Patents

Literature

60results about How to "Good magnetic isolation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

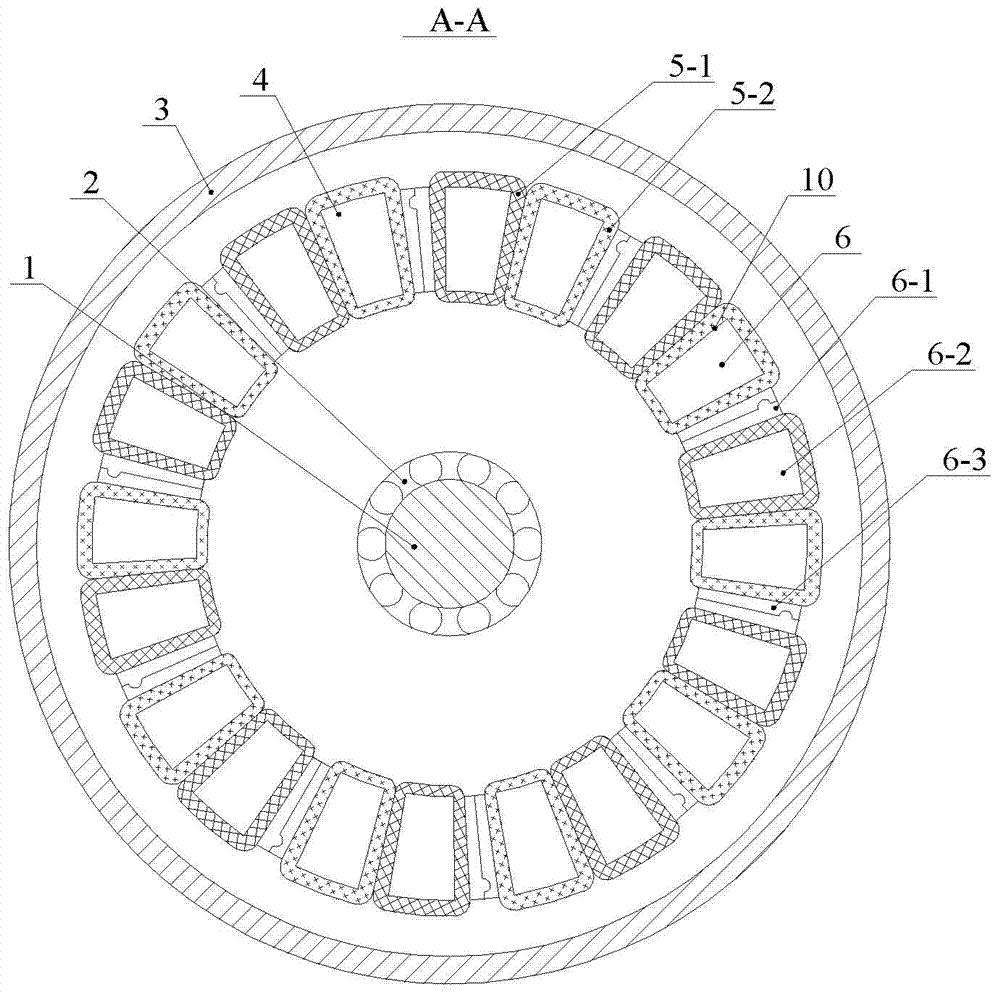

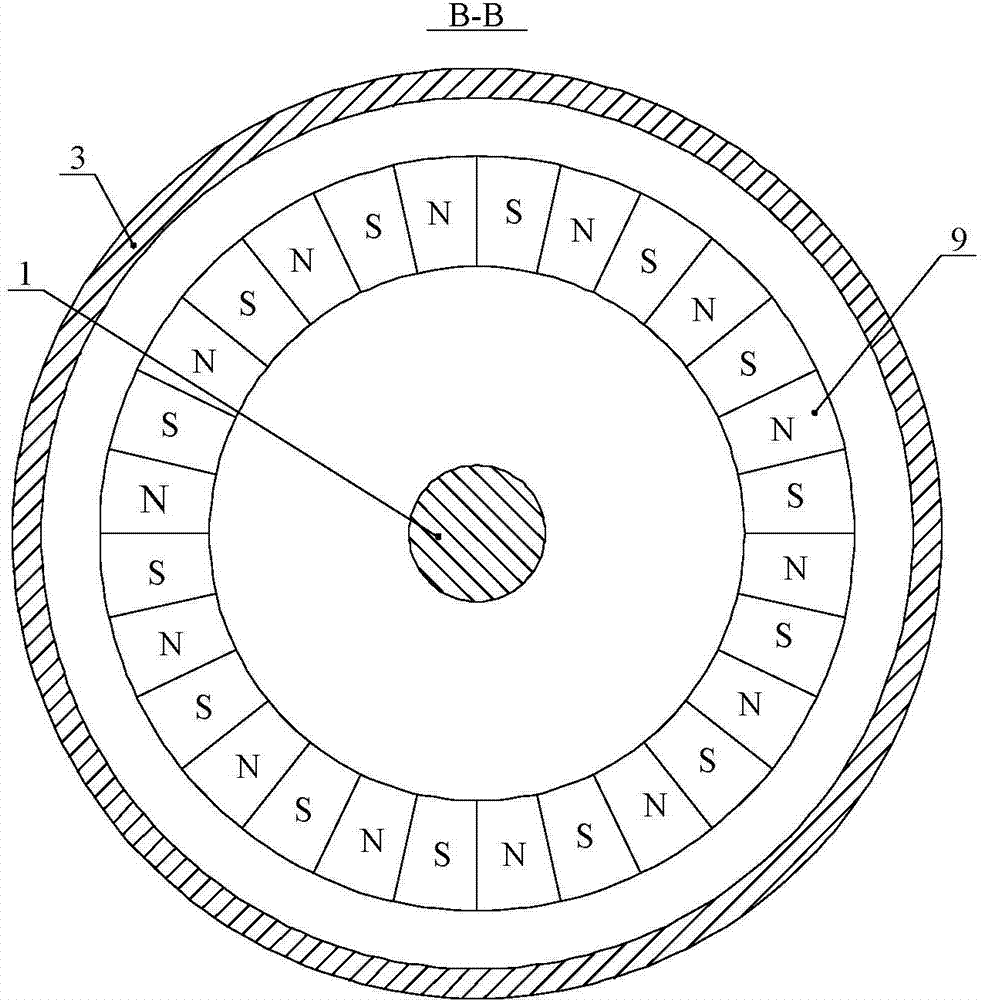

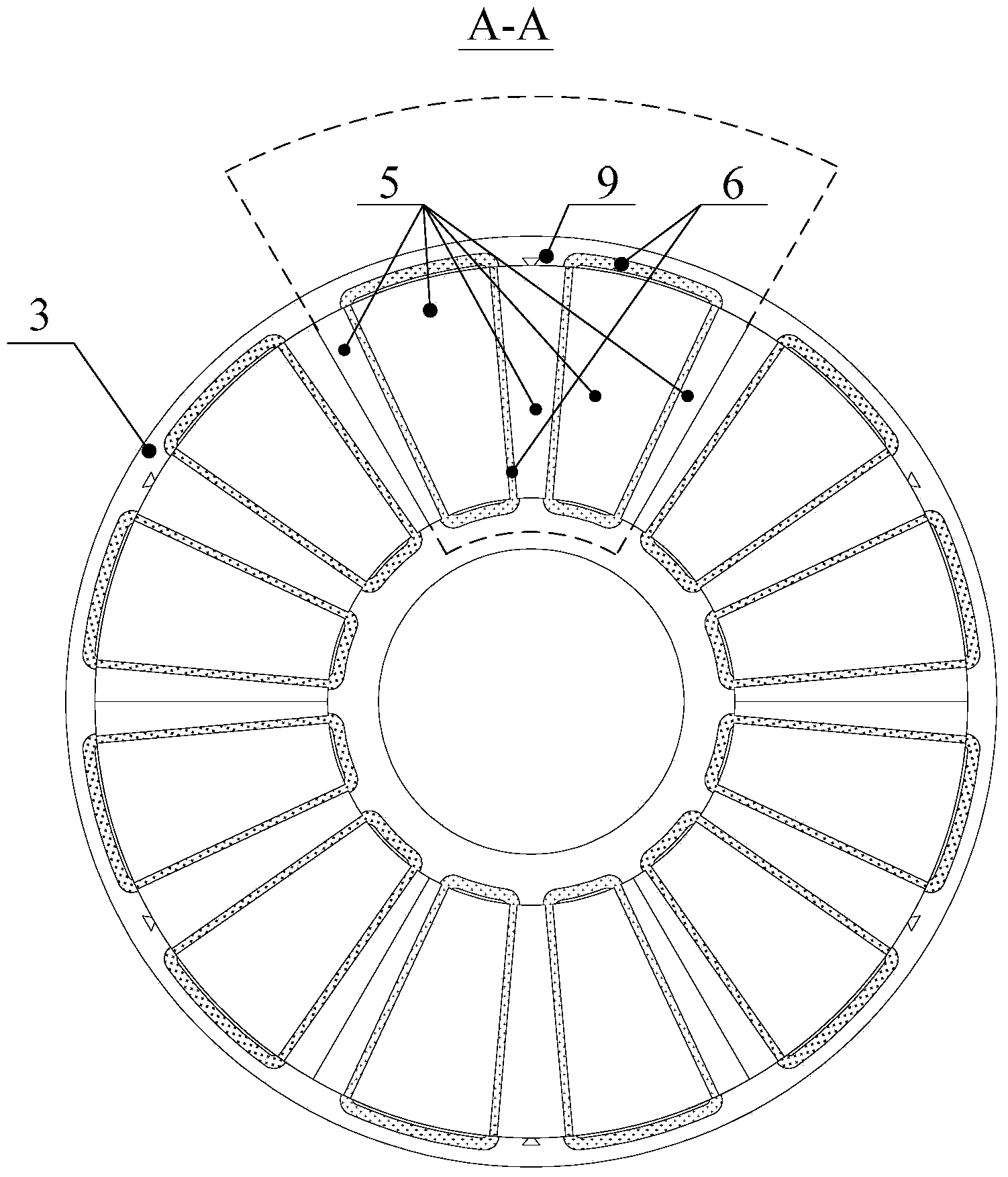

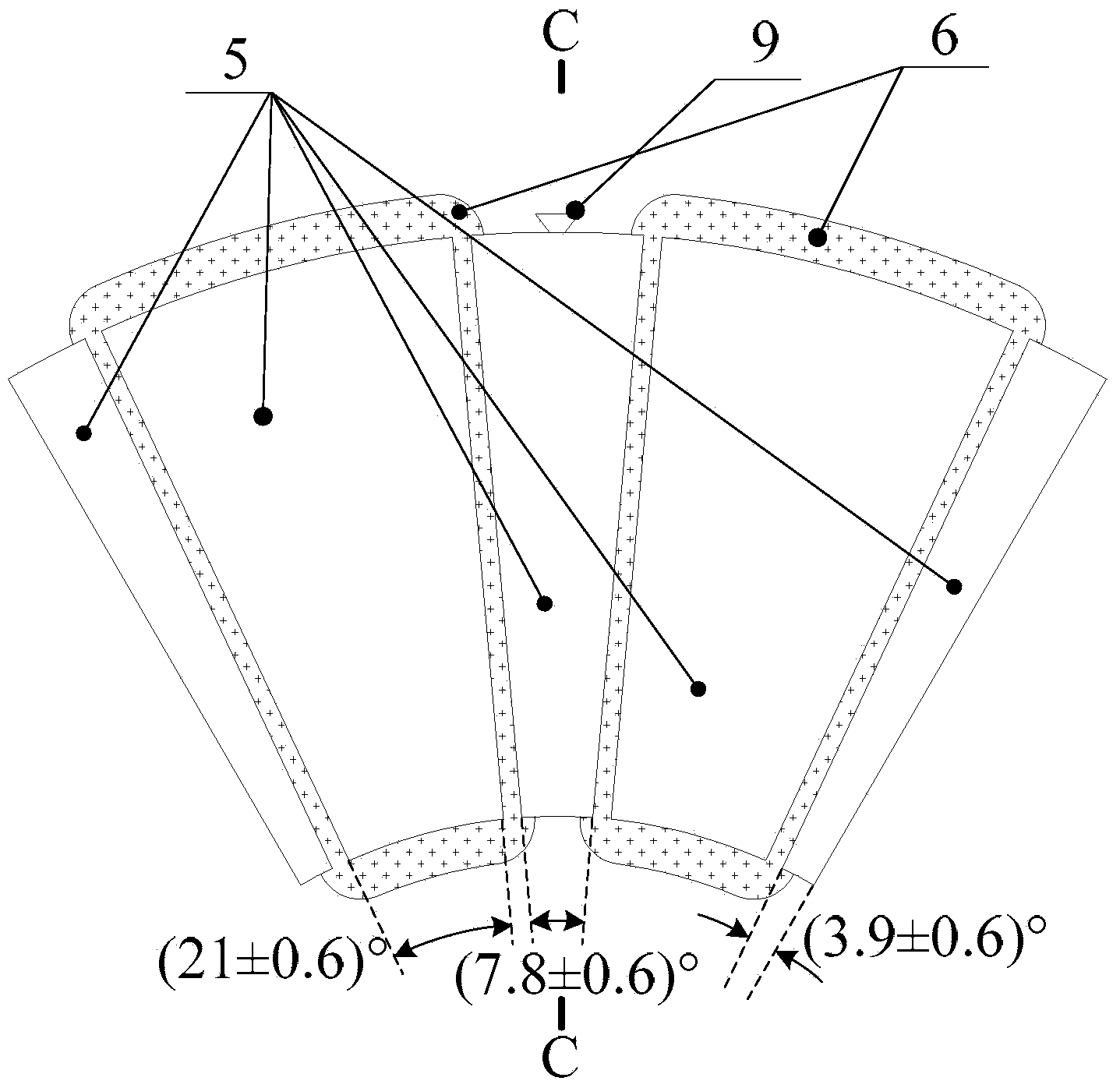

Radial magnetic flux modularization polyphase motor having high magnetism-insulation capability

ActiveCN103762759AImprove reliabilityImprove power densityMagnetic circuit rotating partsMagnetic circuit stationary partsSynchronous motorElectric machine

