Patents

Literature

5270 results about "Membrane electrode assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

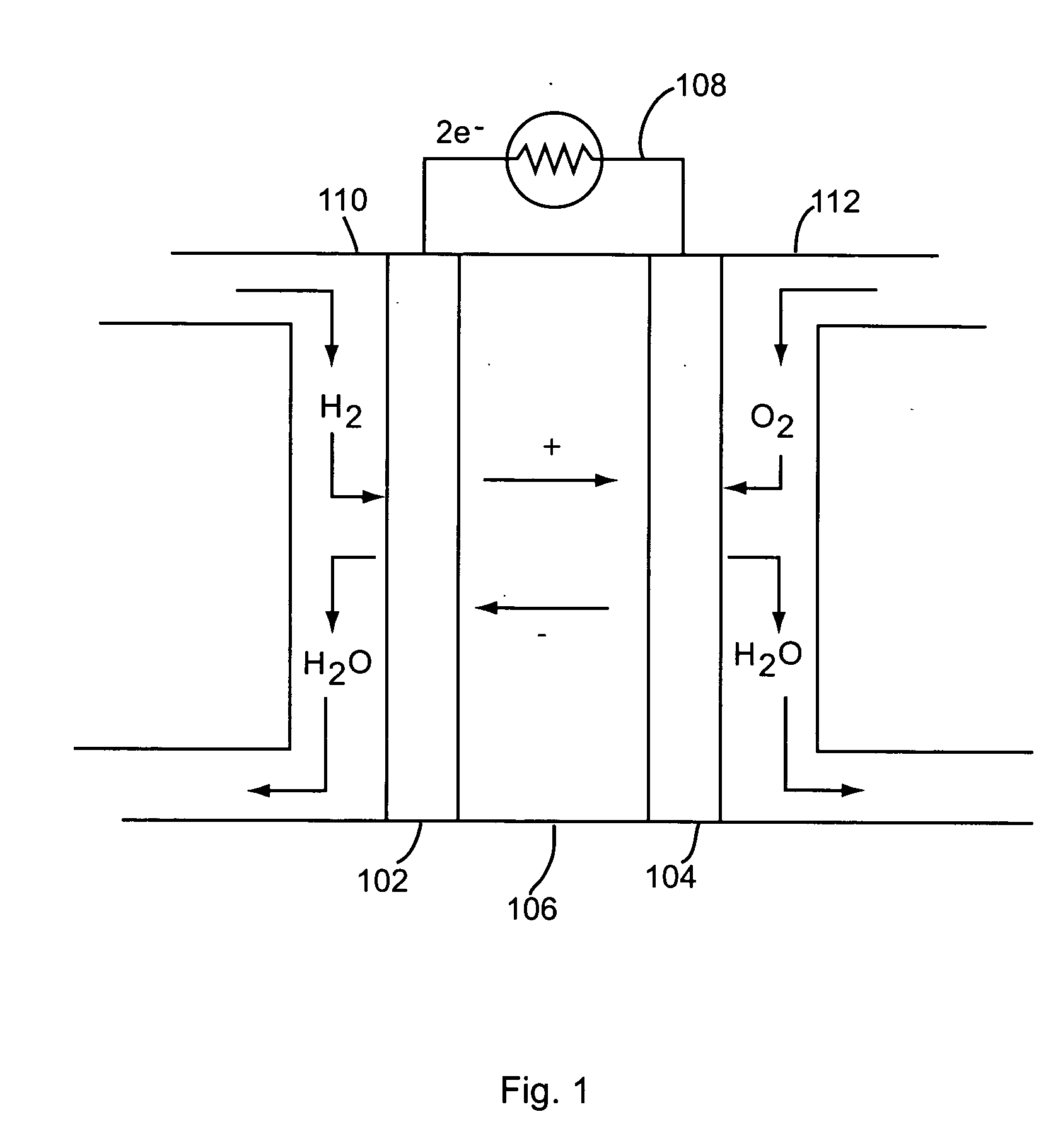

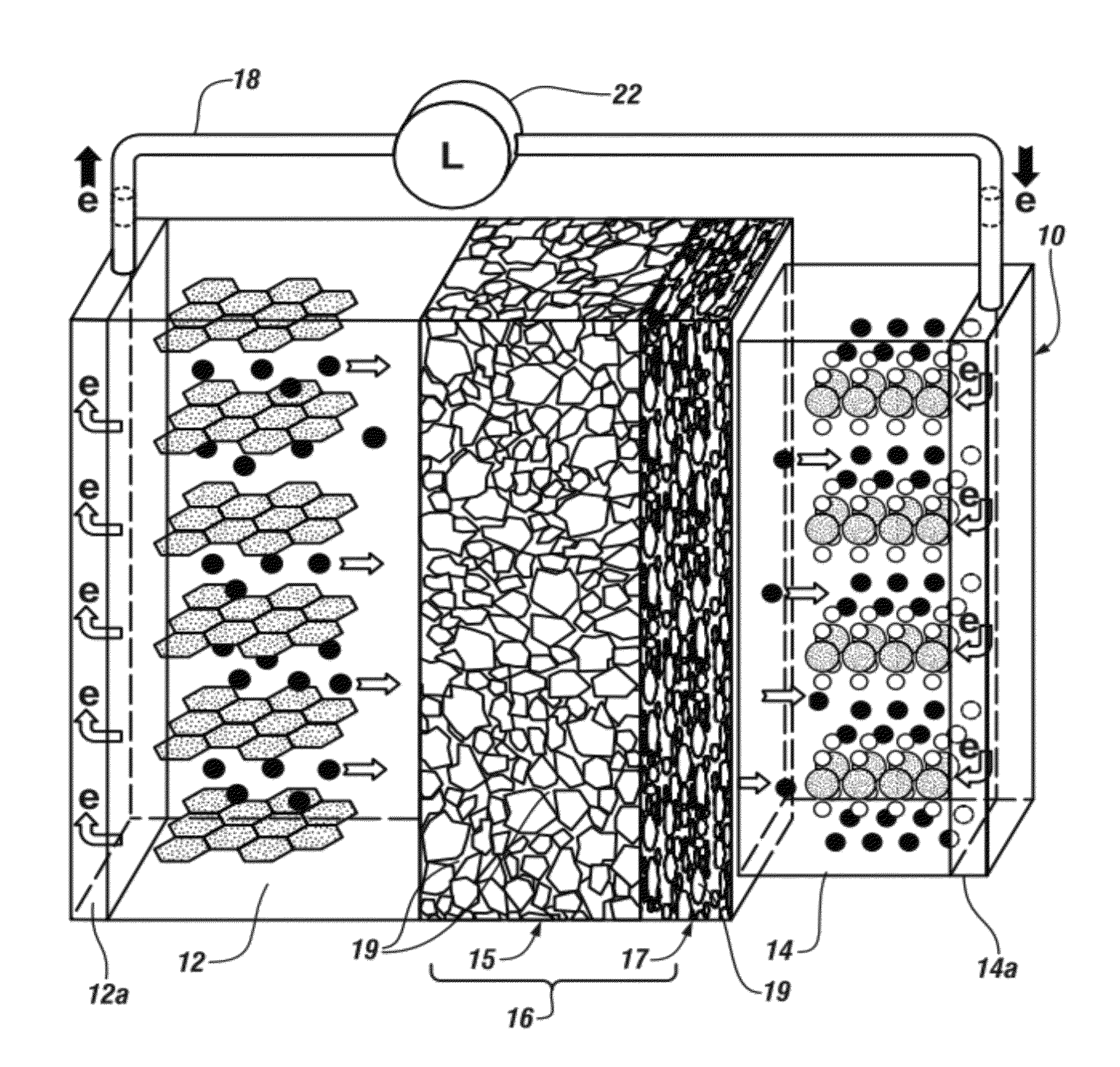

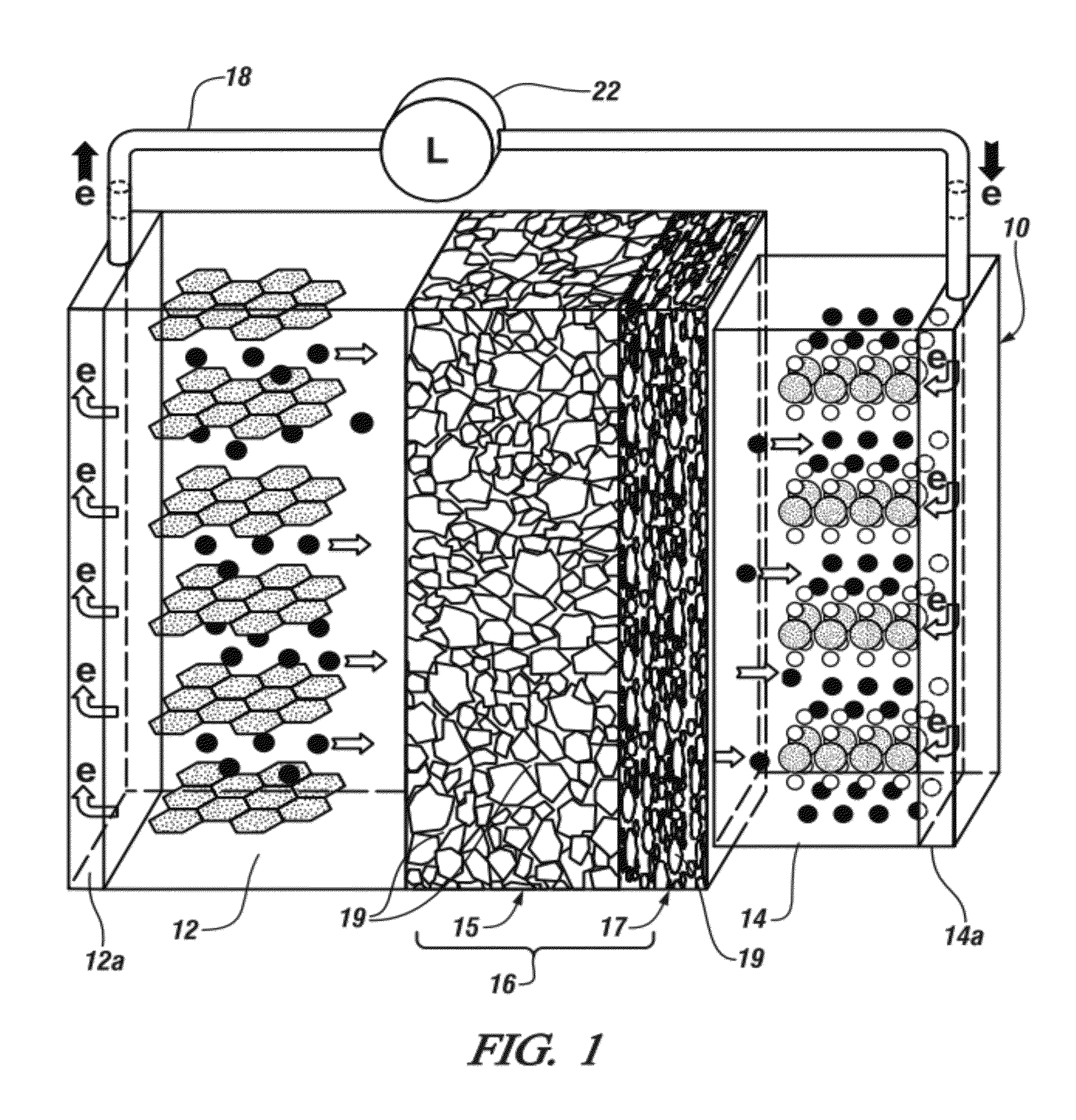

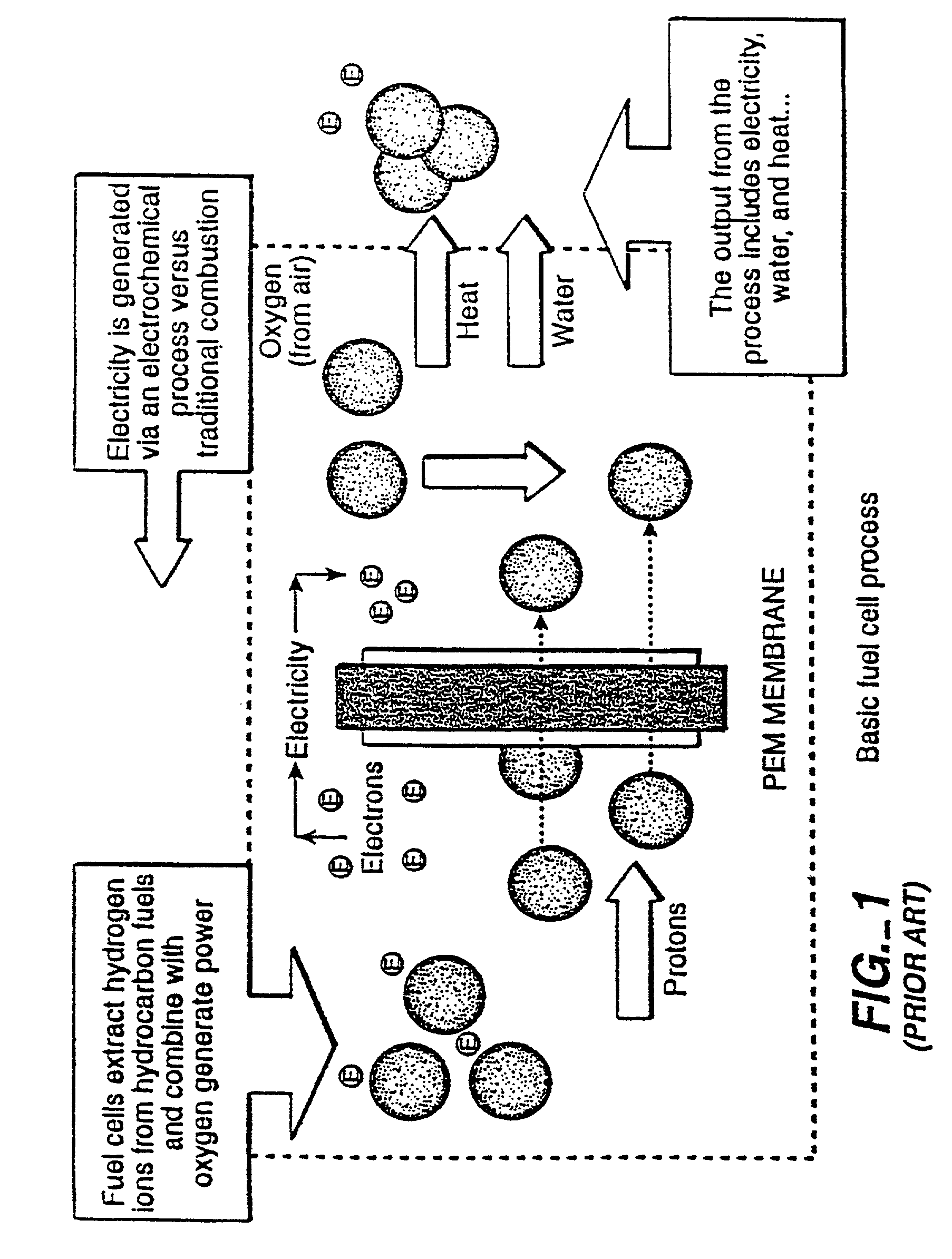

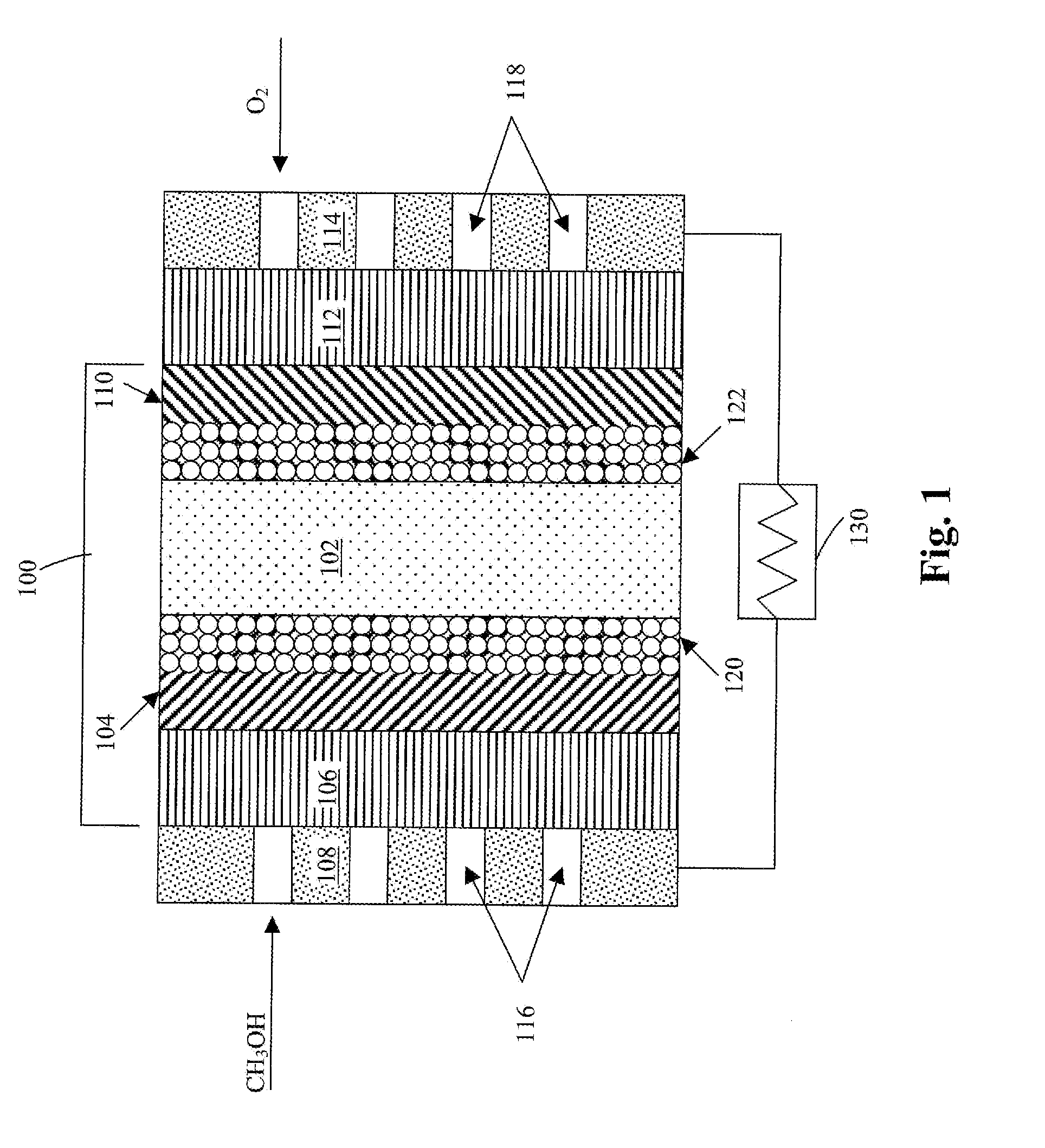

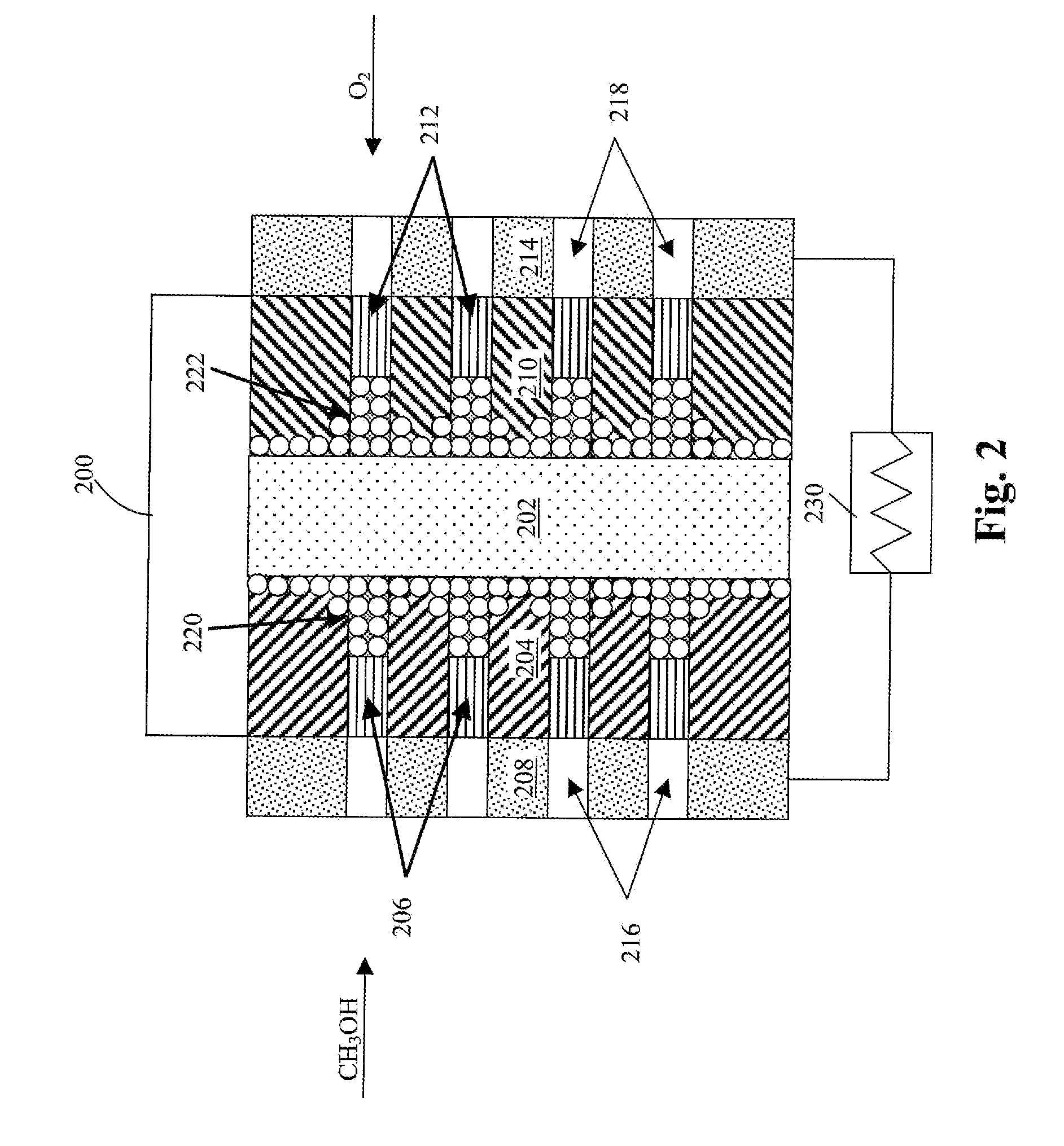

A membrane electrode assembly (MEA) is an assembled stack of proton exchange membranes (PEM) or alkali anion exchange membrane (AAEM), catalyst and flat plate electrode used in fuel cells and electrolyzers.

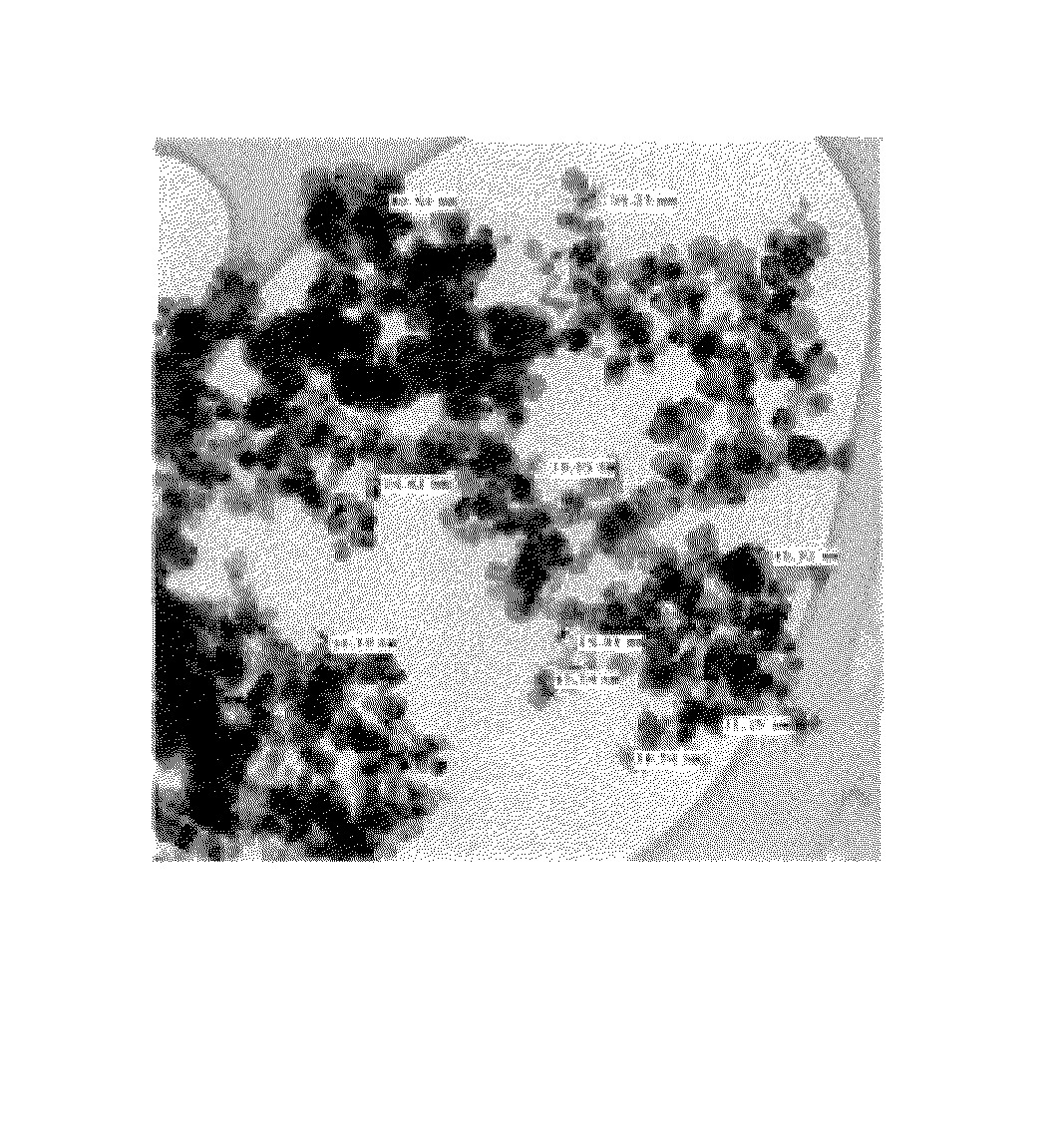

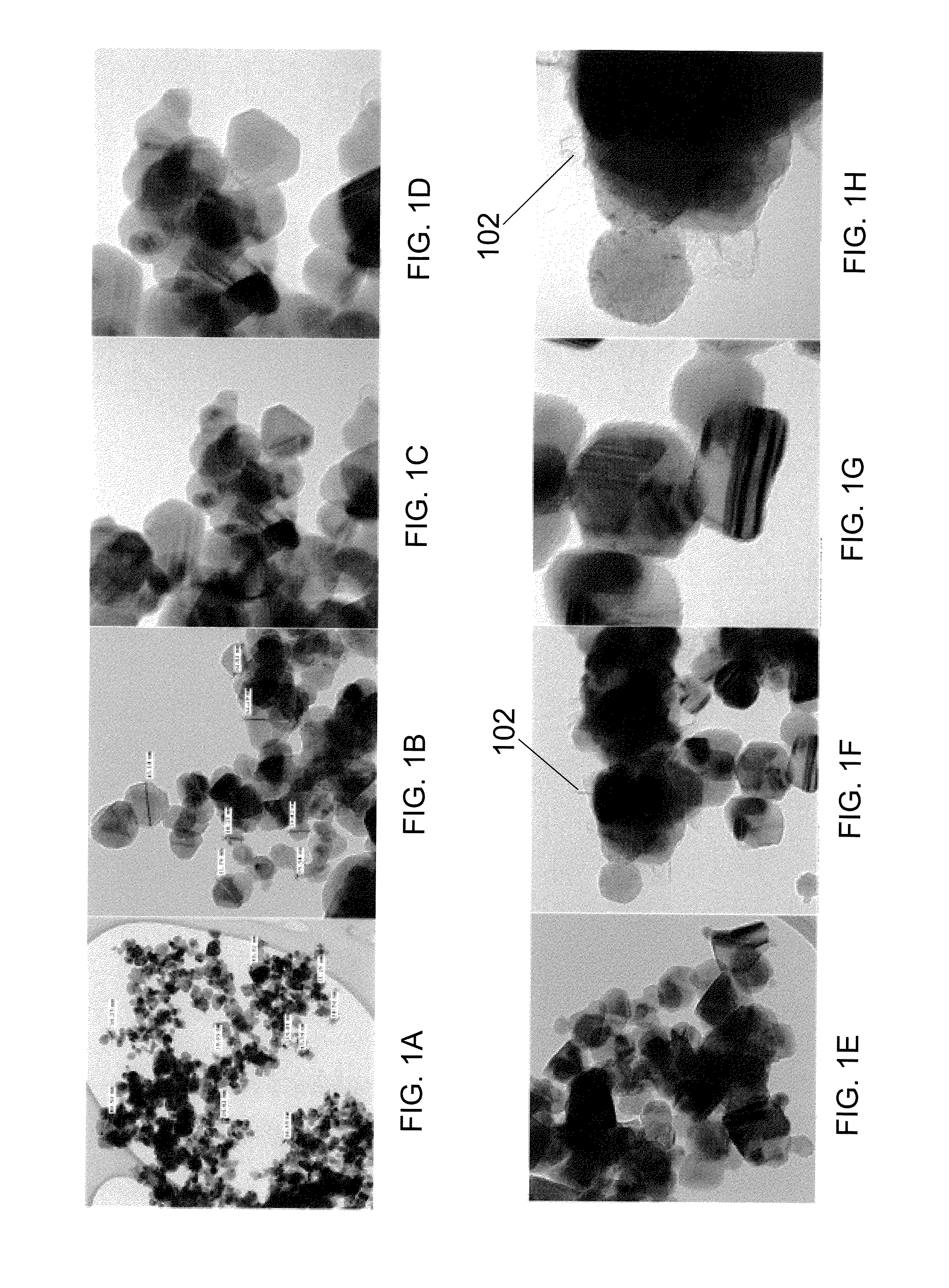

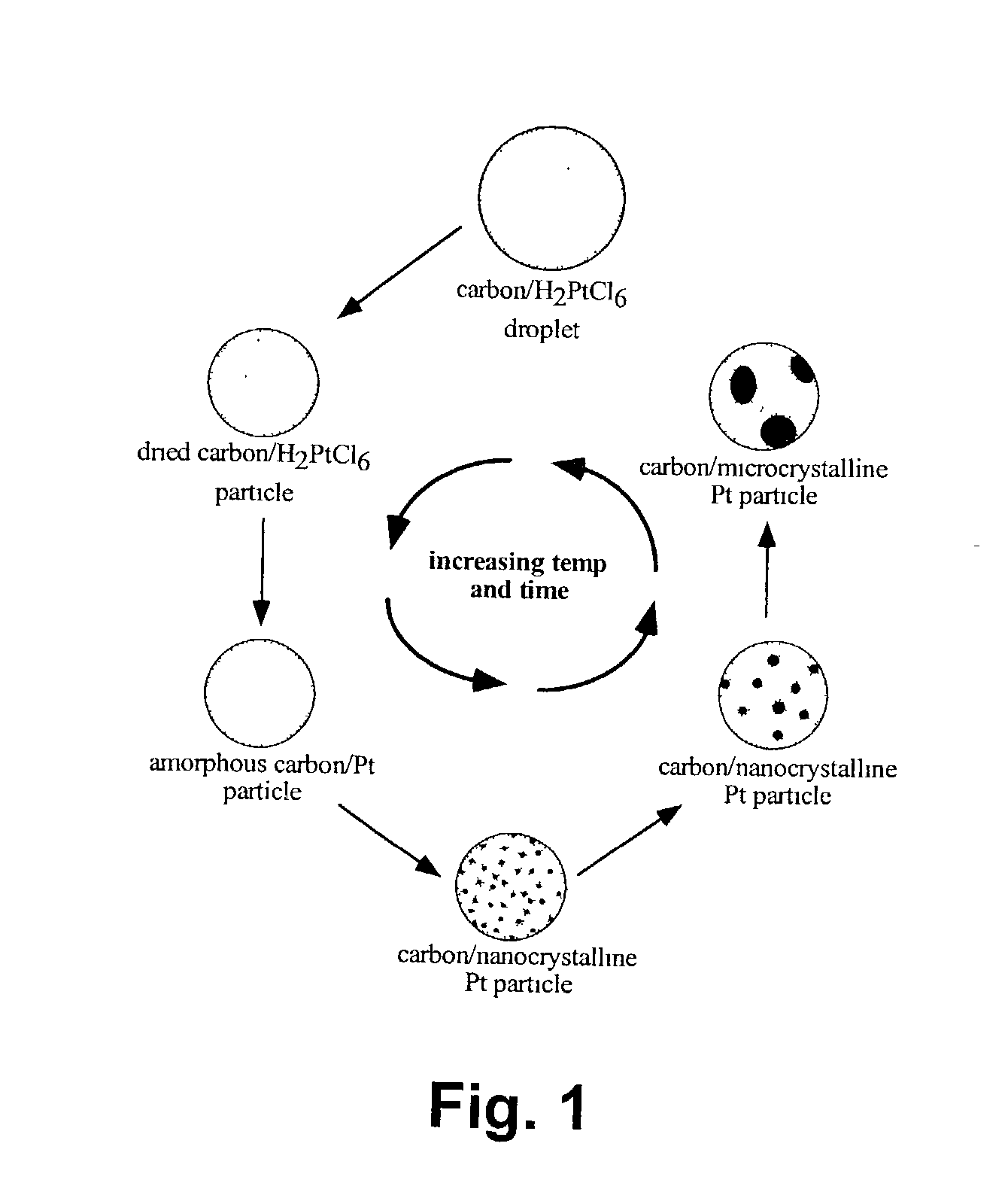

Nanowire-based membrane electrode assemblies for fuel cells

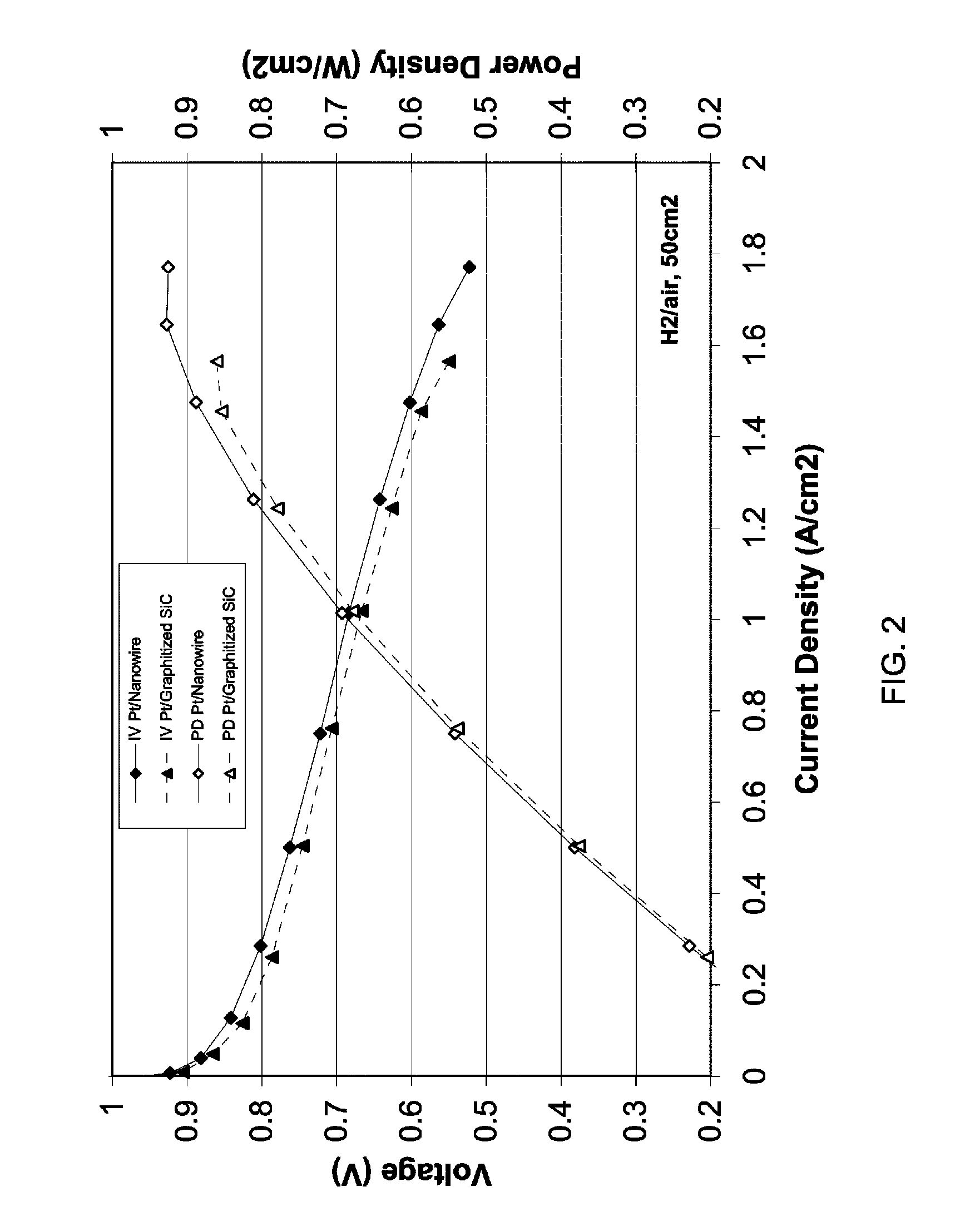

ActiveUS7179561B2High rateLow costMaterial nanotechnologyFinal product manufactureNanowirePtru catalyst

