Patents

Literature

129results about How to "Avoid size change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

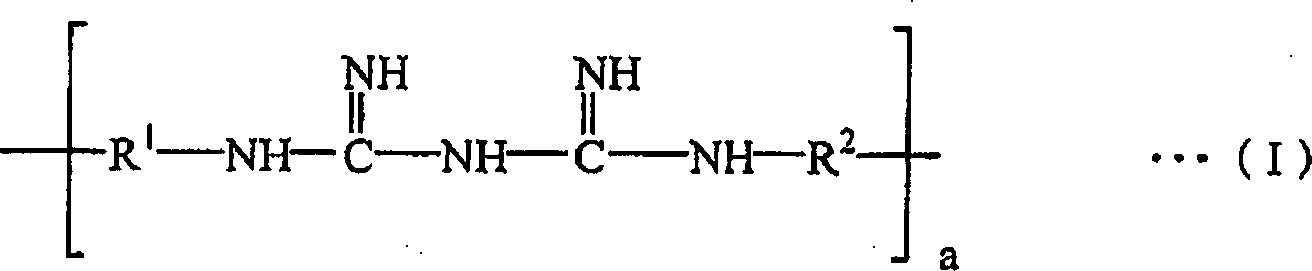

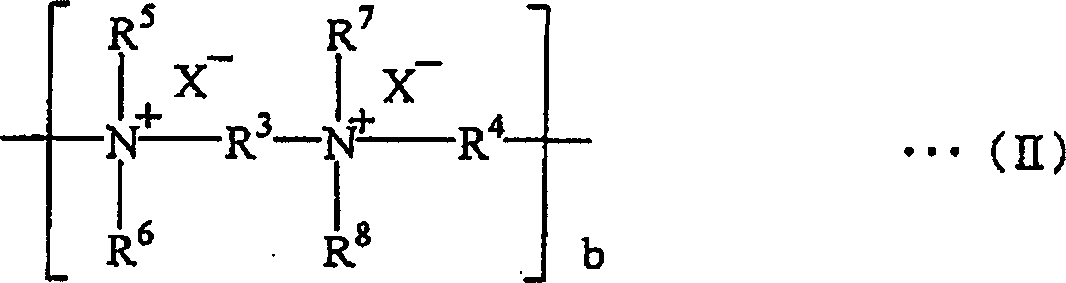

Detergent For Lithography And Method Of Forming Resist Pattern With The Same

InactiveUS20090004608A1Easy to optimizeReduce surface tensionAnionic surface-active compoundsNon-surface-active detergent compositionsResistLithographic artist

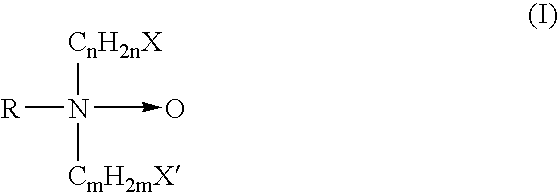

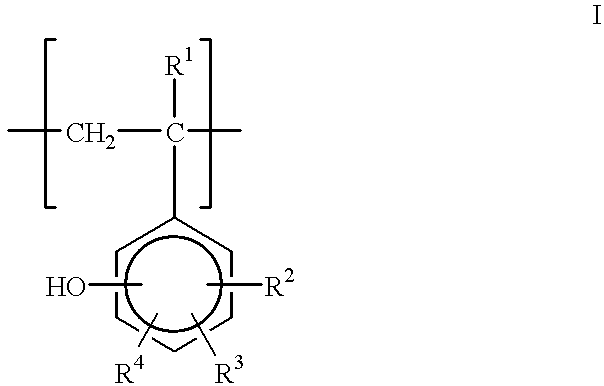

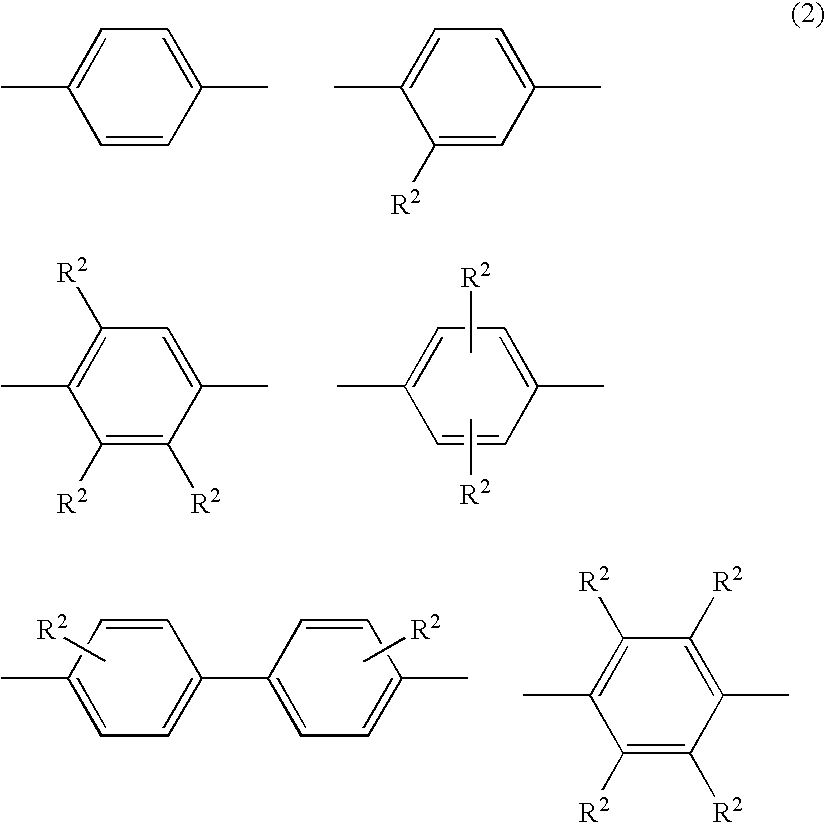

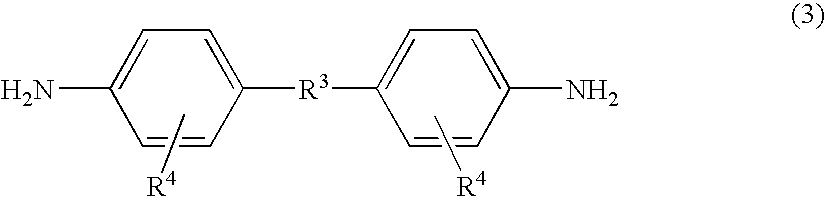

Conventional detergents for lithography which contain a surfactant as an active ingredient should have a reduced surfactant concentration because heightened surfactant concentrations result in dissolution of the resin component of a photoresist composition and hence in a dimensional change of a resist pattern. However, the conventional detergents have had a drawback that such a low concentration unavoidably reduces the ability to inhibit pattern falling and defect occurrence. A detergent for lithography is provided which is an aqueous solution containing (A) at least one member selected among nitrogenous cationic surfactants and nitrogenous ampholytic surfactants and (B) an anionic surfactant. This detergent retains a low surface tension even when it has a low concentration. It is effective in inhibiting pattern falling and defect occurrence. It can also inhibit resist patterns from fluctuating in dimension.

Owner:TOKYO OHKA KOGYO CO LTD

Process for filling apertures in a circuit board or chip carrier

InactiveUS6225031B1Avoids introducing dimensional changeNot adversely dimensional stabilityPrinted circuit aspectsSemiconductor/solid-state device manufacturingChip carrierElectrical and Electronics engineering

Apertures in a circuit board or chip carrier are filled with a cured photosensitive dielectric material by substantially filling the apertures in the circuit board or chip carrier and applying a layer of a thickness to the circuit board or chip carrier with a positive photosensitive dielectric material, exposing the photosensitive dielectric material to actinic radiation in such a way as to leave material located in apertures unexposed to the radiation; baking the structure so as to harden the unexposed photosensitive dielectric material and developing the exposed dielectric material in order to remove it leaving behind cured photosensitive dielectric material in the apertures.

Owner:IBM CORP

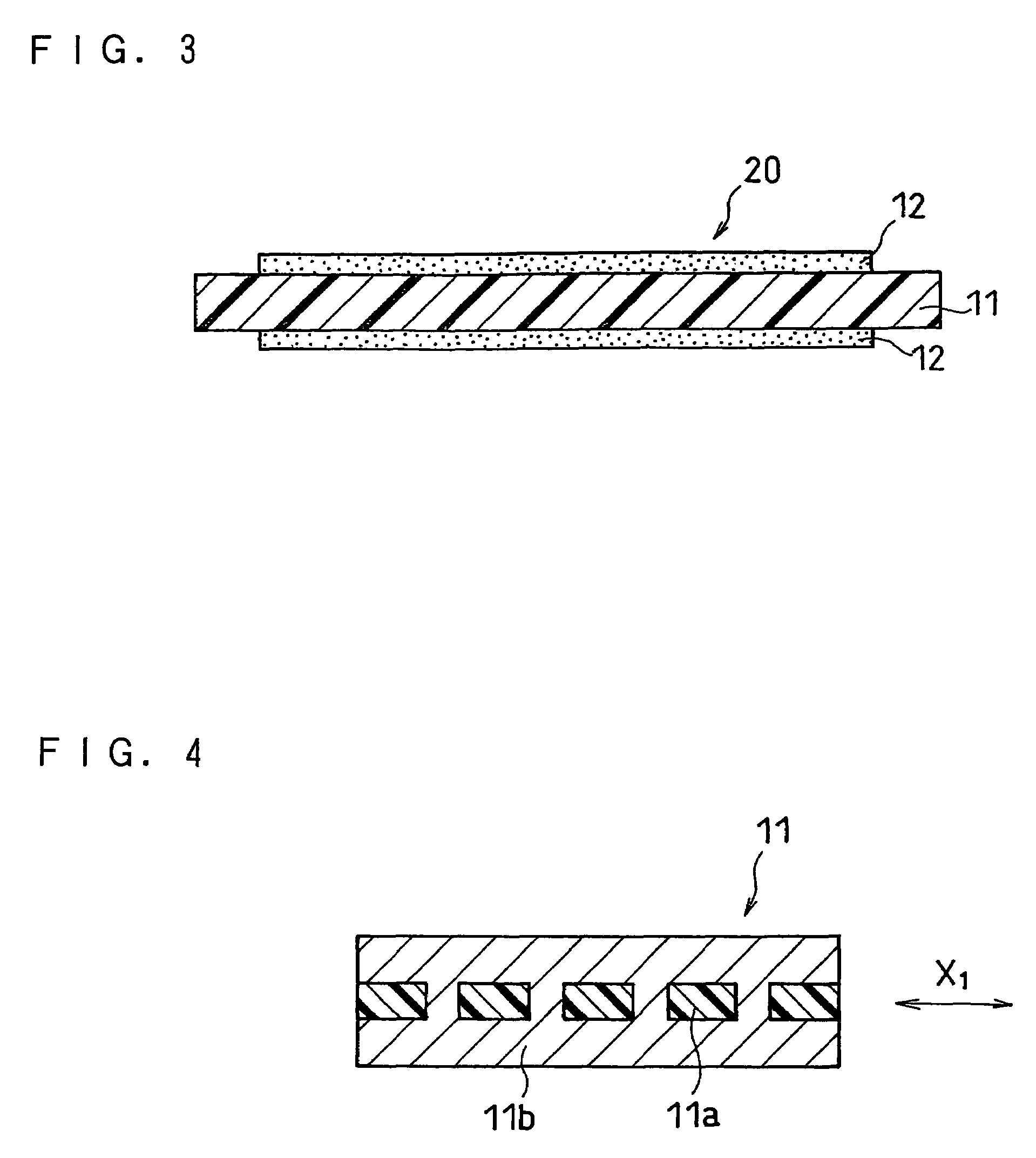

Adhesive Film and Use Thereof

ActiveUS20080305346A1Reduce generationAvoid size changeSemiconductor/solid-state device detailsSolid-state devicesHeat resistanceThermoplastic polyimide

Disclosed in an adhesive film which enables to obtain a flexible metal clad laminate which is suppressed in dimensional change when produced by heat roll lamination. Such an adhesive film comprises a heat-resistant layer containing a highly heat resistant polyimide and an adhesive layer which is formed on at least one surface of the heat-resistant layer and contains a thermoplastic polyimide. In this adhesive film, the thermal shrinkage ratio in the TD direction is not less than +0.01%, and the thermal shrinkage ratio in the MD direction is not more than −0.02%. Consequently, when a metal layer and the adhesive film are bonded together by heat roll lamination and the resulting laminate is subjected to a treatment with heating, occurrence of dimensional changes can be sufficiently suppressed.

Owner:KANEKA CORP

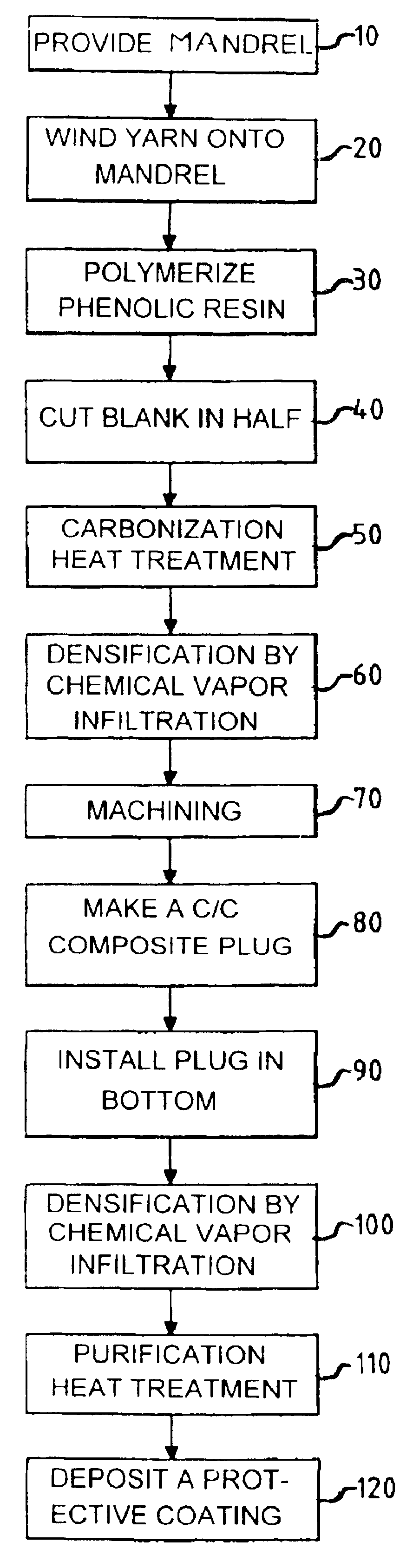

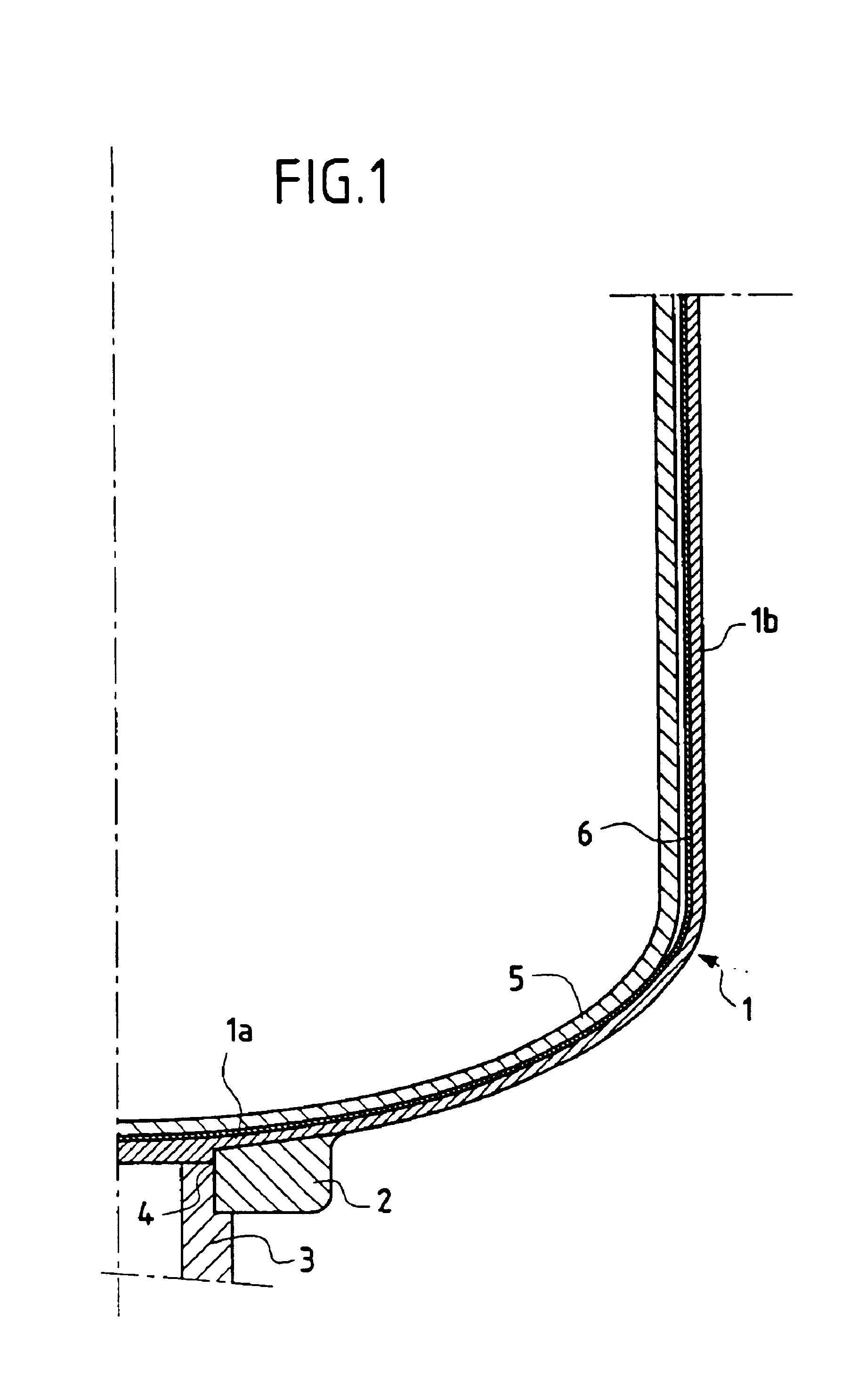

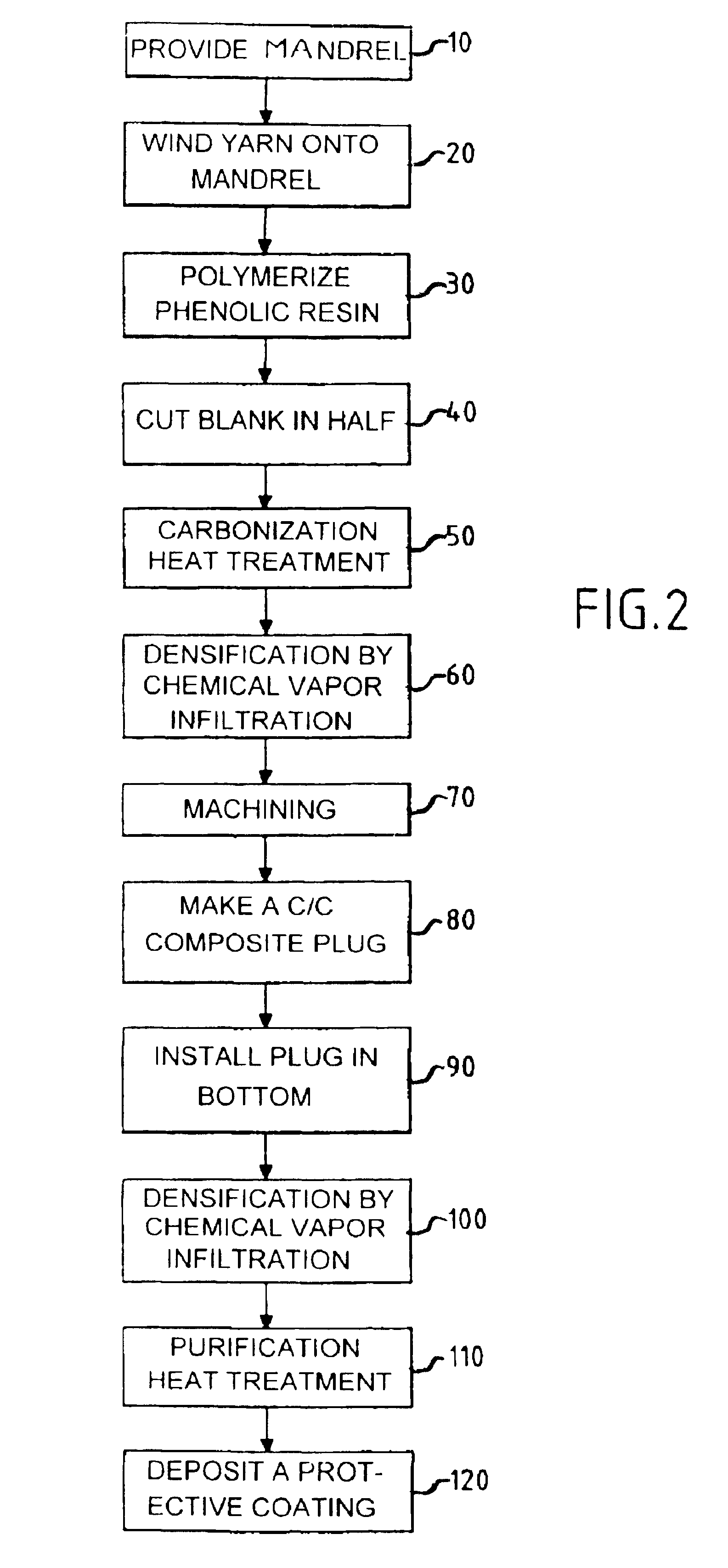

Method of manufacturing a thermostructural composite material bowl, in particular for an installation that produces silicon single crystals

InactiveUS6783621B1Low costOvercome difficultiesAfter-treatment apparatusPolycrystalline material growthYarnGas phase

A composite material bowl 36 comprising fiber reinforcement densified by a matrix is made by winding a yarn on a preform 28 having an axial passage 30 through its bottom, densifying the preform by chemical vapor infiltration, and closing the passage by a plug 34. Prior to densification, the preform can be consolidated. A final chemical vapor infiltration step can be performed after the plug has been put into place.

