Adjusting mechanism for packaging device for paper boxes of different specifications and sizes

An adjustment mechanism and size adjustment technology, applied in packaging and other directions, can solve problems such as inability to perform carton packaging operations, inability to locate and control cartons, and achieve good neutrality, high transmission ratio, and low transmission vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

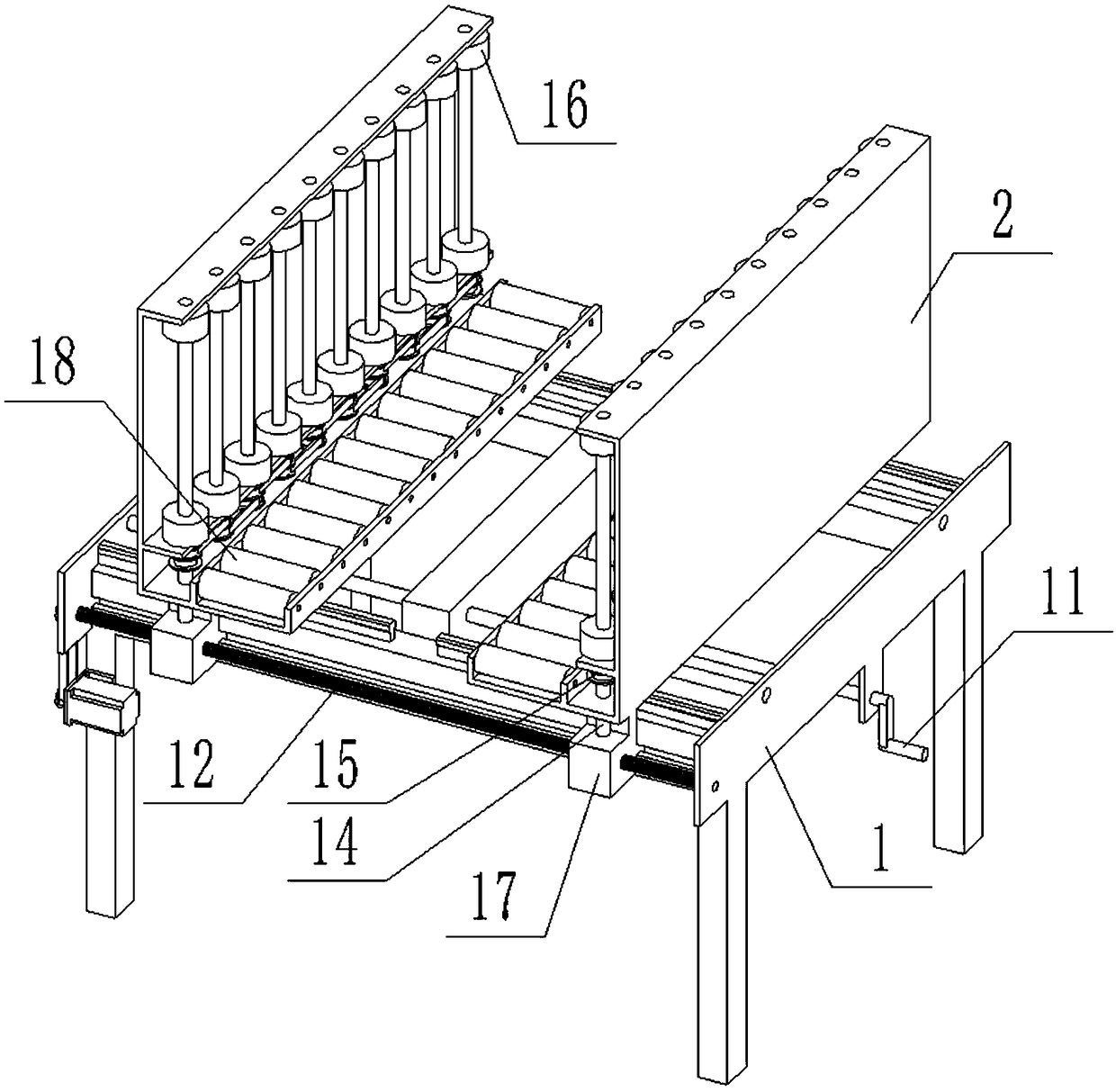

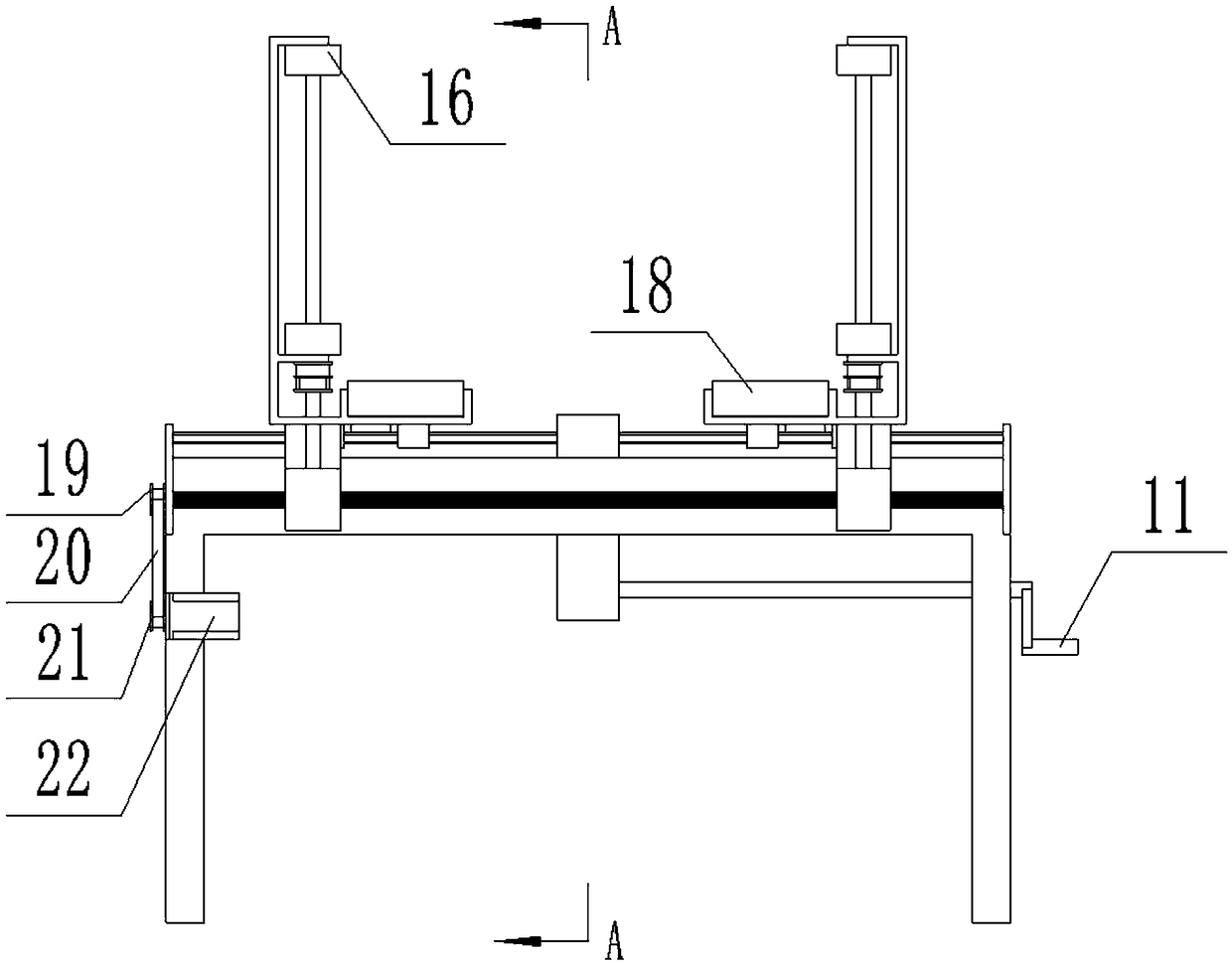