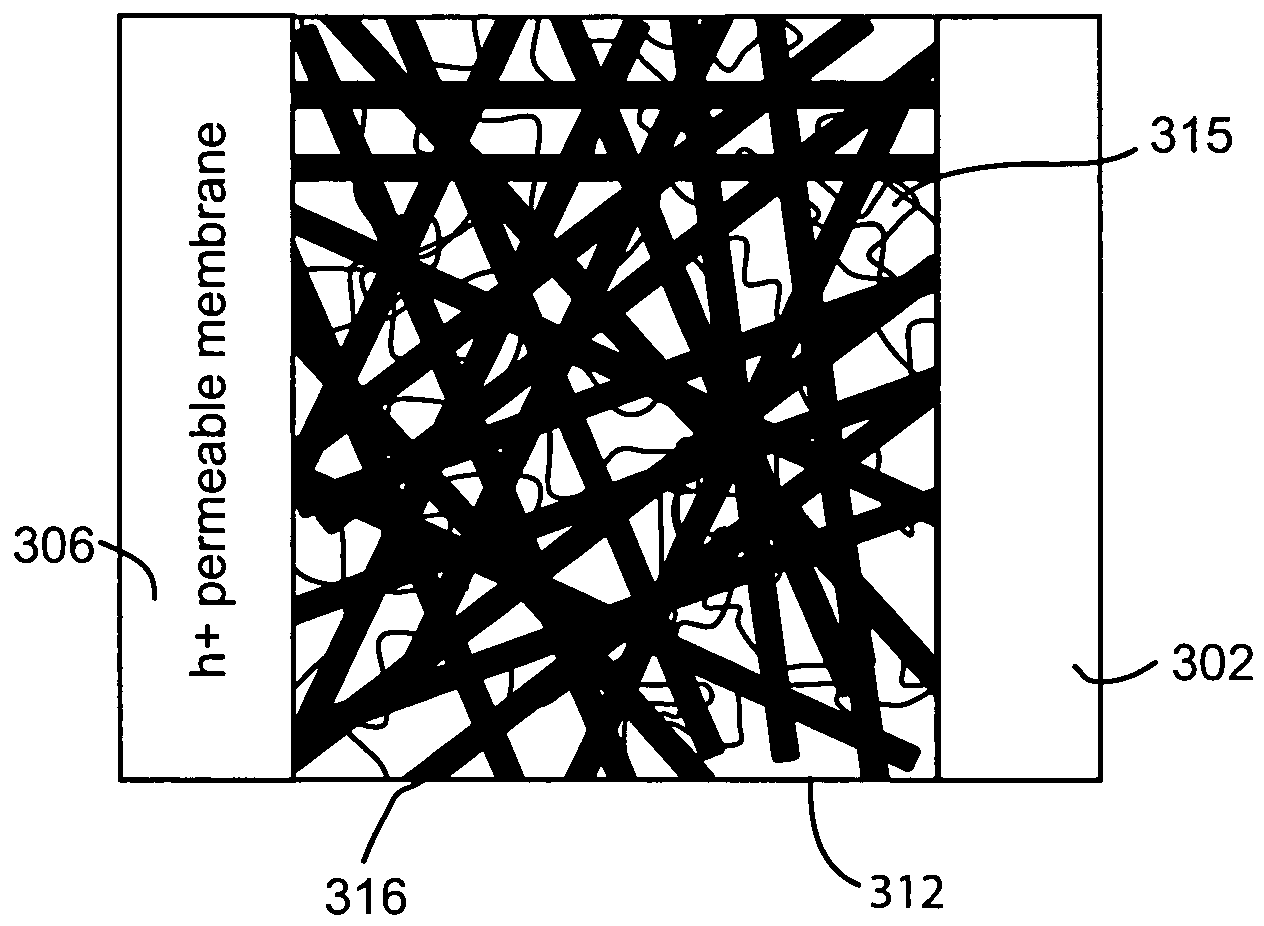

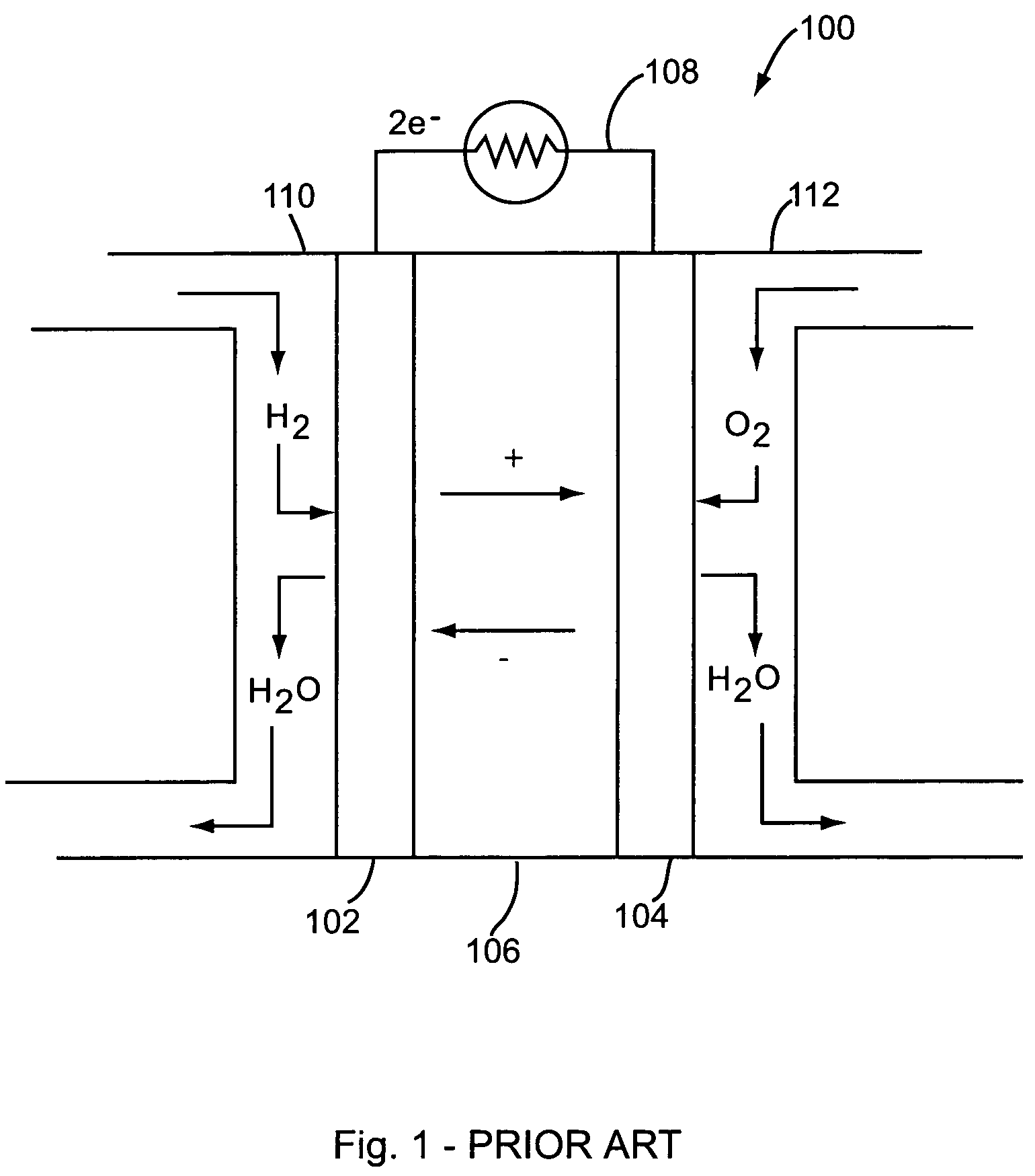

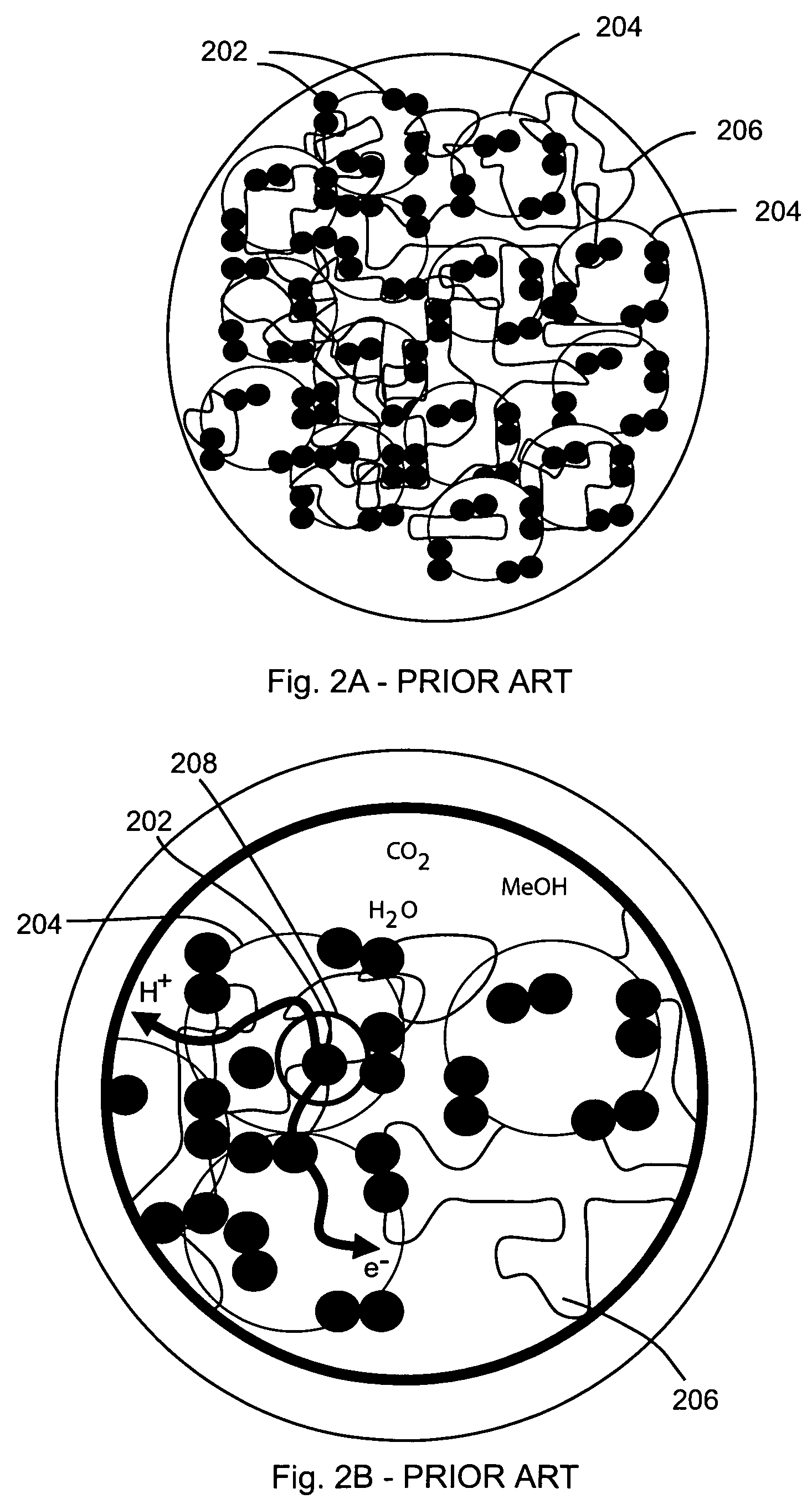

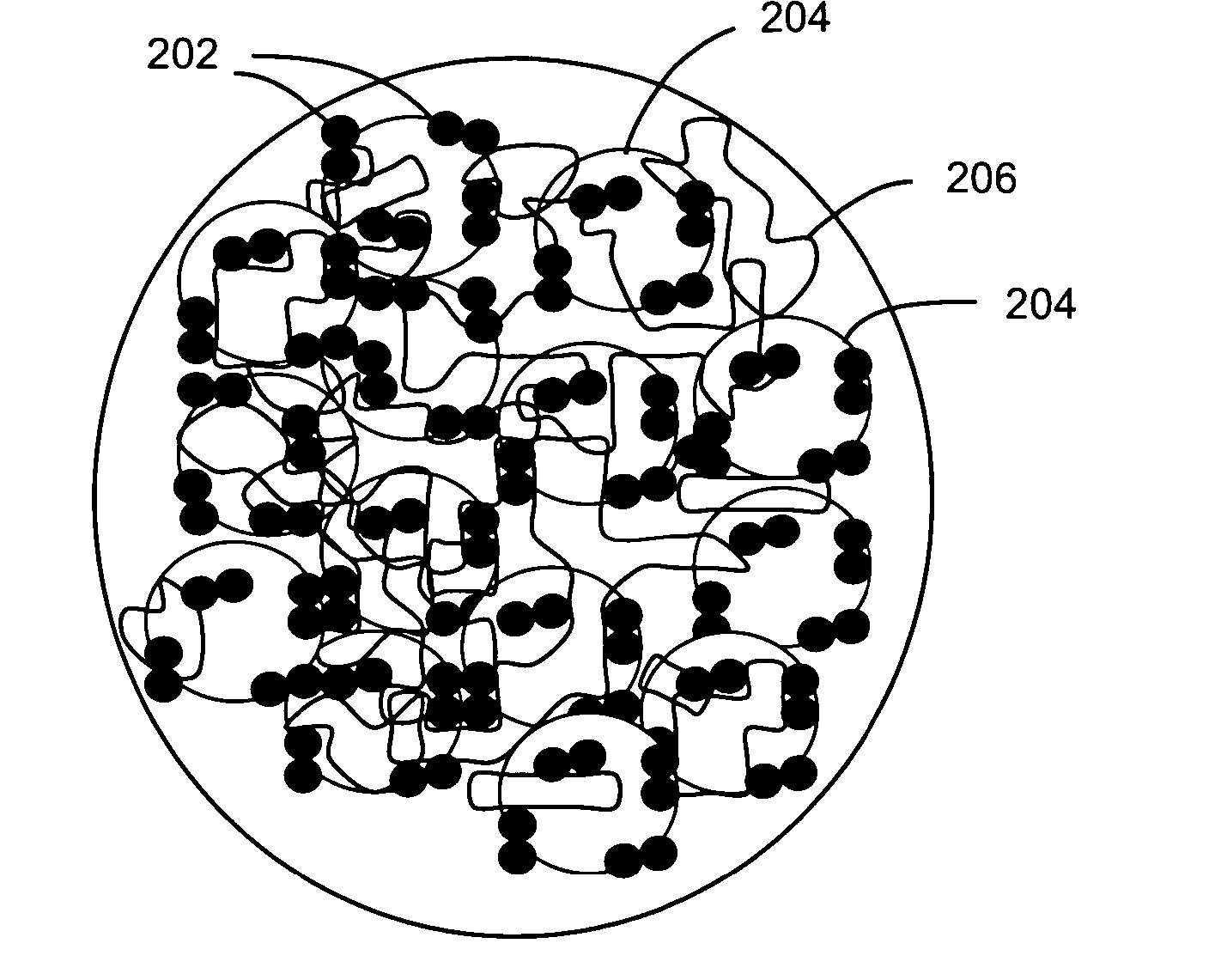

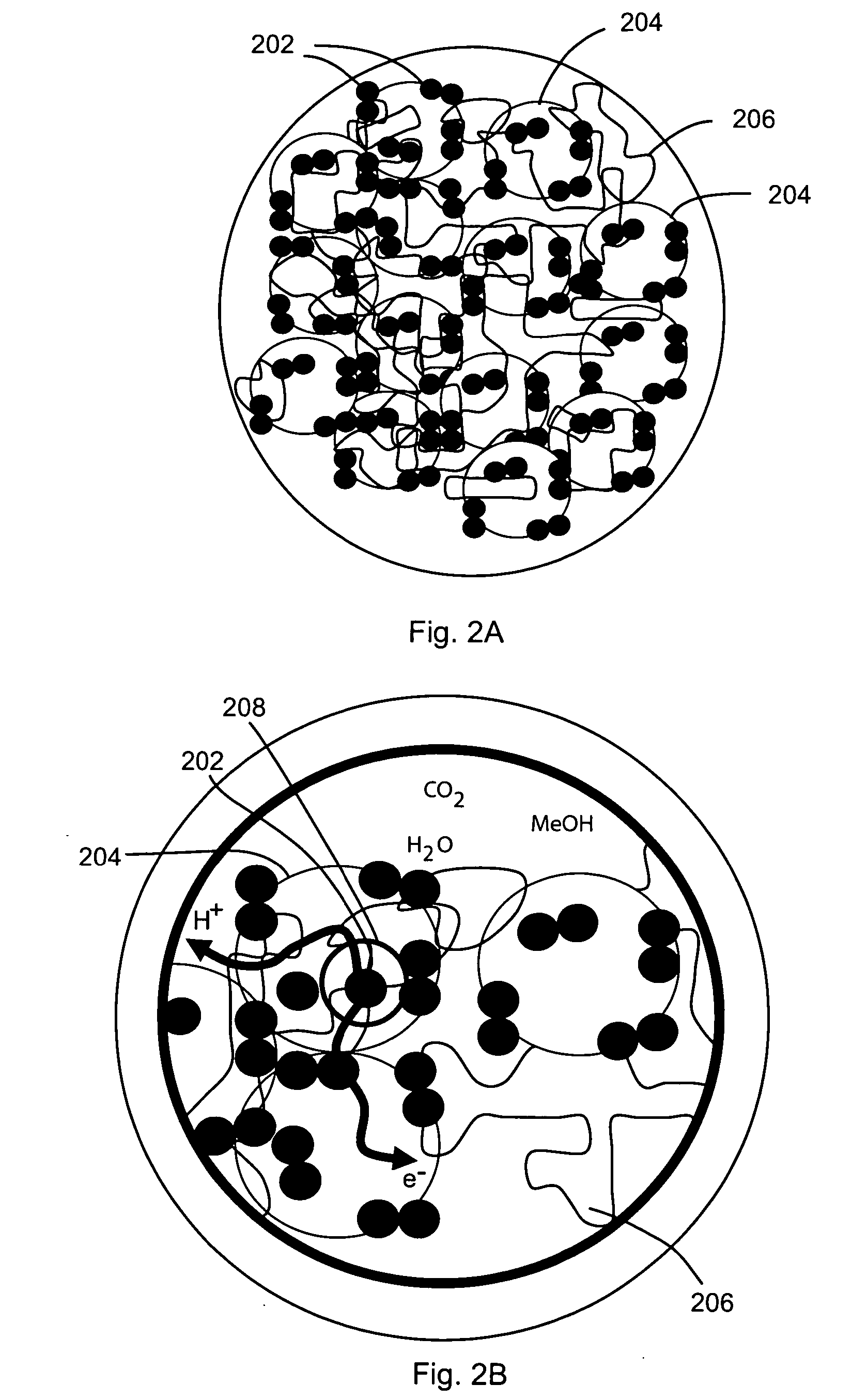

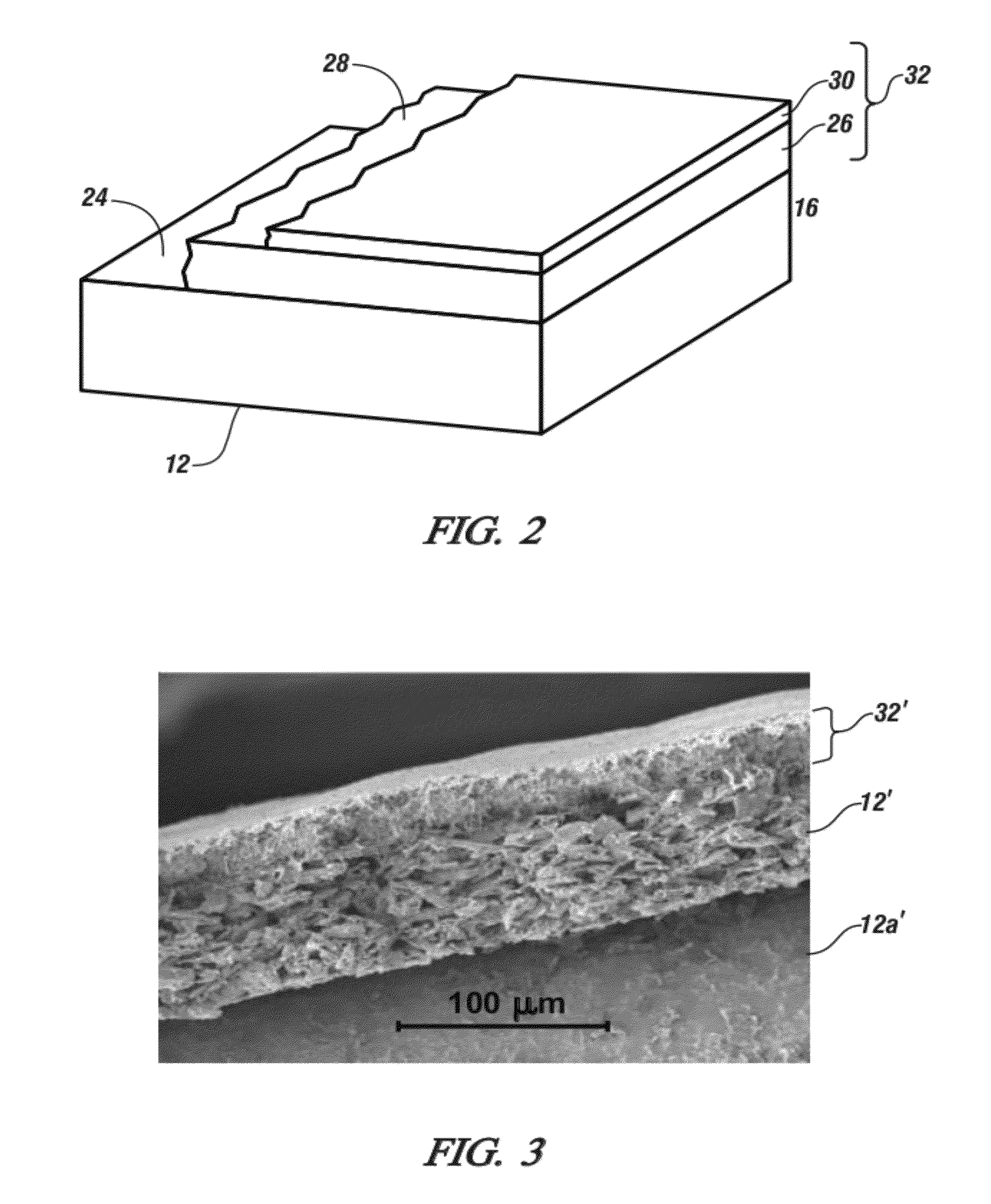

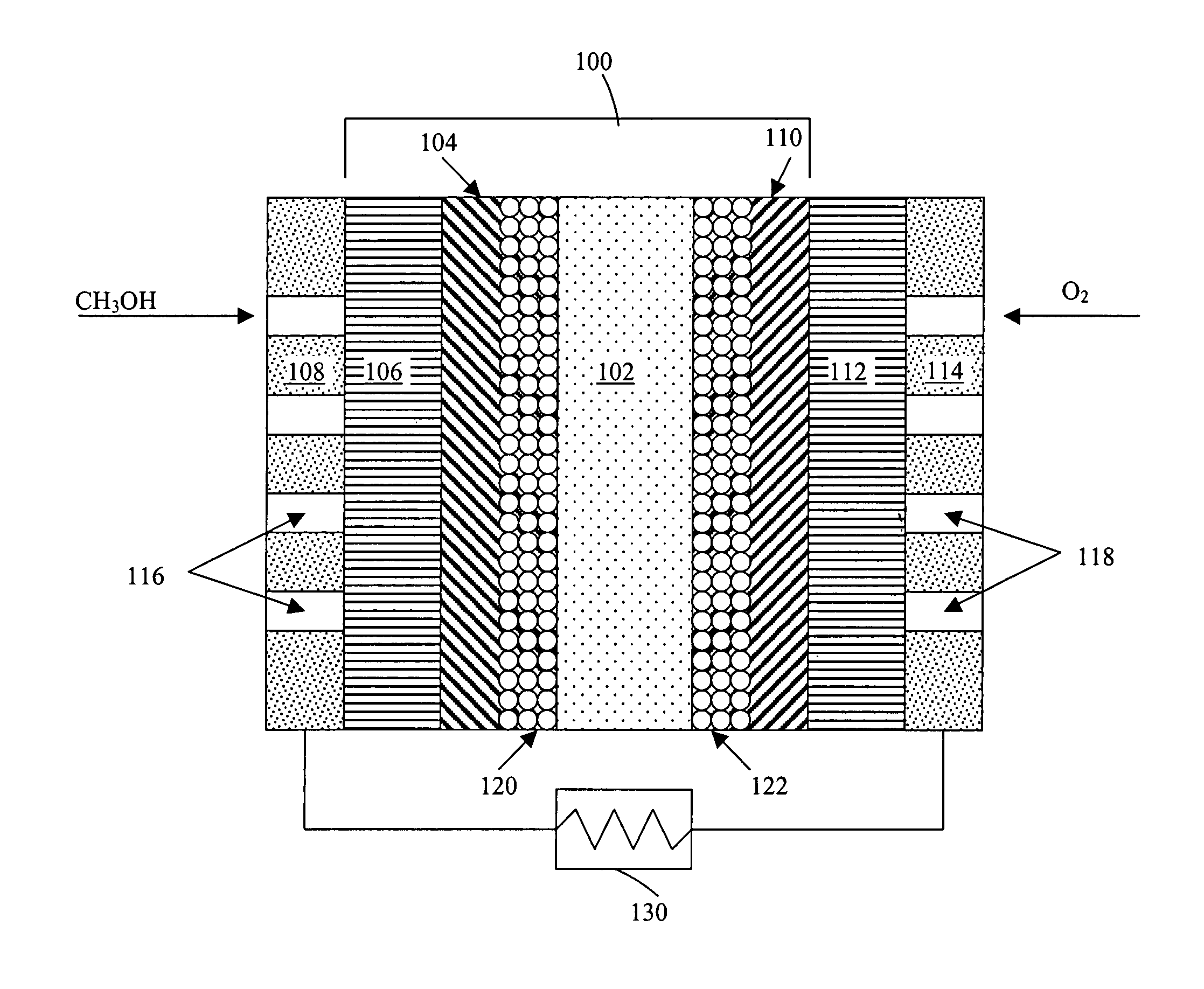

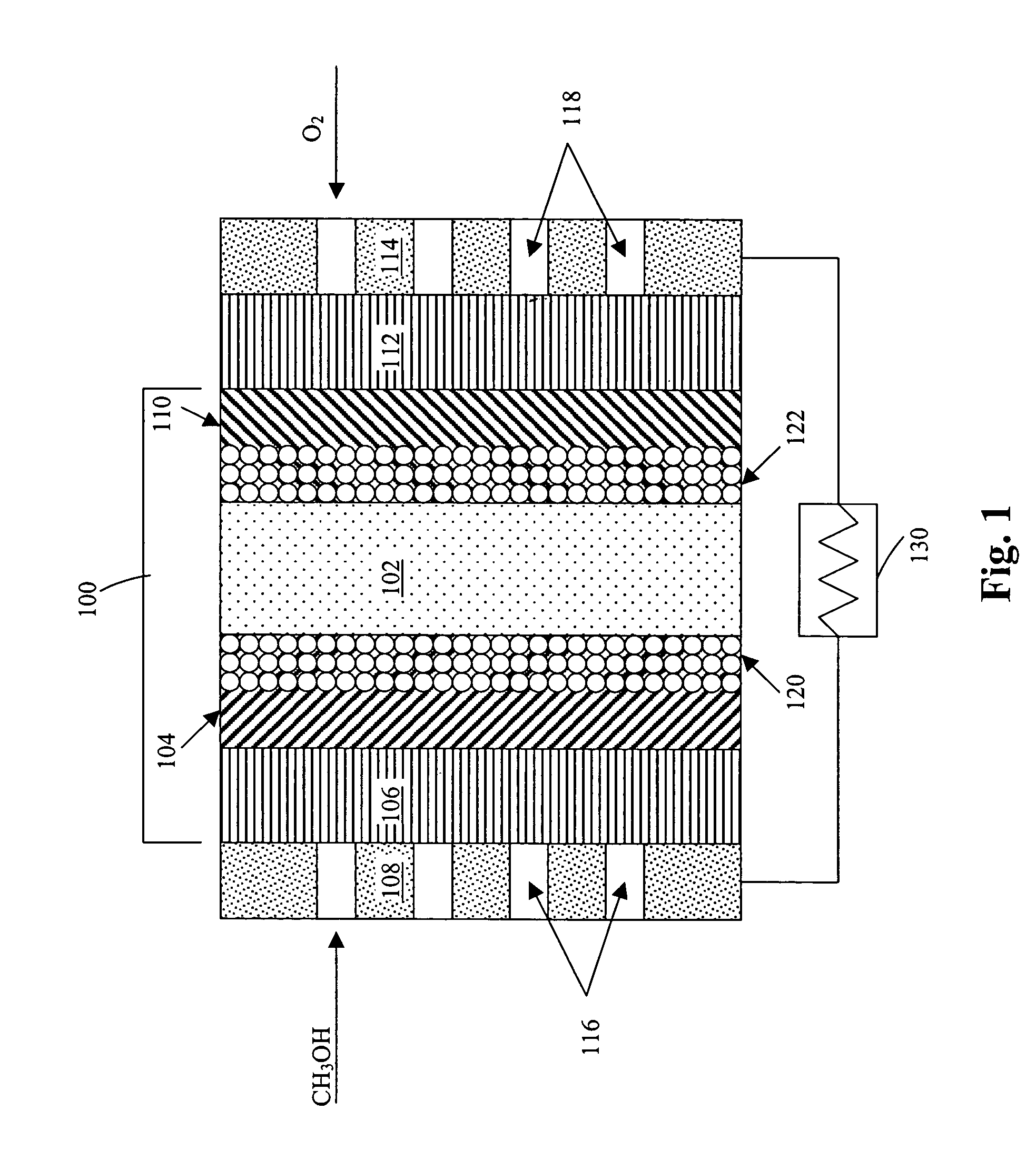

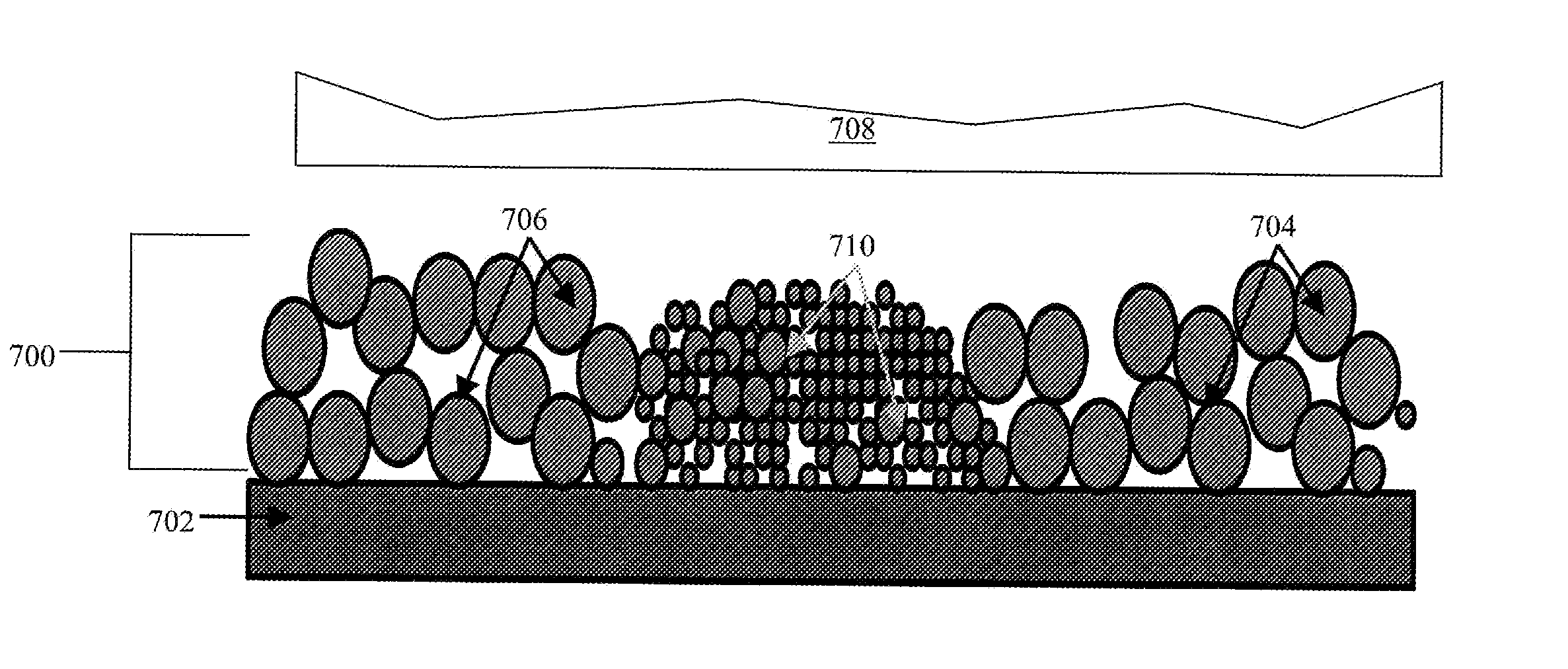

The present invention discloses nanowires for use in a fuel cell comprising a metal catalyst deposited on a surface of the nanowires. A membrane electrode assembly for a fuel cell is disclosed which generally comprises a proton exchange membrane, an anode electrode, and a cathode electrode, wherein at least one or more of the anode electrode and cathode electrode comprise an interconnected network of the catalyst supported nanowires. Methods are also disclosed for preparing a membrane electrode assembly and fuel cell based upon an interconnected network of nanowires.

Owner:ONED MATERIAL INC

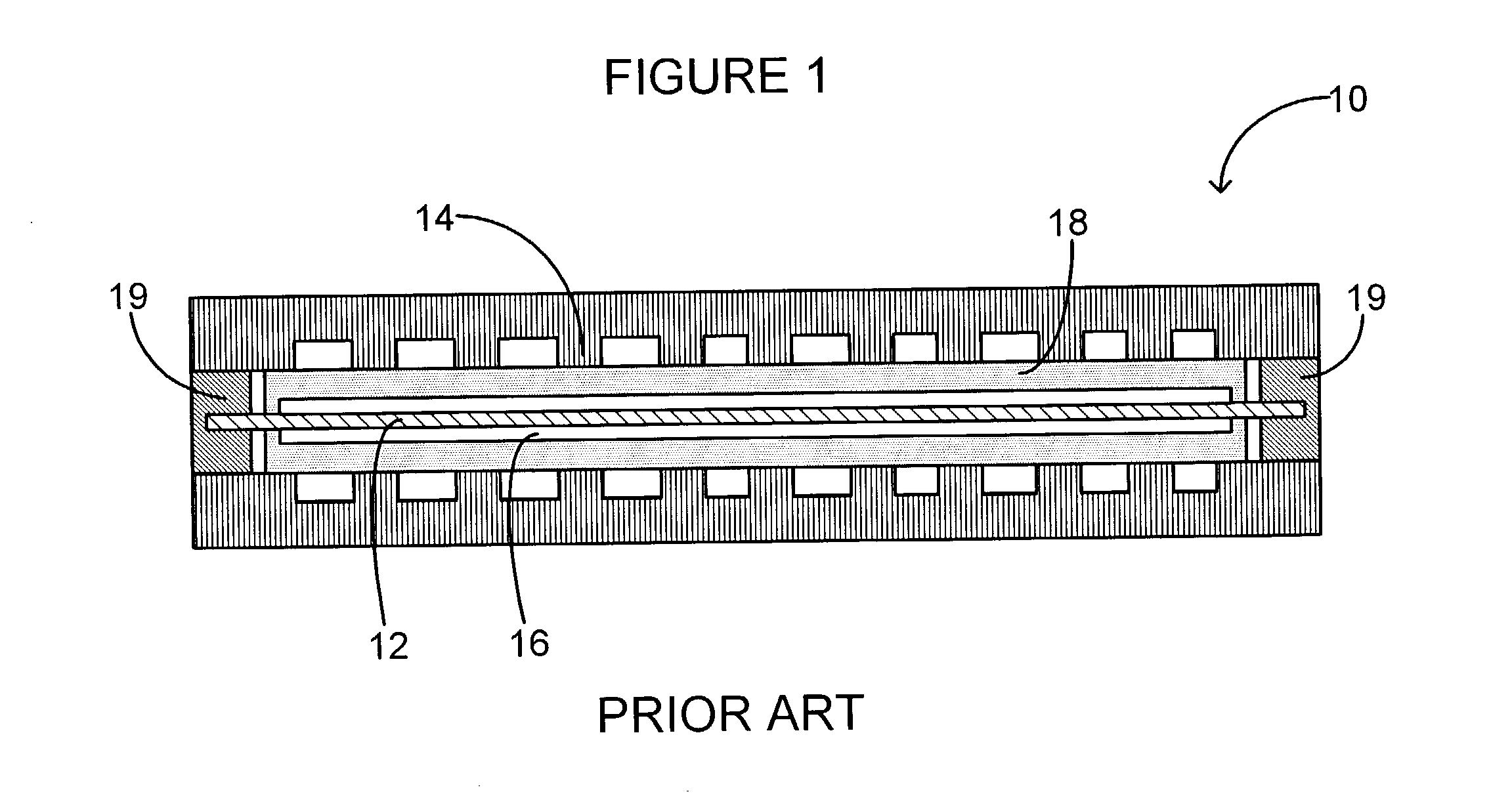

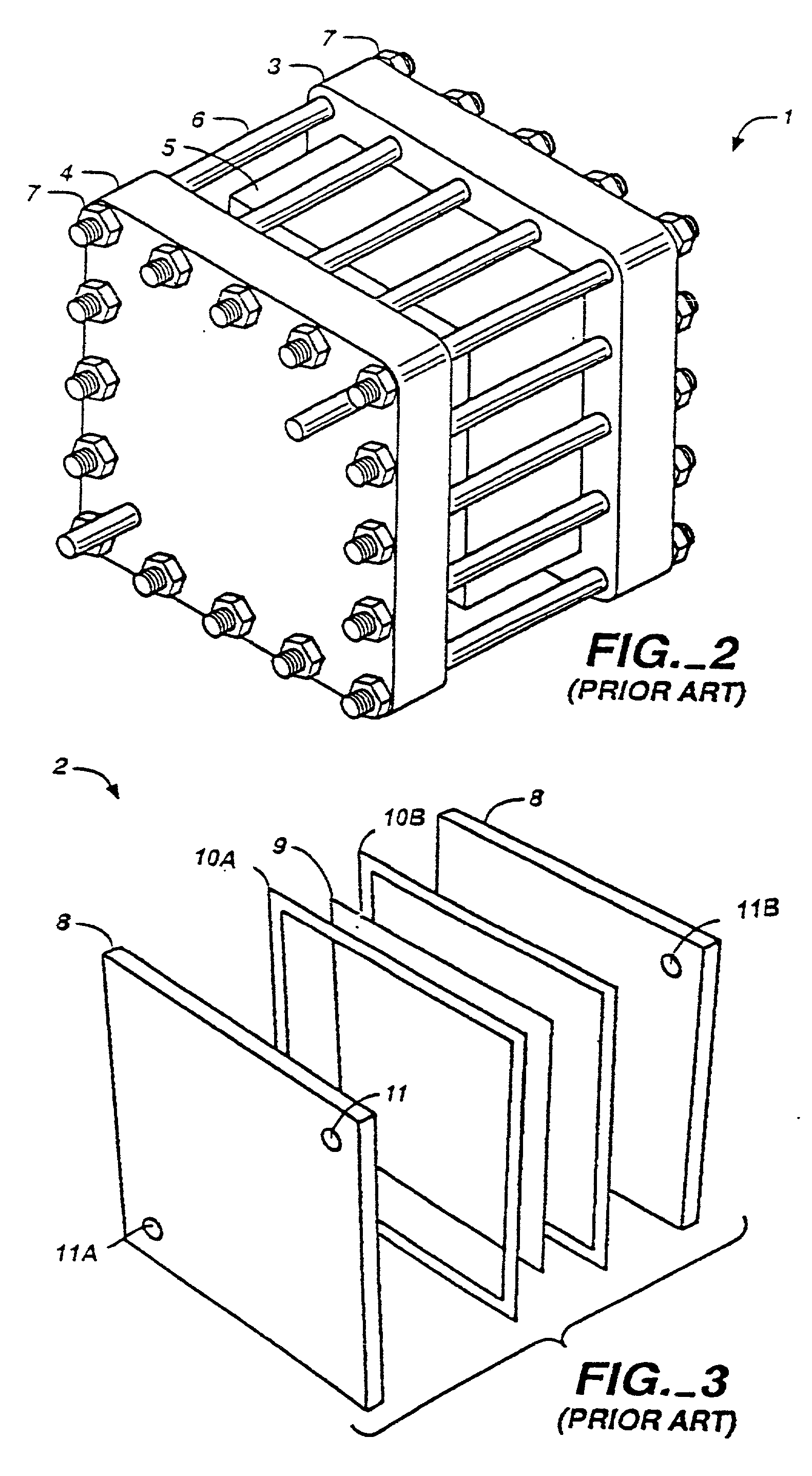

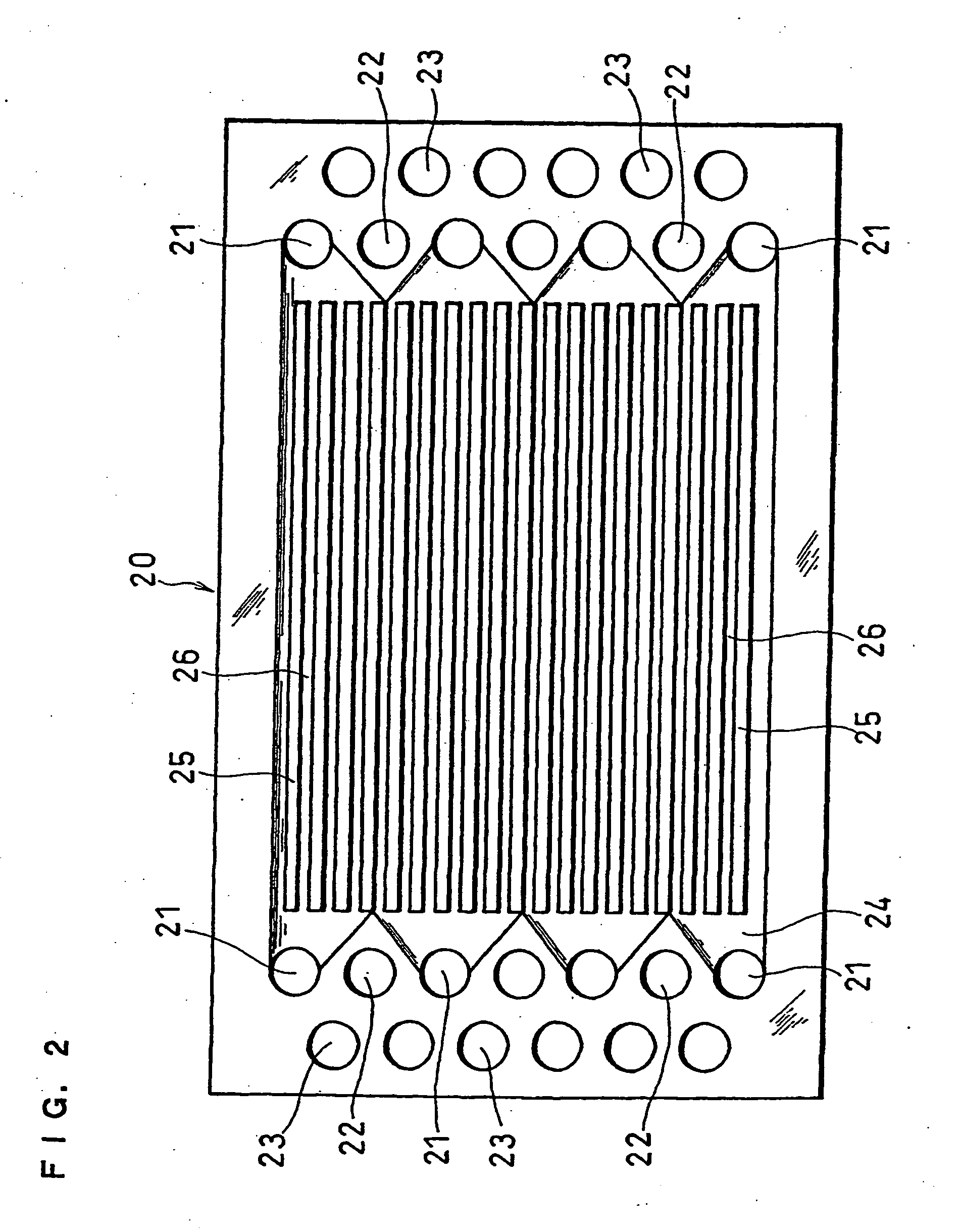

Fuel cell platelet separators having coordinate features

InactiveUS6051331ASimple designEvenly distributedSolid electrolytesFuel cells groupingLaser etchingFuel cells