Owner:SNECMA MOTEURS SA

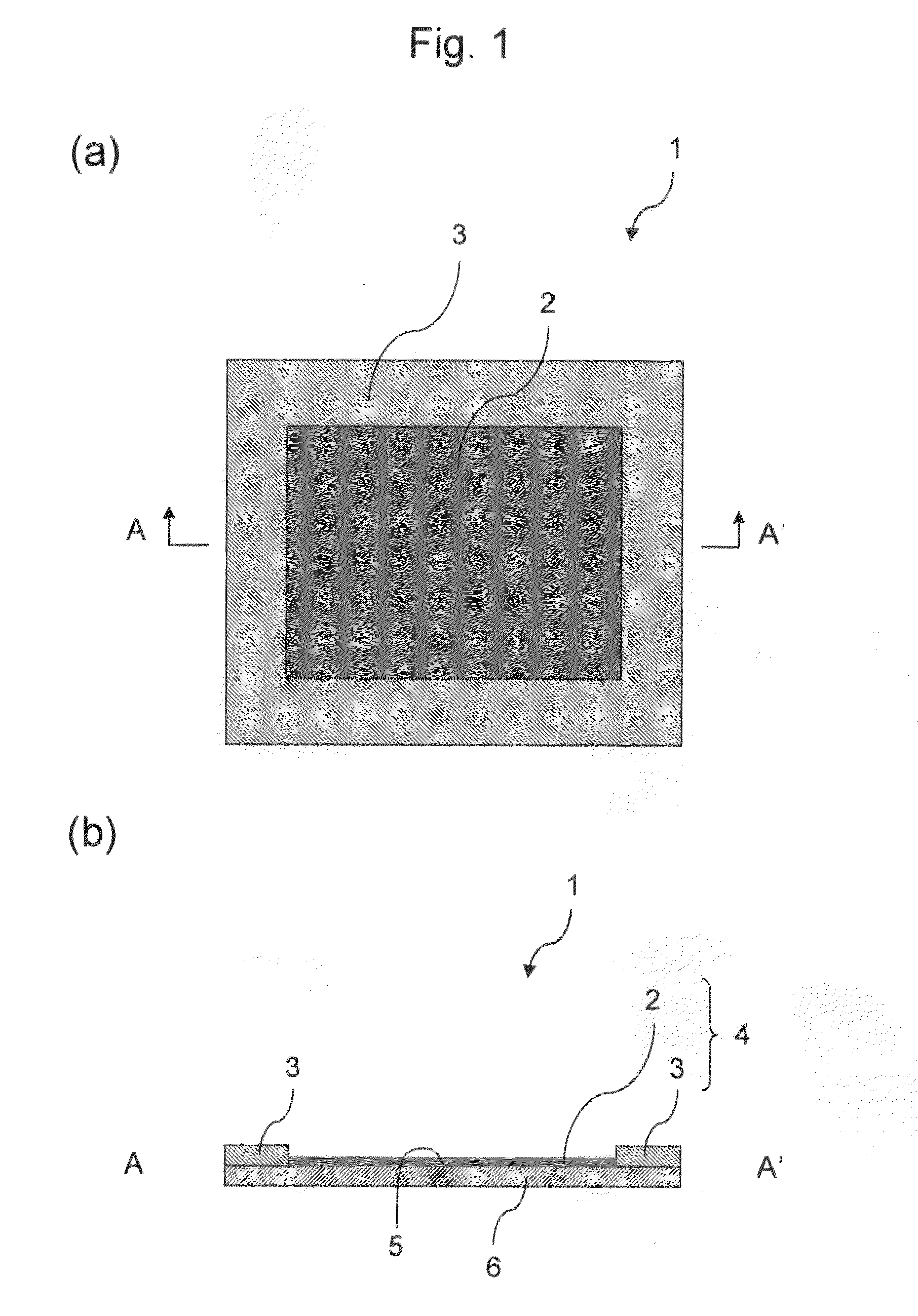

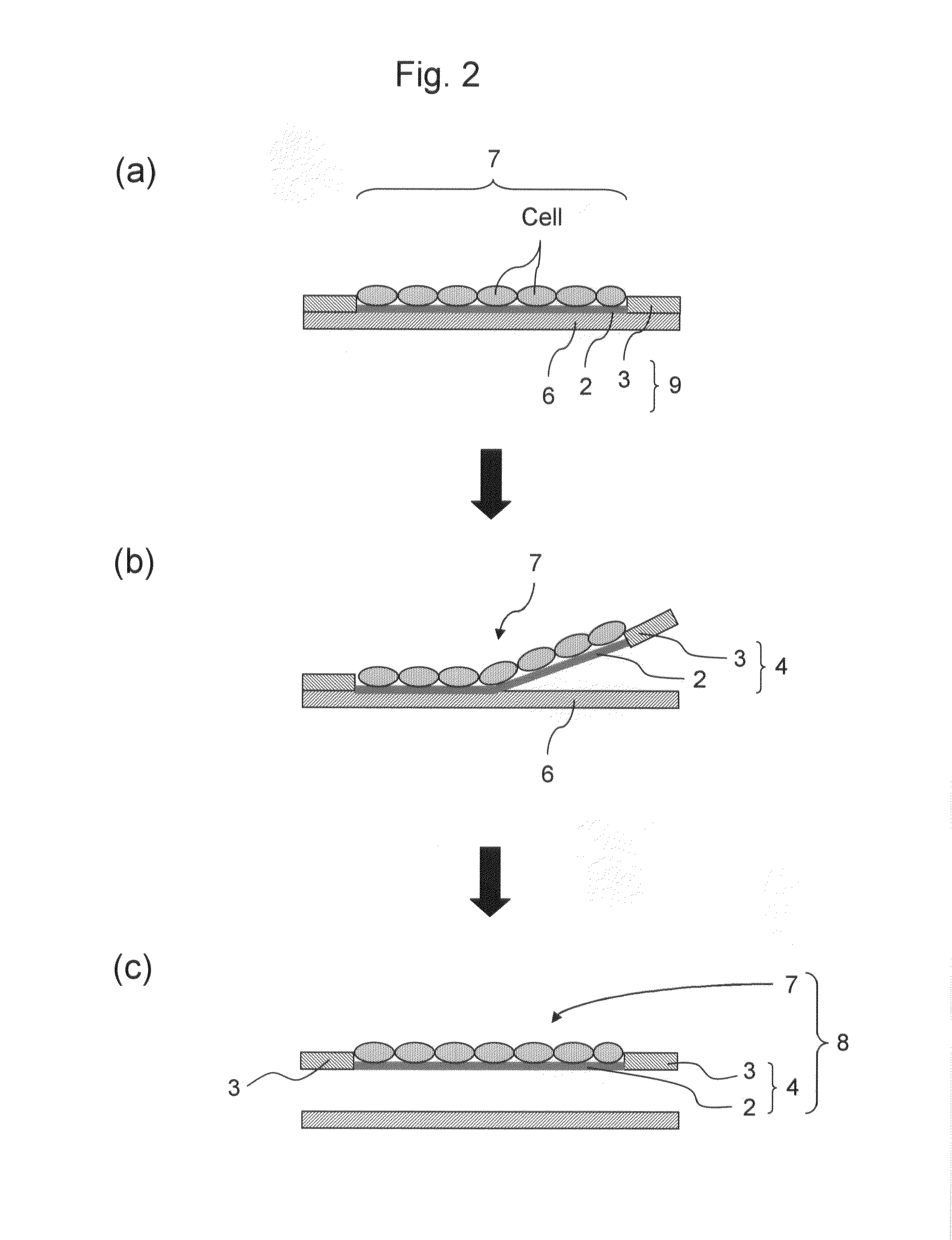

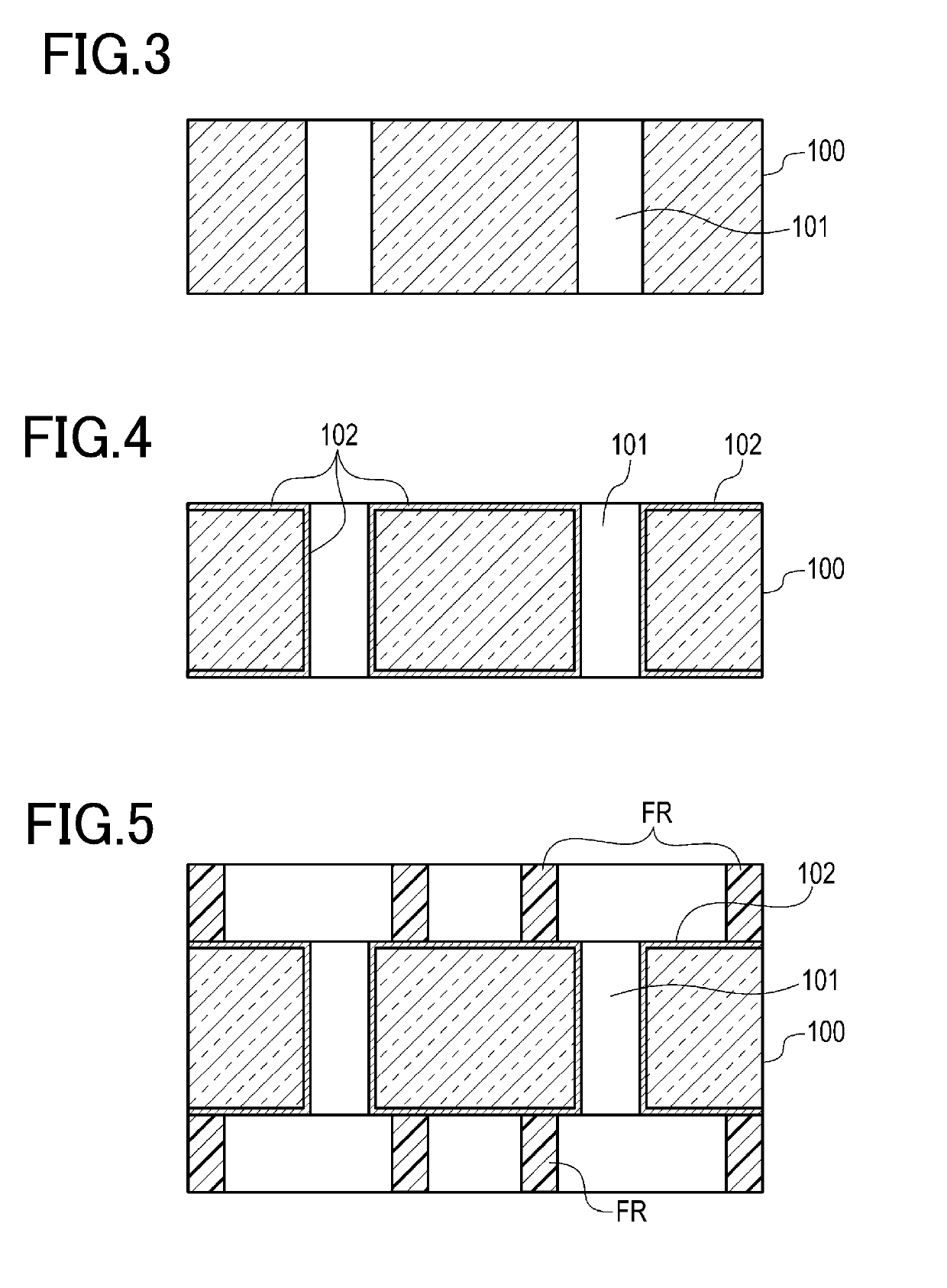

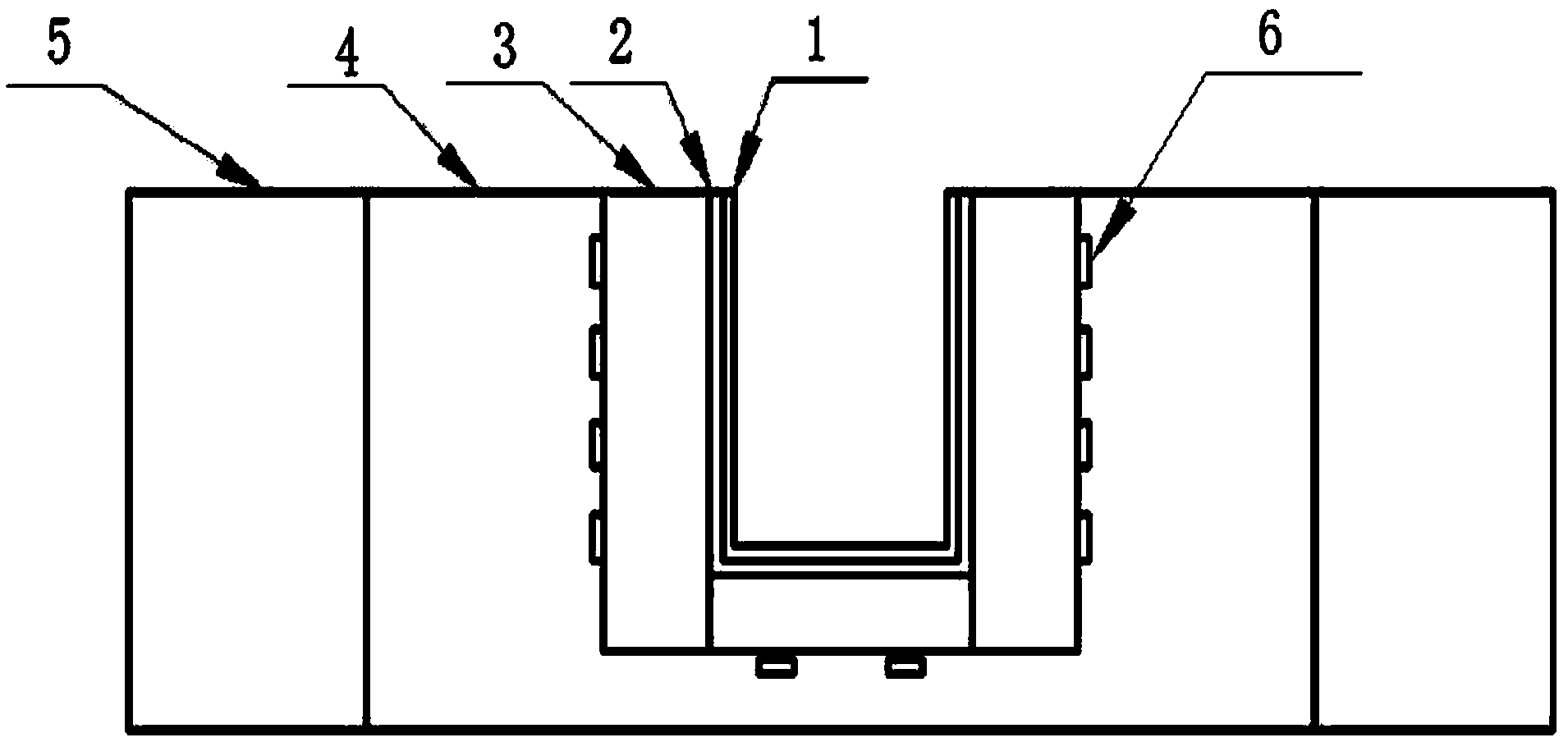

Cell sheet having good dimensional stability, method for production thereof, and cell culture carrier for use in the method

ActiveUS20110151565A1Reduce thicknessEasy to separateAnimal cellsLamination ancillary operationsCell adhesionAdhesion process

It is an object of the present invention to provide a cell culture carrier for producing a cell sheet that can be readily detached from a cell culture carrier and is inhibited from contracting after being detached.The cell culture carrier 1 of the present invention comprises: a support-held culture membrane 4 comprising an organic thin film 2 having cell adhesion properties and biodegradability and a frame-like support 3 fixed on the periphery of the organic thin film for maintaining the dimensions of the organic thin film; and a base substrate 6 having a surface 5 with a static water contact angle of 45° or less, wherein the support-held culture membrane 4 is detachably placed on the surface 5 of the base substrate.

Owner:DAI NIPPON PRINTING CO LTD

Novel processing technique of paper board cylinder

ActiveCN101670688APerformance impactPrevent intrusionPaper/cardboard wound articlesCardboardManufacturing technology

The invention relates to a novel processing technique of a paper board cylinder, belonging to the technical field of manufacturing of an ultrahigh voltage and high capacity transformer. The technicalscheme comprises the following steps: blanking, meichen the extra toe of a donkey, vacuum-drying, molding, xunchen extra toe of the donkey, vacuum-drying and then spraying oil. As all insulating partsare immersed in the transformer oil when being used for an oil immersed transformer, the transformer oil does not have any influence to the performance of an insulating cylinder; and but the transformer oil can effectively block humidity from invading the paper board, thus avoiding the paper cylinder from absorbing moisture and expanding in the processes of storage and use. The novel processing technique has the beneficial effects of: guaranteeing manufacturing size of the paper cylinder, avoiding the size change of the paper cylinder in the storage and use, and meeting the requirements of the ultrahigh voltage and high capacity transformer to the paper board cylinder.

Owner:BAODING TIANWEI BAOBIAN ELECTRICAL

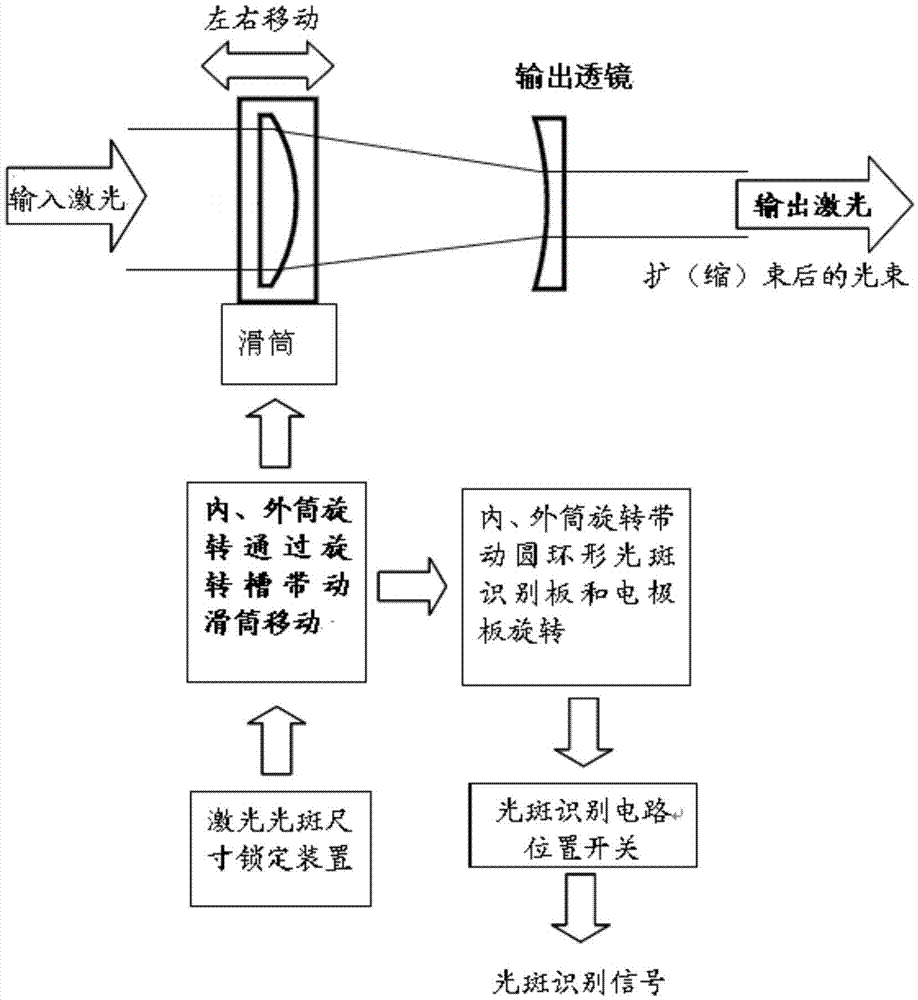

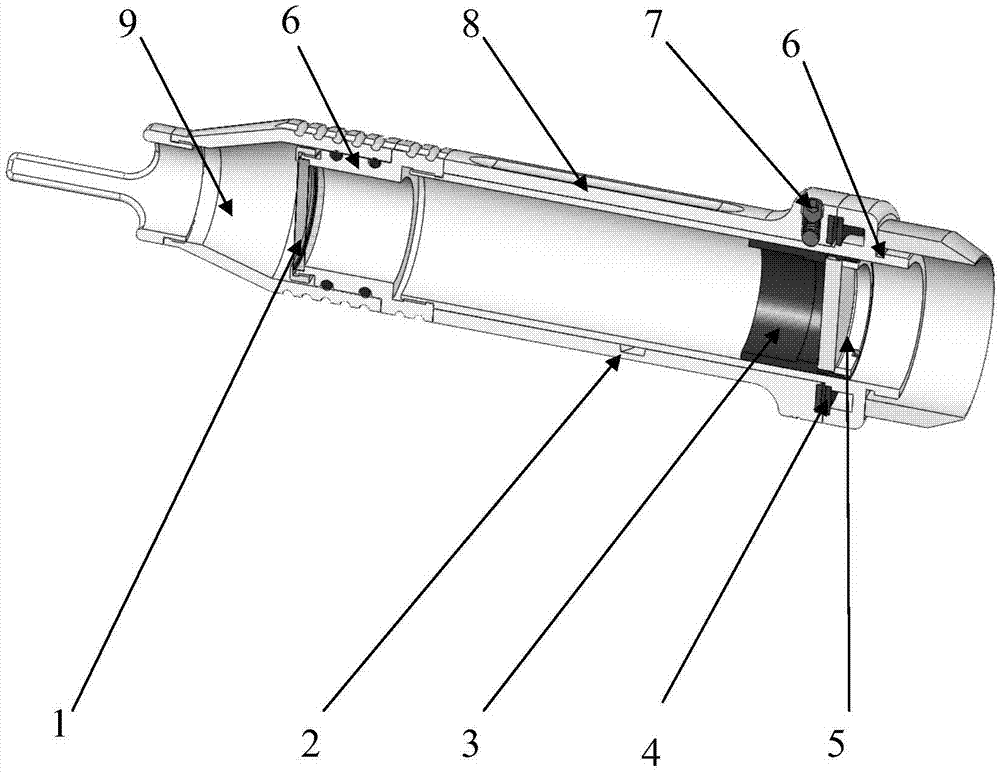

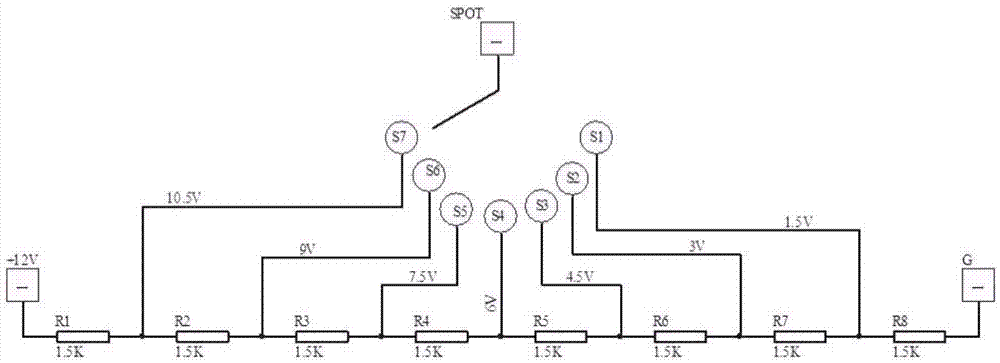

Hand tool for laser spot size adjustment and recognition

ActiveCN106924882APrevent spot size variationAvoid size changeLight therapyMeasurement deviceVolumetric Mass Density

The invention relates to a hand tool for laser spot size adjustment and recognition, which comprises a laser spot size adjustment system, a laser spot size locking device, and a spot position measurement device, wherein the laser spot size adjustment system is located in a hand tool shell; the laser spot size locking device is located at the upper part of the tail end of the hand tool shell; the spot position measurement device is located at the lower part of the tail end of the hand tool shell; the spot position measurement device performs output through a cable; the laser spot size adjustment system is used for outputting laser spots of different sizes; and the spot position measurement device is used for outputting positioning signals of the spots. Thus, a doctor can accurately control the treatment energy (power) density during a laser treatment process, the energy (power) density of spots and laser can be timely and conveniently adjusted for different disease treatment types and target tissues, and a role of accurately controlling the treatment dose can be achieved.

