Patents

Literature

875 results about "Polymer electrolyte fuel cells" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

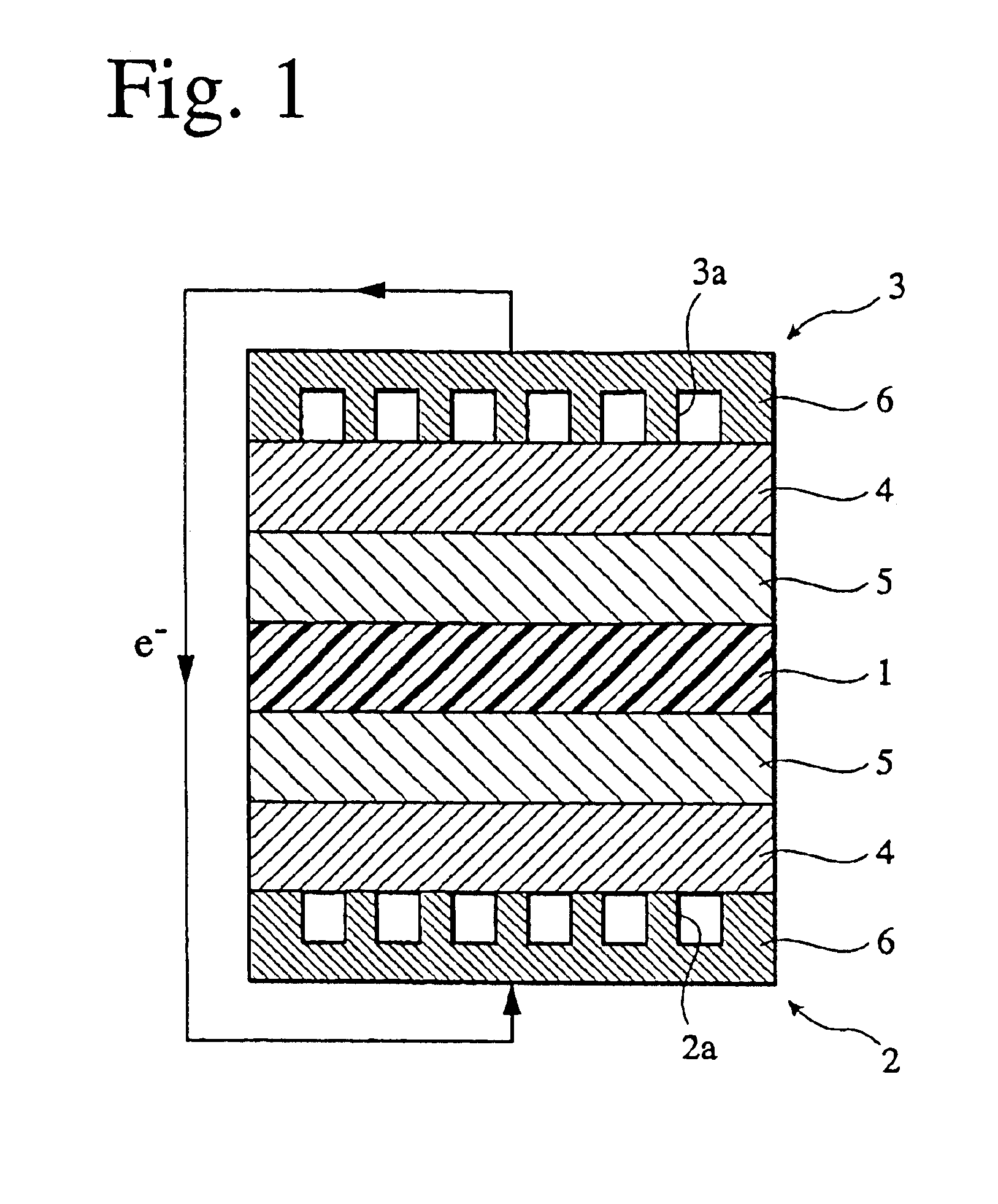

Polymer Electrolyte Membrane (PEM) fuel cells used in automobiles—also called Proton Exchange Membrane fuel cells—use hydrogen fuel and oxygen from the air to produce electricity.