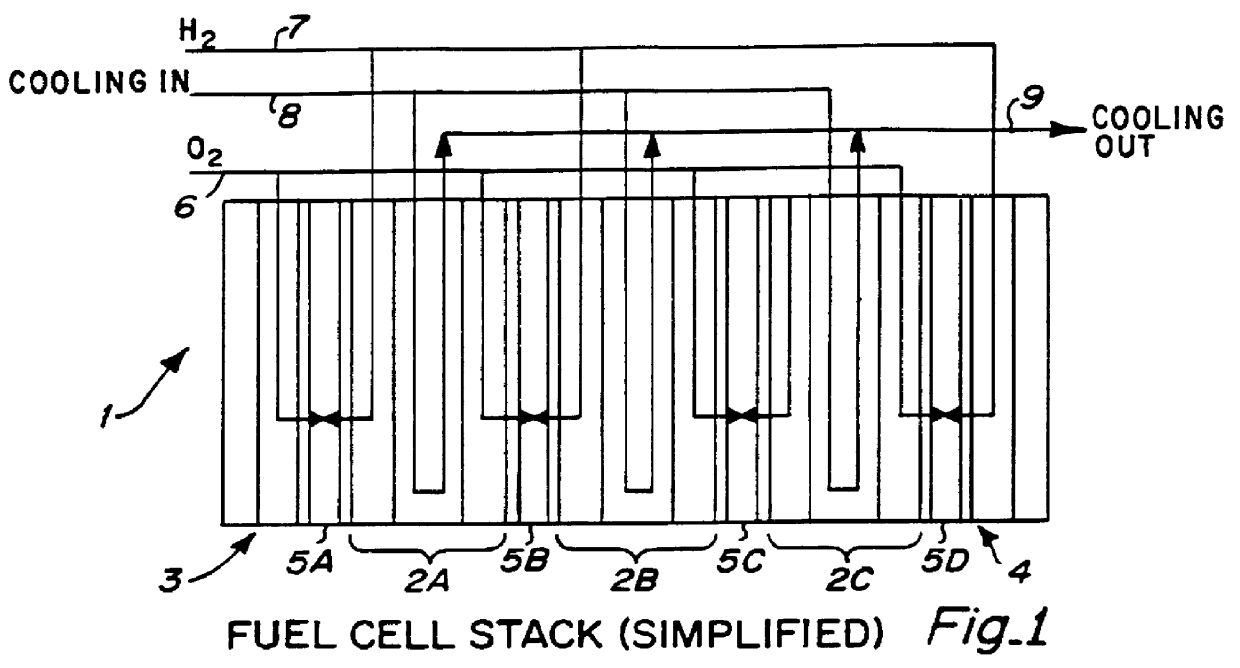

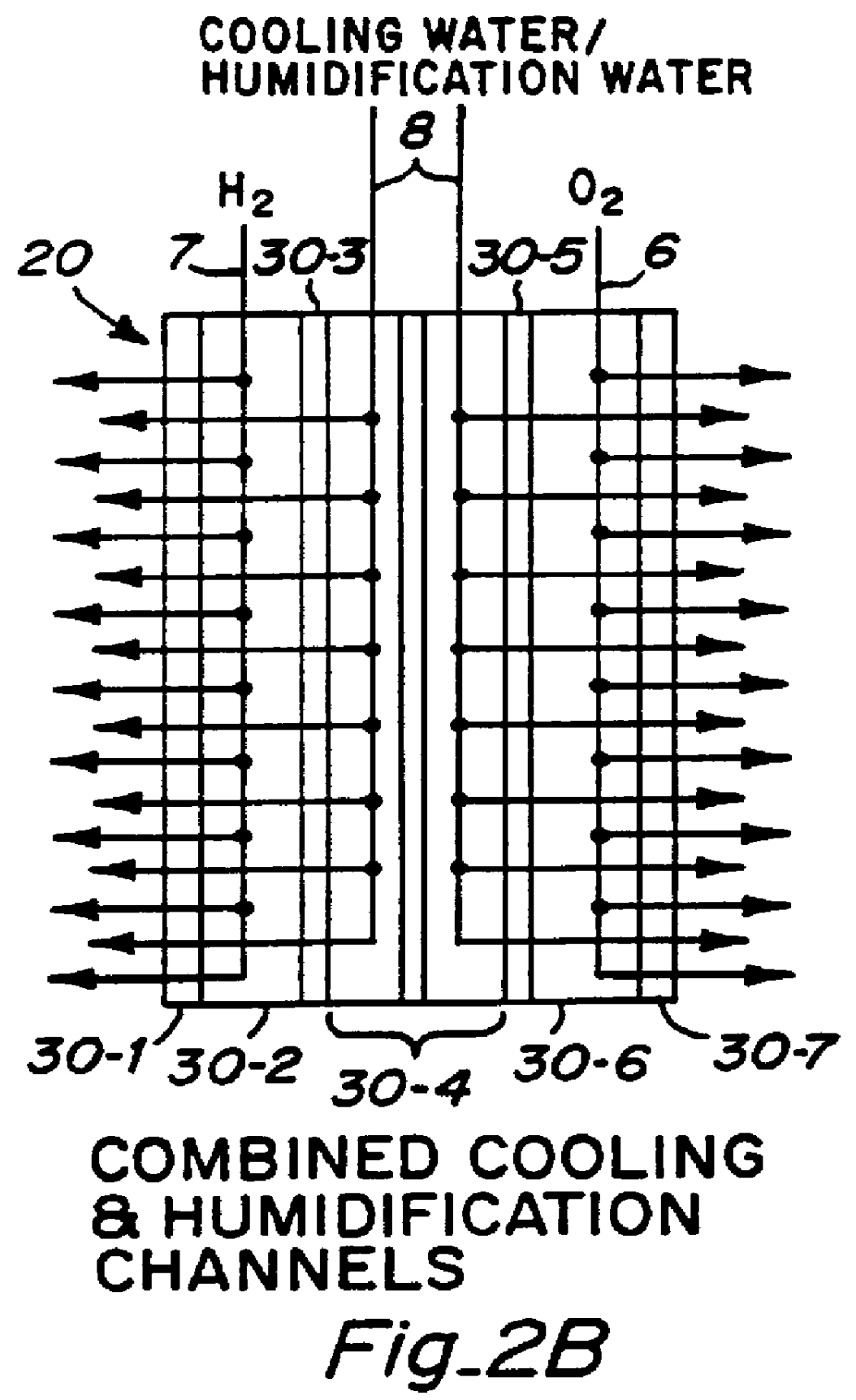

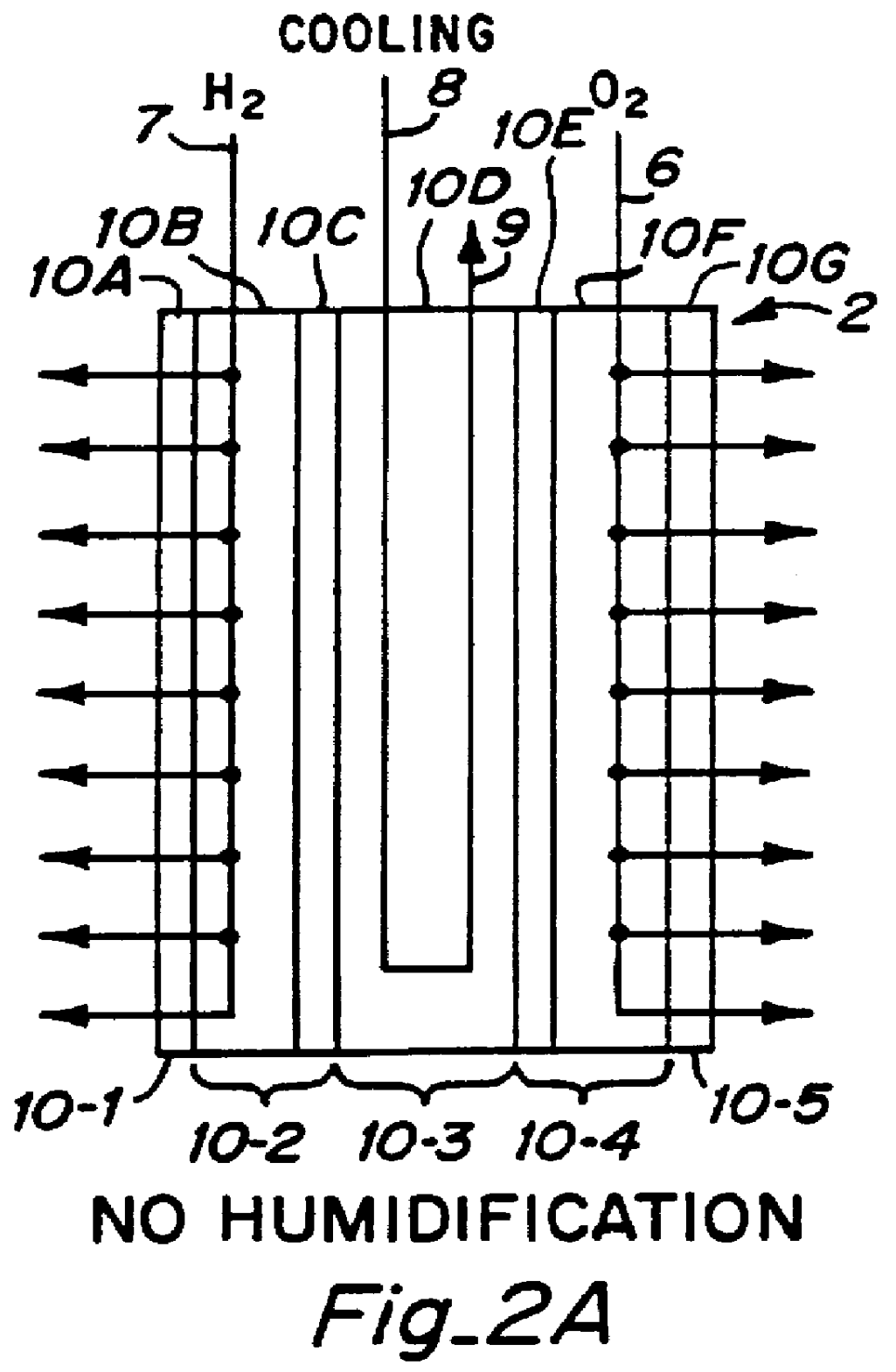

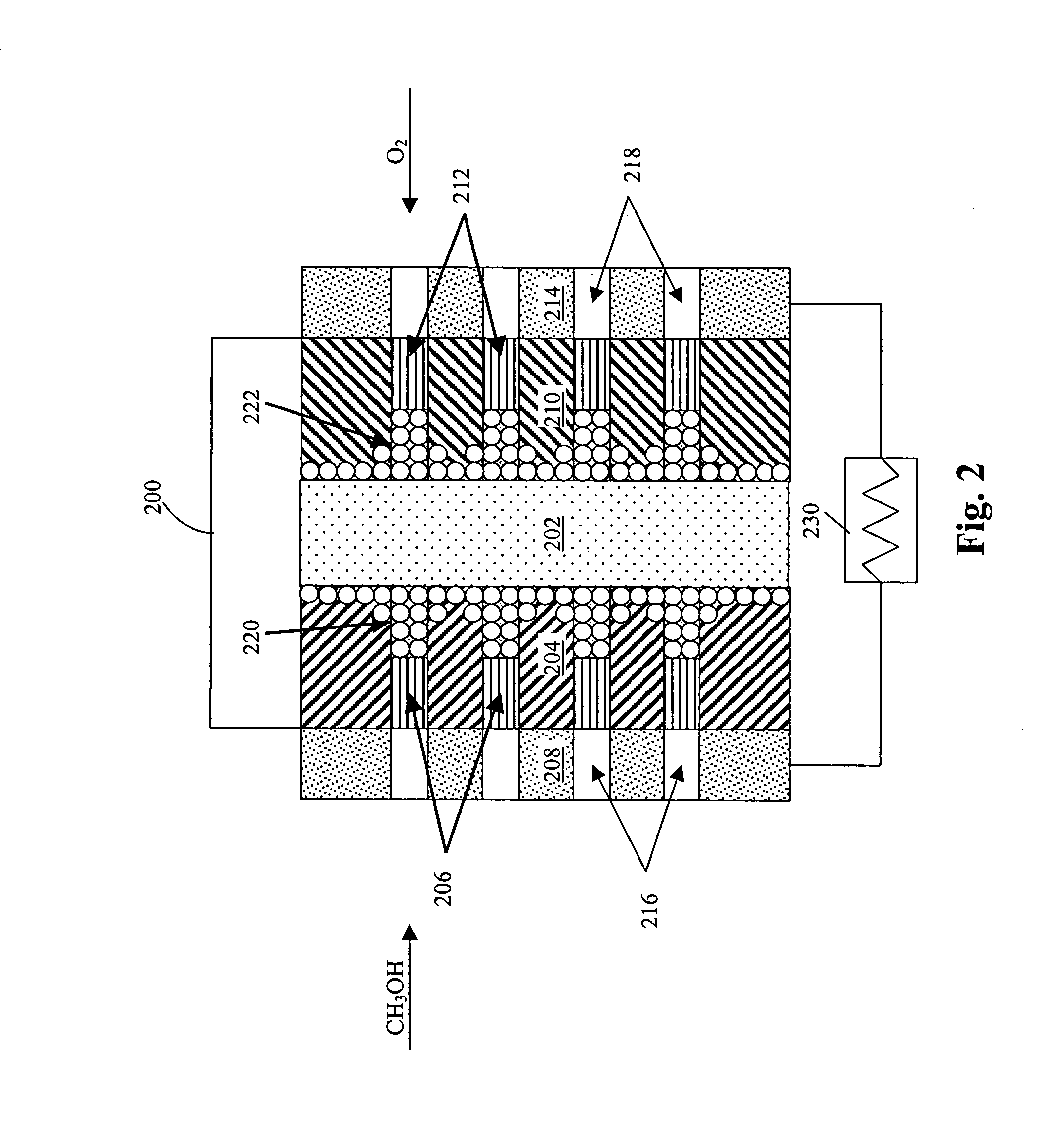

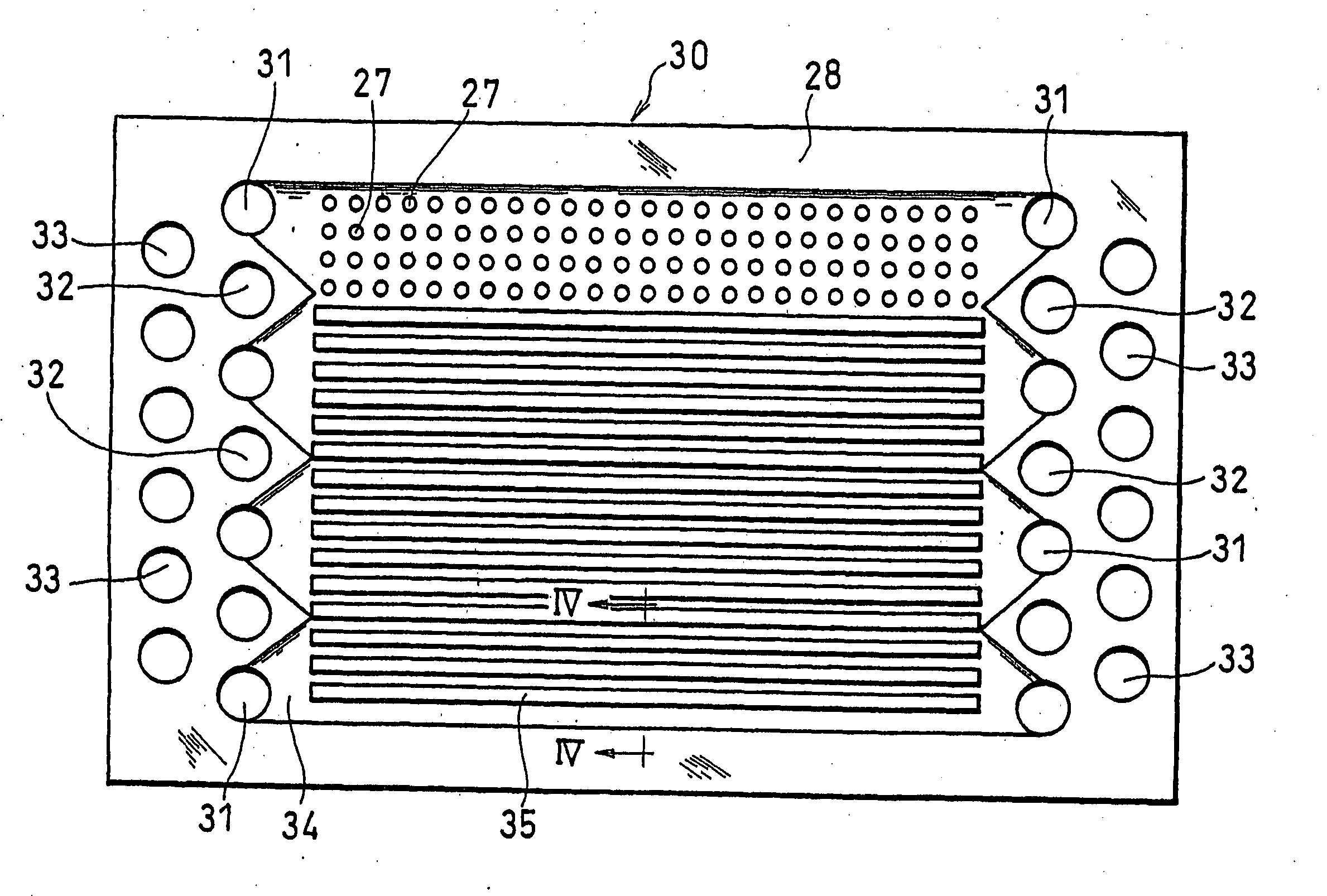

PCT No. PCT / US95 / 13325 Sec. 371 Date Sep. 28, 1997 Sec. 102(e) Date Sep. 28, 1997 PCT Filed Oct. 10, 1995 PCT Pub. No. WO96 / 12316 PCT Pub. Date Apr. 25, 1996Fuel cell stacks comprising stacked separator / membrane electrode assembly fuel cells in which the separators comprise a series of thin sheet platelets, having individually configured serpentine micro-channel reactant gas humidification active areas and cooling fields therein. The individual platelets are stacked with coordinate features aligned in contact with adjacent platelets and bonded to form a monolithic separator. Post-bonding processing includes passivation, such as nitriding. Preferred platelet material is 4-25 mil Ti, in which the features, serpentine channels, tabs, lands, vias, manifolds and holes, are formed by chemical and laser etching, cutting, pressing or embossing, with combinations of depth and through etching preferred. The platelet manufacturing process is continuous and fast. By employing CAD based platelet design and photolithography, rapid change in feature design can accommodate a wide range of thermal management and humidification techniques. One hundred H2-O2 / PEM fuel cell stacks of this IFMT platelet design will exhibit outputs on the order of 0.75 kW / kg, some 3-6 times greater than the current graphite plate PEM stacks.

Owner:H POWER

Nanowire-based membrane electrode assemblies for fuel cells

ActiveUS20060188774A1Higher catalytic metal utilization rateLow costMaterial nanotechnologyFinal product manufactureNanowirePtru catalyst

The present invention discloses nanowires for use in a fuel cell comprising a metal catalyst deposited on a surface of the nanowires. A membrane electrode assembly for a fuel cell is disclosed which generally comprises a proton exchange membrane, an anode electrode, and a cathode electrode, wherein at least one or more of the anode electrode and cathode electrode comprise an interconnected network of the catalyst supported nanowires. Methods are also disclosed for preparing a membrane electrode assembly and fuel cell based upon an interconnected network of nanowires.

Owner:ONED MATERIAL INC

Method of fabricating fuel cells and membrane electrode assemblies

InactiveUS20040053100A1Low production costOvercome limitationsFuel cells groupingCell electrodesElectrical resistance and conductancePower battery

The application relates to a method of fabricating micro fuel cells and membrane electrode assemblies by thin film deposition techniques using a dimensionally stable proton exchange membrane as a substrate. The application also relates to membrane electrode assemblies and fuel cells fabricated in accordance with the method. The method includes the steps of successively depositing catalyst, current collector and flow management layers on the membrane substrate in predetermined patterns. Since the fuel cell is formed layer by layer, the need for assembly and sealing of discrete components is avoided. The method improves the contact resistance between the current collectors and catalyst layers and reduce ohmic losses, thereby avoiding the need for end plates or other compressive elements. This in turn reduces the overall thickness of the manufactured fuel cell. Since the fuel cell layers are optionally flexible, the devices may be fabricated using a continuous roller process or other automated means. The method minimizes production costs and costs of non-essential materials and is particularly suitable for low power battery replacement applications.

Owner:NAT RES COUNCIL OF CANADA

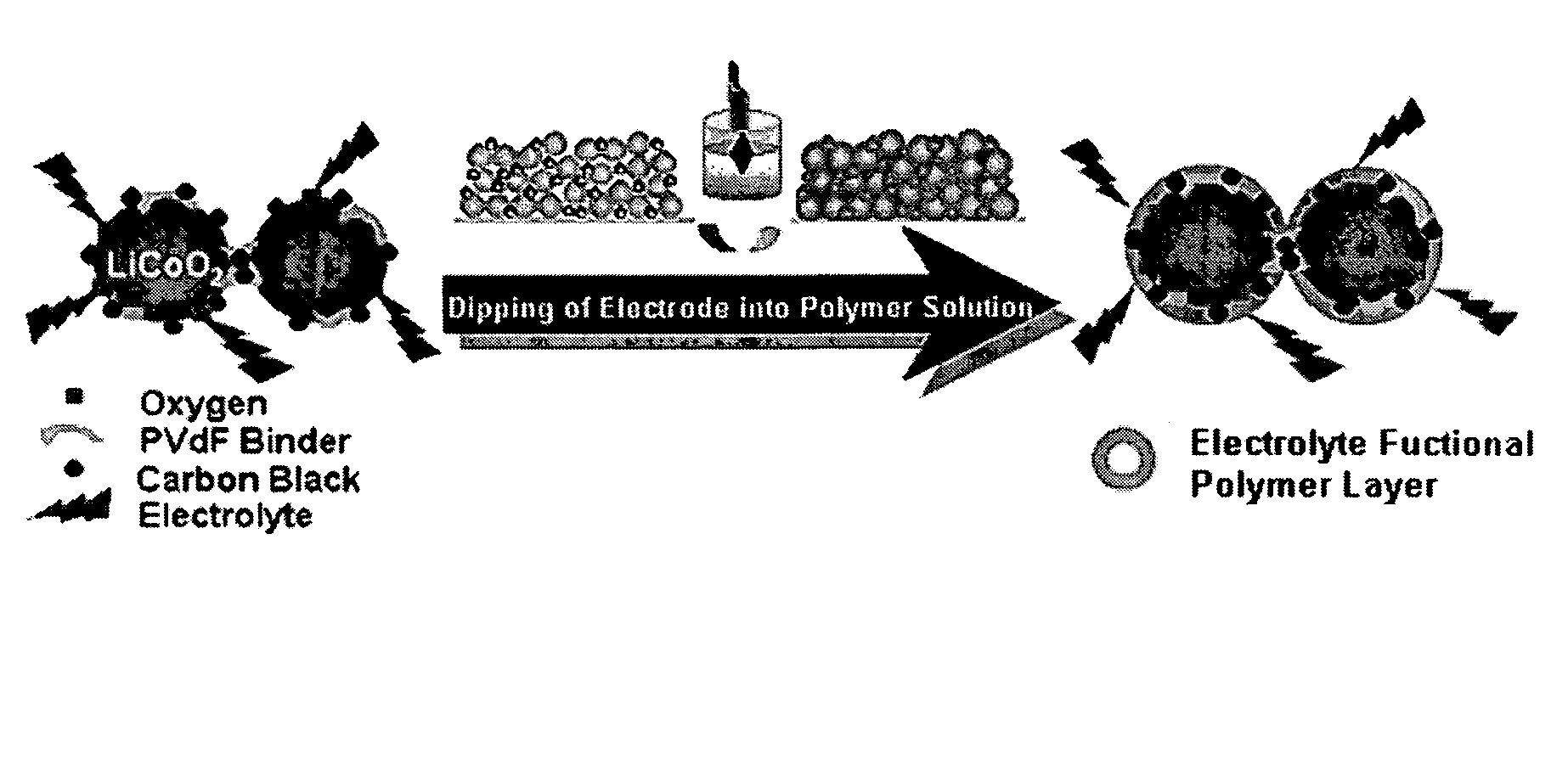

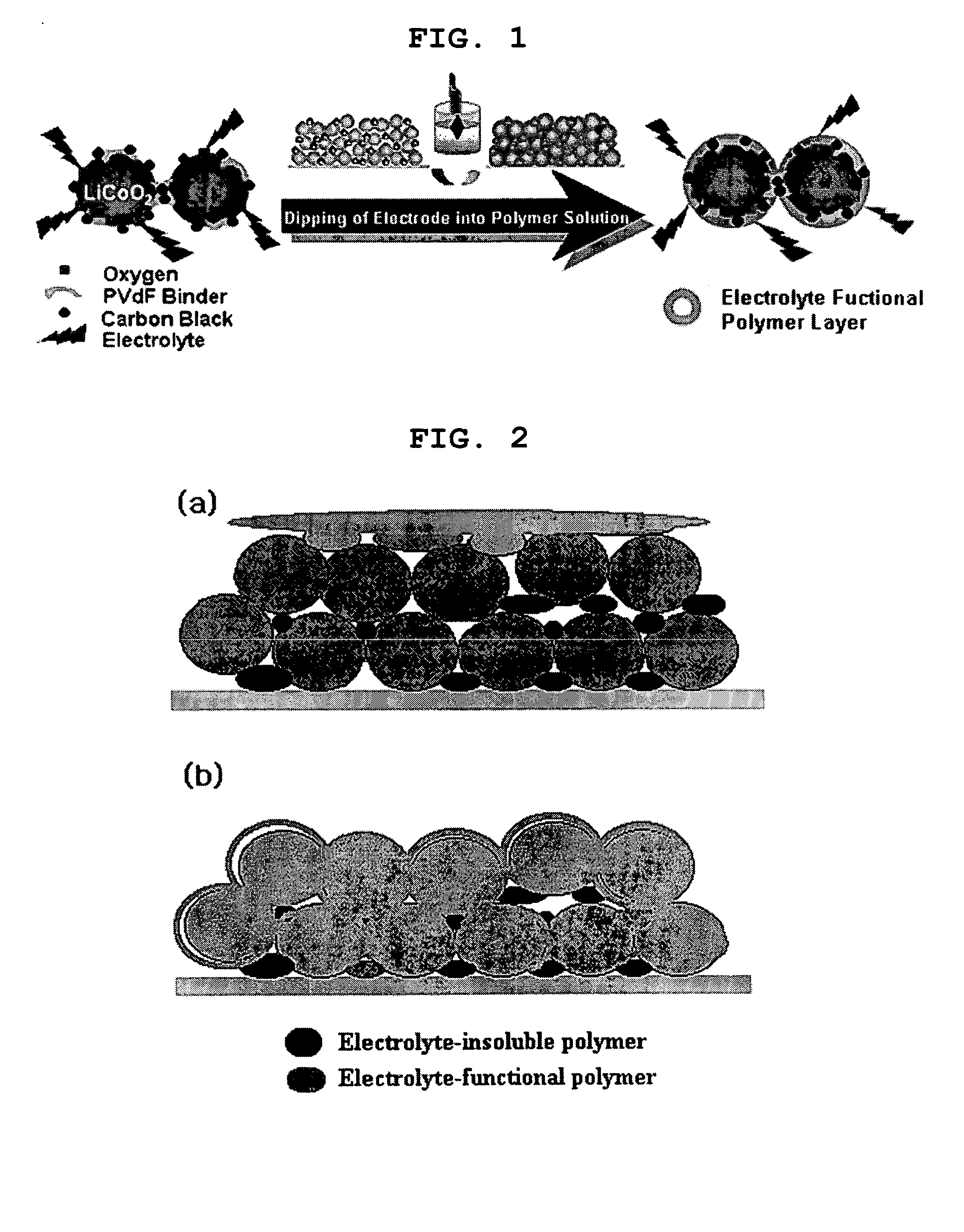

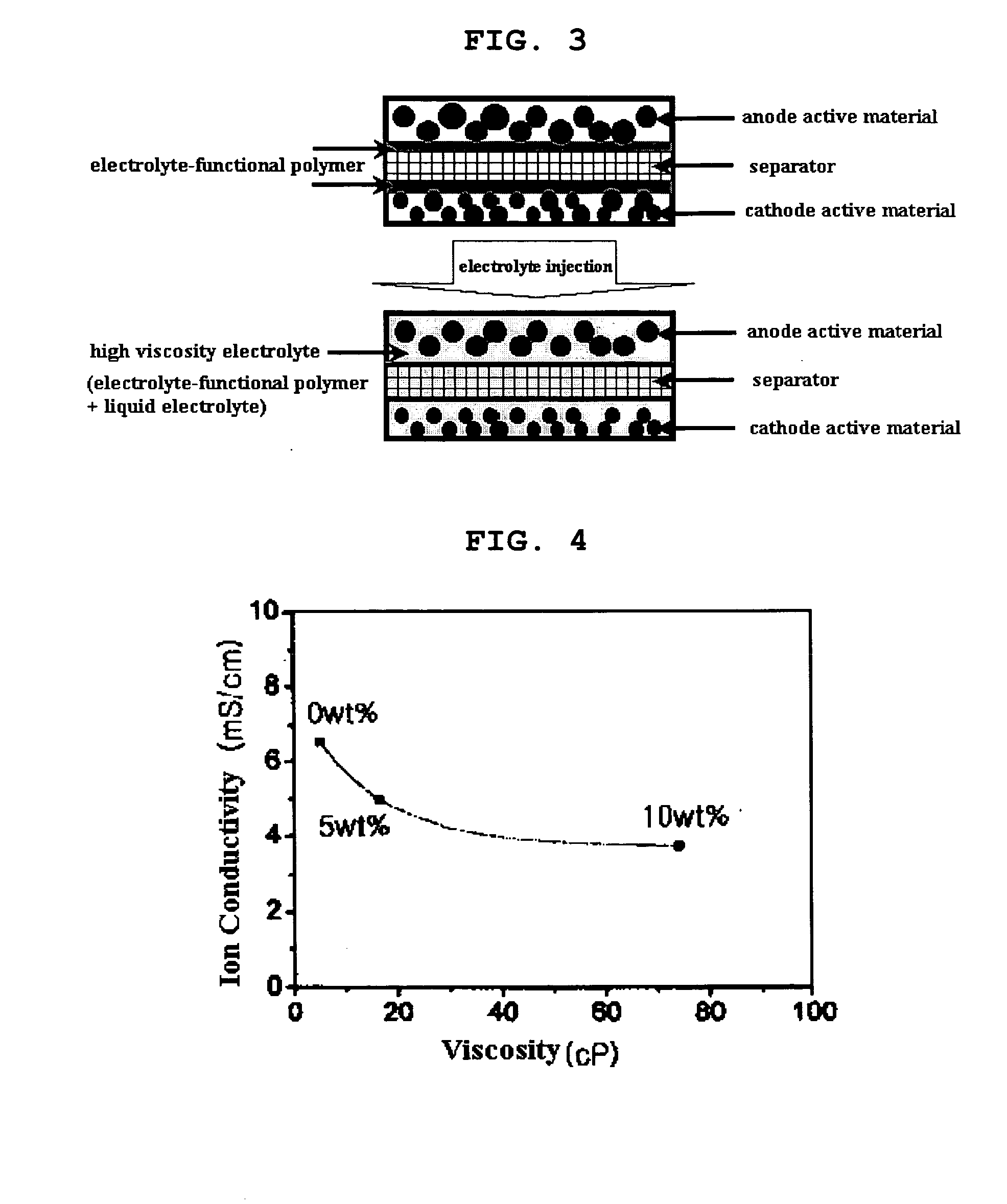

Functional polymer film-coated electrode and electrochemical device using the same

ActiveUS20050118508A1Lower performance requirementsImprove battery safetyGel electrodesElectrode carriers/collectorsSlurryPolymer thin films

The present invention provides an electrode in which an electrode active material particles as being interconnected are applied on current collector, wherein the interconnected surface of electrode active material particles is coated with a polymer, the polymer being present as an independent phase, while maintaining a pore structure formed among the interconnected electrode active material particles as well as an electrochemical device including the electrode. Also, the present invention provides a method for manufacturing an electrode coated with a polymer present on an interconnected surface of electrode active material as an independent phase, while maintaining a pore structure formed among the electrode active material particles, which comprises the steps of: (a) coating slurry for an electrode including an electrode active material on a current collector and drying it to form an electrode; and (b) dipping the electrode obtained from step (a) into a solution containing the polymer dissolved therein and a method for manufacturing an electrochemical device comprising the electrode obtained by the above method. The electrode coated with a polymer as an independent phase provides an electrochemical device with improved safety and prevents degradation of performance of an electrochemical device.

Owner:LG ENERGY SOLUTION LTD

Membrane-electrode unit for polymer electrolyte fuel cells and processes for their preparation

InactiveUS6309772B1Simplify gas transportBroaden accessSolid electrolytesFinal product manufactureIonomerPolymer electrolytes

A membrane-electrode unit for polymer-electrolyte fuel cells. The membrane-electrode unit consists of a polymer electrolyte membrane and porous reaction layers applied to both sides comprising a catalyst and a proton-conducting polymer, a so-called ionomer. The membrane-electrode unit is characterized in that one part A1 of the catalyst of the reaction layers is saturated with the ionomer and is embedded in the ionomer whereas one part A2 of the catalyst is kept free from the ionomer, where the parts A1 and A2 are in a weight ratio of 1:1 to 20:1.

Owner:UMICORE AG & CO KG +1

Nanostructured catalyst supports

The present invention relates to SiC nanostructures, including SiC nanopowder, SiC nanowires, and composites of SiC nanopowder and nanowires, which can be used as catalyst supports in membrane electrode assemblies and in fuel cells. The present invention also relates to composite catalyst supports comprising nanopowder and one or more inorganic nanowires for a membrane electrode assembly.

