Partial-compensation aspherical reflector surface shape detection method

A technology of reflecting mirror surface and detection method, which is applied to measurement devices, instruments, optical devices, etc., can solve the problems of inability to measure the compensation effect of the compensator alone, complicated processing and adjustment, difficult processing and adjustment, etc., and achieves simple experimental operation. Ease of operation, short test time, simple data processing and mathematical operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

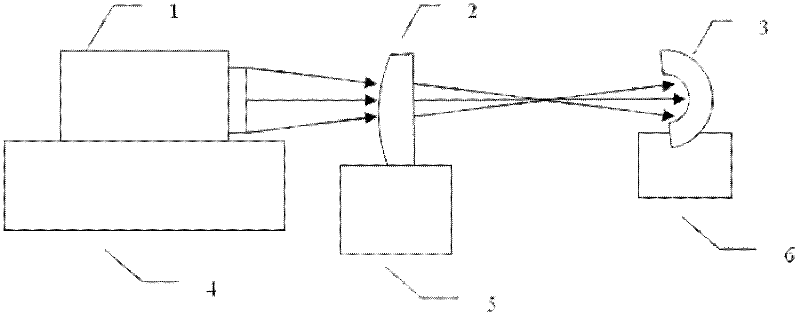

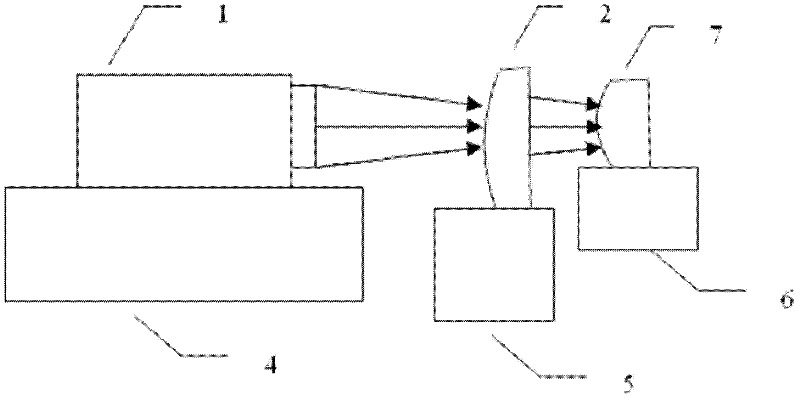

[0027] Such as Figure 2-Figure 4 As shown, the device for realizing the method for detecting the surface shape of partially compensated aspheric mirrors of the present invention includes a laser interferometer 1 , a partially compensated element 2 , a standard spherical mirror 3 , an adjustment mechanism 4 , an adjustment structure 5 , and an adjustment structure 6 .

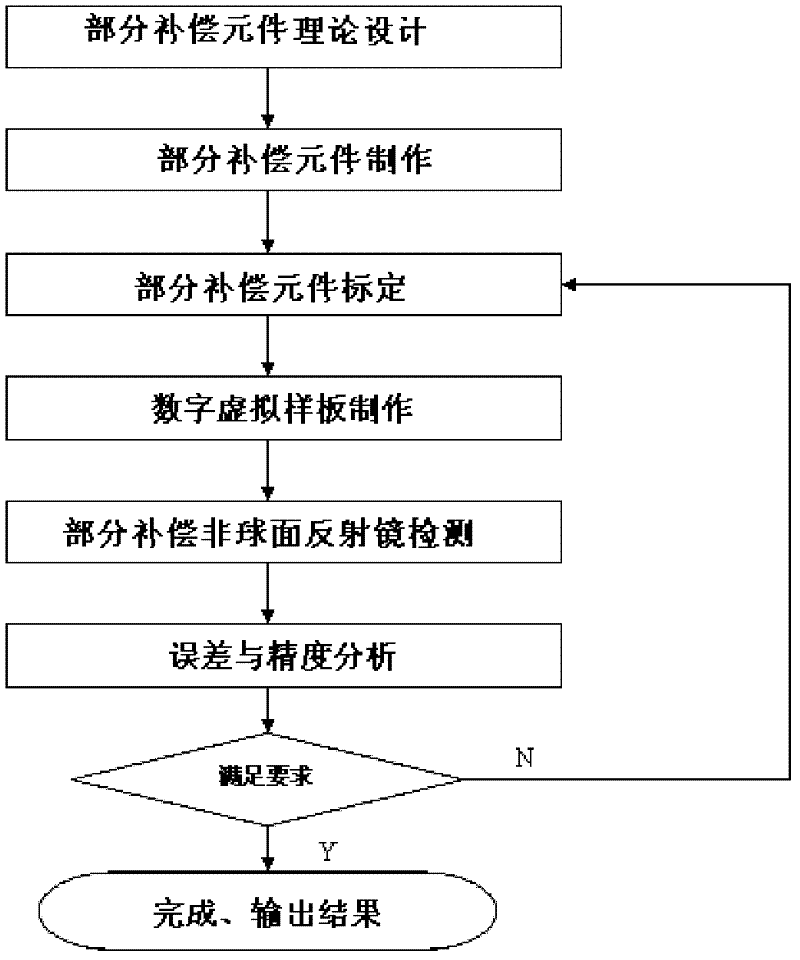

[0028] Such as figure 1 As shown, the partial compensation aspheric surface shape detection method of the present invention is as follows:

[0029] 1) First, design a monolithic lens as part of the compensation element 2 according to the mathematical equation of the aspheric mirror to be tested.

[0030] The design principle of the partial compensation element 2 is that the standard plane or standard spherical wave emitted by the interferometer 1 passes through the partial compensation element 2, and the outgoing wave surface is incident on the aspheric mirror to be tested and then reflected with the reference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com