Patents

Literature

115results about How to "Avoid stripping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for depositing metal or hard ornament film on plastic substrate

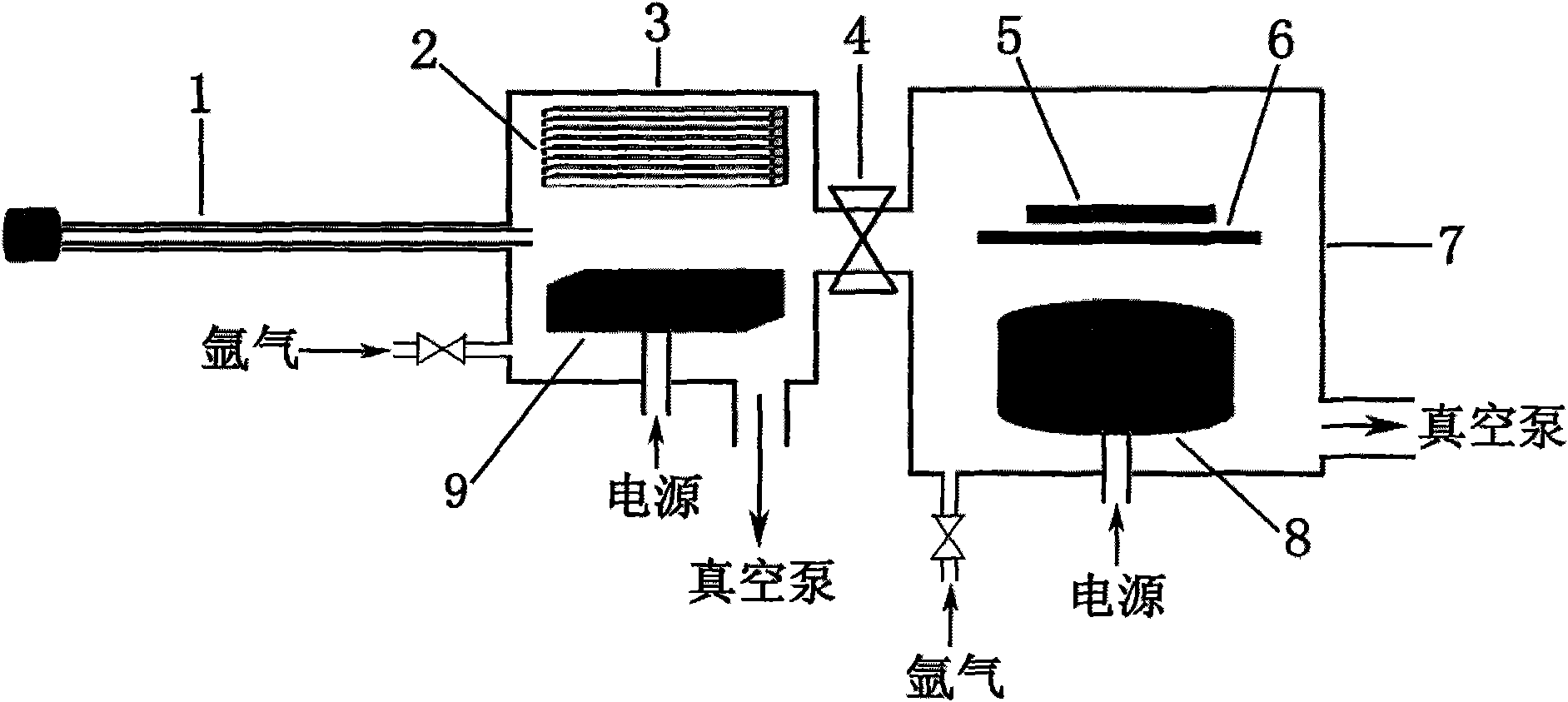

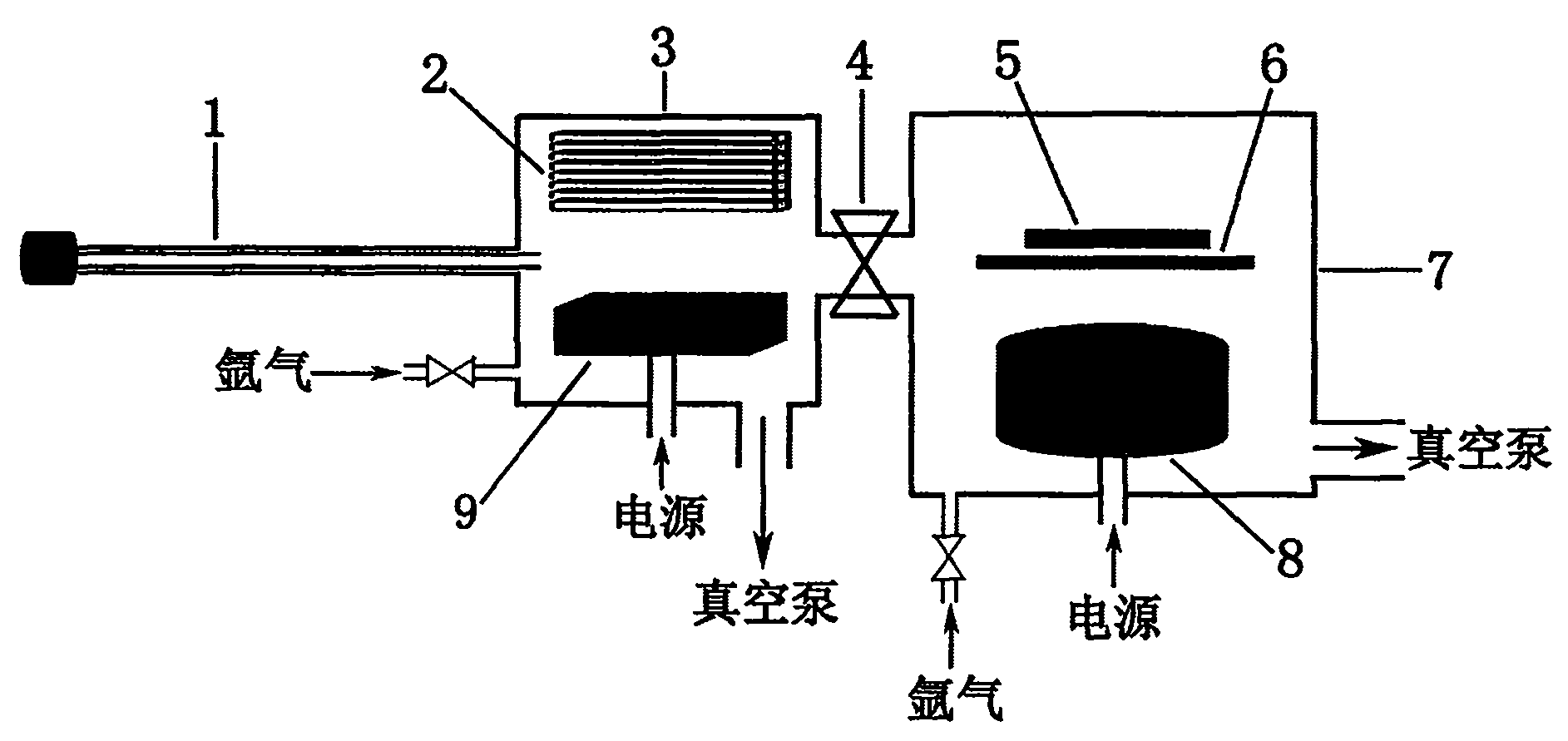

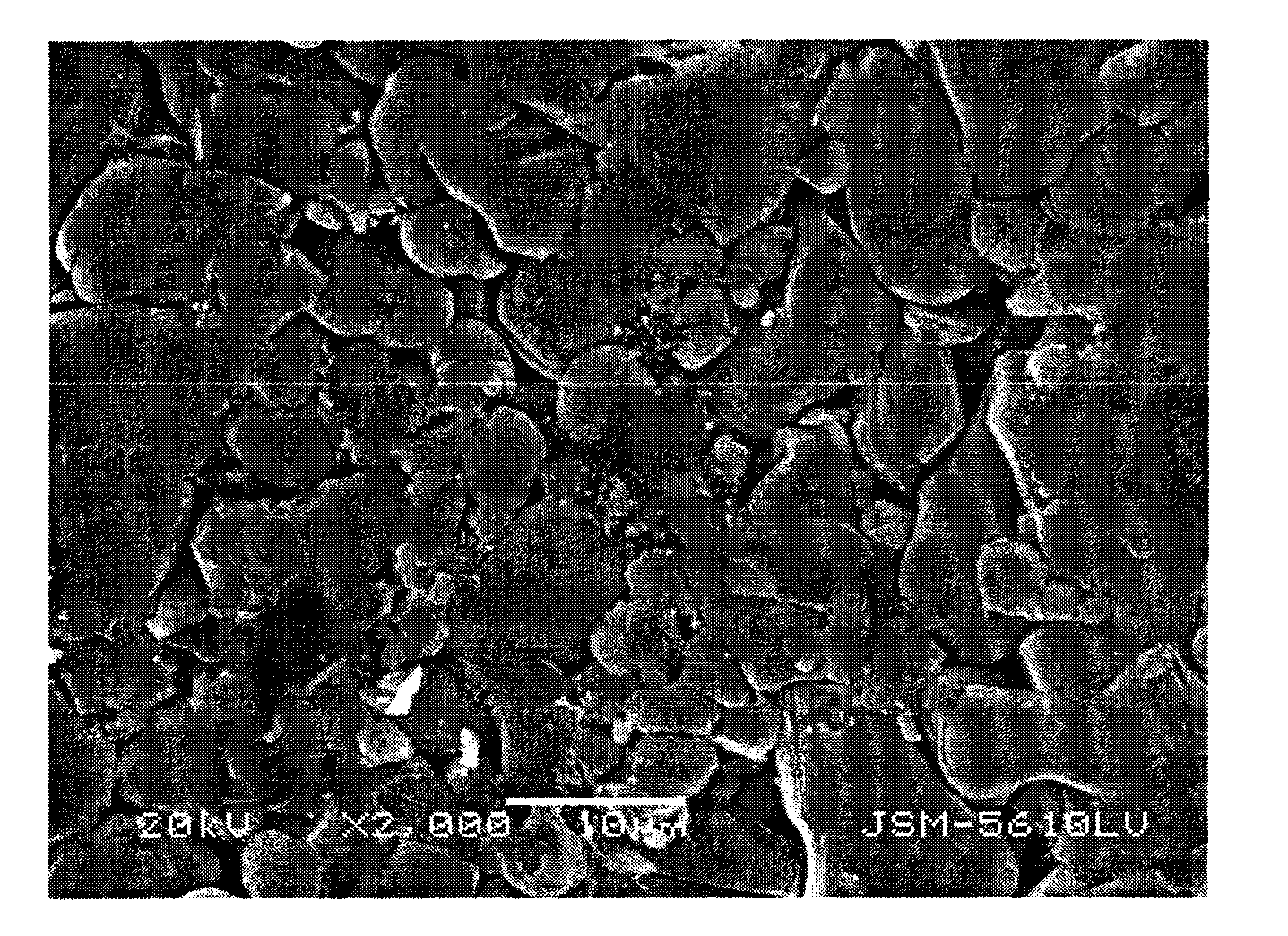

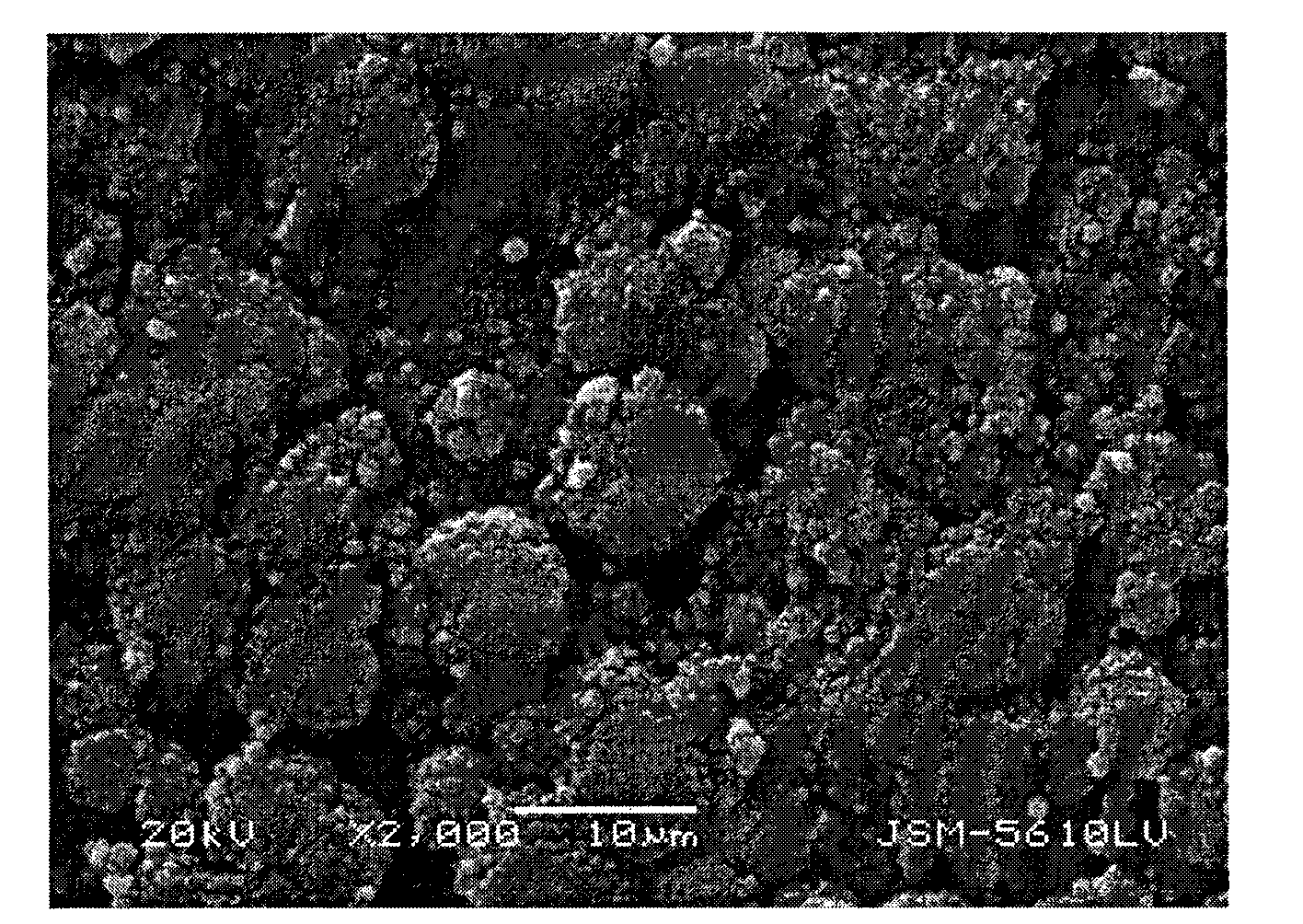

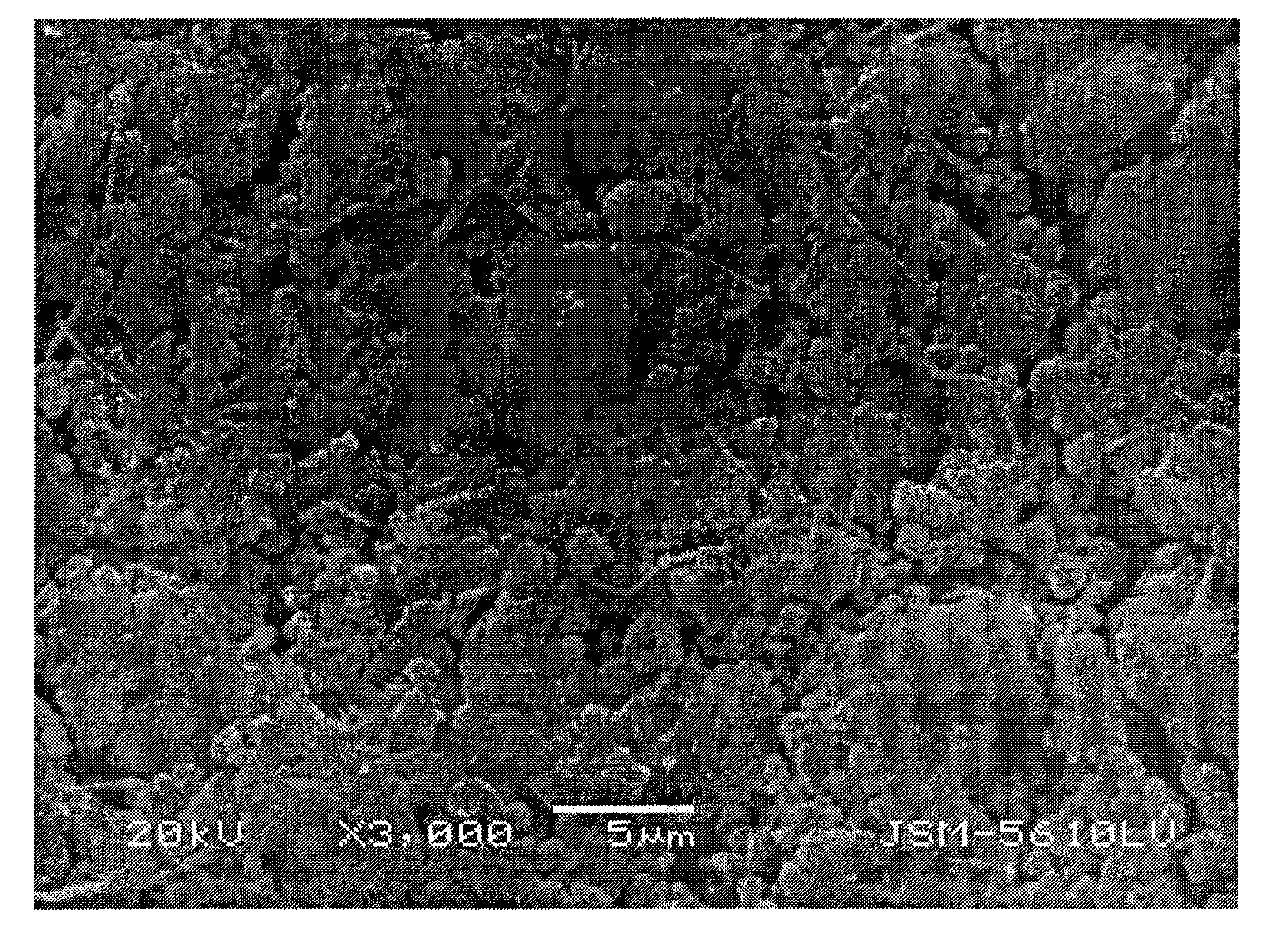

InactiveCN101985738AImprove bindingAvoid strippingVacuum evaporation coatingSputtering coatingIridiumRadio frequency magnetron sputtering

The invention relates to a method for depositing a metal or hard ornament film on a plastic substrate. In the method, the metal or hard ornament film is prepared on the surface of a plastic substrate material by using a radio frequency magnetron sputtering technology, and good binding force exists between the prepared ornament film and the substrate. The plastic substrate material comprises ABS plastic (terpolymer of acrylonitrile-butadiene-styrene), PMMA (polymethyl methacrylate) organic glass, PE (poly ethylene) plastics, PP (polypropylene) plastics and the like. The metal ornament film comprises chromium, nickel, titanium, aluminum, aurum, silver, iridium or alloys and the like, and the hard ornament film comprises metal nitrides, carbon compounds, oxides, diamonds and the like. The method has the advantages of simple operation, no pollution and low cost, and the prepared film is good in adhesive force.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