Owner:ONED MATERIAL INC

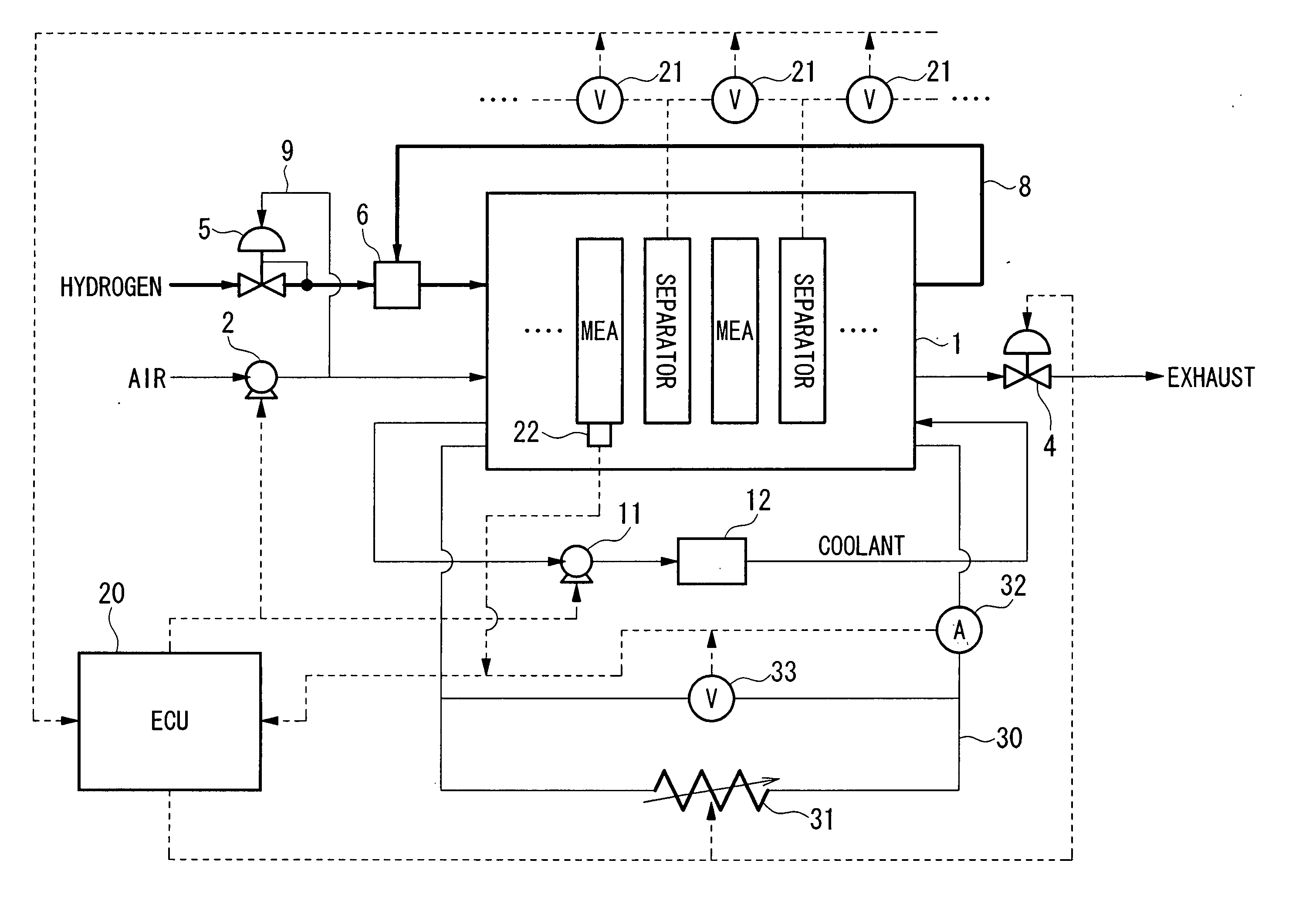

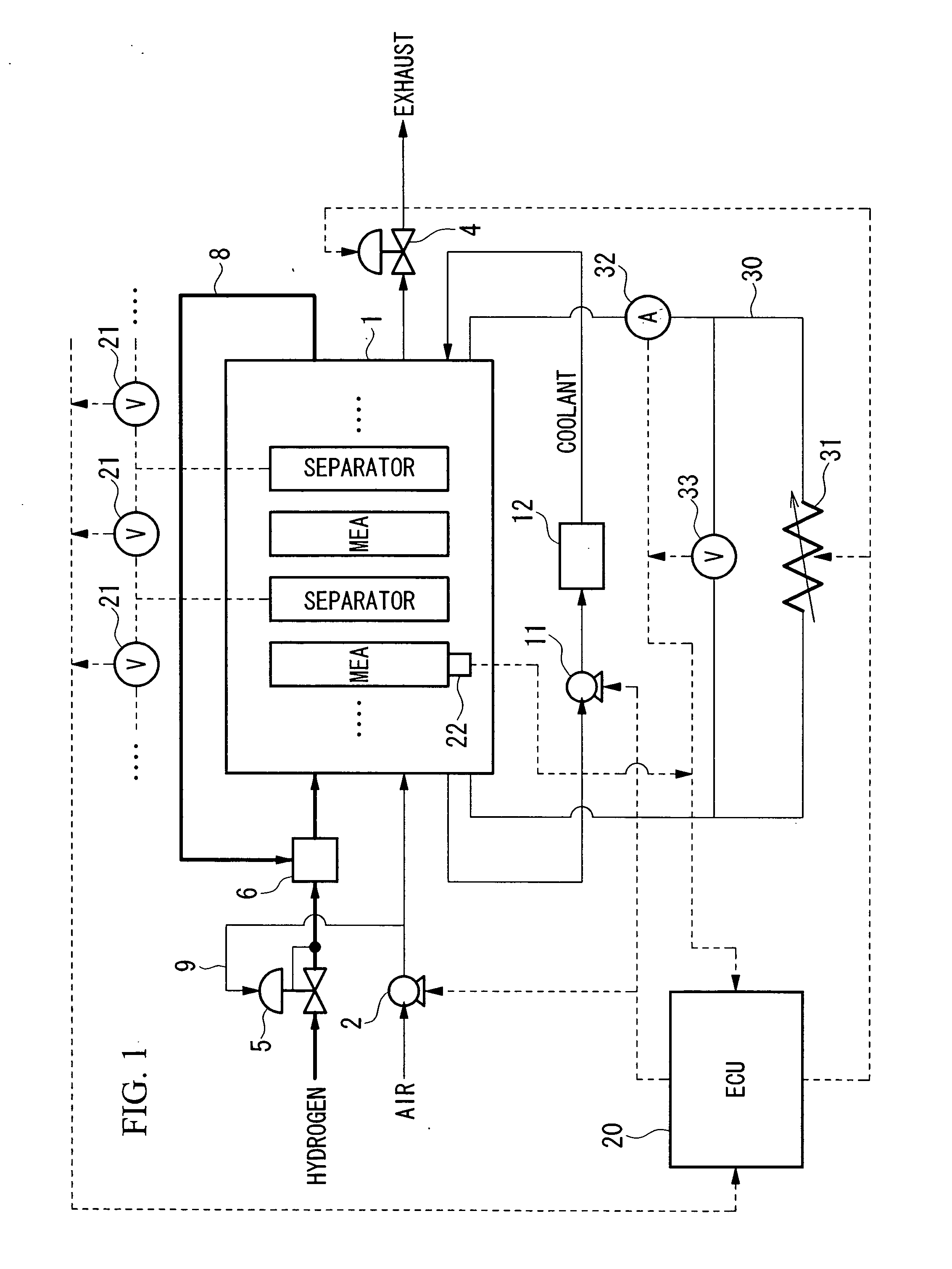

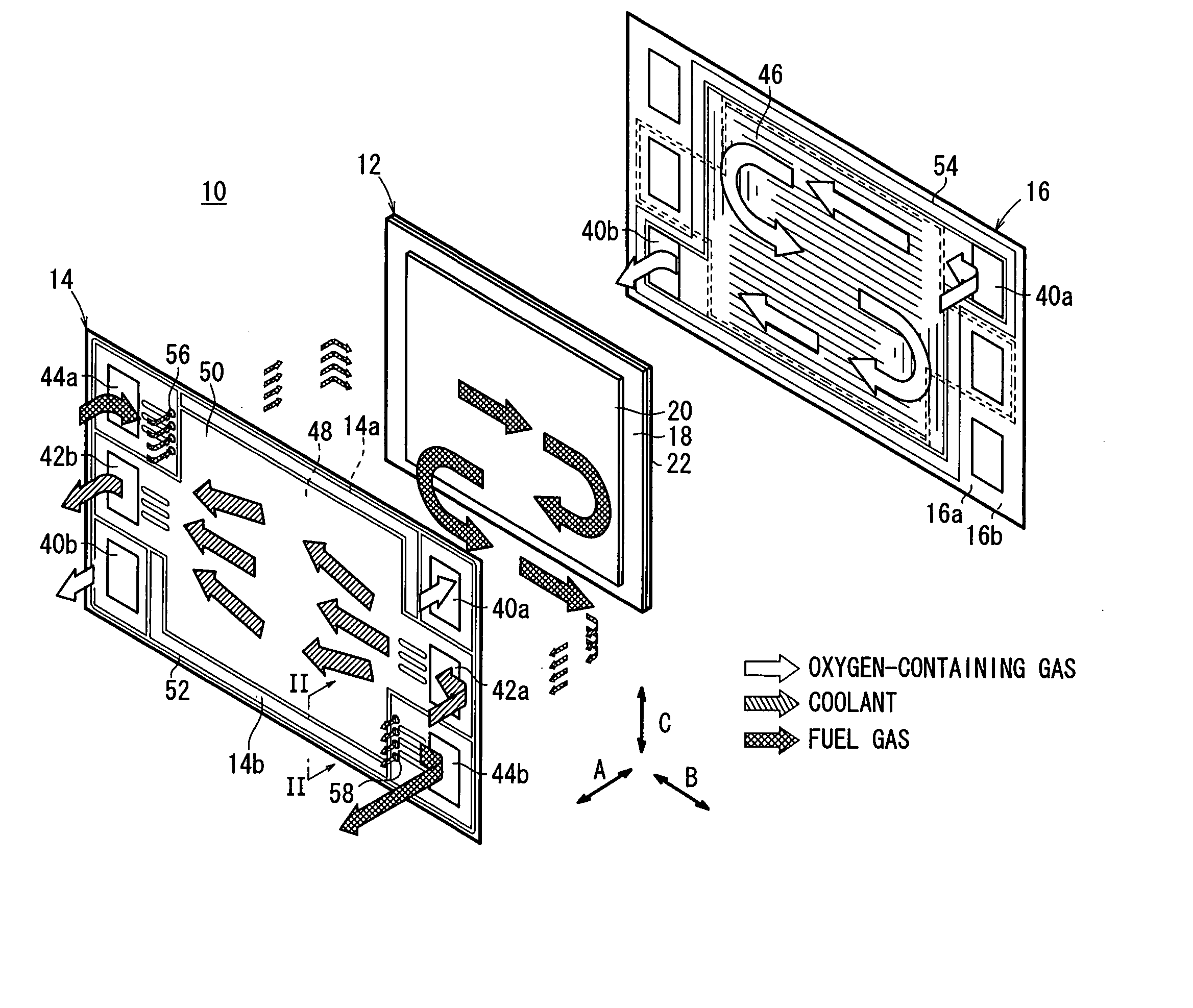

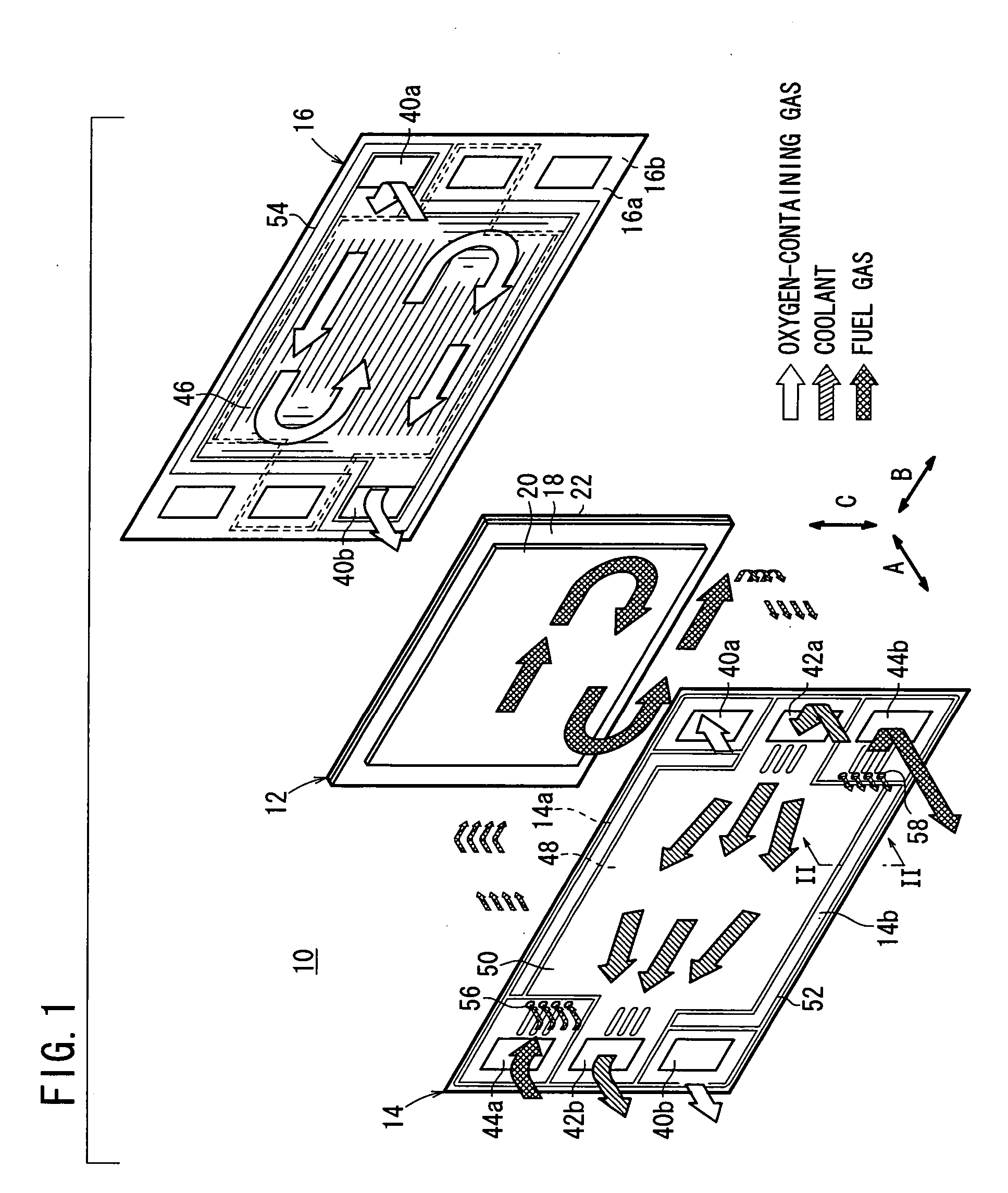

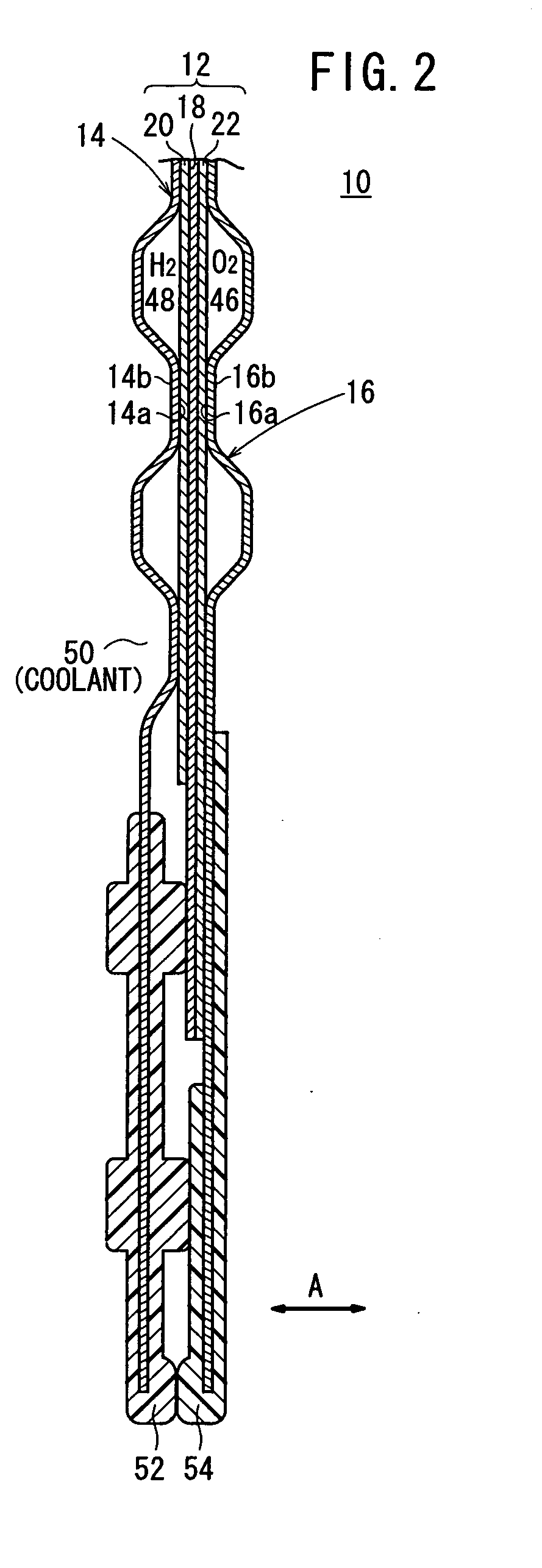

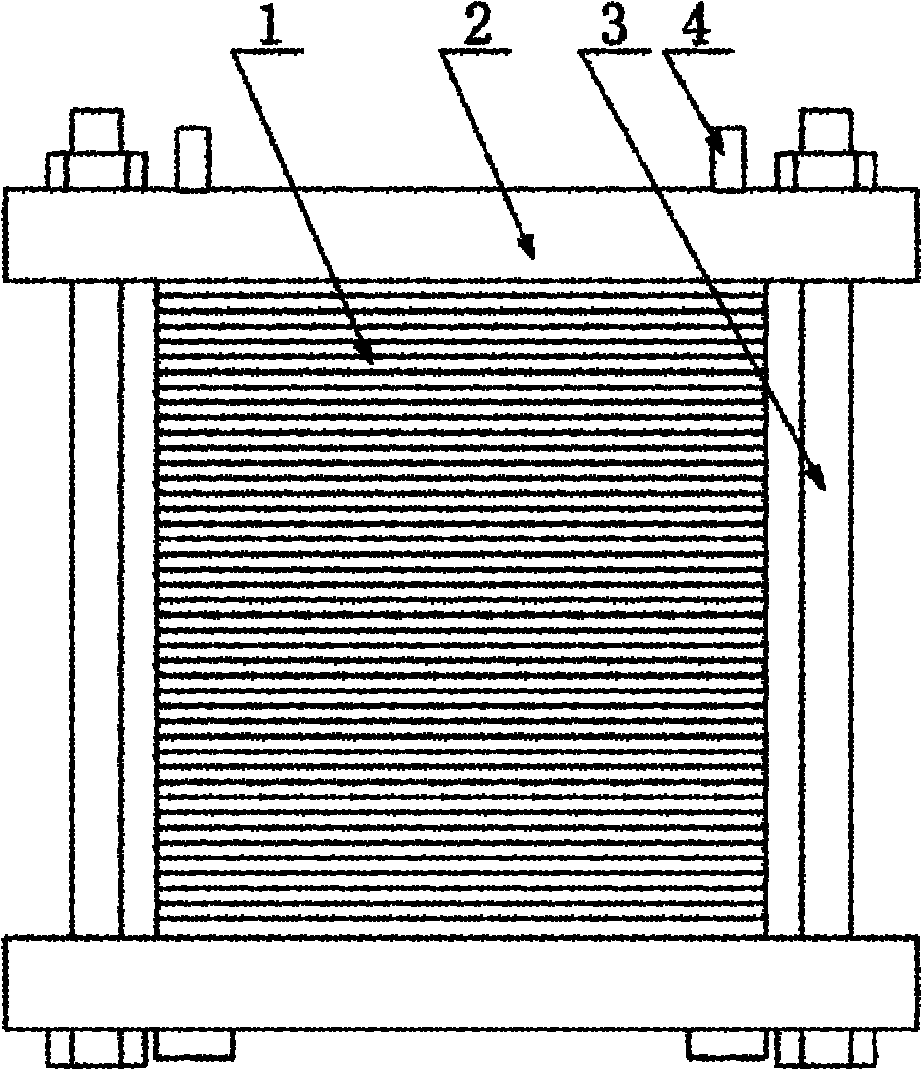

Method and system for starting up fuel cell stack at subzero temperatures, and method of designing fuel cell stack

InactiveUS20050053810A1Shorten warm-up timeSmall heat capacityFuel cells groupingFuel cell auxillariesPolymer electrolytesFuel cells

A method of starting up at a subzero temperature a solid polymer electrolyte fuel cell stack that is formed by stacking a plurality of layers of separators and membrane electrode assemblies having a solid polymer electrolyte membrane and electrodes. The method includes a step of using a solid polymer electrolyte fuel cell stack in which the separators are made from metal and have a cross-sectional waveform structure, and a space that is formed between at least a portion of the separators and separators that are placed adjacent to this portion of the separators is used as a coolant flow passage.

Owner:HONDA MOTOR CO LTD

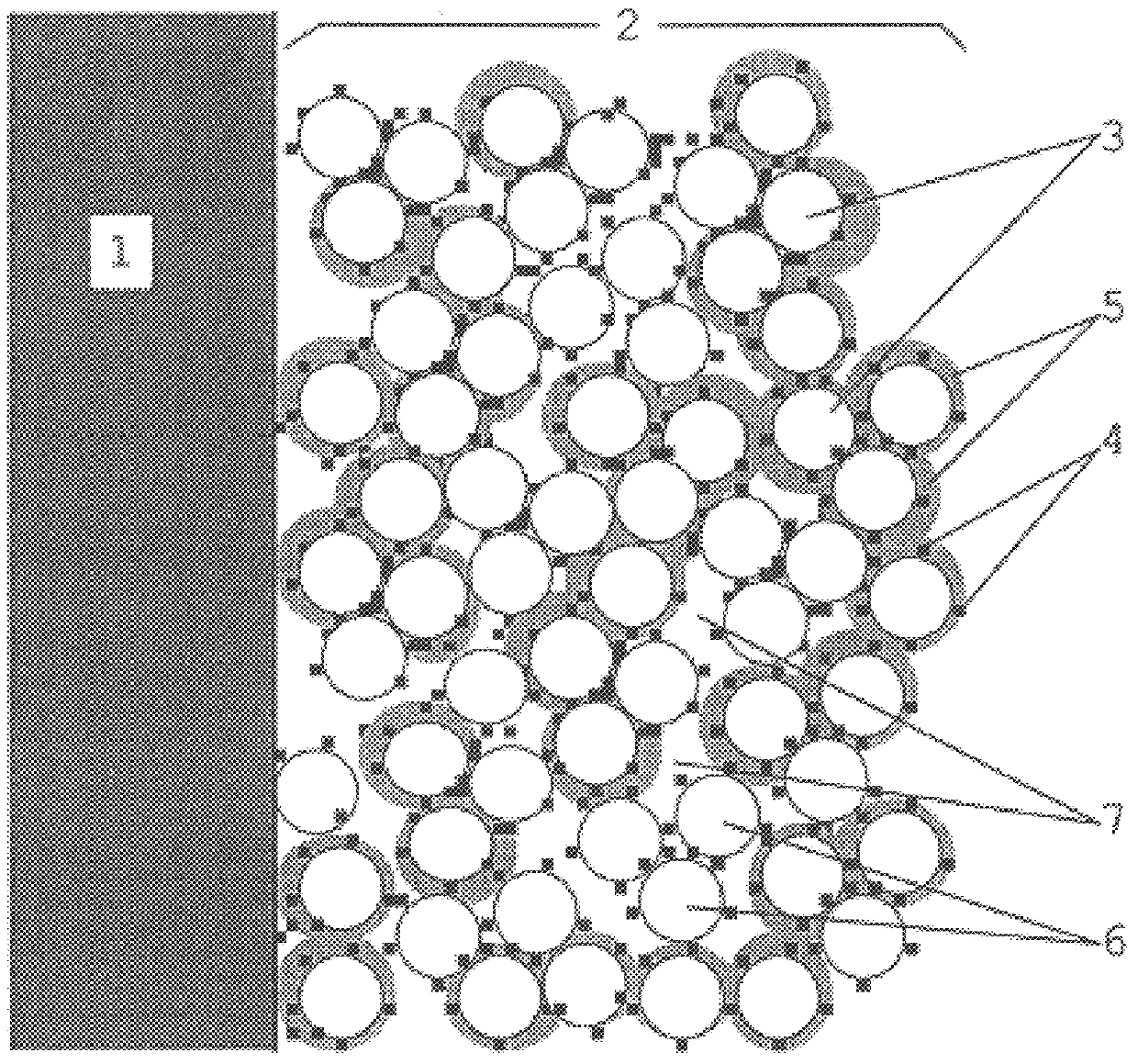

Integral bi-layer separator-electrode construction for lithium-ion batteries

InactiveUS20120231321A1Improve temperature resistanceImprove the immunityFinal product manufacturePrimary cellsEvaporationSlurry

A porous bi-layer separator composed of a first layer with a contacting array of non-conducting particles overlaid with a second layer of a microporous polymer layer, may be fabricated on the electrode surface of the anode of a lithium-ion battery to form an integral electrode-separator construction. The bi-layer separator may prevent development of a direct electronic path between the anode and cathode of the battery while accommodating electrolyte solution and enabling passage of lithium ions. Such an integral separator should be mechanically robust and tolerant of elevated temperatures. Exemplary bi-layer separators may be fabricated by sequential deposition of solvent-containing slurries and polymer solutions with subsequent controlled evaporation of solvent. The elevated temperature performance of lithium-ion battery cells incorporating such integral electrode-bi-layer separators was demonstrated to exceed the performance of similar cells using commercial and experimental single layer polymer separators.

Owner:GM GLOBAL TECH OPERATIONS LLC

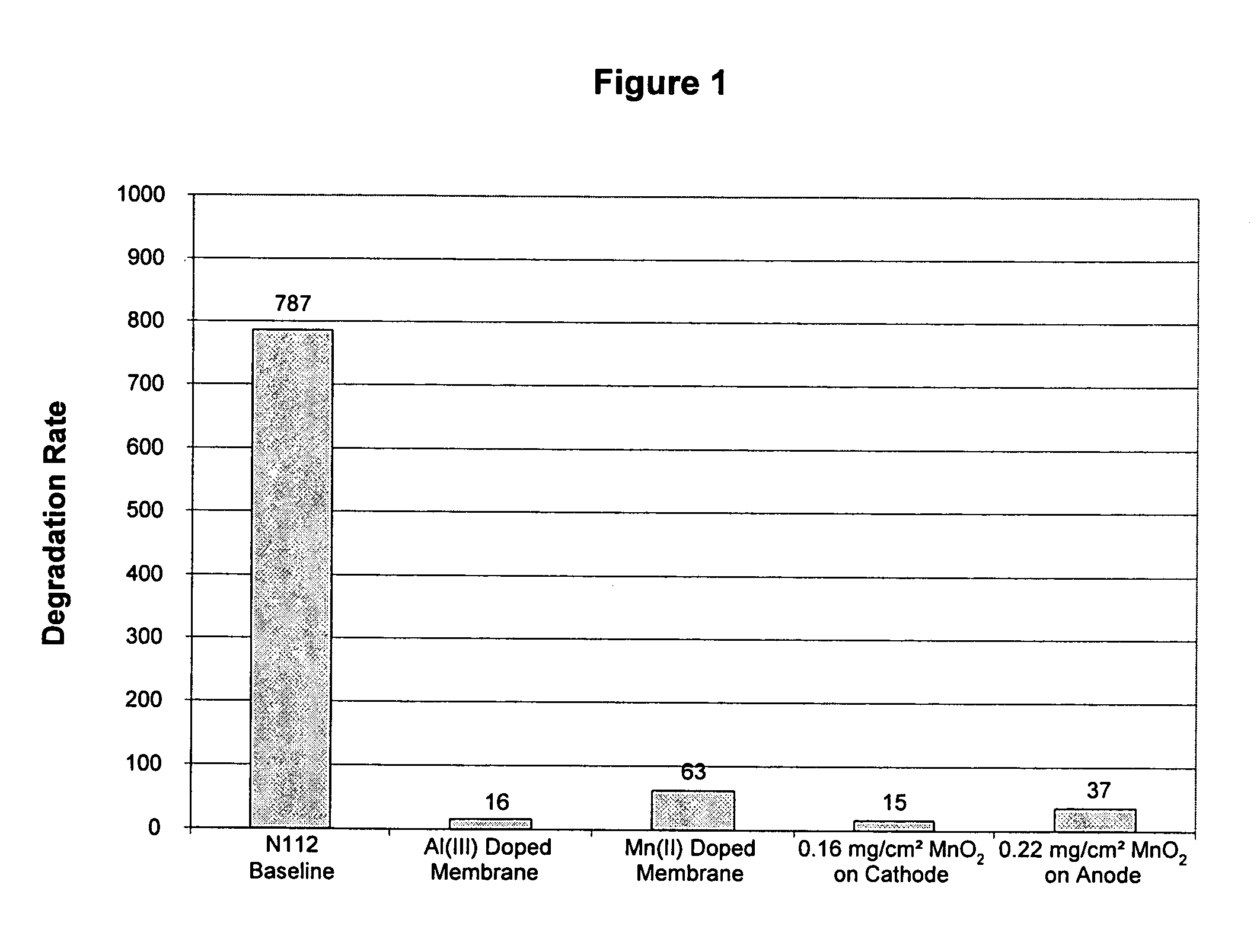

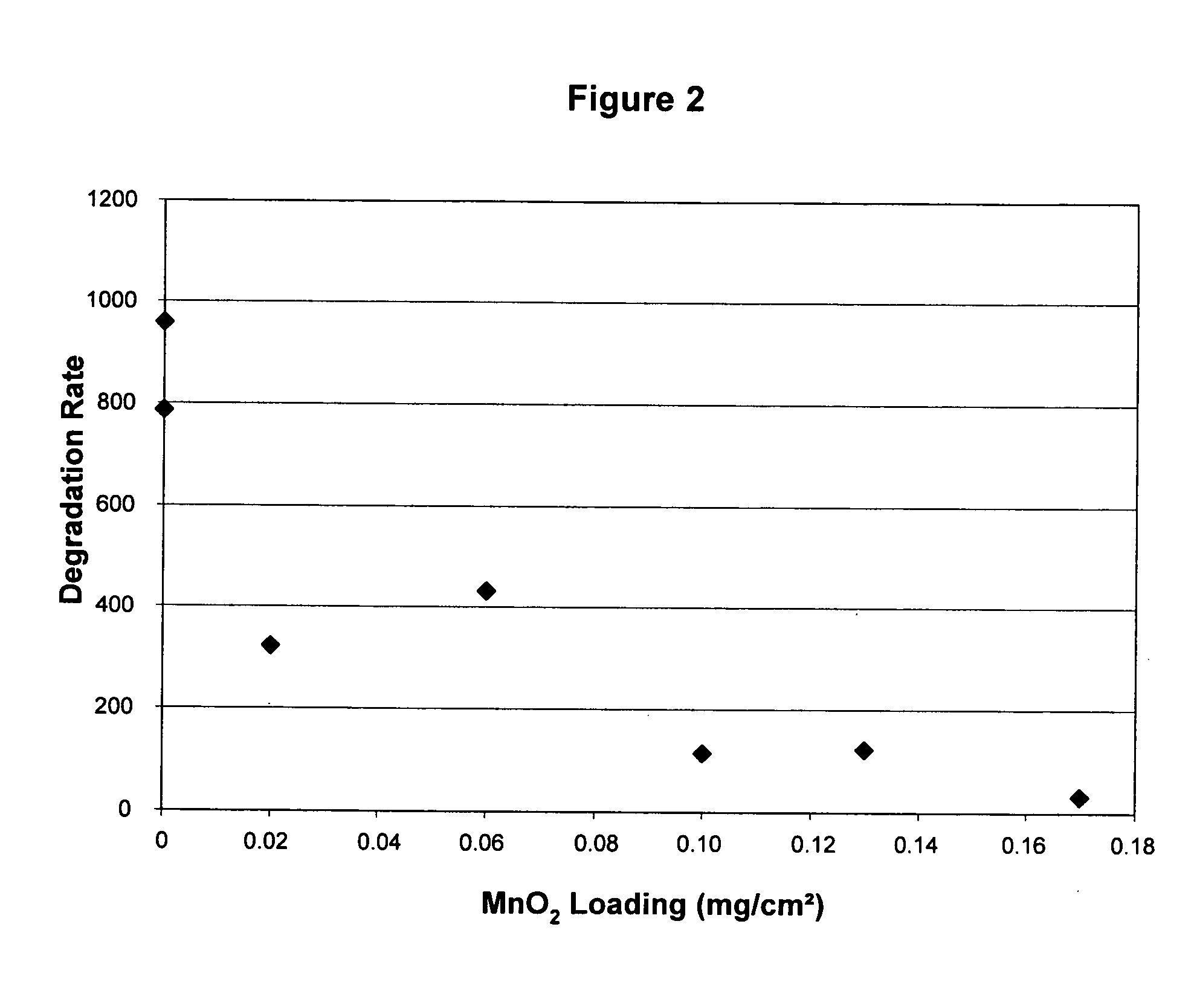

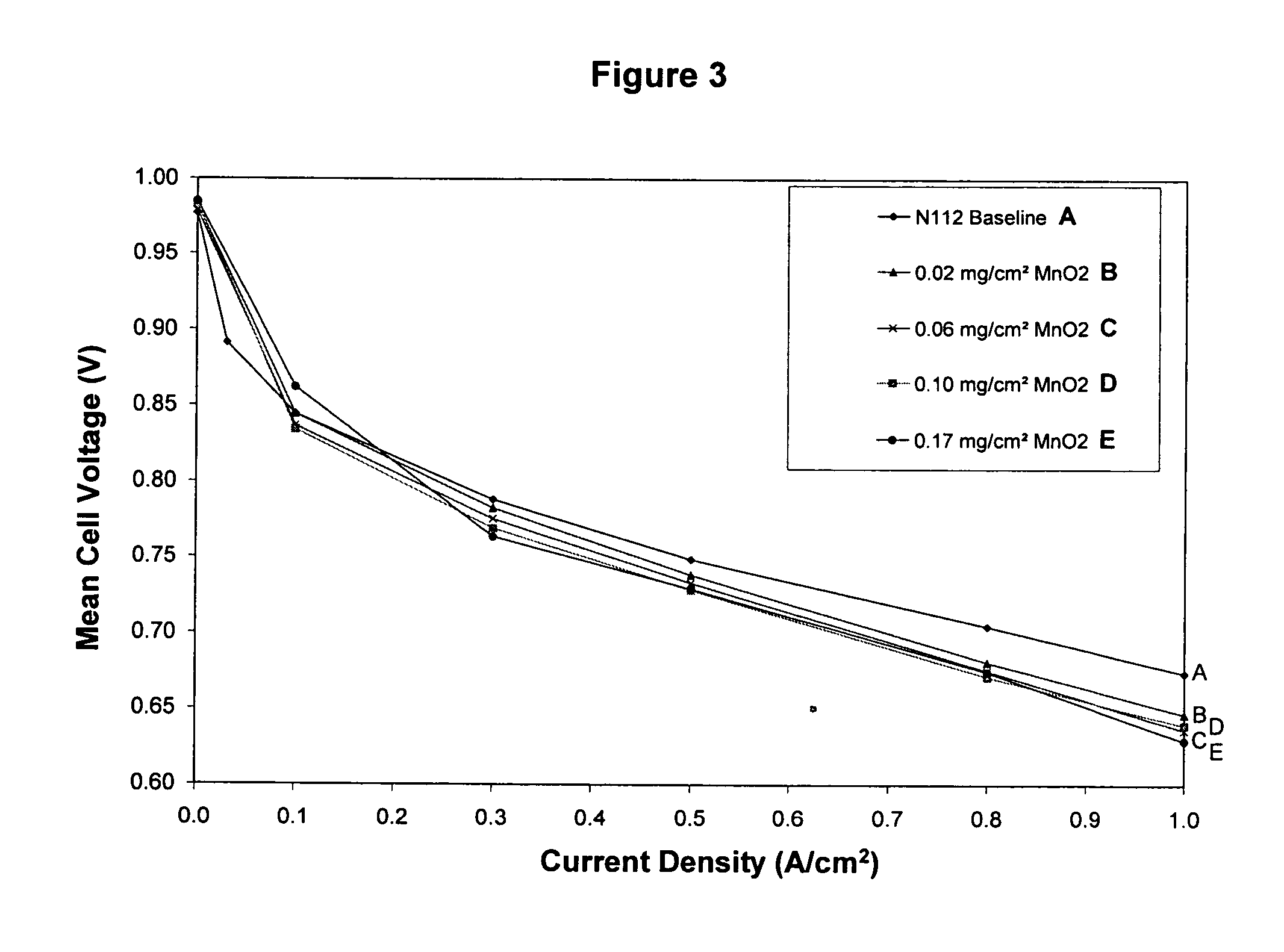

Reduced degradation of ion-exchange membranes in electrochemical fuel cells

ActiveUS20050136308A1Easy loadingIncreased susceptibilityFuel cells groupingIon-exchanger regenerationHydrogen peroxide breakdownScavenger

A significant problem in PEM fuel cell durability is in premature failure of the ion-exchange membrane and in particular by the degradation of the ion-exchange membrane by reactive hydrogen peroxide species. Such degradation can be reduced or eliminated by the presence of an additive in the anode, cathode or ion-exchange membrane. The additive may be a radical scavenger, a membrane cross-linker, a hydrogen peroxide decomposition catalyst and / or a hydrogen peroxide stabilizer. The presence of the additive in the membrane electrode assembly (MEA) may however result in reduced performance of the PEM fuel cell. Accordingly, it may be desirable to restrict the location of the additive to locations of increased susceptibility to membrane degradation such as the inlet and / or outlet regions of the MEA.

Owner:BDF IP HLDG

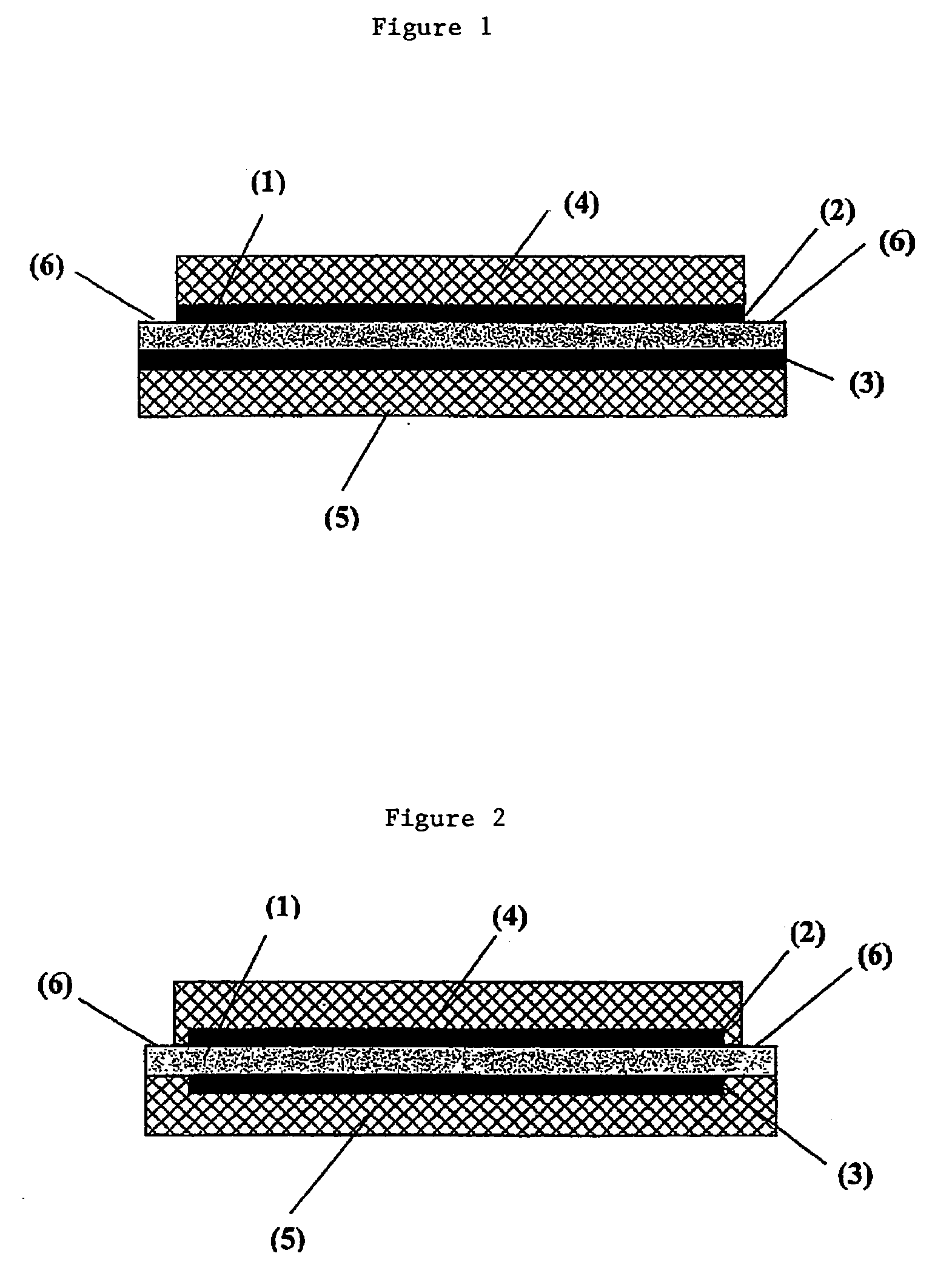

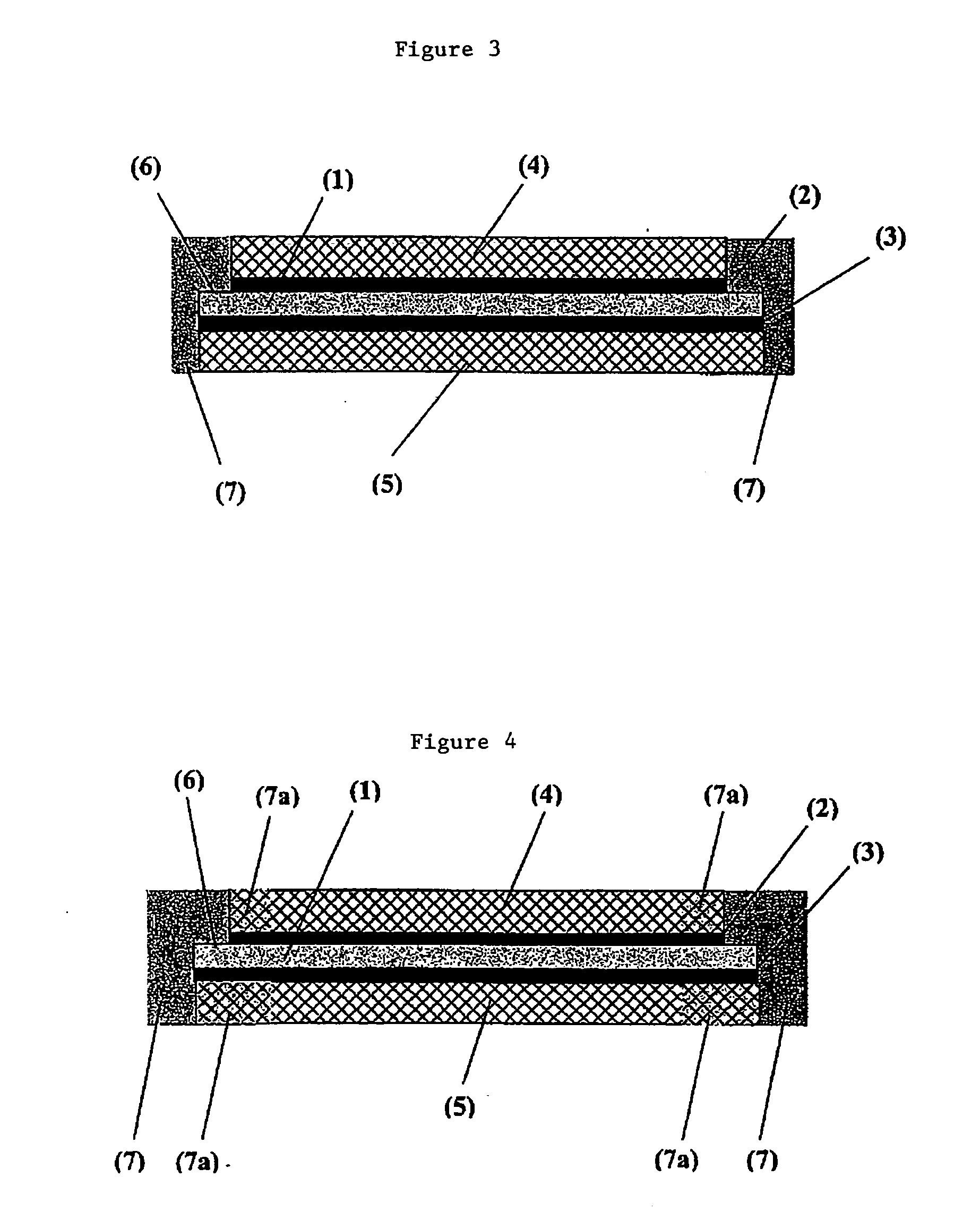

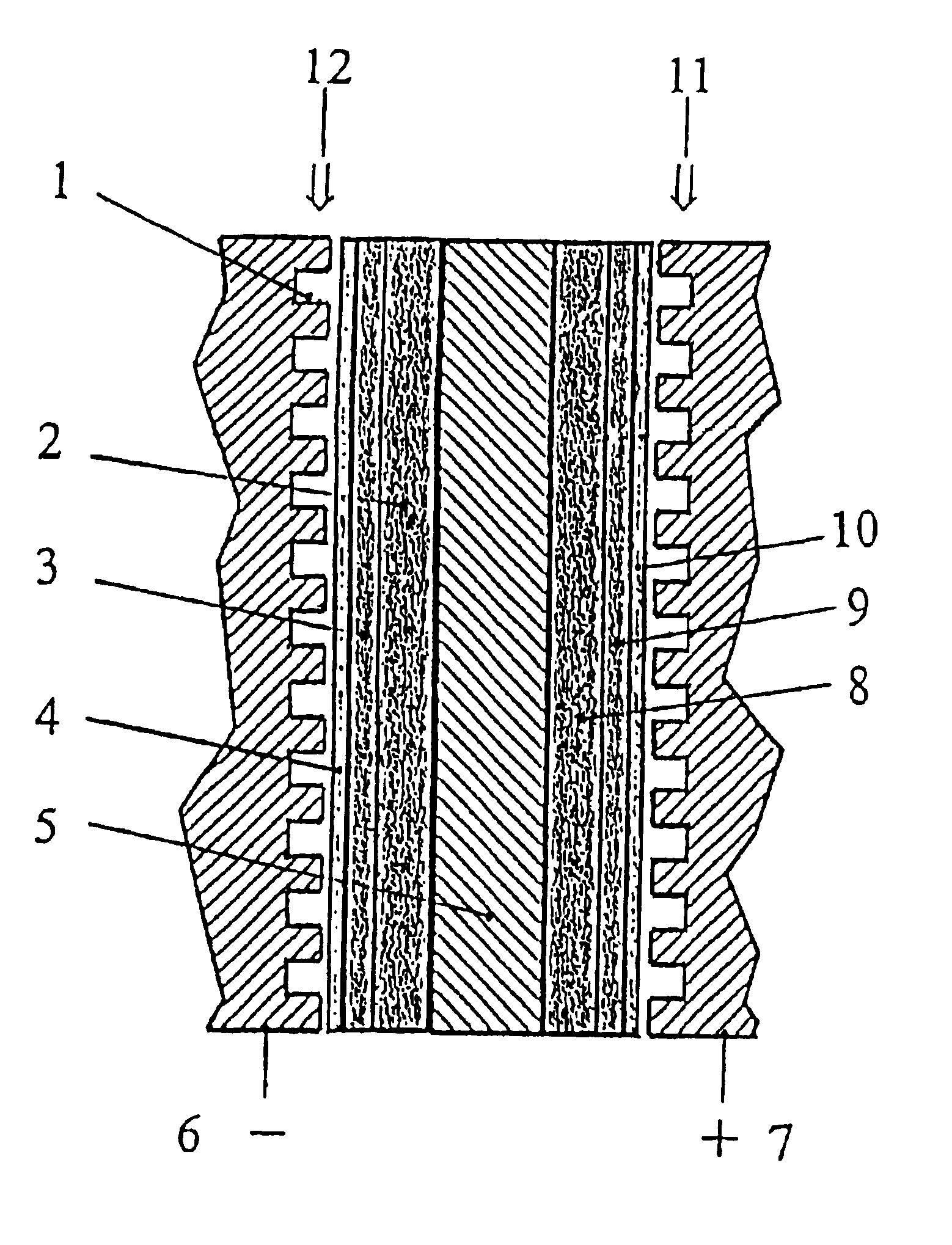

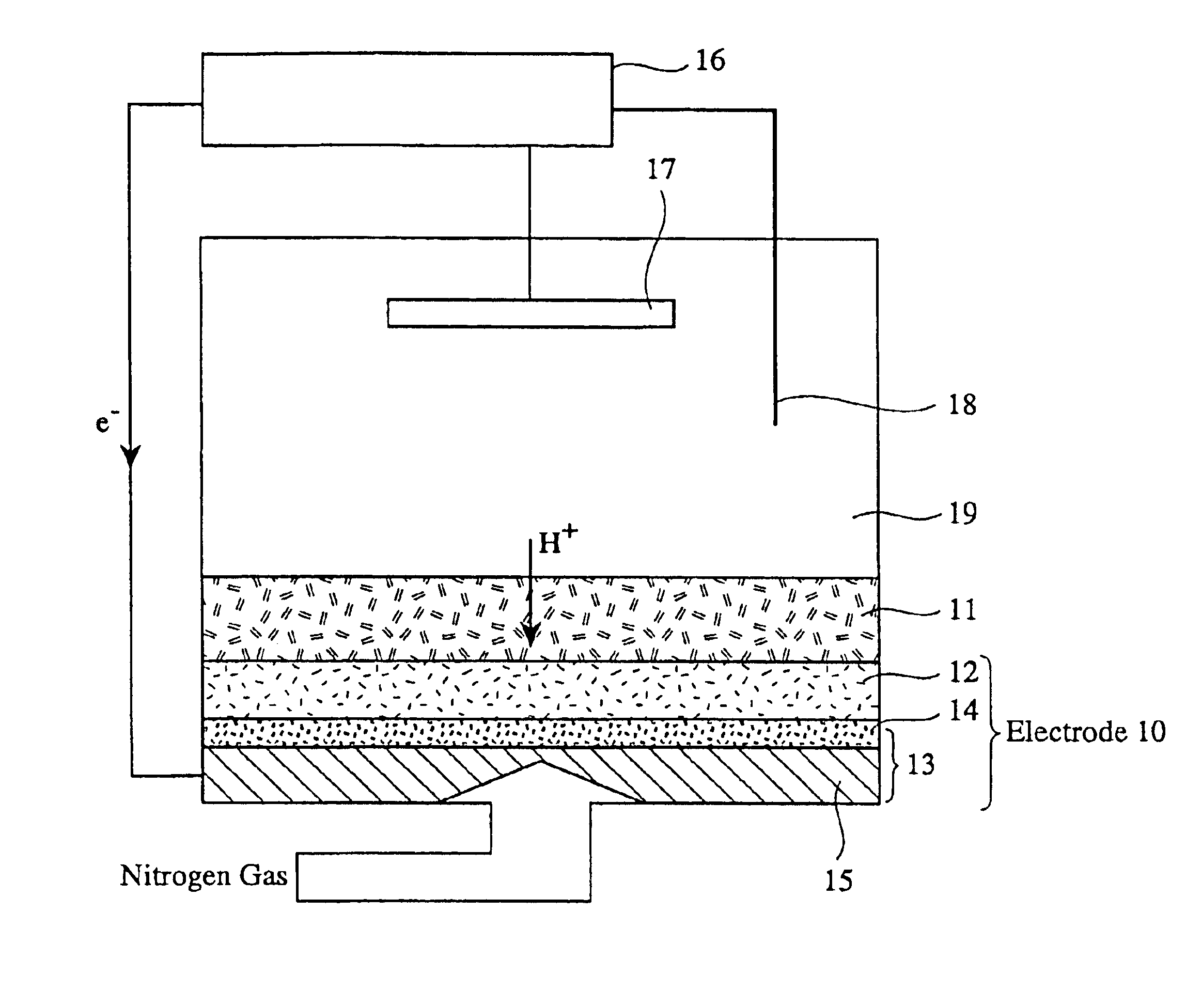

Membrane electrode unit for electrochemical equipment

InactiveUS20050014056A1Good design conceptOvercome disadvantagesCellsFuse device manufactureSpecial designEngineering