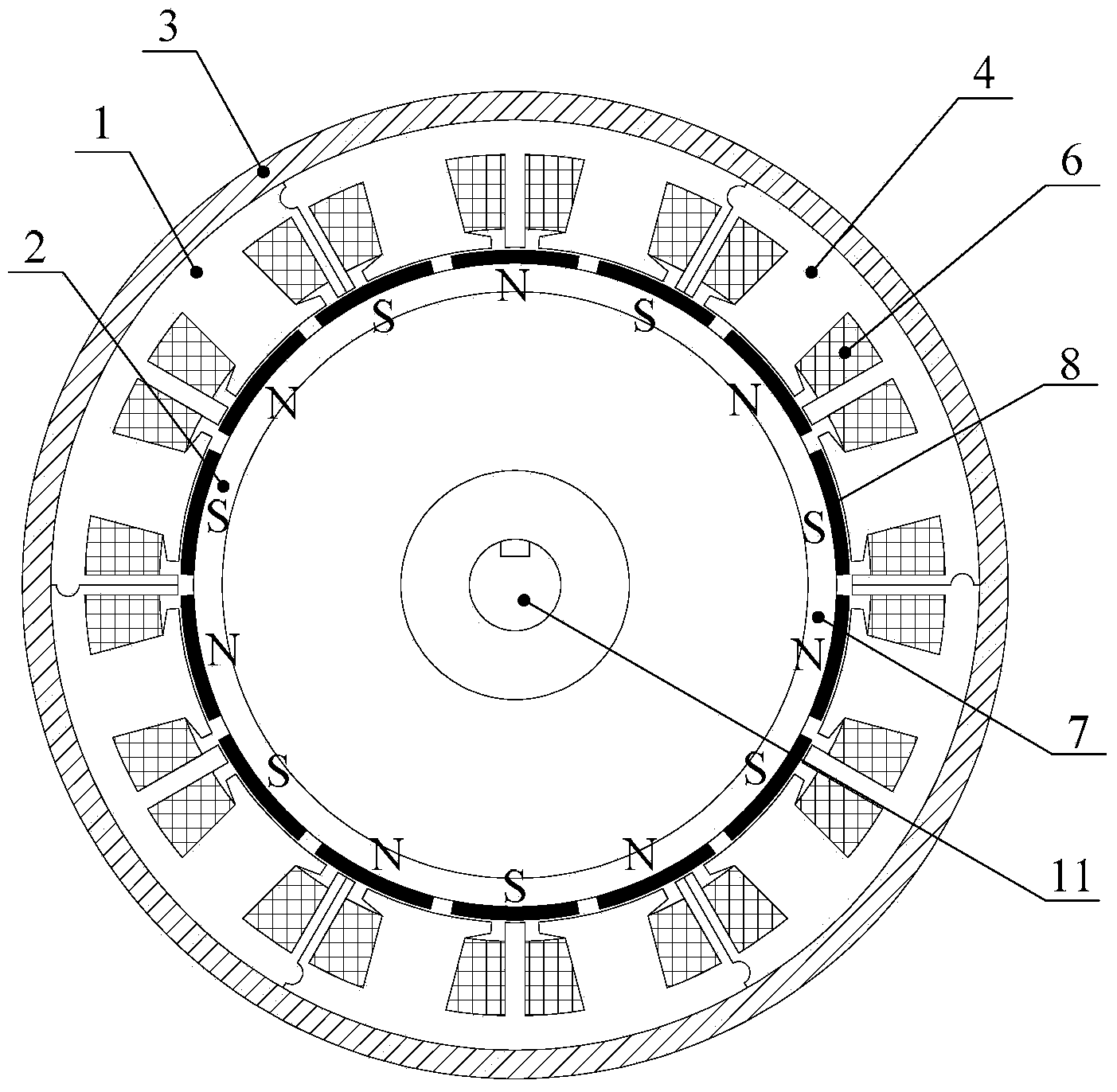

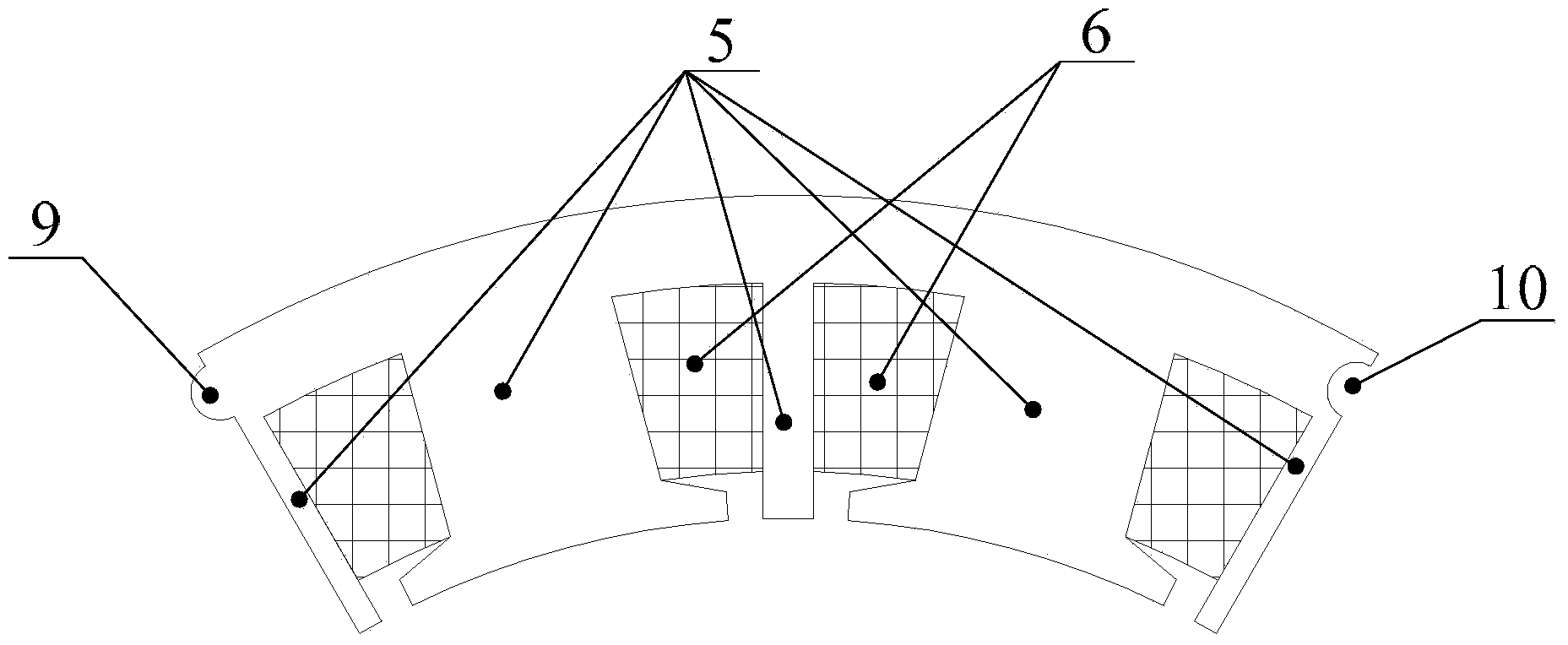

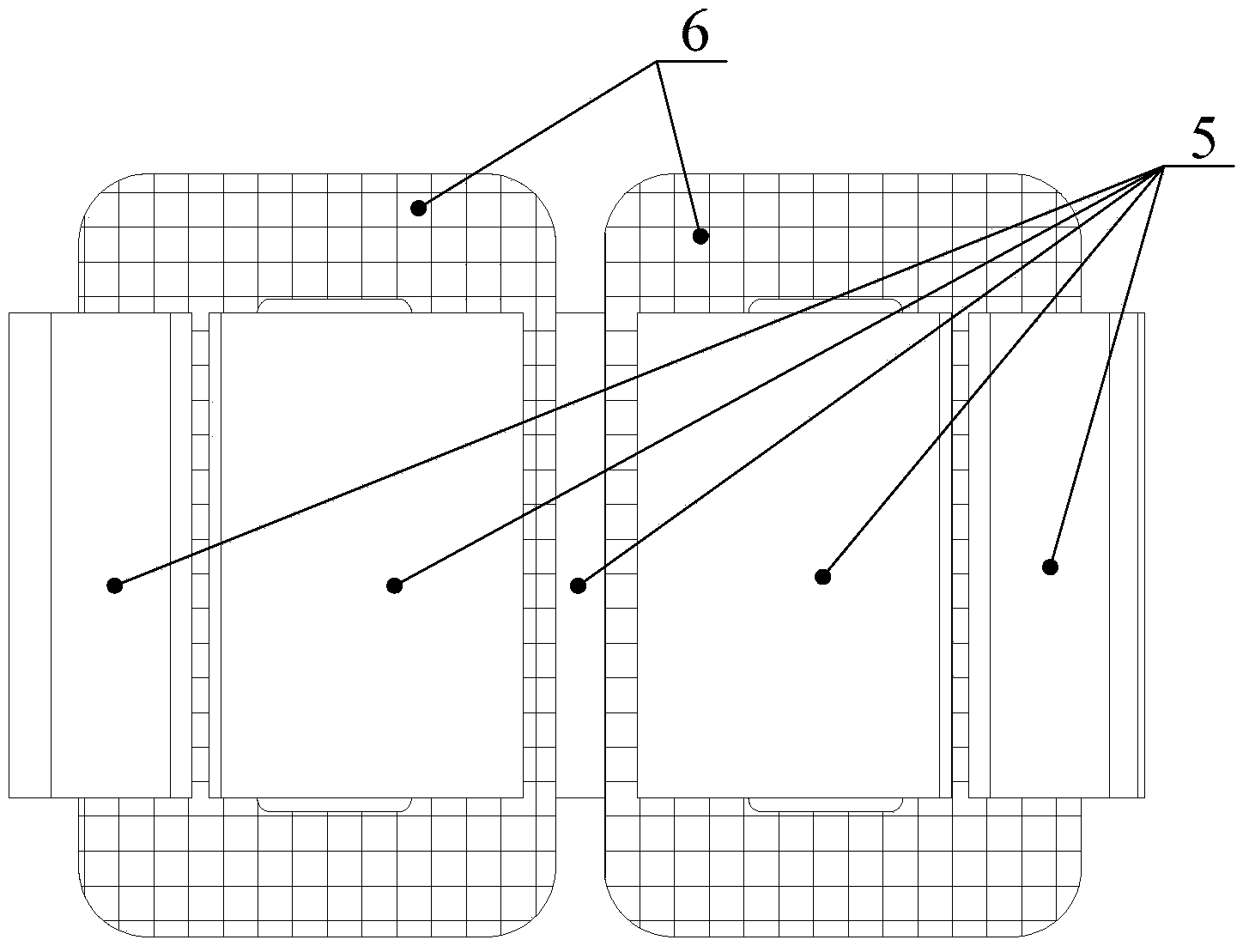

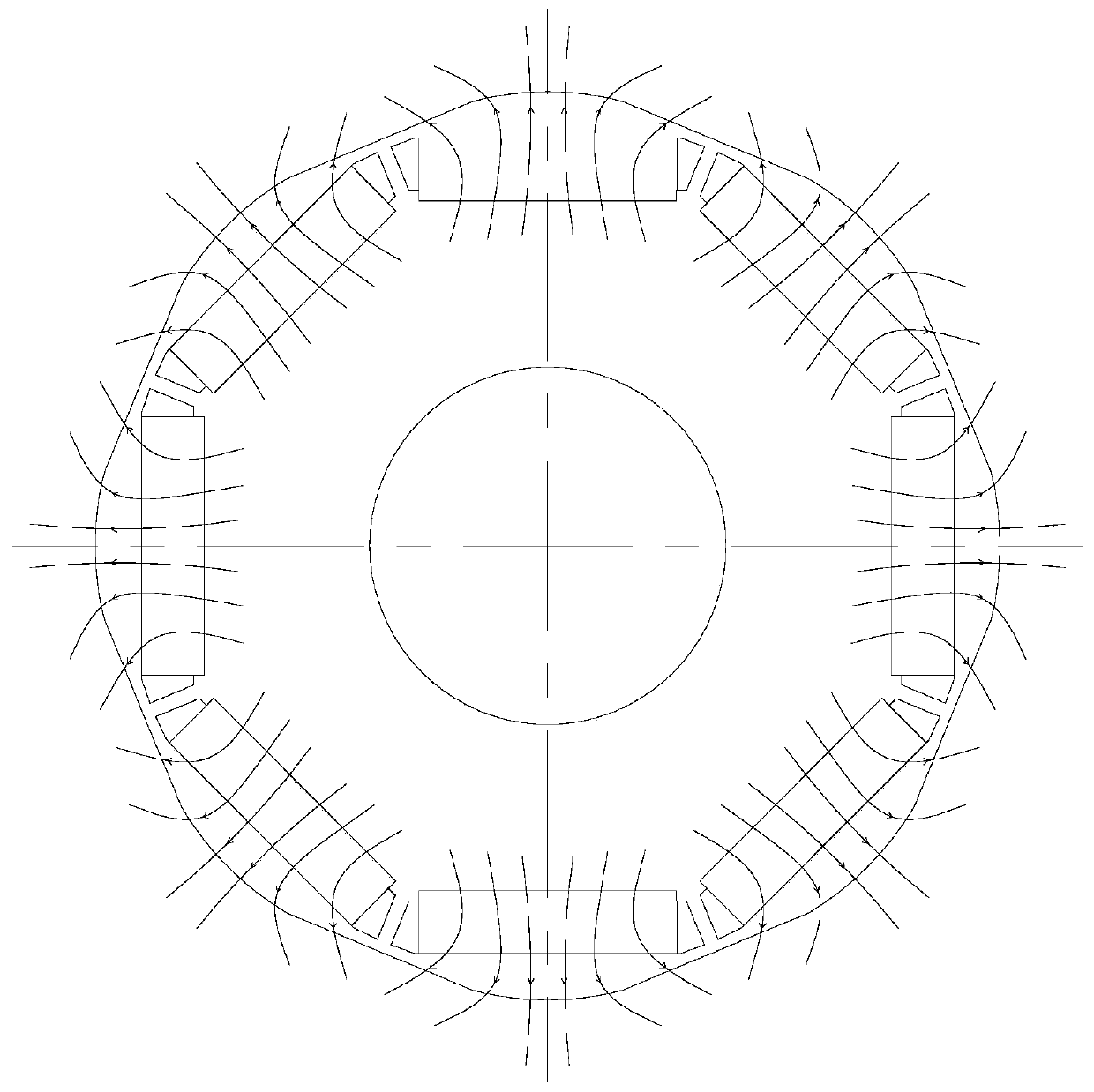

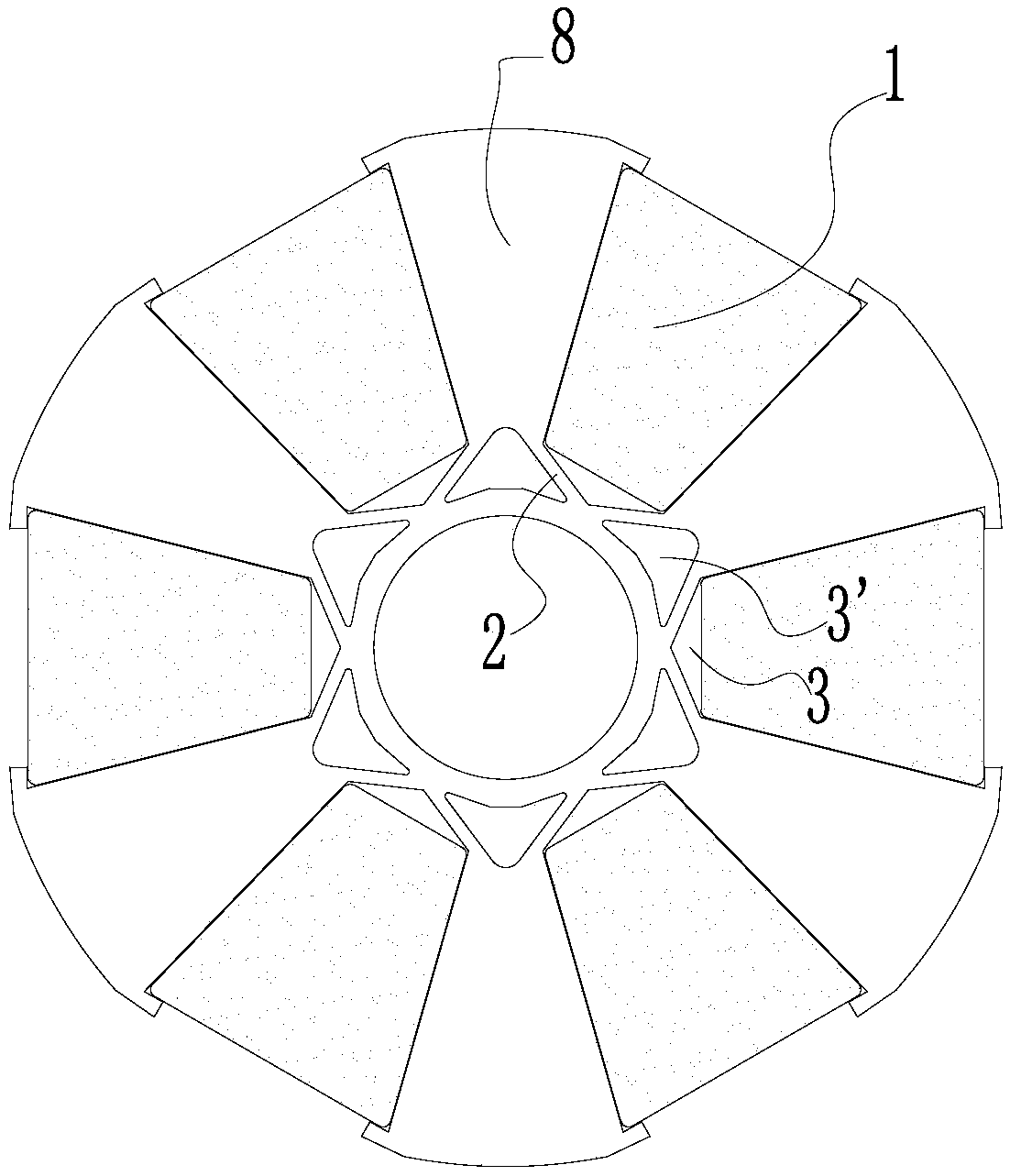

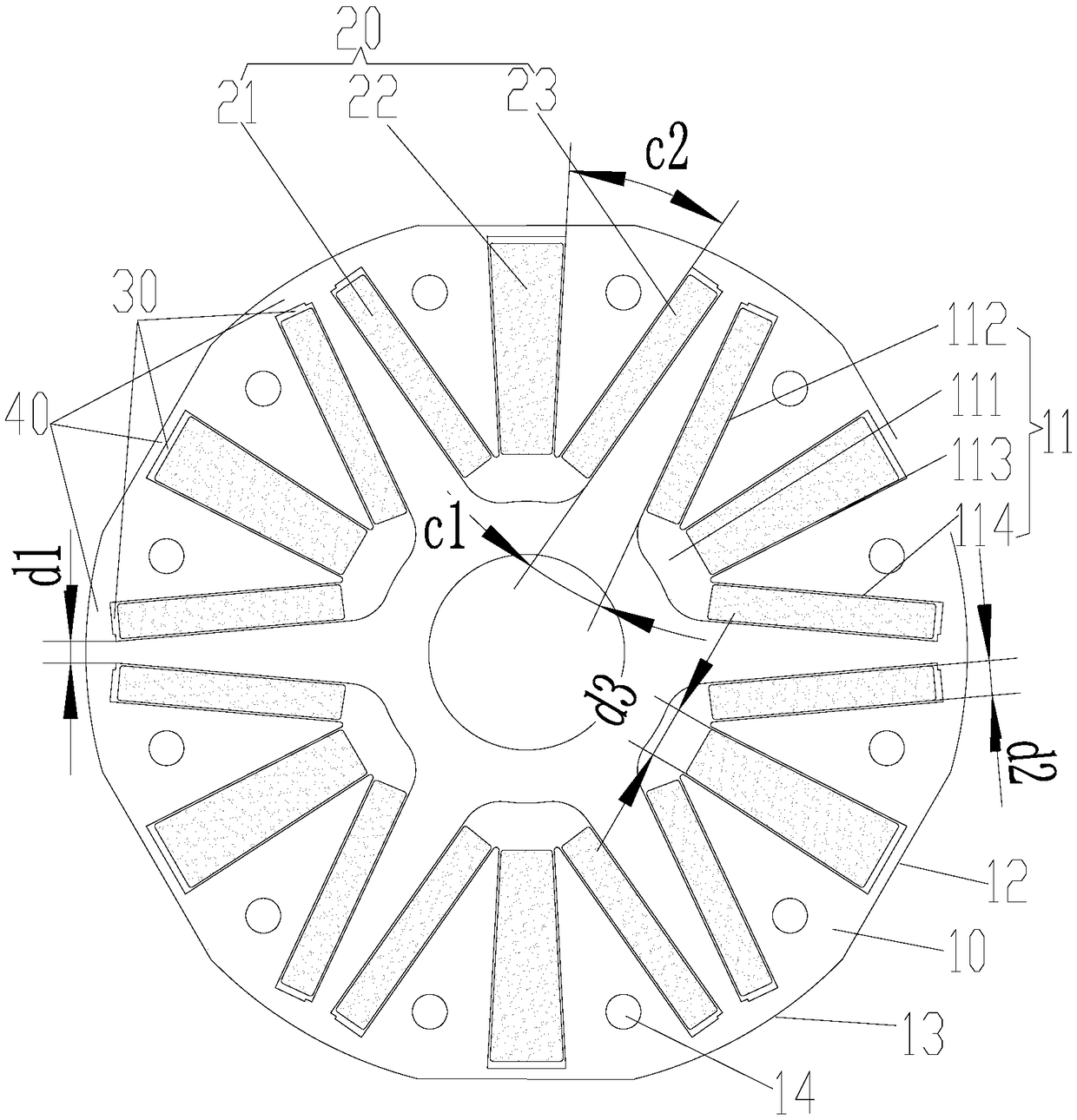

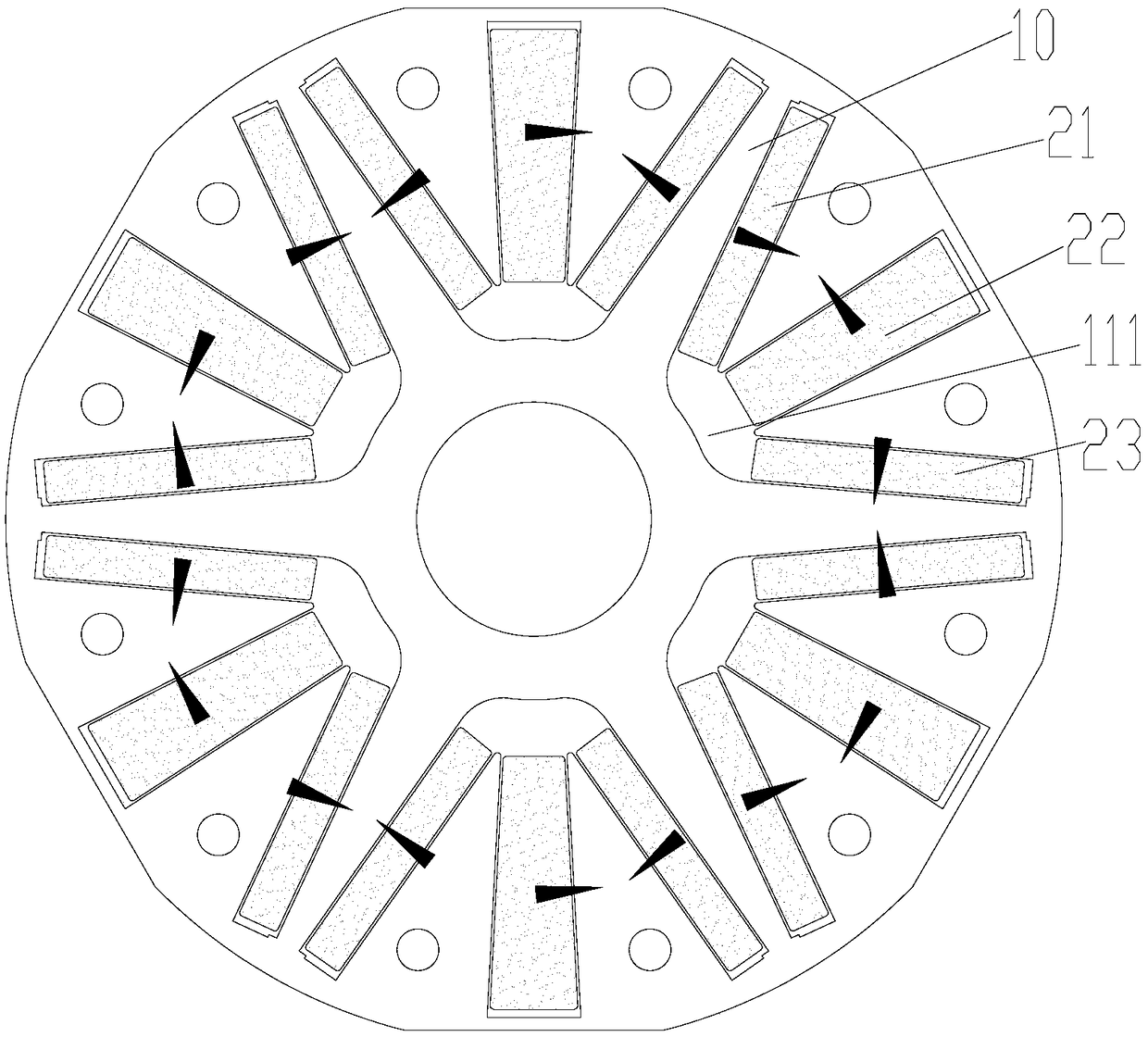

The invention discloses a radial magnetic flux modularization polyphase motor having the high magnetism-insulation capability and belongs to the field of motors. The radial magnetic flux modularization polyphase motor having the high magnetism-insulation capability solves the problems that when a phase winding of an existing polyphase permanent magnetic synchronous motor has a short circuit, fault-tolerant control difficulty is large, and due to the disperse distribution of winding space, fault insulation is not facilitated, and design of a modularization structure is not facilitated. The radial magnetic flux modularization polyphase motor having the high magnetism-insulation capability comprises modularization stators, a rotor, a motor shell and a main shaft. The rotor is arranged on the main shaft, the modularization stators are arranged on the outer portion of the rotor, and air gaps exist between the modularization stators and the rotor. The surfaces of the outer circles of the modularization stators are fixed to the surface of the inner circle of the motor shell. Each modularization stator comprises N identical stator modules, wherein the N identical stator modules are spliced to form a disc shape. Each stator module comprises a stator iron core, five stator teeth and two concentrated wound windings. According to the rotor, the surface of the outer circle of a rotor iron core is provided with 2N+ / -2 permanent magnets which are oppositely arranged in the circumference direction in an alternative mode and perform magnetizing in the radial direction.

Owner:HARBIN INST OF TECH

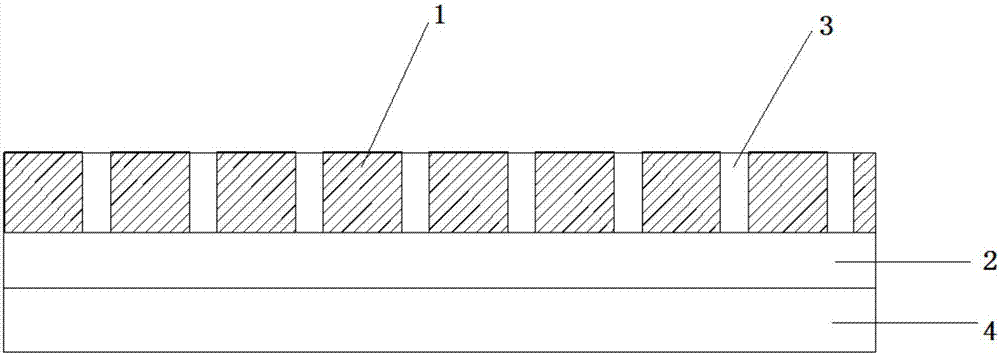

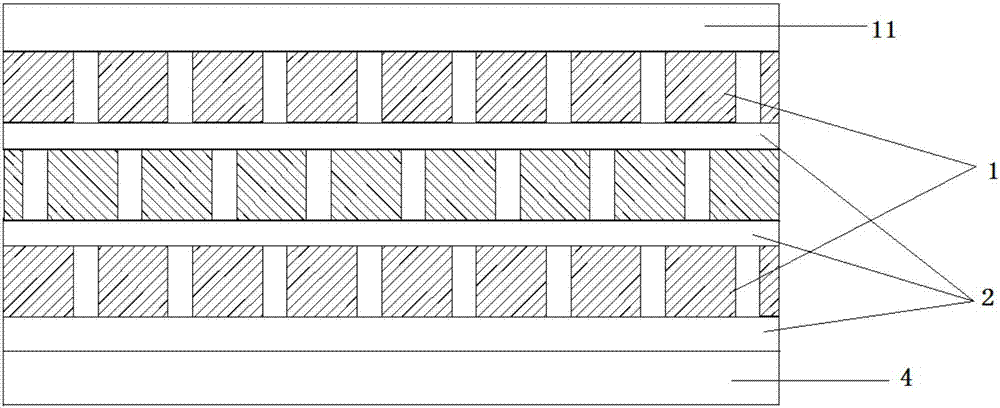

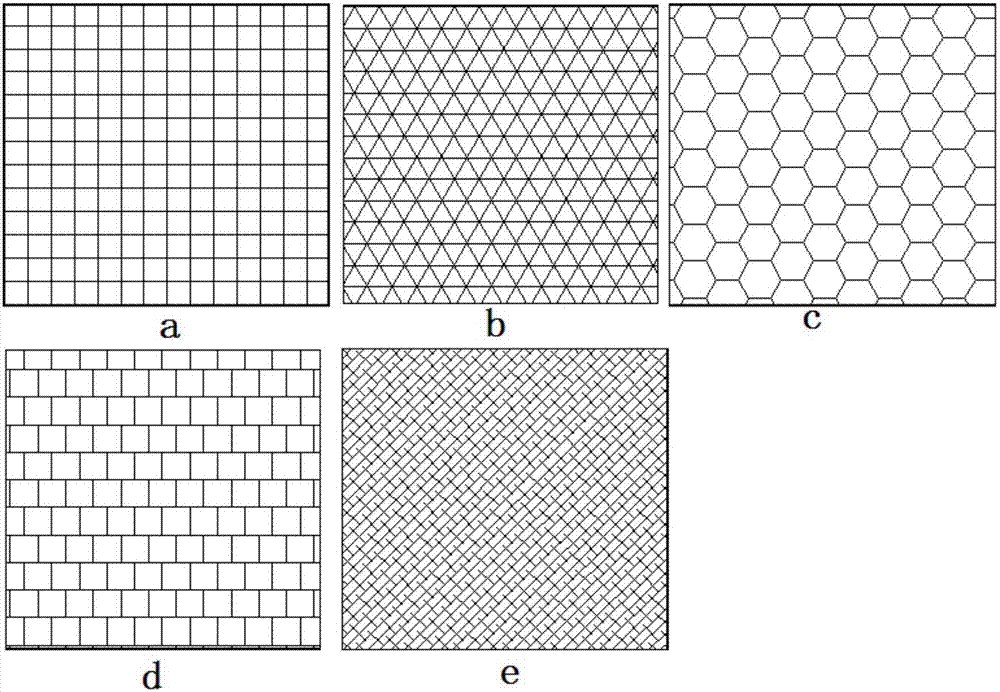

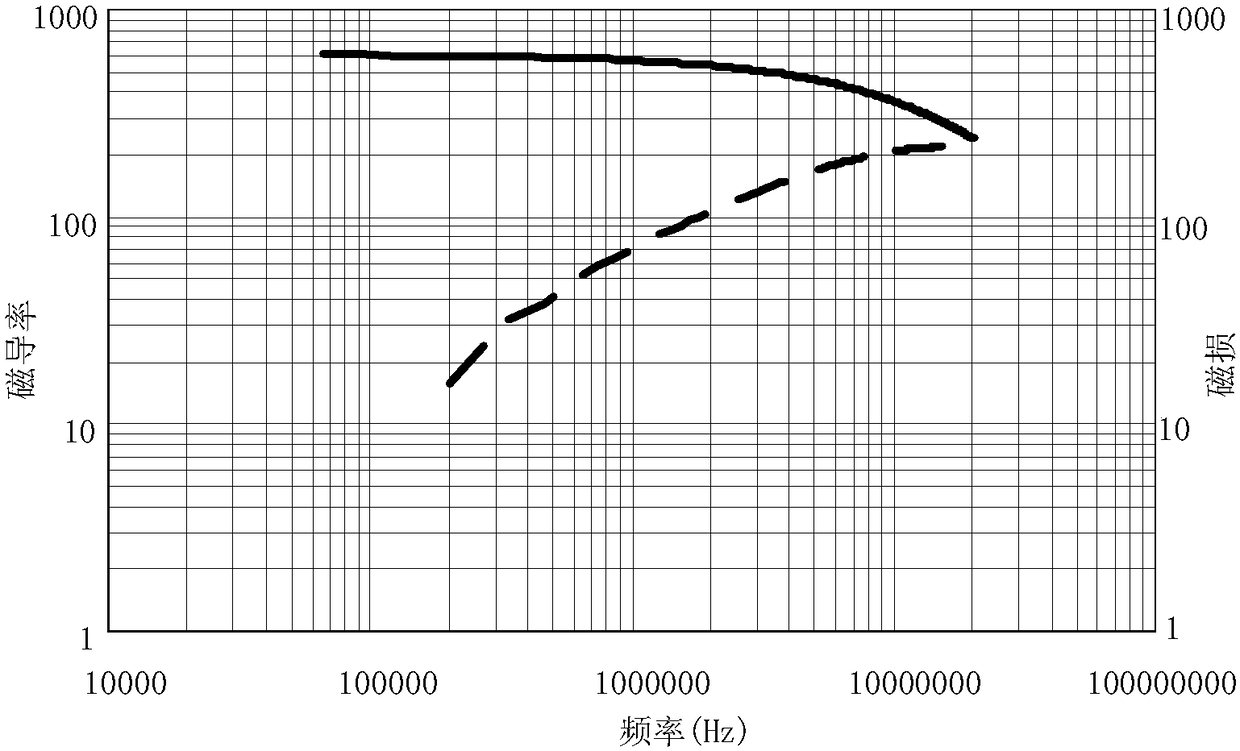

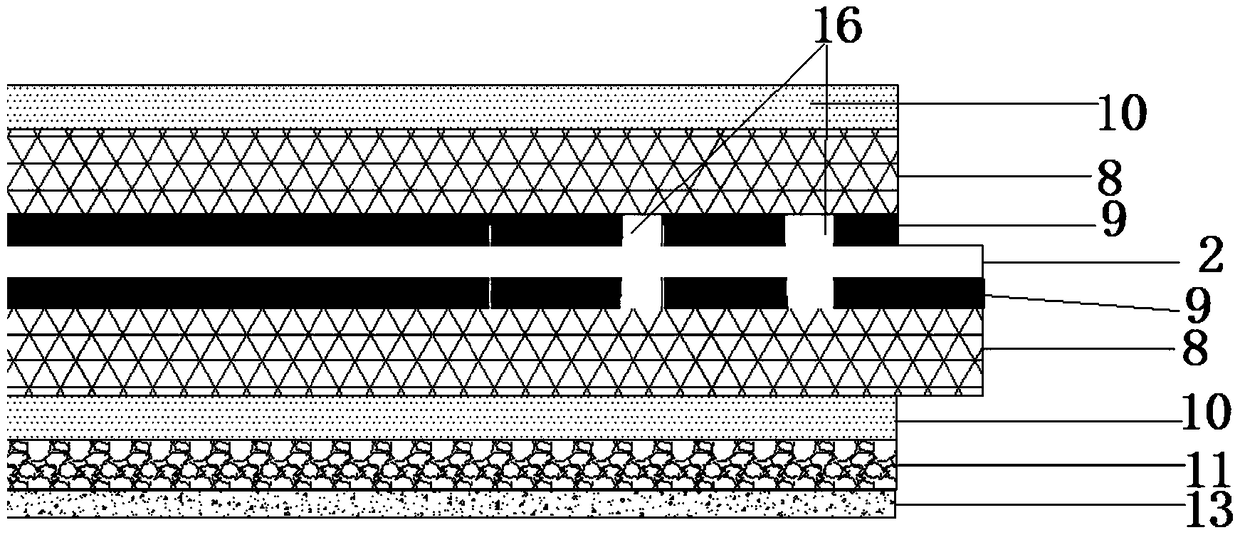

Magnetic isolation sheet applied to wireless charging and near field communication (NFC) and fabrication process of magnetic isolation sheet

InactiveCN107979966AStable working frequencyThe overall thickness is thinShielding materialsMagnetic tapeAdhesive

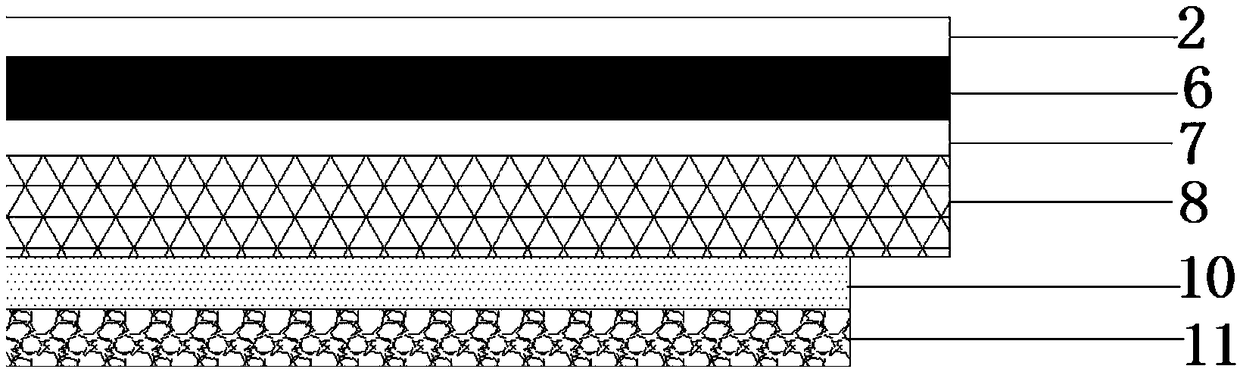

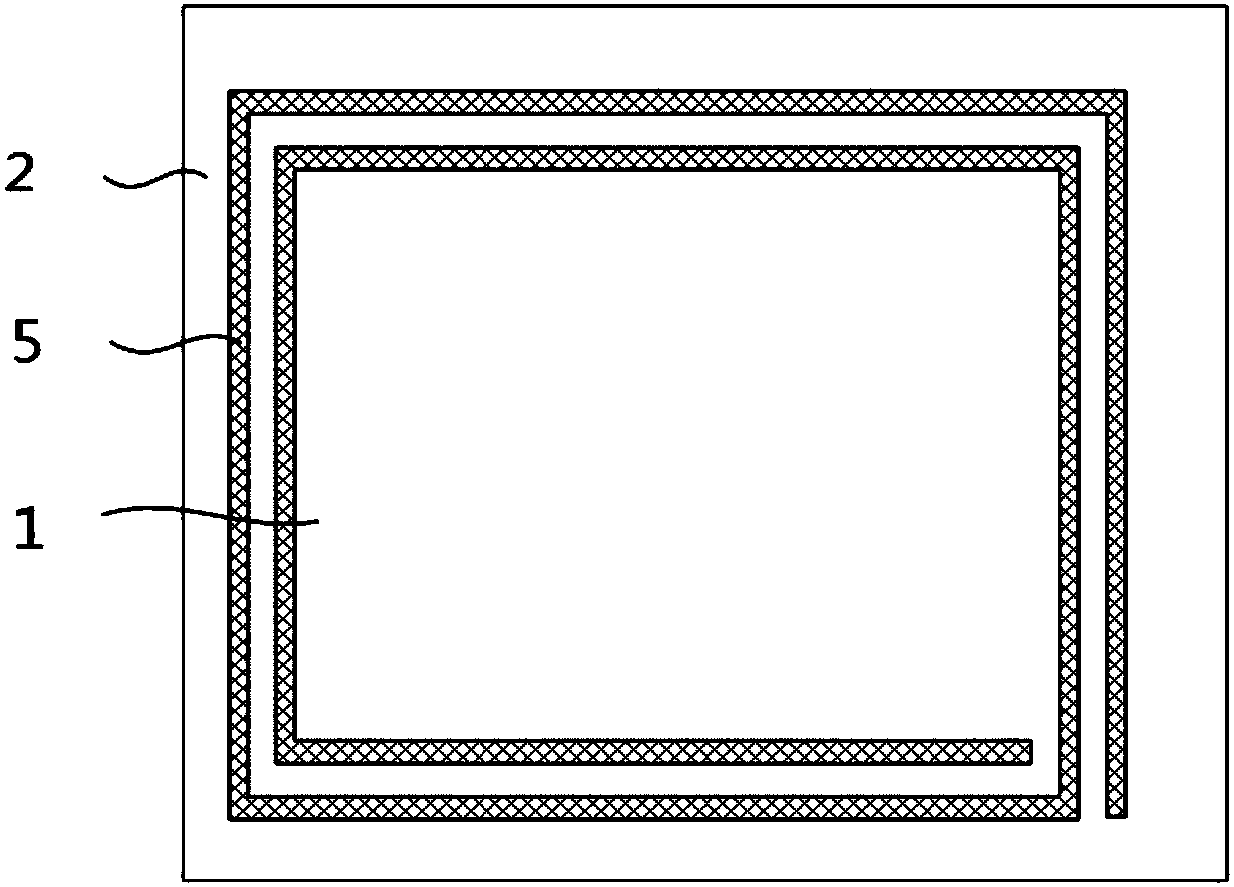

The invention discloses a magnetic isolation sheet applied to wireless charging and near field communication (NFC). The magnetic isolation sheet comprises at least one magnetic isolation unit, whereinthe magnetic isolation unit comprises a soft magnetic strip and a double-side adhesive tape, wherein the soft magnetic strip is of a sheet structure with two exposed surfaces, the double-side adhesive tape covers one of the exposed surfaces, and the other exposed surface of the soft magnetic strip is pressed to form a mesh-shaped line. The invention also discloses a fabrication process of the magnetic isolation sheet applied to wireless charging and NFC. The fabrication process comprises the steps of constructing a magnetic isolation unit, in which the double-side adhesive tape is pasted ontoone of the exposed surfaces of the soft magnetic strip by taking the soft magnetic strip of the sheet structure with the two exposed surfaces as an element, and the other exposed surface of the softmagnetic strip is pressed to form the mesh-shaped line; and constructing the magnetic isolation sheet. The magnetic isolation sheet applied to wireless charging and NFC, fabricated by the fabricationprocess has the advantages of thin thickness, good magnetic isolation capability, high charging efficiency, NFC working frequency stability and high product stability, and the process and the materialcost are greatly reduced.

Owner:SHANGHAI LINEPRINTING MATERIALS CO LTD

Modularization disc multi-phase permanent magnet synchronous motor based on single-layer and double-layer mixed windings

ActiveCN104767340AContains the impact of faults relative to other phasesImprove efficiencyMagnetic circuit stationary partsSynchronous machines with stationary armatures and rotating magnetsElectromagnetic couplingElectric machine

The invention relates to a modularization disc multi-phase permanent magnet synchronous motor based on single-layer and double-layer mixed windings and belongs to the field of permanent magnet motors. The modularization disc multi-phase permanent magnet synchronous motor aims at solving the problems that when faults such as winding short circuits occur in a conventional disc multi-phase permanent magnet synchronous motor, the fault isolation difficulty is high, and the motor modularization design difficulty is high due to the high interphase electromagnetic coupling degree. The modularization disc multi-phase permanent magnet synchronous motor comprises a main shaft, a bearing, a motor shell, one or two stators and a disc permanent rotor, wherein the stators and the disc permanent rotor are arranged in the motor shell, each stator is formed by splicing 2n+1 stator modules, each stator module comprises 2n concentrated windings and a stator iron core, each stator iron core is provided with 2n+1 stator grooves, and one concentrated winding is wound on each armature tooth. Every two adjacent concentrated windings are identical in number of turns and opposite in winding direction. The disc permanent rotor comprises a disc rotor iron core and a plurality of permanent magnets, wherein the permanent magnets carry out magnetizing in the axial direction, and the magnetizing directions of the permanent magnets are opposite.

