Patents

Literature

191results about How to "Improve process precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

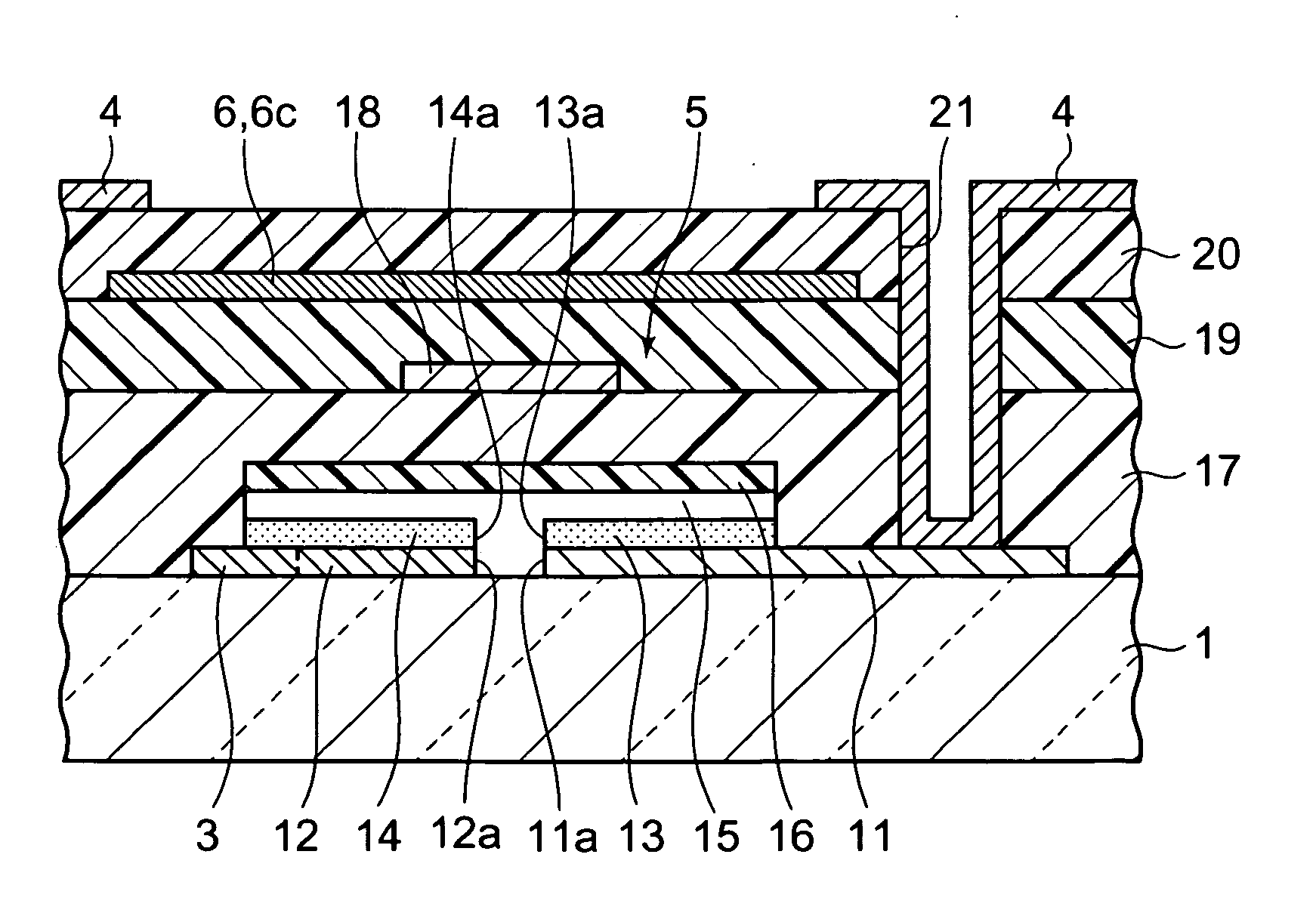

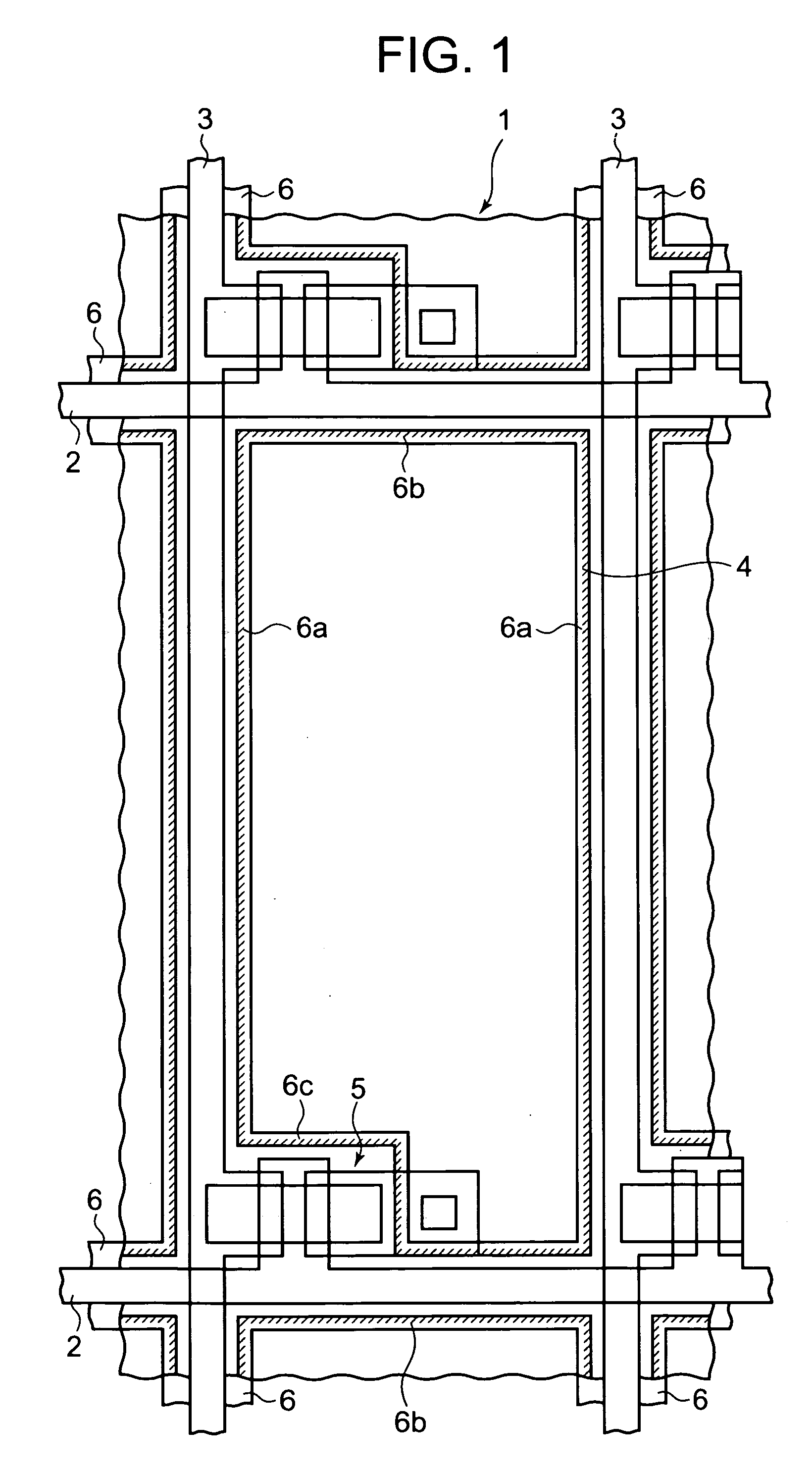

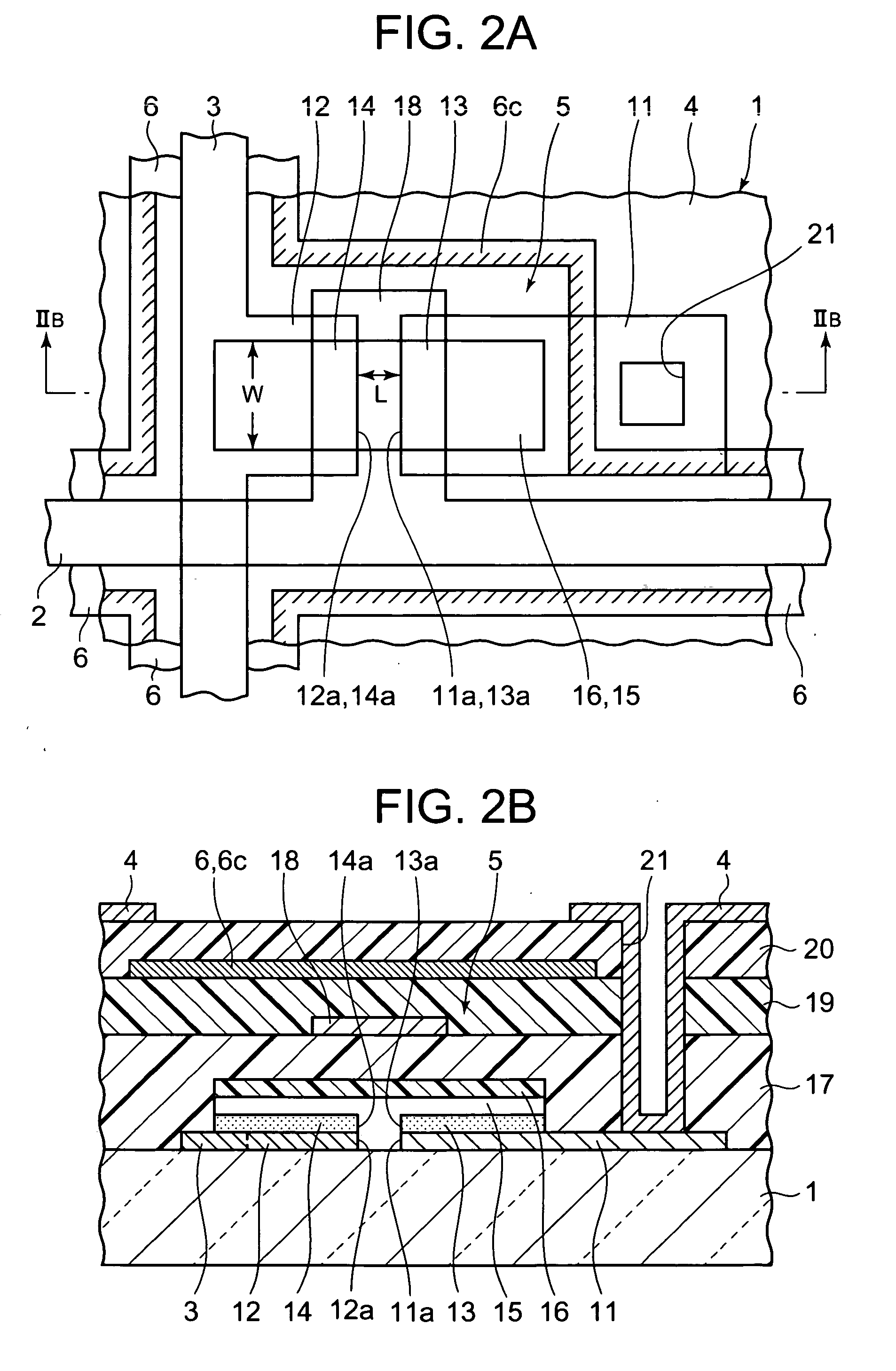

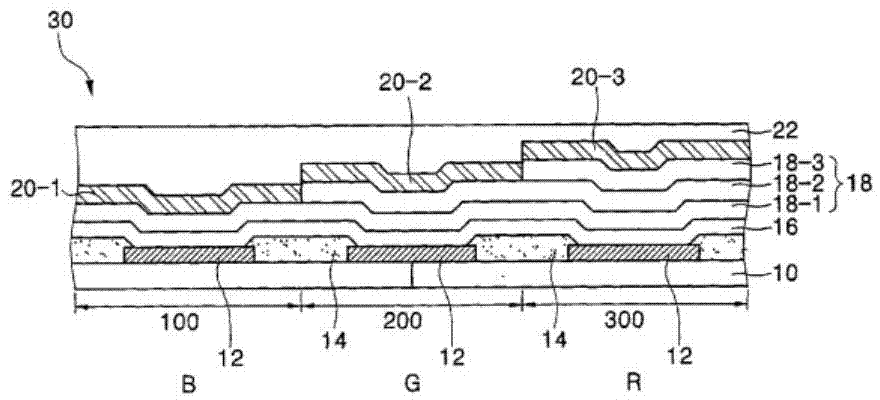

Thin film transistor having oxide semiconductor layer and manufacturing method thereof

ActiveUS20060284172A1Etch resistance of resist is lowPromote meltingSolid-state devicesSemiconductor/solid-state device manufacturingZincSemiconductor

A thin film transistor has a semiconductor thin film including zinc oxide, a protection film formed on entirely the upper surface of the semiconductor thin film, a gate insulating film formed on the protection film, a gate electrode formed on the gate insulating film above the semiconductor thin film, and a source electrode and drain electrode formed under the semiconductor thin film so as to be electrically connected to the semiconductor thin film.

Owner:SAMSUNG DISPLAY CO LTD

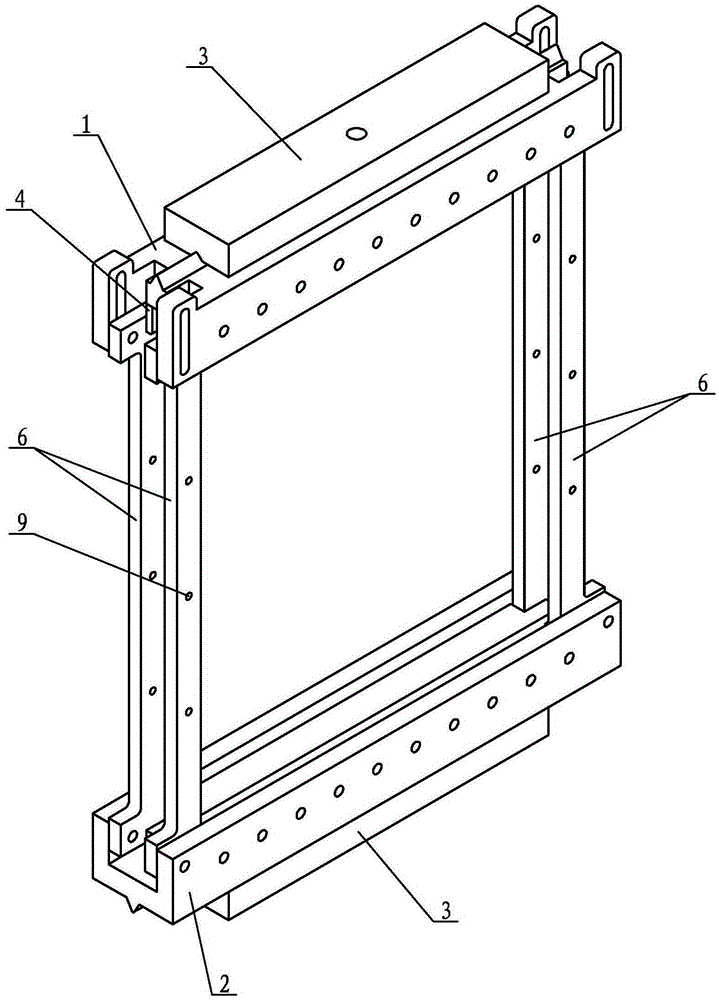

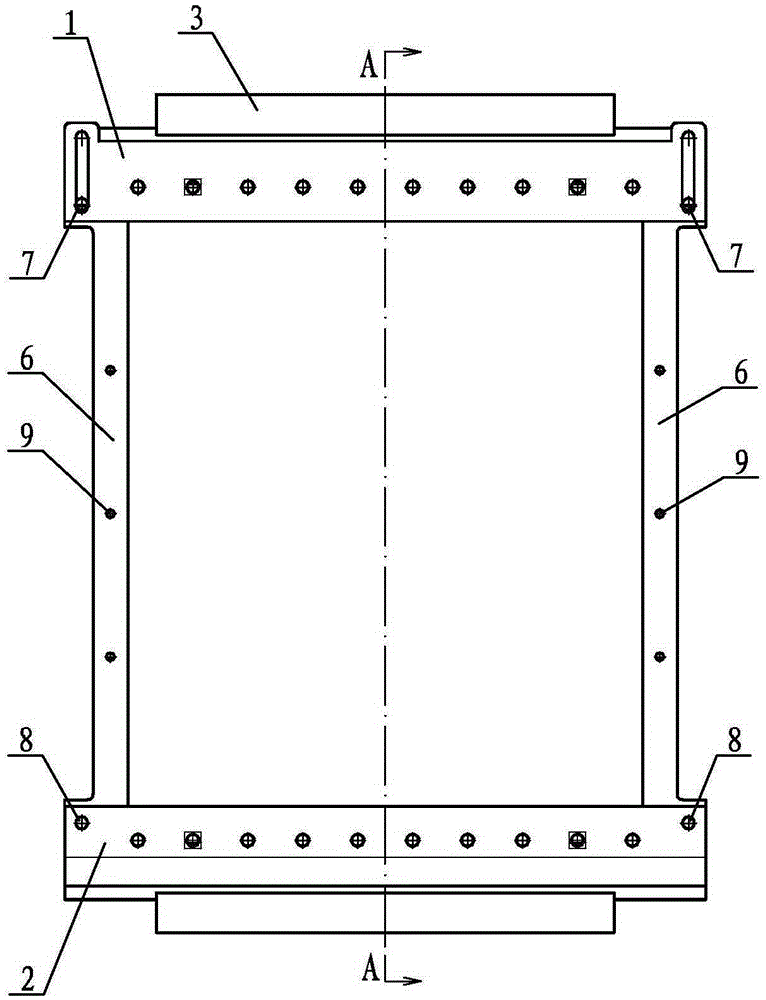

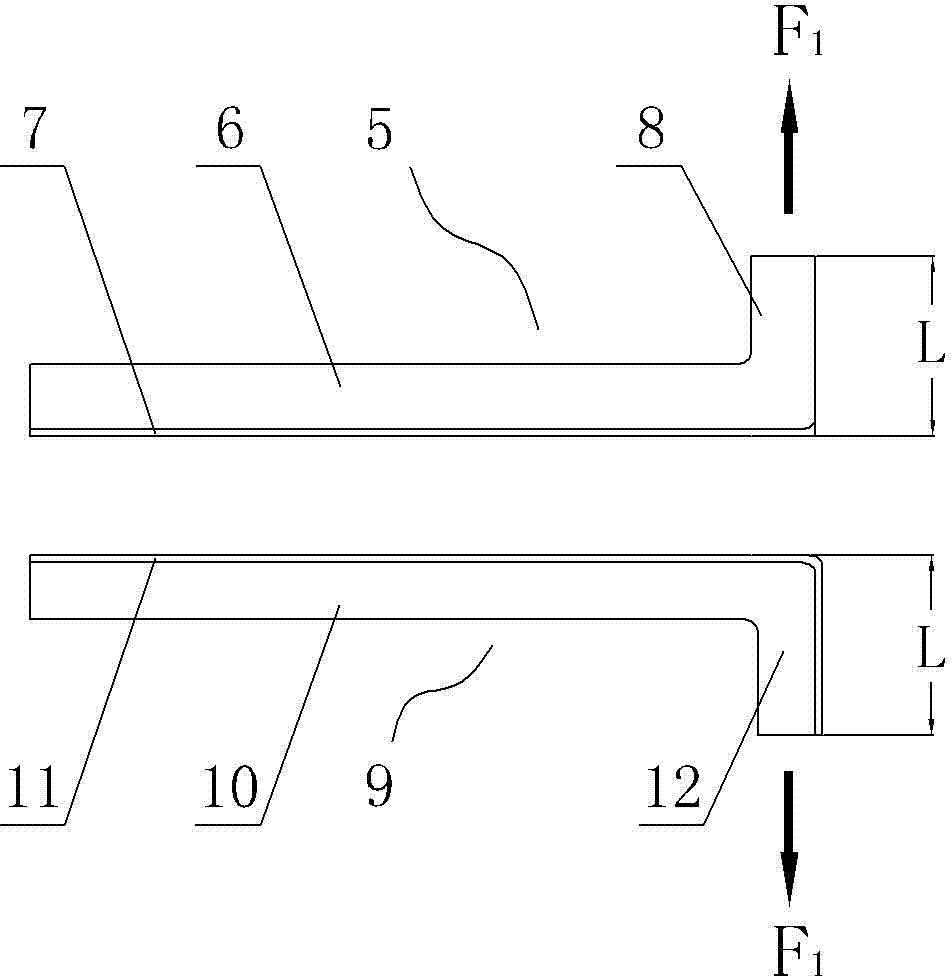

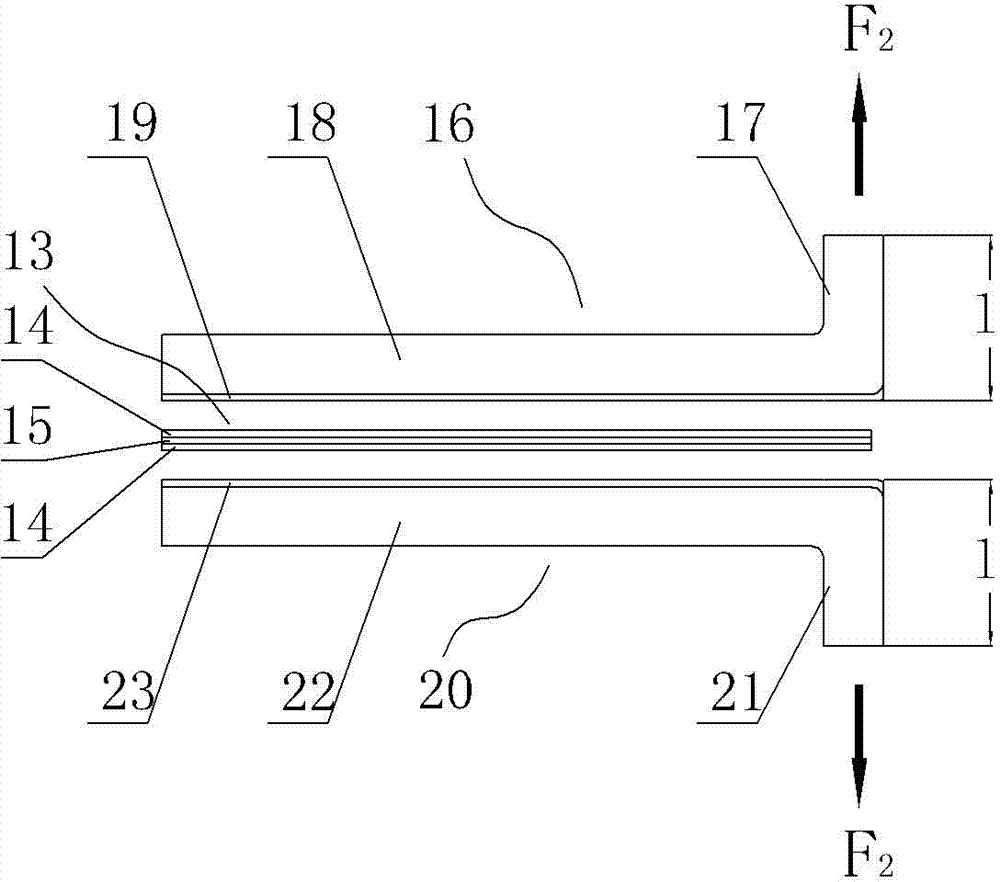

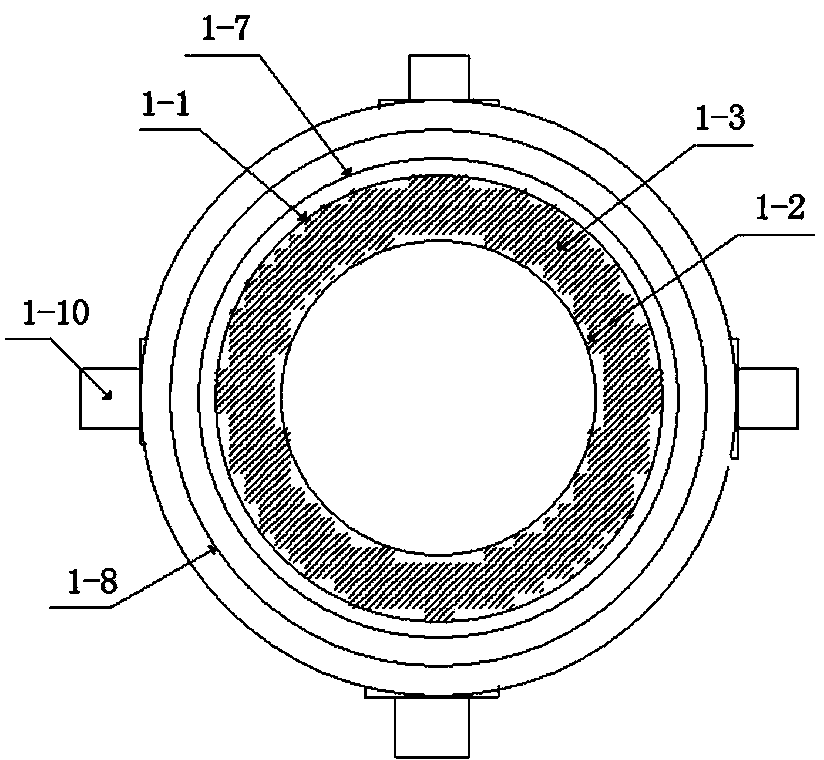

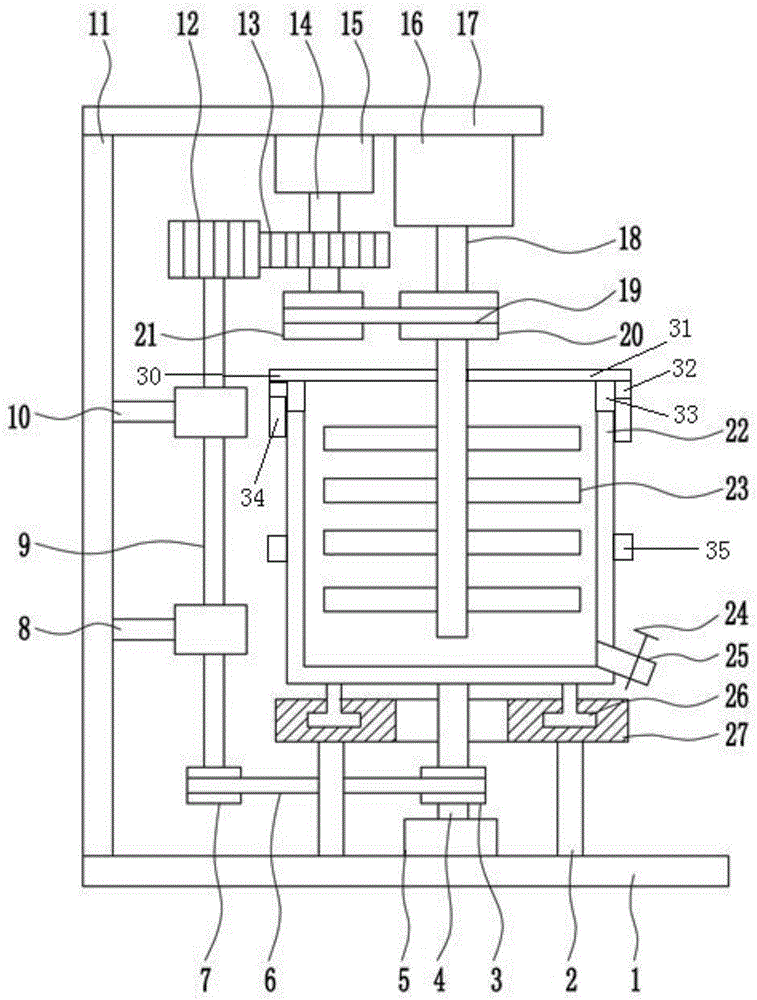

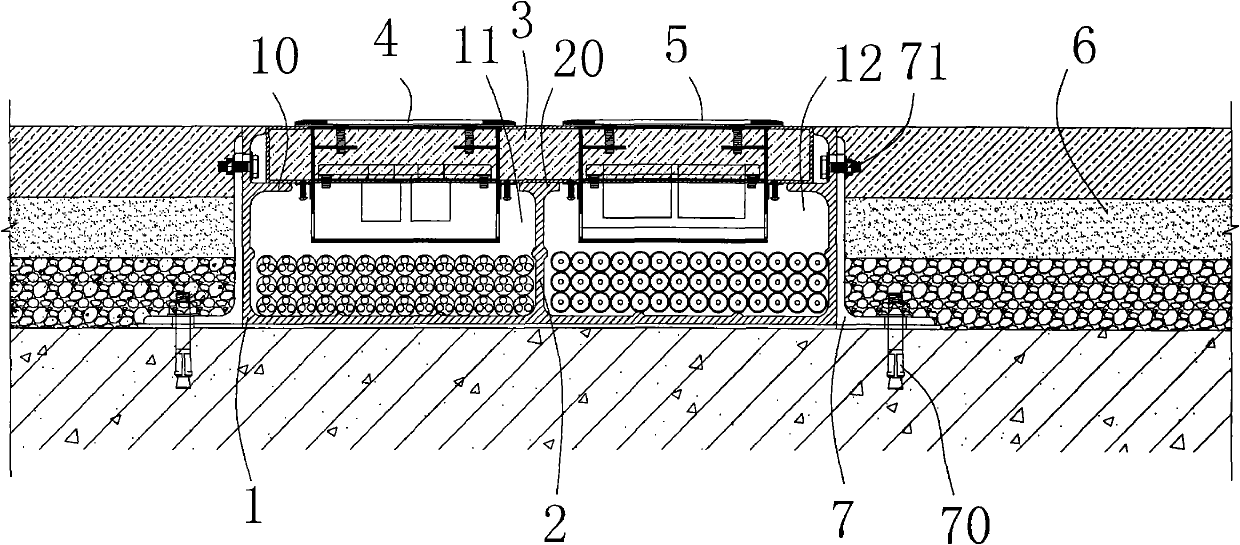

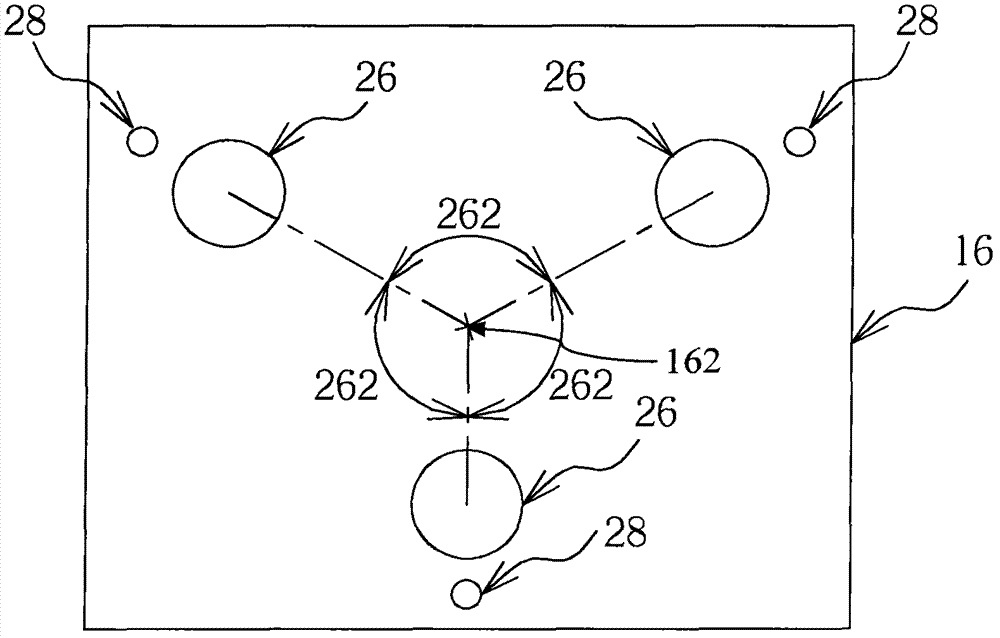

Assembly clamper for sandwich structure board lateral compression test

ActiveCN105241751AGuaranteed internal and external symmetry of strainEasy to assembleStrength propertiesSandwich boardLateral compression

The invention relates to an assembly clamper for sandwich structure board lateral compression test. In the prior art, when the large-size and non-symmetrical sandwich board is subjected to the lateral compression performance test, the centering of the compression center is difficult, and the deflection is high. A purpose of the present invention is to solve the problems in the prior art. According to the assembly clamper, an upper clamping head and a lower clamping head are arranged in an upper-lower manner, the deep groove of the upper clamping head and the U-shaped groove of the lower clamping head are oppositely arranged, four vertical position limiting plates are arranged between the upper clamping head and the lower clamping head in a rectangular manner, the upper ends of each vertical position limiting plate are positioned inside the deep groove, the lower ends of each vertical position limiting plate are positioned inside the U-shaped groove, the upper ends between the two transverse and parallel vertical position limiting plates are provided with a universal pad block and an adjustment pad block, the lower ends between the two transverse and parallel vertical position limiting plates are provided with a universal pad block and an adjustment pad block, the two universal pad blocks are oppositely arranged in an upper-lower manner, the two adjustment pad blocks are oppositely arranged in an upper-lower manner, two end plates are respectively arranged on the upper end and the lower end of the upper clamping head and the lower clamping head, and the upper cone column on the upper clamping head and the lower cone column on the lower clamping head are respectively embedded into the corresponding V-shaped grooves. The assembly clamper of the present invention is used for the sandwich structure board lateral compression test.

