Patents

Literature

351 results about "Manufacturing cell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing cells are sets of machines that are grouped by the products or parts they produce in a lean manufacturing environment. This system is used in the cellular manufacturing concept, which is distinct from the traditional functional manufacturing system in which all similar machines are grouped together.

Integrated polymer and metal case ammunition manufacturing system and method

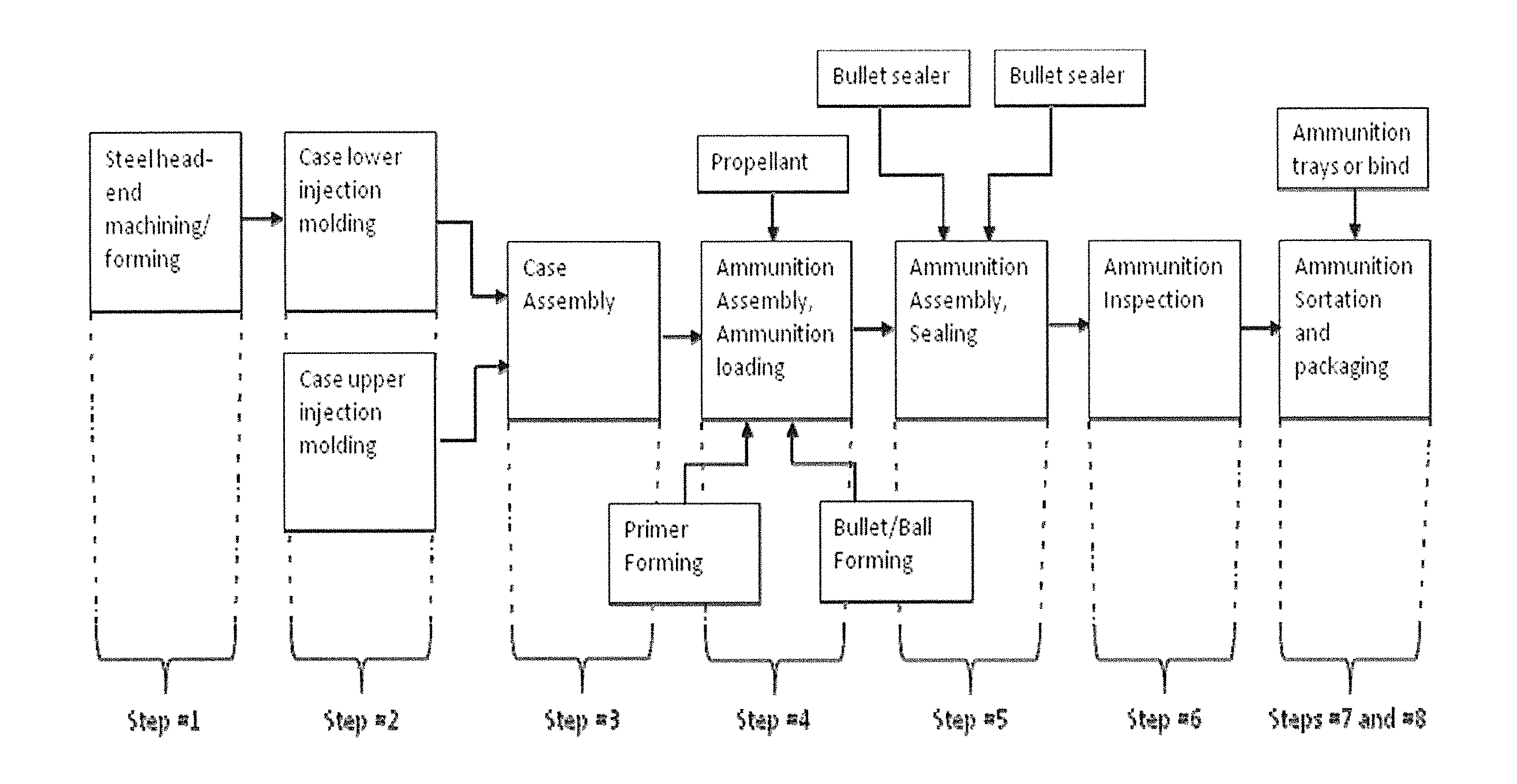

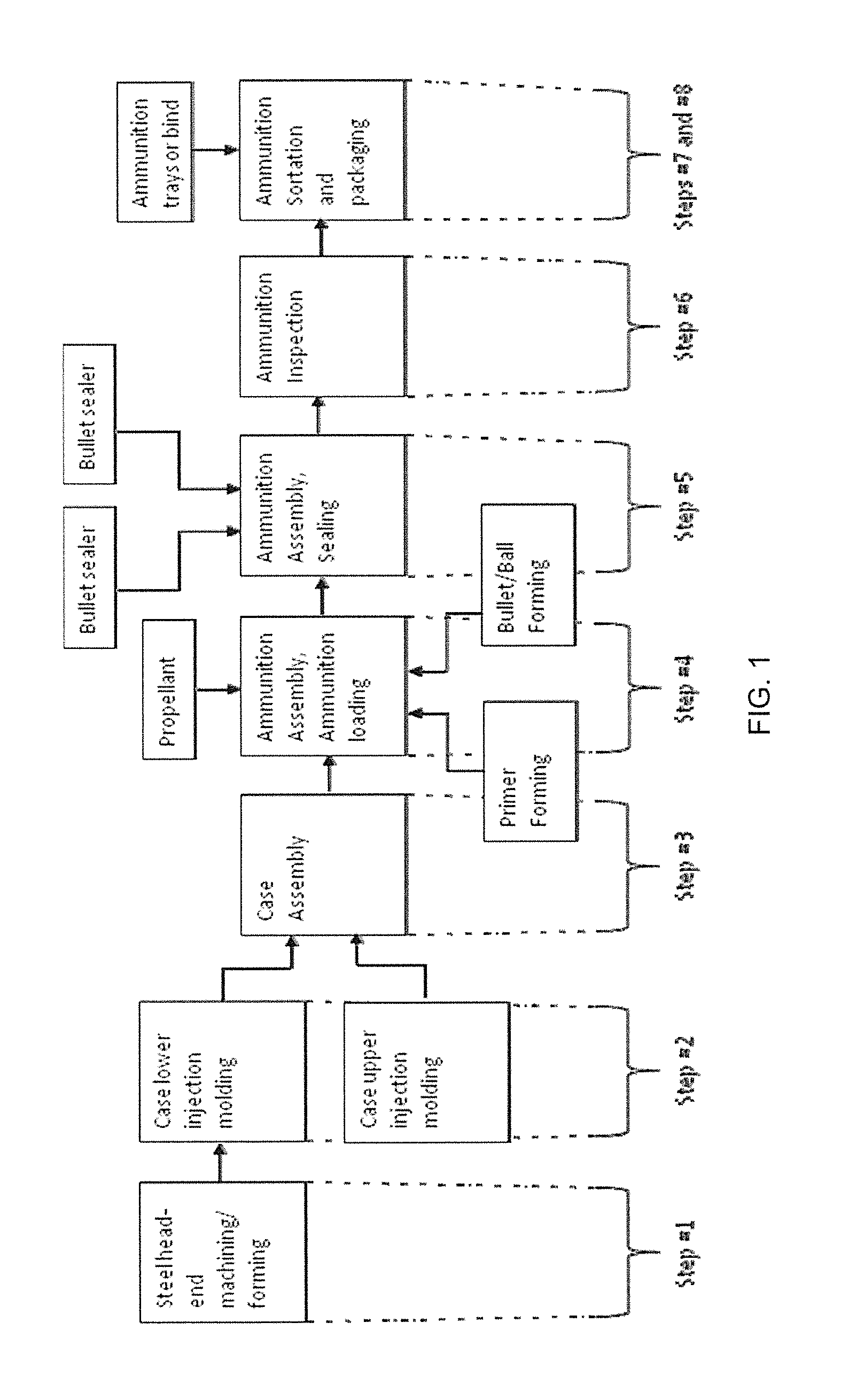

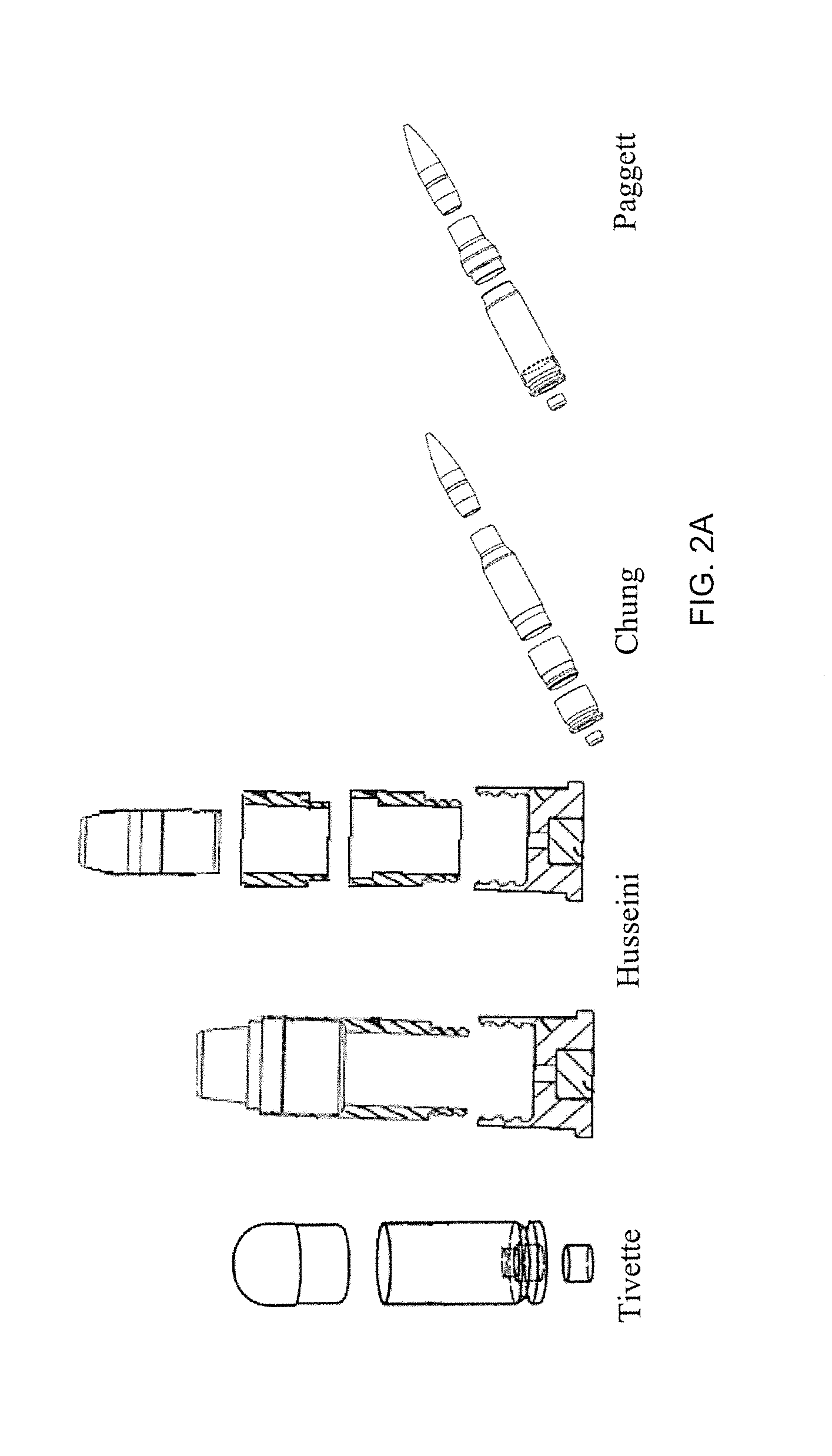

A fully automated, integrated, end-to-end synchronized and compact manufacturing system produces polymer or metal case ammunition. Manufacturing stations support case assembly, sealing (gluing / welding), final product inspection, cartridge packaging or binning, and loading. Station modularity facilitates rapid changeover to accommodate ammunition of differing calibers. Sensors and apparatus may be provided to place a manufacturing cell in a wait state until all components or materials are received in a preferred orientation for proper assembly. The system may join and use multipart cases, each including a lower portion with a head end attached thereto and at least one upper portion having a necked-down transition to the open top end. Elevator feeders, vibratory bowl feeders, and robotic pick-and-place feeders may be used to deliver components for assembly.

Owner:CYBERNET SYST

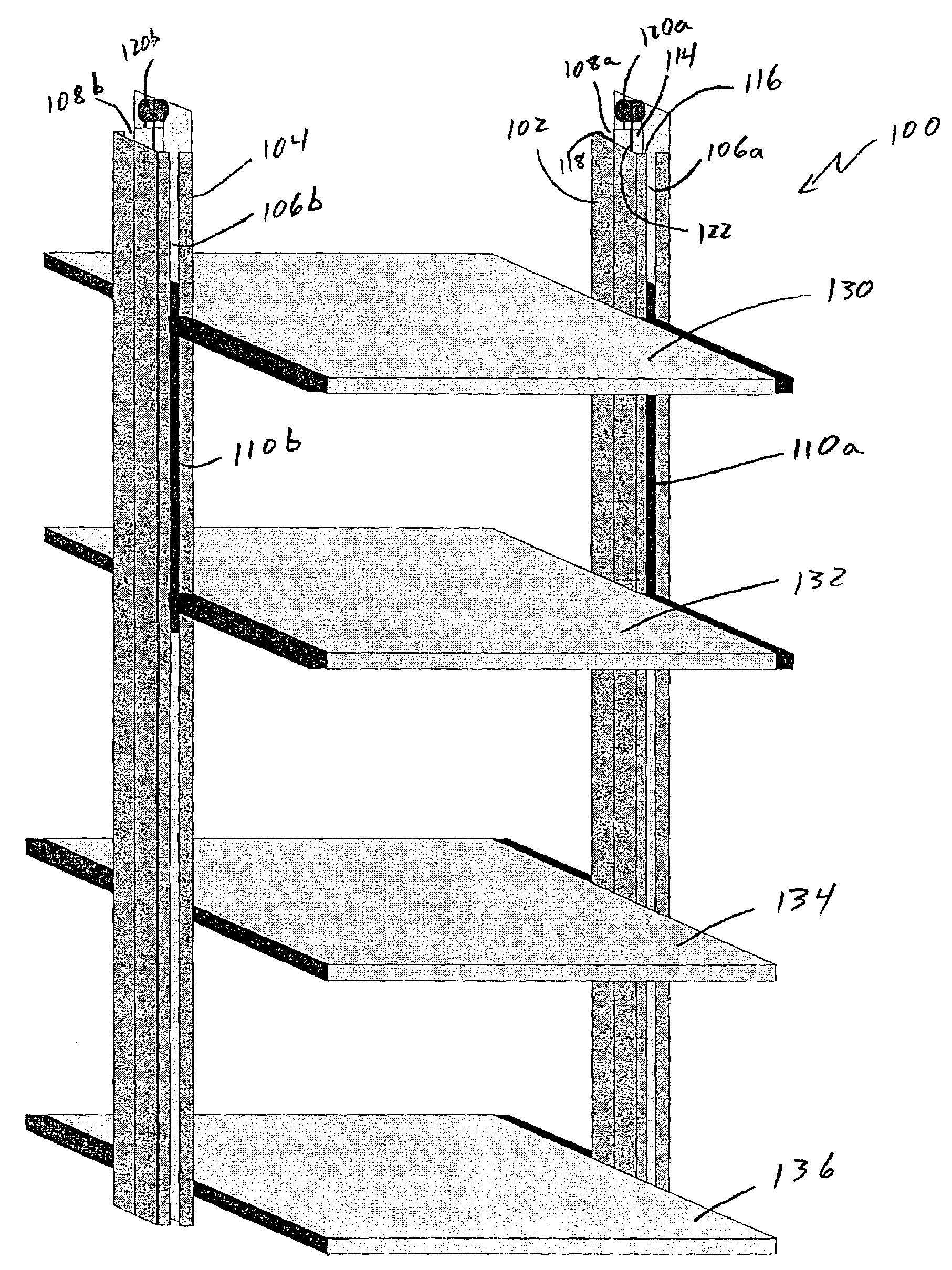

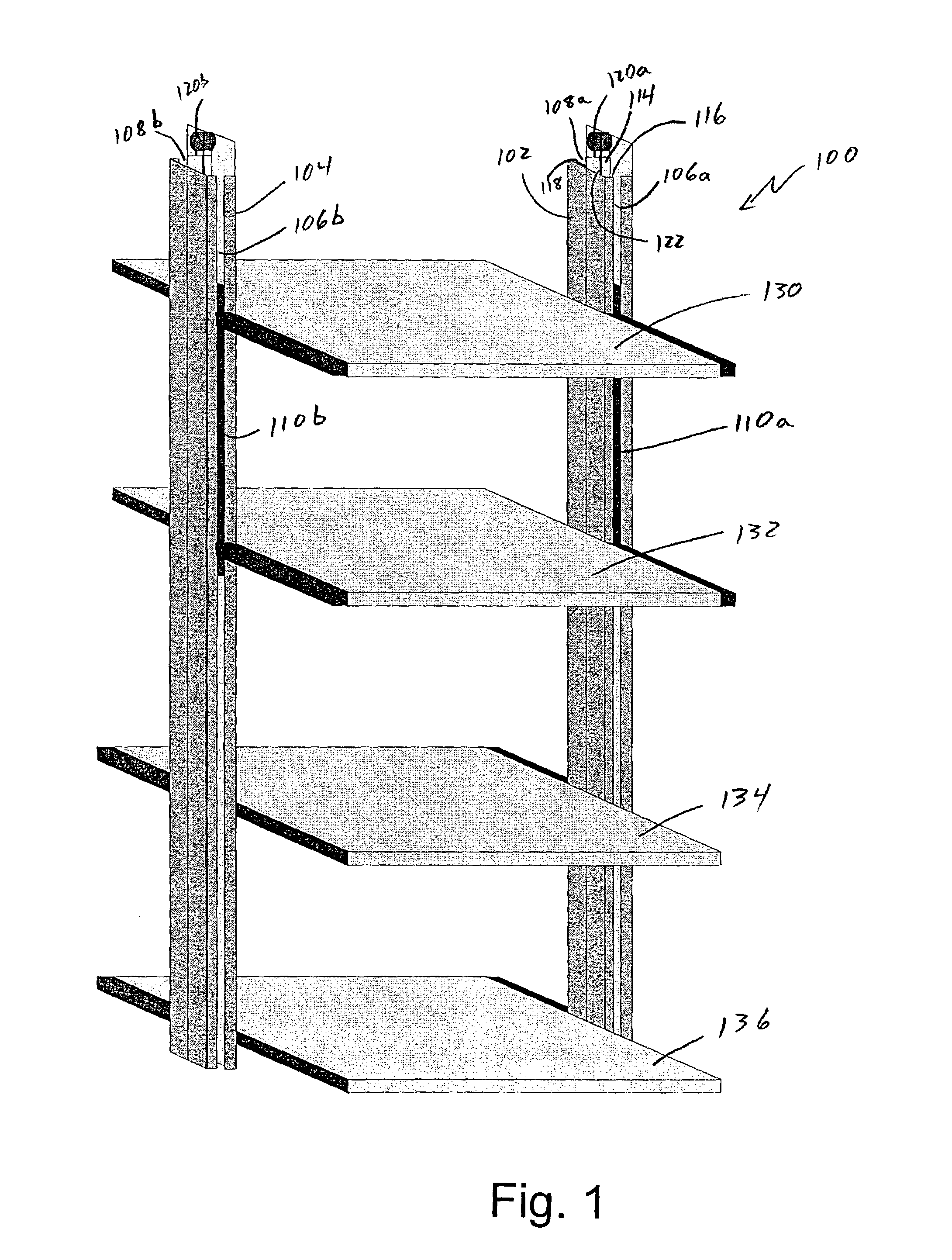

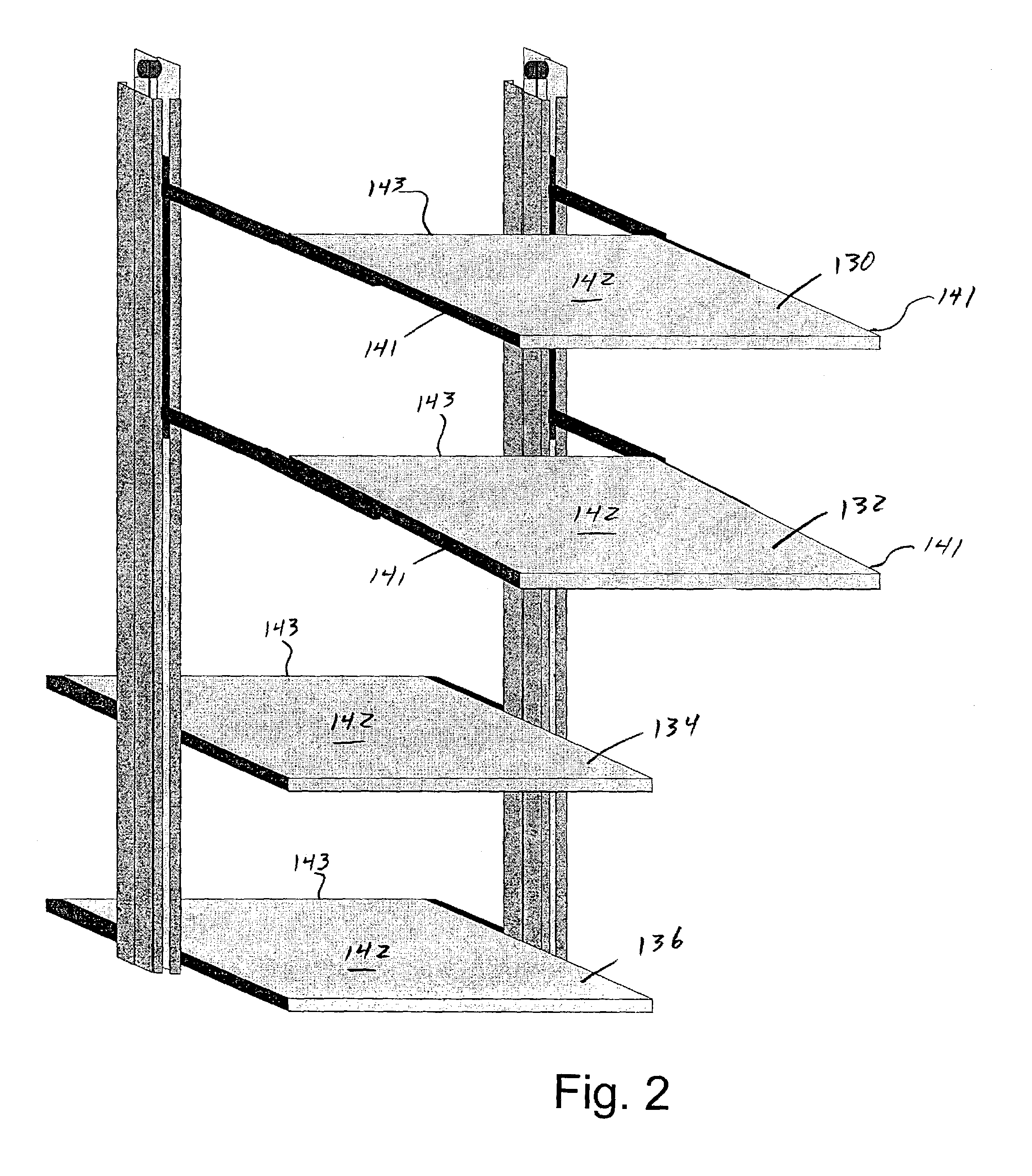

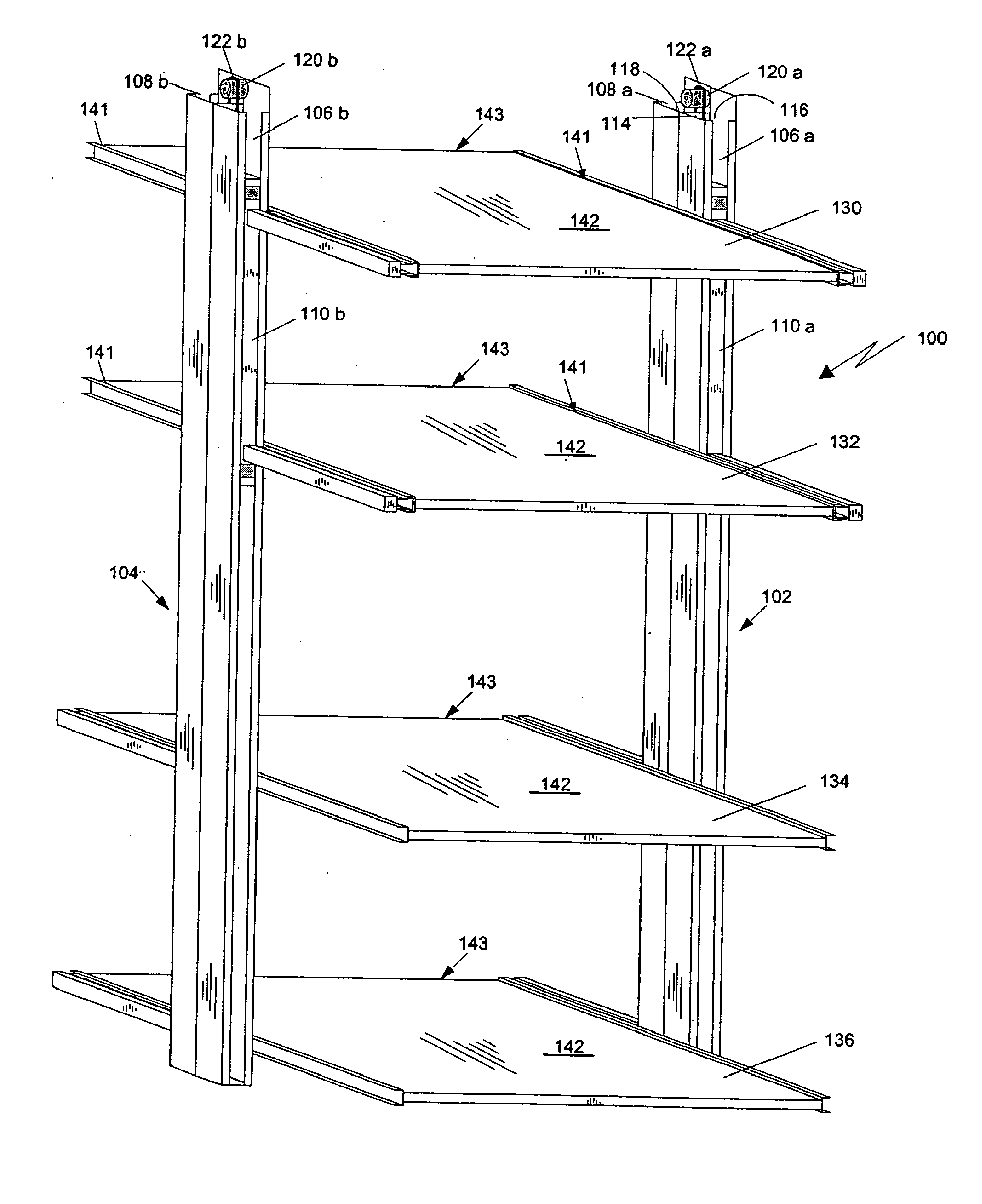

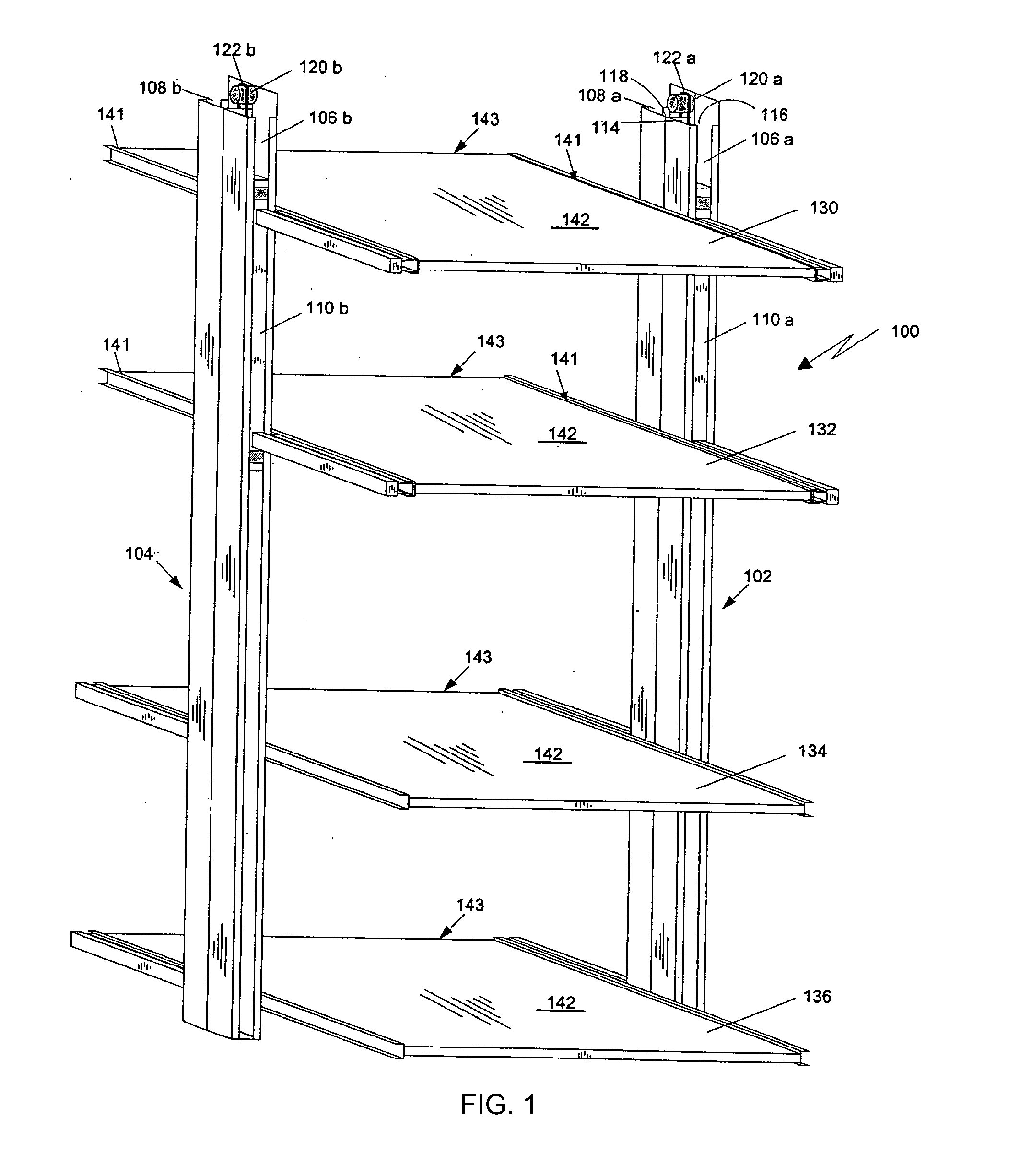

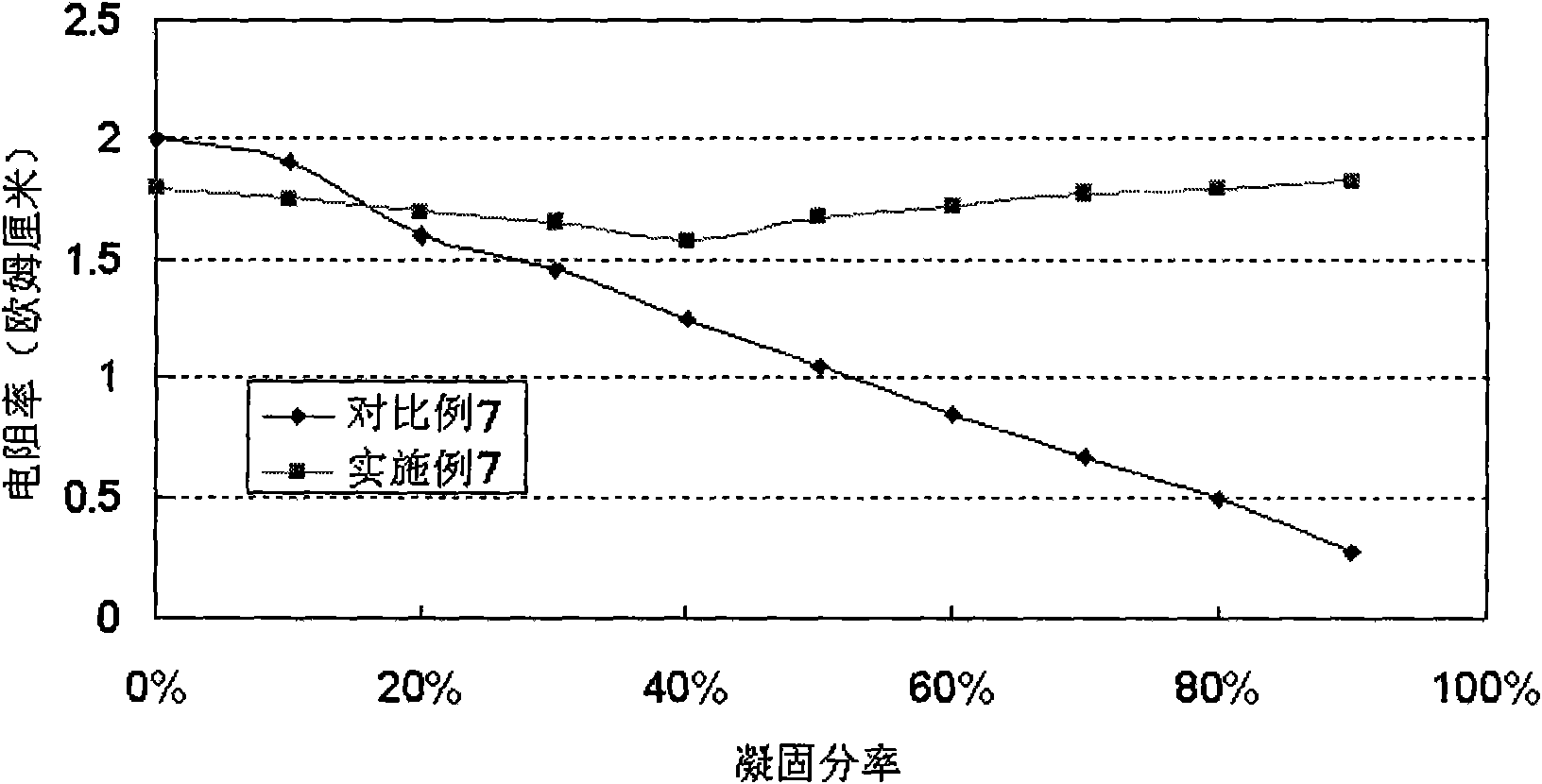

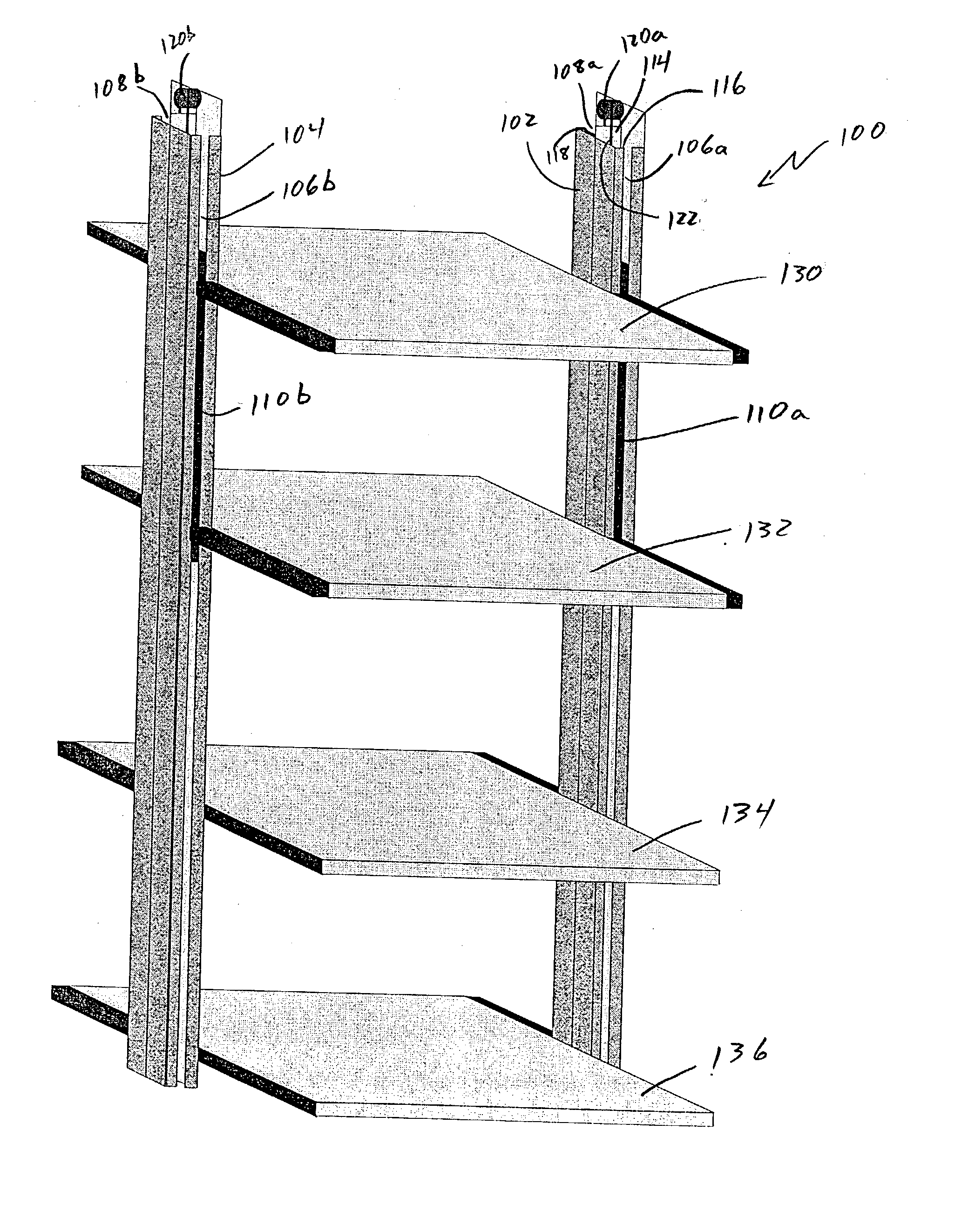

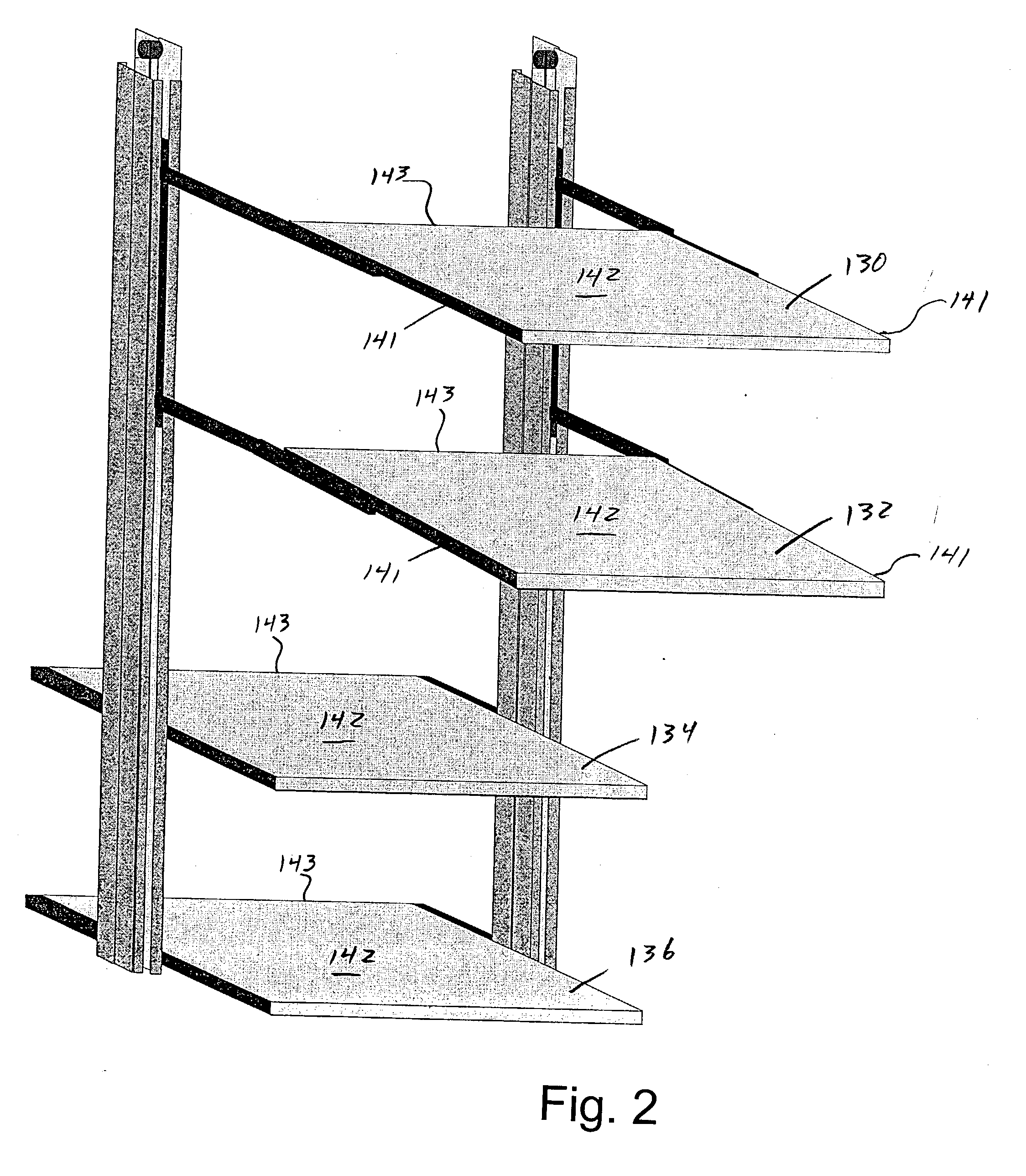

Shelving system

InactiveUS6976598B2Easy accessEfficient and reliableFolding cabinetsDismountable cabinetsEngineeringManufacturing cell

The present disclosure provides enhanced storage systems that facilitate efficient storage of, and access to, a variety of items and products. Exemplary systems according to the present disclosure include Mechanisms that permit reliable and efficient repositioning of one or more shelves, thereby enhancing utilization and efficiencies associated therewith. Shelving systems facilitate synchronized vertical motion of shelving units, e.g., based on coordinated pulley / cable systems, and advantageously include spring designs that facilitate controlled vertical motion of shelving units, e.g., based on fluid movement and / or discharge from the spring design. Shelves and / or shelving units may be readily repositioned at elbow or eye level, and repositioned at their respective initial positions in an efficient and advantageous manner. The shelving systems may be original manufacture units or may be designed for use in retrofitting existing shelving systems.

