Method for detecting interface binding strength of aluminum-steel composite material for soldering

A composite material and interface combination technology, which is applied in the direction of analyzing materials, measuring devices, and adopting mechanical devices, can solve problems such as unsatisfactory bending test results, unsuitable leader preparation, and low tensile strength, so as to ensure correct peeling, Elimination of peeling operation, high process precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

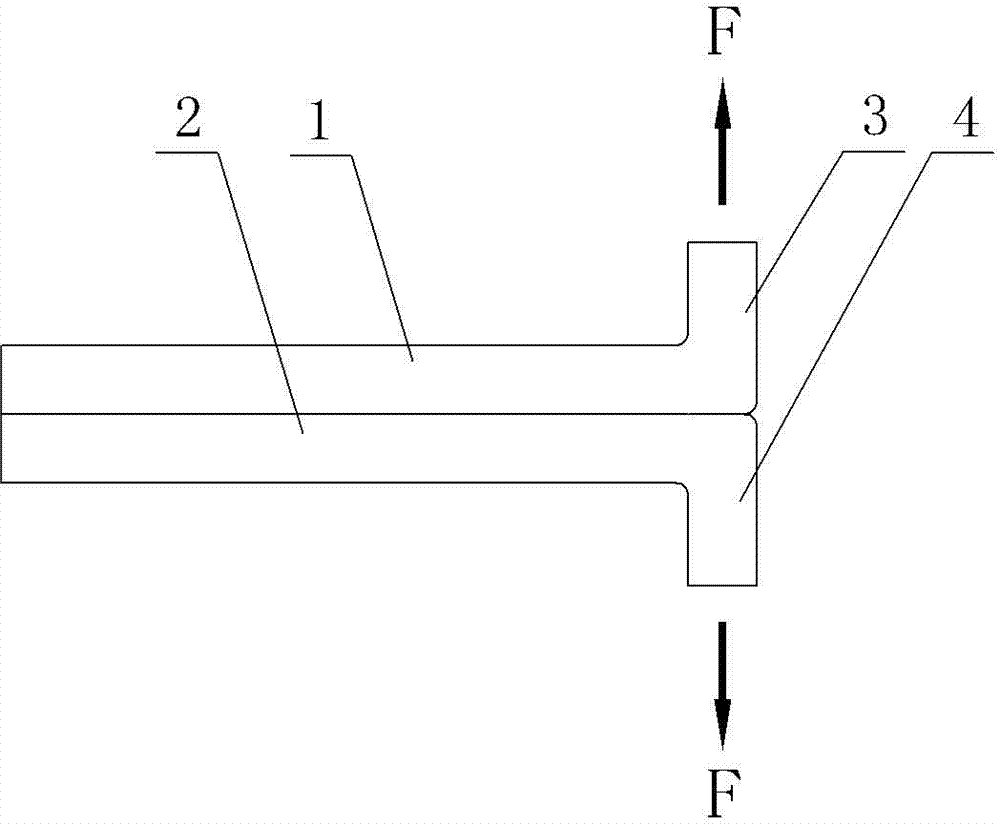

Embodiment 1

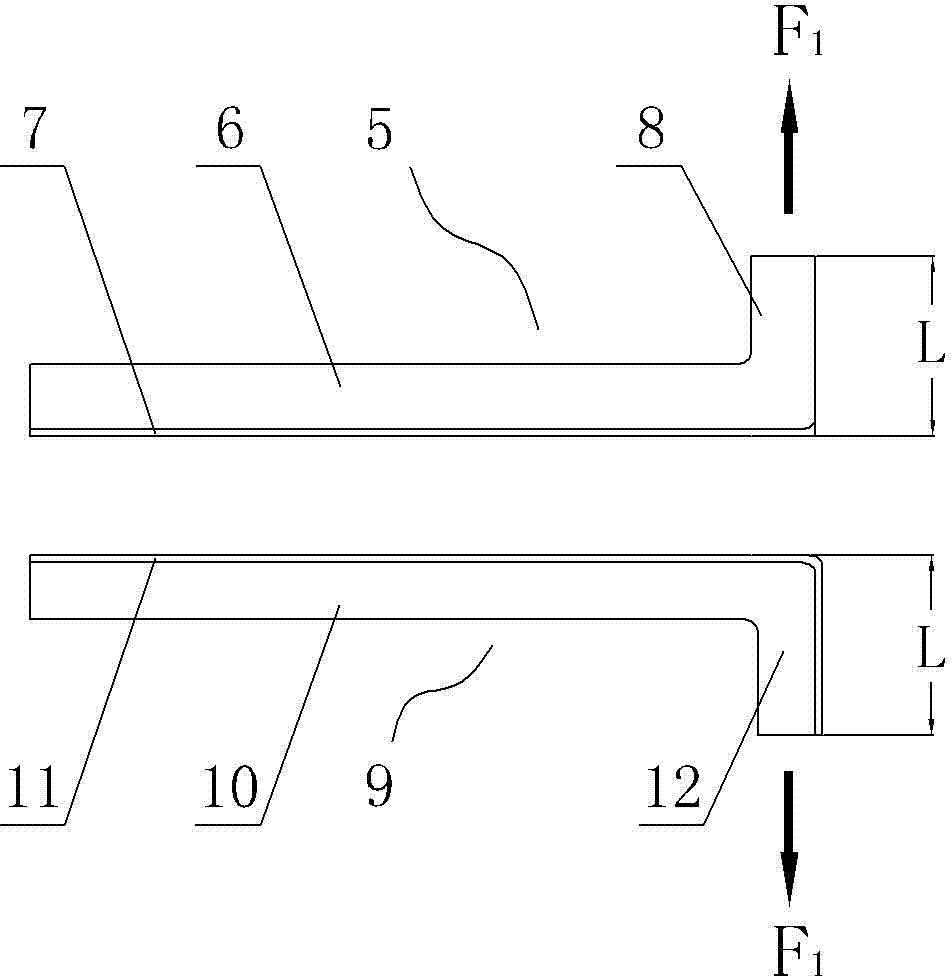

[0026] In this embodiment, the metal reinforcement layer is a 4343 / 3003 single-sided aluminum alloy composite strip, 10 in the figure is a 3003 aluminum layer, which is used as the base layer, and 11 is a 4343 aluminum layer, which is used as a skin layer for brazing connection with the sample.

[0027] A method for detecting the interfacial bonding fastness of aluminum-steel composite materials for brazing, such as figure 2 As shown, the specific steps are as follows:

[0028] 1. Cut sample 5 and single-sided aluminum alloy composite strip 9 with a thickness of 1.5mm, a length of 200mm, and a width of 25mm. The length of sample 5 is parallel to the rolling direction, and the single-sided aluminum alloy composite strip 9 is 4343 The thickness of the aluminum layer 11 is 0.12mm;

