Patents

Literature

188results about How to "Solving precise measurements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

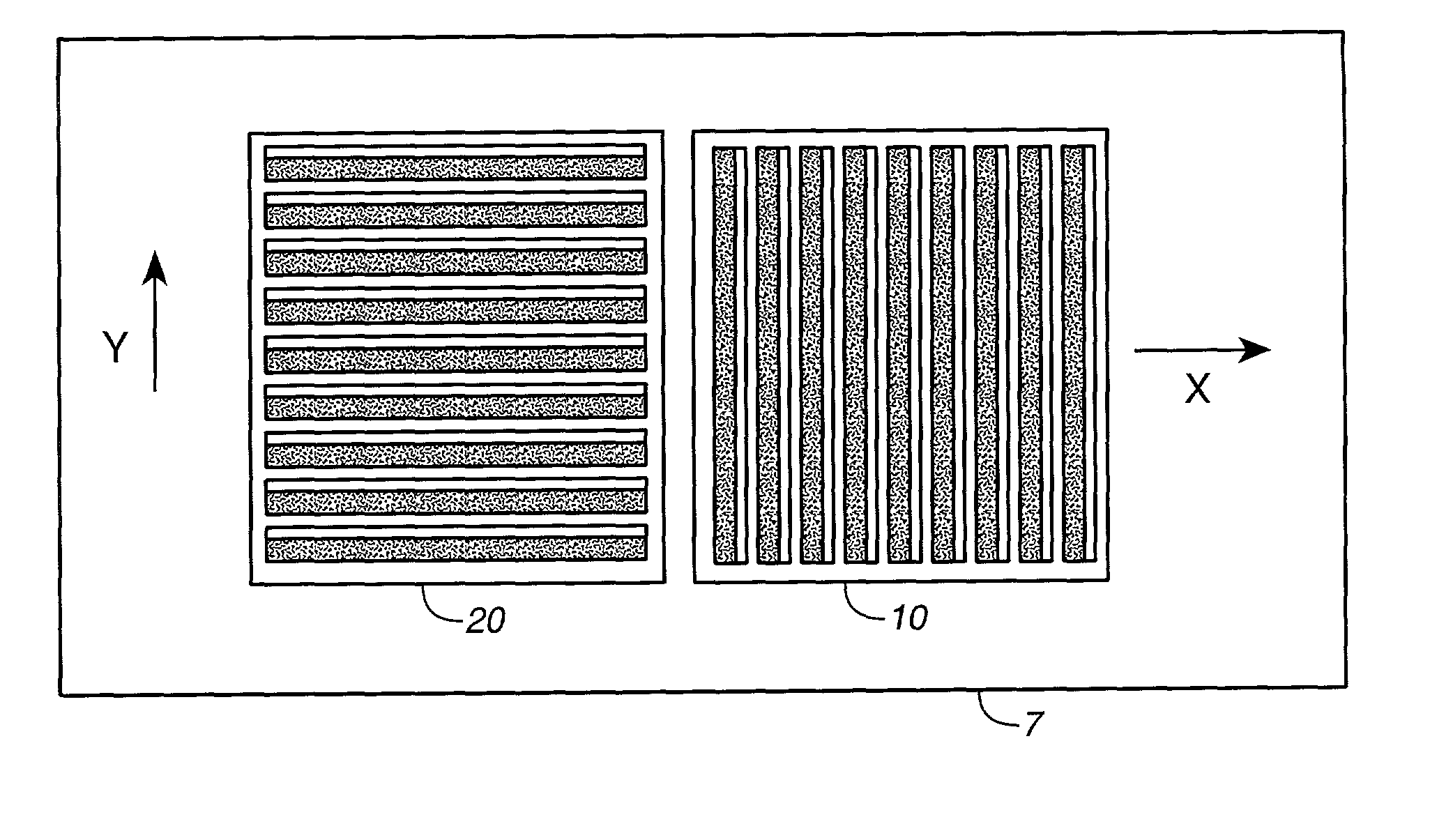

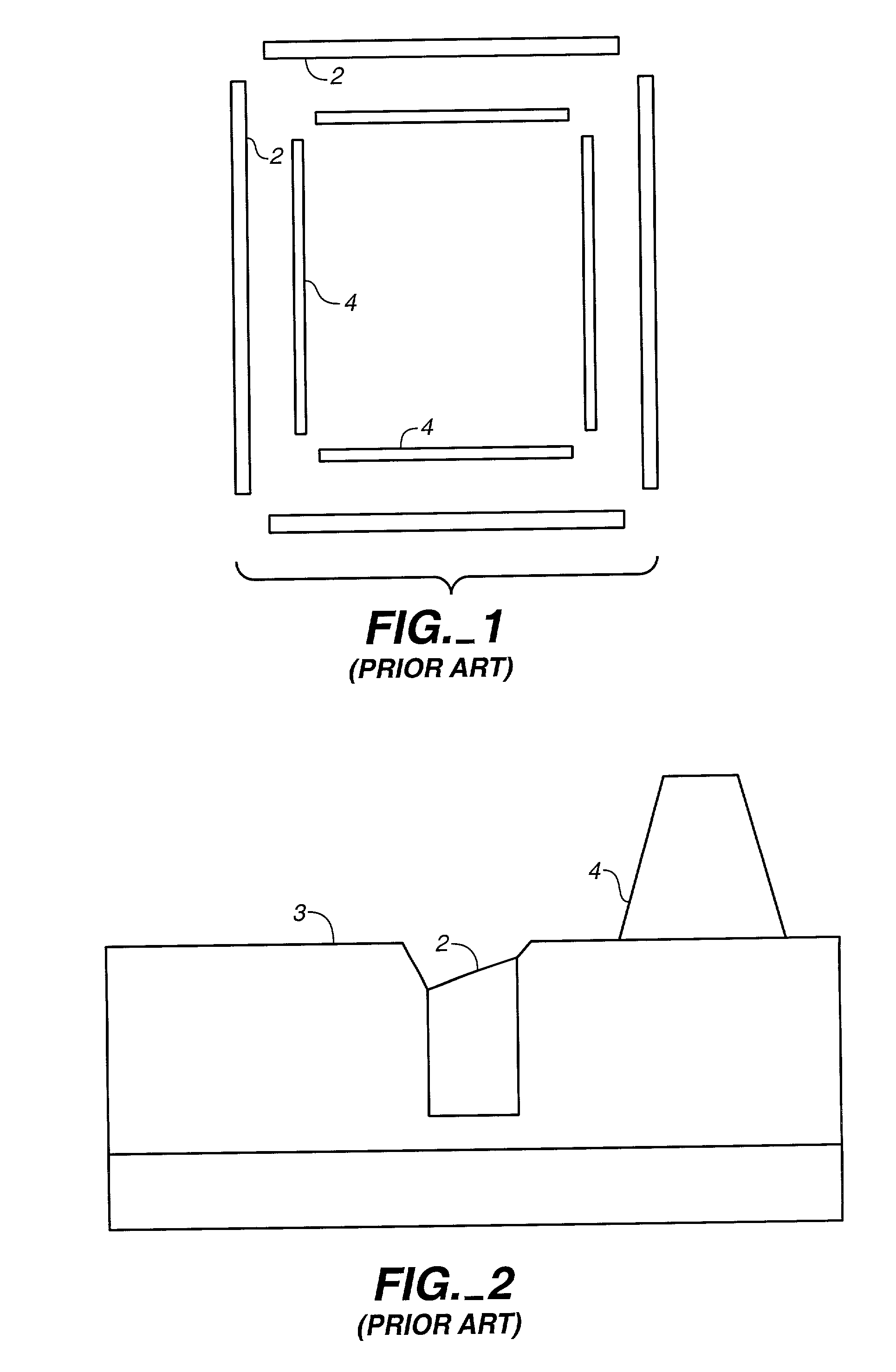

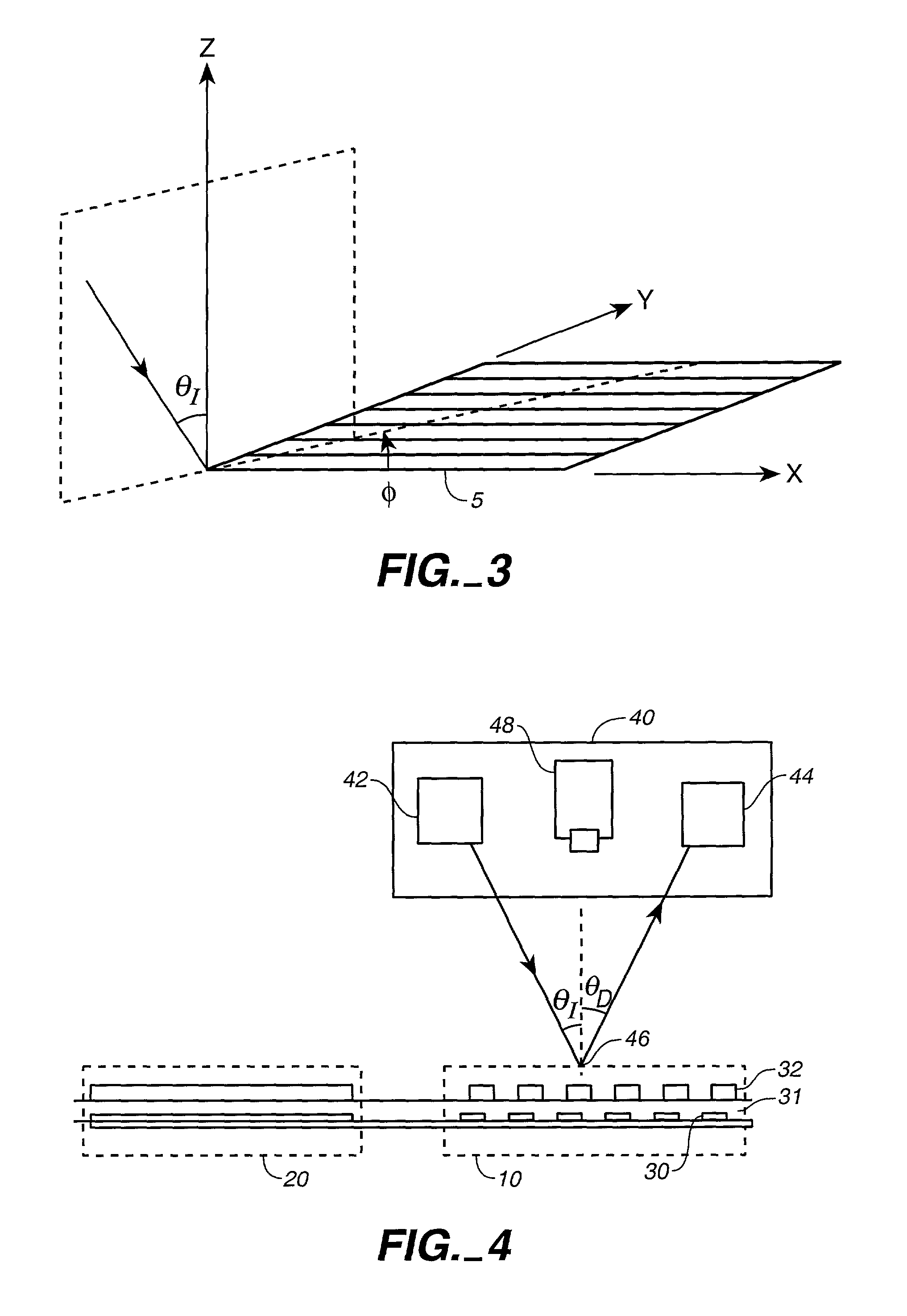

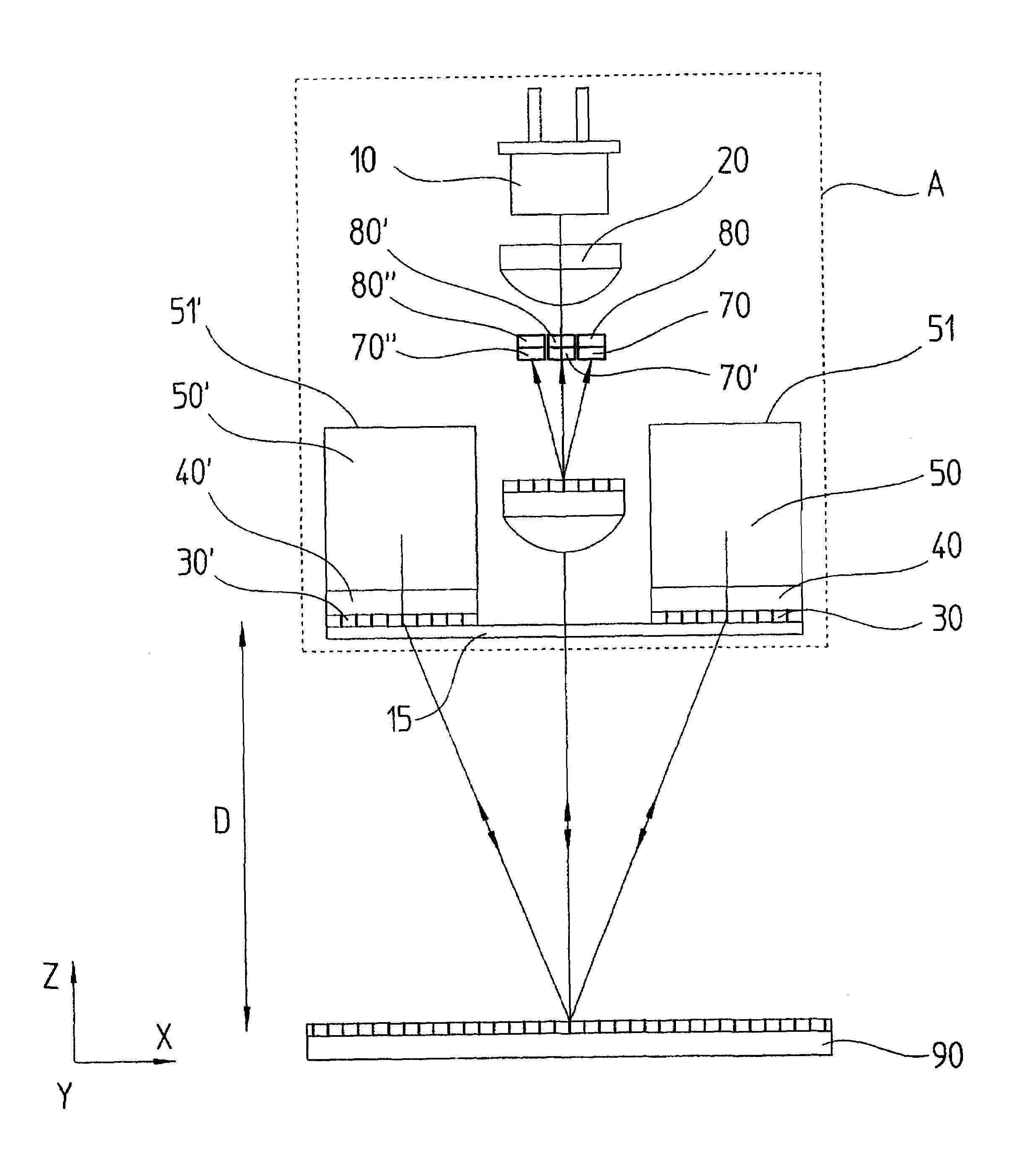

Overlay alignment metrology using diffraction gratings

InactiveUS20020158193A1Limited space availableOvercome difficultiesBeam/ray focussing/reflecting arrangementsSemiconductor/solid-state device testing/measurementMetrologyAngle of incidence

Alignment accuracy between two or more patterned layers is measured using a metrology target comprising substantially overlapping diffraction gratings formed in a test area of the layers being tested. An optical instrument illuminates all or part of the target area and measures the optical response. The instrument can measure transmission, reflectance, and / or ellipsometric parameters as a function of wavelength, polar angle of incidence, azimuthal angle of incidence, and / or polarization of the illumination and detected light. Overlay error or offset between those layers containing the test gratings is determined by a processor programmed to calculate an optical response for a set of parameters that include overlay error, using a model that accounts for diffraction by the gratings and interaction of the gratings with each others' diffracted field. The model parameters might also take account of manufactured asymmetries. The calculation may involve interpolation of pre-computed entries from a database accessible to the processor. The calculated and measured responses are iteratively compared and the model parameters changed to minimize the difference.

Owner:TOKYO ELECTRON LTD

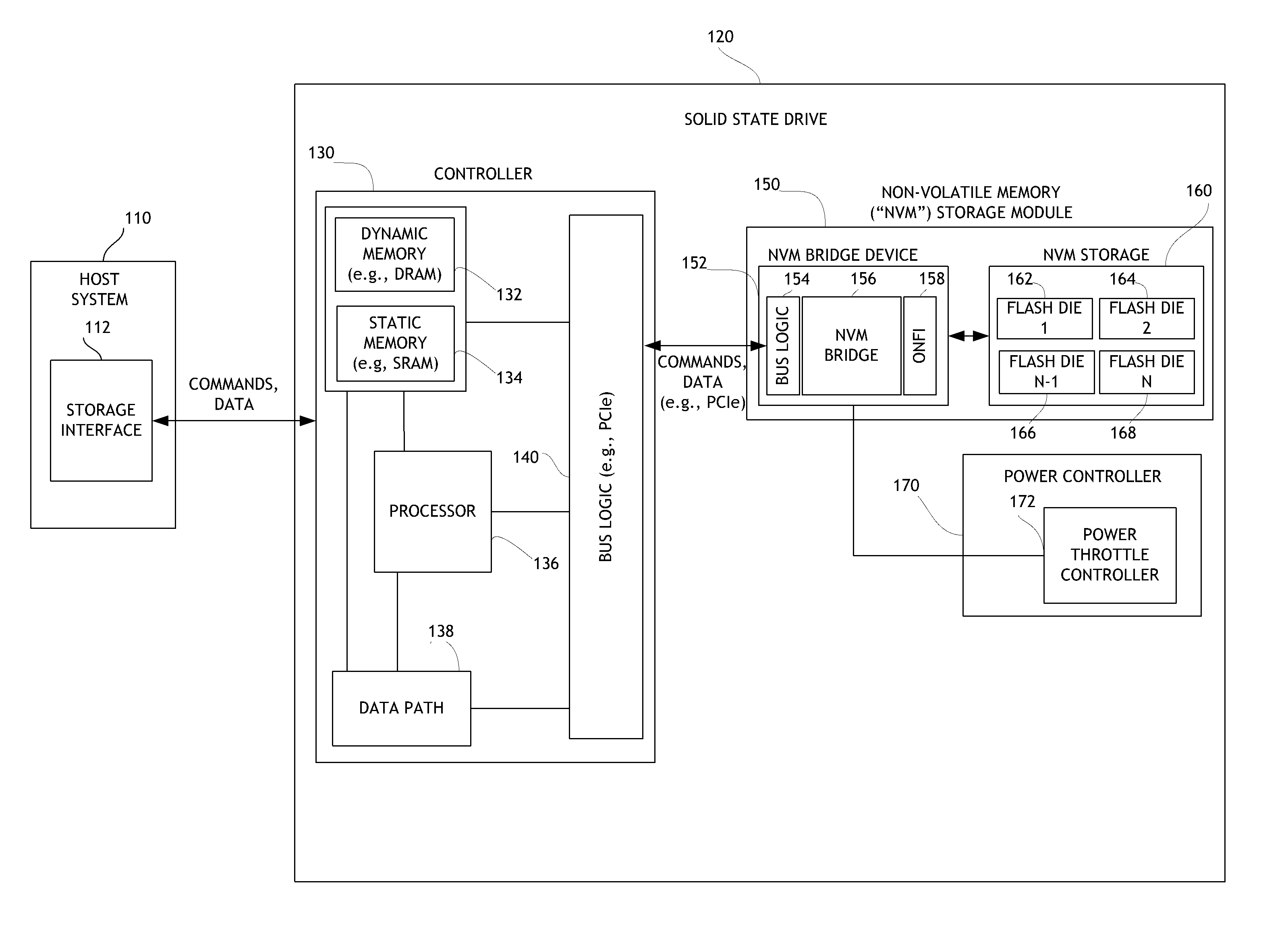

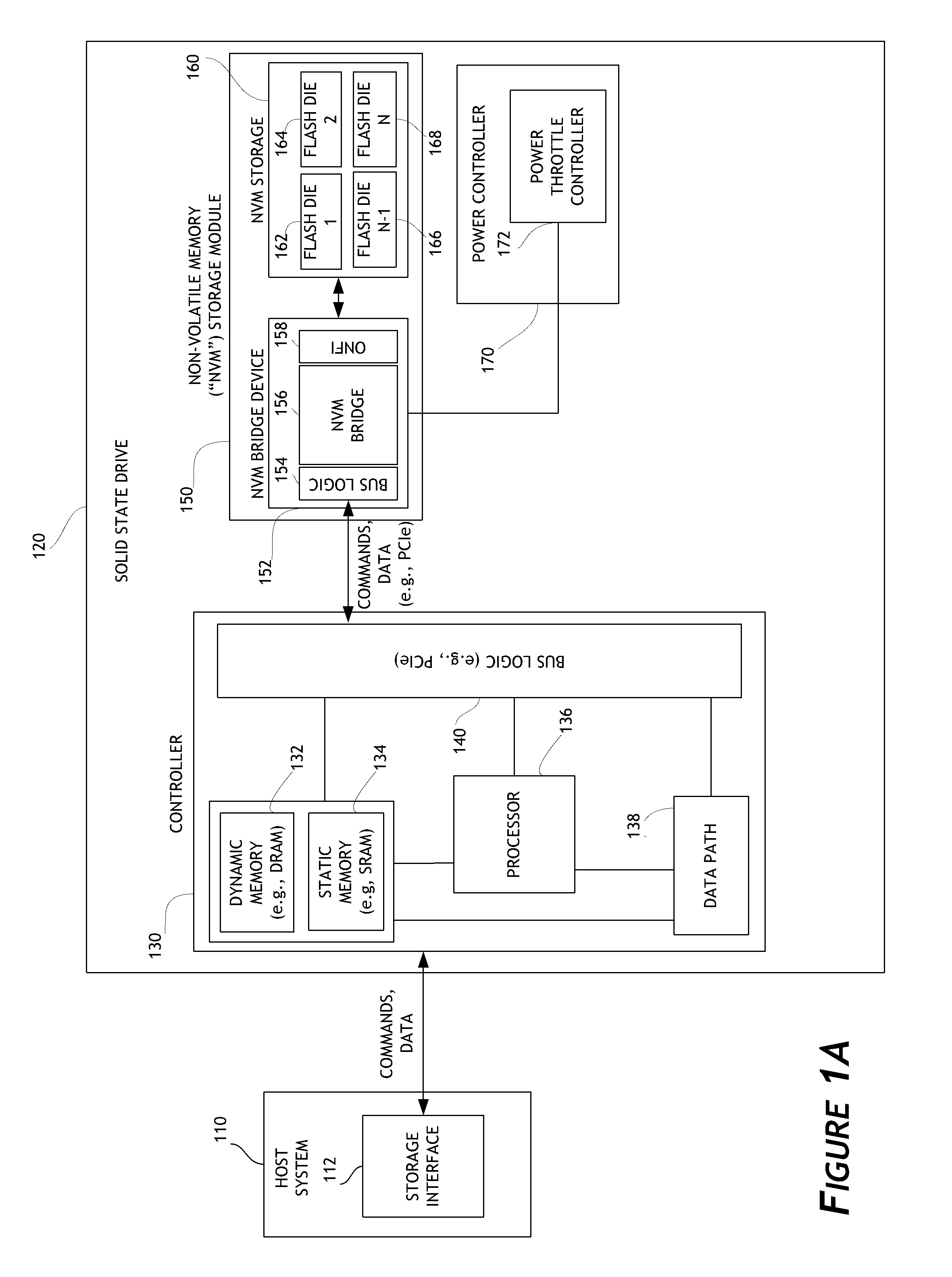

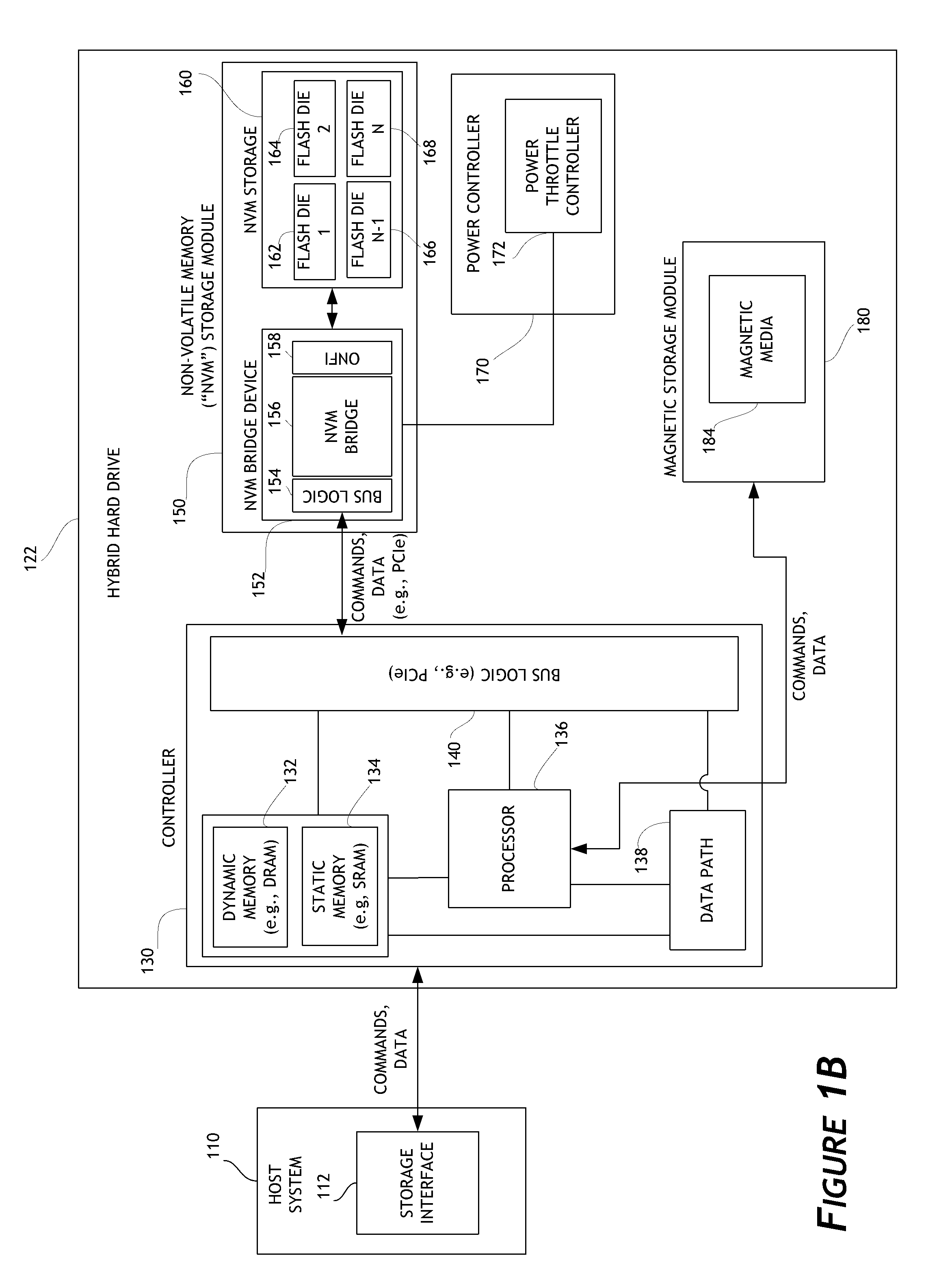

Systems and methods for error injection in data storage systems

ActiveUS8707104B1Solving precise measurementsTested and reliableDetecting faulty computer hardwareRead-only memoriesSolid-state storageHybrid storage system

Embodiments of the solid-state storage system provided herein are configured to perform improved mechanisms for testing of error recovery of solid state storage devices. In some embodiments, the system is configured to introduce or inject errors into data storage commands or operations performed in the non-volatile memory. Injected errors include corruption of data stored in the non-volatile memory, deliberate failure to execute storage operations, and errors injected into communication protocols used between various elements of the device. In some embodiments, injected errors can include direct errors that trigger an immediate execution of error recovery mechanisms and delayed errors that trigger execution of error recovery mechanisms at a later time. Error recovery mechanisms can be tested in an efficient, reliable, and deterministic manner to help ensure effective operation of storage devices. The integrity of non-volatile memory can also be tested.

