Patents

Literature

254results about How to "Low manufacturing and maintenance costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

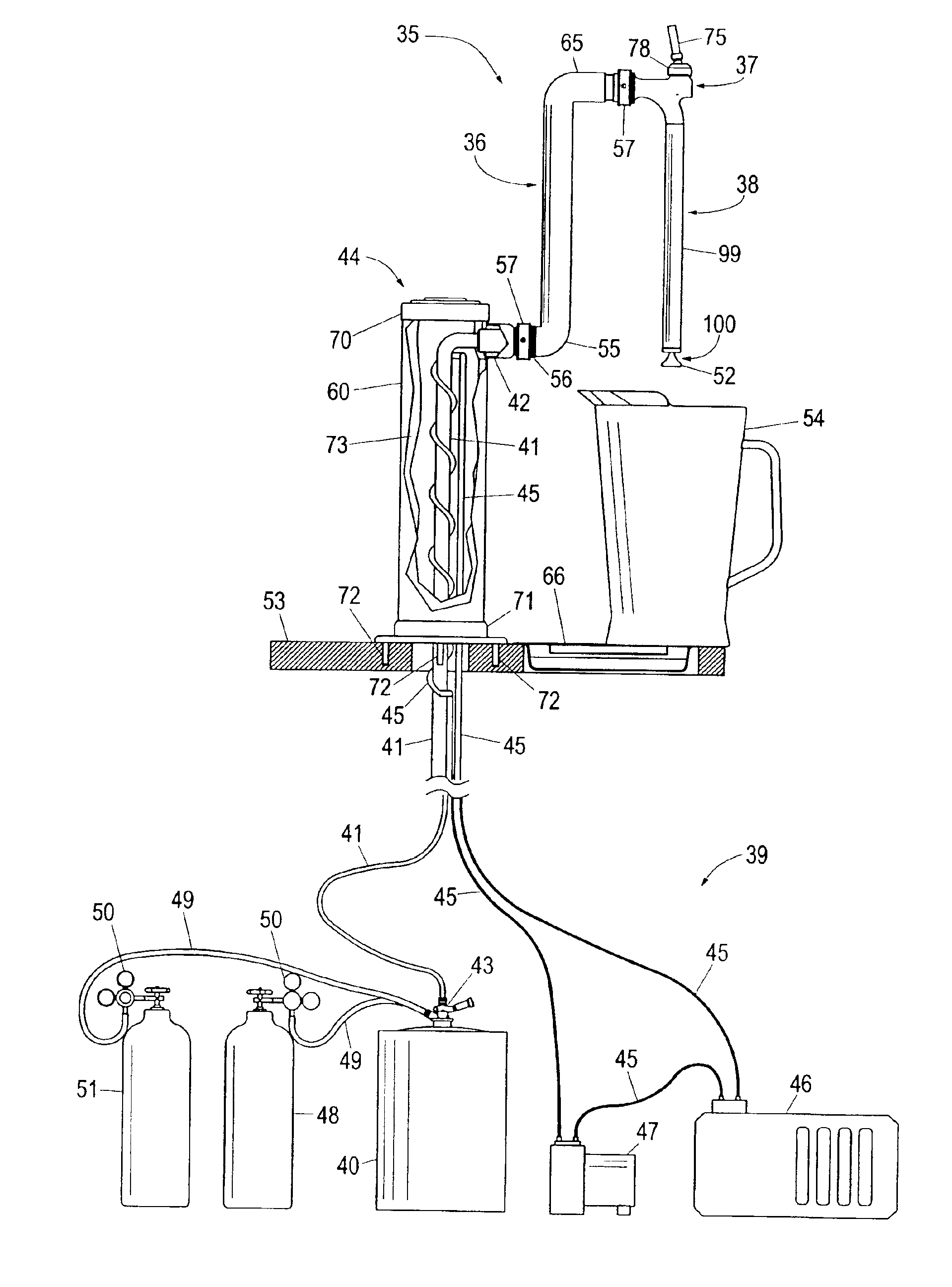

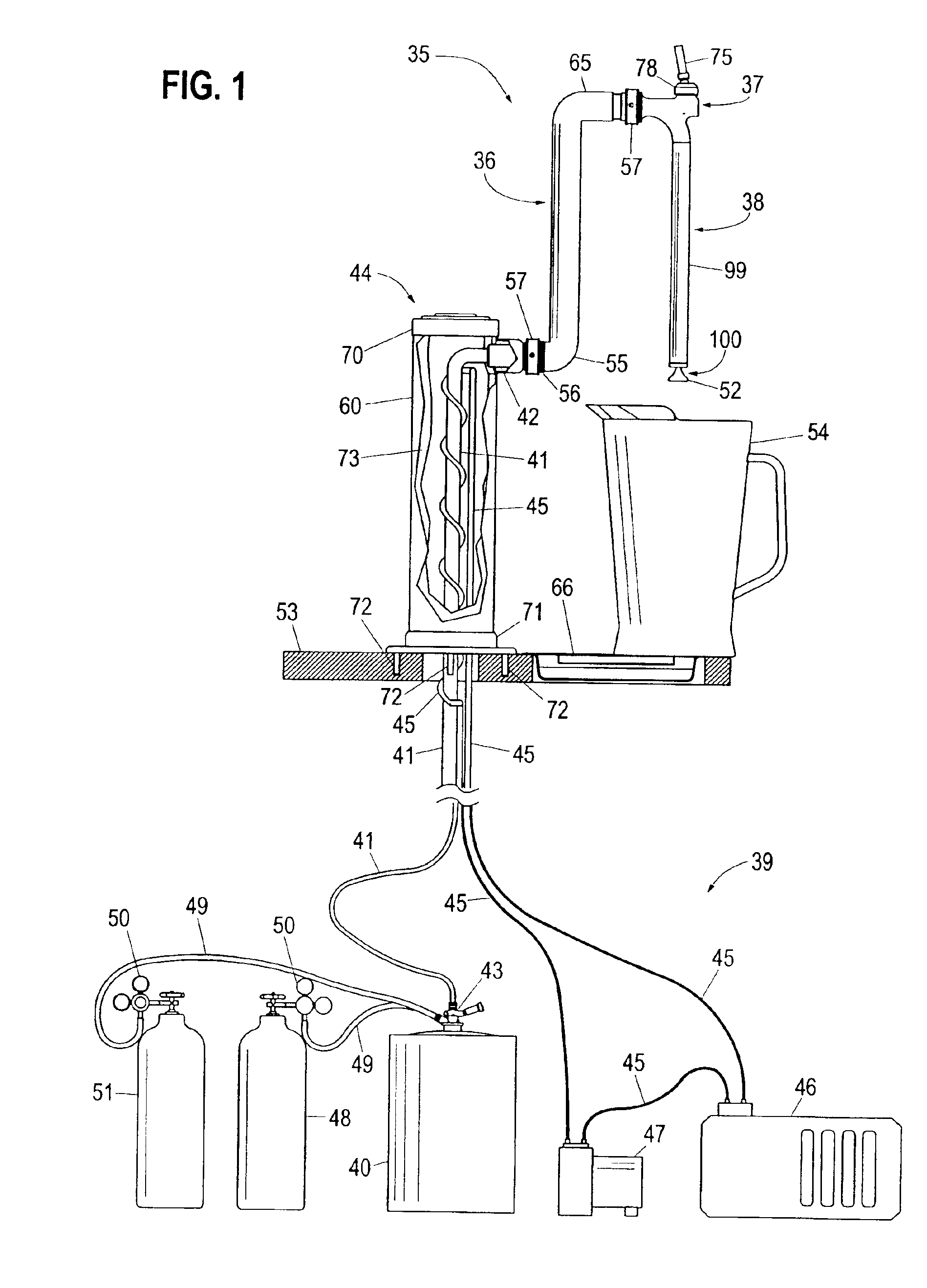

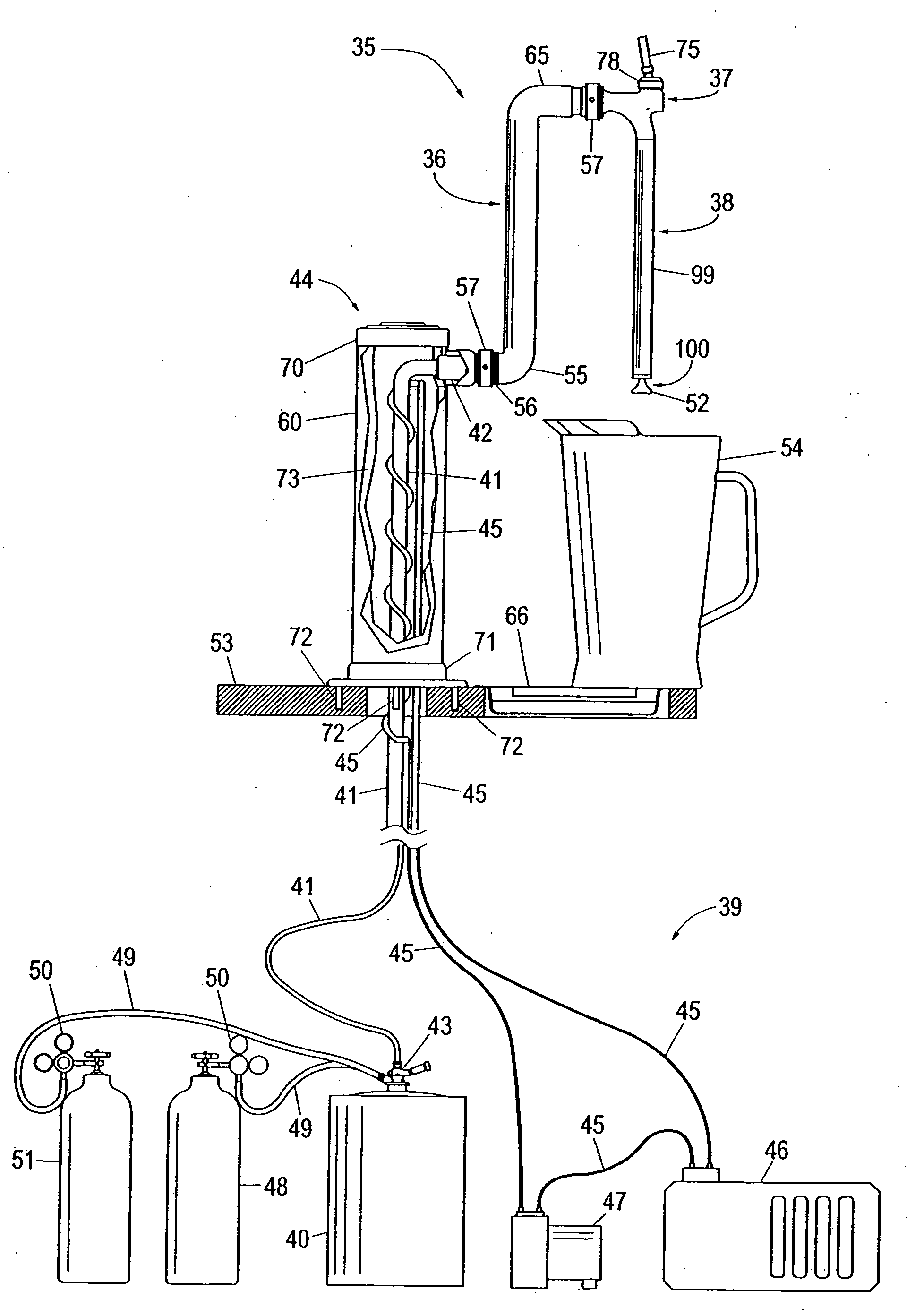

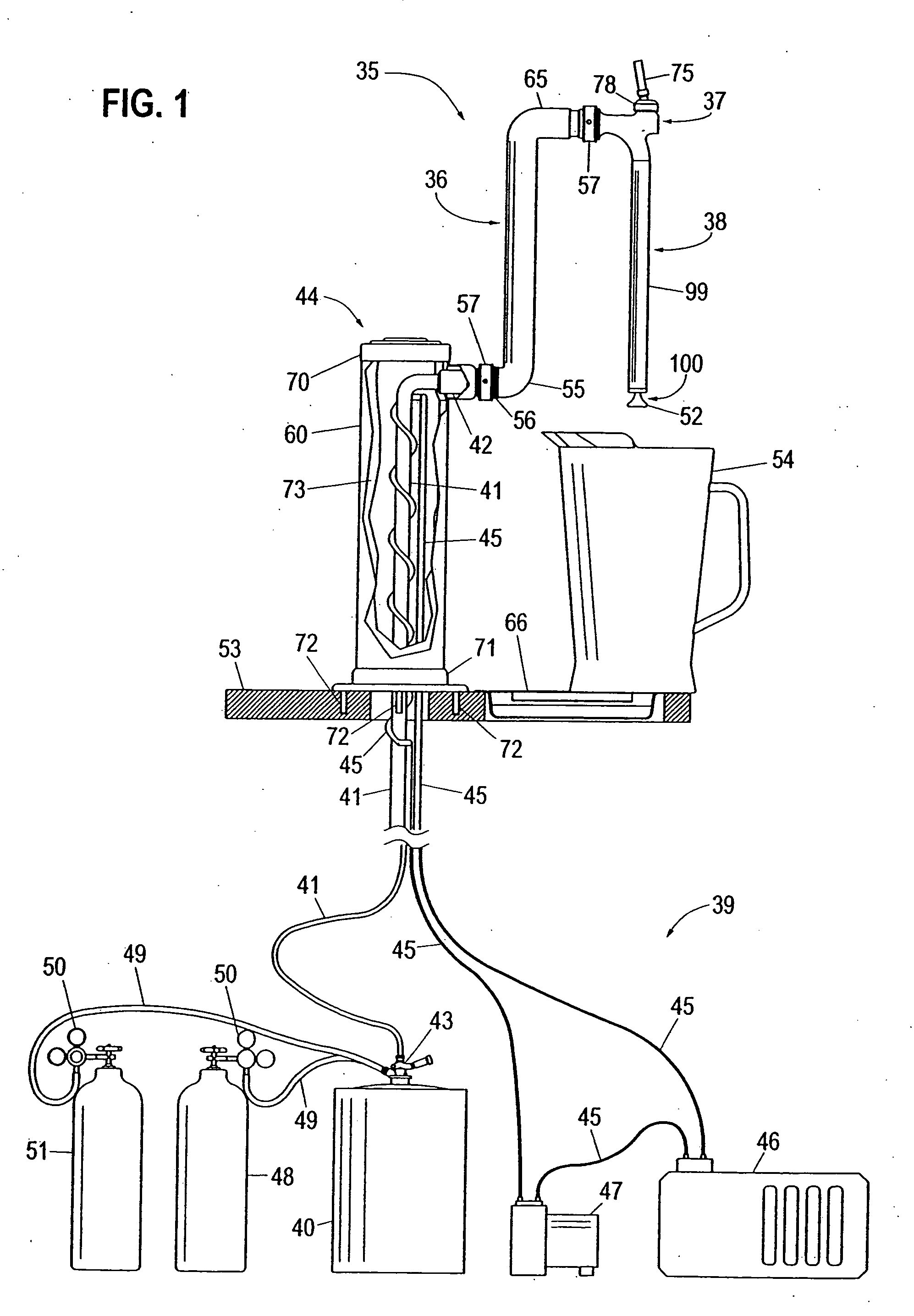

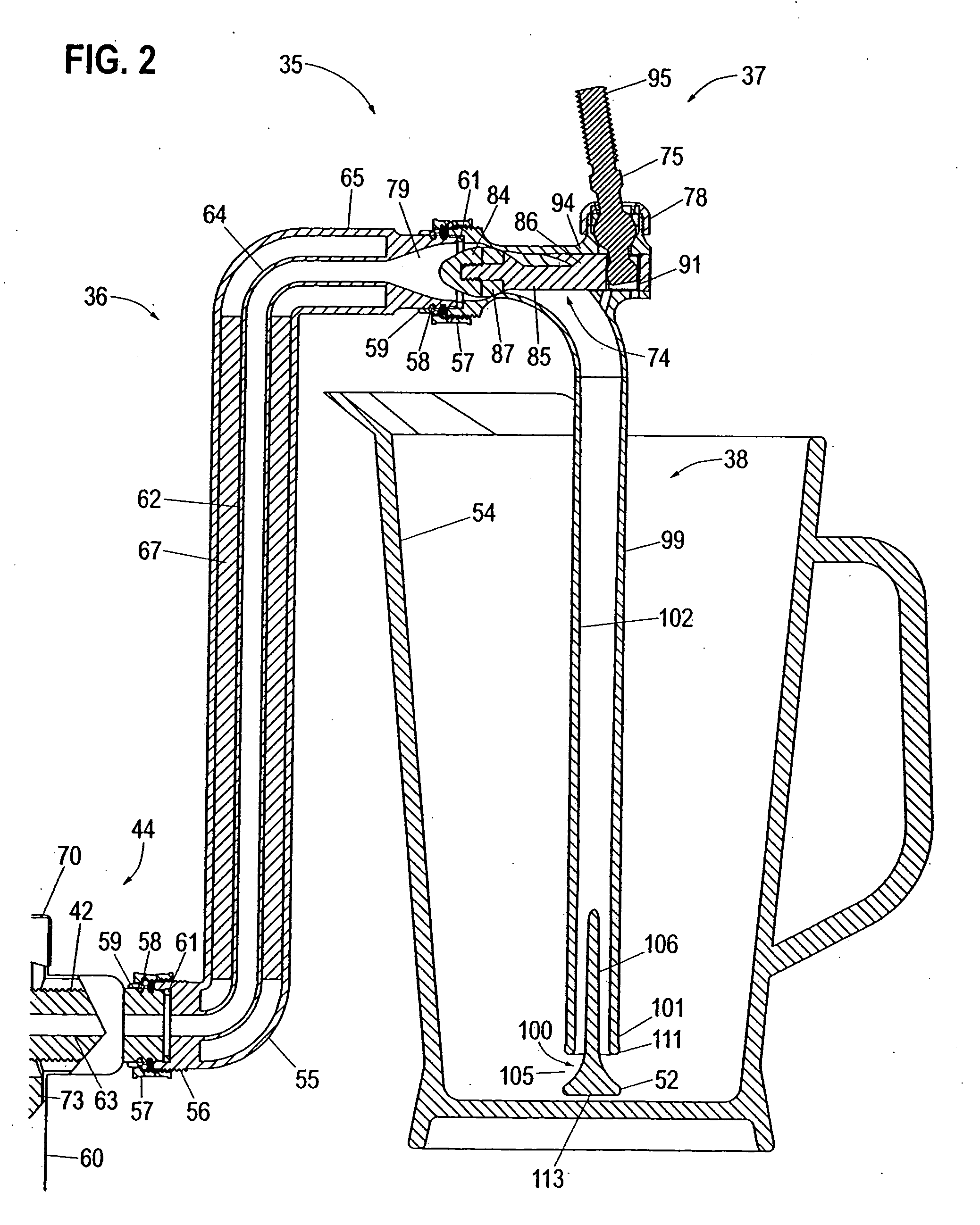

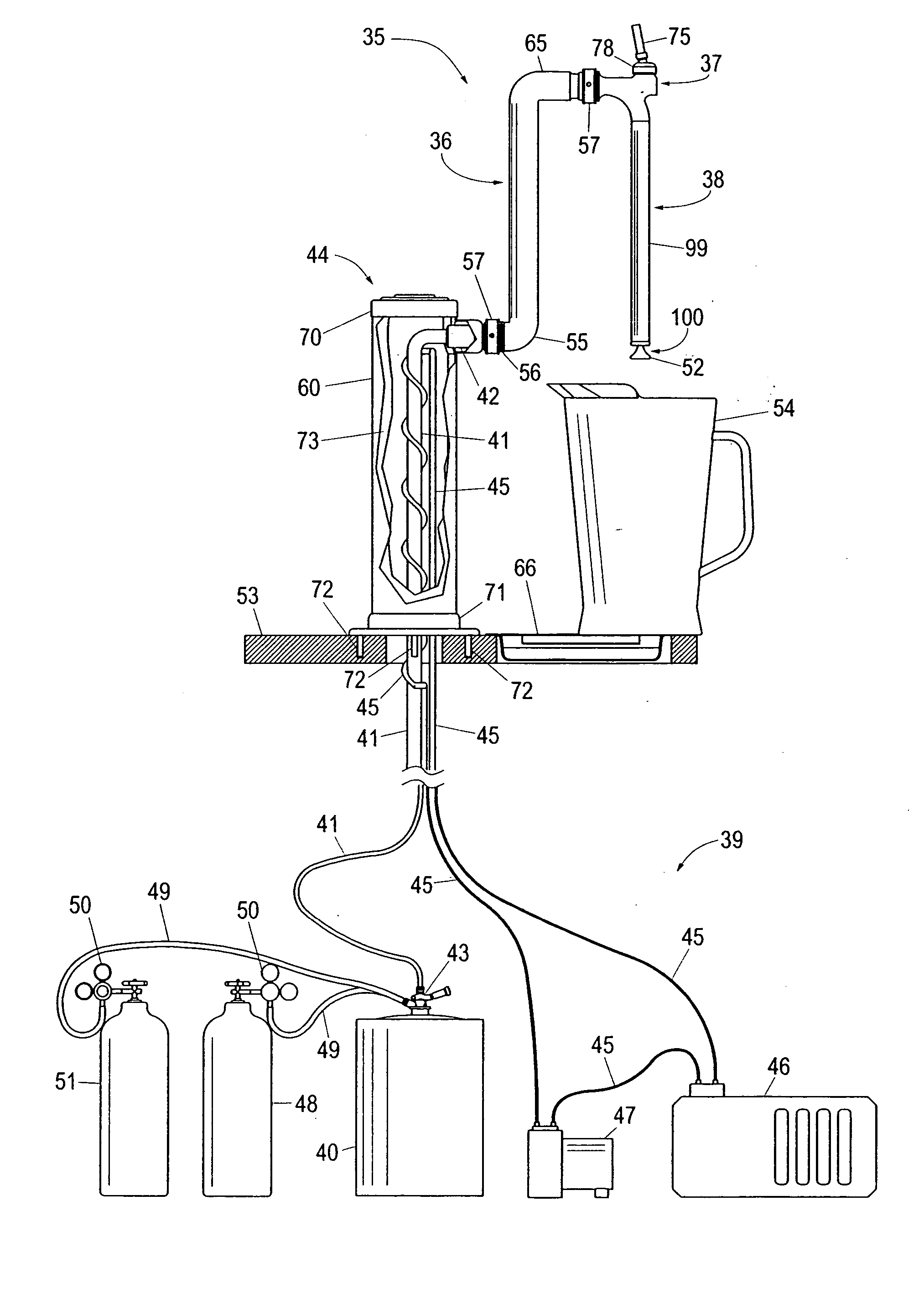

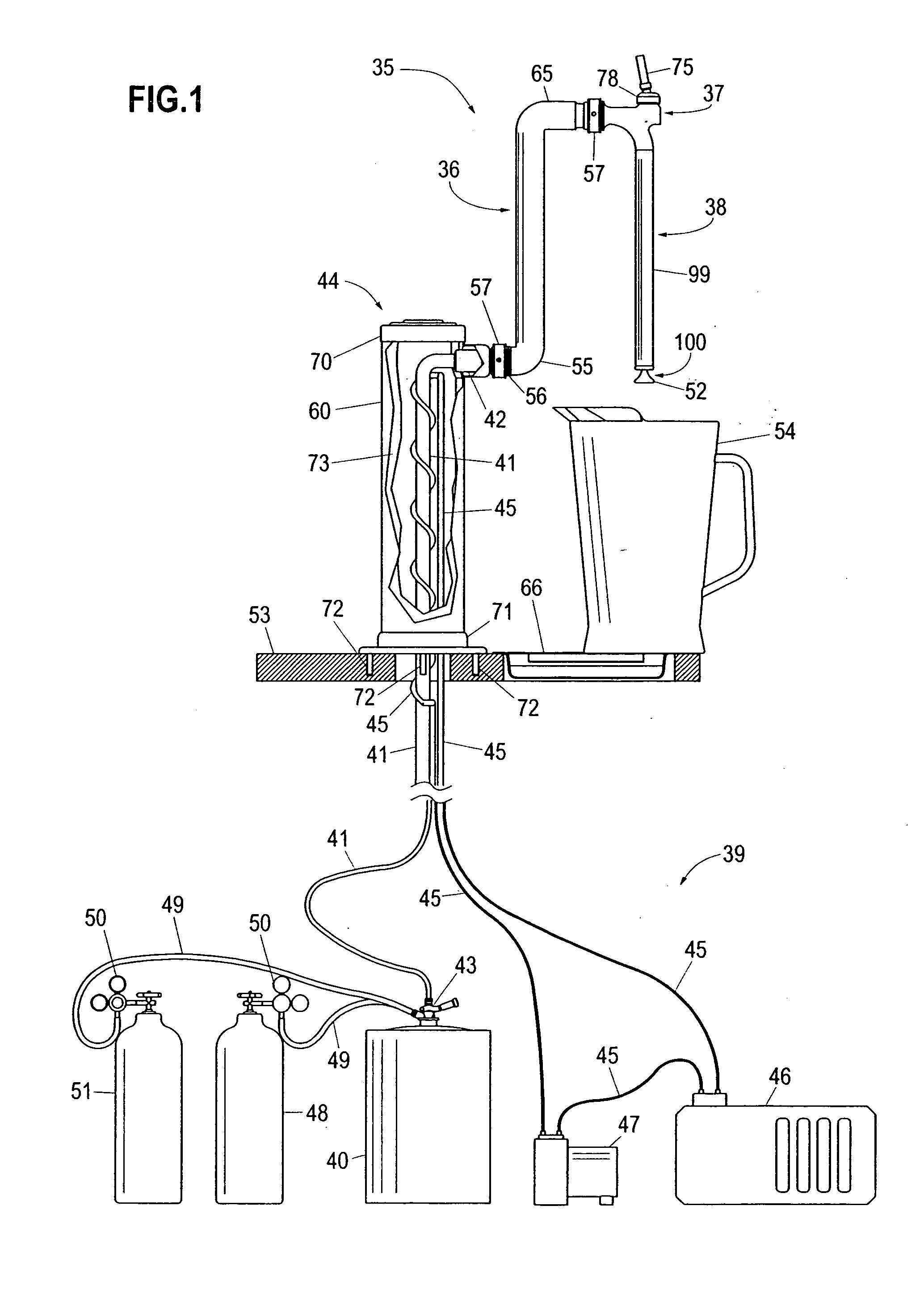

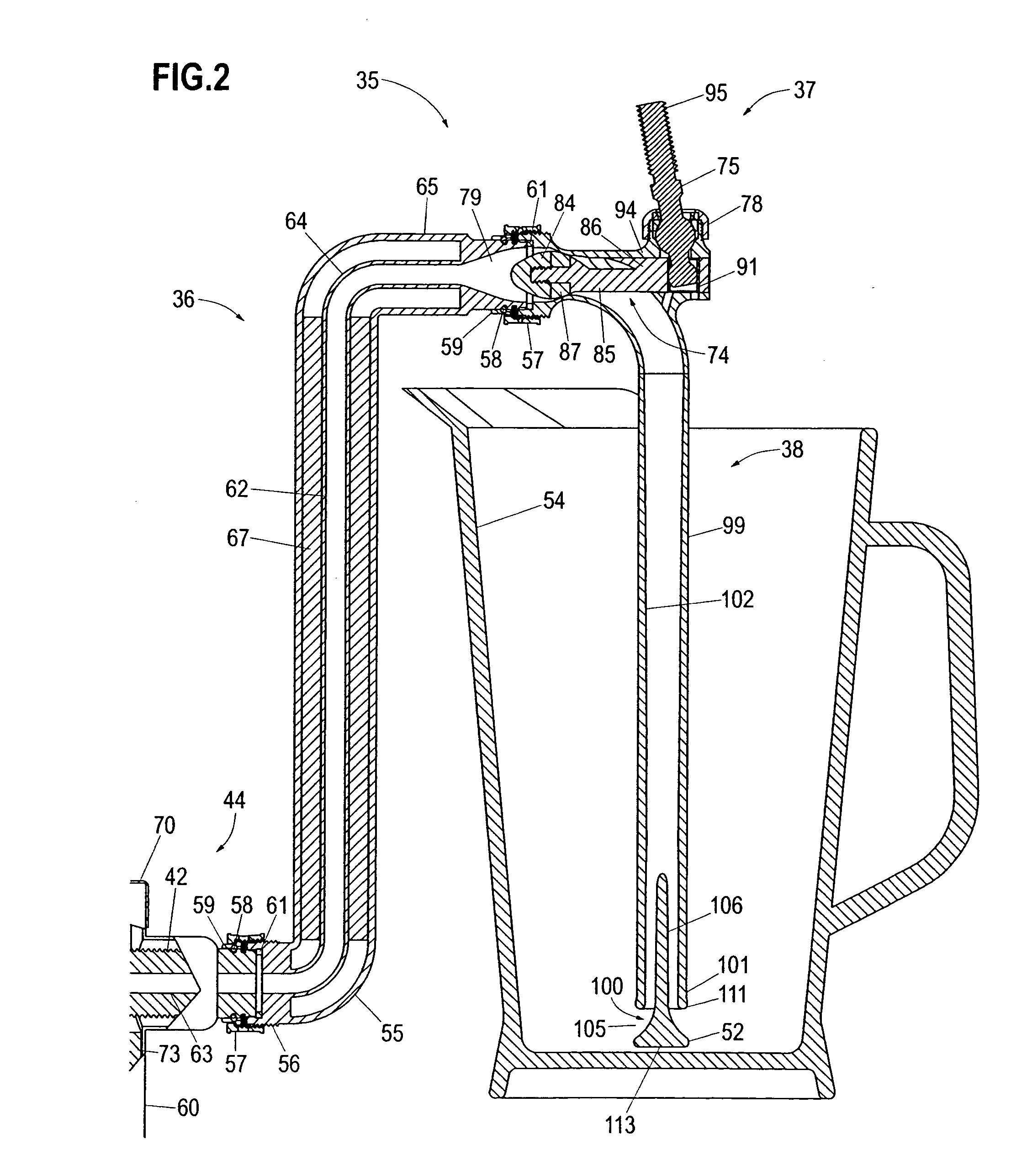

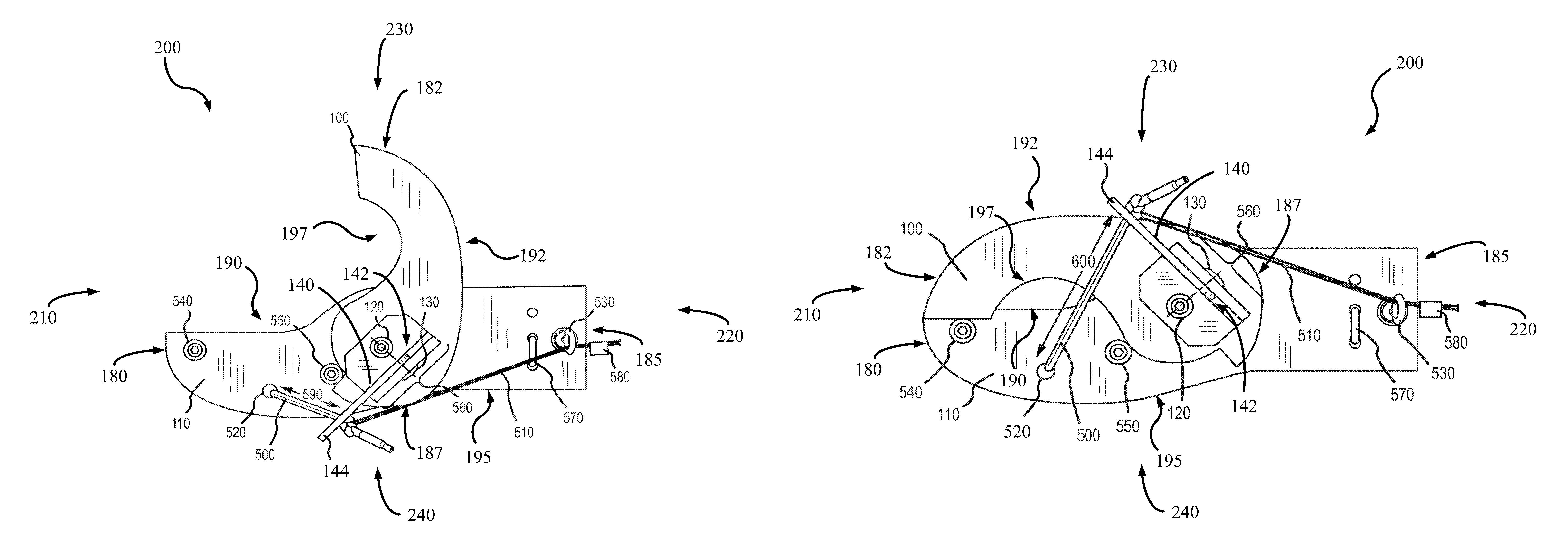

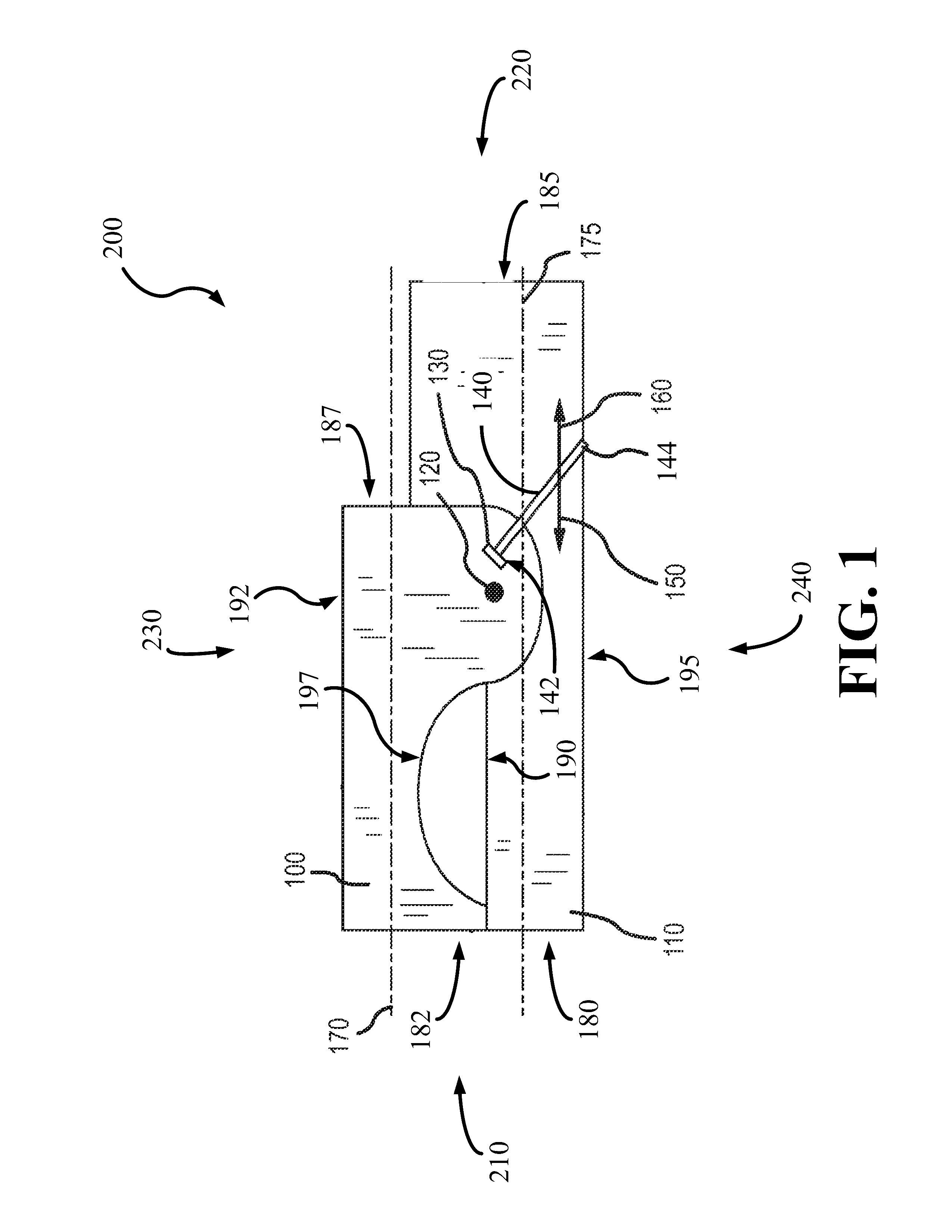

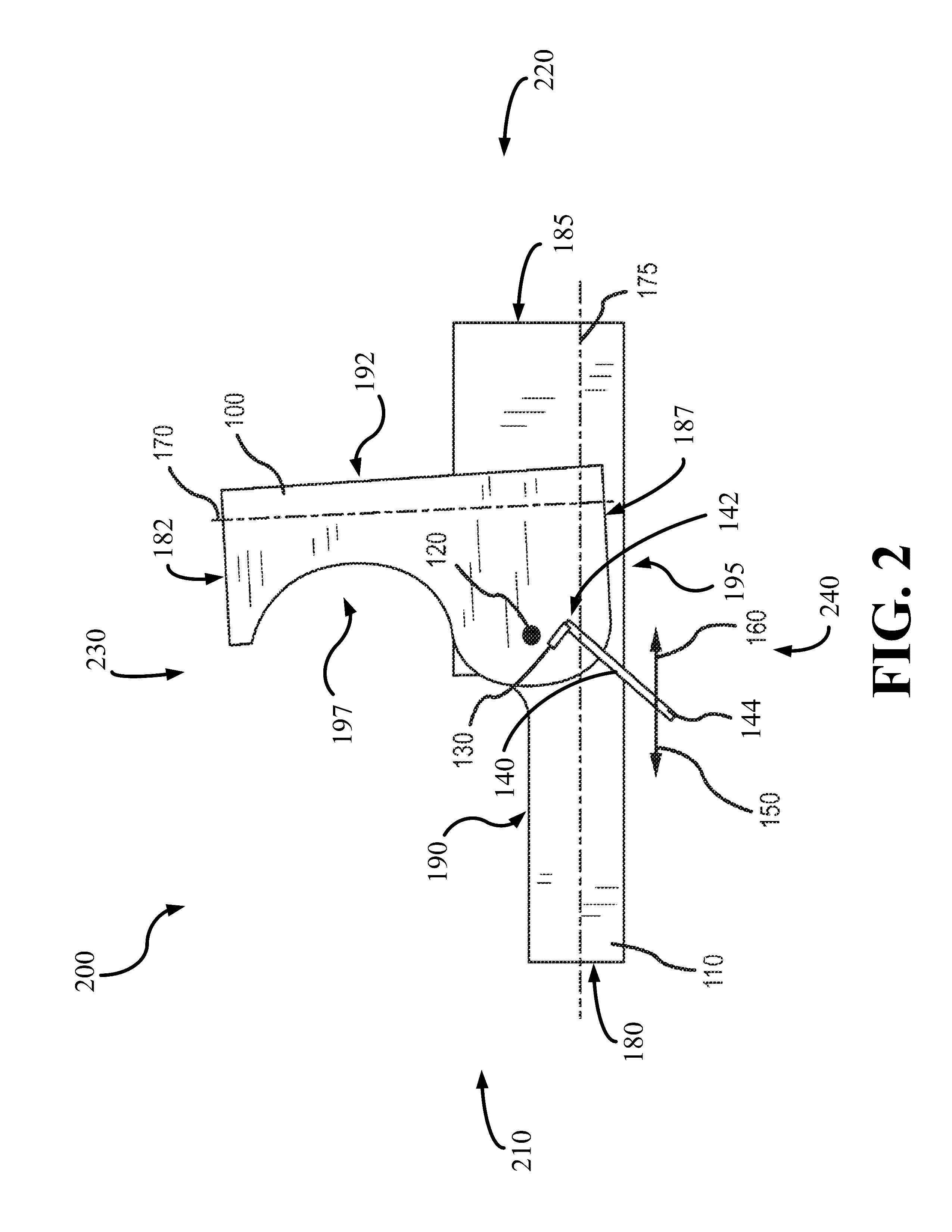

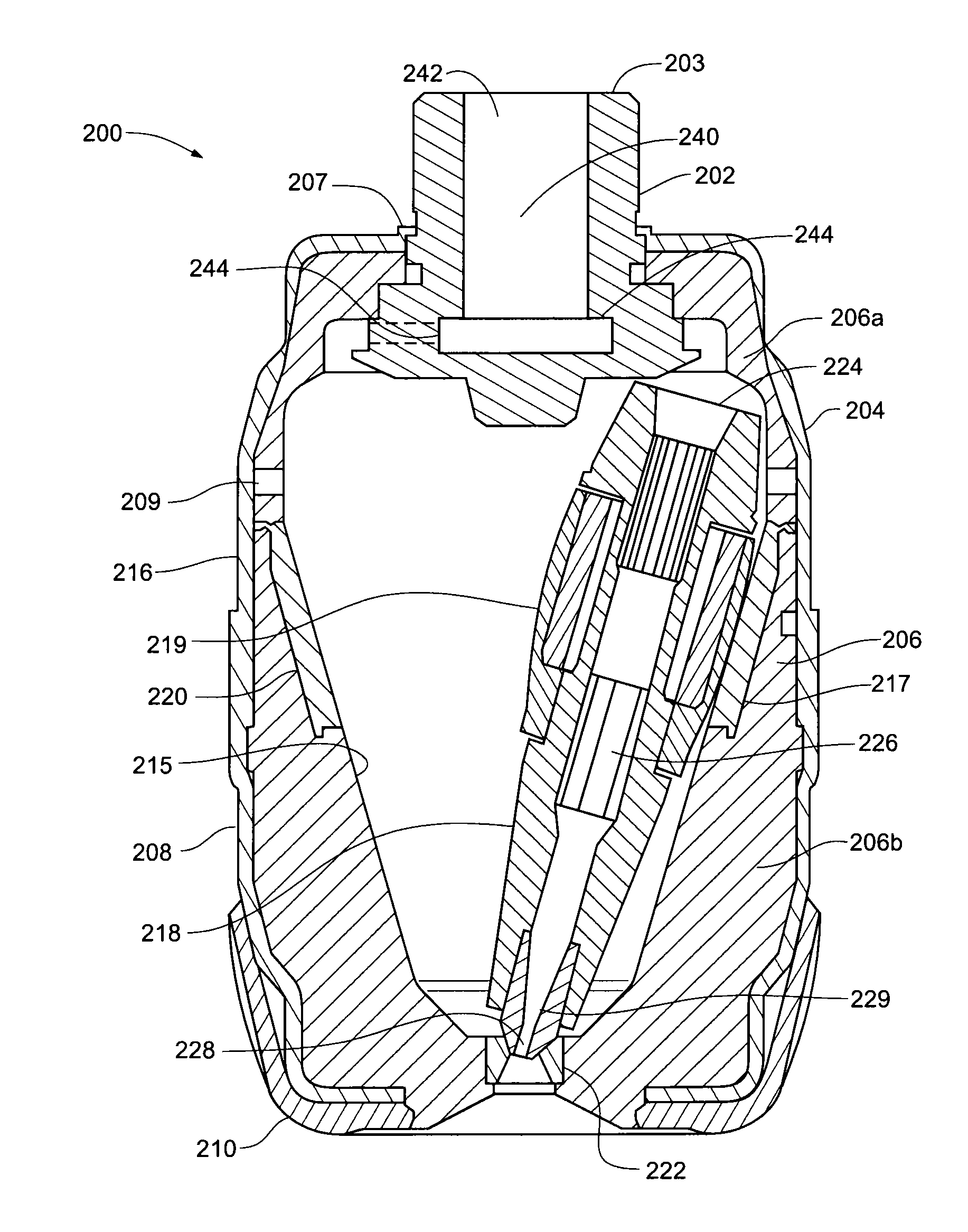

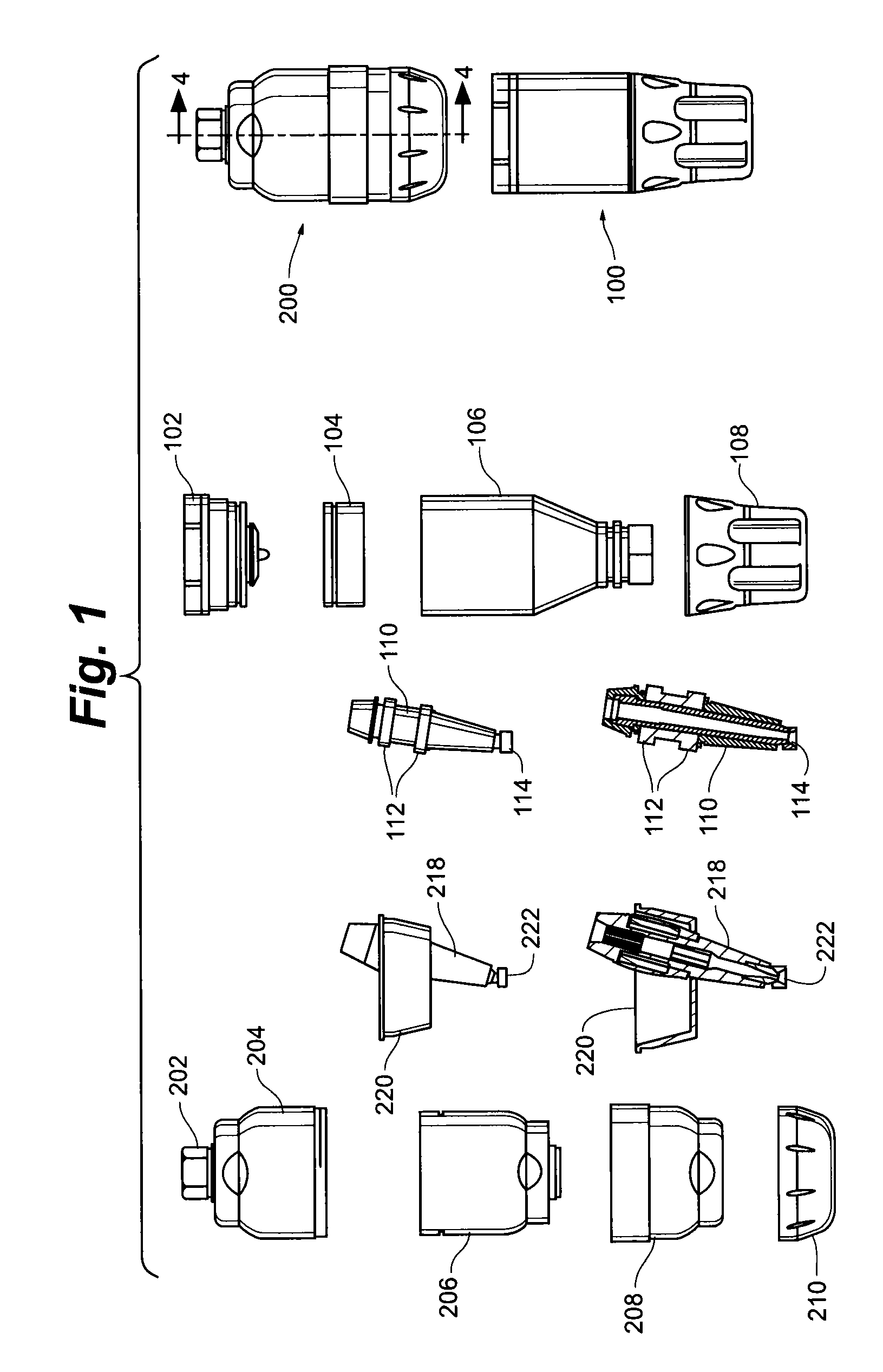

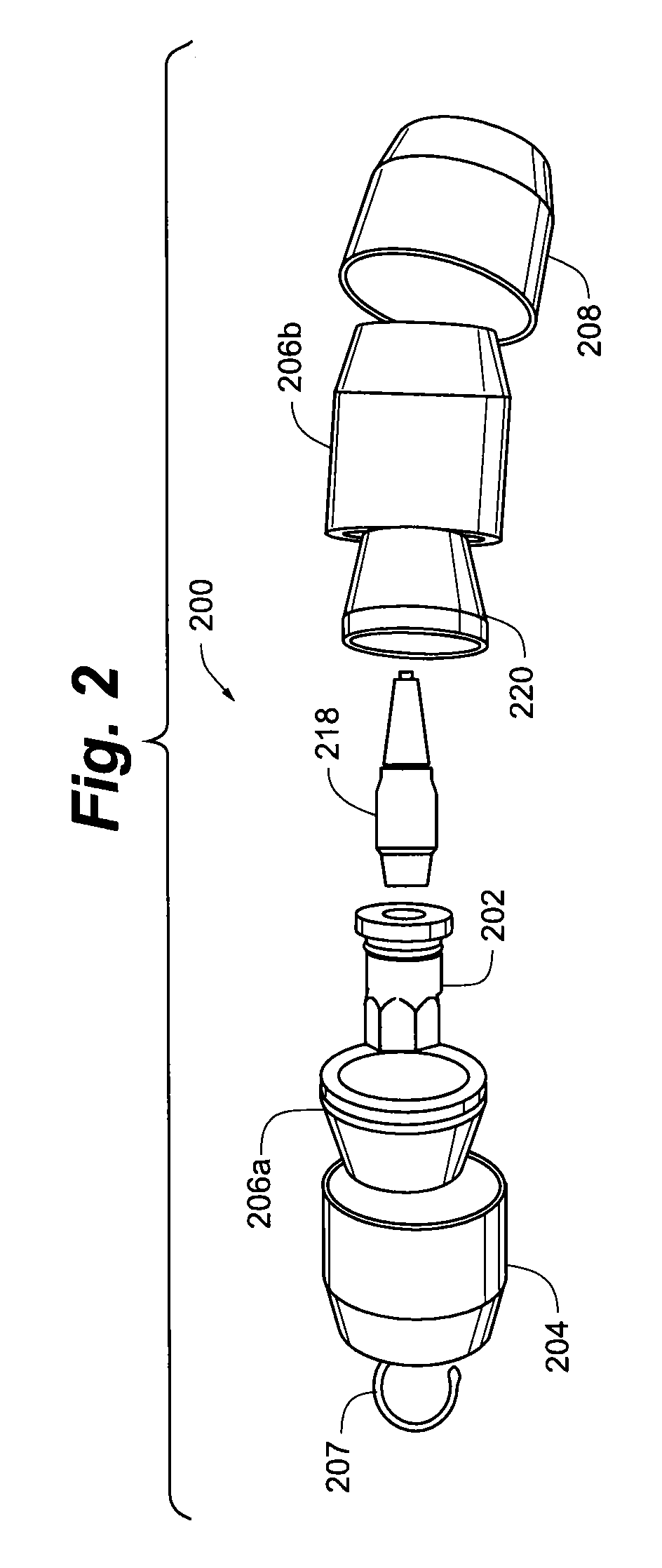

Beverage dispensing apparatus

InactiveUS7040359B2Low manufacturing and maintenance costsReduce the cross-sectional areaBarrels/casks fillingLiquid flow controllersEngineeringNozzle

A removable nozzle for attachment to a conventional faucet of a beverage dispensing device to permit the dispensing of a pressurized beverages at a high flow rate without producing excessive foaming comprising a streamlined valve assembly and a downward extending nozzle assembly which permits a range of containers to be filled from the bottom.

Owner:LAMINAR TECH

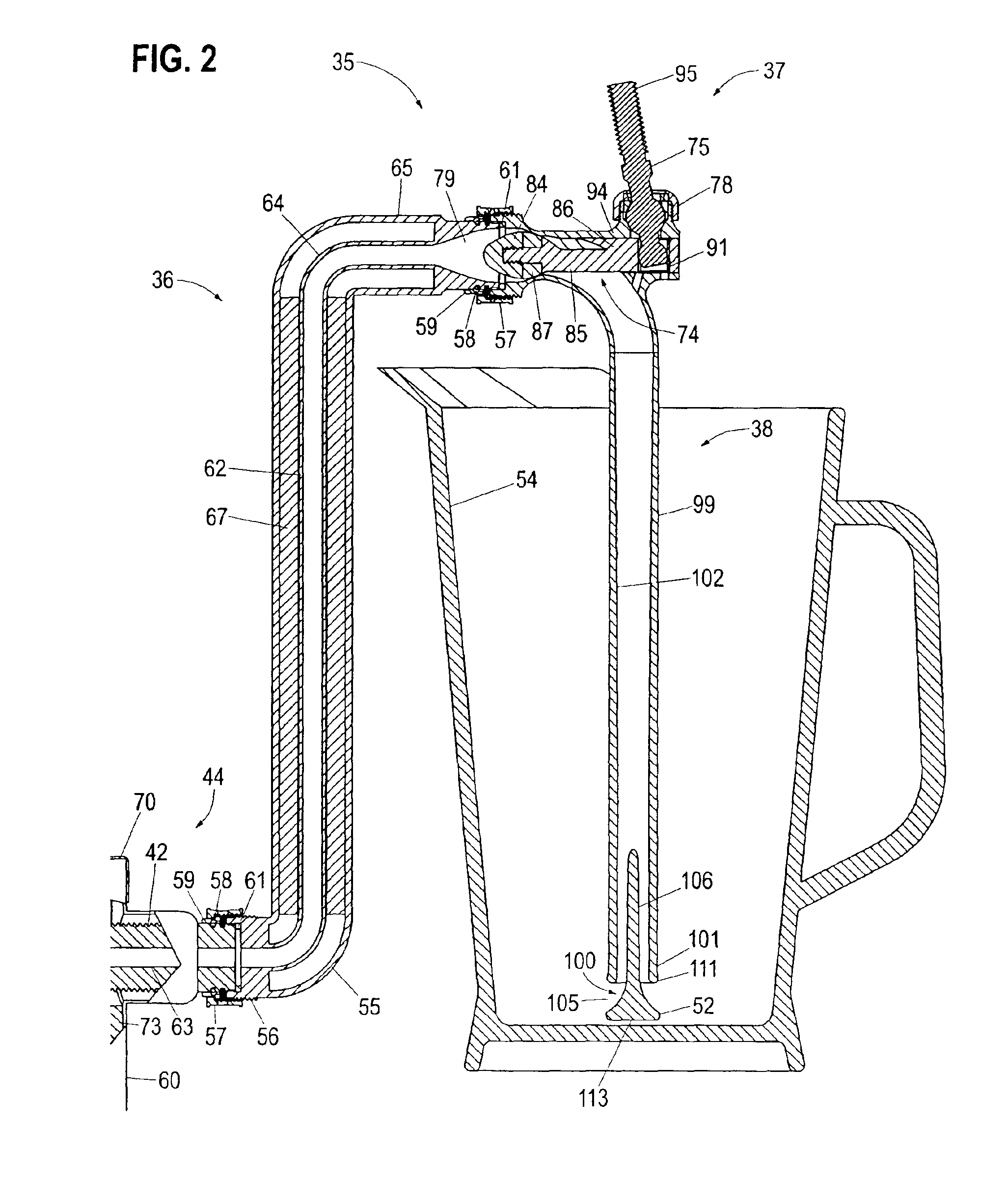

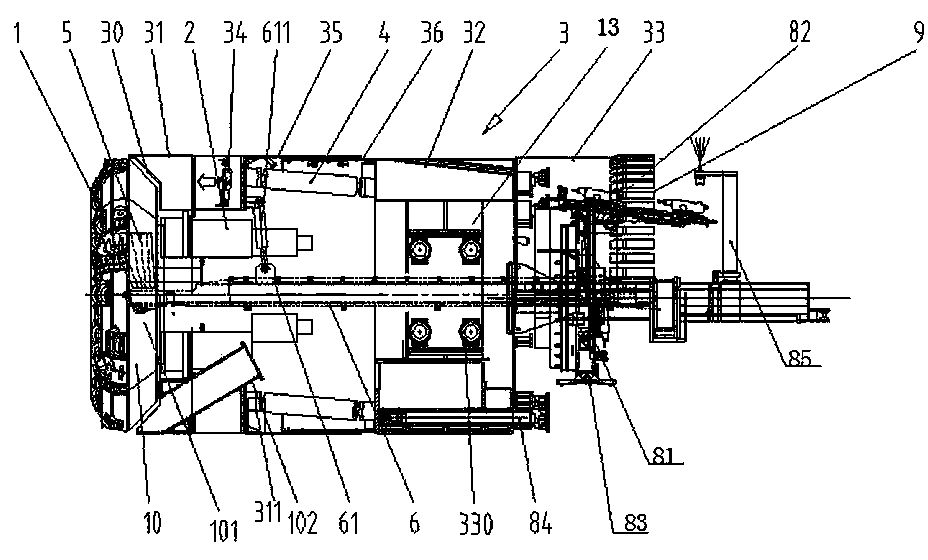

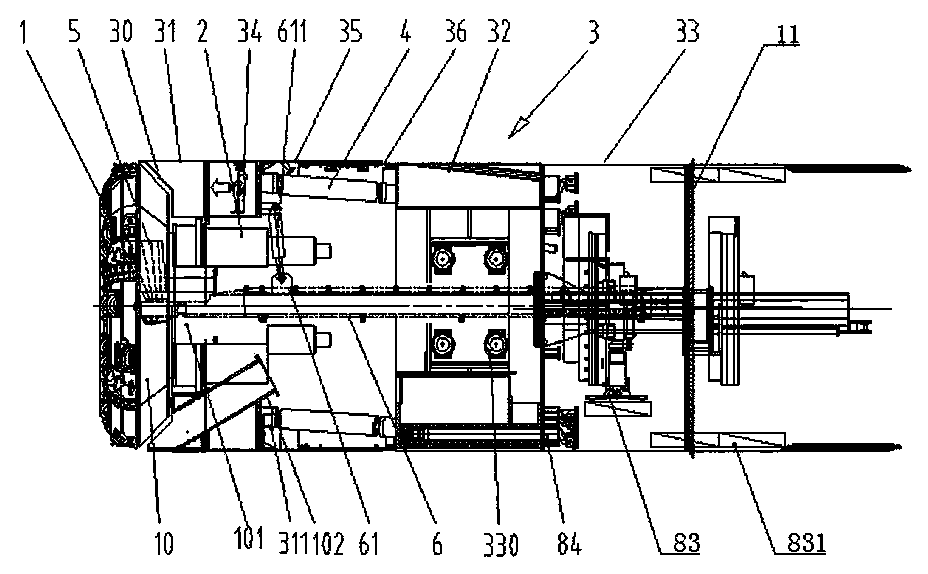

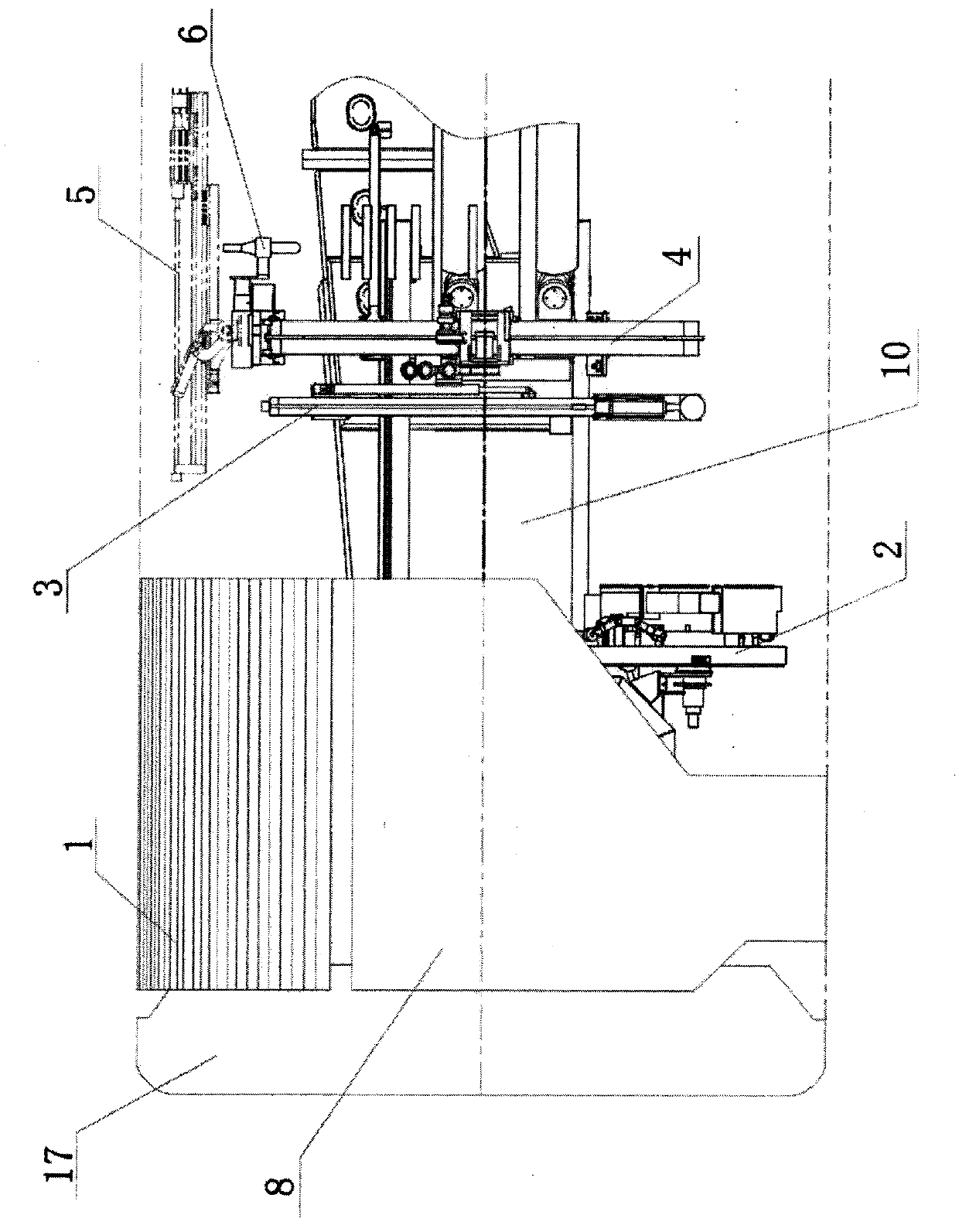

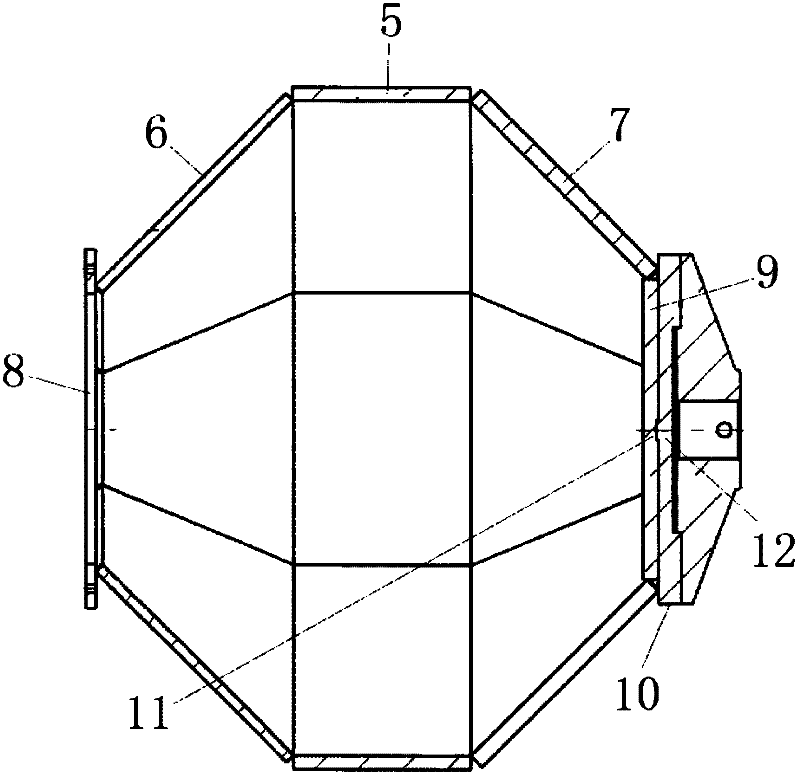

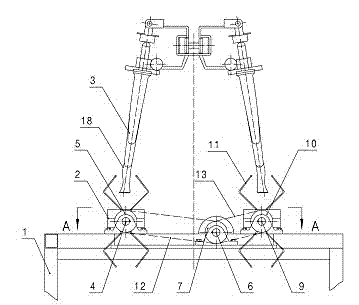

