Machining equipment for vanadium-titanium magnetite and machining technology of vanadium-titanium magnetite

A technology of vanadium titanomagnetite and processing equipment, which is applied in the furnace type, furnace, shaft furnace and other directions, can solve the problems of weak reducing ability and low extraction rate, and achieves convenient manufacturing and processing, easy extraction and processing, and simple and reasonable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

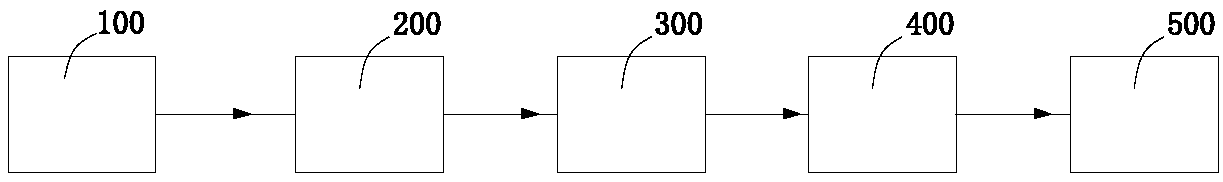

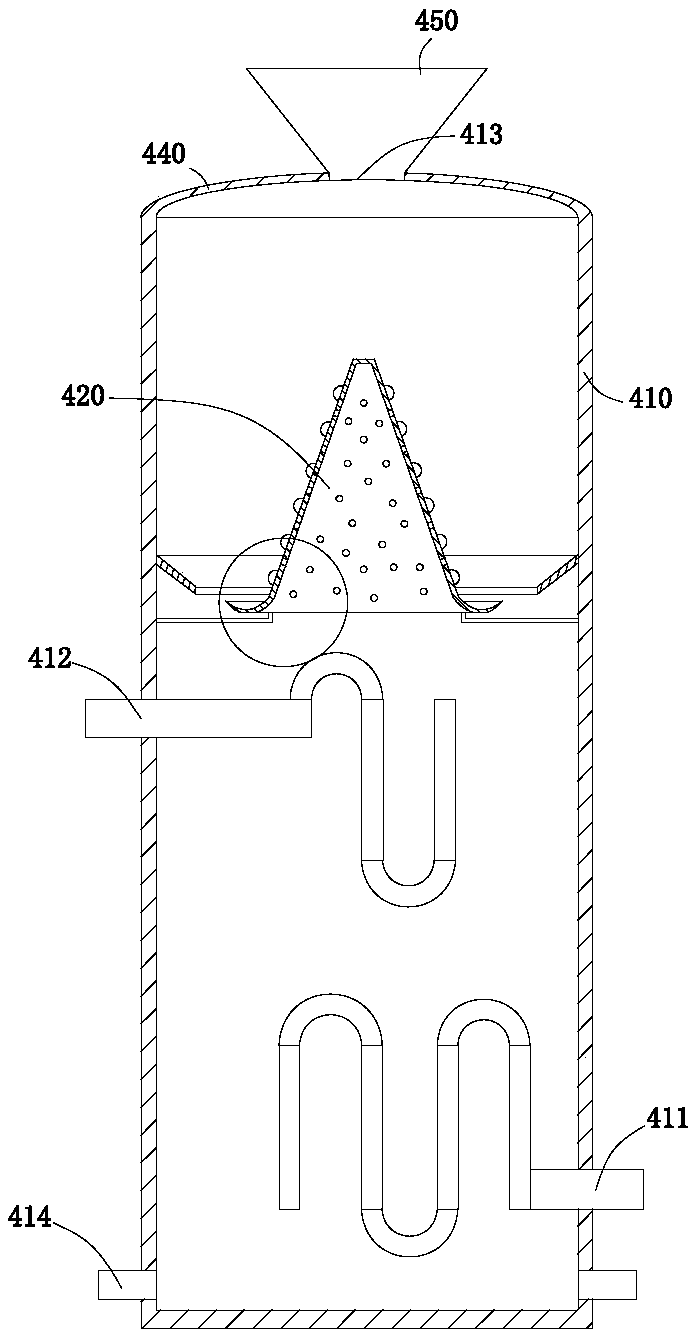

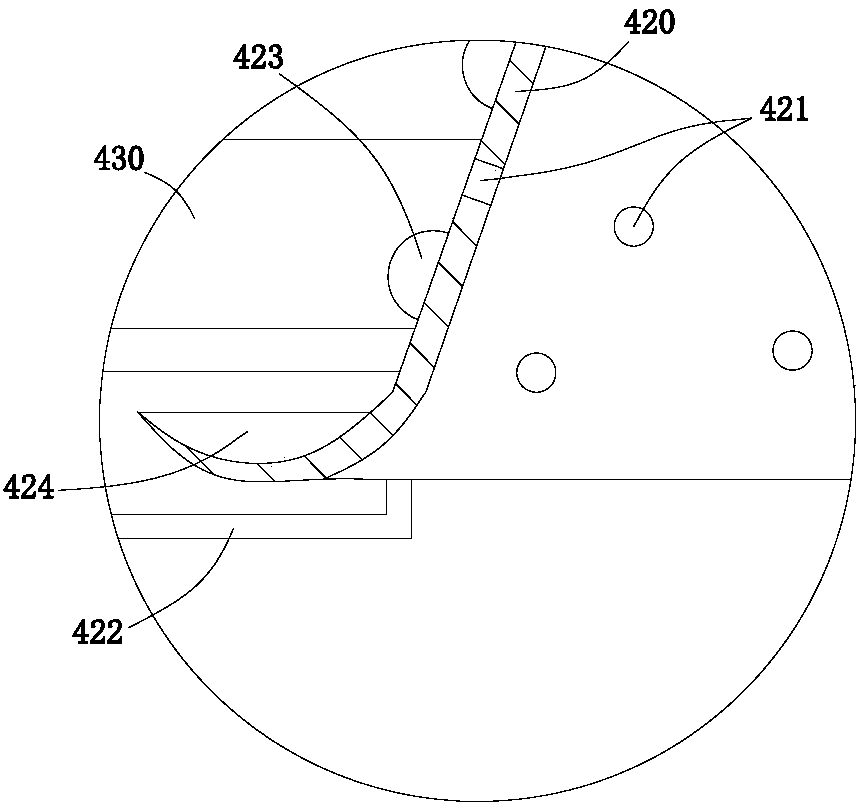

[0045] see figure 1 - Figure 4 , the embodiment of the present invention provides a vanadium-titanium magnetite processing equipment, including a batching unit 100 , a drying unit 200 , a pellet manufacturing unit 300 , a reduction unit 400 and a separation unit 500 .

[0046] The batching unit 100 includes a batching chamber, and the batching chamber can be a metal tank, such as a steel tank, a steel alloy tank, a round tank or a square tank, and a stirring assembly is installed at the bottom of the batching chamber, and the stirring assembly can be powered by a motor. The stirring shaft rotates to realize the stirring of raw materials. The raw materials include vanadium-titanium magnetite, a catalyst and a binder. The catalyst can be an existing material, such as coke, and the binder can be water. The batching room is provided with a raw material outlet, and a hopper is installed at the raw material outlet, and the hopper is transported to the drying unit 200 by means of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com