Owner:WESTERN DIGITAL TECH INC

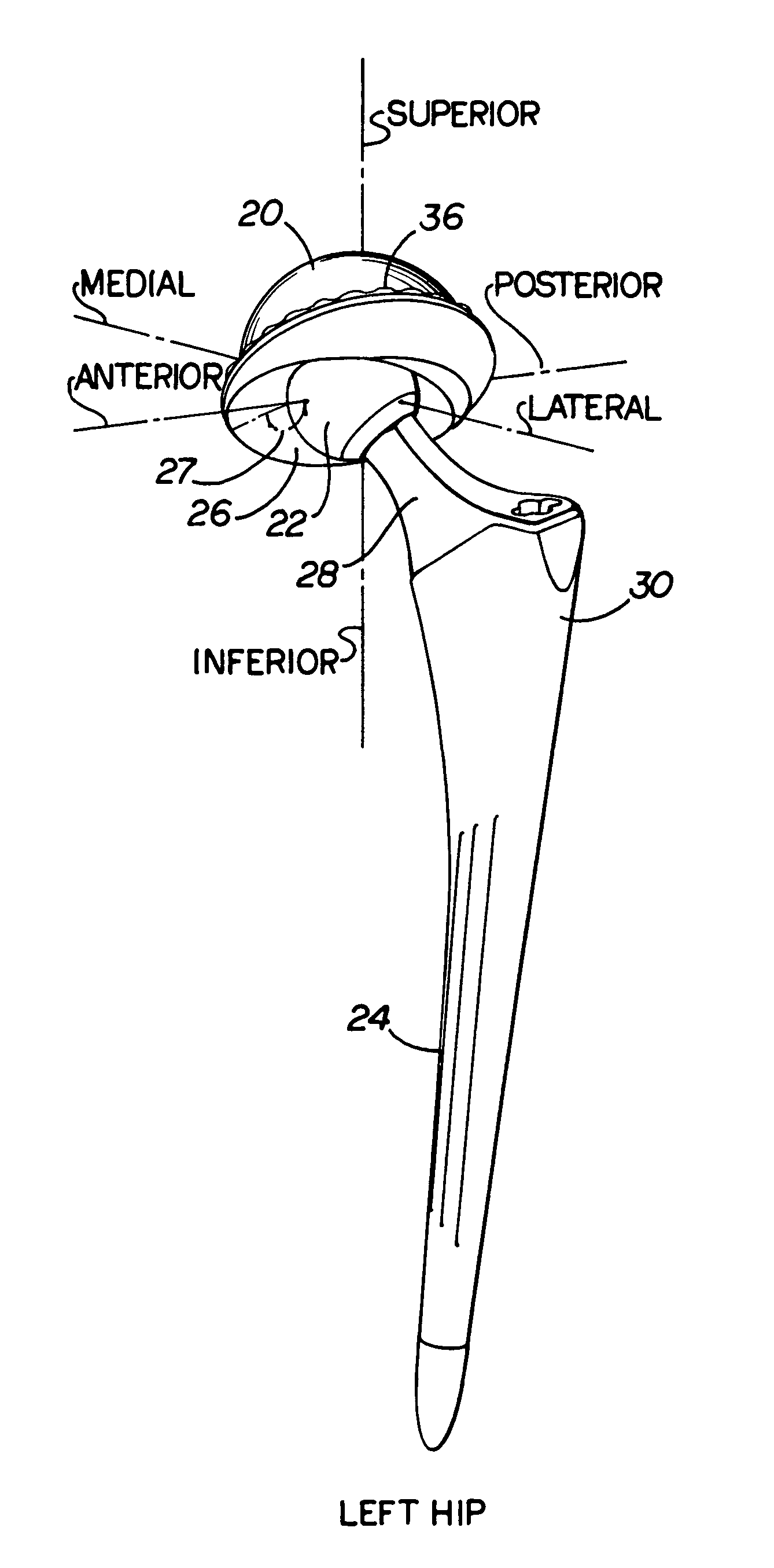

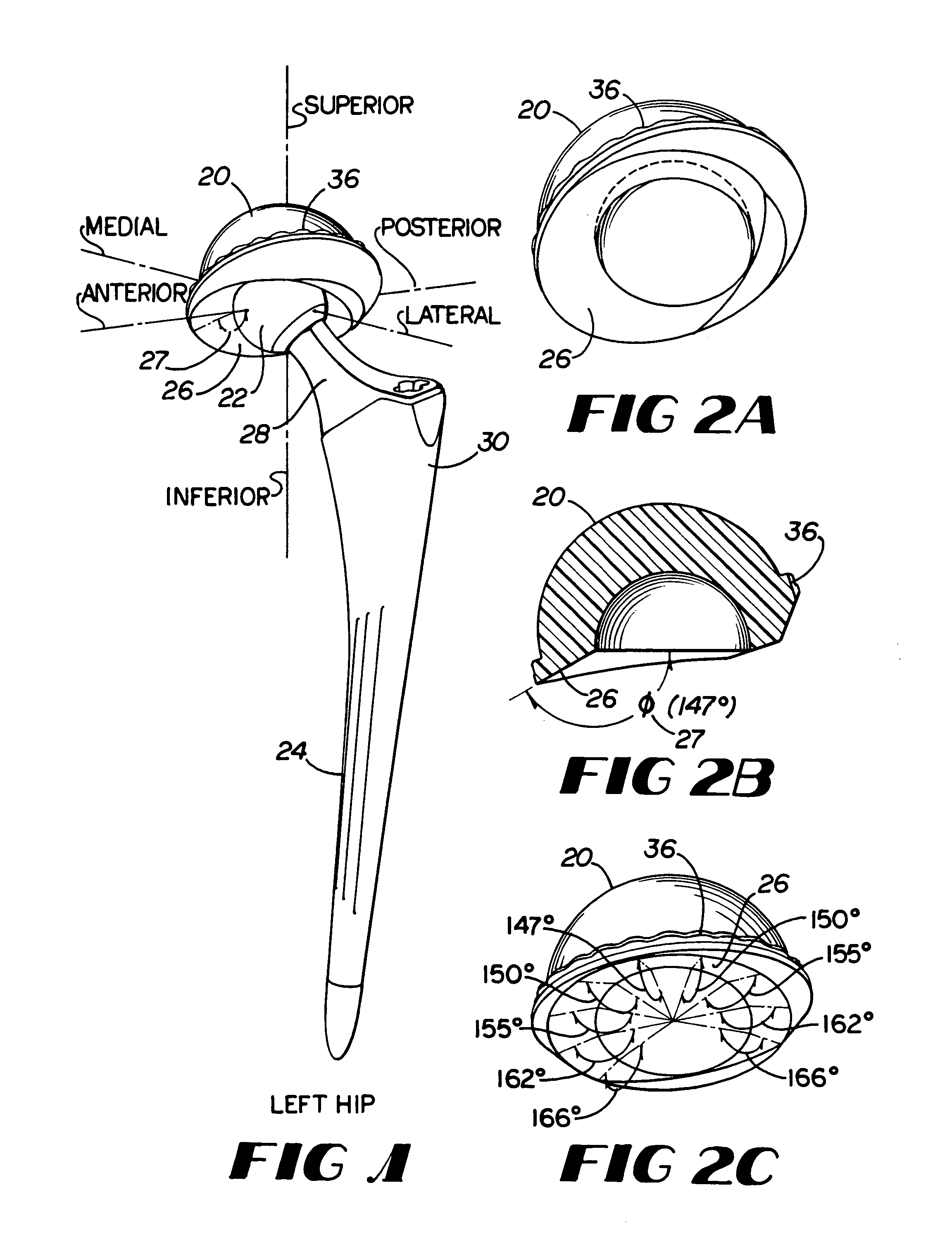

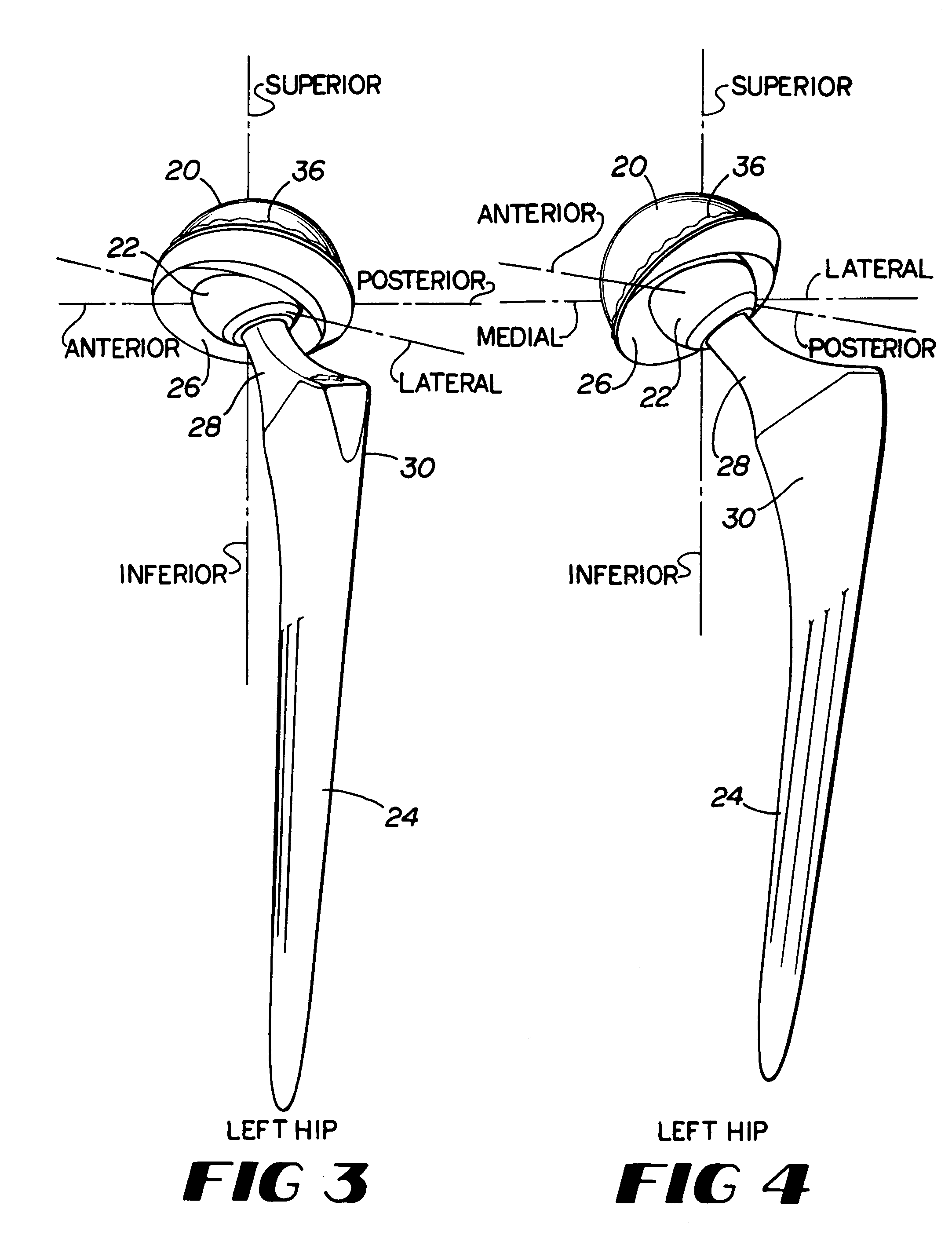

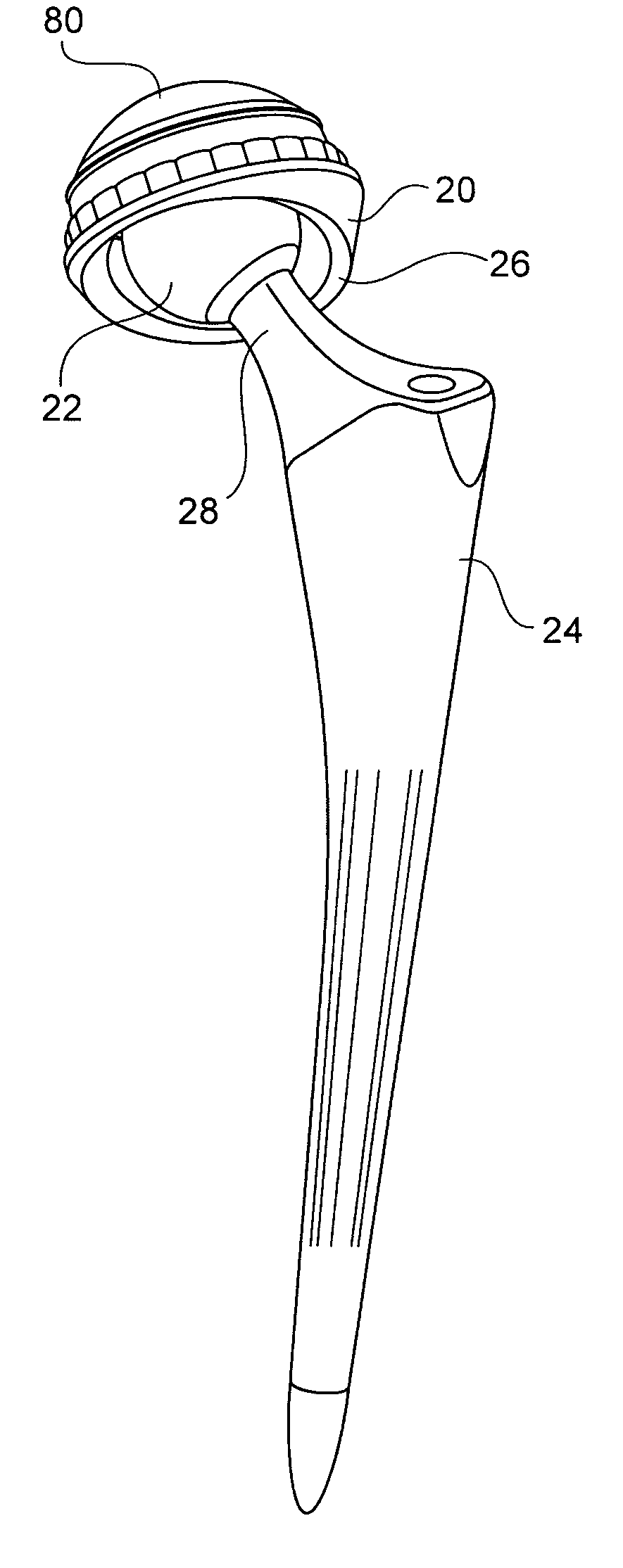

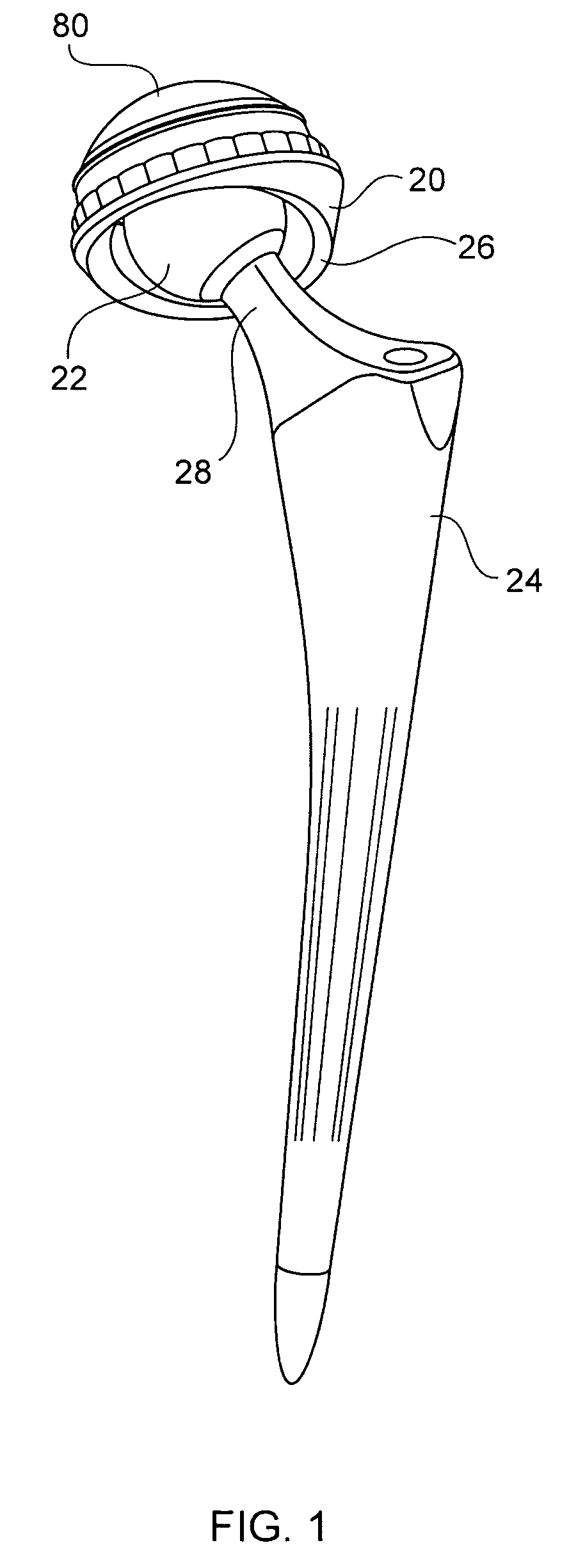

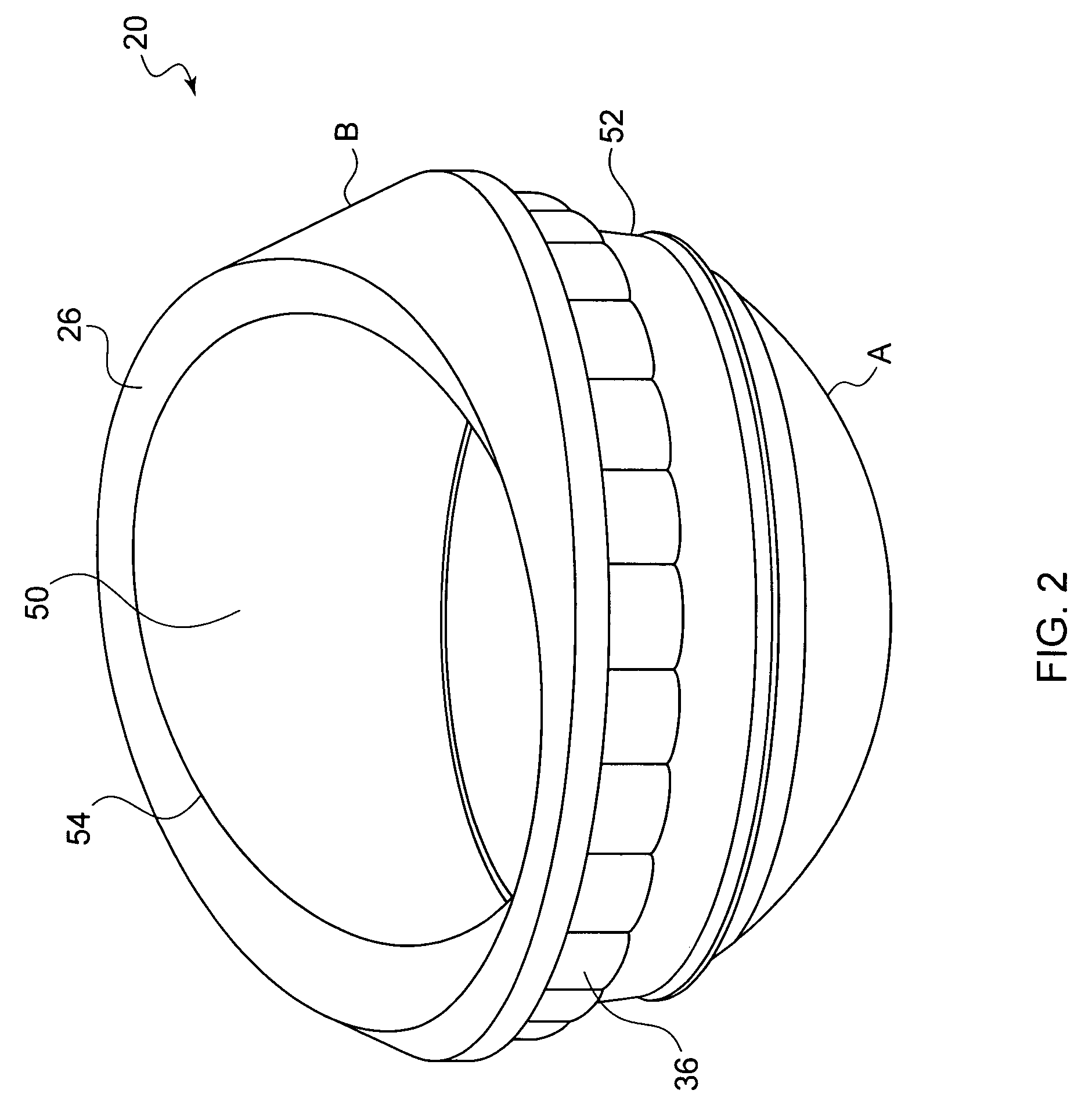

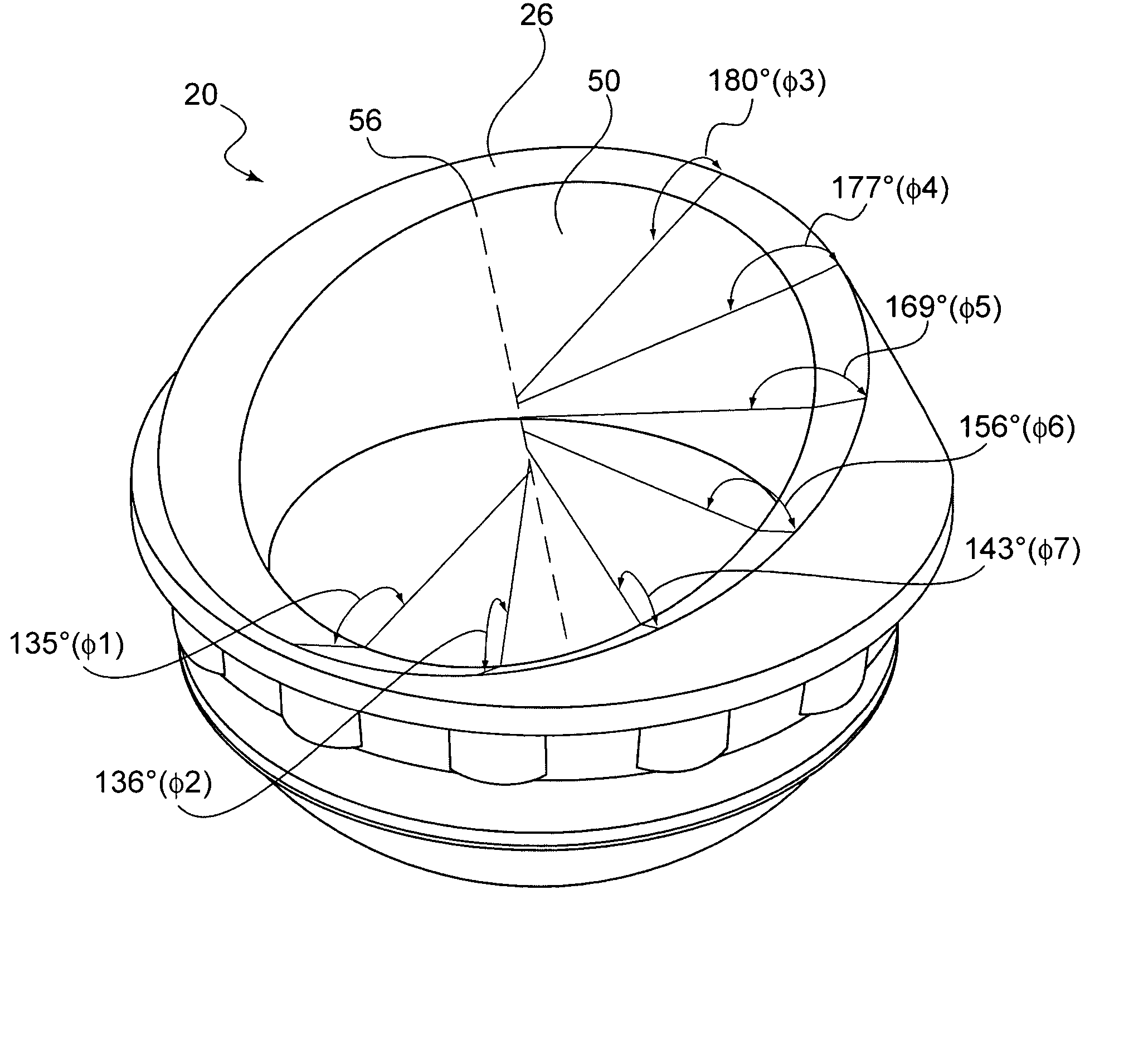

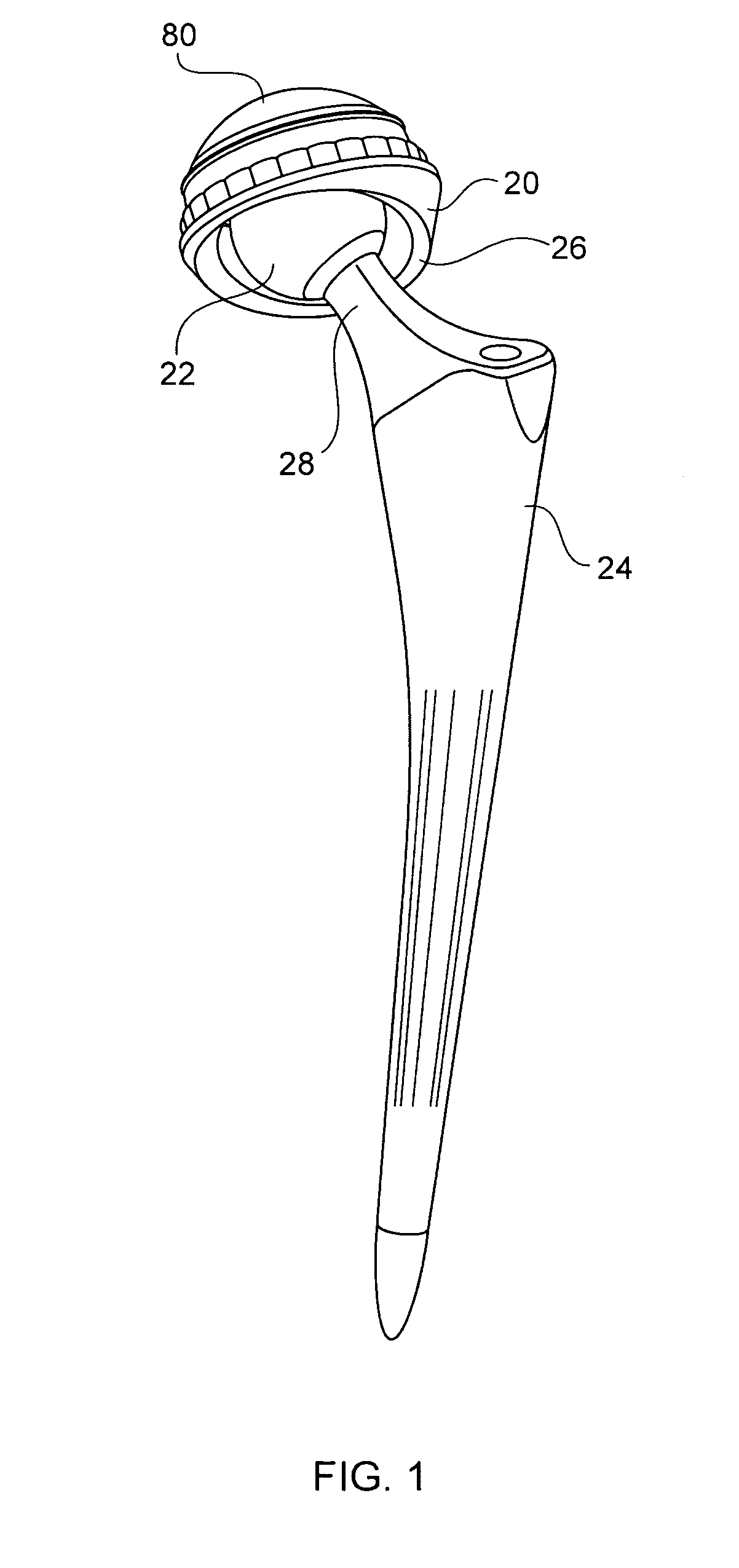

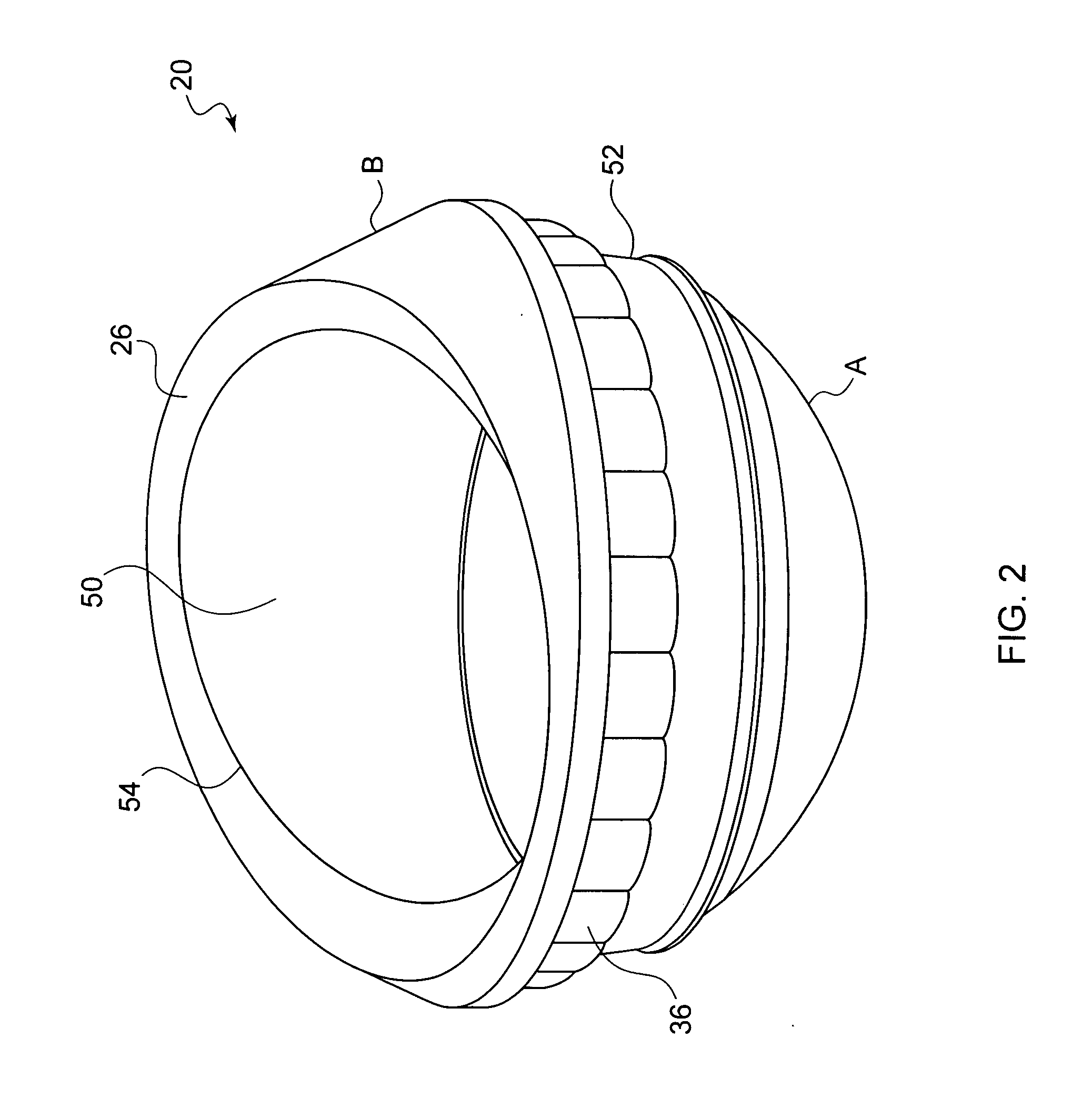

Variable geometry rim surface acetabular shell liner

InactiveUS7074241B2Extended range of motionMinimize interferenceJoint implantsFemoral headsEdge surfaceCoxal joint

An acetabular shell liner having a variable rim surface geometry, which improves range of motion of the femoral component within the liner and decreases the incidence of dislocation and subluxation, and methods of making and using the acetabular shell liner. Prosthetic devices, more particularly hip joint prostheses, containing the acetabular shell liner having a variable rim surface geometry are also provided.

Owner:SMITH & NEPHEW INC

Variable geometry rim surface acetabular shell liner

InactiveUS7682398B2Minimize interferenceExtended range of motionJoint implantsFemoral headsEdge surfaceRange of motion

There is provided an acetabular shell liner, and particularly a constrained liner, having a variable rim surface geometry to improve the range of motion of a femoral component within the liner and decrease the incidence of dislocation and subluxation. There are also provided methods of making and using the acetabular shell liner. Prosthetic devices, and particularly hip joint prostheses, containing the acetabular shell liner having a variable rim surface geometry are also provided.

Owner:SMITH & NEPHEW INC

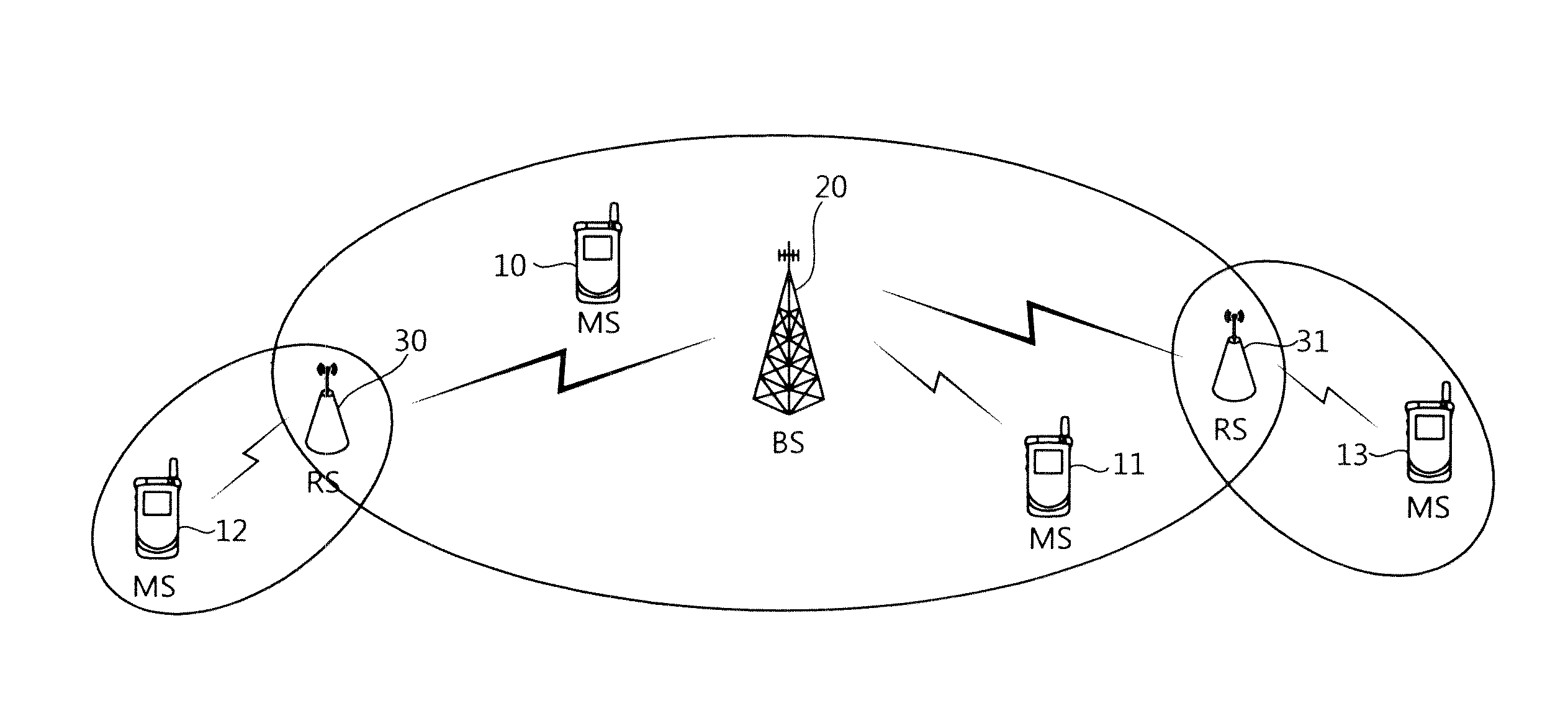

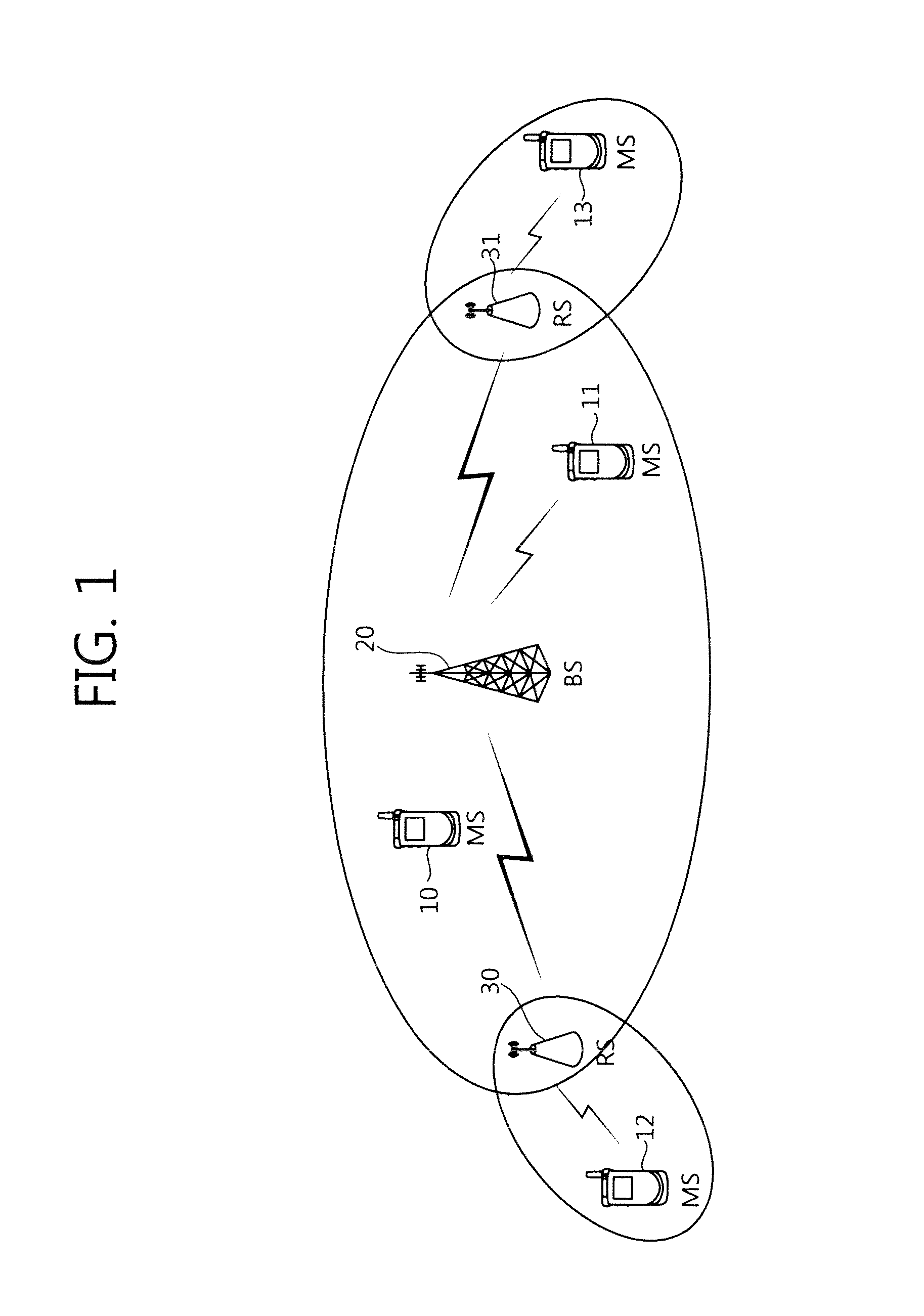

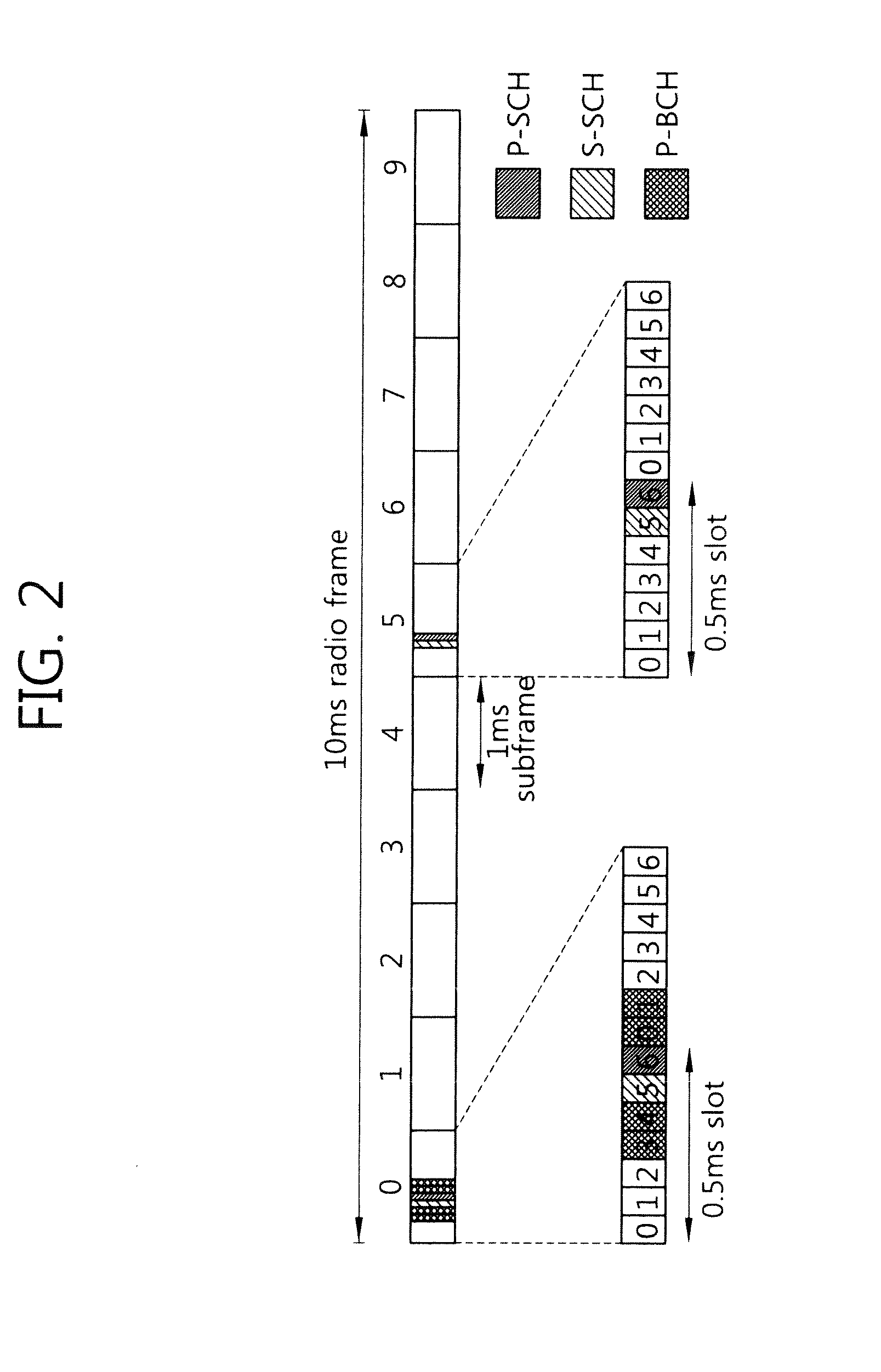

Method and apparatus of communication using subframe between base station and relay

ActiveUS20100034135A1Solving precise measurementsFrequency-division multiplex detailsNetwork topologiesSubframeMobile station

Provided is a communication method of a relay station in a wireless communication system, the communication method comprising the steps of configuring subframes dedicated for a backhaul link between a base station and the relay station and receiving a signal from the base station via the subframes dedicated for the backhaul link, wherein access of a legacy mobile station to at least a part of the subframes dedicated for the backhaul link is restricted.