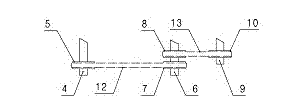

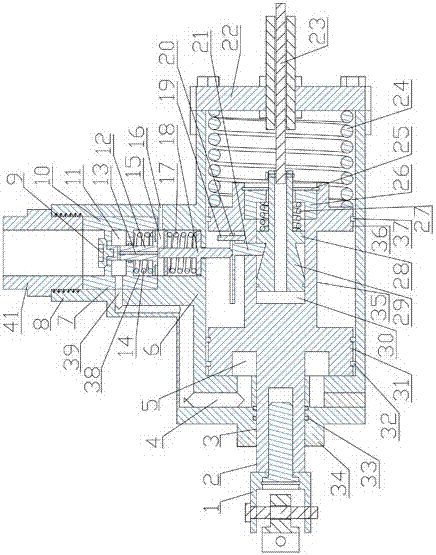

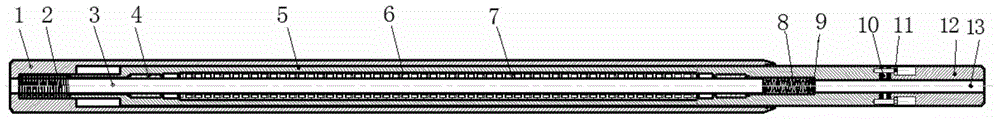

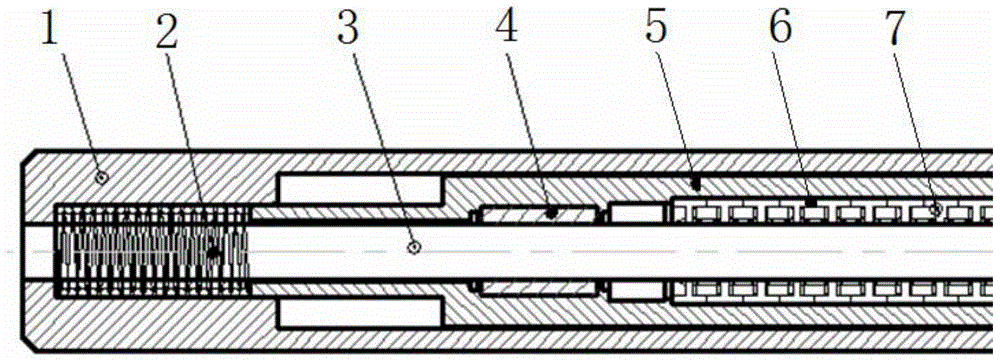

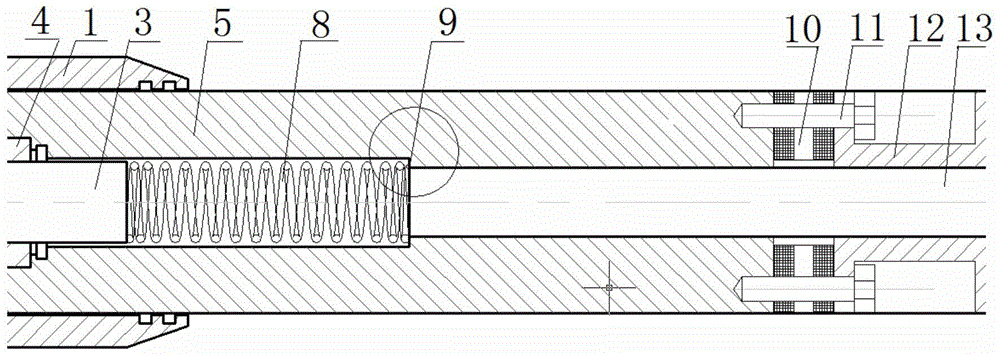

Combined type double-shield tunneling machine

ActiveCN104196538AIncrease the lengthShorten the lengthUnderground chambersTunnel liningSupporting systemDual mode

The invention discloses a combined type double-shield tunneling machine which comprises a cutter, an anterior shield, a cab, a main driving device, an inside-and-outside stretching shield, a V-shaped arrangement main propelling system, a hinge system, a supporting shield, a boot supporting system, a tail shield, an auxiliary propelling system, a dual-mode deslagging system, an integration supporting system and the like. Four working modes including of the double shielding modes including the support boot and segmental lining mode and the support boot and anchor-plate timbering mode, the single shielding mode and the ERB mode can be achieved, and efficient tunneling, efficient deslagging and efficient timbering are achieved under the hard rock, sandy soil and soft soil geological conditions. The combined type double-shield tunneling machine has the outstanding advantages that one device can meet various complex-geology tunneling construction requirements, the geology applicability of the tunneling machine is greatly improved, the frequency of tunneling machine replacement in tunnel construction is decreased, and production efficiency is greatly improved.