Owner:ENGEL ZACKARY

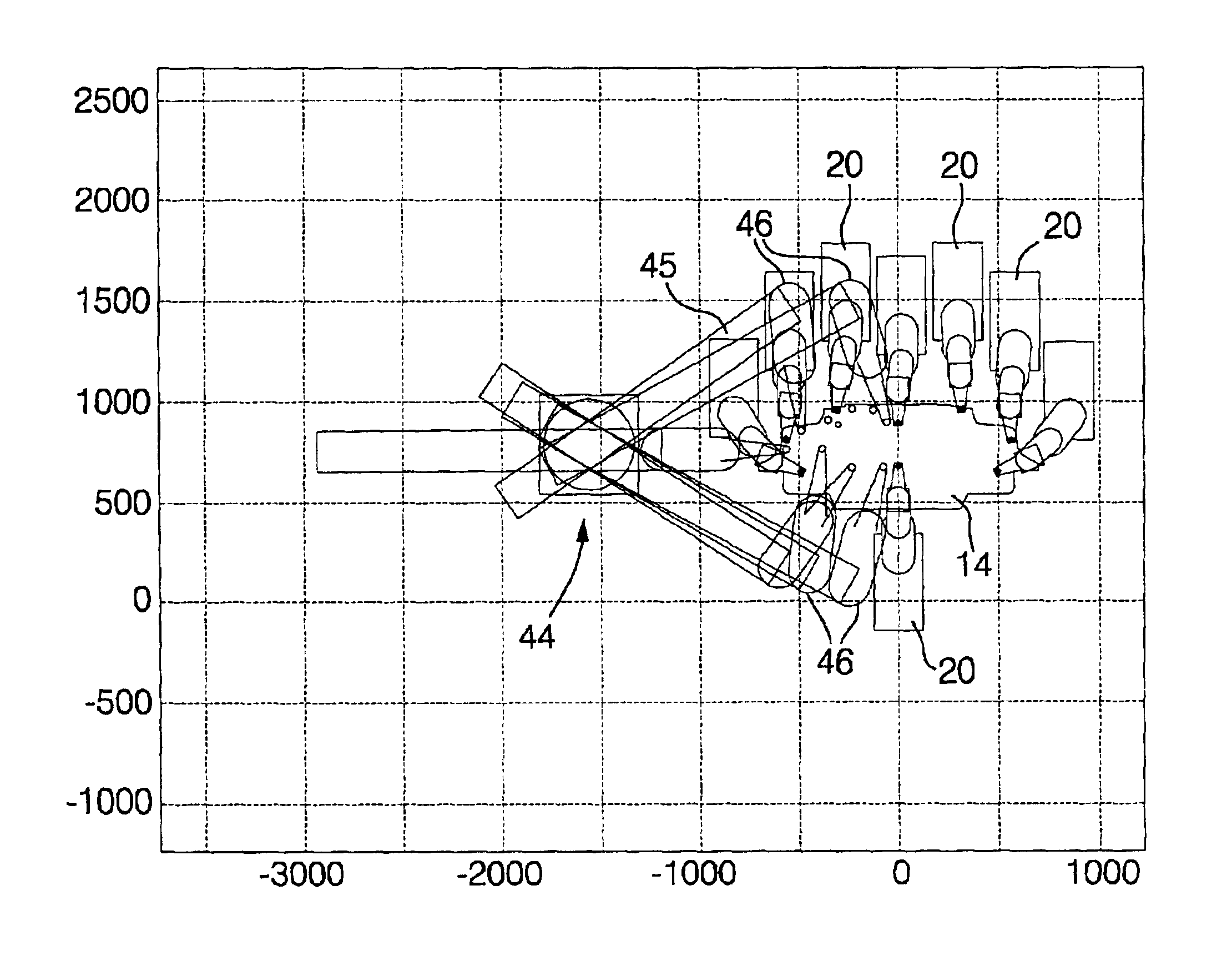

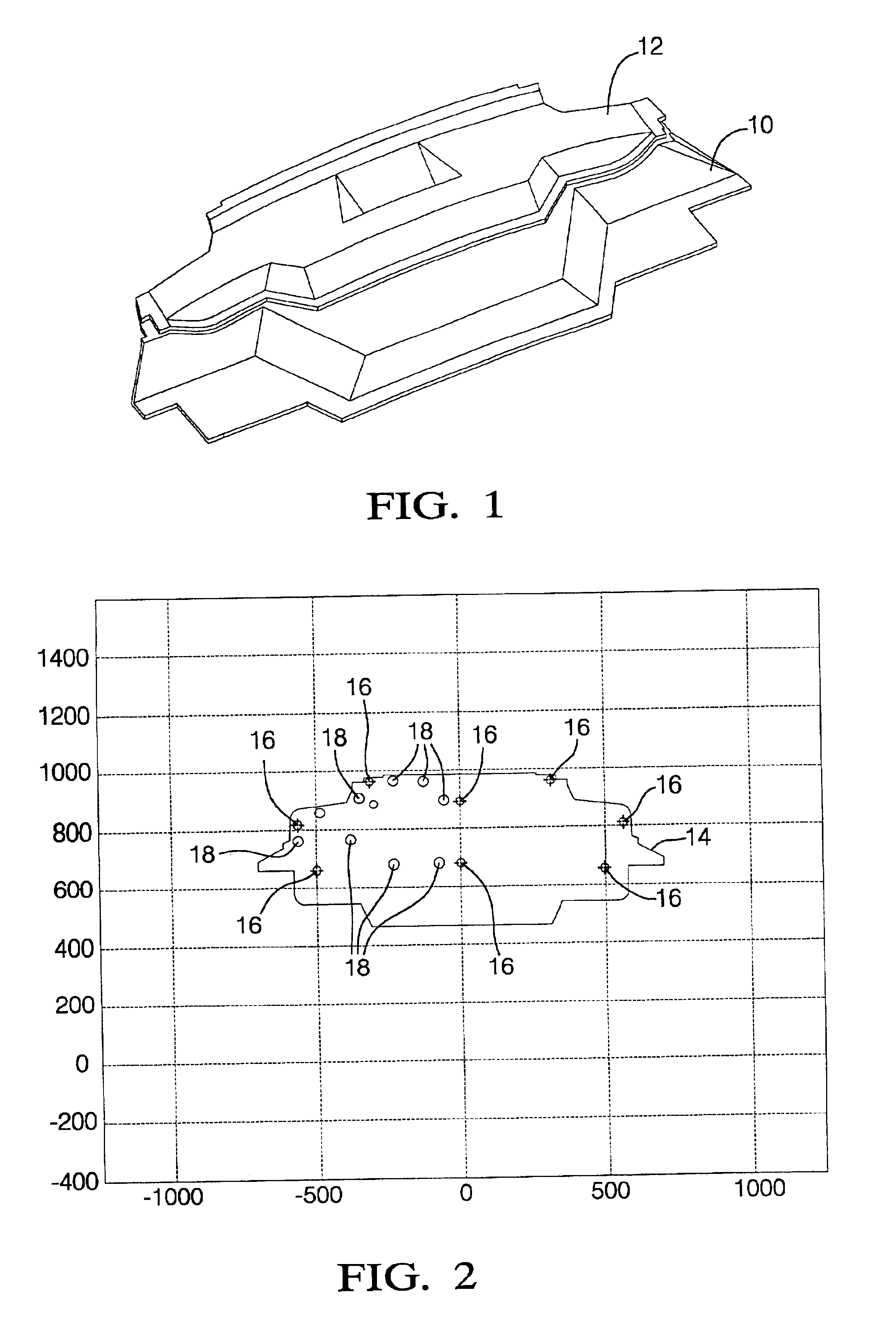

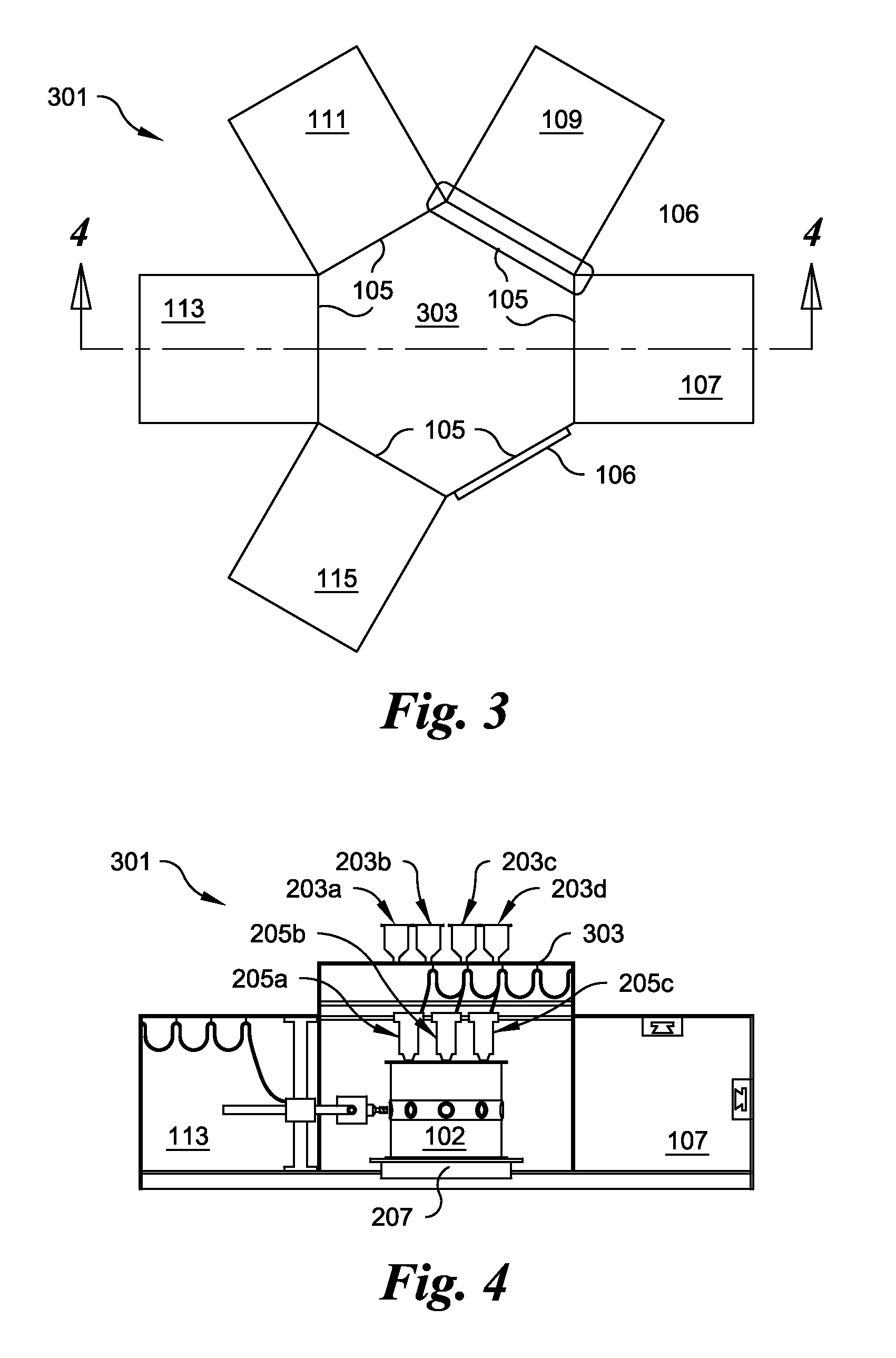

Method for computer-aided layout of manufacturing cells

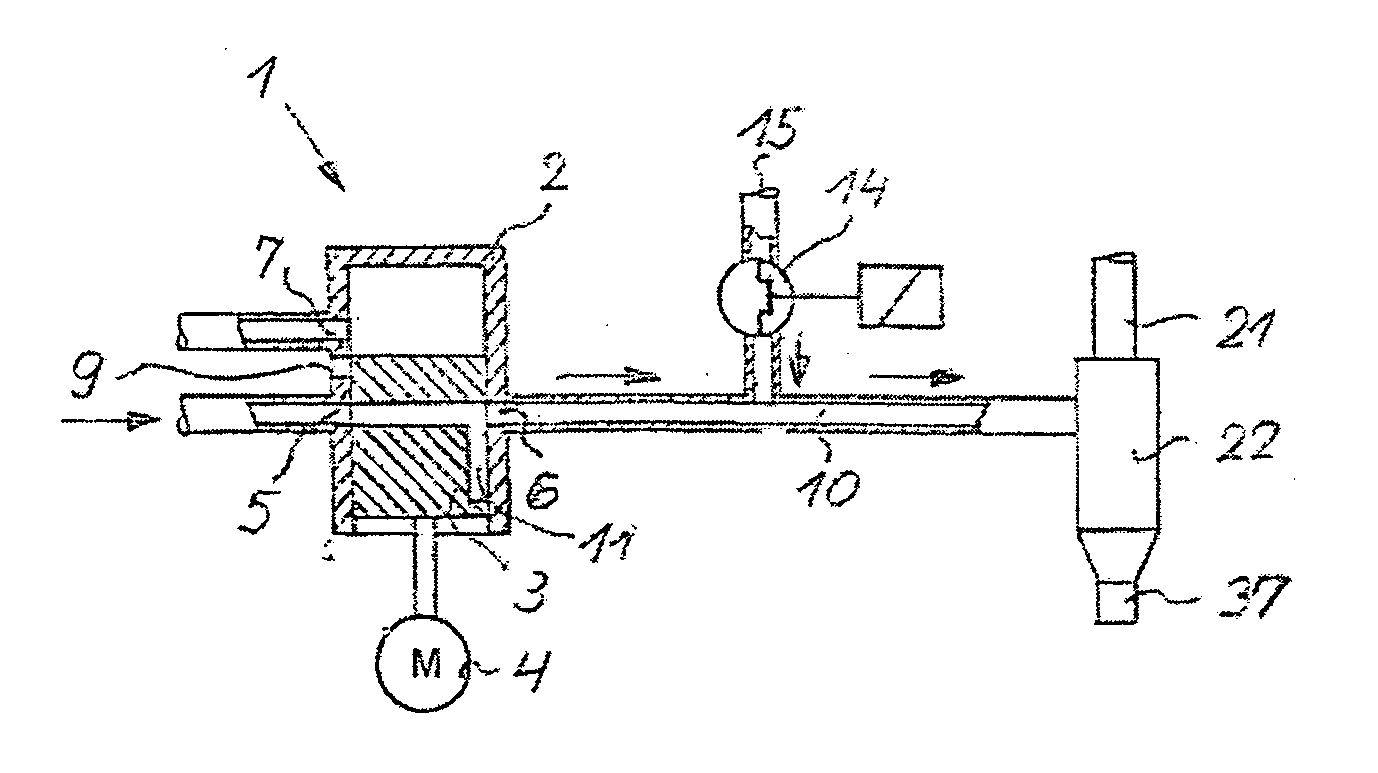

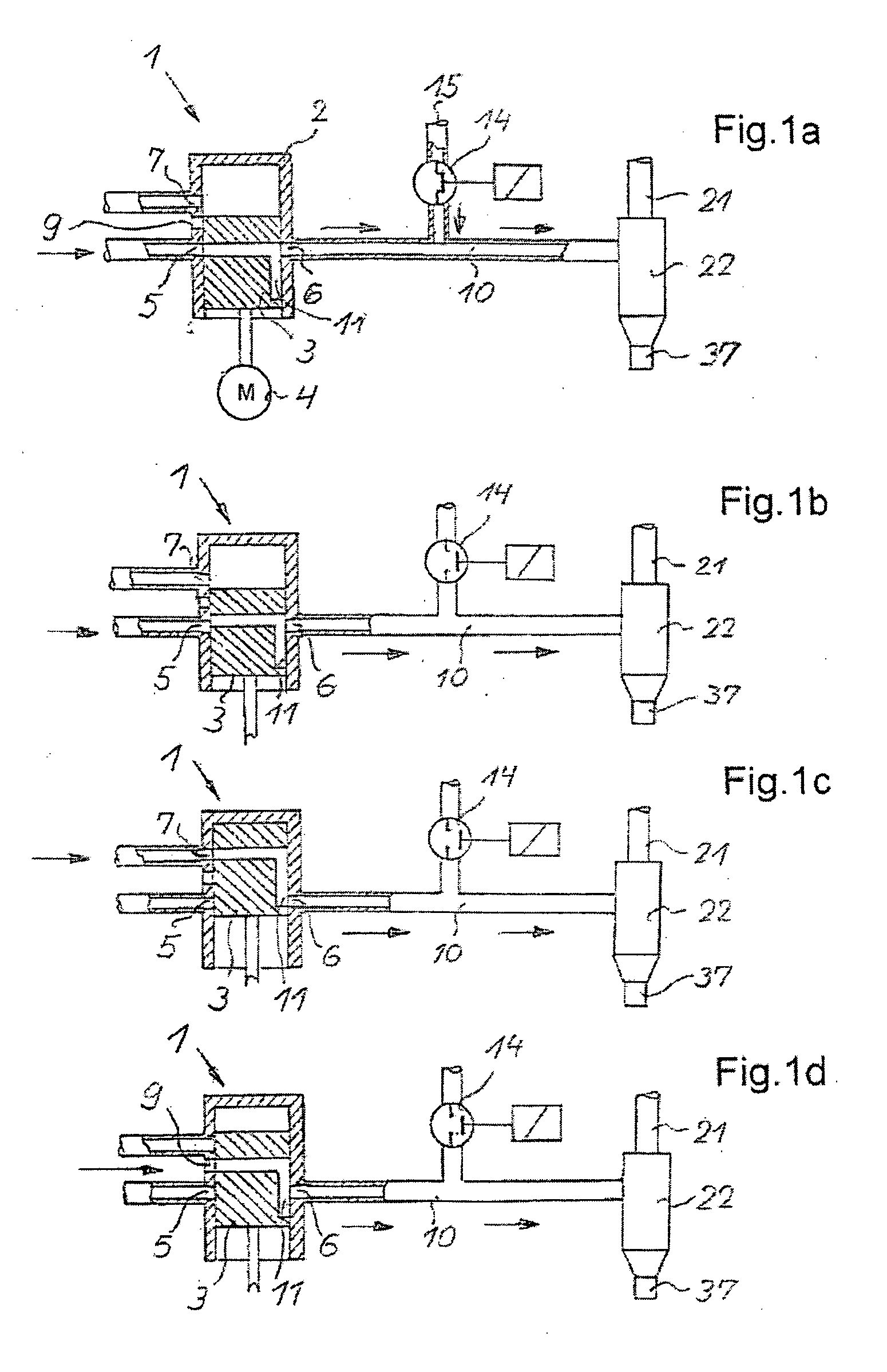

A computer assisted method is disclosed for making an optimized layout of a manufacturing cell to be used, for example, to locate, hold and process workpieces, such as in robotic welding of an assembly of stamped sheet metal parts. The items to be processed and employed in the cell are identified by physical structure and kinematic characteristics and given an initial location to start the process. Further movements of the parts toward attraction points and away from repelling points are evaluated on the computer by an optimization program to arrive at an optimized cell layout.

Owner:GM GLOBAL TECH OPERATIONS LLC

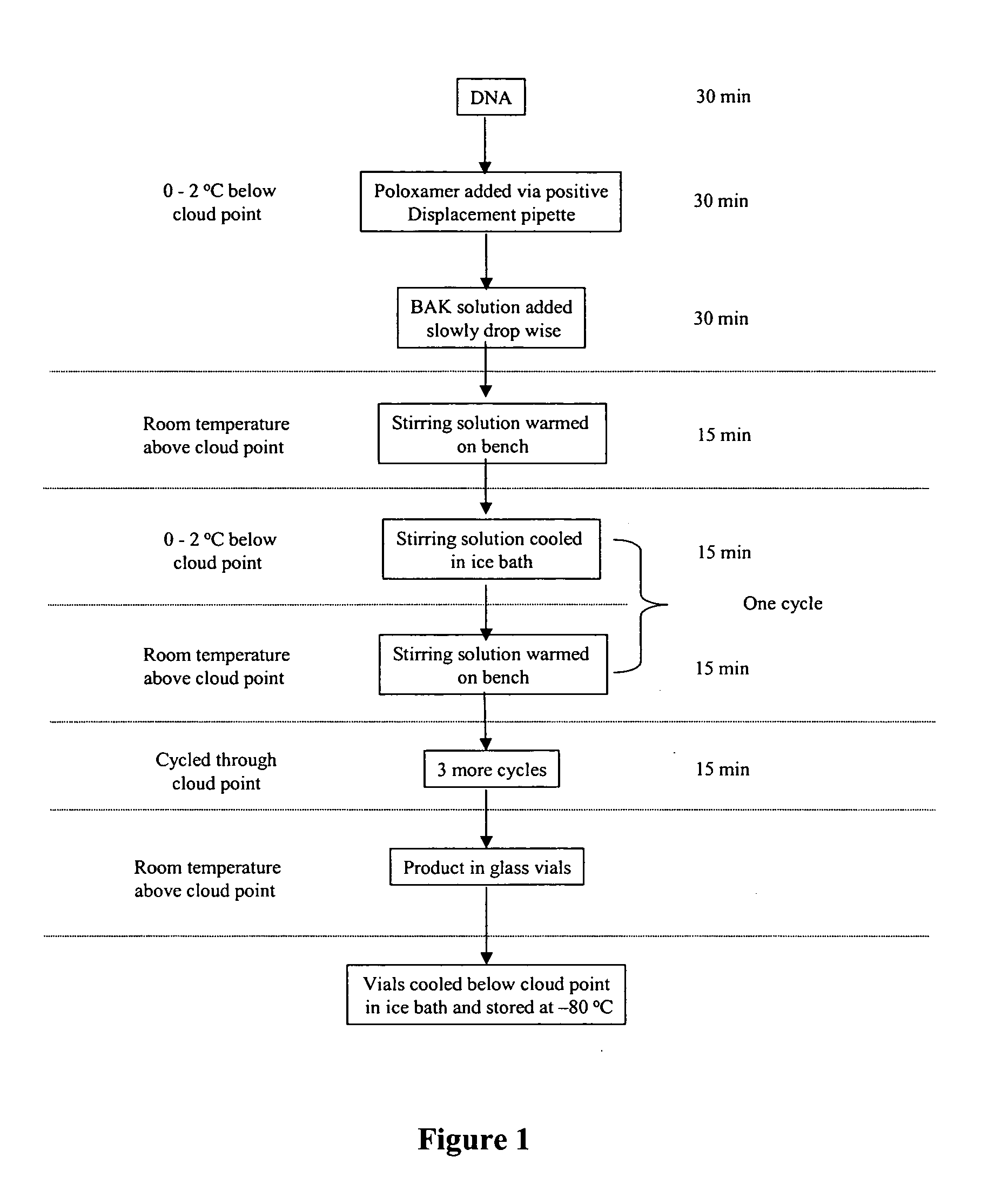

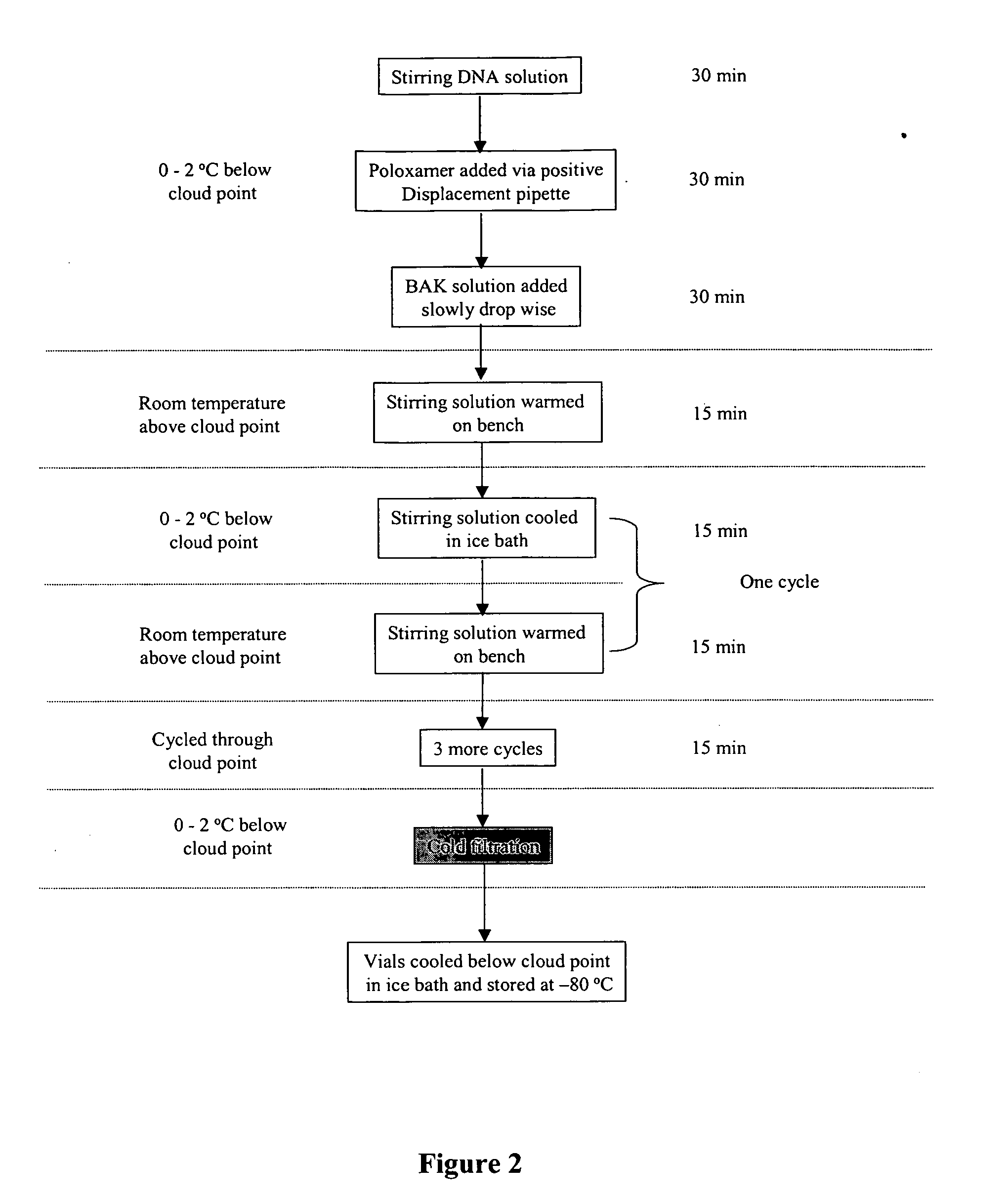

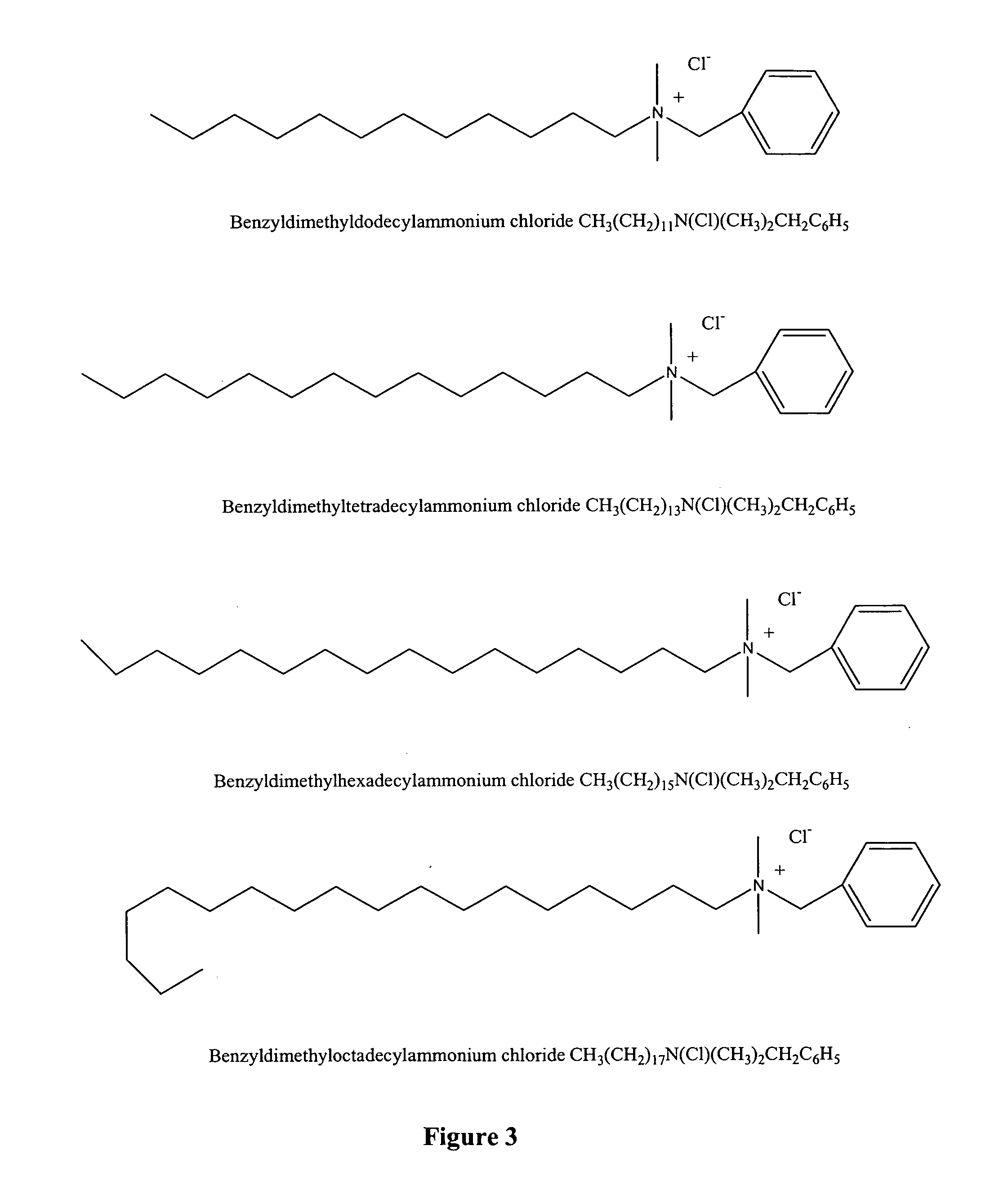

Methods for producing block copolymer/amphiphilic particles

InactiveUS20060134221A1Enhance immune responsePowder deliveryAntiinfectivesLipid formationManufacturing cell

The invention relates to a method for manufacturing cell delivery particles, pharmaceutical component-particle dispersions, compositions comprising cell delivery particles and pharmaceutical compositions comprising pharmaceutical component-particle dispersions. The method comprises homogenization of mixtures comprising amphiphilic components and a block copolymer to form stable particles. The invention is also directed to cell delivery particles and pharmaceutical component-particle dispersions produced by the claimed methods and compositions comprising same. In certain embodiments, the cell delivery particles may further comprise co-lipids. The invention further relates to methods of generating an immune response, treating or preventing a disease or condition, or delivering a biologically active molecule to cells in vitro comprising administration of the pharmaceutical compositions described herein.

Owner:VICAL INC

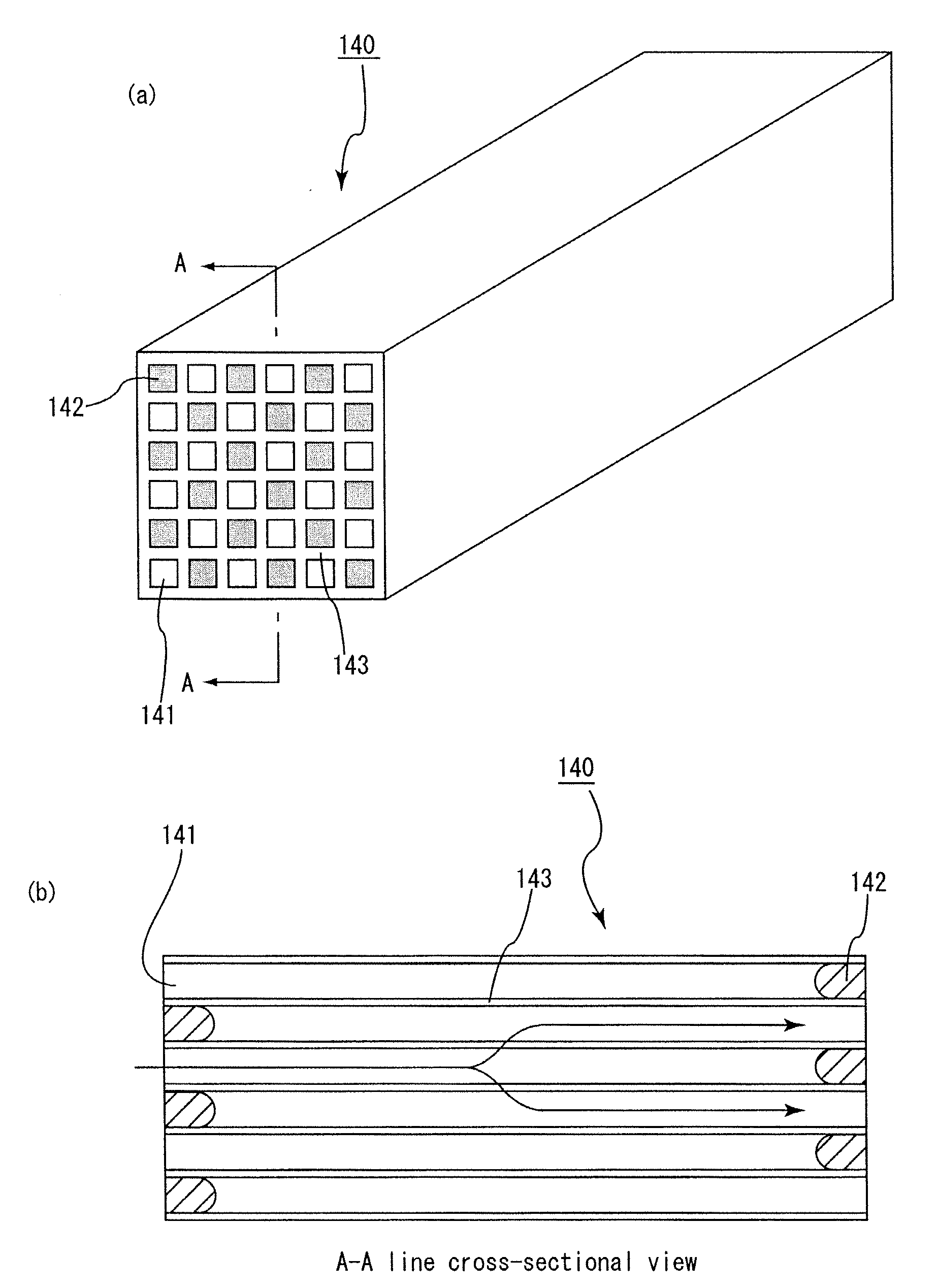

Molded body treating apparatus, sealing method of honeycomb molded body, and method for manufacturing cell-sealed honeycomb fired body

ActiveUS20080116601A1Internal combustion piston enginesDispersed particle filtrationHoneycombEngineering

A molded body treating apparatus includes a support, at least one flat plate and a first movement mechanism. The support is configured to support a honeycomb molded body which has a first end portion and a second end portion in a longitudinal direction of the honeycomb molded body and which includes a plurality of cells each extending along the longitudinal direction from a first end at the first end portion to a second end at the second end portion. Either the first end or the second end of each of the plurality of cells is sealed with a plug material paste. The first movement mechanism is configured to move the at least one flat plate along the longitudinal direction to press the either one of the first and second end portions.

Owner:IBIDEN CO LTD

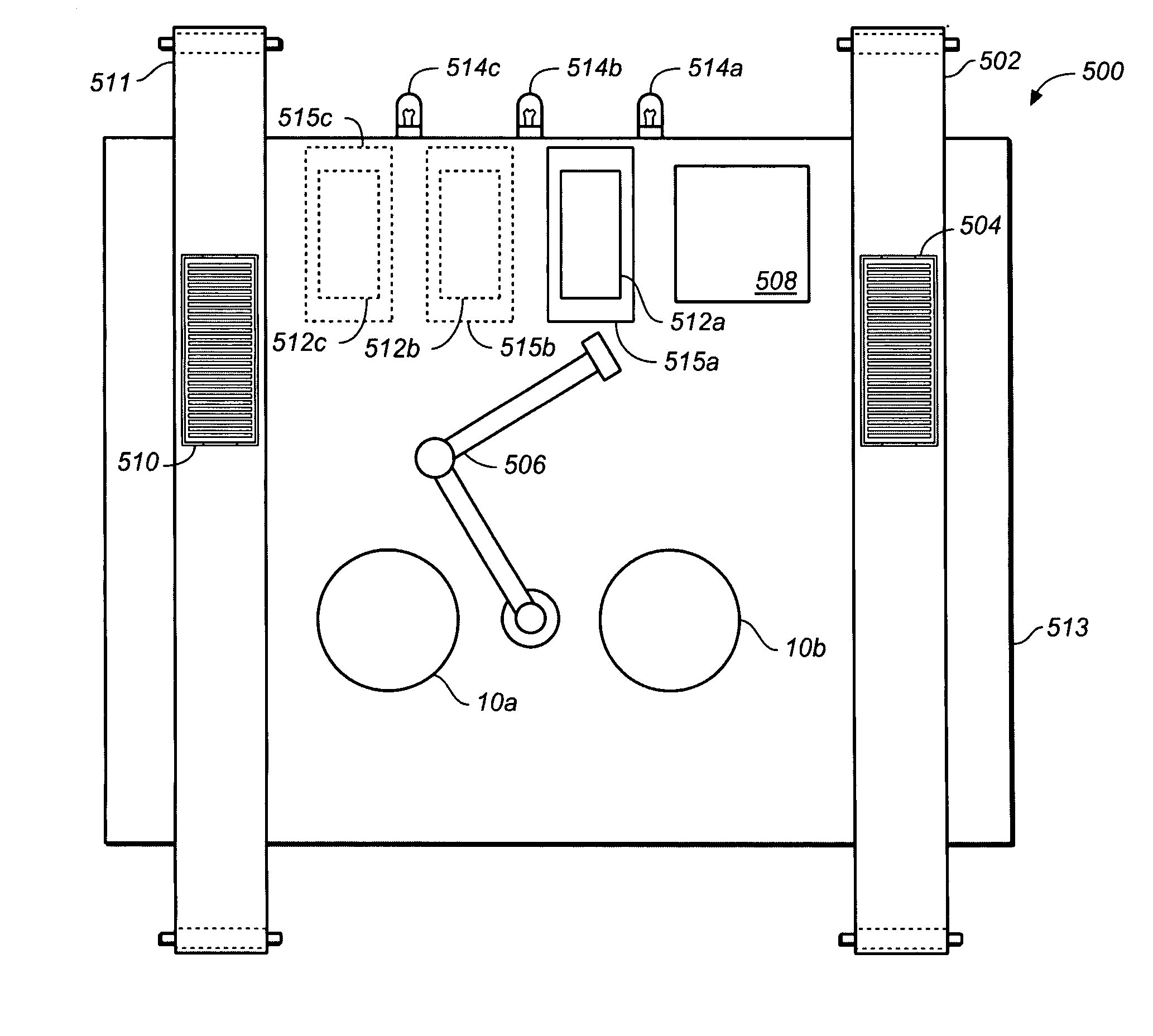

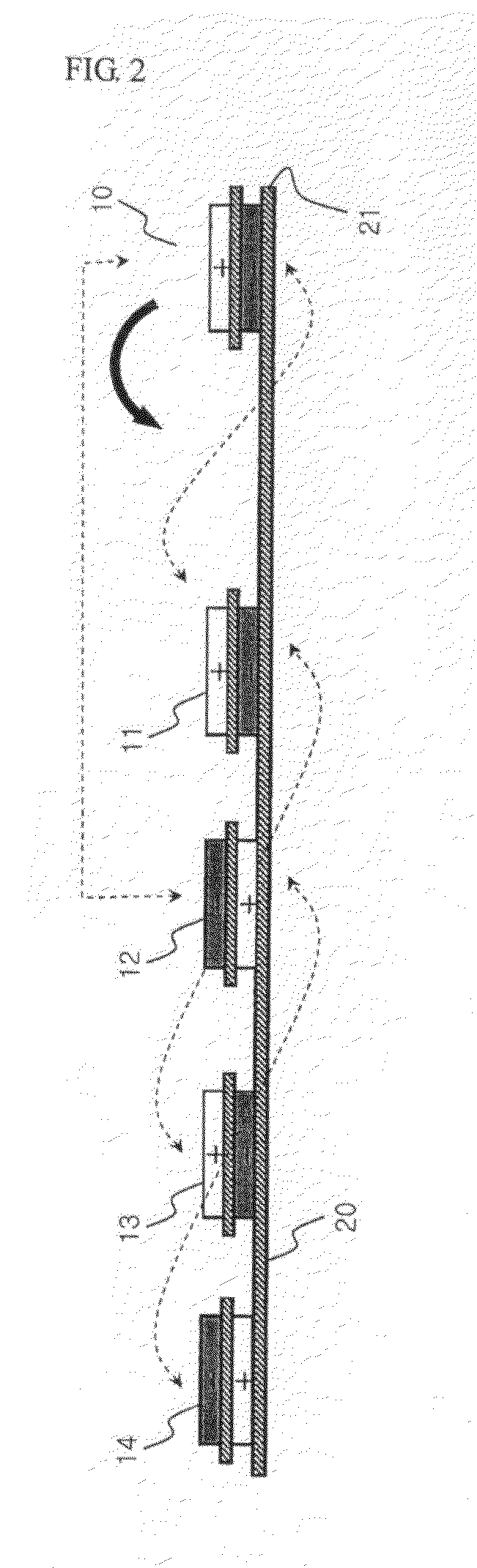

Robotic system for optically inspecting workpieces

InactiveUS7239970B2Easy to replaceProgramme controlTelevision system detailsRobotic systemsRobotic arm

A manufacturing cell for inspecting workpieces such as magnetic disk substrates comprises an input conveyor for providing workpieces to be tested, one or more testers for inspecting the workpieces, and three or more output receptacles for receiving tested workpieces. One or more robotic arms move the workpieces from the input conveyor to the tester and from the tester to one of the output receptacles depending upon the results of the test performed by the tester. The output receptacles include a pass receptacle, a reject receptacle, and at least an additional receptacle for workpieces that are to be re-worked or studied further. If the additional receptacle is full, workpieces that would otherwise be provided to the additional bin are placed in the reject receptacle. The reject receptacle is very large, so that it is rarely filled to capacity.