Owner:LG ELECTRONICS INC

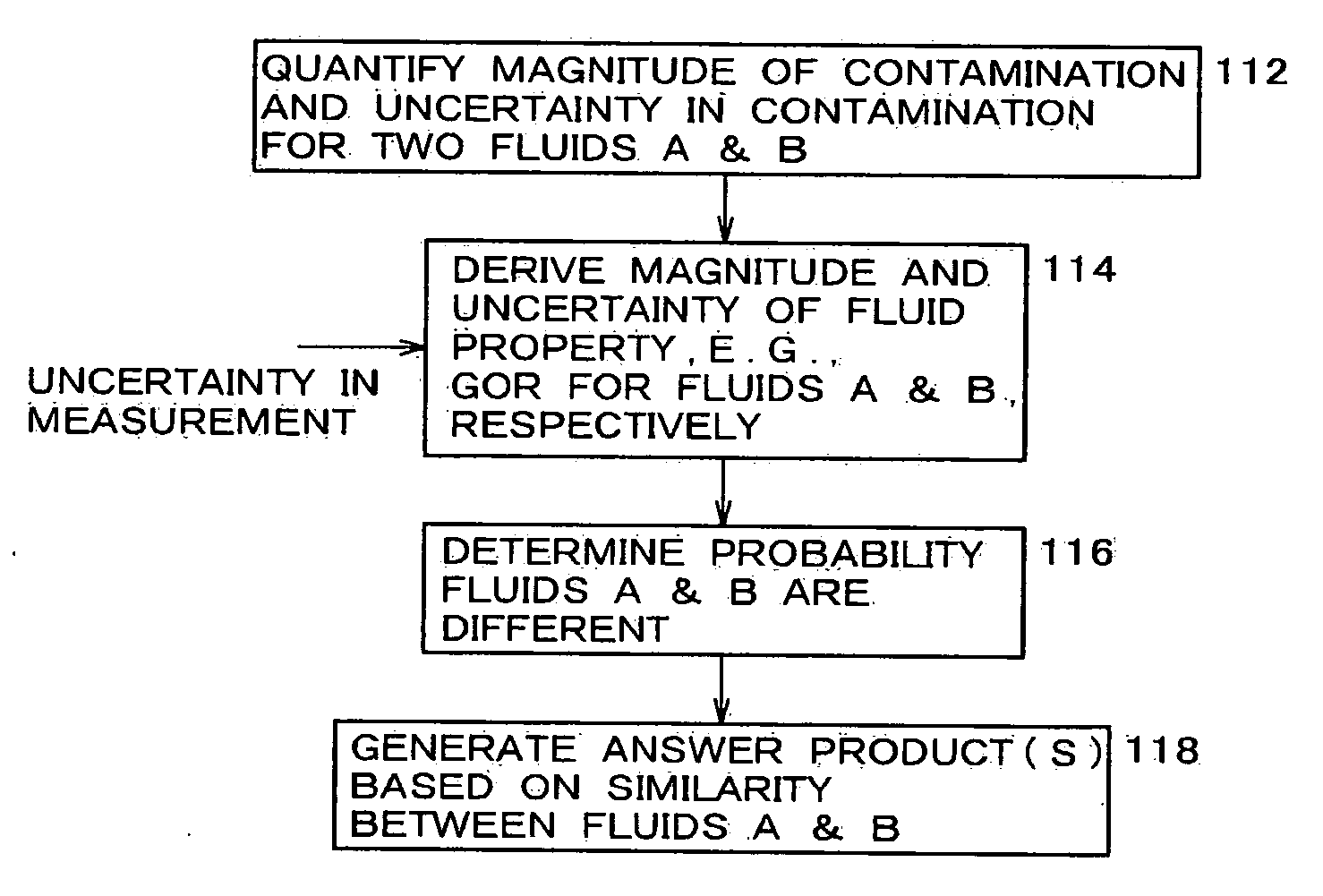

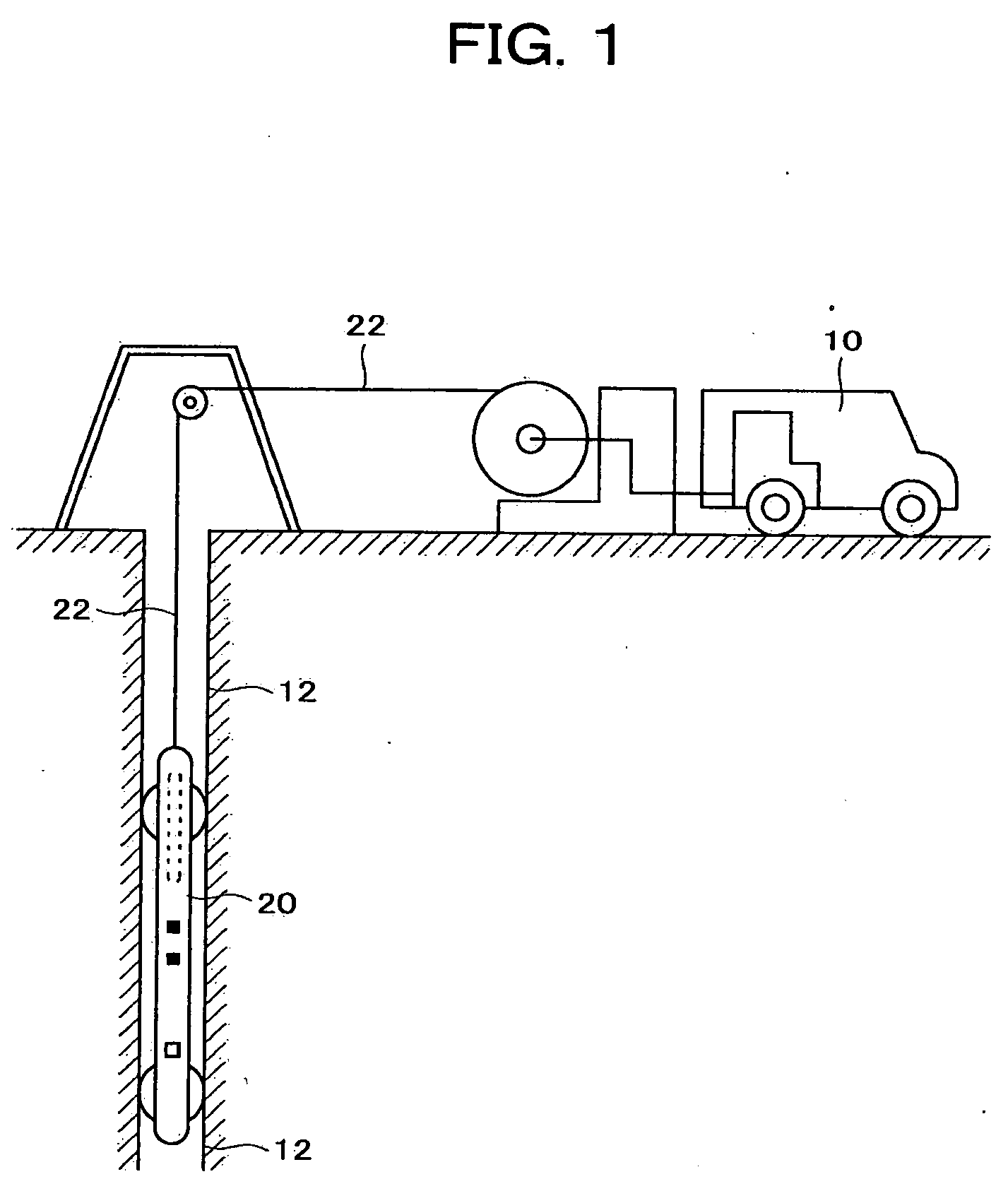

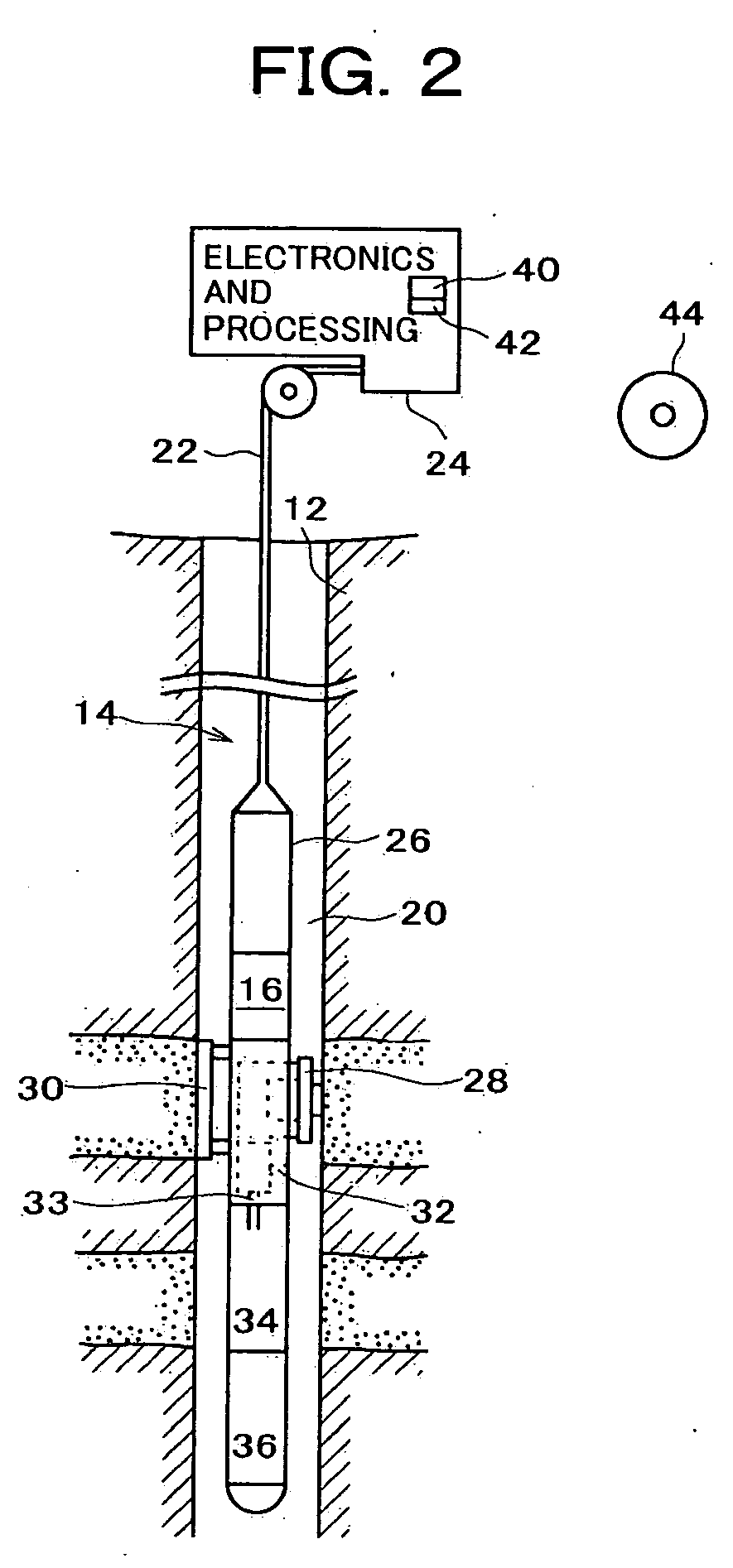

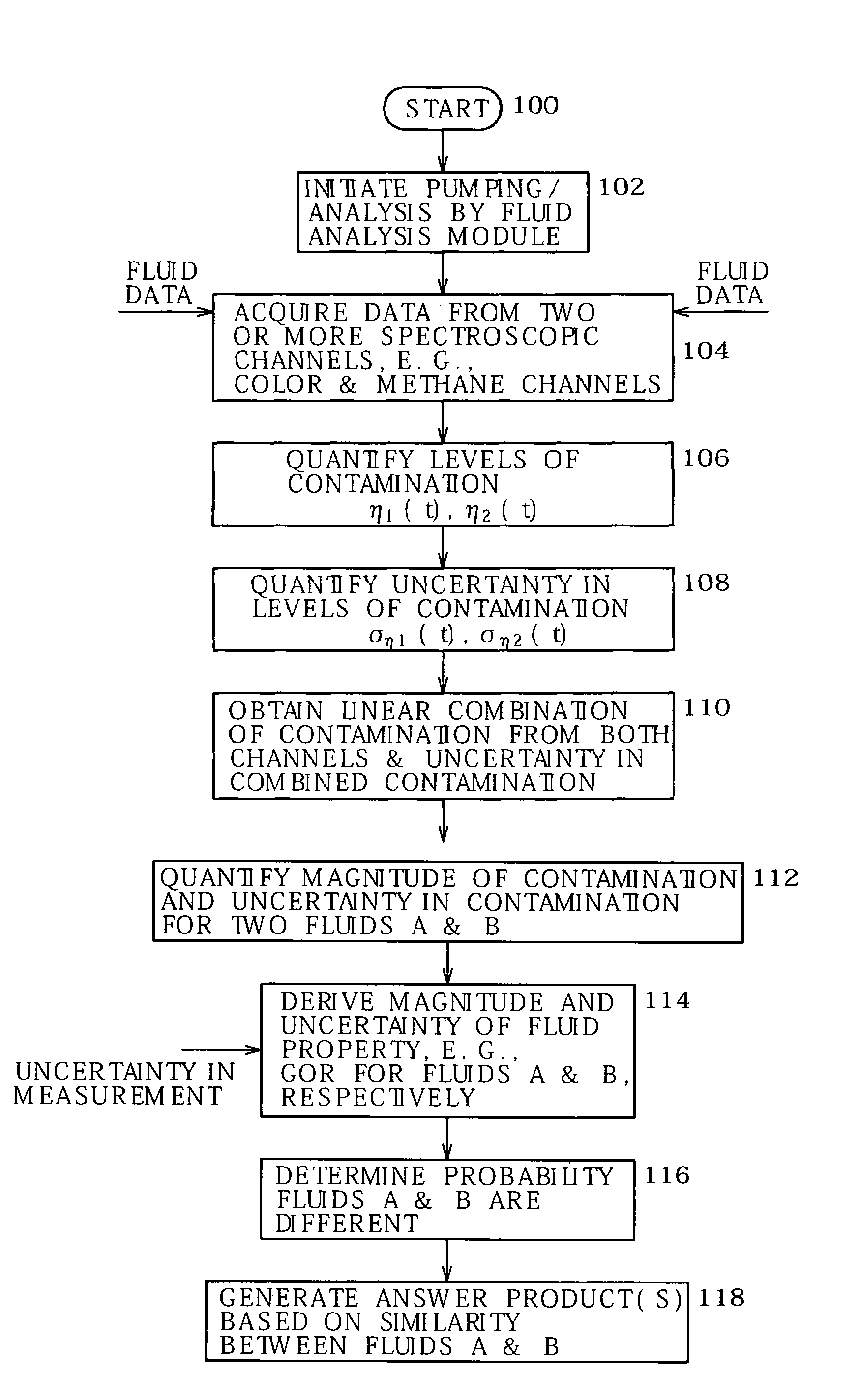

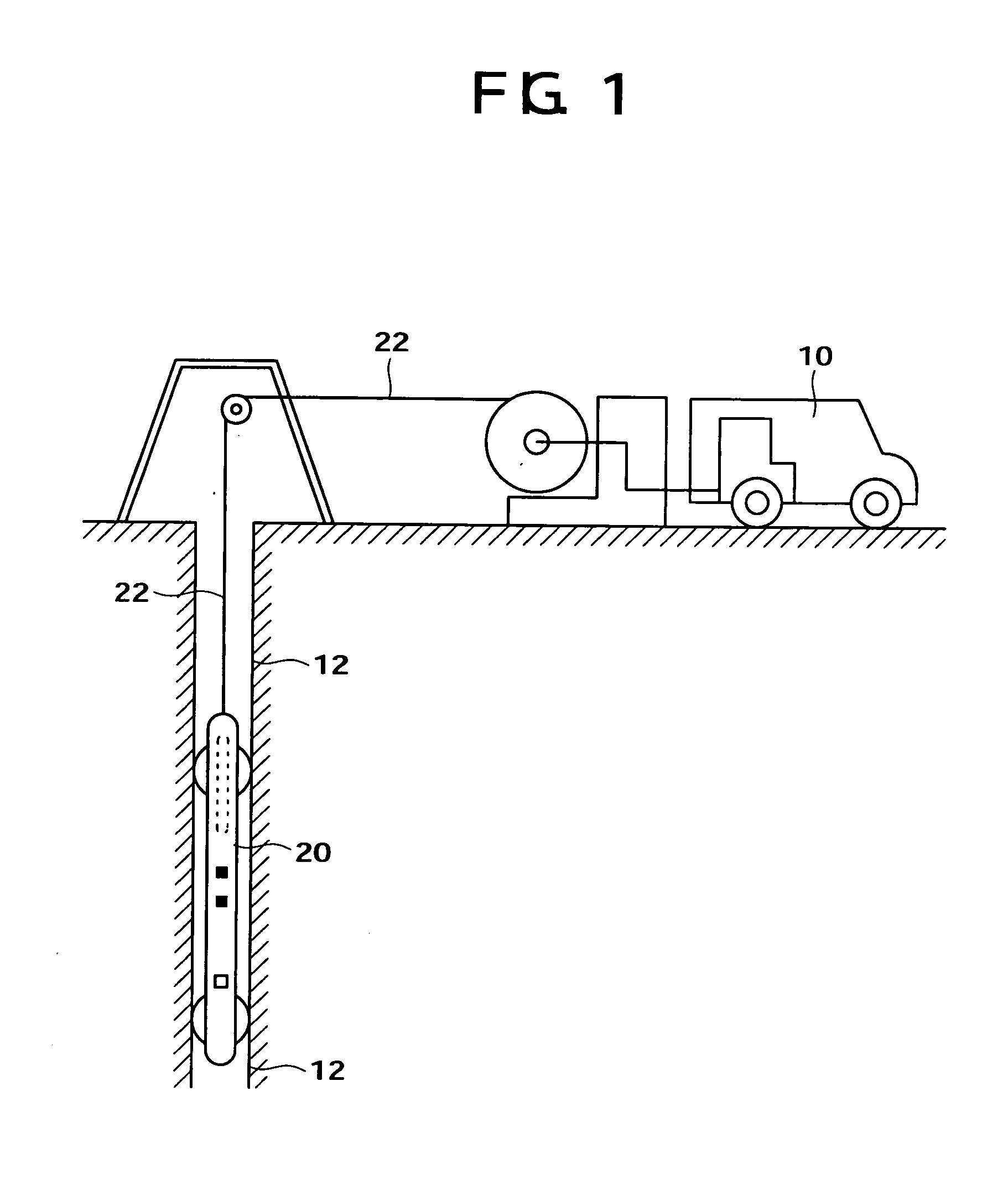

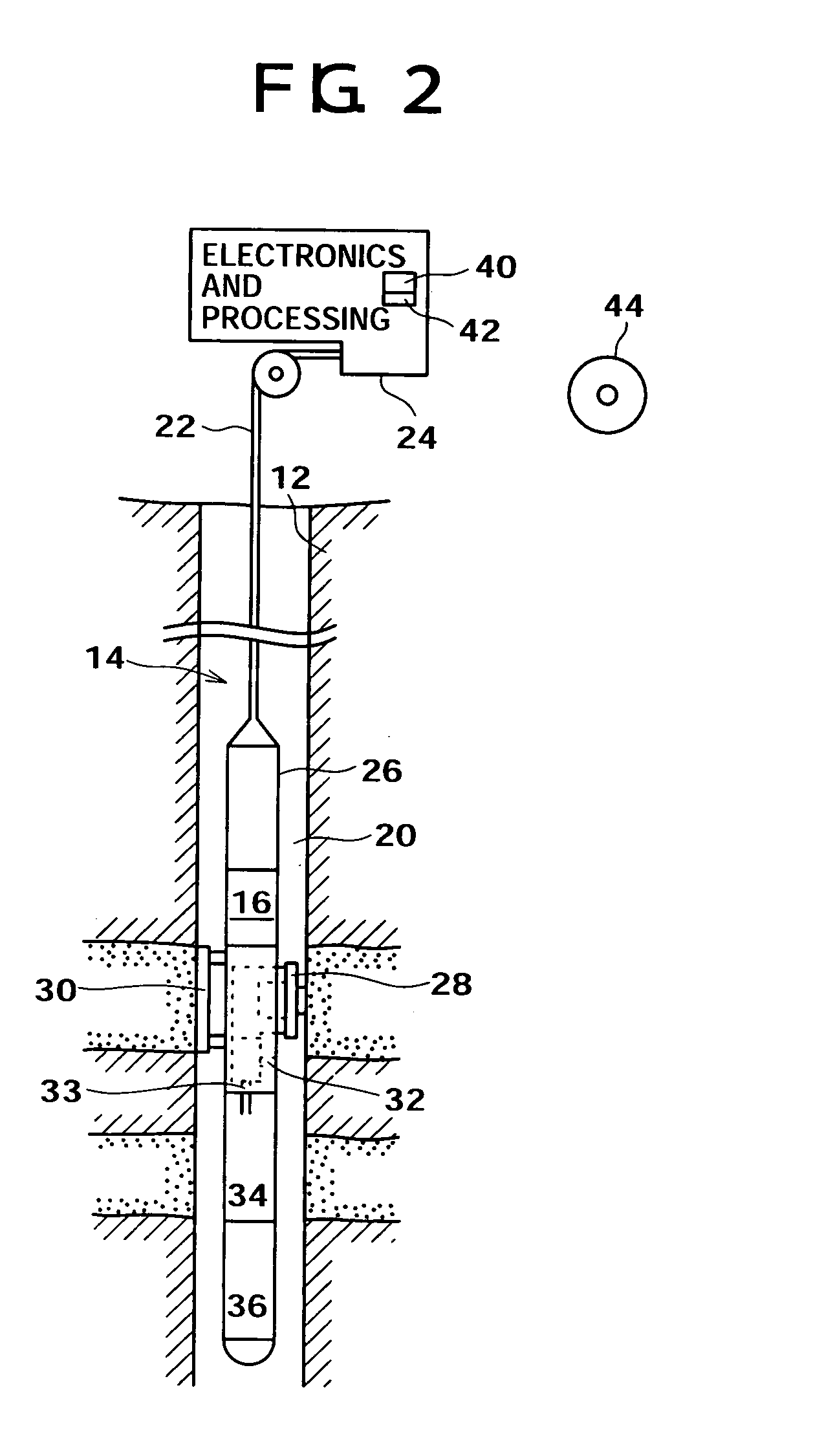

System and methods of deriving fluid properties of downhole fluids and uncertainty thereof

ActiveUS20060155474A1Less sensitive to systematic error in dataGood basisElectric/magnetic detection for well-loggingSurveyFormation fluidContamination

Methods and systems are provided for downhole analysis of formation fluids by deriving fluid properties and associated uncertainty in the predicted fluid properties based on downhole data, and generating answer products of interest based on differences in the fluid properties. Measured data are used to compute levels of contamination in downhole fluids using an oil-base mud contamination monitoring (OCM) algorithm. Fluid properties are predicted for the fluids and uncertainties in predicted fluid properties are derived. A statistical framework is provided for comparing the fluids to generate, in real-time, robust answer products relating to the formation fluids and reservoirs thereof. Systematic errors in measured data are reduced or eliminated by preferred sampling procedures.

Owner:SCHLUMBERGER TECH CORP

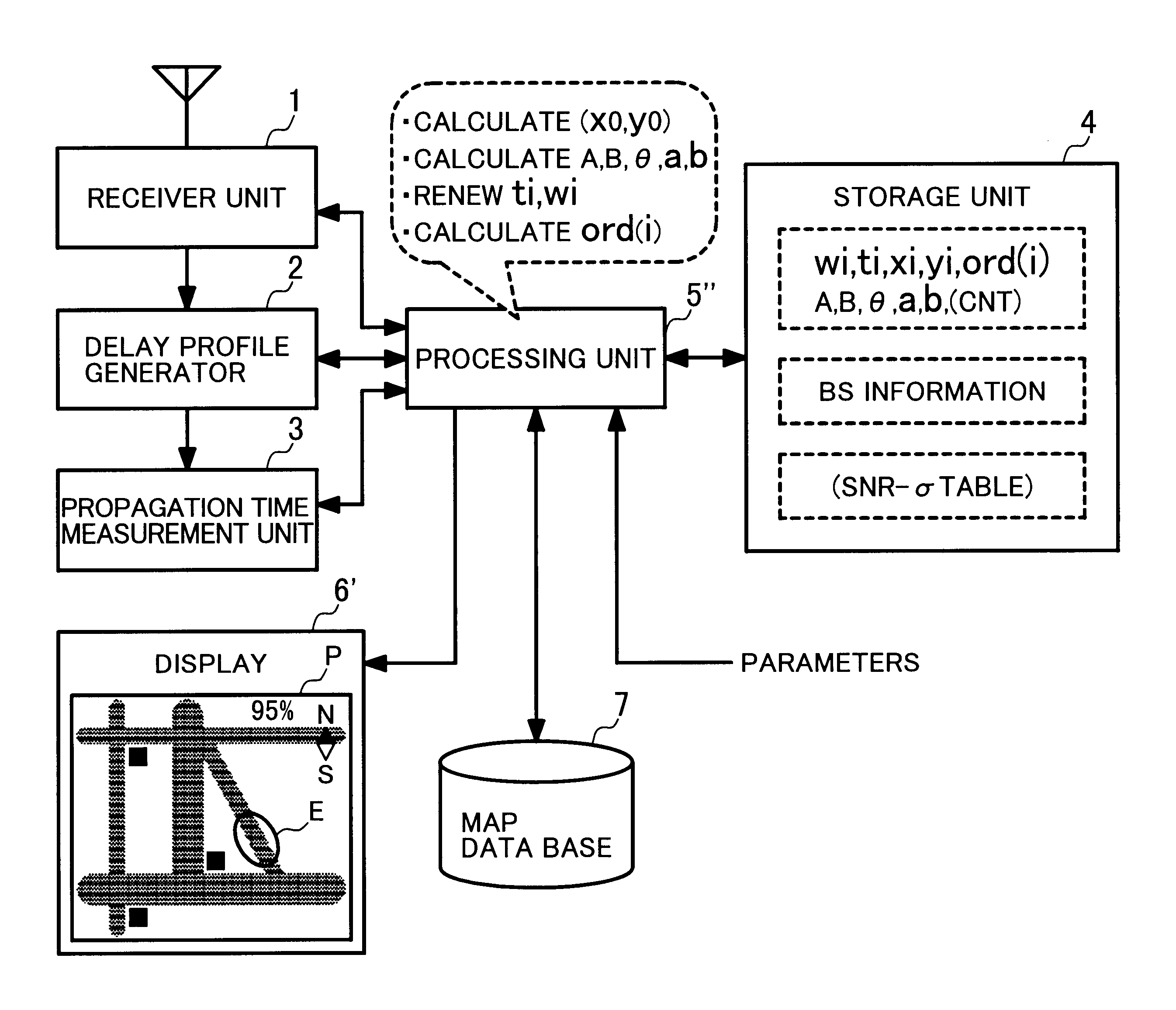

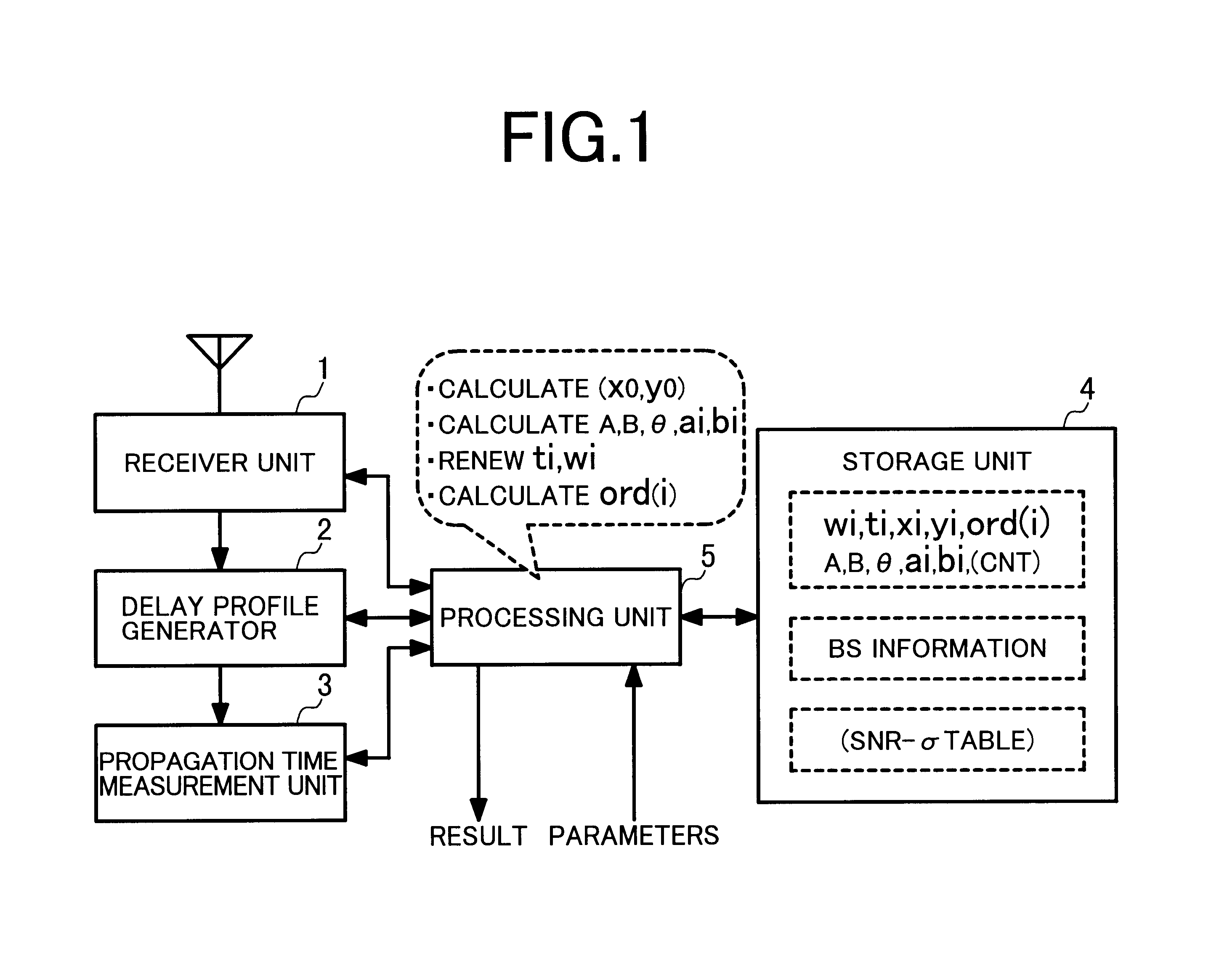

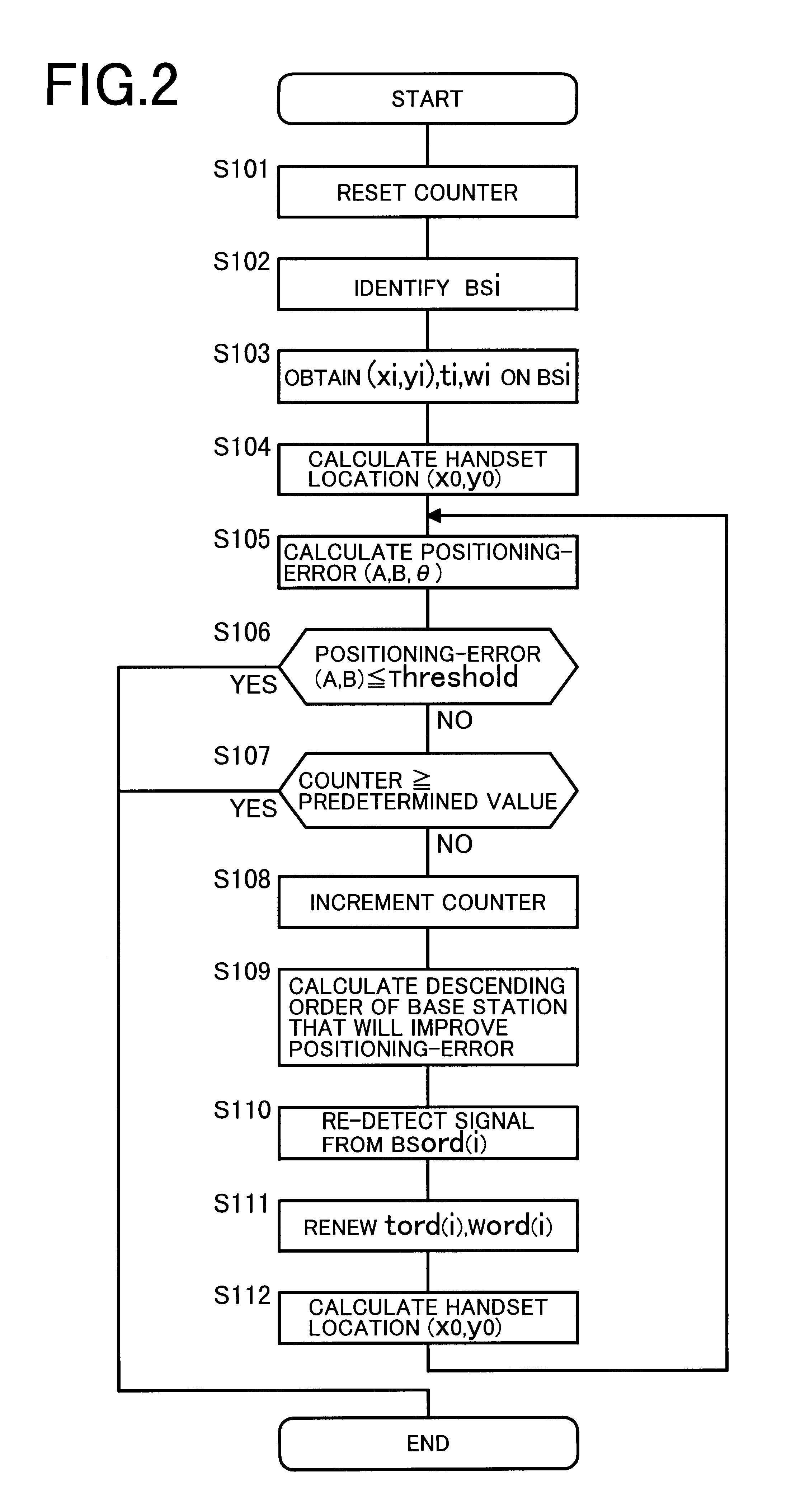

Location detection method, location detection system and location detection program

InactiveUS6865394B2Increase in powerIncrease in timeBeacon systems using radio wavesRoad vehicles traffic controlLocation detectionPropagation delay

A positioning method, which is related to a technique to measure a correct position of a terminal by preventing time required for the position measurement, of calculating a position of a receiver according to signals from a plurality of wireless transmitters includes a first step of measuring propagation delay time of the signal from each of the wireless transmitters and calculating a position of the receiver and a standard deviation about measuring distance error, a second step of calculating a positioning error of the receiver a third step of determining, according to the positioning error calculated by the second step, wireless transmitters in directions nearer to a direction in which the positioning error is large, and a fourth step of re-detecting signals from the wireless transmitters determined by the third step and thereby re-calculating the position of the receiver.

Owner:HITACHI LTD

System and methods of deriving fluid properties of downhole fluids and uncertainty thereof

ActiveUS7305306B2Less sensitive to systematic error in dataGood basisElectric/magnetic detection for well-loggingSurveyFormation fluidContamination

Owner:SCHLUMBERGER TECH CORP

Variable geometry rim surface acetabular shell liner

InactiveUS20070106389A1Extended range of motionMinimize interferenceJoint implantsFemoral headsEdge surfaceRange of motion

There is provided an acetabular shell liner, and particularly a constrained liner, having a variable rim surface geometry to improve the range of motion of a femoral component within the liner and decrease the incidence of dislocation and subluxation. There are also provided methods of making and using the acetabular shell liner. Prosthetic devices, and particularly hip joint prostheses, containing the acetabular shell liner having a variable rim surface geometry are also provided.

Owner:SMITH & NEPHEW INC

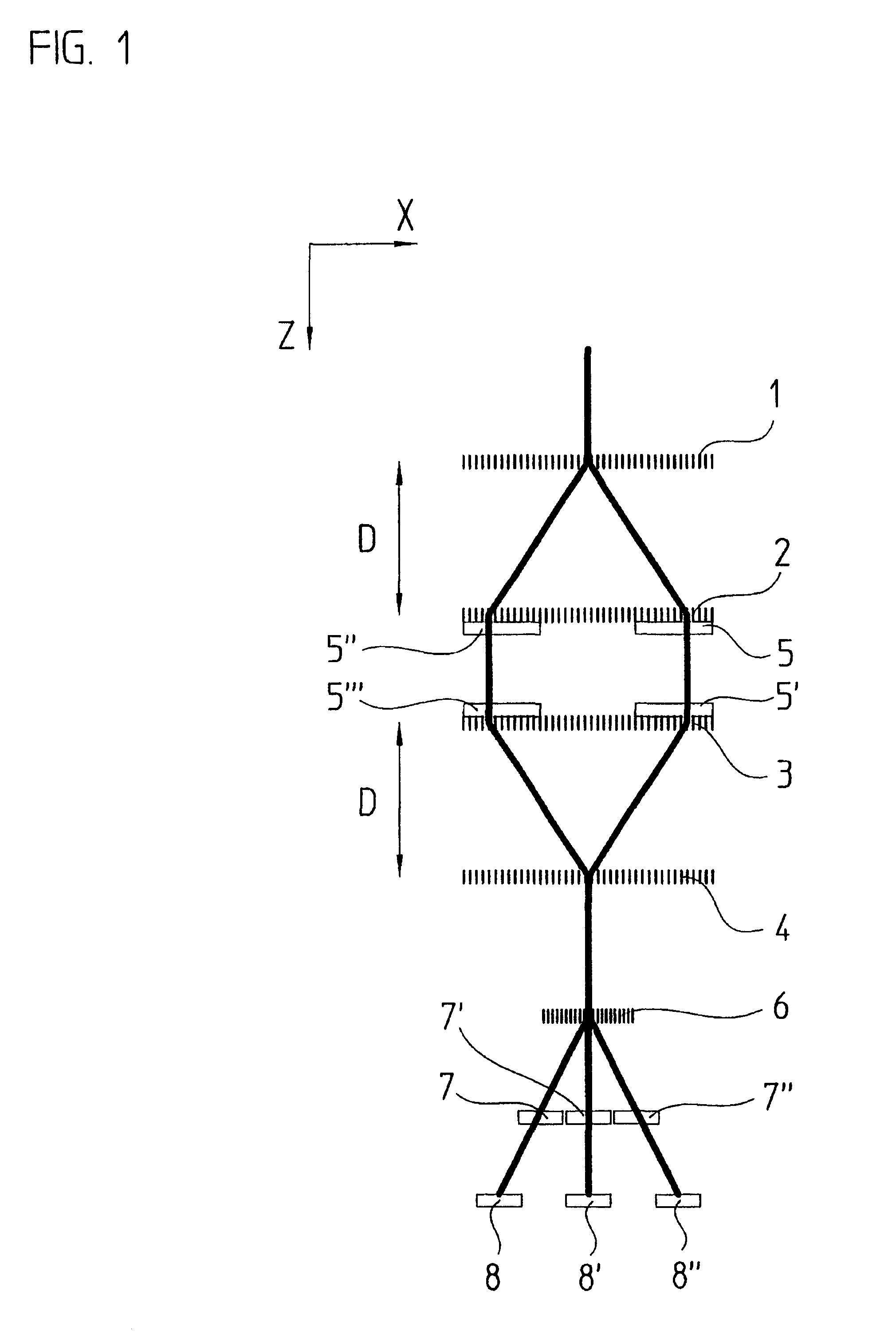

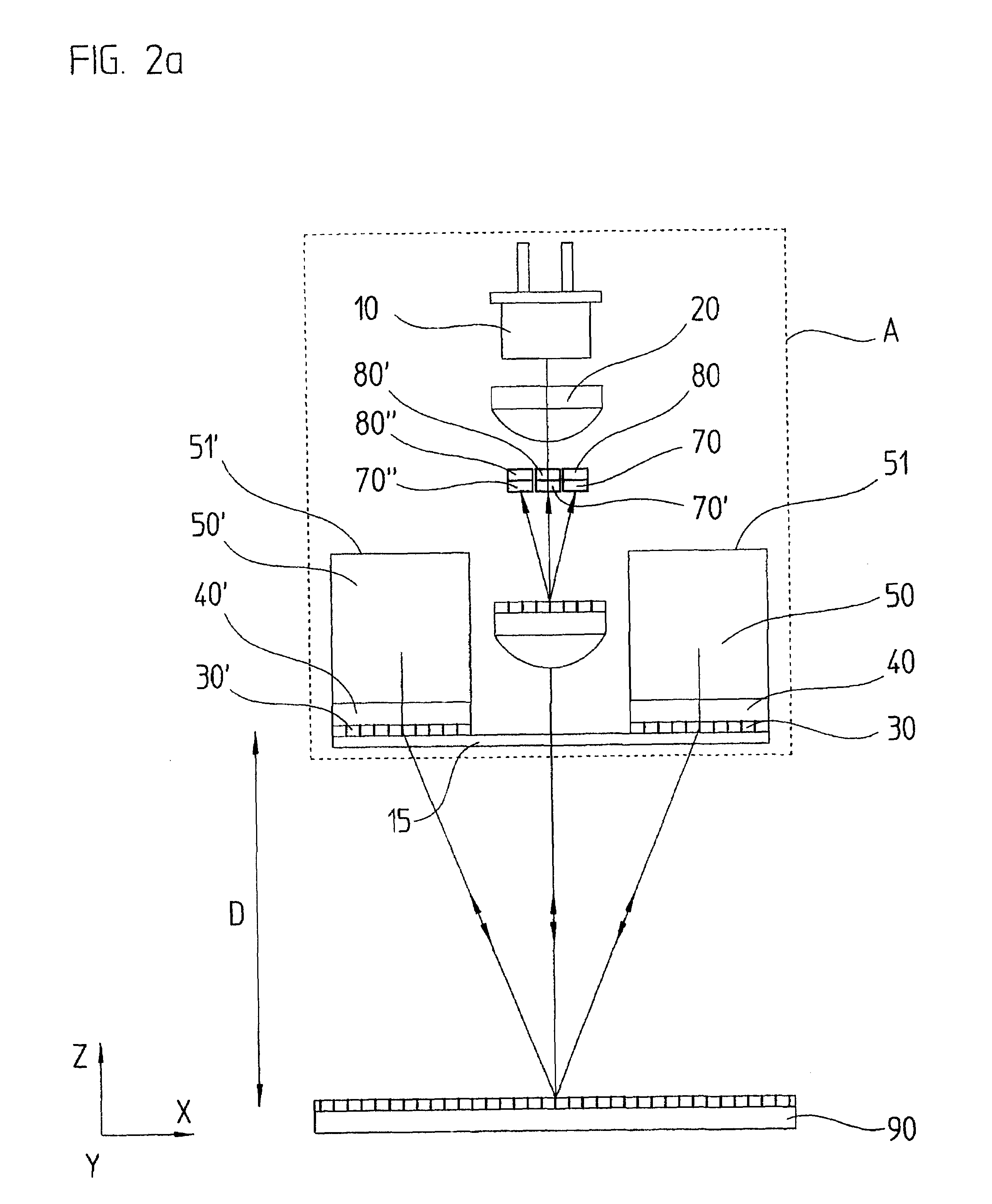

Position measuring device

InactiveUS7019842B2Accurate measurementSolving precise measurementsMaterial analysis by optical meansUsing optical meansGratingPhotovoltaic detectors

A position measuring device for detecting the relative position of a scanning unit and a scale. The position measuring device includes a scale and a scanning unit that is displaced with respect to the scale in a measuring direction. The scanning unit includes a scanning grating, a ridge prism and an optoelectronic detector element. The ridge prism having a ridge that is oriented parallel with the measuring direction, the ridge prism acts as a retro-reflector in a second direction which is aligned in a plane of the scale vertically with respect to the measuring direction.

Owner:DR JOHANNES HEIDENHAIN GMBH

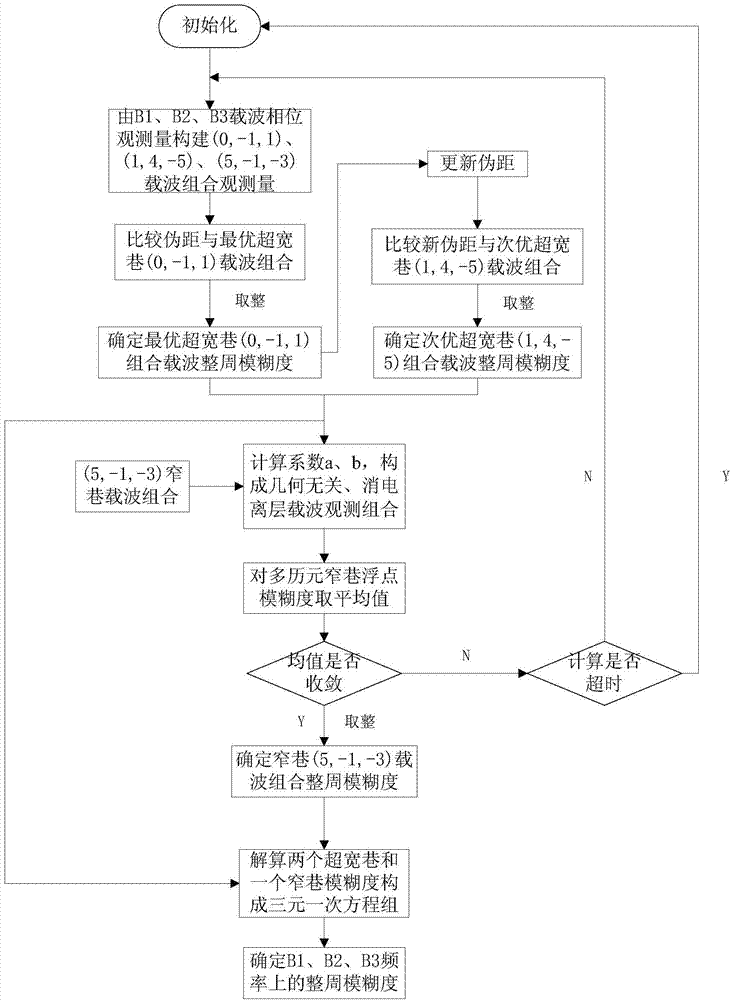

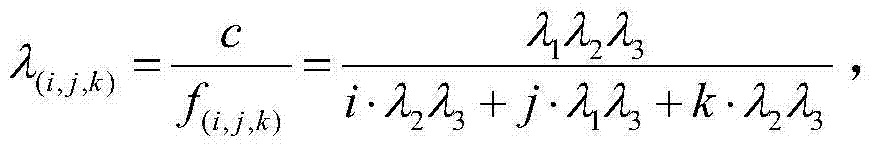

Method for determining whole-cycle ambiguity of three-frequency carrier phase of BeiDou navigation system

The invention provides a method for determining a whole-cycle ambiguity of a three-frequency carrier phase of a BeiDou navigation system. The method comprises the steps of by utilizing the advantage of high determination accuracy rate of a whole-cycle ambiguity of a BeiDou ultra-wide lane carrier phase combination, firstly determining whole-cycle ambiguities of two groups of ultra-wide lane carrier phase combinations, and correcting a pseudo-range initial value through the whole-cycle ambiguities of the ultra-wide lane carrier phase combinations; meanwhile, removing influences from an orbit error, a clock error and an ionized layer error in original observed quantity by combining with carrier phase observation quantity of geometry-free de-ionized layer composed of a narrow lane carrier phase combination, so as to enable the resolution of the whole-cycle ambiguity of the narrow lane carrier phase combination to be only affected by random measurement noise; taking an average value of combined observation quantity of multiple epochs to remove random noise error and determine the whole-cycle ambiguity of the narrow lane carrier phase combination; finally, determining the whole-cycle ambiguity of the carrier phases of three frequencies B1, B2 and B3 by resolving a system of linear equations which is composed of the whole-cycle ambiguities of the two ultra-wide lane carrier phase combinations and the whole-cycle ambiguity of the narrow lane carrier phase combination.

