Radial magnetic flux modularization polyphase motor having high magnetism-insulation capability

A technology with isolation capability and radial magnetic flux, applied in the direction of magnetic circuit static parts, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., which can solve the problem of difficult fault-tolerant control and unfavorable fault isolation. The design is modularized. structure and other problems, to achieve the effect of convenient large-scale processing and manufacturing, low manufacturing and maintenance costs, and high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

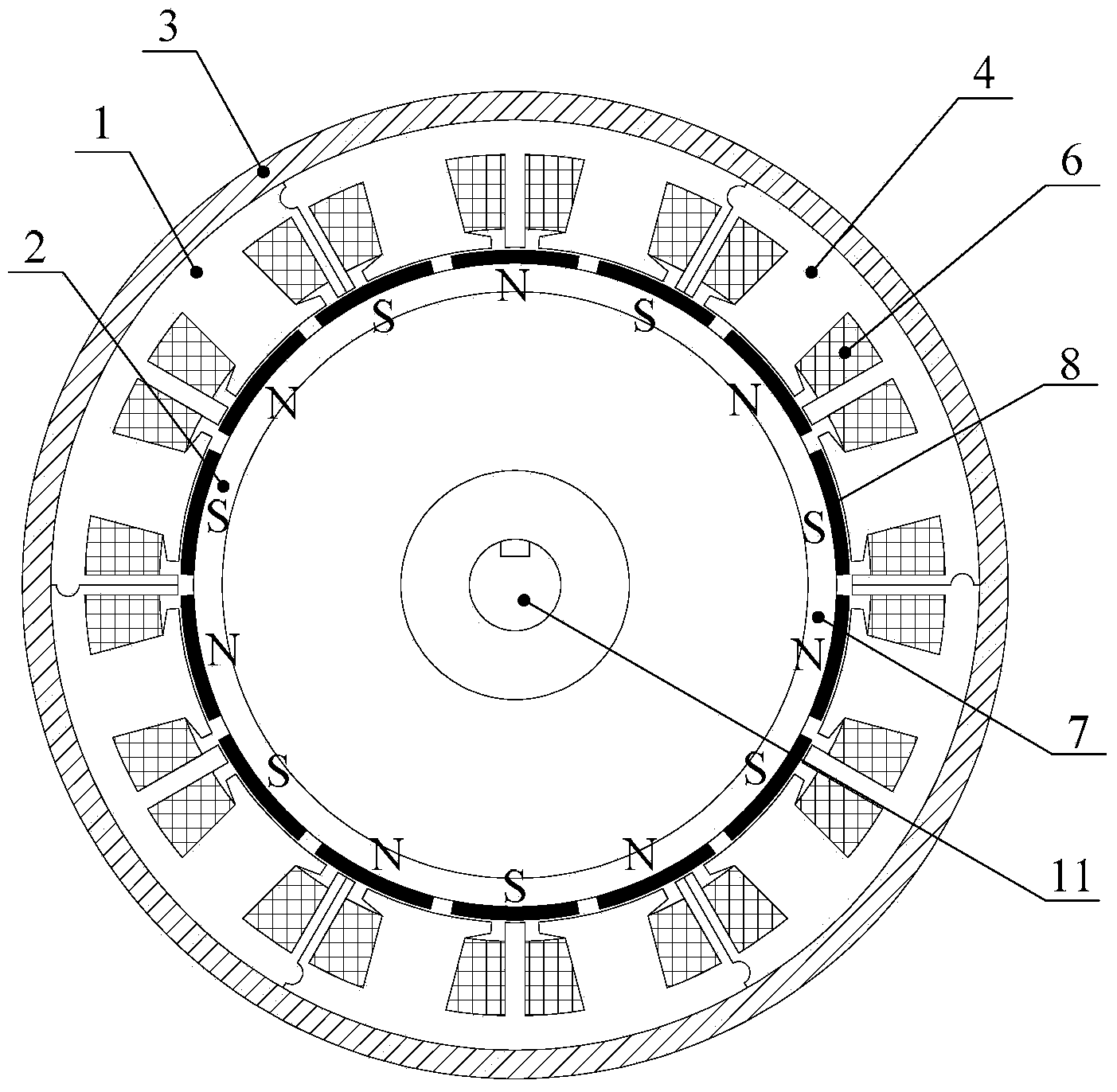

[0019] Specific implementation mode one: the following combination Figure 1 to Figure 7 This embodiment is described. The radial flux modular multiphase motor with high magnetic isolation capability described in this embodiment includes a modular stator 1, a rotor 2, a casing 3 and a main shaft 11,