Owner:WD MEDIA

System and method for an integrated additive manufacturing cell for complex components

ActiveUS7777155B2Easy to handleEasy to operateProgramme controlAdditive manufacturing apparatusManufacturing technologyAlloy

An integrated additive manufacturing cell (IAMC) that combines conventional manufacturing technologies with additive manufacturing processes is disclosed. Individual IAMCs may be configured and optimized for specific part families of complex components, or other industrial applications. The IAMCs incorporate features that reduce hardware cost and time and allow for local alloy tailoring for material properties optimization in complex components.

Owner:RTX CORP

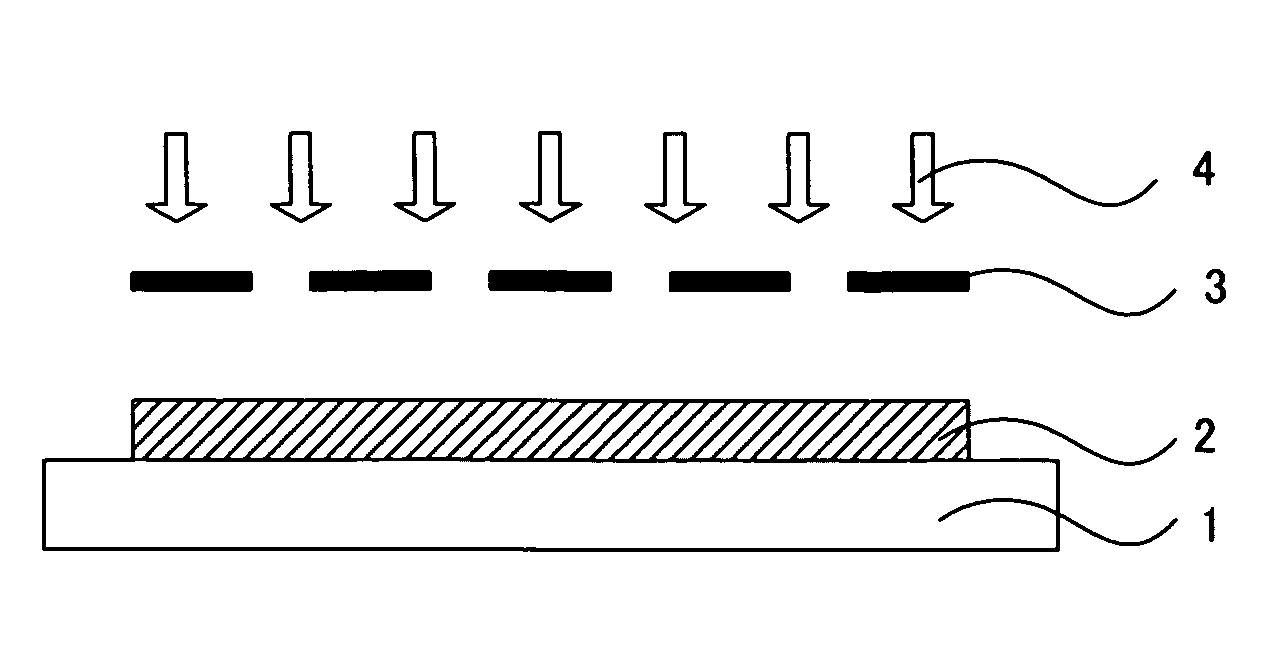

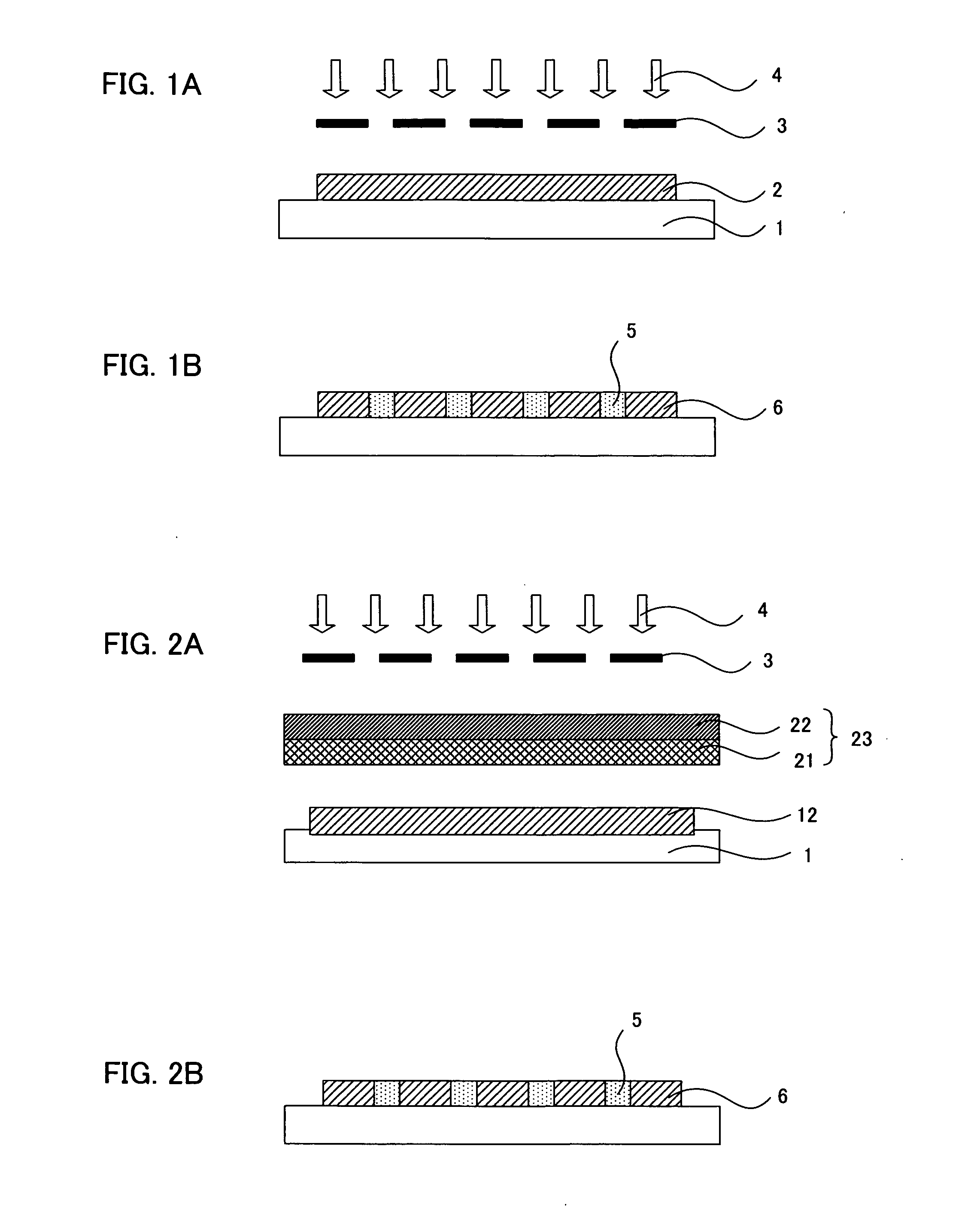

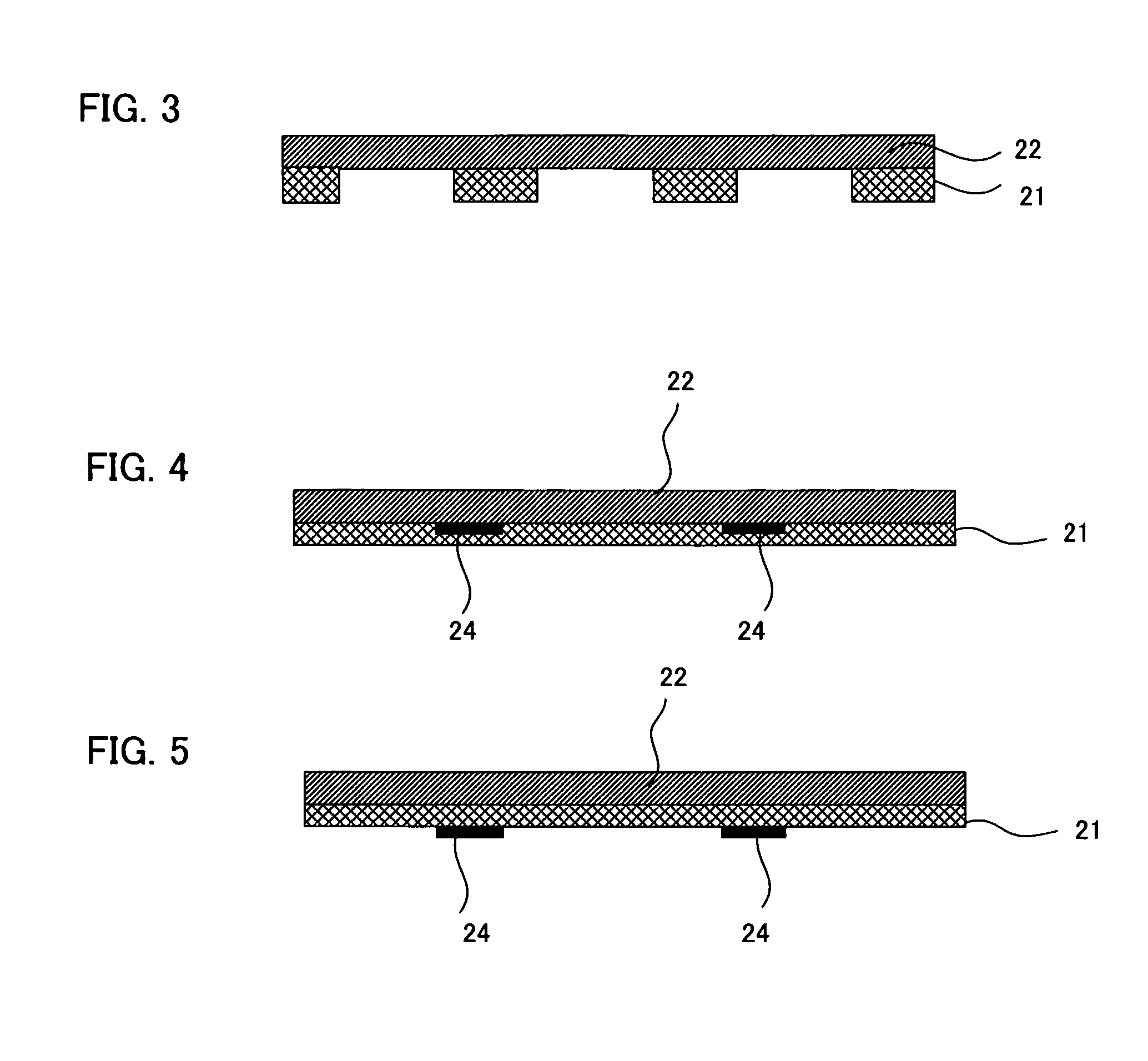

Method for manufacturing cell culture substrate

InactiveUS20050279730A1Bioreactor/fermenter combinationsBiological substance pretreatmentsAdhesion processCell culture media

A main object of the invention is to provide a new method for producing a cell culture substrate used to cause cells to adhere in a highly precise form onto a base material and then culture the cells. To attain the object, the invention provides a method for producing a cell culture substrate comprising: a patterning substrate forming process of forming, on a base material, a cell culture patterning layer wherein a cell adhesion portion having cell adhesive properties and a cell adhesion-inhibiting portion having cell adhesion-inhibiting properties can be formed by action of a photocatalyst by energy irradiation, thereby forming a patterning substrate; an energy irradiating process of irradiating the energy onto the cell culture patterning layer, thereby forming the cell adhesion portion and the cell adhesion-inhibiting portion in a pattern form by action of the photocatalyst; and a cell-containing liquid applying process of applying a cell-containing liquid onto the cell adhesion portion by a region-selecting applying method of applying the cell-containing liquid selectively onto the patterned cell adhesion portion.

Owner:DAI NIPPON PRINTING CO LTD

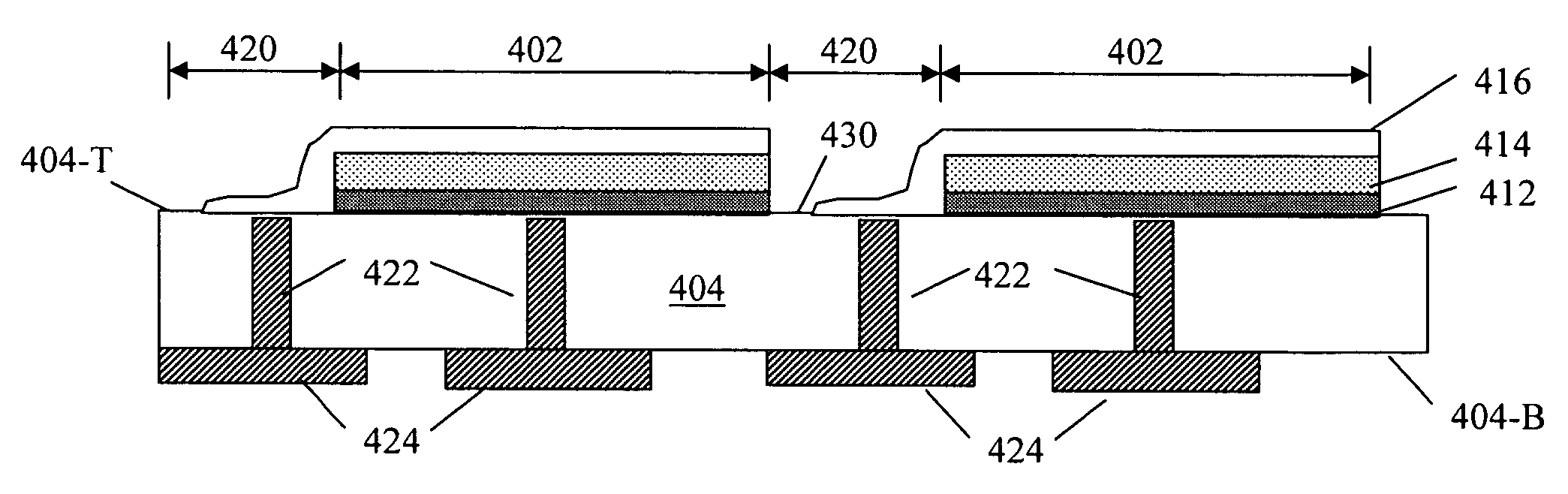

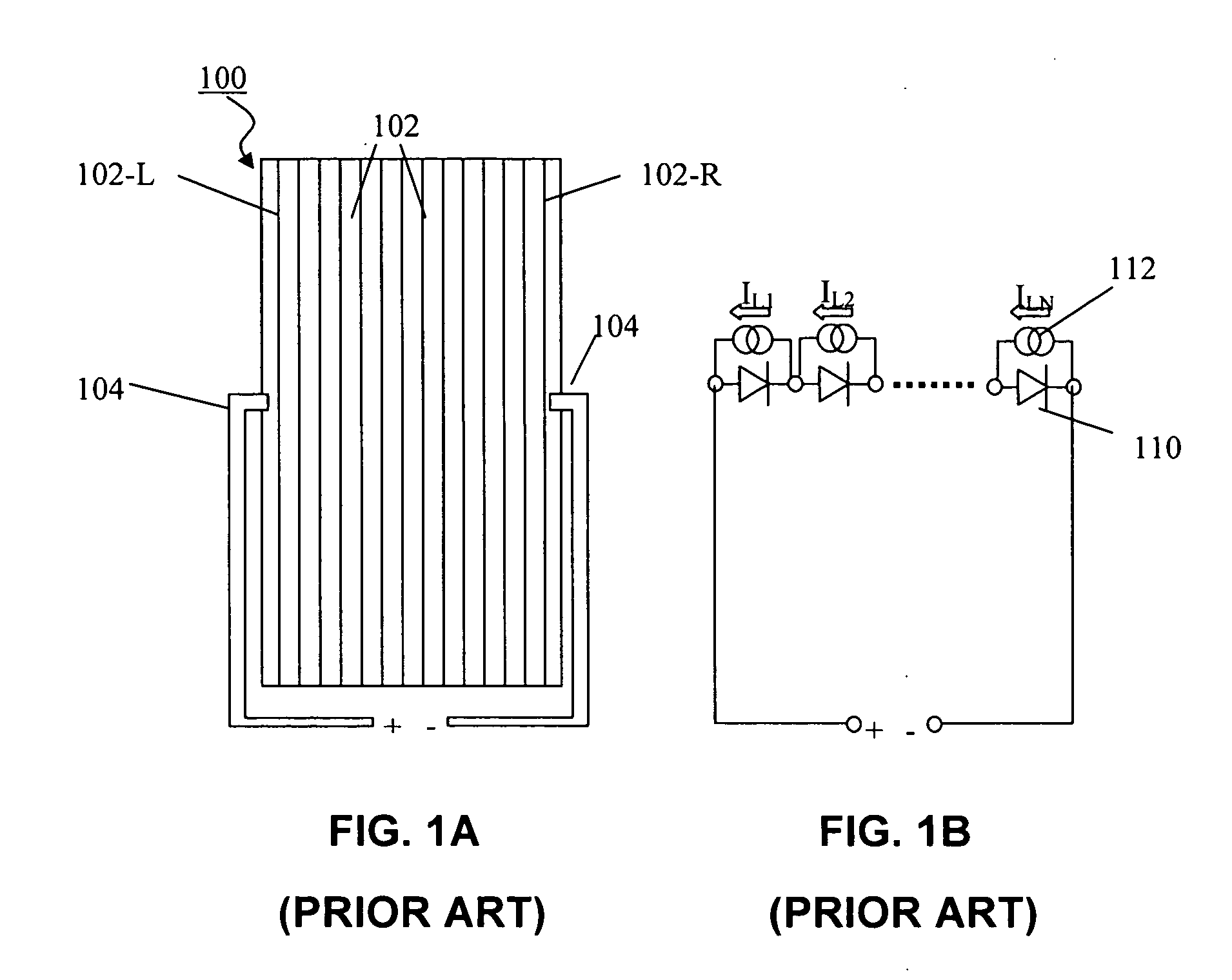

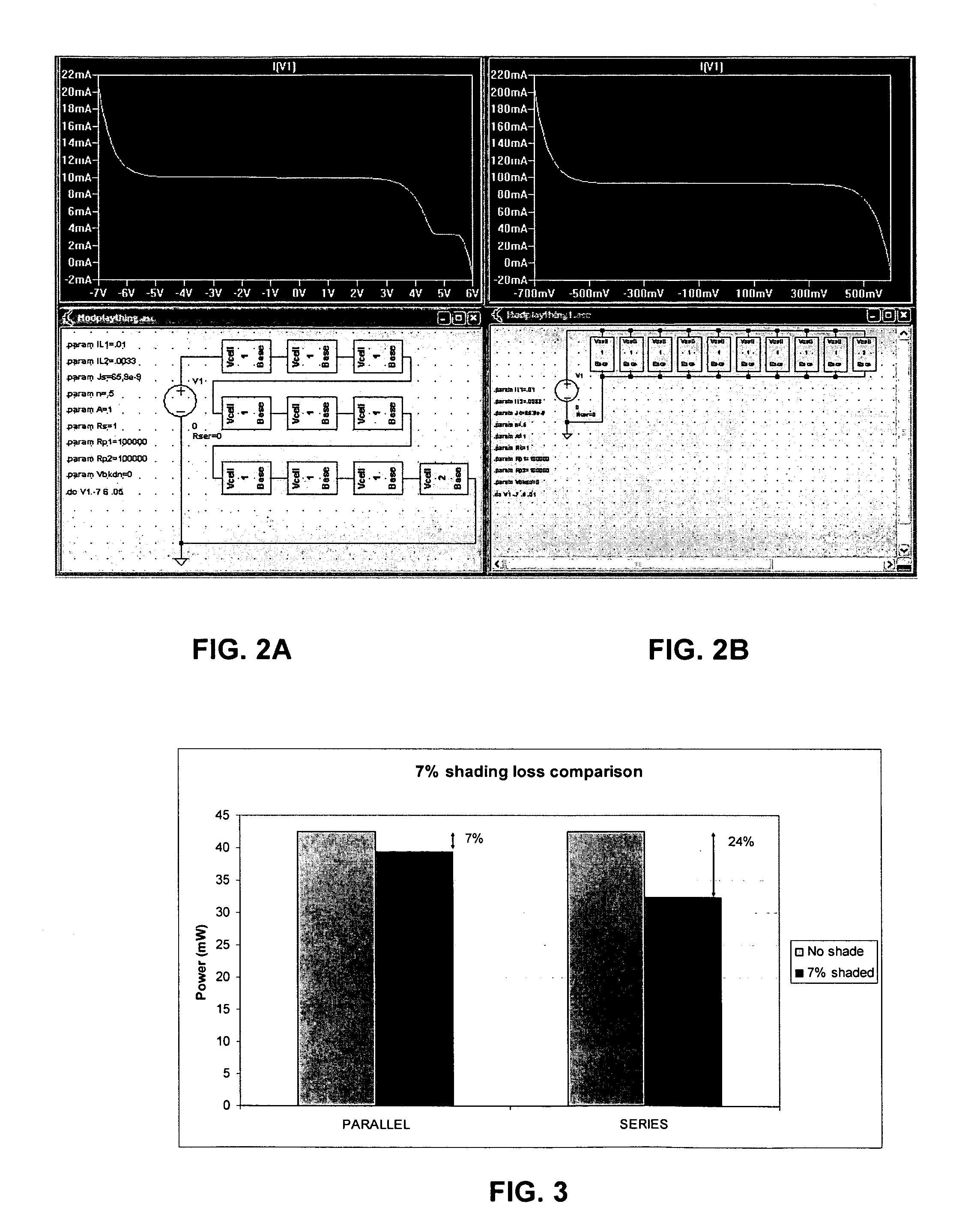

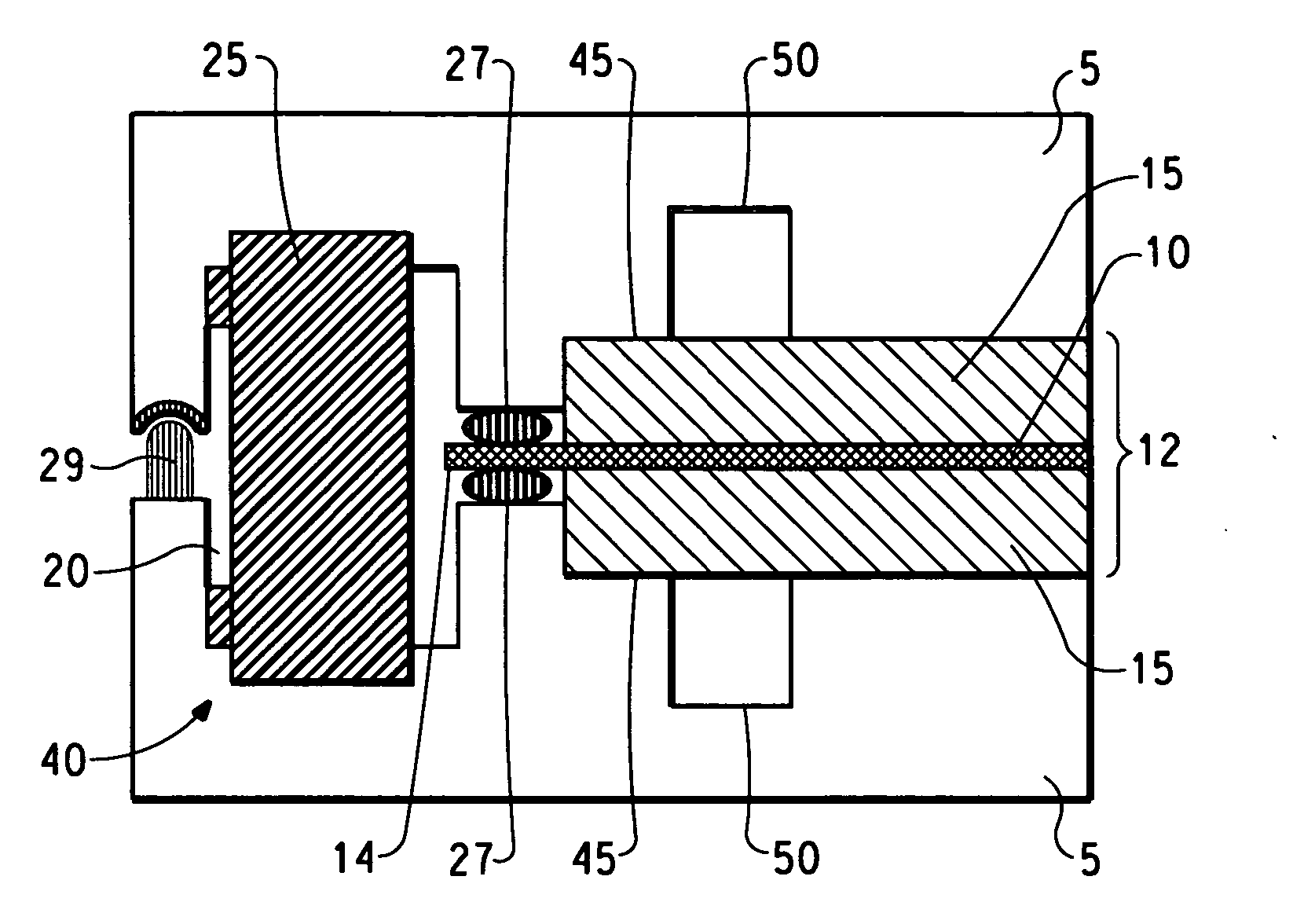

Thin film photovoltaic module wiring for improved efficiency

InactiveUS20080023065A1Reduce line widthReduce process complexityPhotovoltaic energy generationSemiconductor devicesManufacturing cellParallel arrangement

The present invention relates to configuring and wiring together cells in TF PV modules. According to one aspect, cells are fabricated on one plane on a top surface of a substrate, with wiring patterned on a parallel plane, and vias formed to provide connections between the cell plane and wiring plane. In one embodiment, the wiring plane is on the back surface of the substrate and vias are formed through the substrate. In another embodiment, the wiring plane is on the top surface of the substrate underneath the cell plane and an insulating layer, with the vias formed through the insulating layer. In another embodiment, the cell plane formed on the top surface includes superstrate cells that are illuminated through a transparent substrate, with an insulator between the cell plane and an upper wiring plane. According to another aspect, the heavy bus bar connections in the wiring plane can carry large currents and do not block light impinging on the cells. According to further aspects, the wiring plane enables use of parallel cell connections that provide immunity to shading, as described above. Moreover, these connections can be wired in a variety of methods, allowing use of series-parallel arrangements so that, for example, local regions could be parallel connected while larger regions series connected.