Owner:BEIJING RES INST OF TELEMETRY +1

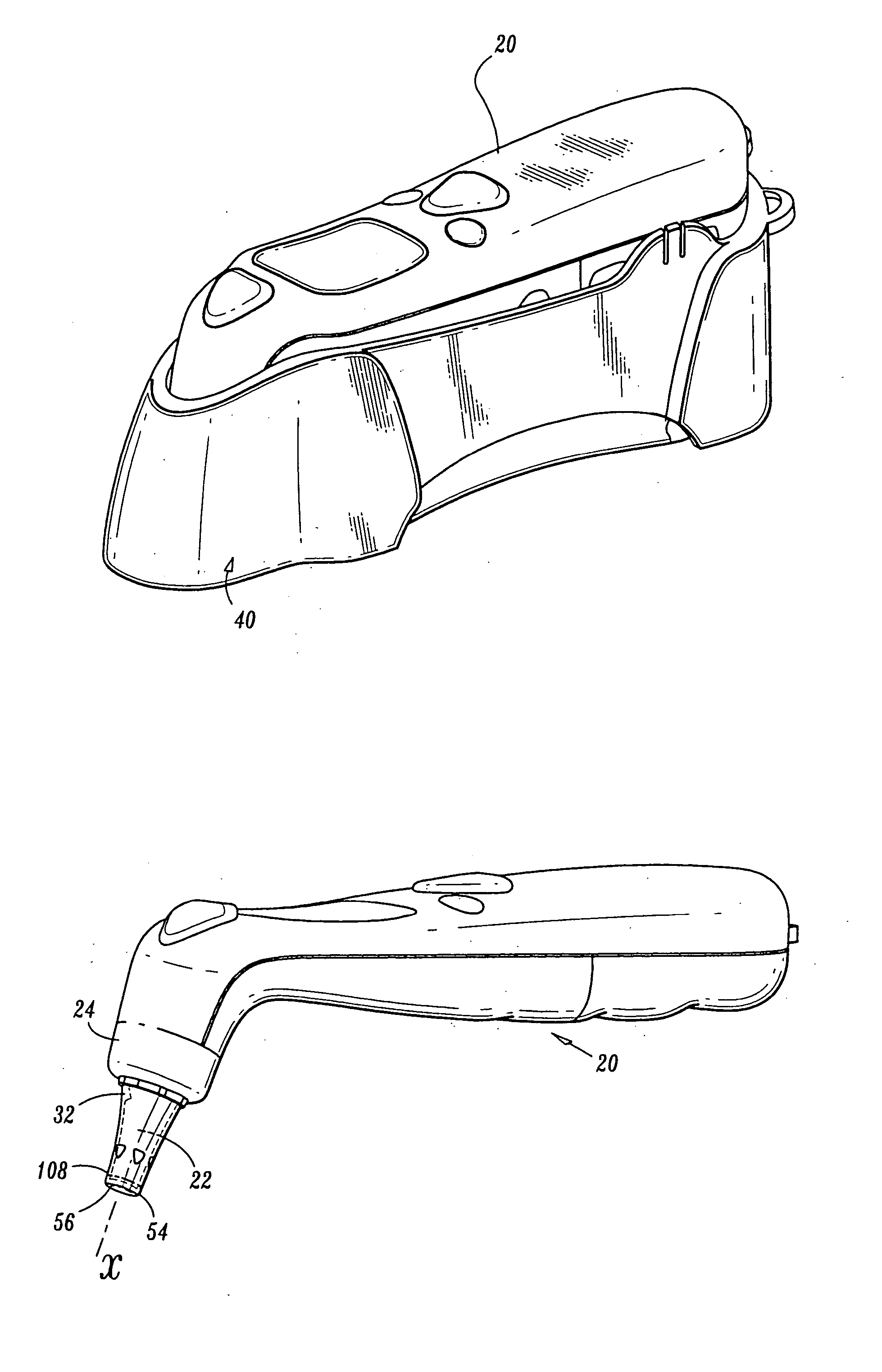

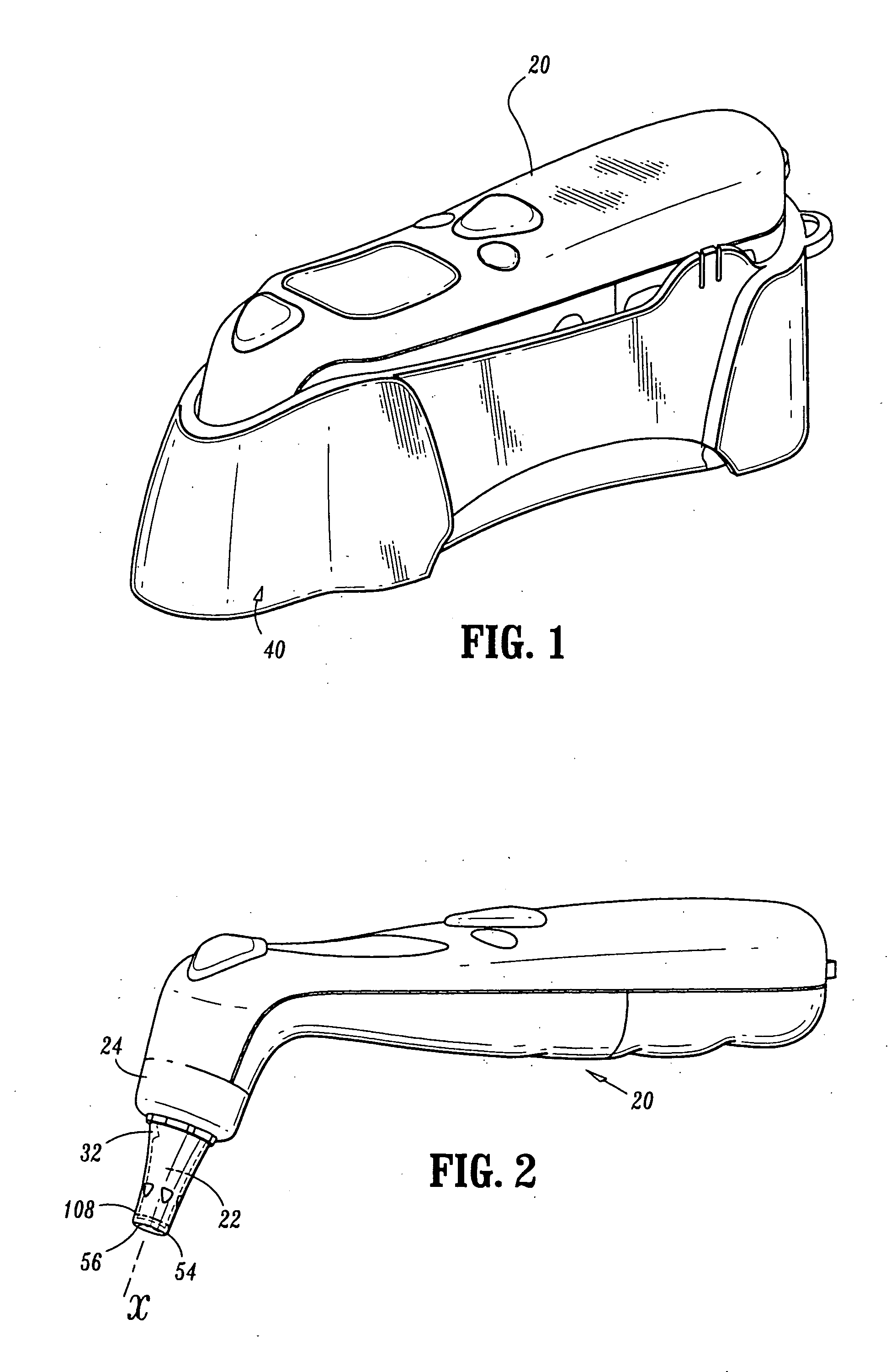

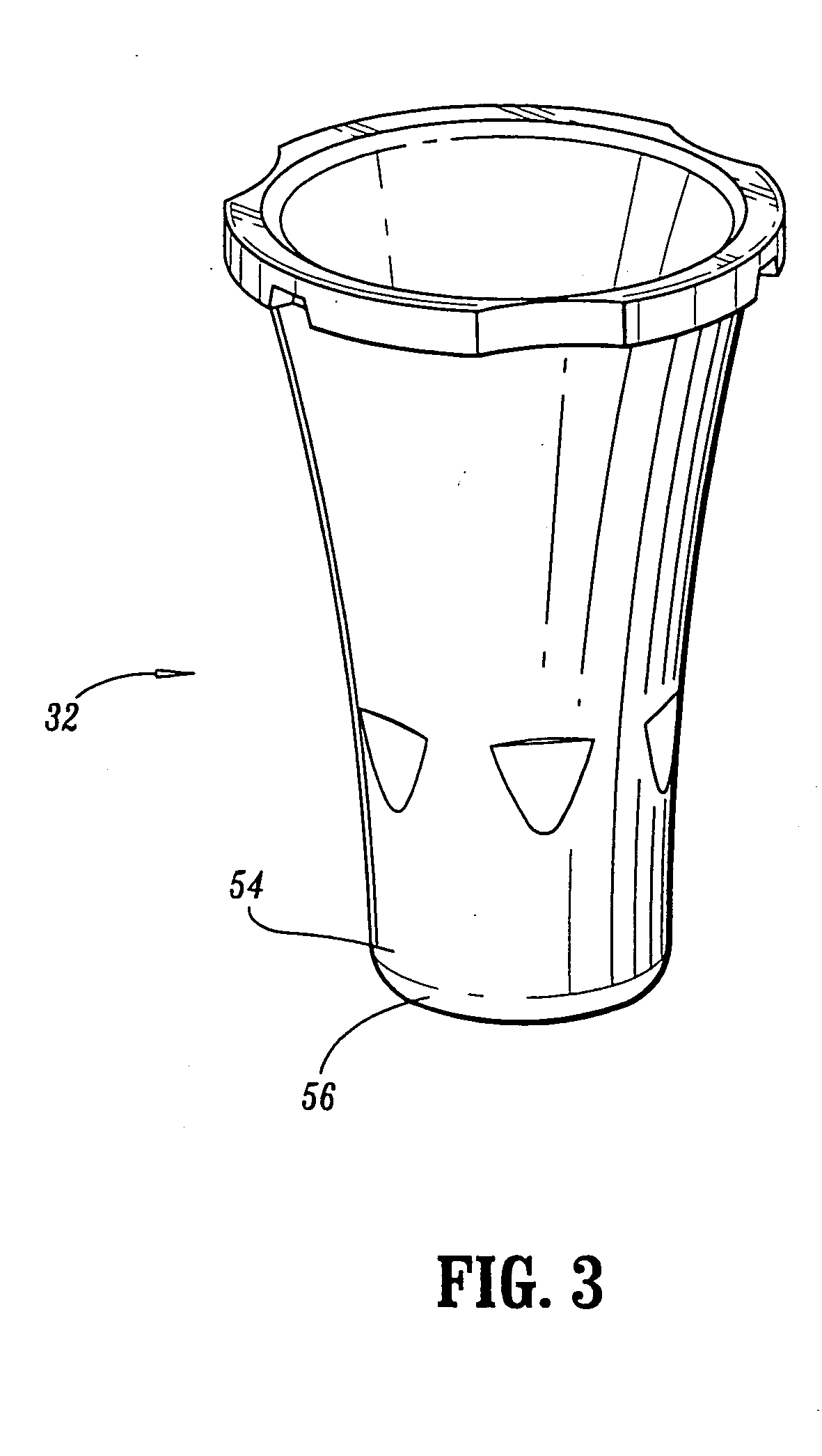

Thermal tympanic thermometer tip

InactiveUS20040240516A1Minimizes temperature readingStable designThermometer detailsRadiation pyrometryHeat fluxNose

The present disclosure provides a tympanic thermometer including a heat sensing probe defining a longitudinal axis and an outer surface extending from a distal end of the tympanic thermometer. The heat sensing probe includes a sensor housing extending to a distal end thereof. A sensor can is mounted with the sensor housing and a nozzle is mounted onto the sensor housing. The sensor can includes temperature sensing electronics for sensing temperature via the heat sensing probe. The nozzle includes a base disposed with the sensor housing and an elongated cylindrical nose portion disposed about the sensor housing. The nozzle is configured to direct heat flux to the distal end of the heat sensing probe. A probe cover is mountable to the distal end of the tympanic thermometer. The probe cover has an inner surface configured to engage an outer surface of the nozzle. The sensor can preferably include a lip extending radially therefrom and contacting the nozzle at at least one contact point to provide heat flux to the sensor can.

Owner:CARDINAL HEALTH IRELAND UNLTD

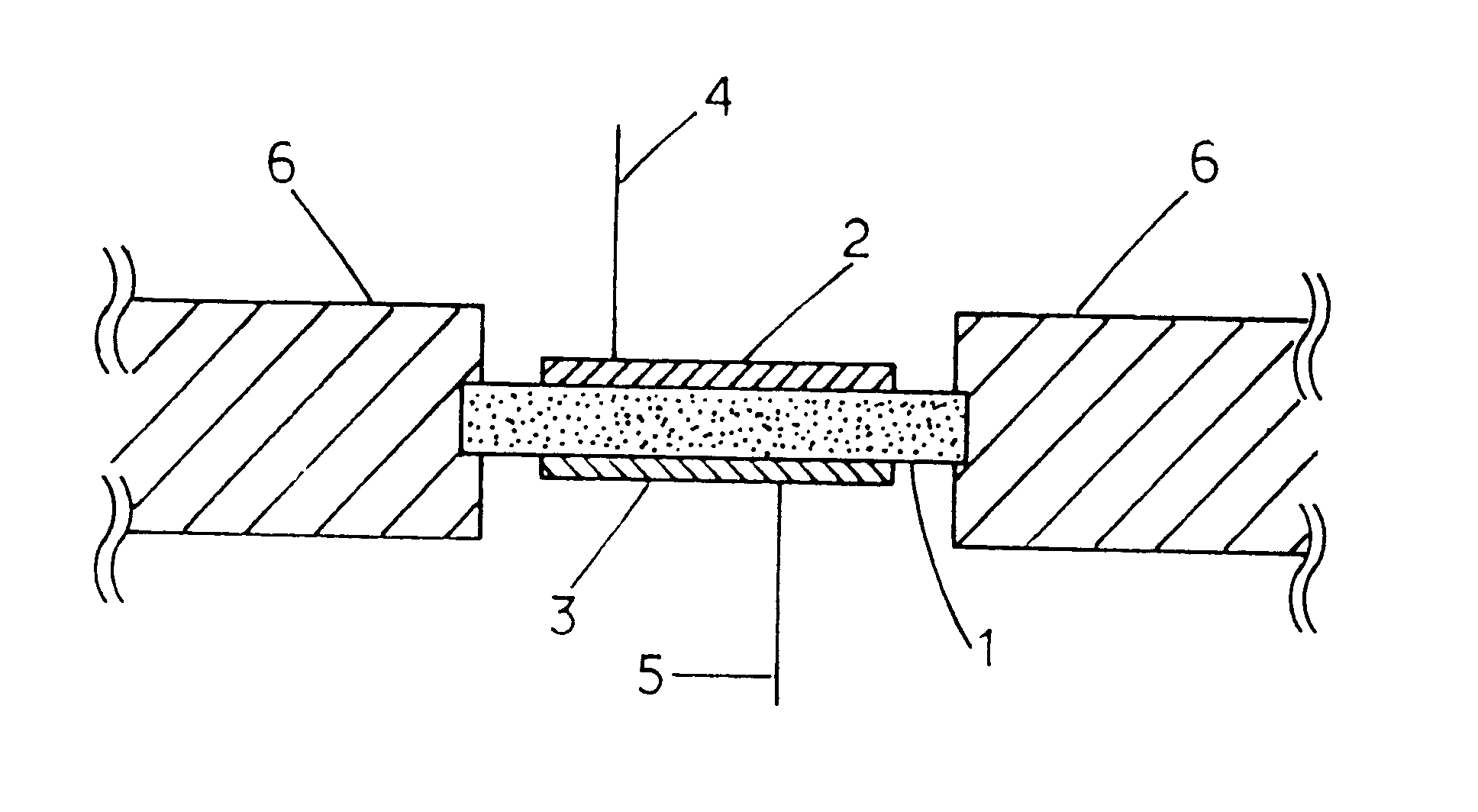

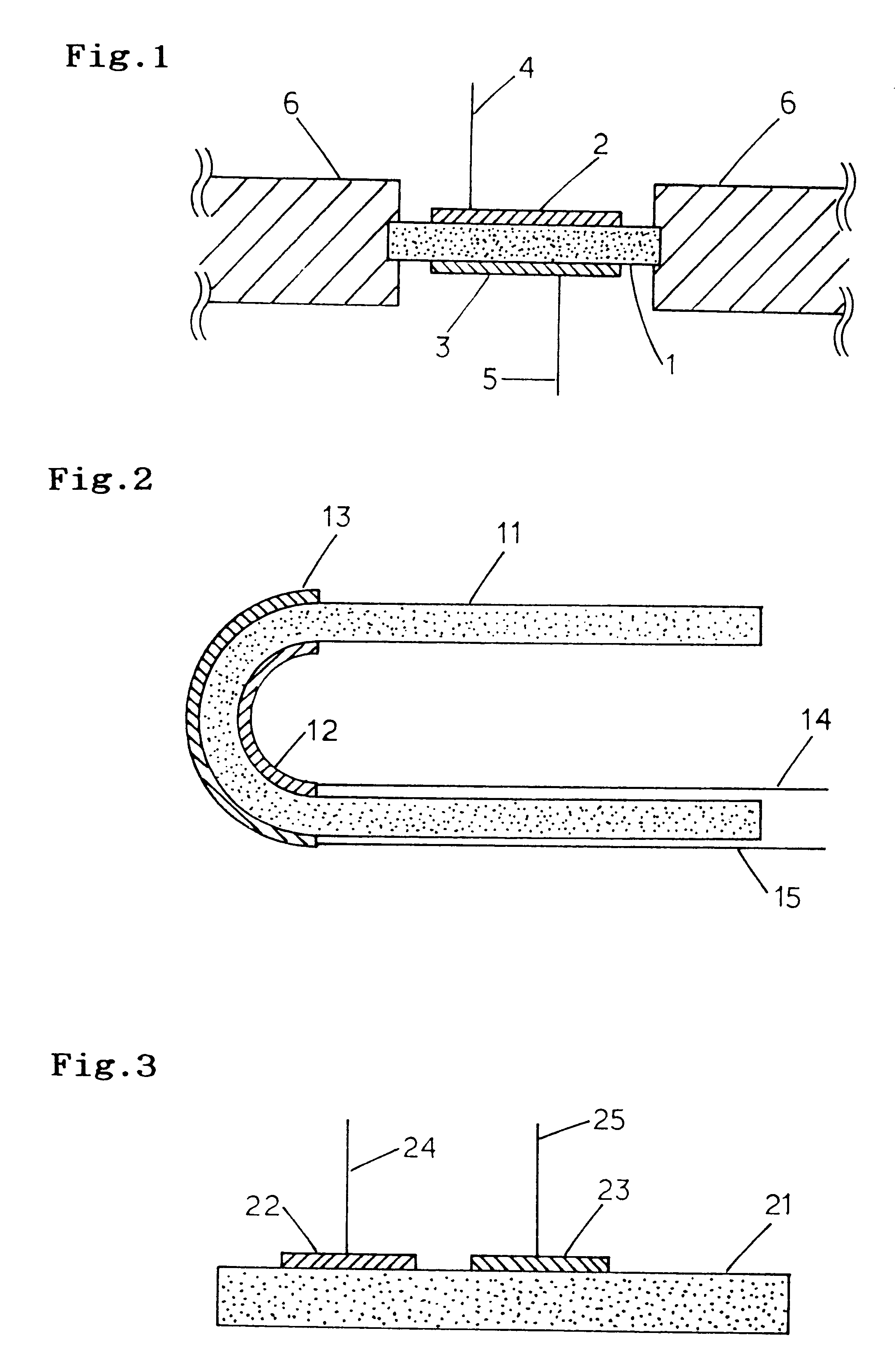

Carbon monoxide gas sensor and measuring device using the same sensor

InactiveUS6254749B1High selectivityHigh sensitivityWeather/light/corrosion resistanceVolume/mass flow measurementElectricityMeasurement device

In a CO gas sensor composed of a CO gas sensing electrode 3 being made of Au or an Au alloy and a reference electrode 2 electrically connected to at least part of a surface of a solid electrolyte having an oxygen ion transfer property, which is superior in CO gas selectivity, in particular, reducing the affect of the co-existing oxygen to CO, and which works with a high precision at a high temperature, and in a CO gas measuring device using the gas sensor, the gas sensor being capable of determining a CO gas concentration by measuring a electromotive force change due to adsorption / oxidization of the carbon monoxide gas in the sensing electrode 3 when a constant current is caused to flow between the reference electrode 2 and the sensing electrode 3 or a current value caused by the oxidizing reaction of the carbon monoxide gas in the sensing electrode when a voltage is kept constant between the reference electrode 2 and the sensing electrode 3.

Owner:NGK INSULATORS LTD

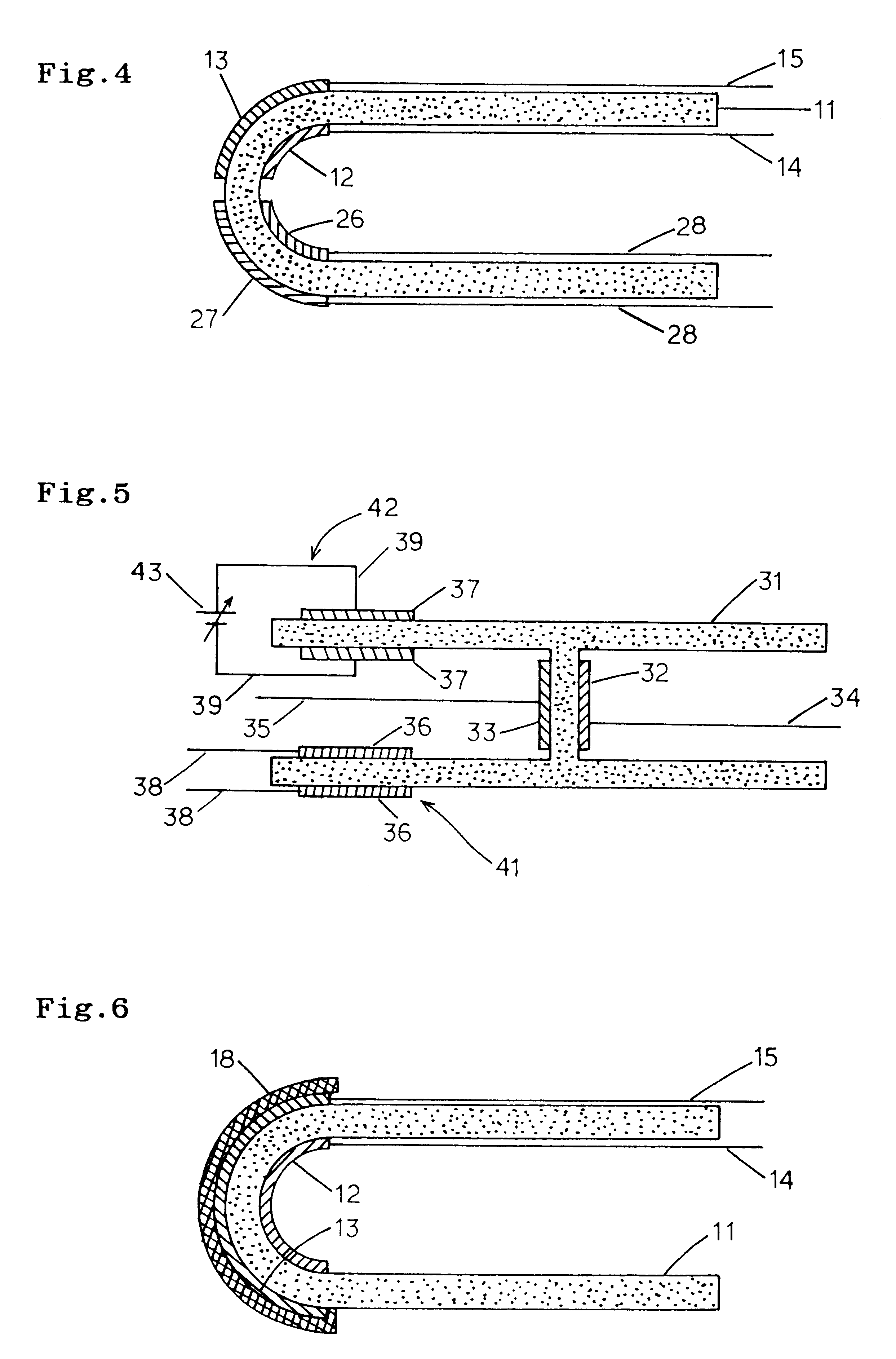

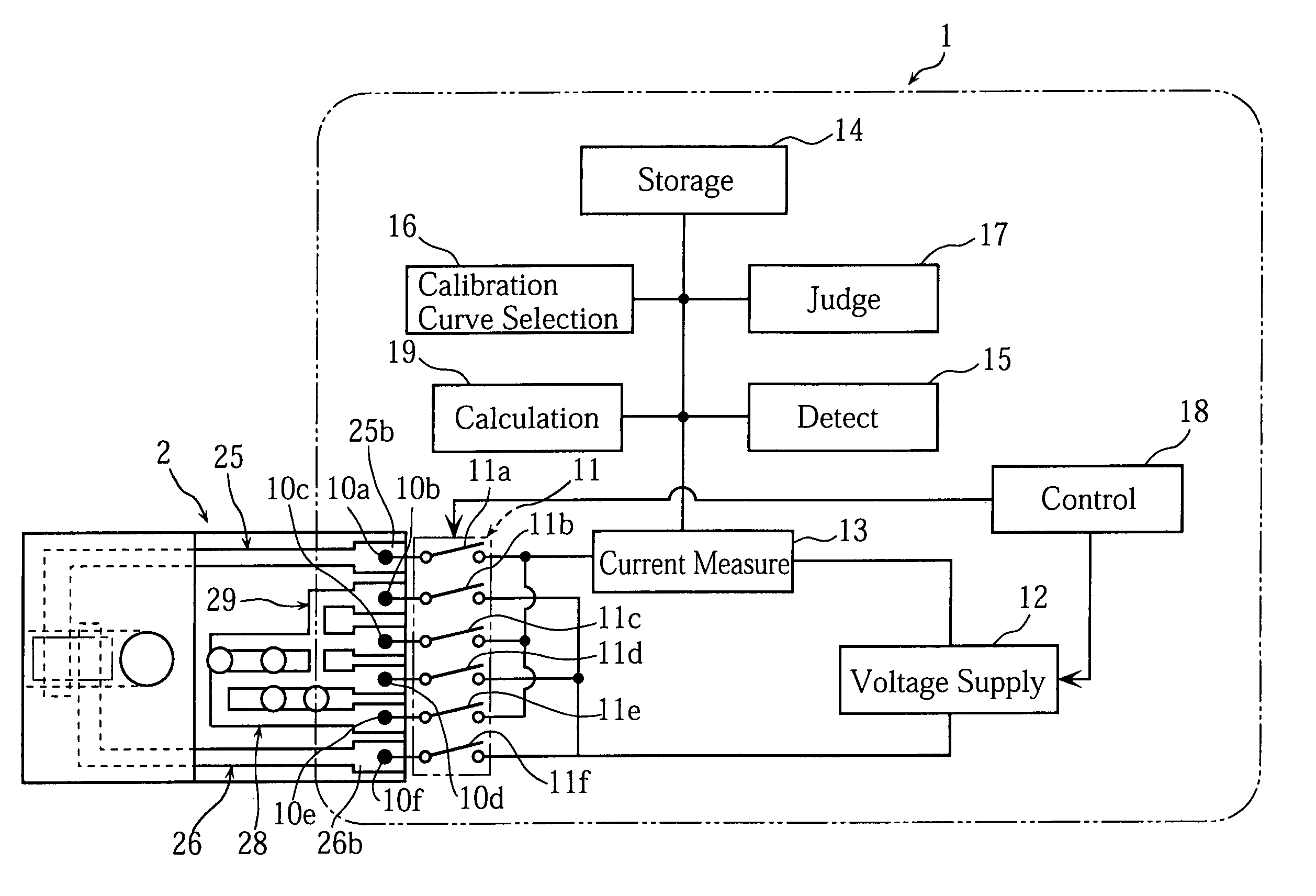

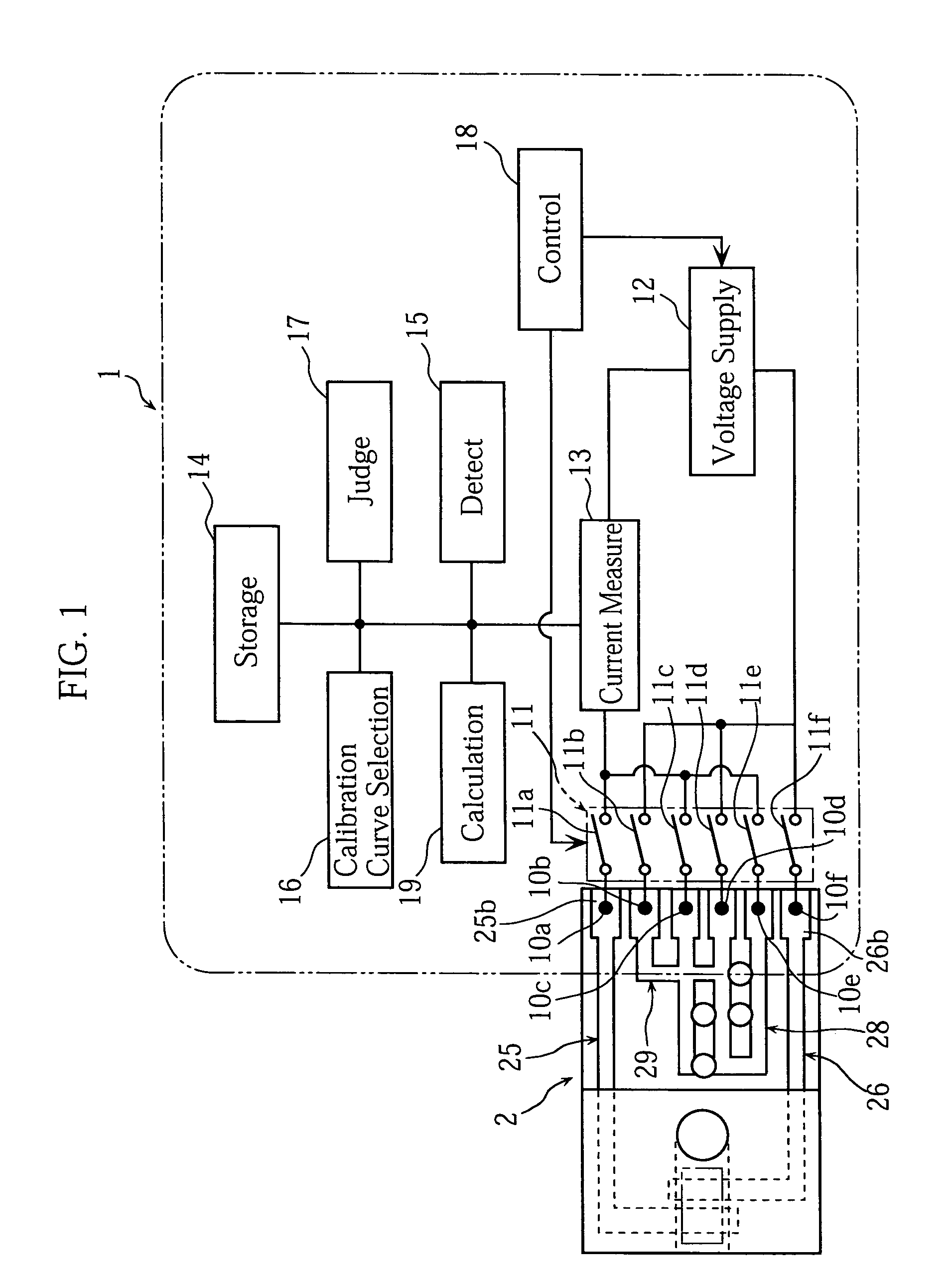

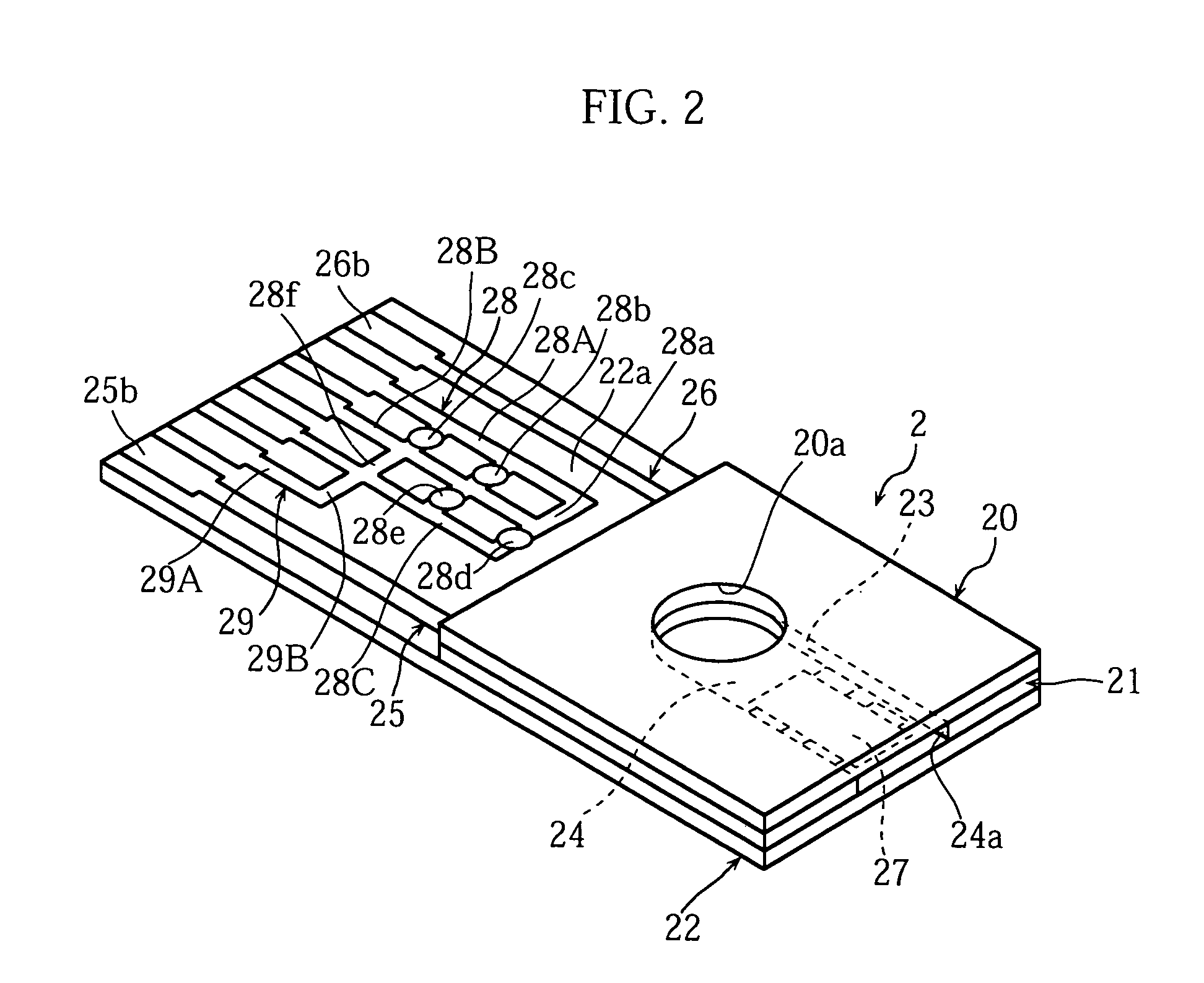

Measuring instrument and concentration measuring device

ActiveUS7491303B2Prevents incorrect concentration measurementProduction cost advantageImmobilised enzymesBioreactor/fermenter combinationsElectricityMeasuring instrument

The measurement instrument includes an attribute information output section to output attribute information about the attributes of the measurement instrument as an electric physical value. The attribute information is based on at least one of the conditions including a resistance of the attribute information output section, a location of the attribute information output section, and the size of a region on which the attribute information output section is formed. The attribute information may be used to select the calibration curve suitable for the measurement instrument. The attribute information may be one that relates to a specific measurement standard applied to the measurement instrument.

Owner:ARKRAY INC

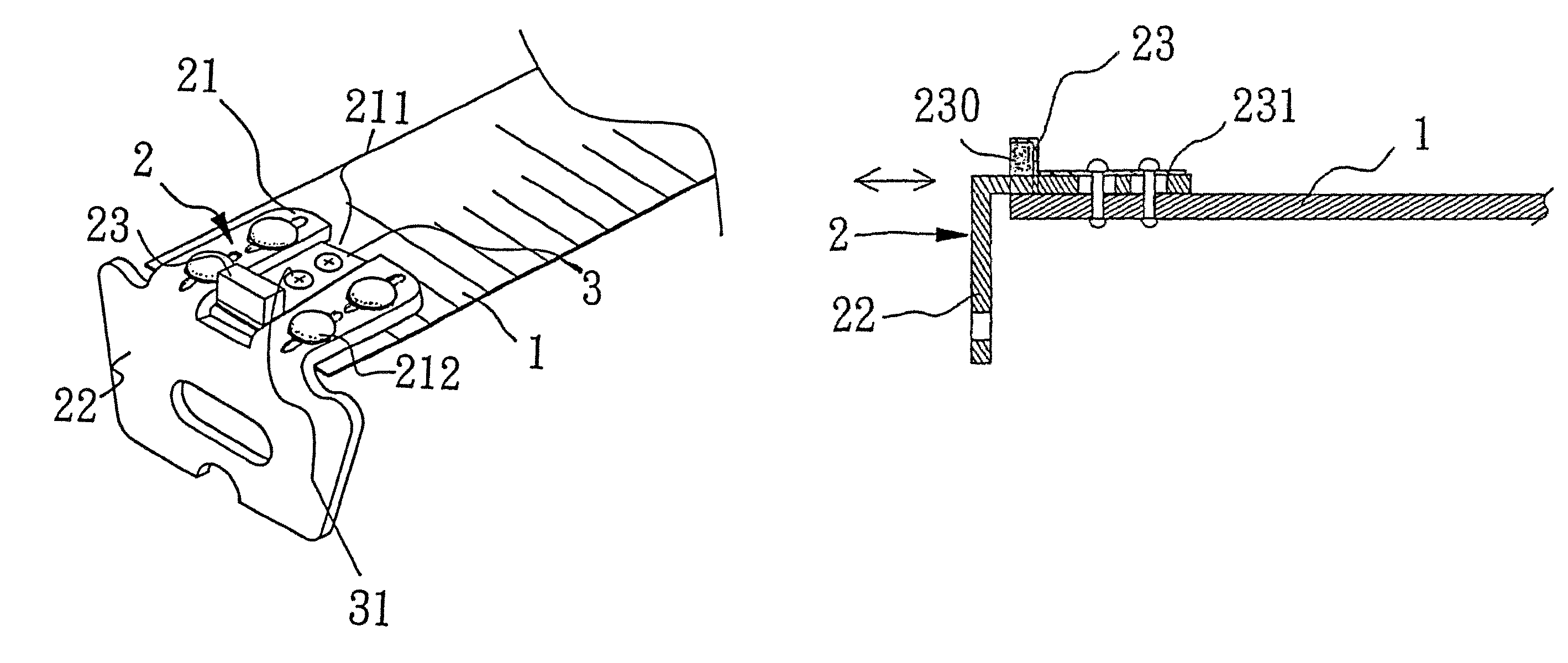

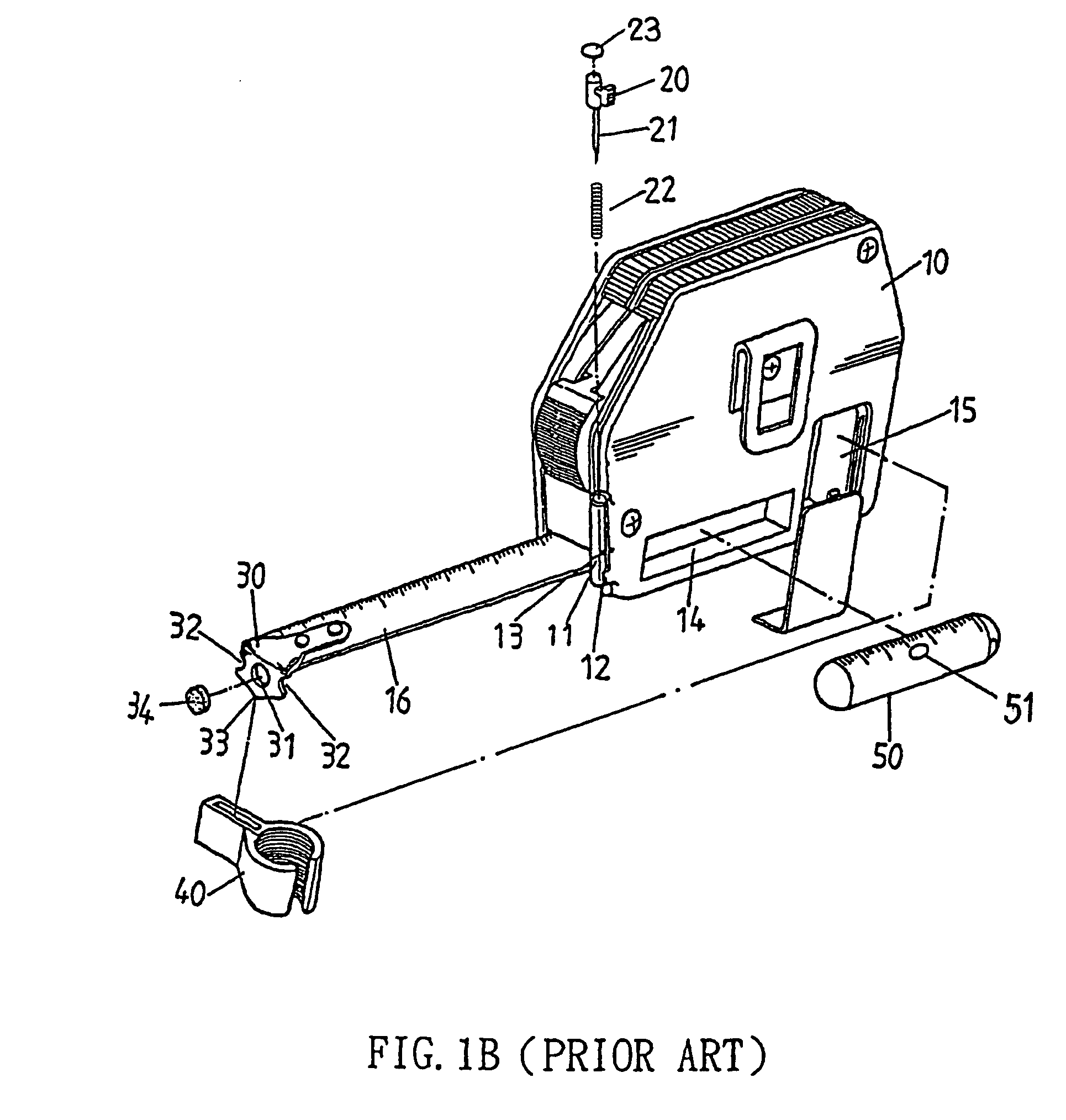

Structure of a measuring tape device

ActiveUS7669347B1Simple structureSolving precise measurementsRulers for direct readingMeasuring tapesAccuracy and precisionElectrical and Electronics engineering

An improvement on the structure of a measuring tape device is that a magnetic mechanism is secured at the distal end of a measuring tape. The magnetic mechanism is not placed onto the leg piece of the hook member and thus is not formed as part of the body of the hook member of the measuring tape. The front end of the magnetic mechanism is placed in alignment with the “0” cm mark on the measuring tape. During measuring process of an object of measurement and a designated point, the magnetic mechanism allows the measuring tape to be magnetically attached to the surface of the object and anchored at the exact starting point of measurement, and therefore, the measuring precision will not be skewed because of thickness of the hook member or because of the gap caused by the movable mechanics of the hook member.

