roasting of the vanadium minerals and has broad application prospects.

Owner:SICHUAN CHUANWEI GRP CO LTD +1

Detecting tool and method for crystallizer protective slag

InactiveCN1788883AEasy to operateEasy to makeCasting parameters measurement/indication devicesCopper platingAsbestos

The present invention is protecting slag detecting tool and method for detecting the thickness of the liquid slag layer, the sintered layer and the powder slag layer of the protecting slag in crystallizer of continuous slab casting machine. The detecting tool consists of copper pipe handle, wood or asbestos board, wooden clamp on the board, iron nail, and copper coated iron wire or one iron wire and one copper wire in the same length through the copper pipe and the board. During use, the copper coated iron wire or the iron wire and copper wire is inserted into molten steel inside the crystallizer for 4 sec before being withdrawn while the board is floated on the molten steel surface. The thickness of the liquid slag layer, the sintered layer and the powder slag layer is detected based on the corrosion and color change of the copper coated iron wire or the iron wire and copper wire. The detecting tool of the present invention has the service life as long as 600 heats of steel.

Owner:宝钢集团上海梅山有限公司

Online shaft neck repairing method

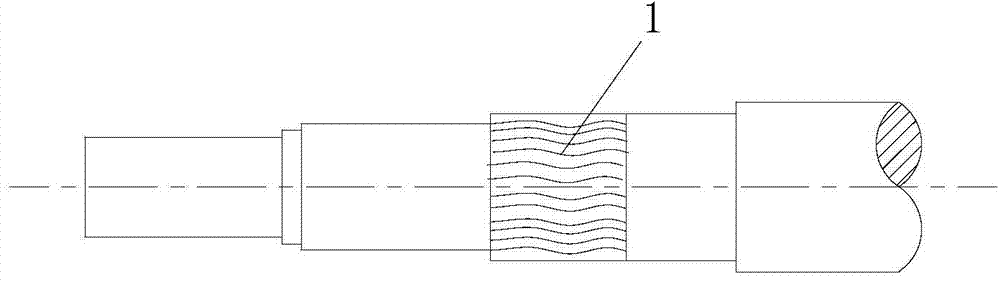

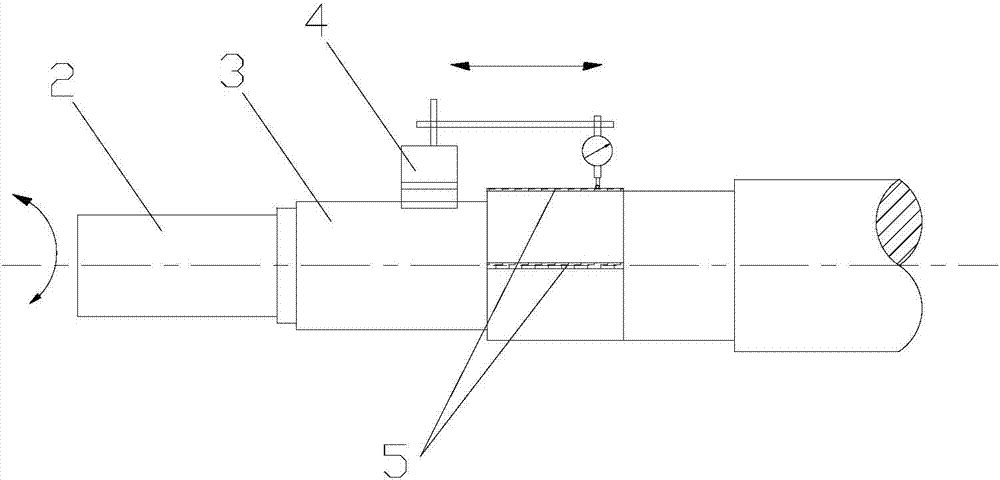

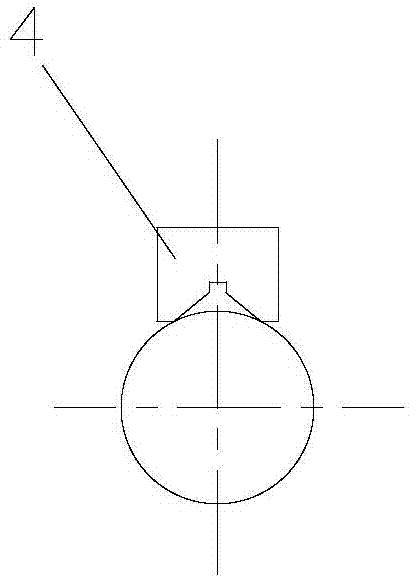

The invention relates to an online shaft neck repairing method. The online shaft neck repairing method includes: grinding a worn shaft neck coarsely; welding weld ribs; finishing the weld ribs; machining a bush; mounting the bush and replacing a bearing sequentially on the shaft neck provided with the weld ribs and completing repairing after post processing. By the method, the shaft neck at the cooperative positions of two ends of a shaft and the inner ring of the bearing can be repaired online, repairing time and cost can be favorably saved, and production can be ensured to run smoothly.

Owner:NANJING MEISHAN METALLURGY DEV +1

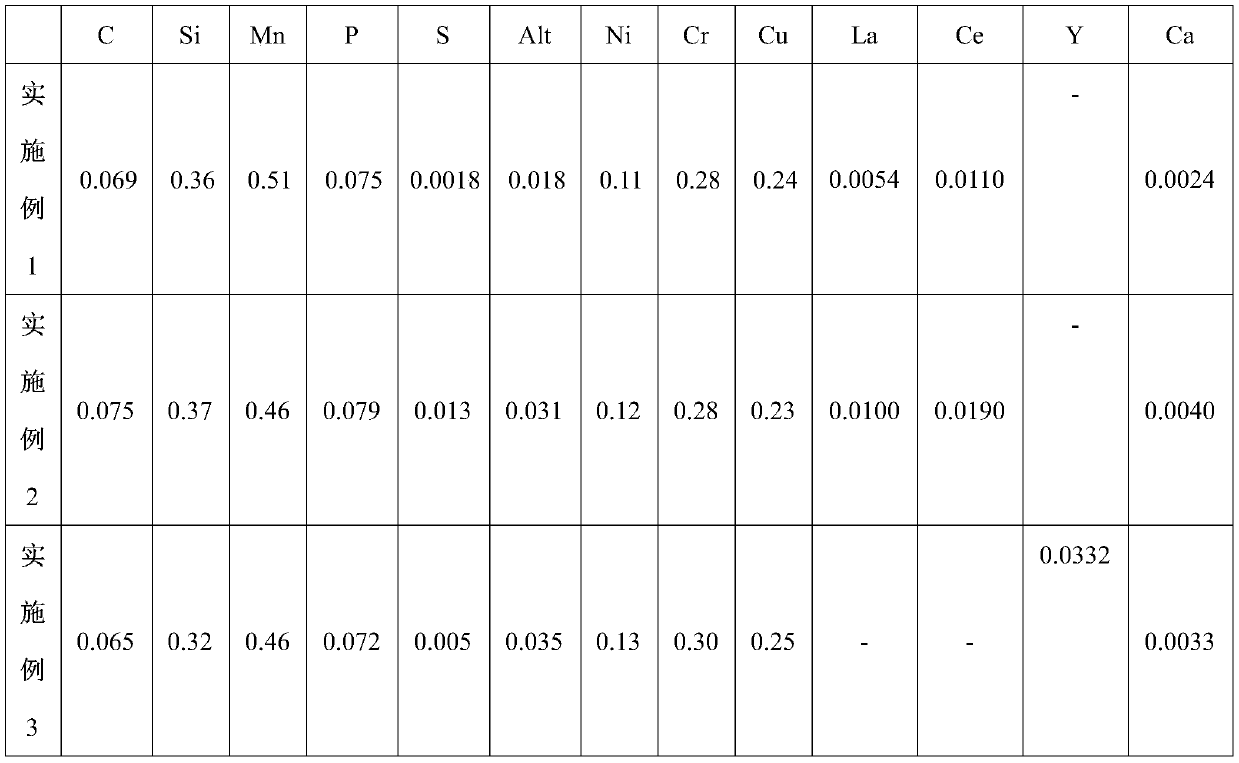

Rare earth weathering steel rich in alloying rare earth elements and manufacturing method of rare earth weathering steel

InactiveCN110923572AGood mechanical propertiesImprove cold forming propertiesSteelmakingRare-earth element

The invention discloses rare earth weathering steel rich in alloying rare earth elements and a manufacturing method of the rare earth weathering steel. The rare earth elements are one or more of threeelements of Ce, La and Y, in terms of mass percentage wt%, the content of the alloying rare earth elements is controlled within 0.005 wt% to 0.045 wt% through the process of feeding rare earth wiresinto steelmaking, weathering steel with a yield strength level of more than 355 MPa and an atmospheric corrosion resistant performance [a 240-hour periodic infiltration test, the corrosion rate is less than or equal to 1.2 g / (m<2>*hr)] which is equivalent to Q355GNH in national standard 'weathering structural steel' GB / T4171-2008, good mechanical properties, cold formability and welding performance are achieved, and the rare earth weathering steel can be widely applied to steel structure projects of vehicles, container manufacturing and construction, bridges, tower and mast structures and thelike.

Owner:SHANGHAI UNIV +2

Carbon ramming material for blast furnace and preparation method for carbon ramming material

The invention relates to a carbon ramming material for a blast furnace and a preparation method for the carbon ramming material. The carbon ramming material for the blast furnace comprises the following components in part by weight: 35 to 65 parts of component A, 25 to 55 parts of component B, 5 to 16 parts of corundum with the granularity of less than 0.1 millimeter, and 8 to 15 parts of thermosetting phenol resin; the component A is electrically calcined anthracitic coal or mixture of electrically calcined anthracitic coal and artificial graphite, and the granularity of the component A is 0.1 to 5 millimeters; the component B is one of natural graphite, silicon carbide, electrically calcined anthracitic coal, artificial graphite and mixture of electrically calcined anthracitic coal and artificial graphite, and the granularity of the component B is less than 0.1 millimeter; and the electrically calcined anthracitic coal is formed at the temperature of between 1,700 and 2,400 DEG C. The carbon ramming material for the blast furnace has good heat conducting performance.

Owner:武钢集团有限公司

Converter steelmaking method for increasing scrap steel ratio per ton of steel

InactiveCN108103262AIncrease the amount of participationReduce adverse effectsManufacturing convertersProcess efficiency improvementMaterials preparationSteelmaking

A converter steelmaking method for increasing the scrap steel ratio per ton of steel comprises the steps of scrap steel preheating, molten iron preparation, scrap steel material preparation, converteroperation, operation after a converter, treatment outside the converter, and the like. According to the converter operation step, scrap steel molten steel, a scrap steel material and molten iron which are added into the converter comprise, by weight, 33-45% of the scrap steel molten steel, 9-12% of the scrap steel material and the balance the molten iron. According to the converter steelmaking method for increasing the scrap steel ratio per ton of the steel, the adding amount of scrap steel per ton of the steel is increased in the premises of ensuring the molten steel quality and meeting thetapping temperature requirements, and meanwhile, the adverse effect of the coal gas preheated scrap steel on the environment is eliminated, so that the scrap steel ratio per ton of the steel is further increased, and the iron loss is greatly reduced; and researches show that the scrap steel ratio per ton of the steel can reach 40% or above in the premise of ensuring normal production and the molten steel quality by adopting the converter steelmaking method.

