Manual spring tension and compression testing machine

A testing machine, stretching and compressing technology, applied in elastic testing, testing of machine/structural components, measuring devices, etc., can solve the problems of inapplicability to on-site operations, manual misoperation, high purchase cost, etc., to achieve accurate and convenient readings, The effect of expanding the hand force and simplifying the structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in detail below in conjunction with accompanying drawing:

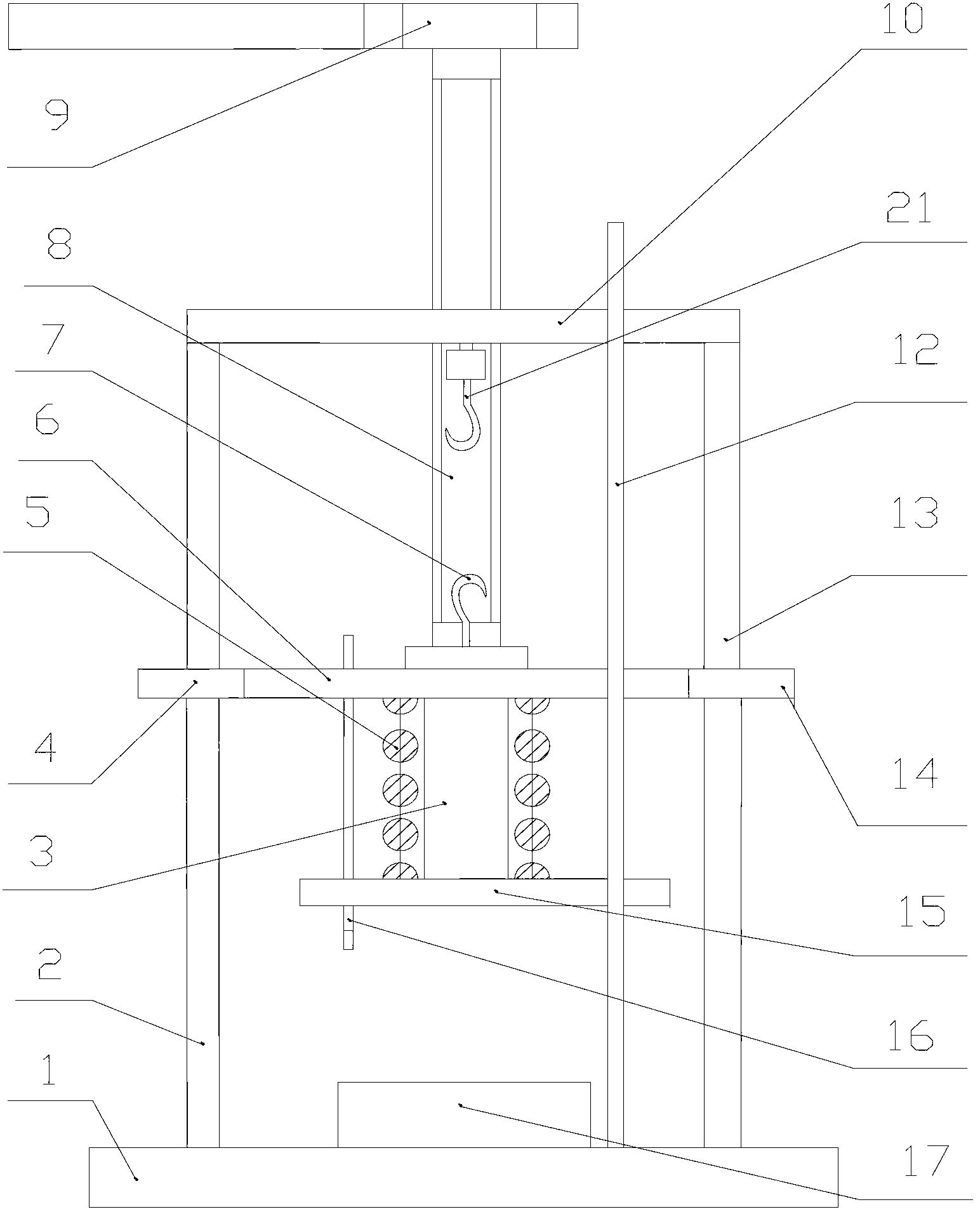

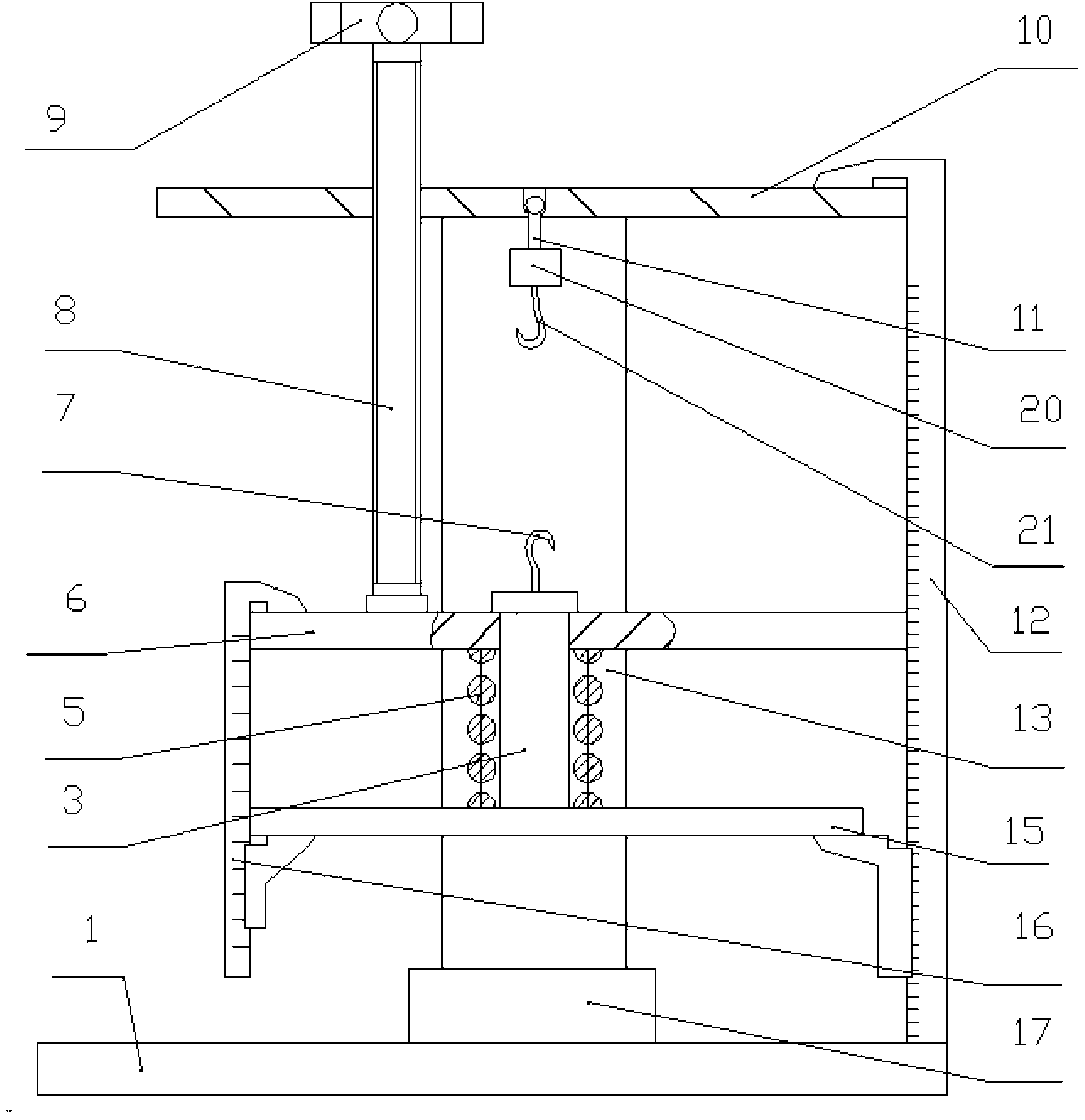

[0025] Such as figure 1 and figure 2 As shown, the manual spring tension-compression testing machine of the present invention includes a frame, a measuring mechanism, a transmission mechanism and a tension-compression fixture mechanism.