Owner:TECHTRONIC POWER TOOLS TECHNOLOGY LTD

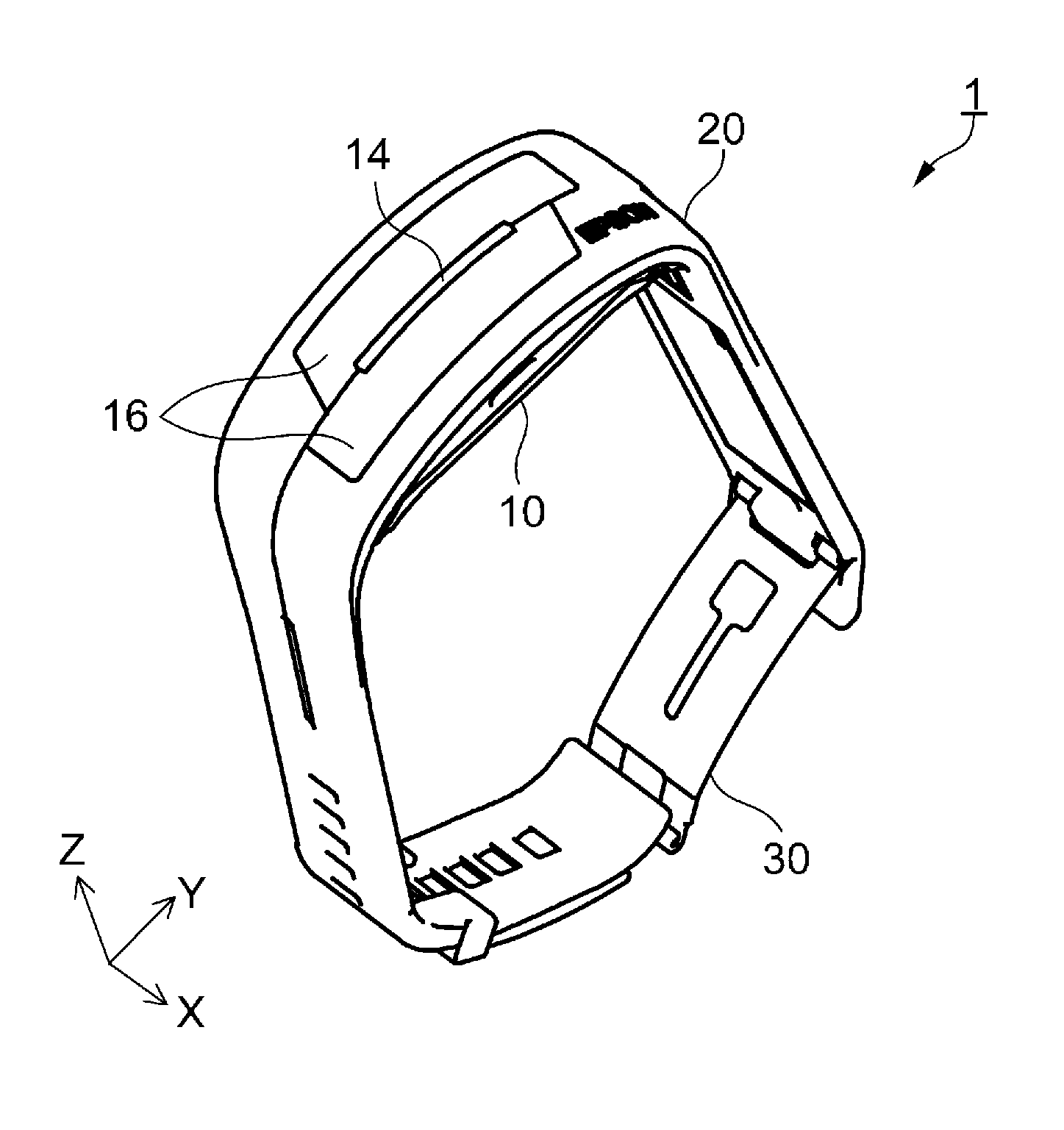

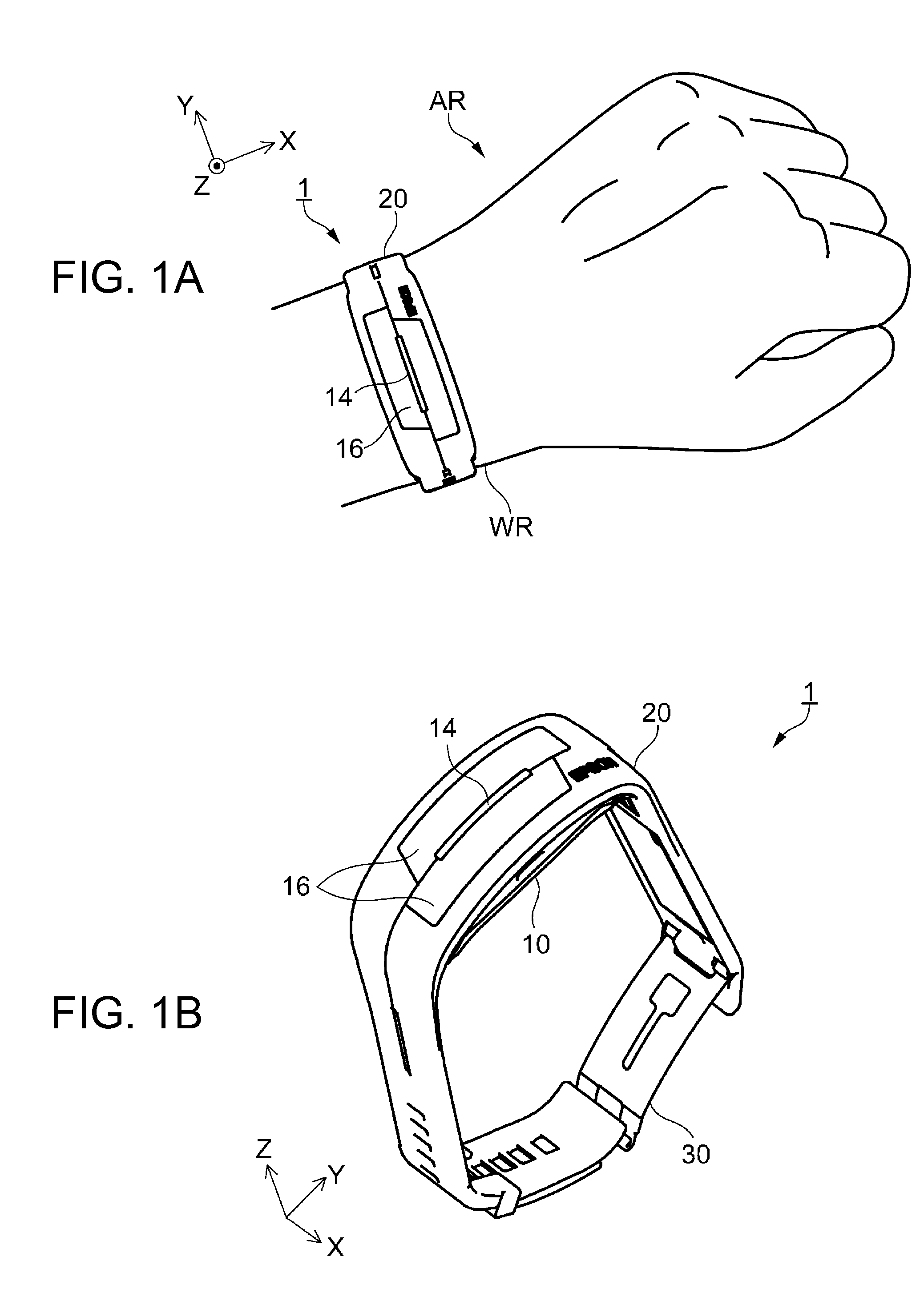

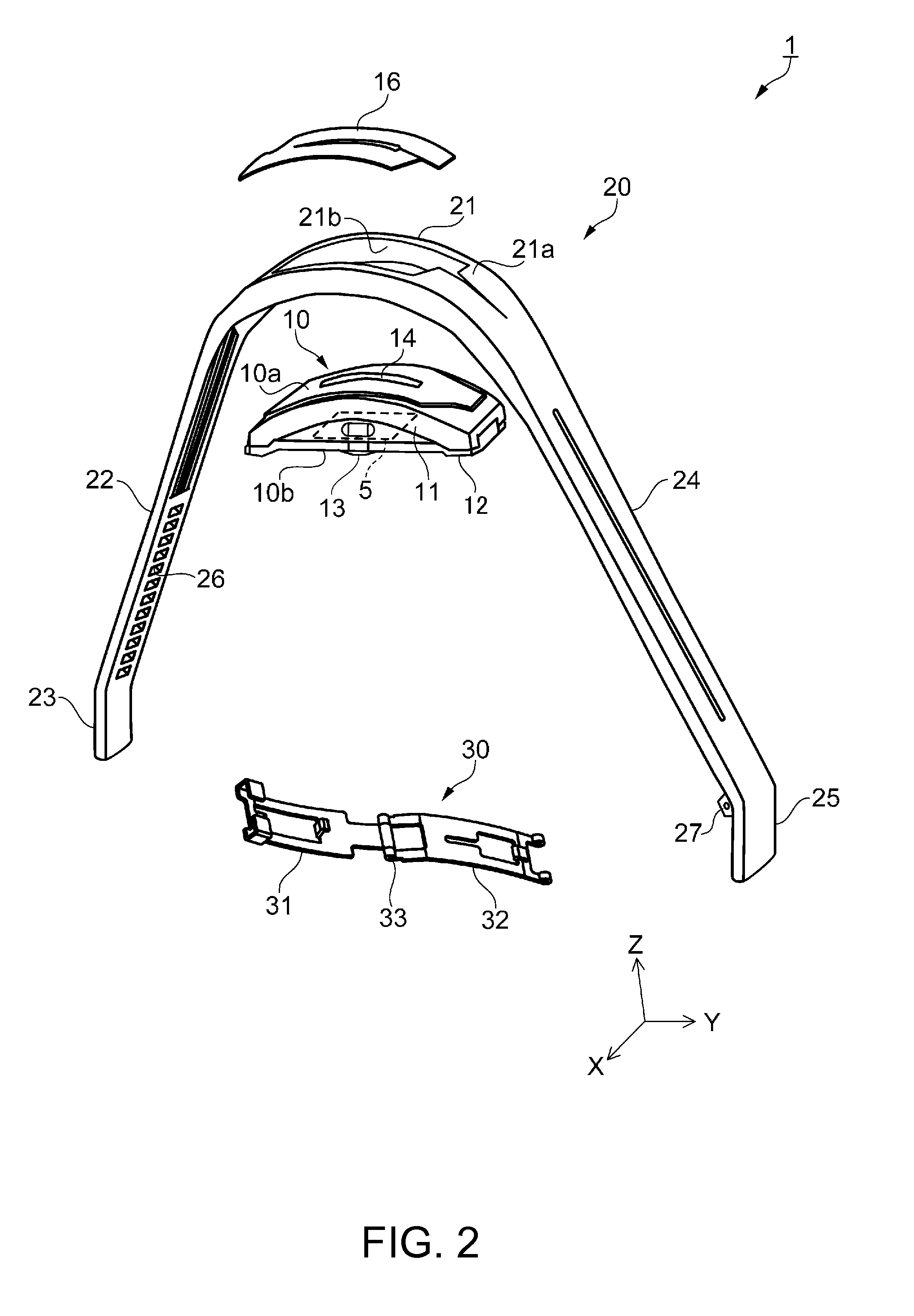

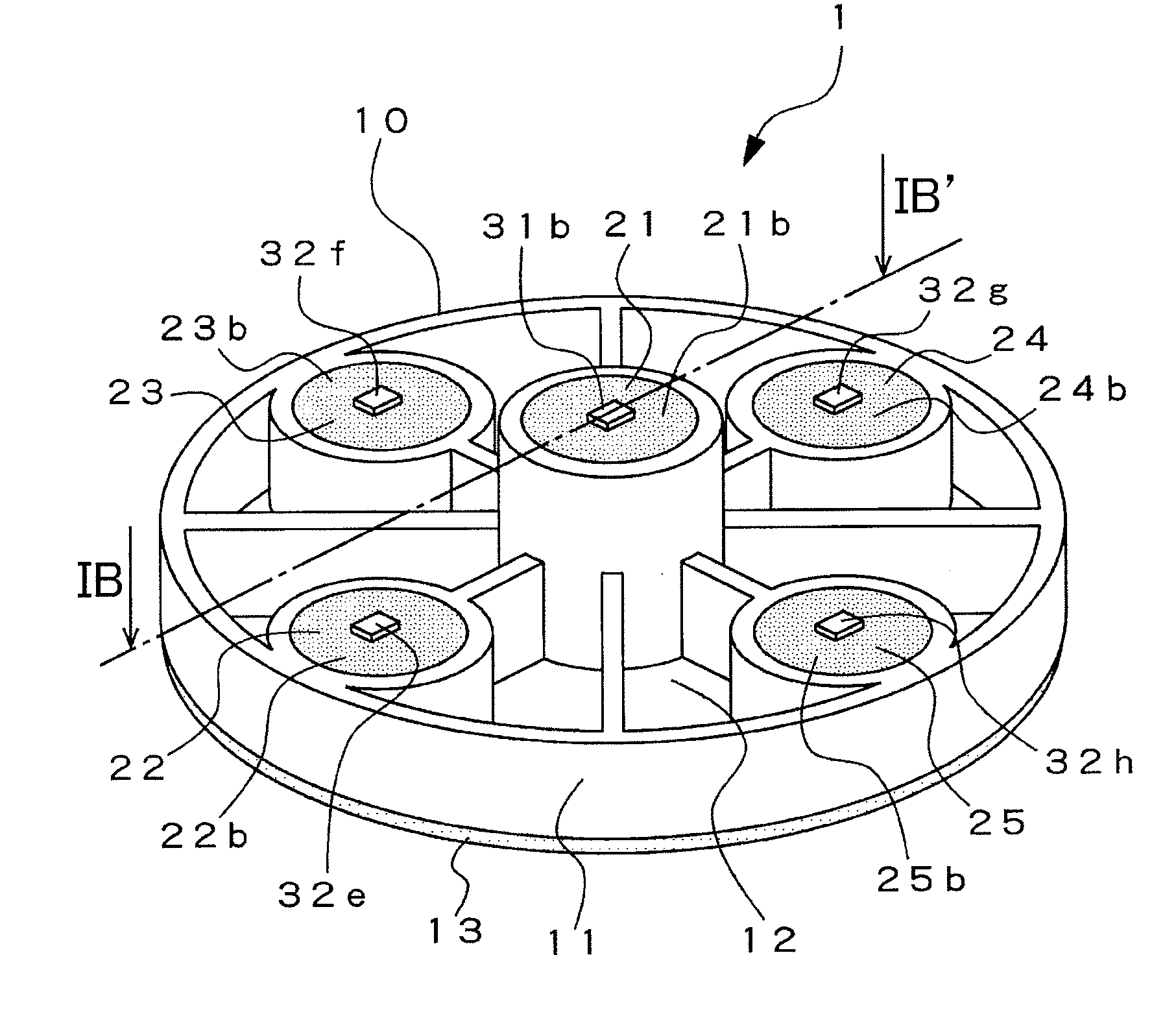

Biological information measuring apparatus

ActiveUS20160143584A1Reduce intensitySpoiling sensation of wearingInertial sensorsTelemetric patient monitoringBiological bodyMeasuring instrument

A biological information measuring apparatus (measuring apparatus) includes a band which fixes a case unit to a living body. The band is provided with a recessed groove part on a side facing the living body. The groove part has a depth of 1020 μm or more and 1140 μm or less.

Owner:SEIKO EPSON CORP

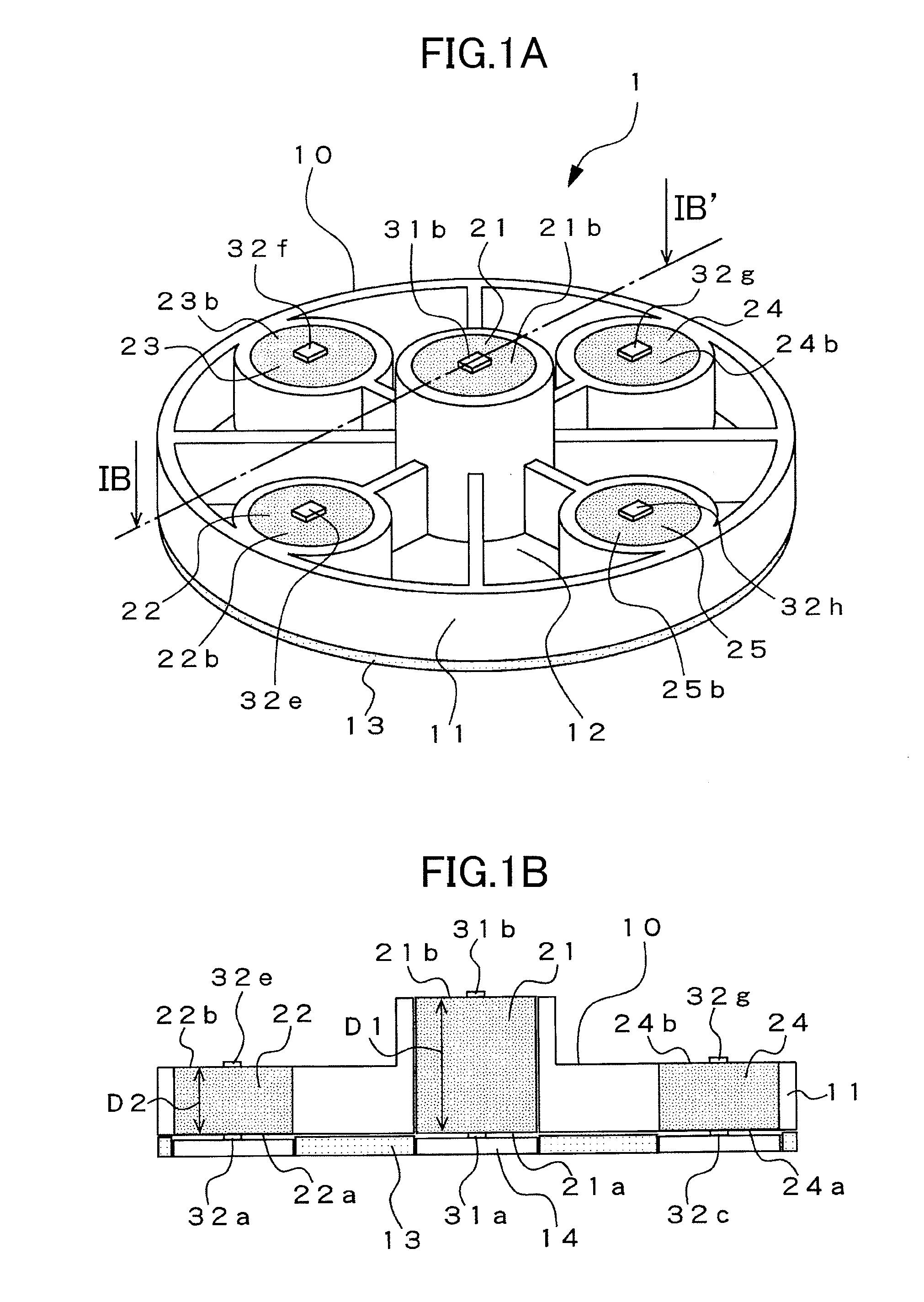

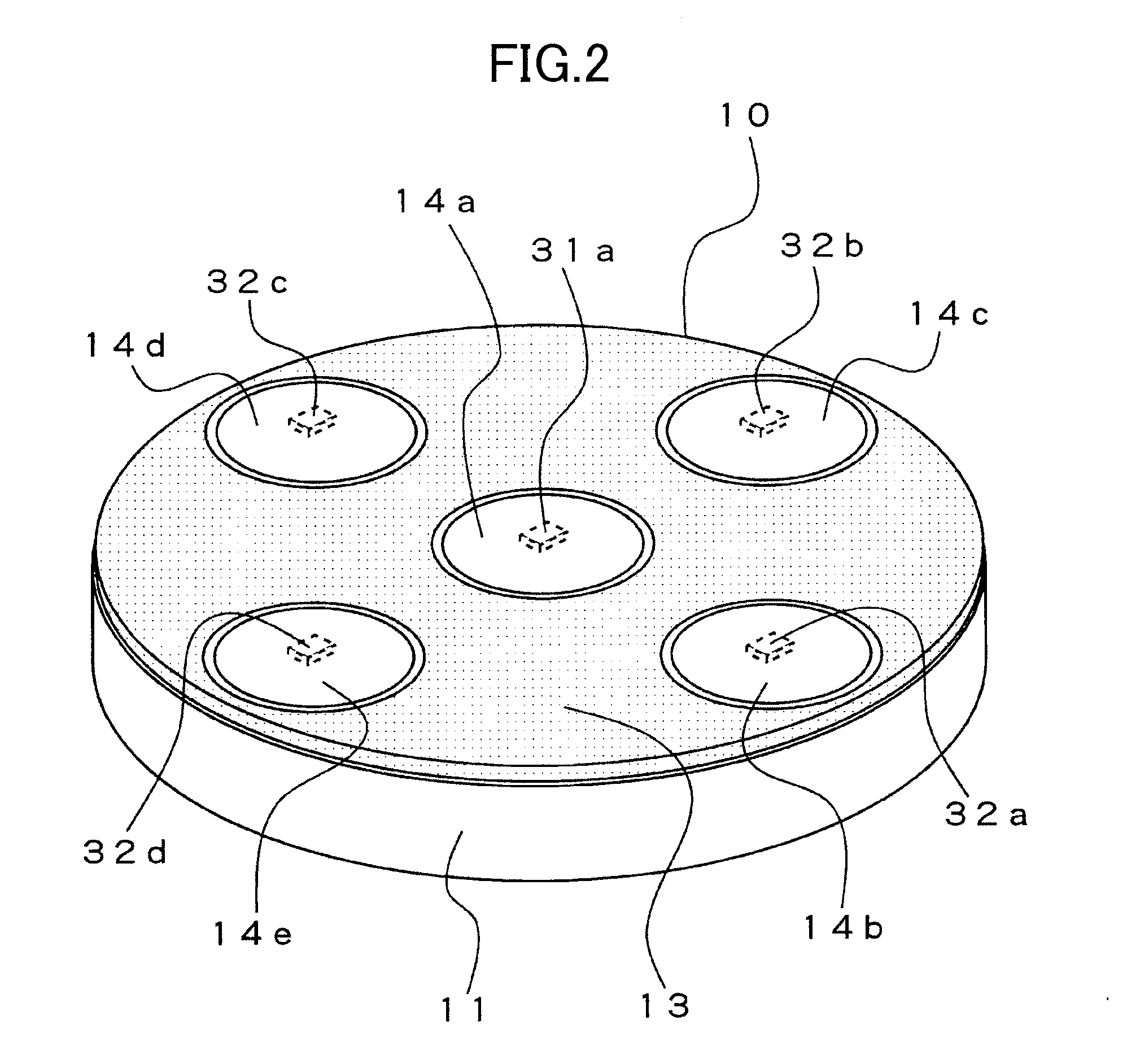

Temperature measuring device

InactiveUS20120128024A1Inaccurate temperature measurementLow thermal conductivityThermometers using electric/magnetic elementsBody temperature measurementHeat fluxHeat flow

In order to improve precision in measuring a deep body temperature by suppressing a heat flux in a plane direction while achieving satisfactory contact between a temperature sensing element and a skin, there is provided a temperature measuring device (1) including: temperature sensing elements (31a, 31b, and 32a to 32h) provided to at least one of inlets (21a to 25a) and outlets (21b to 21b) of first and second heat flow path members (21 to 25), respectively; and a casing (11) having a lower thermal conductivity than thermal conductivities of the first and second heat flow path members (21 to 25), for supporting the first and second heat flow path members (21 to 25), in which a gaseous layer or a vacuum layer (12) is formed among the first and second heat flow path members (21 to 25).

Owner:CITIZEN WATCH CO LTD

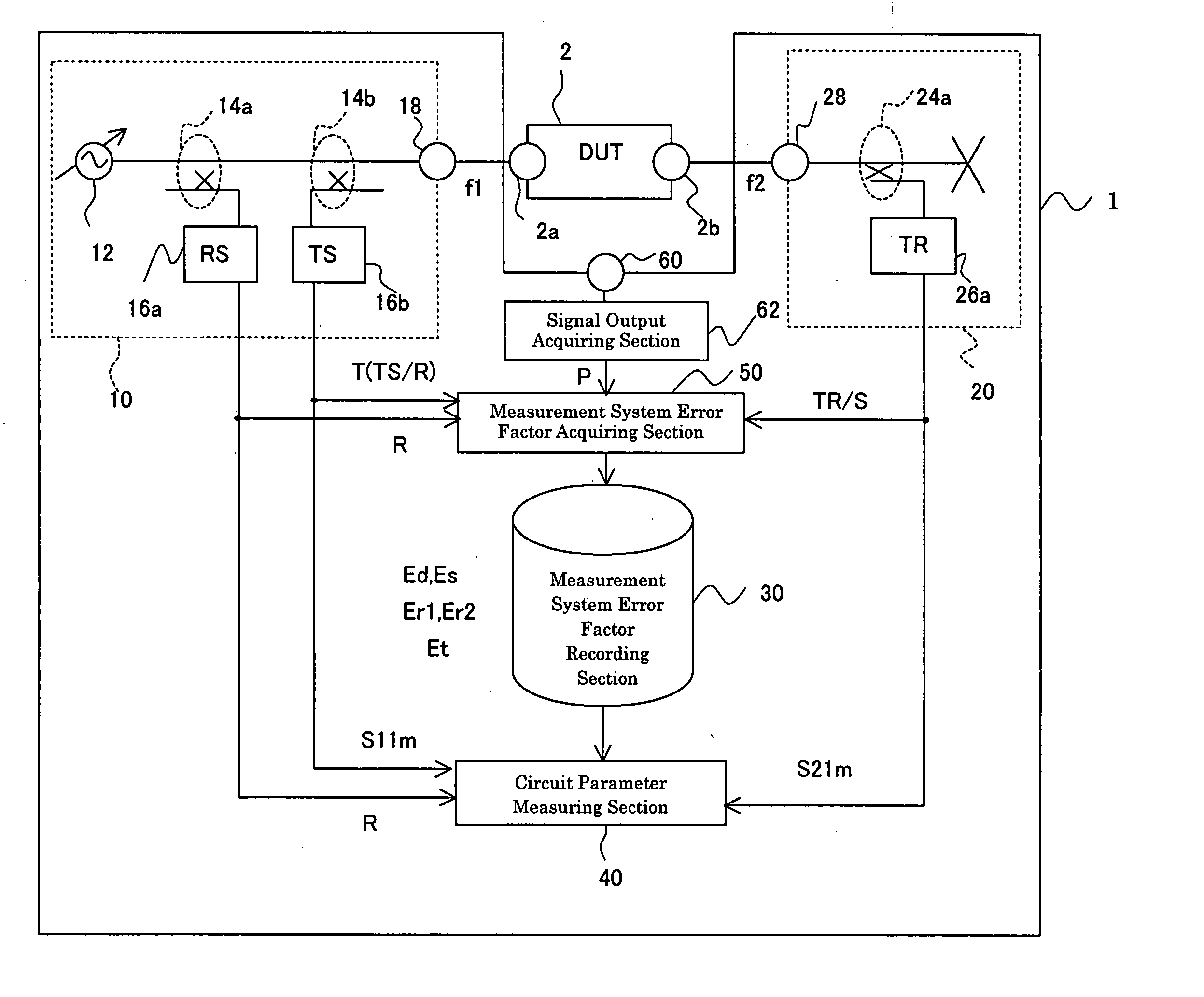

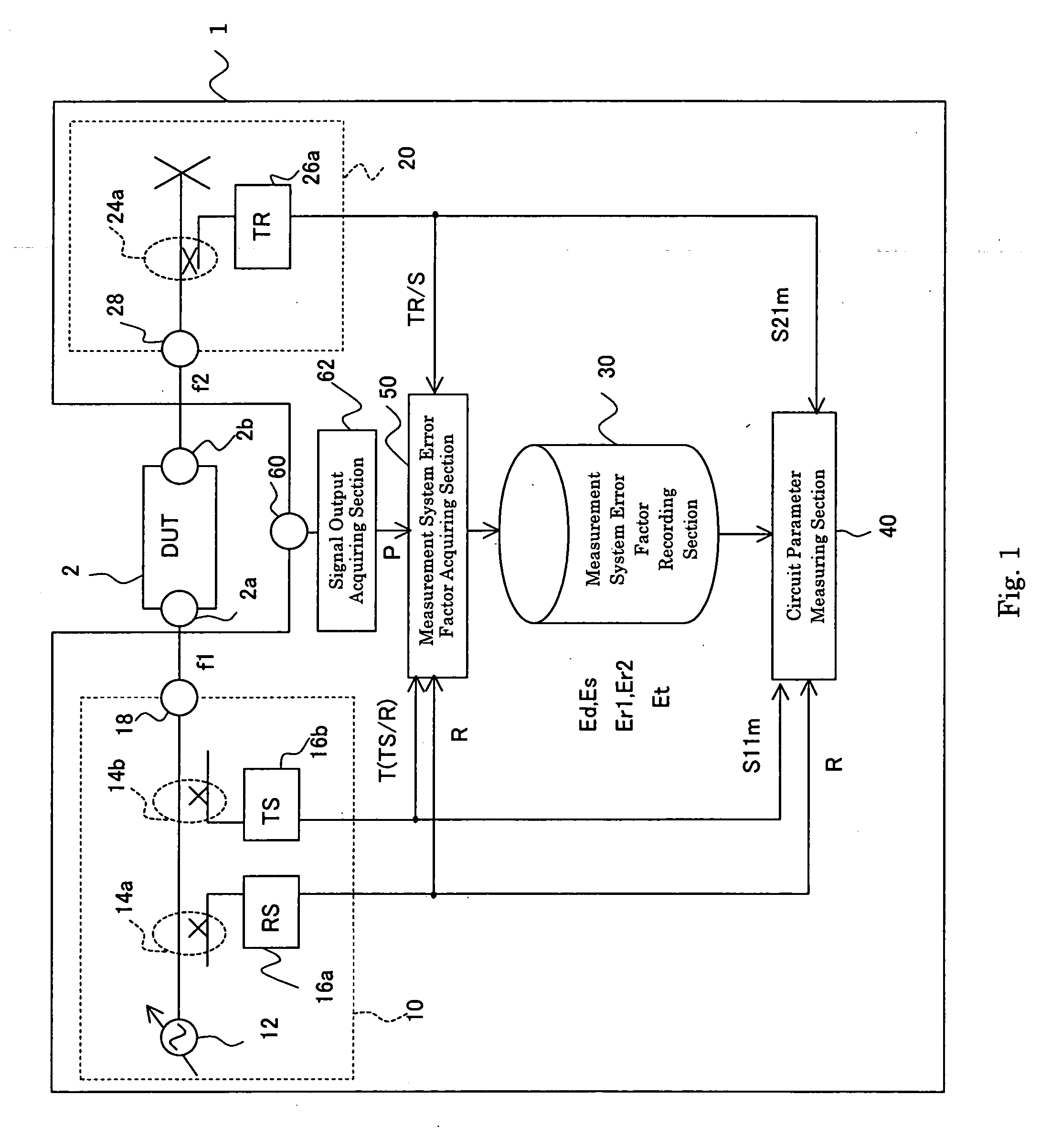

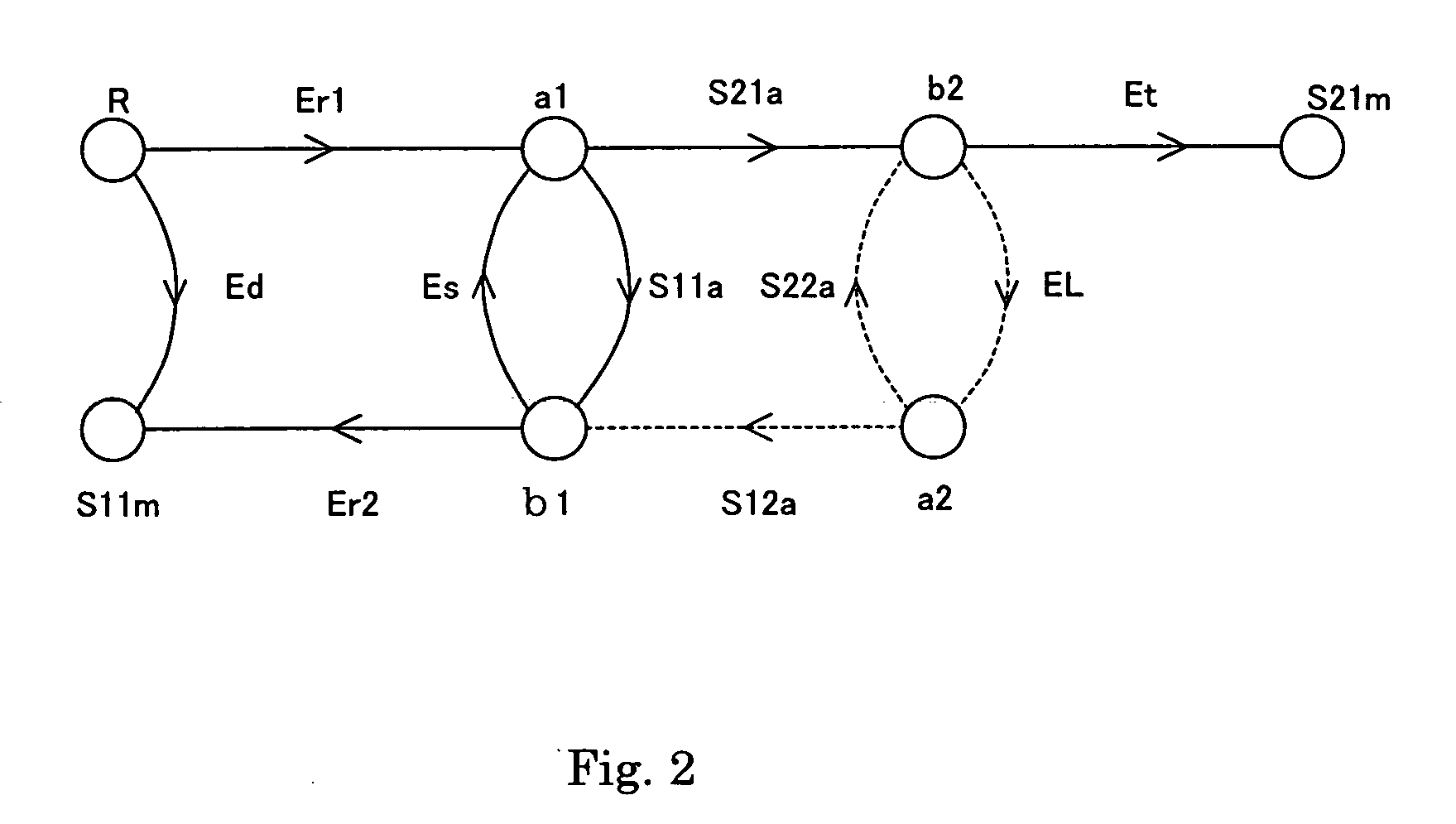

Network analyzer, network analyzing method, automatic corrector, correcting method, program, and recording medium

InactiveUS20060005065A1Measuring system is not accurateCorrect measurement system errorResistance/reactance/impedenceError detection/correctionEquipment under testWattmeter

The error of a measurement system can be corrected even if the frequency of an input signal of a device under test is different from that of the output signal. A signal output acquiring section acquires the power of the input signal by means of a power meter not shown in the drawing. Thus, errors due to frequency tracking can be separated depending on the direction in a signal flow graph. Since a receiver measures the parameter concerning the received signal when a signal source is directly connected to receiving means, the measurement system error factor of the receiving means can be acquired. The parameter of a device under test can be measured while the error is corrected when the results of measurement, concerning the device under test of receivers are combined.