Owner:HARBIN INST OF TECH

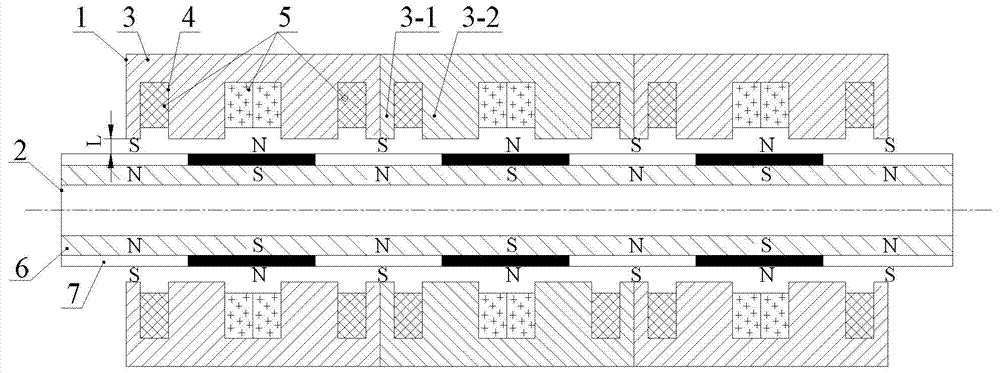

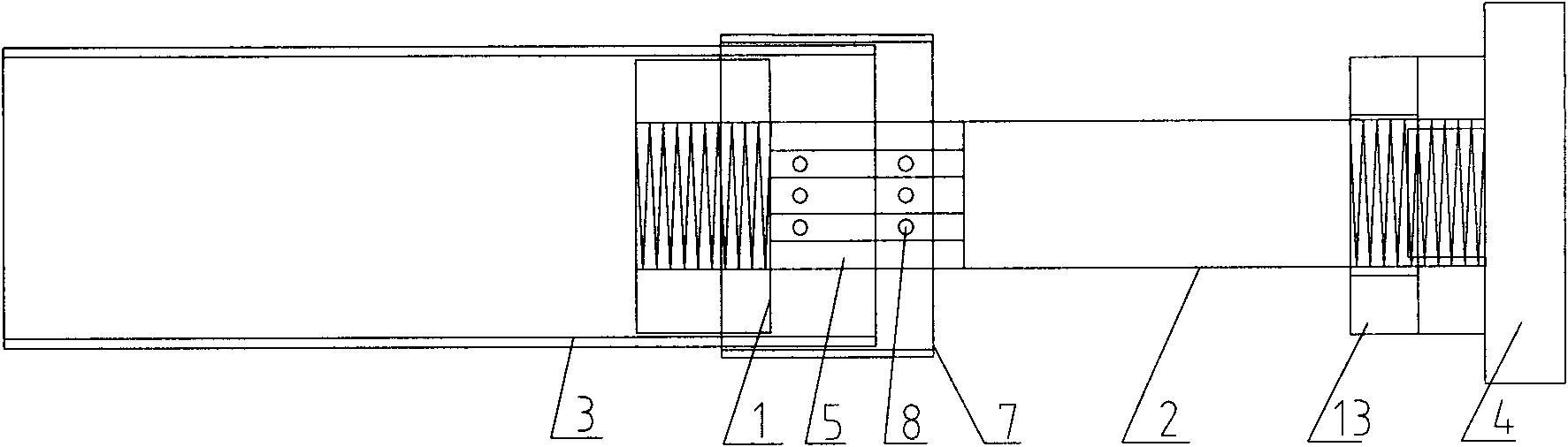

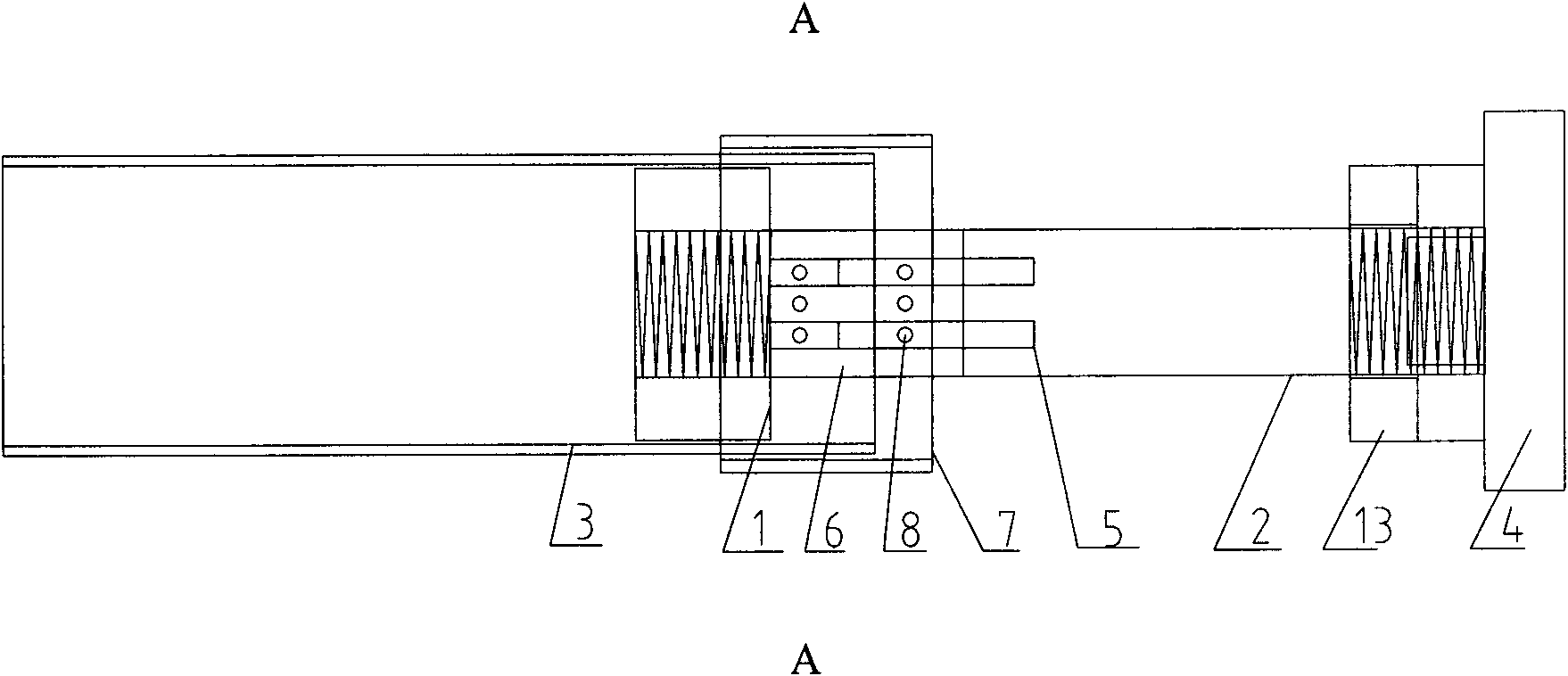

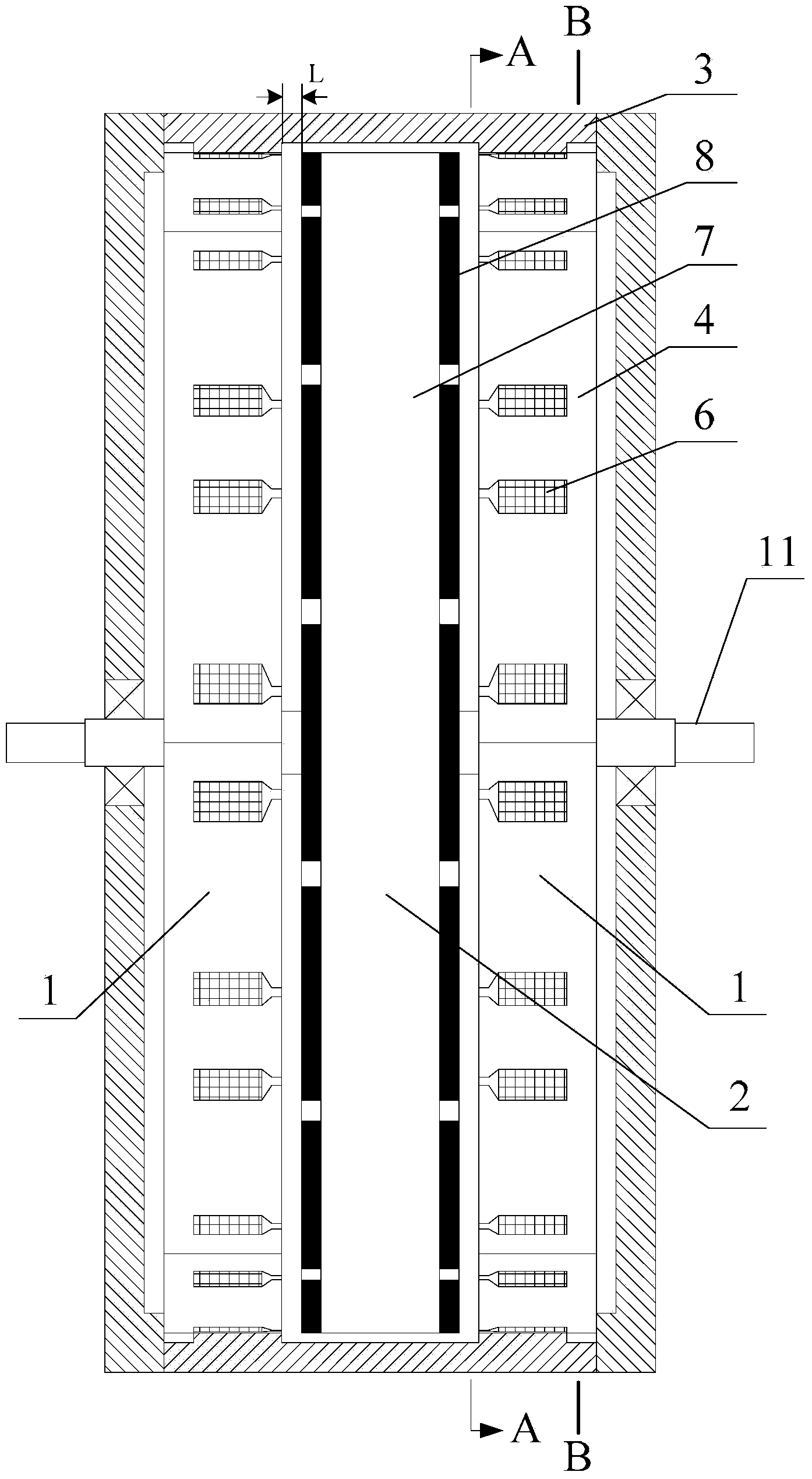

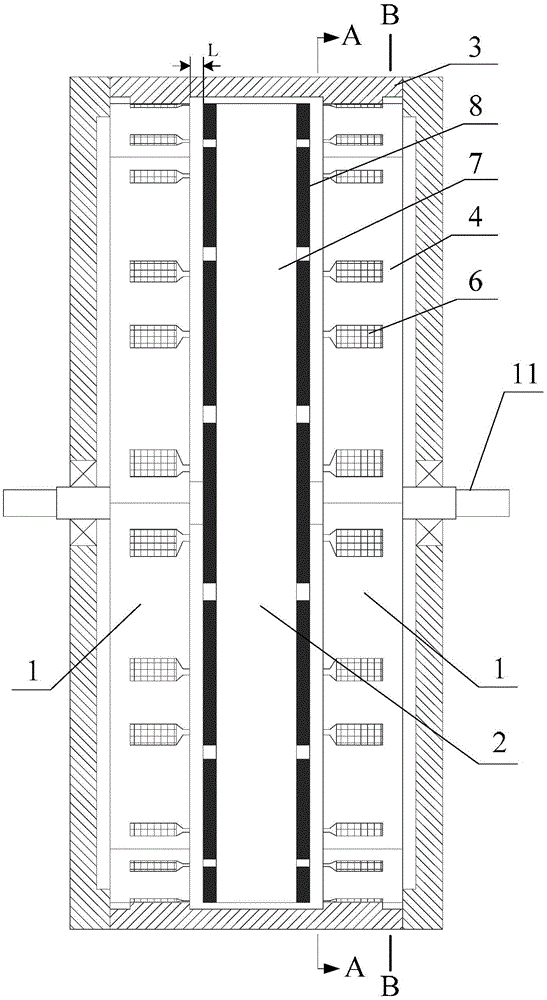

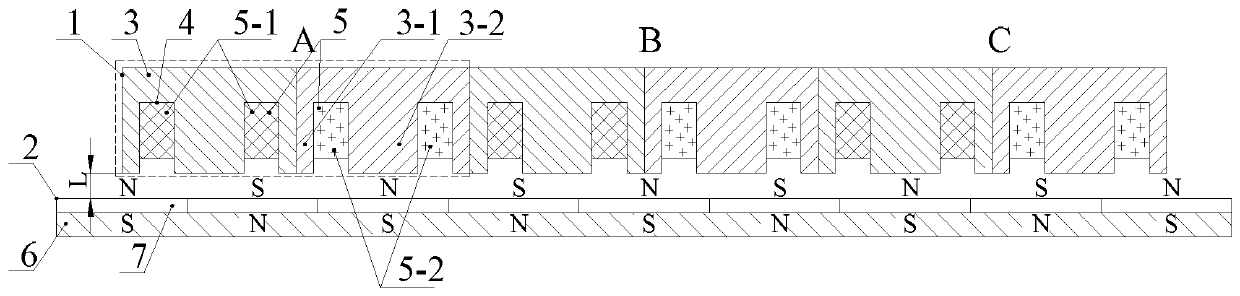

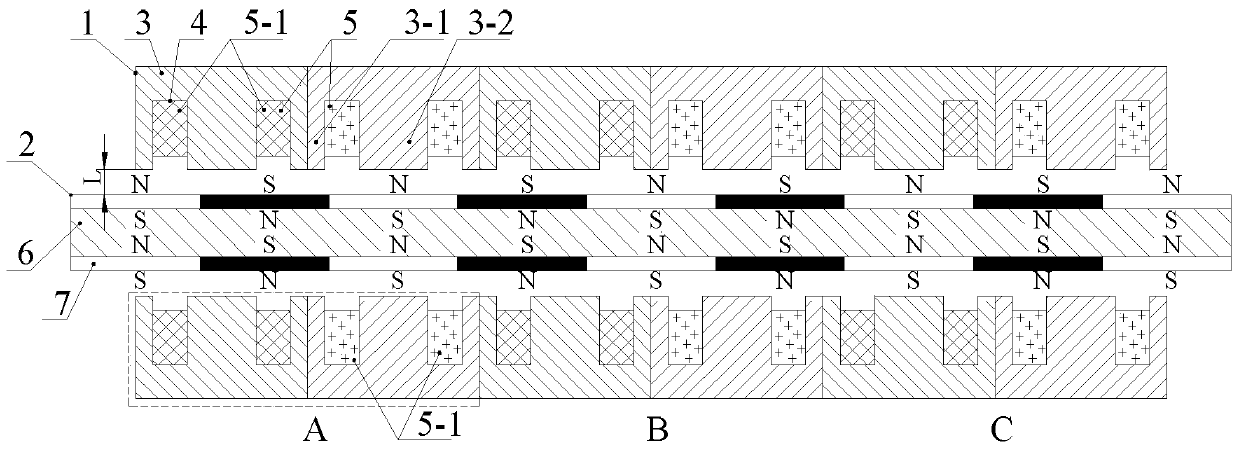

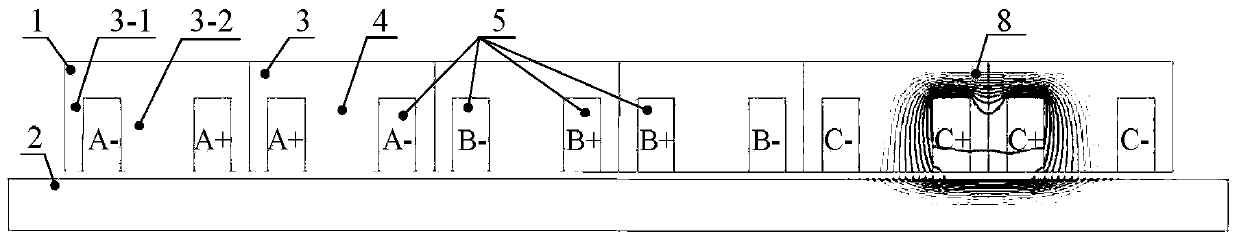

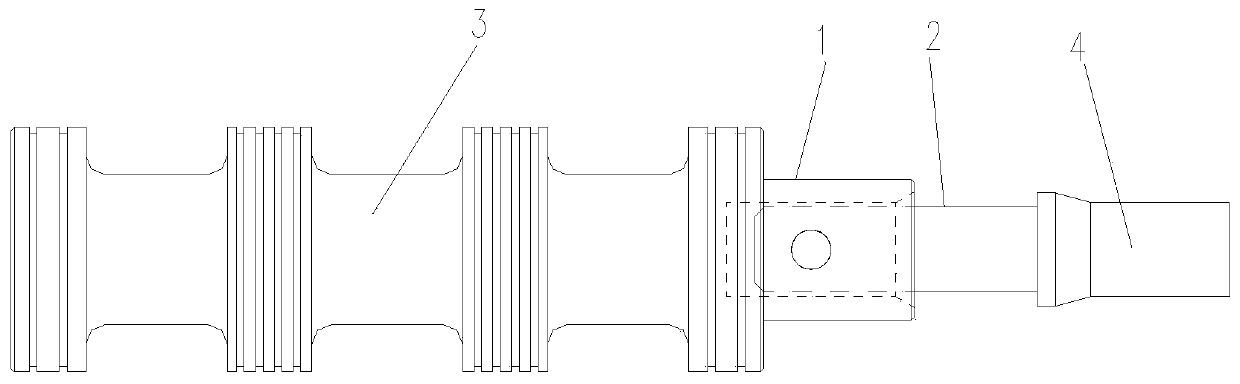

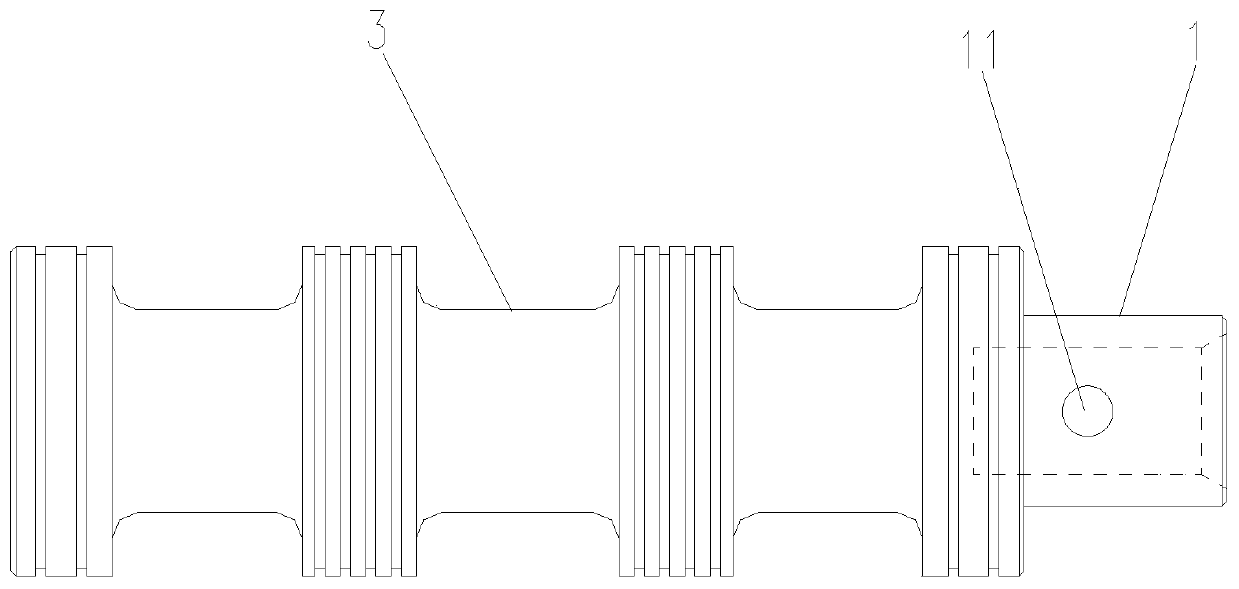

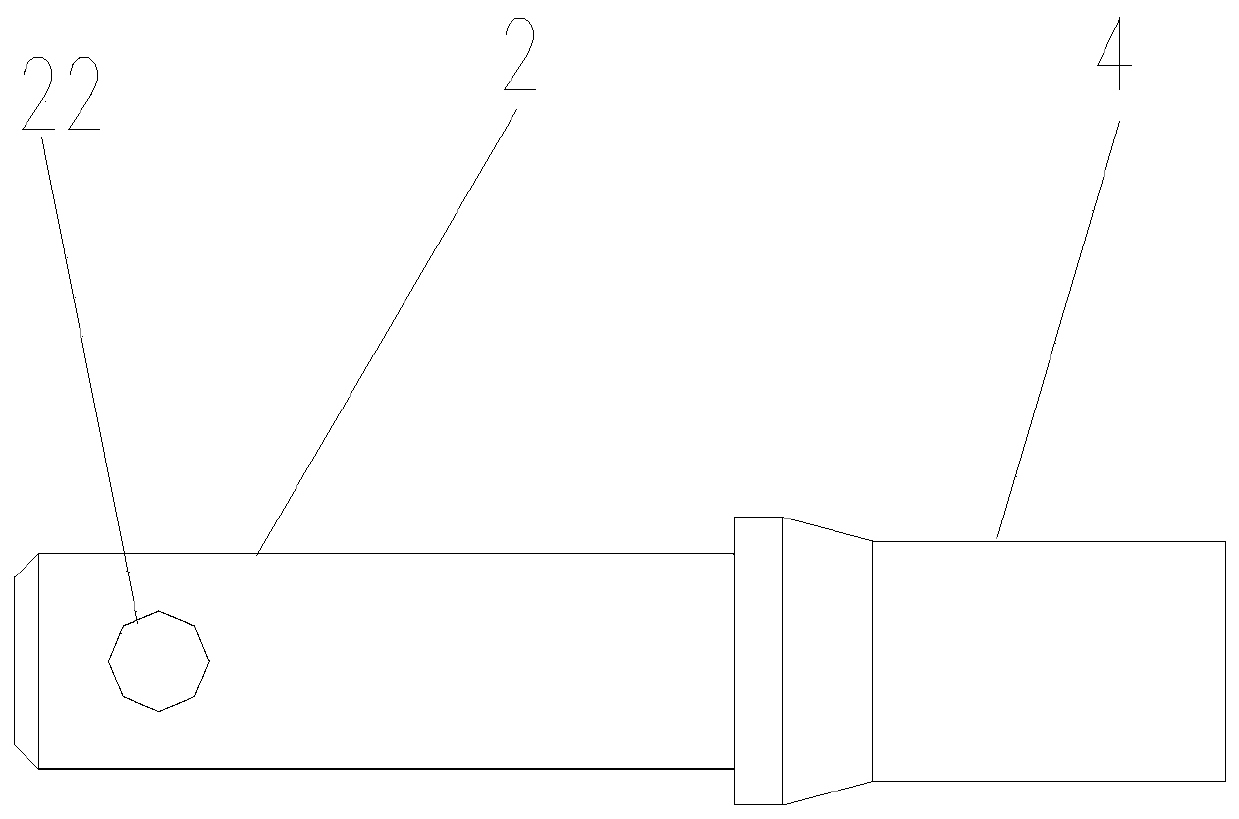

Modularization cylindrical multi-phase permanent magnet linear motor based on single-layer and double-layer mixed windings

ActiveCN104767350AContains the impact of faults relative to other phasesImprove reliabilityPropulsion systemsPermanent magnet rotorElectromagnetic coupling

The invention relates to a modularization cylindrical multi-phase permanent magnet linear motor based on single-layer and double-layer mixed windings and belongs to the field of permanent magnet motors. The modularization cylindrical multi-phase permanent magnet linear motor aims at solving the problems that when faults such as winding short circuits occur in a conventional multi-phase permanent magnet linear motor, the fault isolation difficulty is high, and the motor modularization design difficulty is high due to the high interphase electromagnetic coupling degree. The modularization cylindrical multi-phase permanent magnet linear motor comprises a stator and a permanent magnet rotor, wherein the stator can be arranged inside or outside the permanent magnet rotor, and an air gap exists between the stator and the permanent magnet rotor. The stator is formed by splicing m identical stator modules which are spliced into a cylinder in the axial direction. Each stator module comprises a stator iron core, 2n armature teeth, two fault tolerant teeth and 4n annular concentrated windings. The permanent magnet rotor is formed by splicing permanent magnets and a stator iron core, and the permanent magnet rotor can be of a surface attaching structure or a Halbach structure or an axial magnetizing structure or the like.

Owner:成都川哈工机器人及智能装备产业技术研究院有限公司

Clamp for assembling annular extruding permanent magnet magnetic system and assembly method thereof

InactiveCN101961855AGood magnetic isolation effectEasy to installWork holdersMetal-working hand toolsEngineeringNon magnetic

The invention relates to a clamp for assembling an annular extruding permanent magnet magnetic system and an assembly method thereof. The clamp comprises an inner ring shaft of which two ends are respectively provided with external thread sections, a plurality of nylon sleeves of which the bore diameter is greater than the external diameter of the inner ring shaft, a nylon positioning sleeve which is matched with the external thread sections of the inner ring shaft and is machined with internal threads, a nylon limit sleeve which is matched with the external thread sections of the inner ring shaft and is machined with the internal threads and is provided with an external baffle ring at one end of the inner ring shaft, a non-magnetic conducting magnet steel protective cylinder and a non-magnetic conducting stainless steel pressing cylinder which is machined with a plurality of threaded holes around the circumference of the non-magnetic conducting stainless steel pressing cylinder, wherein puller bolts are arranged in the threaded holes; wall thicknesses of sleeve sections of the nylon sleeve, the nylon positioning sleeve and the nylon limit sleeve are greater than the height of assembled strip magnet steel; the inner diameter of the magnet steel protective cylinder is greater than outer diameters of the sleeve sections of the nylon sleeve, the nylon positioning sleeve and the nylon limit sleeve; and the inner diameter of the non-magnetic conducting stainless steel pressing cylinder is greater than the outer diameter of the magnet steel protective cylinder.

Owner:HENAN POLYTECHNIC UNIV

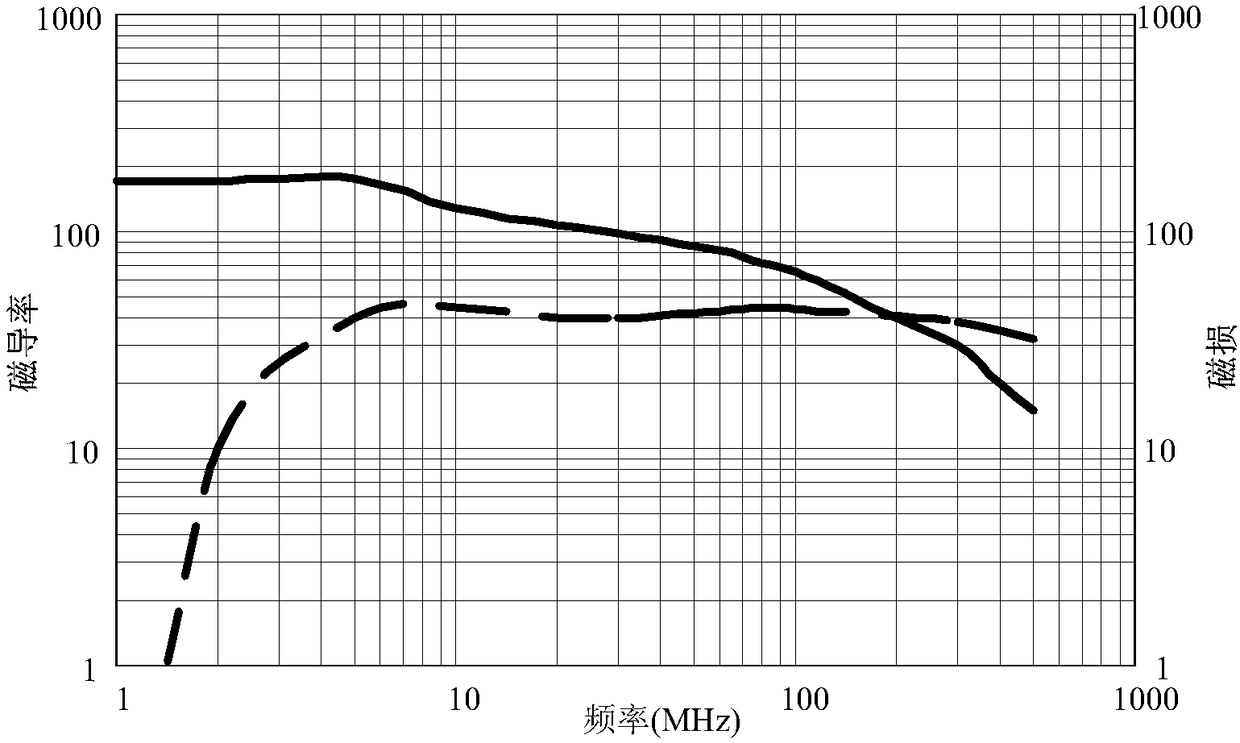

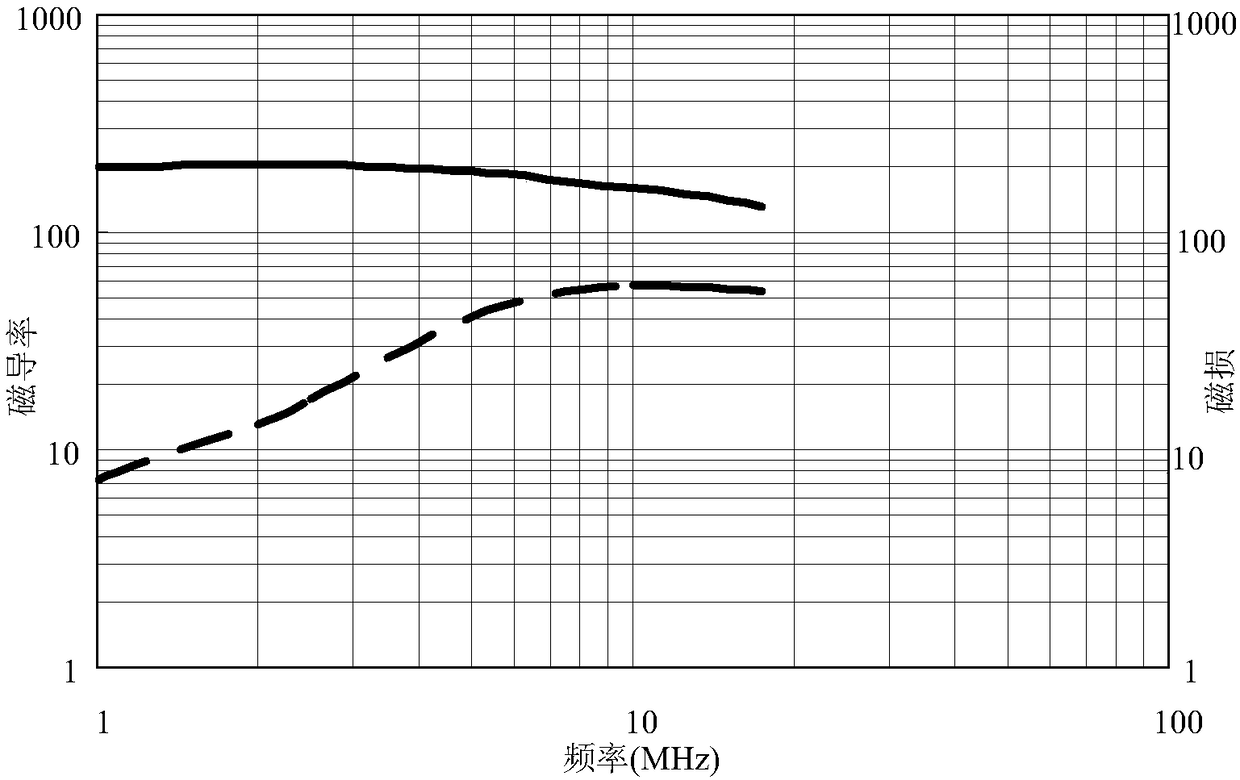

Composite laminated magnetic material structure for electromagnetic shielding and preparation method thereof

PendingCN108575079AHigh application frequencyAvoid exceptionLamination ancillary operationsMagnetic/electric field screeningAdhesiveComposite laminates

The invention provides a composite laminated magnetic material structure for electromagnetic shielding and a preparation method thereof. The composite laminated magnetic material structure for electromagnetic shielding comprises a soft magnetic alloy steel strip material structure and a ferrite magnetic material layer or a magnetic power adhesive layer, wherein the soft magnetic alloy steel stripmaterial structure comprises at least one soft magnetic alloy steel strip material layer; and the ferrite magnetic material layer or the magnetic power adhesive layer are attached to the surface of the soft magnetic alloy steel strip material structure. The composite laminated magnetic material structure for electromagnetic shielding is a composite laminated structure comprising the soft magneticalloy steel strip material layer and the ferrite magnetic material layer or the magnetic power adhesive layer, thereby being capable of integrating performance advantages of the two materials, havingan excellent magnetic isolating effect, reducing a problem of heating energy consumption, greatly expanding the application frequency (100kHz-20MHz) of the magnetic material, being capable of simultaneously meeting electromagnetic shielding requirements of wireless charging such as Qi and A4WP, and having important significance for improving the charging efficiency and the charging distance.

Owner:SHANGHAI LIANGZI HUIJING ELECTRONICS CO LTD

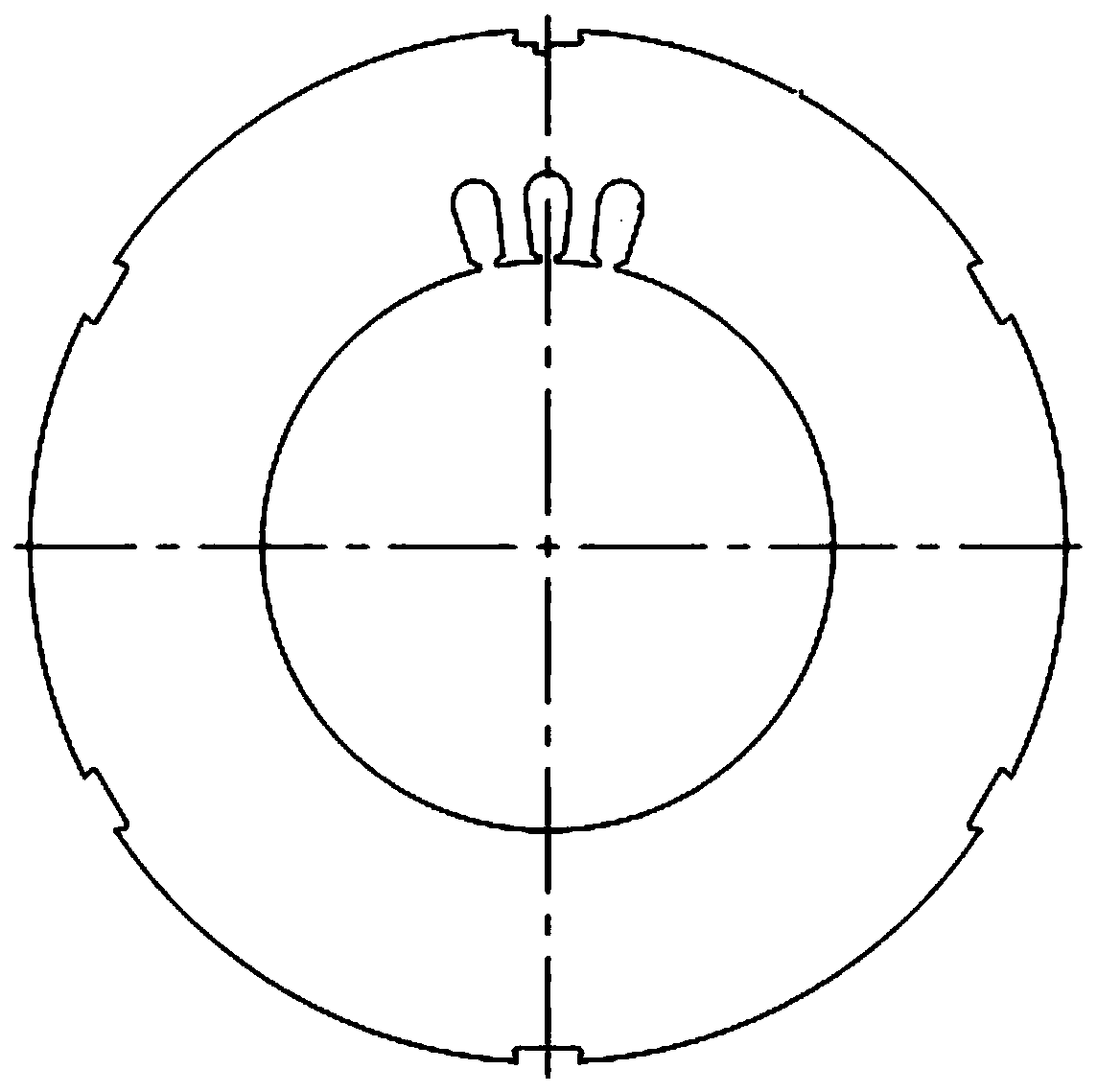

Rotor core of brushless motor

PendingCN105871096AImprove efficiencyReduce the temperatureMagnetic circuit rotating partsManufacturing stator/rotor bodiesBrushless motorsMagnetic flux leakage

The invention discloses a rotor core of a brushless motor and belongs to the field of motors. The rotor core of the brushless motor solves the technical problem that the magnetic flux leakage phenomenon of a rotor of a brushless motor in the prior art is serious, and comprises a core body. The core body comprises laminated rotor stamped sheets. Each rotor stamped sheet comprises a body, core sheets arranged at intervals in the circumferential direction of the body, and splicing blocks located between the adjacent core sheets, wherein magnetic shoe grooves are formed between the splicing blocks and the core sheets, and the splicing blocks and the body are spaced to form broken bridges. Besides, for every two adjacent rotor stamped sheets, the core sheets on the lower layer rotor stamped sheet are located under the splicing blocks on the upper layer rotor stamped sheet.

