Patents

Literature

84results about How to "Correct measurement error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calibration compensation method for triaxial vector sensor and biaxial vector sensor

InactiveCN101887068ACorrect measurement errorMeasurement Error CalibrationElectrical measurementsTesting/calibration of speed/acceleration/shock measurement devicesObservational errorMathematical model

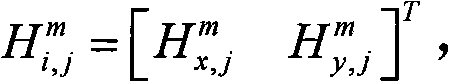

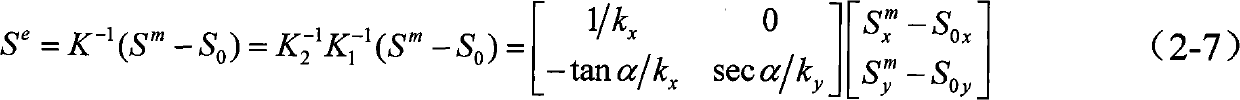

The invention relates to error correction of a vector sensor, in particular to a calibration compensation method for a triaxial vector sensor and a biaxial vector sensor, and solves the problems that the calibration compensation method of the existing multi-axial vector sensor fails to take all factors causing measurement error into account and the like. In the method, an error correction mathematical model of the vector sensor is built according to the relation of actually measured output Sm and theoretical output Se of the vector sensor, i.e. Sm=KSe + S0 and according to an error coefficient matrix K=K1K2, wherein, K1 and K2 are respectively a sensitivity error coefficient matrix of the triaxial vector sensor and a non-orthogonal error coefficient matrix among three measured axes; and an effective method is utilized to obtain correct zero-offset S0 and a correction coefficient matrix K-1 in the error correction mathematical model, and finally the error correction mathematical model of the measured vector sensor is obtained to carry out calibration compensation on the measuring result of the vector sensor. The method achieves calibration compensation taking into account of all the factors causing the measurement error of the multi-axial sensor, thus improving the accuracy of measuring results; and the method has concise and convenient process and no excessively high requirements on hardware equipment, thus being suitable for various vector sensors.

Owner:ZHONGBEI UNIV

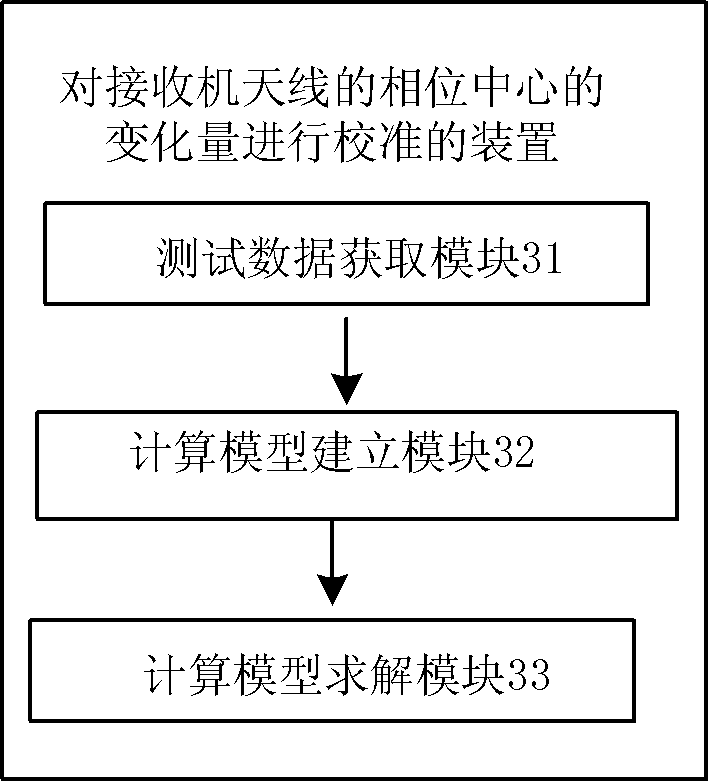

Method for calibrating phase center of receiver antenna and apparatus thereof

ActiveCN102323489AExact calibration valueCorrect measurement errorAntenna radiation diagramsObservational errorRegression analysis

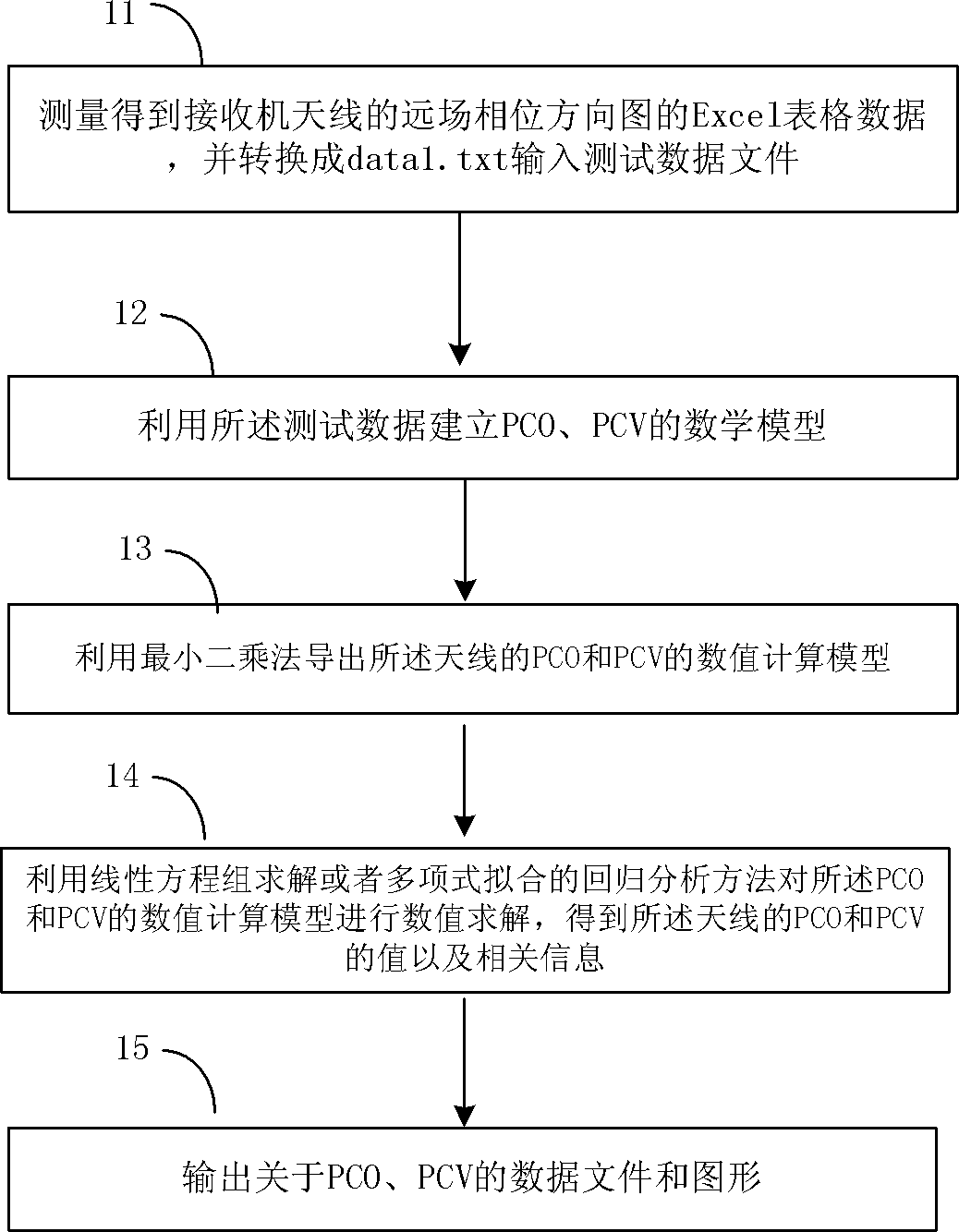

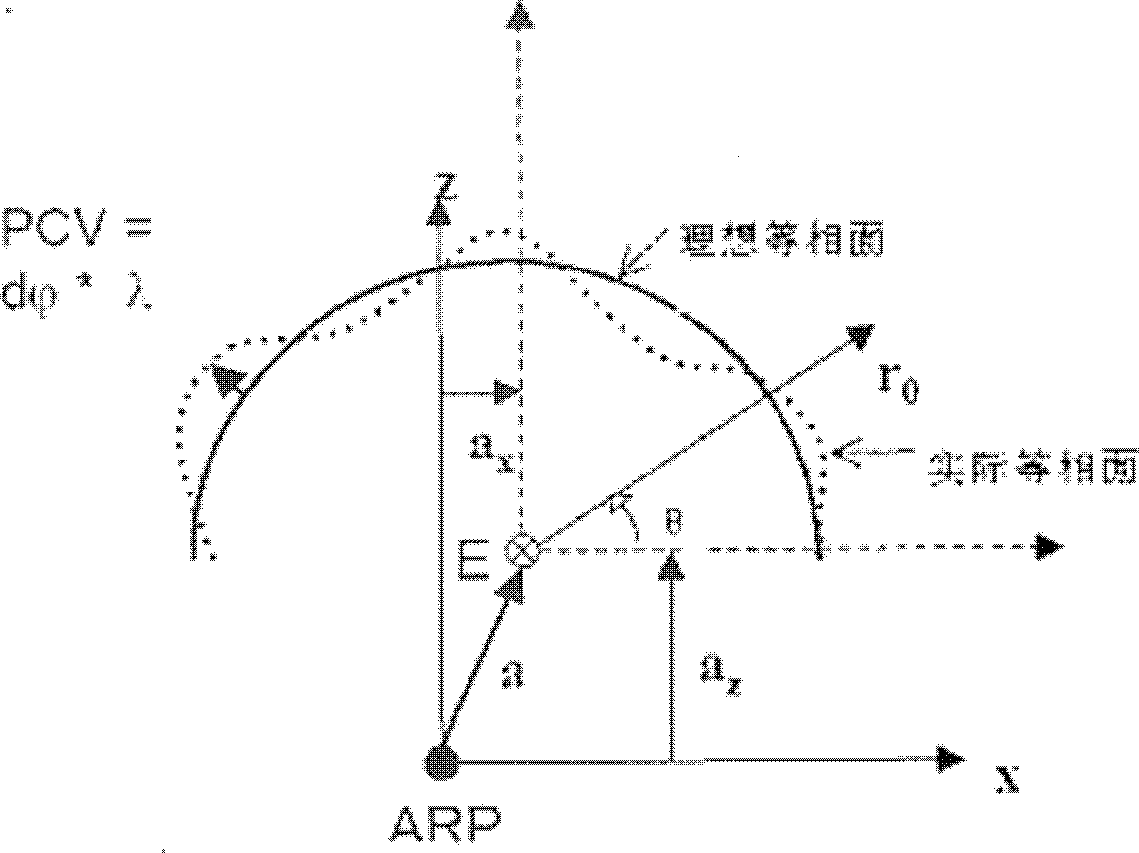

An embodiment of the invention provides a method for calibrating a phase center of a receiver antenna and an apparatus thereof. The method comprises the following steps: measuring and obtaining far field phase directional diagram data of a receiver antenna and taking the far field phase directional diagram data as input test data; establishing mathematical models of Phrase Center Offset (PCO) andPhase Center Variation (PCV) of the receiver antenna by utilizing the input test data; exporting PCO and PCV value calculation models of the antenna by utilizing a least square method, and carrying out numerical solution on the PCO and PCV value calculation models by utilizing a linear equation group solution or polynomial fitting regression analysis method to obtain PCO and PCV values of the antenna. According to the embodiment of the invention, absolute positioning (phase) of PCO and PCV of the receiver antenna can be obtained, and a measurement error brought by antenna phase center change can be accurately corrected to raise measurement precision of a GNSS (Global Navigation Satellite System) receiver.

Owner:北京华力创通科技股份有限公司

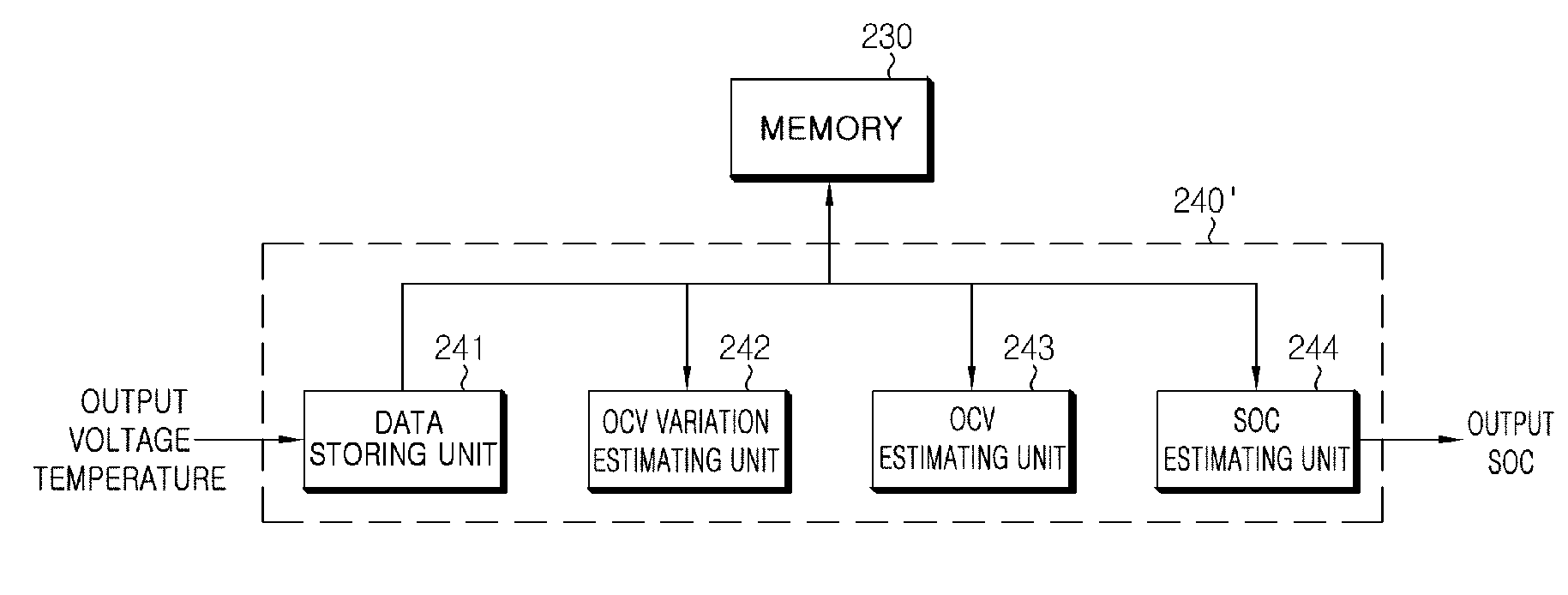

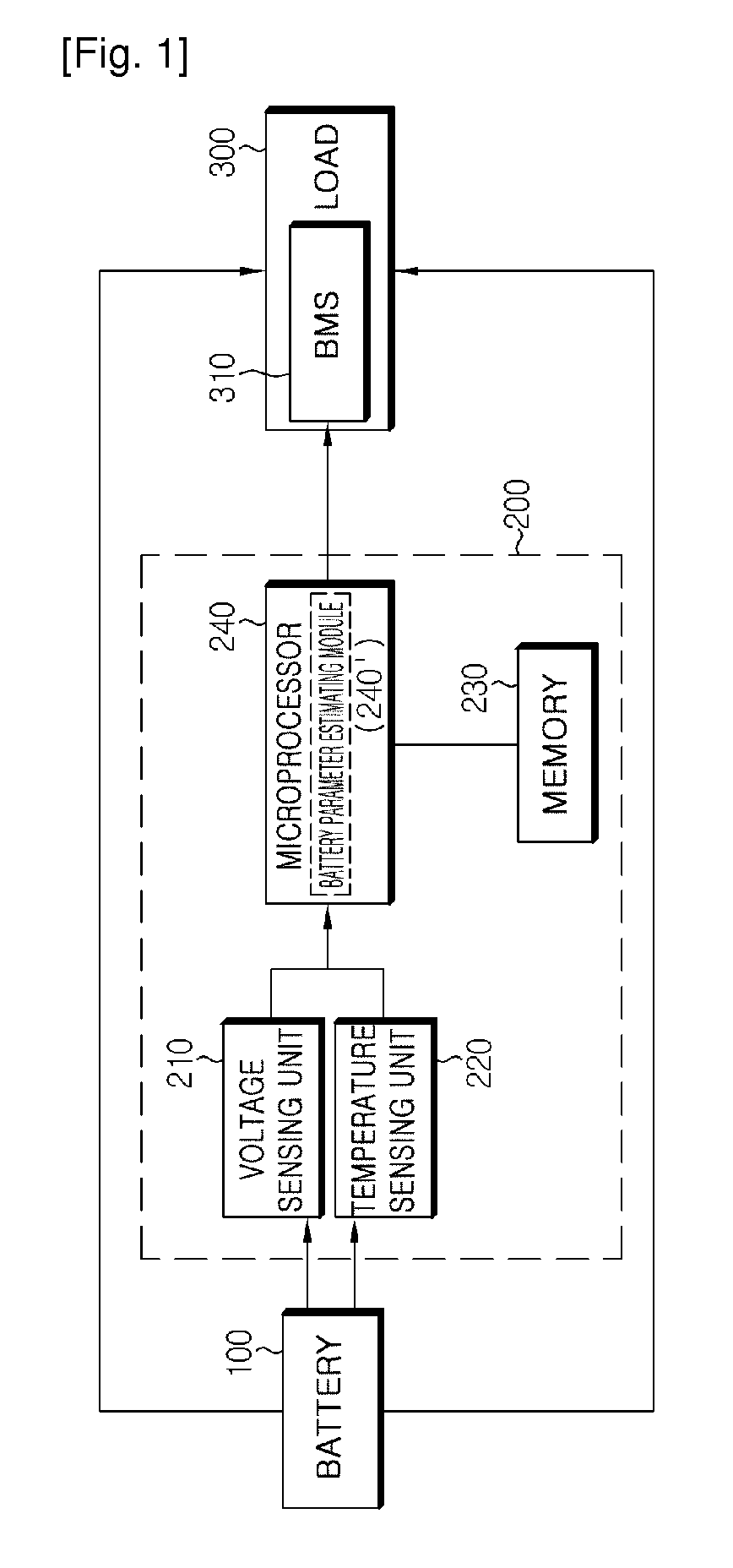

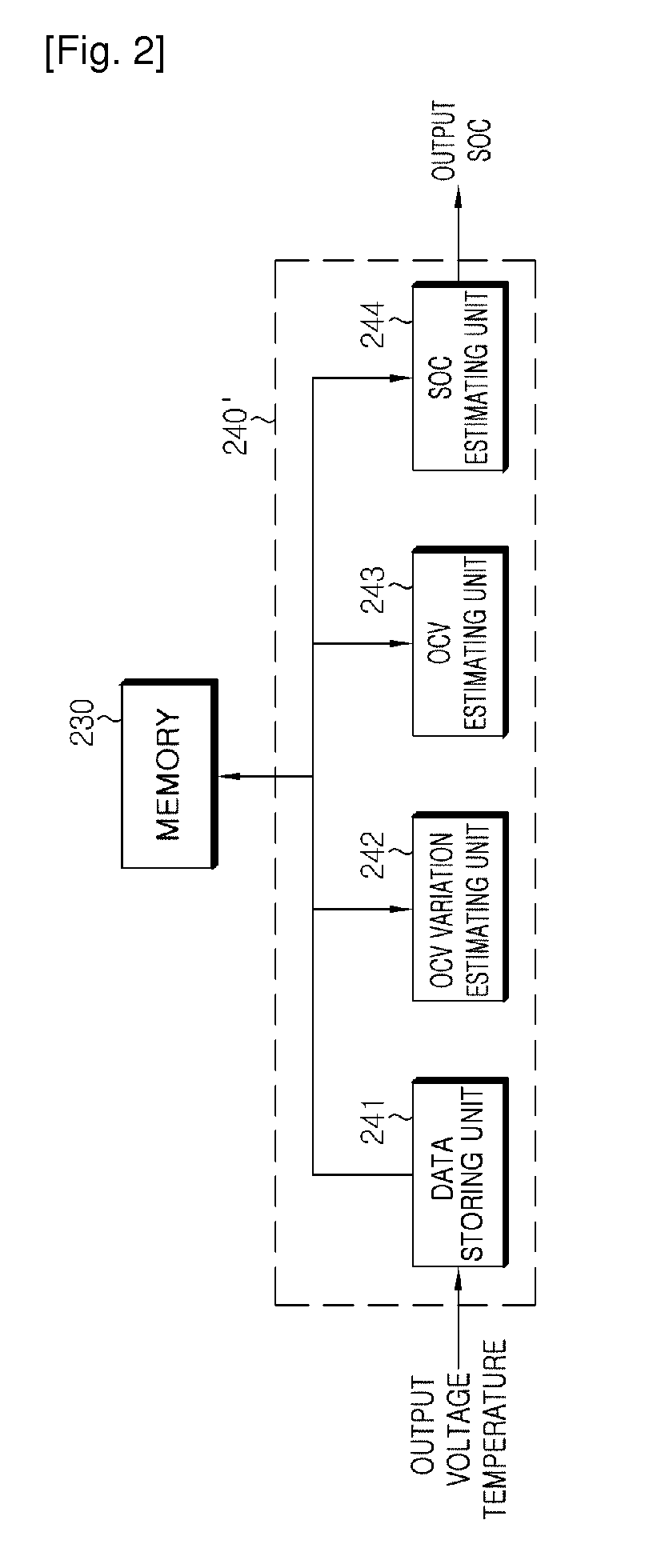

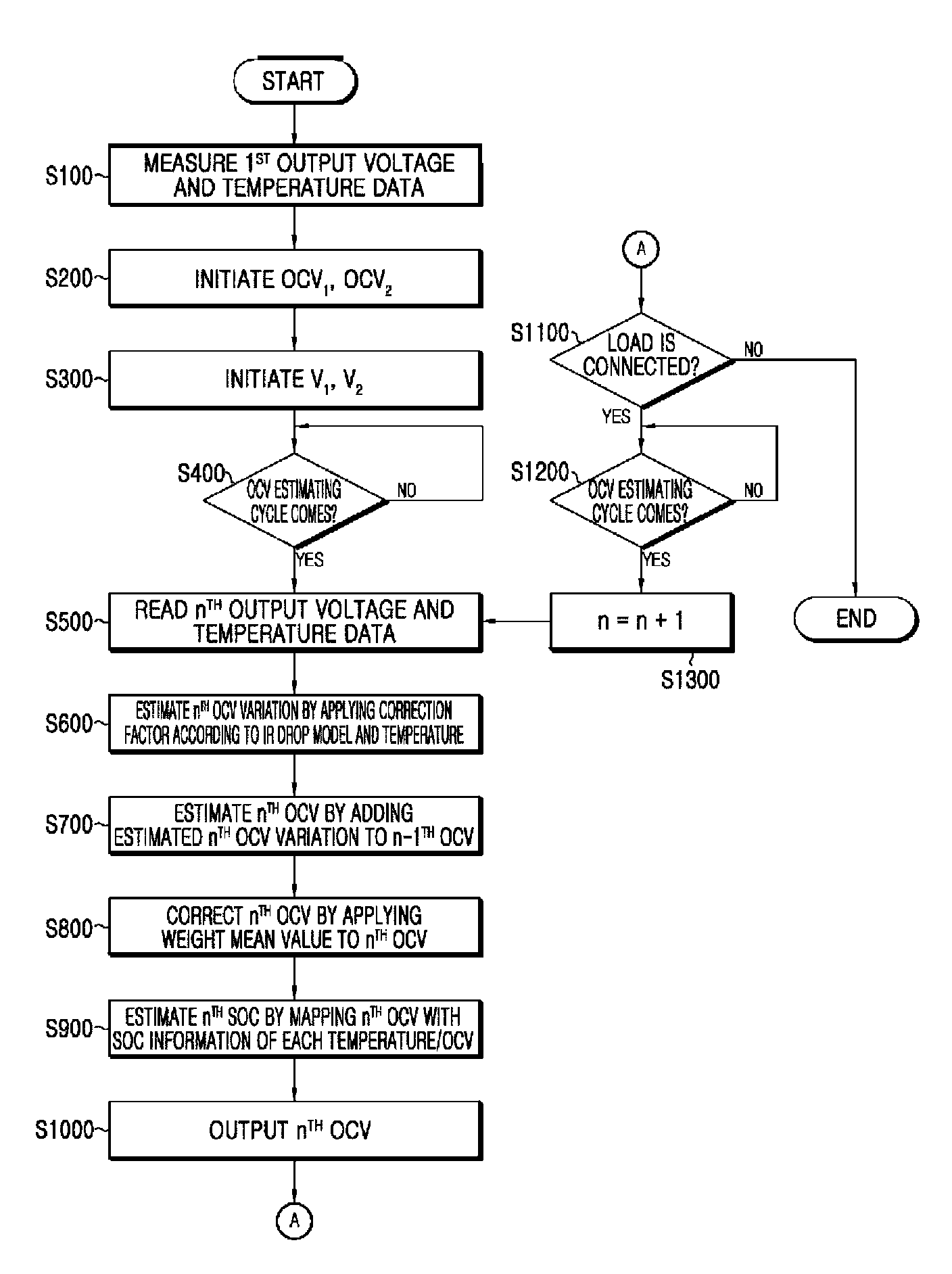

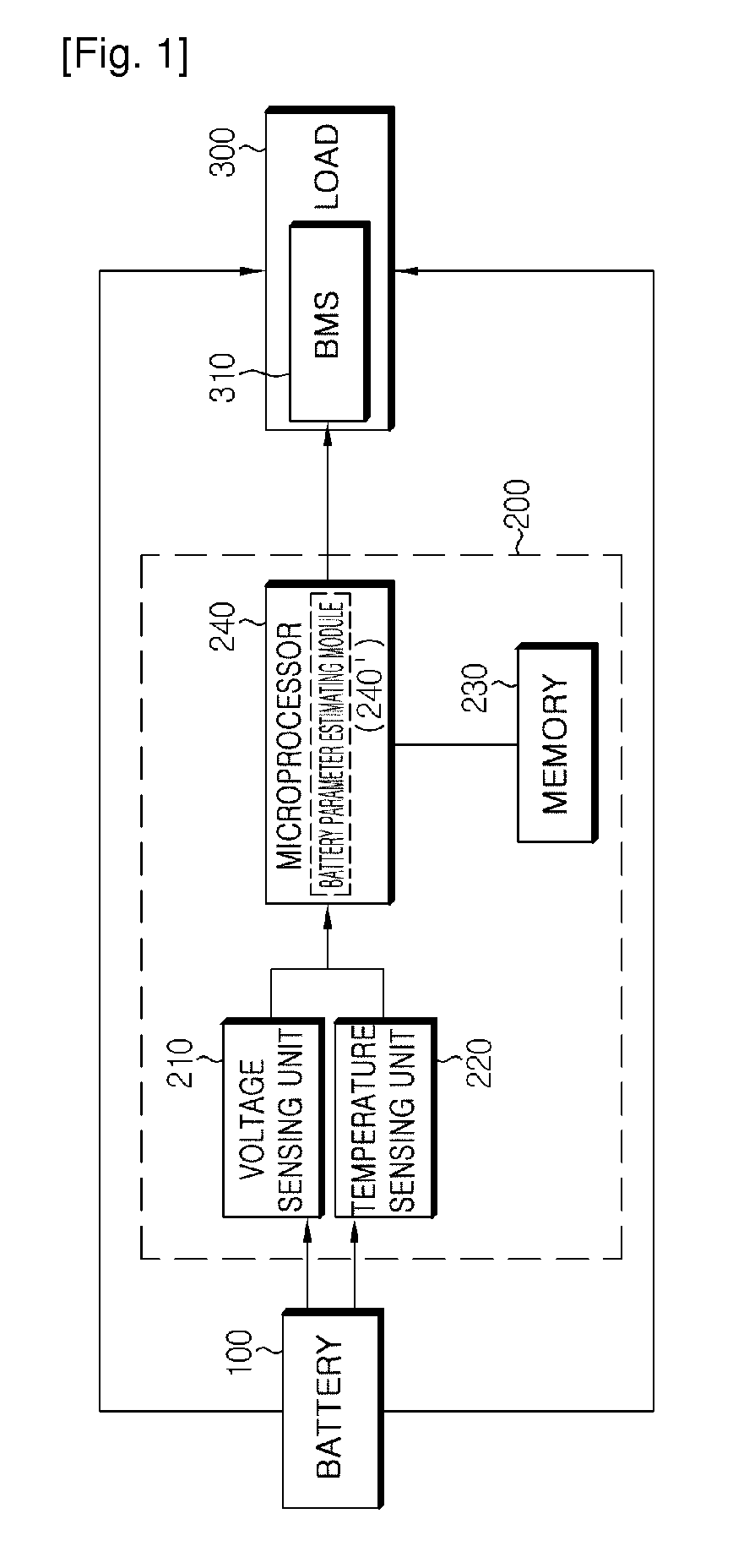

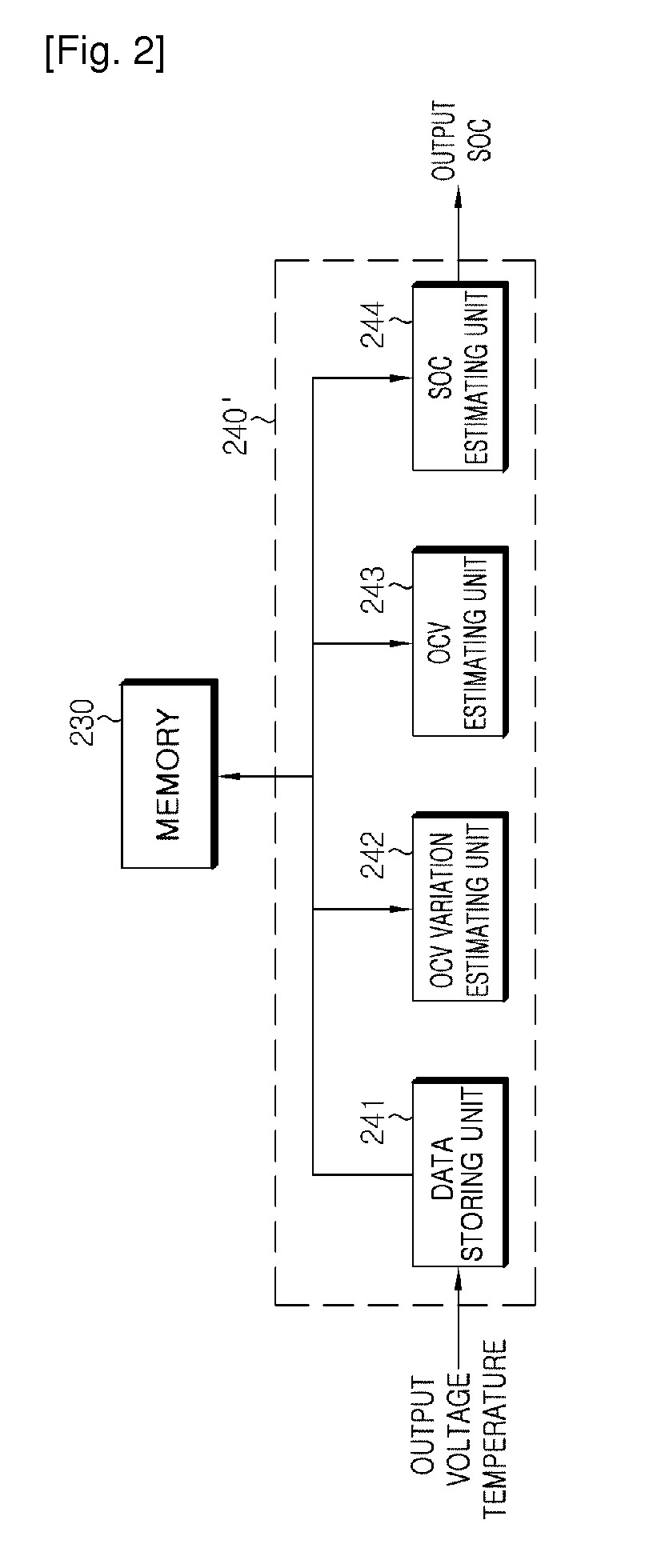

Apparatus for estimating open circuit voltage of battery, apparatus for estimating state of charge of battery, and method for controlling the same

ActiveUS20100174499A1Easily and accurately open circuit voltageCorrect measurement errorElectrical testingSpecial data processing applicationsElectrical batteryMathematical model

An apparatus for estimating an OCV of a battery includes a voltage sensing unit for measuring a battery output voltage; a temperature sensing unit for measuring a battery temperature; a data storing unit for periodically receiving the battery output voltage and temperature data from the sensing units and storing the data in a memory; an OCV variation estimating unit for calculating an OCV variation from a varying pattern of battery output voltages measured in the past and at the present, stored in the memory, by applying a mathematical model defining a correlation between the varying pattern and the OCV variation, and estimating an OCV at a current stage by reflecting a correction factor corresponding to the battery temperature on the calculated OCV variation; and an OCV estimating unit for estimating an OCV at the current stage by reflecting the estimated OCV variation on the OCV estimated at a last stage.