Owner:HARBIN INST OF TECH

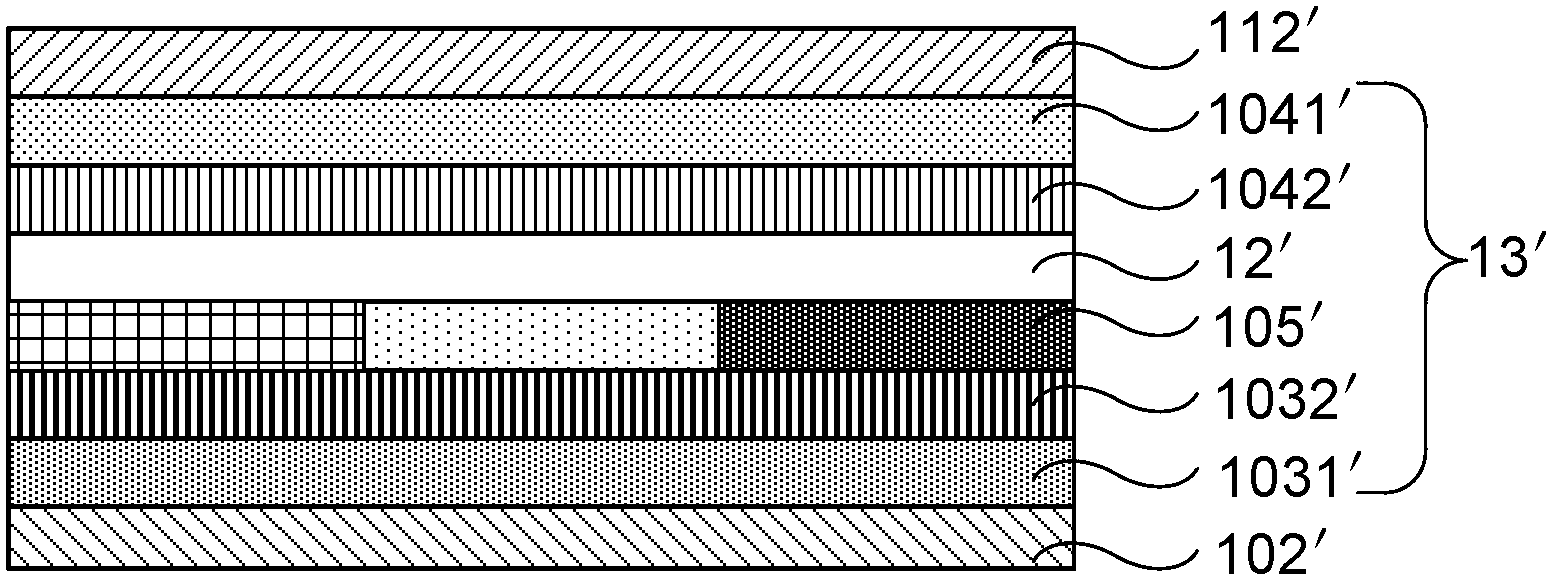

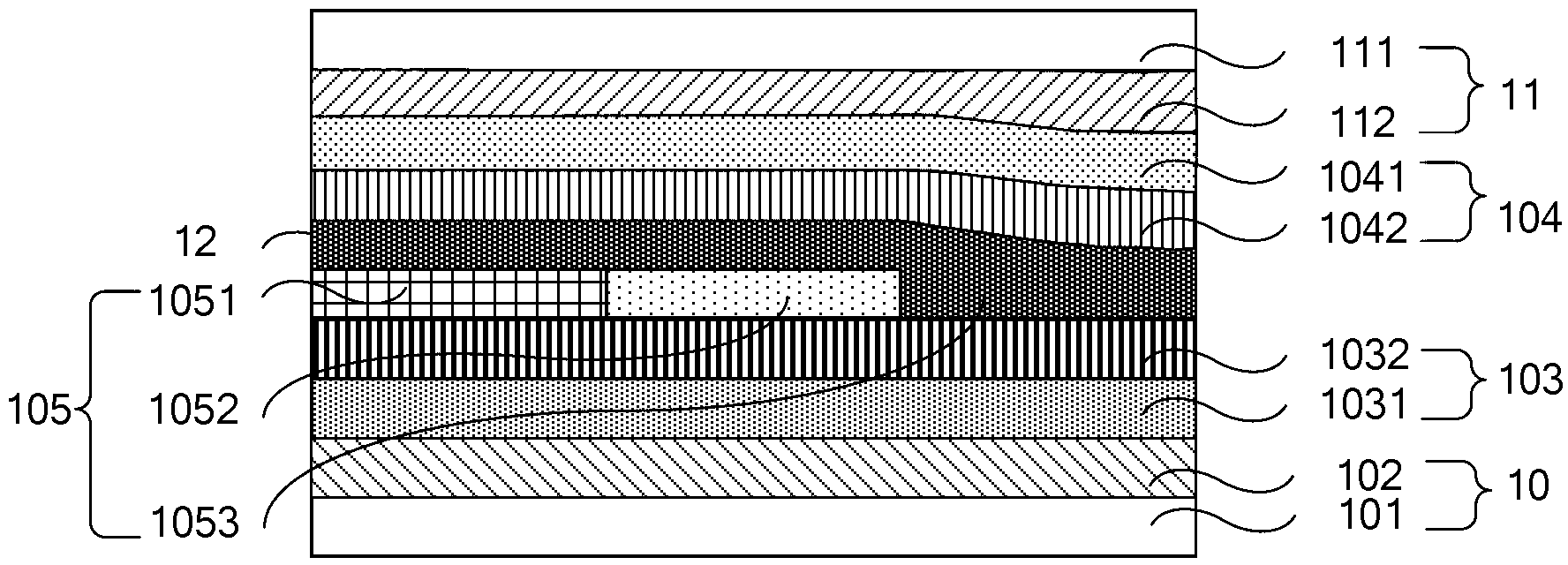

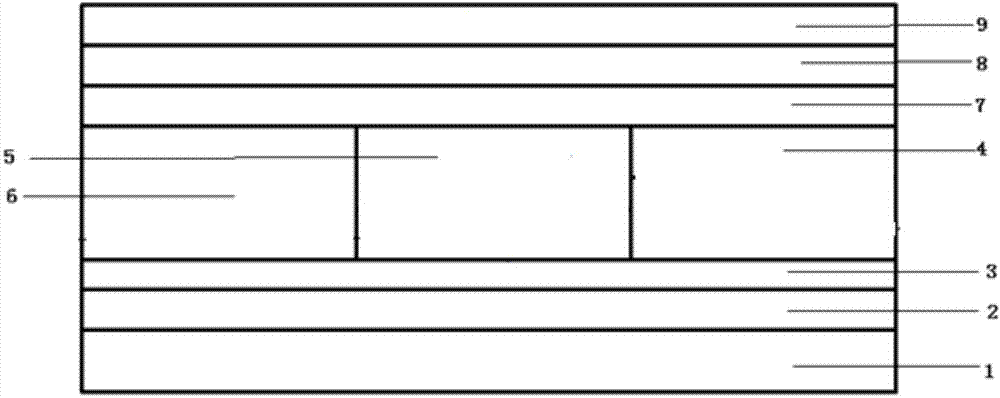

Organic light emitting diode (OLED) device and manufacturing method and display device thereof

InactiveCN103325952AEasy to produceAvoid systematic errorsFinal product manufactureSolid-state devicesOrganic filmComposition process

The invention discloses an organic light emitting diode (OLED) device and a manufacturing method and a display device thereof, relating to the technical field of display. The production process of the OLED device can be simplified, the production cost is reduced, and the product quality is improved. The OLED device comprises a first electrode, a second electrode and an organic film layer, wherein the organic film layer comprises a hole layer, an electronic layer and an organic luminous layer positioned between the hole layer and the electronic layer; the organic film layer also comprises a hole barrier layer; the organic luminous layer comprises a first luminous unit, a second luminous unit and a third luminous unit; the hole barrier layer and the third luminous unit are formed through a one-step composition process. The OLED device is suitable for manufacturing a display panel.