Fuel cell

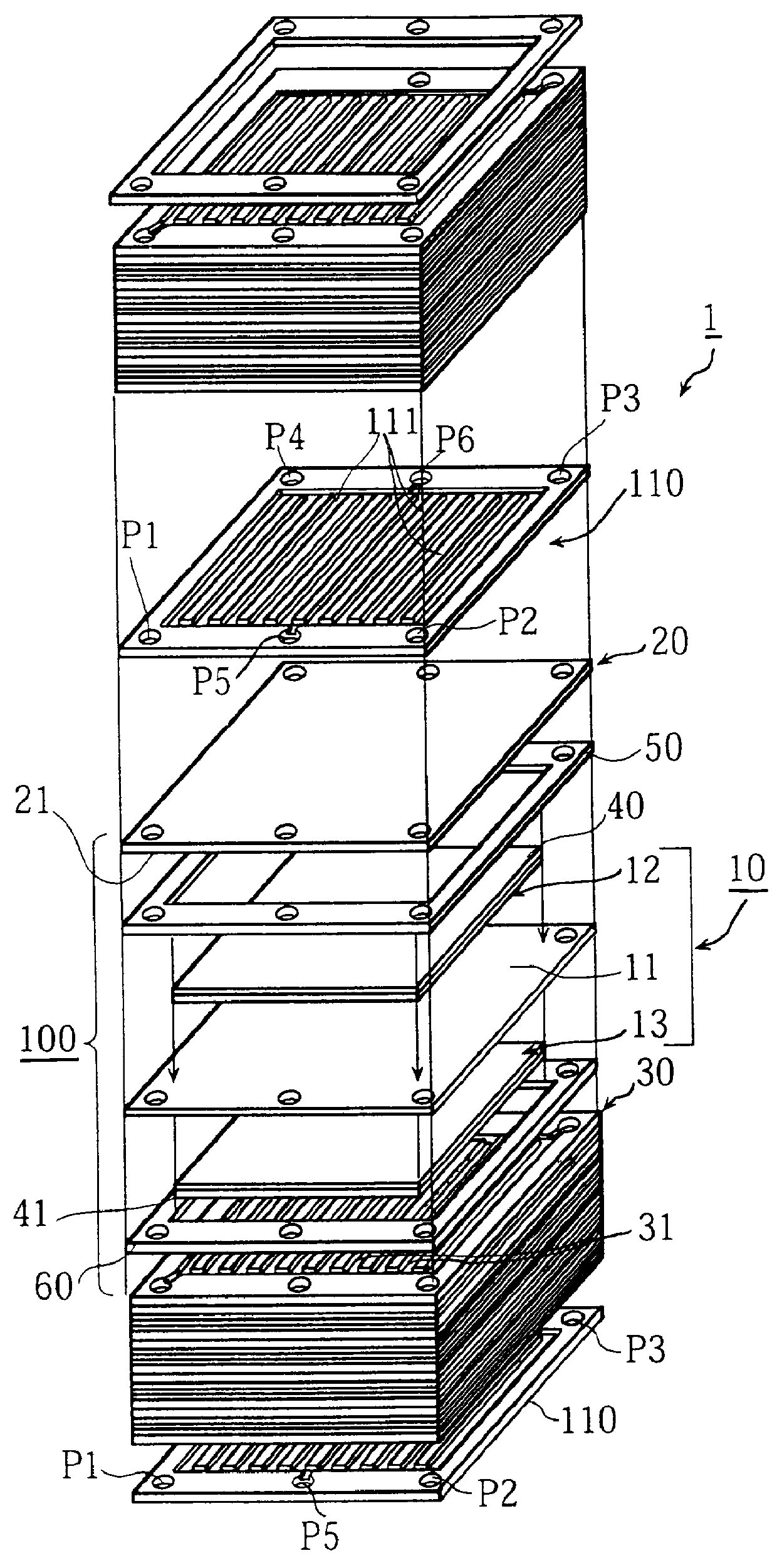

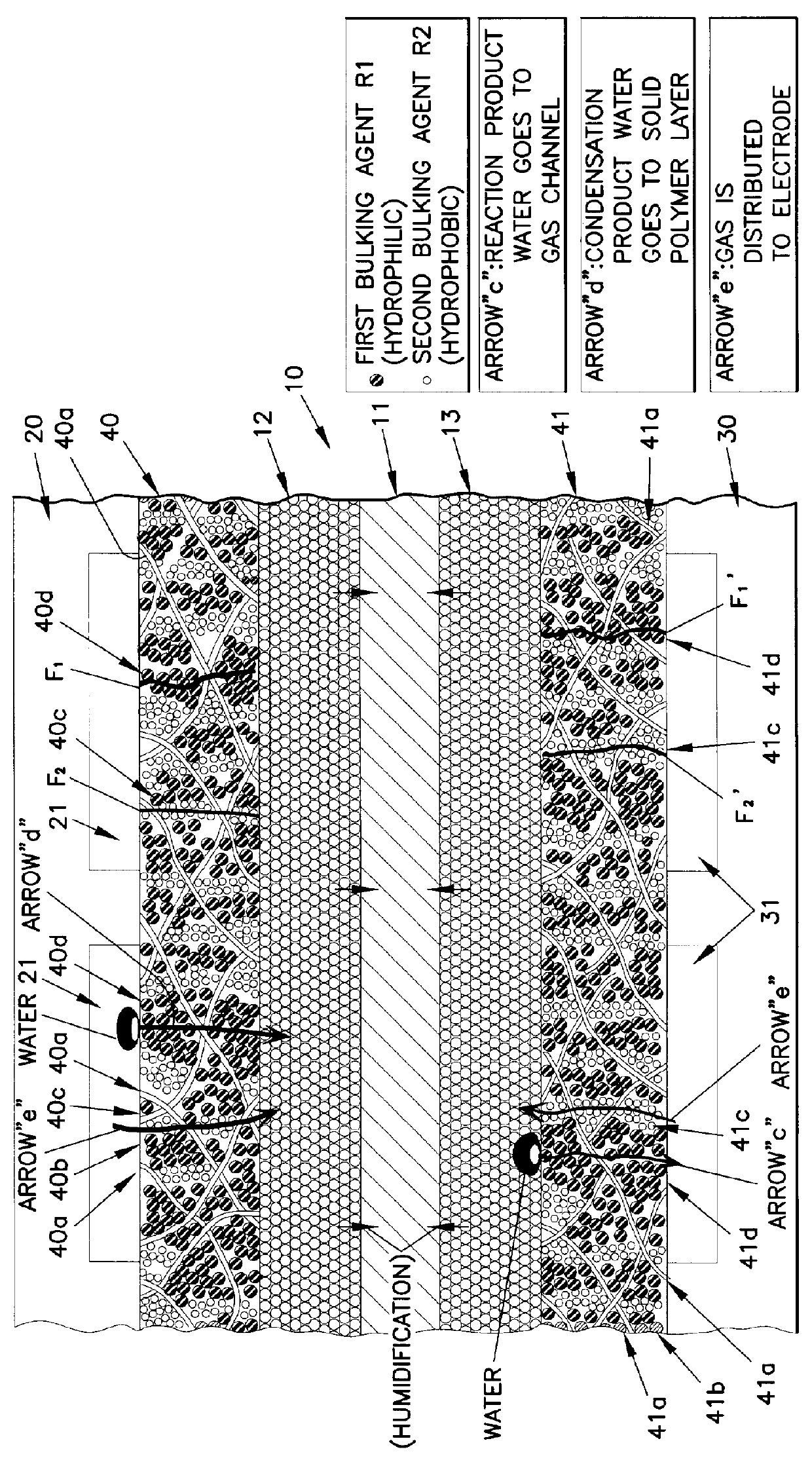

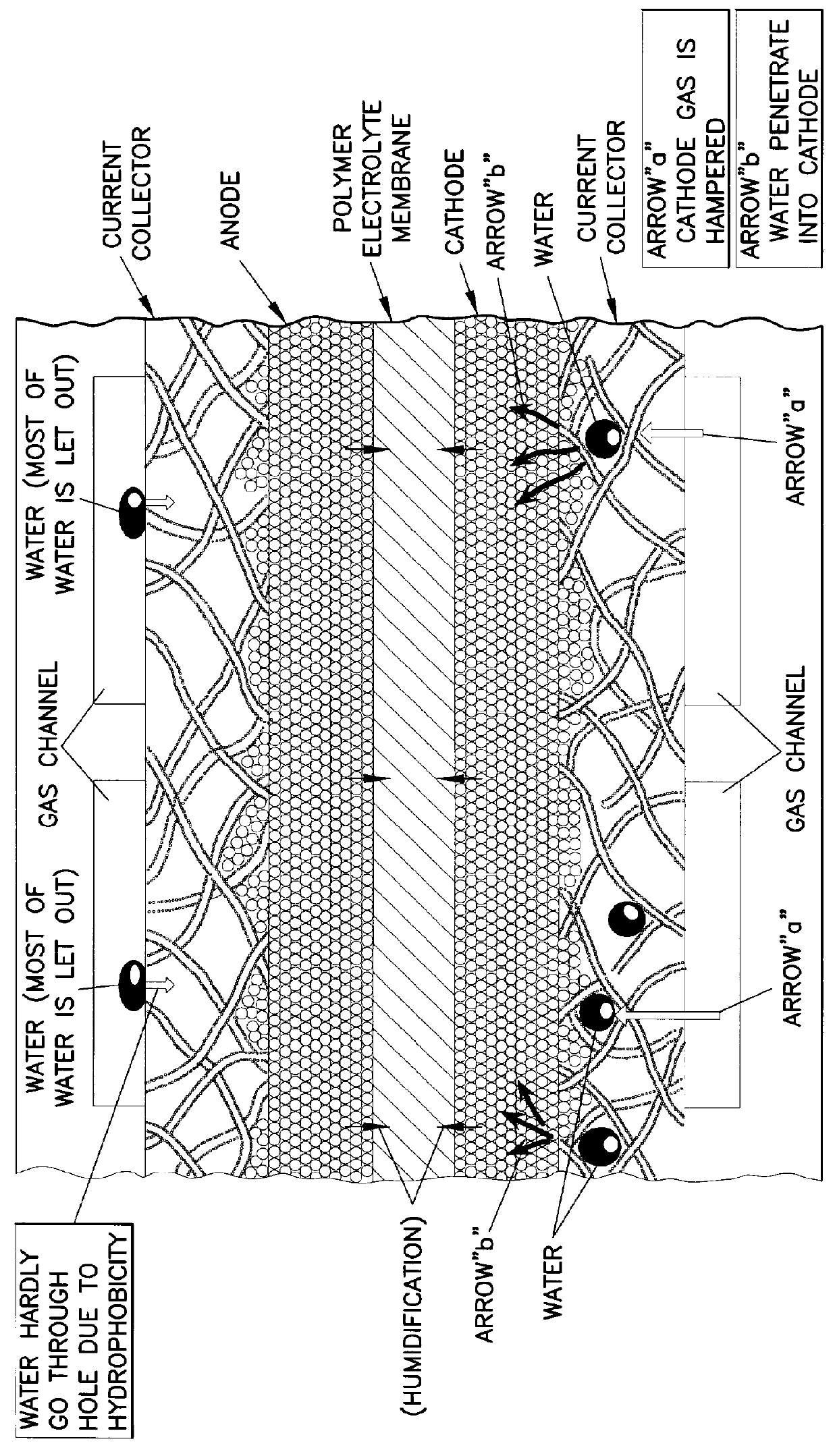

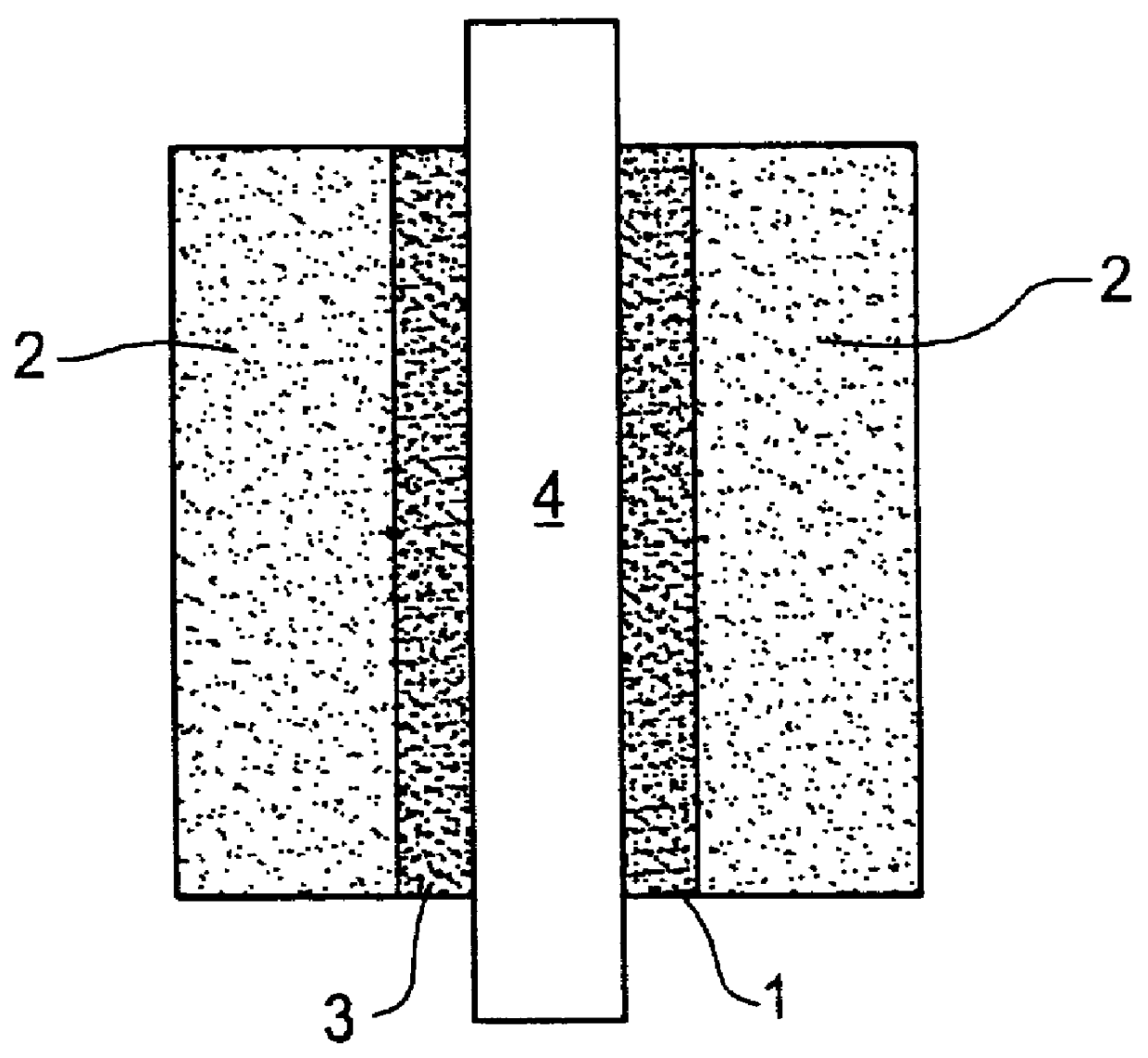

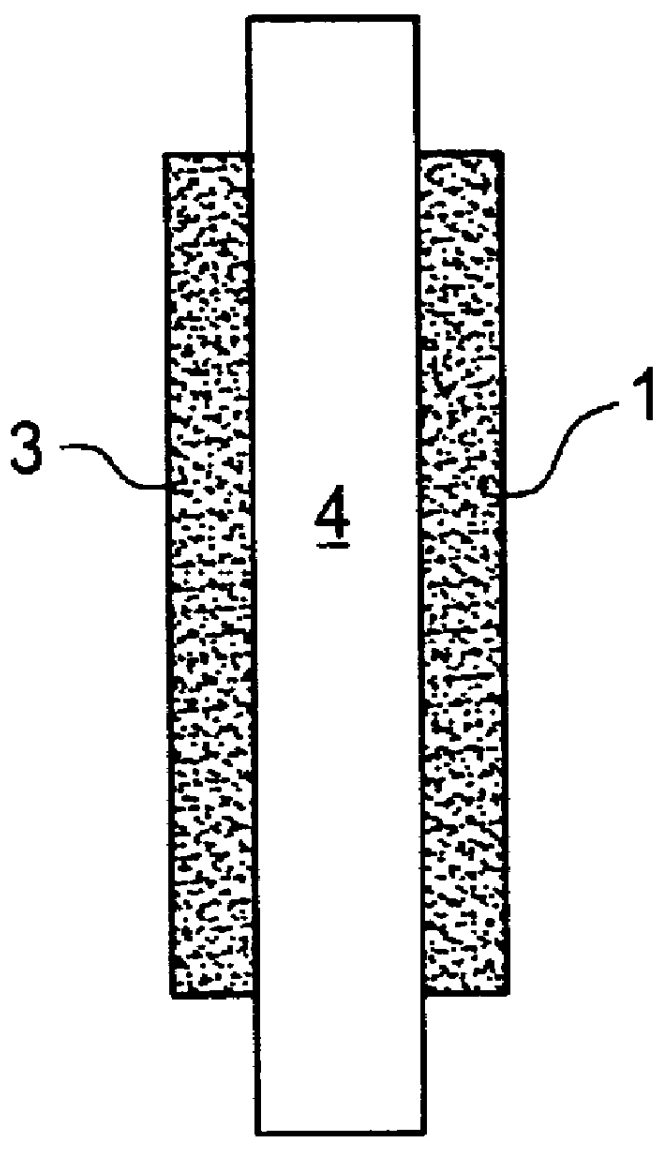

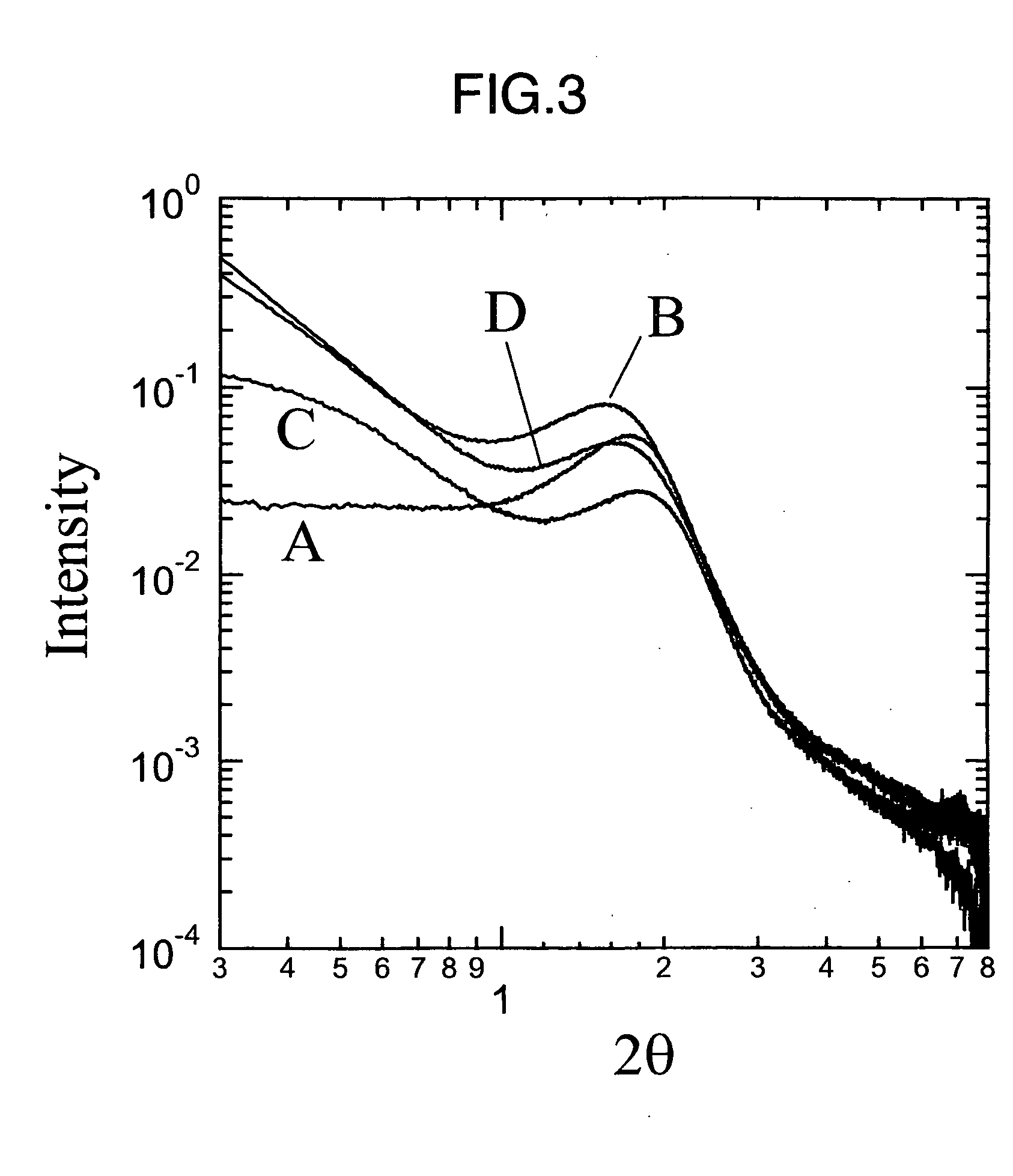

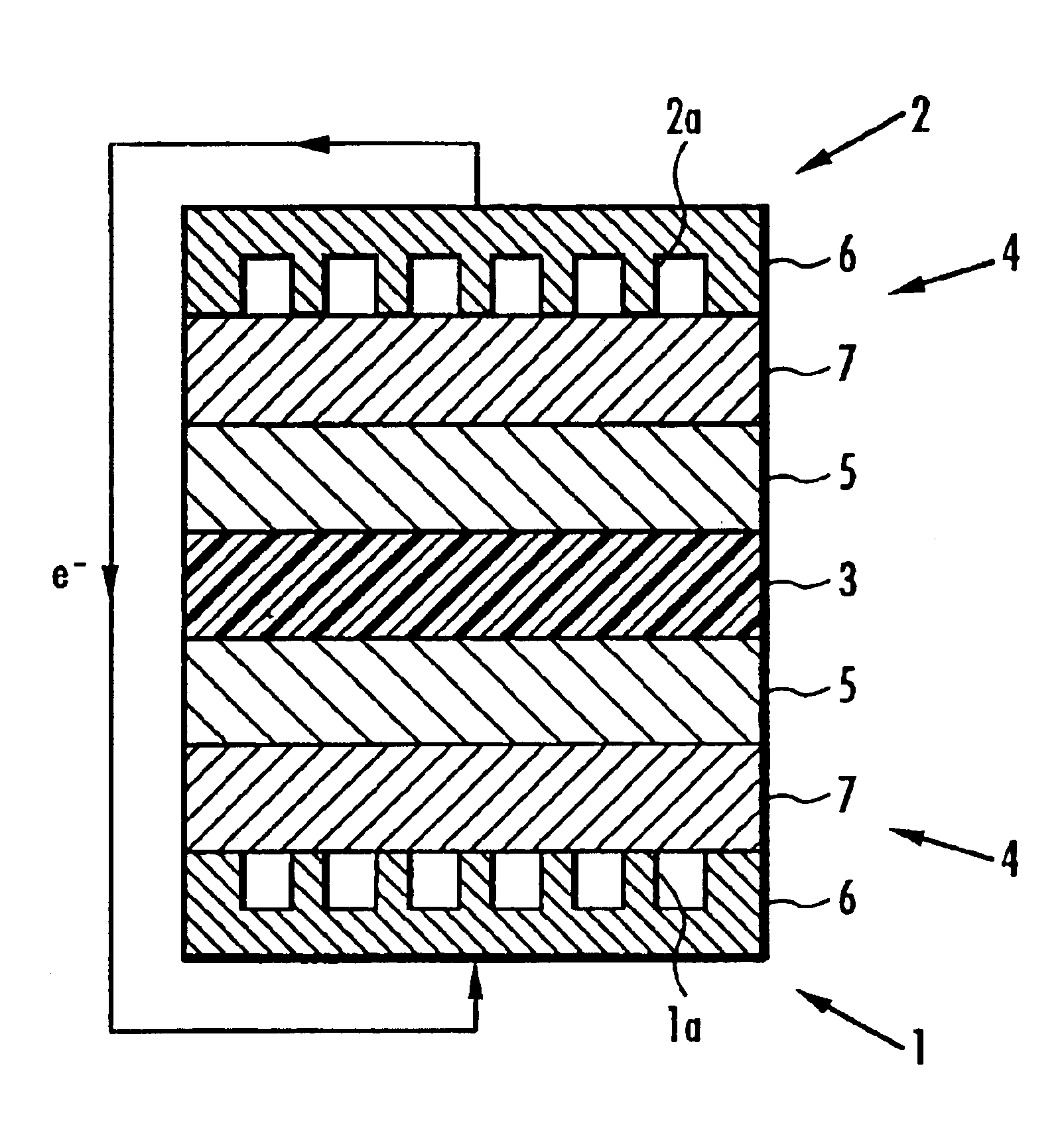

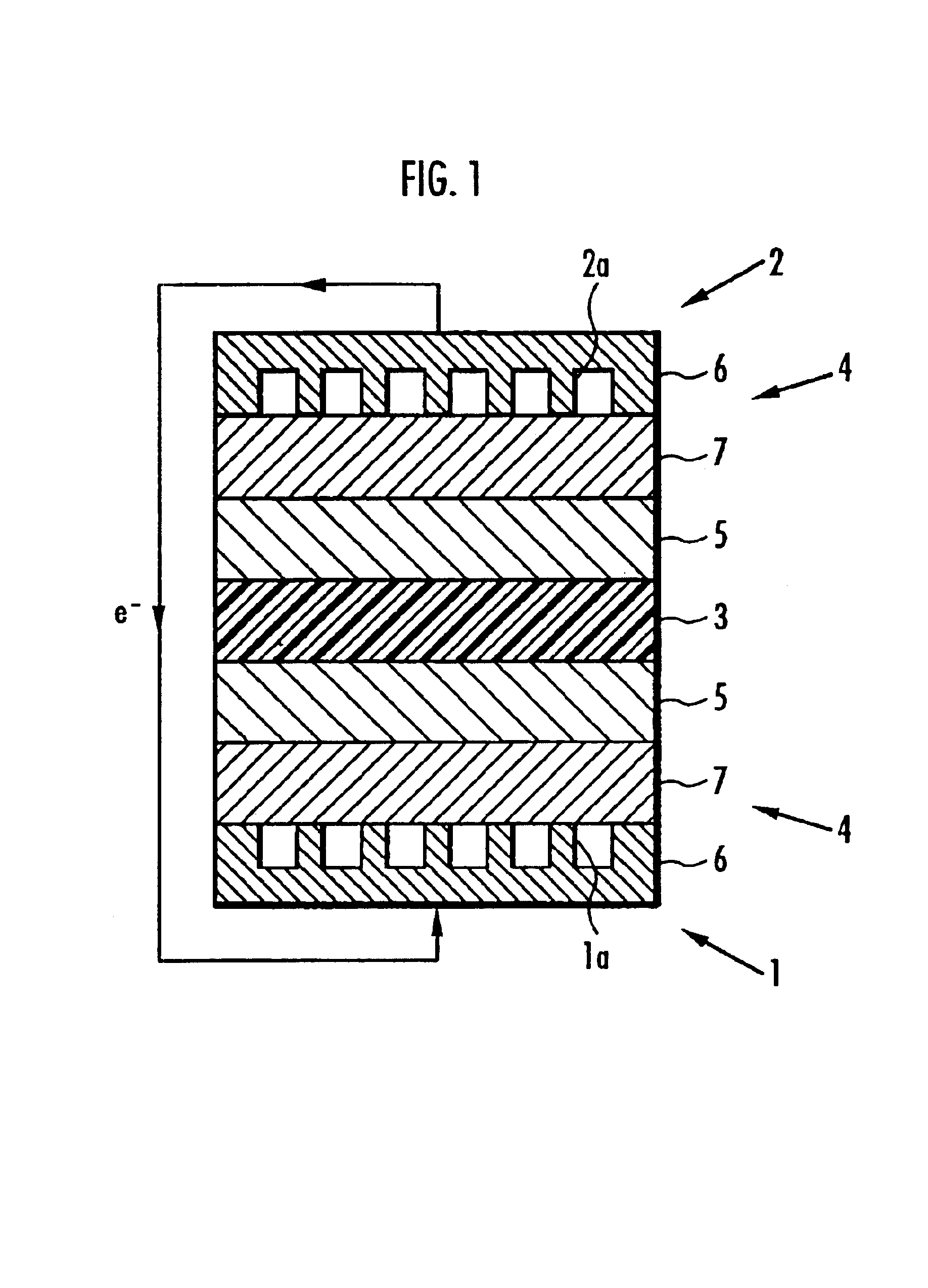

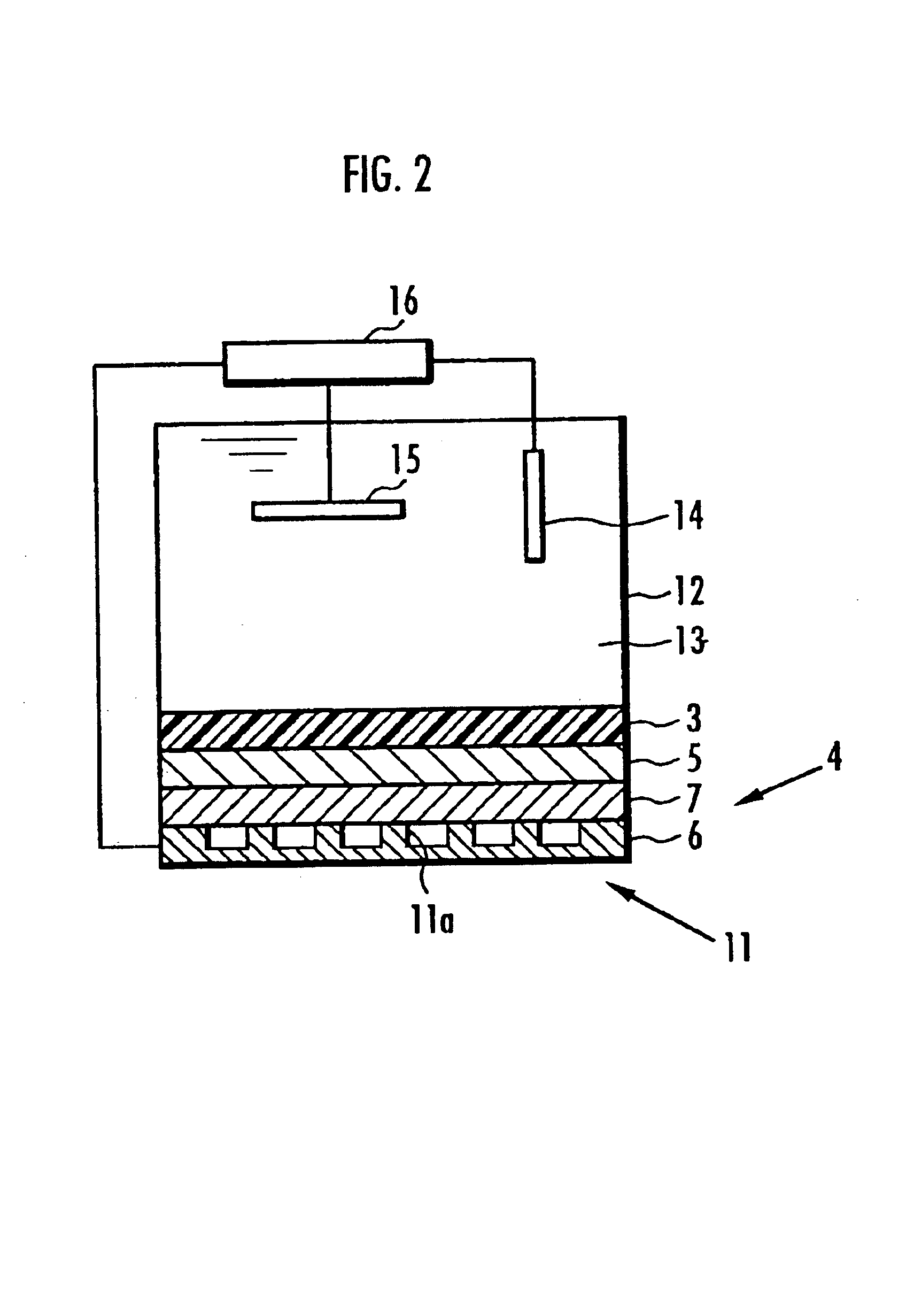

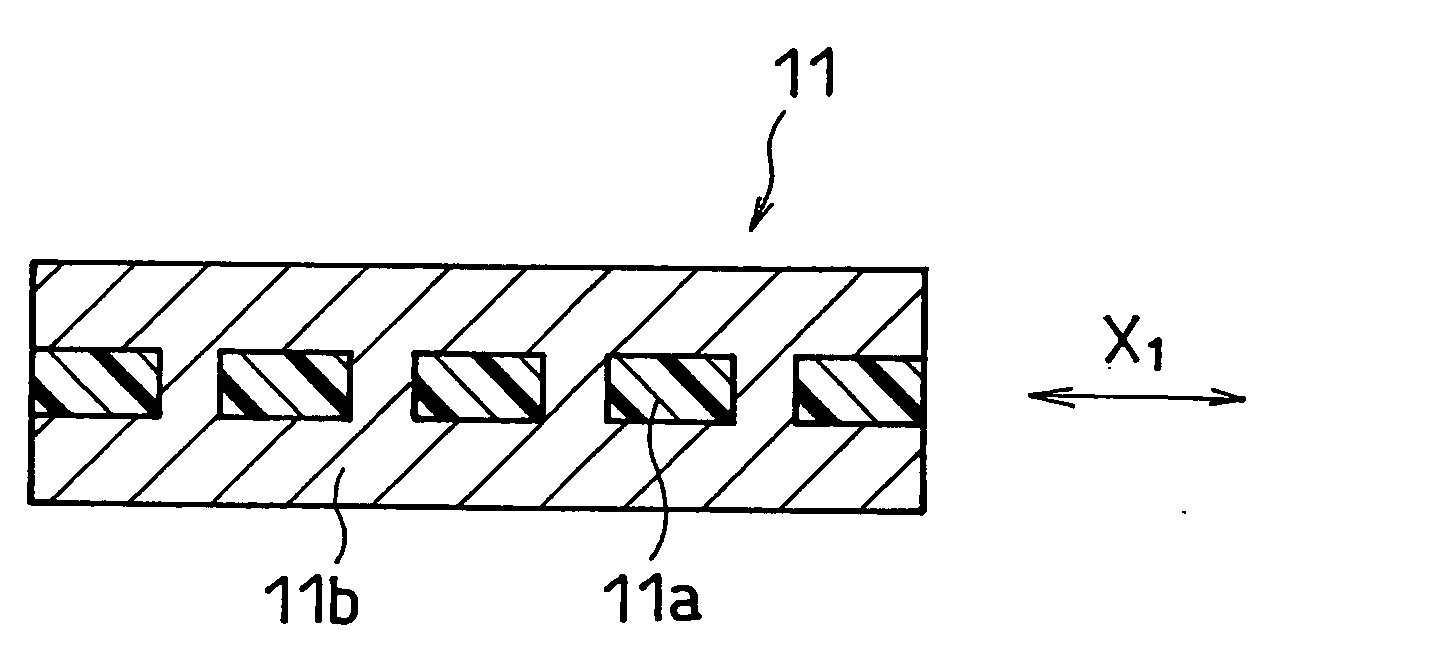

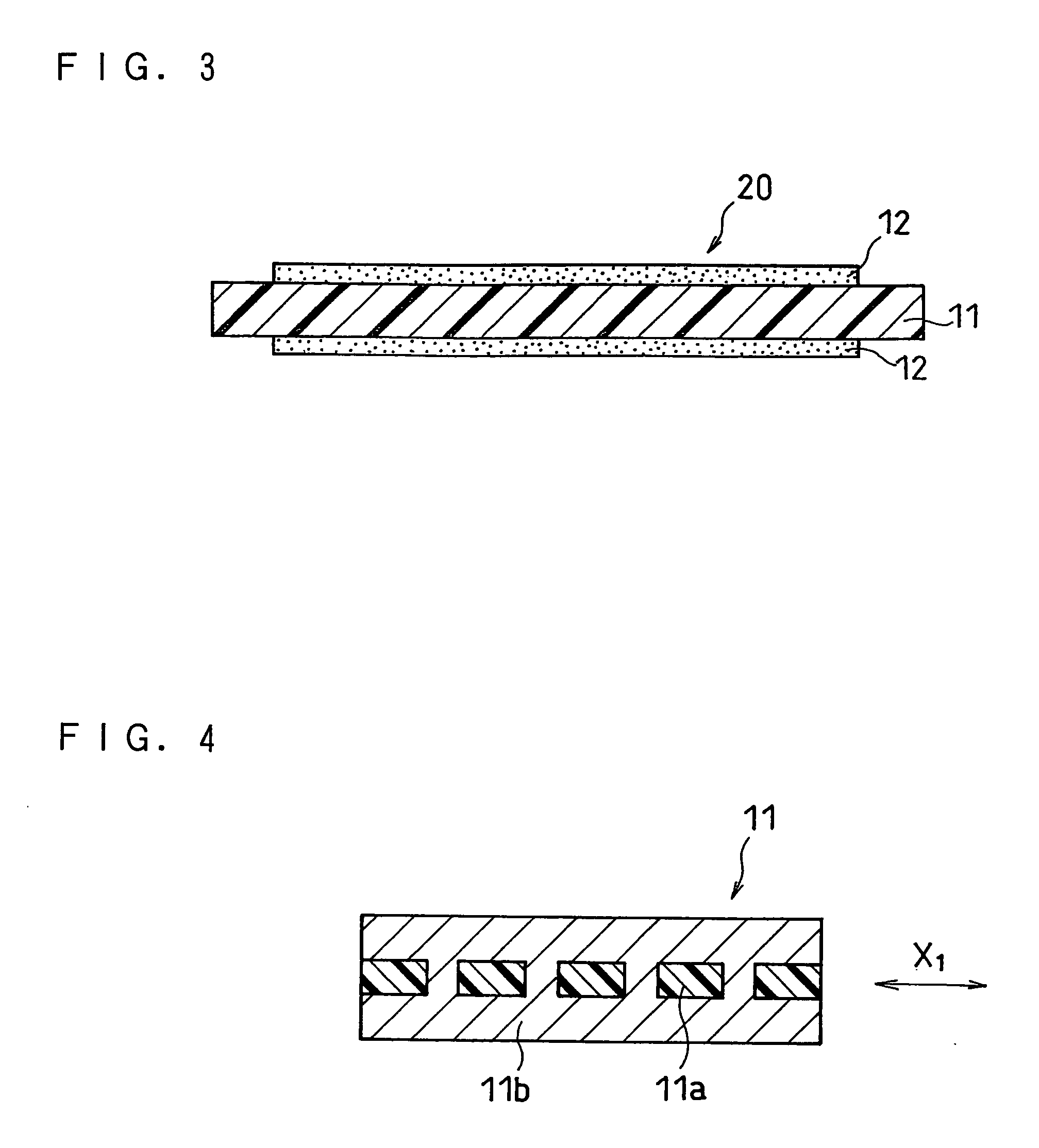

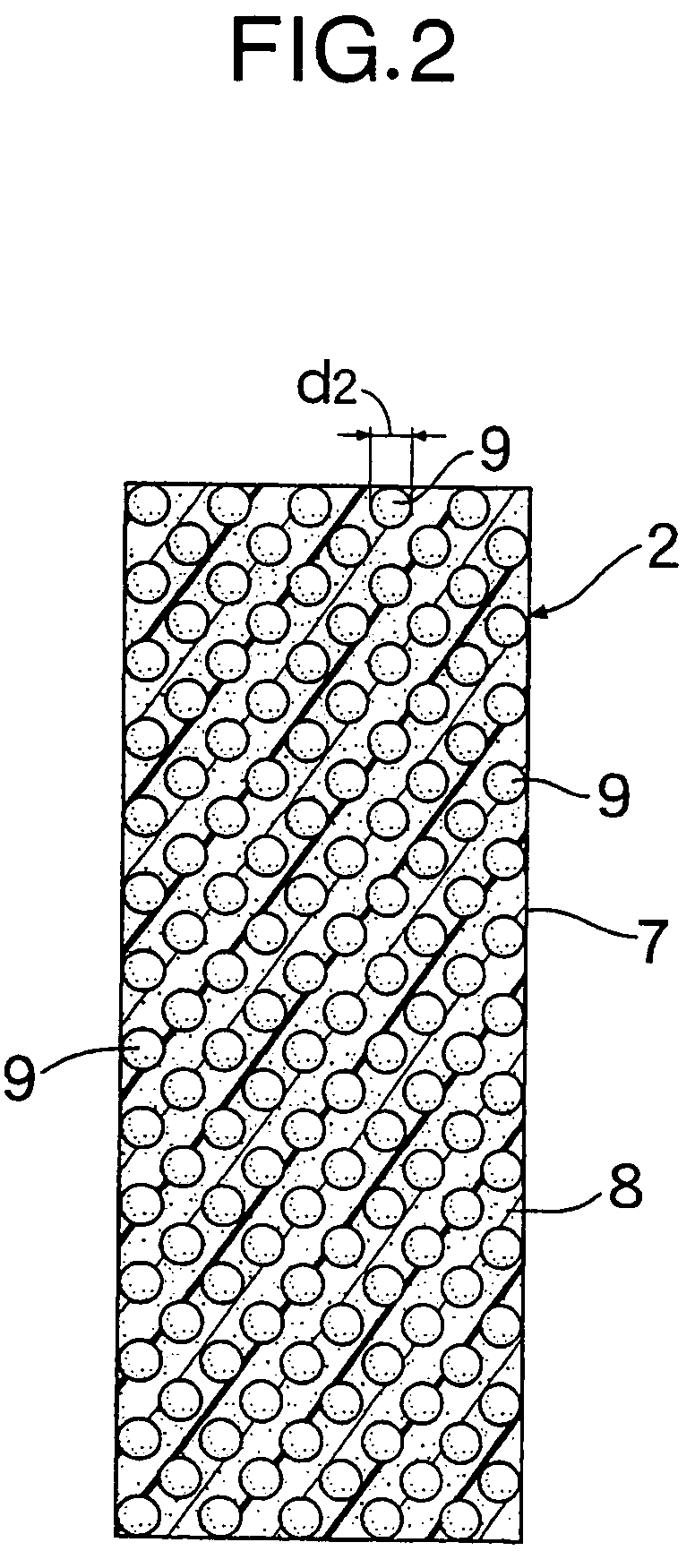

InactiveUS6083638AEfficient humidificationSolid electrolytesFuel cells groupingPorous substratePolymer electrolytes

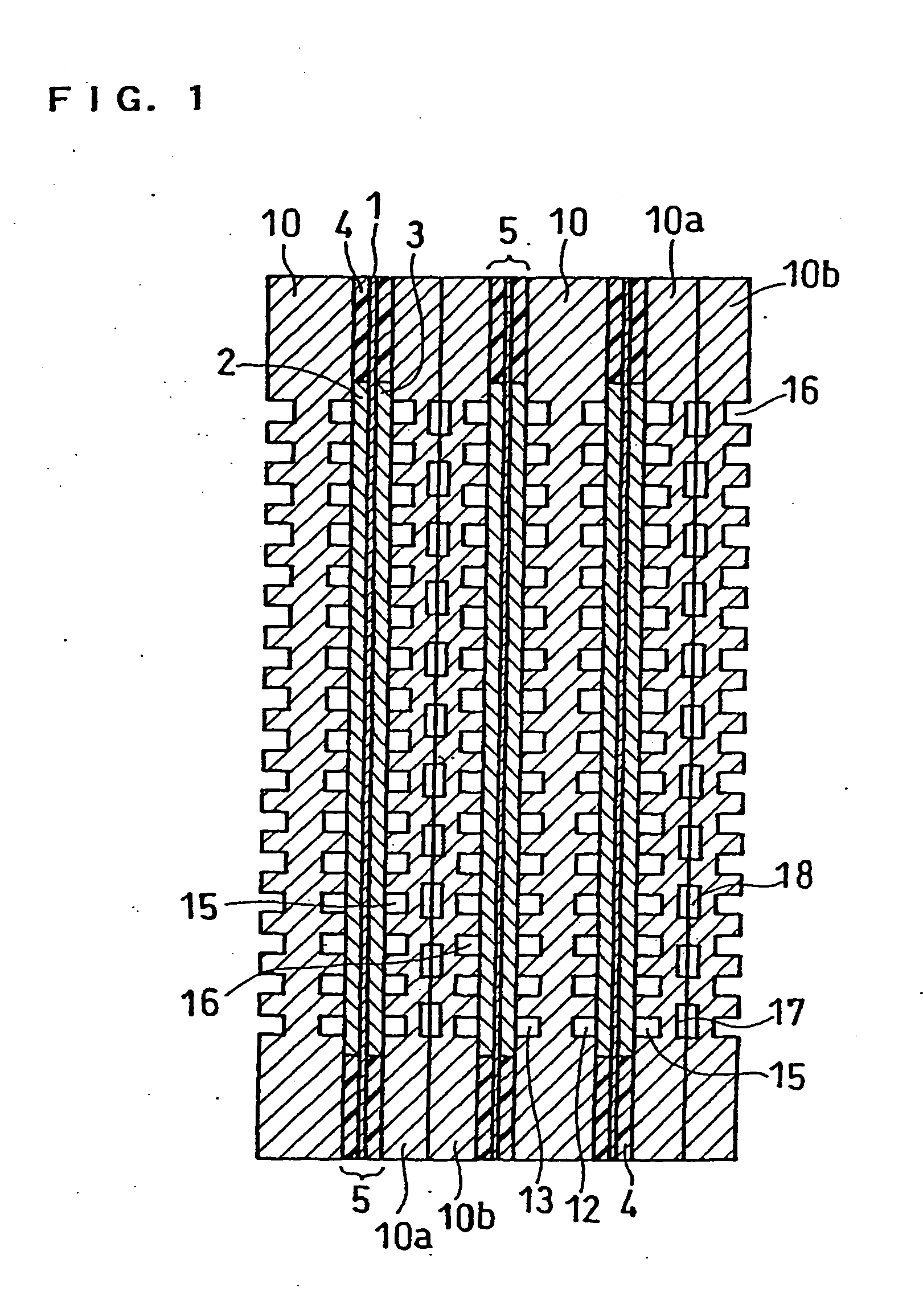

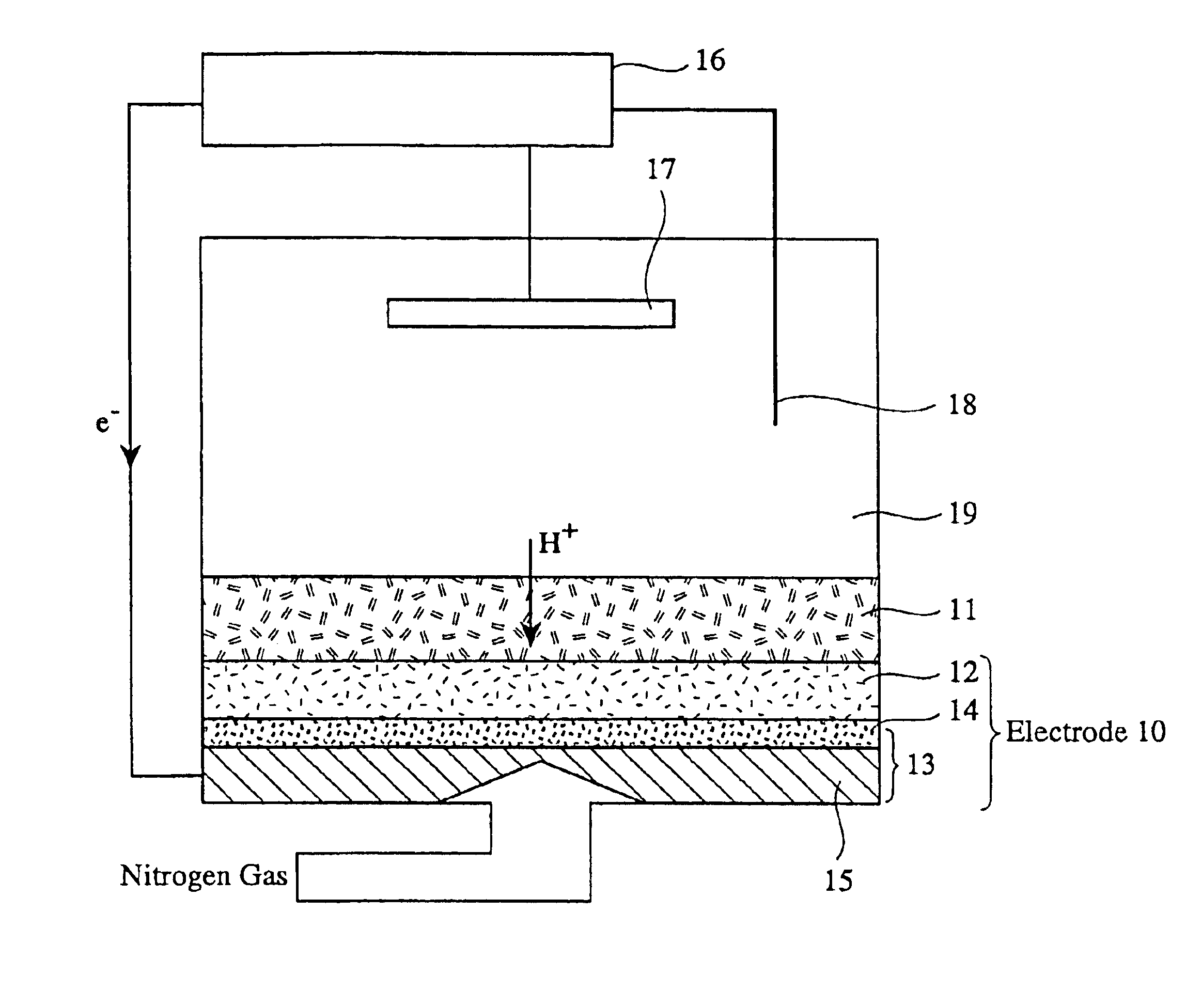

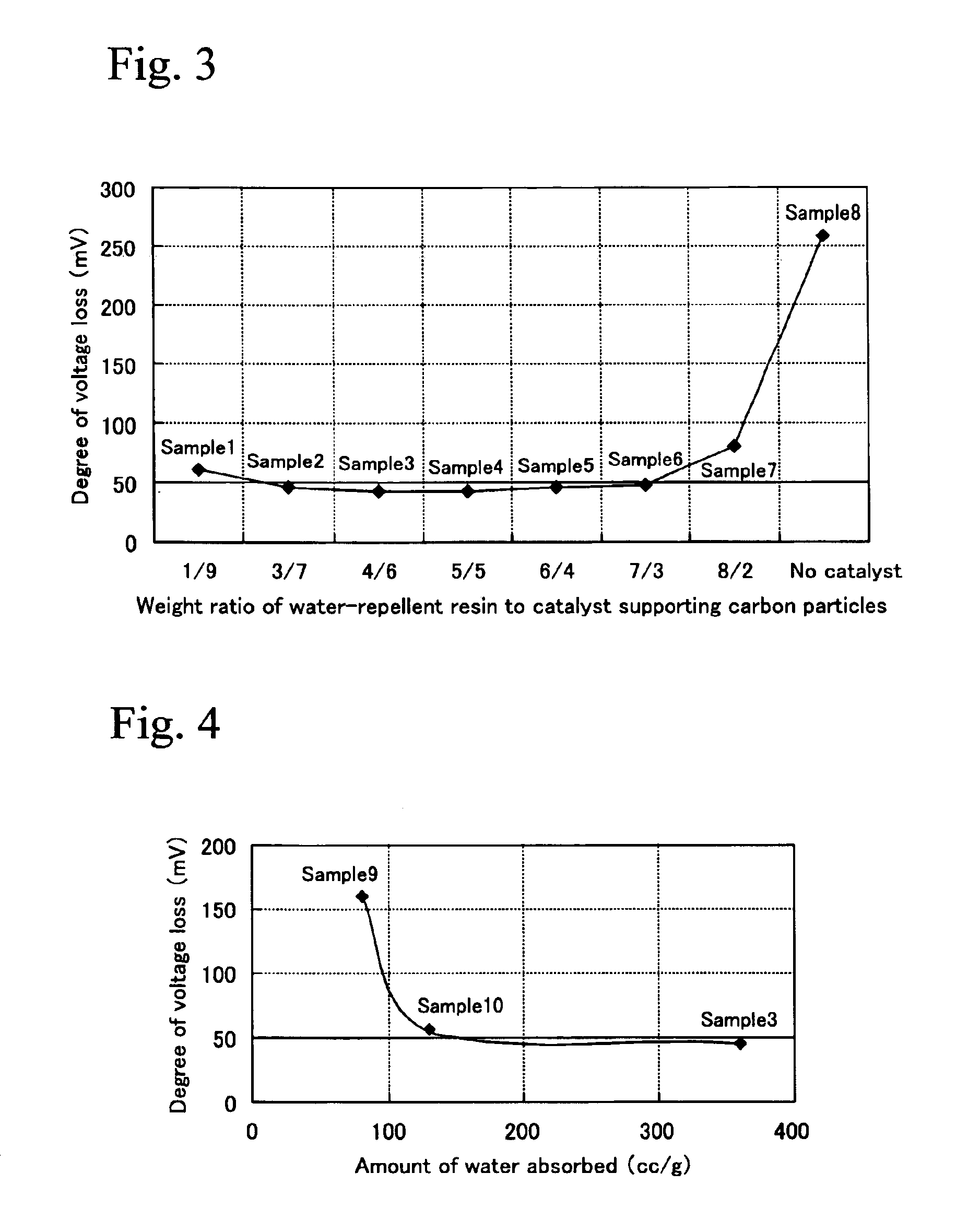

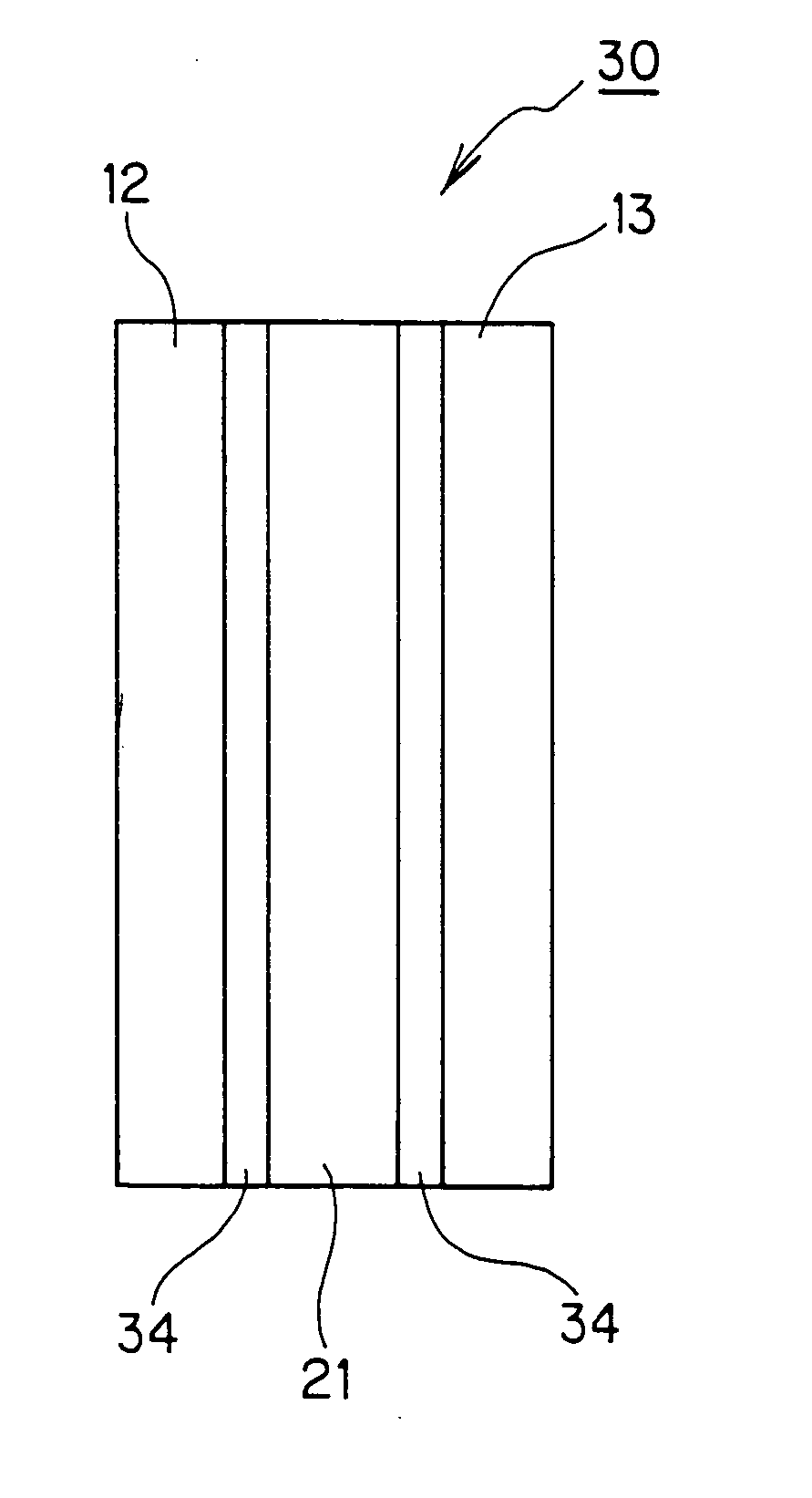

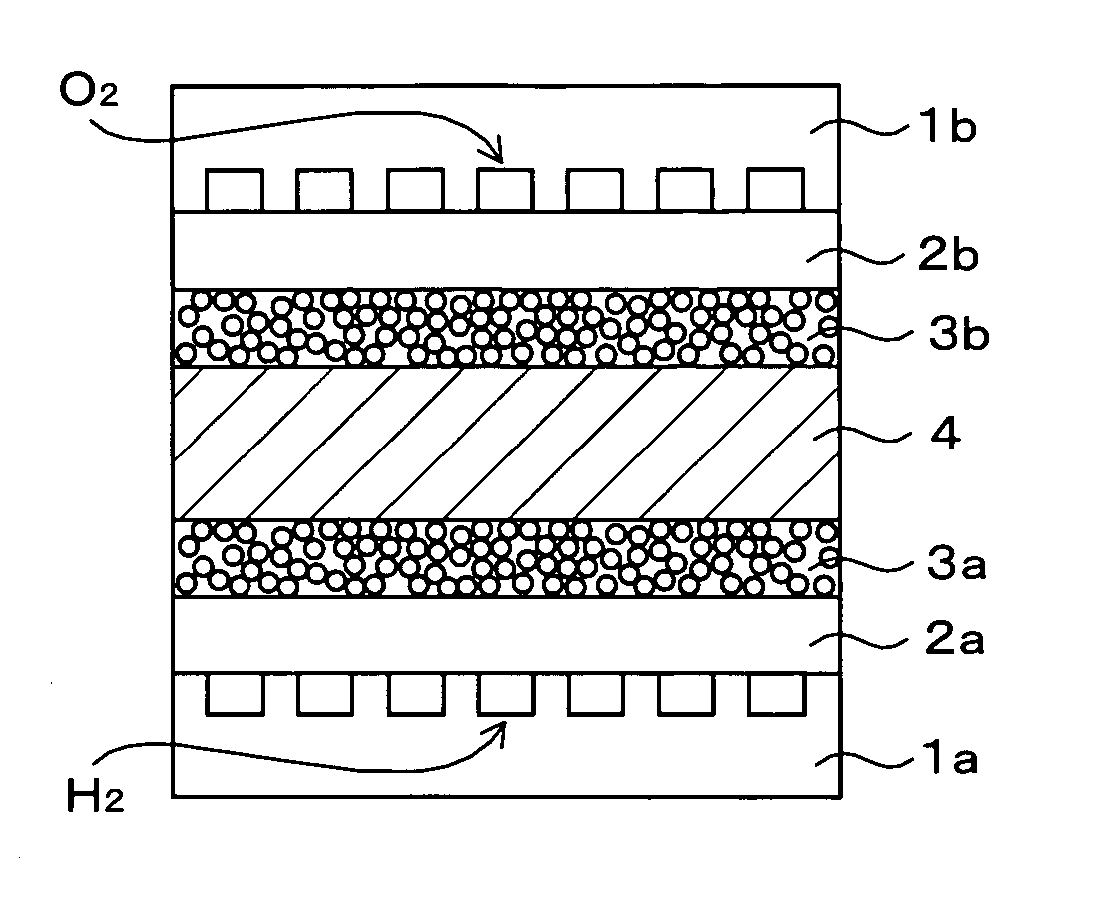

A current collector includes a thin porous substrate and a hydrophilic material, where the hydrophilic material is provided to holes of the thin porous substrate or surfaces of skeleton elements of the porous substrate so that hydrophilic areas formed by the hydrophilic material successively pass through the thin porous substrate between both surfaces of the thin porous substrate. In the current collector, water is let out through the hydrophilic areas and does not stay on an interface between an electrode and the current collector so that reaction gas is not hampered and is supplied, unlike a conventional current collector. When the current collector is applied to a polymer electrolyte fuel cell, water is supplied with reliability through the hydrophilic areas to a polymer electrolyte membrane so that the polymer electrolyte membrane is effectively humidified. The current collector applied to a cathode achieves a profound effect because reaction product water tends to stay around a cathode of any types of fuel cells. The current collector also includes gas flow paths which are surrounded by particles of a hydrophobic material and pass through the thin porous substrate between both surfaces of the thin porous substrate. As a result, gas permeability of the current collector is maintained with reliability.

Owner:SANYO ELECTRIC CO LTD

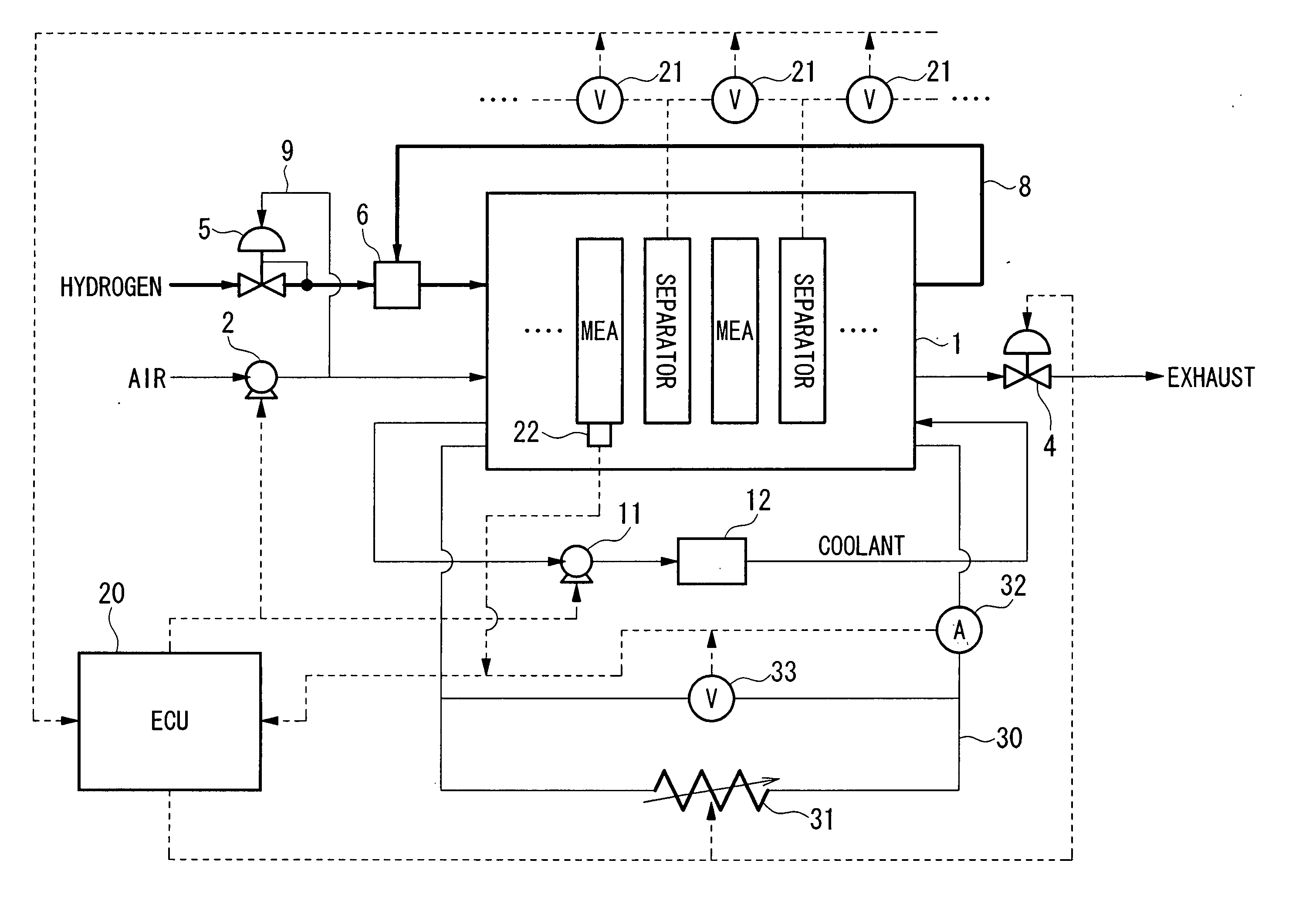

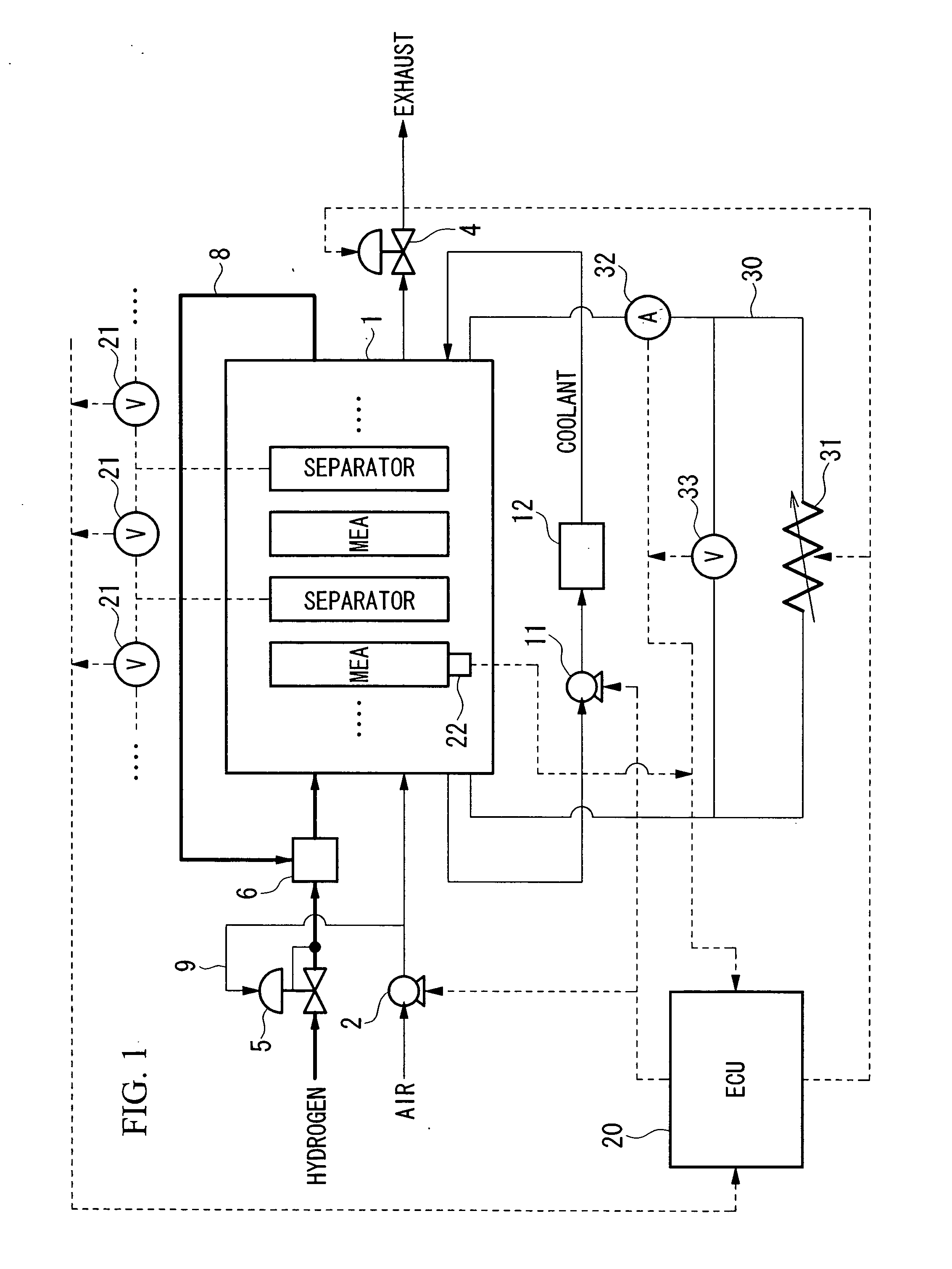

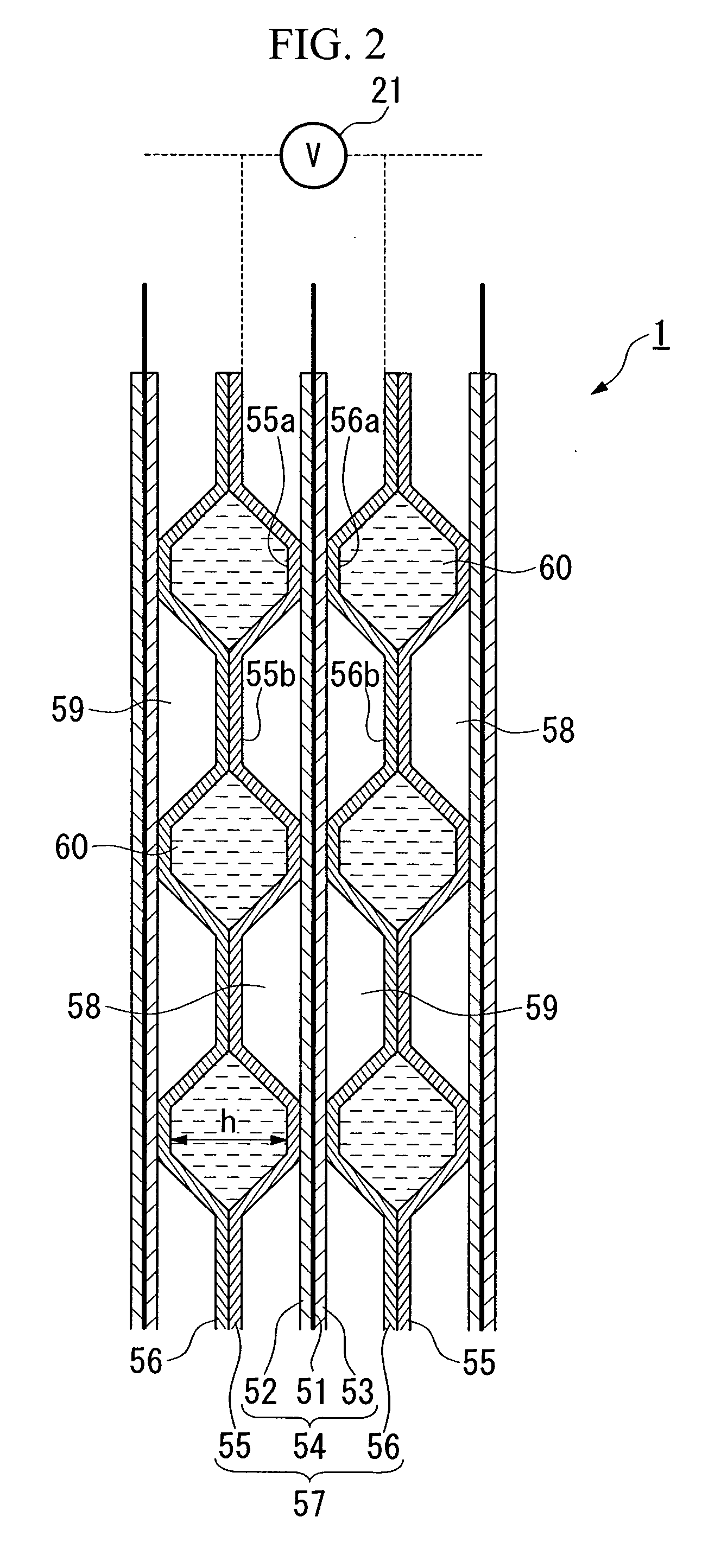

Method and system for starting up fuel cell stack at subzero temperatures, and method of designing fuel cell stack