Owner:WUHAN MIRACLE LASER SYST

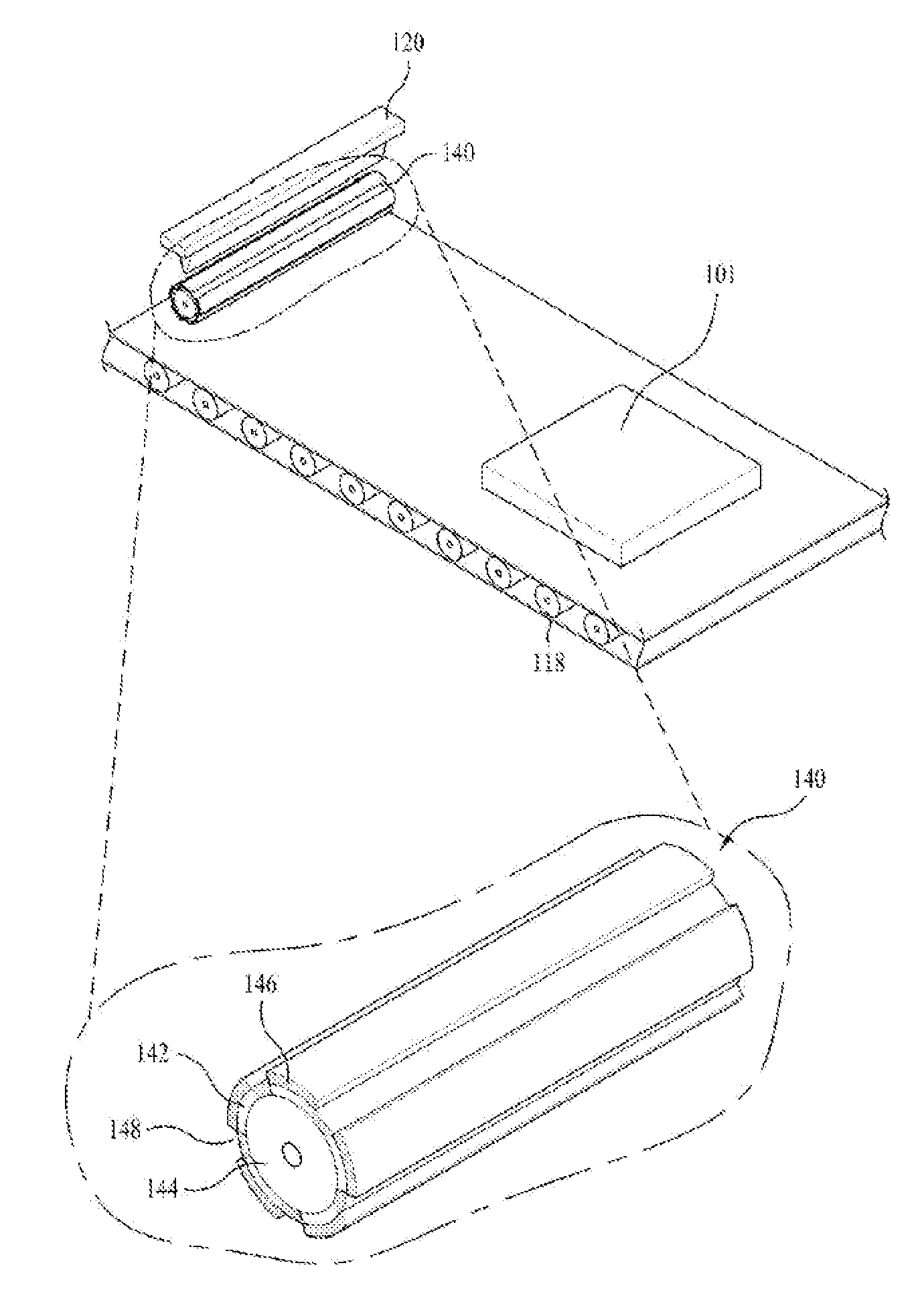

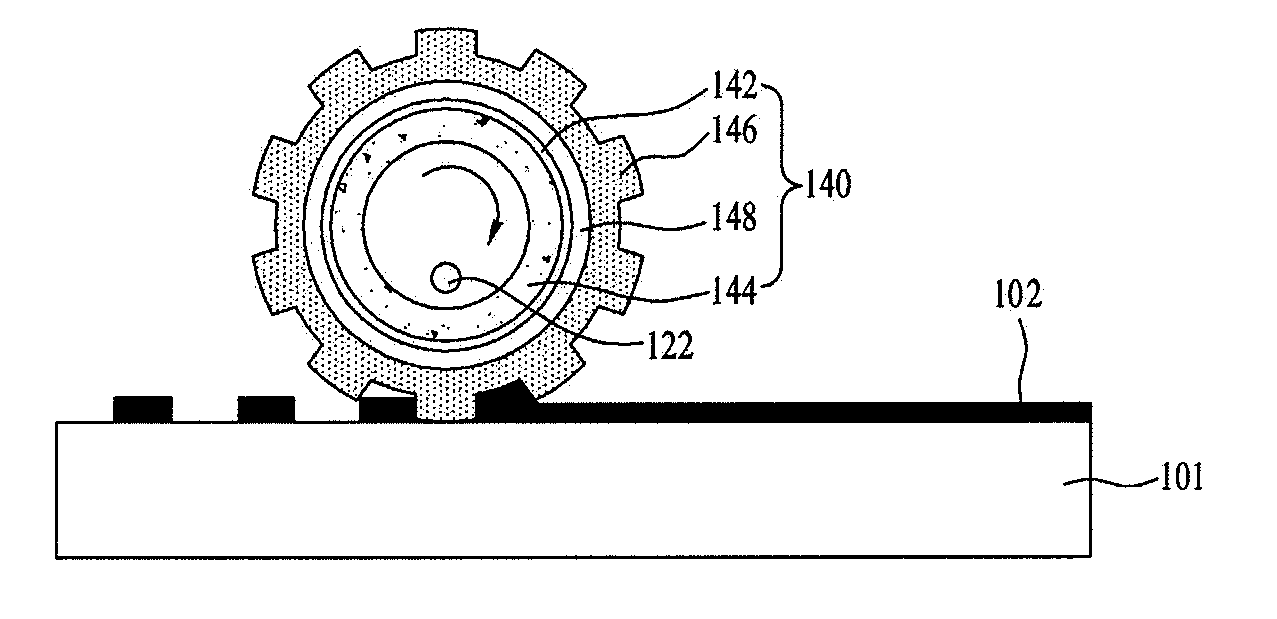

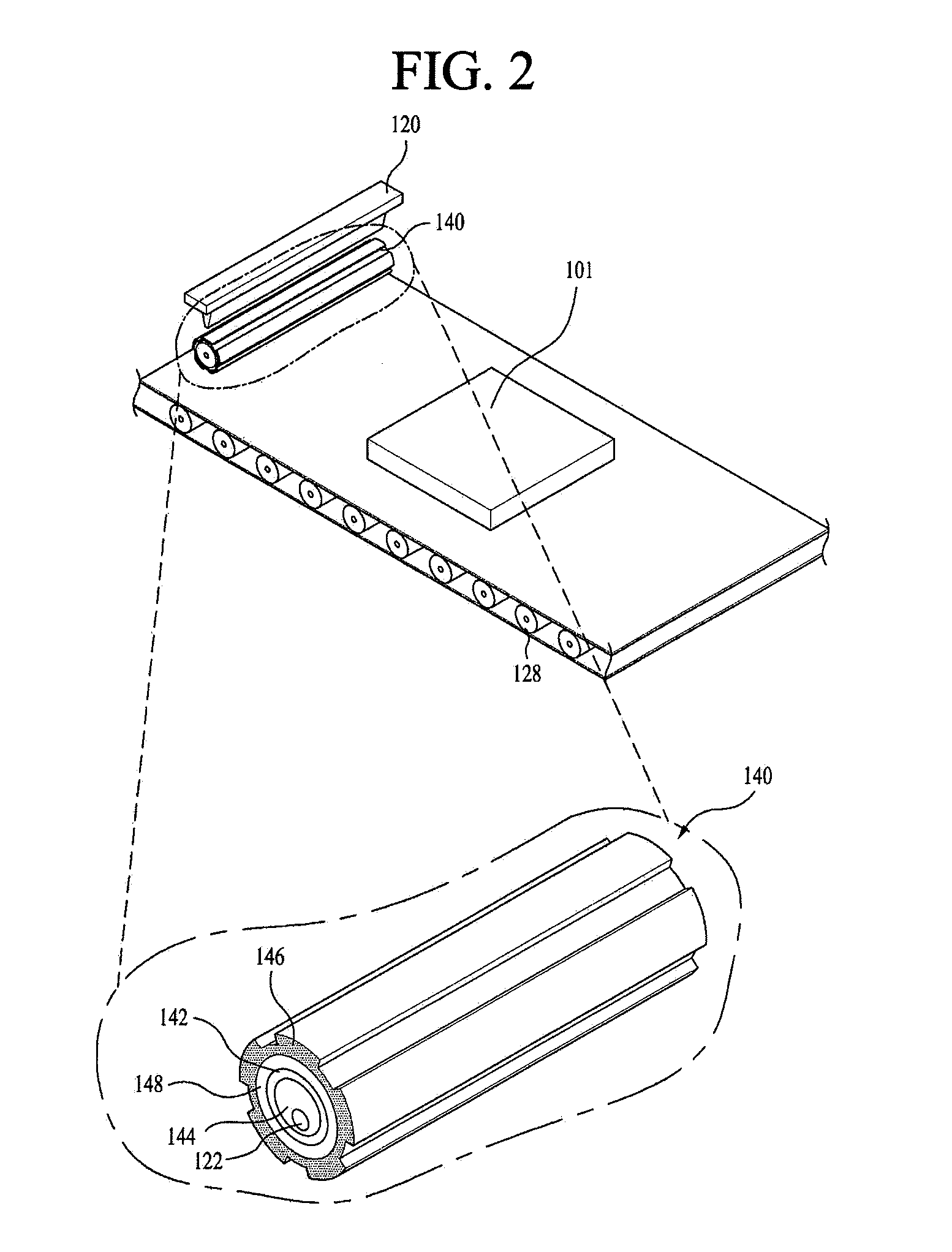

Roll mold, method for fabricating the same and method for fabricating thin film pattern using the same

ActiveUS20110203723A1Avoid size changeSimple manufacturing processPhotomechanical apparatusLaminationSurface layer

The present invention provides a roll mold, a method for fabricating the same and a method for fabricating a thin film pattern using the same, to prevent dimensional variation of the mold and simplify the overall process. The method for fabricating a roll mold includes providing a rigid substrate or flexible substrate provided with a master pattern, providing a base roller arranged on the substrate provided with the master pattern, forming a mold surface layer on the substrate provided with the master pattern, forming an adhesive resin layer on the mold surface layer or the base roller, rolling the base roller over the rigid substrate or flexible substrate to form the adhesive resin layer and the mold surface layer on the base roller, and curing the adhesive resin layer and mold surface layer formed on the base roller to adhere the adhesive resin layer and the mold surface layer to the base roller and fix the same thereon.

Owner:LG DISPLAY CO LTD

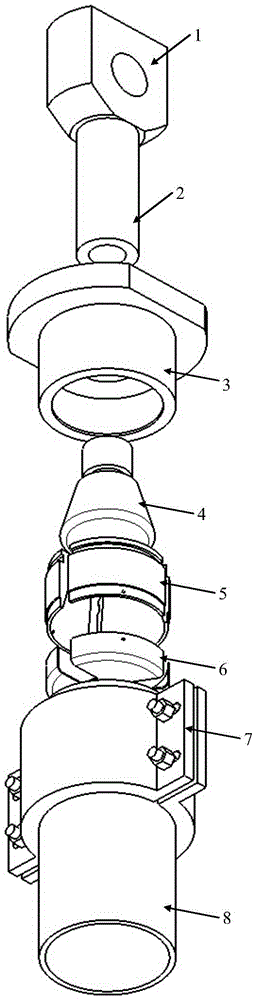

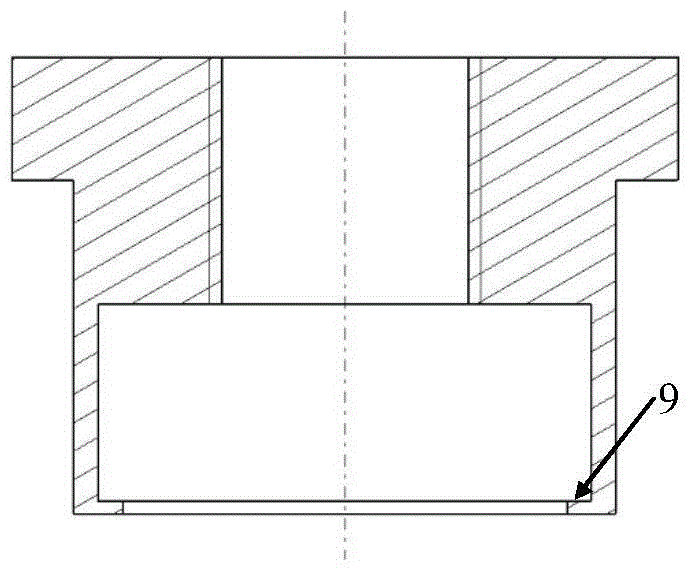

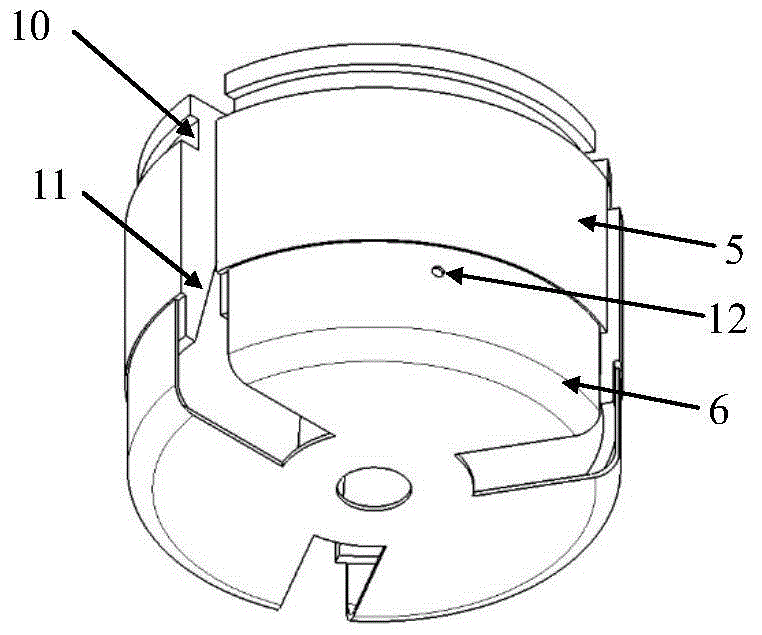

Inner wall self-locking overall pipe high-temperature tension test clamp

The invention discloses an inner wall self-locking overall pipe high-temperature tension test clamp. The clamp comprises a connector with one end connected with a tester pull rod, and a sliding locking part for locking the inner wall of a pipe body of an overall pipe; the sliding locking part expands outwards through inner bevels at the upper ends of sliding blocks to be clamped into a conical surface at the lower end of a cone linkage sliding core for connection, the connector enters a hollow hole of a locking nut through a threaded rod to be connected with the cone linkage sliding core, the locking nut is rotated downwards, the cone linkage sliding core pushes the three sliding blocks downwards to be kneaded inwards in the radial direction till a snap ring at the lower open end of the locking nut is clamped into a sliding block circular groove, elastic locking rings slightly protrude downwards to drive the sliding blocks to shrink inwards, the inner conical bevels of the sliding blocks are promoted to be attached to the conical surface of the cone linkage sliding core, the sliding blocks are driven to move downwards, outward pre-tightening force is provided, and the inner wall of the pipe is clamped. The clamp has the advantages that installation is convenient and rapid, the size is small, universality is good, no chock plug is needed, clamping is firm, and the situation that a sample is broken at the clamping end is avoided.

Owner:PLA NO 5719 FACTORY

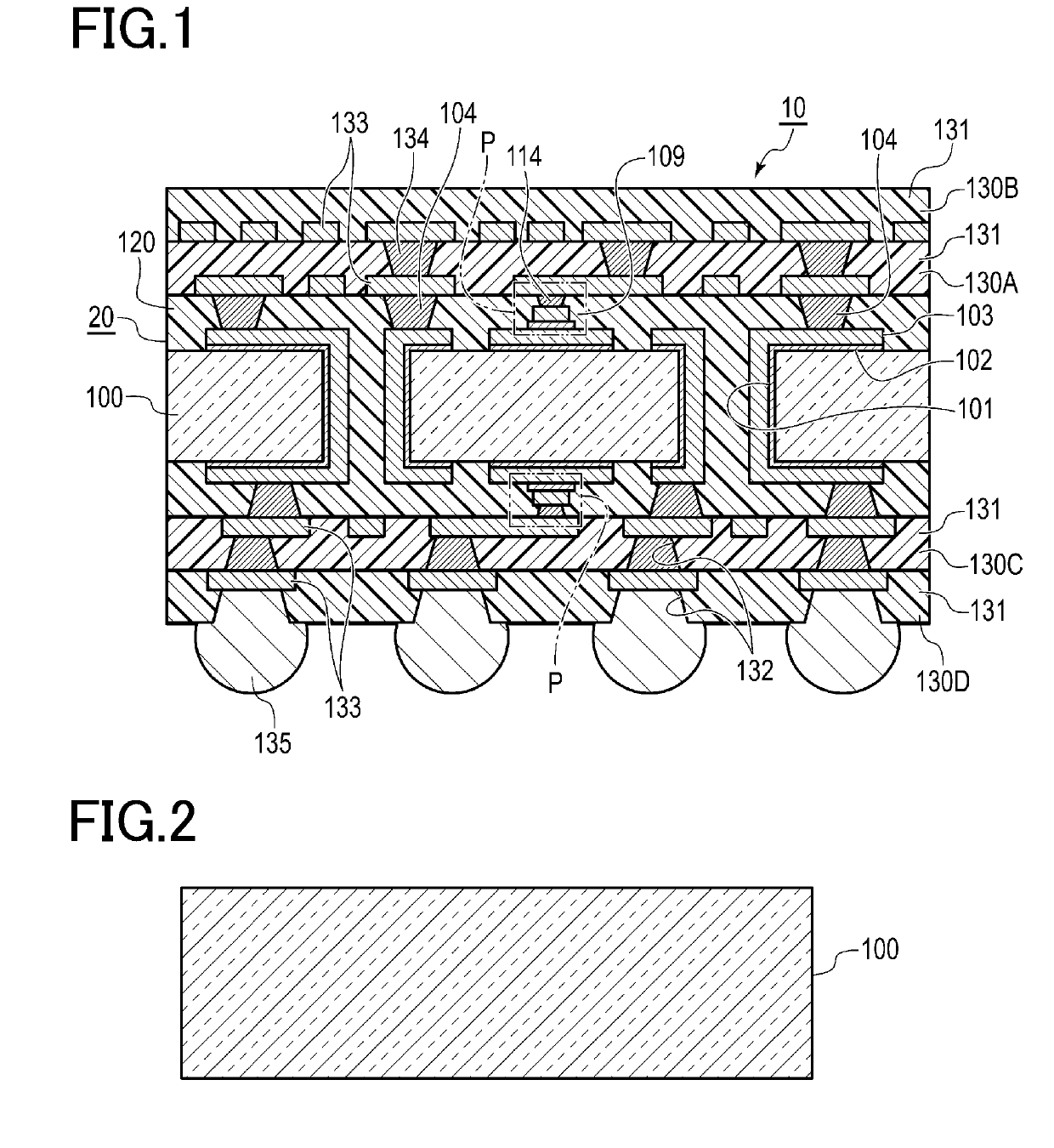

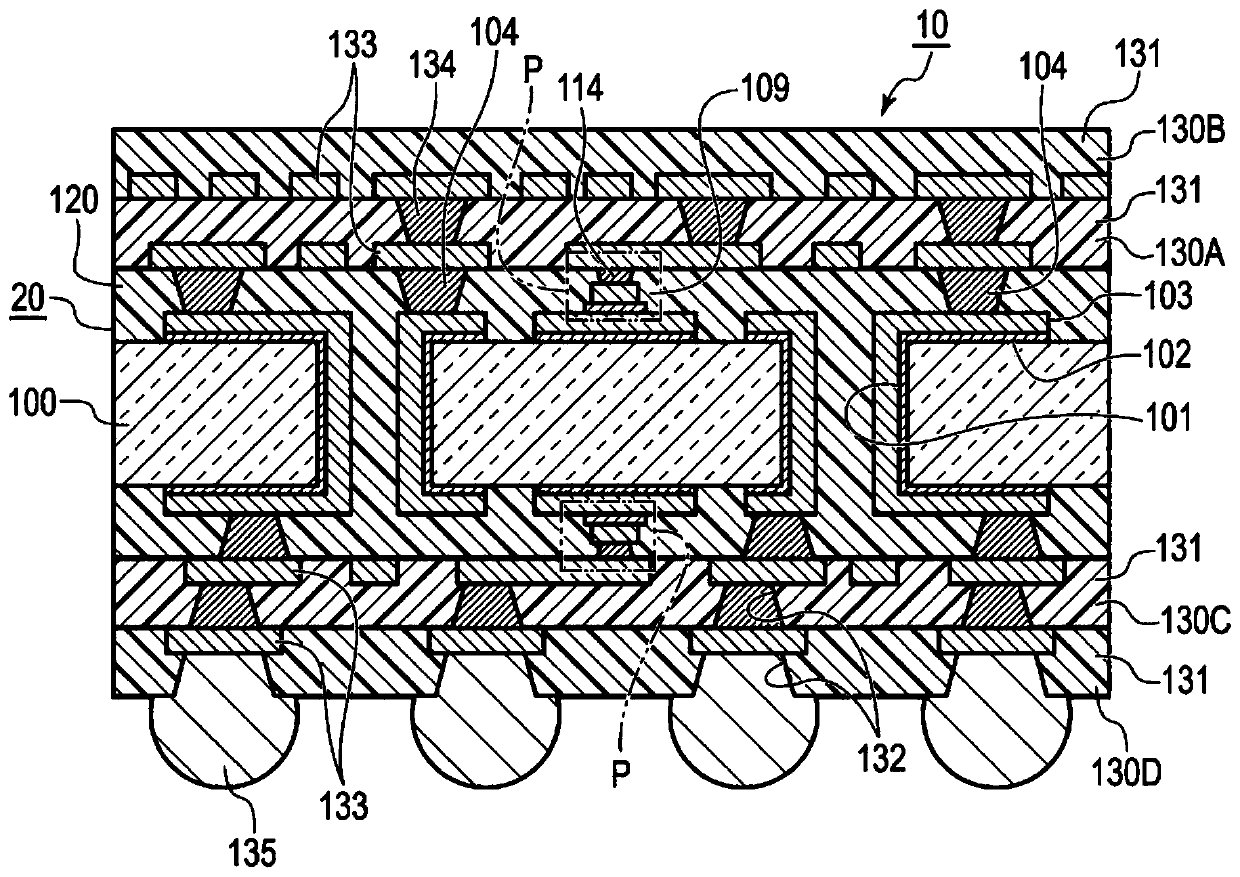

Electronic component and method of producing electronic component

ActiveUS20190269013A1Improve reliabilityReduction factorSemiconductor/solid-state device detailsSolid-state devicesOptoelectronicsCopper

An electronic component includes a glass base in which through holes are formed passing through both surfaces thereof; an insulating resin layer laminated on each of both surfaces of the glass base and including a copper plated layer formed therein; and a capacitor including a lower electrode formed on the copper plated layer, a dielectric layer laminated on the lower electrode, and an upper electrode laminated on the dielectric layer. In the electronic component, the upper electrode has a region that is parallel to the copper plated layer and is formed so as to be smaller than a region of the dielectric layer parallel to the surface of the copper plated layer or a region of the lower electrode parallel to the surface of the copper plated layer.