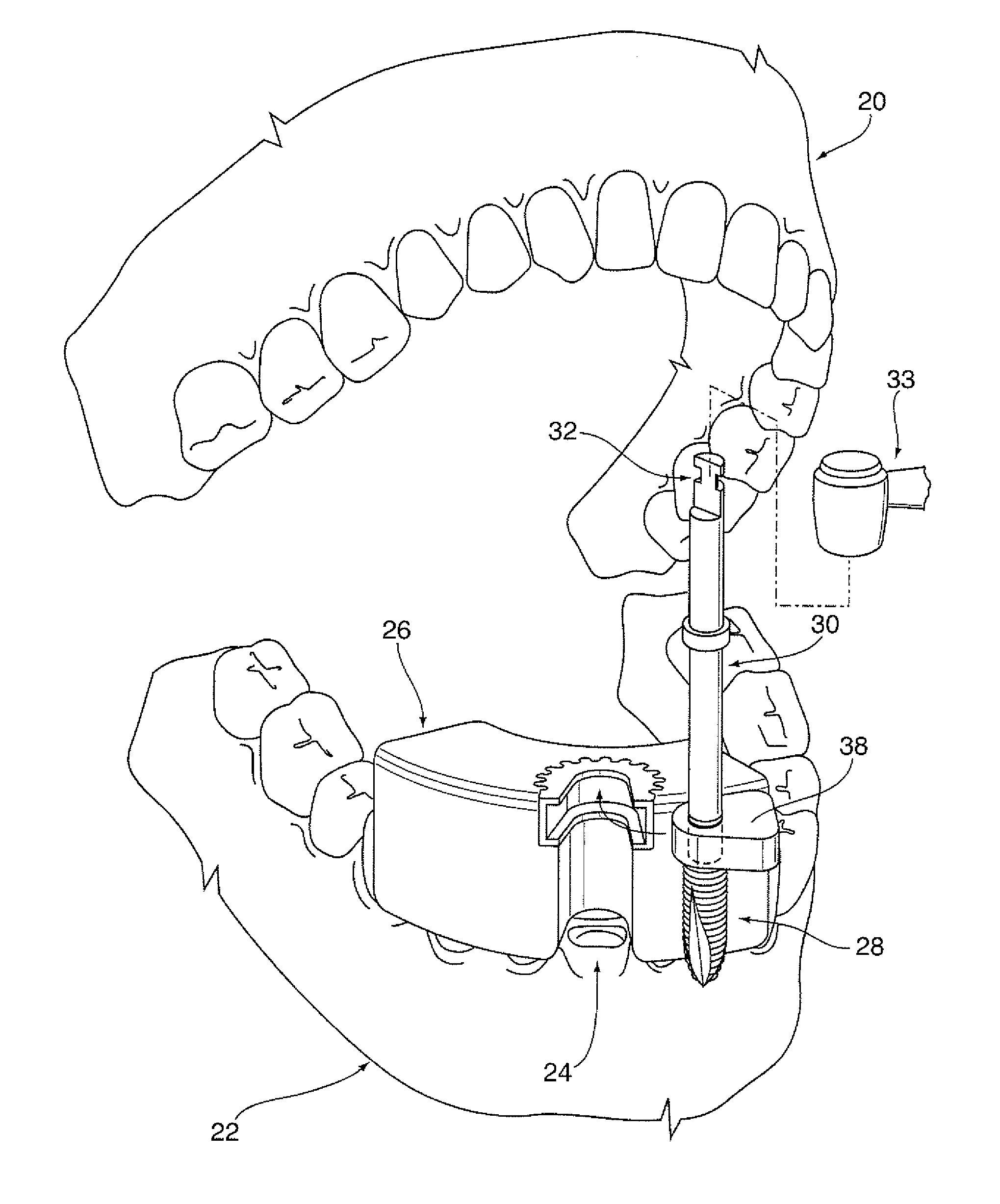

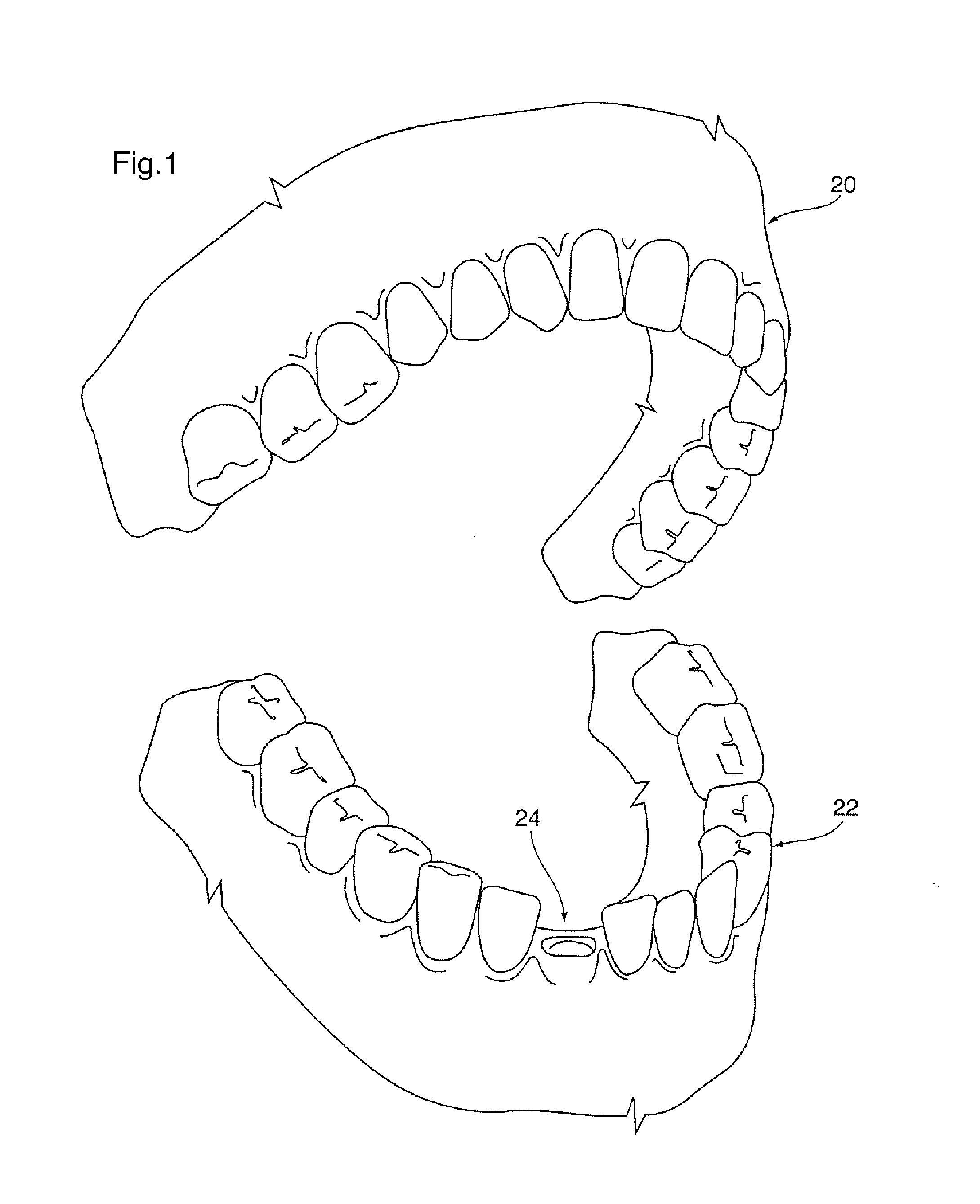

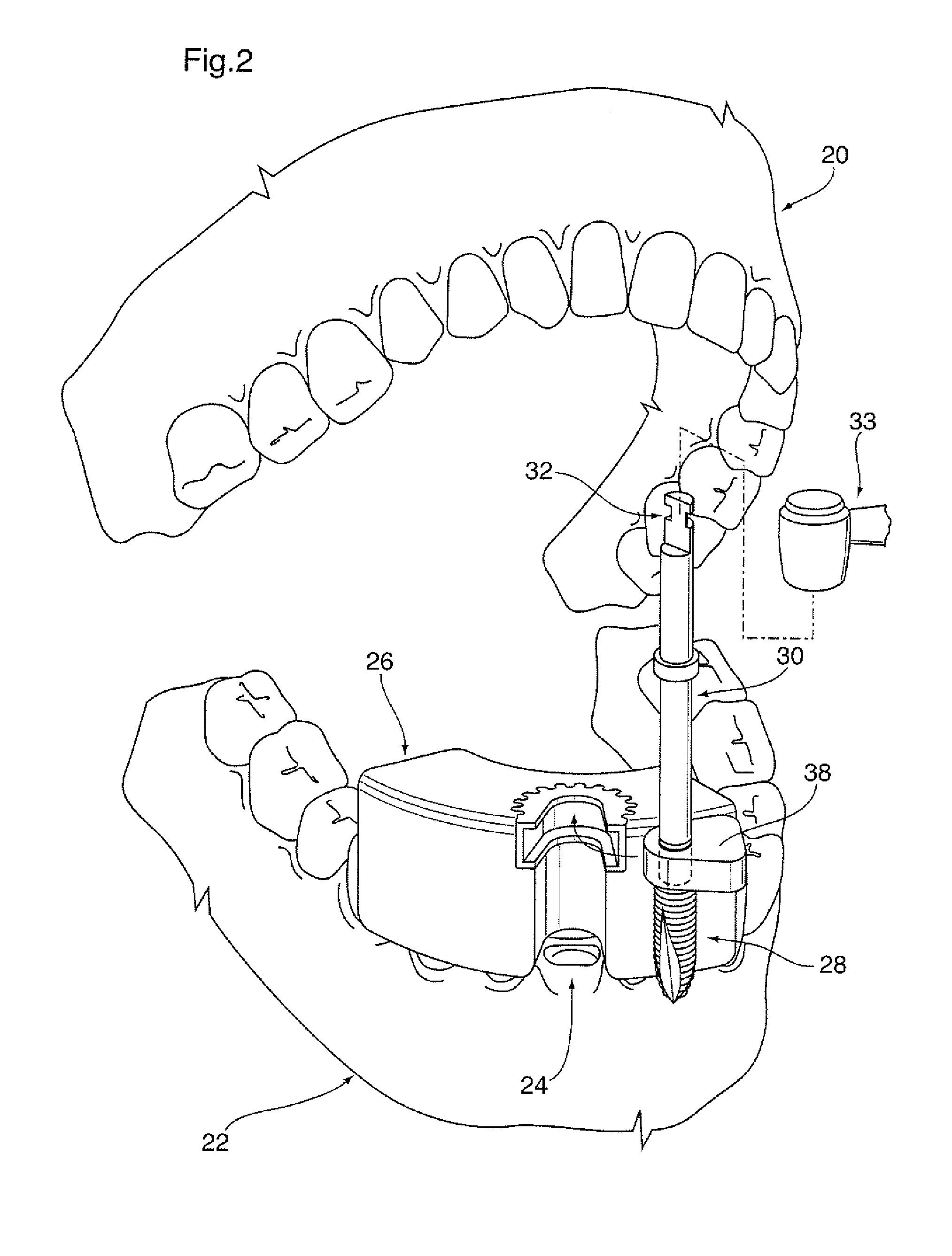

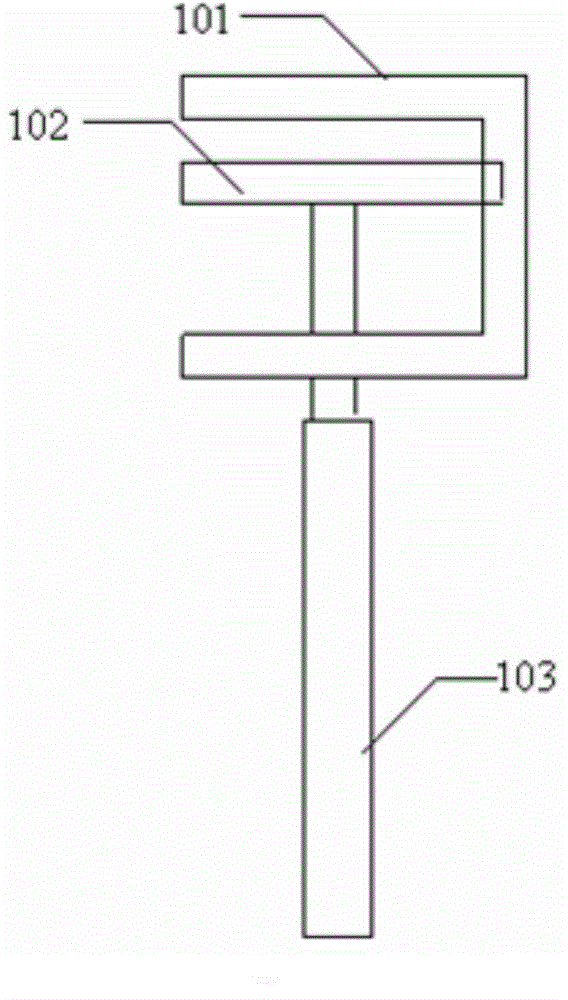

Dental implant positioning system

InactiveUS20140093838A1Inhibit bindingAvoid strippingDental implantsDental toolsDrive shaftEngineering

A system is disclosed for installing a dental implant in a jawbone of a patient. The system includes a threaded drive shaft rotatable about an axis and guide means for supporting the drive shaft with its axis oriented in a path along which the implant is to be installed. The guide means has a threaded bore for receiving a drive shaft and an opening which extends parallel to the axis of the drive shaft and opens radially outwardly from the bore. The drive shaft can then be engaged with and disengaged from the guide means by radial displacement of the shaft parallel to its axis. A drill is adapted to be releasably coupled to a leading end portion of the drive shaft and may be a self-drilling implant. Means is provided for rotating the drive shaft in a direction to cause the drill to penetrate the jawbone of the patient.

Owner:CARMICHAEL ROBERT P +1

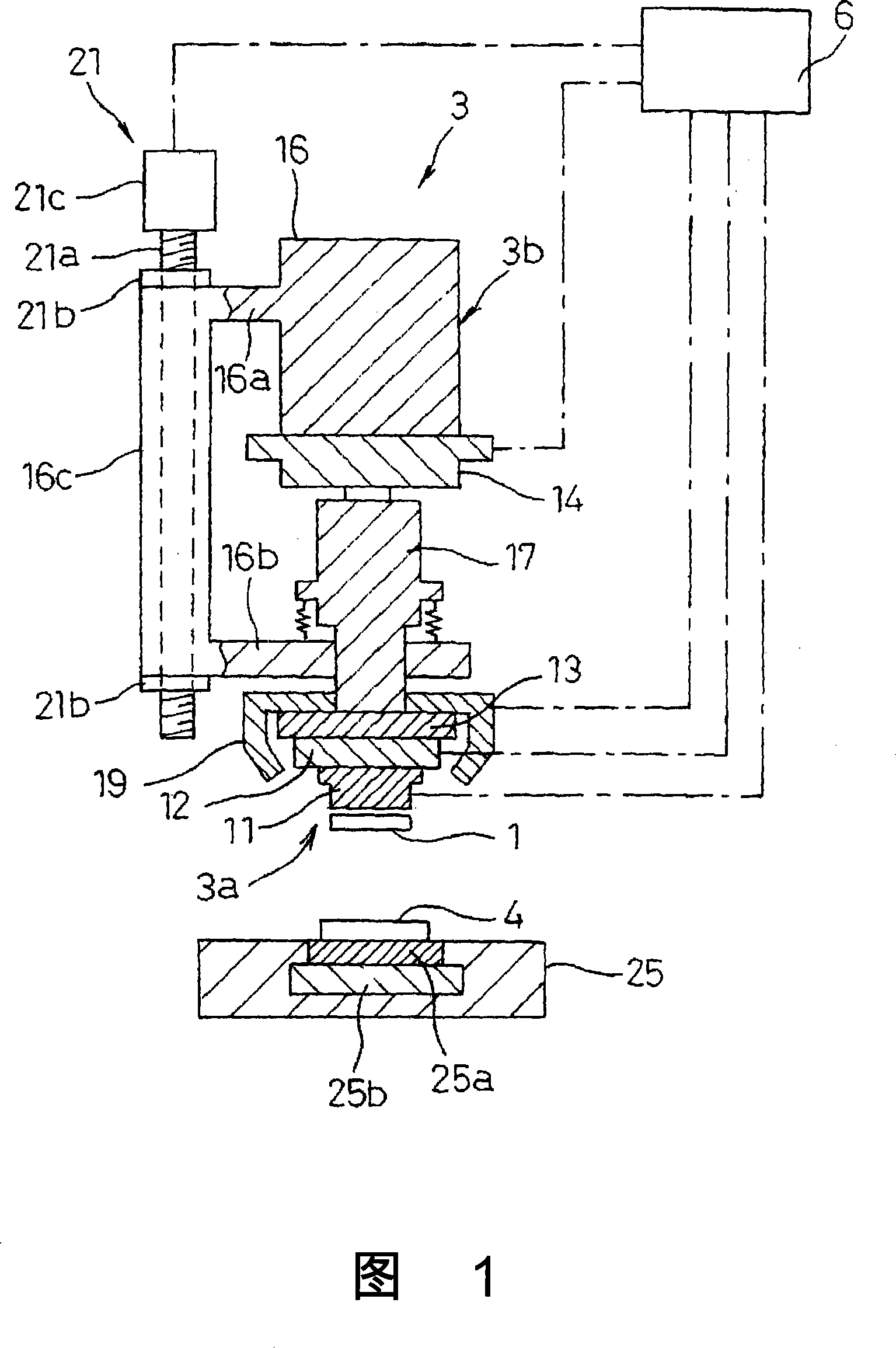

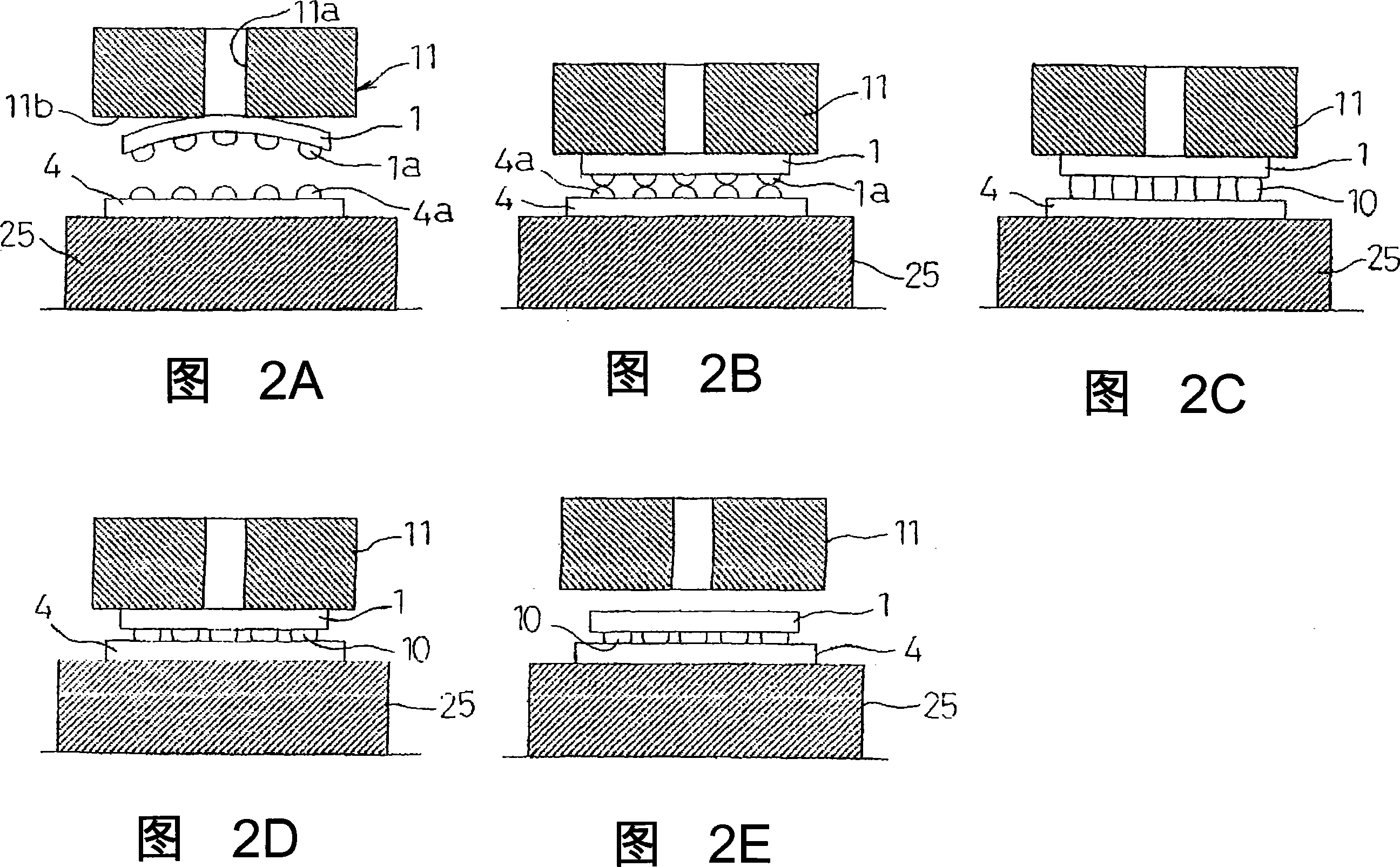

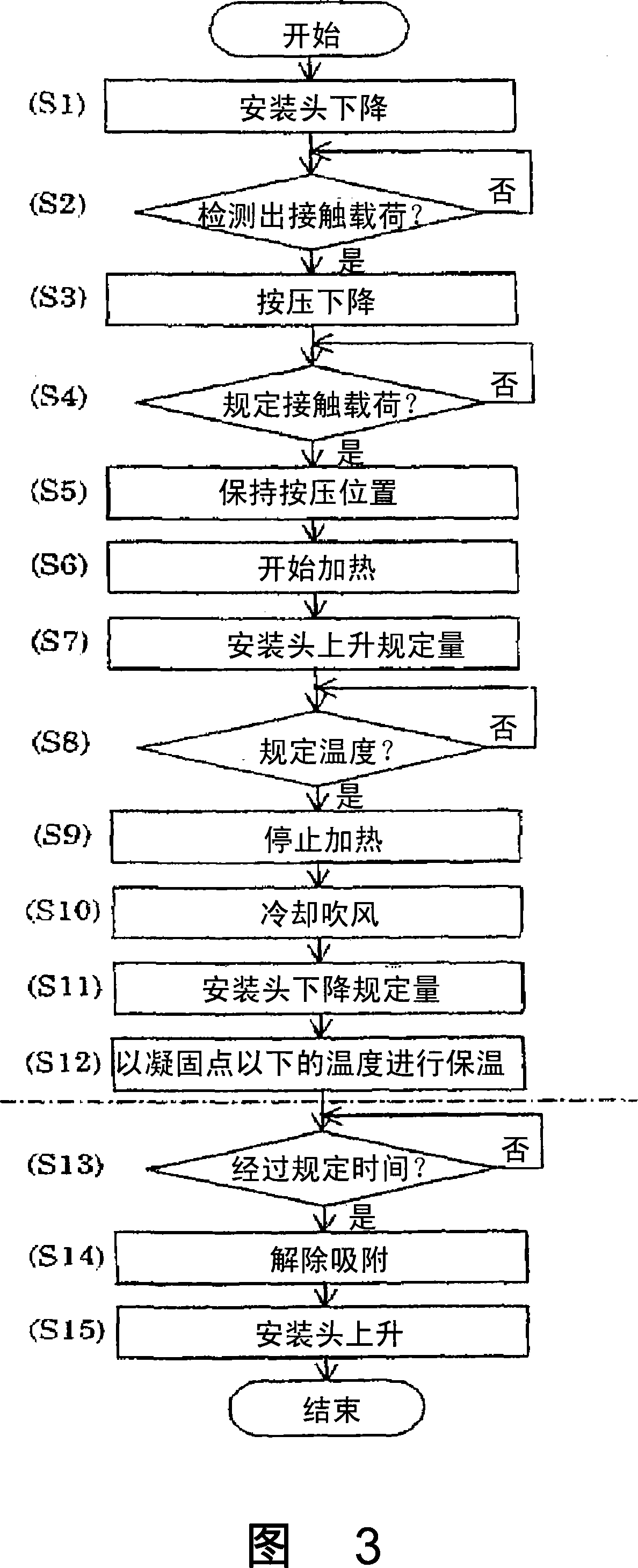

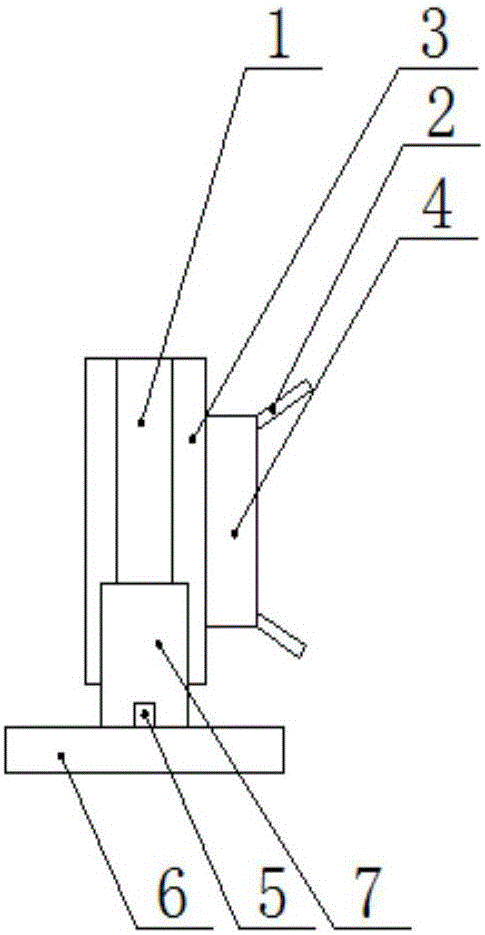

Component mounting method and component mounting apparatus

InactiveCN1965401AAvoid strippingRelative interval increasePrinted circuit assemblingFinal product manufactureEngineeringThermal expansion

There has been a possibility of deteriorating planarity of a thin IC chip due to process distortion and deformation generated when sucking the IC chip by a suction nozzle. The deformation is corrected by pressing the thin IC chip on a board (4) with a prescribed load by a suction nozzle (11) having a suction plane (11b) formed flat. A reduction of a prescribed opposing interval between the IC chip and the board (4), due to thermal expansion caused by heat applied for melting a solder bump (1a) formed on an electrode, is corrected by controlling rising of the suction nozzle (11). A peeling action of the melting part, due to a part which has heat- expanded and contracted by cooling, is corrected by controlling descending of the suction nozzle (11). Thus, an electronic component mounting method and an electronic component mounting apparatus are provided for correctly mounting even the electronic components, such as the thin IC chip easily deformed and the IC chip wherein a multitude of electrodes are formed at a narrow pitch.

Owner:PANASONIC CORP

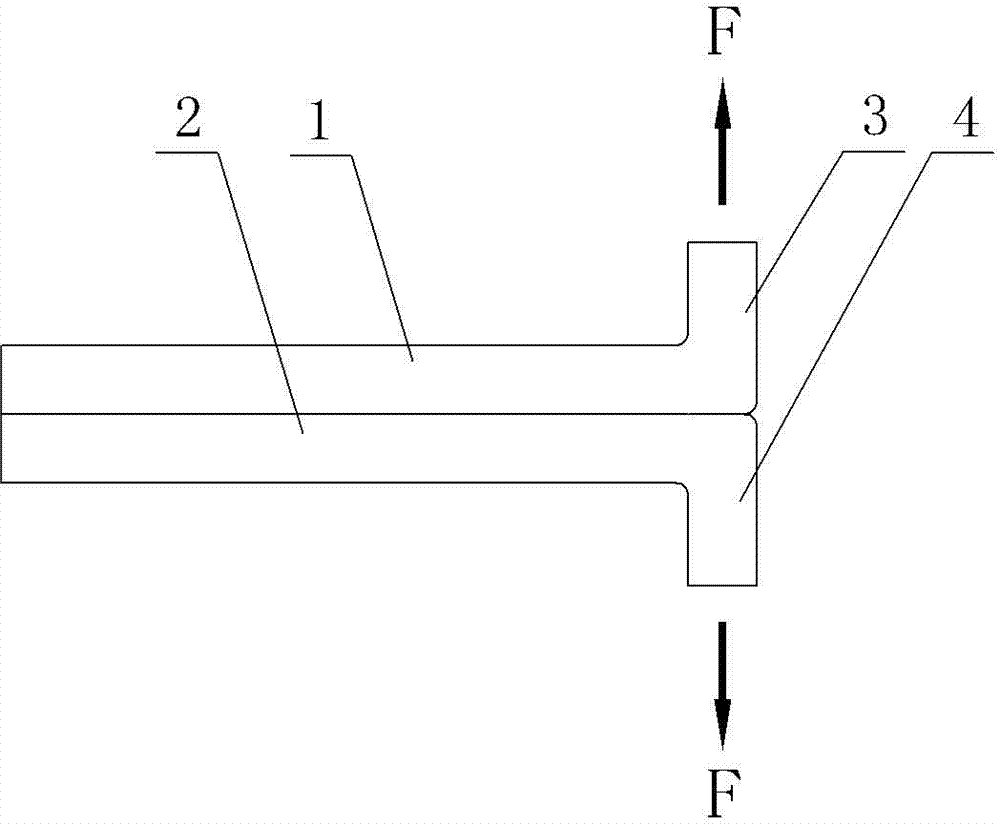

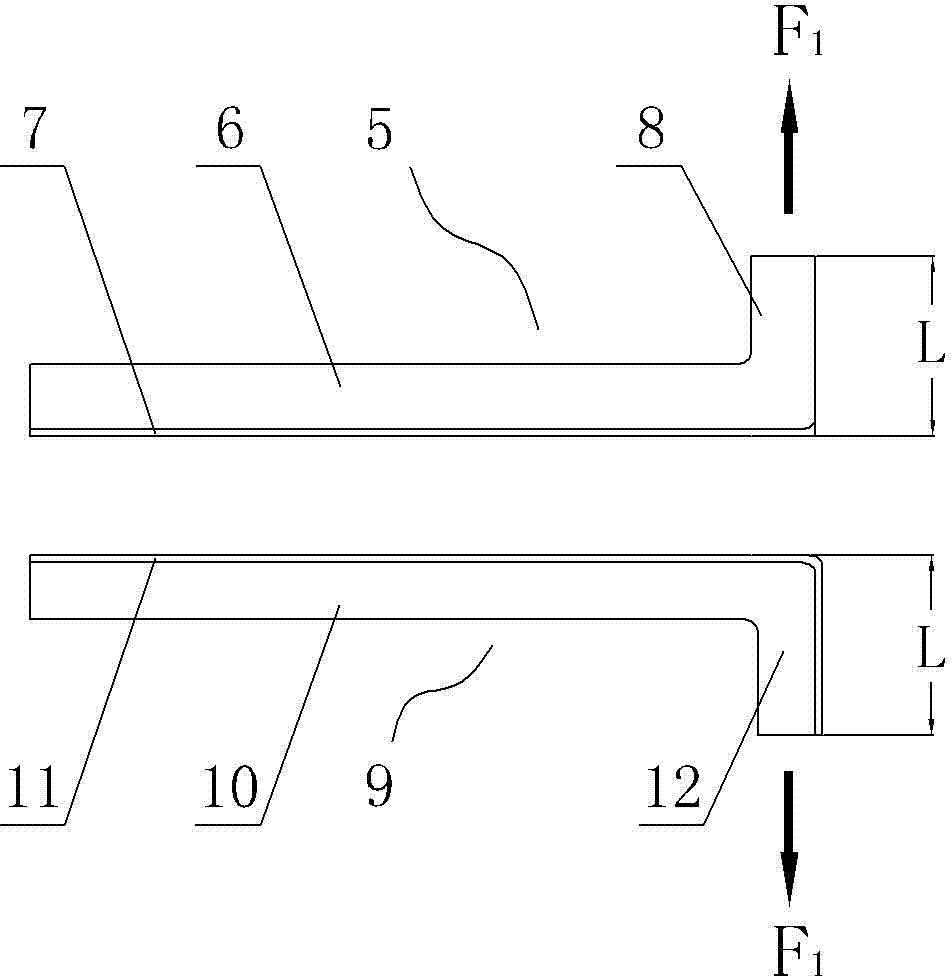

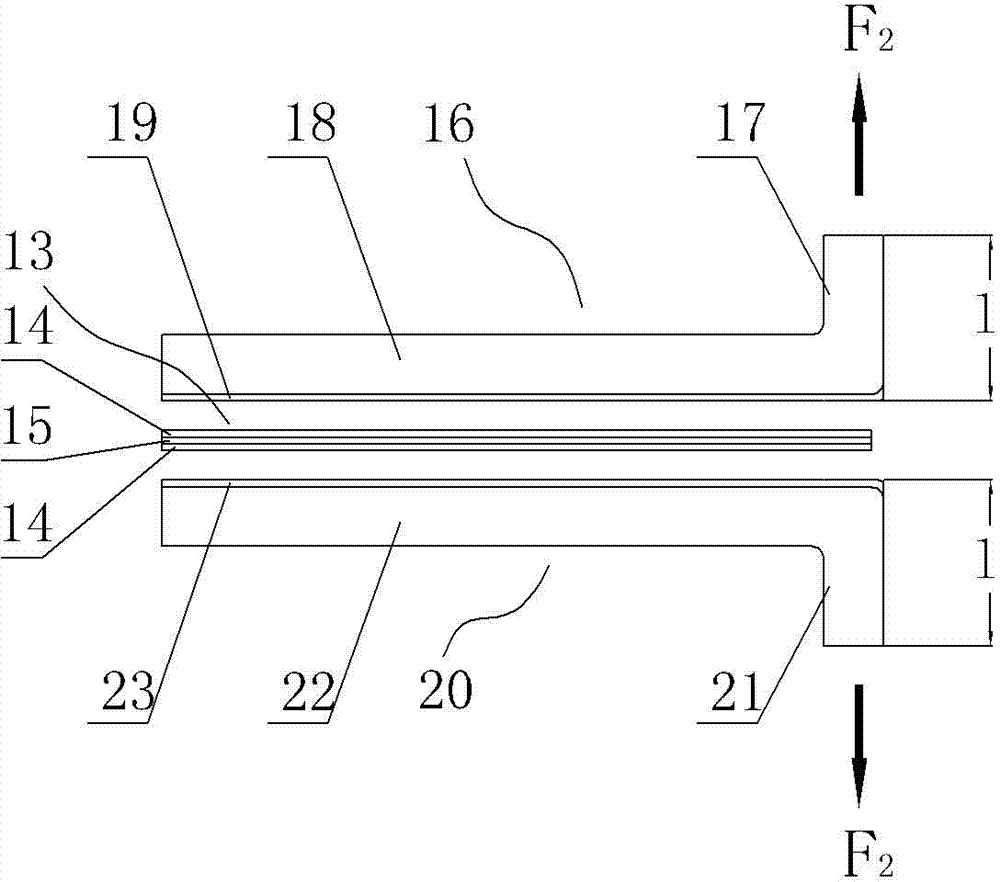

Method for detecting interface binding strength of aluminum-steel composite material for soldering

ActiveCN103776762AMake sure to peel off properlySmooth peelingUsing mechanical meansMaterial analysisTest sampleSoldering

The invention provides a method for detecting the interface binding strength of an aluminum-steel composite material for soldering. The method can be used for accurately detecting the aluminum-steel interface binding strength and quantifying the interface binding effect of the aluminum-steel composite material for the soldering. The method comprises the following steps: firstly, preparing a test sample of the aluminum-steel composite material and carrying out a stripping test on the test sample; and calculating according to a test result to obtain a binding strength value of an aluminum-steel interface. The method is characterized in that the preparation of the test sample comprises the following steps: soldering and connecting a metal reinforced layer on the surface of an aluminum layer of the sample and forming a compound layer by the metal reinforced layer and the aluminum layer of the sample. The binding strength of the metal reinforced layer in the compound layer and the aluminum layer of the sample is greater than the binding strength of the aluminum-steel interface; in the stripping test, the compound layer and a steel layer in the sample are stripped by a tension tester.

