Patents

Literature

112 results about "Lateral compression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

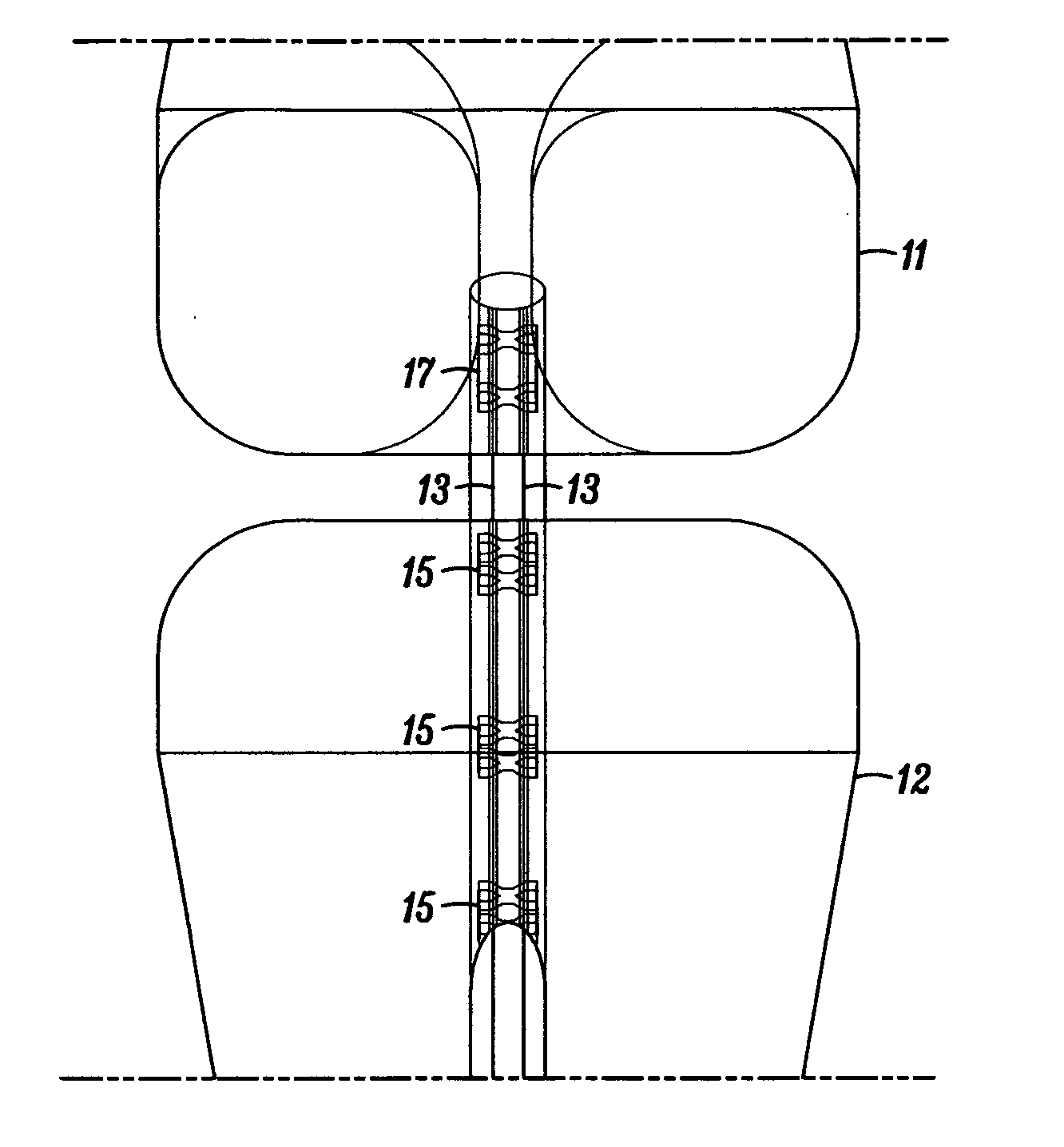

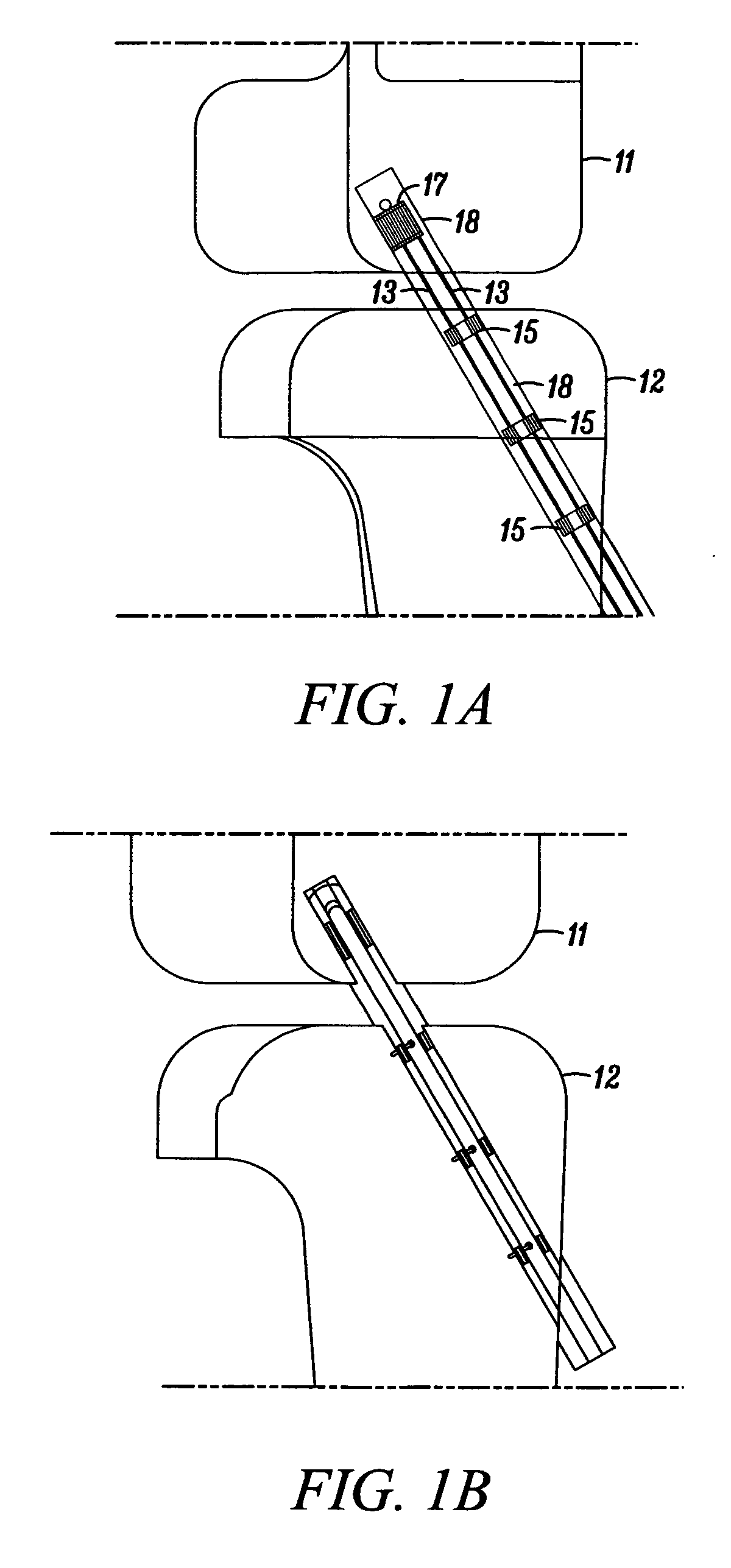

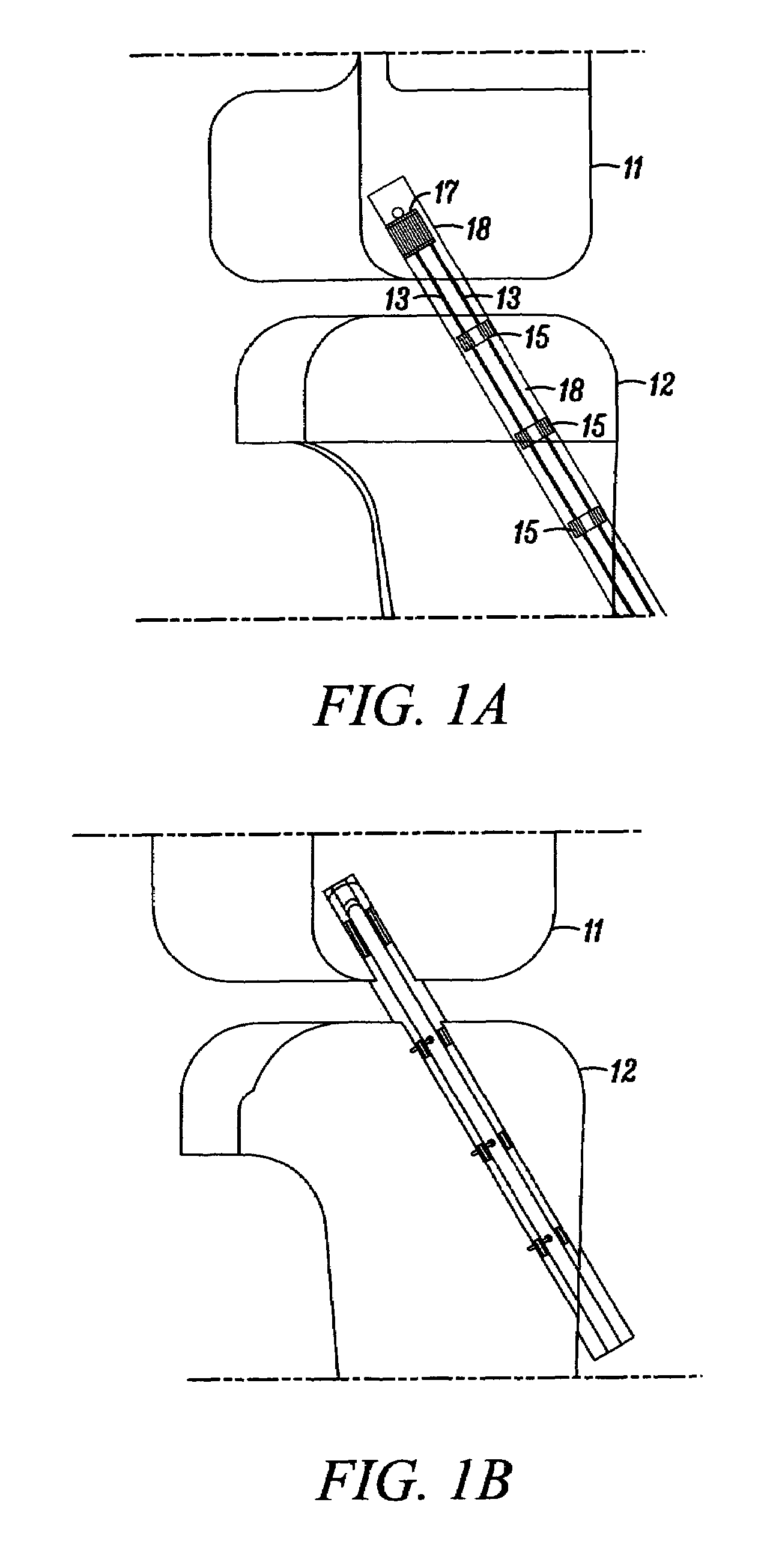

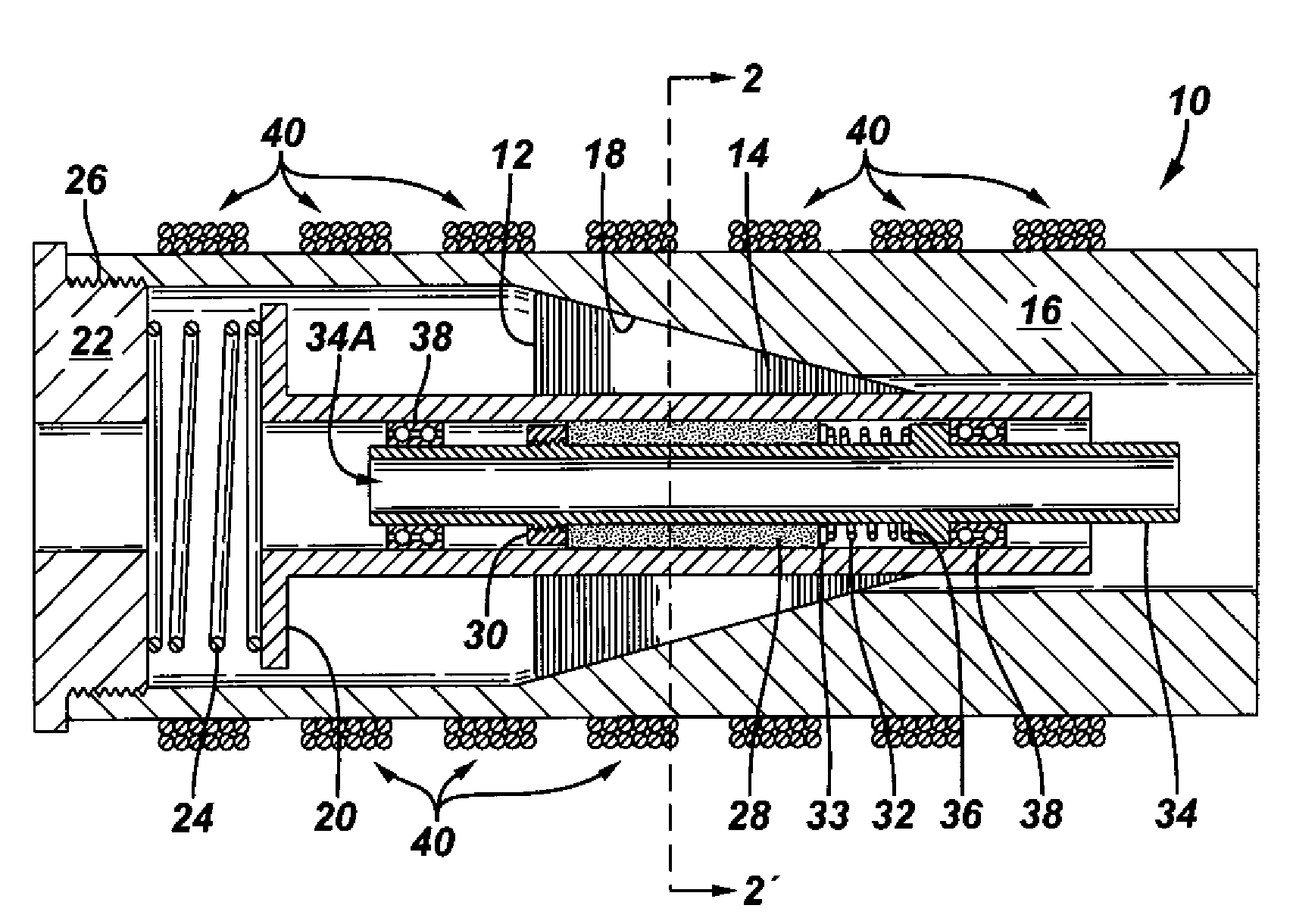

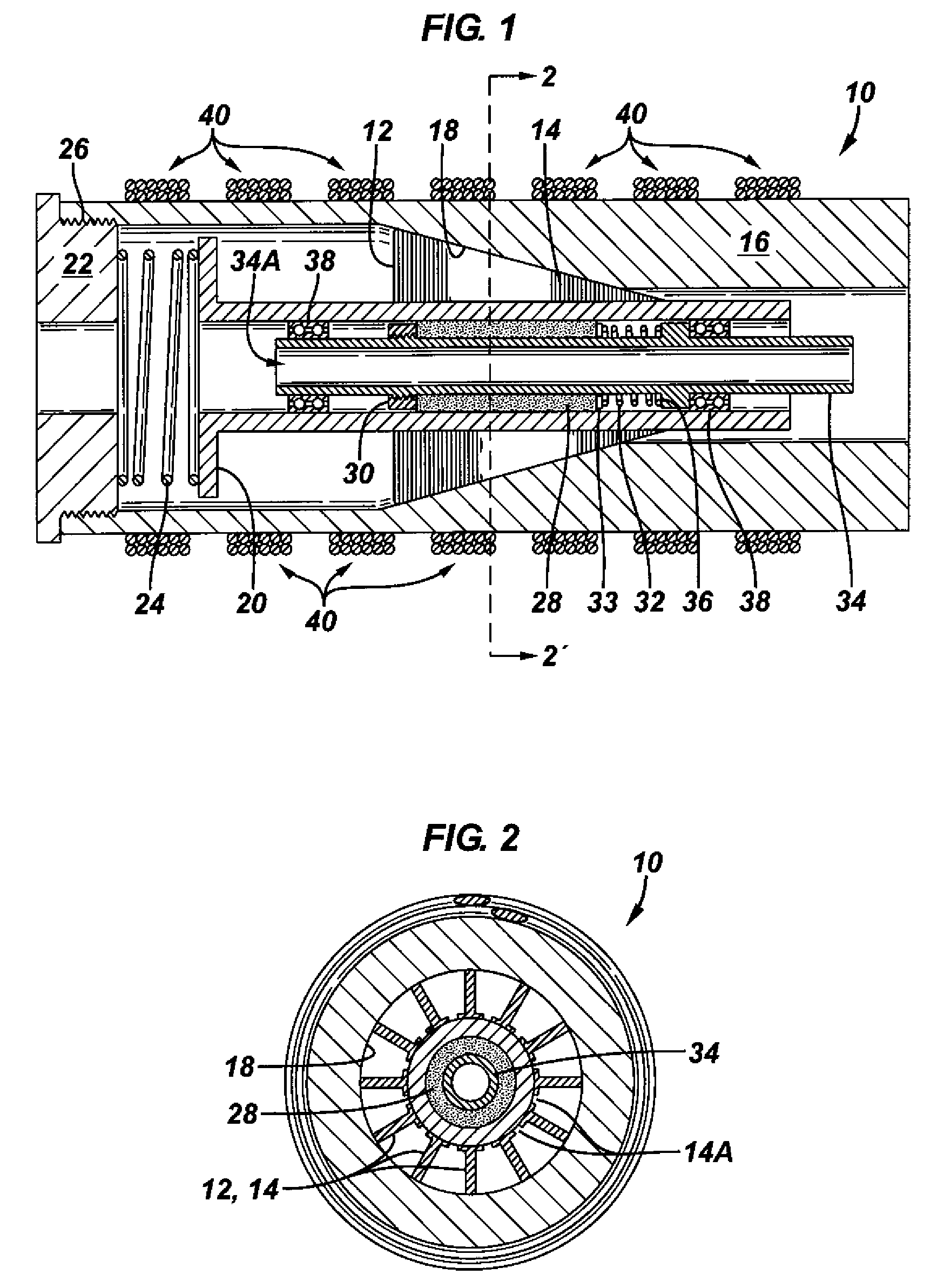

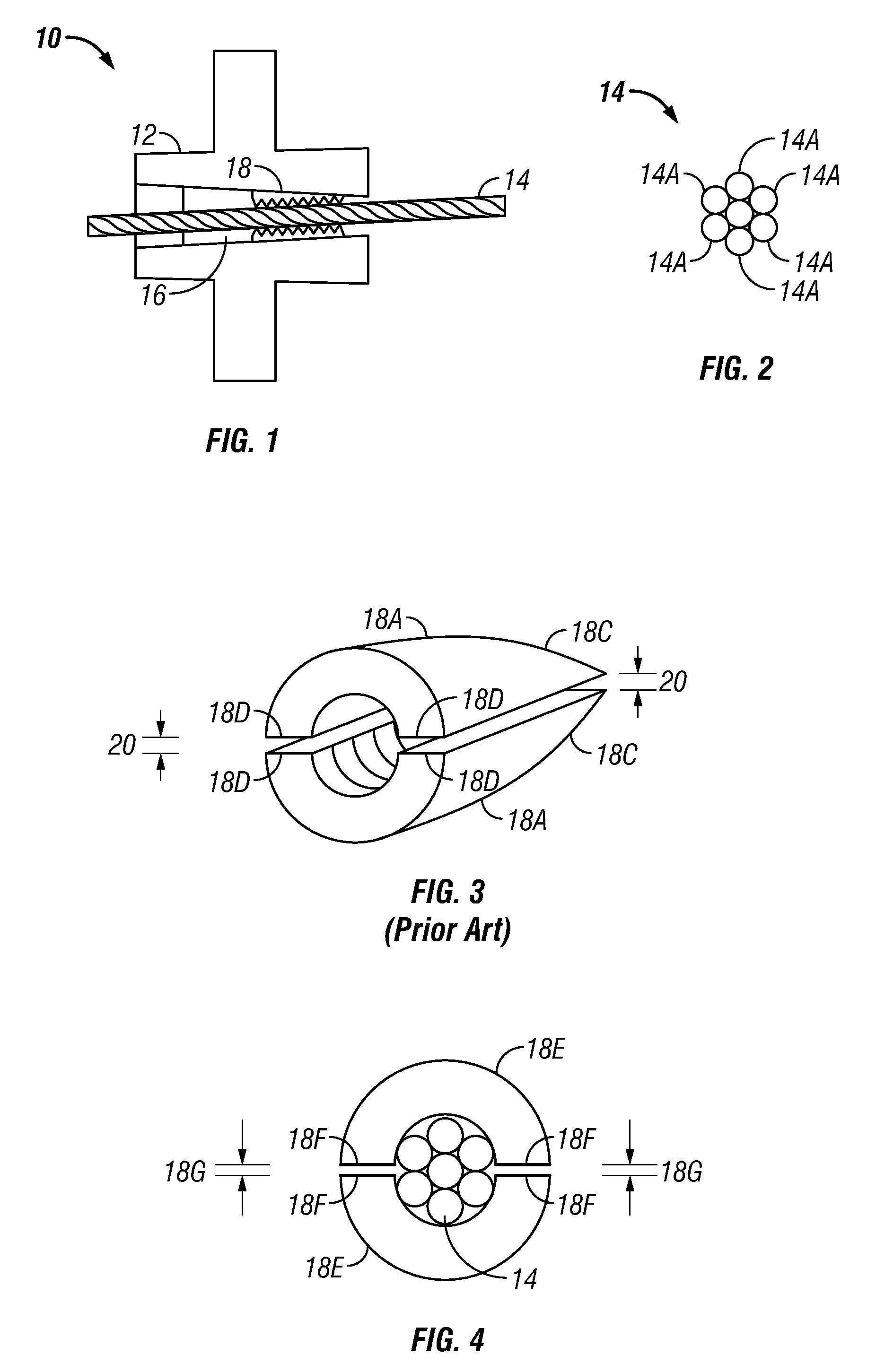

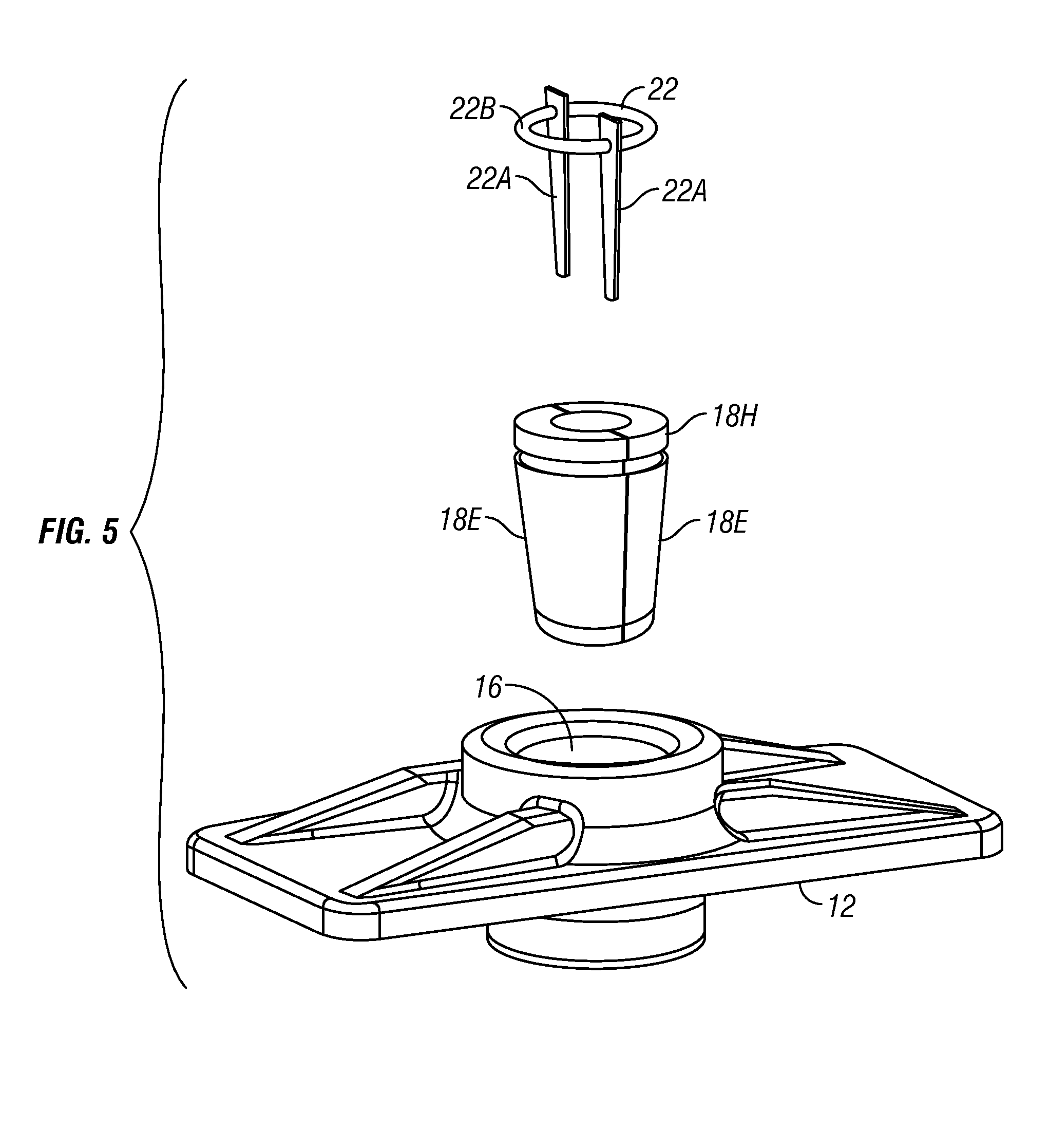

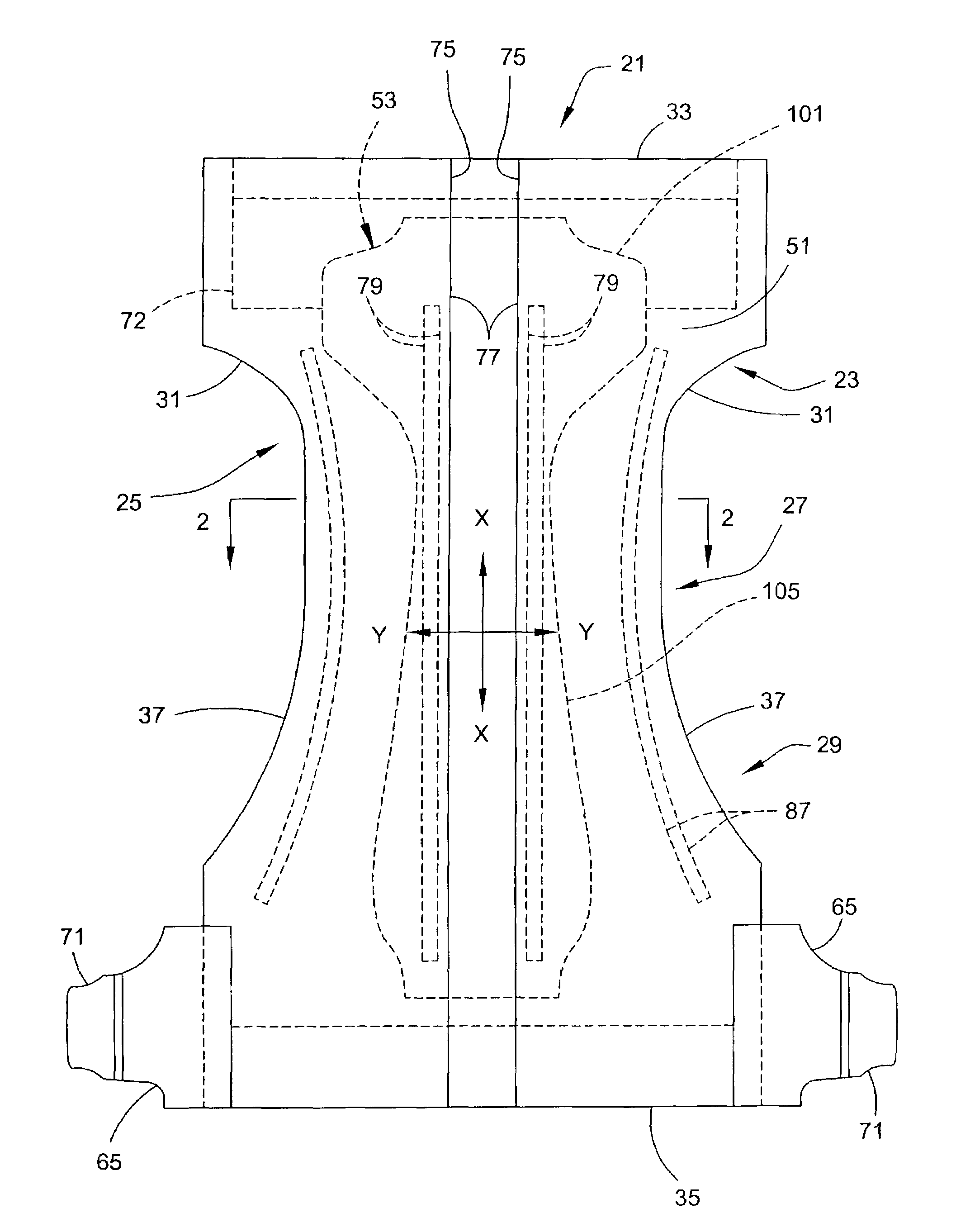

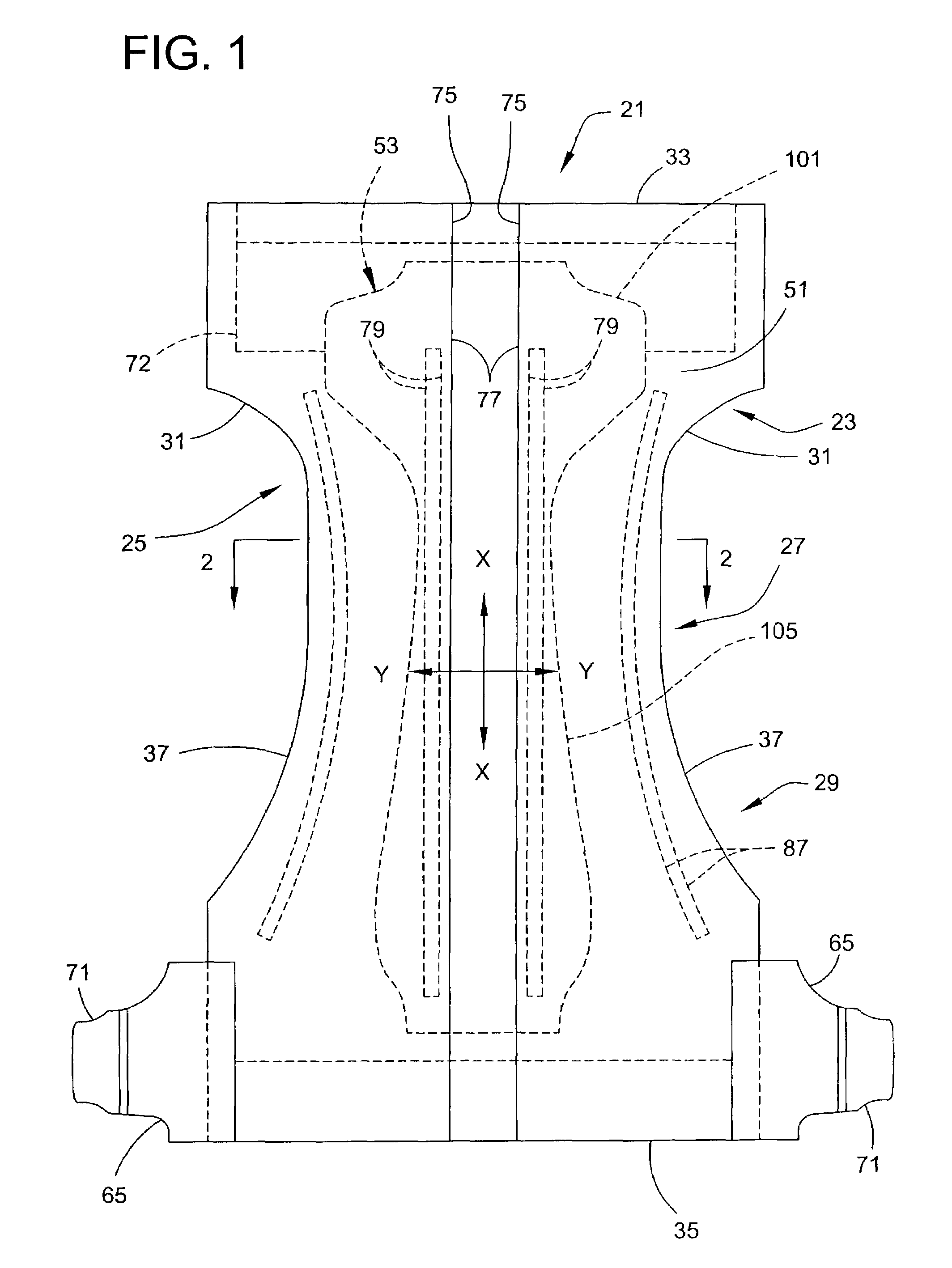

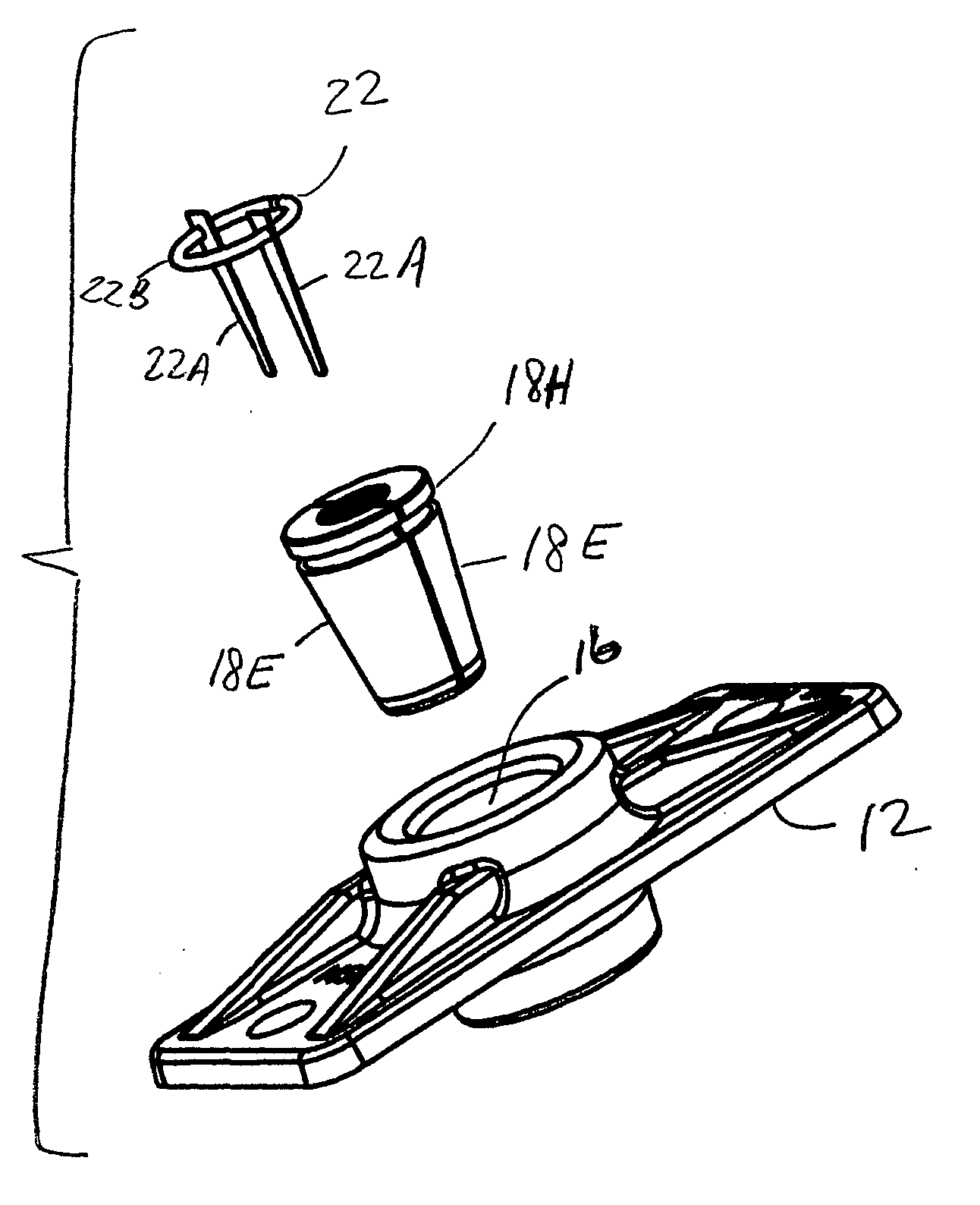

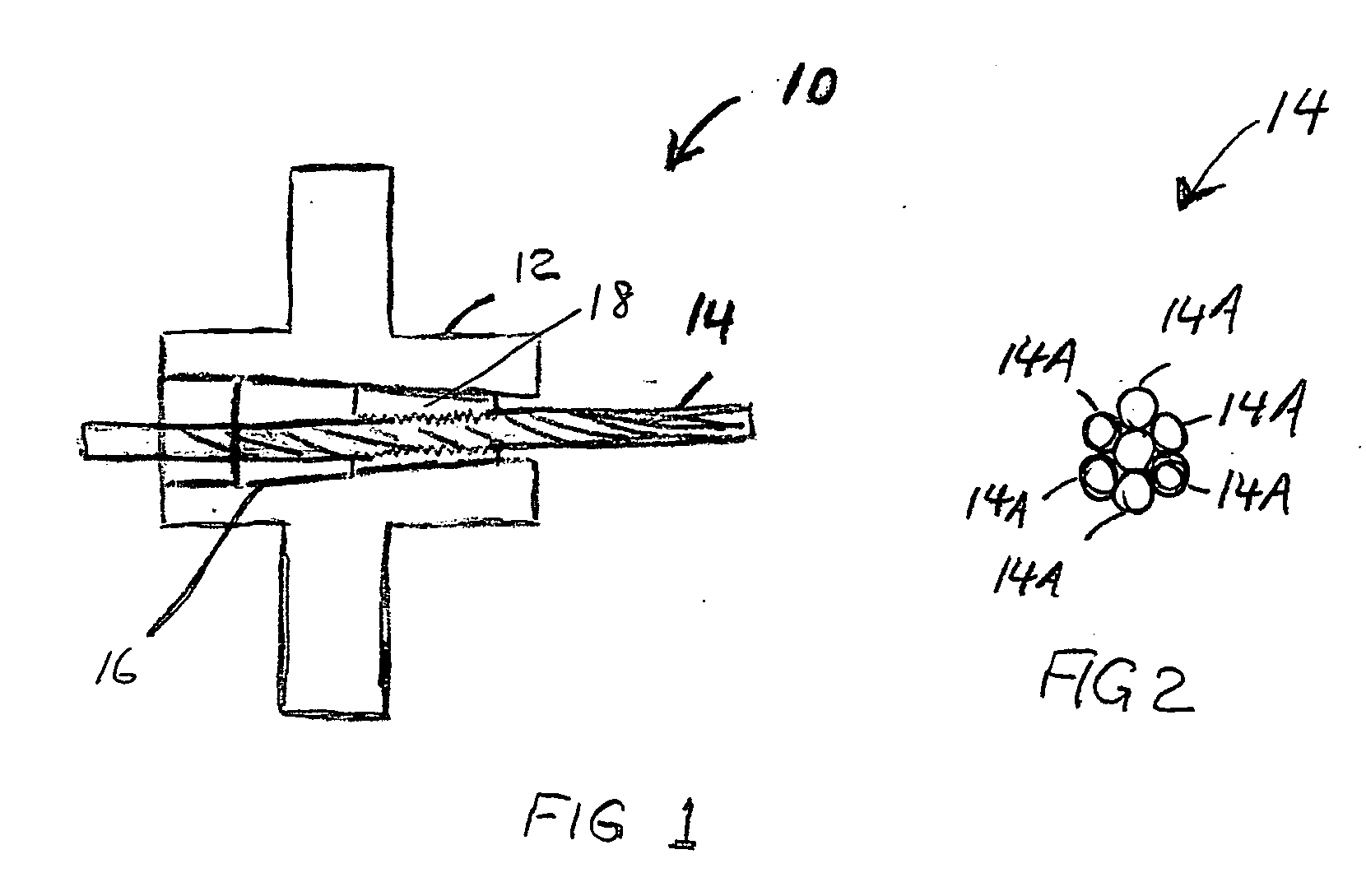

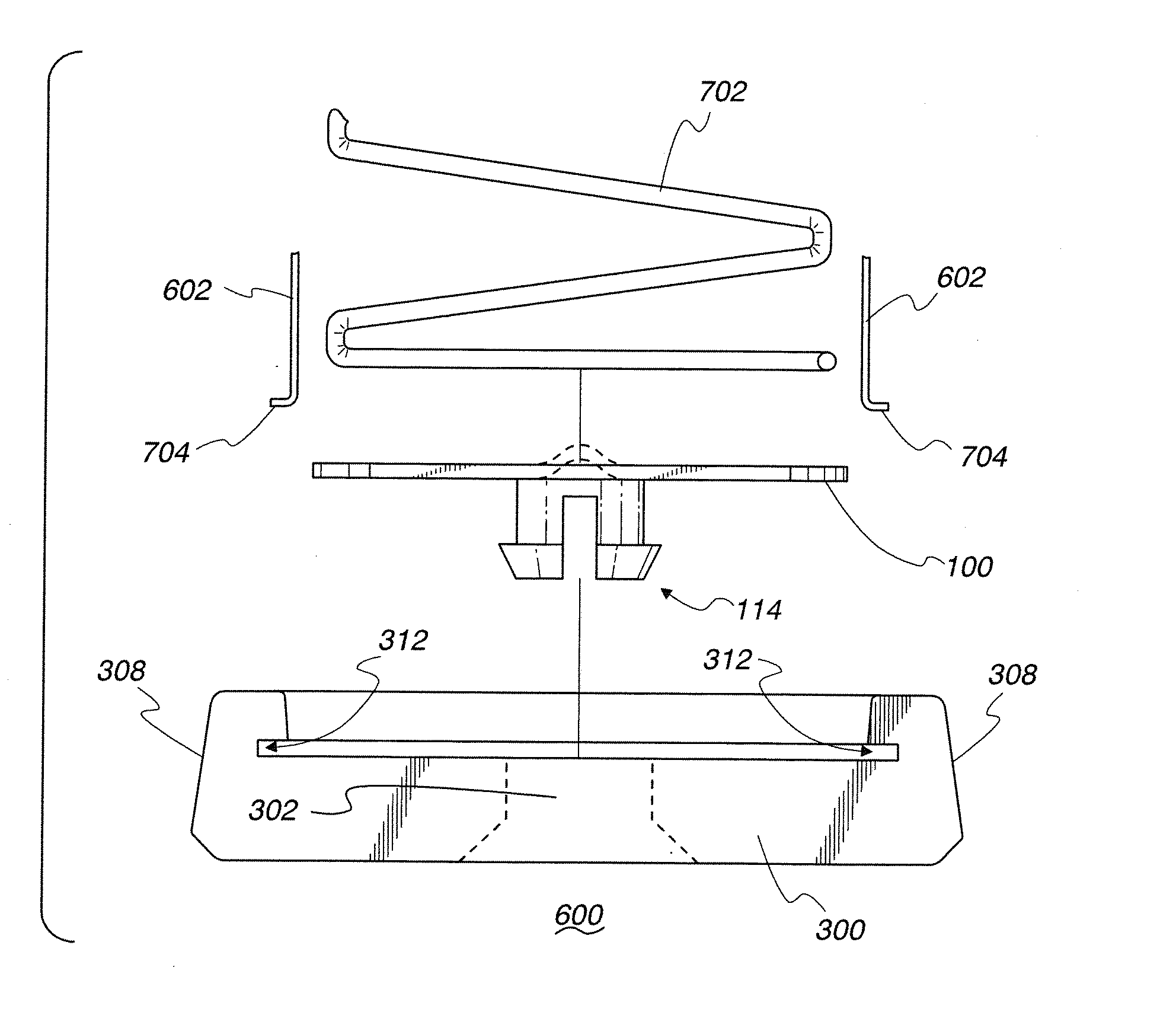

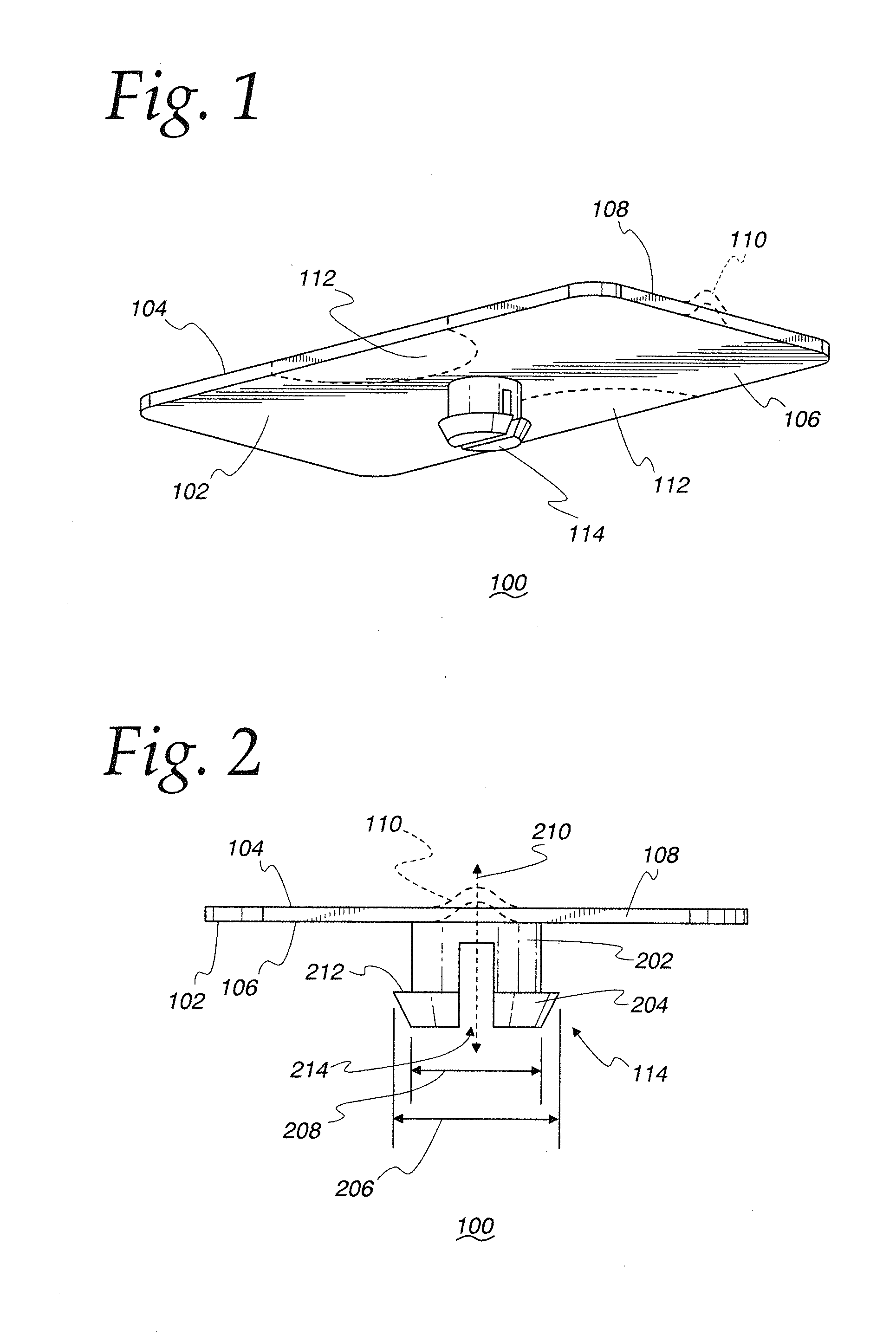

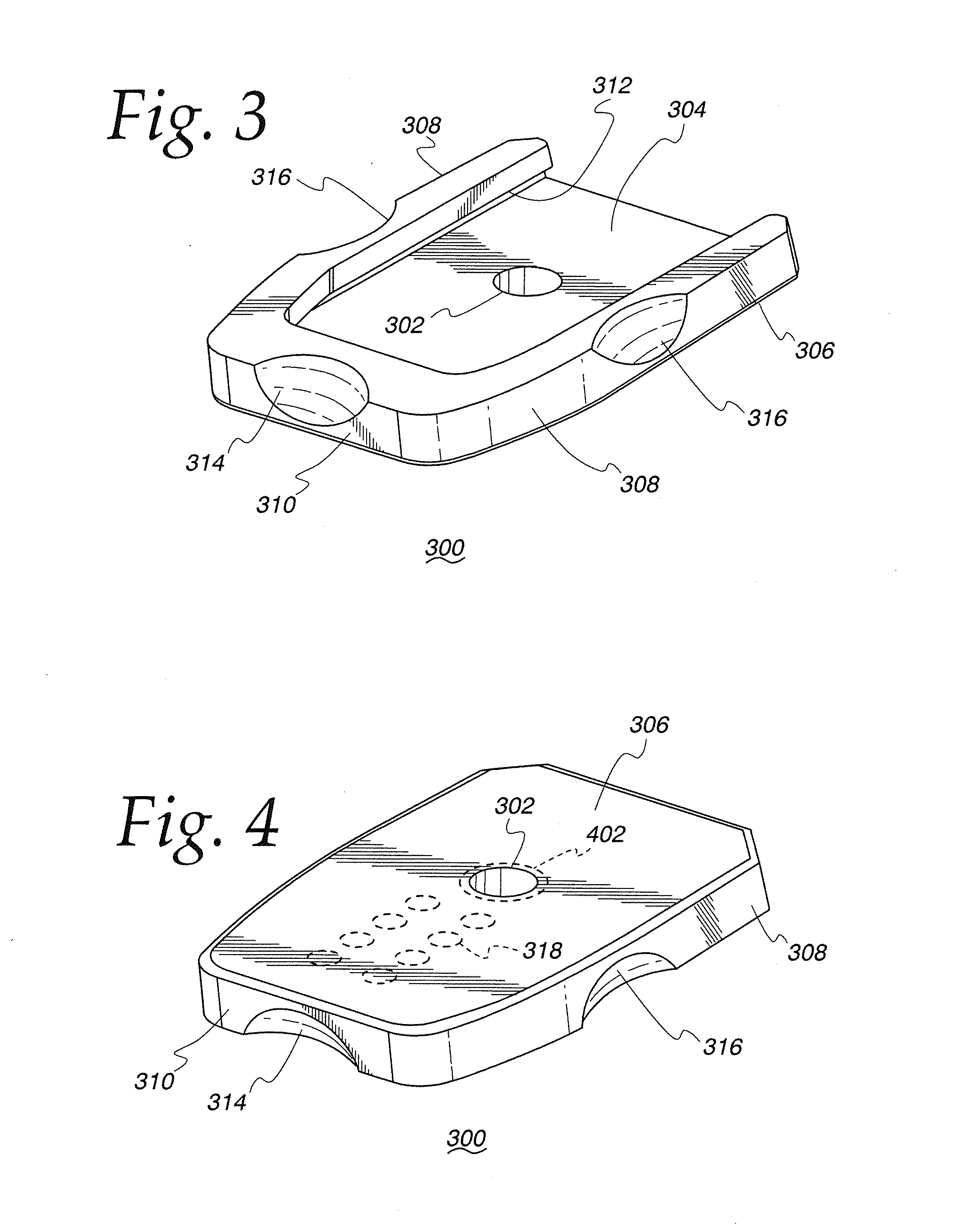

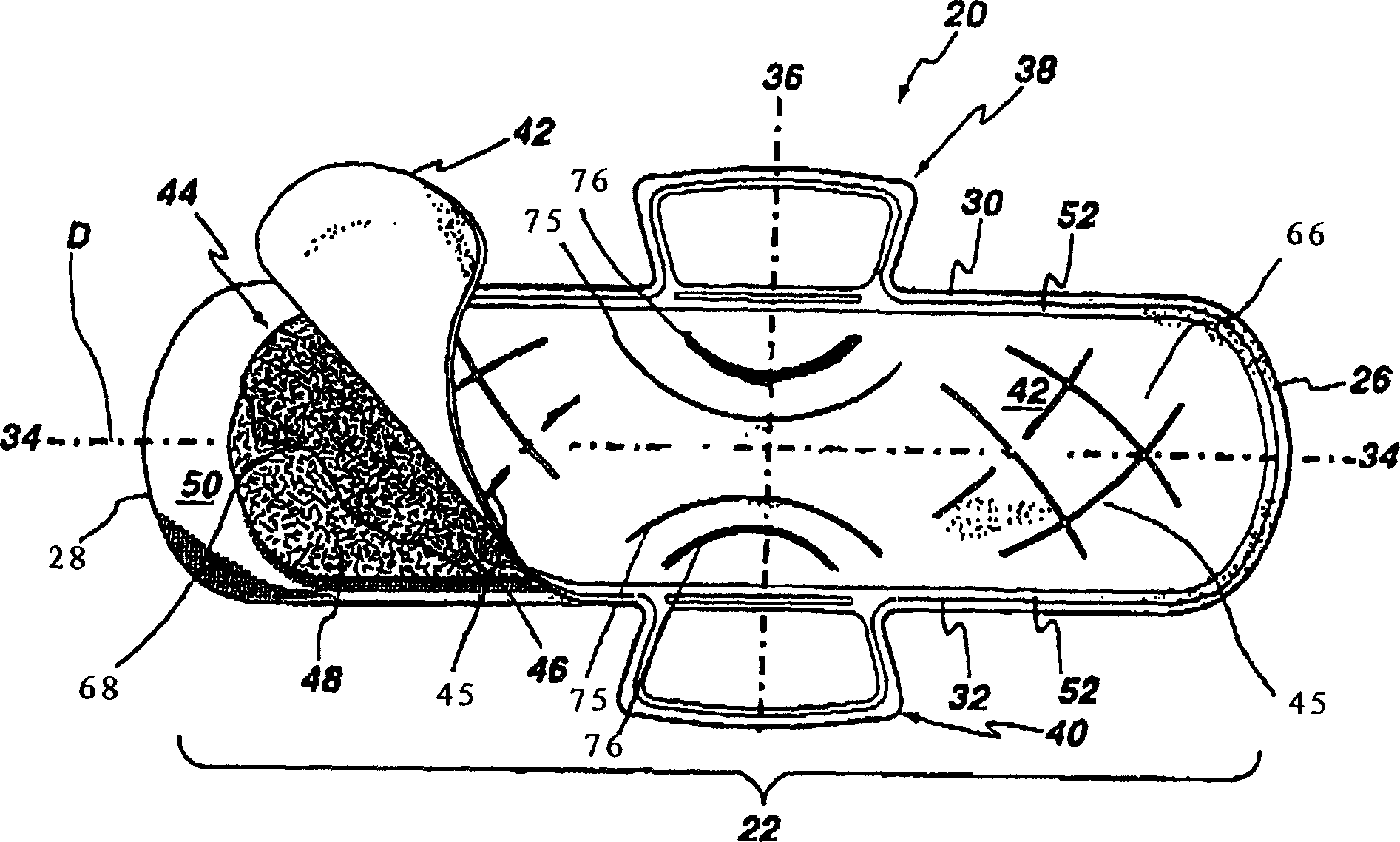

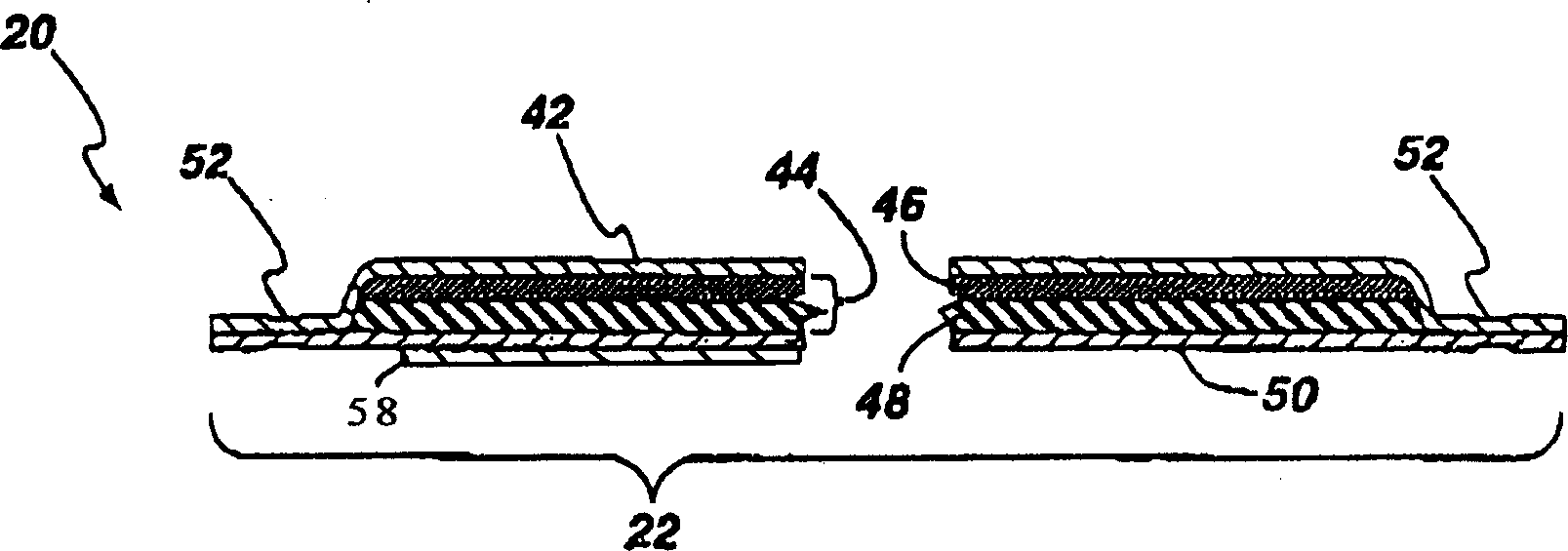

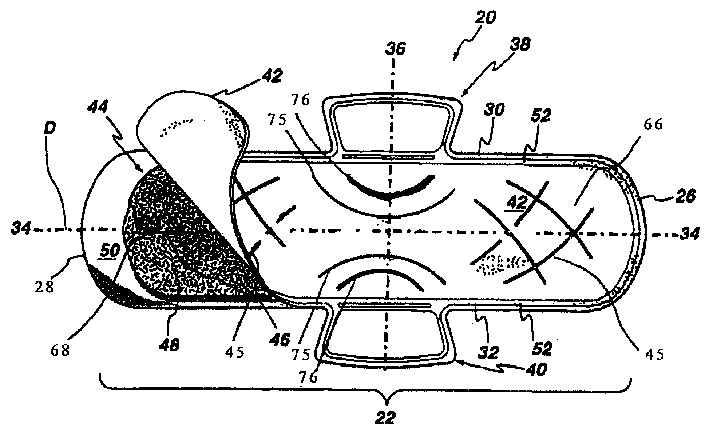

Devices, systems and methods for material fixation

InactiveUS20060155287A1Easy to manufactureEasy to useSuture equipmentsLigamentsBone tunnelLateral compression