Owner:LG ENERGY SOLUTION LTD

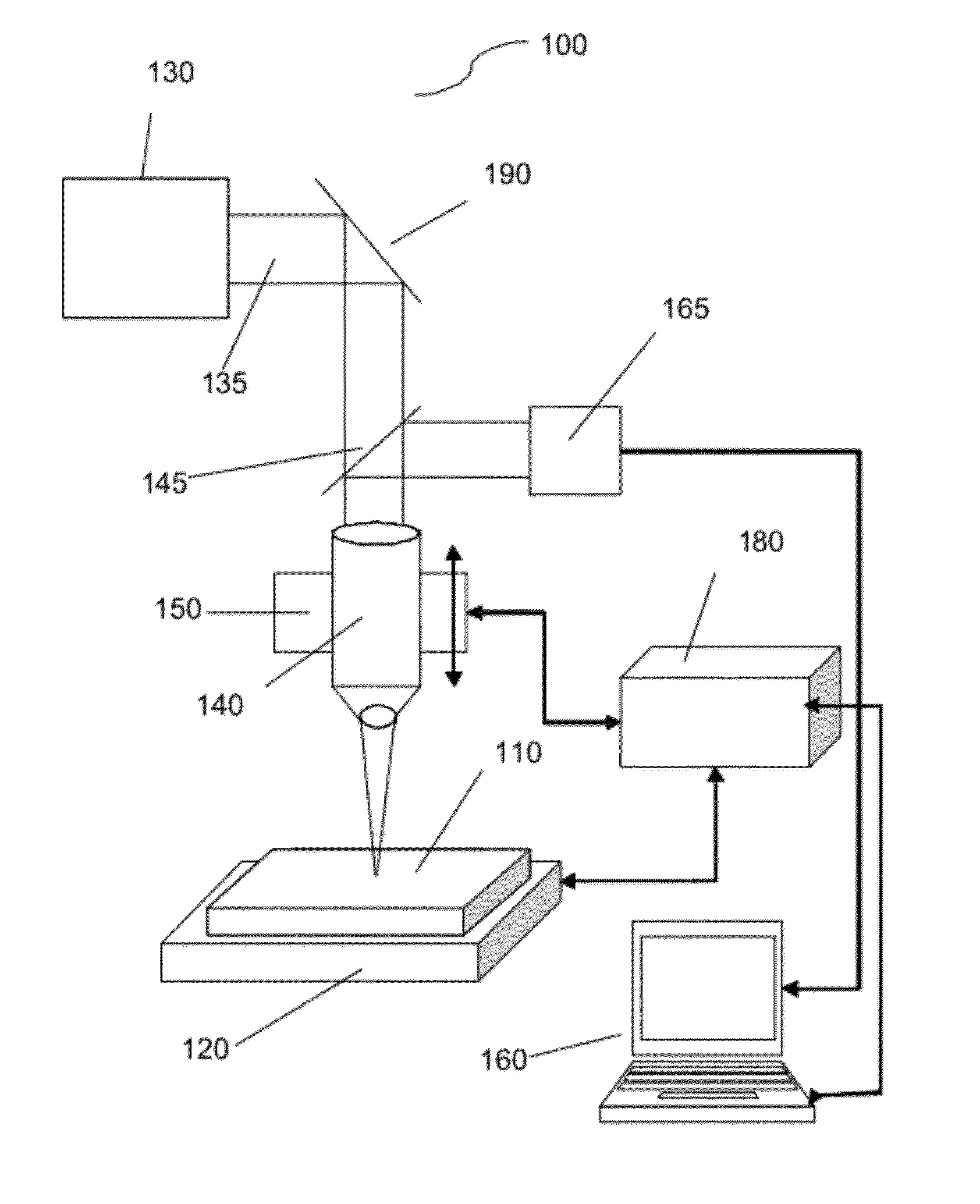

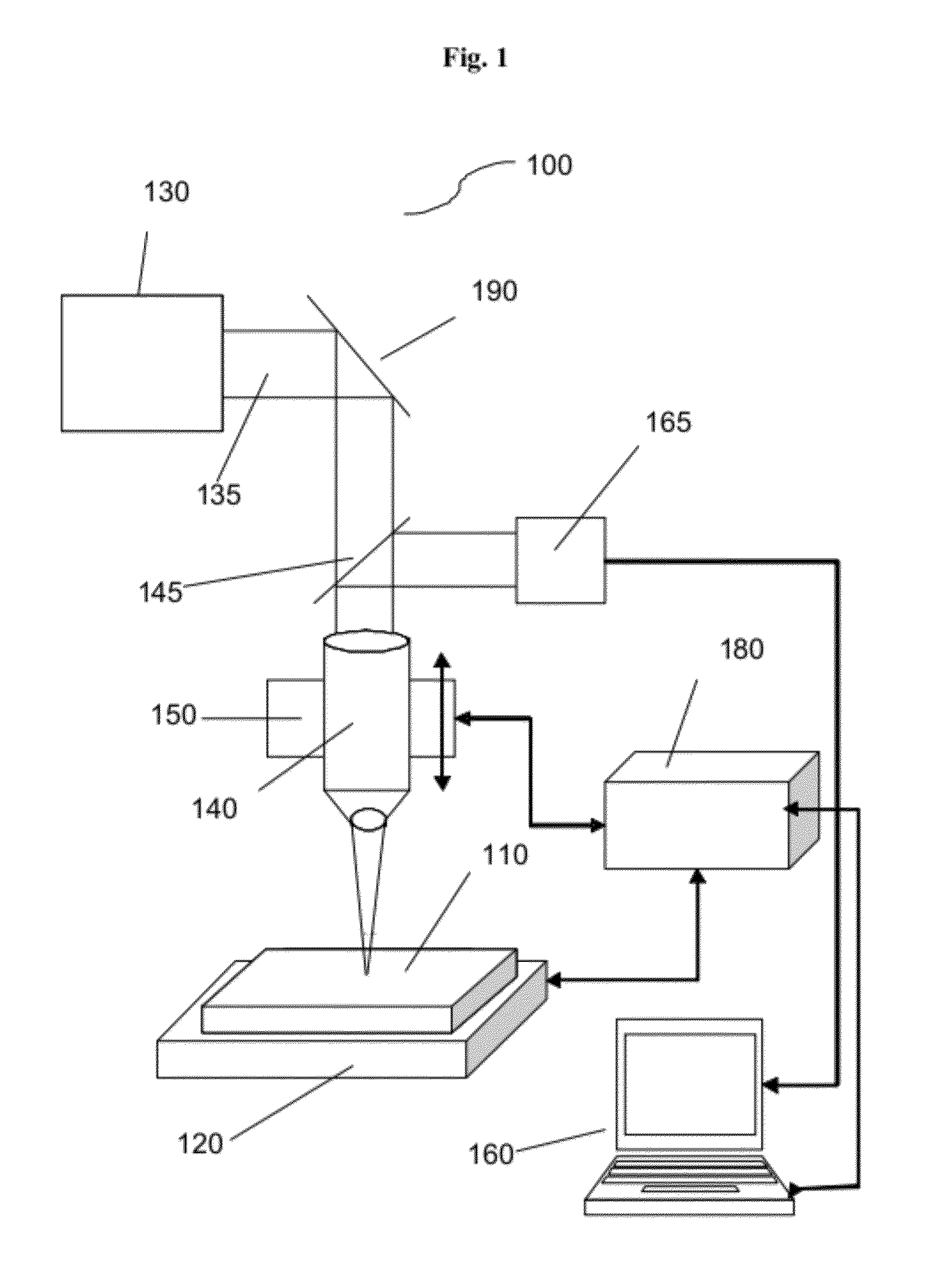

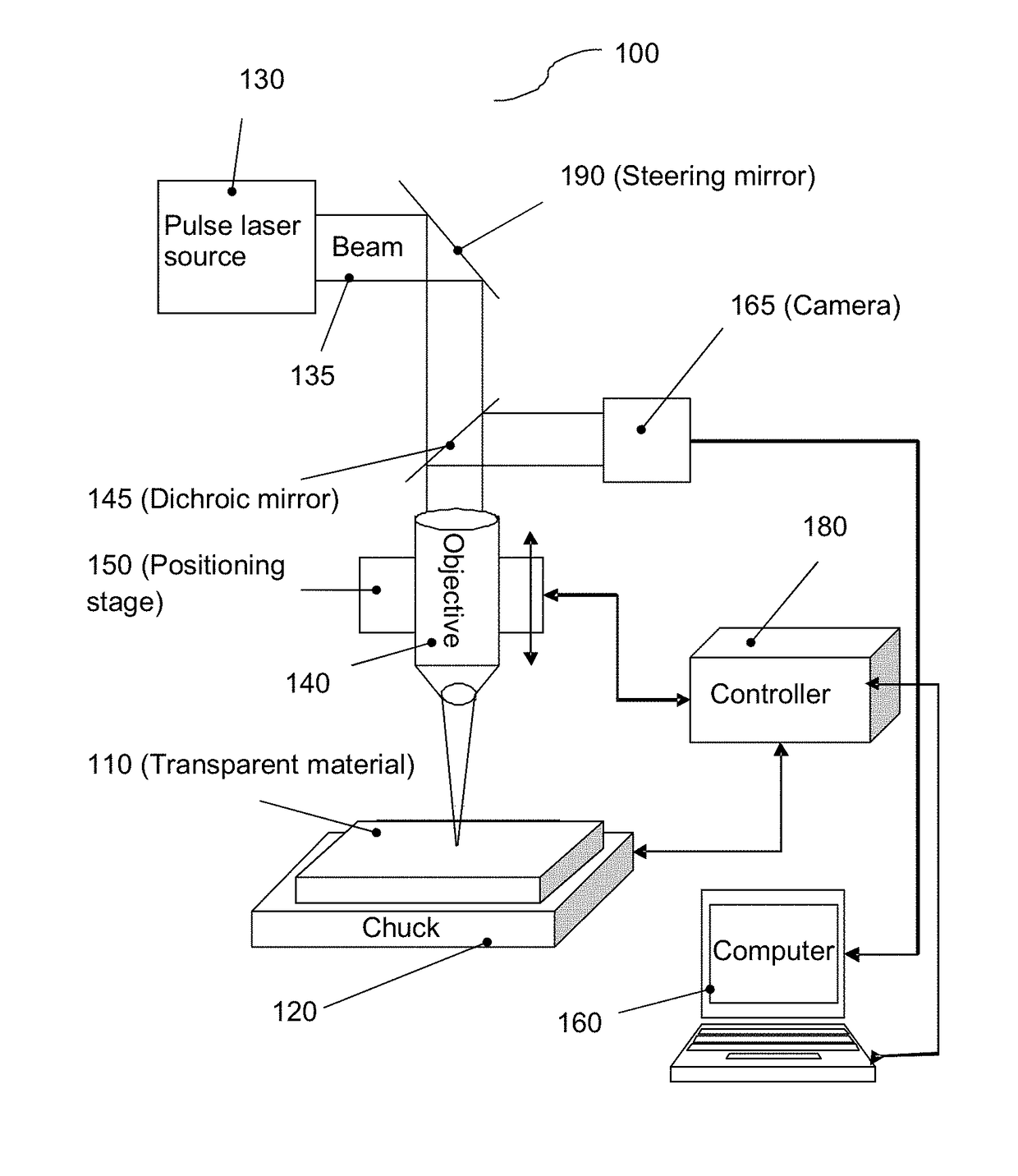

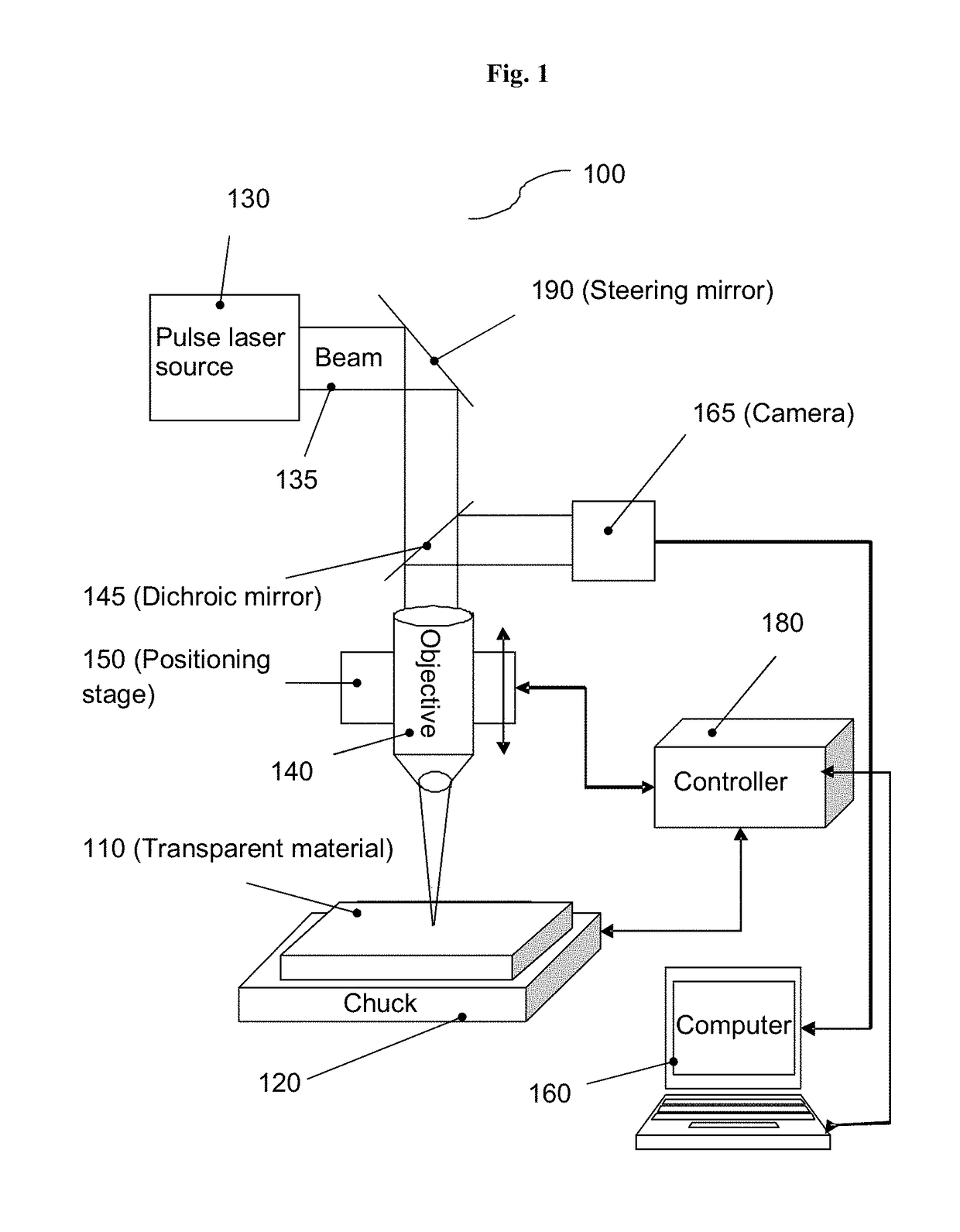

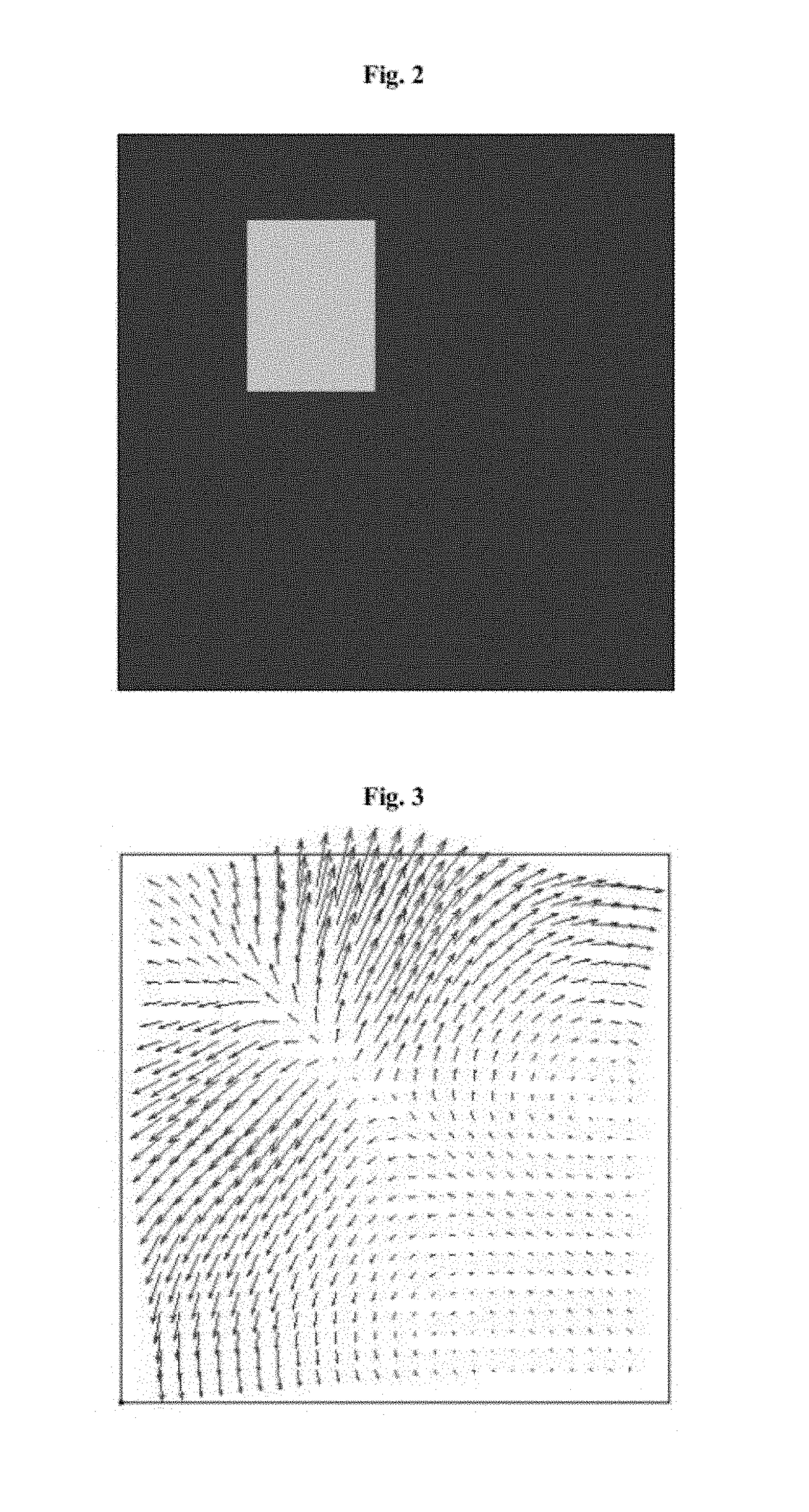

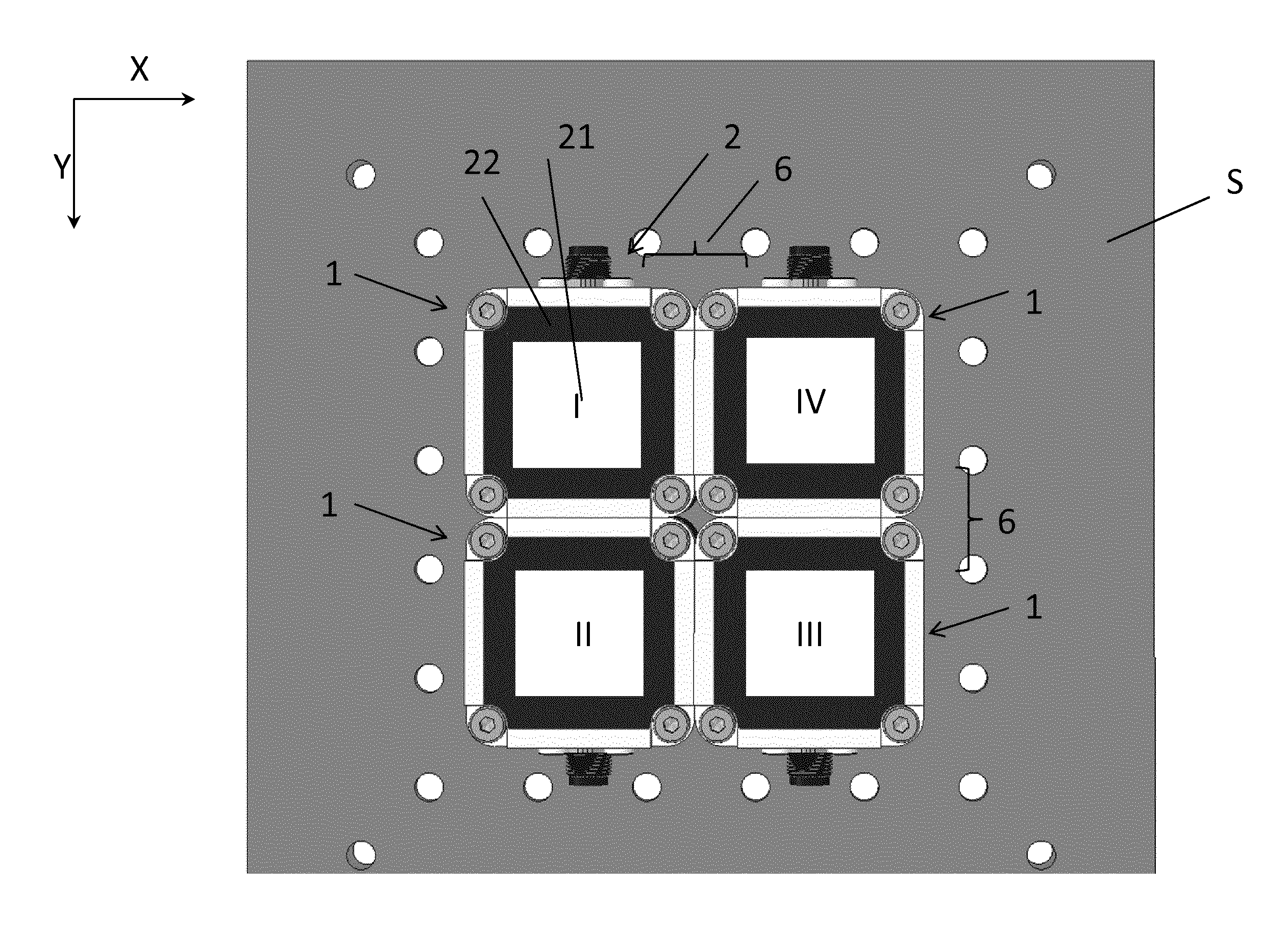

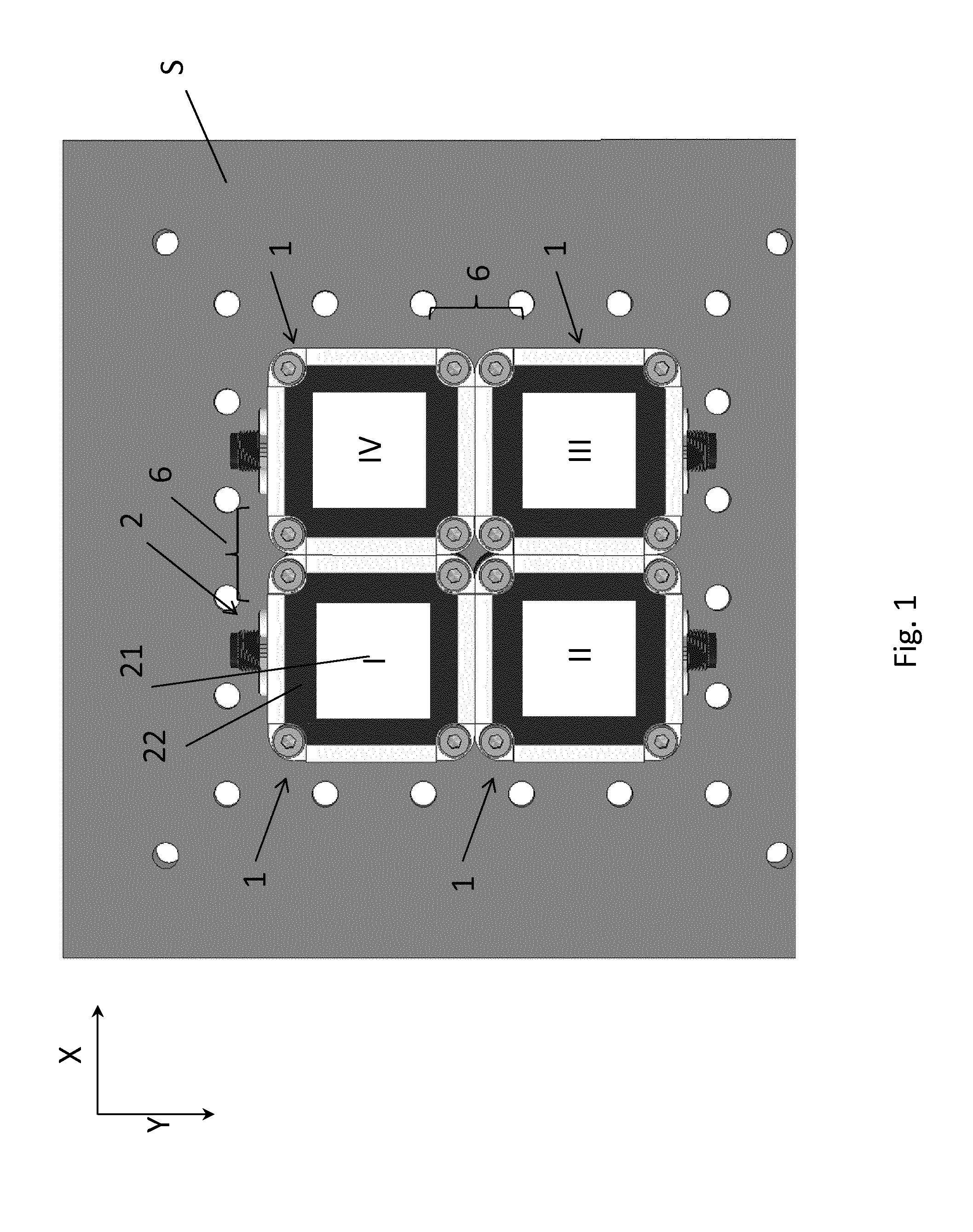

Method And Apparatus For The Determination Of Laser Correcting Tool Parameters

ActiveUS20120084044A1Minimum additional effortCorrect measurement errorNanoinformaticsPhotomechanical apparatusOptoelectronicsLaser beams

The invention relates to a method for determining at least one unknown laser beam parameter of a laser beam used for correcting errors of a transparent material including inducing a first persistent modification in the material by an interaction with the laser beam having a first set of laser beam parameters, measuring the induced first persistent modification of the material, calculating a second persistent modification in the material using a model describing persistent modifications in the material with a second set of laser beam parameters, wherein the first set of laser beam parameters comprises the second set of laser beam parameters and the at least one unknown laser beam parameter, setting up a target functional including the first persistent modification and the second persistent modification, and determining the at least one unknown laser beam parameter by minimizing the target functional.

Owner:CARL ZEISS SMS GMBH

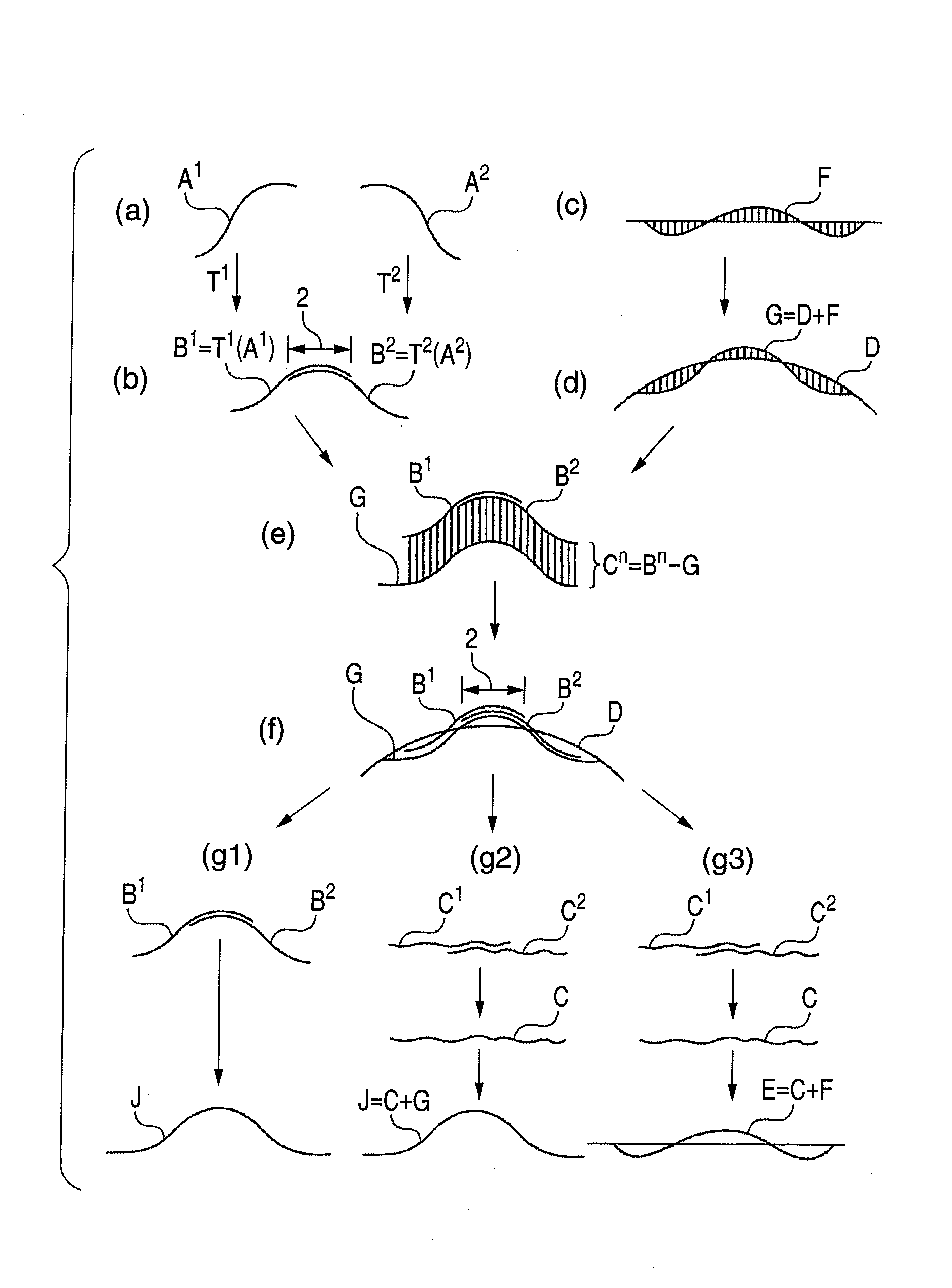

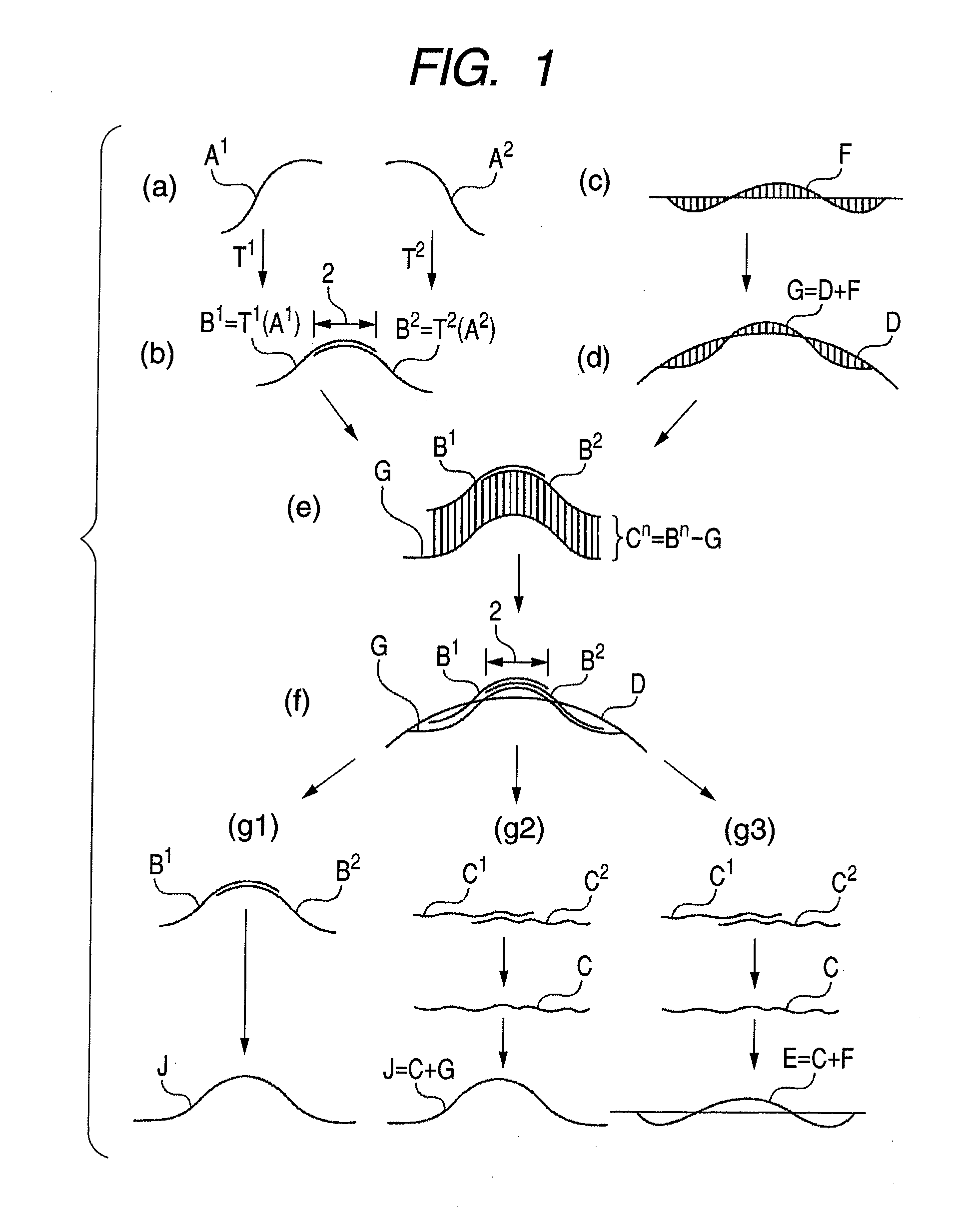

Shape measurement method of synthetically combining partial measurements

InactiveUS20090306931A1Accurately determineEffective shapingFeeler-pin gaugesMechanical counters/curvatures measurementsAlgorithmTransformation parameter

Coordinate transformation parameters are adopted at the time of synthetically combining partial measurement data so as to eliminate the setting error that can get in when a workpiece is set in position on a measuring machine. Then, a shape parameter is adopted to estimate the approximate error shape of the entire workpiece and the approximate error shape is removed from the measurement data. As a result, the residuals are reduced if the measurement data are those of three-dimensional sequences of points. Differences are small when small residuals are compared so that the mismatch is reduced. According to the present invention, the entire measurement data can be synthetically combined without using the conventional concept of overlap.