Owner:ADVANTEST CORP

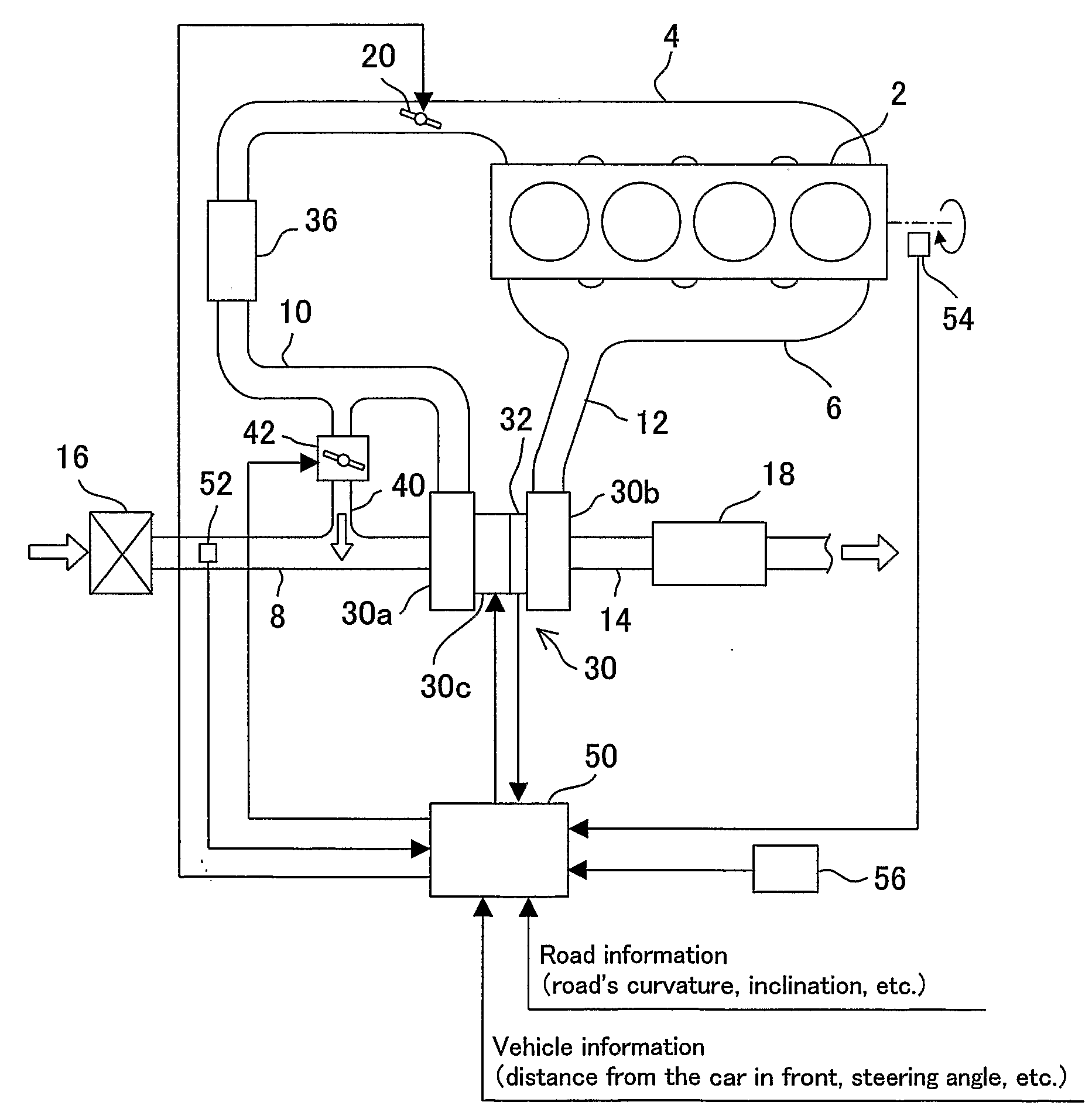

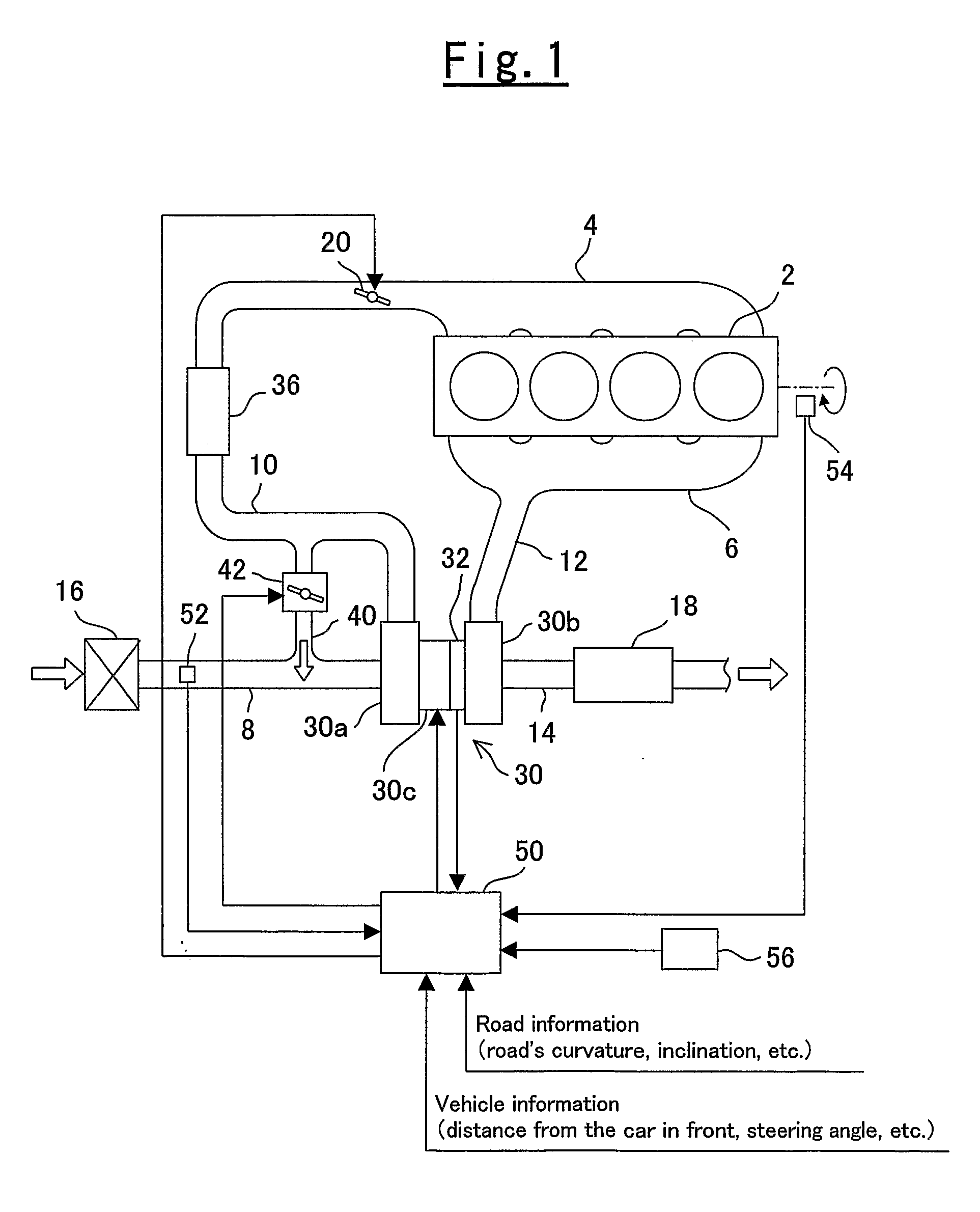

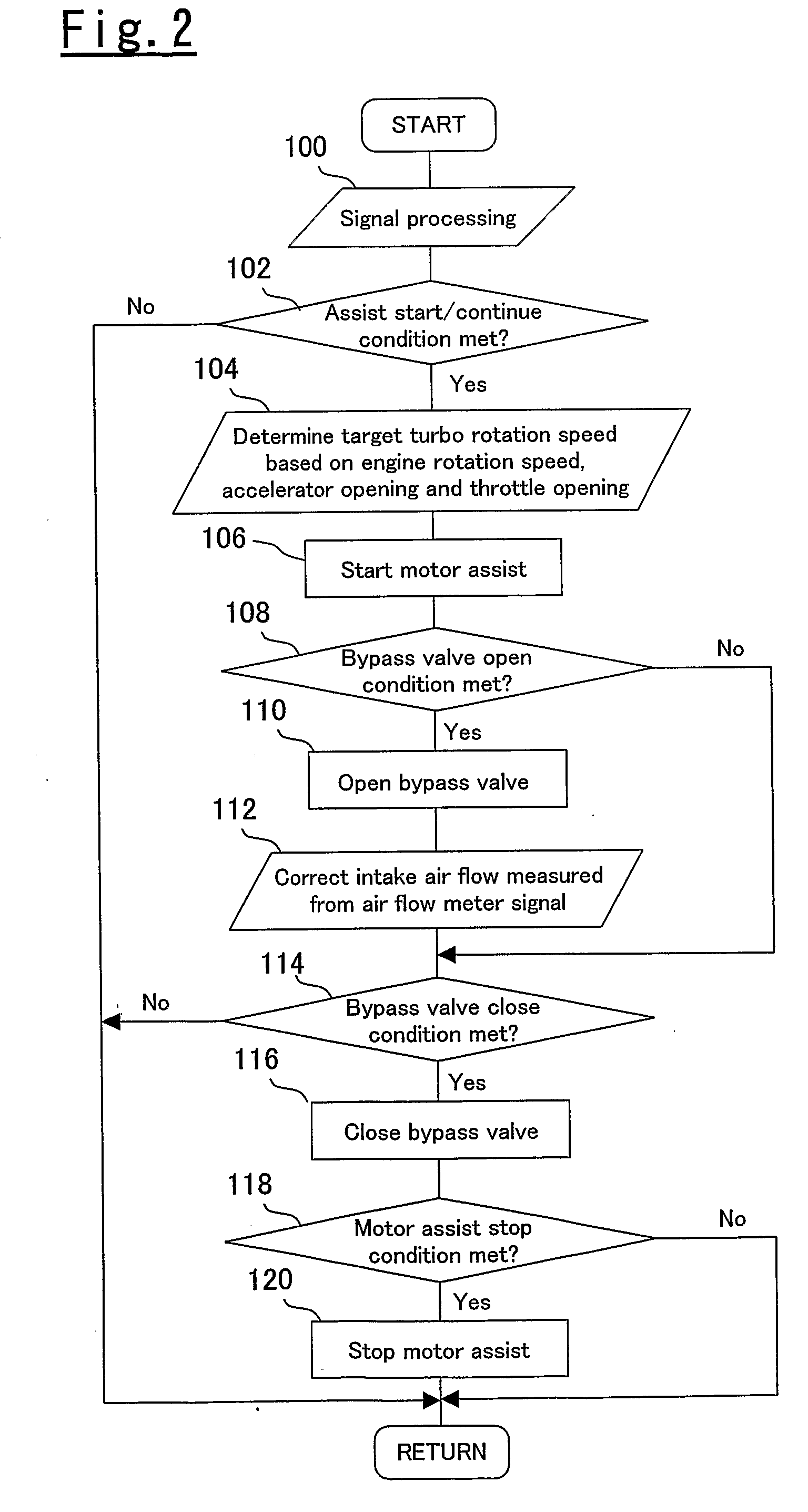

Control apparatus for internal combustion engine having motor-driven supercharger

InactiveUS20090222188A1Increase rotation speedReduce the differenceAnalogue computers for vehiclesElectrical controlMotor driveExternal combustion engine

The air flow inhaled into the internal combustion engine is calculated based on the operation state of the electric motor, the operational state of the bypass valve and the signal of the intake air flow sensor. Immediately after the bypass valve is opened when the electric motor is running, the air flow inhaled into the internal combustion engine may be calculated by acquiring the bypass air flow through the bypass passage and using the acquired bypass air flow to correct the intake air flow measured from the signal of the intake air flow sensor. Based on the calculated air flow inhaled into the internal combustion engine, control parameters which concern the output power of the internal combustion engine are adjusted.

Owner:TOYOTA JIDOSHA KK

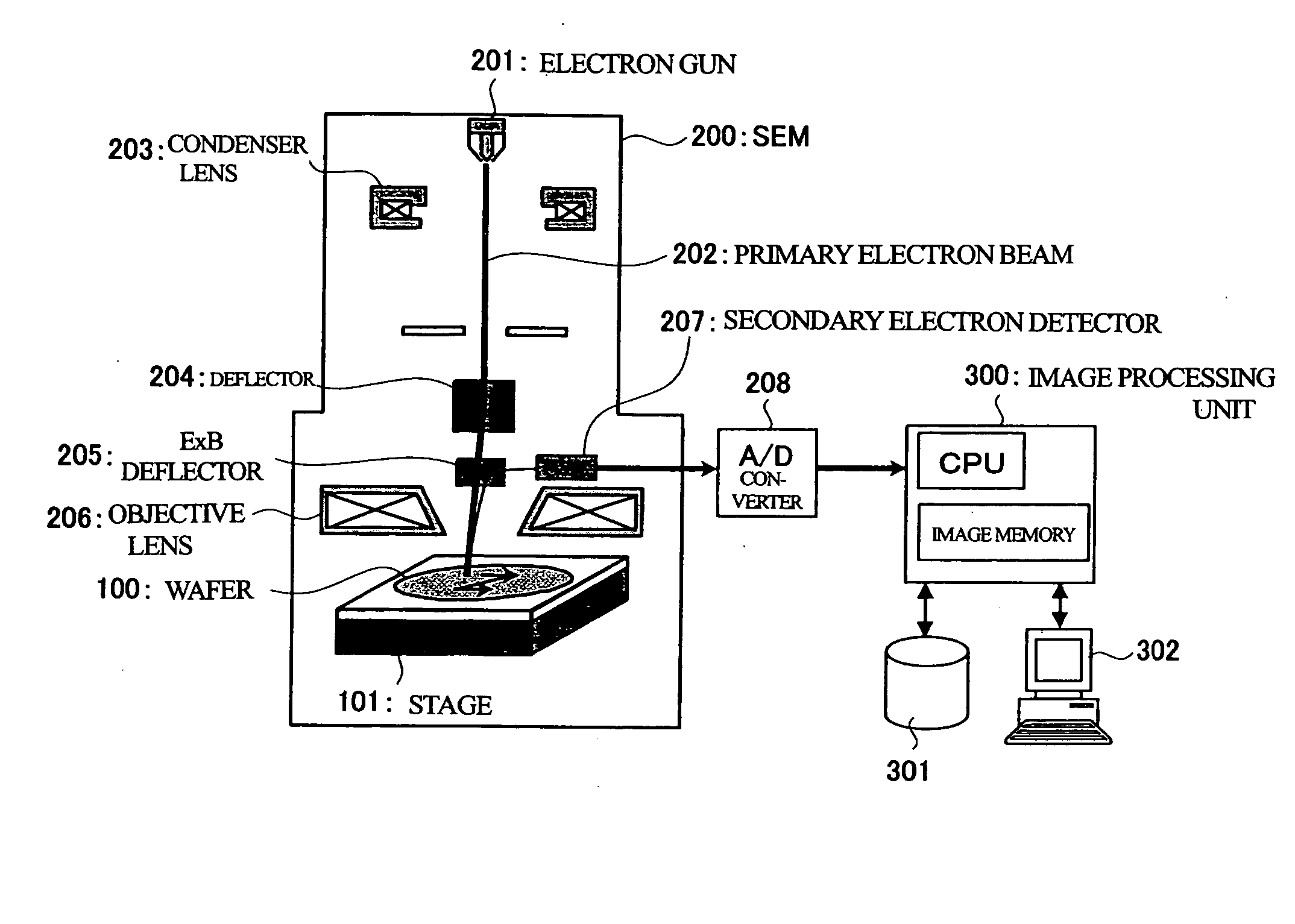

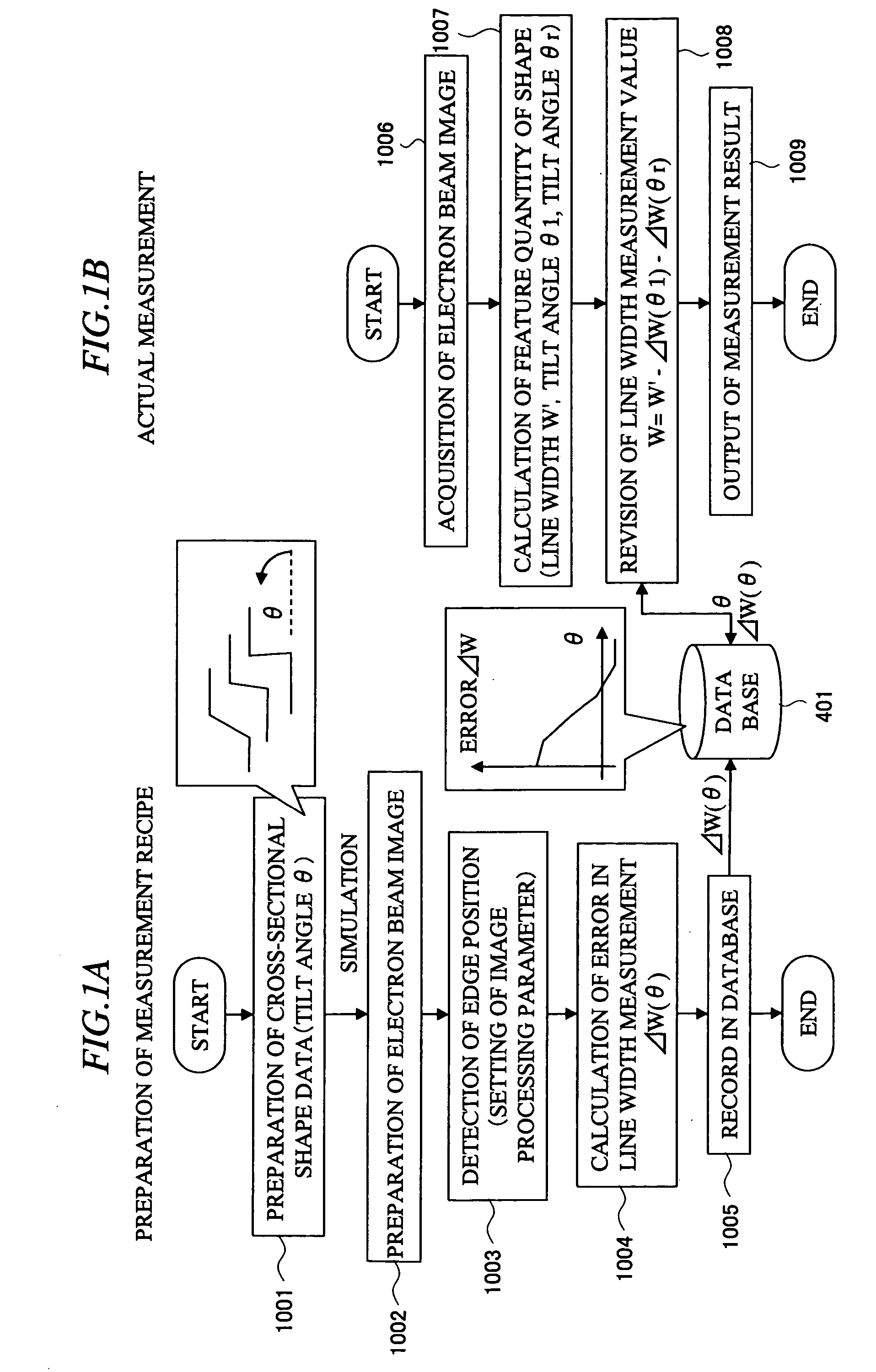

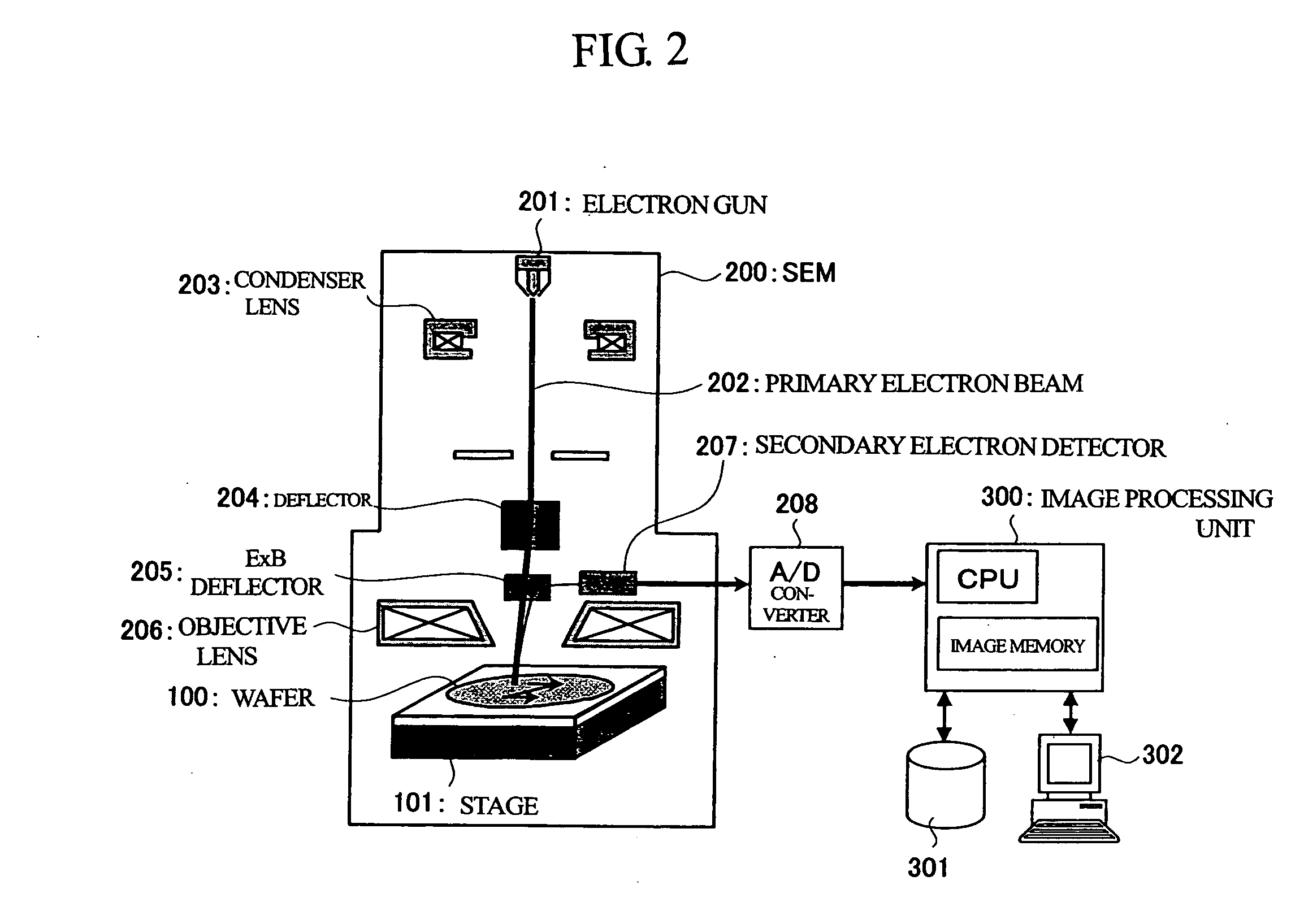

Method of measuring pattern dimension and method of controlling semiconductor device process

ActiveUS20050116182A1Precise DimensionsReduce the amount of calculationMaterial analysis using wave/particle radiationSemiconductor/solid-state device testing/measurementDevice materialDimension measurement

This invention provides a method of measuring semiconductor pattern dimensions capable of realizing a stable and highly precise pattern dimension measurement technique even when the pattern cross-sectional shapes are changed and making the calculation amount relatively small to reduce the calculation time. More specifically, the relationship between cross-sectional shapes of a pattern and measurement errors in a specified image processing technique is evaluated in advance by the electron beam simulation in a pattern measurement system in a length measuring SEM, and in the actual dimension measurement, dimensions of an evaluation objective pattern are measured from image signals of a scanning electron microscope, and errors of the dimensional measurement of the evaluation objective pattern are estimated and revised based on the relationship between cross-sectional shapes of a pattern and measurement errors evaluated in advance, thereby realizing highly precise measurement where dimensional errors depending on pattern solid shapes are eliminated.

Owner:HITACHI HIGH-TECH CORP

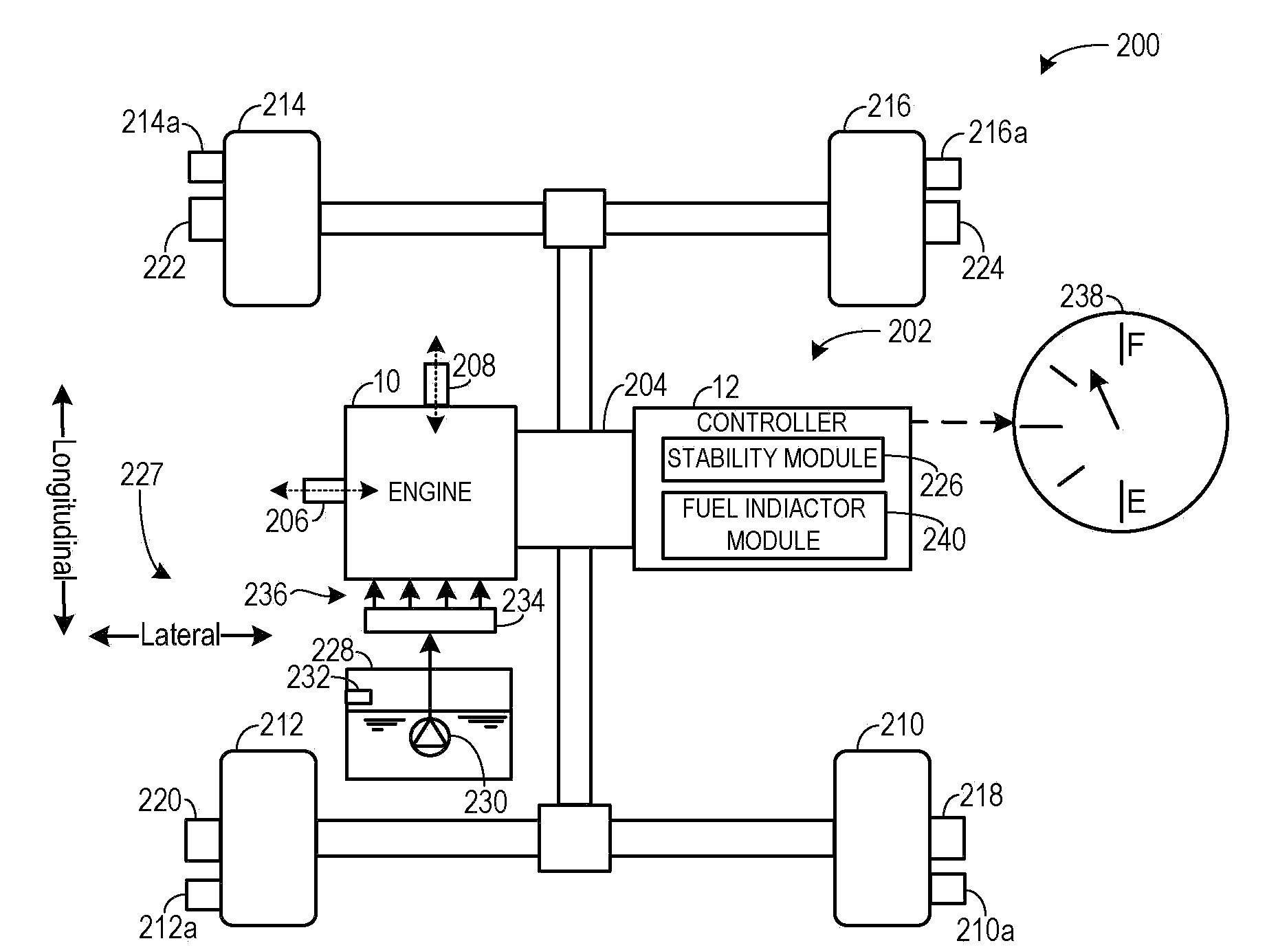

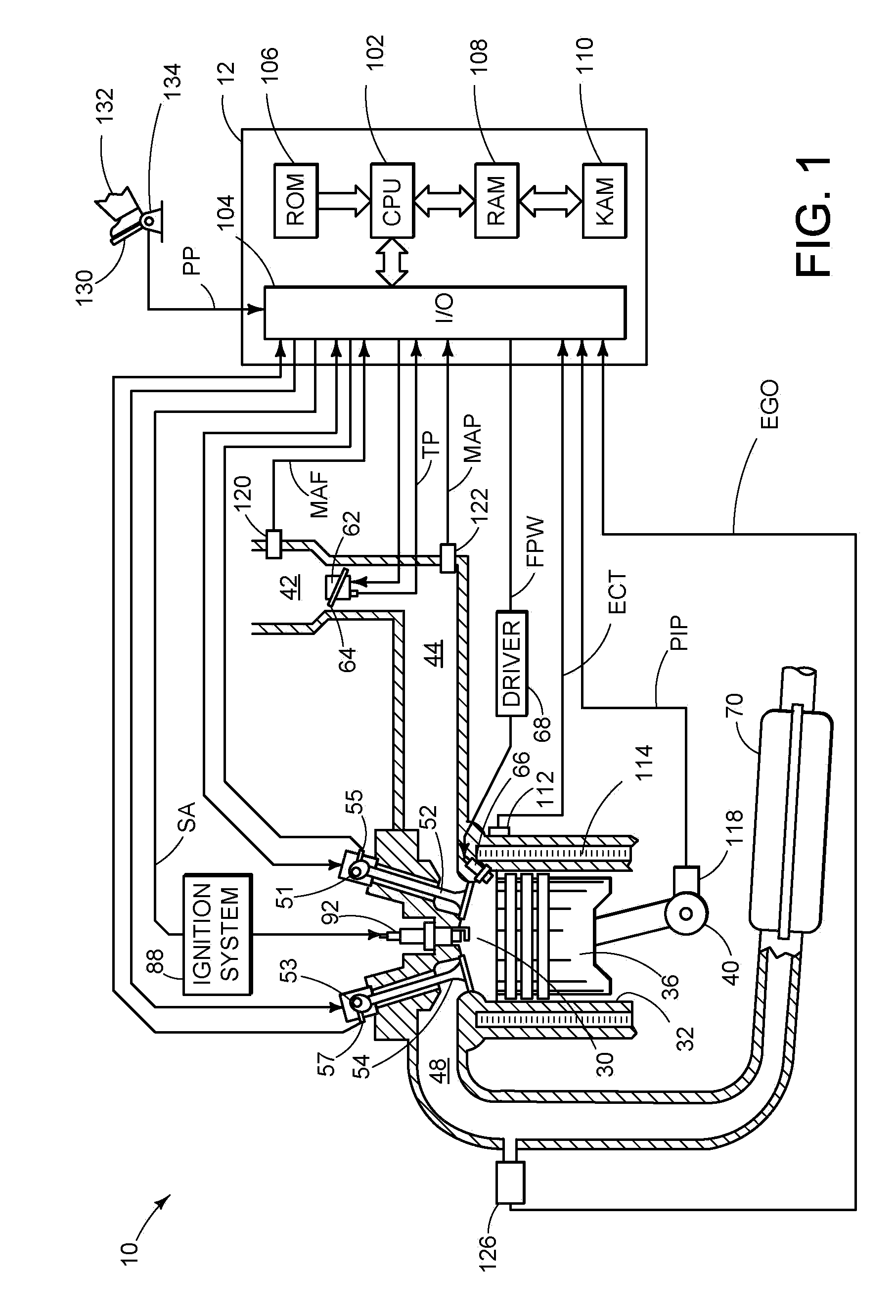

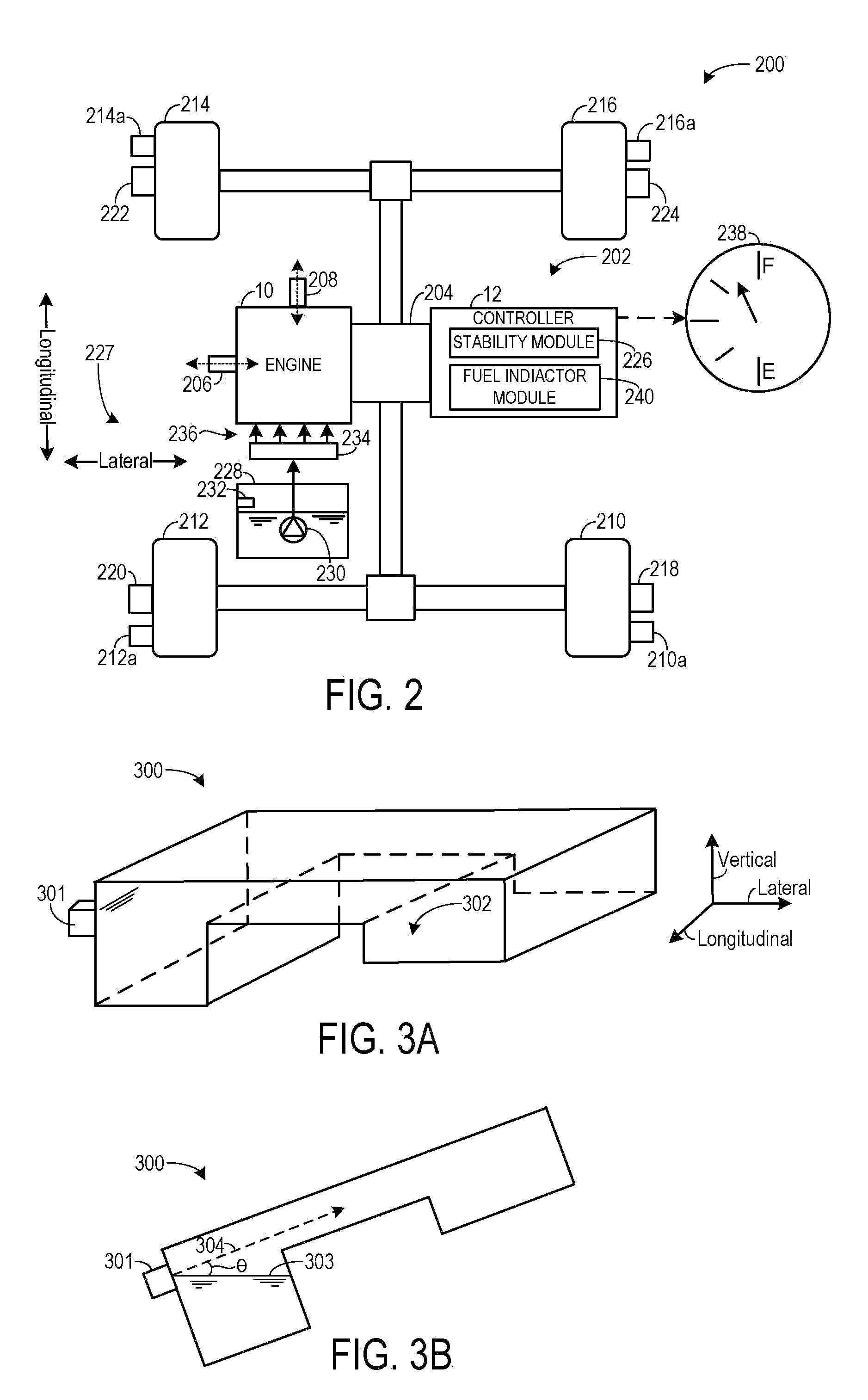

Fuel indicator method

ActiveUS20110010070A1Accurate readingSolving precise measurementsAnalogue computers for vehiclesTesting/calibration apparatusFuel tankAutomotive engineering

A method for operating a vehicle is provided. The method includes, in one example during a first a rate of change of an inclination of the vehicle, adjusting a fuel level indication based on the inclination and a level of fuel within the fuel tank; and during a second rate of change of the inclination different from the first rate of change, adjusting the fuel level indication based on actual fuel consumption of the engine. In this way, it is possible to provide an accurate fuel level indication based on the inclination when the inclination is not changing too quickly. However, when inclination is changing quickly and may give degraded level readings, it is still possible to provide an accurate fuel level by transiently estimating fuel usage and using, for example, a previous fuel level reading from when the inclination was not changing too quickly.

Owner:FORD GLOBAL TECH LLC

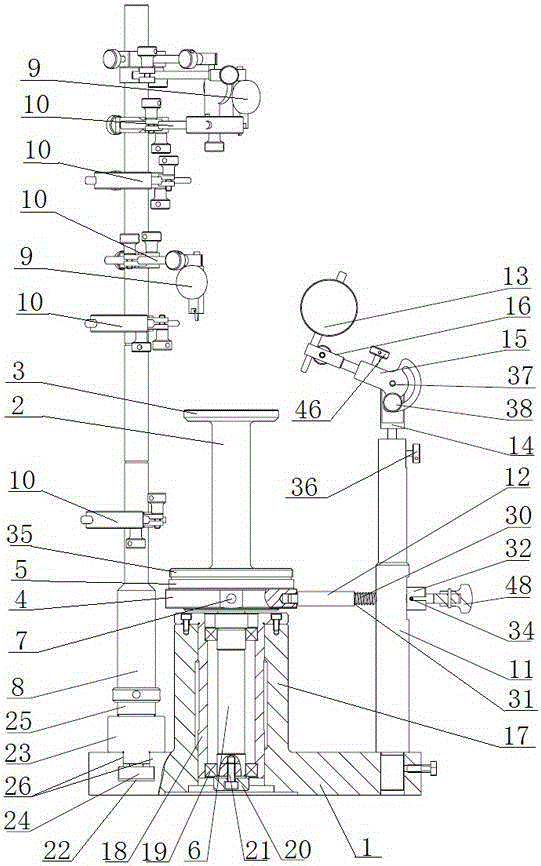

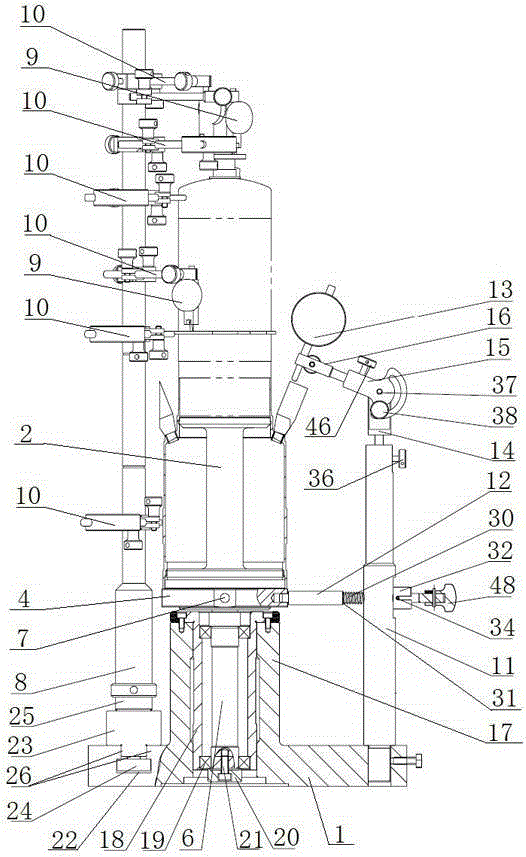

Cylinder part outer contour geometric tolerance measuring instrument

ActiveCN105203005ASolving precise measurementsSolve the problem of deformation affecting detectionMechanical counters/curvatures measurementsMeasuring instrumentEngineering

The invention discloses a cylinder part outer contour geometric tolerance measuring instrument which comprises a positioning device, a first measuring device, a second measuring device and a base, wherein the positioning device comprises a positioning mandrel; a first outer circle surface is arranged on the upper section of the positioning mandrel, and a positioning end surface and a second outer circle surface are arranged on the lower section of the positioning mandrel; the bottom end of the positioning mandrel is a cylindrical section; indexing holes are formed in the positioning end surface uniformly; the first measuring device comprises a meter frame rod vertically fixed on the base and capable of moving forwards and backwards, and a plurality of lever dial gages; the lever dial gages are connected with the meter frame rod through first fixing adjusting structures; the second measuring device comprises a fixing rod vertically fixed on the base, an indexing device on the fixing rod and a multiple-degree-of-freedom meter frame adjusting device; the first measuring device and the second measuring device are respectively positioned on the two sides of the positioning device. The cylinder part outer contour geometric tolerance measuring instrument is simple in structure, accurate and reliable in measurement, convenient to operate, low in manufacturing cost, convenient to move, and flexile and changeable in positioning mode and can measure a plurality of beats at the same time.