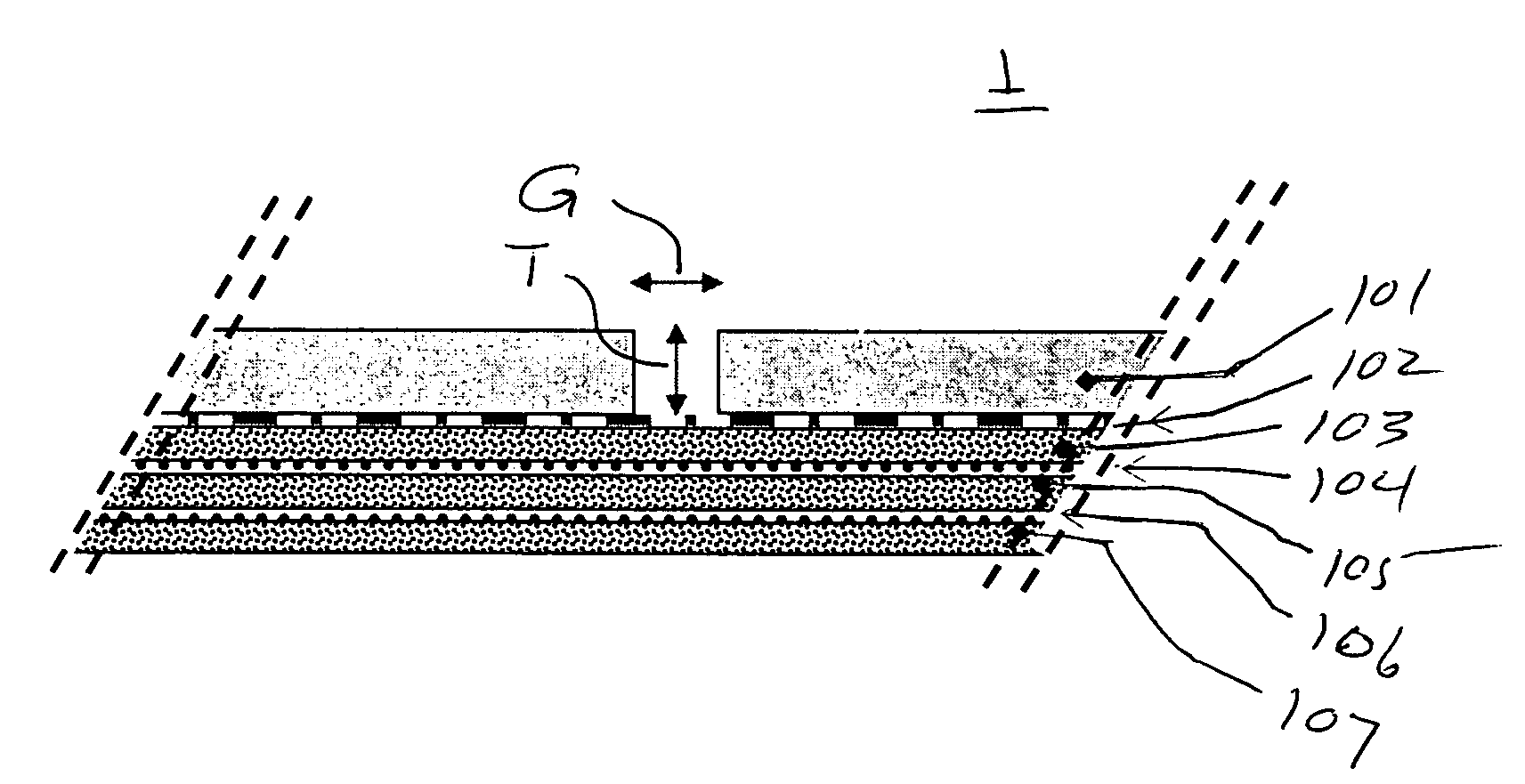

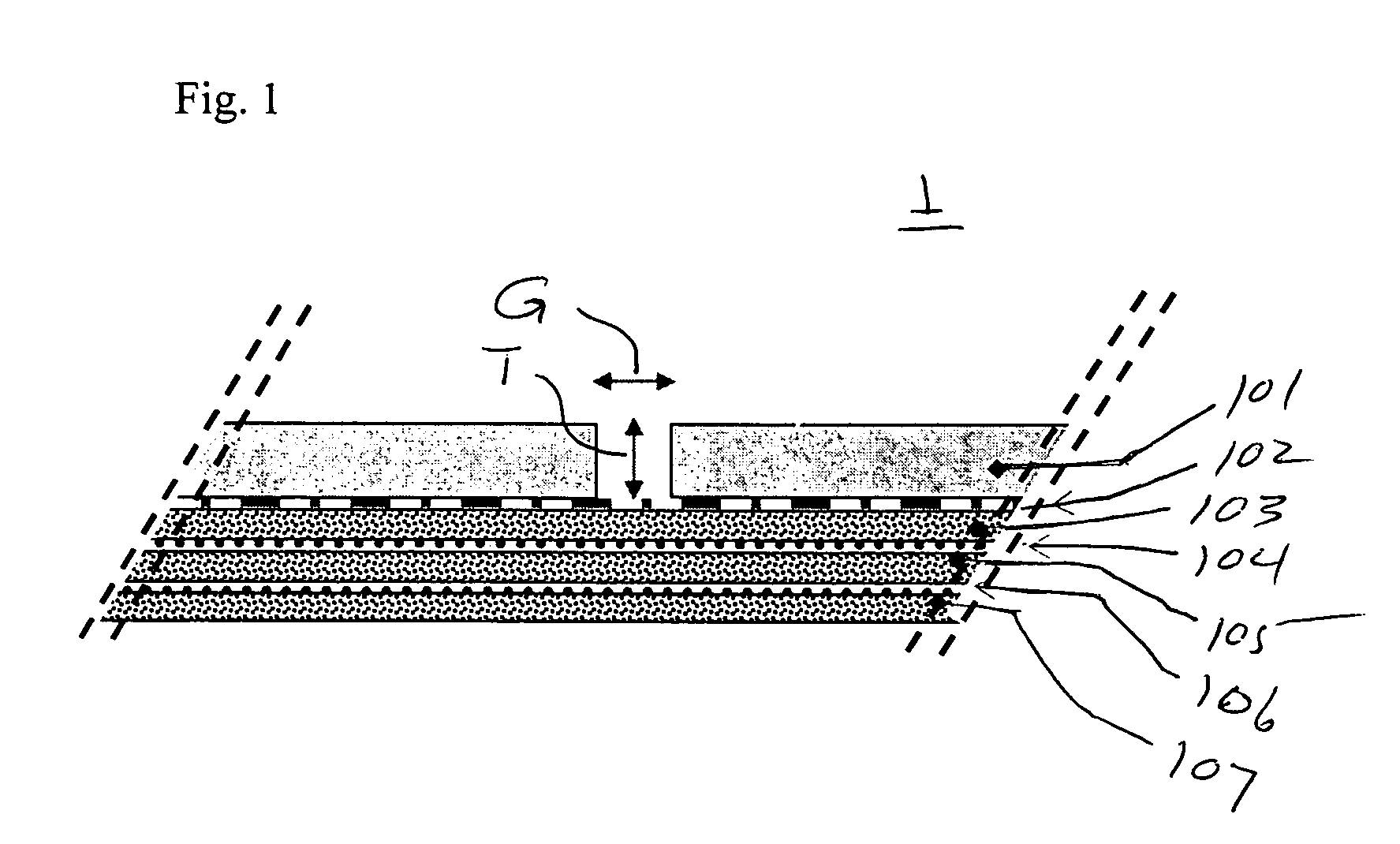

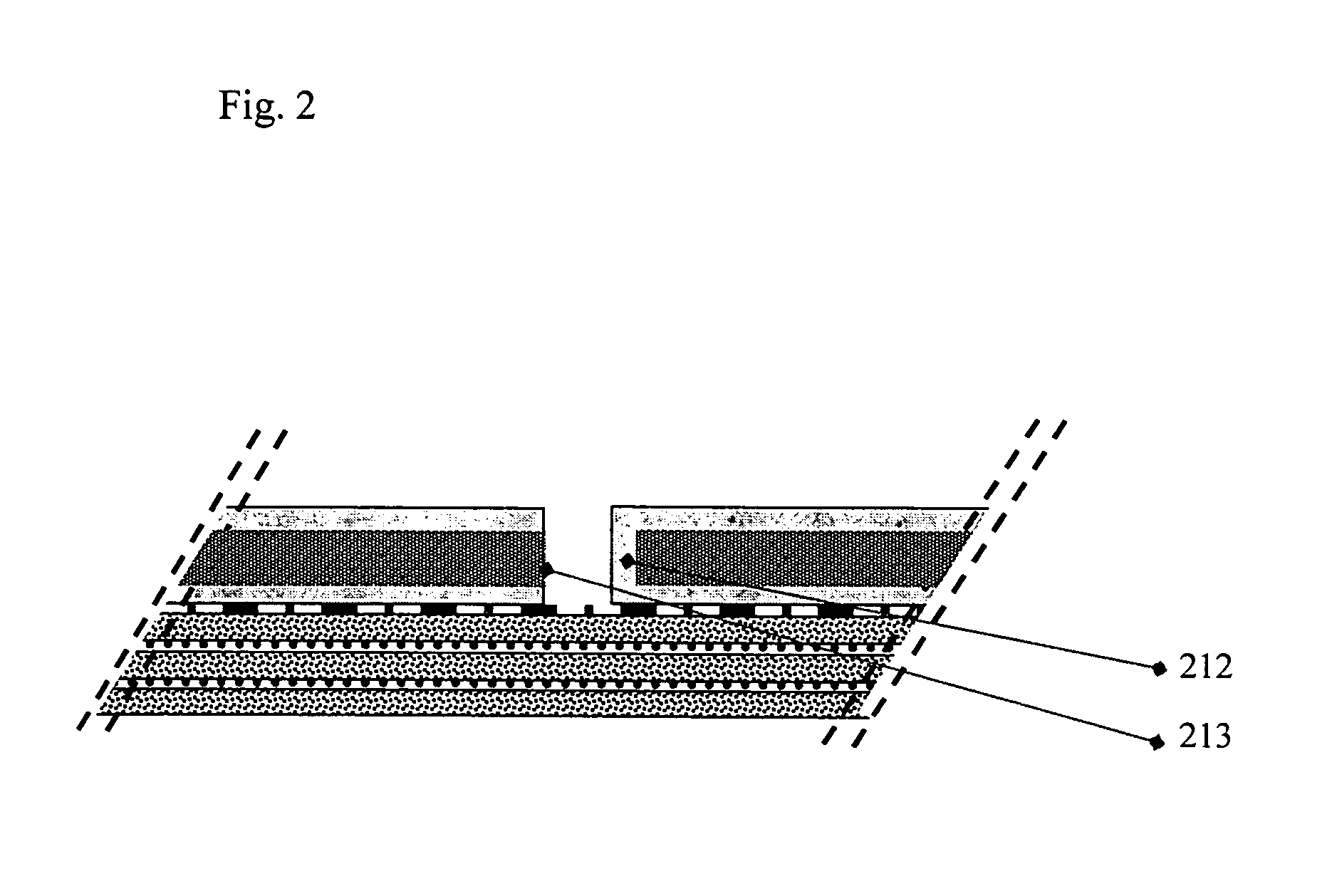

Devices, systems and methods for fixation of tendon to bone are described. An exemplary surgical implant is a modified bone anchor that is able to grasp the tendon and hold it firmly in a bone tunnel. Once deployed, the anchor delivers lateral compression to the tendon, providing direct tendon to bone compression to facilitate healing. The anchor has different versions which allow it to be attached to the tendon prior to insertion into the bone tunnel, or be inserted between tendon arms when the surgical procedure dictates. The resulting tendon to bone compression allows for the firm fixation in a manner markedly simpler than traditional techniques. A modification of this anchor can also allow the anchor to grasp and hold suture. This variation facilitates the technique for knotless rotator cuff repair.