Owner:CANON KK

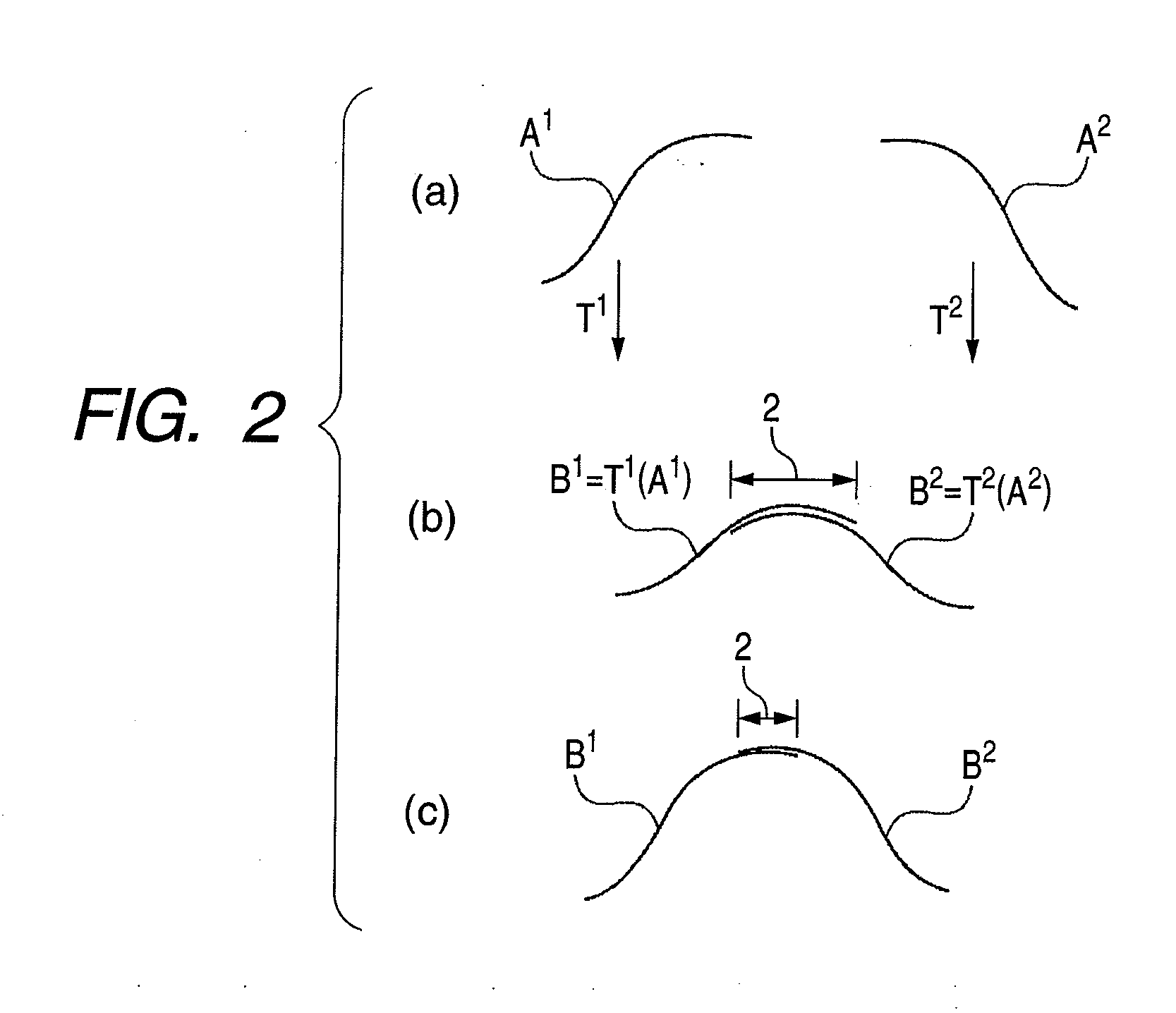

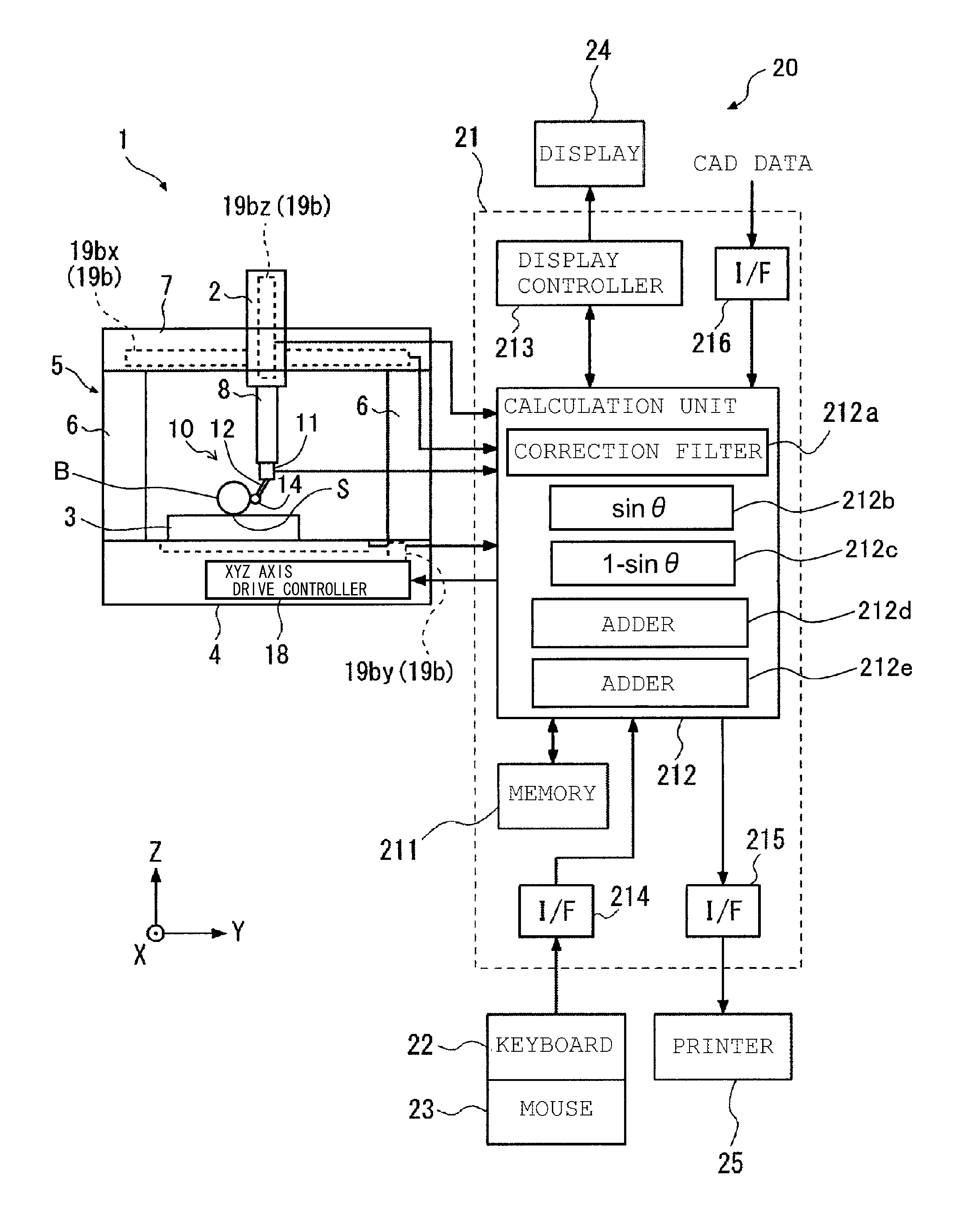

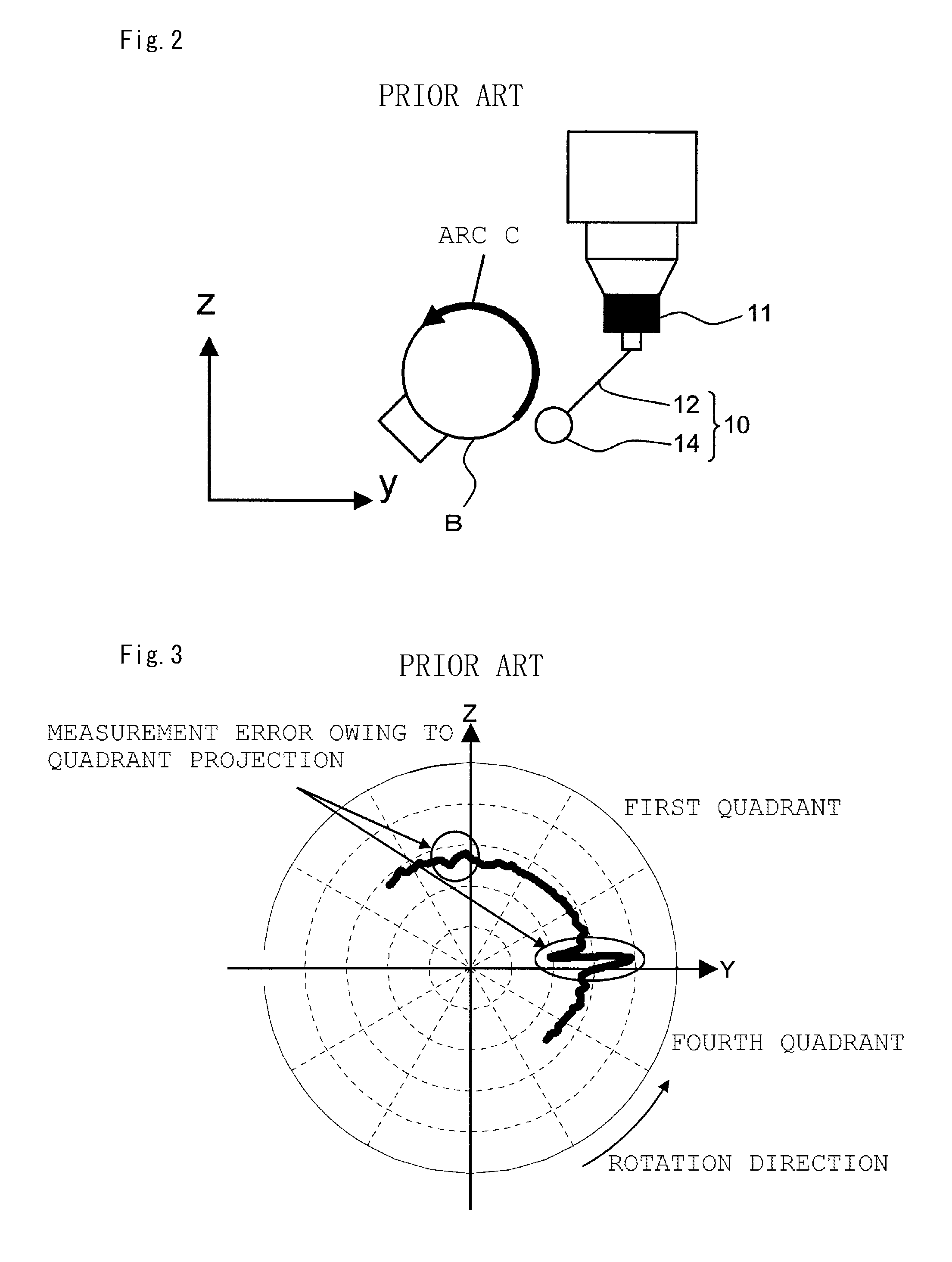

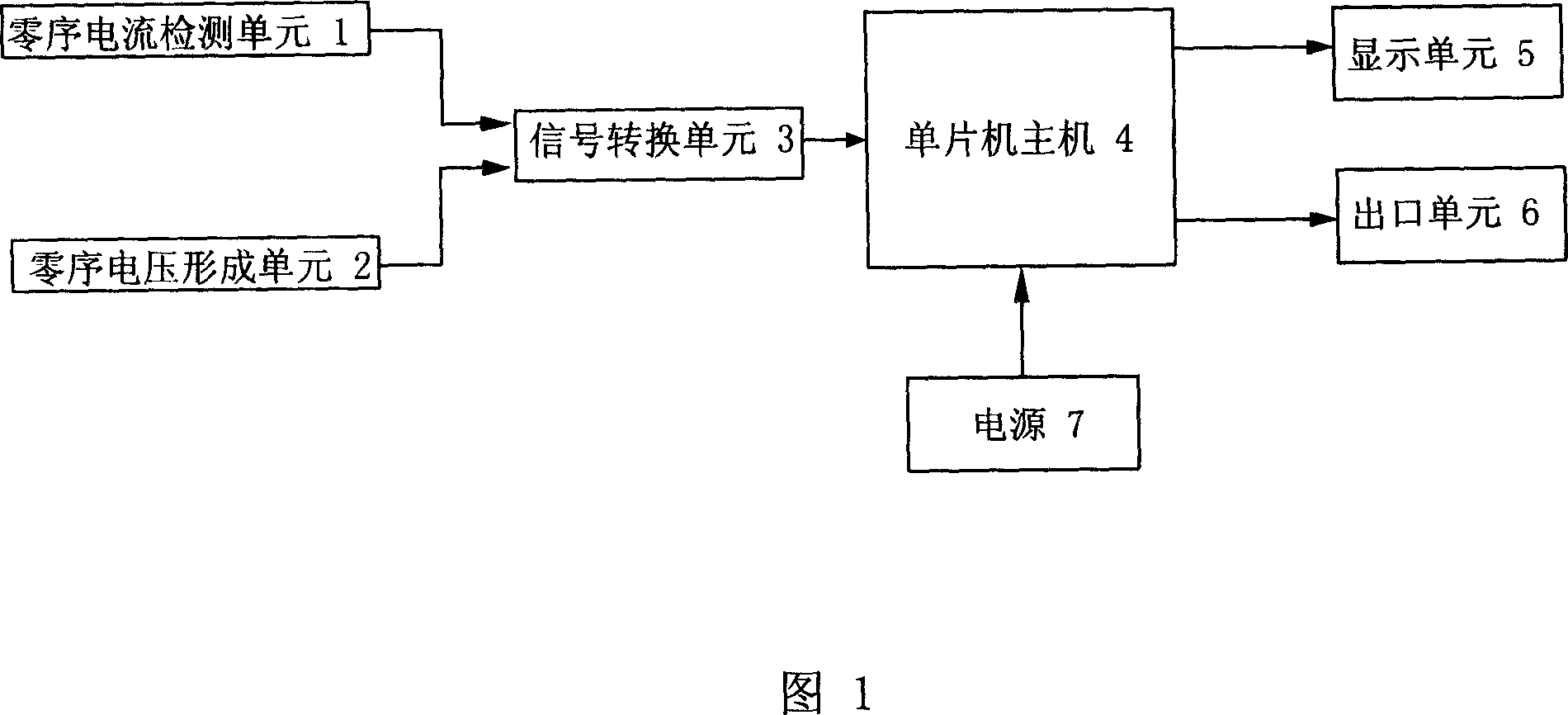

Method of correcting measurement error of shape measuring apparatus, and shape measuring apparatus

ActiveUS20160018218A1High measurement accuracyCorrect measurement errorMechanical measuring arrangementsEngineeringObservational error

In a shape measuring apparatus having a scanning probe to perform scanning measurement using a tip ball provided at an end of a stylus with the tip ball being in contact with an object to be measured, a tip ball displacement detector detects a displacement of the tip ball of the scanning probe, a displacement of a moving mechanism that relatively moves the object to be measured and the scanning probe is detected, and an angle formed by a contact direction of the tip ball with the object to be measured and an axial direction of the stylus is calculated. The displacement of the tip ball that is detected by the tip ball displacement detector is corrected on the basis of the angle, and a corrected value of the displacement is outputted. The corrected value is added to the displacement of the moving mechanism to calculate a measurement value.

Owner:MITUTOYO CORP

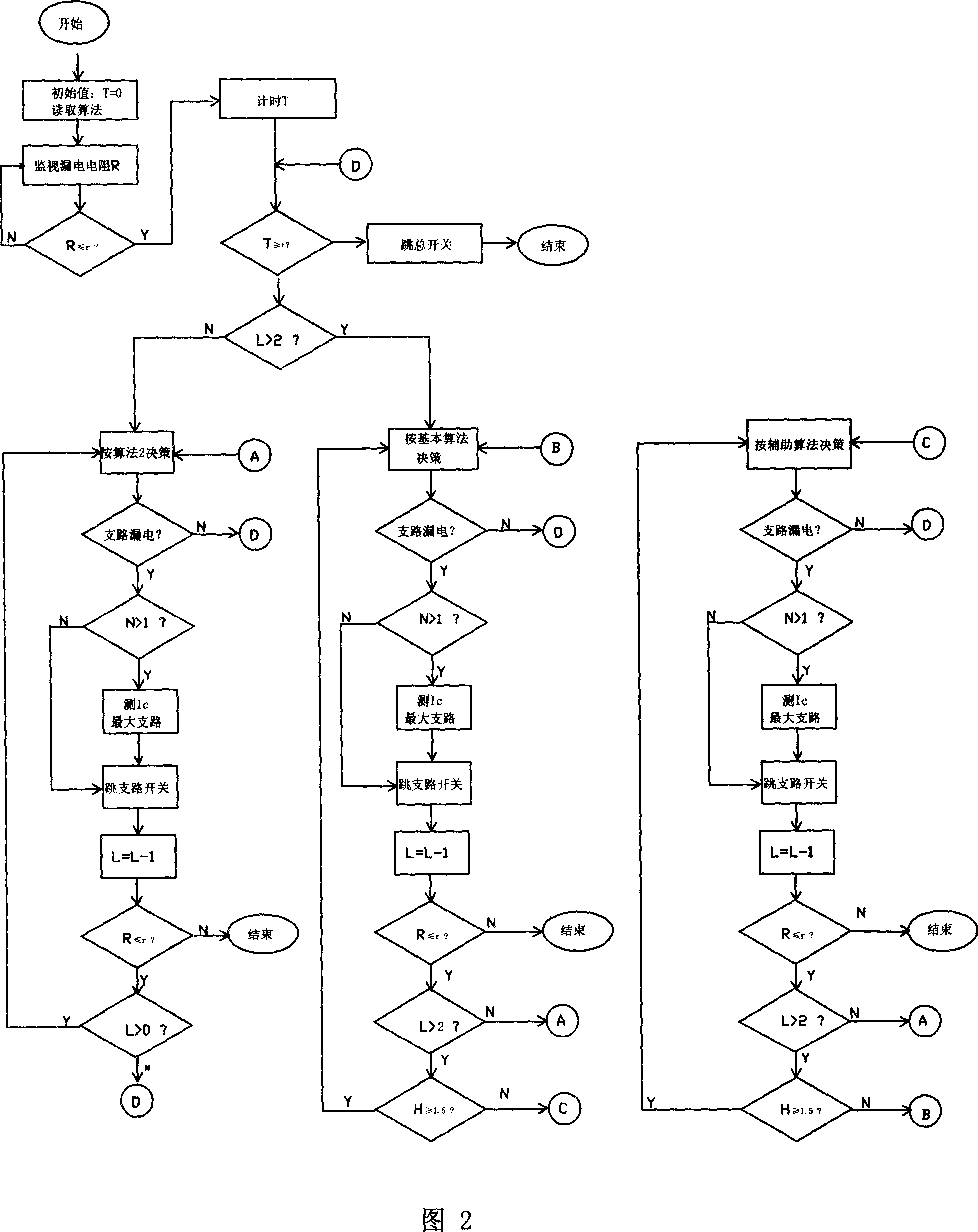

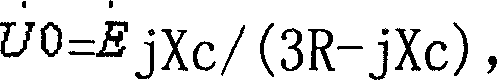

Non-grounding neutral point system low-voltage leakage protection method and its equipment

InactiveCN101026295AEliminate the effects ofAffects automatic correctionsEmergency protective arrangements for automatic disconnectionCapacitanceLow voltage

The method and equipment is in use for system of its neutral point not connected to ground under well of coal mine. Using centralized control mode, the method centralizes zero sequence current (ZSC) of each branch switch to a device. The device controls each branch switch and main switch. Comparing with prior art, the invention eliminates not unitive criteria for electric leakage of each branch switch and main switch; eliminates unwanted operation factors from influence of change of system voltage and system capacitance on corresponsive zero sequence voltage (ZSV) of leakage resistance. Integrated applying three types of algorithm including method of abrupt change quantity of ZSC, phase method of ZSC and ZSV, and relative phase comparison method of ZSC, the invention selects one of the algorithms automatically based on relative merits and physical circumstances of system. When leakage occurred at multiple branches, the invention trips off the branch with largest leakage current.

Owner:王小华

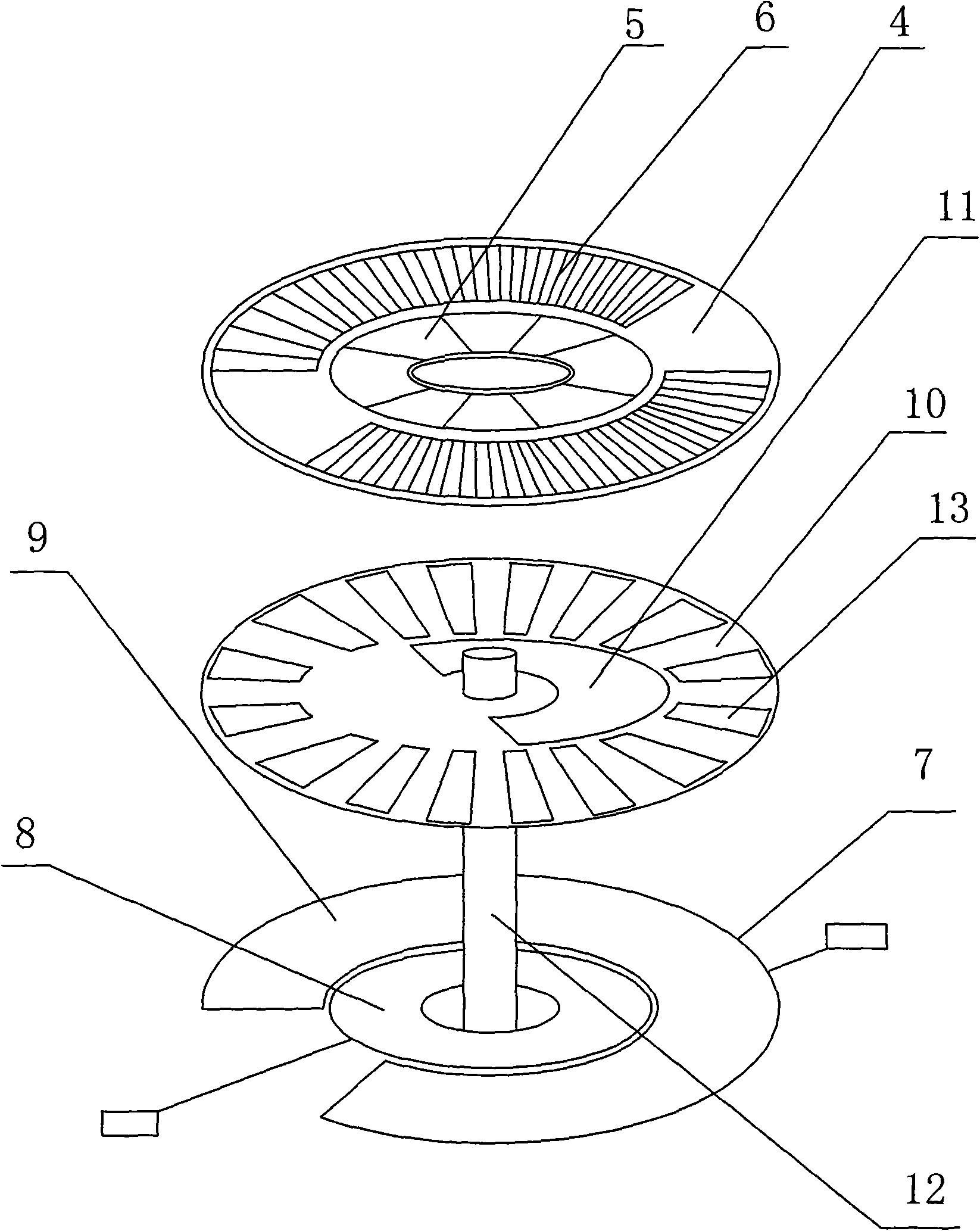

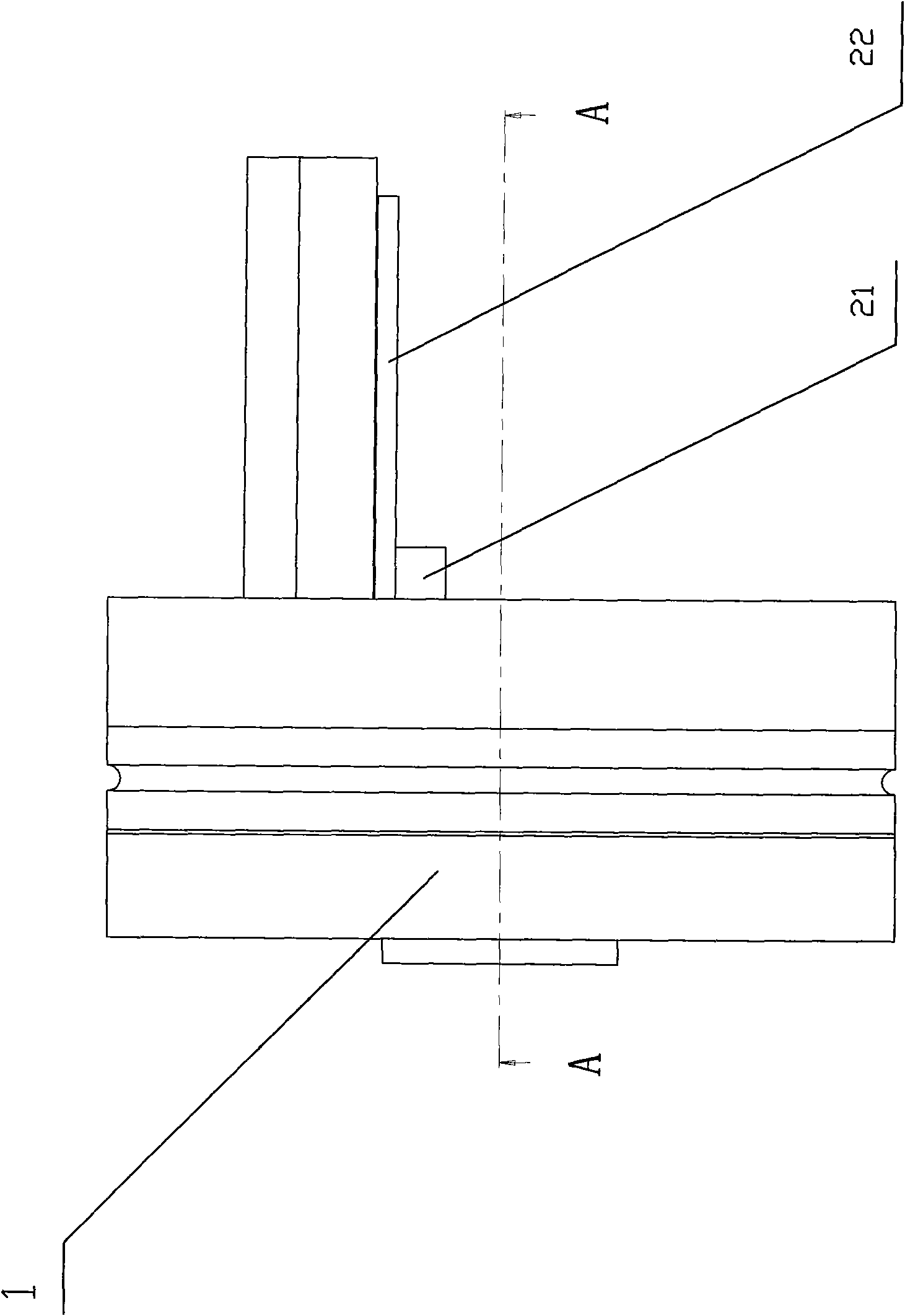

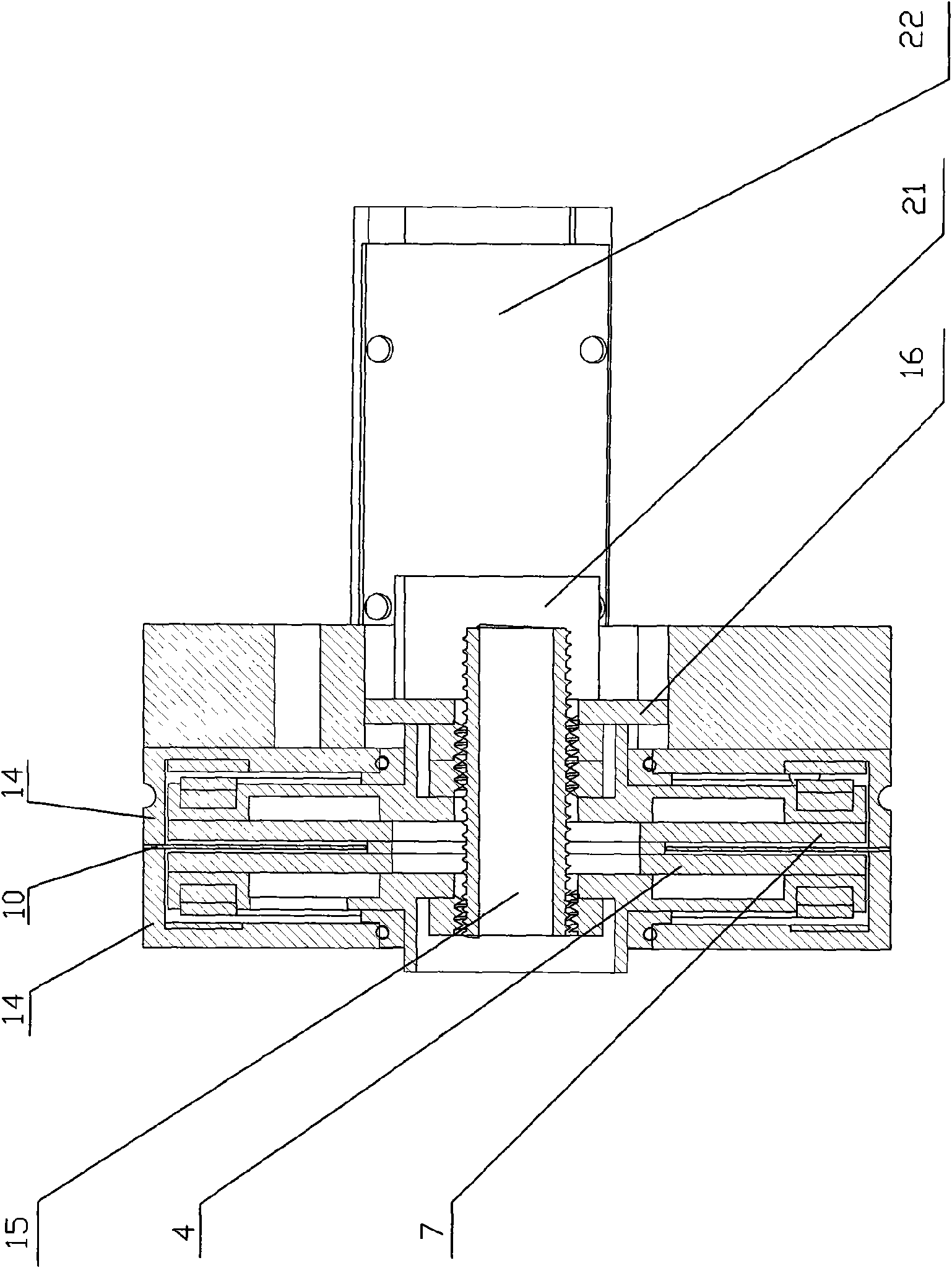

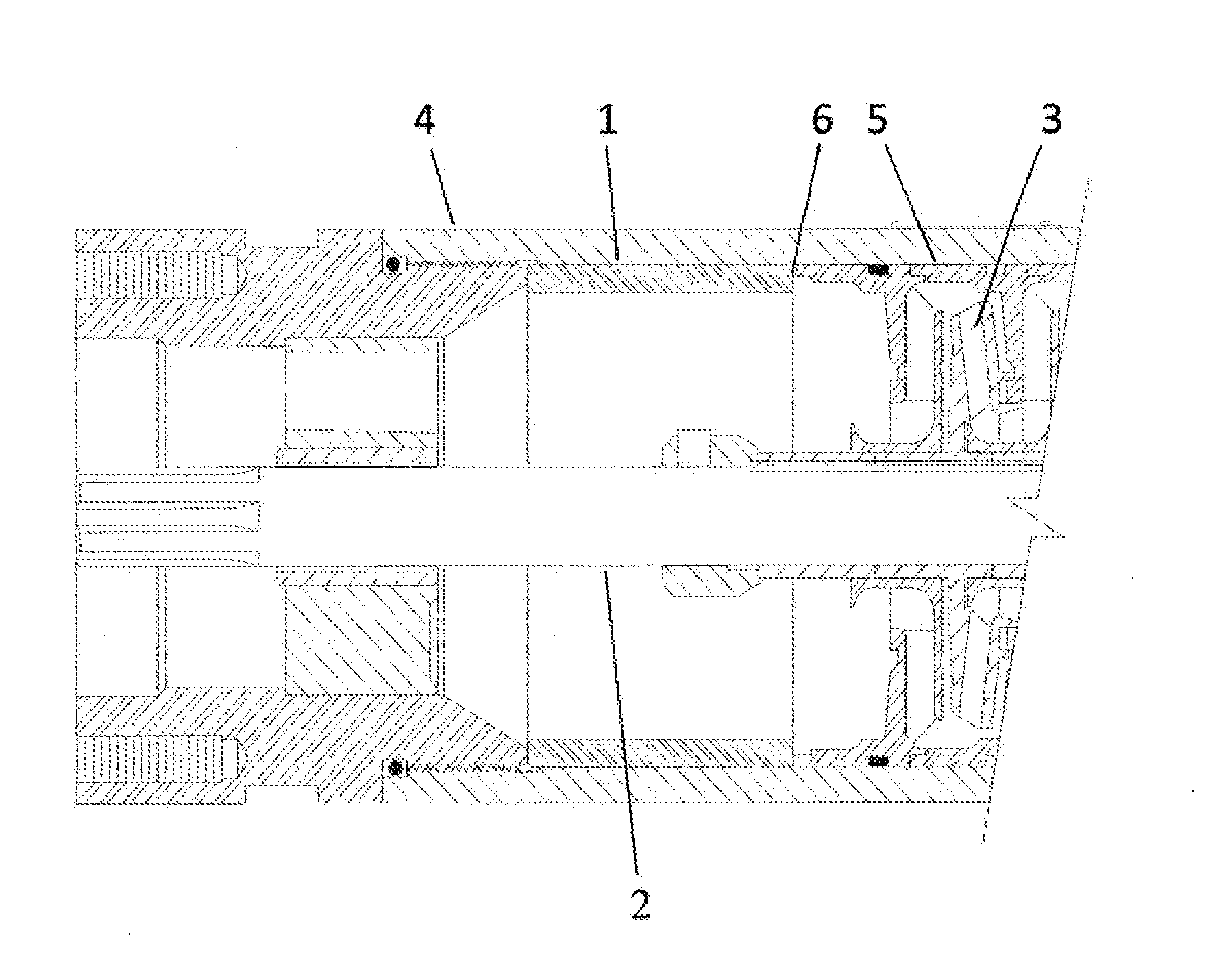

Capacitance measuring sensor device in absolute position

InactiveCN101556170AImprove anti-interference abilityReduce energy consumptionConverting sensor output electrically/magneticallyGratingPhase difference

The invention discloses a capacitance measuring sensor device in an absolute position, which comprises a capacitive grating sensor, a measurement signal processor, a data processor and a display, wherein the capacitive grating sensor comprises a one-grade or multi-grade calibration sensor and a measurement sensor and a memory electronic element is used for memorizing a phase value and a phase difference of the calibration sensor and the measurement sensor so as to determine a counting zero of the measurement; the calibration sensor has absolute measurement function in an effective working range and the pitch score of the measurement sensor is larger than or equal to the pitch score of the calibration sensor. As for measurement in an absolute circumferential position, the capacitive grating sensor is a round capacitive grating sensor comprising a one-grade or multi-grade calibration sensor and the measurement sensor; as for measurement in an absolute angle (arc) position, the capacitive grating sensor comprises a one-grade round grating calibration sensor and a flexible hinge grating measurement sensor; as for measurement in an absolute linear position, the capacitive grating sensor comprises a one-grade or multi-grade calibration sensor and a linear measurement sensor.