Owner:APPLIED MATERIALS INC

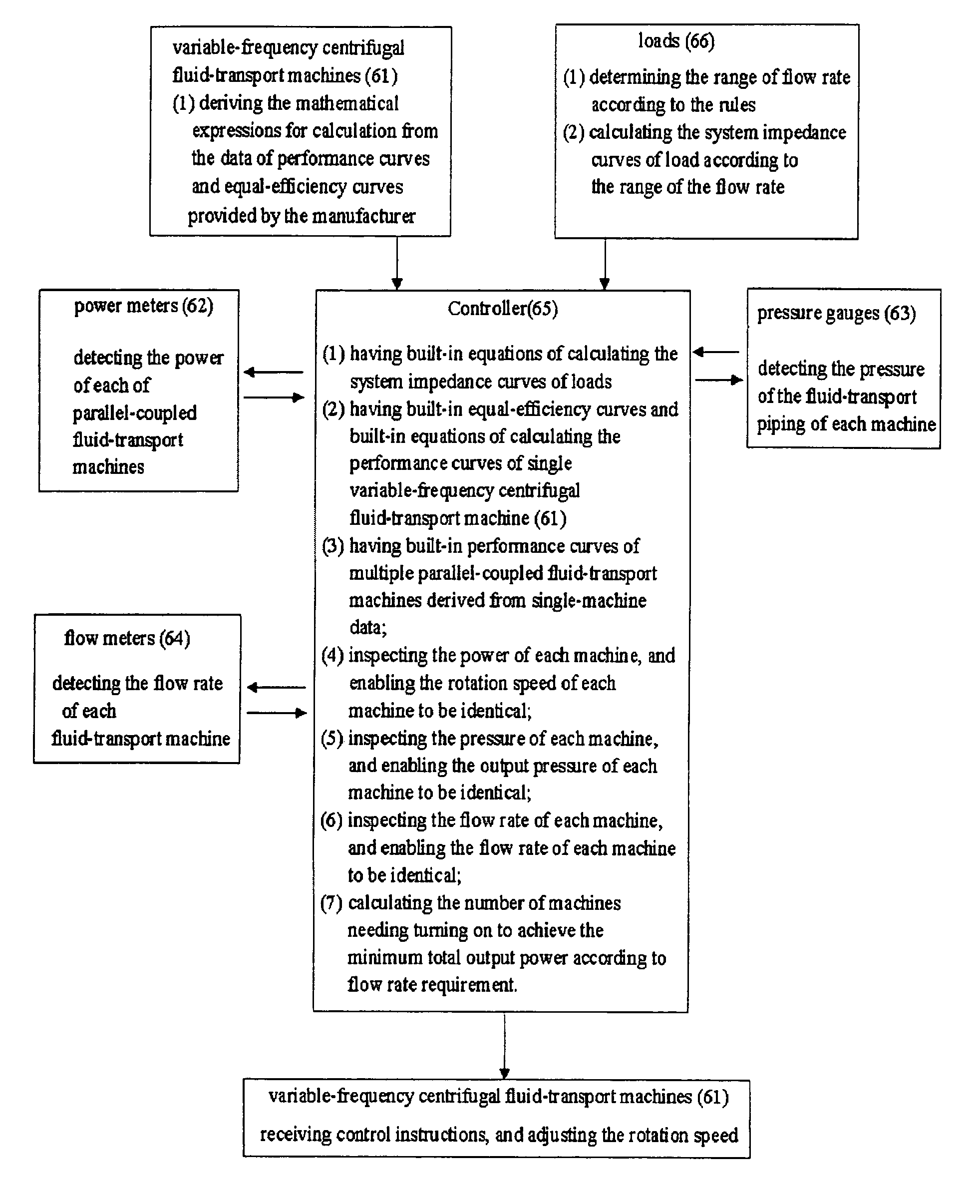

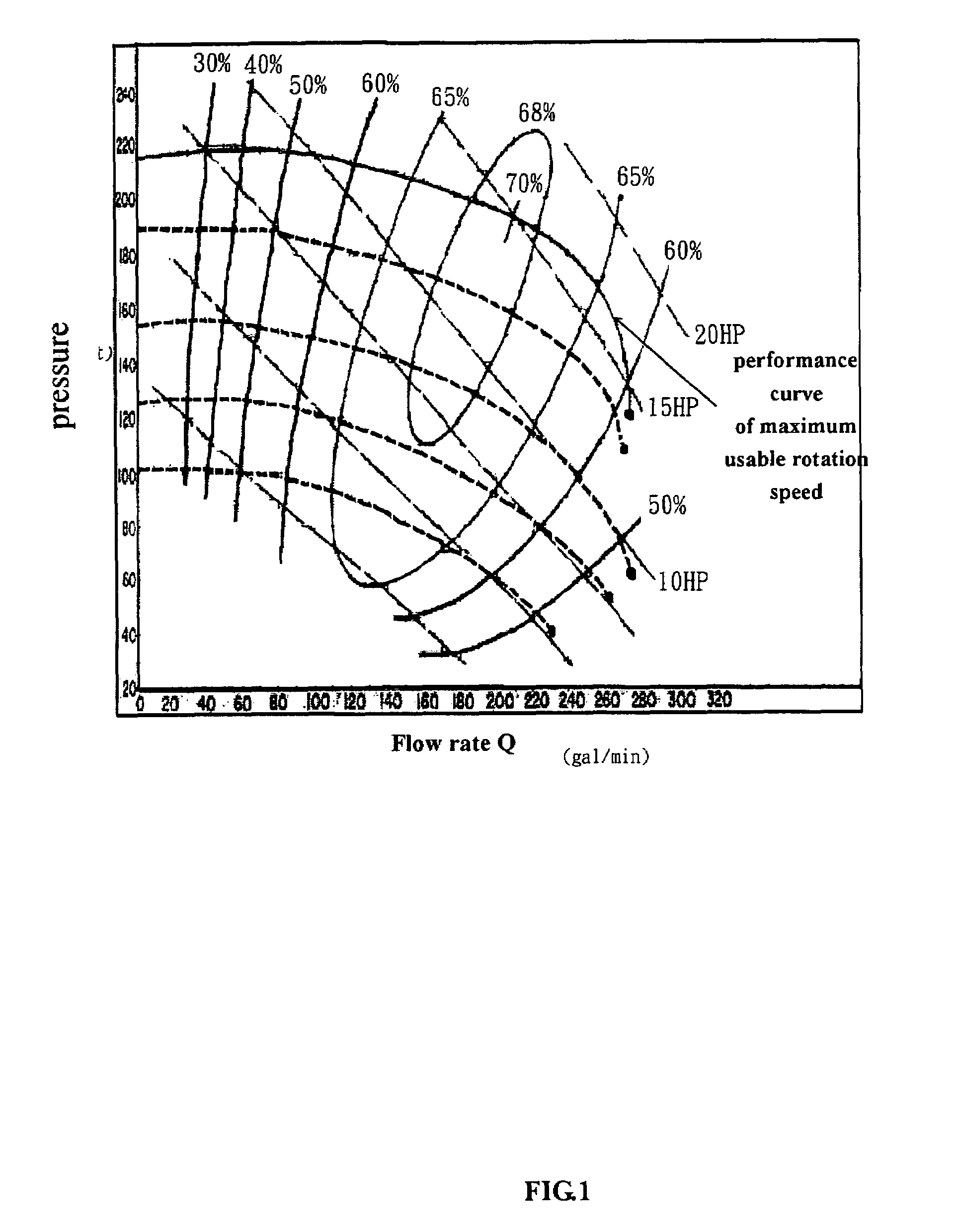

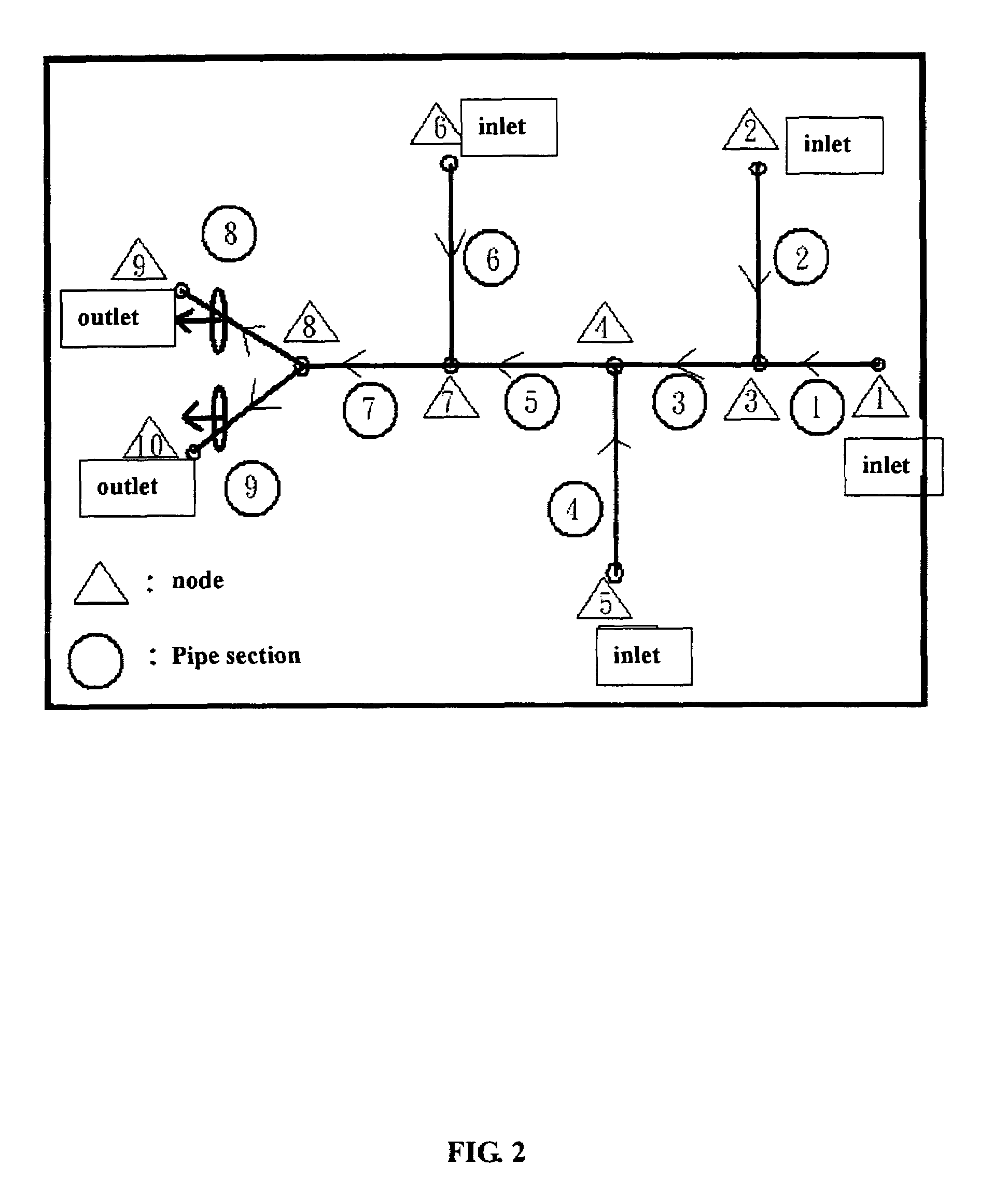

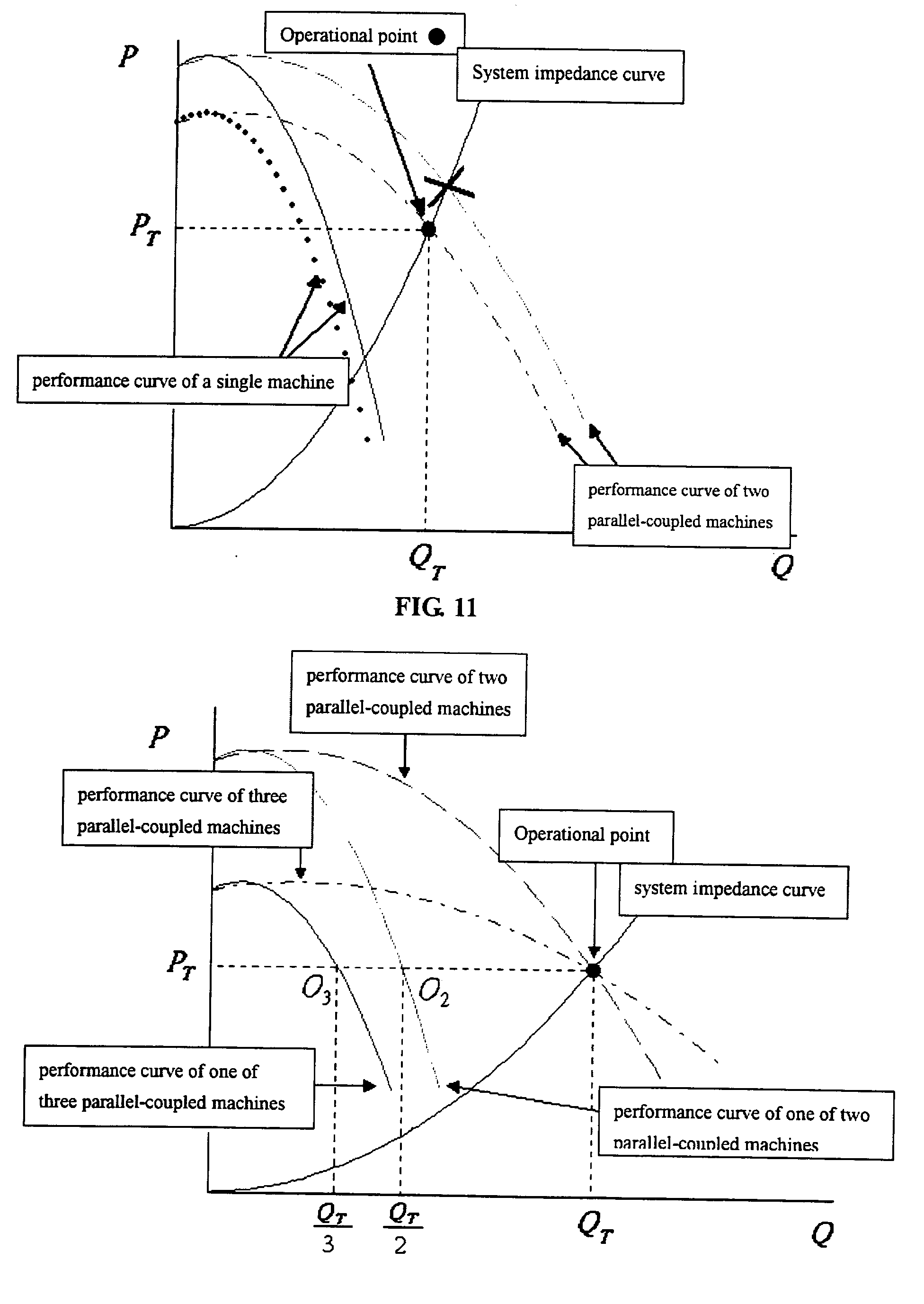

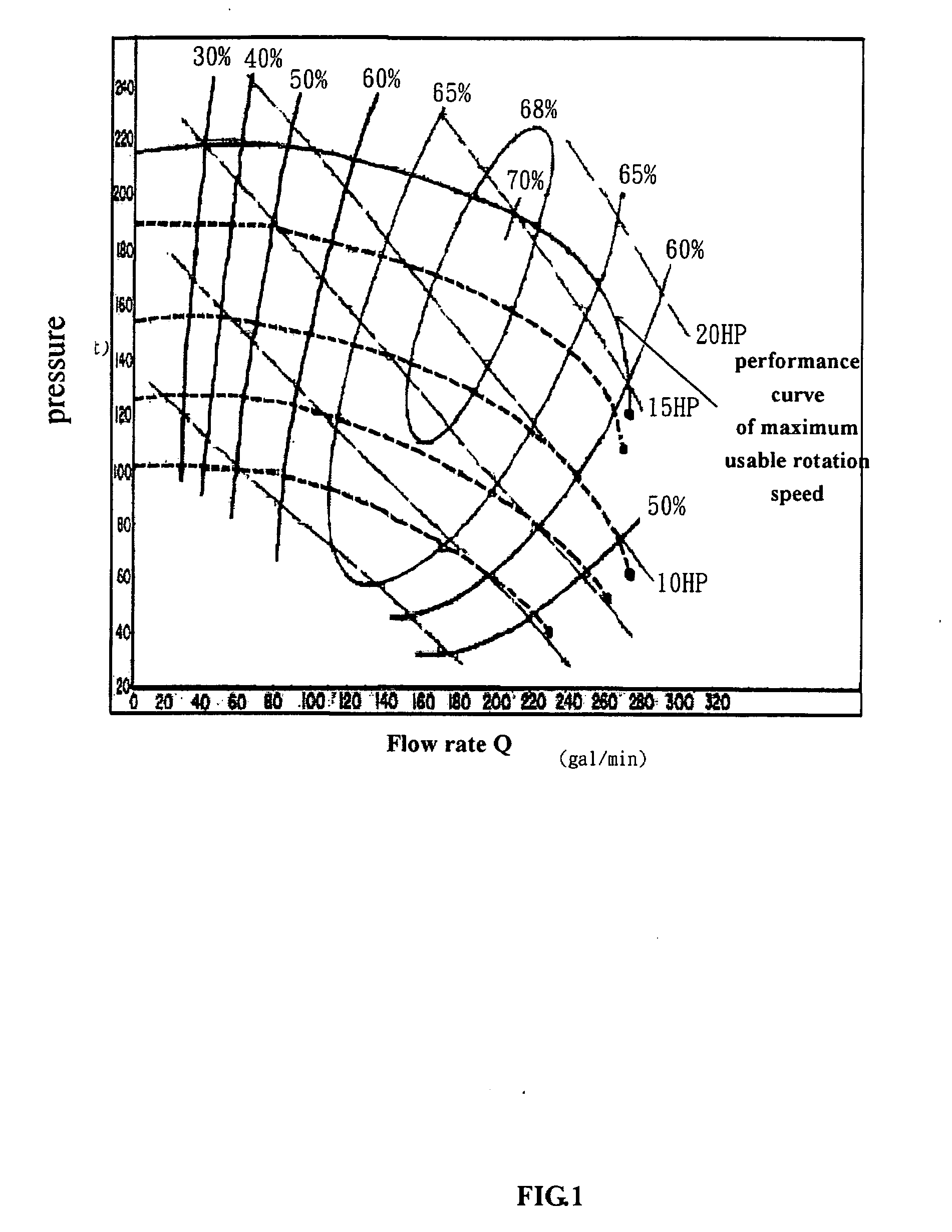

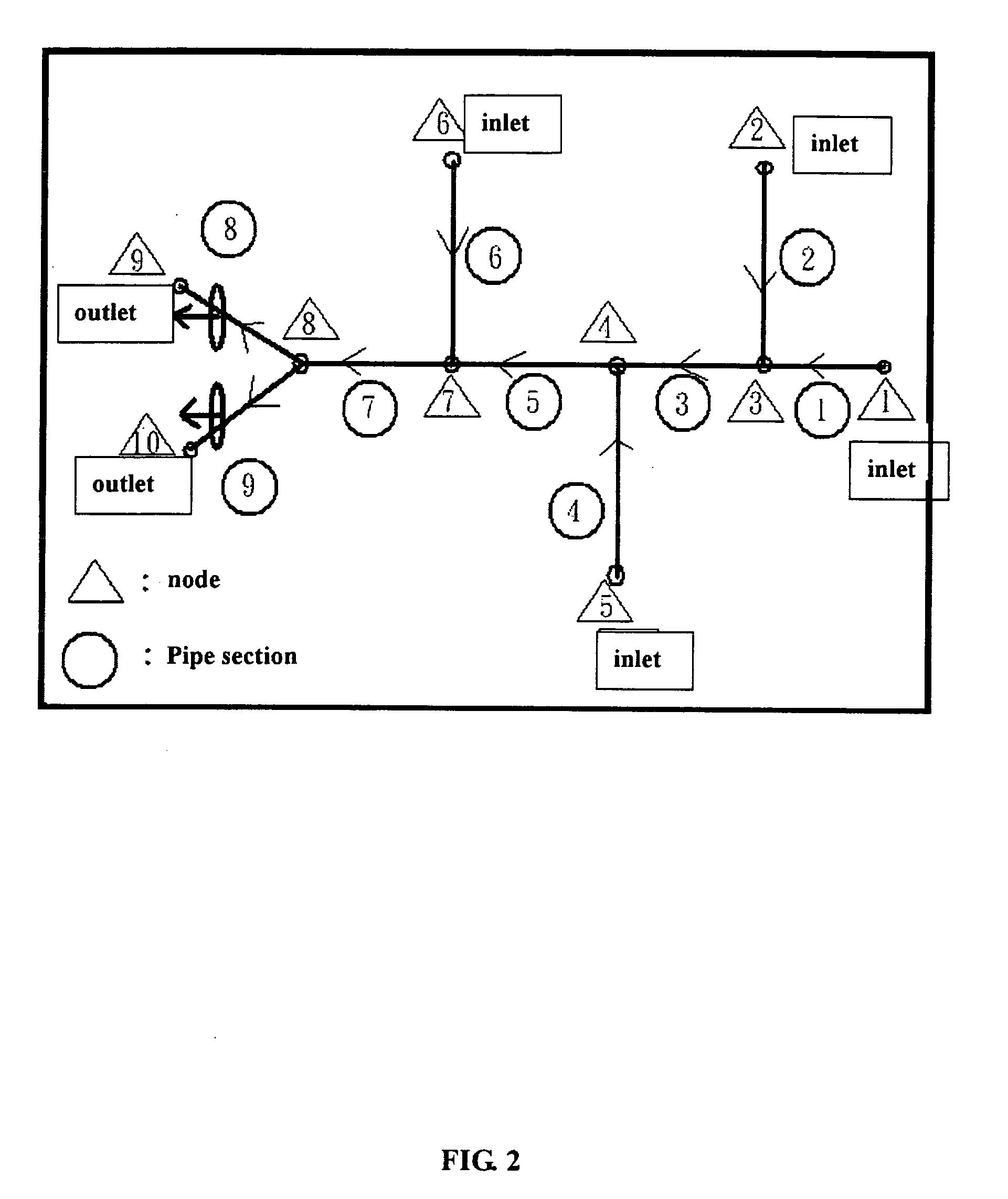

Operation method of energy-saving fluid transporting machineries in parallel array with constant pressure

The present invention discloses a system of energy-efficient and constant-pressure fluid-transport machines coupled in parallel, which can flexibly and massively provide gas and water to every fabrication unit. The system of the present invention comprises: variable-frequency centrifugal fluid-transport machines, pressure gauges, power meters, flow meters, and controllers. The performance curves of the abovementioned system of fluid-transport machines coupled in parallel and the system impedance curves of the loads are analyzed theoretically and built in the controllers together with the equal-efficiency curves provided by the manufacturer. When the system is operating, the data detected by the pressure gauges, power meters, and flow meters are compared with the built-in data to obtain the optimal energy-efficient conditions as the operational criteria of the system of the present invention.

Owner:HUANG WEN CHENG

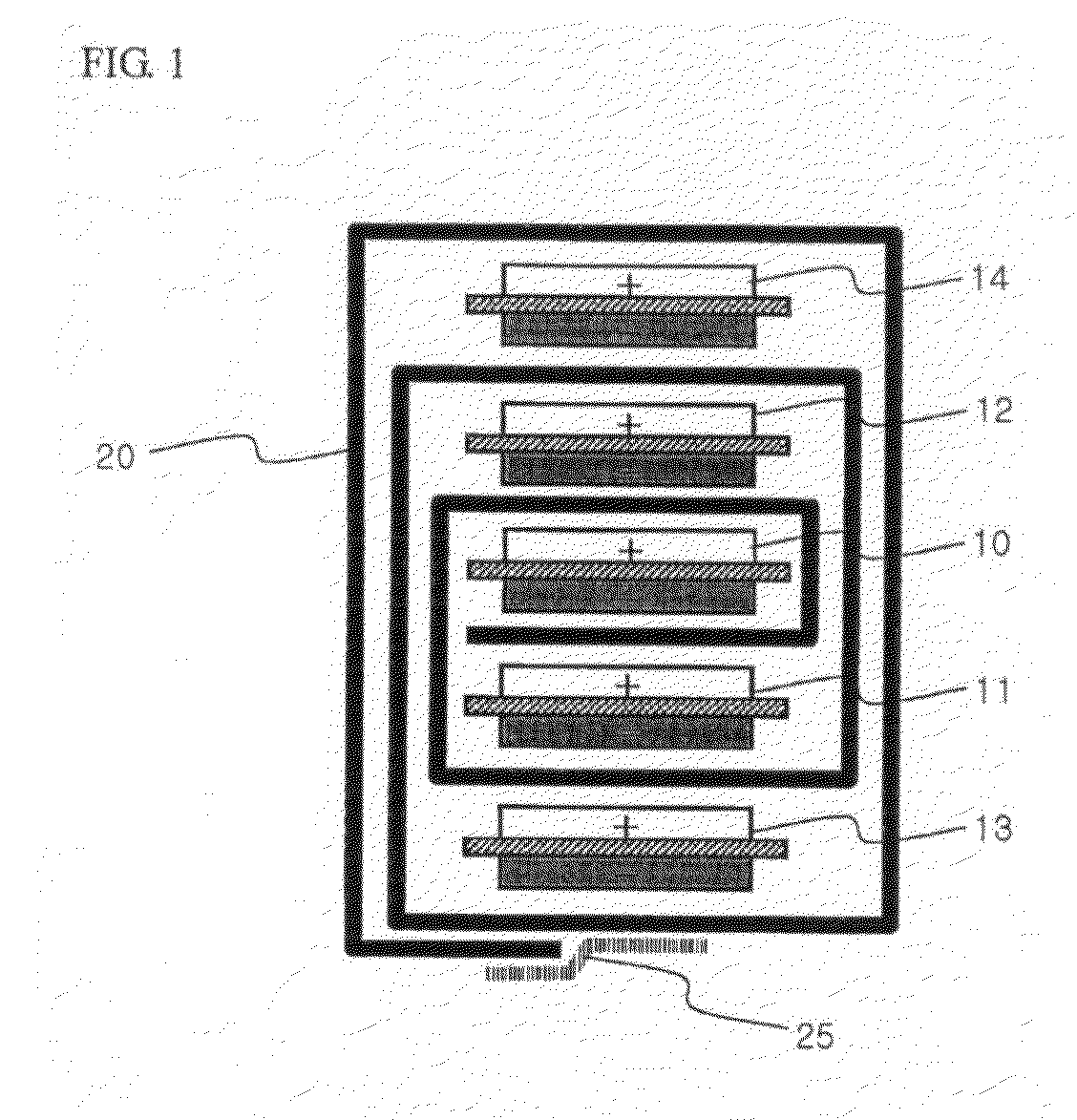

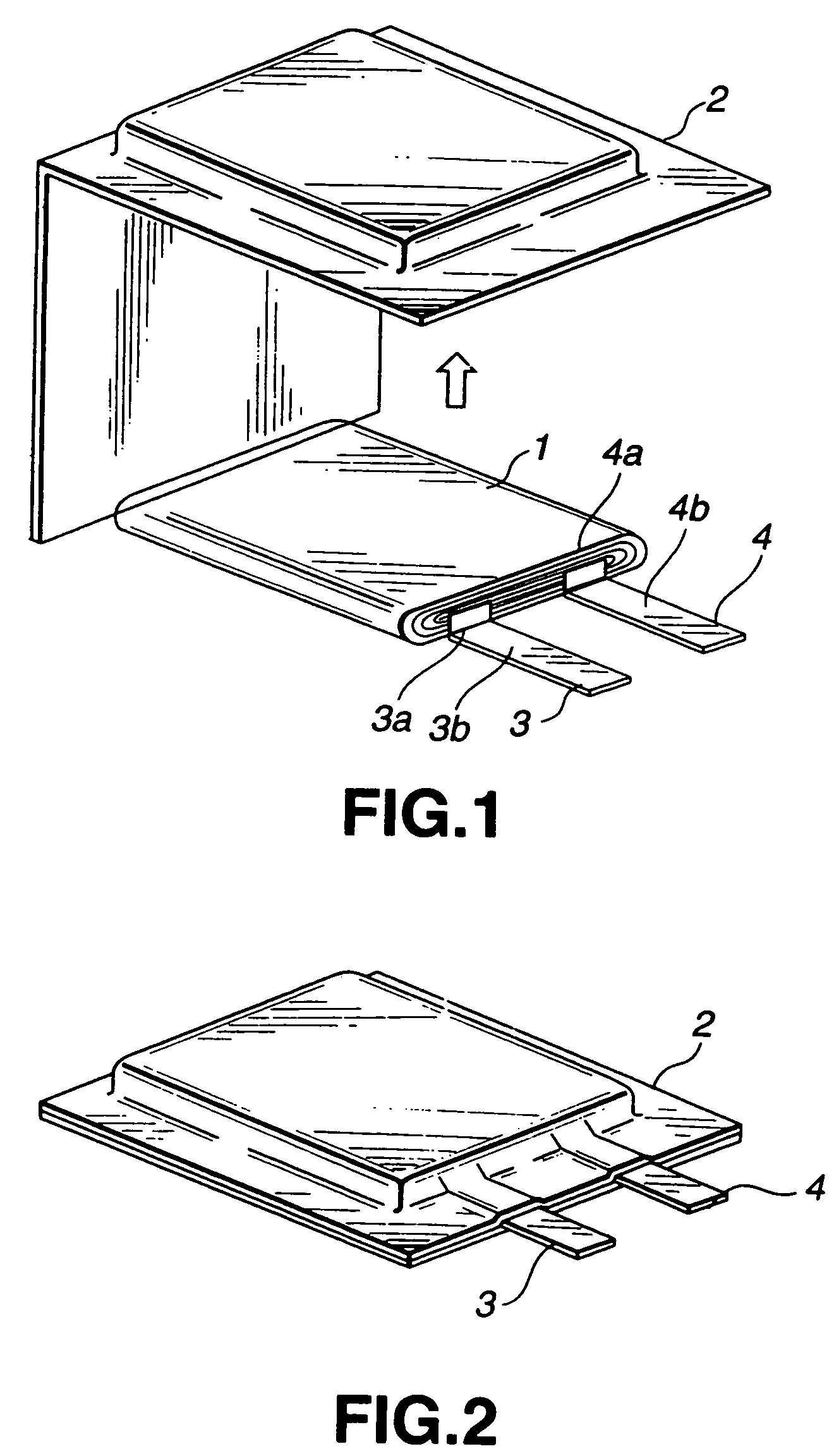

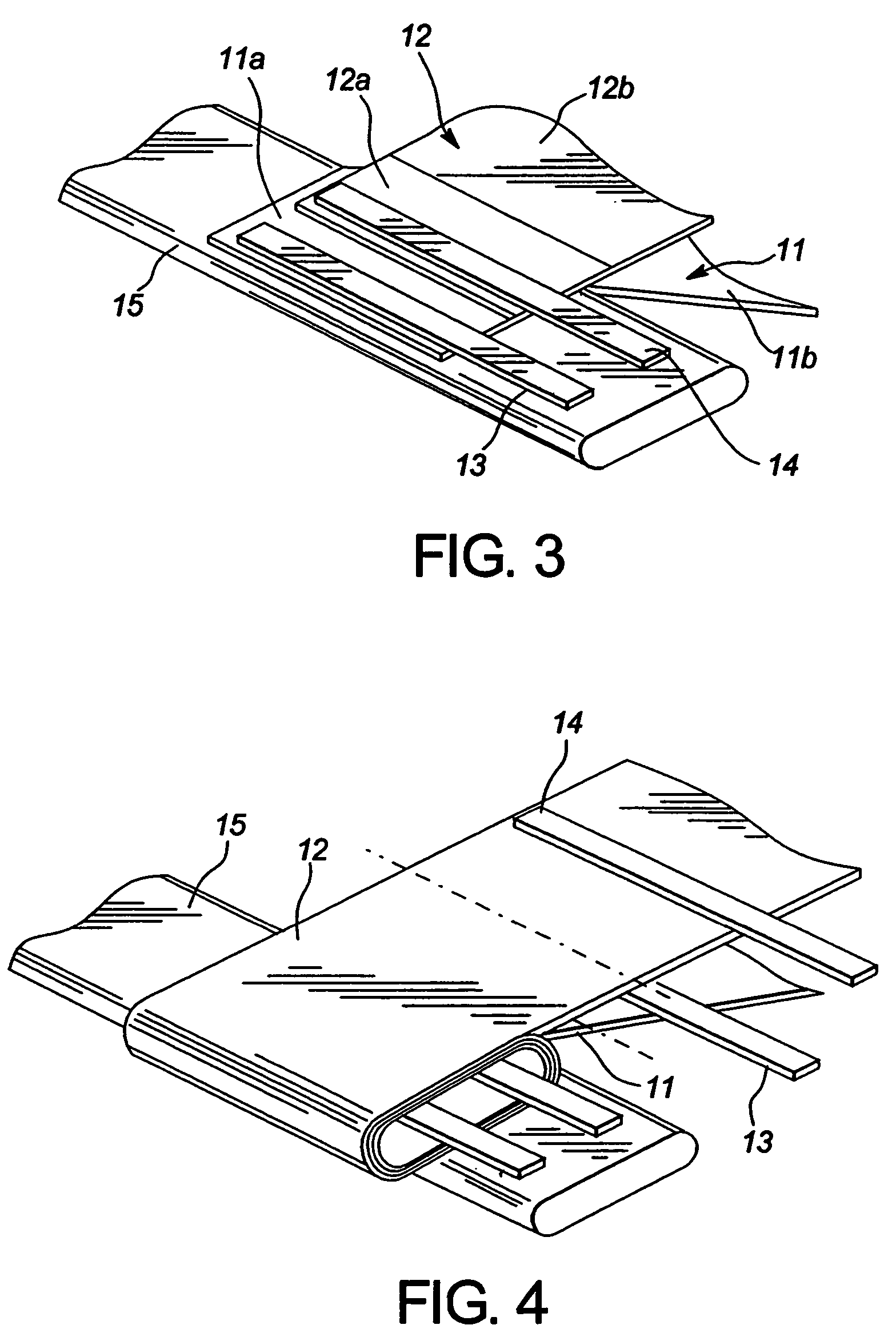

Stack and folding-typed electrode assembly and method for preparation of the same

ActiveUS20100279161A1Easy to useImprove performanceFinal product manufactureElectrode carriers/collectorsElectrical polarityEngineering

Disclosed herein is a method of locating a plurality of pull cells constructed in a cathode / separator / anode structure, as basic units, on a separator sheet having a continuous length, further locating a unit electrode or a bi-cell on the separator sheet, and winding the pull cells and unit electrode or the bi-cell to continuously manufacture a stacking / folding type electrode assembly constructed in a structure in which anodes are located at the outermost electrodes forming the outside of the electrode assembly, respectively, wherein the method including a step of continuously supplying a cathode sheet, an anode sheet, a first separator sheet, and a second separator sheet, to manufacture the unit cells, successively arranging the unit cells on the second separator sheet from a first stage to an n stage, and winding the unit cells, a step of arranging cathode tabs and anode tabs at the respective stages, while the cathode tabs and the anode tabs are opposite to each other, and arranging electrode tabs having the same polarity between the neighboring stages, while the electrode tabs are opposite to each other, such that the electrode tabs having the same polarity are located all together at predetermined positions of the wound electrode assembly, and a step of supplying electrodes the number of which is odd from two electrode sheets and electrodes the number of which is even from one electrode sheet.

Owner:LG ENERGY SOLUTION LTD

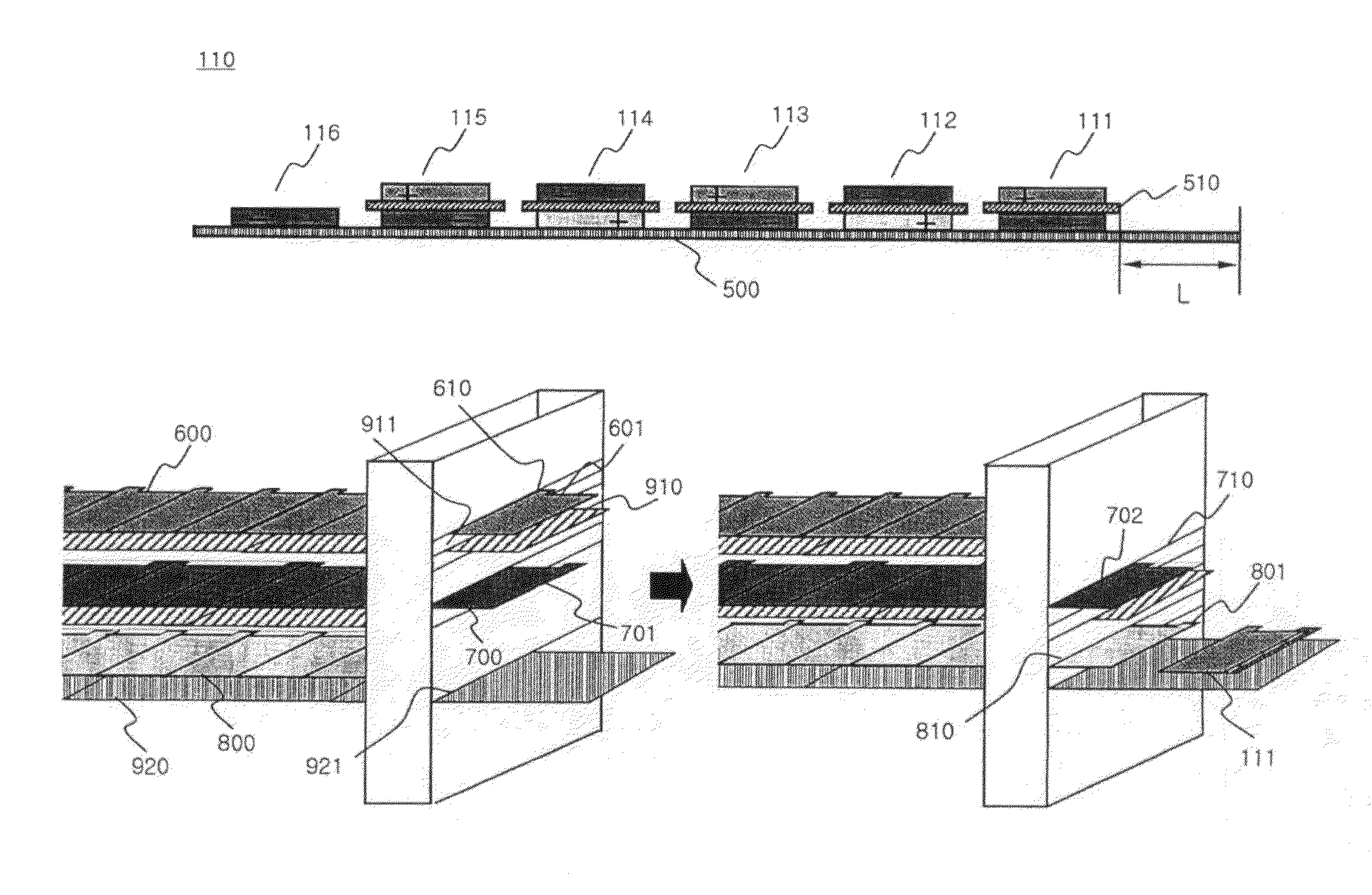

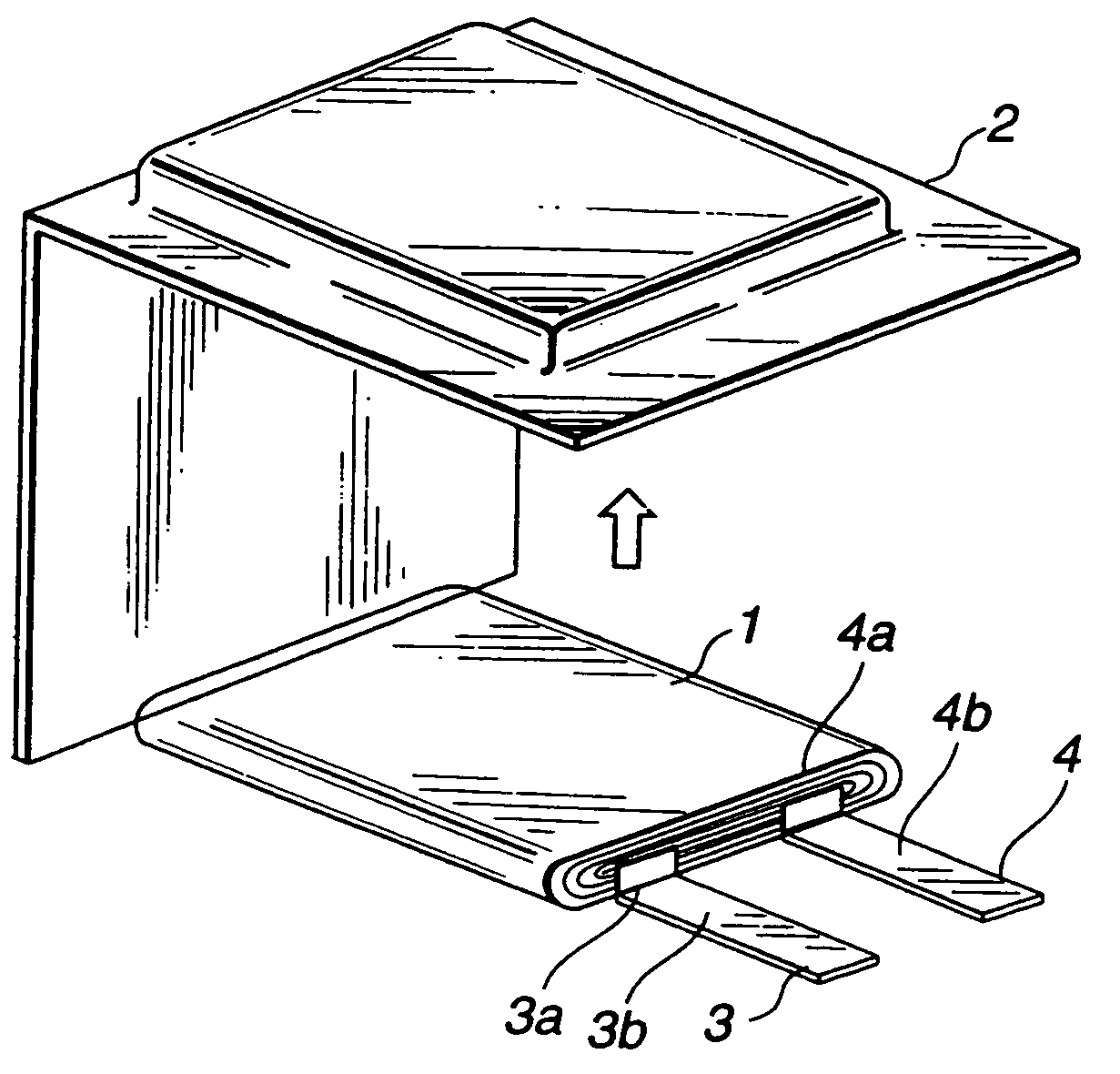

Non-aqueous electrolyte cell and manufacturing method therefor

InactiveUS7157179B2Easy to produceHigh positioning accuracyNon-aqueous electrolyte accumulatorsFinal product manufactureEngineeringManufacturing cell

A non-aqueous electrolyte cell in which the cell capacity is improved and positioning accuracy of external terminals is assured. A unit cell is housed in an exterior packaging material of a laminated film and encapsulated on heat sealing. To elongated positive and negative electrodes of the unit cell are electrically connected electrode terminal leads which are exposed to outside of the exterior packaging material as the leads are surrounded by heat fused portions. The unit cell is a wound assembly of the positive and negative electrodes each of which is includes of a current collector carrying a layer of an active material. The electrode terminal leads are mounted on the current collectors of the positive and negative electrodes in the vicinity of the innermost turn of the wound assembly. In manufacturing the unit cell, the positions of the electrode terminal leads are detected and positioned with respect to the flat winding arbor. The positive and negative electrodes then are wound on the winding arbor.

Owner:MURATA MFG CO LTD

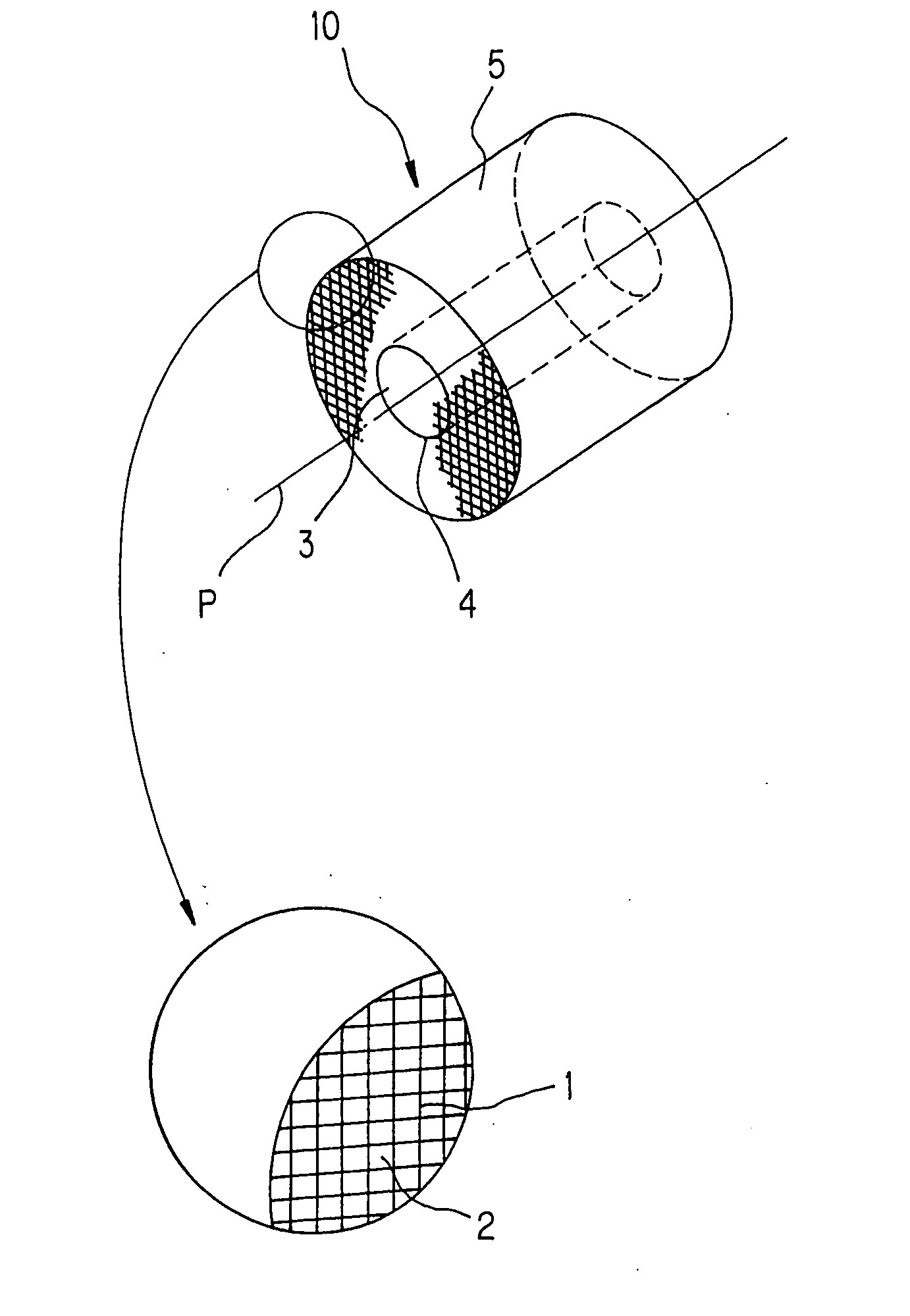

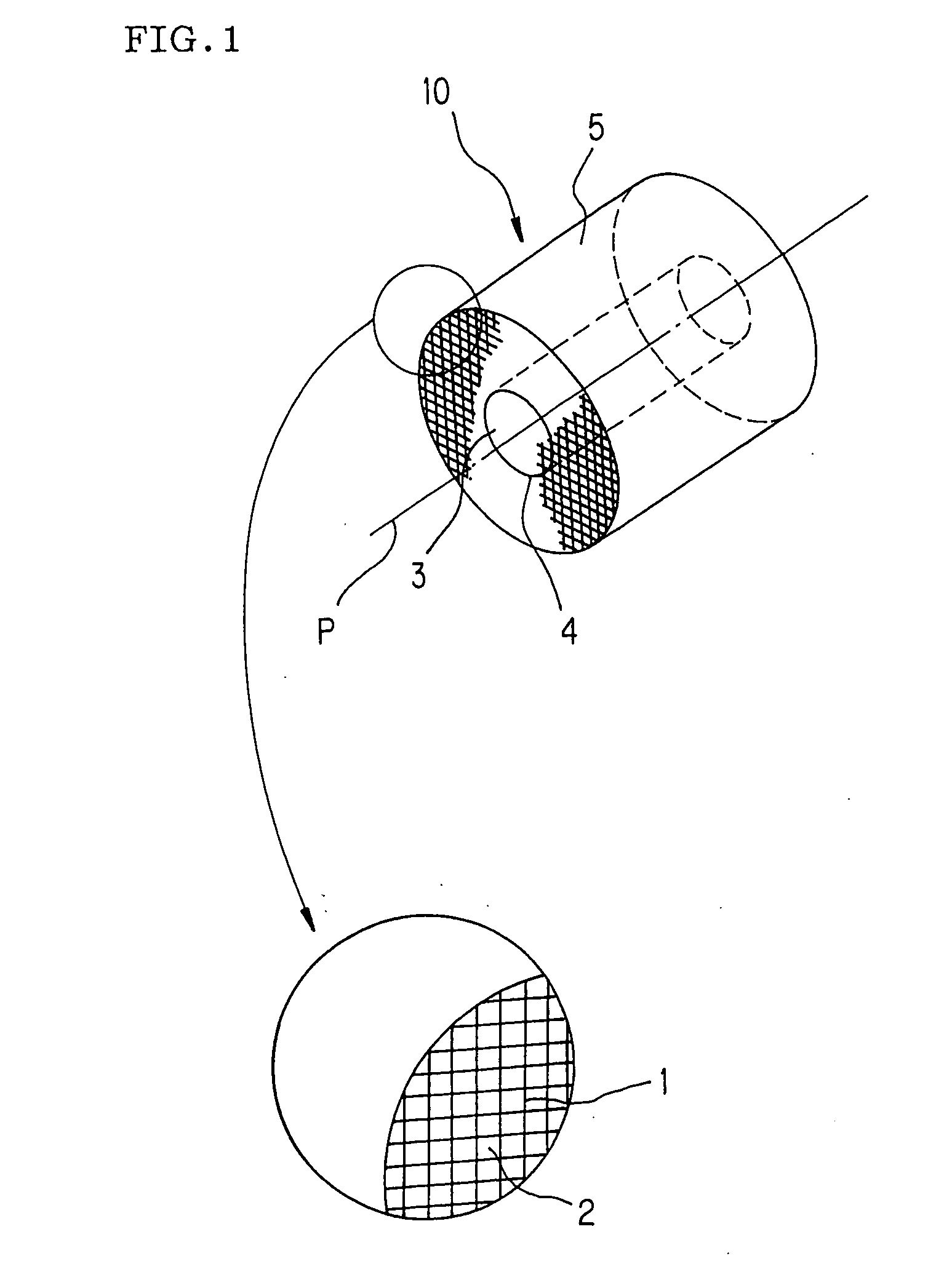

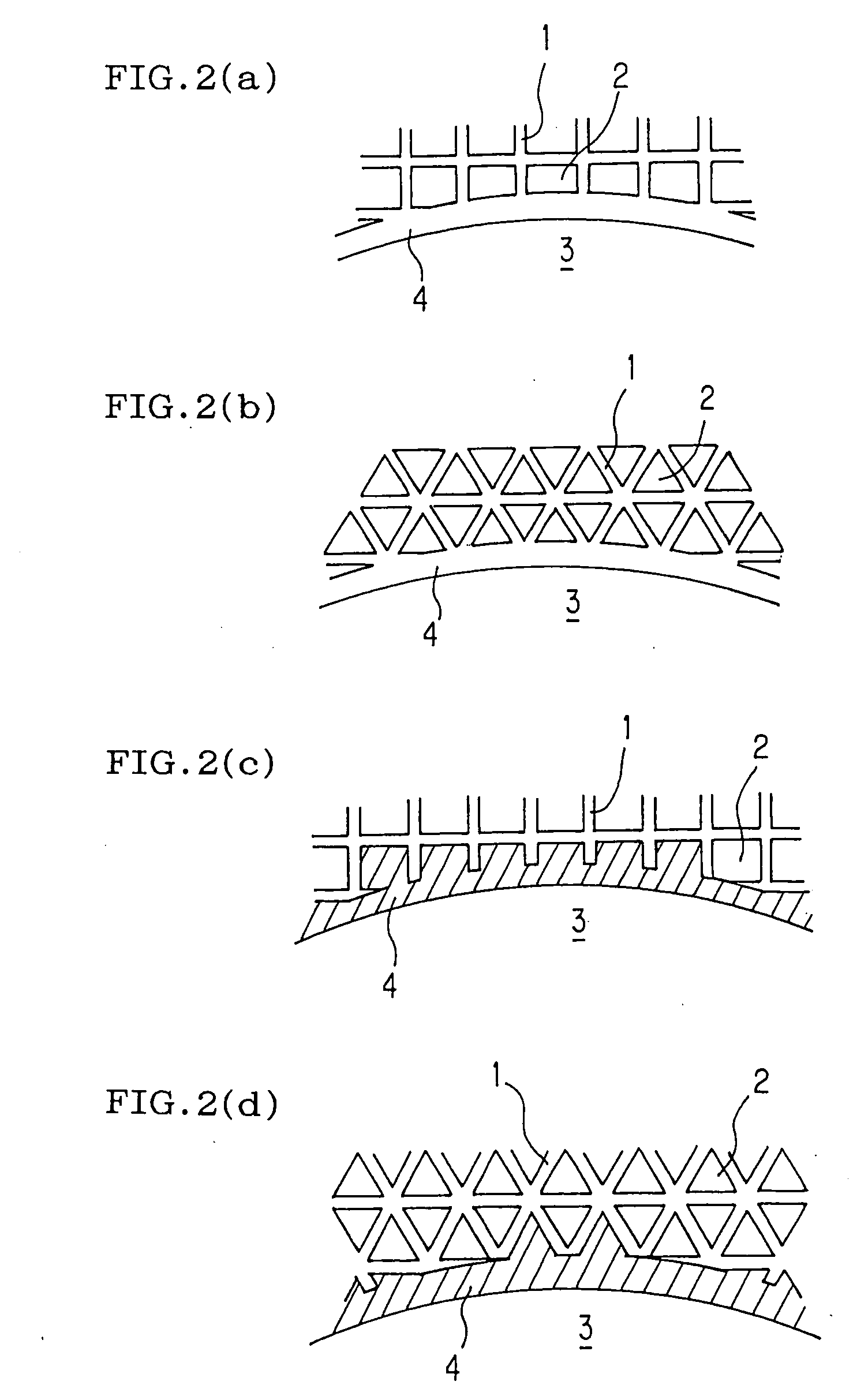

Cell structural body, method of manufacturing cell structural body, and catalyst structural body

ActiveUS20050107244A1Excellent isostatic breaking strengthHigh breaking strengthCombination devicesMolecular sieve catalystsPtru catalystEngineering

A cell structure 10 having a plurality of cells 2 which are partitioned with partition walls 1 to form a honeycomb and which are flow paths of fluid, an outer wall 5 which encloses the cells 2 and a cavity 3 which pierces in the direction of a central axis P of the structure through a portion including the central axis P or a given axis parallel to the central axis P, where the cell structure further has an inner wall 4 on the inner surface of the cavity 3, a method for producing the cell structure, and a catalyst structure. The cell structure having the cavity has an excellent isostatic breaking strength and can exhibit proper sealing function in its cavities. Furthermore, a method for producing the cell structure, the catalyst structure, etc. are provided.