Owner:CAYENNE MEDICAL INC

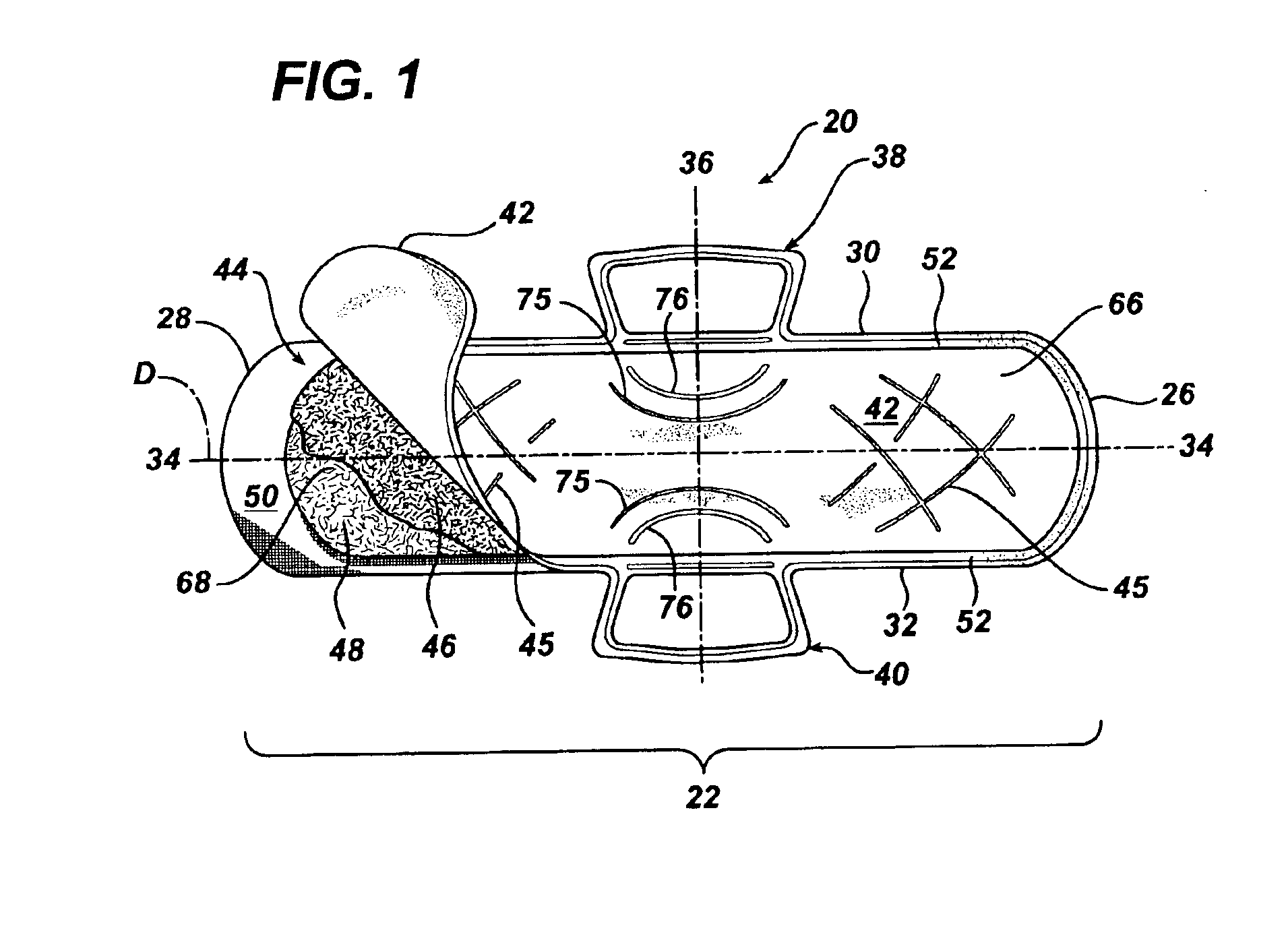

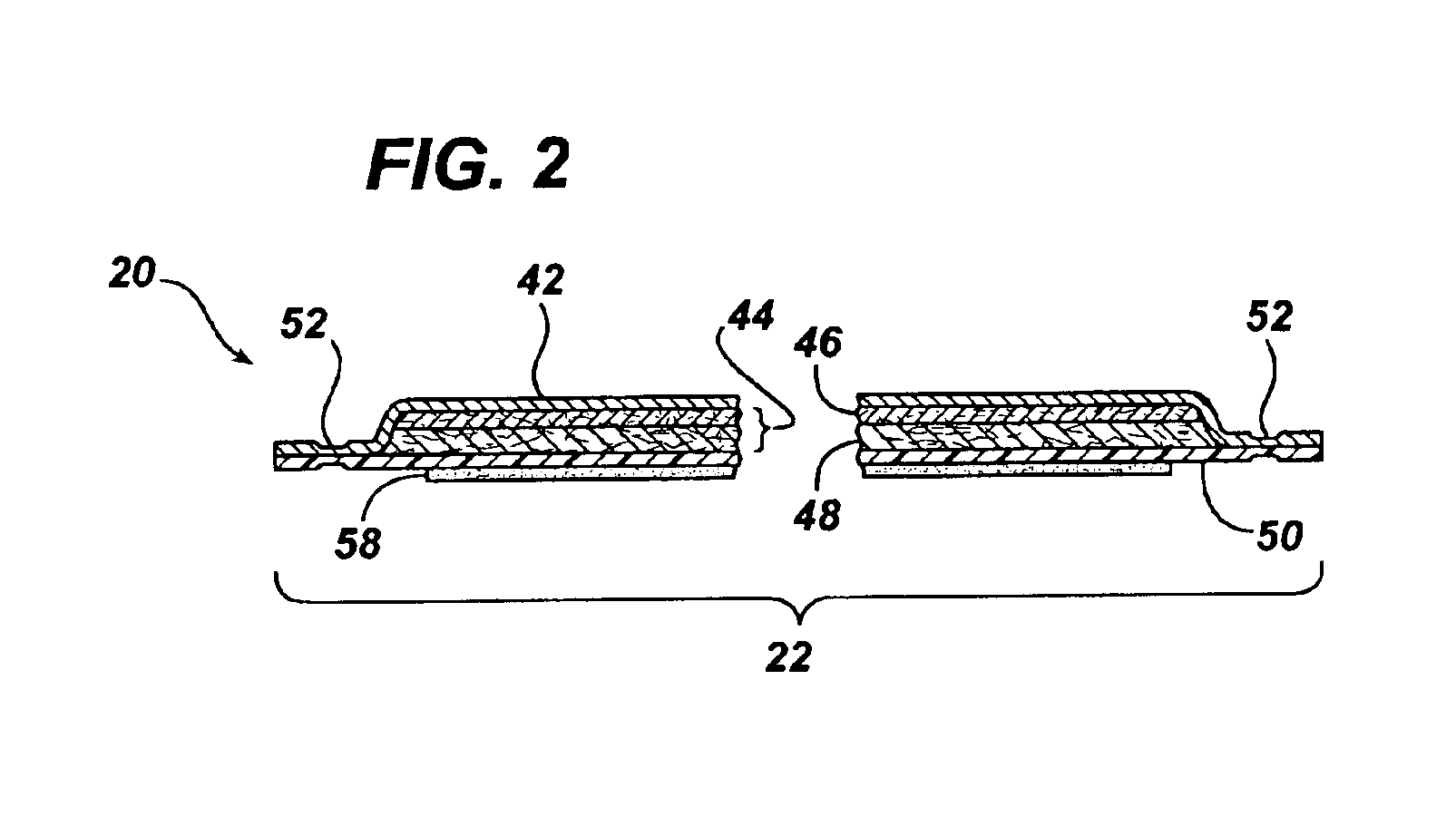

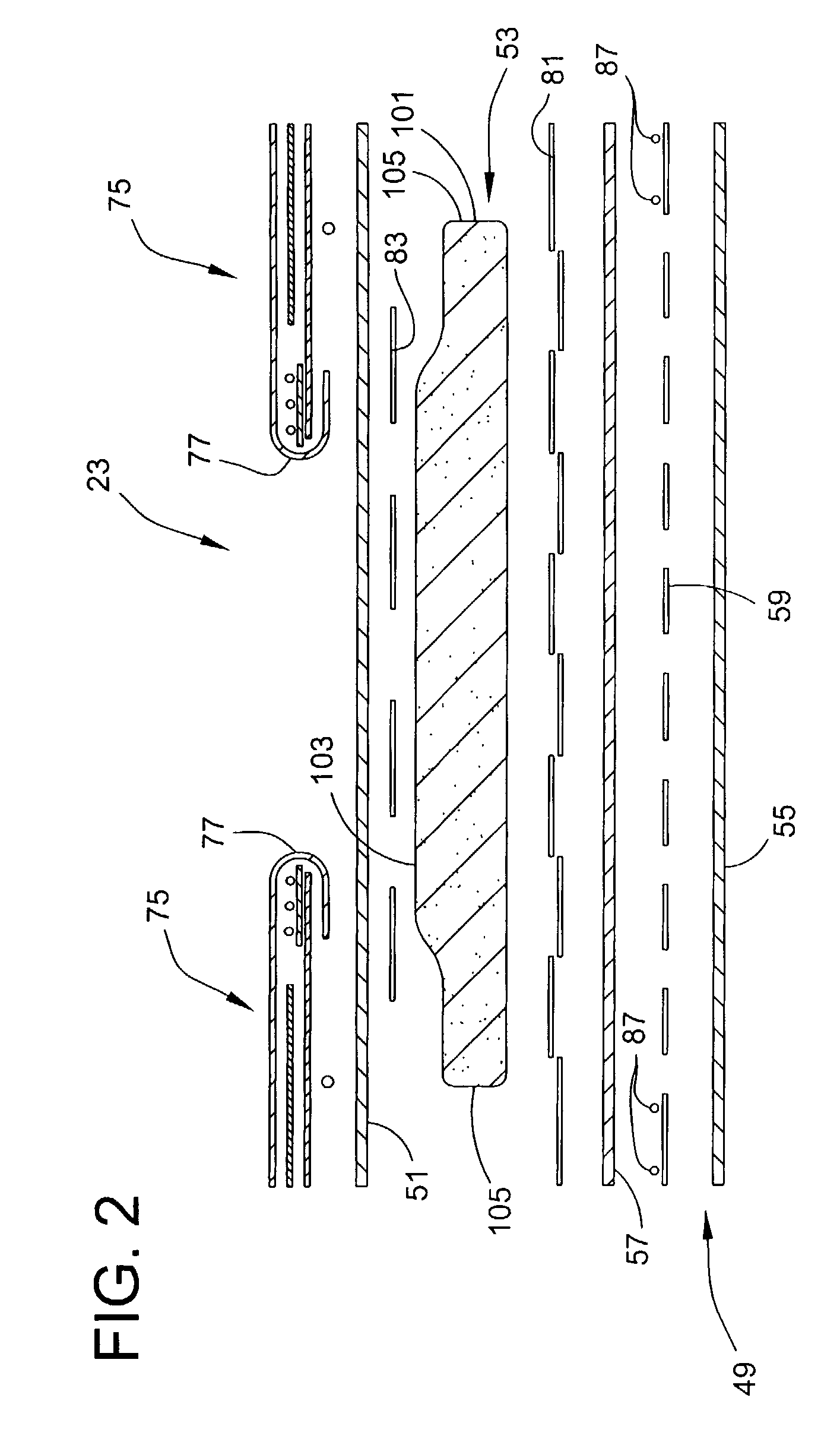

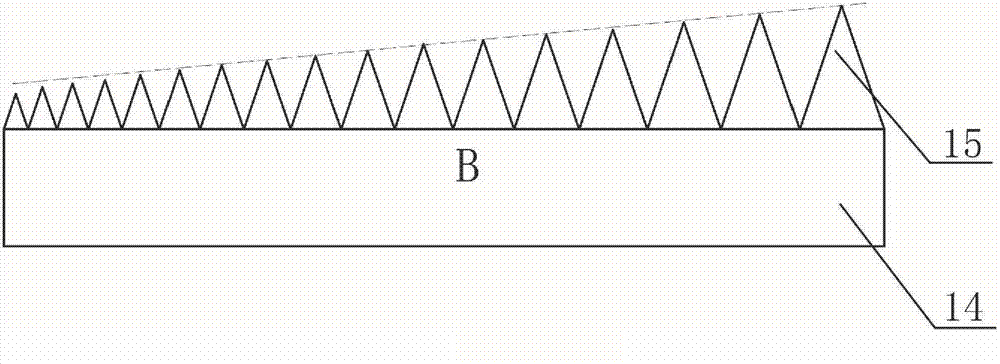

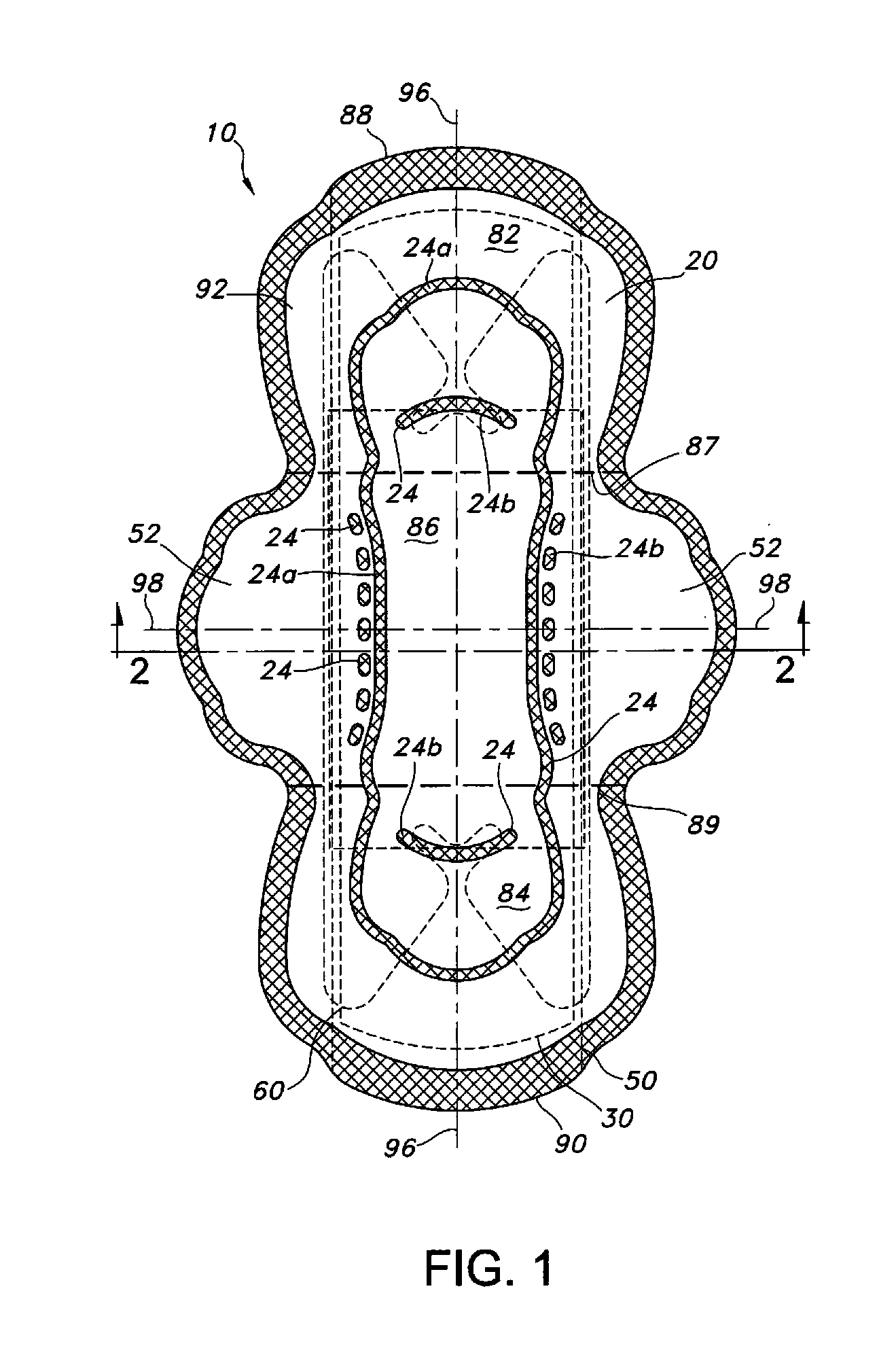

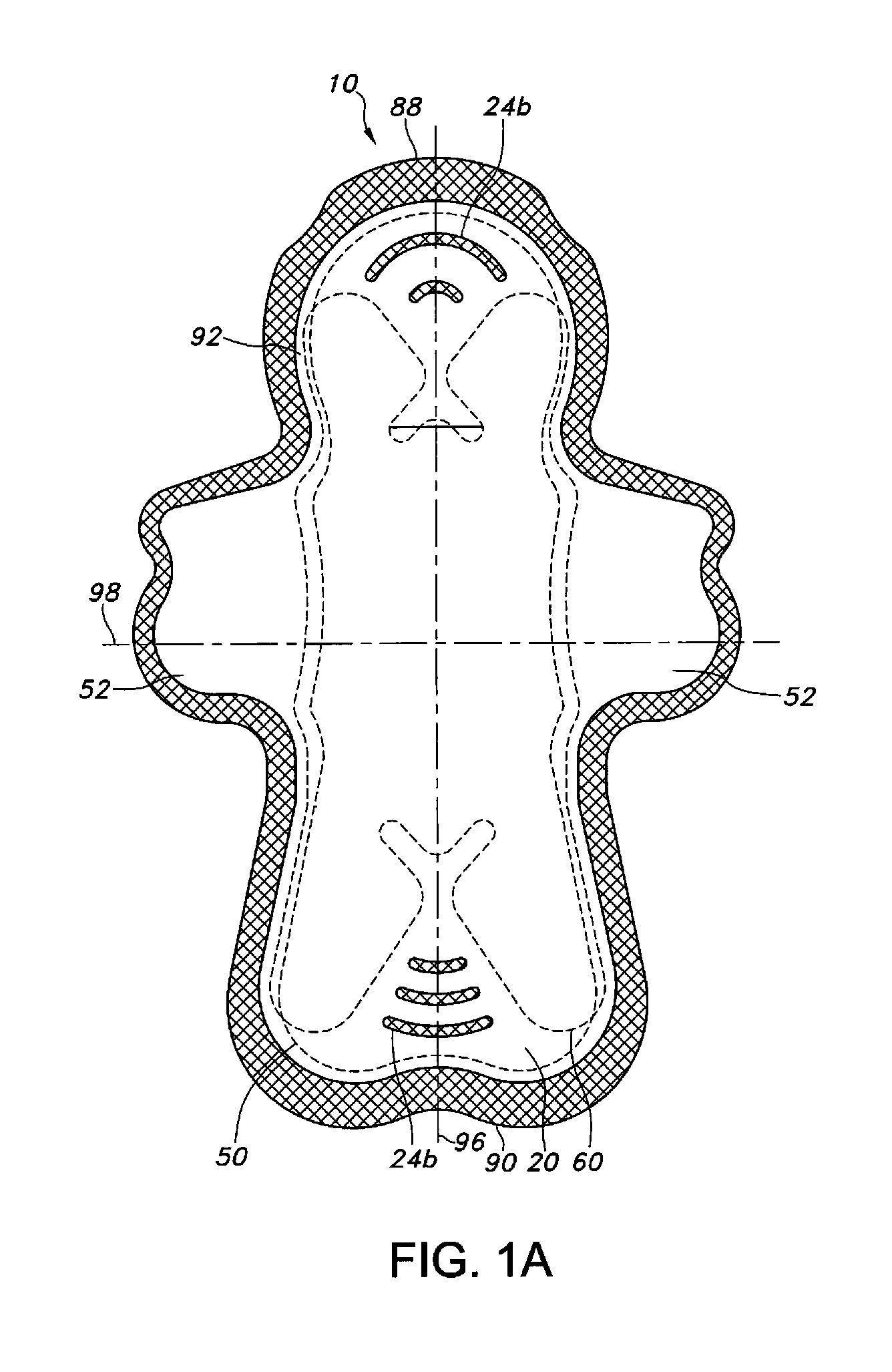

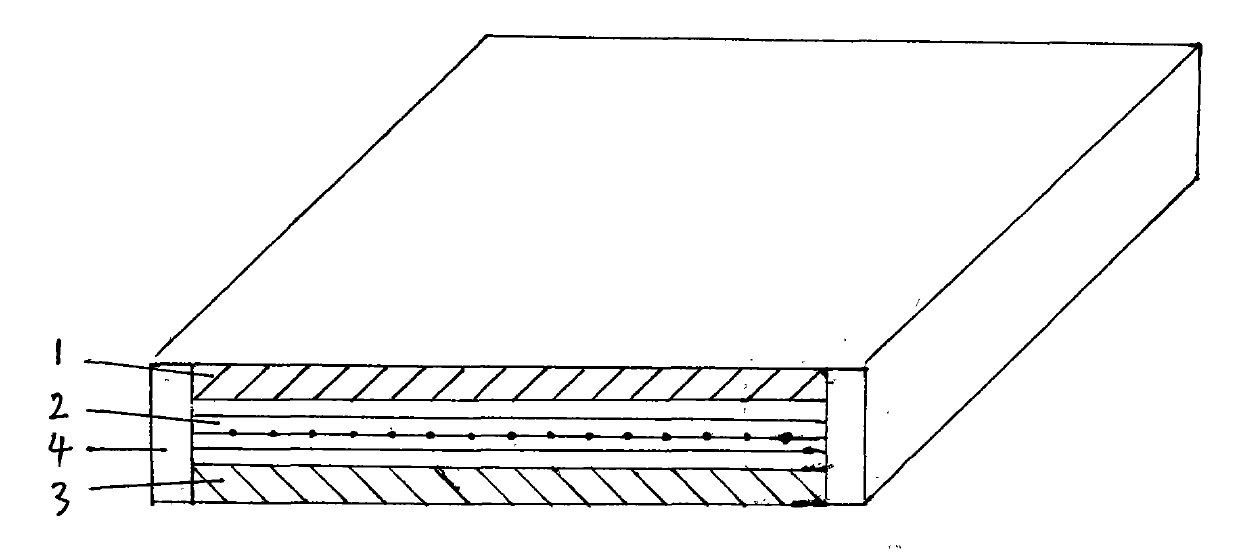

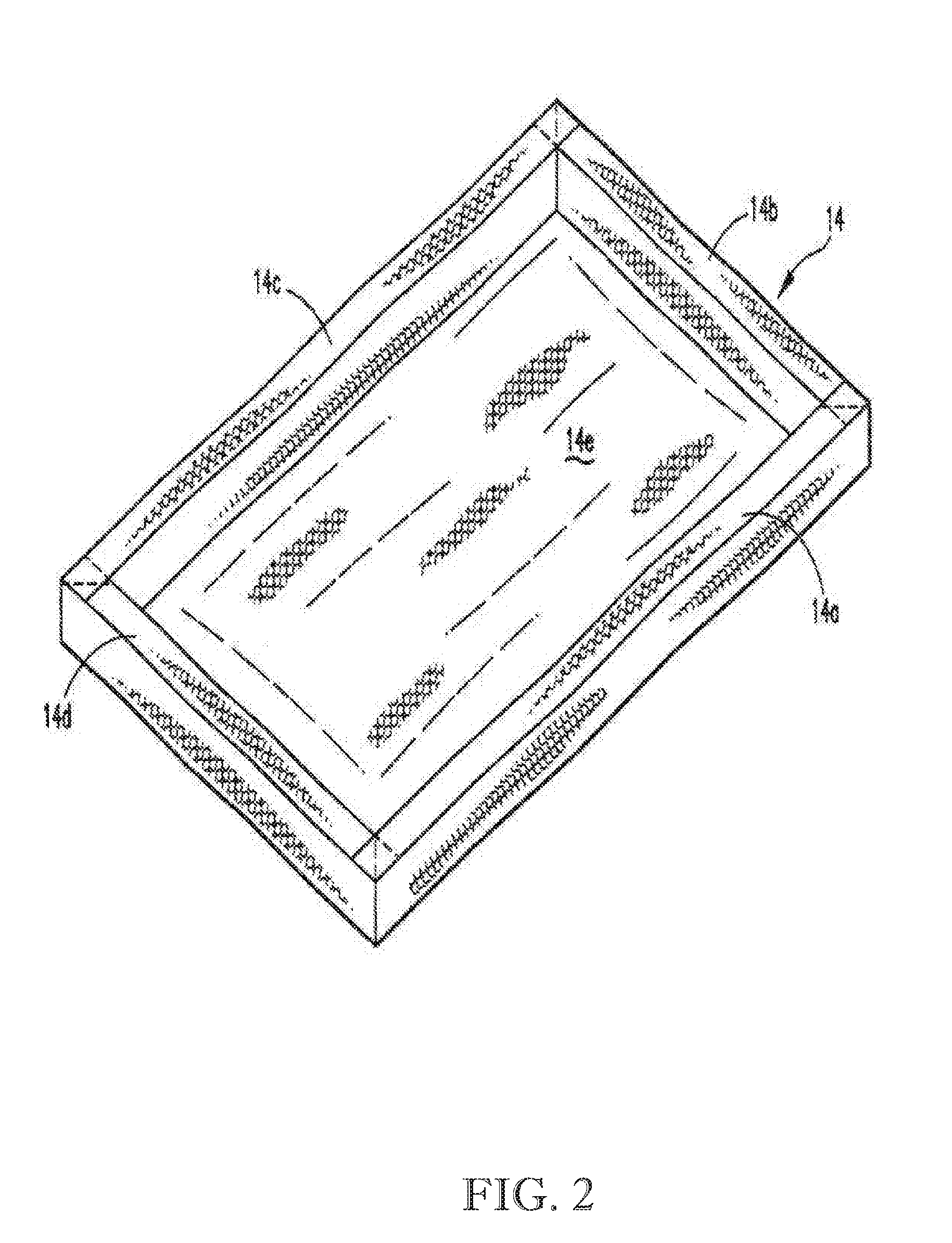

Thin comfortable sanitary napkin having reduced bunching

A sanitary napkin for placement in a crotch portion of an undergarment of a wearer having a longitudinal axis and being further characterized by having a preferential bending zone extending obliquely in relation to the longitudinal axis, each preferential bending zone being located solely in an end region and does not extend into a central region of the napkin. The preferential bending zone may be created by mechanically embossing the surface of the sanitary napkin to locally densify the absorbing materials of the article. The preferential bending zone causes the end regions of the sanitary napkin to resist lateral compression forces exerted by the thighs of the wearer and thereby prevents bunching of the article on the undergarment. The central region 70 of the sanitary napkin conforms to the wearer's body providing greater comfort for the wearer of the napkin.

Owner:EDGEWELL PERSONAL CARE BRANDS LLC

Devices, systems and methods for material fixation

InactiveUS7651528B2Easy to manufactureEasy to useSuture equipmentsLigamentsBone tunnelLateral compression

Devices, systems and methods for fixation of tendon to bone are described. An exemplary surgical implant is a modified bone anchor that is able to grasp the tendon and hold it firmly in a bone tunnel. Once deployed, the anchor delivers lateral compression to the tendon, providing direct tendon to bone compression to facilitate healing. The anchor has different versions which allow it to be attached to the tendon prior to insertion into the bone tunnel, or be inserted between tendon arms when the surgical procedure dictates. The resulting tendon to bone compression allows for the firm fixation in a manner markedly simpler than traditional techniques. A modification of this anchor can also allow the anchor to grasp and hold suture. This variation facilitates the technique for knotless rotator cuff repair.