Owner:TOPPAN PRINTING CO LTD

Roll mold, method for fabricating the same and method for fabricating thin film pattern using the same

ActiveUS20120038084A1Avoid size changeSimple manufacturing processConfectionerySemiconductor/solid-state device manufacturingSurface layerOptoelectronics

Discussed are a roll mold, a method for fabricating the same and a method for fabricating a thin film pattern using the same, to prevent dimensional variation of the mold and simplify the overall process. The method for fabricating a roll mold includes providing a substrate provided with a master pattern layer, sequentially forming a mold surface layer and a solid suffer layer on the substrate provided with the master pattern layer to provide a flat panel mold, forming an adhesive resin layer on the base roller aligned on the flat panel mold, and rolling the base roller provided with the adhesive resin layer over the flat panel mold to adhere the flat panel mold to the base roller through the adhesive resin layer.

Owner:LG DISPLAY CO LTD

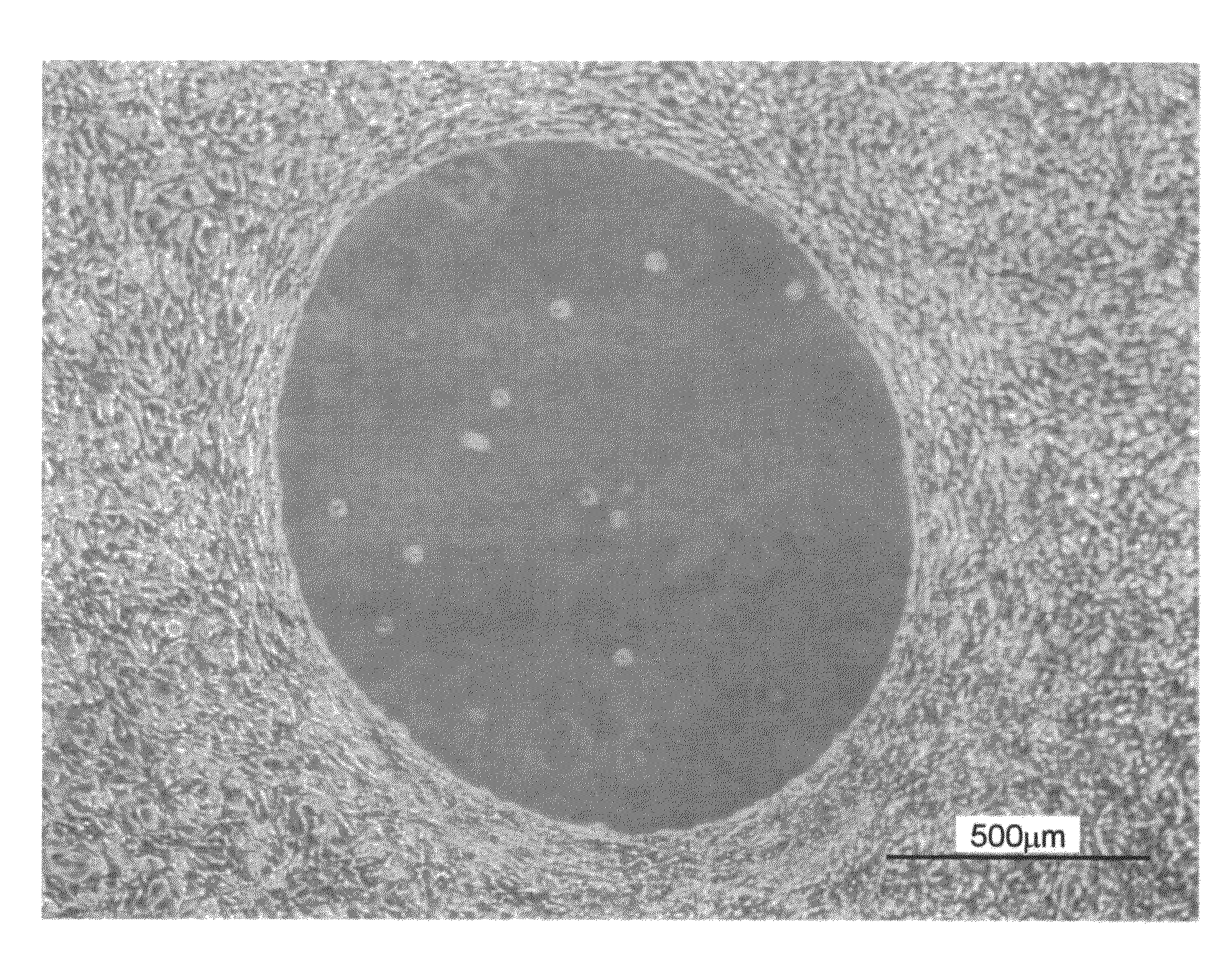

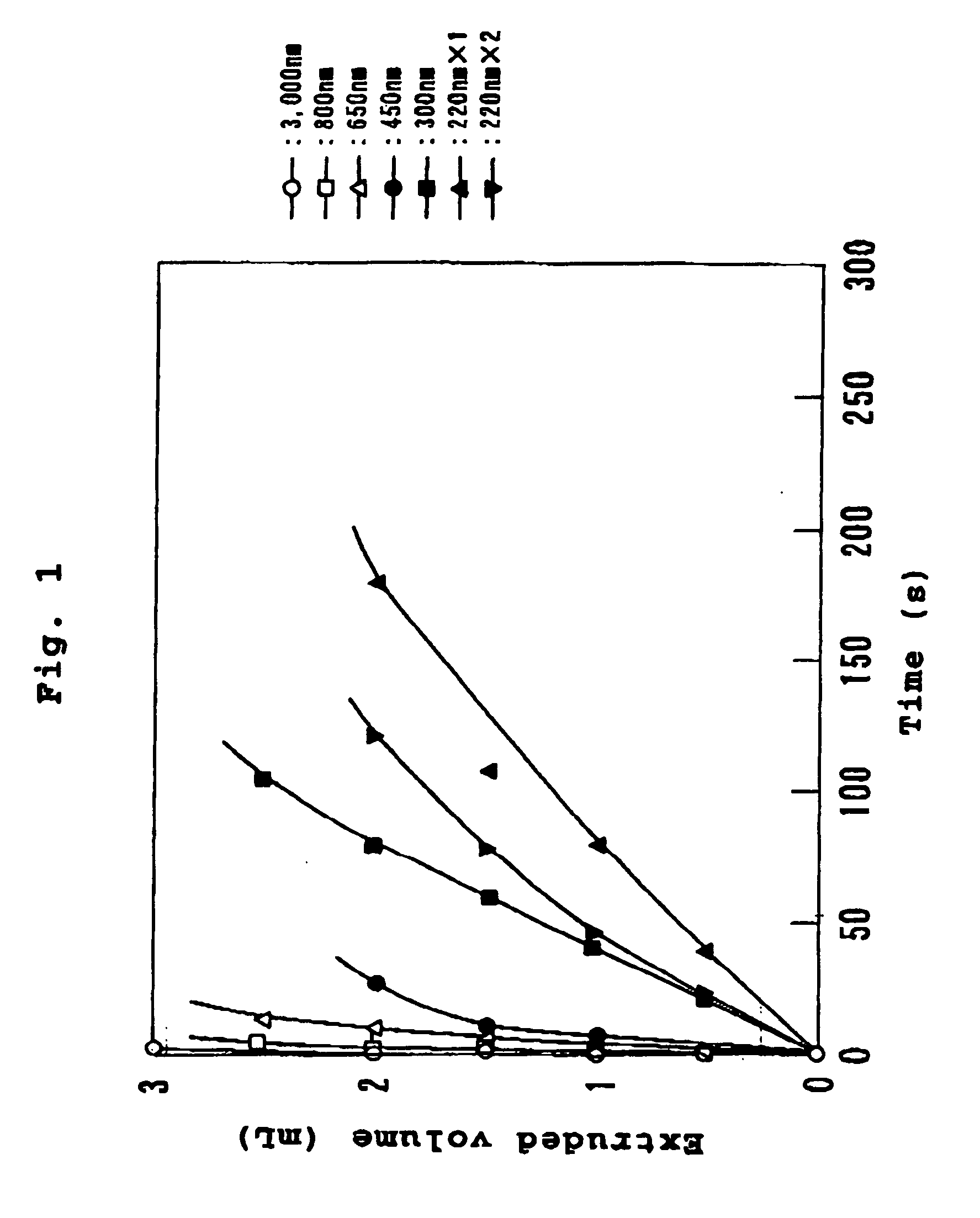

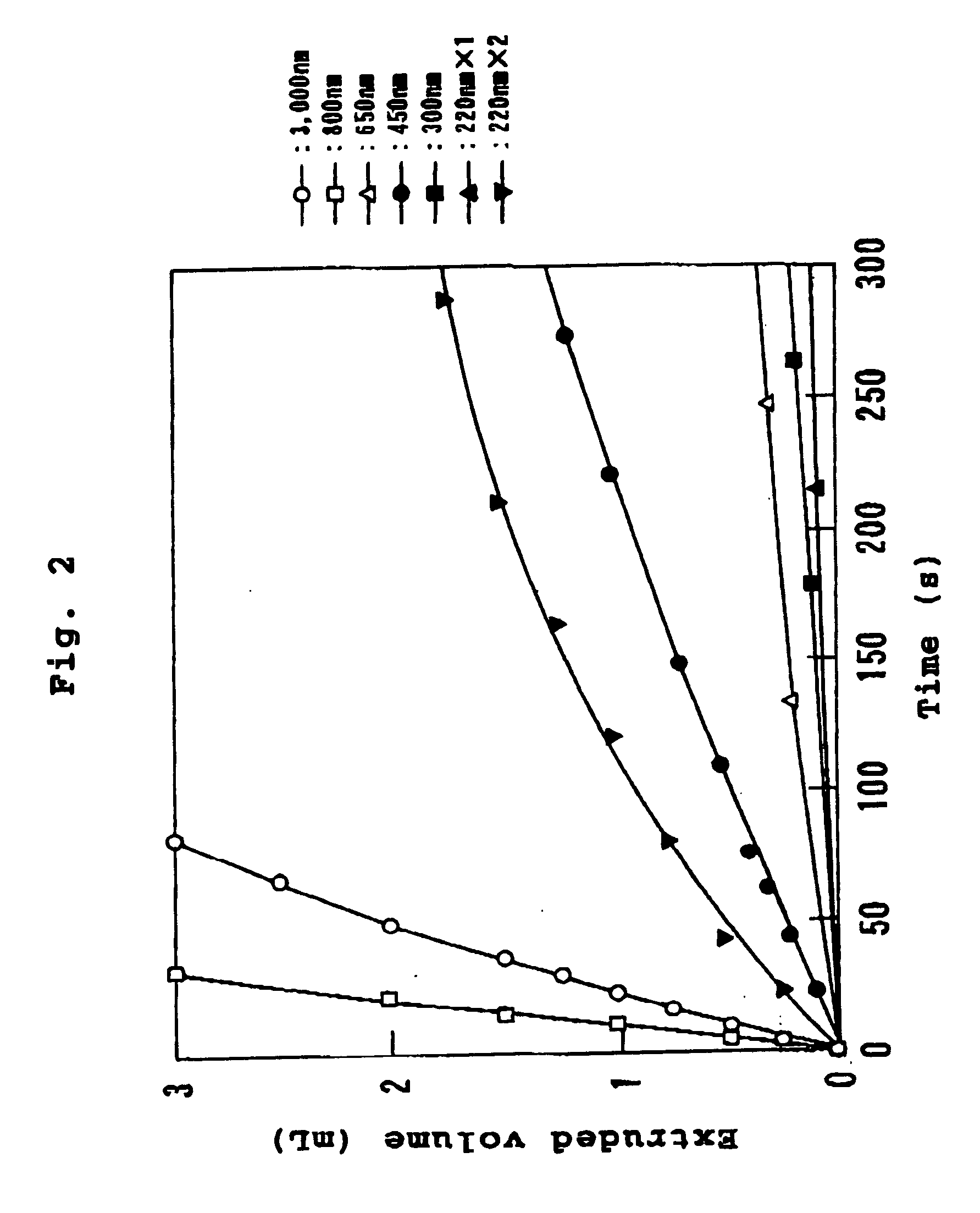

Method for preparing microsome dispersion

InactiveUS20040057988A1Safe and simple encapsulationImprove efficiencyLiposomal deliveryMicroballoon preparationHigh concentrationLipid formation

A method for preparing a vesicle dispersion wherein a water-soluble substance is encupsulated in the vesicle, which comprises successively performing: a step of dispersing at least one lipid in an aqueous medium to pre-construct a vesicle dispersion, a step of drying the pre-constructed vesicles to obtain dried vesicle, a step of re-dispersing the dried vesicles in an aqueous solution of the water-soluble substance, and a step of passing the resultant vesicle dispersion through a filter. The method enables the efficient and simple preparation of safe vesicles with a useful substance in high concentration encupsulated therein, with a narrow size distribution, in high yield.

Owner:WASEDA UNIV

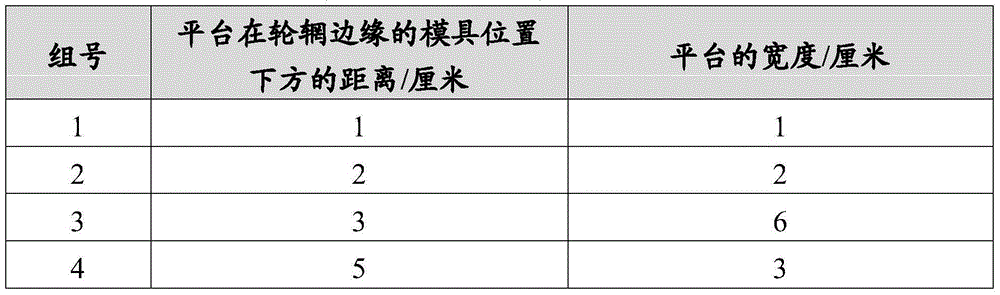

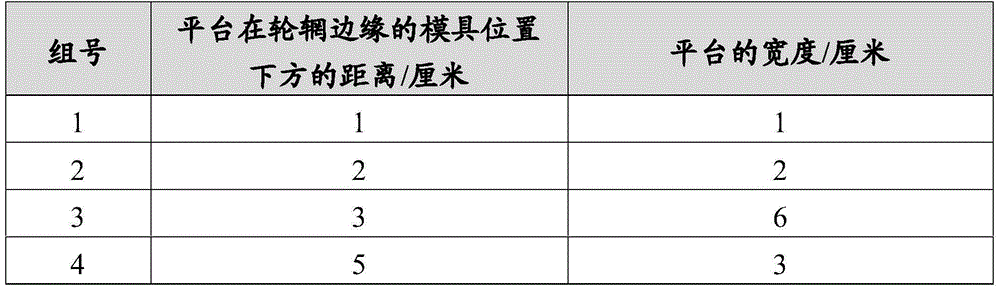

Die for spinning and casting aluminum alloy wheel

InactiveCN104588503ASolve the effective swellingSolve the problem of inconsistencyShaping toolsMetallurgyAlloy wheel

The invention relates to a lower die of a die for spinning and casting an aluminum alloy wheel. The lower die is characterized in that the lower die further comprises a platform which is arranged below a die position corresponding to the wheel rim. The lower die is additionally provided with the platform, so that the problem that thermal processing on a blank is influenced due to unevenness of the back end surface of the wheel after being spun and cast is prevented.

Owner:CITIC DICASTAL

3D printing method of fiber-grade flame retardant product based on reactive extrusion

InactiveCN105818384ABroaden your optionsAchieve stabilityAdditive manufacturing apparatusPolyesterFiber

The invention relates to a 3D printing method of a fiber-grade flame retardant product based on reactive extrusion. According to the 3D printing method, polymerization reaction is performed on a lactam monomer and / or a lactone monomer and an assistant and a plasticizer after fusing under the action of a catalyst, and a flame retardant is added before polymerization or during polymerization to obtain a target polymer; then the target polymer is subjected to fused deposition 3D printing, and then is subjected to thermal treatment, thus obtaining a final product. According to the invention, a high-precision high-adaptation 3D printer is adopted, the forming precision is high, the efficiency is high, the mechanical property of a product is good, and the dispersibility of a functional component is good; and a process of preparing a product directly from a polymeric monomer is adopted, and therefore, the production flexibility is improved, and the conditions of edge warping of nylon, polyester and other semi-crystalline polymers caused by crystallization and large temperature difference, and even failure in printing can be avoided. The method can widen the species of fused deposition 3D printing materials, can improve the quality of products, and is wide in application in the fields of automotive materials, engineering plastics, building materials and the like.

Owner:DONGHUA UNIV

Preparation method of high-capacity silicon-carbon composite negative electrode material with core-shell structure for lithium-ion battery

ActiveCN111354937AImprove structural stabilityAlleviate volume changesSecondary cellsNegative electrodesCarbon compositesLithium intercalation

The invention discloses a preparation method of a high-capacity silicon-carbon composite negative electrode material with a core-shell structure for a lithium-ion battery. The high-capacity silicon-carbon composite negative electrode material with the core-shell structure contains a silicon substance and a carbon substance, and the molar ratio of Si to C is 0.003-0.316. According to the invention,the problems in the prior art are solved, and the negative electrode material not only improves the structural stability of the core material silicon but also can effectively reduce the volume changeand particle fragmentation of an electrode in the lithium intercalation and deintercalation process. Meanwhile, the capacity bottleneck of a shell material carbon is solved, a difference between theresistance and the discharge potential of the core material and the shell material is reduced such that the core material and the shell material can reach a relatively consistent level in the aspect of lithium ion de-intercalation, and the advantage complementation between the core material silicon and the shell material carbon is realized. The coating effect is fully exerted, the structure of thesubstance is stabilized, and the safety stability and the electrochemical performance of the material are improved.