InactiveUS20050053810A1Shorten warm-up timeSmall heat capacityFuel cells groupingFuel cell auxillariesPolymer electrolytesFuel cells

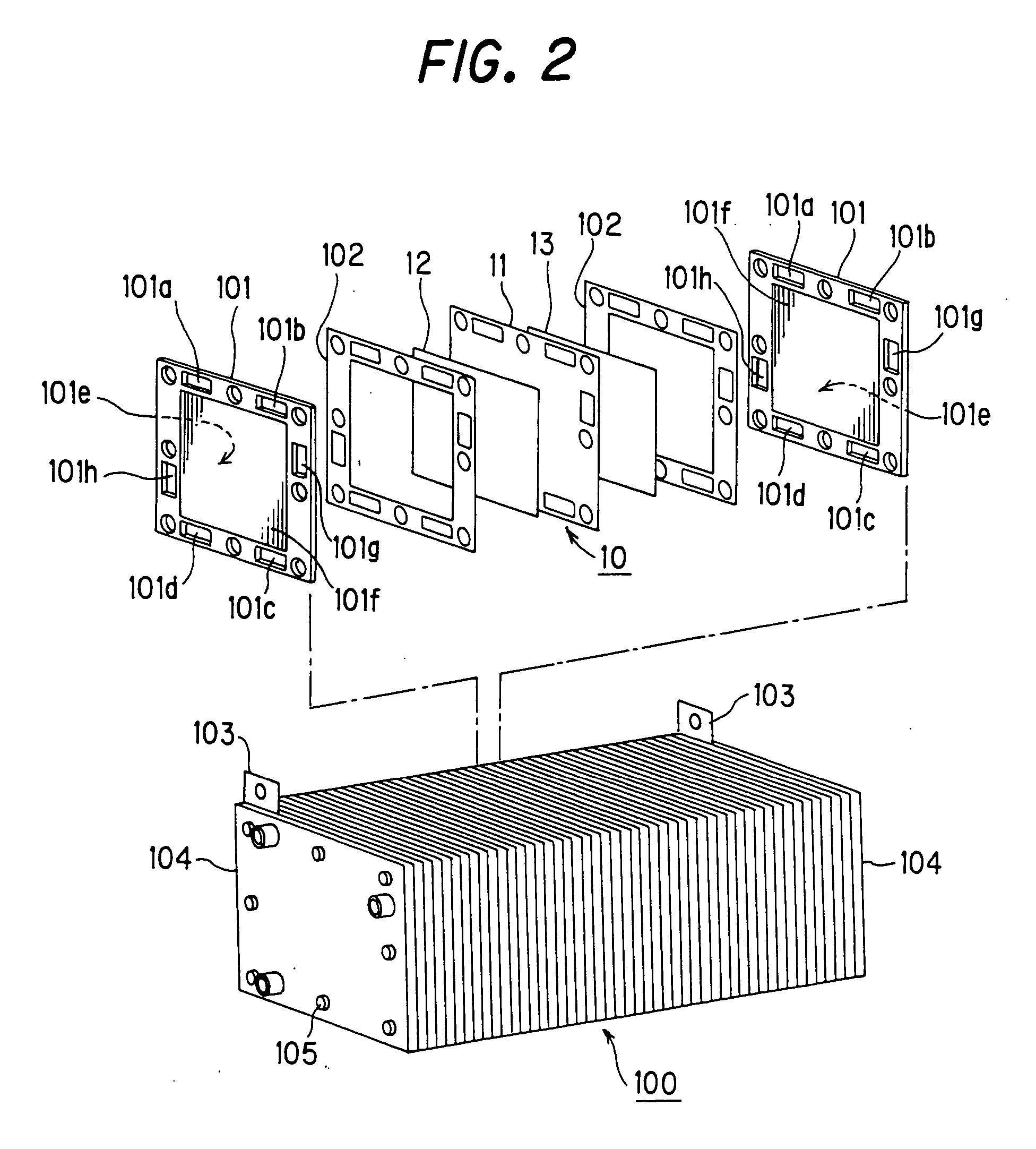

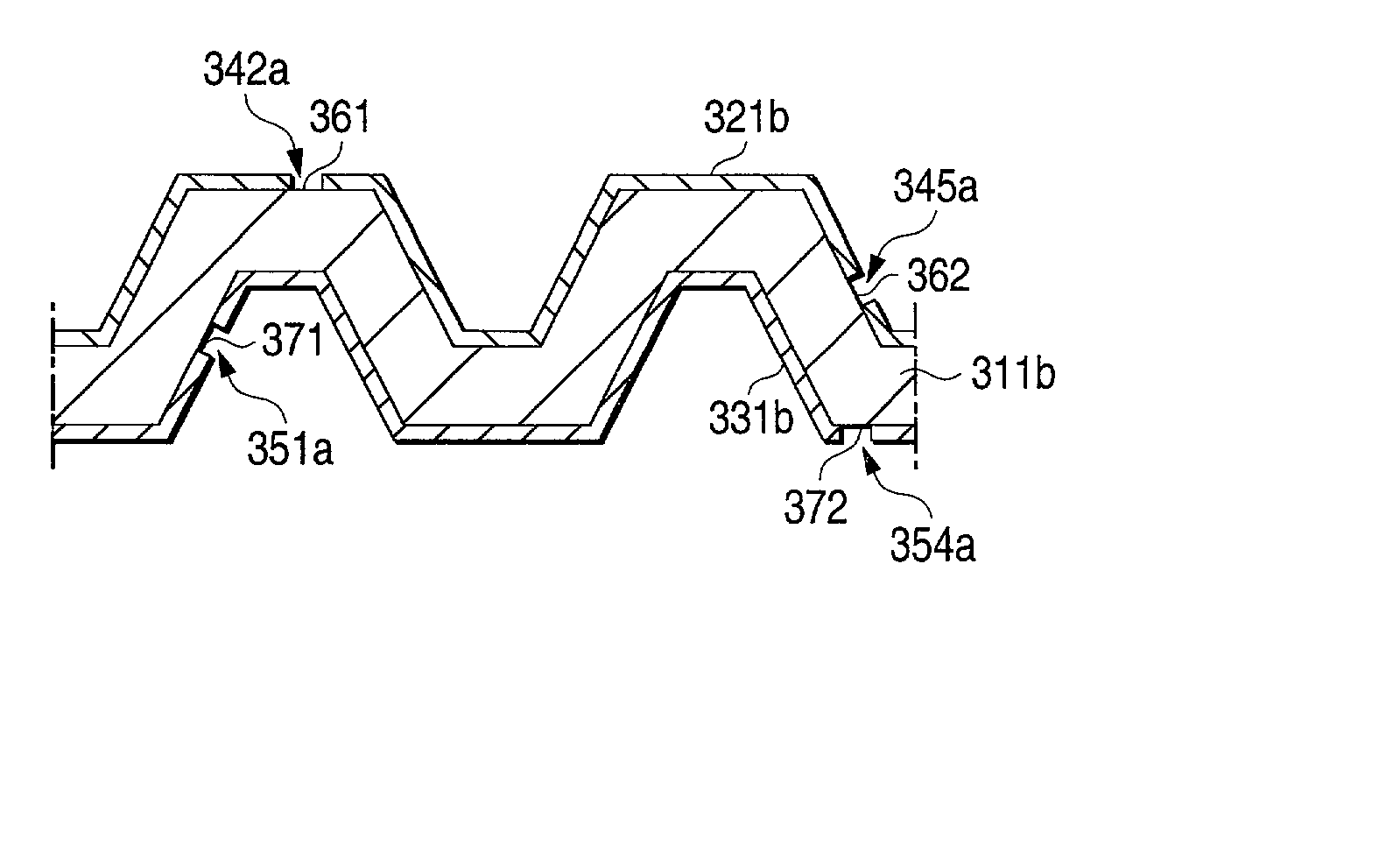

A method of starting up at a subzero temperature a solid polymer electrolyte fuel cell stack that is formed by stacking a plurality of layers of separators and membrane electrode assemblies having a solid polymer electrolyte membrane and electrodes. The method includes a step of using a solid polymer electrolyte fuel cell stack in which the separators are made from metal and have a cross-sectional waveform structure, and a space that is formed between at least a portion of the separators and separators that are placed adjacent to this portion of the separators is used as a coolant flow passage.

Owner:HONDA MOTOR CO LTD

Catalyst layer for polymer electrolyte fuel cells

A catalyst layer on a substrate material which contains a proton-conducting polymer (ionomer), electrically conductive carbon particles and fine particles of at least one precious metal. The catalyst layer is obtainable by coating the substrate material with an ink which contains a dispersion of the carbon particles and at least one organic precious metal complex compound in a solution of the ionomer, and drying the coating below a temperature at which the ionomer or the substrate material is thermally damaged, the precious metals in the complex compounds being present with an oxidation number of 0 and the complex compounds being thermally decomposed during drying to form the fine precious metal particles.

Owner:UMICORE AG & CO KG +1

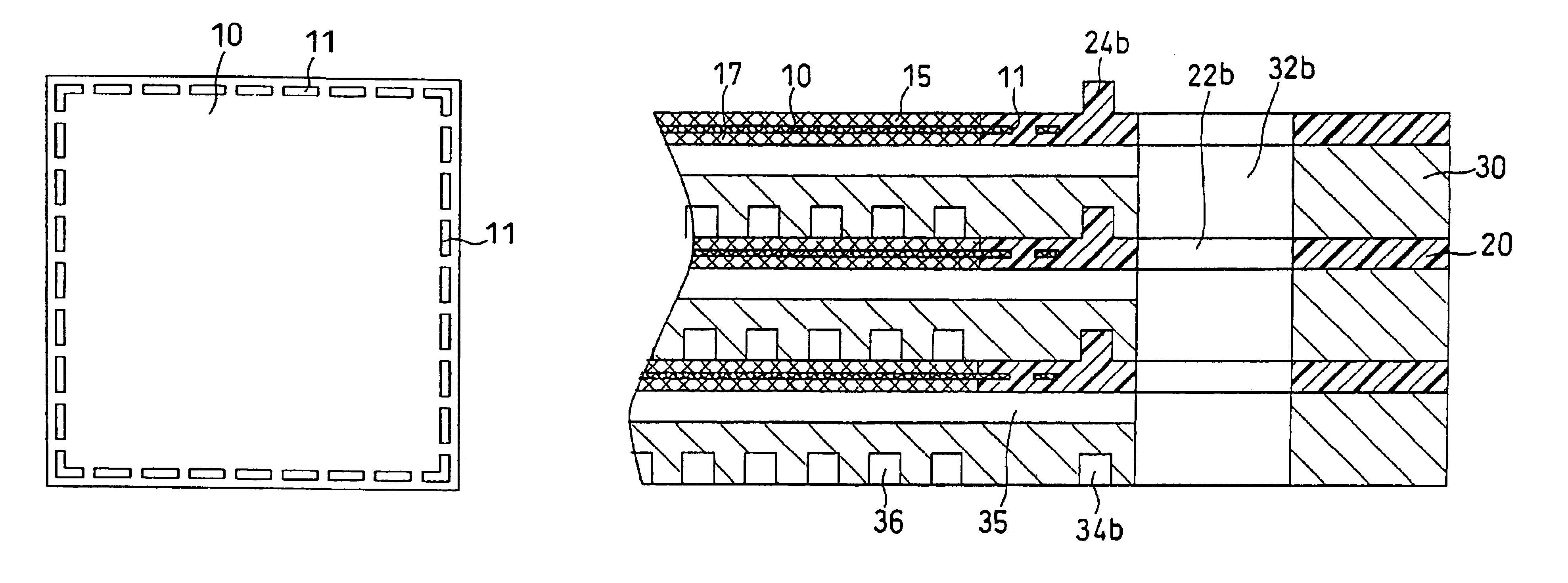

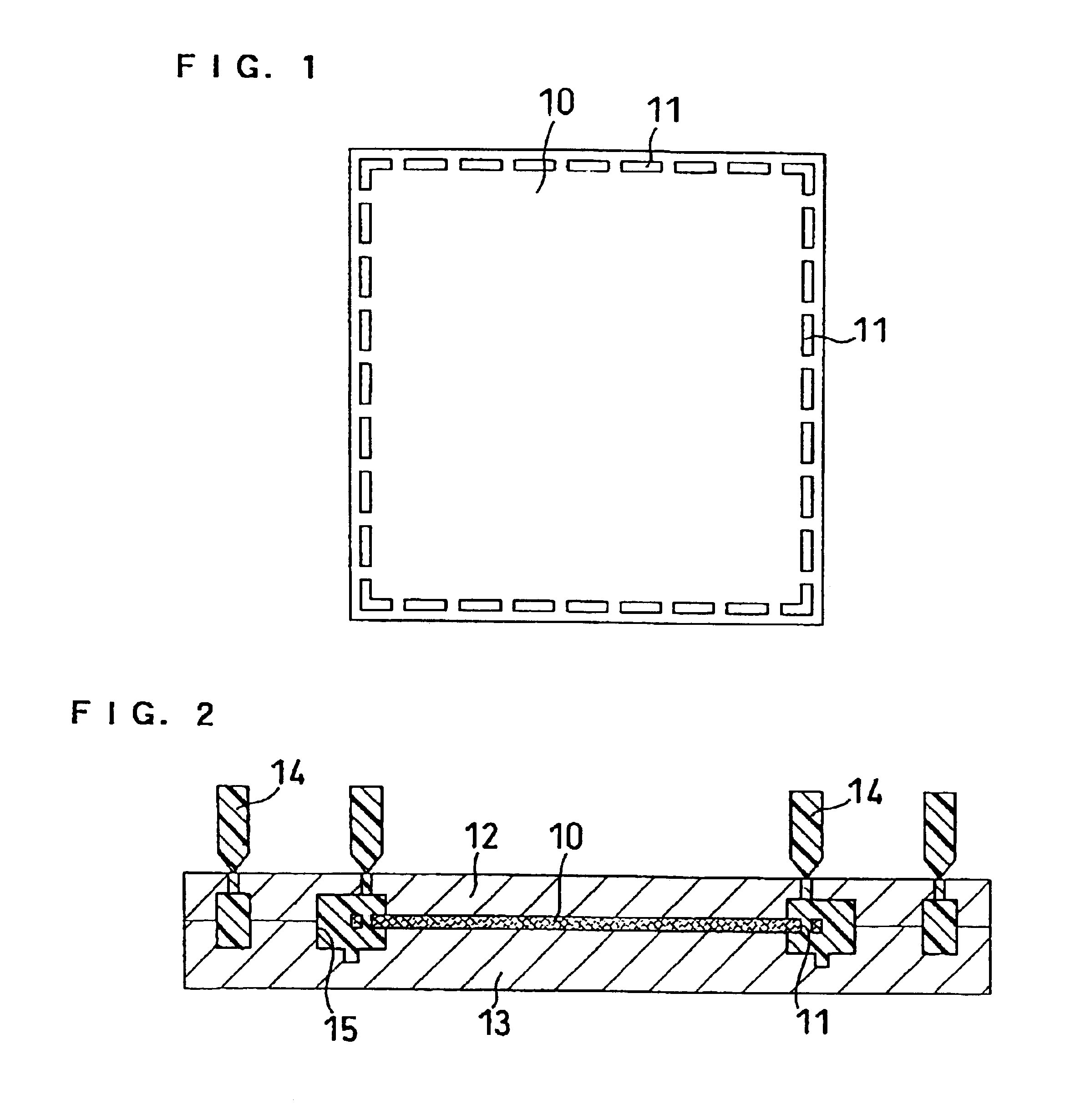

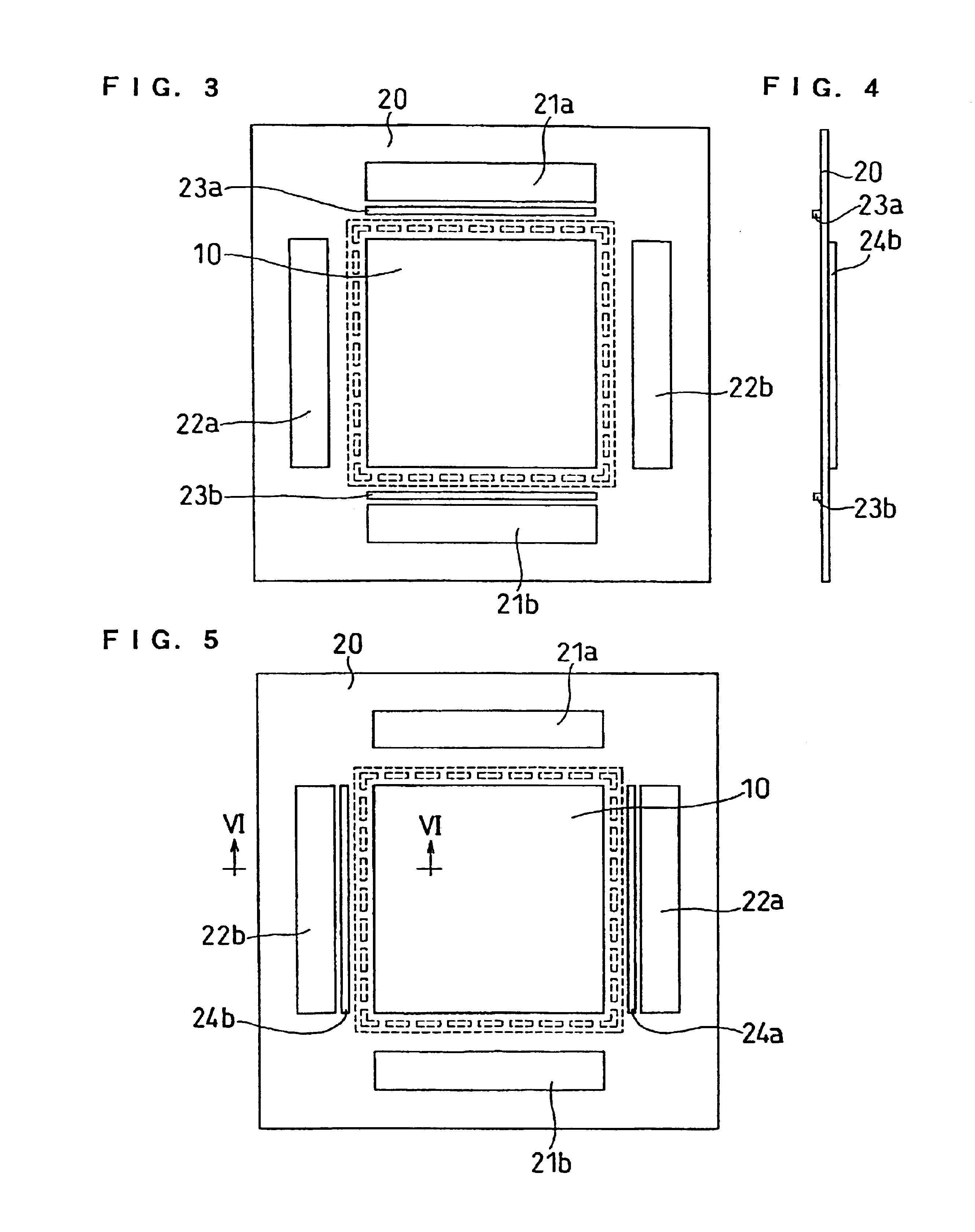

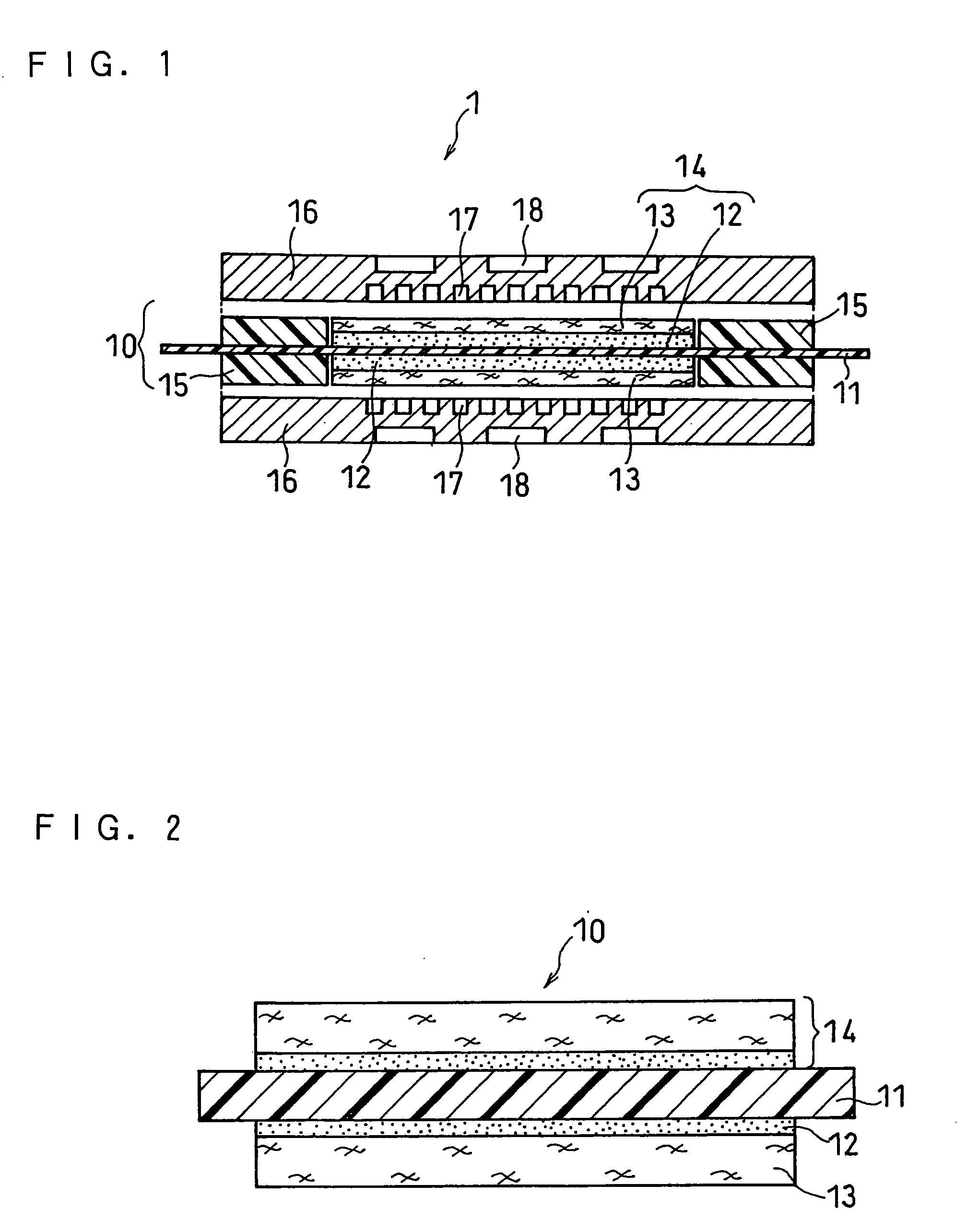

High polymer electrolyte fuel cell and electrolyte film-gasket assembly for the fuel cell

InactiveUS6840969B2Prevent gas leakageImprove sealingFuel cells groupingPrimary cellsPolymer electrolytesFuel cells

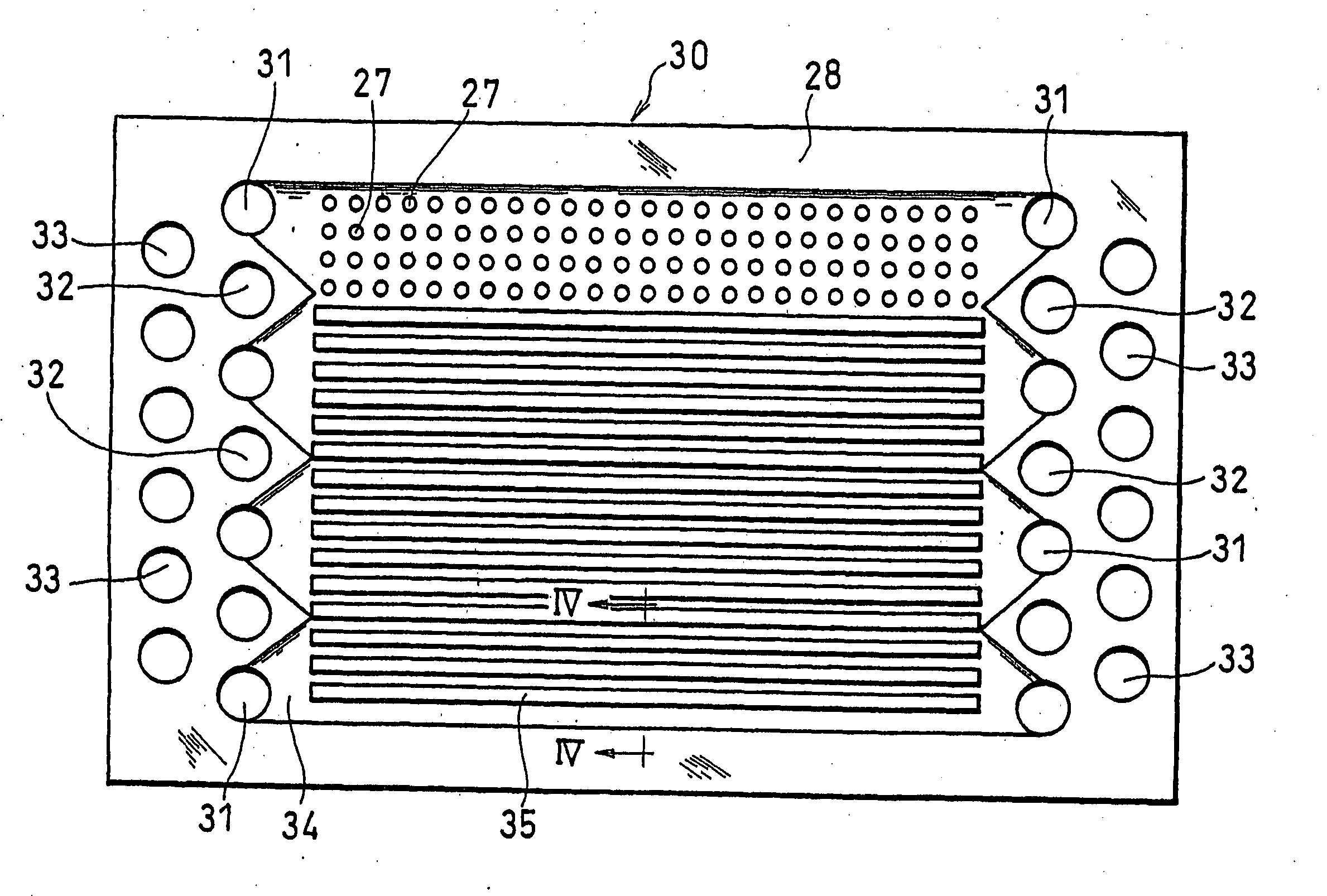

An electrolyte membrane-gasket assembly for a fuel cell, including a polymer electrolyte membrane and a gasket, made of a seal material, covering the peripheral portion of the electrolyte membrane, in which the electrolyte membrane has a sequence of a plurality of through-holes in the peripheral portion, and a portion of the gasket covering one surface of the electrolyte membrane and a portion covering the other surface are connected to each other through the through-holes of the electrolyte membrane. This assembly provides a polymer electrolyte fuel cell free from gas cross leakage caused by a detachment of the gasket from the polymer electrolyte membrane. It is preferable to further include catalyst layers carried on both surfaces of the polymer electrolyte membrane, respectively, and protective films covering, respectively, sections spanning from the peripheral portion of each of the catalyst layers to the peripheral portion of the polymer electrolyte membrane.