Owner:CAYENNE MEDICAL INC

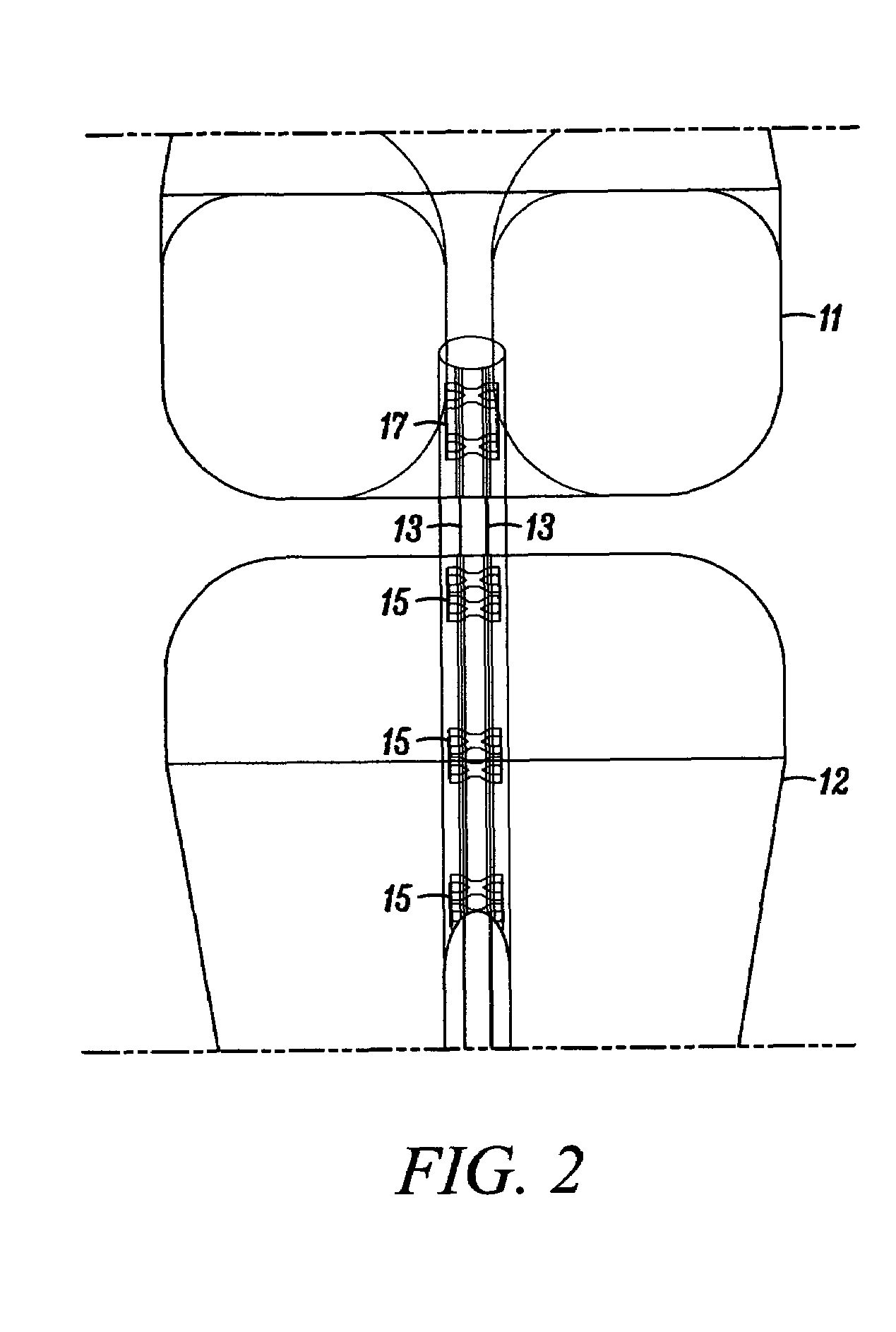

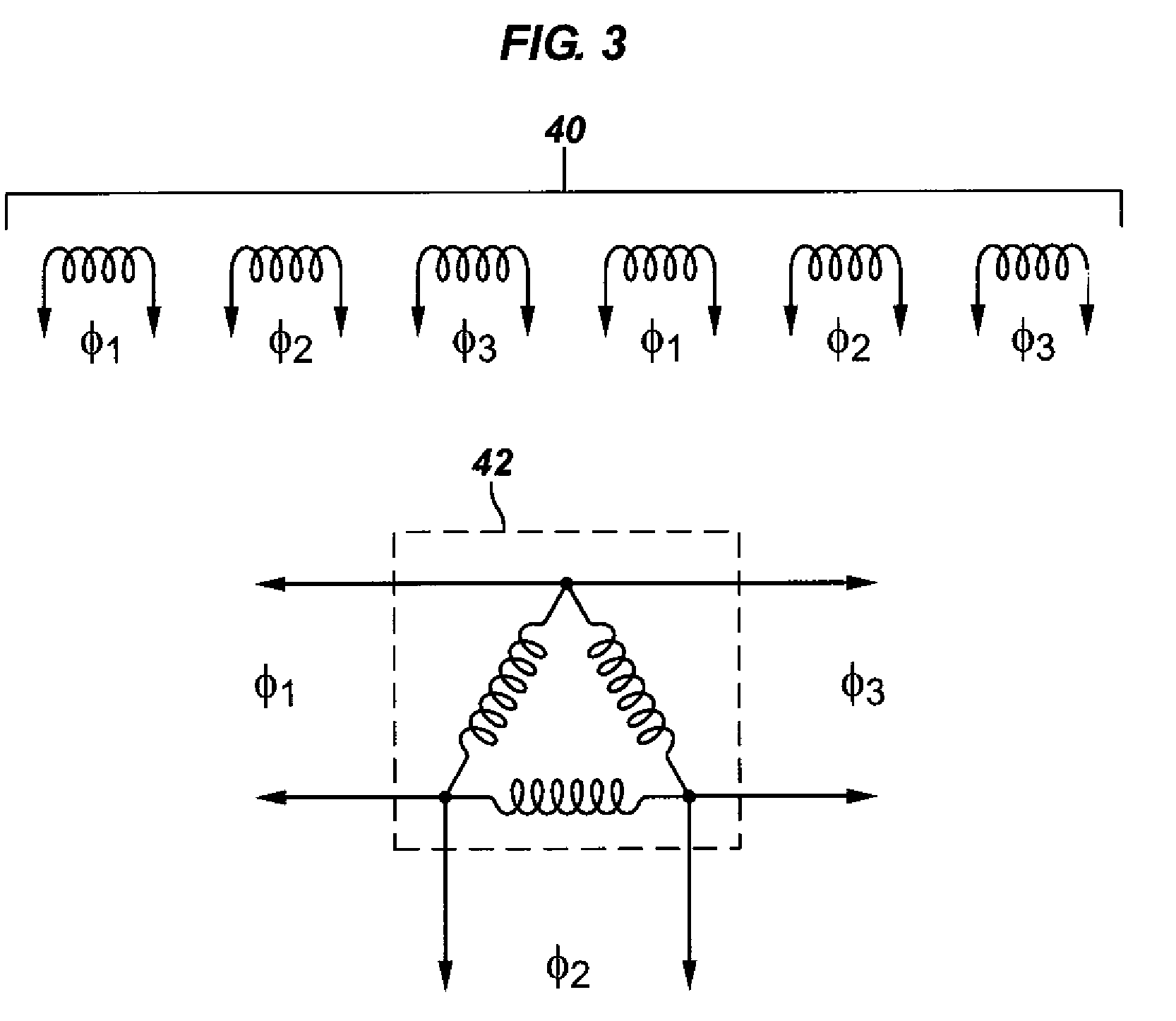

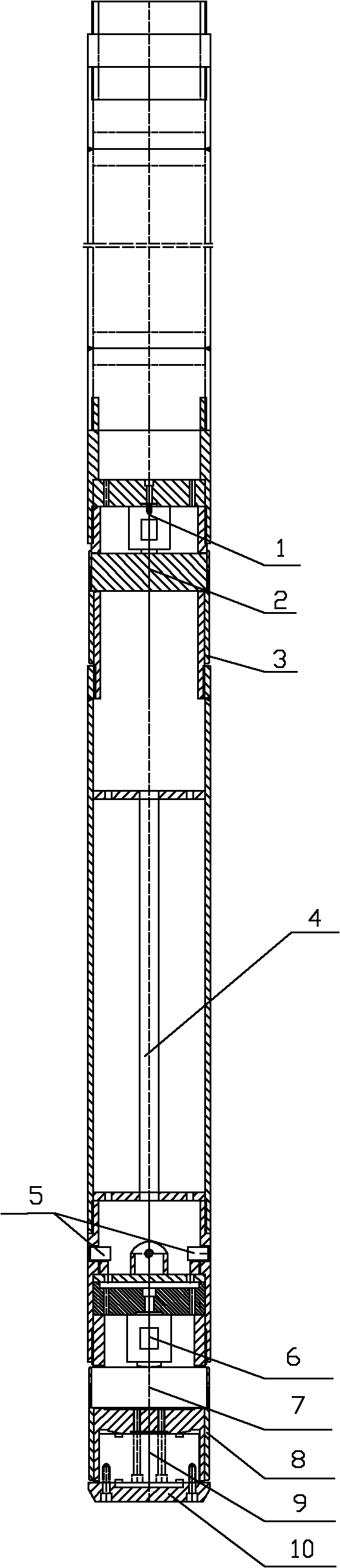

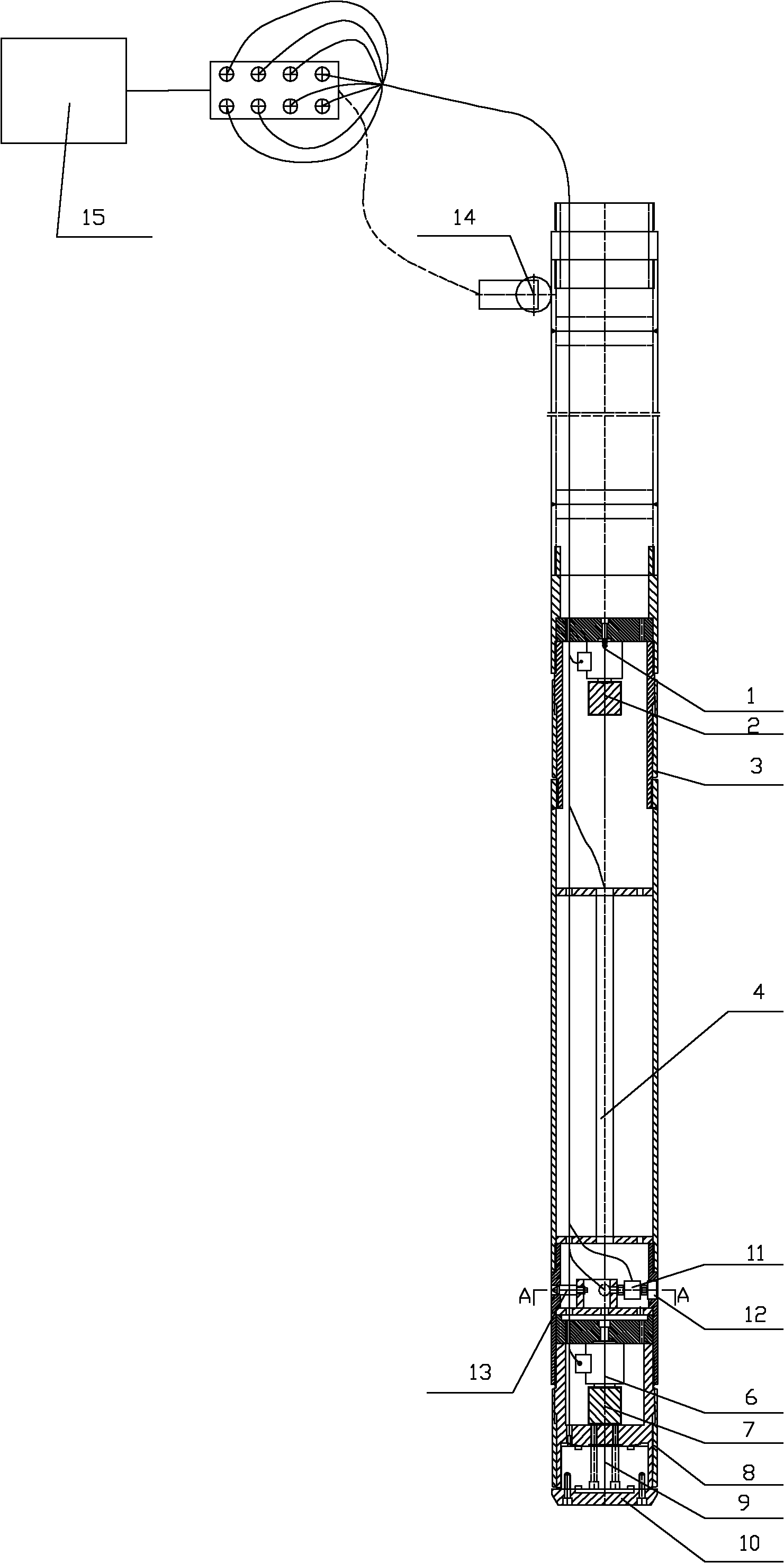

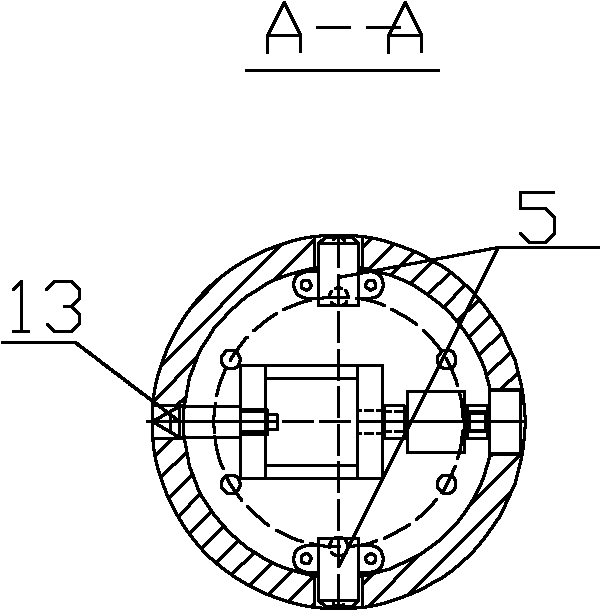

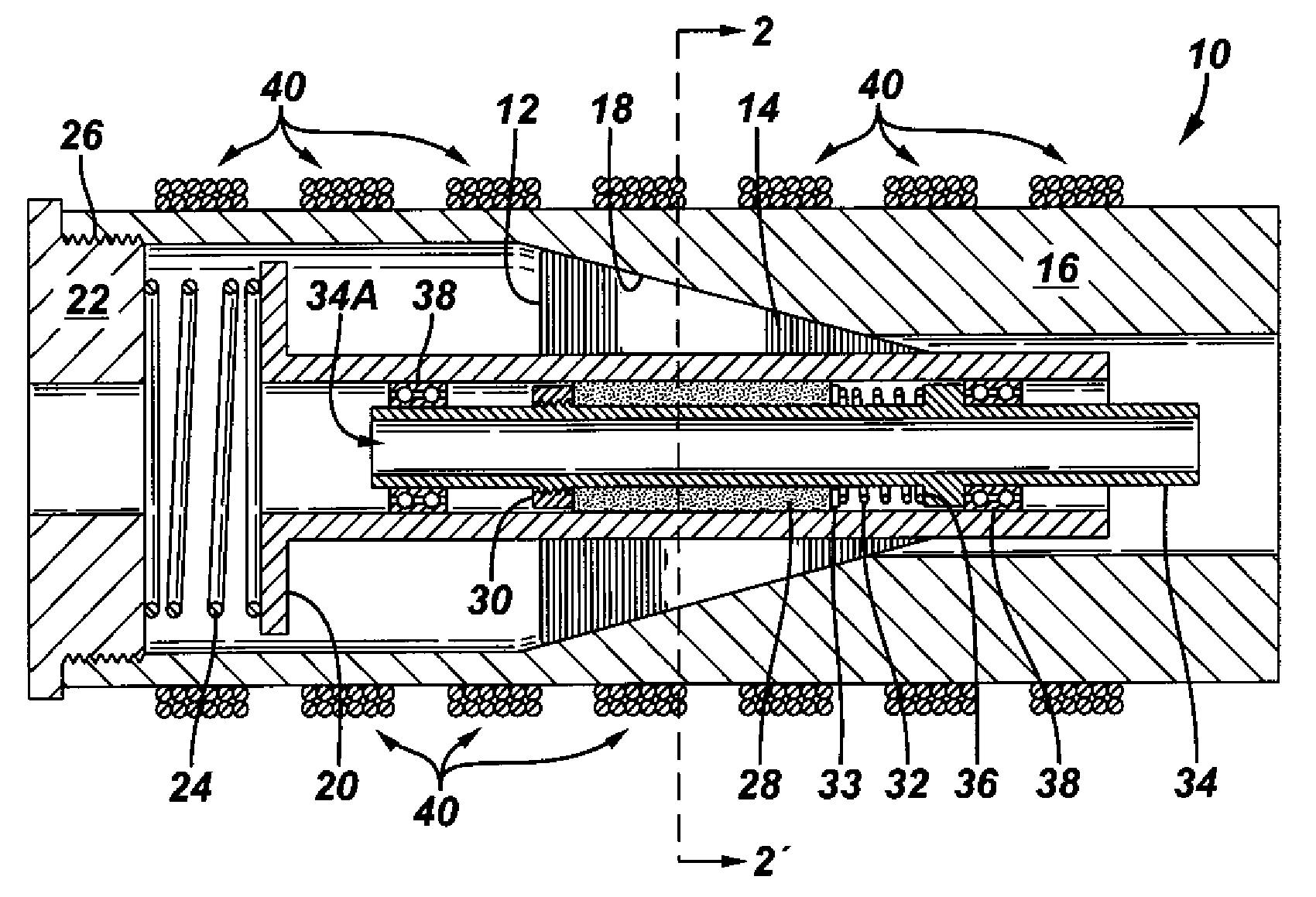

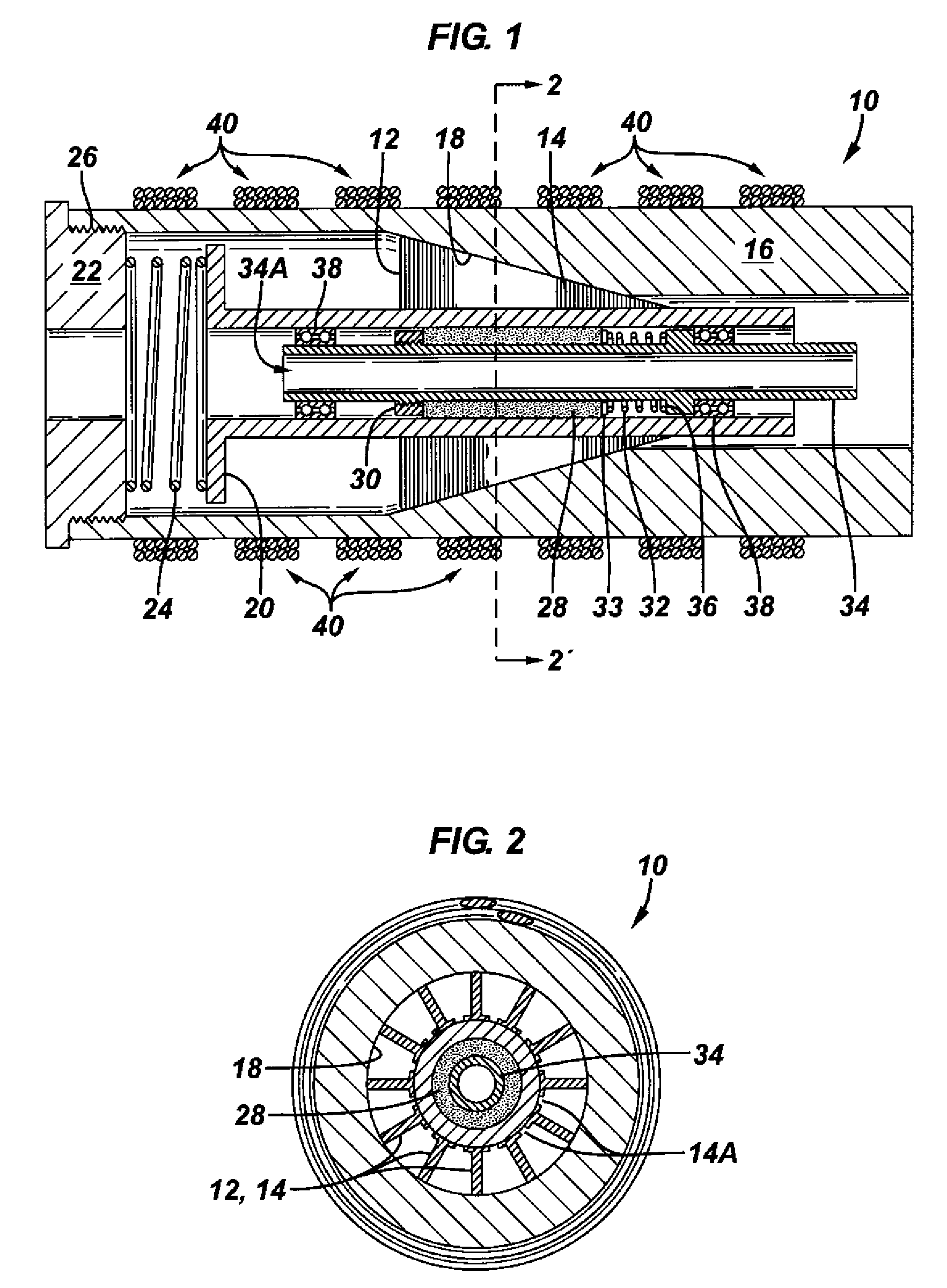

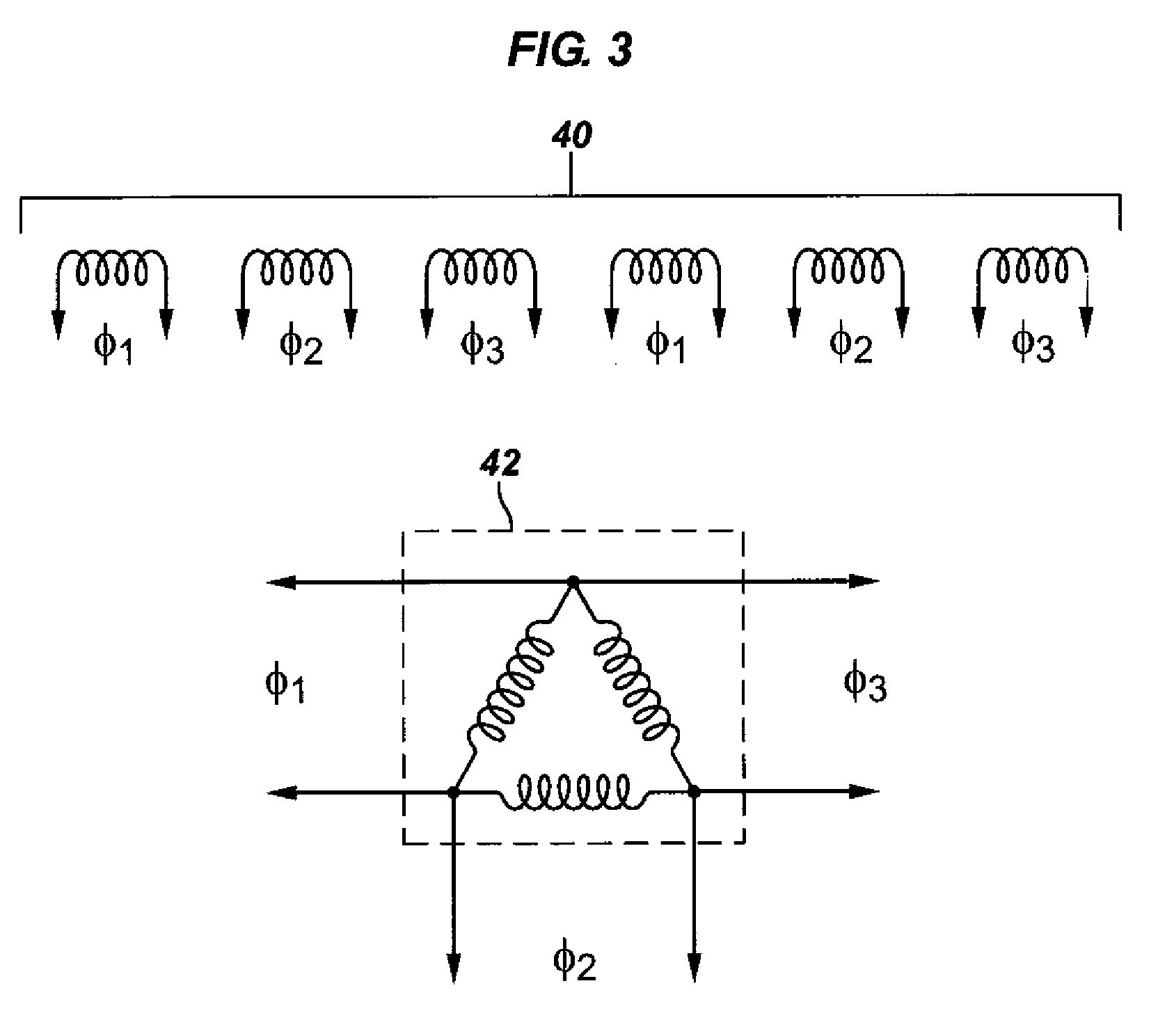

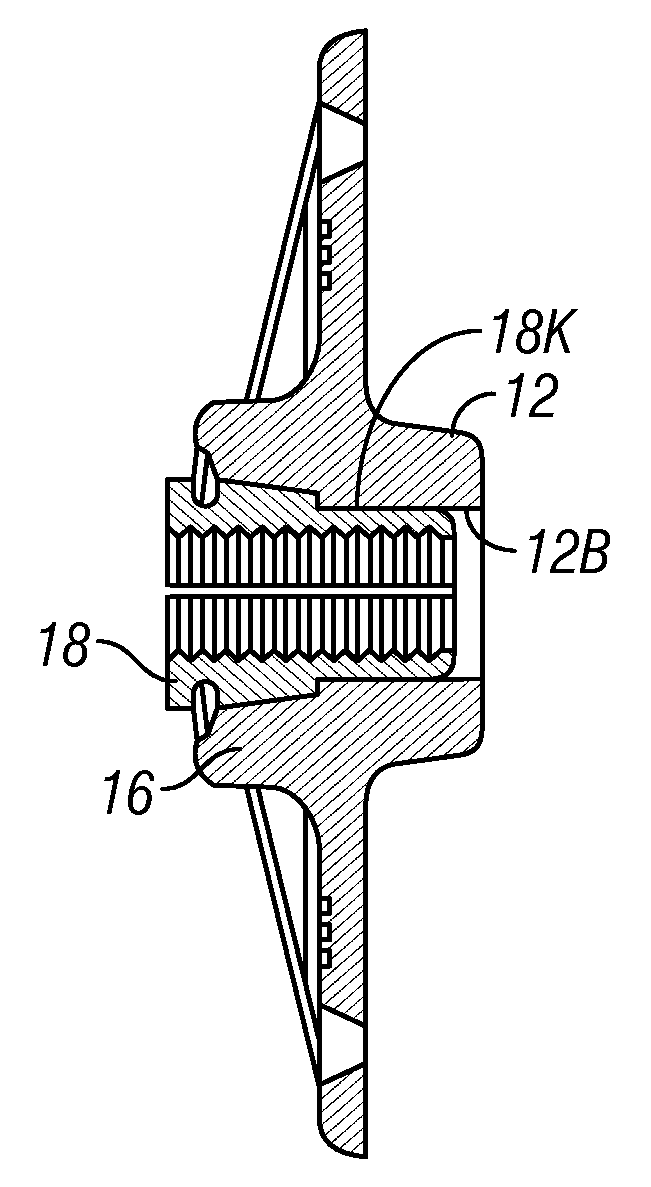

Linear actuator using magnetostrictive power element

InactiveUS7675253B2Piezoelectric/electrostriction/magnetostriction machinesFluid removalLateral compressionLinear actuator

A linear actuator includes a substantially cylindrical magnetostrictive element disposed in a housing. A retainer is cooperatively engaged with the housing and an exterior of the magnetostrictive element such that relaxed portions of the magnetostrictive element are frictionally retained in the retainer. An actuator rod is functionally coupled to one longitudinal end of the magnetostrictive element. A biasing device is disposed between the housing and the retainer to maintain the retainer in lateral compression. The actuator includes magnets arranged to induce peristaltic motion in the magnetostrictive element.

Owner:SCHLUMBERGER TECH CORP

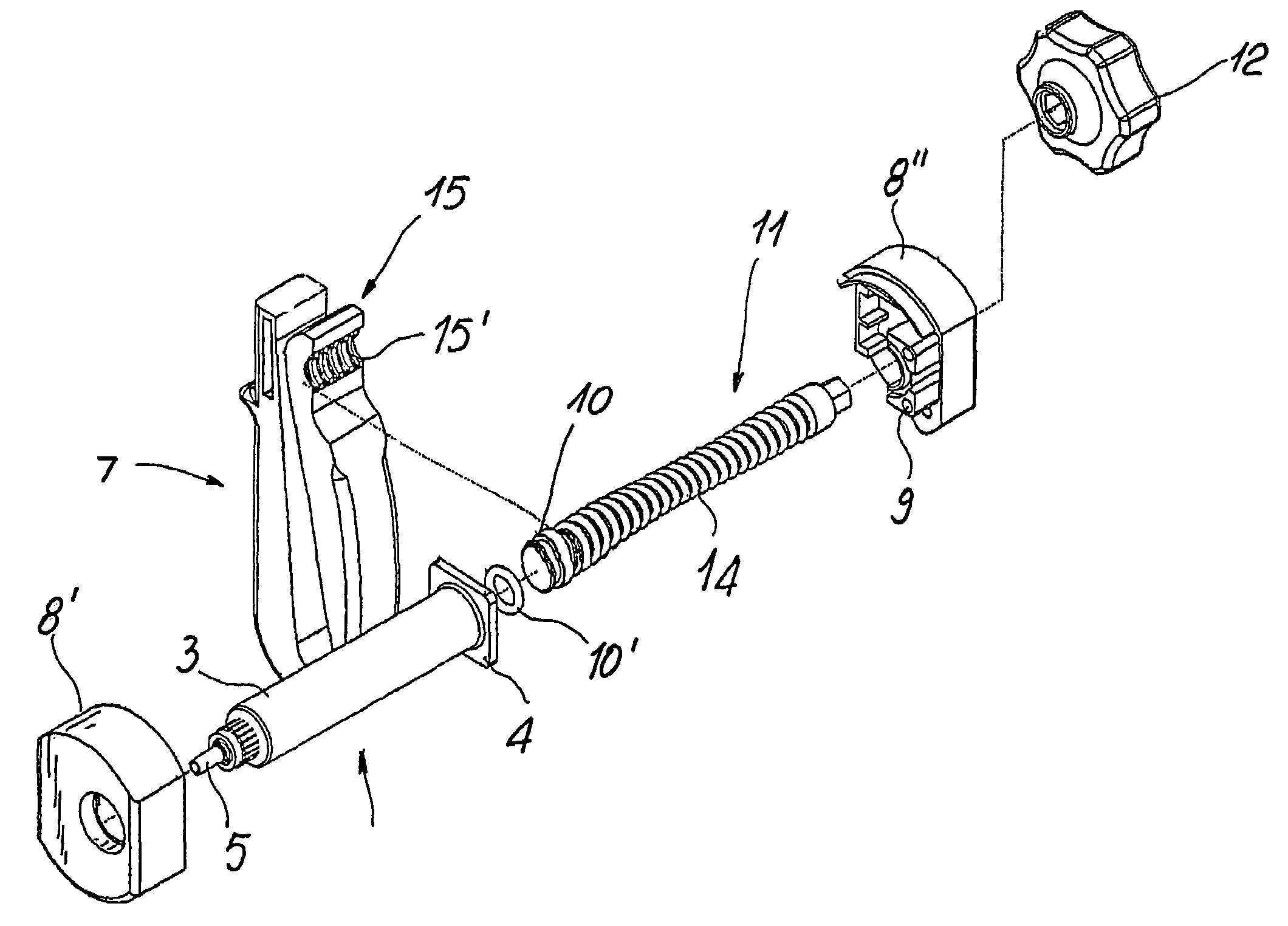

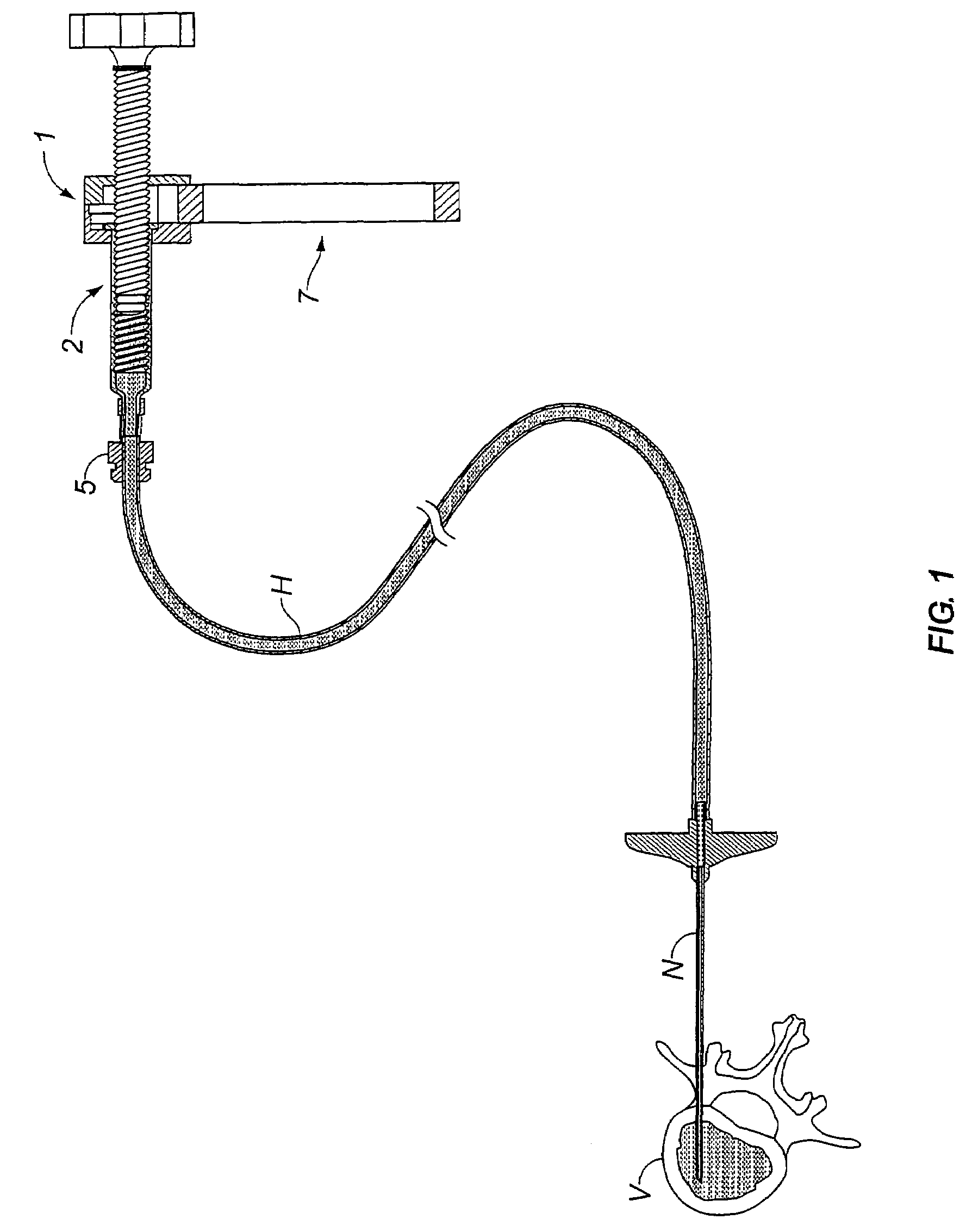

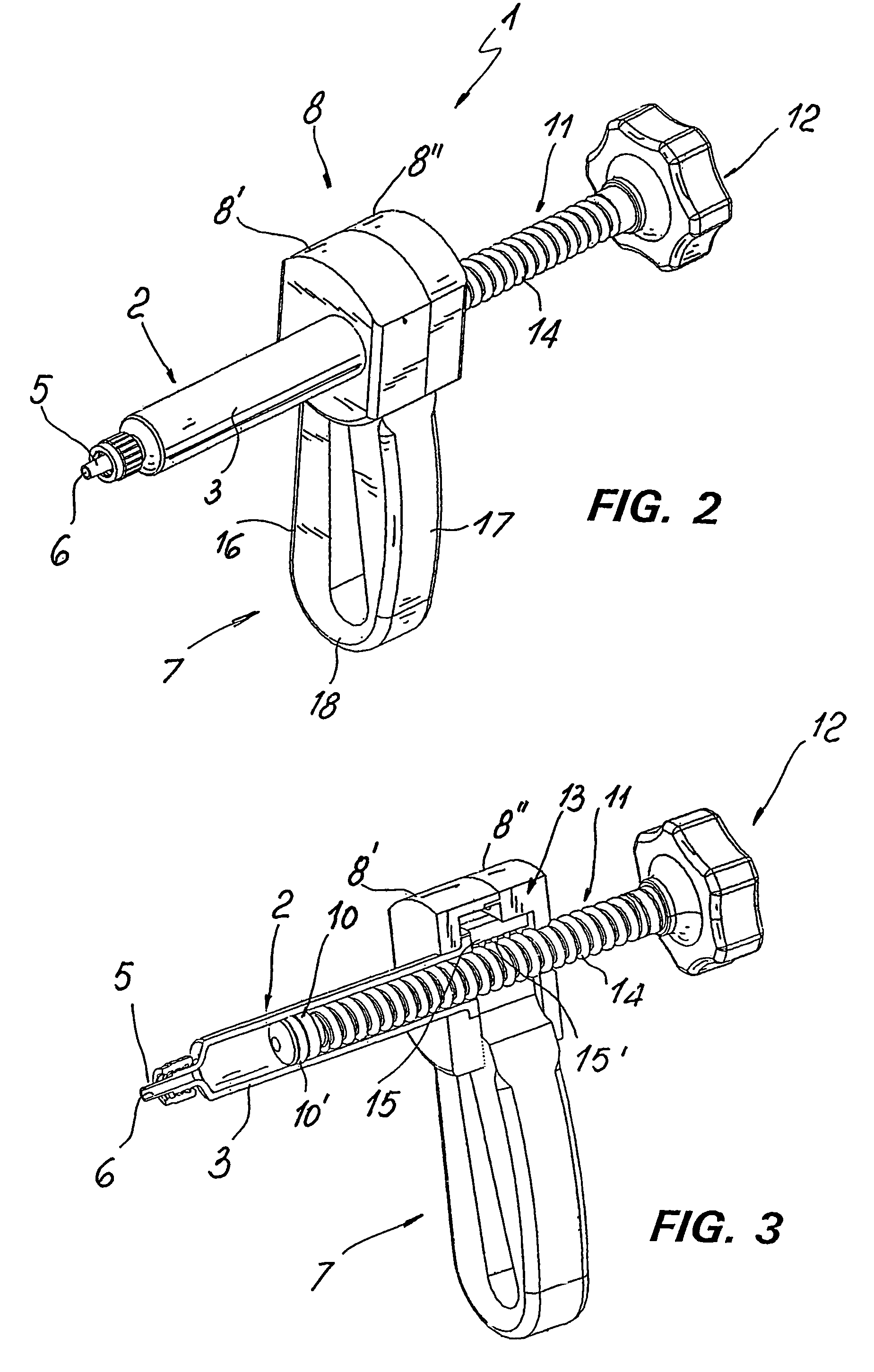

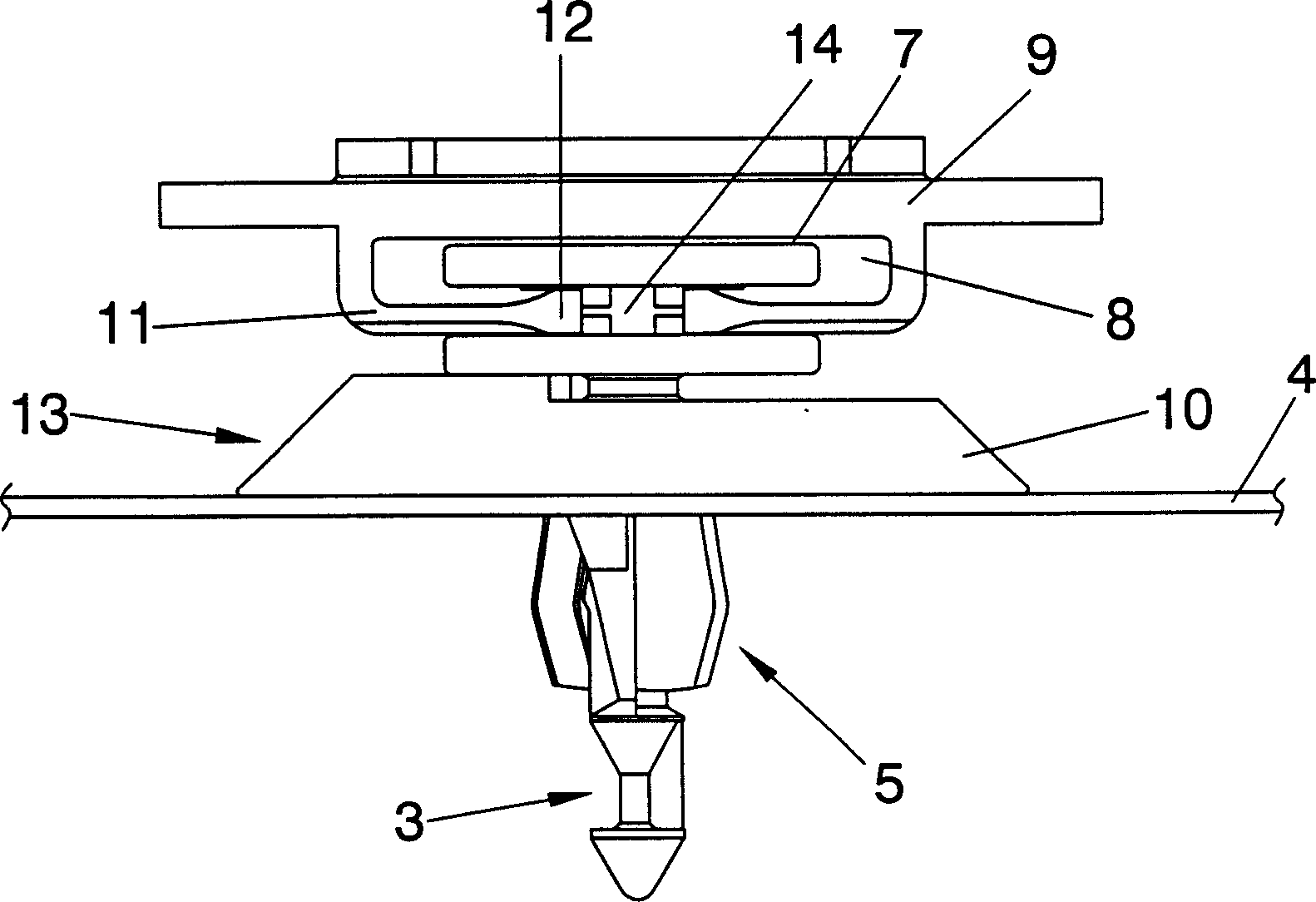

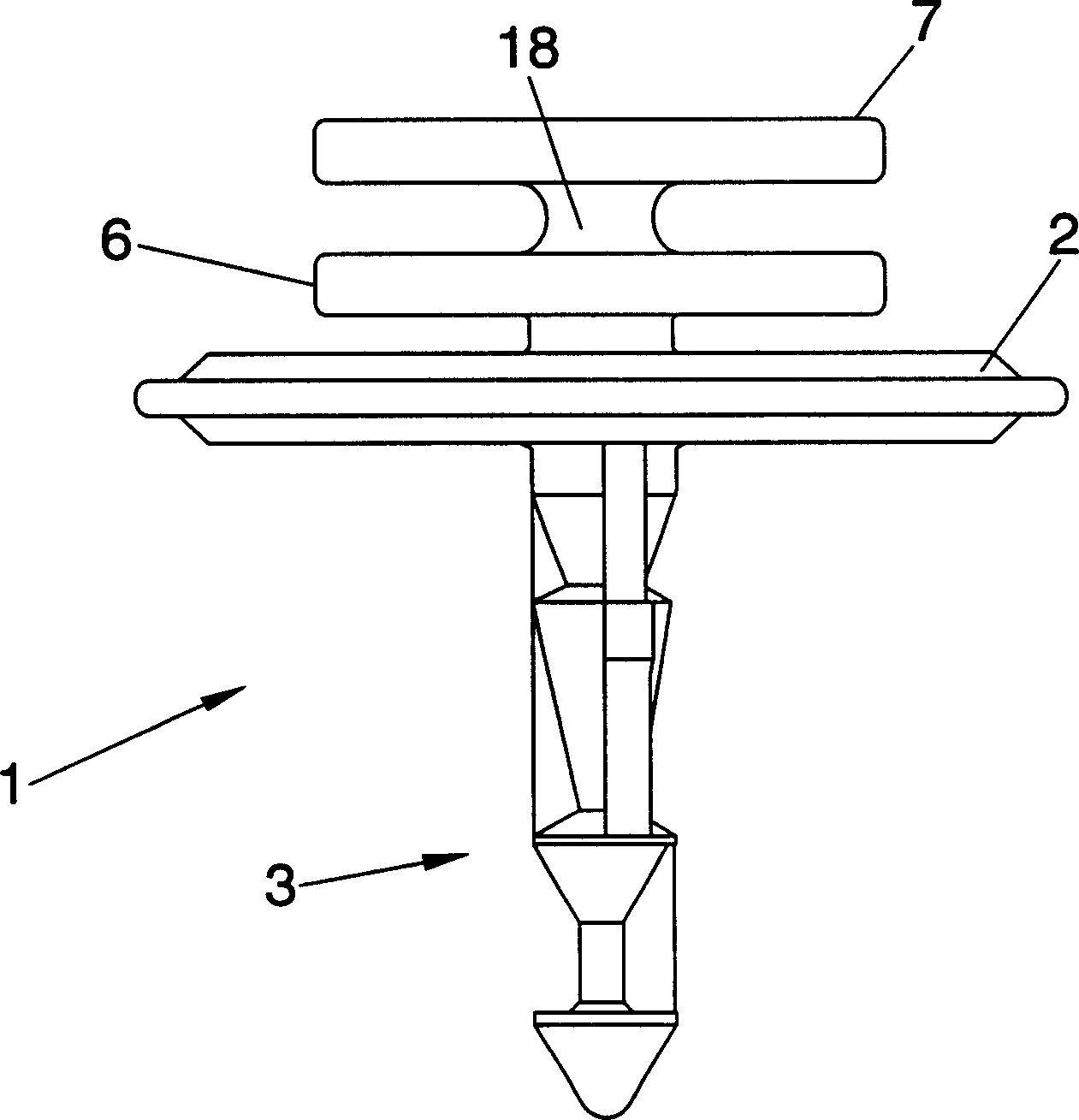

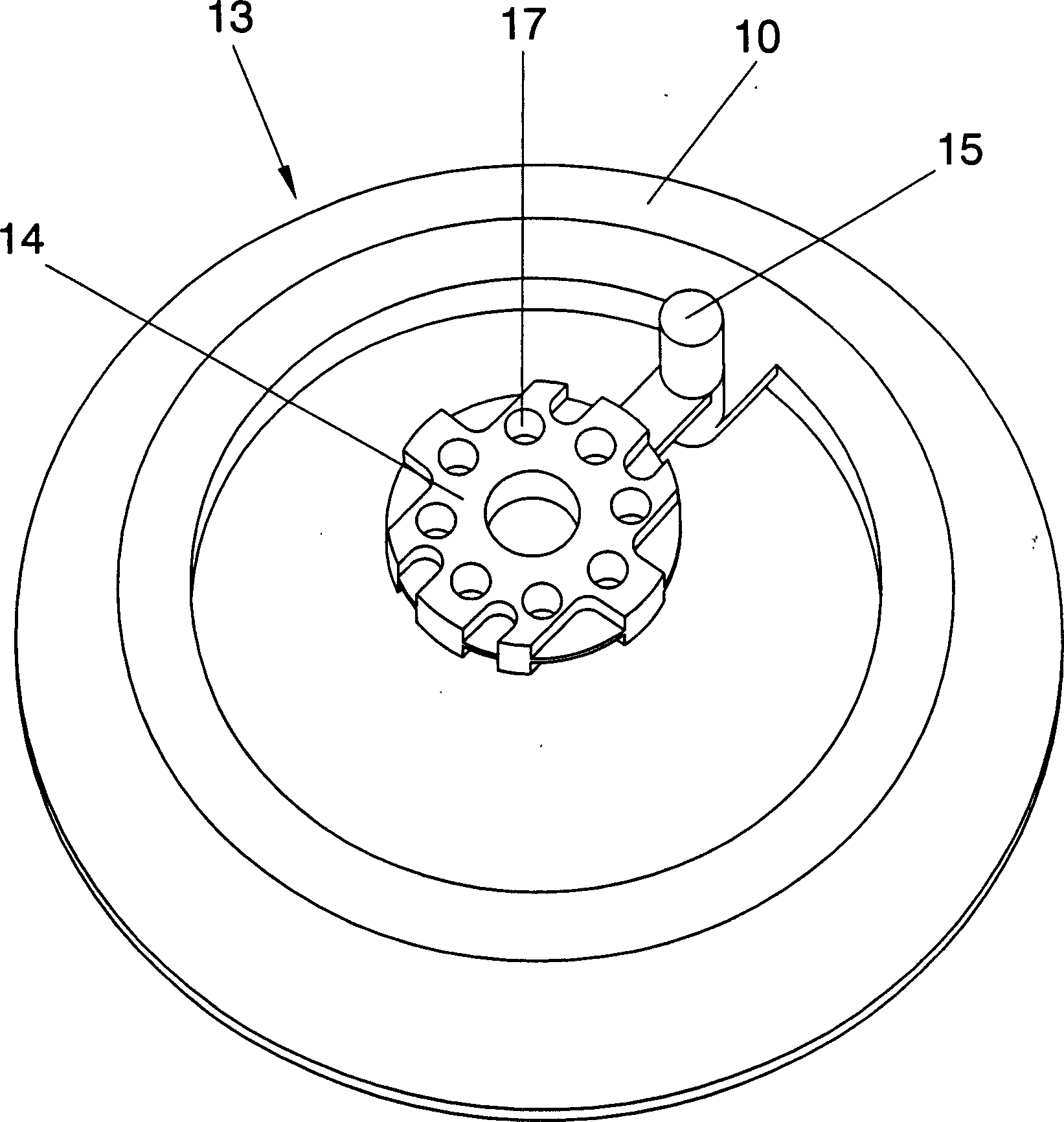

Device for the manual metering of a medical fluid, particularly bone cement

ActiveUS7270667B2High effectivenessEasy to handleLiquid surface applicatorsDiagnosticsLateral compressionEngineering

A device for the manual metering of a medical fluid, such as a hardening resin of the bone cement type, comprises a chamber for the fluid to be metered (2, 102) with an end opening (6), a gripping handle (7, 107), a piston (10, 110) which is housed in the chamber (2, 102) and provided with an operating member (12) for a user, and screw-type actuating means (13) arranged in between the operating member (12) and the piston (10) so as to perform the longitudinal movement thereof and pressurise the fluid to be metered. The screw means (13) may be modified so as to change from an operative configuration, where the piston is fed micrometrically, to an inoperative configuration, where the piston may move freely. The screw means (13) comprise an outer thread (14, 114) associated with the piston (10) and a female-thread element (15, 115) formed integrally on the handle (7, 107); the handle may be deformed elastically by means of transverse compression so as to change the screw means (13) from their operative configuration to their inoperative configuration.