Owner:LONG POWER SYST NANTONG CO LTD

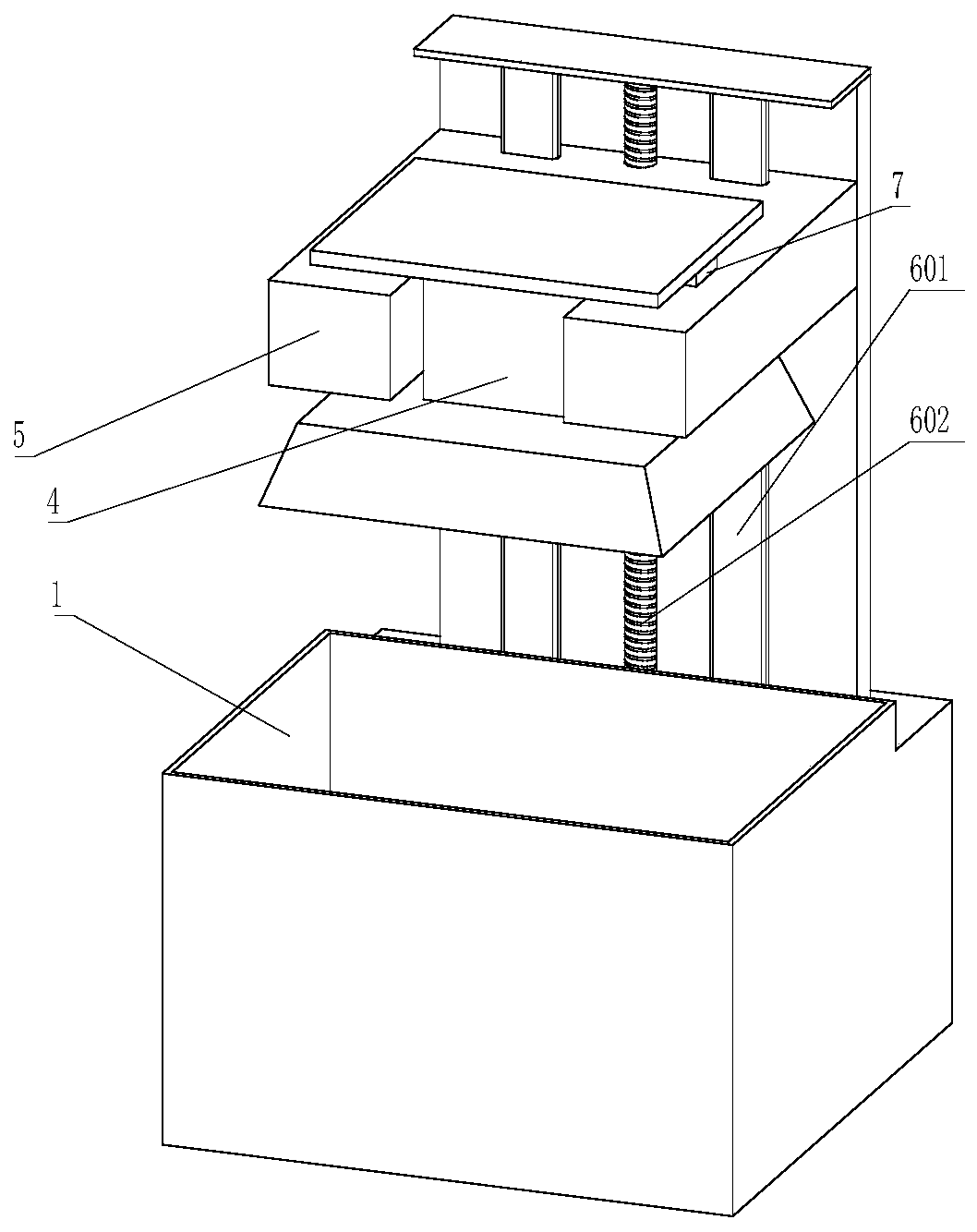

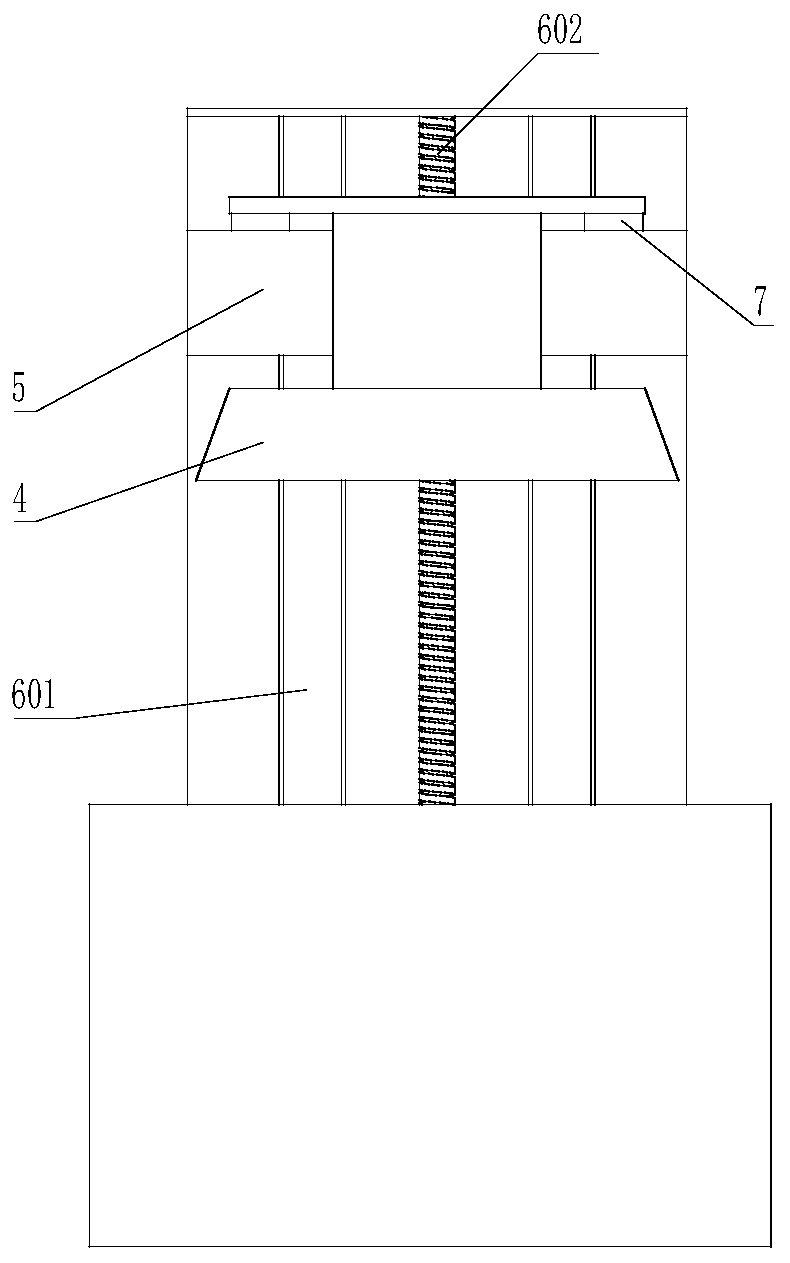

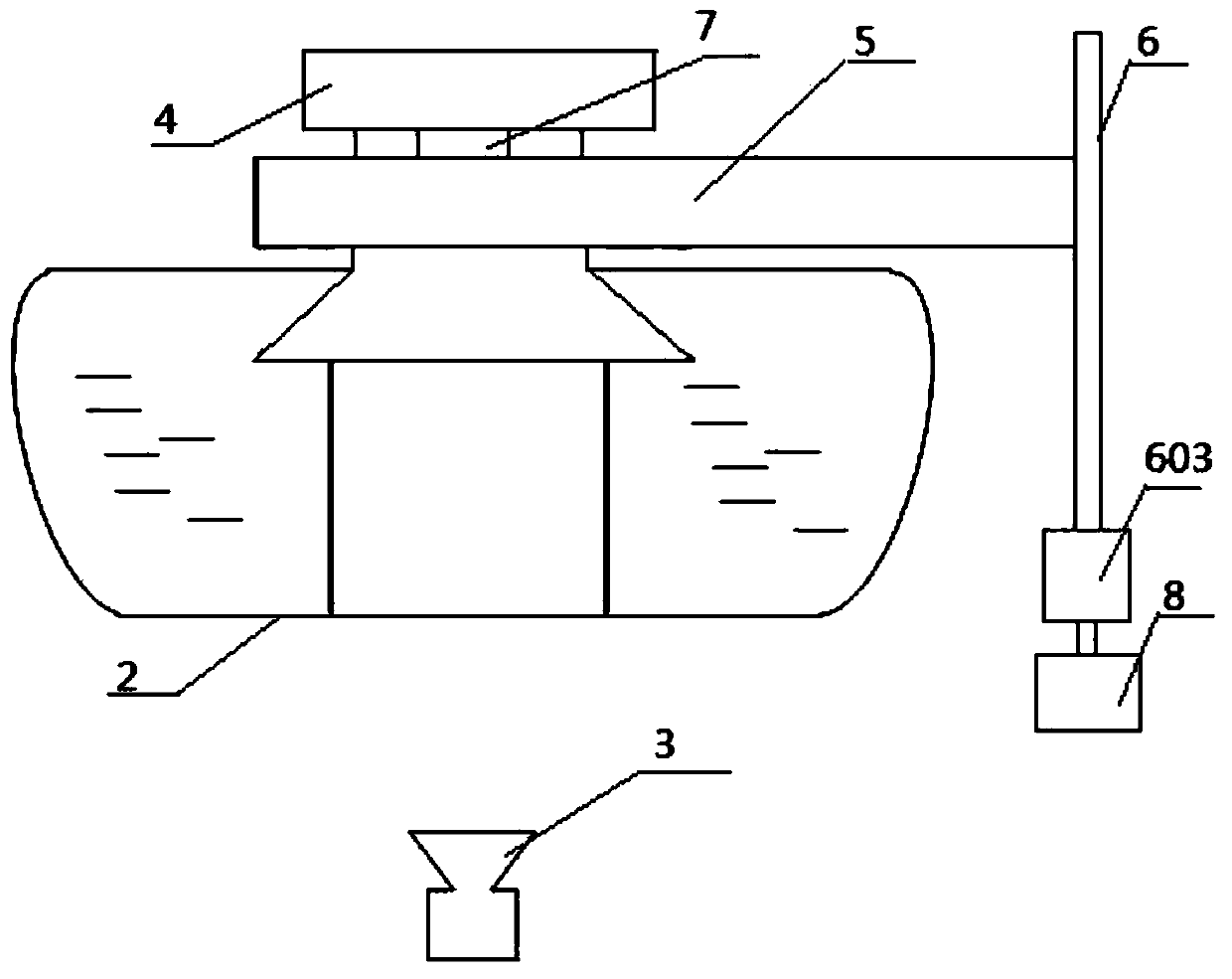

Photo-curing 3D printer and 3D printing method

ActiveCN111300817AAdjust the lifting speed in timeFree from reciprocating motionAdditive manufacturing apparatus3D object support structuresComputer printing3d printer

The invention relates to the technical field of 3D printing, in particular to a photo-curing 3D printer and a 3D printing method. The photo-curing 3D printer comprises a container filled with photosensitive resin, a transparent film is arranged at the bottom of the container, an optical machine is arranged at the bottom of the container, a printing platform is arranged above the container and connected with a lifting mechanism through a platform support, the lifting mechanism is connected with a printing control module used for controlling the lifting speed, the platform support is provided with a pressure sensor for detecting the pressure of the printing platform, the lifting mechanism is connected with a displacement detection piece for detecting the movement displacement of the liftingmechanism, and the pressure sensor and the displacement detection piece are both connected with the printing control module. The photo-curing 3D printer and the 3D printing method can not only avoid the reciprocating motion of the printing platform, but also can control the deformation degree of the transparent film and improve the printing success rate.

Owner:安徽光理智能科技有限公司

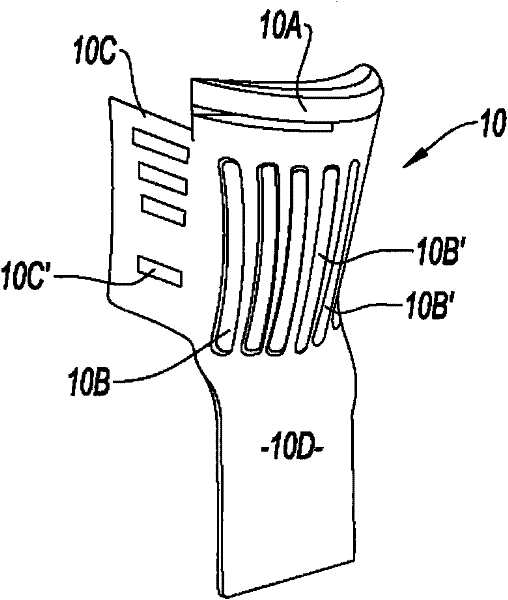

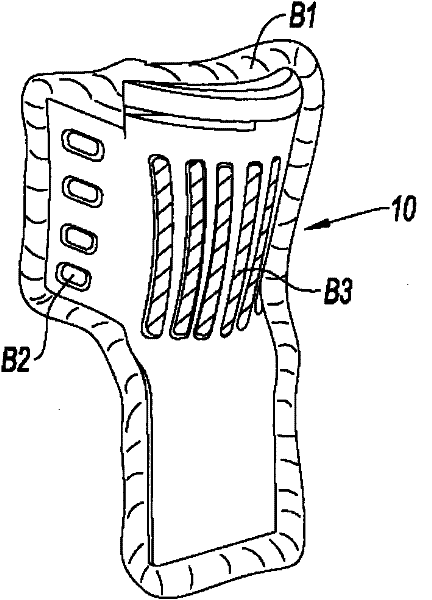

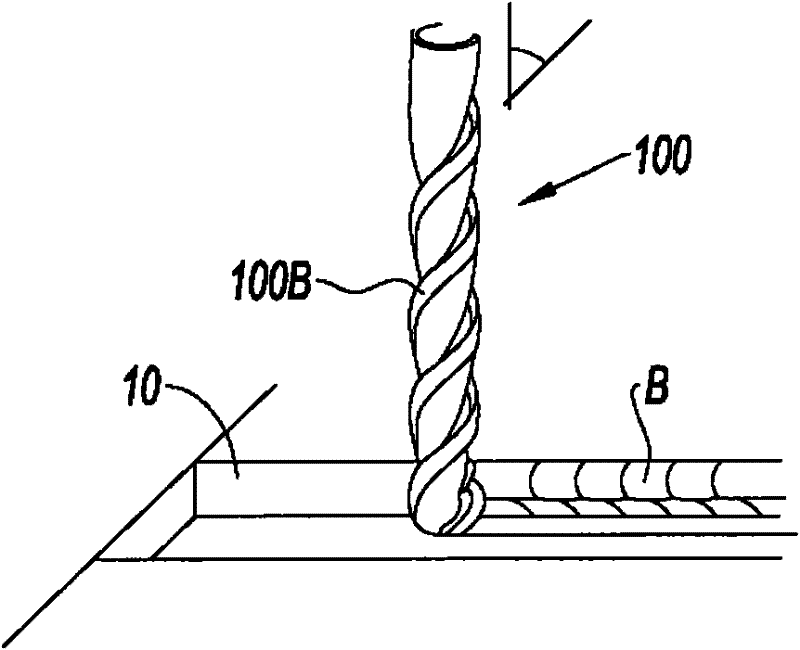

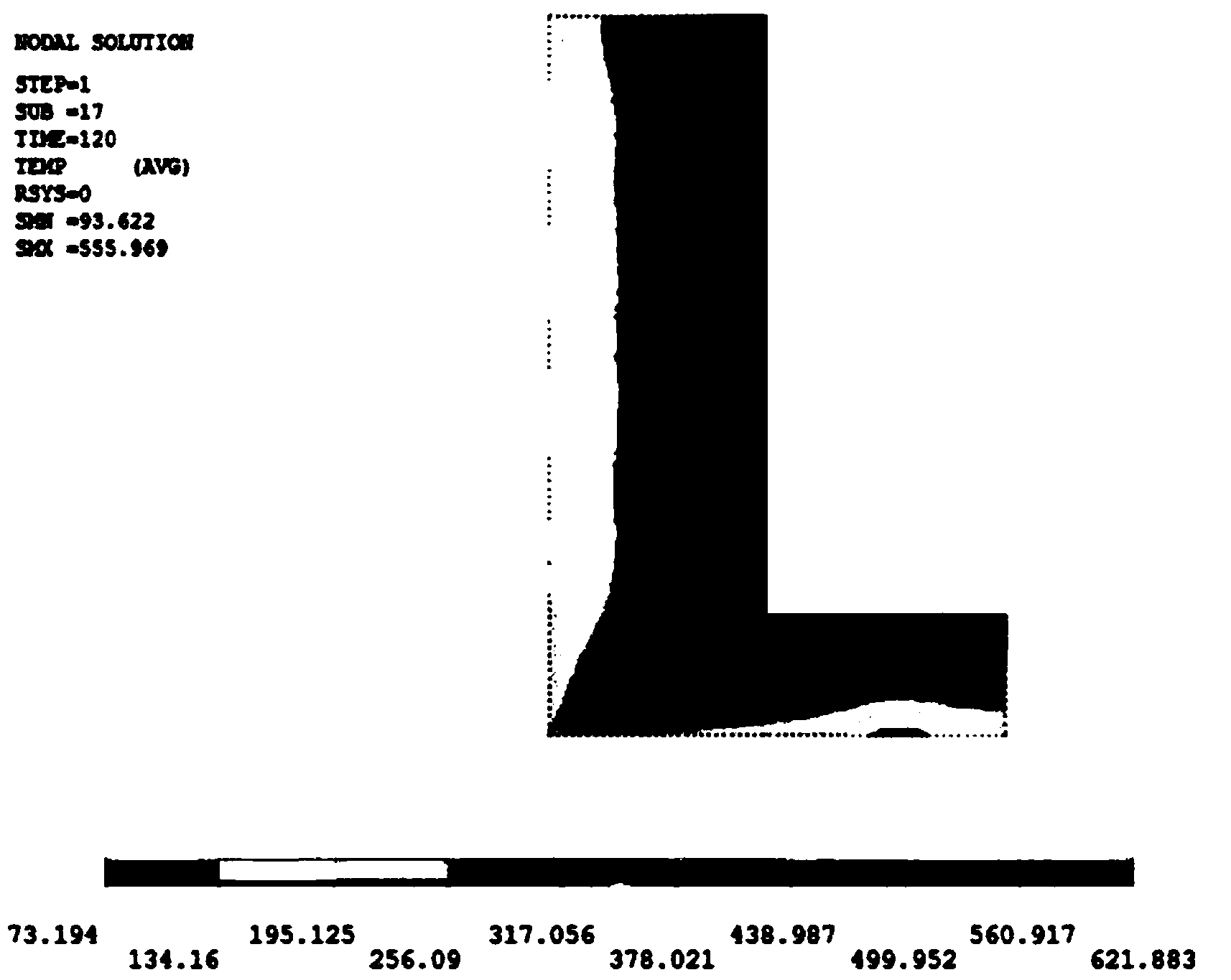

Method for deburring a ceramic foundry core

ActiveCN102056717AAvoid size changeReduce breakage rateEdge grinding machinesCeramic shaping apparatusFoundryMetallurgy

The present invention relates to a method for deburring a ceramic foundry core (10) obtained by injecting a ceramic paste, said paste including a binder having a predetermined glass transition temperature, into a mold and having at least one surface portion with a surplus of material forming a burr (B) to be eliminated. The method is characterized in that it includes the following stages: a) disposing and attaching the molded, unfired foundry core (10) onto a mounting (300); b) placing a milling tool (100), having an elongated shape with a helically cut edge, onto a tool holder; c) causing the tool to rotate around its axis and touching the milling tool to said surface portion to be deburred; and d) freezing (400) the surface portion to be deburred such that the foundry core is maintained at a temperature lower than said glass transition temperature during the deburring operation.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Detergent for lithography and method of forming resist pattern with the same

InactiveUS8367312B2Easy to optimizeReduce surface tensionAnionic surface-active compoundsNon-surface-active detergent compositionsResistDissolution

Conventional detergents for lithography which contain a surfactant as an active ingredient should have a reduced surfactant concentration because heightened surfactant concentrations result in dissolution of the resin component of a photoresist composition and hence in a dimensional change of a resist pattern. However, the conventional detergents have had a drawback that such a low concentration unavoidably reduces the ability to inhibit pattern falling and defect occurrence. A detergent for lithography is provided which is an aqueous solution containing (A) at least one member selected among nitrogenous cationic surfactants and nitrogenous ampholytic surfactants and (B) an anionic surfactant. This detergent retains a low surface tension even when it has a low concentration. It is effective in inhibiting pattern falling and defect occurrence. It can also inhibit resist patterns from fluctuating in dimension.

Owner:TOKYO OHKA KOGYO CO LTD

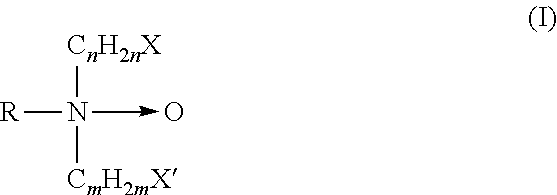

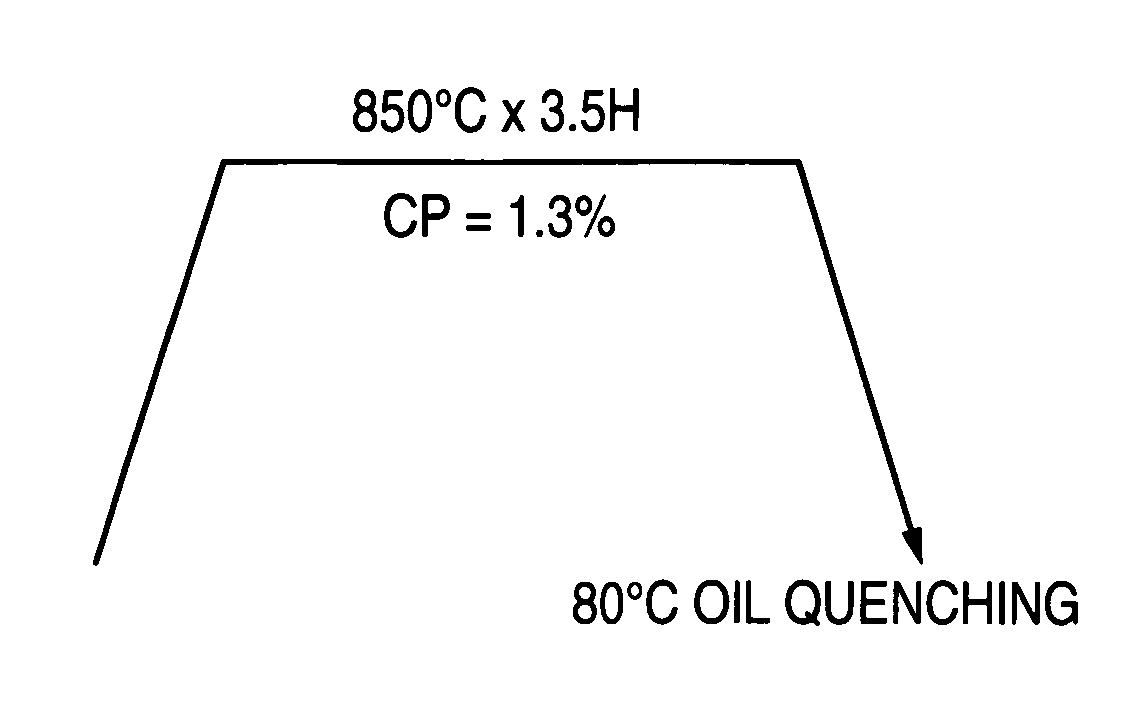

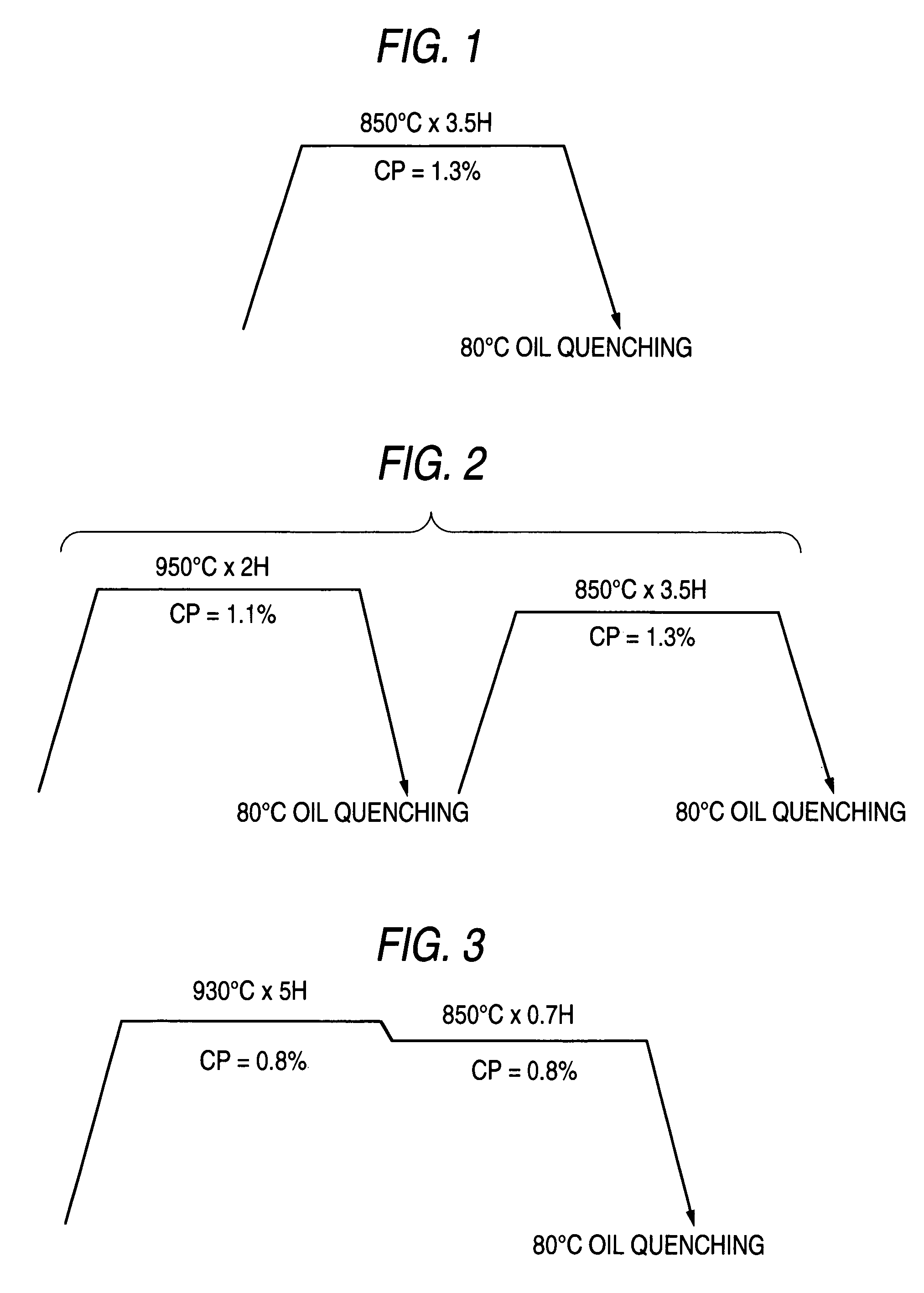

Carburized roller member made of high carbon chromium steel

ActiveUS7207933B2Slide life be heightenIncreased strengthValve arrangementsCam-followersChromiumHardness

