A microwave on-line detection and elimination method for composite filter rods

A composite filter rod and filter rod technology, which is applied in the direction of using microwave flaw detection, can solve the problems of inability to detect composite filter rod dislocation and phase shift, etc., and achieve the effects of fast detection speed, high reliability and accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below with embodiment and accompanying drawing.

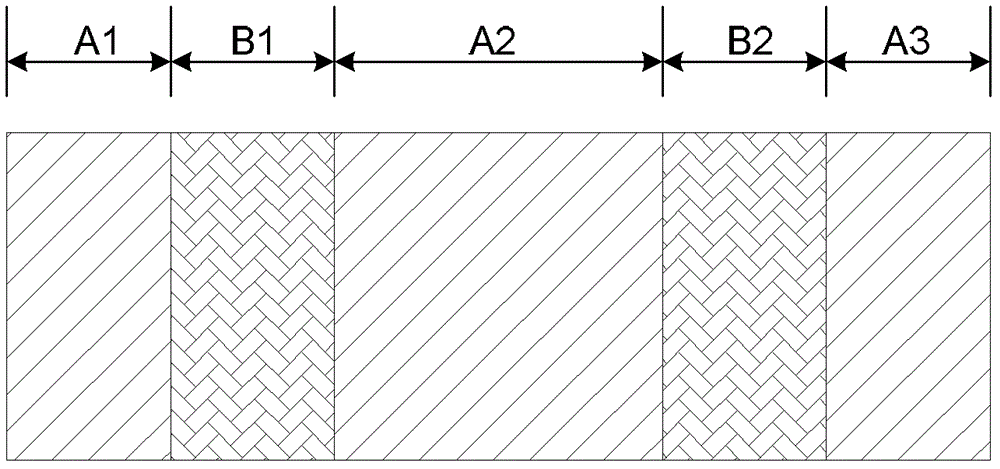

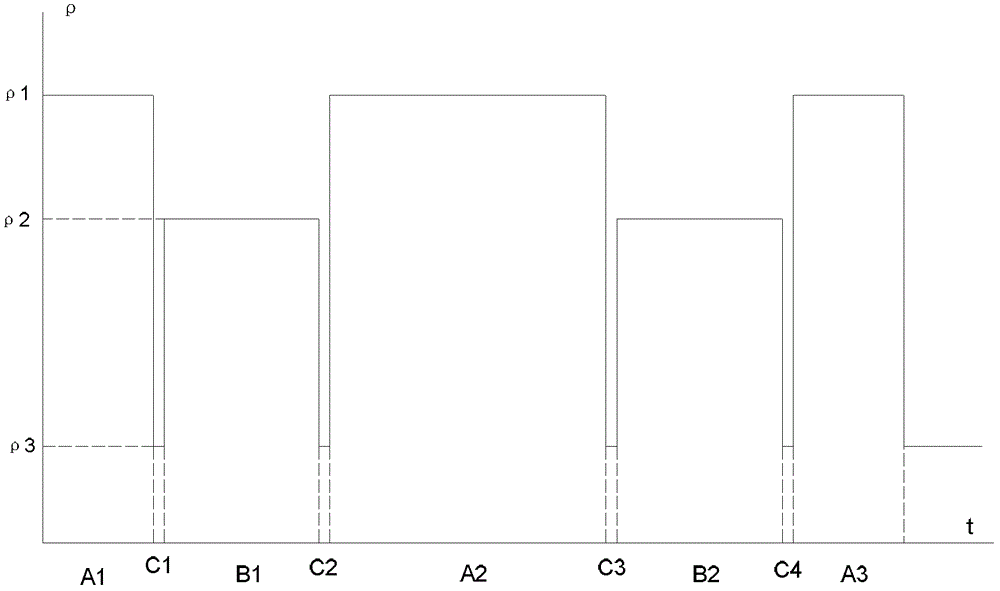

[0042] The present invention is used for the microwave on-line detection and elimination method of composite filter rod comprising the following steps:

[0043] S1: given the density requirement value and filter rod length requirement value of each segment filter rod and the gap length requirement value of the gap between each segment filter rod;

[0044] S2: Input the microwave signal to the empty microwave cavity, and obtain the output standard microwave power attenuation A 0 and the standard microwave resonant frequency f 0 ;

[0045] S3: When the tested composite filter rod passes through the microwave resonant cavity sequentially from beginning to end, the microwave power attenuation A and the microwave resonant frequency f corresponding to each sampling point on the tested composite filter rod are respectively obtained by inputting microwave signals to the microwave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com