Owner:中船(青岛)轨道交通装备有限公司

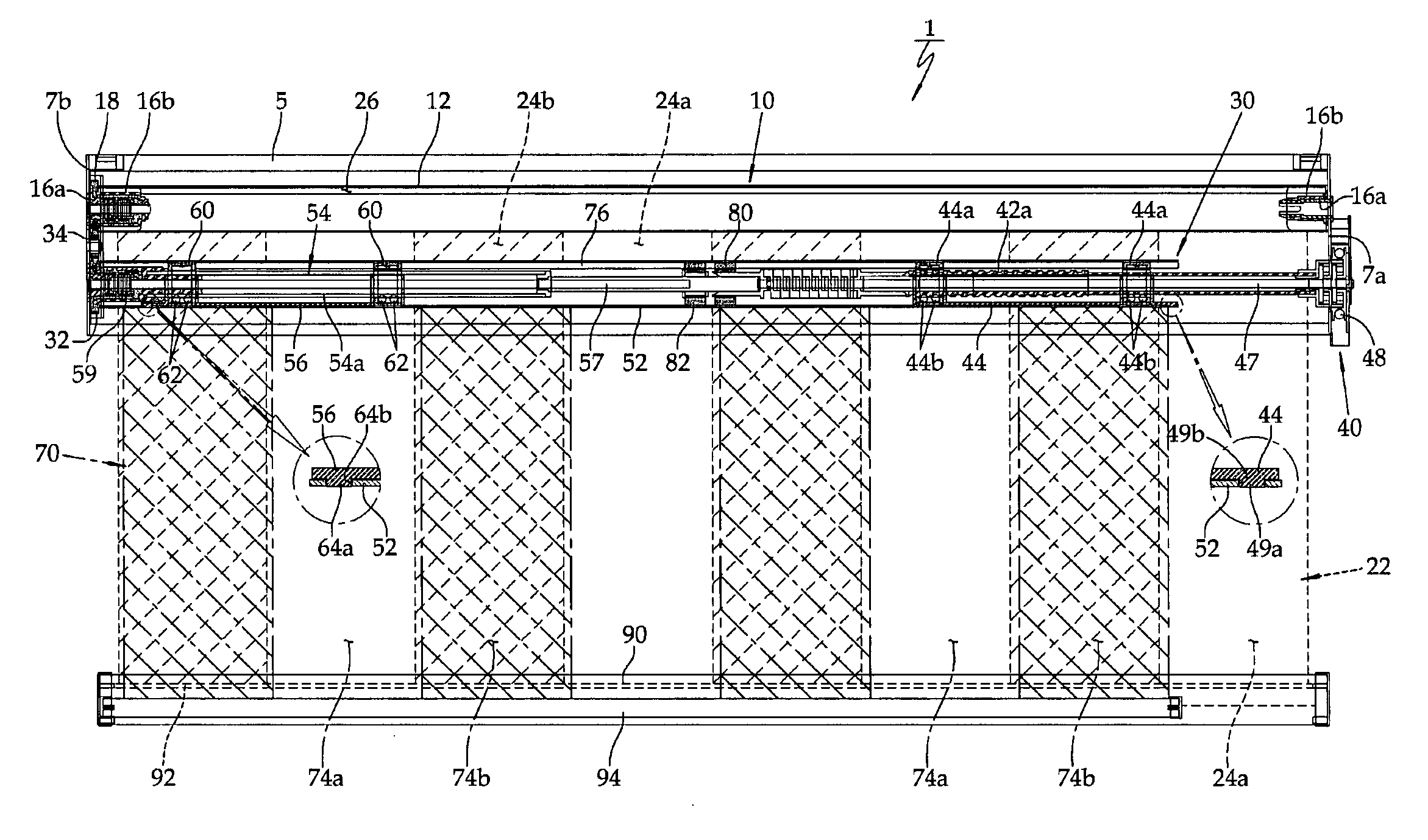

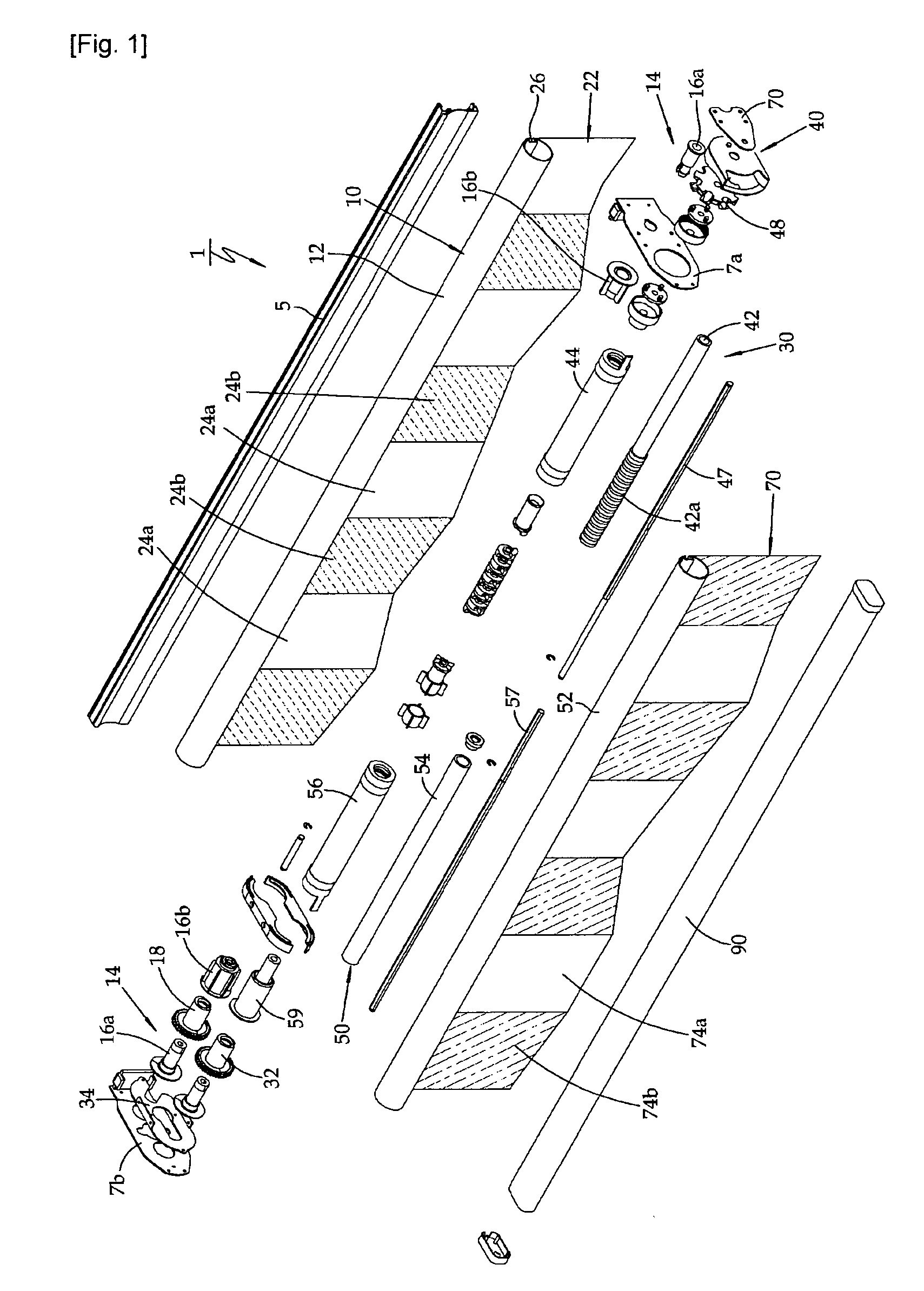

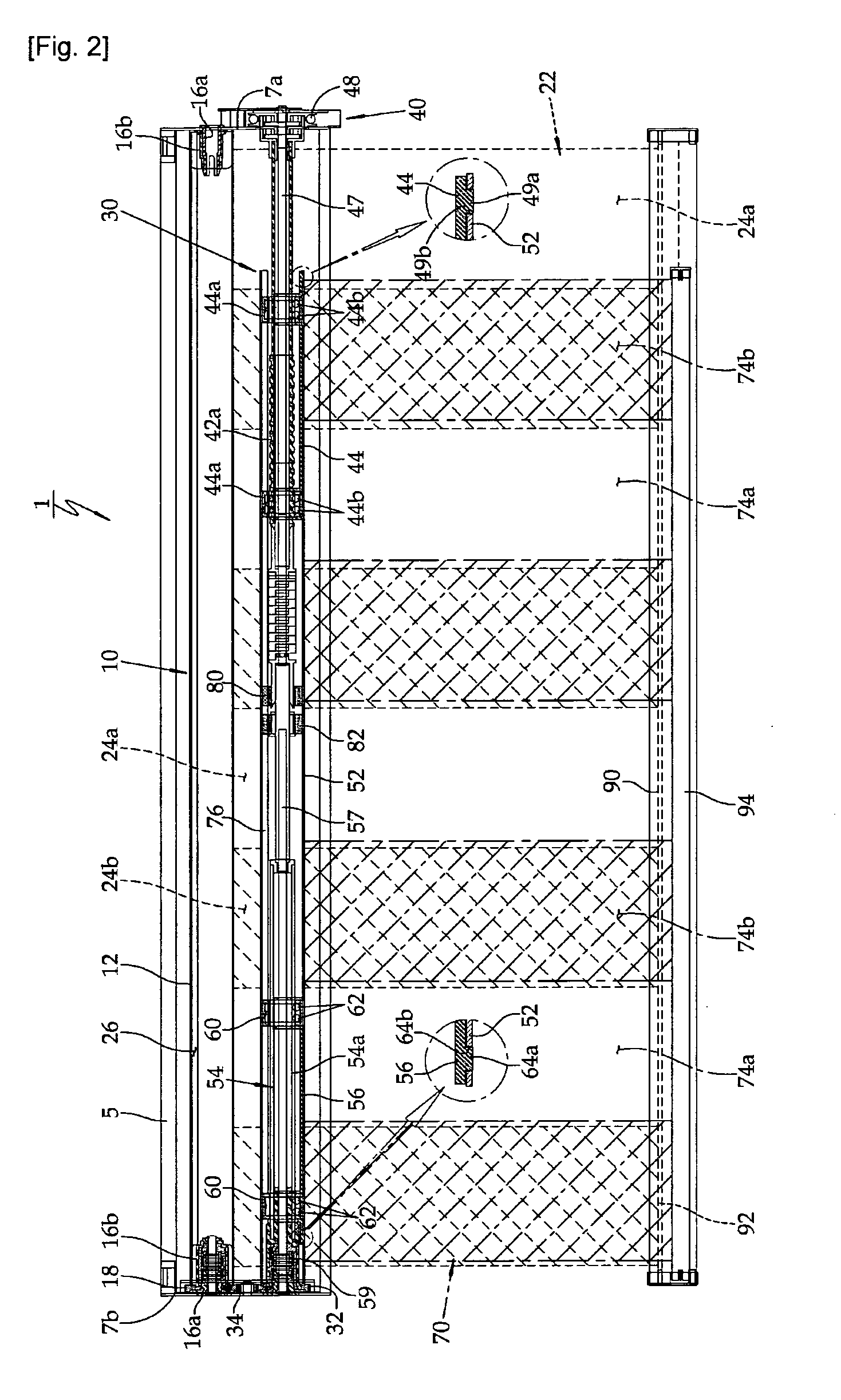

Dual roll blind system

InactiveUS20090283224A1Simple structureReduce maintenance costsScreensShutters/ movable grillesEngineeringScrew thread

A dual roll blind system is able to adjust a light shading degree and comprises a winding roll which includes a roll casing rotatably supported between both side plates of a ceiling bracket; a driving winding roll which includes a moving member disposed between both side plates in parallel with the winding roll and is thread-engaged with a screw shaft rotating by means of a blind winding device of one side, a straight moving member which is provided for left and right straight movements by restricting the rotation of the moving member, and a roll casing engaged with the moving member and the straight moving member; a first blind raw material of which upper end is fixed at the winding roll and in which a light transmission part and a light non-transmission part having constant widths are alternately formed in a width wise direction; a second blind raw material of which upper end is fixed at the driving winding roll and which has a light transmission part and a light non-transmission part corresponding to the first blind raw material and is movable left and right; and a counter weight bar which fixes a lower end of the first blind raw material with a lower end of the second blind raw material being slidably inserted into the counter weight bar in a parallel direction.