Owner:江南工业集团有限公司

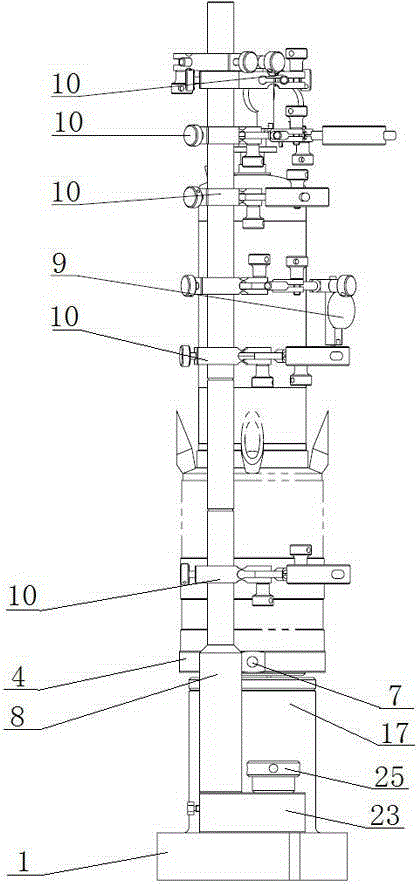

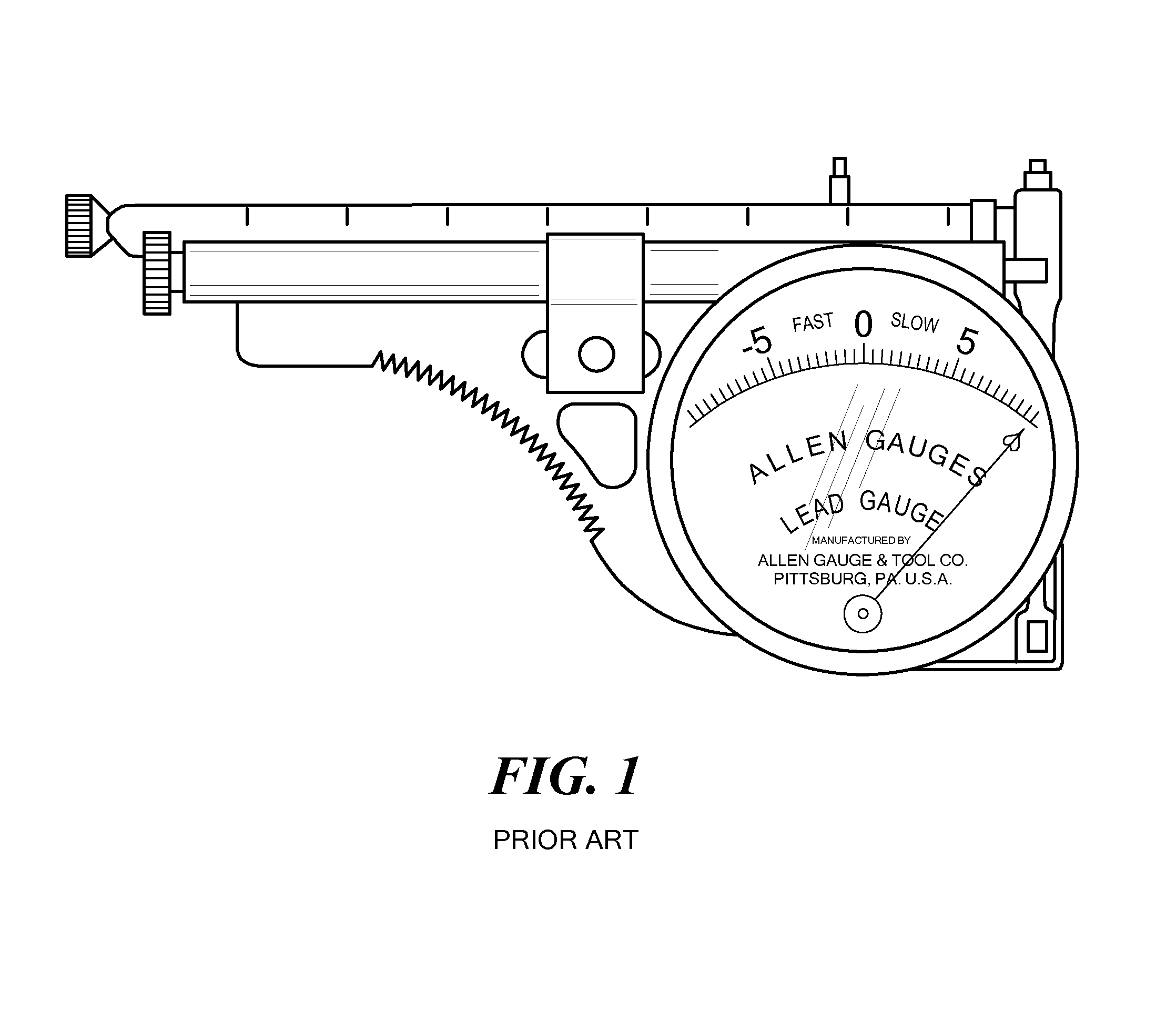

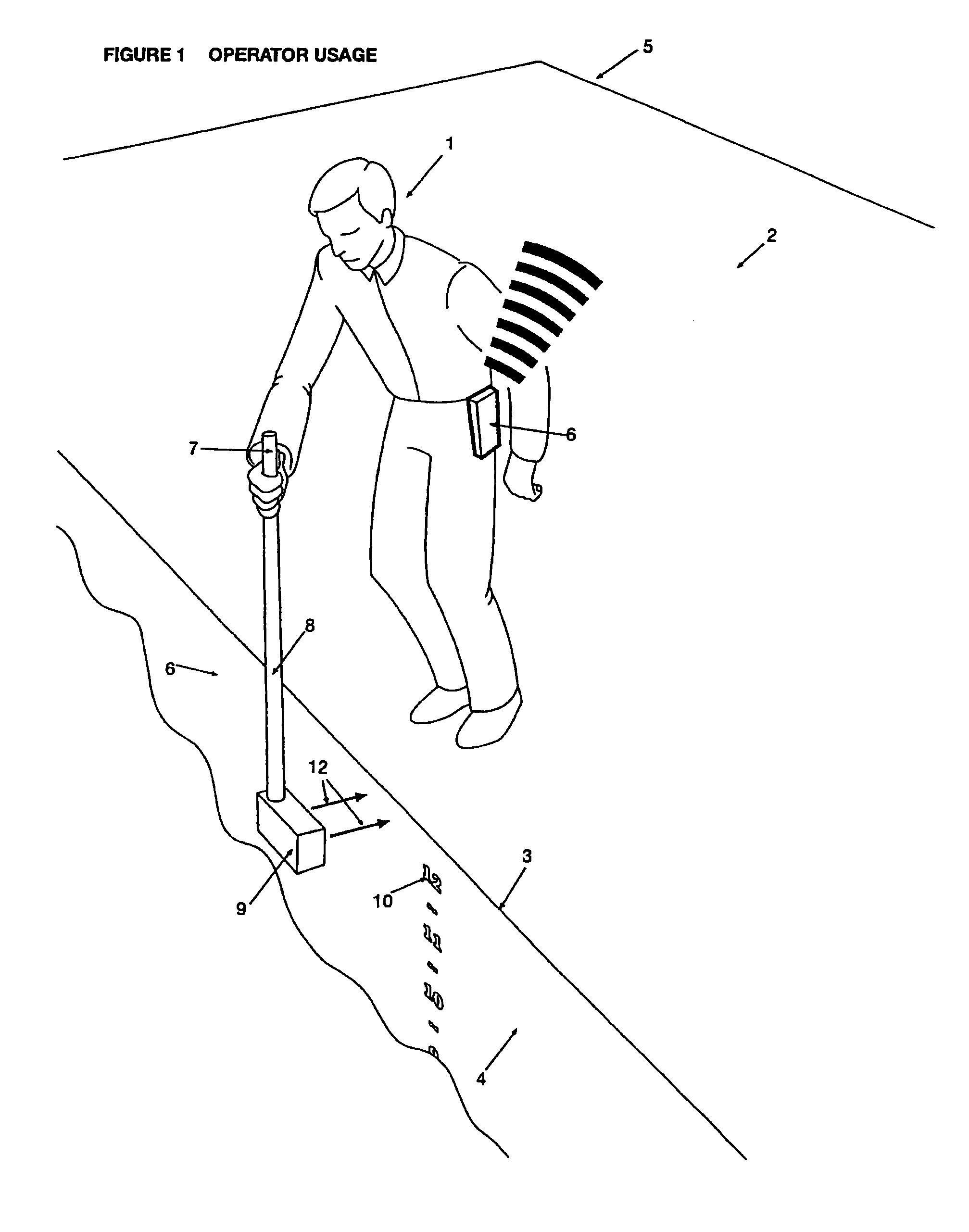

Determining thread lead or pitch accurately

InactiveUS20130104407A1Reduce repetitionsReduce errorsMechanical counters/curvatures measurementsMechanical clearance measurementsMetrologyLaser probe

Apparatus and methods are provided for measuring thread leads or pitches using a metrology probe. The probe may be, for example, either a contact probe or a laser probe. The probe is mounted on the end of an articulating arm that has sensors to provide precise three-dimensional coordinates of the probe's location and orientation. The probe determines surface coordinates of the threaded object repetitively in different locations according to a program provided by a computer connected to the arm. When enough data have been gathered, the computer calculates and outputs a surface profile of the threaded object, including a lead or pitch measurement.

Owner:HEXAGON TECH CENT GMBH

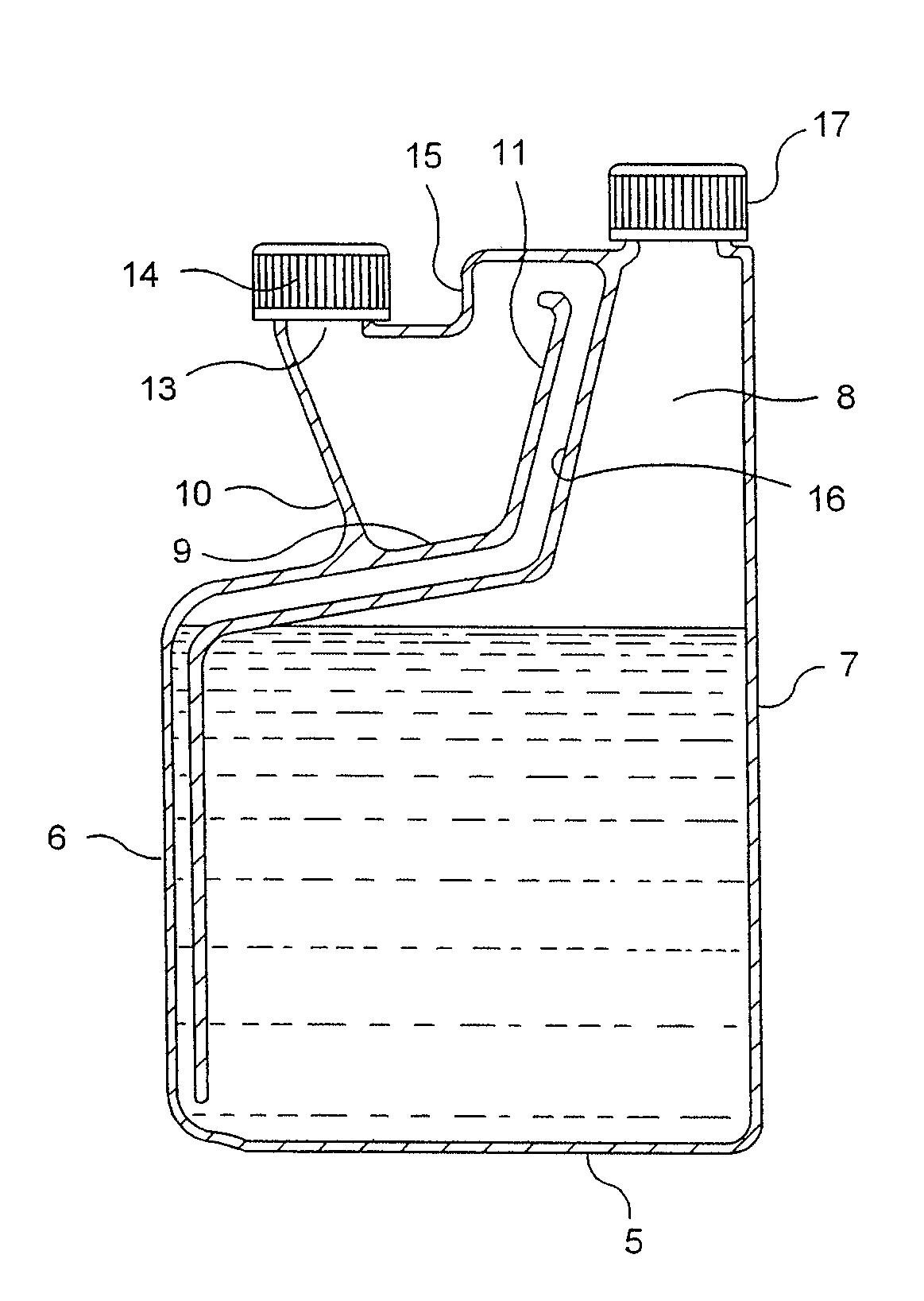

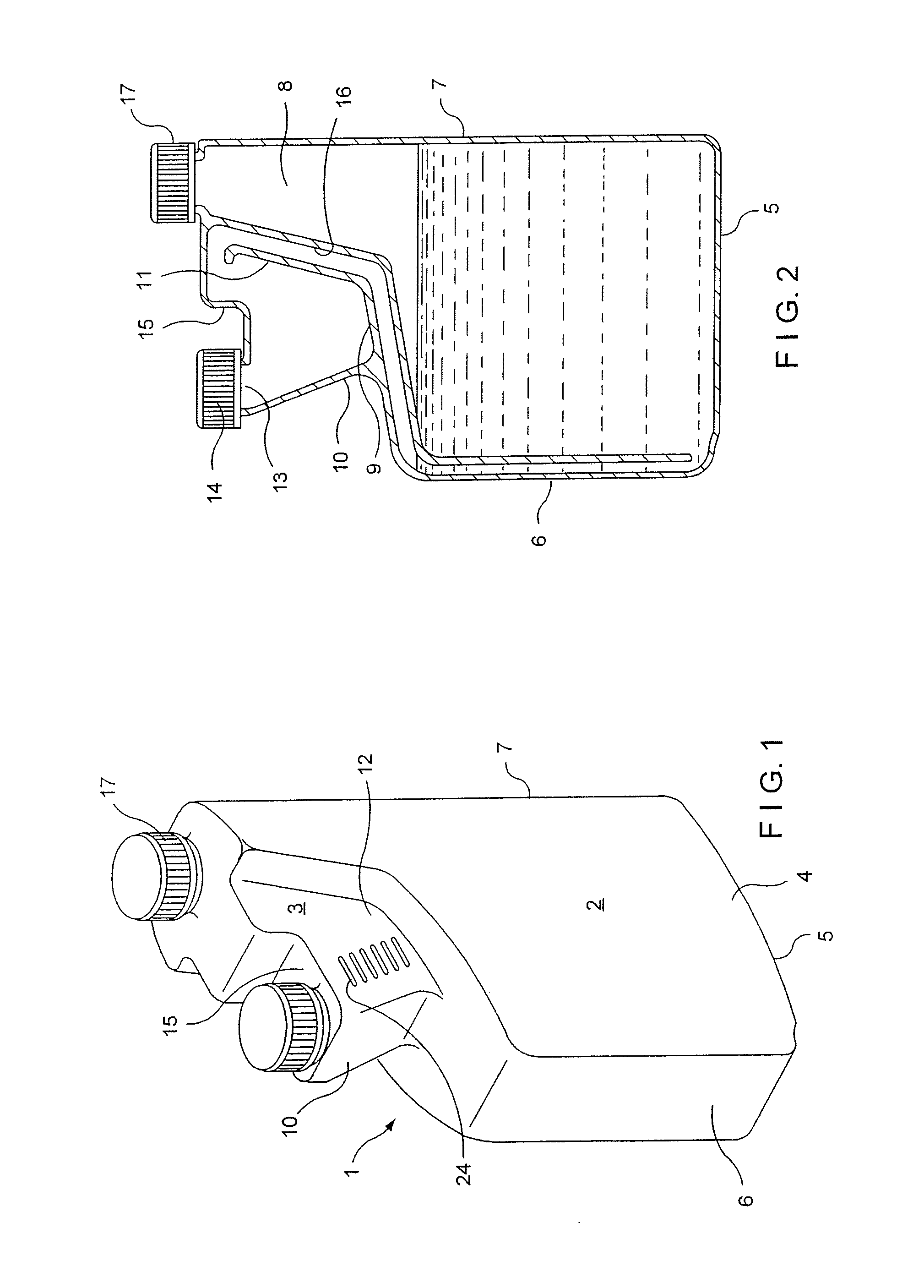

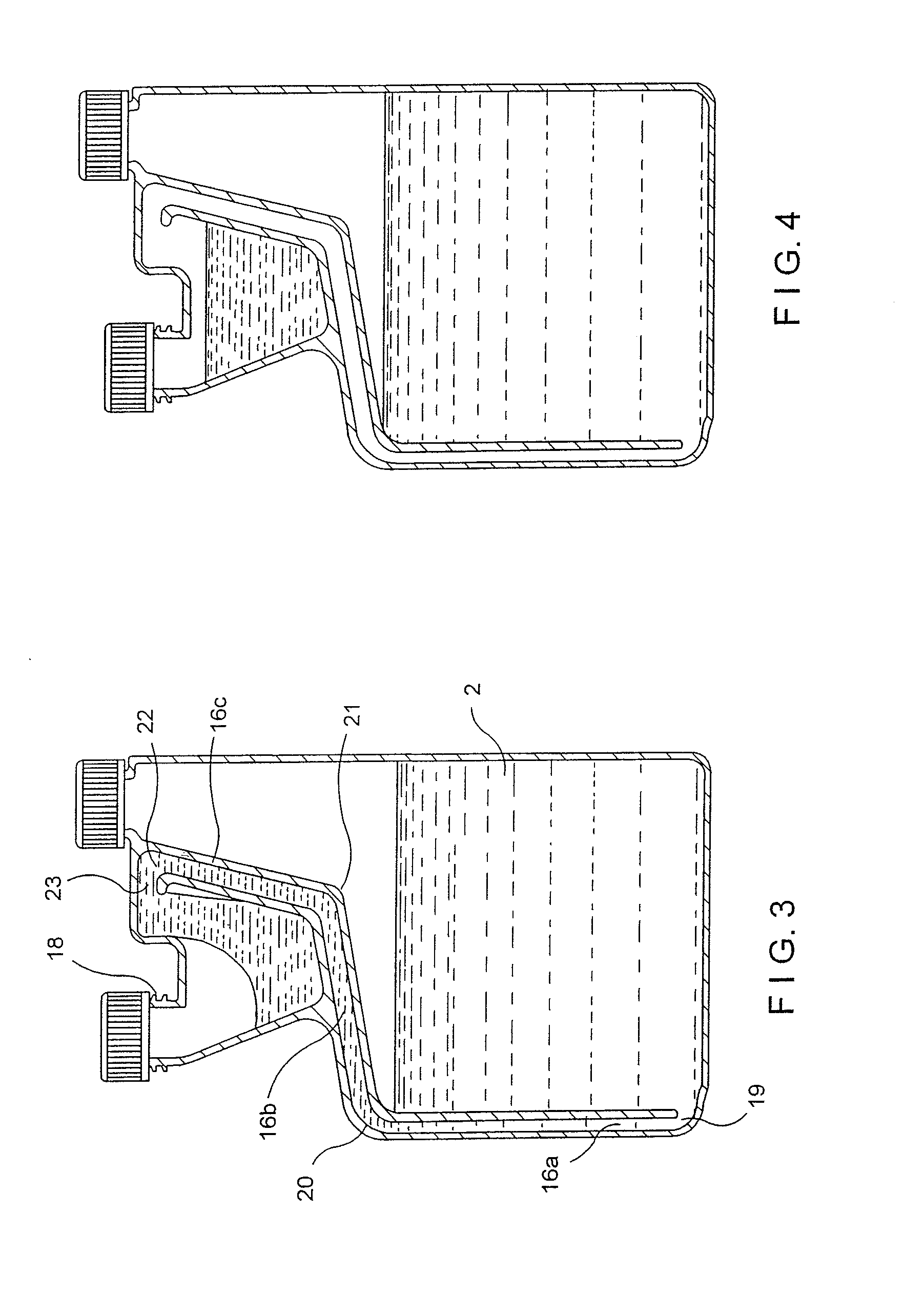

Measuring and dispensing container

ActiveUS20110127297A1Avoid turbulenceRisk minimizationMovable measuring chambersBottlesMechanical engineeringEngineering

Owner:JENNINGS ROBERT M +1

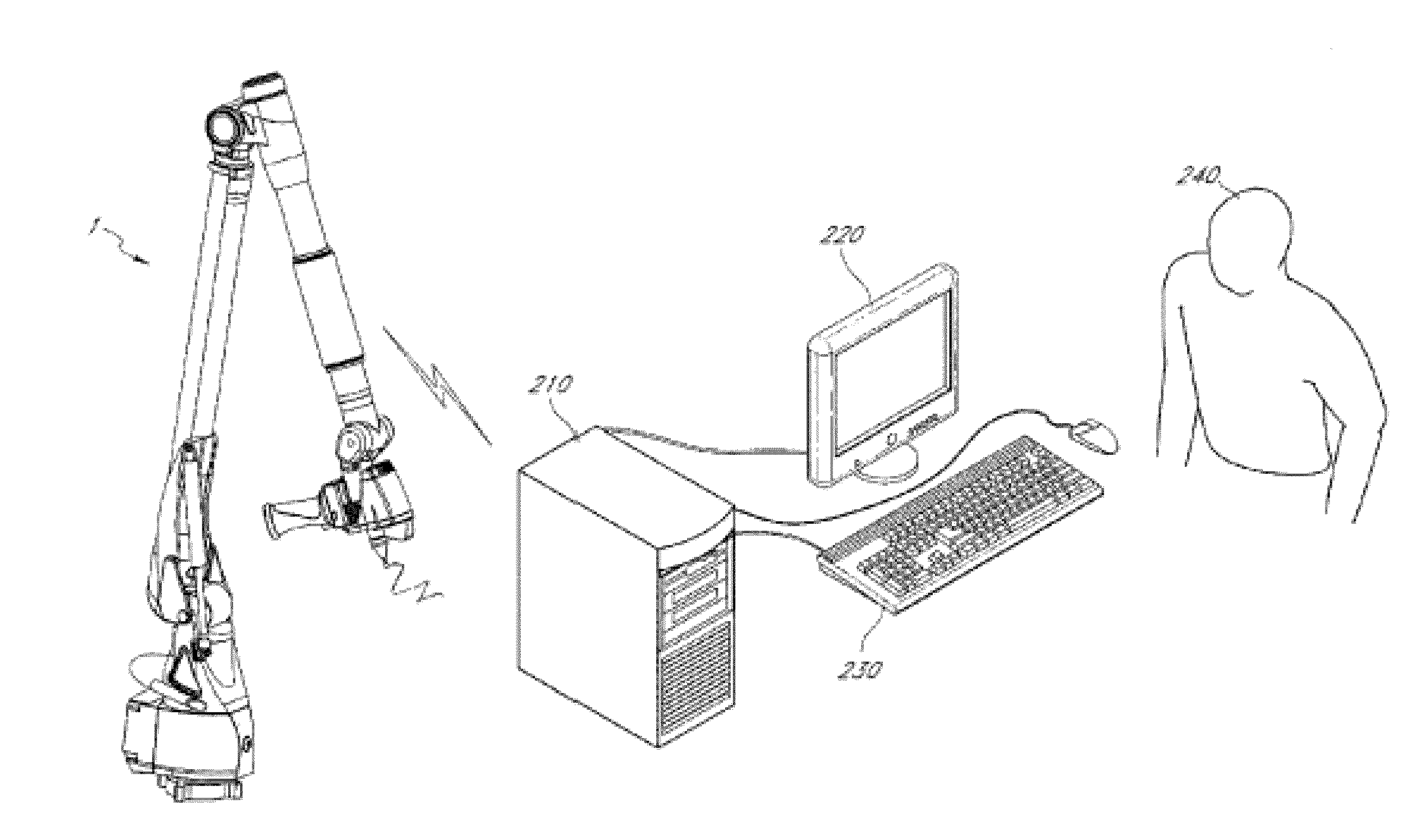

Method and reference model for checking a measuring system

ActiveUS20140365140A1Avoid poor resultsSolving precise measurementsImage enhancementImpression capsReference modelComputer vision

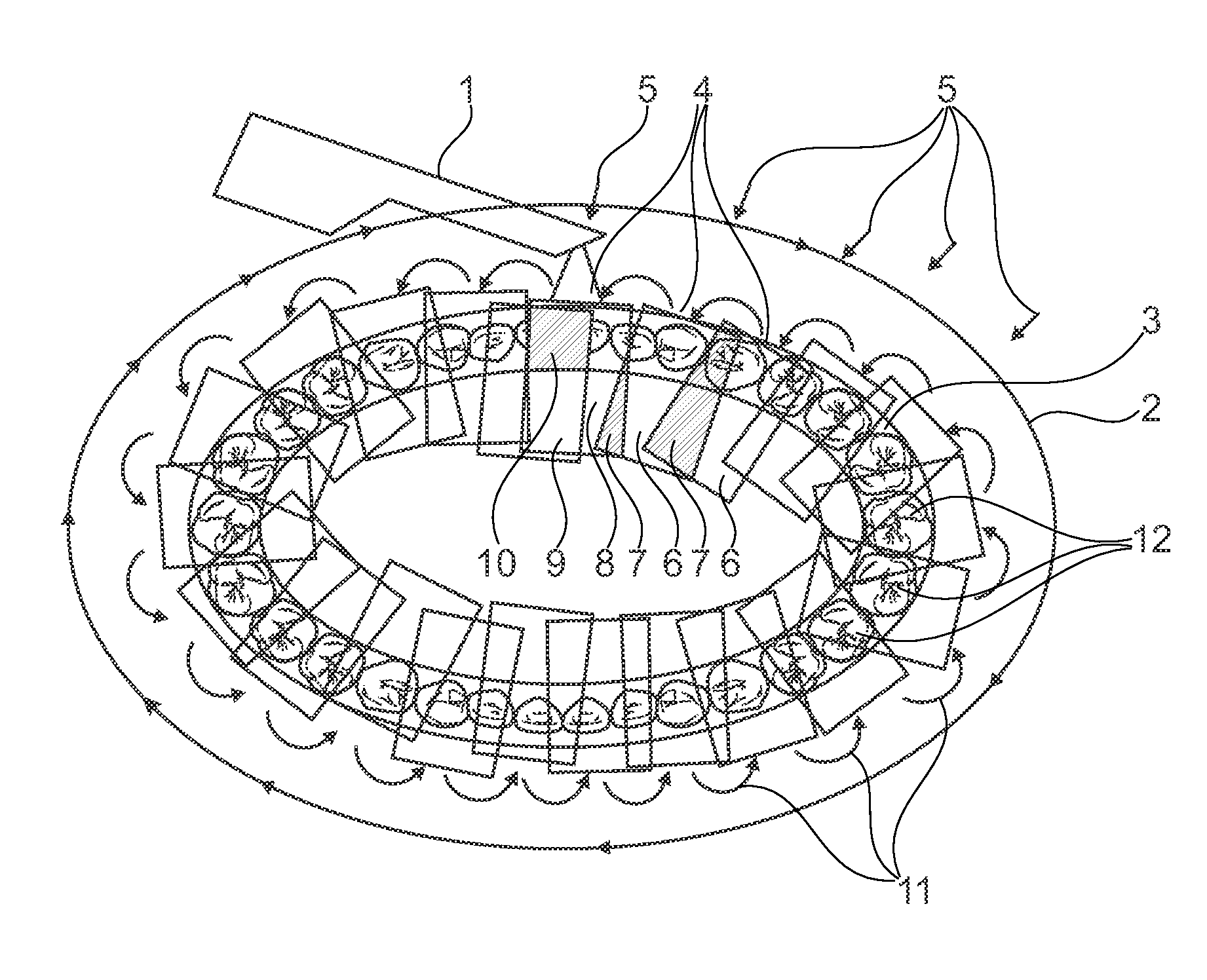

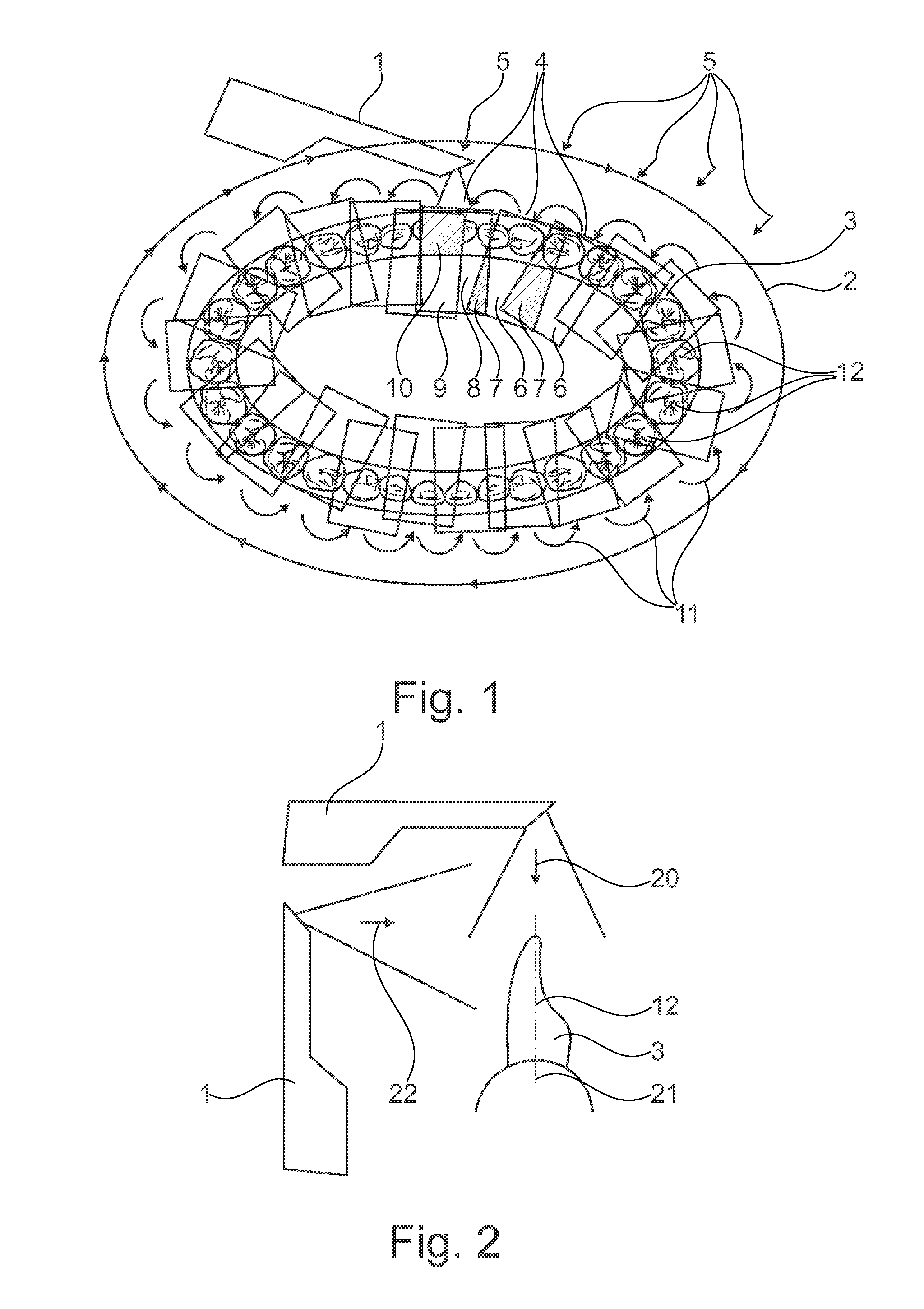

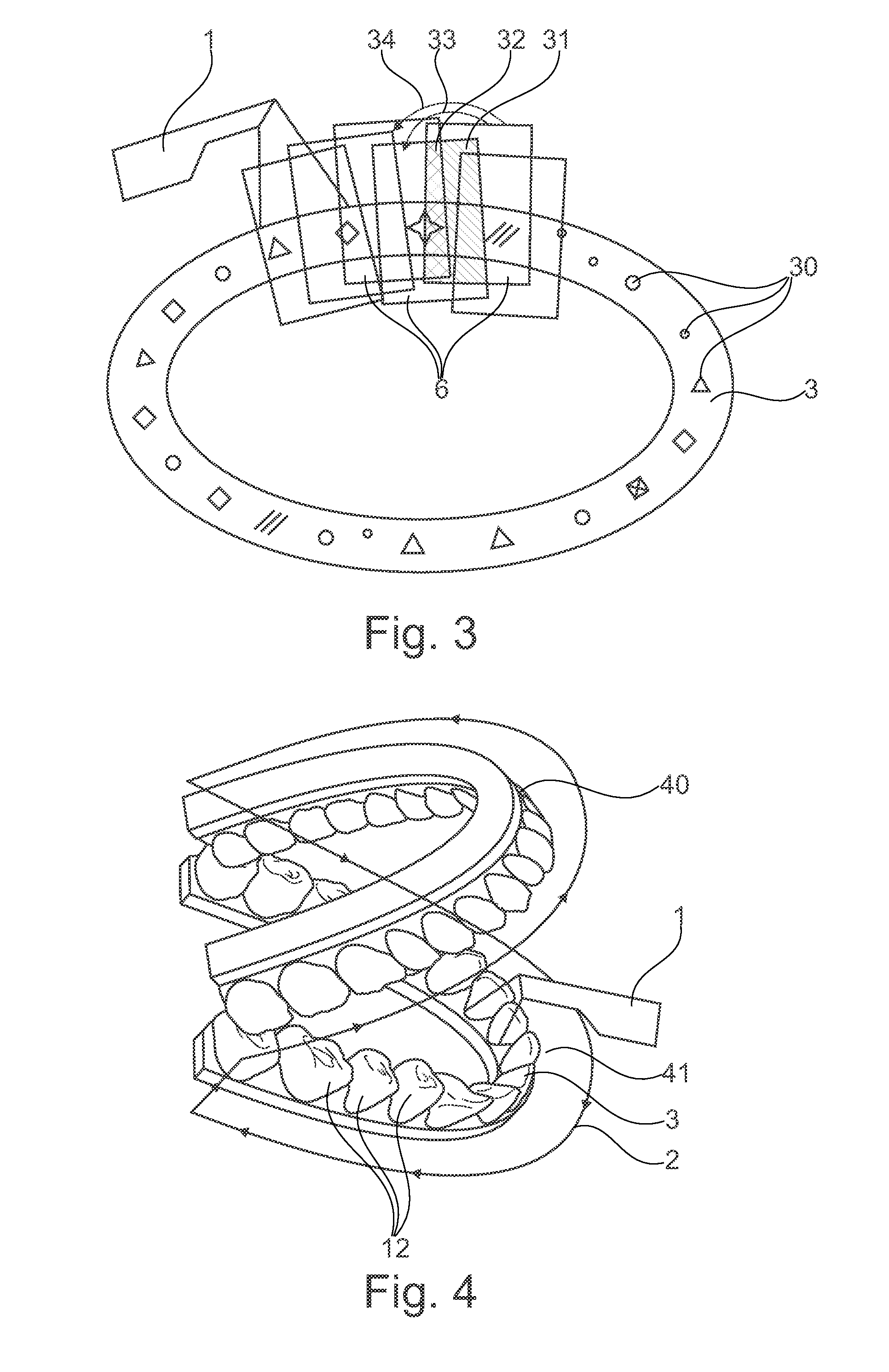

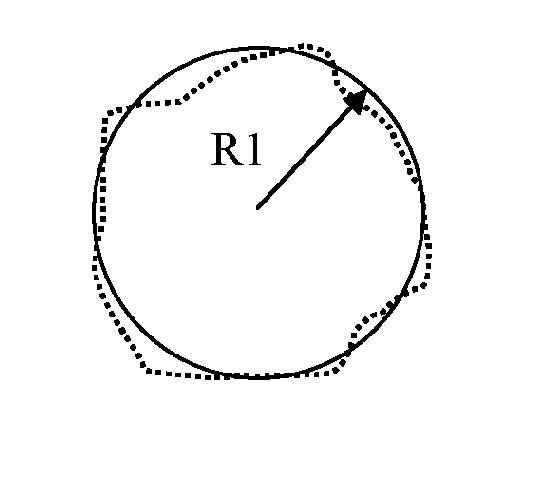

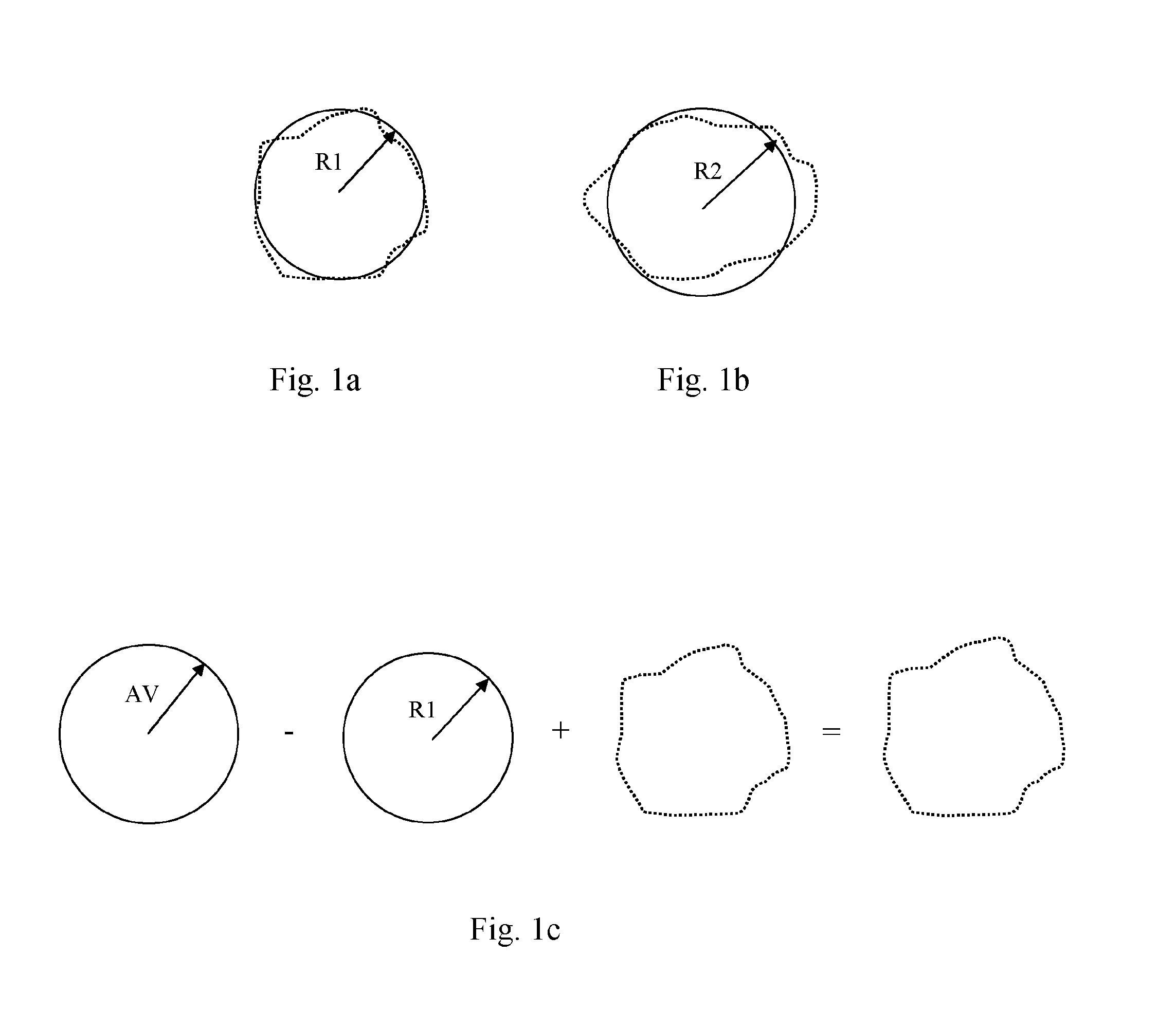

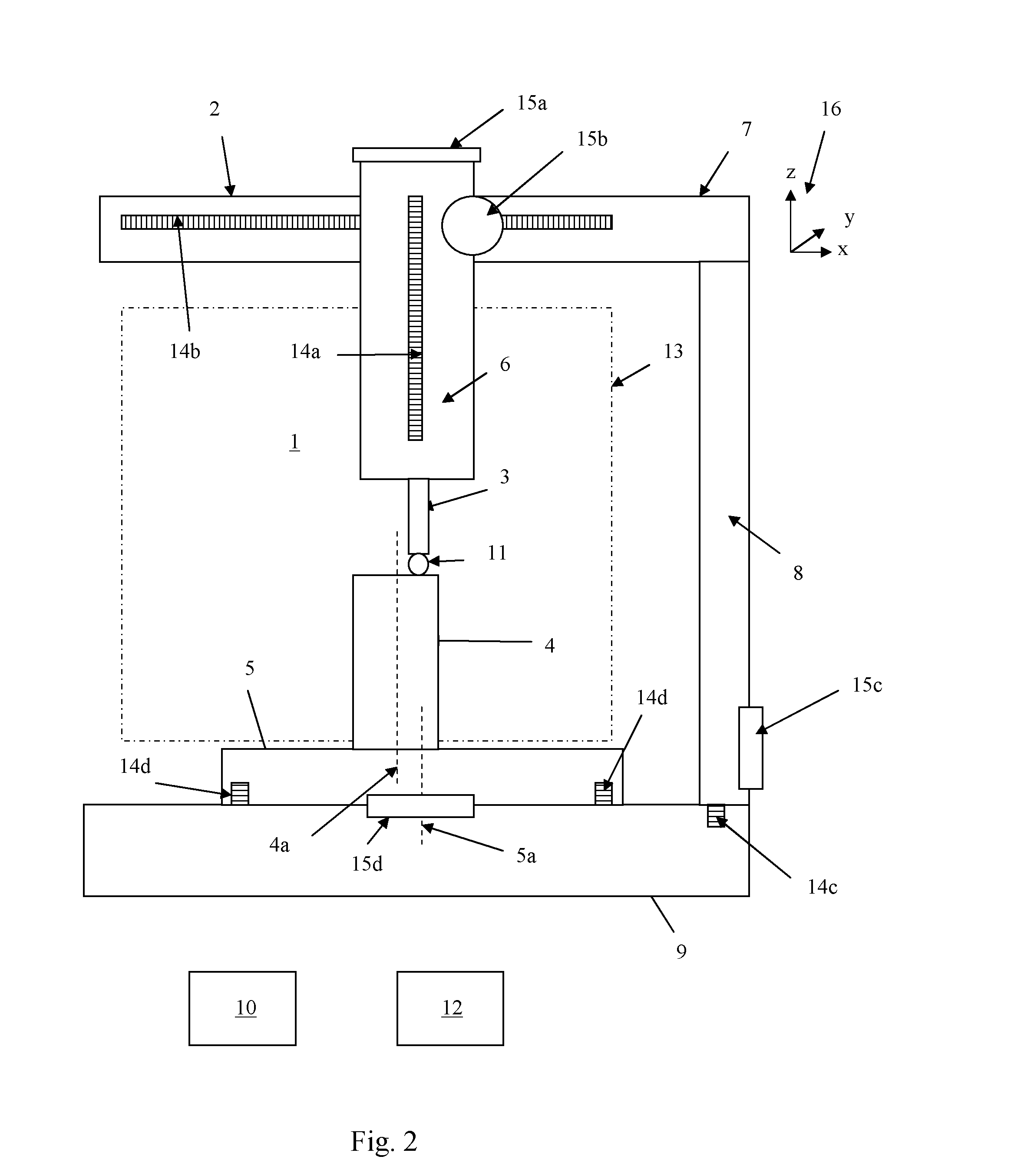

The invention relates to a reference object (3) and a method for checking a measuring system (1), wherein a plurality of three-dimensional recordings (4, 8) of a reference object are recorded from different recording directions (5) by means of the measuring system (1). The reference object (3) has a closed shape, wherein each of the three-dimensional recordings (4) is registered with at least the preceding recording (4). In the case of a faulty calibration and / or in the case of a faulty registration, the individual recordings (4, 8) are deformed compared to the actual shape of the reference object (3), so that the deformation continues when assembling the individual three-dimensional recordings (4) to form an overall recording (54) and the generated overall recording (54) deviates in its dimensions from the dimensions of the reference object (3) as a result thereof. At least one object region (10) of the reference object (3) is measured twice, at the beginning of a circuit and at the end of the circuit, wherein a distance (55) is determined in the overall recording (54) between a first position of the object region (10) in a first recording at the beginning of the circuit and a second position of the object region (10) in a second recording at the end of the circuit.