Owner:银邦(安徽)新能源材料科技有限公司

Method for preparing brain tissue frozen section

The invention discloses a method for preparing a brain tissue frozen section, belonging to the fields of biology and medical experiments. The method comprises (1) a step of tissue extraction, immobilization and dehydration, namely a step of subjecting an animal brain tissue to immobilization and gradient dehydration; (2) a step of freezing pretreatment, namely a step of washing the brain tissue with a PBS solution, wiping the brain tissue, leveling the brain tissue, wrapping the brain tissue with tin foil paper, freezing the brain tissue in a rapid freezing zone of a freezing microtome, and then taking the tissue out for subsequent treatment; (3) a step of semi-embedding treatment, namely a step of subjecting the brain tissue to semi-embedded treatment, and allowing the tissue to stand for1 minute; (4) a step of frozen sectioning, namely a step of fixing a sample holder to a probe of the microtome, and performing continuous coronal frozen sectioning; and (5) a step of section collection, namely a step of collecting sections of desired positions into a six-pore plate containing a frozen preserving fluid, and storing the sections at -20 DEG C for long time. Semi-embedding treatmentis adopted to treat the brain tissue, and therefore, influences of an embedding agent on the brain tissue are avoided, and sections are complete and free of ice crystals, and have good immunofluorescent staining properties.

Owner:SHANDONG UNIV OF TRADITIONAL CHINESE MEDICINE

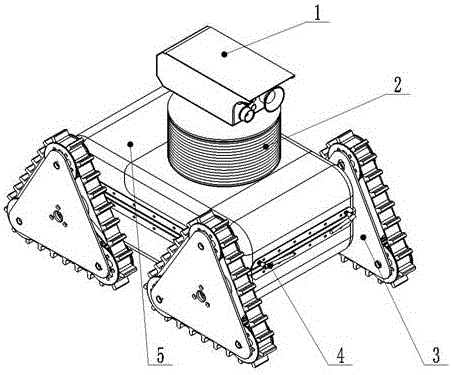

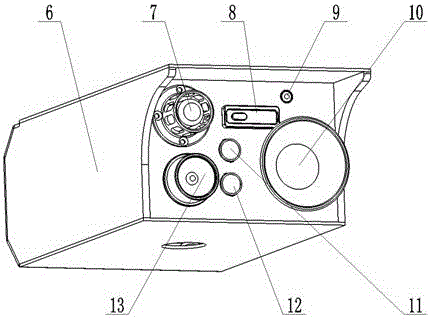

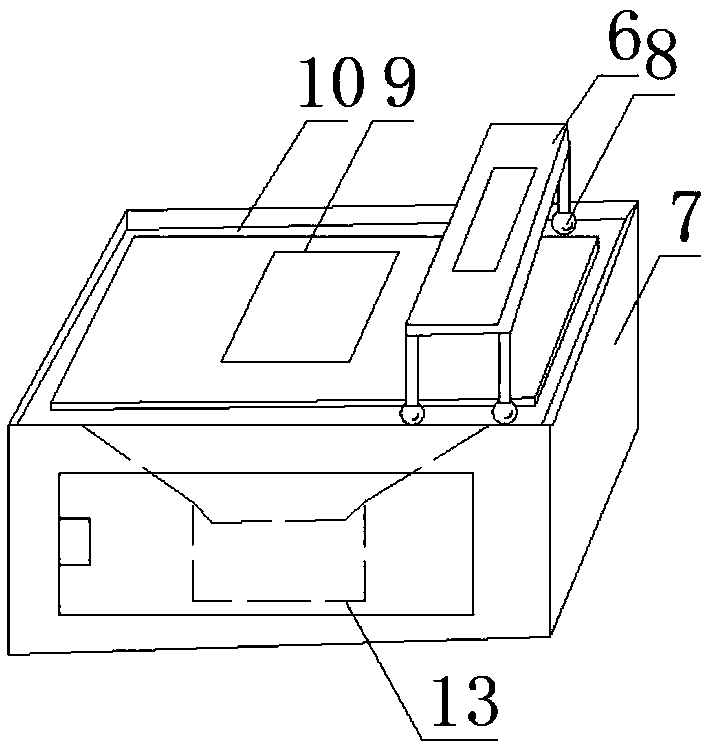

All-terrain inspection robot

PendingCN107176218AEasy to controlImprove obstacle performanceEndless track vehiclesTerrainLaser ranging

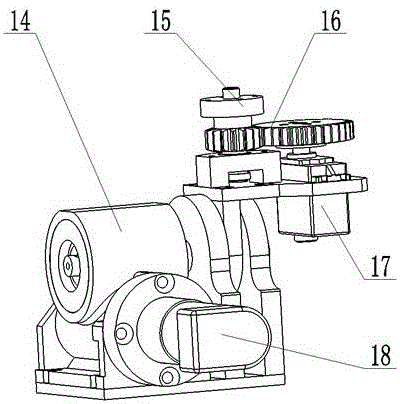

An all-terrain inspection robot relates to a robot, the robot includes a robot detection device (1), a pan / tilt (2), a triangular drive train (3), a wireless antenna (4), and a robot body (5); The device (1) includes a protective sealing cover (6), a temperature sensor (7), a laser ranging (8), an indicator light (9), a high-definition visible light camera (10), a sound probe (11), an infrared probe (12), The flashlight (13); the cloud platform includes a worm gear reducer (14), a detection device butt joint flange (15), an acceleration gear set (16), a rotating motor (17), and an elevation motor (18); There are crawlers, and the triangular driving wheel train is connected to the motor; the wireless antenna is provided with receiving and transmitting signal devices; the robot of the present invention can be widely used in complex terrain power inspections, space detection, explosion rescue and other occasions.

Owner:北方智能装备有限公司

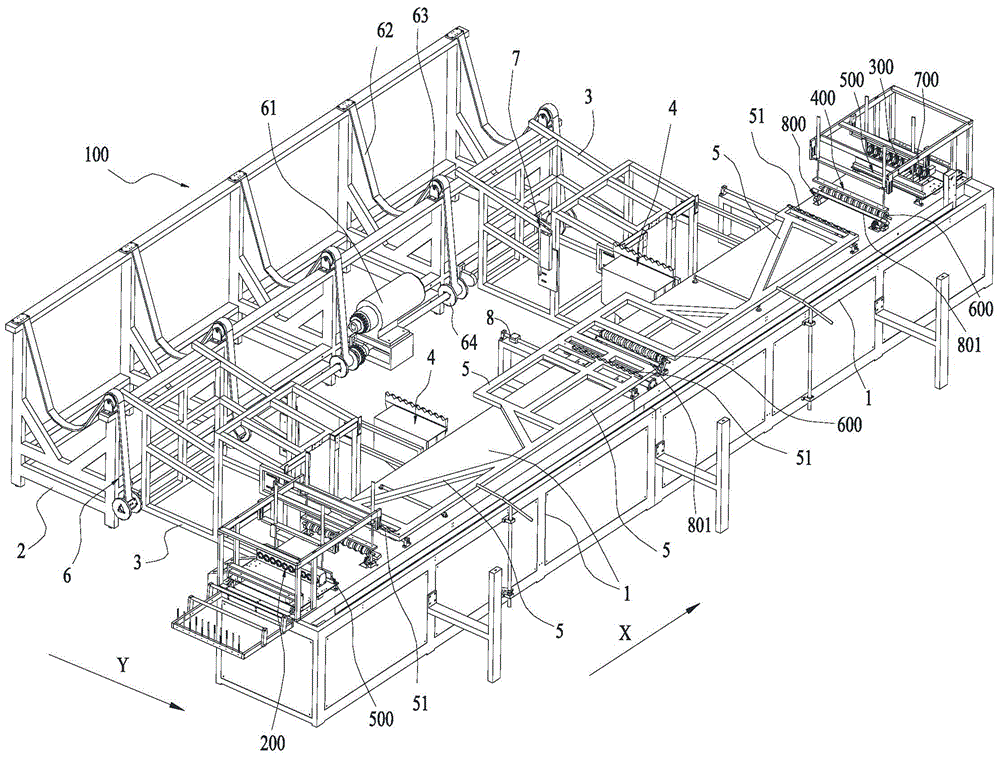

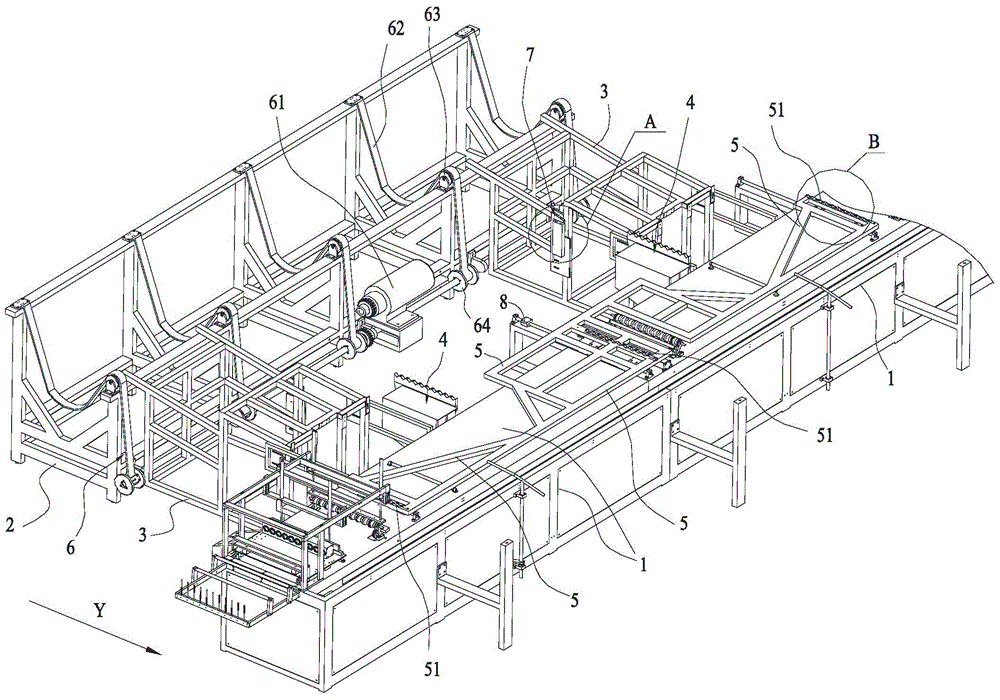

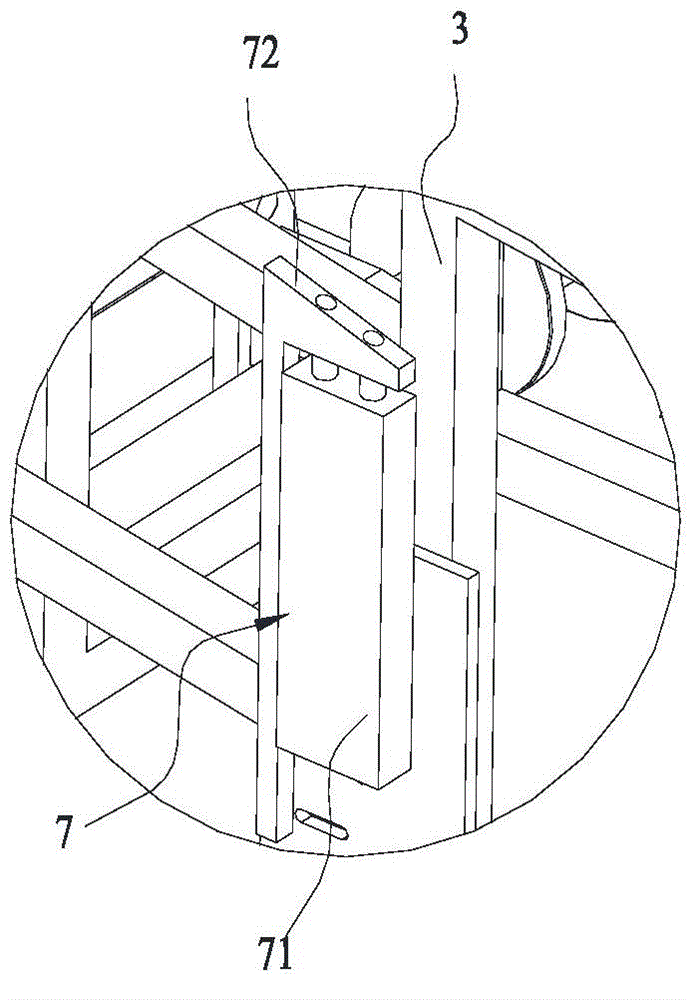

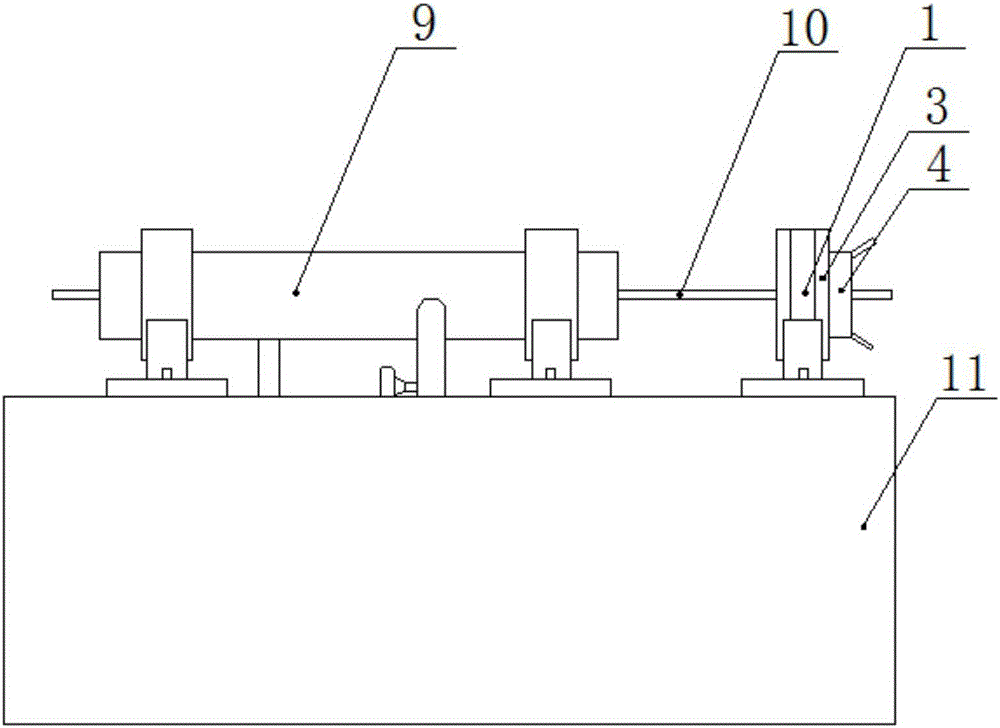

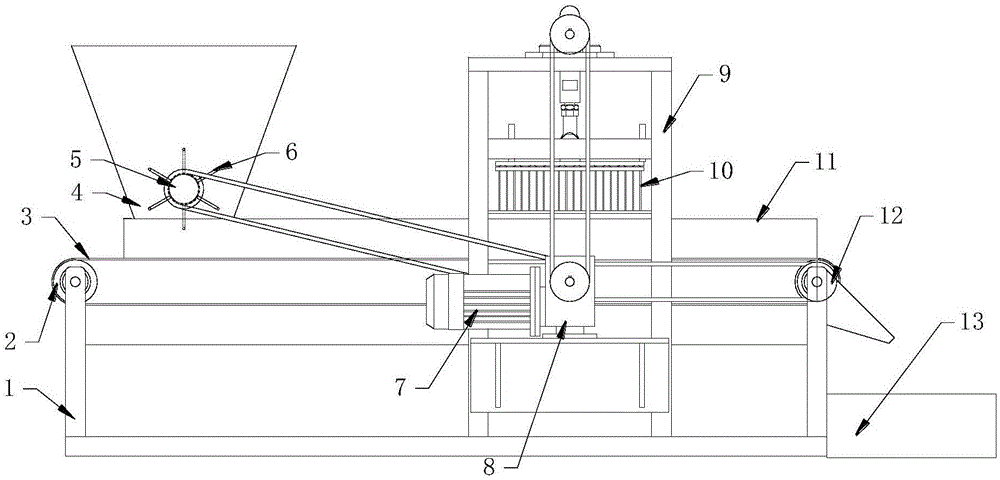

Pipe packing machine

ActiveCN104443482AReduced straightness requirementsLow failure rateWrappingRod-shaped articlesEngineeringFront and back ends

The invention discloses a pipe packing machine which comprises a rack, an automatic feeding device, magnetic isolating type film penetrating devices, film clamping devices, compressing devices and sealing devices. Driving supporting wheels used for supporting and limiting pipes and driving packing films on the pipes to move backwards and locating devices used for locating the rear ends of the pipes are arranged on the rack. The magnetic isolating type film penetrating devices are arranged at the front end of the rack and used for opening the packing films, sleeving the front ends of the pipes with the packing films and locating the front ends of the pipes. The film clamping devices slide in the front-back direction of the rack and used for clamping the packing films opened by the magnetic isolating type film penetrating devices and sleeving the rear ends of the pipes with the packing films from the front ends of the pipes. The compressing devices are suspended above the rack and used for compressing the pipes downwards. The sealing devices are suspended above the rack and located at the front end and the rear end of the rack respectively, and the sealing devices are used for carrying out edge cutting and sealing on the packing films. The pipe packing machine can complete the motion of sleeving the pipes with the packing films automatically, stably and effectively, and the films can be prevented from falling off.

Owner:FOSHAN CHUANGLIBAO PACKAGING MACHINERY

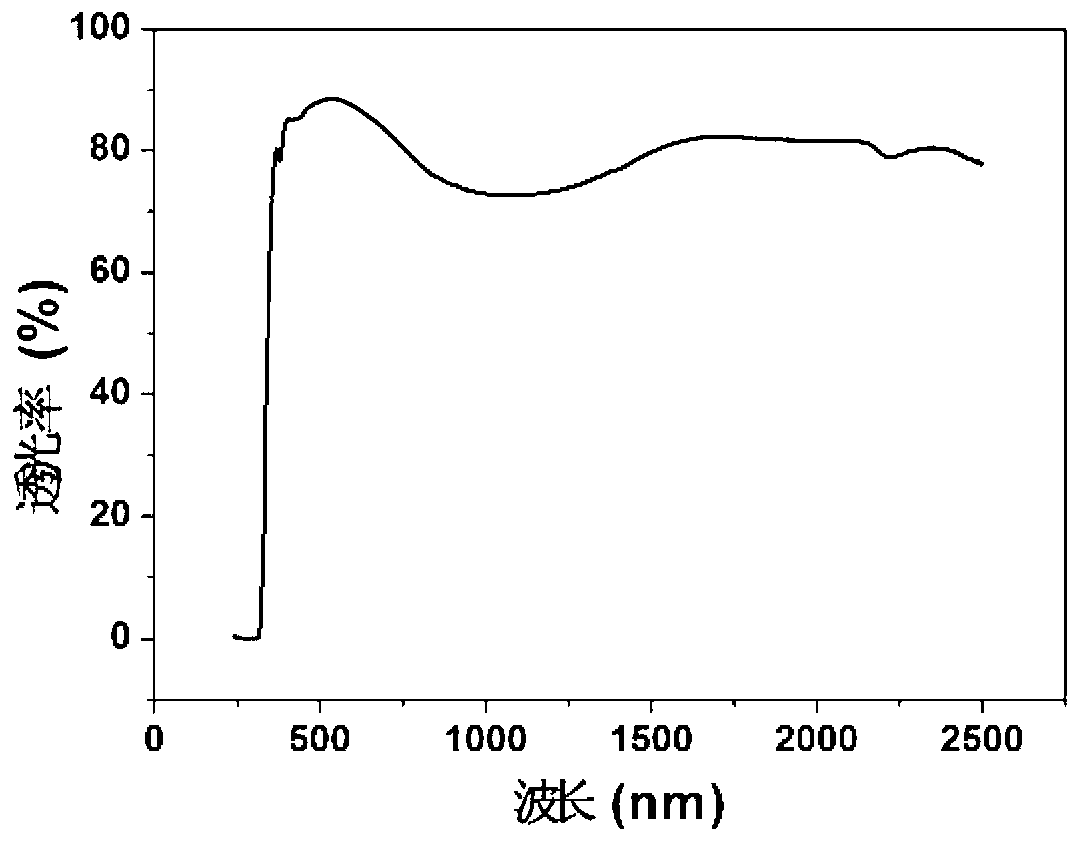

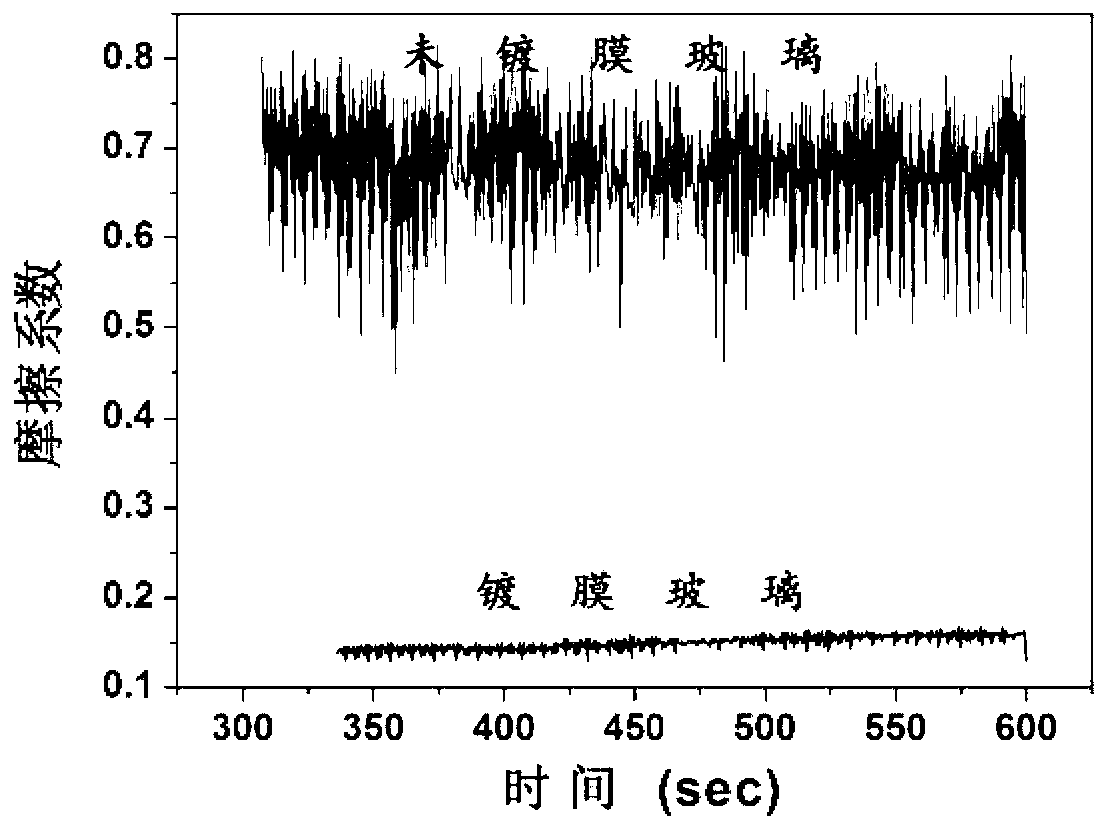

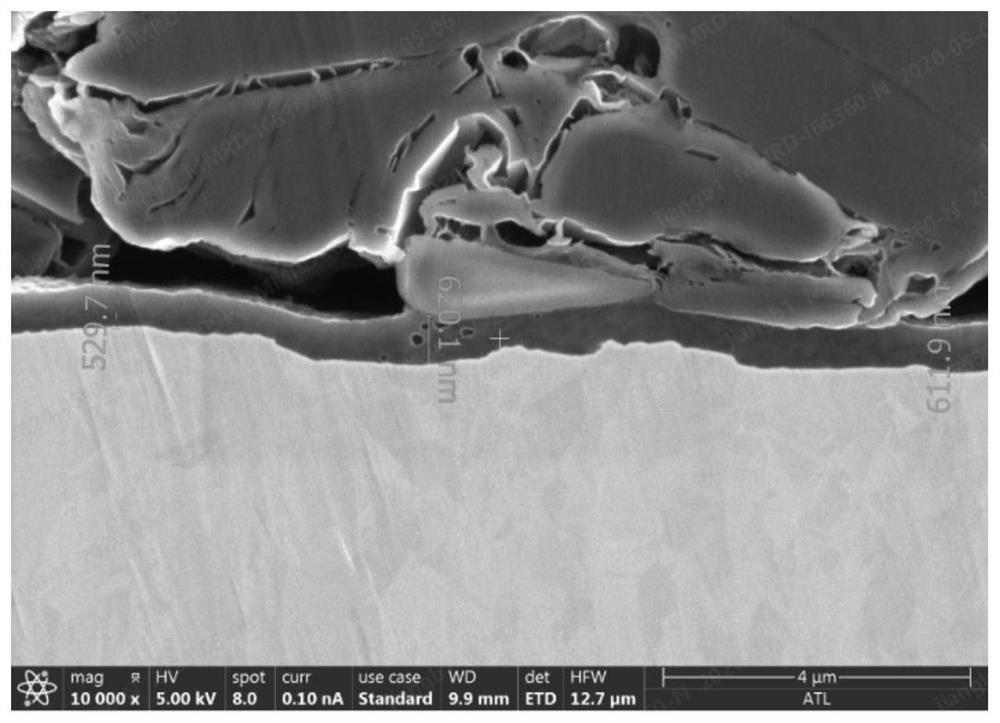

Glass substrate and preparation method thereof

The invention discloses a glass substrate and a preparation method thereof. The surface of the glass substrate is deposited with a layer of transparent, abrasion-resistant, scratch-resistant and hard diamond-like carbon film. The glass substrate of the invention has high visible light transmittance and high solar spectrum transmittance, and the abrasion resistance of the glass substrate is greatly improved compared with the uncoated glass substrates.