Owner:钟胜 +2

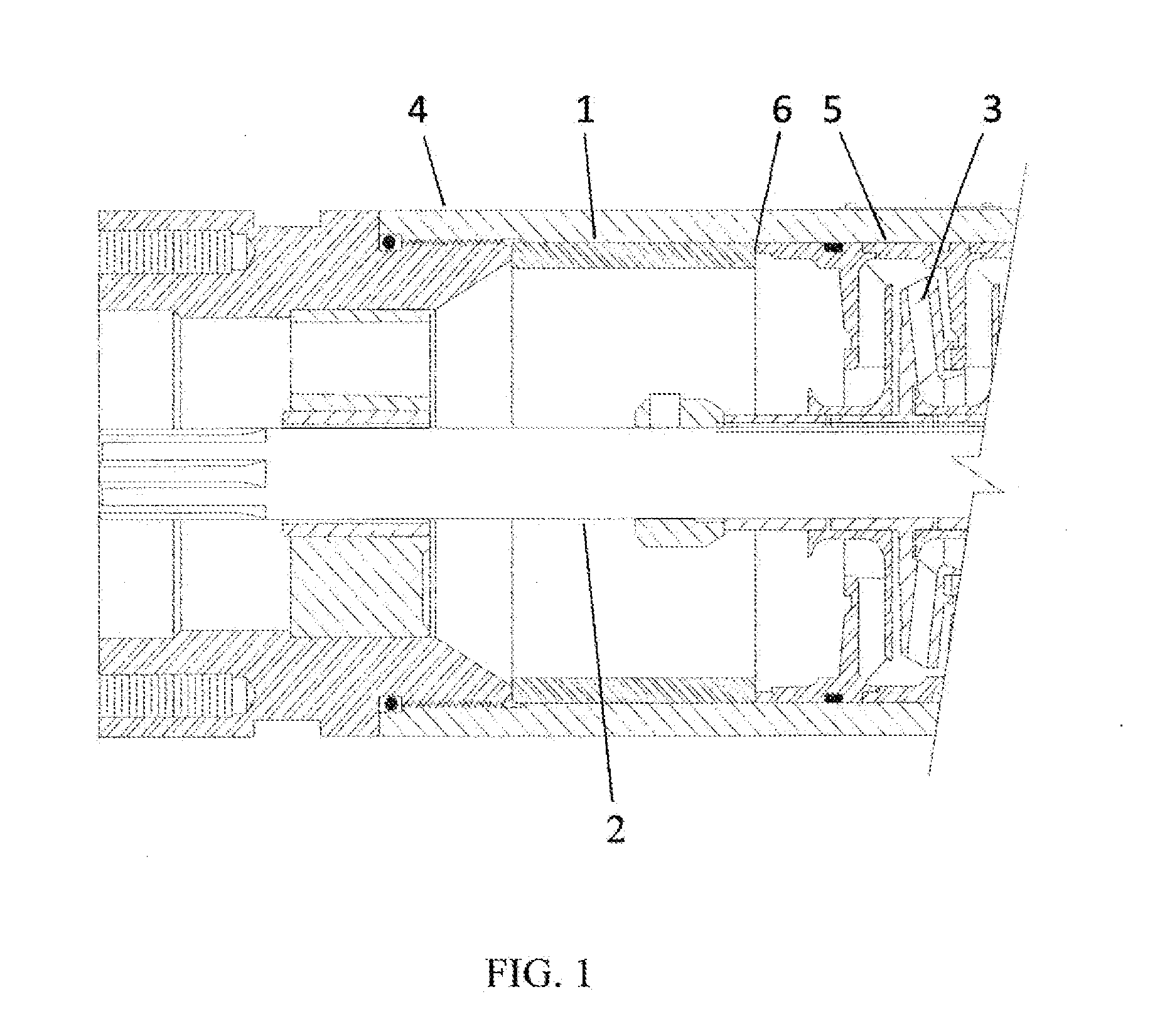

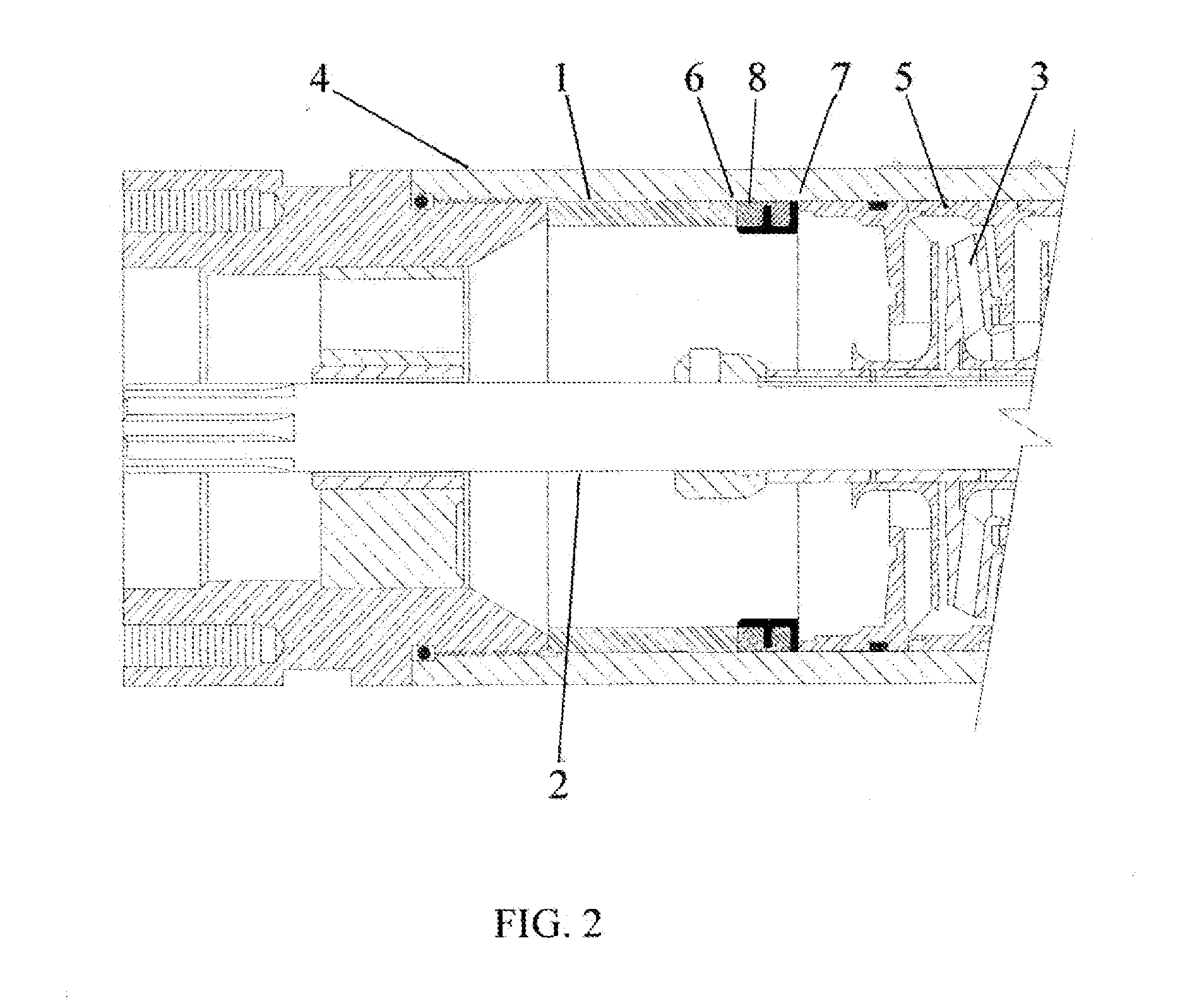

Dynamic compression compensator for submersible pumps

InactiveUS20120282119A1Relieve precise measurement errorCorrect measurement errorPositive displacement pump componentsPump installationsEngineeringSubmersible pump

A dynamic variable compression ring for use in submersible pumps. where the variable compression ring compensates for metal compression ring measurement errors during assembly. The dynamic variable compression ring also allows for thermal heating of the internal pump components, thus maintaining the desired diffuser compression values.

Owner:FLOYD RAYMOND

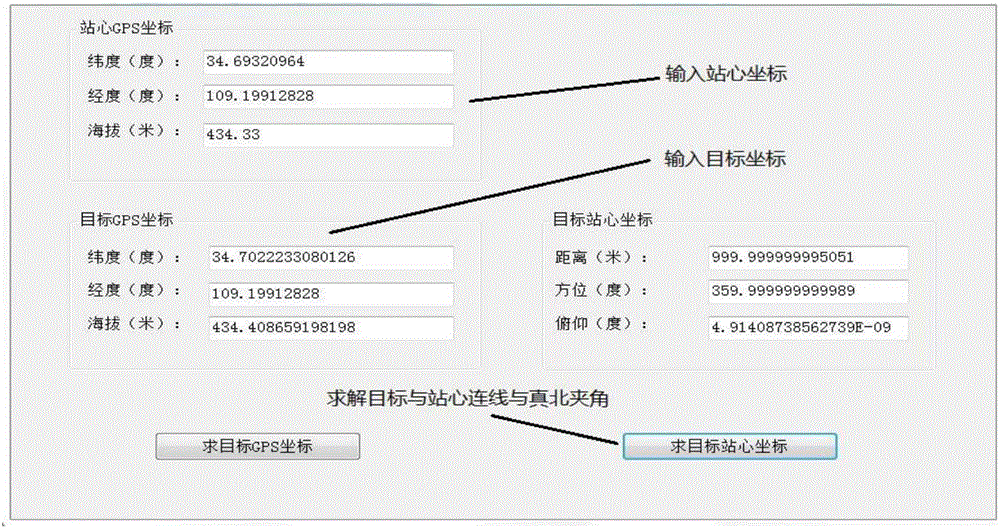

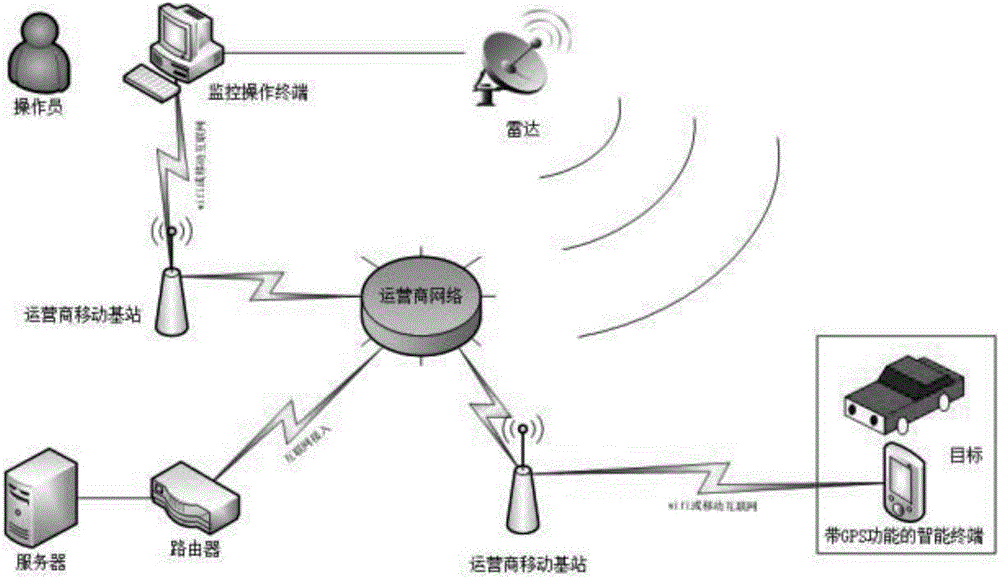

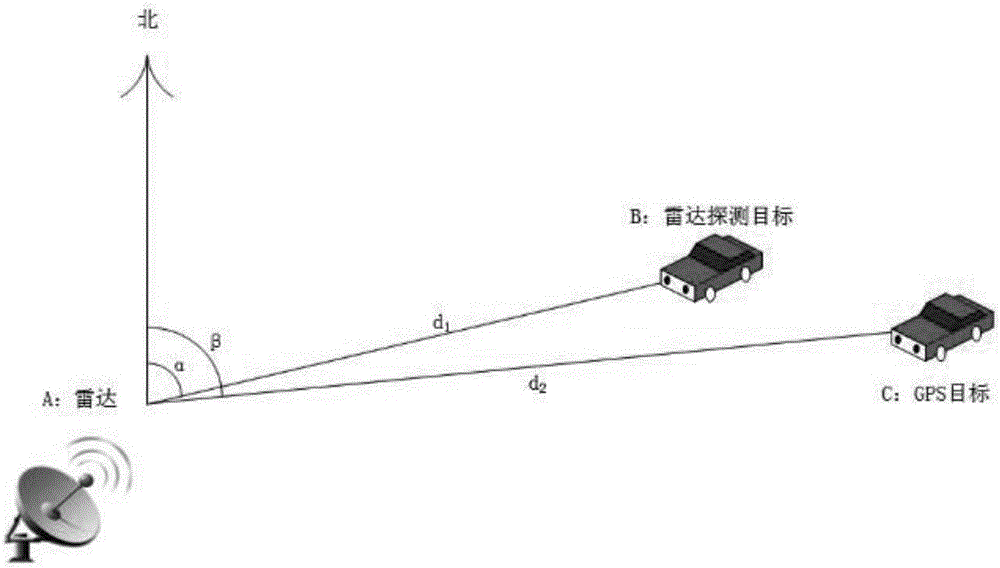

System for high-precision correction of monitoring radar measurement error and correction method

InactiveCN106814349ACorrect measurement errorFit closelyWave based measurement systemsThe InternetComputer terminal

The invention relates to the field of a radar measurement error modification technology, more particularly to a system for high-precision correction of a monitoring radar measurement error and a correction method. The system is composed of a server, a radar, a monitoring operation terminal, and an intelligent terminal. The server is based on the Internet and is provided with a public coordinate forwarding module. The monitoring operation terminal and a radar carry out information exchange and is superposed with a digital map. The intelligent terminal including a coordinate obtaining and reporting module reports coordinate information of the location point of the intelligent terminal to the server by a mobile base station; and the server forwards the received location point coordinate information to the monitoring operation terminal by the internet. With cooperation with a target, pure radial movement and pure tangential movement are made to correct an angle and a distance error. The system has the following advantages: when a mobile carrier carries the intelligent terminal, a geodetic coordinate system and radar coordinate system are normalized to realize high-precision positioning displaying of a target trace point in a practical map, so that monitoring information outputted by a radar terminal becomes precise.

Owner:西安寰达导航科技有限公司

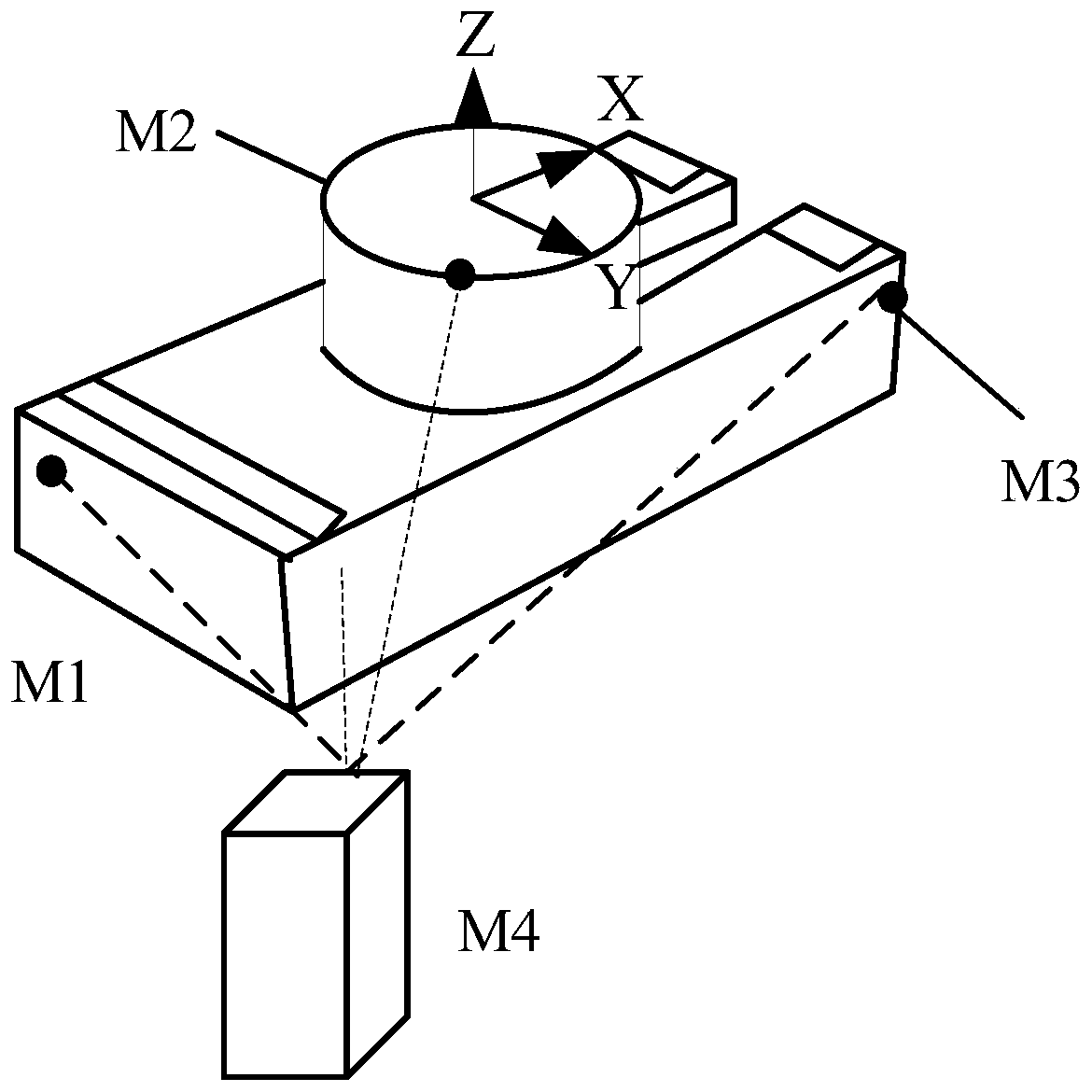

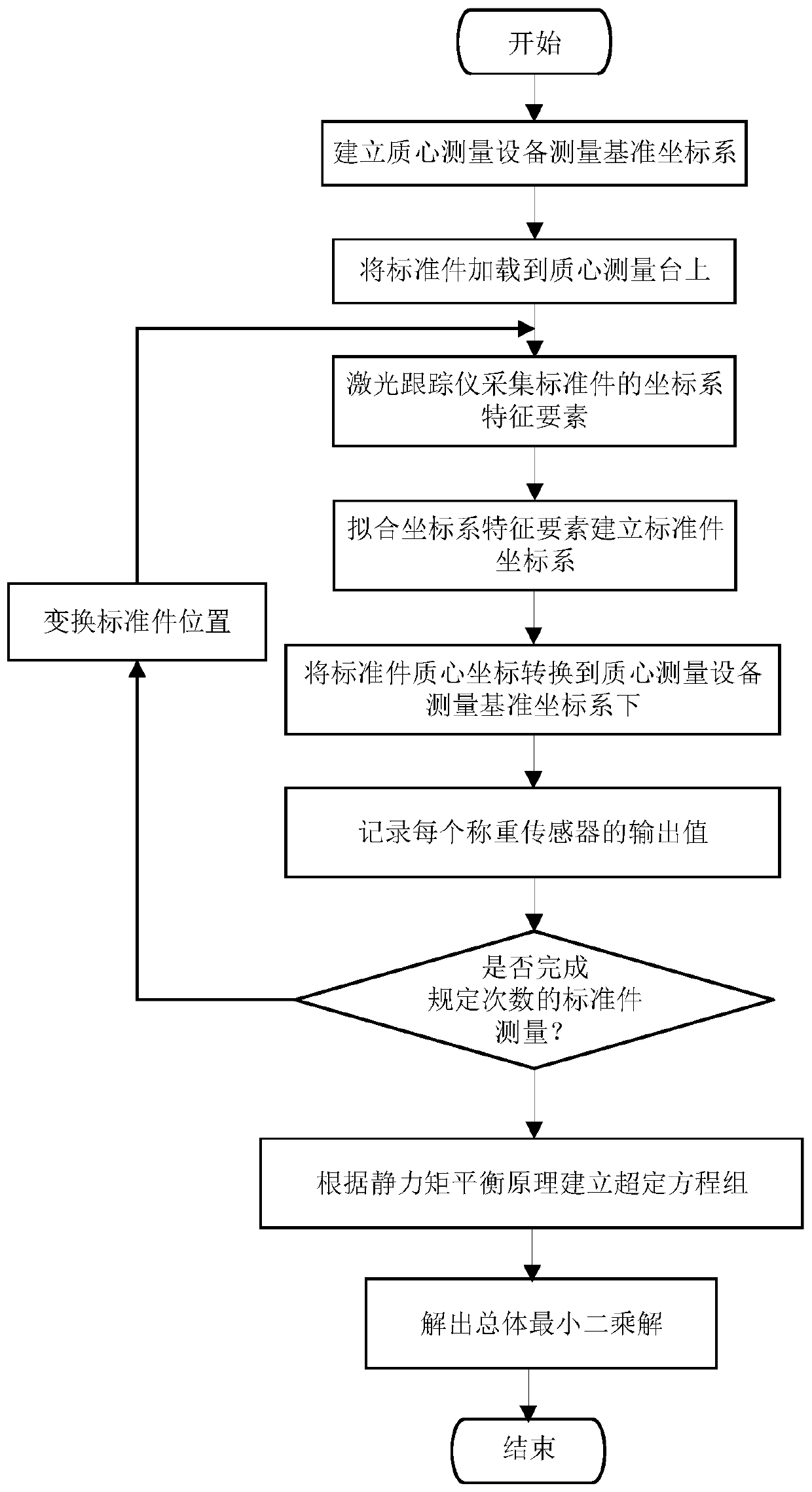

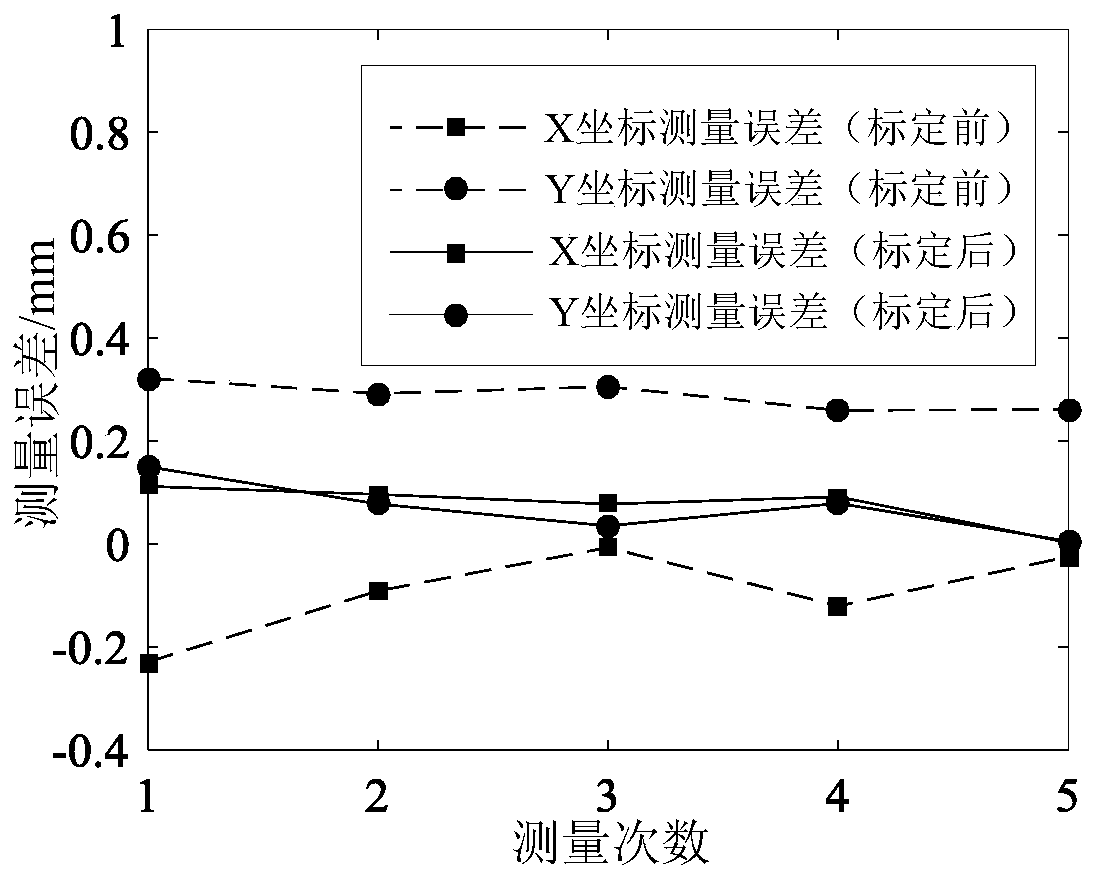

Force bearing point position calibration method for weighing sensor of multi-point mass center measurement equipment

InactiveCN110715769AHigh measurement accuracyCorrect measurement errorStatic/dynamic balance measurementClassical mechanicsEngineering

The invention relates to a force bearing point position calibration method for a weighing sensor of multi-point mass center measurement equipment. The method comprises the steps of building a measurement reference coordinate system of the mass center measurement equipment by coordinate measurement equipment; respectively arranging standard pieces at a plurality of positions, measuring mass centerpositions of the standard pieces respectively by the coordinate measurement equipment when the standard pieces are arranged at different positions, and recording an output value of each weighing sensor when the standard pieces are arranged at different positions; building a static moment balance equation comprising force bearing point coordinate of each weighing sensor; and solving the static moment balance equation to obtain the force bearing point coordinate of each weighing sensor of the mass center measurement equipment. By the method, a measurement error caused by deviation of the force bearing point of the weighing sensor relative to an actual-measurement position before unloading during product loading of the mass center measurement equipment can be corrected, and the measurement accuracy of the multi-point mass center measurement equipment is remarkably improved.