Owner:BOE TECH GRP CO LTD

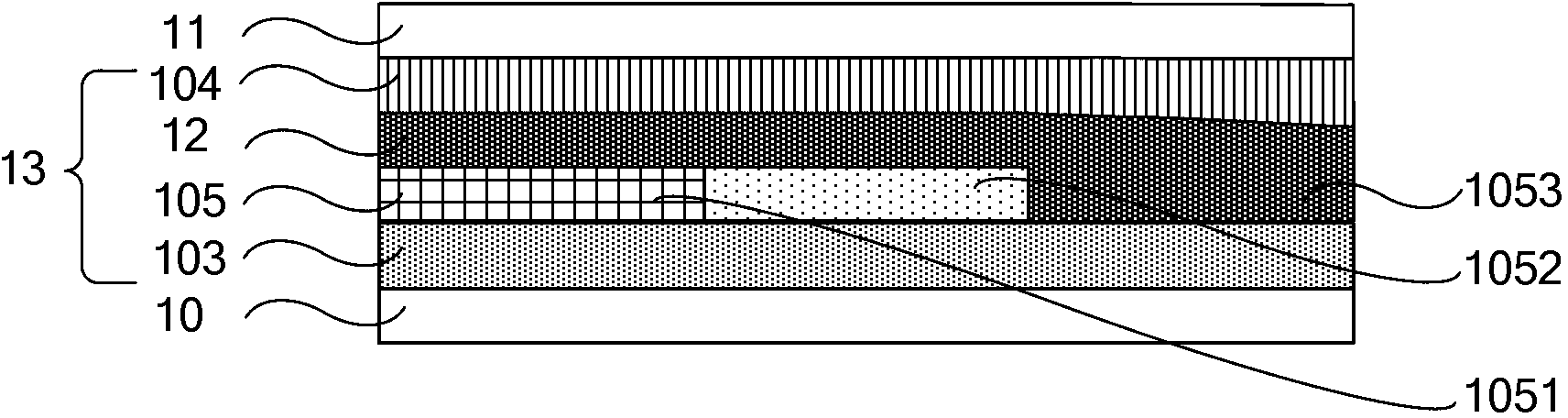

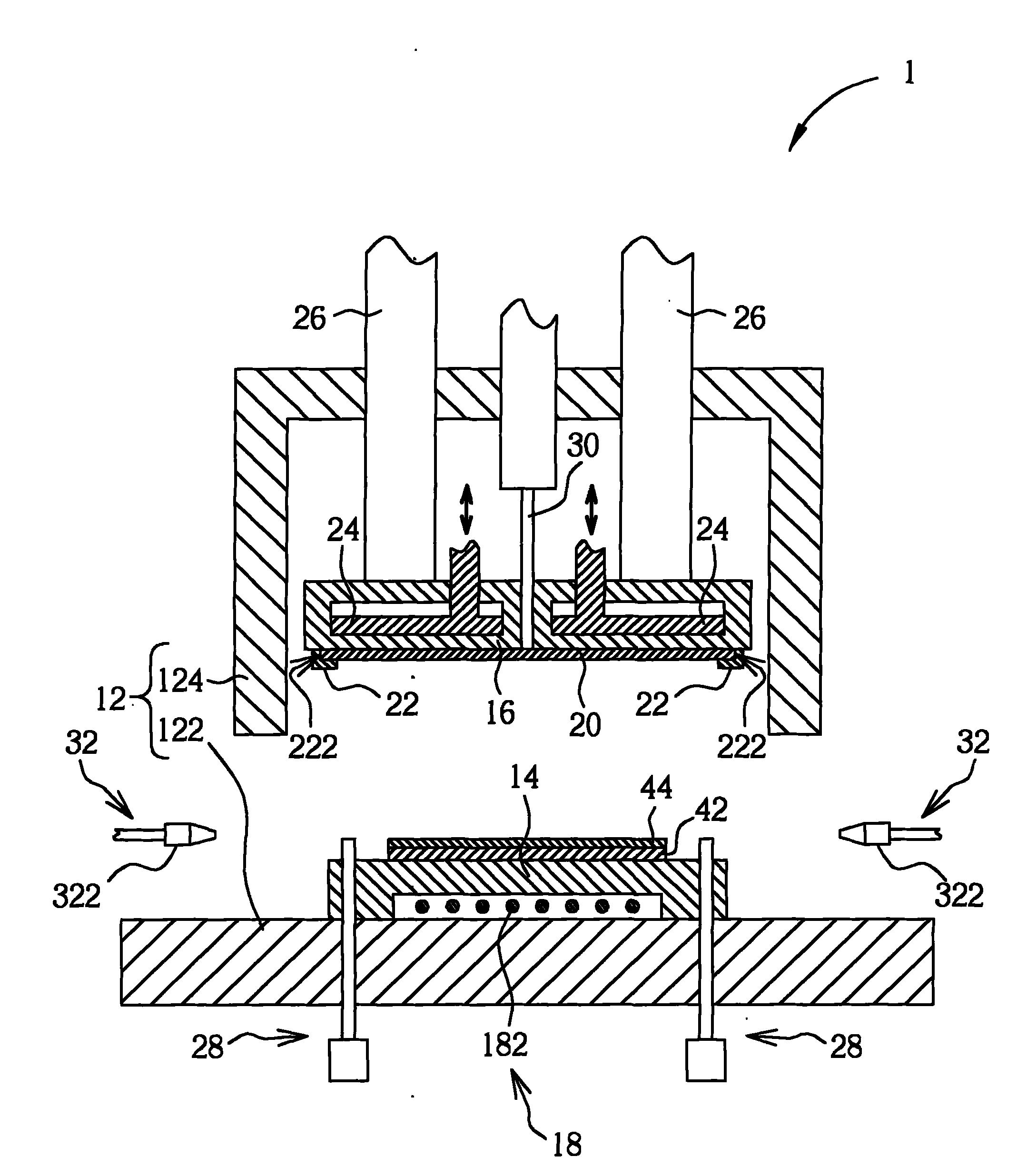

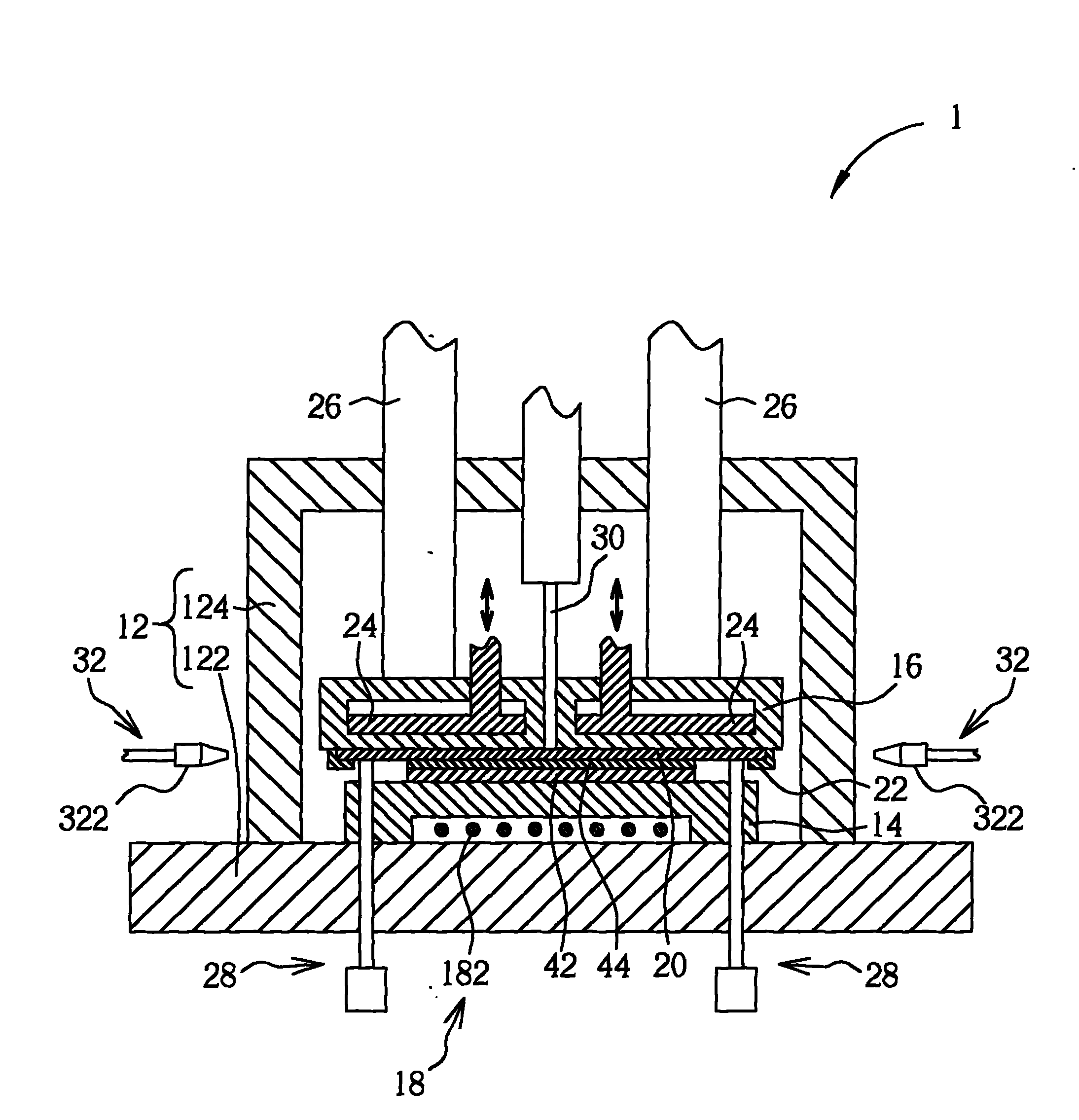

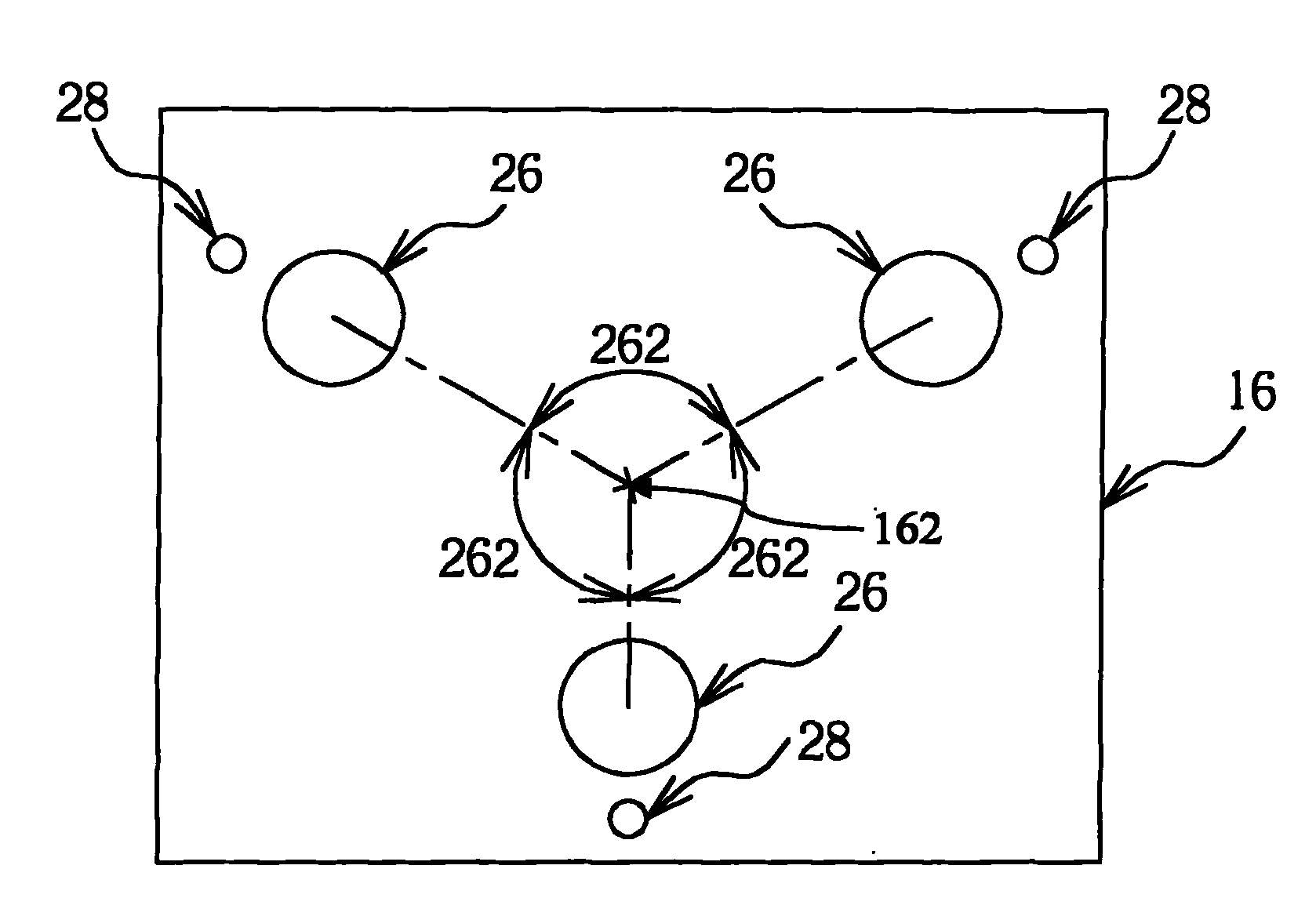

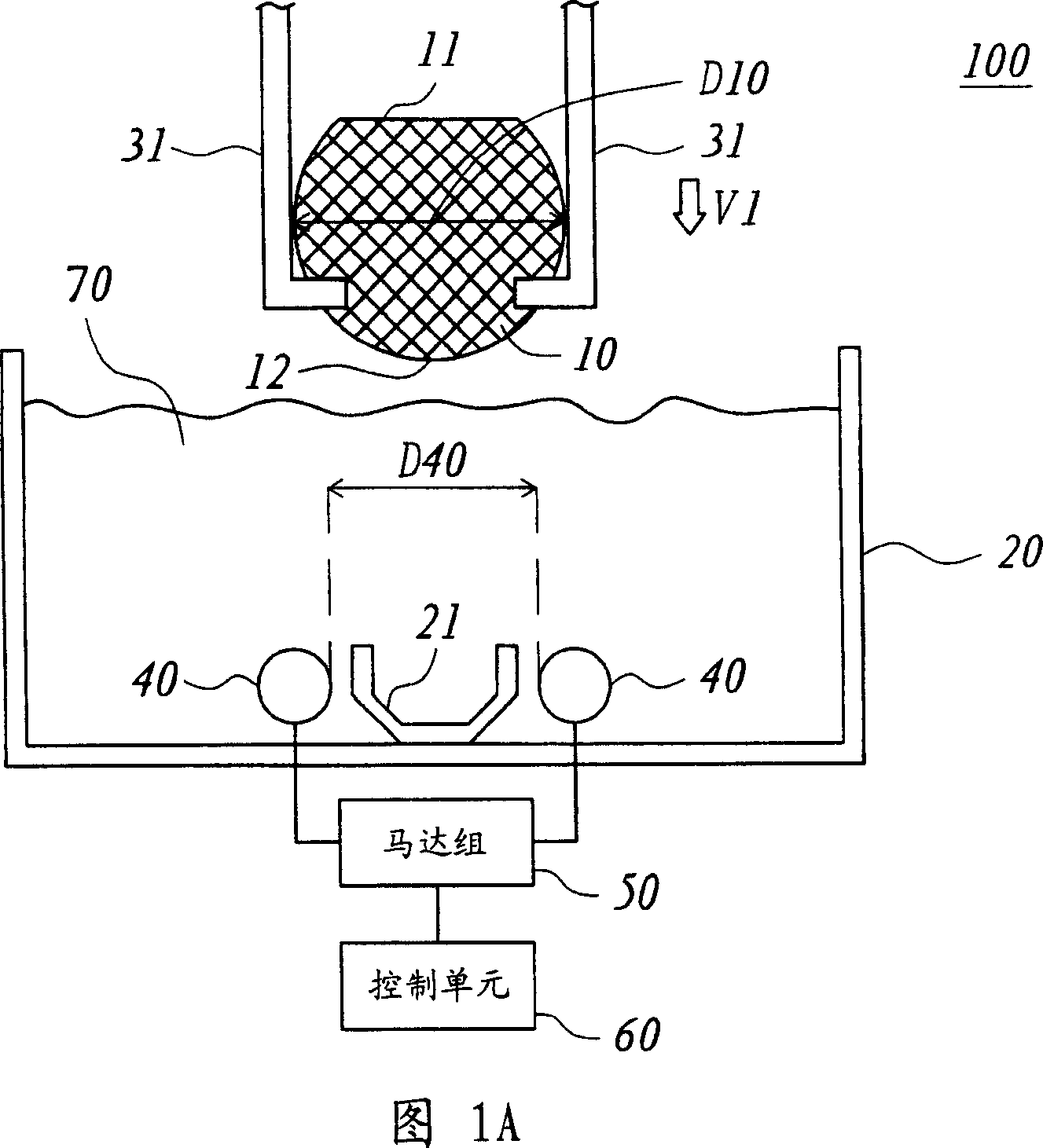

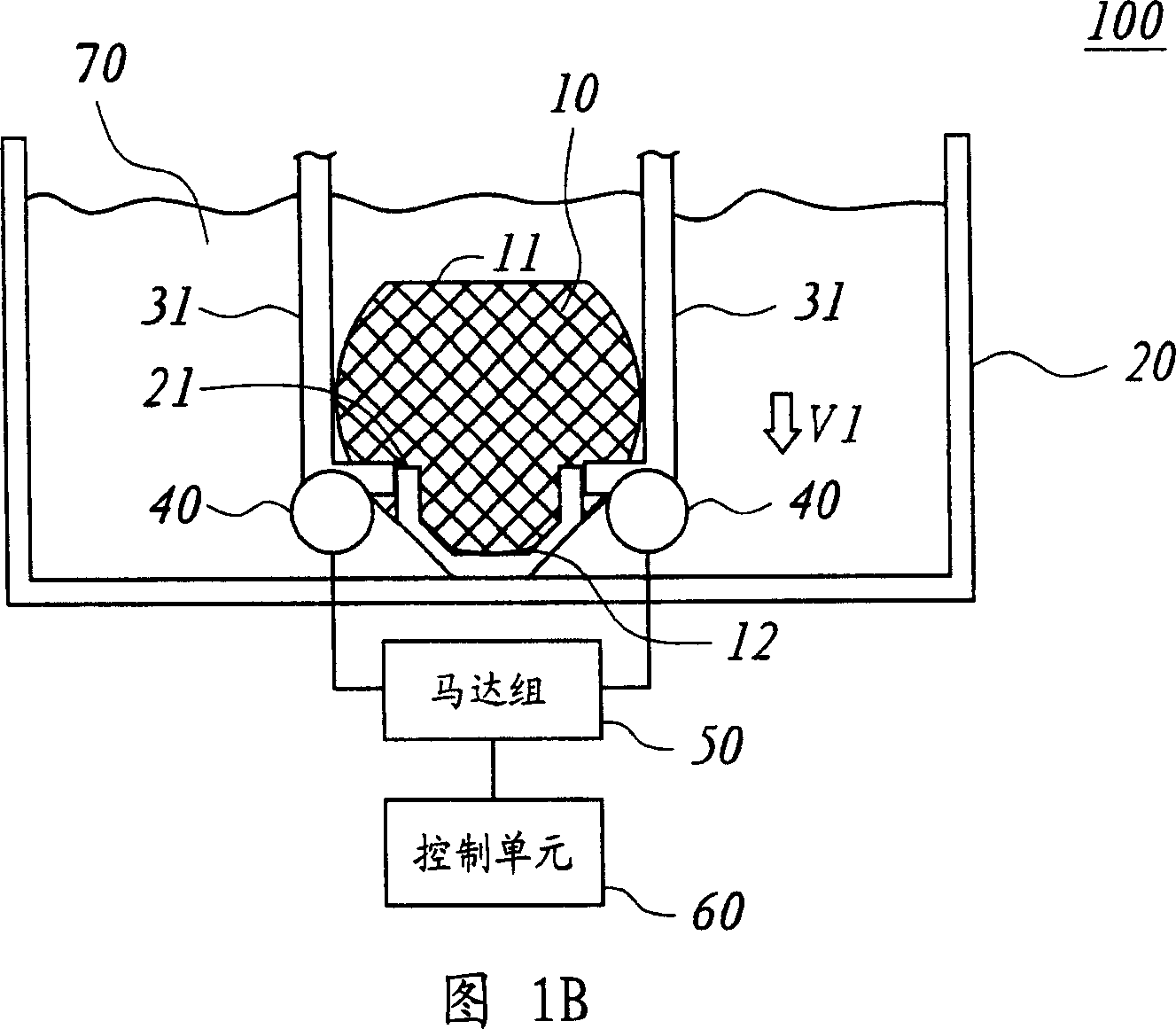

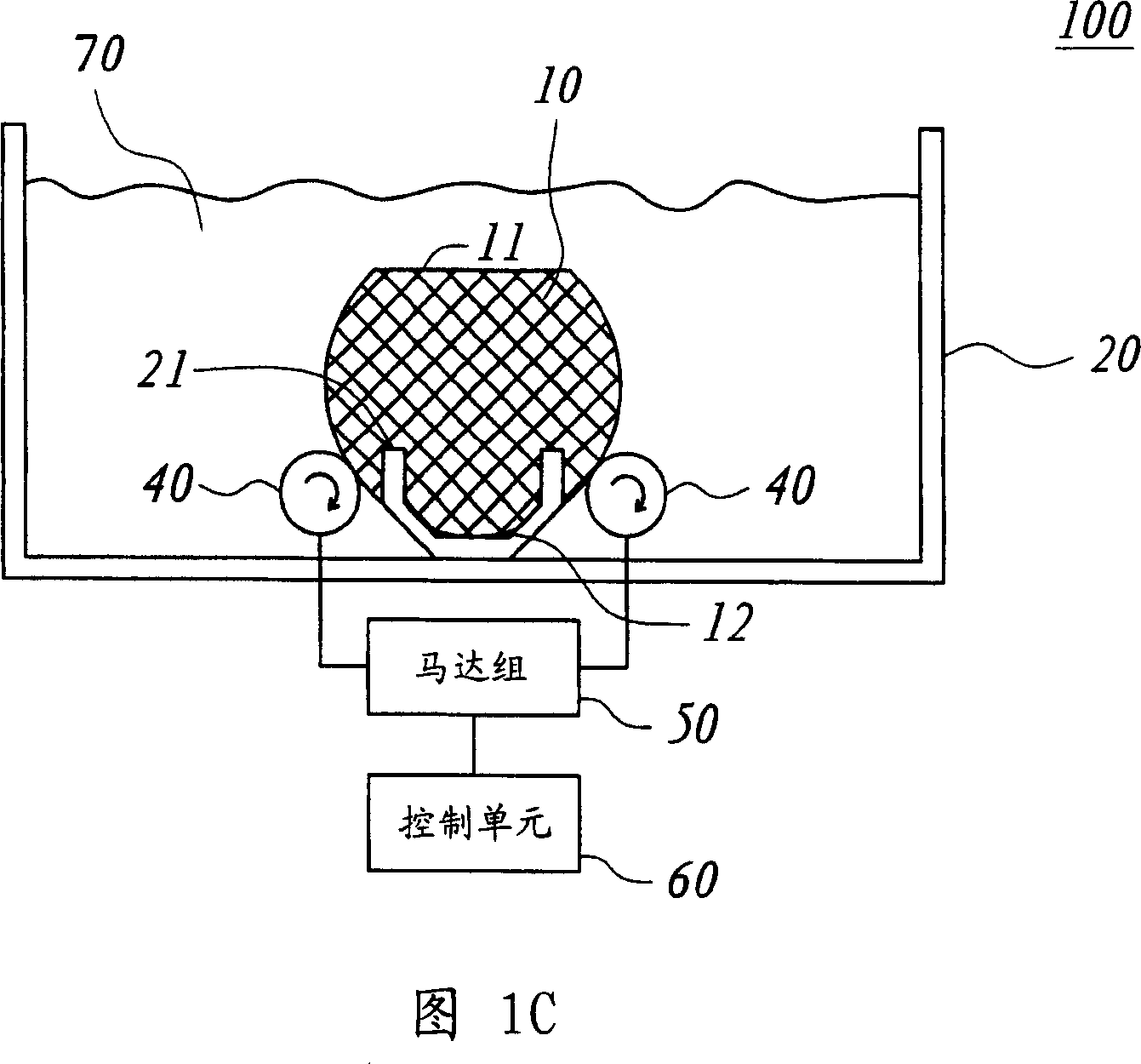

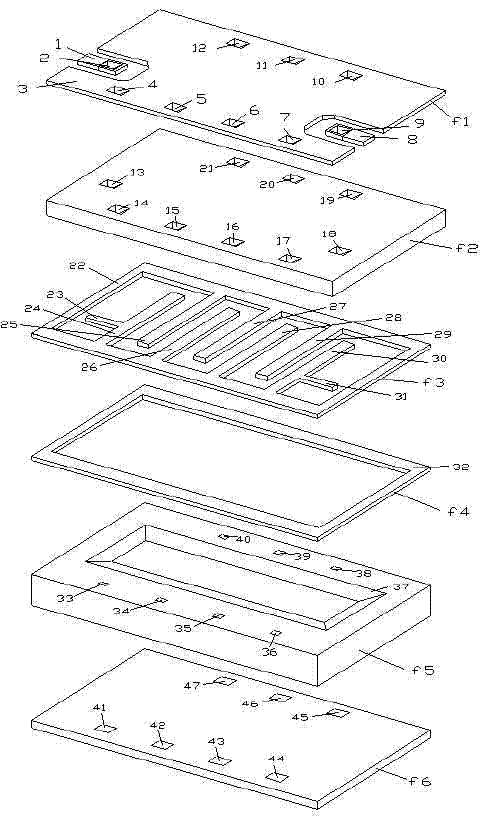

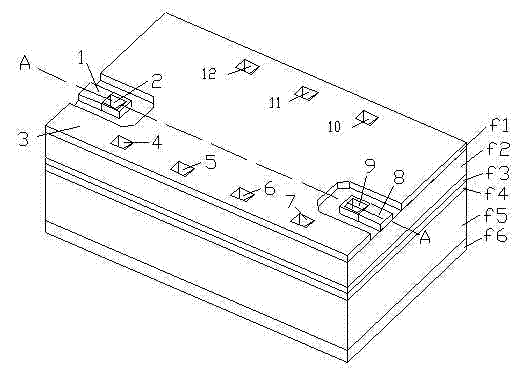

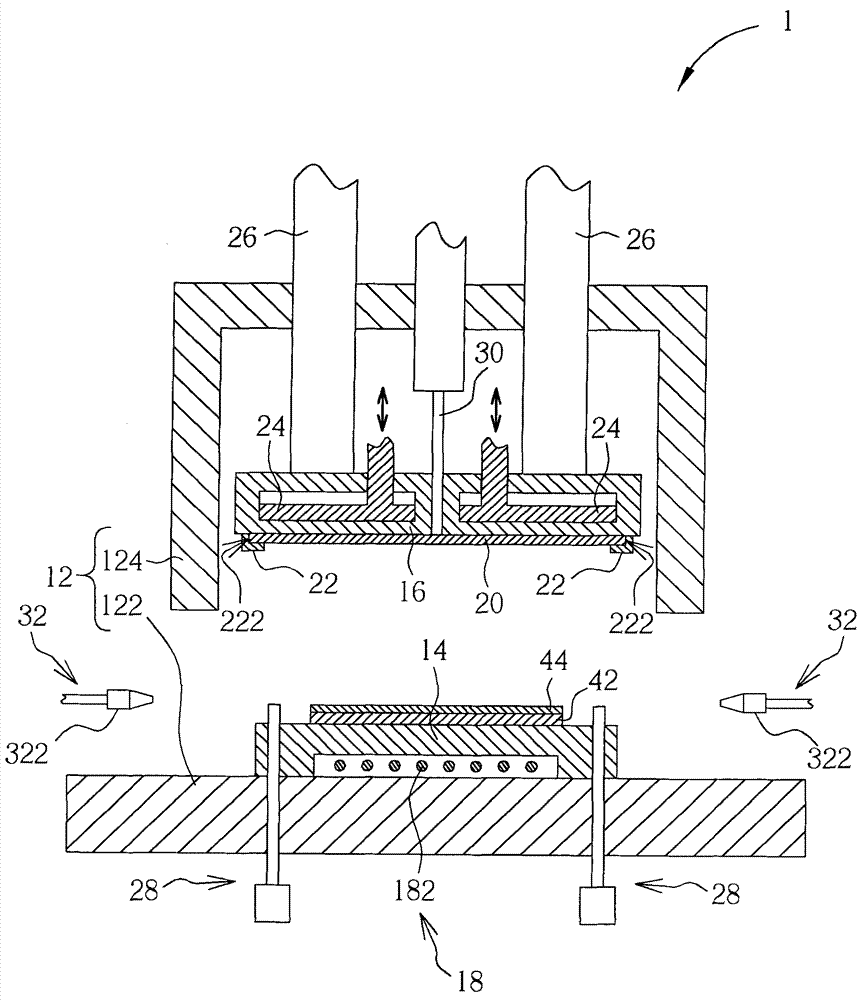

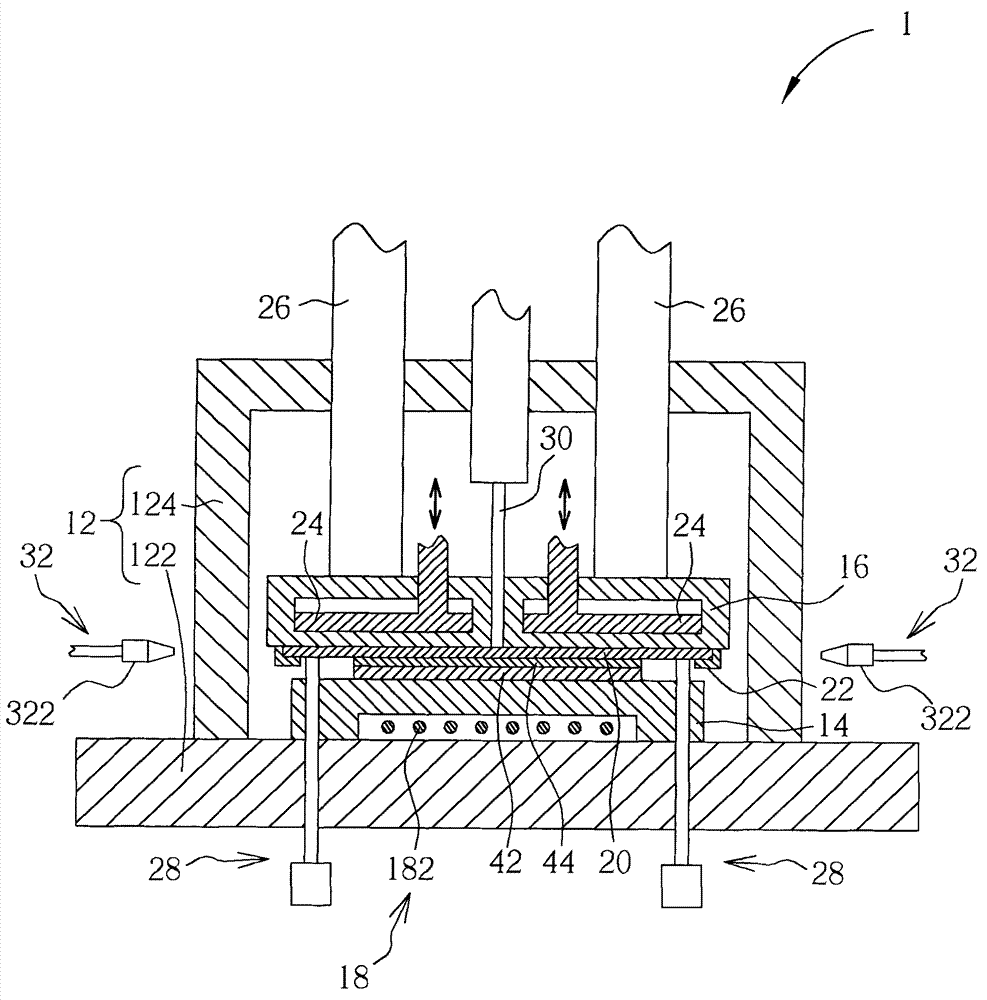

Vacuum imprinting device, vacuum compressing device and manufacturing method of layered optical component

InactiveCN102173238AInhibition of air bubblesImprove process precisionLaminationLamination apparatusEngineeringVacuum chamber

The invention discloses a vacuum imprinting device, a vacuum compressing device and a manufacturing method of a layered optical component, wherein, the vacuum imprinting device and the vacuum compressing device respectively comprise a vacuum chamber, a downloading platform, an uploading platform and a curing device. The uploading platform which is opposed to the downloading platform is equipped inside the vacuum chamber and moving towards the downloading platform so as to apply imprinting or flatting operations. The curing device is used for curing an optical glue layer in order to form an optical layer. The manufacturing method comprises the steps of respectively applying the vacuum imprinting device and the vacuum compressing device on a base plate to form a plurality of optical layers and then shaping layered optical components. By applying devices in vacuum conditions so as to form optical glue layers, a bubble phenomenon generated in the layered structure of the optical layers after the optical layers are cured is effectively prevented in the invention.

