Object surface three-dimensional morphology feature measurement method, device and equipment and storage medium

A technology of three-dimensional shape and object surface, which is applied in the field of optical inspection, can solve the problems of low measurement accuracy, low measurement efficiency, and no consideration of filtering, etc., and achieve the effect of improving accuracy, improving efficiency, and correcting measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

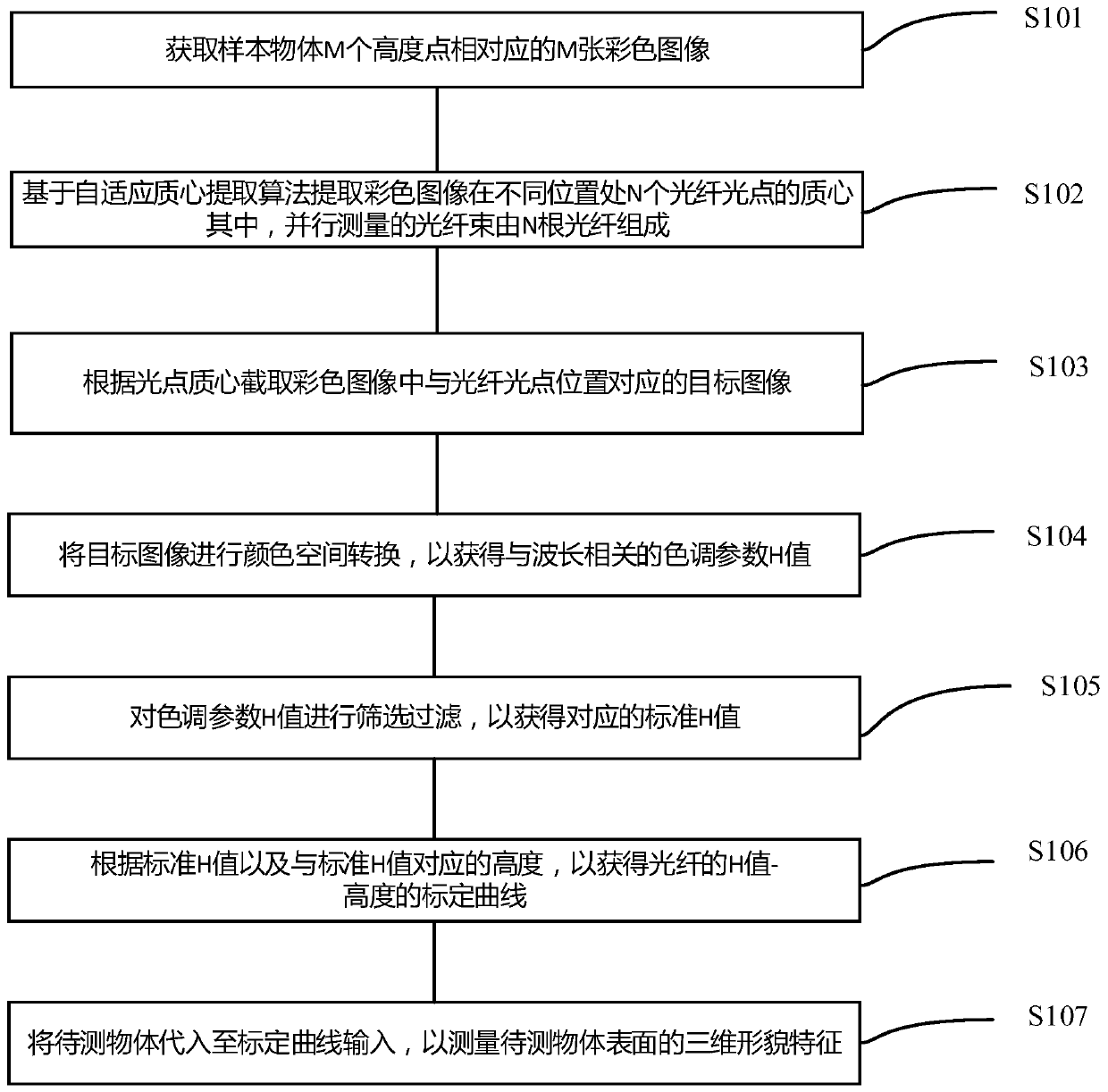

[0062] See figure 1 with figure 2 The present invention provides a method for measuring three-dimensional topographic features of an object surface, which can be executed by a three-dimensional topographic feature measuring device (hereinafter referred to as "measurement device"), in particular, by one or more processes in the measuring device It mainly includes the calibration process and the measurement process. Among them, the calibration process sequentially calibrates the N fibers that make up the fiber bundle. The measurement process is to combine the calibration curve with the color of the object to be measured after the calibration of the N fibers is completed. The image is processed with data to obtain the three-dimensional topographical characteristics of the surface of the measured object.