Owner:KIM JUNG MIN

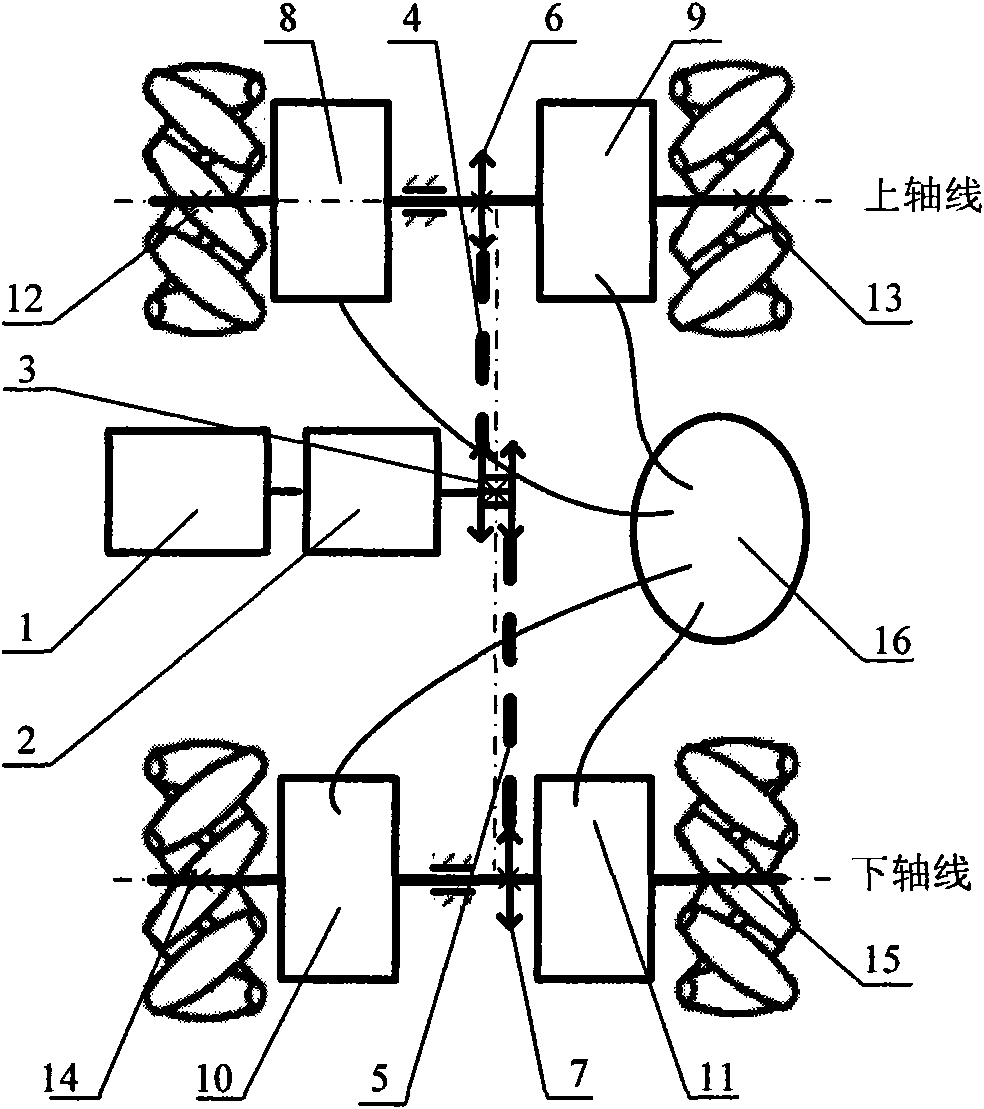

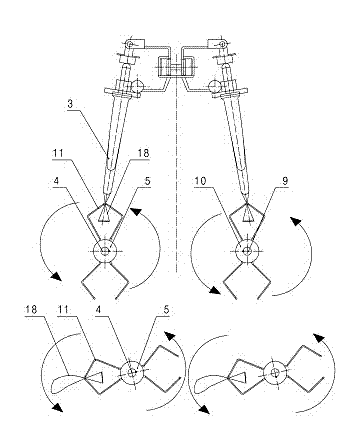

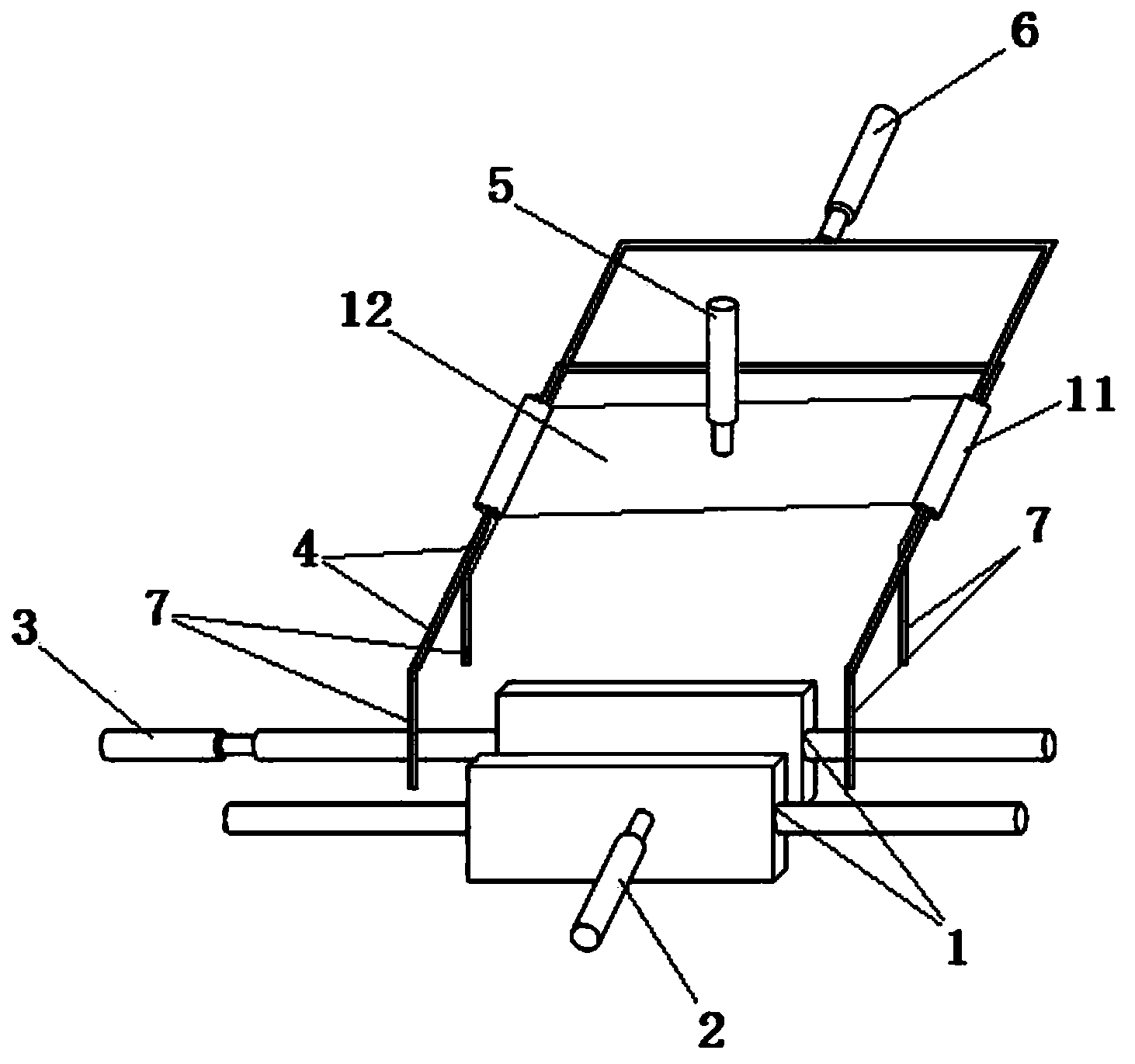

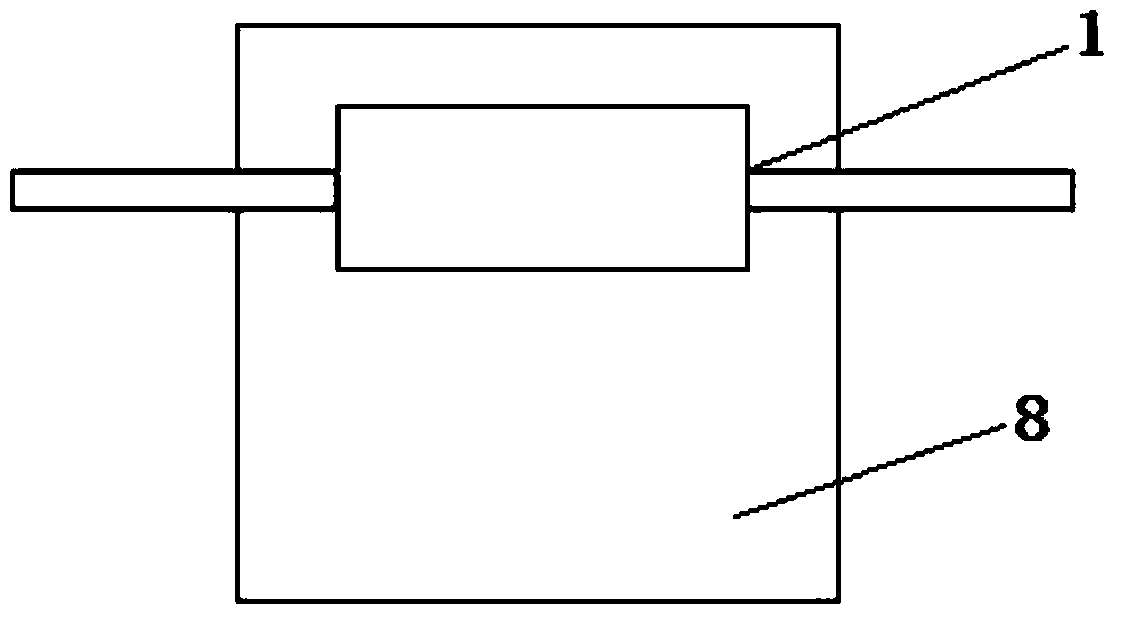

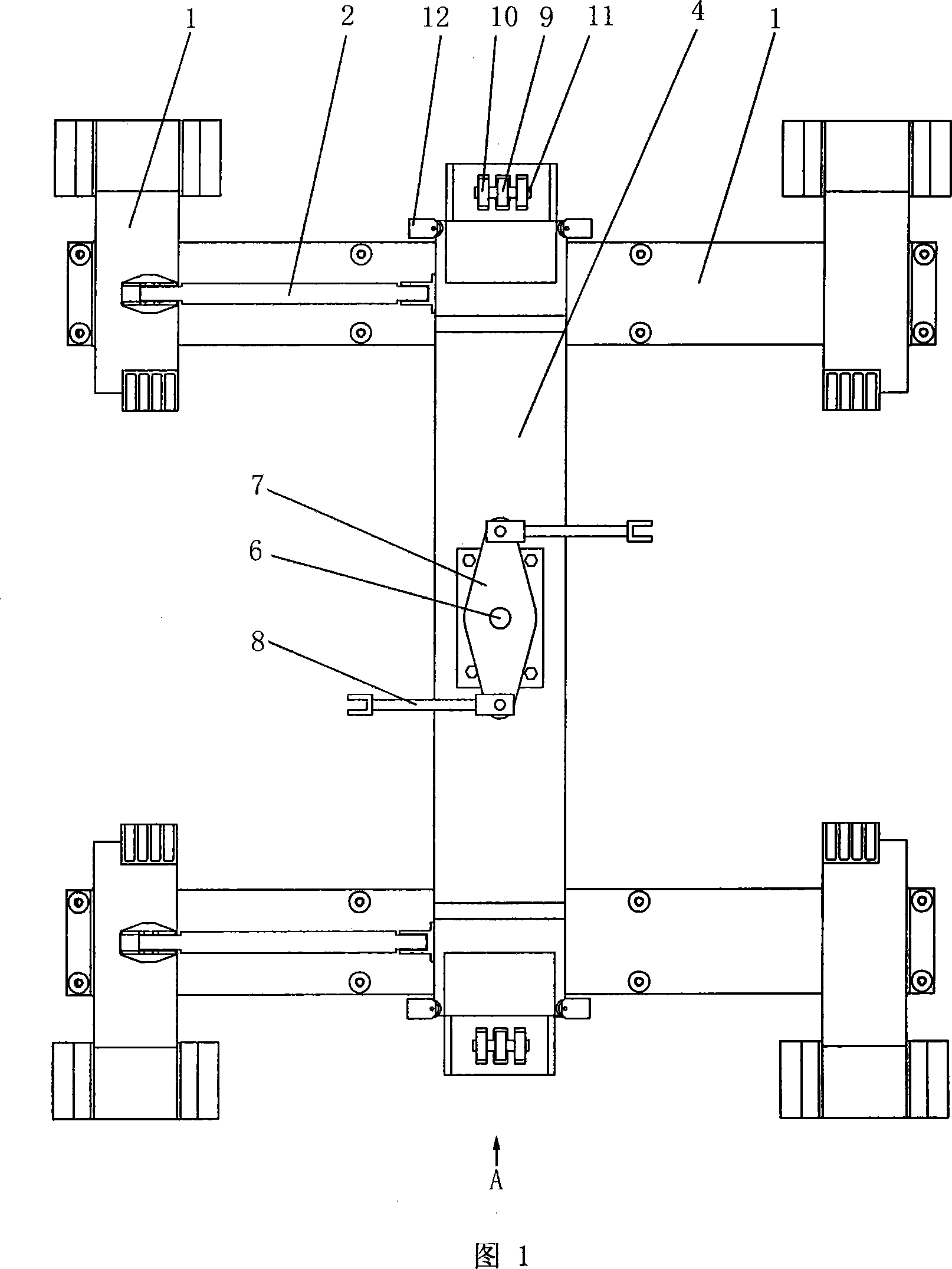

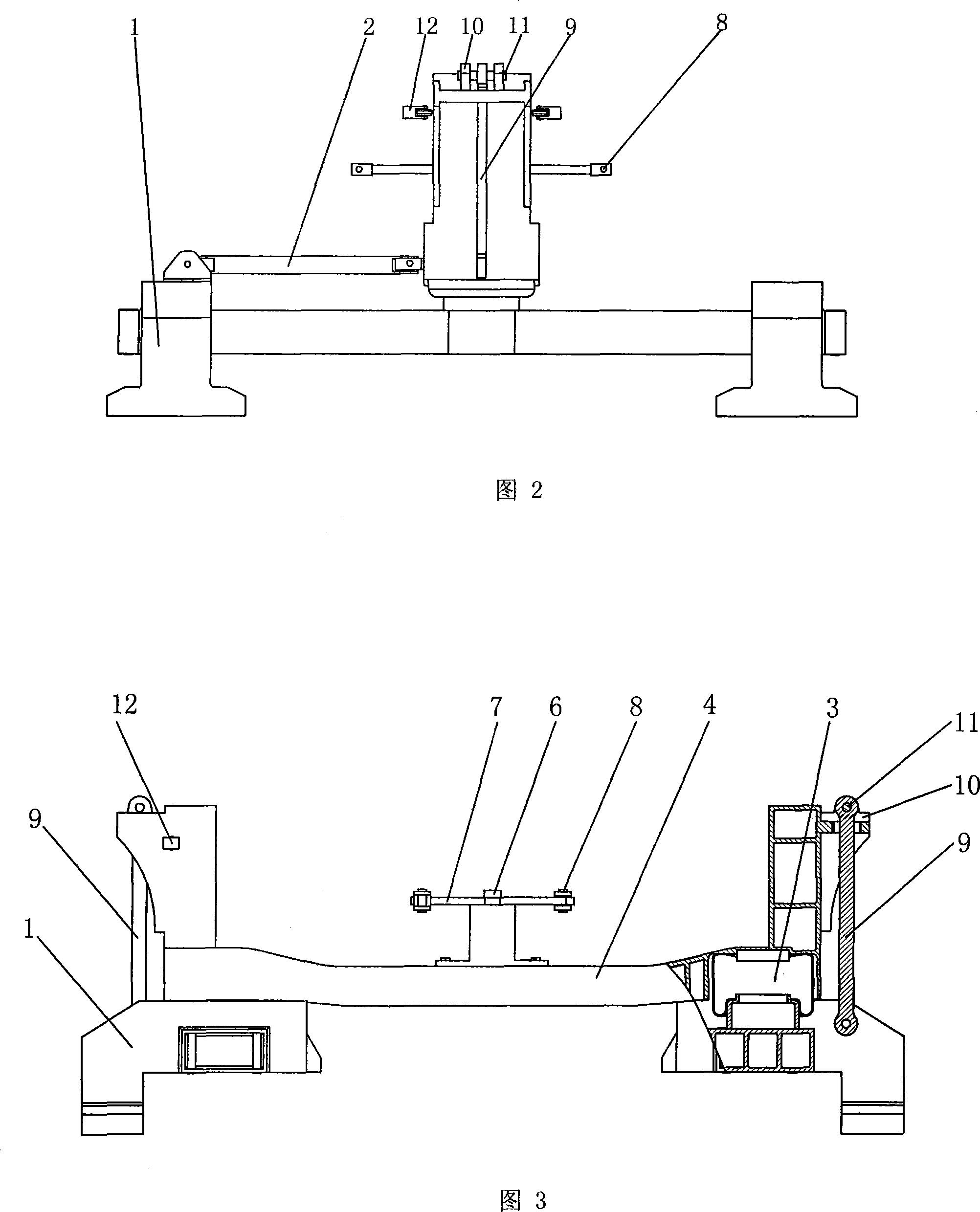

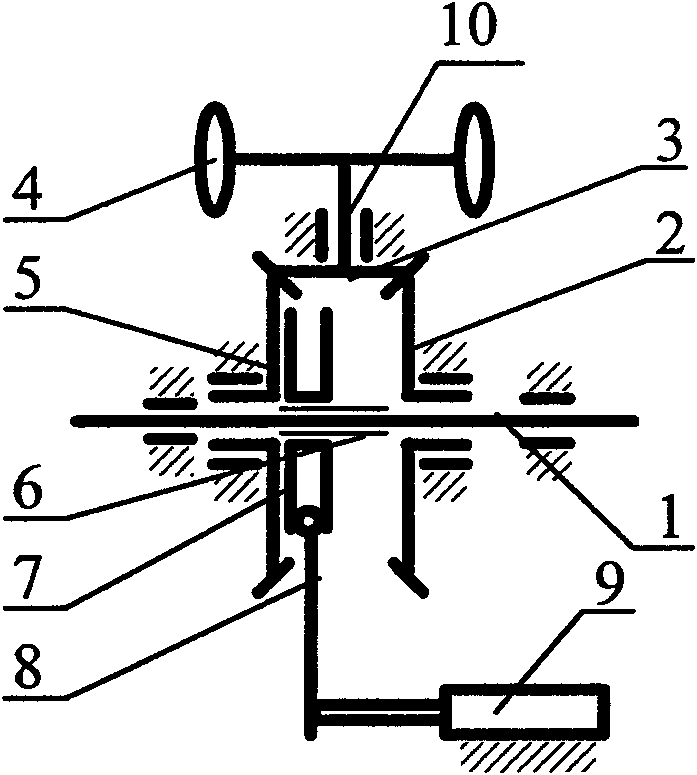

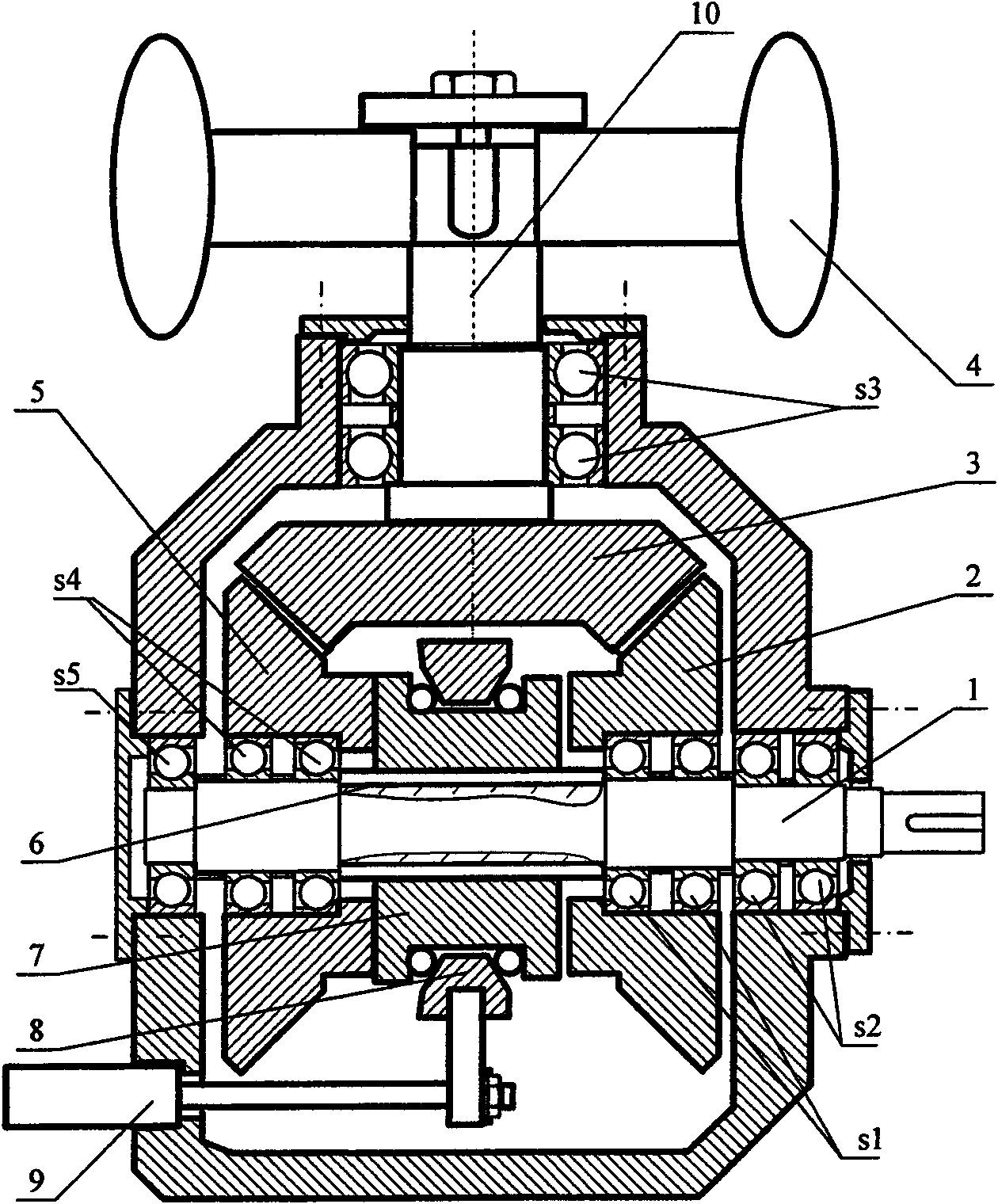

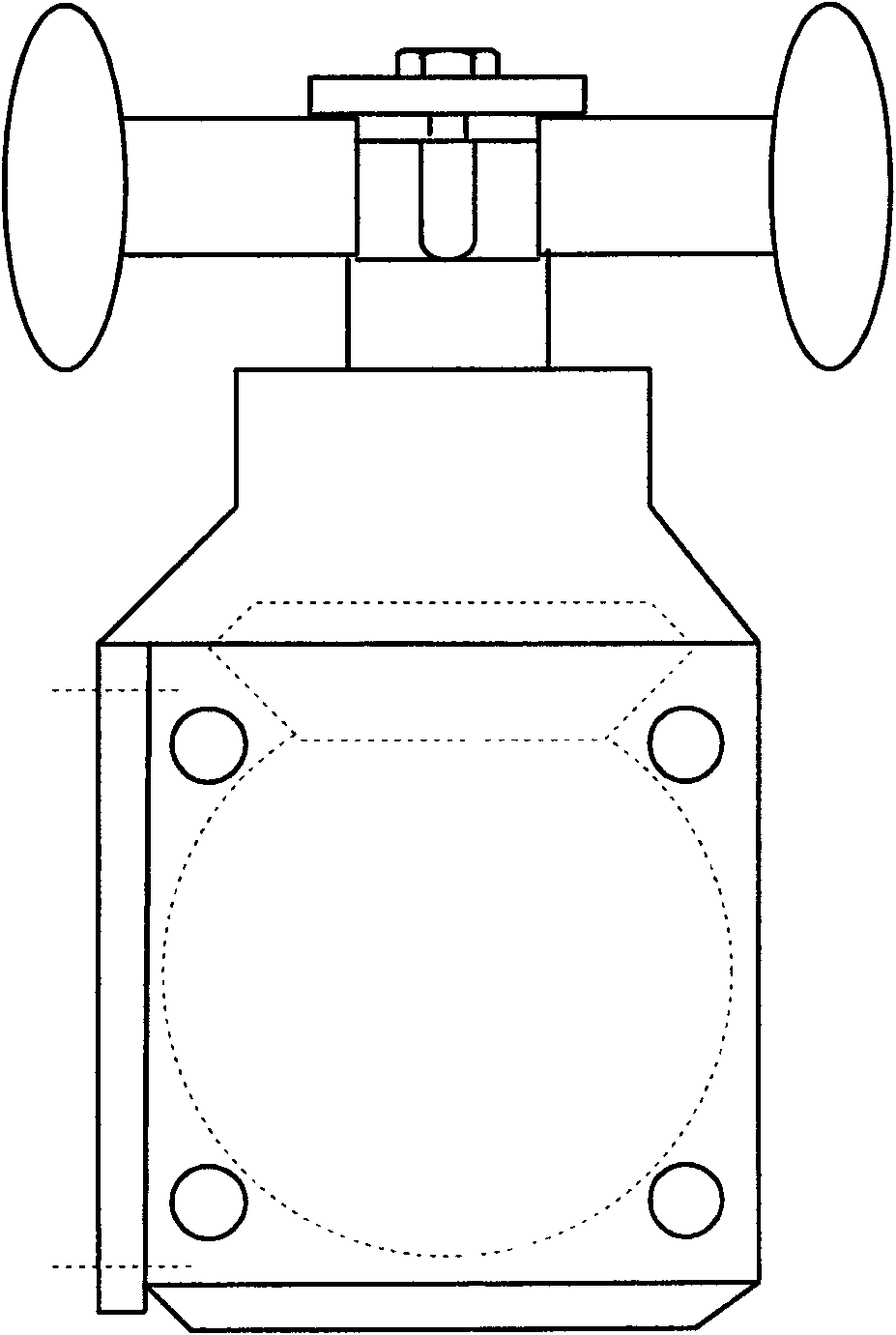

Mecanum wheel all-directional moving vehicle and driving method thereof

The invention relates to a Mecanum wheel all-directional moving vehicle which comprises a vehicle frame, a rotary power source, a first reverser, a second reverser, a third reverser, a fourth reverserand a controller, wherein the vehicle frame is provided with a first Mecanum wheel, a second Mecanum wheel, a third Mecanum wheel and a fourth Mecanum wheel; the rotary power source is used for simultaneously driving the four Mecanum wheels; and the first reverser is arranged between the rotary power source and the first Mecanum wheel, the second reverser is arranged between the rotary power source and the second Mecanum wheel, the third reverser is arranged between the rotary power source and the third Mecanum wheel, and the fourth reverser is arranged between the rotary power source and thefourth Mecanum wheel. The driving method comprises the following steps: driving power output by one rotary power source is simultaneously transmitted to the first reverser, the second reverser, the third reverser and the fourth reverser through a driving mechanism, and then, the first reverser, the second reverser, the third reverser and the fourth reverser respectively transmit the obtained driving power to the first Mecanum wheel, the second Mecanum wheel, the third Mecanum wheel and the fourth Mecanum wheel of the Mecanum wheel all-directional moving vehicle according to the output direction determined by the controller.

Owner:SOUTHEAST UNIV

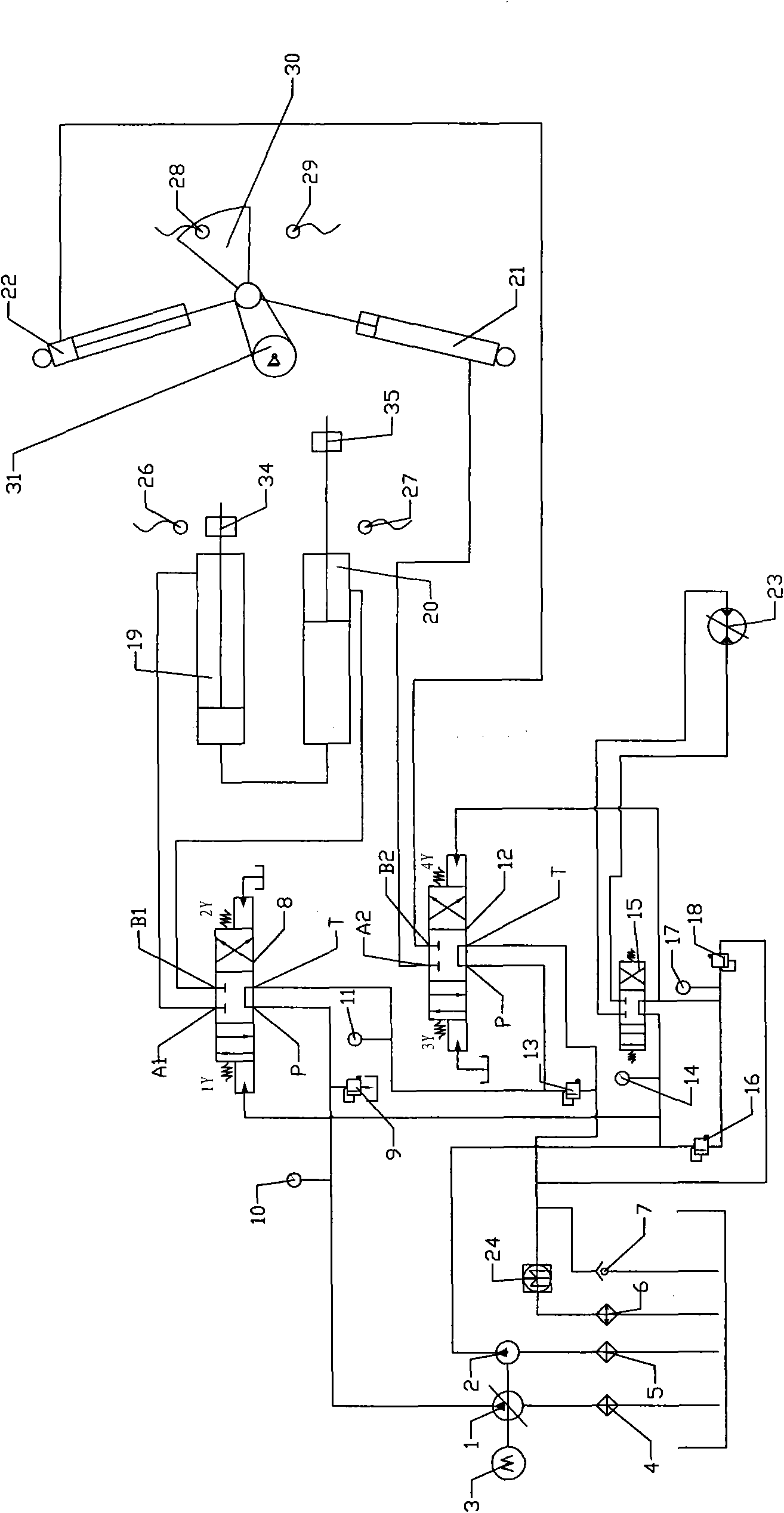

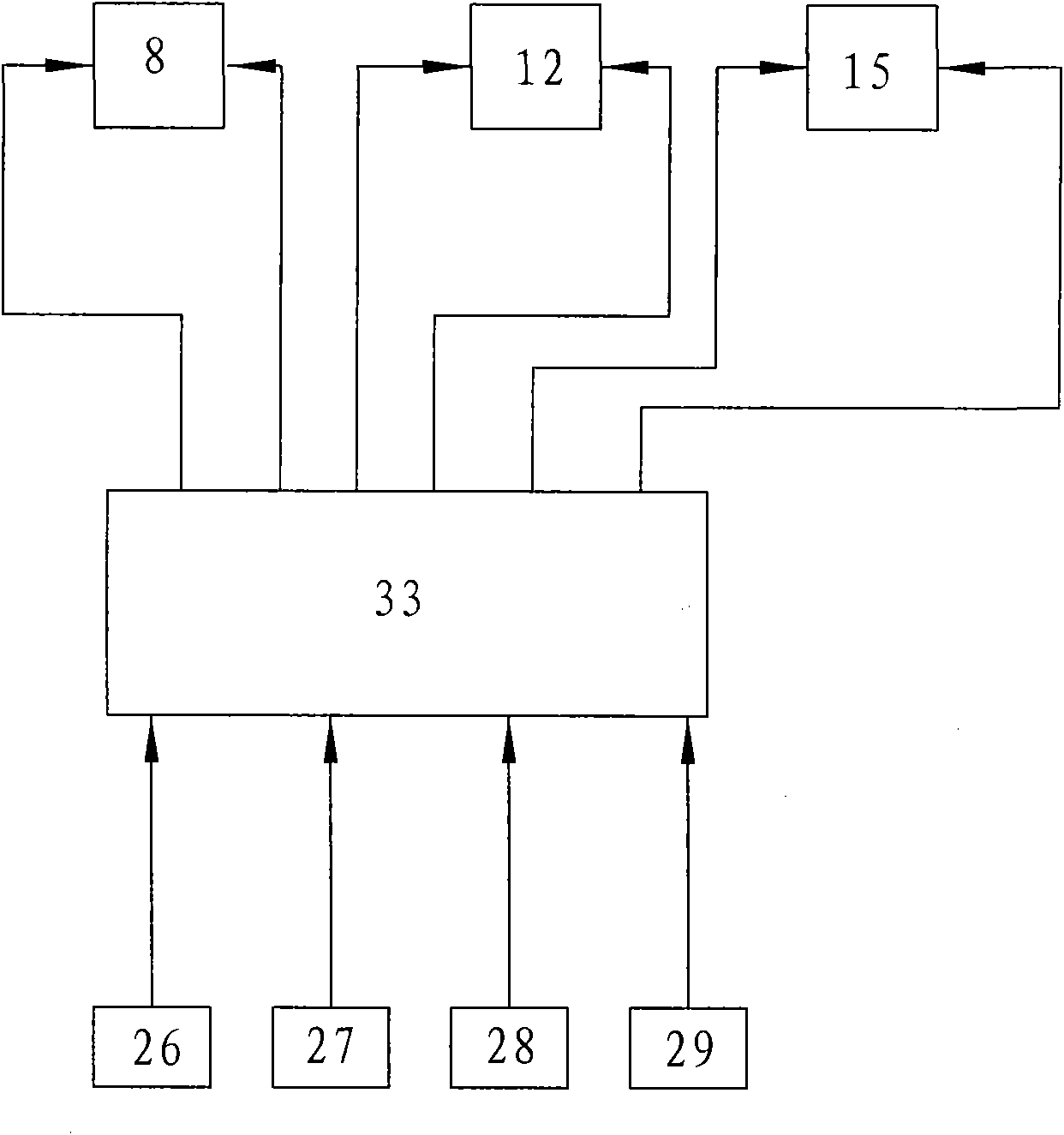

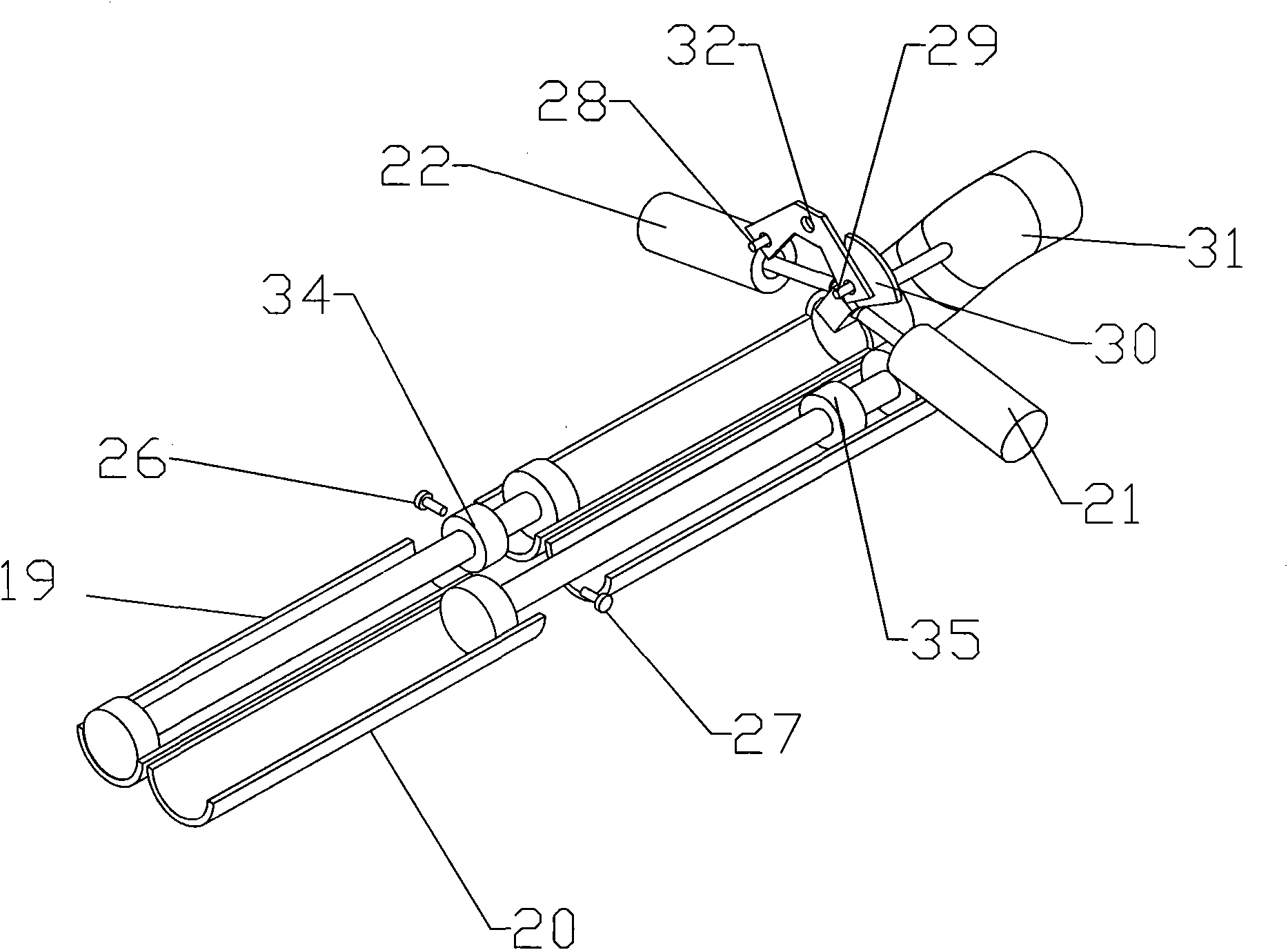

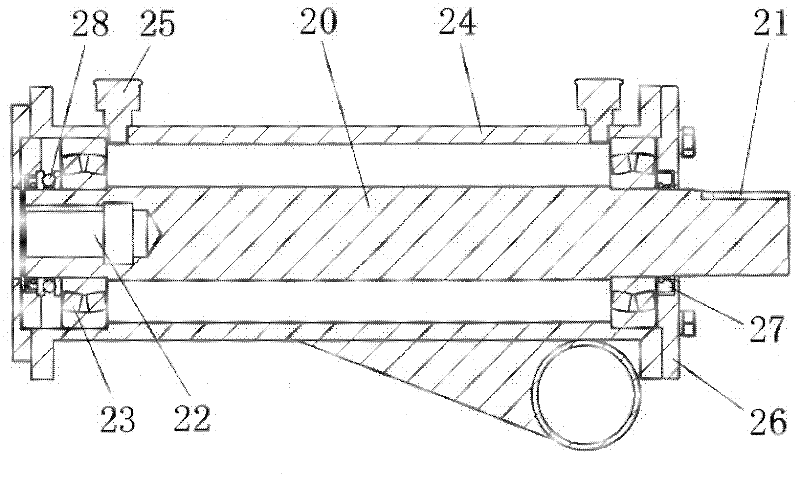

Electro-hydraulic control system for concrete or coal slime conveying device and method for controlling system

InactiveCN101865189ALower oil temperatureLow manufacturing and maintenance costsFluid-pressure actuator componentsLow noiseControl system

The invention discloses an electro-hydraulic control system for a concrete or coal slime conveying device and a method for controlling the system. The electro-hydraulic control system comprises a programmable logic controller PLC, a swinging S tube, a sensor, a pumping oil cylinder, a hydraulic pump, an overflow valve, three M-shaped three-position four-way electro-hydraulic directional control valves, an oil tank, an oil stirring path, a pumping oil path and a swinging oil path, wherein a T port of a first M-shaped three-position four-way electro-hydraulic directional control valve is connected with a P port of a second M-shaped three-position four-way electro-hydraulic directional control valve; the baffles of the pumping oil cylinder and the swinging oil cylinder act on the sensor, so that a signal is emitted from the sensor and received by the PLC; the PLC sequentially acts on the two electro-hydraulic directional control valves according to a program set therein; and the two electro-hydraulic directional control valves control the on-off of oil paths flowing to the pumping oil cylinder and the swinging oil cylinder. The electro-hydraulic control system has the advantages of low oil temperature, low noise, long service life, low manufacturing and maintenance cost, low energy consumption and high reliability.

Owner:秦月明

Beverage dispensing apparatus

InactiveUS20060032869A1Reduce maintenance costsReduce manufacturing costPowdered material dispensingSpray nozzlesEngineeringVALVE PORT

A removable nozzle for attachment to a conventional faucet of a beverage dispensing device to permit the dispensing of a pressurized beverages at a high flow rate without producing excessive foaming comprising a streamlined valve assembly and a downward extending nozzle assembly which permits a range of containers to be filled from the bottom.

Owner:LAMINAR TECH

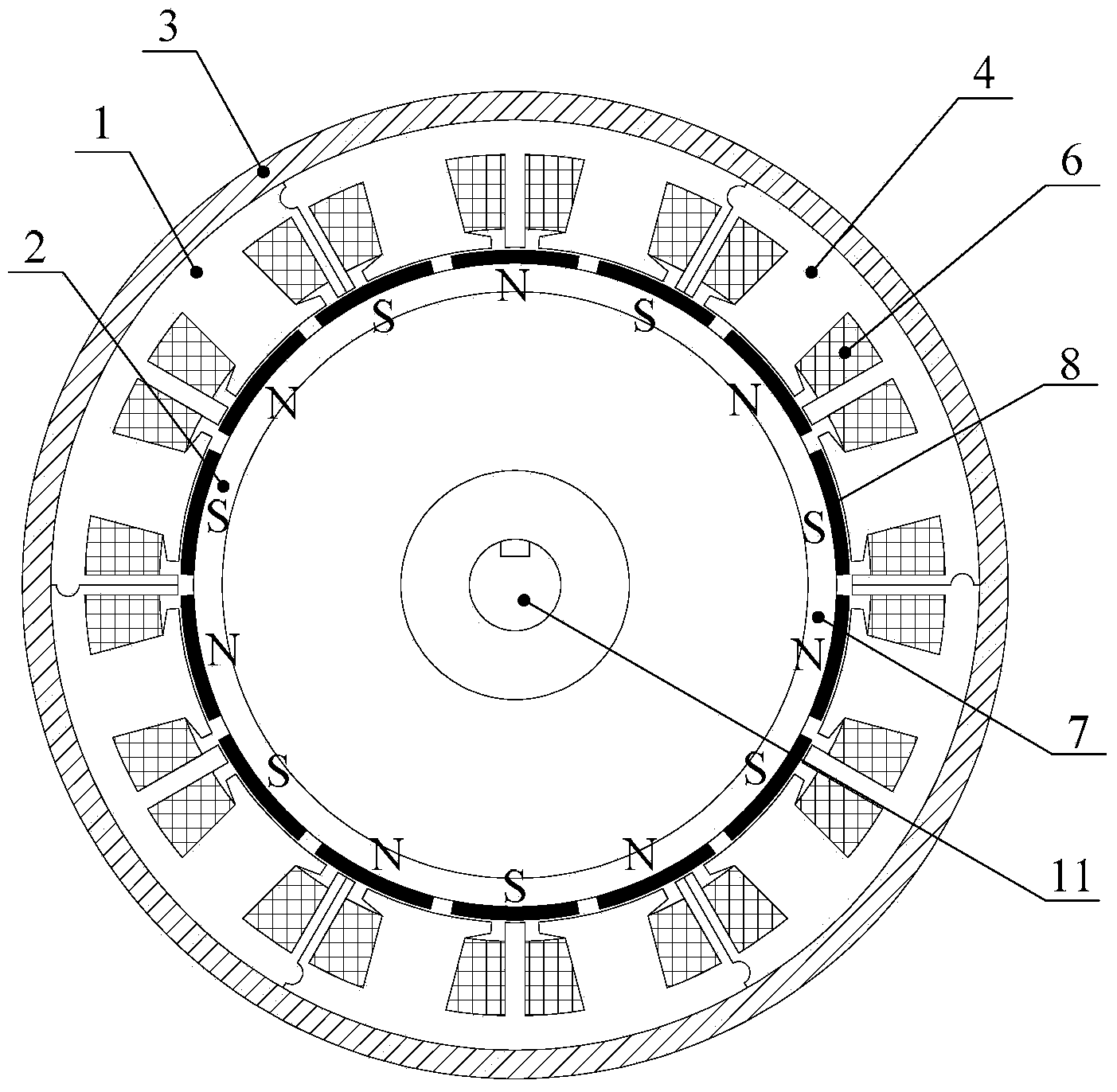

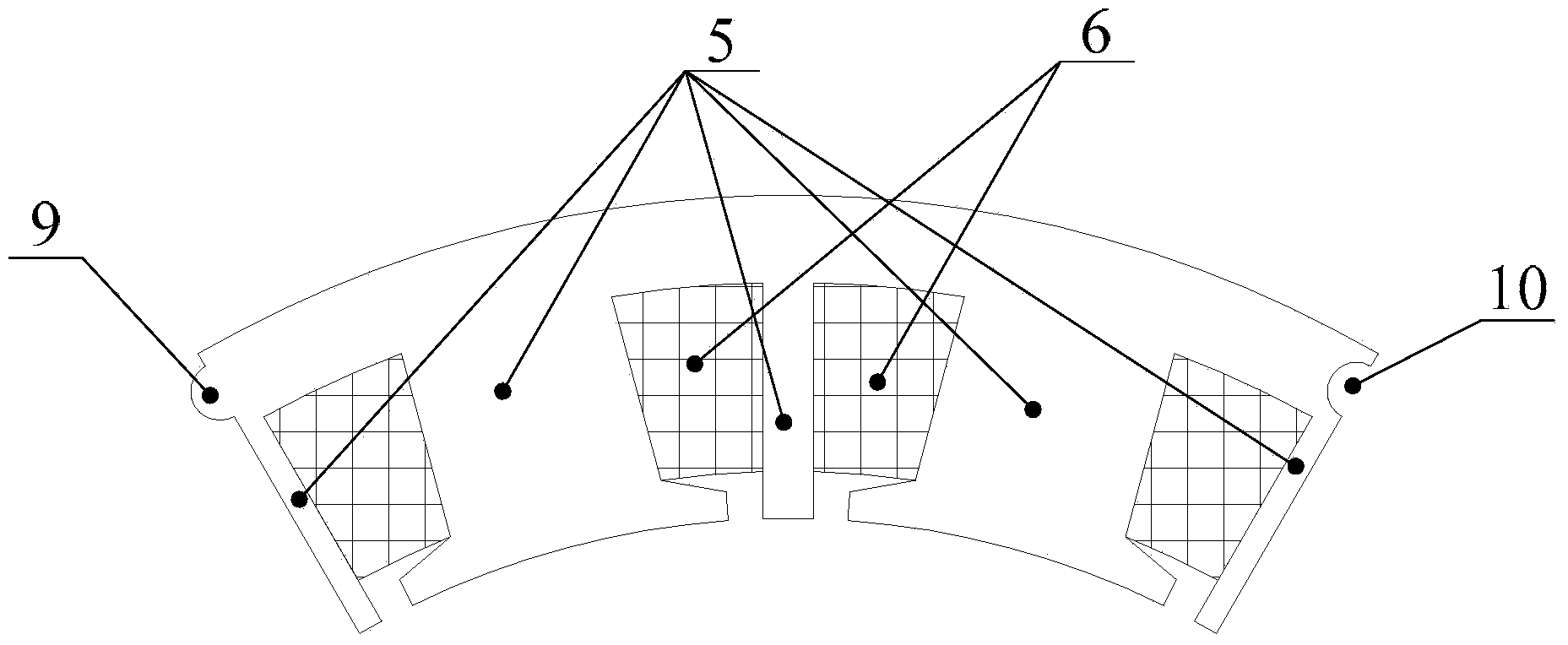

Radial magnetic flux modularization polyphase motor having high magnetism-insulation capability

ActiveCN103762759AImprove reliabilityImprove power densityMagnetic circuit rotating partsMagnetic circuit stationary partsSynchronous motorElectric machine

The invention discloses a radial magnetic flux modularization polyphase motor having the high magnetism-insulation capability and belongs to the field of motors. The radial magnetic flux modularization polyphase motor having the high magnetism-insulation capability solves the problems that when a phase winding of an existing polyphase permanent magnetic synchronous motor has a short circuit, fault-tolerant control difficulty is large, and due to the disperse distribution of winding space, fault insulation is not facilitated, and design of a modularization structure is not facilitated. The radial magnetic flux modularization polyphase motor having the high magnetism-insulation capability comprises modularization stators, a rotor, a motor shell and a main shaft. The rotor is arranged on the main shaft, the modularization stators are arranged on the outer portion of the rotor, and air gaps exist between the modularization stators and the rotor. The surfaces of the outer circles of the modularization stators are fixed to the surface of the inner circle of the motor shell. Each modularization stator comprises N identical stator modules, wherein the N identical stator modules are spliced to form a disc shape. Each stator module comprises a stator iron core, five stator teeth and two concentrated wound windings. According to the rotor, the surface of the outer circle of a rotor iron core is provided with 2N+ / -2 permanent magnets which are oppositely arranged in the circumference direction in an alternative mode and perform magnetizing in the radial direction.