Owner:CHINA BUILDING MATERIALS ACAD +1

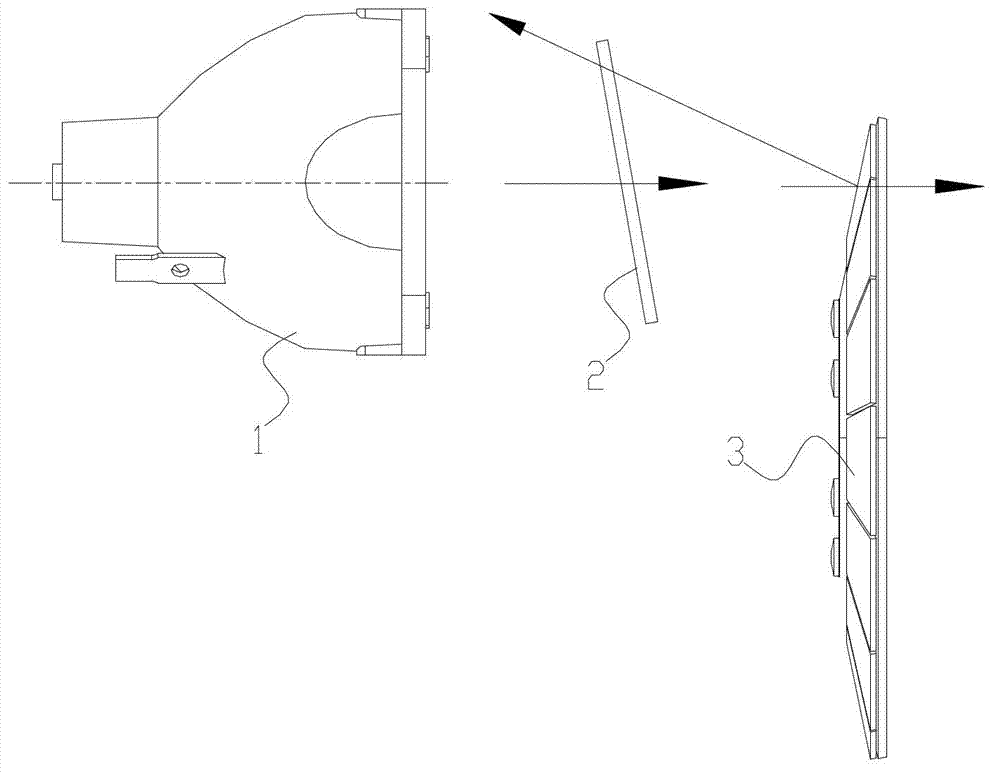

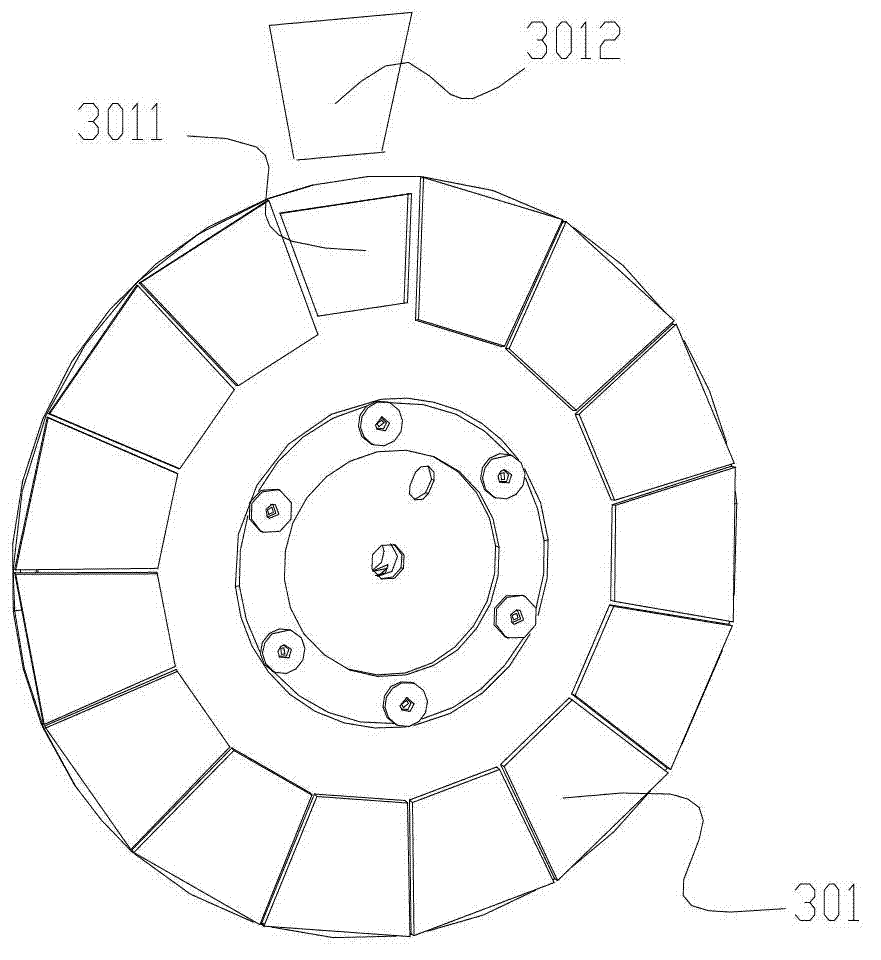

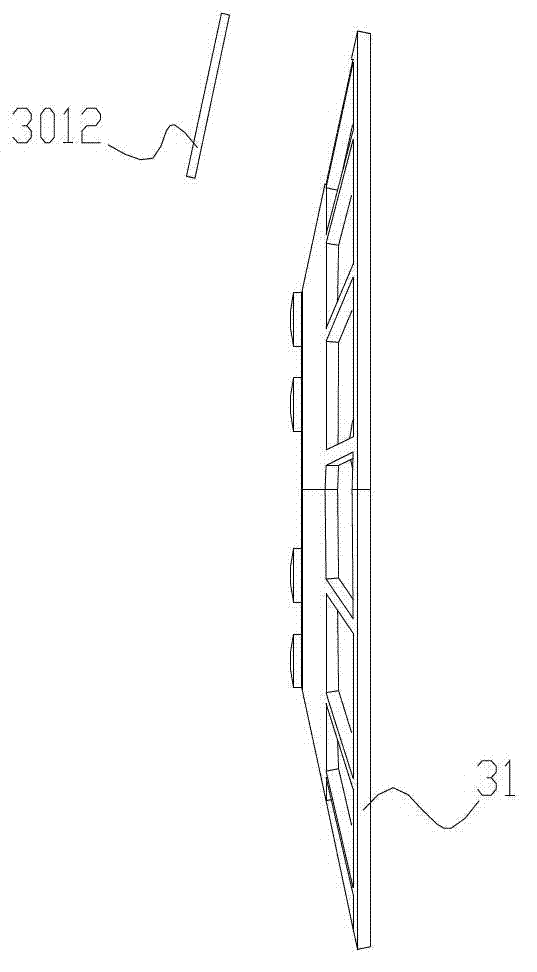

Stage lighting color filter device

ActiveCN102767792AExtended service lifeReduce the temperatureLighting heating/cooling arrangementsSpectral modifiersStage lightingEngineering

The invention discloses a stage lighting color filter device which comprises a color filter wheel and a lamp body. The color filter wheel is located in front of the lamp body, a color filter strip is arranged around the center of the color filter wheel, one end of the color filter strip close to the center of the color filter wheel serves as an inner end of the color filter strip, the inner end of the color filter strip is protruded towards one side of the lamp body, so that the color filter strip has an angle of inclination relative to the front end face of the lamp body, and the lamp body is opposite to the color filter strip. The stage lighting color filter device can lower temperature of a central zone of the lamp body and prolongs service life of the lamp body.

Owner:PR LIGHTING

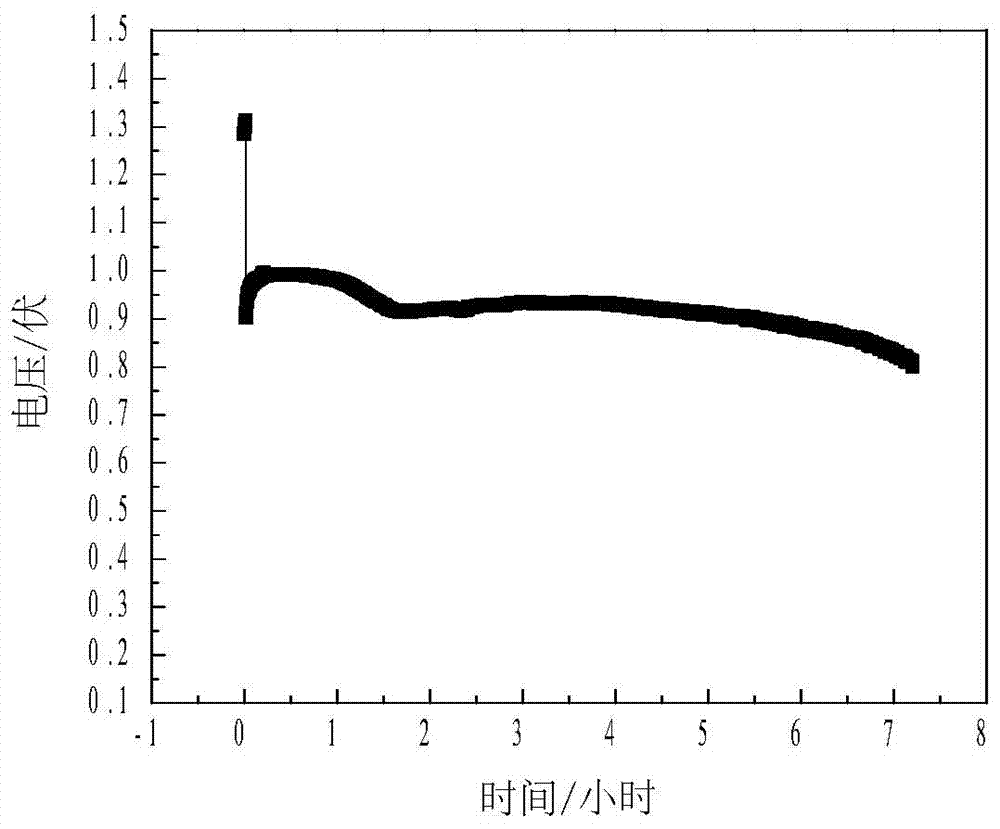

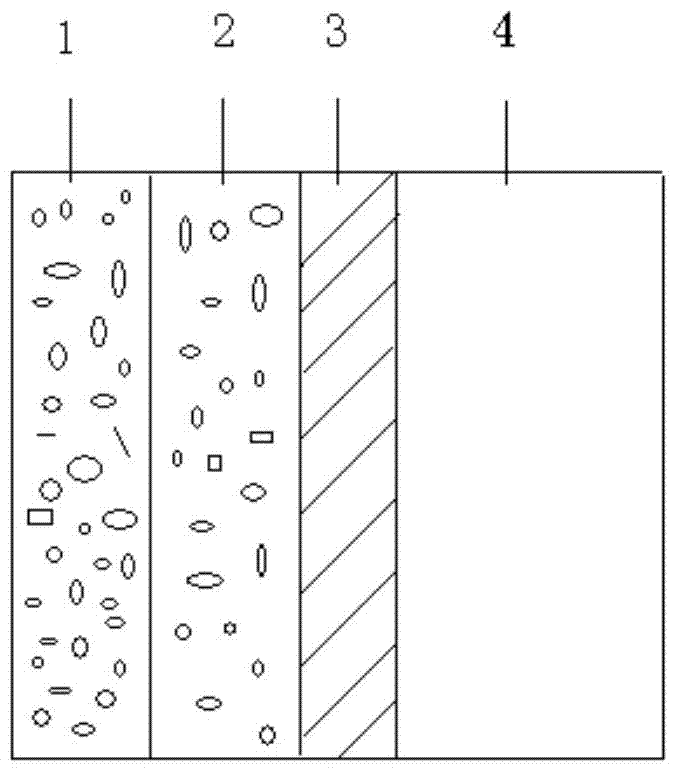

Double hydrophobic layer air cathode used for metal/air battery

An air cathode used for a metal / air battery mainly includes a first hydrophobic breathable layer, a second hydrophobic breathable layer, a collector and a catalyst layer which are sequentially layered and superposed; and the first hydrophobic breathable layer porosity is greater than the second hydrophobic breathable layer porosity. Compared with the prior art, the pore structures of the first hydrophobic breathable layer and the second hydrophobic breathable layer in the air electrode are different, on the one hand, air mass transfer at the air electrode side of the metal / air battery can be facilitated, on the other hand, electrolyte leakage can be effectively prevented, electrolyte water evaporation and moisture entering into the air can be reduced, and the battery stability can be improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

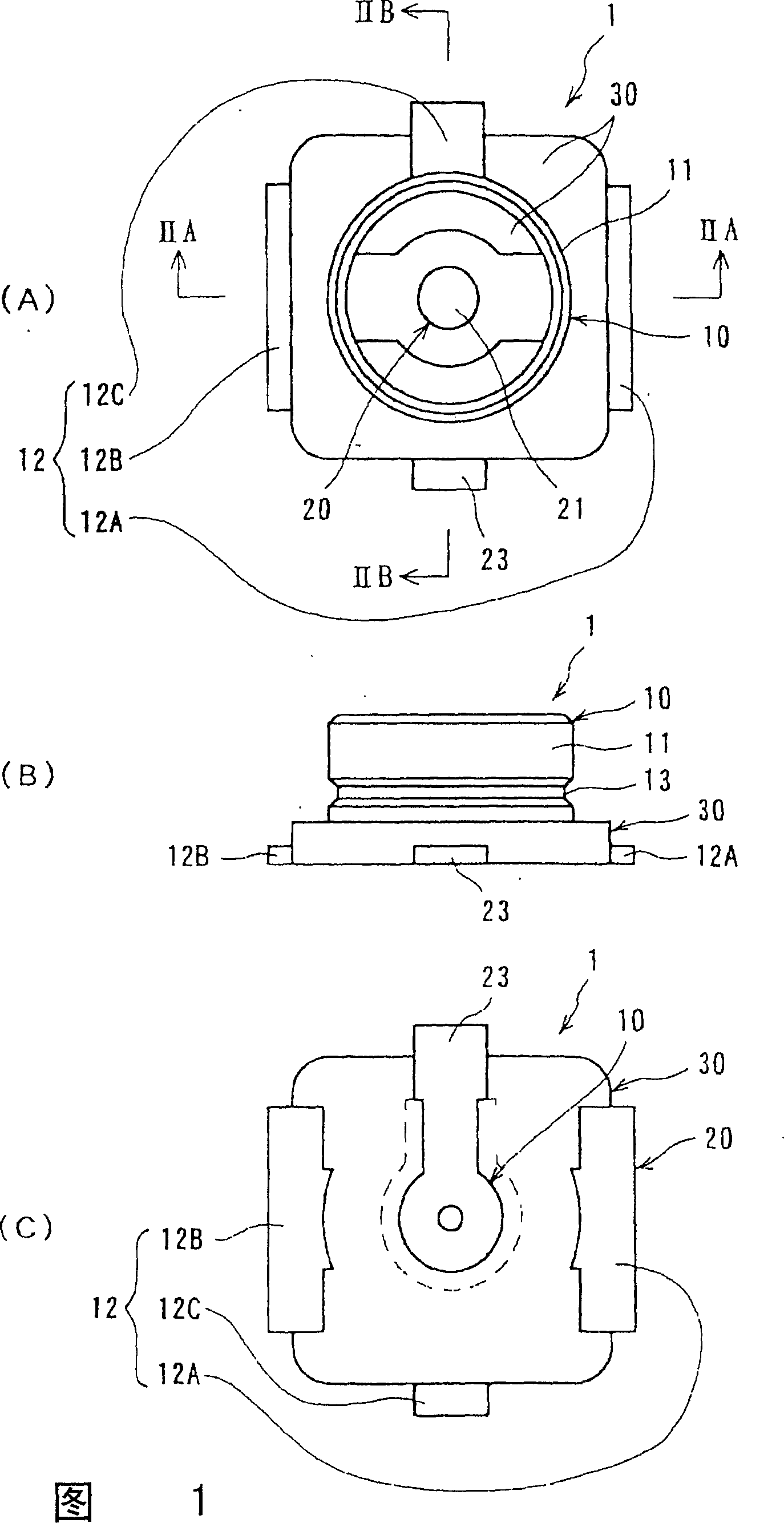

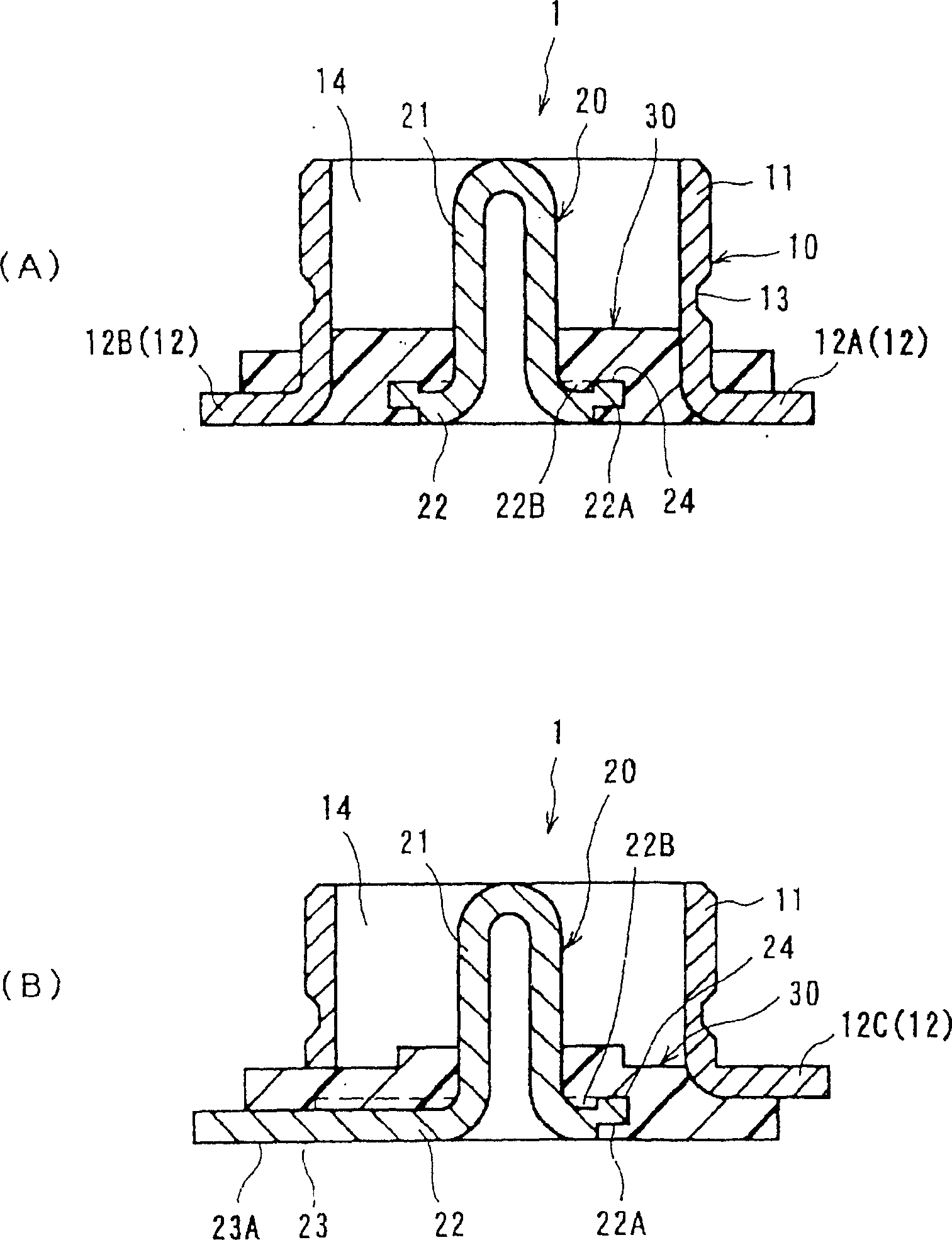

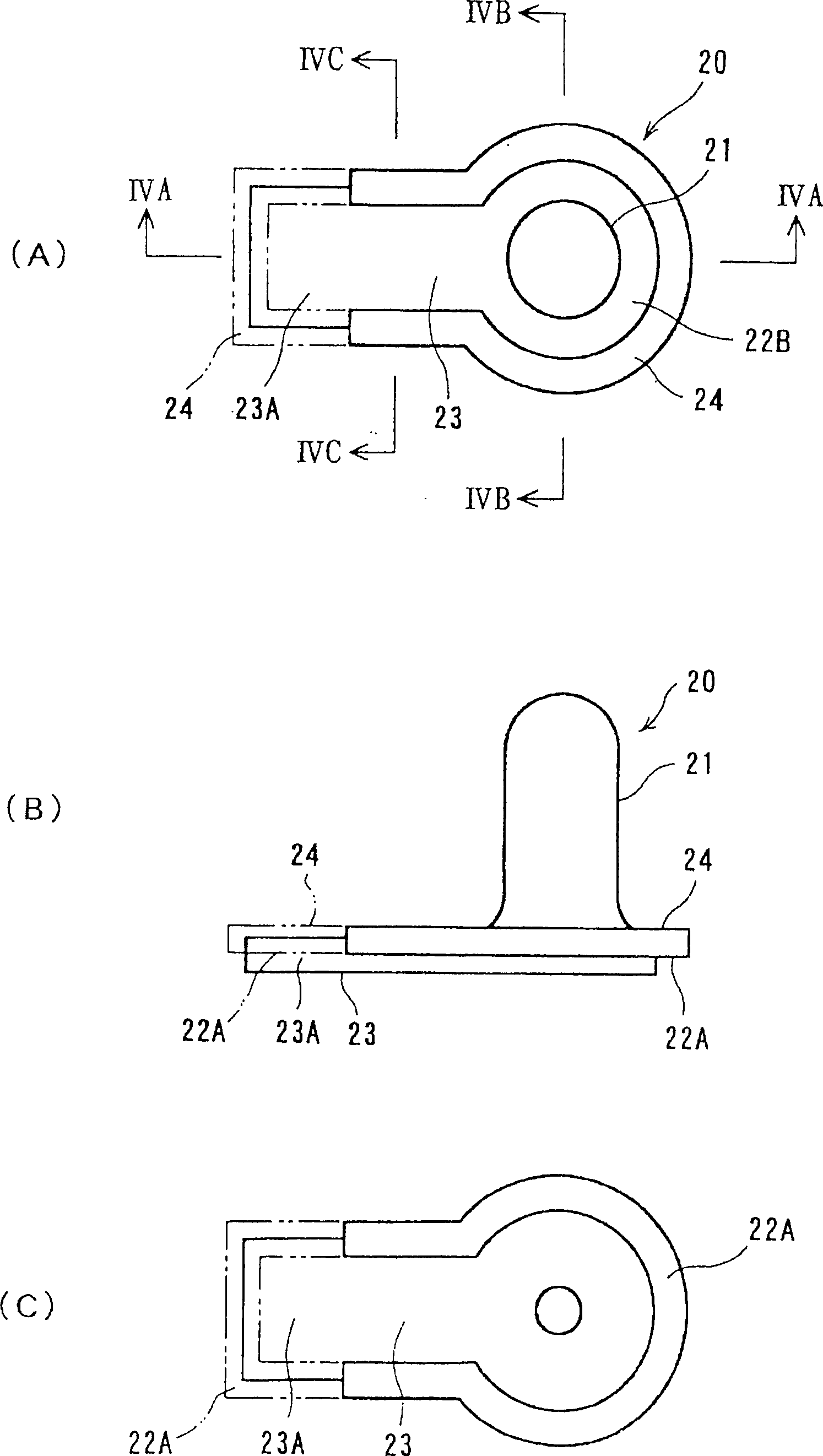

Coaxle electric connector

ActiveCN1512634AImprove retentionImprove engagement forceLine/current collector detailsTwo pole connectionsElectrical conductorEngineering