Owner:PANASONIC CORP

Polymer electrolyte membrane fuel cells

InactiveUS6946211B1Improve performanceImprove toleranceSolid electrolytesPrimary cellsThermoplasticGas diffusion electrode

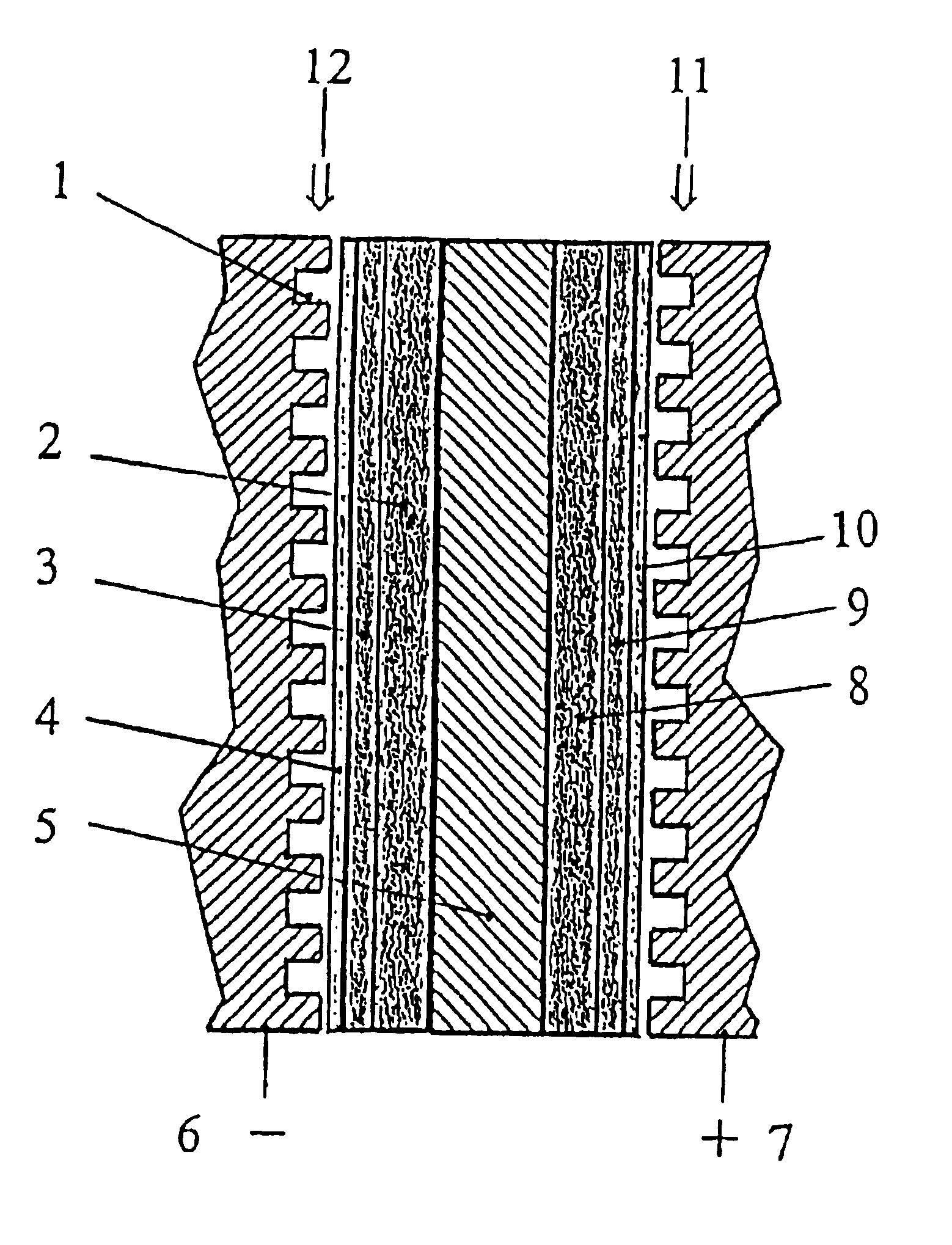

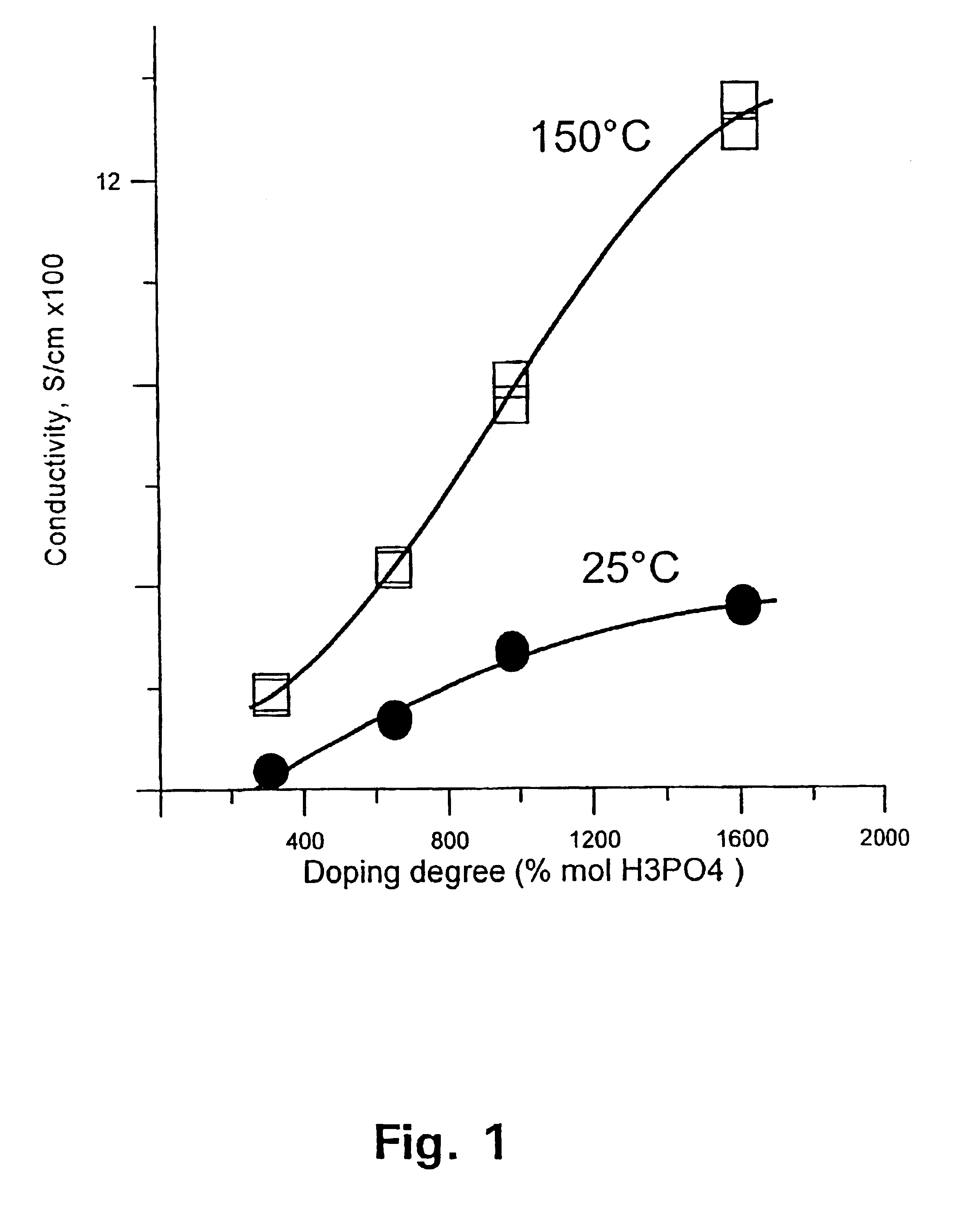

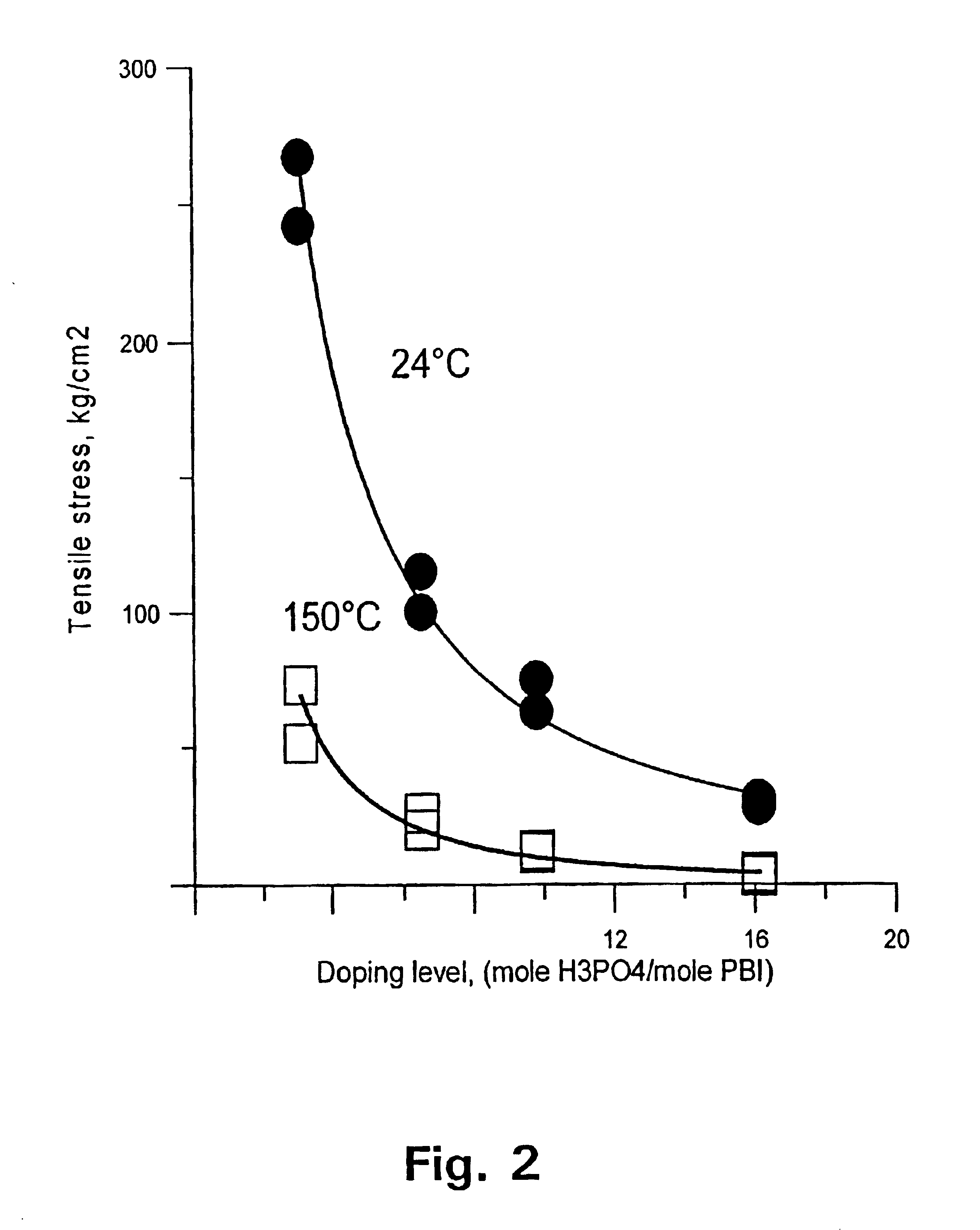

A method for preparing polybenzimidazole or polybenzimidazole blend membranes and fabricating gas diffusion electrodes and membrane-electrode assemblies is provided for a high temperature polymer electrolyte membrane fuel cell. Blend polymer electrolyte membranes based on PBI and various thermoplastc polymers for high temperature polymer electrolyte fuel cells have also been developed. Miscible blends are used for solution casting of polymer membranes (solid electrolytes). High conductivity and enhanced mechanical strength were obtained for the blend polymer solid electrolytes. With the thermally resistant polymer, e.g., polybenzimidazole or a mixture of polybenzimidazole and other thermoplastics as binder, the carbon-supported noble metal catalyst is tape-cast onto a hydrophobic supporting substrate. When doped with an acid mixture, electrodes are assembled with an acid doped solid electrolyte membrane by hot-press. The fuel cell can operate at temperatures up to at least 200° C. with hydrogen-rich fuel containing high ratios of carbon monoxide such as 3 vol % carbon monoxide or more, compared to the carbon monoxide tolerance of 10-20 ppm level for Nafion®-based polymer electrolyte fuel cells.

Owner:DANISH POWER SYST

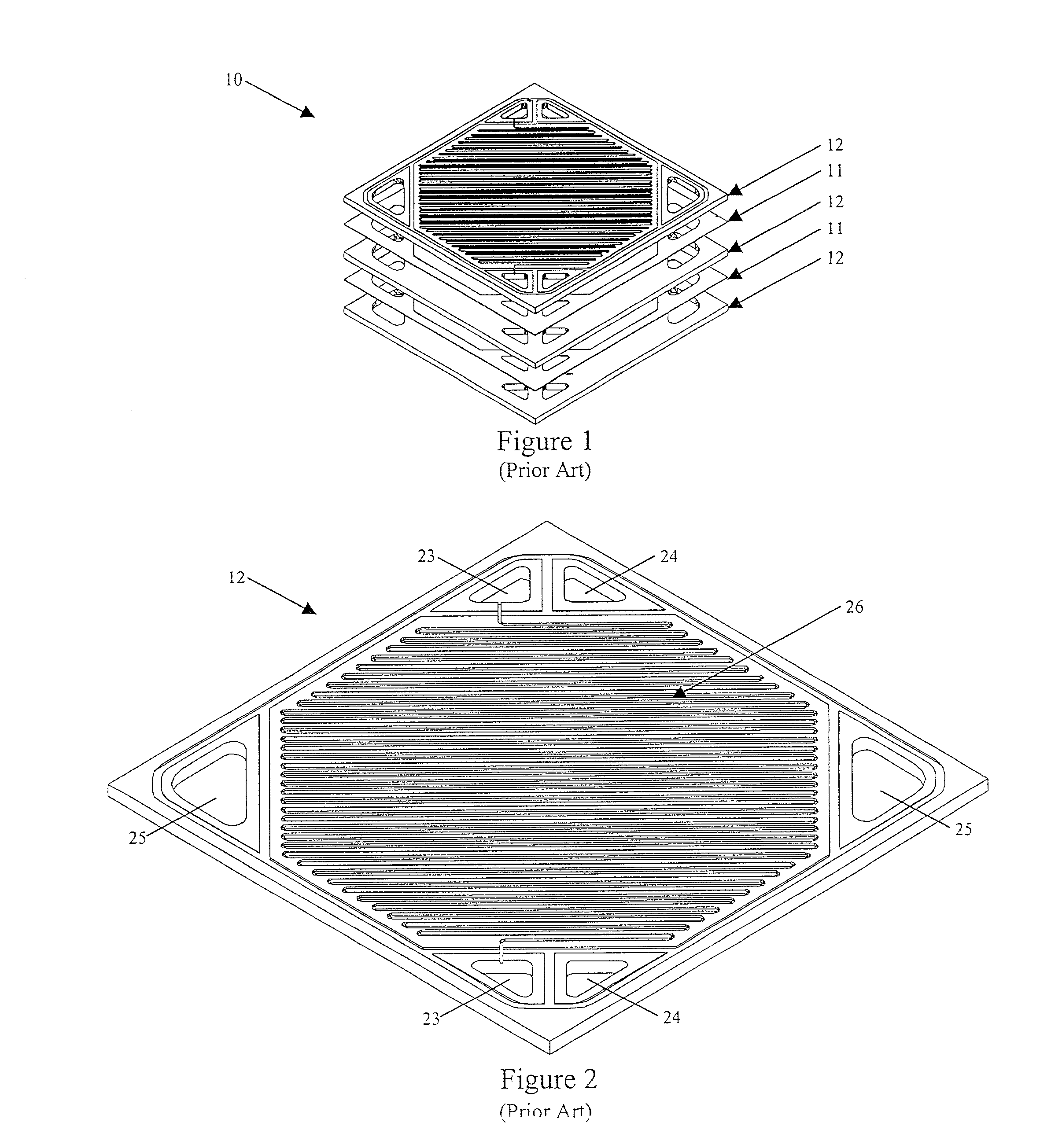

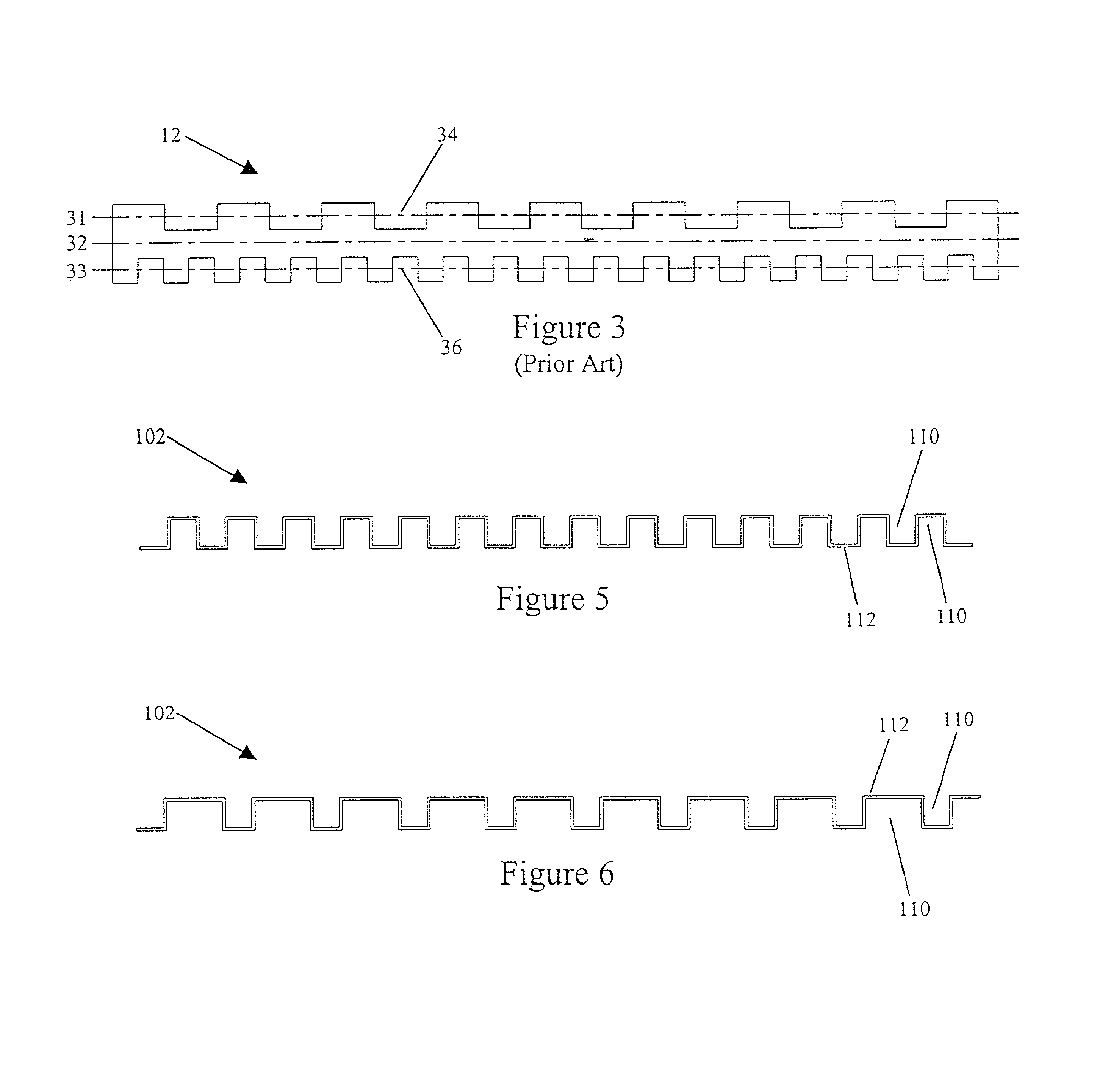

Corrugated flow field plate assembly for a fuel cell

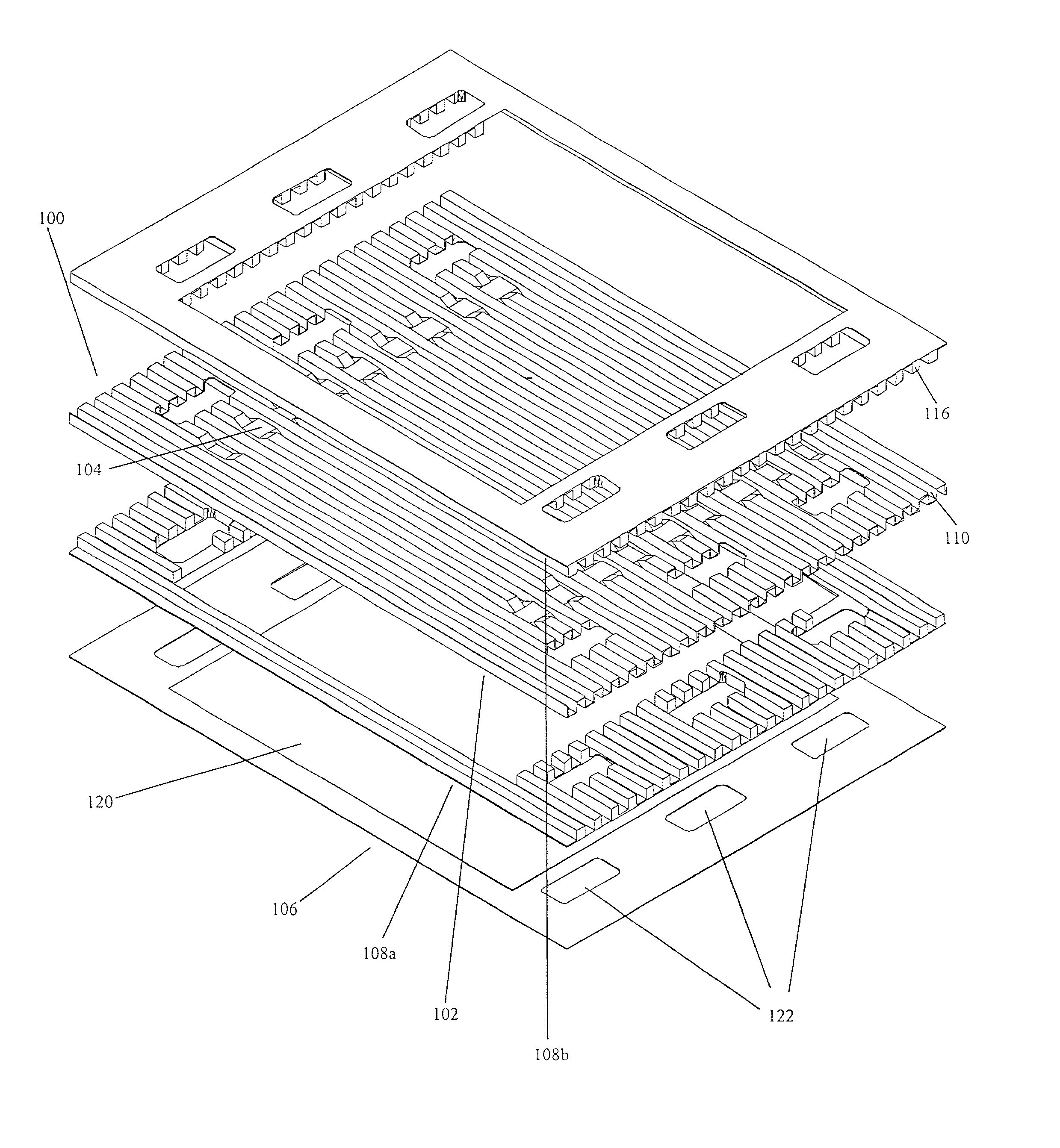

InactiveUS20020081477A1Reduced operating requirementsEasy to shapeFuel cells groupingFuel cell auxillariesFuel cellsChannel coupling

Corrugated flow field plates for use in fuel cells typically comprise a plurality of parallel open-faced fluid flow channels for the fuel cell reactants. Complex flow paths, such as serpentine flow paths, may be created in such corrugated flow field plates by incorporating channel couplings within the plate or by attaching coupling subassemblies to the plate. The plates are particularly suitable for use in solid polymer electrolyte fuel cells.

Owner:BDF IP HLDG

Liquid composition, process for its production and process for producing membrane-electrode assembly for polymer electrolyte fuel cells

ActiveUS20060019140A1Improve the immunityIncreased durabilityIon-exchanger regenerationFinal product manufacturePolymer scienceHigh energy

An electrolyte membrane is prepared from a liquid composition comprising at least one member selected from the group consisting of trivalent cerium, tetravalent cerium, bivalent manganese and trivalent manganese; and a polymer with a cation-exchange group. The liquid composition is preferably one containing water, a carbonate of cerium or manganese, and a polymer with a cation-exchange group, and a cast film thereof is used as an electrolyte membrane to prepare a membrane-electrode assembly. The present invention successfully provides a membrane-electrode assembly for polymer electrolyte fuel cells being capable of generating the electric power in high energy efficiency, having high power generation performance regardless of the dew point of the feed gas, and being capable of stably generating the electric power over a long period of time.

Owner:ASAHI GLASS CO LTD

Membrane electrode assembly for polymer electrolyte fuel cell

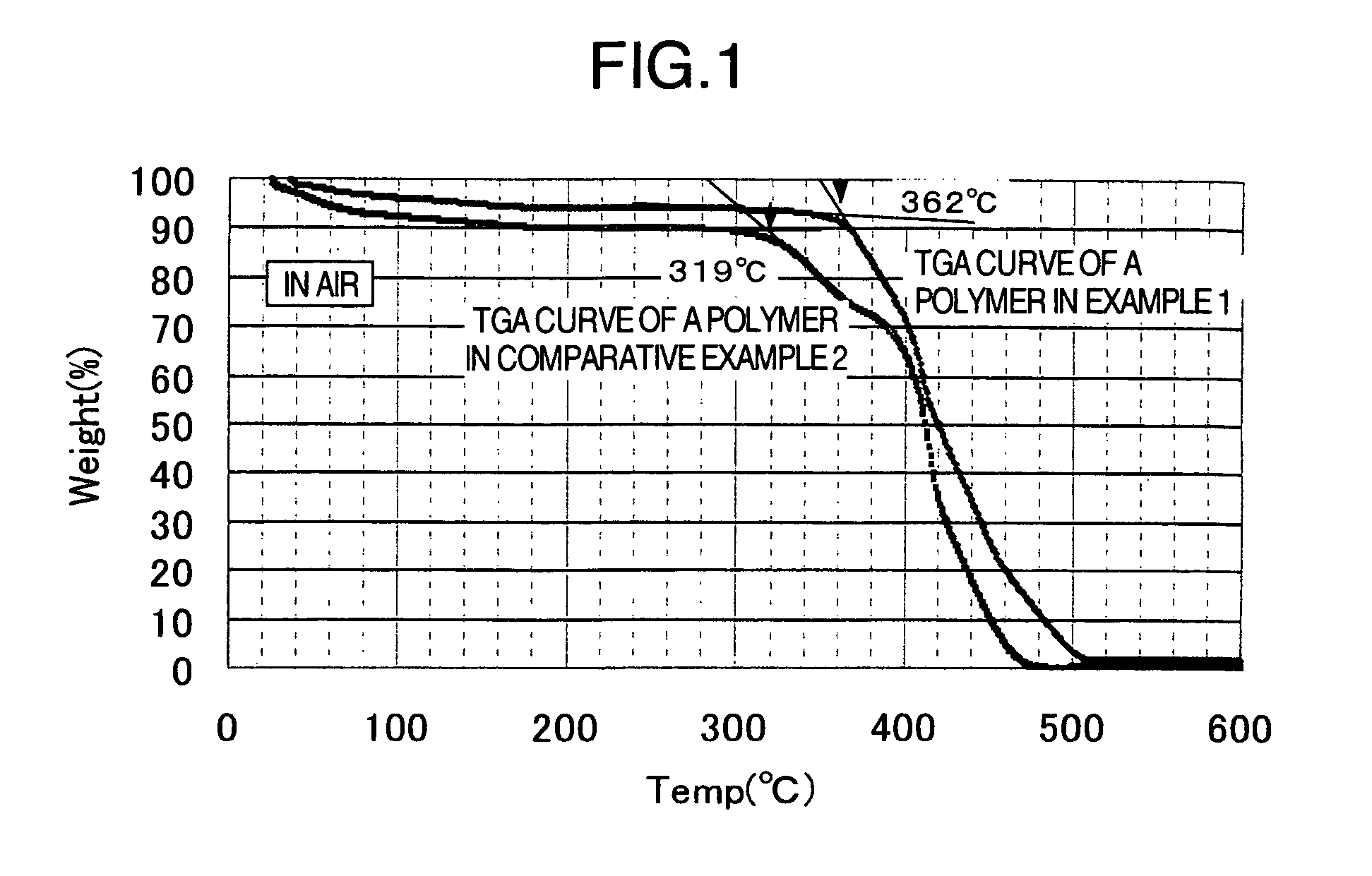

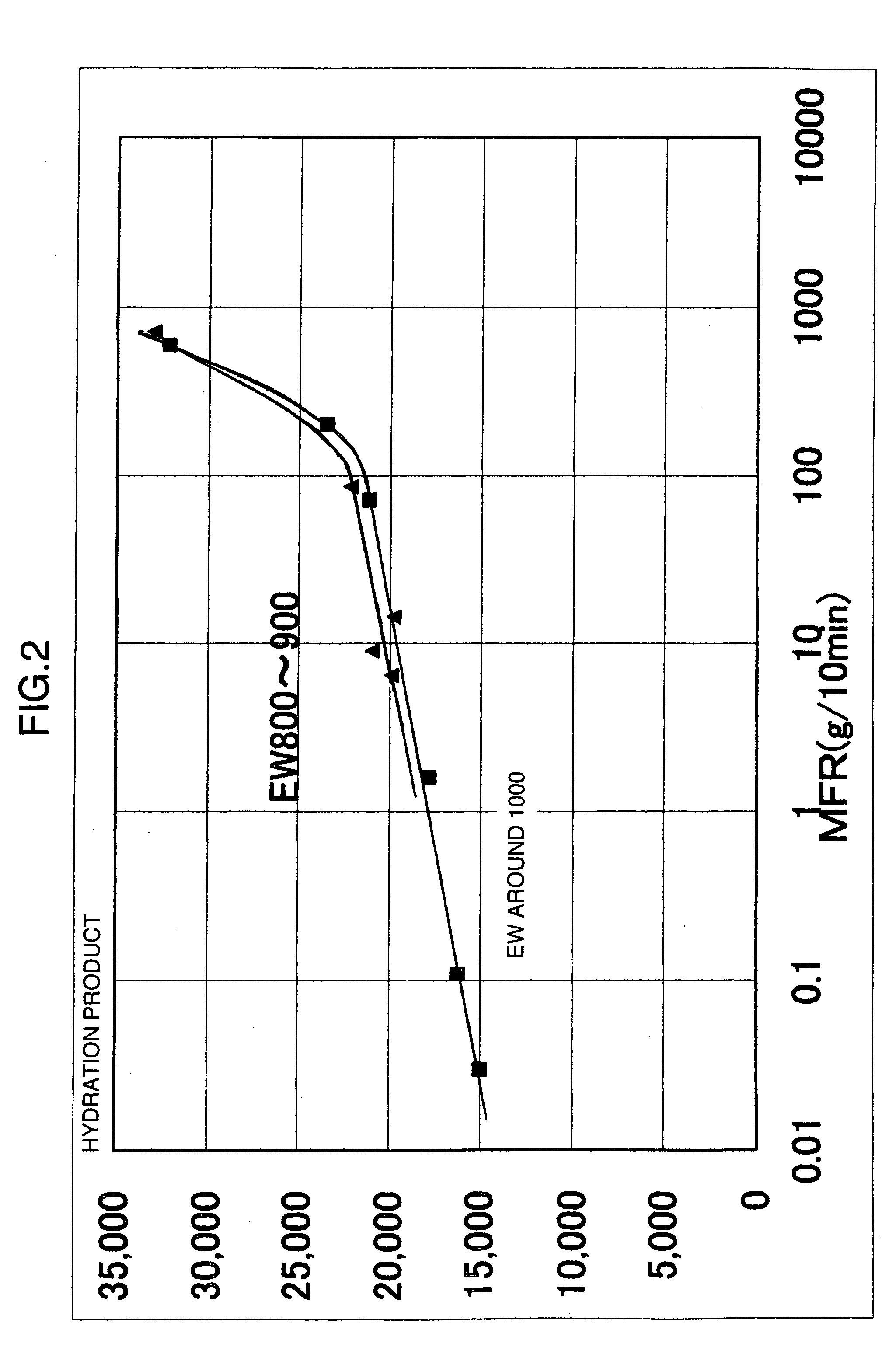

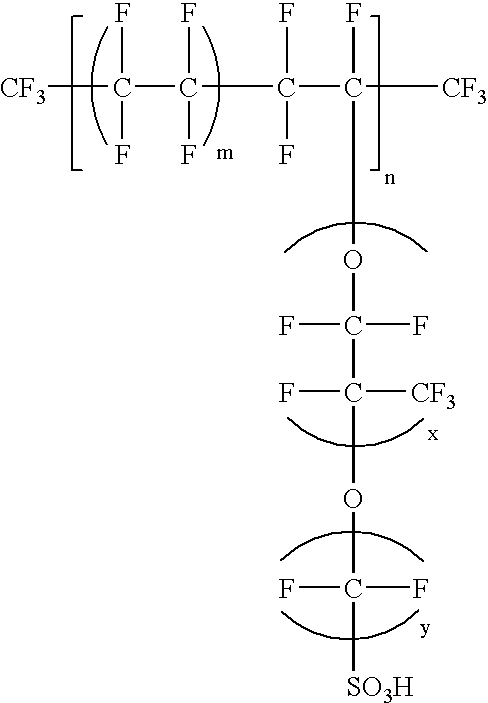

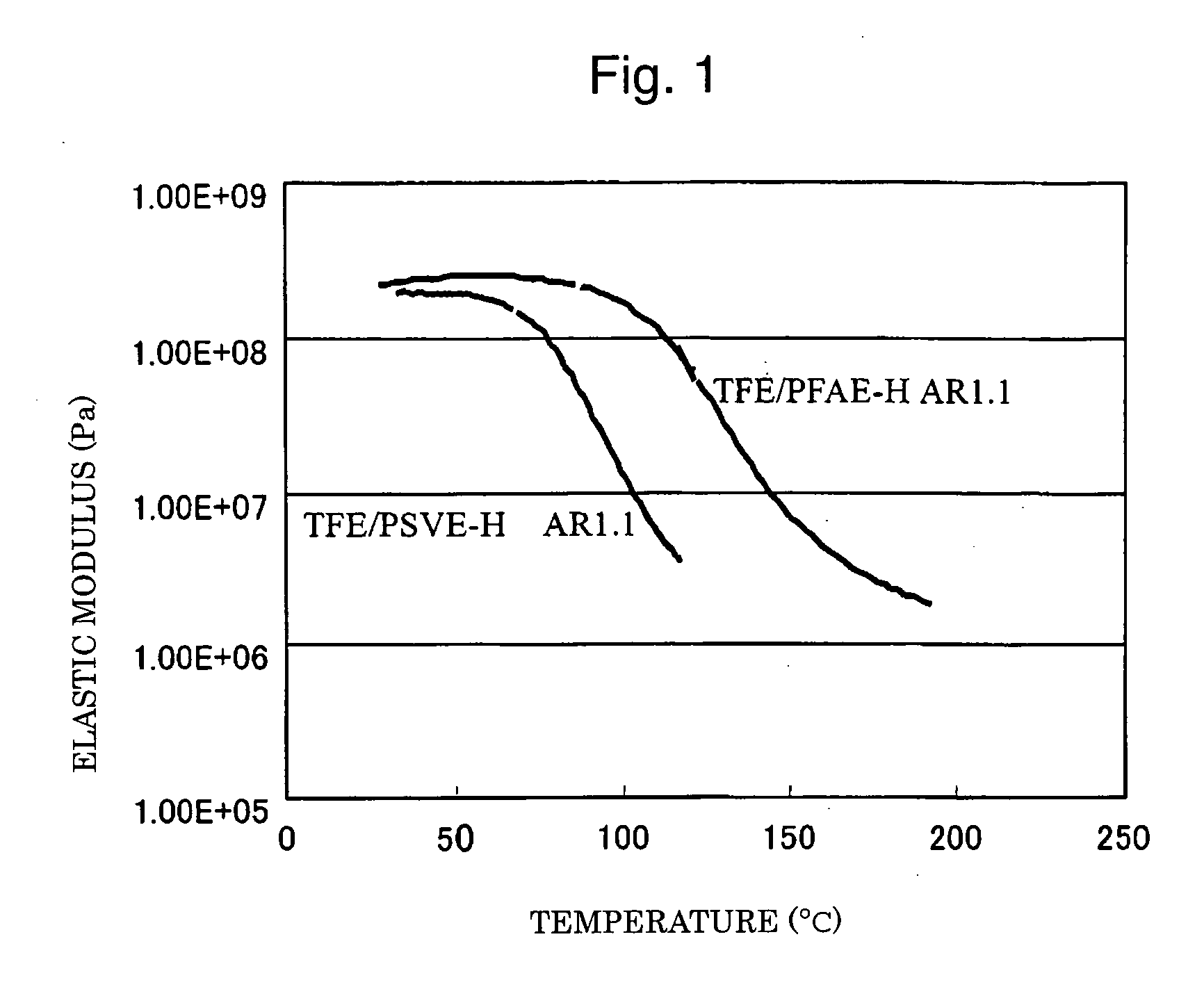

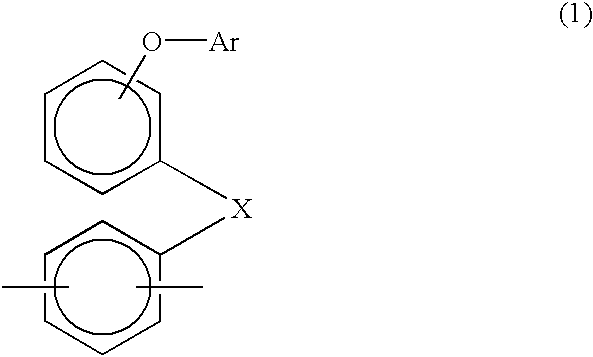

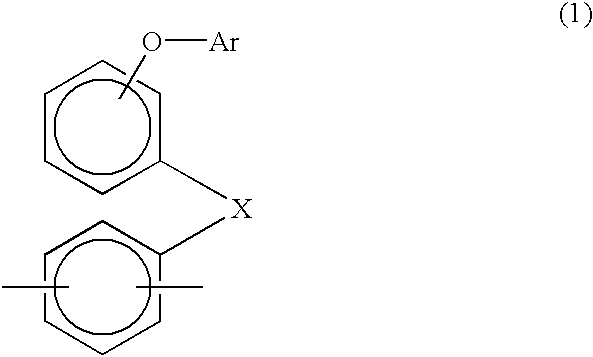

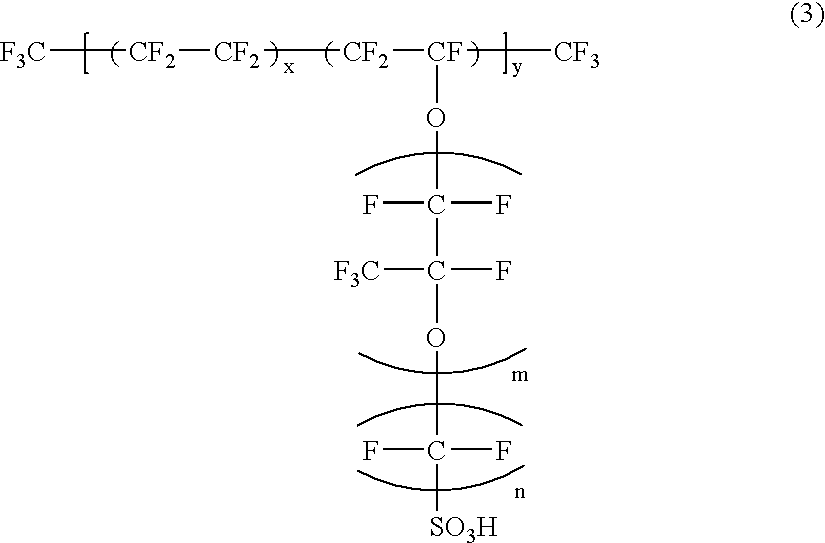

InactiveUS20050130006A1Good chemical stabilityImprove heat resistanceElectrolyte holding meansSolid electrolytesCarbon numberPolyelectrolyte

A membrane electrode assembly for a polymer electrolyte fuel cell characterized by using, as solid polyelecrolyte of at least one of a membrane and a catalyst binder, a fluorinated sulfonic acid polymer with a monomer unit represented by the following general formula (3): (wherein Rf1 is a bivalent perfluoro-hydrocarbon group having a carbon number of from 4 to 10), wherein said fluorinated sulfonic acid polymer has melt flow rate (MFR) not higher than 100 g / 10 min at 270° C. when a —SO3H group in said polymer is converted to —SO2F.