Owner:JTEKT CORP

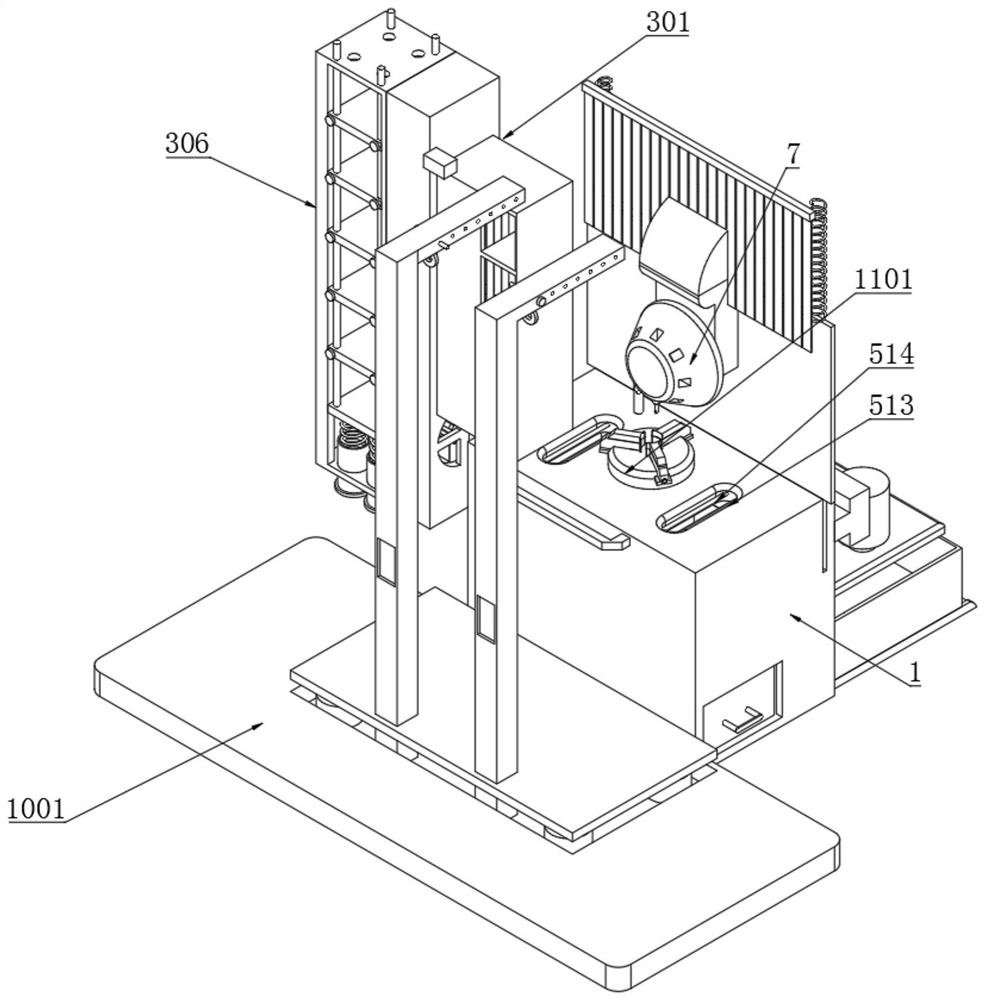

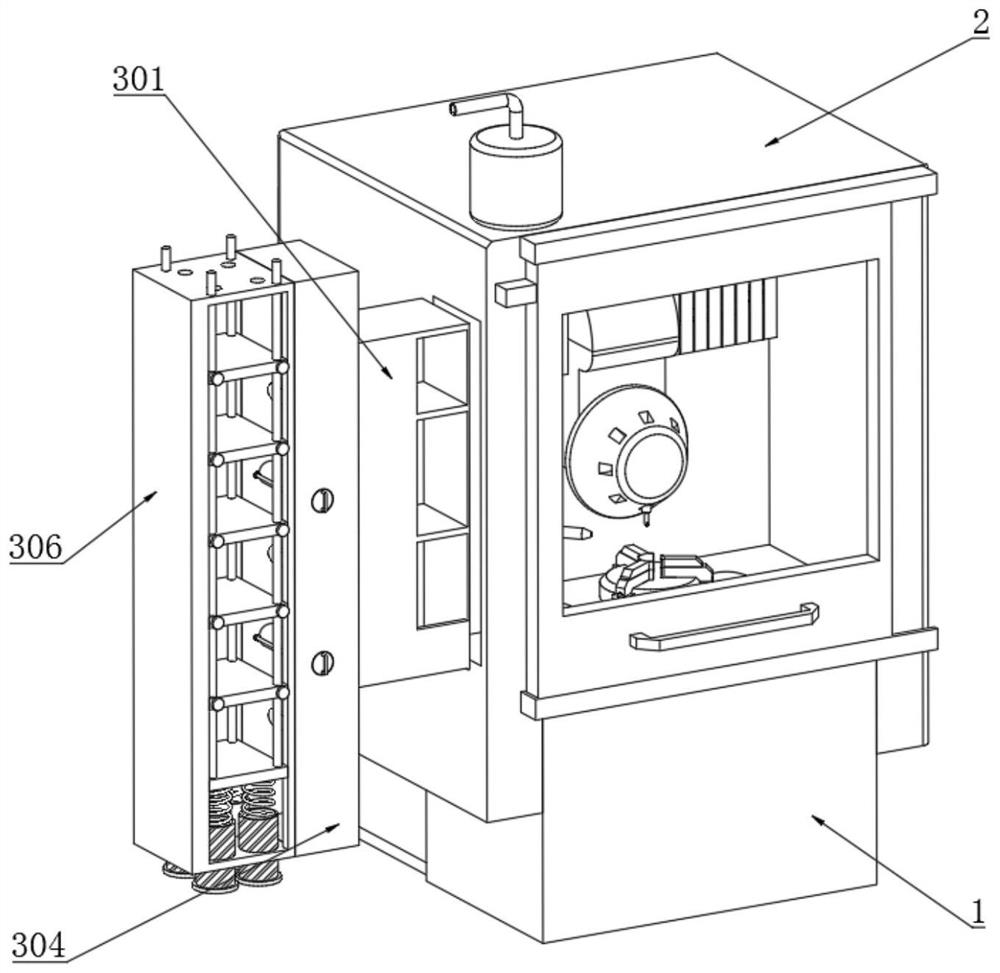

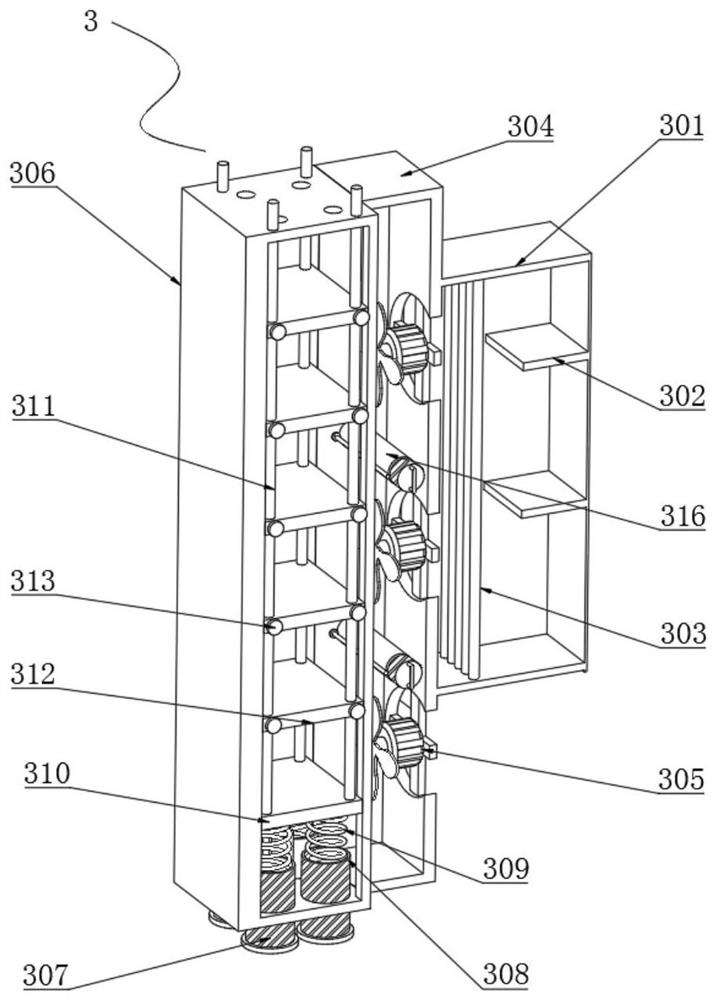

Multi-dimensional protective cutting treatment machine tool

ActiveCN112658689AScientific and reasonable structureEasy to useIncreasing energy efficiencyOther manufacturing equipments/toolsEngineeringMachine tool

The invention discloses a multi-dimensional protective cutting treatment machine tool which comprises an operation table, a protective shell is installed at the top end of the operation table, a heat treatment assembly is installed on the side end face of the protective shell, a heating box is fixedly installed on the inner side of an installation groove, and an air bellow is fixedly connected to the side, away from the protective shell, of the heating box. The multi-dimensional protective cutting treatment machine tool is scientific and reasonable in structure and safe and convenient to use, a to-be-machined workpiece needing to be machined and cut is placed on a partition plate in the heating box to be preheated, the situation that the size of the workpiece is changed due to deformation caused by rapid temperature change during cutting machining is prevented, and then the to-be-machined workpiece is dried and heated, so that the to-be-machined workpiece is ensured not to rust before entering next working procedure, a proximity switch and a fan are used in cooperation, heat energy generated by a resistance heating rod can be reasonably distributed and utilized, the heat utilization rate is increased, energy is saved, and therefore the defect of heat treatment of the machine tool is further overcome.

Owner:HEBEI INST OF MACHINERY ELECTRICITY

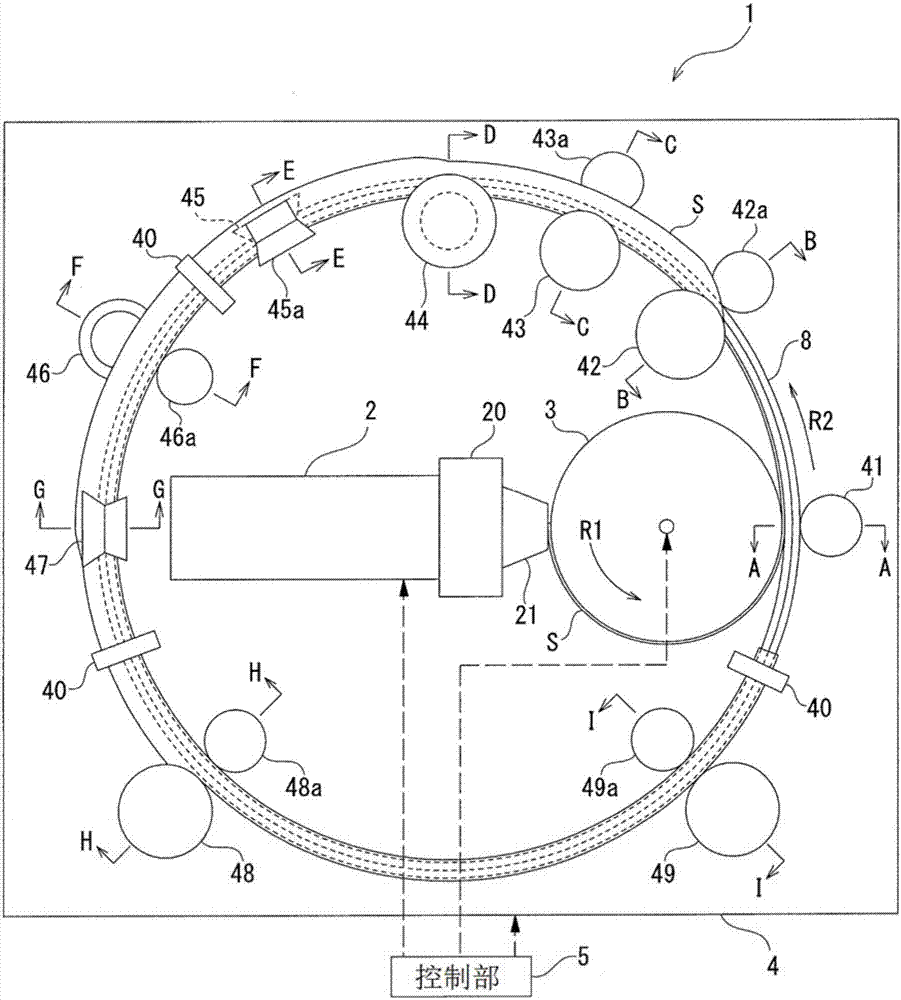

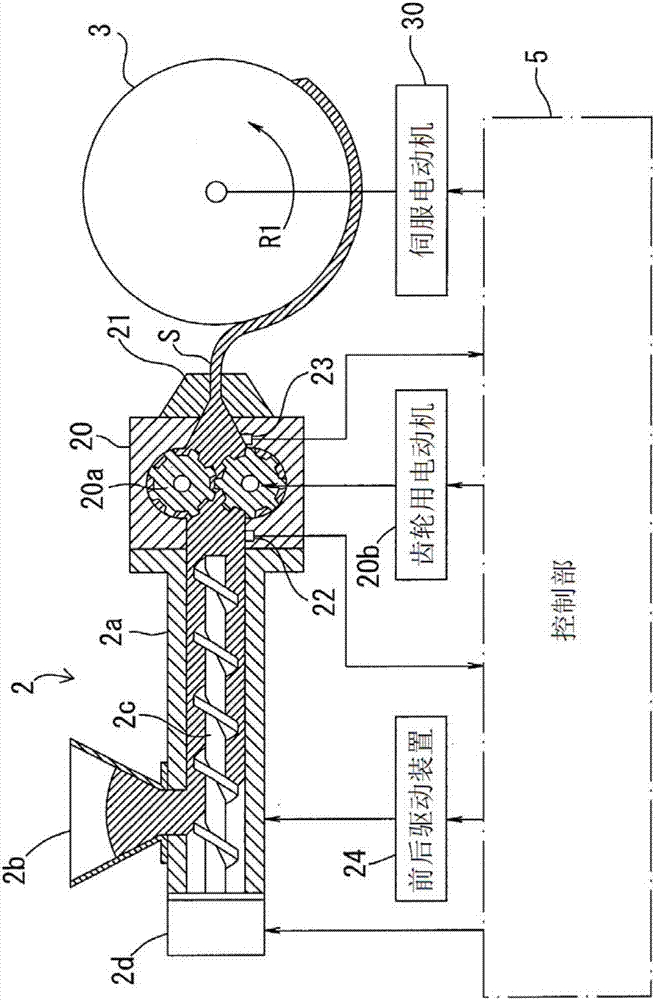

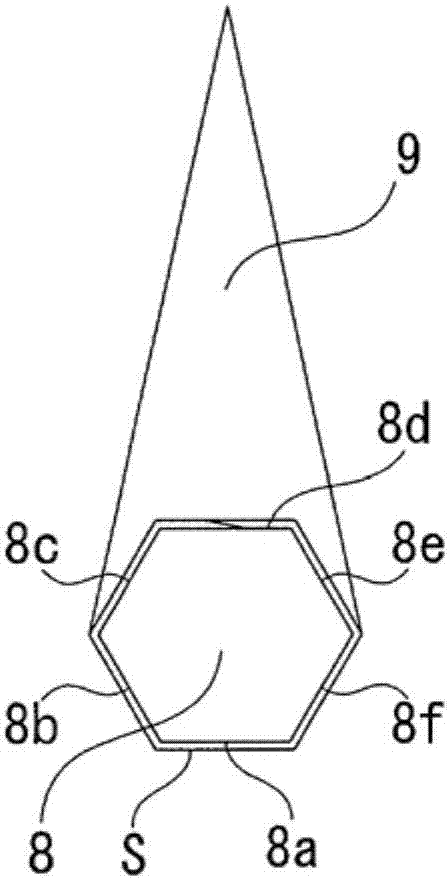

Bead core covering method and bead core covering device

A bead core covering method for covering an annular bead core (8) with a belt-like rubber sheet (S) includes winding the rubber sheet (S) extruded by an extruding machine (2) via a mouth piece (21) around an outer peripheral surface of a rotary drum (3) from a leading end portion, attaching a part in a width direction of the rubber sheet (S) on the outer peripheral surface of the rotary drum (3) to an outer surface of the bead core (8), which rotates, from the leading end portion before the rubber sheet is wound over an entire periphery of the outer peripheral surface of the rotary drum (3), and wrapping a remaining portion in the width direction of the rubber sheet (S) attached to the outer surface of the bead core (8) along a cross-sectional shape of the bead core (8).

Owner:TOYO TIRE & RUBBER CO LTD

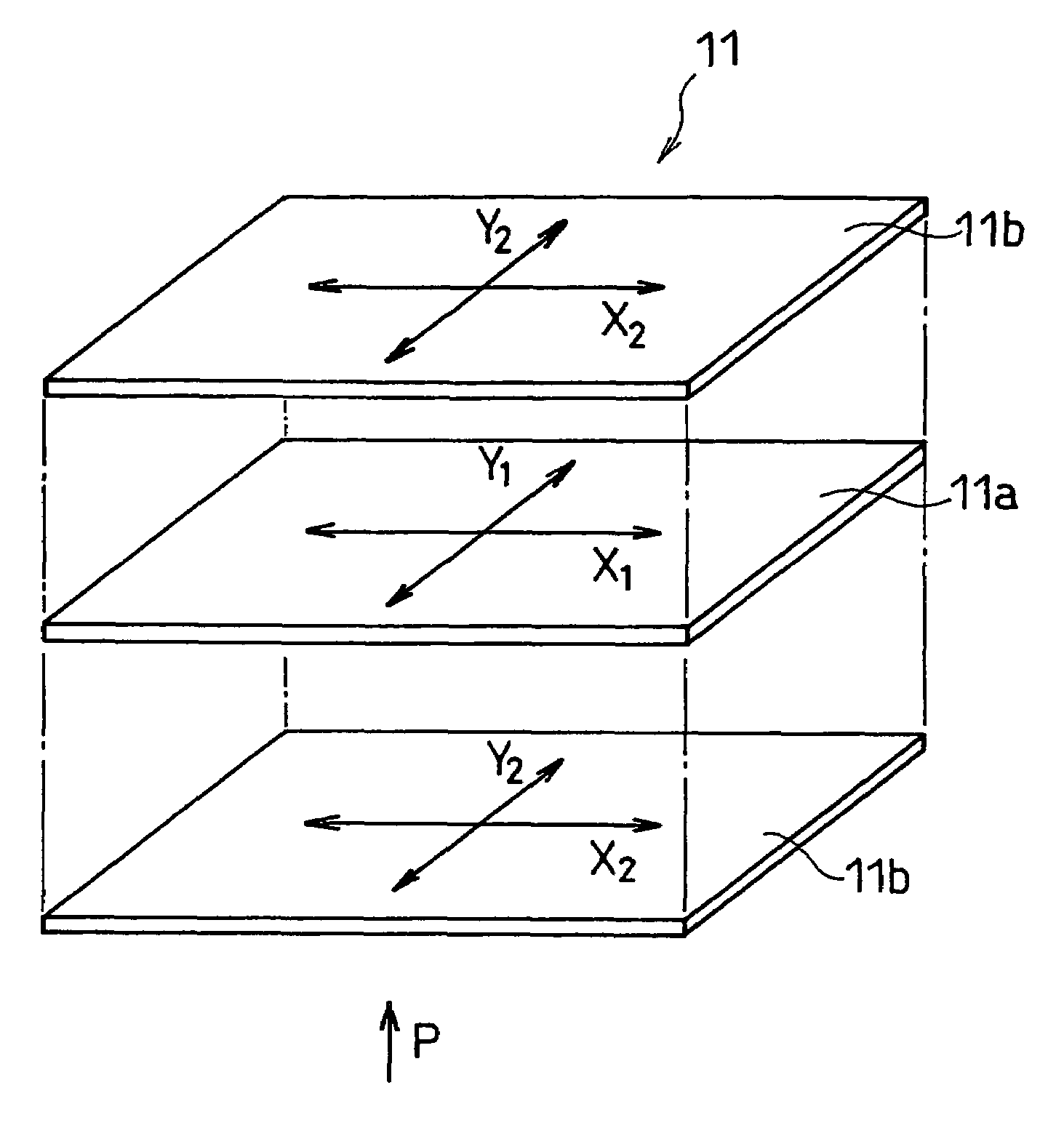

Composite electrolyte membrane, catalyst-coated membrane assembly, membrane-electrode assembly and polymer electrolyte fuel cell

InactiveUS7622215B2High modulusIncrease chanceElectrolyte holding meansFuel cells groupingCoated membranePolymer electrolytes

To provide a polymer electrolyte membrane having excellent size stability and excellent mechanical strength that can sufficiently prevent the size change due to the swelling condition, the displacement of the polymer electrolyte membrane and the formation of wrinkles during the production of the polymer electrolyte fuel cell, and can prevent damage during the production and operation of the polymer electrolyte fuel cell. In a composite electrolyte membrane including a porous reinforcement layer made of a resin and an electrolyte layer made of a polymer electrolyte and laminated at least one main surface of the reinforcement layer, the direction having a high tensile modulus of elasticity in the reinforcement layer is substantially corresponded with the direction having a high rate of size change in the electrolyte layer.

Owner:PANASONIC CORP

Ferrous metal liquid die forging mould and manufacturing method thereof

ActiveCN103706777AImprove working environmentAvoid Rapid Exception FailuresCoatingsThermal insulationCopper

The invention relates to a ferrous metal liquid die forging mould and a manufacturing method of the metal liquid die forging mould. A zirconium oxide or aluminum oxide coating is arranged on the inner surface of a mould cavity, diatomite thermal insulation coatings are arranged on the surface of the coating, the mould is sleeved with a copper sleeve, the copper sleeve is provided with a spiral cooling water channel which is arranged on the two sides and the bottom of the mould, and the copper sleeve is further sleeved with a supporting sleeve. The method comprises the following steps that (1), the mould is designed and manufactured according to a liquid die forge piece to be formed; (2), the zirconium oxide or aluminum oxide coating is sprayed on the inner surface of the mould cavity; (3), the mould is sleeved with the copper sleeve, the spiral cooling water channel is arranged on the copper sleeve, and the spiral cooling water channel is arranged on the two sides and the bottom of the mould; (4), the copper sleeve is sleeved with the supporting sleeve; (5), before each liquid die forge piece is forged, the diatomite thermal insulation coatings need to be sprayed on the surface of the coating of the mould. According to the ferrous metal liquid die forging mould and the manufacturing method of the metal liquid die forging mould, the temperature of the mould is decreased, and the service life of the ferrous metal liquid die forging mould is prolonged.