Owner:AU OPTRONICS CORP

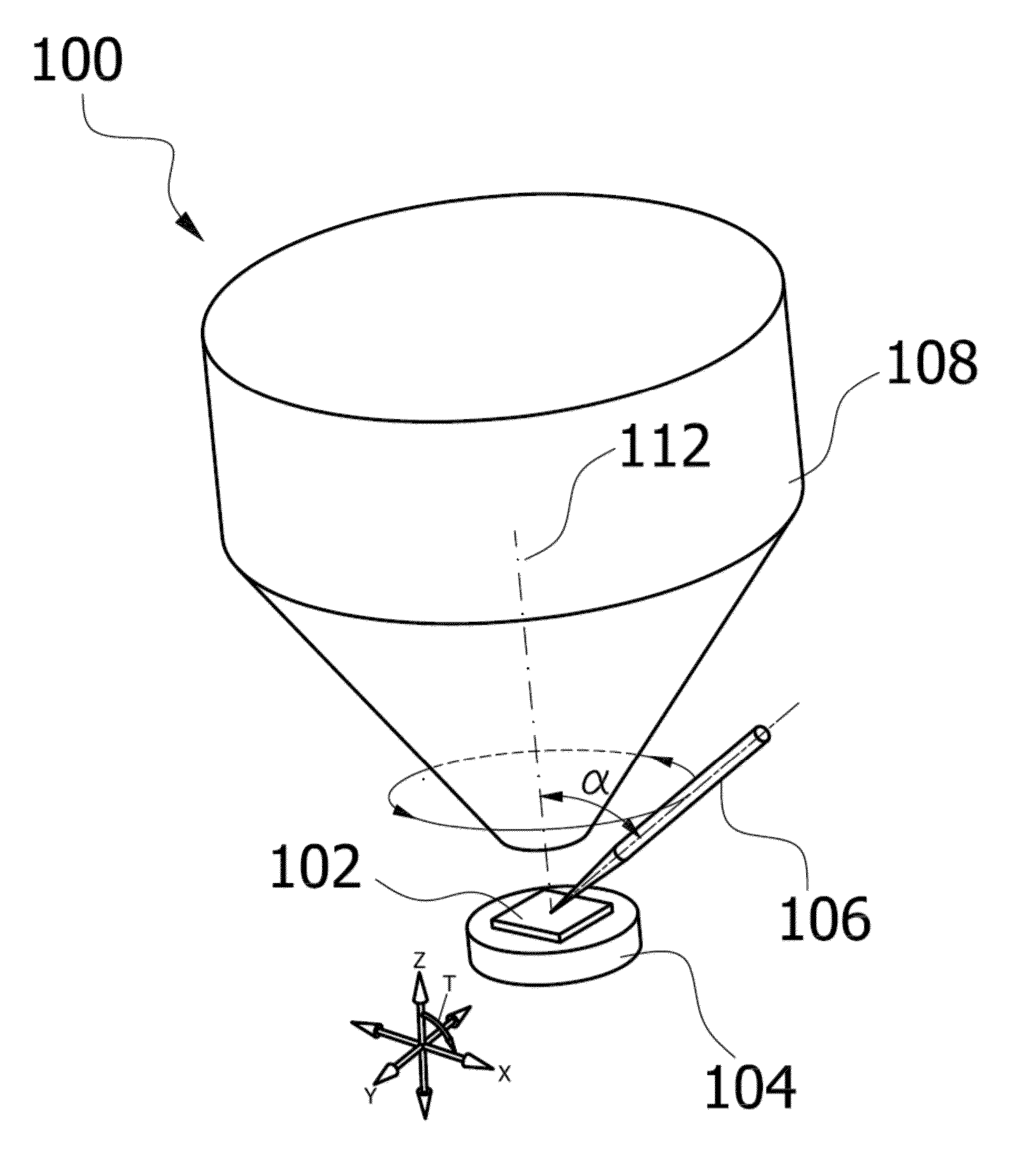

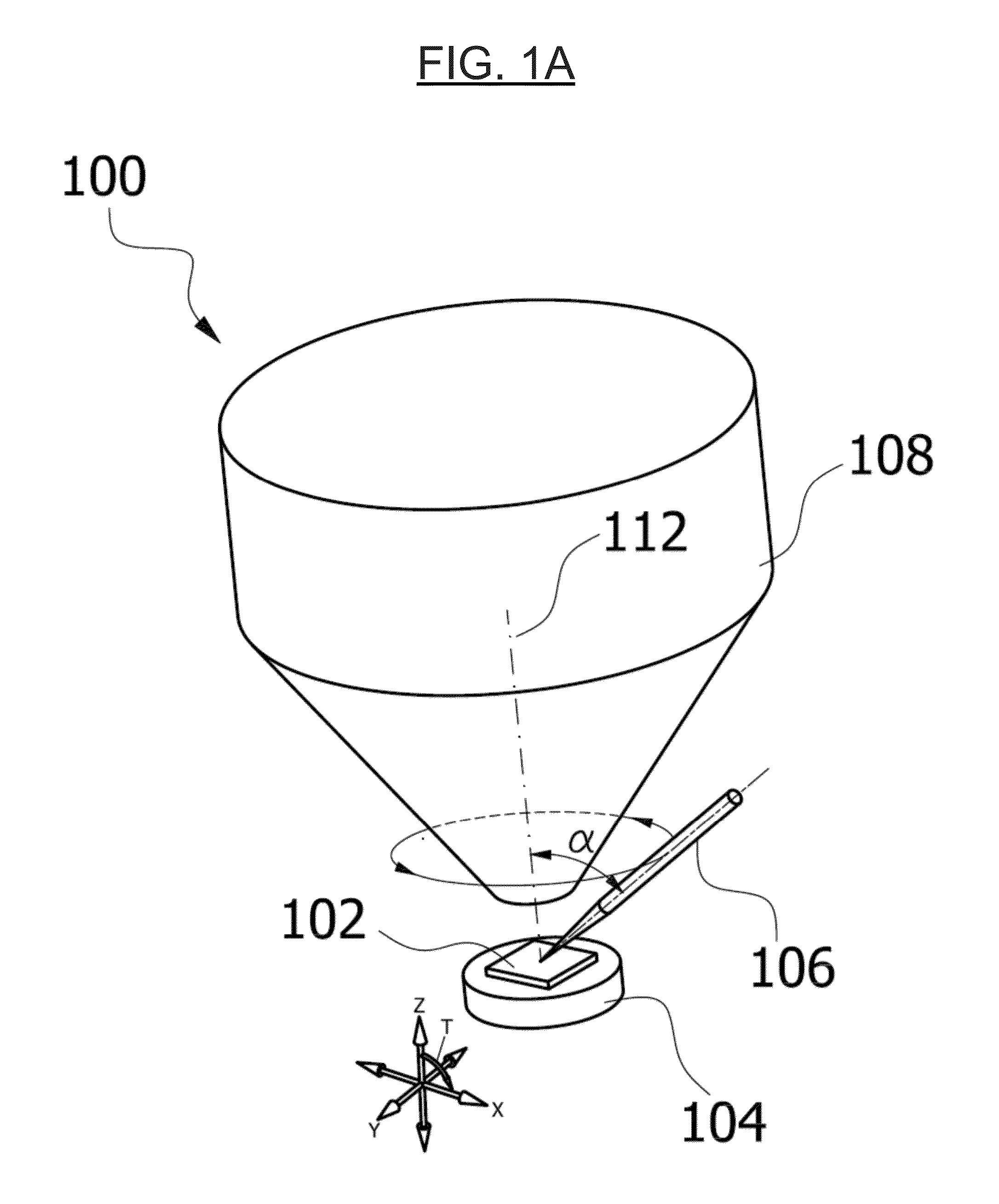

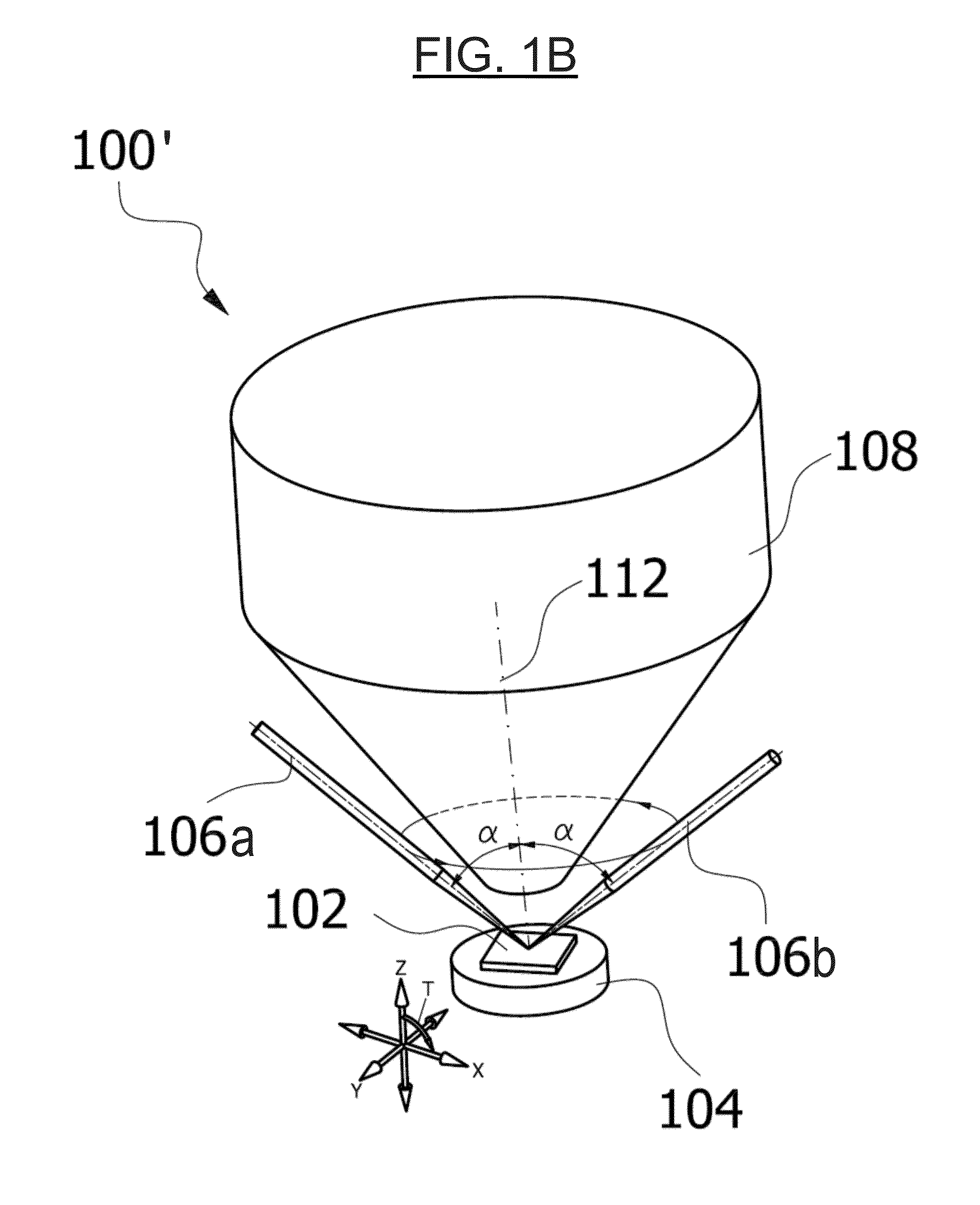

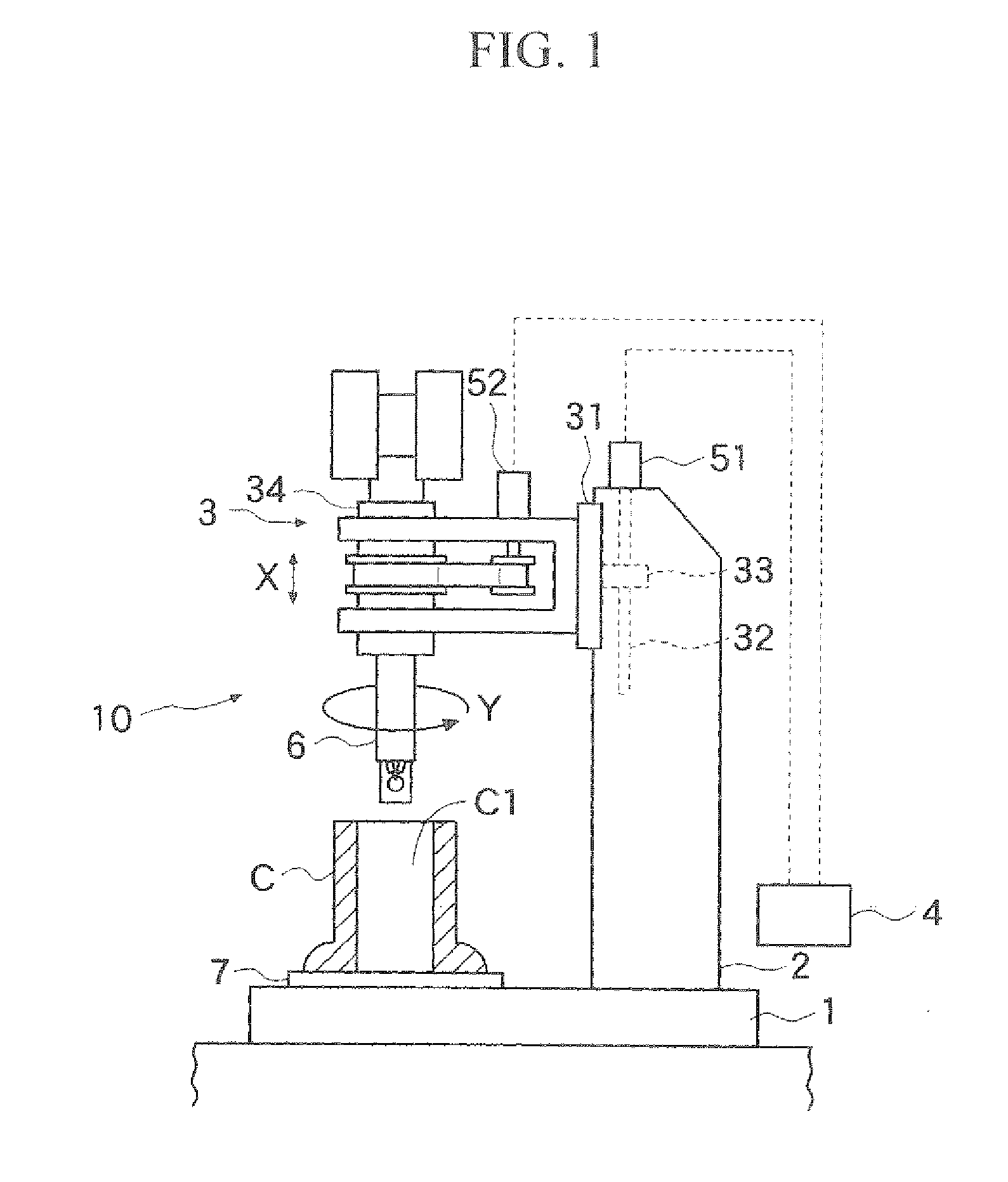

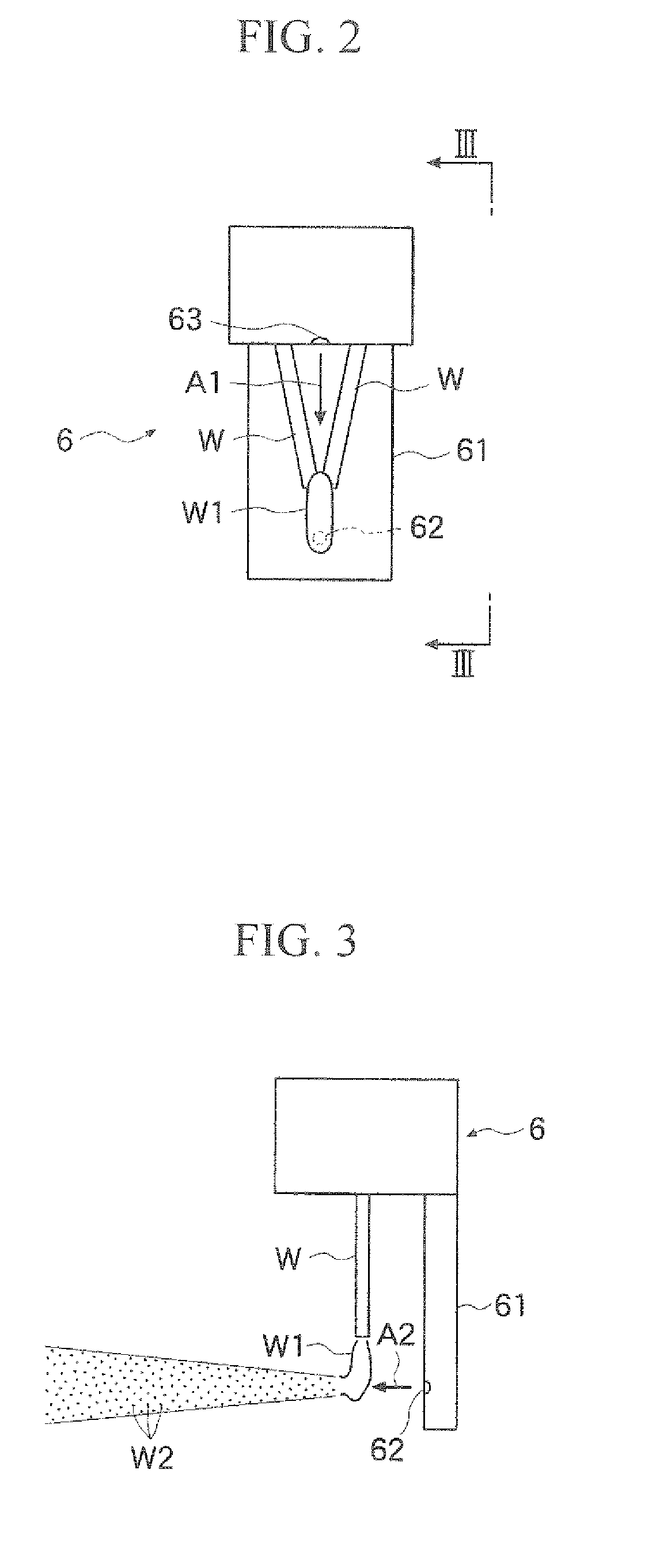

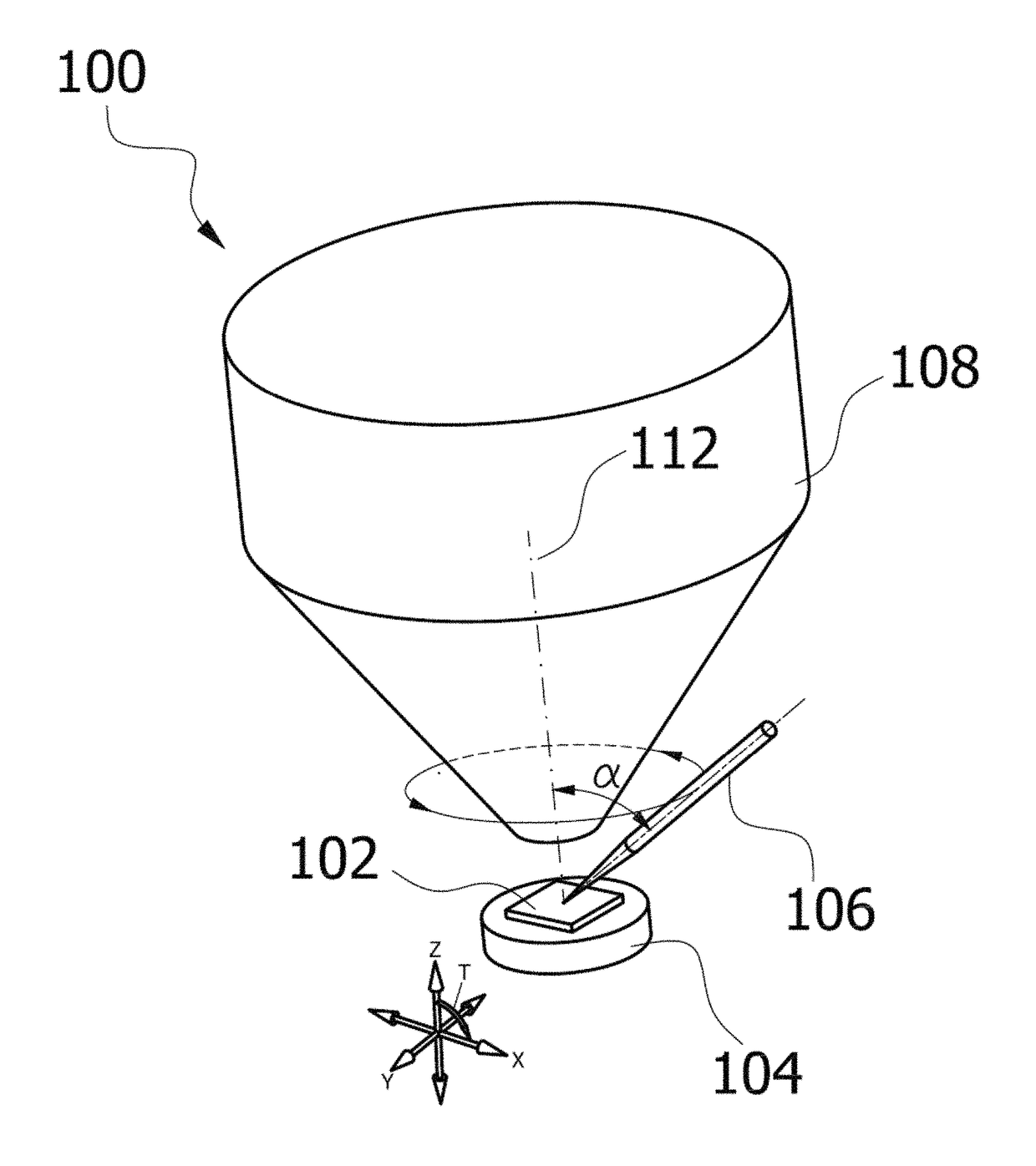

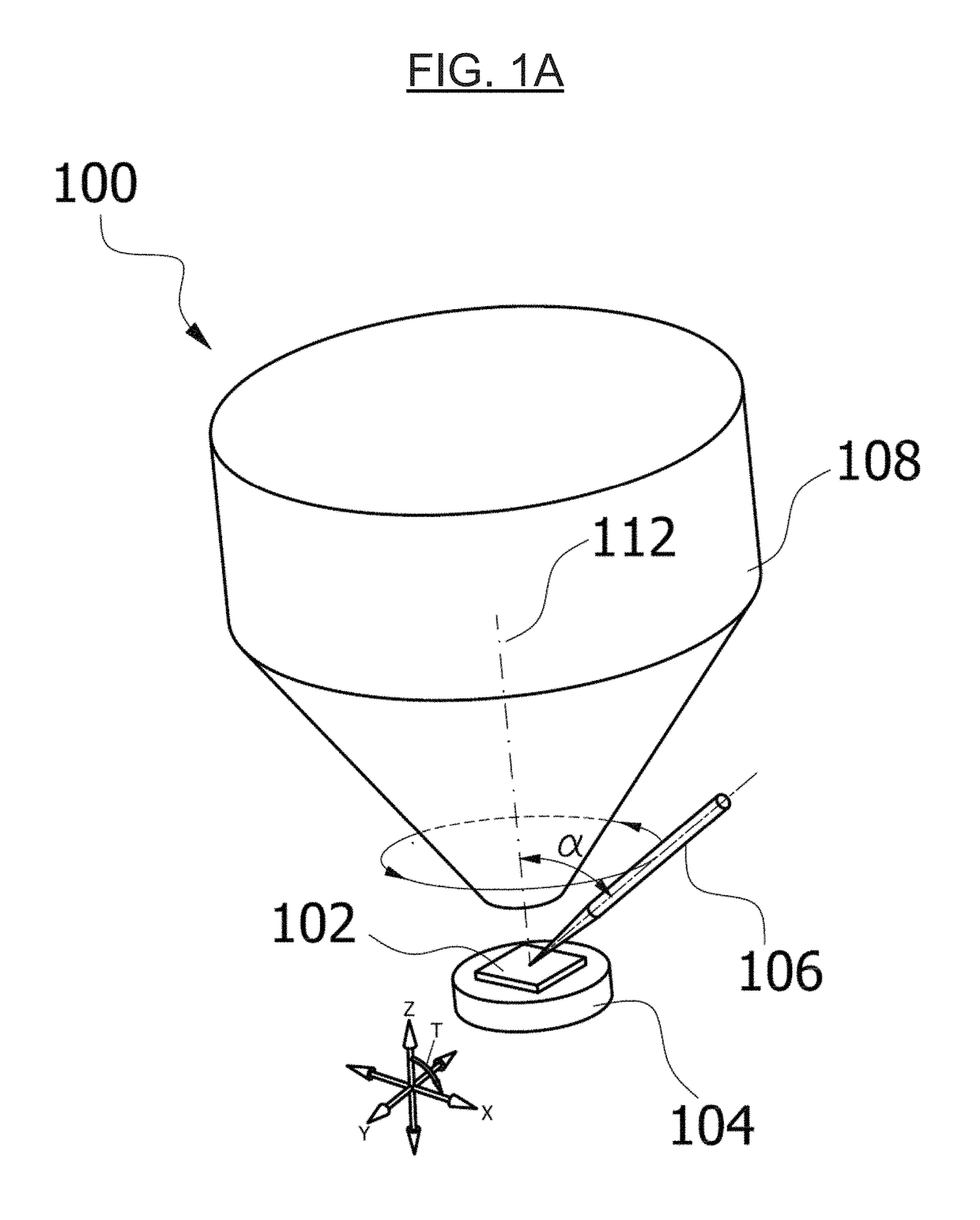

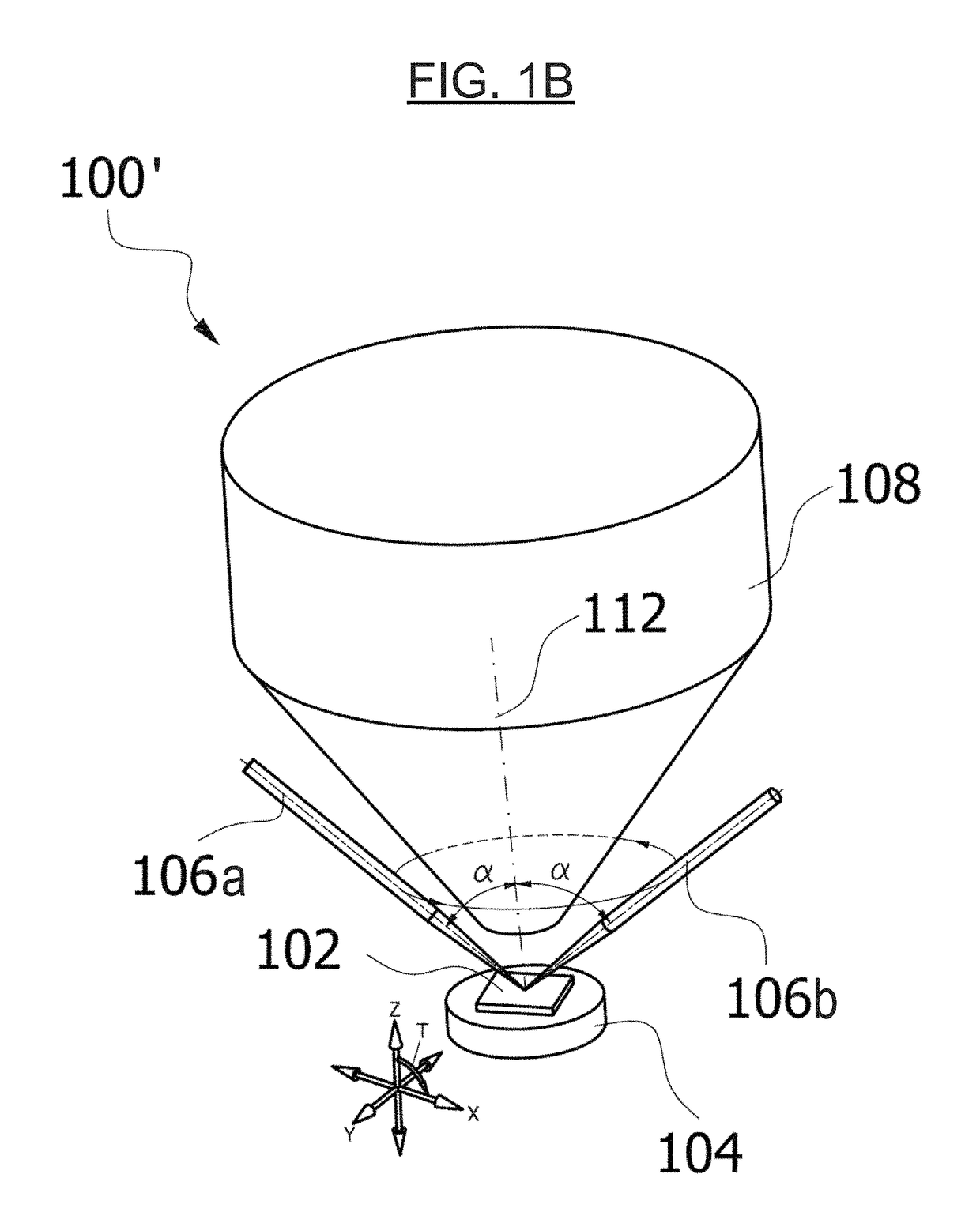

Methods, Apparatuses, Systems and Software for Treatment of a Specimen by Ion-Milling

ActiveUS20150255248A1Increase speedConvenient platformCellsElectric discharge tubesIon beamMachining process

Methods, apparatuses, systems and software for ion beam milling or machining are disclosed. The apparatus includes a specimen holder, a table, one or more ion sources, rotatable ion optics, and an imaging device. The specimen holder is configured to hold a specimen in a stationary position during milling or machining. The table is configured to change the stationary position of the specimen holder in any of three orthogonal linear directions and an angular direction. The rotatable ion optics are configured to emit an ion beam towards a predetermined location on the specimen from any of the one or more ion sources at any angle around an axis that is orthogonal to a horizontal surface of the table when the angular direction of the table is 0°. The imaging device is configured to generate an image of the specimen including the predetermined location, thereby enabling real-time monitoring of the milling or machining process.

Owner:IB LABS

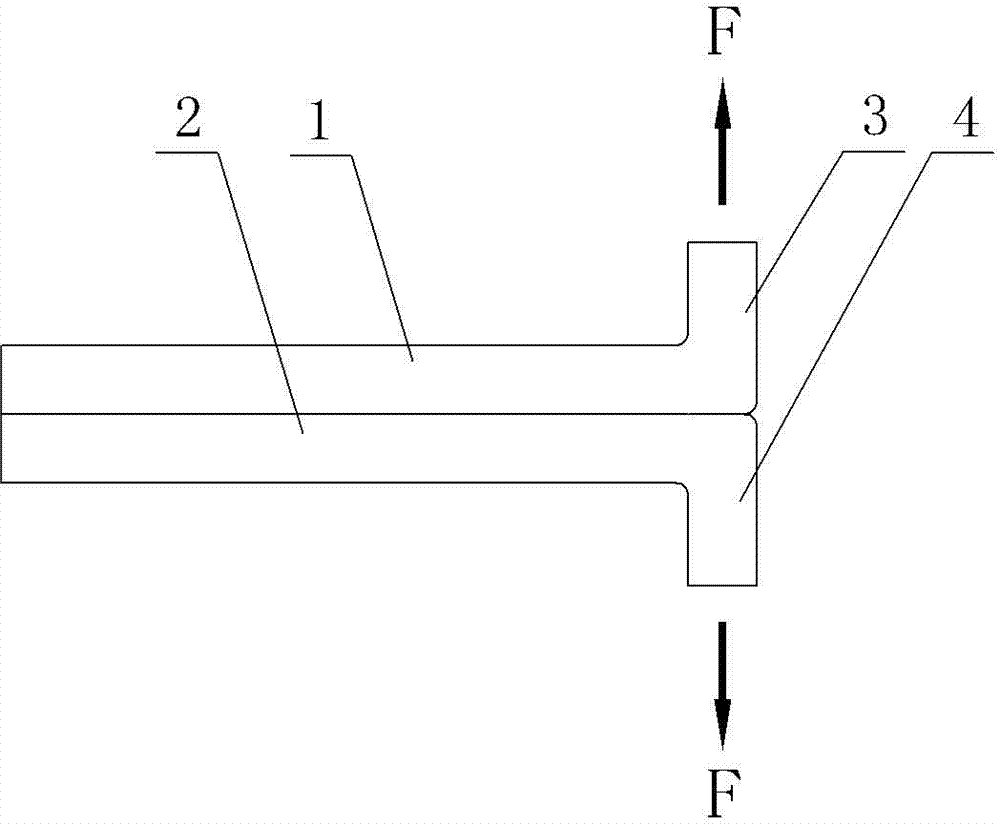

Method for detecting interface binding strength of aluminum-steel composite material for soldering

ActiveCN103776762AMake sure to peel off properlySmooth peelingUsing mechanical meansMaterial analysisTest sampleSoldering

The invention provides a method for detecting the interface binding strength of an aluminum-steel composite material for soldering. The method can be used for accurately detecting the aluminum-steel interface binding strength and quantifying the interface binding effect of the aluminum-steel composite material for the soldering. The method comprises the following steps: firstly, preparing a test sample of the aluminum-steel composite material and carrying out a stripping test on the test sample; and calculating according to a test result to obtain a binding strength value of an aluminum-steel interface. The method is characterized in that the preparation of the test sample comprises the following steps: soldering and connecting a metal reinforced layer on the surface of an aluminum layer of the sample and forming a compound layer by the metal reinforced layer and the aluminum layer of the sample. The binding strength of the metal reinforced layer in the compound layer and the aluminum layer of the sample is greater than the binding strength of the aluminum-steel interface; in the stripping test, the compound layer and a steel layer in the sample are stripped by a tension tester.

Owner:银邦(安徽)新能源材料科技有限公司

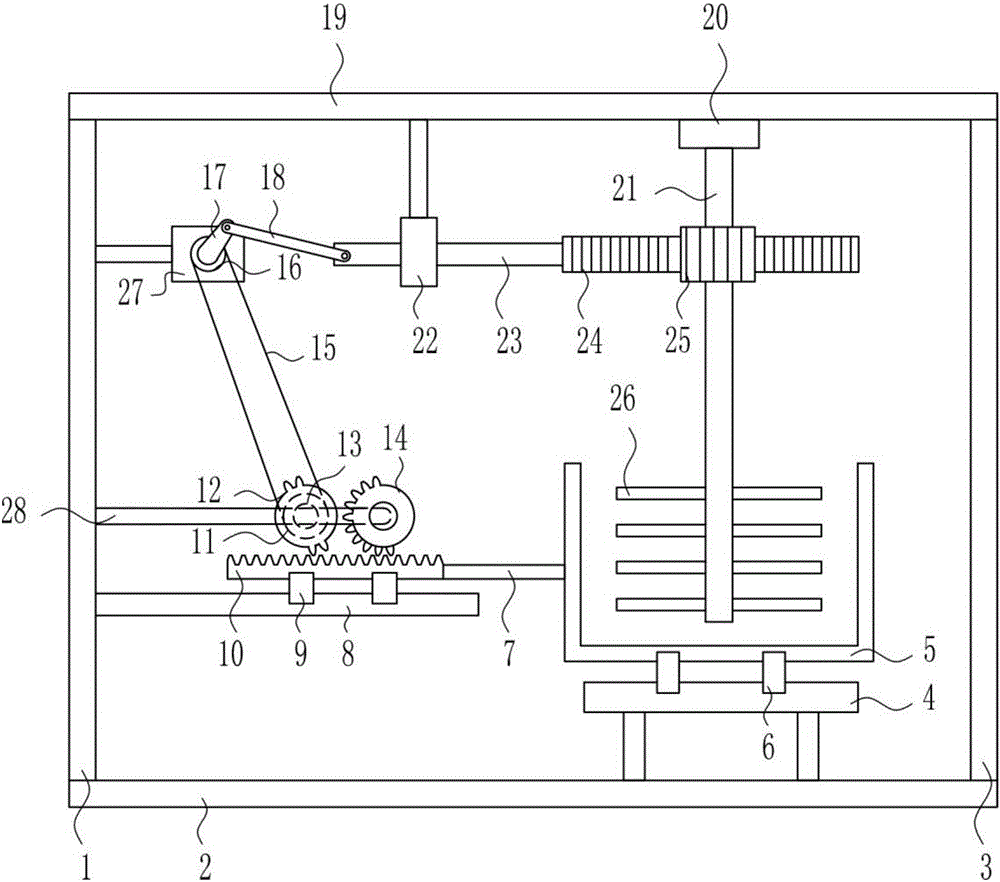

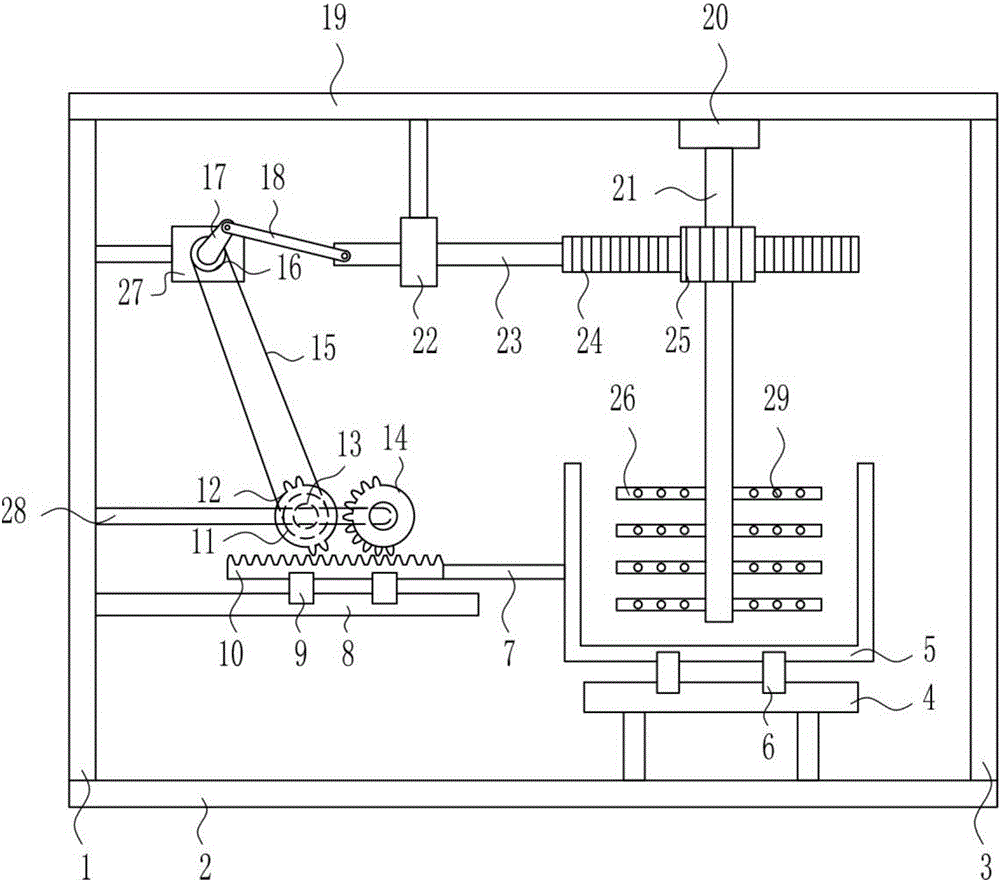

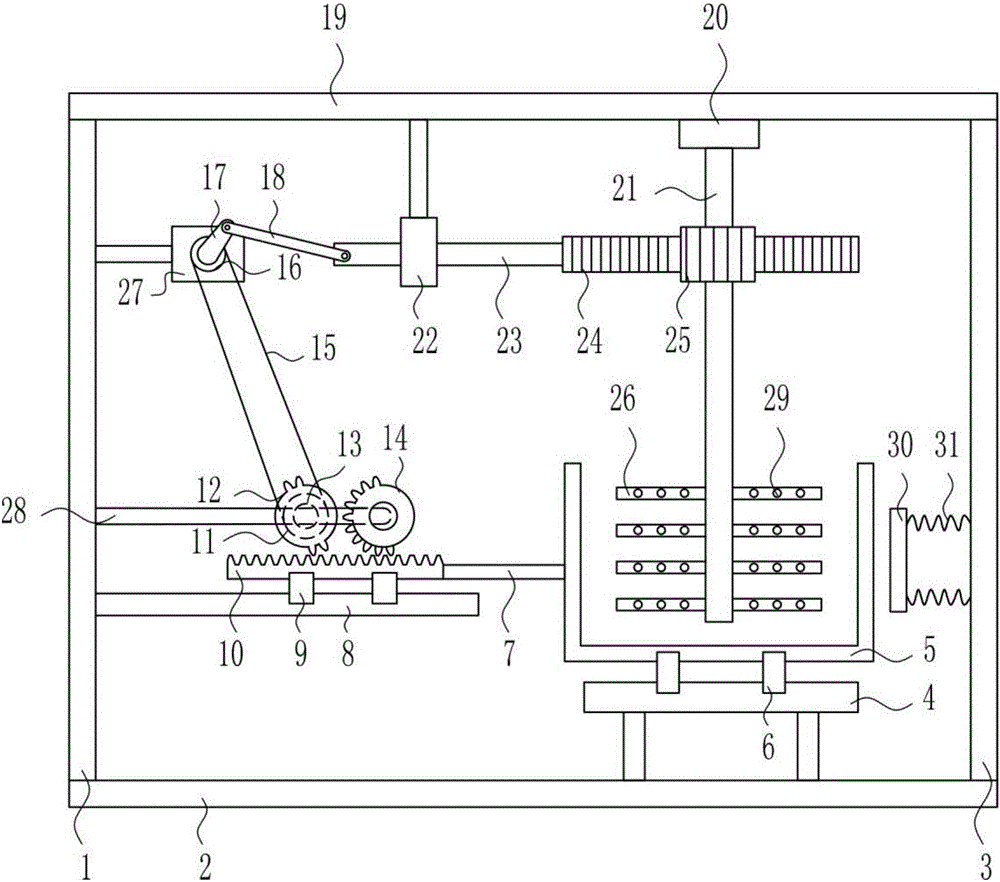

Quick mud stirring device for planting loquats

InactiveCN106215788AStir wellReduce dosageShaking/oscillating/vibrating mixersTransportation and packagingTeeth missingEngineering

The invention relates to a mud stirring device for planting loquats, in particular to a quick mud stirring device for planting loquats. Mud can be uniformly stirred by the quick mud stirring device for planting the loquats, and the quick mud stirring device is novel in structure and high in stirring speed. The quick mud stirring device for planting the loquats comprises a left frame, a bottom plate, a right frame, a first slide rail, a stirring frame, first sliders, a push rod, a second slide rail, second sliders, a second rack, a large belt pulley, a tooth-missing gear and the like. The left frame, the first slide rail and the right frame are sequentially arranged on the top of the bottom plate from the left to the right, the first sliders are slidably connected onto the first slide rail, and the stirring frame is arranged on the tops of the first sliders. The quick mud stirring device has the advantages that the mud can be uniformly stirred by the quick mud stirring device, and the quick mud stirring device is novel in structure and high in stirring speed; the mud can cover saplings of the loquats, the root systems of the saplings can be protected, transpiration of water can be reduced, and accordingly the survival rate of the loquats can be increased.