Owner:ASAHI KASEI KK

Polymer electrolyte membrane and solid polymer electrolyte fuel cell using same

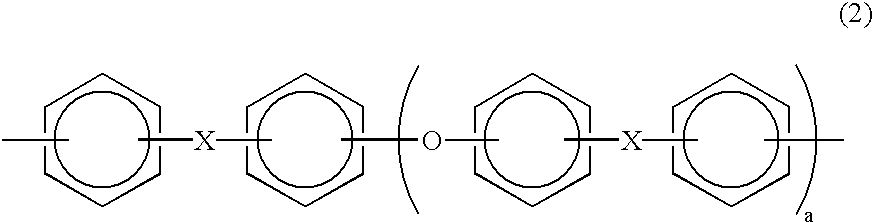

InactiveUS6933068B2Improve adhesionHigh mechanical strengthSemi-permeable membranesIon-exchanger regenerationPolymer electrolytesPolymer science

A composite polymer electrolyte membrane is formed from a first polymer electrolyte comprising a sulfonated polyarytene polymer and a second polymer electrolyte comprising another hydrocarbon polymer electrolyte. In the first polymer electrolyte, 2-70 mol % constitutes an aromatic compound unit with an electron-attractive group in its principal chain, while 30-98 mol % constitutes an aromatic compound unit without an electron-attractive group in its principal chain. The second polymer electrolyte is a sulfonated polyether or sulfonated polysulfide polymer electrolyte.

Owner:HONDA MOTOR CO LTD +1

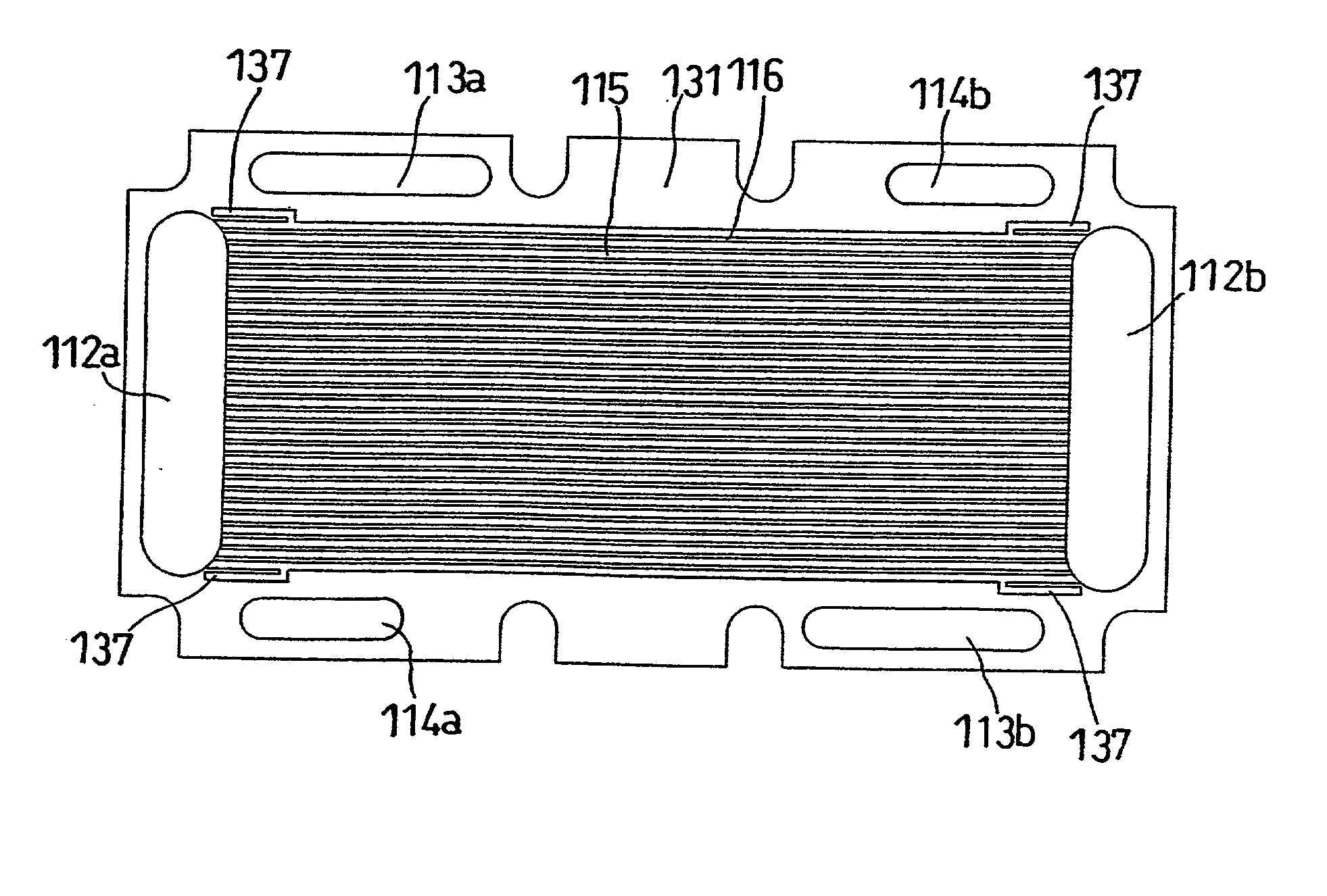

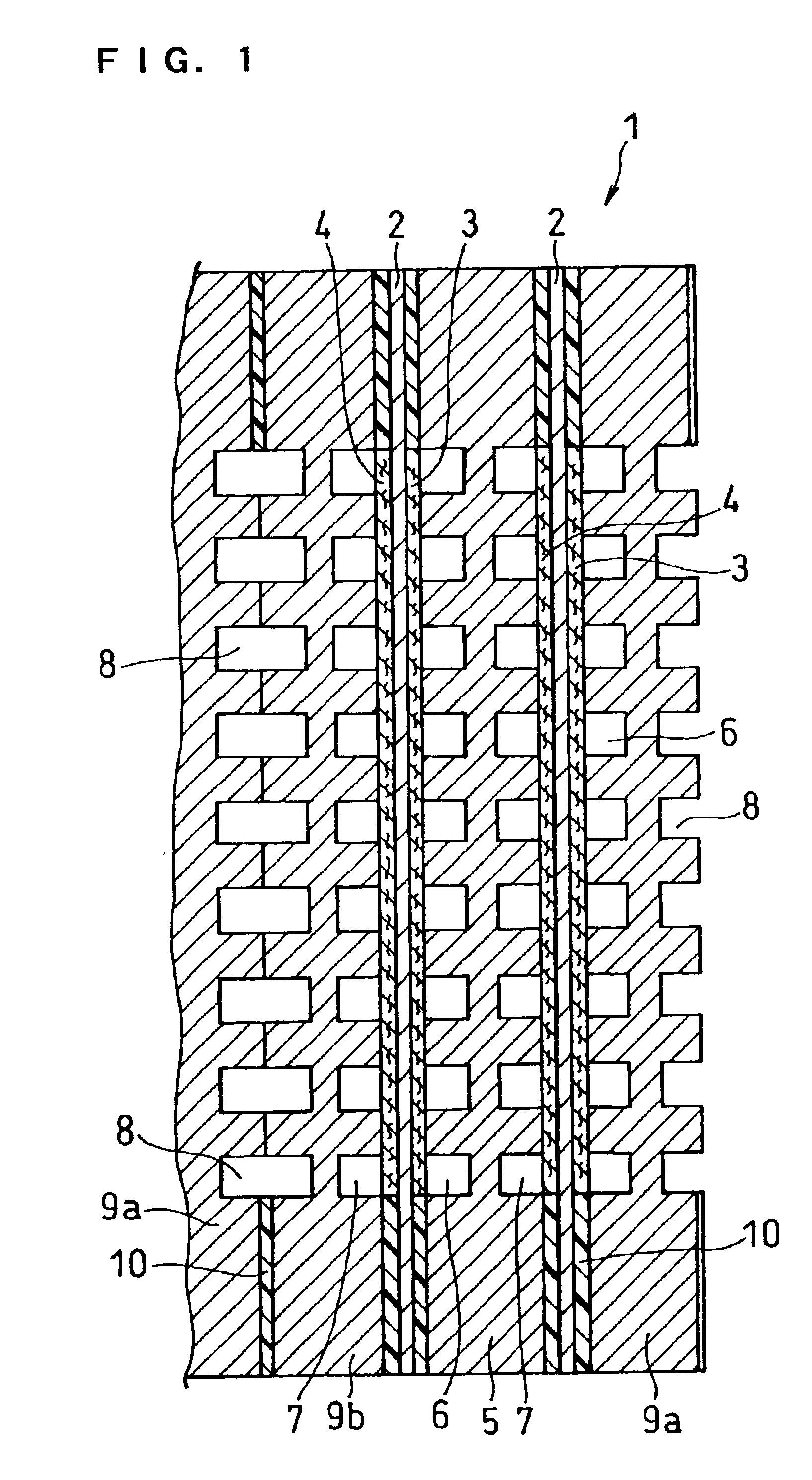

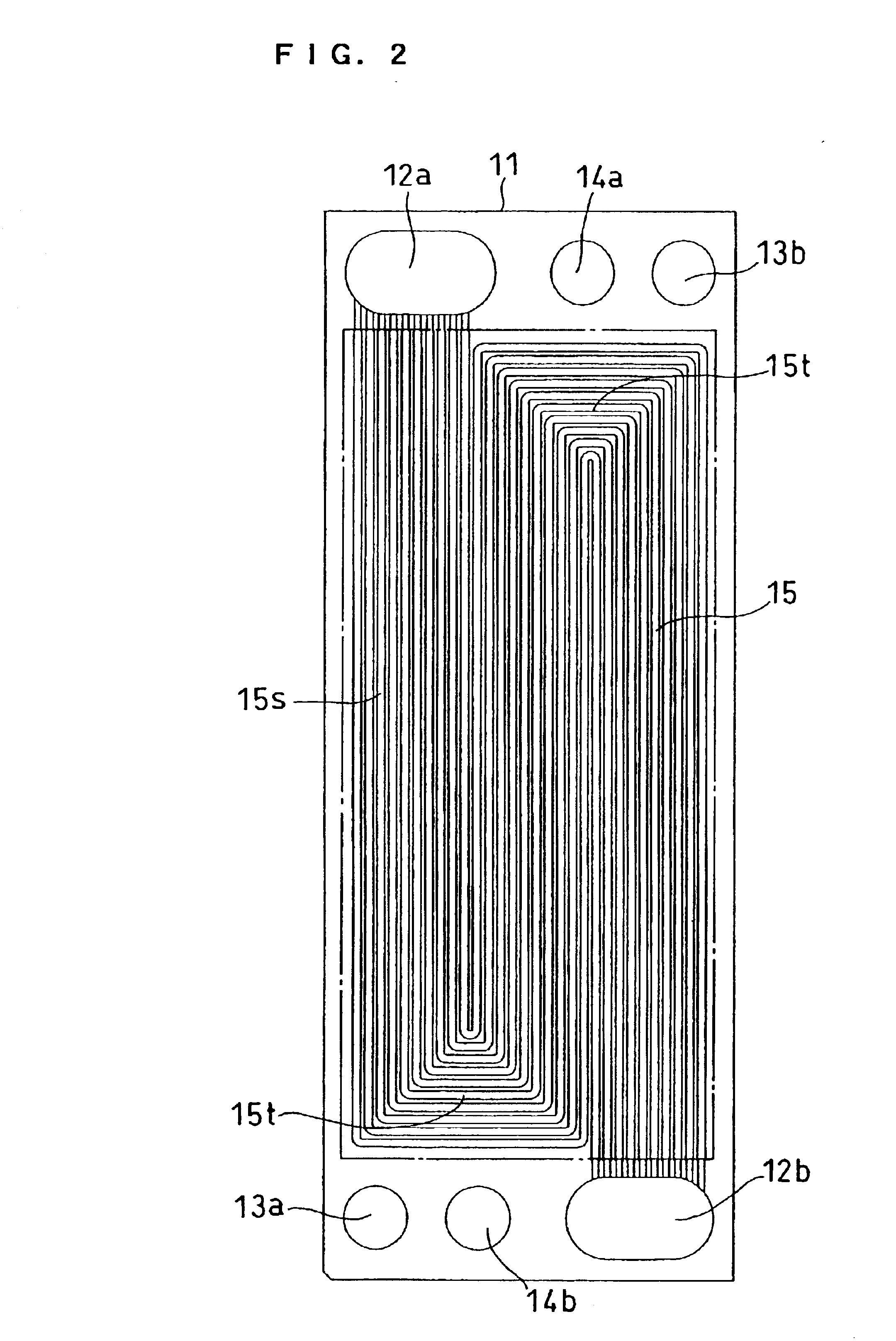

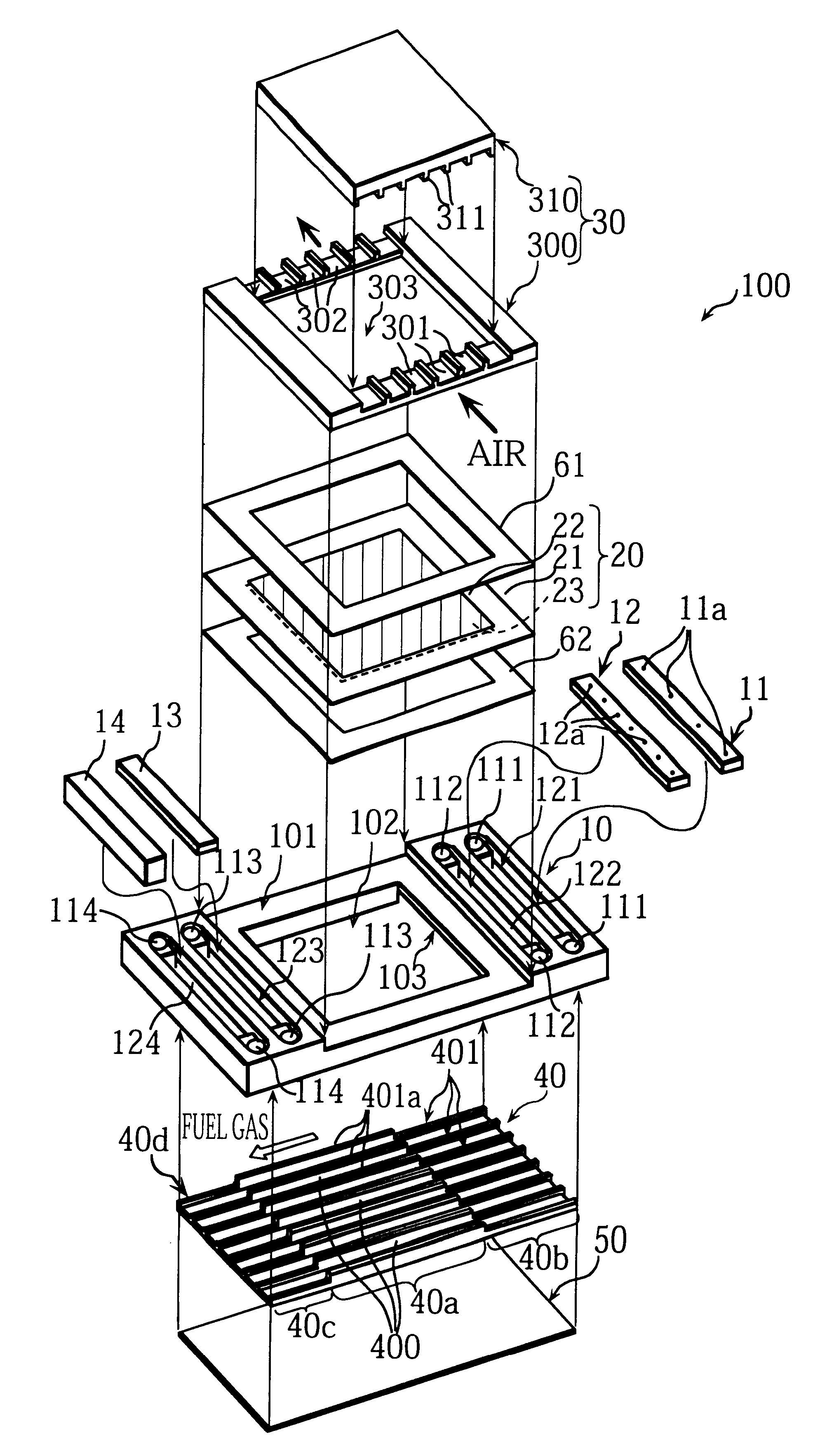

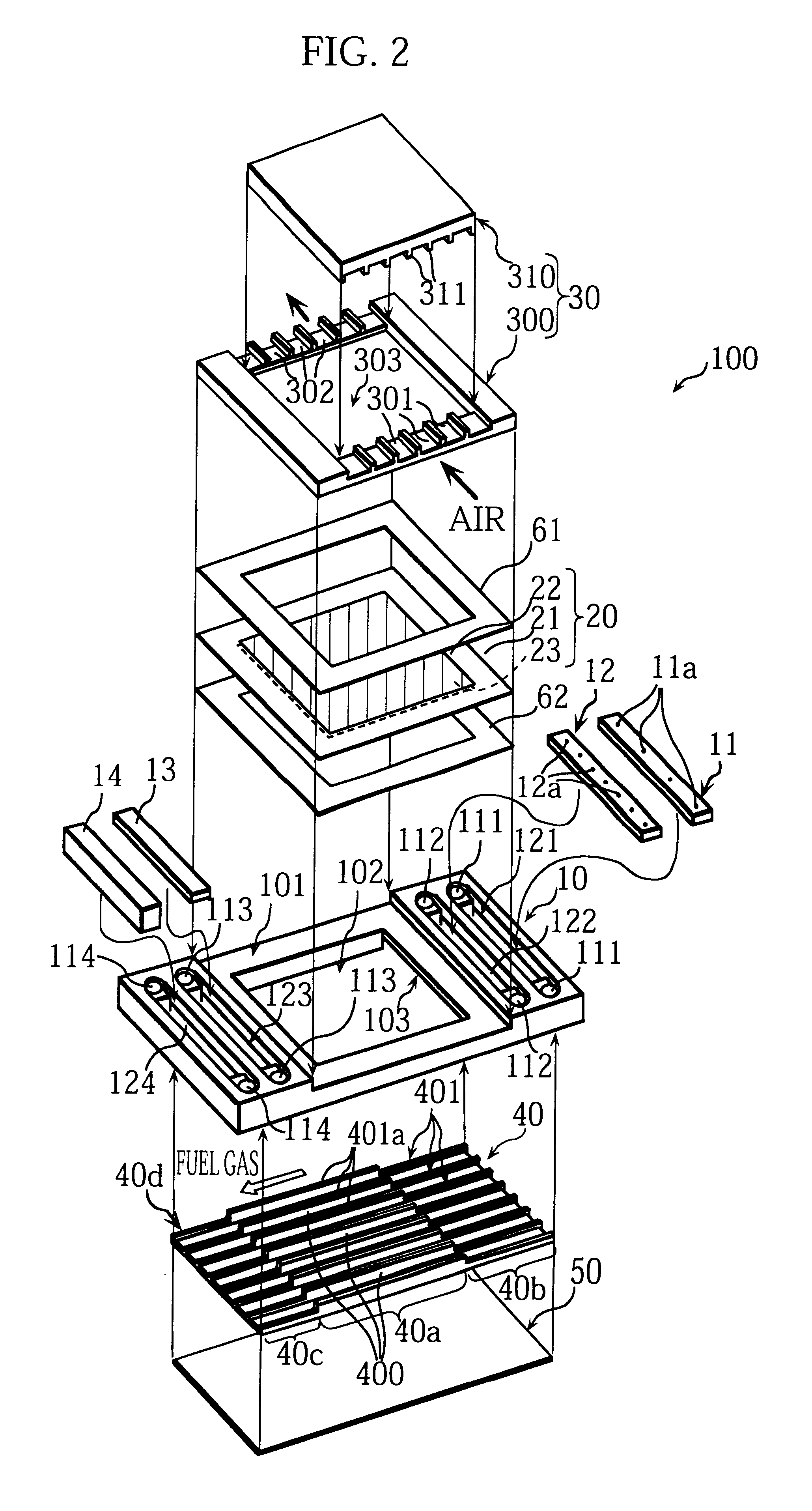

Polymer electrolyte fuel cell

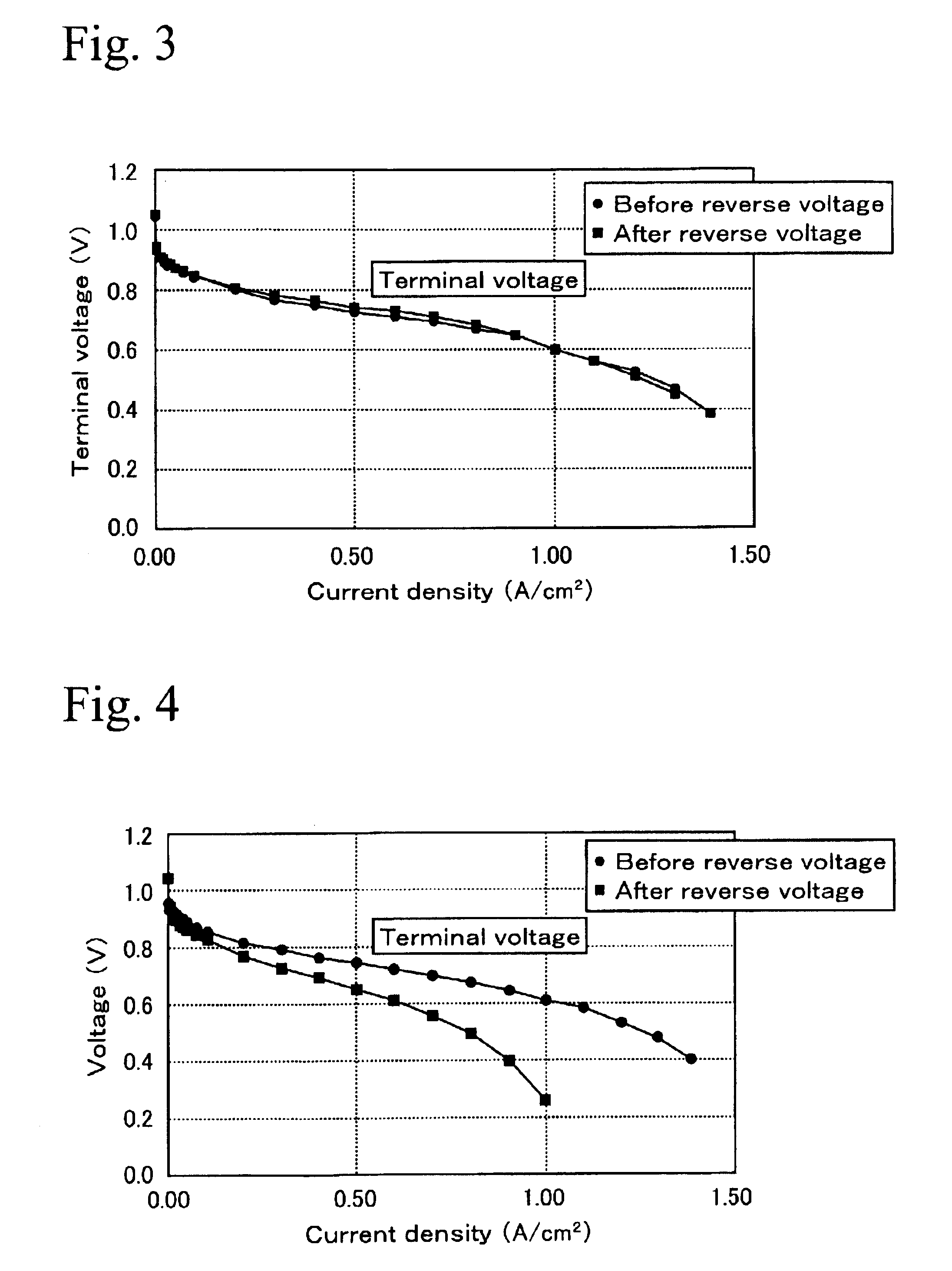

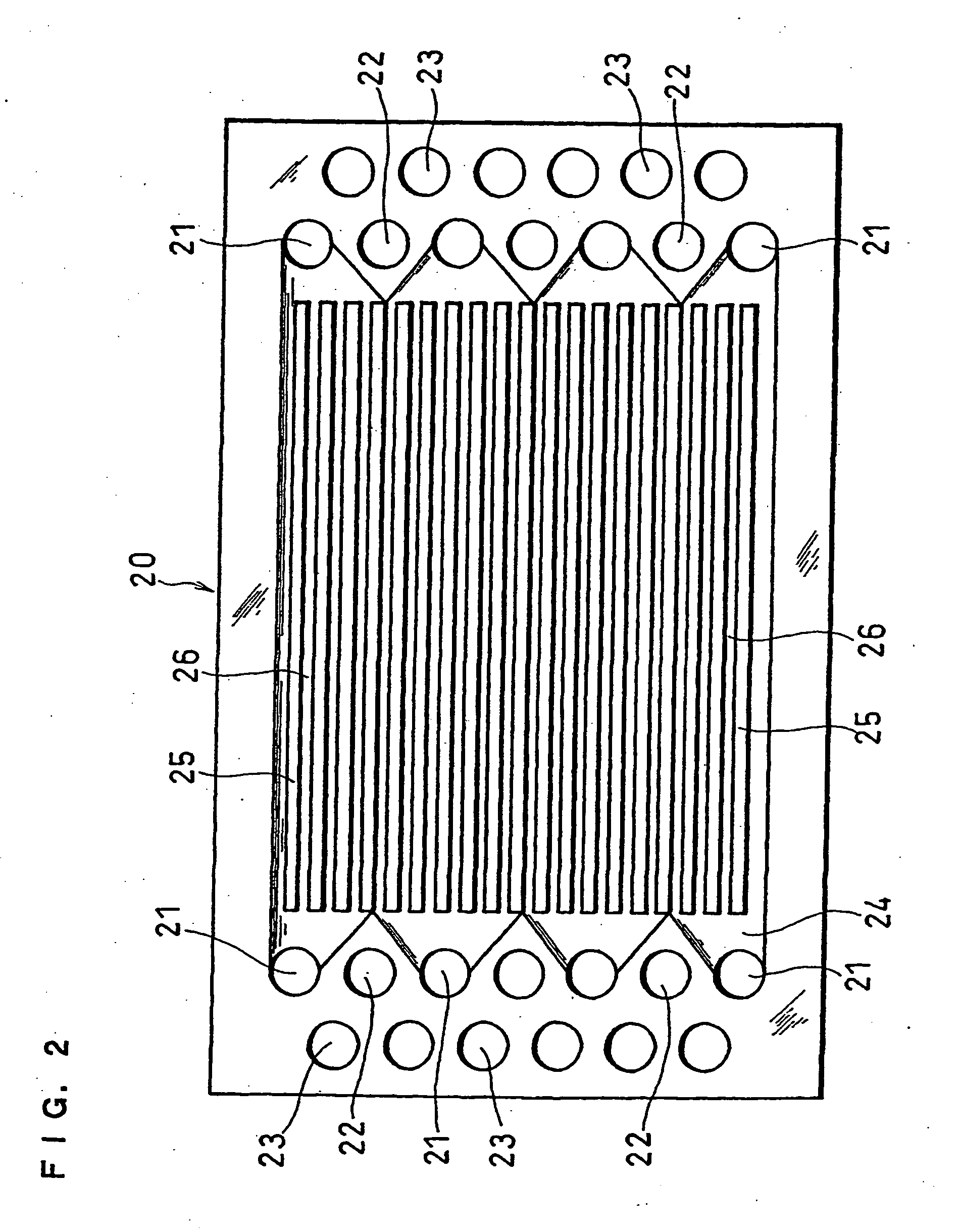

A polymer electrolyte fuel cell of the present invention includes a hydrogen ion-conductive polymer electrolyte membrane, an anode and a cathode sandwiching the hydrogen ion-conductive polymer electrolyte membrane, an anode-side conductive separator plate having a gas flow channel for supplying a fuel gas to the anode, and a cathode-side conductive separator plate having a gas flow channel for supplying an oxidant gas to the cathode. Each of the anode-side conductive separator plate and the cathode-side conductive separator plate is rectangle in shape and has an oxidant gas manifold aperture for an inlet arranged on one short side thereof, an oxidant gas manifold aperture for an outlet arranged on the other short side thereof, a fuel gas manifold aperture for an inlet and a fuel gas manifold aperture for an outlet arranged on different longitudinal sides thereof, and a cooling water manifold aperture for an inlet and a cooling water manifold aperture for an outlet arranged on the different longitudinal sides thereof. The respective fuel gas manifold apertures are disposed opposite to the cooling water manifold apertures. The oxidant gas manifold apertures, the fuel gas manifold apertures, and the cooling water manifold apertures have openings of different shapes.

Owner:PANASONIC CORP

Membrane electrode assembly for polymer electrolyte fuel cell

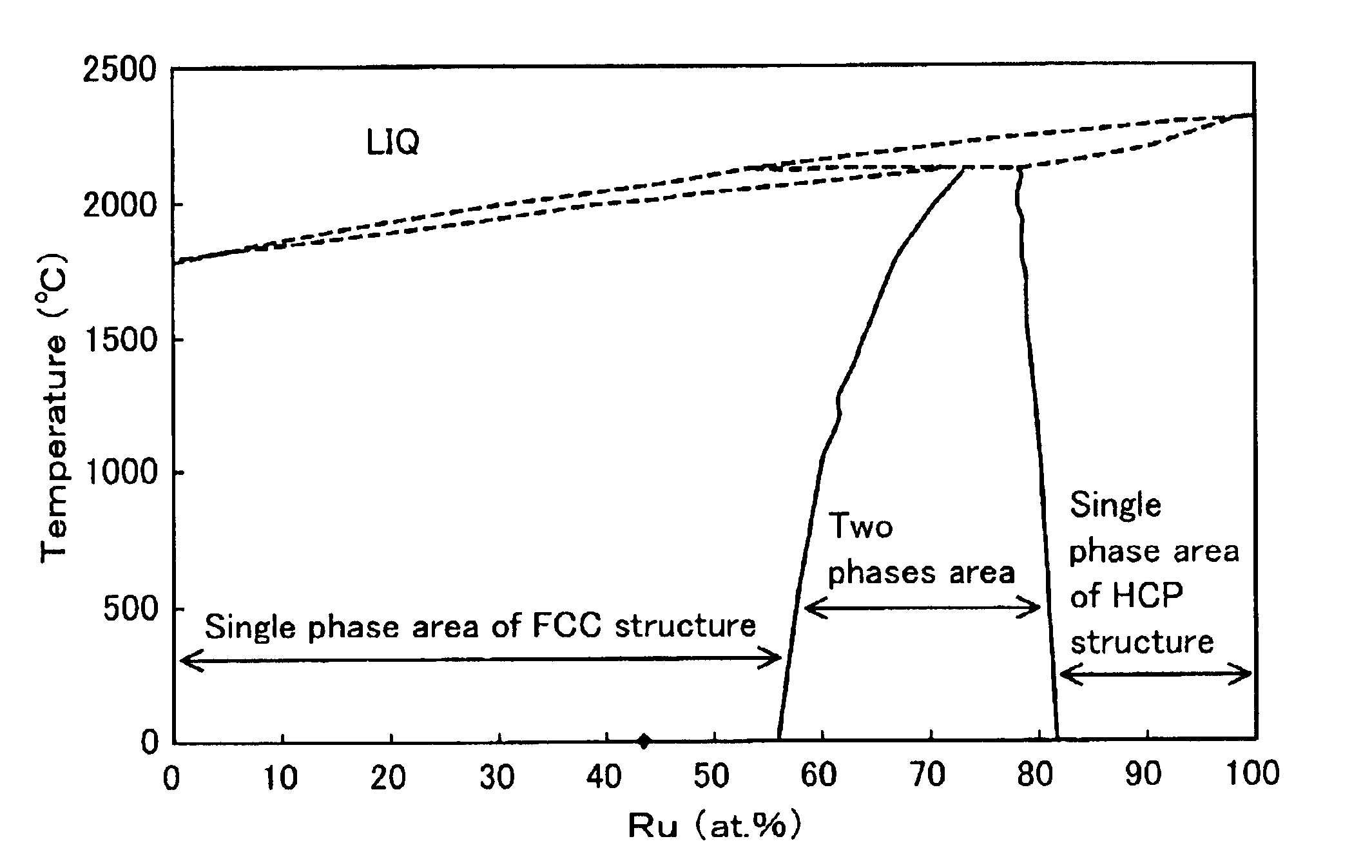

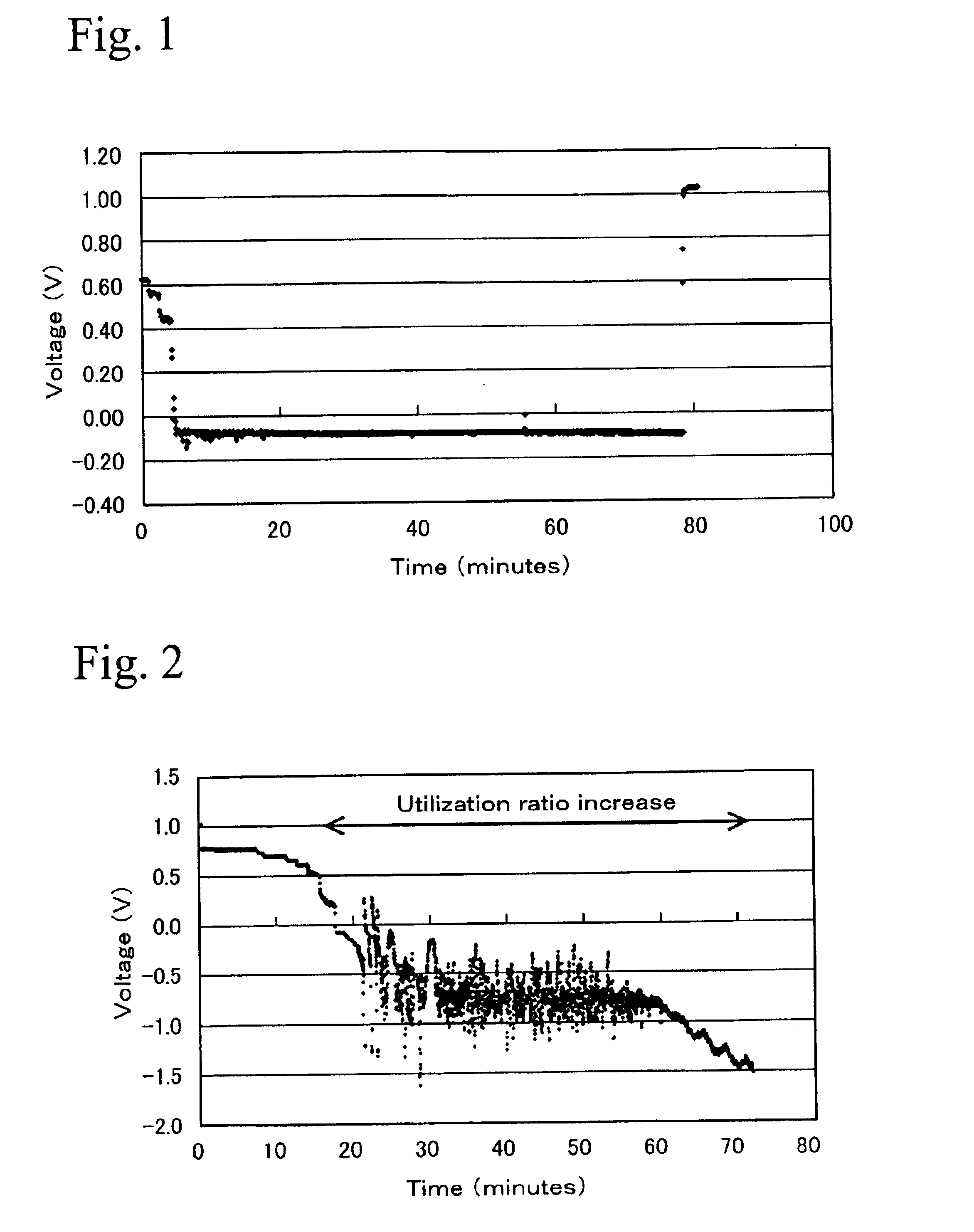

InactiveUS6875537B2Terminal voltage droppingReduce deteriorationActive material electrodesSolid electrolyte fuel cellsPolymer electrolytesFuel cells

A membrane electrode assembly for polymer electrolyte fuel cells comprises a cathode electrode, an anode electrode, and a polymer electrolyte membrane placed between these electrodes, and a catalyst material of Pt—Ru alloy is contained in the anode and the crystal of Pt—Ru alloy is mainly of a face-centered cubic structure.