Owner:WUHAN UNIV OF TECH

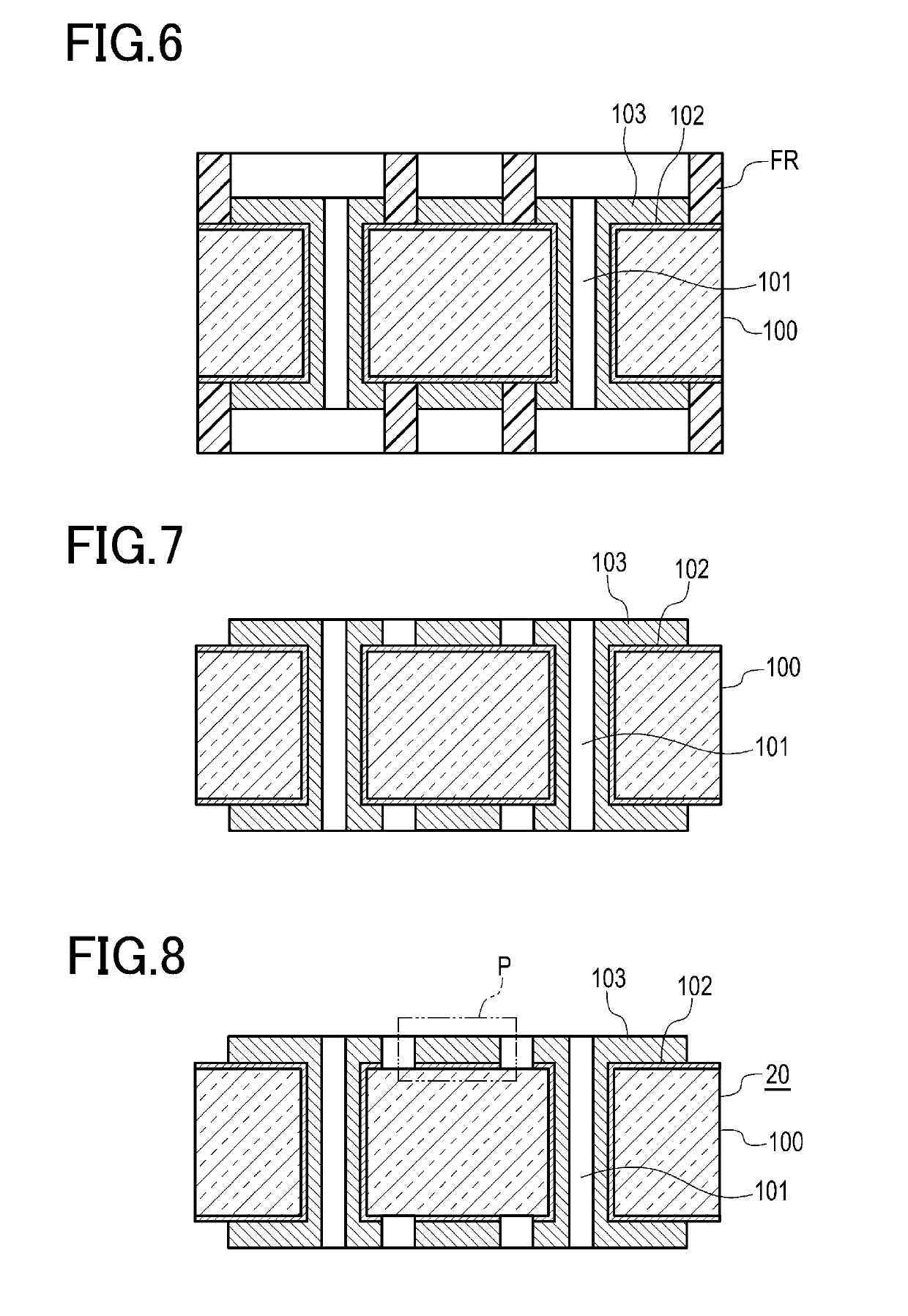

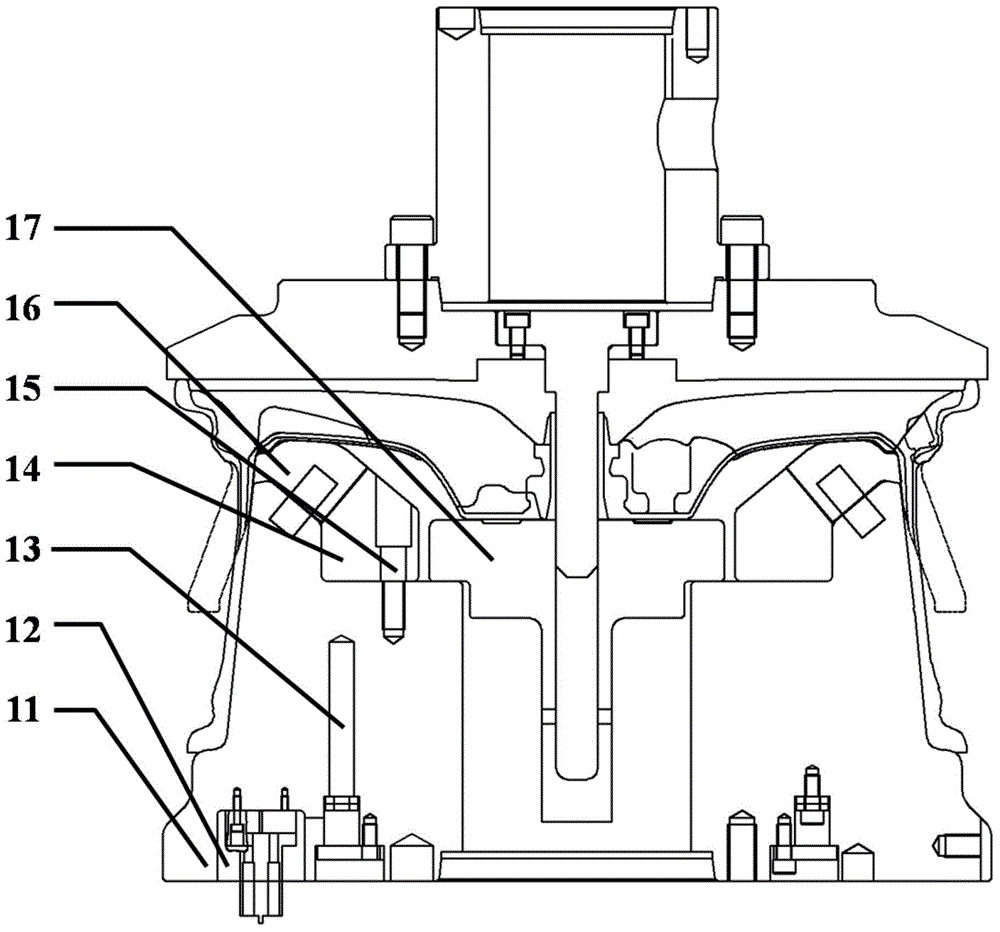

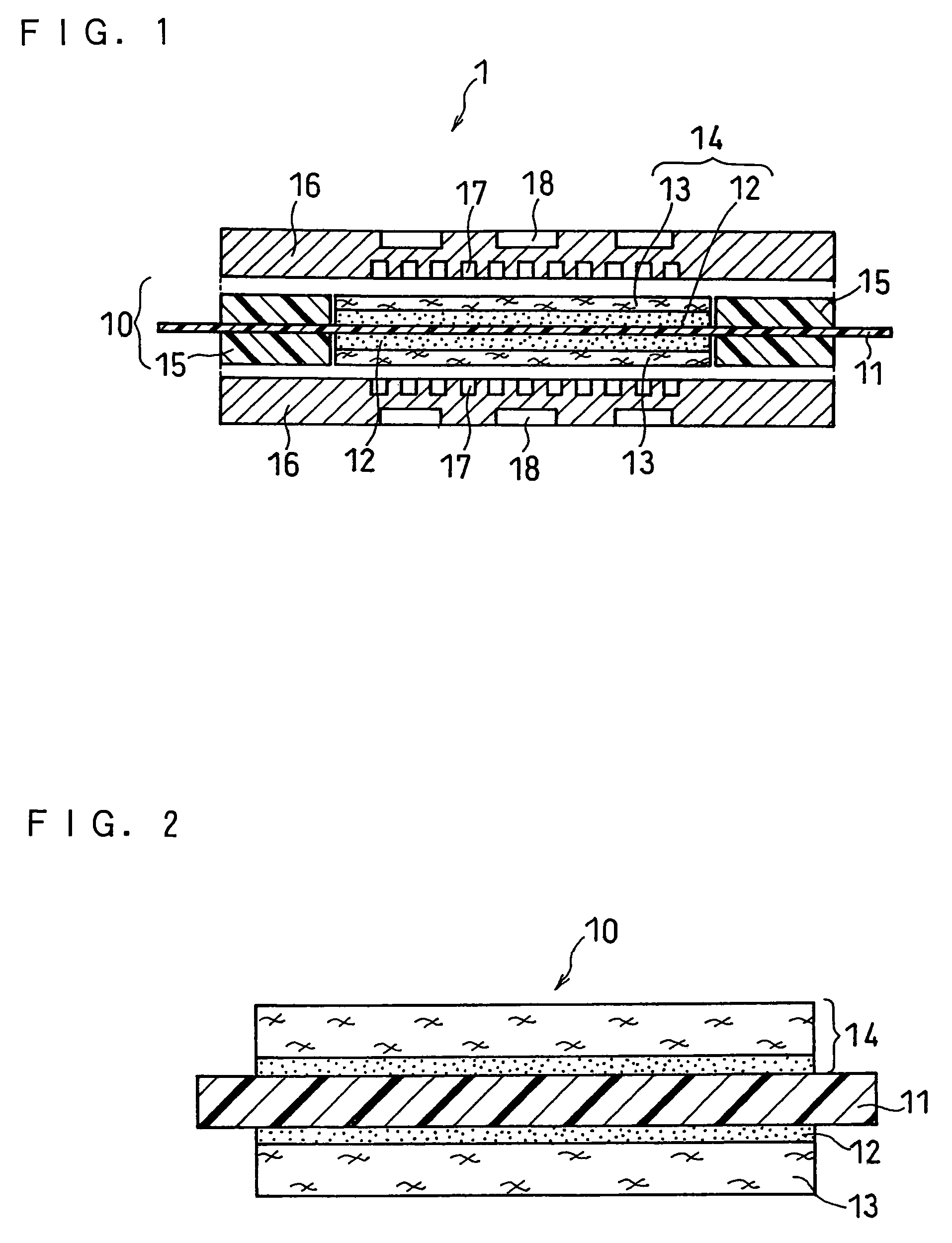

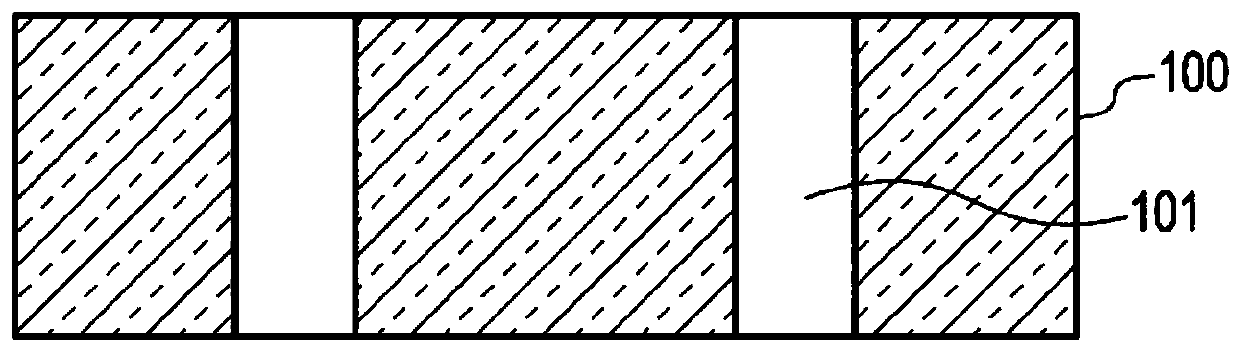

Electronic component and method for manufacturing electronic component

ActiveCN109964544AGuaranteed connection reliabilityAvoid short circuitSemiconductor/solid-state device detailsSolid-state devicesMiniaturizationThin membrane

An electronic component according to the present invention is provided with: a glass base material (100) having a through-hole (101) formed so as to pass through both surfaces thereof; an insulating resin layer (120) that is stacked on each of both surfaces of the glass base material (100) and that has a copper-plated layer (103) formed in the interior thereof; and a capacitor (109) having a lowerelectrode (110) formed on the copper-plated layer (103), a dielectric layer (111) formed so as to be stacked on the lower electrode (110), and an upper electrode (112) formed so as to be stacked on the dielectric layer (111). A region of the upper electrode (112), said region being along the surface of the copper-plated layer (103), is formed so as to be smaller than a region of the dielectric layer (111), said region being along the surface of the copper-plated layer (103), and a region of the lower electrode (110), said region being along the surface of the copper-plated layer (103). This provides a glass core substrate having a thin-film capacitor with a highly reliable MIM structure and also achieves a compact size, a small thickness, and high reliability.

Owner:TOPPAN INC

Liquid preparation for contact lens

InactiveCN1835771AAvoid size changePrevent precipitationBiocideLens cleaning compositionsDisinfectantGlycollic acid

To provide a liquid preparation for contact lens wherein: the liquid preparation for contact lens assures an excellent disinfecting effect and a sufficiently high degree of safety to the eyes of the lens wearer; the liquid preparation for contact lens does not adversely affect the contact lens, such as a change of the size of the contact lens; and the liquid preparation for contact lens advantageously restrains a generation of deposits on the lens. The liquid preparation for contact lens is prepared, so as to comprise: at least one disinfectant selected from the group consisting of germicidal biguanides and germicidal quaternary ammonium salts (component A); glycolic acid and / or asparatic acid (component B); and 2 ۥ amino ۥ 2 ۥ methyl ۥ 1, 3-propanediol or a salt thereof (component C), wherein the component B and the component C fulfill a predetermined molar ratio.