Owner:NGK INSULATORS LTD

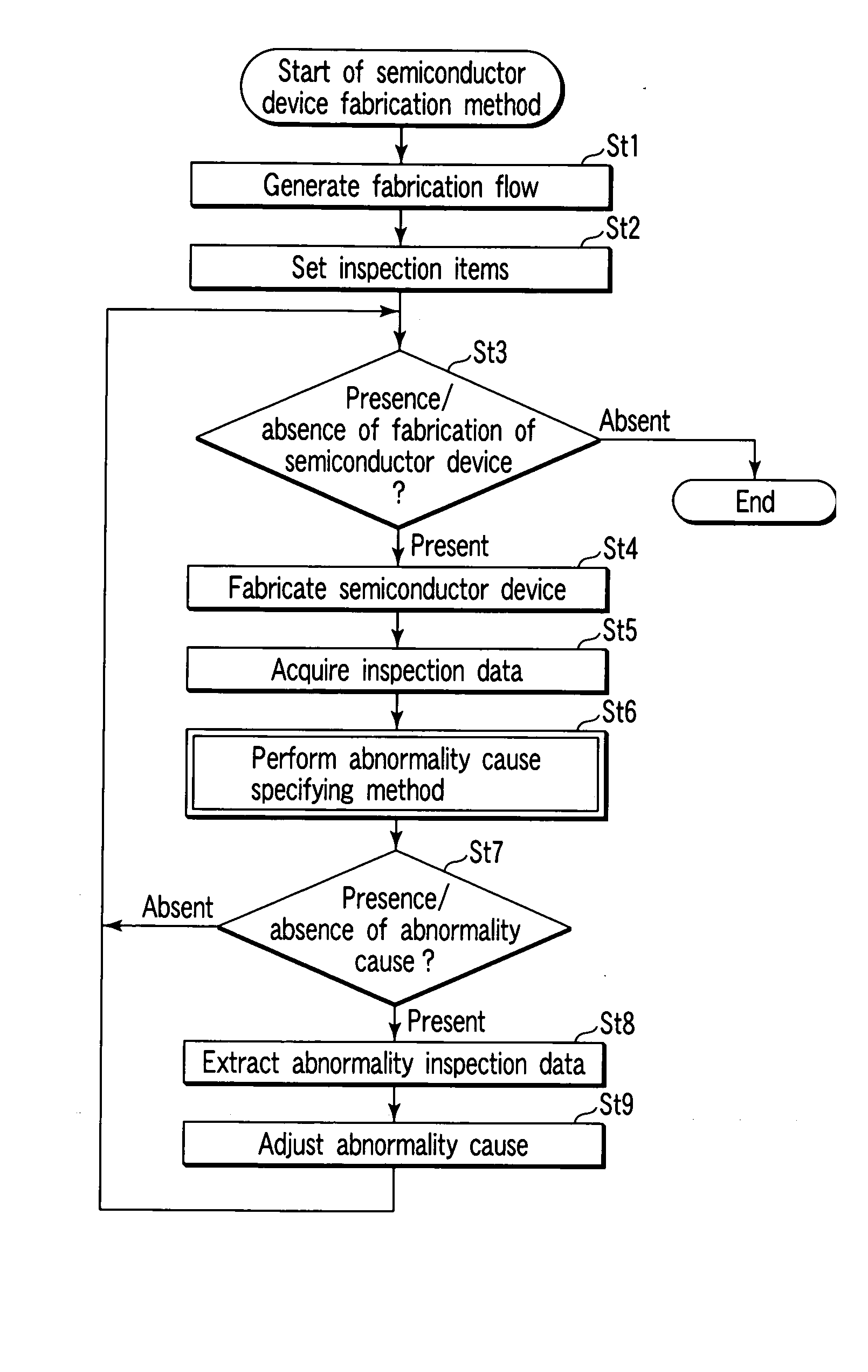

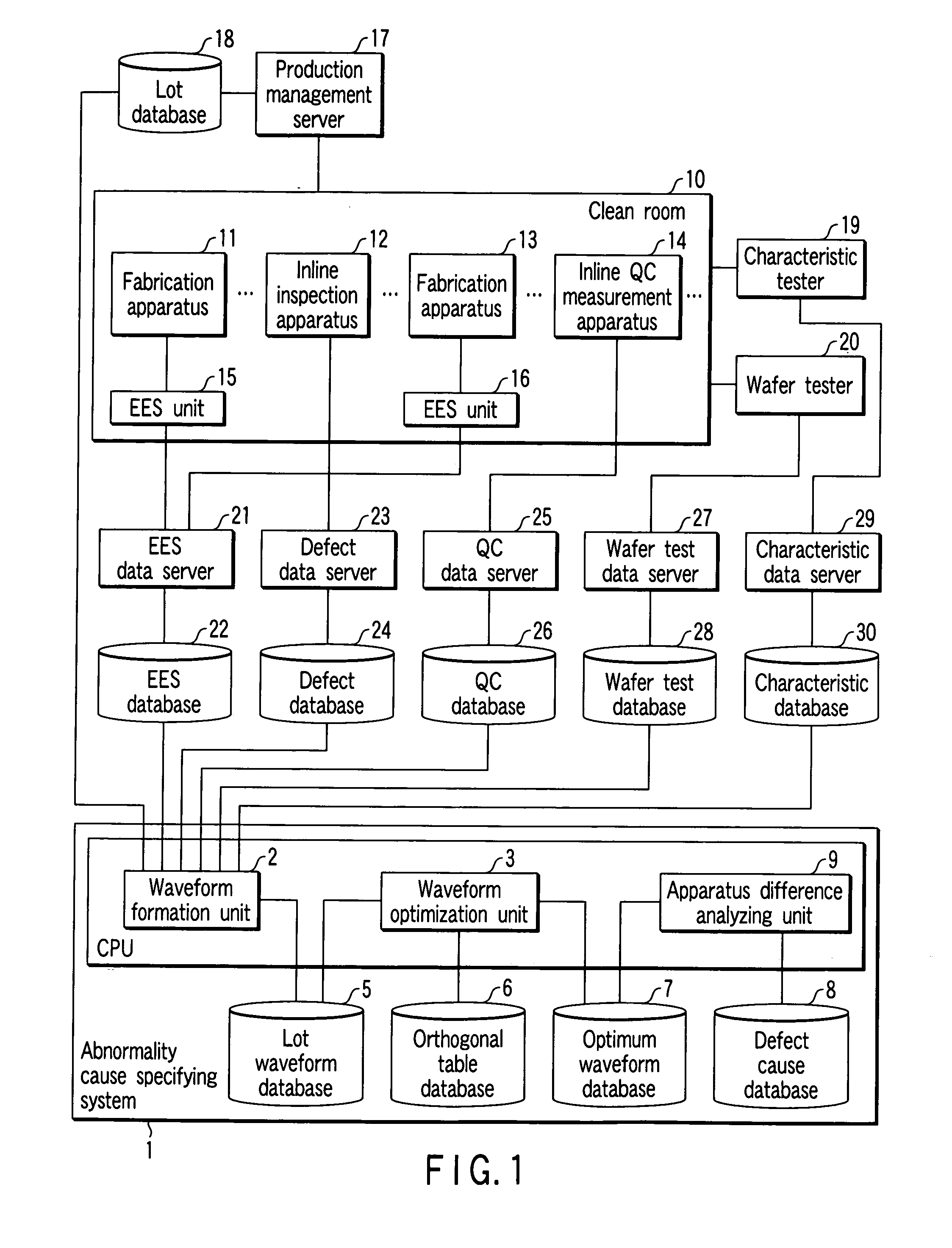

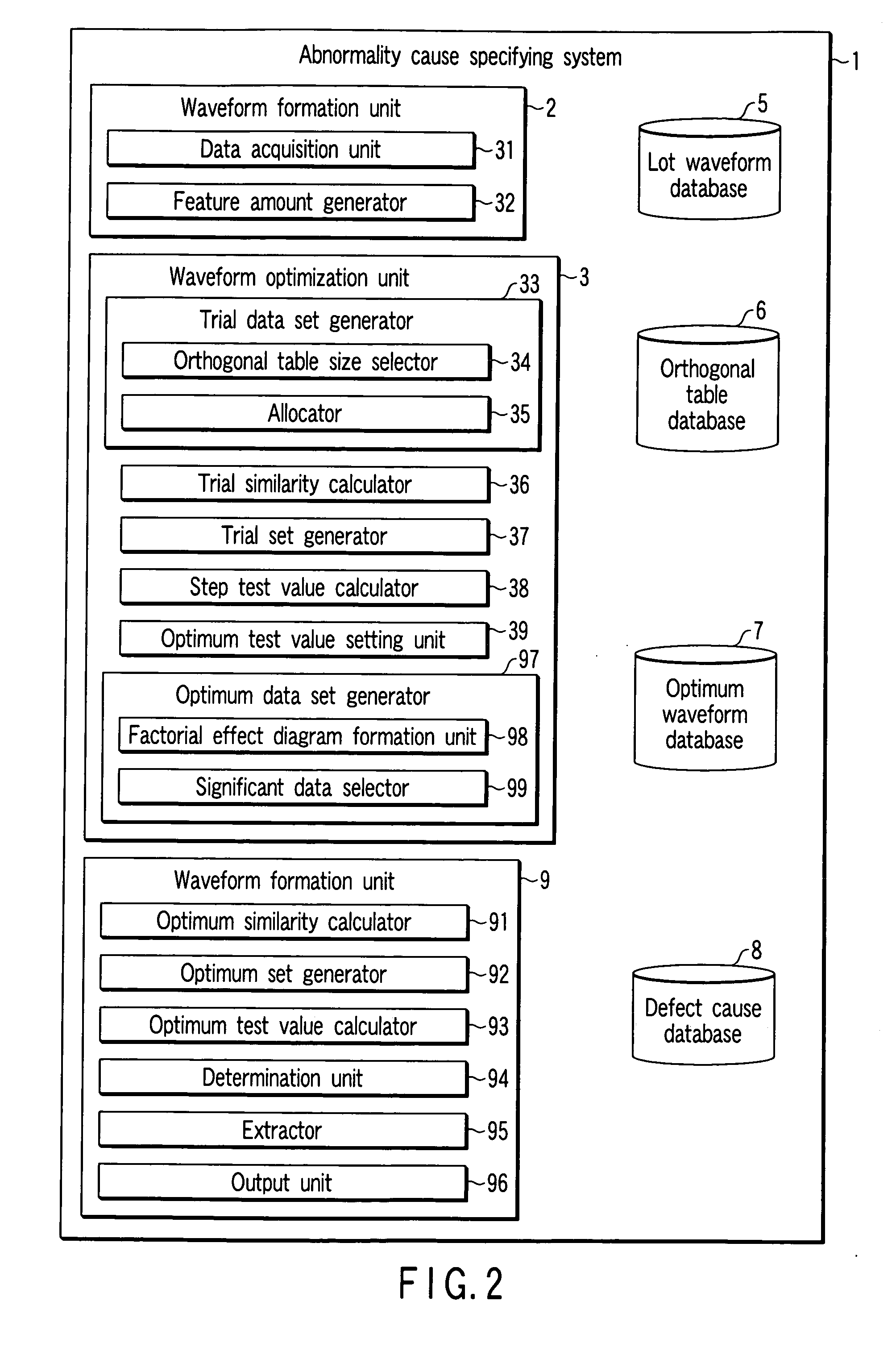

Abnormality cause specifying method, abnormality cause specifying system, and semiconductor device fabrication method

InactiveUS20060281199A1Semiconductor/solid-state device testing/measurementTesting/monitoring control systemsManufacturing cellComputer science

A feature amount is generated by standardizing inspection data related to a fabrication unit for each type, a similar set including fabrication units corresponding to similar feature amounts is formed by comparing the feature amounts, and apparatus difference analysis is performed between a plurality of fabrication units forming the similar set. A two-level orthogonal table is used to determine whether to adopt a feature amount of each type, and some feature amounts are not used in the apparatus difference analysis and the like by optimizing the smaller-the-better characteristic or the larger-the-better characteristic of a test value of the apparatus difference analysis, thereby reducing the calculation amount and accurately and efficiently specifying an abnormality cause.

Owner:KK TOSHIBA

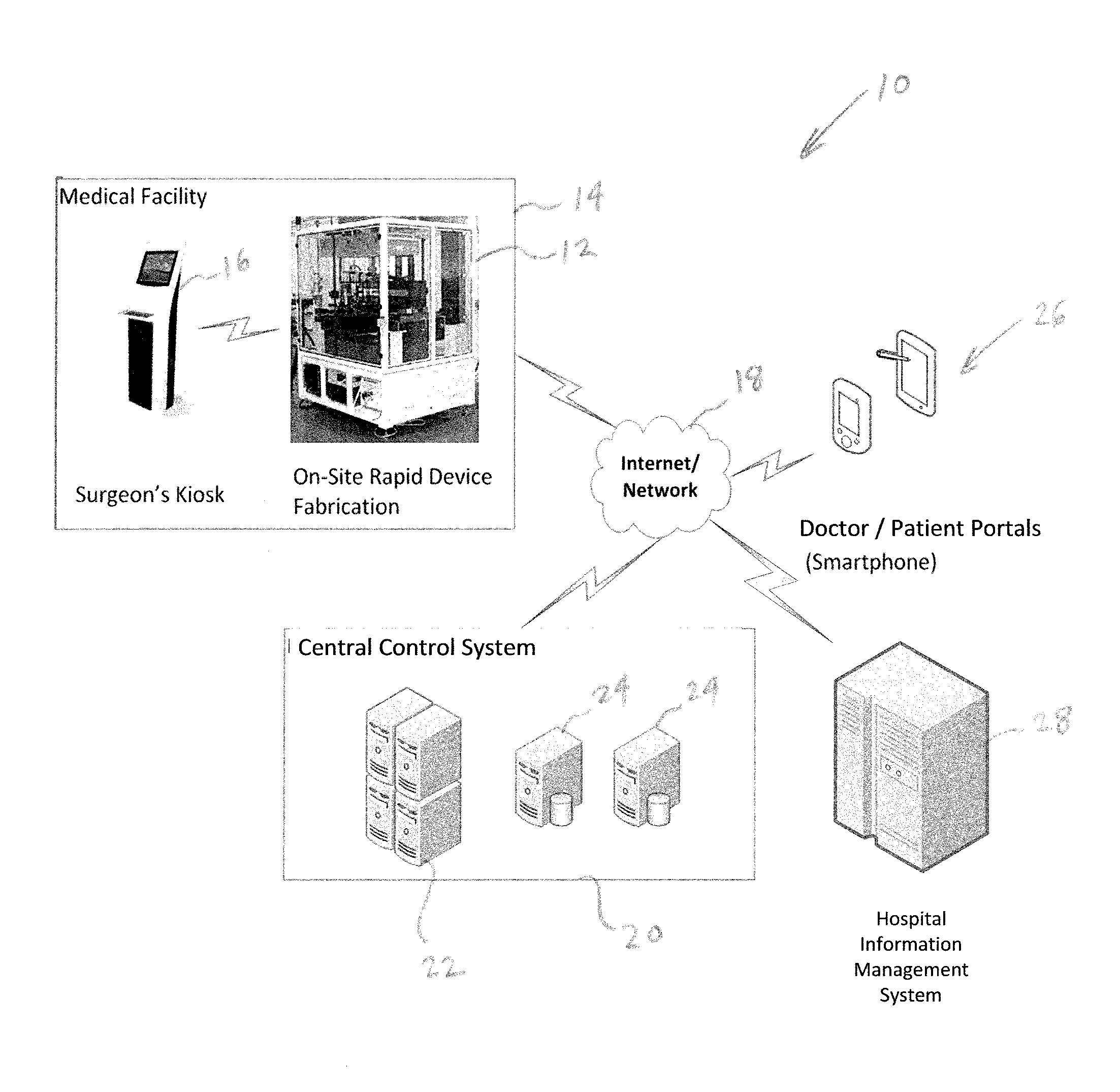

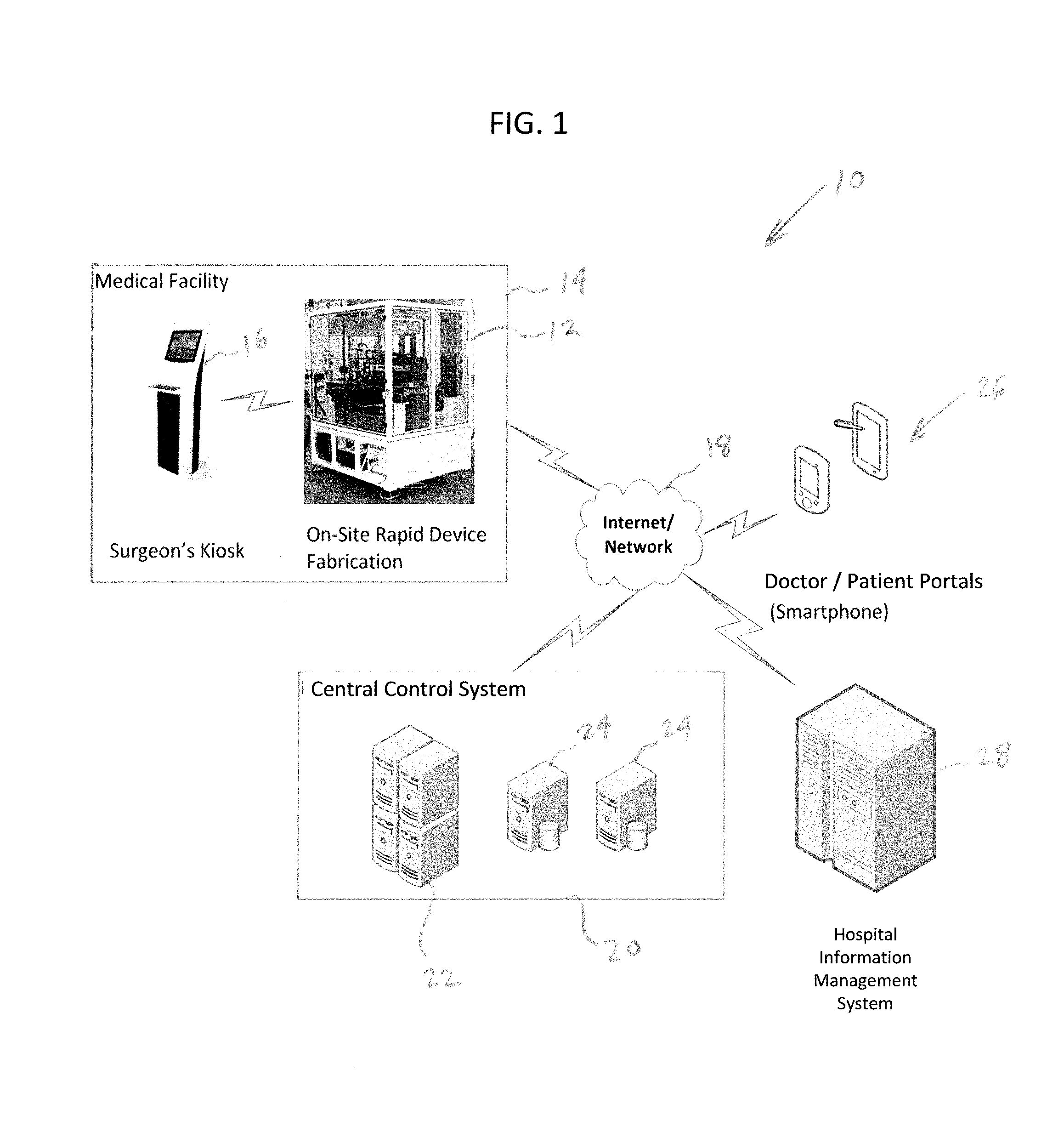

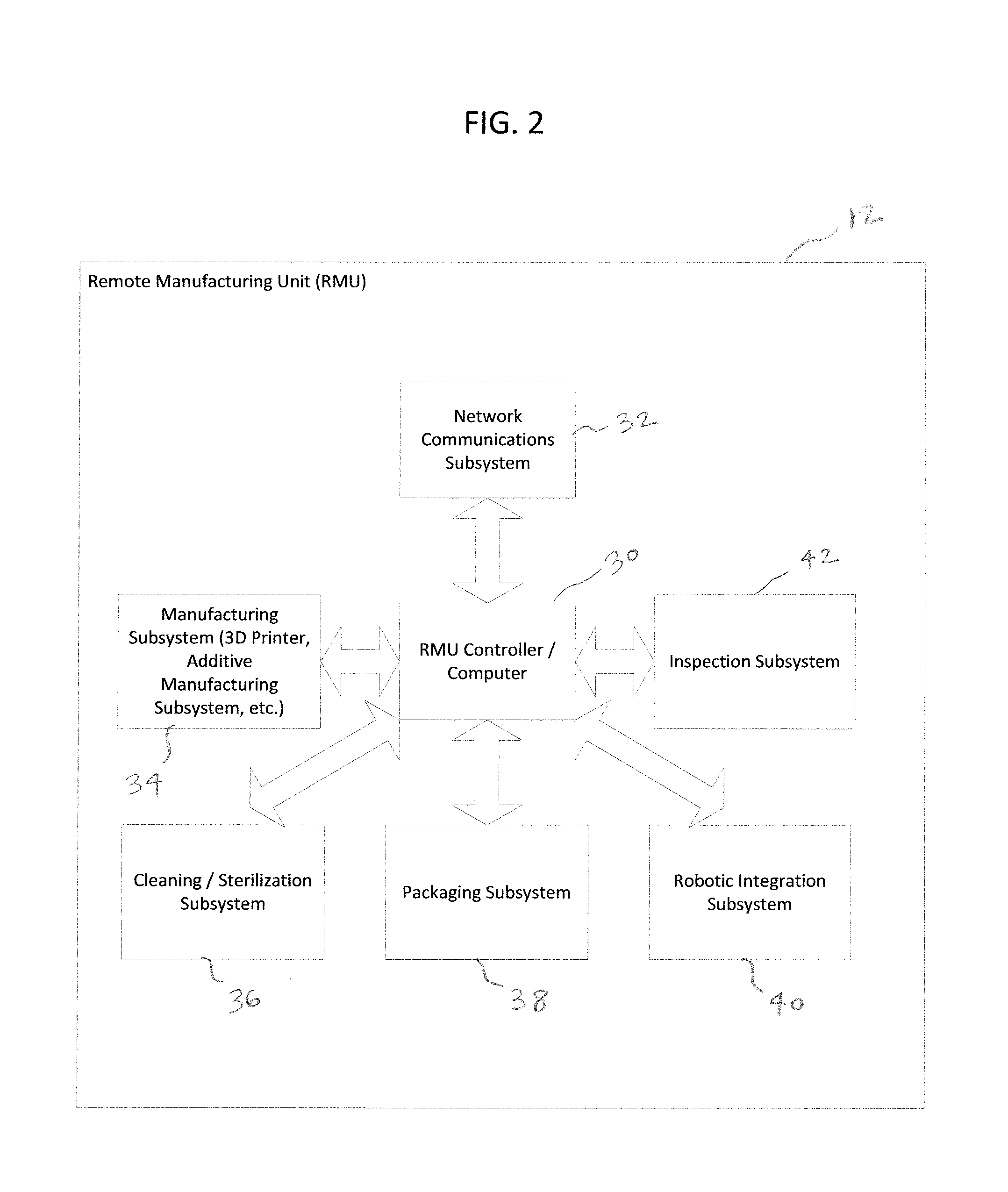

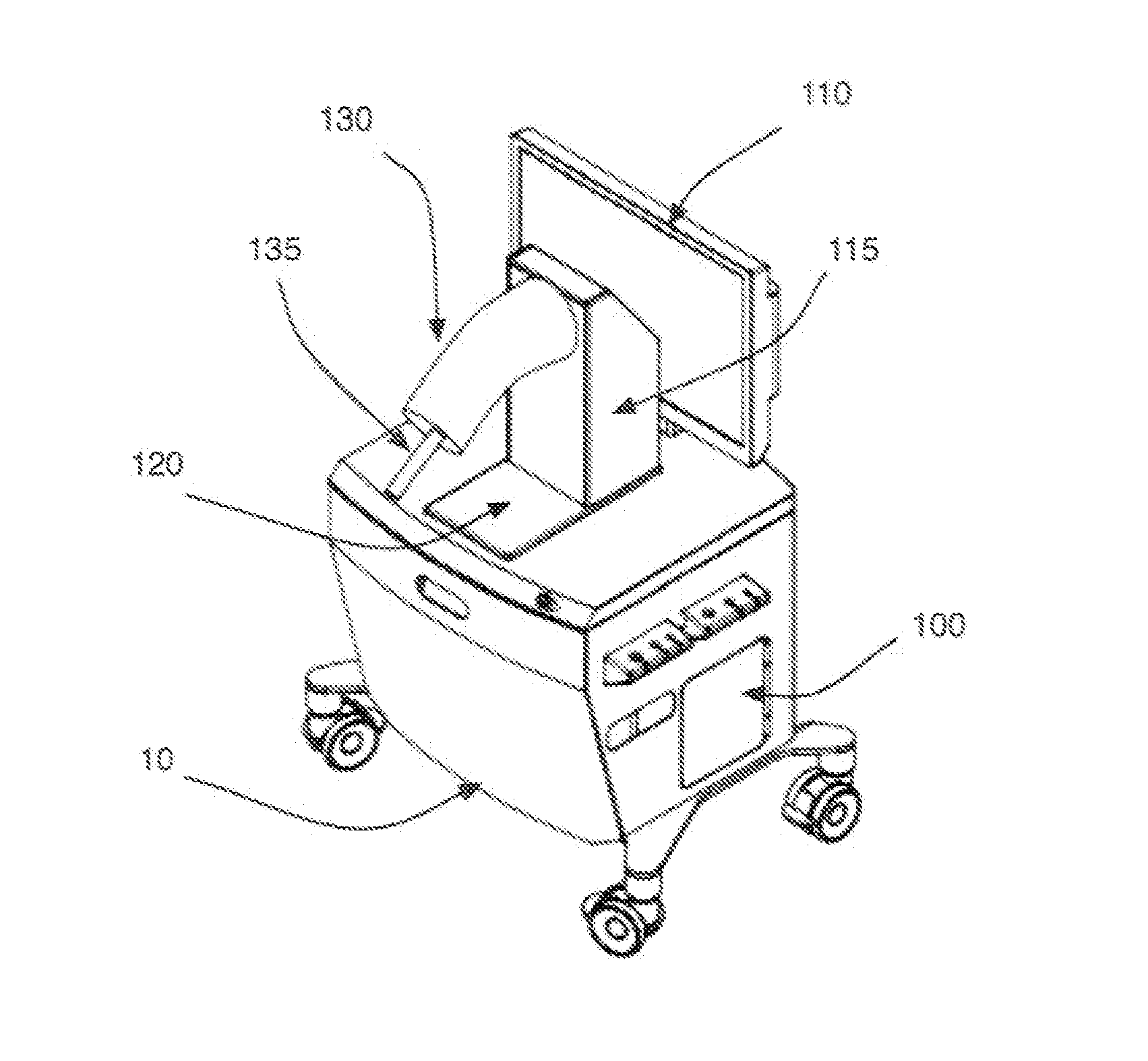

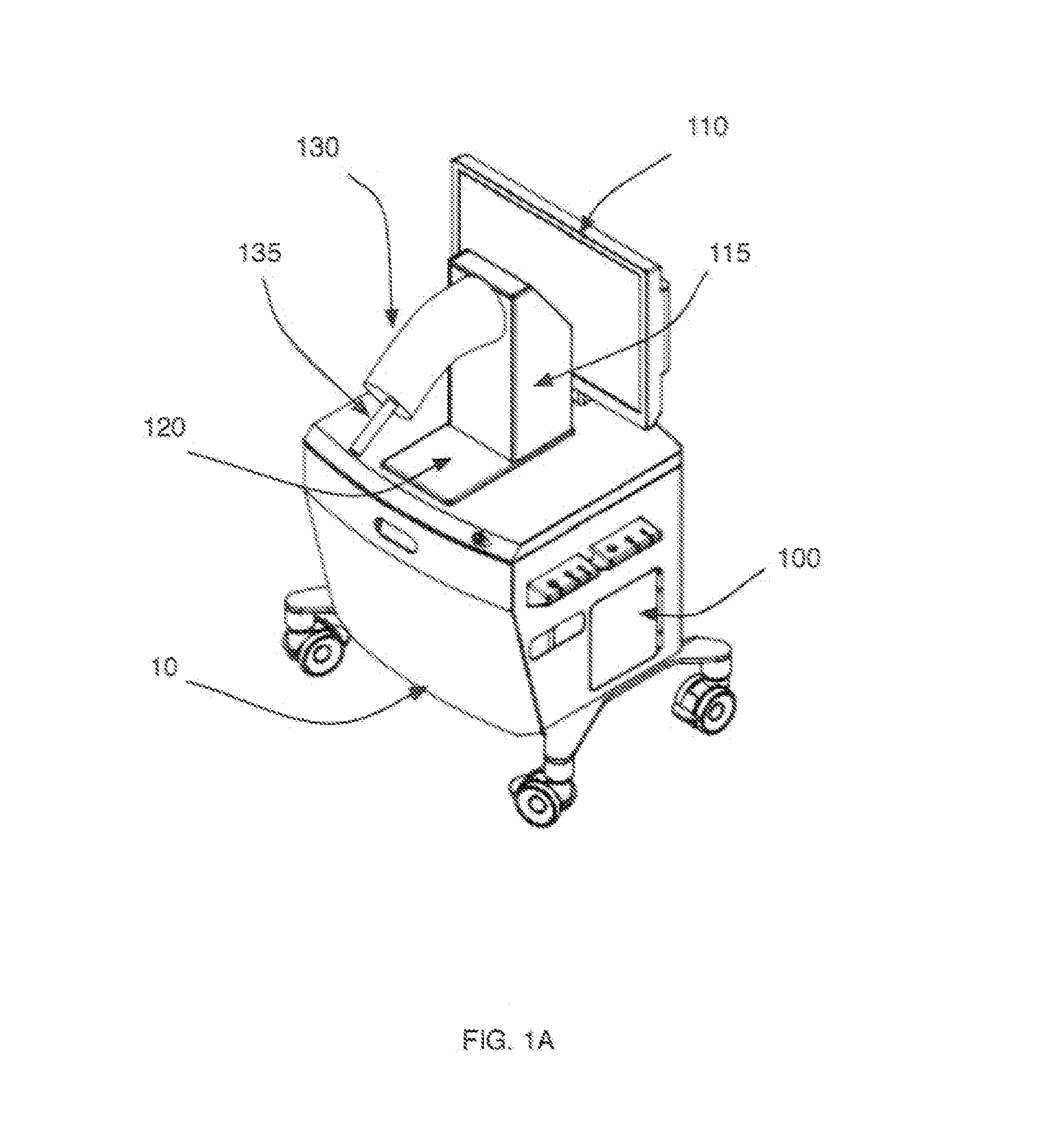

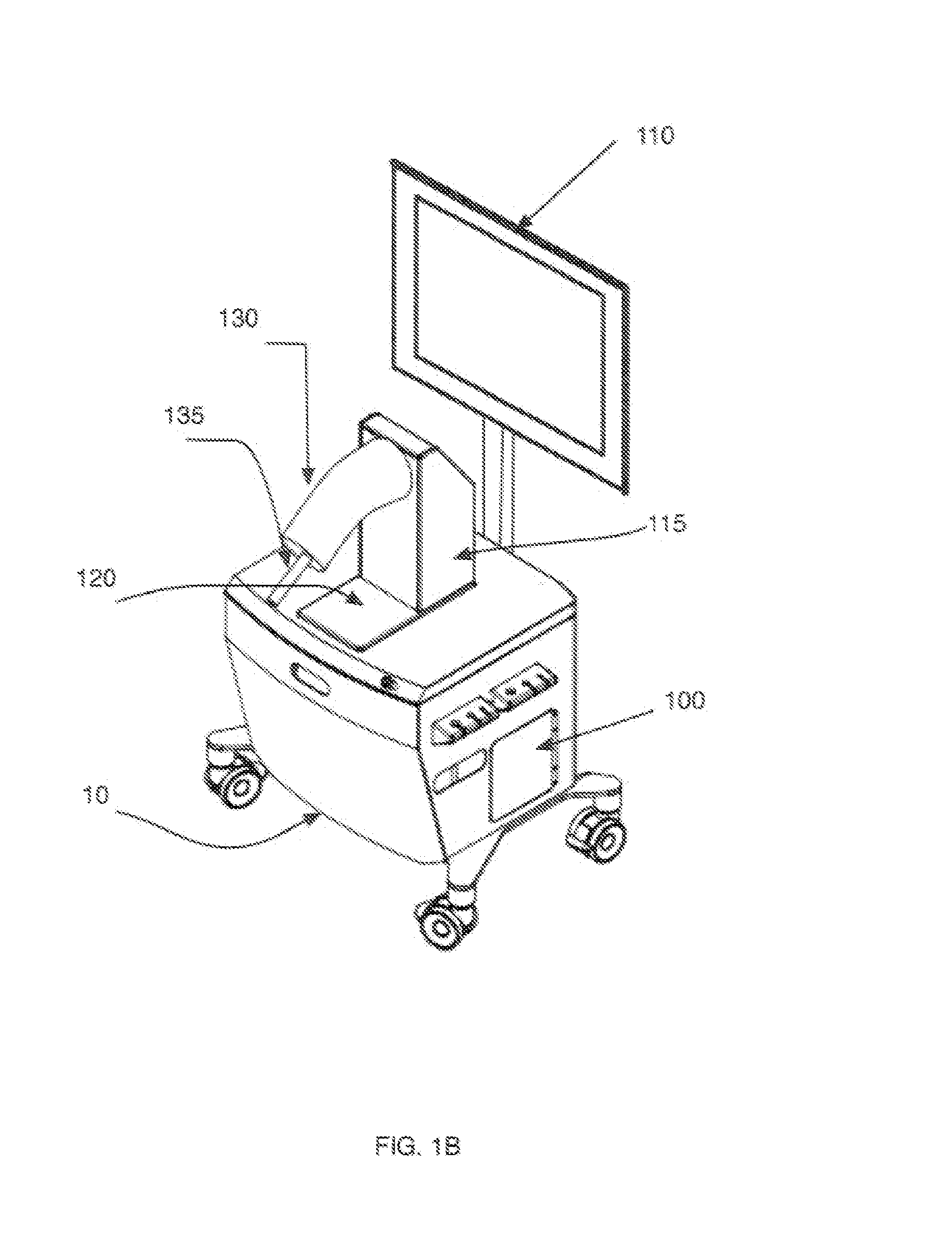

Systems and Methods for Remote Manufacturing of Medical Devices

InactiveUS20140277659A1Fast preparationSpecial data processing applicationsProgramme total factory controlManufacturing technologyMedical product

A system and method for remote manufacturing of medical devices are provided. The system can be installed at a facility (e.g., at a hospital or other medical facility), and includes a remote manufacturing unit (RMU) that allows for customized, rapid fabrication of medical devices at the medical facility using suitable manufacturing techniques such as three-dimensional (3D) printing, additive manufacturing, subtractive manufacturing, etc. The RMU can communicate with a computer system which presents a healthcare professional with a digital catalog of medical products, and allows the healthcare professional to select and customize a desired device to be manufactured at the facility.

Owner:BIOMET MFG CORP

Medical Simulation System and Method with Configurable Anatomy Model Manufacturing

ActiveUS20150325151A1Easy to trainEasy maintenanceSurgical navigation systemsEducational modelsDisplay deviceManufacturing cell

Simulation systems and methods may enable medical training. A manufacturing unit may receive data from a configuration unit indicating identification and manufacturing parameters for an anatomy model. A data processing unit may receive data from the configuration unit identifying the anatomy model, and data from a calibration unit indicating a position and / or orientation of a position and orientation sensor relative to the anatomy model. The data processing unit may also receive data from the position and orientation sensor indicating a position and / or orientation of the anatomy model. The data processing unit may generate a virtual image using the data from the position and orientation sensor, the data from the calibration unit, and the data from the configuration unit. The data processing unit may render the virtual image to a display.

Owner:VIRTAMED

System of energy-efficient and constant-pressure parallel-coupled fluid-transport machines

The present invention discloses a system of energy-efficient and constant-pressure parallel-coupled fluid-transport machines, which can flexibly and massively provide gas and water to every fabrication unit. The system of the present invention comprises: variable-frequency centrifugal fluid-transport machines, pressure gauges, power meters, flow meters, and controllers. The performance curves of the abovementioned system of parallel-coupled fluid-transport machines and the system impedance curves of the loads are analyzed theoretically and built in the controllers together with the equal-efficiency curves provided by the manufacturer. When the system is operating, the data detected by the pressure gauges, power meters, and flow meters are compared with the built-in data to obtain the optimal energy-efficient conditions as the operational criteria of the system of the present invention.

