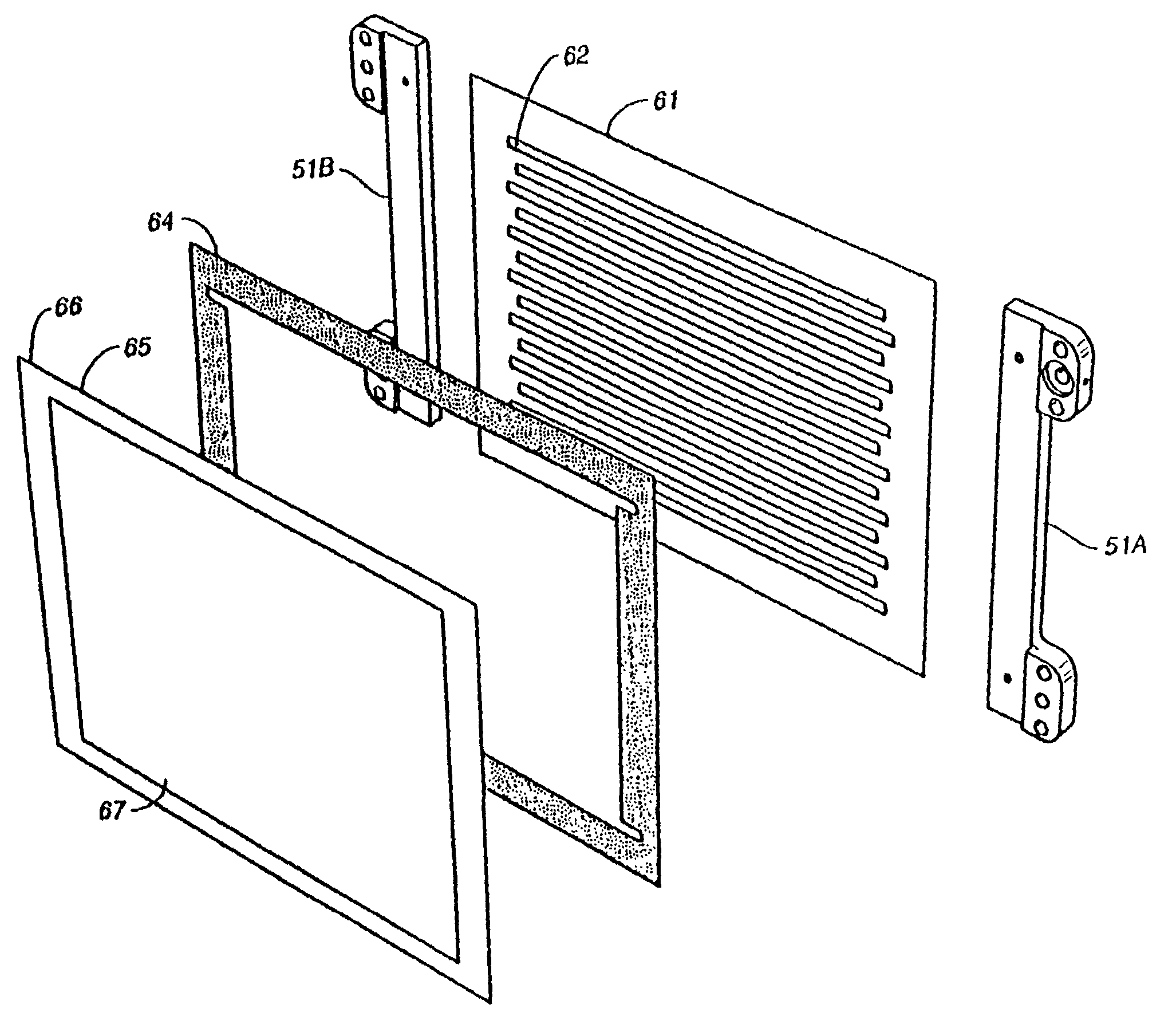

Integrated and modular BSP/MEA/manifold plates for fuel cells

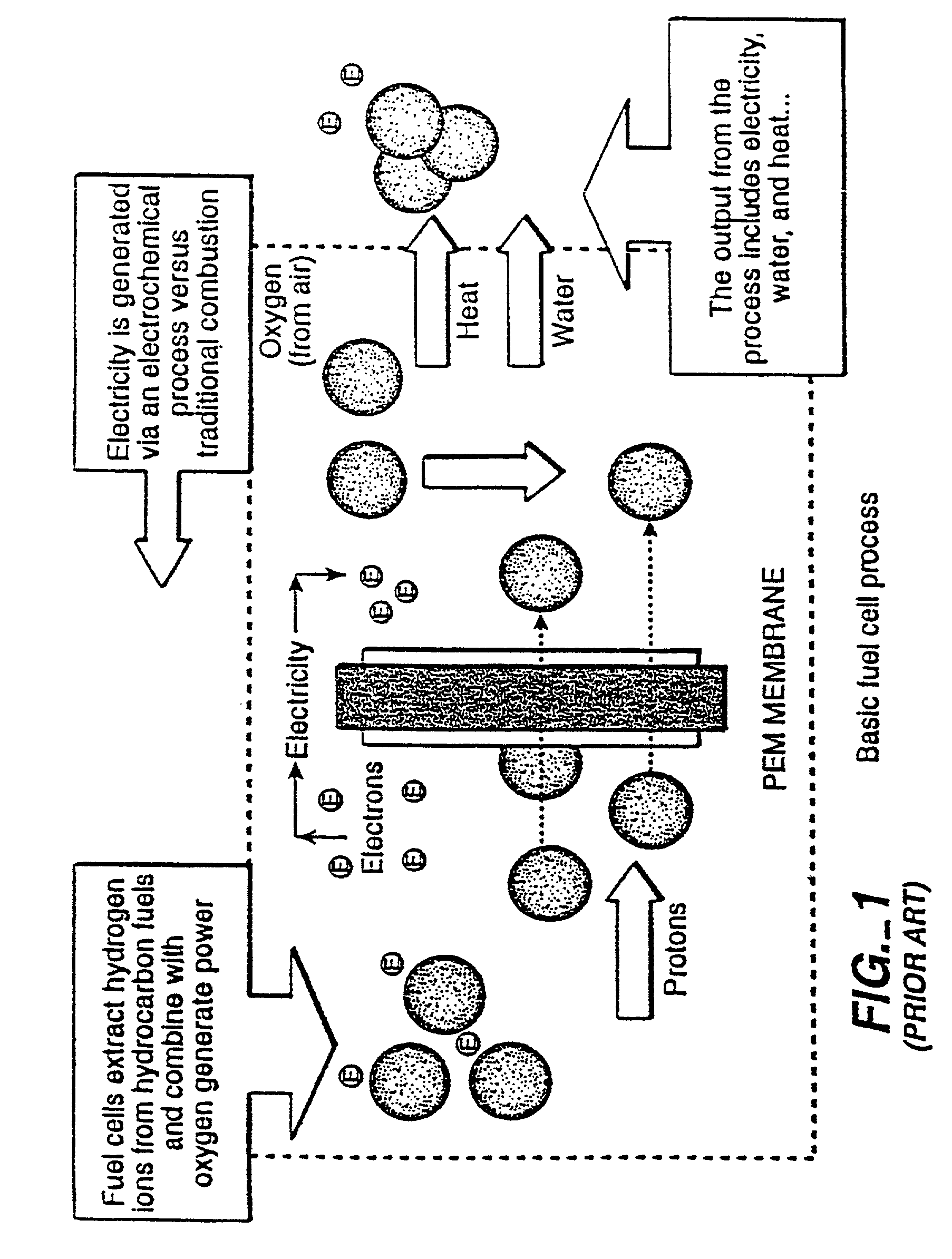

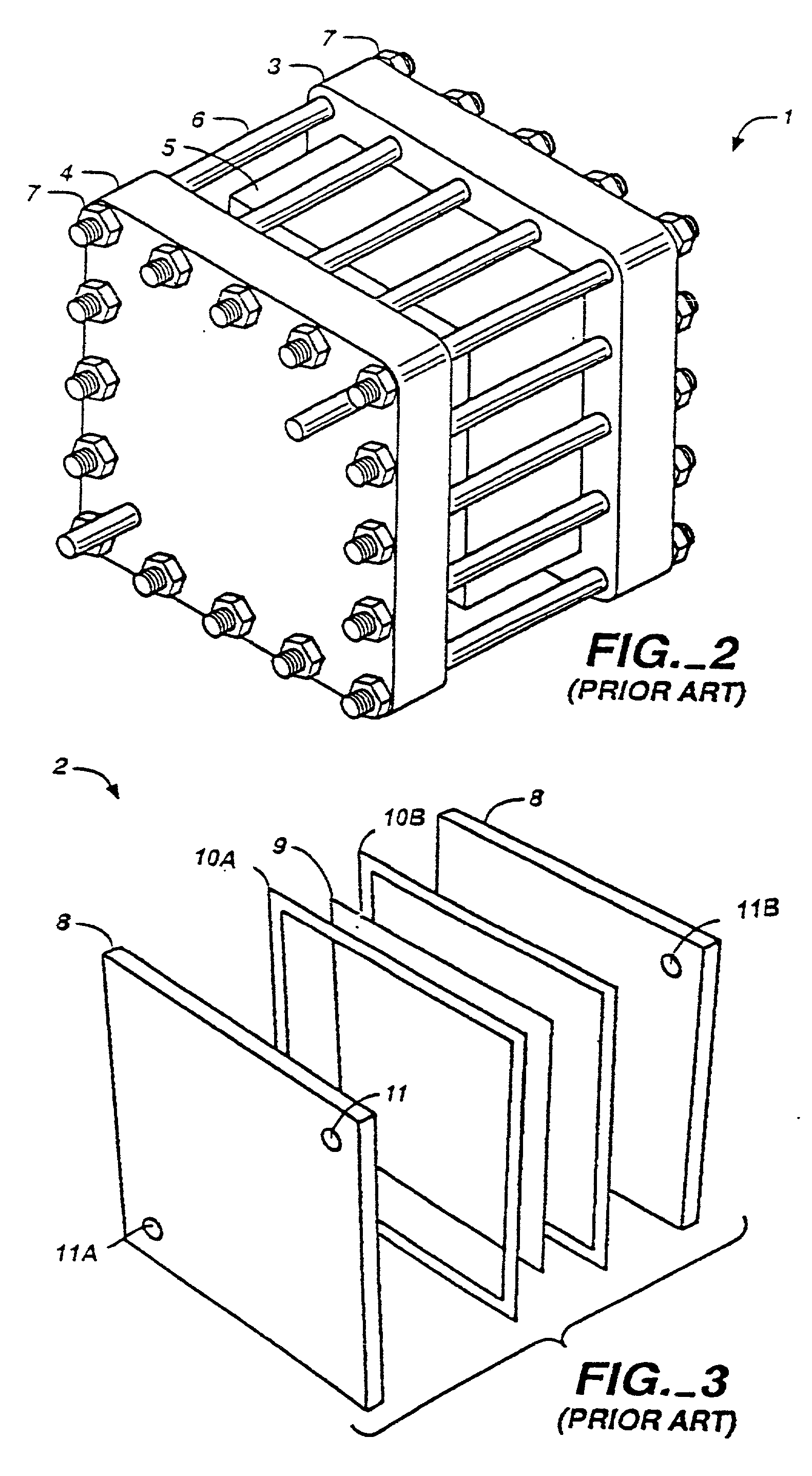

a fuel cell and modular technology, applied in the field of integrated and modular bsp/mea/manifold plates for fuel cells, can solve the problems of poor electrical conduction, lower cell performance, and assembly of a traditional pem cell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Definitions

[0062] As described herein

[0063] "BSP" refers to bipolar separator plates which term is conventional in the art.

[0064] "Flexible" refers to the BSP and / or MEA ability to flex with the forces and pressures of operation. The bonds between the components are substantially leak free. This flexibility assures that electrical contact is maintained by the compliant contacts as referenced in U.S. Ser. No. 60 / 226,471, filed Aug. 18, 2000; and U.S. Ser. No. ______, filed Apr. 13, 2001 (Express Mail No.: EL700013365US).

[0065] "Materials of construction" refers to the conventional materials that one of skill in the art would normally select to produce a conventional fuel cell. Unless otherwise noted herein for the present invention, conventional materials of construction are used.

[0066] "MEA" refers to the membrane electrode assembly.

[0067] "PEM" refers to proton exchange membrane--a component of a MEA and fuel cell.

[0068] "Module" refers to identical single interchangeable se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| flexible | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com