Owner:屏边县昌源果蔬产销专业合作社

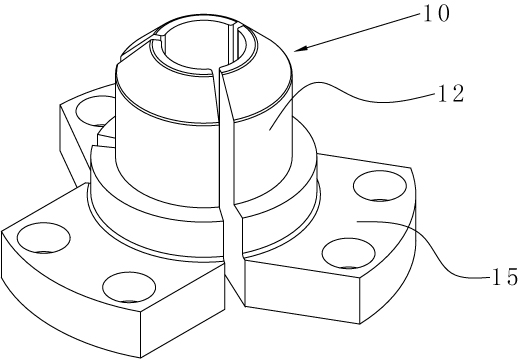

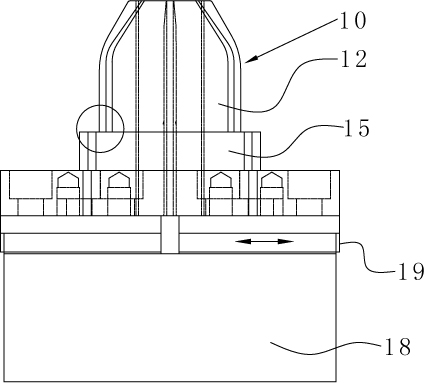

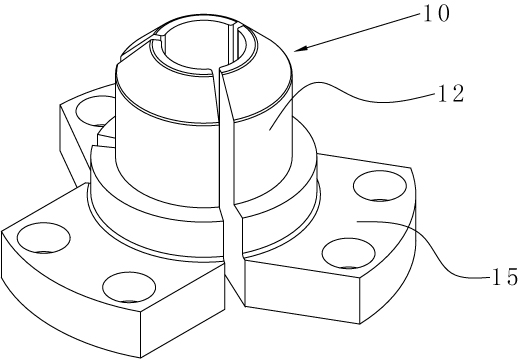

Round pin-inserted positioning device and tensioning and positioning round pin thereof

ActiveCN102121496AGuaranteed positioning accuracyGuaranteed positional stabilityWelding/cutting auxillary devicesBoltsEngineeringCar door

Owner:GUANGQI HONDA

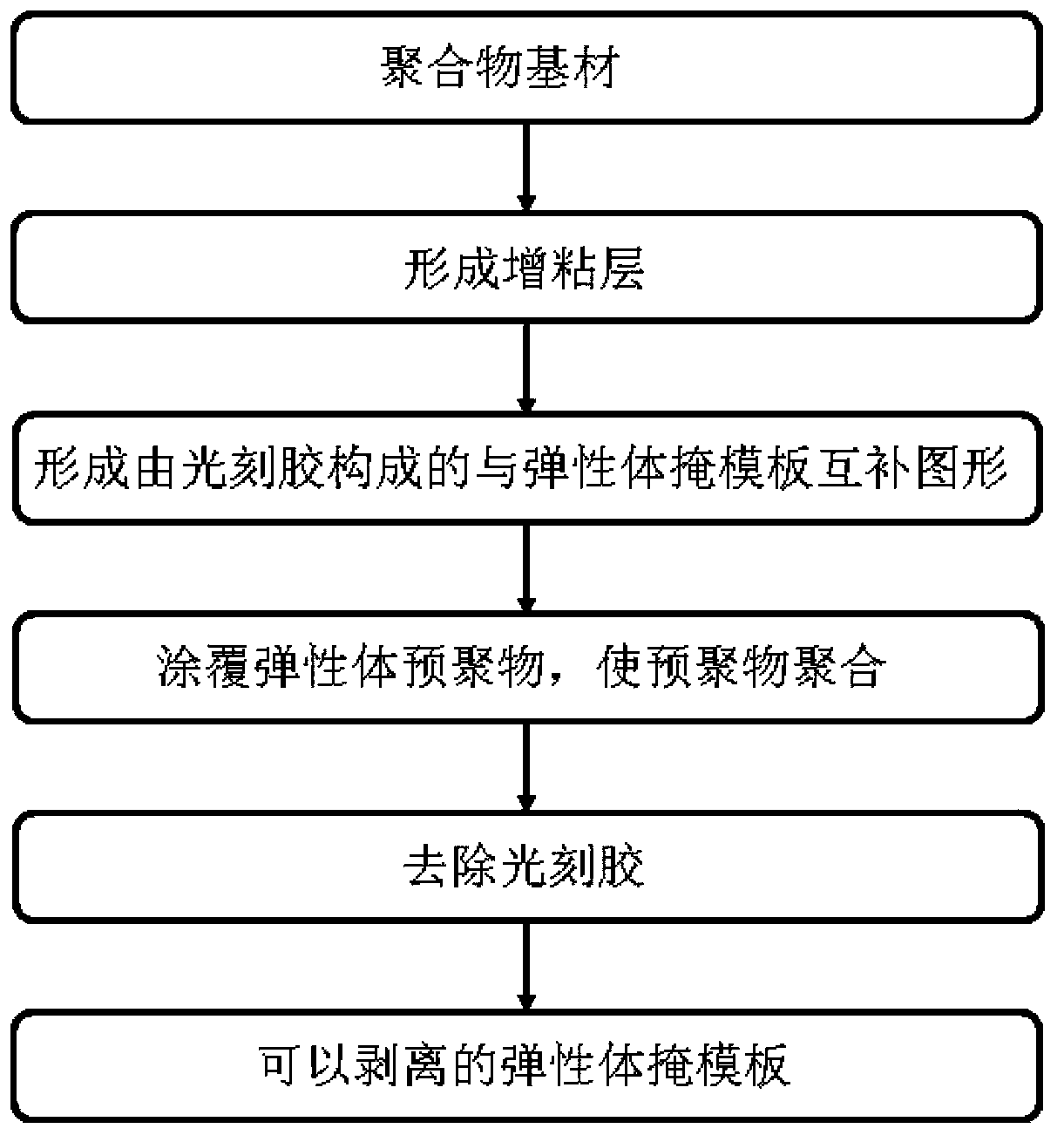

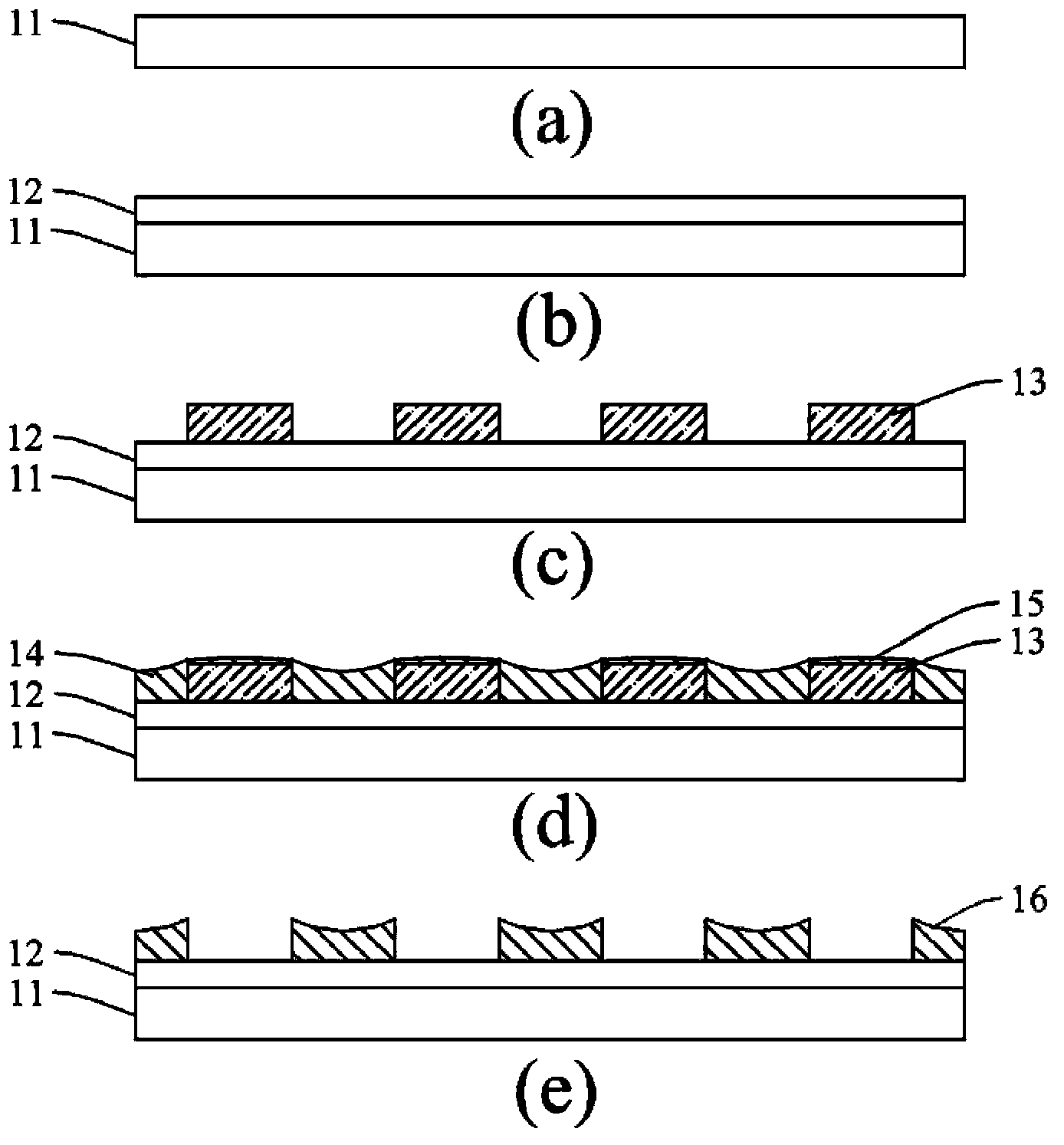

Method for forming peelable elastomer mask plate on surface of polymer base materials

InactiveCN103579531AAvoid difficultiesEasy to processSolid-state devicesSemiconductor/solid-state device manufacturingElastomerPolymer substrate

The invention discloses a method for forming a peelable elastomer mask plate on the surface of polymer base materials. The method comprises the steps that firstly, a coating layer for improving caking property is preformed on the surface of the polymer base materials; secondly, patterns, complementary with the mask plate, formed by photoresist are formed on the surface of the polymer base materials through the photolithography technique; thirdly, an elastomer coating layer with a certain thickness is formed again; fourthly, the photoresist is removed, and the peelable elastomer mask plate is obtained. The elastomer mask plate is used for forming patterned photoelectric functional devices on the polymer base materials.

Owner:西安宙斯光电科技有限公司

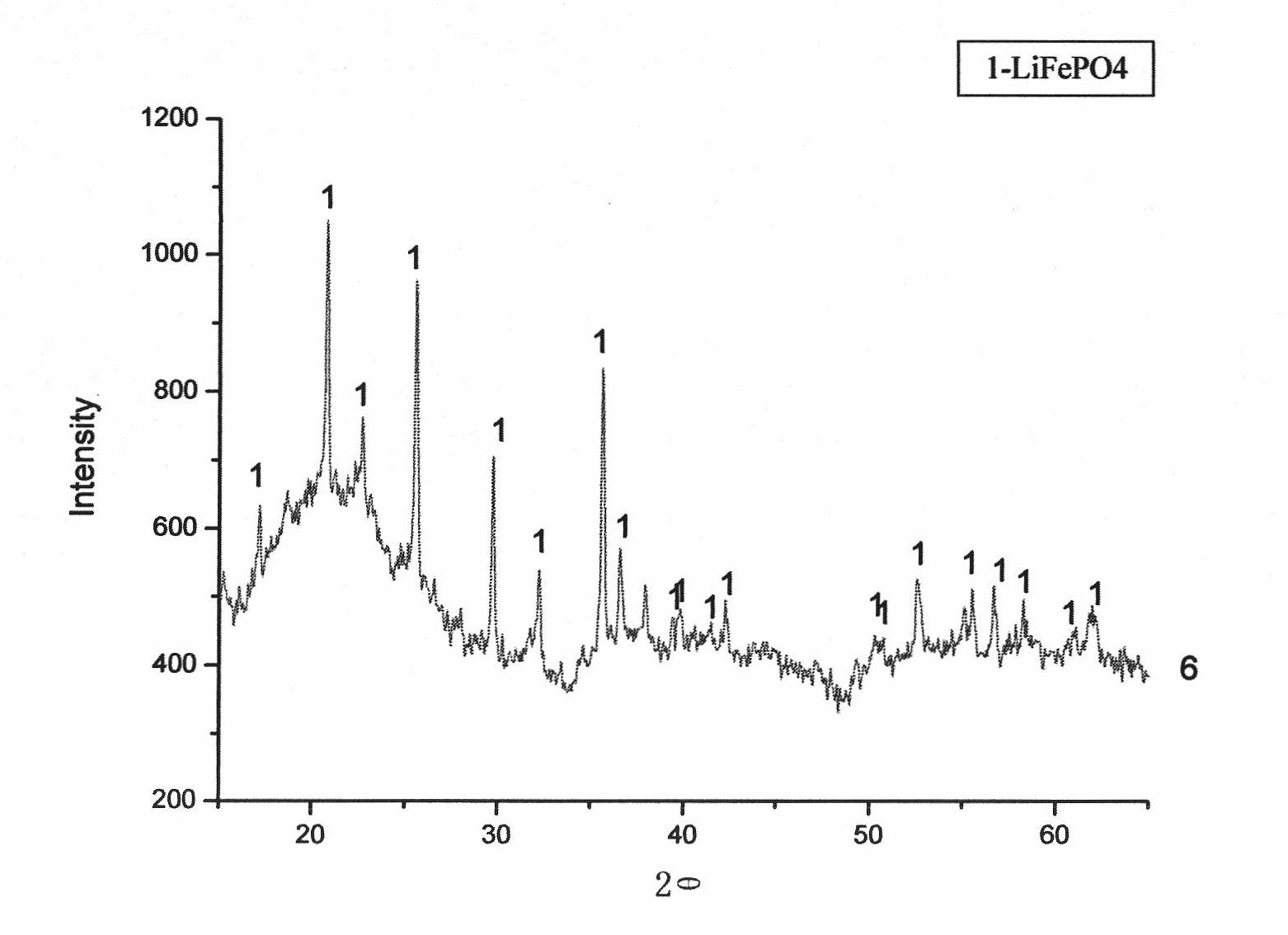

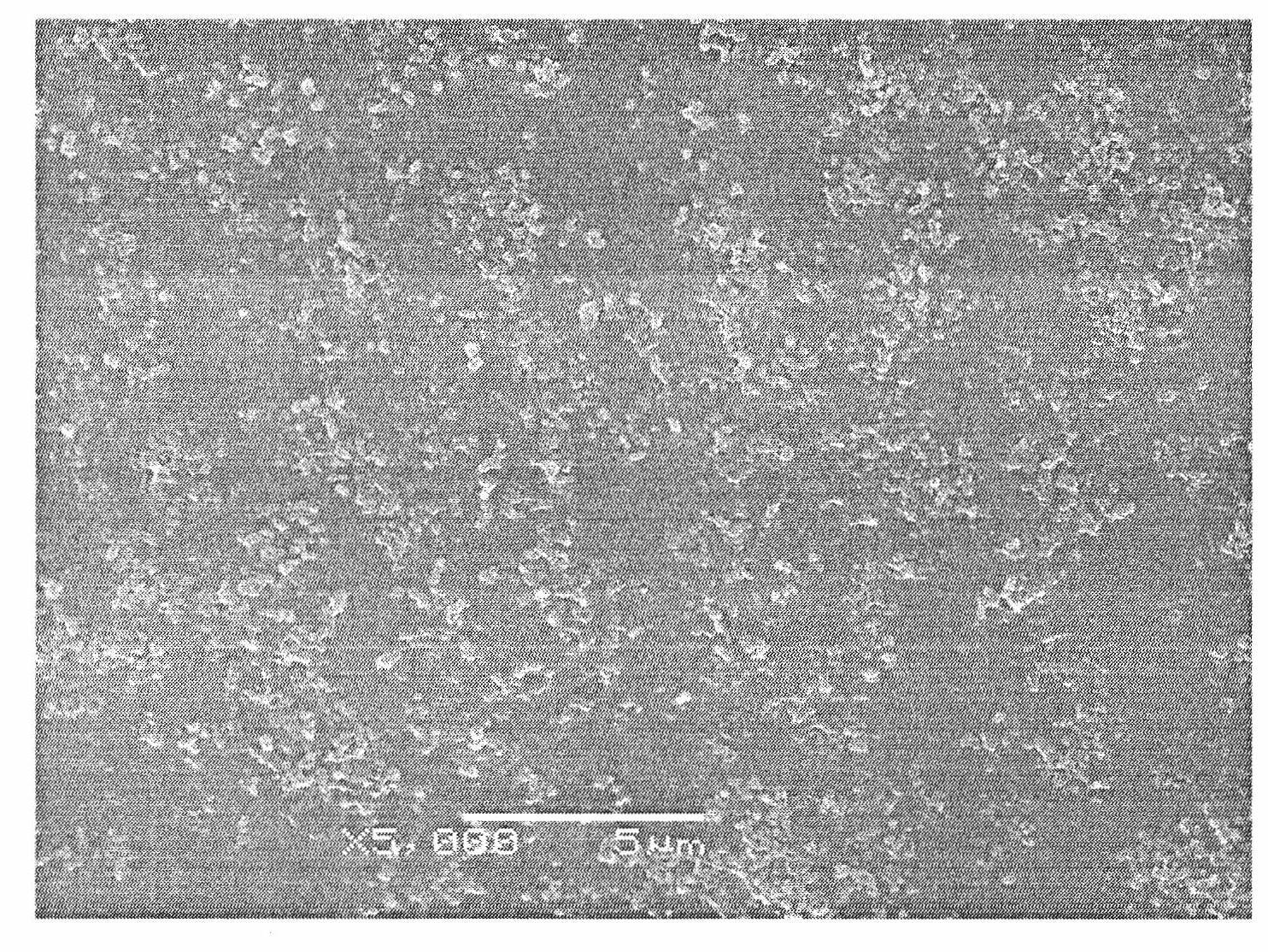

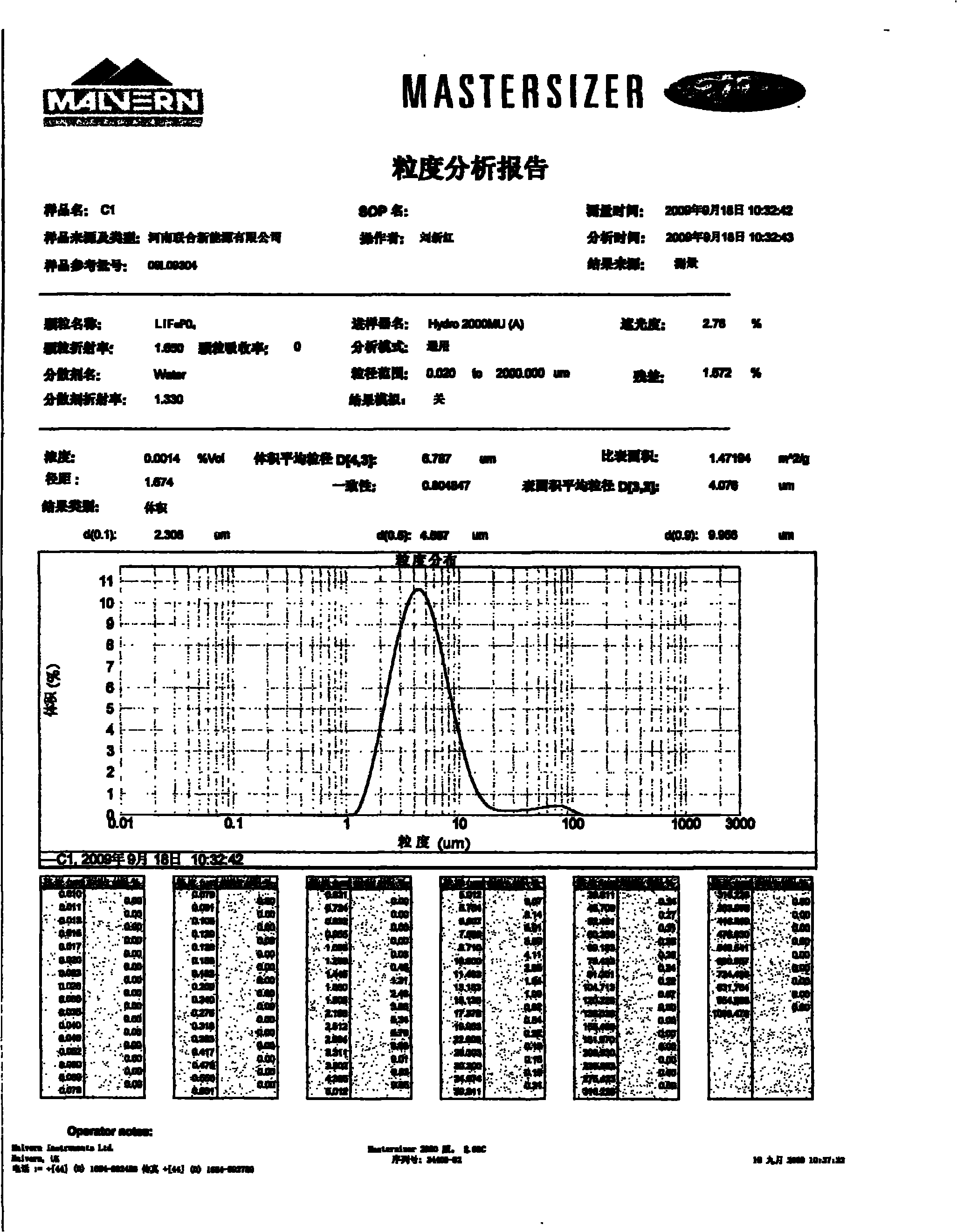

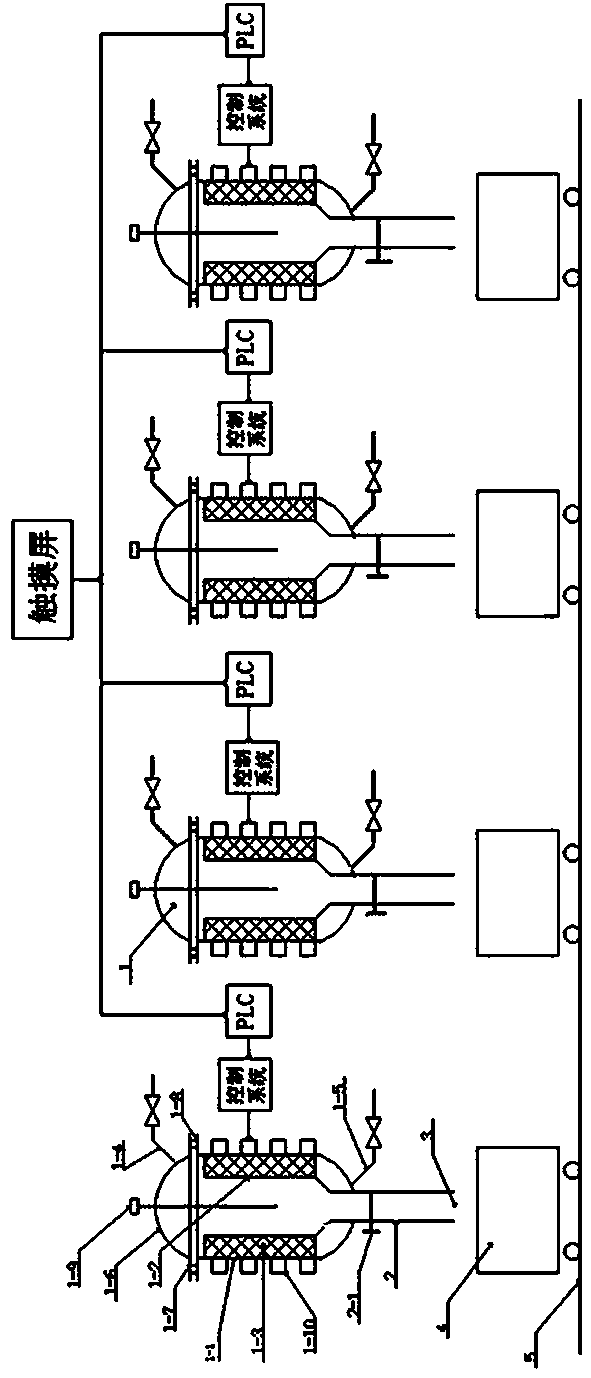

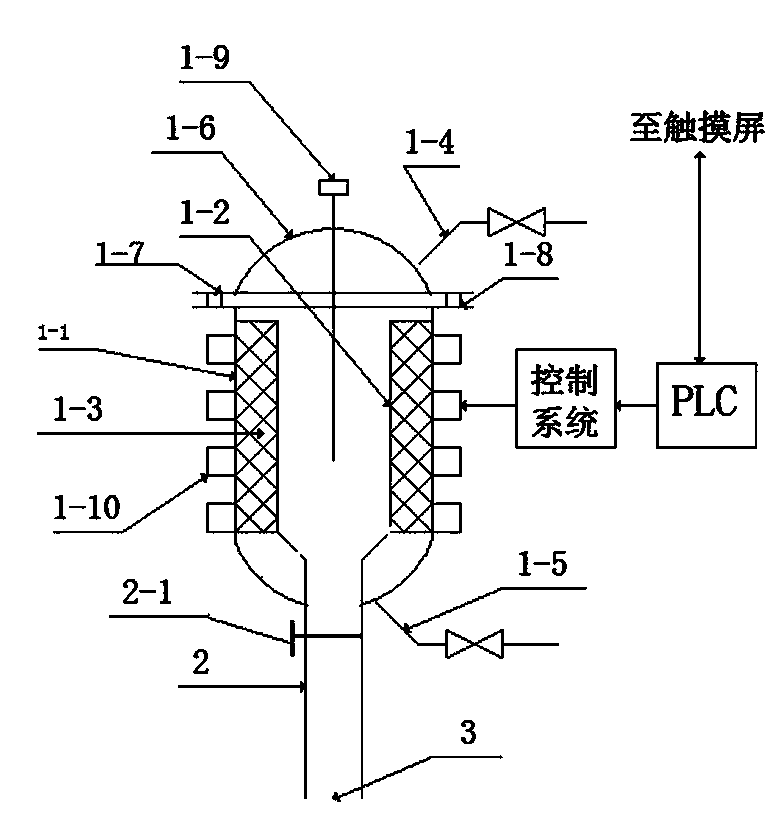

Method for preparing lithium iron phosphate by sintering lithium iron phosphate precursor and microwave sintering equipment

InactiveCN102092699APromote densificationEvenly distributedCell electrodesPhosphorus compoundsLithium iron phosphateControl treatment

The invention discloses a method and equipment for preparing lithium iron phosphate from a lithium iron phosphate precursor. The method comprises the three process steps of pretreatment of the lithium iron phosphate precursor material, pre-sintering and sintering; and in a non-oxidizing environment, the precursor material is heated by a certain number of microwave heaters, and the three process steps are finished by controlling treatment temperature and treatment time to finally prepare the lithium iron phosphate product. The equipment comprises a material inlet, a material feeding ventilation chamber, a pretreatment unit furnace, a pre-sintering unit furnace, a sintering unit furnace, a material discharging ventilation chamber, a cooling material discharging mechanism, a material outlet,a vacuumizing device, a protective gas input device and an equipment control circuit. In the method, the pretreatment and pre-sintering process steps are added to optimize a lithium iron phosphate microwave sintering process and solve keys problems on product quality control. The equipment provided by the invention realizes continuous microwave sintering by a plurality of unit furnaces so as to improve the sintering efficiency and realize large-scale industrial production.