The invention concerns a membrane electrode unit (MEU) for electrochemical equipment, especially for membrane fuel cells. The membrane electrode unit has a “semi-coextensive” design and contains an ionically conductive membrane, two catalyst layers, and gas distributor substrates of different sizes on the front and back sides. The first gas distributor substrate has smaller surface dimensions than the ionically conductive membrane, while the second gas distributor substrate has the same area as the ionically conductive membrane. The membrane electrode unit has, because of its special design, a stable structure that can be handled well, and which exhibits advantages for sealing the reactive gases off from each other and in its electrical properties. In particular, the hydrogen penetration current is distinctly reduced. The membrane electrode unit is used in PEM fuel cells, direct methanol fuel cells, electrolyzers, and other electrochemical equipment.

Owner:UMICORE AG & CO KG

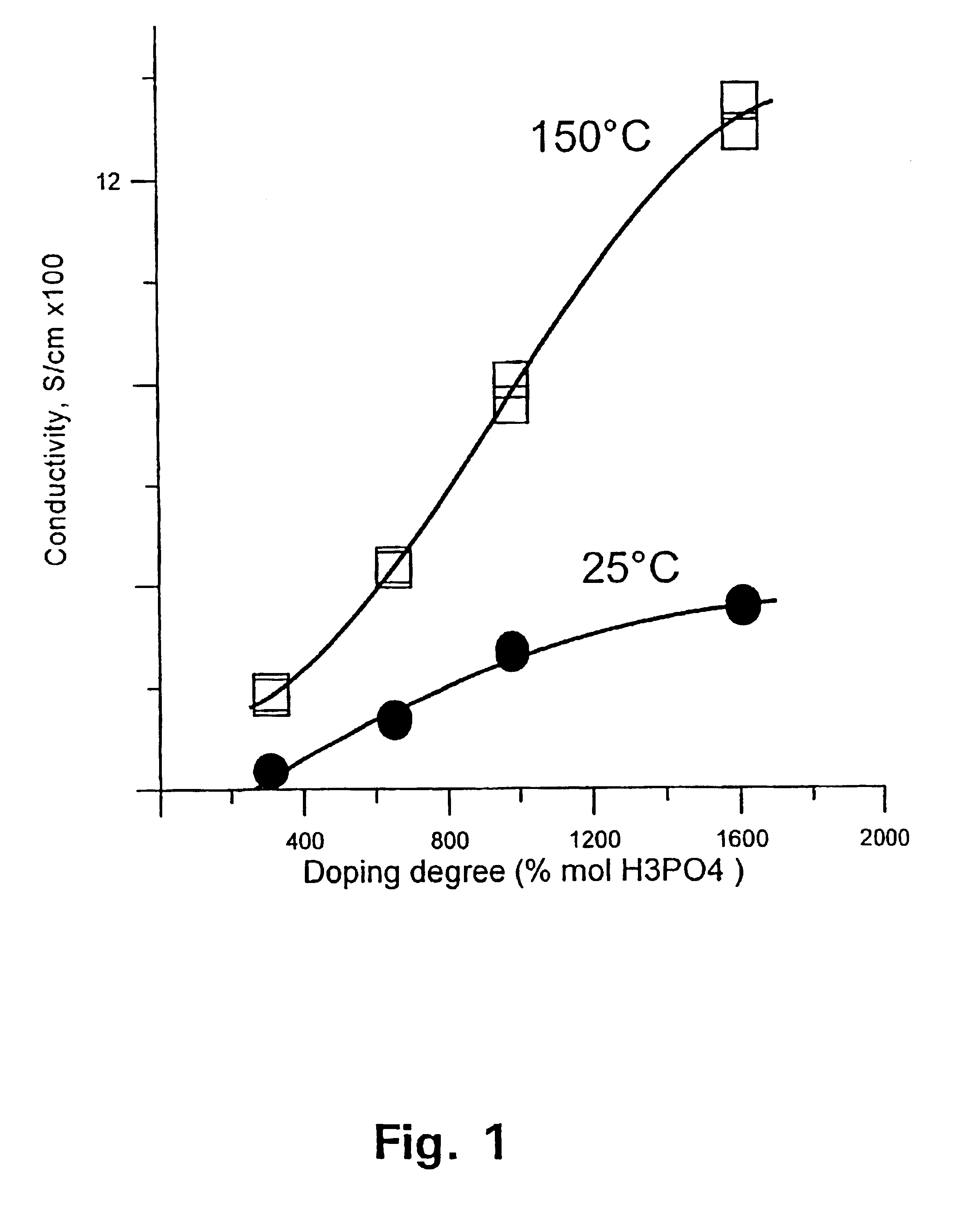

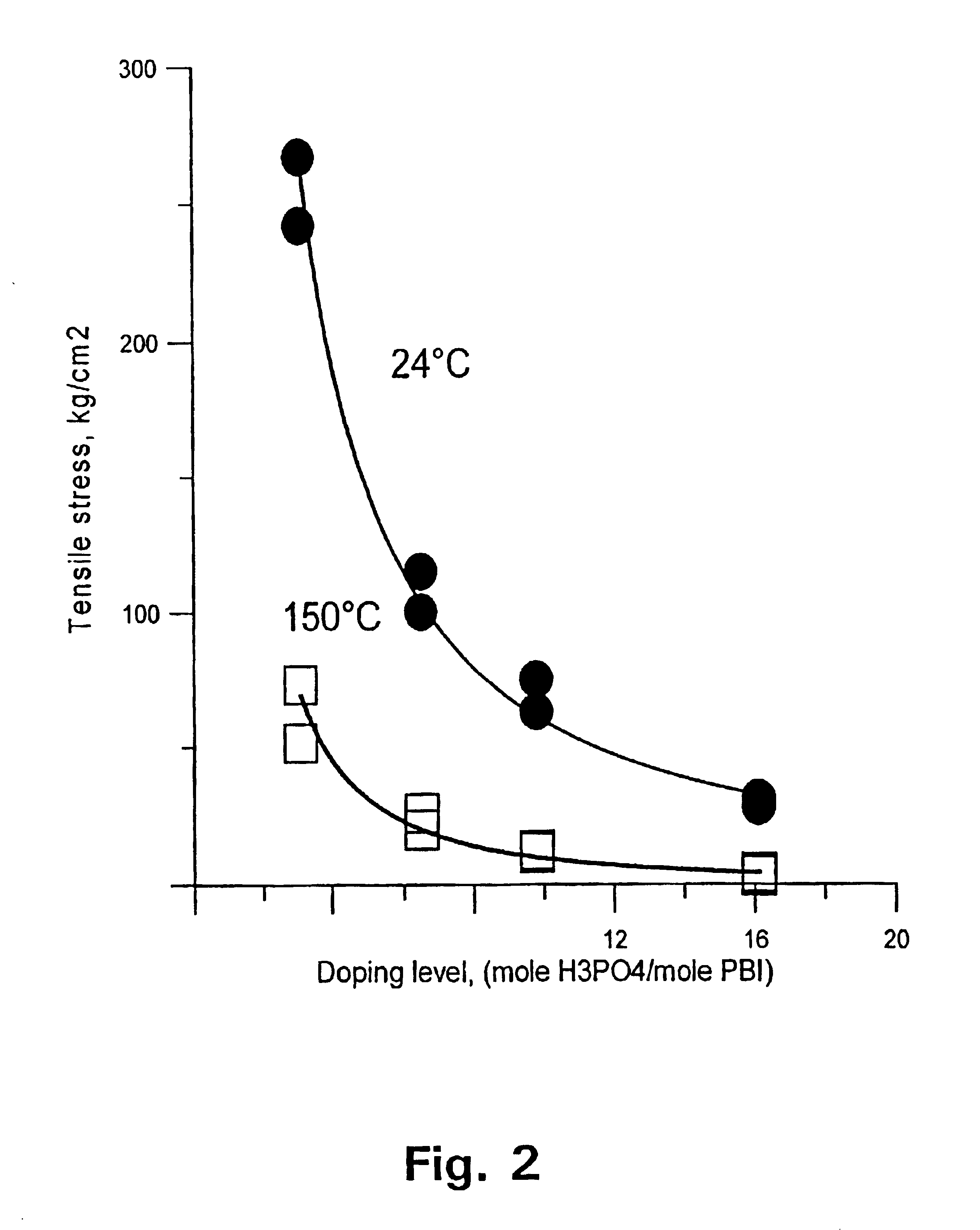

Polymer electrolyte membrane fuel cells

InactiveUS6946211B1Improve performanceImprove toleranceSolid electrolytesPrimary cellsThermoplasticGas diffusion electrode

A method for preparing polybenzimidazole or polybenzimidazole blend membranes and fabricating gas diffusion electrodes and membrane-electrode assemblies is provided for a high temperature polymer electrolyte membrane fuel cell. Blend polymer electrolyte membranes based on PBI and various thermoplastc polymers for high temperature polymer electrolyte fuel cells have also been developed. Miscible blends are used for solution casting of polymer membranes (solid electrolytes). High conductivity and enhanced mechanical strength were obtained for the blend polymer solid electrolytes. With the thermally resistant polymer, e.g., polybenzimidazole or a mixture of polybenzimidazole and other thermoplastics as binder, the carbon-supported noble metal catalyst is tape-cast onto a hydrophobic supporting substrate. When doped with an acid mixture, electrodes are assembled with an acid doped solid electrolyte membrane by hot-press. The fuel cell can operate at temperatures up to at least 200° C. with hydrogen-rich fuel containing high ratios of carbon monoxide such as 3 vol % carbon monoxide or more, compared to the carbon monoxide tolerance of 10-20 ppm level for Nafion®-based polymer electrolyte fuel cells.

Owner:DANISH POWER SYST

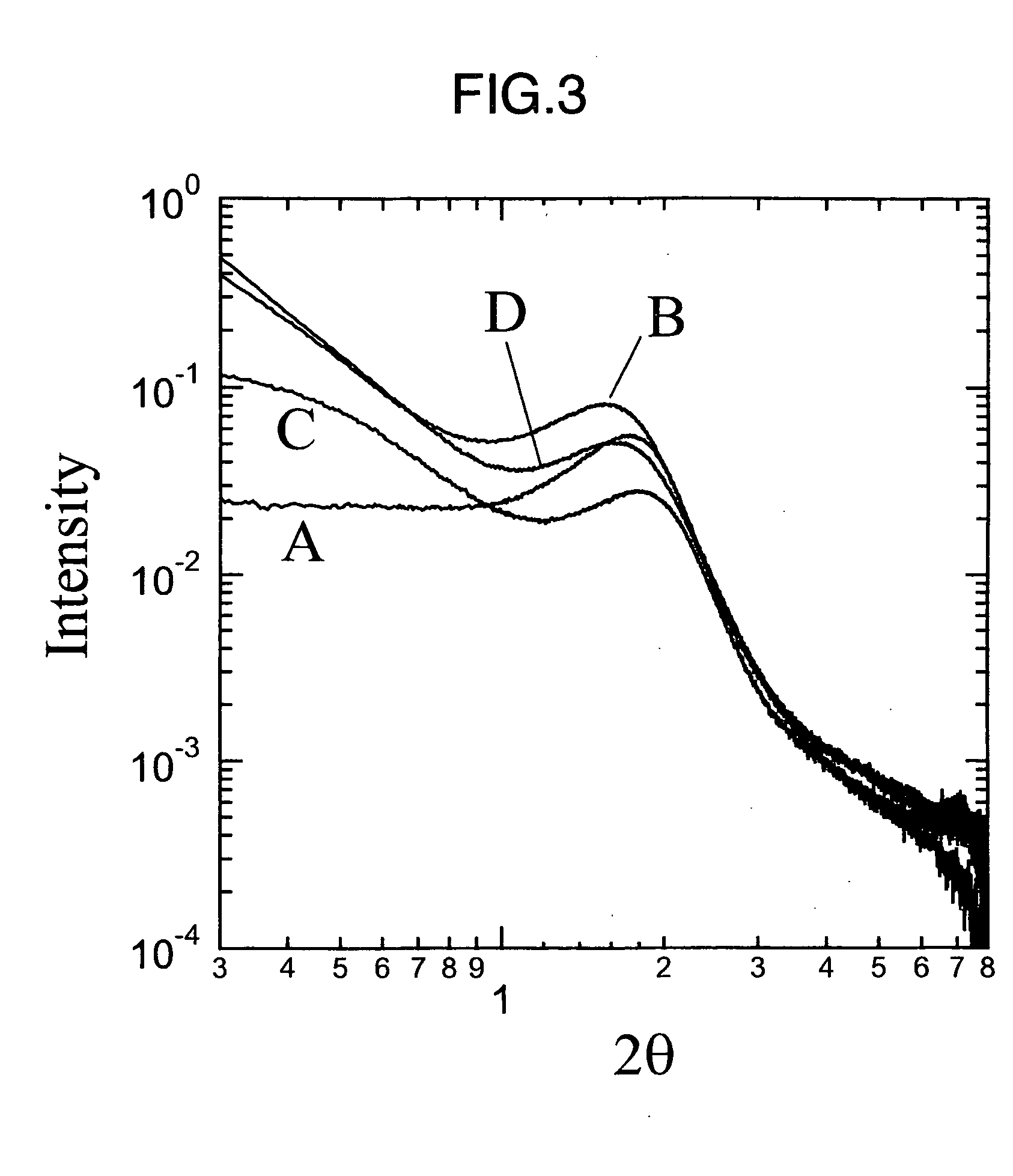

Liquid composition, process for its production and process for producing membrane-electrode assembly for polymer electrolyte fuel cells

ActiveUS20060019140A1Improve the immunityIncreased durabilityIon-exchanger regenerationFinal product manufacturePolymer scienceHigh energy

An electrolyte membrane is prepared from a liquid composition comprising at least one member selected from the group consisting of trivalent cerium, tetravalent cerium, bivalent manganese and trivalent manganese; and a polymer with a cation-exchange group. The liquid composition is preferably one containing water, a carbonate of cerium or manganese, and a polymer with a cation-exchange group, and a cast film thereof is used as an electrolyte membrane to prepare a membrane-electrode assembly. The present invention successfully provides a membrane-electrode assembly for polymer electrolyte fuel cells being capable of generating the electric power in high energy efficiency, having high power generation performance regardless of the dew point of the feed gas, and being capable of stably generating the electric power over a long period of time.

Owner:ASAHI GLASS CO LTD

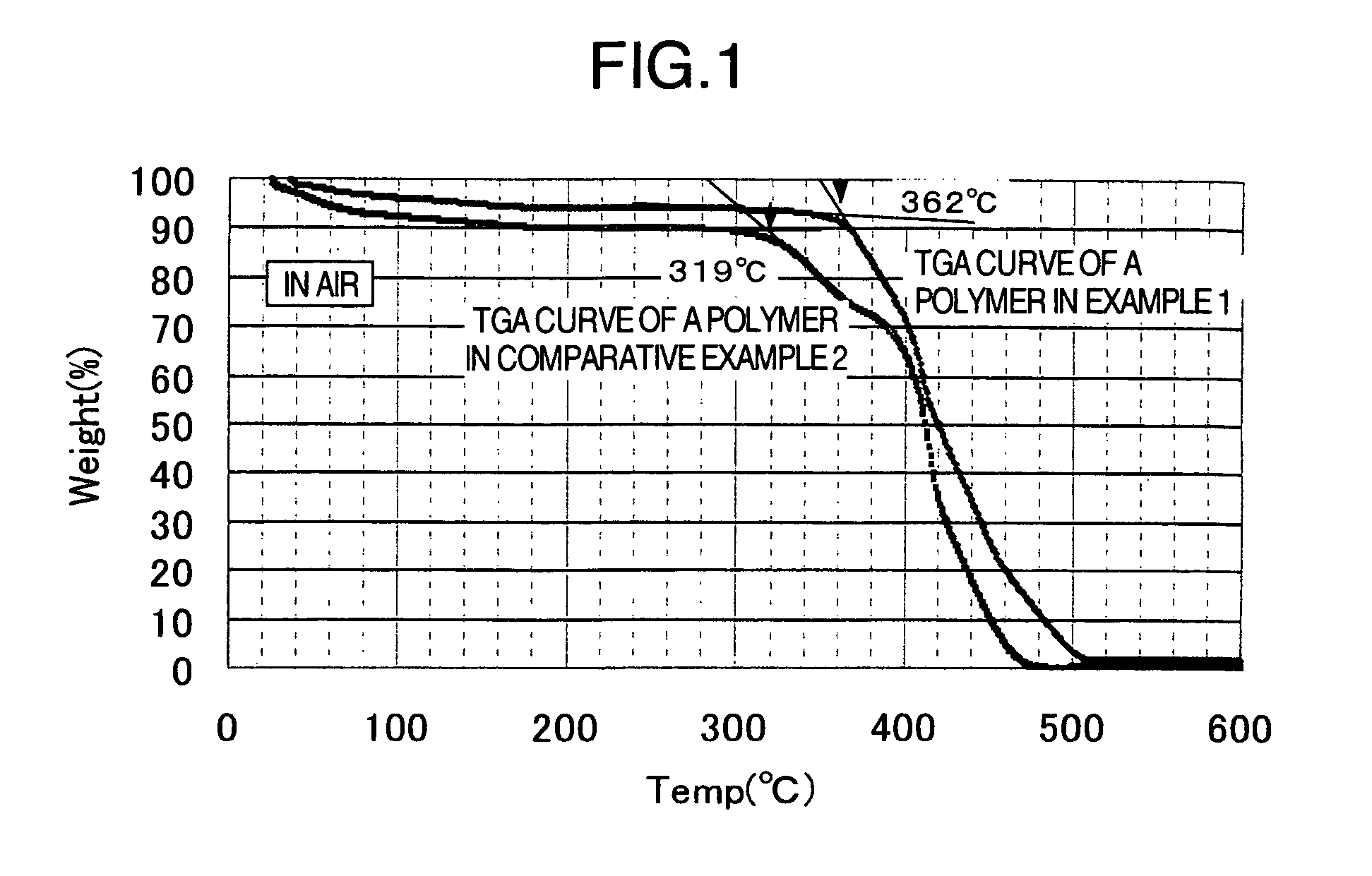

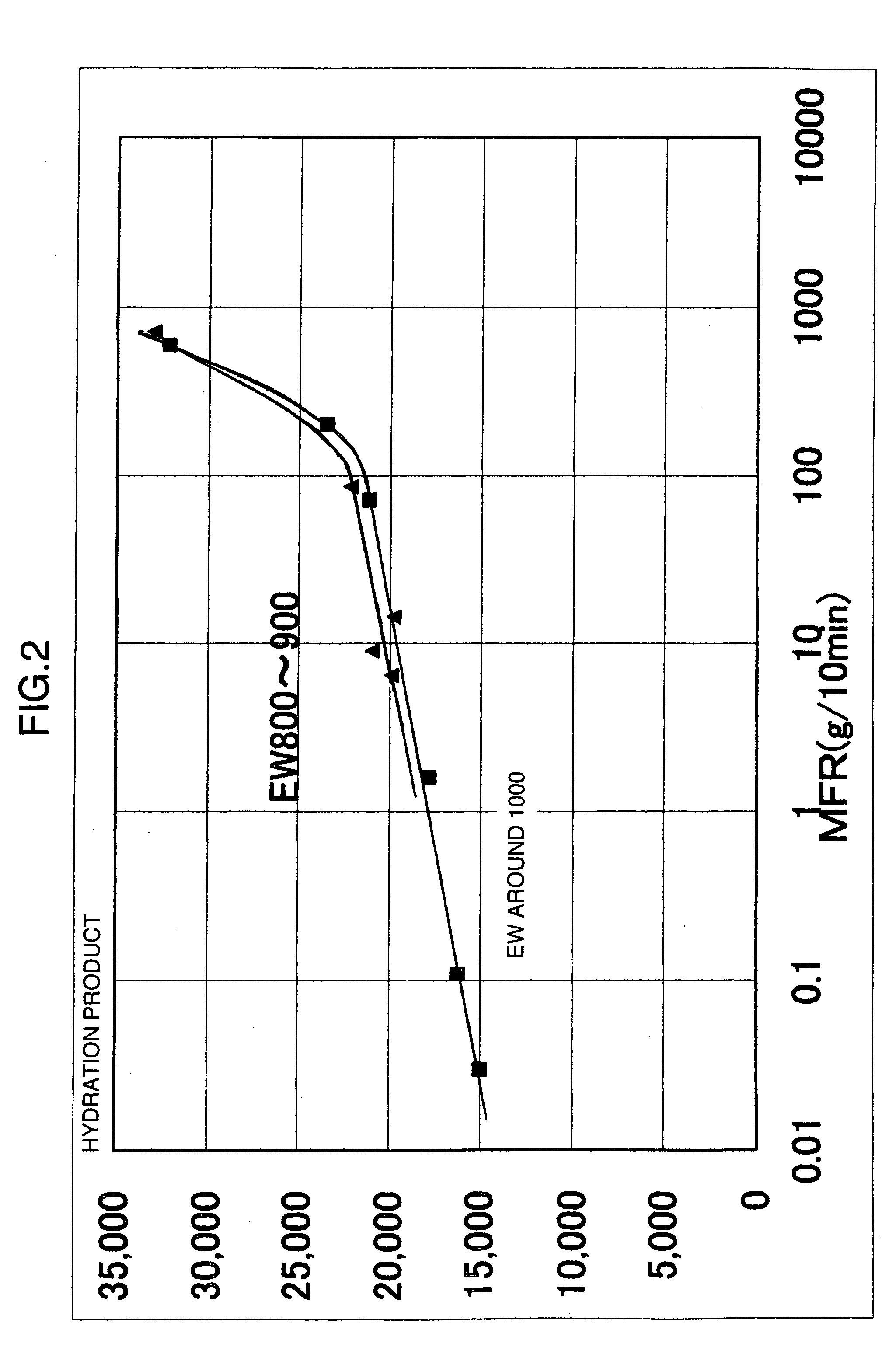

Membrane electrode assembly for polymer electrolyte fuel cell

InactiveUS20050130006A1Good chemical stabilityImprove heat resistanceElectrolyte holding meansSolid electrolytesCarbon numberPolyelectrolyte

A membrane electrode assembly for a polymer electrolyte fuel cell characterized by using, as solid polyelecrolyte of at least one of a membrane and a catalyst binder, a fluorinated sulfonic acid polymer with a monomer unit represented by the following general formula (3): (wherein Rf1 is a bivalent perfluoro-hydrocarbon group having a carbon number of from 4 to 10), wherein said fluorinated sulfonic acid polymer has melt flow rate (MFR) not higher than 100 g / 10 min at 270° C. when a —SO3H group in said polymer is converted to —SO2F.

Owner:ASAHI KASEI KK

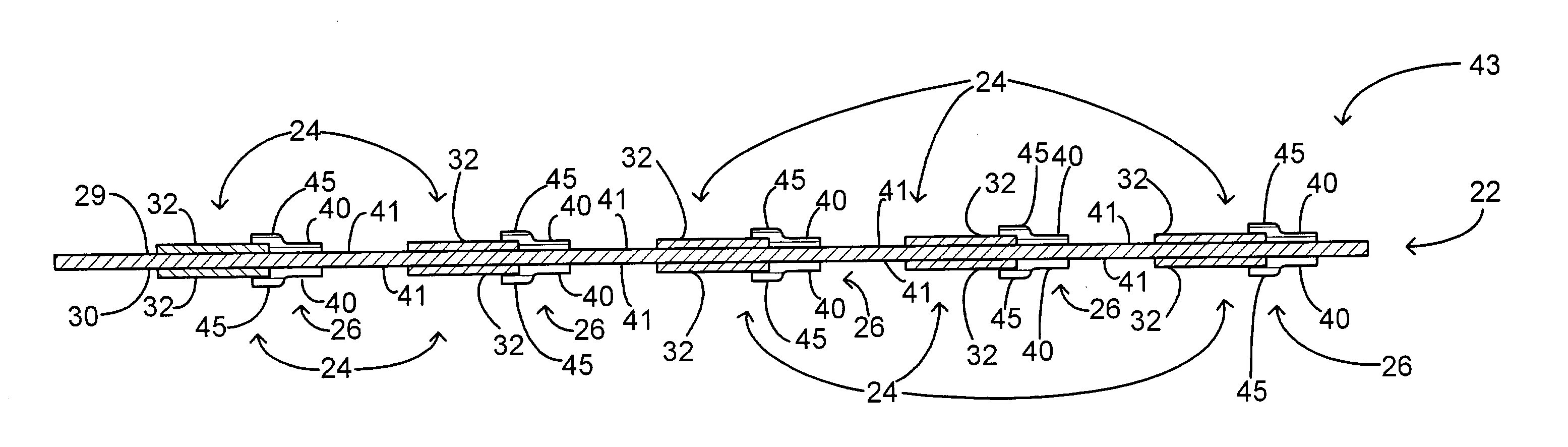

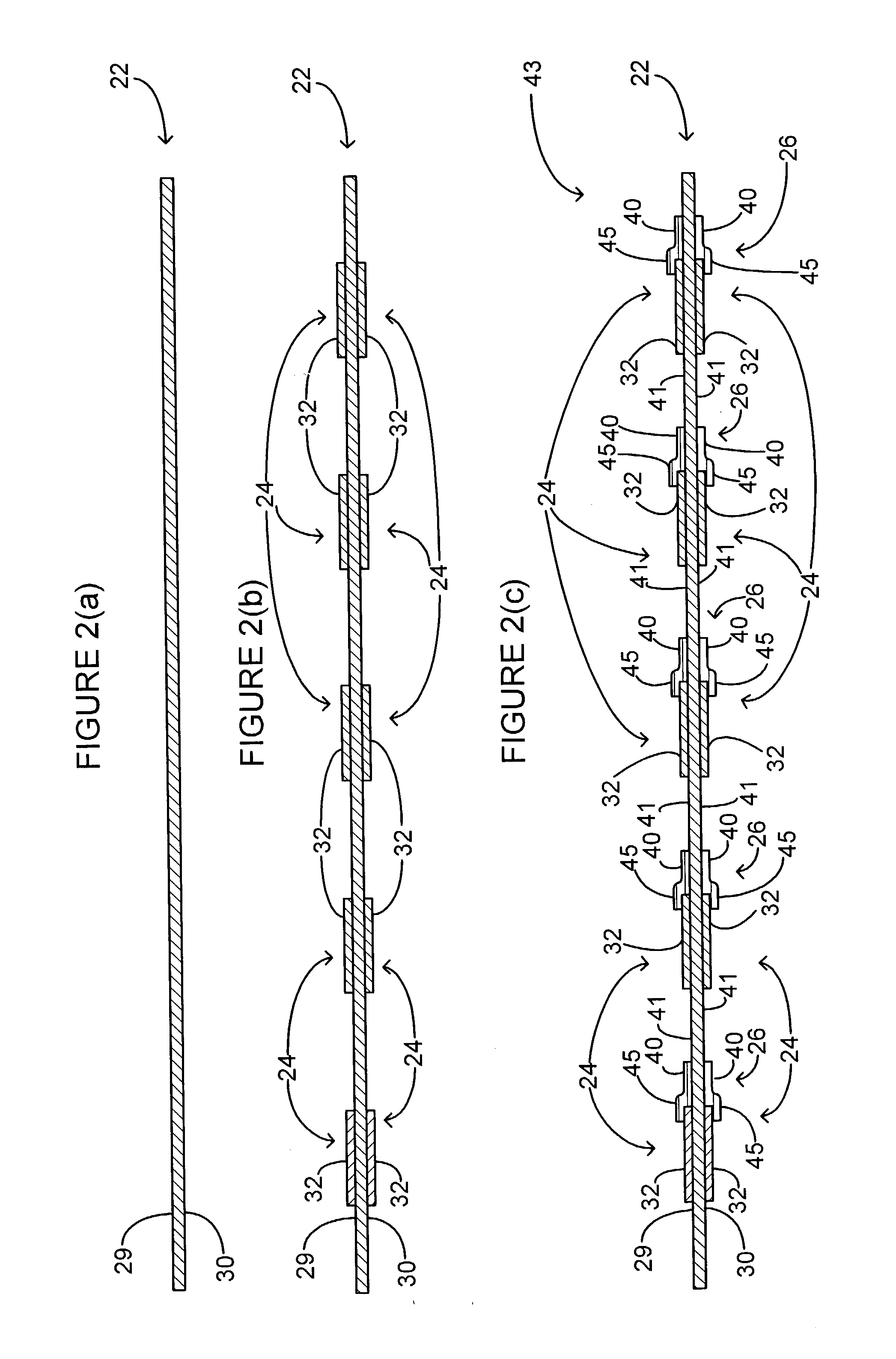

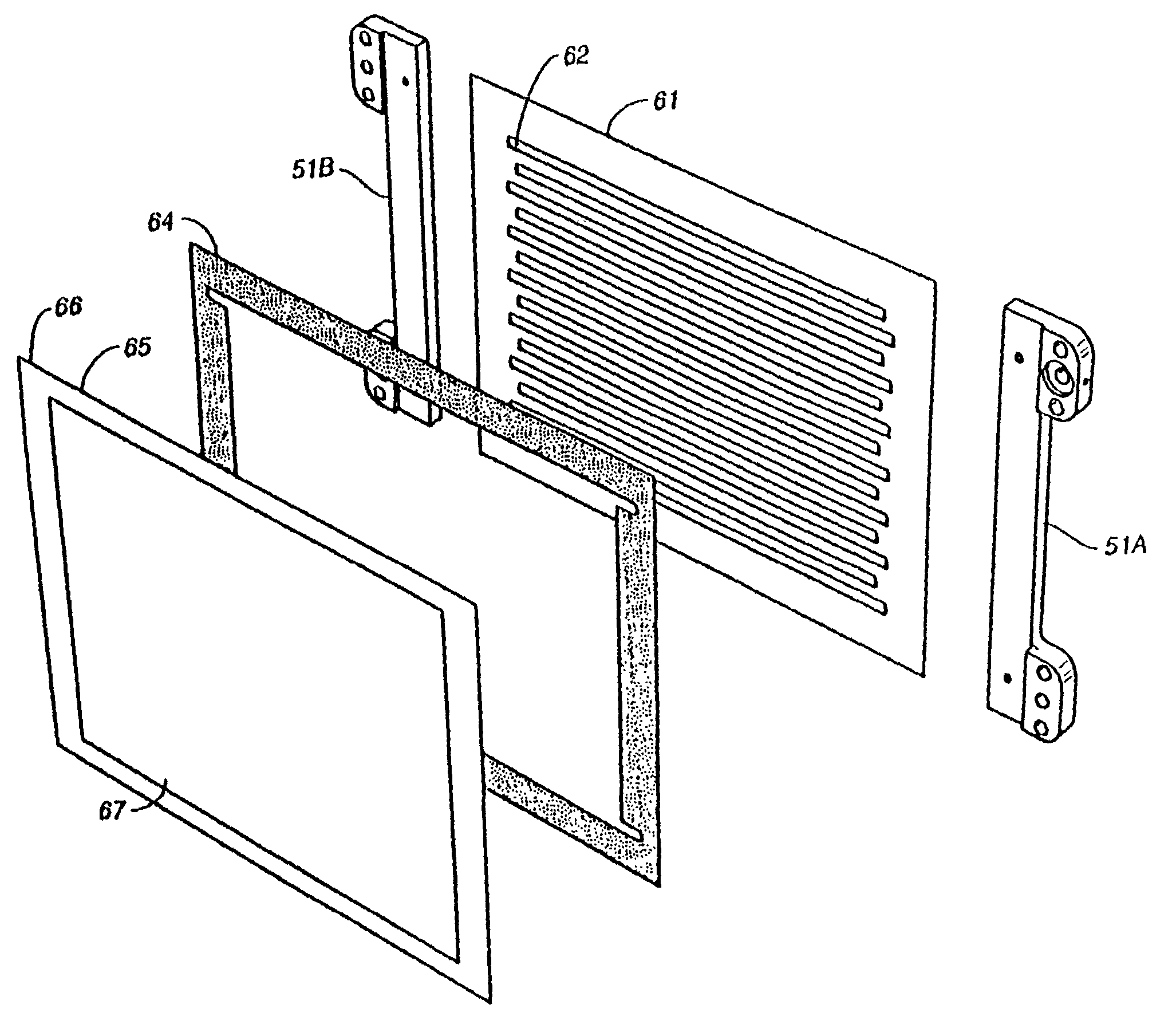

Integrated and modular BSP/MEA/manifold plates for fuel cells

The present invention concerns improvements in fuel cell fabrication. It concerns an improved, integrated and modular BSP / MEA / Manifolds, which facilitates single cell (module) leak and performance testing prior to assembly in a fuel cell stack as well as facilitating manufacturing and cost reduction. In particular, the present invention relates to a fuel cell, which includes: a) A single flexible or ridged separator plate; b) a flexible membrane electrode assembly; c) a flexible bond interposed between said single flexible or ridged separator plate and said flexible membrane electrode assembly, wherein said flexible bond between said flexible or ridged separator plate and said flexible membrane electrode assembly comprises the fuel cell, and wherein said flexible bond is an adhesive bond which encapsulates edge portions of said flexible or ridged separator plate and said flexible membrane electrode assembly and wherein said flexible bond seals the edge portions of said flexible membrane assembly to prevent the release of reactants from the fuel cell. In some embodiments the adhesive bond comprises a flexible gasket; d) manifold for the delivery and removal of reactants and reactant products to and from the fuel cell reactive areas where said manifolds may be either a single or multiple manifolds; and e) a bond interposed between said manifold and said single flexible or ridged separator plate, wherein said bond affixes said manifold to said flexible or ridged separator plate and wherein said bond provides a seal between said manifold and said flexible or ridged separator plate to prevent the release of reactants from the fuel cell. It also eliminates some gaskets and simplifies assembly.