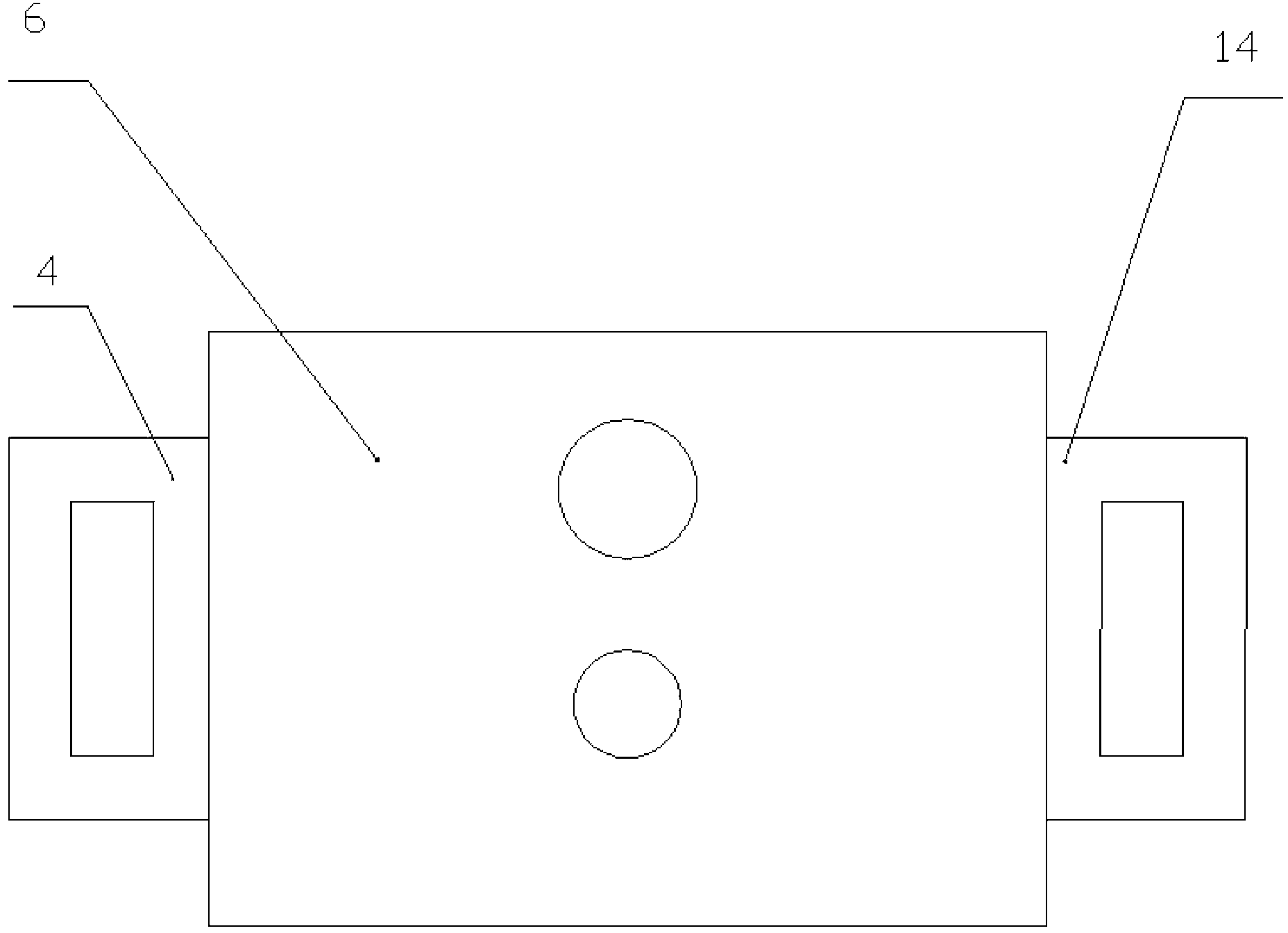

[0026] Described frame is made up of base 1, left linear guide rail 2, right linear guide rail 13, upper beam 10, middle beam 6, left connecting sleeve 4 and right connecting sleeve 14.

[0027] The measuring mechanism is composed of a large-range vernier caliper 12 , a small-range vernier caliper 16 and a spring 5 .

[0028] The transmission mechanism is composed of a transmission screw 8, a screw nut 18, a handle 9, a bearing cover bolt 22, a bearing cover 23 and two angular contact ball bearings 19 with the same structure.

[0029] The base 1 is a rectangular flat structure, which facilitates the placement of the manual spring tension ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com