[0029] 2. Bend the free end one 8 of the sample on the same side and the free end two 12 of the single-sided aluminum alloy composite strip 9 outward by 90°, so that the sample after brazing forms a...

Embodiment 2

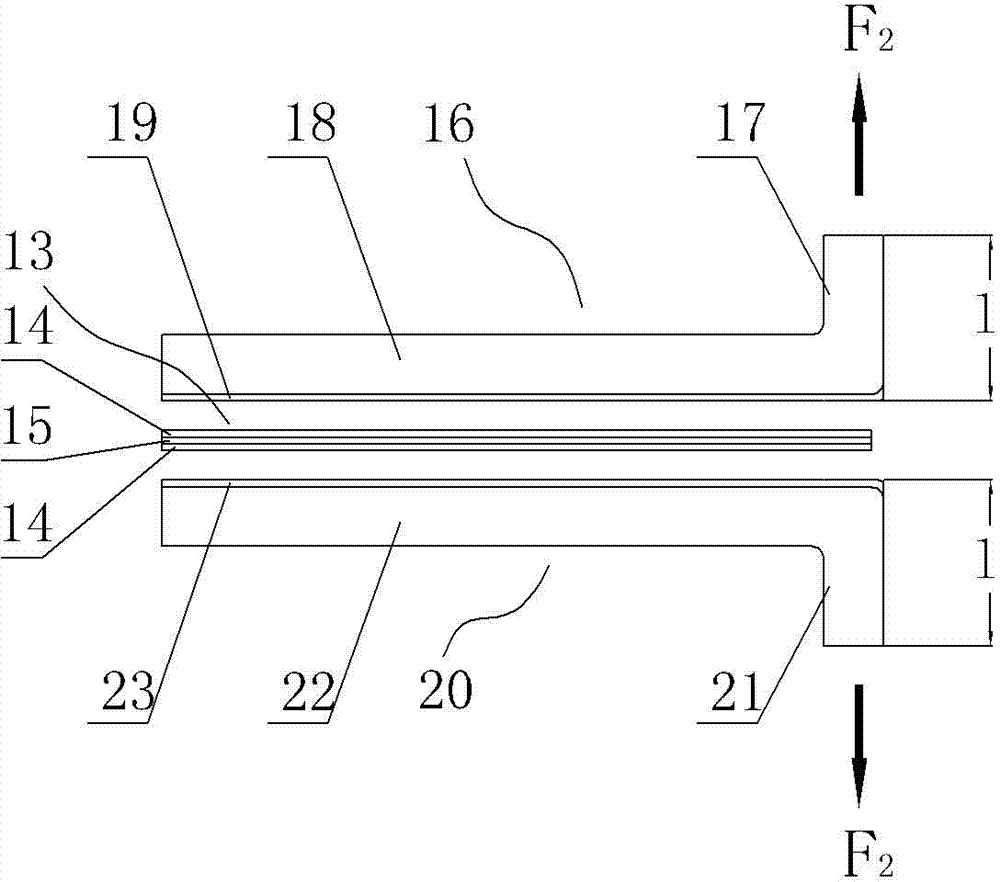

[0035] In this embodiment, the metal reinforcing layer is 4343 / 3003 / 3003 double-sided aluminum alloy composite strip, image 3 Among them, 14 is the 4343 aluminum layer, which is used as the skin layer brazed with the aluminum layer of the sample, and 15 is the 3003 aluminum layer, which is used as the base layer.

[0036] A method for detecting the interfacial bonding fastness of aluminum-steel composite materials for brazing, such as image 3 As shown, the specific steps are as follows:

[0037]1. Cut sample one 16, sample two 20, and a double-sided aluminum alloy composite strip 13 with a thickness of 1.5mm and a width of 25mm. The length of samples 16 and 20 is 200mm, and the strength of the double-sided aluminum alloy composite strip 13 is 150mm, the length of sample one 16 and sample two 20 is parallel to the rolling direction, wherein the thickness of the 4343 aluminum layer of the double-sided aluminum alloy composite strip 13 is 0.12mm;

[0038] 2. Bend the free end...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com