Owner:HIROSE ELECTRIC GROUP

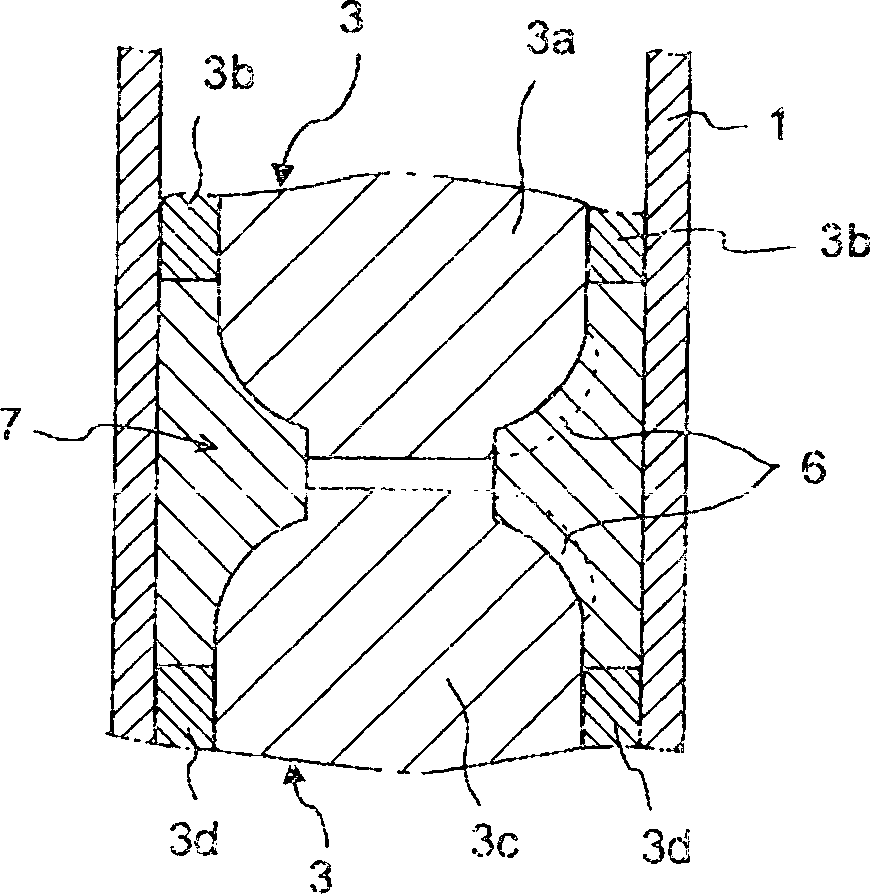

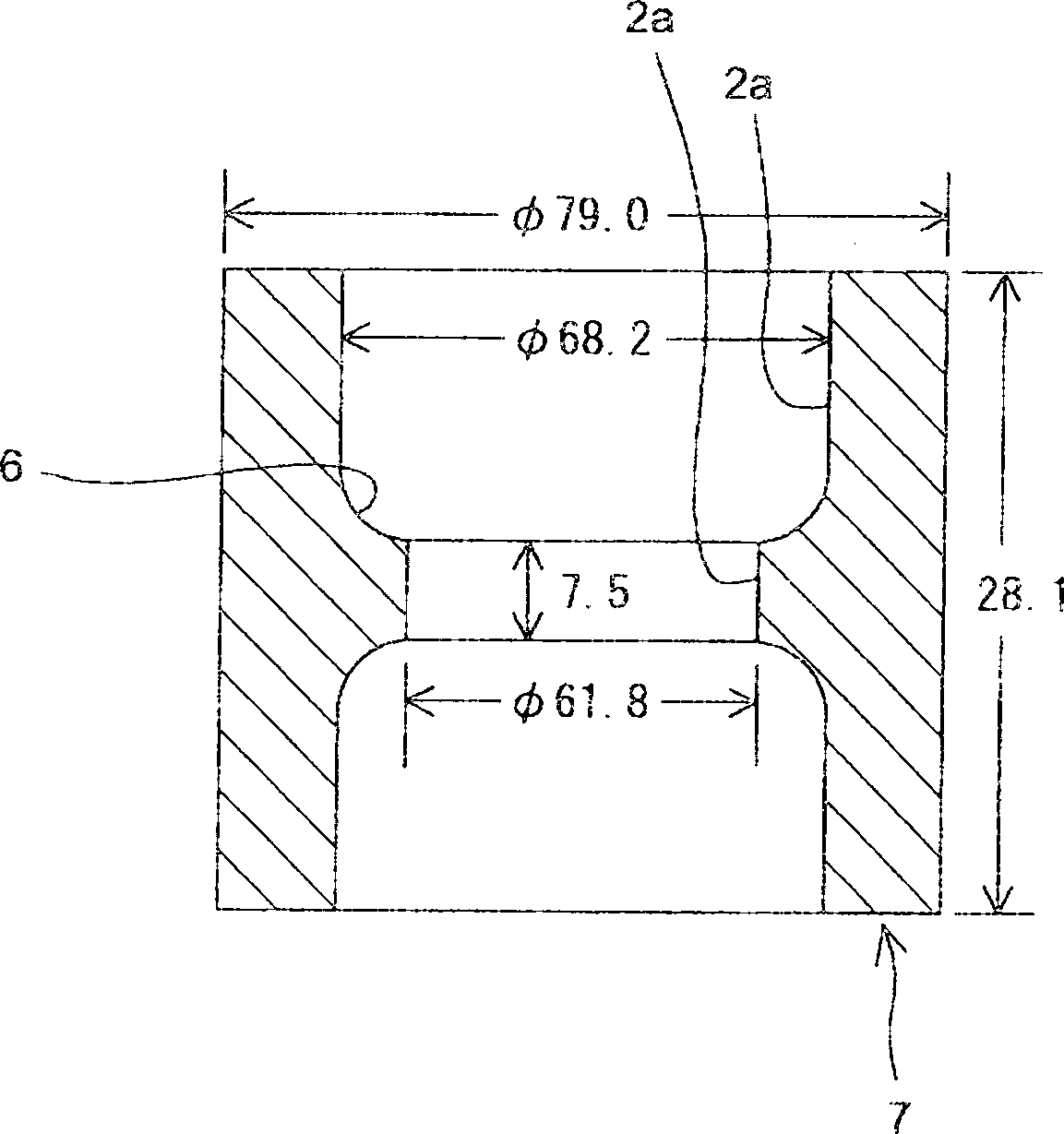

Method for manufacturing mechanical part excellent in rolling fatigue life

ActiveCN102574196AClose or reduce voidsAvoid strippingRolling contact bearingsShaftsNon-metallic inclusionsHydrostatic stress

Provided is a method for manufacturing a mechanical part (7) which has a rolling portion (6) on which a rolling element rolls and which is excellent in rolling fatigue life. An annular blank (2) to form the rolling portion (6) is subjected to cold forging by applying hydrostatic stress onto an inner diameter surface (2a) of the annular blank (2), whereby the rolling portion (6) on which the rolling element rolls is formed on the inner diameter surface (2a) of the annular blank (2) and the inner diameter of the portion of the annular blank (2) other than the rolling portion (6) is increased. Thus, an interface state between non-metallic inclusions contained in the steel material of which the annular blank (2) is made and the steel material, which is the matrix phase, is improved, and the annular mechanical part (7) having on the inner diameter portion the rolling portion (6) which is excellent in rolling fatigue life is manufactured.

Owner:SANYO SPECIAL STEEL COMPANY

Electrode sheet and electrochemical device and electronic equipment comprising same

PendingCN112151753AAvoid strippingImproved shape stabilityNegative electrodesNon-aqueous electrolyte accumulator electrodesPhysicsElectrically conductive

The invention relates to the technical field of energy storage, particularly to an electrode sheet, and an electrochemical device and electronic equipment comprising the same. The electrode sheet provided by the invention comprises a current collector and a diaphragm, wherein the diaphragm comprises a bottom coating arranged on the surface of the current collector and an active substance layer arranged on the surface of the bottom coating, the bottom coating comprises a first binder and a first conductive agent, and the binding power of the diaphragm and the current collector is greater than or equal to 20 N / m. According to the invention, the problem that in the prior art, due to the fact that the bonding force of the active material part close to the surface of the current collector is low, the electrode sheet is prone to stripping can be solved.

Owner:NINGDE AMPEREX TECH

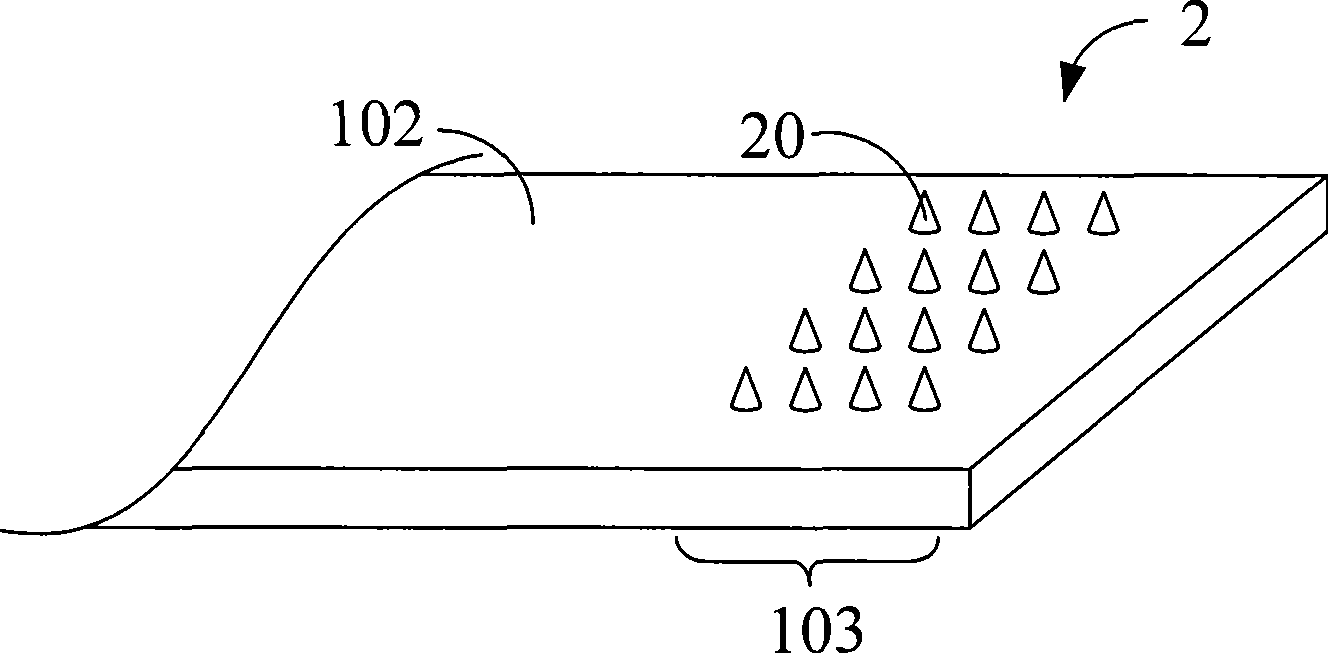

Battery electrode, preparation method thereof and battery

ActiveCN102054979ALower internal resistanceImprove rate charge and discharge performanceElectrode carriers/collectorsLi-accumulatorsMicro nanoPower flow

The invention provides a battery electrode, a preparation method thereof, and a battery. The battery electrode comprises a current collector and an active substance layer coated on the current collector; a micro-nano particle layer is adhered to the surface of the active substance layer; the active substance layer comprises electrode active substance and electrode binder; the micro-nano particle layer comprises micro-nano dry powder particles; and the micro-nano dry powder particles comprise dry powder particles of the micro-nano electrode active substance. Interface impedance between the electrode and electrolyte is reduced and rate discharge performance of the battery is improved; a micro-nano active material reduces serious volume effect of the material; and specifically, the micro-nano particle layer may not comprise the binder preferably, so that the large-current discharge characteristic of the battery is improved further. The method is simple and is easy to implement; and the combinability between the micro-nano particle layer and the active substance layer is high, and the surface of the active substance layer is not polluted by the substances of an upper layer.

Owner:SHANGHAI BYD

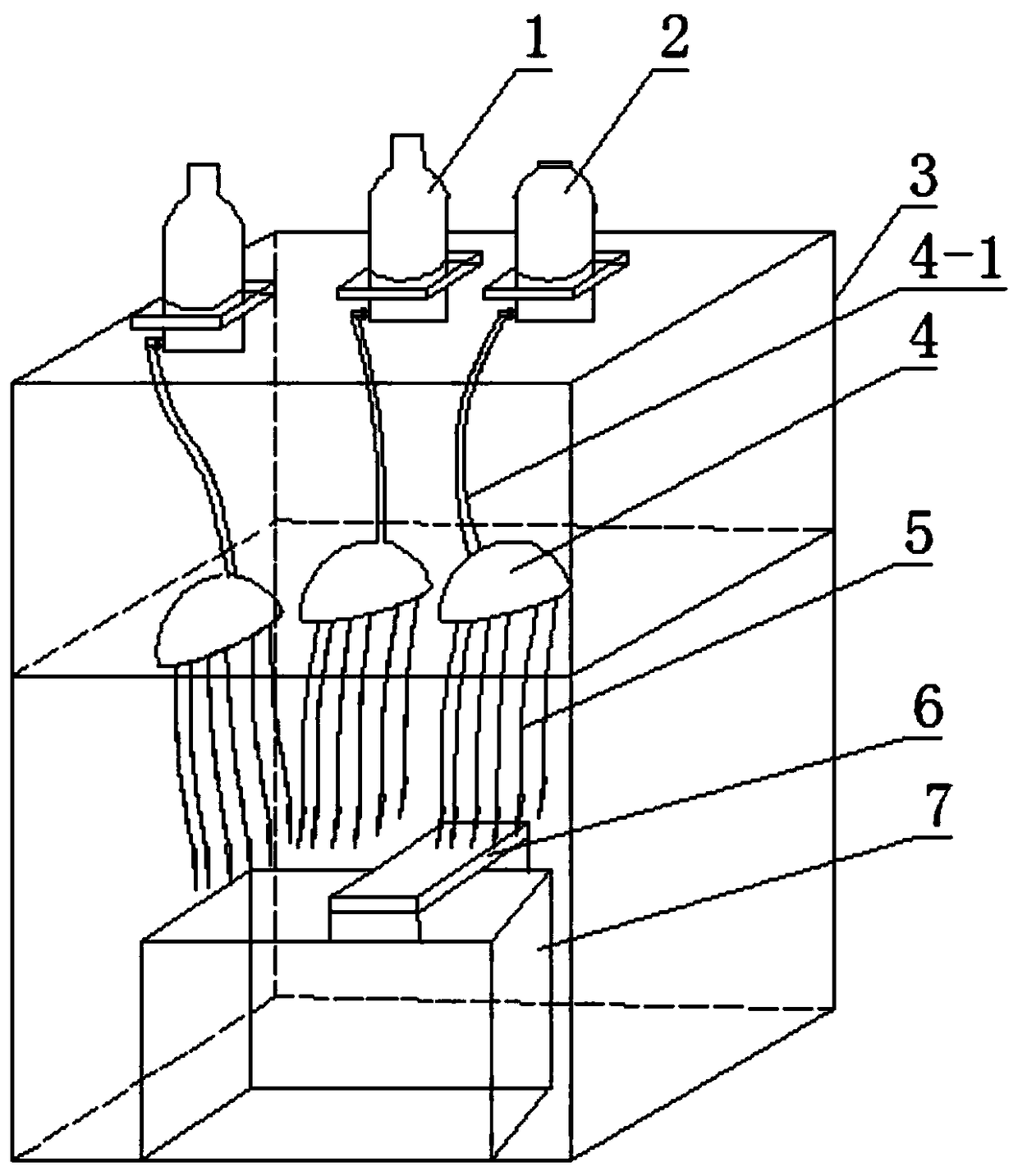

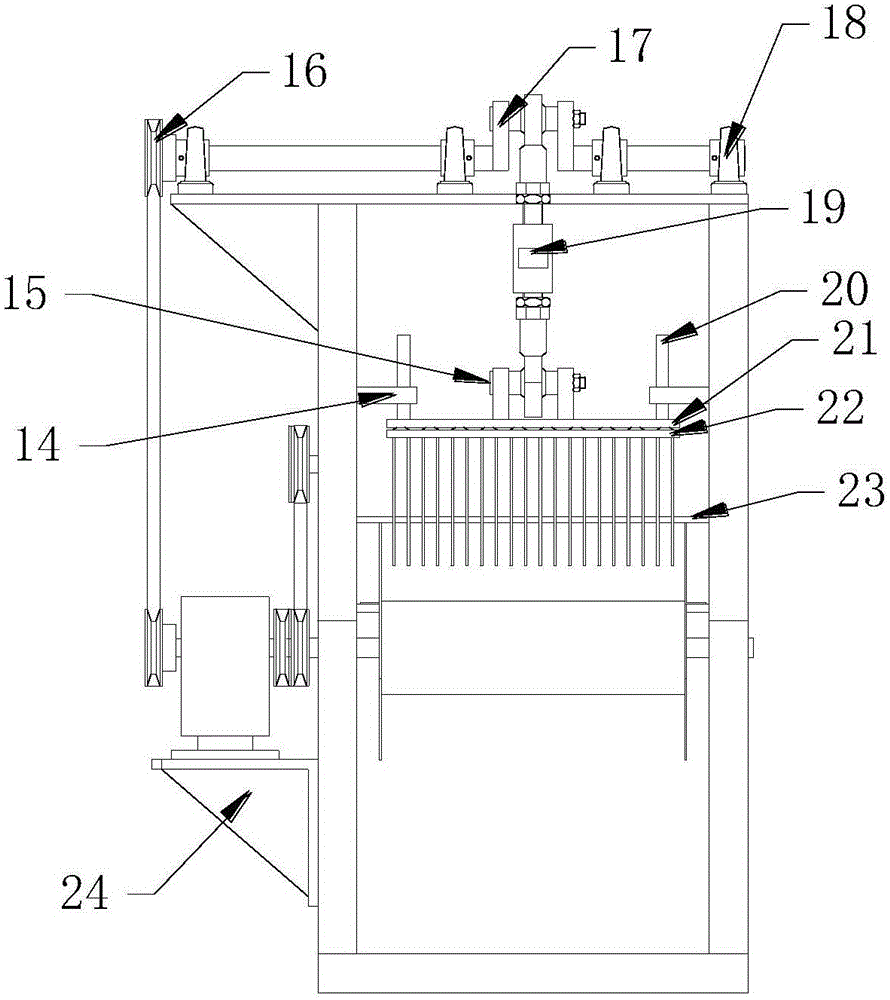

HE dyeing device suitable for batch dyeing of various tissues

PendingCN109283033ASave operating timeEasy to operatePreparing sample for investigationDyeingDrainage tubes

The invention relates to an HE dyeing device suitable for batch dyeing of various tissues. The HE dyeing device comprises a stainless steel multilayer supporting frame, a light-proof liquid storage bottle, a washing liquid storage bottle, a circular porous flow splitting disk, a dropping liquid conduit, a supporting bottom box and a rotatable angle objective table. According to the HE dyeing device provided by the invention, the circular porous flow splitting disk is arranged at a liquid flow conduit, which is similar to a shower head sprinkler type structure, a plurality of drainage tubes areadded, switches are arranged on the drainage tubes, and the number of the switches can be appropriately adjusted according to the experimental needs, and batch dyeing can be simultaneously performedto shorten the operation time; and the rotatable angle objective table is installed in a pulley, the location and angle can be adjusted by a handle, a glass slide neck and liquid waste drainage channel are arranged on the objective table, so that glass slides can be well fixed, and the problem of mutual contamination between the glass slides is solved.

Owner:TIANJIN KANGTING BIOLOGICAL ENG GRP CO LTD

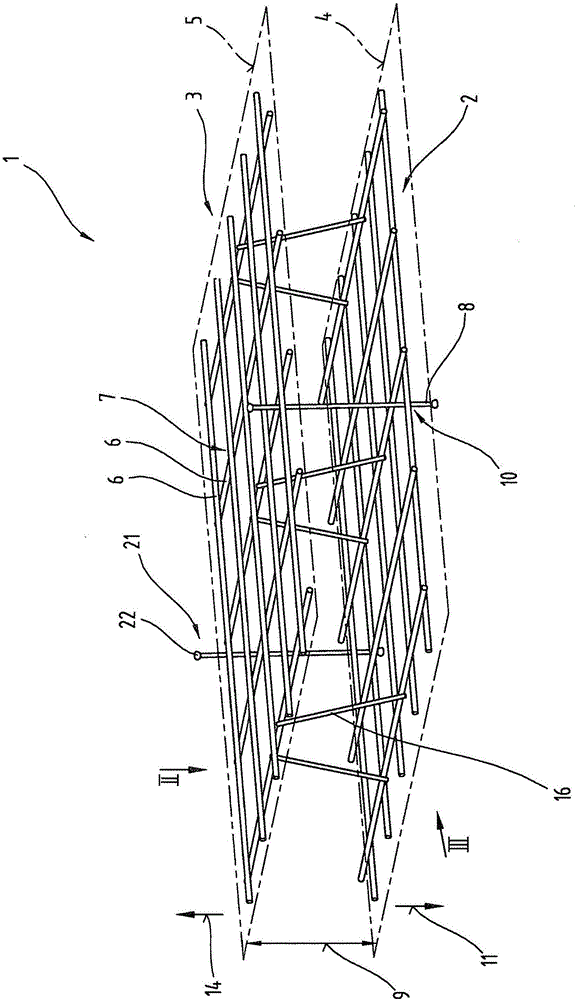

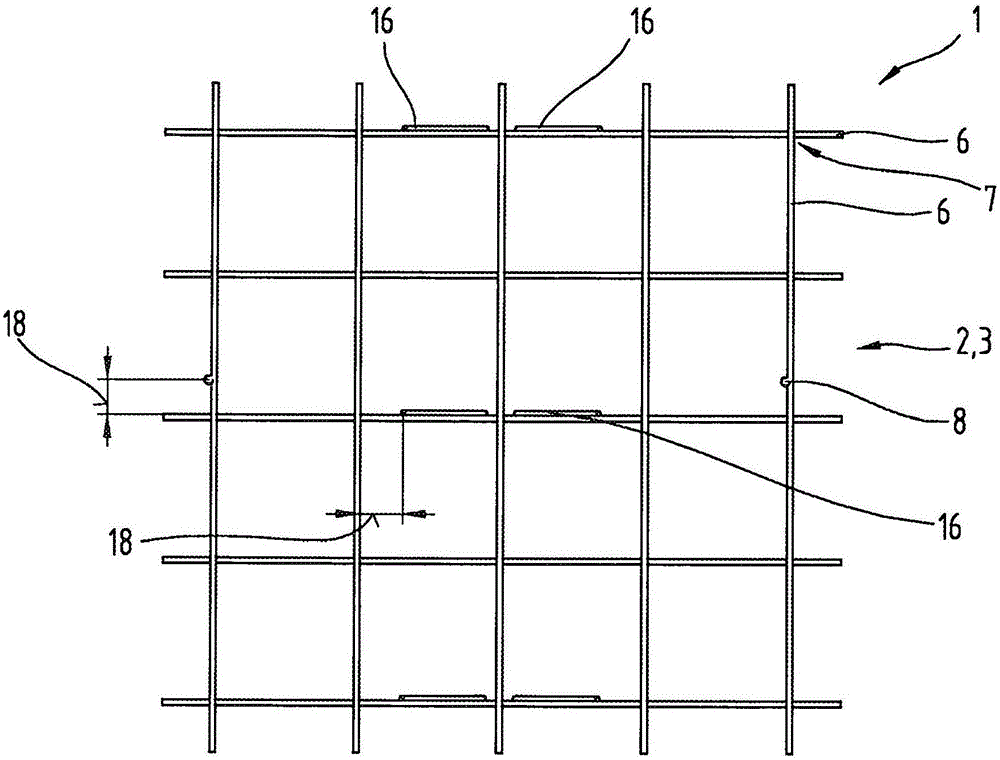

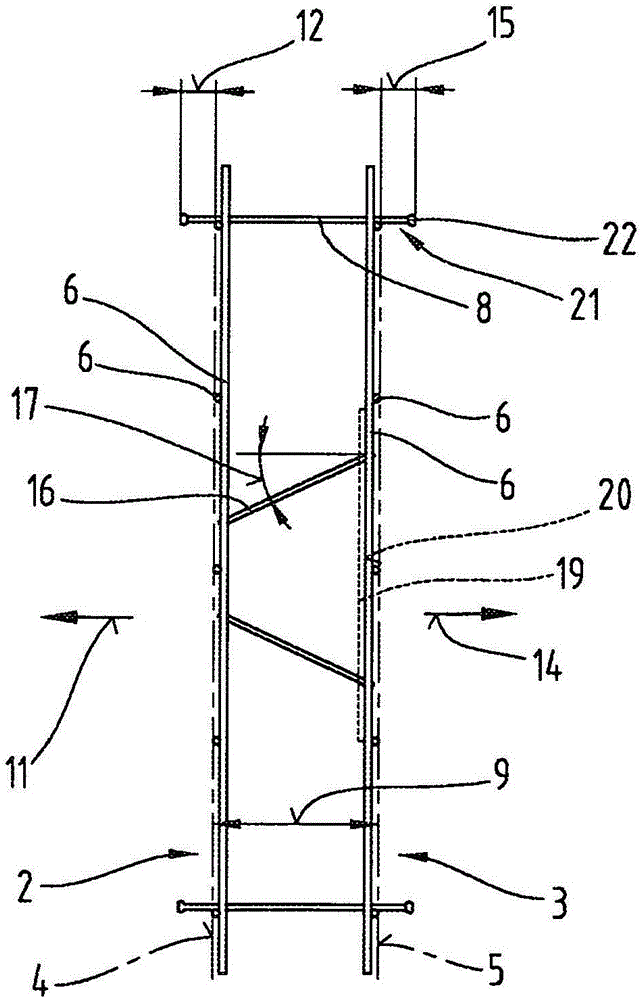

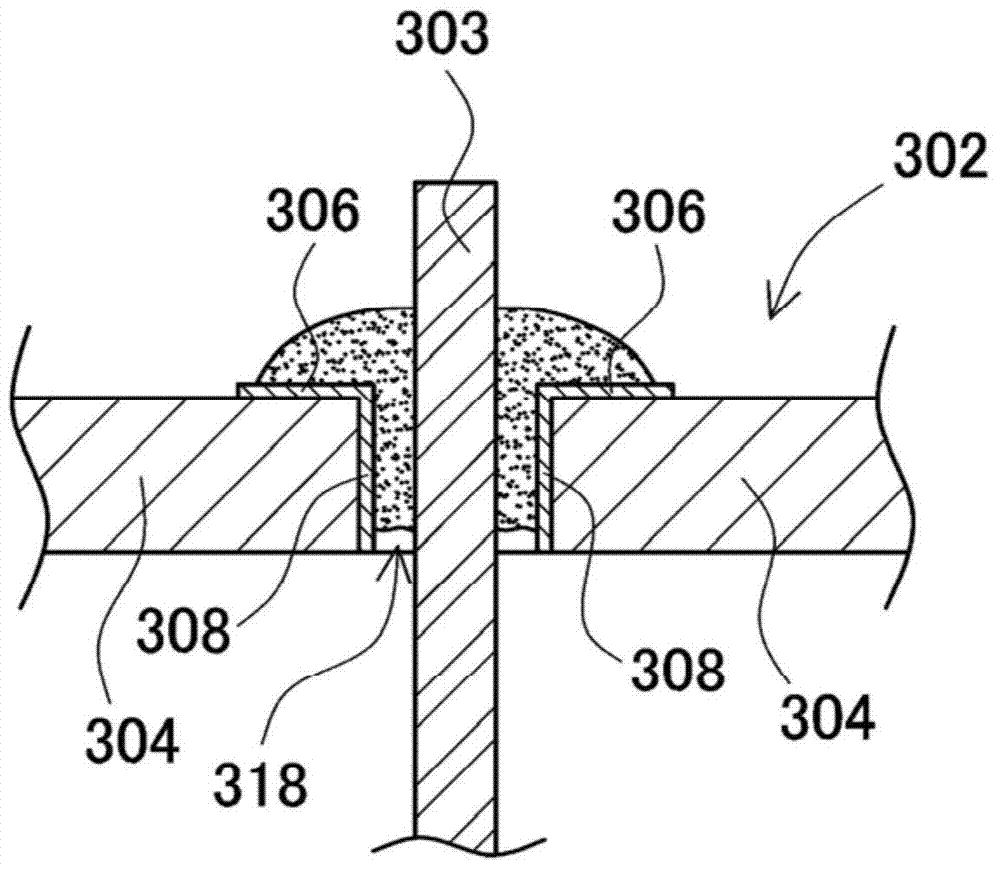

Reinforcing element and method for producing a reinforcing element

InactiveCN106794596AReduce weightEasy to manufactureConstruction materialWallsElectrical resistance and conductanceDouble wall