Owner:浙江希尔富电气股份有限公司

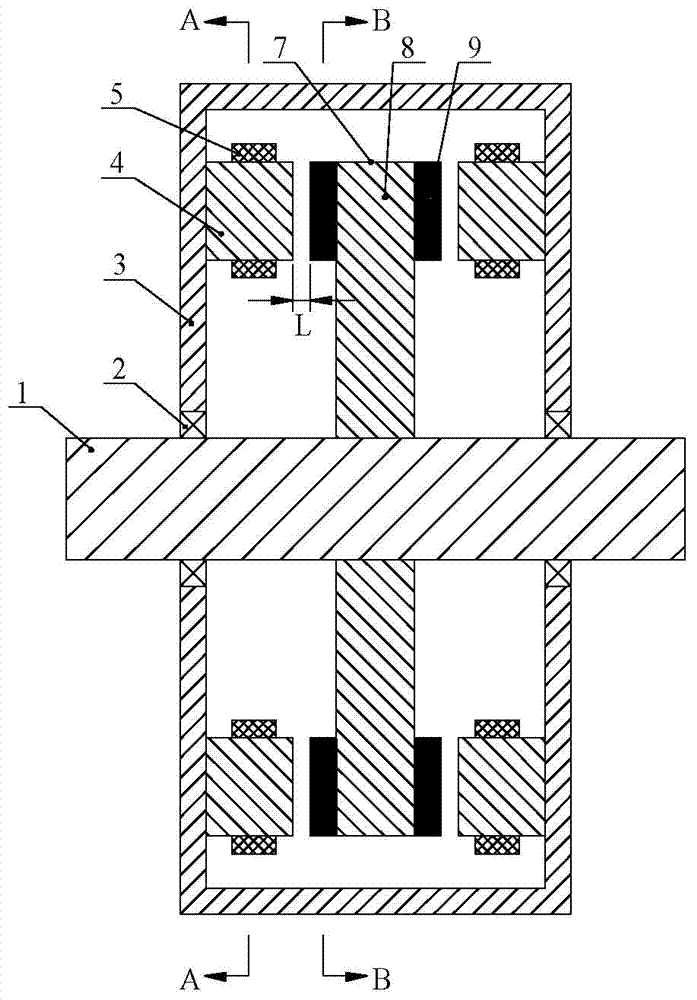

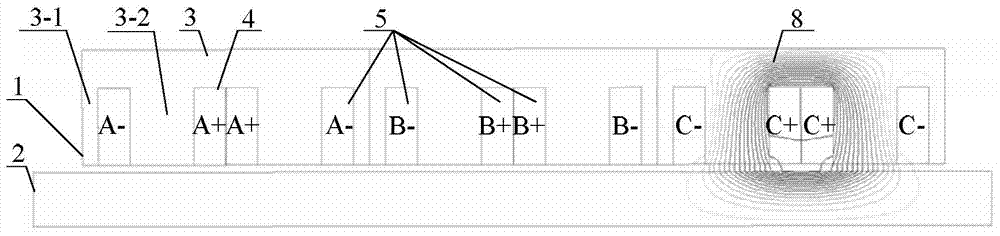

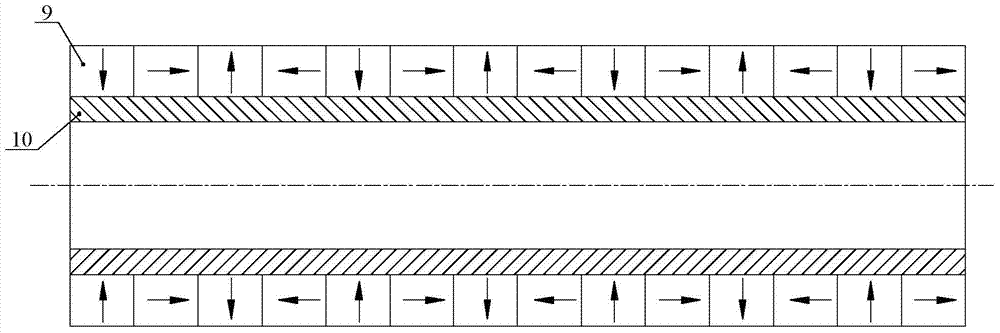

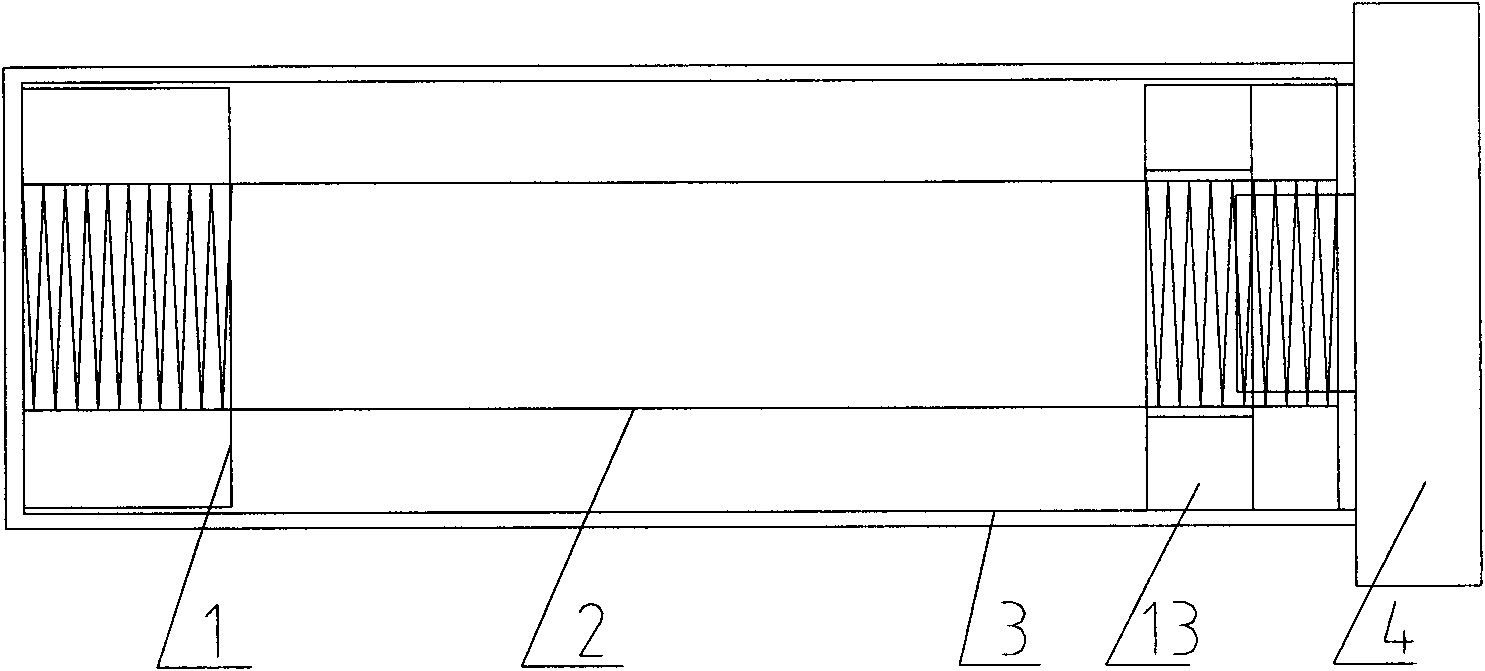

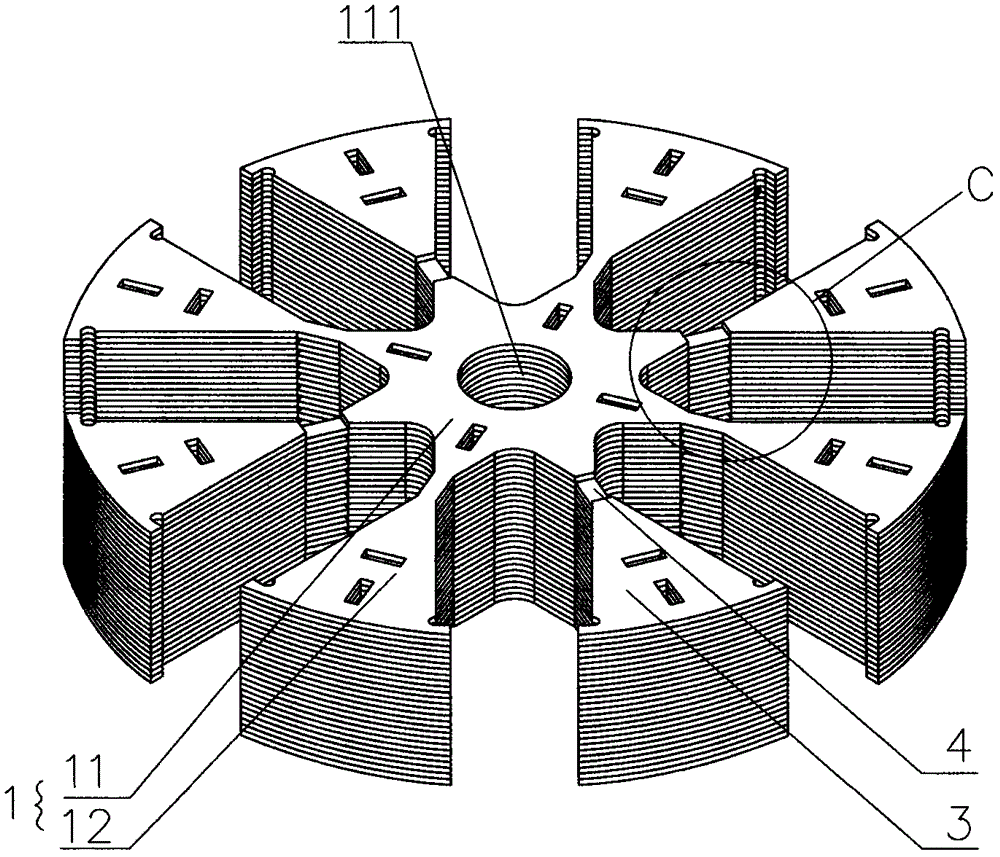

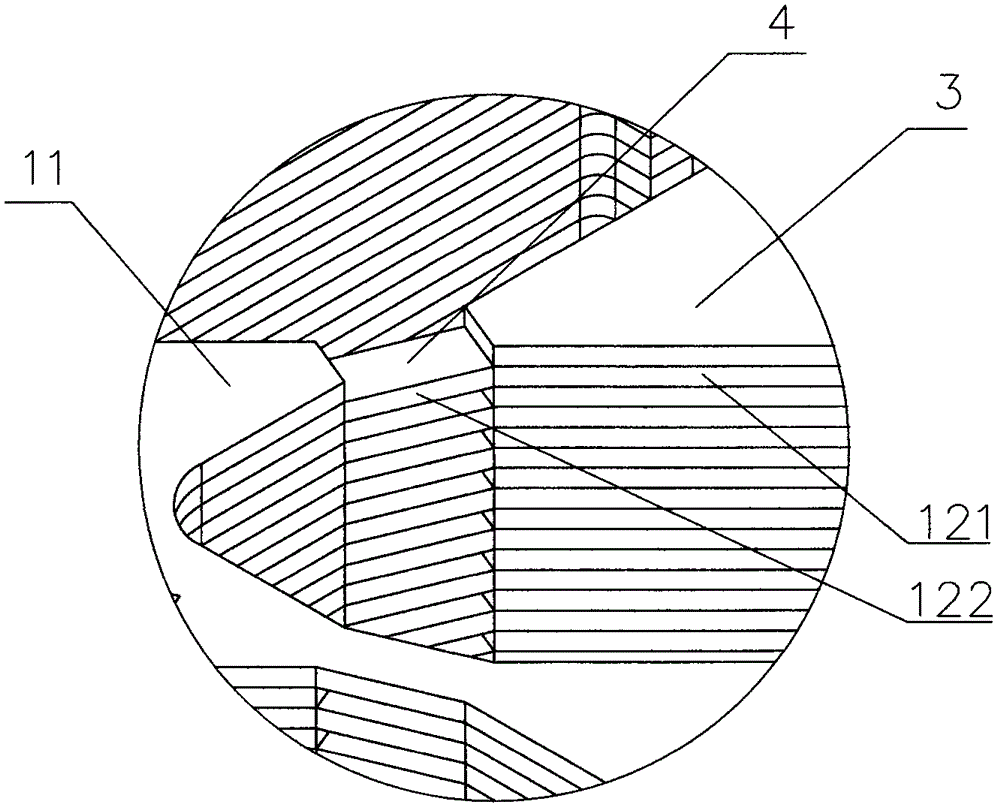

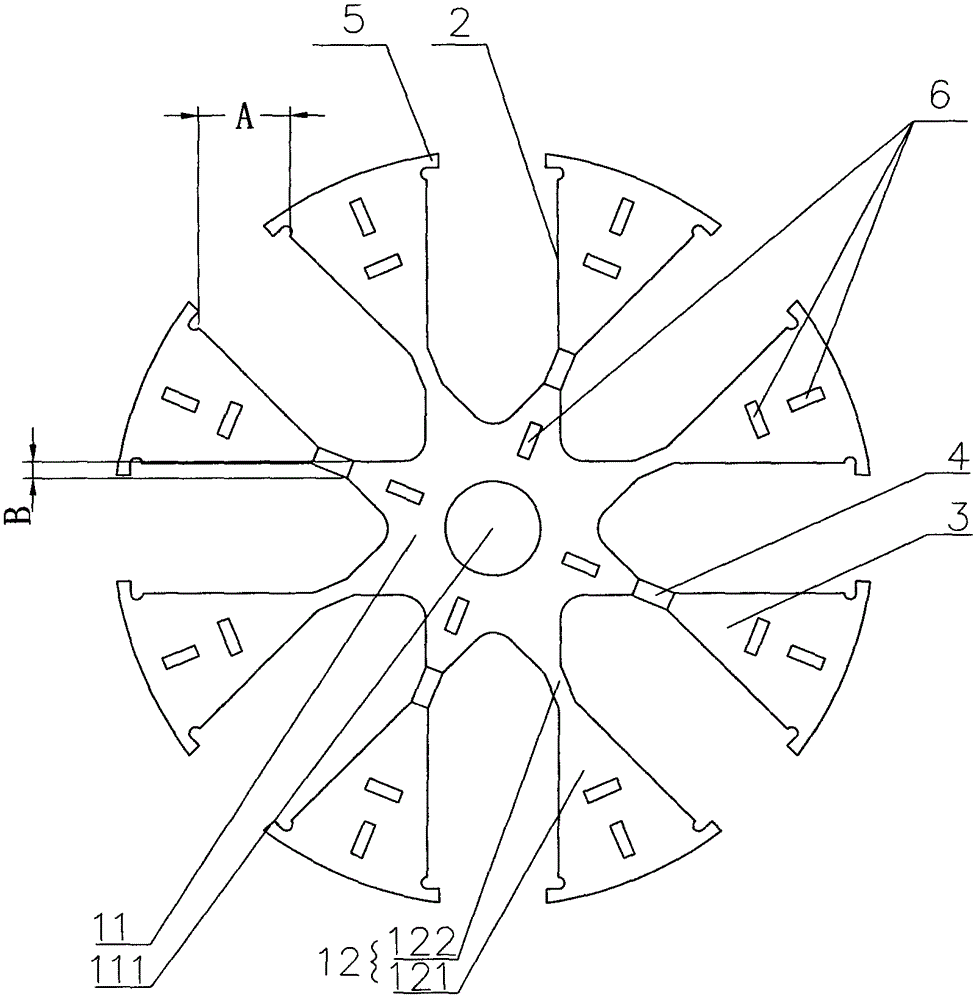

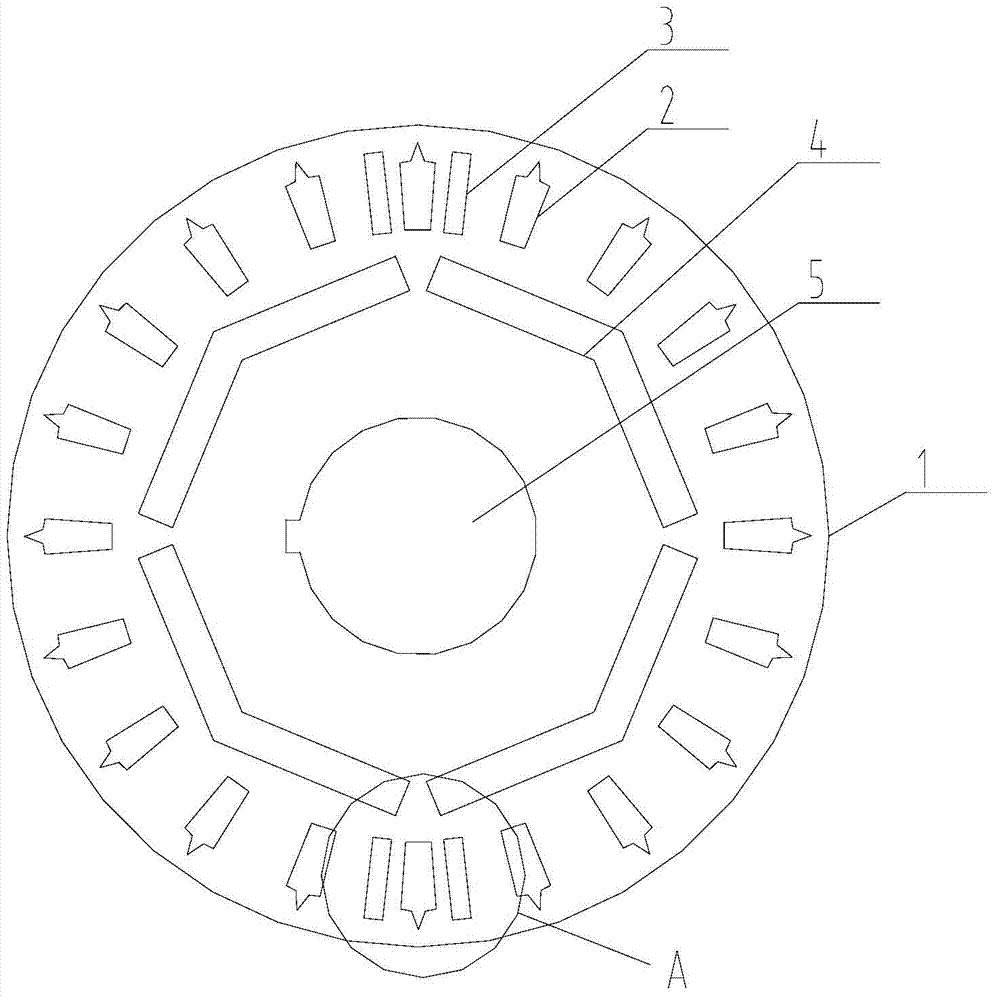

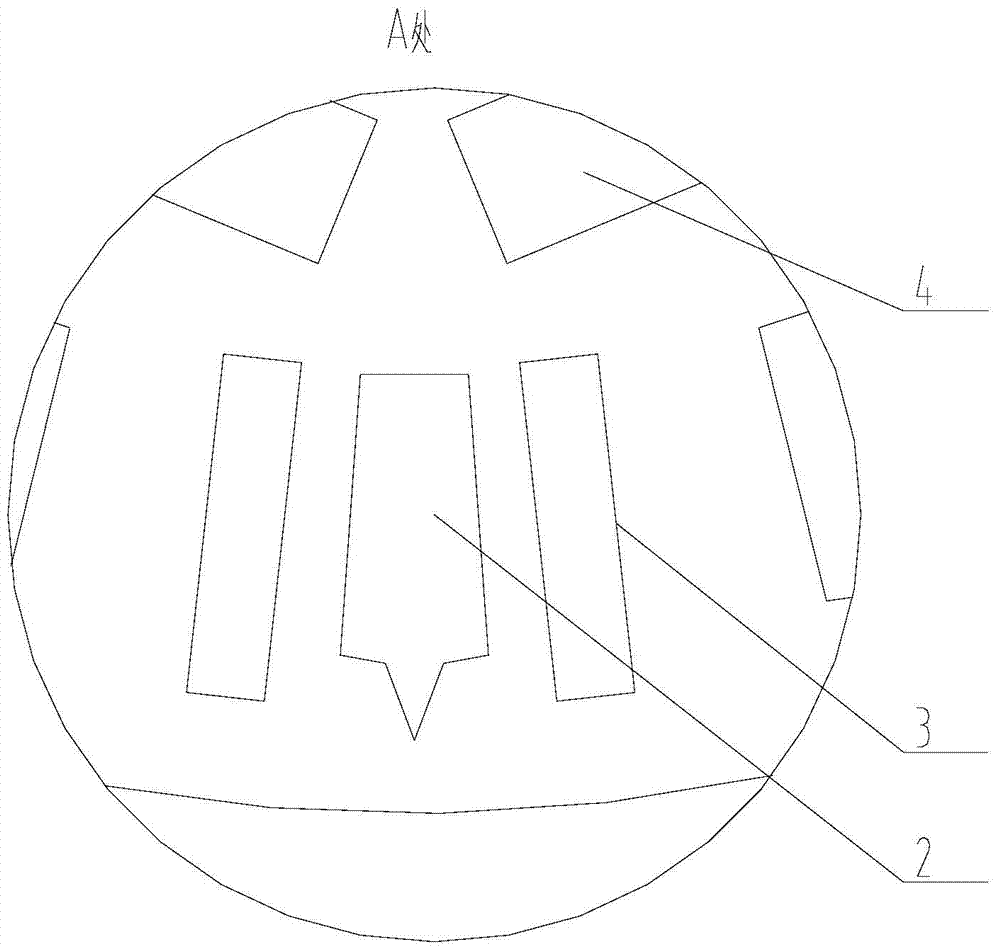

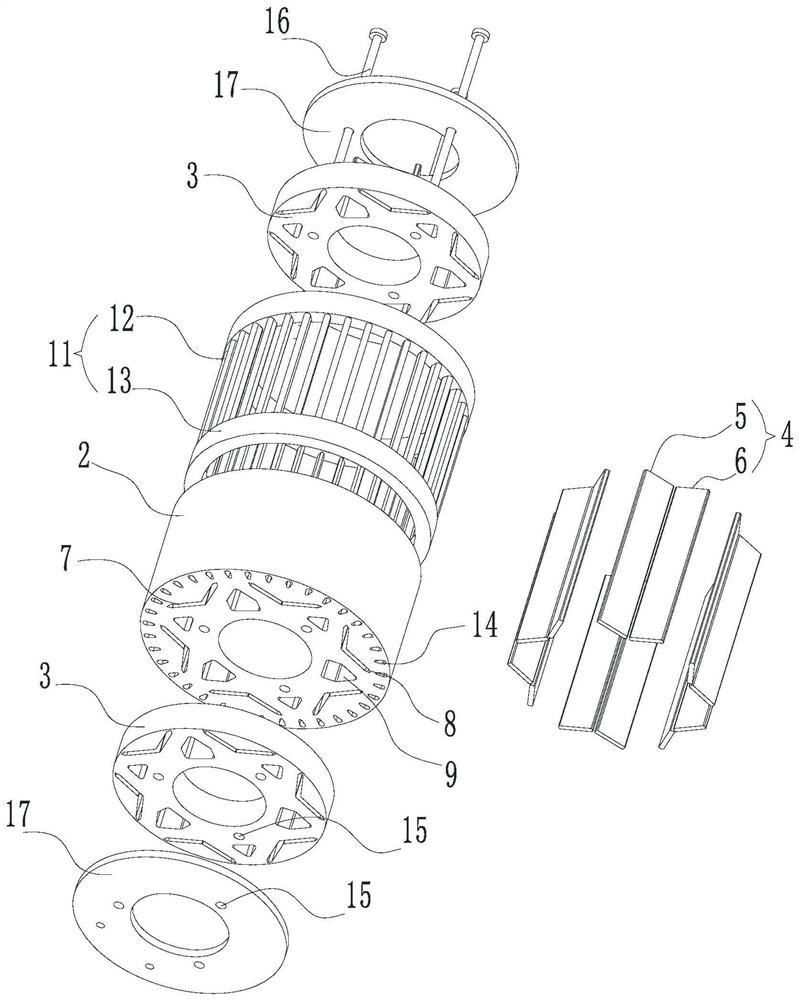

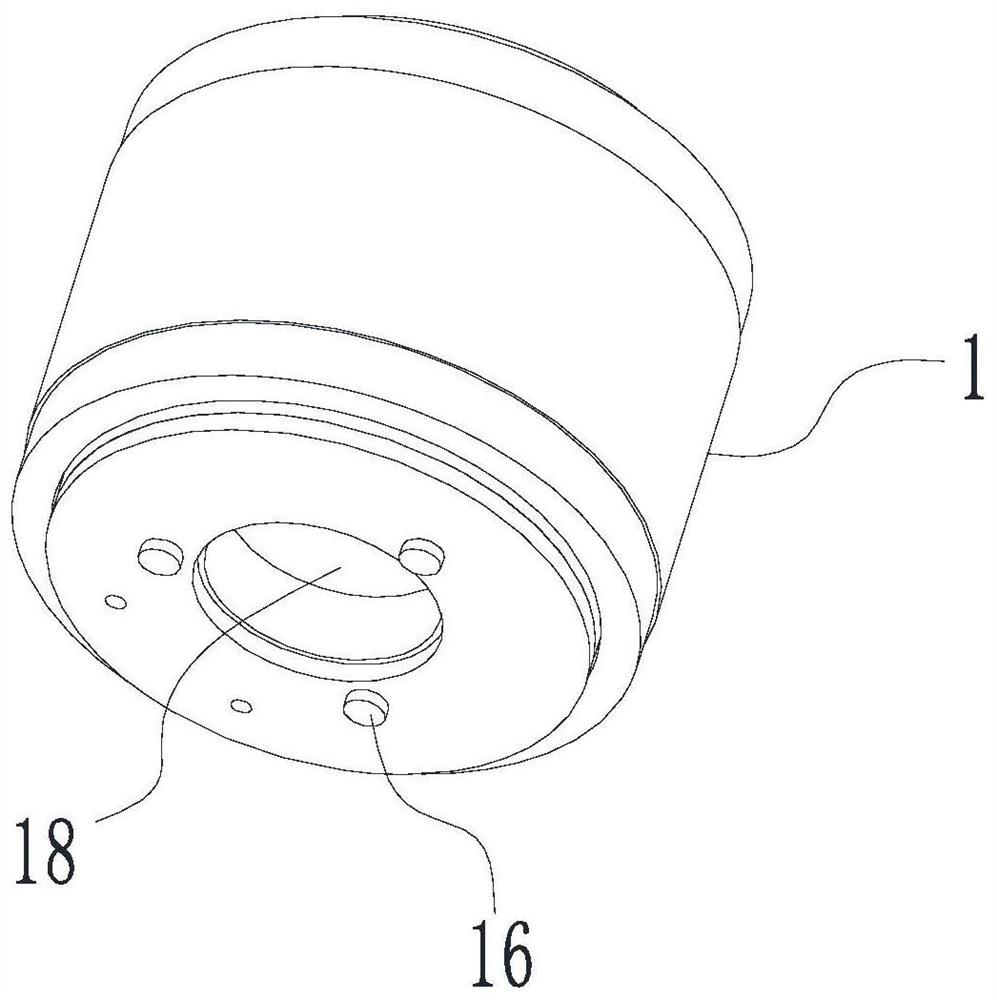

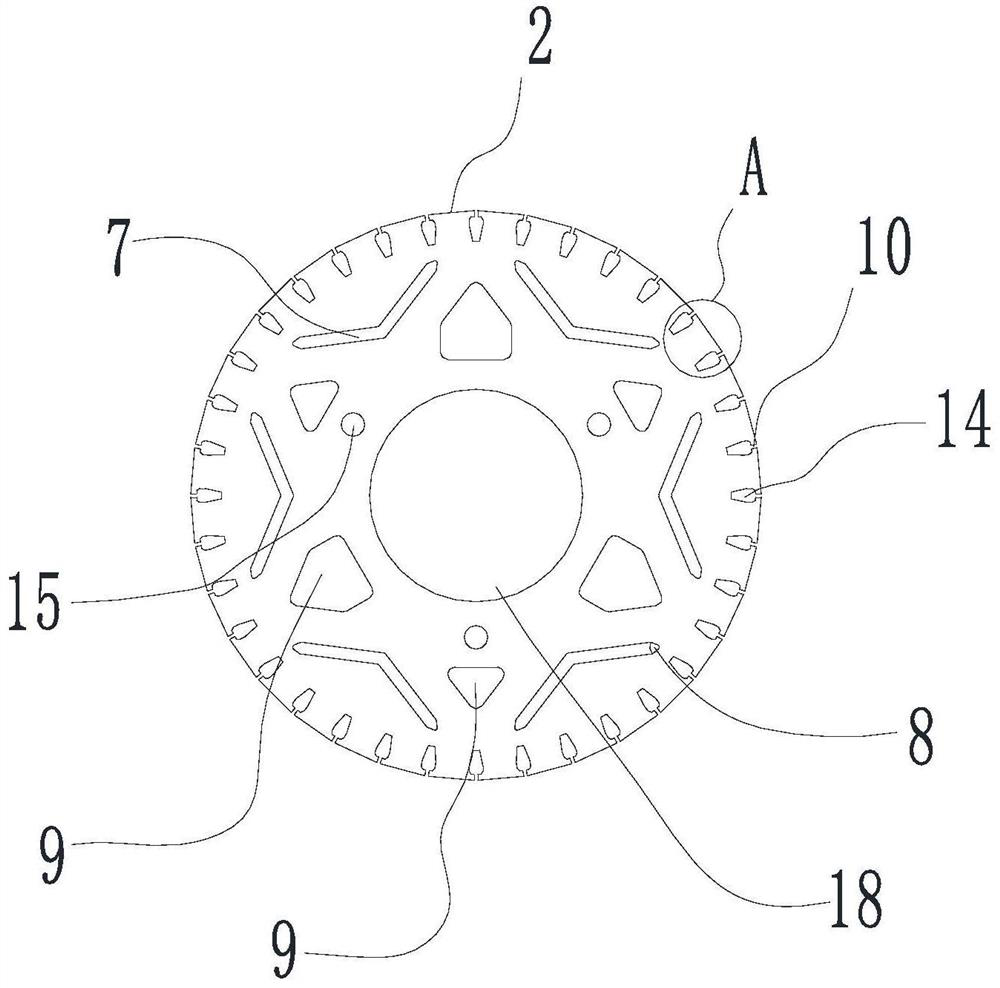

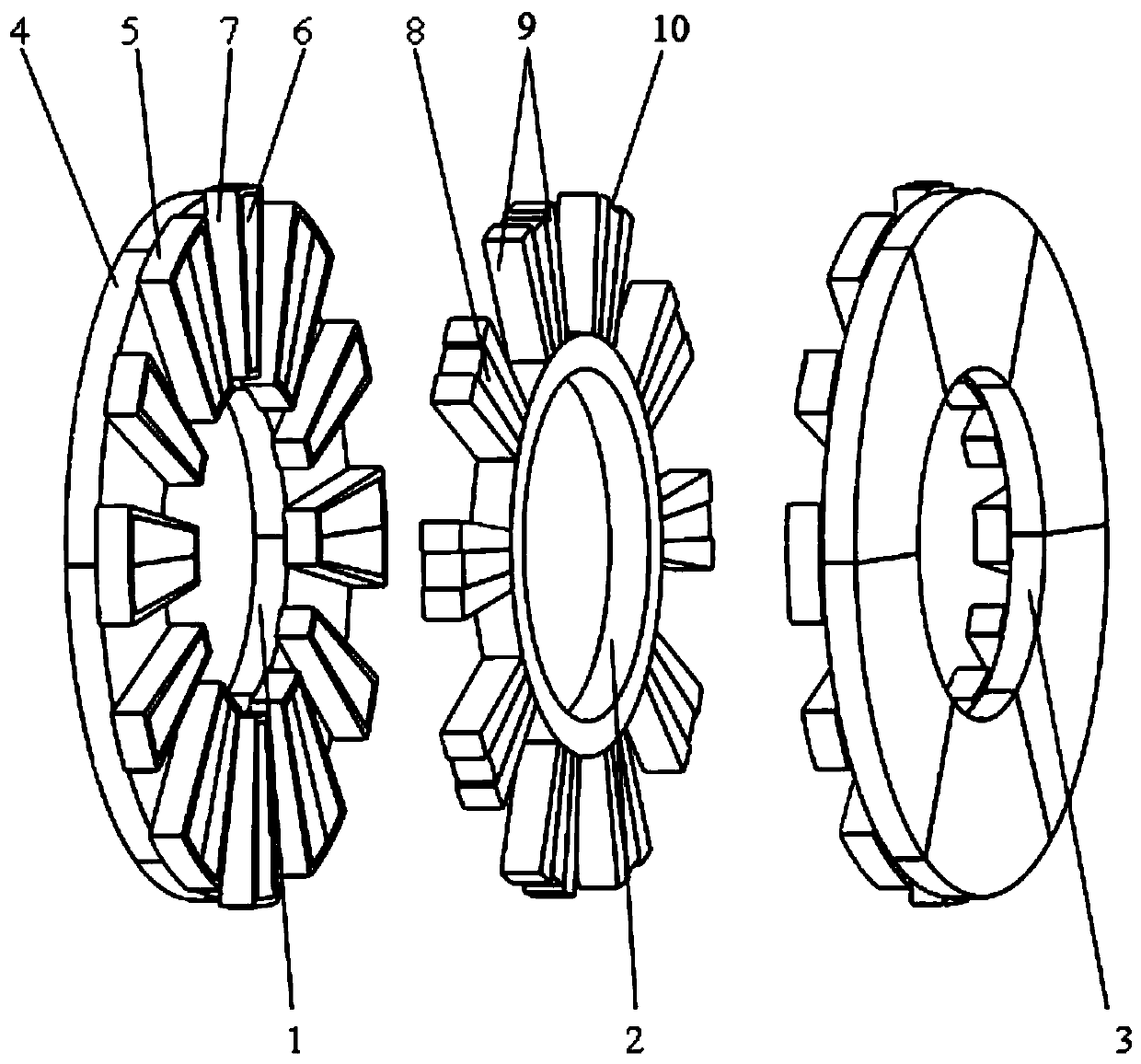

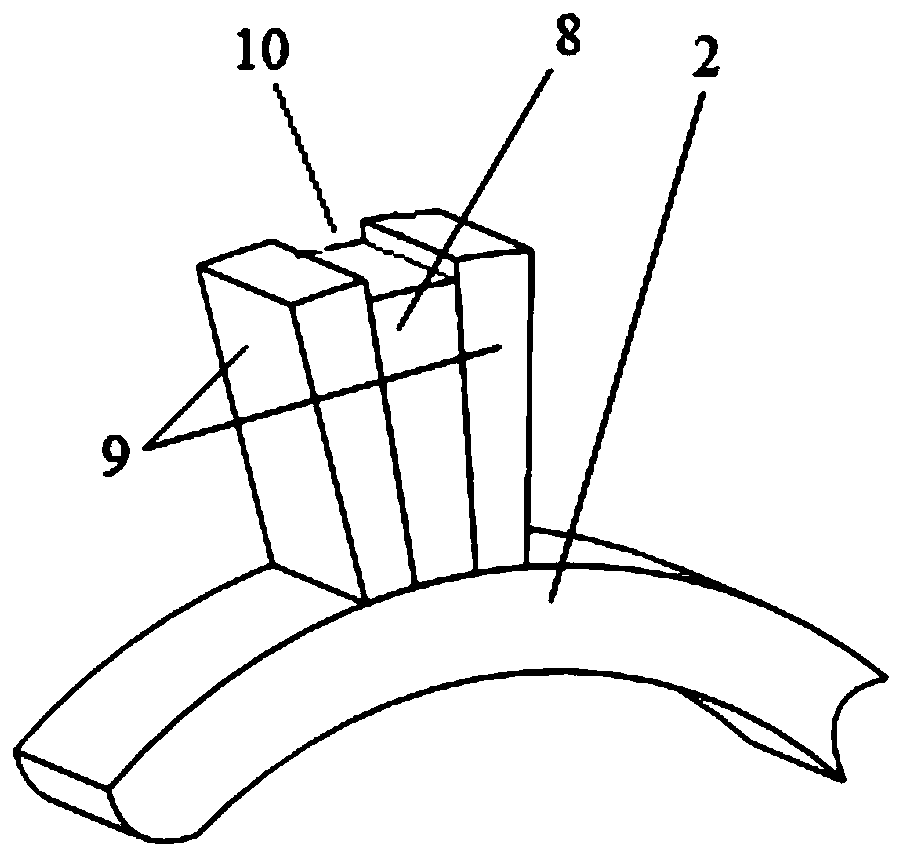

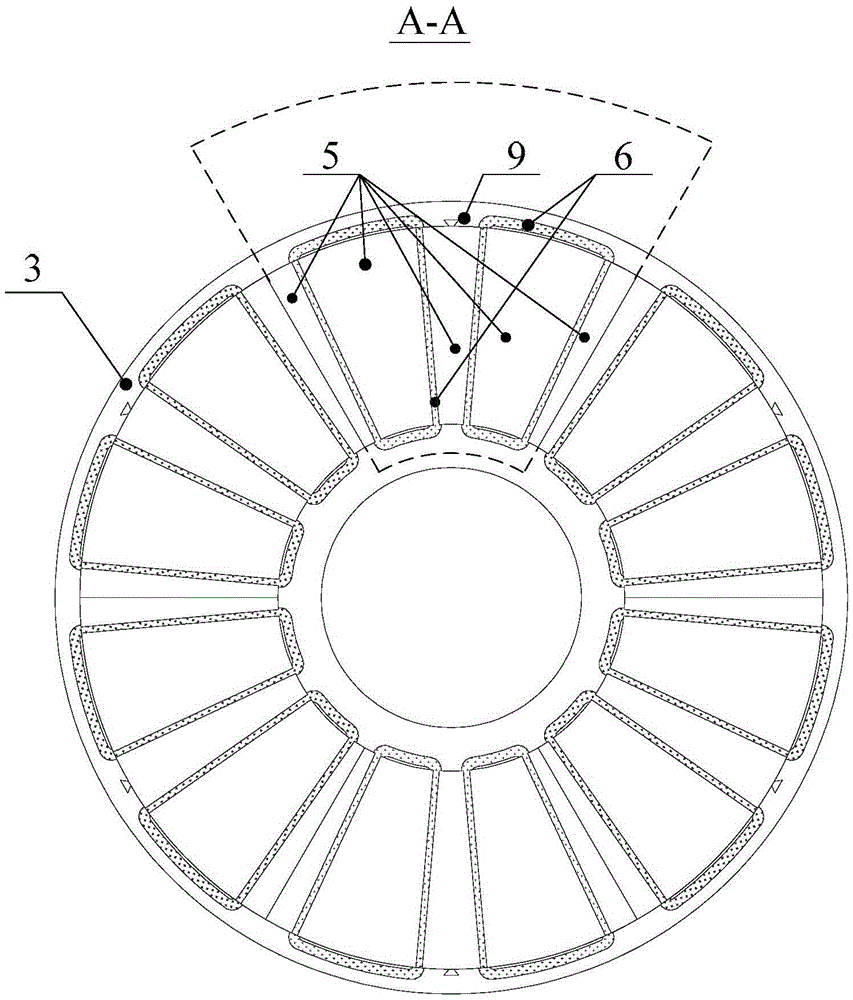

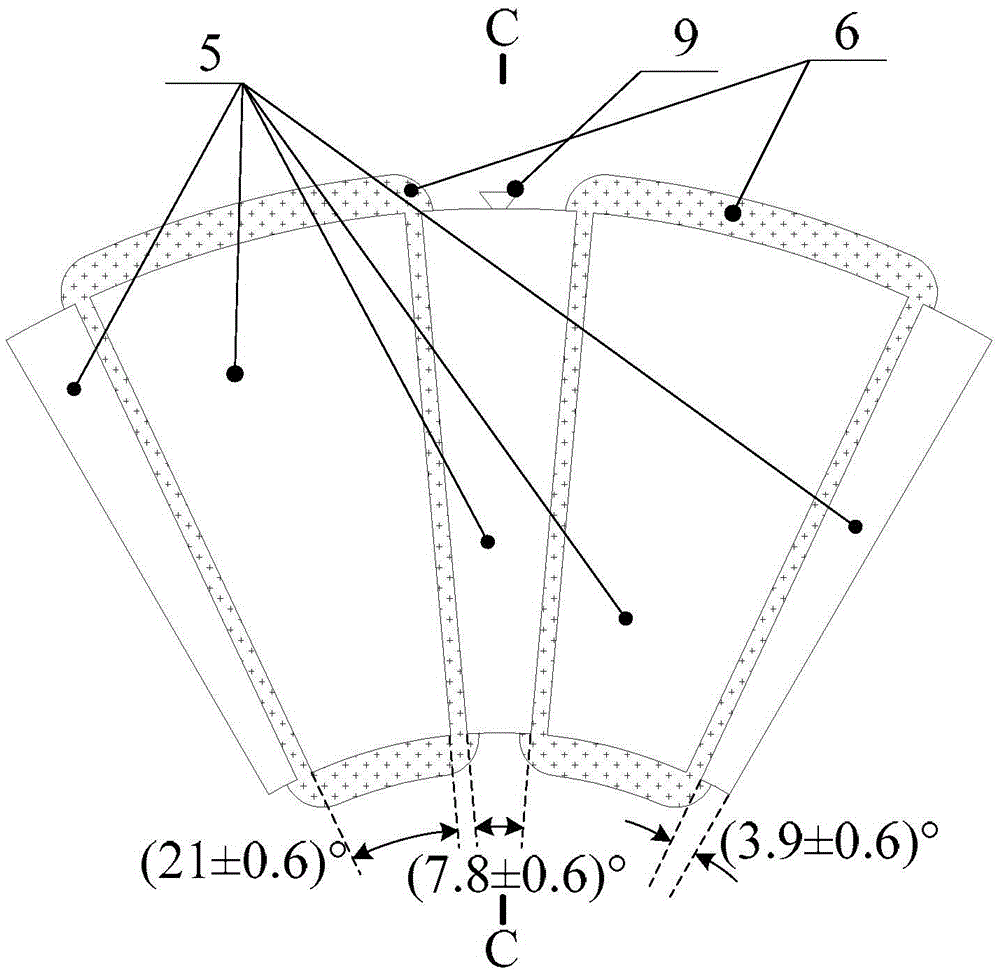

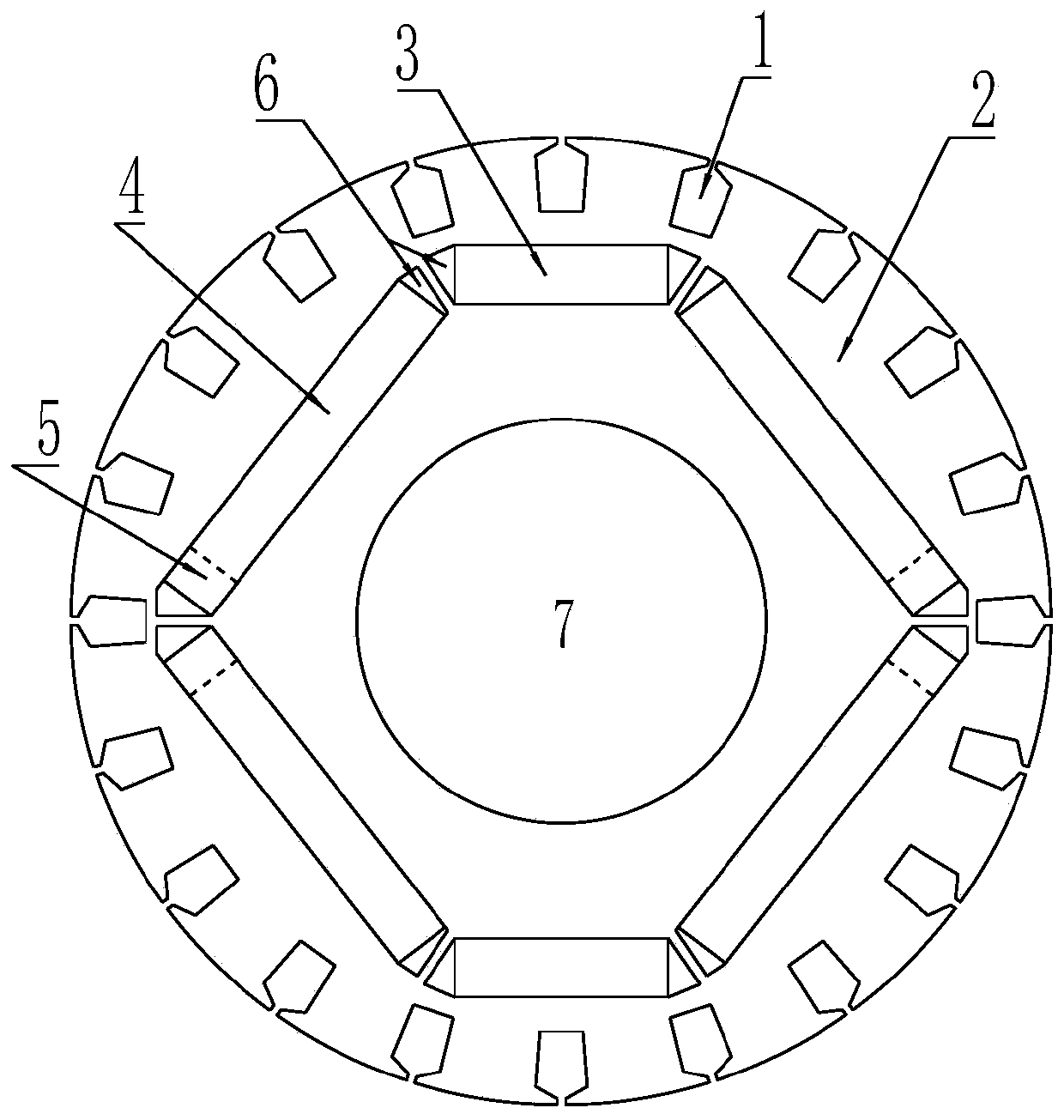

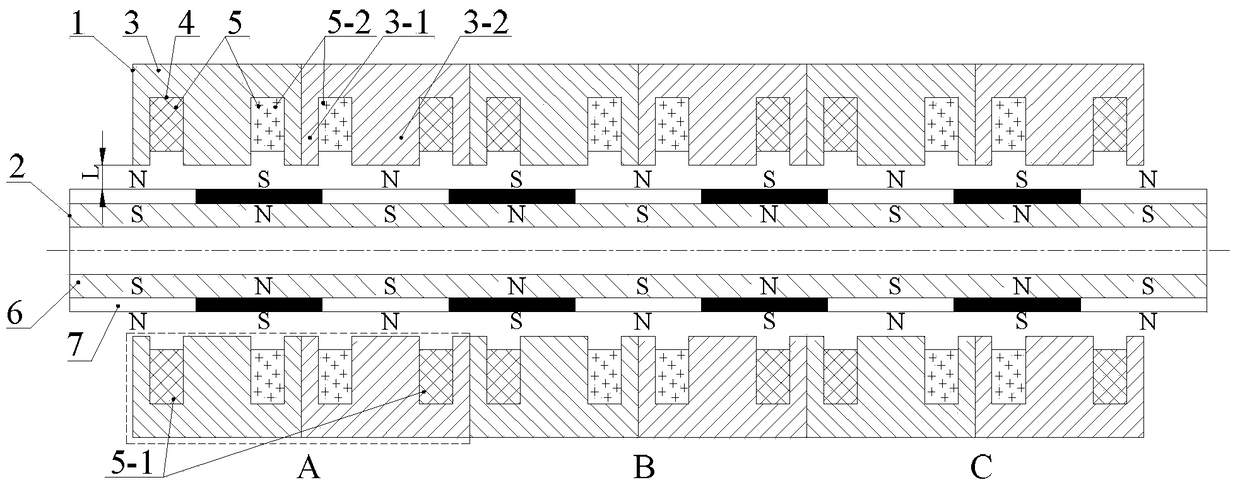

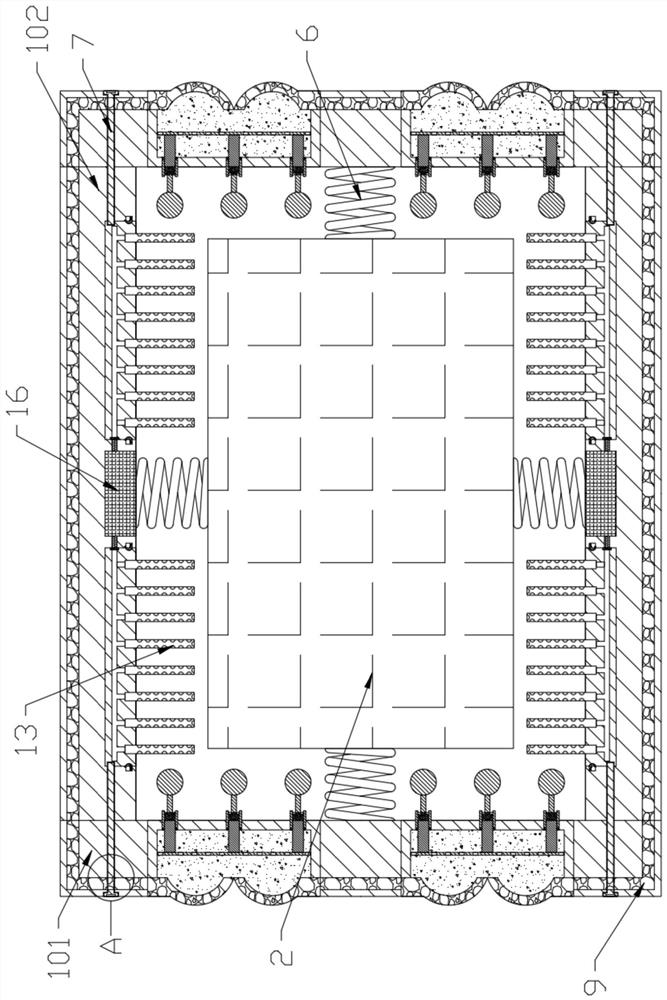

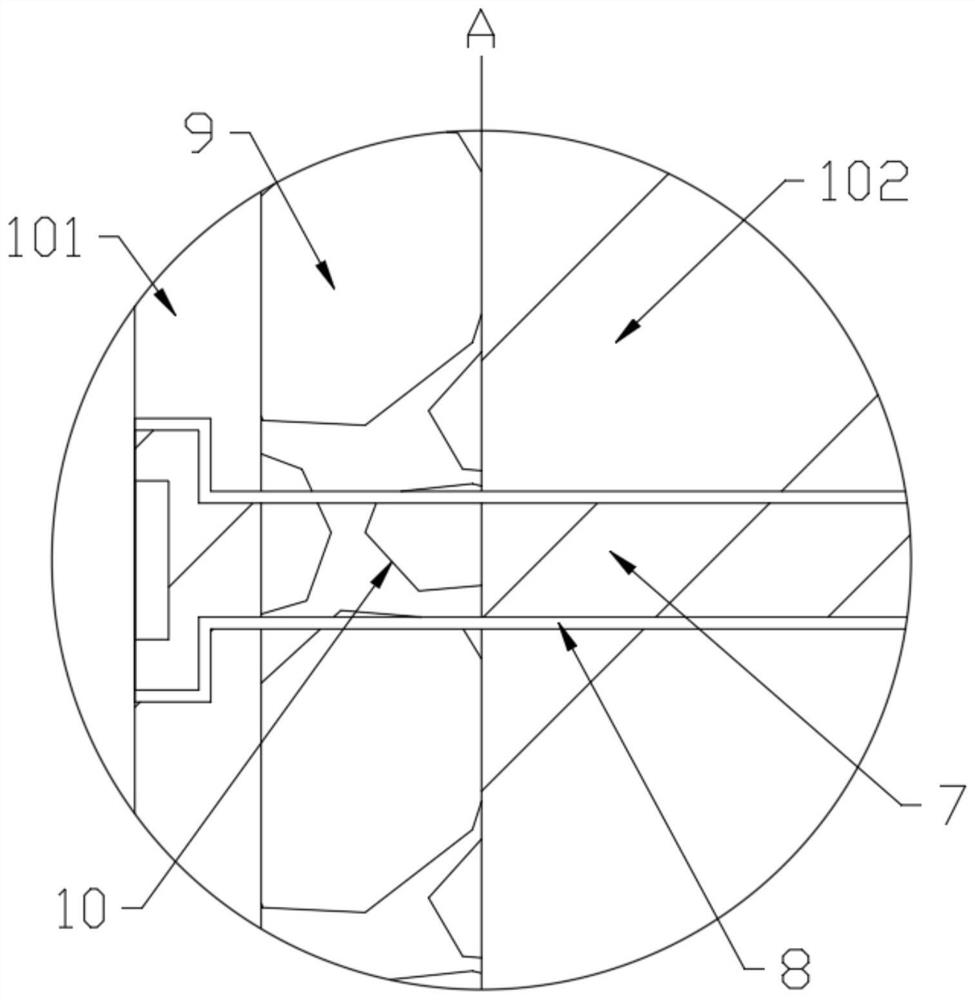

Axial magnetic flow modularized multi-phase motor having high magnetic isolation capacity

ActiveCN103746532AImprove power densityImprove reliabilitySynchronous machines with stationary armatures and rotating magnetsElectric machinePermanent magnet synchronous motor

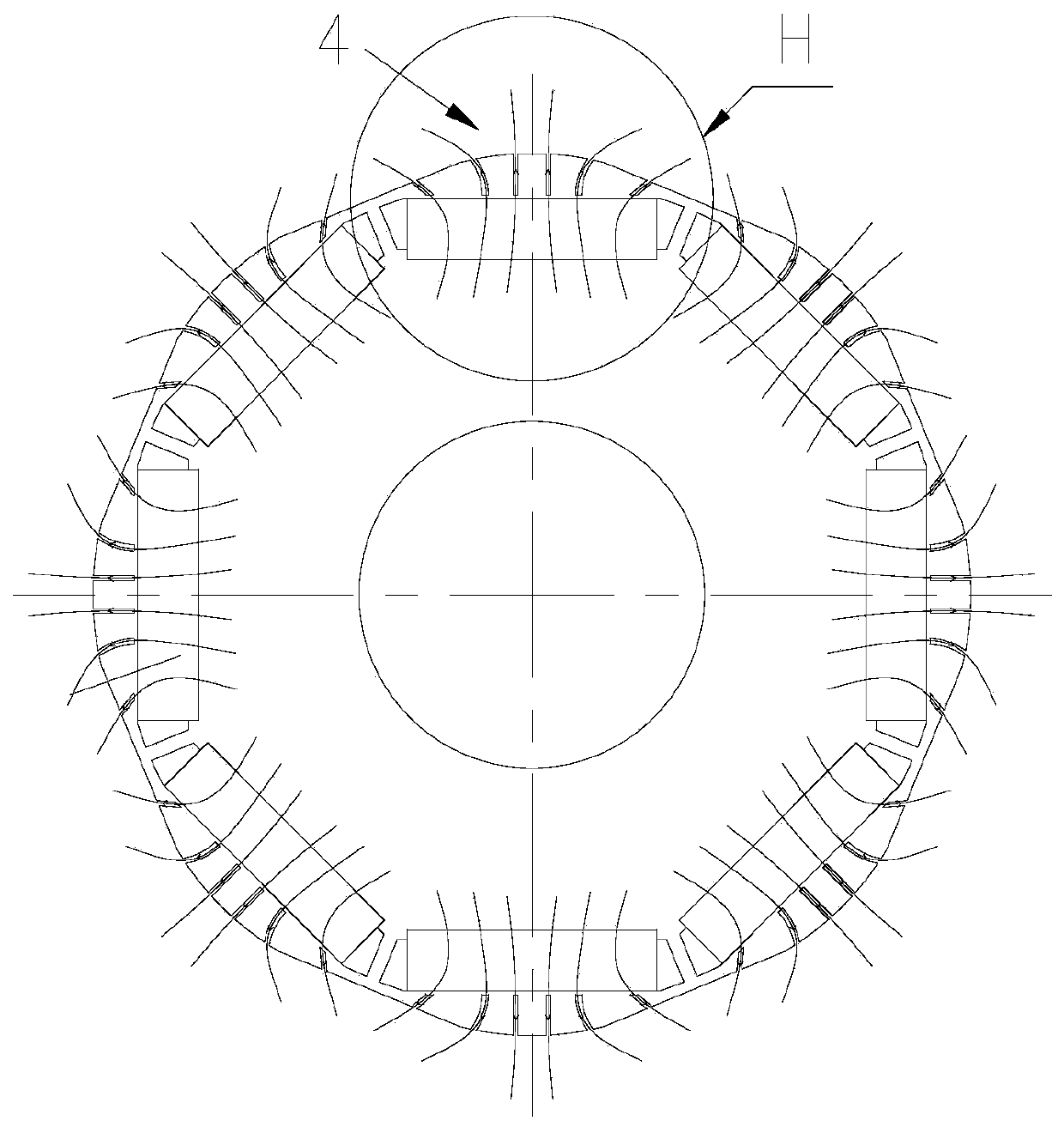

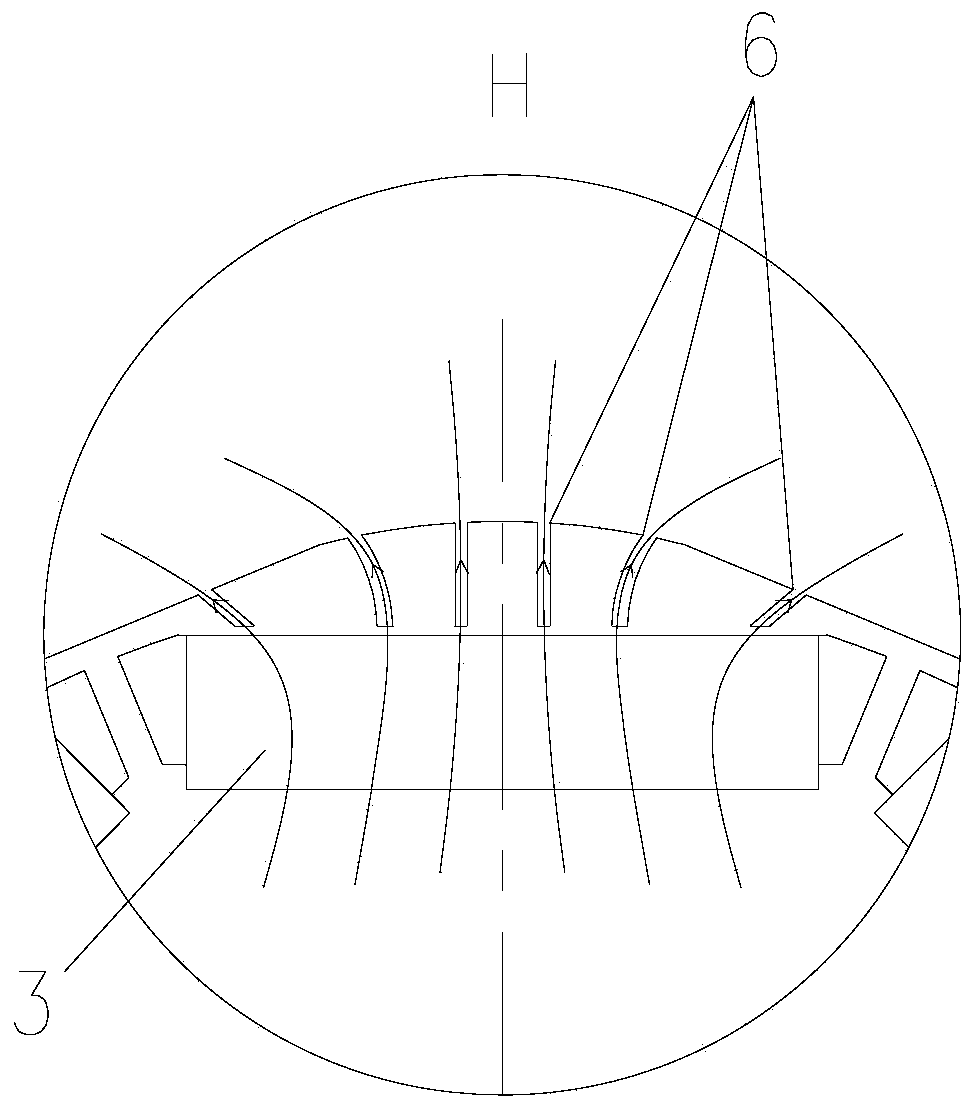

The invention discloses an axial magnetic flow modularized multi-phase motor having a high magnetic isolation capacity, belongs to the field of motors, and aims to solve the problem of high fault-tolerant control difficulty in case of short circuit of one phase of winding in the conventional multi-phase permanent magnet synchronous motor and the problem of badness to fault isolation and modularized structural design due to dispersed distribution of a winding space. The axial magnetic flow modularized multi-phase motor comprises two modularized stators, a disk-type rotor, a shell and a main shaft, wherein the two modularized stators and