Owner:JADOO POWER SYST LLC +1

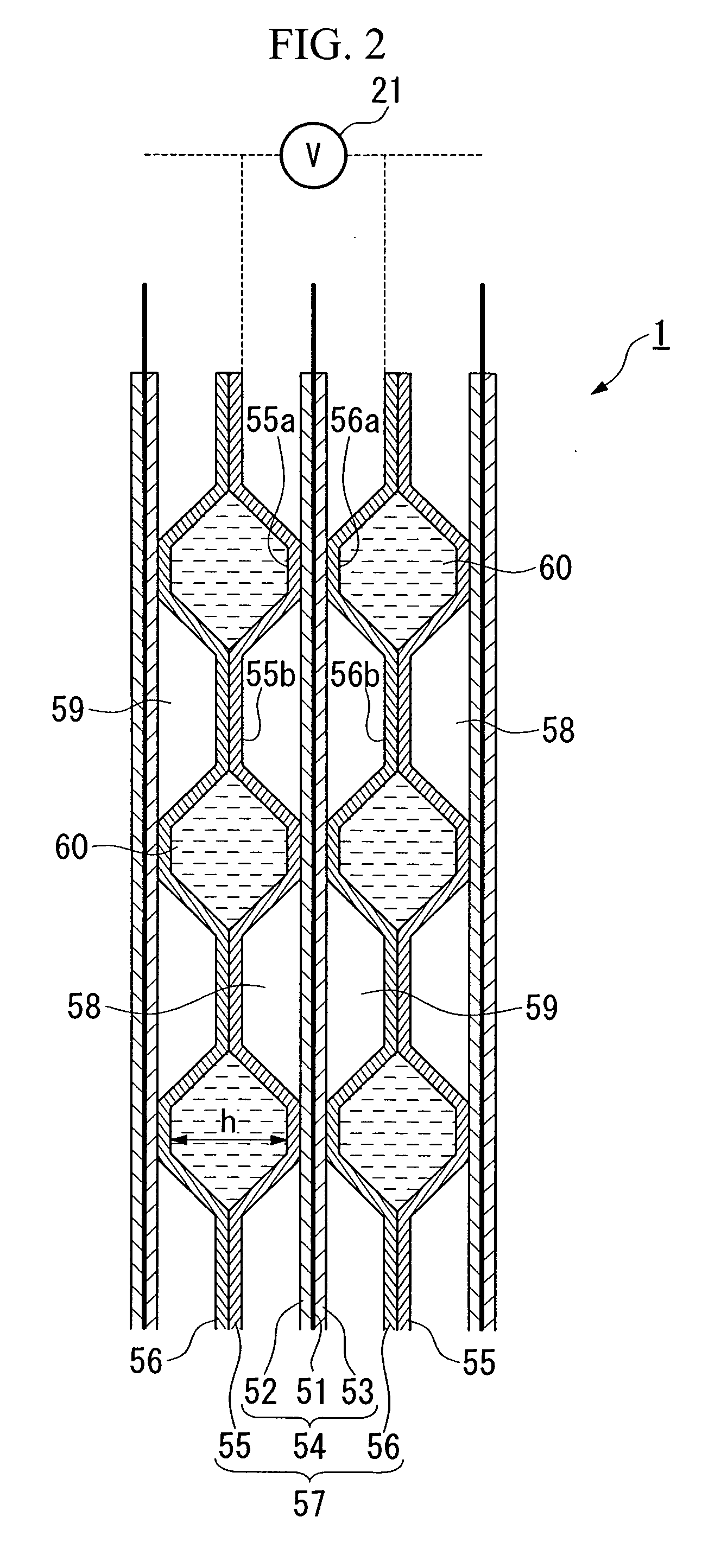

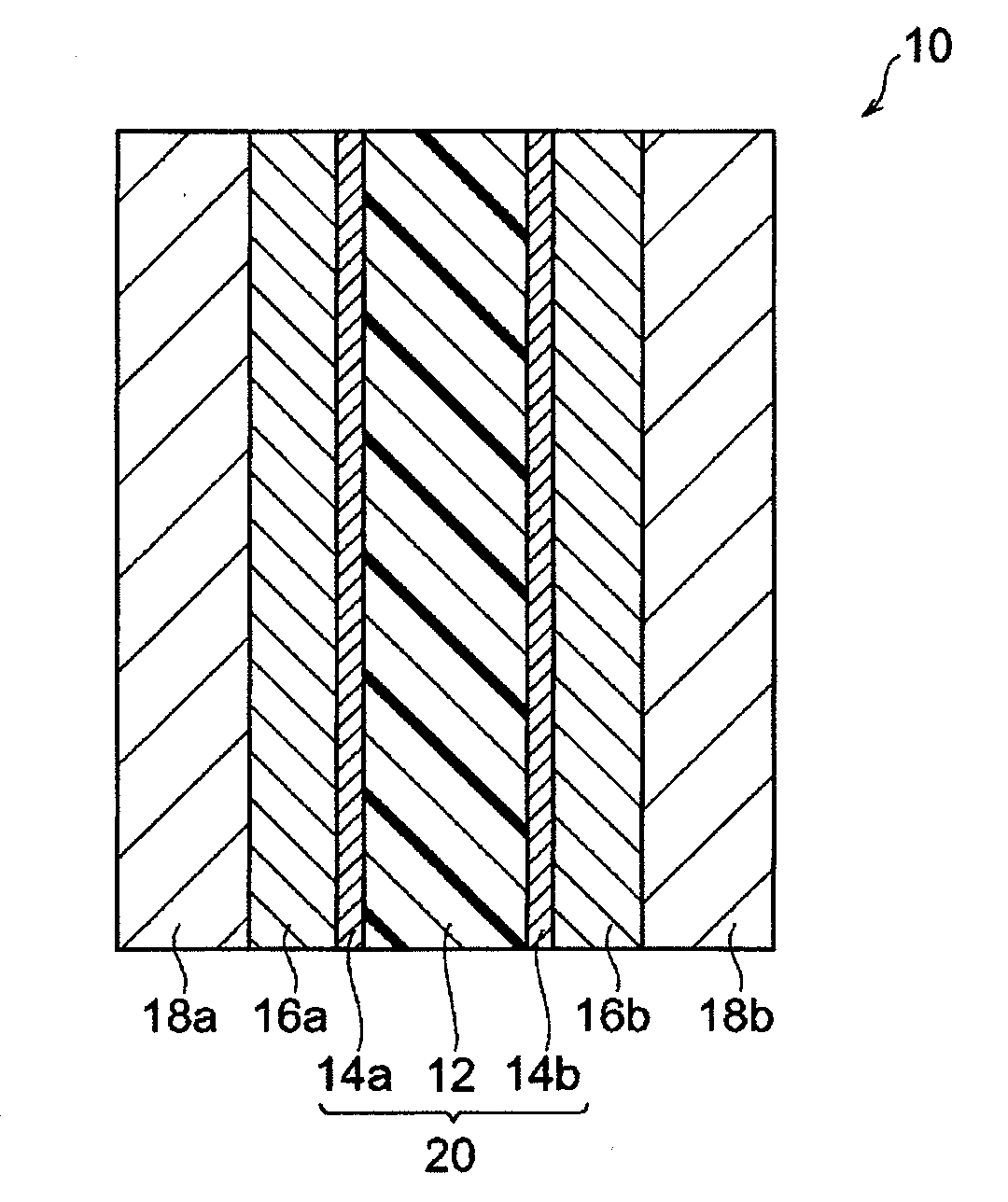

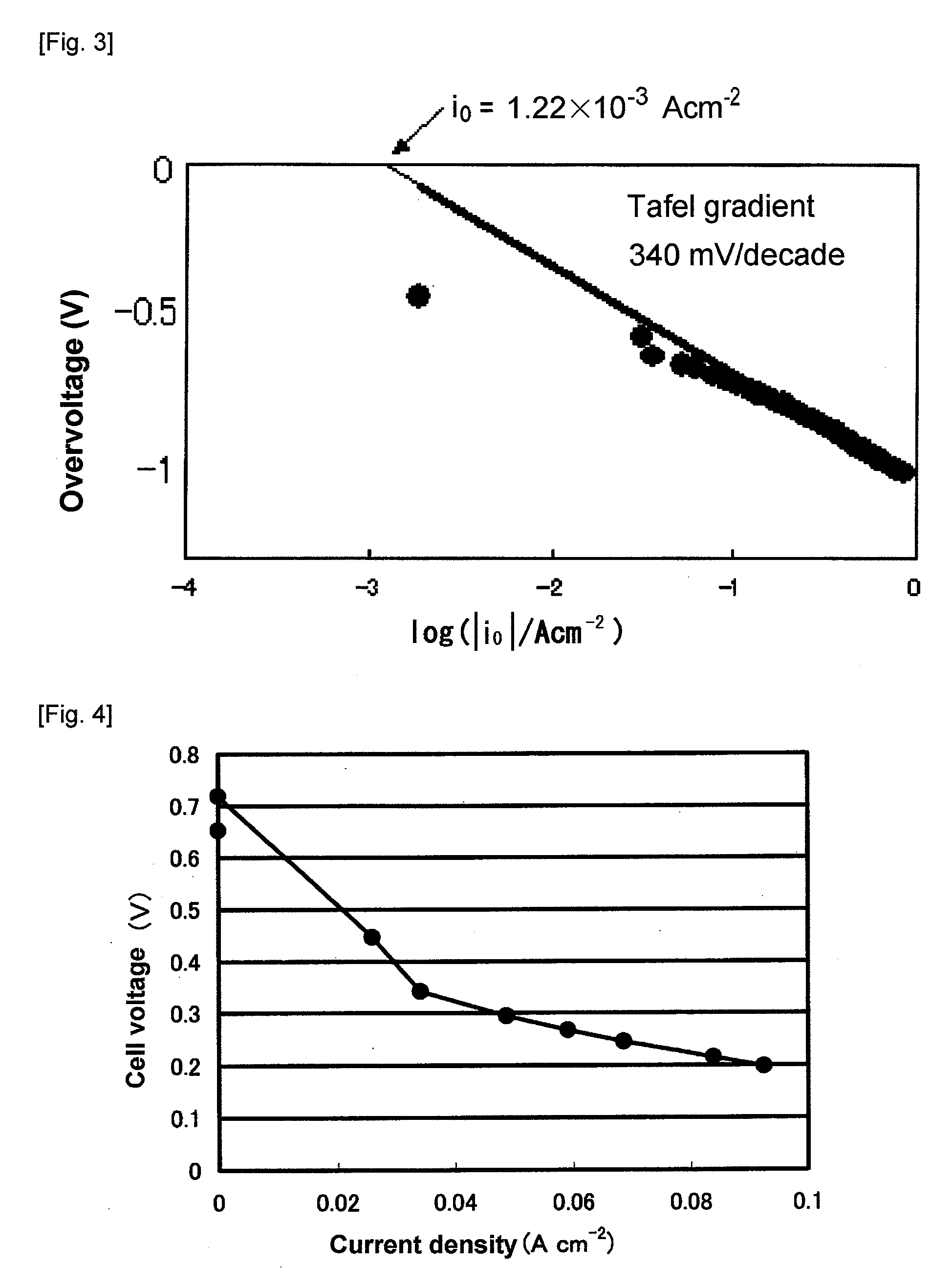

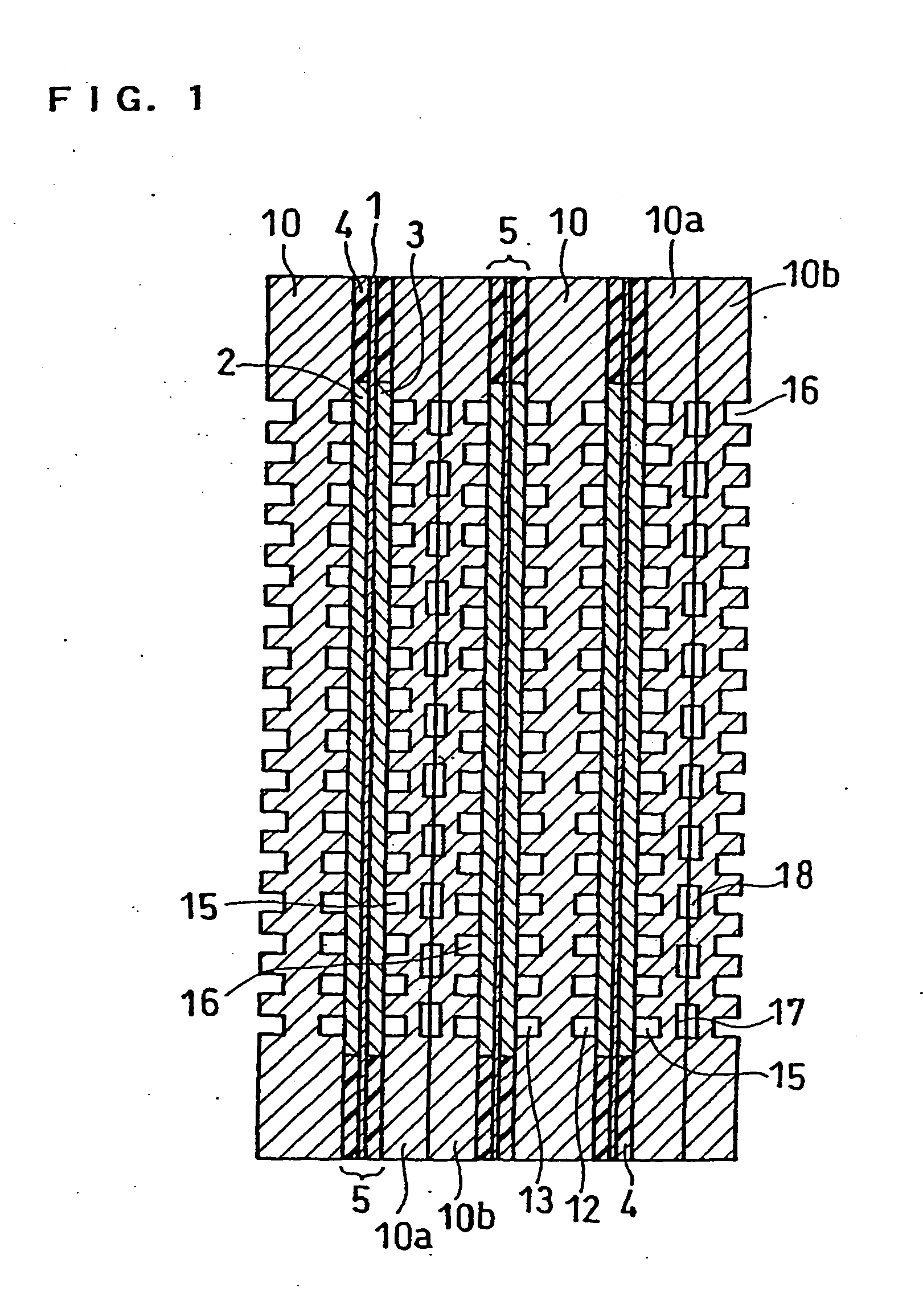

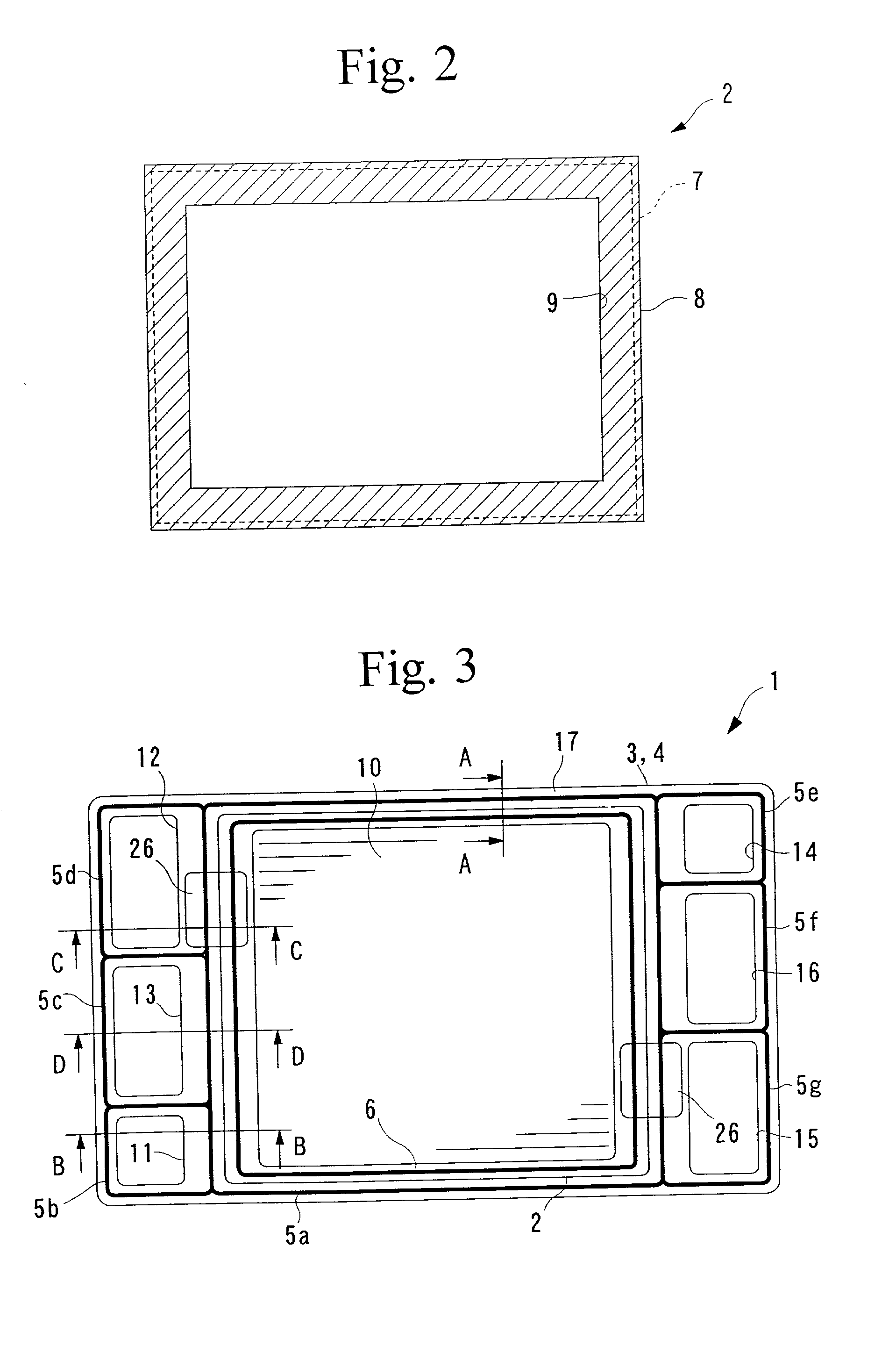

Membrane electrode assembly and fuel cell

InactiveUS20050142397A1Avoid damageDesired performanceFuel cells groupingFuel cell auxillariesPolymer electrolytesFuel cells

A membrane electrode assembly includes an anode, a cathode, and a solid polymer electrolyte membrane interposed between the anode and the cathode. The anode and the cathode include gas diffusion layers and electrode catalyst layers. Mixture layers are provided over predetermined areas H around surfaces of the electrode catalyst layers. The electrode catalyst layers and adhesive layers are mixed in the mixture layers, respectively.

Owner:HONDA MOTOR CO LTD

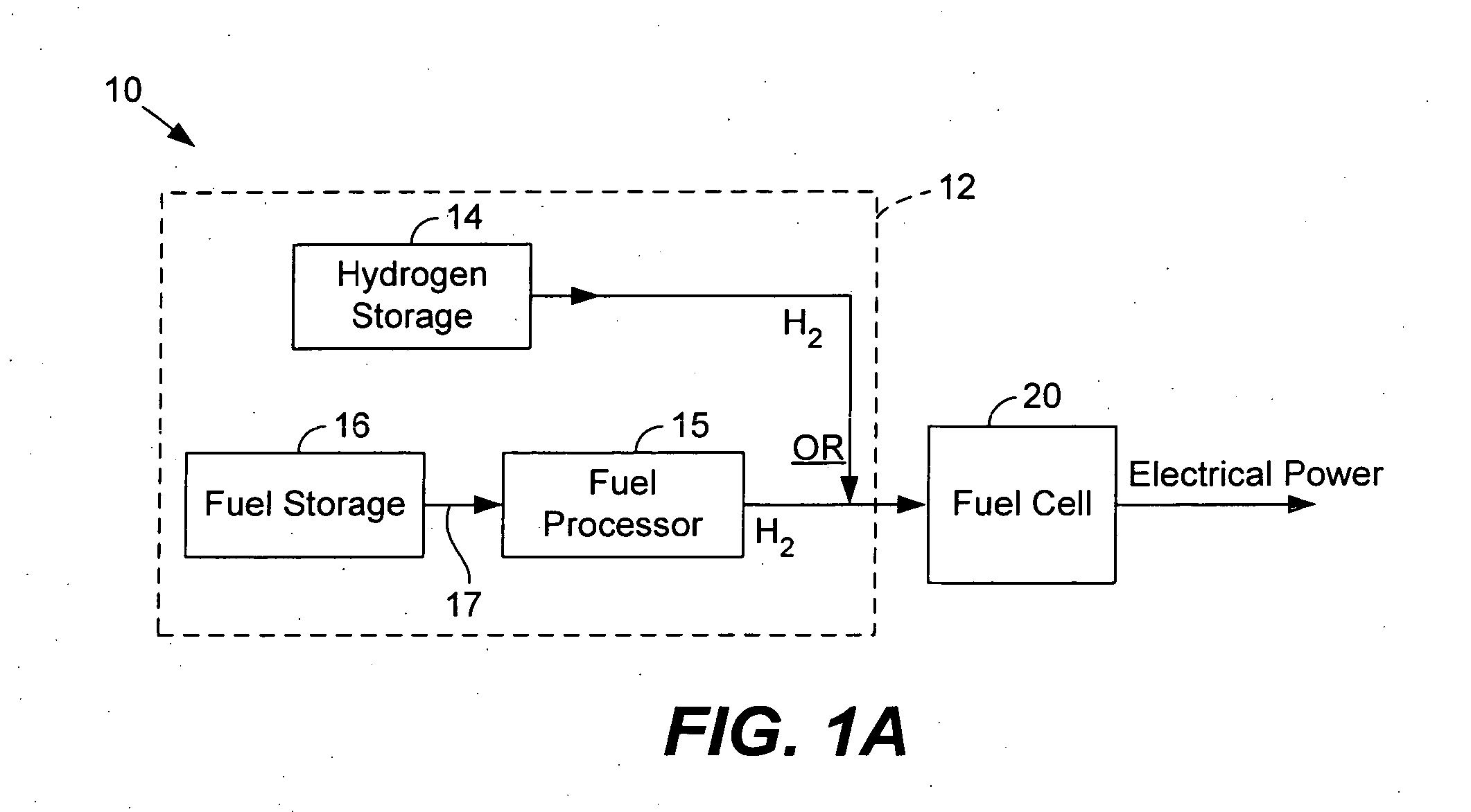

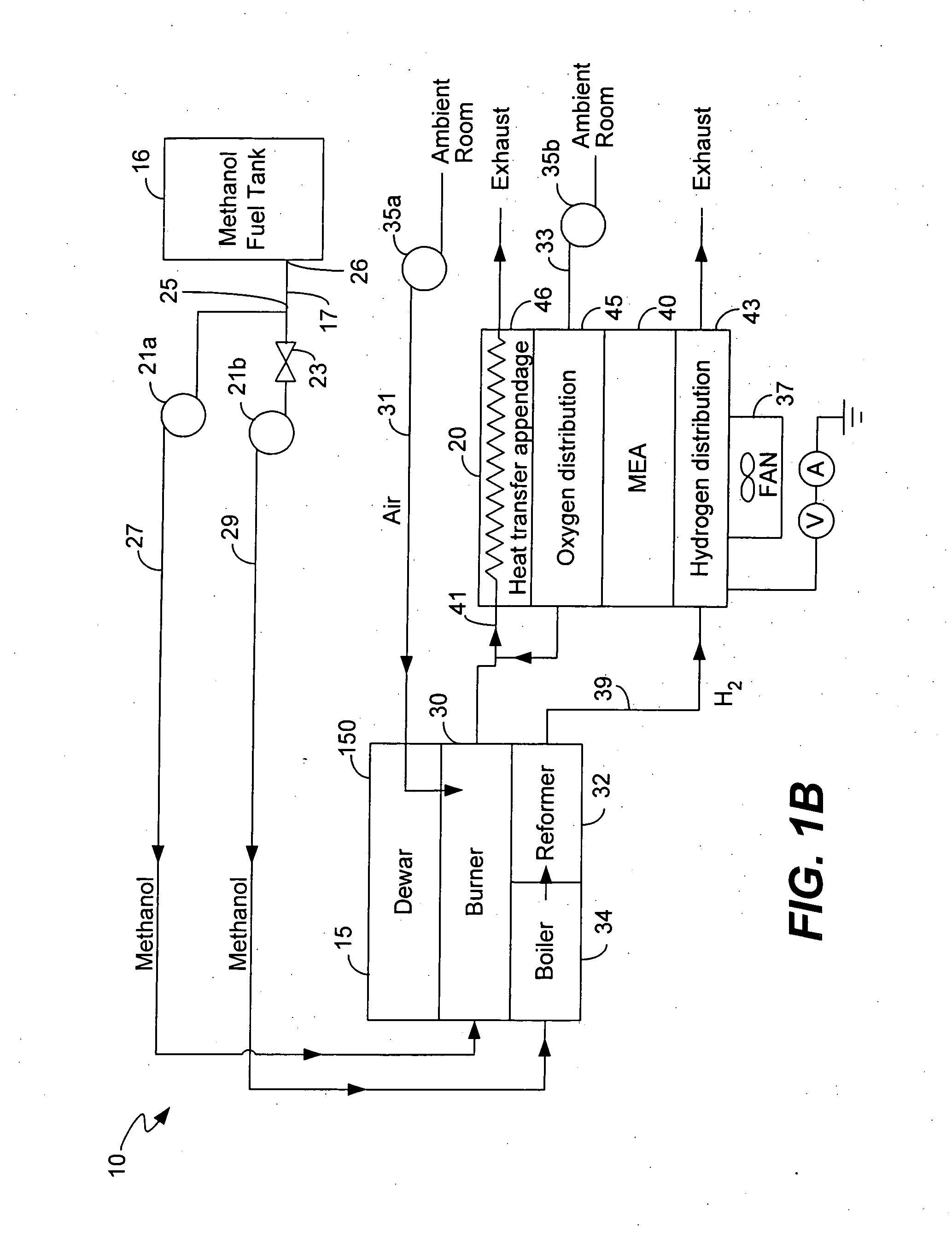

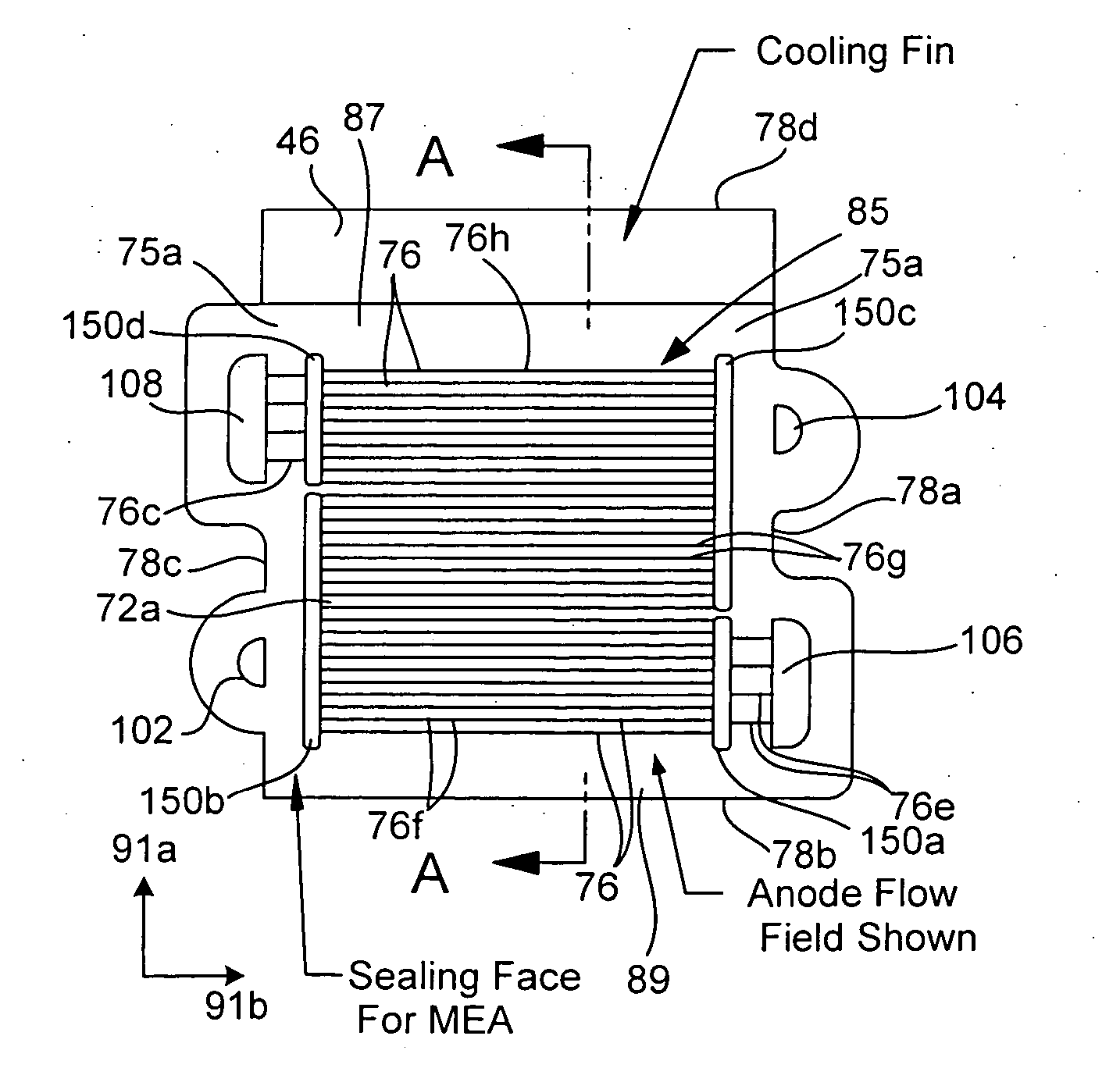

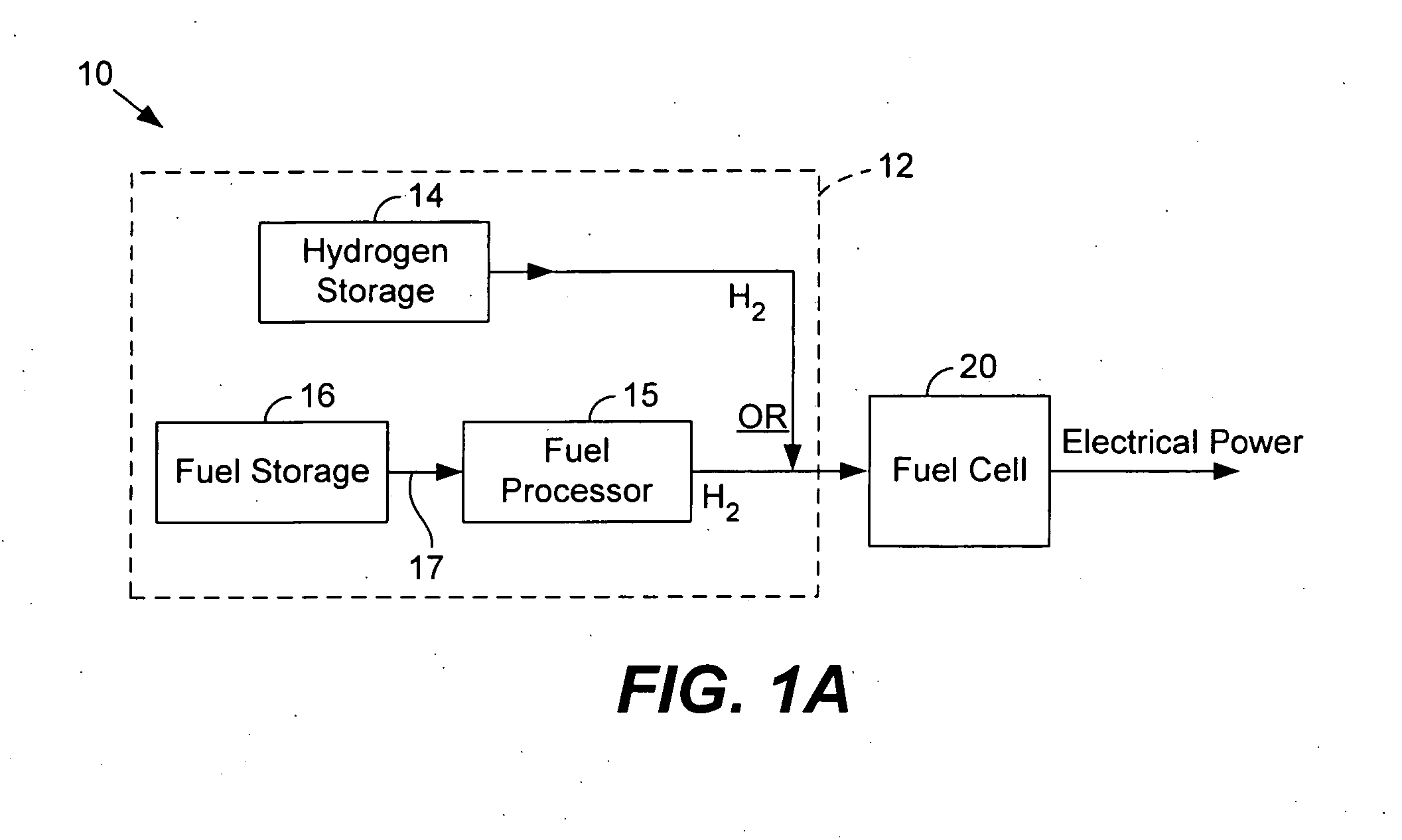

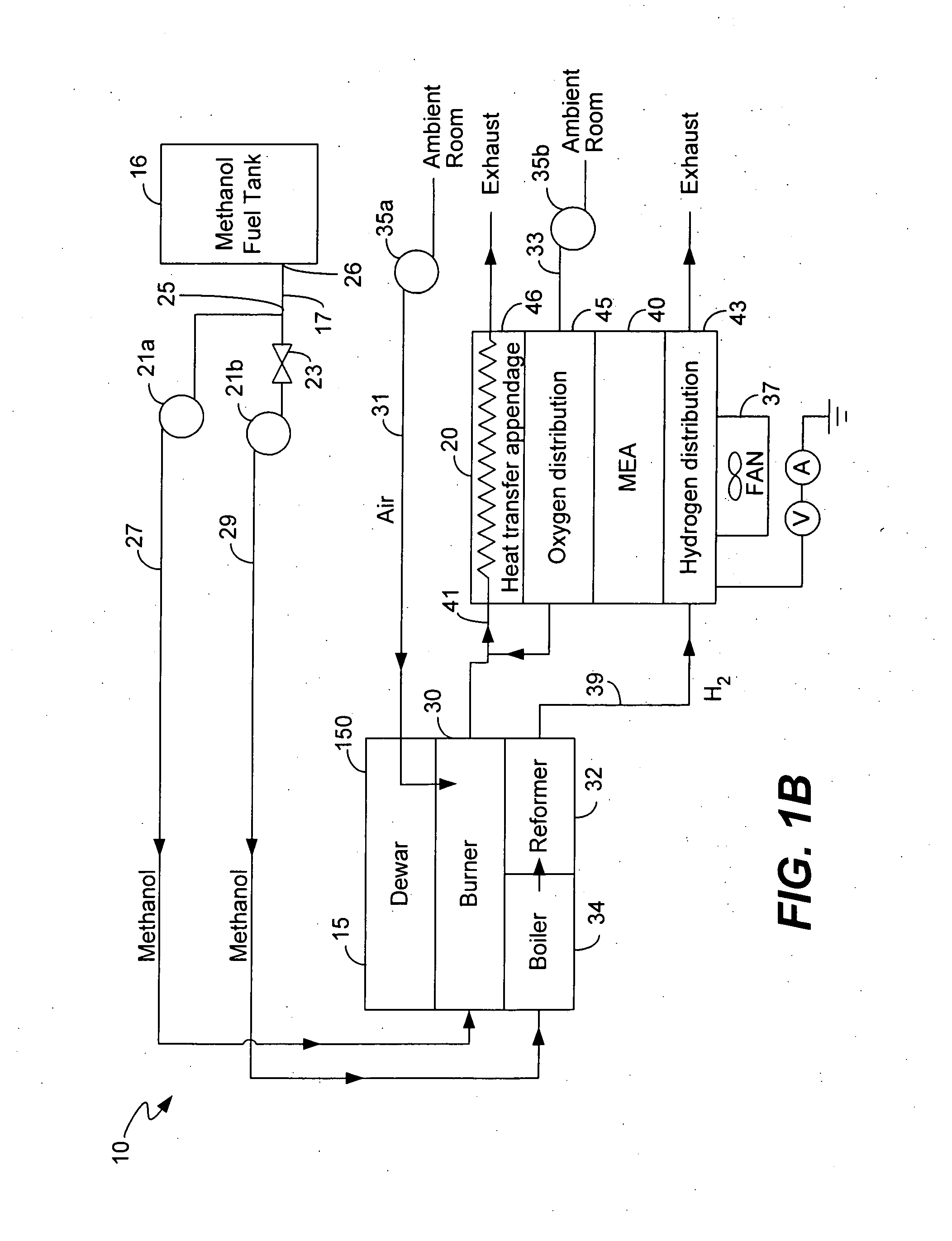

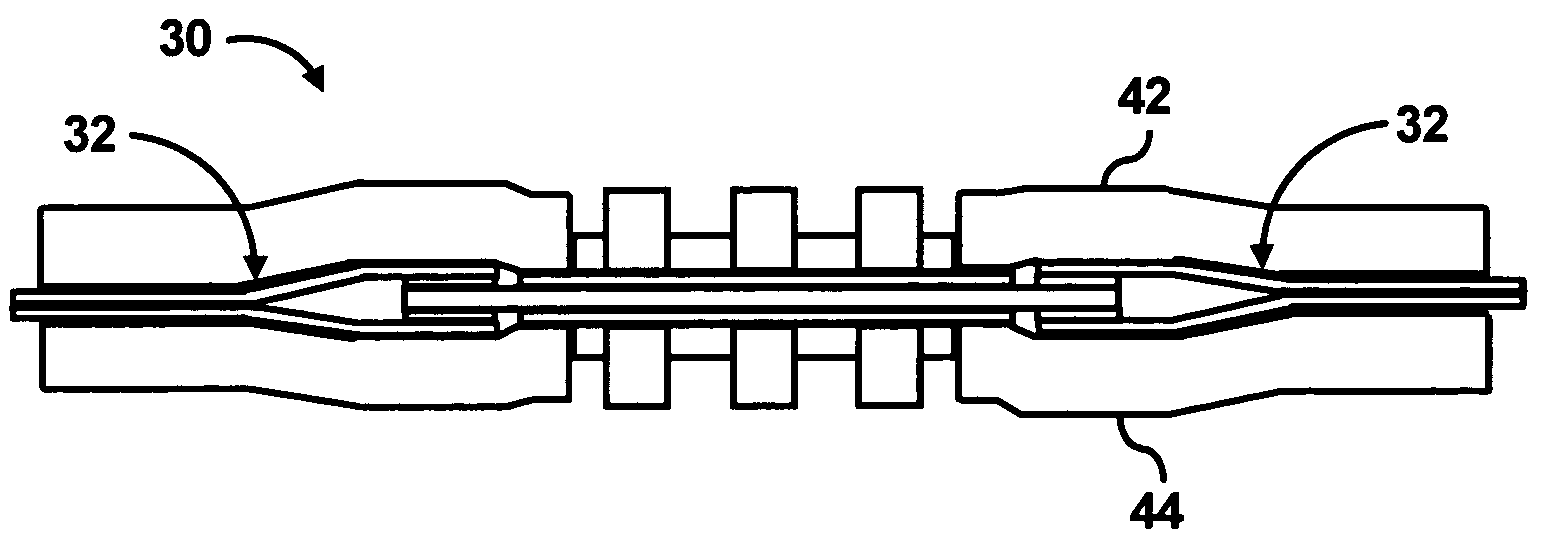

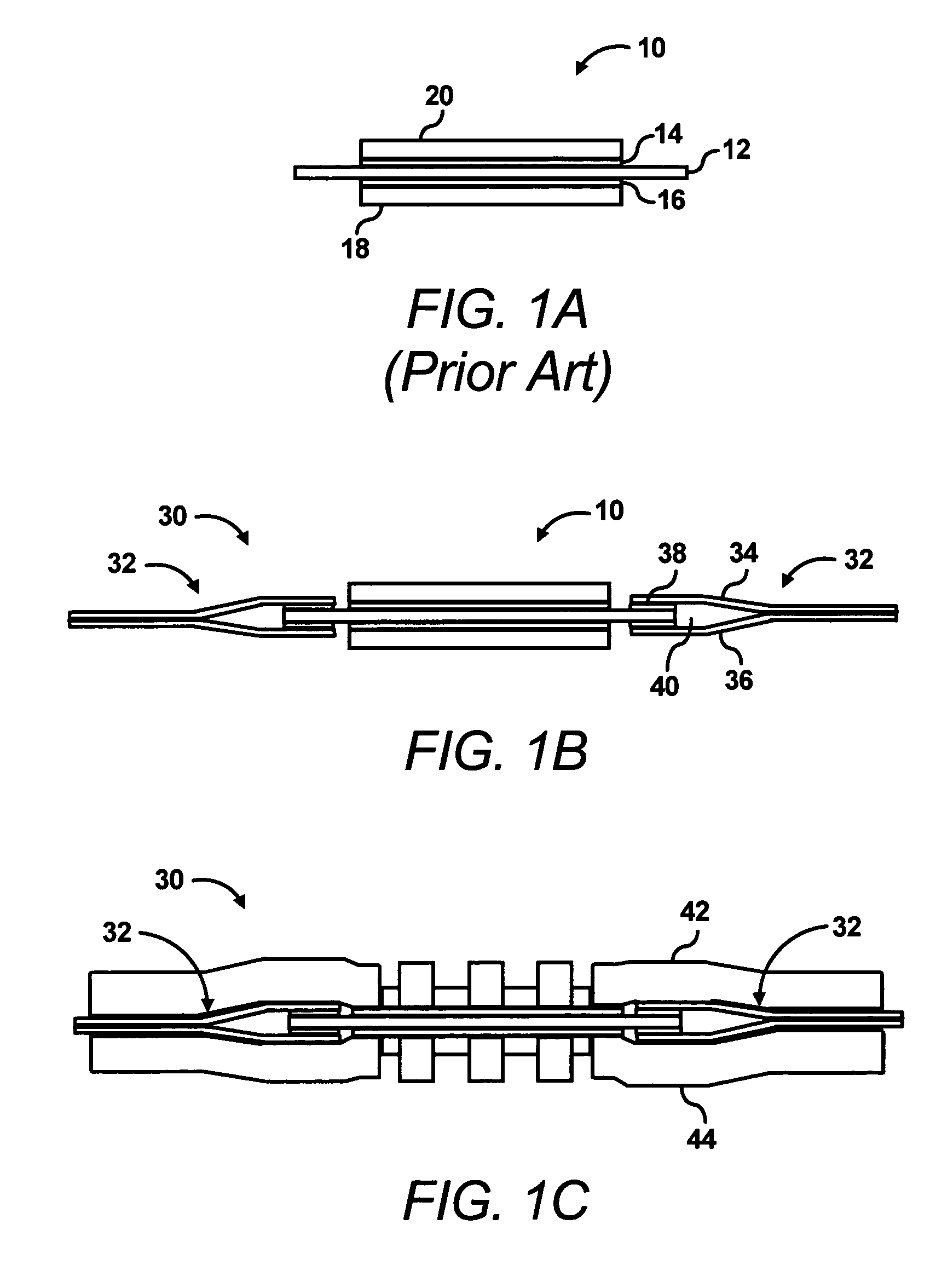

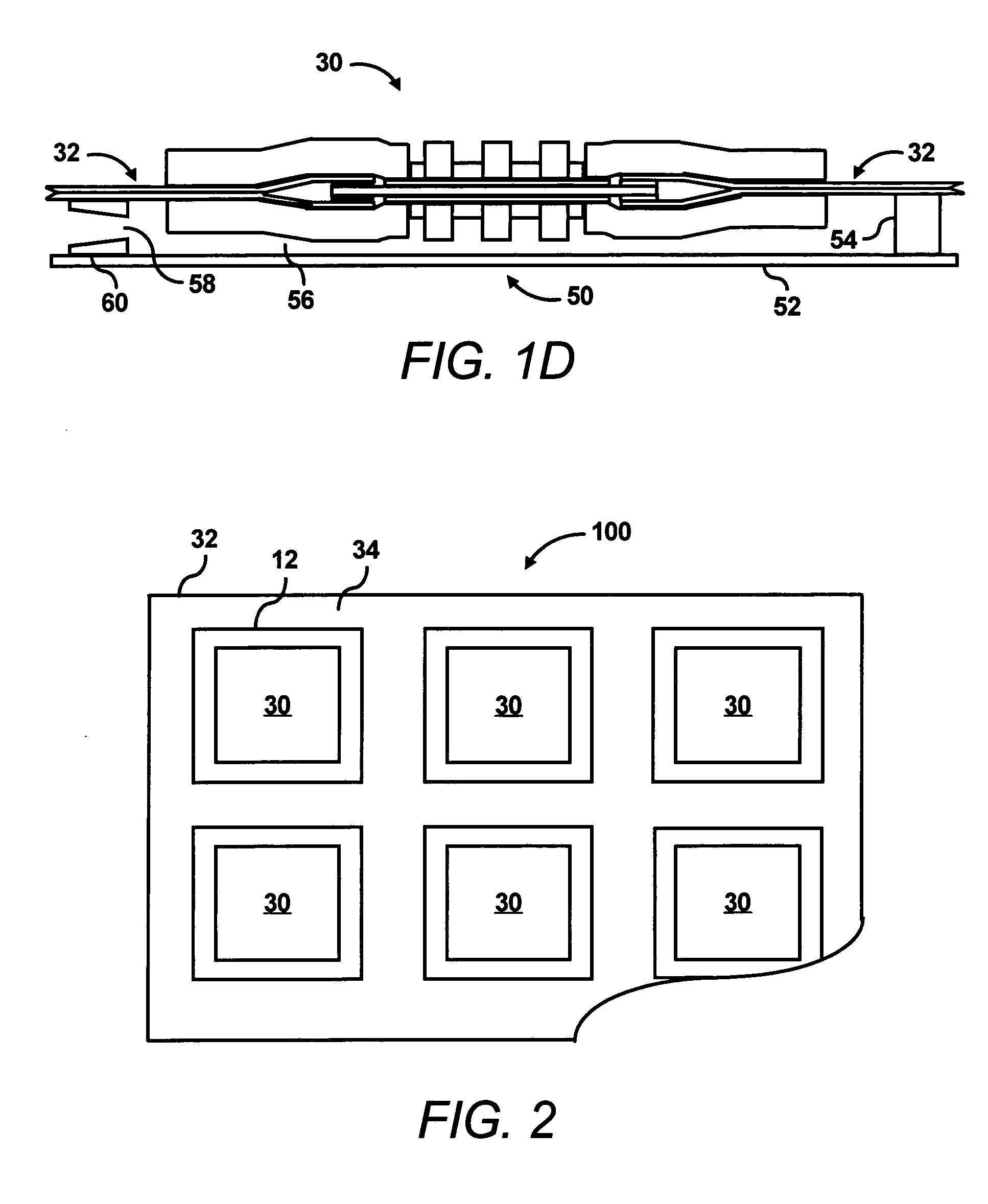

Micro fuel cell thermal management

ActiveUS20050008911A1Improves fuel cell thermal managementFacilitates thermal communicationFuel cell heat exchangeFuel cells groupingSingle plateEngineering