The invention relates to a reinforcing element (1), comprising a first reinforcing mat (2) and a second reinforcing mat (3) having metal mat rods (6), which are welded at angles to each other at junction points (7), which reinforcing mats (2, 3) are held spaced apart from each other at a normal distance (9) by rod-shaped spacers (8) with respect to the first mat plane (4) and the second mat plane (5) of the reinforcing mats. The spacers (8) are metal and are permanently connected to individual mat rods (6) of the first reinforcing mat (2) and of the second reinforcing mat (3) by welding connections (10), preferably resistance welding connections, wherein at least individual spacers (8) protrude outward at least beyond the first mat plane (4) of the first reinforcing mat (2) in a direction (11) pointing away from the second reinforcing mat (3) by a first protrusion length. The invention further relates to a double wall equipped with the reinforcing element and to methods for producing the reinforcing element and the double wall.

Owner:胡贝特拉佩斯托费尔

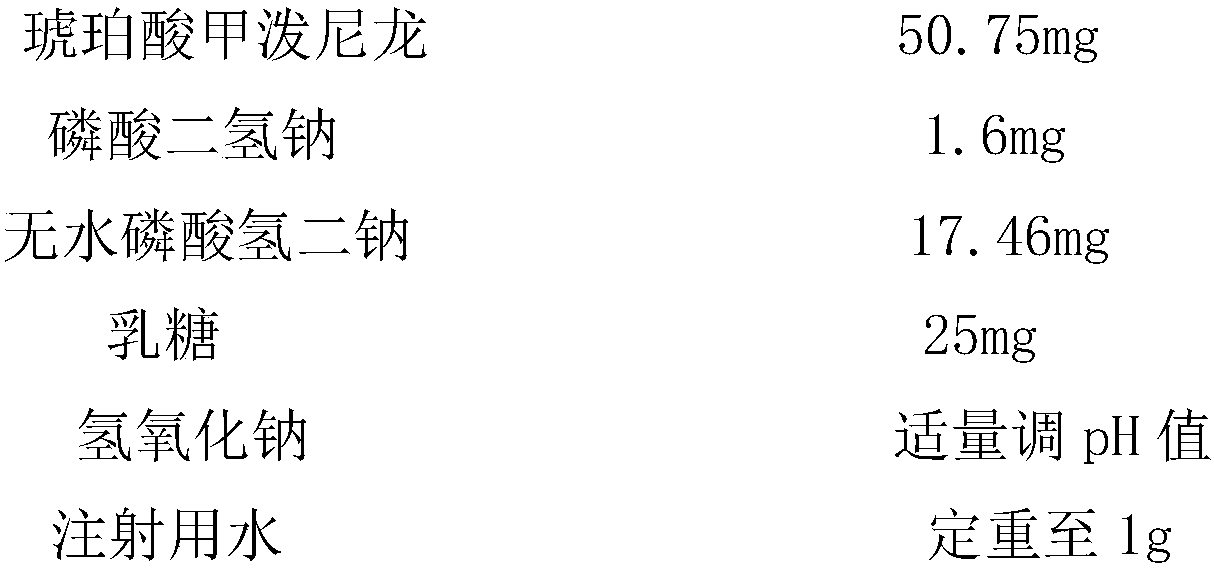

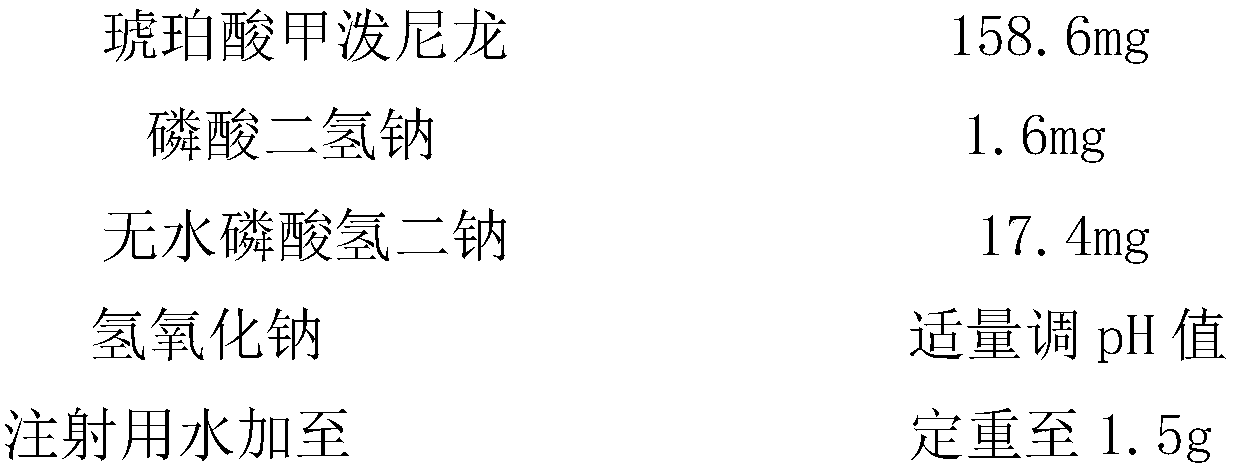

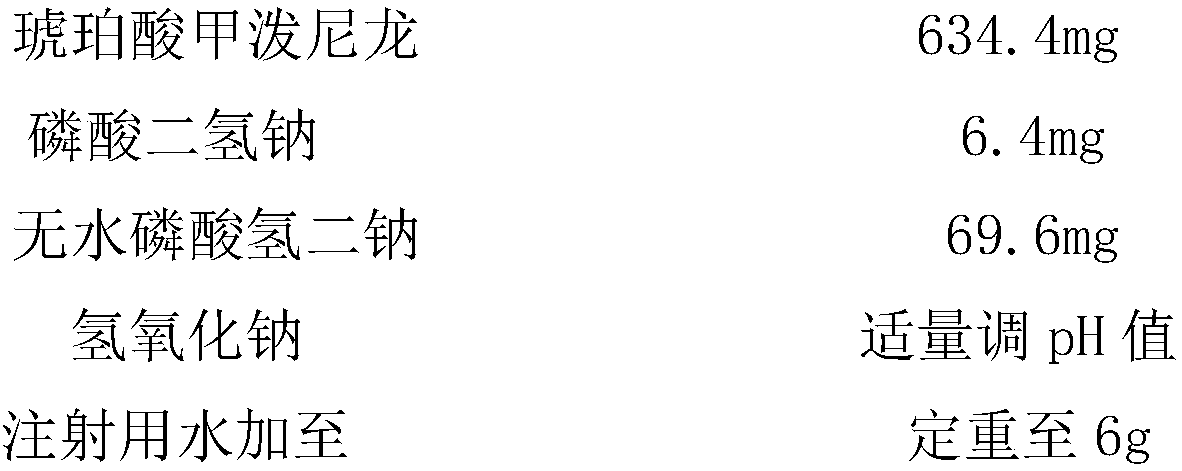

Methylprednisolone sodium succinate for injection

ActiveCN108498468AAvoid strippingGuarantee product qualityOrganic active ingredientsPowder deliveryHydrogen phosphatePhosphoric acid

The invention discloses methylprednisolone sodium succinate for injection. The specification of methylprednisolone sodium succinate for injection is 40 mg, and methylprednisolone sodium succinate forinjection is prepared from 50.75 mg of methylprednisolone hemisuccinate, 1.6 mg of sodium dihydrogen phosphate, 17.46 mg of anhydrous sodium hydrogen phosphate and 25 mg of lactose, the pH value is adjusted with a proper amount of sodium hydroxide, and the weight is metered to 1 g by adding water for injection. When the specification of methylprednisolone sodium succinate for injection is 125 mg,methylprednisolone sodium succinate for injection is prepared from 158.6 mg of methylprednisolone hemisuccinate, 1.6 mg of sodium dihydrogen phosphate and 17.4 mg of anhydrous sodium hydrogen phosphate, the pH value is adjusted with a proper amount of sodium hydroxide, and the weight is metered to 1.5 g by adding water for injection. Methylprednisolone sodium succinate for injection has the advantages of being high in stability and fewer in individual impurity and total impurity.

Owner:HUBEI RENMIN PHARMACEUTICAL CO LTD

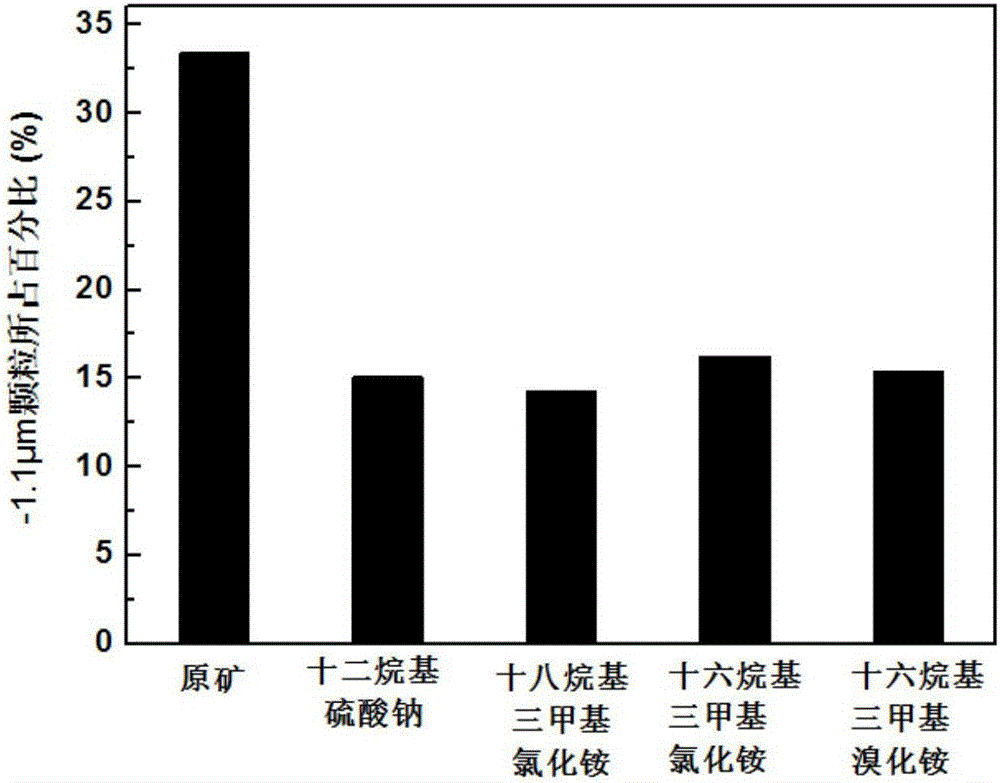

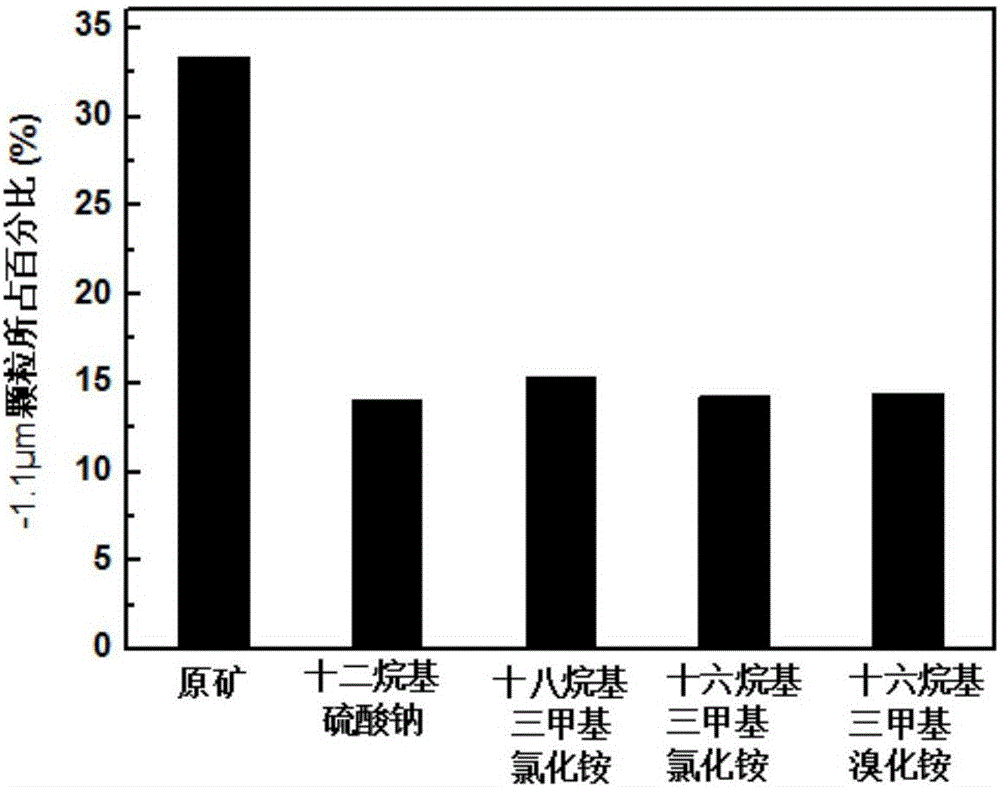

Method for preventing montmorillonite from stripping in aqueous solution

InactiveCN106145442AAvoid strippingReduce fine particle contentWaste water treatment from quariesWater treatment compoundsMontmorilloniteSlurry

The invention relates to a method for preventing montmorillonite from stripping in an aqueous solution. The method comprises the following steps: firstly dissolving an agent into water to make an agent solution, wherein the agent concentration of the agent solution is 40-80 g / L; then mixing a montmorillonite mineral with the agent solution, wherein the mass ratio of the montmorillonite mineral to the agent solution is (50-100):1; putting the mixture into an ore grinding machine, and mixing at the rotating speed of 100-200rev / min for 50-70 minutes, wherein the agent is lauryl sodium sulfate, octadecyl trimethyl ammonium chloride, cetyl trimethyl ammonium chloride, or cetyl trimethyl ammonium bromide. The method is used to fulfill the purpose of preventing montmorillonite mineral from stripping in water, and prevents the montmorillonite mineral from forming a fine particle in the aqueous solution, the carrying of slurry in the floatation of the montmorillonite mineral is reduced, meanwhile, the efficiency of solid-liquid separation in treatment of tail water of an ore treatment plant is also improved.

Owner:WUHAN UNIV OF TECH

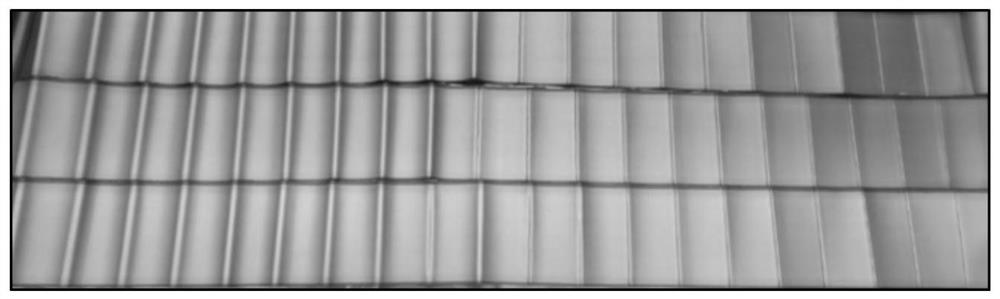

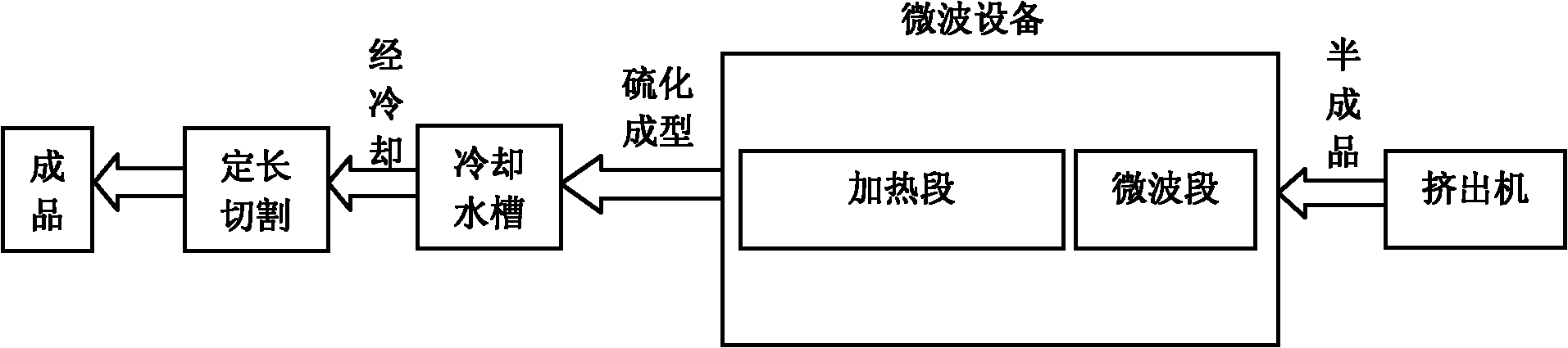

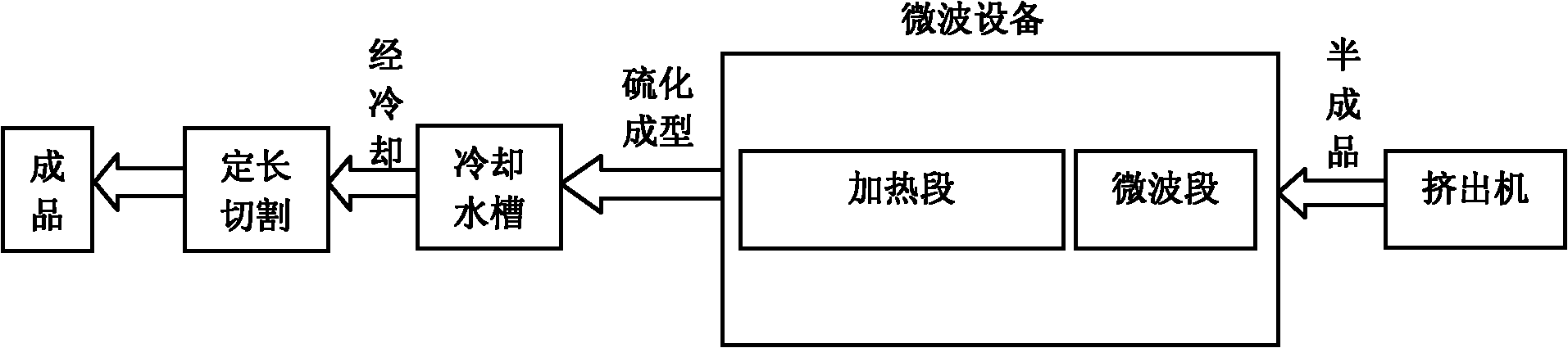

Rubber lantern ring produced by micro wave curing process

The invention relates to a rubber lantern ring produced by a micro wave curing process. The process comprises the following steps of: extruding mixing rubber by an extruder, wherein the temperature setting of the extruder is that: the temperature of an extruder head is between 60 and 80 DEG C, the temperature of an extruding section is between 55 and 75 DEG C, and the temperature of a plasticizing section and a feeding section is less than 45 DEG C; introducing the extruded semi-finished product into micro wave curing equipment directly for curing, wherein the micro wave curing equipment has five micro wave bands, namely two micro wave bands before closing a micro wave device and 3 micro wave bands after opening the micro wave device, the total power of micro waves is kept between 3,000 and 6,000 W, the temperature of the micro wave bands is set to be 150 DEG C, and the temperature of a heating band is set to be between 170 and 190 DEG C, 190 and 210 DEG C and 210 and 230 DEG C respectively from front to back; and after cooling, cutting according to the size requirement of the product. The inside and outside of the product are heated simultaneously under the action of the micro waves and reach preset curing temperature quickly, so the curing efficiency is improved greatly. In addition, micro wave curing belongs to a continuous curing process, so links of placing, core rod sleeving, stripping cleaning and the like can be saved in the production process.