Owner:HENAN UNION NEW ENERGY

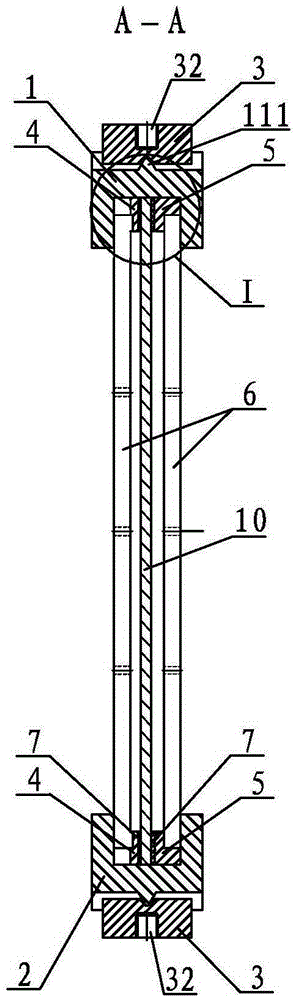

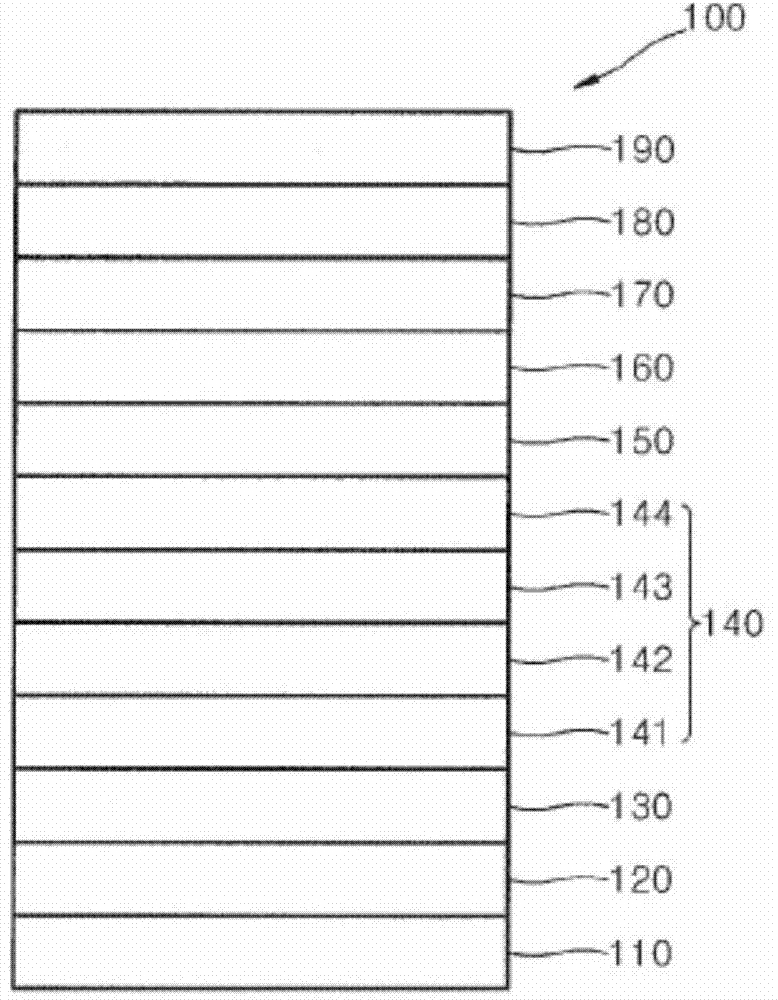

Organic electroluminescence device

ActiveCN104505464AReduce the number of alignmentsImprove process precisionSolid-state devicesSemiconductor/solid-state device manufacturingElectronic transmissionHole injection layer

The invention relates to an organic electroluminescence device which comprises a substrate, and a first electrode layer, a plurality of luminous units and a second electrode layer which are formed on the substrate in sequence, wherein the luminous units comprise a hole injection layer, a hole transmission layer, a luminous layer and an electronic transmission layer which are arranged on the first electrode layer in sequence; the hole transmission layer is prepared from a first hole transmission material and a second hole transmission material; the triplet energy level T1 of the first hole transmission material is greater than or equal to 2.48eV, and the HOMO energy level is smaller than or equal to -5.5eV; the HOMO energy level of the second hole transmission material is greater than -5.5eV; furthermore, the HOMO energy level difference between the first hole transmission material and the second hole transmission material is smaller than or equal to 0.2eV. The hole transmission layer is higher in triplet energy level T1 and migration rate, and the preparation technology is simple, so that the beneficial effects of obviously reducing the power consumption of the device and greatly improving the efficiency are achieved.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT +1

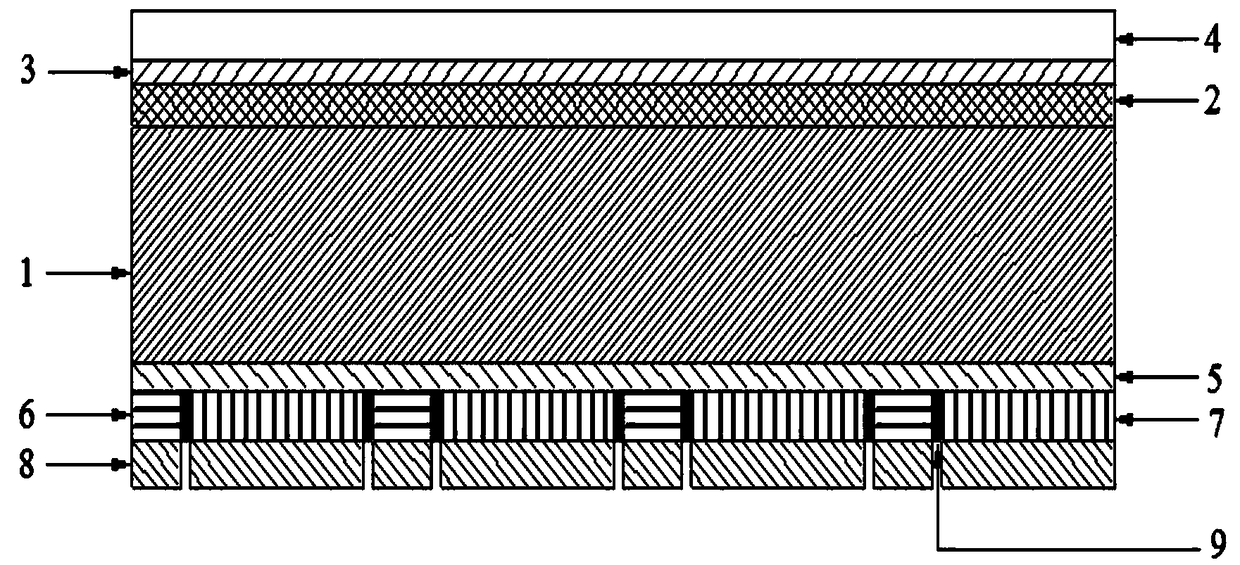

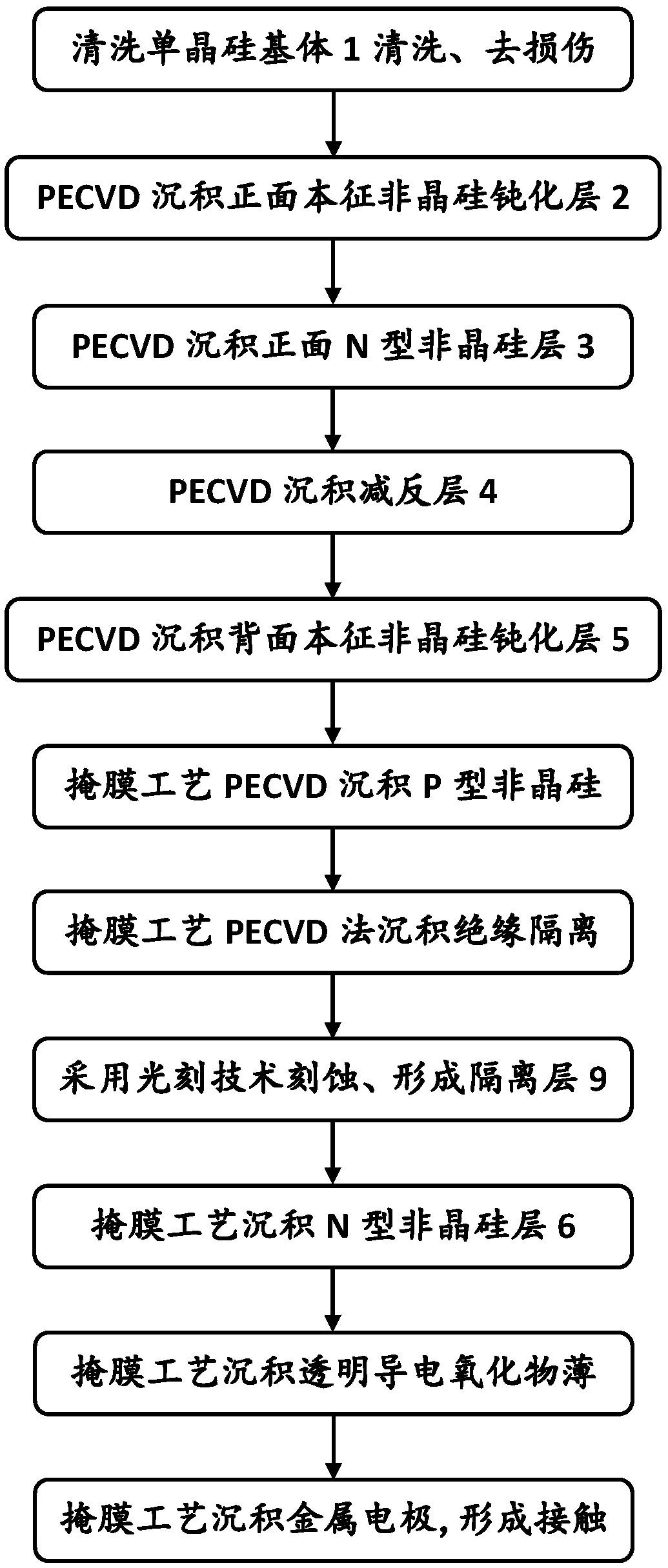

A preparation method of a back-contact heterojunction solar cell

ActiveCN109216509AReduce widthIncrease collection rateFinal product manufacturePhotovoltaic energy generationHeterojunctionContact layer

The invention discloses a preparation method of a back-contact heterojunction solar cell. A pre-passivation layer of intrinsic amorphous silicon, an N-type amorphous silicon layer and an anti-reflection layer are sequentially deposited on the front side of the washed and dedamaged layer and the velveted monocrystalline silicon substrate; Depositing an intrinsic amorphous silicon back passivation layer on the back surface of the battery; The P-type amorphous silicon layer is deposited on the surface of the back passivation layer by a mask method, and then the insulation isolation layer betweenthe P-type amorphous silicon layer and the N-type amorphous silicon layer is directly deposited, and the insulation isolation layer is etched according to the preset width of the insulation isolationlayer by a photolithography method; Further depositing an N-type amorphous silicon layer on the back surface by a mask method; At last, that transparent conductive film is sequentially deposite by adopting a mask proces, and the metal film forms a contact layer, thereby completing the preparation of the solar cell of the invention. The invention improves the preparation process precision of the back surface structure pattern of the HBC single crystal silicon solar cell, reduces the width of the isolation layer, and improves the collection probability of the photogenerated carriers and the short-circuit current density of the HBC solar cell.

Owner:XIAN UNIV OF TECH

Magnesite/dolomite microwave light-burning device and method

Owner:山东派智新能源科技有限公司

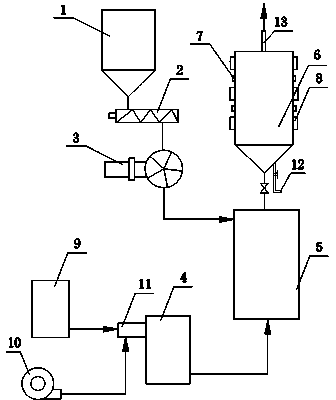

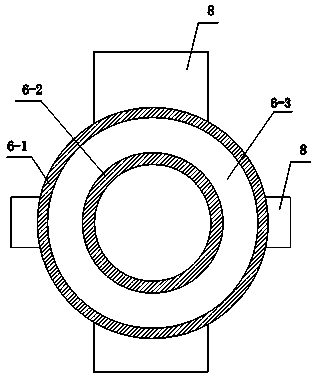

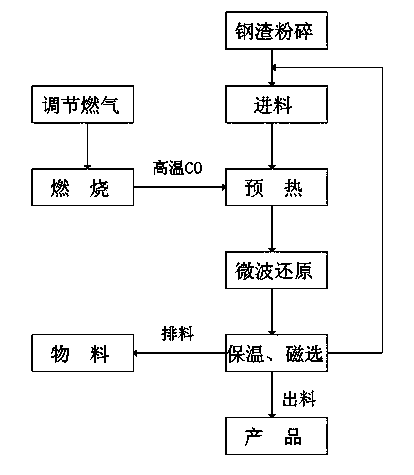

Magnetic separation device and method for reducing hematite-containing material by utilizing microwave

The invention relates to a device and a method for reducing hematite-containing materials by utilizing microwave heat treatment and carrying out magnetic separation. The device comprises a material bin, a screw feeder, a star type feeding machine, a preheating reacting furnace and a microwave magnetic separator. When the magnetic separation is carried out, the materials are crushed and then added to the material bin, powdery materials enter the preheating reacting furnace through the screw feeder and the star type feeding machine for preheating, and the preheated powdery materials enter the microwave magnetic separator through an air inlet pipe for the microwave heat treatment and the magnetic separation; products subjected to the magnetic separation are discharged through an ore discharge pipe from a discharge port, and other materials are discharged through an outlet pipe from the discharge port. The device disclosed by the invention can be used for reducing the weak magnetic Fe2O3 contained in the materials into strong magnetic Fe3O4 through the microwave heating and separating the iron ore concentrates through the magnetic separation, integrally and simultaneously carries out the reduction and the magnetic separation, has the advantages of small investment, low energy consumption, large treatment quantity, water saving, no air pollution, wide application range and relatively popularization prospect, is simple in equipment, and can be used for treating multiple hematite-containing materials which include ores, such as steel slag, low-grade limonite and iron ores.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Wet process device for etching wafer, and wet process etching method

InactiveCN1959938AAvoid uneven etchingImprove process precisionSemiconductor/solid-state device manufacturingPhysics

Owner:MACRONIX INT CO LTD

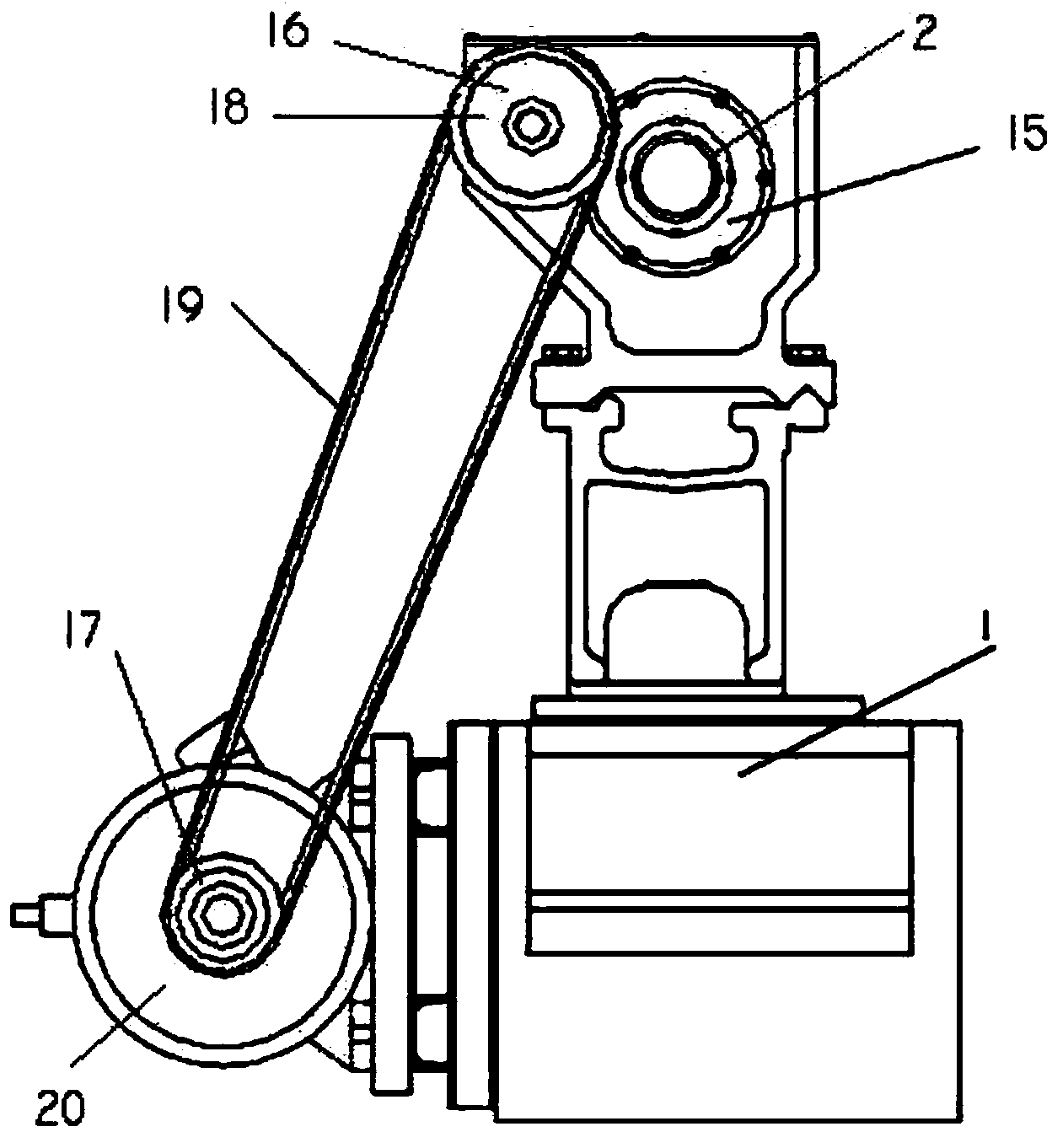

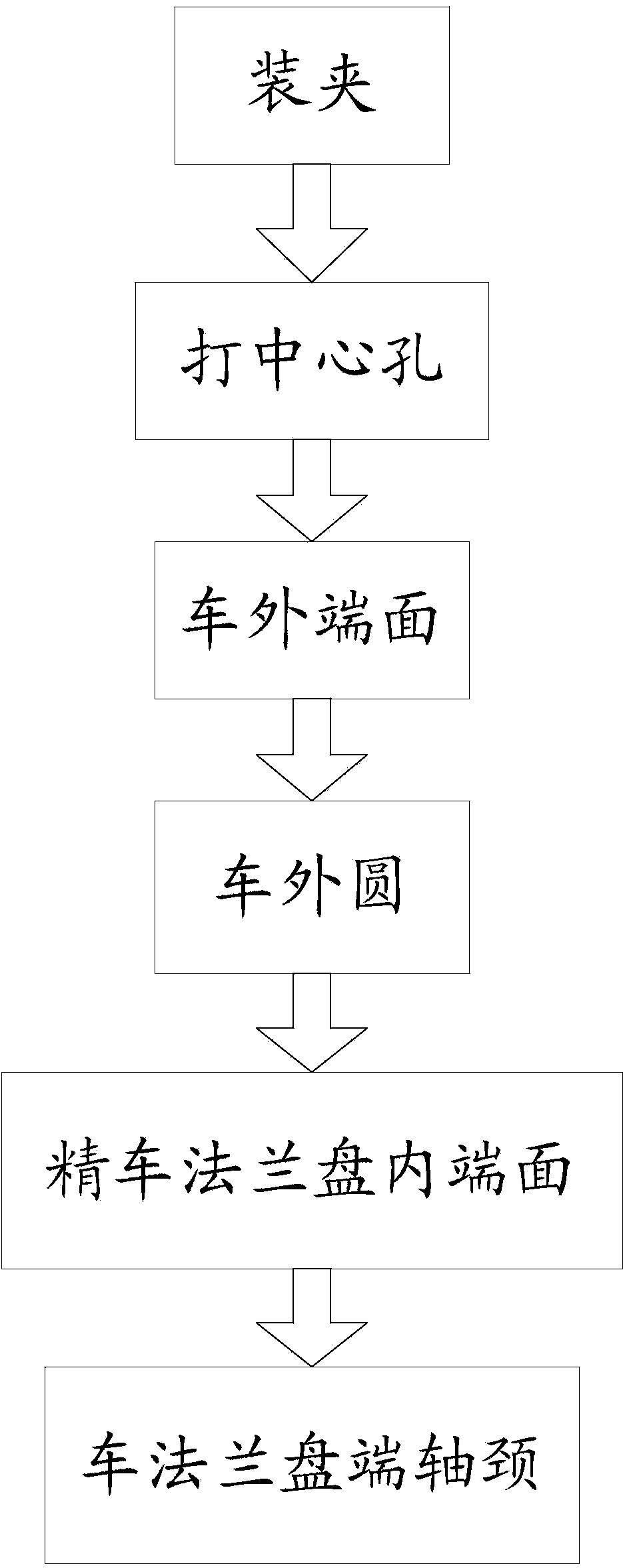

Numerical control processing machine tool of automobile half shaft

ActiveCN103447823AGuaranteed clamping rigiditySimple processOther manufacturing equipments/toolsDriving apparatusMilling cutterEngineering

The invention relates to a numerical control processing machine tool of an automobile half shaft. The numerical control processing machine tool has the characteristics that a clamping device is arranged at the middle part of a tool body, and the two edges are clamped simultaneously, so that the clamping rigidity is guaranteed, and further a workpiece can bear larger cutting force in the turning processing process; a left sliding turning device and a right sliding turning device are respectively controlled by two sets of independent numerical control systems to process a half shaft blank, so that multiple processing steps can be carried out on one machine tool simultaneously, and not only is the process is simplified, but also the working efficiency is improved; by control of a numerical control system, the accuracy of the process is also improved; simultaneously the machine tool adopts a turning tool for processing. Compared with the prior art adopting a milling cutter, the numerical control processing machine tool of the automobile half shaft has the advantage that the cost is reduced.

Owner:湖北神力汽车零部件股份有限公司

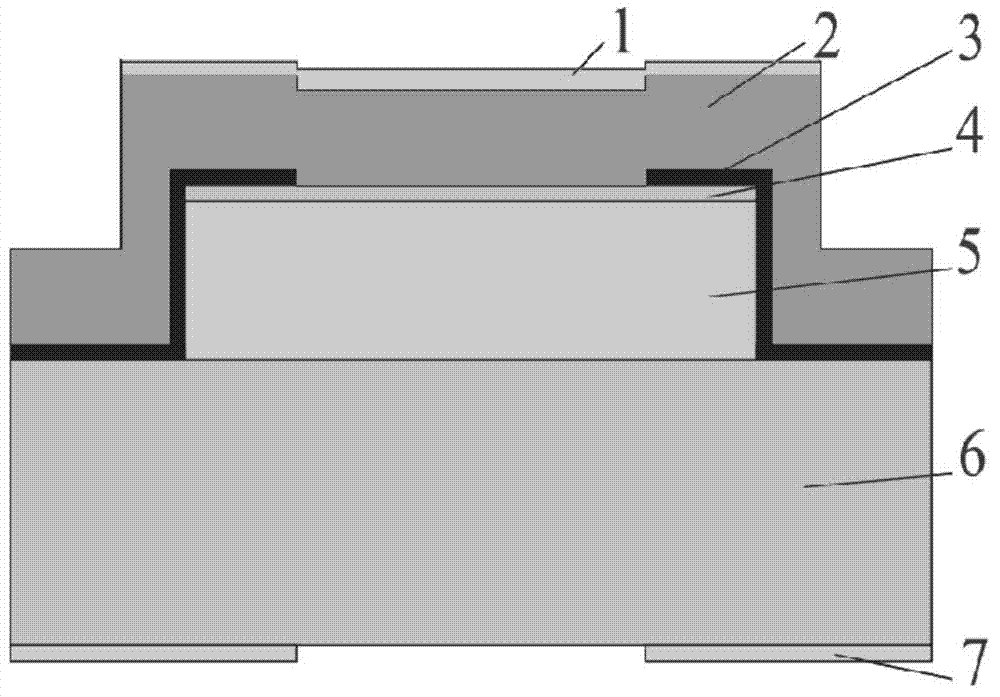

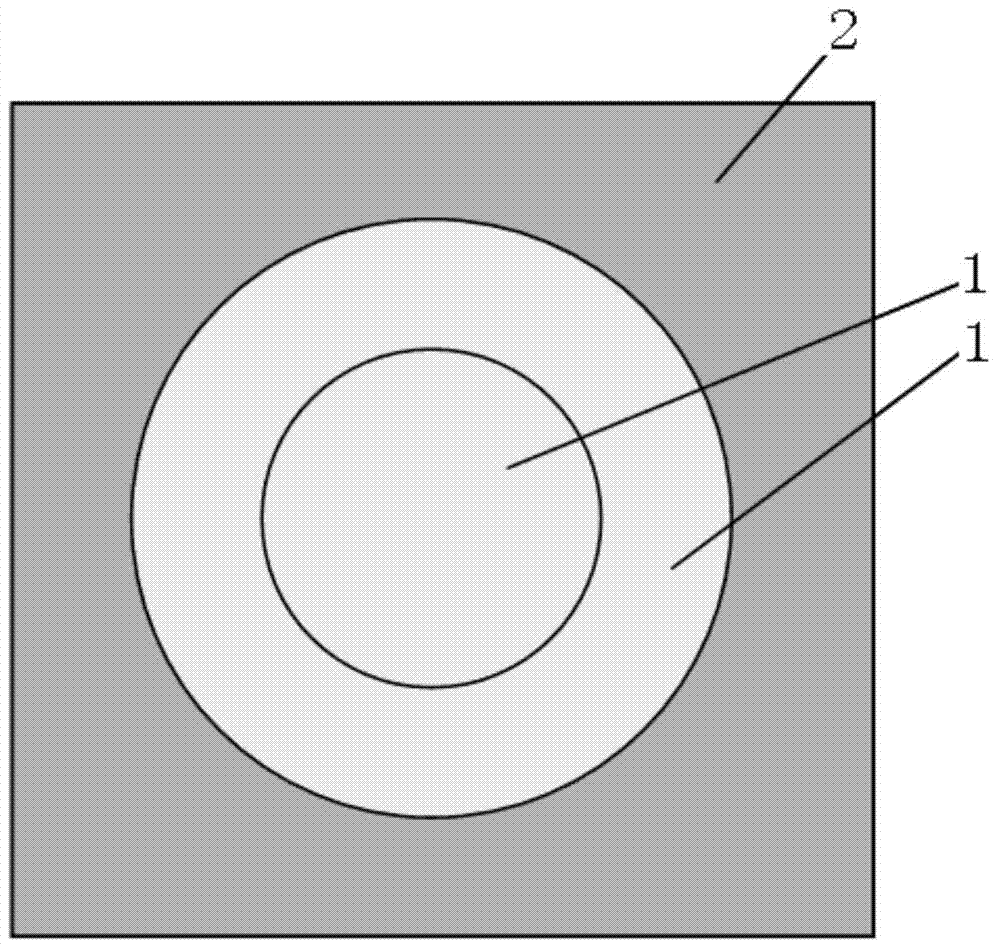

Dielectric film current limiting type vertical cavity surface emitting laser and manufacturing method thereof

ActiveCN103872580AAvoid pollutionImprove process precisionLaser detailsLaser optical resonator constructionDielectricVertical-cavity surface-emitting laser

The invention relates to a dielectric film current limiting type vertical cavity surface emitting laser and a manufacturing method of the emitting laser, belongs to the field of a semiconductor laser, and solves the problems of low process precision, poor reliability and poor performance consistency in the prior art. The dielectric film current limiting type vertical cavity surface emitting laser structurally comprises an N-surface electrode, a substrate layer, an N type DBR layer, an active layer, a dielectric film current limiting layer, a P type DBR layer and a P-surface electrode in arrangement from bottom to top. The method provided by the invention is characterized in that the N type DBR layer and the active layer sequentially grow on the substrate layer, the N type DBR layer and the active layer are etched into a cylindrical table top, in addition, the substrate layer is exposed, the dielectric film current limiting layer grows on the surface of the cylindrical table top and the surface of the substrate layer, a current limiting window is etched at the dielectric film current limiting layer, and in addition, the active layer is exposed; the P type DBR layer grows on the upper surface of the dielectric film current limiting layer and the upper surface of the active layer in an epitaxy way; the P-surface electrode and the N-surface electrode are respectively manufactured on the upper surface of the P type DBR layer and the lower surface of the substrate layer.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