Owner:ZHEJIANG SCI-TECH UNIV

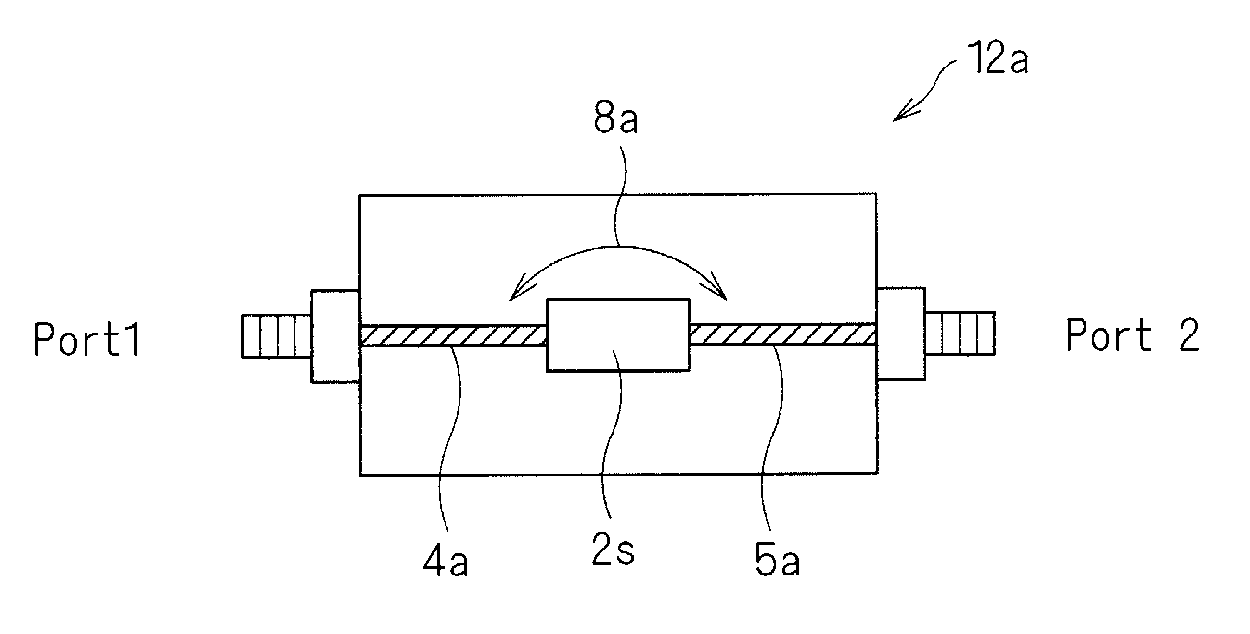

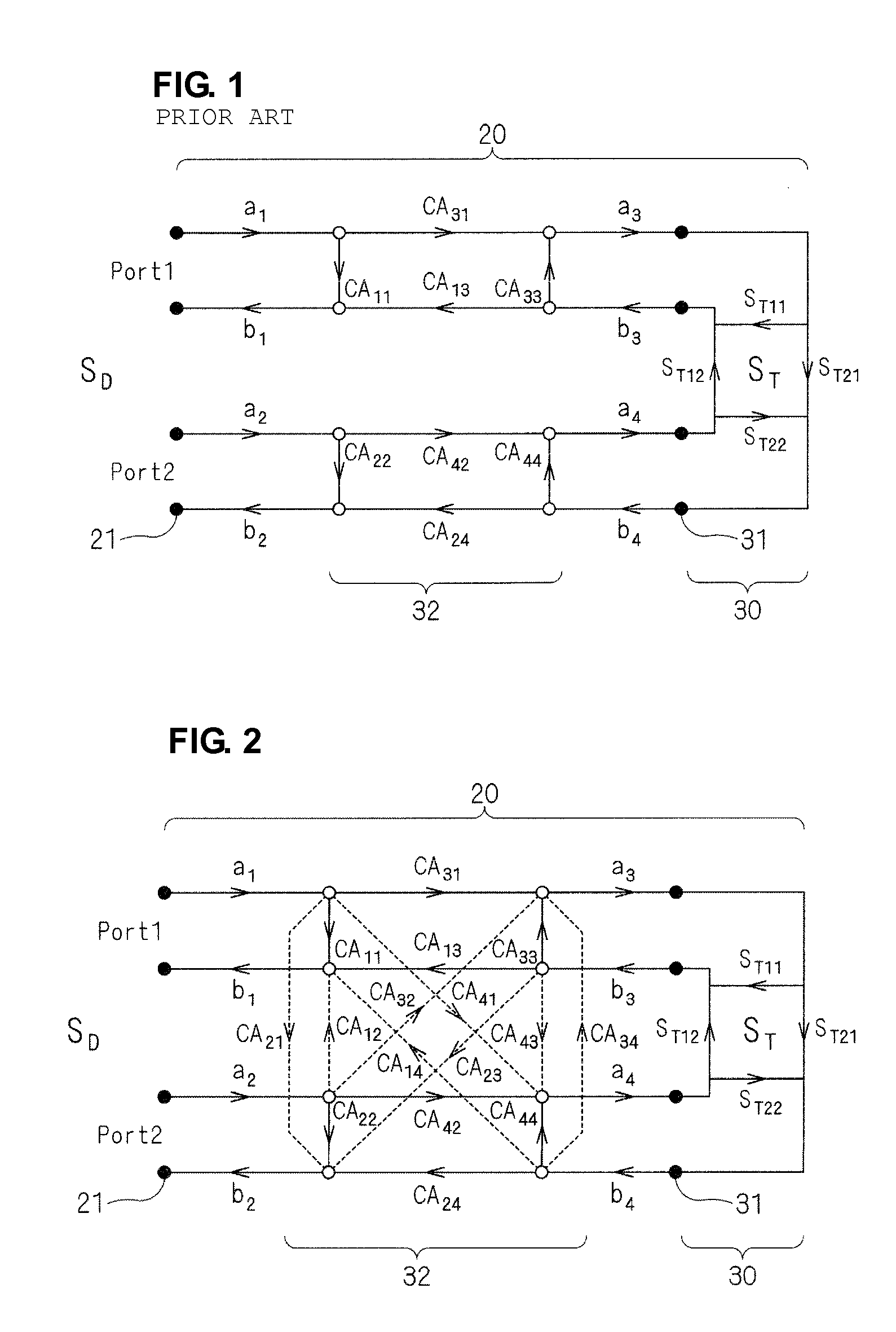

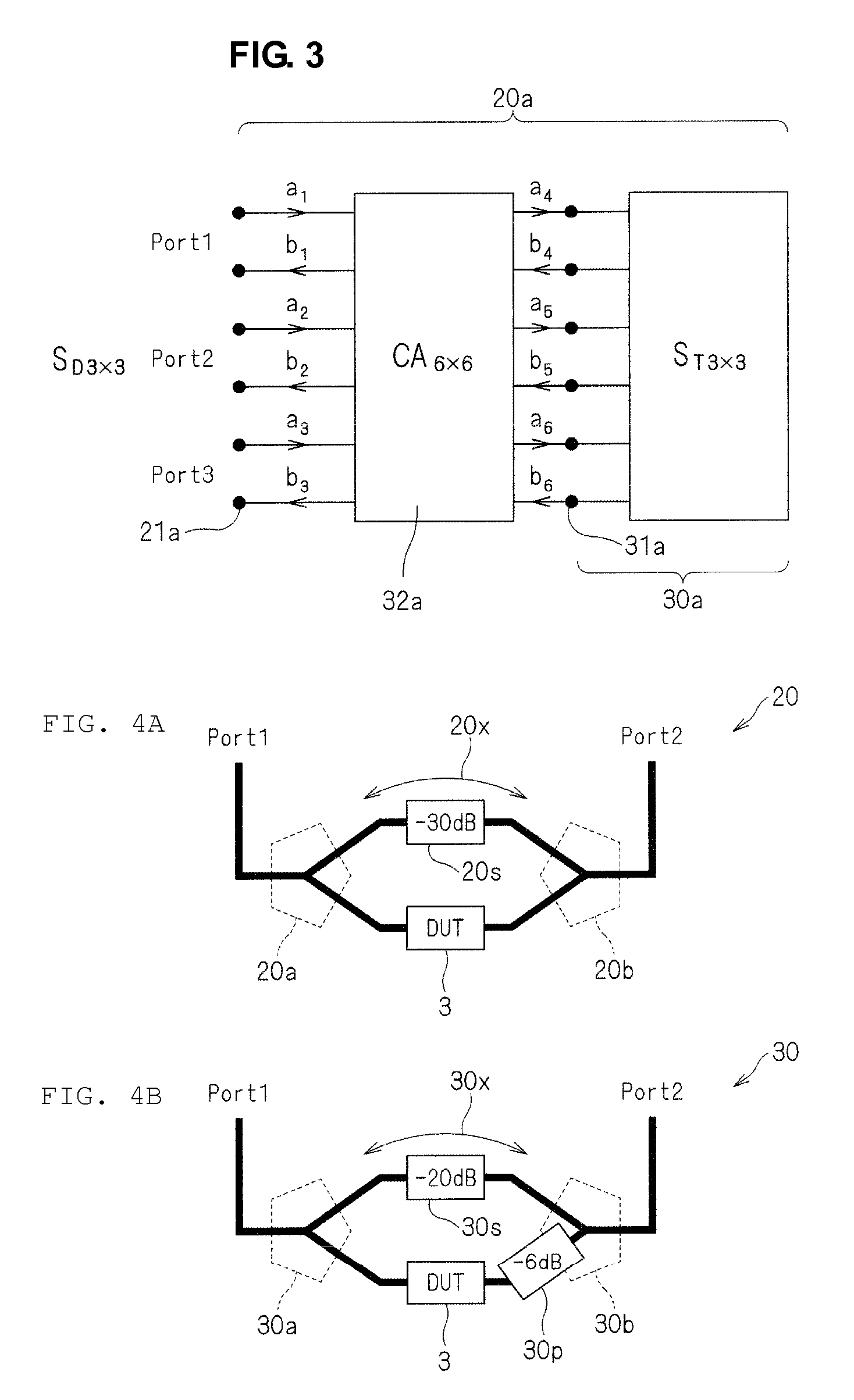

Method for correcting measurement errors and electronic component characteristics measuring device

ActiveUS20110178751A1High precisionCorrection errorResistance/reactance/impedenceTesting/calibration of speed/acceleration/shock measurement devicesElectricityMeasurement device

A method for correcting measurement errors and an electronic component characteristics measurement device improve correction precision by eliminating correction errors caused by leakage signal components between ports of the measurement jigs. An equation that correlates measurement values in a test measurement jig mounted state with measurement values in a standard measurement jig mounted state is determined from a result of measuring electrical characteristics of correction data obtaining samples having different electrical characteristics from each other in a state in which they are mounted on a standard measurement jig and on a test measurement jig. The equation is an equation that assumes the presence of leakage signals that are directly transmitted between at least two ports of at least one of the standard measurement jig and the test measurement jig. By using the equation determined by measuring the electrical characteristics on an arbitrary electronic component in a state in which it is mounted on the test measurement jig, the electrical characteristics that would be obtained if measured on the electronic component in a state in which it is mounted on the standard measurement jig are calculated.

Owner:MURATA MFG CO LTD

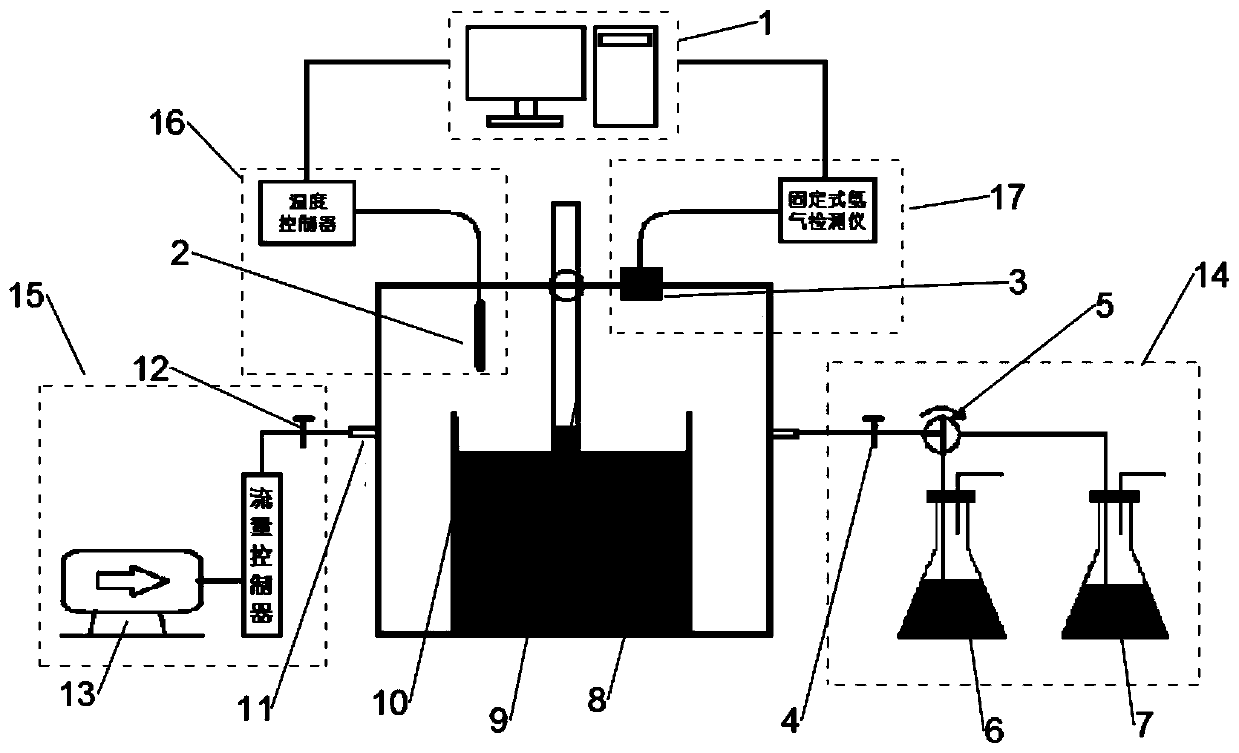

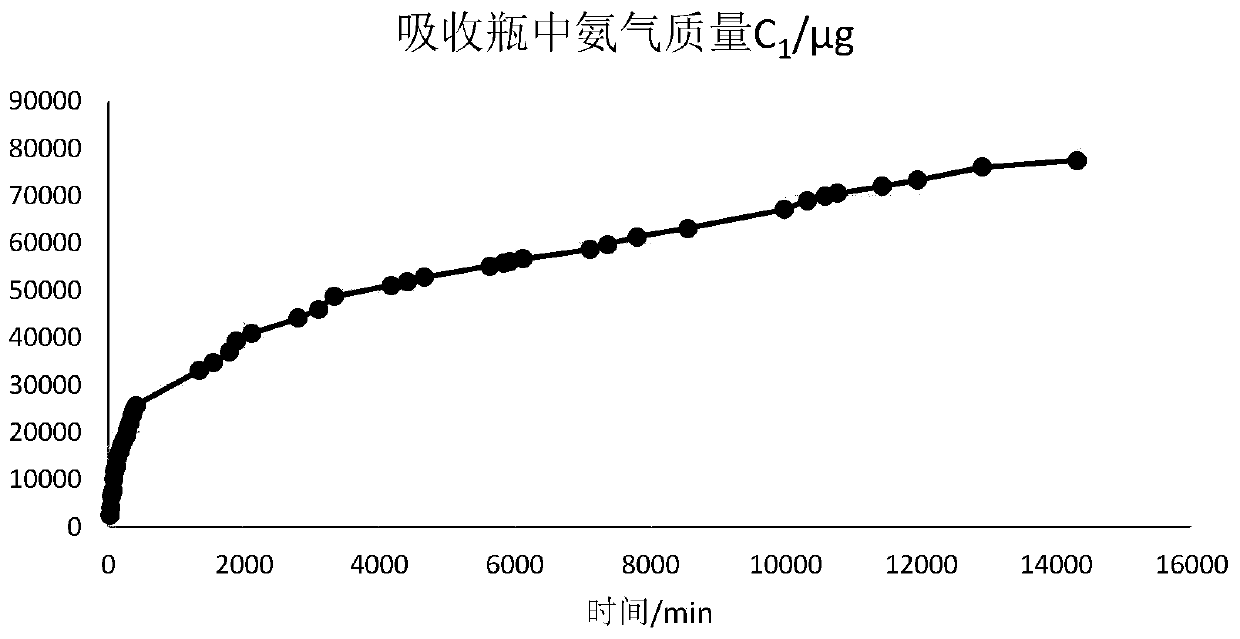

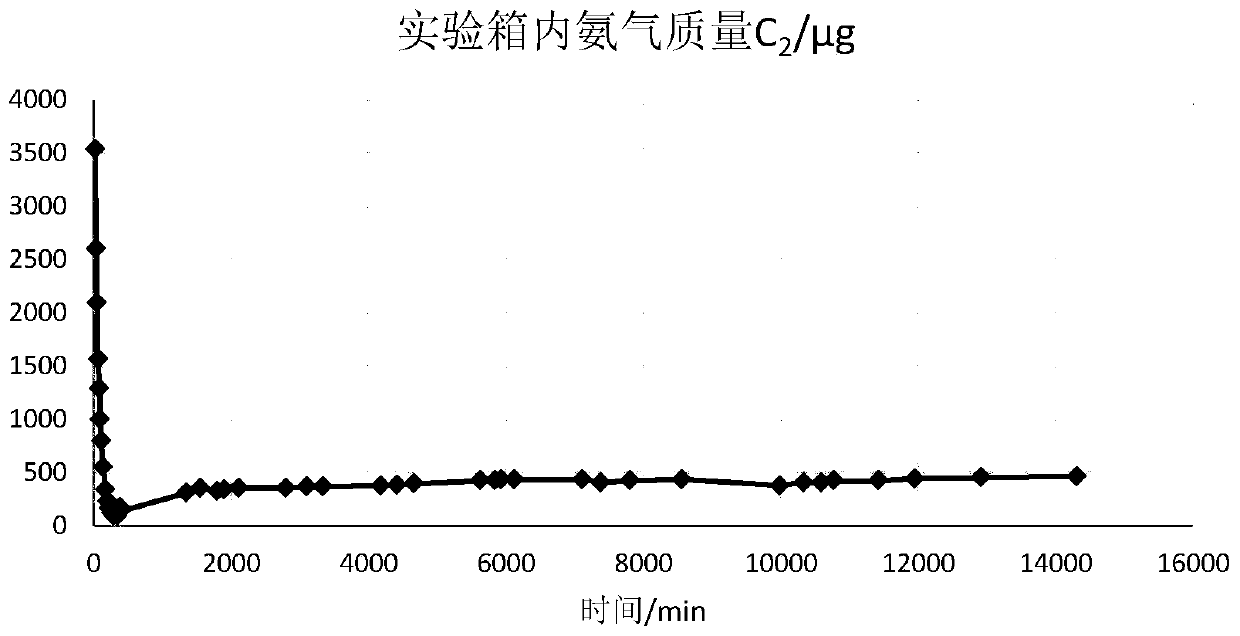

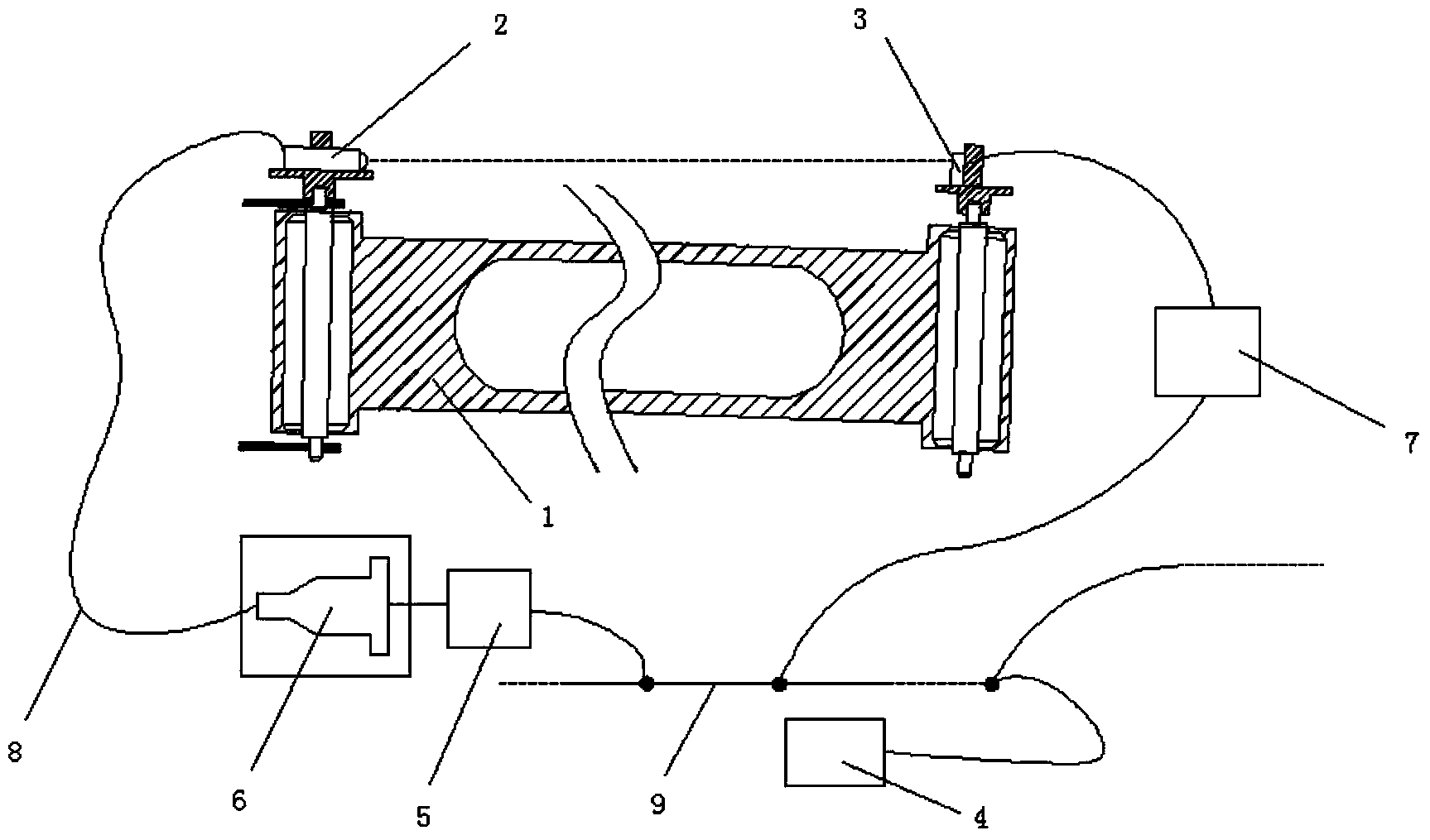

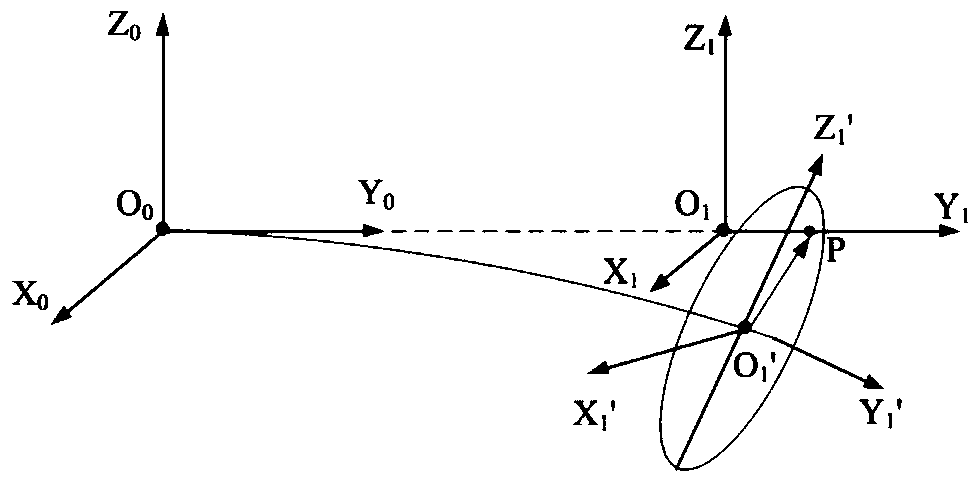

Continuous measuring device and method for ammonia gas releasing amount in concrete

PendingCN109827917ARealize real-time detectionIngenious designMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsTemperature controlControl system

The invention, which relates to the technical field of ammonia gas detection, discloses a continuous measuring device for the ammonia gas releasing amount in concrete, thereby solving a problem of theexisting device cannot continuously absorb and measure ammonia gas in concrete. The device comprises a data acquisition system, an experimental box, an ammonia gas absorption device, an air supply system, a temperature control system and an automatic ammonia concentration detection system. The data acquisition system is a host computer; and the two ends of the data acquisition system are respectively connected with the temperature control system and an automatic ammonia gas concentration detection system. In addition, the invention also discloses a continuous measuring method for the ammoniagas releasing amount in concrete. According to the invention, the vibration and hardening process of concrete is simulated by regulating the environmental conditions of the temperature and wind speedin the experiment box, thereby realizing real-time detection of the ammonia gas releasing amount in the whole process of concrete pouring and maintenance and thus filling the blank of the ammonia gasreleasing amount detection method in the concrete pouring process.

Owner:CHINA THREE GORGES PROJECTS DEV CO LTD +2

High-precision measuring device for measuring joint type equipment member bar deformation

InactiveCN103438816ACorrect measurement errorHigh measurement accuracyUsing optical meansTime errorJoint coordinates

The invention discloses a high-precision measuring device for measuring joint type equipment member bar deformation. The high-precision measuring device for measuring joint type equipment member bar deformation is a real-time error compensation device aiming at solving the problem that an armed lever member bar deforms elastically in the measuring process of the geometric dimension of a parallel dual-joint coordinate measuring machine. The high-precision measuring device for measuring joint type equipment member bar deformation is based on the laser detection principle and combined with the elastic deformation of an electronic circuit detection armed lever relative to a reference beam, and on-line correction of the error is achieved. The high-precision measuring device for measuring joint type equipment member bar deformation is easy to assemble, convenient and fast to use, light and handy in structure and easy to operate. By means of the high-precision measuring device for measuring joint type equipment member bar deformation, the measuring error of the parallel dual-joint coordinate measuring machine can be well corrected, and therefore measuring precision is improved.

Owner:HEFEI UNIV OF TECH

Apparatus for estimating open circuit voltage of battery, apparatus for estimating state of charge of battery, and method for controlling the same

ActiveUS8175826B2Easily and accurately open circuit voltageCorrect measurement errorElectrical testingSpecial data processing applicationsElectrical batteryMathematical model

An apparatus for estimating an OCV of a battery includes a voltage sensing unit for measuring a battery output voltage; a temperature sensing unit for measuring a battery temperature; a data storing unit for periodically receiving the battery output voltage and temperature data from the sensing units and storing the data in a memory; an OCV variation estimating unit for calculating an OCV variation from a varying pattern of battery output voltages measured in the past and at the present, stored in the memory, by applying a mathematical model defining a correlation between the varying pattern and the OCV variation, and estimating an OCV at a current stage by reflecting a correction factor corresponding to the battery temperature on the calculated OCV variation; and an OCV estimating unit for estimating an OCV at the current stage by reflecting the estimated OCV variation on the OCV estimated at a last stage.

Owner:LG ENERGY SOLUTION LTD

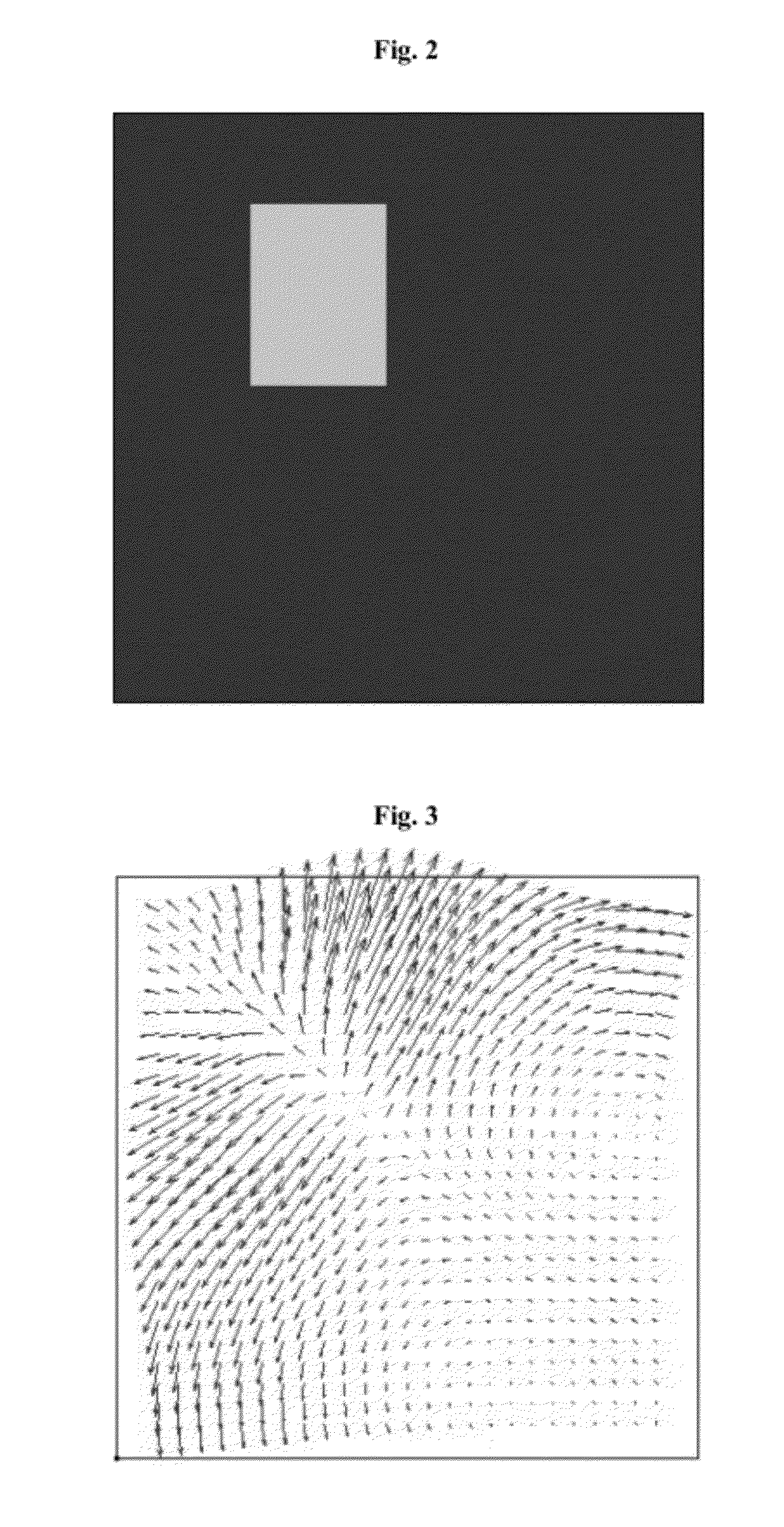

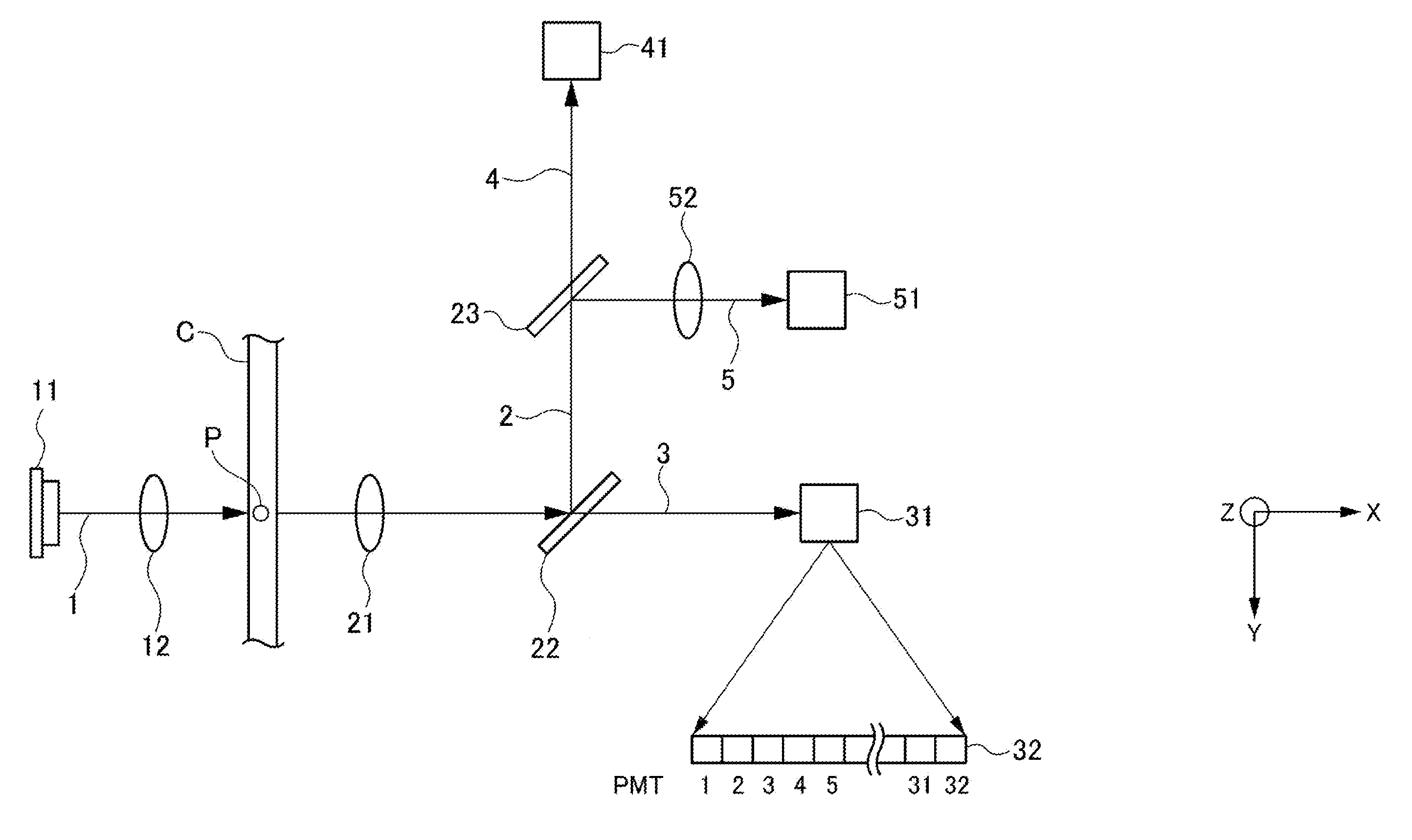

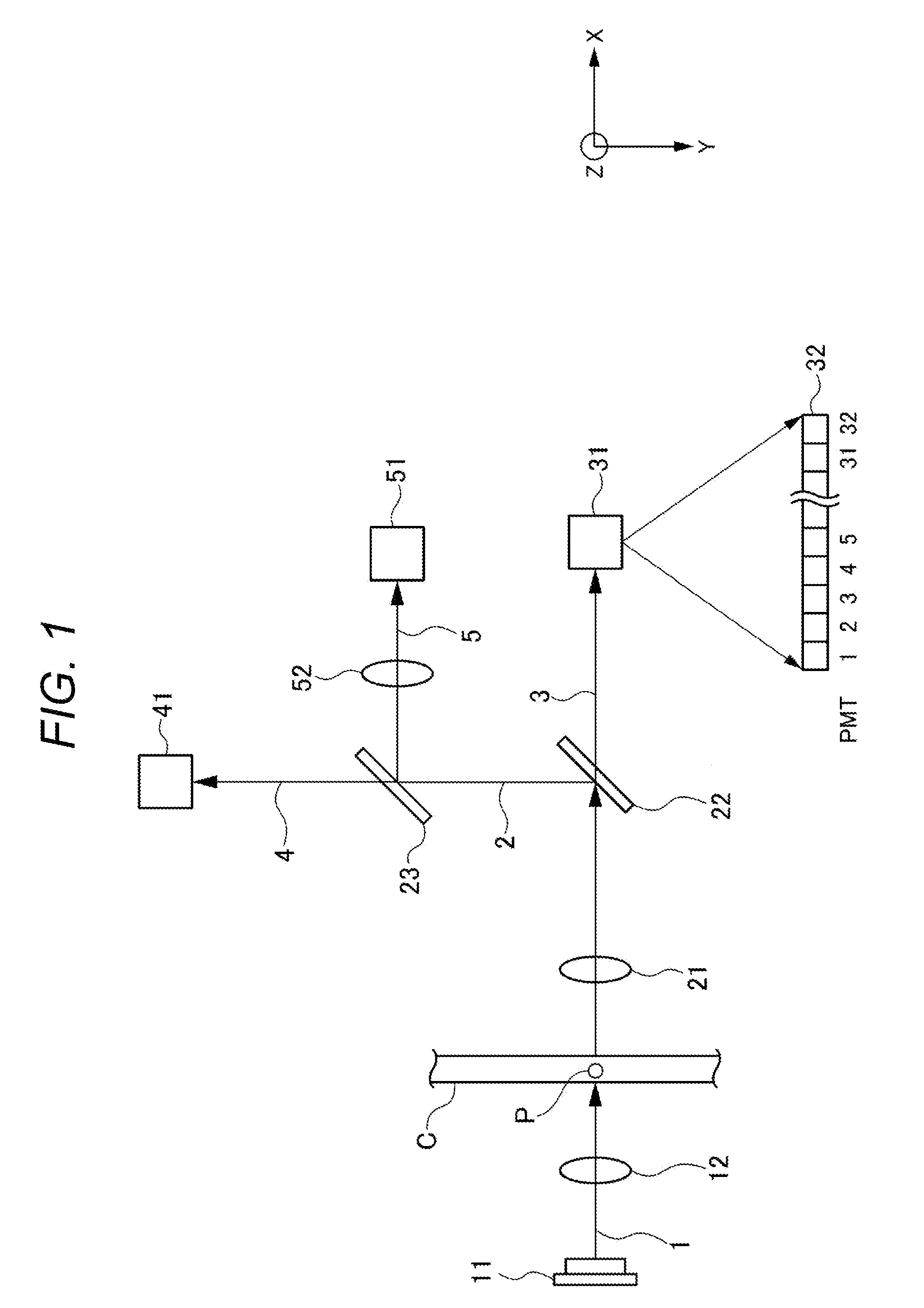

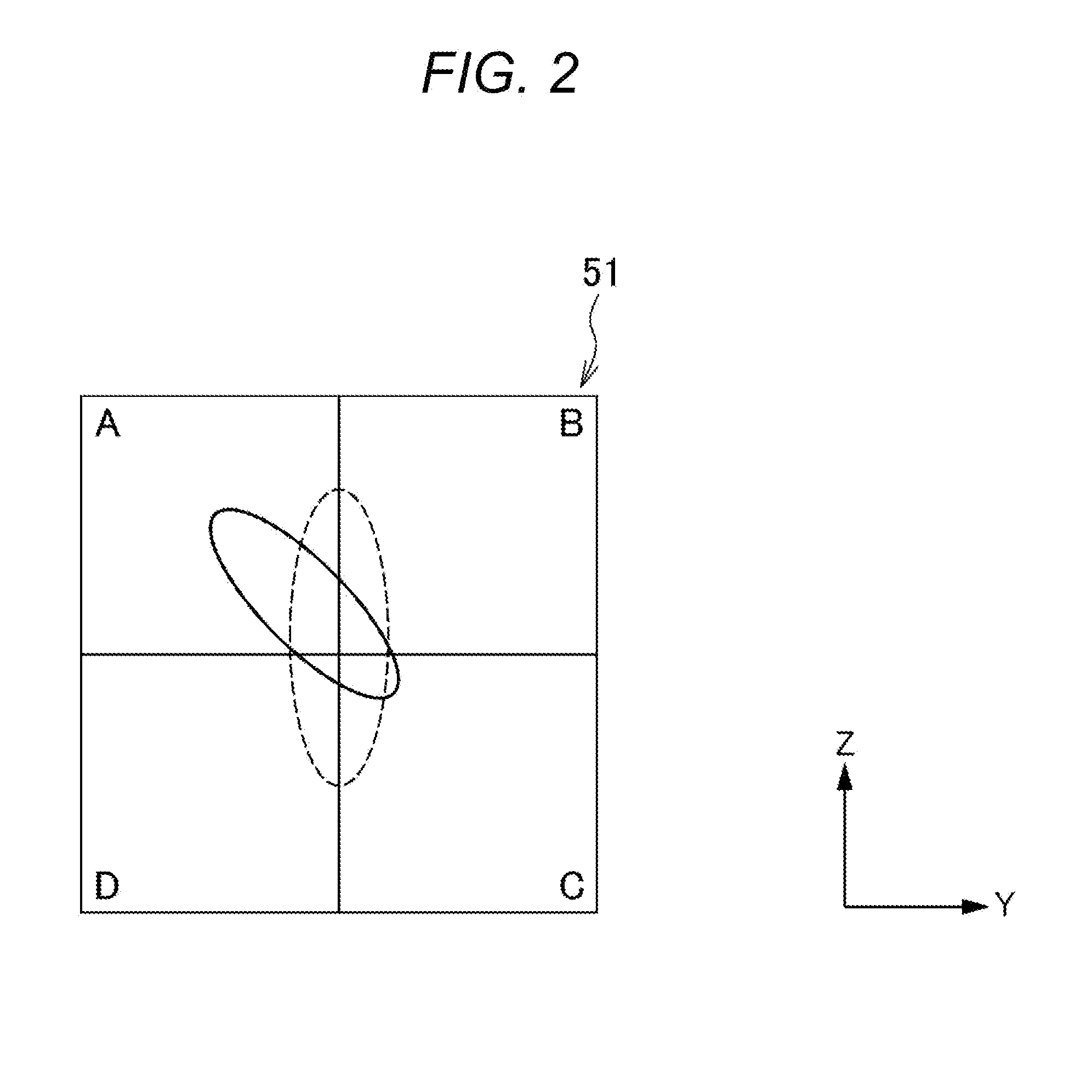

Data correction method in fine particle measuring device and fine particle measuring device