Owner:TANGSHAN DELONG STEEL CO LTD

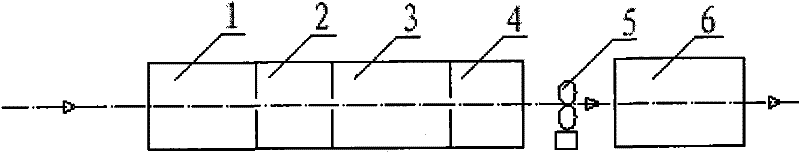

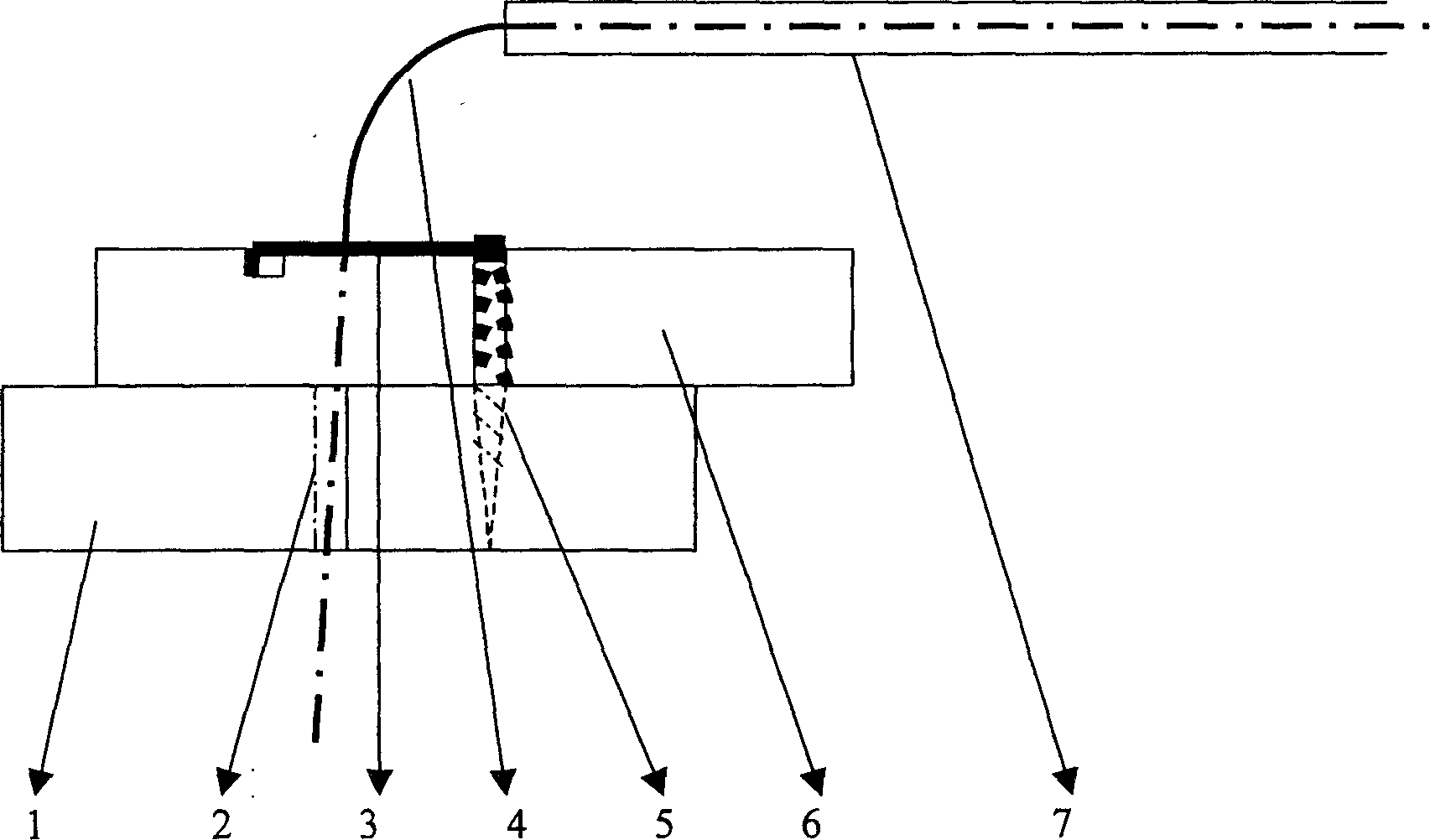

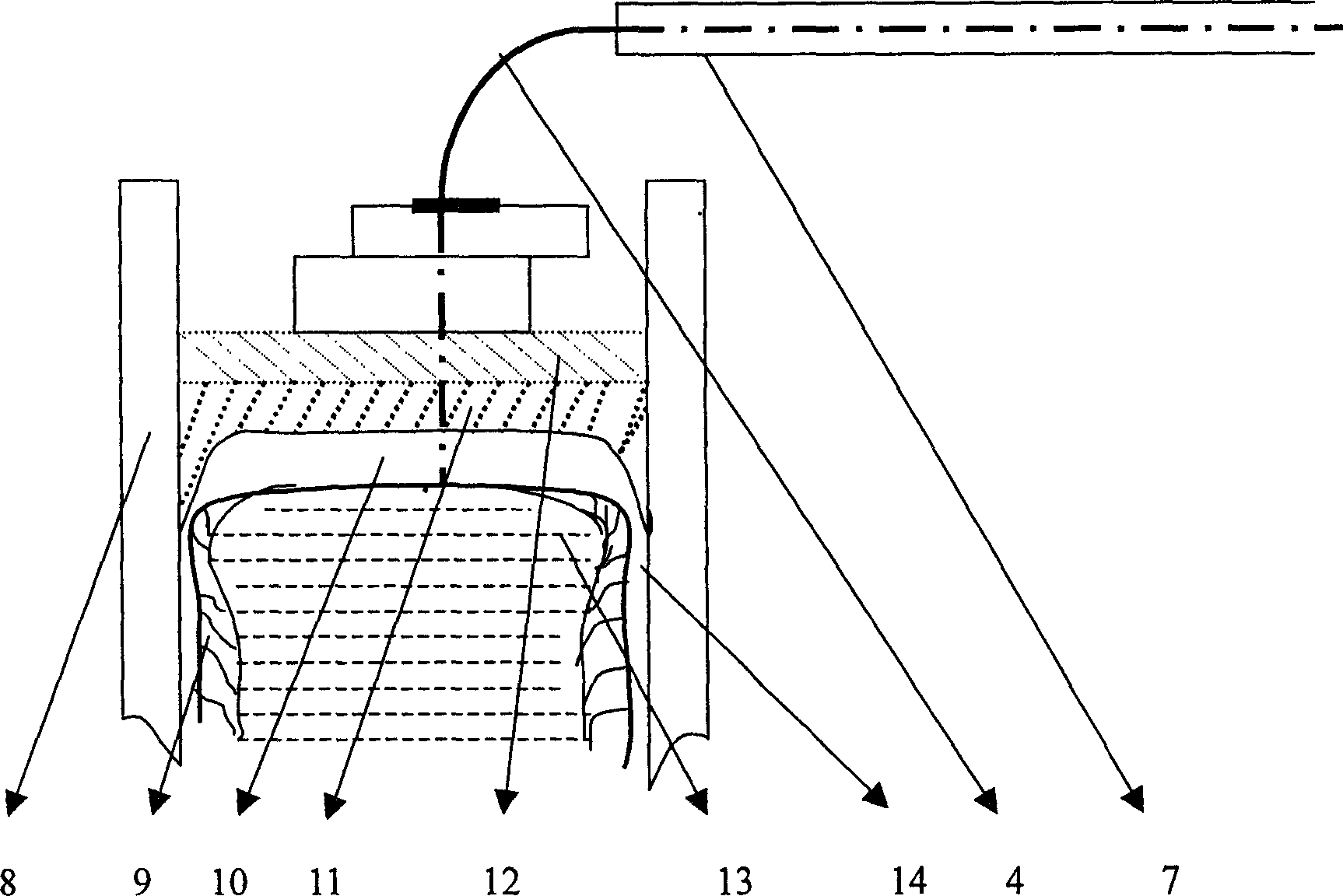

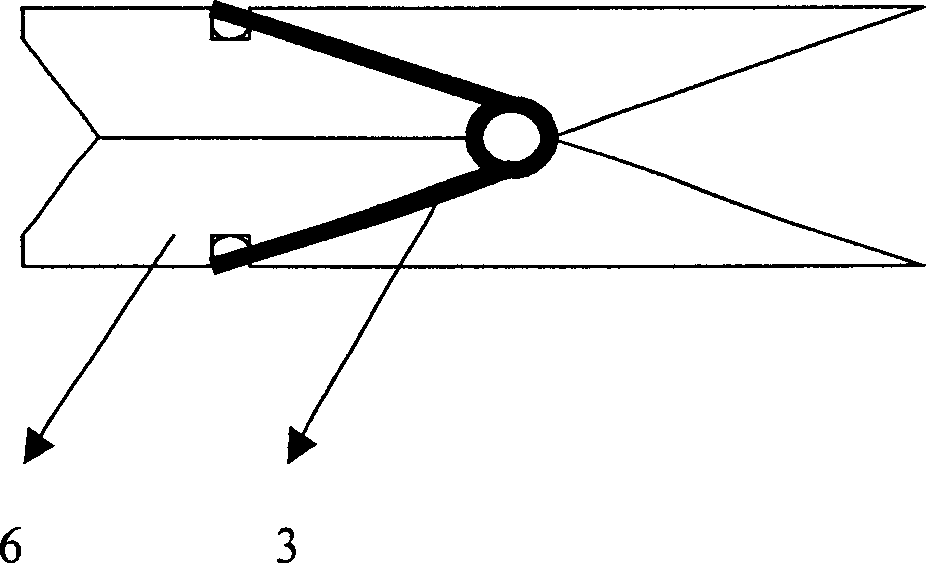

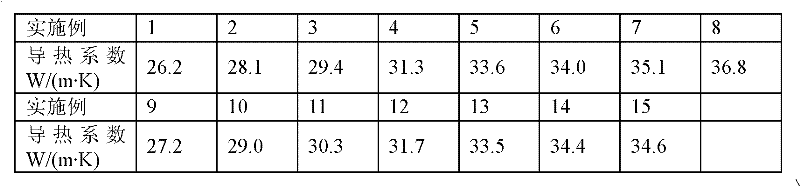

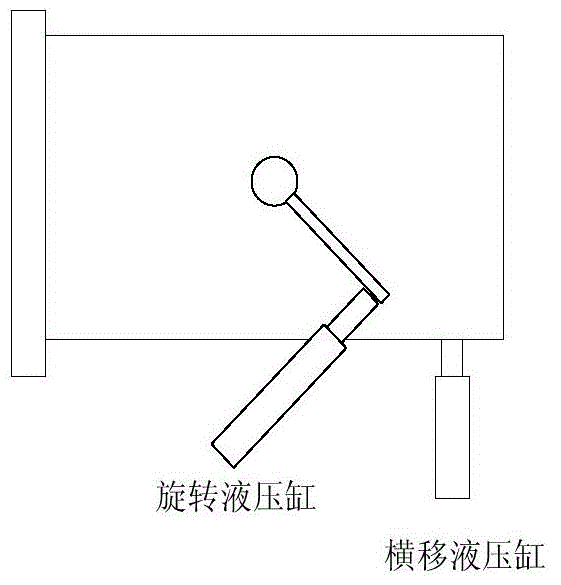

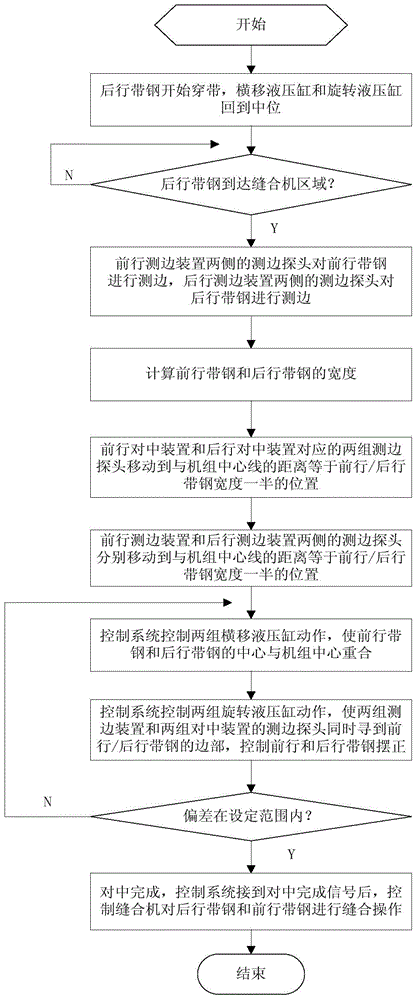

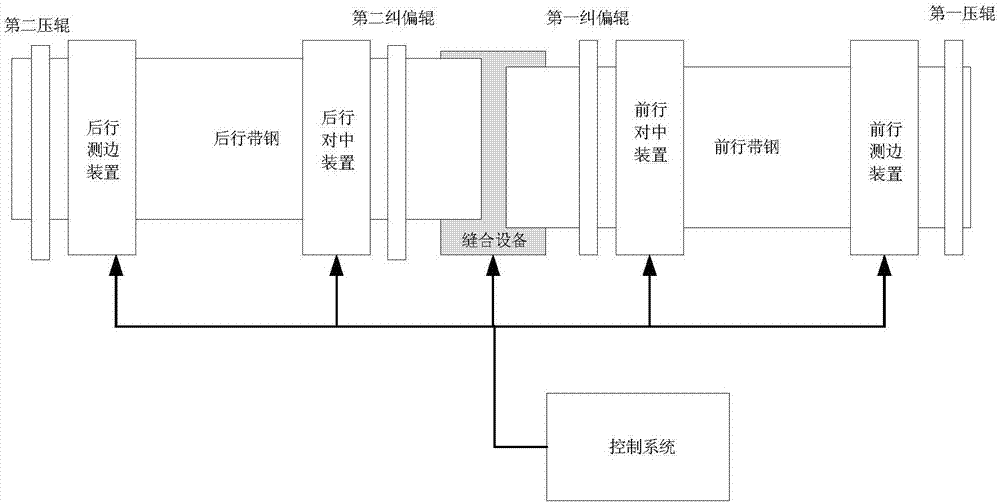

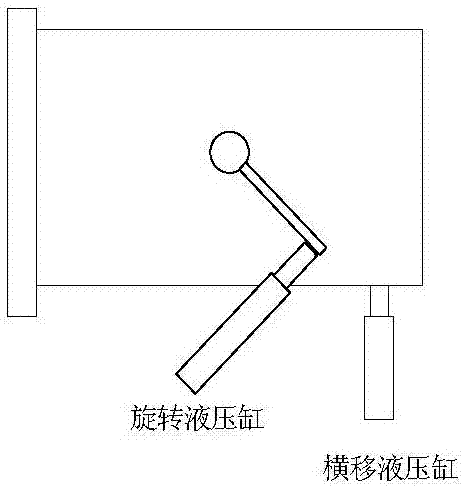

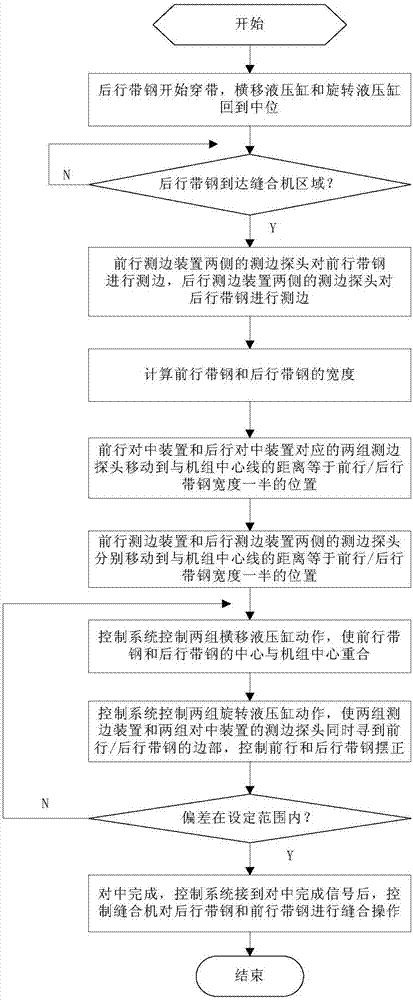

Control method and equipment for suturing and centering thin strip steel for continuous annealing furnace