the disk-type rotor are arranged inside the shell; one modularized stator, the disk-type rotor and the other modularized stator are arranged in sequence on the main shaft in an axial direction; air gaps are formed between the two modularized stators and the disk-type rotor along the axial direction; in each modularized stator, N same stator modules are spliced into a disk; each stator module comprise a stator core, five stator teeth and two centrally-wound windings; in the disk-type rotor, a disk surface on any side of the rotor core is provided with 2N+ / -2 permanent magnets magnetized oppositely and alternatively in the axial direction.

Owner:HARBIN INST OF TECH

Brake system-used brushless motor rotor punching sheet structure

PendingCN110401278AIncrease the quadrature axis equivalent reluctanceReduce nonlinear effectsMagnetic circuit rotating partsBrushless motorsPunching

The invention discloses a brake system-used brushless motor rotor punching sheet structure, which comprises a rotor punching sheet. The circle center of the rotor punching sheet is provided with a rotating shaft groove; the periphery of the rotating shaft groove of the rotor punching sheet is uniformly provided with a plurality of magnetic steel grooves along a circumferential direction; a magnetic isolation groove is arranged at each magnetic steel groove and at the outer edge of the rotor punching sheet; the included angle between the center line of the magnetic isolation groove and the magnetic line of the rotor punching piece is 0 DEG; and a magnetic isolation filling block is arranged in the magnetic isolation groove. The a-axis equivalent reluctance of the motor can be increased, andthe brake system-used permanent magnet brushless motor parameter nonlinear influences caused by cross coupling of d-axis and a-axis magnetic circuits can be reduced.