Owner:MENICON CO LTD

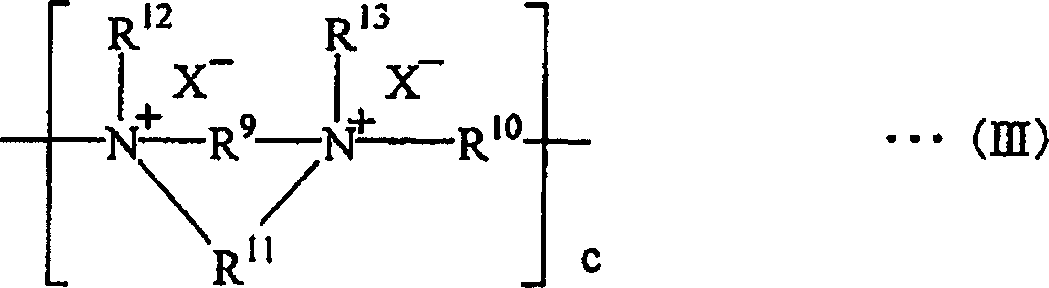

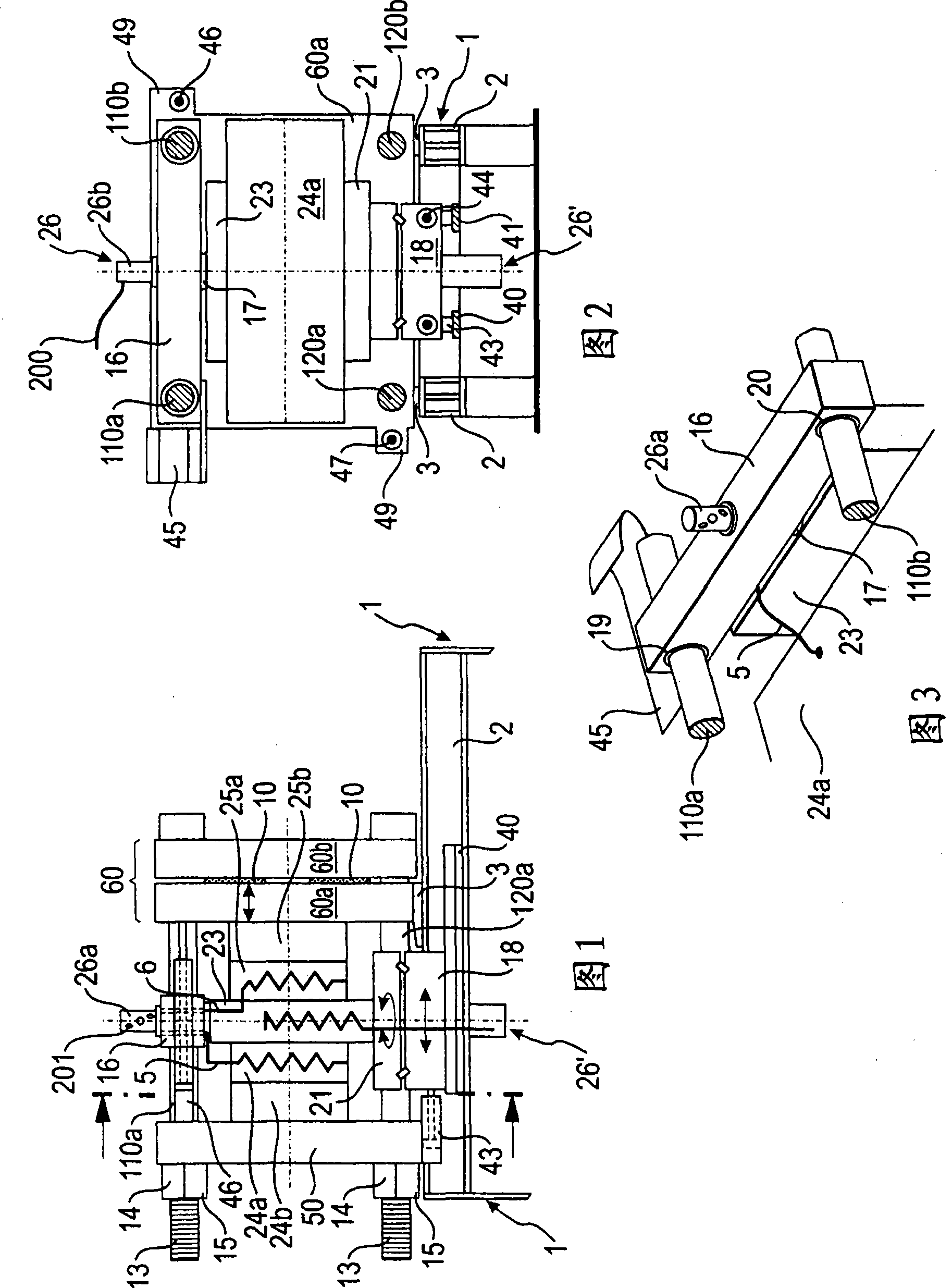

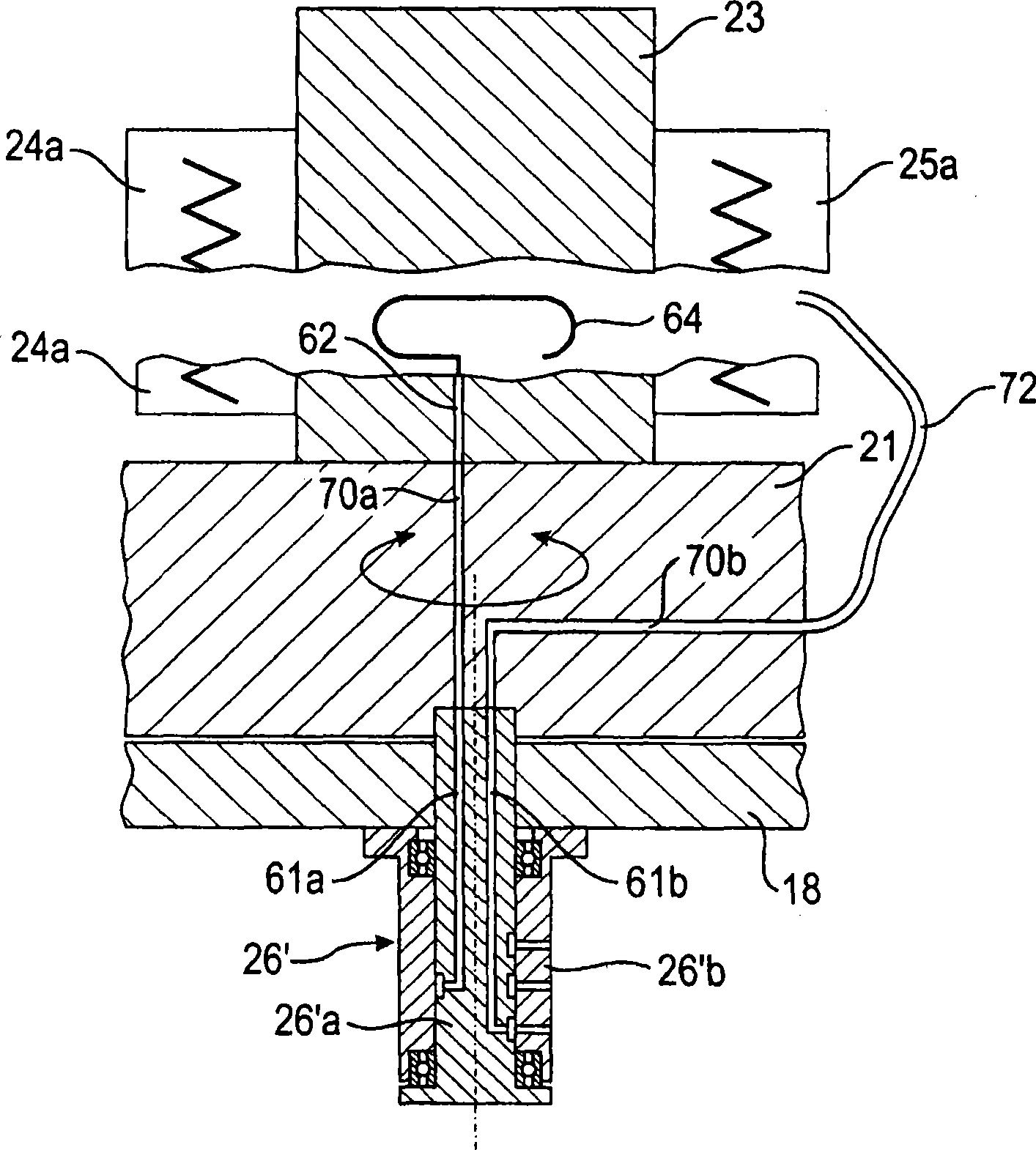

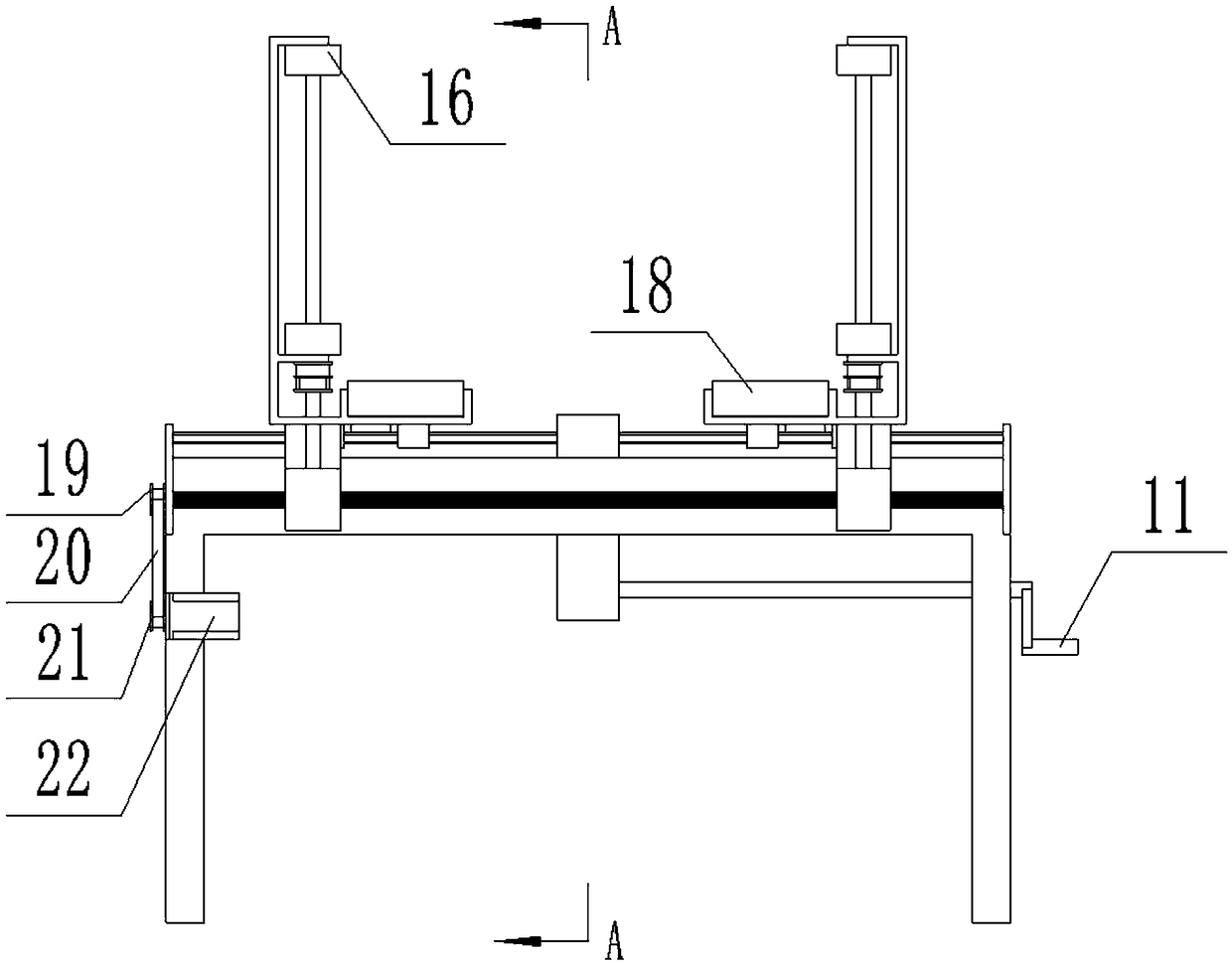

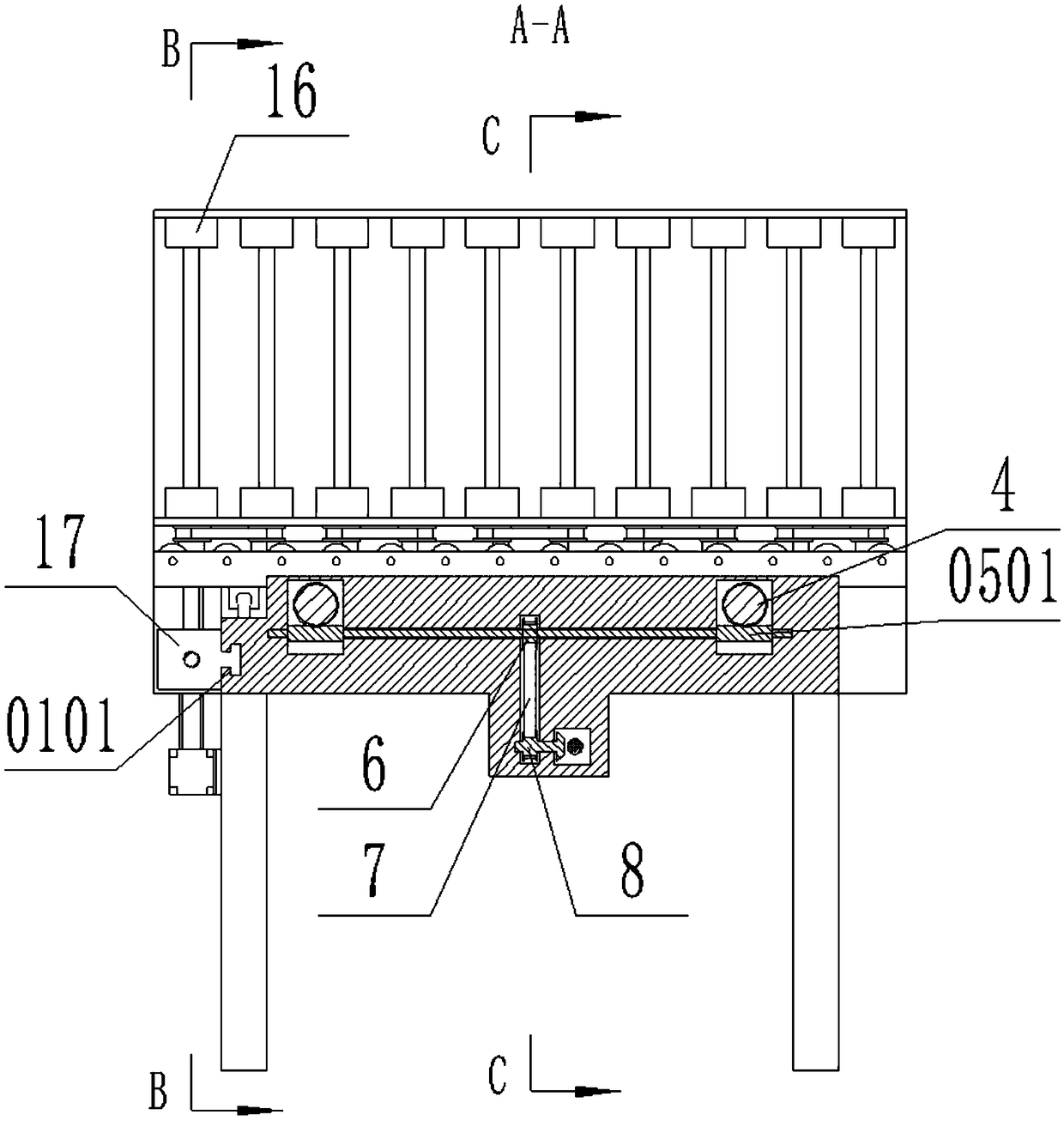

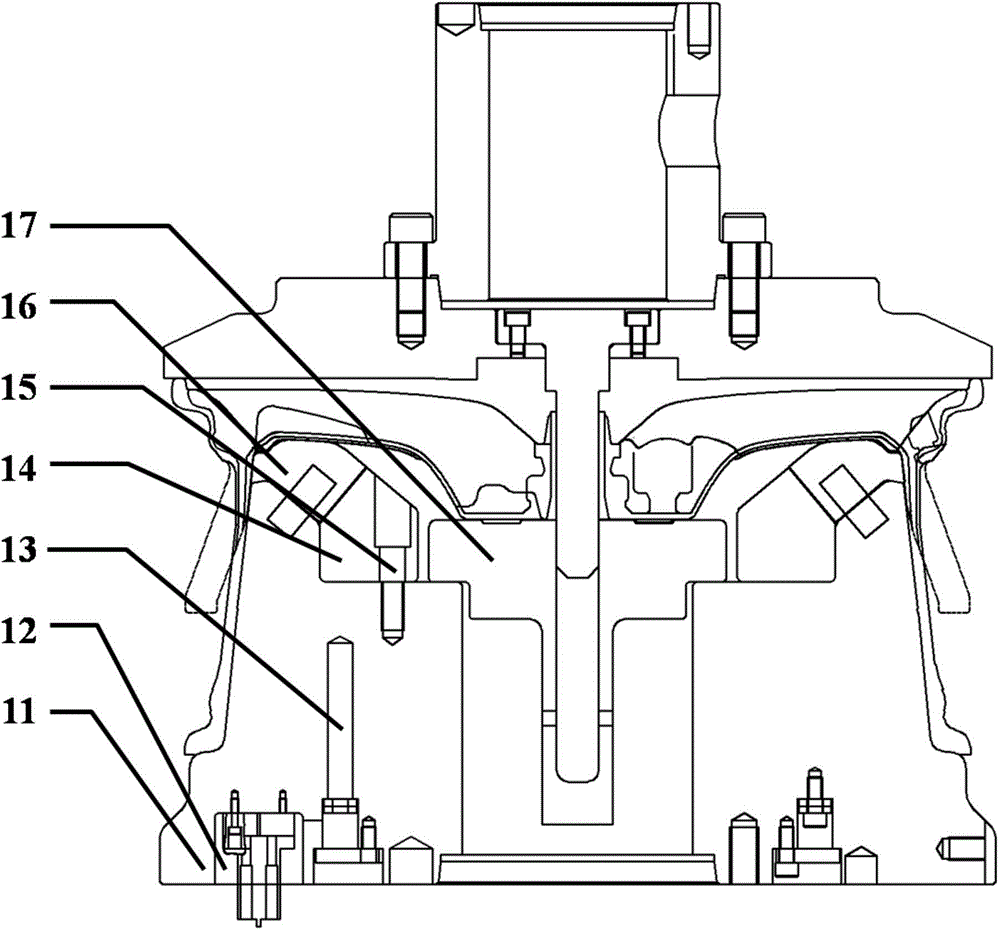

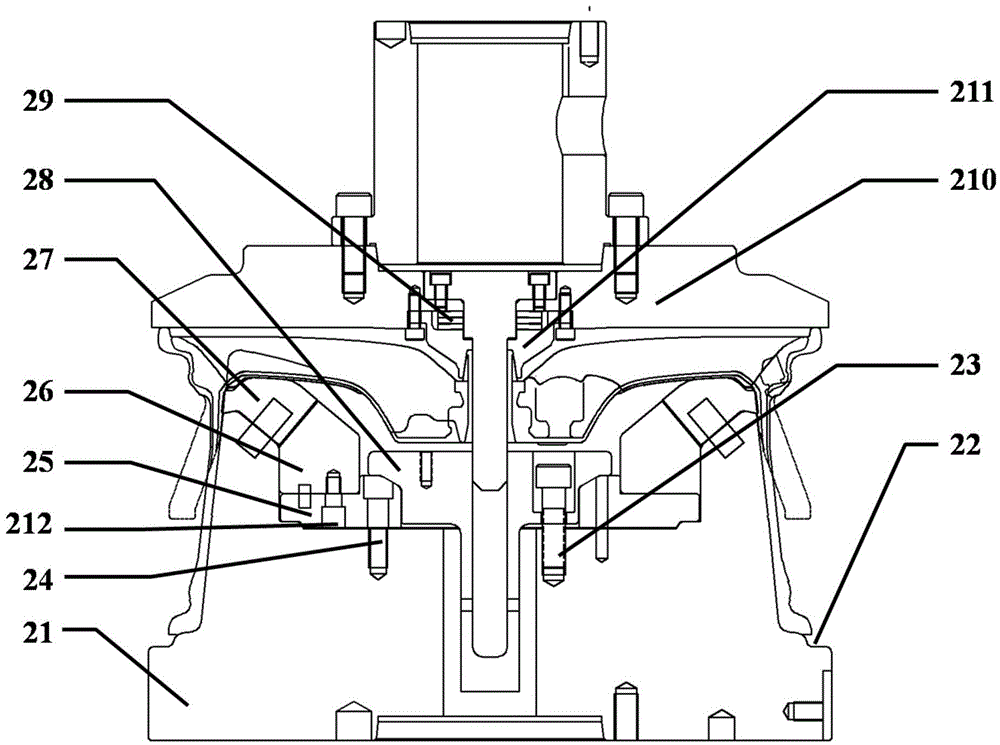

Injection molding part producing method

The present invention describes a device for producing an injection molding part, including a mold support (23) and one or more injection molds (24, 25) with half-molds (24a, 25a) that are attached on the mold support (23), where separate temperature adjustment (64, 99a, 99b) is provided for the mold support (23) and the half-molds (24a, 25a). By means of setting a separate temperature adjustmentfor a positioning plate or a cube-shaped mold support and each half-mold fixed on the mold support, it is able to avoid mold support size change or to only allow a size change on each mold clamping plate independent of the half-mold temperature adjustment. Thus, each half-mold on the mold support may align to the corresponding half-mold on the mold clamping plate accurately.

Owner:KRAUSSMAFFEI TECH GMBH

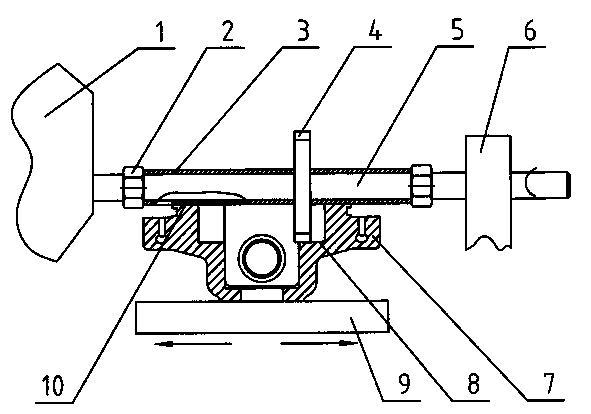

Method for processing bearing seat cylinder surface on variable housing of plunger pump

InactiveCN103752922AIncrease productivityAvoid size changeMilling equipment detailsPlunger pumpEngineering

The invention provides a method for processing a bearing seat cylinder surface on a variable housing of a plunger pump. The method is characterized in that an angle head is mounted on a main shaft of a machine tool; a circular cutter is mounted on a transmission shaft of the angle head; a bearing seat is mounted on a clamp which is mounted on four horizontal axles; the angle head and the circular cutter can extend into an inner chamber of the bearing seat to process together; the main shaft of the machine tool rotates to drive the transmission shaft of the angle head to rotate so as to drive the circular cutter to rotate, and a workbench moves left and right to realize cutting and feeding, thus the cylinder surface on one side of the bearing seat can be processed; and when the four axles rotate at 180 degrees together with the bearing seat and the clamp, the cylinder surface on the other side of the bearing seat can be processed. According to the method, the angle head and the circular cutter extend into the inner chamber of the bearing seat to process; a small cylinder surface for process of the variable housing is removed; and the process is reduced, so that the production efficiency and product reliability can be improved.

Owner:SHAOYANG VICTOR HYDRAULICS

Functional fiber-grade 3D printing method based on reactive extrusion

InactiveCN105922577AHigh forming precisionWiden your optionsAdditive manufacturing apparatusPlasticizerHeat treated

The invention relates to a functional fiber-grade 3D printing method based on reactive extrusion. A lactam monomer and / or lactone monomer, an assistant and a plasticizer are fused and have a polymerization reaction under the catalyst effect, a functional agent is added before polymerization or in the polymerization process, and target polymer is obtained; the target polymer is subject to fused deposition 3D printing, and then subject to heat treatment, and a final product is obtained; and according to heat treatment, heat preservation is carried out for 3 min to 60 min at the temperature ranging from 100 DEG C to 180 DEG C. A high-precision high-adapting 3D printer is adopted, the molding precision is high, the efficiency is high, the mechanical property of the product is good, and functional components are good in dispersibility; a technology for directly making the product from the polymeric monomer is adopted, the production flexibility is improved, and meanwhile, the condition that due to crystallization and the large temperature difference of semi-crystalline polymer of nylon, polyester and the like, edge warping is caused, and even printing cannot be carried out is avoided; and the kind of the fused deposition 3D printing material is widened, the quality of the product is improved, and the method has the wide application to the fields of automobile materials, engineering materials, structural parts and the like.

Owner:DONGHUA UNIV

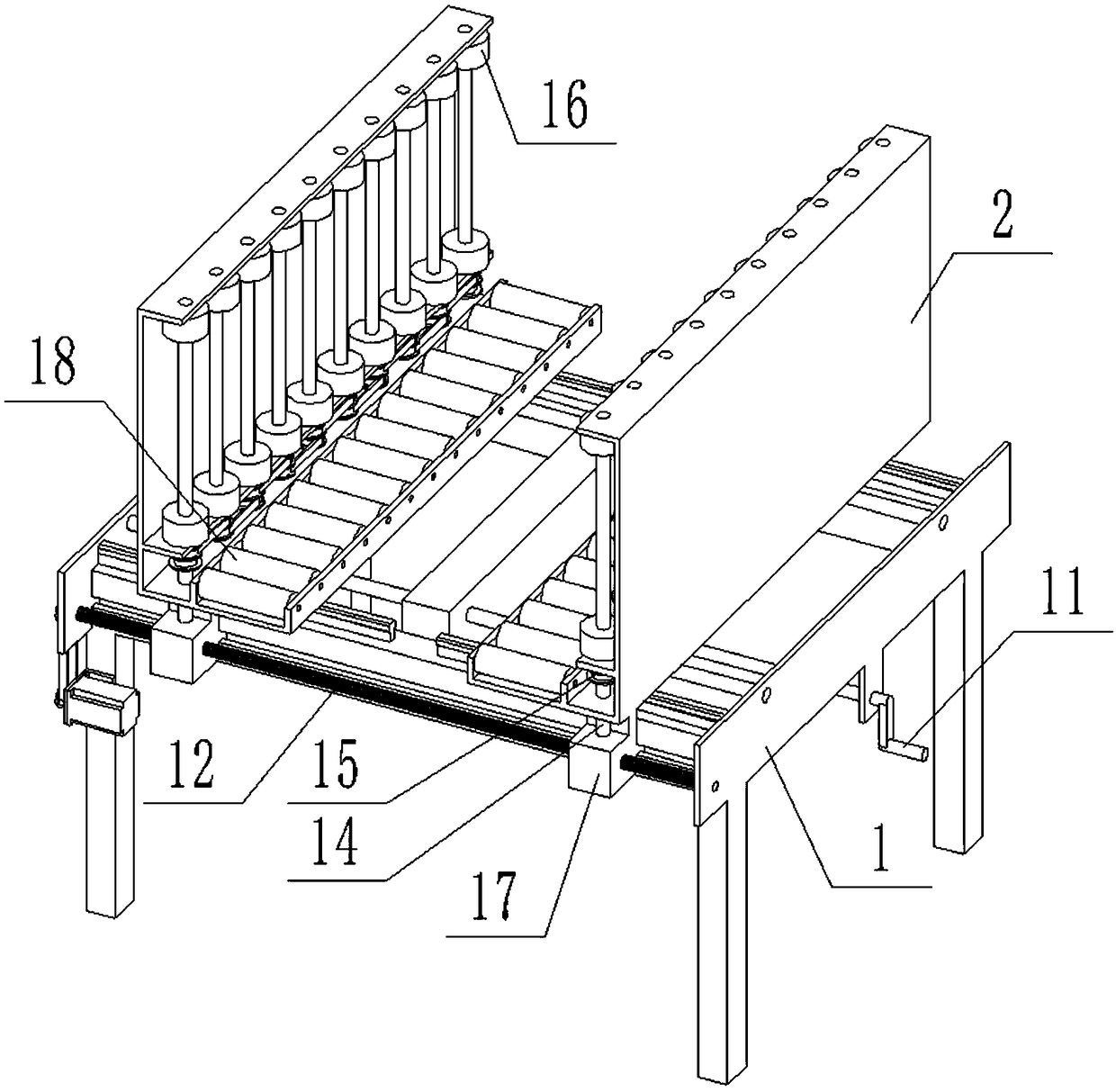

Adjusting mechanism for packaging device for paper boxes of different specifications and sizes

The invention provides an adjusting mechanism for a packaging device for paper boxes of different specifications and sizes. The mechanism comprises a base, a T-shaped groove and a guiding motor; the left and right sides of the top of the base are each in sliding connection with a set of sliding supports; the front and back end faces of the base are each axially connected with a set of lead screws;the rear end face of a driving belt pulley is coaxially and fixedly connected with a set of driven bevel gears with the adjustable size; the two adjacent sets of guiding belt pulleys are sequentiallyconnected through a transmission belt; a plurality of sets of bottom rollers are evenly distributed and axially connected to the lower portions of the sliding supports. By adopting a worm and gear transmission mechanism, transmission vibration is little, the high transmission ratio can be obtained, hand cranking strength is lowered, meanwhile, the worm and gear have the self-locking capability, size changes of the adjusting mechanism are avoided, by adopting a spline shaft, a driving bevel gear can be driven to slide on a spline shaft, transmission is not affected, and motion of the guiding wheel is not affected when the width is adjusted.

Owner:日照环宇包装股份有限公司

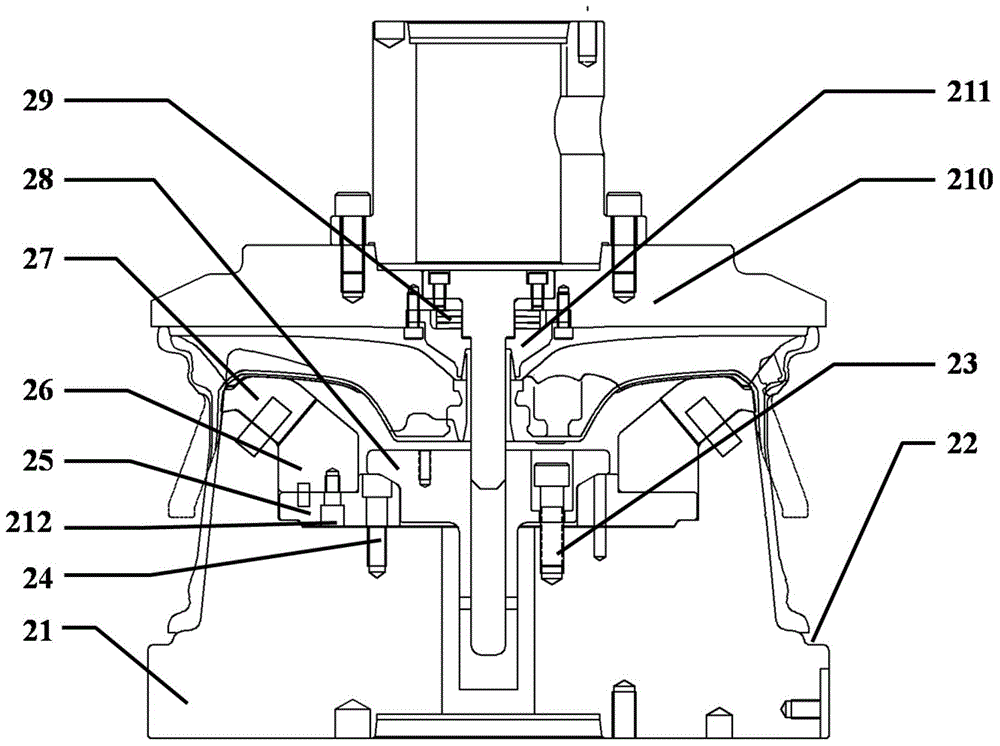

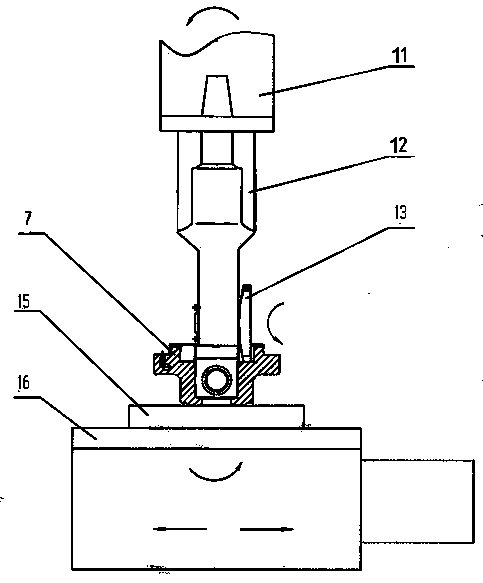

Die for spinning and casting aluminum alloy wheel

InactiveCN104588507AEasy to locate and installSmooth expansionShaping toolsRimsAlloy wheelMaterials science

The invention relates to a lower die of a die for spinning and casting an aluminum alloy wheel. The lower die is characterized in that the lower die comprises a cushion plate 25, a guide block 26 and a movable block 27 at the wheel cavity position, wherein the cushion plate 25 is fixedly arranged on a bottom die 21 through a bolt 24; the guide block 26 is fixedly arranged on the cushion plate 25 through a bolt 212. As the connection mode of the guide block and the new lower die is optimized, and the cushion plate is additionally arranged, the fit clearance between the guide block and the movable block is adjusted, so that the movable block can be mounted and positioned more easily and expanded smoothly. As the connection mode of the guide block and the new lower die is optimized, and the cushion plate is additionally arranged, the movable block can be effectively expanded, therefore, the problem of the inner diameter inconsistency of the blank is solved, the change on the size of the blank after spinning is avoided, meanwhile, the rigid impact of the die on the wheel is also relieved.

Owner:CITIC DICASTAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com