Owner:TECRES SPA

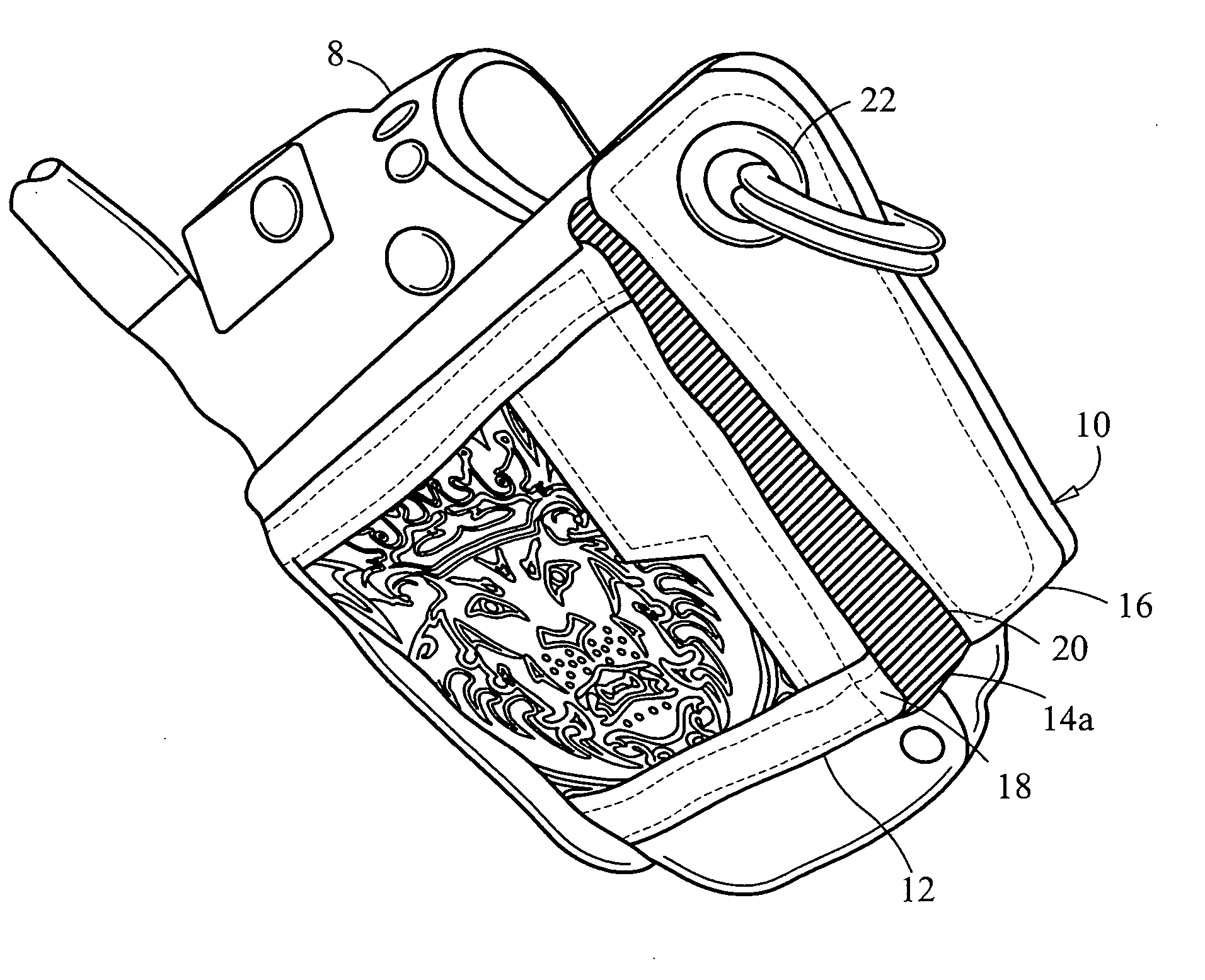

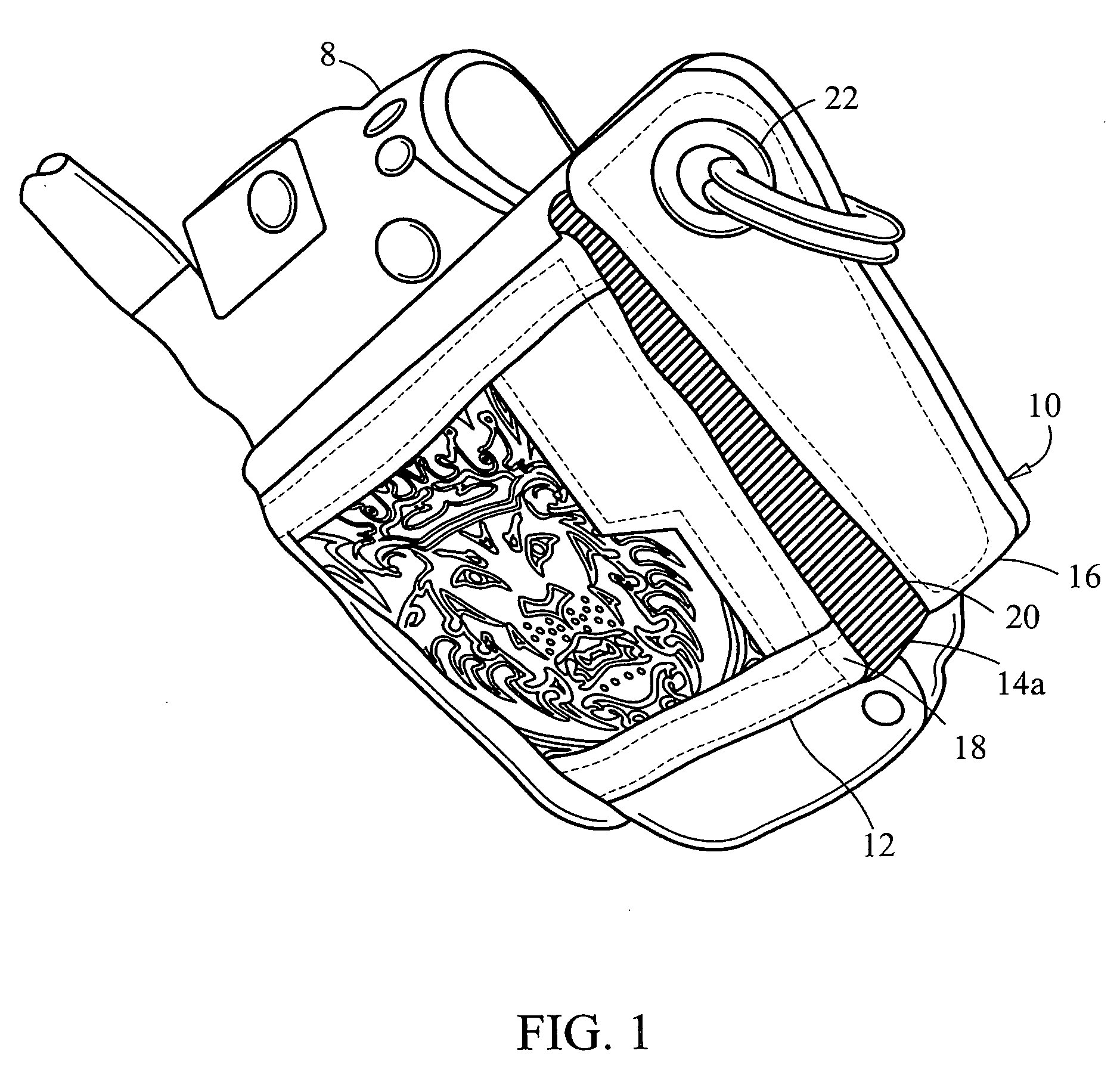

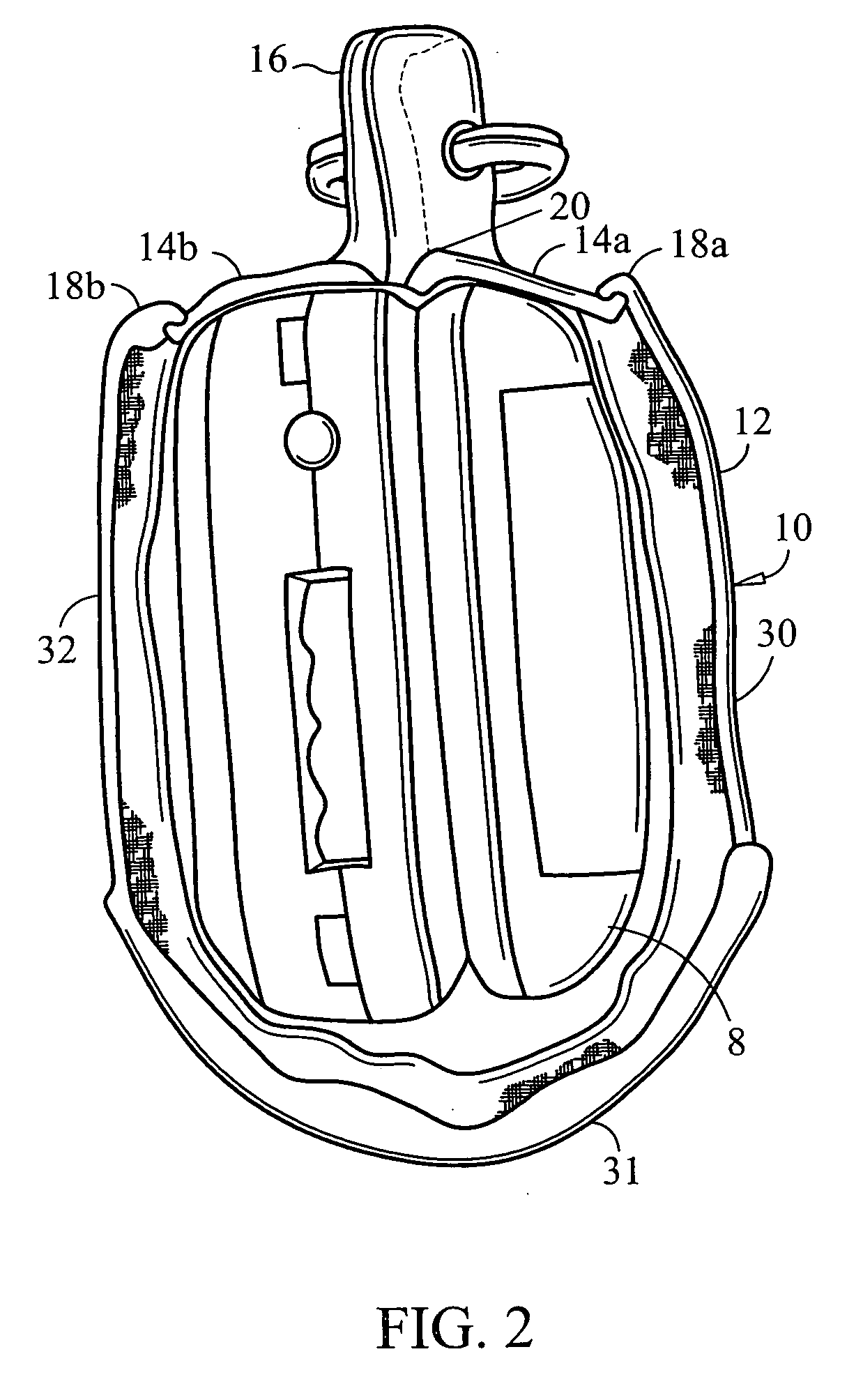

Wrap-around carrying case for cell phone or other personal electronic device

InactiveUS20060105821A1Reduce and avoid damageControl damageTravelling carriersHoldersEngineeringLateral compression

The carrying case includes front, rear and other sides having at least one swath of elastic material to laterally compress the phone or personal electronic device in the carrying case. The addition of releasable fasteners and / or a strap permits adjustment of the lateral compression. The fasteners may replace the elastic panel. The further addition of a base or bottom cap limits shock and protects the bottom of the carried device. A laterally extending tab can be utilized to enhance further portability of the carrier. A swing cap may be utilized to cover the top end of the carried device.

Owner:FINDINGS & MFG

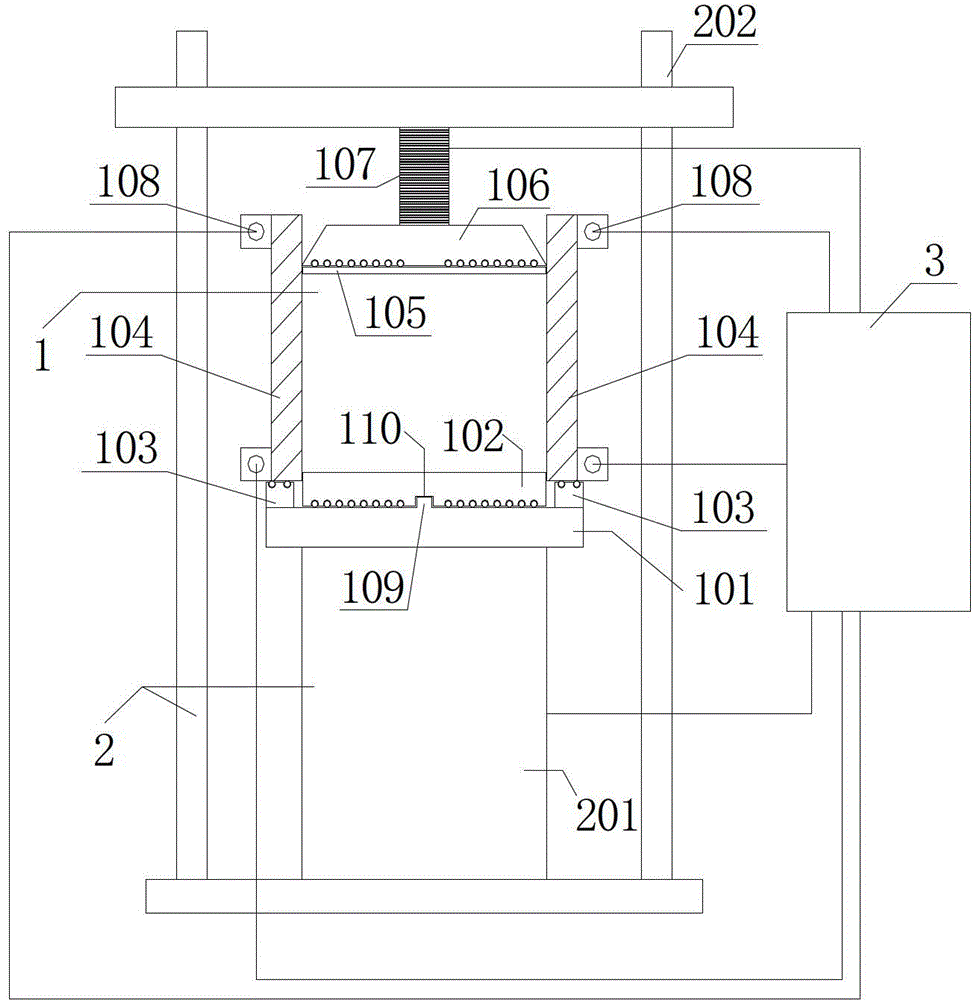

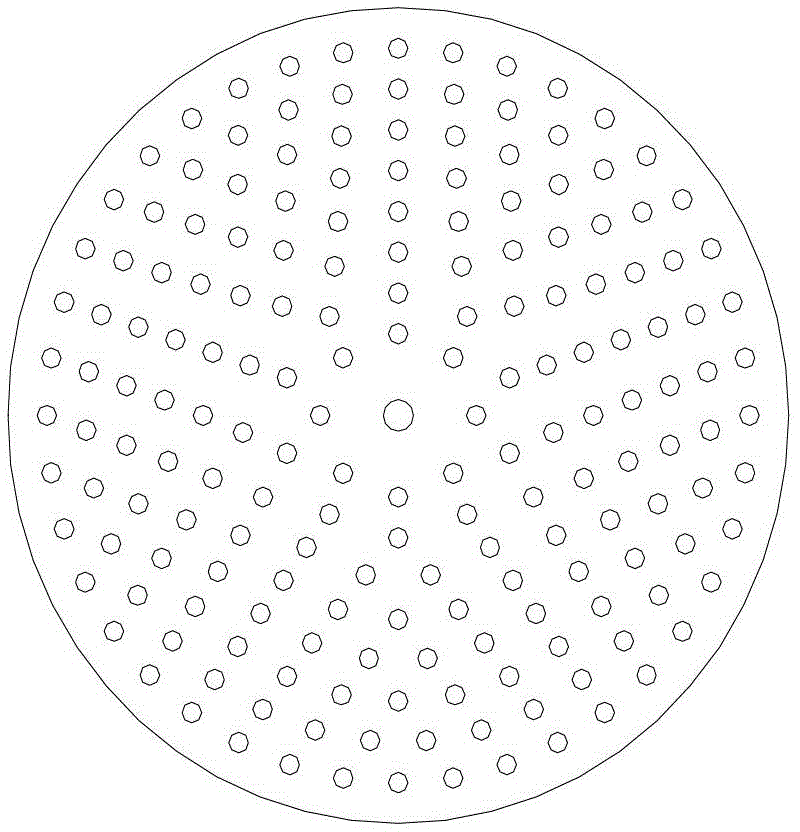

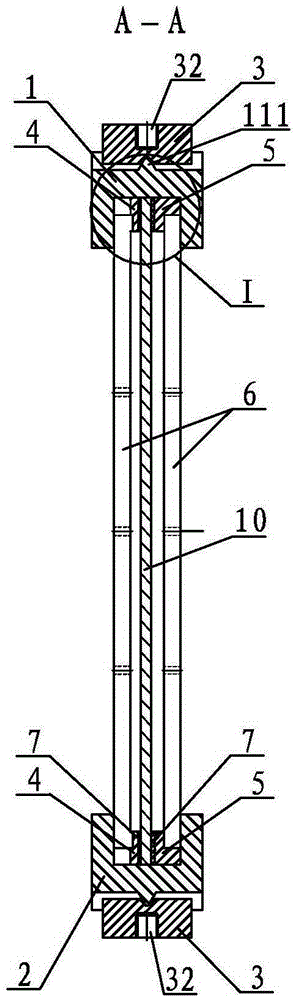

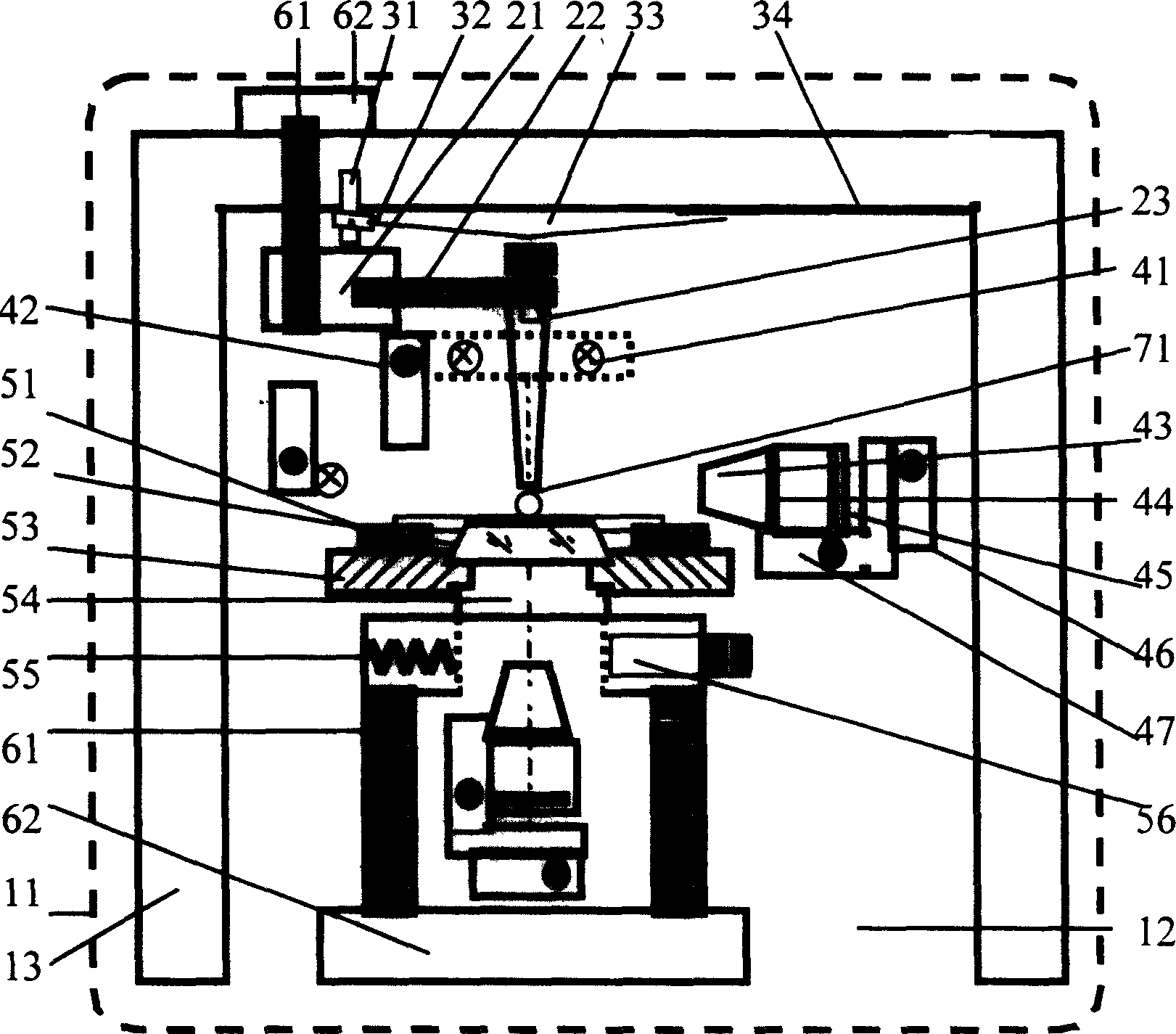

Earth mass stillness lateral-compression coefficient determinator

InactiveCN102980809ASimple structureEasy to useMaterial strength using tensile/compressive forcesLateral compressionEngineering

The invention provides an earth mass stillness lateral-compression coefficient determinator which comprises a pressure chamber, a loading device and a measurement control device, wherein the loading device is arranged on the top or bottom of the pressure chamber; the pressure chamber comprises a base, a bottom plate and a supporting pad which are arranged on the base, a sample drum arranged on the supporting pad, an upper pressure plate matched with the top opening of the sample drum, and a pressurization cover plate and a loading sensor which are successively arranged on the upper pressure plate from top to bottom; the bottom plate is a rounded bottom plate composed of two hemicycle metal plates with same semidiameter, and the sample drum is composed of two semicircle drums on the outer side wall of the sample drum and is connected with the two semicircle drums through at least two pairs of pull pressure sensors; the upper pressure plate is composed of a hemicycle metal plate; and the signal interface of a measurement control device is respectively connected with the loading device, the loading sensor and the pull pressure sensor, the measurement control device outputs a signal to the loading device, and the loading sensor and the pull pressure sensor output signals to the measurement control device. The determinator provided by the invention has the advantages of simple structure and wide application range.

Owner:HOHAI UNIV

Soil body in situ test device and test method applying same

ActiveCN102011389AAccurately judge the natureAccurate estimateIn situ soil foundationPore water pressureLateral compression

The invention relates to a soil body in situ test device, comprising a steel tube with the same shape of tubular pile as well as a data collector; wherein one end part of the steel tube is provided with a pile point plate and a first pressure sensor used for sensing pressure born by the pile point plate, the pile point plate is vertical to the side wall of the steel tube; more than one side wall friction drum is arranged along the radial direction of the steel tube, and each side wall friction drum is provided with a second pressure sensor used for sensing the friction force born by the side wall friction drum; the side wall friction drum forms one part of the side wall of the steel tube; one part of the side wall of the steel tube is set to be a movable lateral compression plate and is provided with a third pressure sensor used for sensing the pressure born by the lateral compression plate; the side wall of the steel tube is internally provided with a pore pressure gauge and a camera; and electrical signals sent by the first, second and third pressure sensors and the pore pressure gauge are all collected by the data collector. The device can test and read multiple data, thus being convenient for accurately analyzing soil body properties. The invention also discloses an in situ test method applying the device.

Owner:广东永基建筑基础股份有限公司

Linear actuator using magnetostrictive power element

InactiveUS20080111431A1Piezoelectric/electrostriction/magnetostriction machinesDirectional drillingLateral compressionLinear actuator

A linear actuator includes a substantially cylindrical magnetostrictive element disposed in a housing. A retainer is cooperatively engaged with the housing and an exterior of the magnetostrictive element such that relaxed portions of the magnetostrictive element are frictionally retained in the retainer. An actuator rod is functionally coupled to one longitudinal end of the magnetostrictive element. A biasing device is disposed between the housing and the retainer to maintain the retainer in lateral compression. The actuator includes magnets arranged to induce peristaltic motion in the magnetostrictive element.

Owner:SCHLUMBERGER TECH CORP

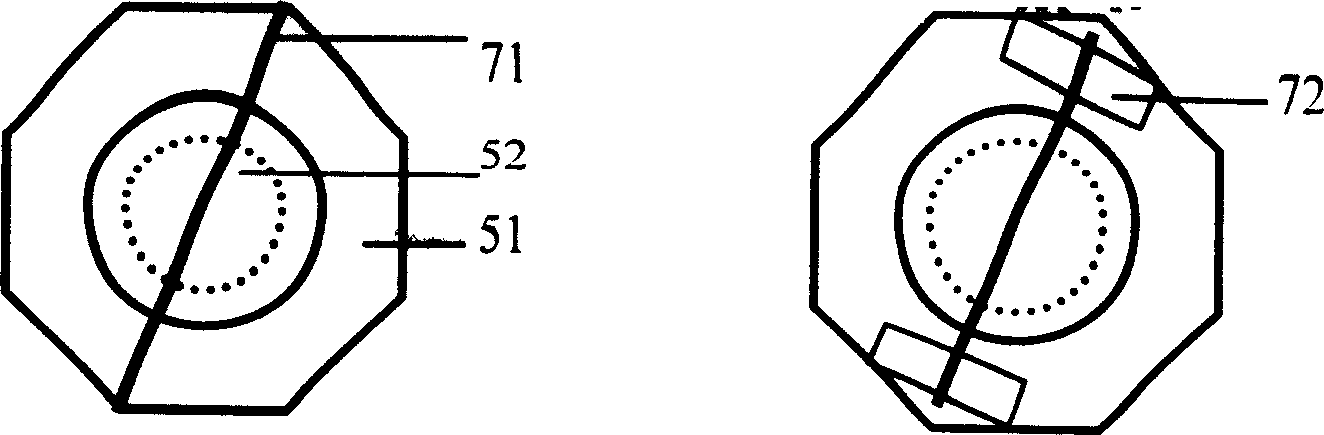

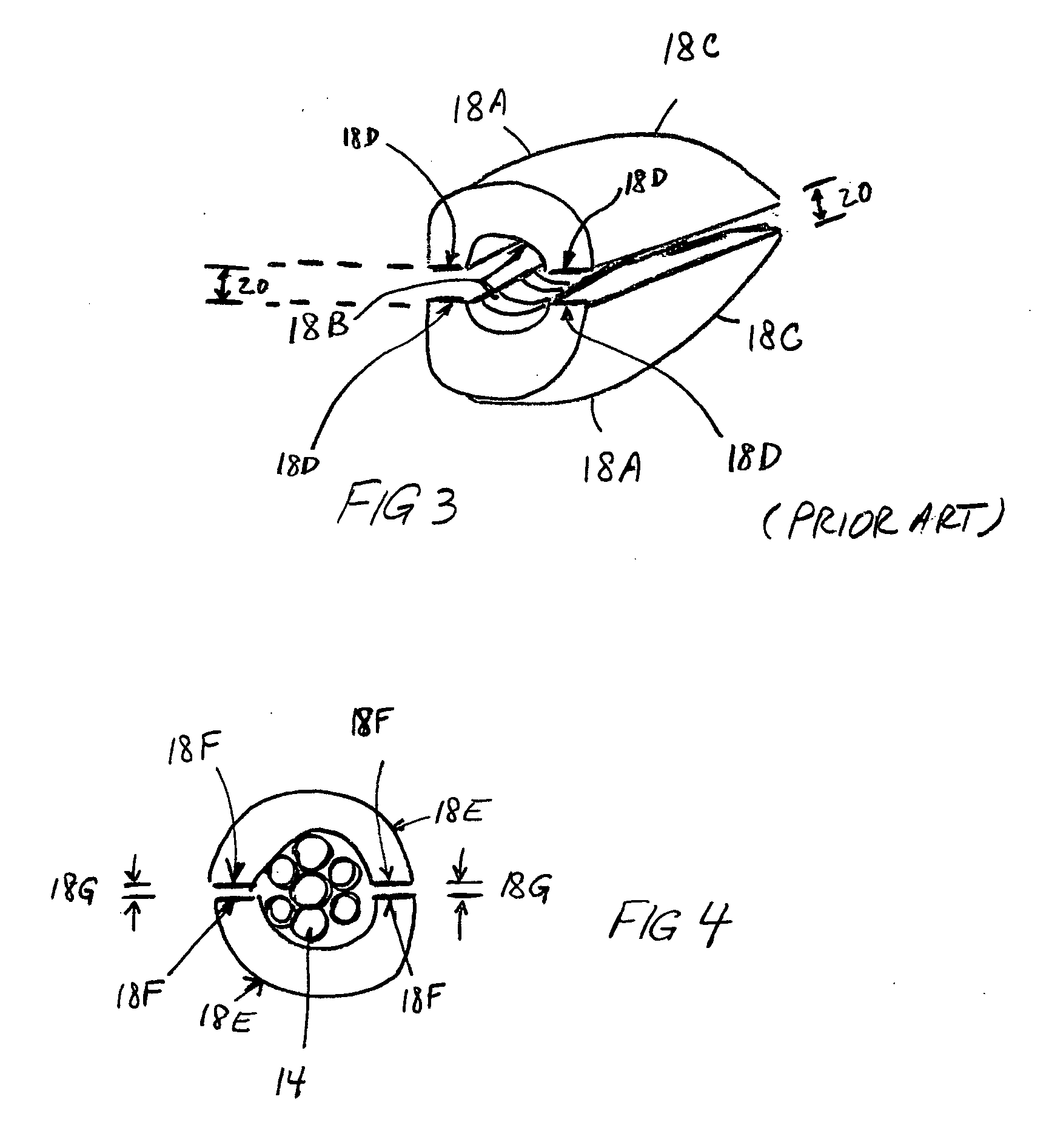

Anchor wedge configuration for tendon anchors

A wedge for a tendon retaining anchor includes at least two circumferential wedge segments adapted to be placed on an exterior of a tendon. The wedge segments have an exterior surface adapted to cooperate with a receiving bore of a load transfer device and an interior surface having gripping elements thereon. A circumferential dimension of the wedge segments is selected so that a total uncompressed gap between circumferential ends of the wedge segments when the segments are applied to an exterior surface of the tendon is at most about 2.4 times a height of the gripping elements. In another aspect, a tendon retaining system includes an anchor having a wedge receiving bore and wedge segments adapted to cooperate with the wedge receiving bore. The wedge segments include gripping elements on an interior surface thereof. The system includes a device adapted to limit lateral compression of the wedge segments.

Owner:PRECISION HAYES INT INC

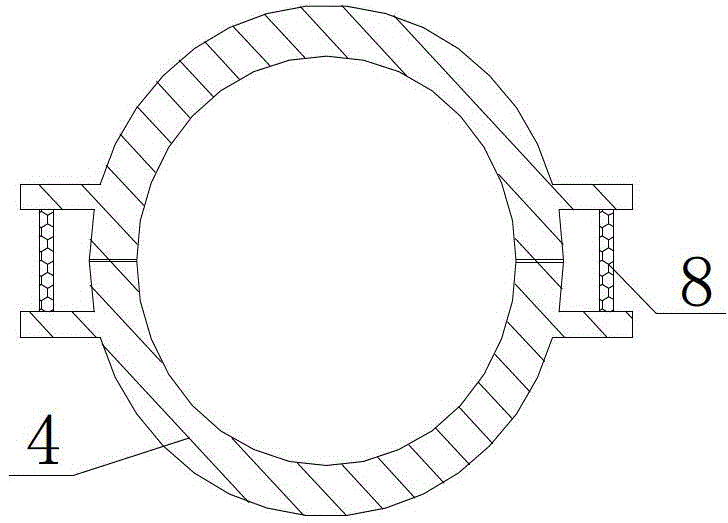

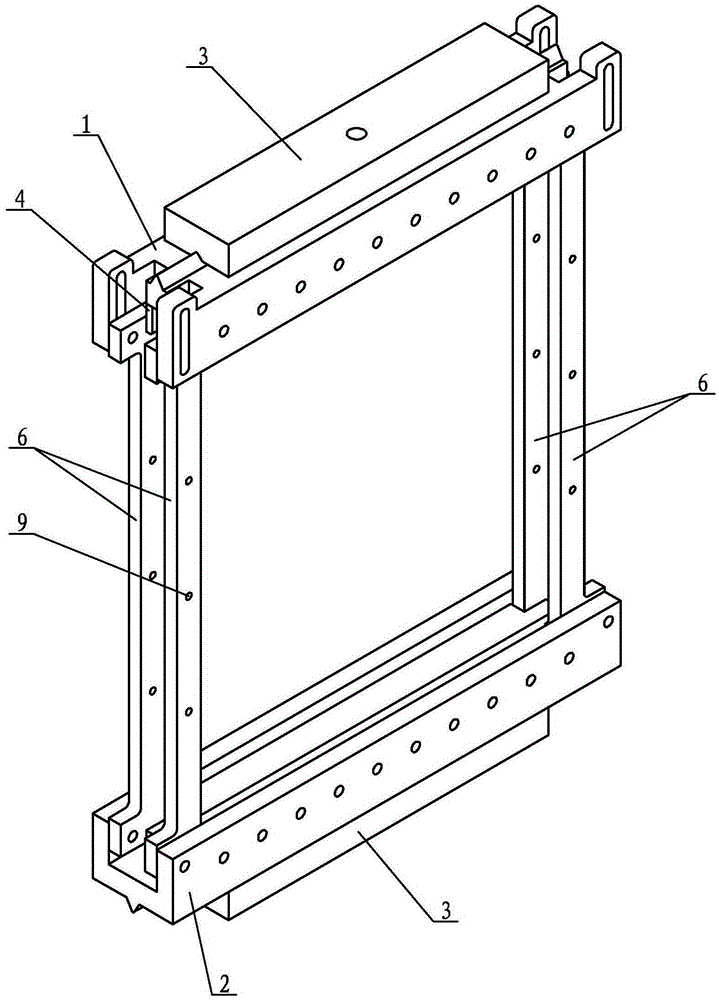

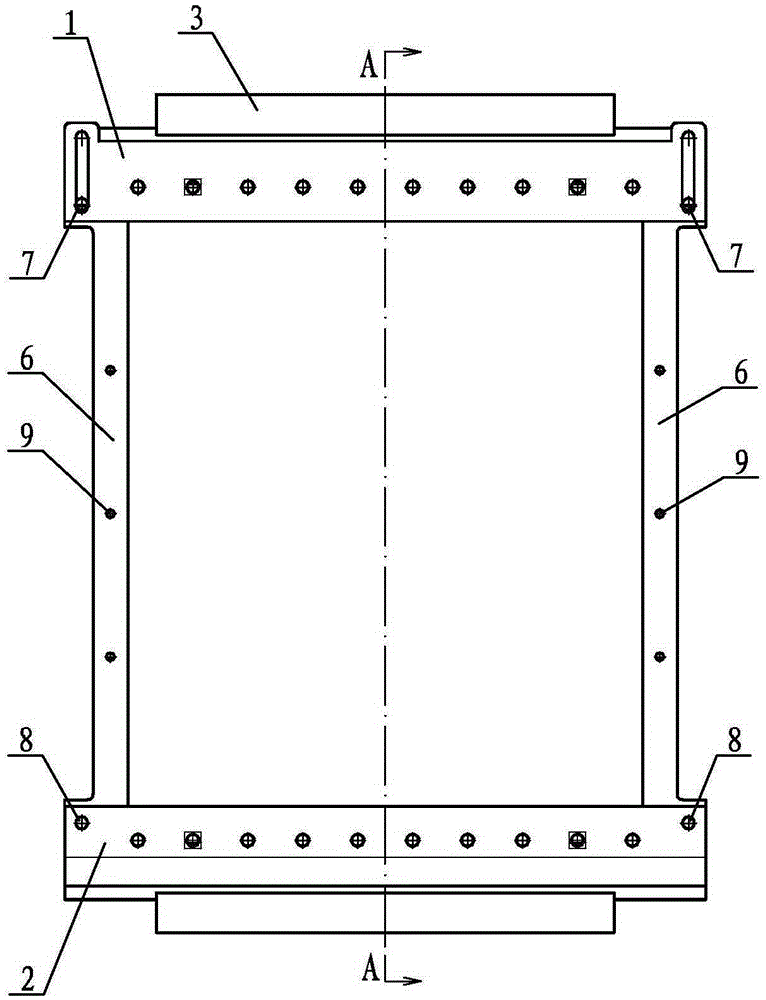

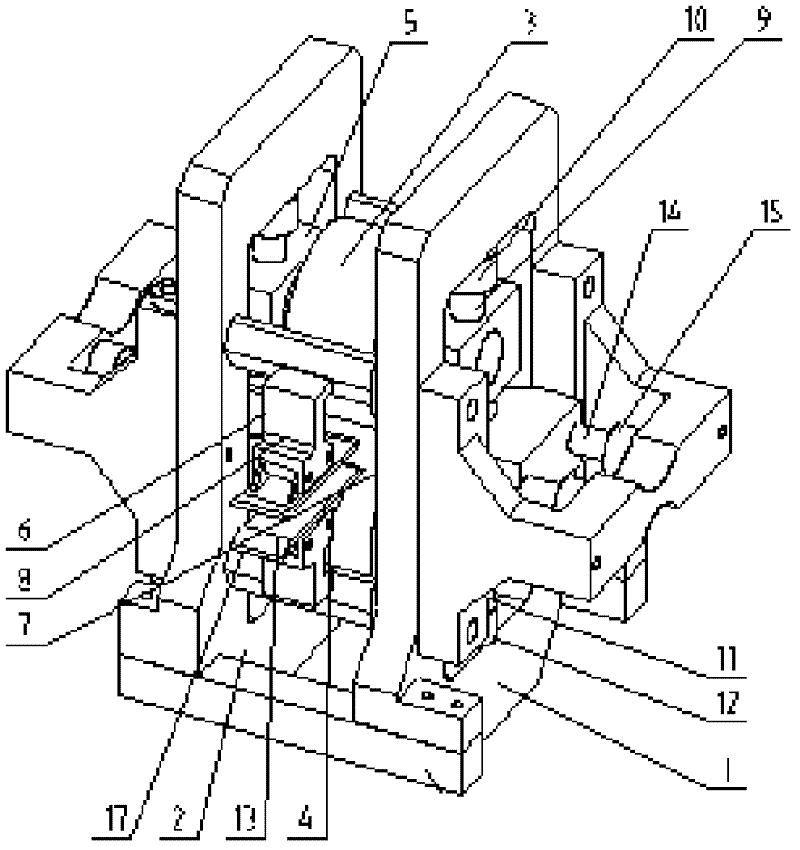

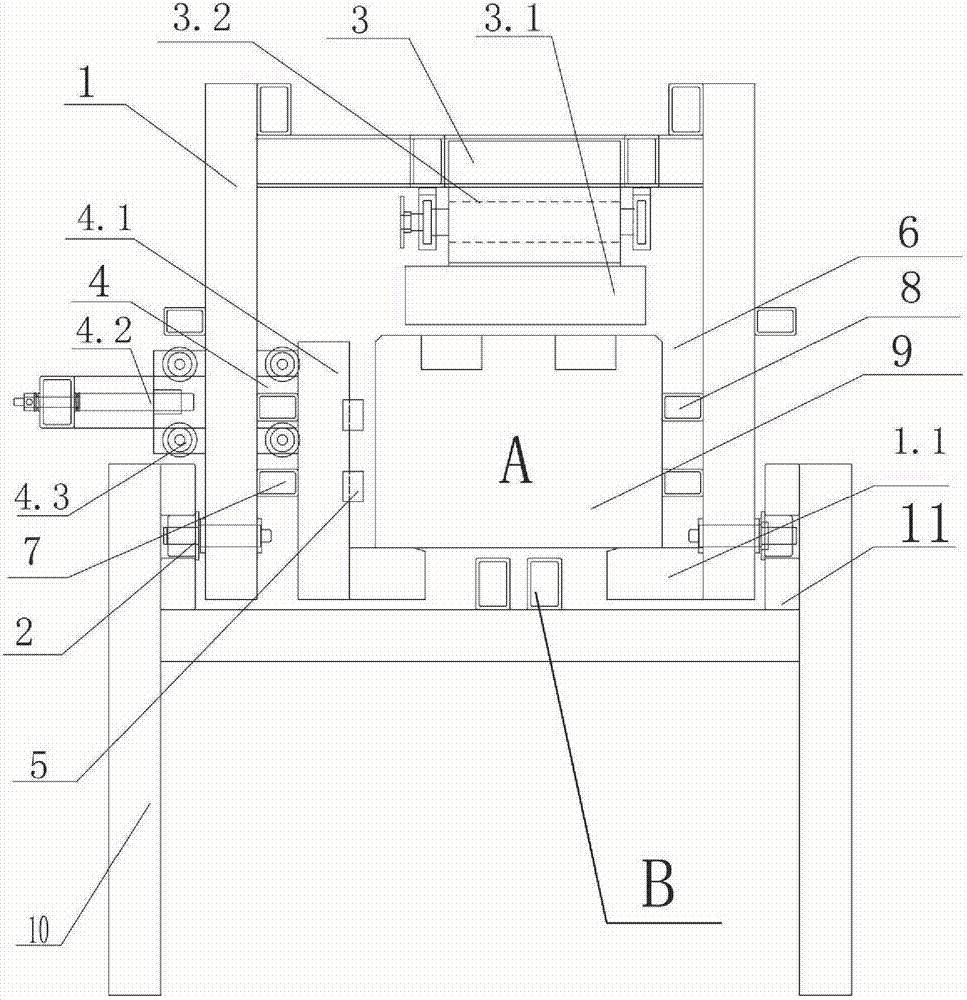

Assembly clamper for sandwich structure board lateral compression test

ActiveCN105241751AGuaranteed internal and external symmetry of strainEasy to assembleStrength propertiesSandwich boardLateral compression

The invention relates to an assembly clamper for sandwich structure board lateral compression test. In the prior art, when the large-size and non-symmetrical sandwich board is subjected to the lateral compression performance test, the centering of the compression center is difficult, and the deflection is high. A purpose of the present invention is to solve the problems in the prior art. According to the assembly clamper, an upper clamping head and a lower clamping head are arranged in an upper-lower manner, the deep groove of the upper clamping head and the U-shaped groove of the lower clamping head are oppositely arranged, four vertical position limiting plates are arranged between the upper clamping head and the lower clamping head in a rectangular manner, the upper ends of each vertical position limiting plate are positioned inside the deep groove, the lower ends of each vertical position limiting plate are positioned inside the U-shaped groove, the upper ends between the two transverse and parallel vertical position limiting plates are provided with a universal pad block and an adjustment pad block, the lower ends between the two transverse and parallel vertical position limiting plates are provided with a universal pad block and an adjustment pad block, the two universal pad blocks are oppositely arranged in an upper-lower manner, the two adjustment pad blocks are oppositely arranged in an upper-lower manner, two end plates are respectively arranged on the upper end and the lower end of the upper clamping head and the lower clamping head, and the upper cone column on the upper clamping head and the lower cone column on the lower clamping head are respectively embedded into the corresponding V-shaped grooves. The assembly clamper of the present invention is used for the sandwich structure board lateral compression test.

