Method for deburring a ceramic foundry core

A technology for ceramic cores and casting molds, which is applied in ceramic molding machines, manufacturing tools, and machine tools suitable for grinding the edges of workpieces, etc. Better trim quality, reduced number of initial cracks, good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

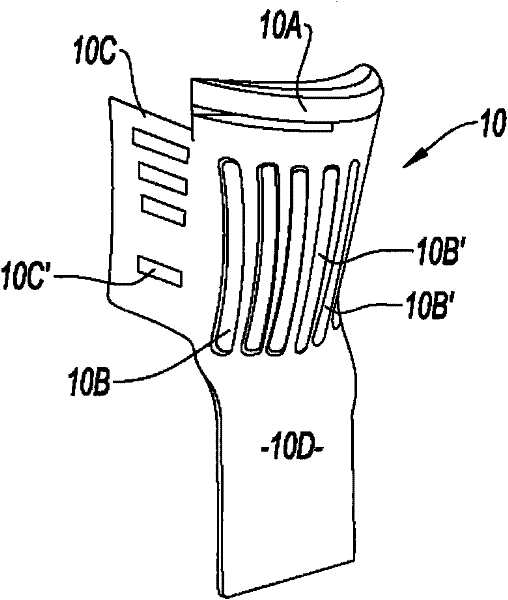

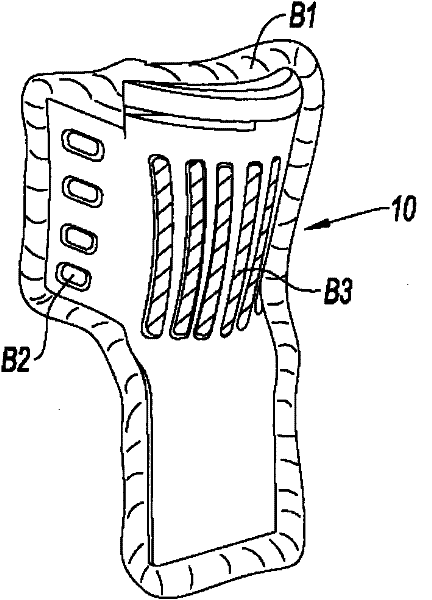

[0027] figure 1 The example components shown include core elements for a turbine hollow blade. The envelope of this element 10 has the shape of the melted-out cavity of a hollow blade. The element 10 comprises an upper part 10A which will form the slot part of the blade. The space separating this part from the central body 10B will form the upper transverse wall of the hollow blade. This central part 10B is continued downwards by a root 10D which serves to grip and secure the core in a shell mold which can be used to pour molten metal. The central part is hollowed out by longitudinal openings 10B' which will form internal partitions to define passages for cooling fluid through the blade cavities. The part 10B is continued laterally on one side by a thinner portion of the trailing edge 10C and includes an opening 10C' which will form a partition to set an outward opening along the trailing edge of the blade for emptying the cooling fluid. aisle. The core is used to be remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com