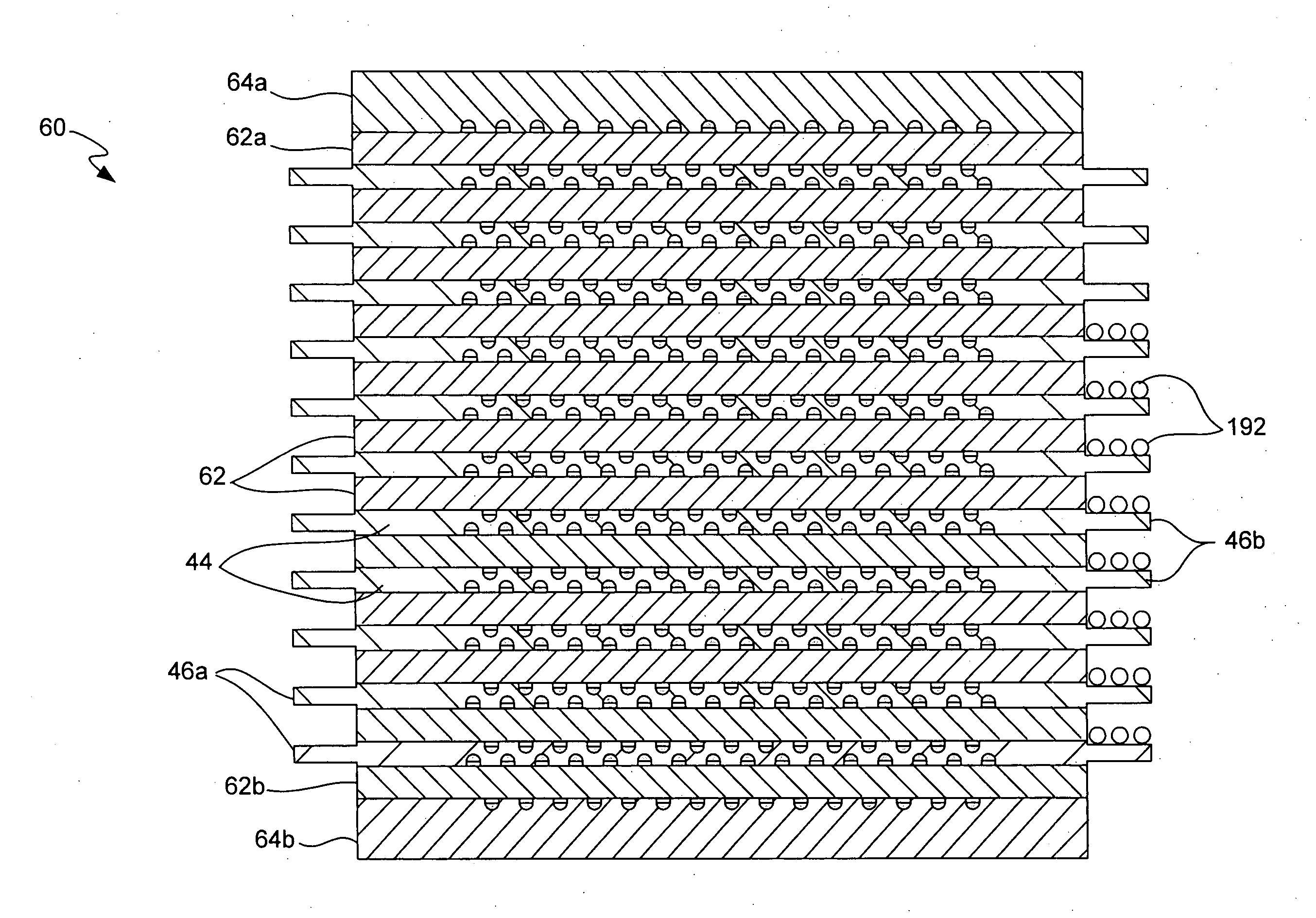

The present invention relates to fuel cells and components used within a fuel cell. Heat transfer appendages are described that improve fuel cell thermal management. Each heat transfer appendage is arranged on an external portion of a bi-polar plate and permits conductive heat transfer between inner portions of the bi-polar plate and outer portions of the bi-polar plate proximate to the appendage. The heat transfer appendage may be used for heating or cooling inner portions of a fuel cell stack. Improved thermal management provided by cooling the heat transfer appendages also permits new channel field designs that distribute the reactant gases to a membrane electrode assembly. Flow buffers are described that improve delivery of reactant gases and removal of reaction products. Single plate bi-polar plates may also include staggered channel designs that reduce the thickness of the single plate.

Owner:ULTRACELL LLC

Micro fuel cell architecture

InactiveUS20050014059A1Improved thermal managementFacilitate communicationFuel cell heat exchangeLayered productsSingle plateEngineering

The present invention relates to fuel cells and components used within a fuel cell. Heat transfer appendages are described that improve fuel cell thermal management. Each heat transfer appendage is arranged on an external portion of a bi-polar plate and permits conductive heat transfer between inner portions of the bi-polar plate and outer portions of the bi-polar plate proximate to the appendage. The heat transfer appendage may be used for heating or cooling inner portions of a fuel cell stack. Improved thermal management provided by cooling the heat transfer appendages also permits new channel field designs that distribute the reactant gases to a membrane electrode assembly. Flow buffers are described that improve delivery of reactant gases and removal of reaction products. Single plate bi-polar plates may also include staggered channel designs that reduce the thickness of the single plate.

Owner:ULTRACELL LLC

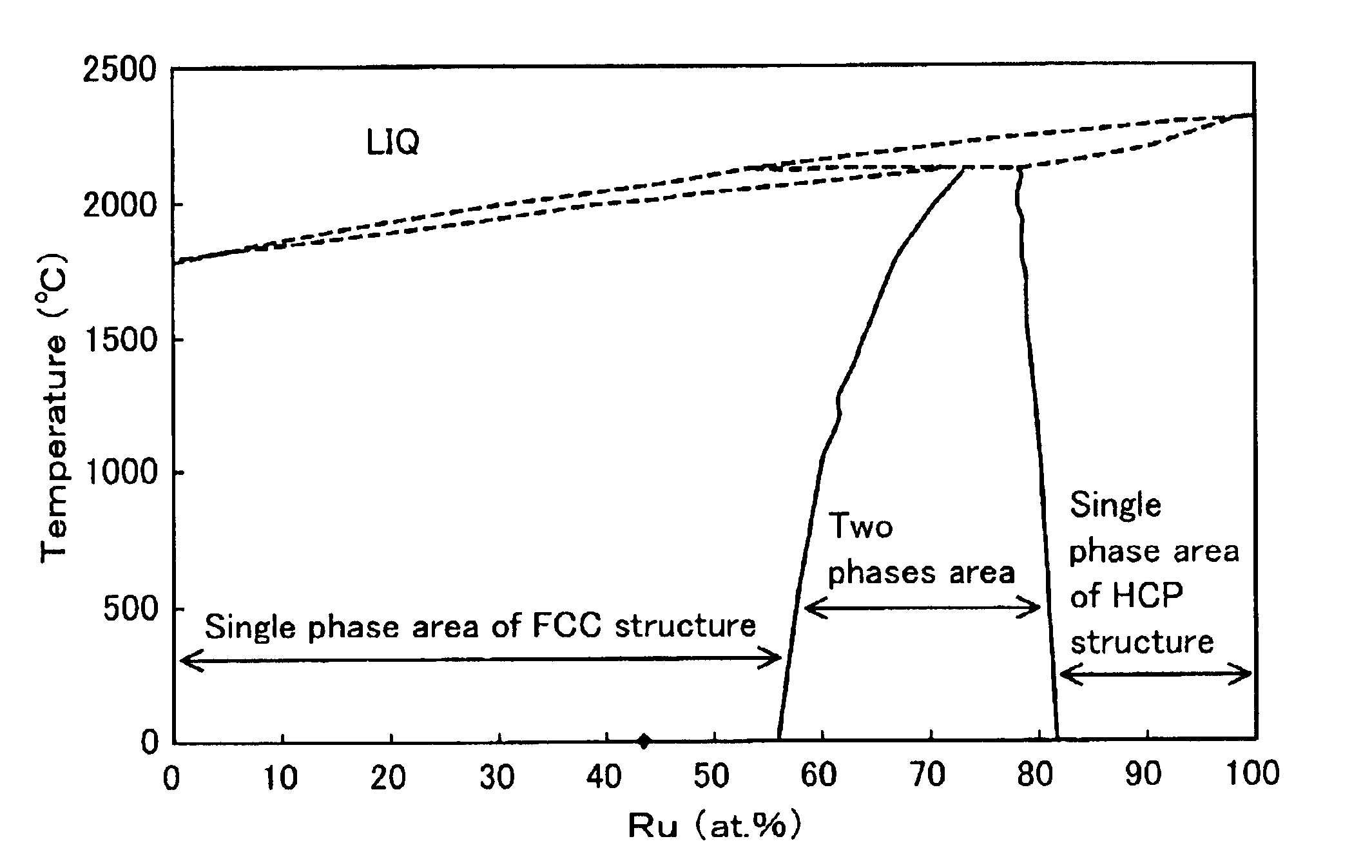

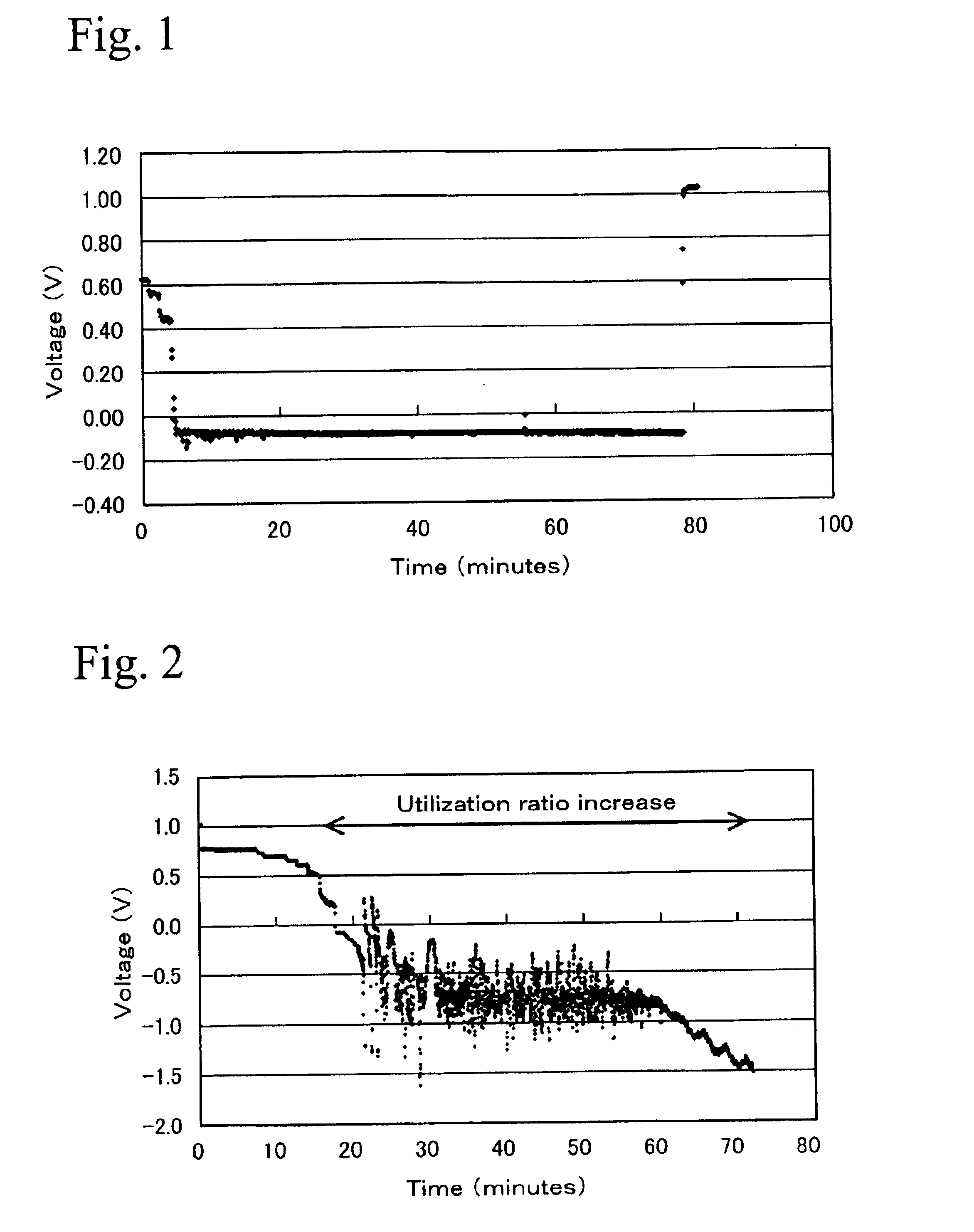

Membrane electrode assembly for polymer electrolyte fuel cell

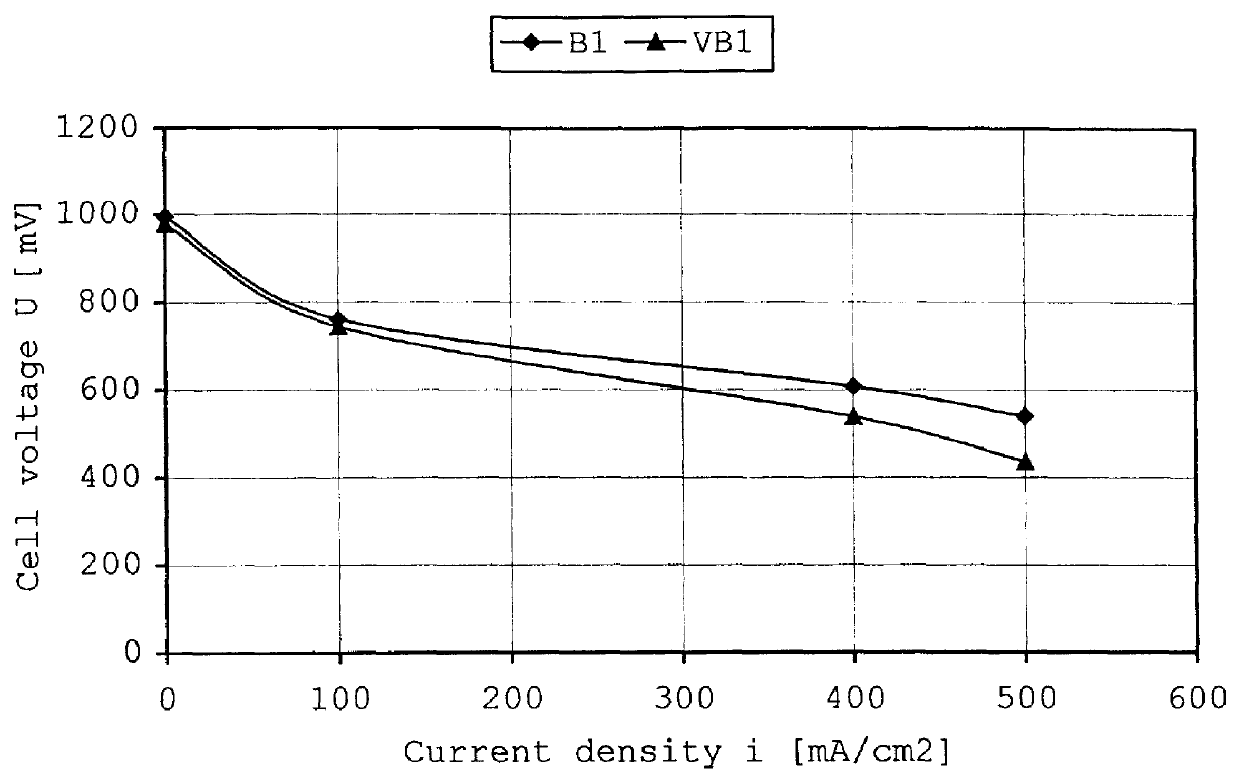

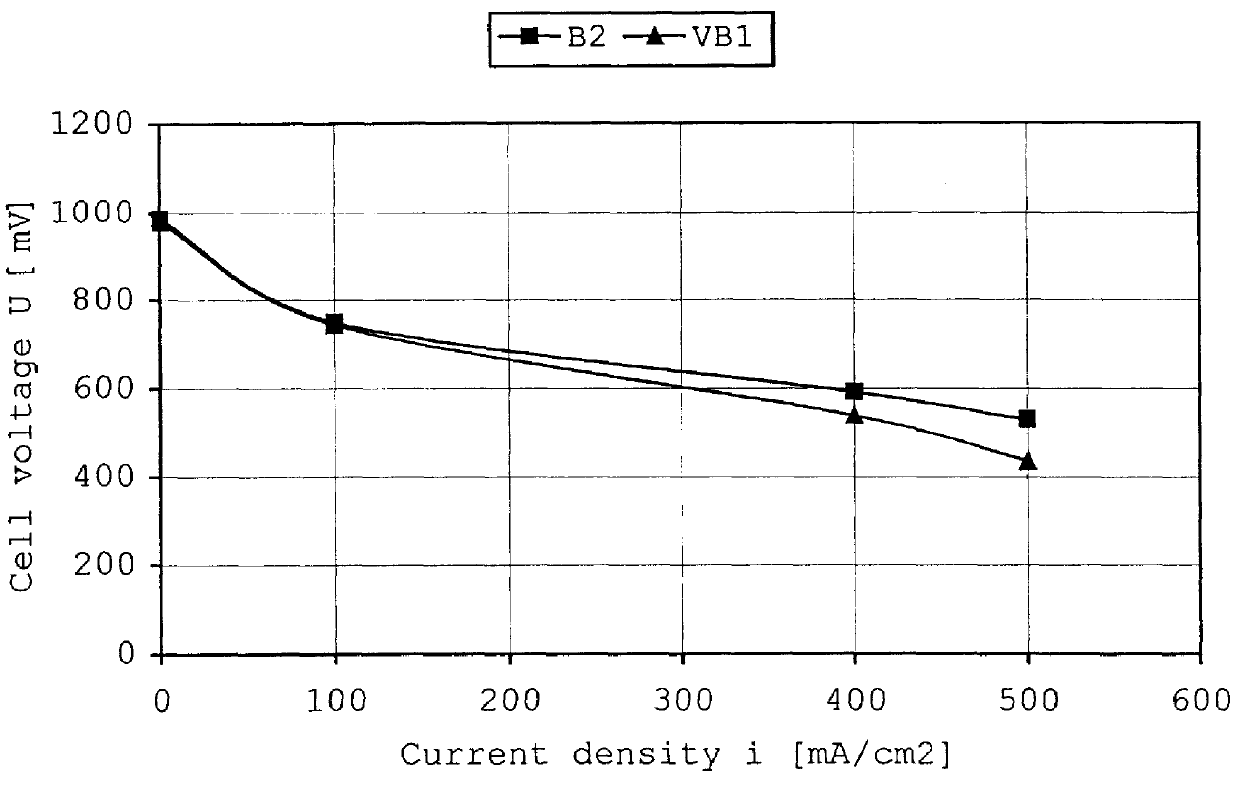

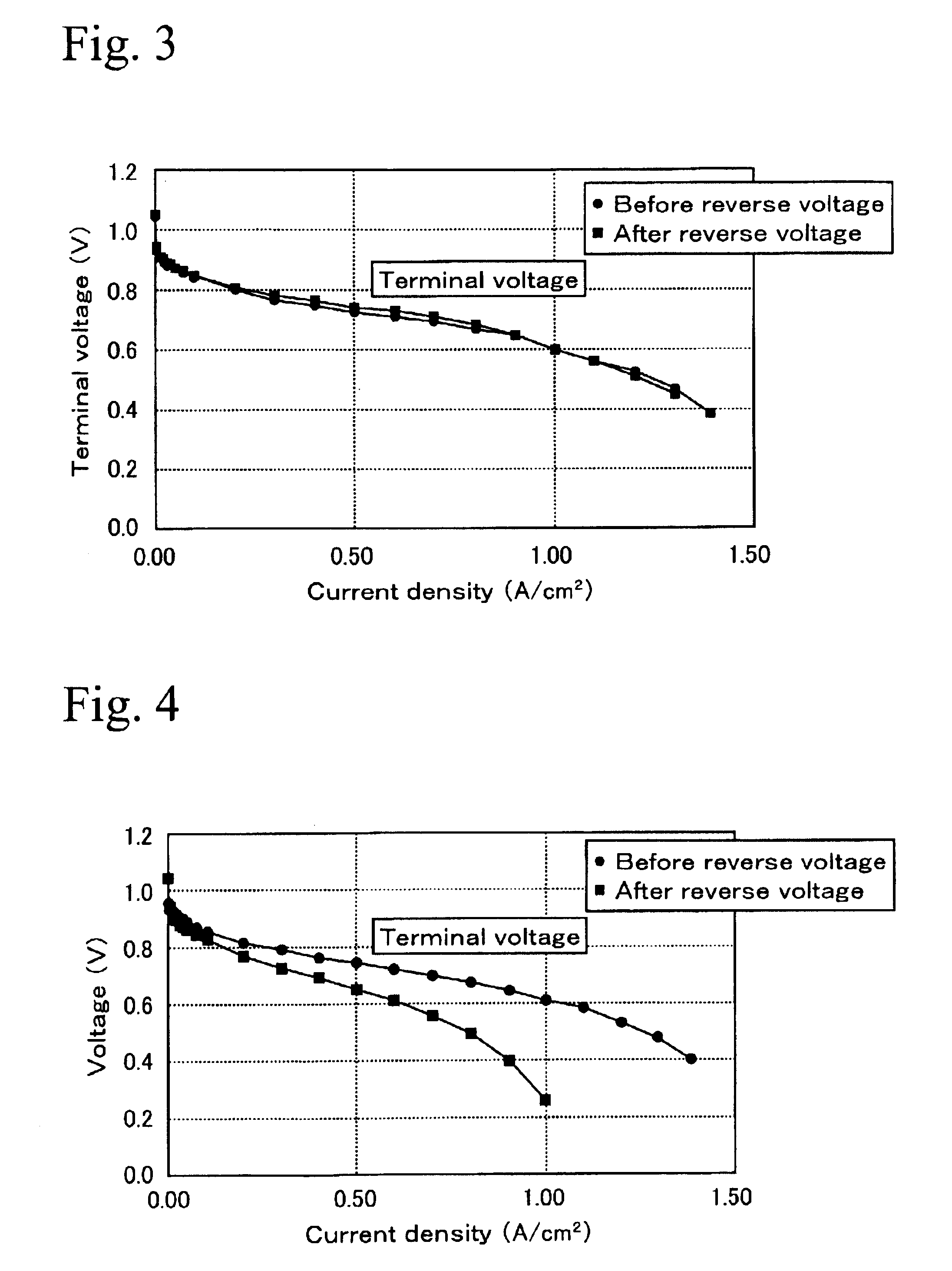

InactiveUS6875537B2Terminal voltage droppingReduce deteriorationActive material electrodesSolid electrolyte fuel cellsPolymer electrolytesFuel cells

A membrane electrode assembly for polymer electrolyte fuel cells comprises a cathode electrode, an anode electrode, and a polymer electrolyte membrane placed between these electrodes, and a catalyst material of Pt—Ru alloy is contained in the anode and the crystal of Pt—Ru alloy is mainly of a face-centered cubic structure.

Owner:HONDA MOTOR CO LTD

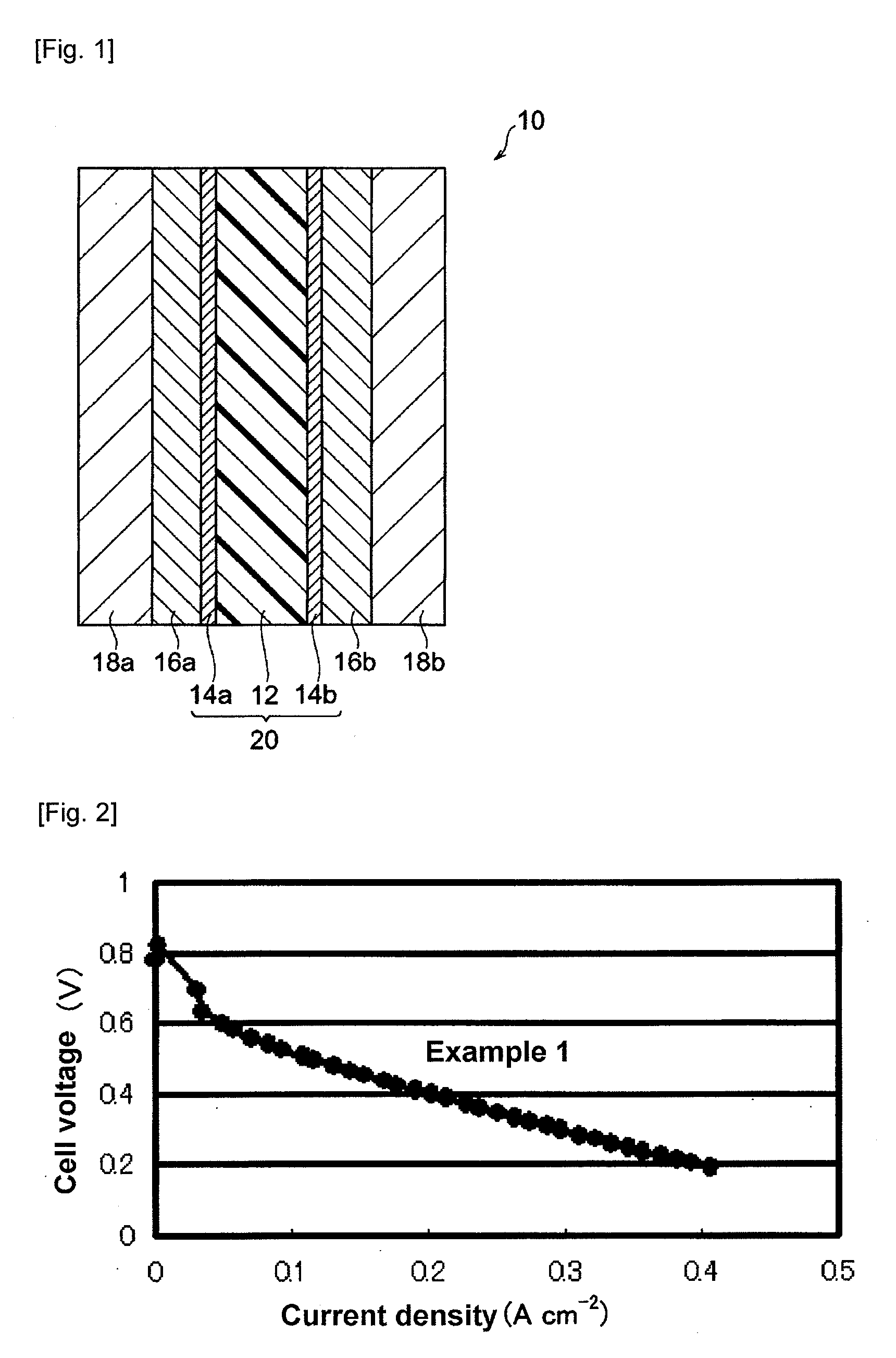

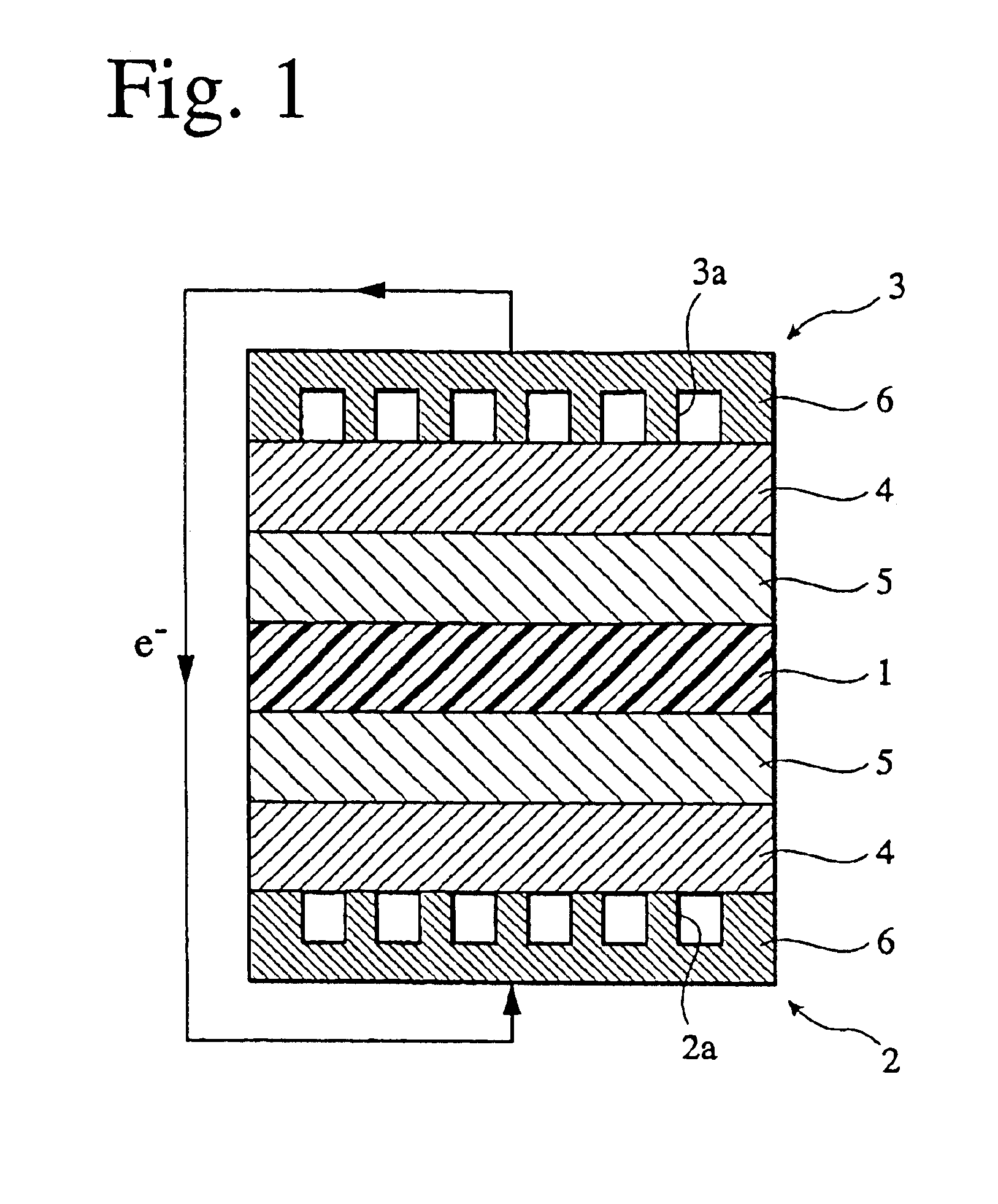

Membrane-electrode assembly and fuel battery using the same

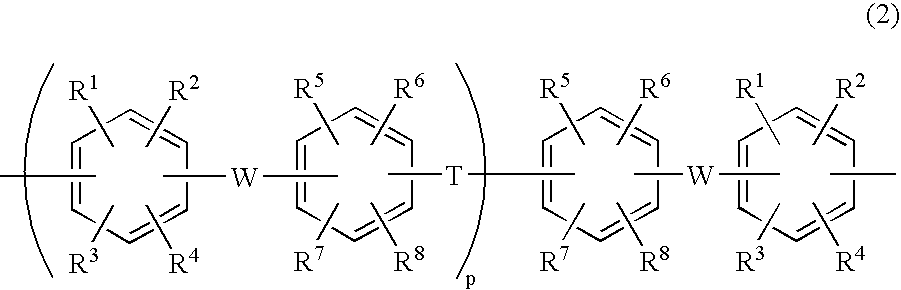

InactiveUS20100086823A1Improve stabilityFuel cells groupingCell electrodesFuel cellsExchange current density

A membrane-electrode assembly, containing an electrode catalyst containing a base metal complex, in which exchange current density i0 obtained from a Tafel plot, which is related to current density and voltage, is 5.0×10−4 Acm−2 or more, and in which a Tafel slope obtained from the Tafel plot is 450 mV / decade or less; anda membrane-electrode assembly, containing catalyst layers each containing an electrode catalyst on both sides of an electrolyte membrane, in which at least one of the catalyst layers comprises a non-noble metal-based electrode catalyst, and in which the electrolyte membrane is a hydrocarbon-based electrolyte membrane.

Owner:SUMITOMO CHEM CO LTD

Method of producing membrane electrode assemblies for use in proton exchange membrane and direct methanol fuel cells

Compositions and methods for the manufacture of electrodes for fuel cells. The compositions and methods are particularly useful for the manufacture of anodes and cathodes for proton exchange membrane fuel cells, particularly direct methanol fuel cells. The methods can utilize direct-write tools to deposit ink compositions and form functional layers of a membrane electrode assembly having controlled properties and enhanced performance.

Owner:CABOT CORP

Polymer electrolyte fuel cell and method of manufacturing the same

InactiveUS20040197633A1Improves product water-removal efficiencyEvenly distributedFuel cell heat exchangeFinal product manufacturePolymer electrolytesFuel cells

The present invention relates to a polymer electrolyte fuel cell comprising: an electrolyte membrane-electrode assembly including an anode, a cathode and a polymer electrolyte membrane interposed therebetween; an anode-side conductive separator plate having a gas flow channel for supplying a fuel gas to the anode; and a cathode-side conductive separator plate having a gas flow channel for supplying an oxidant gas to the cathode. A conductive separator plate made of carbon has poor wettability with water. This has posed the disadvantage that variations in performance are induced by nonuniform gas distribution among cells due to the accumulation of product water or humidifying water in the gas flow channel on the surface of the separator plate. The present invention employs a conductive separator plate comprising a conductive carbon having a hydrophilic functional group, at least in a portion of the gas flow channels, thereby preventing water from accumulating in the gas flow channels.