Owner:HARBIN INST OF TECH

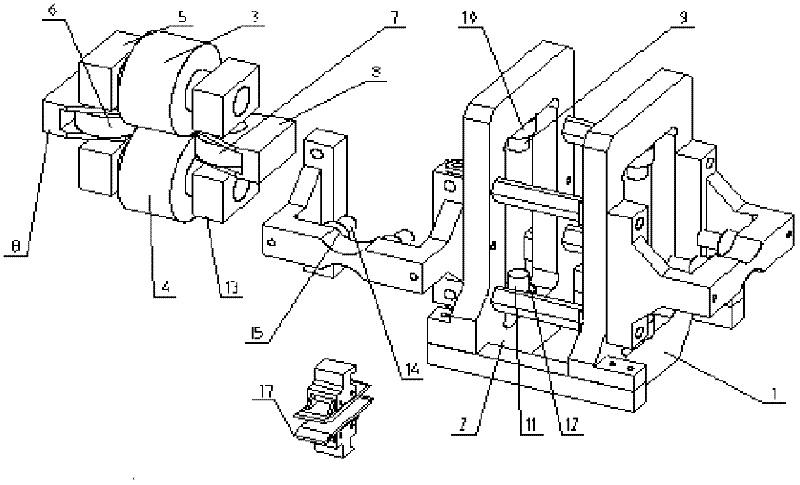

Compact chuck type universal mill

InactiveCN102363156AIncrease stiffnessHigh control precisionMetal rolling stand detailsGuiding/positioning/aligning arrangementsLateral compressionEngineering

The invention provides a compact chuck type universal mill, which comprises stands, a roll system and a guide and guard device, wherein the roll system comprises horizontal rolls, bearing seats, vertical rolls and vertical roll boxes, wherein a press-down device is arranged between the stands and the upper horizontal bearing seat; a press-up device is arranged between the stands and the lower horizontal roll bearing seat; a lateral compression device is arranged between the operating side vertical roll box and the operating side stand; and the operating side stand can move. High-accuracy large-sized section steel can be produced by using a closed stand and a fully hydraulic press-down device. The operating side stand is made to be movable; and when the roll system is replaced, only the operating side stand is required to be moved away to completely expose the roll system, the roll changing is realized so that the roll changing time is saved, the operating efficiency of the mill is increased, and the universal mill can be conveniently converted into a two-roll mill for use. The size of a window of the stands is reduced, so that the size of the entire mill is reduced and the weight of equipment is reduced; and the guide and guard device is integrated with the roll system, reversible rolling is realized.

Owner:中重科技(天津)股份有限公司

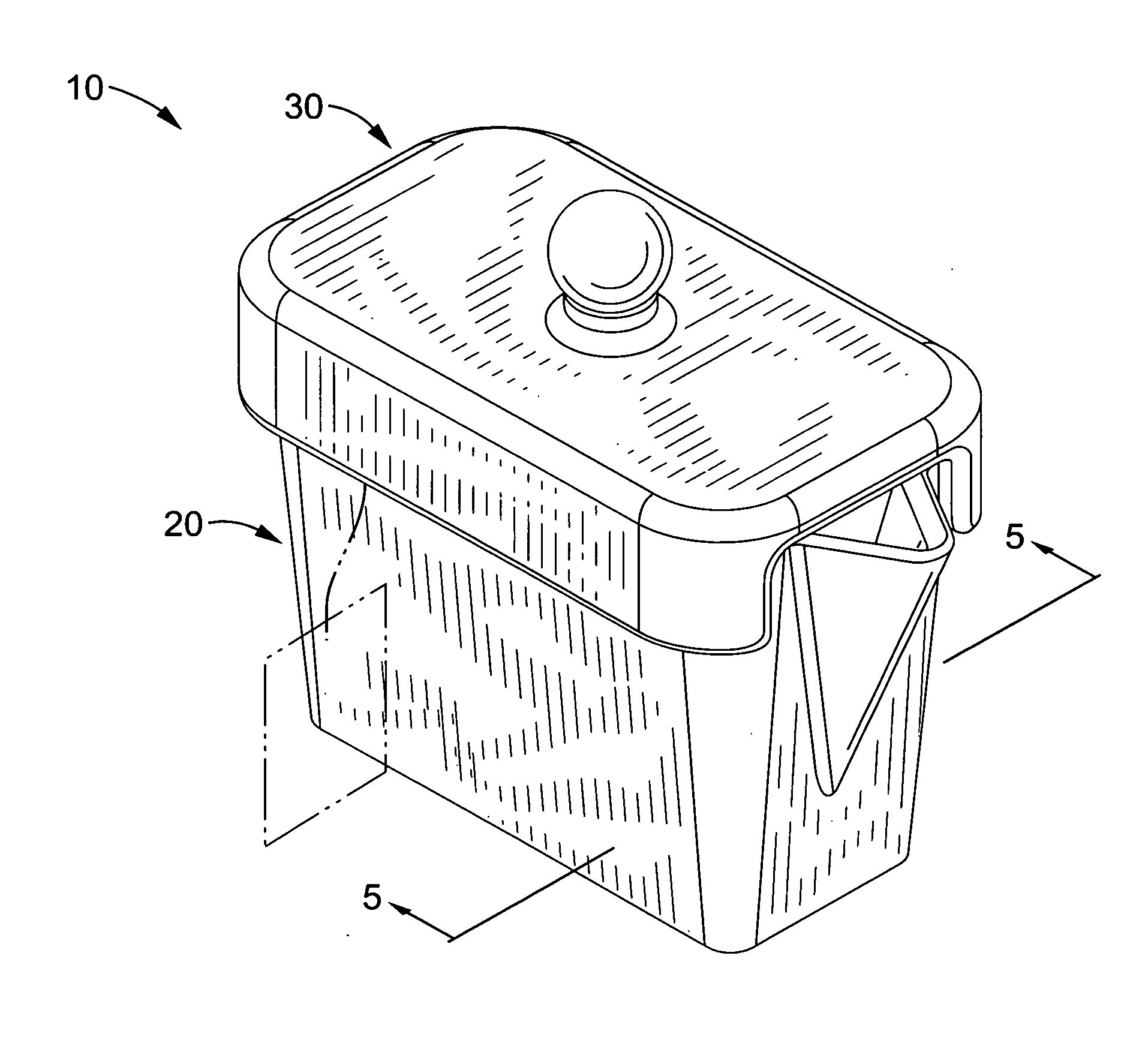

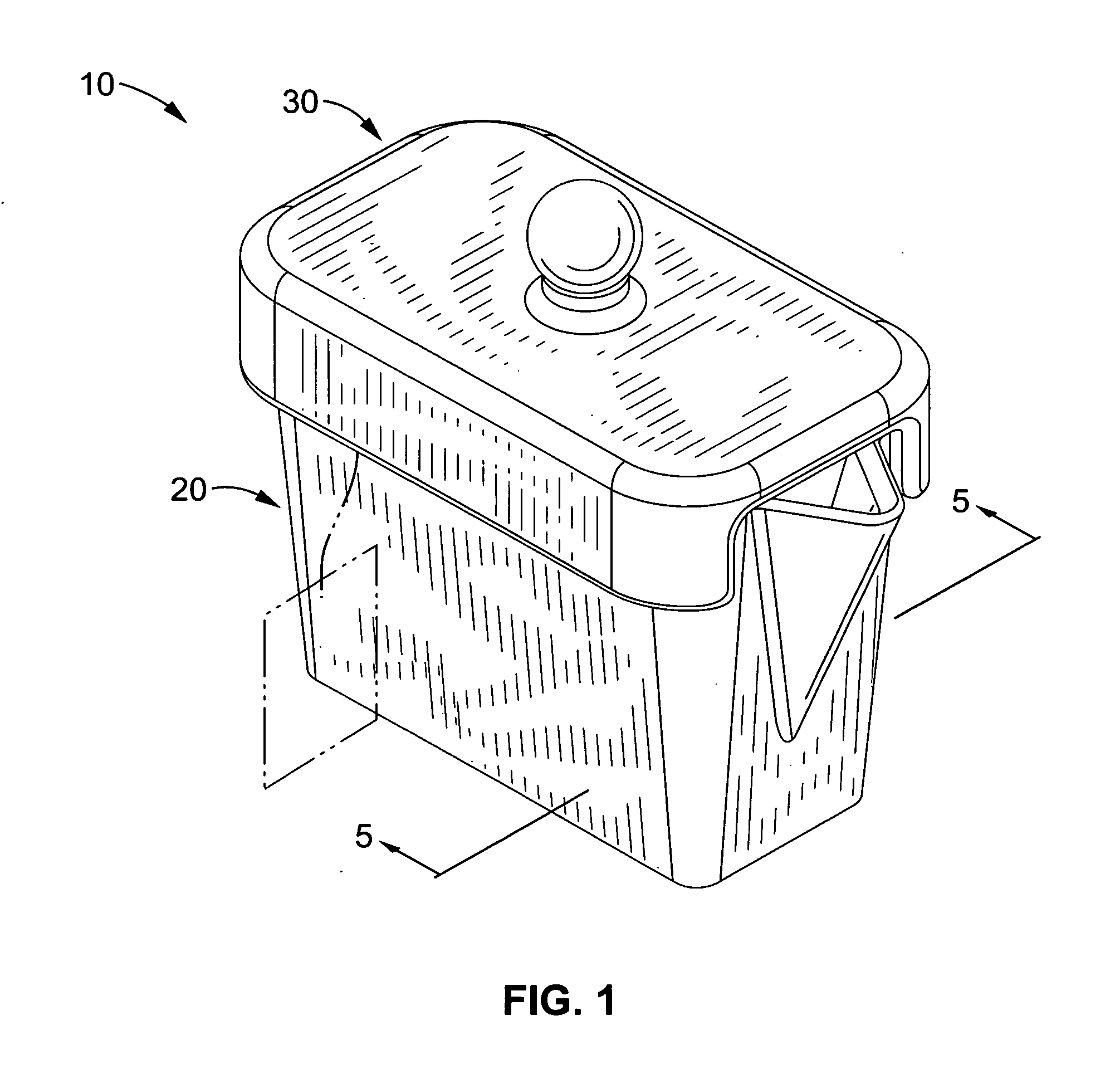

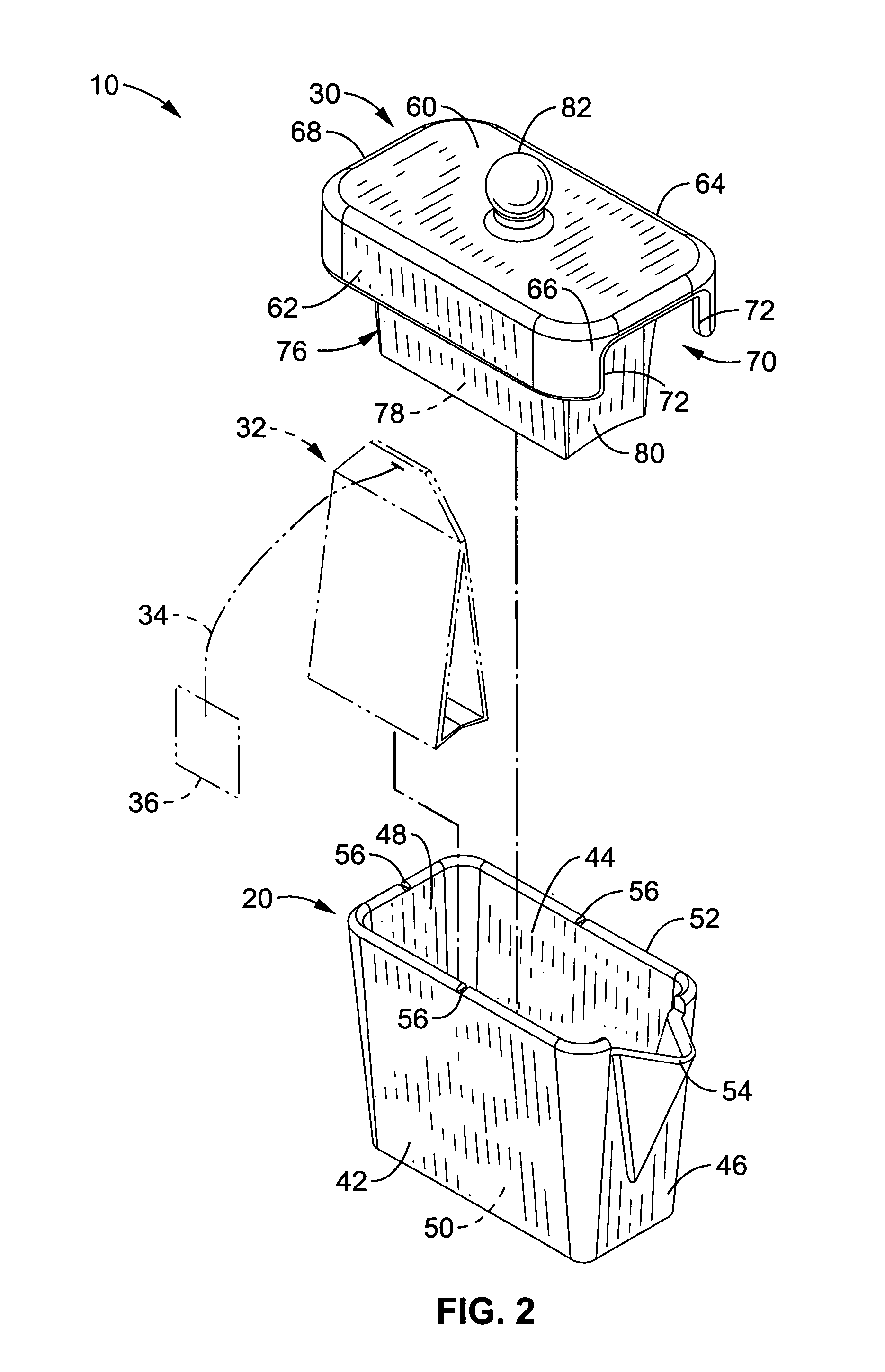

Method and apparatus for collecting liquid and extracting tea essence from a tea bag

InactiveUS20050120884A1High strengthBrewing of cold tea can be facilitatedJuice extractionBeverage vesselsEngineeringLateral compression

A tea bag press and container assembly configured for receiving a tea bag during or after brewing, which conceals the wet tea bag, collects dripping liquid, and extracts tea liquid essence by efficiently compressing the wet tea bag vertically or sidewardly. In a vertical compression embodiment, a lid has an integral press element that compresses the tea bag against a tea bag support means in the bottom of the container upon applying pressure to the lid. In a sideward compression embodiment, a flexible container retains the tea bag during sideward compression, such as between the thumb and fingers, for releasing tea liquid from the bag. The tea bag press-container assembly is designed to reduce staining and mess on saucers, tables and fabric caused by a dripping tea bag and provides efficient extraction and pouring of tea liquid into an existing beverage, or the brewing of an additional beverage.

Owner:US THERMOELECTRIC CONSORTIUM

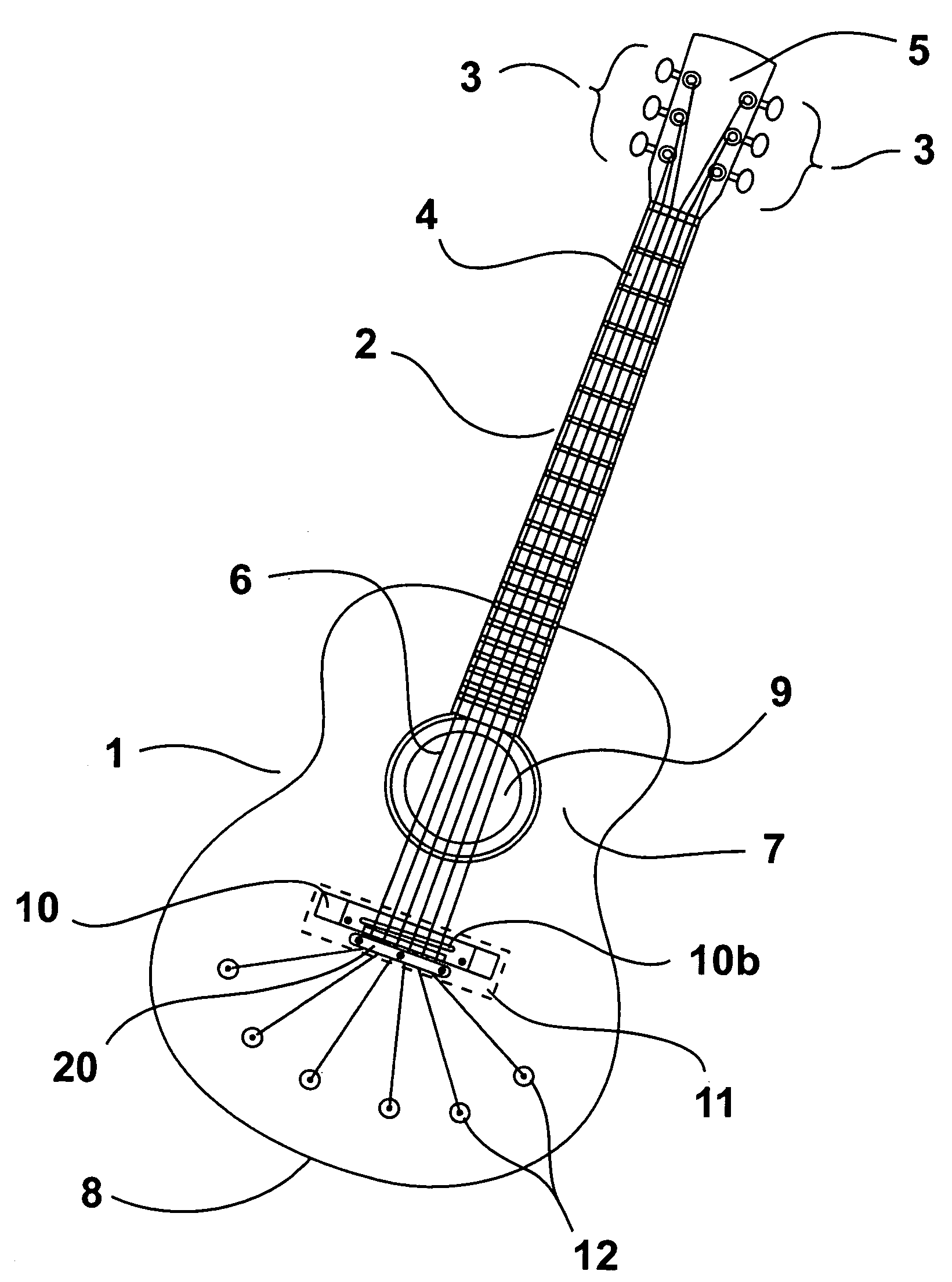

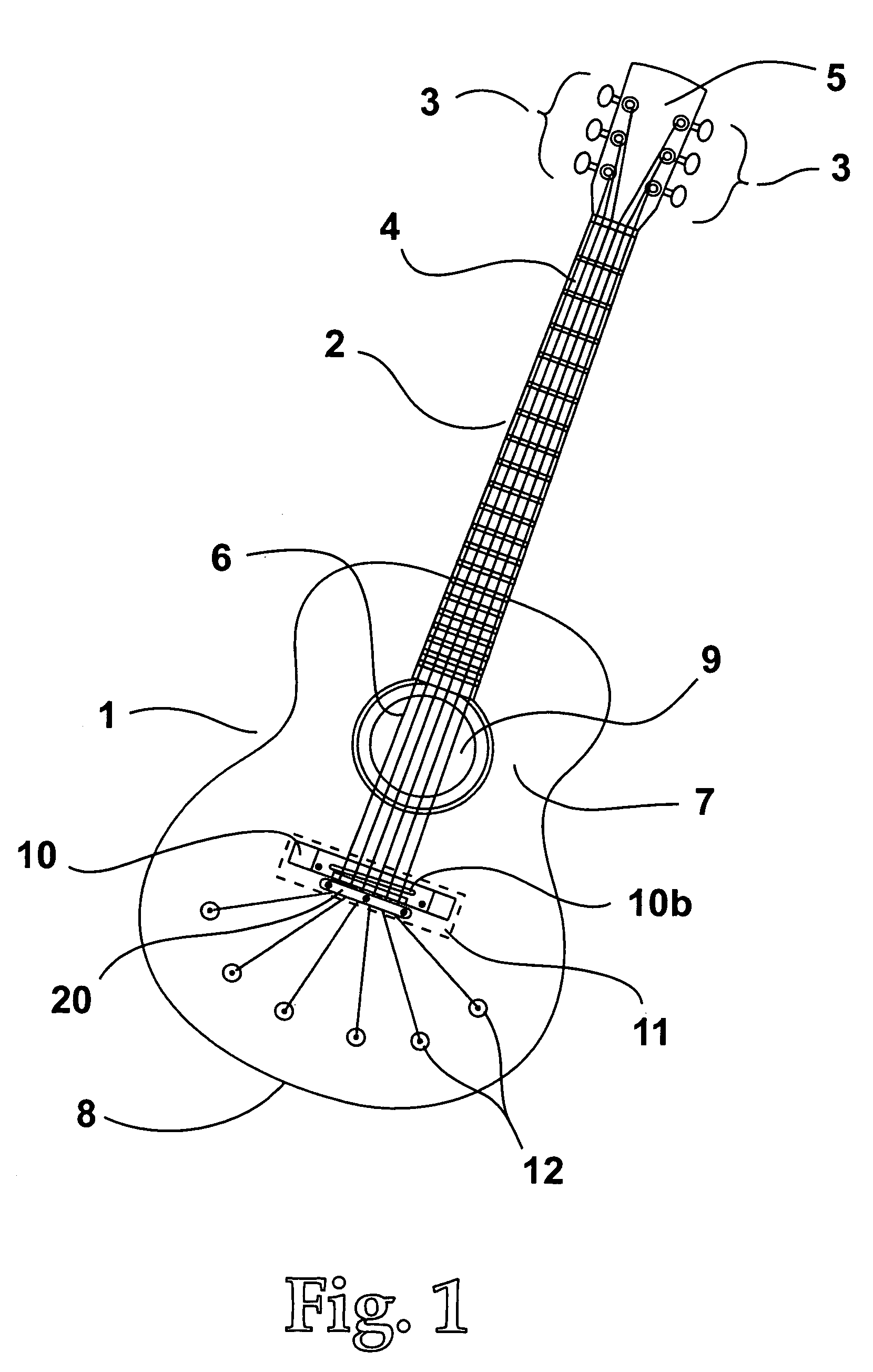

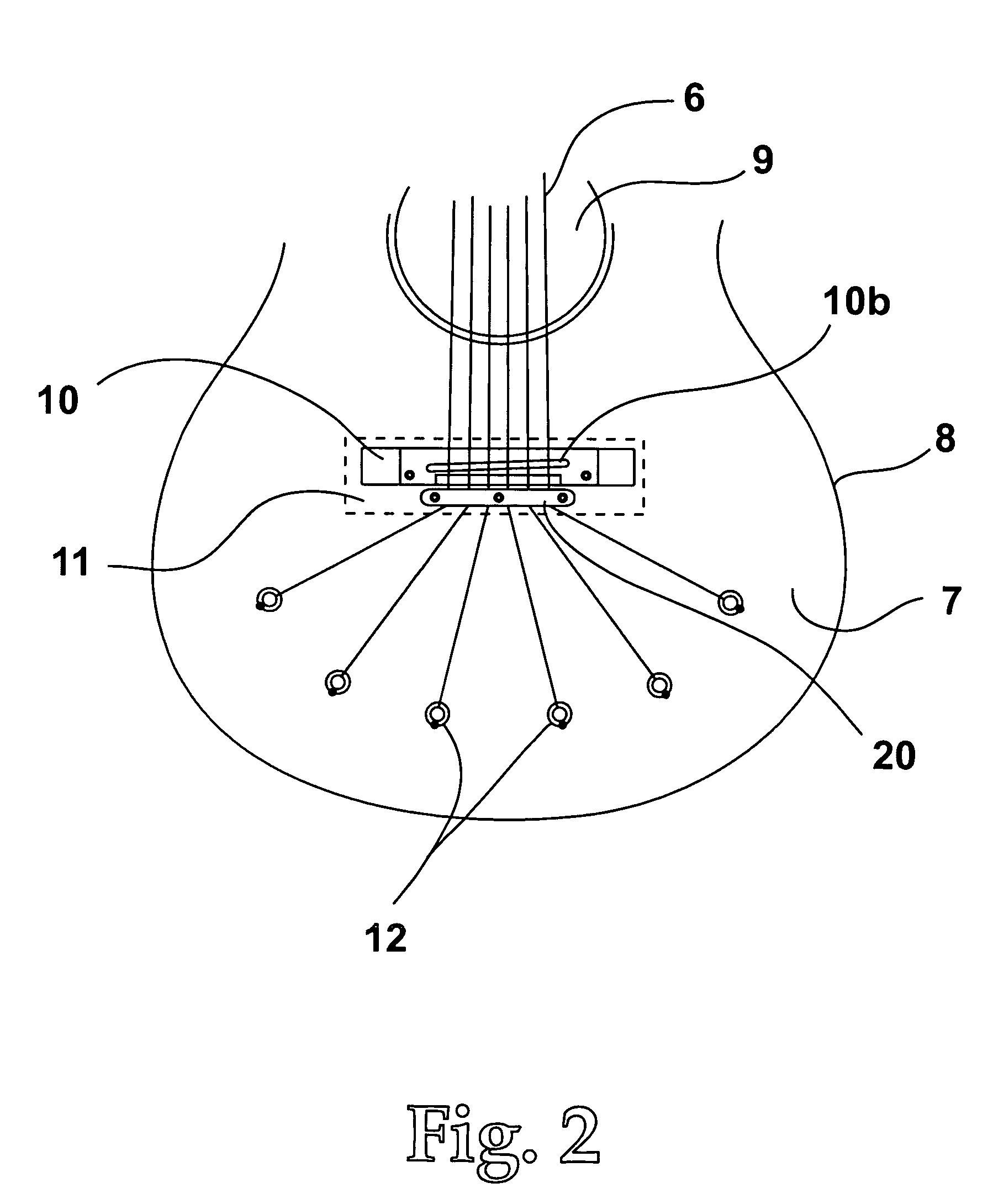

String instrument

A stringed musical instrument, such as a guitar, whereby the lower end of the strings are anchored to the soundboard itself with one or more of the string anchors being positioned past the bridge. This arrangement provides an offset of the lateral compressive forces to the entire soundboard, therefore allowing the soundboard to vibrate more freely in response to the string vibration, and creating an acoustical perpetuating effect. Due to the inherent strength to this design, internal soundboard bracing can be minimized in weight and size as well, which offers a fuller and louder sound, with an increase in sonic balance and sustain.

