Quantitative line scanning method for curved sample based on electronic probe

An electronic probe and line scanning technology, which is applied in measuring devices, material analysis using wave/particle radiation, instruments, etc., can solve the problem that the electronic probe can only analyze flat samples, so as to improve the inspection efficiency and accuracy, The effect of expanding the sample range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

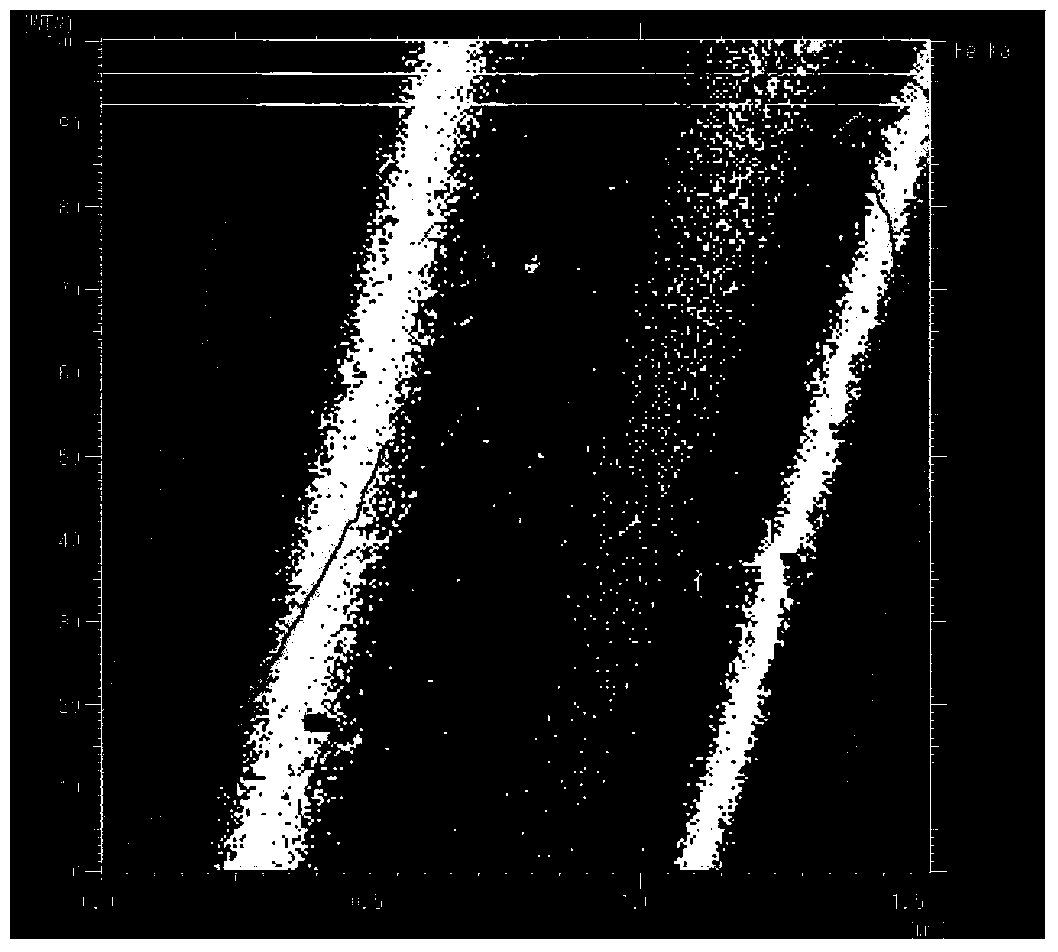

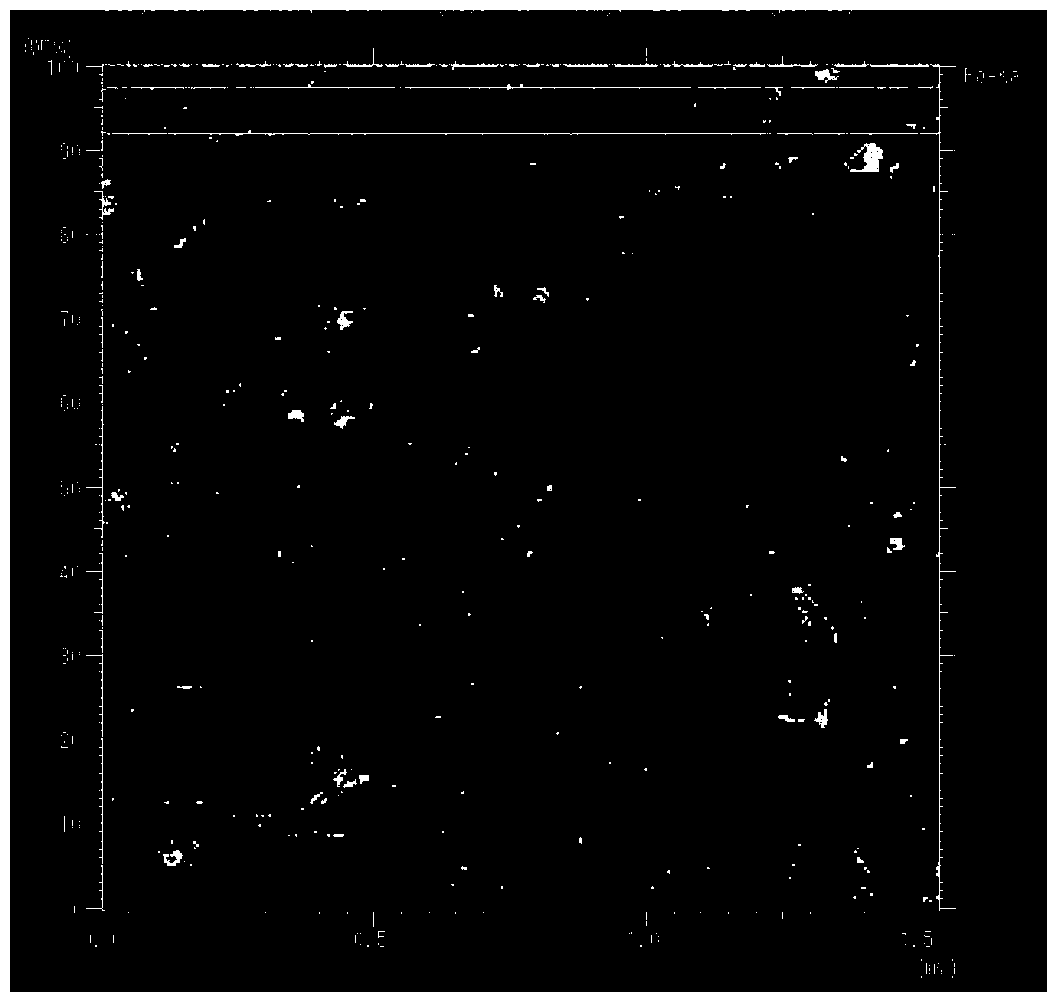

Image

Examples

Embodiment Construction

[0023] EXAMPLES The curved surface sample quantitative line scanning method of the present invention is used to conduct line scanning analysis on uneven samples. The steps are as follows:

[0024] 1. Put the clean analysis sample into the electron probe sample chamber, and use the backscattered electron image to find the sample analysis area.

[0025] 2. During the measurement, select the working parameters of the electron microscope, the accelerating voltage is 15kV, the electron beam current is 100nA, and the beam spot size is 1?. Surface distribution map parameter selection: the scanning method is sample stage scanning, the minimum moving step is 1.0°, the coordinates are manually positioned, and Trace Map selects YES. The dwell time of the sample stage scanning is 30ms, and the moving step is 6.0 X 6.0 ?. The correction parameters of the curved surface sample are set to 9×9 grids. After reading the current point coordinates, move to the next point coordinates, manually...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com