Owner:HARBIN INST OF TECH

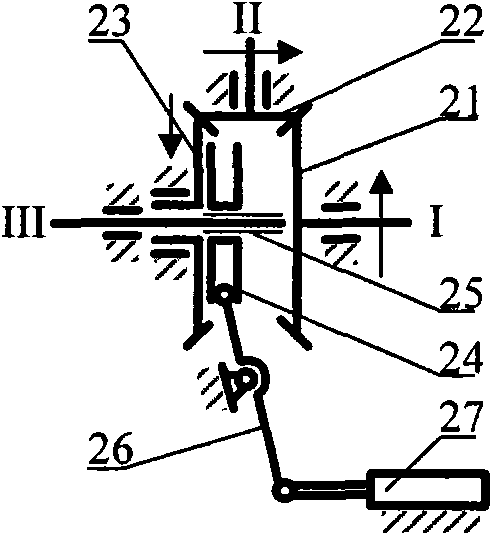

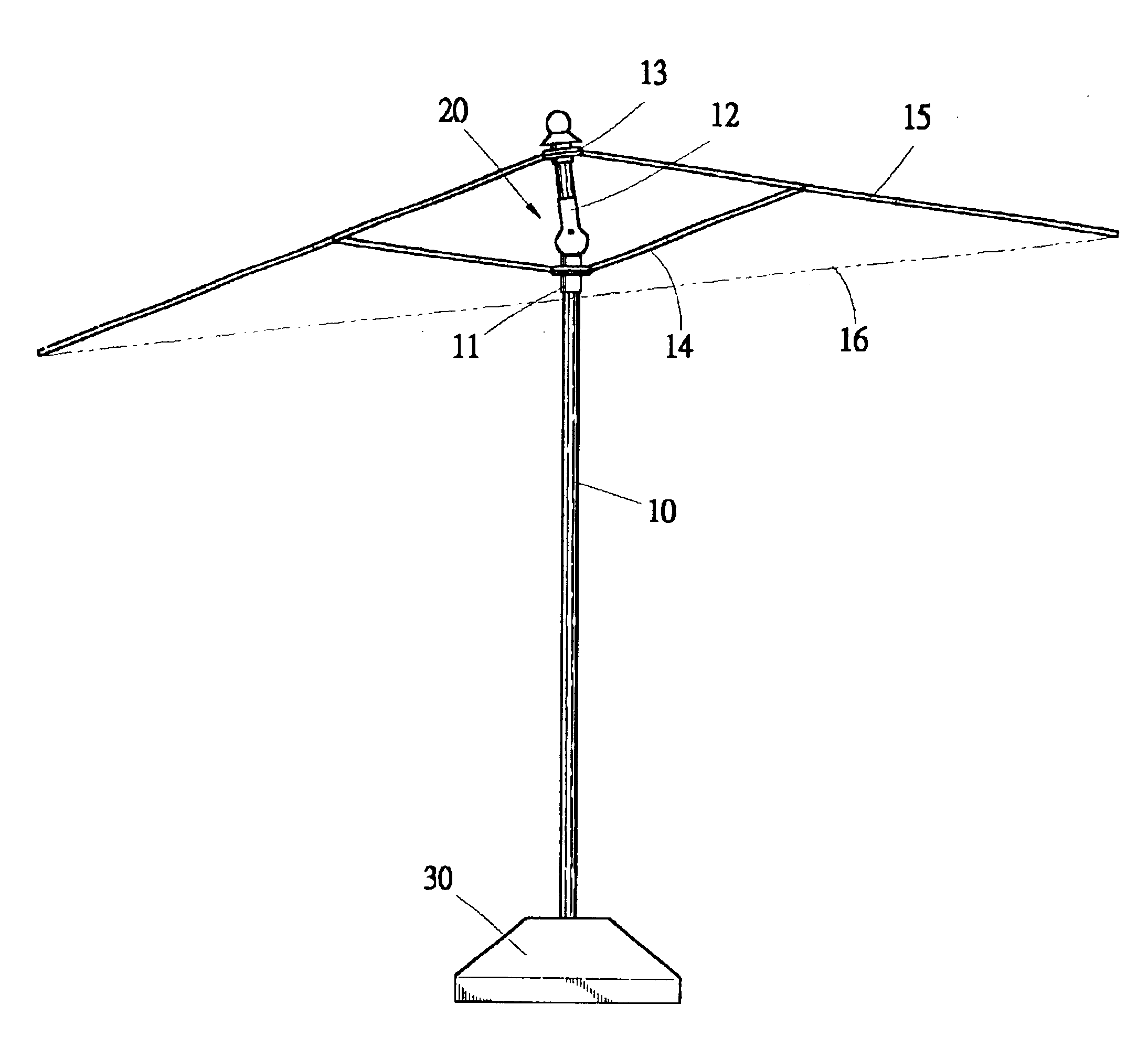

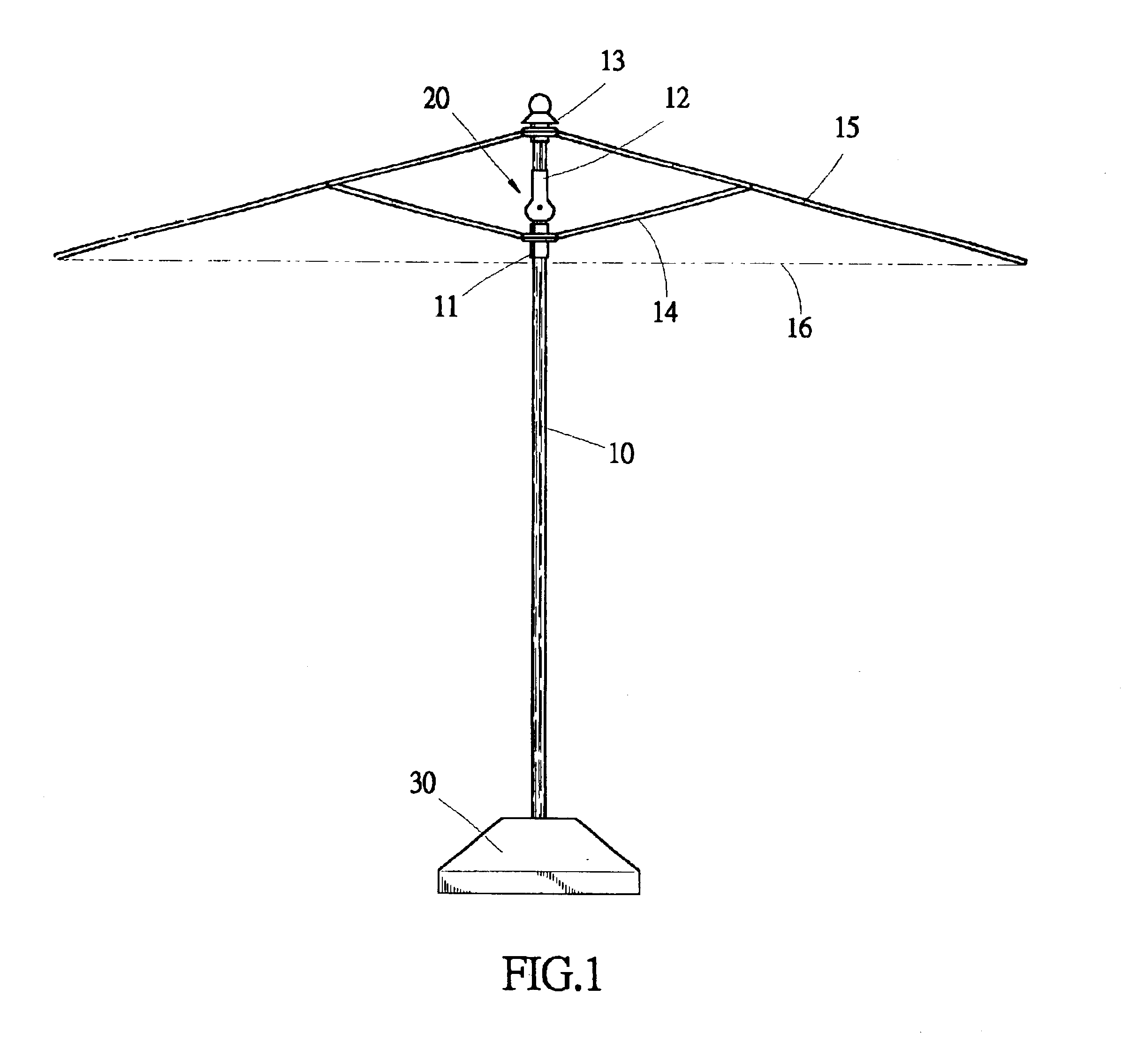

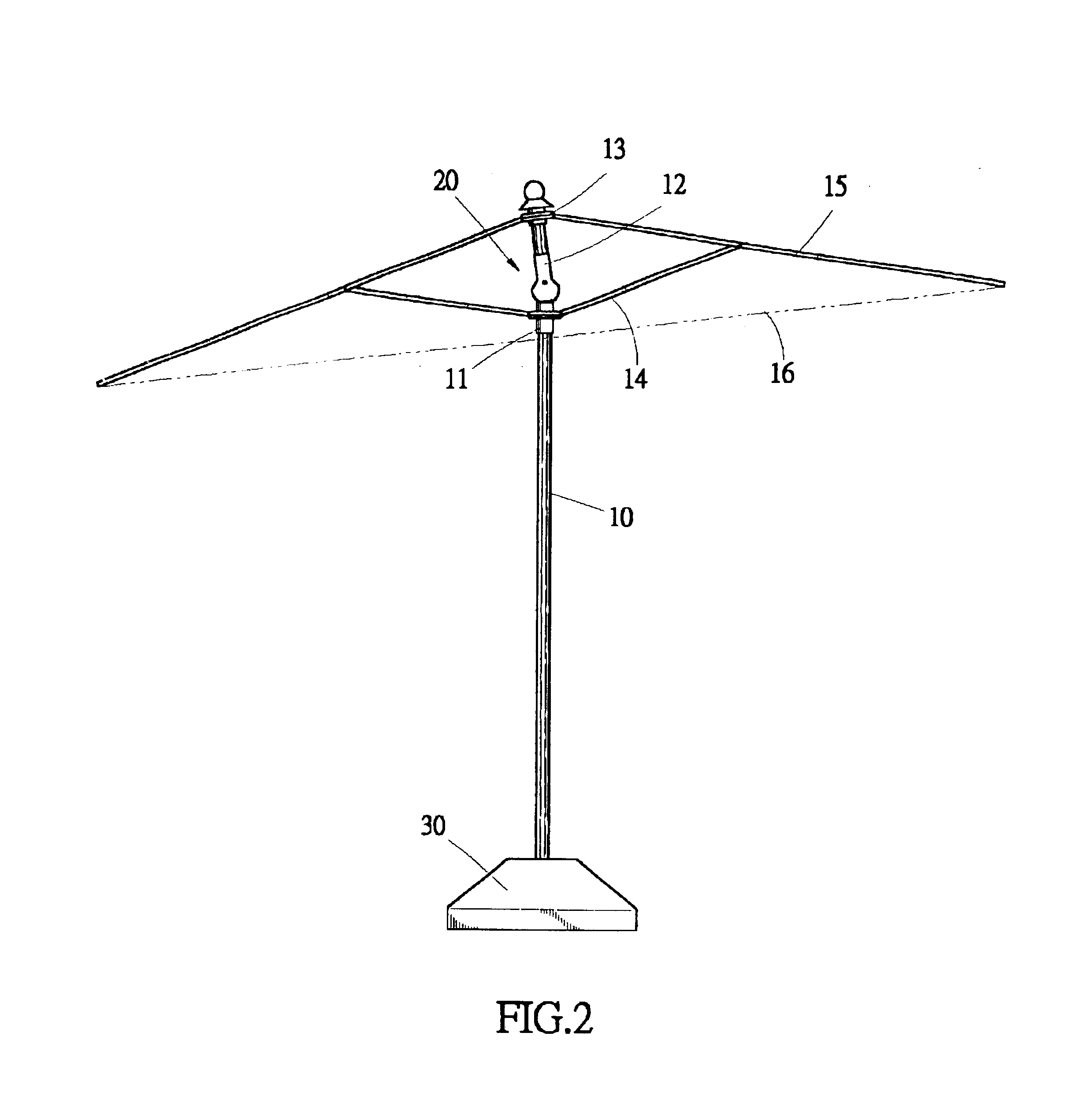

Umbrella canopy orientating device

InactiveUS6848459B2Simple structureEasy to operateWalking sticksUmbrellasNeutral positionEngineering

An umbrella canopy orientating drive is applied to a large-sized umbrella. The umbrella has a central rod comprised of an upper section to which a canopy is attached and a lower section positionable on a fixed surface. The umbrella canopy orientating device includes a diverging portion having a skirt-like opening to receive the lower section of the central rod; a tube portion receiving the lower end of the upper section of the central rod; a pair of pin holes formed on the diverging portion; a pin hole formed through the upper end of the lower section; and a pin inserted through the pin holes of the diverging portion and the pin hole of the lower section to pivot the diverging portion and lower section, whereby the upper section and thus the canopy are allowed to rotate about the pivot pin with respect to the lower section between a neutral position and an inclined position to orientate the canopy in an inclined direction with respect to the lower section.

Owner:MA JOEN SHEN

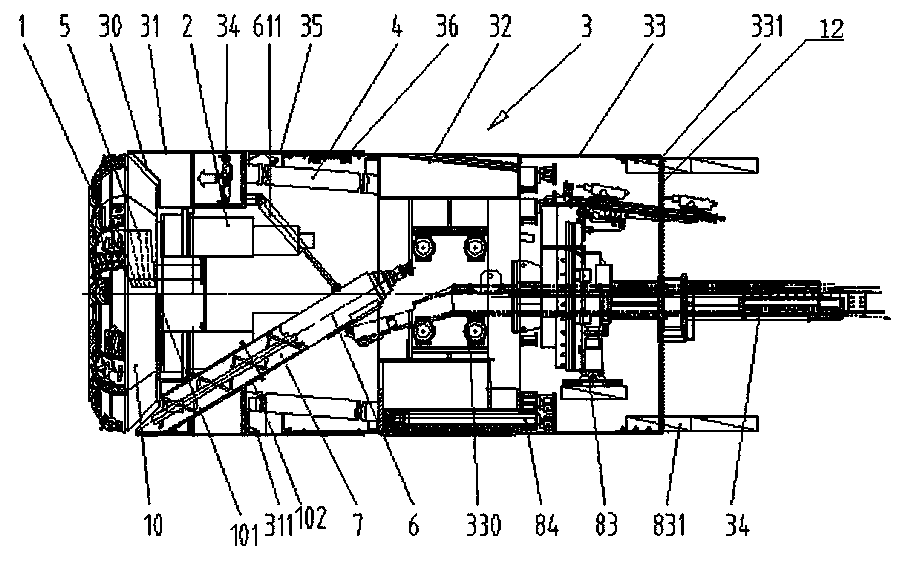

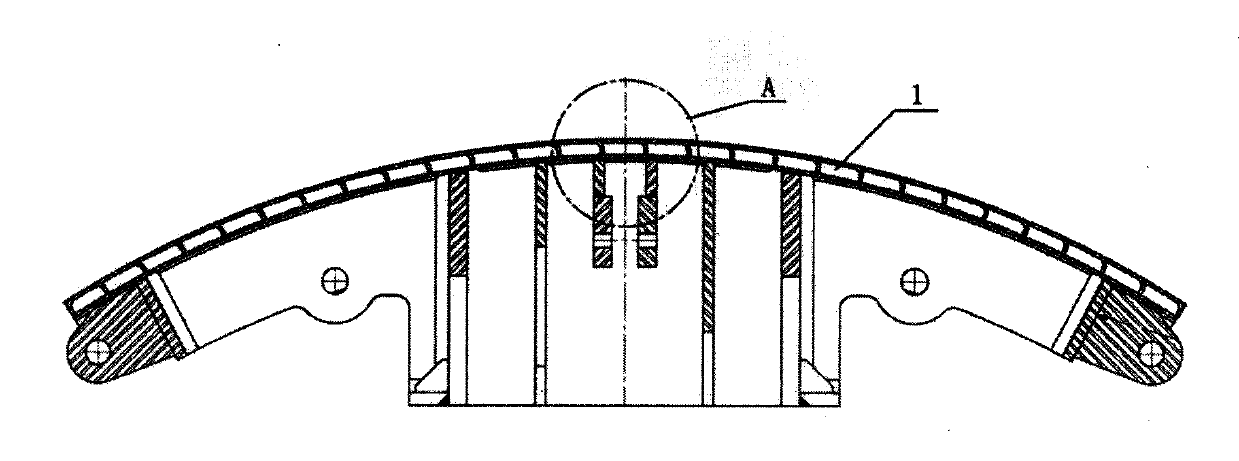

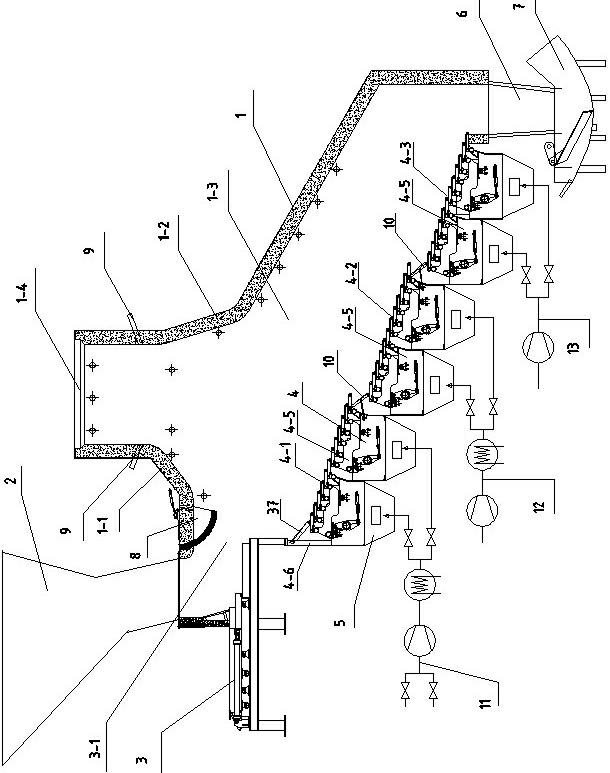

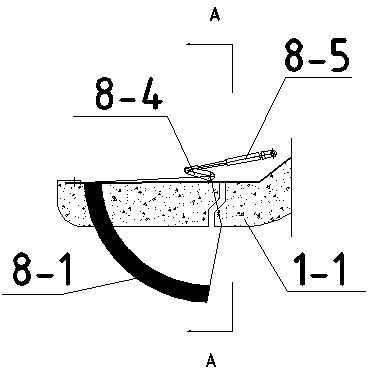

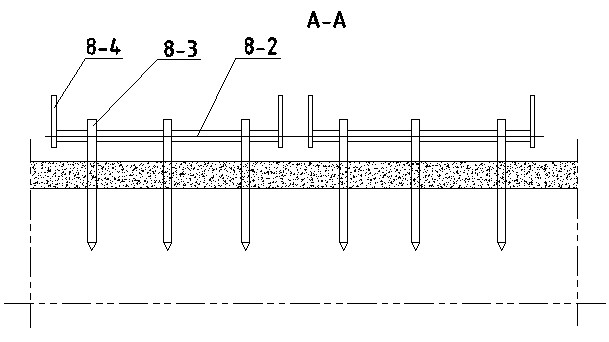

Support system for open-type full cross-section rock tunnel boring machine and support method

ActiveCN107288648AImprove adaptabilityImprove tunneling efficiencyUnderground chambersHydro energy generationSupporting systemEngineering

The invention discloses a support system for an open-type full cross-section rock tunnel boring machine and a support method. The support system comprises a reinforcing steel bar row storage and installation assembly, a steel arch installer, an anchor rod drilling machine, an advancing drilling machine and a temporary whitewashing manipulator. The reinforcing steel bar row storage and installation assembly is arranged on a top shield of the tunnel boring machine, the steel arch installer comprises a support frame and a steel arch grabbing manipulator, and the anchor rod drilling machine, the advancing drilling machine and the temporary whitewashing manipulator are arranged on a main beam of the rear side of the top shield of the tunnel boring machine. According to the support system for the open-type full cross-section rock tunnel boring machine and the support method, combined utilization of multiple support methods can be achieved, and the adaptability of the open-type TBM dealing with the adverse stratum is enhanced; seamless connection and support between a reinforcing steel bar row and the shield can be achieved, and the damage to equipment and the personnel casualties caused by falling down of surrounding rocks are avoided; and installation of the reinforcing steel bar row and synchronous construction of anchor rods in the tunneling process of the open-type TBM can be achieved, and the tunneling efficiency of the open-type TBM is improved.

Owner:STATE KEY LAB OF SHIELD & TUNNELING TECH +1

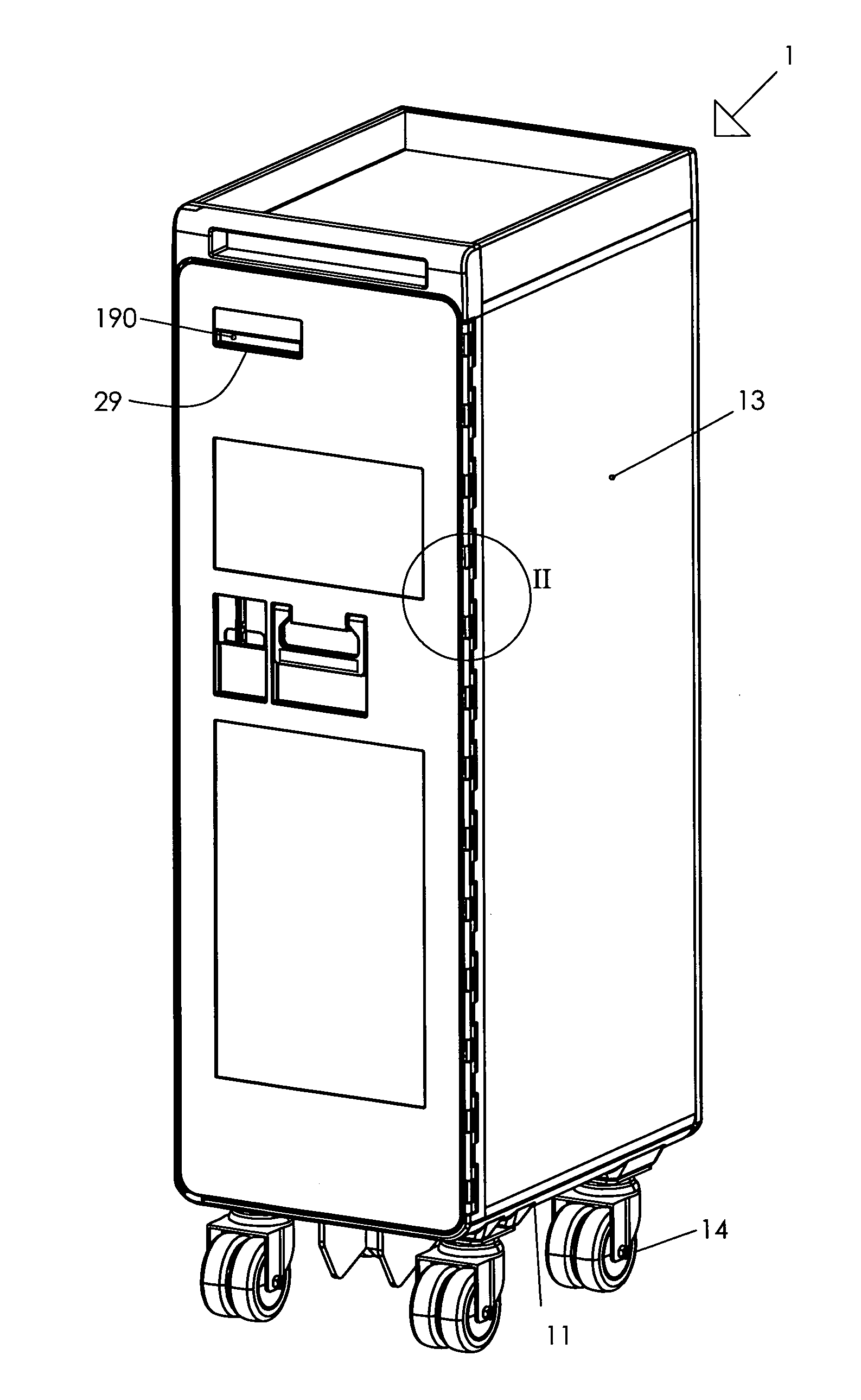

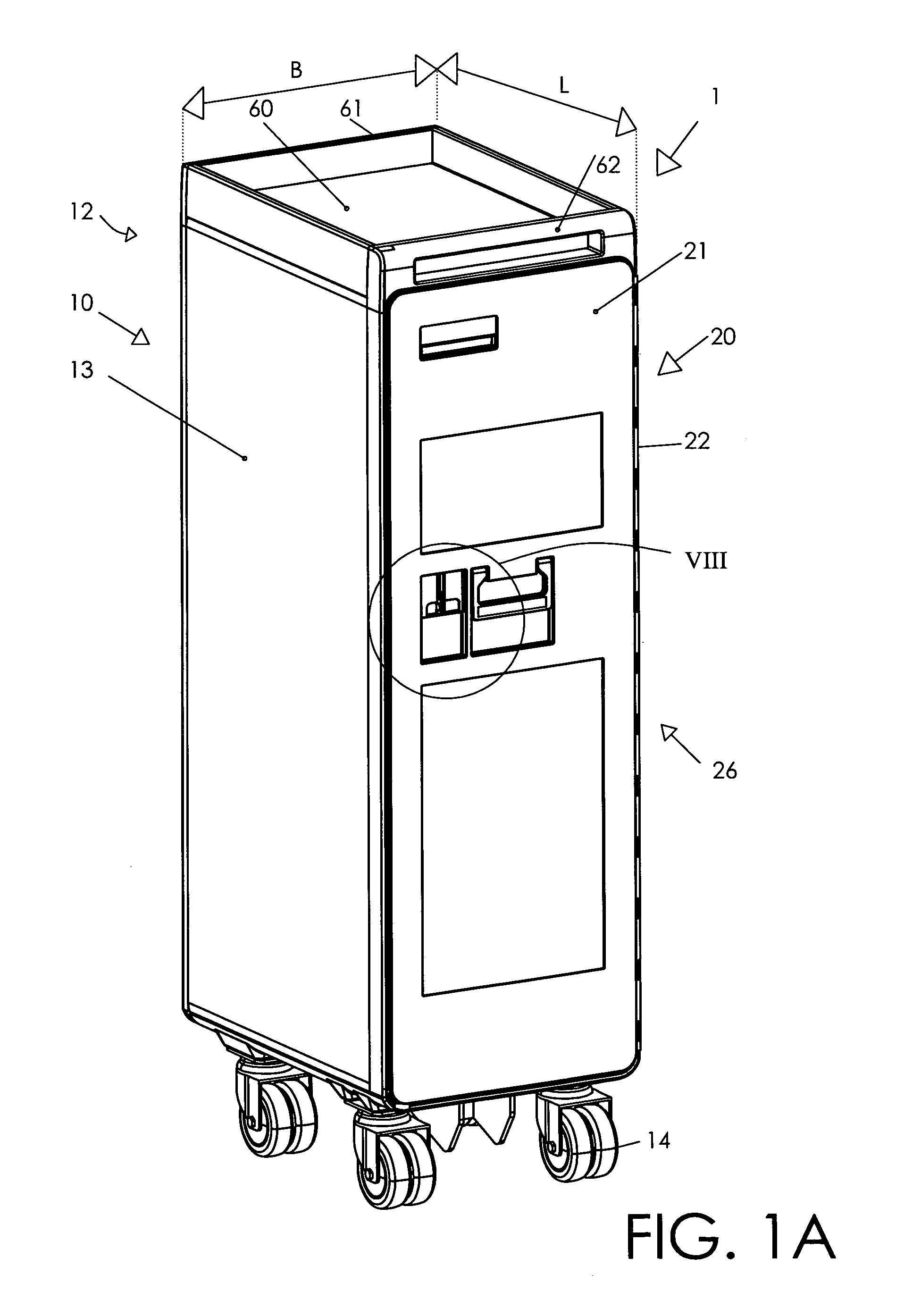

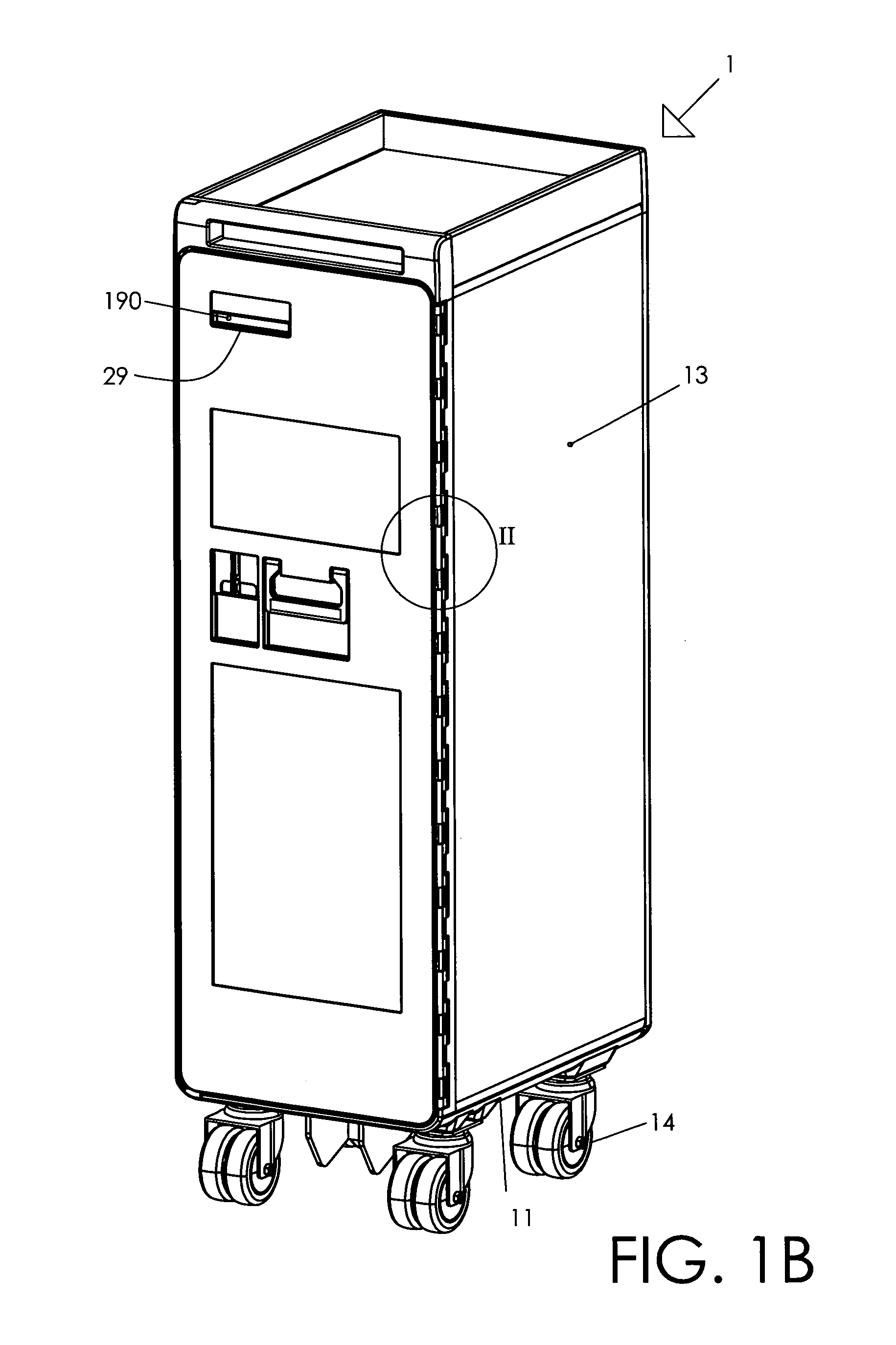

Airline cart

ActiveUS8360447B2Reduce weightLow manufacturing and maintenance costsWing accessoriesWing fastenersJet aeroplaneEngineering

A cart for distributing for instance food in aisles of airplanes is described. The cart comprises a cabinet-shaped body (10) as well as a door (20) coupled hingedly to the body, capable of being closed by means of a lock system (100). The lock system is a multipoint lock system (100), wherein a bolting of the door with respect to the body is accomplished at a plurality of positions along a free vertical side edge (23) of the door.