Owner:TIANJIN PENGYI GRP CO LTD

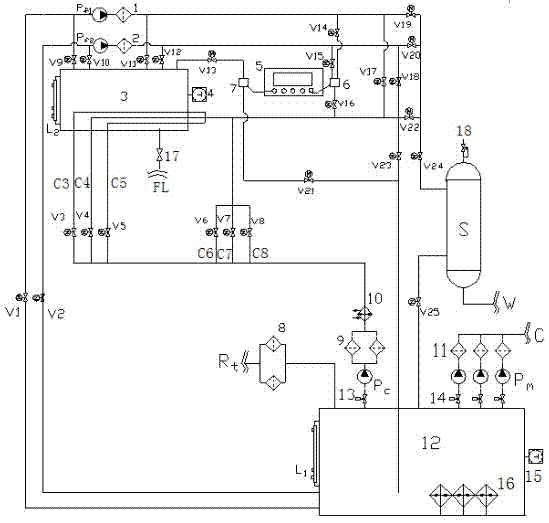

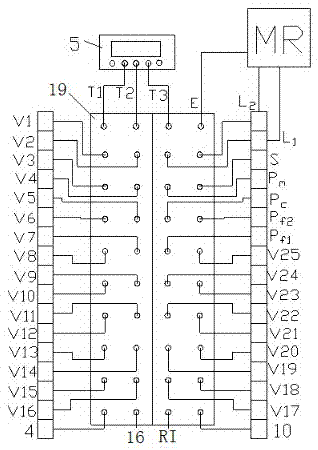

Pre-flushing refined filtration oil filling circuit device

ActiveCN106958558AAvoid abnormal wearAvoid stuck faultsFluid-pressure actuator componentsFiltrationFuel tank

The invention relates to a pre-flushing refined filtration oil filling circuit device. The pre-flushing refined filtration oil filling circuit device is characterized by comprising a first refined filter, a second refined filter, a pre-flushing oil tank, a temperature controller, a main system oil return filter set, a main oil tank circulating filter, a main oil tank, an oil-water-gas separator, a main system circulating pump, a first high-flow flushing pump set, a second high-flow flushing pump set, a circulating pump and a main control cabinet. The main control cabinet is used for conducting logic control over elements including an electric control valve. The pre-flushing oil tank temperature controller is installed on the pre-flushing oil tank to detect and control the temperature of the pre-flushing oil tank. A main oil tank oil return filter is connected to the main oil tank and used for filtering return oil of a main system. The main system circulating pump and the circulating filter are connected to the main oil tank and used for conducting continuous circulating filtering on oil in the main system oil tank. The oil-water-gas separator is connected with the pre-flushing oil tank and the main oil tank through the electric control valve.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

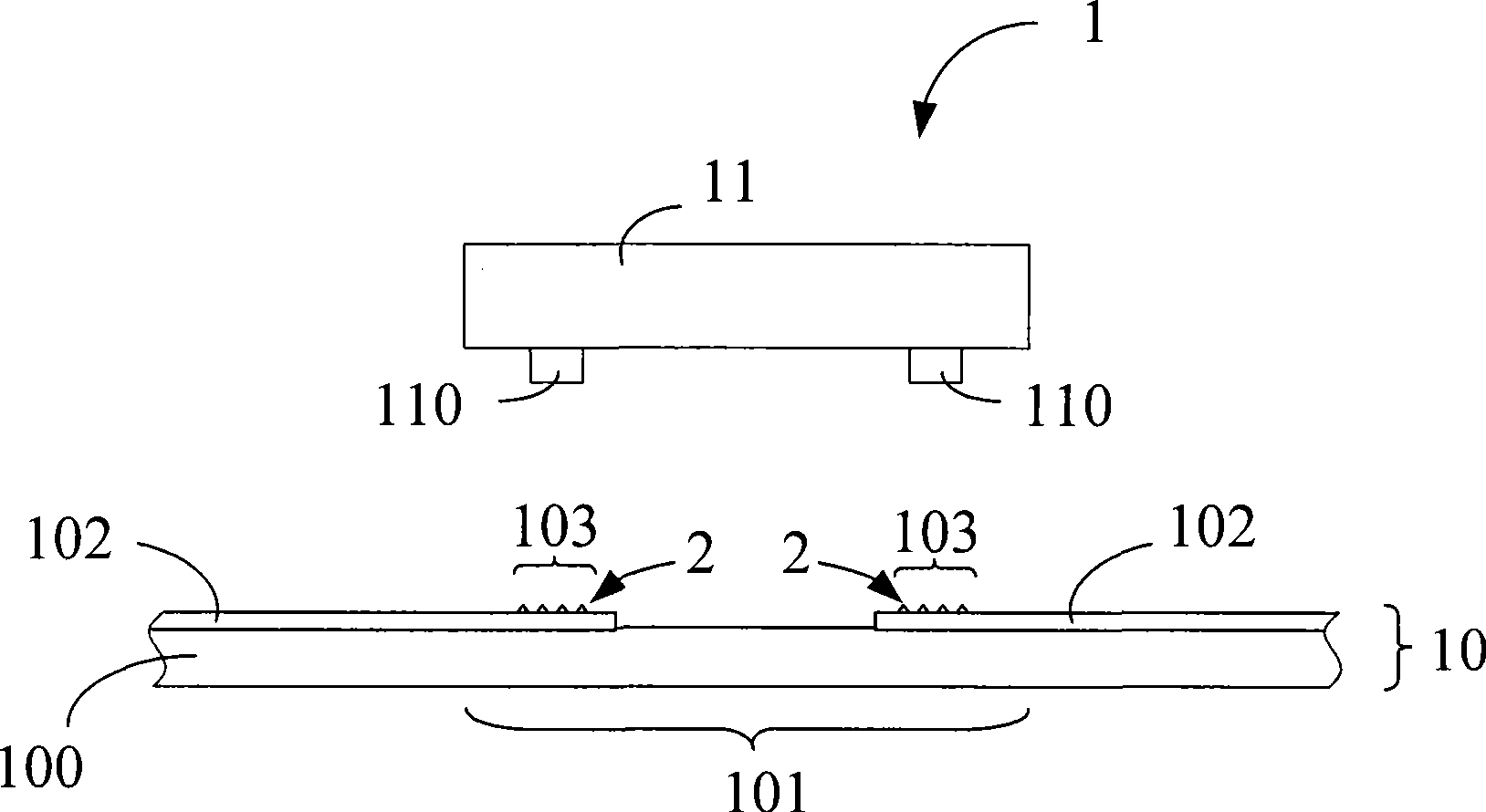

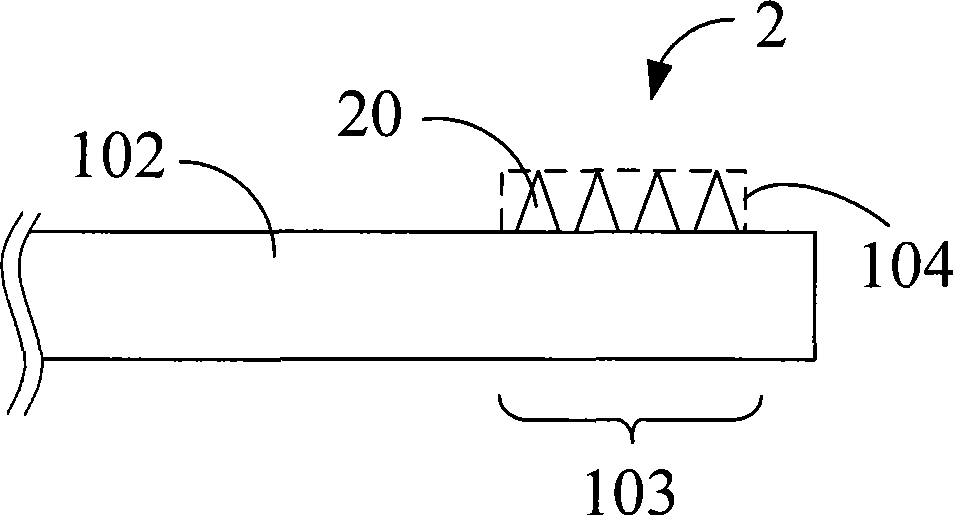

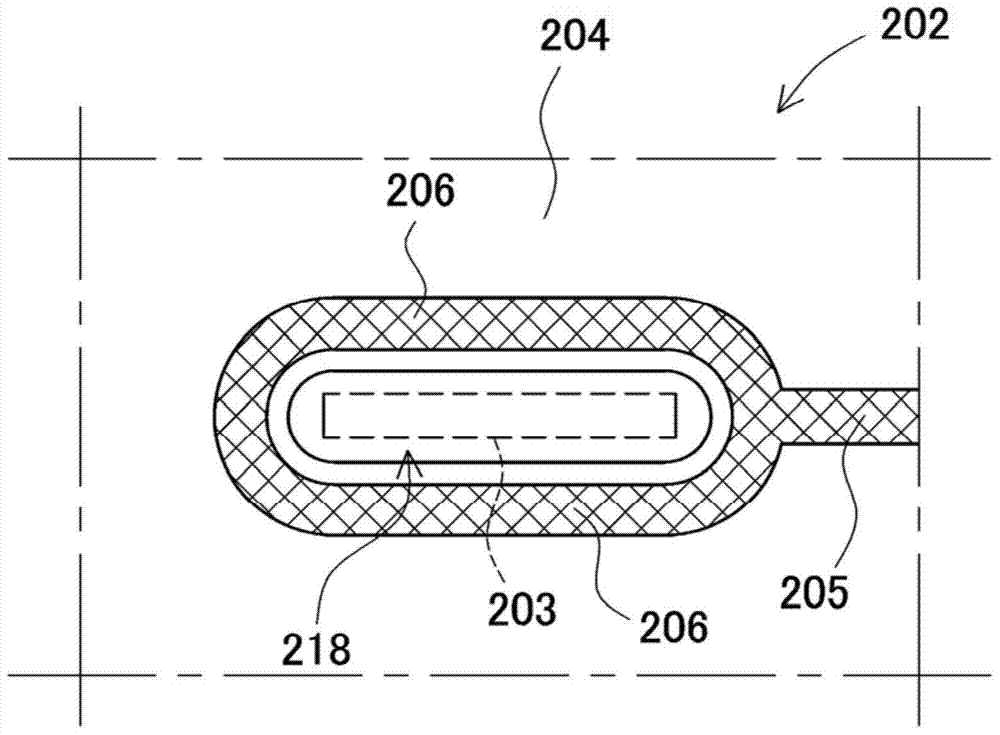

Chip encapsulation substrate assembly and chip encapsulation construct

InactiveCN101414596AAvoid strippingIncrease contact areaSemiconductor/solid-state device detailsSolid-state devicesEngineeringDielectric layer

The invention relates to a chip packaging substrate assembly for a chip packaging structure and the chip packaging structure containing the chip packaging substrate assembly, and the chip packaging substrate assembly comprises a flexible dielectric layer and a plurality of pins and chips. A chip bonding area is defined on the flexible dielectric layer; a plurality of pins are formed on the flexible dielectric layer, the inner ends of the various pins are further extended into the chip bonding area, acute raised structures are formed on the various inner ends; each chip is provided with a plurality of bumps, when in para-position combination of the chips and the chip bonding area, the acute raised structures can be correspondingly embedded in a plurality of bumps.

Owner:CHIPMOS TECH INC

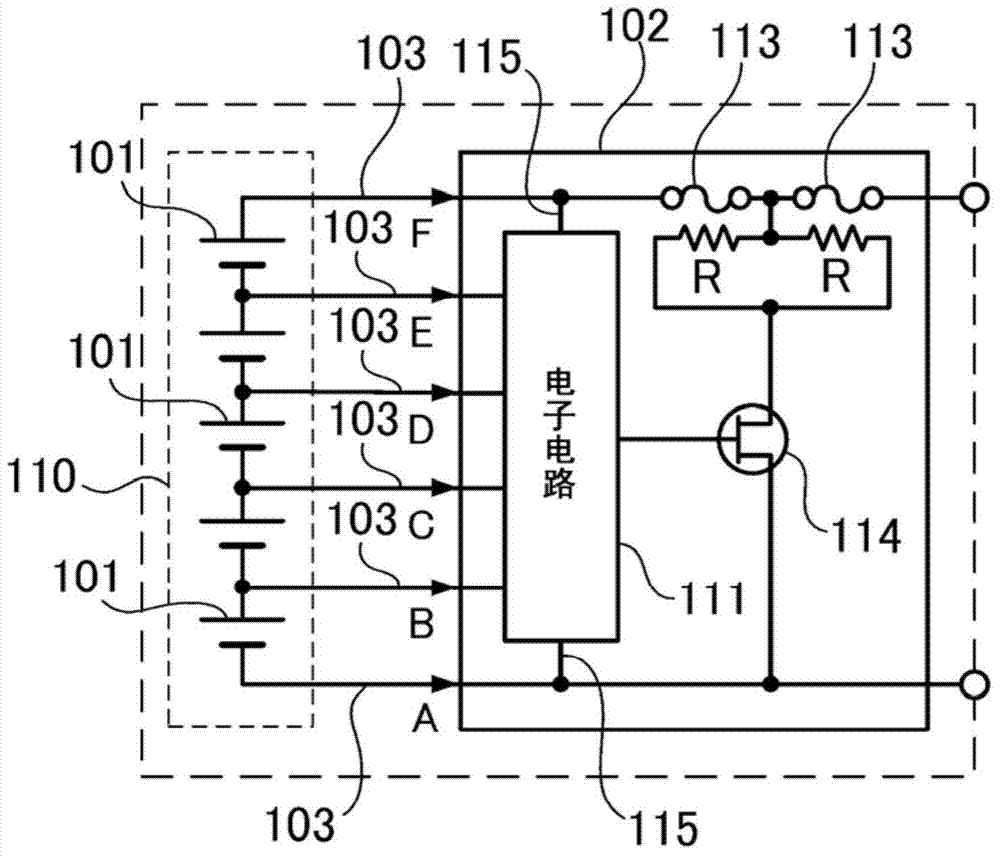

Battery pack

The present invention is provided with the object of having guide wires connected ideally with the connection plate of an electric circuit substrate in a welding order. Therefore, the battery pack of the invention is provided with plural battery electrode terminals that are connected in series and are connected to an electric circuit substrate throguh guide wires. The electric circuit substrate is provided with plural connection plates on an insulation substrate and are connected with the electric circuit. At least one of the connection plates is provided with a first connection plate portion connected with the electric circuit and a severing connection plate structred by a second connection plate portion. The severing connection plate makes the first connection plate portion and the second connection plate portion disposed on the surface of the insulation substrate in an un-connected manner and there is a fiber-welding gap. The electric circuit substrate is provided with a throughhold connecting with the second connection plate portion; when the through hole is inserted to the second connection plate portion throguh a guide wire in a welding manner, the fiber welding materials enable the first connection plate portion and the second connection plate portion to be mutually connected.

Owner:PANASONIC ENERGY CO LTD MORIGUCHI SHI

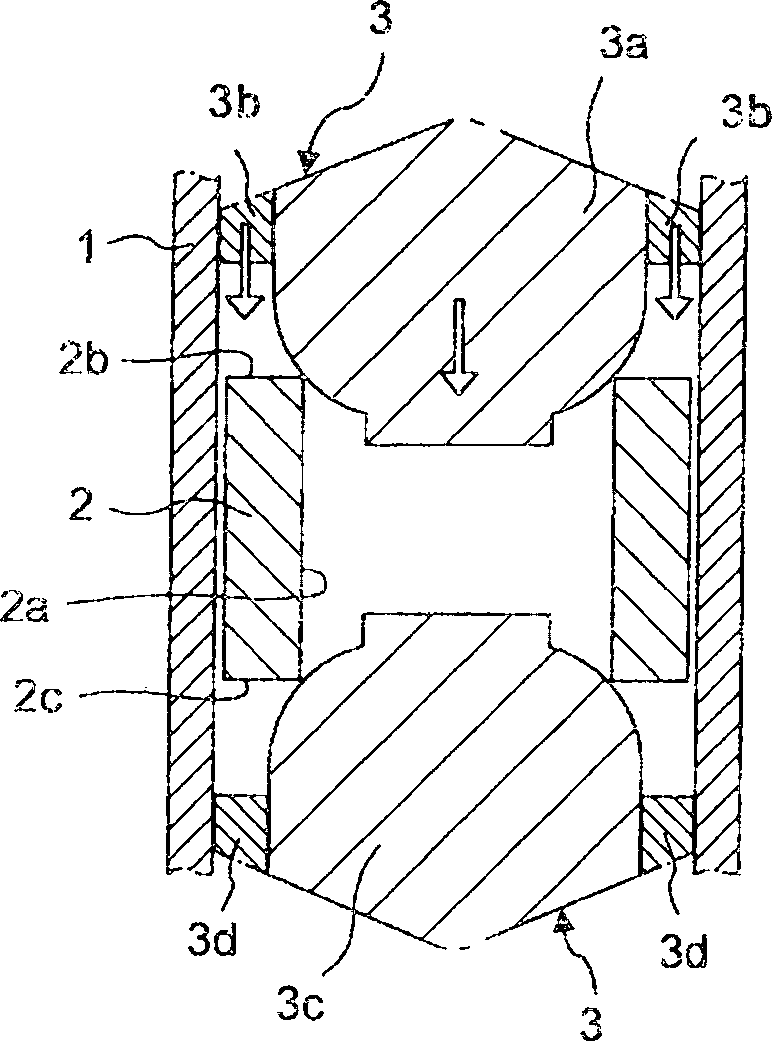

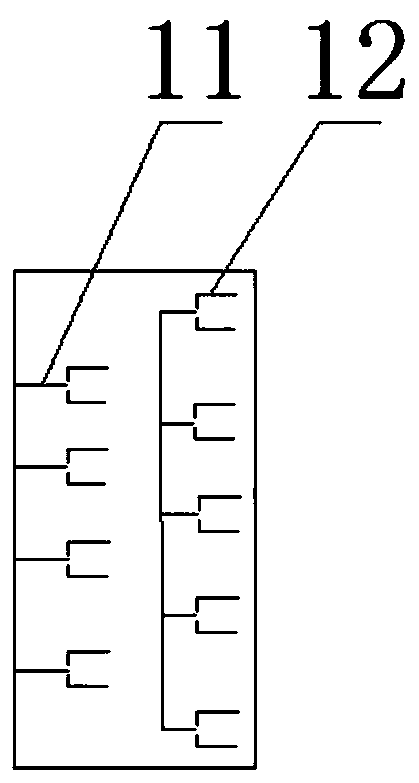

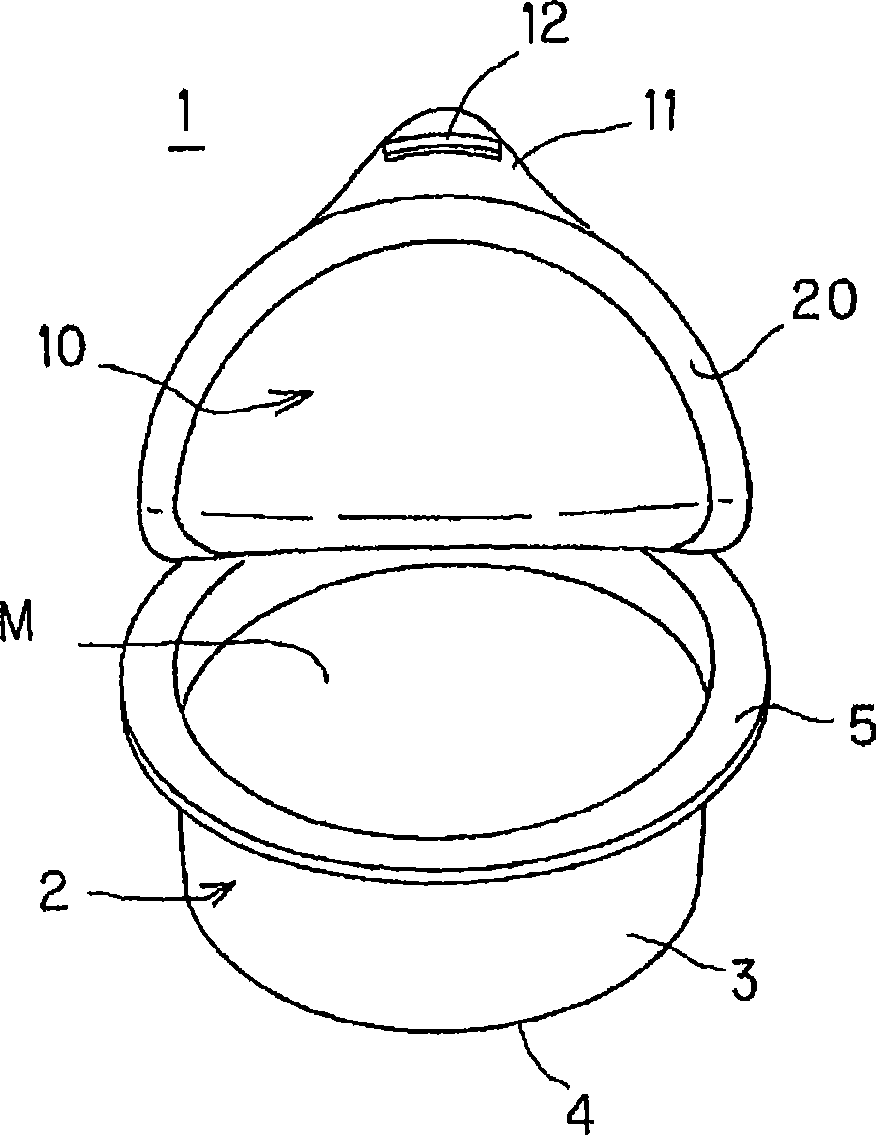

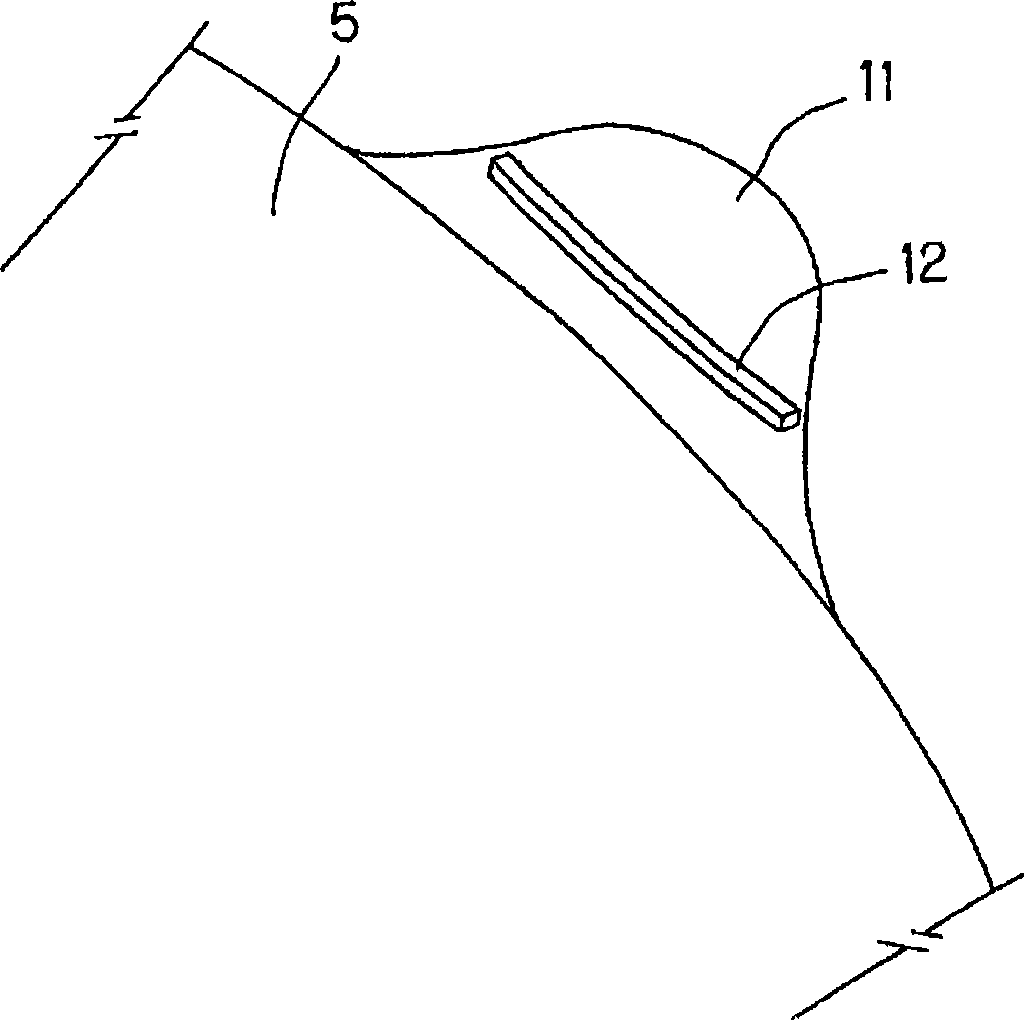

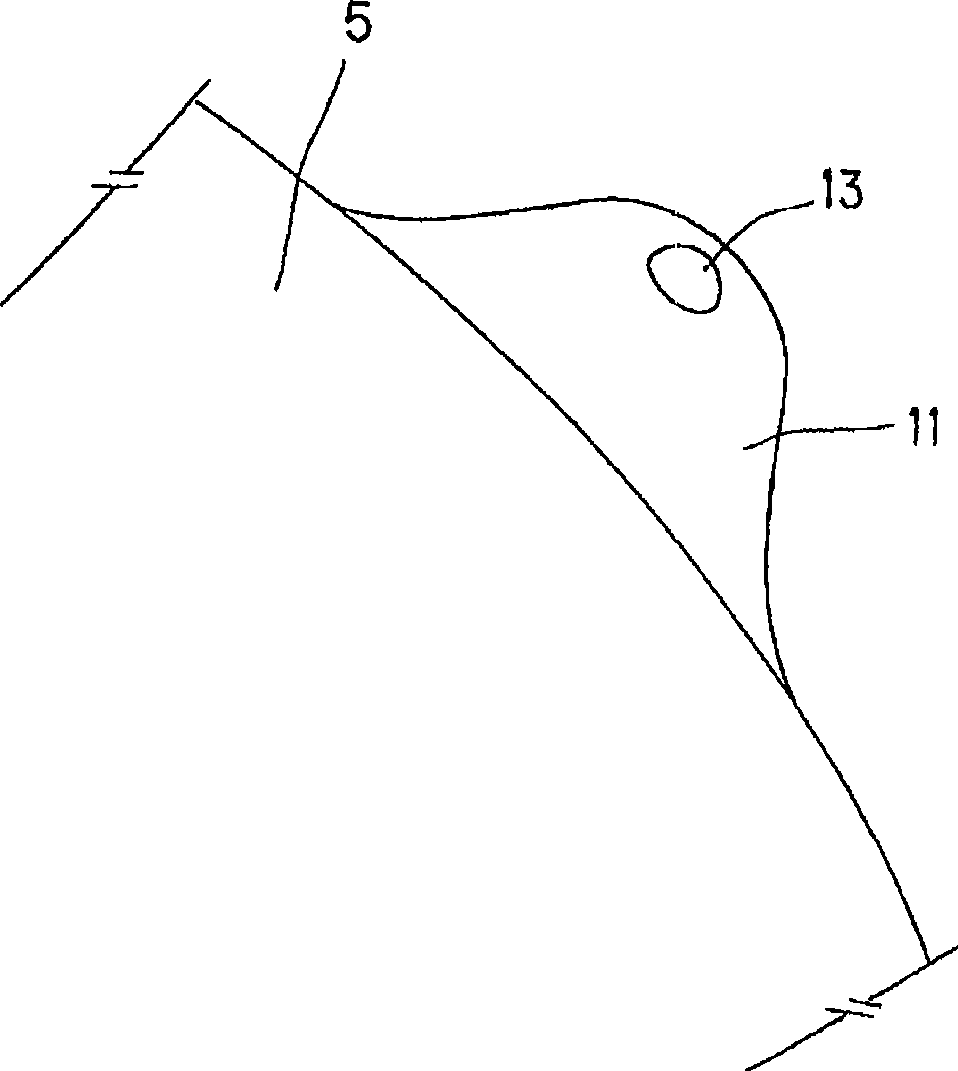

Packaging body

A packaging body (1) that is unsealed by peeling off a lid member from a container, wherein the unsealing is facilitated. The packaging body (1) has the container (2) open in the upper part and also has the lid member (10) placed on the upper part of the container to close it. The portion between a flange (5) formed on the upper part of the container (2) and the peripheral edge of the lid member (10) is processed to facilitate peeling off of the lid member (10), and the packaging body (1) is unsealed by peeling off the lid member (10) from the container (2). A tab (11) is formed on the lid member (10), and the tab (11) projects outward from the peripheral edge that is in intimate contact with the flange section (5). A fingerhold (12) is provided on the backside of the tab (11).