Owner:HUANG WEN CHENG

Shelving System With Rotational Functionality

InactiveUS20150096950A1Easy accessEfficient and reliableRevolving cabinetShow shelvesEngineeringManufacturing cell

The present disclosure provides enhanced storage systems that facilitate efficient storage of, and access to, a variety of items and products. Exemplary systems according to the present disclosure include mechanism(s) that permit reliable and efficient repositioning of one or more shelves, thereby enhancing utilization and efficiencies associated therewith. Shelving systems according to the present disclosure facilitate synchronized vertical motion of shelving units, e.g., based on coordinated pulley / cable systems, and advantageously include spring designs that facilitate controlled vertical motion of shelving units, e.g., based on fluid movement and / or discharge from the spring design. Rotational motion of the shelves relative to a stationary rod may be provided. Shelving units may be readily repositioned at elbow or eye level, and repositioned at their respective initial positions in an efficient and advantageous manner. The shelving systems may be original manufacture units or may be designed for use in retrofitting existing shelving systems.

Owner:ENGEL ZACKARY

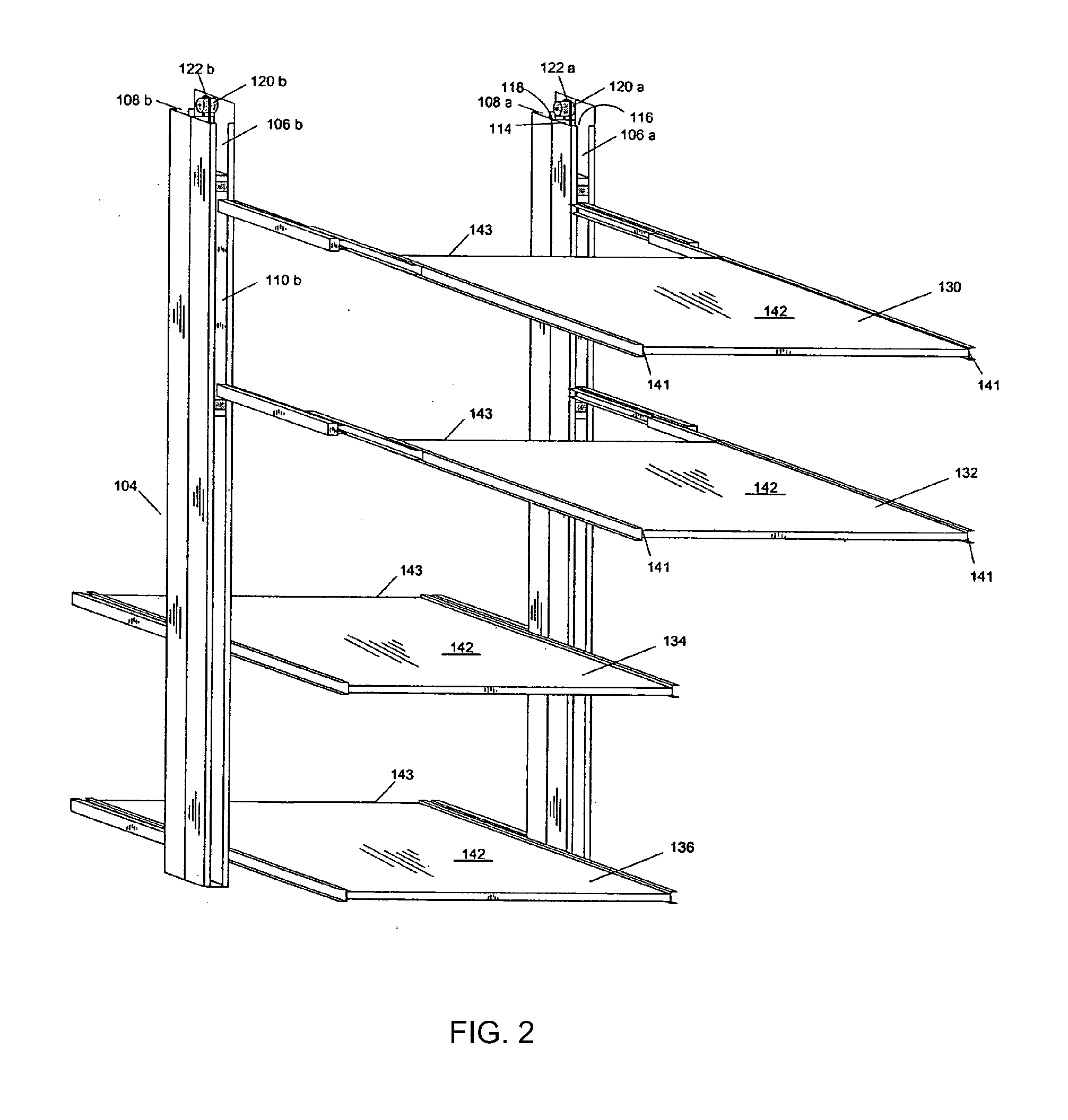

Unitized electrochemical cell sub-assembly and the method of making the same

InactiveUS20060073373A1Fuel cells groupingFinal product manufactureEngineeringIon-exchange membranes

Disclosed is a unitized electrochemical cell sub-assembly having a first separator plate and a second separator plate that each has a first surface. A recess is located in at least one of the first surfaces to define a chamber adjacent the periphery of the plates when the plates face each other. A membrane electrode assembly (MEA) comprising an ion exchange membrane and a pair of gas diffusion layers is disposed on and between each of the first surfaces between the two plates when the plates face each other so that the peripheral edge of the ion exchange membrane is located within the chamber. Also located in the chamber is a non-conductive sealant polymer that seals and joins the first and second plates to each other, and that seals and joins the first and second plates to the edge of the ion exchange membrane. Also disclosed is a fabrication method for making the unitized electrochemical cell sub-assembly.

Owner:EI DU PONT DE NEMOURS & CO

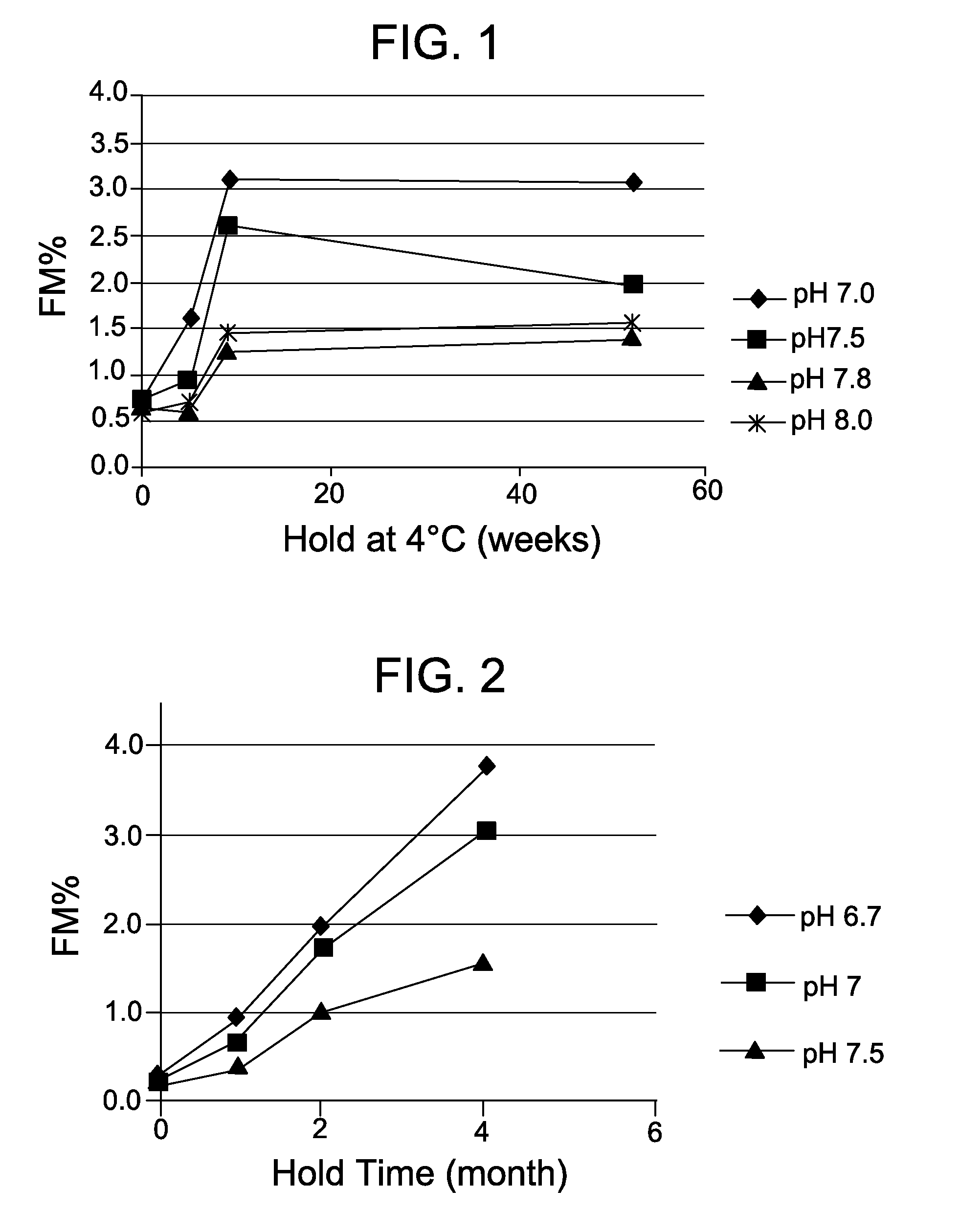

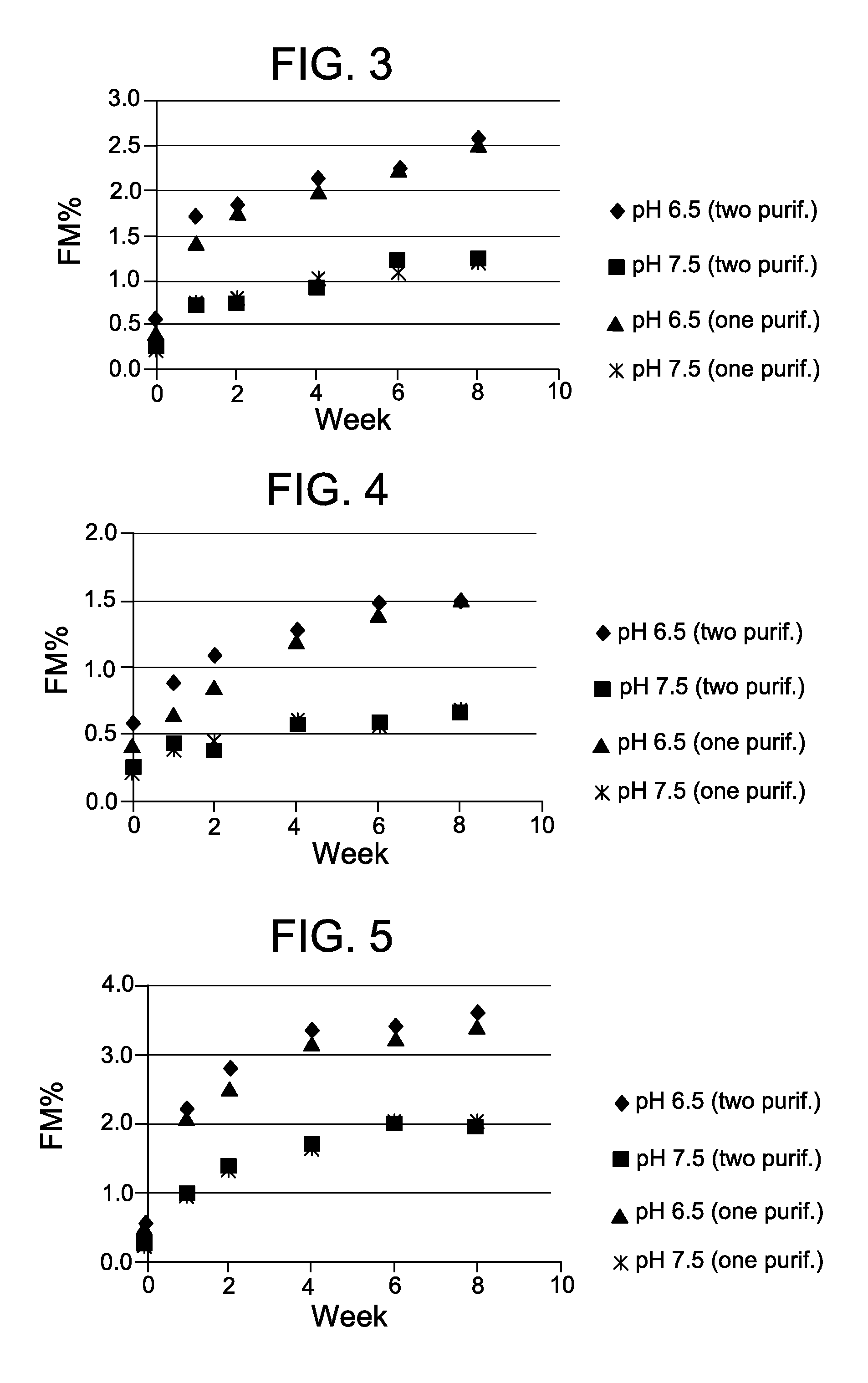

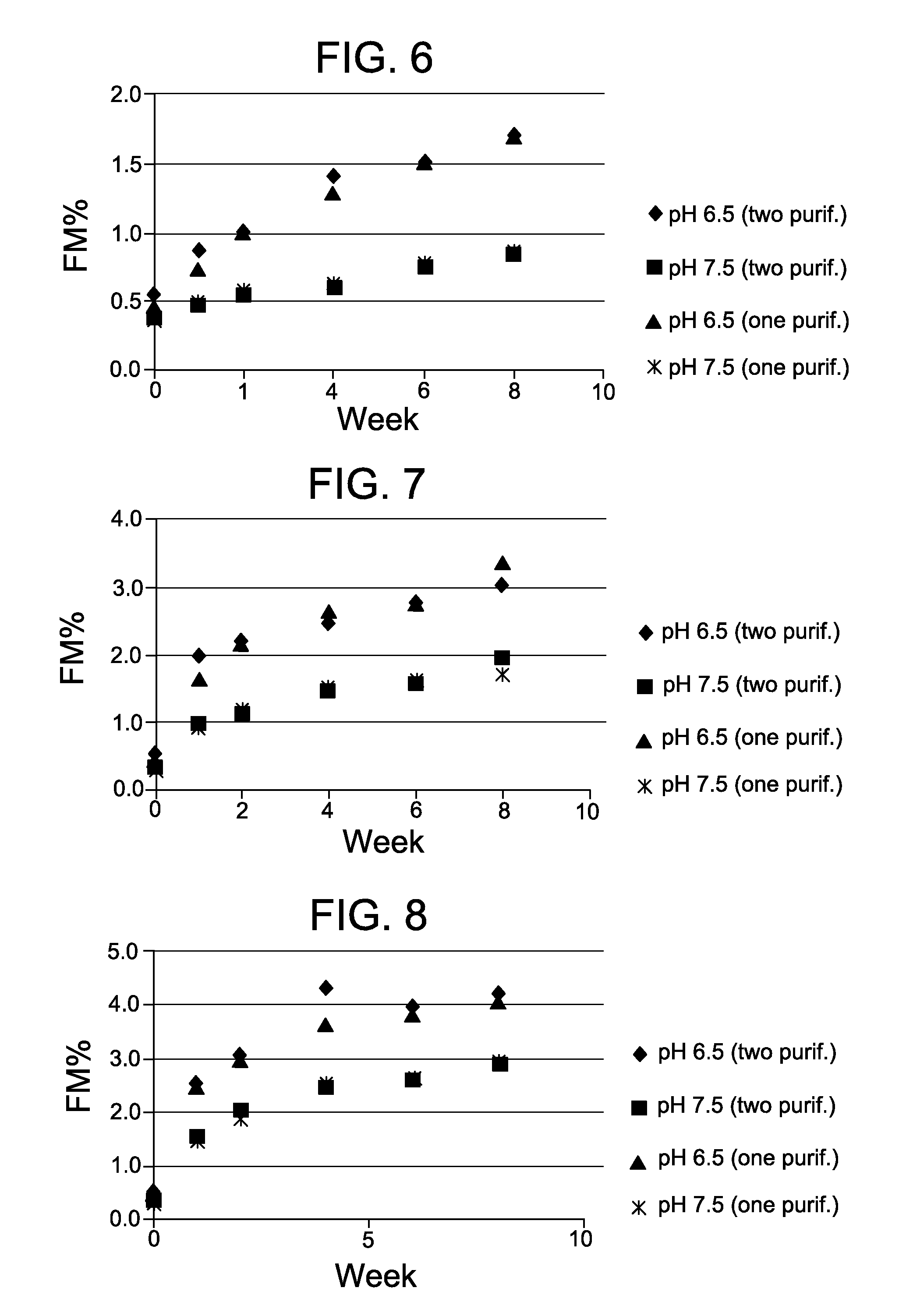

Process for preparing stable antibody maytansinoid conjugates

InactiveUS20150306242A1Organic active ingredientsImmunoglobulins against cell receptors/antigens/surface-determinantsCell bindingCytotoxicity

The invention provides processes for manufacturing cell-binding agent-cytotoxic agent conjugates of improved stability comprising performing the modification reaction at a high pH. The inventive processes comprise contacting a cell-binding agent with a bifunctional crosslinking reagent in a solution having a pH of 7.1 to 9 to covalently attach a linker to the cell-binding agent and thereby prepare a mixture comprising cell-binding agents having linkers bound thereto.

Owner:IMMUNOGEN INC

Multi-path valve arrangement in a beverage making unit

ActiveUS20100147158A1Easy to cleanOperating means/releasing devices for valvesMixing methodsBody positionsEngineering

A multi-path valve arrangement in a beverage making unit by which, optionally, various beverages can be prepared. The multi-path valve arrangement includes a multi-path valve with a housing provided with a cold milk inlet, a cold water inlet, a valve outlet and an air opening. A valve body in the housing is suited to connect the cold milk inlet having an adjustable throttling with the valve outlet. The valve body is set by a step motor which is connected with a programmable control of the valve body position.

Owner:EUGSTER FRISMAG

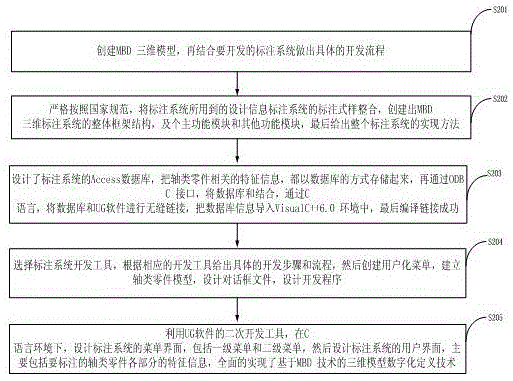

MBD based three-dimensional model design information tagging system and method

InactiveCN105005653AReduce the probability of participation errorsReduce digital system requirementsSpecial data processing applicationsDesign informationManufacturing cell

The invention discloses an MBD based three-dimensional model design information tagging system and method. The system comprises a related database unit, a MBD design information based manufacturing unit, an ODBC interface, a UG software secondary development tool unit, a marking part information unit, a part information viewing unit and a marking feature information unit. The method comprises steps of: firstly, creating an overall framework of an MBD three-dimensional marking system, a main function module and other function modules; designing an Access database of the marking system, and performing seamless connection between the database and the UG software through the ODBC interface; introducing database information into Visual C ++ 6.0 environment; creating a customized menu, establishing a shaft parts model, designing a dialog file and designing a development program; and designing a user interface of the marking system by using a secondary development tool of the UG software. According to the system and method provided by the invention, the accuracy and comprehensiveness of the data can be ensured, and the system and method can be more applicable to related development technologies of technology modernization in the aeronautics and astronautics fields.