Owner:BABICZ JEFFREY T

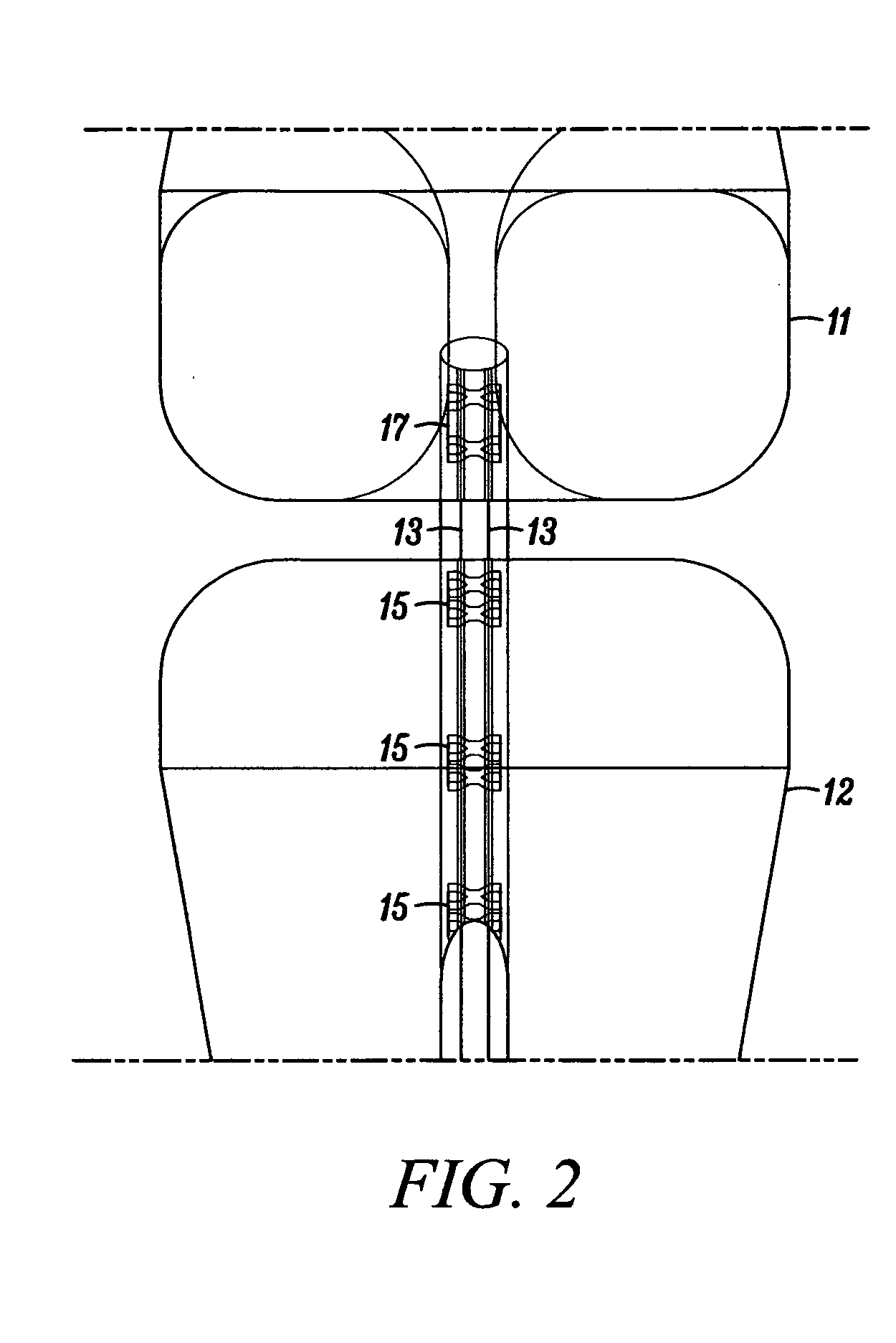

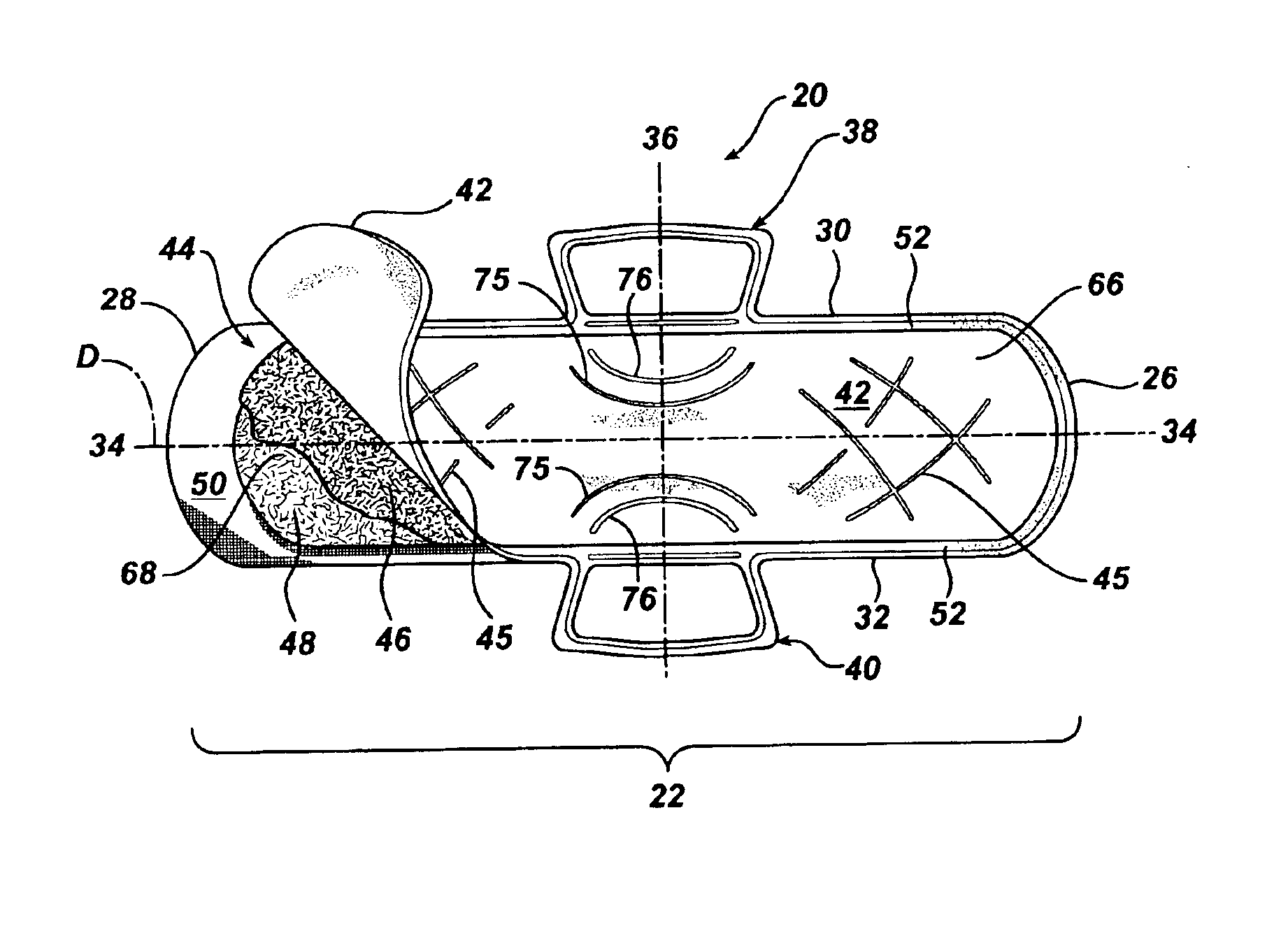

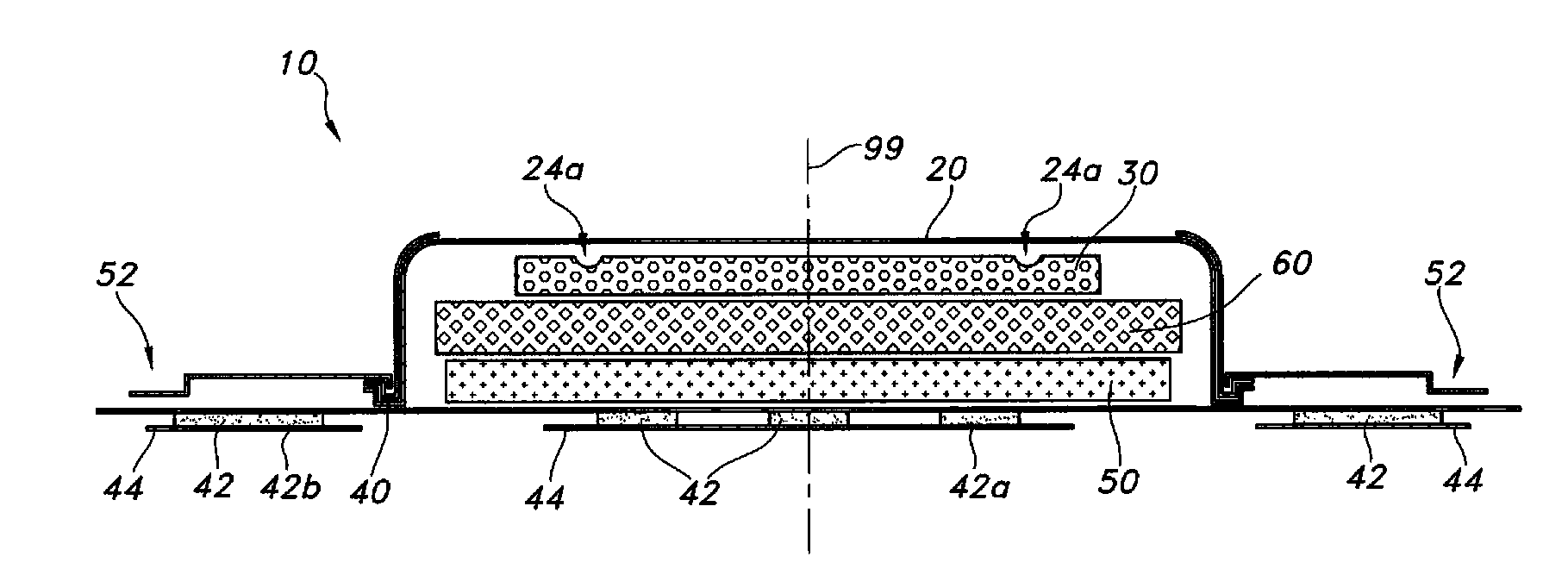

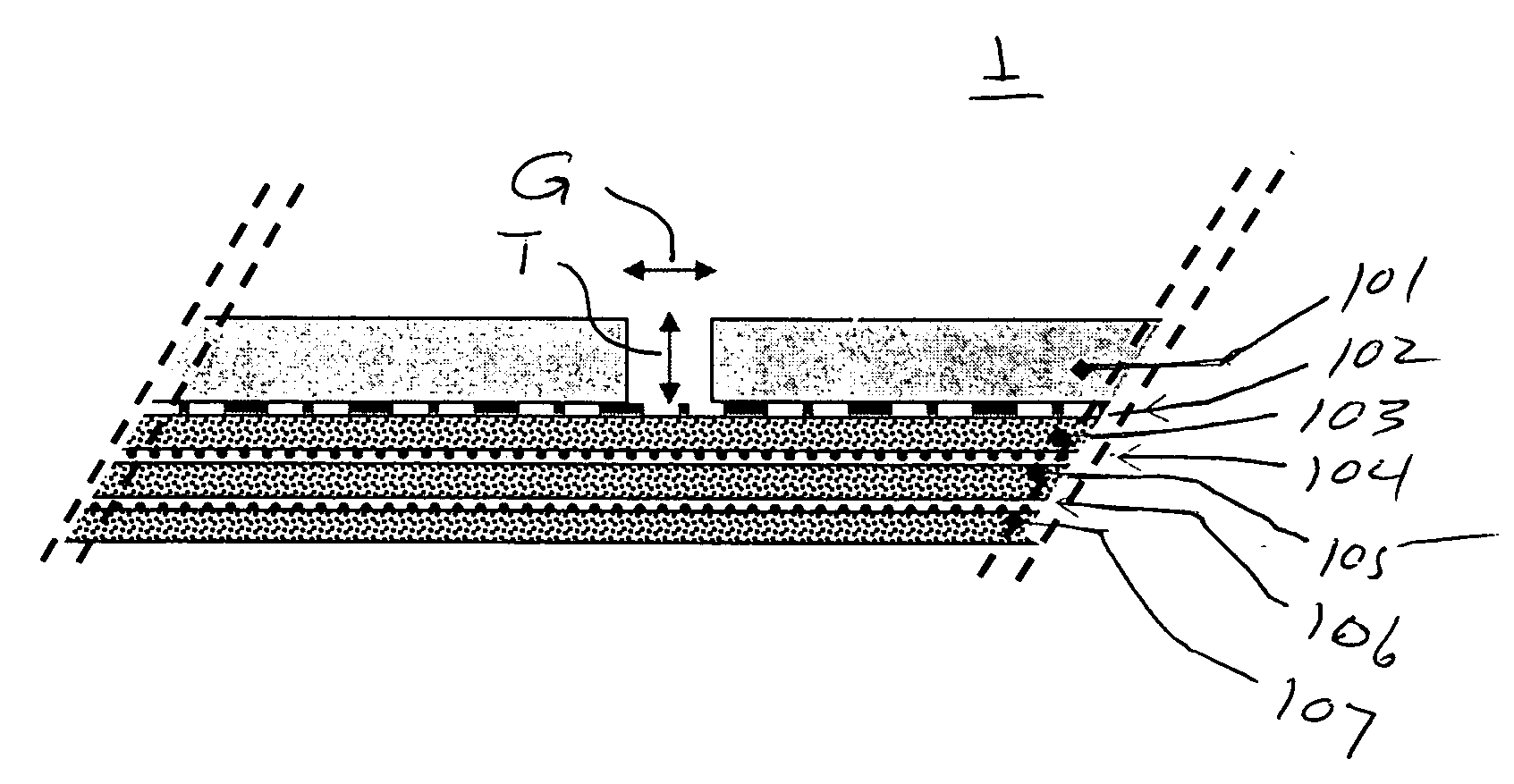

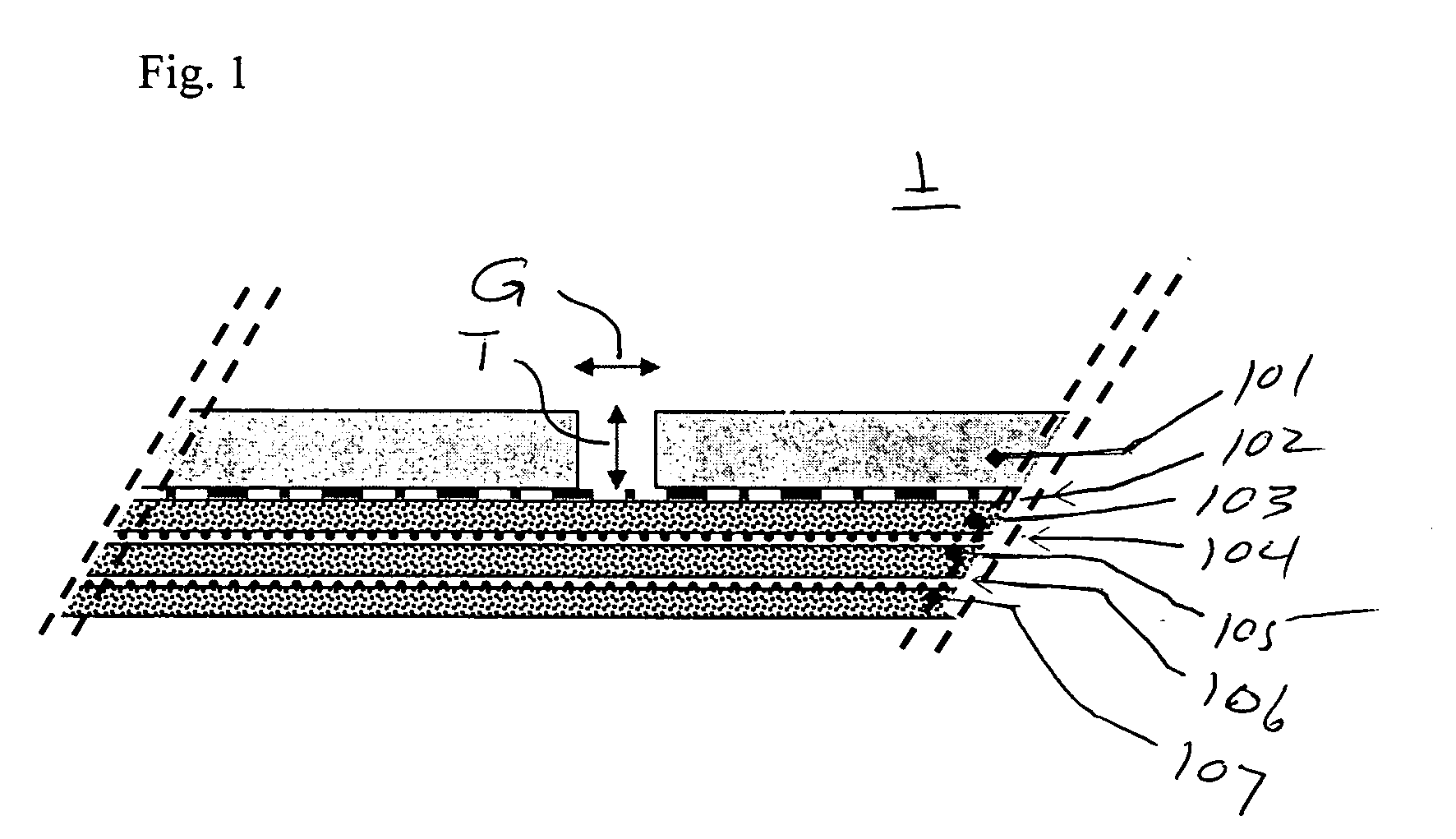

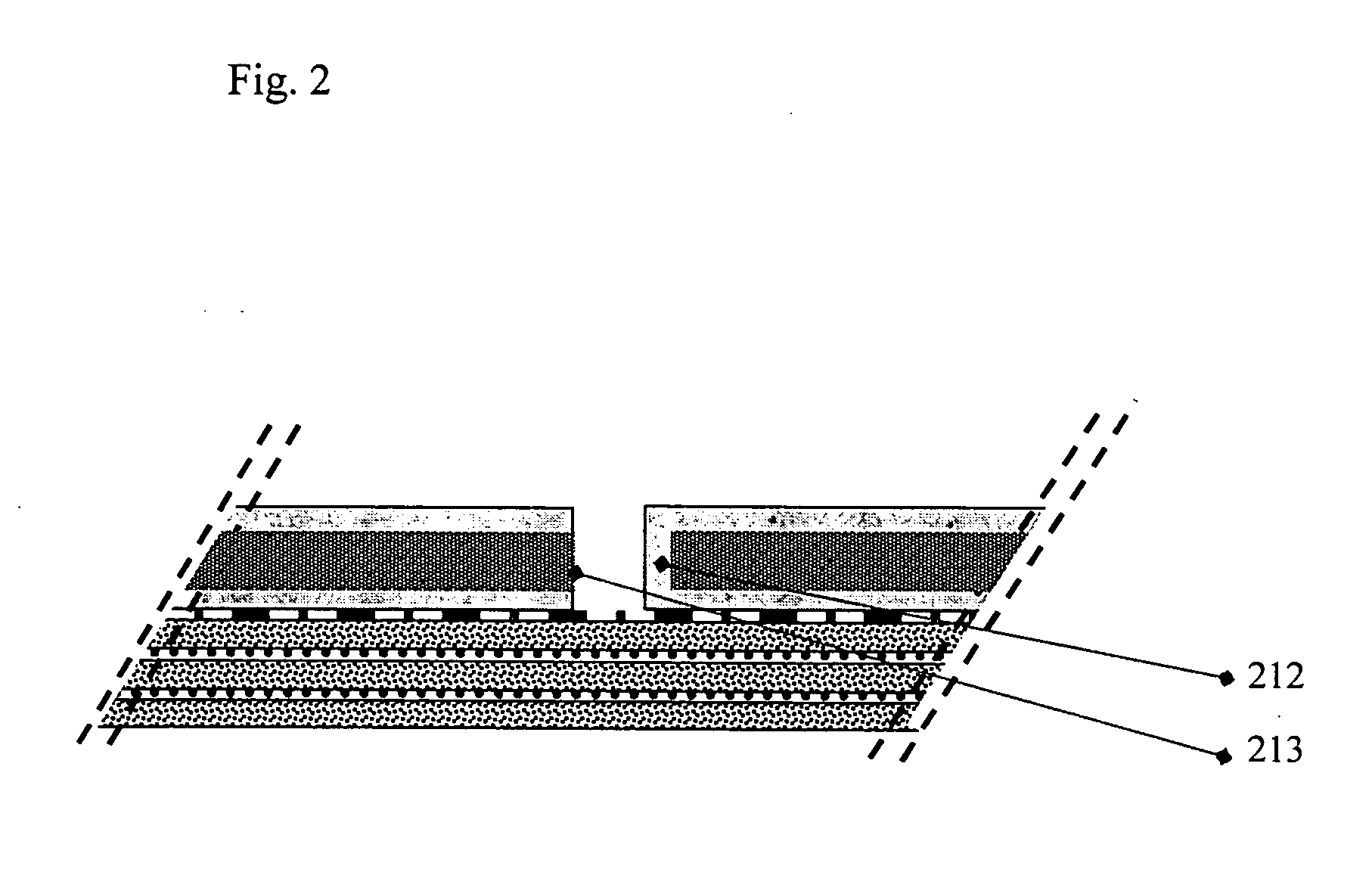

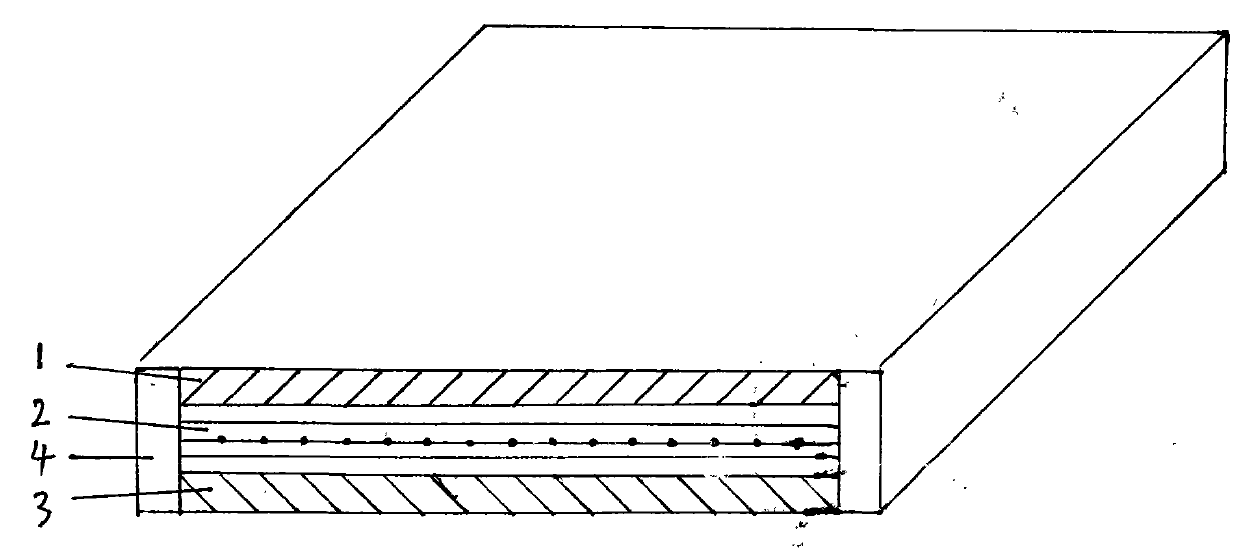

Absorbent article with stabilized absorbent structure having non-uniform lateral compression stiffness

An absorbent article having a liner adapted for contiguous relationship with the wearer's body, an outer cover in generally opposed relationship with the liner, and an absorbent body disposed between the liner and the outer cover. An absorbent structure of the absorbent body has a length, a thickness, a width, a longitudinal axis and a non-uniform lateral compression stiffness across its width. The non-uniform lateral compression stiffness is such that the absorbent structure assumes a pre-determined, or non-random buckled configuration under lateral compression thereof. In one embodiment, the buckled configuration is generally symmetric about a plane normal to the absorbent structure and in which the longitudinal axis of the absorbent structure lies.

Owner:KIMBERLY-CLARK WORLDWIDE INC

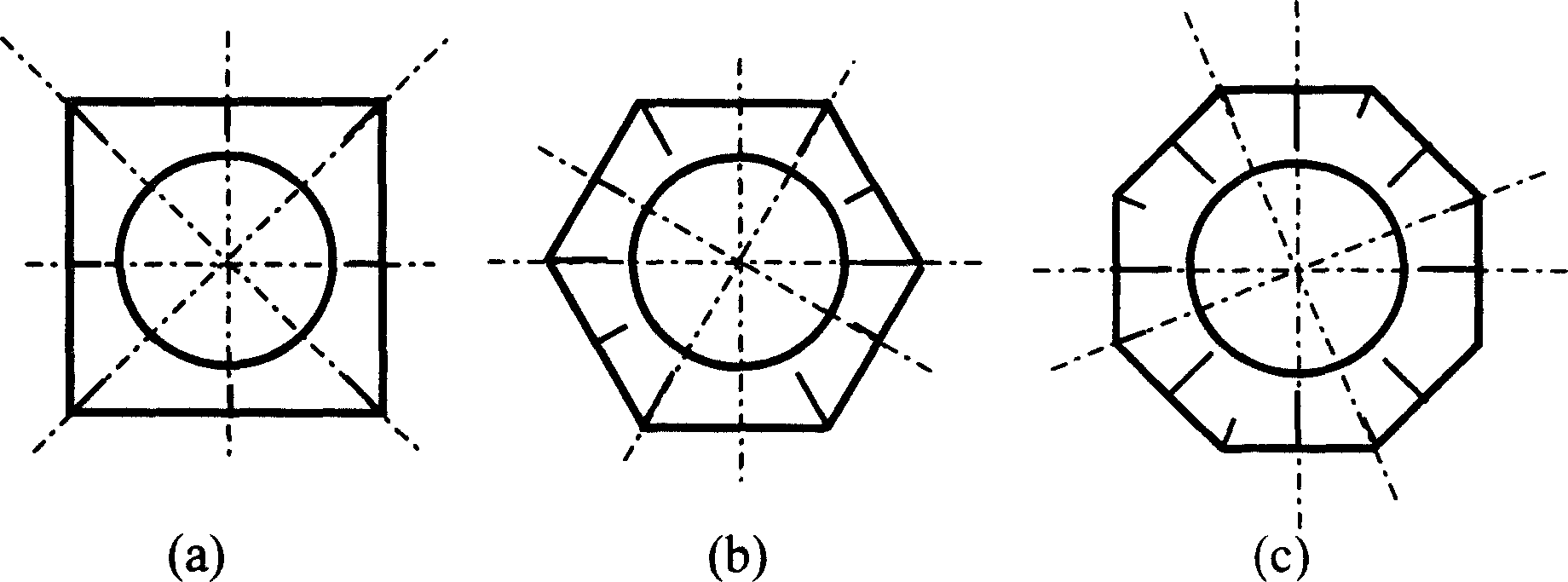

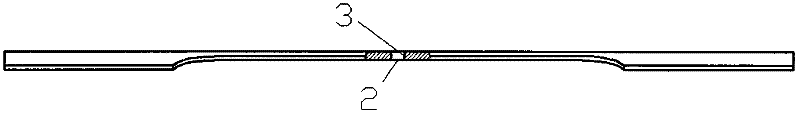

Measuringm ethod and device for fiber material transverse compression property

InactiveCN1587965ASolving precise measurementsAccurate Lateral Compression MeasurementOptical rangefindersPhotogrammetry/videogrammetryFiberObservational error

The invention relates to lateral compression performance measuring method and device of fibrous material, comprising the parts of fiber lateral cimpression element using pressure head on cantilever beam to lateral compress filament and overlapping fiber sample in multiangular tray, fiber deformation observing parts using two objectives with different direction finish stereo-observation and measurement to compressed fiber, compressive stress measuring elements with deflection correction to put in real time change of stress of pressure head in computer and the deflection correction is to correct vertical compressed displacement by small deflection deflection of cantilever beam when laser reflects measuring compression. By using multiple measurement of stress and conformational change and compact and novel design, lateral compression shape measurement is fast, accurate, overall, its measurement error has decreased greatly and the method is suitable for various kinds of fibrous material.

Owner:DONGHUA UNIV

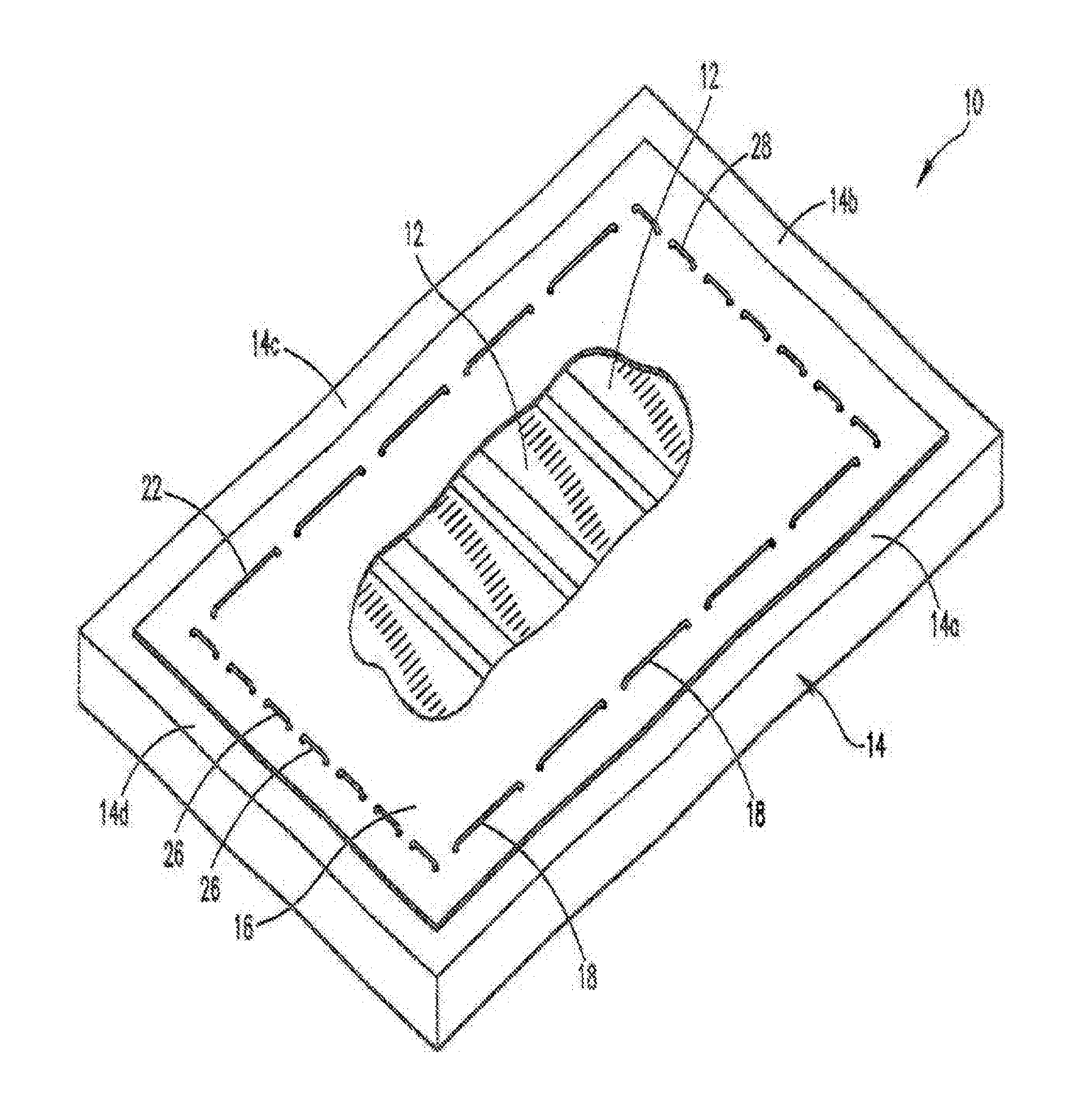

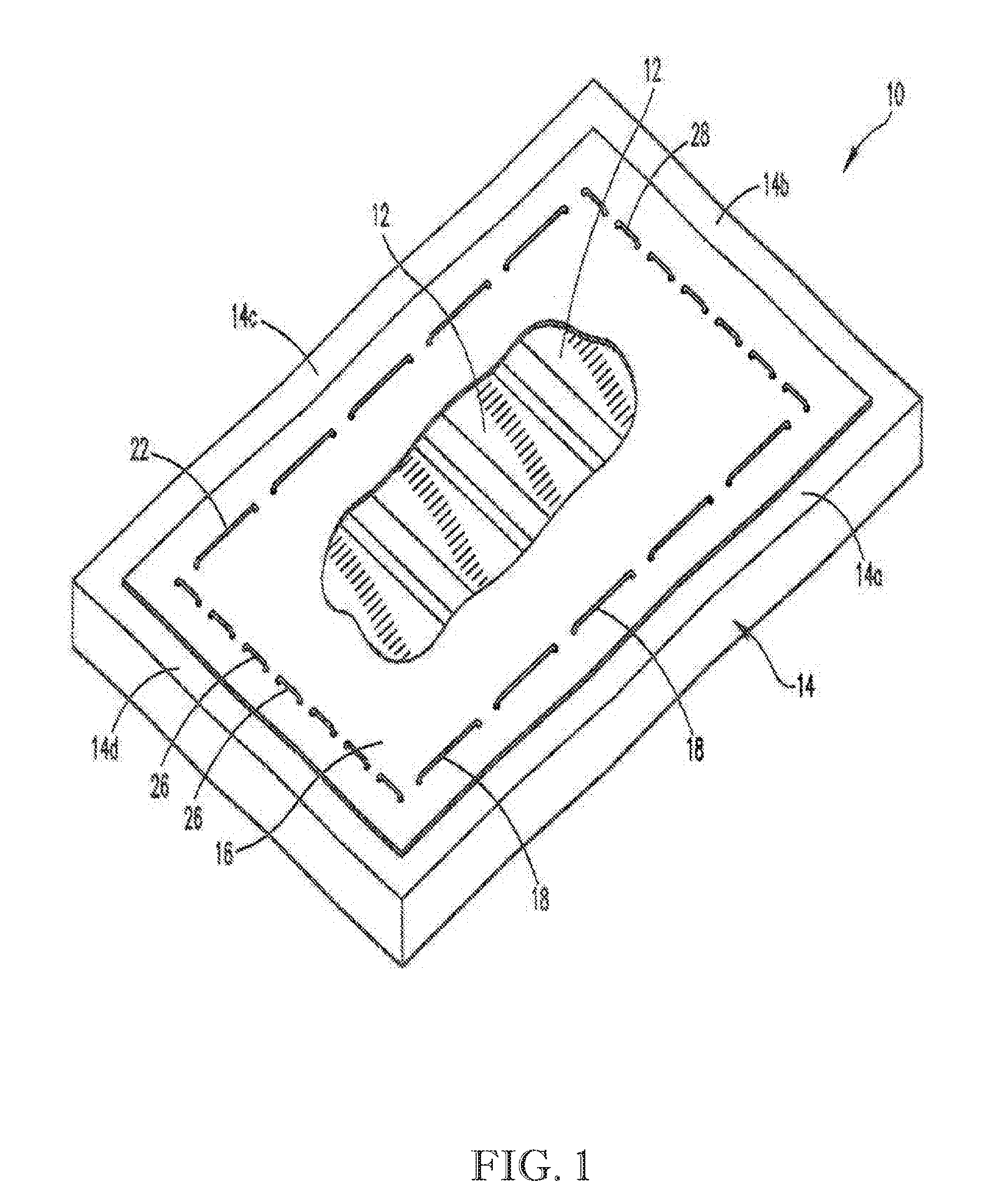

Flexible penetration resistant composite materials structure with critical gap geometry in a solids layer

ActiveUS7393588B1Prevent and limit destructive distortionPromote effective responseArmourSynthetic resin layered productsLateral compressionEngineering

A flexible, penetration resistant structure has a solids layer with a pattern of intersecting gap lines with critical gap cross section geometry, a flexible fiber or fabric layer backing, and a critical bonding layer attaching the solids layer to the flexible backing layer; where the gap geometry upon impact by a select penetrator type causes a controlled response and distributes impact energy in the structure, placing elements of the solids layer adjacent to the impact point mainly in vertical and lateral compression, the bonding layer mainly in shear, the fabric layer beneath the point of impact mainly in bending pressure, and the fibers within the fabric layer, particular those fibers perpendicular to the axis of the gap segment impacted, mainly in tension; and where the applicable class of penetrators is loosely defined as within a certain range of striking energy per unit area of penetrator contact area cross section.

Owner:WARWICK MILLS INC

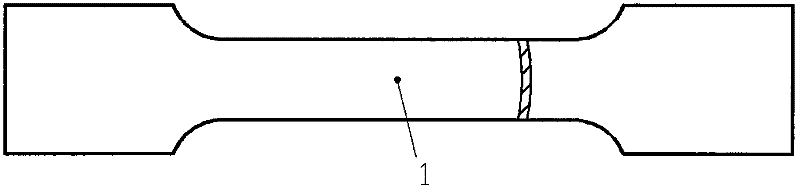

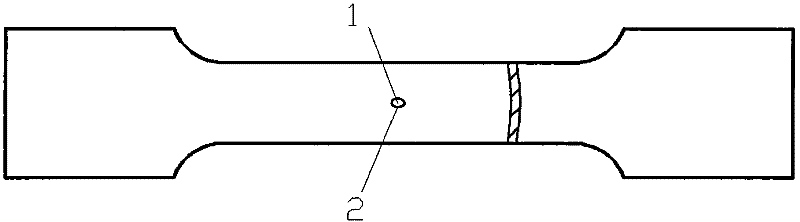

Test sample and method for testing performance parameters of pipe under complex stress state

ActiveCN102410957AFit plane stress-strain propertiesLarge strain rangeMaterial strength using tensile/compressive forcesTest performanceAxial compression

The invention relates to a test sample and method for testing performance parameters of a pipe under the complex stress state. A common uniaxial tension arc-shaped test sample is processed into an arc-shaped test sample with an elliptical hole. The center line of a long shaft of the elliptical hole is in superposition with a center line in the length direction of the uniaxial tension arc-shaped test sample; and the center of the circle of the elliptical hole is in superposition with the center of the shape of the arc-shaped tension test sample with the elliptical hole. Two sections of pipe compressed test samples are cut out along the axial direction of the pipe to be tested. The verticality of the cross section of each pipe compressed test sample to the axial line of the pipe is 0.08-0.1, and the degree of roughness of the cross section of each pipe compressed test sample is 0.8-0.2. The tension testing is performed on the arc-shaped tension test sample with the elliptical hole, the axial compression testing is performed on the pipe compressed test samples, the lateral compression testing is performed on the pipe compressed test samples and reverse engineering is further performed on obtained force-displacement data, thereby testing the performance parameters of the pipe under the complex stress state.By adopting the whole set of test sample for testing the performance parameters of the pipe under the complex stress state and the testing method, the testing precision and the efficiency of the performance parameters of the pipe are improved.

Owner:JIANGSU NEW HENGJI SPECIAL EQUIP

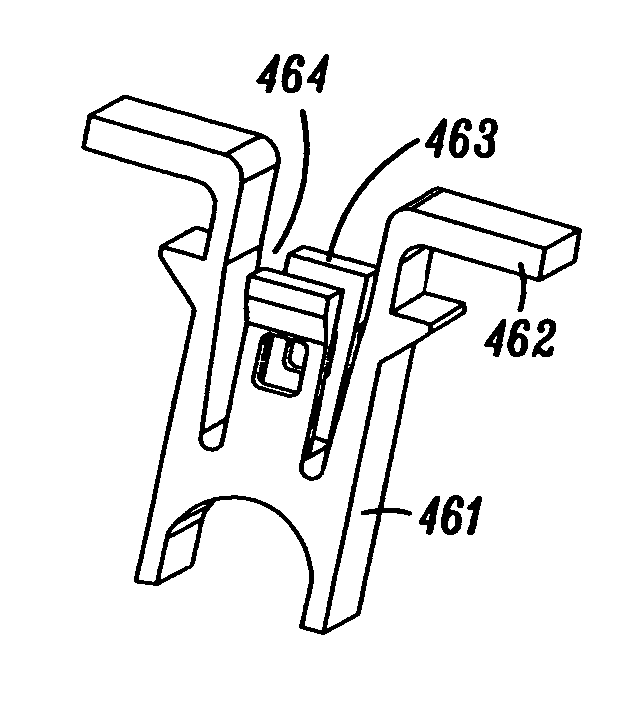

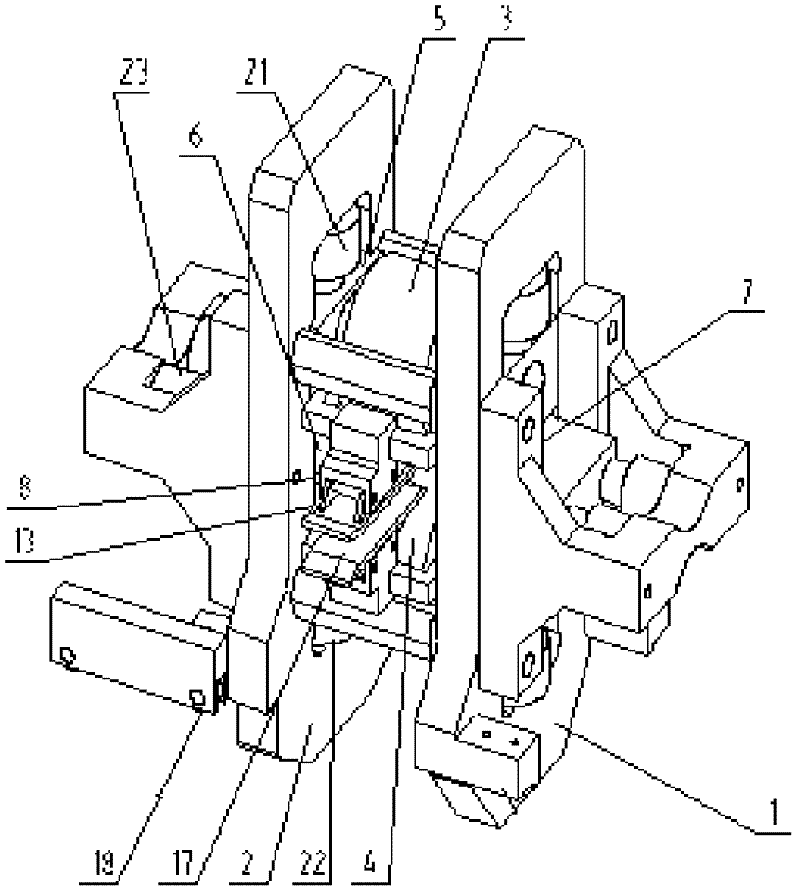

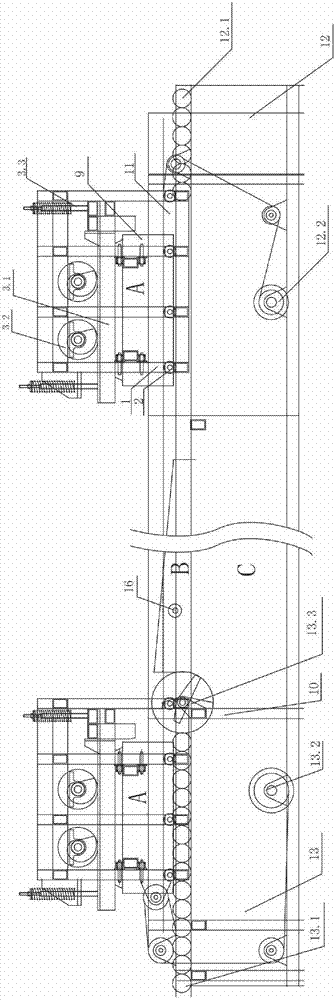

Slotting unit of anode carbon block

InactiveCN102814867AEfficient compressionSimple structureStone-like material working toolsAgricultural engineeringCompression device

The invention discloses a slotting unit of an anode carbon block, comprising a motor, a frame (1) and a rack (10). The slotting unit of the anode carbon block is characterized by further comprising a movable vehicle (A), a slotting saw blade (B) and a cutting bracket (C). The bottom of the frame (1) of the movable vehicle is provided with a rail wheel (2), the upper part of the frame (1) is provided with an upper compression device (3), and the lateral part of the frame (1) is provided with a lateral compression device (4). The upper compression device (3) comprises an upper compression plate (3.1) and an upper compression device; and the upper compression device is arranged at the top of the upper compression plate (3.1). The lateral compression device (4) comprises a lateral compression plate (4.1) and a lateral compression device; the lateral compression plate (4.1) is in an L shape; and the lateral compression device is arranged on the lateral part of the lateral compression plate (4.1). The slotting unit of the anode carbon block is simple in structure and low in manufacturing cost, and can effectively compress the anode carbon block and drag the anode carbon block to move so as to realize the slotting work to the anode carbon block.