Owner:VDL FIBERTECH IND BV

Beverage dispensing apparatus

InactiveUS20050072487A1Reduce maintenance costsReduce manufacturing costLiquid flow controllersSpray nozzlesEngineeringVALVE PORT

Owner:LAMINAR TECH

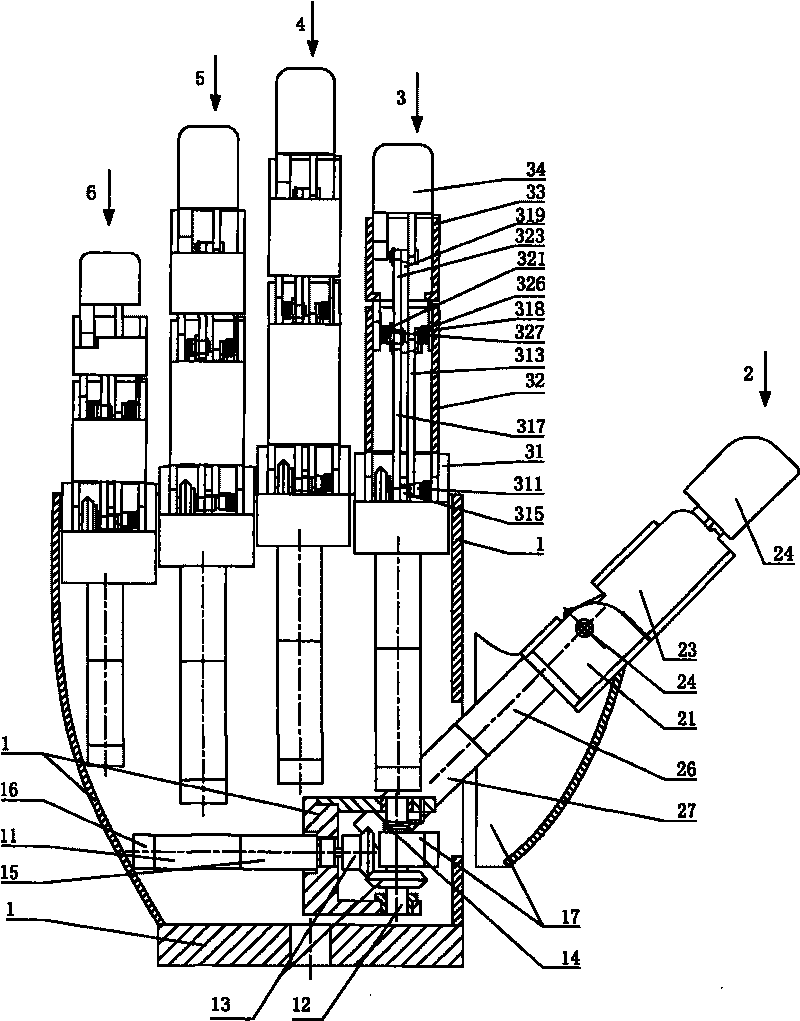

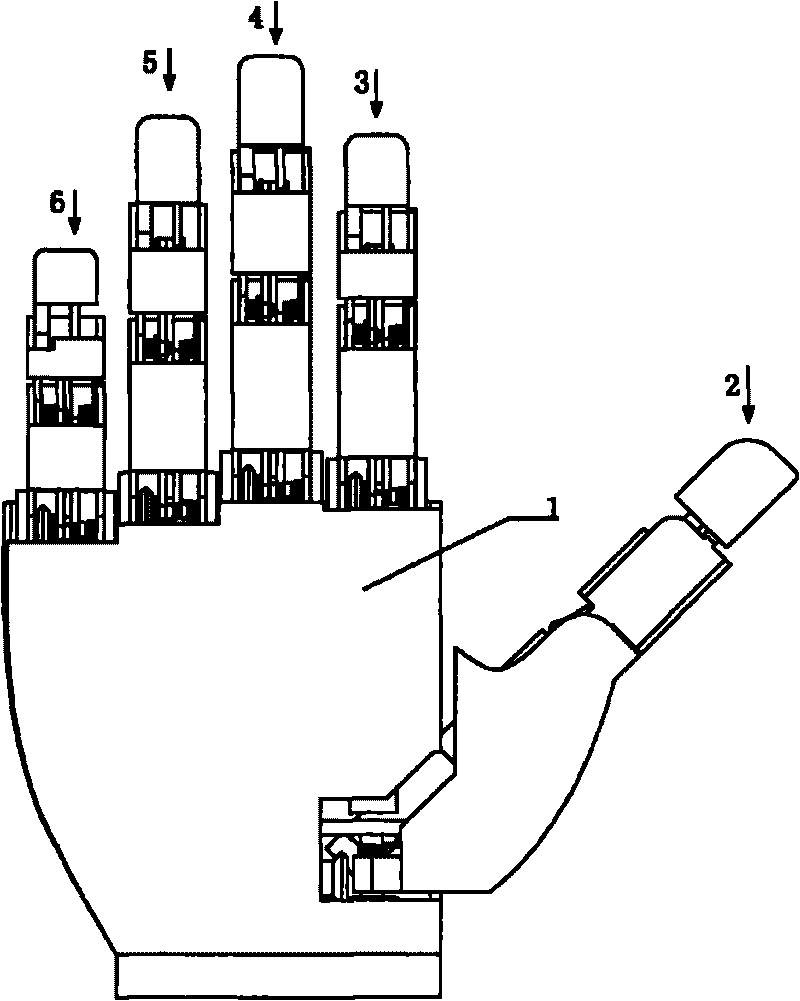

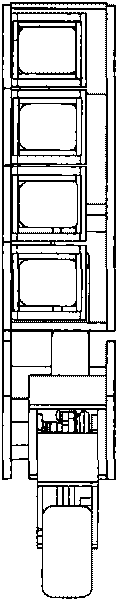

Coupling underactuated integrated bionic hand device

InactiveCN101716767AImprove general performanceSuitable for long-term useJointsGripping headsLittle fingerEngineering

The invention relates to a coupling underactuated integrated bionic hand device, belonging to the technology field of humanoid robots; the bionic hand device comprises a thumb, a forefinger, a middle finger, a third finger, a little finger and a palm. The device comprises five individually controlled fingers and fifteen joint freedom degrees and is driven by six motors, and the device realizes the functions of highly simulating the appearance of a human hand and grabbing action and is suitable for the humanoid robot. The forefinger, the middle finger, the third finger, and the little finger adopt modular structures, and the commonality of parts is strong. All fingers utilize a connecting rod and a spring piece to form a coupling driving mechanism and an underactuated driving mechanism which are integrated, thereby comprehensively realizing special effect of integrating the coupling and underactuated self-adaption grabbing process. In the grabbing process, the device is turned by a coupling mode before an object is touched, the object is grabbed in a turning way by adopting an underactuated self-adaption mode after the object is touched, and the device can be automatically adaptive to the size and shape of the object. The output power of the bionic hand device is strong, the grabbing action is stable, the range of the grabbed objects is wide, the requirement to a control system is low, the structure is simple and the coupling underactuated integrated bionic hand device is suitable for long-time usage.

Owner:WUXI RES INST OF APPLIED TECH TSINGHUA UNIV +1

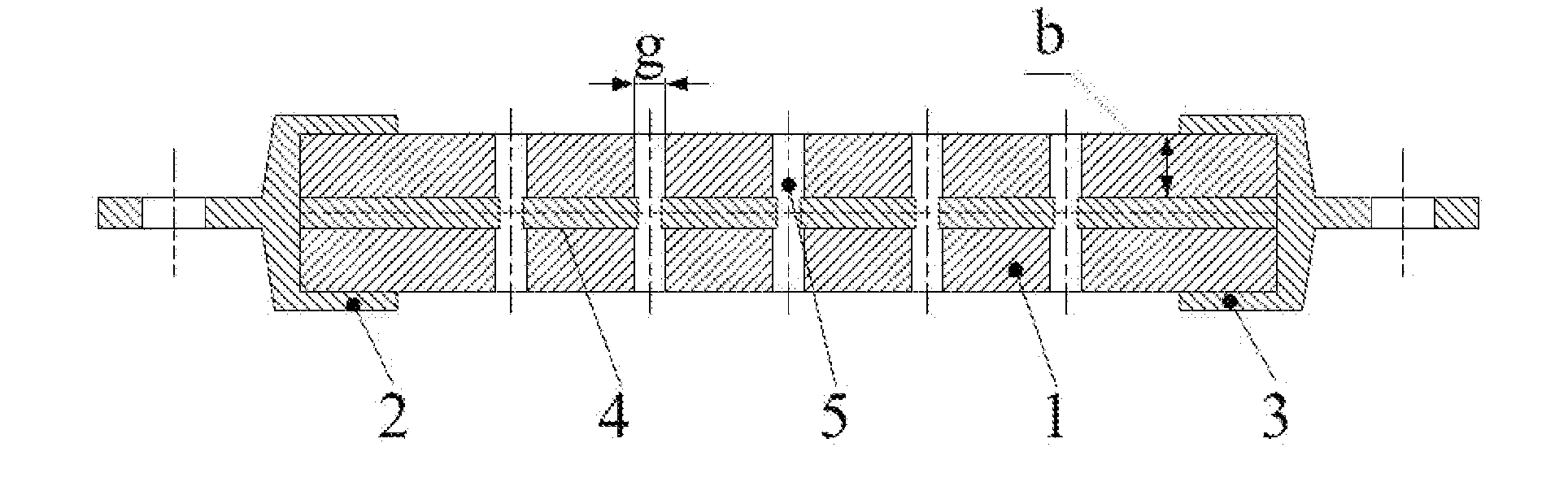

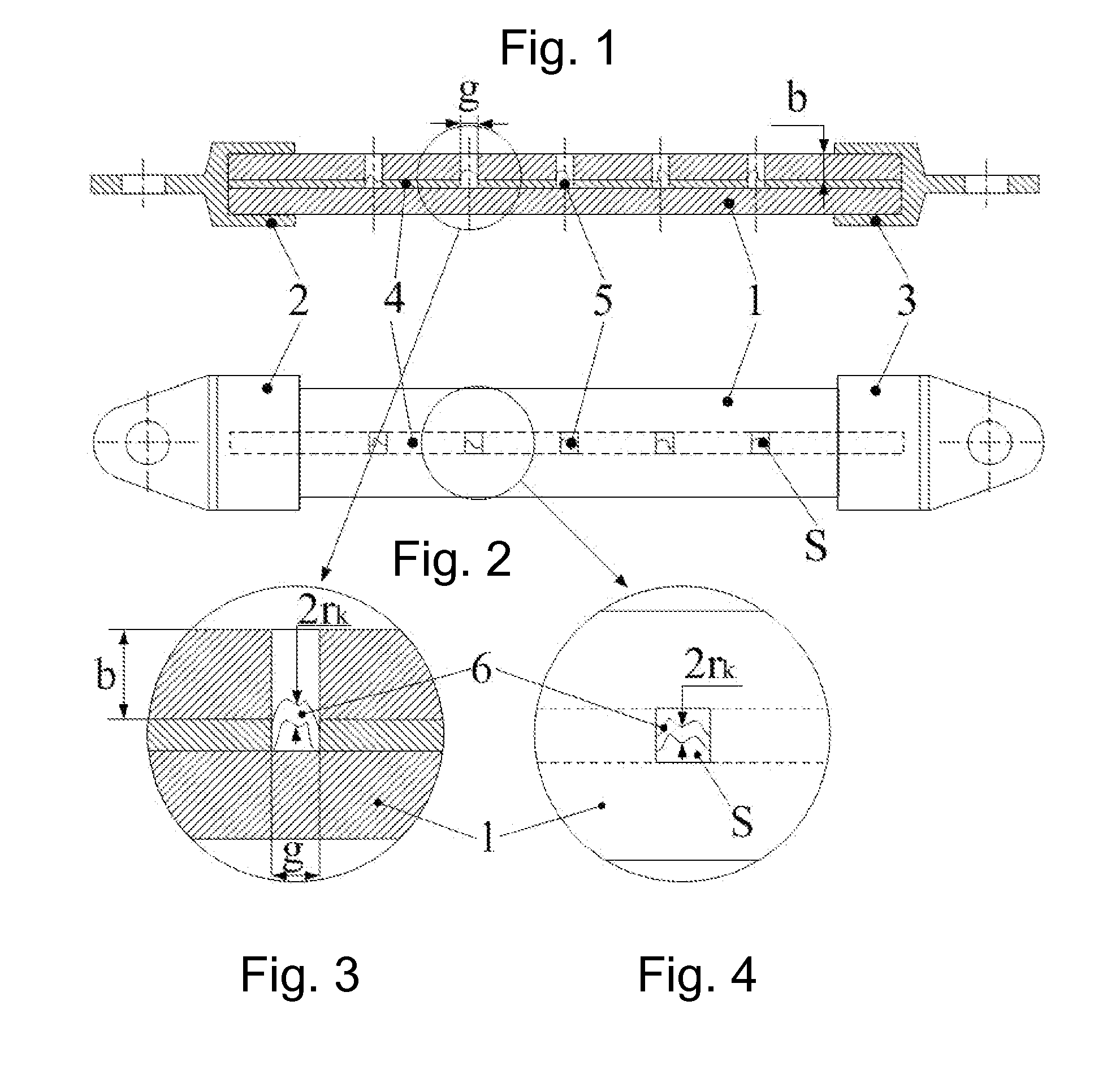

Lightning arrester and a power transmission line provided with such an arrester

ActiveUS20110304945A1Improve reliabilityReduce maintenance costsInstallation of lighting conductorsEmergency protective arrangement detailsElectric power transmissionDielectric

A lightning arrester for protecting elements of electrical facilities or a power transmission line comprises an insulating body which is made of a solid dielectric, preferably in the form of a bar, a strip or a cylinder, two main electrodes that are mechanically coupled to the insulating body and two or more intermediate electrodes. The intermediate electrodes, preferably made in the form of bars or cylinders, are arranged between the main electrodes so that said intermediate electrodes are mutually shifted along the longitudinal axis of the insulating body or along a spiral line. Such design makes it possible to form a discharge channel between the adjacent electrodes. Furthermore, said electrodes are located inside the insulating body and are separated from the surface of the body by an insulation layer. Discharge chambers formed as cavities or through bores opened to the surface of the insulating body are arranged between the pairs of the adjacent electrodes. Dimensions of the chambers are selected such that a discharge is easily blown out from the chambers to the surface of the insulating body, thereby increasing the efficiency of the discharge current quenching. In the preferred embodiments, the arrester is provided with an additional electrode for reducing a flashover voltage. Various embodiments of a power transmission line using the arrester of the invention are also disclosed.

Owner:OTKRYTOE AKTSIONERNOE OBSCHESTVO NPO STREAMER

Tilting-type roller polisher machine

InactiveCN102398205ALow manufacturing and maintenance costsExtended service lifeEdge grinding machinesPolishing machinesSteel platesOpen structure

The invention discloses a tilting-type roller polisher machine. The roller (4) of the polisher machine is spliced by steel plates in different thicknesses. A feed port (8) is arranged at one end of the roller (4) while the other end opposite to the feed port (8) is driven by a rotary force to rotate automatically. The angles of depression and elevation of the roller (4) driven by a tilting force are adjusted. The roller provided by the invention is an open roller without a lining spliced by steel plates in different thicknesses so that the high temperature-resisting and wear-resisting properties of the roller are improved. As the roller provided by the invention is an open structure, the roller will not produce high pressure and high temperature steam during work so that the roller can be directly overturned to pour out the workpiece and grinding materials in the unloading process without problem of high pressure and high temperature steam jet produced to scald personnel or pollute the work site and ambient environment.

Owner:ZHEJIANG HUMO POLISHING GRINDER MFG

Unit modular large household refuse incineration furnace

The invention discloses a unit modular large household refuse incineration furnace and relates to household refuse incineration treatment equipment. The unit modular large household refuse incineration furnace comprises an incineration grate mechanism, air chambers and air supply systems, wherein the incineration grate mechanism comprises a drying section grate, a burning section grate, a burnout section grate and a rack; the drying section grate, the burning section grate and the burnout section grate respectively comprise two groups of grate units; each group of grate units comprises a spindle, a partition plate, a front wall plate, a rear wall plate and a grate with stepped drop; each grate comprises two groups of edge modules and at least one group of middle modules; each edge module and each middle module respectively consist of a plurality of grate sheets; each group of edge modules is fixed on the corresponding rack through a sidewall protection plate device; each air chamber is formed below each middle module and each edge module; an air inlet is formed at the lower end of each air chamber and connected with the corresponding air supply system; and each air supply system comprises a drying section air supply system, a burning section air supply system and a burnout section air supply system. The unit modular large household refuse incineration furnace is stable in operation, low in energy consumption and long in service life.

Owner:江苏楹能环保科技发展有限公司

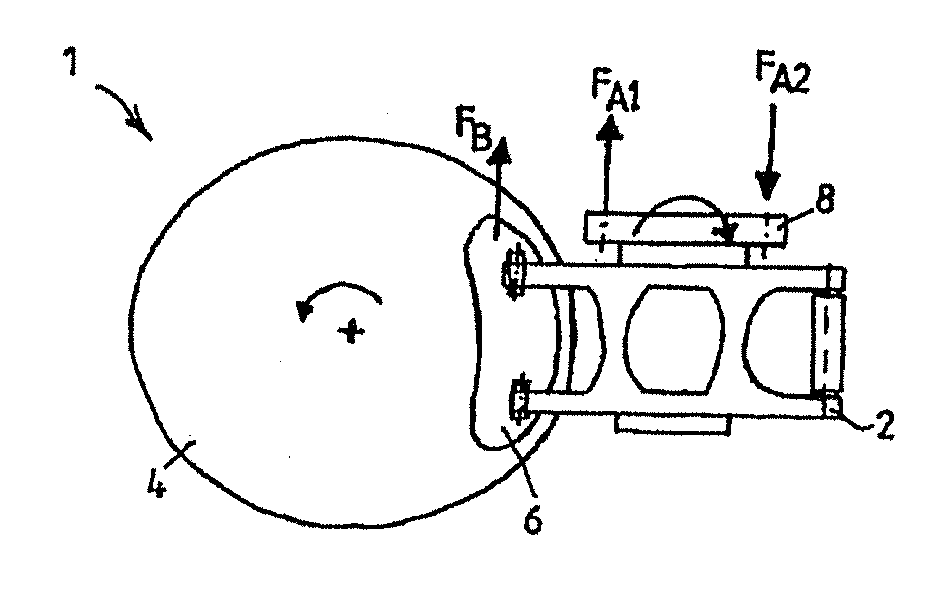

Brake system of a rail vehicle with compensation of fluctuations of the friction conditions

ActiveUS20120018260A1Reduce maintenance costsReduce manufacturing costMechanically actuated brakesDigital data processing detailsTime profileEngineering

A brake system of a rail vehicle, having at least one brake actuator with at least one brake disk and at least one brake lining, which interacts with the brake disk, for generating a braking force. Also disclosed is a sensor device to measure the time profile of at least one variable, representing fluctuations in the friction conditions between the wheel or wheel set assigned to the brake actuator and the rail and / or between the brake disk assigned to the brake actuator and the at least one brake lining, and to output a signal dependent on the measured variable to a control device which adapts the braking force generated by the brake actuator as a function of the deviation of the time profile of the measured variable from a predefined or expected time profile of the variable.

Owner:KNORR BREMSE SYST FUR SCHIENENFAHRZEUGE GMBH

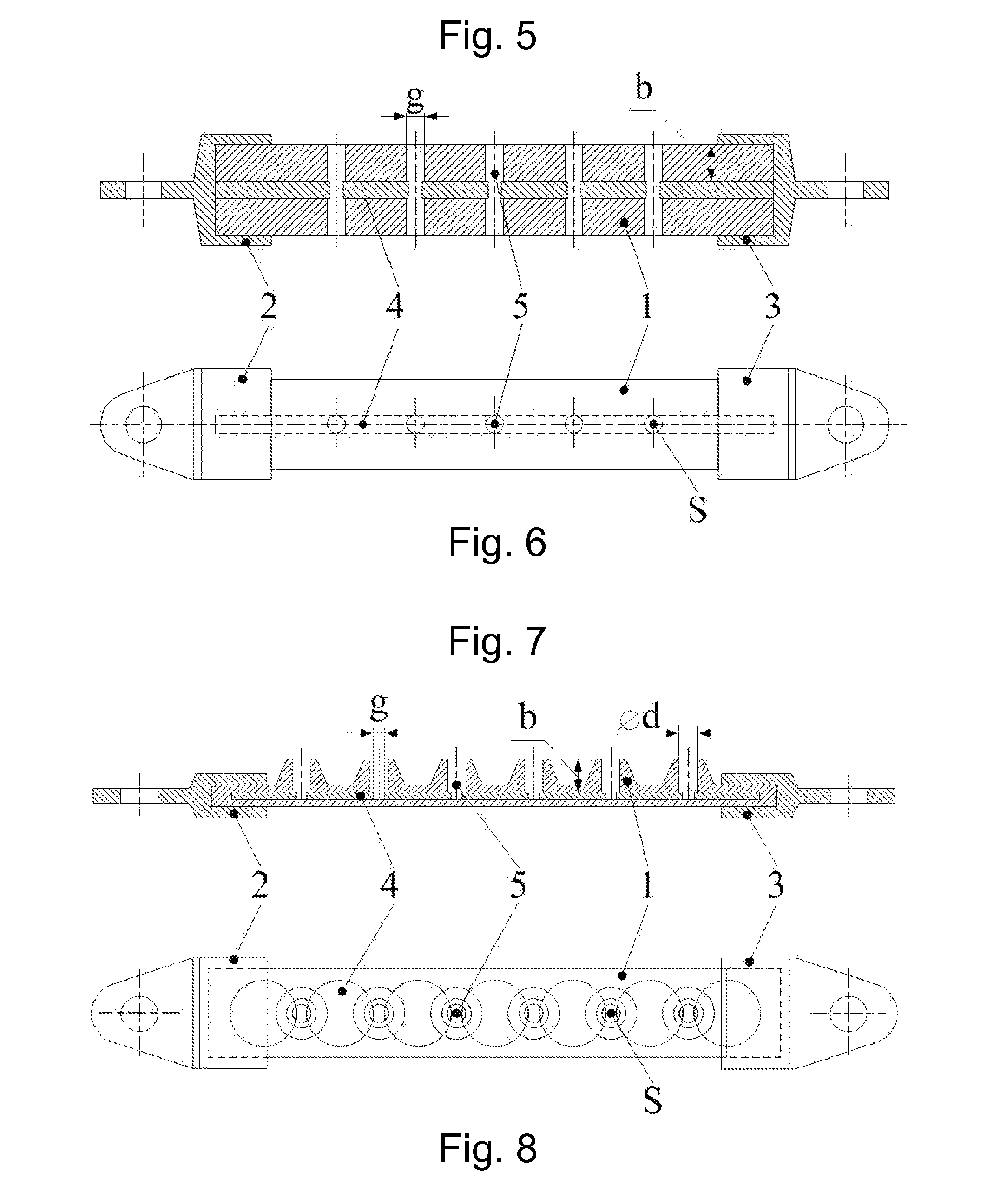

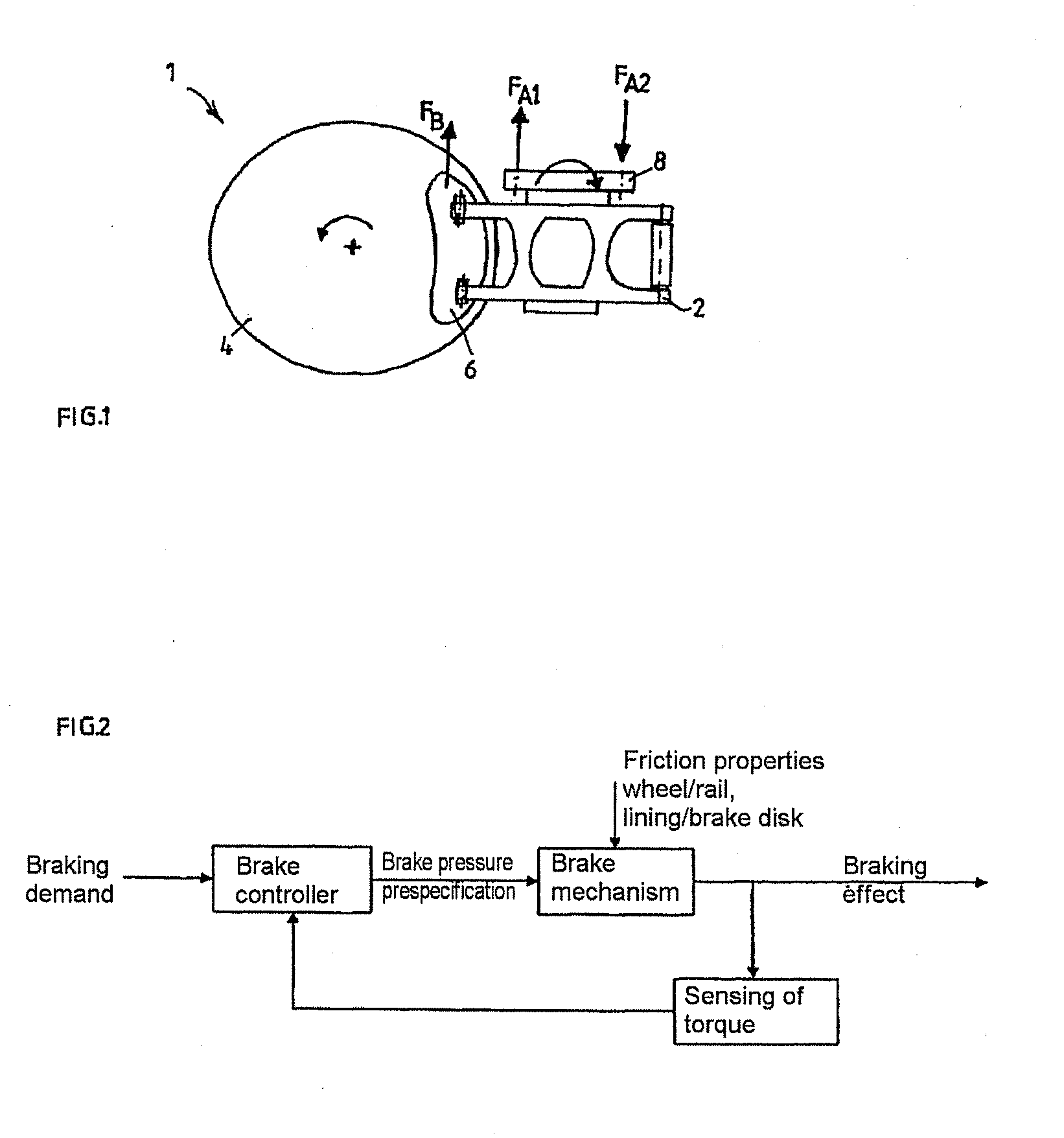

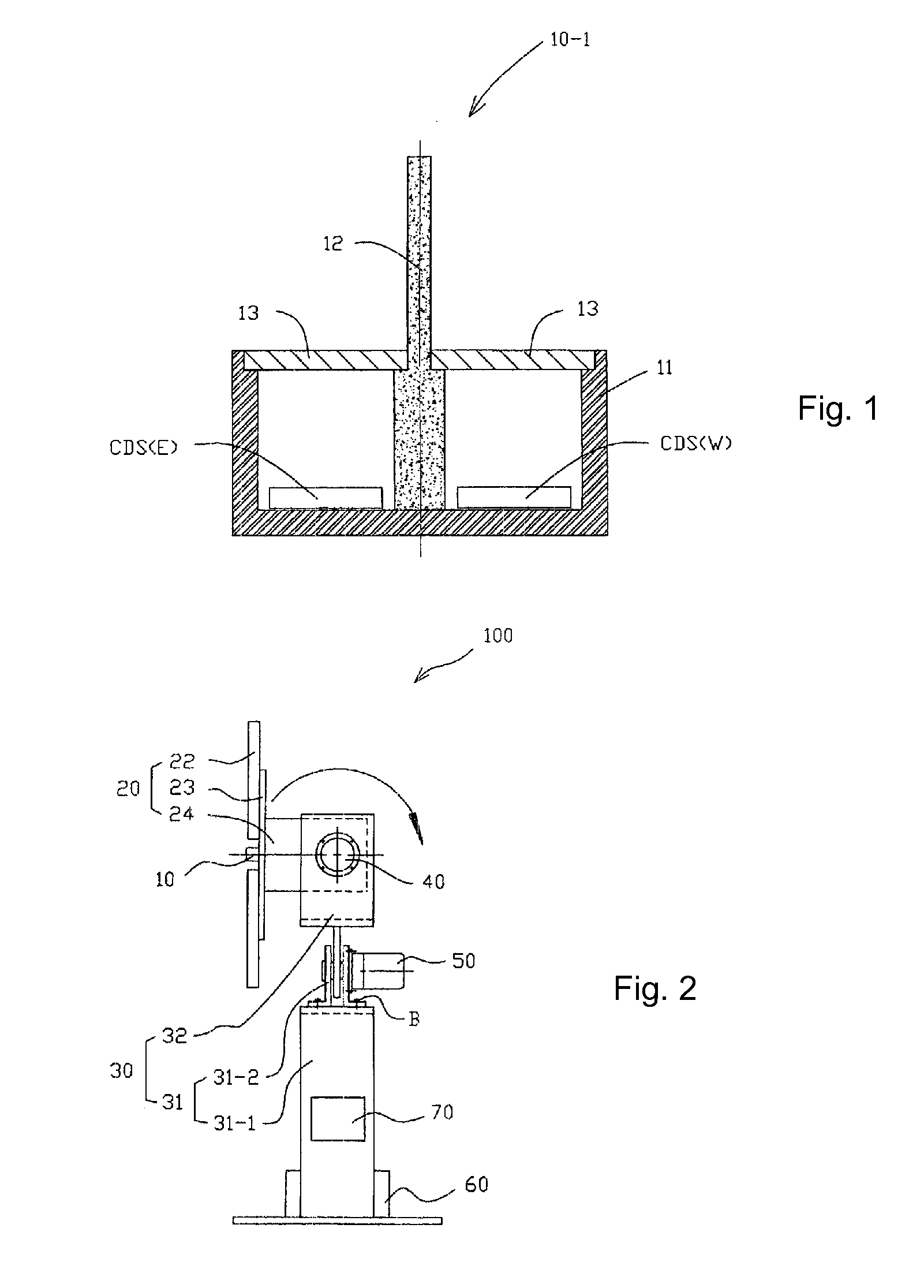

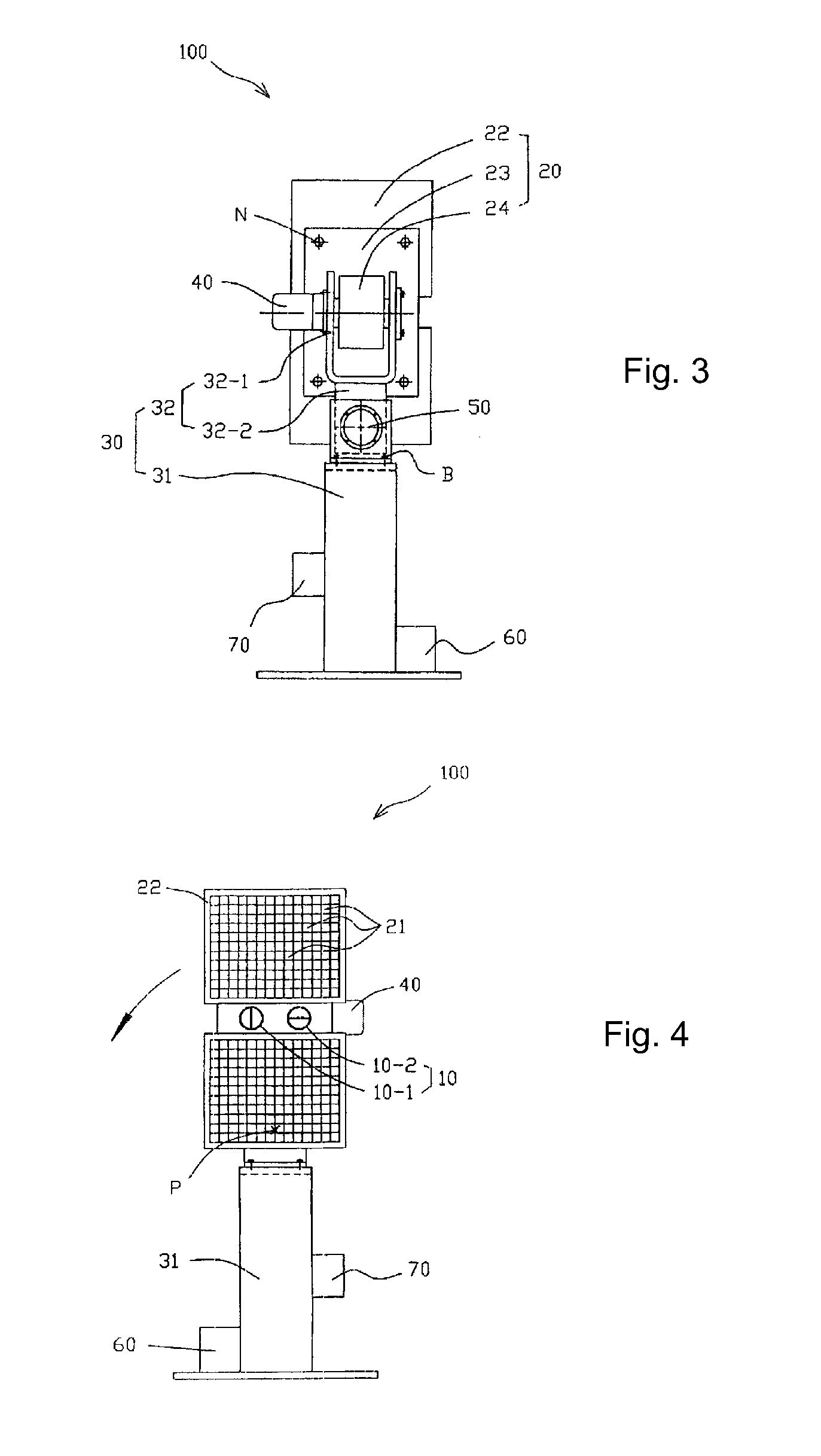

Sun Following Sensor Unit And A Sun Following Apparatus Having The Same Therewith

InactiveUS20100192940A1Simple structureLow manufacturing and maintenance costsPhotovoltaic supportsSolar heating energyLower limitEngineering

The present invention relates to a sun tracking sensor unit and a sun tracking apparatus having the same. There is provided a sun tracking apparatus, which comprises a sun tracking sensor unit 10 comprising an upright barrier 12 for partitioning a sensor case into four specific areas of east, west, south and north, CDS elements CDS(E), CDS(W), CDS(S), and CDS(N) respectively disposed in the four areas partitioned by the upright barrier 12, and the sensor case 11 functioning as a body for supporting the upright barrier and the CDS elements; a solar panel combination 20 including a solar panel 22 having a plurality of solar cells attached thereon and a solar support body 24 coupled to a rear thereof; a housing 30 functioning as a body for supporting the sun tracking sensor unit 10 and the solar panel combination 20; and an east-west driving motor 40 and a south-north driving motor 50, coupled to the housing to adjust an angle of the solar panel by rotating the solar support body respectively in east-west and south-north directions. Accordingly, its tracking accuracy is high due to the lower limit of trackable illumination intensity, and its whole structure is simple, thereby having a low manufacturing and maintenance cost.