Owner:HONDA MOTOR CO LTD

Polymer electrolyte fuel cell and method of manufacturing the same

InactiveUS20040197633A1Improves product water-removal efficiencyEvenly distributedFuel cell heat exchangeFinal product manufacturePolymer electrolytesFuel cells

The present invention relates to a polymer electrolyte fuel cell comprising: an electrolyte membrane-electrode assembly including an anode, a cathode and a polymer electrolyte membrane interposed therebetween; an anode-side conductive separator plate having a gas flow channel for supplying a fuel gas to the anode; and a cathode-side conductive separator plate having a gas flow channel for supplying an oxidant gas to the cathode. A conductive separator plate made of carbon has poor wettability with water. This has posed the disadvantage that variations in performance are induced by nonuniform gas distribution among cells due to the accumulation of product water or humidifying water in the gas flow channel on the surface of the separator plate. The present invention employs a conductive separator plate comprising a conductive carbon having a hydrophilic functional group, at least in a portion of the gas flow channels, thereby preventing water from accumulating in the gas flow channels.

Owner:PANASONIC CORP

Polymer electrolyte membrane, method for producing same, and membrane electrode assembly and polymer electrolyte fuel cell comprising same

InactiveUS6926984B2Low dependency of ionSufficient power-generating performanceElectrolyte holding meansSolid electrolytesFiberPolymer science

A polymer electrolyte membrane obtained by subjecting a sulfonated polyarylene membrane having an initial water content of 80-300 weight % to a hot-water treatment. A composite polymer electrolyte membrane comprising a matrix made of a first sulfonated aromatic polymer having a high ion exchange capacity, and a reinforcing material constituted by a second sulfonated aromatic polymer having a low ion exchange capacity in the form of fibers or a porous membrane.

Owner:HONDA MOTOR CO LTD

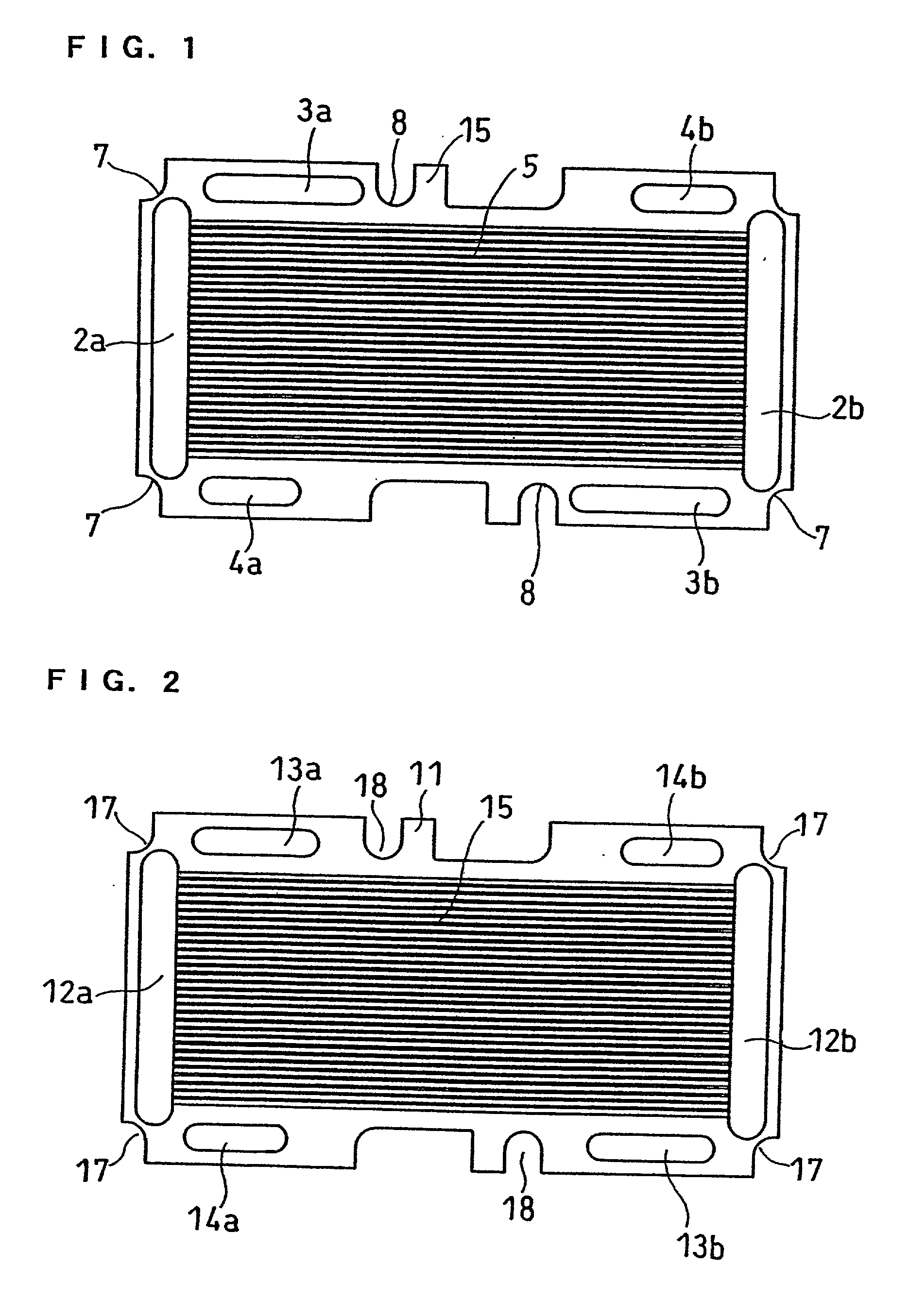

Polymer electrolyte fuel cell

InactiveUS6884536B1Easy to optimizeFuel cells groupingFuel cell auxillariesFuel cellsConductive polymer

A polymer electrolyte fuel cell comprising a hydrogen-ion conductive polymer electrolyte membrane, an anode and a cathode sandwiching the hydrogen-ion conductive polymer electrolyte membrane, an anode-side conductive separator plate having gas flow channels for supplying a fuel gas to the anode, and a cathode-side conductive separator plate having gas flow channels for supplying an oxidant gas to the cathode, wherein the anode-side and cathode-side conductive separator plates have a substantially rectangular part in contact with the anode or cathode in which the length of a longer side is equal to or more than twice the length of a shorter side, and the oxidant gas flow channels have a linear part formed along the longer side of the rectangular part.

Owner:PANASONIC CORP

Polymer electrolyte fuel cell, electrolyte material therefore and method for its production

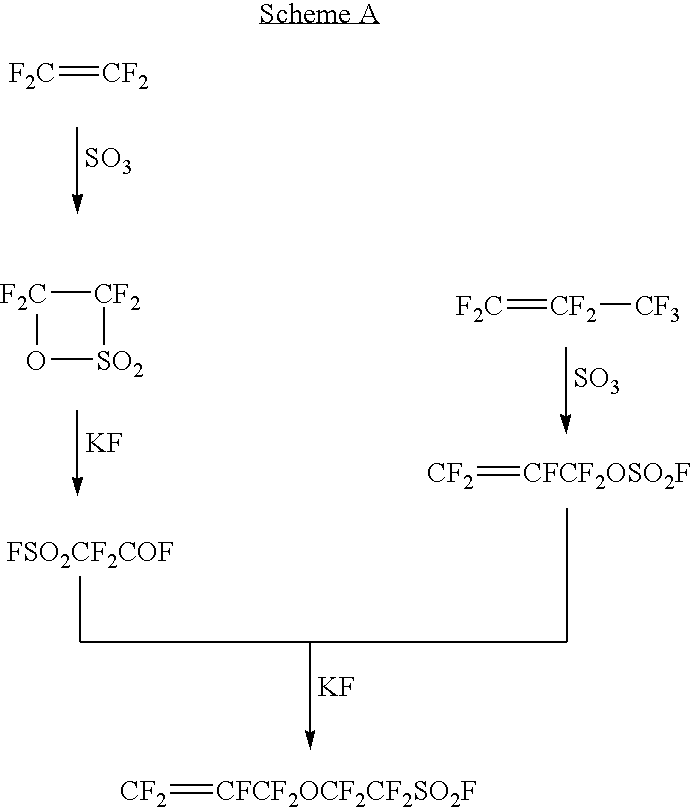

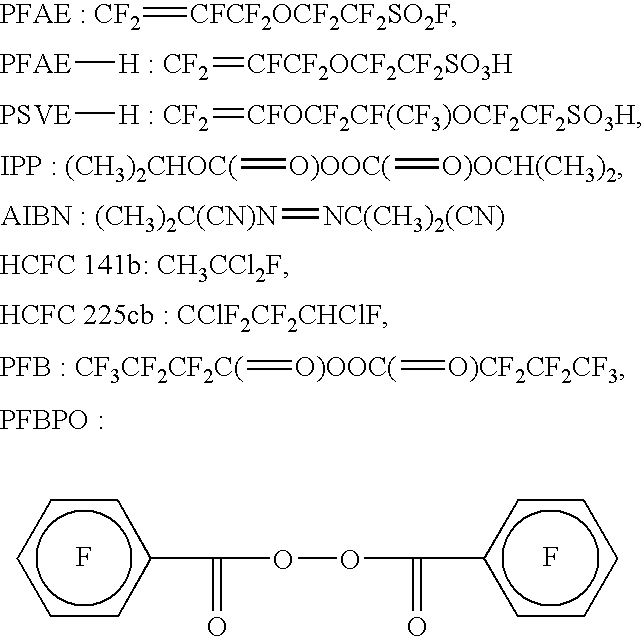

InactiveUS20050037265A1Easy to synthesizeSufficient molecular weightSolid electrolytesCell electrodesTetrafluoroethyleneFuel cells

An electrolyte material for a polymer electrolyte fuel cell, which is made of a copolymer comprising repeating units based on CF2═CFCF2OCF2CF2SO3H and repeating units based on tetrafluoroethylene and which has an ion exchange capacity of from 0.9 to 1.5 (meq / g dry resin). This electrolyte material has ion conductivity and durability equal to conventional electrolyte material, is easy to synthesize, has a softening point higher than electrolyte material heretofore widely used for application to fuel cells and is suitable for operation of a polymer electrolyte fuel cell at a temperature higher than the conventional material.

Owner:ASAHI GLASS CO LTD

Polymer electrolyte membrane, method for producing same, and membrane electrode assembly and polymer electrolyte fuel cell comprising same

InactiveUS20020164513A1Low dependency of ion conductivitySufficient power-generating performanceElectrolyte holding meansSemi-permeable membranesFiberPolymer science

A polymer electrolyte membrane obtained by subjecting a sulfonated polyarylene membrane having an initial water content of 80-300 weight % to a hot-water treatment. A composite polymer electrolyte membrane comprising a matrix made of a first sulfonated aromatic polymer having a high ion exchange capacity, and a reinforcing material constituted by a second sulfonated aromatic polymer having a low ion exchange capacity in the form of fibers or a porous membrane.

Owner:HONDA MOTOR CO LTD

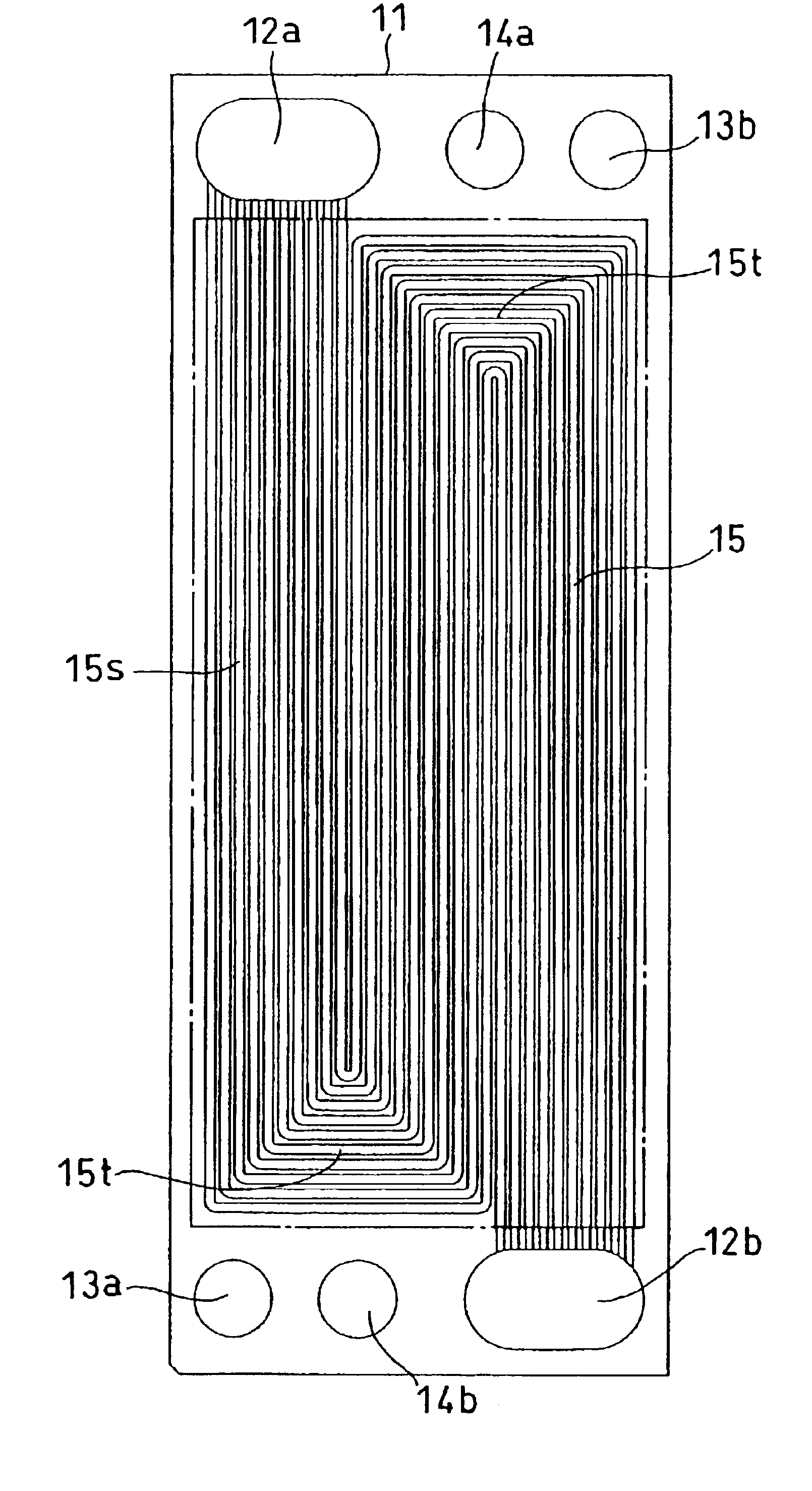

Membrane/electrode assembly for polymer electrolyte fuel cells and polymer electrolyte fuel cell

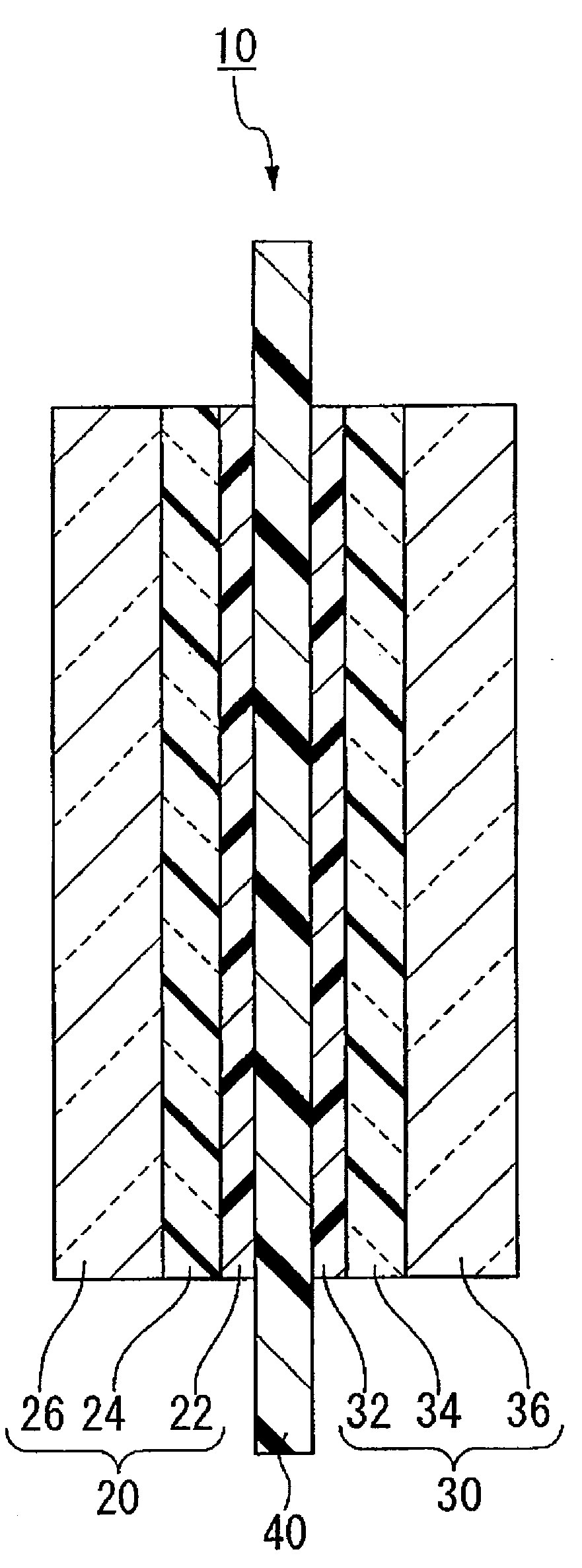

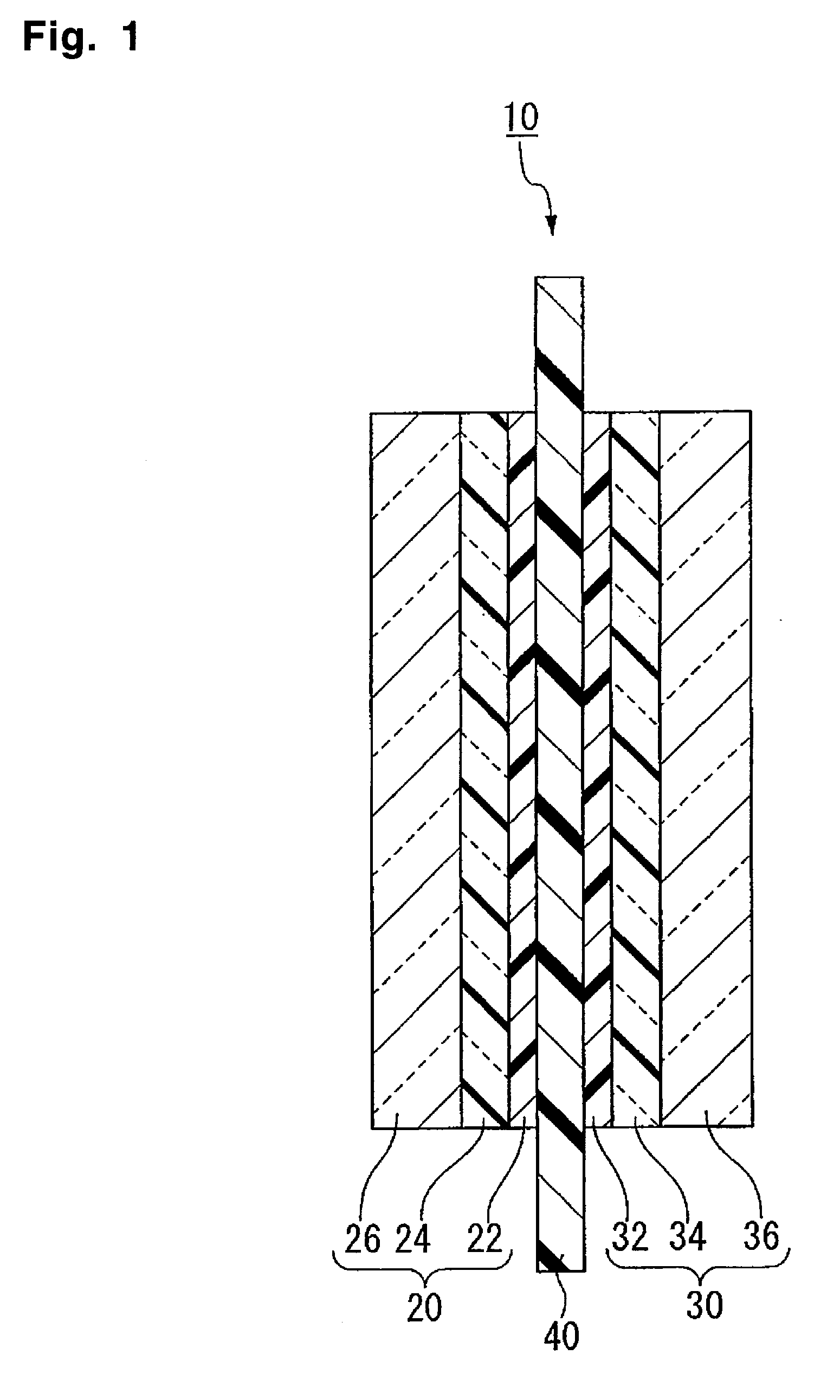

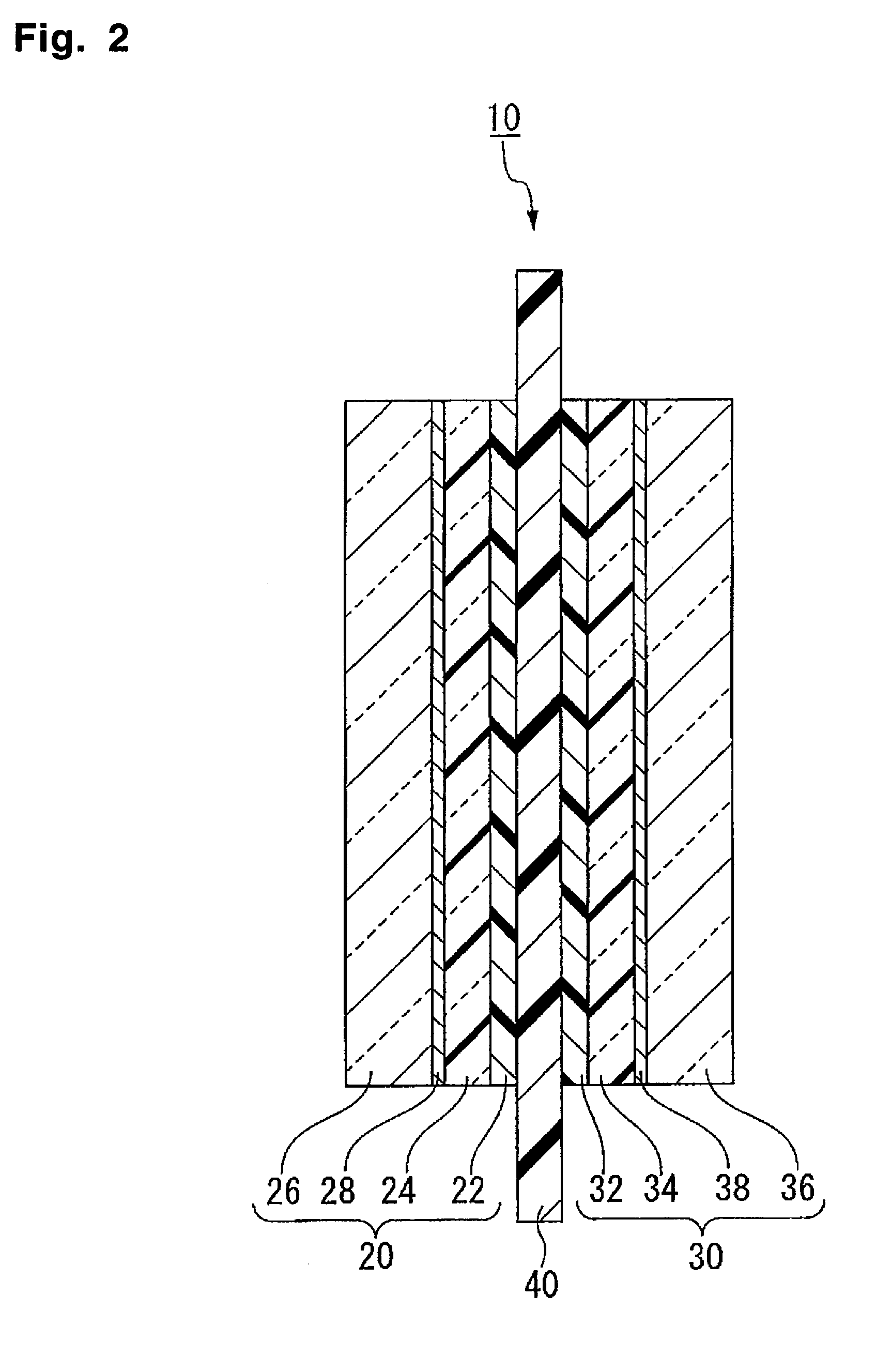

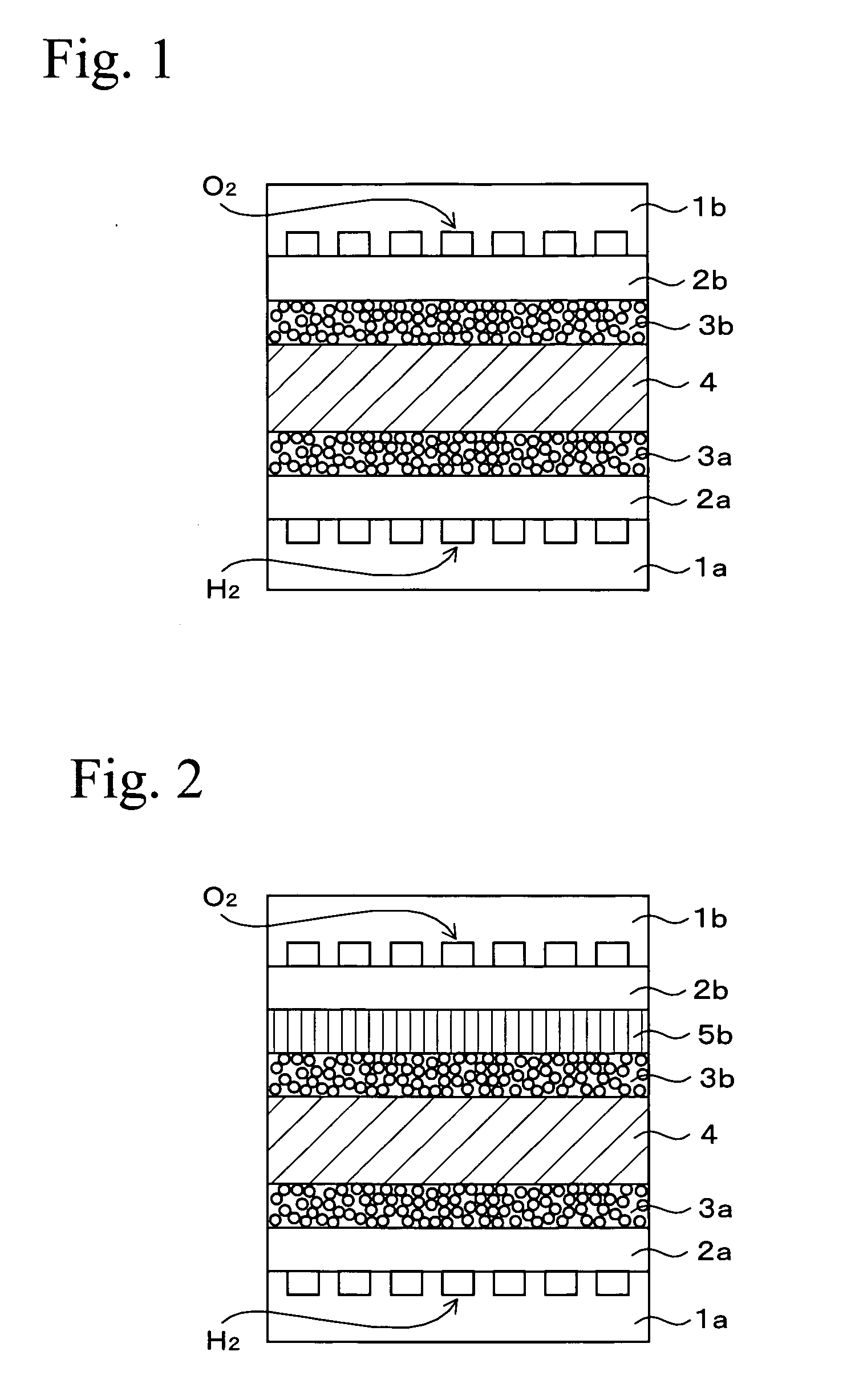

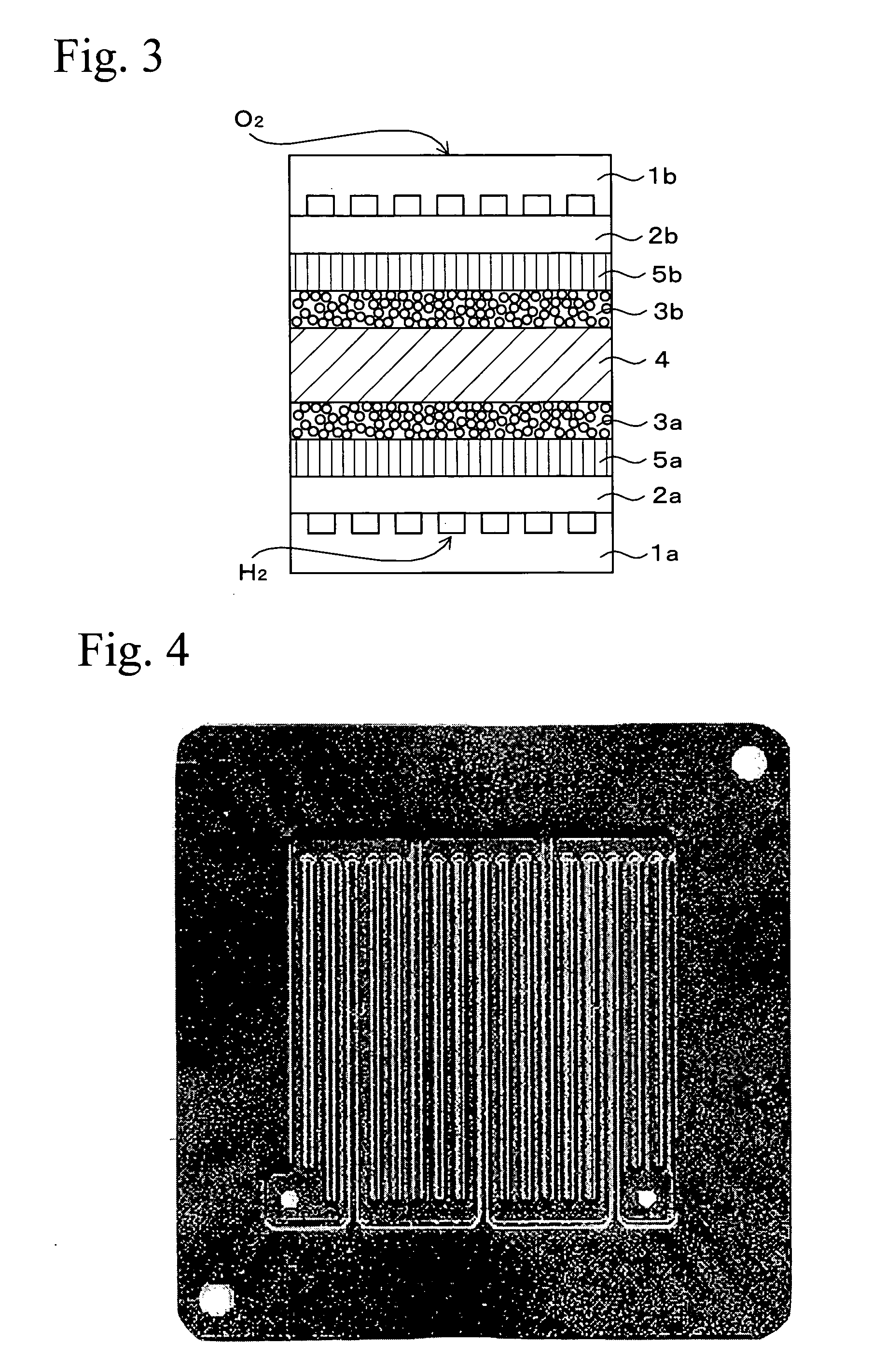

ActiveUS20090246592A1Increase power generation capacityHigh mechanical strengthElectrolyte holding meansSolid electrolyte fuel cellsFiberEngineering

To provide a membrane / electrode assembly for polymer electrolyte fuel cells, which is capable of providing high power generation performance even under a low humidity condition and has sufficient mechanical strength and dimensional stability, and which has an excellent durability even in an environment where moistening and drying are repeated, and a polymer electrolyte fuel cell which is capable of providing high power generation performance even under a low humidity condition.A membrane / electrode assembly 10 is used, which comprises a cathode 20 having a catalyst layer 22, an anode 30 having a catalyst layer 32, and a polymer electrolyte membrane 40 interposed between the catalyst layer 22 of the cathode 20 and the catalyst layer 32 of the anode 30, wherein at least one of the cathode 20 and the anode 30 further has a reinforcing layer 26 comprising a porous sheet-form reinforcing material made of a polymer, and an electrically conductive fiber.

Owner:ASAHI GLASS CO LTD

Membrane electrode assembly for polymer electrolyte fuel cell

ActiveUS6847518B2Reduce depositionPower generation efficiency deterioratesLiquid electrolytic capacitorsCell electrodesPolymer electrolytesFuel cells

A membrane electrode assembly for a polymer electrolyte fuel cell has a polymer electrolyte membrane, an anode, and a cathode having a catalytic layer and a diffusion layer. The alloy catalyst contains ruthenium in the anode diffusion layer. The assembly has less loss of efficiency, particularly when operated at high potentials.

Owner:HONDA MOTOR CO LTD +1

Solid polymer electrolyte membrane and production method of the same

ActiveUS20060199062A1Increased durabilityImprove stabilityCellsSolid electrolytesPolymer electrolytesPolymer science

An object of the present invention is to provide a solid polymer electrolyte membrane in which a polyazole-based compound is uniformly mixed with a perfluorocarbonsulfonic acid resin. Thus, the present invention provides a solid polymer electrolyte membrane for solid polymer electrolyte fuel cell, which has high durability, as well as a membrane electrode assembly and a solid polymer electrolyte fuel cell, each containing the same. The inventive solid polymer electrolyte membrane is produced by a method which comprises a polymer electrolyte-containing solution preparation step of dissolving a perfluorocarbonsulfonic acid resin (component A) having an ion-exchange capacity of 0.5 to 3.0 meq / g, a polyazole-based compound (component B) and an alkali metal hydroxide in a protic solvent to prepare a polymer electrolyte-containing solution in which a weight ratio of the component A to component B, (A / B), is from 2.3 to 199 and a total weight of the component A and the component B is from 0.5 to 30% by weight; and a membrane formation step of forming a membrane from the polymer electrolyte-containing solution.