ActiveUS20150112627A1Accurate measurementCorrect measurement errorPolarisation-affecting propertiesScattering properties measurementsFluorescenceParticle flow

To provide a technique capable of highly accurately measure the intensity and the spectrum of fluorescence and scattered light by effectively correcting measurement error that occurs due to variation of flow positions of fine particles in a channel. A data correction method for a fine particle measurement device is provided, which includes an intensity detection procedure capable of detecting light generated from a fine particle by emitting light onto the fine particle flowing through a channel, and obtaining intensity information about the light, a position detection procedure capable of obtaining position information about the fine particle, and a correction procedure for correcting the intensity information on the basis of the position information.

Owner:SONY CORP

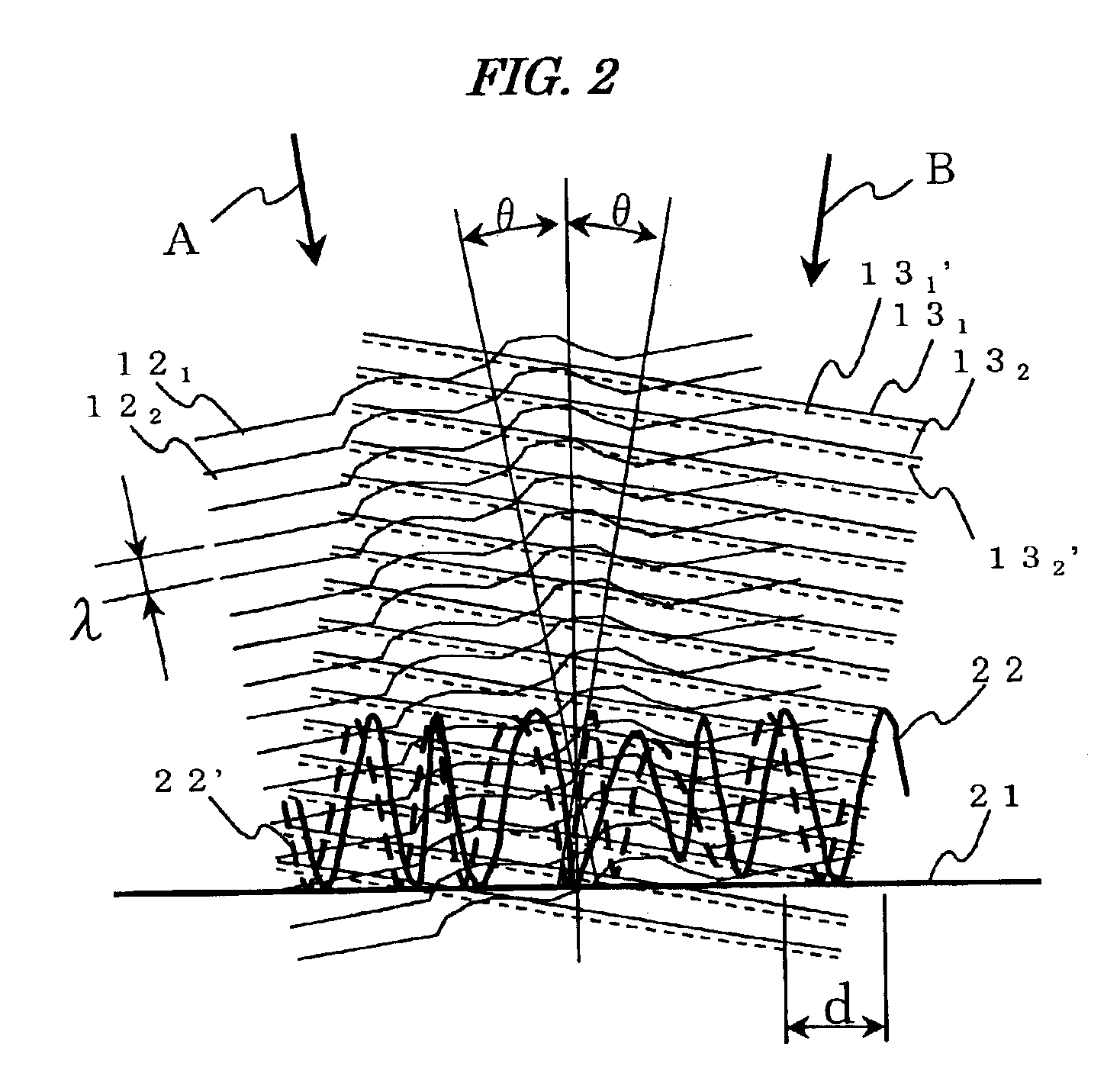

Interference measuring device

InactiveUS6950195B2Small spreadImprove accuracyElectric discharge tubesUsing optical meansMeasurement deviceLight beam

In an interference measuring device, which includes: a coherent beam generating source; a sample to be measured; a lens system for forming an image of the sample to be measured on an observing plane; an interference element for splitting a coherent beam into two systems, and forming an interference image on the observing plane or a plane equivalent thereto; an image pickup element for picking up the interference image on the observing plane; and a calculating device having functions of capturing and storing the interference image converted to electric signals by the image pickup element, and determining the phase distribution changed by the sample to be measured from the interference image by calculation, wherein a means for removing the phase change distribution due to the interference element is provided.

Owner:JAPAN SCI & TECH CORP +1

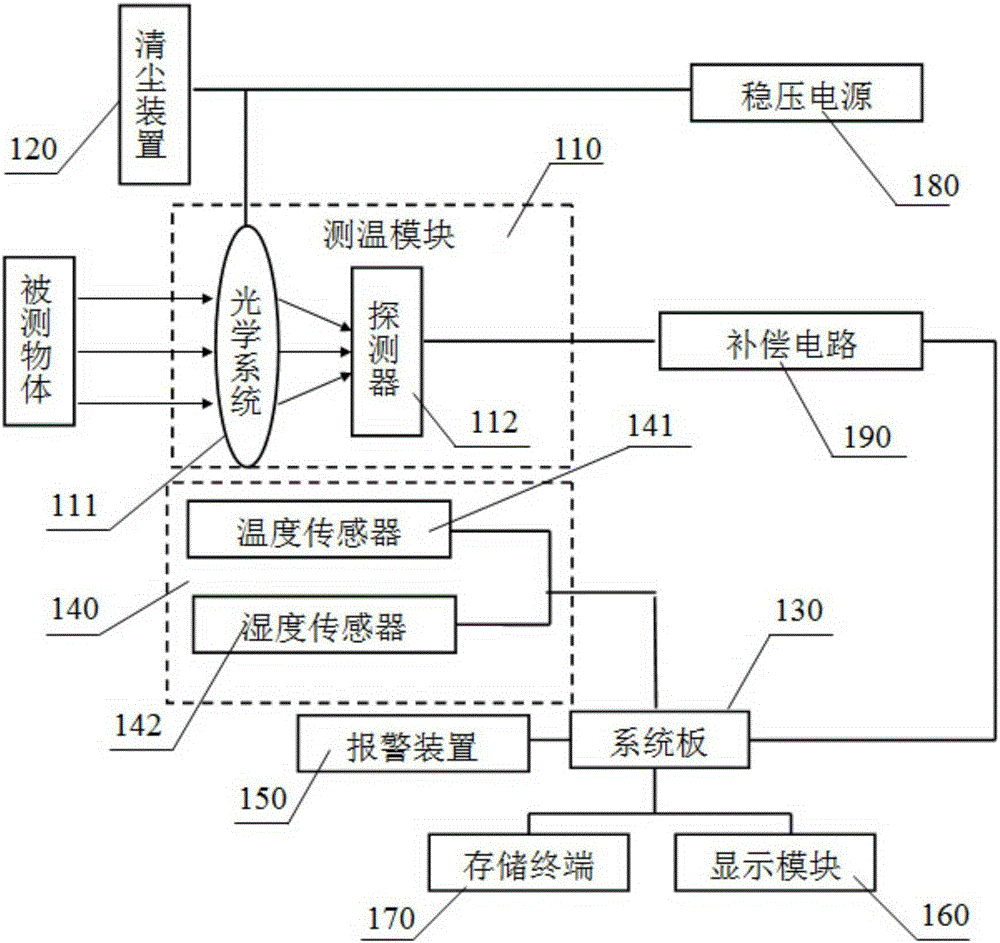

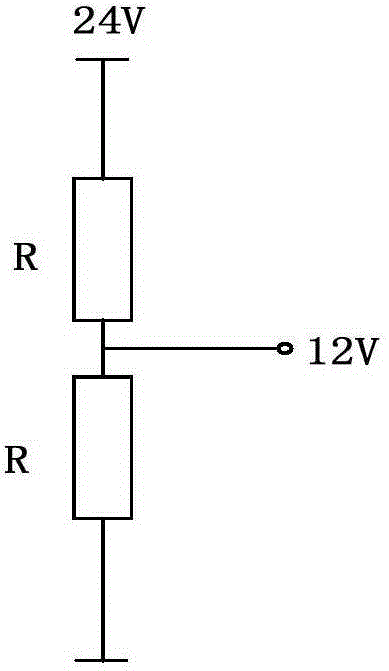

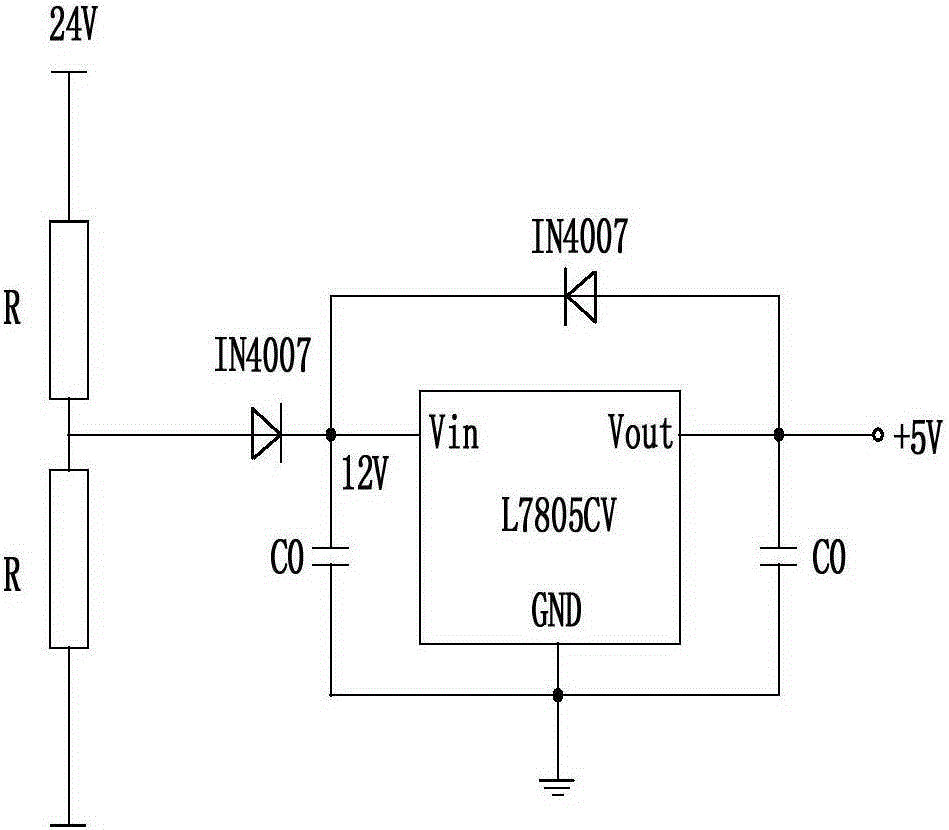

Anti-recoil device temperature automatic measuring instrument and control method thereof

InactiveCN105241579AImprove protectionEasy maintenanceThermometer detailsThermometer applicationsMeasuring instrumentEngineering

The present invention discloses an anti-recoil device temperature automatic measuring instrument which comprises a temperature measurement module formed by an optical system and a detector, a dust cleaning device which is used for cleaning the dust in an air media and improving the measurement precision, and a system module which calibrates a measured temperature value through an environment sensor and is provided with a buzzer for over-temperature alarm. The invention also discloses an anti-recoil device temperature automatic measurement control method, the optical system converges the energy of target radiation to a detector, an intermediate temperature is obtained through calibrating an apparent temperature, the intermediate temperature error correction is carried out through environment temperature and humidity values to obtain an actual temperature, the temperature of a measured object can be precisely measured in real time, the effects of supervision and safety for the correct operation of a shooter are achieved, and the anti-recoil device temperature automatic measuring instrument and the method have a very practical significance for the use and safeguard of future equipment.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

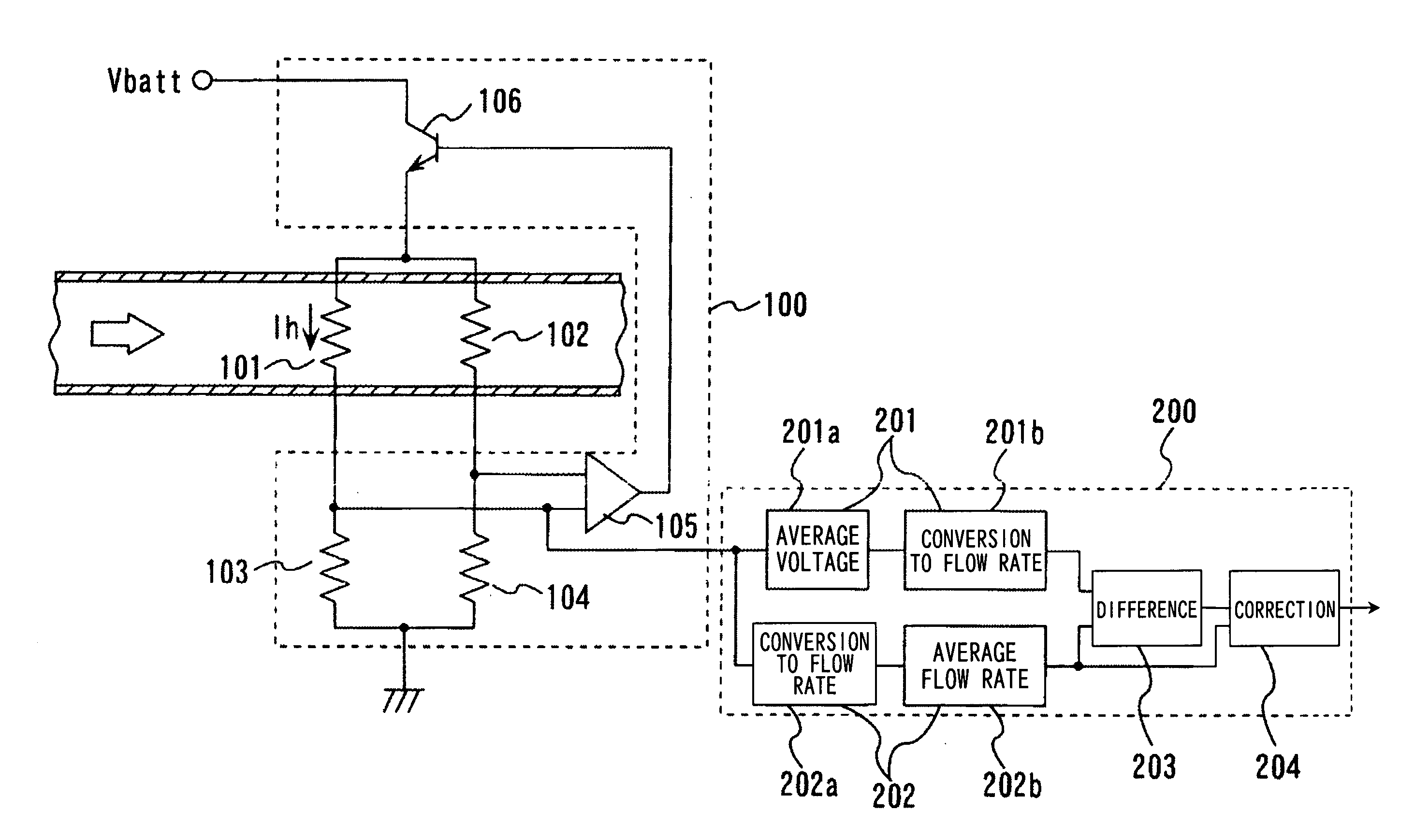

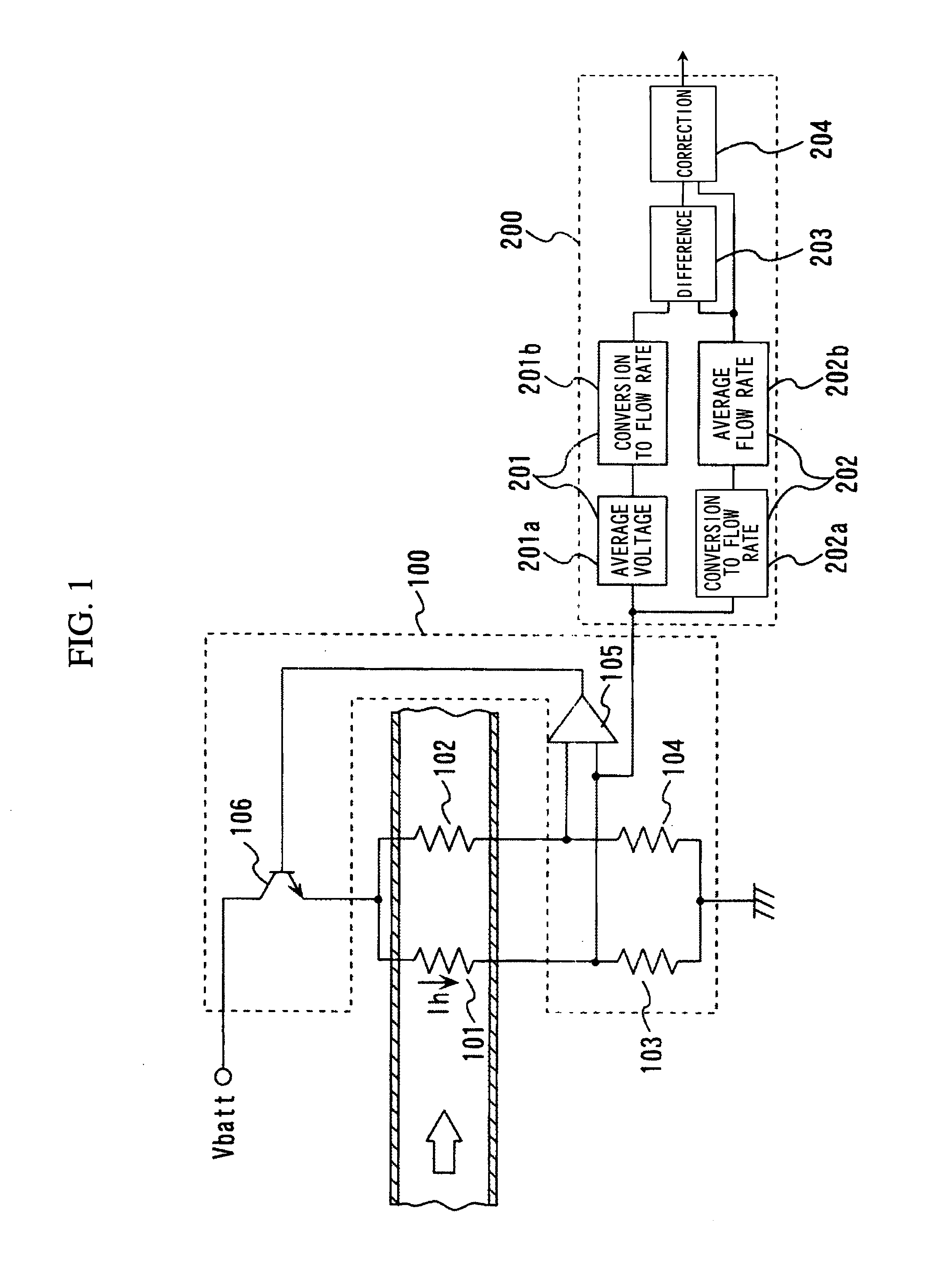

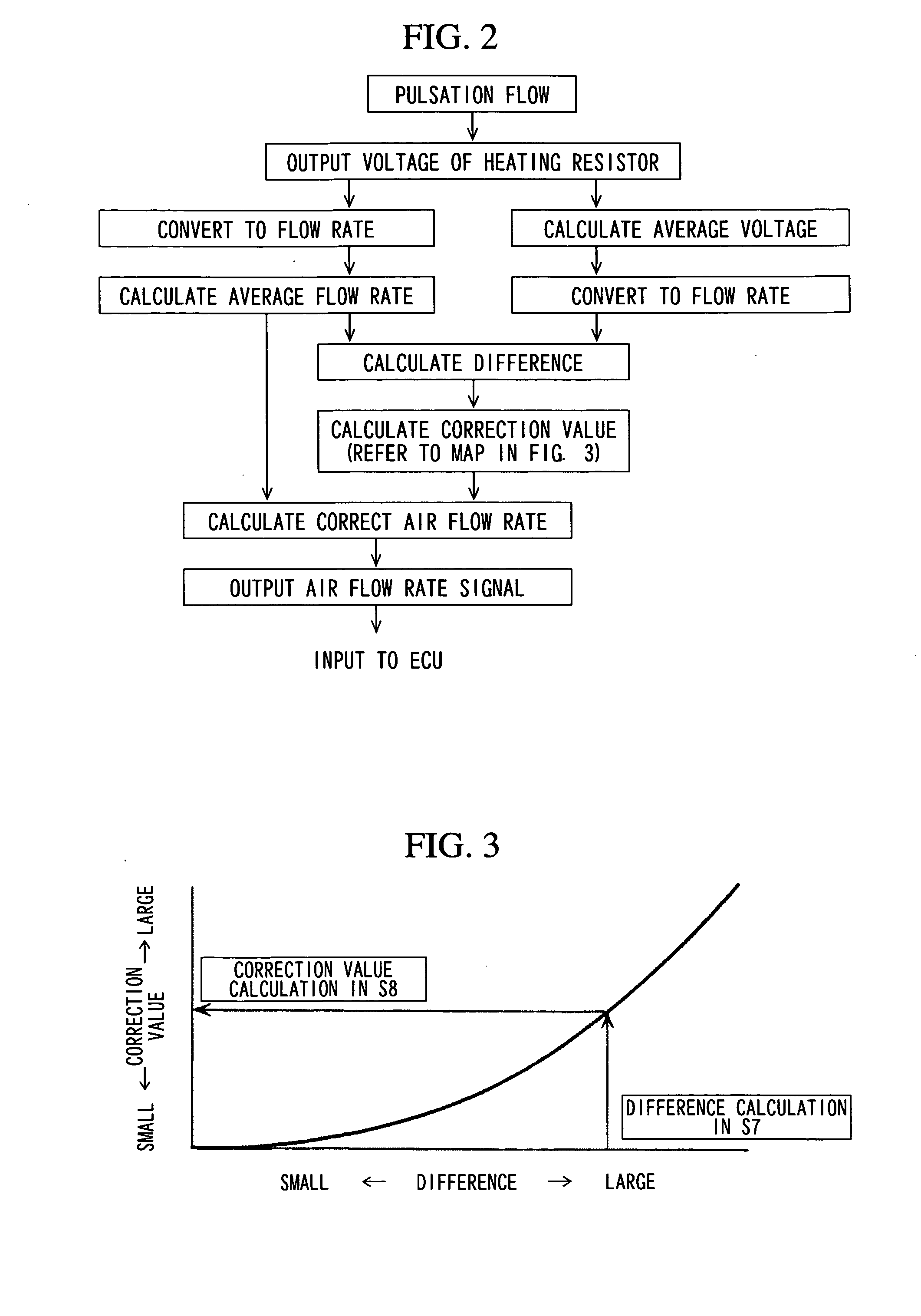

Heating resistor type air flow rate measuring device and method of correcting measurement error

InactiveUS20060212250A1Correct measurement errorTesting/calibration apparatusVolume flow proportion measurementElectrical resistance and conductanceObservational error

A measurement error attributable to intake air pulsation of a heating resistor type air flow rate measuring device is corrected. A measurement error correction method not dependent on an intake system of a vehicle is provided. An output from a sensing circuit is sampled at prescribed time intervals. Output values thus sampled are successively converted to flow rate values. A first flow rate value is determined by averaging the flow rate values thus obtained in a prescribed amount of time. Separately, the output from the sensing circuit is averaged for a prescribed amount of time. The average output value thus obtained is converted to a second flow rate value. A correction value for correcting a measurement error is determined based on a difference between the first and second flow rate values.