Owner:PANASONIC CORP

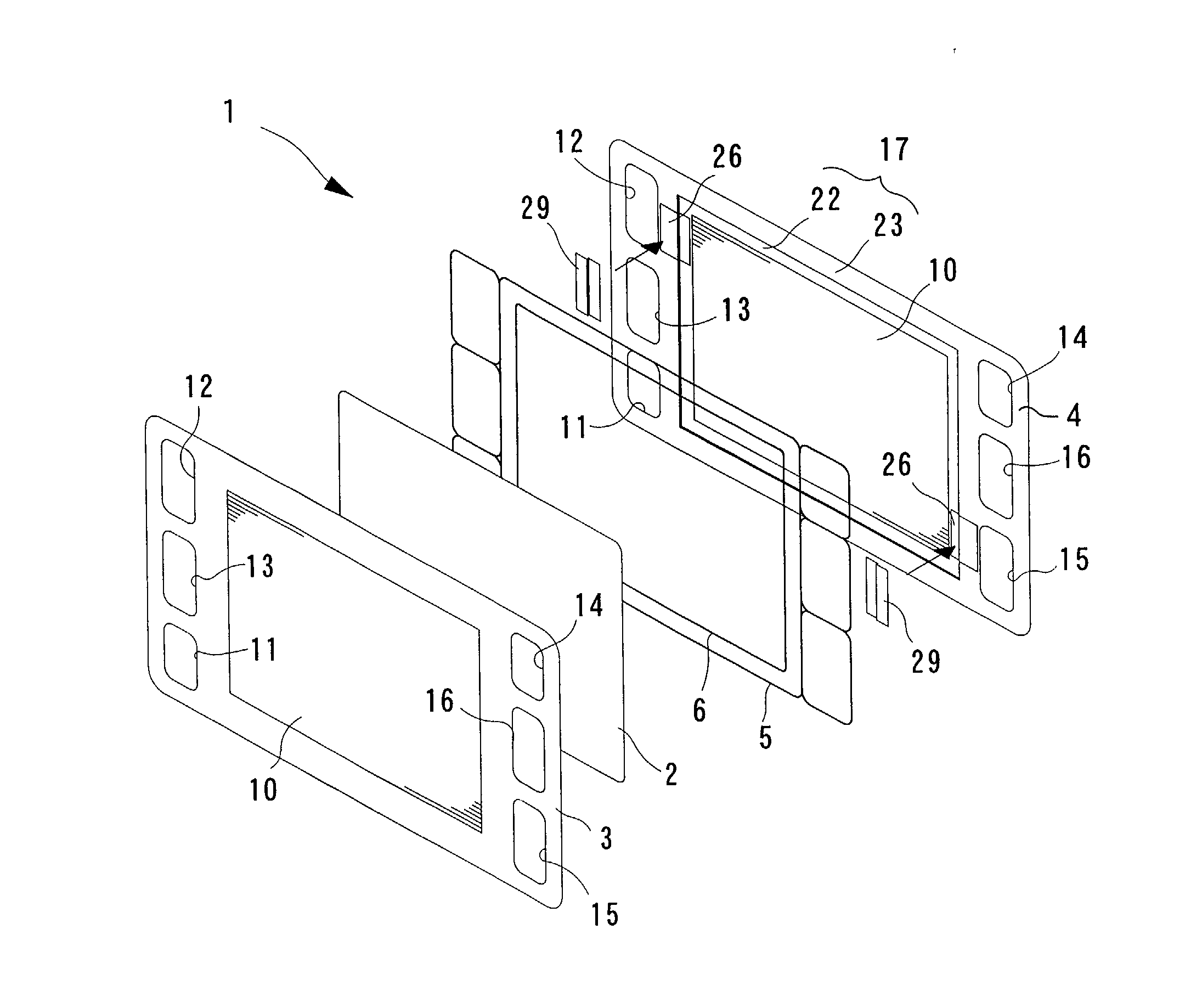

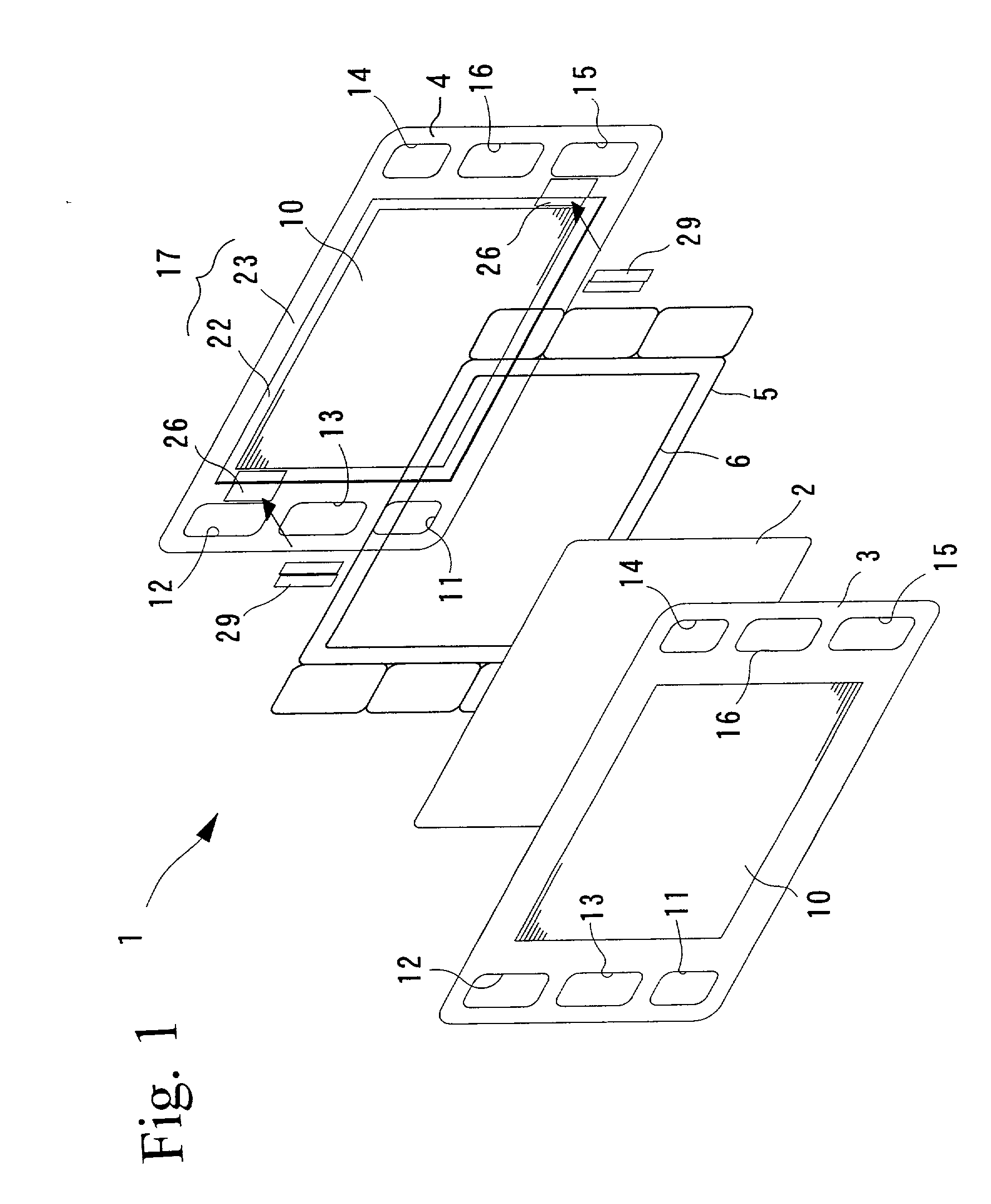

Fuel cell and fuel cell stack

InactiveUS20020127461A1Reduce thicknessImprove sealingSolid electrolytesFuel cells groupingPolymer electrolytesFuel cells

The present invention provides a fuel cell comprising a pair of separators sandwiching outsides of a membrane electrode assembly composed of a pair of electrodes provided on both sides of a solid polymer electrolyte membrane, an outer seal member sandwiched by a pair of separators at a position surrounding an outer periphery of the membrane electrode assembly, an inner seal member sandwiched by one of the pair of separators and an outer periphery of the electrolyte membrane, and a backing member opposing to the inner seal member interposing the electrolyte membrane, wherein steps are formed at contact surfaces of the inner seal member and the outer seal member on one of the pair of separators.

Owner:HONDA MOTOR CO LTD

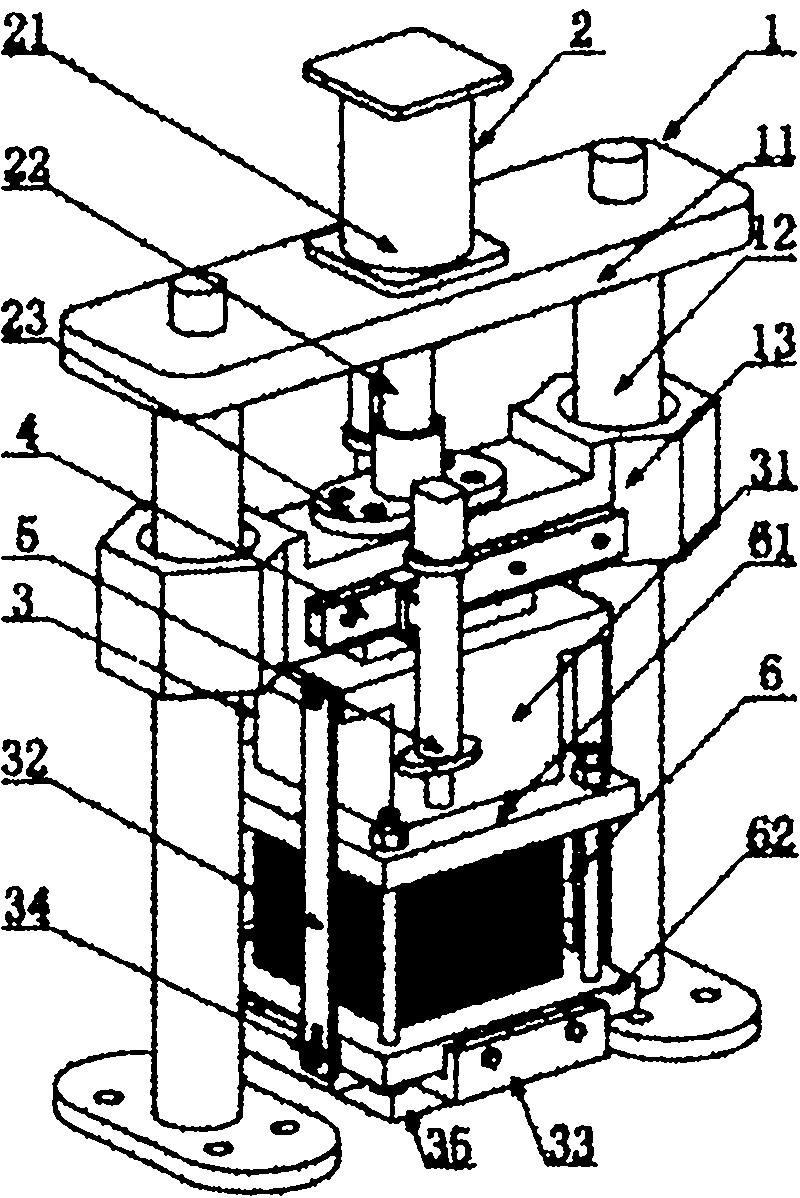

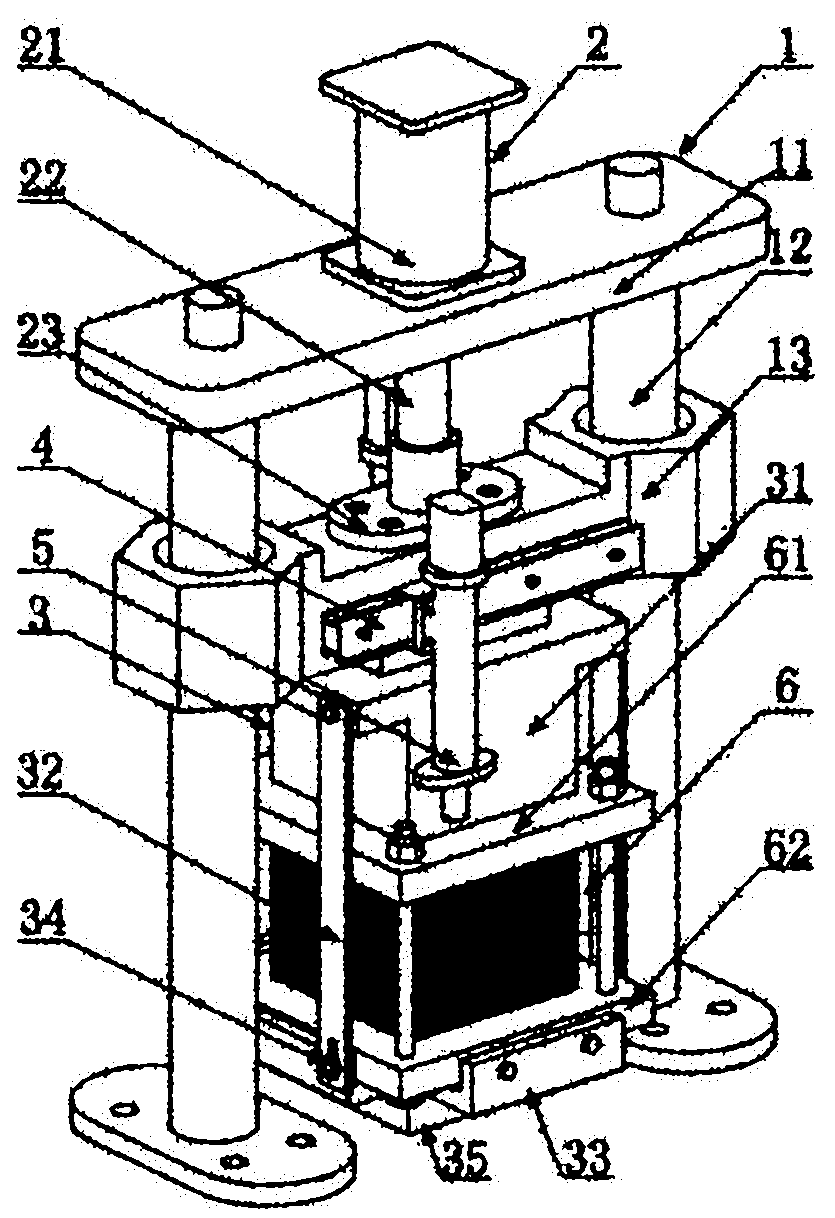

Device for automatically assembling fuel battery galvanic pile

The invention provides a device for automatically assembling a fuel battery galvanic pile and belongs to the technical field of fuel batteries. The device comprises a stander, a pressure adjustable compression device, an automatic guide rod pull and location device and an automatic nut twisting device, wherein the pressure adjustable compression device and the automatic guide rod pull and location device are respectively fixed at two ends of the stander; and the automatic nut twisting device is movably arranged on the stander. By the device, the integration of combination and assembly of a galvanic pile component can be realized, so the automation degree is higher, the operation is convenient and quick, and the assembling efficiency of the fuel battery is improved; by exchanging an upper pressing block and a tray, the device can be applicable to fuel battery galvanic piles of various specifications and sizes, the uniformity is high, and the equipment cost for assembling the fuel batteries of different types can be reduced; by the upper pressing block ,a uniform assembling pressure can be provided, so a bipolar plate inside the galvanic pile is contacted with a membrane electrode assembly (MEA) uniformly, the contact resistance is reduced and the performance of the fuel battery is improved.

Owner:上海氢晨新能源科技有限公司

Fuel cell assembly gasket for fuel containment

InactiveUS20050095490A1Prevent leakageFuel cells groupingCell component detailsPolymer electrolytesFuel cells

A fuel cell assembly includes a membrane electrode assembly having a substantially solid polymer electrolyte membrane positioned between opposed catalyst layers. The polymer electrolyte membrane has a dimension that is relatively larger than a comparable dimension of at least one of the catalyst layers, such that the polymer electrolyte membrane has an uncovered portion. The fuel cell assembly also includes a gasket attached to the uncovered portion of the polymer electrolyte membrane. The gasket extends beyond a periphery of the polymer electrolyte membrane and the gasket is formed of a polymer material. In addition, the gasket is configured to substantially seal the edges of the polymer electrolyte membrane to substantially prevent leakage of fuel or oxidant between an anode side and a cathode side of the membrane electrode assembly.

Owner:HEWLETT PACKARD DEV CO LP

Membrane electrode assemblies for use in fuel cells

InactiveUS20030064265A1High purityImprove electrocatalytic activityGranule coatingCell electrodesCarbon compositesFuel cells

Owner:CABOT CORP

Novel membrane electrode assembly and its manufacturing process

InactiveUS20070275291A1Reduce electric resistanceReduce resistance protonSolid electrolytesFinal product manufacturePtru catalystMembrane electrode assembly

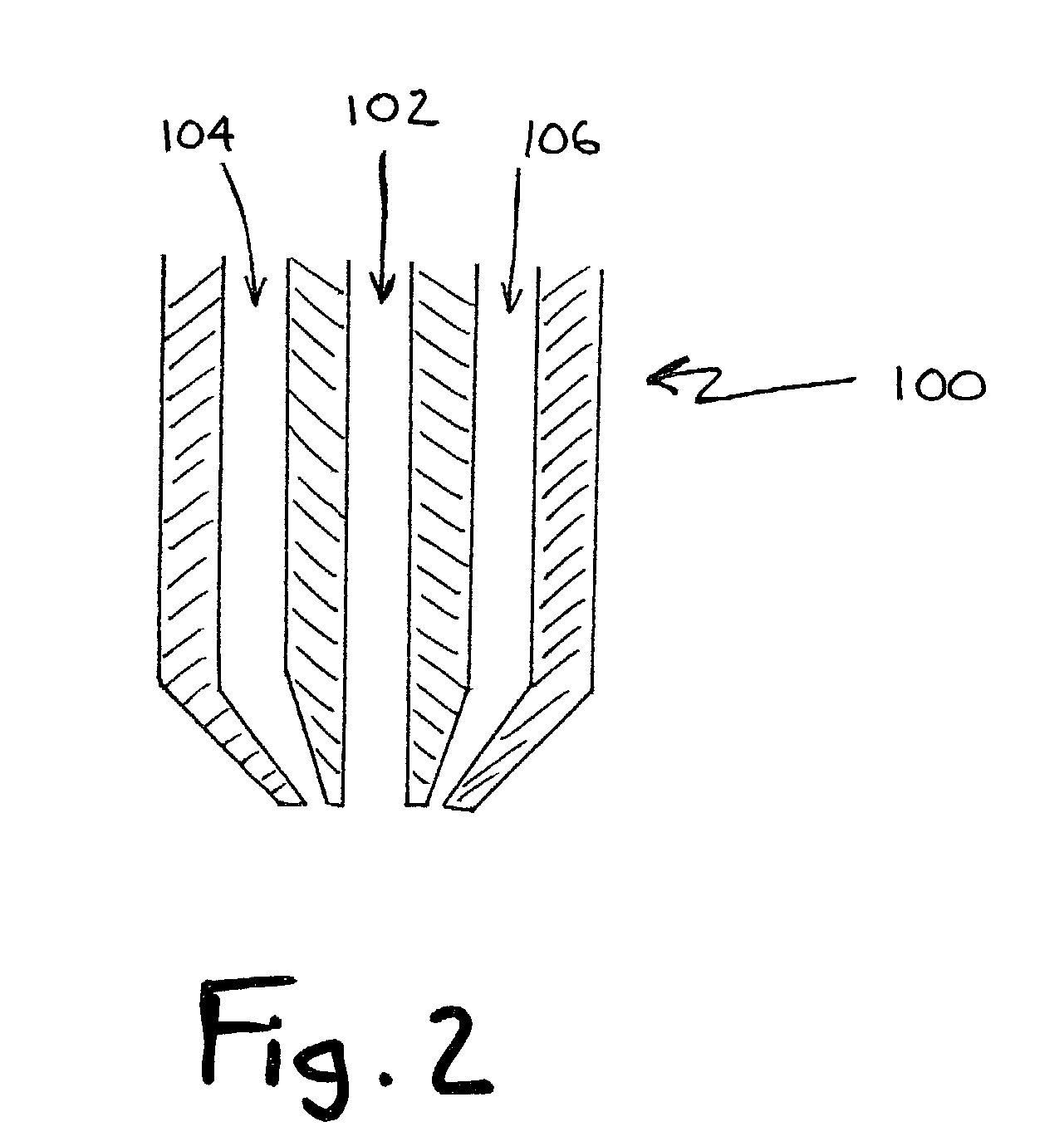

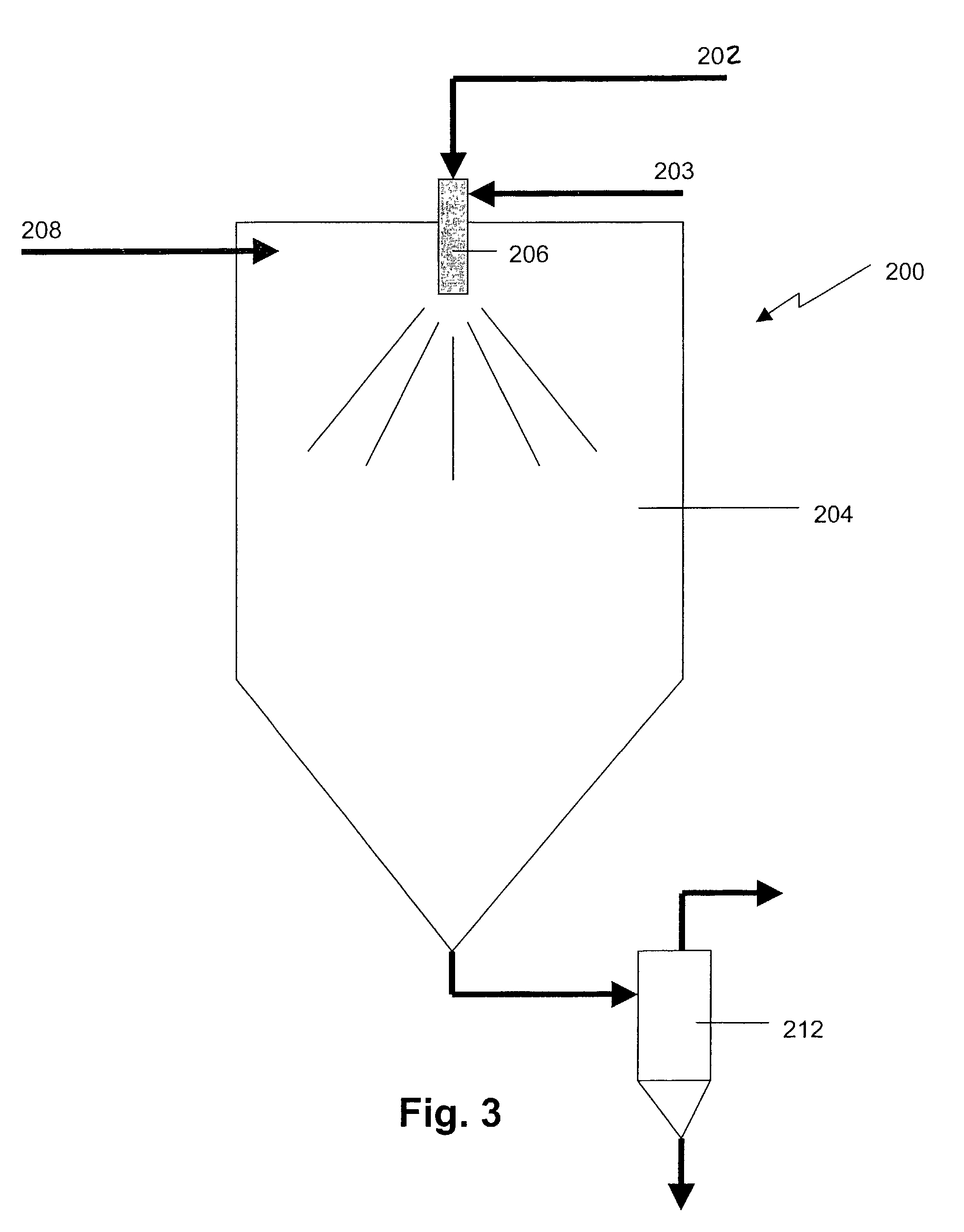

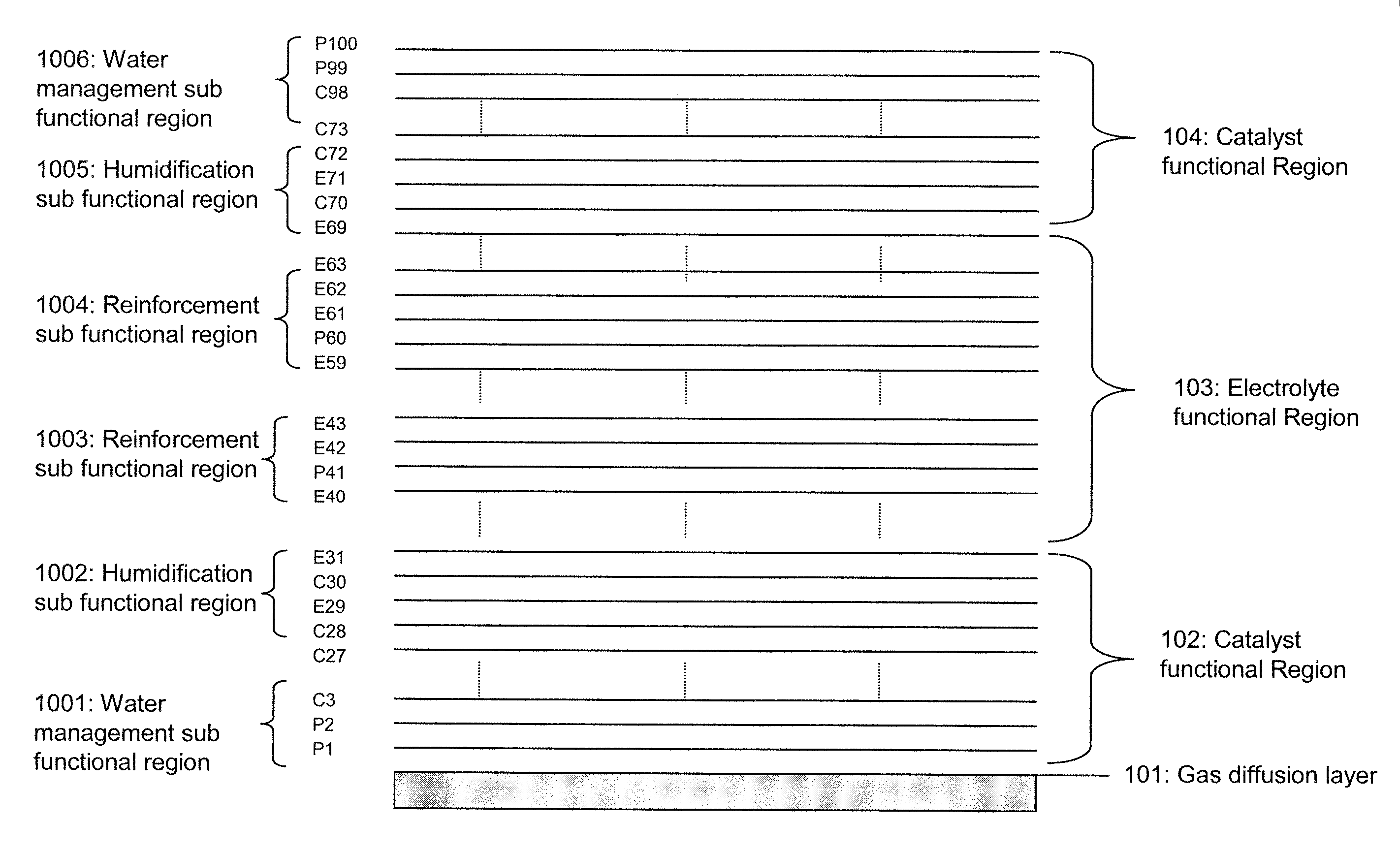

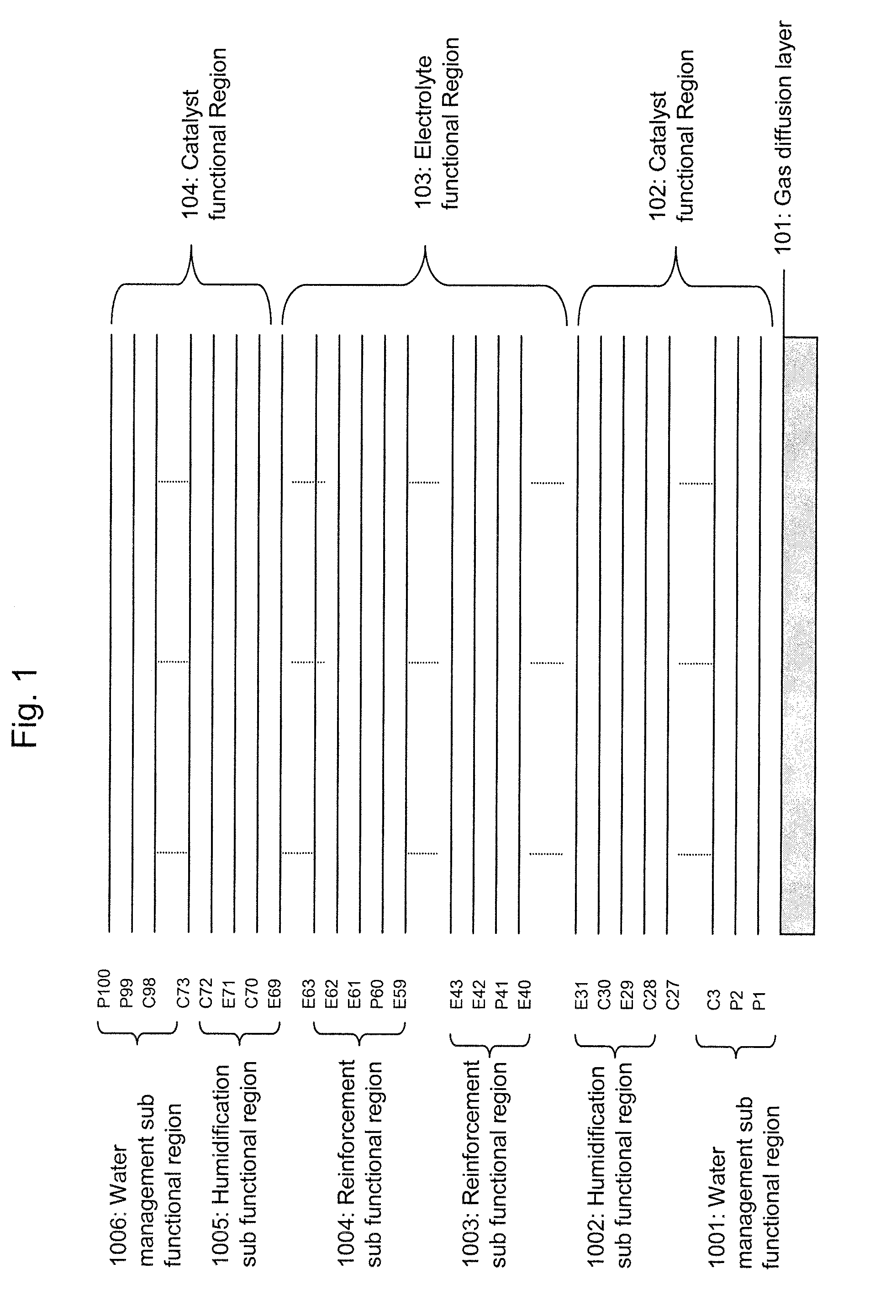

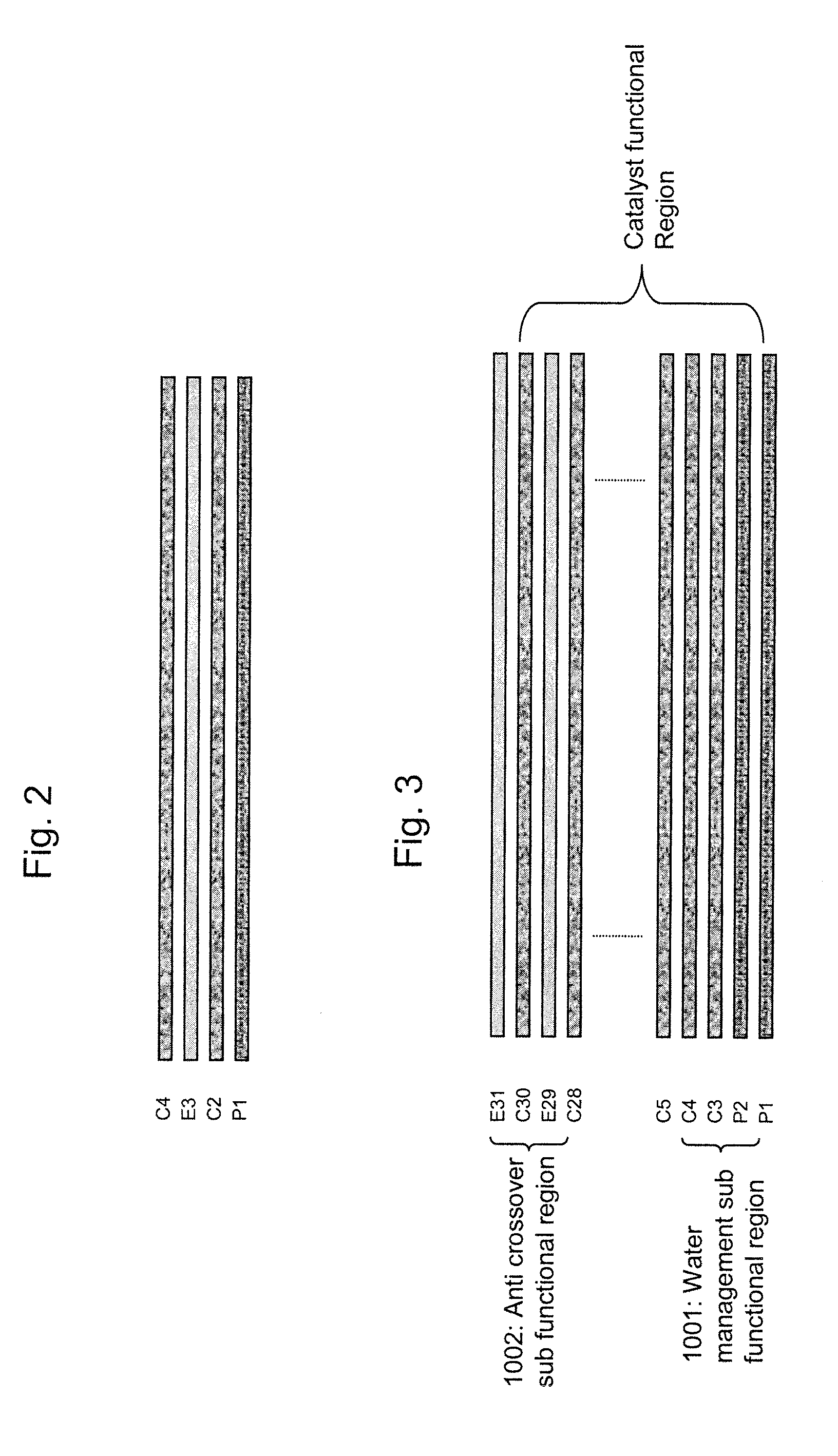

A membrane electrode assembly including a gas diffusion layer and a layered structure made up of from 4 to 1000 layers including layers of a first type and layers of a second type, wherein the layers of the first type are electrolyte layers and the layers of the second type are catalyst layers, the layered structure having one or more catalyst functional regions, each made up of layers of the first and second types, and one or more electrolyte functional regions, each made up of layers of the first and second types.

Owner:SHANGHAI HORIZON FUEL CELL TECH

Method of producing membrane electrode assemblies for use in proton exchange membrane and direct methanol fuel cells

InactiveUS20060269824A1Improve performanceCell electrodesFinal product manufactureMethanol fuelProton

Compositions and methods for the manufacture of electrodes for fuel cells. The compositions and methods are particularly useful for the manufacture of anodes and cathodes for proton exchange membrane fuel cells, particularly direct methanol fuel cells. The methods can utilize direct-write tools to deposit ink compositions and form functional layers of a membrane electrode assembly having controlled properties and enhanced performance.

Owner:CABOT CORP

Polymer electrolyte membrane, method for producing same, and membrane electrode assembly and polymer electrolyte fuel cell comprising same

InactiveUS6926984B2Low dependency of ionSufficient power-generating performanceElectrolyte holding meansSolid electrolytesFiberPolymer science

A polymer electrolyte membrane obtained by subjecting a sulfonated polyarylene membrane having an initial water content of 80-300 weight % to a hot-water treatment. A composite polymer electrolyte membrane comprising a matrix made of a first sulfonated aromatic polymer having a high ion exchange capacity, and a reinforcing material constituted by a second sulfonated aromatic polymer having a low ion exchange capacity in the form of fibers or a porous membrane.

Owner:HONDA MOTOR CO LTD

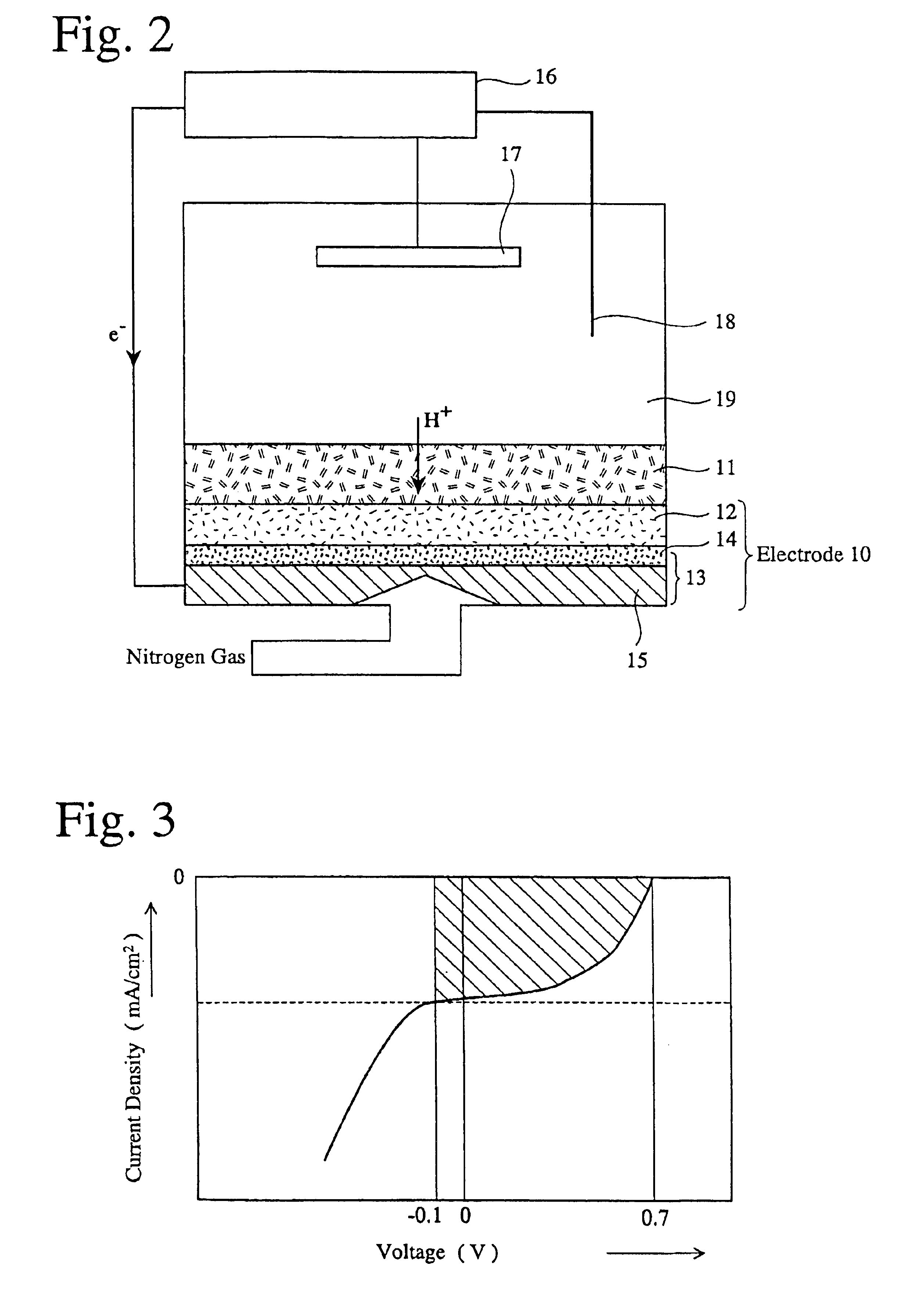

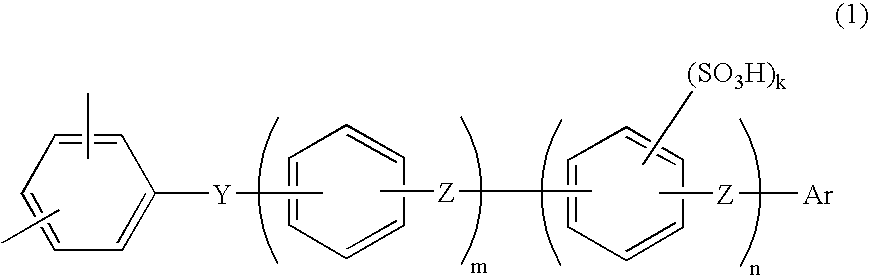

Membrane-electrode assembly for fuel cell

InactiveUS20060127728A1Improve creep resistanceIncreased durabilitySemi-permeable membranesActive material electrodesPolymer electrolytesPtru catalyst

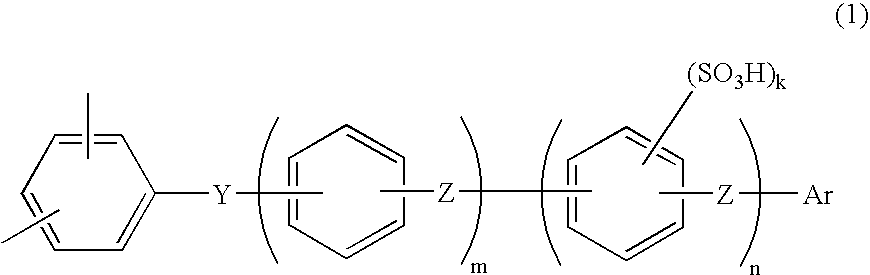

The present invention provides a membrane-electrode assembly for fuel cell which comprises a solid polymer electrolyte membrane comprising a specific polyarylene having a sulfonic acid group and has excellent creep resistance, power generation performance and durability against power generation under high-temperature environment. The membrane-electrode assembly is characterized in that a pair of electrodes each comprising a gas diffusing layer and a catalyst layer are joined to both sides of a solid polymer electrolyte membrane so that the catalyst layer side comes into contact with the membrane, said membrane comprises a sulfonated polyarylene comprising constituent unit represented by the following formula (1): wherein Y is a group represented by —C(CF3)2—, (CF2)i—, wherein i is an integer of 1 to 10, —SO— or —SO2—; Z is a divalent electron-donating group or a direct bond; Ar is an aromatic group having a substituent represented by —SO3H; m is an integer of 0 to 10; n is an integer of 0 to 10; and k is an integer of 1 to 4.

Owner:JSR CORPORATIOON +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com