ActiveCN105618596AReduce the risk of belt breakageImprove sewing precisionMetal-working feeding devicesMetal working apparatusHydraulic cylinderStructural engineering

The invention relates to the technical field of strip steel rolling, in particular to a control method and equipment for suturing and centering thin strip steel for a continuous annealing furnace. According to the control method and equipment, centering devices and side measuring devices are respectively adopted in the front and the back of suturing equipment, the centering devices are mainly used for detecting whether the center position of the strip steel moving forwards and the center position of the strip steel moving backwards are located in the center position of a unit, and the side measuring devices are mainly used for detecting whether the strip steel moving forwards and the strip steel moving backwards are placed right, namely whether the center line of the strip steel is parallel with the center line of the unit; a horizontal-moving hydraulic cylinder and a rotating hydraulic cylinder are respectively installed in front and back of the suturing equipment, the strip steel in front of the suturing equipment and the strip steel in back of the suturing equipment can be placed right and centered through cooperation between a first correction roller and a second correction roller, the suturing accuracy can be improved greatly, the strip breakage risk of the unit is lowered, and production is more smooth. According to the control method and equipment, the technical problems that existing control methods are poor in suturing accuracy and the strip breakage risk exists especially when the strip steel in front and the strip steel in back are different in width are solved.

Owner:BAOSHAN IRON & STEEL CO LTD

Coking indirect final cooling tower circulation washing process

InactiveCN101993699ASolve the blockageGuaranteed uptimeOven incrustations prevention/removalCombustible gas purificationBenzeneCooling tower

The invention relates to a coking indirect final cooling tower circulation washing process, which belongs to the technical field of environmental protection and washing treatment and mainly solves the problem that the final cooling part which is not economically and reasonably settled in a long term in the existing coking enterprise is frequently blocked. Indirect final cooling technology, crude benzene separation water and tar mixing washing technology, final cooling tower with upper and lower spraying sections technology and benzene washing tower and final cooling tower water seal technology are integrated into a whole to form combined connection, thereby achieving the effect of reducing energy consumption and environmental pollution and improving social effect and economic effect.

Owner:JILIN DONGSHENG COKING

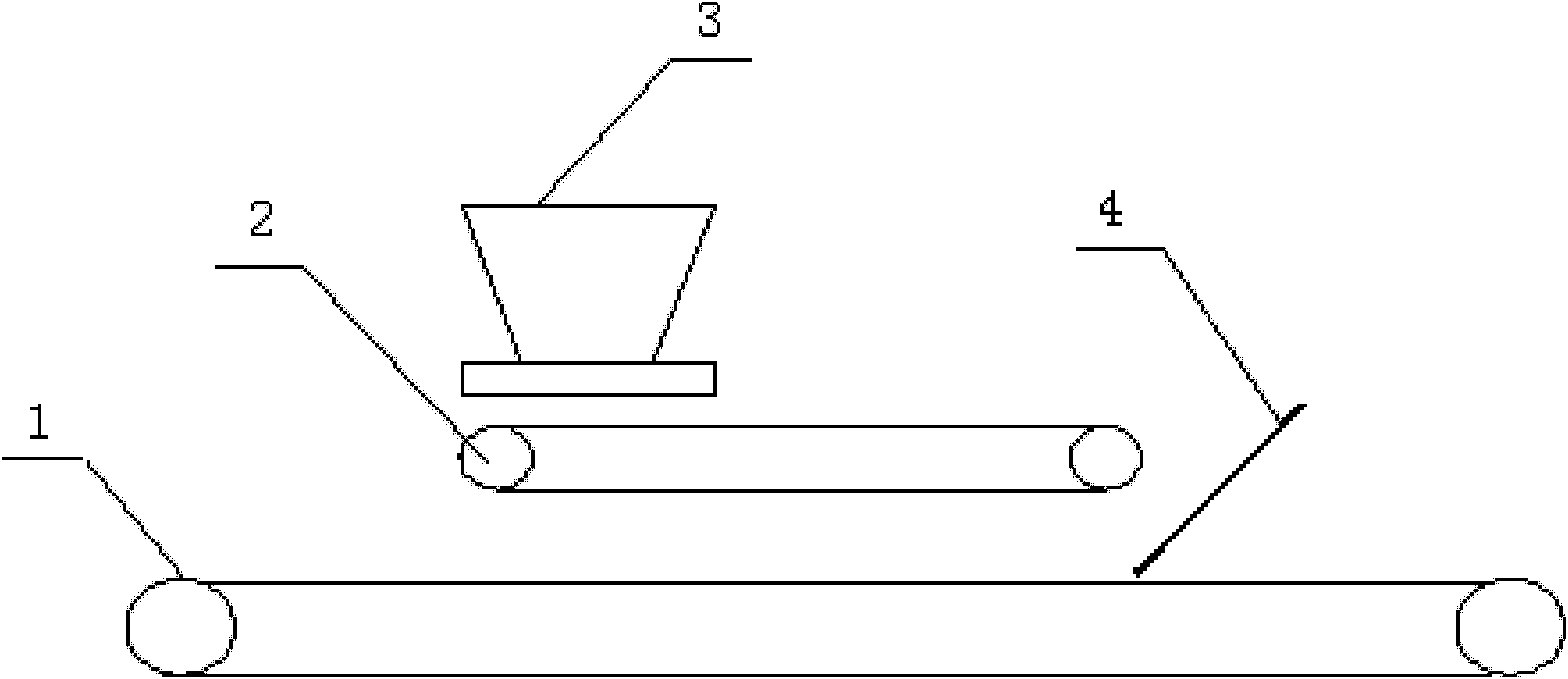

Pellet binder and adding device and adding method thereof

ActiveCN102719664ASufficient and guaranteed sourcesProduction goes straightMixer accessoriesMontmorillonitePoor quality

The invention provides a pellet binder and an adding device and an adding method thereof, wherein the pallet binder is prepared from the raw materials of yellow flower roots, sodium carboxymethylcellulose and montmorillonites. Before adding, according to the weight of the pellet mixture delivered per unit time and per unit length on a material belt, the weight of the binder to be prepared and added and the distribution amount of the binder on an electronic belt scale are correspondingly calculated. The electronic belt scale adds 4-7% by weight of the binder into the pellet mixture, the proportion of the binder being calculated according to the binder weight set to be delivered. The pellet binder has an adequate raw-material source and the auxiliary raw materials contain no harmful components such as ash content, silicon and the like. The pellet binder does not reduce the total iron content, can substitute or partially substitute a bentonite binder, raising the grade of finished product minerals by over 1.0% and reducing SiO2 content by 0.8%. The pellet binder, with a simple preparation method, is suitable for mass production and can satisfy production requirements of various poor-quality concentrates.

Owner:ANGANG STEEL CO LTD

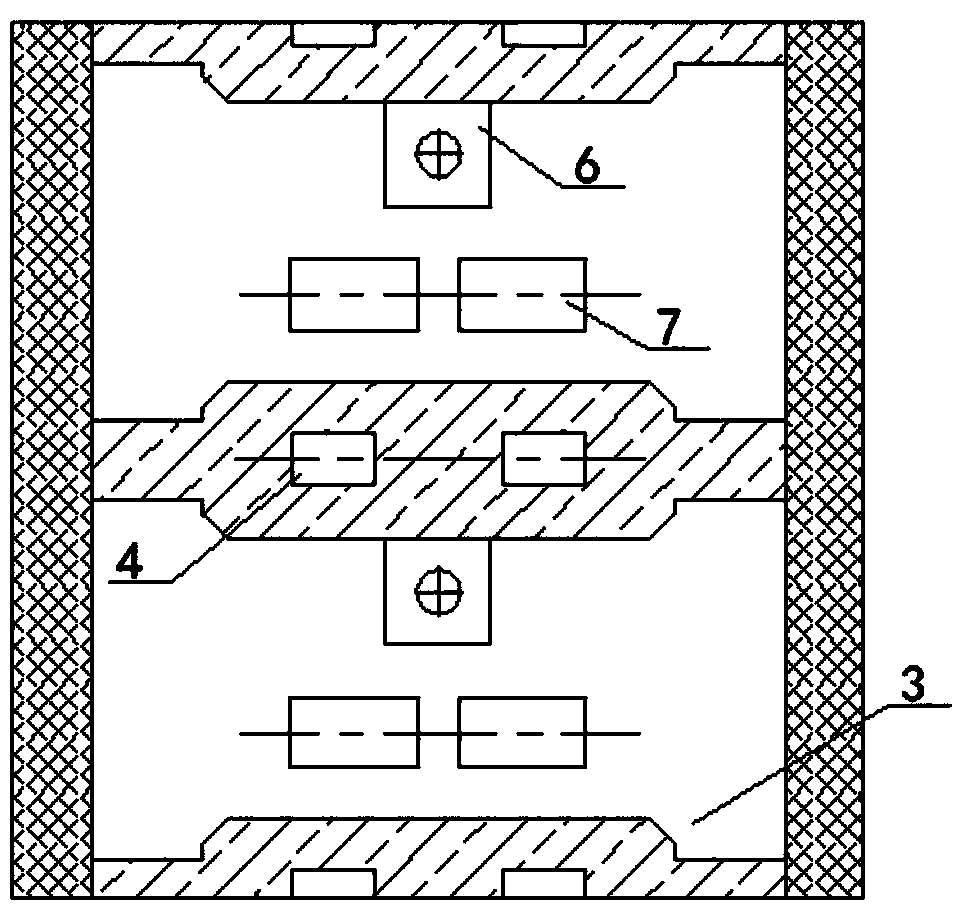

Lightweight fluorine-free environmental protection continuous casting protective slag for enamel steel

The invention discloses lightweight fluorine-free environmental protection continuous casting protective slag for enamel steel. The continuous casting protection slag comprises the following components including, by mass 22%-38% of CaO, 21%-37% of SiO2, 0.8%-3.0% of Al2O3, 1%-7% of MgO, 5%-20% of heating agent Si- Ca, 0.7%-2% of Li2O, 2%-8% of B2O3, 5%-10% of Na2O, 5%-17% of elemental C and unavoidable impurities; and the slag must meet: [CaO] / [Sio2] is greater than or equal to 0.8 and less than or equal to 1.0, namely, the alkalinity of the protective slag is 0.8- 1.0 The ratio of the heatingagent Si-Ca is 36-40 %: 64- 60%. The protective slag of the invention can reduce the occurrence of cold junction steel on a liquid surface by adding suitable heating elements without changing the alkalinity of the protective slag after the addition, and the steel leakage can be avoided; by adjusting a flux, another one or several substances are used for replacing fluoride, so the corrosion of thefluorine to a casting machine and the impact on human body are reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