Owner:陈玉瑞

Anchor wedge configuration tendon anchors

ActiveUS20060117683A1Limit lateral compressionBuilding reinforcementsAnchoring boltsEngineeringLateral compression

A wedge for a tendon retaining anchor includes at least two circumferential wedge segments adapted to be placed on an exterior of a tendon. The wedge segments have an exterior surface adapted to cooperate with a receiving bore of a load transfer device and an interior surface having gripping elements thereon. A circumferential dimension of the wedge segments is selected so that a total uncompressed gap between circumferential ends of the wedge segments when the segments are applied to an exterior surface of the tendon is at most about 2.4 times a height of the gripping elements. In another aspect, a tendon retaining system includes an anchor having a wedge receiving bore and wedge segments adapted to cooperate with the wedge receiving bore. The wedge segments include gripping elements on an interior surface thereof. The system includes a device adapted to limit lateral compression of the wedge segments.

Owner:PRECISION HAYES INT INC

Connection part between a panel and a support

Owner:I T W ESPANA

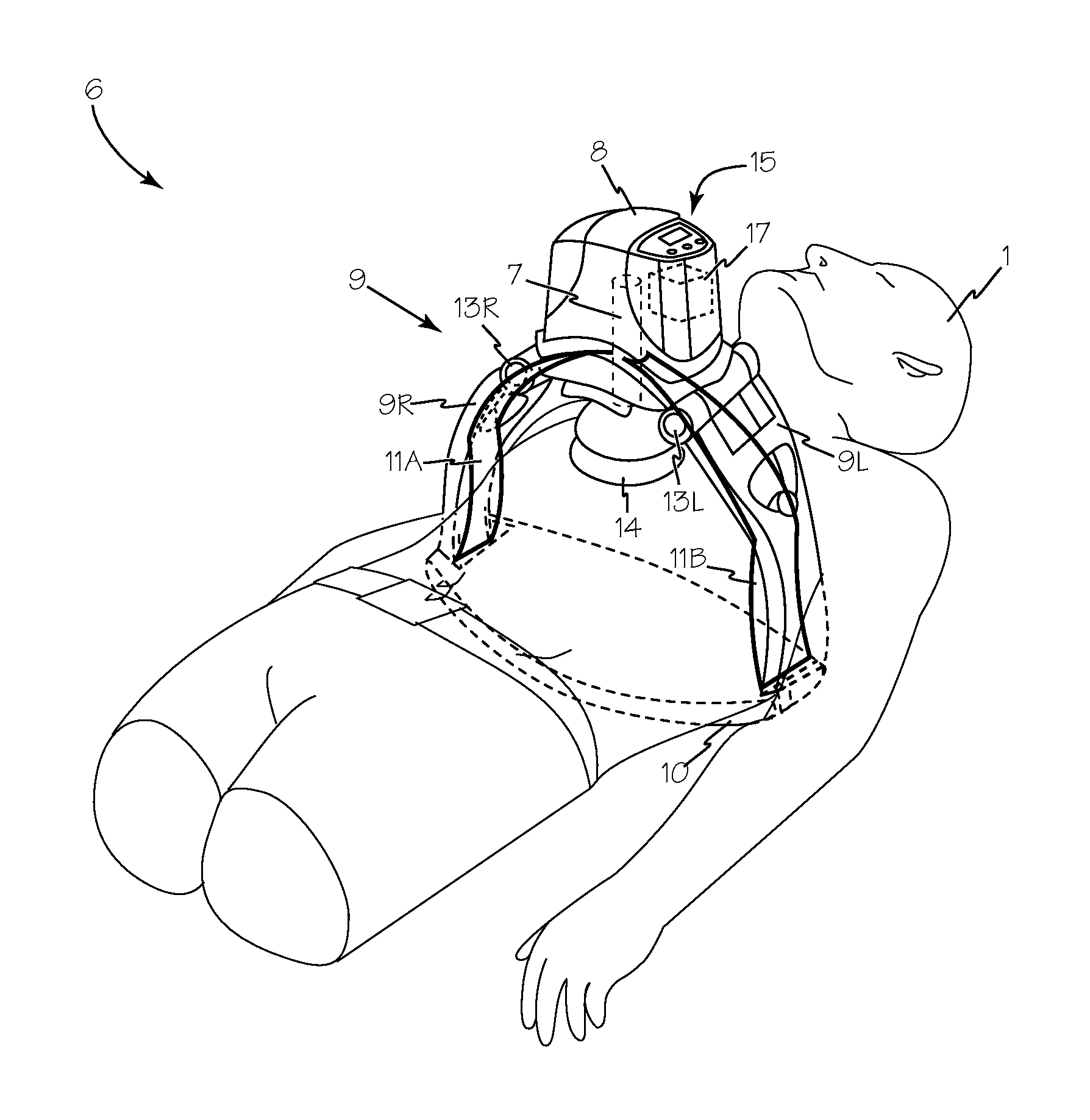

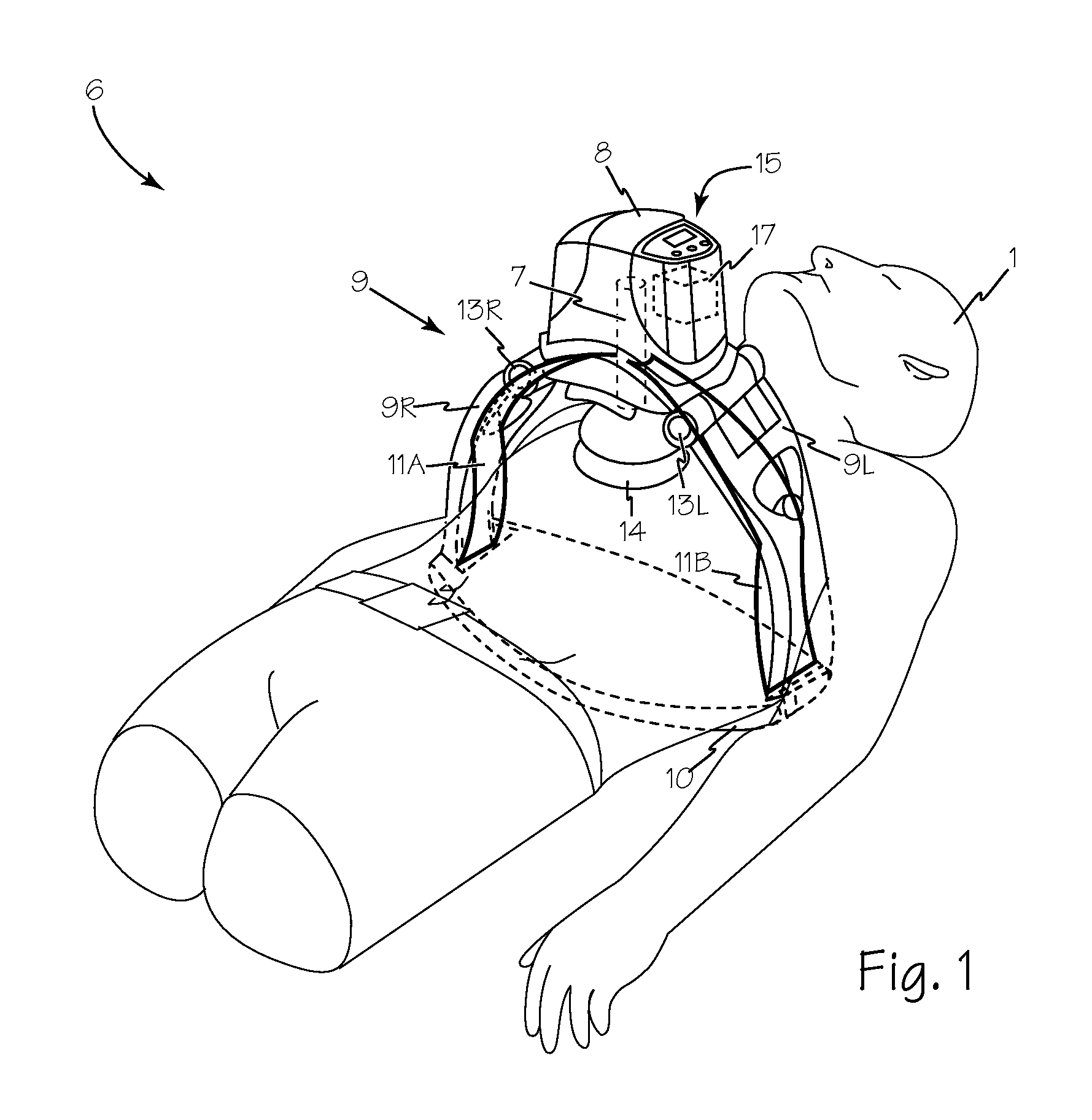

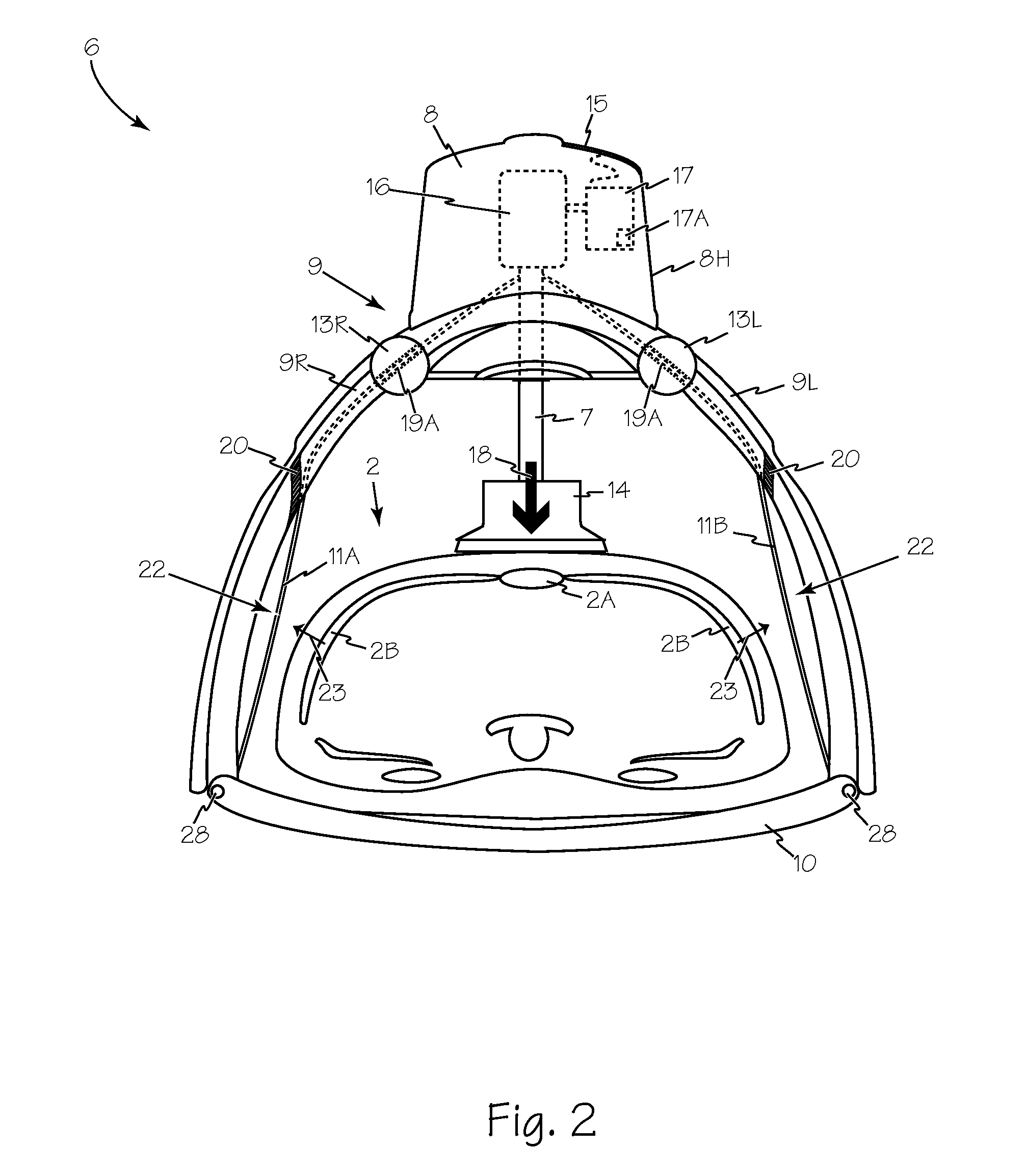

Chest Compression Device

A chest compression device includes a piston to apply compression to the sternum and incorporates leaf springs simultaneously driven by the piston to apply lateral compression to the thorax during chest compressions. A motor in the chest compression device provides motive power to cyclically extend and contract the piston to provide therapeutic chest compressions. One end of each leaf spring is operably connected to the piston and the other end of each leaf spring is secured to the backboard / base or to a support leg of the chest compression device such that during extension of the piston, each leaf spring is compressed against the device base or leg which causes the springs to flex and provide lateral compression of the patient's thorax in addition to the sternal compression of the piston.

Owner:ZOLL CIRCULATION

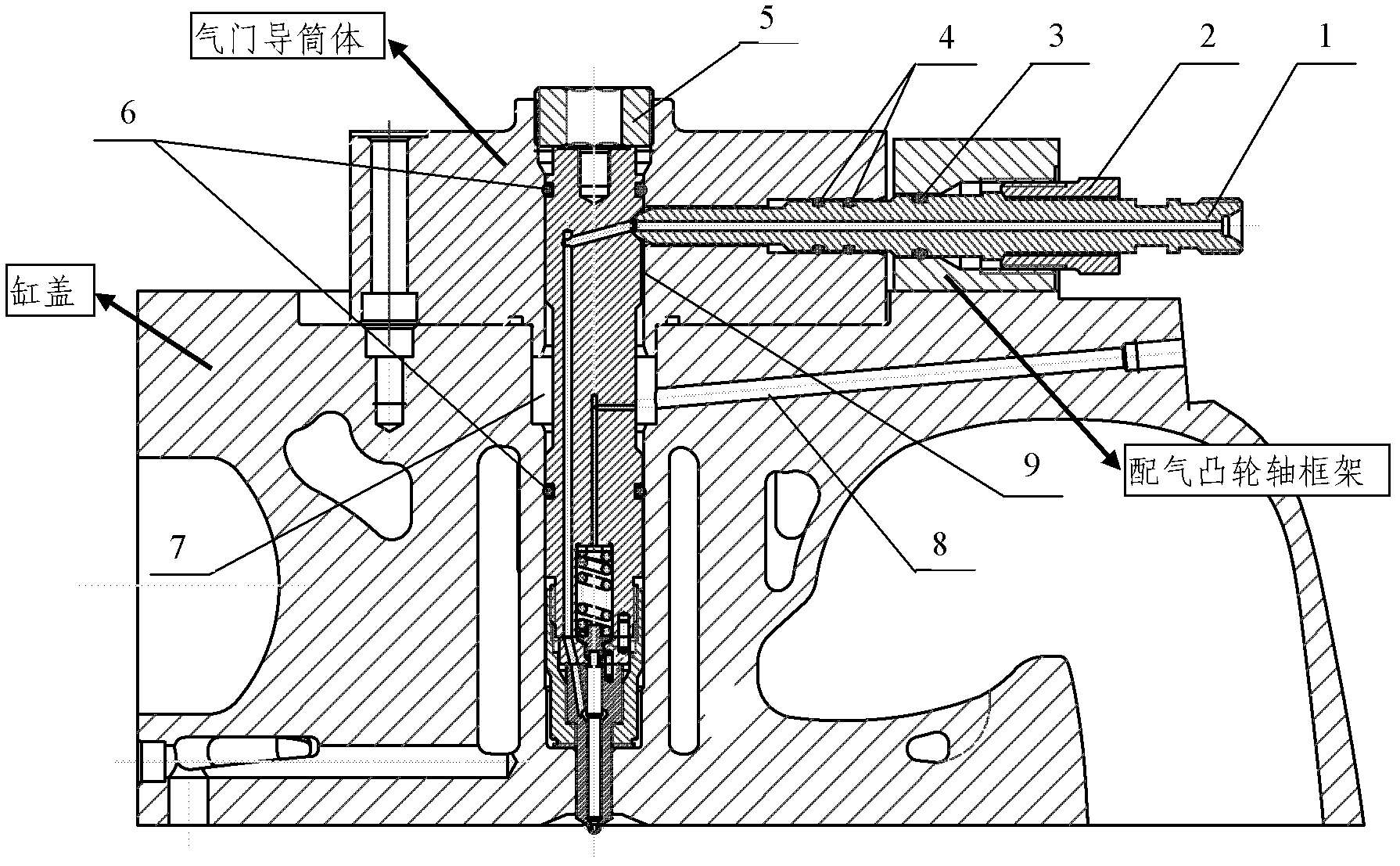

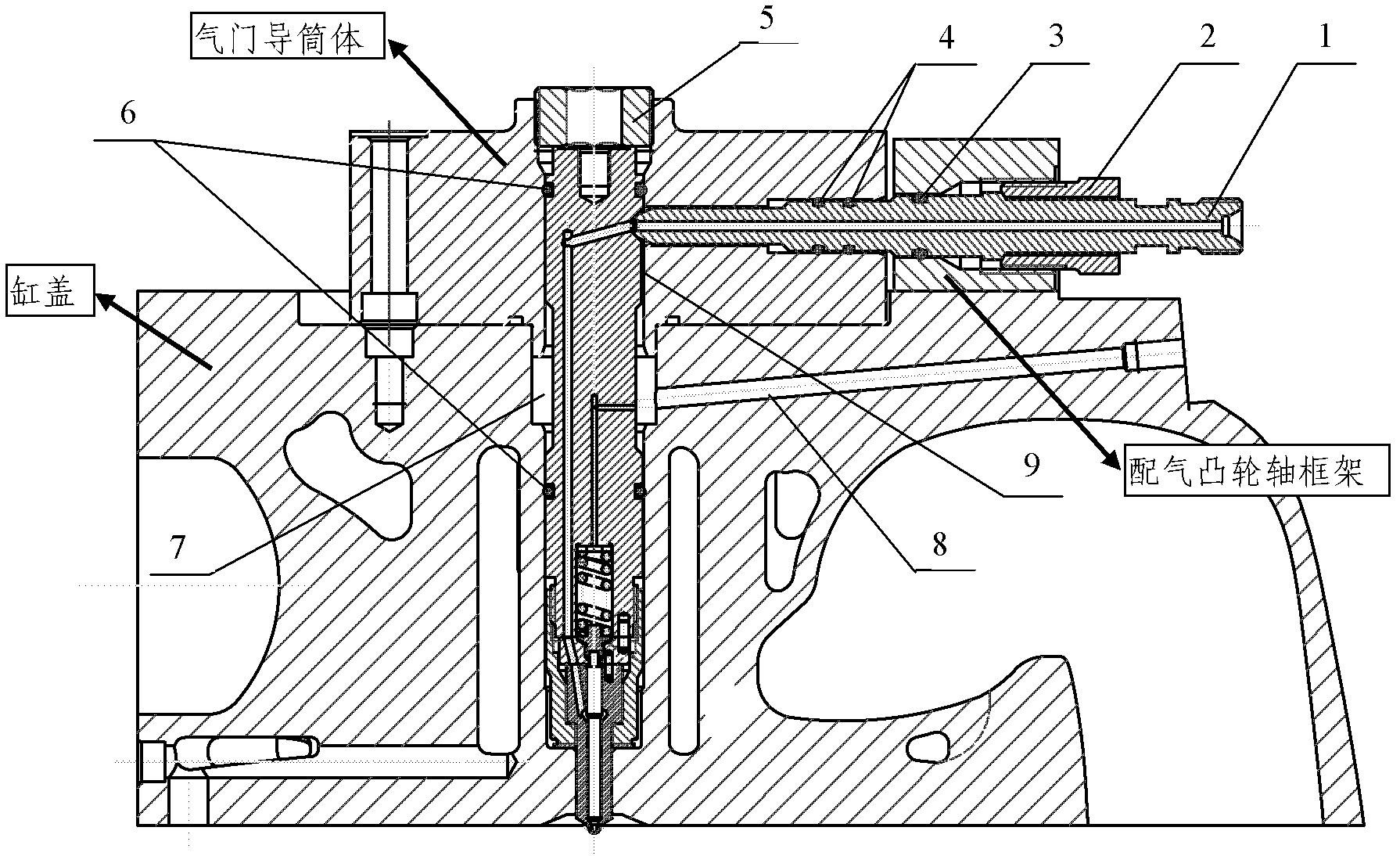

Embedded oil charging structure for high-pressure fuel oil system

InactiveCN102425520AGuaranteed sealing requirementsSmooth oil returnFuel injection apparatusMachines/enginesLateral compressionFuel oil

The invention discloses an embedded oil charging structure for a high-pressure fuel oil system. A lateral oil charging pipe is transversely embedded into a gas distribution camshaft frame and an air valve guide barrel; an oil sprayer is vertically arranged in a cylinder cover and the air valve guide barrel, and is used for charging oil laterally; a lateral oil charging pipe is pressed tightly onto the side wall of the oil sprayer by adopting a lateral compression nut, and is screwed on the gas distribution camshaft frame; an oil sprayer assembly is pressed tightly into a cylinder cover inner hole by adopting a top end compression nut, and is screwed on the air valve guide barrel; two O-shaped sealing rings are distributed on the lateral oil charging pipe and the air valve guide barrel in a matching way; an O-shaped sealing ring is distributed on the lateral oil charging pipe and the gas distribution camshaft frame in a matching way; an O-shaped sealing ring is distributed on the oil sprayer, the air valve guide barrel and the cylinder cover respectively in a matching way; an oil return cavity is communicated with a phi5 oil return channel on the cylinder cover; and an oil leaking groove is formed between the oil charging conical surface of the oil sprayer and the oil return cavity. Due to the adoption of the embedded oil charging structure, a shorter high-pressure oil pipe is realized, the sealing requirements of fuel oil and lubricating oil can be met simultaneously, oil return of the oil sprayer is smooth, and the entire structure is easy to install.

Owner:CHINA NORTH IND GRP NO 70 RES INST

Absorbent Article with Stabilization Member

Owner:KIMBERLY-CLARK WORLDWIDE INC

Ammunition magazine base pad retaining plate

ActiveUS20140047751A1Ammunition loadingOther manufacturing equipments/toolsLateral compressionFlange

An ammunition magazine base pad retaining plate is provided with a protrusion including a shaft portion, a flange portion having a lager cross sectional diameter than the shaft portion, and a longitudinal slot to allow lateral compression. When attached to a magazine base pad in a magazine assembly, the configuration of the base pad retaining plate eliminates the possibility that the base pad retaining plate will disengage from the base pad resulting in catastrophic disassembly of the ammunition magazine.

Owner:APEX TACTICAL SPECIALTIES

Flexible penetration resistant composite materials structure with critical gap geometry in a solids layer

ActiveUS20080160855A1Useful propertyPrevent and limit destructive distortionArmourSynthetic resin layered productsSolid massEngineering

A flexible, penetration resistant structure has a solids layer with a pattern of intersecting gap lines with critical gap cross section geometry, a flexible fiber or fabric layer backing, and a critical bonding layer attaching the solids layer to the flexible backing layer; where the gap geometry upon impact by a select penetrator type causes a controlled response and distributes impact energy in the structure, placing elements of the solids layer adjacent to the impact point mainly in vertical and lateral compression, the bonding layer mainly in shear, the fabric layer beneath the point of impact mainly in bending pressure, and the fibers within the fabric layer, particular those fibers perpendicular to the axis of the gap segment impacted, mainly in tension; and where the applicable class of penetrators is loosely defined as within a certain range of striking energy per unit area of penetrator contact area cross section.

Owner:WARWICK MILLS INC

Sanitary absorbent pad

A sanitary napkin for placement in a crotch portion of an undergarment of a wearer having a longitudinal axis and being further characterized by having a preferential bending zone extending obliquely in relation to the longitudinal axis, each preferential bending zone being located solely in an end region and does not extend into a central region of the napkin. The preferential bending zone may be created by mechanically embossing the surface of the sanitary napkin to locally density the absorbing materials of the article. The preferential bending zone causes the end regions of the sanitary napkin to resist lateral compression forces exerted by the thighs of the wearer and thereby prevents bunching of the article on the undergarment. The central region 70 of the sanitary napkin conforms to the wearer's body providing greater comfort for the wearer of the napkin.

Owner:MCNEIL PPC INC

Three-dimensional circular tube conveying belt

The invention belongs to conveying machines, and relates to a three-dimensional circular tube conveying belt, which solves the problem that the conventional conveying belt can be only elevated upwards within the range of between 0 and 90 degrees. The three-dimensional circular tube conveying belt is implemented by the following special method: both ends of a bearing belt and a backhaul belt are parallel, and the conveying belt is changed into a tubular shape from a parallel shape by a conveyor rounder, so that conveyed materials are wrapped in a tube hermetically; a roller group or a single roller with a circular shape, a square shape, an oval shape, a U shape, a parallel shape and the like is used to overcome the lateral compression and clamping force which are generated by the accumulation of the materials, so that the conveying belt can make a turn in a three-dimensional direction, namely in any directions of horizontal and vertical surfaces, at an angle of between 0 and 360 degrees; and two to three layers of canvas and tyre fabrics which are prepared from nylon, polyester-nylon, terylene, carbon fibers, basalt fibers, aramid fibers and polysulfonamide by dipping gum or ropes arranged at certain intervals are arranged between upper covering glue and lower covering glue to serve as skeleton layers of the conveying belt, and the skeleton layers of the conveying belt are overlaid with side glue mutually to form the conveying belt. The three-dimensional circular tube conveying belt has the advantages of high strength, flexibility, long service and wide application.

Owner:牛国青

Under mattress support

ActiveUS20170049242A1Facilitate lateral compressionSufficient resiliencySofasFluid mattressesEngineeringLateral compression

An under mattress support extends the longevity of an existing mattress that may include concave areas resulting in sagging or soft areas, including a plurality of parallel oriented spaced-apart resilient elongated slat members interconnected by pliable strips to form a parallel slat array. The pliable strip spacing of the parallel resilient slats allows for lateral compression to enhance support. In use, the under mattress support is interposed between a mattress and underlying box spring such that the elongated slats extend along their longitudinal direction from a portion of one side of the mattress to the opposite side of the mattress where the concave portion of a sagging or soft mattress appears during the normal course of use.

Owner:FREN COLLEEN M

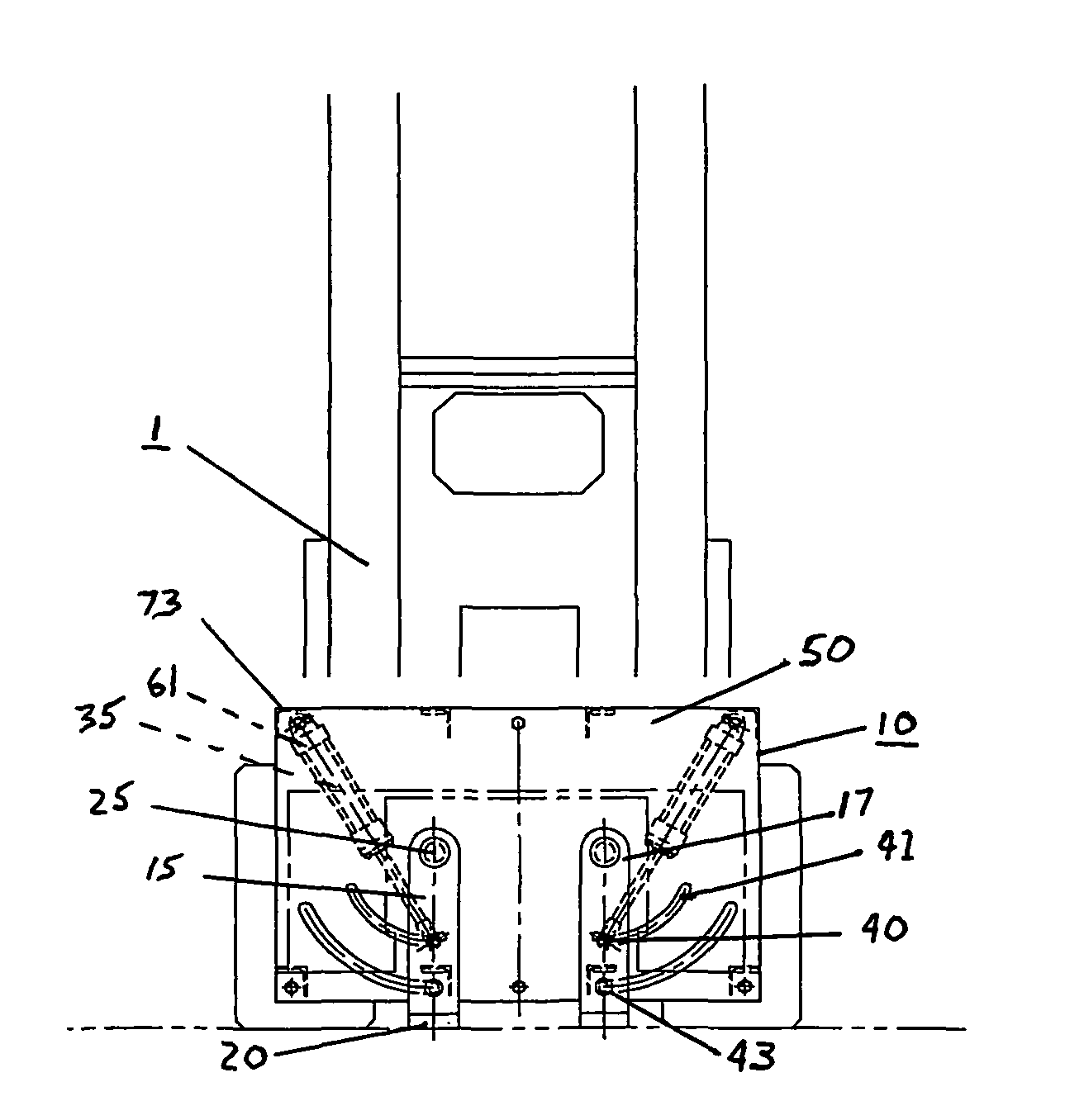

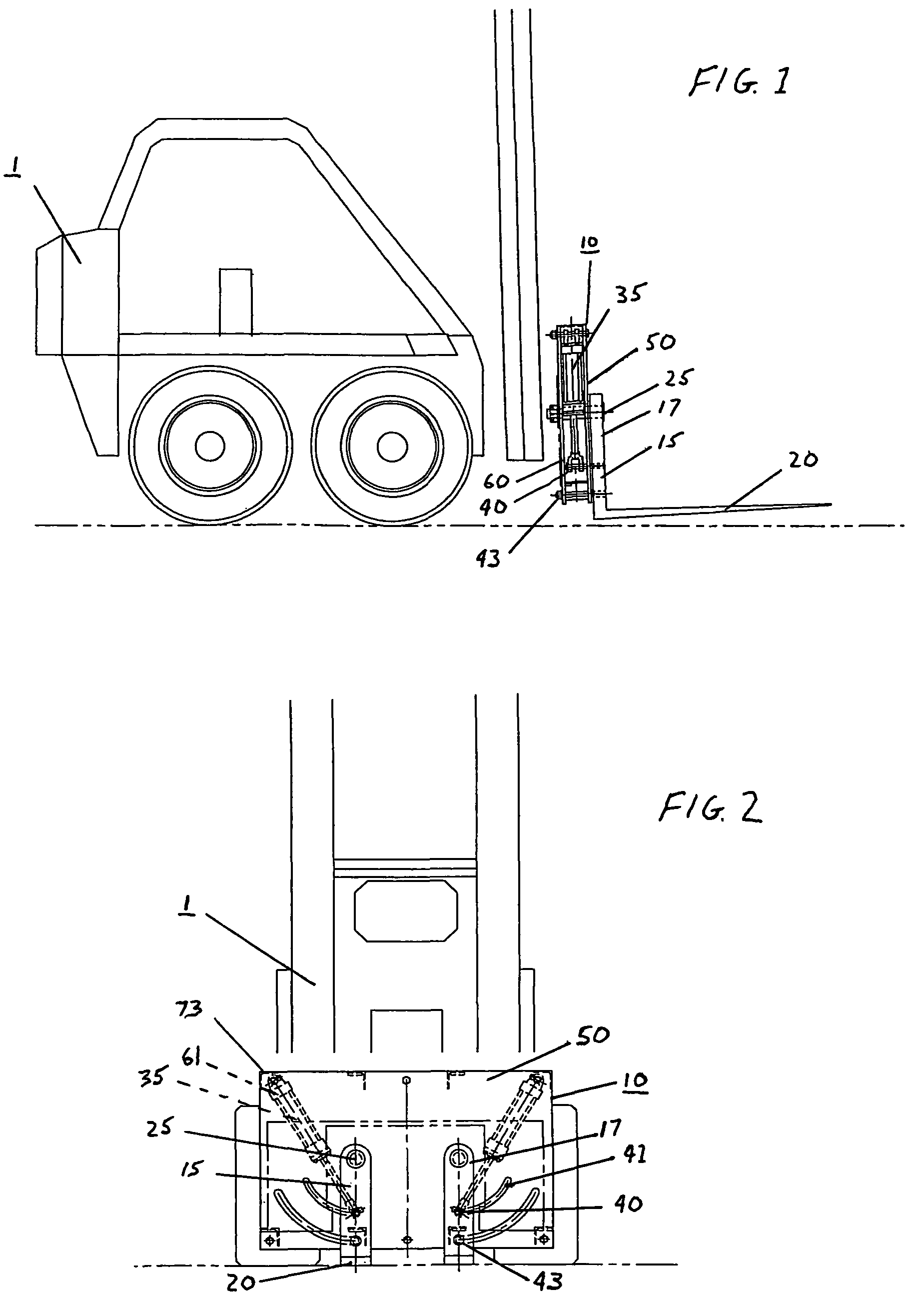

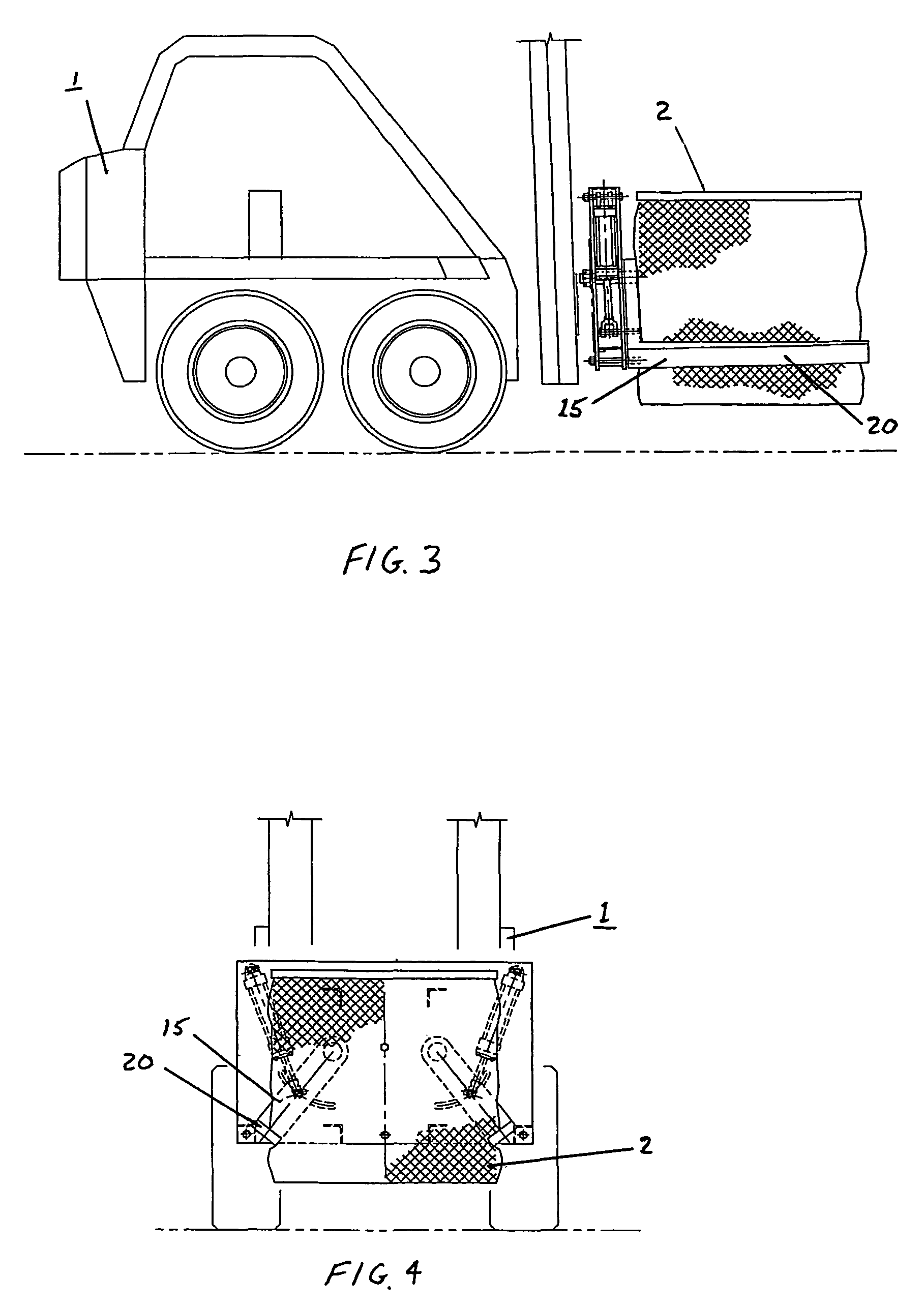

Apparatus and method for the disposal of waste

The present invention comprehends a forklift attachment, generally comprising a pair of forks rotatably mounted to a fork plate using a pair of pivot pins with each pivot pin having a center axis normal to the fork plate. Upper bore pins and lower bore pins are adapted to travel within bores of the fork plate. As such, actuators connected to the upper bore pin rotate the forks about the center axis such that the forks can apply opposing lateral compression forces to a flexible dumpster. In a method for collecting waste, a disposer places the flexible dumpster near the waste disposal site whereby a truck-mounted forklift can be utilized to engage the forks with the side portions of the flexible dumpster for loading and disposal. Accordingly, large dumpsters do not have to dropped off at the waste disposal site and large trucks no longer have to be utilized.

Owner:MILANI THOMAS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com