Owner:NIDEC KAIYU AUTO ELECTRIC JIANGSU

Motor rotor and motor

PendingCN109149823AReduce thicknessReduce the difficulty of magnetizationMagnetic circuit rotating partsElectric machineTorque density

The invention provides an electric machine rotor and an electric machine. A motor rotor includes a rotor core and a permanent magnet, the rotor core is provided with a plurality of claw-shaped mounting grooves in the circumferential direction, The claw-shaped mounting groove comprises a tail magnetic isolation groove and a plurality of long-bar grooves, wherein the long-bar grooves extend along the inner and outer directions of the rotor core, one end of the long-bar grooves close to the inner side of the rotor core is communicated with the tail magnetic isolation groove, the long-bar groovesare located on the side of the tail magnetic isolation groove away from the center of the rotor of the motor, and permanent magnets are arranged in each long-bar groove. The invention adopts a claw-shaped mounting groove to mount a permanent magnet, and the permanent magnet is divided into a plurality of pieces and installed in the claw-shaped mounting groove, so that the thickness of the permanent magnet can be reduced and the magnetization difficulty of the permanent magnet can be reduced. In addition, the surface area of the permanent magnet in the claw-shaped mounting groove in the invention is improved, which can remarkably improve the magnetic convergence ability of the motor rotor, thereby improving the torque density of the motor rotor, and is particularly suitable for improving the magnetic convergence ability of the motor rotor with a small pole number.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Shielded coil module and preparation method thereof

InactiveCN108511912AHighly integratedThe overall thickness is thinDe-icing/drying-out arrangementsScreened loop antennasMicrowaveAdhesive

The invention discloses a shielded coil module and a preparation method thereof. The shielded coil module comprises a base material, a coil on the surface of the base surface, an insulating layer on the coil, and a shielding material layer and a heat dissipating layer which are arranged on the surface of the insulating layer in a covered manner, wherein the base material comprises a PI base material and an EMI microwave absorbing material or a PI single-faced adhesive; if the base material comprises the PI base material and the EMI microwave absorbing material, the coil and the insulating layer are distributed on two sides of the base material to form a double-faced plate, the shielding material layer and the heat dissipating layer are arranged on one face of the double-faced plate and arepositioned below a battery panel; if the base material comprises the PI single-faced adhesive, the coil and the insulating layer are positioned on the side without adhesive to form a single-faced plate, and the shielding material layer and the heat dissipating layer are positioned below the battery panel. The shielded coil module is high in integration level, thin in thickness, good in magnetismisolating capacity and relatively low in working temperature, so that the cost is greatly saved.

Owner:SHANGHAI LINEPRINTING MATERIALS CO LTD

Motor system started without reversing

InactiveCN105449966AEasy to saturateNo-load back electromotive force Eo reducedMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsFrequency conversionPermanent magnet synchronous motor

The invention provides a motor system started without reversing and relates to the field of motor systems. The invention provides the motor system started without reversing, which is compact in structure, is capable of effectively preventing a motor from reversing when started, and thus effectively and thoroughly solves the bottleneck problem that a three-phase frequency conversion permanent magnet synchronous motor firstly reverses and then rotates forwards and the popularization and application of the frequency conversion speed regulation permanent magnet synchronous motor is restricted. The motor system comprises a frequency conversion speed regulator and a three-phase frequency conversion permanent magnet synchronous motor. The air gap magnetic flux of the three-phase frequency conversion permanent magnet synchronous motor is reasonably controlled, that is to say, when the current of the frequency conversion permanent magnet synchronous motor reaches a rated value, the air gap magnetic flux should be in a saturation state, and then, the constructive deviation of the frequency conversion speed regulator relative to the specific position of a rotor of the three-phase frequency conversion permanent magnet synchronous motor can be limited within + / - 30 deg, so that the permanent magnet synchronous motor is 100% prevented from firstly reversing and then rotating forwards when started.

Owner:JIANGSU ELMAER TECH

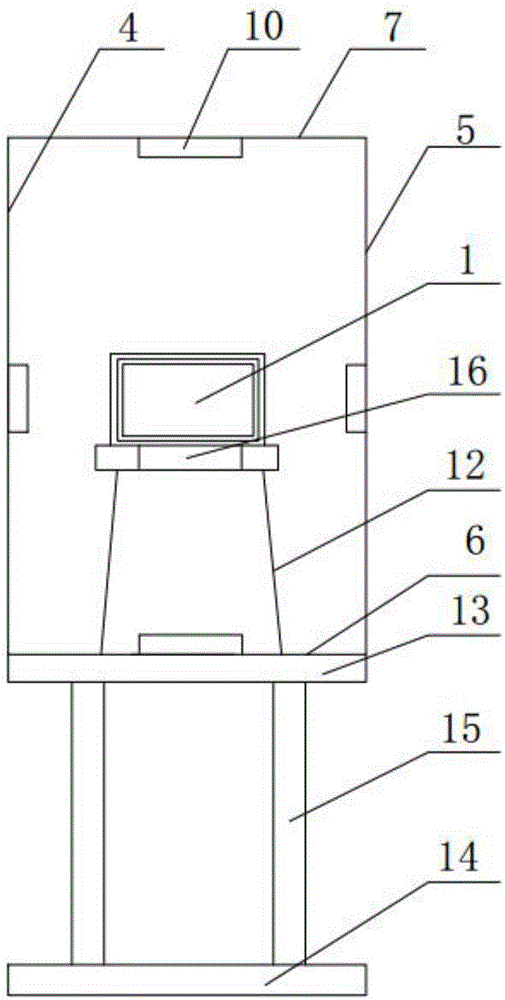

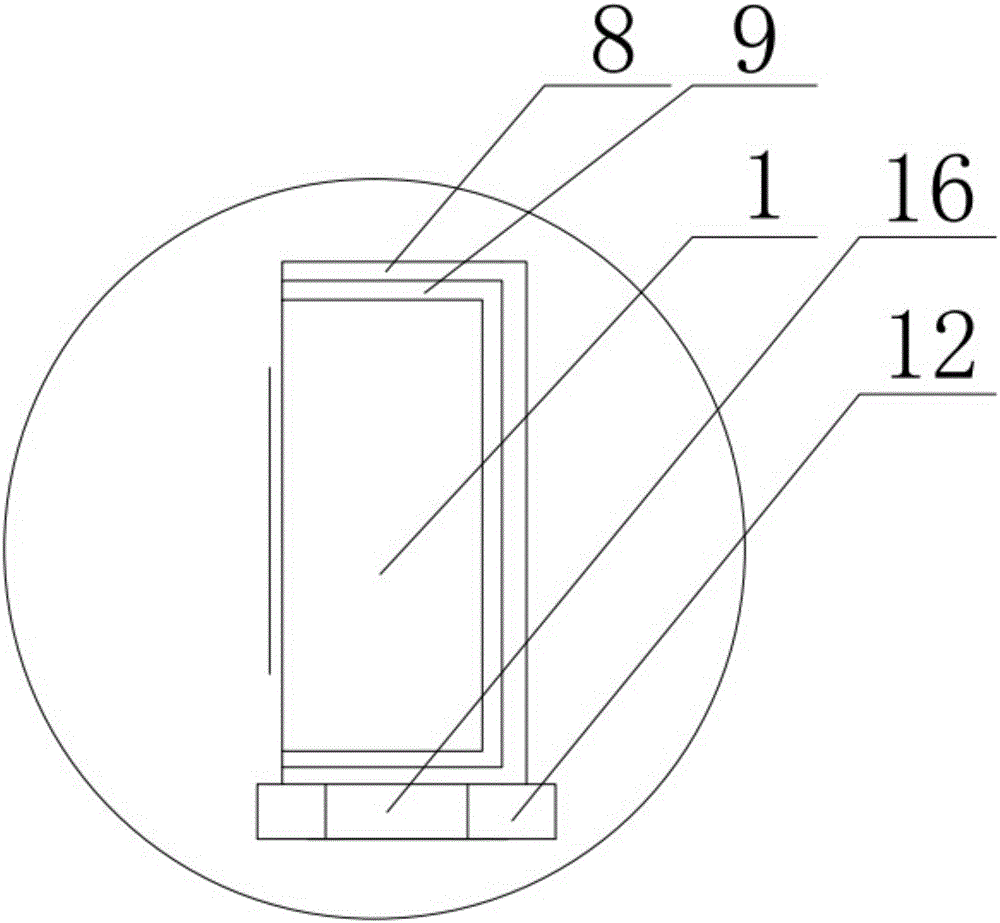

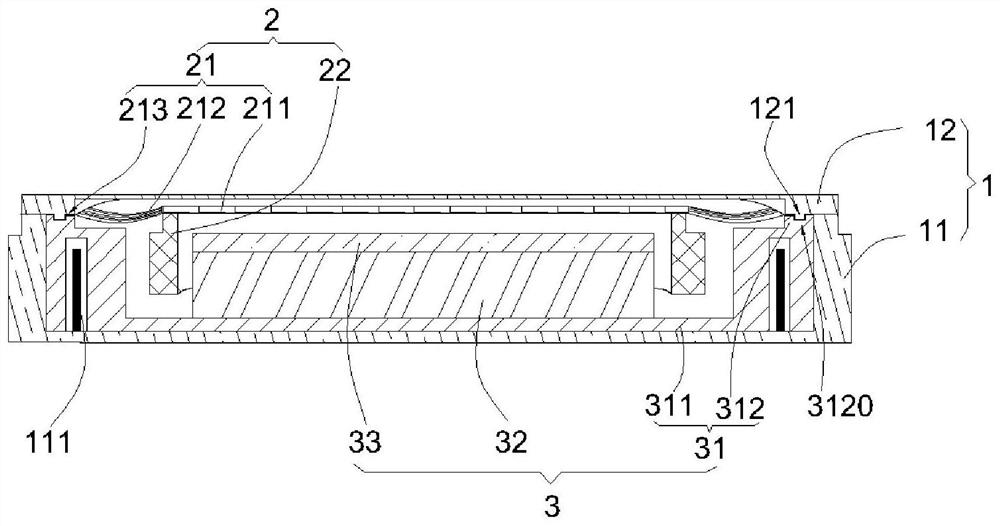

Vibration reduction loudspeaker box system

ActiveCN105142066ANot easy to vibrateImprove sound qualityFrequency/directions obtaining arrangementsEngineeringSound quality

The invention relates to the loudspeaker box system technology field and especially relates to a vibration reduction loudspeaker box system. A loudspeaker box body in the vibration reduction loudspeaker box system adopts an electromagnet to suspend a loudspeaker. A foot stand adopts a hollow column which is filled with a cast iron powder. And a top panel is made of a vibration reduction plate. The column, the top panel and a bottom panel are connected and fixed through spot welding. By using the loudspeaker box system, vibration is small and sound quality is good.

Owner:NINGBO ZHONGRONG ACOUSTICS TECH

Vibration-damping sound box

ActiveCN105163229AReduced stabilityImprove sound qualityFrequency/directions obtaining arrangementsInsulation layerResonance

The invention relates to the technical field of sound systems and in particular relates to a vibration-damping sound box. According to the vibration-damping sound box, an electromagnet is adopted to keep a loudspeaker suspended; besides, a vibration-damping sound insulation layer is arranged outside a sound box housing; such a sound box is low in resonance and capable of producing good-quality sound.

Owner:NINGBO ZHONGRONG ACOUSTICS TECH

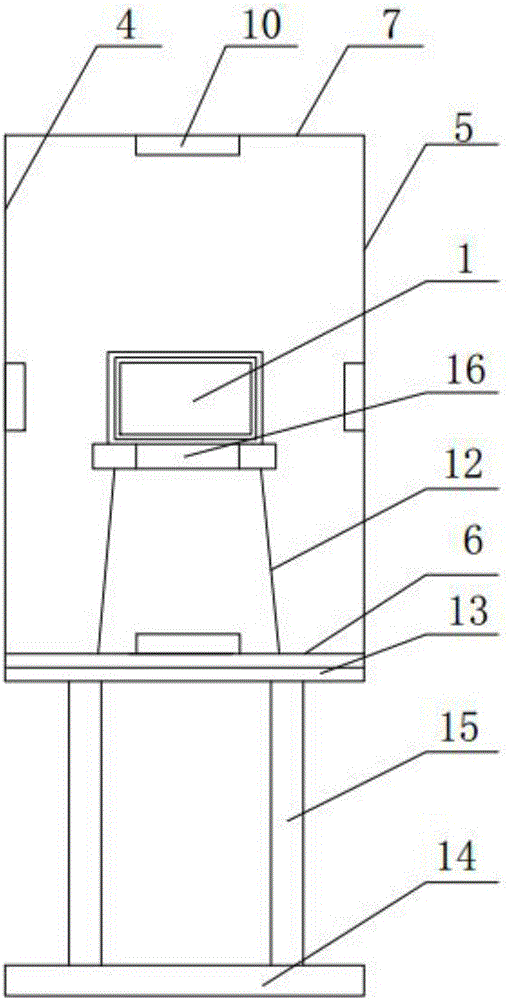

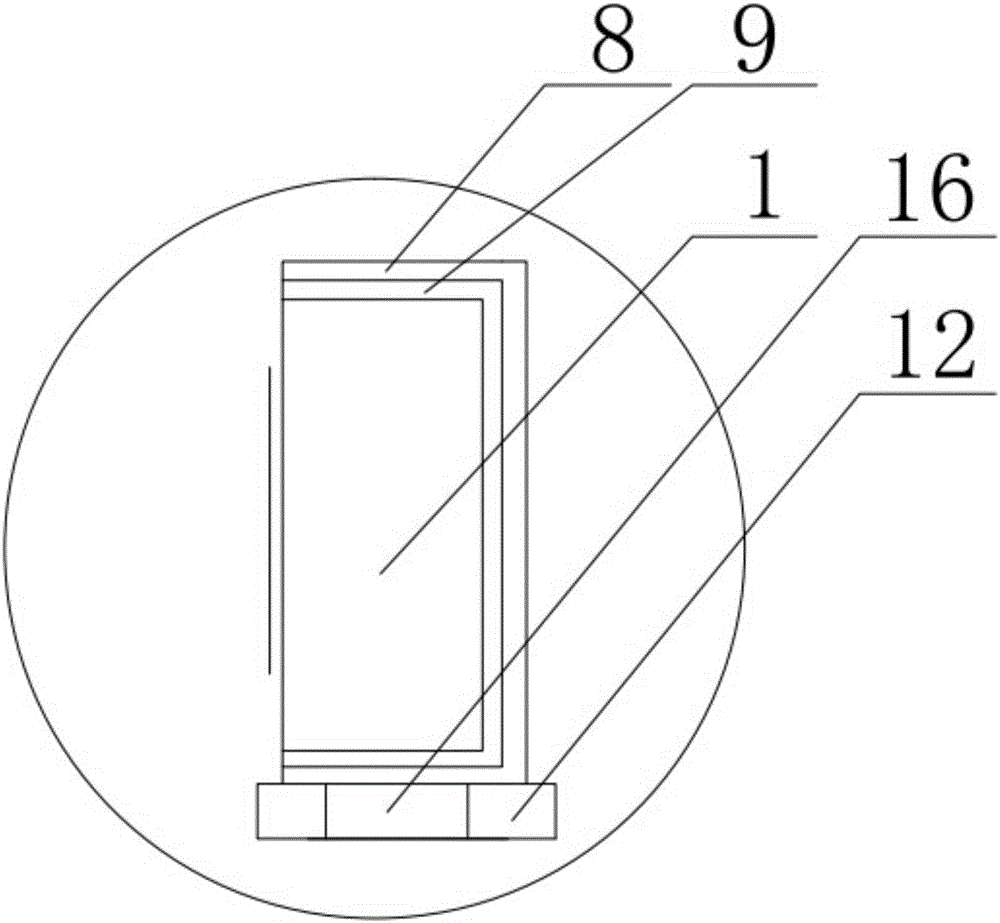

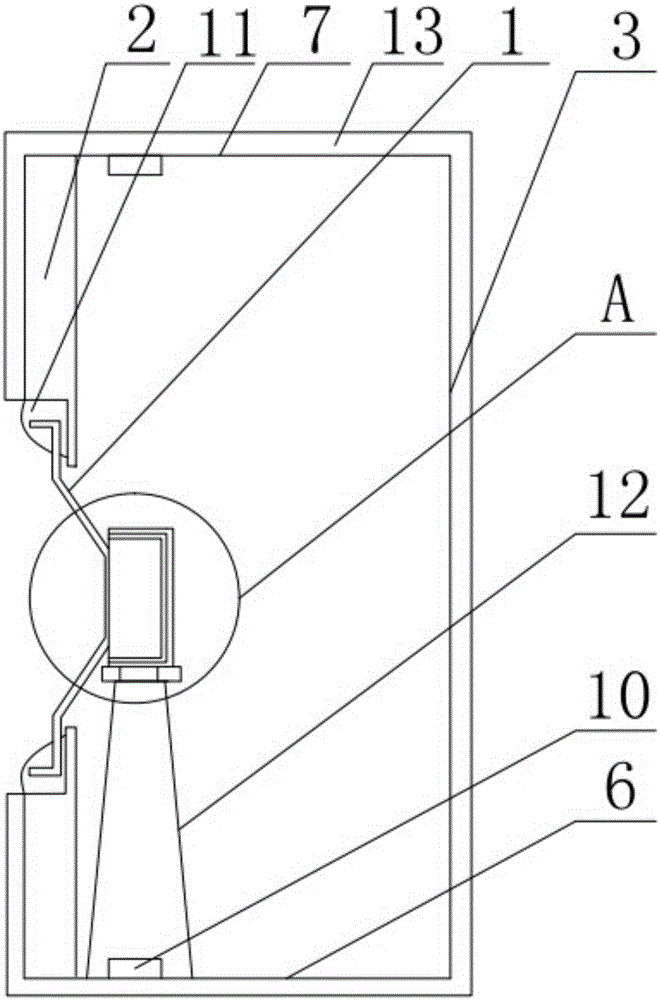

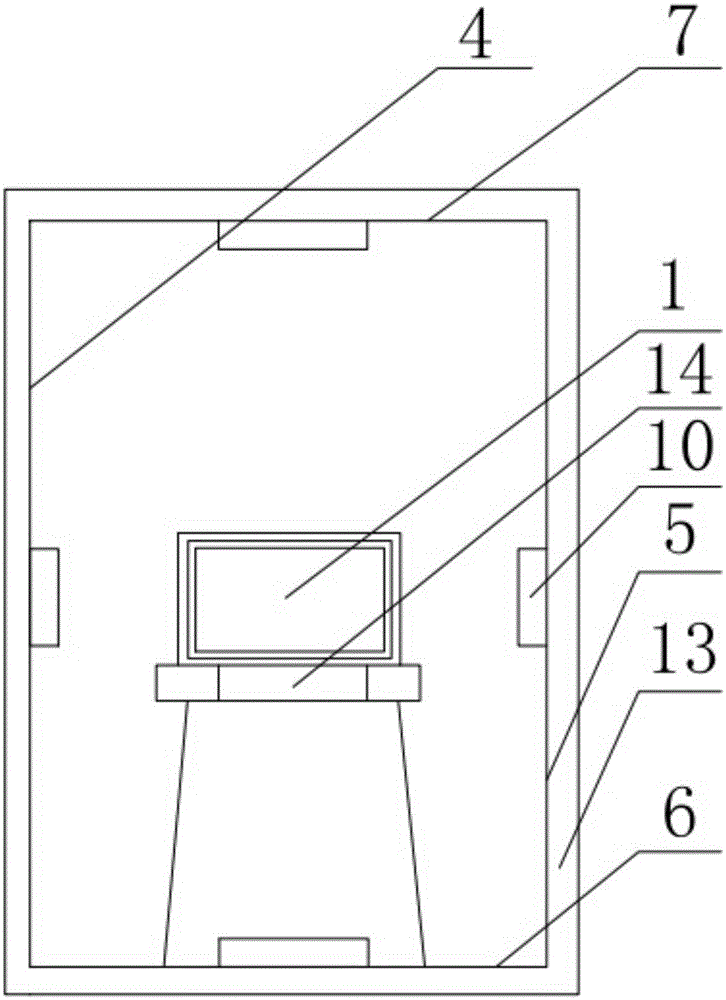

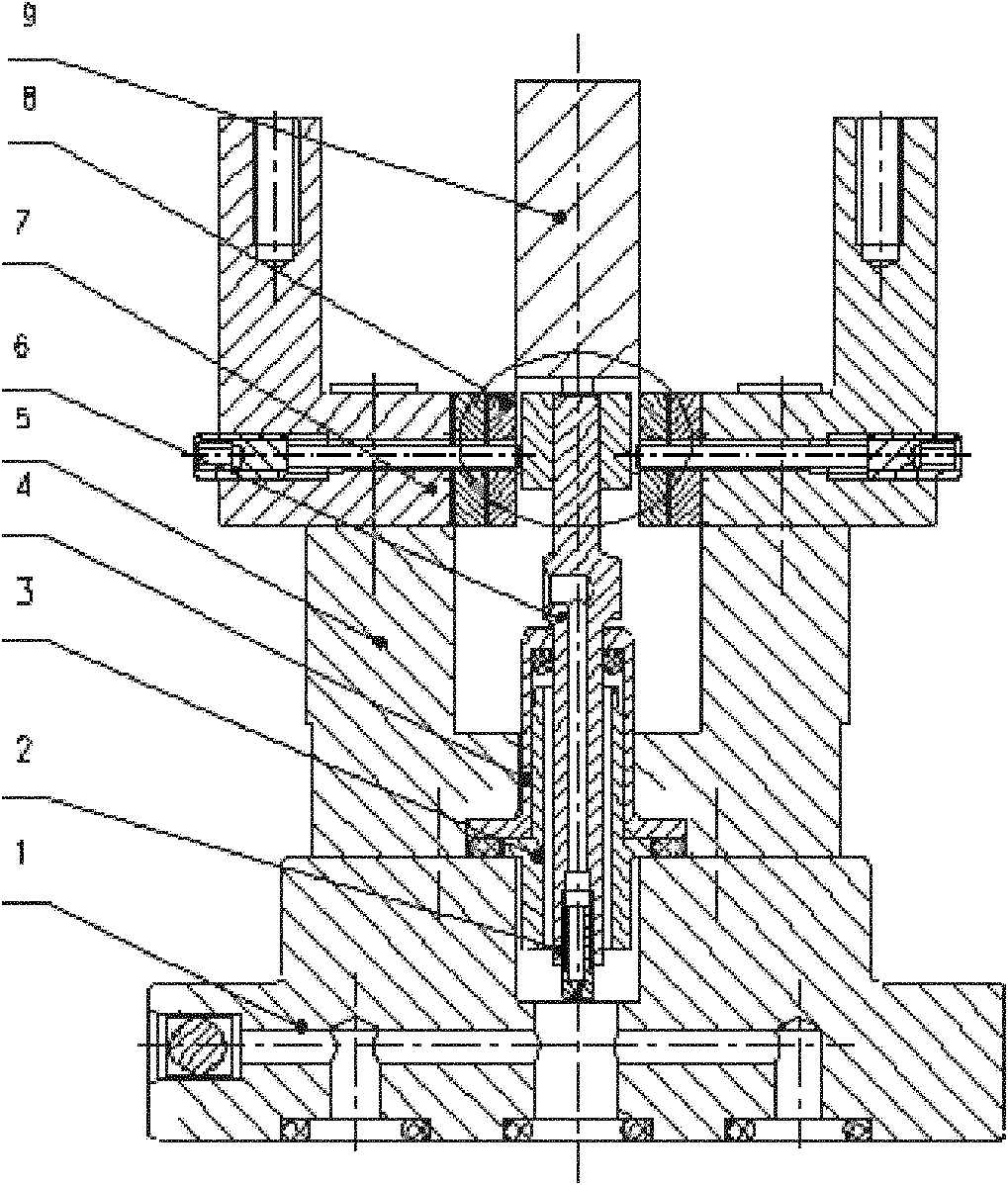

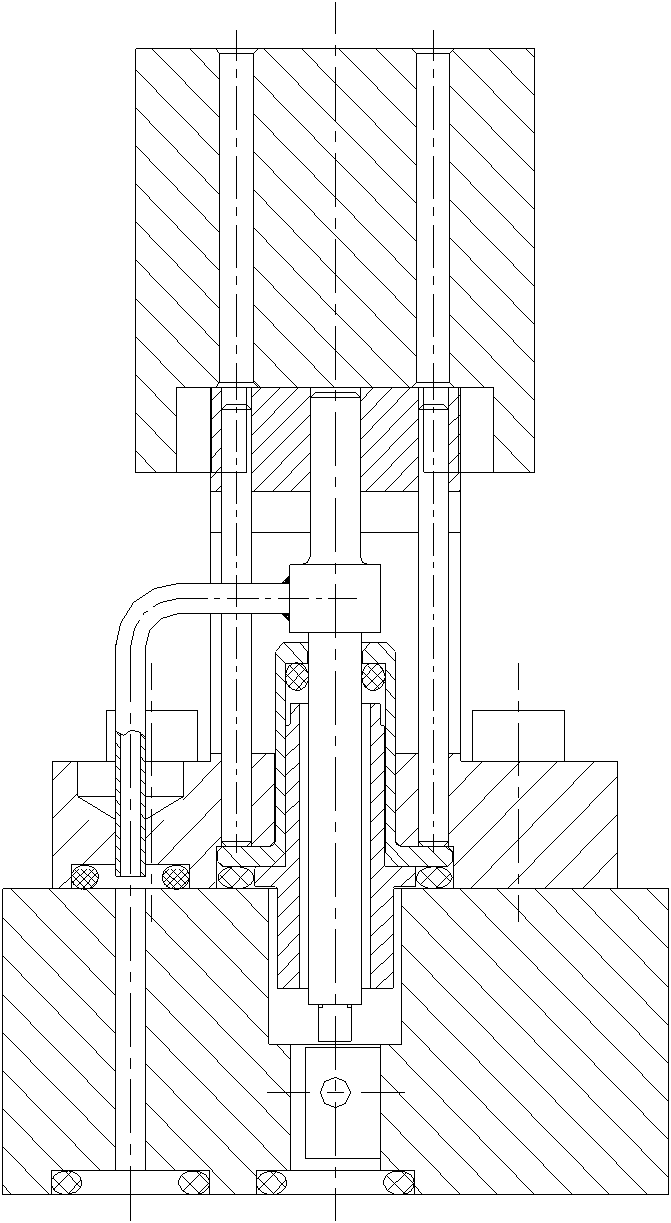

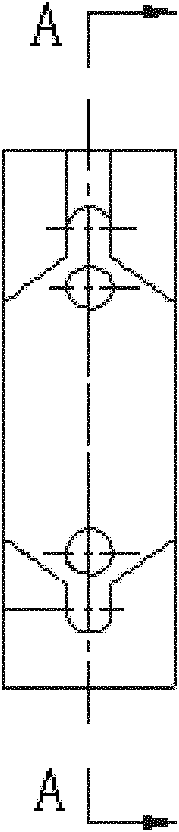

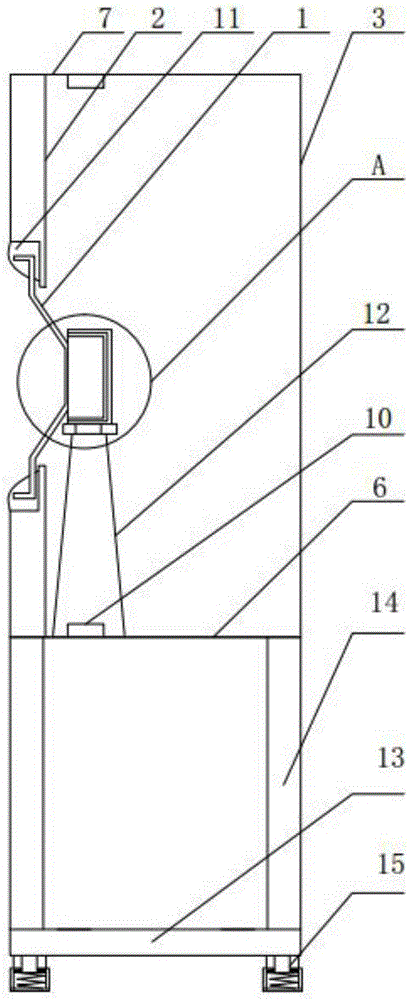

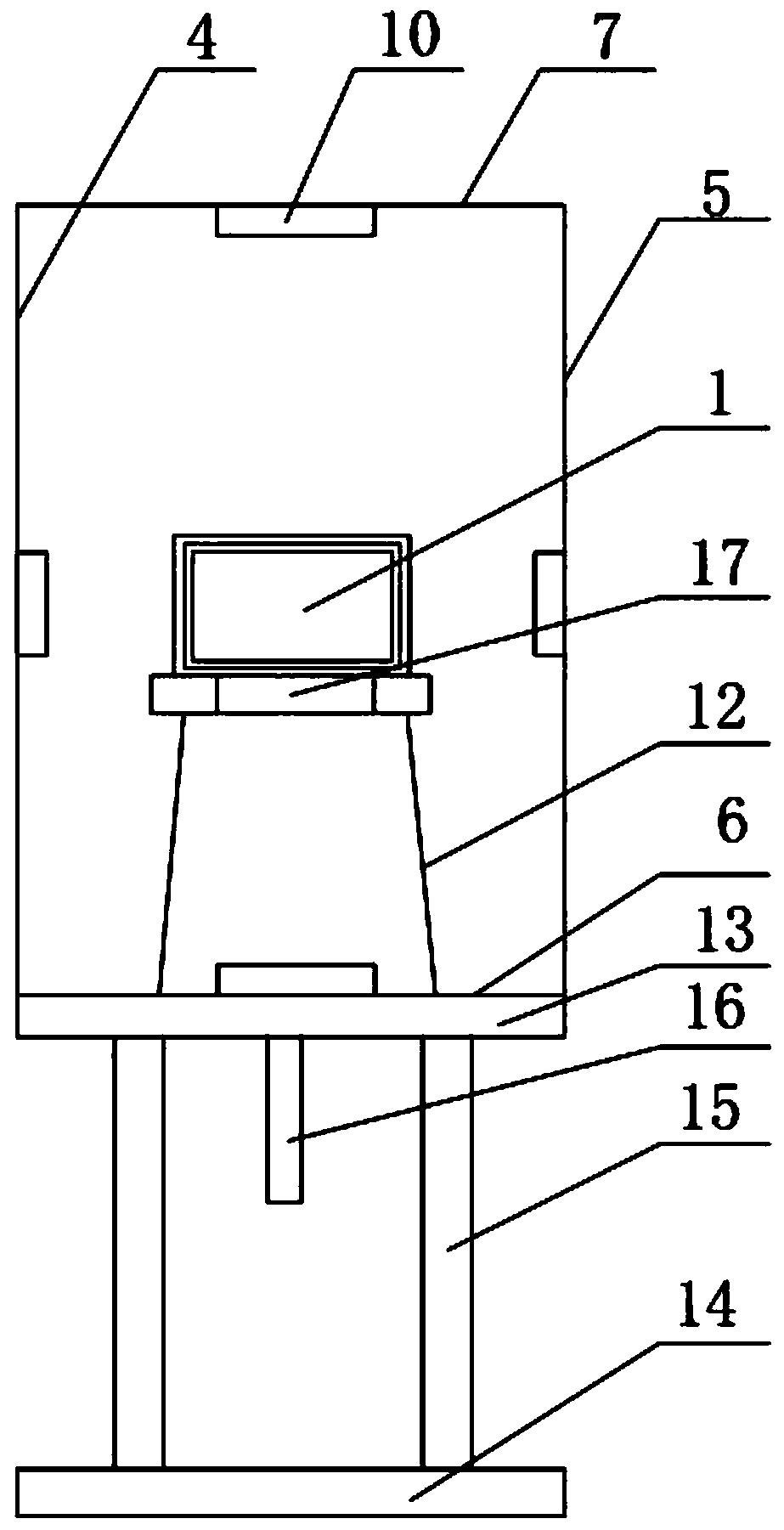

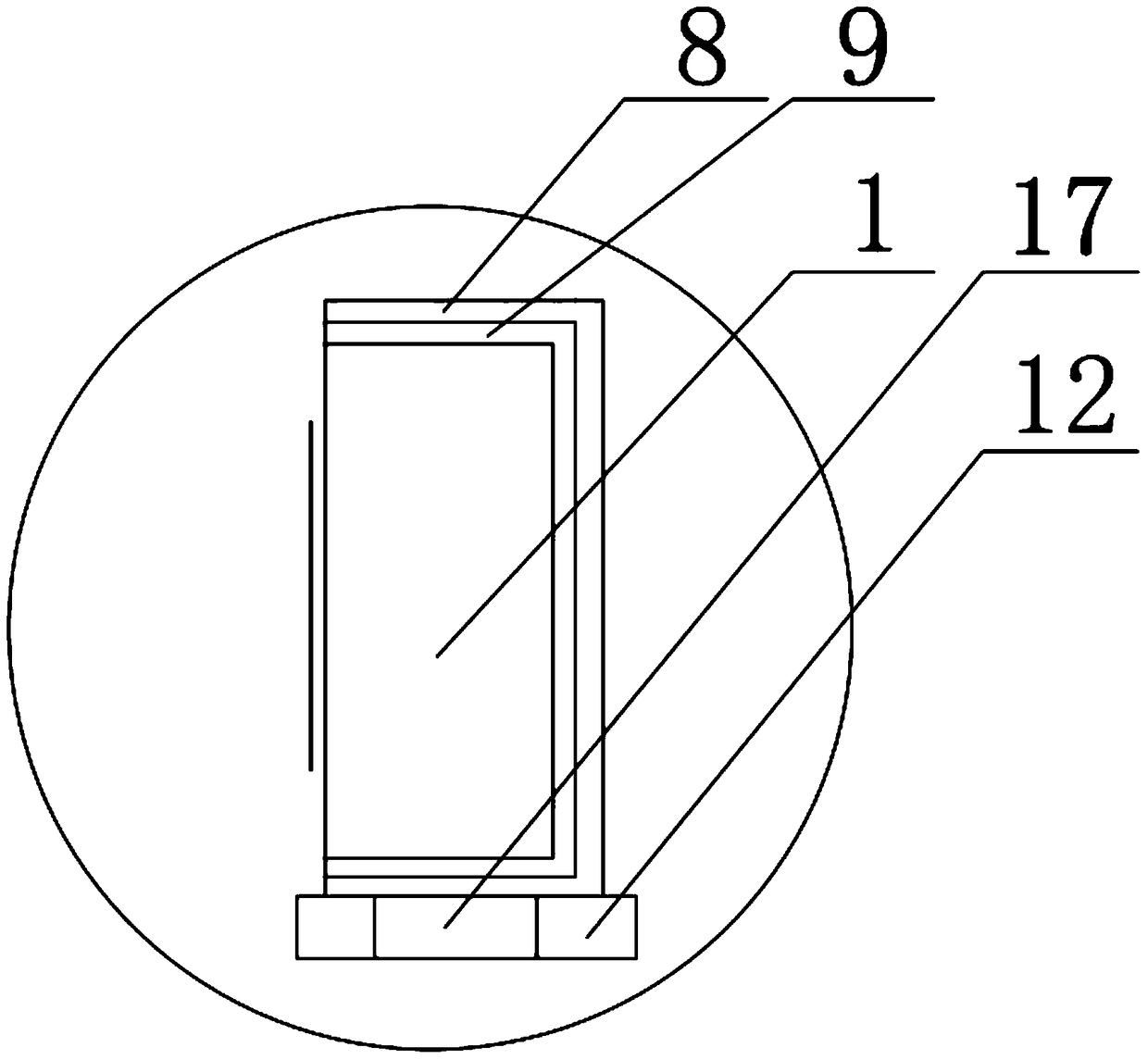

Magnetic steel installation tooling for electro-hydraulic servo valve of hydraulic industry

InactiveCN102032228ASolve the installation methodEasy to produceServomotor componentsElectro hydraulicEngineering

The invention relates to a magnetic steel installation tooling for an electro-hydraulic servo valve of a hydraulic industry, comprising a pilot valve body (1), a nozzle body (2), an intermediate transition body (5), a magnetic seat (7), magnetic steel (8) and a plugging block (9), wherein the intermediate transition body (5) is installed on the pilot valve body (1), and the center line position of the pilot valve body (1) and the intermediate transition body (5) is provided with the nozzle body (2) and a jet pipe (6) in sequence from bottom to top; the nozzle body (2) is connected with the jet pipe (6) through screw threads, the outer side of the jet pipe (6) is provided with a duct (3), and a bushing (4) is sleeved outside the duct (3); the upper part of the intermediate transition body (5) is connected with the magnetic seat (7) through screws, and the magnetic seat (7) is in an L shape and is in bilateral symmetry; the magnetic steel (8) which is fixed through a bolt is stuck to the inner side surface of the sort side of the L shape; and the plugging block (9) is installed among the magnetic steel (8). The invention has the advantages of convenience for operation, reliable positioning and high production efficiency.