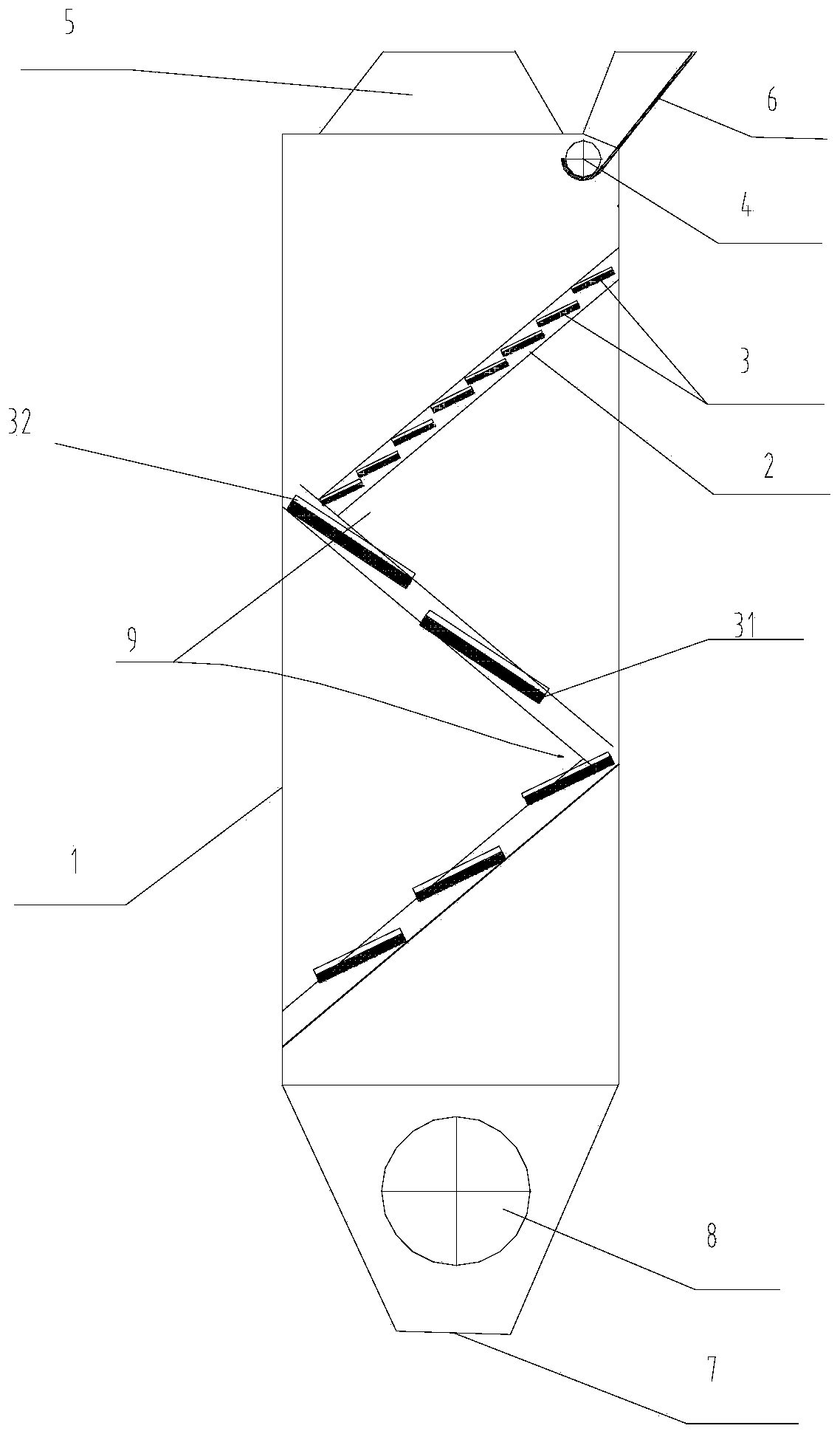

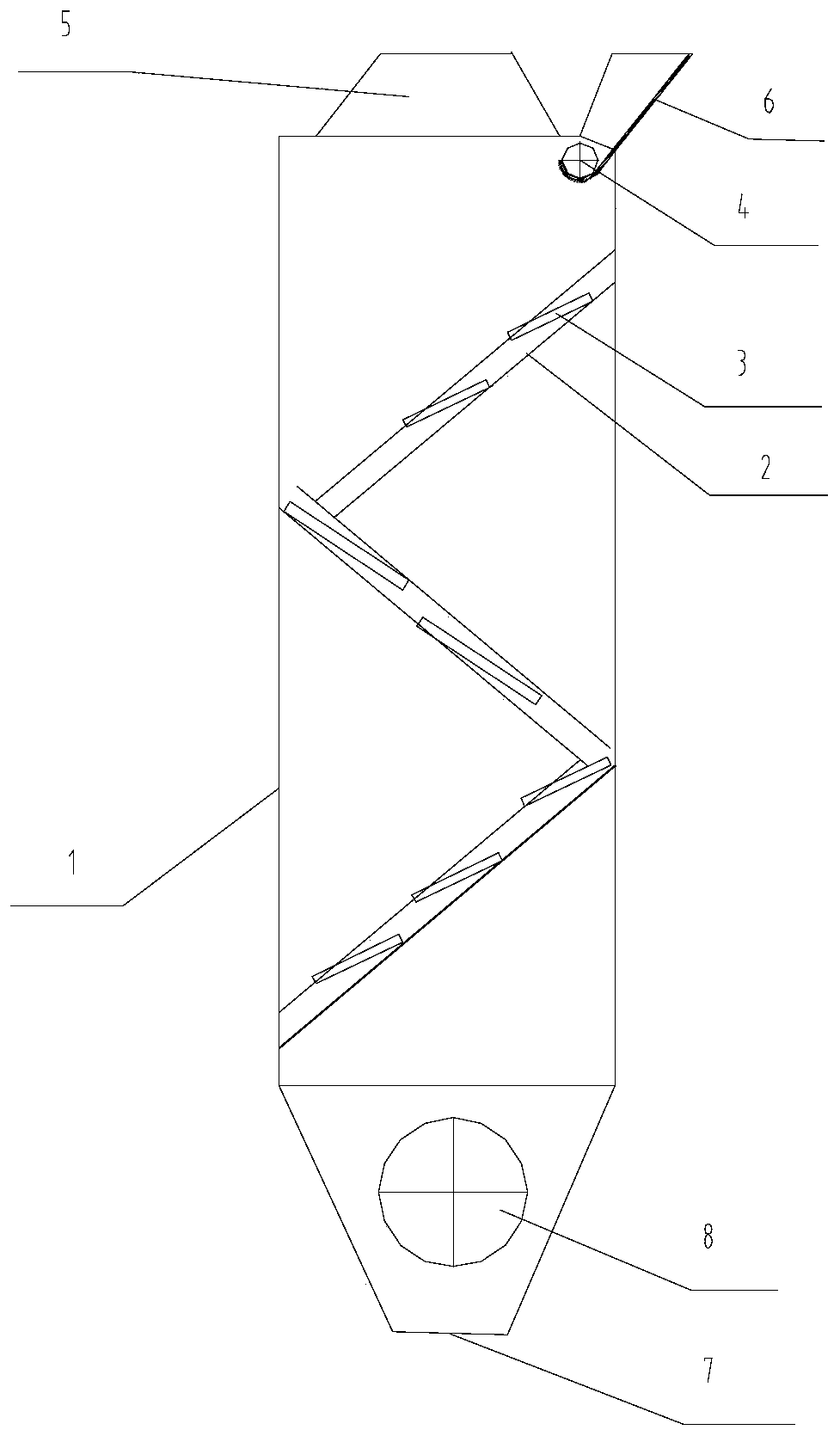

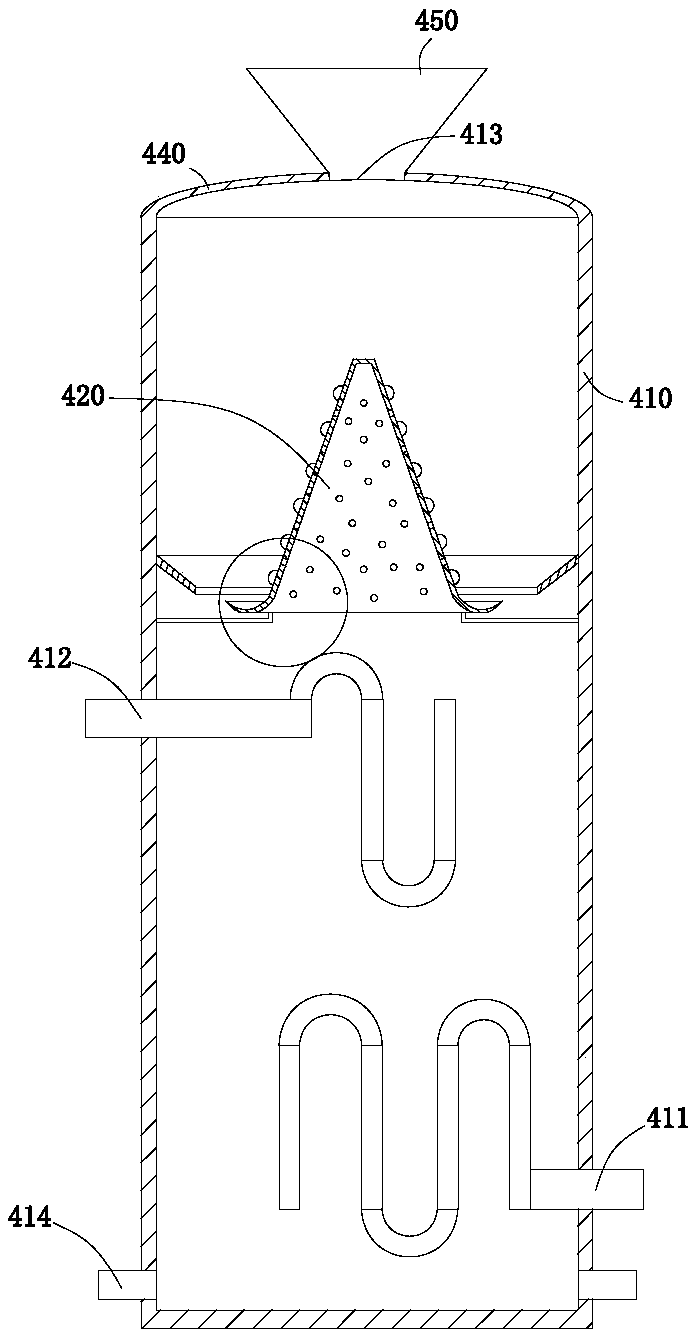

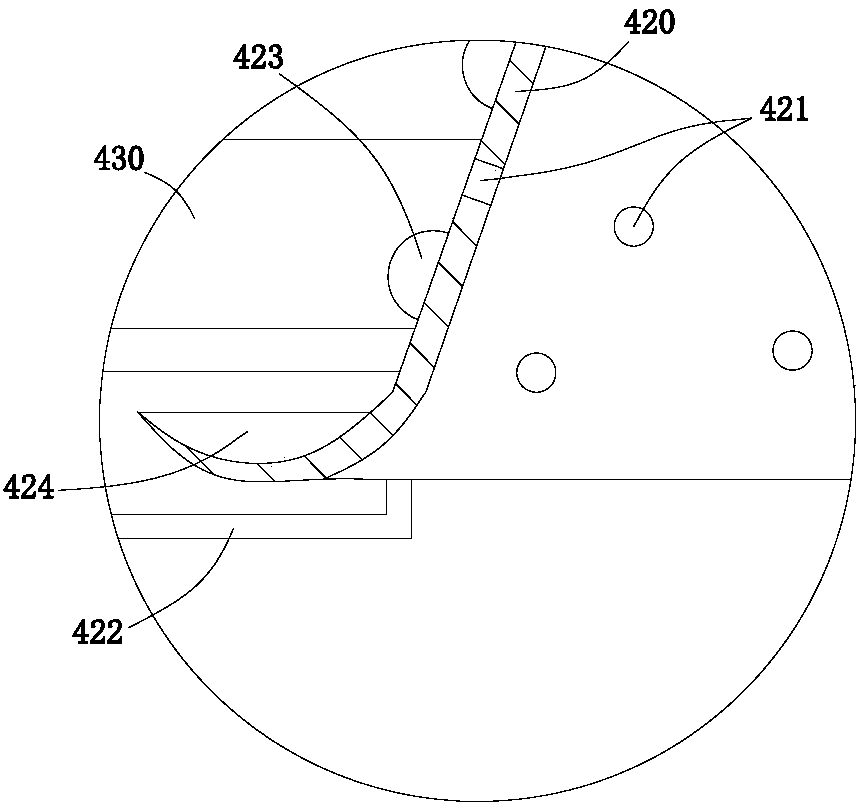

Material drying equipment and application thereof

ActiveCN111380352AReduces the chance of blocking material fallingFalling smoothlyDrying gas arrangementsDrying solid materialsWater vaporProviding material

The invention provides material drying equipment and application thereof, and relates to the technical field of material drying. A material on the upper surface of a material guide plate is low in heat conductivity, so that the whole material guide plate has the characteristics of good surface heat insulation effect and poor heat conductivity, water vapor in the equipment is not likely to condenseon the surface of the material guide plate, the situation that the material is stuck on the material guide plate to be prevented from falling is reduced, the material in the drying equipment can fallsmoothly, and the production is smooth.

Owner:HENAN DRAGON INTO COAL TECH CO LTD +1

Method for preventing longitudinal crack breakout of continuous casting slab

PendingCN113275532AImprove online service lifeAvoid Longitudinal CracksStructural engineeringManufacturing engineering

The invention provides a method for preventing longitudinal crack breakout of a continuous casting slab. The method comprises the steps that, the straightness of a narrow-surface copper plate of a crystallizer, a large-chamfer copper plate and a narrow-face back plate is defined; the relative positions of a wide-surface foot roller and a narrow-face foot roller to the copper plate are defined; the size of an angle seam between a wide-surface copper plate and the narrow-surface copper plate of the crystallizer is defined; the back taper of the wide-surface copper plate and the narrow-surface copper plate of the crystallizer is defined; and the precision of a crystallizer vibration unit is defined. According to the method, online service life of the copper plate of the crystallizer is prolonged, the belly bulging amount of the narrow surface of the continuous casting slab is controlled, longitudinal crack breakout of the corners of the slab is avoided, the downtime of a casting machine due to crystallizer replacement and the like is shortened, the operation rate of the casting machine is improved, and smooth production of a steel rolling interface is ensured.