Owner:SIRONA DENTAL SYSTEMS

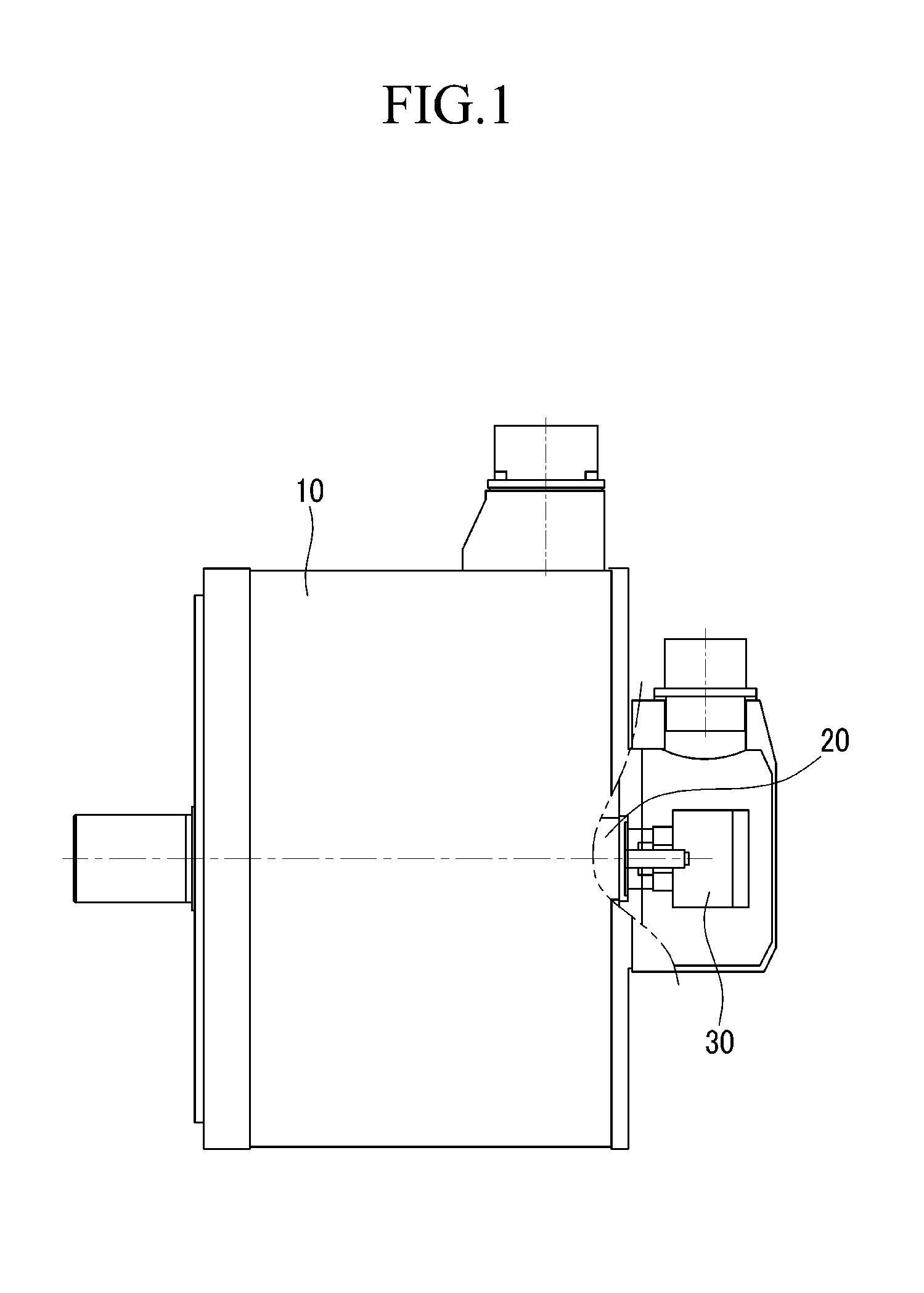

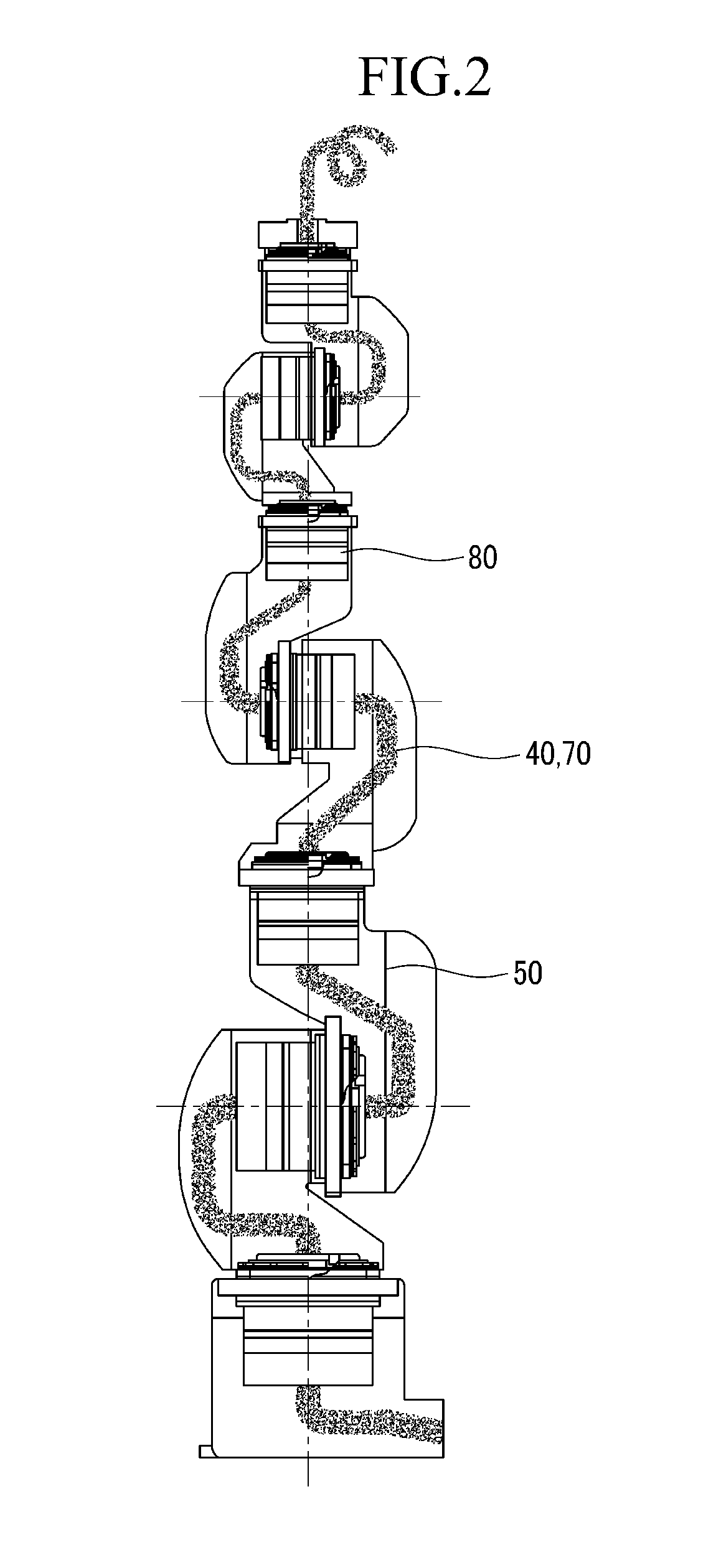

Hollow driving module

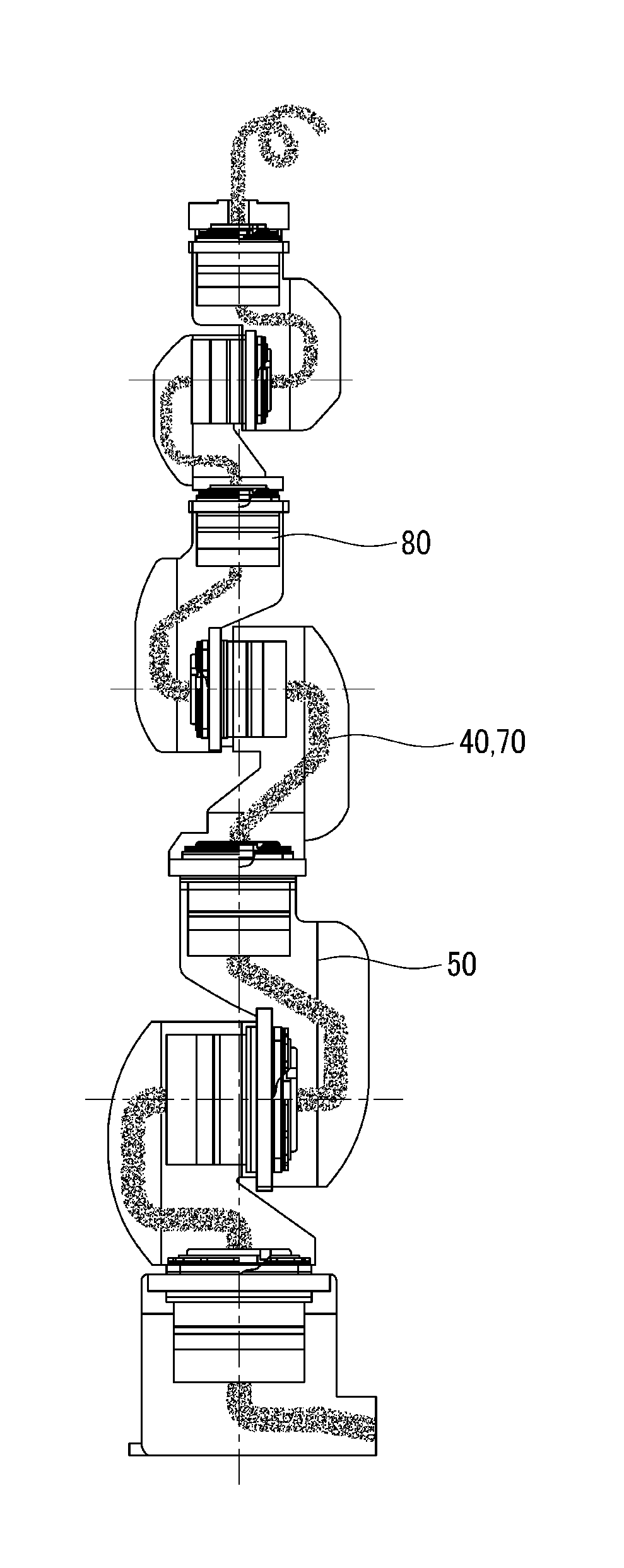

ActiveUS20130257230A1Precise angle of rotationCable twist is preventedDC commutatorStructural associationReduction driveTorque transmission

The present invention relates to a hollow driving module comprising a hollow driving module including a hollow motor including a stator, a rotor rotating with respect to the stator and having a perforated center portion, and a rotation shaft disposed at and coupled to the perforated center portion of the rotor; a decelerator connected with the rotation shaft positioned at an output side of the hollow motor to decelerate rotation of the rotation shaft; a torque transmission unit being connected to an output side of the decelerator to be driven by a decelerated rotation angle; a first encoder positioned at an input side opposite to a side connected with the decelerator of the hollow motor; a second encoder positioned at a side opposite to a side connected with the hollow motor of the first encoder; and a link connection means connecting the second encoder with the torque transmission unit.

Owner:KOREA INST OF MACHINERY & MATERIALS

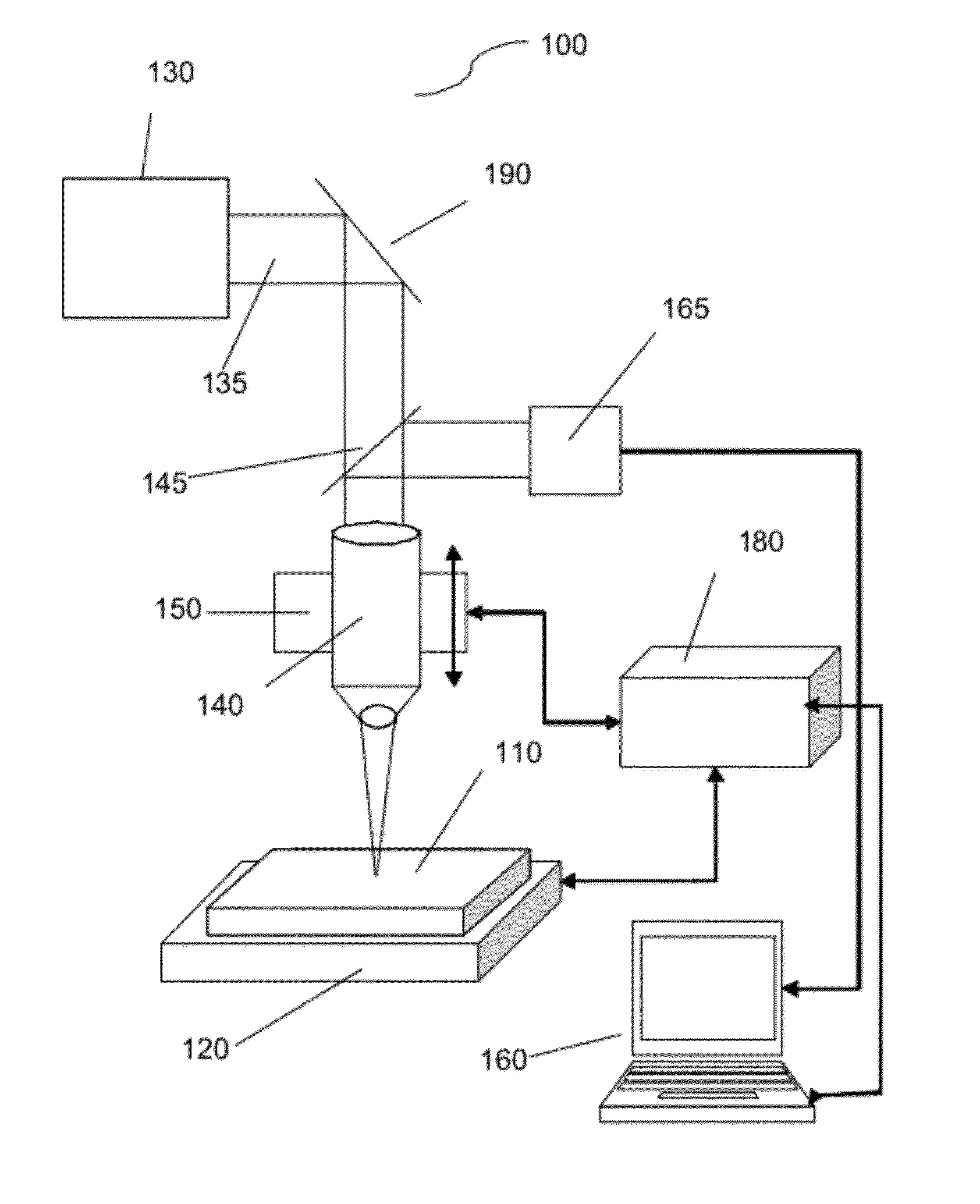

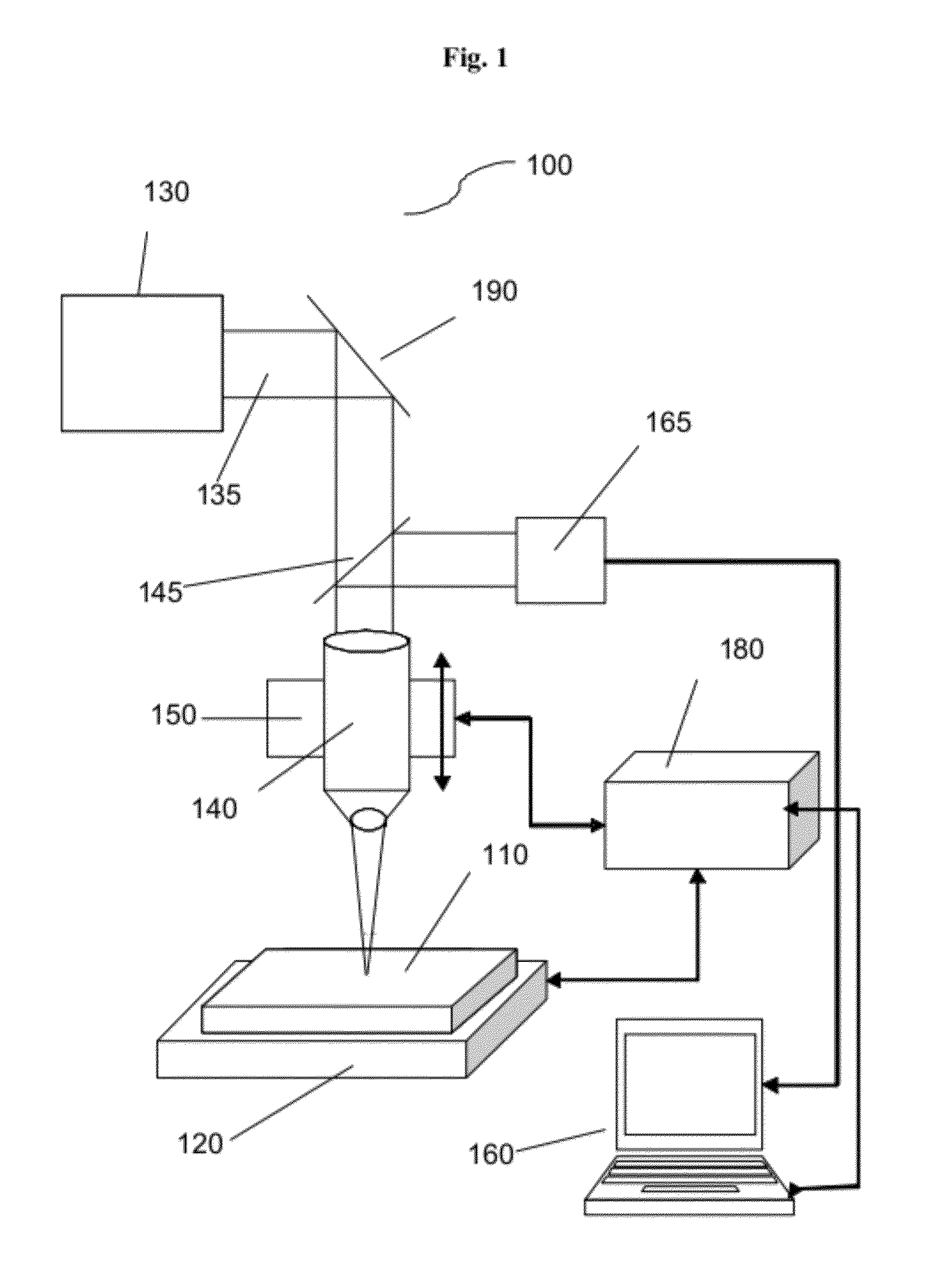

Method And Apparatus For The Determination Of Laser Correcting Tool Parameters

ActiveUS20120084044A1Minimum additional effortCorrect measurement errorNanoinformaticsPhotomechanical apparatusOptoelectronicsLaser beams

The invention relates to a method for determining at least one unknown laser beam parameter of a laser beam used for correcting errors of a transparent material including inducing a first persistent modification in the material by an interaction with the laser beam having a first set of laser beam parameters, measuring the induced first persistent modification of the material, calculating a second persistent modification in the material using a model describing persistent modifications in the material with a second set of laser beam parameters, wherein the first set of laser beam parameters comprises the second set of laser beam parameters and the at least one unknown laser beam parameter, setting up a target functional including the first persistent modification and the second persistent modification, and determining the at least one unknown laser beam parameter by minimizing the target functional.

Owner:CARL ZEISS SMS GMBH

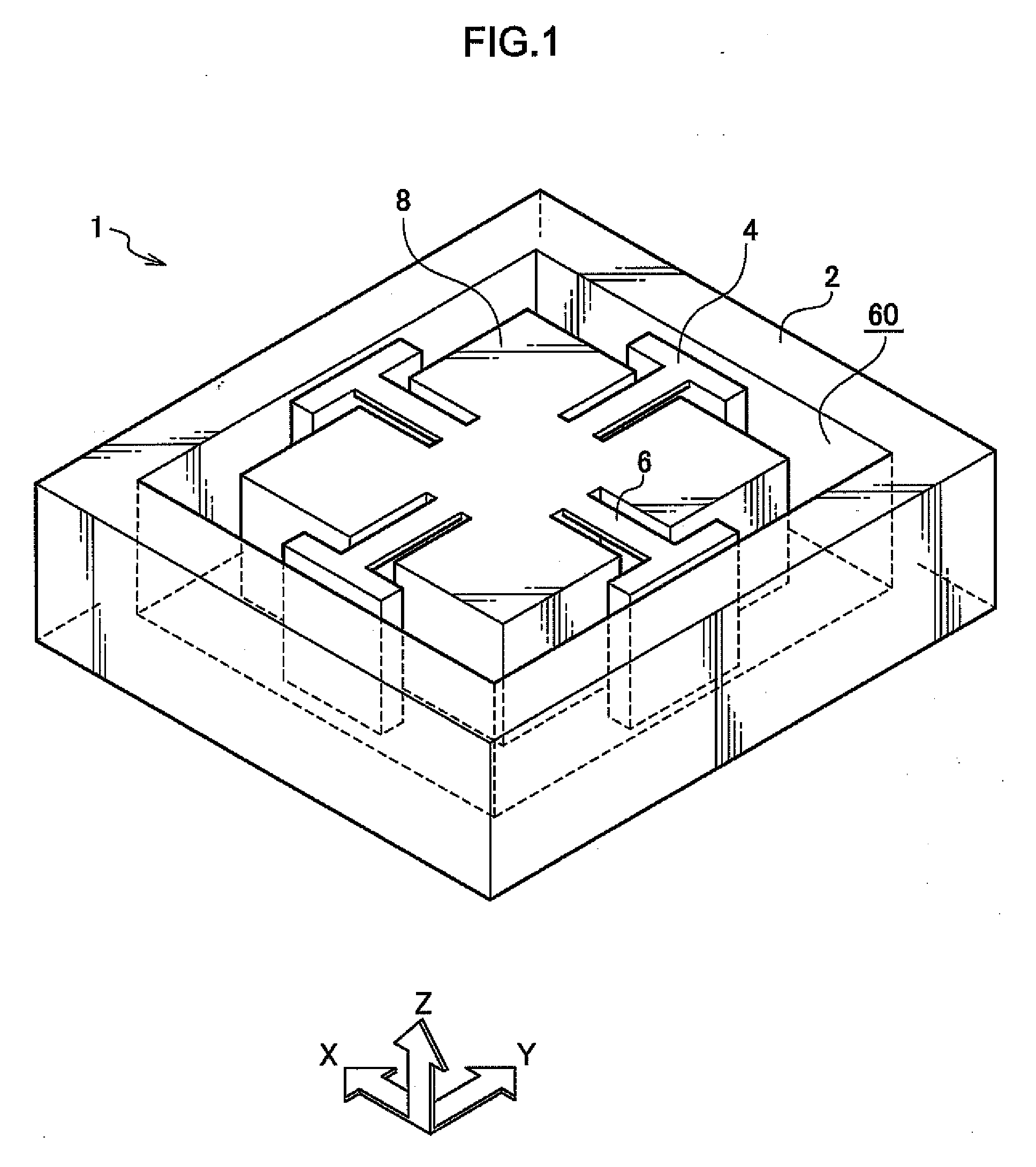

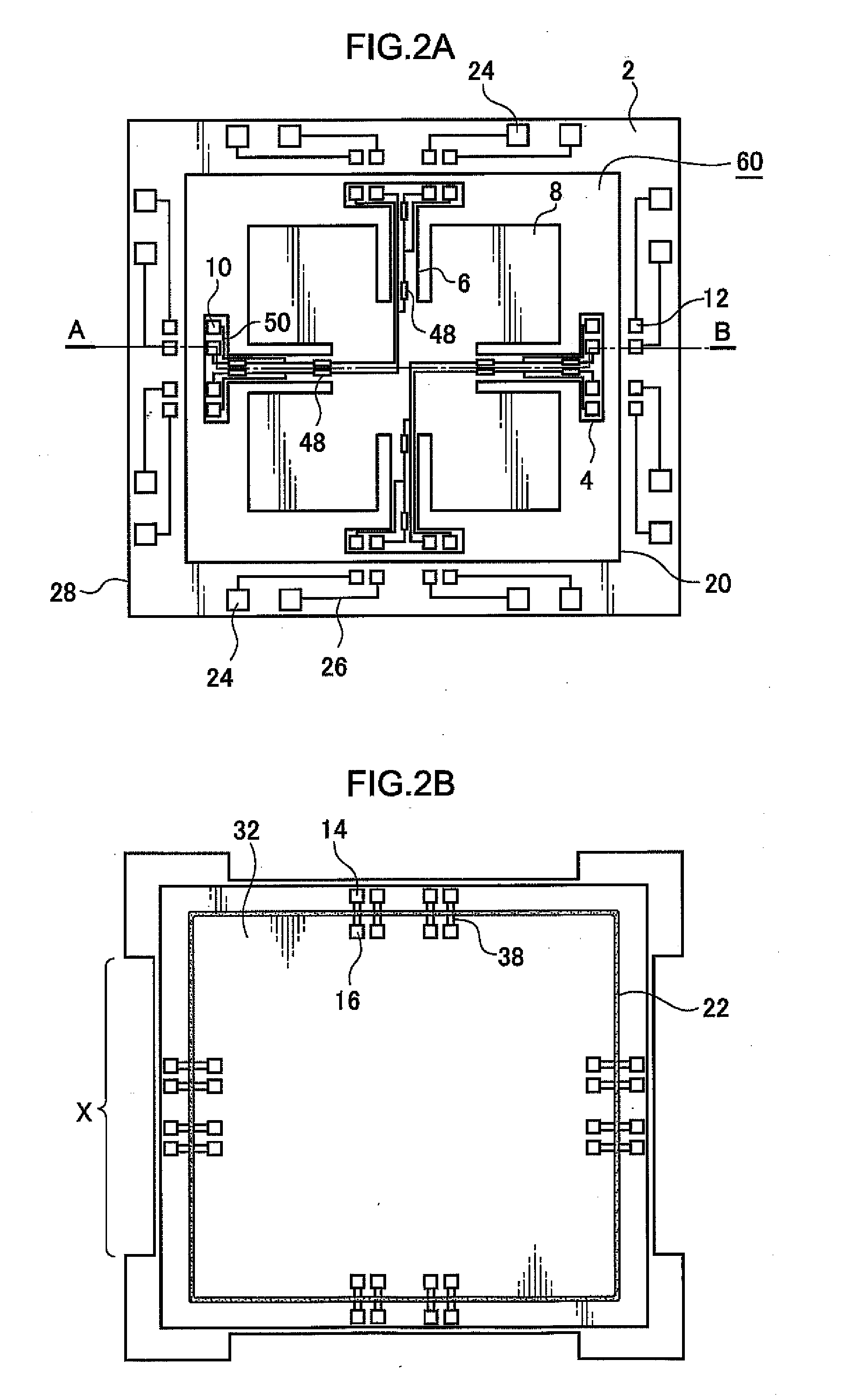

Acceleration sensor and method of fabricating acceleration sensor

ActiveUS20110113881A1Improve seismic performanceAvoid Sealing ProblemsAcceleration measurement using interia forcesWave amplification devicesEngineeringAcceleration Unit

There is provided an acceleration sensor including: a weight portion; plural fixed portions formed above a bottom plate around a periphery of the weight portion; a beam portion coupling the fixed portions and the weight portion, and holding the weight portion at a position separated from the bottom plate; a detection portion provided at the beam portion and detecting deformation of the beam portion; a frame portion provided so as to project out from the bottom plate and surround the fixed portions at a position separated from the fixed portions; and a lid portion of plate shape that seals an opening of the frame portion.

Owner:LAPIS SEMICON CO LTD

Method and apparatus for measuring a part

ActiveUS20150377617A1Reduce measurement uncertaintyAvoid mistakesProgramme controlFeeler-pin gaugesMechanical engineeringEngineering

A method and apparatus for measuring a part with a contact probe mounted on a coordinate positioning machine. The method includes measuring a plurality of points on the part when both the part and contact probe are moving continuously between different positions within the coordinate positioning machine. The probe moves, relative to the part, along a scan path such that substantially coincident points that are closely located together along a curve or surface being measured are measured at relatively far apart positions in the machine and at relatively far apart positions along the scan path.

Owner:RENISHAW PLC

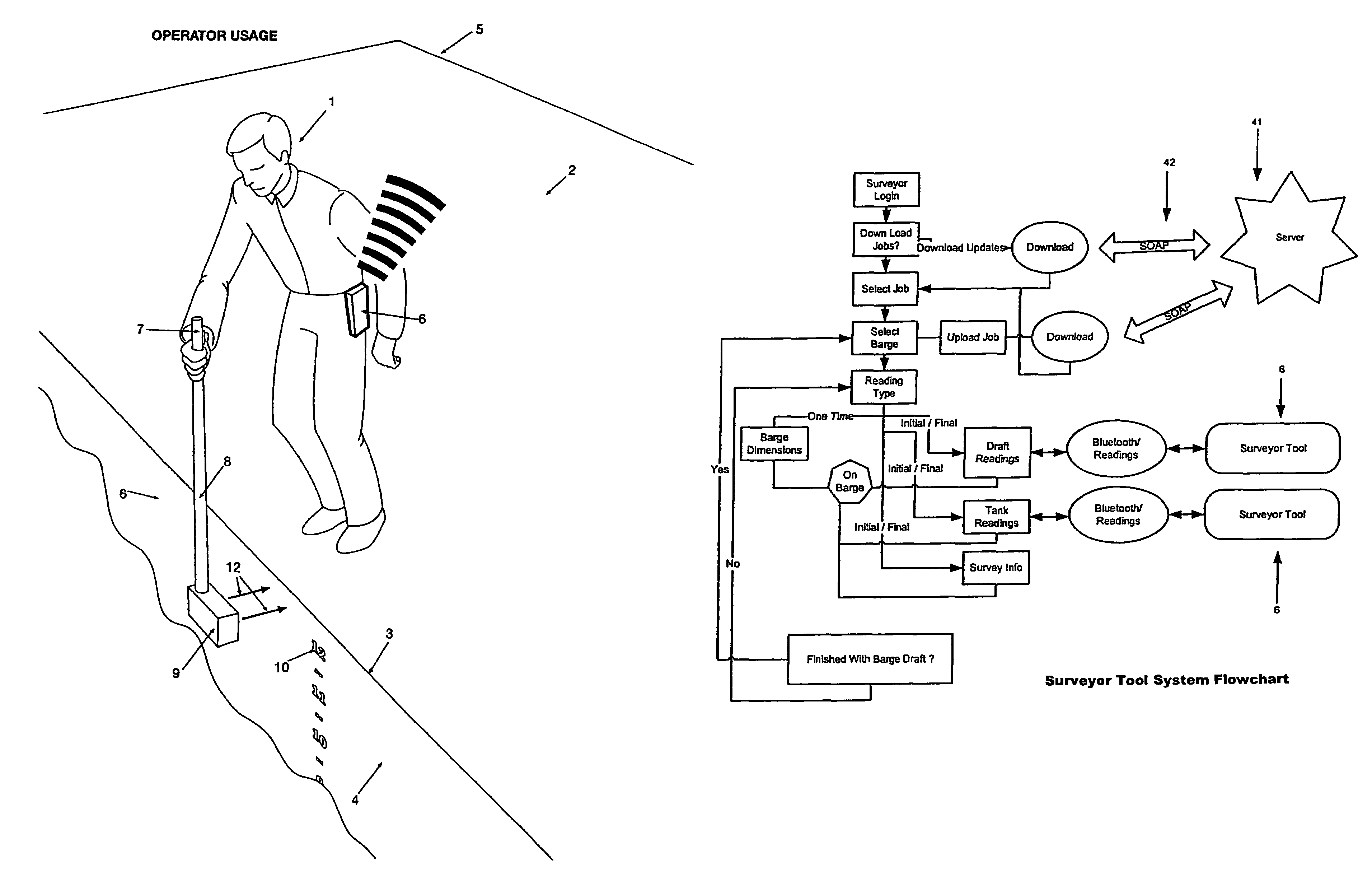

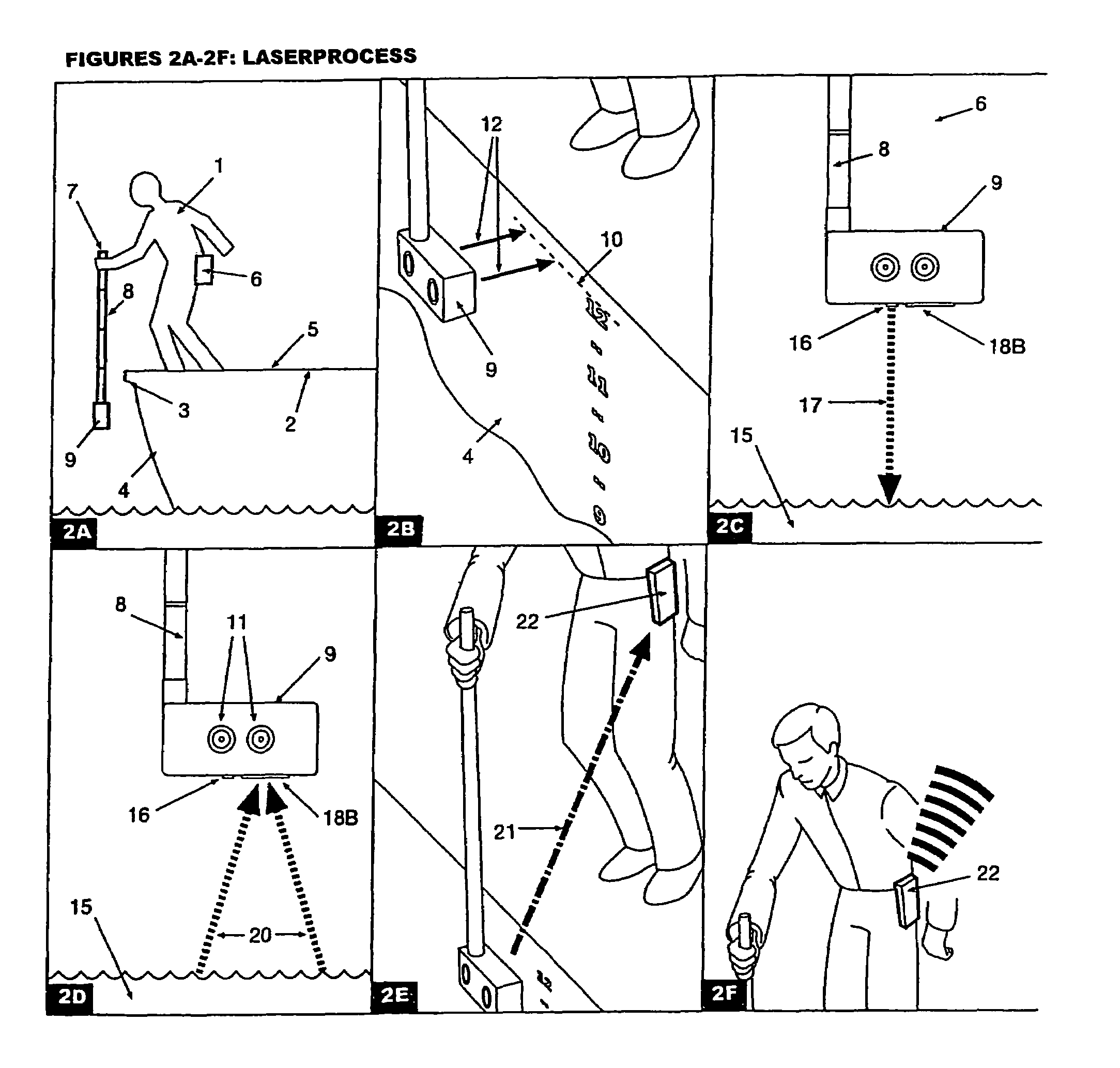

Methods and apparatus to determine vessel draft and amount of cargo loaded in a vessel

InactiveUS7325328B1Precise positioningThe data is accurate and reliableAuxillariesLevel indicatorsLaser transmitterUltrasonic sensor

The present invention discloses the methods and apparatus to acquire, record, and analyze data to determine the draft of a water-borne vessel and / or the amount of cargo that has been loaded in a water-borne vessel. The apparatus includes a portable, handheld housing containing means for use in positioning the housing in a predetermined location and spatial orientation. Such means can include one or more narrow beam emitting devices, such as lasers or other similar devices, or a camera or other image processing level sensors. The housing also containing an ultrasonic transducer and receiver, or alternatively, a laser emitter and receiver, that directs sound pulses or light, respectively, toward the surface of the water body in which the vessel is placed. Within the housing is electrical circuitry to receive either the sound or light beam signals, and from these signals produce a signal representative of the time of travel of the sound pulse or light. This signal will be transmitted wirelessly to a PDA or similar device that utilizes an arraying analytical technique on the received signals to determine the distance of the vessel above the waterline. The data representing the distance of the vessel above the waterline will then be either further processed by the PDA, or transmitted wirelessly to a central computer, for use in conjunction with displacement characteristics and cargo unit weight to determine the amount of cargo that has been loaded in the vessel. A collapsible or telescopic handle or other similar device may be attached to the housing to both facilitate carrying the apparatus to the field site, as well as to facilitate the positioning of the housing at the desired draft line while permitting the marine surveyor to stand on the vessel deck. For ease of use controls for operating the apparatus are preferably attachable to the handle.

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com