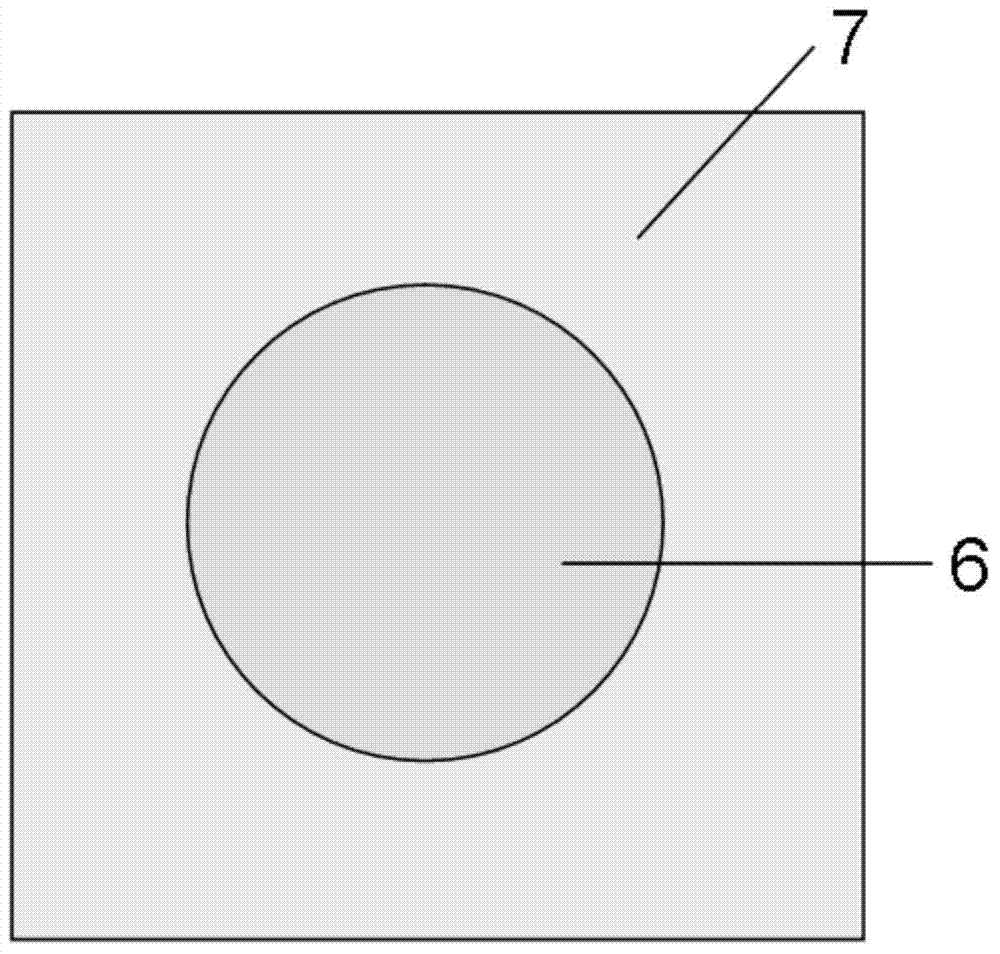

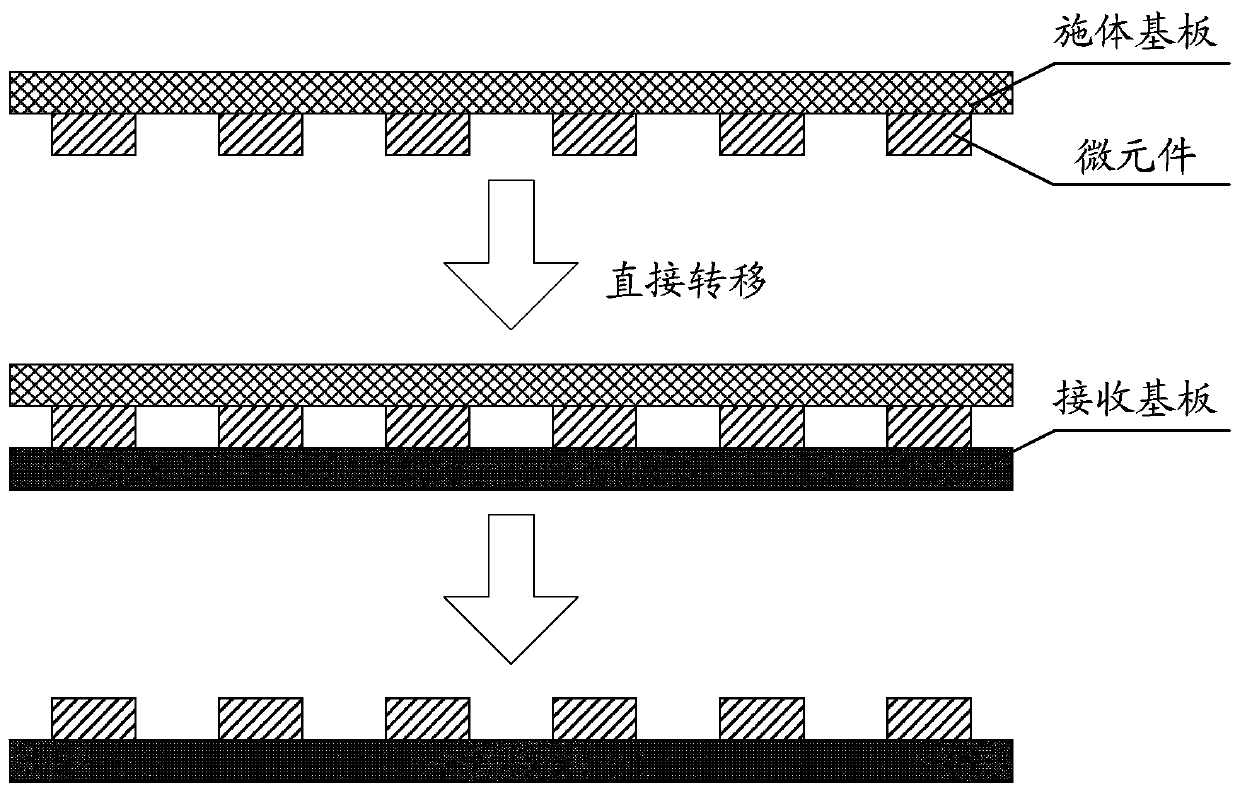

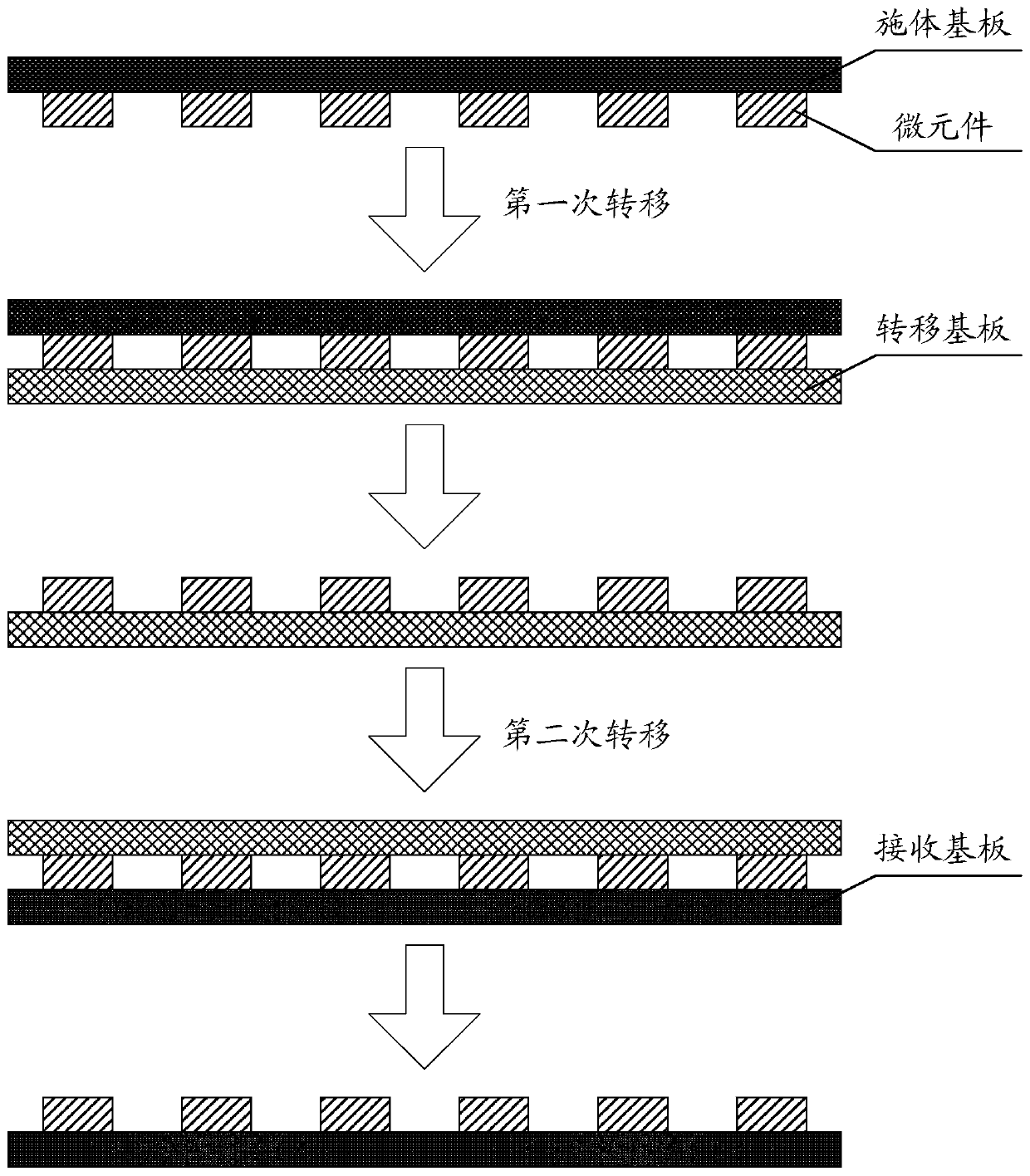

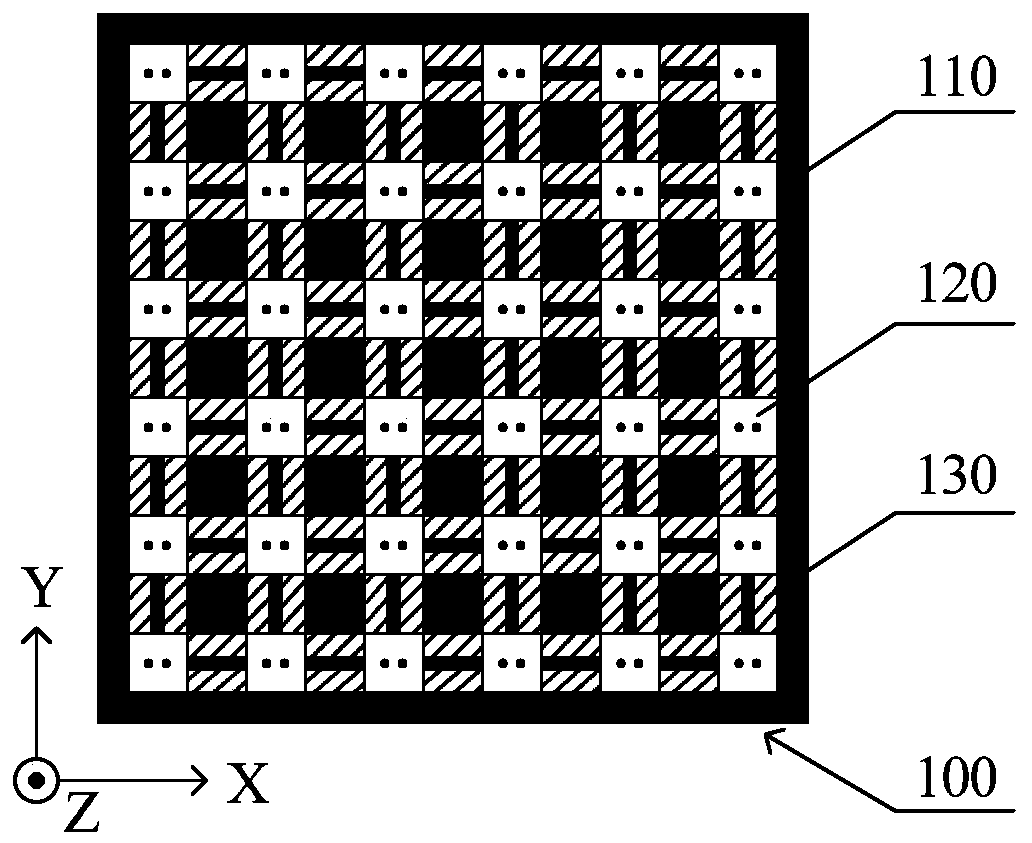

Chip transfer substrate and chip transfer method

ActiveCN109950194AReduce spacingImprove process precisionSolid-state devicesSemiconductor/solid-state device manufacturingElectrical and Electronics engineeringYield rate

An embodiment of the present invention discloses a chip transfer substrate and a chip transfer method. The chip transfer substrate comprises a first base layer, chip bases arranged on the first base layer, and a stretching film layer disposed between adjacent chip bases, wherein the stretching film layer is used for generating extension deformation in performing a first operation and generating contraction deformation in performing a second operation. According to the embodiment of the invention, the problem that the efficiency, the yield rate and the transfer precision of the mass transfer ofchips are difficult to meet micro component manufacturing requirements in an existing micro component manufacturing process is solved.

Owner:BOE TECH GRP CO LTD +1

Spray coating, method of forming same, spray material wire, and cylinder block

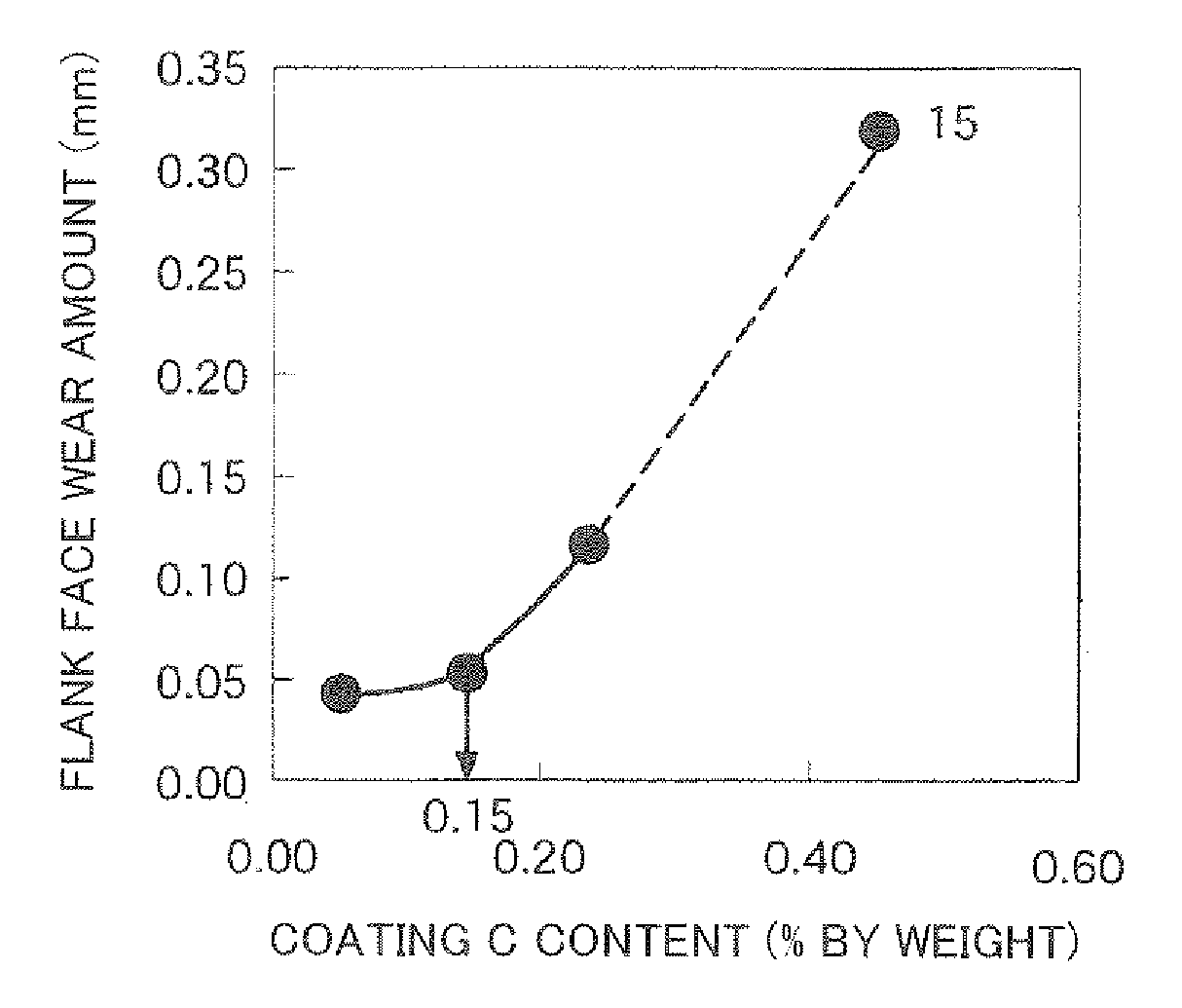

InactiveUS20100108014A1Improve machinabilityIncrease resistanceCasingsLiquid surface applicatorsSpray coatingCylinder block

An arc spray coating that is superior in both wear resistance and machinability, method of forming same, an arc spray wire used to form such a coating, and a cylinder block on whose bore inner surface is formed such an arc spray coating are provided. To this end, the arc spray coating contains Fe as a main component, 0.01% to 0.15% by weight of C, and at least 0.12% by weight of N, and the arc spray wire (wire) contains Fe as a main component, 0.01% to 0.2% by weight of C, and 0.25% to 1.7% by weight of Si, and may further contain at least 11% by weight of Cr as another embodiment.

Owner:TOYOTA JIDOSHA KK

Raw material sealing and mixing device for dry battery production technology

InactiveCN106582394AReduce wasteProtect your healthRotating receptacle mixersTransportation and packagingMixing effectBolt connection

The invention belongs to the technical field of dry battery production, particularly relates to a raw material sealing and mixing device for the dry battery production technology and aims at providing the raw material sealing and mixing device for the dry battery production technology, wherein the raw material sealing and mixing device for the dry battery production technology is easy to operate, small in workload and uniform in mixing. The device comprises a bottom plate, supports, a first large belt wheel, a first rotating shaft, a rotation motor, a first flat belt, a first small belt, a first bearing block, a second rotating shaft, a second bearing block, a sliding block, a sliding rail, a first cover, a second cover, a lower protrusion, a closed ring and the like. A left frame is welded to the left end of the top of the bottom plate, and the supports are symmetrically welded to the right side of the top of the bottom plate. The top ends of the two supports are connected with the sliding rail in a bolt connecting manner. According to the raw material sealing and mixing device, the effects of simple operation, the small workload and uniform mixing are achieved; and the raw material sealing and mixing device has important functions that a good mixing effect is achieved, in addition, the work efficiency is improved, and safety is high.

Owner:陈红

Slot

InactiveCN101997287AGood strengthNo electromagnetic interferenceCable installations on groundElectricityStress point

The invention relates to a slot which comprises a shell used for accommodating a cable, a baffle plate arranged at the middle of the shell, and an openable cover plate matched with the shell, wherein two sides of the shell are provided with first supporting parts used for supporting the cover plate, the upper end of the baffle plate is provided with a second supporting part used for supporting the middle of the cover plate; and the shell is formed by once extrusion of an aluminum alloy. Because the baffle plate is arranged at the middle of the shell, strong electricity and weak electricity are physically isolated without electromagnetic interference; meanwhile, the slot has the advantages of reasonable structure, high process precision, uniform stress point, strong stress, pressure bearing of 500Kg, long service life; due to the arrangement of the openable cover plate, the slot is convenient maintenance; and a decorative material can be attached on the cover plate, thus the slot is attractive and uniform.

Owner:GUANGZHOU HOLDSTORM SCI & TECH

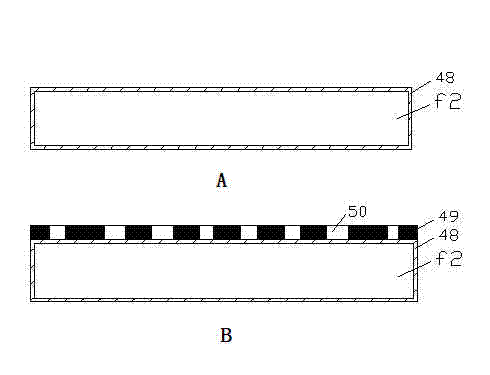

Miniaturization micromechanical filter

ActiveCN102790248AMiniaturizationImprove process precisionSemi-permeable membranesFixed microstructural devicesMiniaturizationEngineering

The invention discloses a miniaturization micromechanical filter. The filter is manufactured based on micromechanical process and formed by overlying upper and lower layers of medium materials, an interdigitated metal electrode layer is arranged on the lower surface of the upper medium layer, ground connection bonding welding rings are arranged on the upper surface of the lower medium layer, cavities prepared by etching process are formed among the welding rings, through holes are arranged on the upper and lower medium layers, metal layers are arranged on the inner walls of the through holes, surface electrode layers are arranged on the surfaces of the upper and lower medium layers, and input and output lead wires are arranged on the surface of the upper medium layer. The filter can meet index requirements of high operating frequency, large bandwidth, small loss and the like of a microwave filter and has the advantages of being small in size, fully sealed and high in reliability.