Owner:CHONGQING IRON & STEEL CO LTD

High-speed bar yield improvement method

InactiveCN110180890AIncrease water pressureUniform heating temperatureTemperature control deviceMetal rolling arrangementsTemperature controlHeating furnace

The invention relates to the technical field of high-speed bar yield improvement, and discloses a high-speed bar yield improvement method. The method comprises the following steps that (1) the yield is improved by controlling a heating zone with the heating temperature controlled at 1,000-1,400 DEG C to be preserved for 4-7 hours, the start heating temperature in a heating furnace is 1,100 DEG C,and the temperature in the heating furnace is controlled higher than or equal to 850 DEG C after the heating is finished; a heating system is strictly executed, and the heating efficiency is improved,so that the billet heating temperature is promoted to be uniform, black marks do not appear, the oxidation burning loss is reduced, the furnace condition is kept normal, the maintenance difficulty ofthe bottom of the heating furnace is reduced, and the production is guaranteed to be smooth. According to the method, less finished scale is generated due to good guide groove air nozzles of water tanks, good water nozzle gaps, correct maintenance and water pressure increase of the water tanks, the yield of high-speed bars is integrally improved from multiple aspects, therefore, it is convenientfor an enterprise to implement the method effectively and efficiently, the implementation efficiency and the yield of the high-speed bars are improved, and the method is convenient to apply.

Owner:成渝钒钛科技有限公司

Sodium-translated roasting method of vanadium minerals

Owner:SICHUAN CHUANWEI GRP CO LTD +1

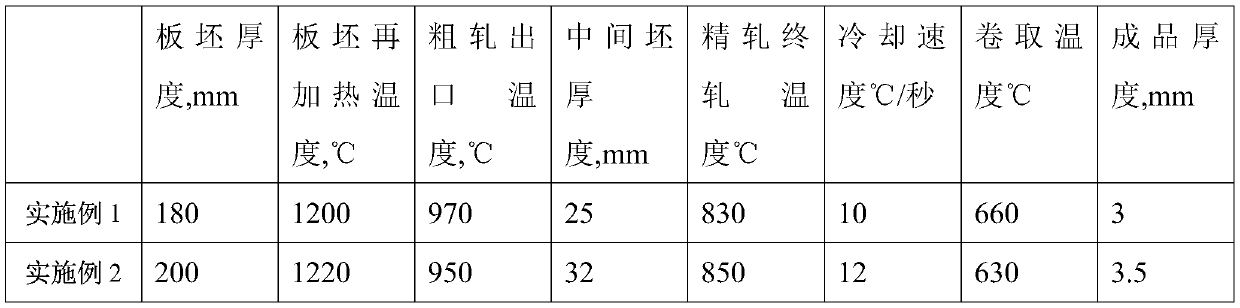

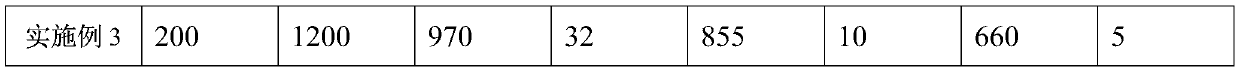

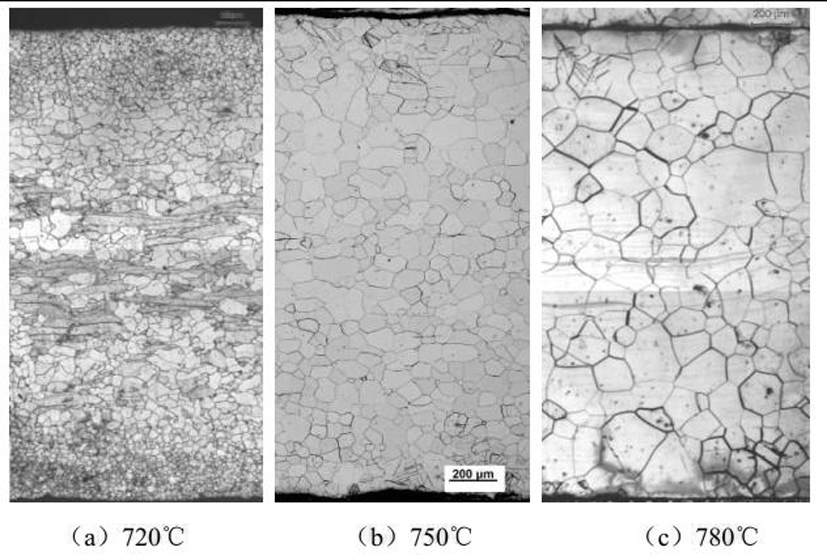

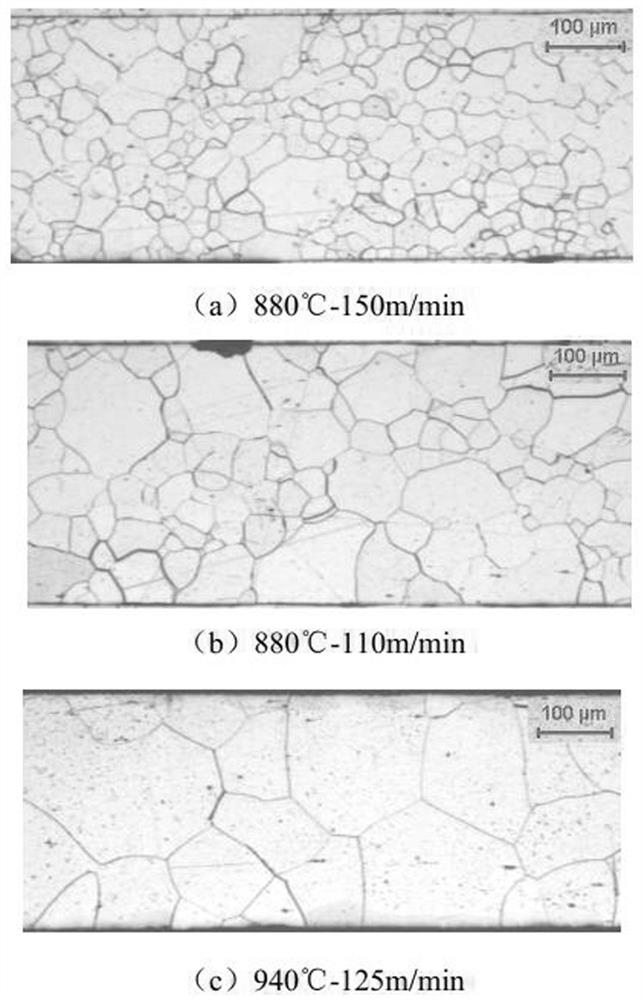

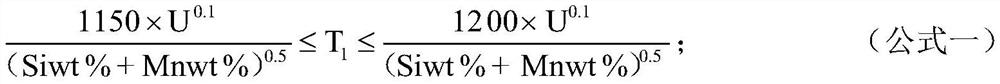

Thin-gauge non-oriented silicon steel and preparation method thereof

The invention discloses thin-gauge non-oriented silicon steel and a preparation method thereof, belongs to the technical field of electrical steel and rolling thereof, and solves the technical problems that traditional high-grade non-oriented silicon steel is low in mechanics and novel ultrahigh-strength silicon steel is poor in magnetism. According to the solution, the preparation method of the thin-gauge non-oriented silicon steel comprises the following steps of converter smelting, RH refining, continuous casting, heating in a heating furnace, hot rolling, normalizing, acid pickling, cold rolling, annealing and coating. Chemical components in RH refined steel, the cooling speed of a casting blank in a secondary cooling area in the continuous casting process, the thickness of a hot-rolled strip in the hot rolling process, the normalizing speed and the normalizing temperature of the normalizing process, the reduction rates of the first pass and the last pass in the cold rolling process and the annealing speed and the annealing temperature of the annealing process are limited respectively. Fine grain strengthening and Si and Mn solid solution strengthening are adopted, and the product has excellent mechanical and magnetic performance, can be used for a stator and a rotor at the same time, and can meet the use requirements of driving motors of most of new energy automobiles at present.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

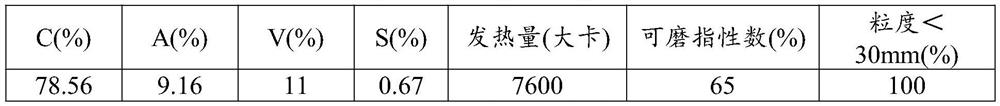

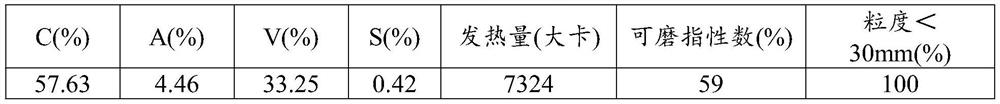

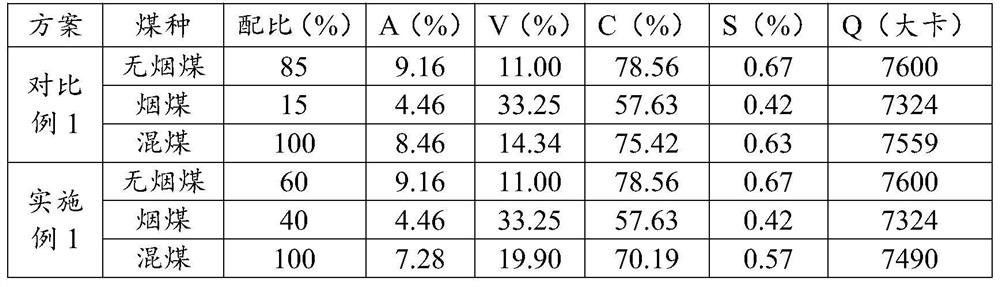

Method for improving blast furnace bituminous coal injection proportion

InactiveCN113151623AImprove stabilityQuality is not affectedBlast furnace detailsMining engineeringBlast furnace smelting

The invention belongs to the technical field of blast furnace smelting, and particularly relates to a method for improving the blast furnace bituminous coal injection proportion. The invention provides the method for improving the blast furnace bituminous coal injection proportion. The method comprises the following steps: smelting in-furnace sintered ore, in-furnace pellet ore, in-furnace lump ore and in-furnace coke under the injection of injection coal; the injection coal comprises the following components in percentage by mass: 60-65% of anthracite and 35-40% of bituminous coal; The initial crushing strength M of the in-furnace coke is greater than or equal to 91%, and the crushing strength after smelting is greater than or equal to 60%. Results of the embodiment show that the method provided by the invention can enable the proportion of the bituminous coal in the blast furnace injection coal to reach more than 40%, and on the premise that smooth production is ensured and the quality of molten iron is not influenced, the use amount of low-quality coal is increased, and the problem of shortage of high-quality coal resources is solved.

Owner:TANGSHAN DELONG STEEL CO LTD

Method for improving yield rate of high speed bar

InactiveCN110180891AHigh yieldUniform heating temperatureMetal rolling arrangementsHeating furnaceHeating temperature

The invention relates to the technical field of yield rate of high speed bars, and discloses a method for improving the yield rate of a high speed bar. The method comprises the following steps that (1), the weight of a steel billet is strictly controlled, so that raw material of a heating furnace is good in quality, if the weight of the steel billet is found to have serious deviation with a setting billet, the interval range of the deviation is larger than or equal to 20, then the adjustment is required immediately through contact with a upper working procedure, the yield rate is determined tothe maximum extent after the steel billet is rolled, the waste rate is reduced, and the waste rate is less than or equal to 5%; (2), a heating system is strictly executed, the heating efficiency andthe heating speed are improved, the heating temperature of the steel billet is promoted to be uniform, and the condition that the temperature is too high or too low is avoided. The method for improving the yield of the high speed bar has the advantage that measurements of setting a heating area and a rolling area are used for improving the yield rate, and the cold shearing loss is controlled by acooling bed finishing zone, the yield rate of the high speed bar is improved, the yield speed of the high speed bar is improved, so that the expenditure of cost is reduced and the waste of enterpriseresources is reduced; the method for improving the high yield rate of the high speed bar is convenient for users to carry out and operate.

Owner:CHENGYU VANADIUM TITANIUM TECH CO LTD

Decarburization and annealing process of high-carbon middle-and-low-grade cold rolling orientation-free silicon steel

ActiveCN102268516BGuaranteed smoothSimple decarburization annealing processFurnace typesHeat treatment process controlFurnace temperatureHigh carbon

The invention provides a decarburization and annealing process of high-carbon middle-and-low-grade cold rolling orientation-free silicon steel. In the process, a horizontal type continuous decarburization and annealing coating unit is adopted, the thickness of a steel belt is 0.35-0.65mm, the operation speed of the steel belt is controlled to 70-100m / min, the tension of the steel belt in a continuous decarburization and annealing furnace is 1800-2200N; the temperatures of various furnace sections are controlled as follows: the furnace temperature of a preheating / oxidation-free heating section is 1000-1100 DEG C, the furnace temperature of a radiant tube heating section is 900-920 DEG C, and the furnace temperature of a soaking section is 850-910 DGE C; apertures of a fan at a cooling section are 25-99% in turn; the pressures in the furnace are as follows: the pressure of an inlet is 25-30Pa, and the pressure of an outlet is 45-50Pa; and H2 and N2 are adopted as protective gas in the furnace, wherein the content of H2 is 25%-35%, the dew point value of the protective gas is 35+ / -5 DEG C, and the flux of the protective gas is 350-420m<3> / h. In the invention, the process is adopted so as to not only ensure that the steel belt is smooth, the magnetic property, magnetic ageing and the like of the steel belt meet technical requirements, the qualified rate of a finished product is improved and waste quantity is reduced but also ensure that production is smoothly carried out.