Owner:XIAN TECH UNIV

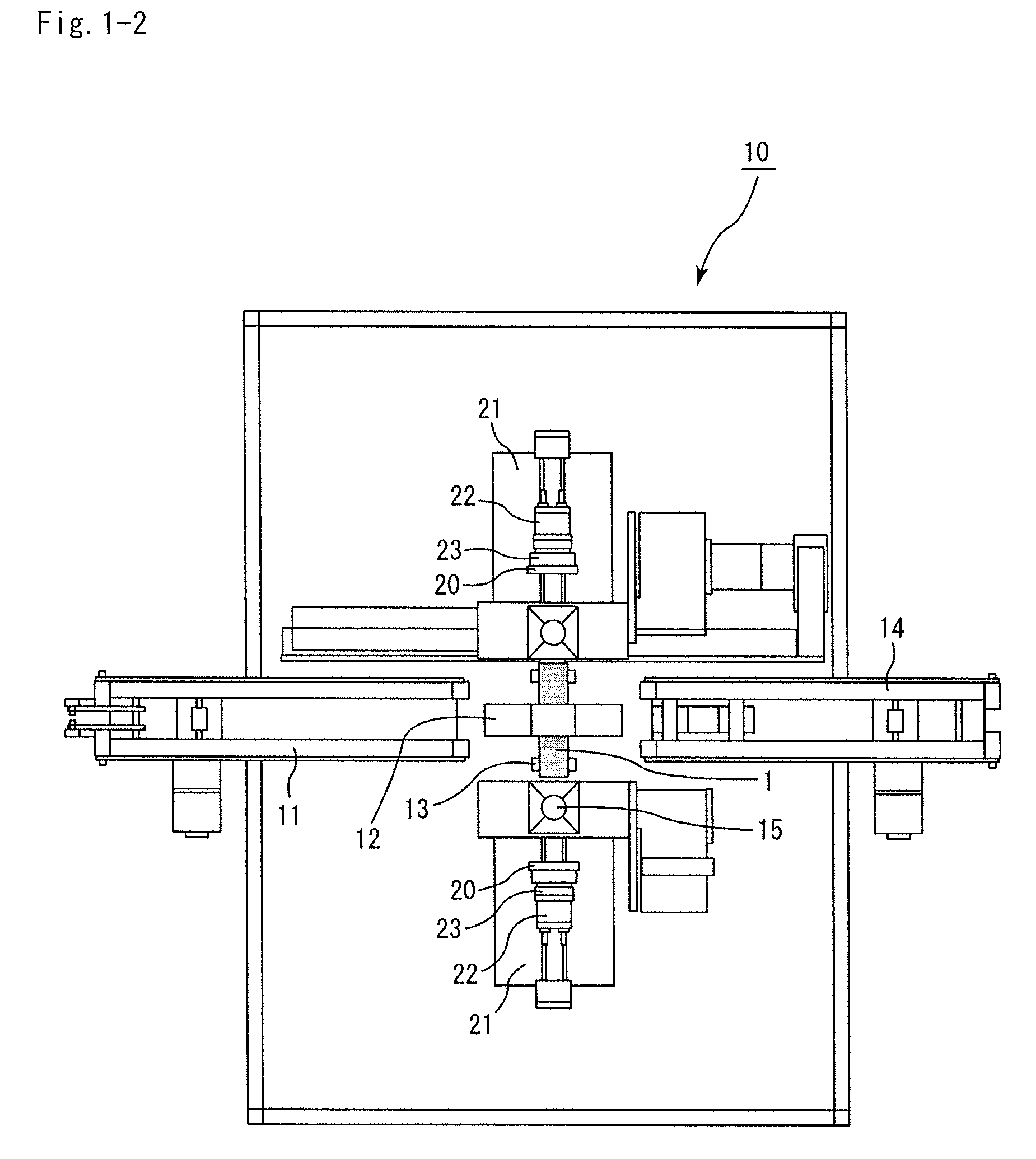

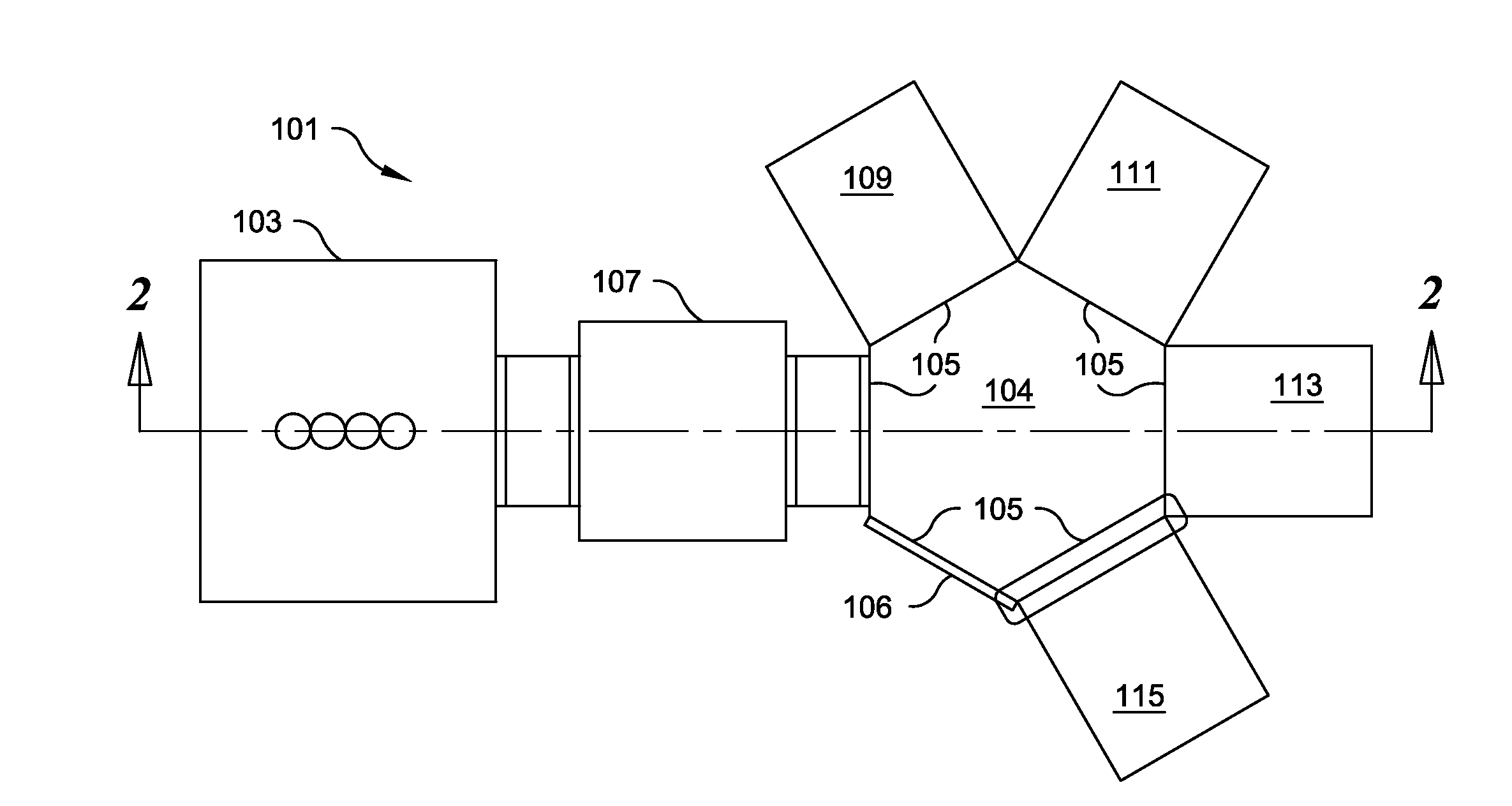

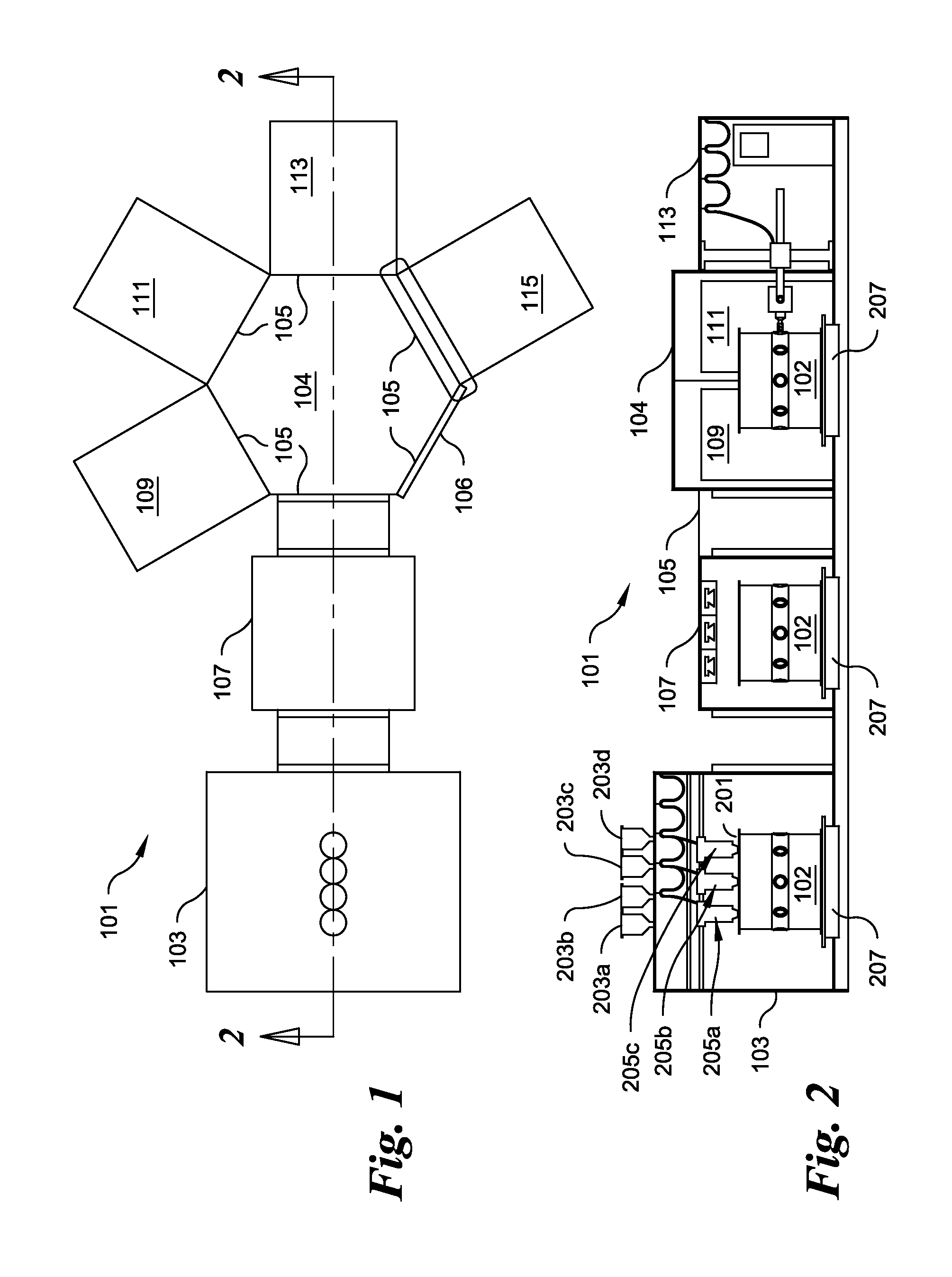

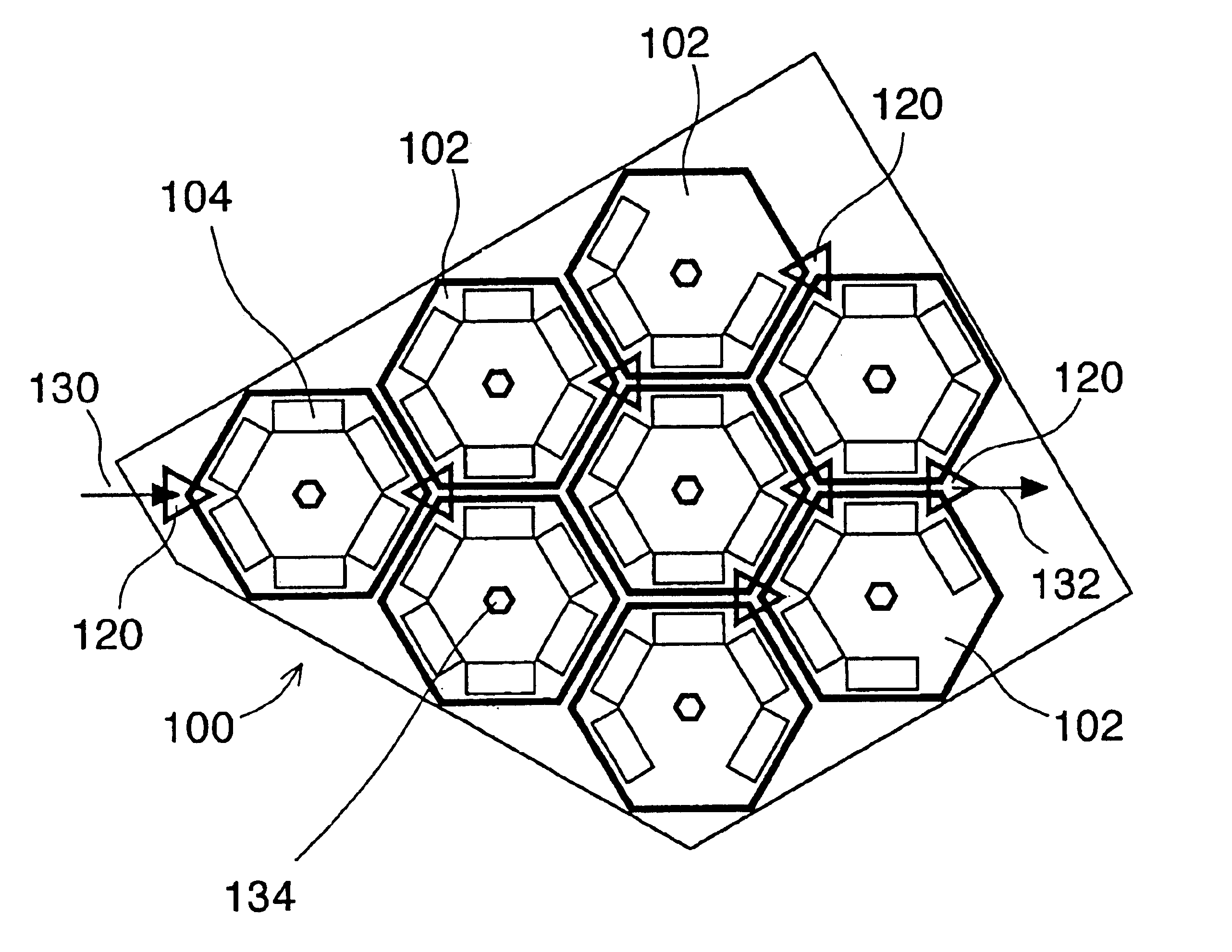

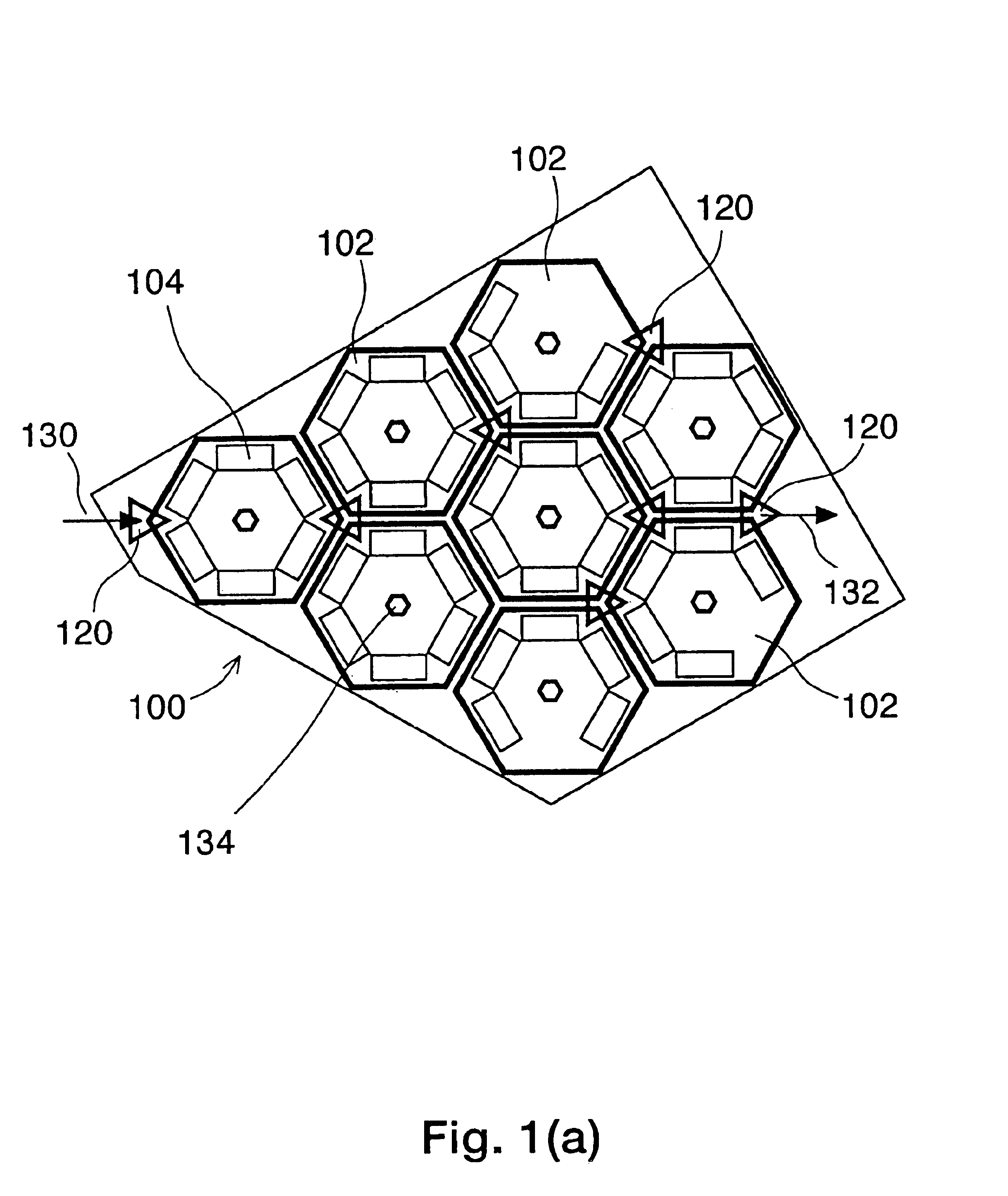

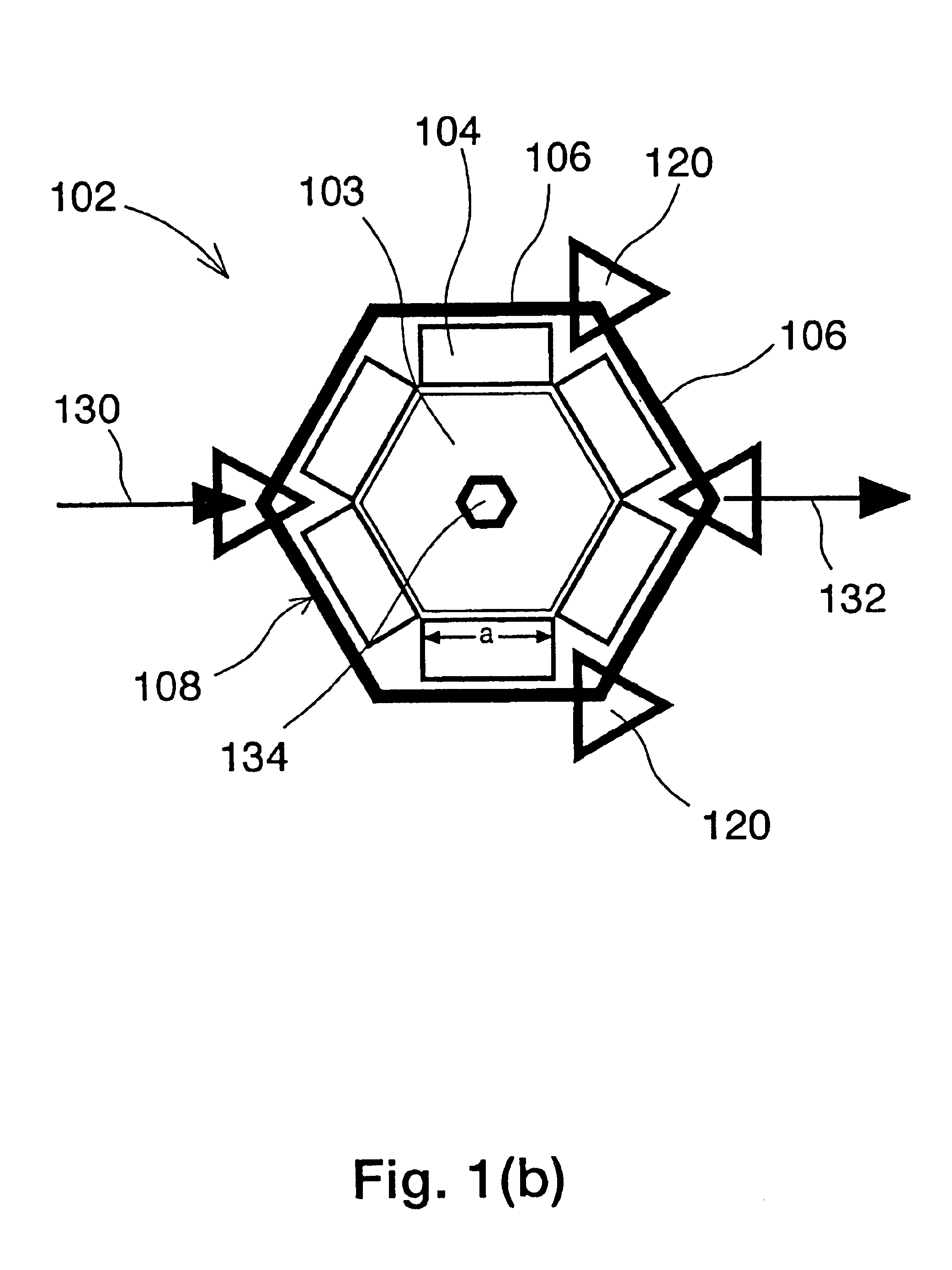

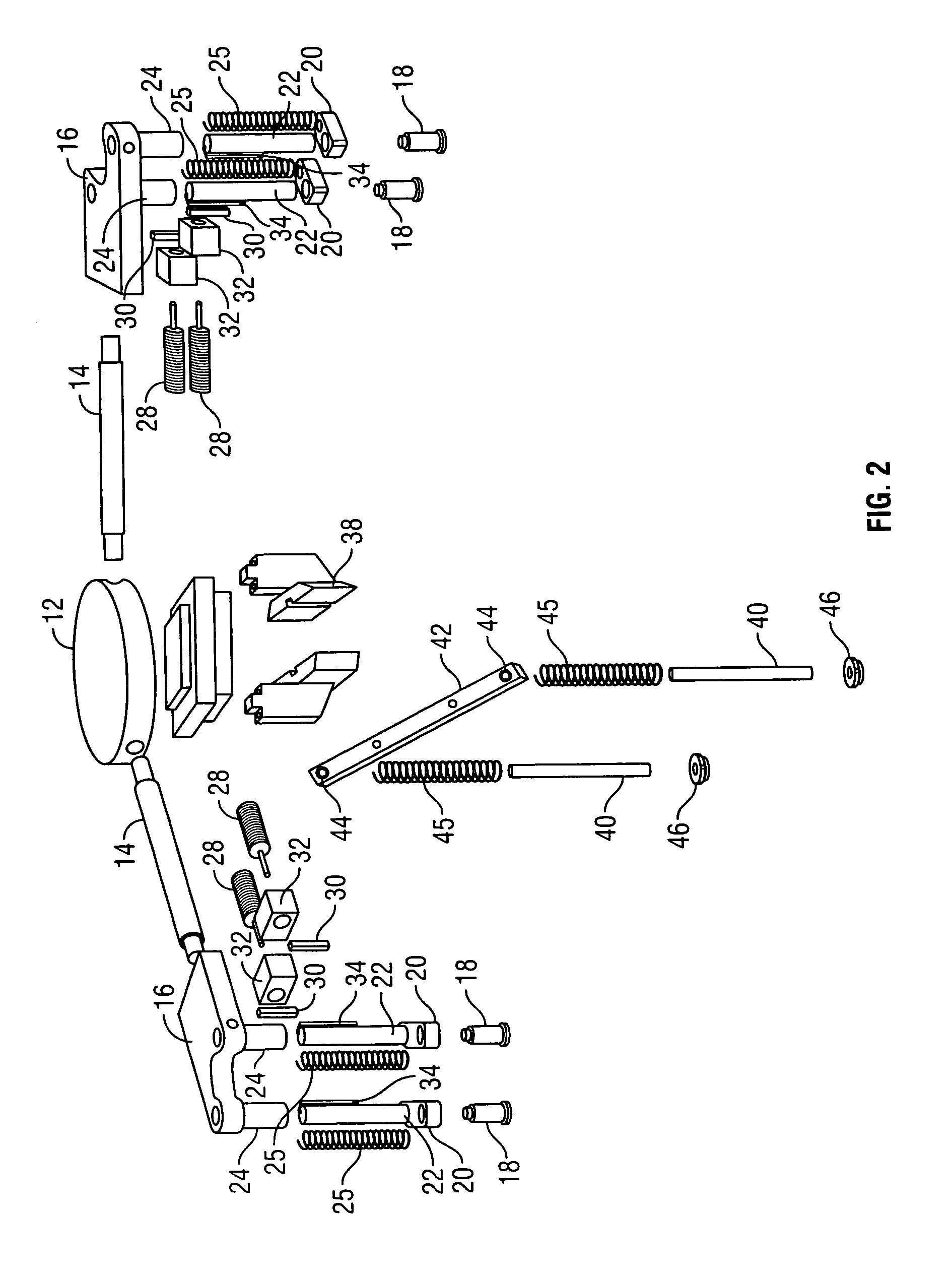

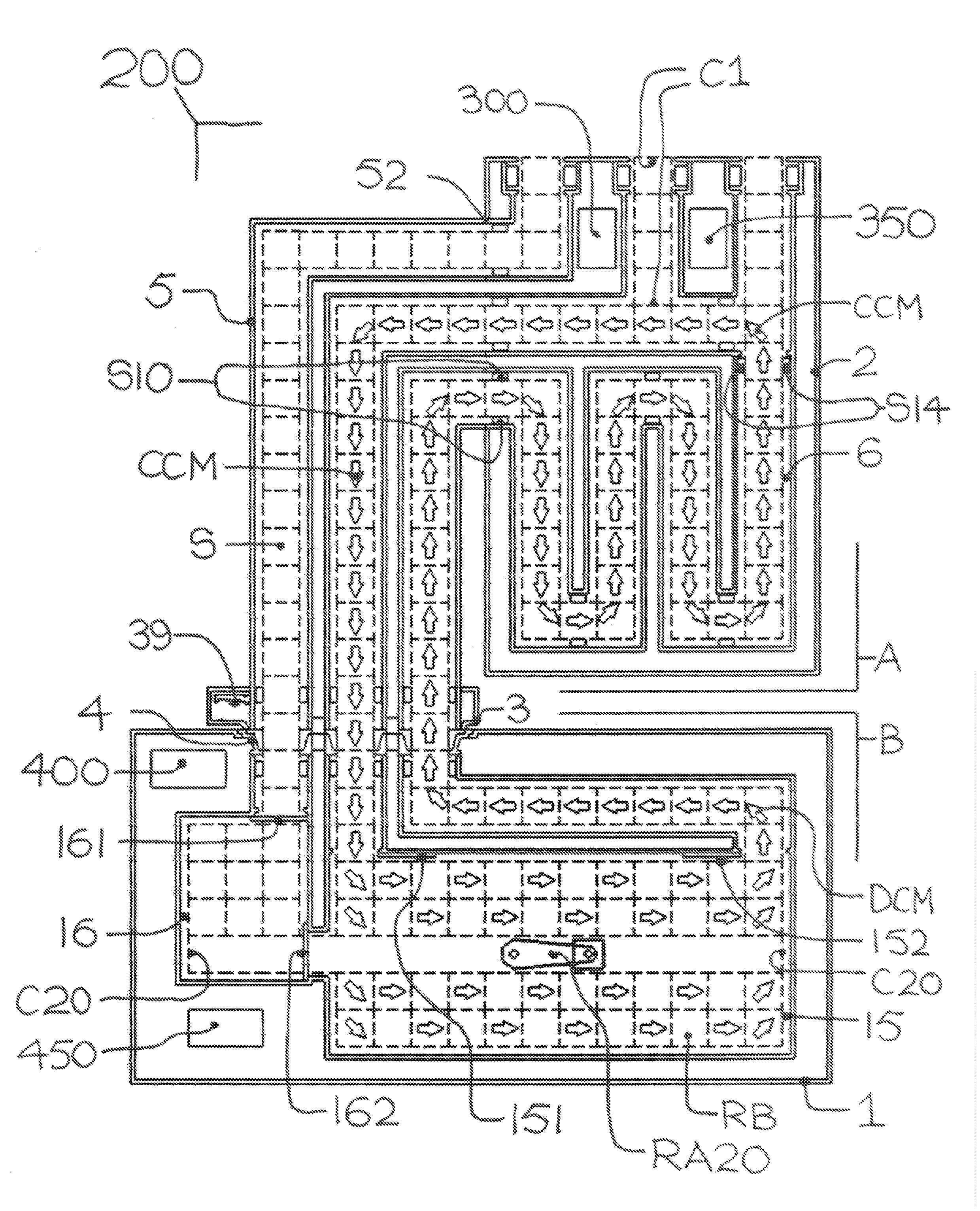

Integrated reconfigurable manufacturing system

An integrated reconfigurable multi-stage manufacturing system and associated methods. The system may include a plurality of manufacturing cells, each cell associated with at least one stage of a manufacturing process. The plurality of cells may include a first cell comprising at least one flexible manufacturing station, a second cell comprising at least one reconfigurable manufacturing station, and a third cell comprising at least one reconfigurable inspection machine. The system may also include a plurality of loop conveyors and a plurality of cell gantries. Each loop conveyor may connect at least two neighboring cells and each cell gantry may transport parts from the cell associated with the cell gantry to at least one loop conveyor. In one embodiment, each cell may be hexagonal, and the manufacturing system may have a honeycomb structure.