Owner:ASAHI KASEI KK

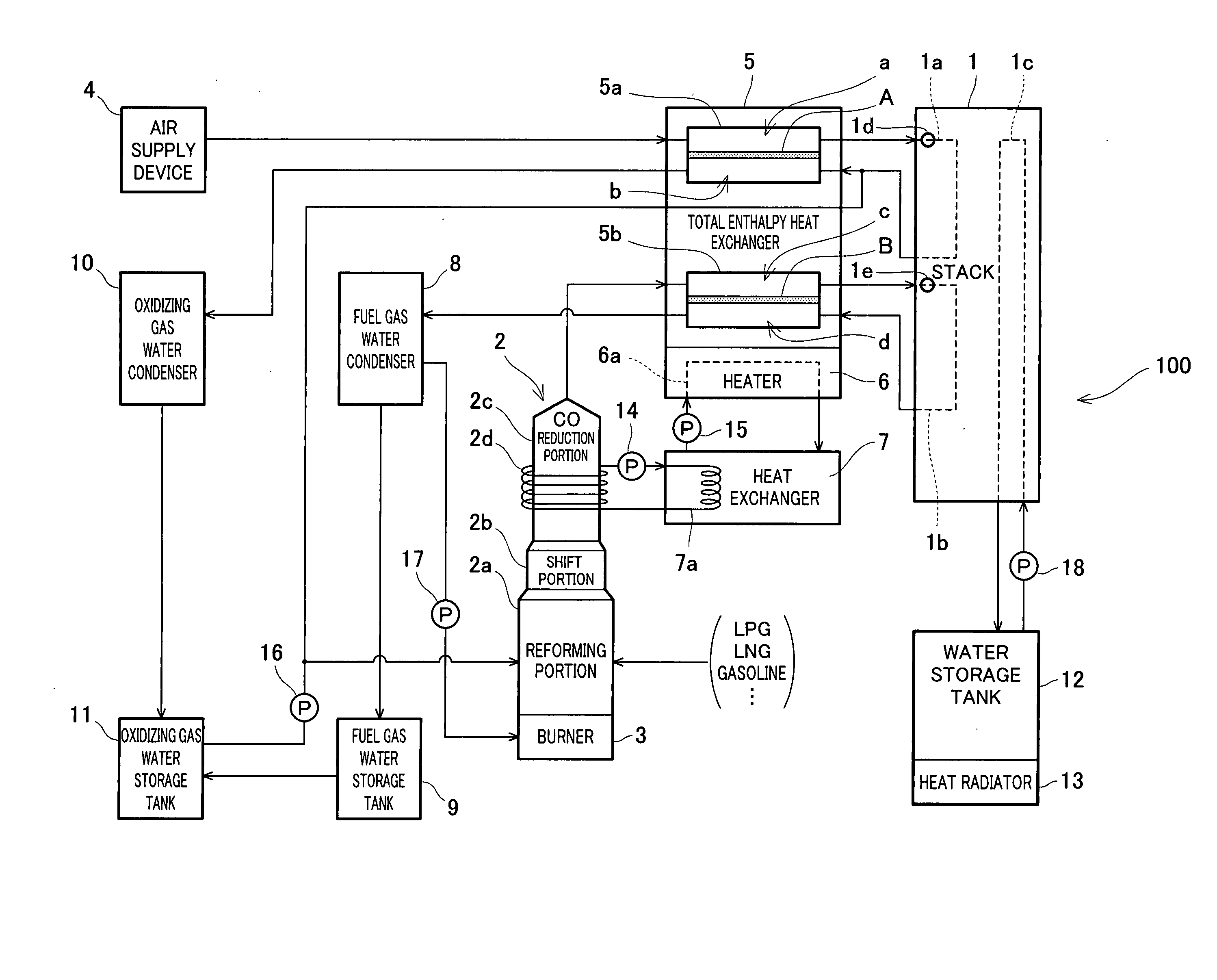

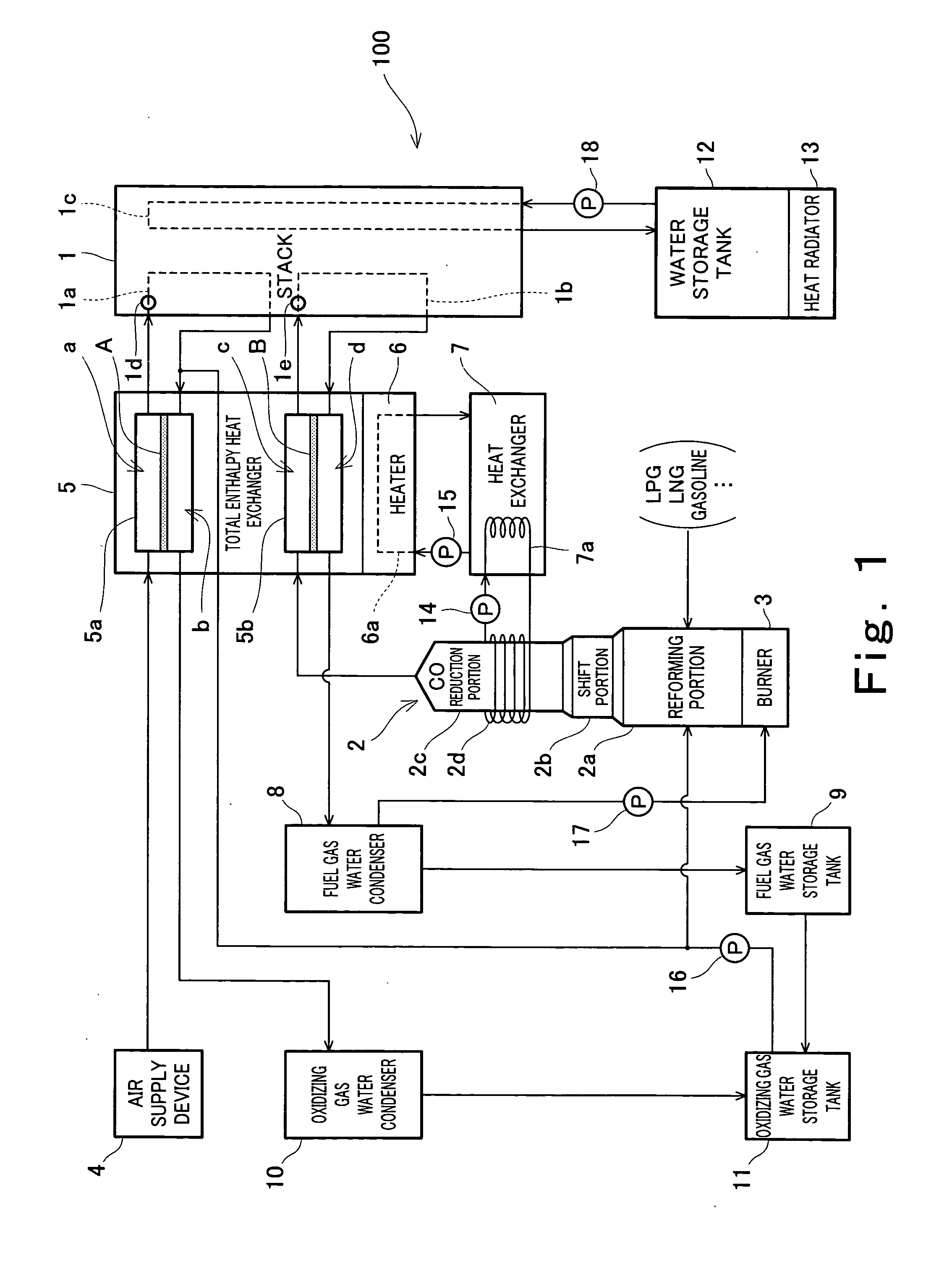

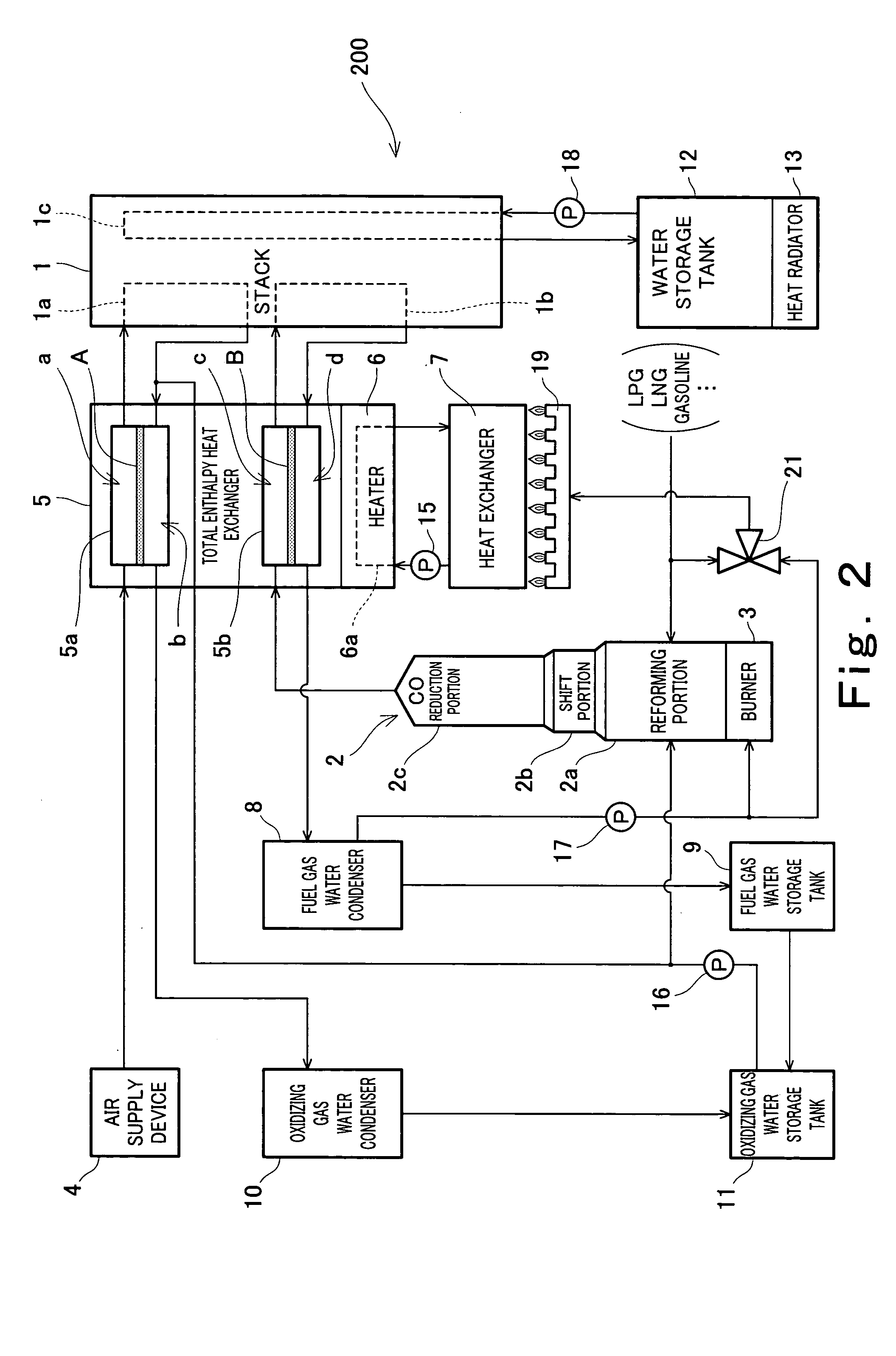

Polymer electrolyte fuel cell system and operation method thereof

InactiveUS20050048338A1Stable supplyReduce heat lossFuel cell heat exchangeWater management in fuel cellsFuel cellsDew

A polymer electrolyte fuel cell system is disclosed, comprising a fuel cell having a predetermined power generation portion configured to operate at a predetermined temperature to generate an electric power using a fuel gas and an oxidizing gas supplied to said fuel cell, and a humidifier configured to humidify the fuel gas and the oxidizing gas, wherein the humidifier is configured to humidify the fuel gas and the oxidizing gas to allow the fuel gas and the oxidizing gas to have dew points higher than the predetermined temperature, the humidified fuel gas and oxidizing gas having the dew points higher than the operating temperature being supplied to the fuel cell.

Owner:PANASONIC CORP

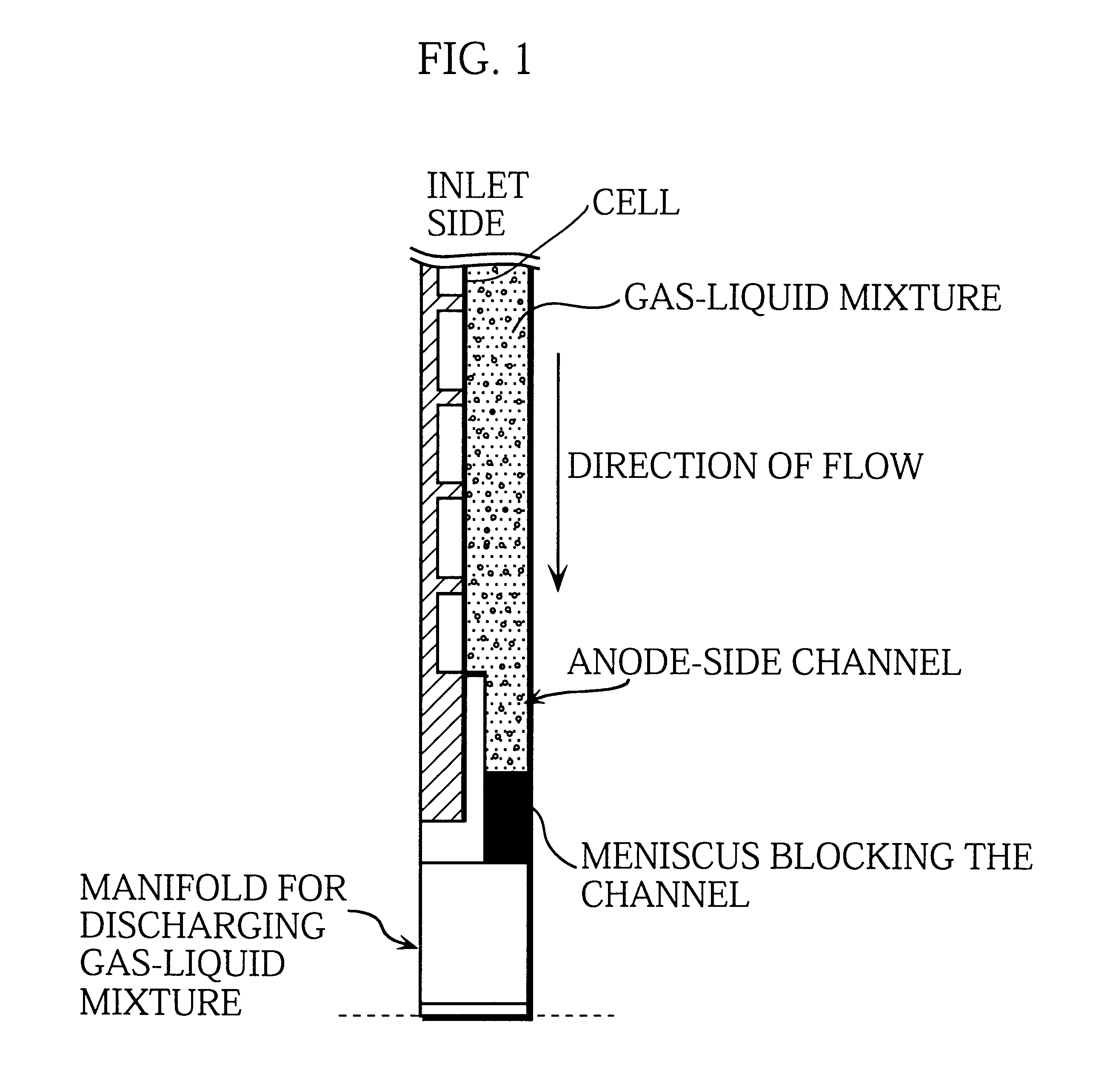

Polymer electrolyte fuel cell showing stable and outstanding electric-power generating characteristics

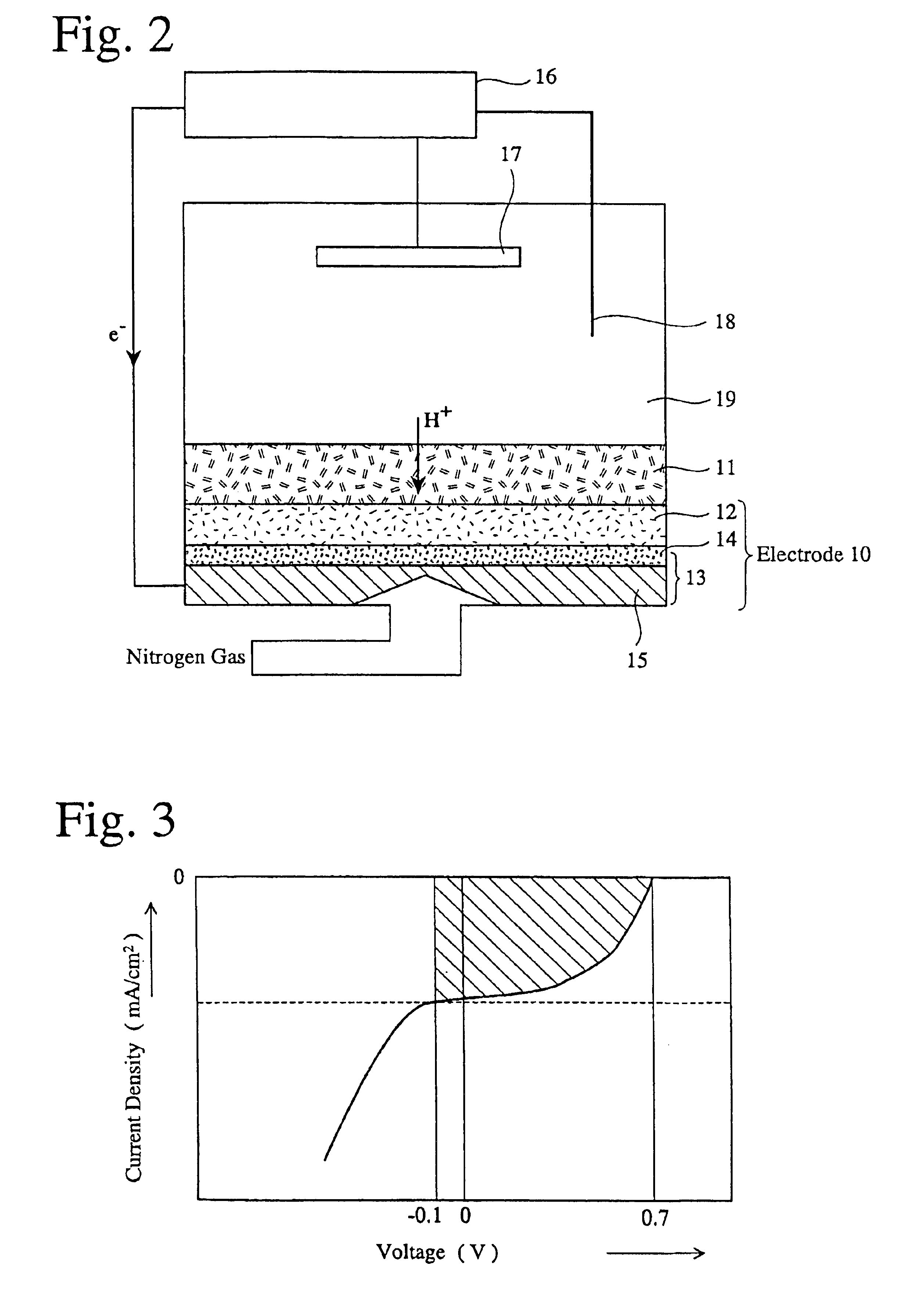

InactiveUS6329094B1Stable power generationAvoid cloggingSolid electrolytesFuel cells groupingFuel cellsWater source

A solid polymer fuel cell which can stably generate electric power for long, because the cell is enabled to uniformly supply a fuel gas to all anodes by means of extended flow passages which are extended from anode-side flow passages and formed on a anode-side plate on the downstream side of the ends of the anodes in the direction of fuel gas flow, a water absorbing means for nearly uniformly performing water absorption, water retention, and drainage on all channels provided at the ends of the extended flow passages, and a selective gas discharging means for discharging a gas more selectively than water on the upstream side of the water absorbing means. In addition, the power generation characteristics and service life of the fuel cell can be improved further, because the cell can maintain a solid polymer film in a moist state as a whole and can efficiently supply the fuel gas to all anodes by a means for distributing the fuel gas to the inlet sections of the anode-side flow passages and a means for distributing water from a water source to the inlet sections of the anode-side flow passages through holes having a prescribed form and leading to the inlet sections of the anode-side flow passages.

Owner:JX NIPPON OIL & ENERGY CORP

Composite electrolyte membrane, catalyst-coated membrane assembly, membrane-electrode assembly and polymer electrolyte fuel cell

InactiveUS20050227132A1High mechanical strengthAvoid size changeElectrolyte holding meansFuel cells groupingCoated membraneWrinkle skin

To provide a polymer electrolyte membrane having excellent size stability and excellent mechanical strength that can sufficiently prevent the size change due to the swelling condition, the displacement of the polymer electrolyte membrane and the formation of wrinkles during the production of the polymer electrolyte fuel cell, and can prevent damage during the production and operation of the polymer electrolyte fuel cell. In a composite electrolyte membrane including a porous reinforcement layer made of a resin and an electrolyte layer made of a polymer electrolyte and laminated at least one main surface of the reinforcement layer, the direction having a high tensile modulus of elasticity in the reinforcement layer is substantially corresponded with the direction having a high rate of size change in the electrolyte layer.

Owner:PANASONIC CORP

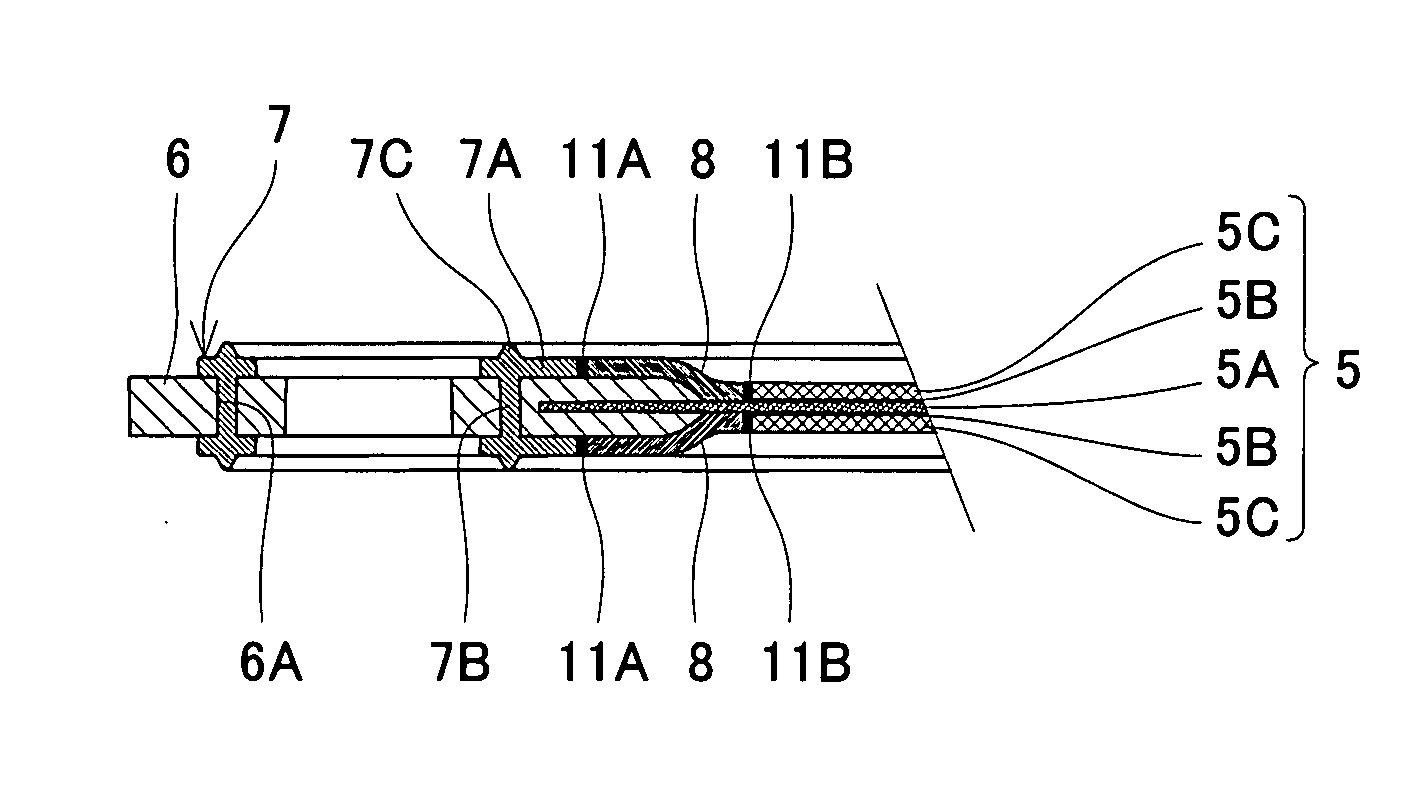

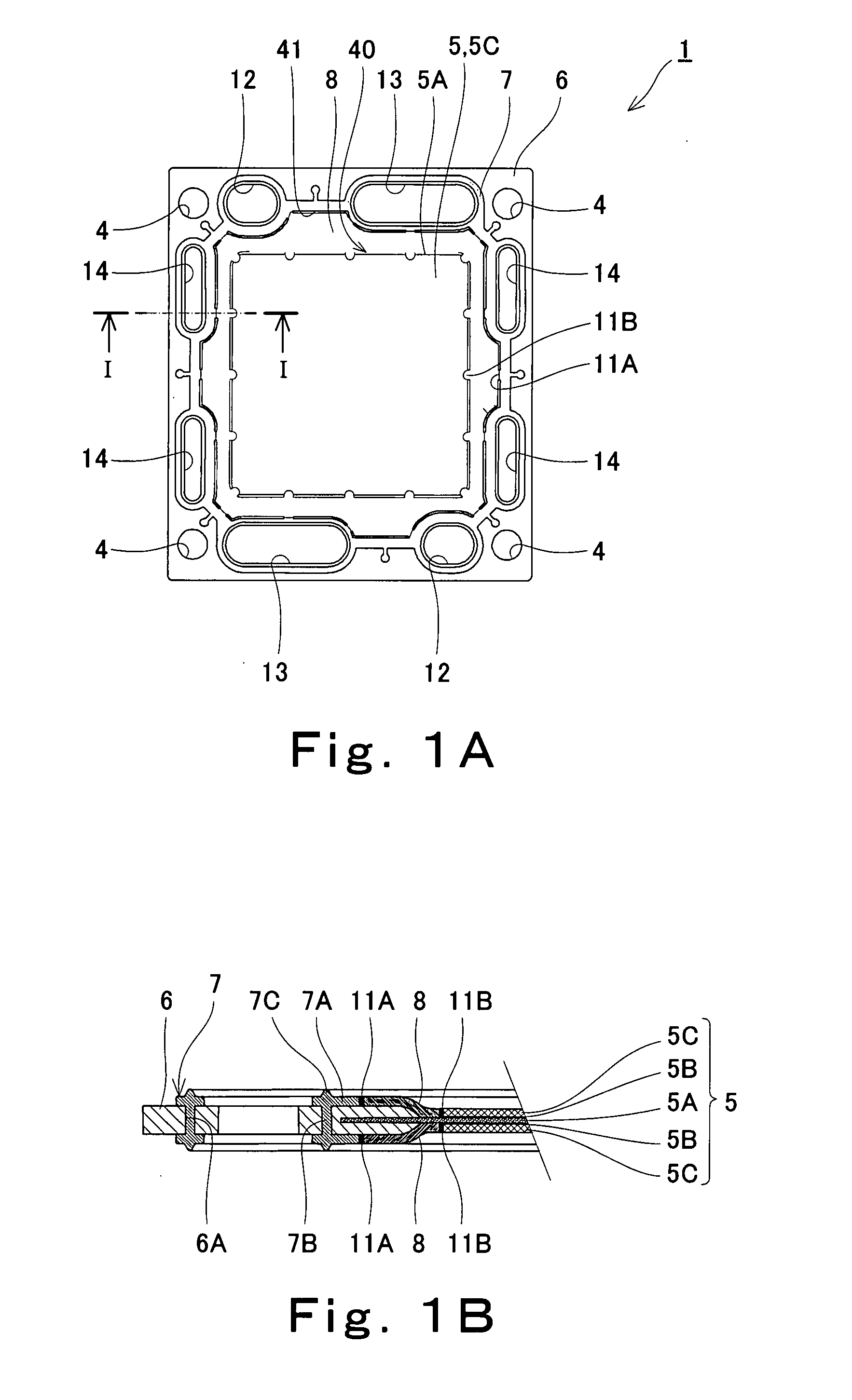

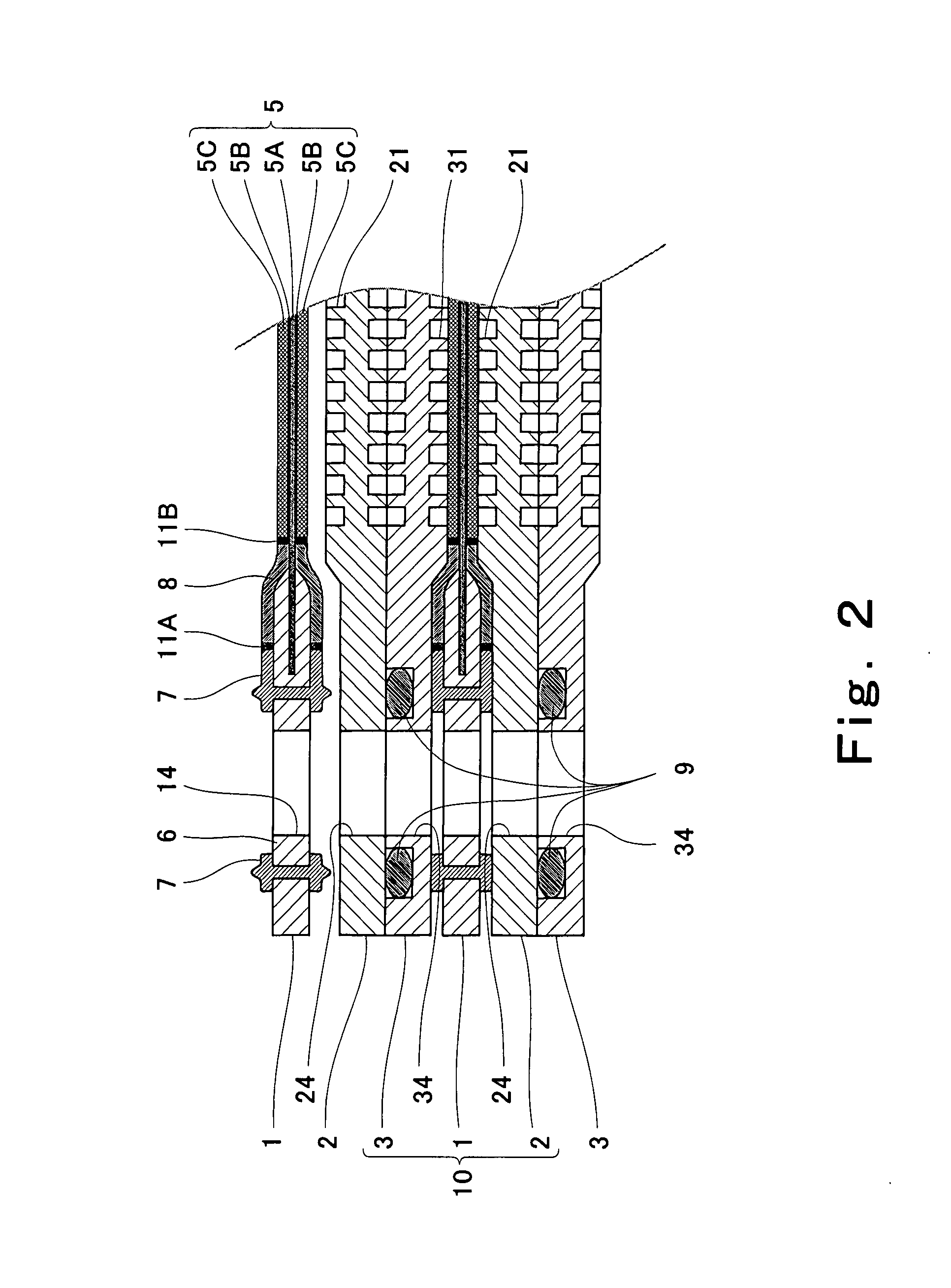

Mea-Gasket Assembly and Polymer Electrolyte Fuel Cell Using Same

InactiveUS20070264557A1Simple structureAvoid flowFuel cells groupingFuel cell auxillariesPolymer electrolytesFuel cells

The invention provides an MEA-gasket assembly (1) comprising: an MEA (5) having a polymer electrolyte membrane (5A), catalyst layers and gas diffusing layers (5C); a plate-like frame (6) which is joined to a portion of the polymer electrolyte membrane (5A) so as to enclose the MEA (5), the portion being located in a peripheral region of the MEA (5) and which has a plurality of fluid manifold holes (12, 13, 14); and an annular gasket (7) formed on both faces of the frame (6), wherein an annular gap formed between the inner peripheral edge of the annular gasket (7) and the outer peripheral edges of the gas diffusing layers (5C) is at least partially closed.