Owner:ANGANG STEEL CO LTD

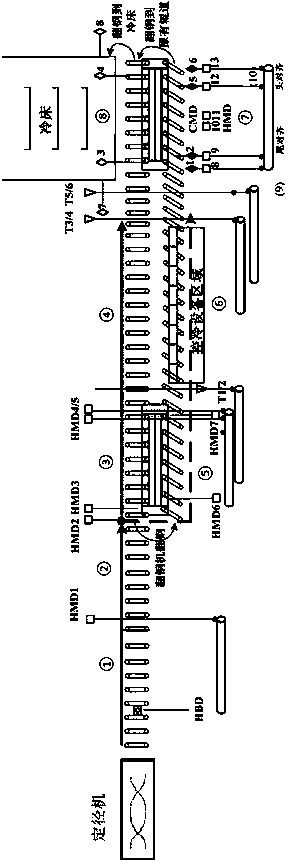

Steel tube on-line cooling roller bed control method

ActiveCN107971353AGuaranteed uptimeEnsure smooth production of steel pipesTemperature control deviceWork treatment devicesSteel tubeEngineering

The invention relates to the steel tube production on-line heat treatment technology. A steel tube on-line cooling roller bed control method can effectively control the roller bed running, starting and stopping, roller beds comprise a main conveying roller bed behind a sizing mill and an on-line cooling roller bed arranged in an on-line cooling production device, and the on-line cooling productiondevice is arranged beside the main conveying roller bed behind the sizing mill in parallel. By means of the steel tube on-line cooling roller bed control method, according to the steel tube real-timetracking position and metal detector detection signals, running, starting and stopping of the main conveying roller bed and the on-line cooling roller bed are controlled, and normal running and steeltube production smoothness of the on-line cooling production device are effectively guaranteed; and in addition, the sizing mill outlet alignment manner and the before-cooling roller bed starting time are optimized, and therefore the on-line cooling production rhythm is accelerated.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Gripping control method in rolling process of heavy rail

ActiveCN103157669AEnough kinetic energyBite smoothlyRoll speed control deviceEngineeringIntelligent control

The invention relates to the field of control of a rolling process, in particular to a gripping control method in a rolling process of a heavy rail. The gripping control method in the rolling process of the heavy rail is characterized in that the rotation speed of a main motor of a universal rolling mill is adjusted, so that a rolling piece obtains enough kinetic energy and grips a hole of a UR roller. The particular operation steps are as follows: (1) before the rolling piece enters the UR roller of the universal rolling mill, hole water is closed, and an automatic rolling program of the universal rolling mill is stopped; (2) after the rolling piece arrives transversely, the rotation speed of the main motor of the universal rolling mill is improved to 100-110 turns per minute; (3) the rolling piece is abraded on the UR roller for 30-40 seconds, and then the rotation speed of the main motor of the universal rolling mill is reduced to 10-20 turns per minute until the rolling piece grips the hole; and (4) after the rolling piece grips the hole by 2-3 meters, the rolling pieces is poured out by hand, and the automatic rolling program of the universal rolling mill is recovered. Compared with the prior art, the gripping control method in the rolling process of the heavy rail has the advantages of enabling the rolling piece to grip the hole of the UR roller smoothly, achieving intelligent control, and being suitable for the heavy rail with the level of more than 50 kilos.

Owner:ANGANG STEEL CO LTD

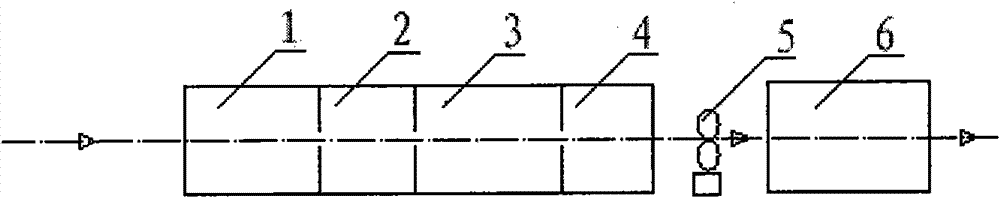

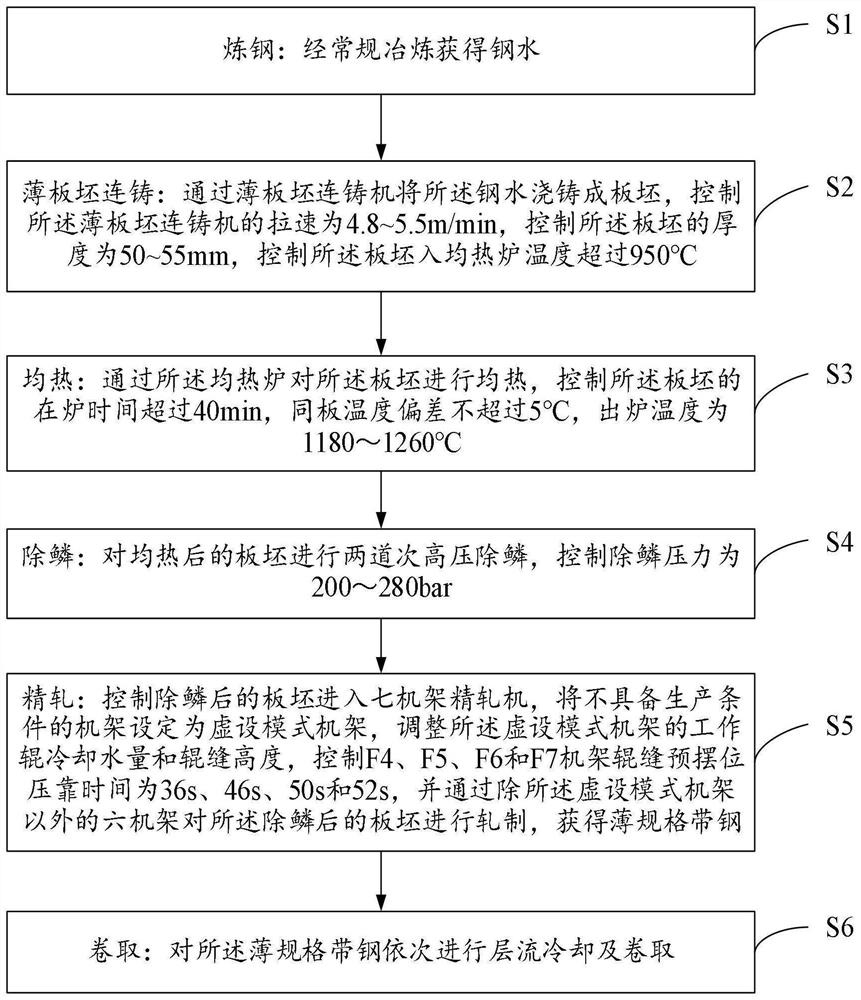

Sheet billet continuous casting and rolling dummy rolling method and control system thereof

ActiveCN111889513AProduction goes straightImprove product qualityRoll force/gap control deviceTemperature control deviceProduction lineStrip mill

The invention relates to the technical field of steel rolling, in particular to a sheet billet continuous casting and rolling dummy rolling method and a control system thereof. The method comprises the steps that steel smelting is conducted; sheet billet continuous casting is conducted; soaking is conducted; descaling is conducted; finish rolling is conducted, specifically, a sheet billet subjected to descaling is controlled to enter a seven-machine-frame finishing mill, machine frames without production conditions are set to be dummy mode machine frames, the flow rate of cooling water and theroller gap height of working rollers of the dummy mode machine frames are adjusted, the roller gap pre-positioning pressing time of the machine frames F4, F5, F6 and F7, and the sheet billet subjected to descaling is rolled through the reset six machine frames to obtain a piece of thin strip steel; and winding is conducted. When one of the machine frames breaks down and does not have the production condition, production can be continued through dummy rolling, accordingly, it is ensured that production of a sheet billet continuous casting and rolling production line is smooth, and the productquality is stable, the operation efficiency of the finishing mill is improved, the abnormal stopping time is shortened, and the production cost is reduced.