Owner:HOSOKAWA YOKO CO LTD

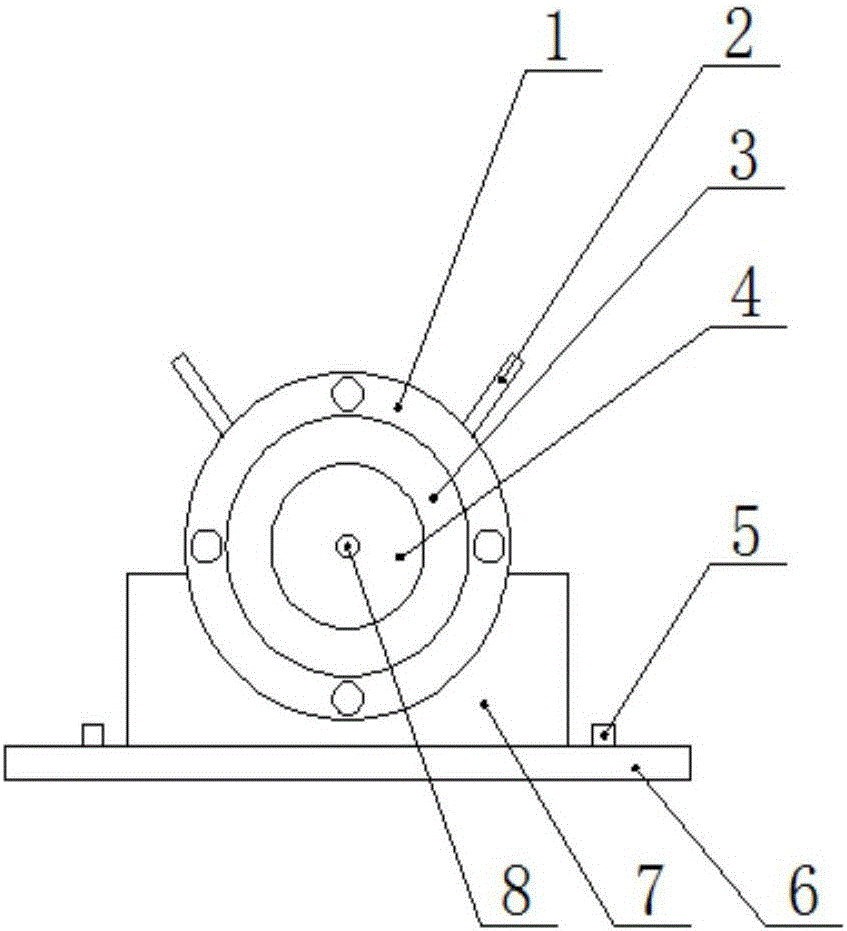

Device capable of scraping optical cable factice effectively

The invention relates to a device capable of scraping optical cable factice effectively, comprising a support plate, a bracket, a flange, an inner sleeve bearing, and an outer sleeve bearing. The flange, the outer sleeve bearing and the inner sleeve bearing are coaxially nested in turn, and the outer sleeve bearing and the inner sleeve bearing are in threaded connection. The device is simple in structure, reasonable in design, strong in practicability, low in manufacture cost, and solid and durable. Excess factice on an optical cable can be scraped through threaded fit between the inner sleeve bearing and the outer sleeve bearing. The technical problems caused by the existing device, such as severe cable core wear, big waste of cable factice, easy blockage of cable core tying yarns and cable appearance defects, are solved. The device is economic and efficient, and is suitable for vigorous popularization and application.

Owner:天津立孚光电科技股份有限公司

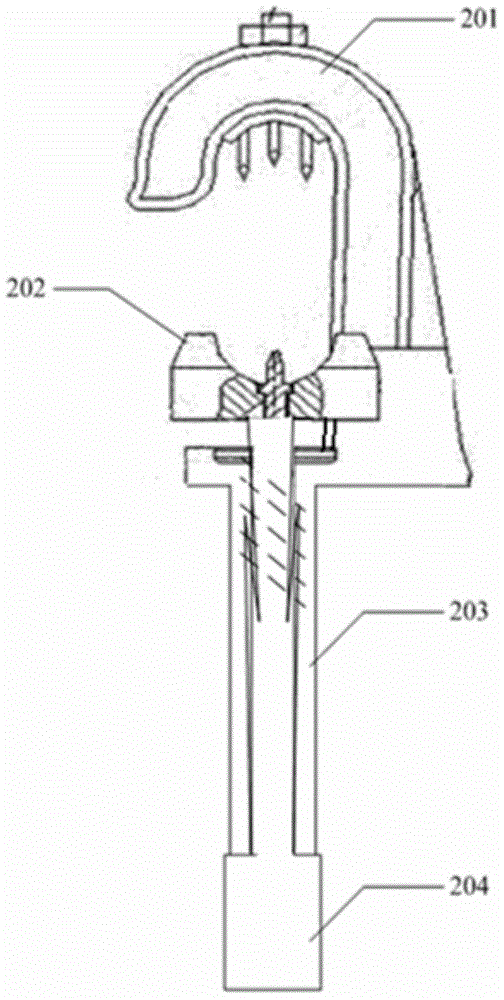

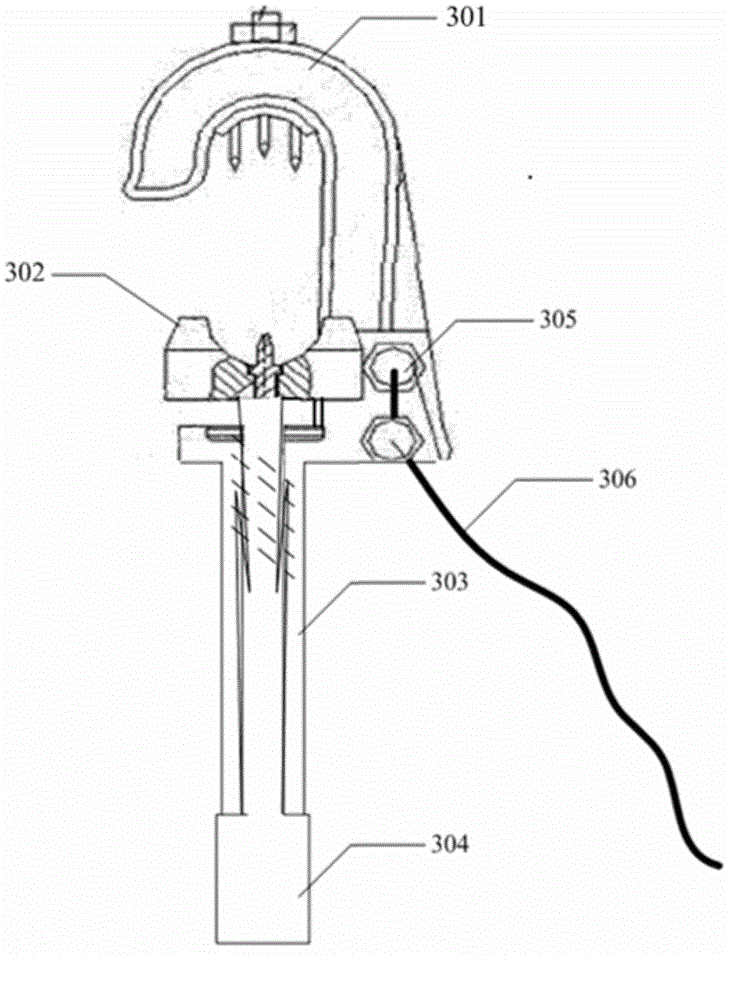

Portable high-voltage grounding wire

InactiveCN104682037AEffectively fixedFast and consistent disassemblyClip conductor connectionElectric connection basesHigh pressureUltimate tensile strength

The invention provides a portable high-voltage grounding wire. The portable high-voltage grounding wire comprises an electric connecting clamp and an operation insulating pipe sleeve, wherein an operation handle is arranged on the electric connecting clamp in a penetrating mode, and the electric connecting clamp is provided with a lower puncture needle; the operation insulating pipe sleeve is fixedly connected with a lead end wire clamp provided with an upper puncture needle; one end of the operation handle is connected with the electric connecting clamp, and the other end of the operation handle stretches out of the operation insulating pipe sleeve; the end, away from the operation handle, of the electric connecting clamp is in contact with the lead end wire clamp. According to the grounding wire, the electric connecting clamp and the operation handle are arranged in the operation insulating pipe sleeve, a user can carry out rotation operation through the operation handle with one hand, the other hand is used for holding the operation insulating pipe sleeve for fixing, both hands are cooperated to realize effective fixation for the portable high-voltage grounding wire; moreover, the disassembly and assembly of the portable high-voltage grounding wire are more coherent and quicker, the lead end wire clamp cannot be driven to rotate, and the labor intensity is reduced; moreover, the upper puncture needle and the lower puncture needle are arranged, so that a lead insulating layer is prevented from being peeled off, and the damages to leads and the personal safety of workers are reduced.

Owner:STATE GRID ZHEJIANG NINGBO FENGHUA POWER SUPPLY CO LTD +2

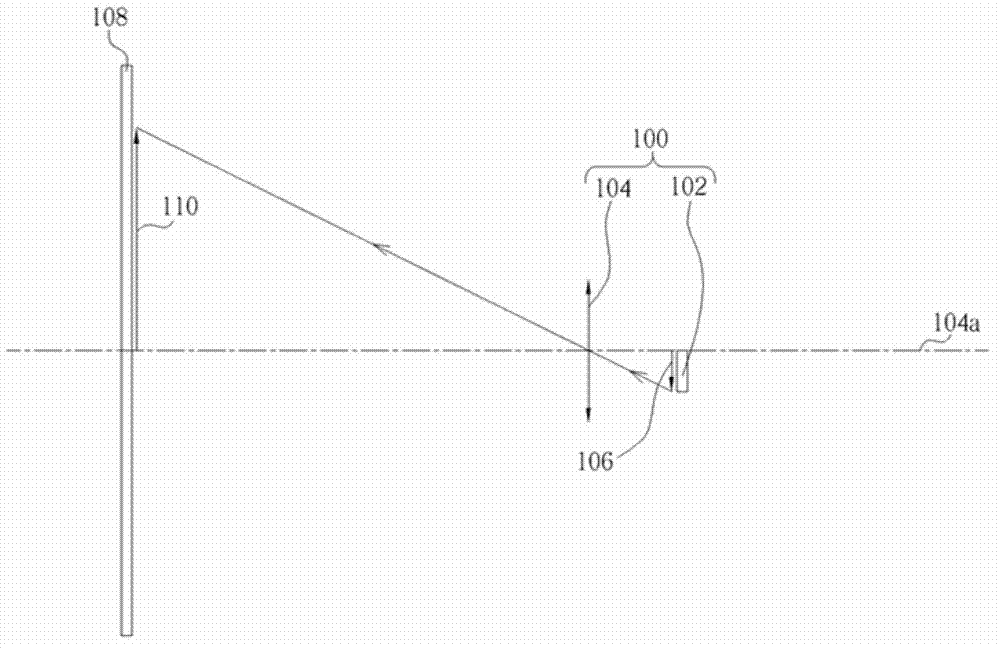

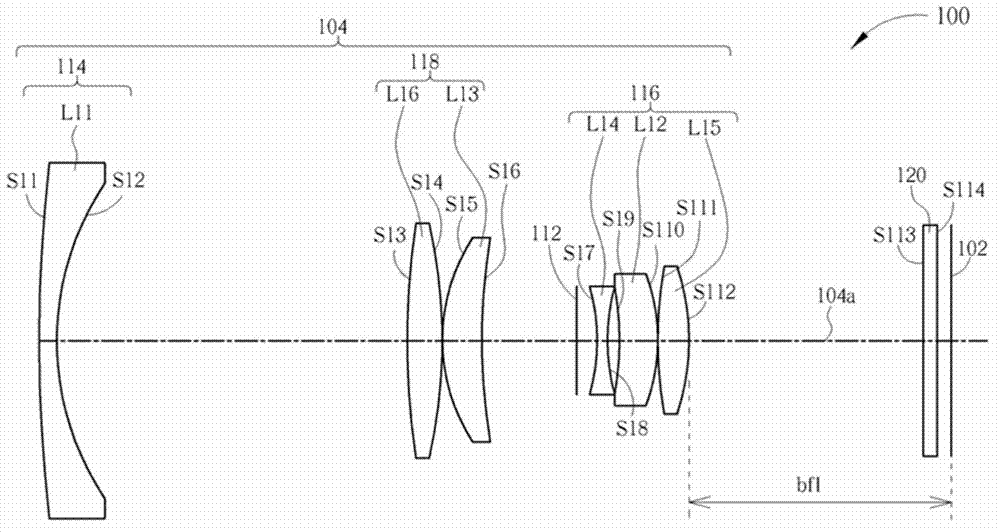

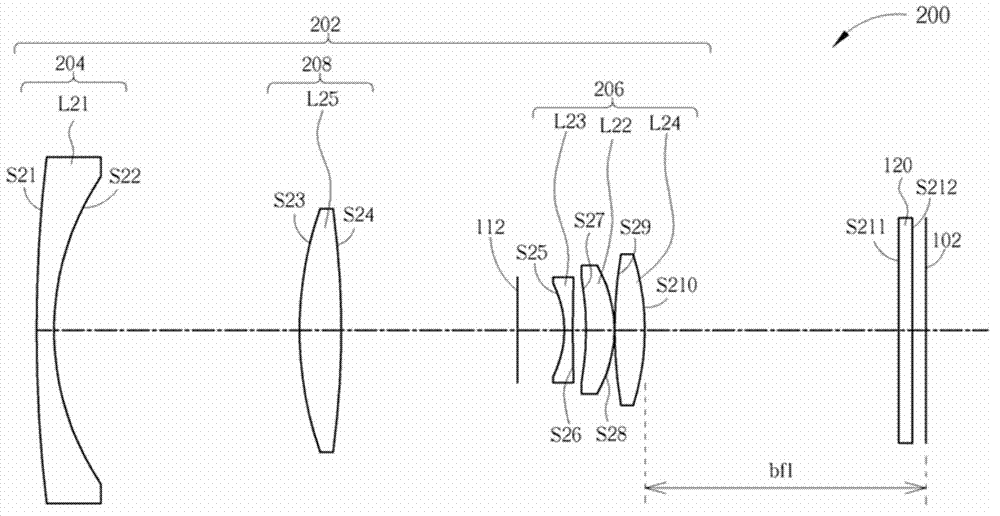

Projection device

ActiveCN103048857ALow costReduce manufacturing costProjectorsOptical elementsCamera lensOptical property

The invention relates to a projection device which is used for projecting images onto a projection screen; the projection device comprises a light valve for providing the images and a non-telecentric projection lens for projecting the images. The non-telecentric projection lens comprises a plurality of spherical lenses which comprise a first lens group and a second lens group. The first lens group is arranged between the light valve and the projection screen, has negative refractive index, and comprises a first meniscus lens. The second lens group is arranged between the first lens group and the light valve, has positive refractive index, and comprises a second meniscus lens. According to the projection device, only the spherical lenses are used, so that the projection device is light in weight, thin in thickness, small in size and lower in production cost. Because glass has a smaller expansion coefficient compared with plastics, stripping or the changes of optical properties caused by the impact of temperature changes can be prevented, so that the impact of the temperature changes on the projection device is reduced, and stable imaging can be maintained under high temperature changes.

Owner:QISDA OPTRONICS (SUZHOU) CO LTD +1

Device for automatically punching chillies

The invention provides a device used for automatically punching chillies. The device comprises a rack, a conveying mechanism, a punching mechanism and a motor, wherein the motor is provided with a speed reducer; the conveying mechanism comprises a conveyor belt, a driven wheel and a driving wheel; the driving wheel and the driven wheel are arranged at the two sides of the rack; the conveyor belt is installed between the driving wheel and the driven wheel; and the punching mechanism is arranged in the middle of the rack and comprises a support frame, a crankshaft, a connecting rod, locating sleeves, directional shafts, a presser, a pin installing plate, punching pins and a punching pin guide plate. The device has a simple structure and a high degree of automation, is convenient to use and can achieve the effects of reducing the dependence of enterprises on workers and effectively reducing the production costs of the enterprises.

Owner:昆明万顺通科工贸有限公司

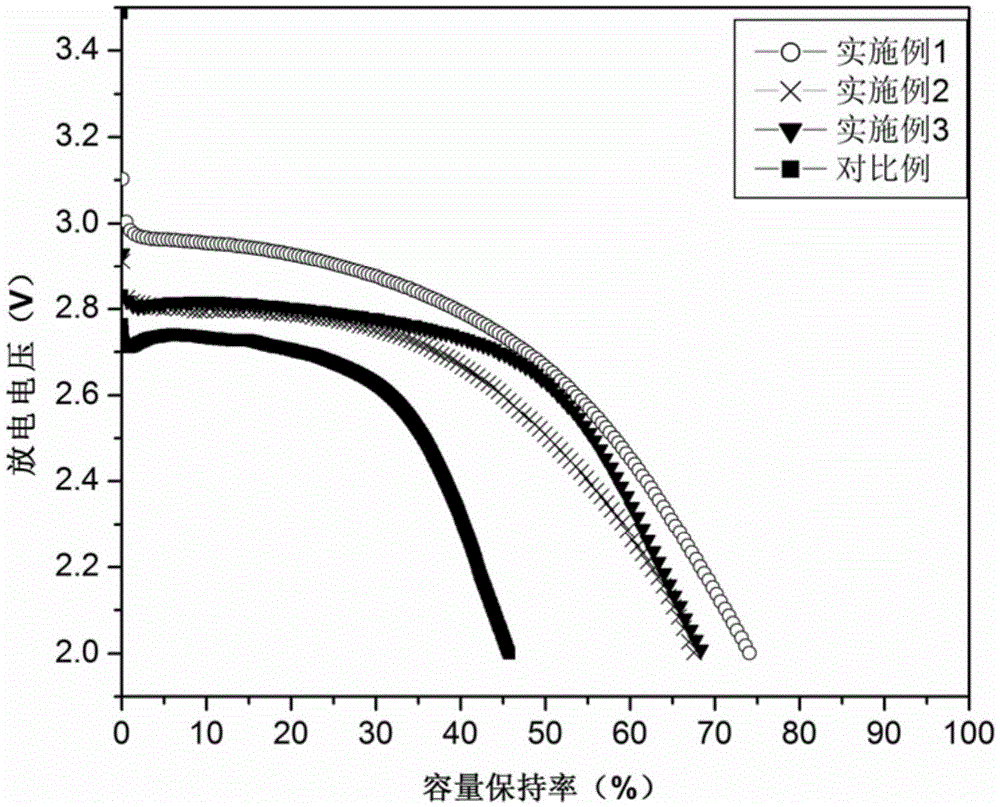

Water-based lithium-sodium ion battery and preparation method and application thereof

ActiveCN111710859ALow priceSolve the key problems of mass productionFinal product manufactureElectrode carriers/collectorsCarbon compositesElectrolytic agent

The invention discloses a water-based lithium-sodium ion battery and a preparation method and application thereof. The battery takes a lithium manganate material as a positive electrode active substance and a carbon composite sodium titanium phosphate material as a negative electrode active substance; a lithium salt, a sodium salt, a zinc salt and urea are dissolved in water to prepare a mixed electrolyte; graphite, carbon nanotubes, polyvinylidene fluoride and a polymer net are compounded to prepare a graphite-based composite film as positive and negative electrode current collectors; a polepiece is prepared by a coating method, a battery cell is prepared by a lamination method, and a battery is assembled by connecting a stainless steel or graphite nut with a tab. The prepared battery has the advantages of long cycle life, high charge-discharge coulombic efficiency, low self-discharge rate, high energy density, low price, high rate capability and wide use temperature range, and can be used as an electric bicycle power battery or an energy storage battery.

Owner:湖州青钠新能源科技有限公司

Preparation method for tubular membrane of PI(polyimide) non-woven supporting tube

InactiveCN108854577AImprove throughputNarrow pore size distributionSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisOrganic solventHeat resistance

The invention relates to the field of separation membrane preparation, in particular to a preparation method for a tubular membrane of a PI(polyimide) non-woven supporting tube. The method comprises the steps of preparing a membrane casting solution, winding the PI(polyimide) non-woven tube, carrying out scrape coating on the membrane casting solution and carrying out post-treatment on the tube coated with the membrane. The prepared tubular membrane has good high-temperature resistance, low-temperature resistance, chemical corrosion resistance and tensile resistance and can be applied to the fields of water treatment and material separation; due to the heat resistance and the organic solvent resistance of PI(polyimide), the tubular membrane of the PI(polyimide) non-woven supporting tube has great significance in separation of high-temperature and organic liquid; and for some special high-temperature and low-temperature feed liquid, the organic solvent separation effect is good, and thegood performance can be kept for the long-term use.

Owner:TIANJIN POLYTECHNIC UNIV

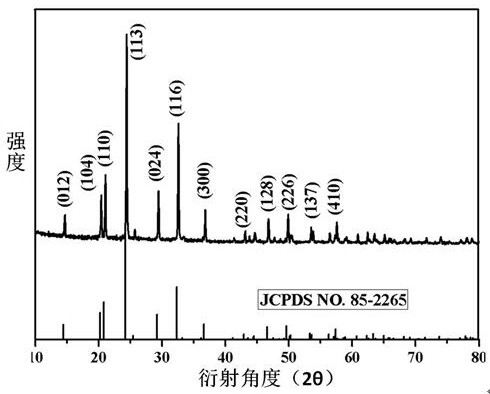

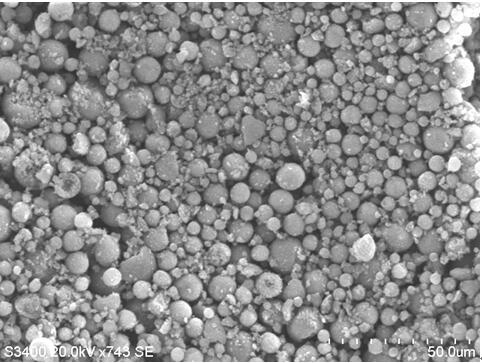

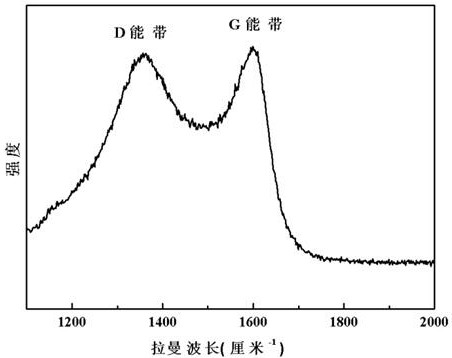

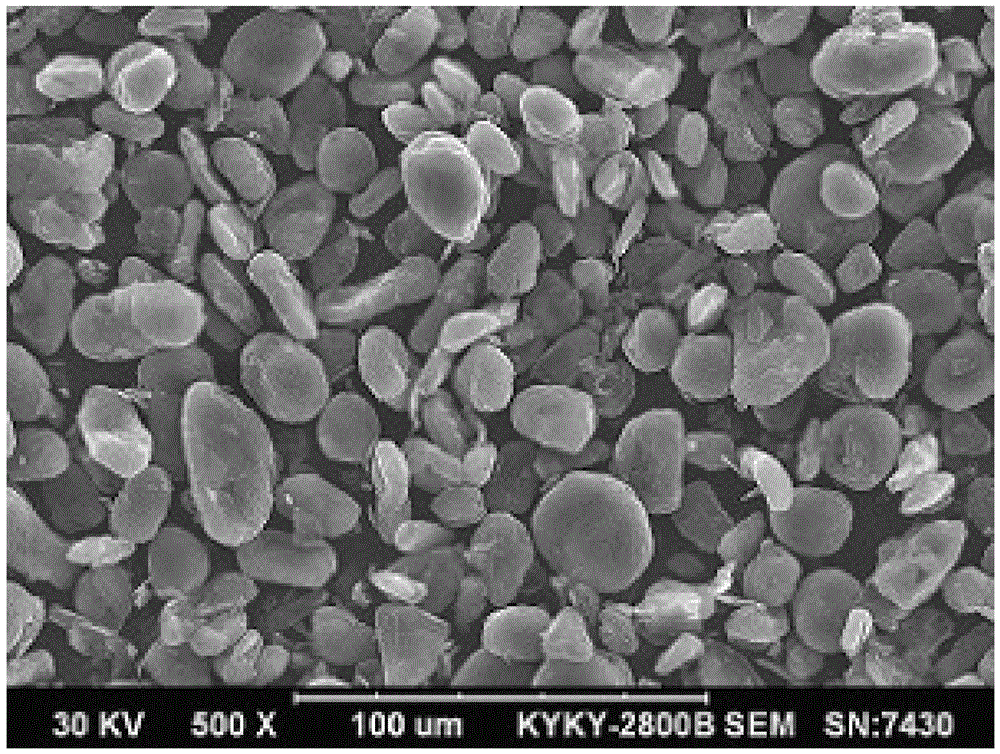

Amorphous carbon coated graphite composite, preparation method thereof and application of amorphous carbon coated graphite composite serving as lithium ion battery cathode material

ActiveCN105529466AAvoid direct contactAvoid strippingCell electrodesSecondary cellsEmulsionAcrylonitrile

The invention discloses an amorphous carbon coated graphite composite, a preparation method thereof and application of the amorphous carbon coated graphite composite serving as a lithium ion battery cathode material. The preparation method of the composite includes mixing template with acrylonitrile monomers, and adding initiator and water for polymerization reaction to obtain a template / polyacrylonitrile composite; dispersing graphite and emulsifier in water to obtain a graphite compound; adding the template / polyacrylonitrile composite into the graphite compound for emulsion reaction, adding acid liquor for etching to remove the template to obtain a porous polyacrylonitrile / graphite composite, soaking the porous polyacrylonitrile / graphite composite in lithium liquor, and drying and splitting the porous polyacrylonitrile / graphite composite after taking out the same from the lithium liquor to obtain the amorphous carbon coated graphite composite. The amorphous carbon coated graphite composite has the advantages of large interlayer spacing, excellent low-temperature performance, high liquid absorbing and retaining ability, high gram volume and the like; lithium is stored in micropores in advance, so that lithium consumption in lithium ion batteries is reduced, first-time reversible capacity of the lithium ion batteries is reduced, and specific capacity of the lithium ion batteries is increased.

Owner:JIAOZUO JUNENG ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com