Owner:SHANGHAI NUOMA HYDRAULIC SYST

Vibration-reducing loudspeaker box system

ActiveCN105245982ANot easy to vibrateImprove sound qualityTransducer casings/cabinets/supportsEngineeringLoudspeaker

The invention relates to the technical field of sound systems, specifically to a vibration-reducing loudspeaker box system. A loudspeaker box main body in the vibration-reducing loudspeaker box system adopts electromagnets to suspend a loudspeaker, and a foot stool is a hollow stand column filled with cast iron powder, and vibration reducing legs are arranged at the bottom of the foot stool. The loudspeaker box system is relative small in vibration, and better in tone quality while producing sound.

Owner:NINGBO ZHONGRONG ACOUSTICS TECH

Sound box system

ActiveCN105120399ANot easy to vibrateImprove sound qualityFrequency/directions obtaining arrangementsEngineeringSound quality

The invention relates to the technical field of sound systems, in particular to a sound box system. A sound box body in the sound box system adopts an electromagnet to levitate a loudspeaker, and foot stands are hollow stand columns filled with cast iron powder. The vibration of the sound box system is smaller and the made sound quality is better.

Owner:NINGBO ZHONGRONG ACOUSTICS TECH

Permanent magnet motor and compressor and air conditioner with same

PendingCN111697781AImprove work efficiencyGood magnetic isolation effectWindings insulation shape/form/constructionMagnetic circuit rotating partsPermanent magnet synchronous motorElectric machinery

The invention discloses a permanent magnet motor and a compressor and an air conditioner with the same. The permanent magnet motor comprises a rotor iron core and a stator iron core, a plurality of permanent magnet grooves are formed in the rotor iron core in the circumferential direction of the rotor iron core, a plurality of permanent magnets are installed in the permanent magnet grooves in a one-to-one correspondence mode, and on the radial section of the rotor iron core, at least one end of the two opposite ends of each permanent magnet groove is communicated with a first magnetism isolation bridge hole. According to the permanent magnet synchronous motor, one end or two ends of the permanent magnet groove are communicated with the first magnetic isolation bridge holes, so that the magnetic isolation capability of the permanent magnet synchronous motor is improved, the magnetic leakage probability is reduced, and the working efficiency of the permanent magnet motor is improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

A rotor permanent magnet type hybrid excitation axial flux switching permanent magnet motor

ActiveCN107769502BIncreased torque/power densityImprove homeostasisMagnetic circuit rotating partsMagnetic circuit stationary partsSynchronous motorConstant power

The invention discloses a rotor permanent magnet type hybrid excitation axial flux switching permanent magnet motor, and belongs to the field of hybrid excitation synchronous motors. The motor comprises a first stator, a rotor and a second stator arranged in a coaxial manner, the rotor is clamped between the first stator and the second stator, each stator is formed by six E-type iron cores, six centralized armature windings, and six centralized excitation windings, and the rotor is formed by ten pairs of rotor poles and ten aluminium-nickel-cobalt permanent magnets. According to the motor, theaxial length is short, the structure is compact, the size is small, and the power and torque densities can be increased; the aluminium-nickel-cobalt permanent magnets are arranged on the rotor so that the torque output capability is great, and the overload capability of the motor is improved; the torque ripple is small, the dynamic and steady-state performances of the system are enhanced, and theoperation is more stable; the reactance of armature reaction is low, an excitation magnetic field and a permanent magnetic field are in a parallel connection relation, and the magnetic adjustment isflexible and convenient; and the permanent magnets are located on the rotor so that a stator magnetic circuit is not easily saturated, and the constant-power speed regulation range of the motor is greatly extended.

Owner:XIAN UNIV OF TECH

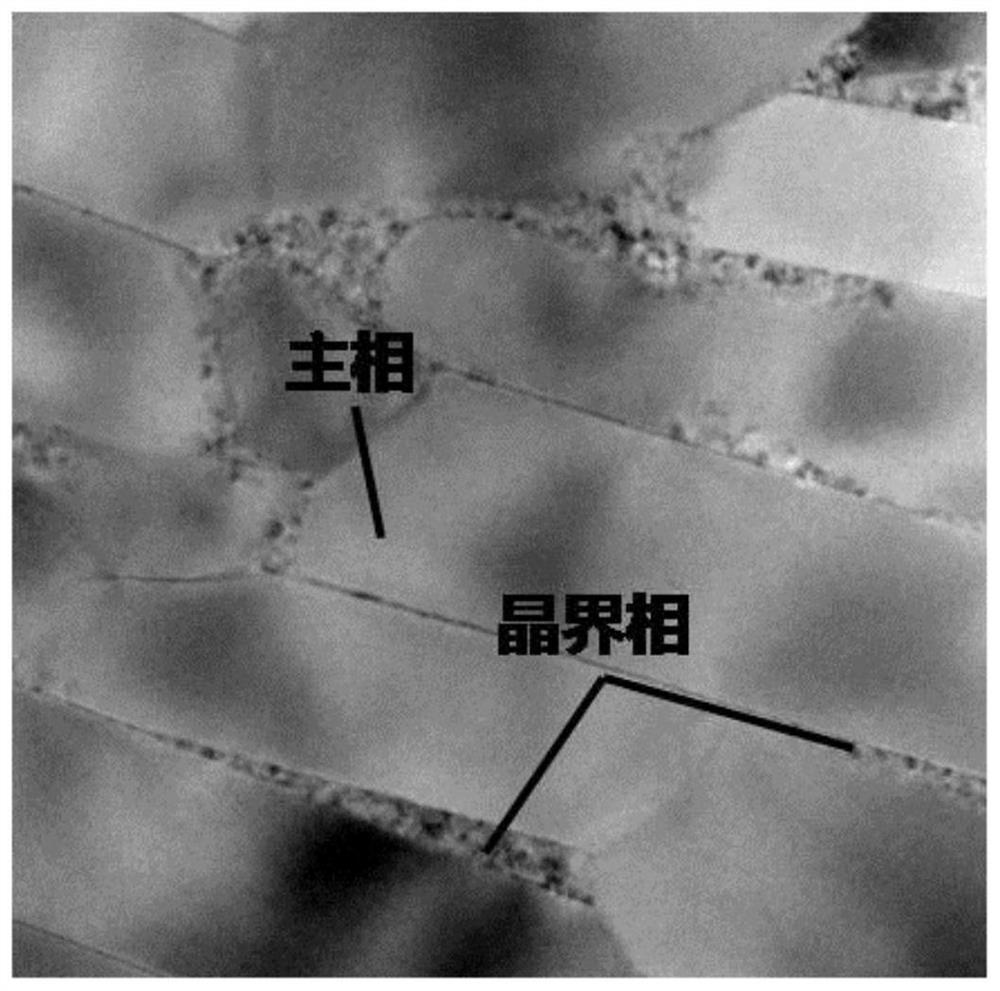

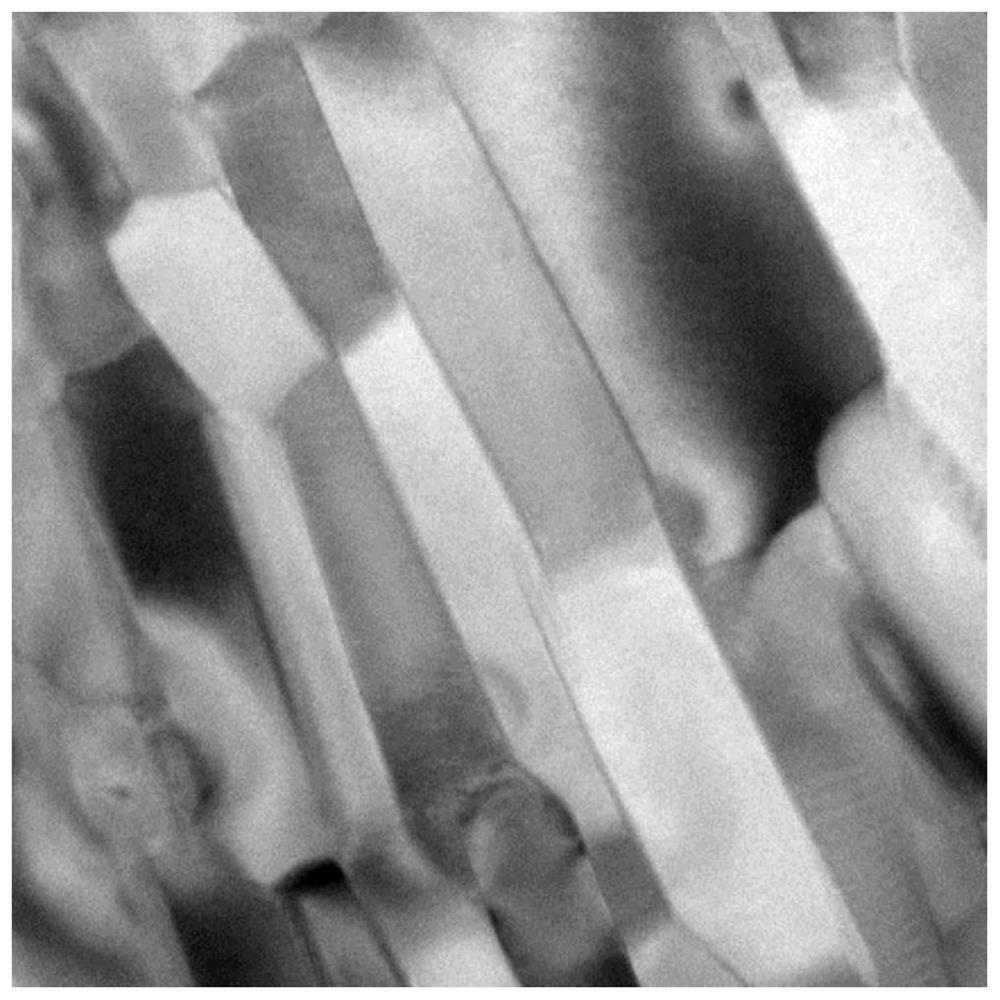

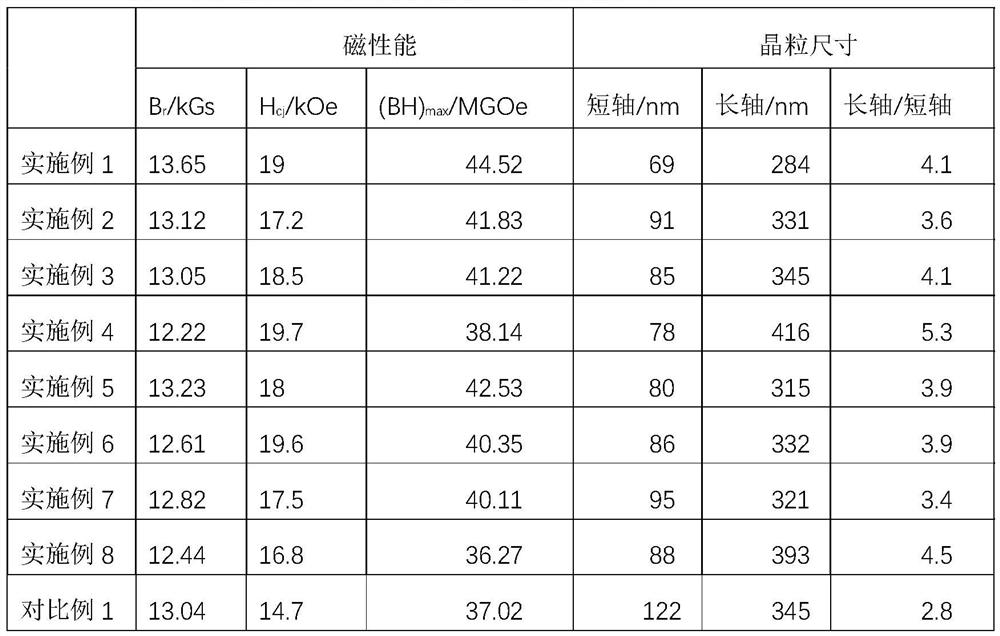

Thermal deformation rare earth permanent magnet material and preparation method thereof

PendingCN113936878APhase ratio increasesAvoid growing upInductances/transformers/magnets manufactureMagnetic materialsThermal deformationAlloy

The invention relates to a thermal deformation rare earth permanent magnet material and a preparation method thereof. Raw materials of the thermal deformation rare earth permanent magnet material comprise main alloy magnetic powder a with the chemical formula being (R11-cCec)xFe100-x-y-zM1yBz according to atomic percent and auxiliary alloy powder with the chemical formula being R2a(Cu1-bM2b)100-a according to atomic percent, wherein 0 <= c <= 1, 12 <= x <= 15, 0 <= y <= 10, 5 <= z <= 7, R1 is at least one of Nd, Pr, Dy, Tb, Ho, La and Gd, M1 is at least one of Si, Mn, Al, Co, Ga and Cu, 60 <= a <= 90, 0 <= b <= 1, R2 is at least one of Nd, Pr, La and Ce, and M2 is at least one of Al, Zn, Ga, Sn and In. According to the material, the low-melting-point auxiliary alloy is diffused into the main alloy powder, so that the melting point of a grain boundary phase of the main alloy magnetic powder is reduced, meanwhile, the proportion of the grain boundary phase is increased, the hot pressing temperature can be reduced to 650 DEG C or below, and the heat deformation temperature can be reduced to 700 DEG C or below, therefore, grain growth is effectively prevented, and the coercive force is improved.

Owner:GRIREM ADVANCED MATERIALS CO LTD +1

Loudspeaker

InactiveCN112804624AReduce the impactAvoid strippingElectrical transducersEngineeringSound production

The present invention provides a loudspeaker. The loudspeaker comprises a basin frame, a vibration system arranged in the basin frame and a magnetic circuit system driving the vibration system, the vibration system comprises a vibrating diaphragm and a voice coil driving the vibrating diaphragm to vibrate, and the magnetic circuit system comprises a magnet yoke, main magnetic steel arranged on the magnet yoke and a magnetic conductive sheet covering the main magnetic steel. A middle gap is formed between the main magnetic steel and the magnet yoke, the voice coil is suspended in the middle gap, the magnet yoke is provided with an accommodating groove, the basin frame is provided with a magnet vane, and the magnet vane is embedded in the accommodating groove. Compared with the prior art, the loudspeaker provided by the invention is good in magnetic isolation effect, stable in performance and good in sound production effect.

Owner:陈恺琳

Axial Flux Modular Multiphase Motor with High Magnetic Isolation Capability

ActiveCN103746532BImprove power densityImprove reliabilitySynchronous machines with stationary armatures and rotating magnetsElectric machinePermanent magnet synchronous motor

The invention discloses an axial magnetic flow modularized multi-phase motor having a high magnetic isolation capacity, belongs to the field of motors, and aims to solve the problem of high fault-tolerant control difficulty in case of short circuit of one phase of winding in the conventional multi-phase permanent magnet synchronous motor and the problem of badness to fault isolation and modularized structural design due to dispersed distribution of a winding space. The axial magnetic flow modularized multi-phase motor comprises two modularized stators, a disk-type rotor, a shell and a main shaft, wherein the two modularized stators and the disk-type rotor are arranged inside the shell; one modularized stator, the disk-type rotor and the other modularized stator are arranged in sequence on the main shaft in an axial direction; air gaps are formed between the two modularized stators and the disk-type rotor along the axial direction; in each modularized stator, N same stator modules are spliced into a disk; each stator module comprise a stator core, five stator teeth and two centrally-wound windings; in the disk-type rotor, a disk surface on any side of the rotor core is provided with 2N+ / -2 permanent magnets magnetized oppositely and alternatively in the axial direction.

Owner:HARBIN INST OF TECH

Vibration-absorbing speaker system

ActiveCN105142066BNot easy to vibrateImprove sound qualityFrequency/directions obtaining arrangementsEngineeringSound quality

The invention relates to the loudspeaker box system technology field and especially relates to a vibration reduction loudspeaker box system. A loudspeaker box body in the vibration reduction loudspeaker box system adopts an electromagnet to suspend a loudspeaker. A foot stand adopts a hollow column which is filled with a cast iron powder. And a top panel is made of a vibration reduction plate. The column, the top panel and a bottom panel are connected and fixed through spot welding. By using the loudspeaker box system, vibration is small and sound quality is good.

Owner:NINGBO ZHONGRONG ACOUSTICS TECH

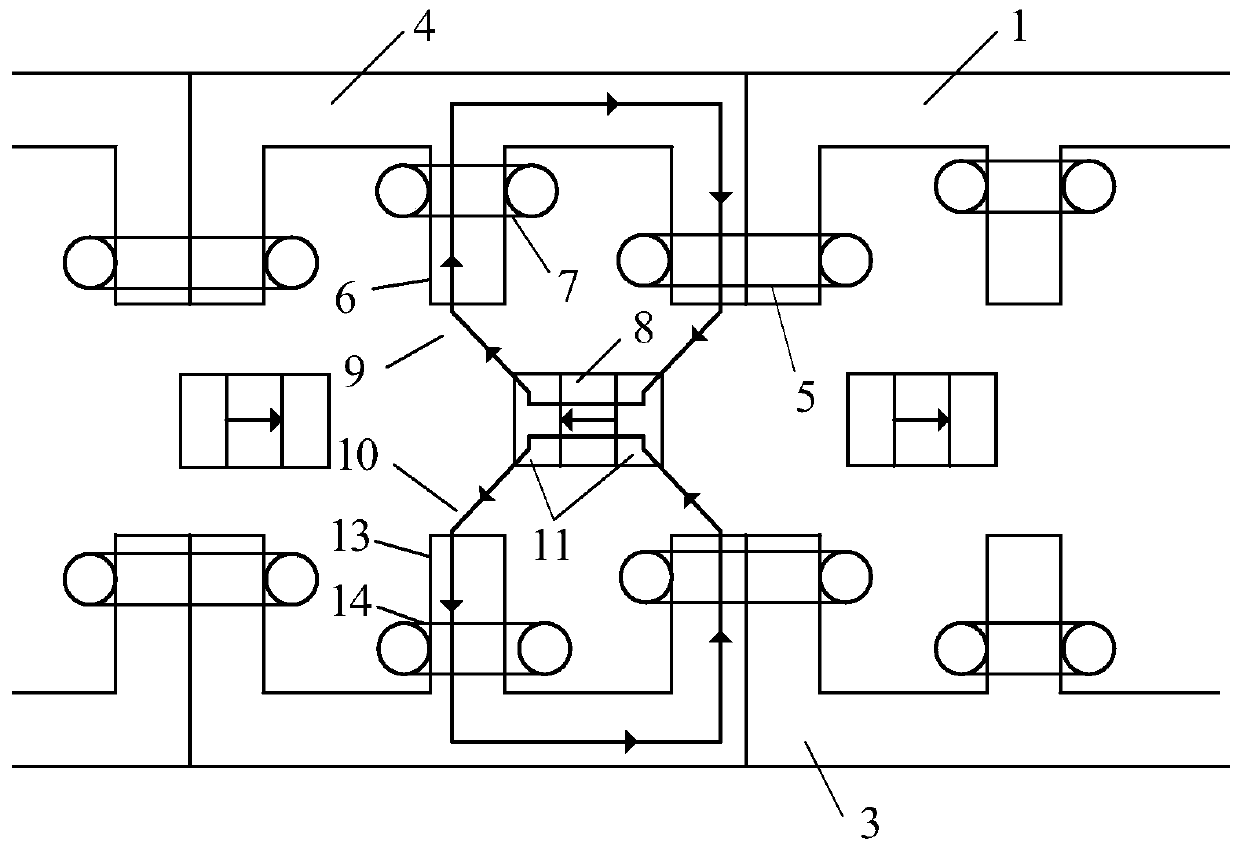

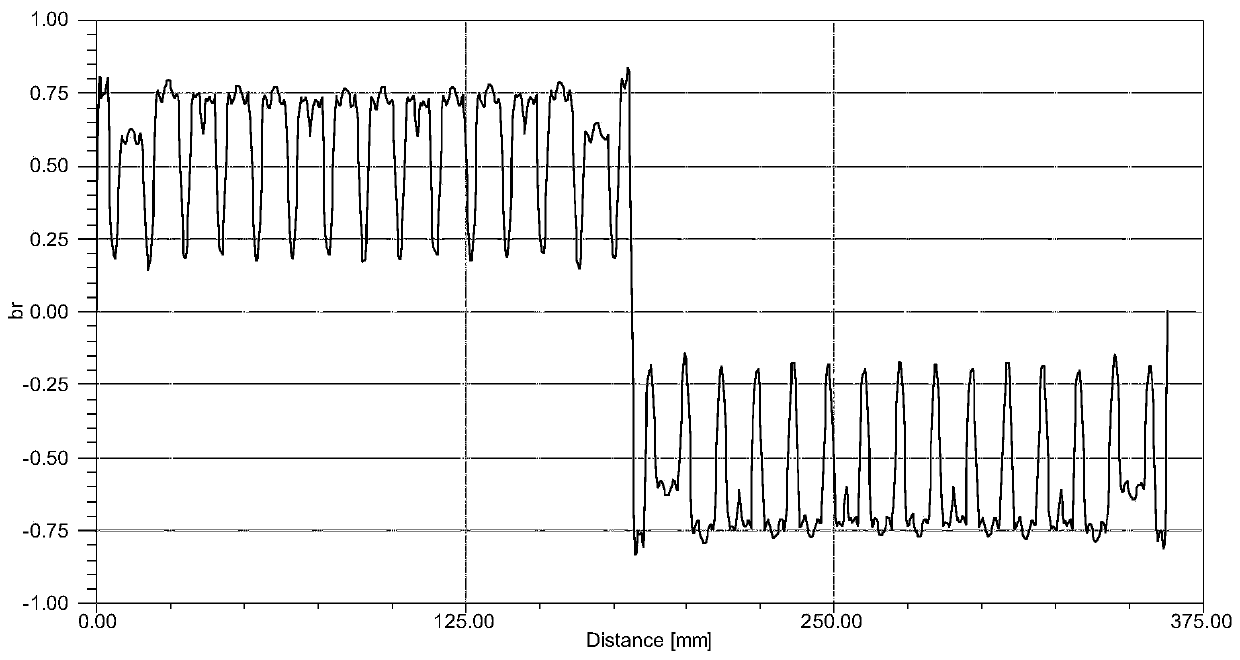

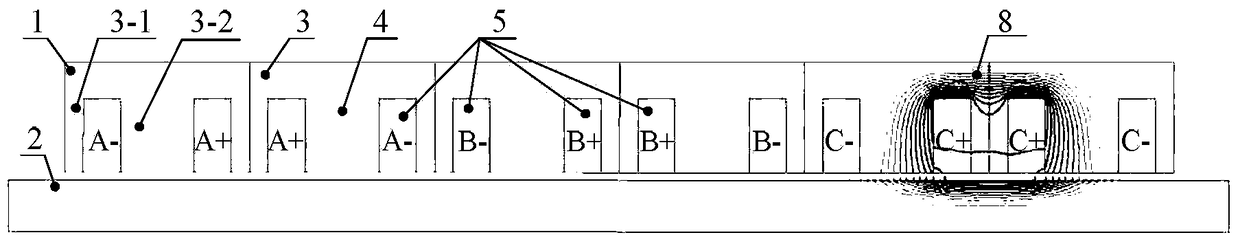

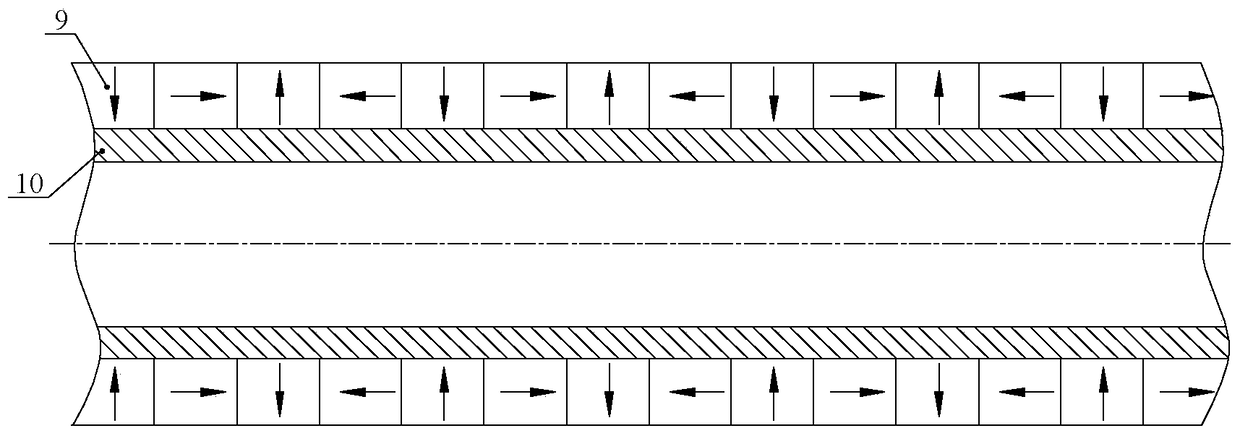

Highly Modular Flat Multiphase Permanent Magnet Linear Motor

ActiveCN104767351BImprove reliabilityContains the impact of faults relative to other phasesPropulsion systemsPermanent magnet rotorElectromagnetic coupling

The invention belongs to the field of permanent magnet motors, and relates to a highly-modularized flat plate type multiphase permanent magnet linear motor. The problems that when a winding short circuit and other failures happen to a conventional multiphase permanent magnet linear motor, the failure isolation difficulty is large, and motor modular design difficulty is large due to the high interphase electromagnetic coupling degree are solved. The highly-modularized flat plate type multiphase permanent magnet linear motor comprises a stator and a permanent magnet rotor, the stator can be arranged on one or two sides of the permanent magnet rotor, and an air gap exists between the stator and the permanent magnet rotor. The stator is formed by assembling 2m stator modules. The stator modules are assembled to be in a flat plate shape in the axial direction. Each stator module comprises a stator iron core, an armature tooth, two fault-tolerant teeth and two concentrated windings. A one-phase module of the highly-modularized flat plate type multiphase permanent magnet linear motor is composed of two adjacent stator modules. The permanent magnet rotor is formed by assembling a permanent magnet and a rotor iron core, and the permanent magnet rotor can be of a surface-mounted structure or a Halbach structure or an axial magnetization structure and the like.

Owner:HARBIN INST OF TECH

Connecting structure of electromagnetic valve and electromagnetic valve

PendingCN111188926AInhibit sheddingAchieve connectionOperating means/releasing devices for valvesMultiple way valvesEngineeringElectromagnetic valve

The invention relates to the field of hydraulic control, in particular to a connecting structure of an electromagnetic valve and the electromagnetic valve. The connecting structure of the electromagnetic valve is arranged on a valve element and a push-pull rod so as to connect the valve element and the push-pull rod; the connecting structure comprises a socket part and an inserting part, wherein the inserting part comprises at least two elastic pieces, and the inserting ends of the elastic pieces are provided with stopping parts; and the socket part is provided with locking parts matched withthe stopping parts, and the at least two elastic pieces are compressed and deformed to be inserted into the socket part and then bounced off, so that the stopping parts and the locking parts are mutually locked. In the prior art, the valve element and the push-pull rod are connected through a pin, which means a part is additionally arranged, so that connection operation becomes complex and the pincannot be completely prevented from falling off. According to the connecting structure of the electromagnetic valve, the above technical problems can be solved.