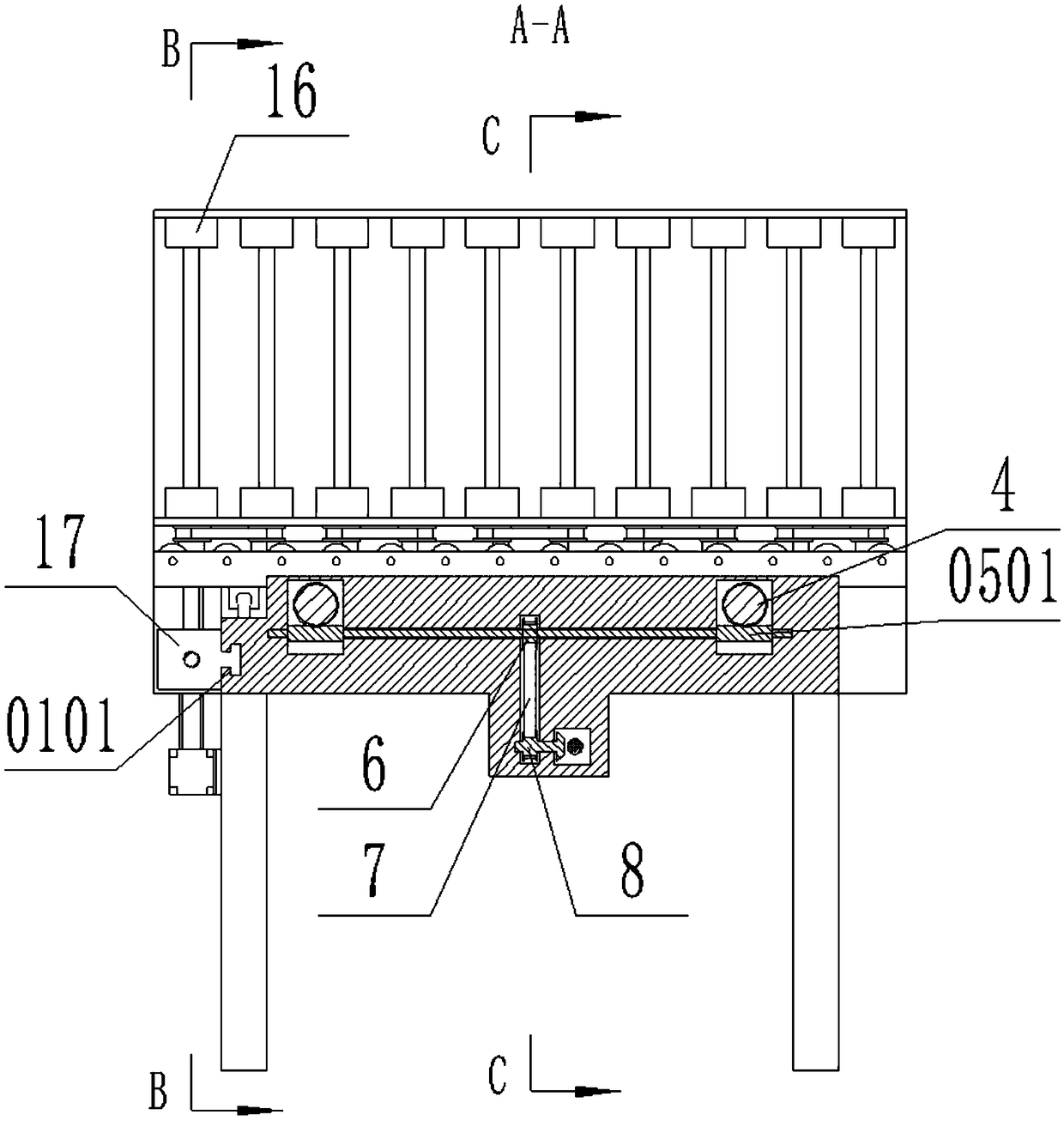

[0033] as attached figure 1 to attach Figure 8 Shown:

[0034]The present invention provides an adjustment mechanism for carton packaging devices of different specifications and sizes, including: a base 1, a T-shaped slot 0101, a square rail 0102, a sliding bracket 2, a lead screw 3, a worm wheel 4, a transmission center shaft 5, a worm 0501, and a Driving pulley 6, transmission belt 7, driving pulley 8, size adjustment driven bevel gear 9, size adjustment driving bevel gear 10, handle 11, spline shaft 12, driving driving bevel gear 13, spline groove 1301, driving shaft 14, guide driven bevel gear 1401, guide pulley 15, guide pulley 16, guide transmission box 17, T-shaped slide block 1701, bottom roller 18, guide driven pulley 19, guide transmission belt 20, The driving pulley 21 and the driving motor 22 are driven; a group of sliding brackets 2 are slidably connected to the left and right sides of the top of the base 1; a group of lead screws 3 are connected to the front a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com