Owner:CHINA ELECTRONICS TECH GRP NO 26 RES INST

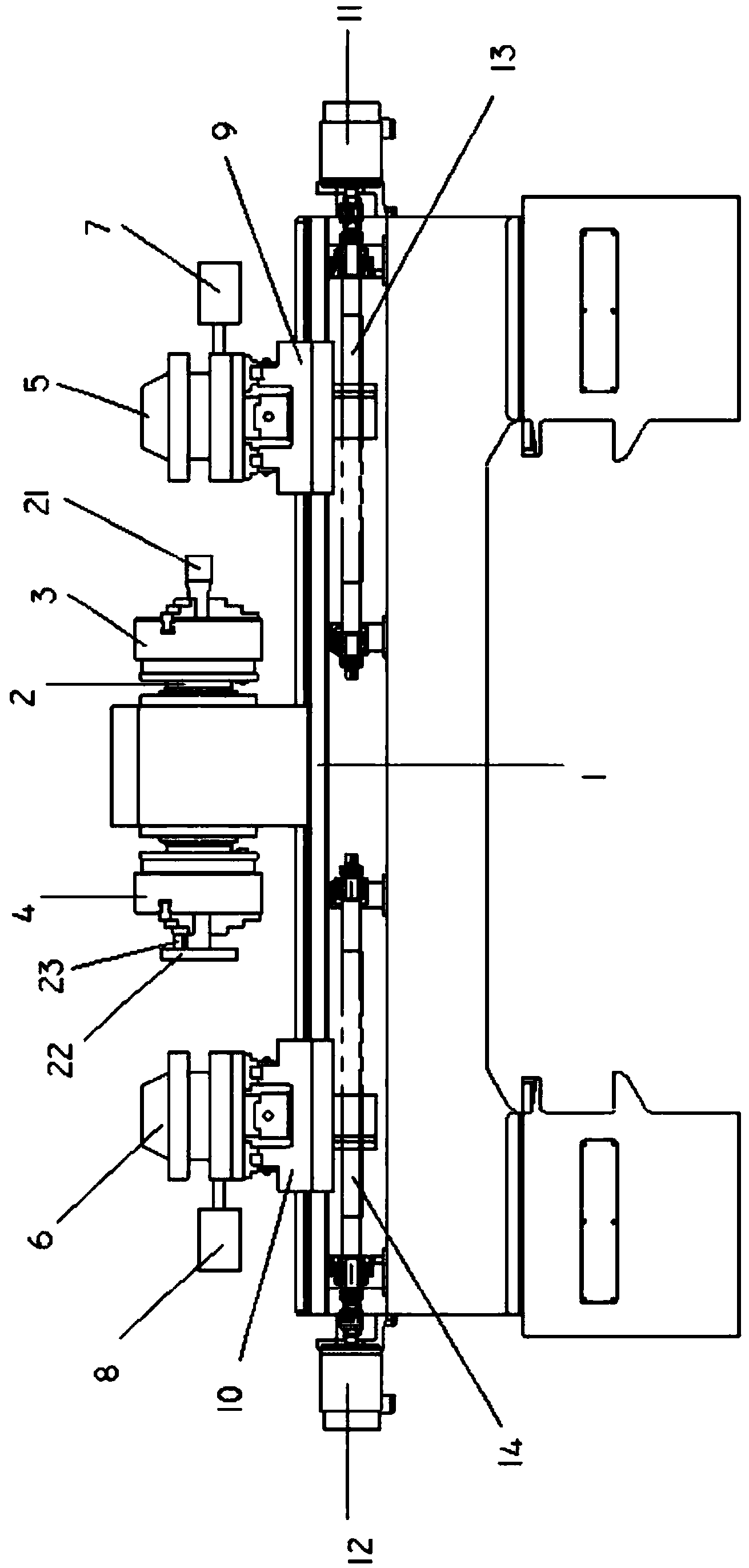

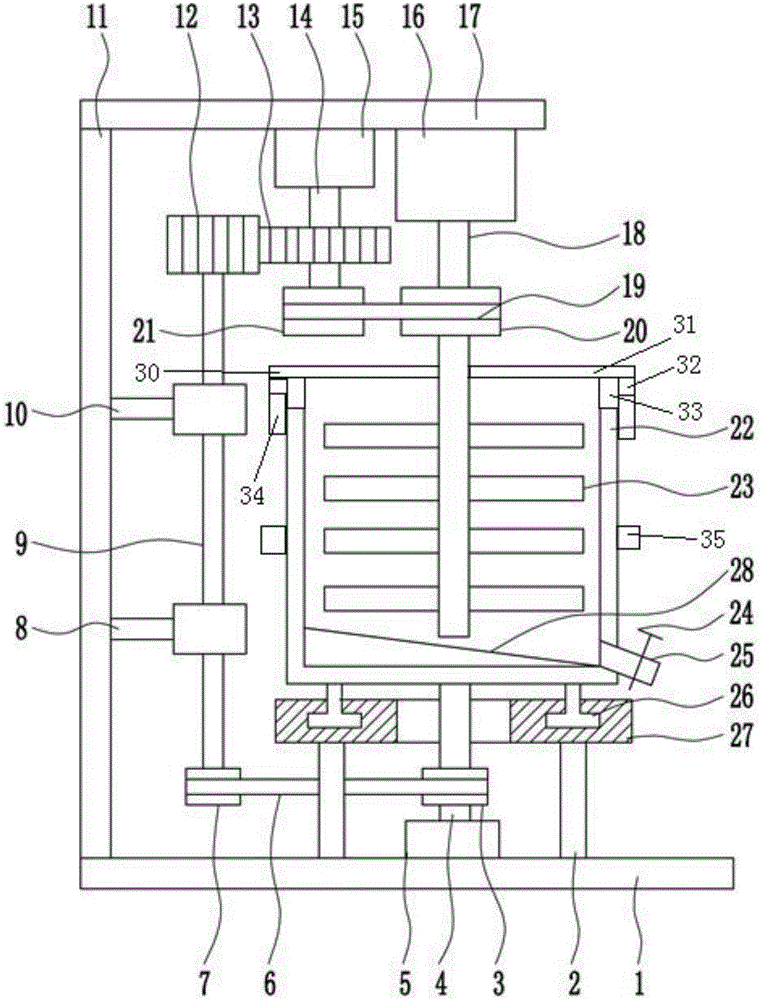

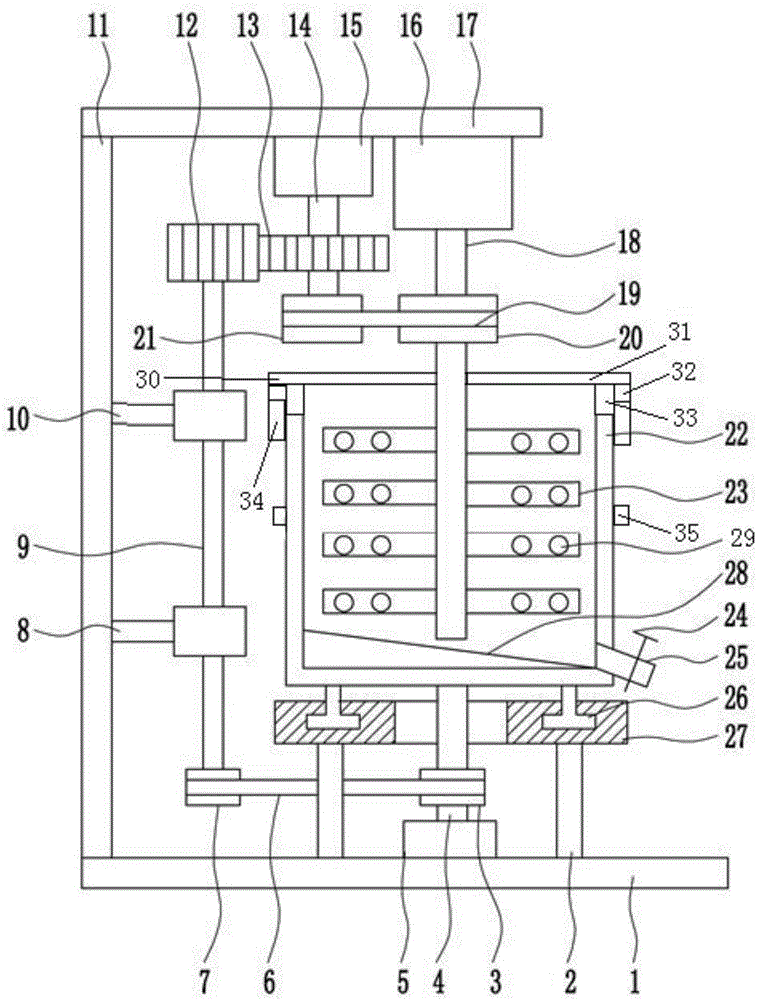

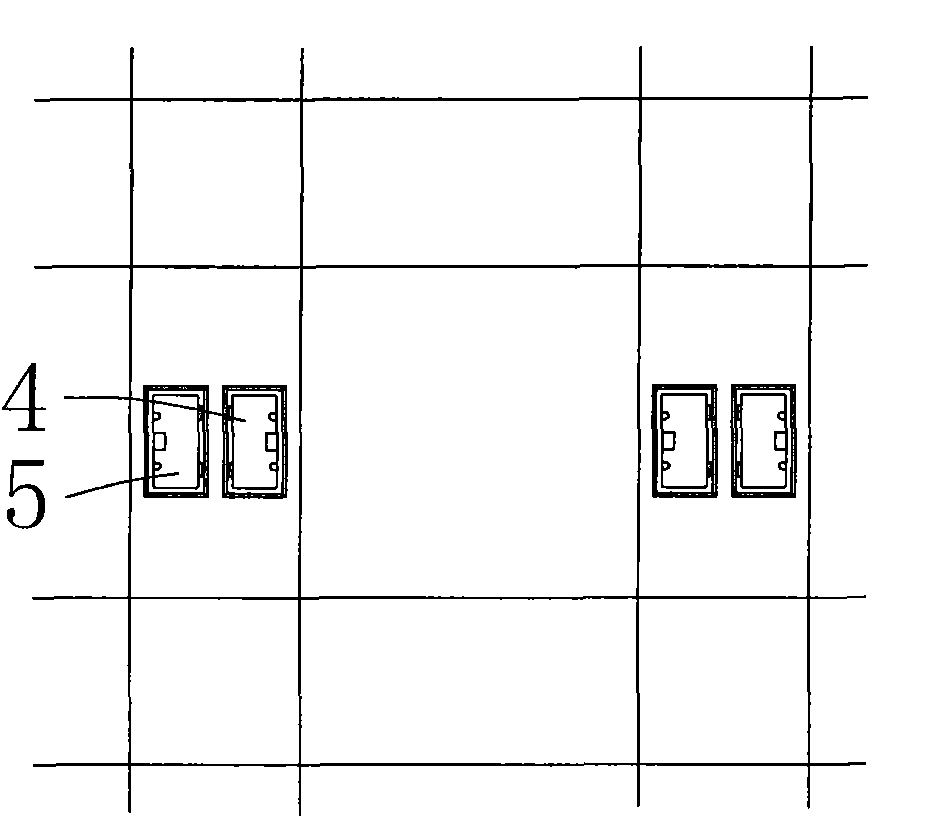

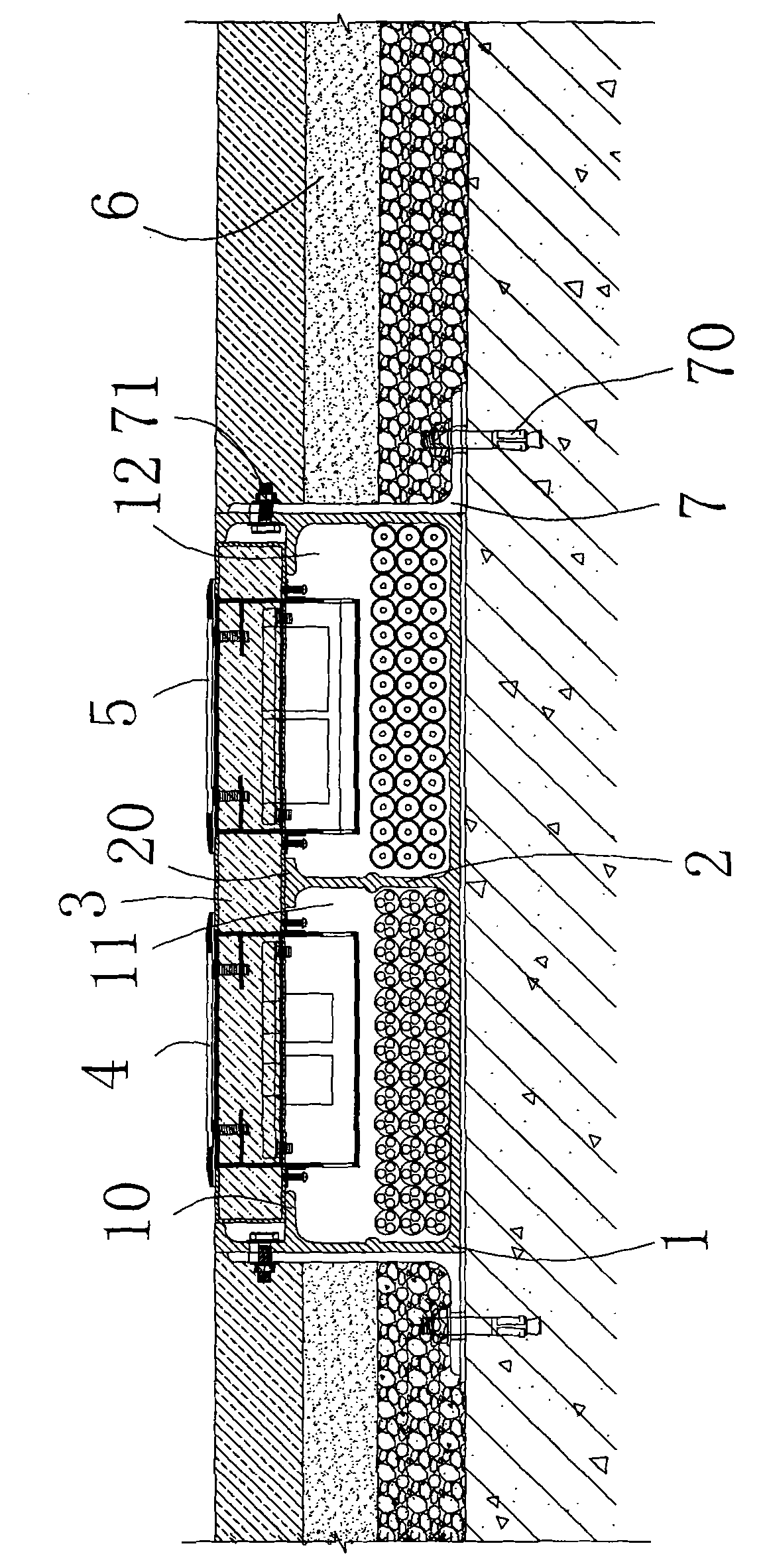

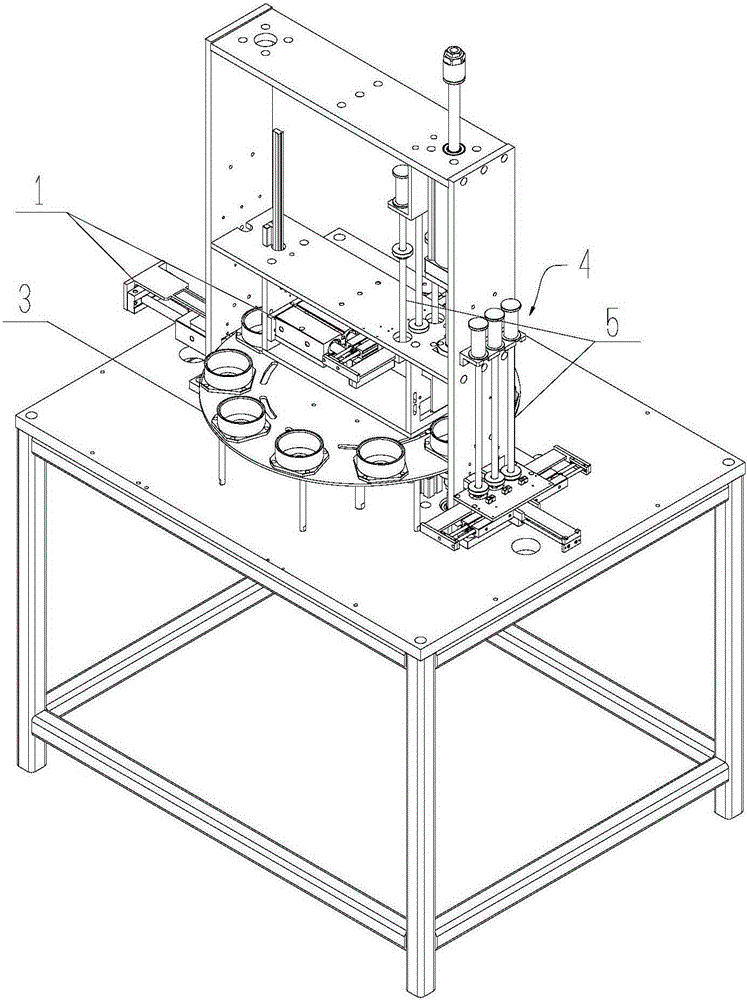

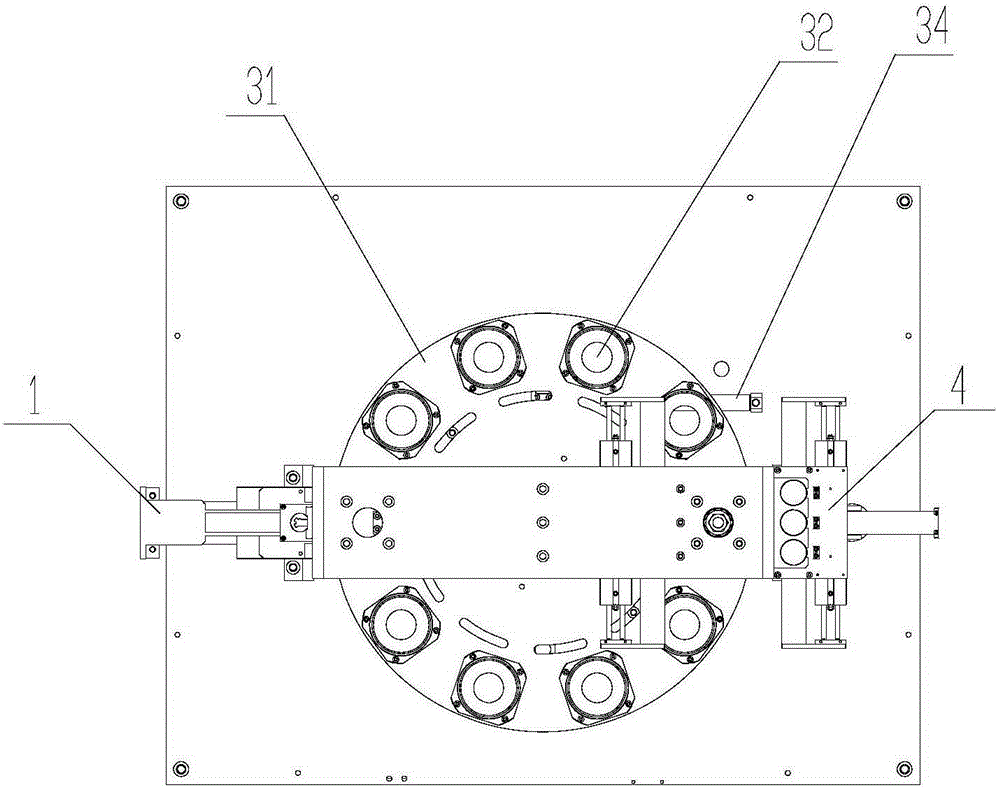

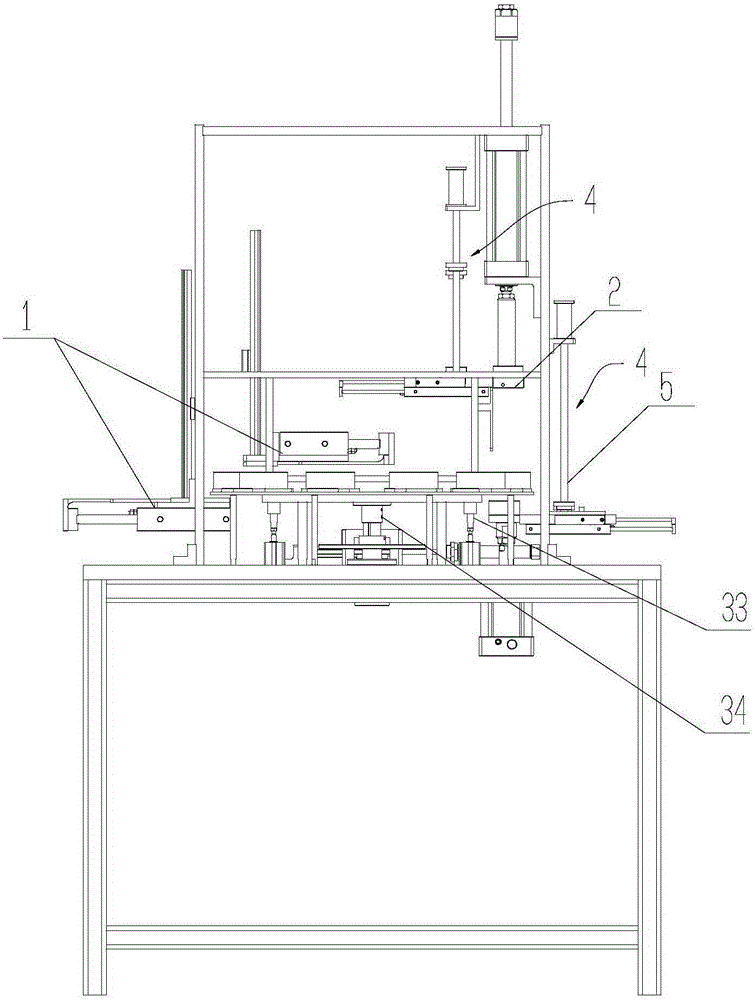

Motor rotor automatic snap spring and bearing pressing machine

ActiveCN105245060AHigh degree of automationImprove yield rateAssembly machinesManufacturing dynamo-electric machinesEngineeringAutomation

The invention relates to a motor assembling processing device field, and particularly relates to a motor rotor automatic snap spring and bearing pressing machine. The motor rotor automatic snap spring and bearing pressing in machine comprises a snap spring pressing in device, a bearing pressing in device, a motor rotor carrying device, a rotor position detection device and a control device; and the control device controls the working conditions of the snap spring pressing in device, the bearing pressing in device and the motor rotor carrying device according to the rotor position detected by the rotor position detection device. The motor rotor automatic snap spring and bearing pressing machine can realize automatic snap spring pressing of the rotor and bearing pressing technology through the mutual operation between a sensor, a control device, a snap spring pressing in device, a bearing pressing in device, and the motor rotor carrying device, which improves the automation level of the motor rotor assembling, reduces the labor cost, improves the rate of the good product of the rotor processing and the technology precision.

Owner:GREE ELECTRIC APPLIANCES INC +2

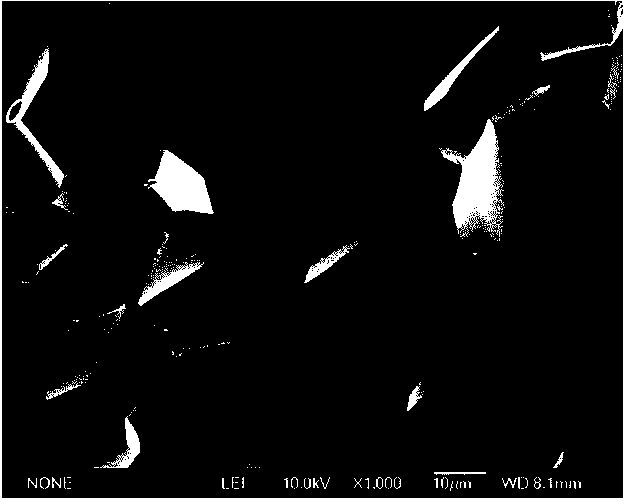

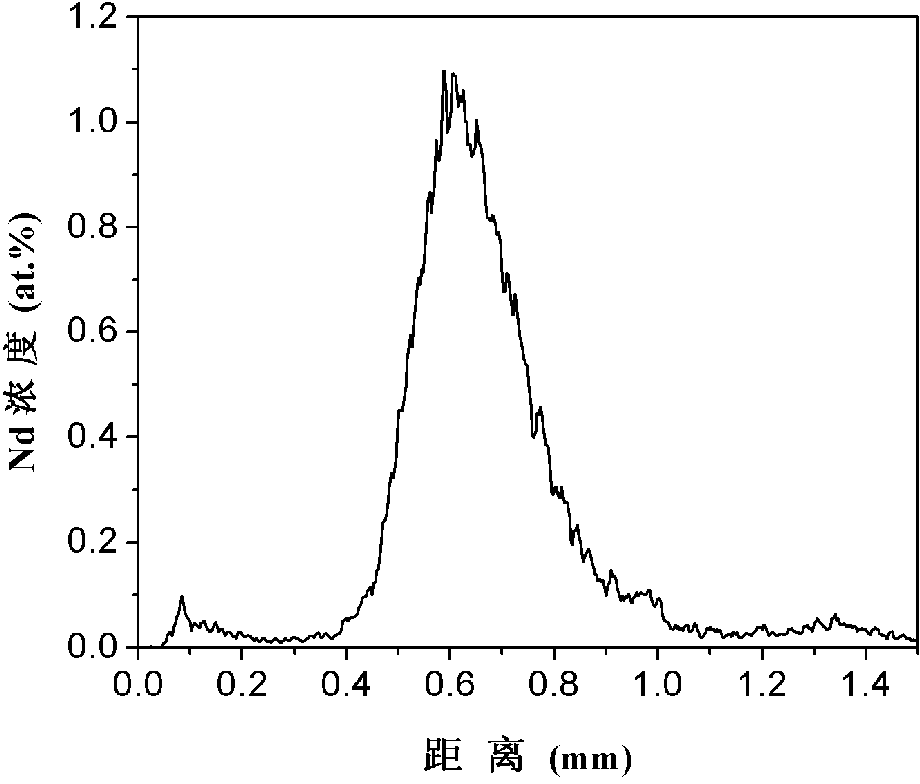

Planar waveguide structure laser ceramic material and preparation method thereof

InactiveCN105000876AReduce thermal effectsReduce manufacturing costActive medium shape and constructionChemical compositionMetallurgy

The present invention relates to a planar waveguide structure laser ceramic material and a preparation method thereof. The material comprises a core layer, an upper cladding layer cladding the core layer, and a lower cladding layer cladding the core layer, wherein the core layer adopts an activation-ion-Ln-doped RAG polycrystalline ceramic and has the chemical composition of (LnxR1-x)3Al5O12, the cladding layer adopts a pure RAG polycrystalline ceramic and has the chemical composition of R3Al5O12, Ln is Nd, Yb, Er, Ho and / or Tm, R is Y or Lu, and x is more than 0 and is less than or equal to 1, and the core layer and the cladding layers are respectively subjected to casting molding, and then are subjected to laminating sintering to prepare the planar waveguide structure laser ceramic material.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Vacuum imprinting apparatus, vacuum press-bonding apparatus, and manufacturing method for laminated optical device

ActiveCN102765240AInhibition of air bubblesImprove process precisionLamination ancillary operationsLaminationEngineeringVacuum chamber

The invention discloses a vacuum imprinting apparatus, a vacuum press-bonding apparatus, and a manufacturing method for laminated optical device. The vacuum imprinting apparatus and vacuum press-bonding apparatus respectively includes a vacuum chamber, a lower stage, an upper stage, and a solidifying device. The upper stage is opposite to the lower stage to be disposed in the vacuum chamber and can move toward the lower stage to perform imprinting or flatly spreading. The solidifying device is used for solidify an optical gel layer into an optical layer. The manufacturing method forms optical layers on a substrate by the vacuum imprinting apparatus and vacuum press-bonding apparatus respectively, further to form the laminated optical device. Thereby, the invention uses machines and tools to form the optical gel layers under a vacuum environment, so as to reduce bubble phenomena in the laminated structure formed by the optical layers after solidified.

Owner:AU OPTRONICS CORP

Methods, apparatuses, systems and software for treatment of a specimen by ion-milling

ActiveUS9911573B2Increase speedConvenient platformElectric discharge tubesPreparing sample for investigationSoftware engineeringIon beam

Methods, apparatuses, systems and software for ion beam milling or machining are disclosed. The apparatus includes a specimen holder, a table, one or more ion sources, rotatable ion optics, and an imaging device. The specimen holder is configured to hold a specimen in a stationary position during milling or machining. The table is configured to change the stationary position of the specimen holder in any of three orthogonal linear directions and an angular direction. The rotatable ion optics are configured to emit an ion beam towards a predetermined location on the specimen from any of the one or more ion sources at any angle around an axis that is orthogonal to a horizontal surface of the table when the angular direction of the table is 0°. The imaging device is configured to generate an image of the specimen including the predetermined location, thereby enabling real-time monitoring of the milling or machining process.

Owner:IB LABS

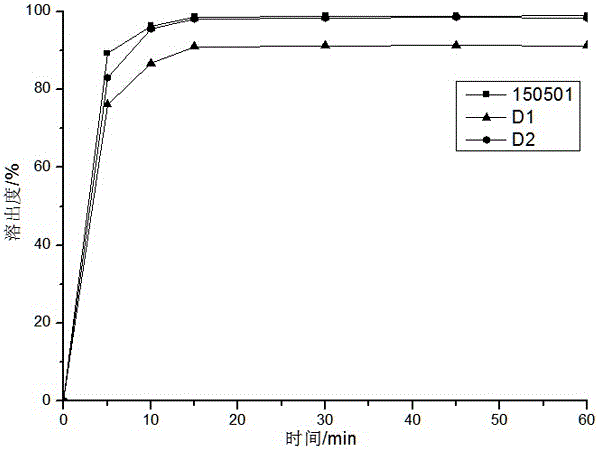

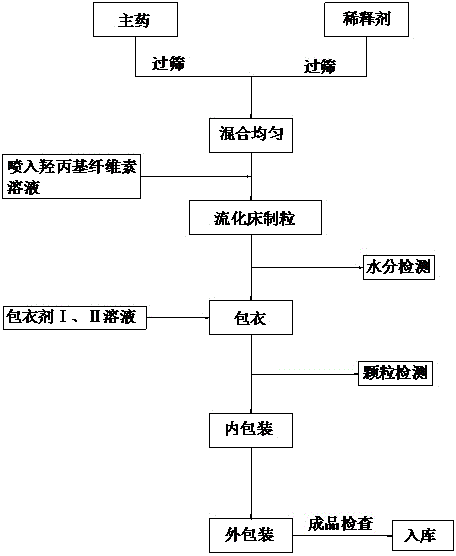

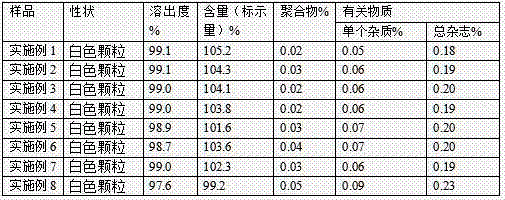

Tebipenem pivoxil granule and preparation method thereof

InactiveCN105963261AImprove stabilityProperly mask the bitternessAntibacterial agentsOrganic active ingredientsHigh humidityDissolution

The invention provides a tipipenem pectin granule and a preparation method thereof, and relates to the technical field of medicine and its preparation. A tipipenem granule, comprising the following raw materials in parts by weight: 600 to 700 parts of tipipenem, 3500 to 4500 parts of diluent, 40 to 50 parts of hydroxypropyl cellulose, and 455 to 470 parts of coating agent I 380-400 parts of coating agent II, the coating agent I is composed of ethyl cellulose suspension and talcum powder at a weight ratio of 10-20:1, the coating agent II is composed of gastric-soluble acrylic resin, Talc powder, hydroxypropyl methylcellulose and aspartame are composed in a weight ratio of 25-40:1-3:1:1.5-2.5. The tipipenem ester granule of the present invention uses tipipenem ester as the main drug, strictly screens and controls the ingredients of the excipients, optimizes the proportion, has stable drug efficacy under high temperature and high humidity environment, safe quality, high dissolution rate and excellent process. Easy to control and suitable for industrial production.

Owner:HENAN QUANYU PHARMA CO LTD

Method for preparing combined thin film

InactiveCN103489750AImprove process precisionSemiconductor/solid-state device manufacturingSputteringOptoelectronics

The invention provides a method for preparing a combined thin film by using a combined laser molecular-beam epitaxy technology. The method includes the steps that a substrate is provided; precursor target materials of a plurality of different components corresponding to all components in the combined thin film are provided; laser bombardment is sequentially conducted on the precursor target materials of the different components, so that a corresponding precursor component is sputtered; a mask plate with mask patterns is provided; the corresponding sputtered precursor component is deposited on the substrate through the mask plate, and thus the combined thin film can be obtained. By means of the method for preparing the combined thin film, mechanical arm movement and continuous constant-speed axial movement are replaced by axial rotation, component uncontinuity caused by the stopping-restarting process of a mask can be avoided, meanwhile, programming is of no need for controlling the rotation of the mask, and therefore the operation complexity of the technology is lowered. In addition, preparation of multi-component thin films can be achieved by the way that the shape and the position of a window in the mask plate are adjusted.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

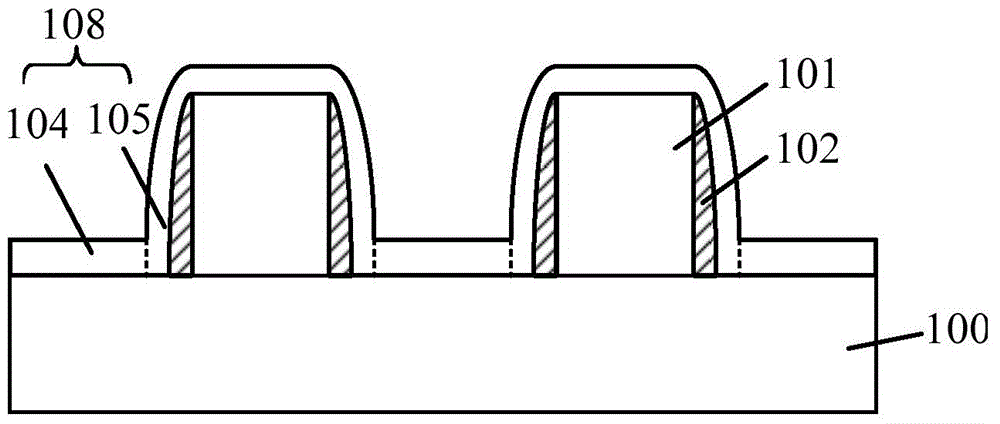

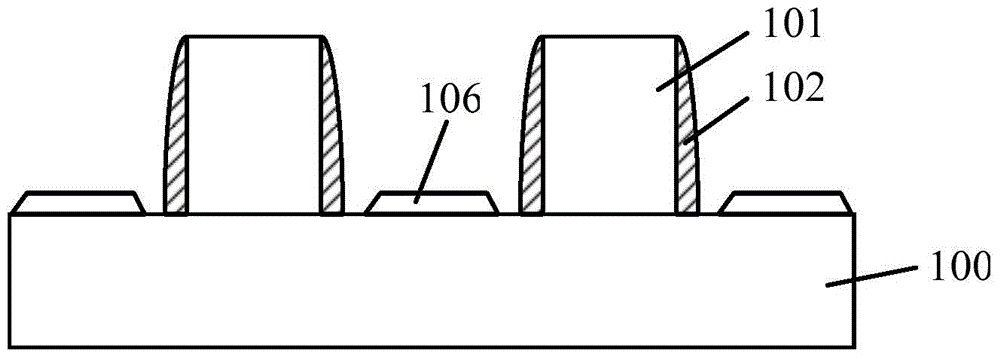

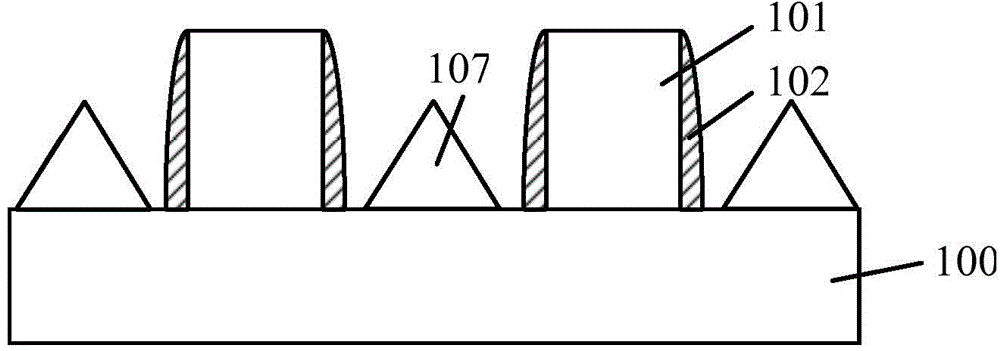

Formation method of semiconductor structure

ActiveCN105097520AAvoid formingReduce formationSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureEpitaxial material

According to a semiconductor structure fabrication method, a semiconductor substrate having gate structures is provided. Sidewalls of the gate structures may be covered by a spacer layer. An epitaxy process is performed to form a semiconductor epitaxial material layer covering the gate structures, the spacer layer, and the semiconductor substrate. Then, an etching process is performed to form a first semiconductor epitaxial layer on the semiconductor substrate at the two sides of the gate structures. Further, a selective epitaxy process is performed by using a deposition gas and an etching gas, forming a second semiconductor epitaxial layer. The formed second semiconductor epitaxial layer may repair or compensate the first semiconductor epitaxial layer along the horizontal direction. The epitaxy process, the etching process, and the selective epitaxy process are repeated successively to form elevated source / drain regions. The formed elevated source / drain regions may have a flat top surface without any angles.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Natural gas metal cutting gas

The invention relates to natural gas metal cutting gas which is prepared from liquefied natural gas and an additive, wherein the additive is prepared from diphenylcarbinol, propylcyclohexanol, tert-butyl methyl ether, methanol, anhydrous ethanol and gasoline. The natural gas metal cutting gas is prepared from the following components in parts by weight: 98.4-98.7 parts of the liquefied natural gas and 1.3-1.6 parts of the additive. The additive is prepared from the following components in parts by weight: 7-30 parts of diphenylcarbinol, 10-20 parts of tert-butyl methyl ether, 40-60 parts of methanol, 2-10 parts of anhydrous ethanol and 3-6 parts of gasoline. According to the natural gas metal cutting gas provided by the invention, the additive and the natural gas jointly take part in combustion reaction in oxygen after the natural gas is liquefied and the natural gas metal cutting gas provides a chemical intermediate for combustion of the natural gas to improve the combustion speed of the natural gas in oxygen so as to improve the combustion temperature; the natural gas metal cutting gas is safe to use, free of tempering if being used for cuing and the like, and moreover, the cutting gas is lower than air in specific gravity, and can be used for indoor operation.

Owner:王景春

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com