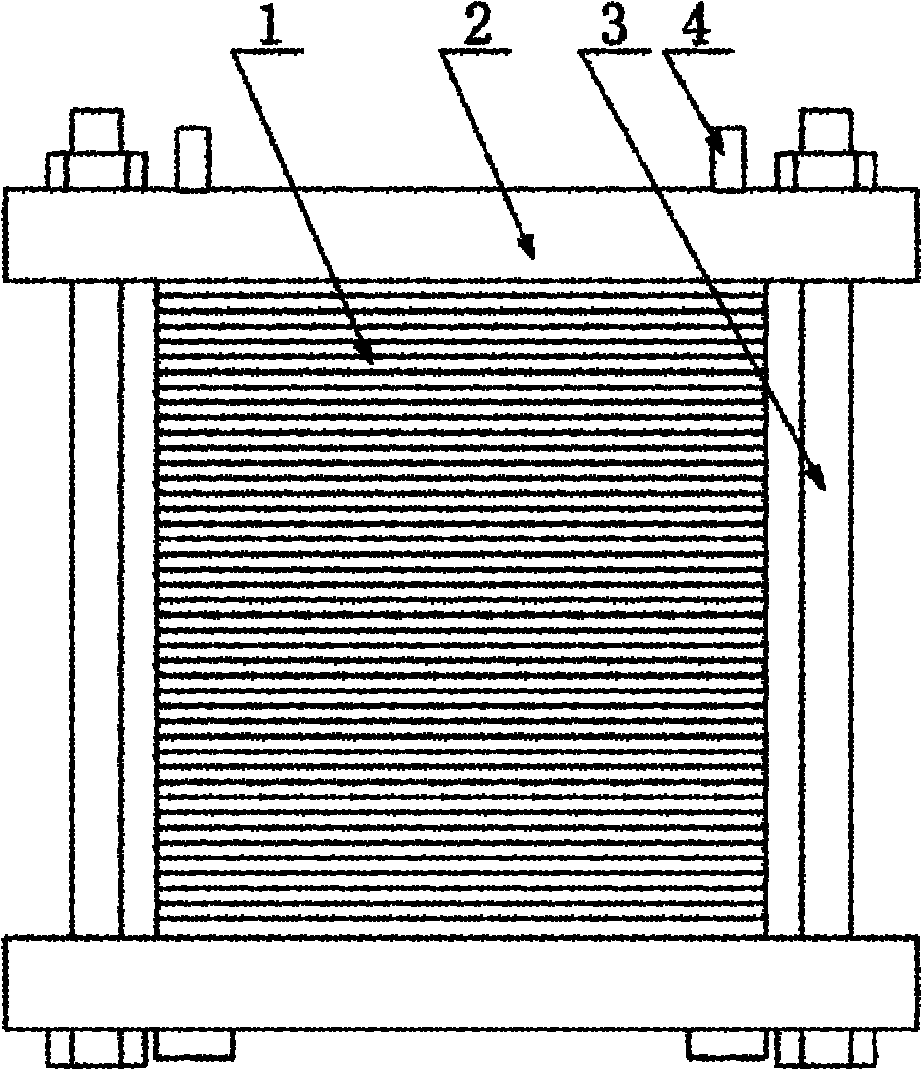

Device for automatically assembling fuel battery galvanic pile

A technology for fuel cell stacks and assembly devices, which is applied in the direction of fuel cells, fuel cell groups, electrochemical generators, etc., and can solve problems such as difficulty in achieving optimal pressing force, unfavorable stack maintenance, and discontinuous changes. Achieve the effects of uniform force, high degree of automation, and uniform contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