Owner:YOON JOO PYOUNG

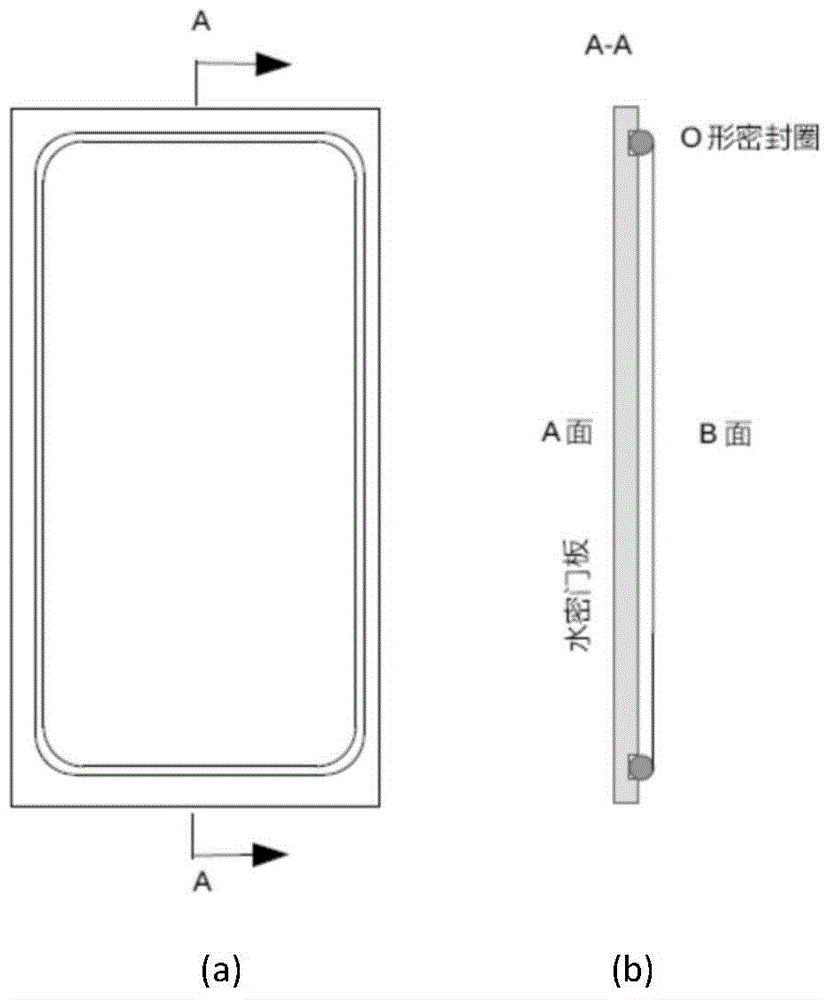

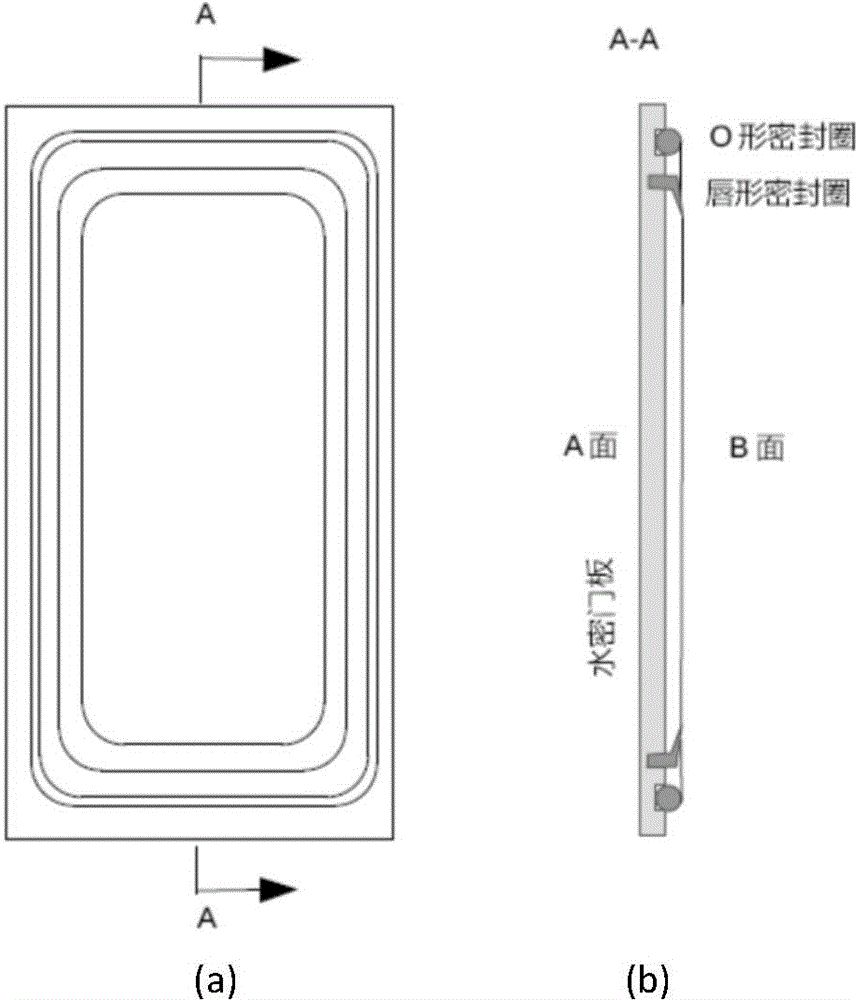

Sealing device for sliding watertight door

InactiveCN104533257AImprove sealingTo overcome the shortcomings of the single application caseSealing arrangementsWing arrangementsUltimate tensile strengthFace seal

The invention discloses a sealing device for a sliding watertight door. The sealing device comprises a sealing assembly and pressing mechanisms arranged on the door frame, wherein the sealing assembly comprises O-shaped sealing rings arranged on the surface of a door plank or the door frame and lip-shaped sealing rings arranged on the inner sides of the O-shaped sealing rings, the lip-shaped sealing rings are in a single opening lip shape, and lip openings face the center of the door plank. The pressing mechanisms comprise wedge-shaped blocks and pressing drive units. After the door plank is driven by a sliding drive unit in place in the sliding direction, the pressing drive units drive the wedge-shaped blocks to move so as to press the door plank to the door frame in the door plank pressing direction, and thus good double-face sealing of the watertight door is achieved through the independent separation operation of sliding and pressing, relative to the door frame, of the door plank, the requirement for evenly sealing the double faces of the watertight door can be met, meanwhile the problem that sealing performance is lowered due to wear to and the shape and mounting state change of the sealing piece caused by opening and closing of a watertight door is solved, and the requirements for the power of a power device and rigidity and strength of a drive device are lowered.

Owner:刘炎

Gloves online release stacking machine

InactiveCN102285055ASimple transmission structureLow manufacturing and maintenance costsCoatingsDrive motorPulley

The invention discloses a glove online de-moulding and stacking machine, which has a simple driving structure and is driven by using an ordinary motor. The glove online de-moulding and stacking machine comprises a machine frame, a pair of rotating shafts, a driving shaft, and a rotation driving device, wherein the rotating shafts and the driving shaft are arranged on the machine frame in parallel; the driving shaft is connected with an output shaft of the rotation driving device; at least one pair of corresponding swing bases is fixed on the pair of rotating shafts; a glove clamping device with an opening and closing mechanism is arranged on the swing bases; a pair of master synchronous belt pulleys is arranged on the rotating shafts; slave synchronous belt pulleys matched with the corresponding master synchronous belt pulleys are respectively arranged on the pair of rotating shafts; and the master synchronous belt pulleys are in meshing drive with the corresponding slave synchronous belt pulleys through synchronous belts. A continuous circulating rotation way is adopted in the glove clamping device, so the driving structure is simpler. In addition, the ordinary motor serves as a driving motor, so the manufacturing cost and the maintenance cost are greatly reduced.

Owner:张家港市益成机械有限公司

Manual spring tension and compression testing machine

InactiveCN103292969AReduce usageLow manufacturing and maintenance costsElasticity measurementElectronic componentCalipers

The invention discloses a manual spring tension and compression testing machine which aims to solve the problems that spring elasticity coefficients are detected by special equipment mostly made of electronic components currently and the special equipment is not applicable to field operation and the like. The manual spring tension and compression testing machine comprises a frame, a measuring mechanism, a transmission mechanism and a tension and compression clamp mechanism. The measuring mechanism comprises a wide-range vernier caliper (12), a small-range vernier caliper (16) and a spring (5). The spring (5) is sleeved on an upper pressing plate guide rod (3), the upper end of the spring (5) is fixed with a middle crossbeam (6), the lower end of the spring (5) is fixed with an upper spring pressing plate (15) of the tension and compression clamp mechanism, an upper measuring jaw of the small-range vernier caliper (16) is fixed with the middle crossbeam (6), a lower measuring jaw of the small-range vernier caliper (16) is fixed with the lower surface of the upper spring pressing plate (15), an upper measuring jaw of the wide-range vernier caliper (12) is fixed with the upper surface of an upper crossbeam (10), and a lower measuring jaw of the wide-range vernier caliper (12) is fixed with the lower surface of the upper spring pressing plate (15).

Owner:JILIN UNIV

Rubbing type bag mouth opening device for automatic packing of packed food

The invention discloses a rubbing type bag mouth opening device for automatic packing of packed food. The rubbing type bag mouth opening device comprises a clamping mechanism and a shoving mechanism, wherein the clamping mechanism switches between a state of clamping a packing bag and a state of loosening the packing bag; two corresponding clamping working faces of two clamping elements clamp the middle parts of two side walls, close to the bag mouth, of the packing bag for rubbing; four hanging hooks of the shoving mechanism are inserted into two almond-like openings formed by rubbing; then the four hanging hooks are positioned at four corners and the bag mouth is pulled open, so a stable quadrangle is formed; a discharging hopper with the corresponding shape is inserted into the bag mouth, so the filling is realized. According to the rubbing type bag mouth opening device disclosed by the invention, the bag mouth of the packing bag can be automatically and reliably opened; in addition, the opening shape of the bag mouth is stable and is tightly jointed with the discharging hopper. The rubbing type bag mouth opening device has the advantages of ingenious design, simple action, high efficiency for work, lower manufacturing and maintaining cost, and high easiness for popularization and application. The production efficiency is improved, the production cost is reduced, and the safety of food is guaranteed.

Owner:临泉县曙光食品有限公司

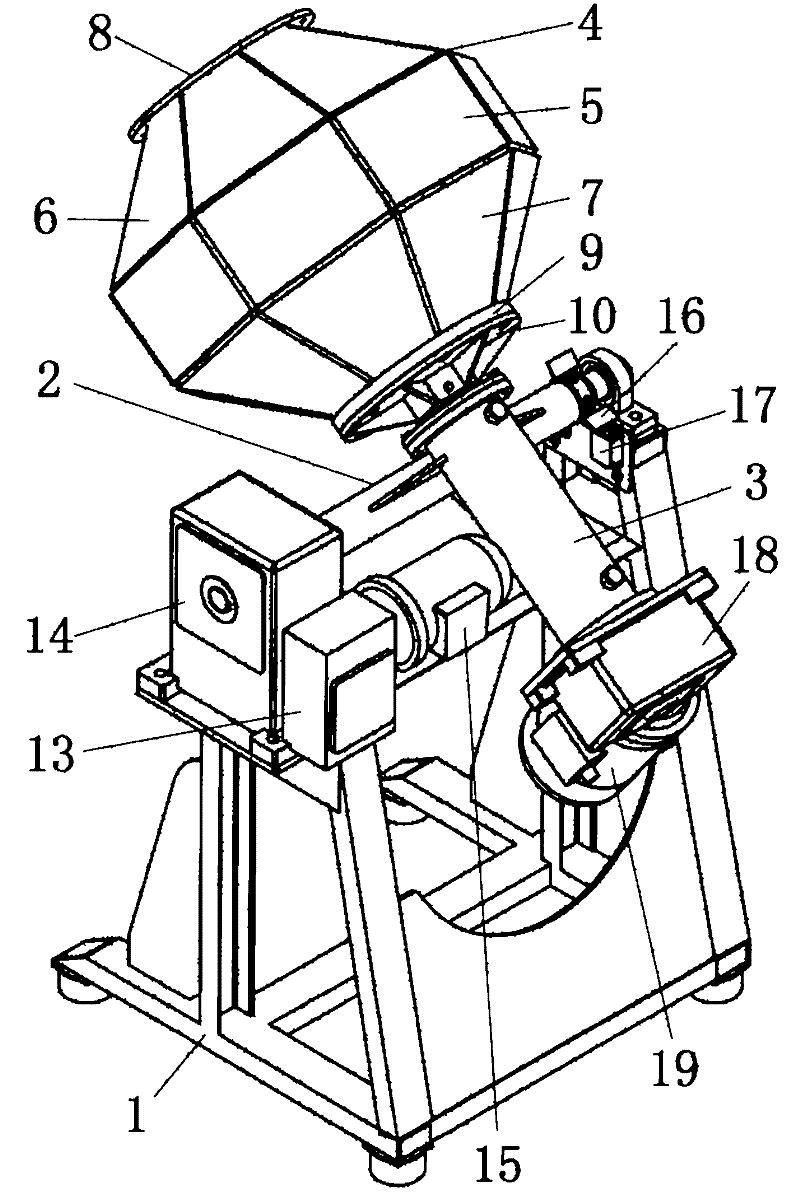

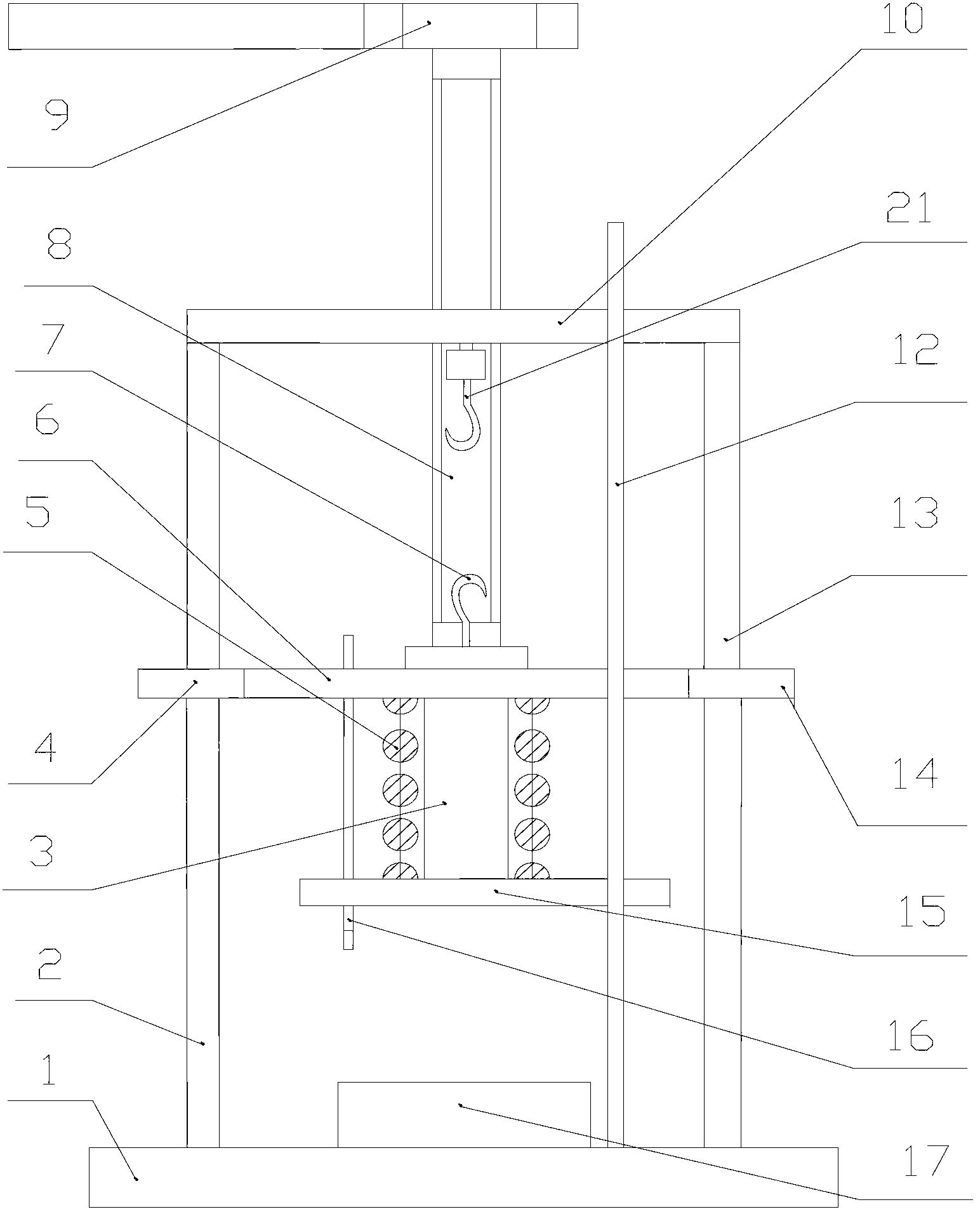

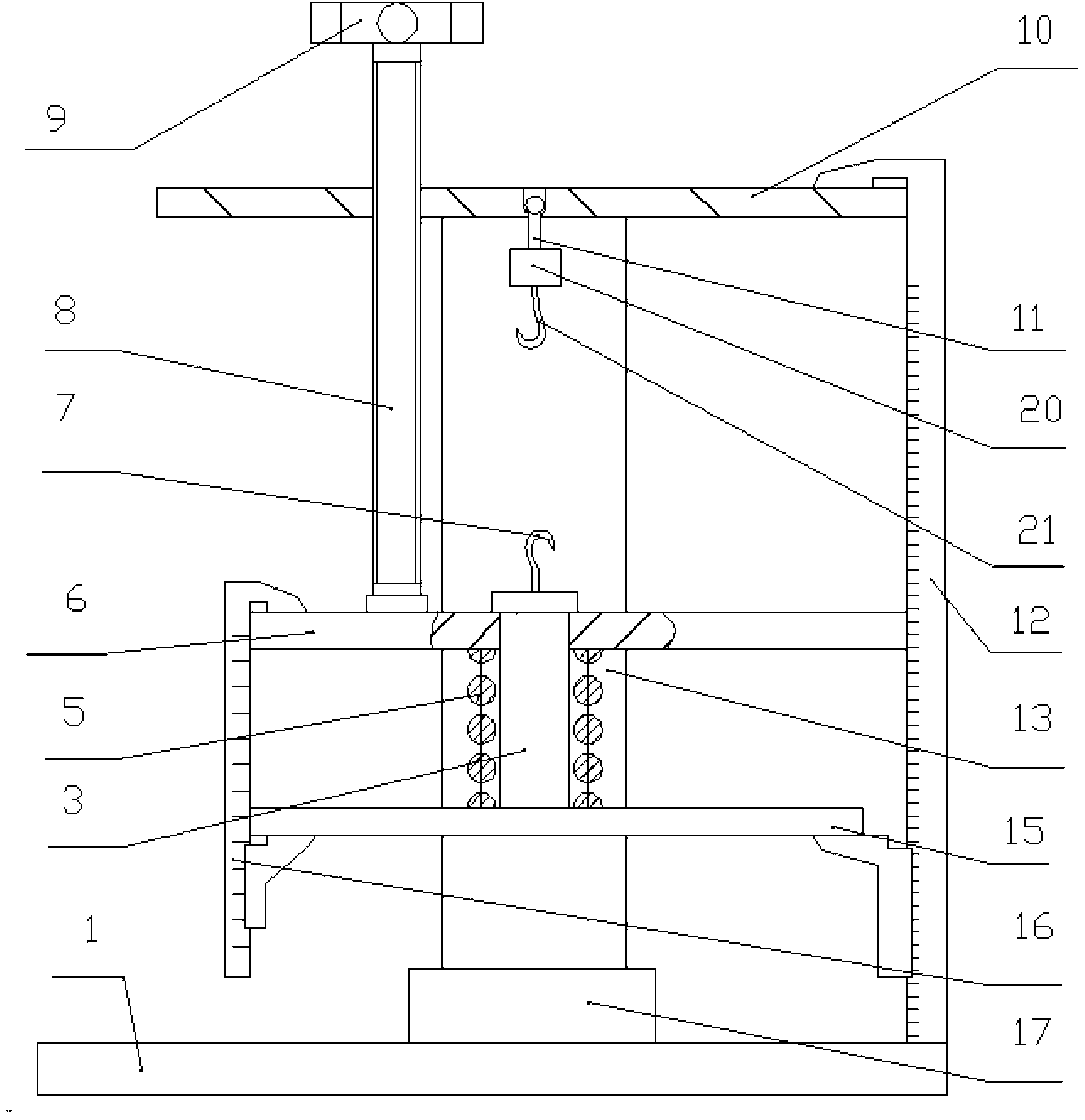

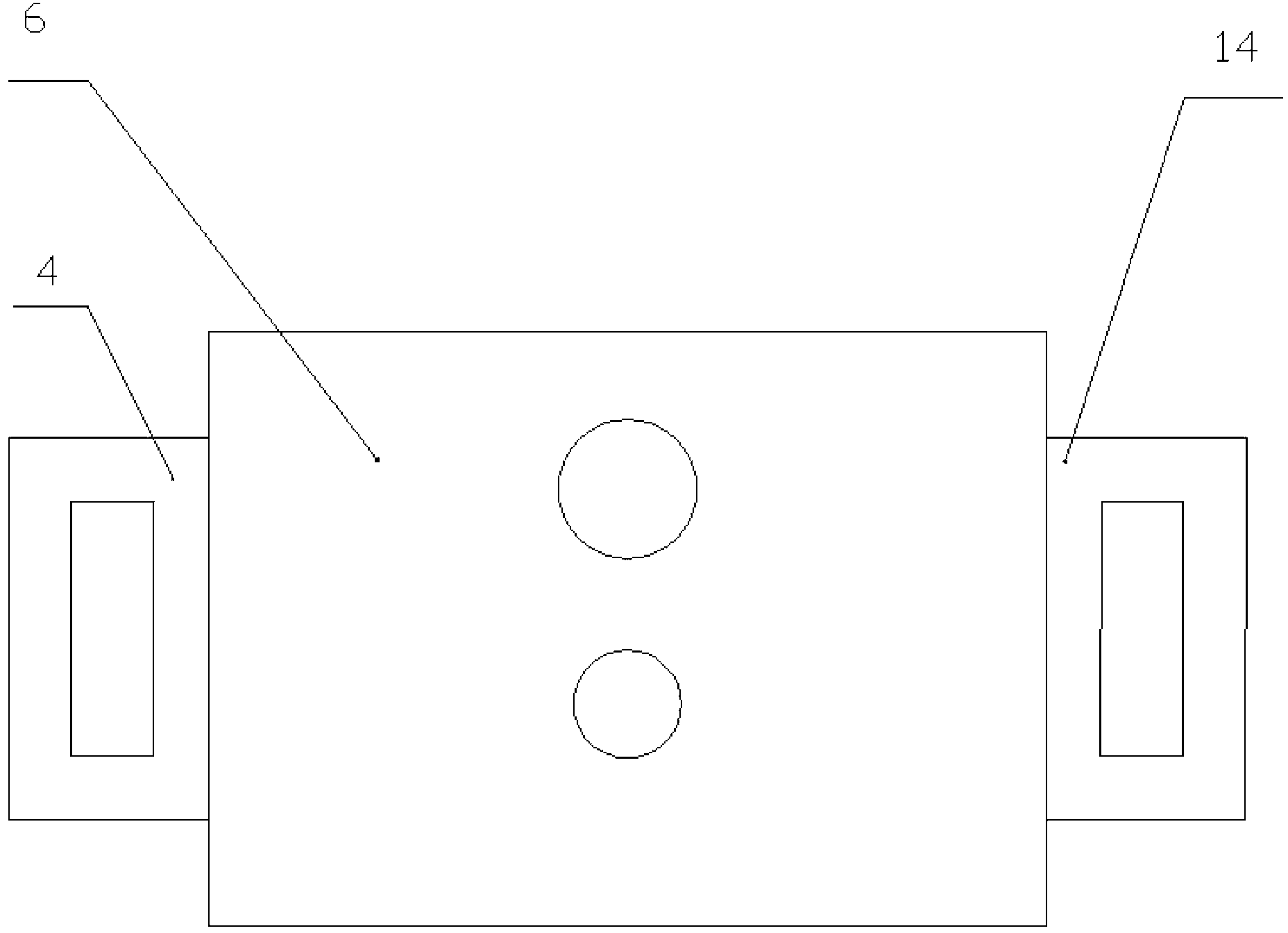

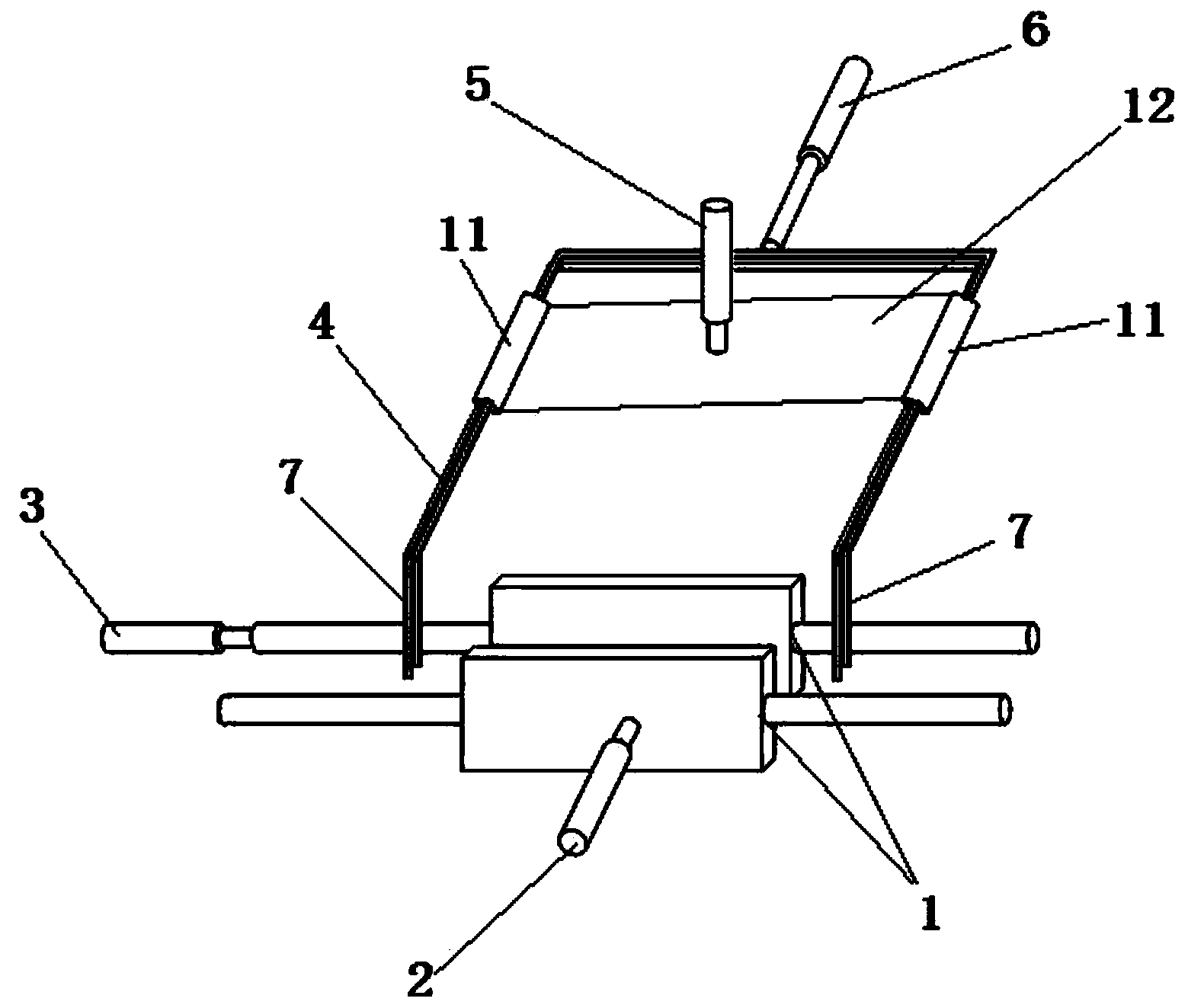

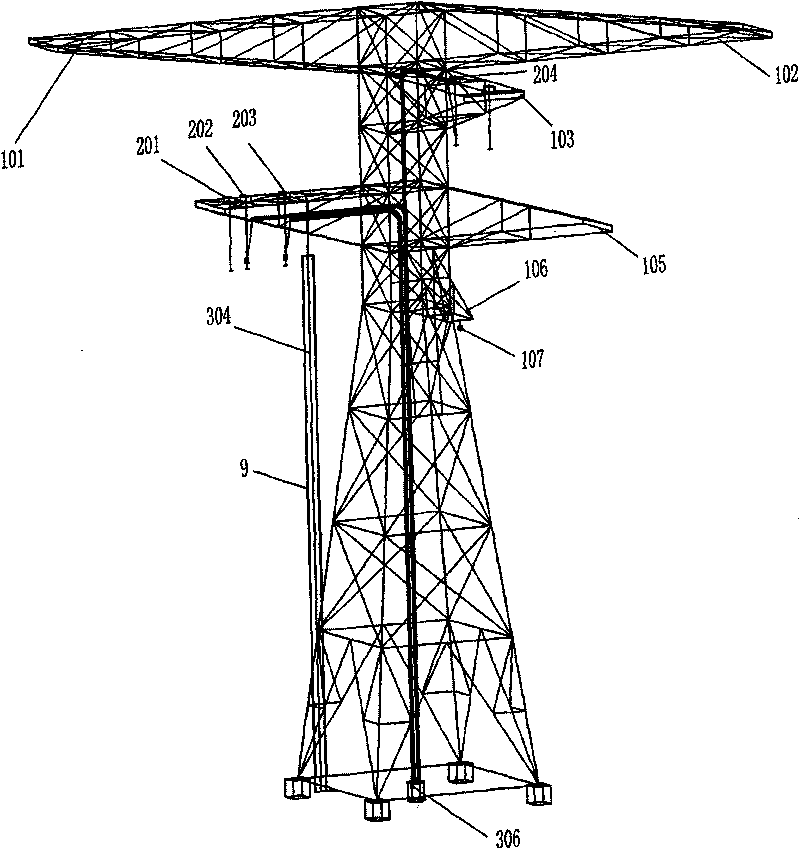

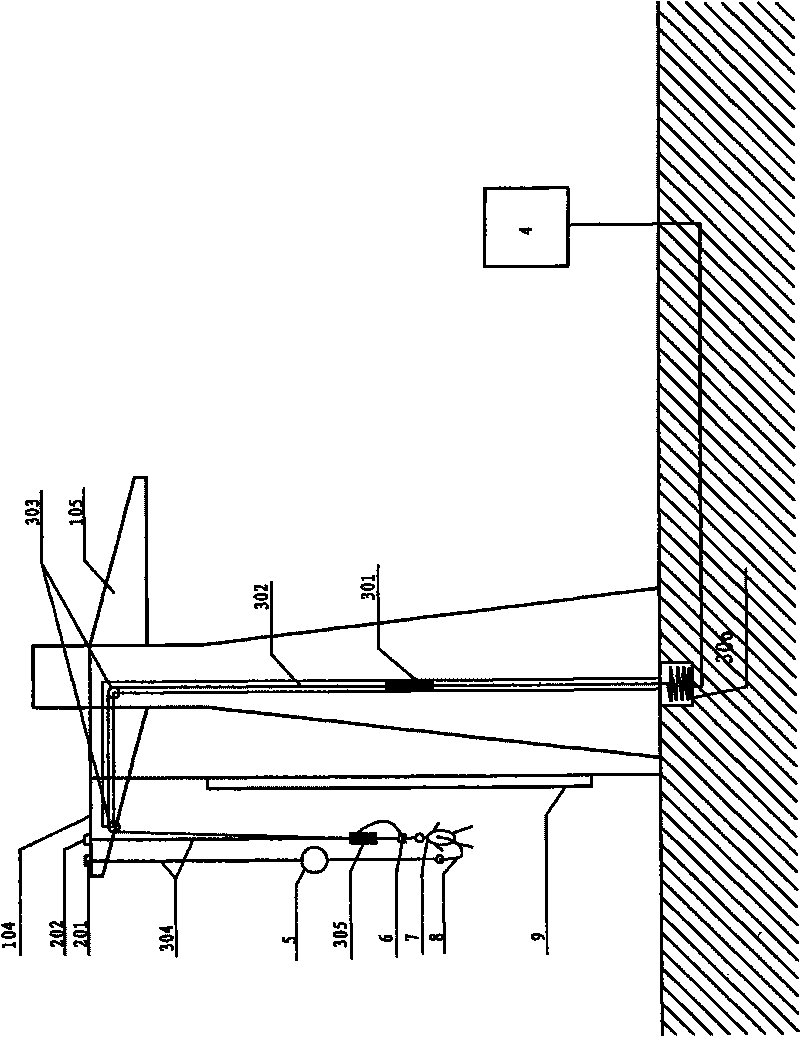

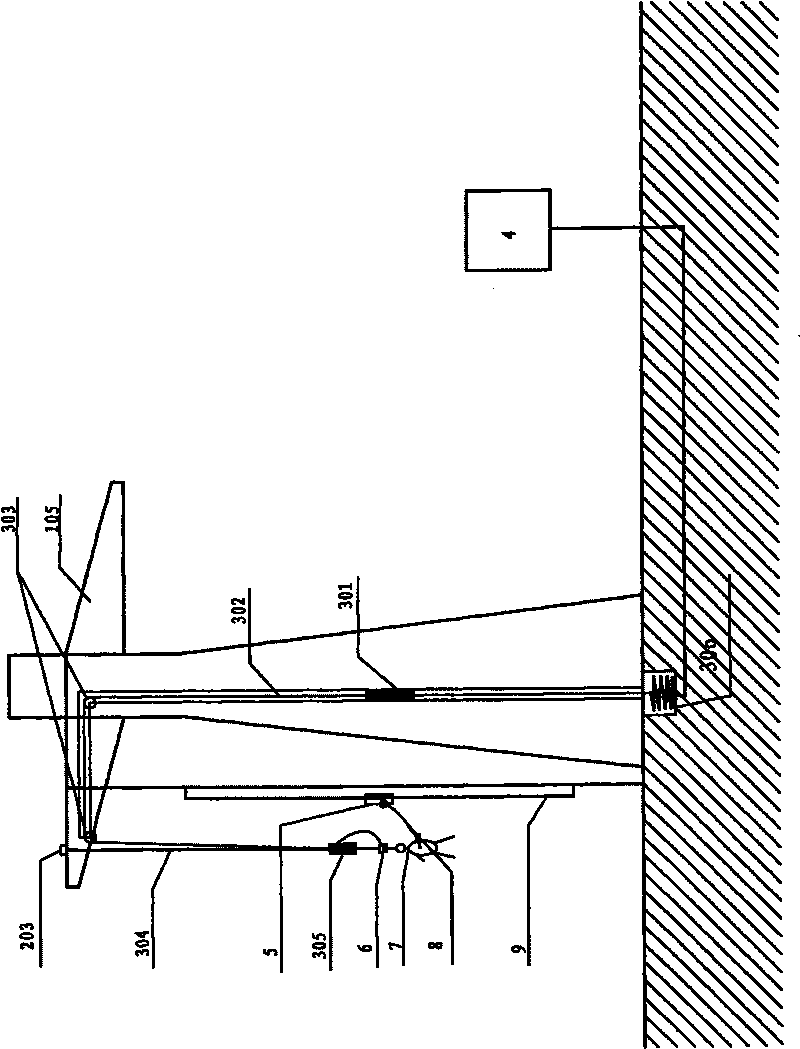

Test tower for multi-functional fall protection device

ActiveCN101762373ALow manufacturing and maintenance costsImprove utilization efficiencyShock testingFall protectionCantilevered beam