Owner:HITACHI LTD

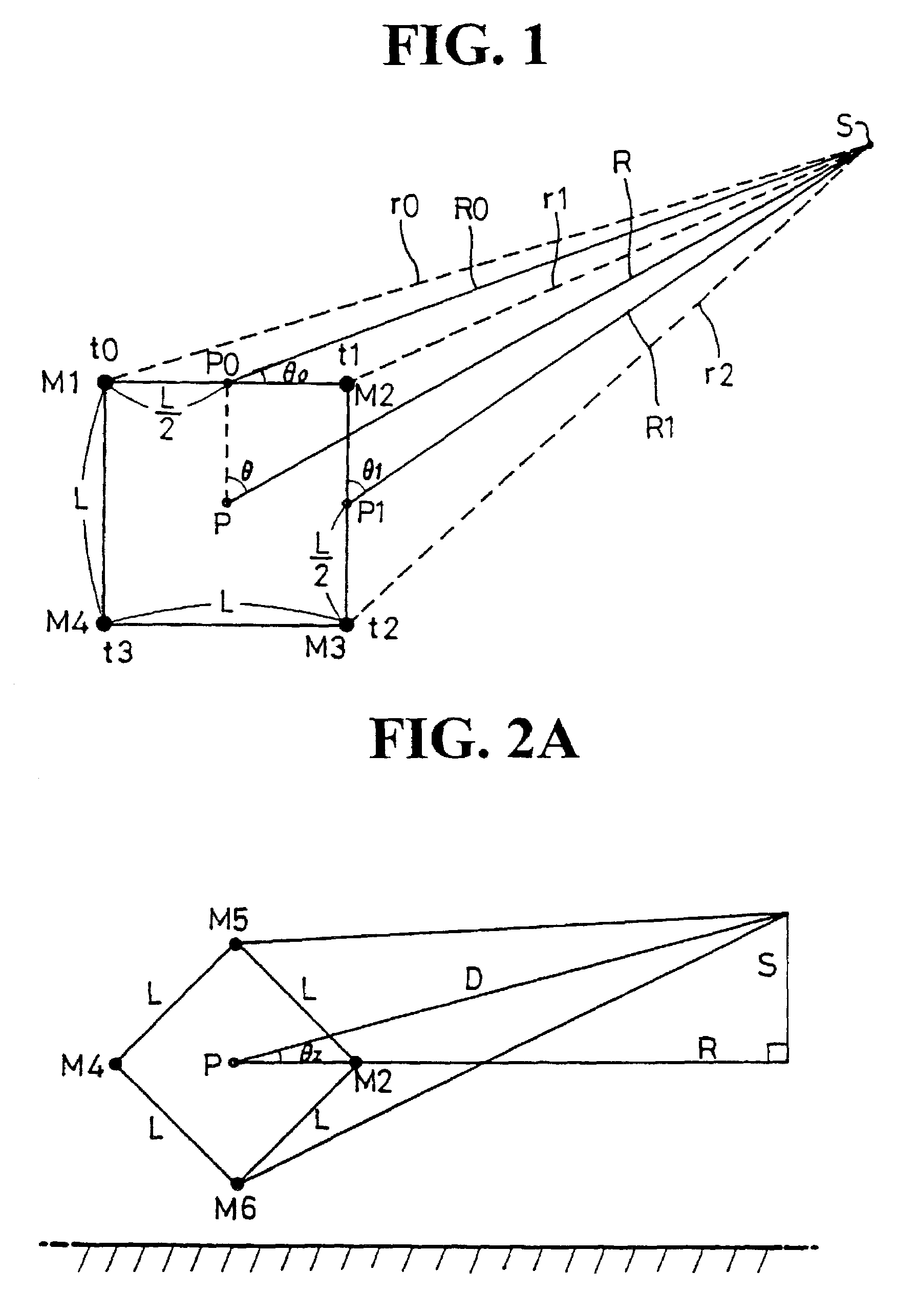

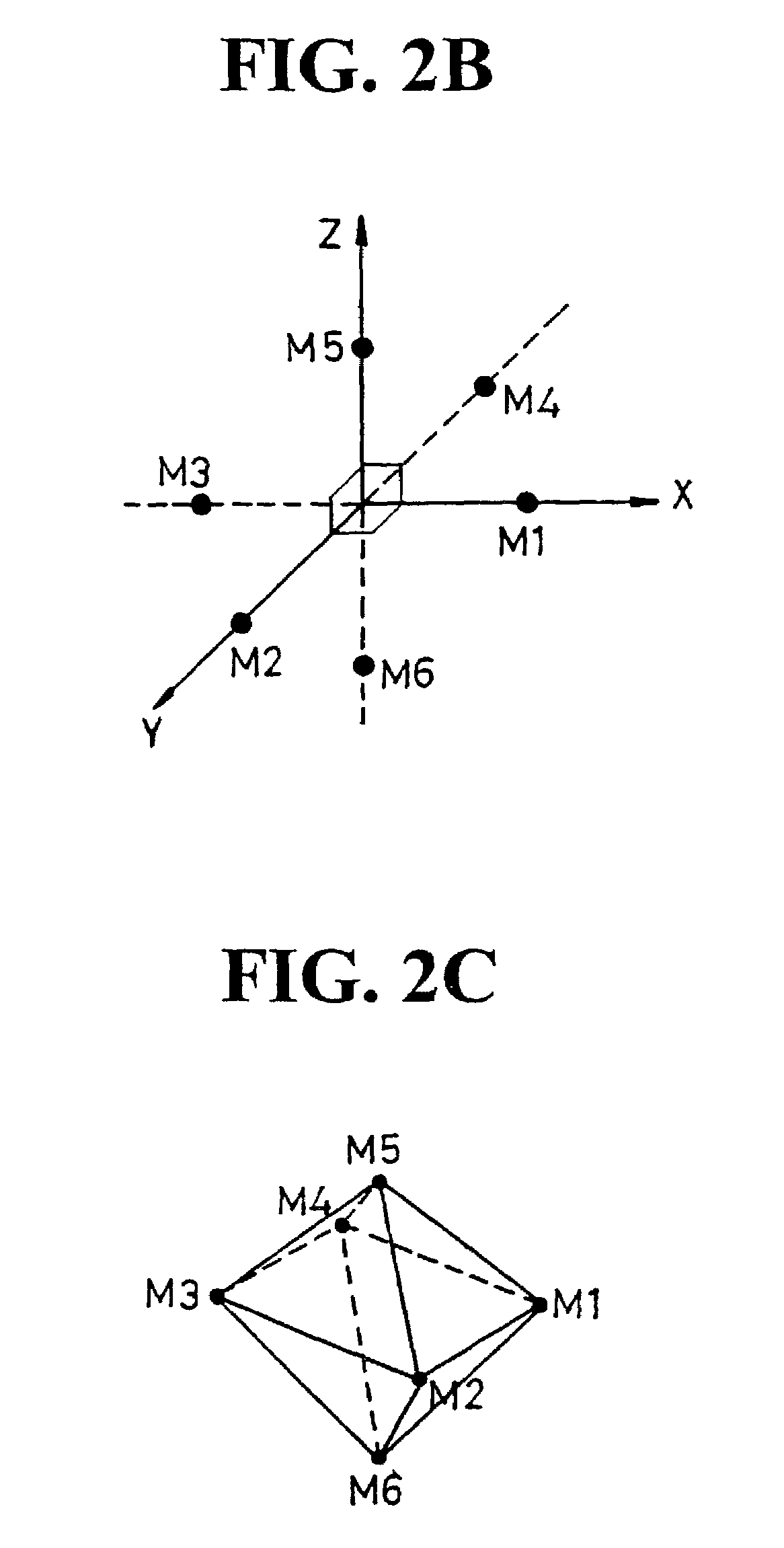

Passive sound telemetry system and method and operating toy using the same

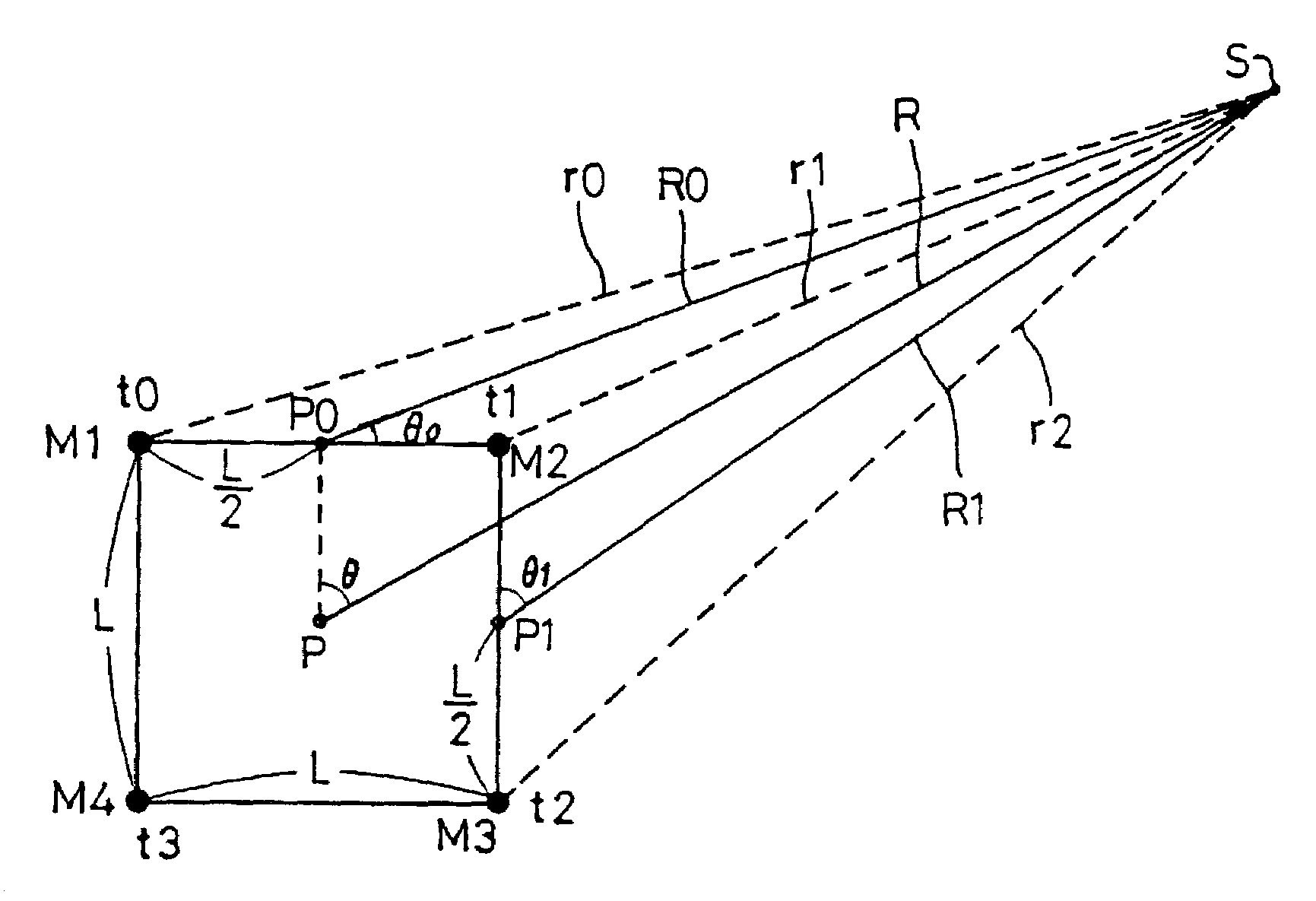

InactiveUS7215785B1Correct measurement errorAccurate dataPosition fixationDirection/deviation determination systemsSound sourcesPhase difference

A passive sound telemetry system and method is provided, in which phase differences are calculated for every pulse from acoustic signals received via three or six acoustic receivers, to measure a distance and angle with respect to a sound source. The system is applied to an operating toy giving chase to a user while following the user command. The telemetry system includes first to fourth acoustic receivers (111–114) contained in the housing for receiving first to fourth acoustic signals from a user, first to fourth zero crossing detectors for generating first to fourth pulse signals based on the first to fourth acoustic signals, earliest reception signal detector for detecting a pulse signal having the earliest phase among the first to fourth pulse signals, first to fourth arrival time difference calculator (70) for calculating arrival time differences between the pulse signal of the earliest phase and the first to fourth pulse signals, respectively, thereby obtaining an angle and a distance between the center of acoustic receivers and the user, based on a time difference between the second and third minimum arrival time difference values.

Owner:JU SANG GYU

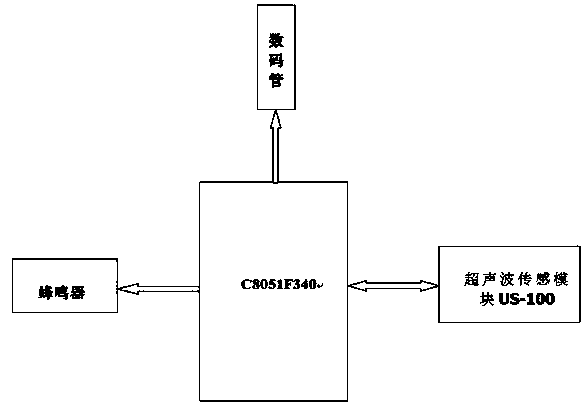

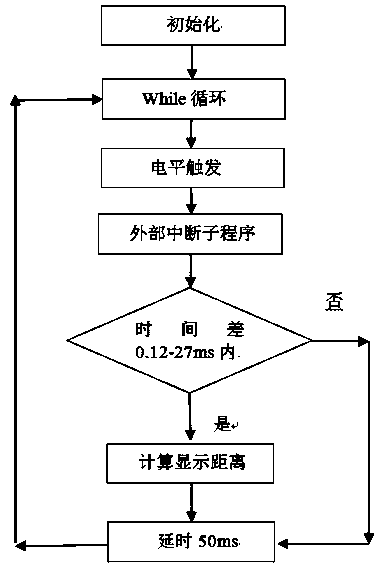

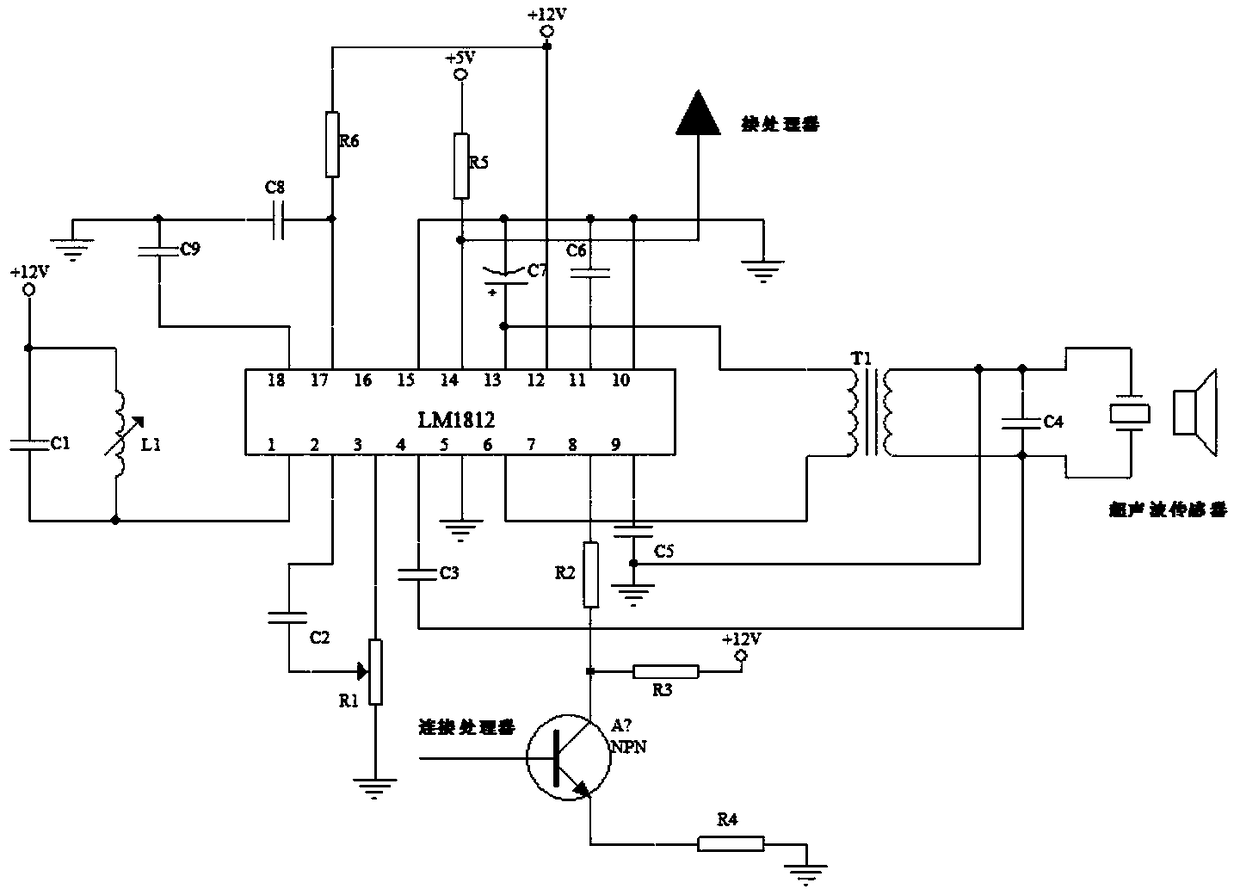

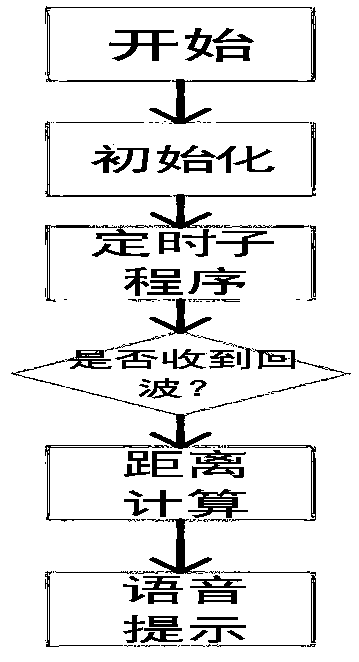

Short-distance ultrasonic wave distance measuring system based on single chip microcomputer

InactiveCN103454642ALow Power Circuit RequirementsReduce mistakesAcoustic wave reradiationUltrasound waveAcoustics

The invention discloses a short-distance ultrasonic wave distance measuring system based on a single chip microcomputer. The short-distance ultrasonic wave distance measuring system mainly comprises an ultrasonic wave sensing module US-100 with the temperature compensating function, the single chip microcomputer C8051F340, a digital display tube and a buzzer. According to the short-distance ultrasonic wave distance measuring system, the distance can be automatically measured in a real-time mode, the short-distance ultrasonic wave distance measuring system is particularly suitable for an automobile reversing radar, and therefore accidents which possibly occur in automobile reversing are avoided. Specifications of electronic devices included in the short-distance ultrasonic wave distance measuring system based on the single chip microcomputer are all of a universal type, and therefore the short-distance ultrasonic wave distance measuring system based on the single chip microcomputer has the advantages of being easy in purchase, simple in process, low in production cost and the like. Within the range of 4.5m, the measuring precision is improved to 0.3cm, and the short-distance ultrasonic wave distance measuring system has the good effect in various distance measuring applications.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

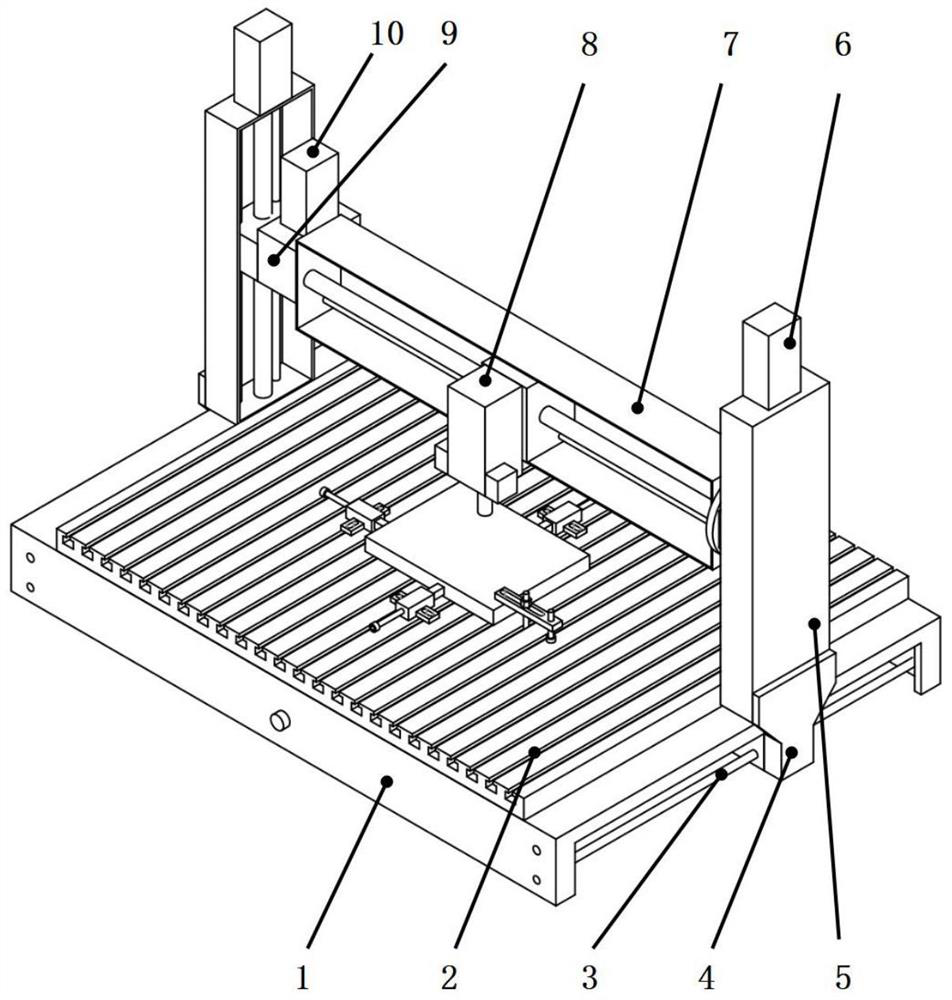

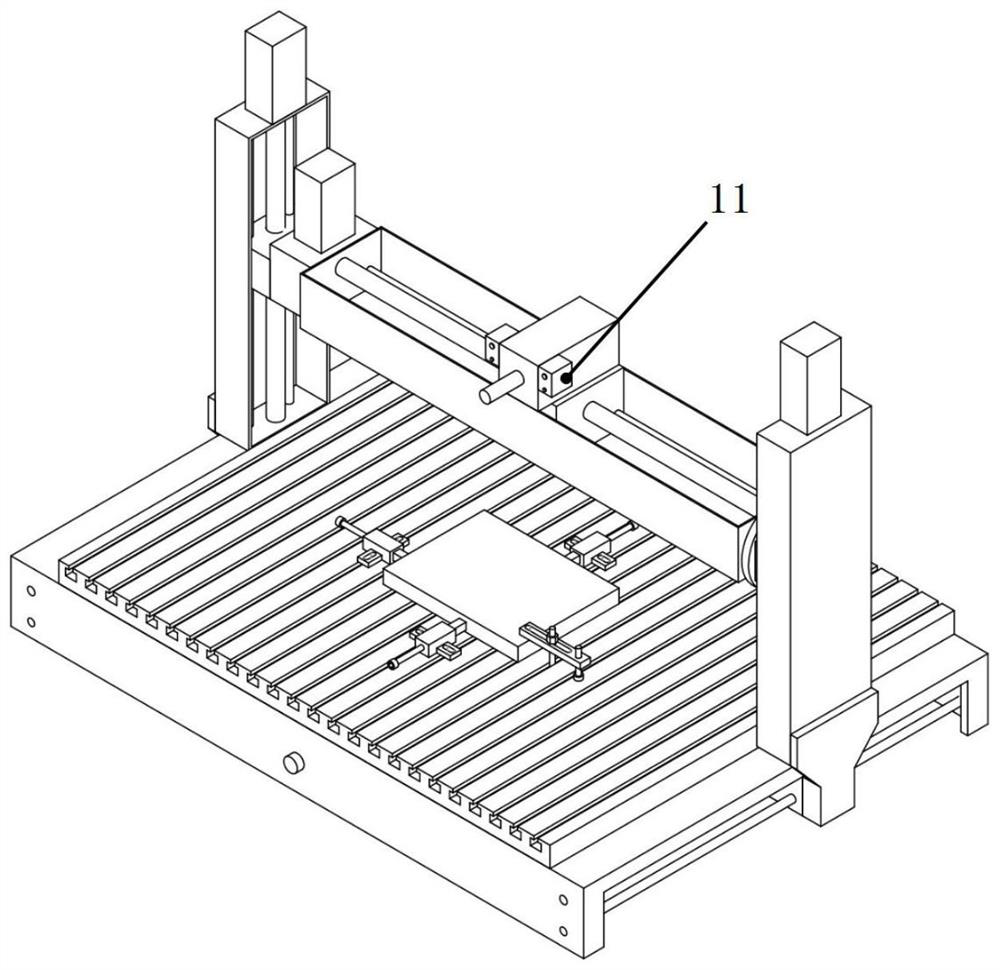

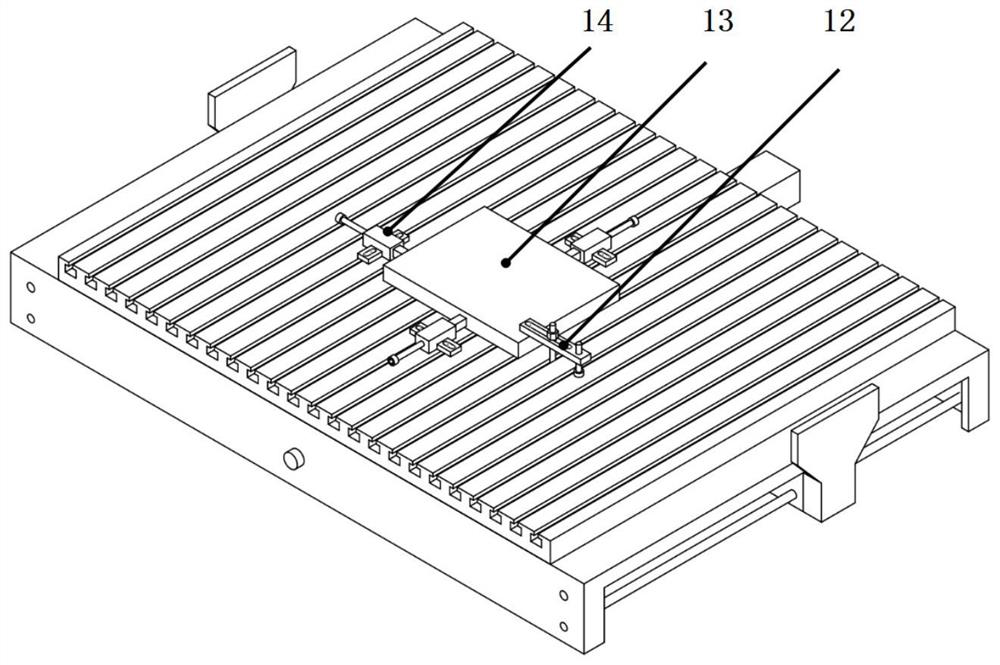

Blind hole method residual stress automatic drilling testing device

InactiveCN113245585AReduce measurement errorEasy to operateFeeding apparatusPositioning apparatusTest sampleClassical mechanics

The invention discloses a blind hole method residual stress automatic drilling testing device. The device comprises a drilling system, a clamping system, a positioning system and an automatic testing system; the drilling system can be used for drilling any plane of a test sample piece; the clamping system is used for clamping in a pushing and pressing manner, so that the clamping stress can be reduced to the greatest extent, and the measurement error is reduced; the positioning system can automatically identify the position of a strain gauge and calculate the coordinates of a drilling position; and the automatic testing system performs automatic tool setting and automatic drilling according to the position of the strain gauge identified by an image, and after drilling is finished, software calculates the residual stress of different depths and surface layers of the sample piece according to a strain value after feeding each time and the actual drilling hole diameter measured by the image identification.

Owner:BEIHANG UNIV +1

Method and apparatus for the determination of laser correcting tool parameters

ActiveUS9753366B2Correct measurement errorSolving precise measurementsNanoinformaticsPhotomechanical apparatusOptoelectronicsLaser beams

Owner:CARL ZEISS SMS GMBH

Devices and Methods for Determining a Magnetic Field Distribution of a Magnet Along A Main Surface of Said Magnet

ActiveUS20150276895A1Large degree of design freedomEasy to scanMagnetic sensor arraysMagnitude/direction of magnetic fieldsComputer moduleCamera module

Owner:MAGCAM

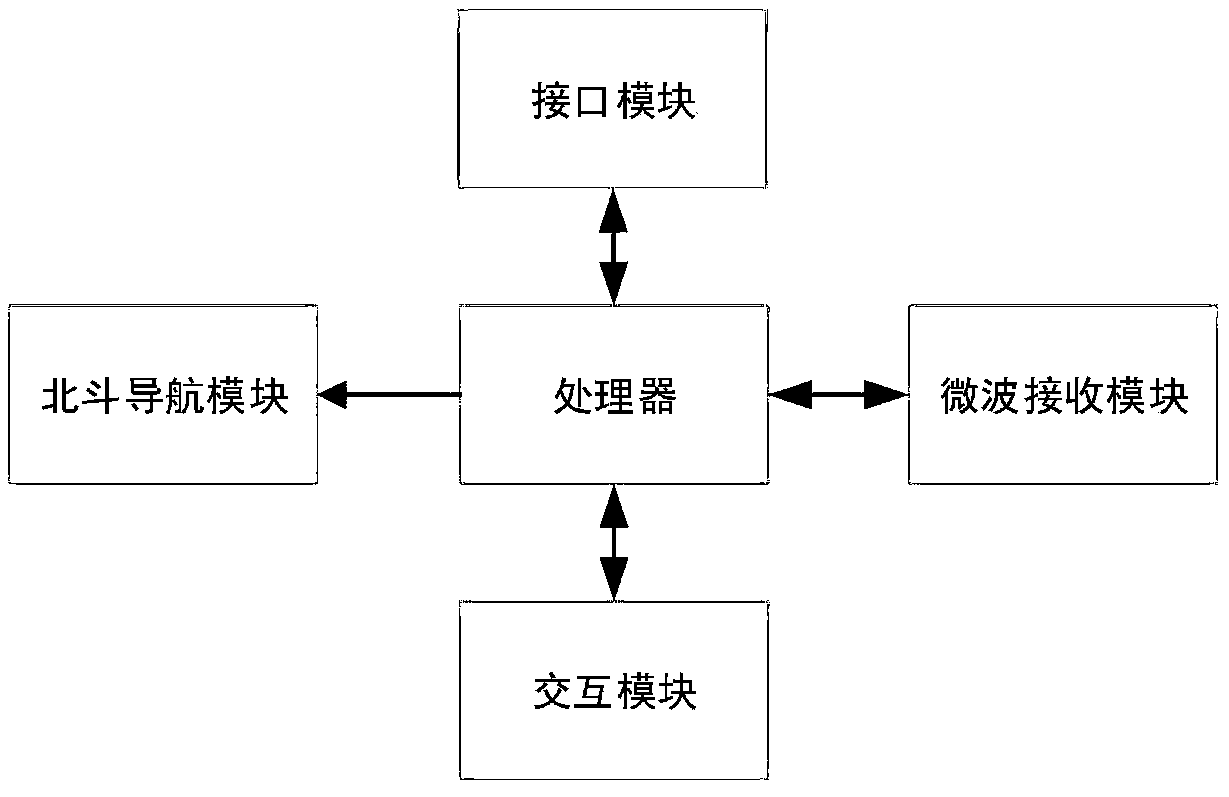

Joint positioning system and joint positioning method for metering device

PendingCN109100754AGuaranteed traceabilityReal-time implementation returnsSatellite radio beaconingMicrowaveEngineering

The invention discloses a joint positioning system for a metering device. The system comprises a processor unit, a navigation module, a microwave receiving module, an interface module and an interaction module, wherein the navigation module, the microwave receiving module, the interface module and the interaction module are electrically connected with the processor unit respectively. The joint positioning system for the metering device adopts a joint positioning method of navigation positioning and microwave positioning to be able to control the positioning accuracy within 1 meter, which greatly improves the efficiency of positioning. At the same time, the invention also relates to a joint positioning method for the metering device.

Owner:GUIZHOU POWER GRID CO LTD

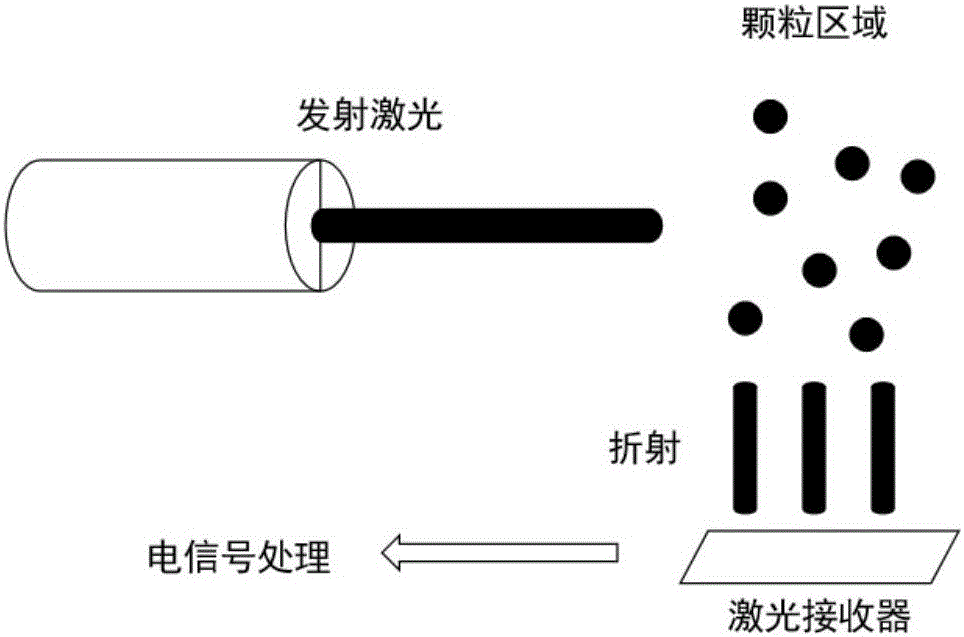

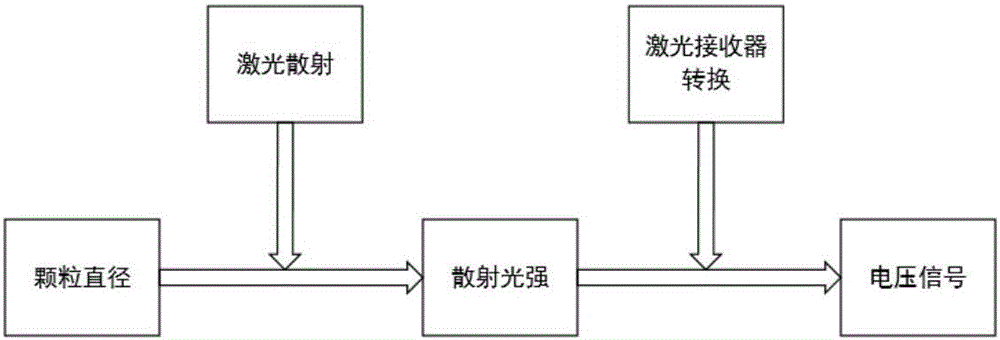

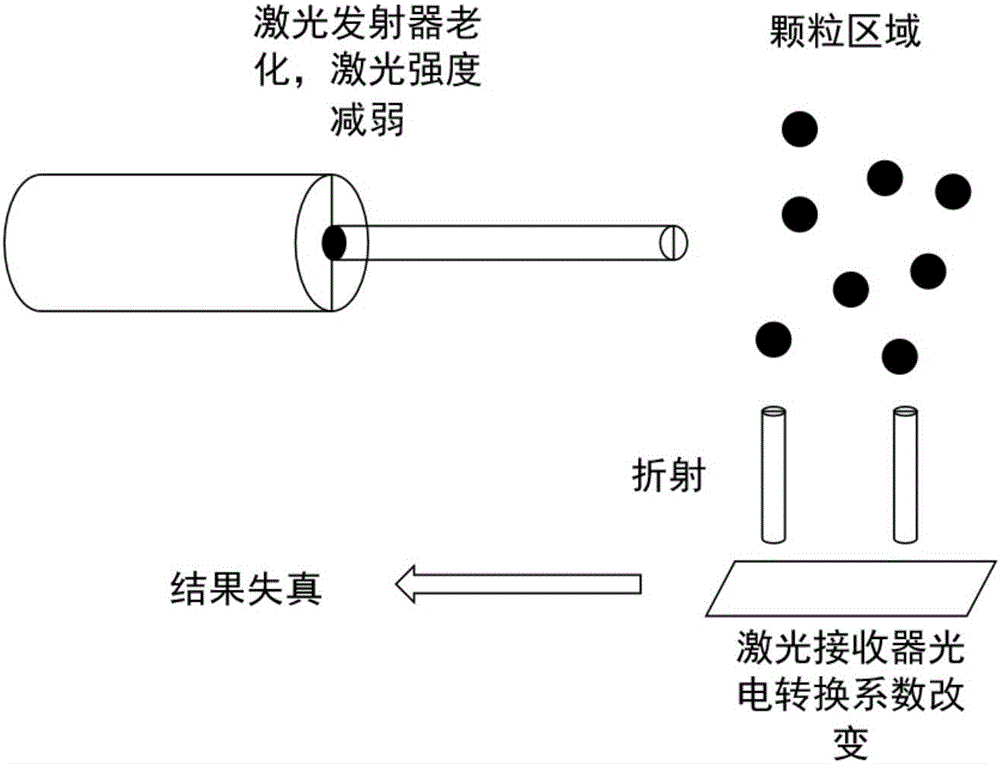

Method for improving measurement result accuracy of laser particle counter

InactiveCN106018200ACorrect measurement errorImprove measurement resultsParticle size analysisIndividual particle analysisLaser transmitterOptoelectronics

The invention provides a method for improving the measurement result accuracy of a laser particle counter. The laser particle counter comprises a plurality of laser transmitters. The method comprises the following steps: when the performance degradation of a main laser transmitter causes a calibration coefficient to distort, enabling a standby laser transmitter to work to carry out secondary calibration on the calibration coefficient of the main laser transmitter; and after the performance of the main laser transmitter degrades to a certain degree, using the standby laser transmitter, and starting the standby laser transmitter to serve as a new main laser transmitter. The method has the beneficial effects that a measurement error of the laser particle counter due to the performance degradation of the laser transmitter in a use process is corrected so as to improve the measurement result of the laser particle counter, and meanwhile, the service life of the laser particle counter is prolonged.