Owner:PANASONIC CORP

Polymer electrolyte fuel cell

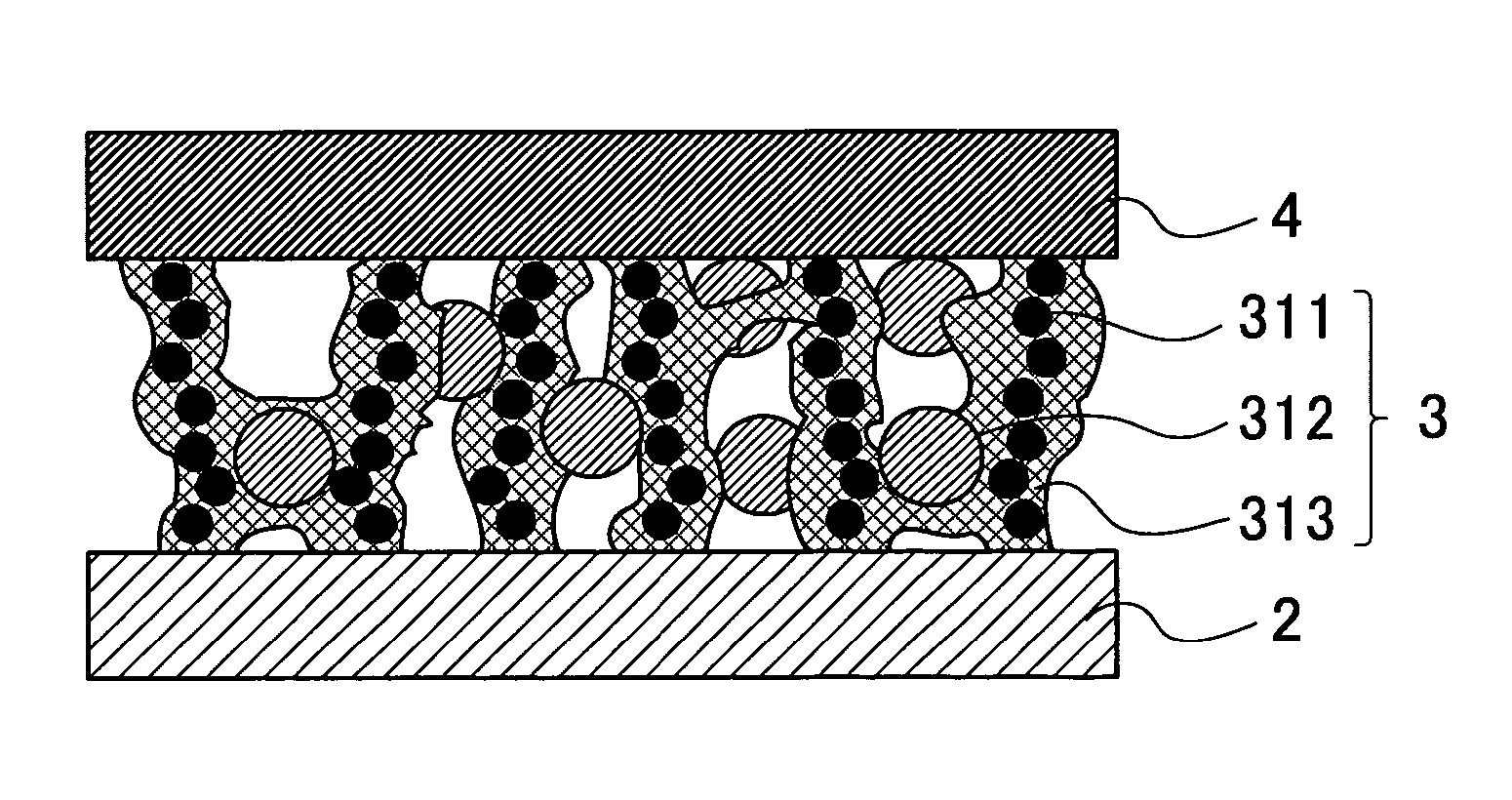

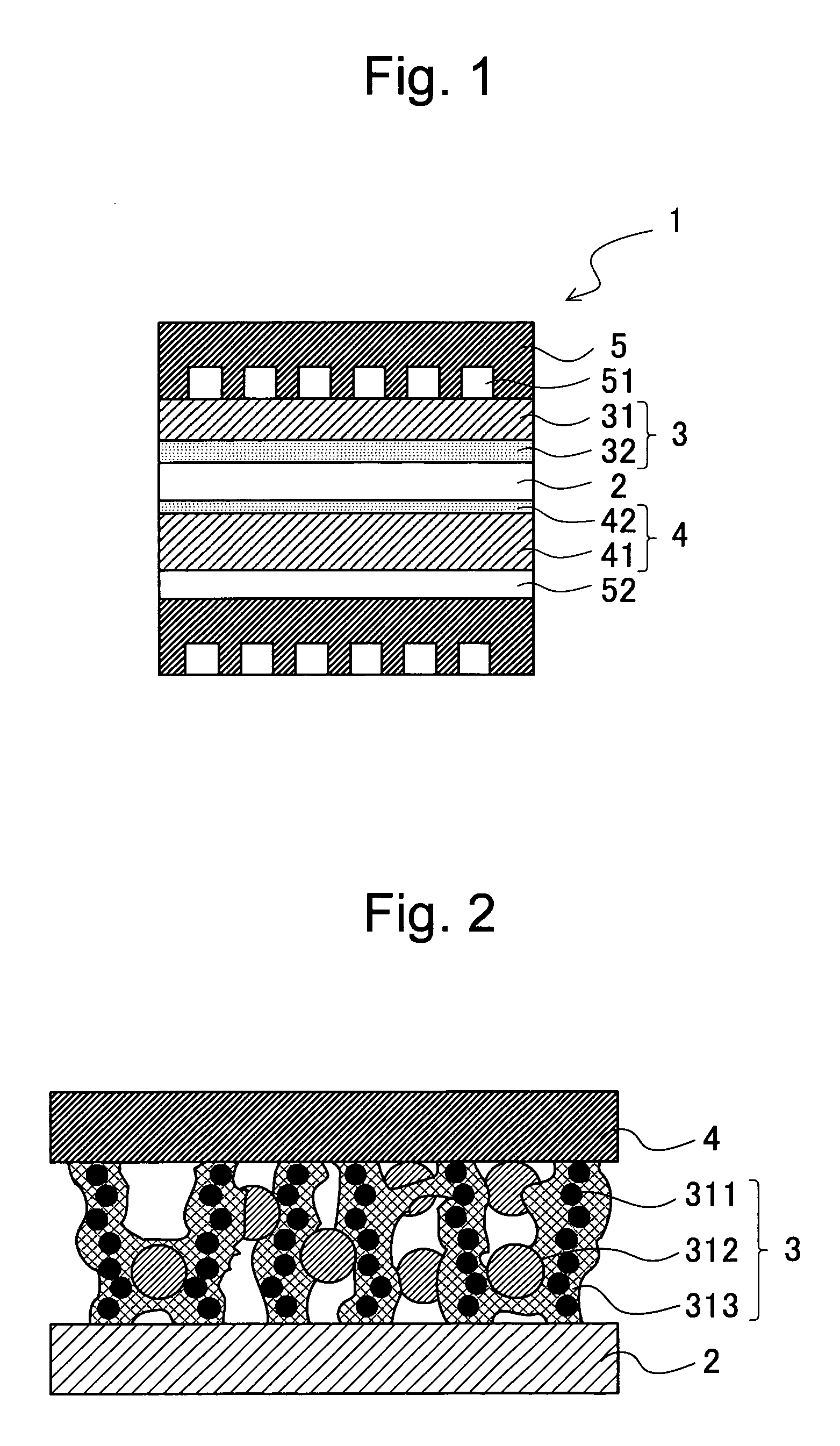

ActiveUS20040131919A1Reduce wasteCarry lotActive material electrodesSolid electrolyte fuel cellsPolymer electrolytesFuel cells

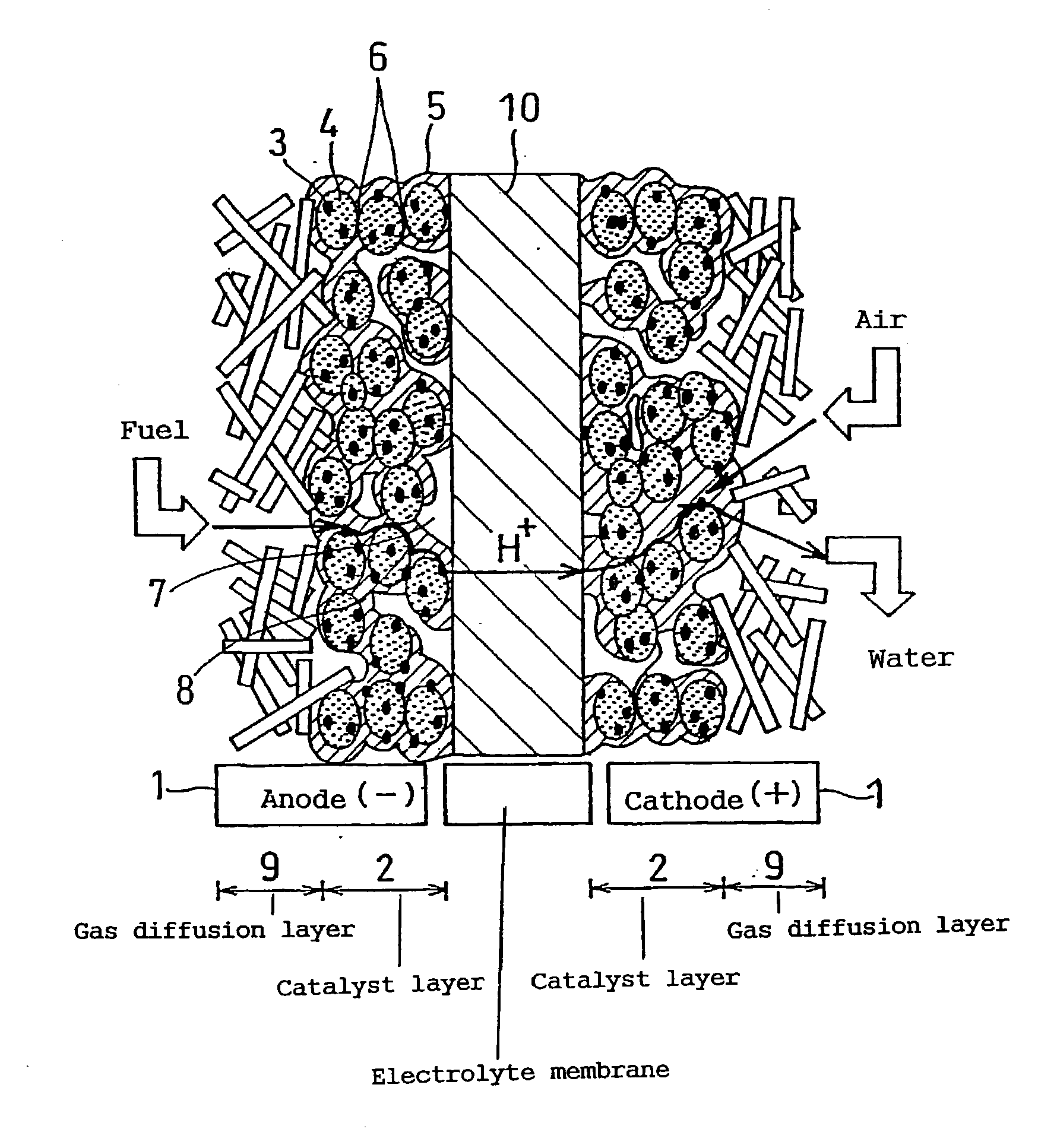

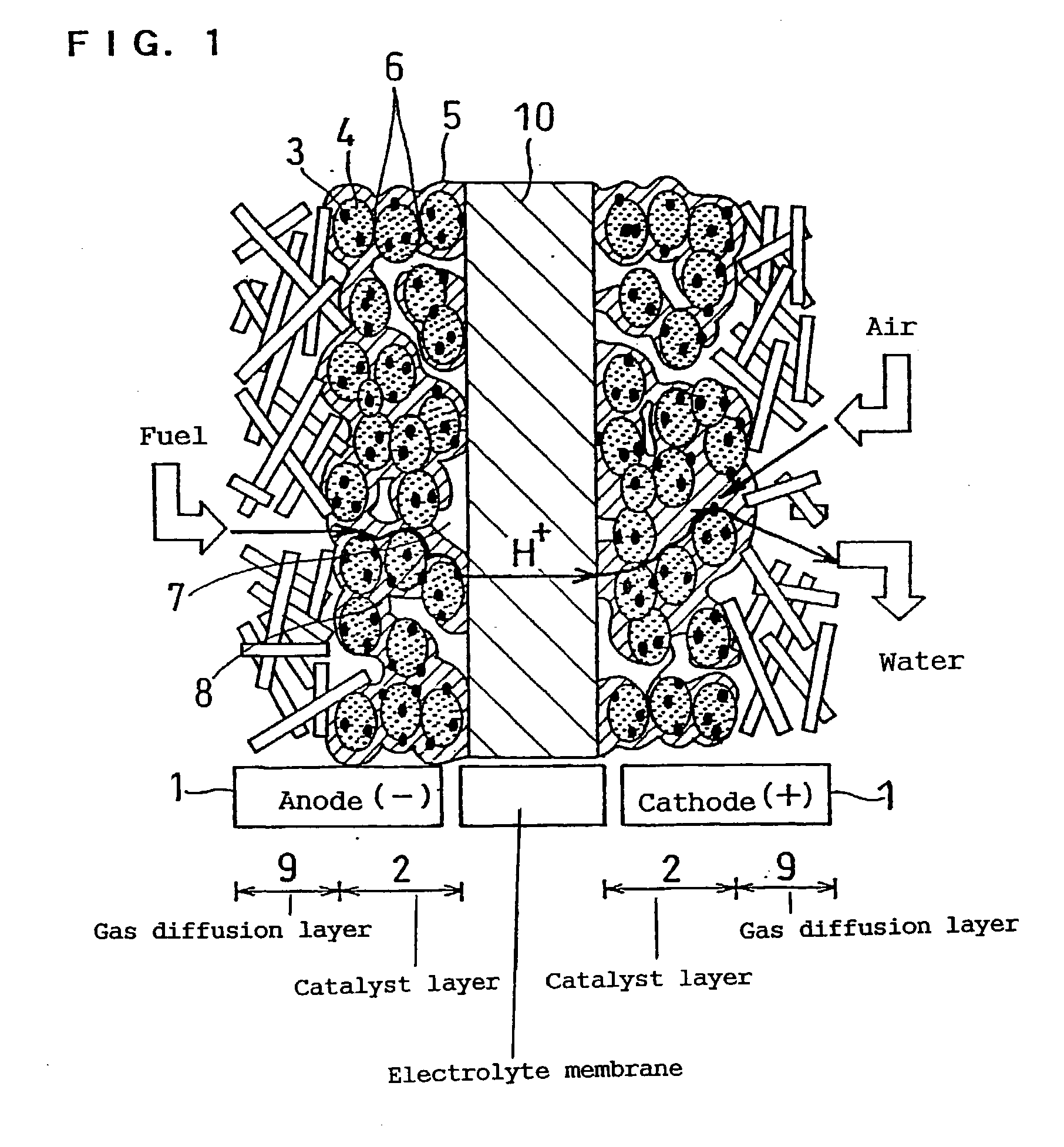

In a polymer electrolyte fuel cell including a hydrogen ion conductive polymer electrolyte membrane; a pair of electrodes composed of catalyst layers sandwiching the hydrogen ion conductive polymer electrolyte membrane between them and gas diffusion layers in contact with the catalyst layers; a conductive separator plate having a gas flow channel for supplying a fuel gas to one of the electrodes; and a conductive separator plate having a gas flow channel for supplying an oxidant gas to the other electrode, in order to bring a hydrogen ion conductive polymer electrolyte and a catalyst metal of the catalyst layers containing the hydrogen ion conductive polymer electrolyte and conductive carbon particles carrying the catalyst metal sufficiently and uniformly into contact with each other, the polymer electrolyte is provided in pores of an agglomerate structure of the conductive carbon particles. Consequently, the reaction area inside the electrodes is increased, and higher performance is exhibited.

Owner:PANASONIC CORP

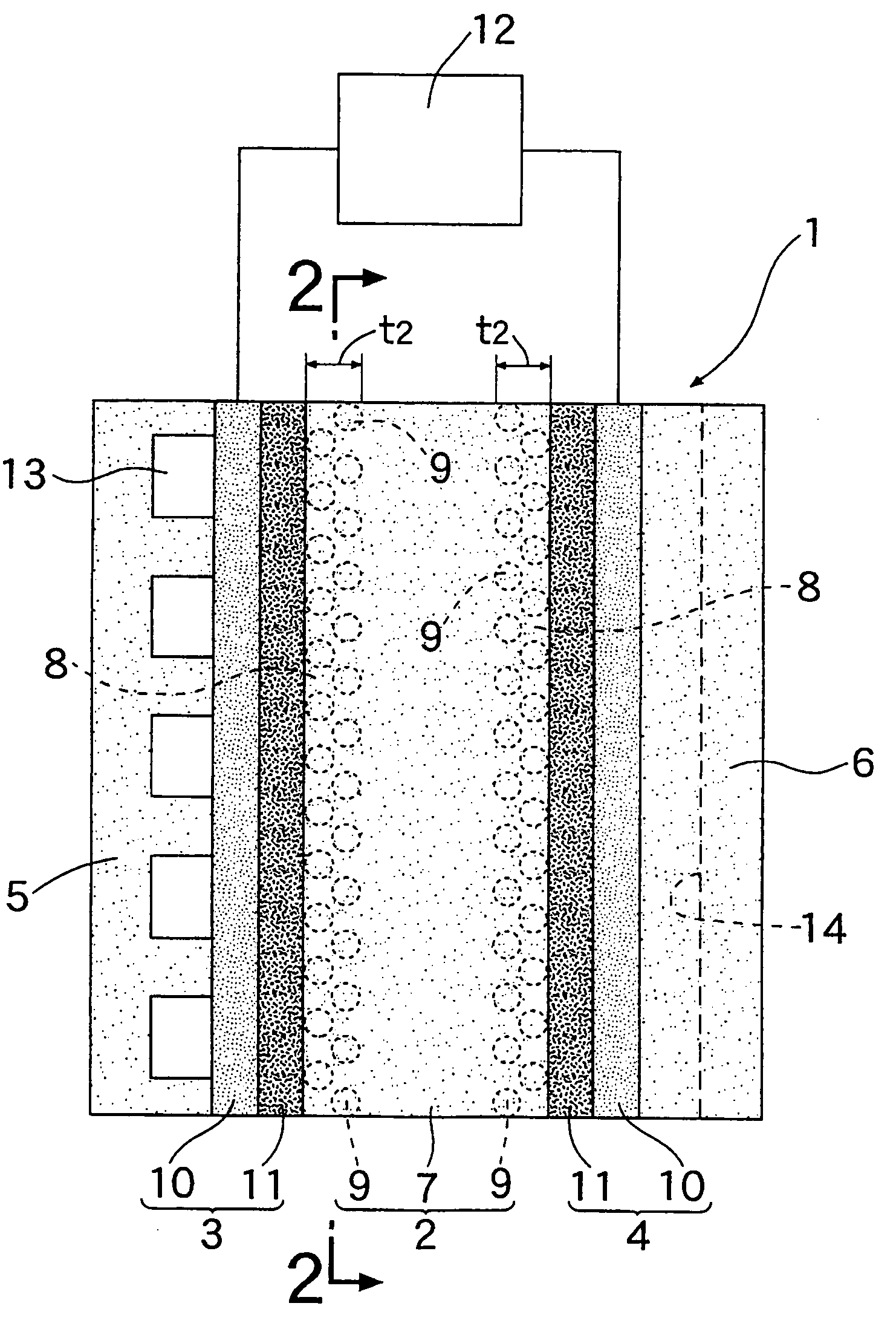

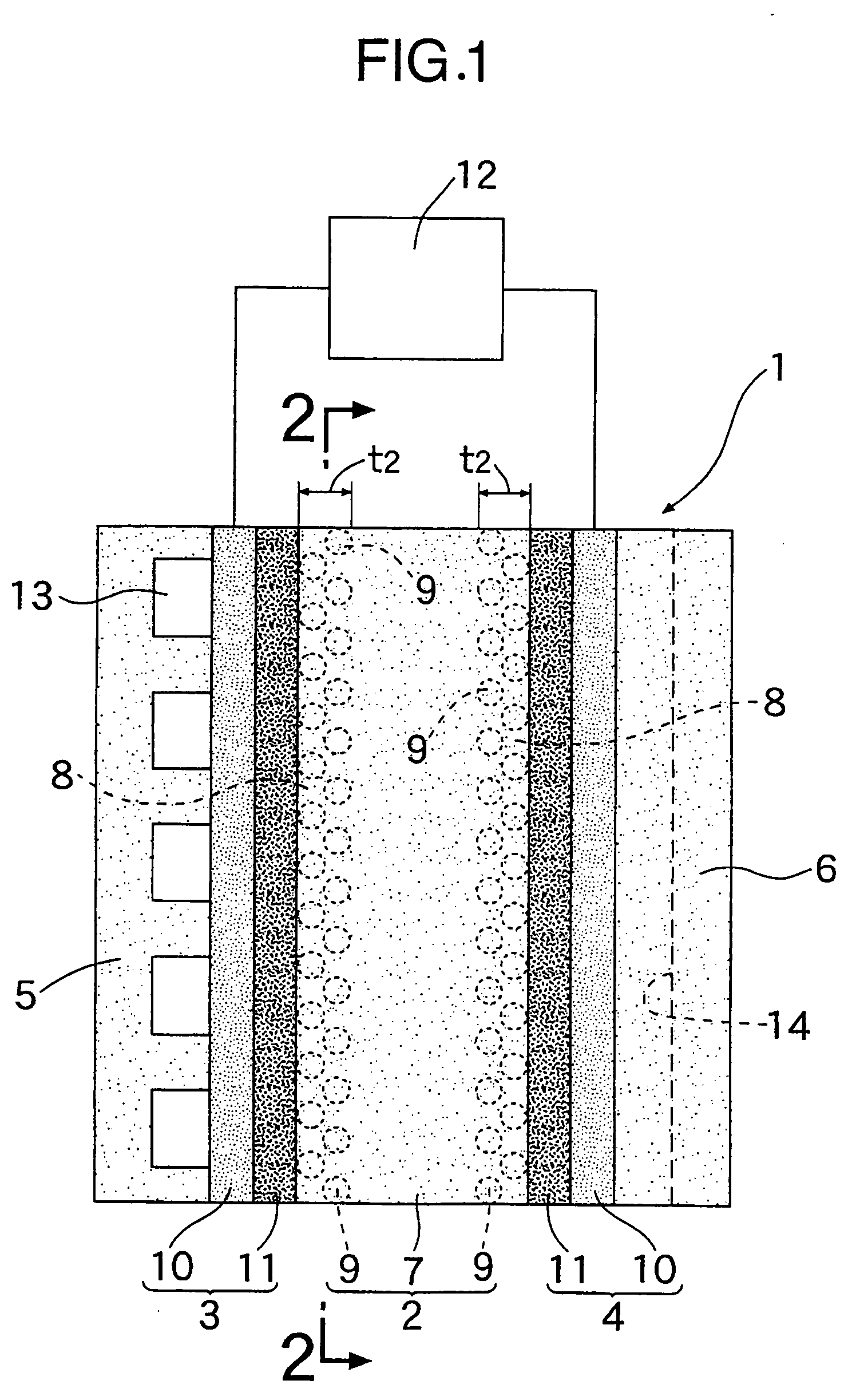

Active solid polymer electrolyte membrane for solid polymer electrolyte fuel cell

InactiveUS20050175886A1Improve fuel cell performanceImprove performanceSolid electrolytesFuel cell auxillariesPolymer electrolytesSurface layer

An active solid polymer electrolyte membrane provides an enhancement in power-generating performance. The active solid polymer electrolyte membrane in a solid polymer electrolyte fuel cell includes a solid polymer electrolyte element, and a plurality of noble metal catalyst grains which are carried by an ion exchange in a surface layer located inside a surface of the solid polymer electrolyte element and which are dispersed uniformly in the entire surface layer. The surface layer has a thickness t2 equal to or smaller than 10 μm. An amount CA of noble metal catalyst grains carried is in a range of 0.02 mg / cm2≦CA<0.14 mg / cm2.

Owner:HONDA MOTOR CO LTD

Solid polymer electrolyte fuel cell and method for manufacturing the same

ActiveUS20060019147A1Increase power generationSolve the lack of durabilityFinal product manufactureFuel cell auxillariesAlloyConductive materials

A solid polymer electrolyte fuel cell comprises: a plurality of electrode structures comprising an anode and a cathode, and polymer electrolyte membrane held between the anode and the cathode, and a plurality of separators for holding the respective electrode structures, with a fuel gas passage for supplying and discharging fuel gas containing hydrogen on a surface opposing the anode; and an oxidant gas passage for supplying and discharging oxidant gas on a surface opposing the cathode. The catalyst layer of the anode comprises a mixture of an ion conductive material, a platinum powder and / or platinum alloy powder and a carbon, the platium powder and / or platinum alloy powder and carbon substantially exist independently from each other, and the catalyst layer of the cathode comproses a metal support mixture in which the ion conductive material and the electro-conductive material having the supported catalyst material are mixed.

Owner:HONDA MOTOR CO LTD +1

Polymer electrolyte fuel-cell separator sealing rubber composition

InactiveUS6875534B2Long-term serviceImprove permeabilitySpecial tyresCell component detailsFuel cellsWeather resistance

A rubber composition comprising (A) a polyisobutylene polymer having an allyl radical at an end, (B) an optional organpolysiloxane, (C) an organohydrogenpolysiloxane having at least two SiH radicals per molecule, and (D) a platinum group metal catalyst forms a seal member on a periphery of one side of a polymer electrolyte fuel-cell separator. Due to improved acid resistance, weather resistance, creep resistance and gas permeability, the seal member remains effective for a long period of time.

Owner:SHIN ETSU CHEM IND CO LTD

Solid polymer electrolyte membrane electrode assembly and solid polymer electrolyte fuel cell using same

InactiveUS20060099475A1Inhibit deteriorationReduce frequencySolid electrolytesFuel cells groupingPolymer electrolytesFuel cells

A solid polymer electrolyte membrane electrode assembly (cell) comprising a fuel electrode membrane disposed on one surface of a solid polymer electrolyte membrane, and an oxidant electrode membrane disposed on the other surface of the solid polymer electrolyte membrane, and wherein ions of at least one metal of Ce, Tl, Mn, Ag and Yb are contained in the solid polymer electrolyte membrane of the cell; and a solid polymer electrolyte fuel cell using the cell.

Owner:MITSUBISHI HEAVY IND LTD

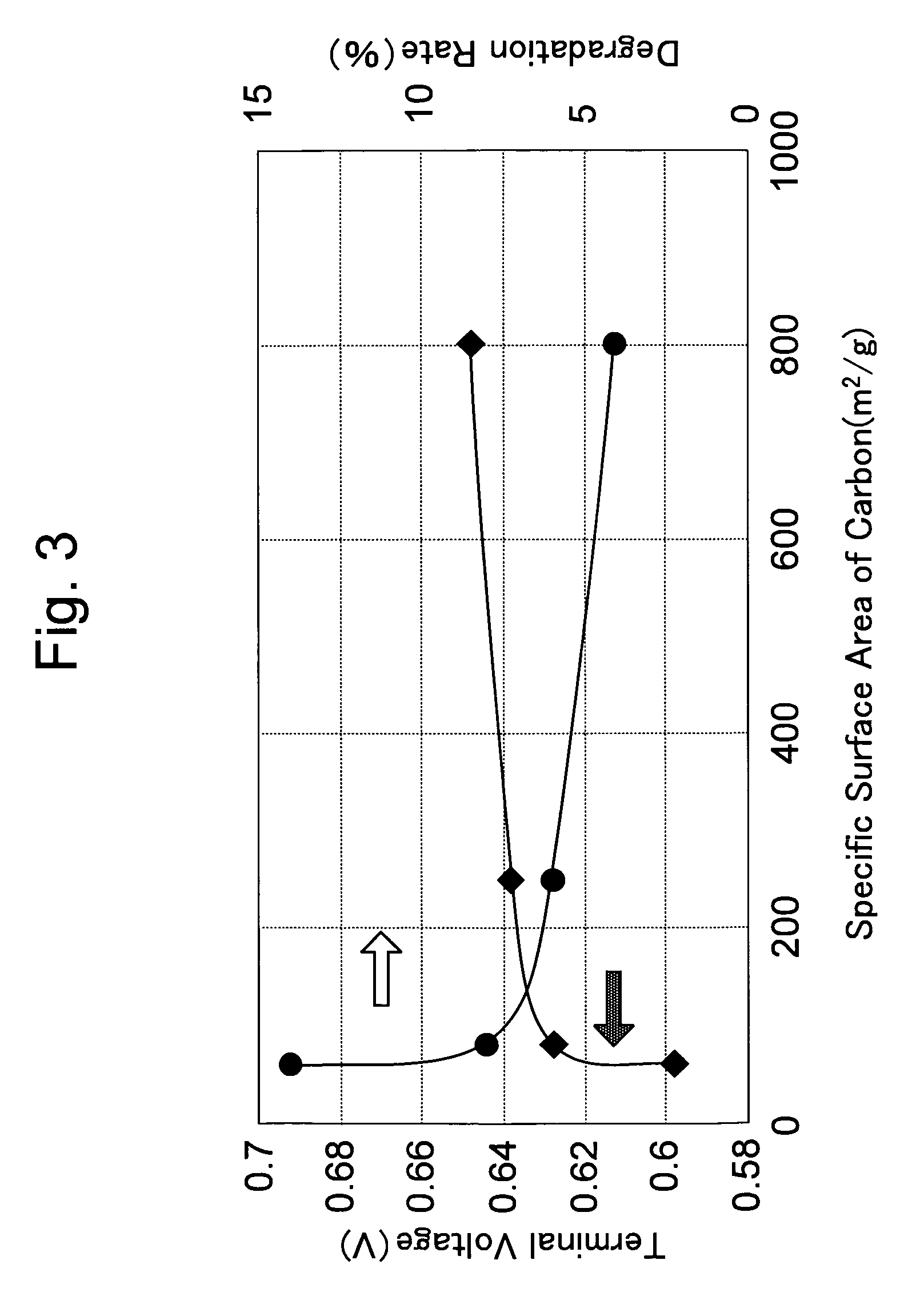

Polymer electrolyte fuel cell

InactiveUS20050227138A1High voltageImprove power generation efficiencySolid electrolytesSemi-permeable membranesFiberCarbon fibers

A polymer electrolyte fuel cell consists of plural units, and the unit has an anode side separator, an anode diffusion layer, an anode catalytic layer, polymer electrolyte membrane, a cathode catalytic layer, a cathode diffusion layer, and a cathode side separator. The cathode catalytic layer further includes a catalyst in which platinum or platinum alloy is supported on a carbon supporting body having an average lattice space d002 of [002] surface of 0.338 to 0.355 nm and specific surface area of the supporting body of 80 to 250 m2 / g, electrolyte containing ion exchange resin, and vapor grown carbon fiber. Furthermore, a water holding layer containing ion exchange resin, carbon particles, and vapor grown carbon fiber is arranged at an interface of the cathode diffusion layer and the cathode catalytic layer.

Owner:HONDA MOTOR CO LTD +1

Corrosion-resistant metallic member, metallic separator for fuel cell comprising the same, and process for production thereof

InactiveUS20030068523A1A large amountIncrease contact resistanceFinal product manufacturePretreated surfacesAir tightnessContact resistance

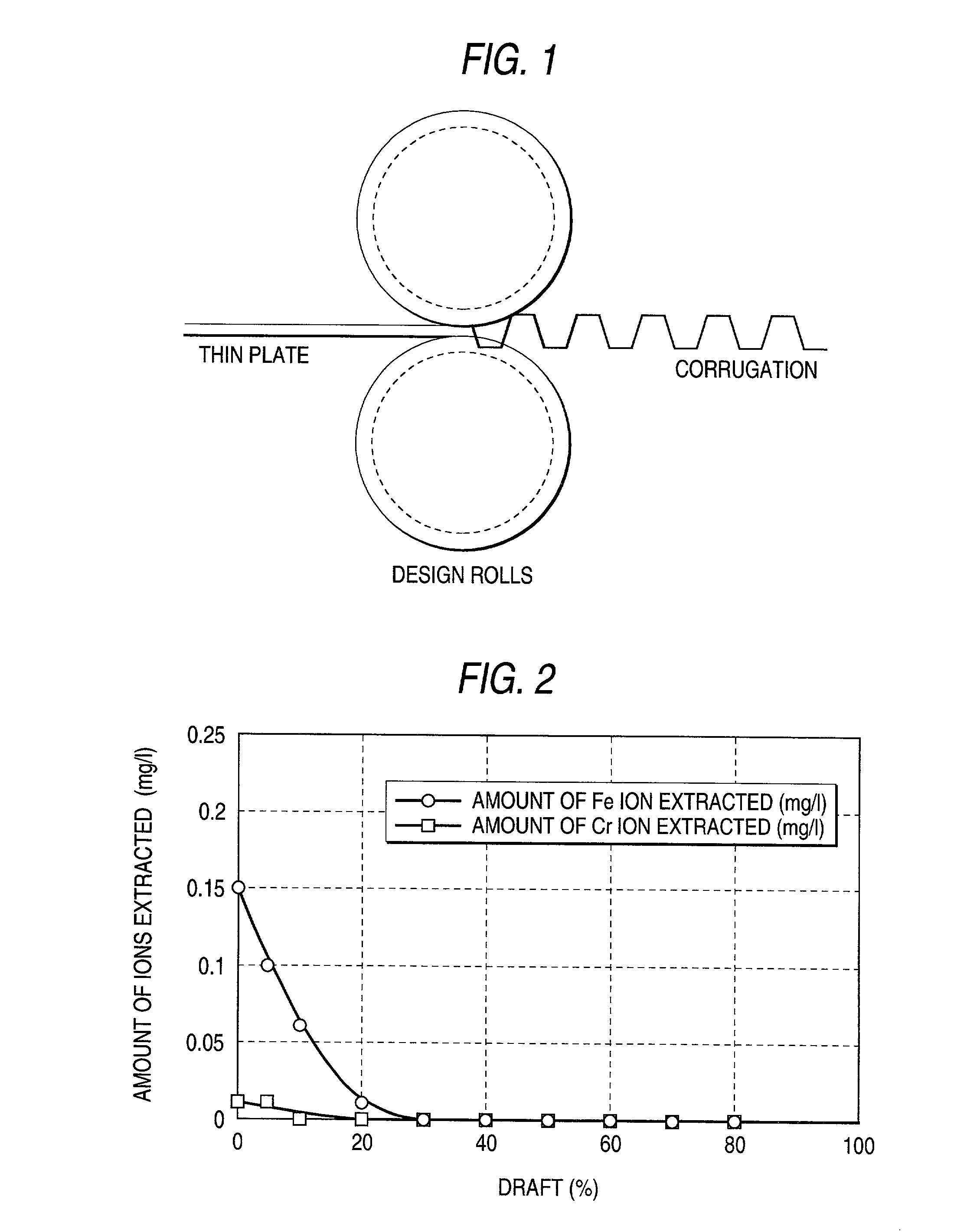

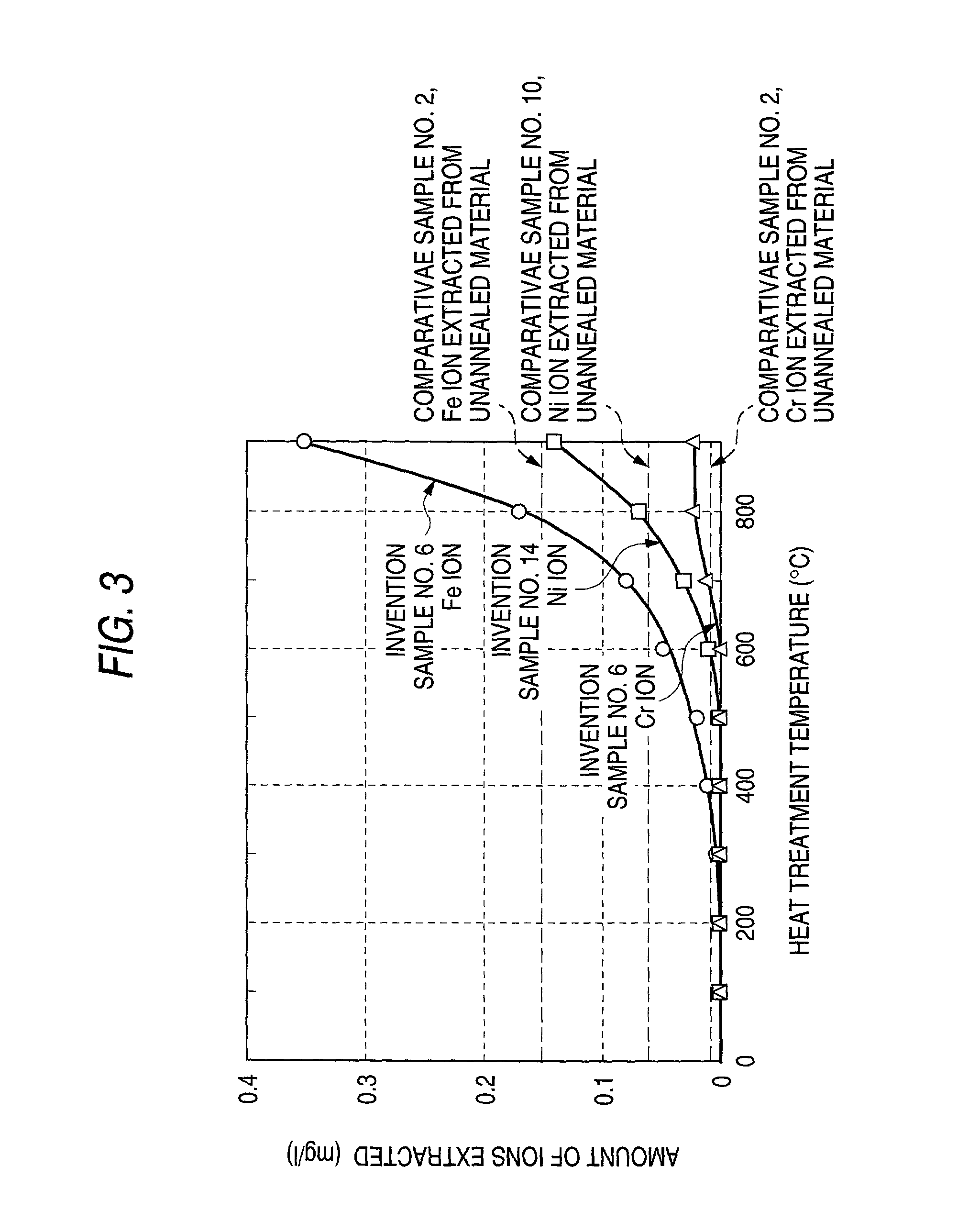

A highly corrosion-resistant material and a corrosion-resistant member which are improved in corrosion resistance, adhesion, contact electrical resistance, electrical conductivity, airtightness, etc. and are suitable for use as, e.g., a metallic separator for polymer electrolyte fuel cells (PEFC); and a process for producing them. A thin noble-metal layer is formed on the desired part of the surface of a metallic base and then subjected to compression working. The coated base may further be subjected to anticorrosive treatment with a liquid phase containing a peroxide or ozone or with an active gas atmosphere.

Owner:DAIDO STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com