The invention discloses a test tower for a multi-functional fall protection device, comprising a tower post, a motor unit, a cable automatic retraction jack and a control system; wherein the tower post comprises a third cantilever beam and a sixth cantilever beam arranged in parallel from top to bottom and a fourth cantilever beam arranged vertically to the third cantilever beam; the cable automatic retraction jack comprises a cable weight block, a cable, a first pulley block, a second pulley block, a steel cable and a steel cable weight block; wherein the first pulley block and the second pulley block are respectively arranged on the fourth cantilever beam and the third cantilever; the motor unit comprises is arranged on the fourth cantilever beam and a first electric motor, a second electric motor and a third electric motor which are arranged on a straight line and parallel to the first pulley block and a fourth electric motor arranged on the third cantilever beam; wherein each electric motor is provided with a clasp, the sixth cantilever bam is also provided with a clasp. The invention can serve several purposes, save manufacturing and maintenance cost, improve utilization ratio and reduce used space.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER

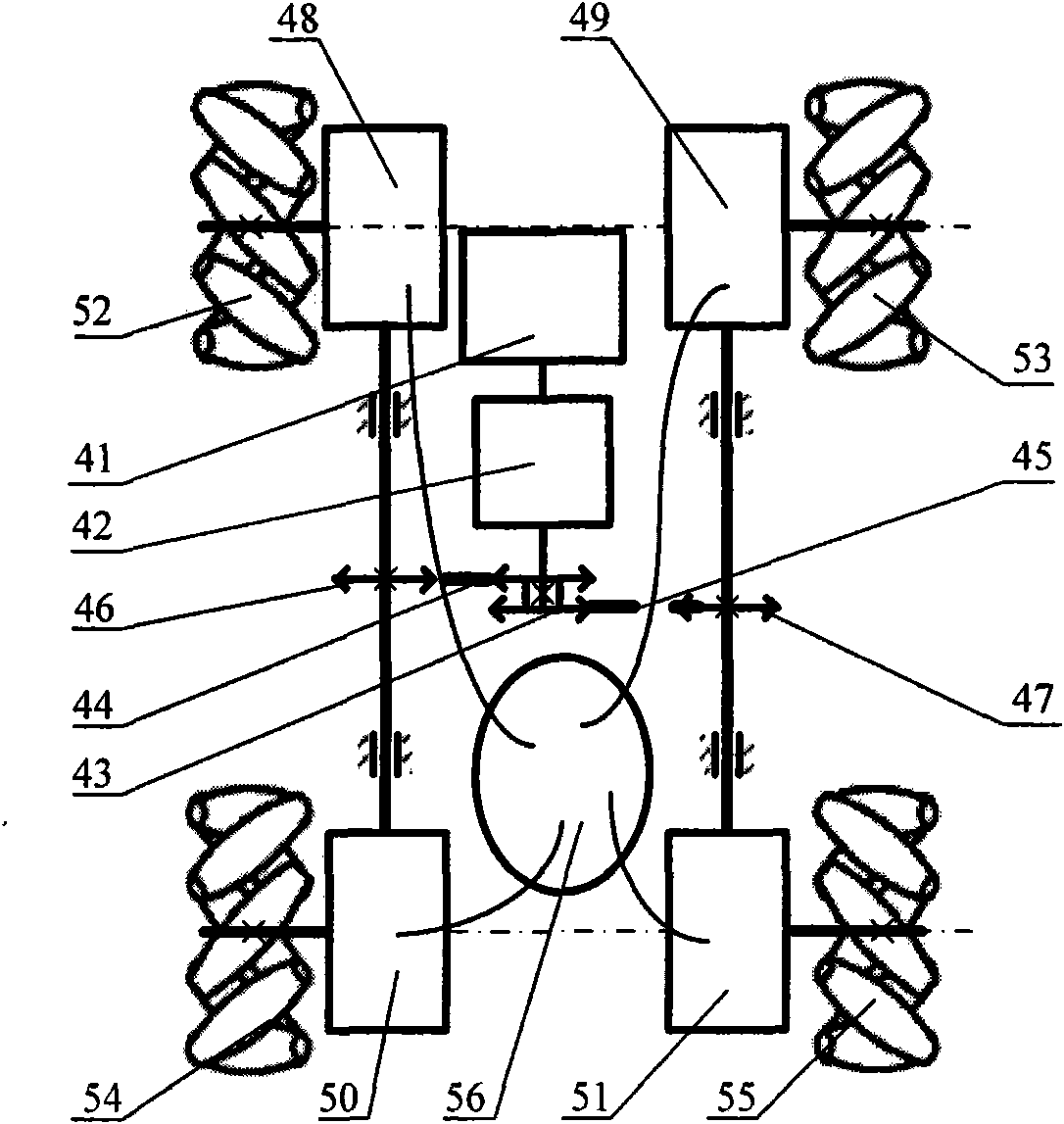

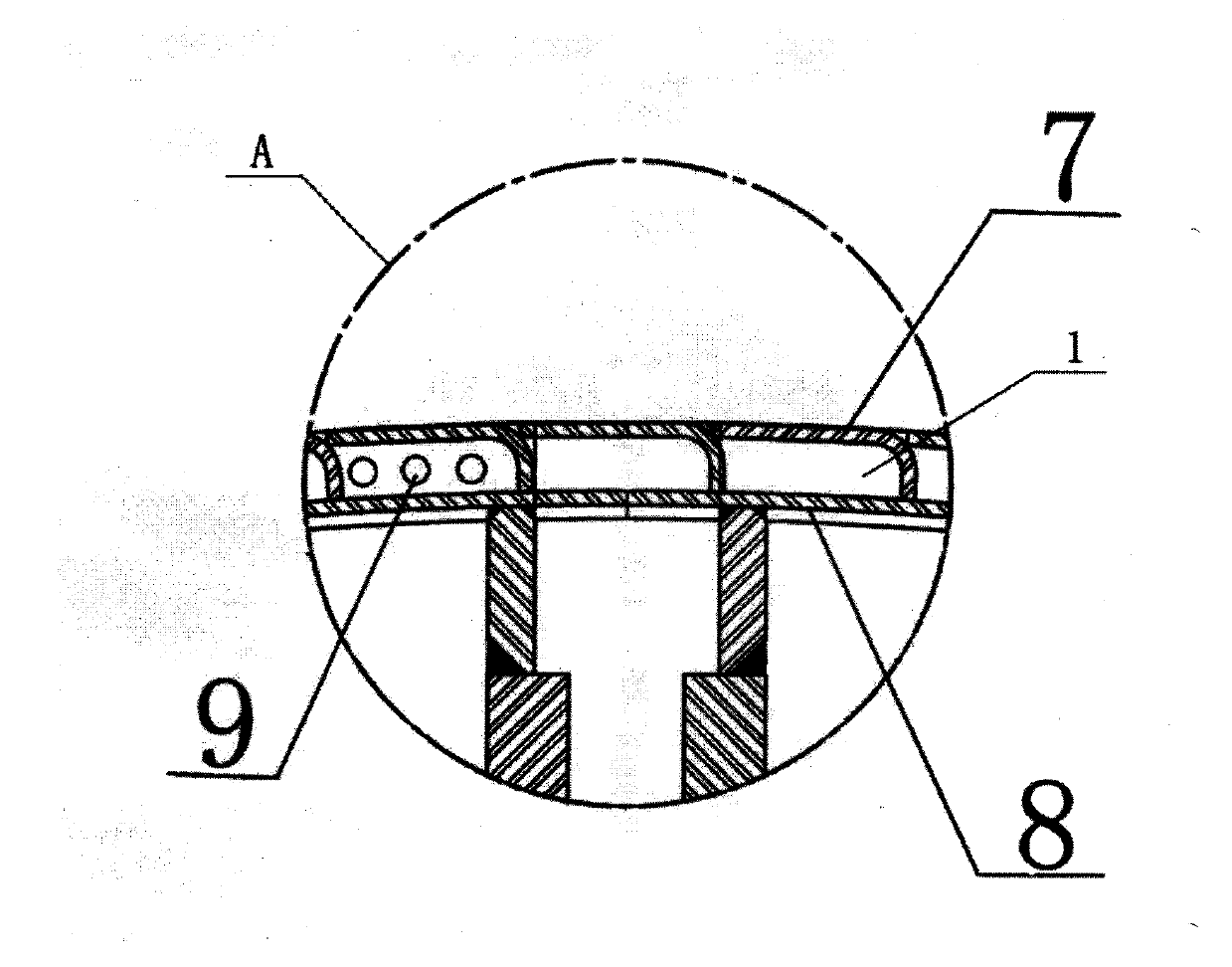

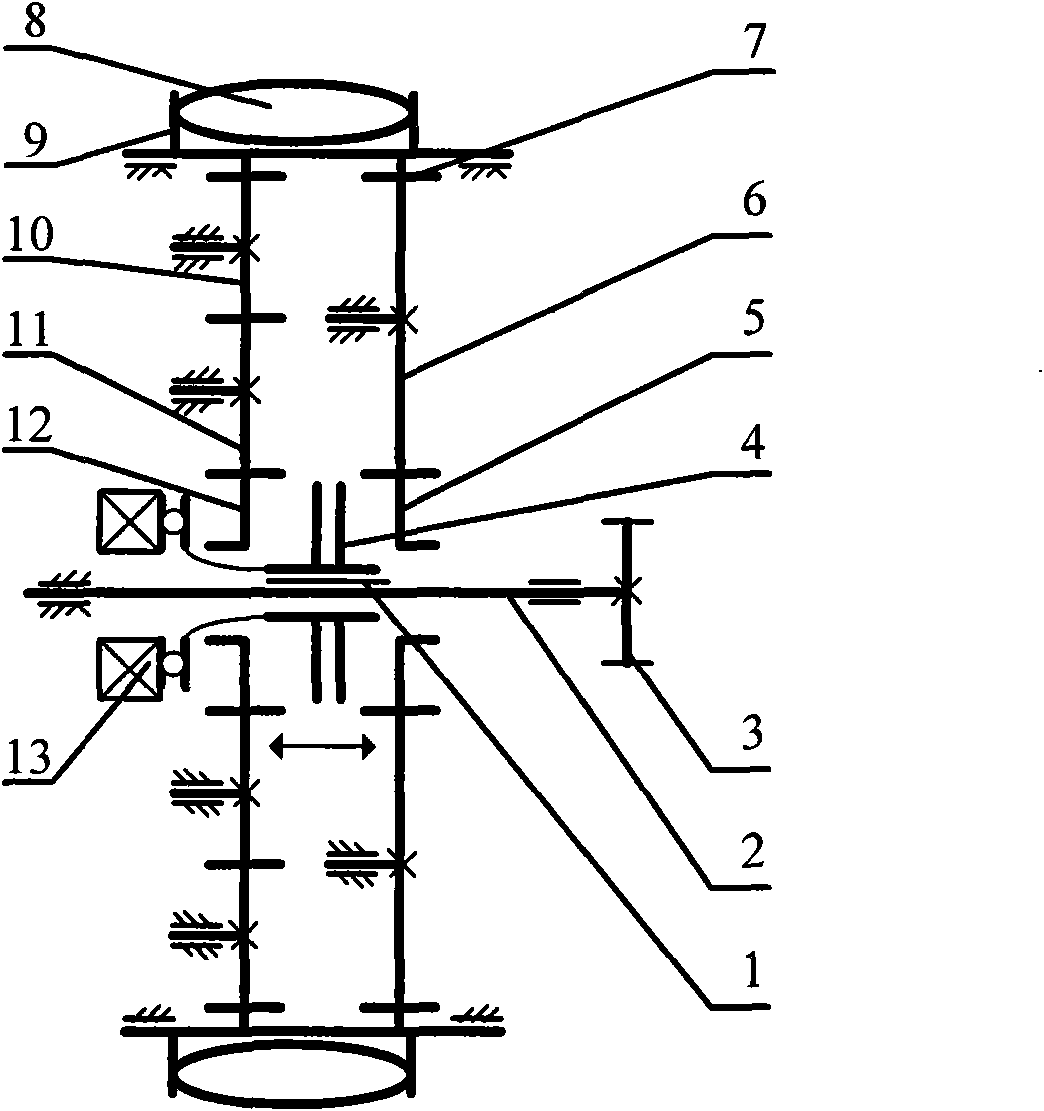

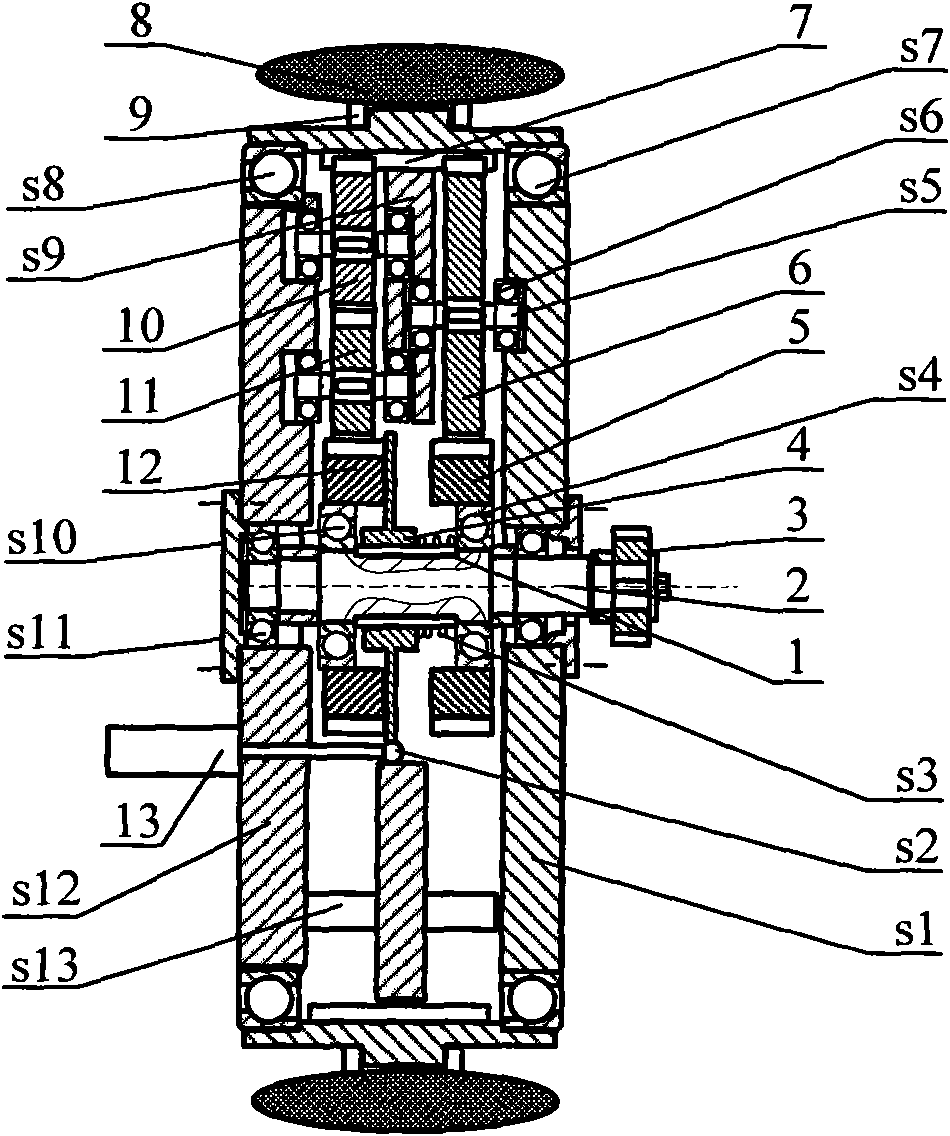

Embedded type straight gear reversing Mecanum wheel

InactiveCN101654039ASimple control systemImprove reliabilityWheelsVehiclesSupporting systemGear wheel

An embedded type straight gear reversing Mecanum wheel comprises a Mecanum wheel body, wherein a supporting system is disposed on the interior of the Mecanum wheel body and is rotatably connected withthe Mecanum wheel body. An internal gear ring flange is disposed on the inner wall of the Mecanum wheel body. A power input shaft is disposed on the supporting system and is located in the gyration center of the Mecanum wheel body. A reversing free central gear and a homodromous free central gear are disposed on the power input shaft. A reverse mechanism is linked on the power input shaft. A reversing driving gear, a first homodromous driving gear and a second homodromous driving gear are rotatably connected on the supporting system. The reversing driving gear is engaged with the reversing free central gear and the internal gear ring flange. The first homodromous driving gear is respectively engaged with the homodromous free central gear and the second homodromous driving gear which is engaged with the internal gear ring flange.

Owner:SOUTHEAST UNIV

Gripping device with switchable prehension modes

Owner:INVISIBLE HAND ENTERPRISES LLC

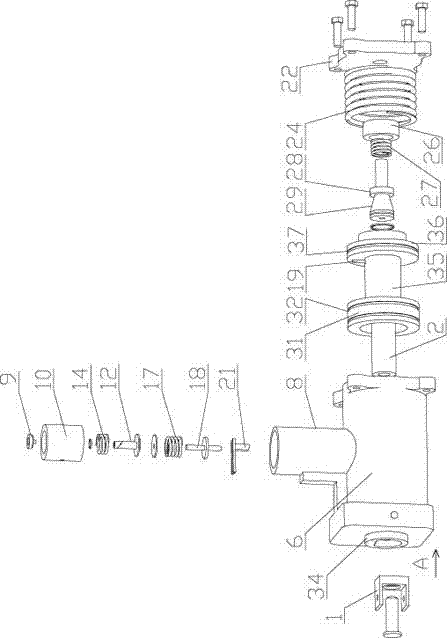

A clutch control valve for a cable-type gas-assisted vehicle

The invention relates to vehicle spare parts and provides an inhaul-cable type clutch control valve for a gas power assistant vehicle. The inhaul-cable type clutch control valve is provided with a cylinder-shaped shell, the left end of the shell is the closed end, and a center hole is formed in the end face of the left end of the shell; an opening is formed in the right end of the shell, the right end of the shell is equipped with an end cap, and a valve body seat sleeve is installed in the middle of the shell. The inhaul-cable type clutch control valve is characterized in that a piston linkage body is installed in the shell, a piston, a pull arm shaft and a linkage shaft are installed on the linkage body, and the pull arm shaft stretches out of the shell and is provided with a cross connection frame; an air pressure cavity is formed between the left end of the piston and the closed end of the shell, a sliding guiding cavity is formed in the linkage shaft, and a tapered sliding seat is installed inside the sliding guiding cavity and equipped with a returning spring; the right end of the sliding seat is connected with an inhaul cable which stretches out of the end cap to be externally connected with a driving piece, and a compressing spring is installed outside the linkage shaft; and a feeding and discharging valve is installed in the valve body seat sleeve and equipped with a jacking rod mechanism, so that air feeding or discharging for the air pressure cavity is achieved. According to the inhaul-cable type clutch control valve for the gas power assistant vehicle, the problems that an existing clutch control valve is complex in structure, high in manufacturing and maintaining cost and prone to being worn are solved, and the inhaul-cable type clutch control valve is suitable for clutch control of passenger cars and goods motor vehicles.

Owner:江金华

Suspension type air spring middle-placed middle-low-speed magnetic suspension train running module

InactiveCN101112874ALow priceEasy to installBogie-underframe connectionsElectric propulsionLow speedAir spring

The invention discloses a middle and low speed maglev train walking module with an air spring arranged in the middle. The invention includes a suspension frame (1), and two traction rods (2) and an air spring (3) which are arranged on the suspension frame (1), wherein, the central position of the suspension frame (1) is transversely provided with a bolster (4); both ends of the bolster (4) are supported on the suspension frame (1) by the air spring (3) below; the external sides at both ends of the bolster (2) are suspended with a hoist rod (9); the other end of the hoist rod (9) is articulated with the vehicle body. The walking mechanism has the advantages of simple structure, low production cost, easy installation and manufacture, large beeline motor power, high efficiency and fast operation speed of the maglev train.

Owner:SOUTHWEST JIAOTONG UNIV

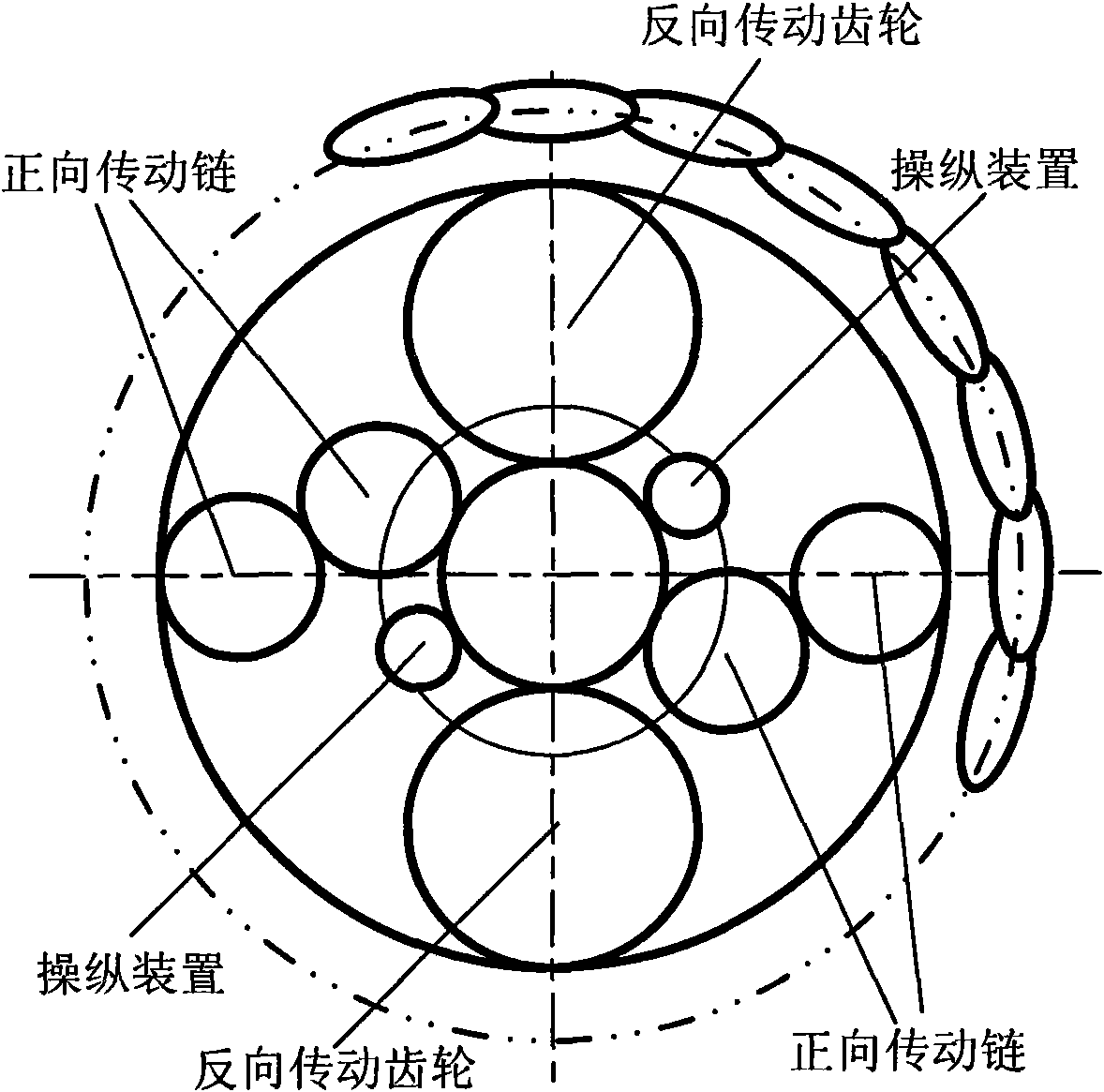

Integrated bevel inverting mecanum wheel

InactiveCN101659287ASame direction of rotationChange direction of rotationVehiclesTransmitted powerGear wheel

An integrated bevel inverting mecanum wheel comprises a mecanum wheel, an input shaft and an output shaft, a right bevel gear and a left bevel gear are idly sheathed on the input shaft, an output bevel gear meshed with the right bevel gear and the left bevel gear is fixedly arranged on the output shaft, the mecanum wheel is arranged on the output shaft, and an inverting driver used for transmitting power from the input shaft to the right bevel gear or the left bevel gear is also arranged on the input shaft. The invention designs a direct drive bevel gear drive chain and a reverse drive bevel gear drive chain between the input shaft and the mecanum wheel, selects the used drive chain by external operational device control to change rotation direction of the mecanum wheel, realizes full omnibearing motion car designed by adopting the integrated bevel gear inverting mecanum wheel and realizes car body motions of ten bearings of forward, backward, left, right, left front 45 degrees, leftrear 45 degrees, right front 45 degrees, right rear 45 degrees, clockwise rotation in place, anticlockwise rotation in place.

Owner:SOUTHEAST UNIV

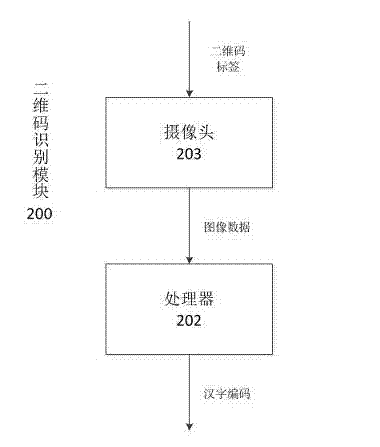

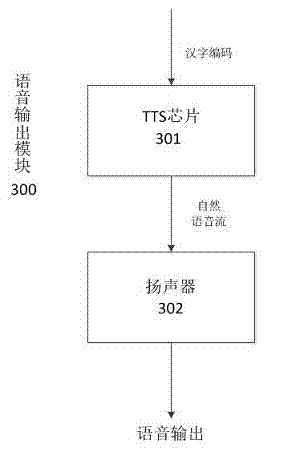

Self-service specification reader and reading system based on two-dimensional code

InactiveCN103366146ASuitable for standalone useSimple structureSensing by electromagnetic radiationComputer moduleDimensional modeling

The invention discloses a self-service specification reader based on two-dimensional code, which comprises a two-dimensional code identification module, a voice output module and a button module. Acquired word information is converted into a voice flow, and the voice flow is output via a loudspeaker. The reader and reading system can help people with visual impairment, such as the elder and the blind, independently reading significant information including medicine specification and the production date of foodstuff; have the advantages including simple structure, convenience in operation, strong practicality, low manufacturing and maintenance cost; and are suitable for scaled popularization and independent use of the elder.

Owner:EAST CHINA NORMAL UNIV

Configurable rotary spray nozzle

ActiveUS8500042B2Low manufacturing and maintenance costsLow costMovable spraying apparatusSpray nozzlesMachiningSpray characteristics

A configurable rotary spray nozzle having lower manufacturing and maintenance costs through the use of an external shell providing strength and resistance to damage such that molded internal components can be utilized to provide the desired spray characteristics. The molded internal wet components can comprise molded polymeric structures that allow for the formation of complex flow geometries and structures that are either impossible or economically impractical to achieve with conventional tooling and machining operations. The use of an external shell provides for use of replacement kits to maintain or otherwise replace worn and / or damaged internal wet components while reusing the external housing. The use of the external shell also allows a user to customize and change spray performance of the configurable rotary spray nozzle by swapping internal wet components having selected flow geometries and characteristics so as to provide a desired spray performance.

Owner:SONNYS HFI HOLDINGS LLC

Hole-bottom tubular linear motor electric impactor

InactiveCN104022616AIncrease electromagnetic forceLaunch fastConstructionsReciprocating drilling machinesTubular linear motorBall bearing

The invention relates to a hole-bottom tubular linear motor electric impactor which comprises a motor outer cylinder, a permanent magnet rod, a linear ball bearing, a rotor, rotor silicon steel sheets and a rotor coil. The motor outer cylinder is an outer shell of a linear motor. The permanent magnet rod is fixed to the motor outer cylinder and serves as a stator of the linear motor. The rotor moves relative to the permanent magnet rod through the linear ball bearing. An iron core composed of the rotor silicon steel sheets is inlaid inside the rotor. A groove is formed in the iron core and internally provided with the rotor coil. A three-phase alternating current winding is adopted for the coil, and the three-phase symmetrical alternating current is led into the coil to generate a traveling wave magnetic field coincident with the rotor in the movement direction. Two damping springs are further arranged to be used for buffering shock. According to the hole-bottom tubular linear motor electric impactor, a movable-coil type structure is adopted, namely, the permanent magnet rod and the iron core are fixed, and the coil is movable. Meanwhile, a buffering gasket is designed between the rotor and a base, and the fatigue resistant service life of the hole-bottom tubular linear motor electric impactor is prolonged. The hole-bottom tubular linear motor electric impactor is simple and firm in structure and low in manufacturing and maintenance cost, the impacting stroke speed and the impacting stroke frequency are easy to adjust, and the hole-bottom tubular linear motor electric impactor is high in efficiency and can be used for deep hole drilling.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com