Owner:武汉钢铁有限公司

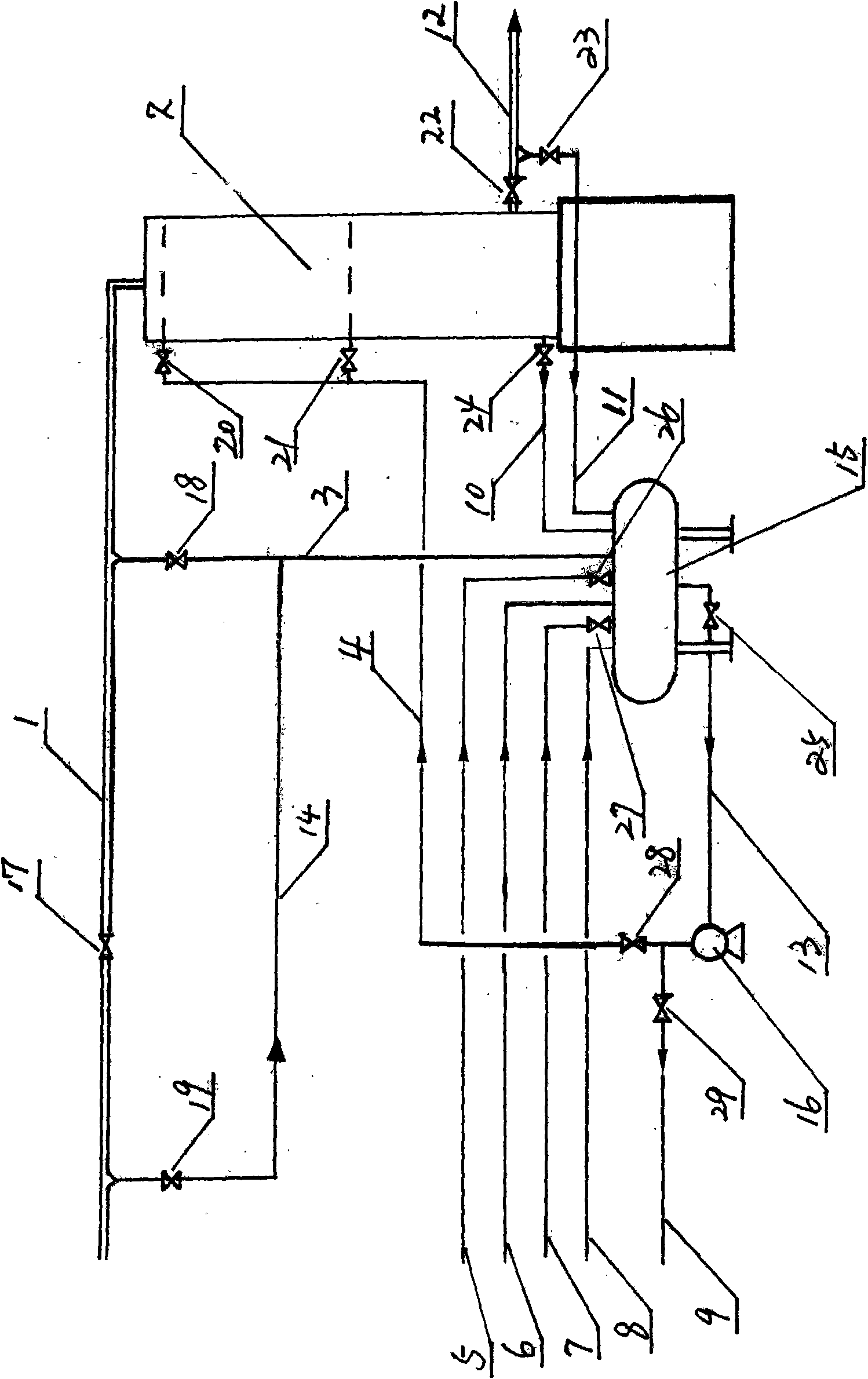

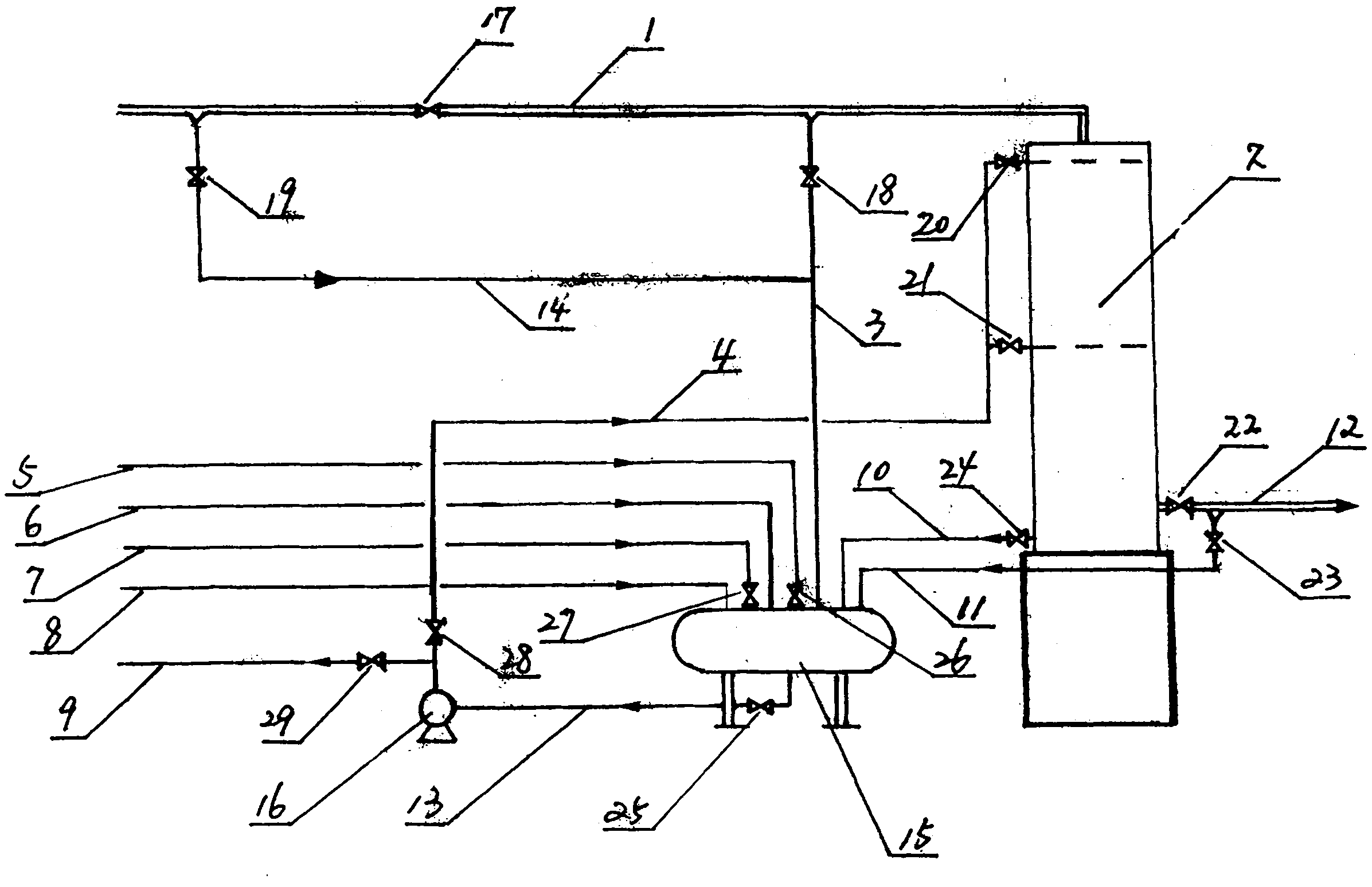

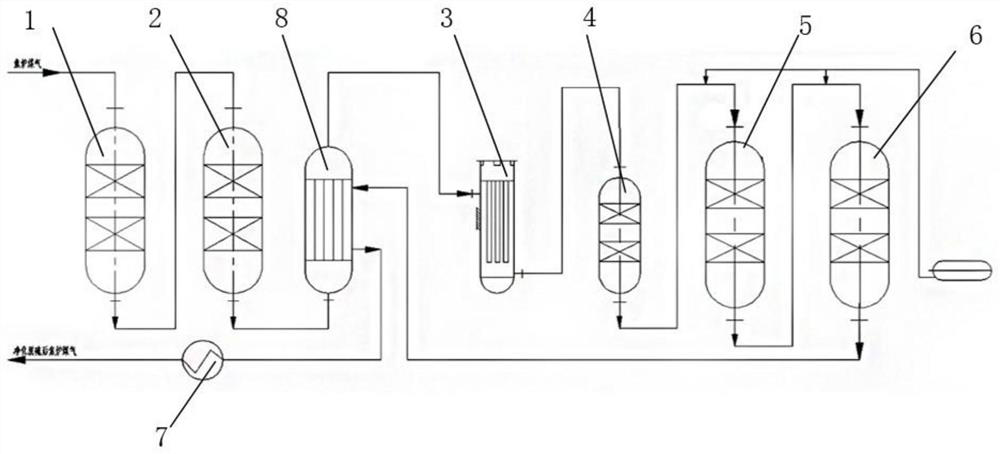

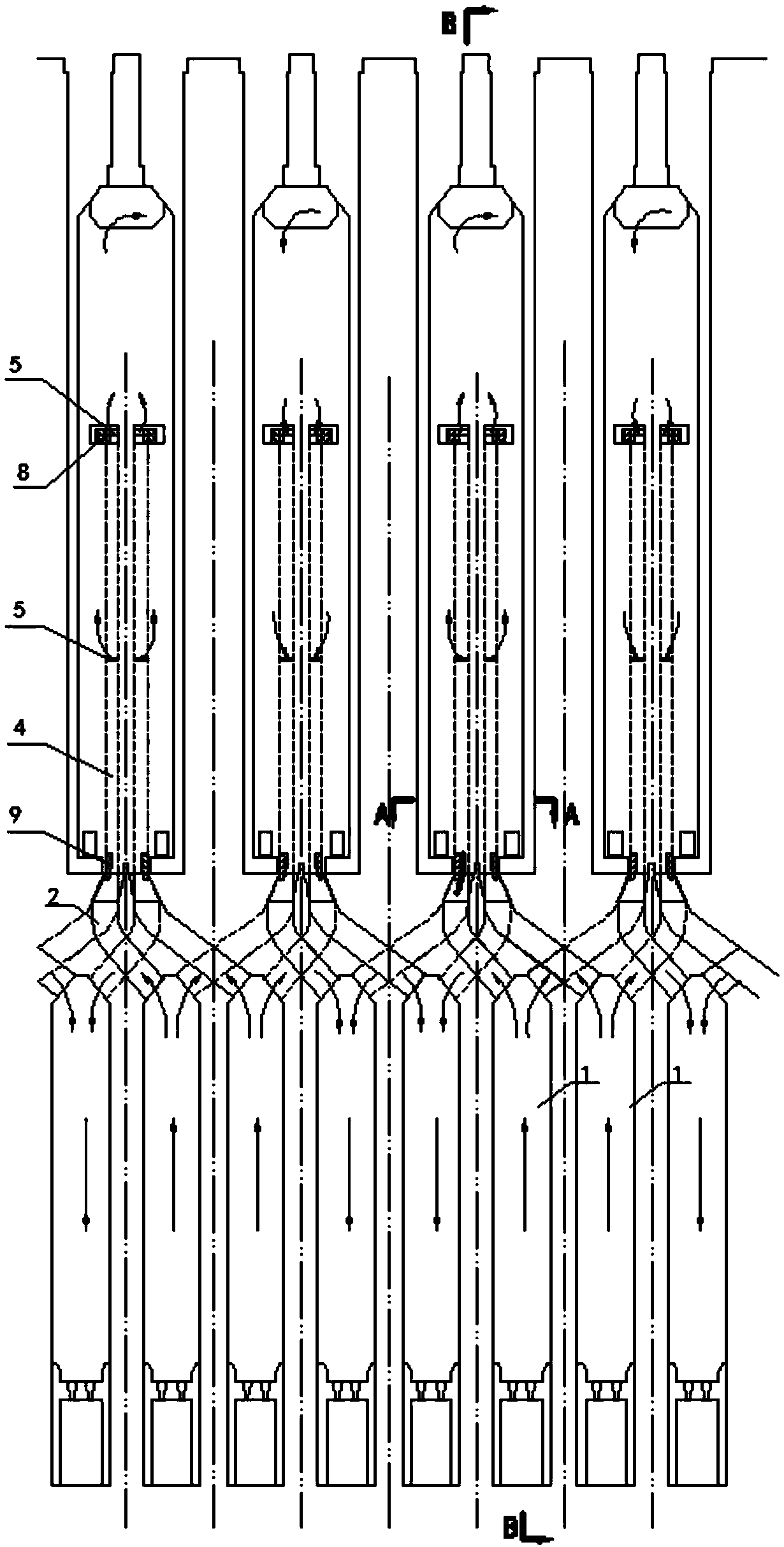

Fine desulfurization system forcoke oven gas

PendingCN112940797AImprove desulfurization effectSmooth processGas purification by catalytic conversionGas contaminants removalThermodynamicsHydrogenation reaction

The invention discloses a fine desulfurization system for coke oven gas. The fine desulfurization system comprises a first filter, a gas holder, a compressor, a second filter, a coarse desulfurization tank, a heater, a pre-hydrogenation reactor, a primary hydrogenation reactor, a fine desulfurization tank and a cooler, wherein the first filter is used for filtering tar in the coke oven gas; the compressor is used for compressing coke oven gas; the second filter is used for filtering tar fog drops in the coke oven gas; the coarse desulfurization tank is used for carrying out inorganic sulfur desulfurization treatment on coke oven gas, and the heater is used for heating the coke oven gas; the pre-hydrogenation reactor is used for carrying out hydro-conversion on coke oven gas to carry out organic sulfur desulfurization treatment; the primary hydrogenation reactor is used for carrying out hydro-conversion on the coke oven gas again to carry out secondary desulfurization treatment on organic sulfur; the fine desulfurization tank is used for carrying out inorganic sulfur desulfurization treatment on the coke oven gas again; and the cooler is used for cooling coke oven gas. Therefore, the impurity sulfur in the coke oven gas can be fully treated, so that the final coke oven gas can meet the desulfurization index.