Owner:SHENZHEN QINGHETAO TECH CO LTD

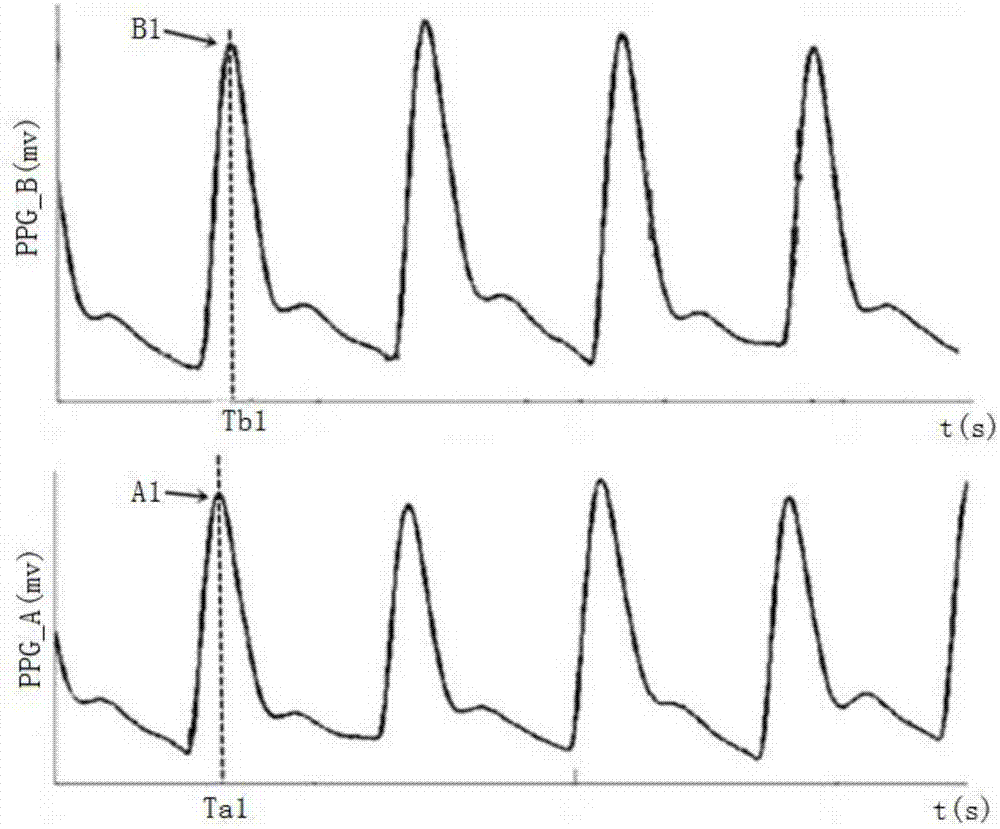

Blood pressure measurement method and device

ActiveCN107960998AHigh precisionReflect physiological blood pressureDiagnostic signal processingEvaluation of blood vesselsConduction pathwayMeasurement device

The embodiment of the invention discloses a blood pressure measurement method and device. The blood pressure measurement device acquires sensor signals of a first detecting point and a second detecting point which are selected by a user and positioned on one artery blood vessel of the user and at different distances from the heart; when receiving a first measurement instruction, the first blood pressure measurement device determines a first height difference which is the height different of the first detecting point and the second detecting point on a first conduction pathway on which first pulse waves pass by the first detecting point and the second detecting point, and the height difference between the first detecting point and the heart of the user is a fixed preset height difference; the blood pressure measurement device determines a target blood pressure measured value corresponding to the first height difference according to preset first rules.

Owner:GUANGDONG TRANSTEK MEDICAL ELECTRONICS CO LTD

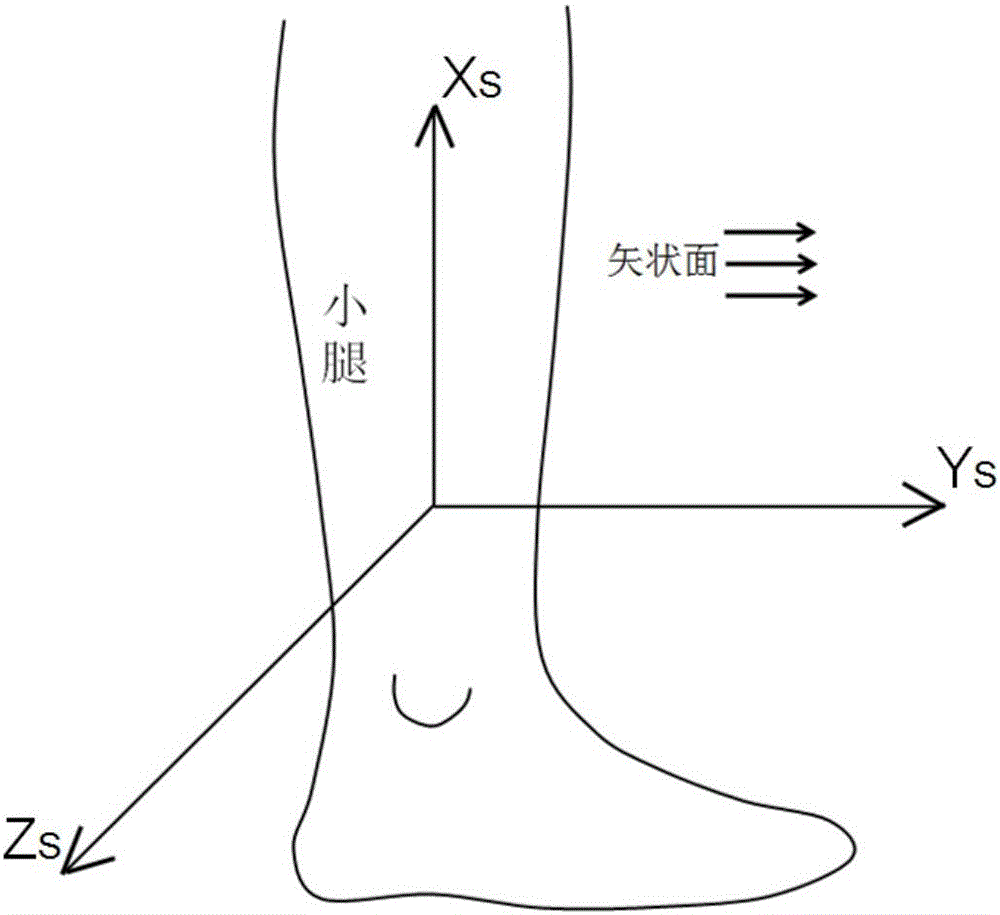

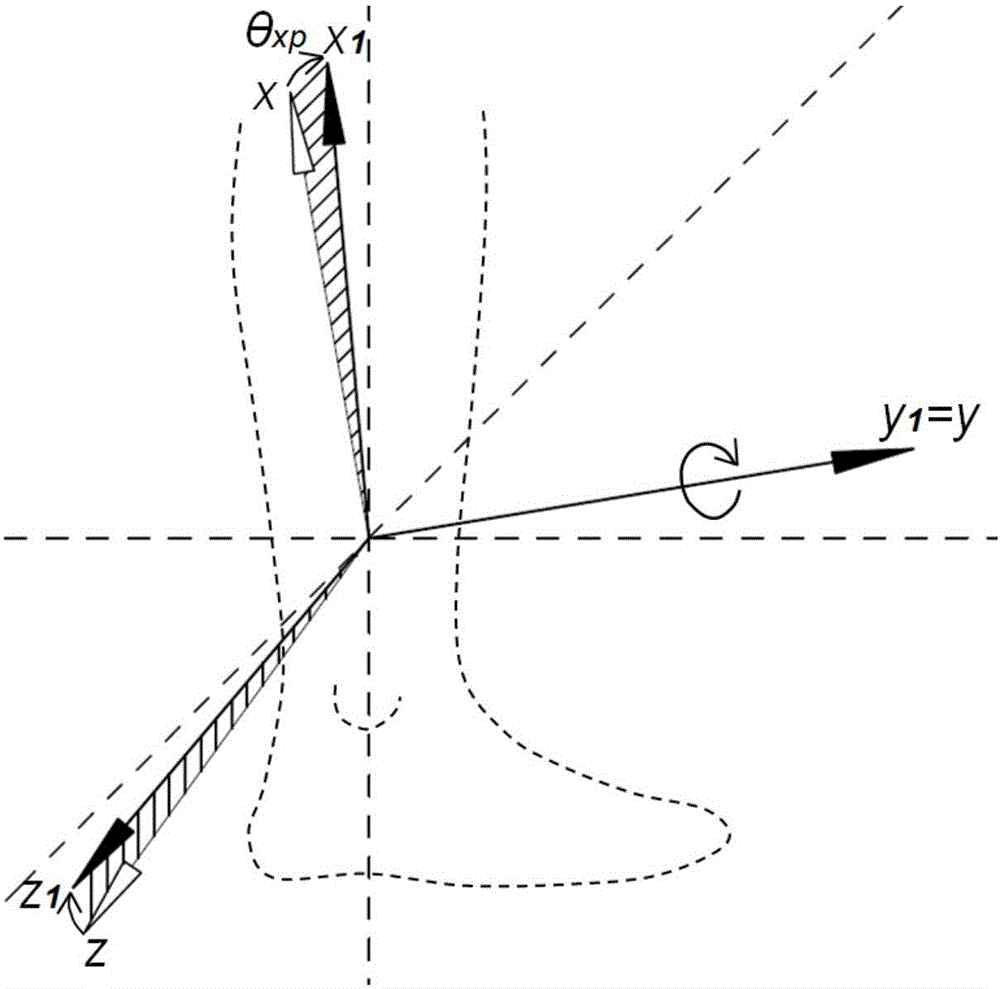

Method for correcting deviation of coordinate axis of inertial sensor

Owner:ZHEJIANG UNIV

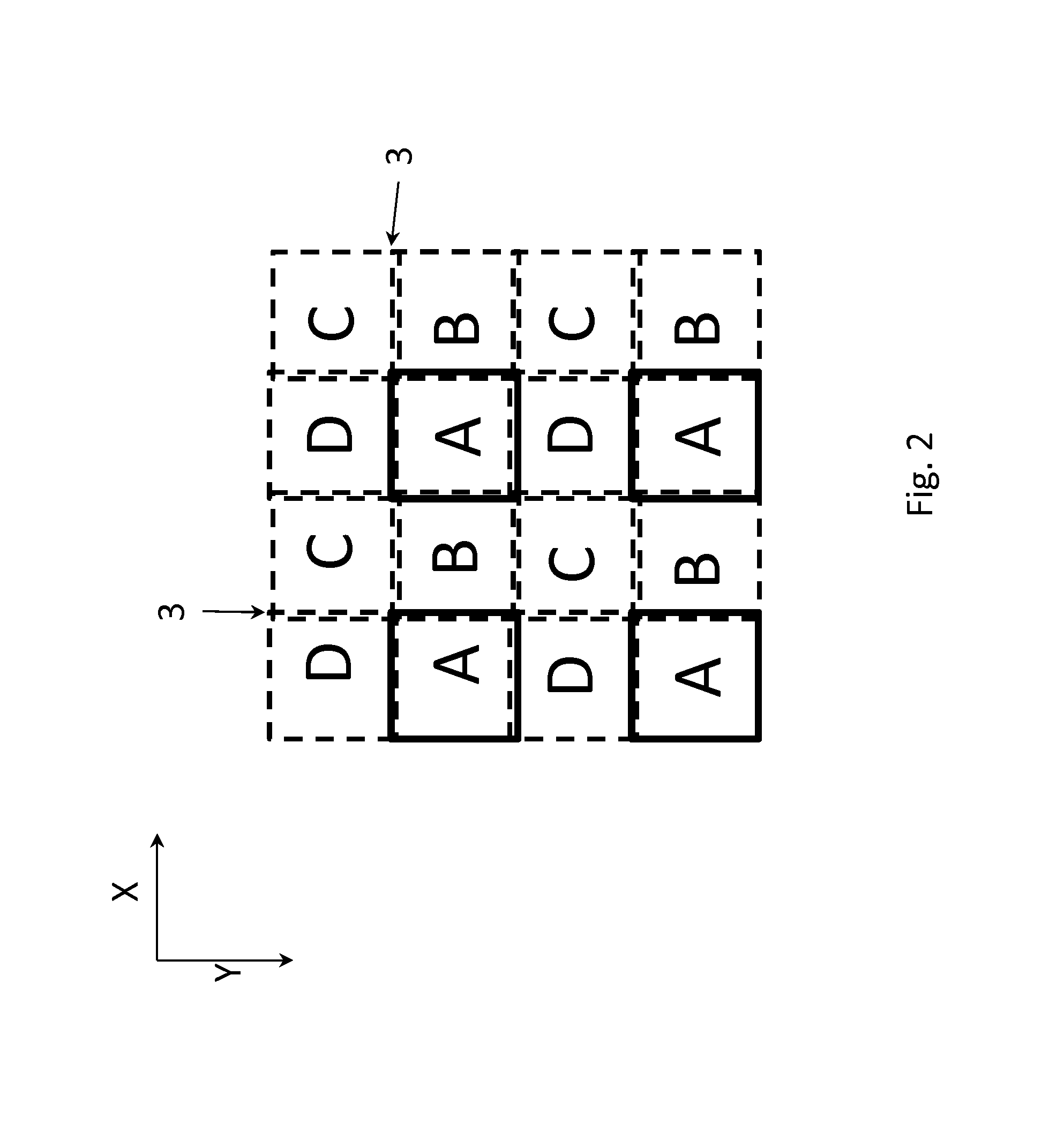

Quantitative line scanning method for curved sample based on electronic probe

InactiveCN103472082ASolve the problem of analyzing only flat samplesCorrect measurement errorMaterial analysis using wave/particle radiationObservational errorElectron probe microanalysis

The invention provides a quantitative line scanning method for a curved sample based on an electronic probe. The method comprises the following steps of searching a sample analysis region through a backscattered electron image; setting the acceleration voltage of an electronic microscope, the size of electronic beams, the size of electronic beam spots, the minimum moving step length of a surface distribution diagram and a grid data lattice; reading the coordinate position of a current point, moving a subsequent point, and reading the coordinates of the moved point until the coordinate positions of all grid points are completely read; performing element characteristic X-ray spectrum analysis to obtain an element strength surface scanning diagram of an analysis region; testing the X-ray strength of a standard sample of an analyzed element, and converting the X-ray strength in an original counting surface scanning result into concentration content to obtain a quantitative surface distribution diagram; performing line scanning to obtain a quantitative line scanning curve of the curved sample. By the adoption of the method, a measurement error caused by unevenness of the surface of the sample can be corrected, the detection efficiency and the detection accuracy are improved, the problem that the electronic probe can be used for analyzing a flat sample only is effectively solved, and the range of samples, which can be analyzed by the electronic probe, is expanded.

Owner:ANGANG STEEL CO LTD

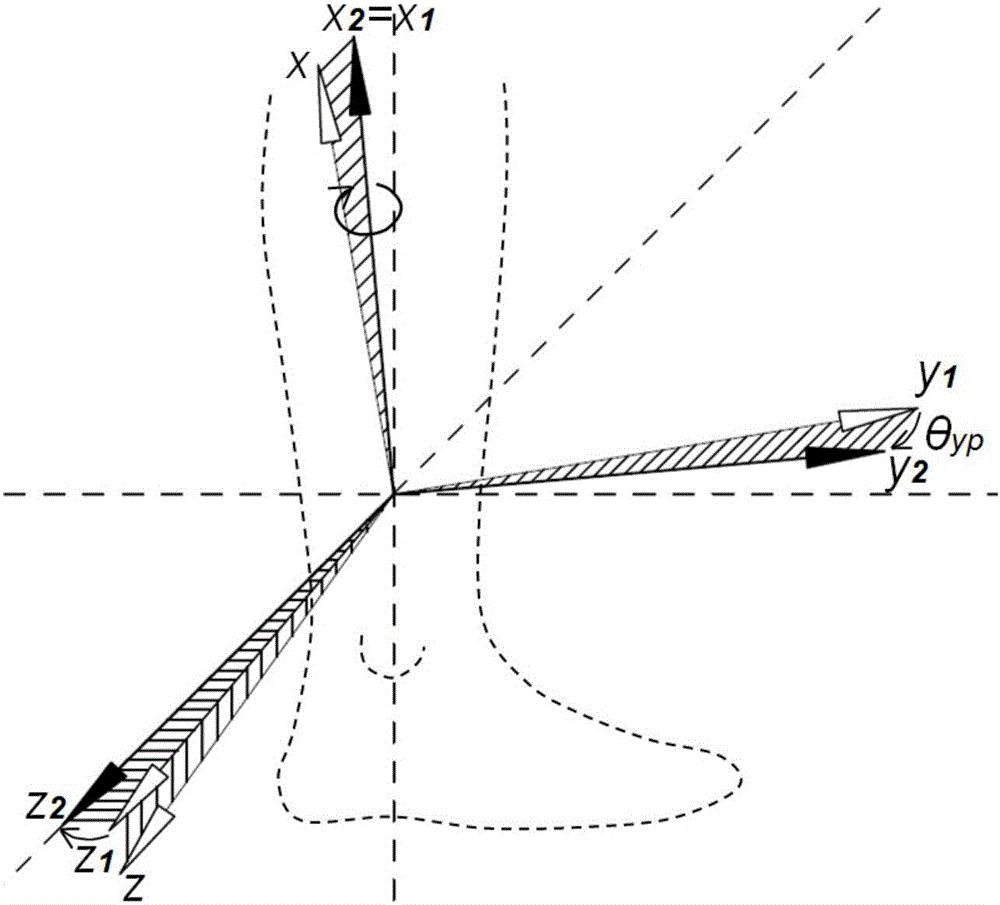

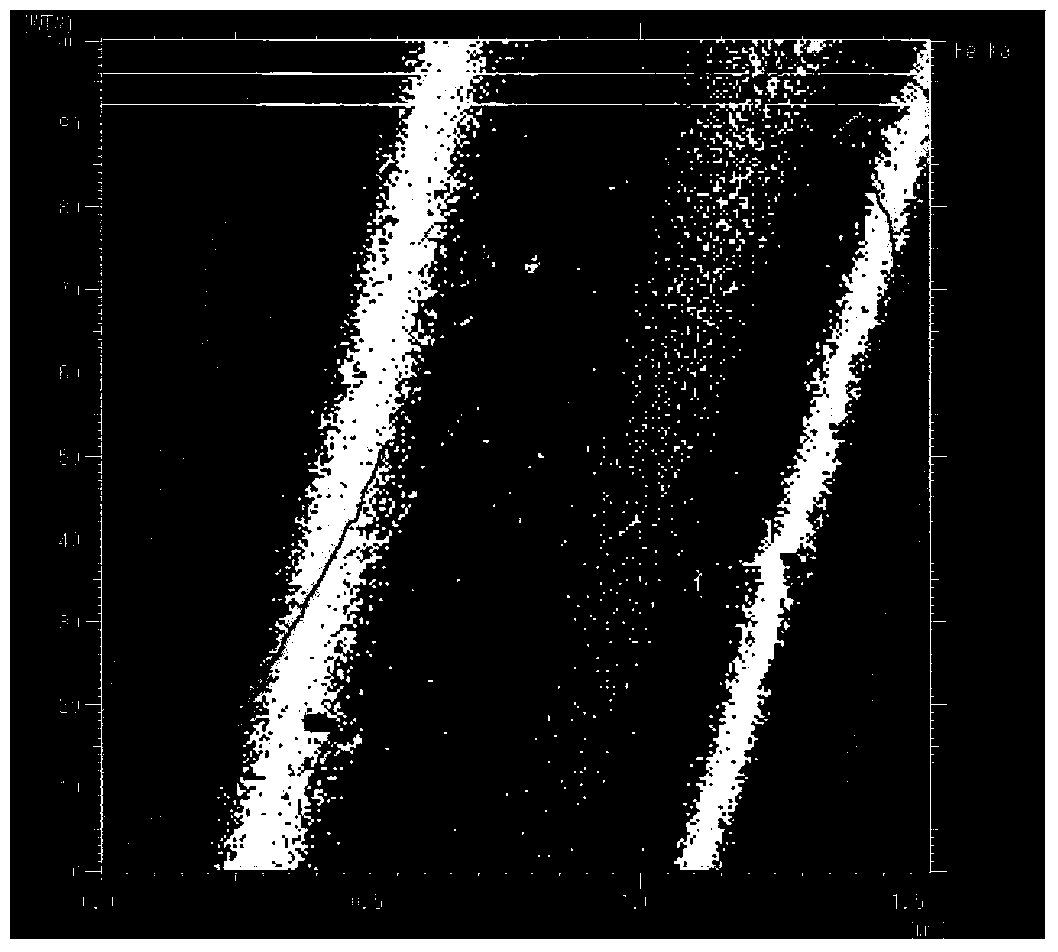

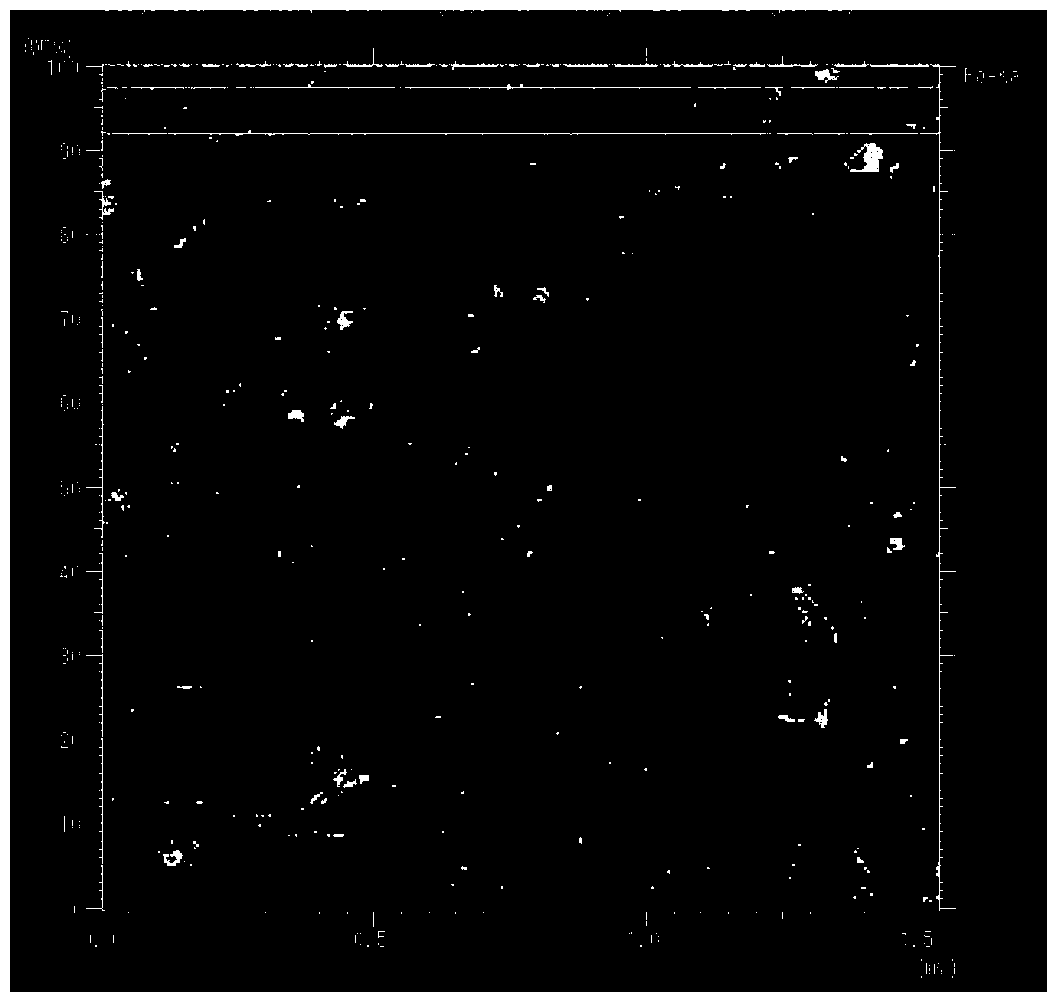

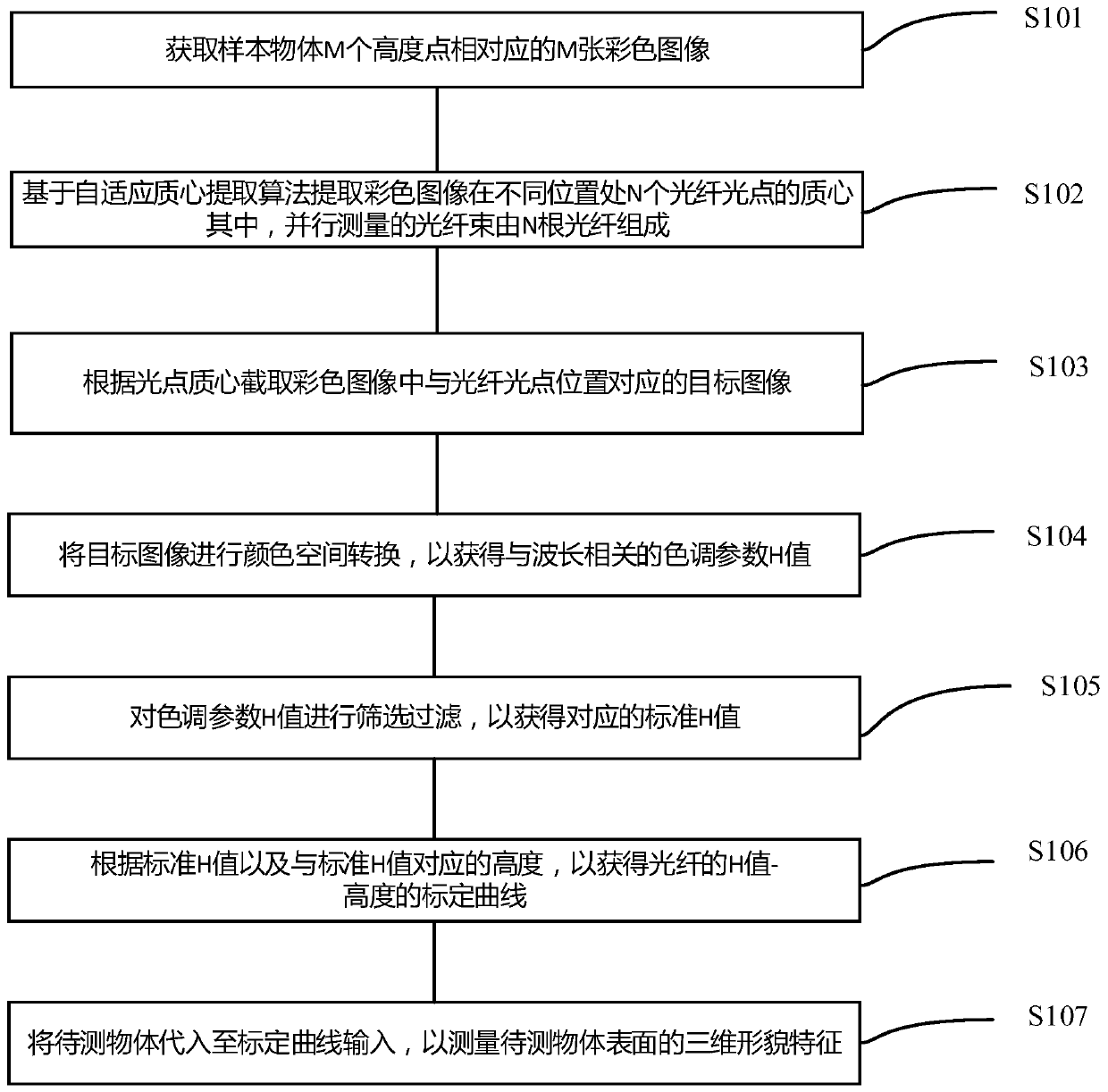

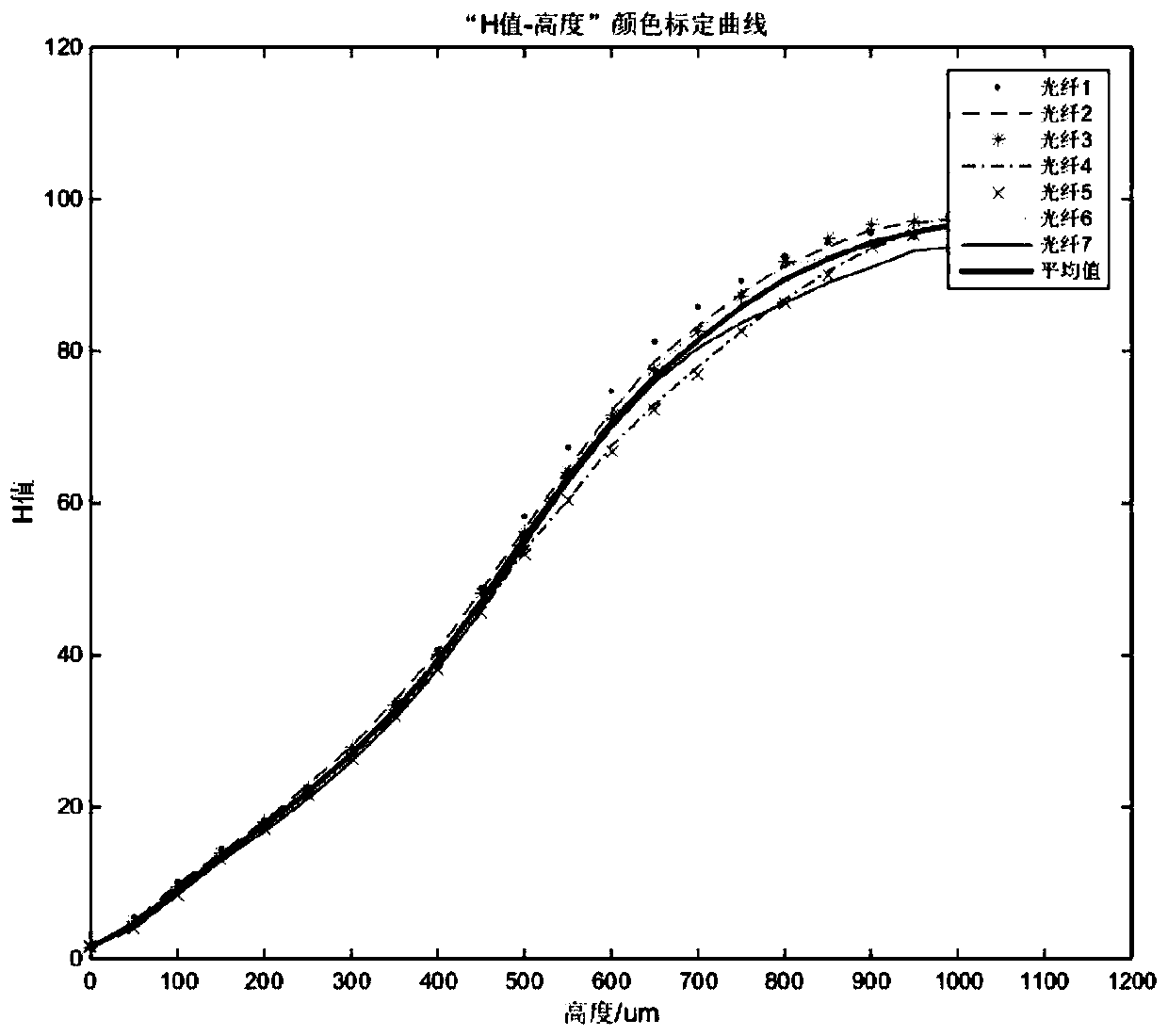

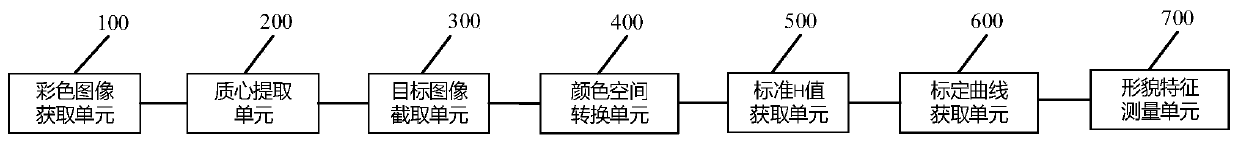

Object surface three-dimensional morphology feature measurement method, device and equipment and storage medium

ActiveCN111288928ARealize measurementRealize CalibrationImage enhancementImage analysisColor imageLight spot

The invention discloses an object surface three-dimensional morphology feature measurement method, device and equipment and a storage medium. The method comprises the steps: M color images corresponding to M height points are acquired; centroids of N optical fiber light spots of the color image at different positions are extracted based on an adaptive centroid extraction algorithm, wherein the optical fiber bundle for parallel measurement is composed of N optical fibers; a target image corresponding to the optical fiber light spot position in the color image is intercepted according to the light spot centroid; color space conversion is conducted on the target image to obtain a hue parameter H value related to the wavelength; the hue parameter H value is screened and filtered to obtain a corresponding standard H value; an H value-height calibration curve of the optical fiber is obtained according to the standard H value and the height corresponding to the standard H value; and the to-be-measured target object is substituted into the calibration curve input, and the three-dimensional morphology feature of the object surface of the to-be-measured target is measured. Measurement errorscaused by transverse crosstalk between adjacent optical fibers can be corrected, and the three-dimensional morphology of the surface of an object can be measured.

Owner:HUAQIAO UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com