[0020] The rotor 2 is arranged on the main shaft 11, the modular stator 1 is arranged outside the rotor 2, and there is an air gap between the modular stator 1 and the rotor 2, and the length of the air gap is L;

[0021] The outer circular surface of the modular stator 1 is fixed on the inner circular surface of the casing 3;

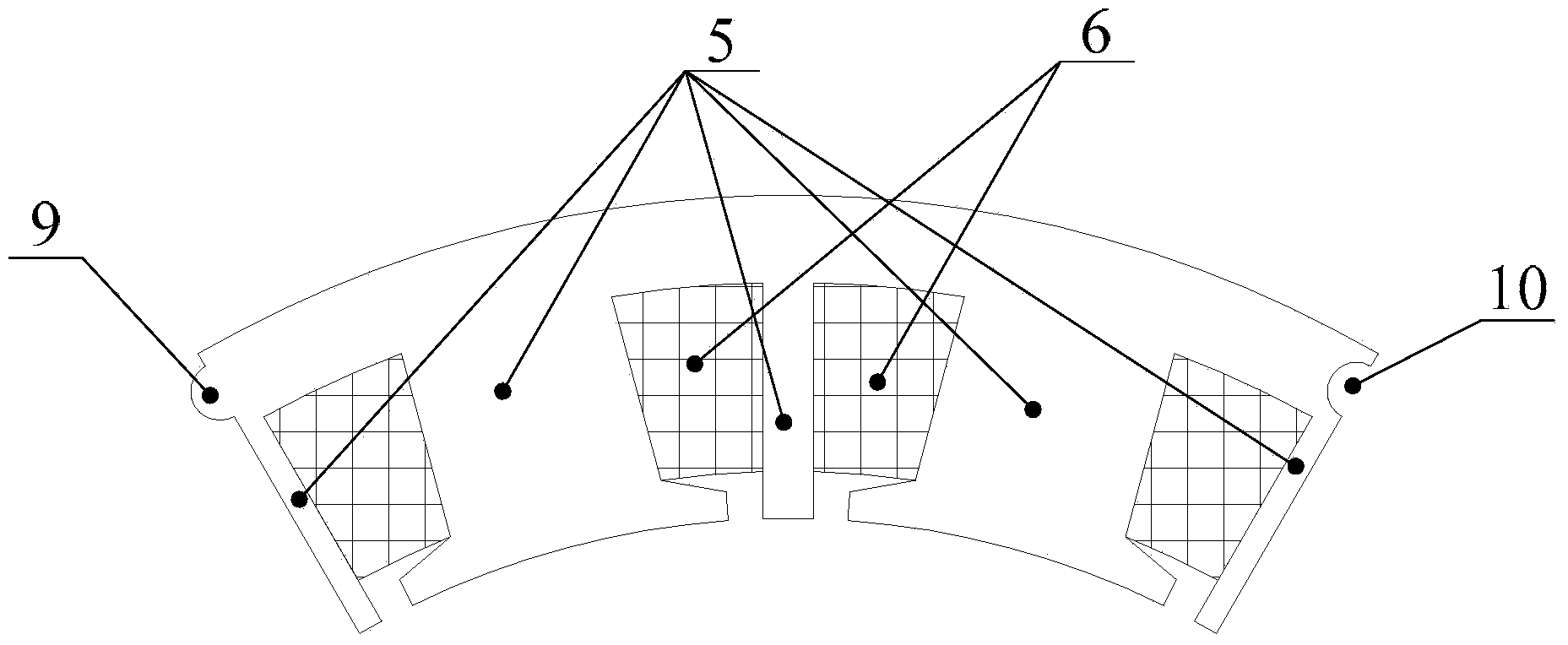

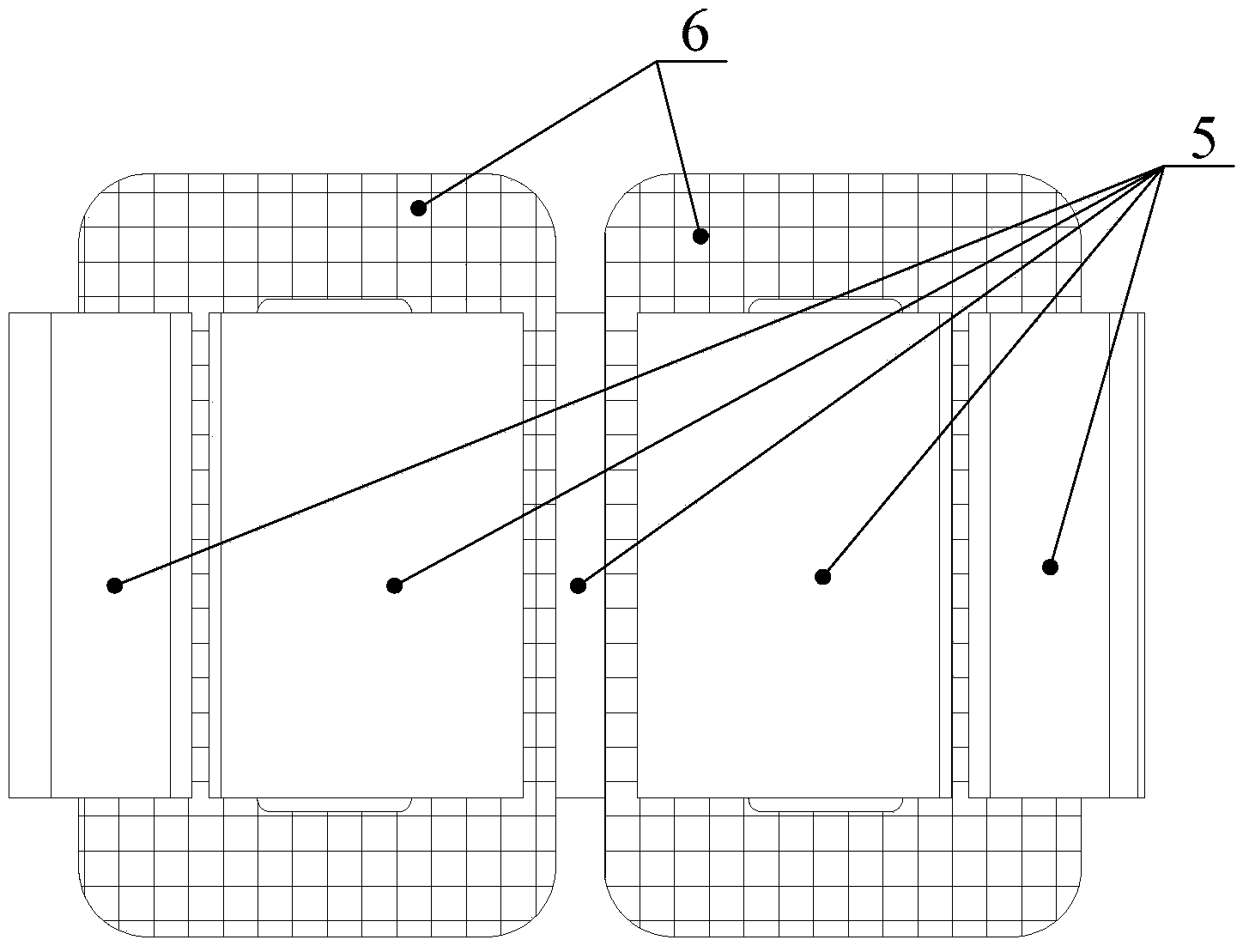

[0022] Each modular stator 1 includes N identical stator modules, and the N identical stator modules are spliced into a disc shape; each stator module includes a stator core 4, five stator teeth 5 and two concentrated windings 6. Five stator teeth 5 are set on the stator core 4; the five stator teeth 5 are the first rectangular stator teeth, the second...

specific Embodiment approach 2

[0040] Specific implementation mode two: the following combination figure 2 and Figure 4 Describe this embodiment. This embodiment will further describe Embodiment 1. A semicircular protruding part 9 is provided on one side of the yoke of the stator core 4 of each stator module, and a semicircular concave part is symmetrically provided on the other side of the yoke. slot 10 , two adjacent stator modules are spliced together through the cooperation of semicircular protrusions 9 and semicircular grooves 10 .

[0041] The semicircular protruding part 9 and the semicircular groove 10 adopt clearance fit, and after splicing N stator modules along the circumferential direction, they are nested in the housing 3 by using the shrink-fit technology.

specific Embodiment approach 3

[0042] Embodiment 3: In this embodiment, Embodiment 1 is further described. The permanent magnet 8 adopts a surface mount type, a Halbach array type or a built-in structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com