Owner:河北荣明环保设备有限公司

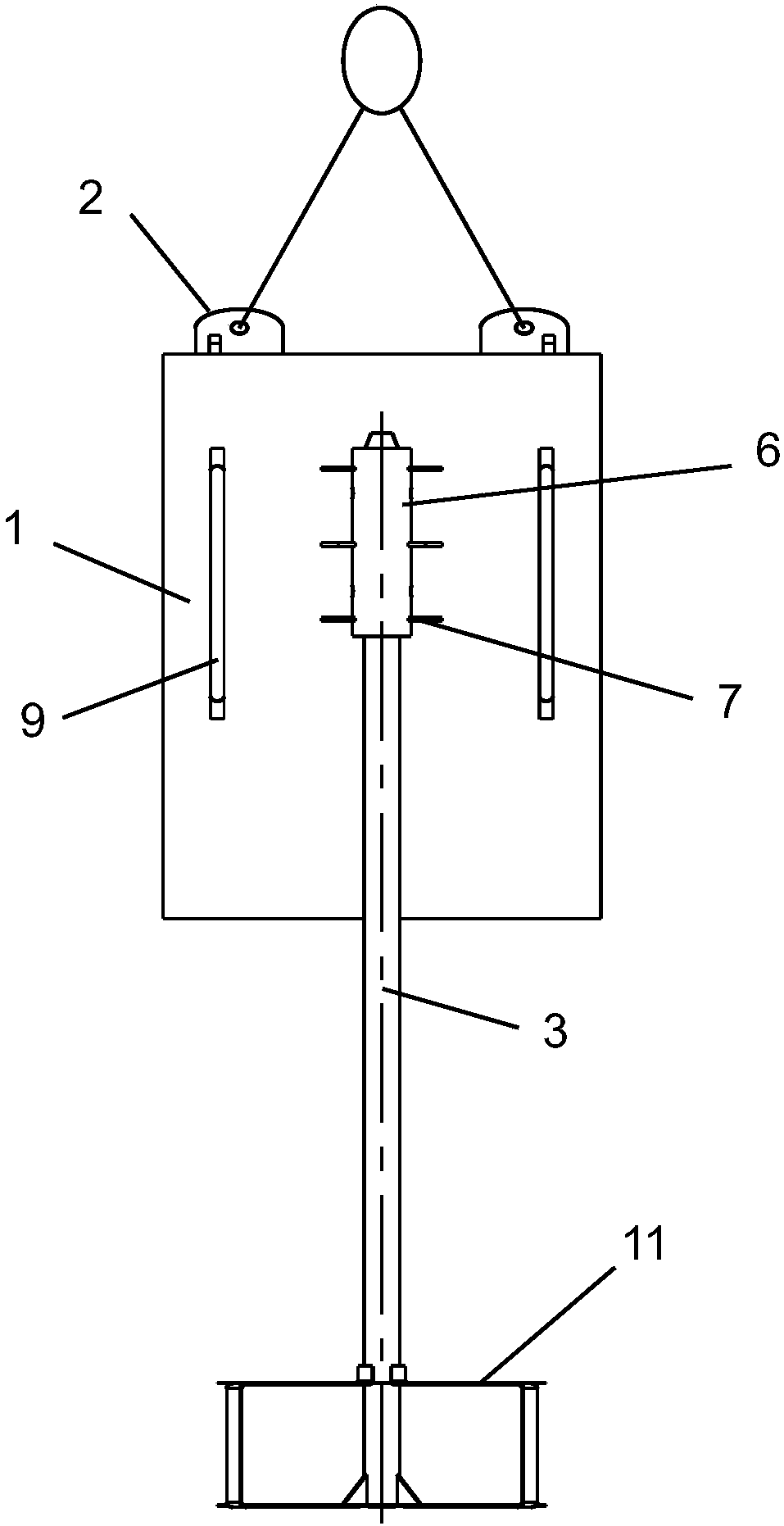

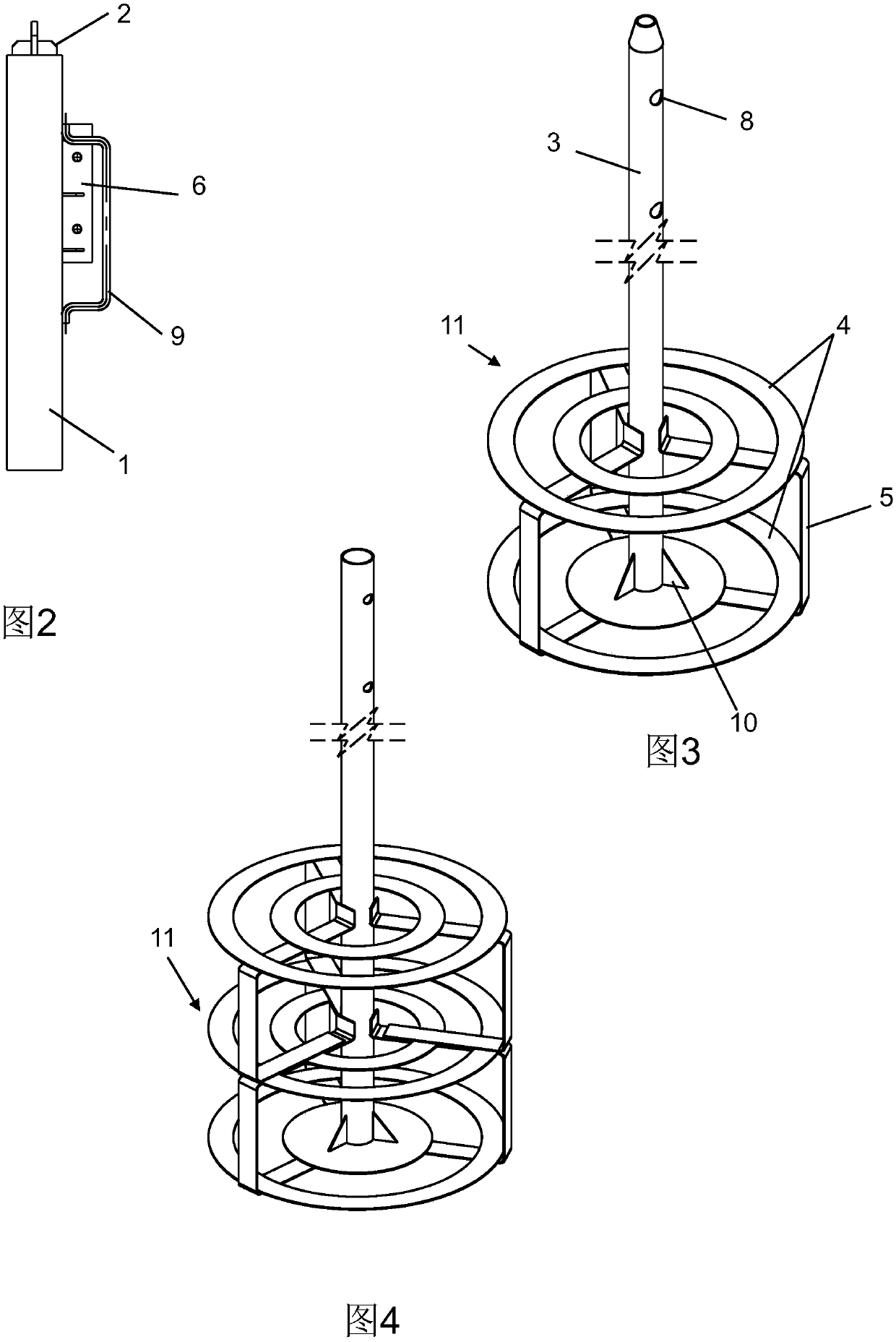

Adding device capable of easily oxidizing precious alloys

InactiveCN110317924AHigh yield of alloying elementsIncrease the yield of precious alloying elementsAlloy elementConcentric ring

The invention discloses an adding device capable of easily oxidizing precious alloys. The adding device comprises a pressing block mechanism and a stock bin mechanism. The pressing block mechanism comprises a pressing block, lifting lugs arranged at the upper end of the pressing block, a detachable connecting part arranged on one side of the pressing block. The stock bin mechanism comprises a multi-layer stock bin and a suspender. The stock bin comprises multiple annular flat steel frames composed of concentric rings, and multiple flat steel connecting beams for radially connecting the concentric rings and axially connecting the adjacent annular flat steel frames, the lower end of the suspender stretches into the center of the stock bin and is connected with the annular flat steel frame atthe bottom-most position, the flat steel connecting beams are connected with the suspender, and the upper end of the suspender is connected with the pressing block through the detachable connecting part. According to the adding device, an original precious alloy adding manner can be changed, cast adding is changed into adding by going deep into the bottom of a steel ladle, the yield of precious alloy elements is increased, and the production cost is reduced.

Owner:宝武特种冶金有限公司

Method for nitrogen increase of nitrogen-containing steel for wind power flange through RH vacuum degassing system

InactiveCN111411198ANitrogen increase is stable and fastImprove nitrogen efficiencyThermodynamicsLow nitrogen

The invention relates to a method for nitrogen increase of nitrogen-containing steel for a wind power flange through a RH vacuum degassing system, and belongs to the technical field of metallurgy. Inorder to solve the problems of low nitrogen increase efficiency, inaccurate nitrogen content control and poor dehydrogenation effects of an existing nitrogen increase method, the method for nitrogen increase of the nitrogen-containing steel for the wind power flange through the RH vacuum degassing system is provided. Argon-nitrogen pipeline switching of the RH vacuum degassing system is utilized,nitrogen serves as lifting gas, stable and quick nitrogen increase is achieved through RH vacuum position nitrogen increase and bottom nitrogen direct introduction for nitrogen increase after vacuum breaking, and then nitrogen soft blowing is used for supplementation of nitrogen increase to precisely control the nitrogen content. Argon soft blowing is utilized to ensure the dehydrogenation effect,and the hydrogen content is controlled to be smaller than or equal to 1.0 ppm. According to the method, by flexibly adjusting switching of the nitrogen and the argon, vacuumizing and soft blowing total time is controlled within 45 minutes, smooth production can be ensured, the nitrogen content of the nitrogen-containing steel for the wind power flange is controlled in an internal control range, and stable control over the performance of steel products is ensured.

Owner:建龙北满特殊钢有限责任公司

A control method and equipment for seaming centering of thin strip steel in continuous annealing furnace

ActiveCN105618596BReduce the risk of belt breakageImprove sewing precisionMetal-working feeding devicesMetal working apparatusStrip steelEngineering

Owner:BAOSHAN IRON & STEEL CO LTD

Machining equipment for vanadium-titanium magnetite and machining technology of vanadium-titanium magnetite

The invention provides machining equipment for vanadium-titanium magnetite and a machining technology of the vanadium-titanium magnetite. The equipment comprises a batching unit, a drying unit, a pellet manufacturing unit, a reducing unit and a separating unit, wherein the batching unit comprises a batching chamber, and the batching chamber is internally provided with a stirring assembly; the drying unit comprises a drying chamber, the drying chamber is internally provided with a heating assembly, and the drying chamber is used for receiving raw materials conveyed out of the batching chamber;the pellet manufacturing unit is used for manufacturing the dried raw materials into pellets, and the reducing unit comprises a reductive vertical furnace, and the reductive vertical furnace is provided with a feeding port, a discharging port, an air inlet and an air outlet; and the pellets enter the reductive vertical furnace from the feeding port, and the separating unit comprises a melt separation furnace; and the discharging port communicates with the melt separation furnace. The machining and manufacturing operation of the vanadium-titanium magnetite is convenient and reliable, the manufactured product is high in value, and the utilization rate of the raw materials is high.

Owner:攀枝花正德环保新材料科技开发有限公司

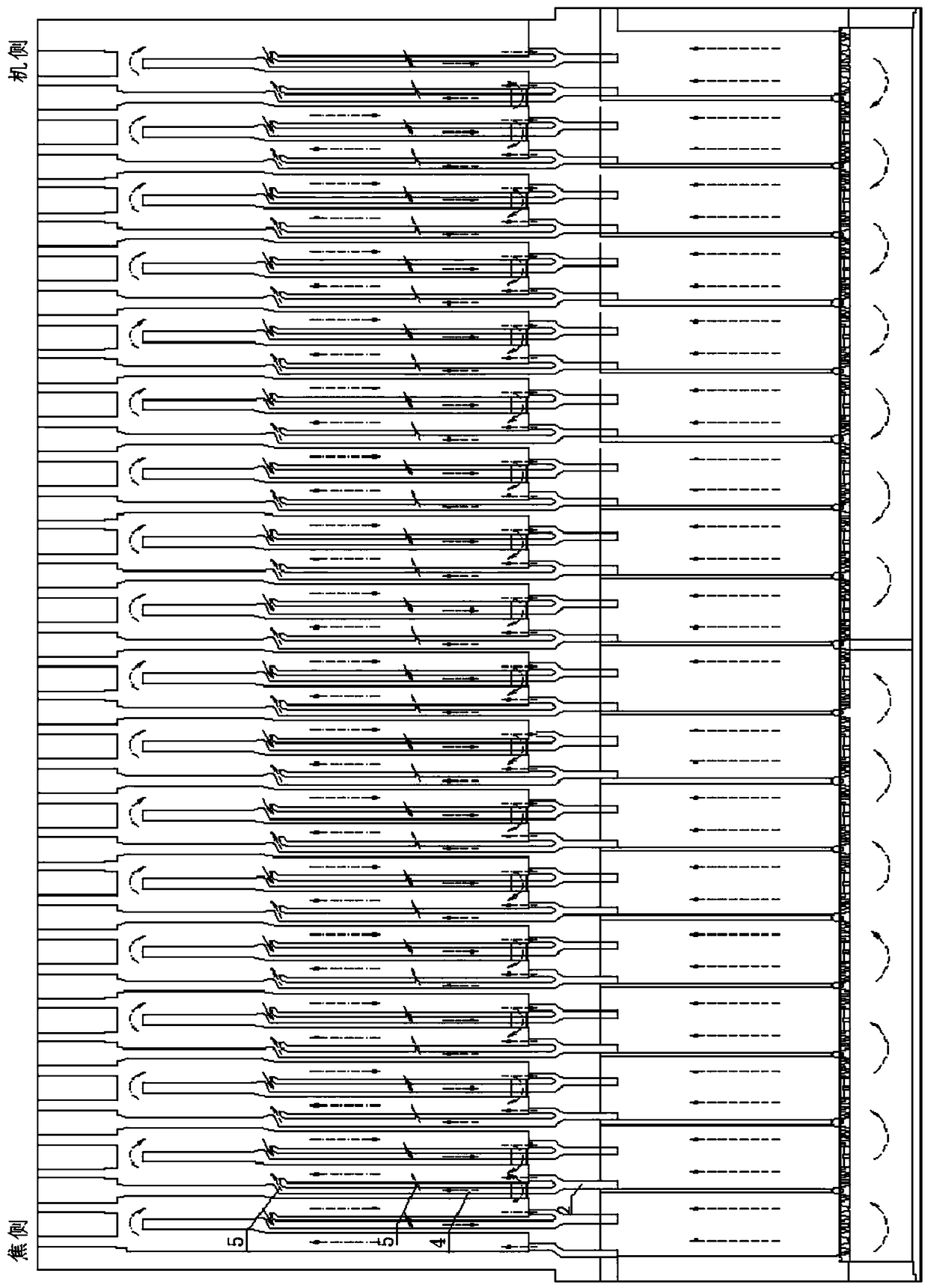

Coke-oven heating system with variable heating height for gas-rich heating and adjustment method thereof

PendingCN108728125AChange heating heightMeet production needsCombustible gas coke oven heatingCombustion chamberCombustion

The invention relates to a coke-oven heating system with variable heating height for gas-rich heating and an adjustment method thereof. The coke-oven heating system comprises small flues, a controllable heat exchange passage, a combustion-supporting gas passage and a combustion chamber connected in order from bottom to top. The number of controllable heat exchange passages corresponding to each combustion chamber is at least two, each of the combustion-supporting gas passages is composed of a lower inclined section and an upper straight section, each of the combustion-supporting gas passages are communicated with a vertical flue through at least one airflow outlet, and at least one of the airflow outlets on each combustion-supporting gas passage is located at a different height; one end ofthe small flue is connected to a branch flue through a small flue connecting pipe and an exhaust gas shutter, and the small flue connecting pipe is provided with an air inlet and an intake air flow adjusting device; a plurality of exhaust disks corresponding to each small flue are arranged in the exhaust gas shutter. The invention can change the height position of the combustion in the vertical flue at any time according to the need to ensure that the heat distribution meets the production demand, and the adjustment method is simple and convenient.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Peritectic steel continuous casting covering slag

The invention discloses peritectic steel continuous casting covering slag, which comprises the following components in percentage by weight: 70 to 78 percent of calcium silicate, 4.5 to 8.5 percent of kieselguhr, 4.5 to 9.5 percent of insulating brick powder, 1 to 7 percent of cryolite, 1 to 7 percent of high-temperature aluminum oxide, 0.5 to 4.5 percent of carbon black, 1 to 5 percent of petroleum coke and 0.5 to 5 percent of expanded graphite. The invention has the advantages that: the peritectic steel continuous casting covering slag has high physical performance and operational performance, and can meet the requirement of peritectic steel continuous casting production of steelmaking enterprises in China at present and create huge economic and social benefits; and the invention has the characteristics that: 1, the covering slag overcomes the surface defects of casting blanks effectively, and the defective index can be reduced by over 20 percent; 2, the covering slag special for special steel can be used for producing the special steel which are not produced previously; and 3, the covering slag is stable, ensures that the production is smooth, and prevents loss caused by accidents such as bleed-out and the like.

Owner:丹东泓辉科大高温材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com