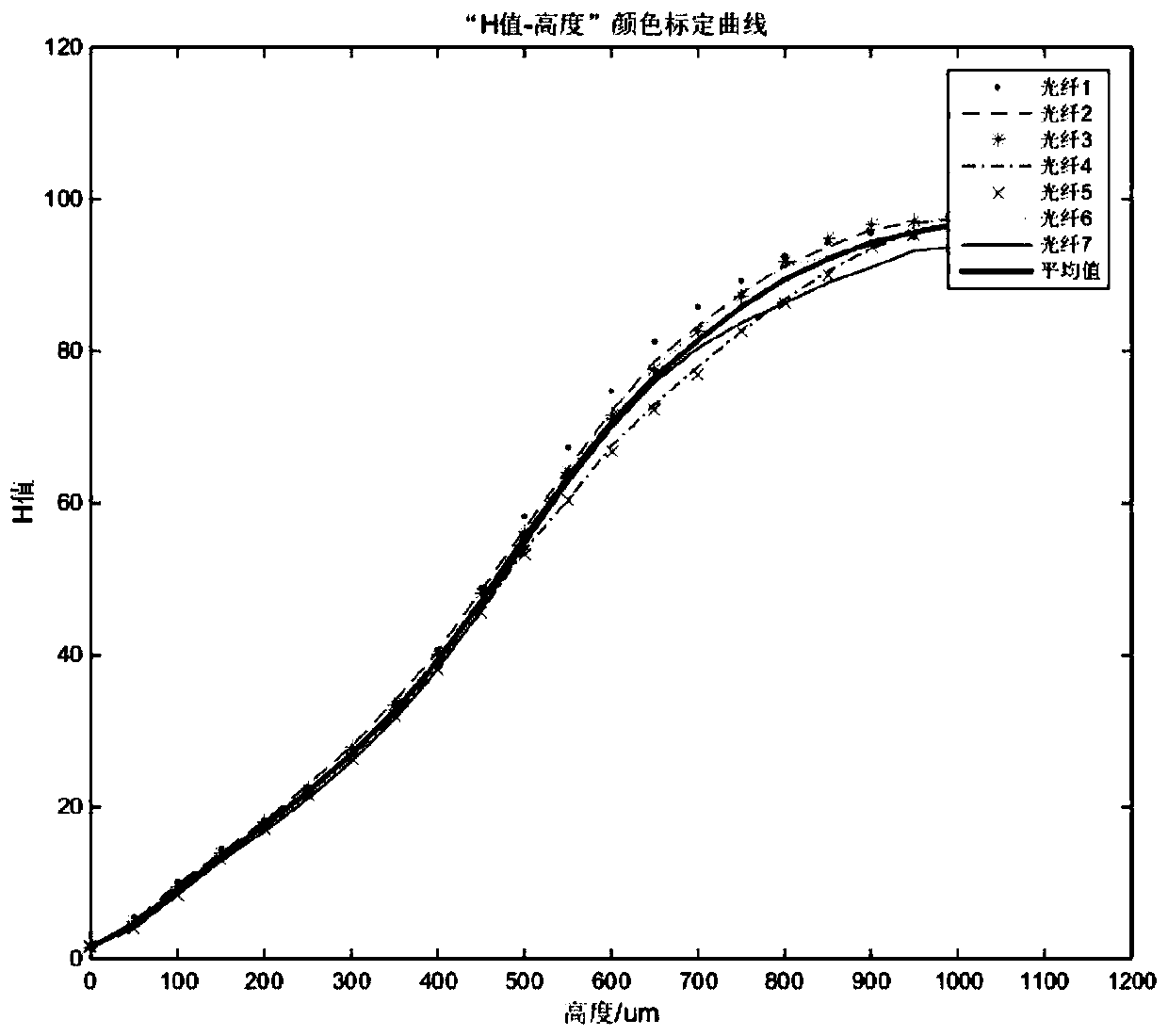

[0063] Specifically, the calibration curve obtained in the calibration process of the present invention refers to the basic "H value-height" curve obtained by taking the object sur...

no. 2 example

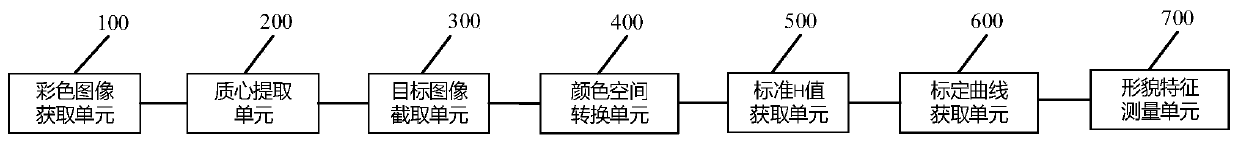

[0082] See image 3 , The implementation of the present invention provides a device for measuring three-dimensional topography features of an object surface, including:

[0083] The color image acquisition unit 100 is configured to acquire M color images corresponding to M height points of the sample object;

[0084] The centroid extraction unit 200 is configured to extract the centroids of the N optical fiber spots of the color image at different positions based on the adaptive centroid extraction algorithm; wherein the optical fiber bundle measured in parallel is composed of N optical fibers;

[0085] The target image interception unit 300 is configured to intercept the target image corresponding to the position of the optical fiber light spot in the color image according to the centroid of the light spot;

[0086] The color space conversion unit 400 is configured to perform color space conversion on the target image to obtain the hue parameter H value related to the wavelength;

[0...

no. 3 example

[0102] The third embodiment of the present invention also provides a device for measuring three-dimensional topography features of an object surface, including a processor, a memory, and a computer program stored in the memory, and the computer program can be executed by the processor to achieve The method for measuring the three-dimensional topographic features of the object surface described in the above embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com