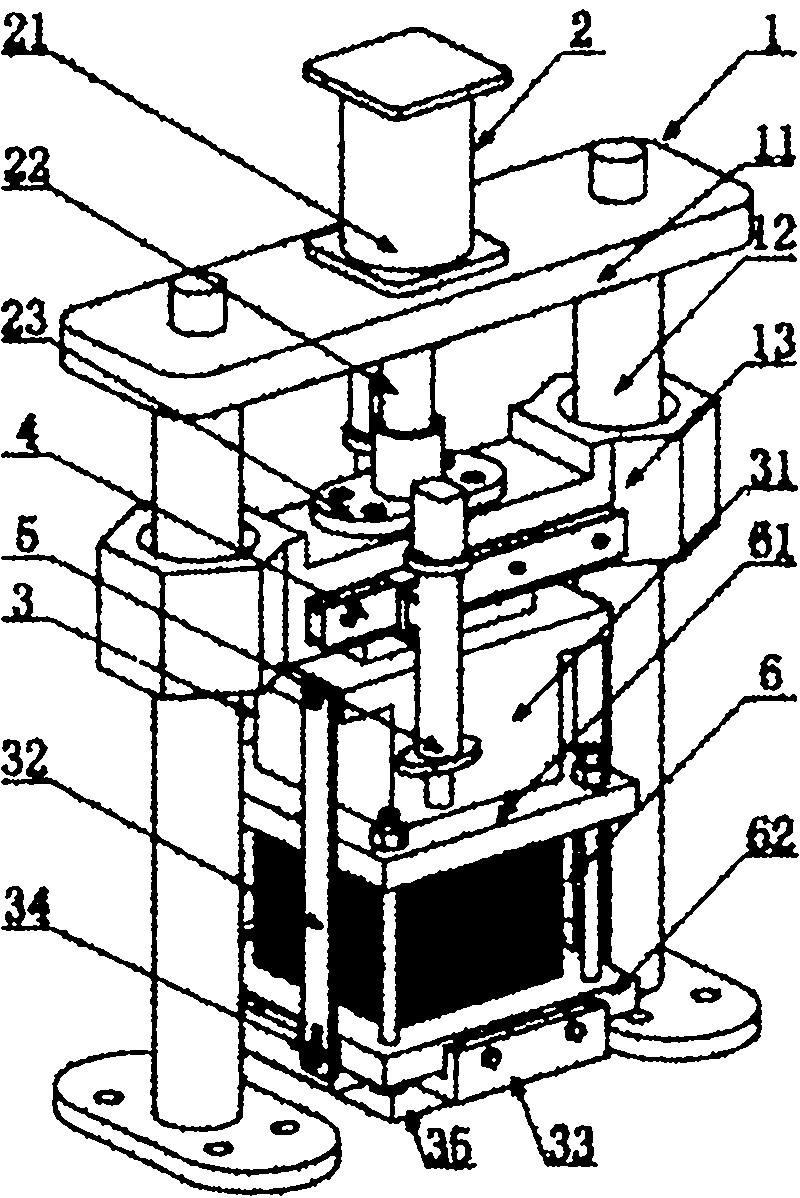

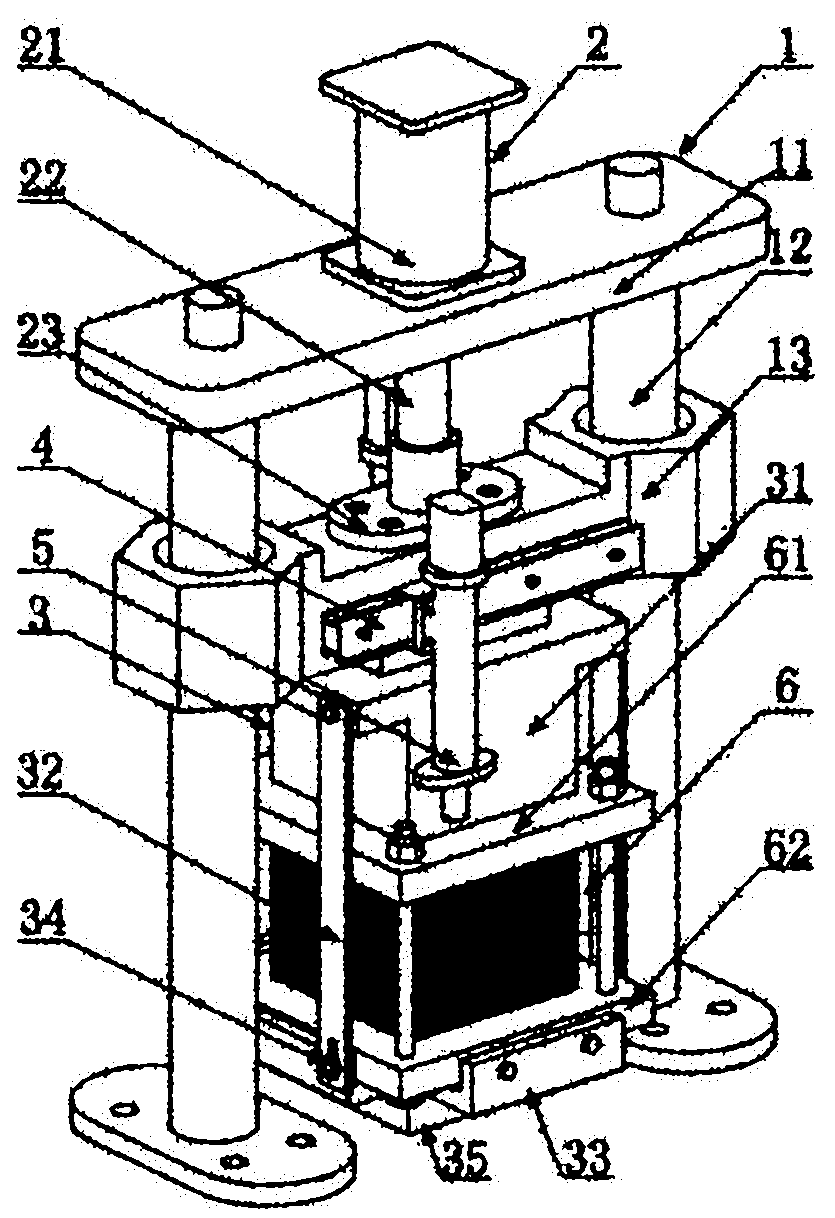

[0019] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

[0020] Such as figure 2 As described, this embodiment includes: frame 1, pressure adjustable pressing device 2, automatic positioning guide rod device 3, guide rail 4 and automatic nut screwing device 5, wherein the frame 1 is fixed on the workbench, The pressure-adjustable hold-down device 2 is arranged on one end of the slide block 13, and is connected to the frame 1, and the automatic pulling positioning guide rod device 3 is arranged on the other end of the slide block 13, and the guide rail 4 is fixed on the slide block 13. On both sides of the block 13, the automatic nut screwing device 5 can slide along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com