Owner:CHANGZHOU KANGSHIDA ELECTROMECHANICAL CO LTD

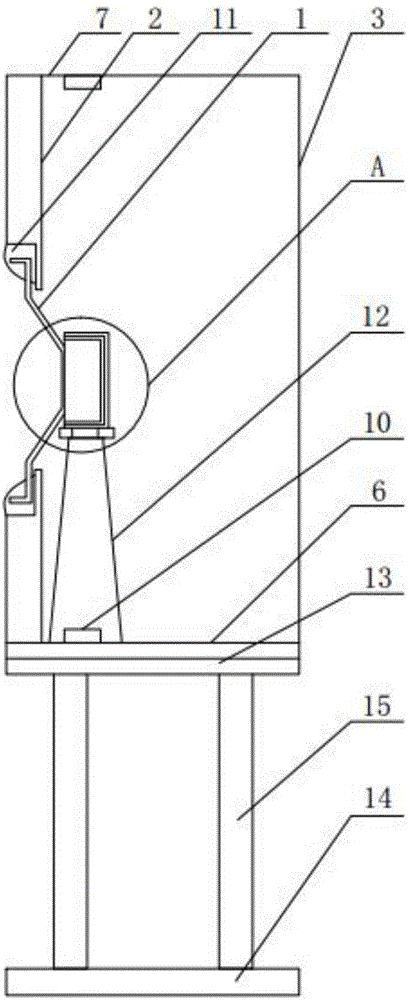

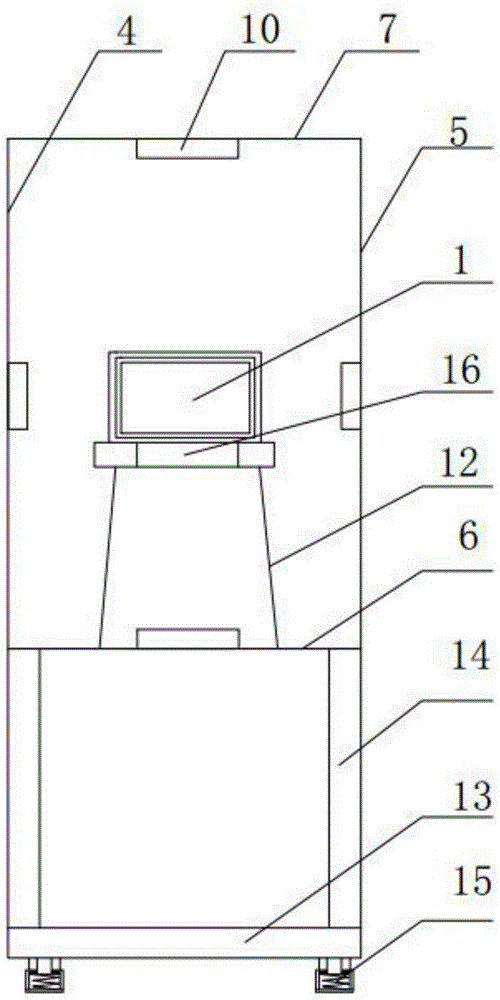

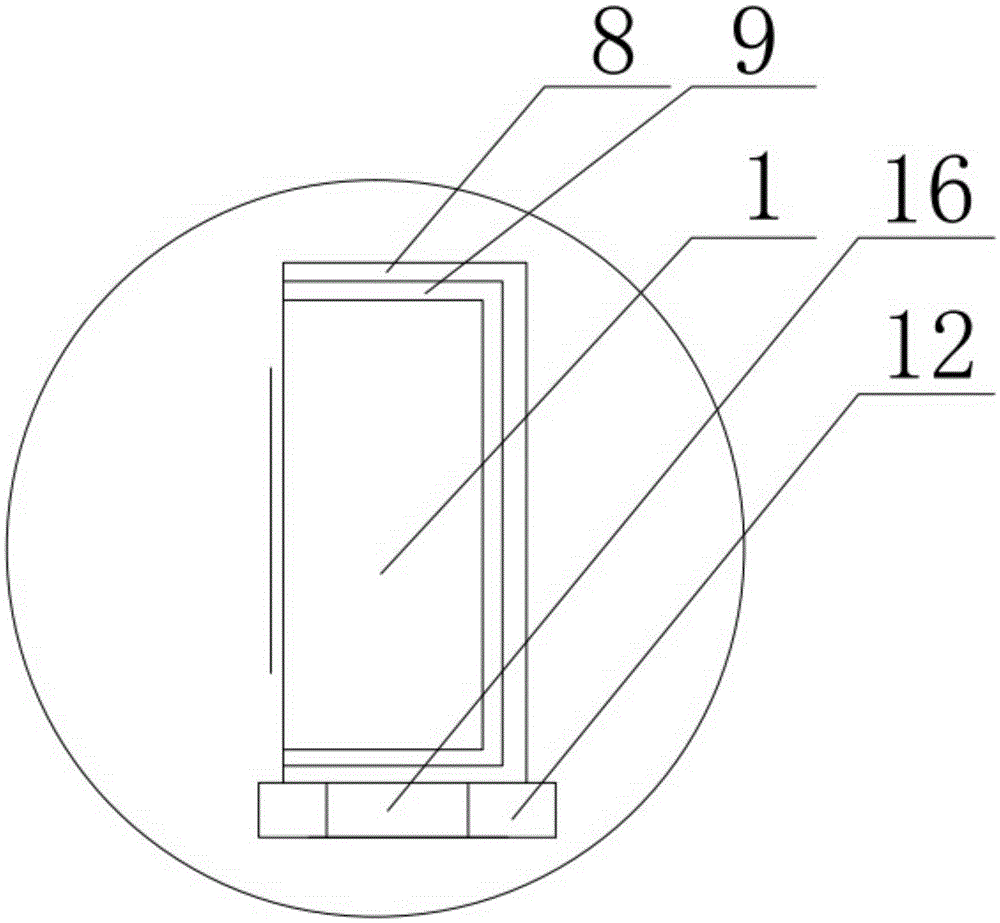

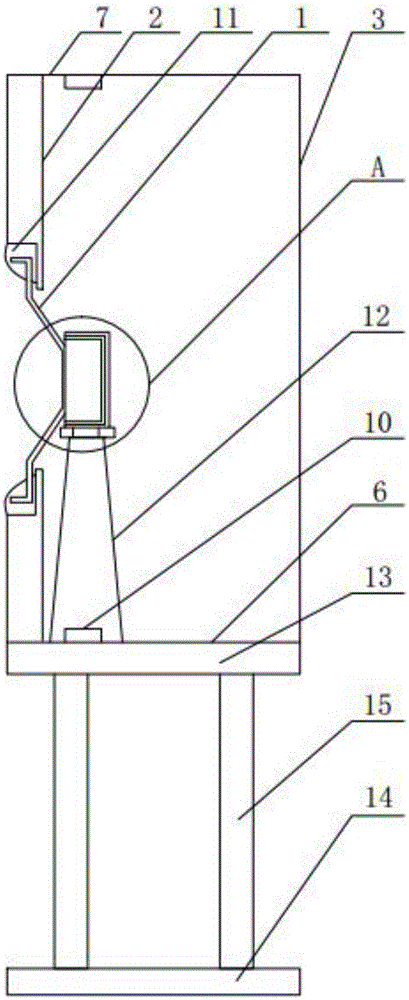

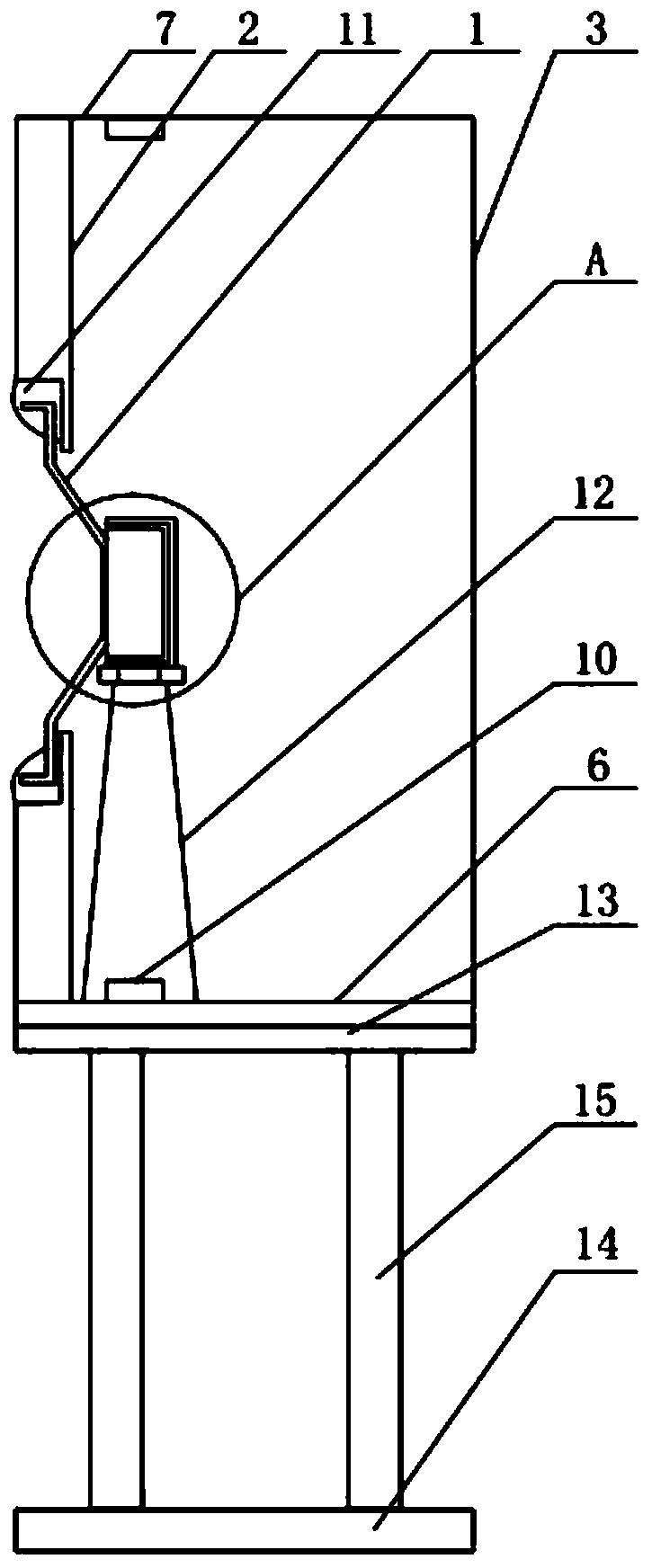

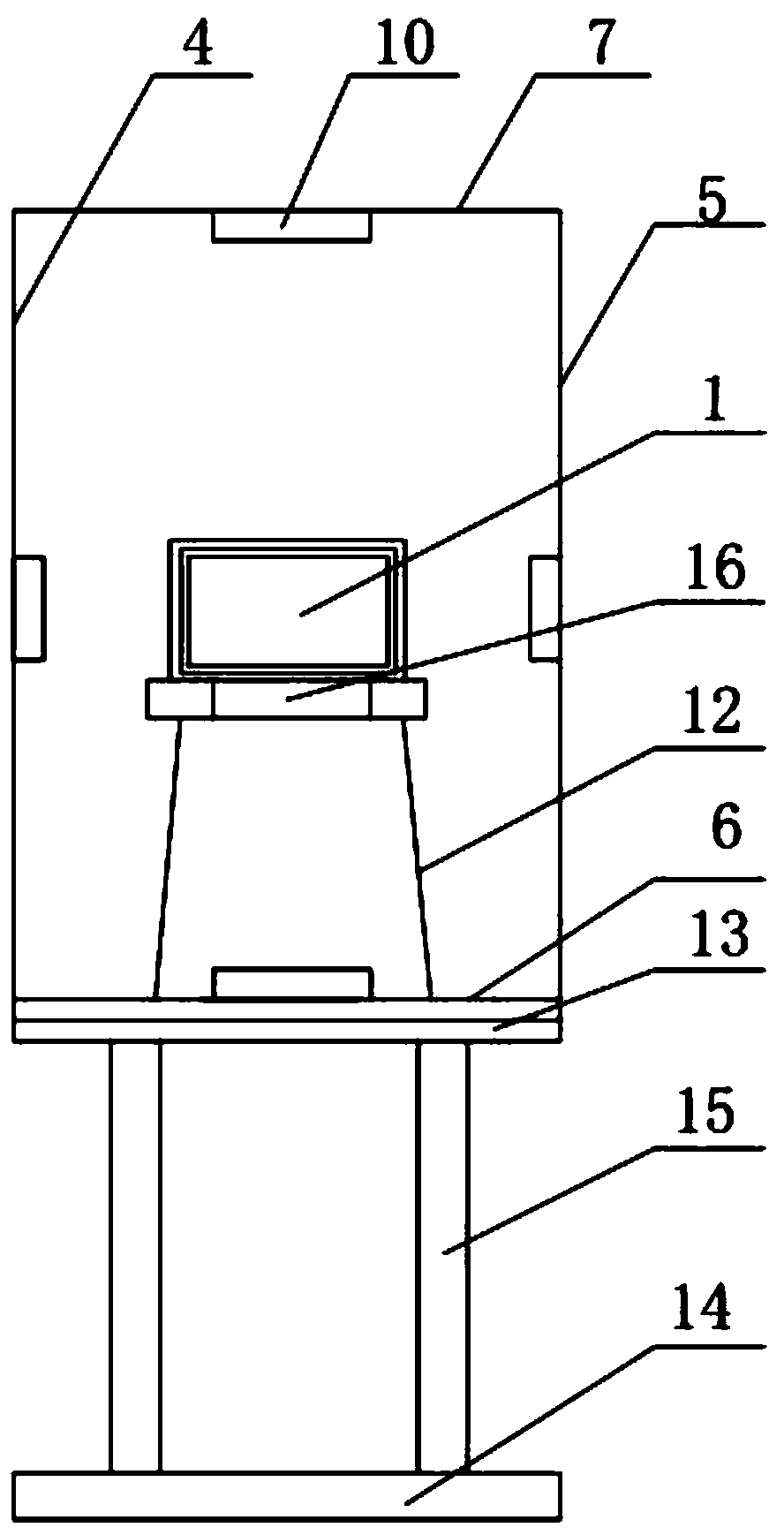

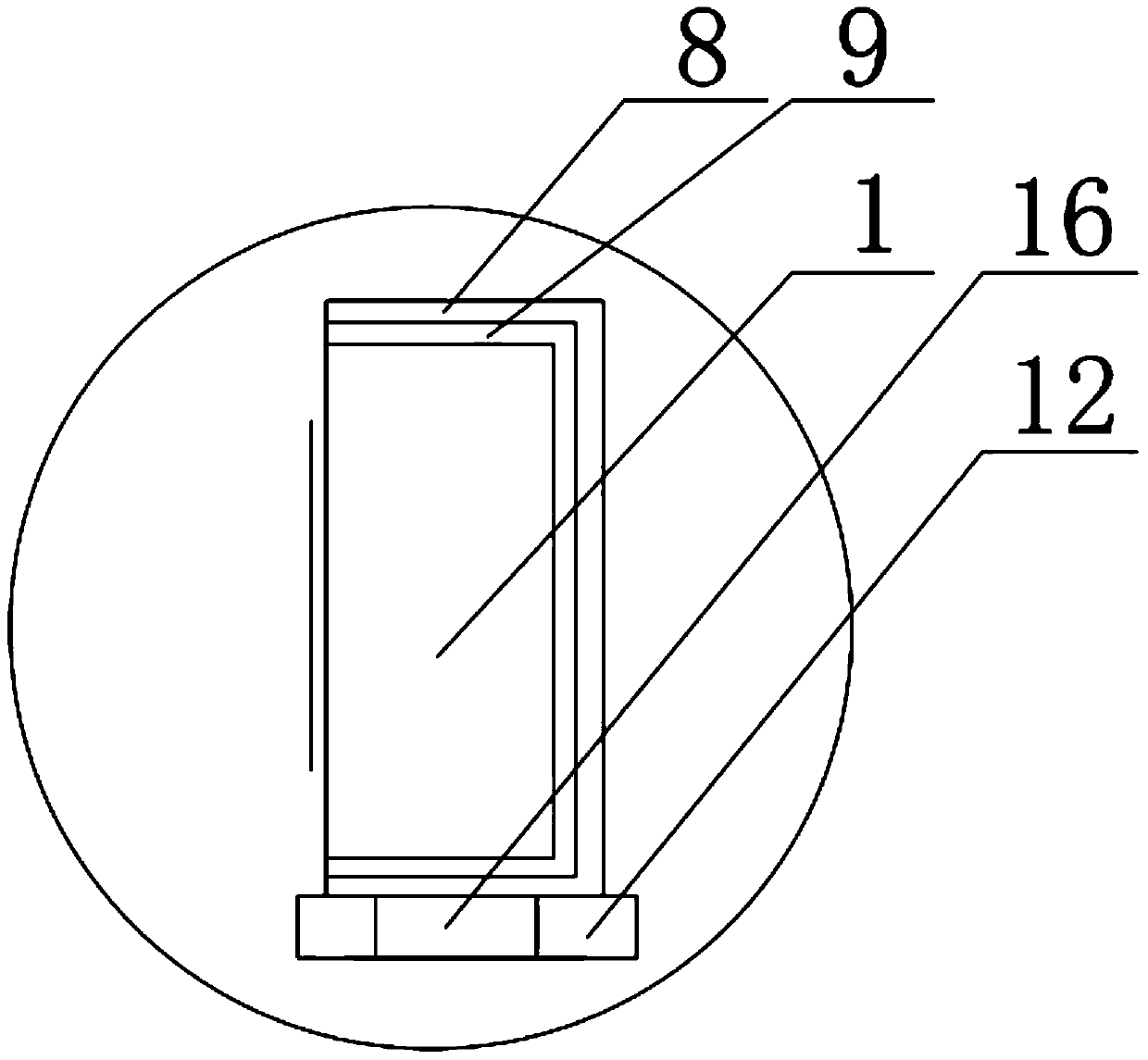

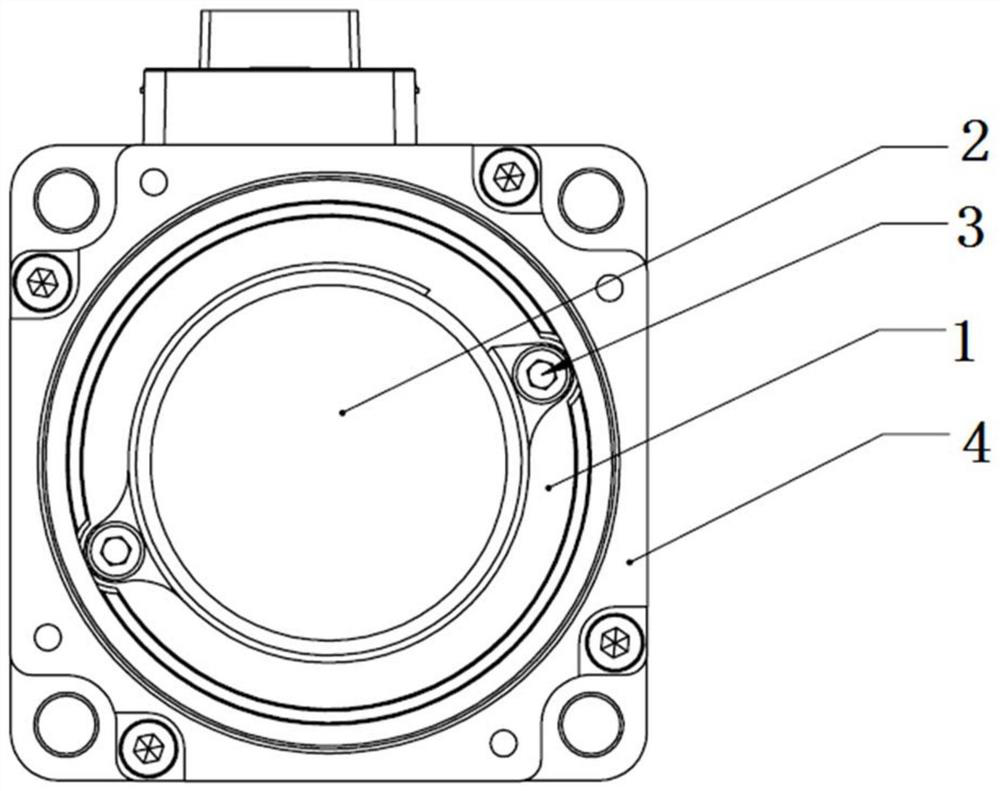

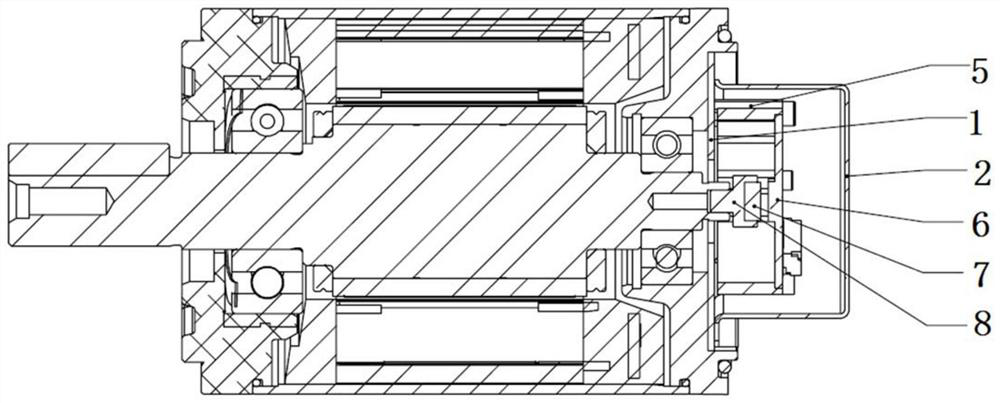

Magnetic isolation device of magnetic encoder

PendingCN111829560AUndisturbedGood magnetic isolation effectConverting sensor output electrically/magneticallyElectric machineEngineering

The invention relates to a magnetic isolation device of a magnetic encoder. The magnetic isolation device is installed between a magnetic encoder body and a motor body, the magnetic encoder body is connected with the motor body, the magnetic isolation device comprises a magnetic isolation structure, the magnetic isolation structure is installed on a rear end cover (4) of the motor body, and the magnetic encoder body is located in the magnetic isolation structure. The encoder body and the motor body are isolated by the magnetic isolation structure, and magnetic field interference from the motorbody is isolated. Compared with the prior art, the magnetic isolation device has the advantages of good magnetic isolation effect, low manufacturing cost, simple structure, convenience in installation and the like.

Owner:SHANGHAI ANPU MINGZHI AUTOMATION EQUIP

A Rotor Structure for Improving Air Gap Flux Density Waveform of 2-pole Self-starting Permanent Magnet Motor

ActiveCN106558932BIncrease display spaceOvercome the disadvantage of limited rotor spaceMagnetic circuit rotating partsManufacturing stator/rotor bodiesConductive materialsNon magnetic

The invention, which belongs to the technical field of motor fittings, particularly relates to a rotor structure capable of improving a gap flux density waveform of a two-pole self-starting permanent-magnet motor. The rotor structure comprises a rotor iron core having a plurality of mouse case slots and permanent magnets installed in permanent-magnet slots. The permanent magnets under two poles employ three-segment type inverted-U-shaped magnetic circuit structures and each of the permanent magnets includes an intermediate-segment permanent magnet and two segments of side permanent magnets; air slots are formed between the two adjacent segments of permanent magnets; the three segments of permanent magnets are arranged in a left-right symmetric mode relative to the central lines of the intermediate-segment permanent magnets; and end portions, far away from mounting slots of the intermediate-segment permanent magnets, of mounting slots of the two segments of side permanent magnets are non-magnetic-conductive material filling parts. The whole rotor structure is in a left-right-symmetric mode relative to the central lines of the intermediate-segment permanent magnets and the rotor is installed at a rotating shaft. Therefore, the gap flux density waveform of the motor can be optimized. On the basis of sinusoidal processing of the gap flux density waveform of the motor, the harmonic contents in the air-gap field and the stator winding can be reduced, the counter-electromotive-force waveform can be optimized, the motor efficiency can be improved; and the motor torque pulsation can be reduced.

Owner:DANDONG SHANCHUAN ELECTRICAL ENG

Highly Modular Cylindrical Multiphase Permanent Magnet Linear Motor

ActiveCN104767353BImprove reliabilityContains the impact of faults relative to other phasesPropulsion systemsElectromagnetic couplingPermanent magnet rotor

The invention belongs to the field of permanent magnet motors, and relates to a highly-modularized cylindrical multiphase permanent magnet linear motor. The problems that when a winding short circuit and other failures happen to a conventional multiphase permanent magnet linear motor, the failure isolation difficulty is large, and motor modular design difficulty is large due to the high interphase electromagnetic coupling degree are solved. The highly-modularized cylindrical multiphase permanent magnet linear motor comprises a stator and a permanent magnet rotor, the stator can be arranged inside or outside the permanent magnet rotor, and an air gap exists between the stator and the permanent magnet rotor. The stator is formed by assembling 2m stator modules. The stator modules are assembled to be cylindrical in the axial direction. Each stator module comprises a stator iron core, an armature tooth, two fault-tolerant teeth and two annular concentrated windings. A one-phase module of the highly-modularized cylindrical multiphase permanent magnet linear motor is composed of two adjacent stator modules. The permanent magnet rotor is formed by assembling a permanent magnet and a rotor iron core, and the permanent magnet rotor can be of a surface-mounted structure or a Halbach structure or an axial magnetization structure and the like.

Owner:HARBIN INST OF TECH

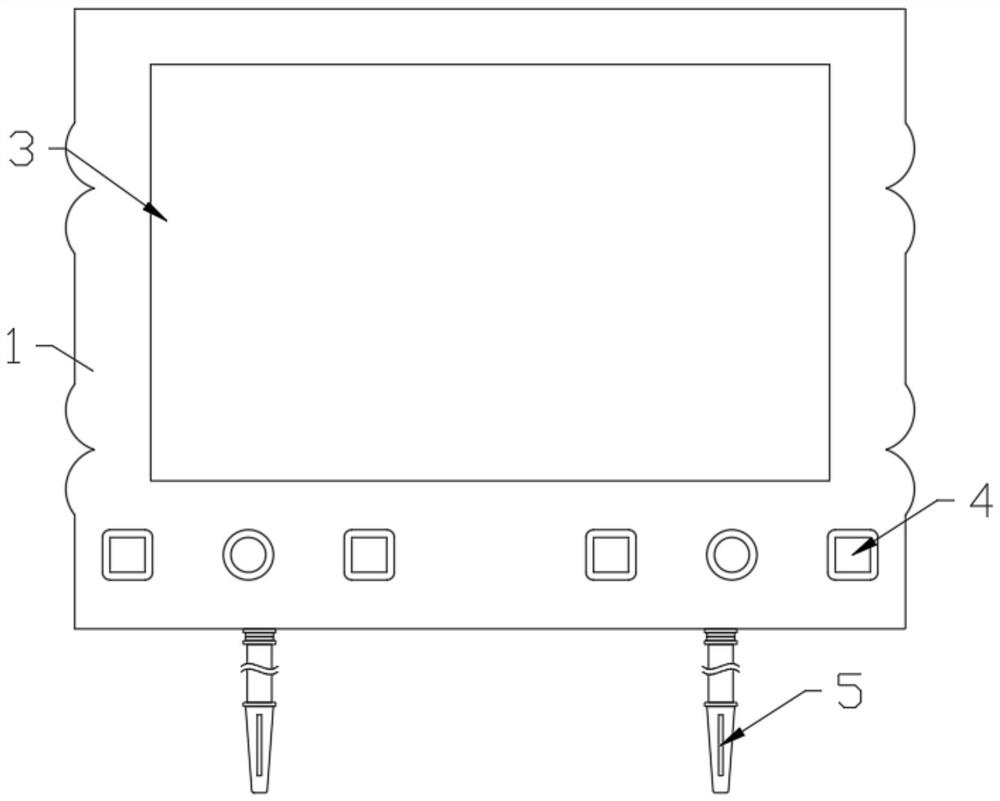

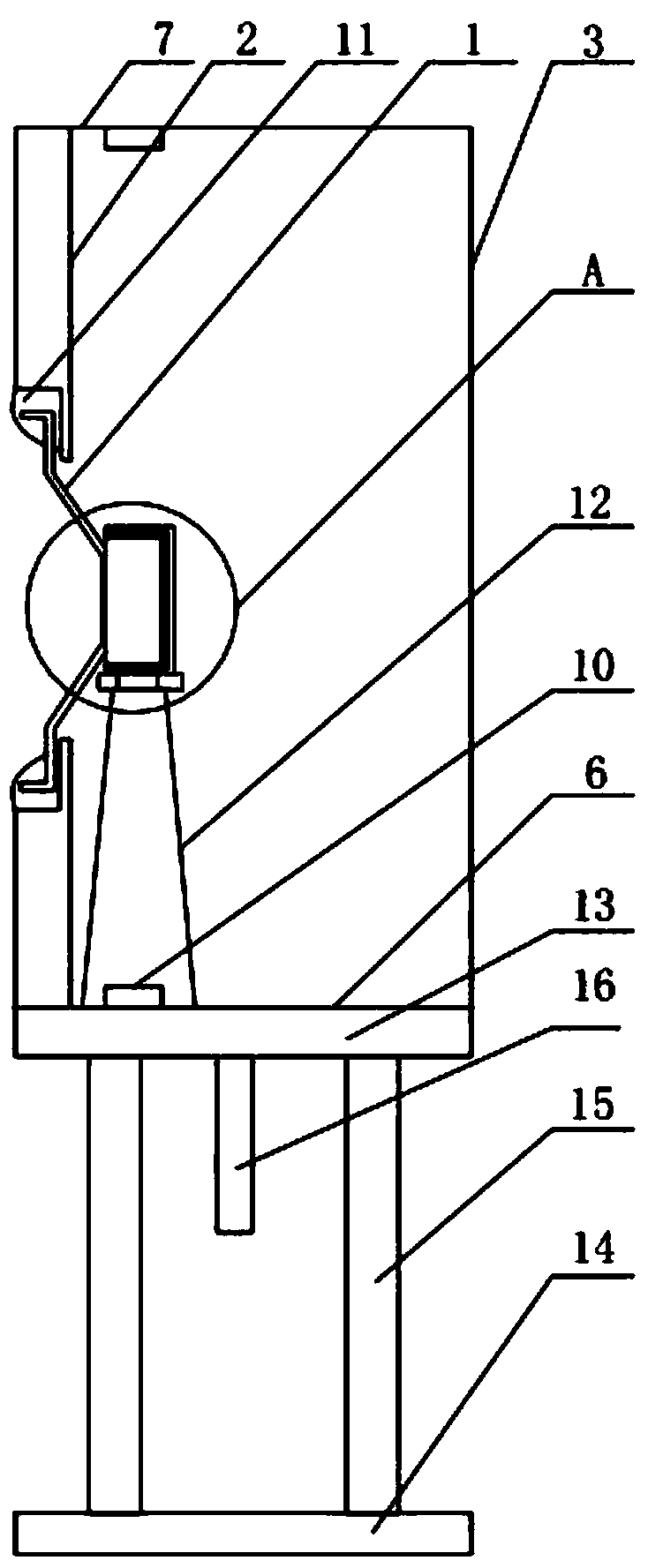

A power display device

ActiveCN111935954BAvoid short circuitHeat dissipation fastMagnetic/electric field screeningCasings/cabinets/drawers detailsDisplay deviceDust control

The invention discloses a power display device, which comprises a casing and a detection body arranged in the casing, a display screen is arranged outside the casing, a plurality of buttons and detection heads are arranged at the lower end of the display screen, and a plurality of first springs and detection heads are arranged in the casing. The main body is connected, and the shell includes side seats and horizontal plates. The side seats are connected to the horizontal plates through several threaded rods. It is a heat dissipation component for absorbing heat inside the housing. By detecting the heat generated by the main body when it is working, the thermoelectric power generation block on the horizontal plate works, and then through the electric shock rod, contact block and wires, the dust collecting plates set on the connecting seat work to attract and collect the dust in the shell , to prevent dust from falling on the detection body; the heat in the housing is absorbed by the heat-absorbing liquid in the heat-absorbing box; the side seat and the horizontal plate are provided with magnetic isolation plates to prevent the magnetic field outside the housing from affecting the detection body.

Owner:国网山东省电力公司曹县供电公司

a speaker system

ActiveCN105142048BNot easy to vibrateImprove sound qualityFrequency/directions obtaining arrangementsTransducer casings/cabinets/supportsEngineeringCast iron

The invention relates to the field of loudspeaker system technology and relates to a loudspeaker system. A loudspeaker of a loudspeaker body in the loudspeaker system is suspended by an electromagnet. Foot stands are of hollow stand columns filled with cast iron. Vibration attenuators are arranged on the foot stands. According to the invention, vibration is small and quality of given-out sound is quite high.

Owner:NINGBO ZHONGRONG ACOUSTICS TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com