Owner:RGT UNIV OF MICHIGAN

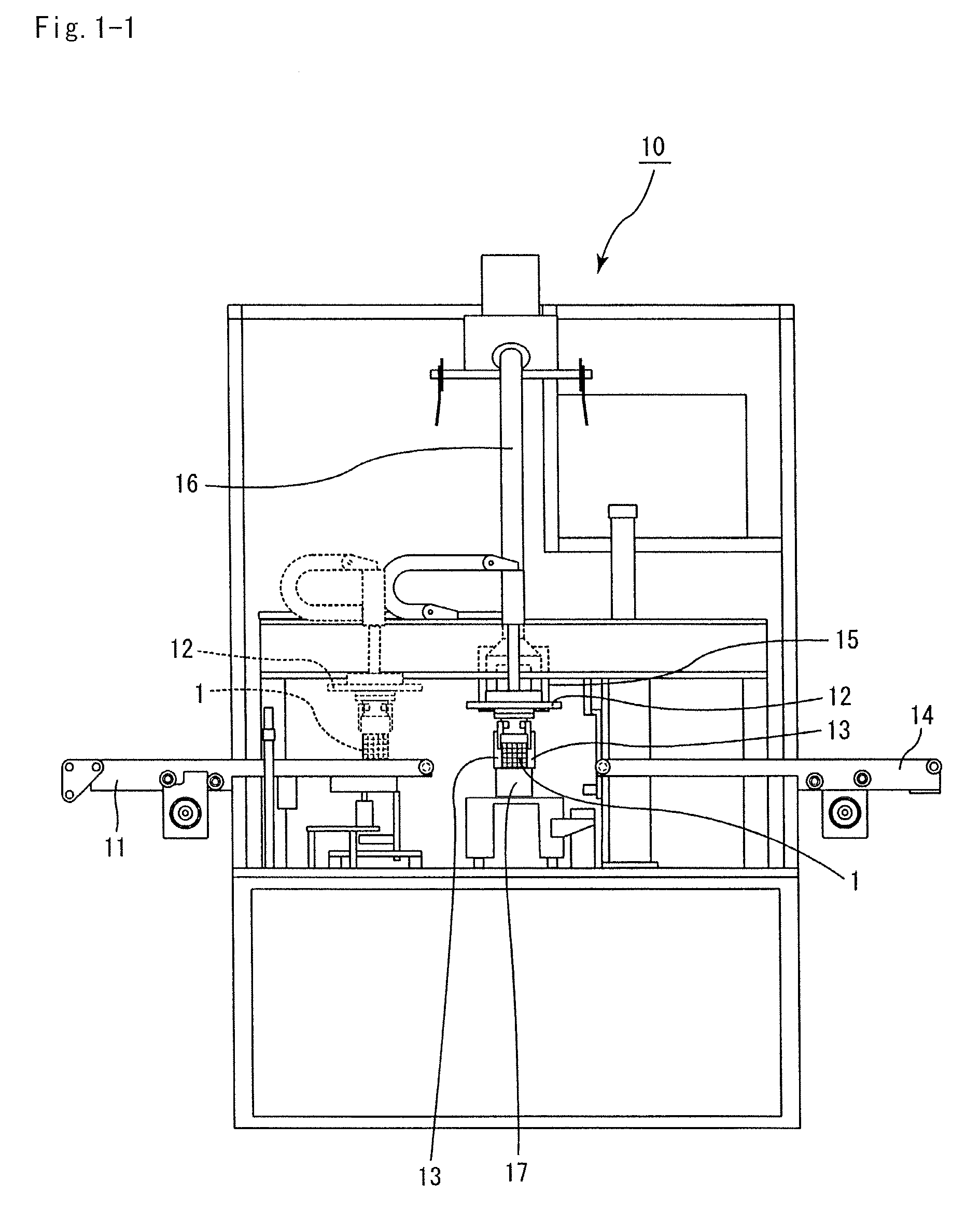

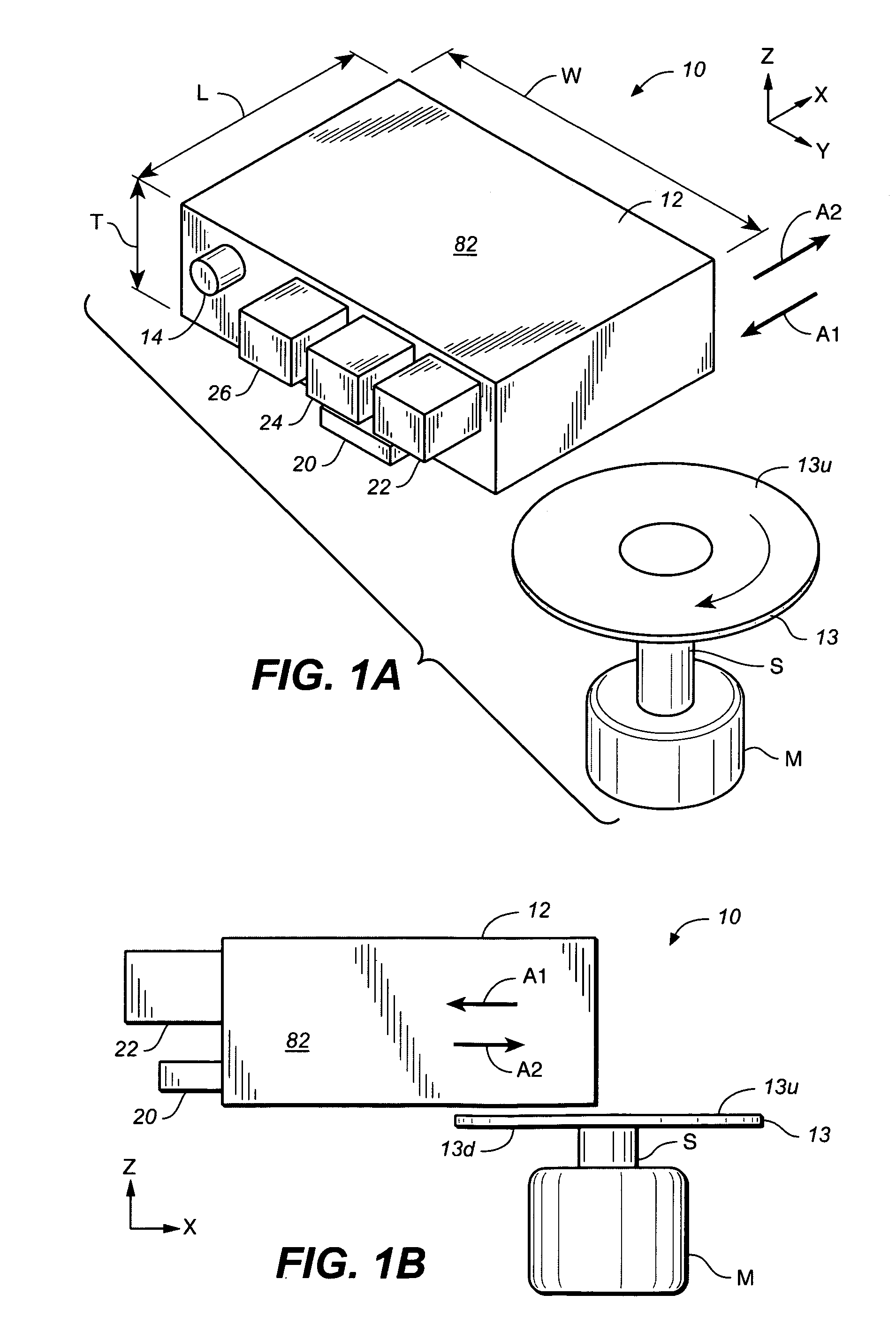

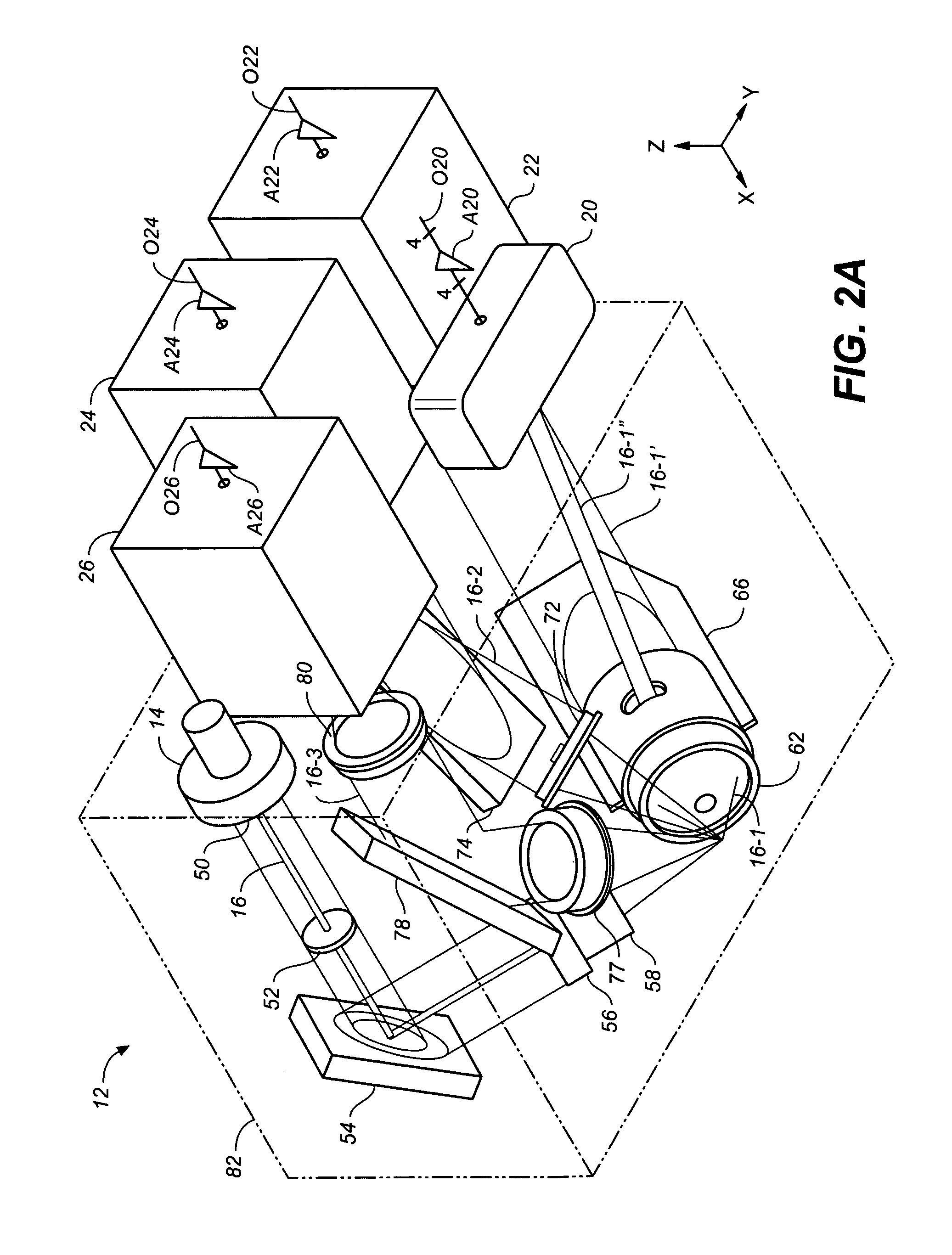

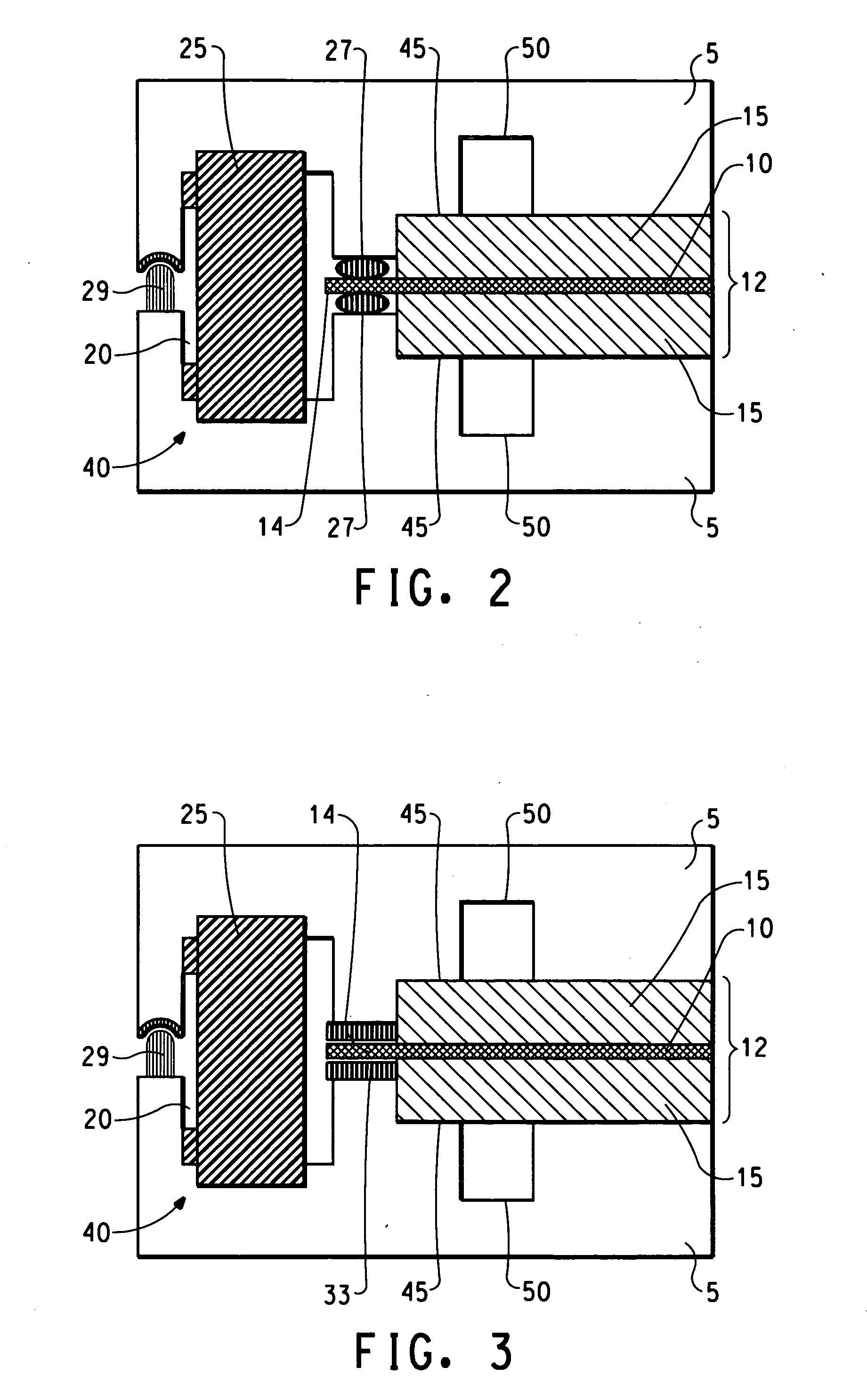

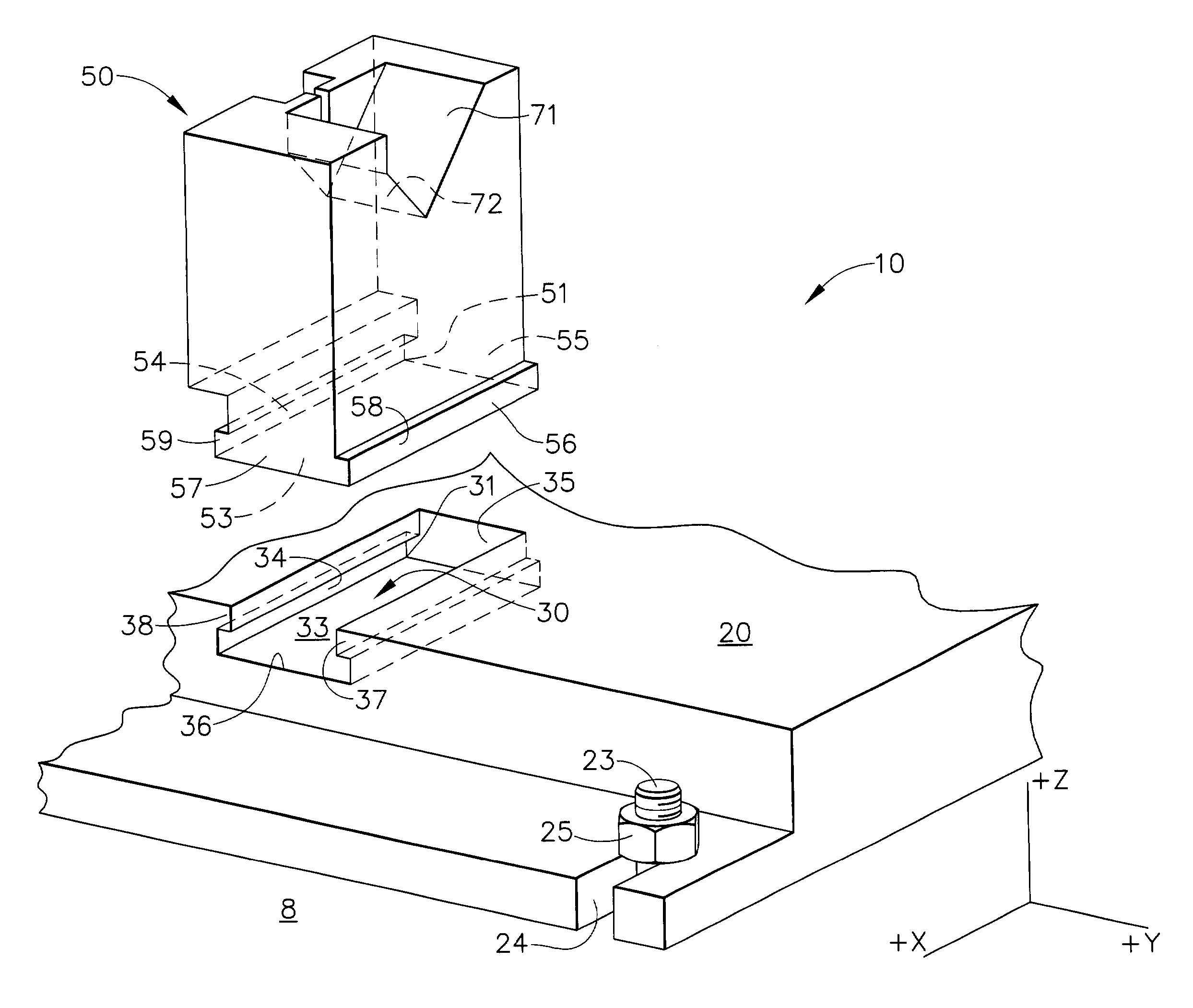

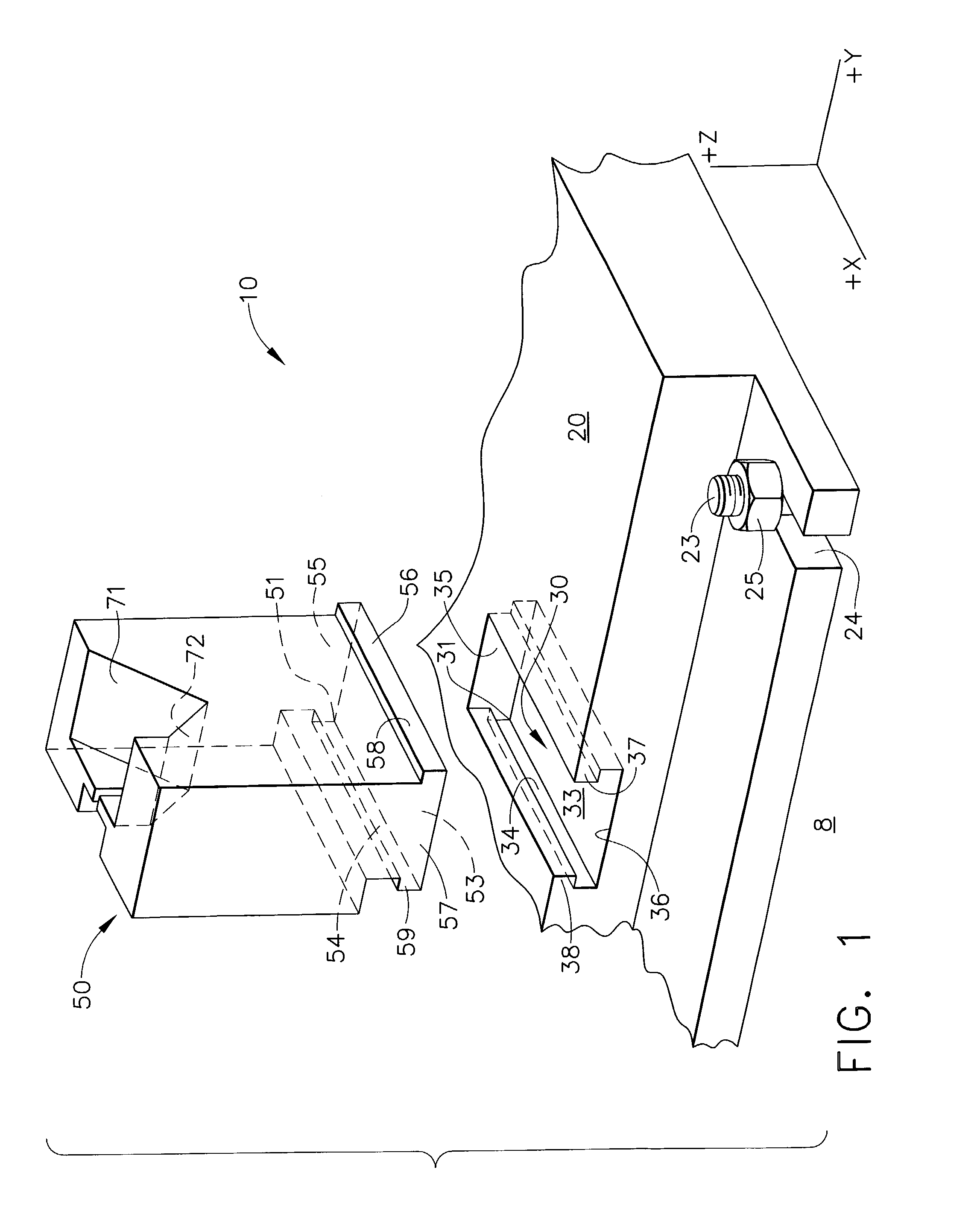

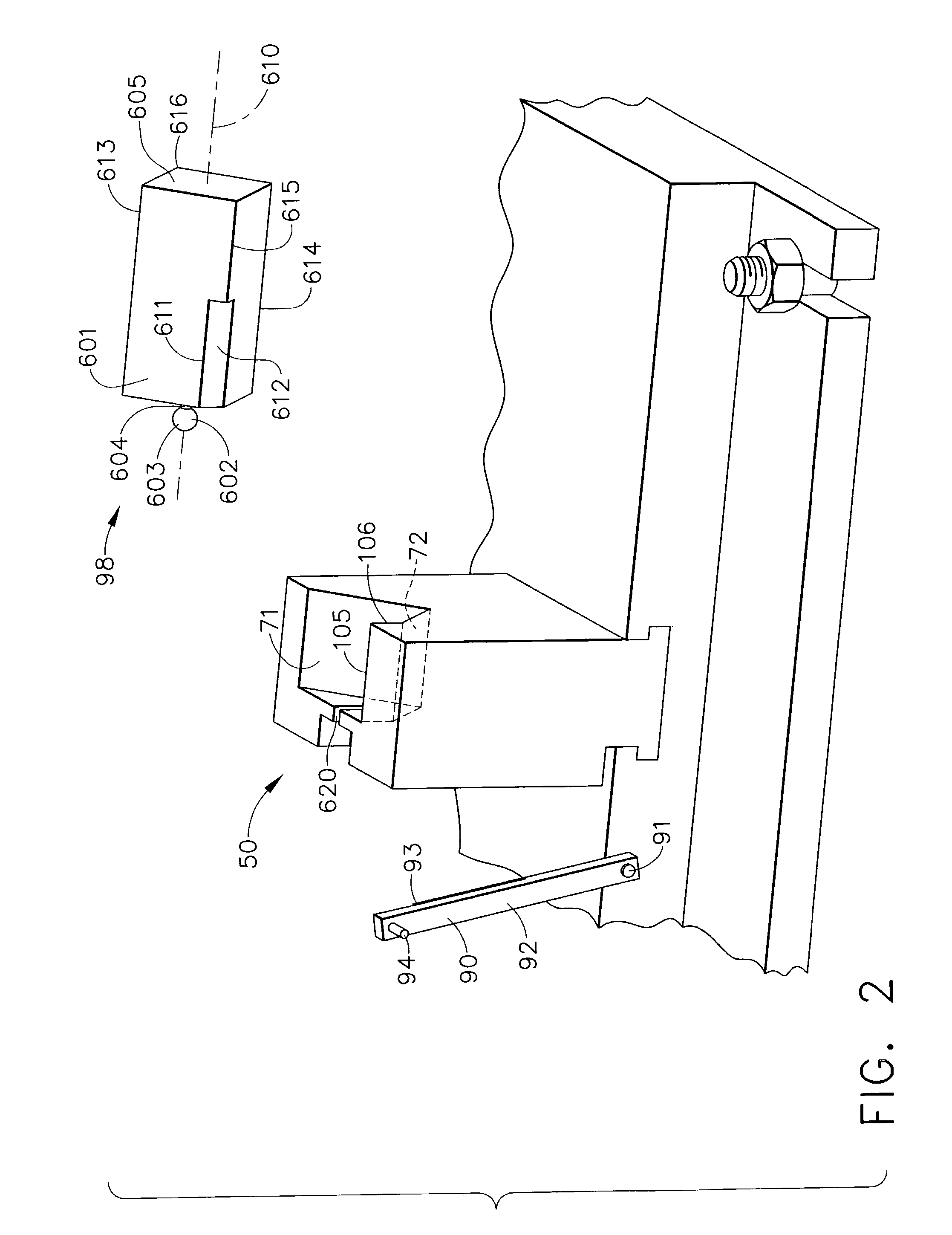

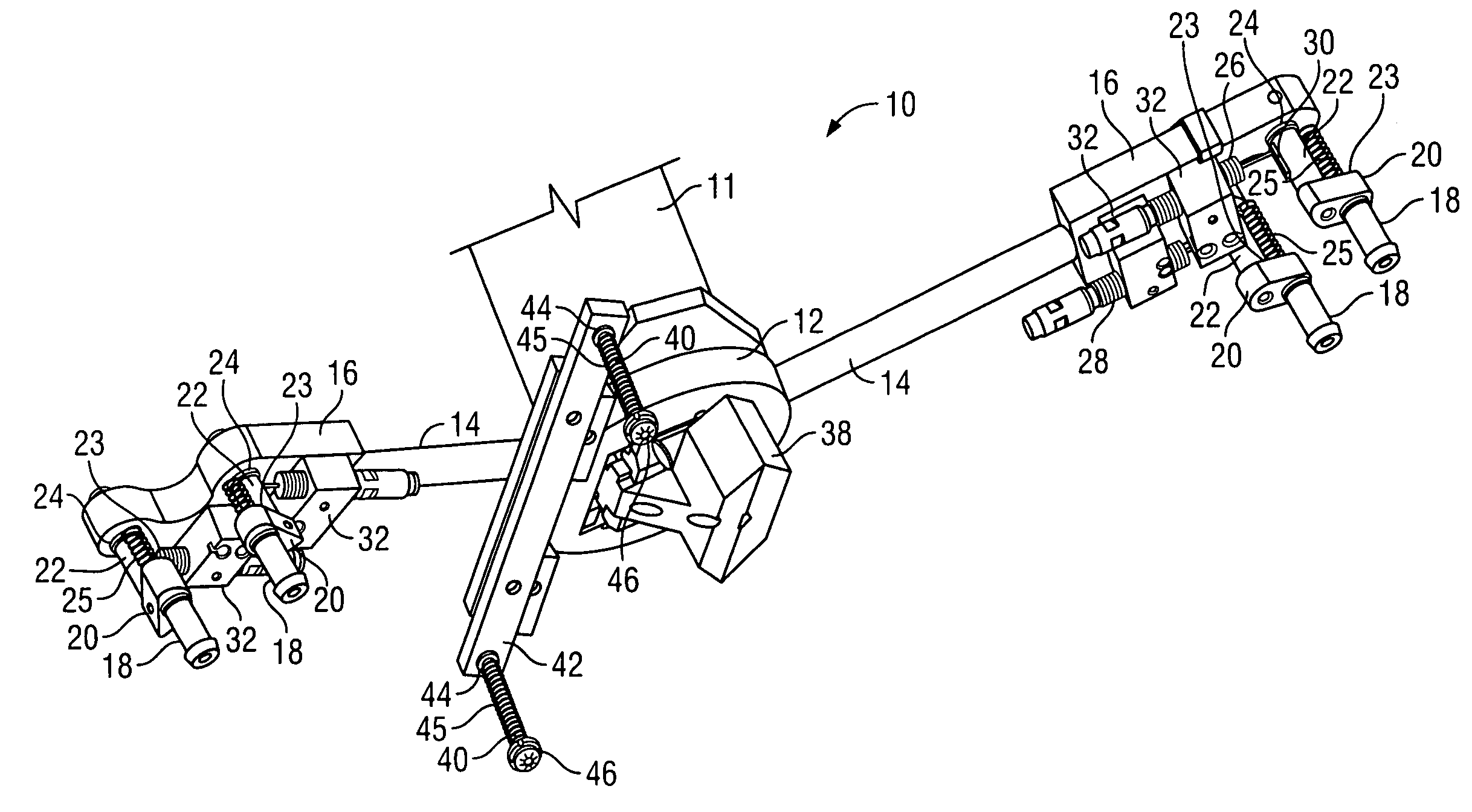

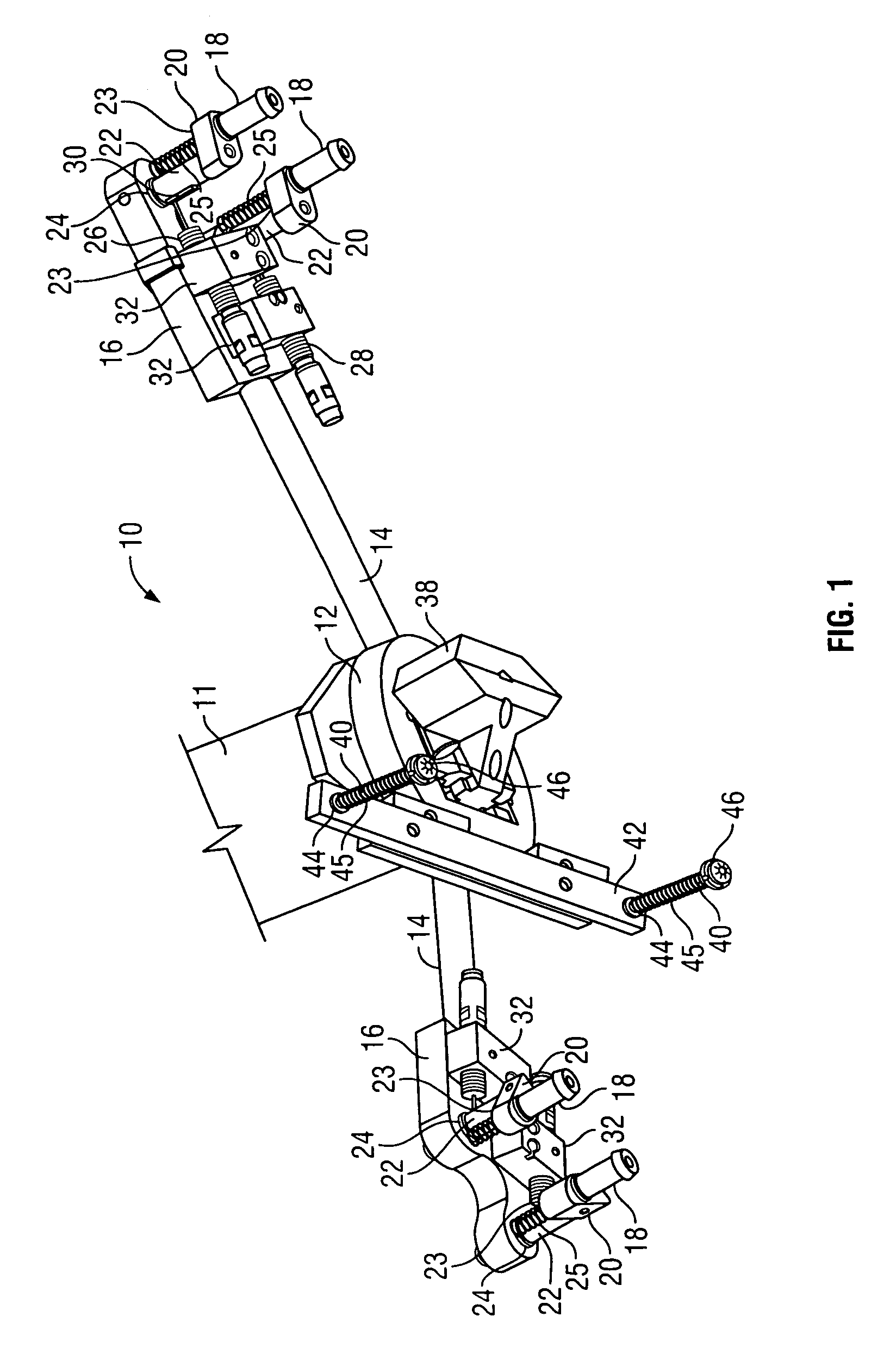

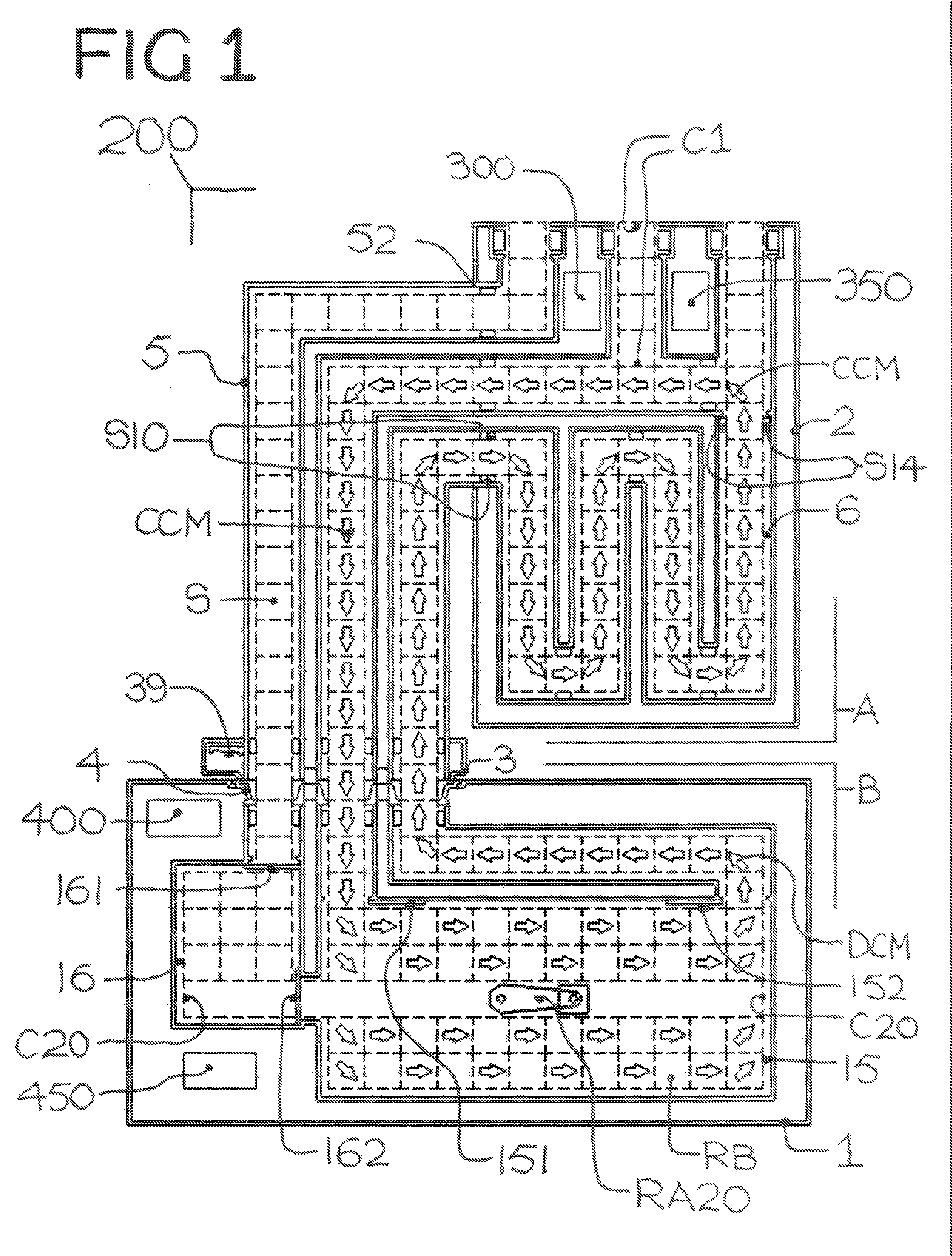

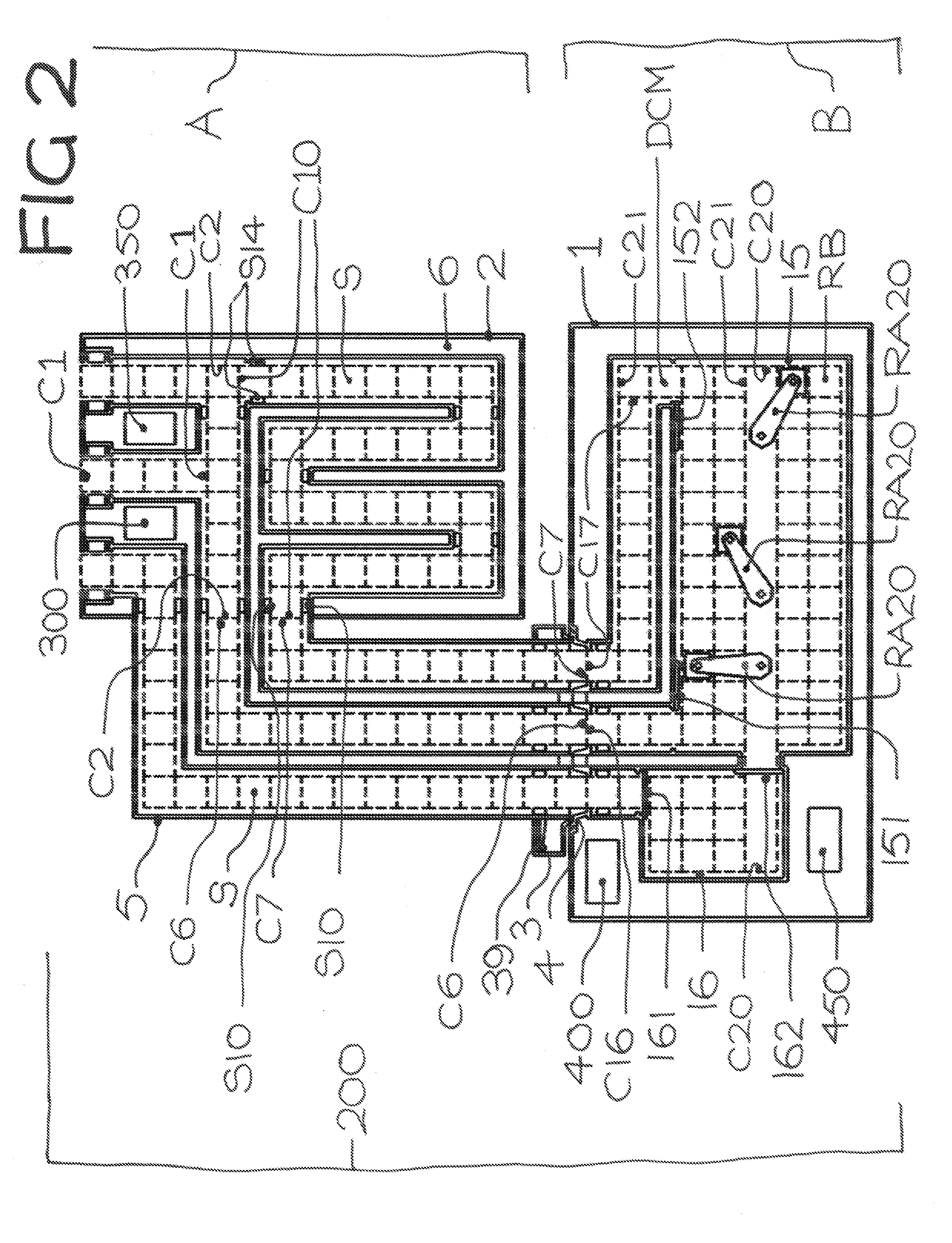

Manufacturing cell using tooling apparatus

A manufacturing cell having a plurality of work stations, where at least one of the work station comprises a metalworking machine, and where at least one metalworking machine is provided with a modular tooling apparatus. The modular tooling apparatus consists of a base having one or more attachment surfaces, and one or more inserts that can be inserted semi-permanently to the attachment surfaces. The attachment surface is typically a pocket in the surface of the base. The insert has a workpiece support feature that can support and / or secure the workpiece into the proper position and orientation for machining. The base, pockets and inserts are configured to provide a characteristic location and orientation for the workpiece relative to the base, and to the metalworking machine. The modular tooling apparatus permits machining a family of workpiece members that are related but different in detail, by inserting an insert member from the family of inserts to properly position and orient the corresponding workpiece member, without needing to change, disconnect, or move the base tooling. The invention also provides a process for performing a plurality of metalworking operations on workpieces, employing the manufacturing cell described hereinabove.

Owner:GENERAL ELECTRIC CO

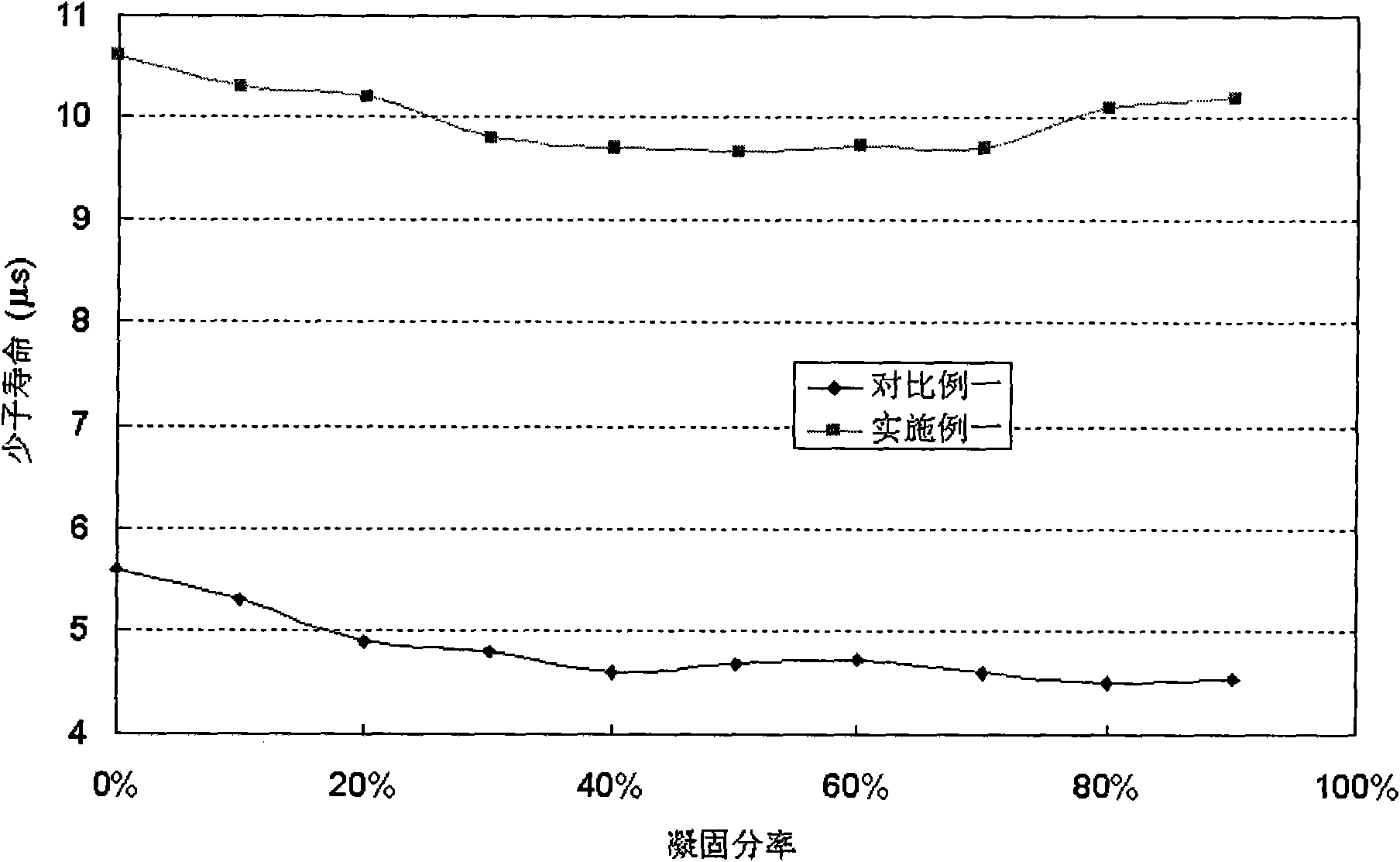

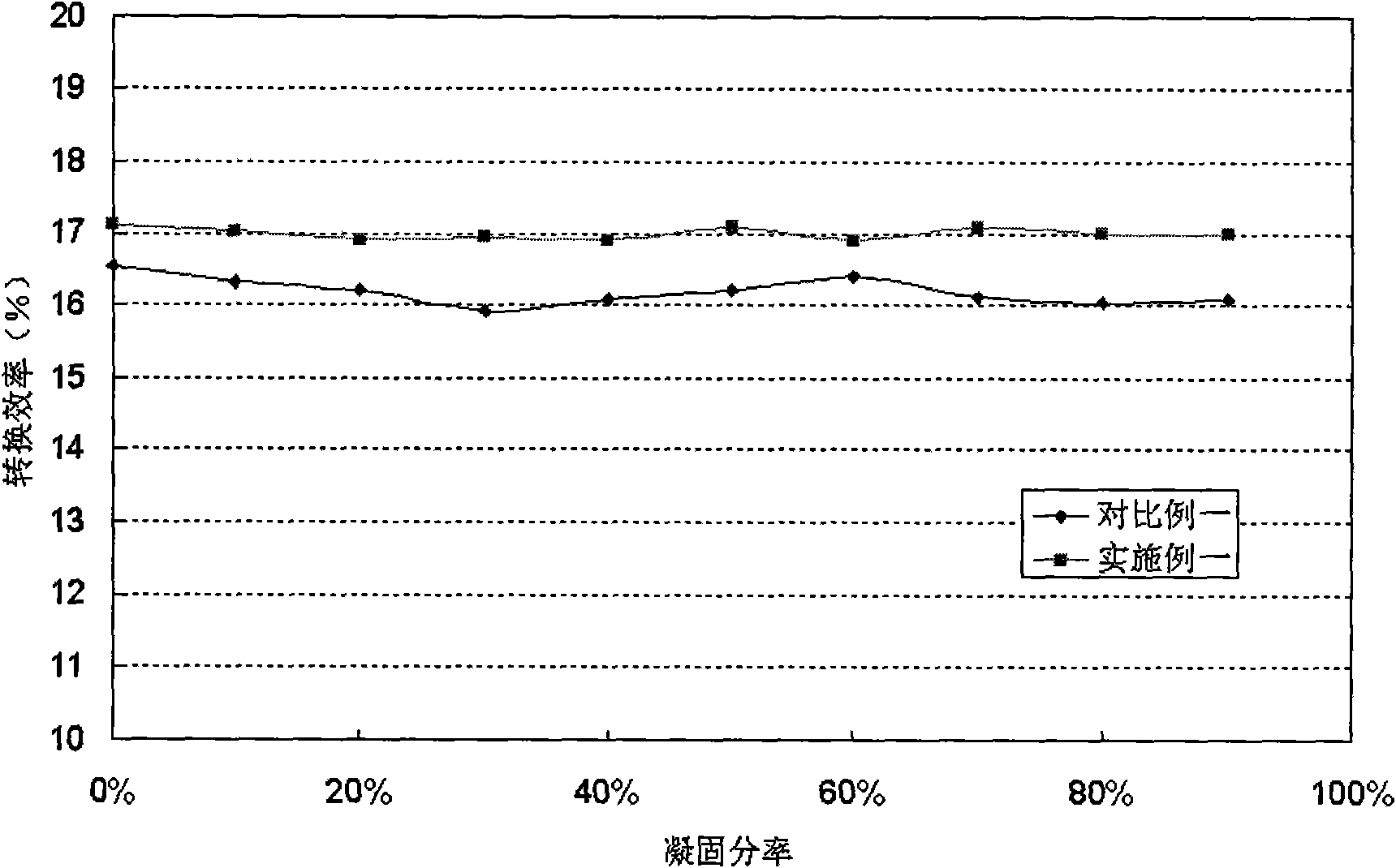

Method for preparing solar energy level silicon crystals containing doped element

InactiveCN101560693AImprove life expectancyAvoid/Minimize Performance ImpactPolycrystalline material growthUnder a protective fluidShielding gasManufacturing cell

The invention discloses a method for preparing solar energy level silicon crystals containing doped element, which is to place molten silicon containing the doped element into a crucible reactor and adopt a directional solidification method or a pulling method to prepare the silicon crystals. In the preparation process of the silicon crystals, protective gas is introduced into a crystal growing furnace and flows through the surface of the molten silicon, and is as follows: a) gas containing hydrogen atoms; or b) a mixture of the gas containing the hydrogen atoms and inert gas. The method obviously improves the minority-carrier lifetime of the silicon crystals by the functions of H on passivation, gettering and the like of impurities and defects in the silicon crystals, and improves the photoelectric conversion efficiency of subsequently manufactured cell slices. The method also adjusts the resistivity of silicon crystals doped with gallium and makes the resistivity of the silicon crystals more uniform in the crystal growing direction. Moreover, the method is simple in operation and easy in industrialized production, and can obviously improve the product quality.

Owner:GREENERGY CRYSTAL TECH

Shelving system

InactiveUS20030189021A1Easy accessEfficient and reliableFolding cabinetsDismountable cabinetsEngineeringManufacturing cell

The present disclosure provides enhanced storage systems that facilitate efficient storage of, and access to, a variety of items and products. Exemplary systems according to the present disclosure include mechanism(s) that permit reliable and efficient repositioning of one or more shelves, thereby enhancing utilization and efficiencies associated therewith. Shelving systems according to the present disclosure facilitate synchronized vertical motion of shelving units, e.g., based on coordinated pulley / cable systems, and advantageously include spring designs that facilitate controlled vertical motion of shelving units, e.g., based on fluid movement and / or discharge from the spring design. Shelves and / or shelving units may be readily repositioned at elbow or eye level, and repositioned at their respective initial positions in an efficient and advantageous manner. The shelving systems may be original manufacture units or may be designed for use in retrofitting existing shelving systems.

Owner:ENGEL ZACKARY

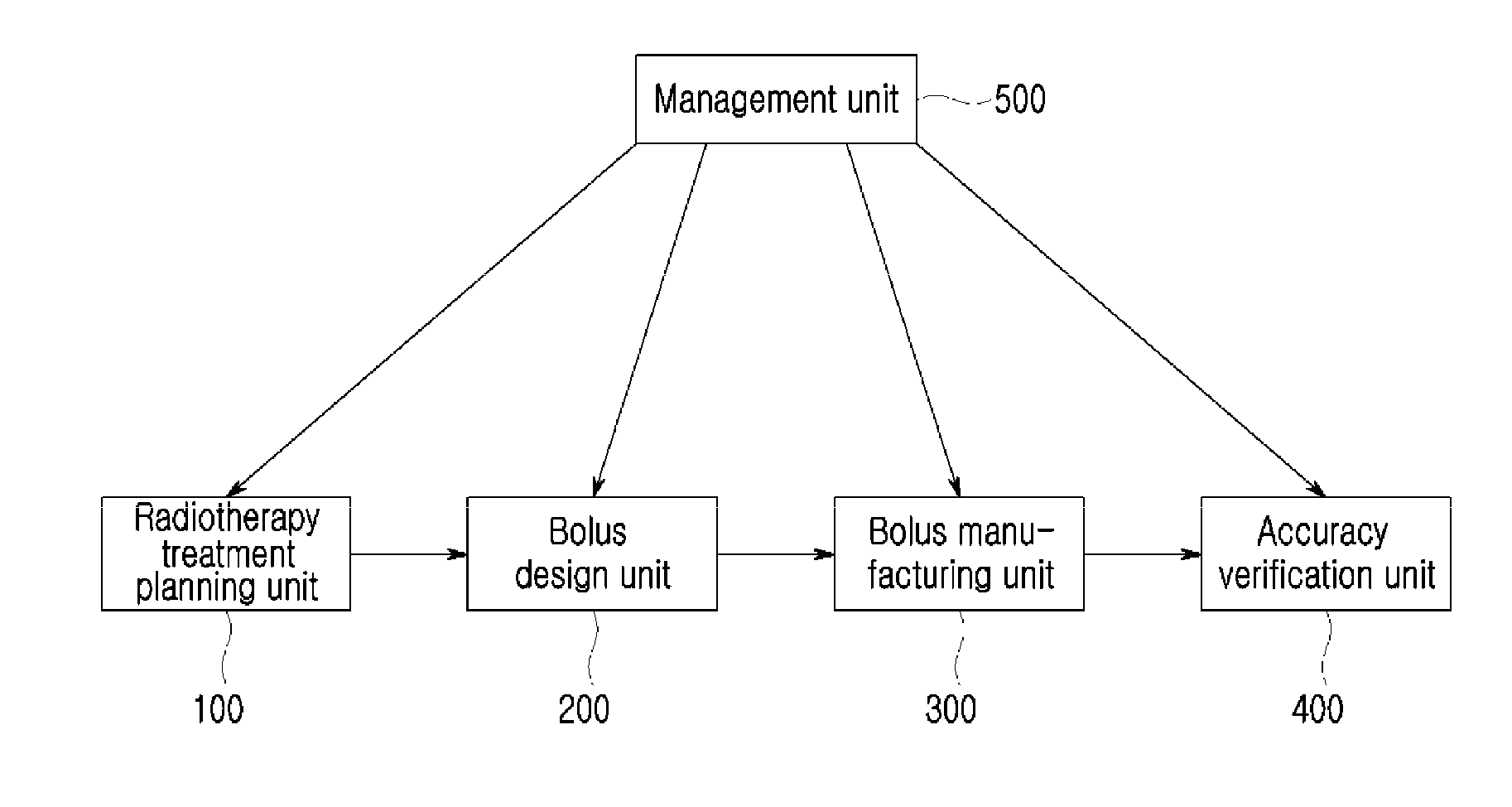

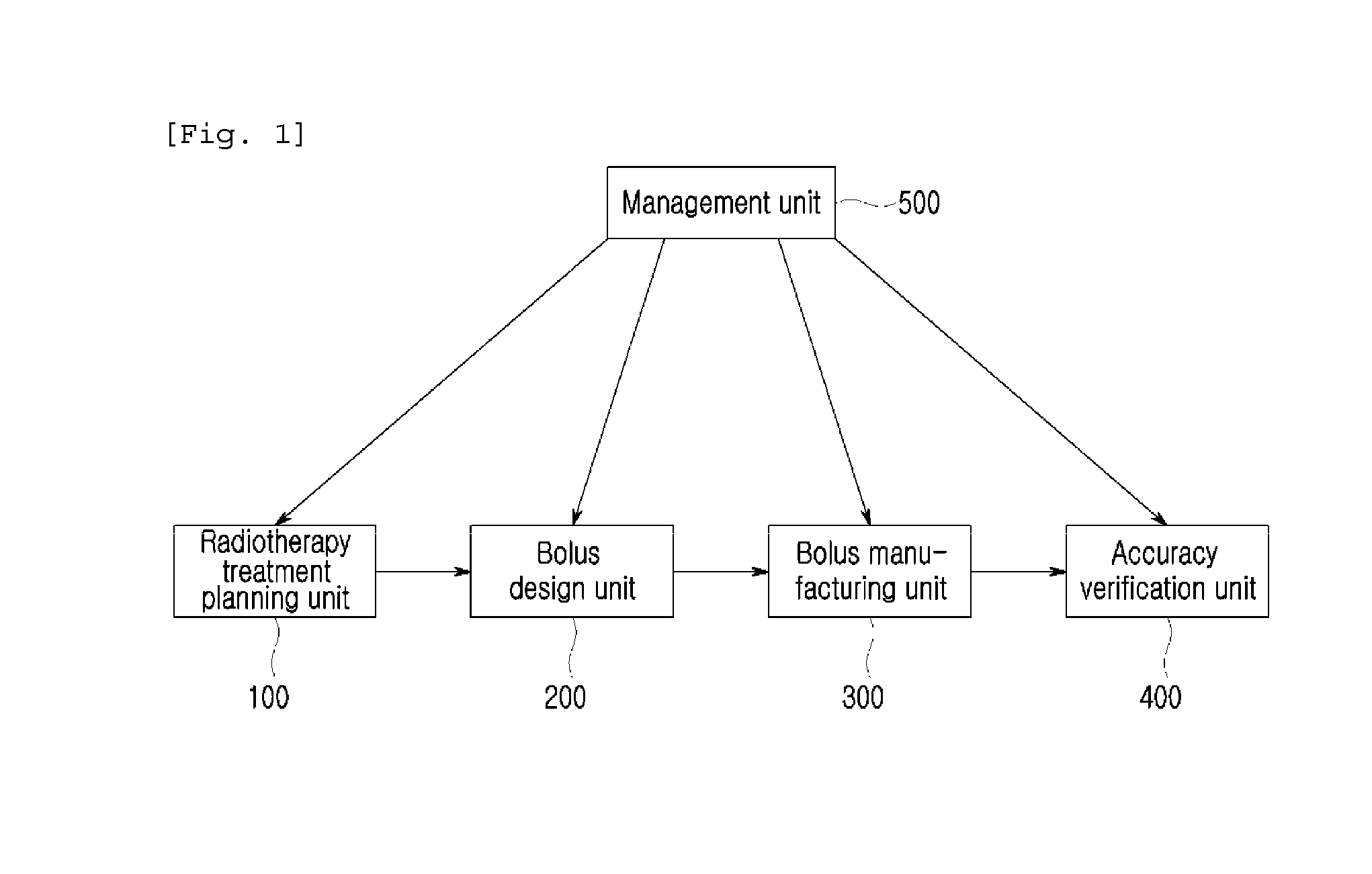

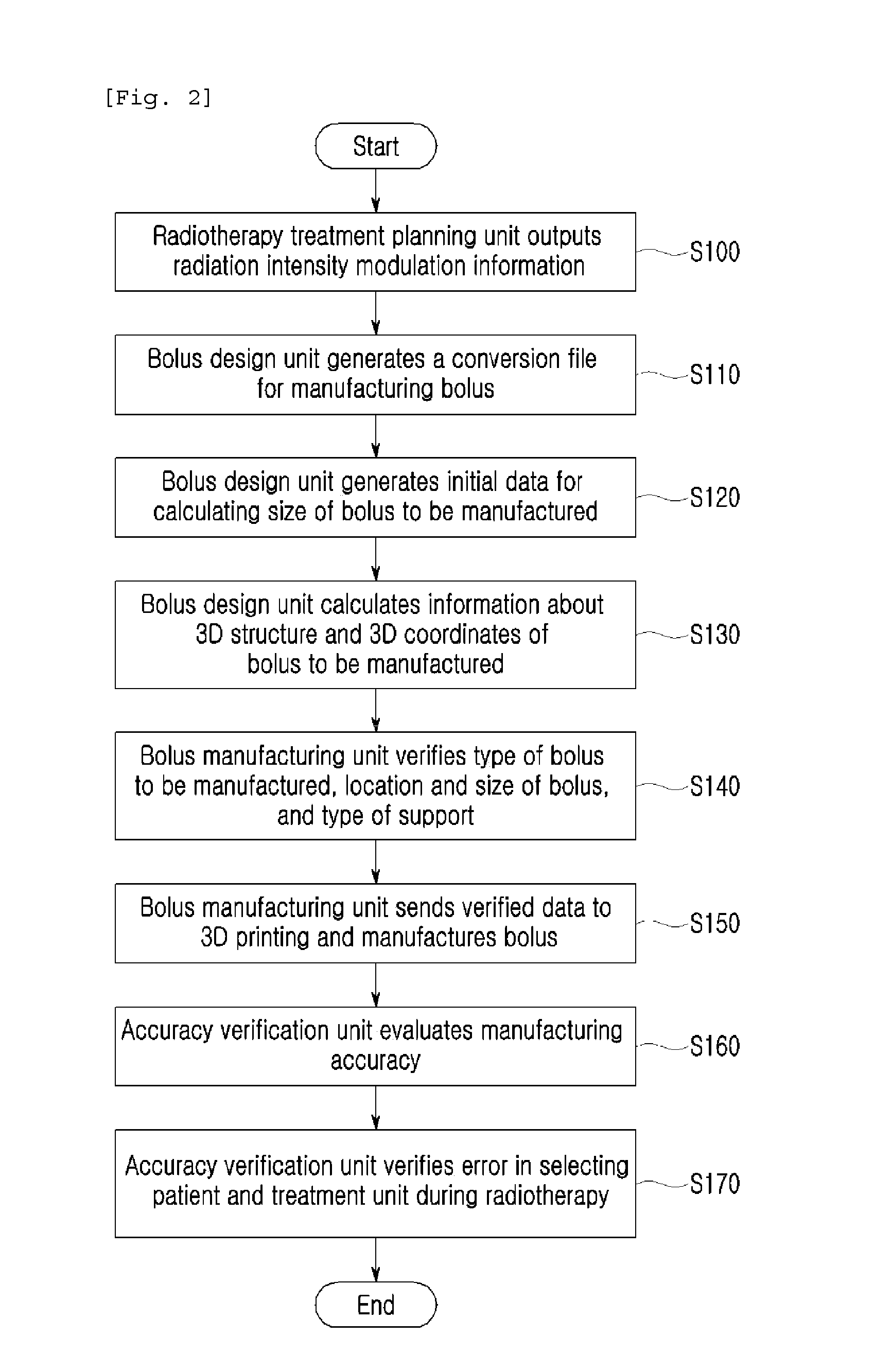

Method and apparatus for manufacturing radiation intensity bolus

ActiveUS20150006098A1Accurately radiatedShorten treatment timeAdditive manufacturing apparatusRadiation/particle handlingManufacturing cellIntensity modulation

Disclosed are a method and an apparatus for manufacturing a radiation intensity bolus. The method comprises the steps of: (a) calculating, by a radiotherapy treatment planning unit, a received 3D radiation dose distribution, planning a bolus to be manufactured, and outputting radiation intensity modulation information; (b) receiving, by a bolus design unit, the radiation intensity modulation information, generating a conversion file for manufacturing bolus, and outputting information about a 3D structure of the bolus to be manufactured; (c) receiving, by a bolus manufacturing unit, the conversion file for manufacturing bolus, verifying a type, location, and size of the bolus to be manufactured, sending the verified data to a 3D printer, and manufacturing the bolus; and (d) obtaining, by an accuracy verification unit, information about a 3D structure of the manufactured bolus and evaluating manufacturing accuracy by comparing the information about the 3D structure of the manufactured bolus with the information about the planned bolus.

Owner:SAMSUNG LIFE PUBLIC WELFARE FOUND

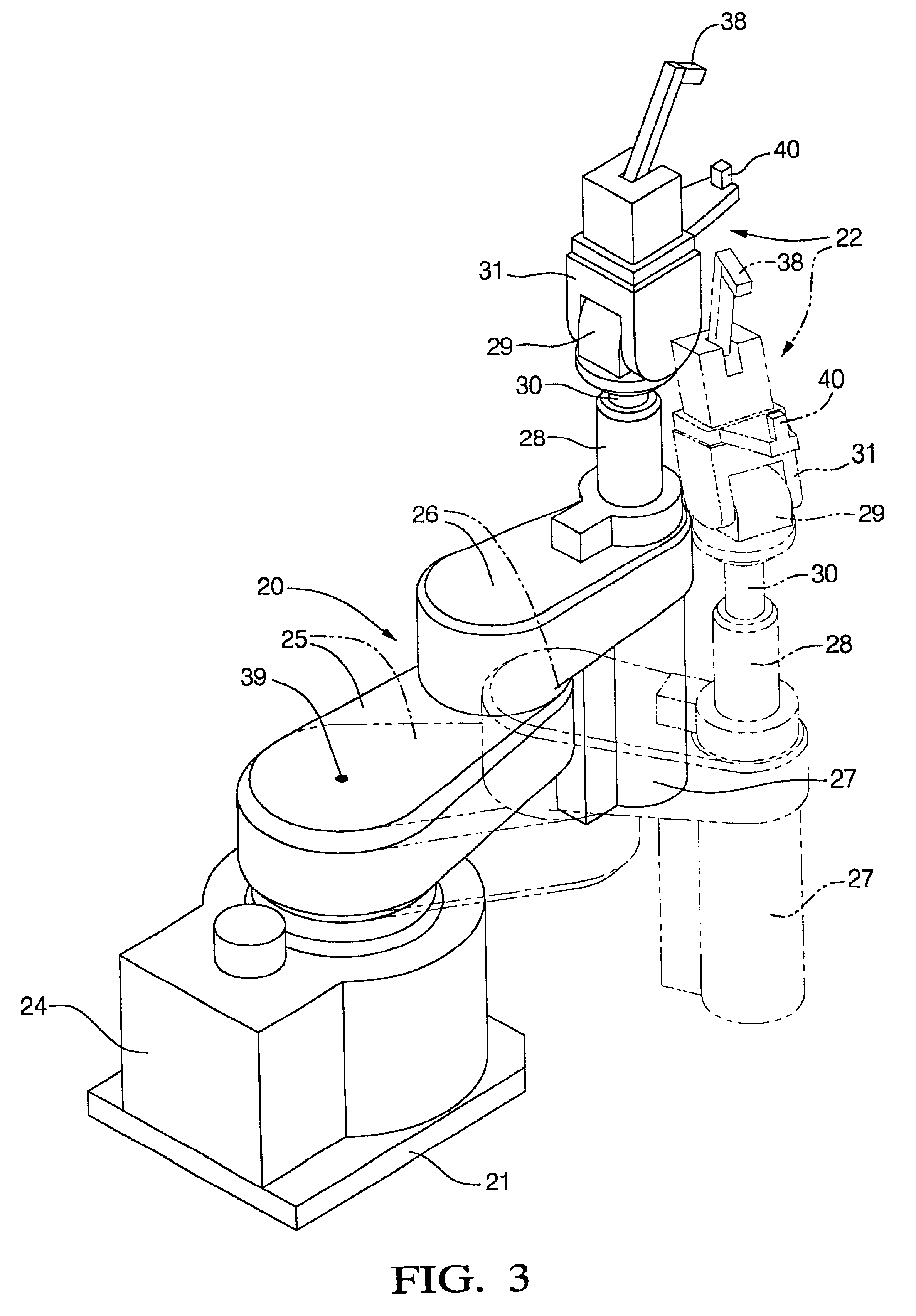

Ophthalmic lens manufacturing system

A tool for gripping ophthalmic lenses including a vacuum gripper, a shaft associated with said vacuum gripper, the shaft having two ends and being slidably attached at one end thereof to a support structure, a resilient member which biases the vacuum gripper in a direction away from said support structure and a locking member which locks the shaft in a desired position during a lens gripping operation.Another embodiment of the present invention includes a lens hold down mechanism for holding lenses in a lens tray.Another embodiment of the present invention includes an electronic communications scheme for a robotic manufacturing operation.Another embodiment of the present invention includes an ophthalmic lens manufacturing cell layout wherein ophthalmic edging machines have an opening that faces away from a robotic arm.Another embodiment of the present invention includes an arrangement for holding an ophthalmic edging machine within an ophthalmic manufacturing cell.

Owner:AIT IND +1

Electric Vehicle Refueling System

InactiveUS20150047947A1Increase valueFeeding apparatusPropulsion by batteries/cellsElectrical batteryEngineering

An enclosed two-part computer controlled cyclical and sequential through-flow conveying, usage and metering System (200) is disclosed, for use in the electric vehicle motive power provision industries, for said two-part enclosed System to sequentially convey small-volume rechargeable Cell-Modules by sequential conveyor-means in a metered through-flow sequential conveying manner within said two-part System wherein the first part is a Stationary Part that includes a specially manufactured Cell-Module dispensing Bowser and a specially manufactured Cell-Module Charging-Bay and wherein the second part is a Movable Part that includes a specially manufactured or specially adapted Cell-Module powered electric Vehicle having a specially manufactured Cell-Module Chamber installed within.A Nozzle (3) and a Portal (4) respectively provide means for the Stationary Part and the Movable Part to exchange a choosable plurality of small-volume rechargeable Cell-Modules (100) and (500).A System (200) provides a succinct fully enclosed matingly-co-operative interconnection means for the System (200) to sequentially dispense Charged Cell-Modules and remove depleted Cell-Modules. The System also removes faulty Cell-Modules and if necessary extinguishes, and isolates for fire safety purposes, over-heating, deformed, or ignited Cell-Modules.The invention provides means that parallel, mimic or improve upon the metered bowser dispensing manner by which a choosable sequential plurality of small volumes of fossil fuel are sequentially delivered to a conventional fossil fuel vehicle by a dispensing bowser at a conventional fuel Service Station facility. The invention also provides optional means for Cell-Modules to be recharged in situ by use of a specially manufactured charger.

Owner:BATTERY FUELING

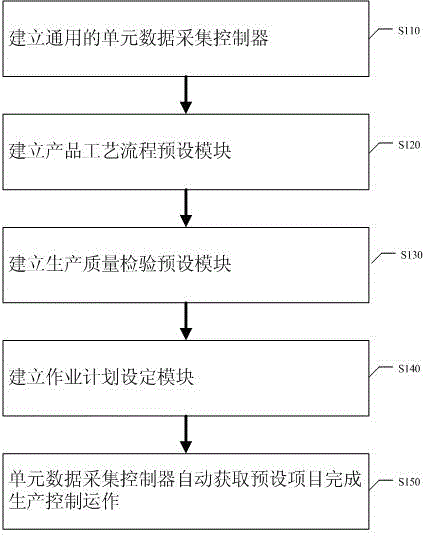

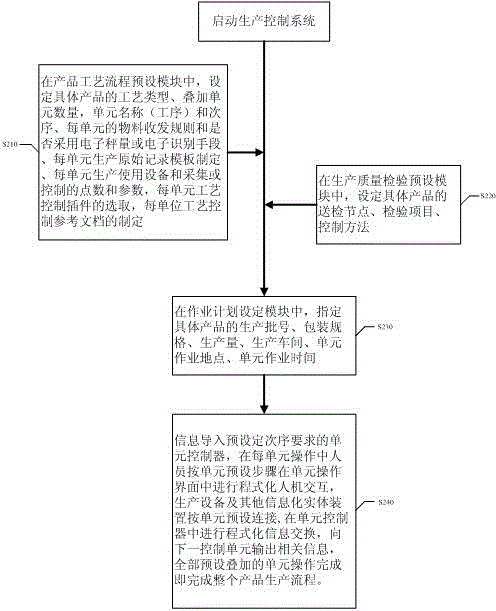

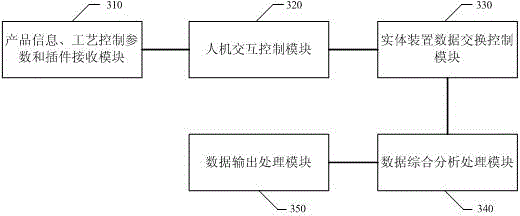

Realization method for general type production and manufacturing unit and control system thereof

ActiveCN104407576AImprove developmentSolve operational problemsTotal factory controlProgramme total factory controlWork planControl system

The invention relates to a realization method for a general type production and manufacturing unit control system. Different technical control processes of product production and manufacturing are decomposed into multiple independent production process computer input and output operation control units which are then substituted by one general virtual control device. The realization method comprises the following steps that one general virtual control device is established; a product technical process preset module is established; a production quality inspection preset module; a work plan setting module is established; and corresponding unit operation performed in a unit data acquisition controller according to a set sequence requirement is performed, stylized information exchange is performed, the related information is outputted to the next control unit and all the preset superimposed unit operation is completed so that the whole product production process is completed. Computer process control difficulty of manufacturing industry intermittence type and discrete type production is mainly solved by the method and the system so that system applicability and work efficiency are enhanced and product technical cost is reduced.

Owner:SHANGHAI YINDAO INFORMATION TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com